GE PXRQ15F00, PNRQ20FCC00, PNRQ20FBL00, PNRQ20FBB00, PNRQ20FWW00 Owner’s Manual

www.GEAppliances.com

Safety Instructions

Safi:ty Instructions .............. 2

Specification Guidelines ......... g

Operating Instructions

About the RO System ......... 4, 5

Installation Instructions

Tools and Materials Required ..... 6

Before Beginning Installation . . .6, 7

Mounting System Installation ..... 8

Feed Water Supply ........... 9-12

Faucet Assembly ............ 13, 14

Battery Installation ............ 14

Filtration Drain Connection . .15, 16

Storage Tank and Startup ....... 17

Care and Cleaning

Prefitte_; Postfiher and

RO Camidge Replacement ...... 18

Sanitization .................. 19

Water Test Kit ................ 20

PXROJ5F

PNRQ15FBL

PNRQ2OFBL

PNRQ2ObWW

PNRQ2OFBB

PNRQ2OFCC

Osmose Inversde

Syst(me de Filtration

La section fran_aise commence a la page 27

¢)

>

Troubleshooting Tips ....... 21-23

Consumer Support

Consumer Support ..... Back Cover

Parts List/Catalog .......... 24, 25

Warranty .................... 26

Tested and Certified byNSF International to

NSF/ANSI Standard 5& See Performance Data

Sheet for the reduction of the claims specified

on the Performance Data Sheet.

Essay_et certifi_ par NSF International

conform_ment aux normes58 NSF/ANSI.

Consuttez ta feuille de donn_es de rendement

pour la r_duction des caract_ristiques indiqu_es

sur la feuille de donn_es de rendement,

Probado y certificado pot NSF International por

cumplir con el est_ndar 58. Vet la hoja de datos

de desempefio para Ia reducci6n de reclamos

especificados en la hoja de datos de desempefio,

Write the model and serial

numbers here:

Osmosis Inversa

Sistema de Filtraci6n

La secci6n en espafiol empieza en la pkgina 55

Model #

Serial #

You can find _eIn oil the bracket.

101019-A

215Cl174P001 49-50130 10-04JR

IMPORTANT SAFETYINFORMAtiON.

READALLINSTRUCtiONS BEFOREUSING.

A WARNING! ro e damagoor ersonalinju

For your safe_ the information in this manual must be followed to minimize the risk of

SAFETYPRECAUTIONS

• Check wifll your state and local public works

deparunent for phnnbing and _nilation codes.

You must follow these guidelines as you install fl:e

Reverse Osmosis system. Usinga qualified installer

is recommended.

• Ifhouse water pres_sure is over the maximum

(1_'0 poumts per s(p_re inch), install a pressure

reducing valve in dm water supply line to the

Reverse Osmosis system.

• Be sure tile water supply confi,)rms with Ihe

Specification Guidelines.ff the water supply conditions

are unk!lowIl, conlact your muIlicipal *_,ater comKomy

or your local bealtb department ff)r a list of

coI _laminaI_tS in your area and a list of lalx)ratories

certified by your slate to analyze drinking waten

WARNING'.Before ruing dm Reverse Osmosis

system fbr the first time, ttle system must be

purged. The Reverse Osmosis cartridge contains

a fbod grade preservative lhat tmtst be purged

from the system. The preservative will give product

water an unpleasant taste and eden

it

WARNING'.DO nol use wilh water that is

Inicrobiologically un,_fe or of unknown quali/y

without adequate disinfection txefbre or after tile

system. SDtems certified fi)r cyst reduction may

be used on disinfected water dial may contain

fiherable cysts.

"I]tis systeln has been tested ffw the trealment of

water conraiuing pentavalent aeueIfiC (alto talowI:

a-s_;(V), _s(+5) or arsenate) al concentrations

of 0.050 mg/L or less. This sysmm re&rues

peIWavalent arm:tic, but ::lay :lot remove olher

forms of arseIfiC. This system is to be/tsed on waler

supplies containing a detectable free dflorine

residual or on water supplies that have been

demonslrated to contain only pentavalent arseIfiC.

Treatment wilh chloramine (combined chlorine)

is not suttl('ient to ensure complete COIlversion of

trivalent _IfiC to penlavaleI:t arseIfiC. Please see

the _IfiC Facls section of the Perfbrmance Data

Sheet fbr filrther infi)rmafion.

This Rever_ OsInosis system contains a replaceable

treaunent Inembrane ca_ridge critical far effective

re&mtlon of'Ibtal Dissolved Solids. The water

should be tested pefiocrmally to verify lhal Ille syslem

is perfbmfing mtist_tofily.

PROPERINSTALLATIONAND MAINTENANCE

This Reverse Osmosis system must be properly instated and located in accordance with the

Installation Instructions before ff is used.

• Install or store wbere it will not be exposed to

tempeImures below fi'eezing or exposed to may lype

of wealher. Water freezing in Ihe system will

damage it. Do not attempt to treat water over 100°E

• Do :lot install on ItOTWA_R. The temperature

of the water supply to tile Reverse Osmosis sys/elgt

UlUSt be between tile uliIliinuin of 40°F aim the Reverse Oslnosis systeIll m:d file refrigerator.

Illaximum of I(X)°E See tile Specification Guidelines. A WARNING:Dkscard all/lIl/a_d paris mM lxtckaging

• Extended non-use ofthe Reverse Osmosis system. Iliatel*ialafter ills_tllatioI L Sluall par_s remaining after

If tile sDtem has not been used fbr one week or

more, open tile RO water taaucet aald allow llle

syslem to drain. (_lose tile RO wamr faucet aud

allow llle s_lem to regenerate the water supply.

• RecomIneuded installation is under the sink`

However, Ihe unit can be installed in a remote

location, up to 20 feet away fi_omtile sink`

• However, adcFHionalmaterials will be required,

including additional robing aim extension phoIm

cable fi_r PNRQ20 models. This extension phone

cable must be 6 conducR)r wire alld conlleCtors;

typical 4 con&rotor wire will not work. See parts

listto obtain additional materials from GE.

• Locating the rank on a i_asement floor, with the

faucet al a first floor sink may result in sxmm loss

of flow ram aald capacity (appro:dmalely 20%).

h:slalfing a second tank will improve tiffs

performance. _M: RVK1T can be used.

• ff Reverm Oslnosis system is connected to a

refrigerator icemaker, a special icemaker

COlmeefion kit is required (RVKIT). Do not use

copper robing for tile colmecfion between the

tile imtallallon couM be a choke haTard.

• Sanitize upon installation of file Reverse Osmosis

system and after servicing inner parts, inchlding

replacement of prefiher, postfilter and Reverse

Osmosis carlridge. It is important to have clean

bands while haI_dling iImer parts of tile system.

See dm SanitizingtheReverseOsmosis&stemsection.

• This Reverse Osmosis system contains a replaceable

treatment component critical ]7_r e]7_:ccglve

reduction of total dis_solved solids. This product

water shall be tested periodically to verify that the

system is performing satisfactorily. See the About

the Water Test Kitsection.

BESURE TOFOLLOWALLAPPLICABLESTATE

AND LOCALCODES.

READAND FOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCtiONS

2

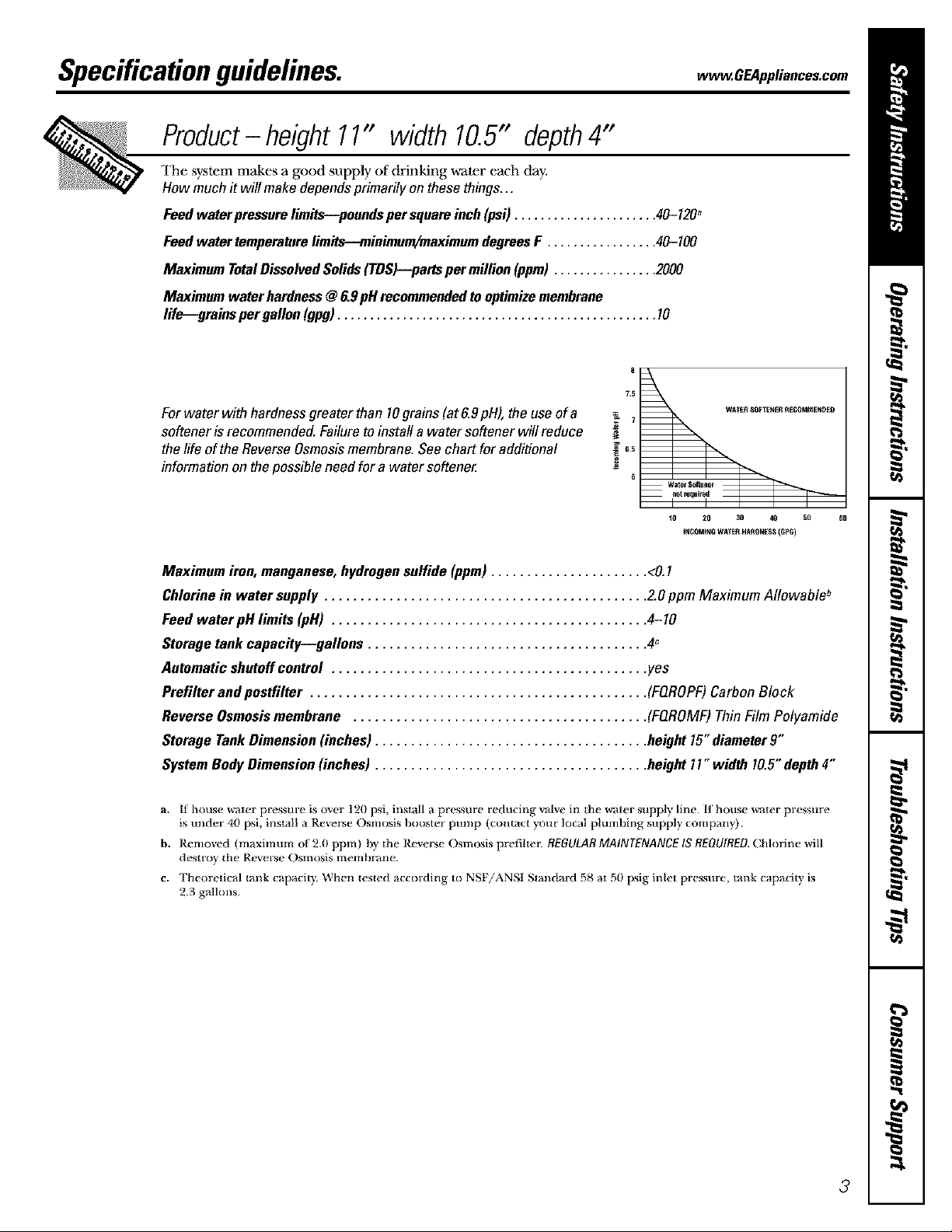

Specificationguidelines. .GE4ppliancns.oom

Product-height11" width10.5" depth4"

Ttle system Illakes a good supply of drinking waler each d_y.

How much itwill make depends primarily on these things...

Feed water pressure limilsipounds per square inch (psi) ...................... 40-120,

Feed water temperature limitsiminimum/maximum degrees F ................. 40-100

Maximum TotalDissolved Solids (TDS)ipatts per million (ppm) ................ 2000

Maximum water hardness @ 6.9 pH recommended to optimize membrane

lifelgrains per gallon (gpg) ................................................. 10

8

7.5

ForwatorwithhardnossgreaterthanlOgrains(at6.gpH),theuseofa _ 7

softener is recommended. Failure to install a water softener will reduce

the life of the Reverse Osmosis membrane. See chart for additional _ __

information on the possible need for a water softene_

6

,Wnot{er_eqS°u_r

10 20 30 48 50 8[_

#l_OM#lt_ WATER _I_DN_SS (t_p_)

'f_ _3_ENE}{ _E_MNEN#EO

Maximum iron, manganese, hydrogen sulfide (ppm) ...................... <6.1

Chlorine in water supply ............................................. ZO ppm Maximum Agowab/e b

Feed water pH limits (pH) ............................................ 4-10

Storage tank capacity--gallons ....................................... 4_

Automatic shutoff control ............................................ yes

Prefilter and pnsffilter ............................................... (FQROPF)Carbon Block

Reverse Osmosis membrane ......................................... (FQROMF) Thin Film Po/yamide

Storage Tank Dimension (inches) ...................................... height 15"diameter 9"

System Body Dimension (inches) ...................................... height 11" width 10.5" depth 4"

a. If house water pressure is over ] 20 psi, install a pressure reducing _-alve in the water supply line. ]i house _-ater pressure

is under 40 psi, install a Reverse Osmosis booster pump (contact your local plumbing supply company).

b. Removed (maximum ot 2.0 ppm)by the Reverse Osmosis prefilter. REGULAR MAINTENANCE IS REQUIRED.Chlorine will

destroy the Reverse Osiylosis iIlelllbr3lle.

c. Theoretical tmtk capacity. When tested according to NSF/ANSI Standard 58 at 50 psig inlet pressure, tank capacity is

2.3 gMlons.

3

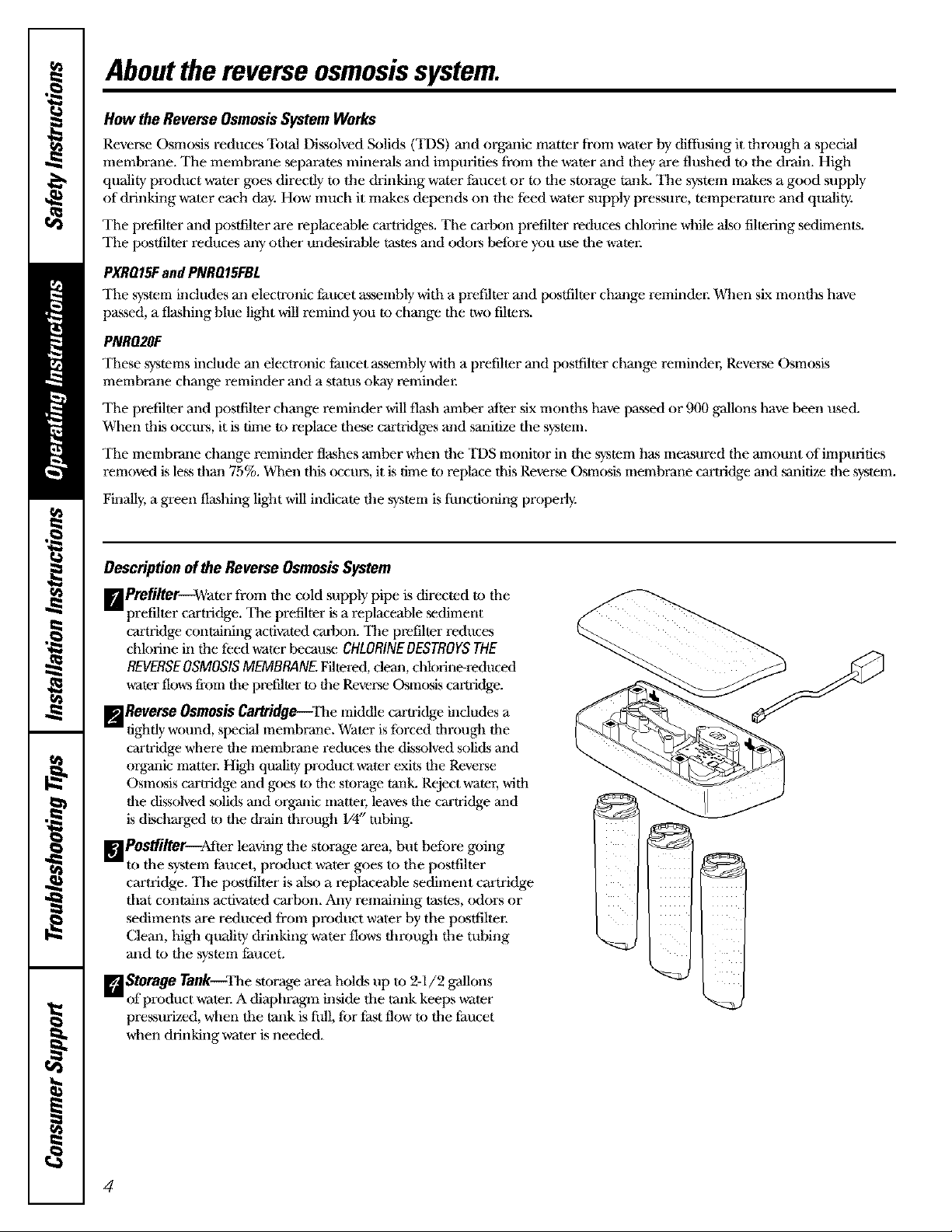

Aboutthe reverseosmosissystem.

