GE PTWN8055MMS, PTWN8050MWW User Manual

GWS 05/06/2011

Copyright 2010

GE Profile 5.2 IEC* cu. ft. Stainless Steel

Capacity Washer

Models:

PTWN8055MMS (Metallic Silver)

PTWN8050MWW (White)

2011 Energy Star® qualified

Service Guide

Pub# 31-9211

Copyright 2011

2

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, & mechanical

experience. Any attempt to repair a major appliance may result in

personal injury & property damage. The manufacturer or seller cannot be

responsible for the interpretation of this information, nor can it assume

any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this product.

If electrical power is required for diagnosis or test purposes, disconnect

the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete

a path to ground are removed for service, they must be returned to their

original position & properly fastened.

Copyright 2011

3

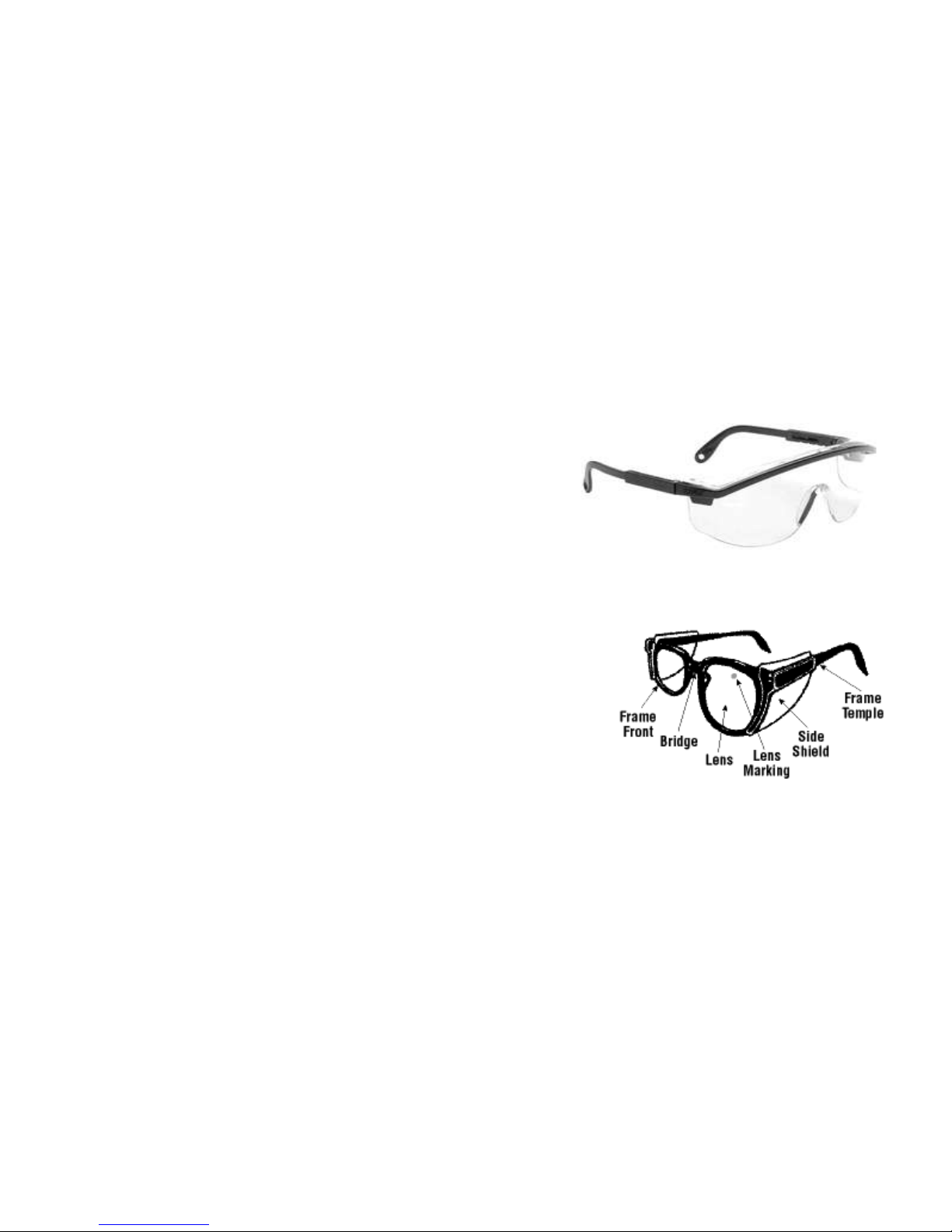

GE Factory Service Employees are required to use safety glasses with side

shields, safety gloves & steel toe shoes for all repairs.

