GE PTU463SAMR, PTV16SAMR, PTQ470SAMR, PTV19SAMR, PTU527SAMR Technician Service Manual

...

g GE Appliances Service Training

_____________________________

TECHNICIAN

SERVICE MANUAL

Refrigerator

MODELS:

PTV15SAMR PTU427SAMR PTQ440SAMR

PTV16SAMR PTU463SAMR PTQ470SAMR

PTV19SAMR PTU527SAMR PTQ530SAMR

PTV20SAMR PTU565SAMR PTQ570SAMR

PTG440SAMR

PTG470SAMR

PTG530SAMR

PTG570SAMR

PUB NO. : SPWR1027E

JULY 2001

Page 1

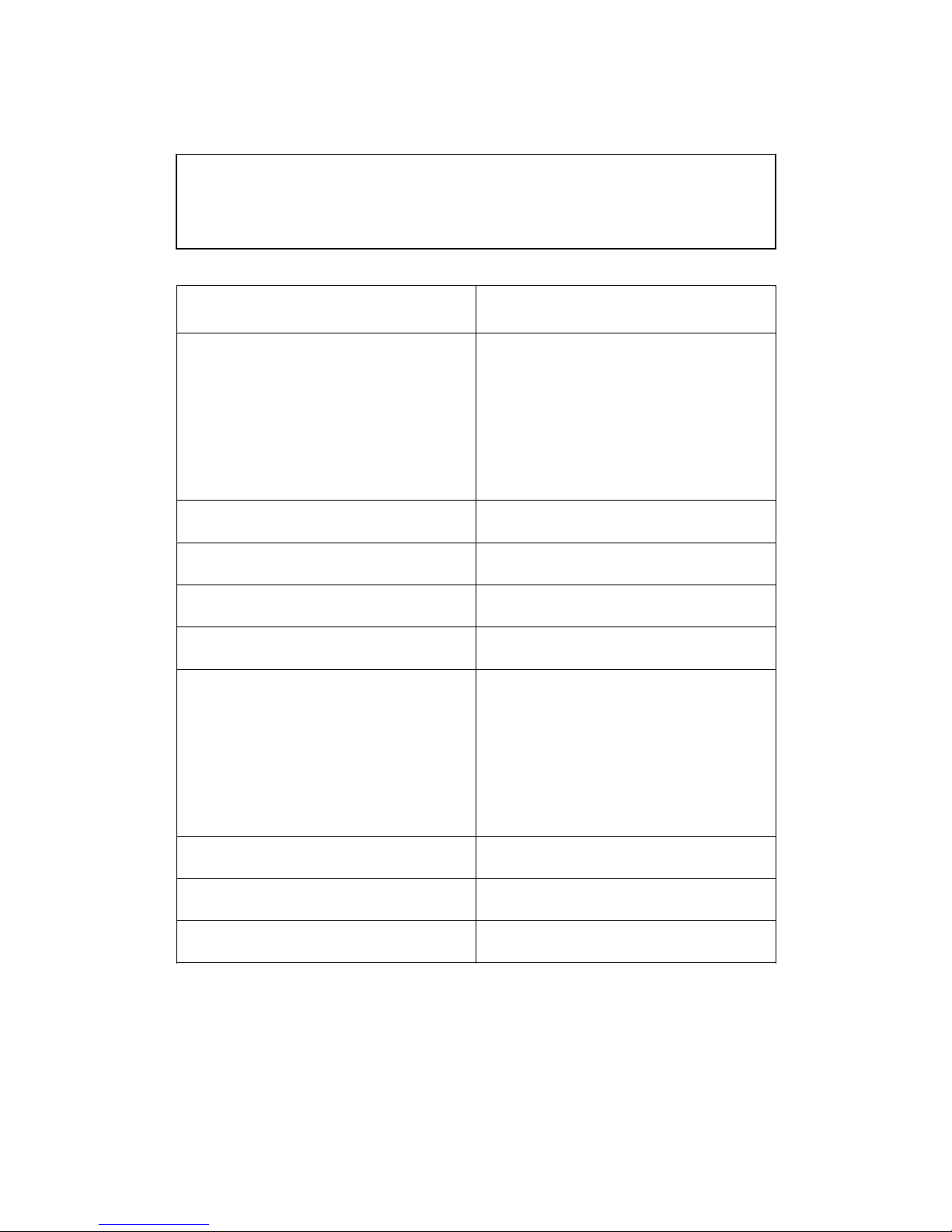

IMPORTANT SAFETY NOTICE

r

r

r

r

The information in this service guide is intended fo

use by individuals possessing adequate backgrounds

of electrical, electronic and mechanical experience.

Any attempt to repair a major appliance may result in

personal injury and property damage. The

manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume

any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before

servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the powe

immediately after performing the necessary checks.

RECONNECT ALL GROUNDING

DEVICES

If grounding wires, screws, straps, clips, nuts, o

washers used to complete a path to ground are

removed for service, they must be returned to thei

original position and properly fastened.

Page 2

THE MANUAL COVERS THE

FOLLOWING MODELS

MODEL # COUNTRY

PTU427SAMR

PTU463SAMR

PTU527SAMR

PTU565SAMR

N/A BANGLADESH

N/A CHINA

N/A HONG KONG

N/A INDIA

PTG440SAMR

PTG470SAMR

PTG530SAMR

AUSTRALIA /

NEW ZEALAND

INDONESIA /

THAILAND /

VIETNAM

PTG570SAMR

N/A JAPAN

N/A KOREA

N/A MALAYSIA

Page 3

THE MANUAL COVERS THE

FOLLOWING MODELS

MODEL # COUNTRY

N/A PAKISTAN

PTV15SAMR

PTV16SAMR

PTV19SAMR

PTV20SAMR

PTQ440SAMR

PTQ470SAMR

PTQ530SAMR

PTQ570SAMR

N/A TAIHITI

N/A TAIWAN

PHILIPPINES

SINGAPORE

Page 4

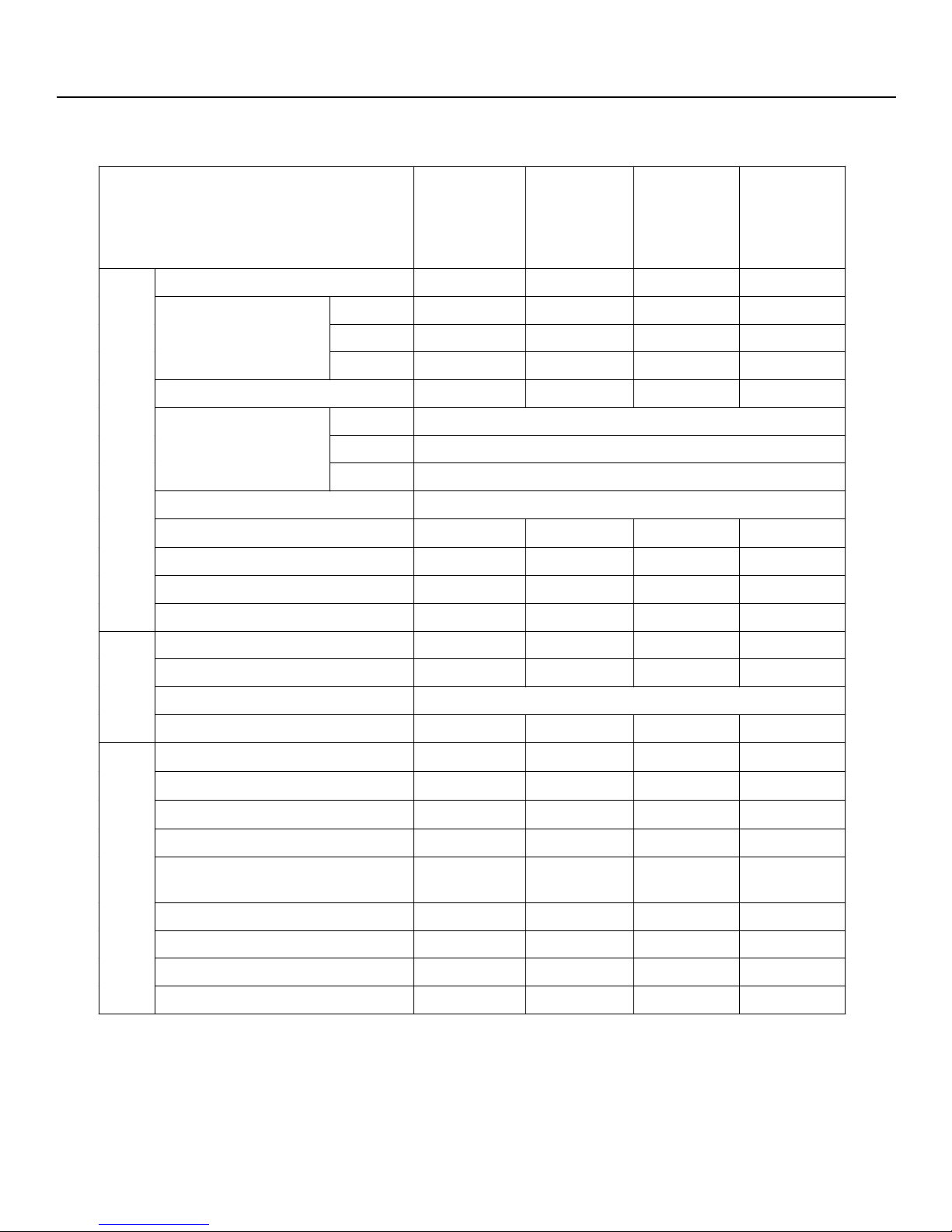

I. SPECIFICATION

PTV16SAMR

PTU463SAMR

PTQ470SAMR

PTG470SAMR

PTU427SAMR

PTQ440SAMR

PTG440SAMR

Models

PTV20SAMR

PTU565SAMR

PTQ570SAMR

PTG570SAMR

PTV19SAMR

PTU527SAMR

PTQ530SAMR

PTG530SAMR

Type 2-door 2-door 2-door 2-door

Height 1803 1703 1774 1674

Width 754 754 674 674Net dimension (mm)

