Page 1

ge.com

Refrigerators

GE Profile

™

Built-In Side by Side

225D2637P001 49-60558 01-08 JR

La section française commence à la page 51

Réfrigérateurs

GE Profile Côte à Côte

Model 42, 48

Write the model and serial numbers

here:

Model # __________________________

Serial # __________________________

Find these numbers on a label inside

the refrigerator compartment at the

top on the right side.

Owner’s Manual and

Installation Instructions

Manuel d’utilisation

et d’installation

Safety Instructions

. . . . . . . . . . .2–4

Operating Instructions

Automatic Icemaker . . . . . . . . . . . . . . .10

Care and Cleaning . . . . . . . . . . . . .12, 13

ClimateKeeper

with Dual Evaporators . . . . . . . . . . . . . . .6

Drawers and Baskets . . . . . . . . . . . . . . .9

Ice and Water Dispenser . . . . . . .10, 11

Refrigerator Doors . . . . . . . . . . . . . . . . . .8

Replacing the Light Bulbs . . . . . . . . . .14

Shelves and Bins . . . . . . . . . . . . . . . . . . . .7

Temperature Controls . . . . . . . . . . . . . . .5

Water Filter . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation Instructions

Anti-Tip Brackets . . . . . . . . . . . . . . . . . .34

Dimensions, Clearances . . . . . . . . . . . .17

Door, Grille Panels . . . . . . . . . . . . . .36–38

Installation Space . . . . . . . . . . . . . . . . . .17

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Panel Dimensions . . . . . . . . . . . . . .21–30

Water Line . . . . . . . . . . . . . . . . . . . . .33, 34

Water Supply . . . . . . . . . . . . . . . . . . . . . .39

Troubleshooting Tips . . . . . .42–44

Normal Operating Sounds . . . . . . . . . .41

Consumer Support

Consumer Support . . . . . . . .Back Cover

Performance Data Sheet . . . . . . . . . . .47

Product Registration . . . . . . . . . . . .49, 50

State of California Water

Treatment Device Certificate . . . . . . .48

Warranty (Canadian) . . . . . . . . . . . . . . .45

Warranty (U.S.) . . . . . . . . . . . . . . . . . . . .46

Page 2

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

Use this appliance only for its intended purpose as described in this Owner’s Manual.

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

■

■This refrigerator must be properly installed

and located in accordance with the Installation

Instructions before it is used.

■

■Do not allow children to climb, stand or hang

on the shelves in the refrigerator. They could

damage the refrigerator and seriously injure

themselves.

■

■Do not touch the cold surfaces in the freezer

compartment when hands are damp or wet.

Skin may stick to these extremely cold surfaces.

■

■Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

■

■In refrigerators with automatic icemakers, avoid

contact with the moving parts of the ejector

mechanism, or with the heating element located

on the bottom of the icemaker. Do not place fingers

or hands on the automatic icemaking mechanism

while the refrigerator is plugged in.

■

■Keep fingers out of the “pinch point” areas;

clearances between the doors and between

the doors and cabinet are necessarily small.

Be careful closing doors when children are

in the area.

■

■Set the master power switch to the O (off) position

before cleaning or making repairs.

NOTE: We strongly recommend that any servicing

be performed by a qualified individual.

■

■Do not refreeze frozen foods that have

thawed completely.

Page 3

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

Installation

Instructions

ge.com

PROPER DISPOSAL OF THE REFRIGERATOR

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous…even if they will sit for “just a few

days.” If you are getting rid of your old refrigerator,

please follow the instructions below to help prevent

accidents.

Before You Throw Away Your Old

Refrigerator or Freezer:

■Take off the doors.

■Leave the shelves in place so that children

may not easily climb inside.

Refrigerants

All refrigeration products contain refrigerants,

which under federal law must be removed prior

to product disposal. If you are getting rid of an

old refrigeration product, check with the company

handling the disposal about what to do.

DANGER! RISK OF CHILD ENTRAPMENT

3

Page 4

4

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped

with a 3-prong (grounding) plug, which mates

with a standard 3-prong (grounding) wall outlet

to minimize the possibility of electric shock hazard

from this appliance.

Have the wall outlet and circuit checked

by a qualified electrician to make sure

the outlet is properly grounded.

If the outlet is a standard 2-prong outlet, it is your

personal responsibility and obligation to have it

replaced with a properly grounded 3-prong wall

outlet.

The refrigerator should always be plugged into its

own individual electrical outlet which has a voltage

rating that matches the rating plate.

This provides the best performance and also prevents

overloading house wiring circuits, which could cause

a fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the

power cord. Always grip plug firmly and pull straight

out from the outlet.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end.

When moving the refrigerator, be careful not to roll

over or damage the power cord.

DO NOT USE AN ADAPTER PLUG OR EXTENSION CORD

(Adapter plugs not permitted in Canada)

Do not use an adapter plug to connect the refrigerator to a 2-prong outlet.

Do not use an extension cord with this appliance.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

