GE PSC21MGM, PSI21MGM, PSC23MGM, PSI23MGM Technical Service Manual

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2001

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Locator Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mechanical Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Component and Connector Locator Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Schematics and Strip Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Illustrated Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

– 1 –

Introduction

2001 Energy SxS models are being introduced in

response to the requirement for more energyefficient refrigerators by mid year 2001, along with

feature and operation enhancements. The primary

differences in this refrigeration system are the

adaptive defrost system (see Pub # 31-9062),

control board, software, and control systems that

operate independently in fresh food and freezer

sections. The new high-efficiency control system

has the ability to cycle components and adjust fan

speeds as required to maintain temperaturesetting ranges in fresh food and freezer sections.

Feedback systems are digital inputs and relay

outputs. Sensors (thermistors) are used to

measure temperature with communications to a

main PC board, which controls the unit

components.

The Refrigerator has touchpad controls to provide

inputs to a microprocessor. The fresh food and

freezer controls are temperature setpoint type and

have settings of 0-9 with 9 being the coldest

temperature possible. The new NO CLEAN

condenser is serviceable from the rear and is

designed to prevent the customer from having to

clean the condenser in normal usage conditions.

The freezer has adjustable shelves, a slide-out

Spillproof shelf, a QuickSpace shelf, and deep

door shelves, based on the model. The fresh food

section has a baking soda holder, a fruit and

vegetable drawer, drawer dividers, an adjustable

humidity drawer, and a convertible meat drawer.

The new high-efficiency refrigerator is a

combination of the most efficient refrigeration

system and the most desirable customer features

available.

Sealed system operation and compressor are

functionally the same as previous models, with

some minor changes.

The Profile Perfomance and Arctica side by side

models are the models affected. These models are

available with a through-the-door chilled water and

ice dispenser, and a built-in water filter feature. On

models requiring icemaker, the newest electronic

icemaker (see Pub. # 31-9063) has been or can

be installed.

– 2 –

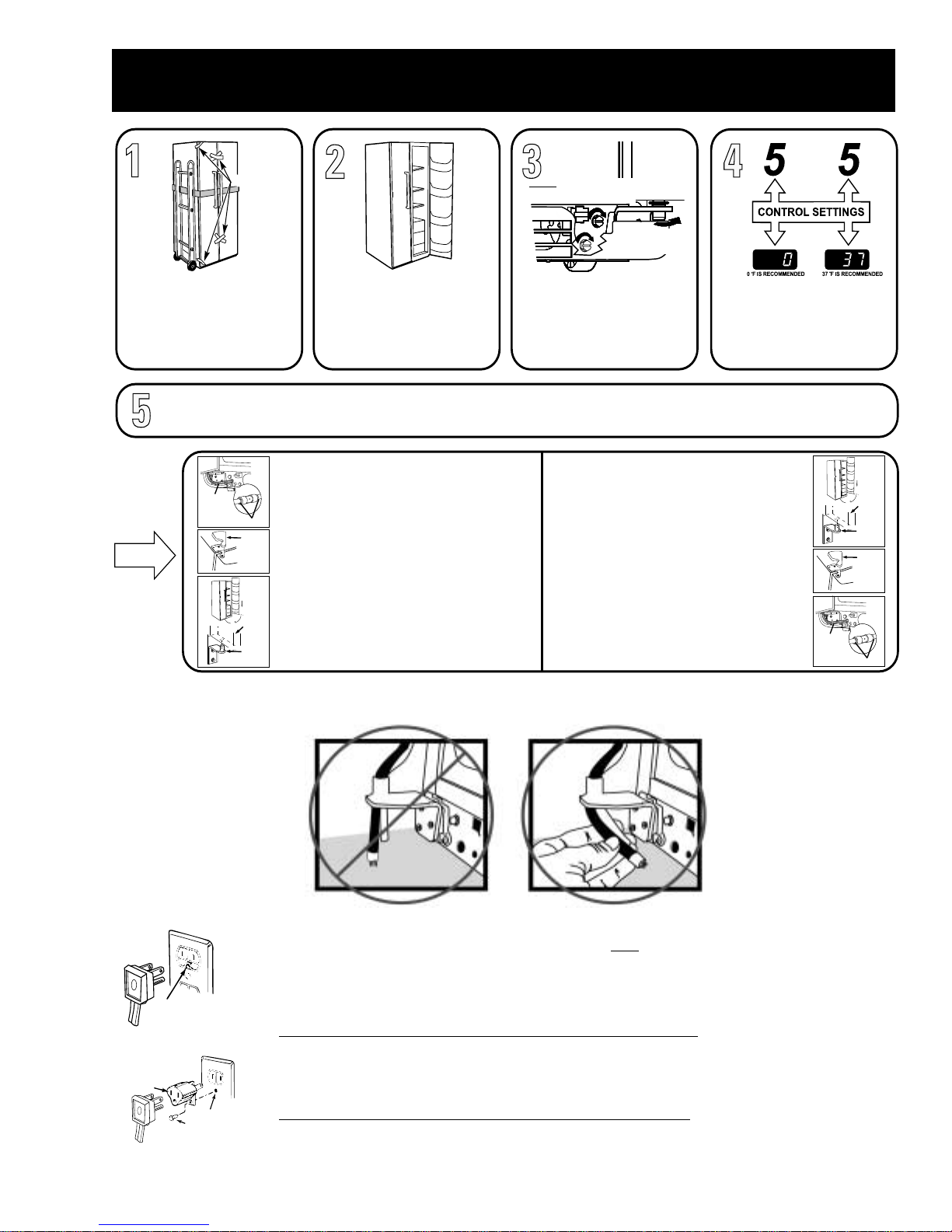

Installation

Use padded hand truck to protect

refrigerator finish. LEAVE TAPE

ON DOORS until refrigerator is in

its final location. TRUCK FROM

SIDE ONLY. Avoid overtightening

strap to prevent damaging doors.

REMOVE ALL CLEAR PROTECTIVE

TAPE FROM TRIMS, then move unit

into position. If entrance is less

than 38″ wide, remove doors prior

to installation and reinstall doors

according to procedure below.

Connect water lines and power cord.

ADJUST FRONT ROLLERS so the

refrigerator is solid on floor and

doors close easily. MAKE SURE

DOORS ARE EVEN AT TOP.

TEMPERATURE CONTROLS ARE

PRESET IN THE FACTORY FOR

RECOMMENDED SETTINGS.

• APPLIANCE POLISH WAX IS RECOMMENDED FOR REMOVING TAPE RESIDUE AND HAND PRINTS FROM REFRIGERATOREXTERIOR.

• REMOVE ALL TAPE ANDOTHER PACKAGING MATERIAL FROM REFRIGERATOR INTERIOR. DO NOT REMOVE SERIAL PLATE.

• REMOVE PROTECTIVE FILM ON TEMPERATURE CONTROL PANEL.

ROLLER HEIGHT

ADJUSTMENT

NOTICE

TAPE

DOOR HEIGHT

ADJUSTMENT

Doors should be in closed position. Near lower hinge

on freezer side, squeeze collar on water line and pull

tubing from coupling. Also, disconnect wiring harness.

Pull water line and harness through lower rail.

Remove top hinge covers to access hinges. Remove

hinges using a Torx T-20.

Carefully rotate door through 90°. Guiding water line

and wiring harness, lift door straight up. Avoid side

loading the bottom hinges. Place doors on a protective

surface. Avoid pinching the water tube and wire

harness at the bottom of the door.

Removing Doors

With Doors 90° open, place doors on bottom hinge.

Carefully rotate doors to closed position. Avoid side

loading the bottom hinges.

Reinstall top hinges and tighten screws firmly.

Reinstall hinge cover. If doors are not level, adjust

bottom right hinges with a

7

⁄16″ open ended wrench.

Insert water tubing back into coupling. It is completely

connected when the mark on the tubing is no longer

visible. Reconnect wire harness. Turn on water supply.

Re-installing Doors

90

HINGE

COVER

DOOR

HINGE

PIN

WIRE

HARNESS

COLLARS

90

HINGE

COVER

DOOR

HINGE

PIN

WIRE

HARNESS

COLLARS

IMPORTANT: PLEASE READ CAREFULLY

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE PROPERLY GROUNDED.

The power cord of this appliance is equipped with a three-prong (grounding) plug that mates with a standard three-prong (grounding) wall receptacle to minimize the

risk of electric shock hazard from this appliance. The customer should have the wall receptacle and circuit checked by a qualified electrician to make sure the receptacle

is properly grounded.

Where a standard two-prong wall receptacle is encountered, it is the personal responsibility and obligation of the customer to have it replaced with a properly grounded

three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR REMOVE THE THIRD (GROUND) PRONG FROM THE POWER CORD.

