GE Roots Centrifugal Compressors Brochure

GE Energy

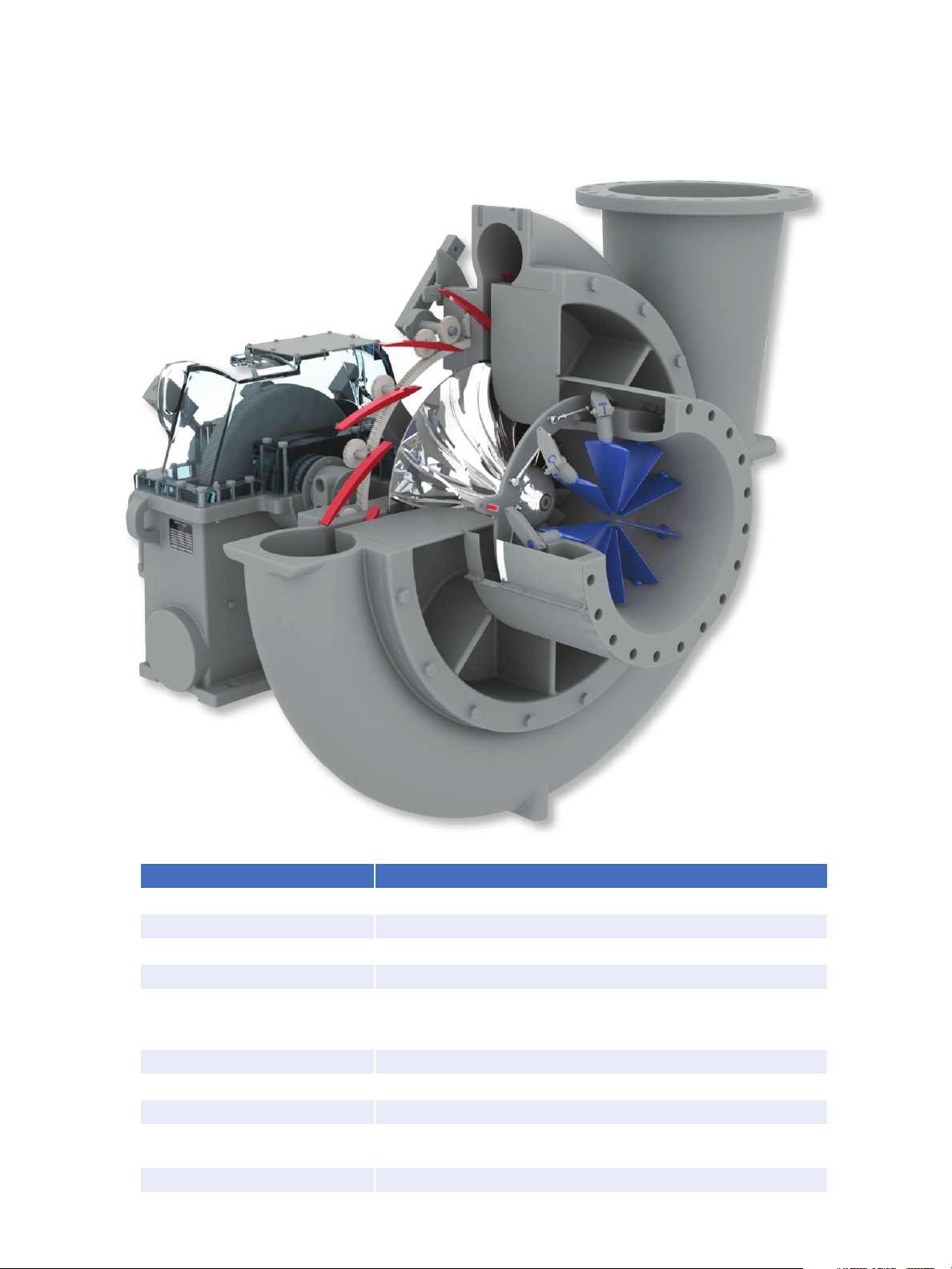

Roots* Centrifugal Compressors

GE continues a history of innovation

and technical leadership

2

GE Energy is a global leader in the design and

manufacture of air and gas handling solutions.