Depth 560 733 706 706

Rated storage volume (liter) F:139 / R:391 F:139 / R:346

System Heater system

Start AutomaticDefrosting

Common

Finish Automatic

Temperature control Automatic (Adjustable)

No frost freezer

ÖÖÖÖ

Interior lamp 1 1 1 1

Caster 2 2

Evaporating pan 1 1 1 1

PTV15SAMR

Ice storage box 1 1 1 1

Transparent plastic shelf 2 2 1 2

Twisted ice tray Twin ice cube maker

Freezer

Transparent door racks 2 2 2 2

Deodorizing device

Multi air flow

Chilled room

ÖÖÖÖ

ÖÖÖÖ

ÖÖÖÖ

Transparent shelf with steel frame 3 2 3 2

Vegetable crisper with moisture

control

Traditional vegetable crisper 1 1 1 1

Refrigerator

ÖÖ

Transparent door racks 4 3 4 3

Large bottle/beer storage rack 1 1 1 1

Egg storage bucket 2 2 2 2

Page 5

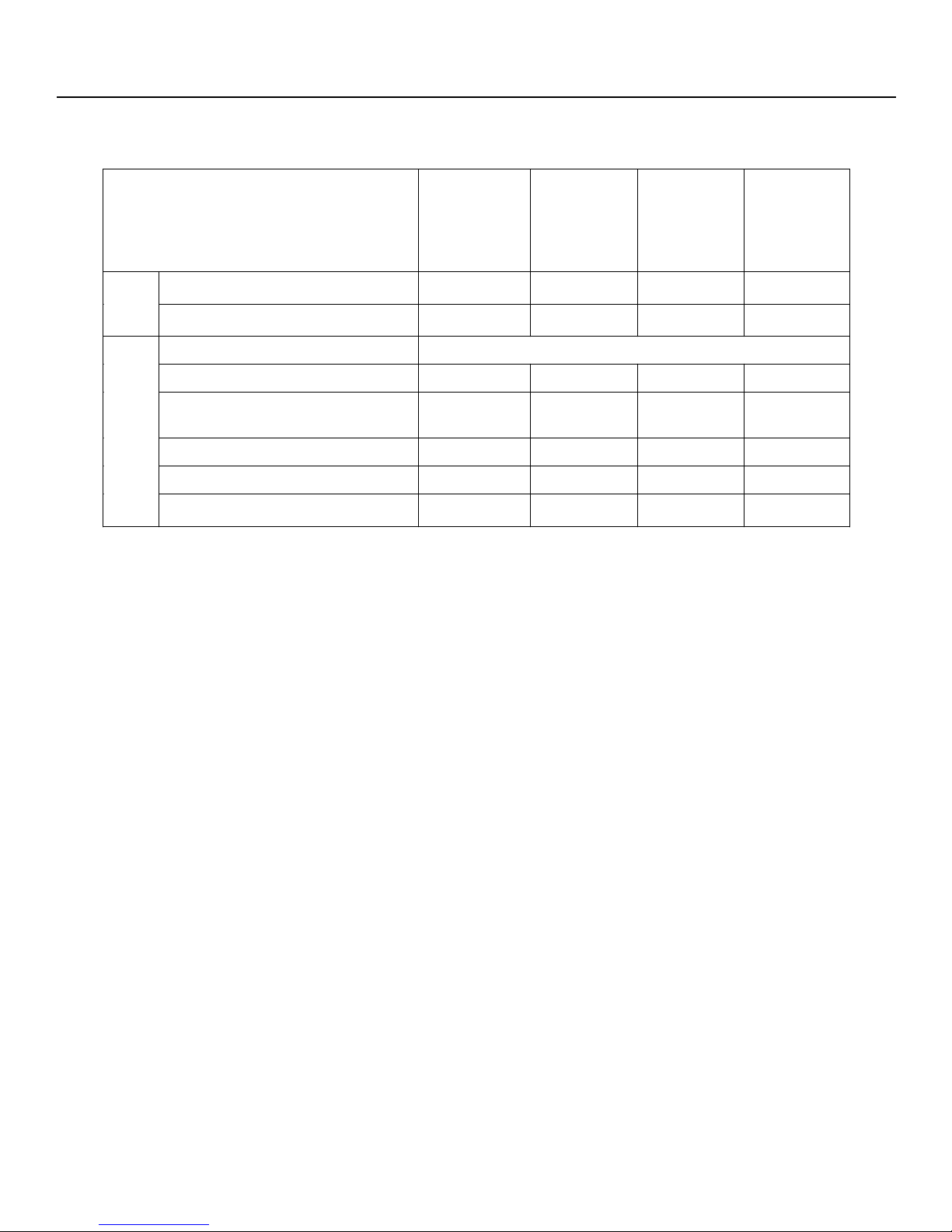

I. SPECIFICATION

PTV20SAMR

Models

Silver

Color

Black

PTU565SAMR

PTQ570SAMR

PTG570SAMR

ÖÖÖÖ

ÖÖÖÖ

PTV19SAMR

PTU527SAMR

PTQ530SAMR

PTG530SAMR

PTV16SAMR

PTU463SAMR

PTQ470SAMR

PTG470SAMR

Rated voltage (V) / Frequency (Hz) 240 VAC / 50 Hz ; 220 VAC / 50 Hz ; 220 VAC / 60 Hz