USAGE

SITUATIONS WHERE THE APPLIANCE’S POWER CORD WILL BE DISCONNECTED INFREQUENTLY

Because of potential safety hazards under certain conditions, we strongly recommend against the use of an adapter plug. However, if you still elect to use an adapter,

where local codes permit, a TEMPORARY CONNECTION may be made to a properly grounded two-prong wall receptacle by the use of a UL listed adapter which is

available at most hardware stores. The larger slot of the adapter must be aligned to provide proper polarity in the connection of the power cord.

CAUTION: Attaching the adapter ground terminal to the wall receptacle cover screw does not ground the appliance unless the cover screw is metal, and not insulated,

and the wall receptacle is grounded through the house wiring. The customer should have the circuit checked by a qualified electrician to make sure the receptacle is

properly grounded. When disconnecting the power cord from the adapter, always hold the adapter with one hand. If this is not done, the adapter ground terminal is very

likely to break with repeated use. Should this happen, DO NOT USE the appliance until a proper ground has again been established.

USAGE

SITUATIONS WHERE THE APPLIANCE’S POWER CORD WILL BE DISCONNECTED FREQUENTLY

Do not use an adapter plug in these situations because frequent disconnecting of the power cord places undue strain on the adapter and leads to eventual failure of the

adapter ground terminal. The customer should have the two-prong wall receptacle replaced with a three-prong (grounding) receptacle by a qualified electrician before

using the appliance.

MAKE SURE PROPER

GROUND EXISTS

BEFORE USE

PREFERRED

METHOD

ENSURE PROPER

GROUND AND

FIRM CONNECTION

TEMPORARY METHOD

(Adapter plugs not

permitted in Canada)

CAUTION: Do NOT allow the connector to contact the floor. Hard contact can damage the connector.

– 3 –

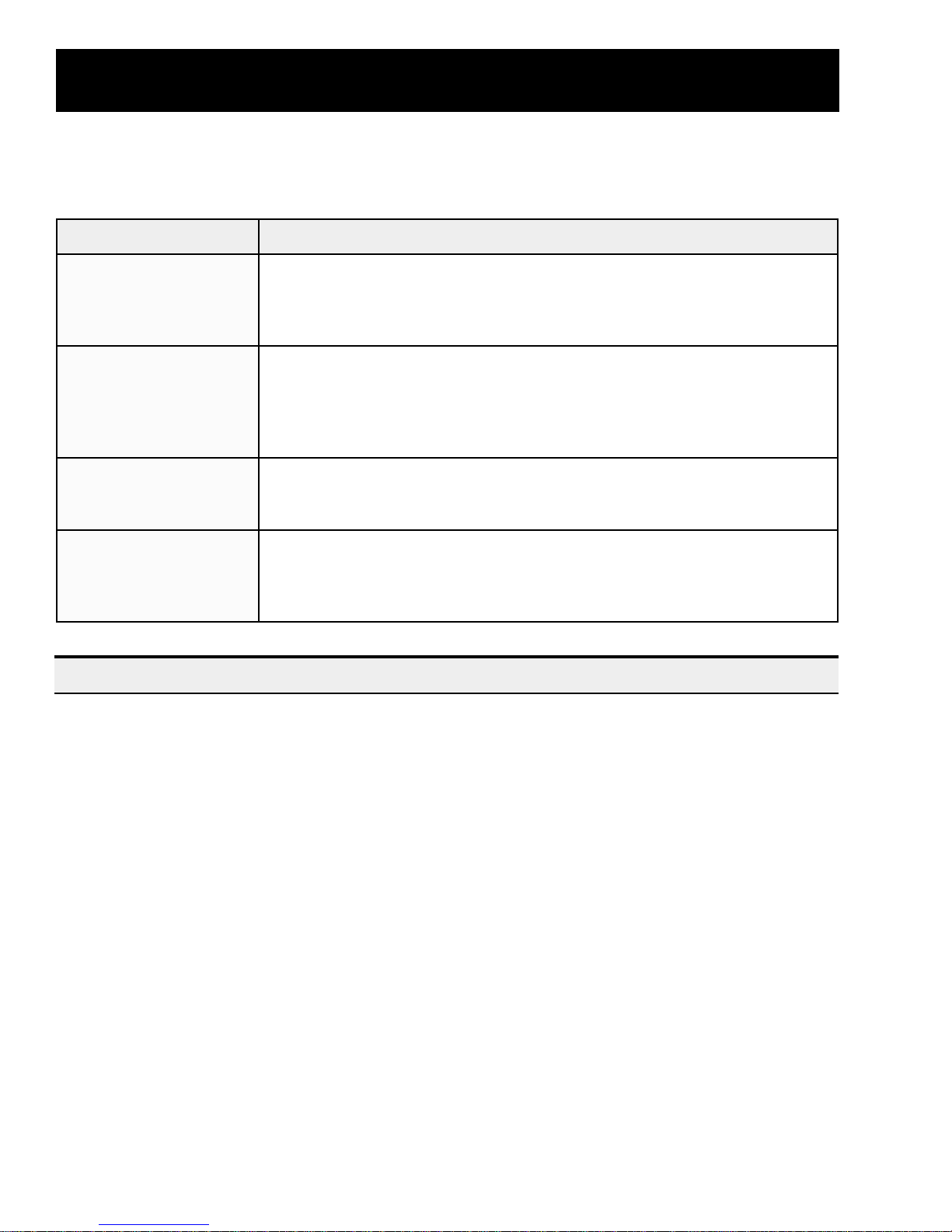

Specifications

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT-RECONNECT ALL GROUNDING DEVICES

All parts of this appliance capable of conducting electrical

current are grounded. If grounding wires, screws, straps,

clips, nuts or washers used to complete a path to ground

are removed for service, they must be returned to

their original position and properly fastened.

ELECTRICAL SPECIFICATIONS

Temperature Control {Position 5) ................. 7-(-11 )°F

Defrost Control ............................................. 60hrs @ 35 min

Overtemperature Thermostat....................... 140-110°F

w/ no door openings

Defrost Thermistor ....................................... 65°F

Electrical Rating: 115V. AC 60 Hz................ 11.6 Amp

Maximum Current Leakage.......................... 0.50 mA.

Maximum Ground Path Resistance ............. 0.14 Ohms

Energy Consumption ................................... KWH/mo.

NO LOAD PERFORMANCE

Control Position MID/MID

and Ambient of:

70°F 90°F

Fresh Food, °F ...........................................34-40 34-40

Frozen Food, °F .........................................(-3) 3 (-3) 3

Run Time, %...............................................<45% <70%

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation

of this information, nor can it assume any liability

in connection with its use.

INSTALLATION

Clearance must be provided for air circulation

A T TOP........................................................................1”

AT SIDES ....................................................................1/8”

A T REAR..................................................................... 1”

AIR FLOW

REFRIGERA TION SYSTEM

Refrigerant Charge (R134a) ....................... 4.75 ounces

Compressor ................................................. 690 BTU/hr

Minimum Compressor Capacity ................... 22 inches

Minimum Equalized Pressure

@ 70°F......................................................... 48 PSIG

@ 90°F......................................................... 60 PSIG

MODELS

PSC21MGM PSI21MGM

PSC23MGM PSI23MGM

REPLACEMENT PAR TS

T emperature Control ............................................... wr55x10023

Relay....................................................................... wr07x10031

Overload................................................................. wr08x10025

Run Capacitor (12

Overtemperature Thermostat ................................ wr50x10015

Defrost Heater Harness & Thermostat ................. wr23x10142

Defrost Heater & Bracket ........................................ wr51x10030

Condenser Fan Motor ............................................. wr60x10042

Evaporator Fan Motor ............................................. wr60x10043

Main Board.............................................................. wr55x10024

Dispenser Board ..................................................... wr55x10029

Thermistor (EV)....................................................... wr55x10025

Thermistor (FZ) ....................................................... wr55x10026

Thermistor (FF) ....................................................... wr55x10027

Thermistor (FF) ..................................................... wr55x10028

FF Fan Motor .......................................................... wr60x10051