Page 5

Consumer SupportTroubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

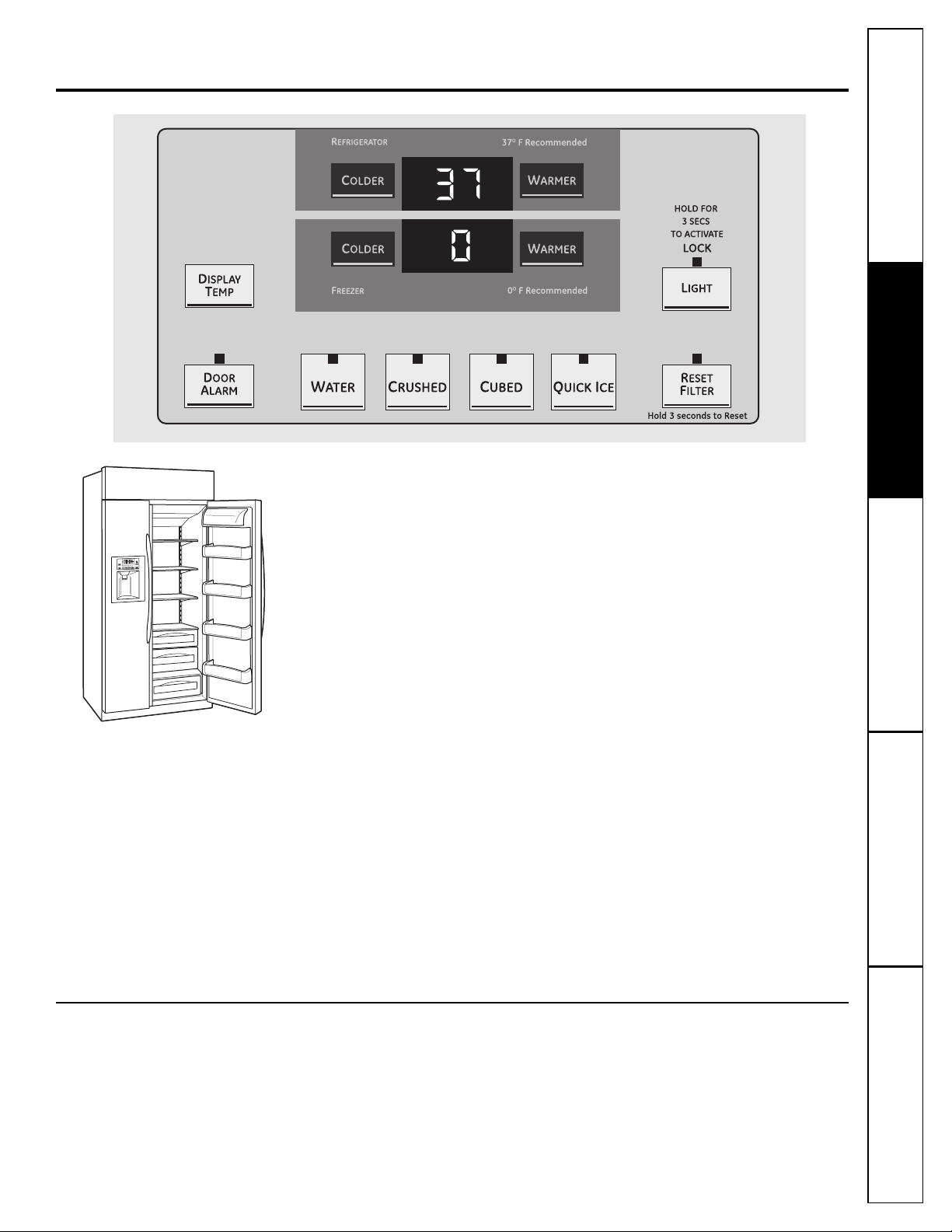

About the temperature controls. ge.com

The temperature controls are preset in the factory at 37°F for

the refrigerator compartment and 0°F for the freezer compartment.

Allow 24 hours for the temperature to stabilize to the preset

recommended settings.

The temperature controls can display both the SET temperature

as well as the actual temperature in the refrigerator and freezer.

The actual temperature may vary slightly from the SET

temperature based on usage and operating environment.

NOTE: The refrigerator is shipped with protective film covering

the temperature controls. If this film was not removed during

installation, remove it now.

The Performance Air-Flow System is designed to

maximize temperature control in the refrigerator

and freezer compartments. This unique special

feature consists of the Air Tower along the back

wall of the refrigerator and the freezer. Placing food

in front of the louvers on these components will not

affect performance.

Performance Air Flow System

To change the temperature, press and release

the WARMER or COLDER button. SET will illuminate in

the display, as well as the set temperature. To change

the temperature, tap either the WARMER or COLDER

button (while SET is illuminated) until the desired

temperature is displayed. Refrigerator temperatures

can be adjusted between 34°F and 47°F and

the freezer temperatures can be adjusted

between –6°F and +8°F.

Once the desired temperature has been set,

the temperature display will clear after 10 seconds.

To display the temperature, the DISPLAY TEMP button

may be tapped.

Several adjustments may be required. Each time you

adjust controls, allow 24 hours for the refrigerator to

reach the temperature you have set.

5

Page 6

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

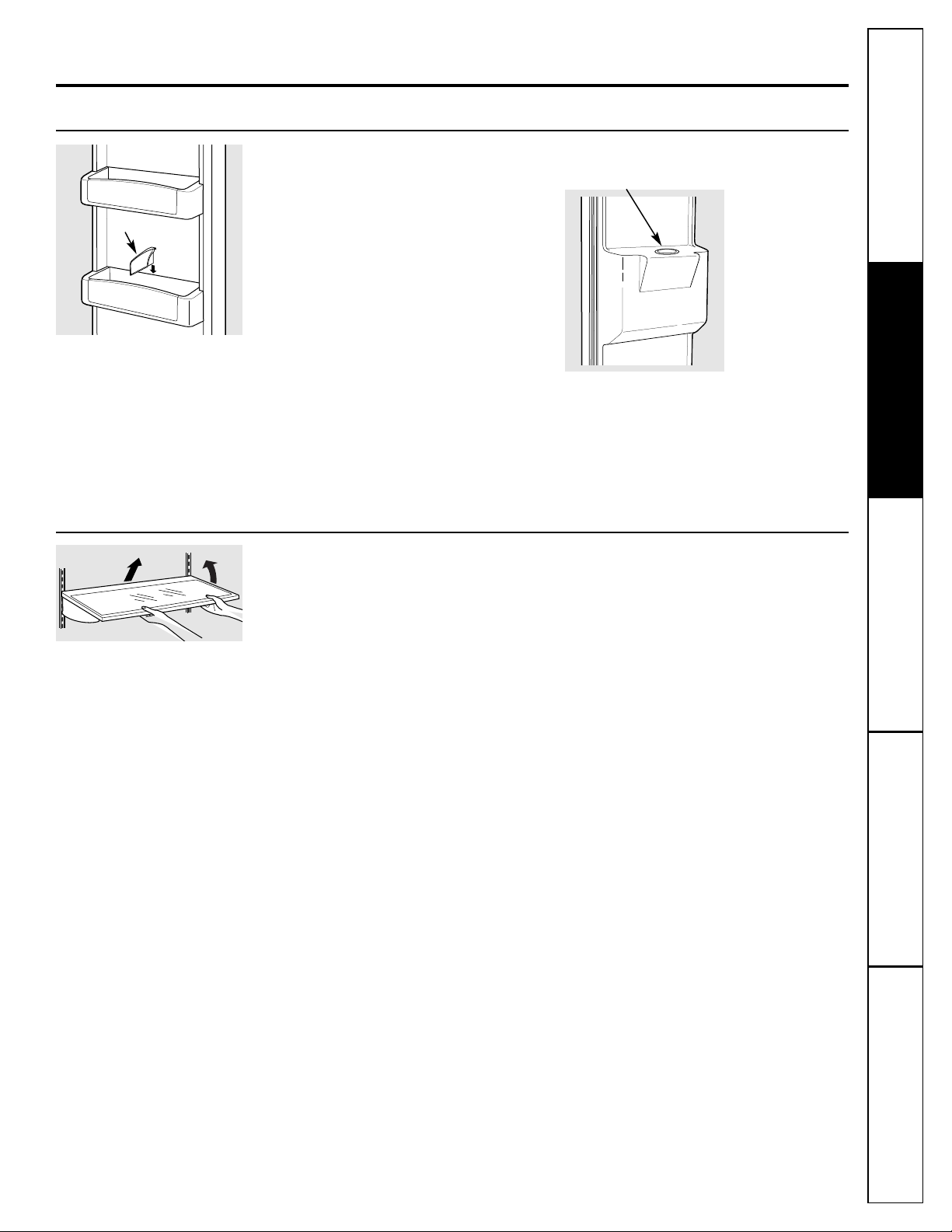

About the water filter.