Dyneema® Cut

Resistant Glove

Safety Glasses

must be

compliant with

ANSI Z87.1-2003

Prescription Safety Glasses

Plano Safety Glasses

Steel Toe Shoes

VR Gloves – provide shock protection

Copyright 2011

4

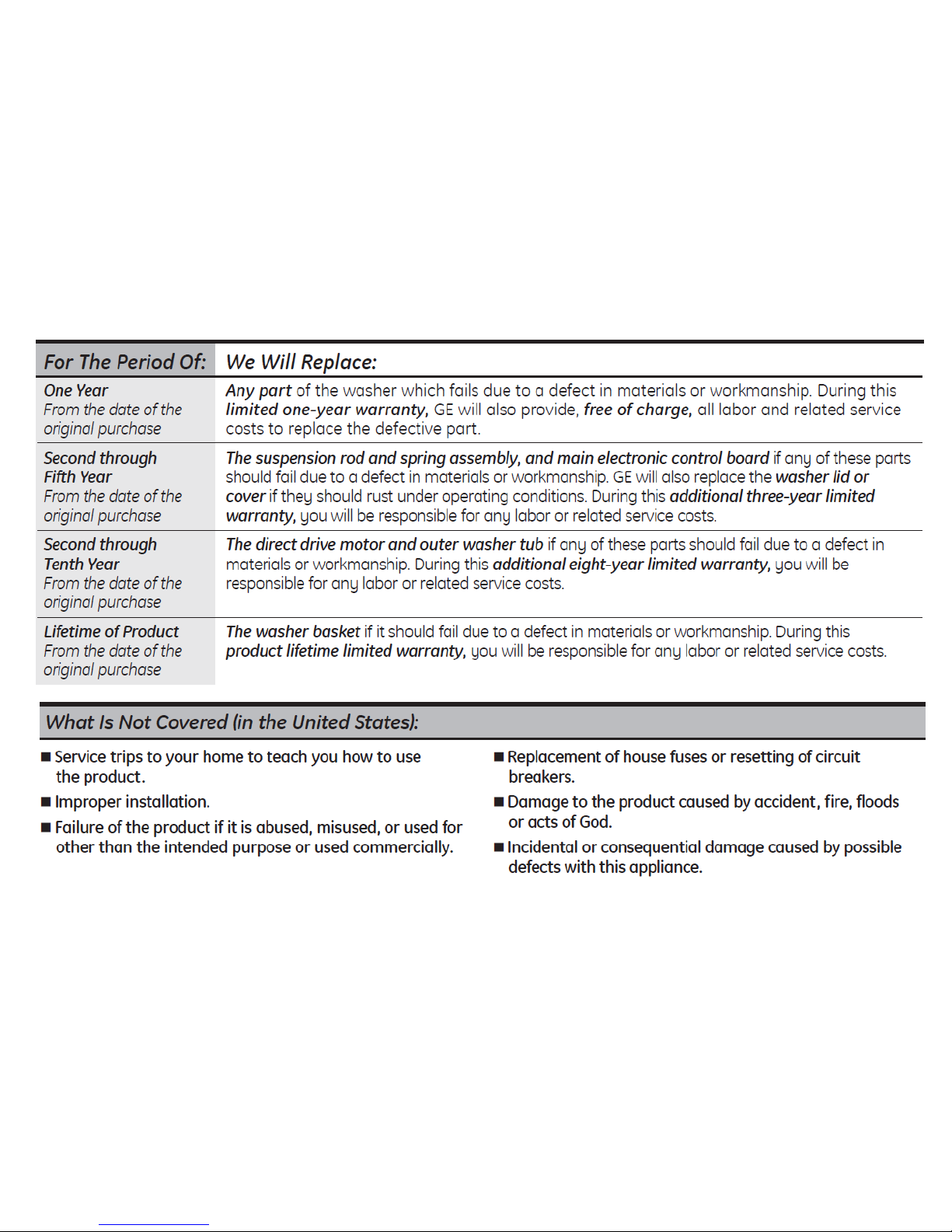

Warranty

Copyright 2011

5

Nomenclature

Copyright 2011

6

Model / Serial Plate

Model / Serial plate is located on the rear of the

backsplash just above the water inlet connections.

