GE PVM9179*K Series Training Bulletin

GE Appliances

Training Bulletin

June 2016

Microwave/OTR Convection

TB13-16

New PVM9179_K Convection Microwave

Features:

• Convection assembly is located on left side

of oven cavity.

• Chef Connect

• Dial and touchpad controls

• 300 CFM exhaust vent fan

• LED cooktop light

• Demo mode

• 1.7 cu. ft. enameled cavity

• 950 watts

• Charcoal filter included for recirculating

configuration

• Removable oven rack and convection rack

Use the complete model number (including engineering digit) when looking up parts.

This Training Bulletin covers some of the differences between the new and previous versions of

the PVM9179.

GE Appliances

Louisville, KY 40225

1

TB13-16

Demo Mode -The DEMO MODE is initiated by holding the “POWER LEVEL” and “START/PAUSE” pads at

the same time for a full 3 seconds. This mode can only be entered during the initial “PRESS CLOCK”

display that occurs when the microwave powers up after a (>25 seconds) power outage.

Error Message – These messages scroll across the display if an error is detected. The control will also

beep 3 times and repeat the signal after approximately 1 minute until power is removed from the

microwave.

Scrolled message Possible cause

• KEYPAD SHORTED -- SERVICE MAY BE NEEDED

• OPEN STEAM SENSOR -- SERVICE MAY BE NEEDED

• SHORTED STEAM SENSOR -- SERVICE MAY BE NEEDED

• OPEN THERMAL SENSOR -- SERVICE MAY BE NEEDED

• SHORTED THERMAL SENSOR -- SERVICE MAY BE NEEDED

• DAMPER STUCK -- SERVICE MAY BE NEEDED

• ABNORMAL HIGH TEMP -- SERVICE MAY BE NEEDED

Keypanel shorted continuously for over 60 sec.

Open humidity sensor

Shorted humidity sensor

Open thermal sensor

Shorted thermal sensor

Stuck damper

If oven temperature is over the set temperature

for 30 minutes.

Performance Test – For all microwave performance tests, measure the line voltage under load. This test

is based on normal voltage variations of 108vac to 132vac. Low voltage will lower output power and

temperature rise.

1. Place beaker WB64X73 containing one liter of water (59° F~ 75 ° F) on turntable and record the

starting water temperature with an accurate thermometer. (DO NOT USE ANY OTHER LOAD OR DISH

AS RESULTS WILL VARY FROM STANDARD)

2. Set time cook for 2 minutes and 3 seconds on HIGH.

3. Turn on the oven.

4. Record the end water temperature.

The minimum difference between the initial and ending temperature should be:

40 ° F @ 120vac

Sensor Cooking (humidity/gas)

All sensor cooking functions use a gas sensor which detects both humidity (steam) and hydrocarbons (food

odors) during the cooking process. Before conducting a sensor test, ensure the microwave has been

plugged into power for at least 5 minutes. This allows the sensor heater to reach proper temperature.

Sensor Test

Press and hold the POWER LEVEL and REHEAT pads at the same time. The display will show a number.

• 15-185 - Normal

• Less than 6 - Indicates a shorted sensor, wiring or main board.

• 213 or higher - Indicates an open sensor, wiring or main board.

Only the heater terminals (BLACK and RED leads) can be checked with an ohmmeter ~30Ω

DO NOT ATTEMPT TO CHECK THE OTHER SENSOR TERMINALS WITH AN OHMMETER AS DAMAGE TO

THE SENSOR CAN OCCUR.