6

Water Filter Cartridge

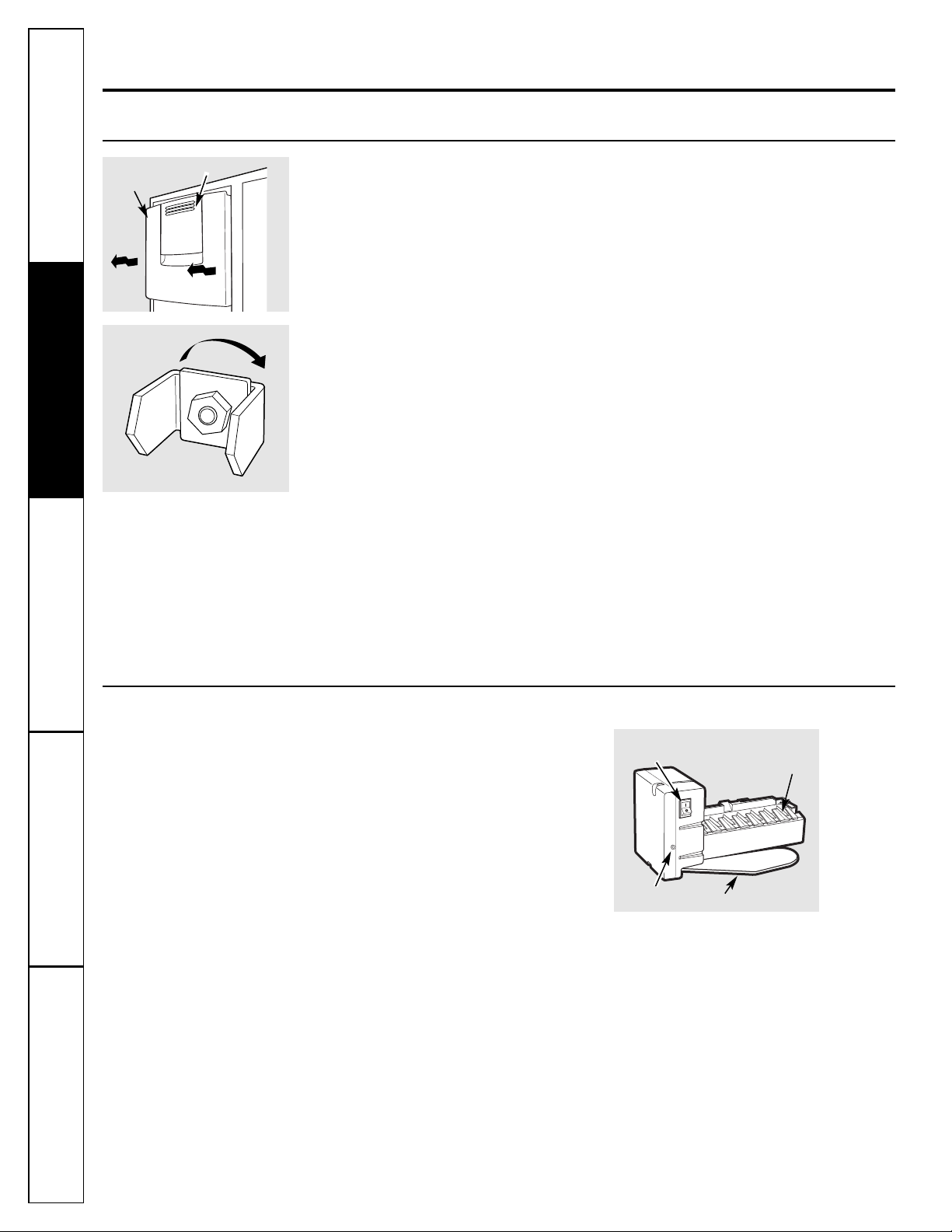

The water filter cartridge is located in the top

grille compartment. Flip up the panel top grille

to access the water filter.

When to Replace the Filter

There is a replacement indicator light for the water

filter cartridge on the dispenser. This light will turn

orange to tell you that you need to replace the

filter soon.

The filter cartridge should be replaced when the

replacement indicator light turns red or if the flow

of water to the dispenser or icemaker decreases.

Installing the Filter Cartridge

The filter cartridge is designed to filter 500 gallons

of water (lasting approximately 12 months).

If you are replacing the cartridge,

first remove the old one by slowly turning

it counterclockwise. Do not pull down

on the cartridge. A small amount of water

may drip down.

Fill the replacement cartridge with water

from the tap to allow for better flow from

the dispenser immediately after installation.

Lining up the arrow on the cartridge

and the cartridge holder, place the top

of the new cartridge up inside the holder.

Do not push it up into the holder.

Slowly turn it clockwise until the filter

cartridge stops. DO NOT OVERTIGHTEN. As

you turn the cartridge, it will automatically

raise itself into position. Cartridge will rotate

about 1/4 turn.

Run water from the dispenser for 3 minutes

(about 1

1

⁄2 gallons) to clear the system and

prevent sputtering.

Press and hold the RESET FILTER button

on the dispenser for 3 seconds.

NOTE: A newly-installed water filter cartridge may

cause water to spurt from the dispenser.

Filter Bypass Plug

You must use the filter bypass plug when

a replacement filter cartridge is not available.

The bypass plug will be taped to the door bin

in the new unit.

NOTE: The dispenser and the icemaker will not

operate without the filter or filter bypass plug.

Replacement Filters:

To order additional filter cartridges in the United

States, visit our Website, ge.com, or call GE Parts

and Accessories, 800.626.2002.

MWF

Suggested Retail $34.95 USD

Customers in Canada should consult the yellow

pages for the nearest Mabe Service Center.