Rated input (W) 180 180 170 170

Refrigerant (R-134a) charging

quantity

weight

Nte weight (Kg) 83 78 74 63

175g 165g 155g

Poor material SS SS SS SS

Source, Comp. & Net

Recessed handle

ÖÖÖÖ

PTV15SAMR

PTU427SAMR

PTQ440SAMR

PTG440SAMR

155g

Page 6

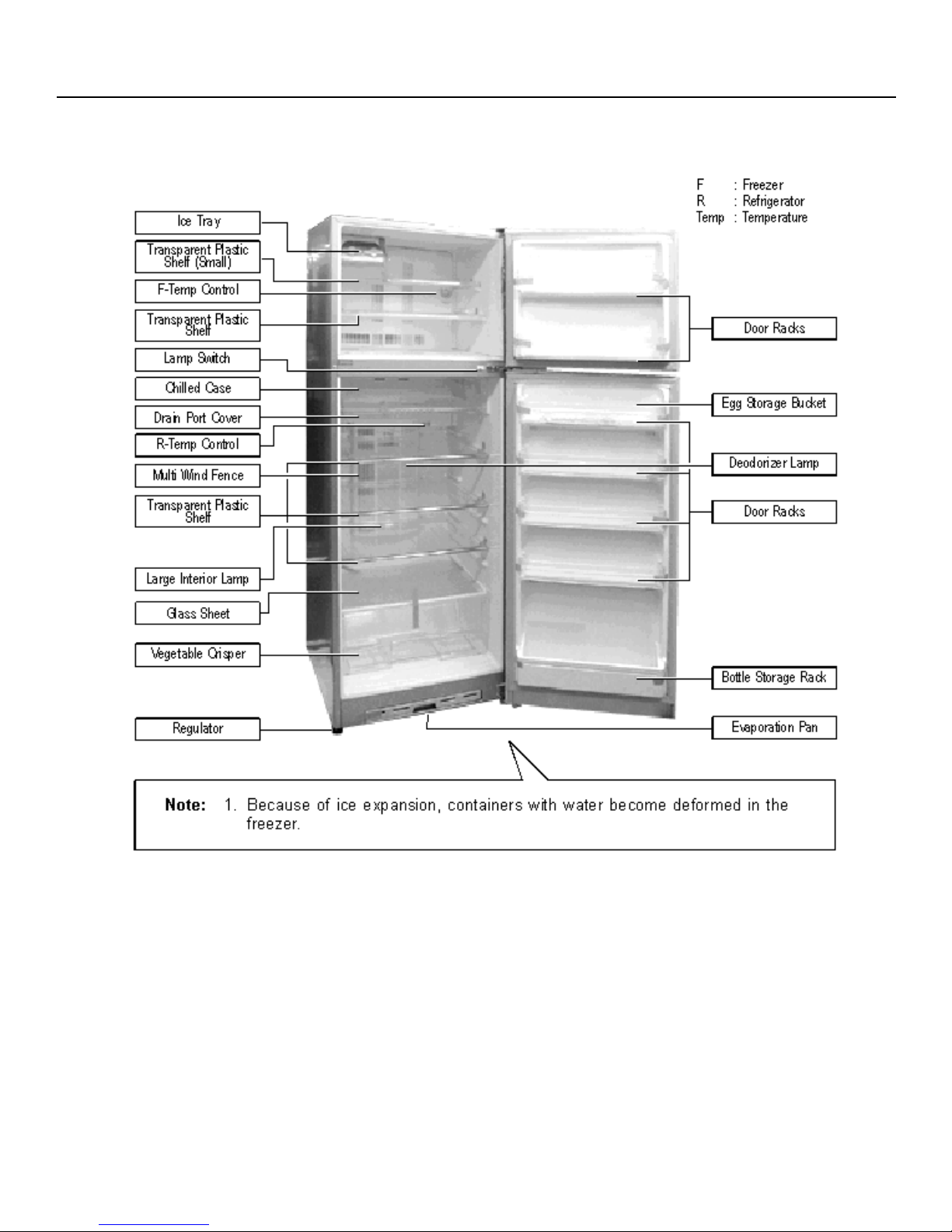

II. PARTS IDENTIFICATION

PTV15SAMR / PTU427SAMR / PTQ440SAMR / PTG440SAMR

PTV16SAMR / PTU463SAMR / PTQ470SAMR / PTG470SAMR

PTV15SAMR / PTU427SAMR / PTQ440SAMR / PTG440SAMR has 2 Transparent Plastic Shelves & 3 Door Racks

PTV16SAMR / PTU463SAMR / PTQ470SAMR / PTG470SAMR has 3 Transparent Plastic Shelves & 4 Door Racks

Features:

Ice tray : Can make and store 1kg of ice cubes.

Chilled Case : The fish and meats which will be cooked within 2 days can store

Evaporation Pan : Water discharged from the refrigerator is evaporated here.

Door Racks (F) : Short-term storage of frozen food.

Egg Storage Basket : Can store 16 eggs.

Door Racks (R) : Short-term storage of refrigerated food.

Bottle Storage Rack : Can store 5 bottles of beer or soda.

Regulator : For regulation of the refrigerator.

here, no thawing is required.

Page 7

II. PARTS IDENTIFICATION

PTV19SAMR / PTU527SAMR / PTQ530SAMR / PTG530SAMR

PTV20SAMR / PTU565SAMR / PTQ570SAMR / PTG570SAMR

PTV15SAMR / PTU427SAMR / PTQ440SAMR / PTG440SAMR has 2 Transparent Plastic Shelves & 3 Door Racks

PTV16SAMR / PTU463SAMR / PTQ470SAMR / PTG470SAMR has 3 Transparent Plastic Shelves & 4 Door Racks

Features:

Ice tray : Can make and store 1kg of ice cubes.

Chilled Case : The fish and meats which will be cooked within 2 days can store

here, no thawing is required.

Evaporation Pan : Water discharged from the refrigerator is evaporated here.

Door Racks (F) : Short-term storage of frozen food.

Egg Storage Basket : Can store 20 eggs.

Door Racks (R) : Short-term storage of refrigerated food.

Bottle Storage Rack : Can store 5 bottles of beer or soda.

Regulator : For regulation of the refrigerator.

Page 8

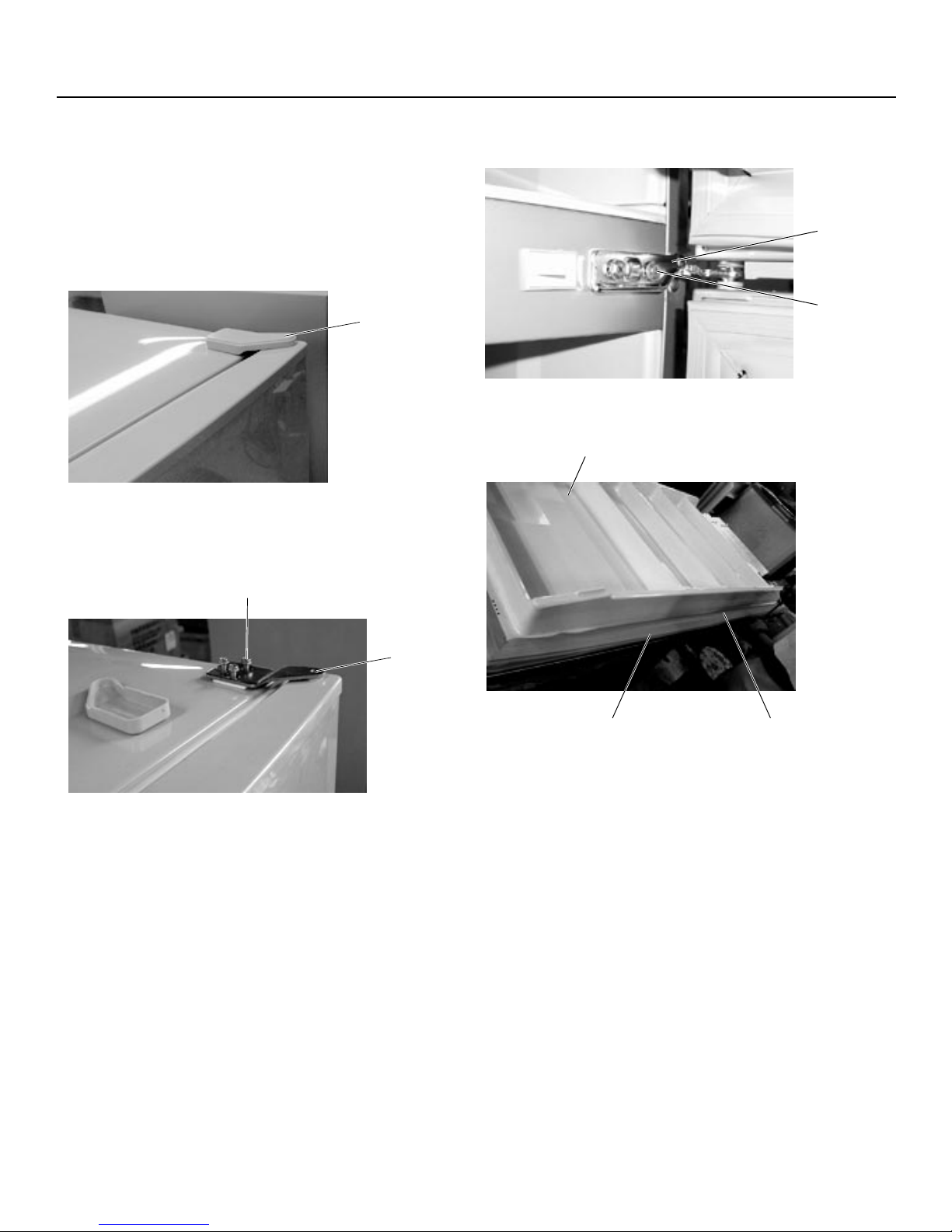

3.1 REPLACEMENT OF DOOR

III. SERVICE GUIDE

3.1.1 Remove the top hinge cover. Twist

and remove carefully not to hurt the

cover and cabinet with driver.

top hinge cover

3.1.2 Remove the screw and top hinge

assy.

screw

top hinge

center hinge

fix screw

3.1.5 Remove the door liner.

door liner

3.1.3 Remove the F door assy slightly and

remove it.

3.1.4 Remove the center hingr and remove

the R door assy.

