Page 1

SPECIFICATIONS

ROOTS™RAM™-VJ WHISPAIR

™

Water-Sealed Vacuum Exhausters

Frames 406J thru 624J

TM

stands for Reliability, Availability and

RAM

Maintainability. Today, more than ever, ROOTS is

committed to supplying our customers with reliable

products manufactured with state-of-the-art CNC

machine tools. Production and inventory are being

scheduled and controlled to ensure these units will be

available when you need them. Design improvements

such as repositionable rugged steel mounting feet and

die-cast aluminum drive end covers and gear covers

help to reduce installation costs and make normal

maintenance easier.

BASIC BLOWER DESCRIPTION

ROOTS™ RAM™ WHISPAIR™ water-sealed vacuum

exhausters are heavy-duty units designed with

integral-shaft ductile iron impellers. Whispair vacuum

exhausters reduce noise and power loss by utilizing

an exclusive wrap-around plenum and proprietary

WHISPAIR™ jet to control pressure equalization –

feeding backflow in the direction of impeller movement,

thereby aiding rotation.

The headplates and rigid, one-piece casing are grey

iron, while the drive end cover and gear cover are

aluminum. Carburized and ground alloy steel spur

timing gears are taper mounted on the shafts, secured

with a locknut. Cylindrical roller bearings are used.

Piston rings reduce air leakage through the shaft

openings in the headplates, and lip-type oil seals

prevent lubricant from entering the air chamber.

RAM™ WHISPAIR™ vacuum exhausters incorporate

splash oil lubrication at both ends of the units. A lip

seal on the drive shaft prevents shaft seal oil leaks.

All frame sizes are designed with detachable rugged

steel mounting feet which permit in-field adaptability

to either vertical or horizontal installation requirements.

The top shaft is extended for drive on side outlet

vacuum exhausters, and the left or right shaft can be

extended for drive on bottom outlet vacuum pumps.

An inlet spray nozzle and seal water flow meter are

supplied for water injection.

DESIGN AND CONSTRUCTION FEATURES

1. Low noise level, less operating power required

2. Improved volumetric efficiency & reduced

operating temperatures

3. Alloy steel timing gears

4. Cylindrical roller bearings

5. Piston ring air seals

6. Lip-type oil and shaft seals

7. Splash oil lubrication

8. Horizontal and vertical configurations available

OPERATING PRINCIPLE

Incoming air is trapped by the impellers. Simultaneously, pressurized air

(right) is being discharged. As the lower impeller passes wrap-around flange,

Whispair jet equalizes pressure between trapped air and discharge area,

aiding impeller movement and reducing power. Impellers move air into the

discharge area (right). Backflow is controlled, resulting in reduction of noise

relative to conventional blowers.

S-59F97 rev.0608

Page 2

PERFORMANCE TABLE

O

R

C

B

U

D

DISCH.

P

P '

AA

AA

INLET

INLET

DISCH.

A

A'

D1

AX AX

O'