Filter

Bypass

Plug

Cartridge

Holder

Place the top of the cartridge up inside

the cartridge holder and slowly turn it

clockwise.

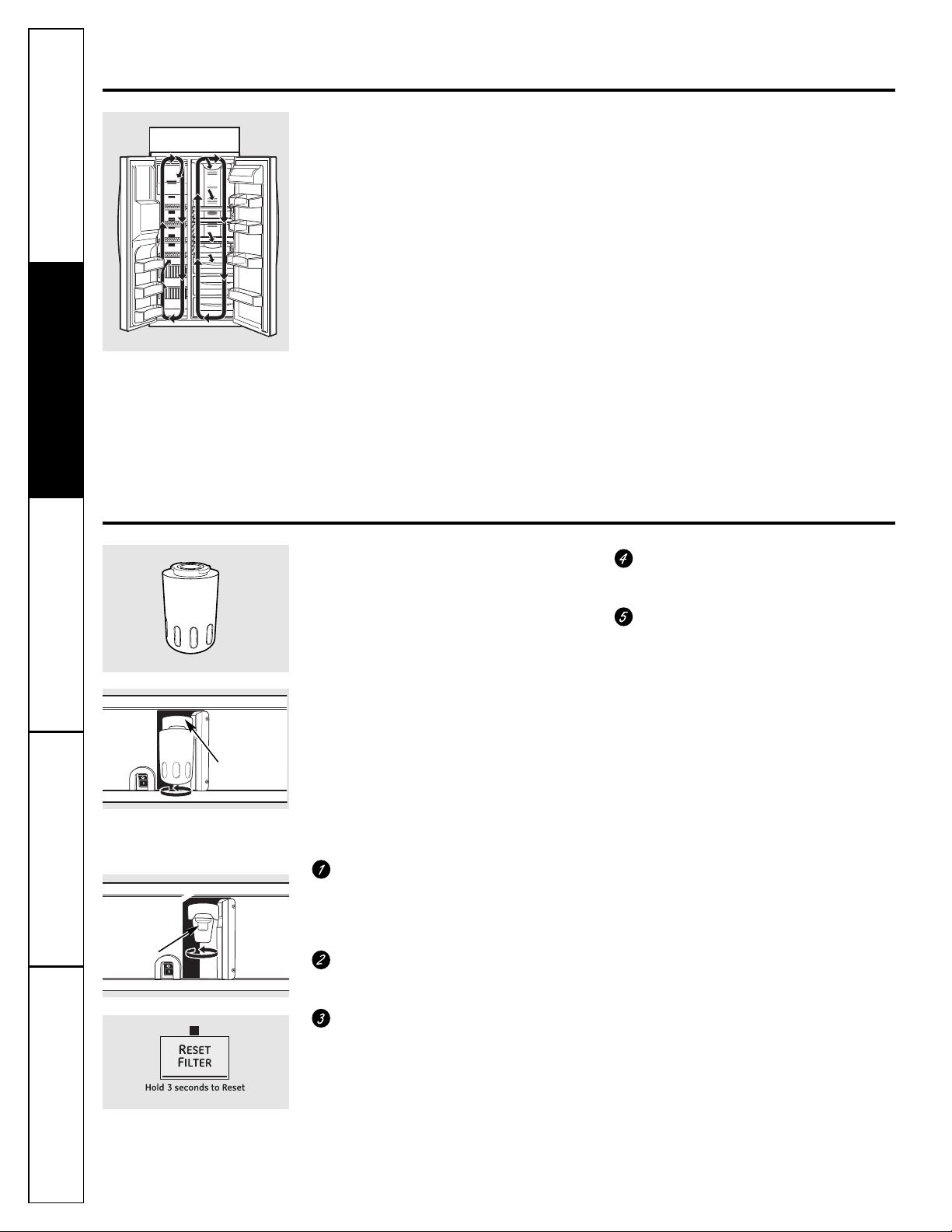

About ClimateKeeper®with dual evaporators.

How it Works

The ClimateKeeper with dual evaporators system features two evaporators—one for the refrigerator and one for the freezer.

This provides two separate cooling systems, and

separates the airflow between the fresh food and

freezer compartments during normal cooling

operations.

The separate airflow system minimizes

the mixing of air between the two compartments,

which reduces fresh food odor transfer to improve

the taste of ice.

The ClimateKeeper system also reduces

the number of defrosting cycles in the freezer

evaporator, thereby reducing freezer burn.

Page 7

7

About the shelves and bins. ge.com

Refrigerator Door Bins and Freezer Door Bins

All door bins, except for the deep gallon

door bin and freezer bins, are adjustable

and can be moved up and down to meet

your storage needs. The deep gallon door

bin and the freezer bins can be removed

for cleaning.

To remove any bin: Lift the bin up and pull

it toward you.

To replace or relocate: Engage the back side

of the bin in the molded supports on the door.

Then push down on the front of the bin.

Bin will lock in place.

The snugger helps prevent tipping, spilling

or sliding of small items stored on the door

shelf. Place a finger on either side of the

snugger near the rear and move it back

and forth to fit your needs.

CAUTION: Make

sure that items do

not block or fall into

the ice chute.

Not all features are on all models.

Refrigerator bins

Spillproof Shelves and Freezer Shelves

The special edges are designed to help

prevent spills from dripping to lower shelves.

To remove shelves:

Tilt shelf up at front, then lift it up and out of

tracks on rear wall of refrigerator.

To replace shelves:

Select desired shelf height. With shelf front

raised slightly, engage top lugs in tracks at

rear of cabinet. Then lower front of shelf until

it locks into position.

Make sure you push the shelves all the way

back in before you close the door.