2

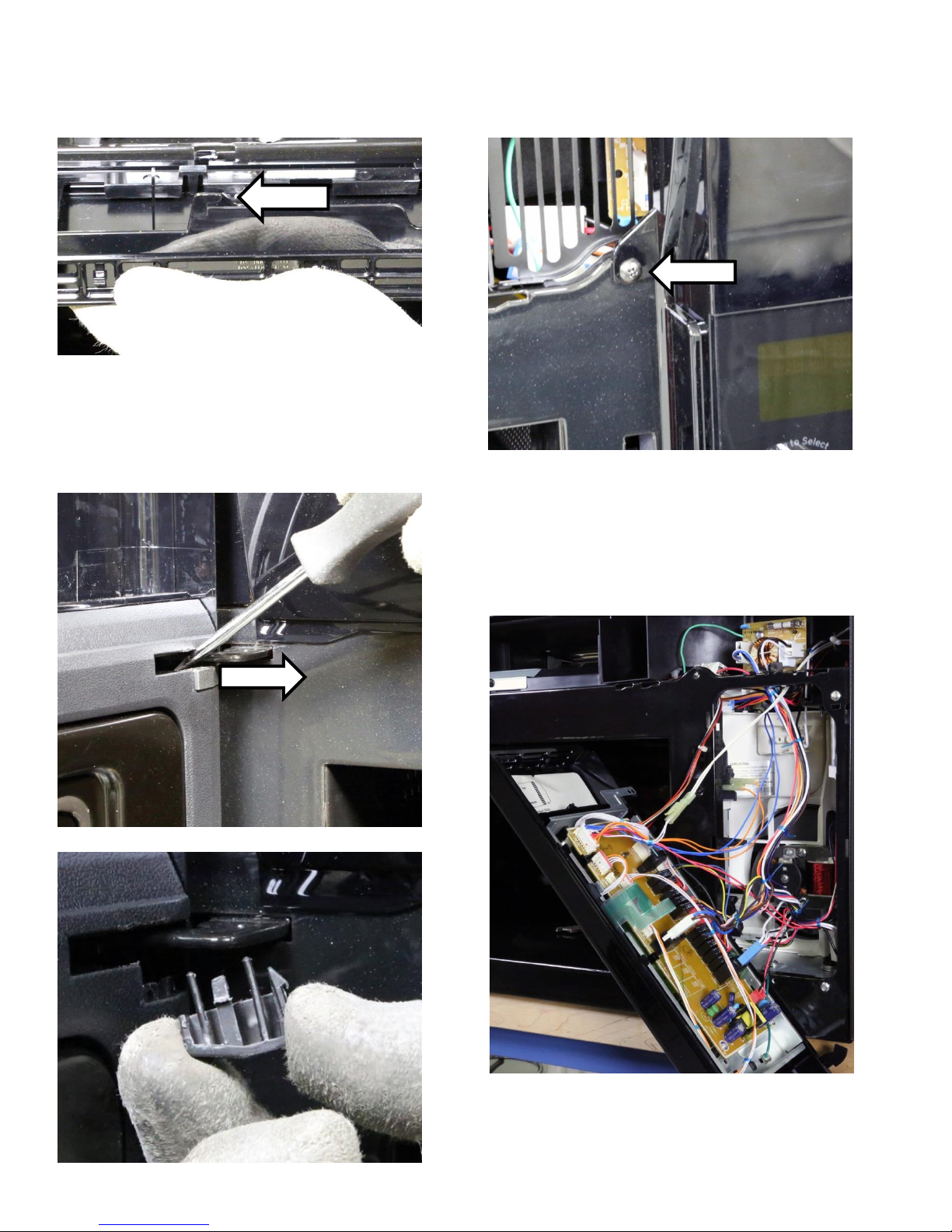

Component Access

Grill – Remove 2 top screws and slide grill to left to

disengage tabs.

tab

Door –Using a small screwdriver, depress the tab

on the end cap under the top hinge to remove the

end cap. Lift up on the door to disengage the door

posts from the hinges.

Control – Remove grill, remove screw and lift

control up to disengage tabs.

Control can be slid up and out of mounting tabs

and rotated to the left for access to the connectors.

