GE PTDS650EM, PTDS650GM SERVICE MANUAL

GE Appliances

Technical Service Guide

December 2010

Profi le Stainless Steel Drum

Gas and Electric Dryers with Steam

TEMPERATURE

SETTINGS

the

STEAM

technology

DRYNESS

SENSOR DRY

STEAM DEWRINKLE

TIME DRY

STEAM REFRESH

START

31-9205

PTDS650EM

PTDS650GM

GE Appliances

General Electric Company

Louisville, Kentucky 40225

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing

adequate backgrounds of electrical, electronic, and mechanical experience. Any

attempt to repair a major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the in ter pre ta tion

of this in for ma tion, nor can it assume any liability in connection with its use.

WARNING

If the information in this manual is not followed exactly, fi re or ex plo sion may result

causing property damage, personal injury or death. If you smell gas:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in the building.

– Immediately call the gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

– If you cannot reach the gas supplier, call the fi re department.

WARNING

To avoid personal injury, disconnect power before ser vic ing this prod uct. If electrical

power is required for di ag no sis or test pur pos es, disconnect the power immediately

after per form ing the nec es sary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a path

to ground are removed for service, they must be returned to their original position

and properly fastened.

GE Appliances

Technical Service Guide

Copyright © 2010

All rights reserved. This service guide may not be reproduced in whole or in part in

any form without written permission from the Gen er al Electric Com pa ny.

– 2 –

Table of Contents

Air Duct Assembly ............................................................................................................................................................21

Airfl ow ....................................................................................................................................................................................14

Blower Wheel ...................................................................................................................................................................... 28

Burner Assembly and LP Conversion ...................................................................................................................... 31

Component Locator Views ...........................................................................................................................................16

Control Board Connector Locator View ................................................................................................................. 18

Control Features ............................................................................................................................................................... 7

Control Panel.......................................................................................................................................................................19

Cycle Matrix Chart ............................................................................................................................................................ 15

Door Switch .........................................................................................................................................................................22

Drive Belt ............................................................................................................................................................................... 24

Drum ....................................................................................................................................................................................... 25

Drum Light Receptacle ...................................................................................................................................................22

Drum Shaft and Bearing ................................................................................................................................................25

Drum Slide Assembly ...................................................................................................................................................... 20

Dryer Components...........................................................................................................................................................19

Dryer Features ................................................................................................................................................................... 11

Electronic Control ............................................................................................................................................................38

Flame Detector ..................................................................................................................................................................33

Front Panel ........................................................................................................................................................................... 20

Gas Valve ..............................................................................................................................................................................32

Gas Valve Coils ...................................................................................................................................................................31

Heater Assembly ...............................................................................................................................................................30

High Limit Thermostat ....................................................................................................................................................37

Idler Assembly .................................................................................................................................................................... 26

Ignitor .....................................................................................................................................................................................33

Ignitor Circuit Operation ................................................................................................................................................34

Inlet Control Thermistor .................................................................................................................................................35

Inlet Safety Thermostat ................................................................................................................................................. 35

Introduction ......................................................................................................................................................................... 4

Moisture Sensor ................................................................................................................................................................23

Motor ...................................................................................................................................................................................... 28