Top freezer bin

Consumer SupportTroubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Do not block

Snugger

Page 8

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

8

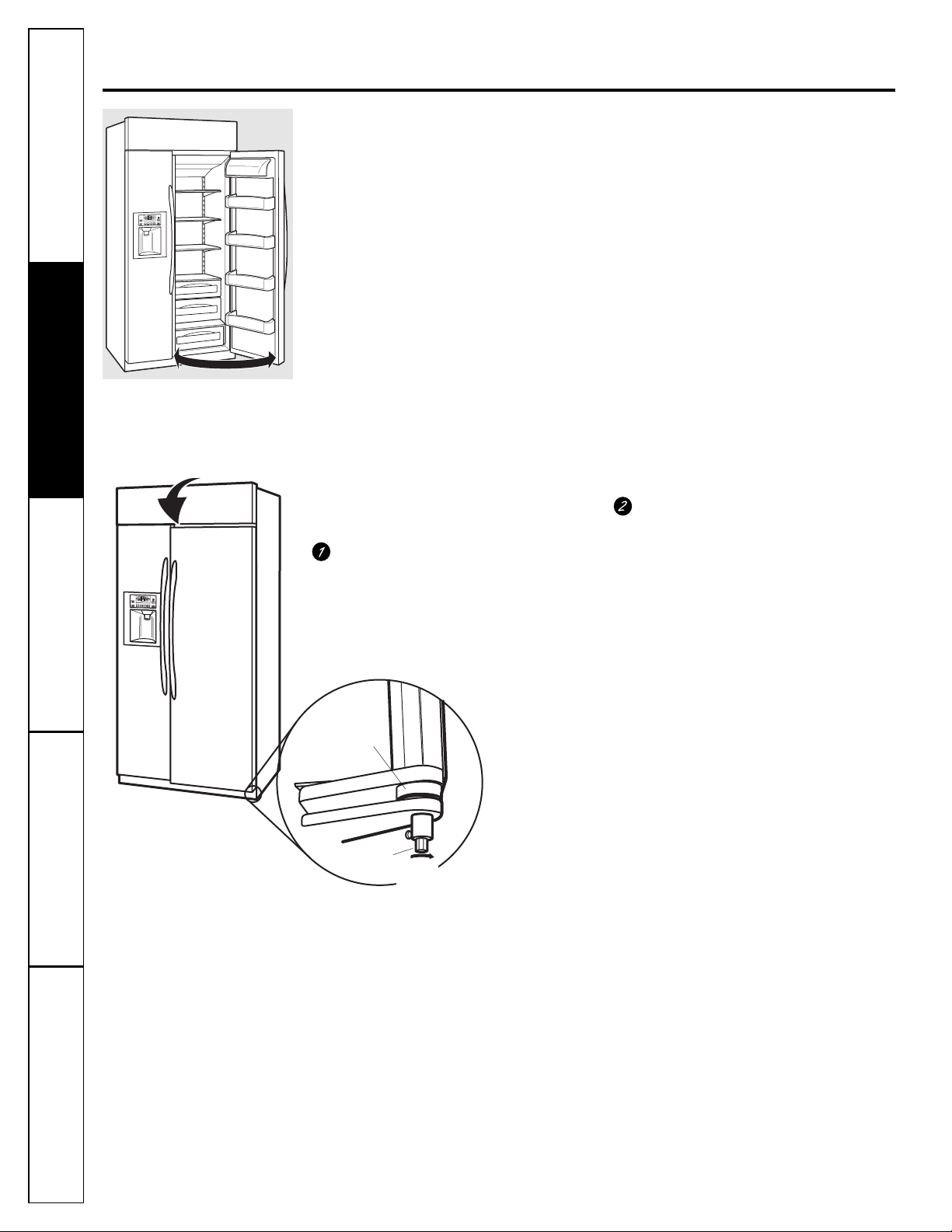

About the refrigerator doors.

Refrigerator Doors

The refrigerator doors may feel different than

the ones you are used to. The secure door

opening/closing feature makes sure the

doors close all the way and are securely

sealed.

When opening and closing the door,

you will notice a stop position. When

the door is at the 90° stop position,

it will automatically close.

The resistance you feel at the stop

position will be reduced as the door

is loaded with food.

When the door is at 90° open,

it will automatically close.

Beyond this stop the door will stay open.

Door Alignment

If doors are uneven, adjust the refrigerator

door.

Using a 7/32″ socket wrench, turn the

door adjusting screw clockwise to raise

the door, counterclockwise to lower

the door. (A nylon plug, imbedded in the

threads of the pin, prevents the pin from

turning unless a wrench is used.)

After one or two turns of the wrench,

open and close the refrigerator door

and check the alignment at the top

of the doors.