How theReverse OsmosisSystem Works

Reverse Osmosis reduces Tolal Dissolved Solids (TDS) and organic matter from waler by diffilsing it through a special

inembrane. Tile meinbrane separates nfinerals and impurities froin tile x_rater and dmy are flushed to tile drain. High

quality product water goes direcdy to dm drinking water fbucet or to 1he storage tank. The system ulakes a good supply

of drinking water each day. How lnuch it maJxes depends on the feed water supply pressure, temperature and quality.

The prefilter and postfiher are replaceable cartridges. The carbon prefiher reduces chlorine while also filtering sediments.

The posltilter reduces any other undesirable tastes and odors before you use the x_-aten

PXRQ15FandPNRQ15FBL

The system includes an eleclronic f_mcet a._sembly *dth a prefiher and posltilter change reminder. When six tllOIlths have

pa._sed,a flashing blue light *rill remind you to change the twofilters.

PNRQ20F

These systems include an electronic fimcet assembly wifla a prefilter aim posltilmr change reminder, Reverse Osmosis

membI_ane change reminder and a status okay reminder.

The prefilmr and posltilter change reminder will flash amber after six months have passed or 900 gallons have been ttsed.

When this occurs, it is time to replace these cartridges and sanitize the system.

The membrane change reminder flashes amber when the TDS moIfitor in the system has measured the amount ofimpm-ifies

removed is le_sthaaa 75%. W]mn this occurs, it is time m replace Ibis Reverse (_mosLs membrane cartridge mad_niti/v the system.

Finally, a green flashiI_glight will indicate the system is fimctioning properly.

Description ofthe Reverse OsmosisSystem

_Prefilter--Water from the cold supply pipe is directed m the

prefiher cartridge. The prefilter is a replaceable rudiment

cartridge containing activated cartxm. The prefiher re(hlces

chk)rine in the riced water because CHLORINEDESTROYSTHE

REVERSE OSMOSIS MEMBRANE Filtered, clema, chlorine-re&iced

,_vtter flo*_ from lhe prefilter to dm Reverse. (_mosis cartridge.

_Reverse OsmosisCartridge--The middle cartridge includes a

tightly wound, special membrane. Water is fbrced through tile

cartridge where the membrane reduces the dissolved solids and

org_aaficmatron High quality product water exits lhe Re_/erse

Osmosis caru'idge and goes Iv)the storage tank. Reject water, with

tim dissolved _)lids and organic malter, leaves the cartridge and

is discharged m the drain throu[01 1/4" tubing.

_]Postfilter--After leaving tile storage area, but before going

to the system tZaucel, product waler goes Io lhe postfilter

carlridge. The postfiher is also a replaceable sediment cartridge

that conlains activated carbon. Any remaining tastes, odors or

sedilnenls are reduced from product waler by the postfiher.

Clean, high quality drinking water flows through the robing

and to lhe systeul faucet.

L_Storage Tank--The storage area holds up to 2-1/2 gallons

of product waler. A diaphragm inside lhe lank keeps water

pressurized, when Ihe lank is dill, for fkst flow to the faucet

when drinking water is needed.

4

www.GEAppliances.com

_tCheck Valvo---The check valve prevents a backward flow of product water from tile storage rank. A backward flow could

cause tile Reverse Osmosis membI_ane I_ nlplure.

_Automatic ShutoffAssembly--Tocoilserve water, tile drinking *_ater system ha.s aI1 autoi_mtic shutofE When the smr'age tank

has filled to capacity and the drinking water t:aucet ksclosed, pressure closes the shutofE Water flow to the Reverse Osmosis

housing ksshut off until drinking x_ater is used again, and pressure drops in the Reverse Osmosis system.

_FIow ContrOl--The flow control regulates the flow of water through the Reverse (Nmosis cartridge at the required rate to

produce high quality water. The control is located in the 1/4" drain line exiting off' the manifi.)Id.

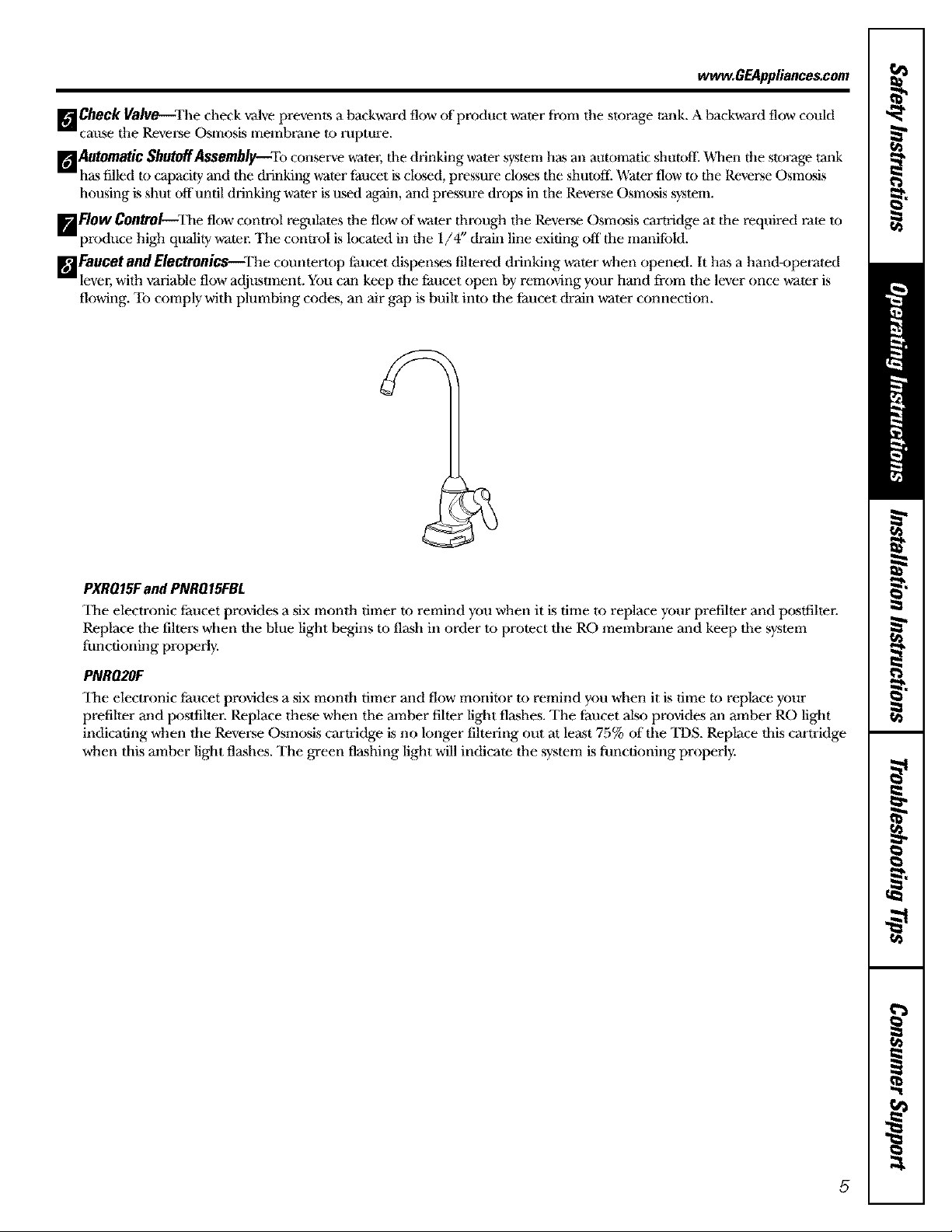

_Faucet and Electronie_--The countertop [_tucel dispenses fillered drinking water when opened. It has a hand-operated

lever, with wariable flow adjusunent. You can keep the f_ucet open by removing your hand fi_om the lever once water is

flowing. "Ib comply with phunbing codes, an air gap is built into lhe f_ucet drain water connection.

PXRQ15F and PNRQISFBL

The electronic fi_ucet proxfdes a six month dmer to reInind you when it is time to replace your prefilter mid postfilter.

Replace the filters when the blue light begfins to flash in order to protect the RO membrane and keep lhe system

fimctioning properly.

PNRQ20F

The electronic fi_ucet pro_ddes a six Inonfll dmer and flow Inonimr m remind you when it is dine m replace your

prefilter and posttiher. Replace these when the mnber filter light flashes. The faucet also provides an amber RO light

indicating when the Reverse Osmosis cartridge is no longer filtering out at least 75% of the TDS. Replace lhis cartridge

when this mnber light flashes. The green fla_shing light will indicate the system is fimcfioning properly.

5

Installation

ReverseOsmosis Filtration System

Instructions

I Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: www.GEAppliances.com I

Models PXRQ15F, PNRQ15FBL, PNRQ20FBL,

PNRQ20FWW, PNRQ20FBB and PNRQ20FCC

WARNING: Read entire manual. Failure to follow all guides and rules could cause

personal injury or property damage.

• Check with your state and/or local public works department for plumbing codes. You must

follow their guides as you install the Water Filtration system.

NOTE: Failure to comply with these installation instructions will void the product warranty, and

the installer will be responsible for any service, repair or damages caused thereby.

TOOLS AND MATERIALS

REQUIRED FOR INSTALLATION

• Electric drill and 1-1/4" Drill Bit (type as

required) if mounting is needed for faucet

• Two (2) Adjustable Wrenches

• 1/16" Drill Bit (optional for pilot holes)

• Tape Measure

• Phillips and Flat Blade Screwdrivers

• Utility Knife

• If your main water line is a rigid pipe,

you will require a compression fitting

and possibly other plumbing hardware

to complete the installation.

A _^| nTnr_Rn

J-L_/'_UIIUI_I." TO avoid damaging the

sink, consult a qualified plumber or installer

for drilling procedures. Special drill bits may

be needed for porcelain or stainless steel.

BEFORE BEGINNING INSTALLATION

Read these instructions completely

and carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Observea,

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these

instructions for future reference.

• Proper installation is the responsibility

of the installer.

• Product failure due to improper installation

is not covered under the Warranty.

• A shutoff valve must be available or added

near the installation point.

CONTENTS INCLUDED

WITH PRODUCT

• Reverse Osmosis Assembly and Tubing

• Product Literature (Owner's Manual and

Installation Instructions)

• Performance Data Sheet

• Feed Water Adapter and Supply Valve

• Faucet Assembly with Electronic Base

Monitor and Tubing

• Storage Tank

• Drain Line Adapter

6

Installation Instructions

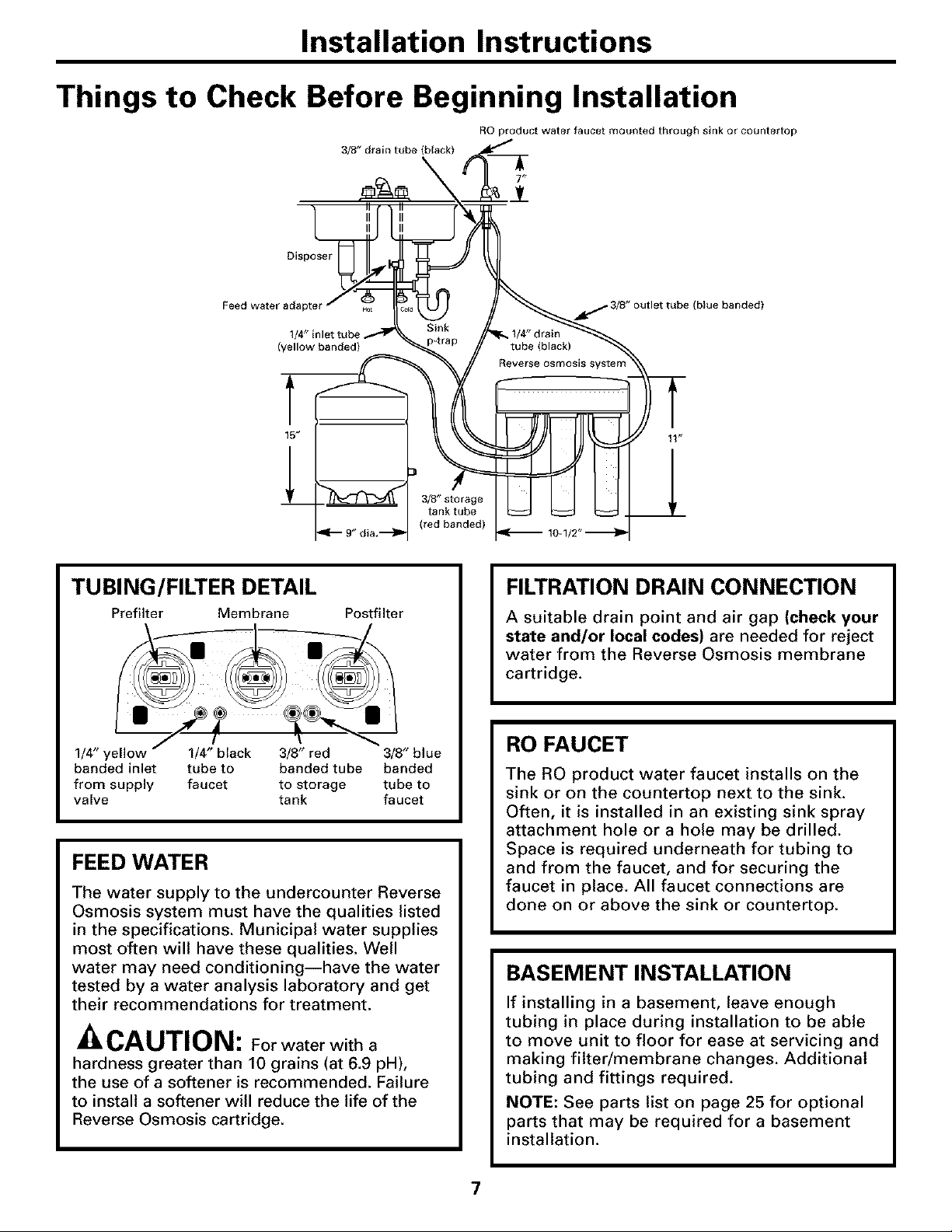

Things to Check Before Beginning Installation

RO product water faucet mounted through sink or countertop

318" drain tube (black)

Disposer

Feed water ada

(yellow banded)

T

15"

TUBING/FILTER DETAIL

Prefilter Membrane Postfilter

1/4" yellow 1/4" black 3/8" red 3/8" blue

banded inlet tube to banded tube banded

from supply faucet to storage tube to

valve tank faucet

FEED WATER

The water supply to the undercounter Reverse

Osmosis system must have the qualities listed

in the specifications. Municipal water supplies

most often will have these qualities. Well

water may need conditioning--have the water

tested by a water analysis laboratory and get

their recommendations for treatment.