Damper................................................................... wr60x10052

u

F)............................................ wr62x10079

– 4 –

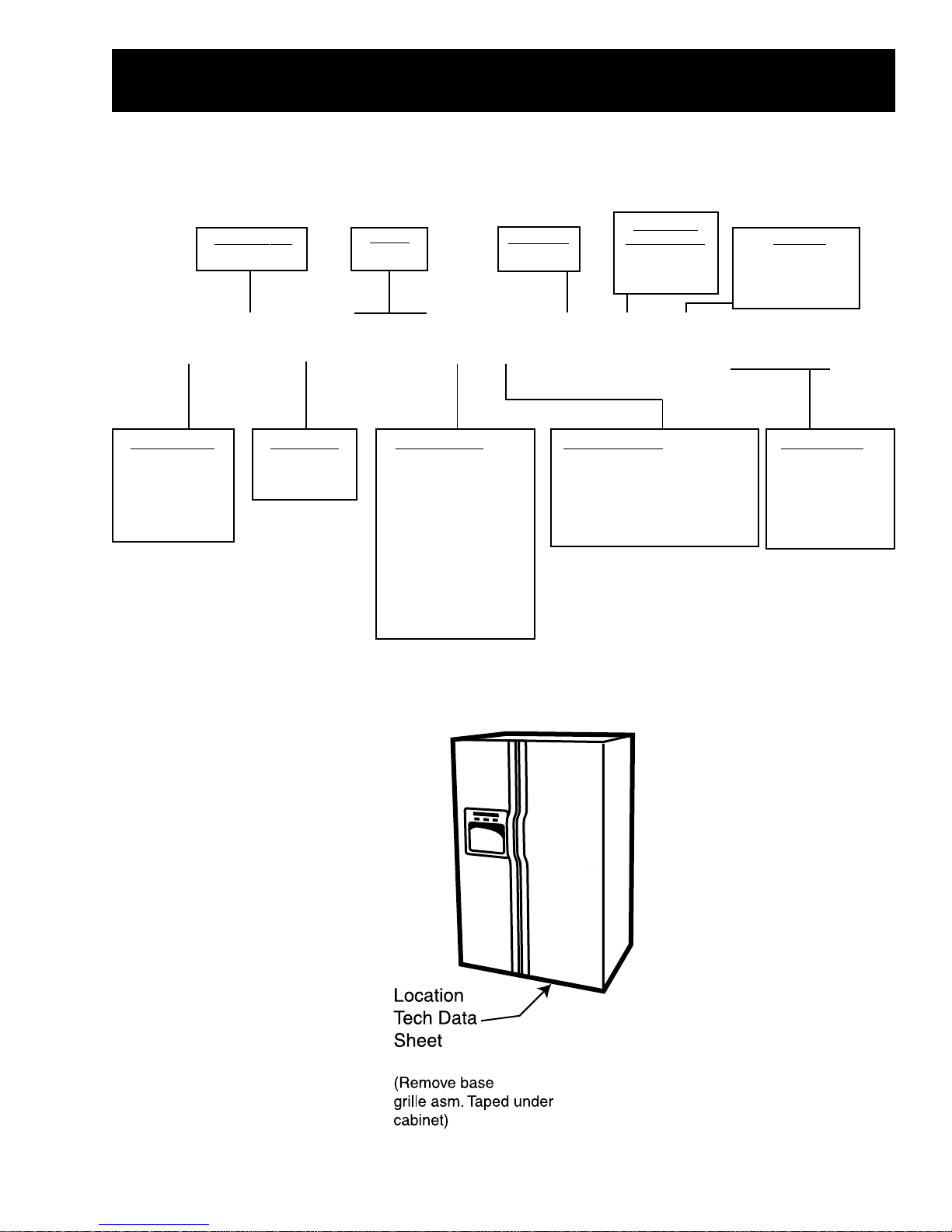

Profile 2001 Models

Nomenclature

CONFIGURATION

S = SIDE-BY-SIDE REF.

VOLUME

23 / 25 / 27 / 29

MODEL YEAR

M = 2001

ENGINEERING

NOMENCLATURE

A = INITIAL DESIGN

B = 1ST REVISION

ETC.

P S S 2 5 I E M A F W W

BRAND/PRODUCT

G = GE

H = HOTPOINT

P = PROFILE (GE)

E = ETERNA (GE)

R = RCA

S = SELECT (GE)T

DEPTH/POWER

S = STANDARD

T = TROPICAL

G = GLOBALT

INTERIOR/SHELVES

D = DELUXE WIRE

I = DELUXE GLASS

J = PREMIUM GLASS

K = SPILLPROOF GLASS

M = SPILLPROOF/SLIDE-OUT

GLASS & QUICKSPACE

Q = SHOWCASE DERIVATIVE

S = STAINLESS STEEL DOORS

U = ABV DERIVATIVE

V = SEARS DERIVATIVE

W = HPS (CONTRACT )

DERIVATIVE

X = REGIONAL DERIVATIVE

ICEMAKER/EXTERIOR

B = NON-DISPENSER/ICEMAKER READY

D = CUBED ICE/WATER

E = CUBED & CRUSHED ICE/ WATER

F = 6 MO. FILTER/CUBED & CRUSHED ICE

G = 1 YR. FILTER/CUBED & CRUSHED ICE

I = IN-LINE FILTER/INDICATOR & C/C/W

DOOR TYPE

F = FLAT DOOR (G-LINE)

(SPACE = FLAT DOOR (S-

& T-LINE

K = RETRO-FIT DOOR

EXTERIOR COLOR

WW = WHITE/WHITE

AA = ALMOND/ALMOND

BB = BLACK/BLACK

CC = BISQUE/BISQUE

WH = WHITE/BLACK

BS = BLACK/STAINLESST

– 5 –

Warranty Information

Sales slip or cancelled check is required as proof of original purchase date to obtain service

under warranty.

All warranty service is provided by our Factory Service Centers or an authorized Customer Care®

technician.

:fOdoirePehTroF :ecalpeRlliWEG

raeYenO

ehtfoetadehtmorF

esahcruplanigiro

sraeYeviF

ehtfoetadehtmorF

esahcruplanigiro

emitefiL

ehtfoetadehtmorF

esahcruplanigiro

syaDytrihT

foetadehtmorF

eht

esahcruplanigiro

trapynA sliafhcihw)egdirtracretlifretawgnidulcxe(rotaregirferehtfo

,ytnarraw ,edivorposlalliwEG ,egrahcfoeerf emoh-nidnaroballla

,edivorposlalliw ,egrahcfoeerf ecalperotecivresemoh-nidnaroballla

.trapevitcefedeht

.dedulcni

trapynA nitcefedaoteudsliafhcihwegdirtracretlifretawehtfo

,edivorposla ,egrahcfoeerf ehtecalperotecivresemoh-nidnaroballla

.trapevitcefed

:revoCtoNlliWEGtahW

• Service trips to your home to teach you

how to use the product.

• Improper installation.

• Failure of the product if it is abused or

used for other than the intended purpose

or used commercially.

• Loss of food due to spoilage.

• Replacement of house fuses or resetting of

circuit breakers.

sihtgniruD.pihsnamkrowroslairetamnitcefedaoteud raey-enolluf

.trapevitcefedehtecalperotecivres

metsysgnitaregirferdelaesehtfotrapynA ,rosserpmoceht(

aoteudsliafhcihw)gnibutgnitcennoclladna,rotaropave,resnednoc

sihtgniruD.pihsnamkrowroslairetamnitcefed ,ytnarrawraey-evif EG

rewardronaphguorht-eesynA napehtfirotaregirferehthtiwdehsinruf

tonerasrevocrewarD.esudlohesuohlamrongnirudskaerbrewardro

sihtgniruD.pihsnamkrowroslairetam ,ytnarrawyad-ytrihtlluf lliwew

• Replacement of the water filter cartridge

due to water pressure that is outside the

specified operating range or due to excessive sediment in the water supply.

• Replacement of water filter cartridge after

its expected useful life, 30 days.

• Damage to the product caused by accident,

fire, floods, or acts of God.

• Incidental or consequential damage caused

by possible defects with this appliance.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to

your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To know what your legal rights are, consult your local or state consumer affairs office or your state’s

Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

– 6 –

Operating Characteristics

Table of Contents

Fresh Food/Freezer Independent Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Normal Operating Characteristics, but Different from Previous Models

Abnormal Operating Characteristics (Incorrect Operation) . . . . . . . . . . . . . . . . 8

Adaptive Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cooling Operation (Adaptive Defrost) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-Chill Operation (Adaptive Defrost). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Defrost Heater Operation (Adaptive Defrost). . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dwell Period (Adaptive Defrost) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Post Dwell (Adaptive Defrost) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Liner Protection Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electronic Icemaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dispensing Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . 8

Quick Ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Door Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dispenser Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dispenser Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hinge System and Door Closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