Bushing

Door Hinge

Case Hinge

7/32" Wrench

Raise

Clockwise

Page 9

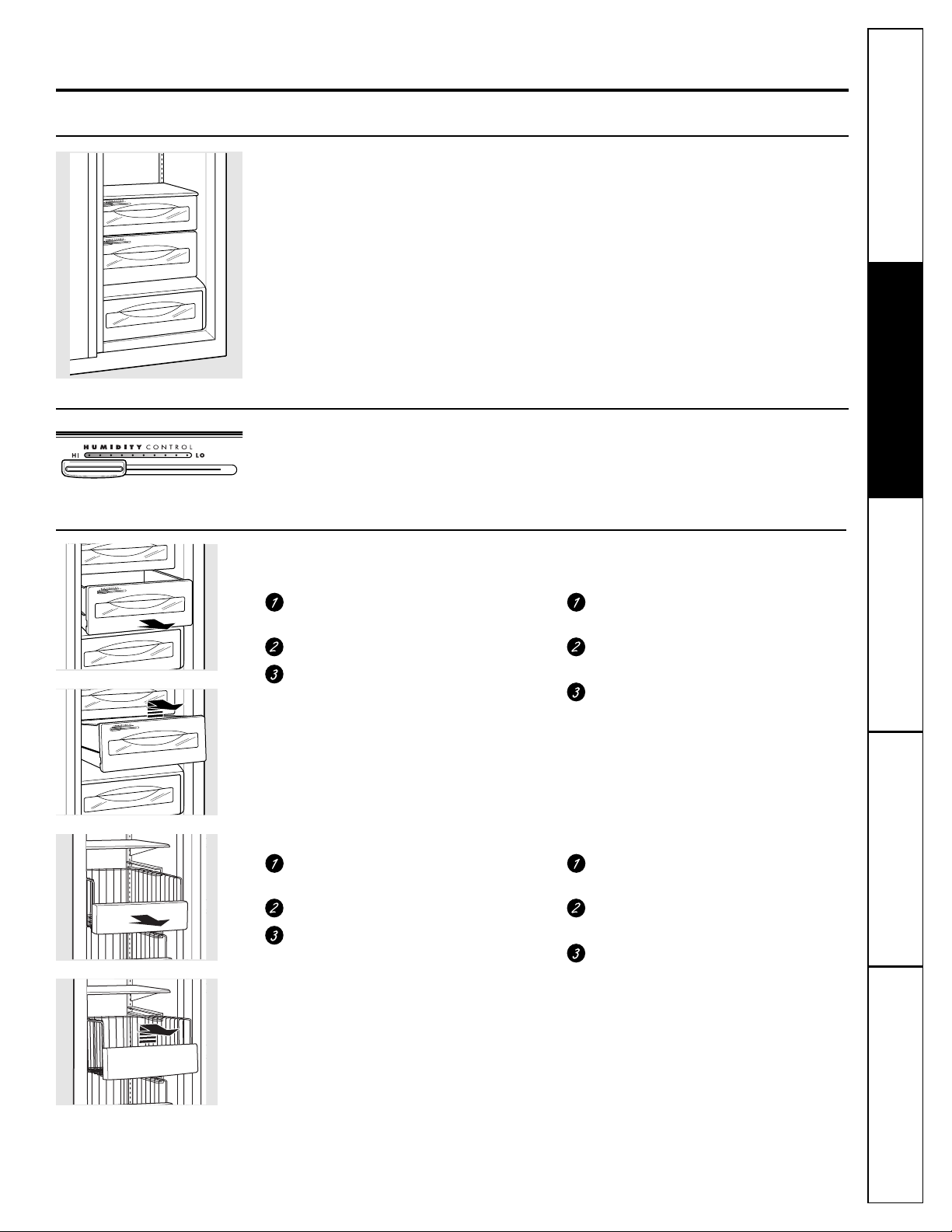

About the drawers and baskets. ge.com

9

Not all features are on all models.

Fruit and Vegetable Drawers

Excess water that may accumulate in the

bottom of the drawers should be wiped dry.

Adjustable Humidity Drawers

Slide the control all the way to the HI setting

to provide high humidity recommended for

most vegetables.

Slide the control all the way to the LO

setting to provide lower humidity levels

recommended for most fruits.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

Installation

Instructions

To remove fresh food drawers:

Pull the desired drawer out to the

stop position.

Lift up slightly on the front of the drawer.

Pull the drawer slightly forward and

out of the refrigerator.

To replace fresh food drawers:

Tip the back rollers of the drawer behind

the rollers in the track.

Lower the front of the drawer into normal

position.

Slide the drawer to the back of the

refrigerator.

To remove freezer baskets:

Pull the desired basket out to the

stop position.

Lift up slightly on the front of the basket.

Pull the basket slightly forward and

out of the freezer.

To replace freezer baskets:

Place the back corners in the rail

with the basket tilted up.

Lower the basket down to the normal

position.

Slide the basket to the back of the freezer.

How to Remove and Replace the Drawers and Freezer Baskets

Page 10

About the ice and water dispenser and automatic icemaker.

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

10

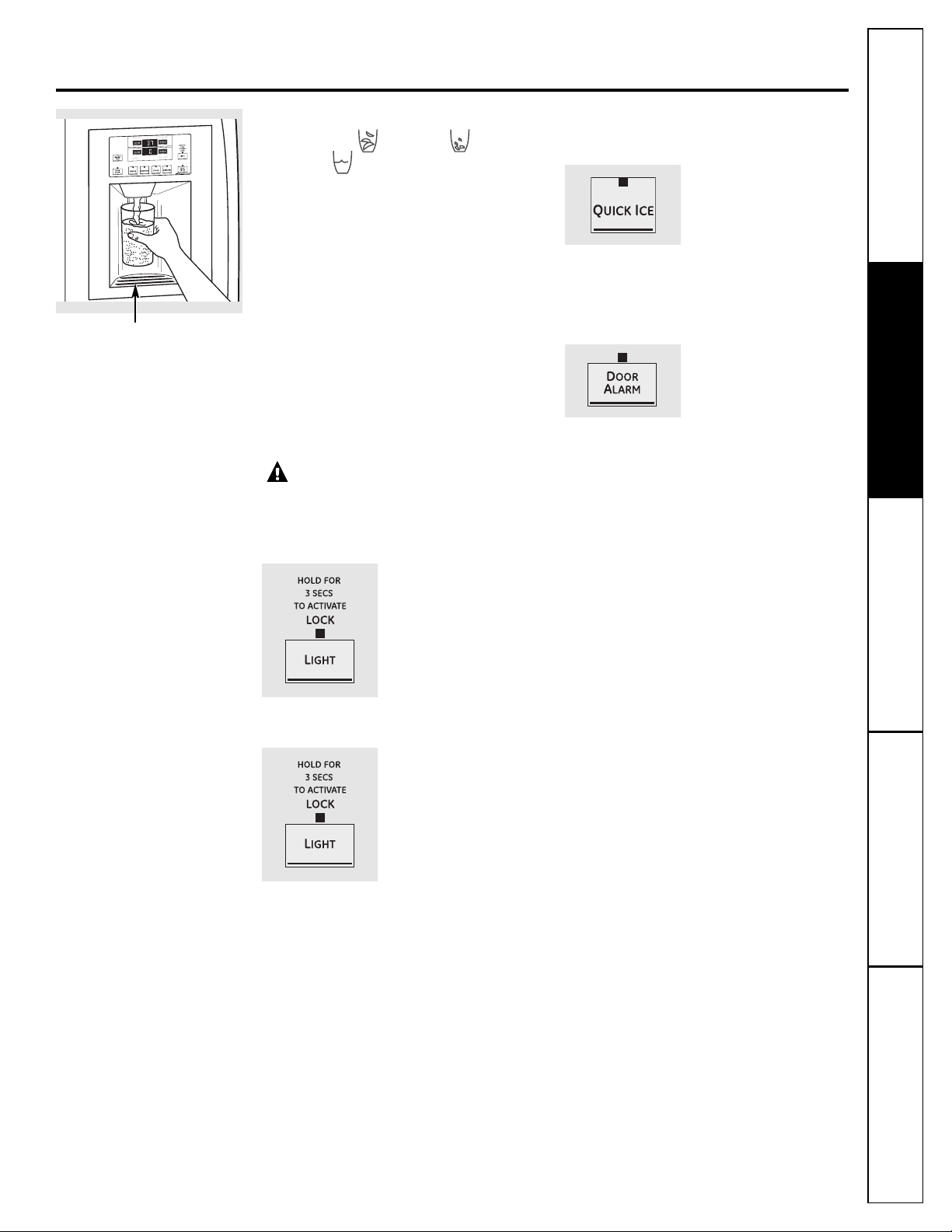

Ice Storage Bin

To remove:

Lift up the access door to reach the

icemaker. Set the icemaker power switch

to the O (off) position. With the access

door closed, support the storage bin at

the bottom while slightly lifting. Pull bin

straight out.

To replace:

Slide the bin back until the tab on

the bin locks into the slot on the shelf.