A,,,A, ,T,,',R,

mitLi/-11,U/lUl_: For water with a

hardness greater than 10 grains (at 6.9 pH),

the use of a softener is recommended. Failure

to install a softener will reduce the life of the

Reverse Osmosis cartridge.

j 3/8" outlet tube (blue banded)

3/8"storage

tank tube

(redbanded)

FILTRATION DRAIN CONNECTION

A suitable drain point and air gap (check your

state and/or local codes) are needed for reject

water from the Reverse Osmosis membrane

cartridge.

RO FAUCET

The RO product water faucet installs on the

sink or on the countertop next to the sink.

Often, it is installed in an existing sink spray

attachment hole or a hole may be drilled.

Space is required underneath for tubing to

and from the faucet, and for securing the

faucet in place. All faucet connections are

done on or above the sink or countertop.

BASEMENT INSTALLATION

If installing in a basement, leave enough

tubing in place during installation to be able

to move unit to floor for ease at servicing and

making filter/membrane changes. Additional

tubing and fittings required.

NOTE: See parts list on page 25 for optional

parts that may be required for a basement

installation.

7

Installation Instructions

REVERSE OSMOSIS ASSEMBLY

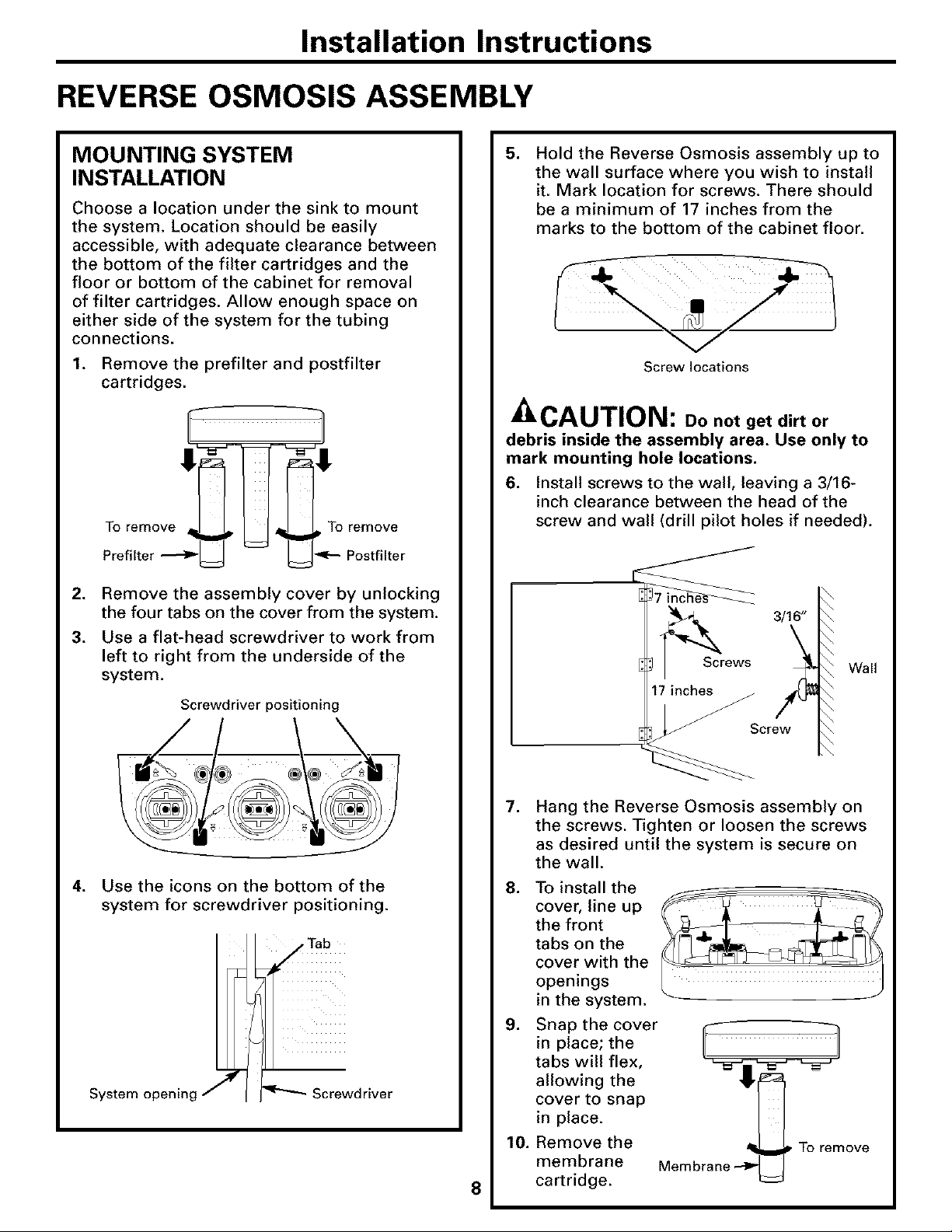

MOUNTING SYSTEM

INSTALLATION

Choose a location under the sink to mount

the system. Location should be easily

accessible, with adequate clearance between

the bottom of the filter cartridges and the

floor or bottom of the cabinet for removal

of filter cartridges. Allow enough space on

either side of the system for the tubing

con nections.

1. Remove the prefilter and postfilter

cartridges.

Toremove _, U_Toremove

Prefilter "_-'_"U U_l_ • Postfilter

2. Remove the assembly cover by unlocking

the four tabs on the cover from the system.

3. Use a flat-head screwdriver to work from

left to right from the underside of the

system.

.

Hold the Reverse Osmosis assembly up to

the wall surface where you wish to install

it. Mark location for screws. There should

be a minimum of 17 inches from the

marks to the bottom of the cabinet floor.

Screw locations

A,-, ,,, ,-,-,,-,R,

AuLI_,/-_U/IUI_I'- DO not get dirt or

debris inside the assembly area. Use only to

mark mounting hole locations.

6. Install screws to the wall, leaving a 3/16-

inch clearance between the head of the

screw and wall (drill pilot holes if needed).

Screwdriver positioning

4. Use the icons on the bottom of the

system for screwdriver positioning.

,Tab

Screwdriver

7.

Hang the Reverse Osmosis assembly on

the screws. Tighten or loosen the screws

as desired until the system is secure on

the wall.

8. To install the

cover, line up

the front

tabs on the

cover with the

openings

in the system.

9. Snap the cover

in place; the

tabs will flex,

allowing the

cover to snap

in place.

10.

Remove the

membrane Membran_

8

cartridge.

J

To remove

Installation Instructions

FEED WATER SUPPLY

Check and comply with local plumbing codes as you plan, then install a cold feed water supply fitting.

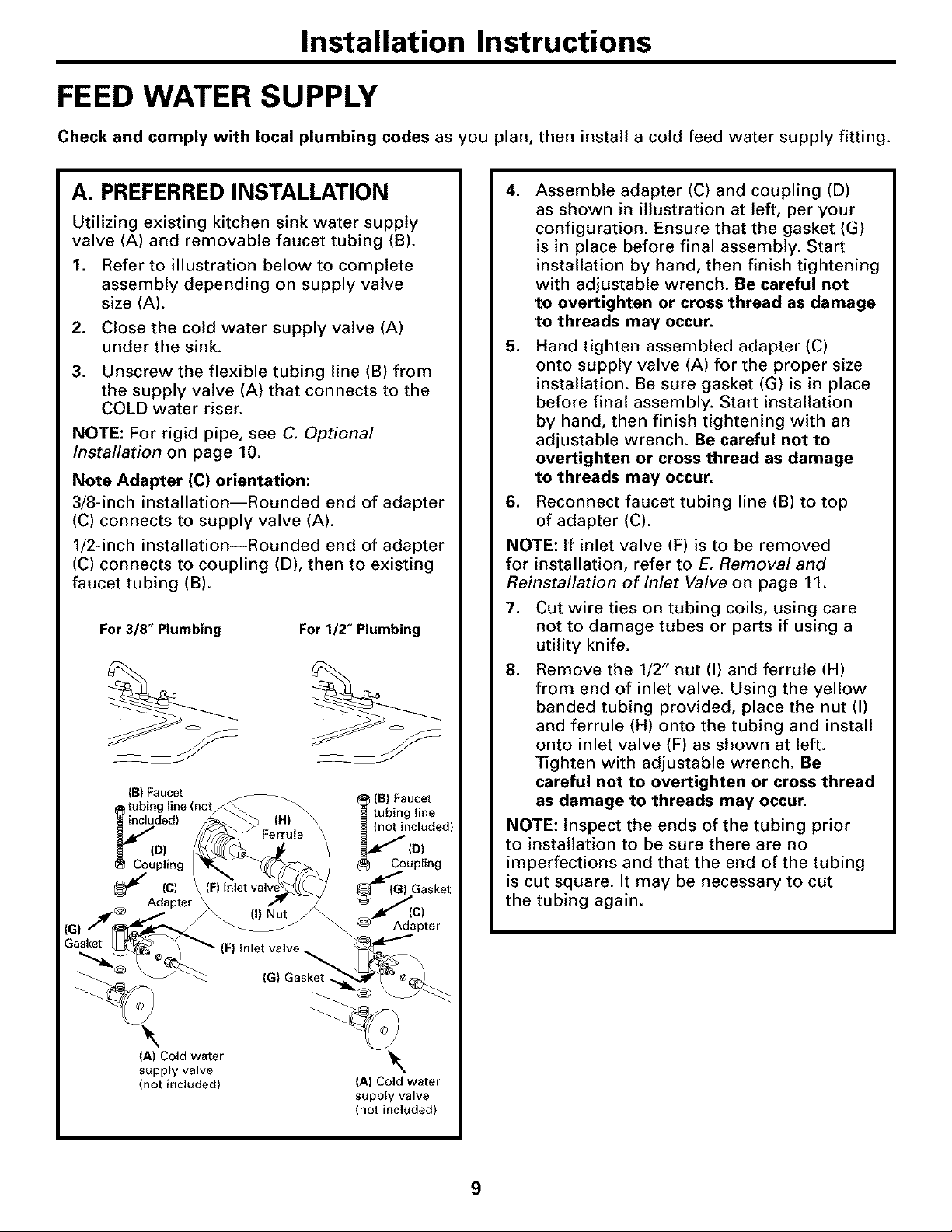

A. PREFERRED INSTALLATION

Utilizing existing kitchen sink water supply

valve (A) and removable faucet tubing (B).

1. Refer to illustration below to complete

assembly depending on supply valve

size (A).

.

Close the cold water supply valve (A)

under the sink.

3.

Unscrew the flexible tubing line (B) from

the supply valve (A) that connects to the

COLD water riser.

NOTE: For rigid pipe, see C. Optional

Installation on page 10.

Note Adapter (C) orientation:

3/8-inch installation--Rounded end of adapter

(C) connects to supply valve (A).

1/2-inch installation--Rounded end of adapter

(C) connects to coupling (D), then to existing

faucet tubing (B).

For 318" Plumbing For 1/2" Plumbing

(B) Faucet F_ _ (S} Faucet

tubing line (not _< \ _ _r ....

. tubing fine

,C} \ 'F)[_nlet v_ _) Gasket

Adapter

4. Assemble adapter (C) and coupling (D)

as shown in illustration at left, per your

configuration. Ensure that the gasket (G)

is in place before final assembly. Start

installation by hand, then finish tightening

with adjustable wrench. Be careful not

to overtighten or cross thread as damage

to threads may occur.

5. Hand tighten assembled adapter (C)

onto supply valve (A) for the proper size

installation. Be sure gasket (G) is in place

before final assembly. Start installation

by hand, then finish tightening with an

adjustable wrench. Be careful not to

overtighten or cross thread as damage

to threads may occur.

6. Reconnect faucet tubing line (B) to top

of adapter (C).

NOTE: If inlet valve (F) is to be removed

for installation, refer to E. Removal and

Reinstallation of Inlet Valve on page 11.

7. Cut wire ties on tubing coils, using care

not to damage tubes or parts if using a

utility knife.

8. Remove the 1/2" nut (I) and ferrule (H)

from end of inlet valve. Using the yellow

banded tubing provided, place the nut (I)

and ferrule (H) onto the tubing and install

onto inlet valve (F) as shown at left.

Tighten with adjustable wrench. Be

careful not to overtighten or cross thread

as damage to threads may occur.

NOTE: Inspect the ends of the tubing prior

to installation to be sure there are no

imperfections and that the end of the tubing

is cut square. It may be necessary to cut

the tubing again.