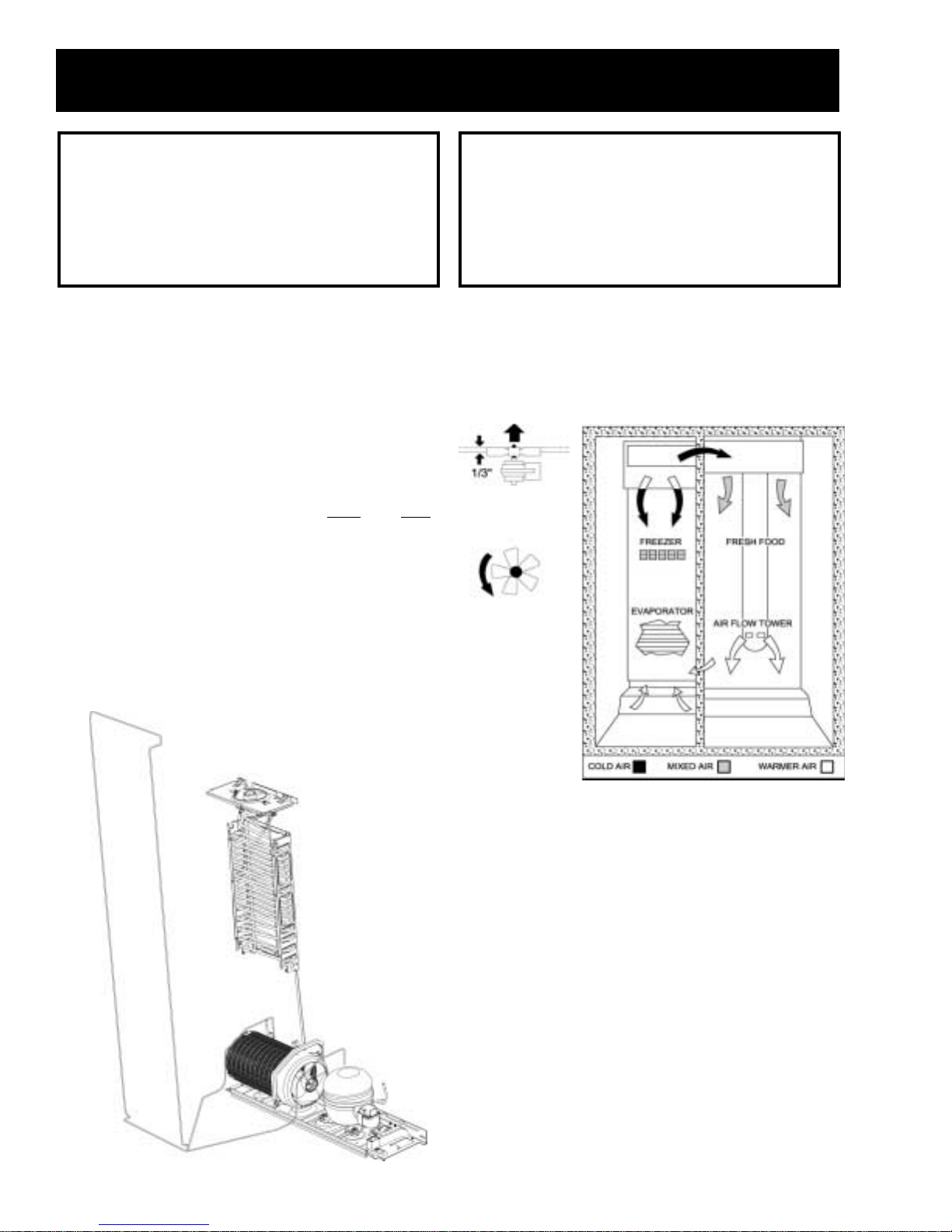

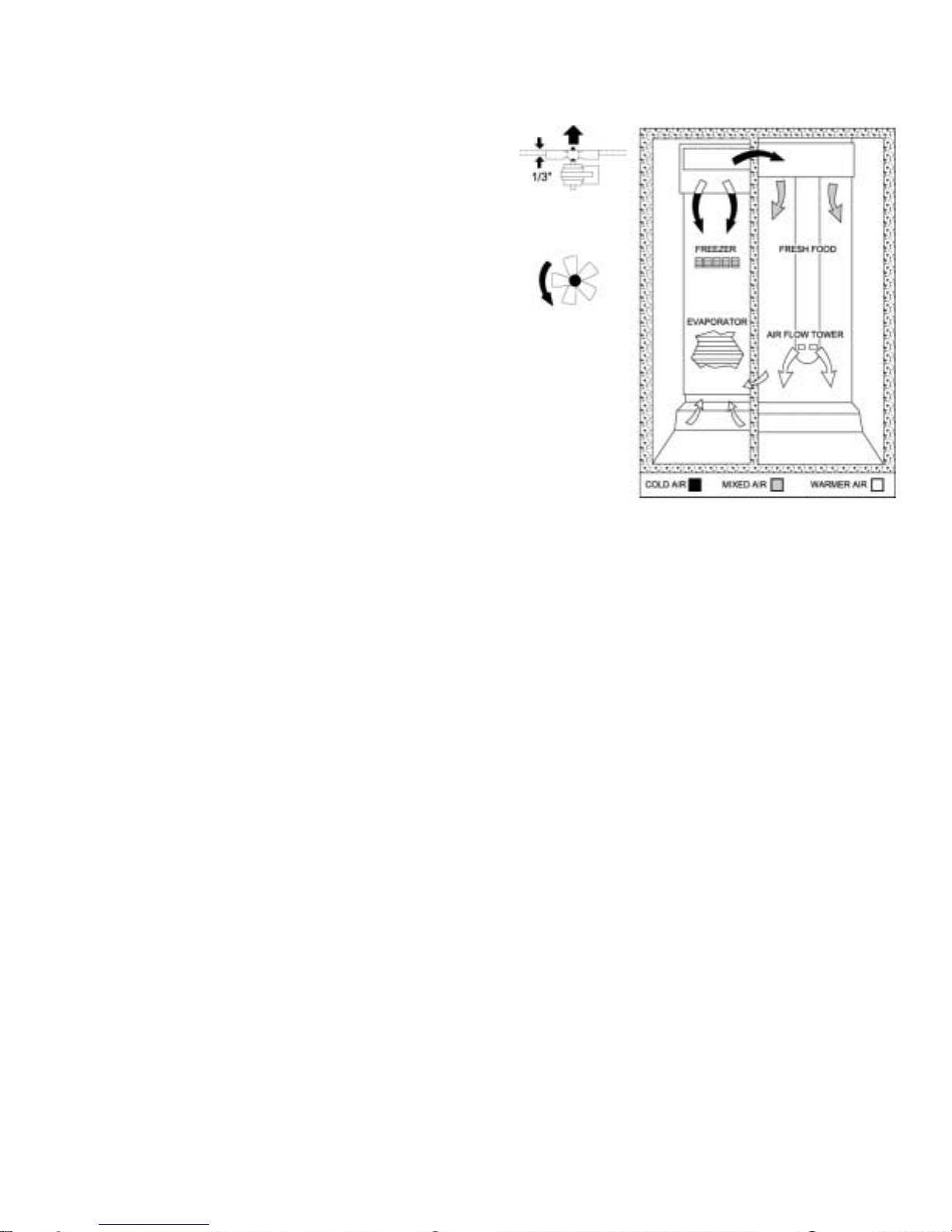

Airflow (Cabinet Interior) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

“Jelly Roll” Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

– 7 –

Fresh Food/Freezer Independent

Operation

Abnormal Operating Characteristics

(Incorrect Operation)

In previous models, the fresh food and freezer

compartment components worked at the same

time. When the fresh food compartment called for

cold air, the freezer compartment components

would work with the fresh food compartment

components. This is called nonindependent

operation.

In this model, the fresh food compartment

components can operate without the freezer

compartment components operating. This is called

independent operation.

Normal Operating Characteristics that May

Occur, but Different from Previous Models

• Icemaker auger rotates clockwise.

• Evaporator fan running, without compressor or

condenser fan. Fresh food fan is on.

• Post dwell (adaptive defrost), compressor and

condenser fan on with evaporator fan off after

defrost cycle.

• Liner Protection Mode, fans come on when the

doors are open for 3 minutes.

• When the doors open, the fans shut off.

• Fresh food fan on and evaporator fan off.

• Evaporator fan on, fresh food fan and

compressor off, and damper shut.

• Rapid fan speed changes, fan takes at least 1

minute to change speeds.

• Compressor running without the condenser fan.

The compressor and condenser fan should

always run at the same time.

• Condenser fan running without the

compressor. The compressor and condenser

fan should always run at the same time.

Adaptive Defrost

Adaptive defrost can be described as a defrost

system that adapts to a refrigerator’s surrounding

environment and household usage.

Unlike conventional defrost systems that use

electromechanical timers with a fixed defrost cycle

time, adaptive defrost utilizes an intelligent,

electronic control to determine when the defrost

cycle is necessary. In order to accomplish the

correct defrost cycle time, the main control board

monitors the following refrigerator operations:

• No airflow to the fresh food compartment when

the evaporator fan is on.

• Evaporator fan and compressor can run

continuously for 8 hours.

• Fans shift speeds, different sound levels can

be noticed when this happens.

• Quick Ice mode, the evaporator fan runs for 48

hours non-stop.

• Response time for drastic temperature change

is 2 to 10 minutes. The main control board will

only respond to 8 degrees of temperature

change per minute as determined by

resistance change of sensor.

• Length of time the refrigerator doors were open

since the last defrost cycle.

• Length of time the compressor has run since

the last defrost cycle.

• Amount of time the defrost heaters were on in

the last defrost.

Adaptive defrost is divided into 5 separate cycles.

Those operations are:

• Cooling Operation

• Pre-Chill Operation

• Defrost Heater Operation

• Dwell Period

• Post dwell

Refer to Pub # 31-9062 for more information about

Adaptive Defrost.