remove screw with driverdoor packing

Page 9

III. SERVICE GUIDE

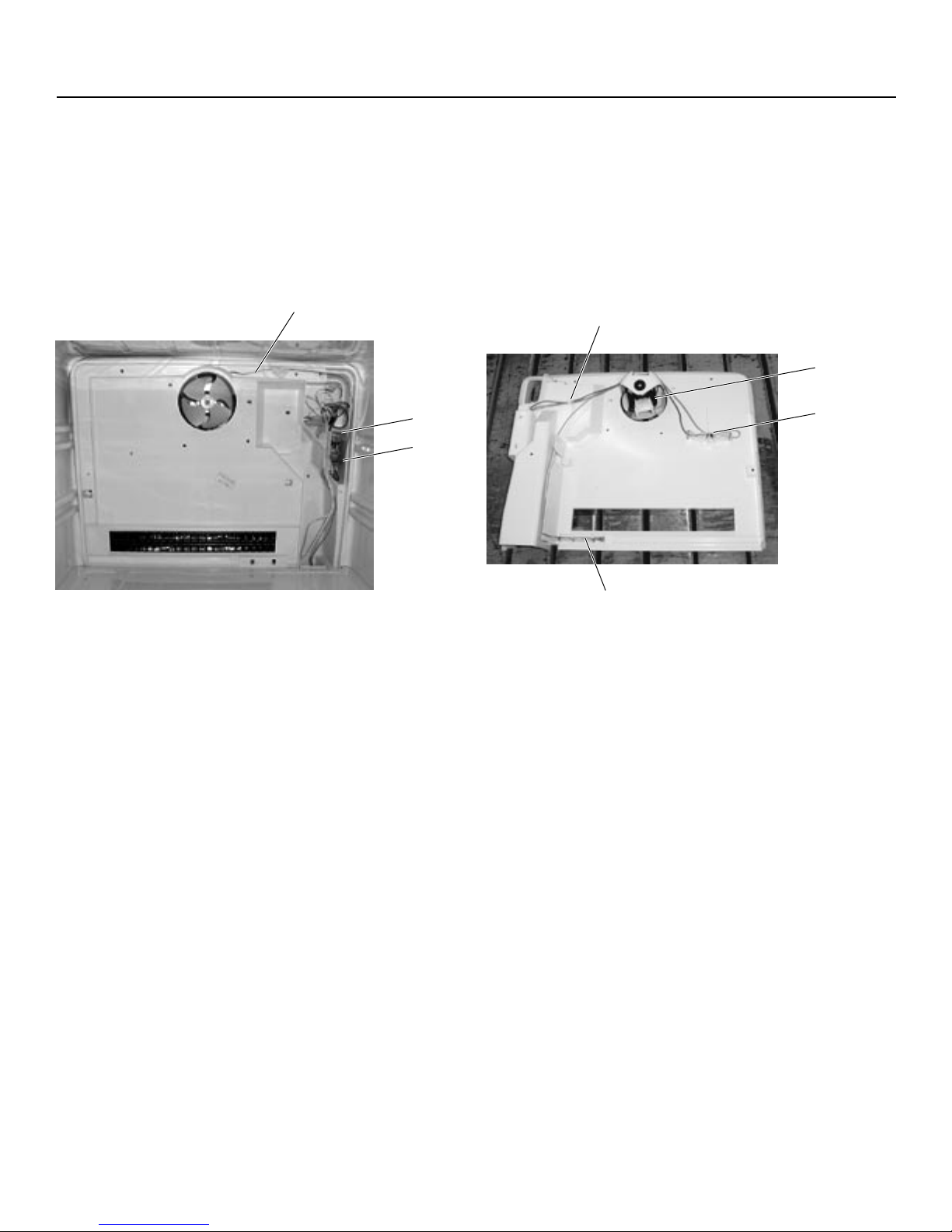

3.2 REPLACEMENT OF HEATER

3.2.1 Draw out the ice storage box.

3.2.2 Pull the case holder of ice silder.

3.2.3 Remove screw and F knob.

3.2.4 Remove F louver and pull the connector.

3.2.7 Remove the heater cover.

3.2.8 Remove the screws (2 pcs).

screw

EV assy

screw

F louver

F knob

screw

EV cover assy

3.2.5 Remove EV cover screw and remove the

EV cover.

fanscrew

connector

F-THM

3.2.6 Remove the EV screw and up the EV

assy.

foil

3.2.9 Rend the al. foil and remove heater

support.

3.2.10 Remove heater.

heaterheater support

screw

heater cover

Page 10

III. SERVICE GUIDE

3.3 REPLACEMENT OF F-THERMO

3.3.1 Remove F-THM screw.

3.3.2 Remove F-THM and replacement.

THM tube

screw

F-THM

3.4 REPLACEMENT OF DEFROST

THERMO

3.4.1 Remove D-band.

3.4.2 Remove D-THM assy and replace it.

D band

fan motor

defrost thermo

fuse

Page 11

III. SERVICE GUIDE

3.5 REPLACEMENT OF DAMPER THERMO

3.5.1 Remove the lamp cover.

3.5.2 Remove the multi air louver screw.

3.5.3 Remove the wiring cover.

3.5.4 Remove the multi air louver assy.

3.5.5 Remove the R control box scrwe.

3.5.6 Remove the R control box assy.

3.5.7 Remove the R air guide.

3.5.8 Remove the damper thermo and replace.

F knob

drain hole cover

screw

R control box assy

multi air louver

R air guide top

R knob sealer

screw

B-THM support

R air guide sealer

damper thermo

R air guide bottom

lamp cover

screw

wiring cover

lamp holder

lamp

screw

Page 12

III. SERVICE GUIDE

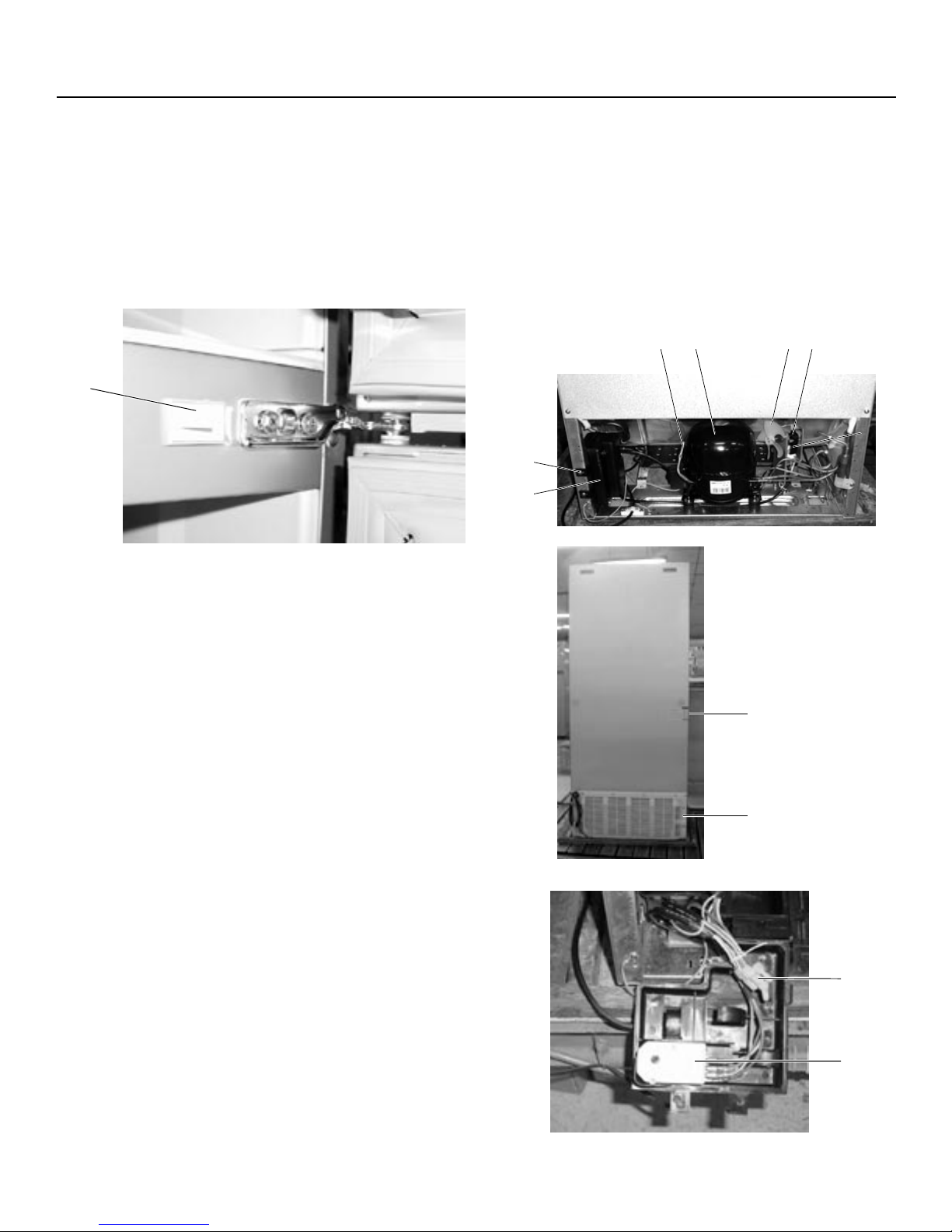

3.6 REPLACEMENT OF DOOR SWITCH

3.6.1 Remove the door switch by using

screwdriver, remove the door switch from

cabinet, takinf care not to damage the

cabinet.