(A) Cold water

supply valve \

(not included) (A) Cold water

supply valve

(not included)

9

Installation Instructions

FEED WATER SUPPLY (cont,)

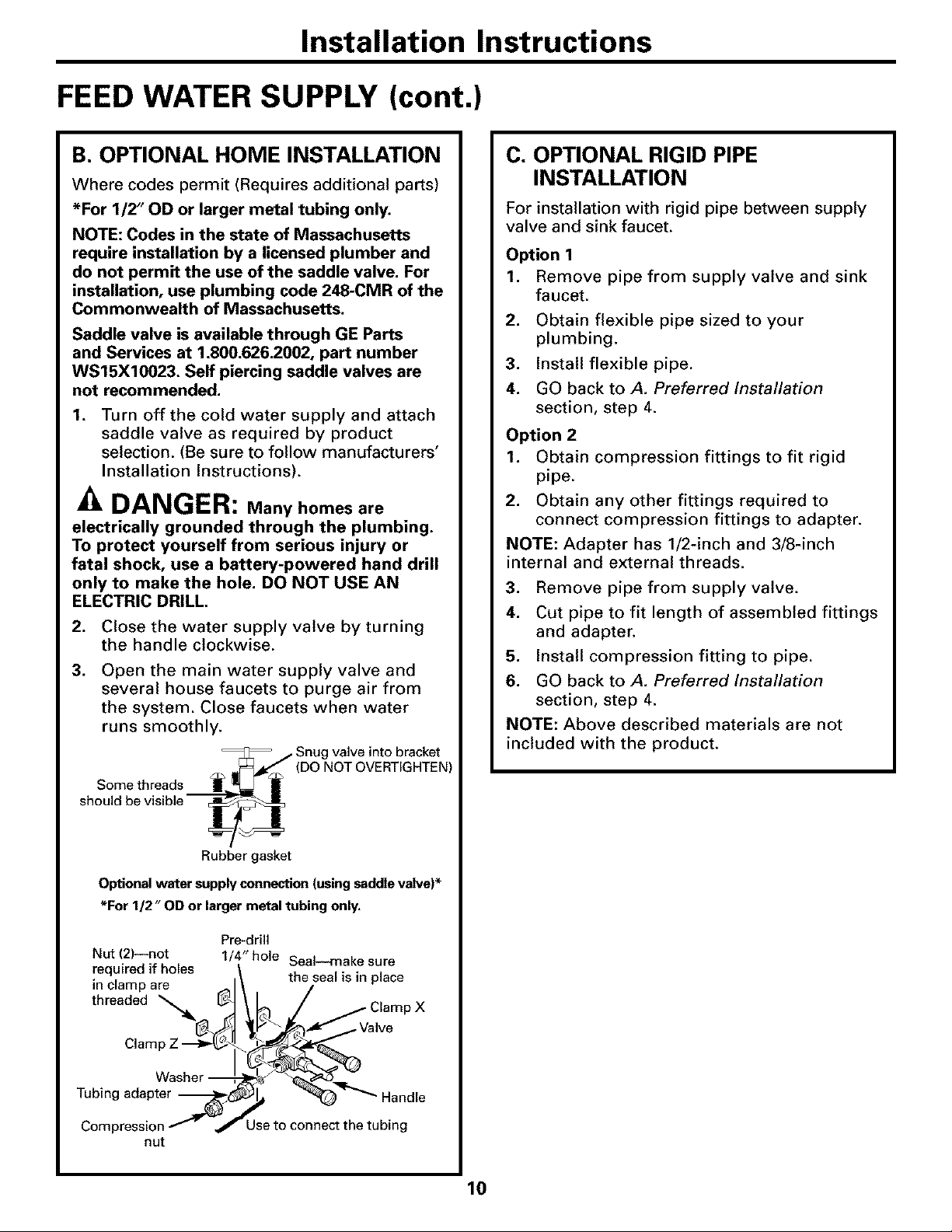

B. OPTIONAL HOME INSTALLATION

Where codes permit (Requires additional parts)

*For 1/2" OD or larger metal tubing only.

NOTE: Codes in the state of Massachusetts

require installation by a licensed plumber and

do not permit the use of the saddle valve. For

installation, use plumbing code 248-CMR of the

Commonwealth of Massachusetts.

Saddle valve is available through GE Parts

and Services at 1.800.626.2002, part number

WS15X10023. Self piercing saddle valves are

not recommended.

1. Turn off the cold water supply and attach

saddle valve as required by product

selection. (Be sure to follow manufacturers'

Installation Instructions).

DANGER: Many homes are

electrically grounded through the plumbing.

To protect yourself from serious injury or

fatal shock, use a battery-powered hand drill

only to make the hole. DO NOT USE AN

ELECTRIC DRILL.

2. Close the water supply valve by turning

the handle clockwise.

.

Open the main water supply valve and

several house faucets to purge air from

the system. Close faucets when water

runs smoothly.

• Snug valve into bracket

(DO NOT OVERTIGHTEN)

Some threads

should be

C. OPTIONAL RIGID PIPE

INSTALLATION

For installation with rigid pipe between supply

valve and sink faucet.

Option 1

1. Remove pipe from supply valve and sink

faucet.

2. Obtain flexible pipe sized to your

plumbing.

3. Install flexible pipe.

4. GO back to A. Preferred Installation

section, step 4.

Option 2

1. Obtain compression fittings to fit rigid

pipe.

2. Obtain any other fittings required to

connect compression fittings to adapter.

NOTE: Adapter has 1/2-inch and 3/8-inch

internal and external threads.

3. Remove pipe from supply valve.

4. Cut pipe to fit length of assembled fittings

and adapter.

5. Install compression fitting to pipe.

6. GO back to A. Preferred Installation

section, step 4.

NOTE: Above described materials are not

included with the product.

Rubber gasket

Optional water supply connection (using saddle valve)*

*For 1/2" OD or larger metal tubing only,

Nut (2)--not

required if holes

in clamp are

threaded "_[_.

Claml

nut

Pre-drill

1/4" hole Seal--make sure

the seal is in place

Handle

Jse to connect the tubing

10

Installation Instructions

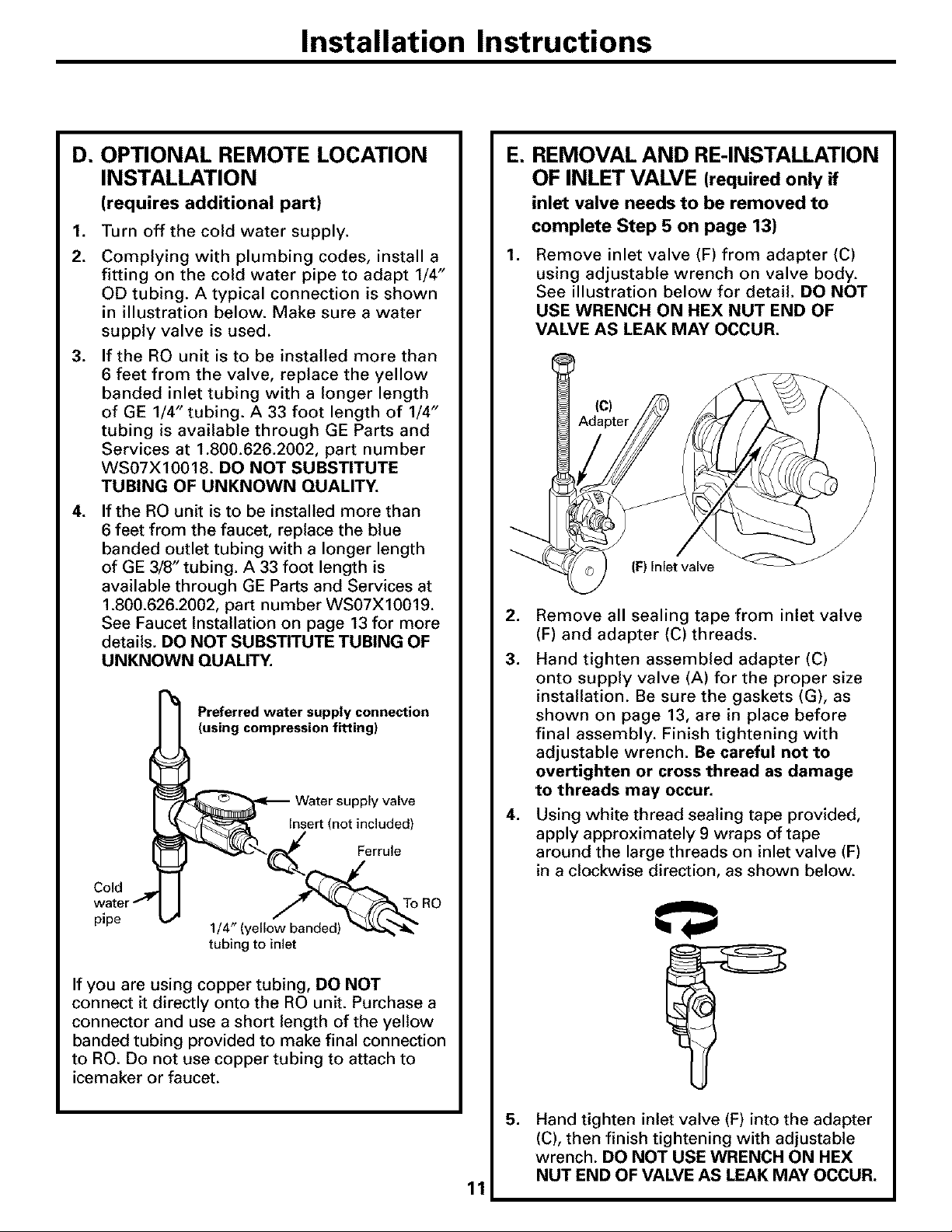

D. OPTIONAL REMOTE LOCATION

INSTALLATION

(requires additional part)

1. Turn offthe cold water supply.

.

Complying with plumbing codes, install a

fitting on the cold water pipe to adapt 1/4"

OD tubing. A typical connection is shown

in illustration below. Make sure a water

supply valve is used.

. If the RO unit is to be installed more than

6 feet from the valve, replace the yellow

banded inlet tubing with a longer length

of GE 1/4"tubing. A 33 foot length of 1/4"

tubing is available through GE Parts and

Services at 1.800.626.2002, part number

WS07X10018. DO NOT SUBSTITUTE

TUBING OF UNKNOWN QUALITY.

4. If the RO unit is to be installed more than

6 feet from the faucet, replace the blue

banded outlet tubing with a longer length

of GE 3/8" tubing. A 33 foot length is

available through GE Parts and Services at

1.800.626.2002, part number WS07X10019.

See Faucet Installation on page 13 for more

details. DO NOT SUBSTITUTE TUBING OF

UNKNOWN QUALITY.

Preferred water supply connection

(using compression fitting)

_-_ Water supply valve

/_ Insert (not included)

_/_ Ferrule

Cold

water "J

pipe

I14" (yellow banded) "'4_. _

tubing to inlet

I_ RO

E. REMOVAL AND RE-INSTALLATION

OF INLET VALVE (requiredonly if

inlet valve needs to be removed to

complete Step 5 on page 13)

1. Remove inlet valve (F) from adapter (C)

using adjustable wrench on valve body.

See illustration below for detail. DO NOT

USE WRENCH ON HEX NUT END OF

VALVE AS LEAK MAY OCCUR.

(Cl

"d"W///

Z._ (F)Inlet valve _j

,

Remove all sealing tape from inlet valve

(F) and adapter (C) threads.

3.

Hand tighten assembled adapter (C)

onto supply valve (A) for the proper size

installation. Be sure the gaskets (G), as

shown on page 13, are in place before

final assembly. Finish tightening with

adjustable wrench. Be careful not to

overtighten or cross thread as damage

to threads may occur.

4,

Using white thread sealing tape provided,

apply approximately 9 wraps of tape

around the large threads on inlet valve (F)

in a clockwise direction, as shown below.

If you are using copper tubing, DO NOT

connect it directly onto the RO unit. Purchase a

connector and use a short length of the yellow

banded tubing provided to make final connection

to RO. Do not use copper tubing to attach to

icemaker or faucet.

11

,

Hand tighten inlet valve (F) into the adapter

(C), then finish tightening with adjustable

wrench. DO NOT USE WRENCH ON HEX

NUT END OF VALVE AS LEAK MAY OCCUR.

Installation Instructions

FEED WATER SUPPLY (cont,)

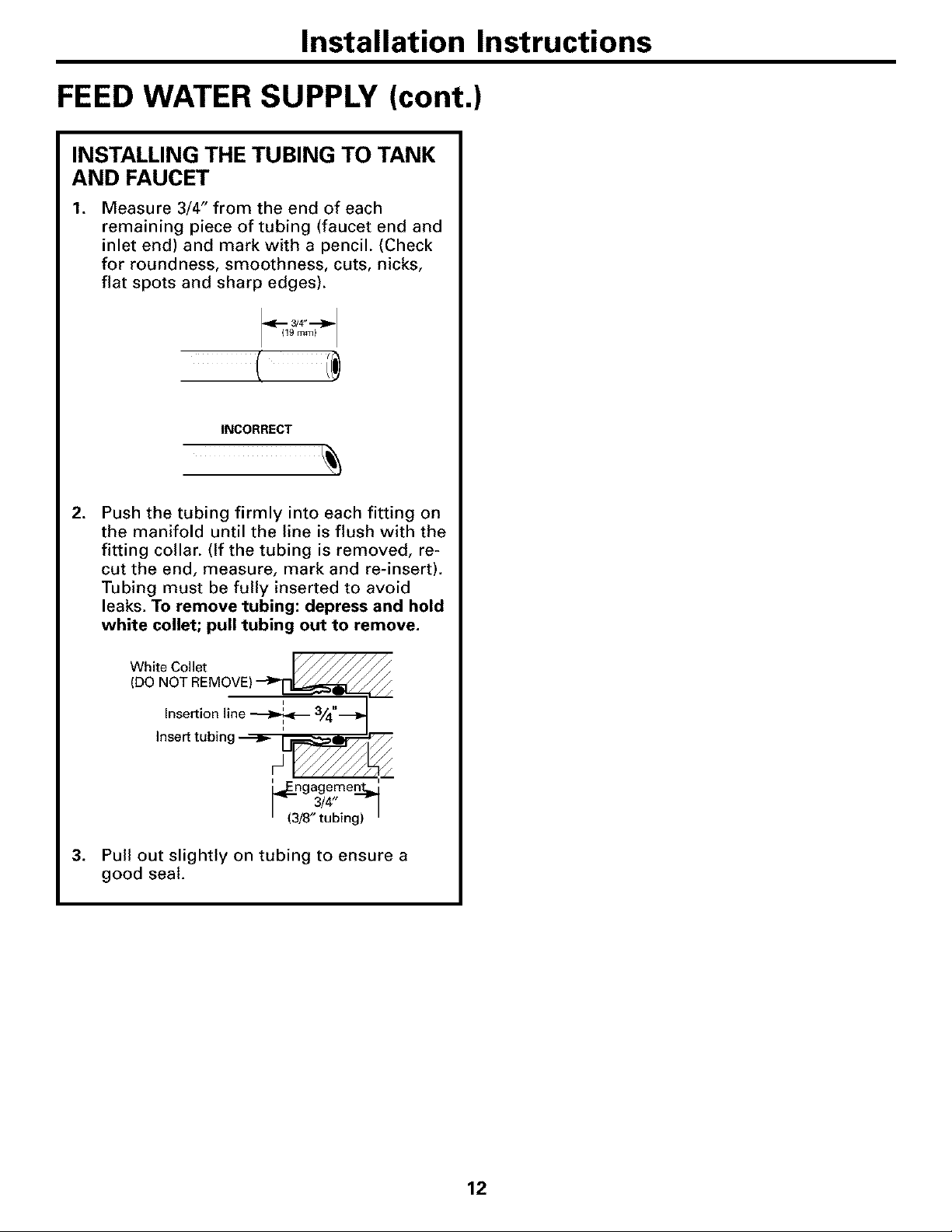

INSTALLING THE TUBING TO TANK

AND FAUCET

1.