– 8 –

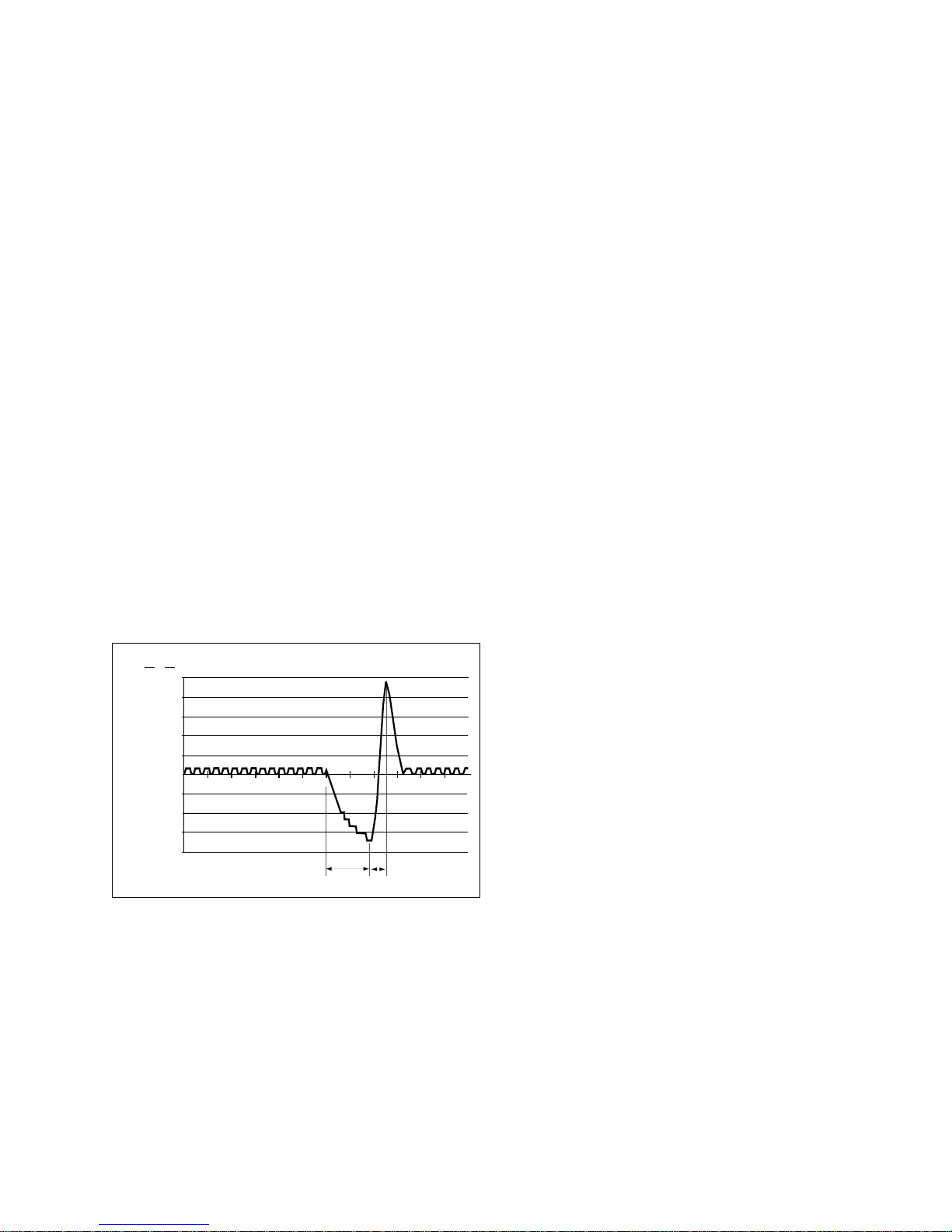

Cooling Operation (Adaptive Defrost)

During the cooling operation, the main control

board monitors door opening (fresh food and

freezer doors) and compressor run times. The

length of time between consecutive defrosts is

reduced by each door opening. If the doors are not

opened, the compressor will run up to 60 hours

between defrosts. If the doors are opened

frequently and/or for long periods of time, the

compressor run time between defrosts will be

reduced to as little as 8 hours.

Pre-Chill Operation (Adaptive Defrost)

When the main control board determines that

defrost is necessary, the main control board will

force the refrigerator into a continuous cool mode

(pre-chill). During pre-chill, the freezer temperature

may be driven below the temperature control panel

display setpoint. However, the fresh food

temperature will be regulated by the damper. Prechill will last for 2 hours if it is not interrupted by

any door openings. If, after 8 hours, the unit has

been unable to complete an uninterrupted pre-chill,

it will proceed to the defrost cycle.

Defrost Heater Operation (Adaptive Defrost)

F

F˚ / C˚

R

E

25˚ / -4˚

E

Z

20˚ / -7˚

E

R

15˚ / -9˚

A

10˚ / -12˚

I

R

5˚ / -15˚

T

E

0˚ / -18˚

M

P

-5˚ / -21˚

E

R

-10˚ / -23˚

A

T

U

-15˚ / -26˚

R

E

-20˚ / -29˚

S

After 2 hours of pre-chill operation or 8 hours of

interrupted pre-chill attempts, the main control

board turns the compressor, condenser fan, and

evaporator fan off. The main control board then

energizes the defrost relay, which completes the

defrost circuit.

During defrost operation, the main control board

monitors the evaporator temperature using

evaporator thermistor inputs. The thermistor will

terminate defrost heater operation usually in less

PRE-CHILL MODE

09:00

08:00

10:00

11:00

12:00

13:00

14:00

15:00

16:00

17:00

18:00

DefrostPre-Chill

than 20 minutes. Typical defrost time is 20-30

minutes.

The defrost system is protected by a defrost

thermostat (switch). The thermostat opens when

the evaporator temperature raises to 140°

Fahrenheit and closes when the evaporator

temperature lowers to 110 degrees Fahrenheit.

Dwell Period (Adaptive Defrost)

After defrost heater operation has been terminated

by the main control board, a 5-minute dwell period

occurs. During this period, the compressor, the

condenser fan, and the evaporator fan remain off.

The remaining frost melting from the evaporator

will continue to drip and drain so the evaporator

will be totally clear of any moisture prior to the

cooling operation. After the 5 minute dwell period,

the unit goes into post dwell.

Post Dwell (Adaptive Defrost)

The post dwell period is designed to cool the

evaporator before circulating air within the

refrigerator. This prevents any residual heat on

the evaporator from being distributed in the

freezer. During this period, the compressor and

condenser fan are on, but all interior fans are off

and the damper is closed. Post dwell times vary

with different models. However, there is a 5minute maximum post dwell time.

Liner Protection Mode

The liner protection mode will activate if either of

the doors have been open for 3 minutes. This

mode will start the fans and close the damper.

This mode is controlled by 2 timers. Timer #1

monitors door-open time. A 3-minute door-open

count begins when the door is opened. If 3

minutes elapse before the door is closed, the liner

protection mode will become active. Once the

door is closed, timer #1 resets and liner protection

mode goes into standby.

In standby, normal fan and damper operations

resume and timer #2 begins a 3-minute doorclosed count. If 3 minutes elapse without a door

opening, liner protection mode will completely

deactivate. If a door is opened within the timer #2

door-closed count, the remaining time in the doorclosed count will be deducted from the timer #1

door-open count.

– 9 –

Electronic Icemaker

Door Alarm

This refrigerator is equipped with an Electronic

Icemaker. Refer to Pub # 31-9063 for more

information.

Dispensing Functions

The water, crushed ice, and cubed ice functions

are controlled by the main control board. To select

a function, press the appropriate pad on the

dispenser. The LED will light to identify the

selection.

To dispense the selected item, depress the

dispenser cradle located in the dispenser recess.

The solenoid and linkage assembly will open the

ice chute door to dispense the ice. If cubed ice is

selected, the crushed ice bypass solenoid will

allow cubed ice to bypass the ice crusher. The ice

chute door must remain open for 5 seconds after

dispensing ceases. After this 5-second delay, the

solenoid and linkage assembly will shut the ice

chute door.

The DOOR ALARM pad is used to turn on and

turn off the door alarm feature. If the feature is on,

the DOOR ALARM LED will flash when the door is

opened. If the door is open for more than 2

minutes, the door alarm will sound. The alarm can

be stopped by pressing the DOOR ALARM pad or

by shutting the door. If the DOOR ALARM pad is

pushed while the door is open, the alarm will stop

but the led will continue to flash until the door is

closed. When the door is closed it will reset the

audible alarm. This feature will be retained in the

event of a power failure.

Dispenser Light

The LIGHT pad turns the dispenser light on and

off. When the light is turned off, it will fade out. The

dispenser light will come on automatically when

the dispenser cradle is depressed and will fade out

5 seconds after it is released. The LIGHT pad will

not turn off the light during dispense.