If the bin does not go all the way back,

remove it and rotate the drive mechanism

1/4 turn. Then push the bin back again.

Important facts about your

ice and water dispenser

■Do not add ice from trays or bags to the

storage bin. It may not crush or dispense

well.

■Avoid overfilling glass with ice and use of

narrow or extra-tall glasses. Backed-up ice

can jam the chute or cause the door in the

chute to freeze shut. If ice is blocking the

chute, poke it through with a wooden

spoon.

■Beverages and foods should not be

quick-chilled in the ice storage bin.

Cans, bottles or food packages in the

storage bin may cause the icemaker

or auger to jam.

■To keep dispensed ice from missing

the glass, put the glass close to, but not

touching, the dispenser opening.

■Some crushed ice may be dispensed

even though you selected CUBED. This

happens occasionally when a few cubes

accidentally get directed to the crusher.

■After crushed ice is dispensed, some water

may drip from the chute.

■The first glass of water dispensed may

be warmer than the following ones.

This is normal.

A newly installed refrigerator may take 12 to 24 hours to begin making ice.

Automatic Icemaker

A newly-installed refrigerator may take

12–24 hours to begin making ice.

The icemaker will produce seven cubes per

cycle—approximately 15 cycles or more in

a 24-hour period, depending on freezer

compartment temperature, room

temperature, number of door openings

and other use conditions.

If the refrigerator is operated before

the water connection is made to the

icemaker, set the power switch to O (off).

When the refrigerator has been connected

to the water supply, set the power switch

to I (on). The green light will come on.

Throw away the first full bucket of ice.

Be sure nothing interferes with the sweep

of the feeler arm.

When the bin fills to the level of the feeler

arm, the icemaker will stop producing ice.

It is normal for several cubes to be joined

together.

If ice is not used frequently, old ice cubes will

become cloudy, taste stale and shrink.

After the icemaker has been turned on again,

there will be a delay of about 45 minutes

before the icemaker resumes operations.

NOTE: In homes with lower-than-average

water pressure, you may hear the icemaker

water valve cycle on several times when

making one batch of ice. Recommended

water pressure is 60 psi.

Icemaker

Feeler Arm

Power

Switch

Green

Power Light

Ice Storage Bin

Access Door

Rotate

Drive

Mechanism

Page 11

11

About the ice and water dispenser. ge.com

To Use the Dispenser

Select CUBED , CRUSHED

or WATER .

Press the glass gently against the middle

of the dispenser pad.

The spill shelf is not self-draining.

To reduce water spotting, the shelf and

its grille should be cleaned regularly.

If no water is dispensed when the

refrigerator is first installed, there may

be air in the water line system. Press

the dispenser arm for at least two

minutes to remove trapped air from

the water line and to fill the water

system. To flush out impurities

in the water line, throw away

the first six glassfuls of water.

CAUTION: Never put fingers

or any other objects into the ice crusher

discharge opening.

Locking the Dispenser

Press the LOCK/LIGHT

button for 3 seconds

to lock the dispenser and

control panel. To unlock,

press and hold the button

again for 3 seconds.

Dispenser Light

This button turns

the night light on the

dispenser on and off.

The light also comes

on when the dispenser

pad is pressed. If this light

burns out, it should be

replaced with a 6 watt

12V maximum bulb.

Quick Ice

When you need ice

in a hurry, press this

button to speed up ice

production. This will

increase ice production

for the following

48 hours or until you

press the button again.

Door Alarm

To turn the Door Alarm

on, press the DOOR

ALARM button once. The

ACTIVE light will come on.

To turn it off, press it

again. When the DOOR

ALARM is active, the

ACTIVE light will flash if

you open the door and

beep if you keep the door

open for more than 2

minutes. The light goes

out and the beeping

stops when you close

the door.

Spill Shelf

Consumer SupportTroubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Page 12

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

12

Cleaning the Outside

The spill shelf and the area beneath it

should be cleaned periodically with a mild liquid

dish detergent.

Dispenser pad. Before cleaning, lock

the dispenser by pressing the LOCK/LIGHT

button for 3 seconds to prevent activating the

dispenser. Clean with warm water and a mild

liquid dish detergent. Rinse thoroughly and

wipe dry. Unlock the dispenser by pressing

the LOCK/LIGHT button for 3 seconds.

Door handles. Clean with a cloth dampened

with soapy water. Dry with a soft cloth.

Do not wipe the refrigerator with a soiled

dish cloth or wet towel. These may leave a

residue that can damage the finish. Do not

use scouring pads, powdered cleaners,

bleach or cleaners containing bleach

because these products can scratch

and damage the finish.

Stainless steel. Regularly clean and polish

the Stainless Steel Doors with a commercially

available stainless steel cleaner such as

Stainless Steel Magic™to preserve and

protect the fine finish. Stainless Steel Magic

is available through GE Parts and Accessories,

800.626.2002, or ge.com. Order part number

WX10X15.

Do not use appliance wax or polish

on the stainless steel.

Cleaning the Inside

Turn off power at the circuit breaker or fuse

box before cleaning. If this is not practical,

wring excess moisture out of sponge or cloth

when cleaning around switches, lights or

controls.

Use warm water and baking soda solution—

about a tablespoon (15 ml) of baking soda

to a quart (1 liter) of water. This both cleans

and neutralizes odors. Thoroughly rinse and

wipe dry.

Other parts of the refrigerator, including

door gaskets, snack pan and vegetable

drawers, ice storage bin and all plastic parts,

can be cleaned the same way.

Do not wash the tray or any plastic

refrigerator parts in the dishwasher.

Avoid cleaning cold glass shelves with hot

water because the extreme temperature

difference may cause them to break.

Handle glass shelves carefully. Bumping

tempered glass can cause it to shatter.

Dispenser drip area.

Care and cleaning of the refrigerator.

Page 13

13

For long vacations or absences, remove

food and unplug the refrigerator. Clean

the interior with a baking soda solution of

one tablespoon (15 ml) of baking soda to one

quart (1 liter) of water. Leave the doors open.

Set the icemaker power switch to the O (off)

position and shut off the water supply to

the refrigerator.

If the temperature can drop below freezing,

have a qualified servicer drain the water

supply system to prevent serious property

damage due to flooding.

ge.com

Preparing for Vacation

Preparing to Move

Secure all loose items such as shelves and

drawers by taping them securely in place

to prevent damage.

CAUTION: Due to the weight

and size of this refrigerator, and to reduce

the risk of personal injury or damage to

the product, A MINIMUM OF 4 PEOPLE ARE

REQUIRED TO BRING THE UNIT INTO THE

HOME AND 2 PEOPLE ARE REQUIRED FOR

PROPER INSTALLATION.