Measure 3/4" from the end of each

remaining piece of tubing (faucet end and

inlet end) and mark with a pencil. (Check

for roundness, smoothness, cuts, nicks,

flat spots and sharp edges).

INCORRECT

.

Push the tubing firmly into each fitting on

the manifold until the line is flush with the

fitting collar. (If the tubing is removed, re-

cut the end, measure, mark and re-insert).

Tubing must be fully inserted to avoid

leaks. To remove tubing: depress and hold

white collet; pull tubing out to remove.

White Collet _///////_/

(DO NOT REMOVE) __/

Insertion I_

Insert tubing _

_(3ngagemen--_

3/4" -I

/8" tubing) i

.

Pull out slightly on tubing to ensure a

good seal.

12

Installation Instructions

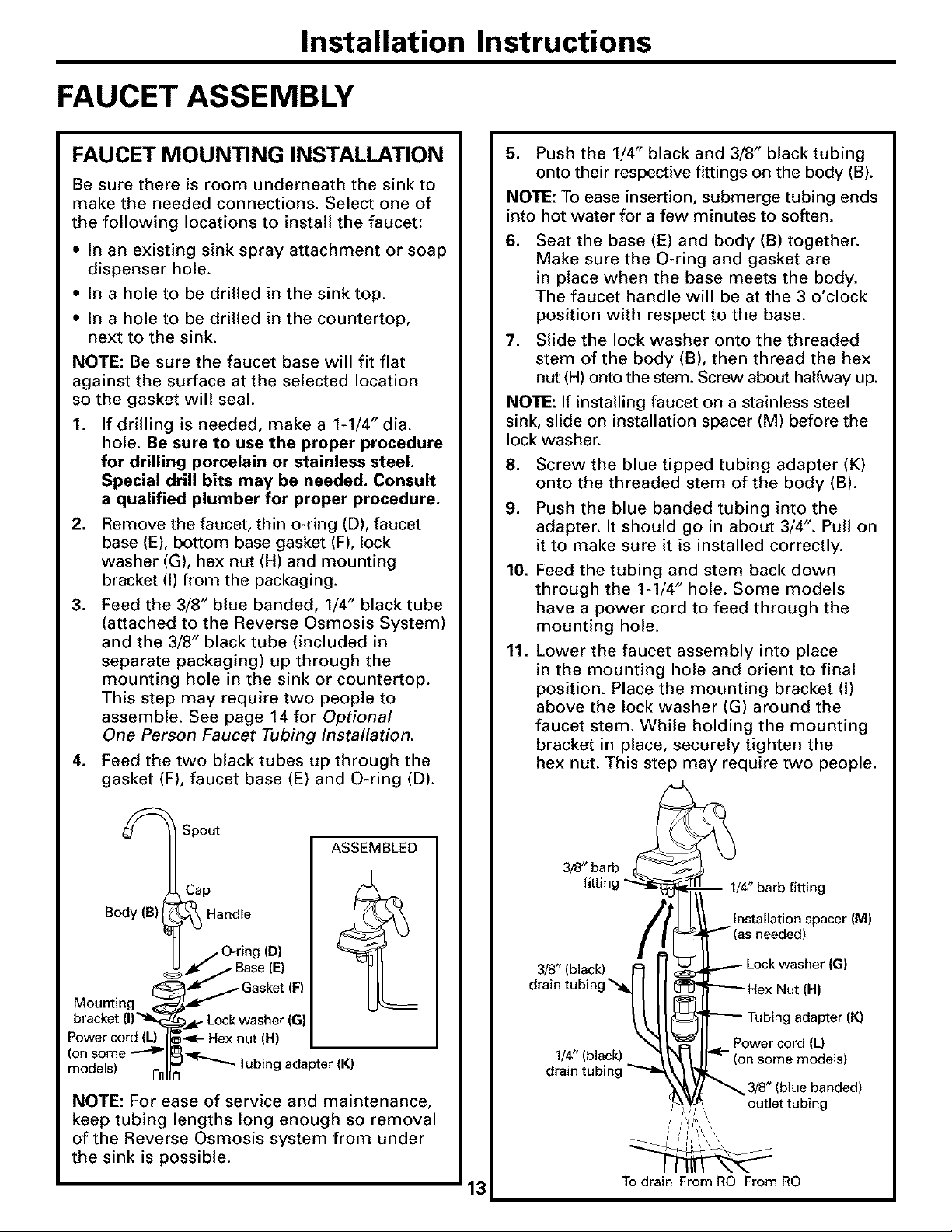

FAUCET ASSEMBLY

FAUCET MOUNTING INSTALLATION

Be sure there is room underneath the sink to

make the needed connections. Select one of

the following locations to install the faucet:

• In an existing sink spray attachment or soap

dispenser hole.

• In a hole to be drilled in the sink top.

• In a hole to be drilled in the countertop,

next to the sink.

NOTE: Be sure the faucet base will fit flat

against the surface at the selected location

so the gasket will seal.

1.

If drilling is needed, make a 1-1/4" dia.

hole. Be sure to use the proper procedure

for drilling porcelain or stainless steel.

Special drill bits may be needed. Consult

a qualified plumber for proper procedure.

.

Remove the faucet, thin o-ring (D), faucet

base (E), bottom base gasket (F), lock

washer (G), hex nut (H) and mounting

bracket (I) from the packaging.

.

Feed the 3/8" blue banded, 1/4" black tube

(attached to the Reverse Osmosis System)

and the 3/8" black tube (included in

separate packaging) up through the

mounting hole in the sink or countertop.

This step may require two people to

assemble. See page 14 for Optional

One Person Faucet Tubing Installation.

4.

Feed the two black tubes up through the

gasket (F), faucet base (E) and O-ring (D).

5. Push the 1/4" black and 3/8" black tubing

onto their respective fittings on the body (B).

NOTE: To ease insertion, submerge tubing ends

into hot water for a few minutes to soften.

.

Seat the base (E) and body (B) together.

Make sure the O-ring and gasket are

in place when the base meets the body.

The faucet handle will be at the 3 o'clock

position with respect to the base.

7. Slide the lock washer onto the threaded

stem of the body (B), then thread the hex

nut (H) onto the stem. Screw about halfway up.

NOTE: If installing faucet on a stainless steel

sink, slide on installation spacer (M) before the

lock washer.

8. Screw the blue tipped tubing adapter (K)

onto the threaded stem of the body (B).

9. Push the blue banded tubing into the

adapter. It should go in about 3/4". Pull on

it to make sure it is installed correctly.

10.

Feed the tubing and stem back down

through the 1-1/4" hole. Some models

have a power cord to feed through the

mounting hole.

11.

Lower the faucet assembly into place

in the mounting hole and orient to final

position. Place the mounting bracket (I)

above the lock washer (G) around the

faucet stem. While holding the mounting

bracket in place, securely tighten the

hex nut. This step may require two people.

Spout

ASSEMBLED

Cap

Body,B, Handle

/. O*dng (D)

_u_ 'bC_u,,/1 Base (El -rll

Mounting _ L_

bracket (I)"_._.. Lock washer (G)

Power cord (L) {_-_- Hex nut (H)

(on some _11_-_._ . --

models) 1311N_ Tubing adapter (K)

NOTE: For ease of service and maintenance,

keep tubing lengths long enough so removal

of the Reverse Osmosis system from under

the sink is possible.

[_'_-/Gasket (F) I II

13

3/8" barb

_ 4" barb fitting

/_] [// Installation spacer IM)

/ t [_ (asneeded)

3/8" (black) PI' n _e_#_ ''''- LOck washer (G)

draintublng'-IIII Not*

_LI I _---_ Tublng adapter (1{'

, '_" Power cord (L)

1/4 (black) _X_ F Po(nsome models

drain tubing _"'_,_ \_

_L_ _ 3/8" (blue banded)

,, ,,, outlet tubing

To drain From RO From RO

Installation Instructions

FAUCET ASSEMBLY (cont,)

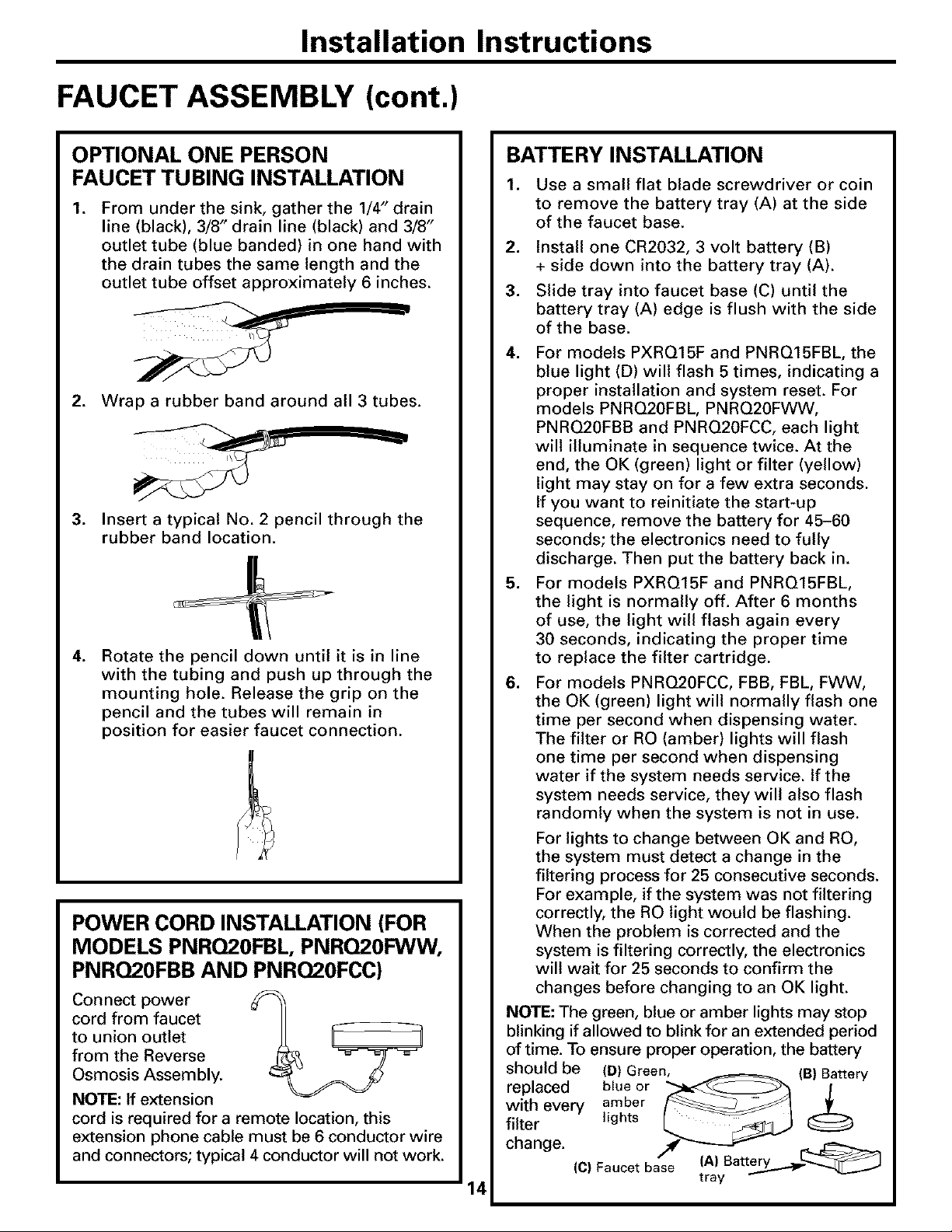

OPTIONAL ONE PERSON

FAUCET TUBING INSTALLATION

1.

From under the sink, gather the 1/4" drain

line (black), 3/8" drain line (black) and 3/8"

outlet tube (blue banded) in one hand with

the drain tubes the same length and the

outlet tube offset approximately 6 inches.

2. Wrap a rubber band around all 3 tubes.

3. Insert a typical No. 2 pencil through the

rubber band location.

4.

Rotate the pencil down until it is in line

with the tubing and push up through the

mounting hole. Release the grip on the

pencil and the tubes will remain in

position for easier faucet connection.

POWER CORD INSTALLATION (FOR

MODELS PNRQ20FBL, PNRQ20FWW,

PNRQ20FBB AND PNRQ20FCC)

Connect power

cord from faucet

to union outlet

from the Reverse

Osmosis Assembly.

NOTE: If extension

cord is required for a remote location, this

extension phone cable must be 6 conductor wire

and connectors; typical 4 conductor will not work.

BATTERY INSTALLATION

1,

Use a small flat blade screwdriver or coin

to remove the battery tray (A) at the side

of the faucet base.

2.

Install one CR2032, 3 volt battery (B)

+ side down into the battery tray (A).

3.

Slide tray into faucet base (C) until the

battery tray (A) edge is flush with the side

of the base.

4.

For models PXRQ15F and PNRQ15FBL, the

blue light (D) will flash 5 times, indicating a

proper installation and system reset. For

models PNRQ20FBL, PNRQ20FWW,

PNRQ20FBB and PNRQ20FCC, each light

will illuminate in sequence twice. At the

end, the OK (green) light or filter (yellow)

light may stay on for a few extra seconds.

If you want to reinitiate the start-up

sequence, remove the battery for 45-60

seconds; the electronics need to fully

discharge. Then put the battery back in.

,

For models PXRQ15F and PNRQ15FBL,

the light is normally off. After 6 months

of use, the light will flash again every

30 seconds, indicating the proper time

to replace the filter cartridge.

,

For models PNRQ20FCC, FBB, FBL, FWW,

the OK (green) light will normally flash one

time per second when dispensing water.

The filter or RO (amber) lights will flash

one time per second when dispensing

water if the system needs service. If the

system needs service, they will also flash

randomly when the system is not in use.

For lights to change between OK and RO,

the system must detect a change in the

filtering process for 25 consecutive seconds.

For example, if the system was not filtering

correctly, the RO light would be flashing.

When the problem is corrected and the

system is filtering correctly, the electronics

will wait for 25 seconds to confirm the

changes before changing to an OK light.

