GE Energy

Roots

*

RAS-J Air & RGS-J

Gas Blowers

Wide range of performance for pressure and vacuum

applications on air or gas service for both dry and

wet (liquid injection) conditions.

GE Energy’s Roots blower models deliver

industrial and high vacuum air and gas

services including single and multiple stage

arrangements. Roots rotary blowers have

been applied to multiple applications in

a very wide range of industries – aeration

for wastewater treatment, pneumatic

conveying for both vacuum and pressure

conditions, steel degassing, vacuum truck,

and many others.

These blowers are available in size ranges

that can be economically direct driven by

an electric motor. They are available with

extensive application engineering, global

service support, and packaging capability.

2

Pressure Pulses per Shaft Revolution

Conventional Blower

WHISPAIR Blower

Discharge Pressure

Discharge Pressure

140%

100%

60%

120%

100%

80%

60

63 125 200

500 1K

2K

4K 8K

70

80

90

100

110

120

Octave Band Level

in dB RE: 2 x 10

-5

Nm

2

Typical Blower Noise Curve

Band Center Frequency

in Cycles Per Second

Conventional Blower

Roots WHISPAIR Blower

The GE proprietary WHISPAIR

*

design reduces stress, vibration and noise in your blower

and piping system. Conventional blowers produce downstream pressure pulse waves

which buffet your air or gas delivery system up to 120 times per second. These pulses

and vibrations can steal power and shorten the life of every bearing, gear and other

drive train component.

WHISPAIR technology reduces the strength of the blower pulse up to 40%, throughout

the air/gas delivery system.

WHISPAIR Technology Features

■

Lower energy consumption. The patented

WHISPAIR jet design precisely meters back-fl ow

and channels air pressure in the direction of

impeller rotation. The result is an extra “push”

that reduces the power required to drive the

impellers.

■

Longer bearing life. Less pulse transmitted

through the impellers means approximately

20% longer bearing life. With less pulse and

vibration, other components such as timing

gears, drive couplings, v-belts and motor

bearings suffer less stress.

■

Less noise. Pressure pulses are often the major

source of blower and gas blower noise. The

pressure equalizing effect of the WHISPAIR

design reduces noise by approximately 5 dBA,

while reducing wear on your piping valves and

sensitive instrumentation.