GE leverages its history of technical innovation to

address key environmental issues and to provide

current best practices in manufacturing to delivery

of its products to customers around the globe.

Here you will fi nd an overview of the engineering

quality and manufacturing expertise that comprises

Roots centrifugal compressors. This is followed by

a look at the three primary compressor models

we produce along with some characteristic

performance data and dimension information.

Then we close with a few words about control

systems, testing, repair services and global

aftermarket coverage.

Reliability

Finite Element Analysis

(FEA) and an extensive

history in compressor

design will help ensure

that we provide our

customers with a reliable

solution that will last well

into the future.

Performance

Computational Fluid

Dynamics (CFD) helps

ensure each compressor

is optimized for performance and effi ciency,

helping to reduce your

power requirements and

the cost over the operating

life of the compressor.

Function

Working hand-in-hand

with your engineers, we

can establish a design that

can be adopted into your

process. Solid (3D)

Modeling aids in visualizing

the compressor’s layout

and optimizing the

footprint while proving

fi t and function.

You

Our Design and

Application Engineers

will evaluate your

given conditions and

specifi cations to

determine a solution

that will perform and

comply to your specifi c

needs.

3

Roots centrifugal compressors deliver high

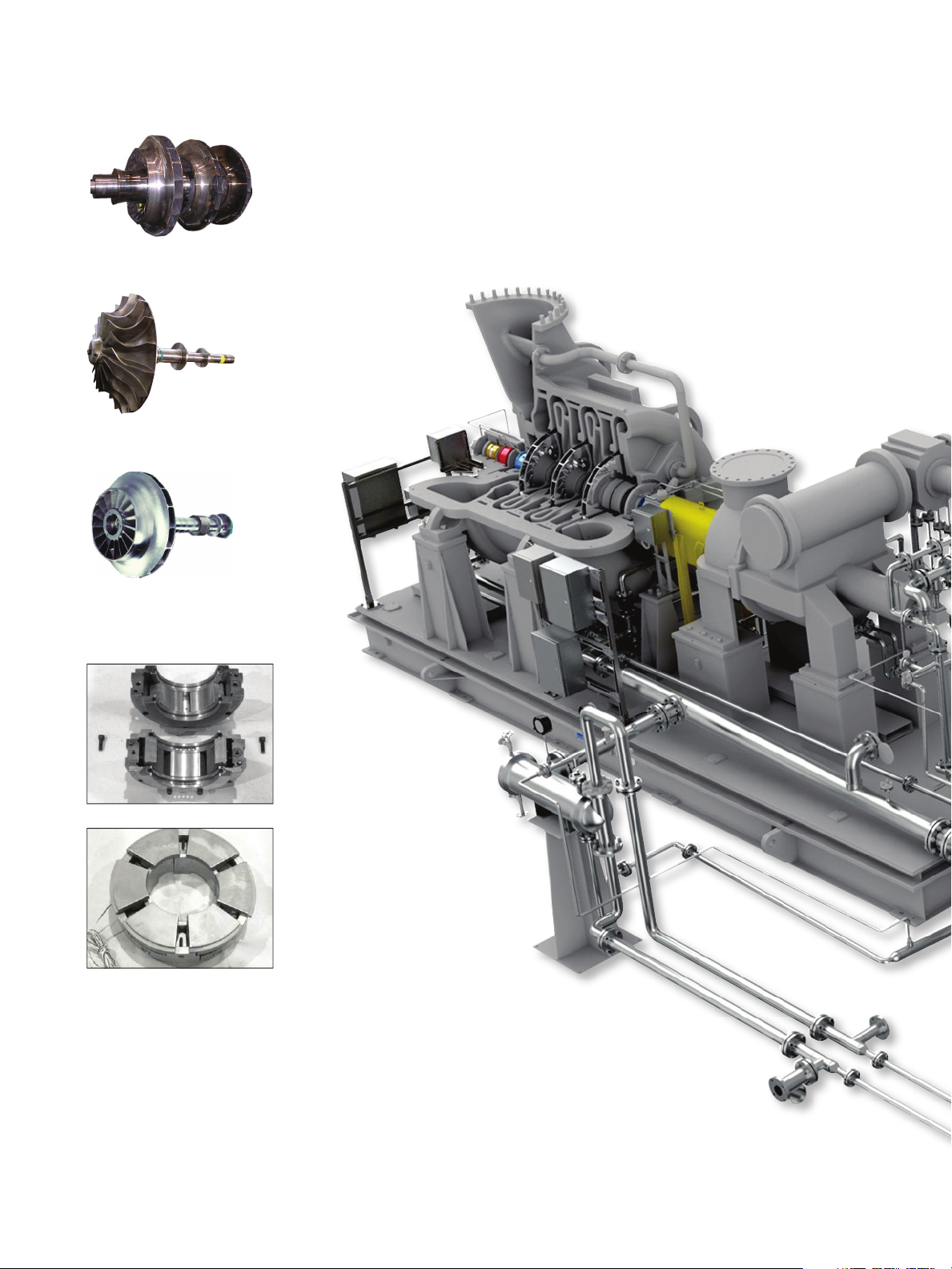

IMPELLERS: Offered in many different designs and

constructions of several different materials, depending upon

the operating conditions and gas being handled. The impeller

is statically and dynamically balanced and then oversped to

15% above maximum operating speed. The impeller is then

Multi-Stage Rotor Assembly

Open Wheeled Rotor Assembly

mounted on the shaft with a suitable locking device and the

rotor assembly is dynamically balanced.

Closed Wheeled Rotor Assembly

Radial - Tilt Pad Bearing

Axial - Multi-Shoe Equalizing

Bearing

BEARINGS: Tilt Pad, Sleeve and Integral Squeeze Film Damper (ISFD)

type bearings are used in the radial (journal) orientation, while

Tapered Land and Multi-Shoe Equalizing are used in the axial

thrust) orientation. Bearing type is selected dependent upon

the compressor type.

4

performance and low maintenance.