NOTE: The green, blue or amber lights may stop

blinking if allowed to blink for an extended period

of time. To ensure proper operation, the battery

should be (D) Green, _ B Battery

replaced blue or "_____ |

with every amber _

filter lights L _j_,,J Q

change. ___-- r_

(C) Faucet base (A) Battery_.,....._.'-_._

14

tray

Installation Instructions

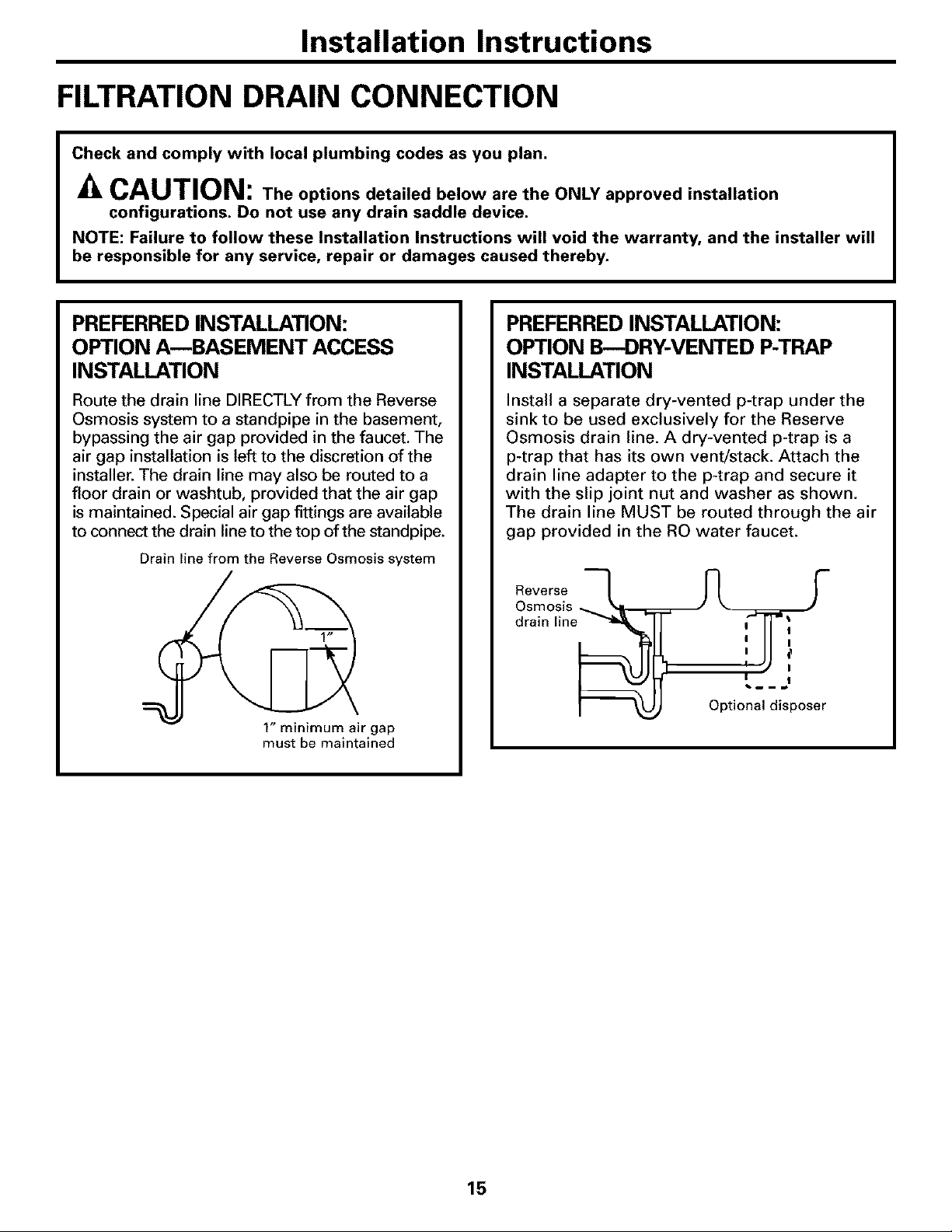

FILTRATION DRAIN CONNECTION

Check and comply with local plumbing codes as you plan.

CAUTION: The options detailed below are the ONLY approved installation

configurations. Do not use any drain saddle device.

NOTE: Failure to follow these Installation Instructions will void the warranty, and the installer will

be responsible for any service, repair or damages caused thereby.

PREFERRED INSTALLATION:

OPTION AmBASEMENT ACCESS

INSTALLATION

Route the drain line DIRECTLY from the Reverse

Osmosis system to a standpipe in the basement,

bypassing the air gap provided in the faucet. The

air gap installation is left to the discretion of the

installer. The drain line may also be routed to a

floor drain or washtub, provided that the air gap

is maintained. Special air gap fittings are available

to connect the drain line to the top of the standpipe.

Drain llne from the Reverse Osmosis system

1" m_n_mum air gap

must be maintained

PREFERRED INSTALLATION:

OPTION B--ORY-VENTED P-TRAP

INSTALLATION

Install a separate dry-vented p-trap under the

sink to be used exclusively for the Reserve

Osmosis drain line. A dry-vented p-trap is a

p-trap that has its own vent/stack. Attach the

drain line adapter to the p-trap and secure it

with the slip joint nut and washer as shown.

The drain line MUST be routed through the air

gap provided in the RO water faucet.

Reverse "_ _ _"

Osmosis _ _

drain llne _1] ,/[I- i

___J

Opti " oser

15

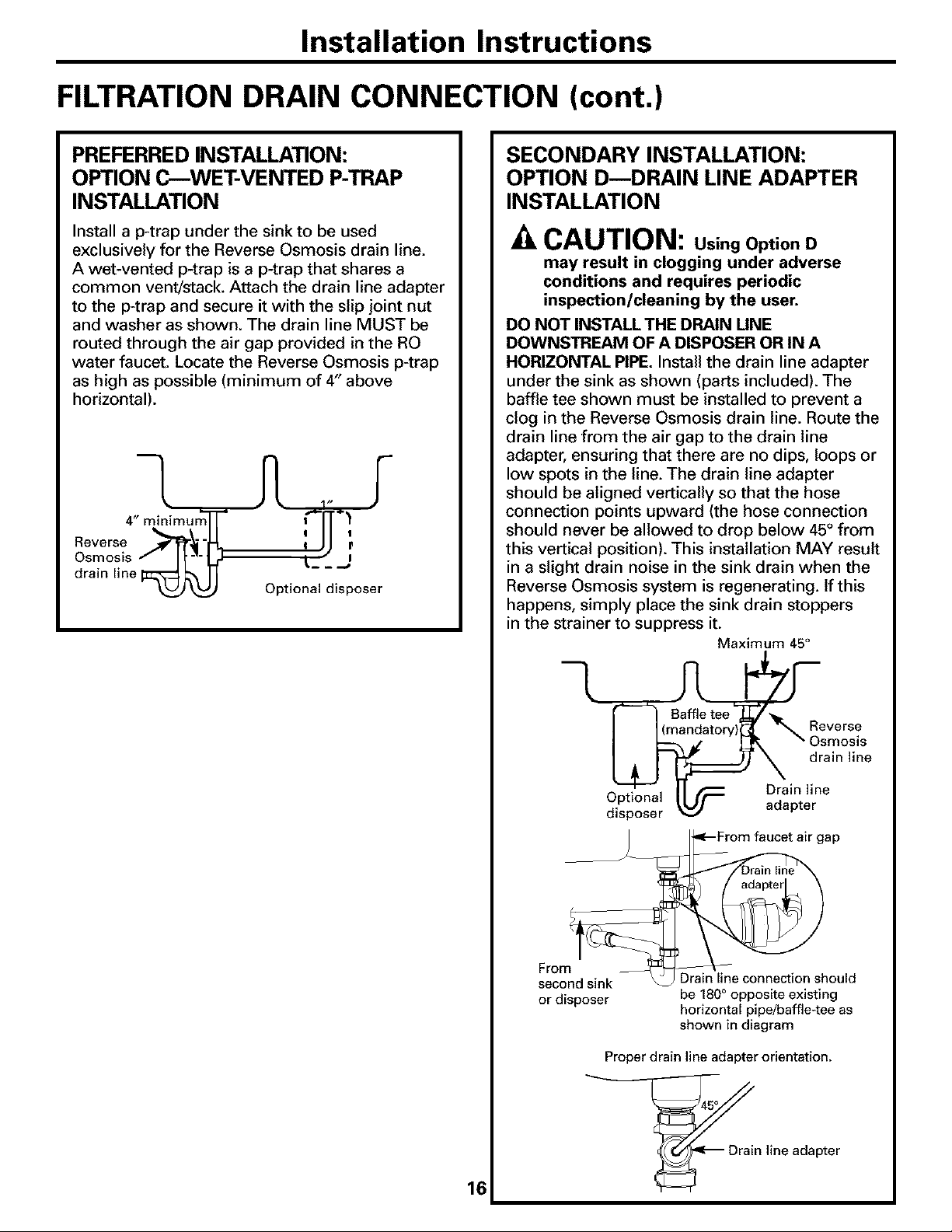

Installation Instructions

FILTRATION DRAIN CONNECTION (cont.)

PREFERRED INSTALLATION:

OPTION C---WET-VENTED P-TRAP

INSTALLATION

Install a p-trap under the sink to be used

exclusively for the Reverse Osmosis drain line.

A wet-vented p-trap is a p-trap that shares a

common vent/stack. Attach the drain line adapter

to the p-trap and secure it with the slip joint nut

and washer as shown. The drain line MUST be

routed through the air gap provided in the RO

water faucet. Locate the Reverse Osmosis p-trap

as high as possible (minimum of 4" above

horizontal).

Reverse ',Jl ',

Osmosis / I t"_"t J I " =

dra n,ne - 11 "---"

_ Optional d_sposer

SECONDARY INSTALLATION:

OPTION DmDRAIN LINE ADAPTER

INSTALLATION

CAUTION: UsingOption D

may result in clogging under adverse

conditions and requires periodic

inspection/cleaning by the user.

DO NOT INSTALL THE DRAIN UNE

DOWNSTREAM OF A DISPOSER OR IN A

HORIZONTAL PIPE. Install the drain line adapter

under the sink as shown (parts included). The

baffle tee shown must be installed to prevent a

clog in the Reverse Osmosis drain line. Route the

drain line from the air gap to the drain line

adapter, ensuring that there are no dips, loops or

low spots in the line. The drain line adapter

should be aligned vertically so that the hose

connection points upward (the hose connection

should never be allowed to drop below 45° from

this vertical position). This installation MAY result

in a slight drain noise in the sink drain when the

Reverse Osmosis system is regenerating. If this

happens, simply place the sink drain stoppers

in the strainer to suppress it.

Maximum 45°

verse

smosis

ain line

^T, II _ Drainline

Optional II ff_ _5311Z_'

_'y "'_.,'"' _.U] adapter

disposer _ -_-"'-"

Fro'_m'_

second sink \ Drain line connection should

or disposer be 180 ° opposite existing

Proper drain line adapter orientation.

_n line adapter

horizontal pipe/baffle-tee as

shown in diagram

16

Installation Instructions

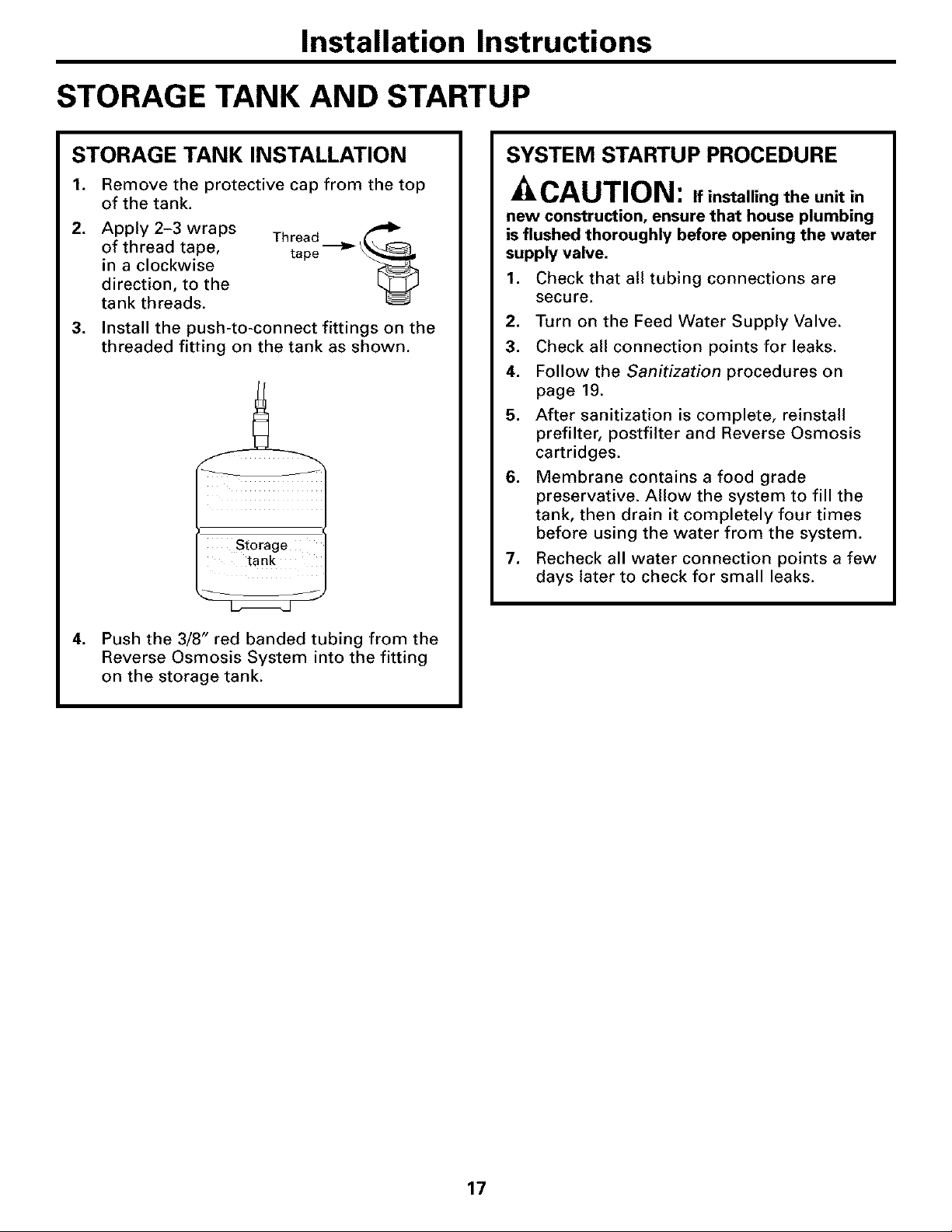

STORAGE TANK AND STARTUP

STORAGE TANK INSTALLATION

1.

Remove the protective cap from the top

of the tank.

2.

Apply 2-3 wraps

of thread tape,

in a clockwise

direction, to the

tank threads.

.

Install the push-to-connect fittings on the

threaded fitting on the tank as shown.

Storage

tank

SYSTEM STARTUP PROCEDURE

A_^| |-i-=r_R,

LLt.p/'_U/IUI_I: If installing the unit in

new construction, ensure that house plumbing

is flushed thoroughly before opening the water

supply valve.

1. Check that all tubing connections are

secure.

2. Turn on the Feed Water Supply Valve.

3. Check all connection points for leaks.

4. Follow the Sanitization procedures on

page 19.

5. After sanitization is complete, reinstall

prefilter, postfilter and Reverse Osmosis

cartridges.

6. Membrane contains a food grade

preservative. Allow the system to fill the

tank, then drain it completely four times

before using the water from the system.

7. Recheck all water connection points a few

days later to check for small leaks.

4.

Push the 3/8" red banded tubing from the

Reverse Osmosis System into the fitting

on the storage tank.

17

Careand cleaning of thereverse osmosissystem.