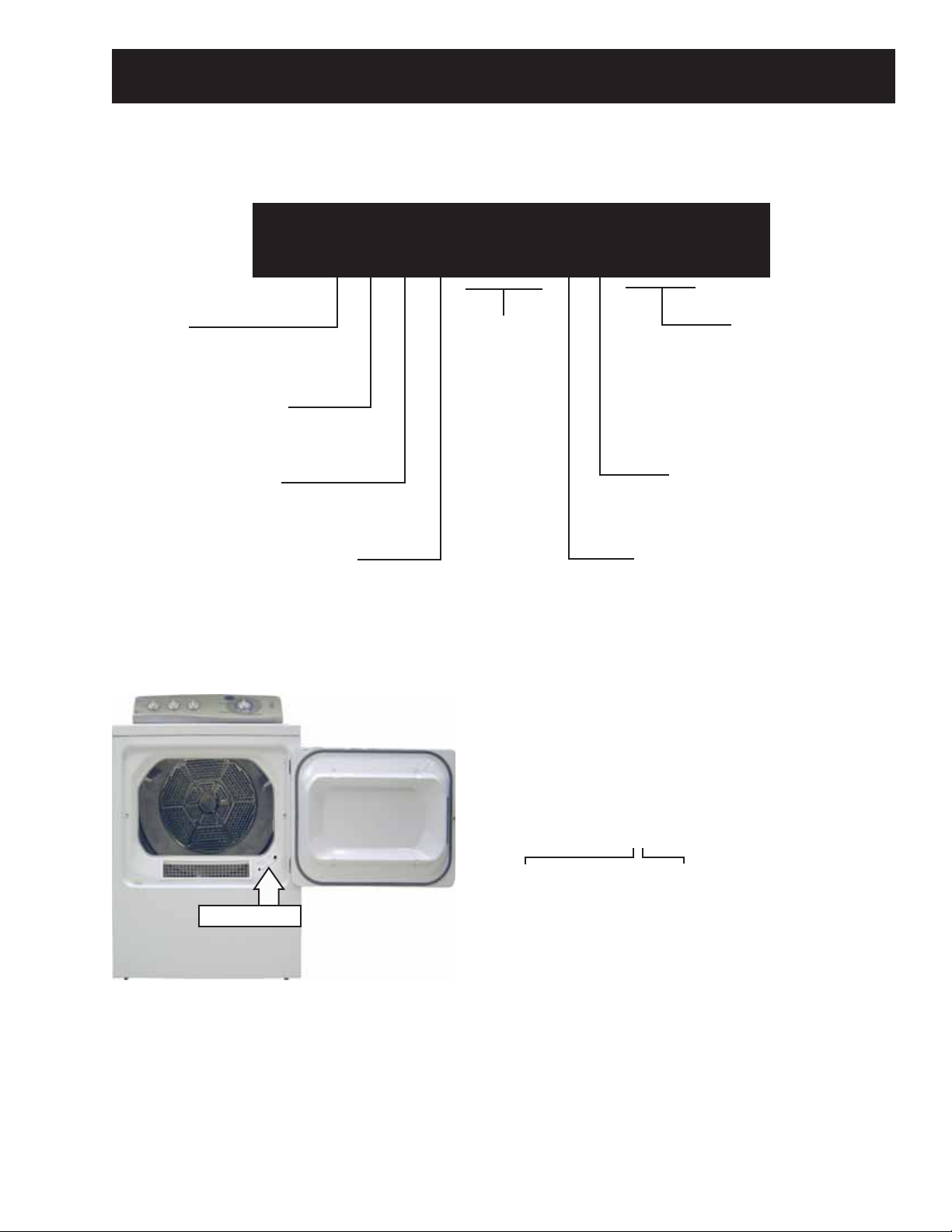

Nomenclature .................................................................................................................................................................... 5

Operation Overview ......................................................................................................................................................... 13

Outlet Control Backup Thermostat ...........................................................................................................................37

Outlet Control Thermistor .............................................................................................................................................36

Reversing the Door ..........................................................................................................................................................12

Schematics and Wiring Diagrams ............................................................................................................................ 43

Service Test Mode .............................................................................................................................................................39

Steam Nozzle ...................................................................................................................................................................... 21

Top Panel .............................................................................................................................................................................. 19

Troubleshooting ................................................................................................................................................................39

Warranty .............................................................................................................................................................................. 45

Water Inlet Valve ..............................................................................................................................................................26

Water Line Connection .................................................................................................................................................. 6

– 3 –

Introduction

Steam and SensorDry Plus™ Features

Profi le 650 model dryers now incorporate two new

steam features. These units do not utilize a separate

steam generator. These dryers use a water valve and

a steam nozzle that functions as a “misting” orifi ce. It

works in conjunction with the

heat generated by the dryer to

de-wrinkle clothing.

Located in the Timed Dry Cycles,

the steam cycles are:

• Steam Refresh - Freshens up

to fi ve slightly wrinkled dry

garments, reducing wrinkles

and odors to extend for

another wear.

• Steam Dewrinkle - Helps

remove stubborn wrinkles

from larger loads, quickly

and conveniently, even from

clothes left in the dryer from

the day before.

A "Y" connector installed on the

washer's cold water inlet hose

supplies water to the dryer. The

water valve inlet is located at the bottom left on the

rear panel of the dryer. A hose carries the water to the

misting orifi ce.

Other Features Include:

• Rotary electronic controls with Adaptive Logic Simplify cycle selection with easy-to-use rotary

dial controls. Adaptive Logic allows the dryer

to adapt to household conditions for effi cient

performance.

• 5 heat selections - Offer enhanced drying

performance and fabric care.

• Cycle countdown display with LED indicators Know exactly how much time is left for each cycle

with bright display and lights.

• Antibacterial cycle - Reduces certain types of

bacteria by 99.9%

• Delicate cycle with low-heat setting - Lowheat setting and gentle wash cycle help

protect delicate garments.

• Deluxe dryer rack - Allows

tumble-free drying of items

like washable sweaters,

sneakers, and stuffed

animals.

• Damp Dry cycle - Allows

you to remove select items

for hang drying or damp

ironing.

• Large 7.0-cubic foot

stainless steel dryer drum

• Drum Lamp

• Dual Thermistors Thermistors are more

sensitive to temperature

changes and can relay the

information faster than

thermostats. The dryer

utilizes dual thermistors to monitor incoming

air temperature as well as air temperature

leaving the drum. The sensors work together

with the heater and the blower to provide

consistent, even heat.

• SensorDry Plus™ - A moisture sensor allows

the control to monitor the fabric for moisture

content and end the cycle at the desired

moisture level.

• Built-in service test mode. Specifi c dryer

components can be operated. Error codes are

recorded and accessible on the control panel

display.

• Flush Door Handle

• Reversible Door

– 4 –

Nomenclature

P T D S 6 5 0 E L W W

Brand

P = Profi le

D = General Electric

Confi guration

T = Top Load

F = Front Load

Product

W = Washer

D = Dryer

Key Feature

S = Steam

N = None

Series

Color

WW = White

BB = Black

MV = Metallic Red

MG = Metallic Gold

MS = Metallic Block

Model Year Designator

L = 2010

Fuel

E = Electric

G = Gas

Nomenclature

The nomenclature tag is lo cat ed on

the front panel inside the door.

Note: The technical sheet is located

inside the control panel.

Serial Number

The fi rst two characters of the serial number

identify the month and year of manufacture.