Copyright 2011

7

Mini-Manual

Mini-Manual is packaged inside a plastic bag and is located

inside the backsplash between the pressure switch and the

water valve assembly.

Copyright 2011

8

Wash Cycles

“Tidal Wave” or “Alpha Wash”

Basket spins at 230 RPM clockwise then counter-clockwise.

“Centrifusion Wash”

Basket spins slowly clockwise then counter-clockwise.

“Infusor Wash”

Tub remains stationary. Infusor turn clockwise then counter-clockwise.

Copyright 2011

9

Dispenser Drawer

• For powder detergent, remove the tray & insert.

• To remove drawer for cleaning, pull out to stop, lift front upwards

and pull completely out of machine.

Copyright 2011

10

HE Detergent

Use & Care recommends the use of HE detergent only.

Copyright 2011

11

Cycle Cancellation

NOTE (1):

If the customer cancels a cycle by pressing the power pad, after four

minutes the pump will turn on and pump the water out of the tub. The

control does not illuminate or does the tub spin, just the pump is

energized till the tub is empty.

Also doesn’t matter if the lid is up or down.

Copyright 2011

12

Cycle Cancellation

NOTE (2):

If the customer pauses a cycle for an extended amount of time, after two

hours have elapsed, the machine will pump out the water in the tub and

shut off.

Also doesn’t matter if the lid is up or down.

Copyright 2011

13

My Cycle

NOTE (2):

When programming the “My Cycle” feature, the customer can not only

program any cycle but can also add any of the cycle additions, on the

right of the display, to the cycle functions. These would include Fabric

Softener, Delay Start, Extra Rise or Soak.

Copyright 2011

14

Jet Spray

“Jet Spray” is used during the rinse cycles in order to use less

water during rinse.

It sprays water over the clothes (spray rinse) as the basket rotates.

Jet Spray is the default rinse type unless either FABRIC

SOFTENER or EXTRA RINSE cycle additions are selected.

Copyright 2011

15

Control Panel

When the fabric softener pad is selected, the machine will provide a

deep rinse instead of the spray rinse.

Copyright 2011

16

Control Panel Components

• To access the control components, first begin by removing five

Phillips screws securing backsplash rear panel.

• Remove rear panel from backsplash assembly.

Copyright 2011

17

Control Panel Components

• Protect top of washer with a towel or rag.

• Tilt front control panel towards front of machine to disengage tabs.

• Lay control panel on it’s face on top of towel.

Copyright 2011

18

Control Panel Components

Pressure Switch

Water valve assembly

Noise Filter

RF choke

Control assembly

Copyright 2011

19

Control Panel Components

To remove metal shield from control board assembly, pull outward

on side tabs.

Caution: Metal edges are sharp

Copyright 2011

20

Control Panel Components

Removing the metal cover will expose the plug connections and the

individual electronic components on the power board.

Copyright 2011

21

Control Panel Components

• To separate the control assembly from front panel, remove ten

(10) Phillips screws.

• Lift board assembly from panel.

Copyright 2011

22

Control Panel Components

Selector buttons or pads are held to the control panel with tabs and are

replaced as a complete assembly.

Copyright 2011

23

Control Panel Components

• The control assembly consists of a Power Board and a Display / Logic

Board.

• They are held together as an assembly by plastic tabs and connected

electrically by two interconnect plugs and cables.

POWER BOARD

DISPLAY / LOGIC BOARD

Copyright 2011

24

Control Panel Components

Red LED indicates that the power board is powered and “awake”.

Copyright 2011

25

Control Panel Components

To separate the two control boards, first pry back plastic tabs then

pry the two boards apart.

Copyright 2011

26

Control Panel Components

Finally, disconnect the two electrical connectors from the Power

Board.

Copyright 2011

27

Water Valve Assembly

(Rear View)

Water valve assembly is accessible after removing the control panel from

the top of the machine.

Copyright 2011

28

Water Valve Assembly

• The water valve consists of a valve body and five solenoid coils.

• It is only available as a complete assembly.

• Each solenoid controls a specific water function.

Copyright 2011

29

Water Valve Assembly

(Front View)

Bleach

Dispenser

Softener

Jet Spray

Cold

Hot

Each coil on the water valve assembly has an approximate resistance

value of 30 Ω and should read 5-6vdc across the coil when energized.

Copyright 2011

30

Water Valve Assembly

Pink colored, plastic pressure fittings are used in the water distribution

system for a tight fit and to reduce the possibility of leaks.

Loading...

Loading...