■

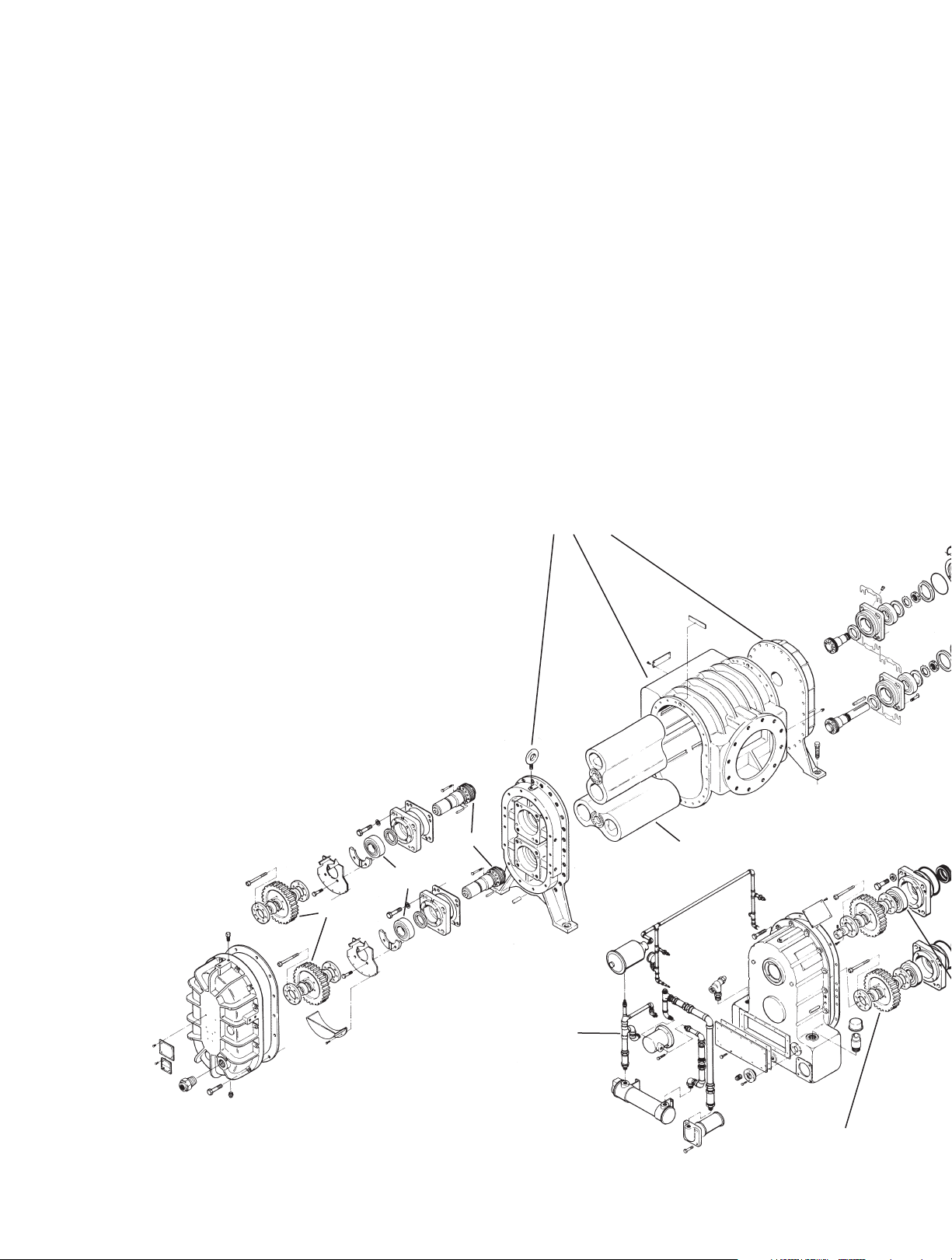

Cylinder and headplates. All RAS-J and

RGS-J blower units are confi gurable to

horizontal or vertical fl ows. Cylinders and

headplates are precision machined grey

iron, with cast ribs for improved strength and

heat transfer. Castings may be subjected to

strenuous pressure and leak testing to help

preserve integrity in the most demanding

applications. Each RGS-J machine is leaked

tested to 1.25 times casing design pressure;

optional hydrostatic testing available to

1.5 times casing design pressure.

■

Impellers. Made from ductile iron with a tensile

strength of 60,000 psi impellers are statically

and dynamically balanced to industry accepted

standards, providing you with years of troublefree performance and durability.

3

■

Shafts. Impeller shafts are alloy steel forgings;

fl ange connected to the impeller bodies with

high-tensile socket head capscrews. Standard

blowers have precision machined labyrinth seals

where the shaft passes the casing headplate.

A single piston ring or multiple piston rings may

also be employed with various purge gas confi gurations to meet customer specifi c requirements.

■

Bearings. Long-life, double - row spherical roller

bearings support the shaft assemblies and

control axial location of the impellers at the

thrust end. An inboard 5th bearing helps

reduce drive shaft stress on 1000J through

1400J frame size, V-belt driven blowers.

■

Timing gears. The impellers rotation is timed by

a pair of precision machined, forged steel gears.

These wide-faced spur gears are manufactured

to AGMA standards and are carburized and

ground with a hardness of 58-60 Rc. Spur gears

do not transmit harmful axial loads to bearings

and motors. On 1000J frame size units the gears

are secured to the shafts by a taper fi t. Larger

sizes use a proven taper locking device providing an easily adjustable mechanical shrink fi t.

No shaft-weakening keyways or locking pins

are required.