Example:

Z - DEC 2010 - T

A - JAN 2009 - S

D - FEB 2008 - R

F - MAR 2007 - M

G - APR 2006 - L

H - MAY 2005 - H

L - JUN 2004 - G

M - JUL 2003 - F

R - AUG 2002 - D

S - SEP 2001 - A

T - OCT 2000 - Z

V - NOV 1999 - V

ZT123456S = December, 2010

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 2010

T - 1998

T - 1986

– 5 –

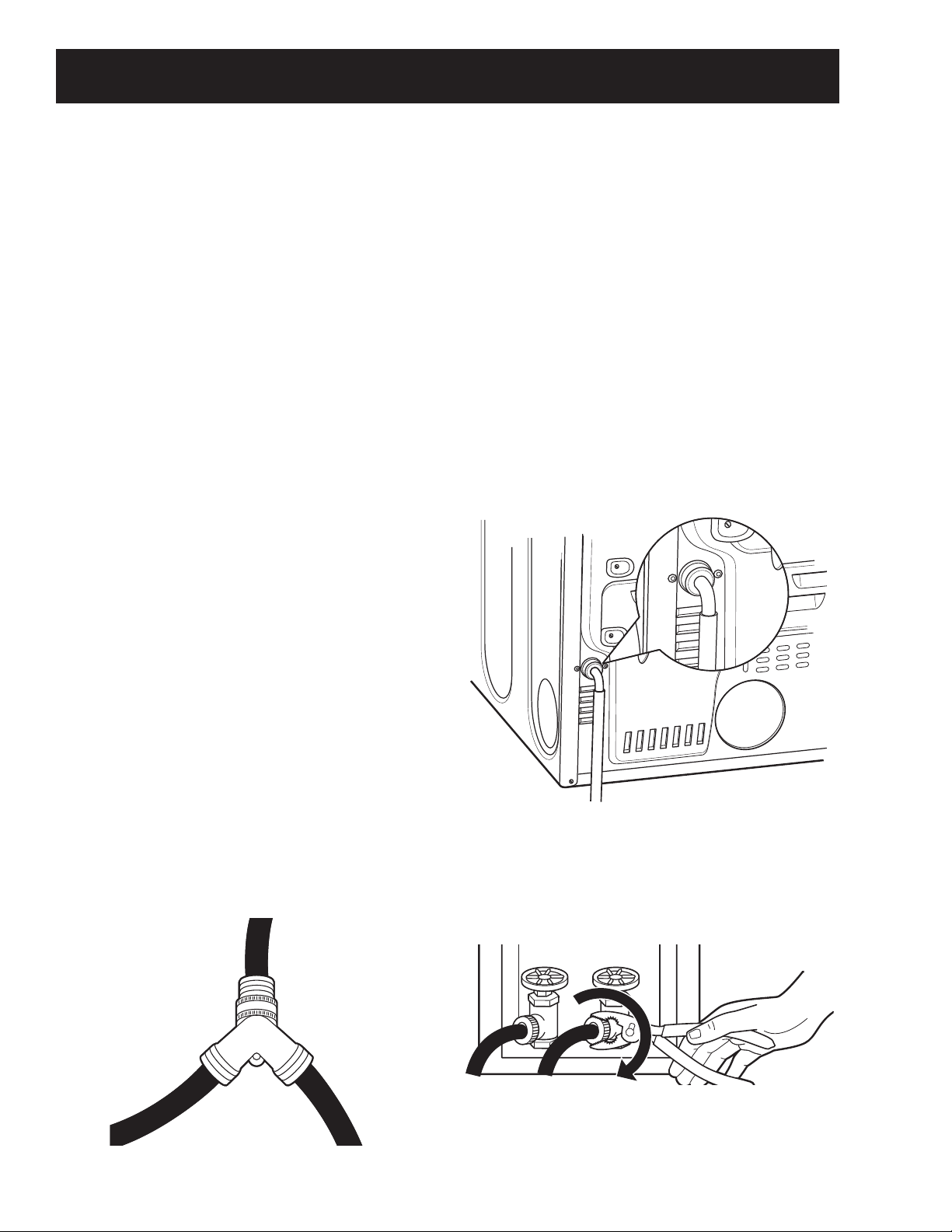

Water Line Connection

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within

42 in. (107 cm) of your washer’s water inlet. The

faucets MUST be 3/4 in. (1.9 cm) garden hose-type

faucets so inlet hoses can be connected. Water

pressure MUST be between 10 and 120 pounds per

square inch. Your water department can advise you

of your water pressure.

Note: A water softener is recommended to reduce

buildup of scale inside the steam nozzle if the home

water supply is very hard.

CONNECTING INLET HOSES

To produce steam, the dryer must connect to the

cold water supply. Since the washer must also

connect to the cold water, a “Y” connector is inserted

to allow both inlet hoses to make that connection at

the same time.

Note: Use the new inlet hoses provided; never use

old hoses.

4. Insert the fi lter screen in the coupling of the

washer’s inlet hose. If a rubber fl at washer is

already in place remove it before installing the

fi lter screen. Attach this coupling to one male

end of the ‘’Y’’ connector. Tighten by hand until

fi rmly seated.

5. Ensure the rubber fl at washer is in place and

attach the dryer’s long inlet hose to the other

male end of the ‘’Y’’ connector. Tighten by hand

until fi rmly seated.

6. Ensure the rubber fl at washer is in place and

attach the other end of the dryer’s long inlet

hose to the fi ll valve connector at the bottom

of the dryer back panel. Tighten by hand until

fi rmly seated.

1. Turn the cold water faucet off. Remove the

washer inlet hose from the washer fi ll valve

connector (cold).

2. Ensure the rubber fl at washer is in place and

screw the female coupling of the short hose

onto the washer fi ll valve connector. Tighten by

hand until fi rmly seated.

3. Attach the female end of the ‘’Y’’ connector to

the male coupling of the short hose. Ensure the

rubber fl at washer is in place. Tighten by hand

until fi rmly seated.

7. Using pliers, tighten all the couplings with an

additional two–thirds turn.

Note: Do not overtighten. Damage to the couplings

may result.

8. Turn the water faucet on.

9. Check for leaks around the ‘’Y’’ connector, faucet

and hose couplings.