door switch

3.7 REPLACEMENT OF D-TIMER

3.7.1 Remove electric box screw.

3.7.2 Remove electric box.

3.7.3 Remove D-timer and replace.

fan fan motor (for compressor)

screw

electric box

charge pipe

compressor

rating label

compressor cover

terminal

defrost timer

Page 13

III. SERVICE GUIDE

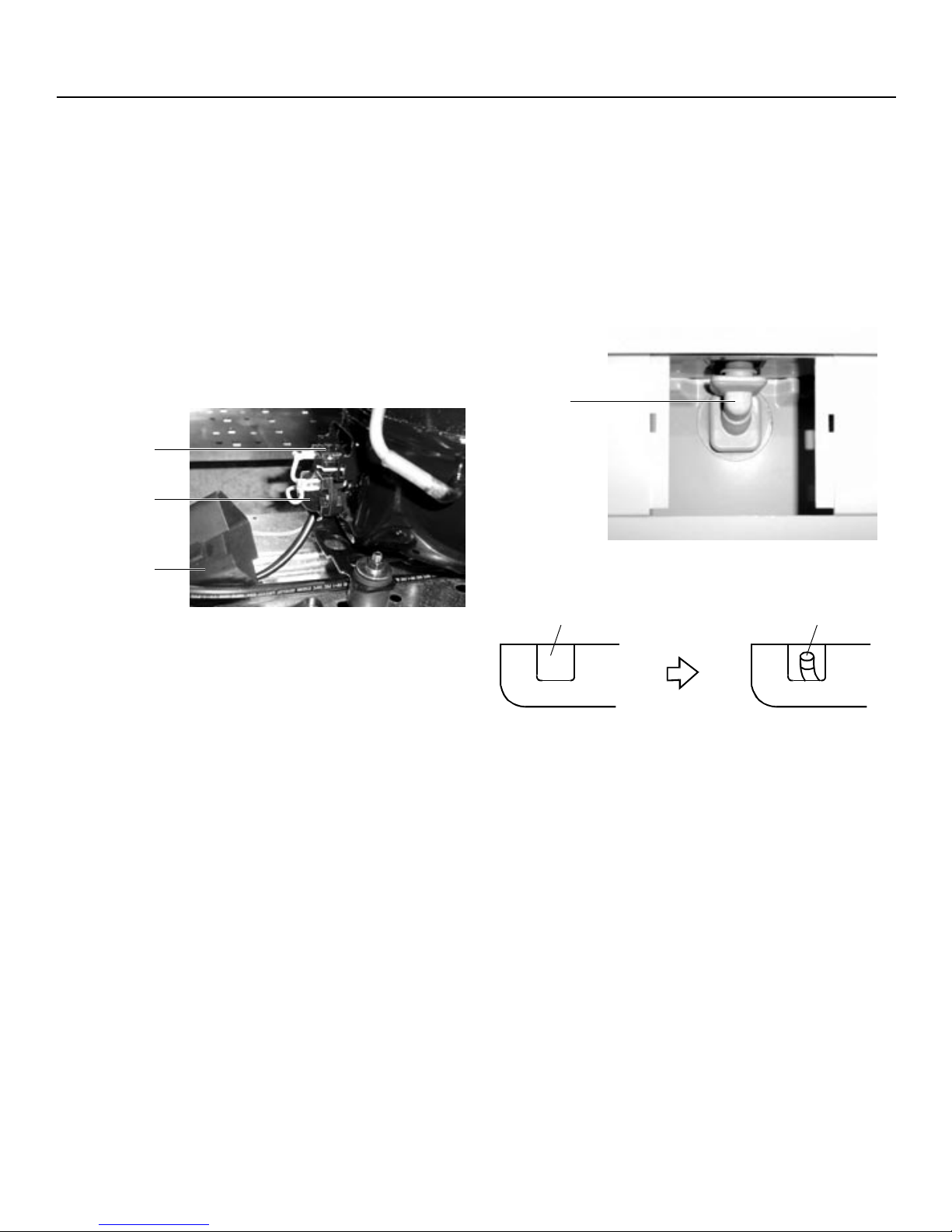

3.8 REPLACEMENT OF PTC & OLP

OVERLOAD RELAY

3.8.1 Remove the compressor cover.

3.8.2 Remove electric box clamp.

3.8.3 Remove electric box.

3.8.4 Remove PTC & OLP and replace PTC &

OLP.

OLP overload relay

start relay

electric box

3.9 HOW TO CLEAN DRAIN PIPE

3.9.1 Remove drain hole cover.

3.9.2 Remove drain connector.

3.9.3 Clean connector & drain pipe.

drain connector

Dismounting and Cleaning of Drainage Pipe

Drainage hole cover Drainage pipe

Control box

Before opening the box After opening the box

3.9.4 Water Drainage

i. The water drainage adapter in the

drawer should be cleaned every 6

months to 1 year to keep it from being

obstructed. This avoids poor drainage

and refrigeration.

ii. The water drained from the refrigerator

is drained into the evaporation pan

from the drainage system.

iii. Water in the evaporation pan shall be

duly evaporated by the radiator. There

is no need to remove it.

iv. After some time, dust or impurity

builds up in the evaporation pan and

produces odor. This should be

cleaned once a month.

Page 14

IV. WIRING DIAGRAM

Be sure to replace the electrical parts with specified ones for maintaining the safety and performance of the set. Because

these are important for maintaining the safety of the set.