+.000

-.001

AF - INLET

AF' - DISCHARGE

FRAME SPEED 16” Hg VAC 20” Hg VAC 22” Hg VAC 24” Hg VAC

SIZE RPM CFM BHP CFM BHP CFM BHP CFM BHP

1530 154 9.3 118 11.4 86 12.5 31 13.6

406J 2325 269 15.0 227 18.2 190 19.8 126 21.4

3200 400 22.4 352 26.7 310 28.8 238 30.9

1530 248 13.6 201 16.8 159 18.4 87 20.0

409J 2325 412 21.6 353 26.4 300 28.8 209 31.2

3200 600 31.4 528 37.8 465 46.0 356 44.3

1530 331 17.9 268 22.2 212 24.4 115 26.5

412J 2325 549 28.1 470 34.6 400 37.8 278 41.0

3200 797 40.4 703 49.0 619 53.3 474 57.6

1530 497 26.6

418J 2325 825 41.4

3200 1197 58.5

1160 695 32.2 614 39.8 538 43.6 420 47.5

616J 1750 1105 49.9 1003 61.2 908 66.9 760 72.6

1160 1566 70.9 1445 85.9 1332 93.4 1156 101.0

2400 1044 47.8

624J 1750 1658 73.8

2400 2350 104.2

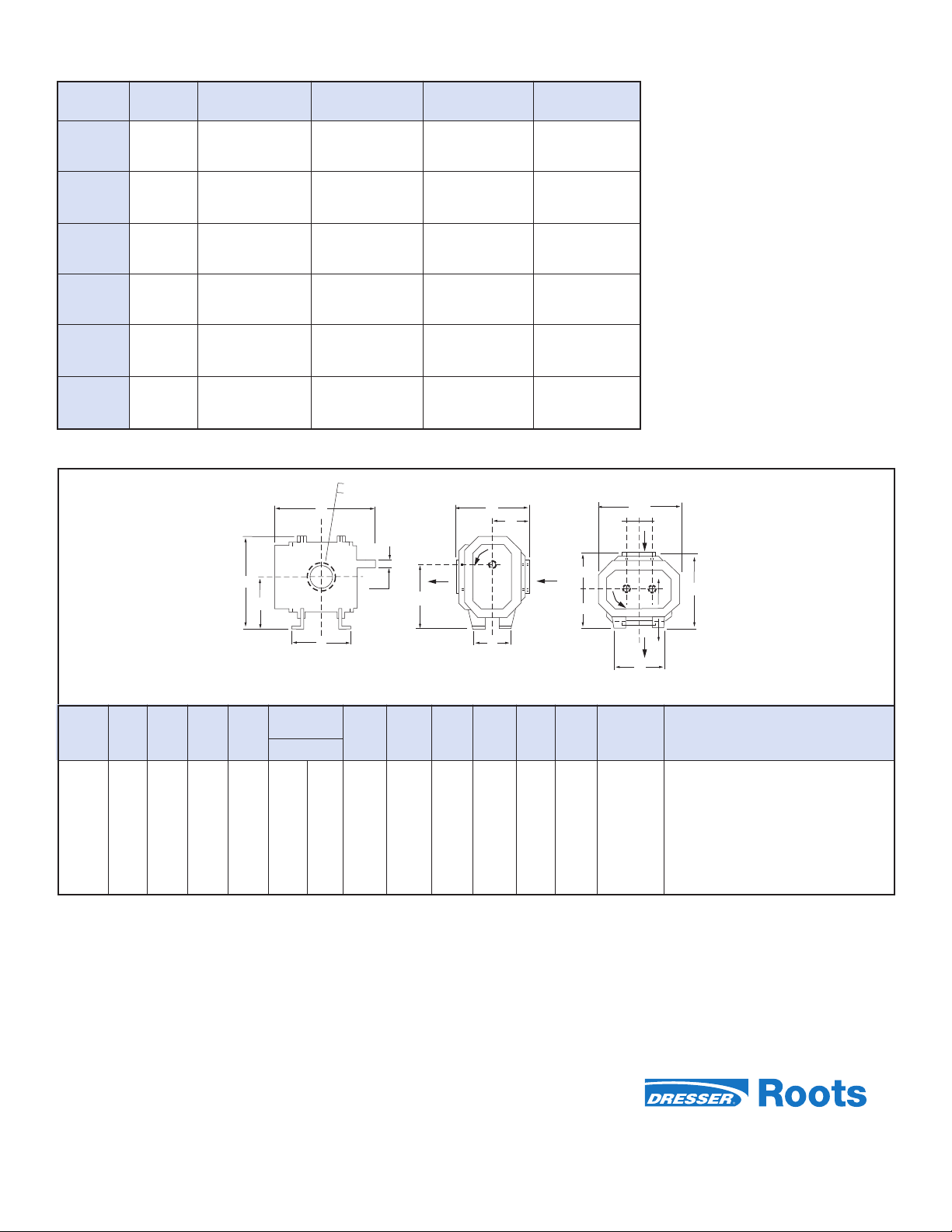

OUTLINE DRAWING & DIMENSIONAL TABLE

NOTES:

1. All dimensions are in inches.

2. Do not use for construction.

Drive Shaft

FRAME A A’ BC O O’ P P’ RU Keyway Inlet Discharge AA AX Net Wt

Location

VERTICAL CONFIGURATION

(Horizontal Air Flow)

HORIZONTAL CONFIGURATION

(Vertical Air Flow)

AF AF’ Approx.

SIZE D D1 Diameter Diameter (lbs)

406J 8.00 11.00 10.75 20.50 11.25 7.50 16.63 14.75 14.50 15.25 9.00 1.500 .375 x.188 4.0 NPT 4.0 NPT 7.25 2.25 300

409J 8.00 11.00 13.75 23.50 11.25 7.50 16.63 14.75 14.50 15.25 9.00 1.500 .375 x.188 5.0 NPT 5.0 NPT 7.25 2.25 350

412J 8.00 11.00 16.75 26.50 11.25 7.50 16.63 13.50 13.00 15.25 9.00 1.500 .375 x.188 6.0 FLG 5.0 FLG 6.00 2.25 400

418J 8.00 11.00 22.75 32.50 11.25 7.50 16.63 14.50 14.00 15.25 9.00 1.500 .375 x.188 8.0 FLG 6.0 FLG 7.00 2.25 500

616J 10.00 16.00 21.44 32.44 15.00 9.00 22.00 16.50 16.25 20.00 12.00 2.000 .500 x .250 8.0 FLG 6.0 FLG 7.50 3.00 800

624J 10.00 16.00 29.44 40.44 15.00 9.00 22.00 17.75 17.50 20.00 12.00 2.000 .500 x.250 10.0 FLG 8.0 FLG 8.75 3.00 1000

WARRANTY PERIOD

Twelve (12) months from date of original unit start-up or 18 months from date of original shipment, whichever occurs first.

Dresser Roots

Houston, Texas Headquarters • U.S. Toll Free Phone: 1-877-363-ROOT(S) (7668) • Direct Phone: +1 832-590-2600

Connersville, Indiana Operations • U.S. Toll Free Phone: 1-877-442-7910 • Direct Phone: +1 765-827-9285

United Kingdom Operations • Phone: +44 (0) 1695 52600

USA/Canada Sales • Phone: +1 773-444-3360

Houston, Texas Factory Service • Phone: +1 713-896-4810

Mexico City Sales and Factory Service • Phone: +52 55 5889 5811

Dubai Sales and Factory Service • Phone: +971 4-8830831

Malaysia Sales • Phone: +60 3 2163 0480

China Sales • Phone: +86 10 8486 2440

Shanghai Factory Service • Phone: +86 21 5858 7638

©2007 Dresser, Inc. all rights reserved. • Printed in the U.S.A. • All information subject to change

without notice. • Universal RAI and EasyAir are registered trademarks of Dresser, Inc. • ROOTS,

RAM X, and WHISPAIR, are trademarks of Dresser, Inc.

S-59F97 rev.0608

www.dresser.com/rootsblowers

Loading...

Loading...