– 6 –

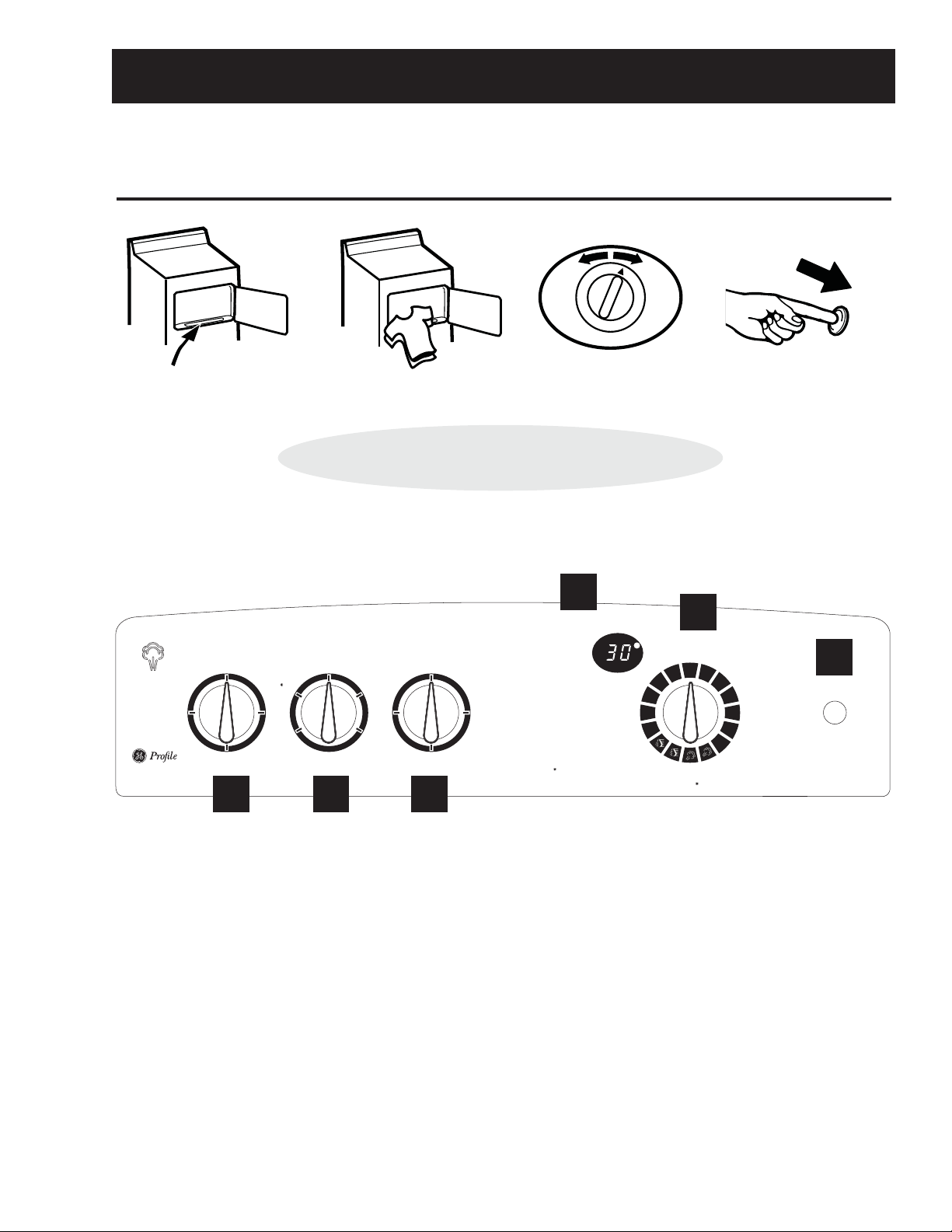

Control Features

Drying

Cooling

Sensing

About the control panel GEAppliances.com

Step 1 Step 2

Step 3

Step 4

• Select Dry Cycle • Shut door

• Clean lint filt er

• Add clothes

• Push START

Quick Start Guide

Note: When making a selection with any knob, simply point the knob anywhere within the shaded range for

NOTE: When making a selection with any knob, simply point the knob anywhere within the shaded range

that setting.

for that setting.

D

Drying

Drying

Cooling

Cooling

Sensing

Sensing

SMALL LOAD

6 to 7 items

E

o

l

C

e

l

p

i

t

l

u

M

COTTONS

EASY

CARE

8

0

1

D

4

3

2

-

T

W

M

G

/

E

0

5

6

S

D

T

P

3 to 5 items

t

h

e

s

C

a

r

e

C

y

c

l

e

s

60

50

TIME DRY

5

40

G

0

0

1

-

2

3

4

D

1

1

1

1

P

0

30 DAMP DRY

0

1

R

e

v

.

4

20 DEWRINKLE

10 QUICK FLUFF

1 to 2 items

STEAM REFRESH

Select HIGH for TEMPERATURE

F

START

PAUSE

Hold 3 Seconds

to STOP

WITH

STEAM

TECHNOLOGY

+

EXTENDED

SIGNAL

TUMBLE

SETTINGS

OFF

8

0

5

1

G

D

0

4

0

3

2

-

T

W

M

G

/

E

0

5

6

S

D

T

P

EXTENDED TUMBLE

N

I

N

G

I

A

M

E

R

E

M

I

T

D

E

T

A

M

I

T

S

E

SENSOR DRY

DELICATES

ANTI-BACTERIAL

TOWELS

LARGE LOAD

STEAM DEWRINKLE

Select HIGH for TEMPERATURE

8 to 13 items

MIXED

LOAD

EXTRA

LOW

LOWMEDIUM

MORE

DRYNESS

DAMP

8

0

5

1

G

D

0

4

0

3

1

2

-

-

2

T

3

4

W

D

M

1

G

1

/

1

E

1

0

5

6

DRY

S

D

T

P

LESS

P

0

0

DRY

1

R

e

v

.