BLACK

LAMP

SWITCH

BLACK

LAMP

BLUE

L

GREEN

GREEN

F-THM

FAN

MOTOR

WHITE

FM

ORANGE

TIMER

REDBLUE

21

TM

34

BROWN

BROWN

CONDENSER

FAN MOTOR

YELLOW

DEFROST

HEATER

D-THM

WHITE

GRAY GRAY

FM

P

T

C

OCR

C

56

MS

COMPRESSOR

Page 15

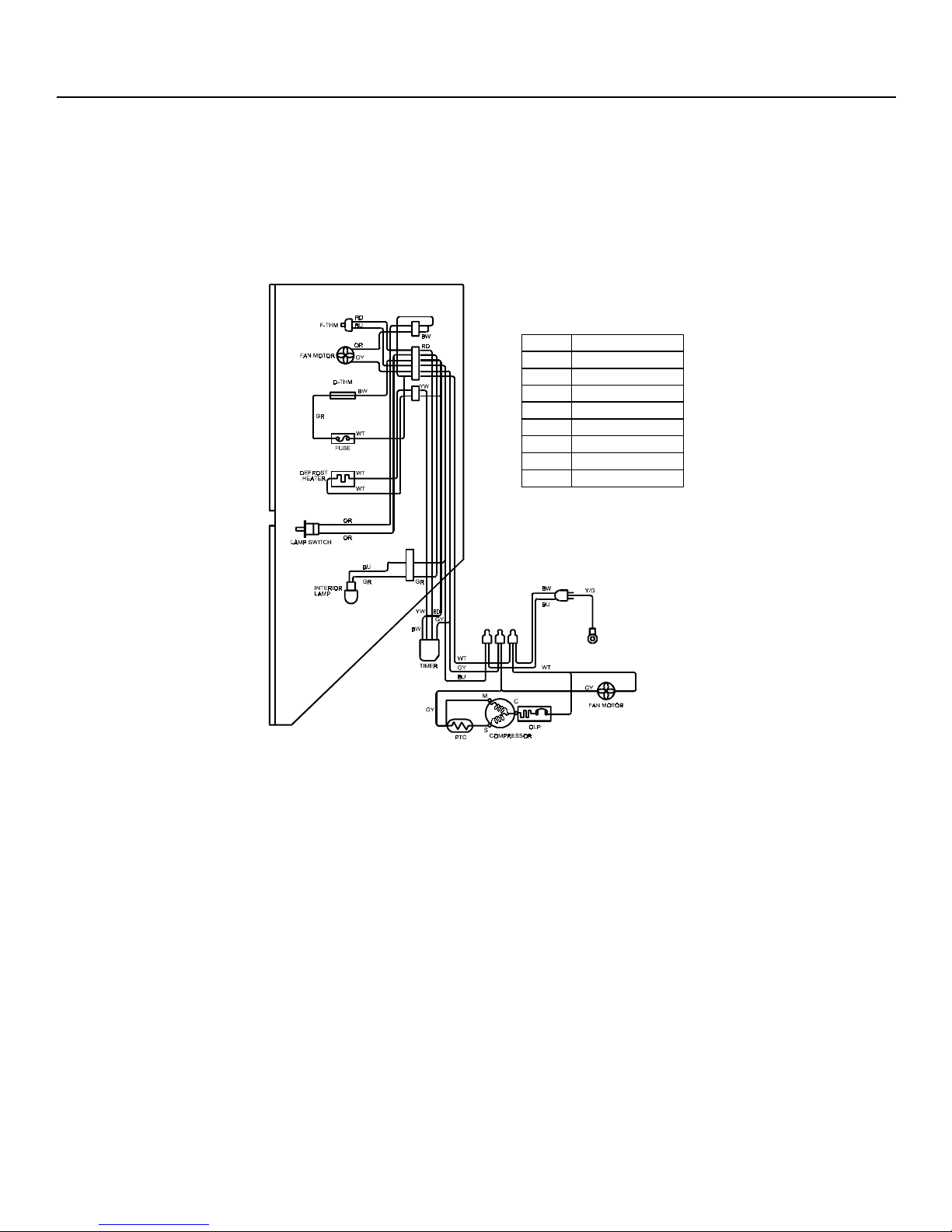

IV. WIRING DIAGRAM

PTV15SAMR / PTU427SAMR / PTQ440SAMR / PTG440SAMR

PTV16SAMR / PTU463SAMR / PTQ470SAMR / PTG470SAMR

Colour Code Table

RED

RD

BLUE

BU

BROWN

BW

ORANGE

OR

GRAY

GY

WHITE

WT

GREEN

GR

YELLOW

YW

YELLOW /GREEN

Y/G

Page 16

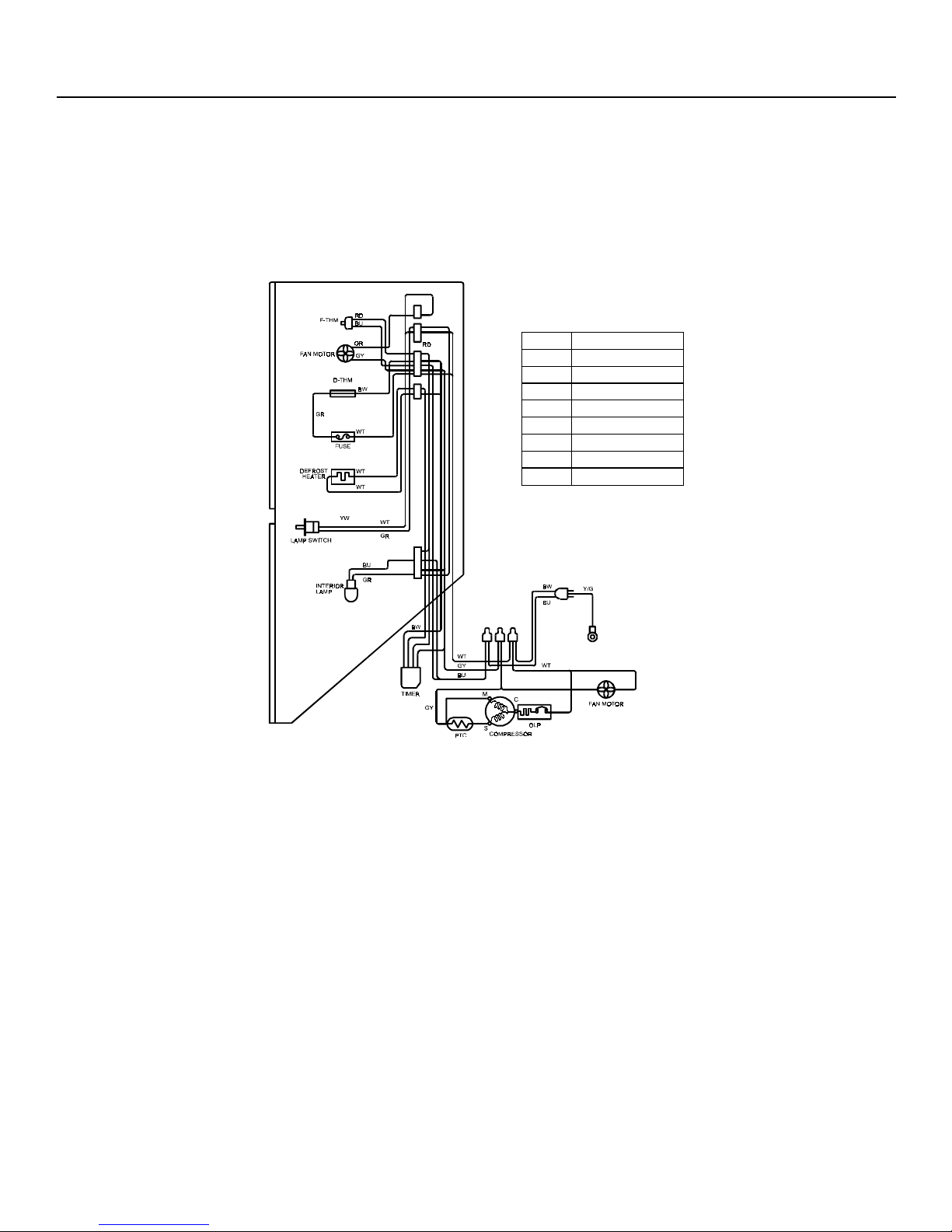

IV. WIRING DIAGRAM

PTV19SAMR / PTU527SAMR / PTQ530SAMR / PTG530SAMR

PTV20SAMR / PTU565SAMR / PTQ570SAMR / PTG570SAMR

Colour Code Table

RD

RED

BU

BLUE

BW

BROWN

OR

ORANGE

GY

GRAY

WT

WHITE

GR

GREEN

YW

YELLOW

Y/G

YELLOW /GREEN

Page 17

5.1 DEFROSTING

5.1.1 No Defrosting Operation Is

Necessary

As this machine is so designed that a

built-in evaporator cools air and a fan

circulates cooled air, neither the

freezer nor the refrigerator is frosted,

though the evaporator is frosted.

The frosted evaporator is defrosted

automatically due to the function of

defrosting timer and heater, requiring

no defrosting operation.

5.1.2 Where is melted ice brought?

i. Melted ice is brought into the

V. FUNCTIONS

evaporating pan at the bottom of

the set and is evaporated here by

the heat of sub condenser.

ii. Be sure to use the evaporating pan

as inserted so as to be level with

the outer case.