■

Lubrication Both RAS-J blowers and RGS-J

blowers offer a positive pressure lubrication

system which can extend bearing life by up to

50%. This system is entirely self-contained and

includes an integral drive oil pump, distribution piping. Every pressure lubrication option

includes, gearbox oil sump, oil fi lter oil cooler,

pressure gauge, relief valve and low oil pressure safety switch. This is a pressure lubrication

system that supplies cool, clean pressurized oil

into every critical area. The Roots RAS-J blower

is also available with an energy-saving splash

lubrication system in place of the pressure

system.

Cylinder and Headplates

Shafts

Bearings

Timing Gears

Lubrication

4

Impellers

Timing Gears

RAS-J/RGS-J Blower

Timing gear locking arrangement

for 1000J frame sizes

Timing

Gear

Locknut

Bearing

Taper Fit Locking Ring Detail Options

Bearing

Carrier

RAS-J/RGS-J Blower

Timing gear locking arrangement

for 1200J – 2000J frame sizes

Timing

Gear

Collar

Locking

Screw

Tapered

Inner Ring

Bearing

Bearing

Carrier

RGS-J Gas Blower

Detail Mechanical Seal

Pressure in this gas area

not to exceed oil pressure

at seal face.

Labyrinth Seal

Shaft Flange

Headplate

Screw

Sealing

Face

Oil

Pressure

Oil Throttling

Passage and

Bearing Feed

O-ring

Oil

Supply

Bearing

Carrier

Shims

Bearing

Shafts

Bearings

Impellers

Cylinder and Headplates

5

Performance Specifi cations

Frame Size

Speed

(rpm

1006 1900 2371 29.0 2328 36.0 2291 42.9 2241 53.3 2196 64.0 2143 78.0 2008 92 1380 470

1009 1900 3605 40.3 3548 40.8 3498 61.7 3432 77.1 3373 92.9 3302 113.8 3090 135 1380 470

1012 1900 4806 52.6 4731 66.6 4664 80.6 4576 101.6 4497 122.7 4403 150.7 4120 179 1240 470

1016 1900 6735 70.3 6649 89.6 6572 108.9 6471 137.8 6380 166.8 915 470

1018 1900 7659 79.1 7561 101.0 7474 123.0 7358 155.9 7256 188.8 805 470

1021 1900 8583 88.8 8473 113.4 7375 138.0 8246 174.9 715 470

1024 1900 9805 101.1 9697 129.2 9568 157.3 635 470

1030 1900 12249 122.1 12091 157.2 11952 192.3 505 510

1212 1600 5881 66.1 5802 83.0 5733 100.0 5641 125.2 5560 150.2 5461 184.0 5373 218 1380 470

1216 1600 7908 86.3 7802 109.0 7709 131.7 7583 165.7 7475 199.8 7342 245.1 1140 470

1220 1600 10000 105.0 9890 133.2 9792 161.5 9663 204.0 9548 246.4 910 470

1222 1600 11243 116.4 11120 148.2 11010 180.0 10865 227.8 10736 275.5 810 470

1225 1600 12512 127.2 12374 162.6 12252 198.0 12091 251.0 725 470

1228 1600 14263 143.0 13151 170.6 13012 208.8 635 470

1236 1600 17994 175.5 17795 226.5 17621 277.4 505 510

1412 1365 7198 85.2 7105 105.3 7024 126.4 6914 157.3 6821 188.2 6706 299.4 6602 271 1380 470

1414 1365 8354 96.9 8274 120.9 8153 144.8 8028 180.6 7917 216.5 7783 264.2 7663 312 1380 470

1418 1365 10668 121.3 10530 151.8 10411 182.4 10251 228.1 10109 274.0 9939 335.0 1145 470