4

TEMPERATURE

NO HEAT

Time Dry Cycle Only

HIGH

8

0

5

1

G

D

0

4

0

1

-

2

3

4

D

1

1

1

1

P

SIGNAL

0

0

1

R

e

v

.

4

3

1

2

-

-

2

T

3

4

W

D

M

1

G

1

/

1

E

1

0

P

5

0

6

0

S

1

D

T

R

P

e

v

.

4

DRY

A B C

– 7 –

(Continued next page)

About the control settings.

End of Cycle Signal

A

This signal will sound just before the end of the cycle to remind you to remove the clothes.

If you select the EXTENDED TUMBLE option, the signal will sound at the end of the drying time and will

sound several times during the EXTENDED TUMBLE cycle. This will remind you that it is time to remove

the clothes.

Note:

• Remove garments promptly at the sound of signal. Place clothes on hangers so wrinkles won’t set

in.

• Use the END OF CYCLE SIGNAL especially when drying fabrics like polyester knits and permanent

press. These fabrics should be removed so wrinkles won’t set in.

• If the beeper is turned off, the dryer will go in Idle state and the control will display a "00" for up to

6 minutes unless the door is opened or the Stop/Cancel key is pressed.

Extended Tumble (Wrinkle Care)

Use this option to minimize the wrinkles in clothes. It provides approximately 1 hour of no-heat

tumbling after the clothes are dry.

If the EXTEND TUMBLE option is selected, at the end of the cycle, "00" will be displayed on the segment

display. At this moment, the control beeps every 90 seconds, provided the user turned the beeper

on. If the user turns off the beeper, then there will not be any beep. If the user deselects (i.e., turns off)

the EXTEND TUMBLE option while the cycle is in EXTEND TUMBLE mode, then the dryer immediately

stops. If the EXTEND TUMBLE and SIGNAL option is selected, the signal will sound every fi ve minutes

while EXTEND TUMBLE is running.

Temperature

B

HIGH

MEDIUM

LOW

EXTRA LOW

NO HEAT

Dryness - Selection only used for SENSOR cycles. TIMED CYCLES run for the selected time at the

C

MORE DRY

DRY

For regular to heavy cottons.

Note: STEAM DEWRINKLE and STEAM REFRESH require the High Temperature setting.

For synthetics, blends, delicates, and items labeled permanent press.

For delicates, synthetics. and items labeled tumble dry low.

For delicates, synthetics. and items labeled tumble dry low.

For fl uffi ng items without heat. For use only with the TIMED DRY cycles.

selected temperatures.

Use for heavy-duty fabrics.

Use for a normal dryness level suitable for most loads. This is the preferred cycle for

energy savings.

LESS DRY

DAMP

Use for lighter fabrics.

For leaving items partially damp.

(Continued Next Page)

– 8 –

About the control settings.

Estimated Time Remaining Display

D

• Displays the approximate time remaining until the end of the cycle.

• If the estimated time remaining is 60 minutes or more, “1H” will flash in the display, followed by the additional

remaining minutes. When the time remaining is less than 60 minutes, the timer will count down.

Message Displayed Description

The message “PAUSE” will scroll across the display

when the dryer’s cycle is paused. The cycle may be

restarted by pressing the START button.

The message “door” will be displayed when the door

is opened during the dryer’s cycle.

The message “HEAt” will be displayed when the start

button is pressed for a steam refresh or de-wrinkle

cycle. Turn the temperature knob to “High” and press

the start button.

Drying Cycles—Sensor cycles automatically determine fabric dryness. Timed cycles run for the selected time.

E

COTTONS For cottons and most linens.

EASY CARE For wrinkle-free, permanent press and delicate items, and knits.

DELICA TES For delicate items, special-care fabrics and knits.

MIXED LOAD For loads consisting of cottons and poly-blends.

TIMED DRY Set the Cycle Selector at the desired drying time.

DAMP DRY For leaving items partially damp.

DEWRINKLE For removing wrinkles from items that are clean and dry or that are very lightly damp.

QUICK FLUFF For freshening or fluffing up already dry clothing, fabric, linens and pillows. Use with NO HEAT.

Provides 10 minutes of no-heat tumbling.

®

DRYEL Designed for use with DRYEL

“dry-clean only” fabric care system. See product package

for directions. For questions or issues related to the use and performance of DRYEL, call

1.800.214.8913, or visit the DRYEL Website at www.dryel.com.

ANTI-BACTERIAL This option reduces certain types of bacteria by 99.9%, including: Staphylococcus aureus,

E

N

D

T

I

I

S

A

E

L

R

Sanitization Performance of

Residential Clothes Dryers

NSF Protocol P154

Pseudomonas aeruginosa and Klebsiella pneumoniae*. The anti-bacterial process occurs

when high heat is used during a portion of the drying cycle.

NOTE: Do not use this cycle on delicate fabrics.

*The Anti-Bacterial Cycle is Certified by NSF International (formerly National Sanitation

Foundation) to NSF Protocol P154 Sanitization Performance of Residential Clothes Dryers.

KNITS For knits with fabric care labels that say “Machine Dry”.

TOWELS For most towels and linens.

– 9 –

(Continued Next Page)

About the control settings.

STEAM REFRESH For slightly wrinkled dry garments. Significantly reduces wrinkles. After the STEAM REFRESH

( on some models) Cycle, the unit will beep (if Signal is selected) and display “00.”

Steam Refresh Large is recommended for 3-5 garments and Small for 1-2 garments.

NOTE: Steam cycles are not intended for use with towels.

NOTE: A single extremely light fabric item may need to have an additional item included in =

the STEAM REFRESH cycle to achieve optimum results.

Important - the temperature setting must be set to HIGH and water must be turned on

before running the STEAM REFRESH cycle.