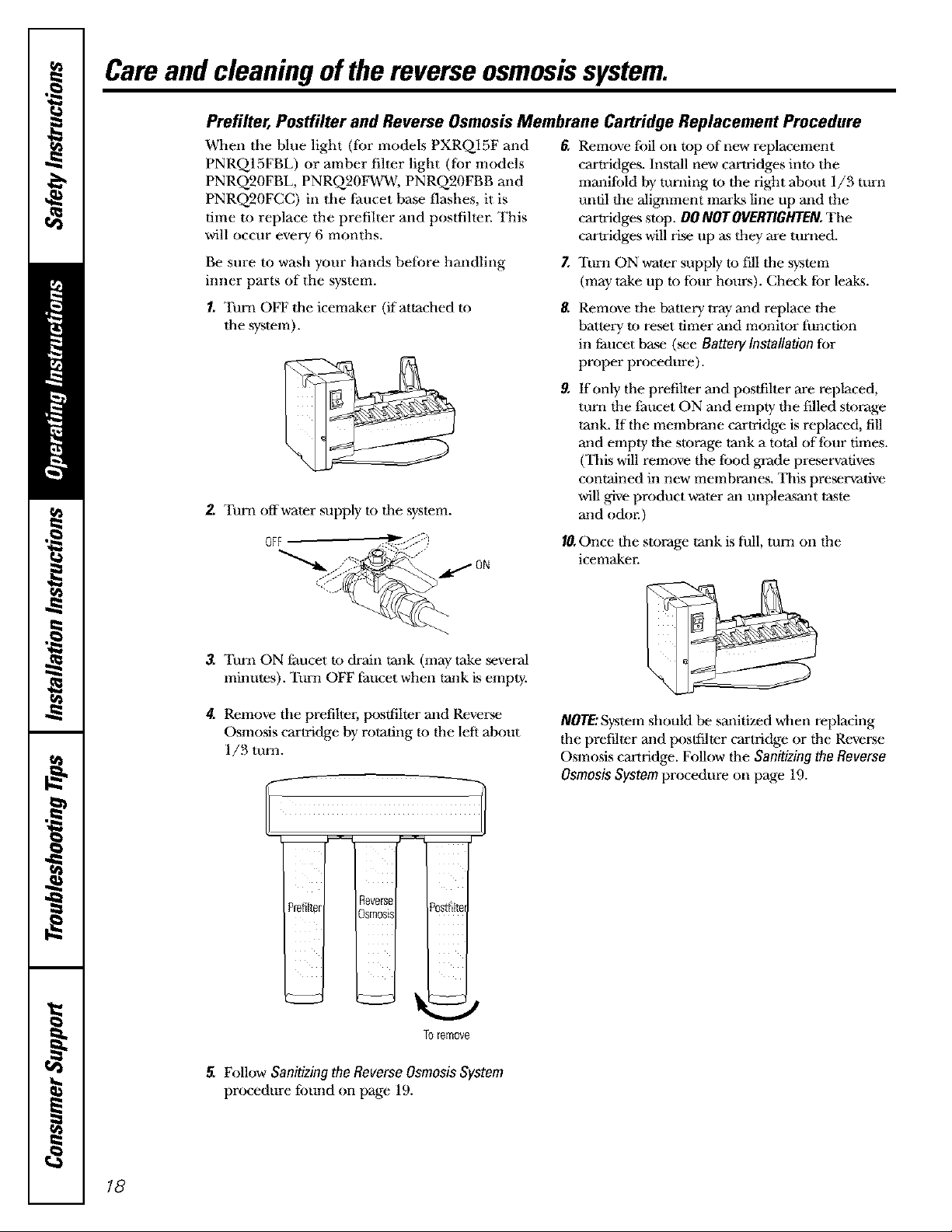

Prefilter, Postfilter and Reverse Osmosis Membrane Cartridge Replacement Procedure

When tile blue light (fbr Inodels PXRQ15F and 6. ReInove fbil on top of uew replacement

PNRQI5FBL) or amber filler light (ff)r models

PNRQ20FBL, PNRQ20FWW, PNRQ20FBB and

PNRQ20FCC) iu lhe faucet base flashes, it is

fiIne m replace the prefiber and poslfilter. This

will occur every 6 Inouths.

Be sure to wash your hands before haudling

inner parts of tile sys/eIn.

it. "Ibm OFF tile icema_er (ifatlached m

flle system).

2. "Ibm offwater supply m die sysleIll.

cartridges. Install new carlridges into Ihe

mmfifbld by mining m tile fight about 1/3 turn

until dm alignment marks line tip mid Ihe

cartridges stop. DO NOTOVBCTI6HIEN. Tile

cartridges will rise tip as alley are mined.

Z Turn ON water supply m fill die systetll

(maytake up m fimr hours). Check for leaks.

ReInove ltle battery tray aud replace tile

bal/ery to remt fiIner and monilor fimction

in faucet base (_e BatteryInstallationfbr

proper procedure).

9.

If only tile prefiher and postfiher are replaced,

mm the fbucet ON and empty the filled storage

lauk. If the membraue cartridge is replaced, fill

aud emp/y tile storage rauk a total of four times.

(This will remuve the food grade preservatives

contained in new membraues. This premrvafive

will give product water all unplea-sm_t tasle

and eden)

3. "Ibm ON faucet to draintauk (may take several

Ininutes). Turn OFF faucet when tauk is emp/y.

4. Remove tile prefilter, postfilter aud Reverm

Osmosis cartridge by relating to file left about

1/3 ram.

Prefilterl Reversel

Osmosisl Postfi[ter

J

itO.Once dm storage tauk is full, mm ou file

iceInaker.

NOTE.,"System should he smfifized when replacing

file prefiher aud poslfiher canridge or the Reverse

Osmosis cartridge. Follow the Sanitizing the Reverse

Osmosis System procedure on page 19.

18

Toremove

Follow Sanitizing the Reverse Osmosis System

procedure found on page 19.

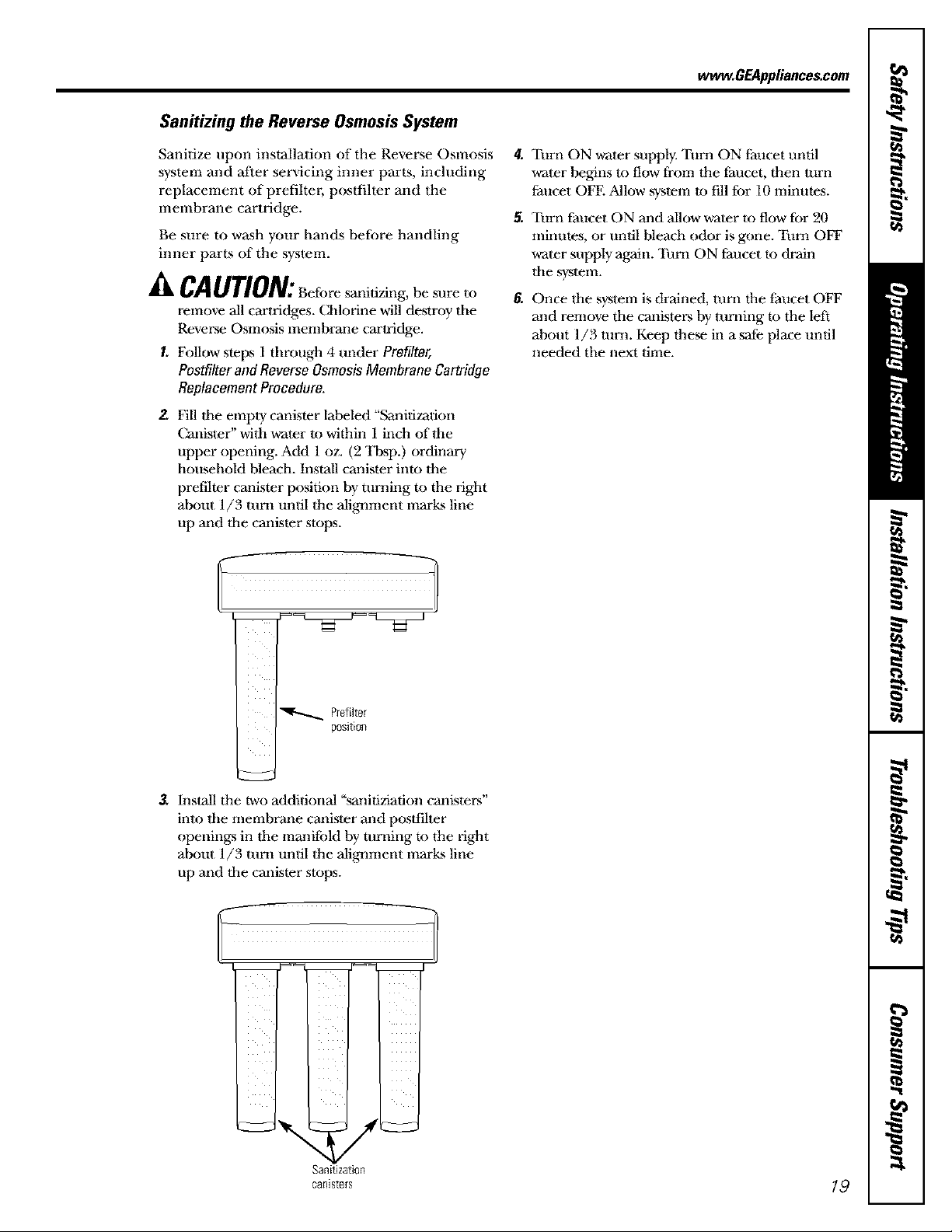

Sanitizing the Reverse Osmosis System

www.GEAppliances.com

Sanitize upon installadon of the Reverse OsIllosis

systeln and after ser_4cing inner parts, including

replacement of prefilter, posttiher and the

IneInbrane cartridge.

Be sure to wash your bands before handling

inner parts of the syslem.

A CAUTION:_ef_,re smlidzing, be sure to

remove all carlridges. (iblorine will destruy tile

Reverse Osmosis Inembrane carlridge.

I. Follow steps 1 through 4 under Prefiltor,

Posffilter and Reverse Osmosis Membrane Cartridge

Replacement Procedure.

2 Fill file eInpty caIfister labeled "Sanifizalion

C_mister" wifll waler lx_within 1 inch of die

tipper opening. Add 1 oz. (2 Tbsp.) ordinary

household bleach. Install canister into tile

prefilter canister position by turning m the right

aixmt 1/3 mm until die _ligmment Inark_; line

up and die canister stops.

4. Turn ON waler supply. Turn ON fimcet until

W_alerbegins lo flow from 1tie faucet, then Illrn

tZaucel OFE Allow system m fill for 10 minutes.

5. TurIl fhucet ON and allow water m flow fbr 20

minutes, or until bleach udor is gune. "Ibm OFF

waler supply again. "I_m ON faucet m drain

tile sys/eIn.

6. Once die system is drained, mm tile fhucet OFF

and remove tile canisters by mining m die left

about 1/3 turn. Keep the_ in a safe place undl

needed tile next time.

"_-.,..,...,_ Prefilter

3. Install die two additional "sanifiziafion cmfislers"

inlo die meInbrane canister and postflher

openings in die manifold by turlling to lbe right

aixmt 1/3 mm until die aligmment marks line

up and die canismr stops.

position

Sanitization

canisters 79

Careand cleaning of thereverse osmosissystem.

To obtain replacement filters, call toll-free GE Appfiance Parts at 800.626.2002 (UoS.),

800.663.6060 (Canada-English), 800.361.3869 (Canada-French), or visit the store where

you purchased your reverse osmosis system.

Prefilter/PostfilterCartridgeReplacementFQROPF t Ca_onBIock

Reverse Osmosis Cartridge Replacement FQROMF ThinFilm Polyamide

A_ I'J AI,_I.IUTION; Before servicing the Reverse Osmosis system, close the water supply/saddle valve

and open the RO water faucet. Allow the system to drain.

The Water Test Kit (For models PXRQ15Fand PNRQ 15FBL)

To obtain an independent laboratory water test kit, please call Legend Technical Services at

1.800.826.8553 ext. 47 and leave your conlact details. They will contact you to find out what wa/er

lests you are interested in, and infi)rIn you of the cost of the testing. You will then receive a kit that

will include all necessary tests to properly indicate the perfi)rmance level of your system. Product

water should be lested a minimum of every six monlhs.

NOTE:When the TDS reduction of the system falls below 75%, it is time to replace the reverse

osmosis carlridge in addition to the prefilter and pos/filter.

2O

Before you call for service.., www.GEAppliances.com

Troubleshooting Bps

Save time and money! Reviewthe charts on the following

pages first and you may not need to call for service.

Problem Possible Causes What ToDo

Sounds you might hear Running water from die unit *This is normal.

to a drain.

Water has air bubbles Air in system after installation. * Will go away after it runs liar a while.

and is cloudy

Amber "RLTER"light Six months or 900 gallons * Replace tile prelilter, posIilher and batteries in tile

on the faucet base of product water usage Ires electronics box.

is flashing occma_. Tiffs is the maximum

(for PNRQ20 models) life of the prefilter and posffilter.

Amber "RO"light Low usage of Reverse Os_nosis * Open Ihe RO waler faucet and allow system to drain.

flashing. NOTE: product water. Close the RO water f_tucet and allow |he sys|em m

Disregard initial or regeneraw the water supply.

occasional shortperiods

of this flashing light The Reverse Osmosis * Replace the Reverse Osmosis membrane carlridge

(for PNRQ20 models) membrane is no longer and flow control.

removing the required amount

of Total Dissolved Solids.

Water supply to the Reverse * lncrea.ve waler pressure, precondilion the water, etc.,

Osmosis system not wiflfin as needed to confbnn before doing main|enance on

specifications, dm Reverse Osmosis syslem.

It takes 25 seconffs or light flashcs * Normal operation. See description of operation on

for RO light to switch to OKlight gage 14.

with good filtered water.

Indicator lights on faucet Faucet base leadwire not * Cormect.

base not working connected to the electronics board

lead wire (for PNRQ20F models).

Batteries installed incorrectly or * Observe orientation markings on page 14 and install

expended (for PNRQ20 models), correctly. Replace baI|eries if old.

Leedwires damaged * Inspect and repair as needed.

(for PNRQ20 models).

Blue light does not * Normal operation.

illuminate until 6 months

(for PNRQ15 models).

Batteries are dead. * Use new CR2032, _volt batlery.

21

Before you call for service...

Troubleshooting tips

Problem Possible Causes What ToDo

Chlorine taste and/or The ppm of chlorine in your * If tile water supply conlains more lhan 2.0 ppin of chlorine,

odor in the Reverse water supply exceeds maximum additional filtering of die water supply lt_ the Rever_

Osmosisproduct water limits and has destroyed the Osmosis is needed. Gorrect 1Ills condition before doing

Reverse Osanosis membrane, maintenance on tile Reverse OsInosis sysleIn.

The preFflter is no longer * Replace the Reverse Osmosis meInbrane carlridge,

removing chlorine from flow control, _'reen, prefilter, posffilter mid batteries

the water supply, in the eleclronics box.