1422 1365 13132 141.0 12992 178.6 12869 215.2 12700 270.8 12561 326.4 945 470

1425 1365 14607 154.4 14452 195.6 14310 236.9 14135 298.8 13973 360.6 840 470

1428 1365 16344 170.0 16170 216.1 16018 262.3 15815 331.5 760 470

1431 1365 18384 188.2 18189 240.1 18017 292.0 17789 369.9 675 470

1435 1365 20446 208.4 20230 266.0 20038 324.0 610 470

1442 1365 24527 249.2 24216 318.5 24037 387.4 505 510

1616 1200 10623 125.5 10493 155.7 10379 186.0 10228 231.4 10093 276.8 9932 337.0 9786 398 1380 470

1620 1200 13269 153.6 13107 91.4 12965 229.2 12275 285.9 12607 342.6 12406 418.2 12223 494 1215 470

1625 1200 16595 183.0 16393 230.2 16215 277.5 15980 348.4 15768 419.3 965 470

1627 1200 18154 194.3 17972 245.3 17811 296.4 17600 373.0 17409 449.5 895 470

1630 1200 20164 212.1 19962 268.8 19784 325.5 19548 410.6 19337 495.6 810 470

1633 1200 22175 230.1 21953 292.4 21757 354.7 21498 448.2 730 470

1636 1200 24205 249.0 24962 317.0 23749 385.0 23465 487.2 675 470

1639 1200 26216 267.0 25953 341.7 25721 415.2 620 470

1643 1200 28897 293.1 28607 374.4 28352 455.6 565 470

1648 1200 32267 327.0 31943 417.8 31659 508.5 505 510

1821 1060 14663 164.3 14479 206.5 15267 266.9 15052 335.5 14860 400.2 14631 489.0 14423 578 1295 470

1824 1060 17856 200.8 17646 251.6 17460 302.4 17214 378.6 16994 454.8 16732 556.4 1140 470

1827 1060 20065 224.2 19829 281.2 19620 338.2 19343 423.9 19097 500.0 18802 623.7 1010 470

1830 1060 22575 246.7 22355 310.2 22162 373.6 21906 468.7 21678 563.8 910 470

1833 1060 25202 269.8 24597 340.6 24741 411.4 24455 517.6 24200 623.8 810 470

1838 1060 28591 299.2 28314 379.6 28069 459.9 26024 580.3 720 470

1841 1060 30845 318.2 30546 405.0 30282 491.5 28076 621.5 660 470

1845 1060 33862 344.6 33533 439.7 33244 534.8 610 470

1849 1060 36879 370.9 36521 474.5 36205 578.0 550 470

1854 1060 40641 408.0 40247 522.0 39900 636.3 505 510

2022 1000 19640 224.7 19437 279.7 19258 334.7 16926 417.0 18810 499.5 18557 609.4 18328 719 1350 470

2026 1000 23128 260.2 22889 325.0 22679 389.7 22399 486.7 22150 583.8 21853 713.0 1145 470

2030 1000 26478 286.9 26252 360.2 26054 433.5 25790 543.3 25555 653.3 24742 800.0 1015 470

2033 1000 29570 312.6 29318 394.3 29069 476.2 28802 599.0 28540 721.7 895 470

2037 1000 33097 342.9 32815 434.5 32567 526.1 32237 663.5 31944 800.0 810 470

2040 1000 35304 362.3 35003 460.0 34738 557.7 34387 704.2 760 470

2044 1000 38831 392.6 38500 500.0 34112 607.5 37822 768.7 690 470

2047 1000 41488 415.7 44130 437.6 40824 645.3 650 470

2050 1000 44130 437.6 43754 559.7 43423 681.8 610 470

2055 1000 48542 480.4 48129 614.8 47765 749.1 545 470

2057 1000 50314 497.2 49886 634.4 49508 775.7 530 510

2060 1000 52955 521.2 52500 667.7 46520 814.3 505 510

2062 1000 50996 536.9 54261 688.4 485 530

2064 1000 56483 552.6 56000 709.0 475 550

2022** 1000 19640 224.7 19437 279.7 19258 334.7 19021 417.0 18810 499.5 18557 609.4 18328 719 1380 470