STEAM For use with larger loads than STEAM REFRESH. Ideal for loads left in dryer for an extended

DEWRINKLE time.

(on some models) STEAM DEWRINKLE Large is recommended for 8-13 garments and Small for 6-7 garments.

NOTE: Steam cycles are not intended for use with towels

Important! - the temperature setting must be set to HIGH and water must be turned on

before running the STEAM DEWRINKLE cycle.

START—Close the dryer door. Press START. Opening the door during operation will stop the dryer. To restart the

F

dryer, close the door and press START to complete the cycle. If the dryer is running, press once to pause the cycle;

press again to continue the cycle. If the dryer is paused for more than 24 hours, the cycle will be cancelled.

To stop the cycle, hold the button for 3 seconds.

NOTE: Drying times will vary according to the type of heat used (Electric, Natural or LP gas), size of load, types

of fabrics, wetness of clothes and condition of exhaust ducts.

Wrinkle Care

G

Use this option to minimize the wrinkles in clothes. It provides approximately 15 minutes of no-heat tumbling

after the clothes are dry.

This option can only be used with the COTTONS, EASY CARE and DELICATES cycles. If you are using CYCLE

SIGNAL and you select the WRINKLE CARE option, a signal will sound at the end of the drying time and several

times during the WRINKLE CARE cycle. This will remind you that it is time to remove the clothes.

If WRINKLE CARE is not ON, the dryer will stop once the timer reaches the WRINKLE CARE mark on the cycle dial.

– 10 –

Dryer Features

Initial estimated cycle times will adjust up or

down during this learning period.

Sensor Dry

Sensor Dry (on some models)

This feature is only activated in the

COTTONS, EASY CARE and DELICATES

cycles.

The SENSOR DRY provides greater

drying accuracy than standard machines,

resulting in shorter dry times and better

clothes care. As the clothes tumble, they

touch a moisture sensor. The sensor will

stop the heating cycle as soon as the

clothes have reached the selected dryness.

Drum Lamp

Before replacing the light bulb, be sure to

unplug the dryer power cord or disconnect

the dryer at the household distribution panel

by removing the fuse or switching off the

circuit breaker. Reach above dryer

from inside the drum. Remove the

replace with the same size bulb.

opening

bulb and

Important

This dryer will adjust the initial estimated

drying time of the sensor dry cycles as it

"learns" its installation and usage profile.

Please allow several weeks for the dryer to

customize itself to "you".

Initial estimated cycle times will adjust up or

down during this learning period.

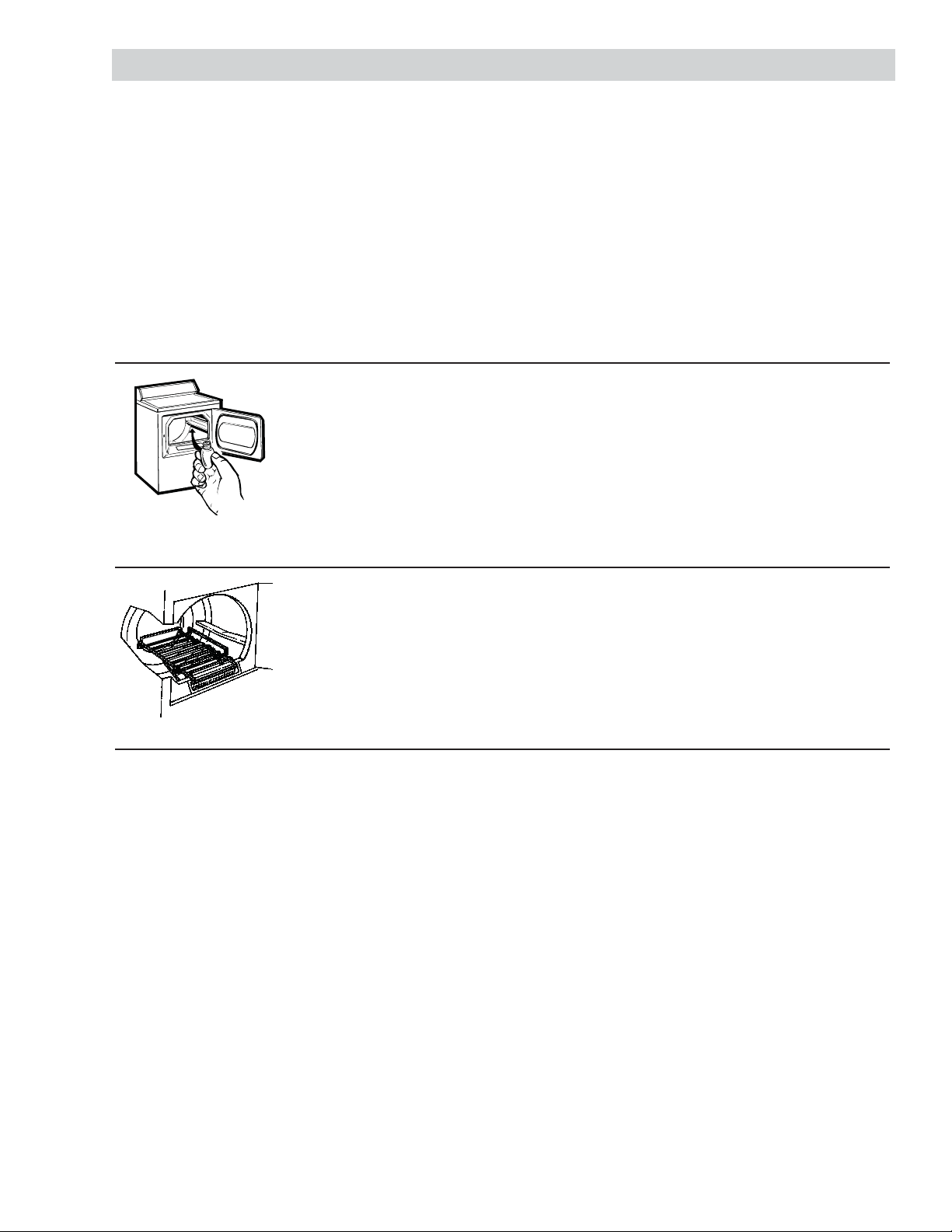

Drying Rack (on some models)

A handy drying rack may be used for drying

delicate items such as washable sweaters.