The dispenser light will come on automatically

when the dispenser cradle is depressed and will

fade out 5 seconds after it is released.

The dispenser selection is recorded in the main

control board. In the event of a power failure, the

last selected function will be restored.

Quick Ice

The quick ice feature is available on some models.

This feature causes the evaporator fan to operate

non-stop for 48 hours (fan may operate in high or

low speed). This enables maximum icemaker

output.

The QUICK ICE pad initiates the quick ice mode

in the refrigerator. Pressing the QUICK ICE pad

lights the LED and sets the evaporator fan to run

at medium speed (unless the main control board

selects high speed) for a 48-hour period. The

evaporator fan is terminated during defrost, dwell,

post dwell, and door openings.

The quick ice selection is stored in the main

control board. The function will be restored in the

event of a power failure.

Dispenser Lock

When the dispenser system is locked, no

dispenser command will be accepted. This

includes the dispenser cradle and will prevent

accidental dispensing that may be caused by

children or pets. If a pad is pressed with the

system locked, it will be acknowledged with 3

pulses of the LOCK LED accompanied by an

audible tone.

To lock or unlock communication between the

dispenser and the main control board, press the

LOCK pad and hold it for 3 seconds. The LOCK

LED will flash while the LOCK pad is pressed.

When the communication is locked, the LOCK

LED will be illuminated.

The status of other functions, selected prior to the

initiation of the lock feature, will be displayed. If the

lock is engaged while a mode is active, the LED

will remain on until that mode times out.

If the lock is engaged when the filter timer expires,

the LED will come on but cannot be reset until the

lock is turned off.

The lock feature will be retained through a power

outage.

– 10 –

Filters

Airflow (Cabinet Interior)

The FreshSaver filter is located on the FRESH

PRODUCE drawer and will last for 1 year. Some

models are equipped with a FreshSaver FILTER

LED. After 1 year of refrigerator operating time,

the FreshSaver FILTER LED will illuminate as a

reminder to the owner to change the filter. The LED

can be reset by pressing and holding the HOLD 3

SECS pad for 3 seconds. The LED will flash while

the pad is pressed, remain illuminated for 3

seconds after the pad is released, and turn off.

Some models are equipped with a water filter that

is located in the upper right-hand corner of the

fresh food compartment. Filters are designed to be

used for up to 18 hours of open valve time or 1

year of clock time.

When 90% of filter time has elapsed (open valve

time or clock time, whichever comes first), the

main control board will illuminate the filter reminder

LED (amber). When 100% of the filter time has

elapsed, the main control board will illuminate the

filter reminder LED (red).

Hinge System and Door Closure

The hinge brackets are not adjustable on the

cabinet. The fresh food door can be adjusted up

and down by using the hinge adjustment pin

(located on the fresh food lower door hinge).

This refrigerator is equipped with a door opening/

closing feature. This feature consists of a springloaded arm located at the bottom of the cabinet for

each door. The arm provides a stop for the door

when the door is partially open and automatically

closes the door when the door is almost closed.

IMPORTANT: The refrigerator rollers must be

adjusted correctly for proper door closure. When

the rollers are adjusted correctly, the door should

close easily when open approximately 45 degrees

(halfway).

AIR FLOW

The freezer cabinet is designed so that air is

drawn into the bottom of the air tunnel and through

the evaporator when the evaporator fan is

operating. The chilled air is then pushed out into

the top of the freezer.

The fresh food compartment receives chilled air

via an electronic damper that is positioned at the

top rear of the refrigerator between the freezer

cabinet and the fresh food cabinet. The damper is

controlled by the main control board and when

open, allows chilled air from the freezer air tunnel

to move into the fresh food air tower. The fresh

food air tower contains a fresh food fan which

draws chilled air from the freezer (through the

damper) into the air tower. The air tower directs

chilled air across the top of the fresh food cabinet

to two outlets. The air tower also directs chilled air

down the back wall of the fresh food cabinet. The

chilled air exits the air tower through vents in the

tower.

Air returns from the fresh food cabinet to the

freezer cabinet via a mullion located to the left of

the FRESH PRODUCE drawer.

– 11 –

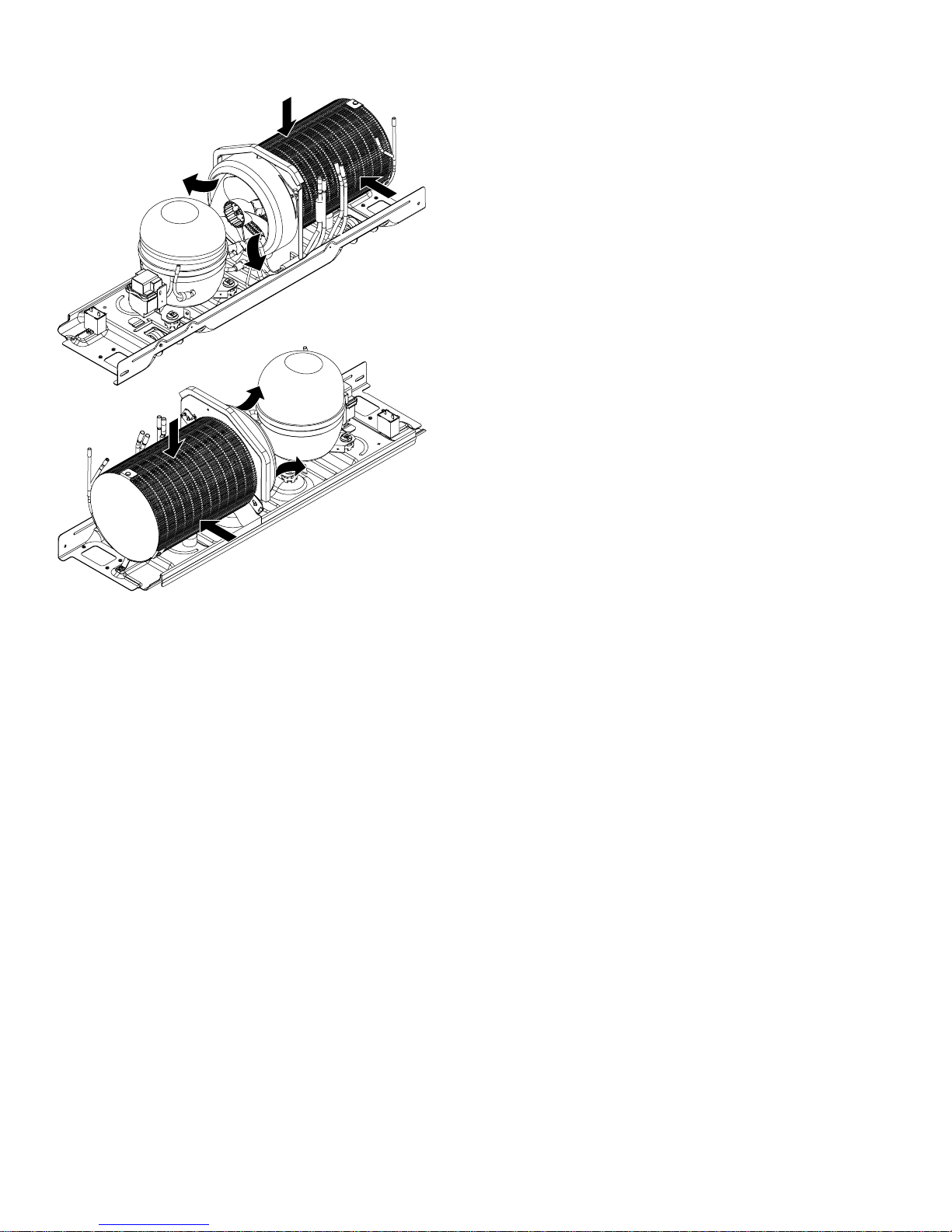

“Jelly Roll” Condenser

GEA00911

The “jelly roll” condenser is a new type of

condenser. The condenser fan is located at one

end of the “jelly roll” condenser and a solid plate is

located at the other end. Air is drawn in through

the outside diameter of the condenser and pulled

out by the condenser fan. The condenser is

located in the machine compartment which can be

accessed from the back of the unit at the bottom.