Page 18

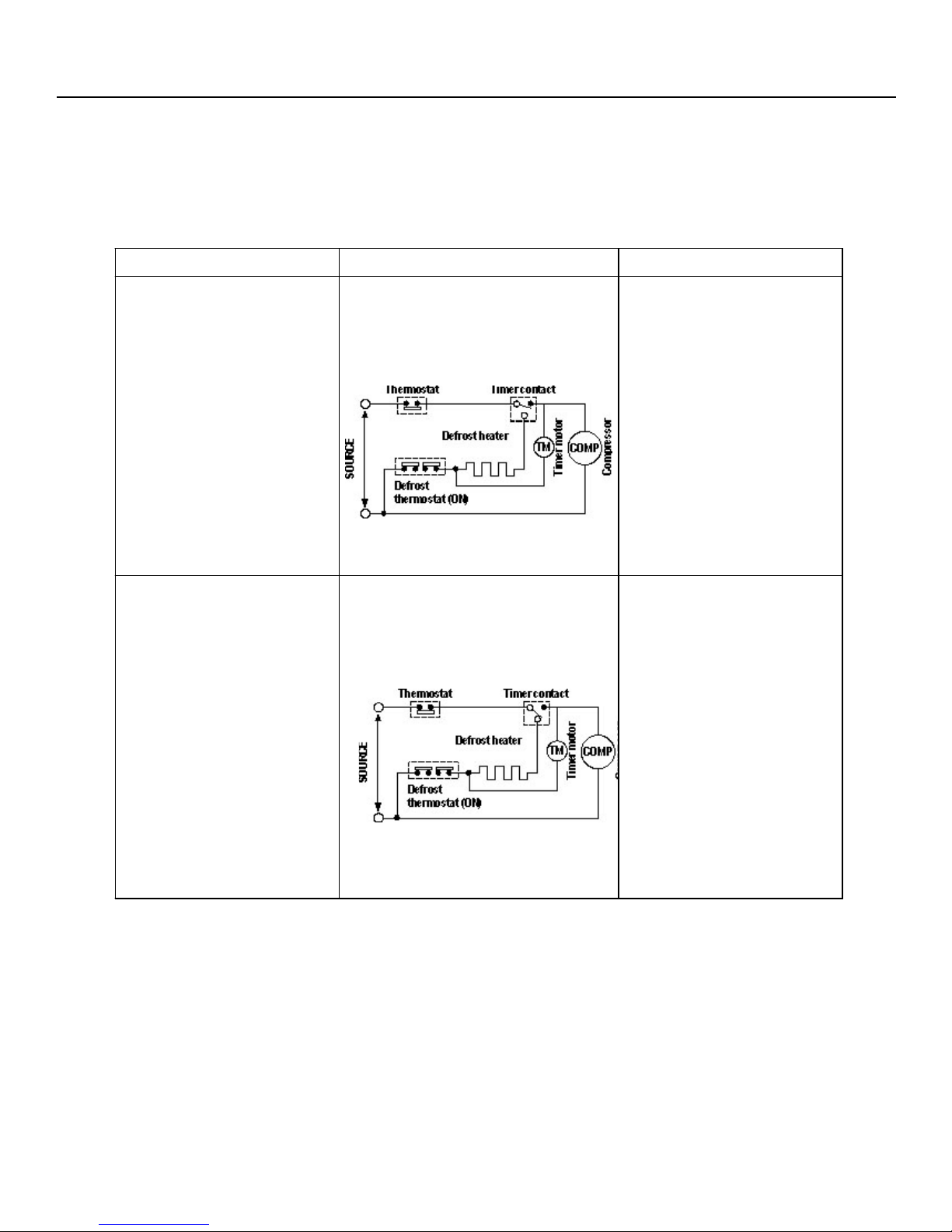

V. FUNCTIONS

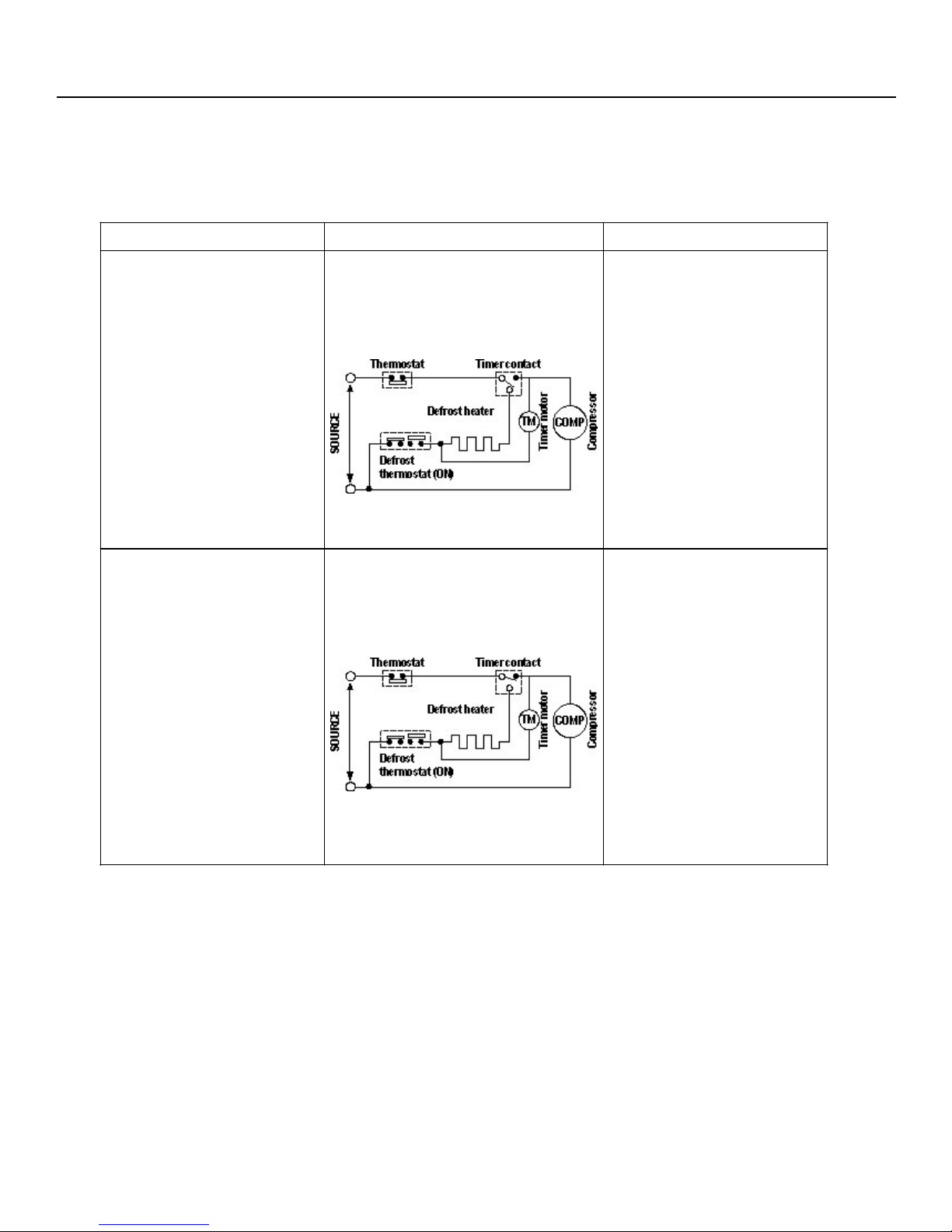

5.1.3 The following circuit diagrams in the table show automatic defrosting function of the refrigerator

with timer and defrost thermostat.

Operation Electric diagram Description

Defrost thermostat ON

1. Cooling (Normal)

·

Compressor running

·

Timer motor running

·

The integration timer

integrates running time of

the compressor. When it

reaches 8 hours 50 min. at

50Hz (10 hours 50 min at

60Hz), the timer contact is

changed to start

defrosting.

2. Defrosting

(Time 20 to 30 min)

Figure F-1

Defrost thermostat ON

·

Compressor stops

·

Timer motor stops

·

Figure F-2

The timer contact is

·

changed to start

defrosting, the timer

motor stops, and power

is supplied to the defrost

heater.

It takes about 20 to 30

·

min. to defrost. When

little frosted the

defrosting takes little

time. When much

frosted, the defrosting

takes much time.

Page 19

Operation Electric diagram Description

3. Drain

(Time approx. 3 min)

V. FUNCTIONS

Defrost thermostat OFF

·

Compressor stops

·

Timer motor running

·

Figure F-3

When the defrost

thermostat becomes OFF,

the timer motor at rest

starts running. During the

operation time (2 min. 48

sec./50Hz; 2 min/ 60Hz)

defrosted water is drained

outside the refrigerator.

4. Cooling start

(Time approx. 5 min)

Defrost thermostat OFF

·

Compressor running

·

Timer motor stops

·

Figure F-4

Timer contact is

·

changed to cooling

operation and the

compressor starts

running and the timer

motor stops.

Defrost thermostat

·

contact becomes ON

when its cooled. (Figure

F-1)

Page 20

V. FUNCTIONS

5.1.4 As a reference to determine the

causes of trouble, malfunction and

phenomena are described. Refer to

the following when repairing

i. Disconnection

As off-cycle defrosting is performed,

the defrosting time is extremely

prolonged. Each time defrostihg is

started, the freezer temperature rises

and a portion of ice and stored foods

are melted.

ii. Melted thermo. fuse or opened-circuit

due to the defect of defrost thermostat

When the above mentioned trouble

occurs in cooling operation, the timer

motor does not run, defrosting will not

take place, and consequently freezing

is caused. In the above mentioned

condition, when the timer shaft is

turned by hand to defrost, the timer

motor runs during the operation time.

However, the motor stops from thetime when the contact is changed,

and freezing causes.

Note :

As the thermo. fuse assembly is

intended to prevent dangers, do not use

it under shorted condition even for a

short period.

Page 21

5.2 DEW PREVENTION

The hot pipe, namely D.P. -condenser, is arranged

around the flange part of cabinet and the C-partition

plate, preventing dew from being generated on the

cabinet.

i. D.P. condenser pipe may be felt hot if

touched by hand while the compressor

is in operation.

ii. If you are asked about this, please

explain that the hot pipe serve to prevent

the dew generation.

V. FUNCTIONS

Hot pipe

Page 22

V. FUNCTIONS

5.3 INSPECTION OF INITIAL STARTING

5.3.1 Inspection of cooling unit

i. Set the temperature control knob to

MAX and check that the compressor

starts to operate.

ii. Check that cool air is blown out of

the cold air outlet of the freezer and

the refrigerator.

iii. When the compressor does not work,

check that the timer is not set to

defrost-position.

iv. It takes about an hour and a half or

two hours to put food in the refrigerator

after starting operation.

Note :

- After return the temperature control

knob to MED position.

5.3.2 Inspection of defrost device

Operate the refrigerator for 20 to 30 min.

and then check the defrost device in the

following procedures. Allow 5 min. to

restart the compressor since immediate

starting after stopping will cause

unsmooth operation.

i. Turn the timer shaft clockwise with a

screw driver. At this time, make

certains the timer clinks and the

compressor stops.

ii. After more than 5 min., turn the shaft

further to operate. Make certain

cooling operation is started again.

Note :

- Its not necessary to switch the timer

by changing of source frequency

(50Hz, 60Hz).

- When the refrigerator is operated

initially after installed, the compressor

may vibrate excessively for 1 to 2 min.

However, vibration becomes normal if

it is continuously operated.