2026** 1000 23128 260.2 22889 325.0 22679 389.7 22399 486.7 22150 583.8 21853 713.0 21584 843 1380 470

2030** 1000 26478 286.9 26252 360.2 26054 433.5 25790 543.3 25555 653.3 25274 800.0 25021 946 1380 470

2033** 1000 29570 312.6 29318 394.3 29069 476.2 28802 599.0 28540 721.7 27632 885.0 27292 1049 1380 470

2037** 1000 33097 342.9 32815 434.5 32567 526.1 32237 663.5 31944 800.0 30928 984.0 30547 1167 1380 470

2040** 1000 35304 362.3 35003 460.0 34738 557.7 34387 704.2 34074 850.7 32990 1046.0 32584 1242 1310 470

2044** 1000 38831 392.6 38500 500.0 34112 607.5 37822 768.7 37478 930.0 36286 1145.0 35839 1360 1250 470

2047** 1000 41488 415.7 44130 437.6 40824 645.3 40411 817.5 40043 998.7 38770 1219.0 1170 470

2050** 1000 44130 437.6 43754 559.7 43423 681.8 42983 865.0 42592 1048.0 41237 1292.4 1105 470

2055** 1000 48542 480.4 48129 614.8 47765 749.1 47282 950.6 46850 1152.0 45361 1420.7 1000 470

2057** 1000 50314 497.2 49886 634.4 49508 775.7 49000 984.5 48560 1193.0 965 470

2060** 1000 52955 521.2 52500 667.7 52107 814.3 51580 1034.0 51110 1254.0 915 470

2062** 1000 54727 536.9 54261 688.4 53850 839.8 53300 1067.0 52820 1294.0 890 470

2064** 1000 56483 552.6 56000 709.0 55578 865.1 55016 1100.0 54515 1334.0 860 470

2070** 1000 61780 600.0 61255 770.6 60792 941.5 60177 1197.8 785 470

2072** 1000 63553 615.4 63012 791.2 62535 967.1 61902 1230.8 765 470

2080** 1000 70607 679.1 70010 874.5 69477 1069.8 68773 1362.9 690 470

mbarg = millibar gauge Tolerences: blower shaft power ± 4%, intake volume ± 5%

** For 40 PSL rating

6

300 mbarg 400 mbarg 300 mbarg 500 mbarg 650 mbarg 800 mbarg 1000 mbarg

1

)

Q(m3/h) Pa(kW) Q(m3/h) Pa(kW) Q(m3/h) Pa(kW) Q(m3/h) Pa(kW) Q(m3/h) Pa(kW) Q(m3/h) Pa(kW) Q(m3/h) Pa(kW) (mbarg) (mbarA)

1

The maximum speed used in performance calculation.

Max

Pressure

Max

Vacuum

Dimensions (Refer to drawings on page 9)