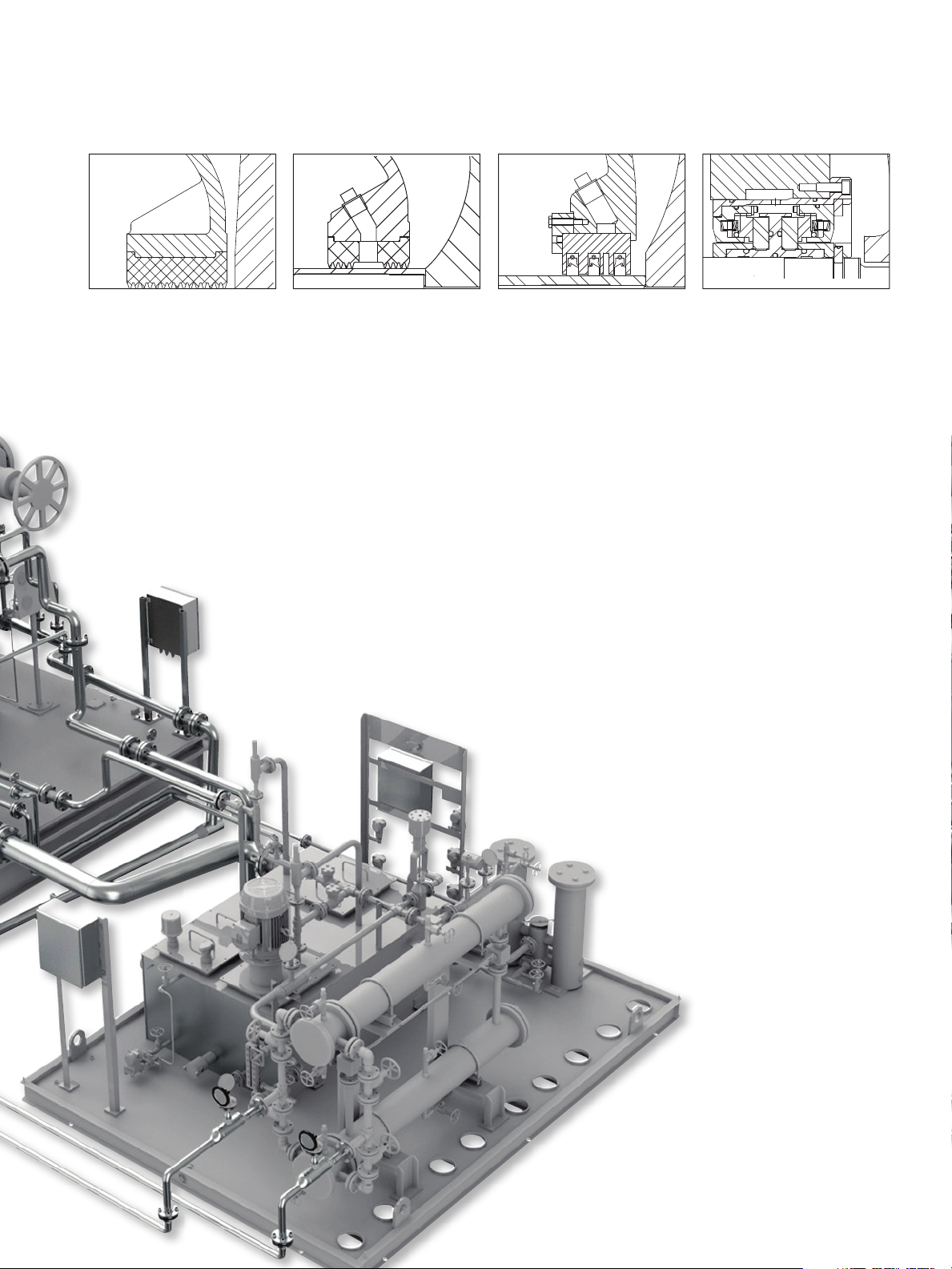

Standard Labyrinth

SEALS: Air applications use the Standard Labyrinth Seal, while Double

Labyrinth, Carbon Ring and Dry Mechanical Seals are used for gas

applications. Buffer and suction ports can be provided for additional

retention of the process gas. Gas-tight shutoff sealing is also available

to ensure gas retention when the compressor is not operating.

Buffered Labyrinth

LUBE OIL SYSTEM: Lube system can be provided in three different

confi gurations: integral, console mounted to the baseplate, and

console mounted off the baseplate. Each system will consist of a

main and auxiliary oil pump, oil cooler, oil fi lter, bypass valve for

temperature control, oil reservoir (minimum 3 minute retention),

and necessary safety switches and gauges.

Buffered Carbon Ring

Double Opposed Dry Gas

Seal w/ Buffer

5

Roots IGCH Compressor

Integrally Geared Dual Vane

Characteristic Value

Flow, SCFM (Nm3/hr)

Polytrophic Head, ft*lbf/lbm (kJ/kg)

Casing Materials

Impeller Materials

Impeller Construction

Discharge Position

Spec. Compliance

Seal Arrangement

Vanes

Bearing Type

6

4,000 to 42,000 (6,280 to 65,980)

10,000 to 40,000 (29.9 to 119.5)

Cast iron, ductile iron (special materials available upon request)

Carbon steel, stainless steel, titanium

Radial, semi-backward leaning and backward leaning blades

(open or closed);

Cast, welded, milled

45° increments, starting at 0° (UP) position

API 617, API 672

Labyrinth, carbon ring, mechanical

Variable or fi xed diffusers with variable axial inlet guide or variable

peripheral inlet guide

Journals: tilt pad & sleeve; thrust: tapered land

Loading...

Loading...