– 12 –

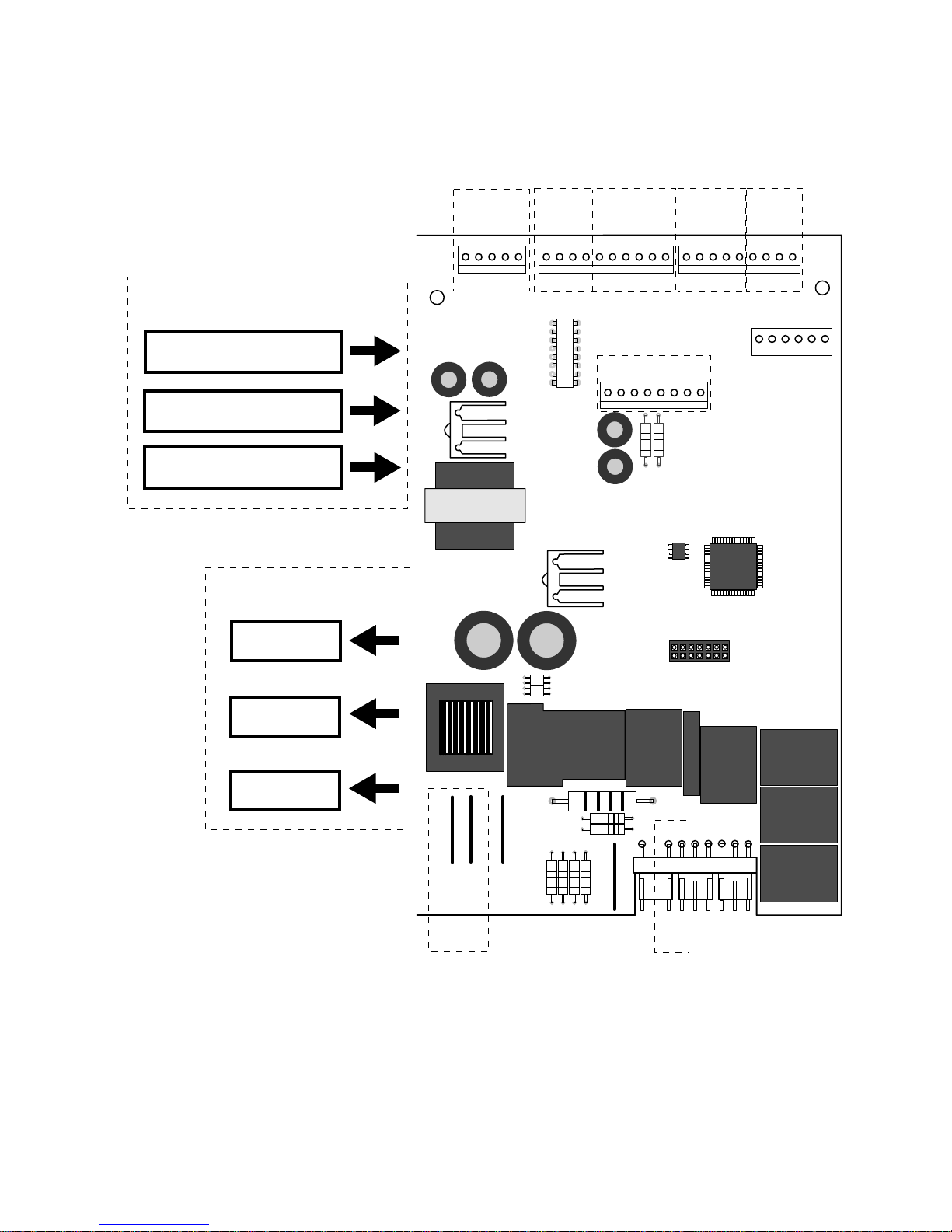

Main Control Board

INPUTS

ACCUMULATED FF AND FRZ

DOOR OPENINGS (MINUTES)

COMPRESSOR RUN TIME

(MINUTES)

DEFROST HEATER ON TIME

(MINUTES)

OUTPUTS

COOLING

2 +12V

1 COMM

3 -COM

4 DI

COMMUNICATION

INPUT/OUTPUT

5 DO

1

DAMPER

COILS

5

1

J4

ENCODER

INPUTS

J3

FAN OUTPUTS

1

THERMISTOR

10

INPUTS

1

8

J1

MODEL

SELECT

1

9

6

J5

J2

PROCESSING

UNIT

1

J6

2

PRE-CHILL

DEFROST

L1

DEFR

COMP

COMPRESSOR

AND

DEFROST

OUTPUTS

LINE

K4

COMP

K3

N

PAN_HTR

DEFROST

DFZ

DOOR

SWITCH

INPUTS

DFF

QC

K5

OCH

J7

K7

COMMON

WATER

PAN/HTR

CRUSHER

AUGER

K6

K2

K1

WATER

C/CR

AUGER

– 13 –

General Locator Views

Temperature

Thermistor

Thermistor

Thermistor

Temperature

Temperature

Controls

Controls

Freezer Light

Freezer Light

Switch

Switch

Evaporator

Evaporator

Fan

Fan

Evaporator

Evaporator

Thermistor

Thermistor

EvaporatorEvaporator

Freezer

Freezer

Thermistor

Thermistor

DamperDamper

Fresh Food

Fresh Food

Thermistor

Thermistor

– 14 –

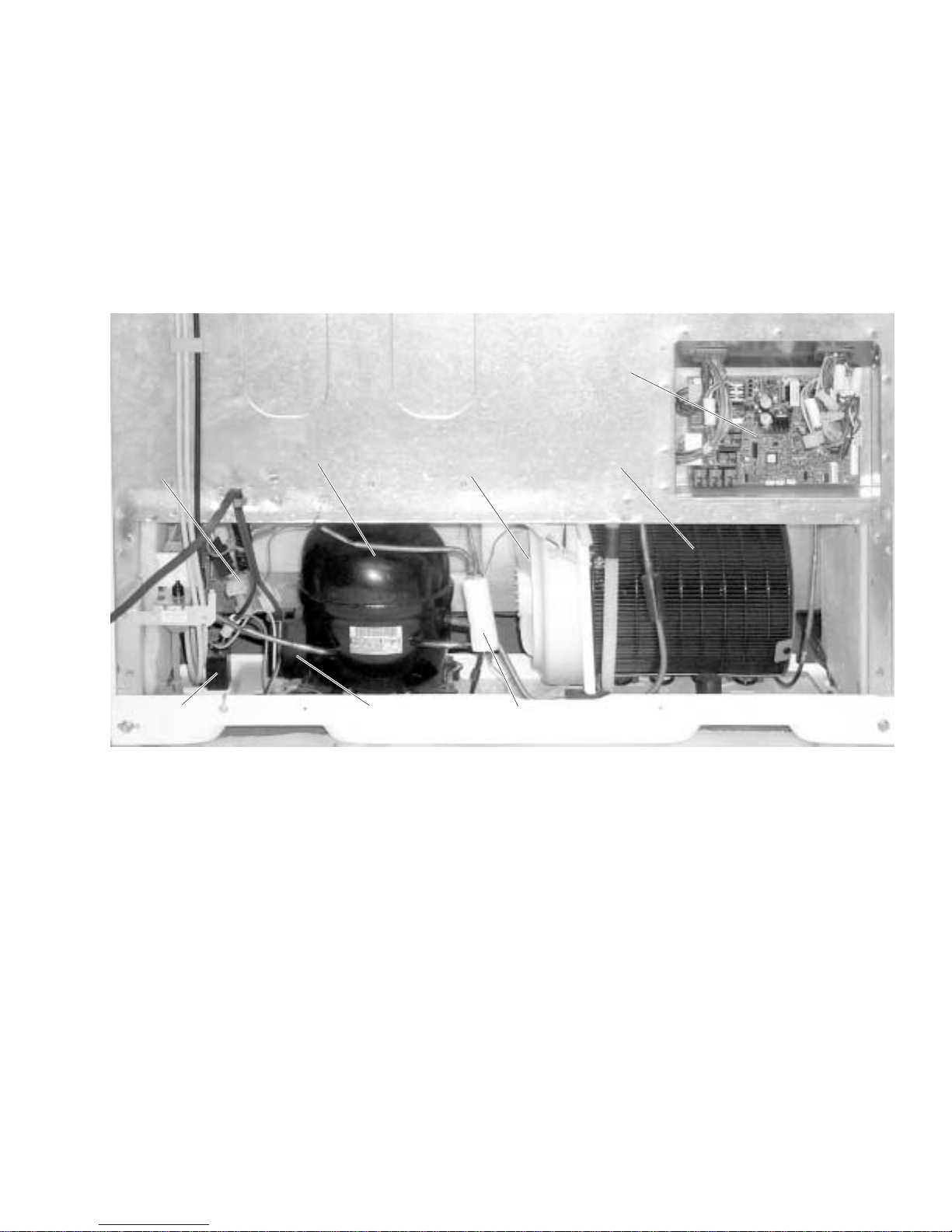

GEA00979

Fresh Food

Fresh Food

Light Switch

Light Switch

Water

Water

Solenoids

Solenoids

CompressorCompressor

Condenser

Condenser

Fan

Fan

Control

Control

Board

Board

Jelly Roll

Jelly Roll

Condenser

Condenser

Overload and Relay

Overload and Relay

(under cover)

(under cover)

DryerDryerCapacitorCapacitor

GEA00977

– 15 –

Mechanical Disassembly

Table of Contents

Door Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Door Gasket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fresh Food Compartment Quick Access Door . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fresh Food Door Light Switch

Fresh Food Compartment Door Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fresh Food Compartment Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fresh Food Compartment Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fresh Food Compartment Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Water Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fresh Food Fan and Mullion Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Deli Fresh Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fresh Food Thermistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Temperature Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Freezer Door Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Doors and Door Hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fresh Food Door Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Roller Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Freezer Compartment Shelves and Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Freezer Door Light Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ice Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ice Dispenser Auger Drive and Cube Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . 25

Icemaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

– 16 –

Freezer Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Evaporator Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Evaporator Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Defrost Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Defrost Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Evaporator Drip Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Freezer Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Condenser Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Main Processor Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Water Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

– 17 –

Door Handle

The door handles allow access into the fresh food

and freezer compartments. They are front

mounted with 1 Torx head screw.