Bottom of end cap shown

3

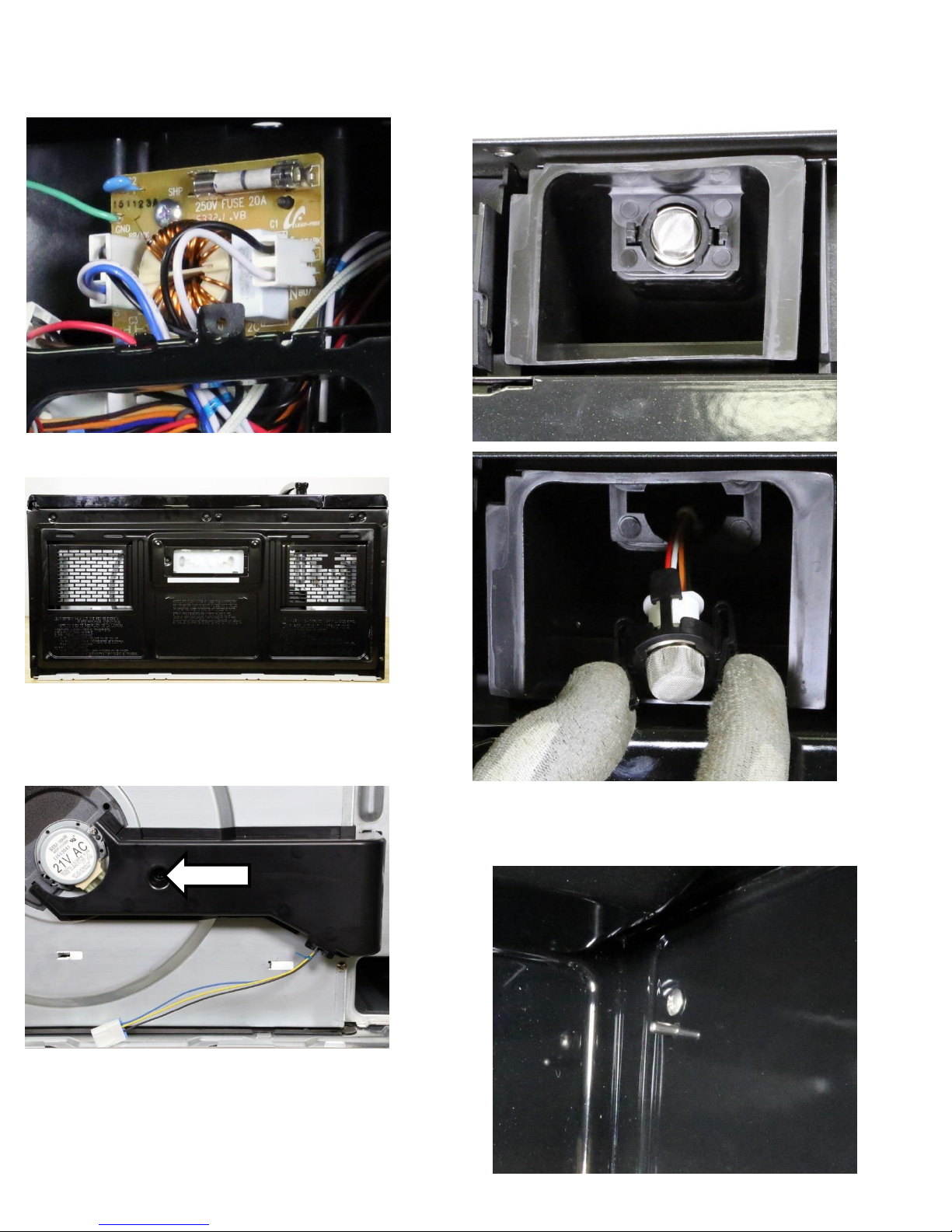

Fuse – Remove grill and remove slotted grill to

access noise filter board and the fuse mounted to it.

Bottom – Remove seven screws.

Sensor (humidity/gas) – Remove the grill, squeeze

tabs on each side of the sensor and pull forward to

disconnect plug.

Turntable motor – Remove the bottom and the

screw that secures air duct. One screw secures the

motor along with one tab.

Turntable spindle – Remove the bottom and the

turntable motor to remove turntable spindle. (not

shown)

Oven sensor – Remove the case. From inside the

oven cavity remove the screw which secures to a

nut behind the sensor.

4

Loading...

Loading...