Frame Size

1006 883 724 730 914 1005 1230 907

1009 883 724 730 914 1081 1307 957

1012 883 724 730 914 1157 1383 1034

1016 886 724 730 914 1272 1497 1139

1018 886 724 730 914 1329 1554 1175

1021 886 724 730 914 1386 1611 1211

1024 886 724 730 914 1462 1688 1411

1030 886 724 730 914 1614 1840 1660

1212 1029 838 842 1016 1157 1267 1436

1216 1029 838 842 1016 1259 1369 1622

1220 1029 838 842 1016 1360 1470 1721

1222 1029 838 842 1016 1424 1534 1810

1225 1029 838 842 1016 1487 1597 1898

1228 1029 838 842 1016 1576 1686 1971

1236 1029 838 842 1016 1767 1877 2211

1412 1200 978 965 1149 1296 1443 2046

1414 1200 978 965 1149 1356 1503 2186

1418 1200 978 965 1149 1457 1605 2327

1422 1200 978 965 1149 1559 1707 2477

1425 1200 978 965 1149 1623 1770 2586

1428 1200 978 965 1149 1699 1846 2694

1431 1200 978 965 1149 1788 1935 2821

1435 1200 978 965 1149 1864 2024 2948

1442 1200 978 965 1149 2054 2202 3216

1616 1365 1130 1099 1295 1227 ------ 2806

1620 1365 1130 1099 1295 1329 ------ 2933

1625 1365 1130 1099 1295 1456 ------ 3085

1627 1365 1130 1099 1295 1506 ------ 3236

1630 1365 1130 1099 1295 1583 ------ 3393

1633 1365 1130 1099 1295 1659 ------ 3552

1636 1365 1130 1099 1295 1735 ------ 3675

1639 1365 1130 1099 1295 1811 ------ 3867

1643 1365 1130 1099 1295 1913 ------ 4024

1648 1365 1130 1099 1295 2040 ------ 3987

1821 1505 1257 1219 1422 1456 ------ 3828

1824 1505 1257 1219 1422 1532 ------ 3978

1827 1505 1257 1219 1422 1608 ------ 4169

1830 1505 1257 1219 1422 1684 ------ 4359

1833 1505 1257 1219 1422 1773 ------ 4550

1838 1505 1257 1219 1422 1887 ------ 4672

1841 1505 1257 1219 1422 1964 ------ 4740

1845 1505 1257 1219 1422 2065 ------ 4931

1849 1505 1257 1219 1422 2167 ------ 5067

1854 1505 1257 1219 1422 2294 ------ 5203

2022 1680 1384 1340 1556 1557 ------ 4831

2026 1680 1384 1340 1556 1659 ------ 5044

2030 1680 1384 1340 1556 1748 ------ 5273

2033 1680 1384 1340 1556 1832 ------ 5502

2037 1680 1384 1340 1556 1934 ------ 5956

2040 1680 1384 1340 1556 1997 ------ 6183

2044 1680 1384 1340 1556 2099 ------ 6409

2047 1680 1384 1340 1556 2175 ------ 6573

2050 1680 1384 1340 1556 2251 ------ 6736

2055 1680 1384 1340 1556 2378 ------ 6958

2057 1680 1384 1340 1556 2429 ------ 7047

2060 1680 1384 1340 1556 2505 ------ 7181

2062 1680 1384 1340 1556 2556 ------ 7270

2064 1680 1384 1340 1556 2607 ------ 7360

2022** 1711 1384 1378 1556 1775 ------ 5211

2026** 1711 1384 1378 1556 1877 ------ 5424

2030** 1711 1384 1378 1556 1965 ------ 5653

2033** 1711 1384 1378 1556 2054 ------ 5882

2037** 1711 1384 1378 1556 2156 ------ 6336

2040** 1711 1384 1378 1556 2219 ------ 6563

2044** 1711 1384 1378 1556 2321 ------ 6789

2047** 1711 1384 1378 1556 2397 ------ 6858

2050** 1711 1384 1378 1556 2473 ------ 6940

2055** 1711 1384 1378 1556 2600 ------ 7087

2057** 1711 1384 1378 1556 2651 ------ 7155

2060** 1711 1384 1378 1556 2727 ------ 7303

2062** 1711 1384 1378 1556 2791 ------ 7530

2064** 1711 1384 1378 1556 2829 ------ 7756

2070** 1969 1753 1448 1556 2981 ------ 9582

2072** 1969 1753 1448 1556 3032 ------ 9696

2080** 1969 1753 1448 1556 3235 ------ 10603

All dimensions in mm.