Page 23

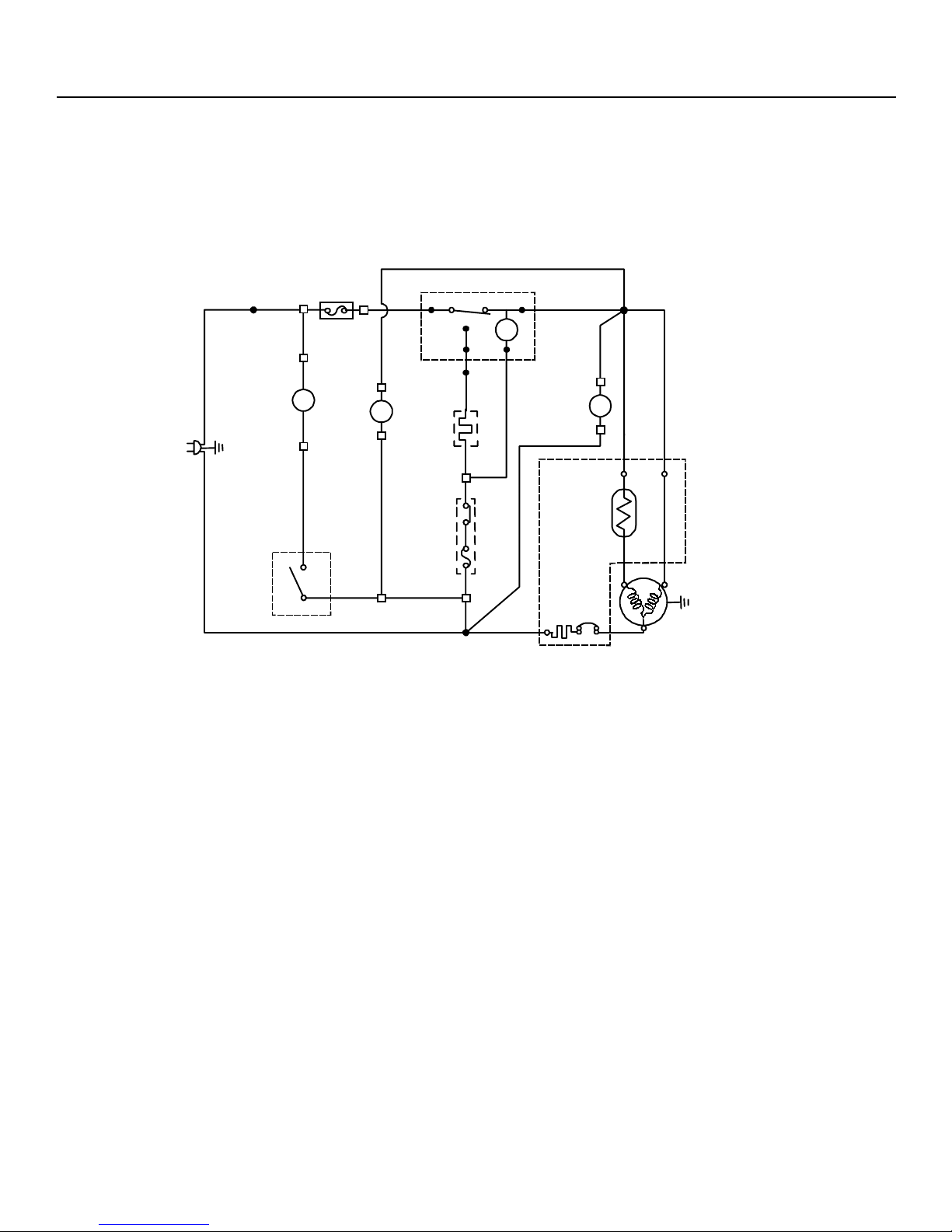

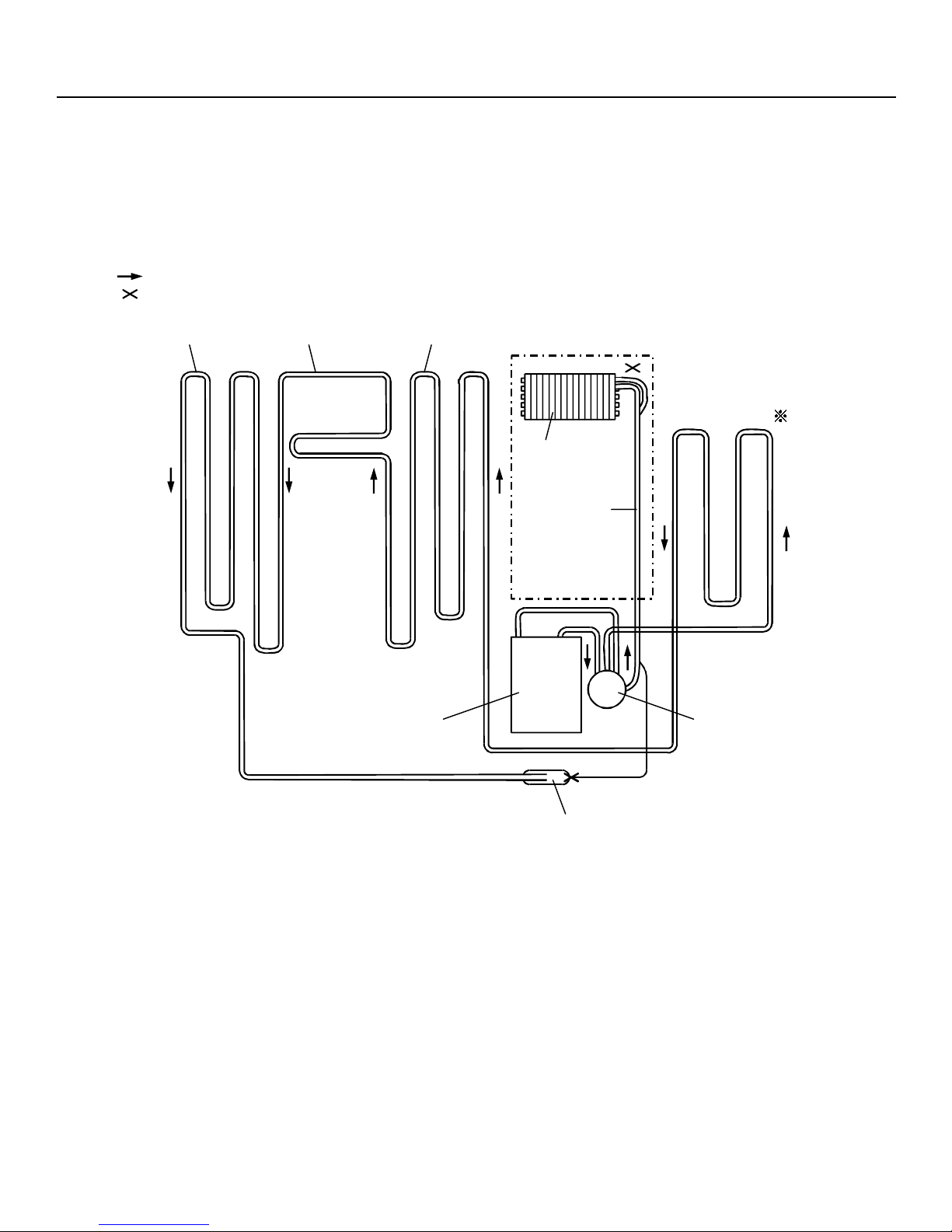

Mark: Refrigerant flow

Mark: Brazing portion

VI. COOLING UNIT

(Side condenser)

Hot pipe

(DP-condenser) (Side condenser)

Bottom condenser

Back condenser

Evaporator

Suction pipe

Compressor

Capillary tube

Dryer

Figure 1 - Cooling Unit

Page 24

VII. ADJUSTMENT

7.1 COMPRESSOR

7.1.1 Role

The Compressor inhales low temp.

and low pressure gas evaporated from

Evaporator of the refrigerator, and

condenses this gas to high temp. and

high pressure gas, and then plays

delivering role to Condenser.

7.1.2 Composition

The compressor is composed of

Compressor Apparatus compressing

gas, Compressor Motor moving

Compressor Apparatus and Case

protecting Compressor Apparatus and

Motor.

There are PTC-Starter, and Over Load

Protector in the Compressor outside.

On the other hand, because the

Compressor consists of 111000 mm

processing precision components and

is sealed after producing without dust

or humidity, deal and repair with care.

7.1.3 Note to Use

i. Be careful not to allow over voltage and

over current.

ii. No Strike:

If applying forcible power or strike

(dropping or careless dealing), poor

operation and noise may occur.

iii. Use proper electric components

appropriate to the compressor.

iv. Note to Keep Compressor:

If Compressor gets wet in the rain and

rust in the pin of Hermetic Terminal, poor

operation and poor contact may cause.

v. Be careful that dust, humidity, and flux

due to welding dont inflow in Compressor

inside in replacing Compressor. Dust,

humidity, and flux due to welding which

inflows to Cylinder may cause lock and

noise.

Page 25

VII. ADJUSTMENT

7.2 PTC-STARTER

7.2.1 Composition of PTC-Starter

i. PTC (Positive Temperature Coefficient)

is no-contact semiconductor starting

device which uses ceramic material

and the material consists of BaTiO3.

ii. The higher the temperature is, the

higher resistance value becomes.

These features are used as starting

device of motor.

7.2.2 Role of PTC-Starter

i. PTC is attached to hermetic

Compressor used for refrigerator,

show case and starts motor.

ii. Compressor for household refrigerator

applies singlephase induction motor.

For normal operation of singlephase

induction motor, in the starting

operation flows in both main coil and

sub coil. After the starting is over, the

current is cut off in sub coil. The

proper features of PTC play the above

all roles. So, PTC is used as a starting

device of motor.

7.2.4 Relation of PTC-Starter and OLP

i. If power off during operation of

Compressor and power on before PTC

is cooled, (instant shut-off within 2

min, or reconnect a power plug due

to misconnecting), PTC isnt cooled

and a resistance value grows. As a

result, current cant flow to the subcoil and motor cant operate and OLP

operates by flowing over current in

only main-coil.

ii. While the OLP repeats on and off

operation about 3-5 times, PTC is

cooled and Compressor Motor

performs normal operation.

iii. If OLP doesnt operate when PTC is

not cooled, compressor motor is worn

away and causes circuit-short and fire.

Therefore, use a proper fixed OLP

without fail.

7.2.5 Note to Use PTC-Starter

i. Be careful to over voltage and over

current.

ii. No Strike:

7.2.3 Motor Restarting and PTC Cooling

i. For restarting after power off during

normal Compressor Motor operation,

plug the power cord after 5 min. for

pressure balance of refrigerating cycle

and PTC cooling.

ii. During normal operation of

Compressor Motor, PTC elements

generate heat continuously. Therefore,

if PTC isnt cooled for a while after

power off, Motor cant operate again.

Dont apply a forcible power or strike.

iii. Keep apart from any liquid. If liquid

such as oil or water inflows into PTC,

PTC materials may break due to

insulation breakdown of material itself.

iv. Dont change PTC at your

convenience. Dont disassemble PTC

and mold. If damaging to outside of

PTGStarter, resistance value alters

and poor starting of Compressor

motor may cause.

v. Use a properly fixed PTG.

Page 26

Loading...

Loading...