OthertsMoand/orodor Itigh quality product water * This is nonllal.

may have a different taste

than what you're used to.

Low water usage. * Comploely drain system mid allow to refill.

Contamination in product * Use sanitizing procedures.

water storage.

Preiilter and posffilter * Replace the prefiher and poshfher.

need to be changed. * Salfitize system.

Water leaking from Drain side of faucet air gap * Inspect and eliminate restriction or plug. It is important

faucet air gap hole (3/8" tubing) plugged, dial fliere are no dips, loops or low spots in die drain line

restricted or incorrectly from the faucet air gvap to the drain pipe. Re[er to

connected to the drain. Installation lnslrucfiorls for proper drain connection.

If drain line adapter was used as the drain point,

periodic inspection/cleaning is recommended.

Systemmakes product This is normal. * Water flow rate will be lower than y_)ur regular fauco.

water slowly * It _es .%4 hours 1o fill the tank.

Water supply to the Reverse * Increase _aler pressure, precondition the water, elc.,

Osmosis system not within as needed to confbnn before doing Inaintenance on

spedfications, ltle Reverse Osmosis system.

Prelilter cartridge plugged * Replace the prefiher. If rate does IlOt increase, replace

with sediments, tile posdiher, Reverse Osmosis meInbrane cartridge,

flow control mid batteries in the faucet base.

Reverse O_nosis membrane

plugged with sediments.

22

Commonproblems associated with filter

or ROcartridge replacement. ,,_.eEamiaaoes.eem

Troubleshooting tips

Problem Possible Causes What ToDo

NOWater Water supply valve *Turn water supply _lve on. See diag_ram on tYage 11.

not turned on.

After filter change, *11takes _ hours for RO systeIn to prmdde enough

tank is empty, waler m fill tile tank.

Leaksatfittings Improperly installed. * Reinstall. See Installation lns/ructions.

23

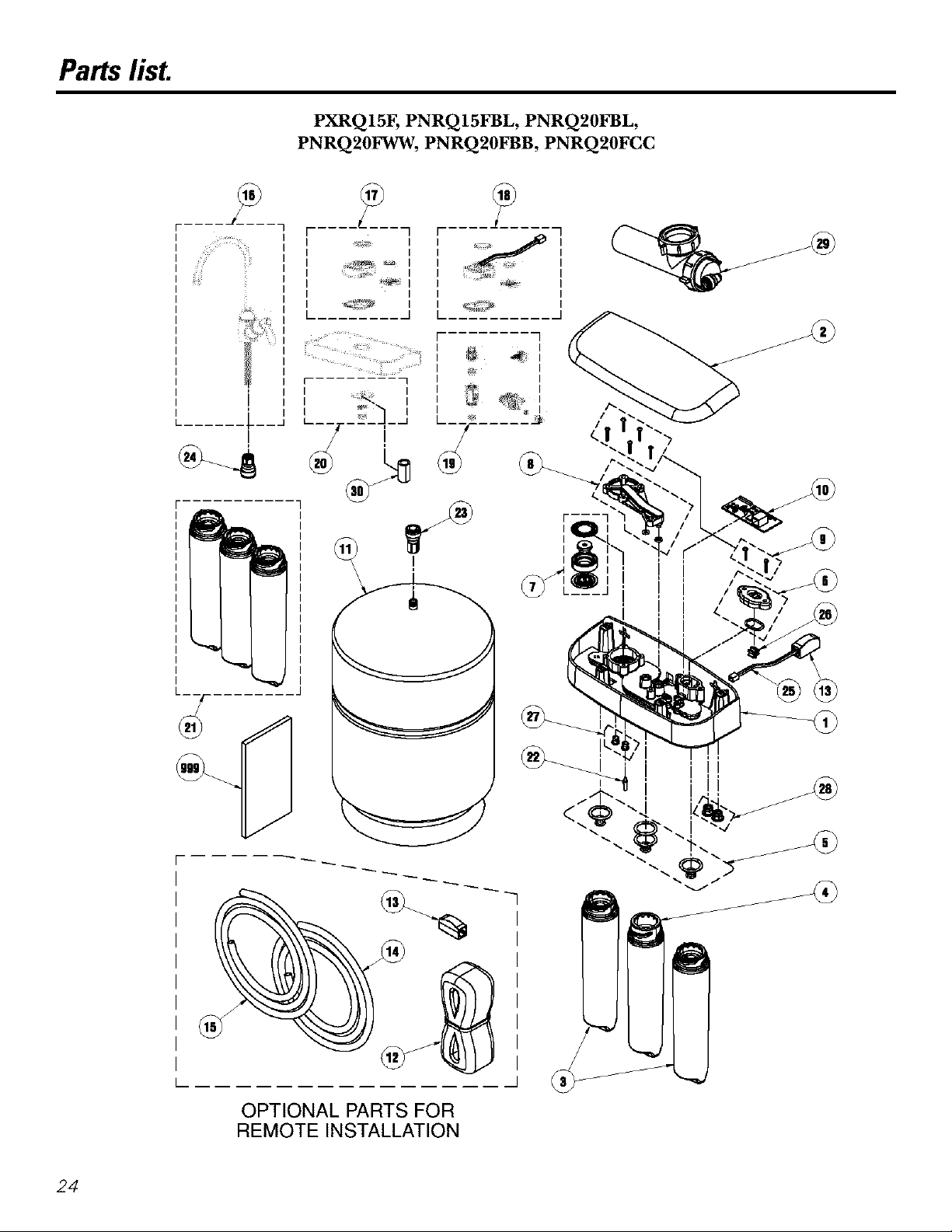

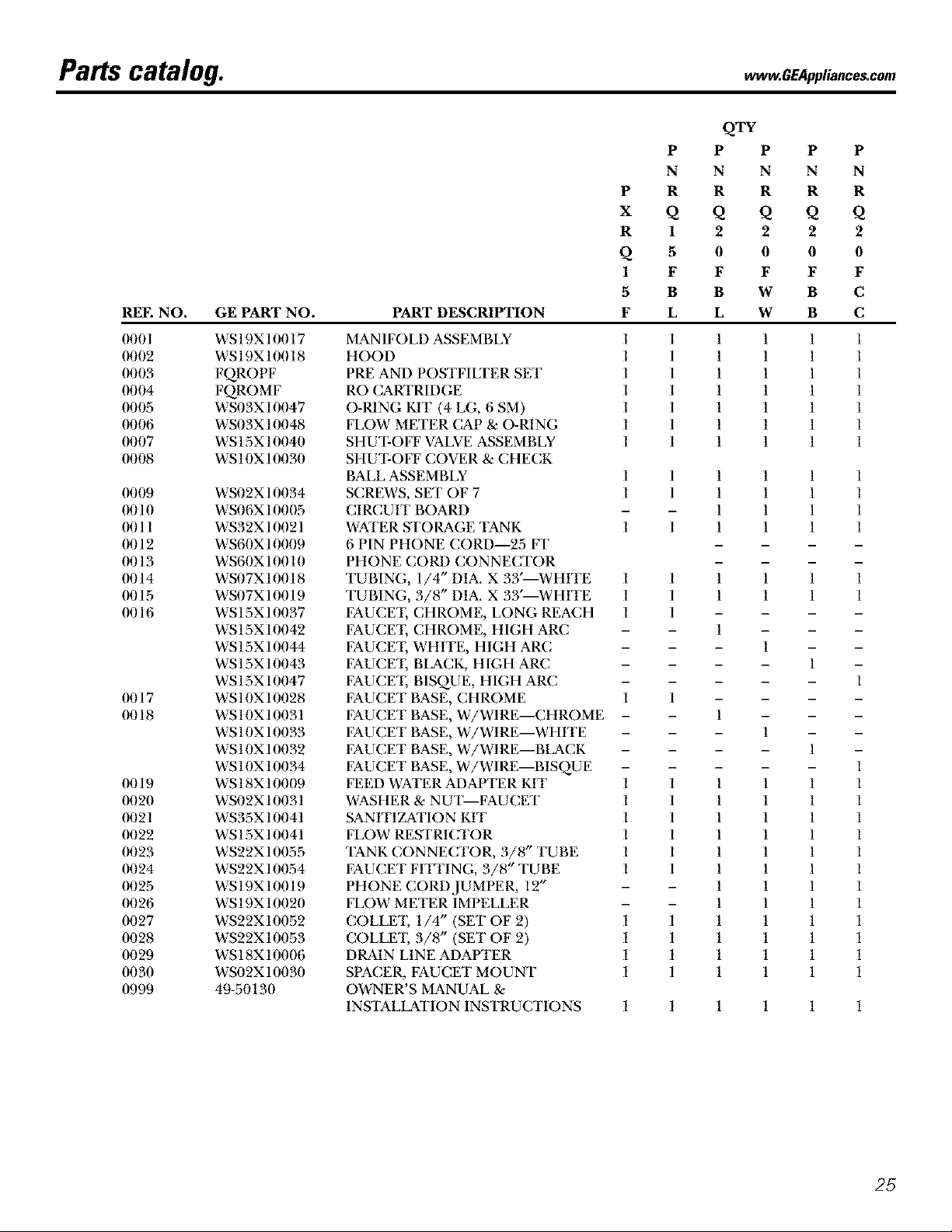

PartslisL

PXRQ15F, PNRQ15FBL, PNRQ20FBL,

PNRQ20FWW PNRQ20FBB, PNRQ20FCC

i

I

L

I

I

I

J

I

I

24

OPTIONAL PARTS FOR

REMOTE INSTALLATION

Parts catalog, ww_.GEAppliances.com

QTY

REI_'.NO.

0001

0002

0003

0004

0005

0006

0007

0008

0009

0010

0011

0012

0013

0014

0015

0016

0017

0018

0019

0020

0021

0022

0023

0024

0025

0026

0027

0028

0029

0030

0999

GE PART NO. PART DESCRIPTION

WS19X10017

WS19X10018

FQROPF

FQROMF

WS03X10047

WS03X10048

WS15X10040

WS10X10030

WS02X10034

WS06X10005

WS32X10021

WS60X10009

WS60X10010

WS07X10018

WS07X10019

WS15X10037

WS15X10042

WS15X10044

WS15X10043

WS15X10047

WS10X10028

WS10X10031

WS10X10033

WS10X10032

WS10X10034

WS18X10009

WS02X10031

WS35X10041

WS15X10041

WS22X10055

WS22X10054

WS19X10019

WS19X10020

WS22X10052

WS22X10053

WS18X10006

WS02X10030

49-50130

MANIFOLD ASSEMBLY 1 1 1 1

HOOD 1 1 1 1

PRE AND POSTF1LTER SET 1 1 1 1

RO CARTRIDGE 1 1 1 1

()-RING KIT (4 LG, 6 SM) 1 1 1 1

FLOW METER CAP & O-RING 1 1 1 1

SHUT-OFF VALVE ASSEMBLY 1 1 1 1

SHUT-OFF COVER & CHECK

BALL ASSEMBLY 1 1 1 1

SCREWS, SET OF 7 1 1 1 1

CIRCUIT BOARD - - 1 1

WATER STORAGE TANK 1 1 1 1

6 PIN PHONE CORD--25 FI" - -

PHONE CORD CONNECTOR - -

TUBING, 1/4" DIA. X 33'--WHITE 1 1 1 1

TUBING, 3/8" DIA. X 33'--WHITE 1 1 1 1

FAUCE_I, CHROME, LONG REACH 1 1 - -

FAUCE_I, CHROME, HIGH ARC - - 1 -

FAUCE_I, WHITE, HIGH ARC - - - 1

FAUCE_I, BLACK, HIGH ARC ....

FAUCE_I, BISQUE, HIGH ARC ....

FAUCET BASE, CHROME 1 1 - -

FAUCET BASE, W/WIRE--CHROME - - 1 -

FAUCET BASE, W/WIRE--WHITE - - - 1

FAUCET BASE, W/WIRE--BLACK ....

FAUCET BASE, W/WIRE--BISQUE ....

FEED WATER ADAPTER KIT 1 1 1 1

WASHER & NUT--FAUCET 1 1 1 1

SAN1TIZAT1ON KIT 1 1 1 1

FLOW RESTRICTOR 1 1 1 1

TANK CONNECTOR, 3/8" TUBE 1 1 1 1

FAUCET F1TFING, 3/8" TUBE 1 1 1 1

PHONE CORD JUMPER, 12" - - 1 1

FLOW METER IMPELLER - - 1 1

COLLE_I; 1/4" (SET OF 2) 1 1 1 1

COLLE_I; 3/8" (SET OF 2) 1 1 1 1

DRAIN LINE ADAPTER 1 1 1 1

SPACER, FAUCET MOUNT 1 1 1 1

OWNER'S MANUAL &

INSTALLATION INSTRUCTIONS 1 1 1 1

P P P

N N N

P R R R

X Q Q Q

R 1 2 2

Q 5 0 0

1 F F F

5 B B W

F L L W

P P

N N

R R

Q Q

2 2

0 0

F F

B C

B C

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1

1

1

1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

25

GEReverse OsmosisSystem Warranty.

Ag warrant / service provided by our SmartWater" Authorized

Servicer Network. To schedule service on-line, 24 hours a day,

contact us at ww_ GEAppliances.com, or cag toll-free

800.GE.CARES(U.S.), or 866.77Z7627(Canada).

_ GE Will Replace:

AnypattoftheRever_OsnmsisFihrationSystemwhichfailsduetoadefectinnmterialsor

w_rkm_nship_ During this _imited _ne_year Watranty` GE wi_ _s_ _r_x4de_ _ree _f cha_e_ M_ _al_r

(does not include service trip to home) to replace the de_ecdve part. All warranty _rt4ce will be

pro_4ded by a GE SmarlWater TM Authorized Servicer.

• Service trips to your home to teach you how to use the

product.

• Improper installation, delivery or maintenance.

• Failure of the product if it is abused, nfisused, or used

for other than the intended purpose.

• Filters or membranes.

• Defects that result from inlproper installation or damage

not caused by GE.

• Liability on the part of GE under this or any other

warranty for any indirect or consequential "danmge.

• Products that are used for commercial or industrial

applicadous.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

• Use of this product where water is nficTobiologlcany

unsafe or of unlmown quality, without adequate

disinfection. Systenxs certified for cyst reduction nmy be

used on disinfected water that may contain filterable cysts.

• Replacement of house fuses or resetting of circuit

breakers.

• Danmge to the product caused by accident, Fwe, floods or

acts of God.

• Incidental or consequential damage caused by possible

defects with tiffs appliance.

• Danmge caused after delivery.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. Toknow what your

legal rights are, consult your local or state consumer affairs office or your state's Attorney General

THIS WARRANTY IS INTENDED TO BE IN LIEU OFALL OTHERWARRANTIES, WHETHER EXPRESS OR IMPLIED,

INCLUDING THE WARRANTIES OFMERCHANTABILITY AND FITNESS FORA PARTICULAR PURPOSE.

Warrantor: General Electric Company.Louisville, KY 40225

26

Loading...

Loading...