** For 40 PSL rating

Horizontal Flow Vertical Flow Both

OPOPCC

Pressure Lubrication

1

Weight (Kg)

7

Dimensions

Horizontal Flow Vertical Flow Both Weight (kg) Inlet Diameter Discharge Diameter

OPOPCC

883 724 730 781 775 1000 880 150 150

883 724 730 781 851 1076 930 250 200

883 724 730 781 927 1153 998 250 200

886 724 730 781 1041 1267 1089 300 250

886 724 730 781 1099 1324 1111 300 250

886 724 730 781 1156 1381 1157 350 300

886 724 730 781 1232 1457 1361 350 300

886 724 730 781 1384 1610 1588 400 350

1029 838 842 933 1018 1127 1406 300 250

1029 838 842 933 1120 1229 1542 350 300

1029 838 842 933 1221 1330 1656 400 350

1029 838 842 933 1284 1394 1724 400 350

1029 838 842 933 1348 1457 1814 400 350

1029 838 842 933 1437 1546 1882 450 400

1029 838 842 933 1627 1737 2109 500 450

1200 978 965 1092 1086 1234 1951 300 250

1200 978 965 1092 1146 1294 2087 350 300

1200 978 965 1092 1248 1395 2223 350 300

1200 978 965 1092 1350 1497 2359 400 350

1200 978 965 1092 1413 1561 2404 450 400

1200 978 965 1092 1489 1637 2563 450 400

1200 978 965 1092 1578 1726 2676 450 400

1200 978 965 1092 1667 1815 2812 500 450

1200 978 965 1092 1845 1992 3062 600 500

1365 1130 1099 1257 1227 ------ 2586 350 300

1365 1130 1099 1257 1329 ------ 2722 400 350

1365 1130 1099 1257 1456 ------ 2858 500 450

1365 1130 1099 1257 1506 ------ 2994 500 450

1365 1130 1099 1257 1583 ------ 3107 500 450

1365 1130 1099 1257 1659 ------ 3289 600 500

1365 1130 1099 1257 1735 ------ 3414 600 500

1365 1130 1099 1257 1811 ------ 3651 600 500

1365 1130 1099 1257 1913 ------ 3629 750 600

1365 1130 1099 1257 2040 ------ 3720 750 600

1505 1257 1219 1372 1456 ------ 3538 450 400

1505 1257 1219 1372 1532 ------ 3674 500 400

1505 1257 1219 1372 1608 ------ 3810 500 400

1505 1257 1219 1372 1684 ------ 4014 600 500

1505 1257 1219 1372 1773 ------ 4219 600 500

1505 1257 1219 1372 1887 ------ 4355 600 500

1505 1257 1219 1372 1964 ------ 4423 750 600

1505 1257 1219 1372 2065 ------ 4581 750 600

1505 1257 1219 1372 2167 ------ 4717 750 650

1505 1257 1219 1372 2294 ------ 4831 750 650

1680 1384 1340 1556 1557 ------ 4445 500 400

1680 1384 1340 1556 1659 ------ 4649 500 450

1680 1384 1340 1556 1748 ------ 4865 600 500

1680 1384 1340 1556 1832 ------ 5080 600 500

1680 1384 1340 1556 1934 ------ 5353 750 600

1680 1384 1340 1556 1997 ------ 5647 750 600

1680 1384 1340 1556 2099 ------ 5942 750 600

1680 1384 1340 1556 2175 ------ 6101 750 600

1680 1384 1340 1556 2251 ------ 6260 750 650

1680 1384 1340 1556 2378 ------ 6487 900 750

1680 1384 1340 1556 2429 ------ 6569 900 750

1680 1384 1340 1556 2505 ------ 6691 900 750

1680 1384 1340 1556 2556 ------ 6772 900 750

1680 1384 1340 1556 2607 ------ 6854 900 750

1711 1384 1378 1556 1775 ------ 4825 500 400

1711 1384 1378 1556 1877 ------ 5029 500 450

1711 1384 1378 1556 1965 ------ 5245 600 500

1711 1384 1378 1556 2054 ------ 5460 600 500

1711 1384 1378 1556 2156 ------ 5733 750 600

1711 1384 1378 1556 2219 ------ 6027 750 600

1711 1384 1378 1556 2321 ------ 6322 750 600

1711 1384 1378 1556 2397 ------ 6722 750 600

1711 1384 1378 1556 2473 ------ 6804 750 650

1711 1384 1378 1556 2600 ------ 6940 900 750

1711 1384 1378 1556 2651 ------ 7008 900 750

1711 1384 1378 1556 2727 ------ 7144 900 750

1711 1384 1378 1556 2791 ------ 7371 900 750

1711 1384 1378 1556 2829 ------ 7598 900 750

1969 1753 1448 1556 2981 ------ 9412 1050 1050

1969 1753 1448 1556 3032 ------ 9525 1050 1050

1969 1753 1448 1556 3235 ------ 10433 1050 1050

All dimensions in mm.