Hook the rack over the lint f ilter so

the rack extends into the dryer drum.

Stainless Steel Drum (on some models)

The stainless steel used to make the

dryer drum provides the highest reliability

available in a GE dryer. If the dryer drum

should be scratched or dented during normal

NOTE:

The drying rack must be used with the

TIMED CYCLE.

Do not use this drying rack when there

are other clothes in the dryer.

use, the drum will not rust or corrode. These

surface blemishes will not affect the function

or durability of the drum.

– 11 –

Reversing the Door

Reversing the Door

Tools needed:

Standard #2 Tape-tipped

Phillips screwdriver putty knife

Open the door and remove the filler plugs opposit e the hinges. With the door

1

completely open, remove the bottom screw from each hinge on the dryer face.

Insert these screws about half way into the TOP holes, for each hinge, on the

opposite side (where you removed the f iller plugs). Apply f irm pressure t o get

the screw started in new holes.

Loosen top screw from each hinge on the dryer face half way. With one hand

2

holding the top of the door and the other hand holding the bottom, remove

the door from the dryer by lifting it UP and OUT.

Rotate the door 180°. Insert it on the opposite side of the opening by moving

3

the door IN and DOWN until the top hinge and the bottom hinge are resting

on the top screws inserted in step 1.

Remove the remaining screws from the side of the opening from which the door

4

was removed. With these screws, secure each hinge at the bottom. Tighten the

two top screws of each hinge. Reinsert the plastic plugs on the side from which

the door was removed.