1. With a small flat-blade screwdriver, slide the

handle trim down and pull it out.

2. Remove the lower Torx head screw.

3. Lift the handle in and upward motion until it

disengages the locking tabs. Pull the handle

outward to remove it.

Fresh Food Compartment Quick Access

Door

The fresh food compartment allows access to the

fresh food compartment without opening the fresh

food door.

1. Open the quick access door and remove the

hinge Torx head screws (2), located on each

side of the door.

Door Gasket

The door gasket is a molded gasket set into a

channel located in the door liner.

1. Open the door.

2. Grasp the gasket and pull in an outward

motion until the molded gasket separates from

the door liner.

2. With a small flat-blade screwdriver, remove the

door frame and door frame assembly.

3. Remove the gasket and slide the door out of

the frame.

4. The quick access door also has an interlock

switch located at the top right-hand side of the

interior frame. Remove the Phillips screw and

slide the switch assembly down and out.

5. Disconnect the wires to the switch and remove

it.

– 18 –

Fresh Food Door Light Switch

GEA00928

GEA00929

In addition to the quick access door light switch,

the fresh food compartment has a door light switch

located in the lower right corner for the

compartment.

1. Use a small flat-blade screwdriver to unlock

the locking tab tabs and pull the switch out until

the wire connector is visible.

2. Disconnect the connector and remove the

switch.

Fresh Food Compartment Drawers

Fresh food compartment drawers are designed for

storage of fruits, vegetables, and deli items. The

drawers are located in the lower portion of the

fresh food compartment.

1. Pull out the drawer until the rollers meet the

mechanical stop.

Fresh Food Compartment Door Shelves

The door shelves allow storage of perishable

items.

1. Tilt the shelf up and slide it out.

GEA00927

Fresh Food Compartment Shelves

These shelves allow the storage of larger items

and pull out for easy access.

1. Pull the shelf out until the shelf stop tab meets

the compartment stop.

2. Tilt the drawer up and pull it out until it is

removed.

Fresh Food Compartment Lights

The fresh food compartment lights are located in

the upper and lower portion of the fresh food

compartment.

1. To access the upper lights, remove the upper

opaque cover by unlocking the tabs and

pulling the cover down.

2. Push the shelf stop tab down and pull the

shelf out until it is removed.

– 19 –

GEA00930

2. To access the lower lights, pull the deli fresh

damper adjusting knob off.

3. Lift the opaque cover off the tabs.

GEA00931

Water Filter

The water filter is located in the upper right-hand

portion of the fresh food compartment. The water

filter, filters water for the ice maker and the water

dispenser. An LED on the temperature control

panel will illuminate when the filter needs to be

changed.

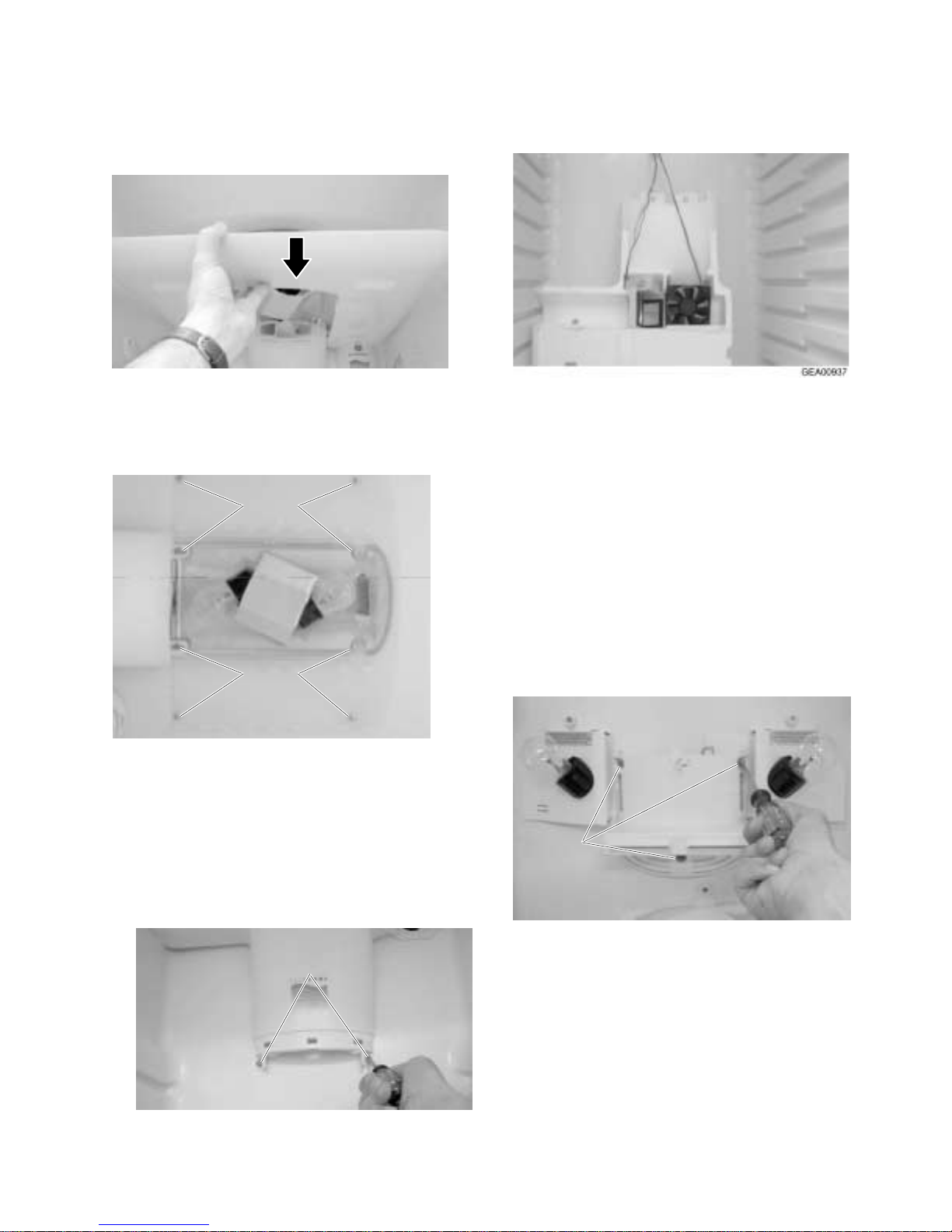

Fresh Food Fan and Mullion Damper

The fresh food compartment fan is located under

the upper ductwork in the fresh food compartment.

This fan distributes cold air from the freezer via the

mullion damper. The mullion damper is located in

the same assembly as the fan. Both are controlled

by the processor.

1. Remove the deli fresh adjusting knob and light

cover.

2. Unlock the upper and lower locking tabs for the

center ductwork and remove. The ductwork is

also fastened with double-sided tape at the

upper and lower portions.

1. Turn the water filter 1/2 turn counterclockwise

and pull it down.

2. To install the filter, push it up while turning 1/2

turn clockwise. Do not force the filter.

– 20 –

3. Remove the upper water filter cover.

Screws

4. Unlock the upper opaque light cover tabs and

remove the cover.

5. Unlock the upper ductwork tabs and remove it.

GEA00934

9. Lay the fan and damper assembly against the

compartment and open the back cover.

10. Disconnect the wire connections and remove

the damper or fan.

6. Remove the Phillips head screws (8) for the

upper light assembly plastic bracket.

ScrewsScrews

ScrewsScrews

GEA00935

7. Pull the stainless steel light bracket down until

the wires are exposed and disconnect them.

8. Remove the Phillips head screws (2) for the

fresh food fan and damper cover and remove

the cover.

Deli Fresh Damper

The deli fresh damper is located at the bottom of

the cold air ductwork. It allows the flow of cold air

to be adjusted to the deli fresh drawer.

1. Remove the deli fresh damper adjusting knob

and the lower light cover.

2. Remove the center ductwork by unlocking

upper and lower tabs. Double-sided tape is

applied to upper and lower areas.

3. Remove the damper Phillips head mounting

screws (3) and remove the damper.

Screws

Screws

ScrewsScrews

GEA00938

Fresh Food Thermistors

The fresh food thermistors are located at the

upper and lower portions of the fresh food

compartment. They send temperature signals to

the processor.

GEA00936

– 21 –

Loading...

Loading...