Splash Lubrication

1

DN DN

8

RAS-J Air WHISPAIR Blower RGS-J Gas WHISPAIR Blower

RAS-J Horizontal Flow

See Note 1 regarding

Drive Shaft location

Disch. Disch.

Inlet

RGS-J Horizontal Flow

See Note 1 regarding

Drive Shaft location

O O

Coupling Drive Coupling Drive

C C

V-belt Drive V-belt Drive

1

C

P P

1

C

RAS-J Vertical Flow RGS-J Vertical Flow

See Note 1 regarding

Drive Shaft location

Disch.

See Note 1 regarding

Drive Shaft location

Disch.

O O

C C

1

C

Coupling Drive Coupling Drive

V-belt Drive V-belt Drive

P P

Inlet

1

C

Inlet

Note 1: Standard drive shaft location is dependent upon frame size:

10xx through 14xx frame sizes - drive shaft is located on the opposite gear end of the machine and is shown in heavy type.

16xx through 20xx frame size - drive shaft is located on the gear end of the machine as shown by dotted lines.

For all direct drive applications torsional analysis of the whole drive train is required and in the case of drivers other than electric motors, gear end drive must be specifi ed.

Frame sizes 10xx through 14xx can be belt driven with the addition of an optional extra bearing and selection of correct pulley combination.

Inlet

9

Each unit tested and certifi ed

Global presence

Each RAS-J blower and RGS-J gas blower is

mechanically tested to ensure that the unit meets

performance specifi cations. Our units are tested

to design extremes of speed, pressure and

temperature. We validate fl ow capacity oil

circulation, operating clearances and vibration

at these critical performance levels. We also offer

testing that meets your special process

requirements and qualifi cations.

Our sales professionals are available around the

globe and we offer blower service and repair

from facilities in Connersville, Indiana, Houston,

Texas, Skelmersdale, United Kingdom, Mexico City,

Mexico, Dubai, UAE, and Shanghai, China.

A network of authorized Roots blowers &

compressors distributors is available around the

globe to support your blower requirements. Each

distributor facility is equipped and staffed with

factory trained service personnel to meet your

unique needs. These facilities regularly service

unit from many OEMs and keep parts on hand for

quick turn-around.

10

GE Energy

Houston, Texas | U.S. Toll Free Phone: 1 877-363-ROOT(S) (7668) | Direct Phone: +1 832-590-2600

Connersville, Indiana Operations

Waukesha, Wisconsin Operations

European Operations

USA/Canada Sales

| Phone: +44 (0) 1695 52600 | Email: roots.europe@ge.com

| Phone: +1 773-444-3360

Houston, Texas Factory Service

Mexico City Sales and Factory Service

Dubai Sales and Factory Service

Malaysia Sales

China Sales

| Phone: +60 3 2267 2600

| Phone: +86 10 8486 2440

Shanghai Factory Service

Visit us online at: www.ge.com/energy

2012 General Electric Company

All Rights Reserved

*Denotes trademark of General Electric Company

| Direct Phone: +1 765-827-9200

| Direct Phone: +1 262-650-5965

| Phone: +1 713-896-4810

| Phone: +52 55 5889 5811

| Phone: +971 4-8855481

| Phone: +86 21 5858 7638

RAS-J Air & RGS-J Gas Blowers_metric

GEA19152M B-5219

5.12

Loading...

Loading...