– 12 –

Operation Overview

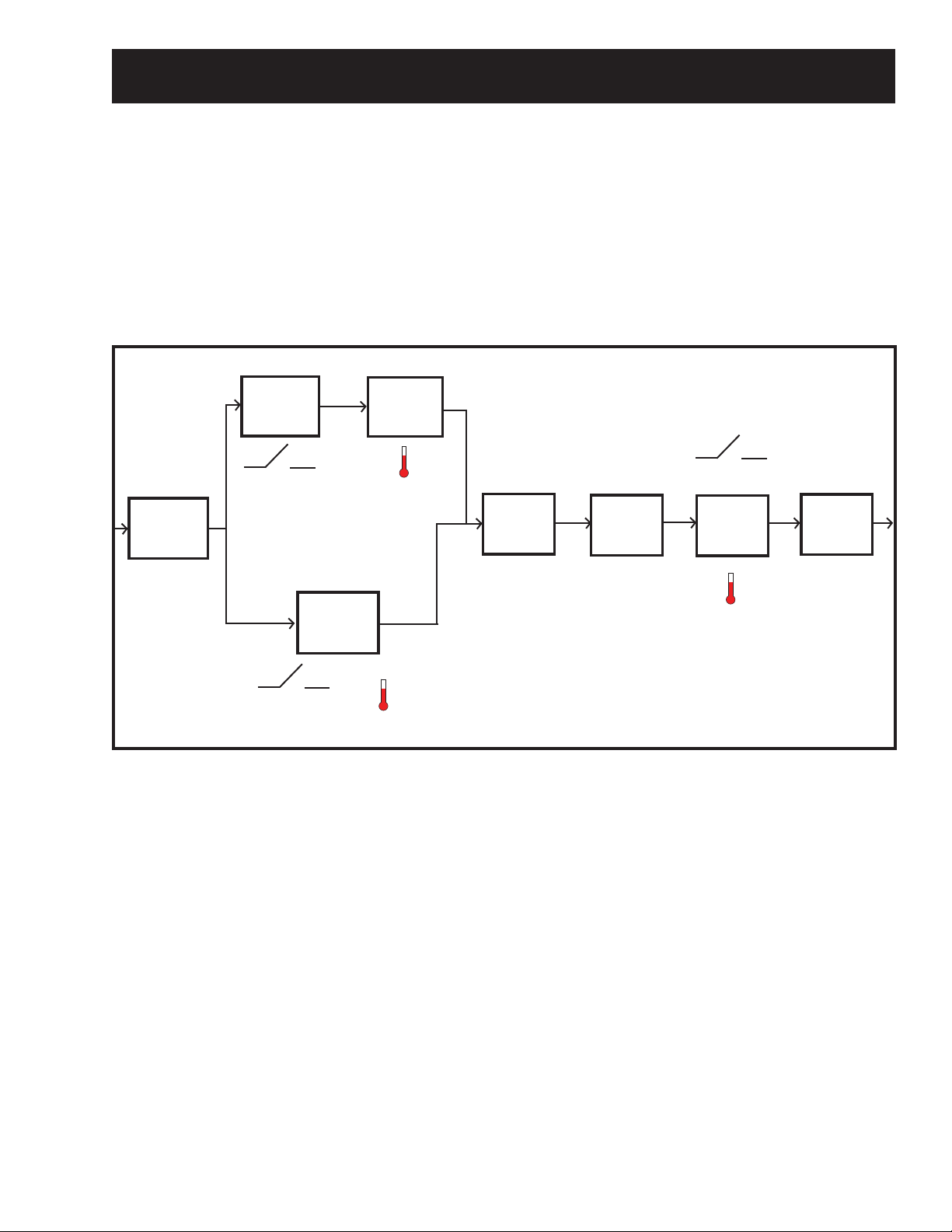

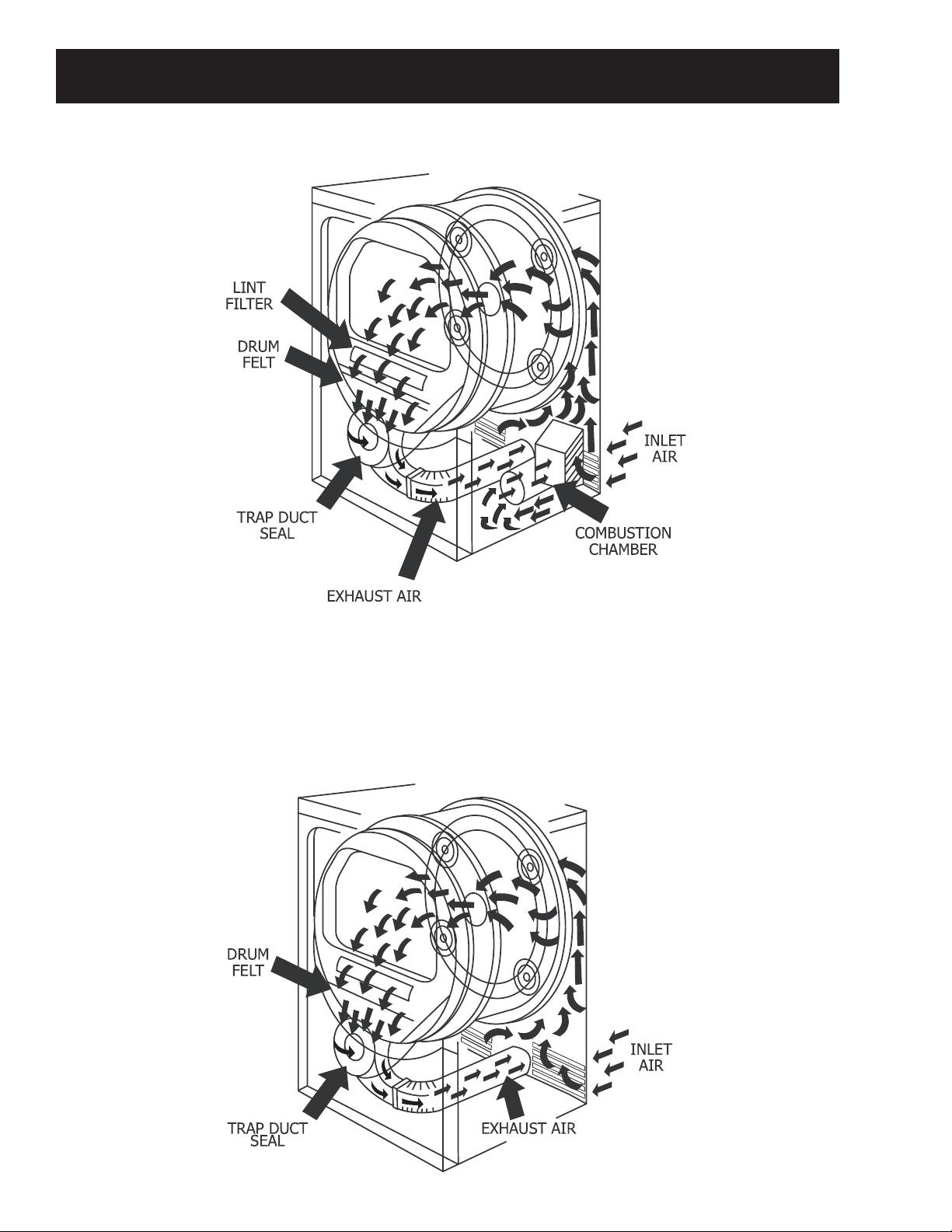

Air enters the dryer cabinet, passing thru the heating elements and into the drum. The hot air heats the wet

clothes and gradually removes their moisture in the form of water vapor. The moist air is vented through

the dryer exhaust. Overall heater temperature is regulated by means of two temperature sensors: an inlet

sensor located near the heating elements, and an outlet sensor located at the blower. An additional safety

thermostat, located near the heating elements, shuts off the heating elements if they overheat. Also, the

outlet backup thermostat, located near the blower, provides additional safety and cycles the heaters if

temperature goes above the outlet temperature range.

Dryer Air Flow System

Gas

Combustion

Chamber

Diffuser

t°

Exhaust

Dryer

Cabinet

t°

Safety thermostat

Pan/Electric

Elements

Inlet temperature

sensor

Heater

Drum

Lint trap

Outlet backup

Blower

Outlet temperature sensor

t°

Safety thermostat

Inlet temperature sensor

The typical dryer cycle progresses as follows:

1. A cycle is selected and the start key is pressed.

2. The motor is activated.

3. The heater elements (burner for gas models) are activated. The elements (burner) cycle on and off to

achieve the desired temperature throughout the heating portion of the cycle.

4. If sensor drying is selected, the heater elements (burner for gas models) are activated. The elements

(burner) cycle on and off until the load has achieved the desired dryness level.

5. If timed drying is selected, the heater elements (burner for gas models) are activated and cycle on and off

for the selected time at the selected temperature.

6. If STEAM DEWRINKLE or STEAM REFRESH is selected, the water valve is activated during heater elements

cycle on time (burner on time for gas models). See Cycle Matrix Chart on page 15.

7. The heater elements (burner for gas models) discontinue operation after the dryness level or elapsed time

has been achieved.

8. The motor continues operating until the clothes temperature drops below specifi ed temperature (Cool

Down).

9. The display turns off.

– 13 –

Airfl ow

– 14 –

Loading...

Loading...