Be sure the refrigerator stays in an upright

position during moving.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

Installation

Instructions

Page 14

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

14

Replacing the light bulbs.

Setting the controls to OFF does not remove power to the light circuit.

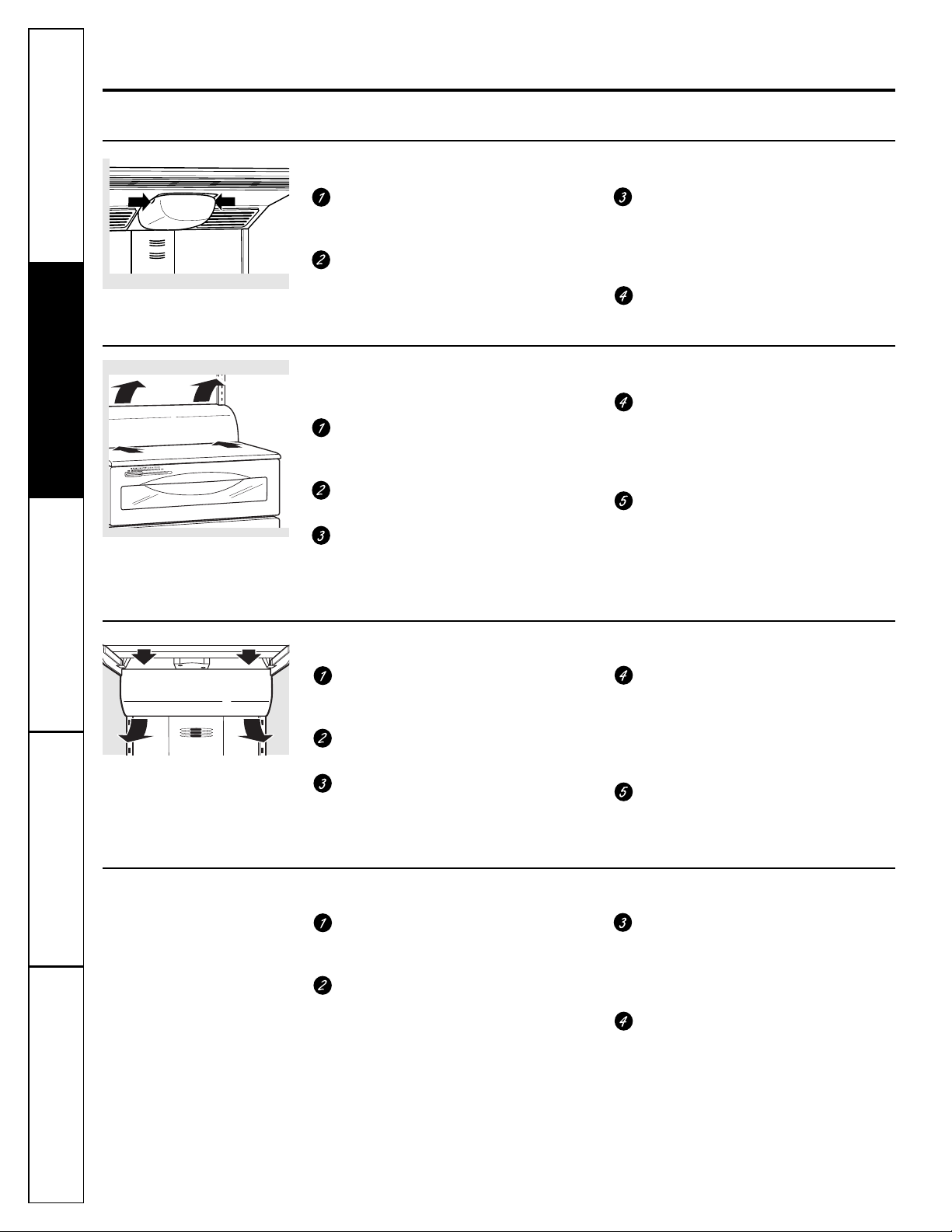

Refrigerator Compartment—Upper Light

Raise the grille panel, set the master

power switch to the O (off) position and

allow lamps to cool.

To remove the light shield, press on

the sides of the shield and pull down.

Replace the bulbs with appliance bulbs

of the same or lower wattage. Replace

the shield by engaging the bottom tab

into the slot and applying light forward

pressure until the shield snaps in place.

Set the master power switch to the I (on)

position and close the grille panel.

Refrigerator Compartment—Lower Light

This light is located above the top drawer.

Raise the grille panel, set the master

power switch to the O (off) position

and allow lamps to cool.

Remove items from the shelf above

the light shield. Remove the shelf.

Use both hands to grasp each end

of the light shield. Press in on the bottom

of the shield with your thumbs while

rotating the cover up and out.

Replace the bulb with an appliance bulb

of the same or lower wattage. Replace

the shield by engaging the bottom tab

into the slot and applying light forward

pressure until the shield snaps in place.

Set the master power switch to the I (on)

position and close the grille panel.

Freezer Compartment

Raise the grille panel, set the master

power switch to the O (off) position and

allow lamps to cool.

Remove the items from the shelf just

below the light shield. Remove the shelf.

To remove the light shield, press down

on the top of the shield and pull the tabs

out of the slots. Tilt the shield forward

and out.

Replace the bulb with an appliance

bulb of the same or lower wattage,

and reinstall the light shield. Replace

the shield by engaging the bottom tab

into the slot and applying light forward

pressure until the shield snaps in place.

Set the master power switch to the I (on)

position and close the grille panel.

Dispenser

Raise the grille panel, set the master

power switch to the O (off) position

and allow lamps to cool.

The bulb is located in the dispenser

under the control panel. Remove

the two screws from the light shield.

Slide the light shield toward the

dispenser to disengage the tabs, then

remove the light shield. Remove the light

bulb by turning it counterclockwise.

Replace the bulb with a bulb

of the same size and wattage. Replace

the light shield by sliding the tabs into

the slots in the front of the dispenser.

Replace the two screws.

Set the master power switch to the I (on)

position and close the grille panel.

(appearance may vary)

Page 15

Installation

Instructions

Built-In Side-By-Side

Refrigerators

PSB42YS, PSB42YG, PSB48YS, PSB48YG

If you have questions, call 800.GE.CARES (800.432.2737) or visit our website at: ge.com

In Canada, call 1.800.561.3344 or visit our website at: www.geappliances.ca

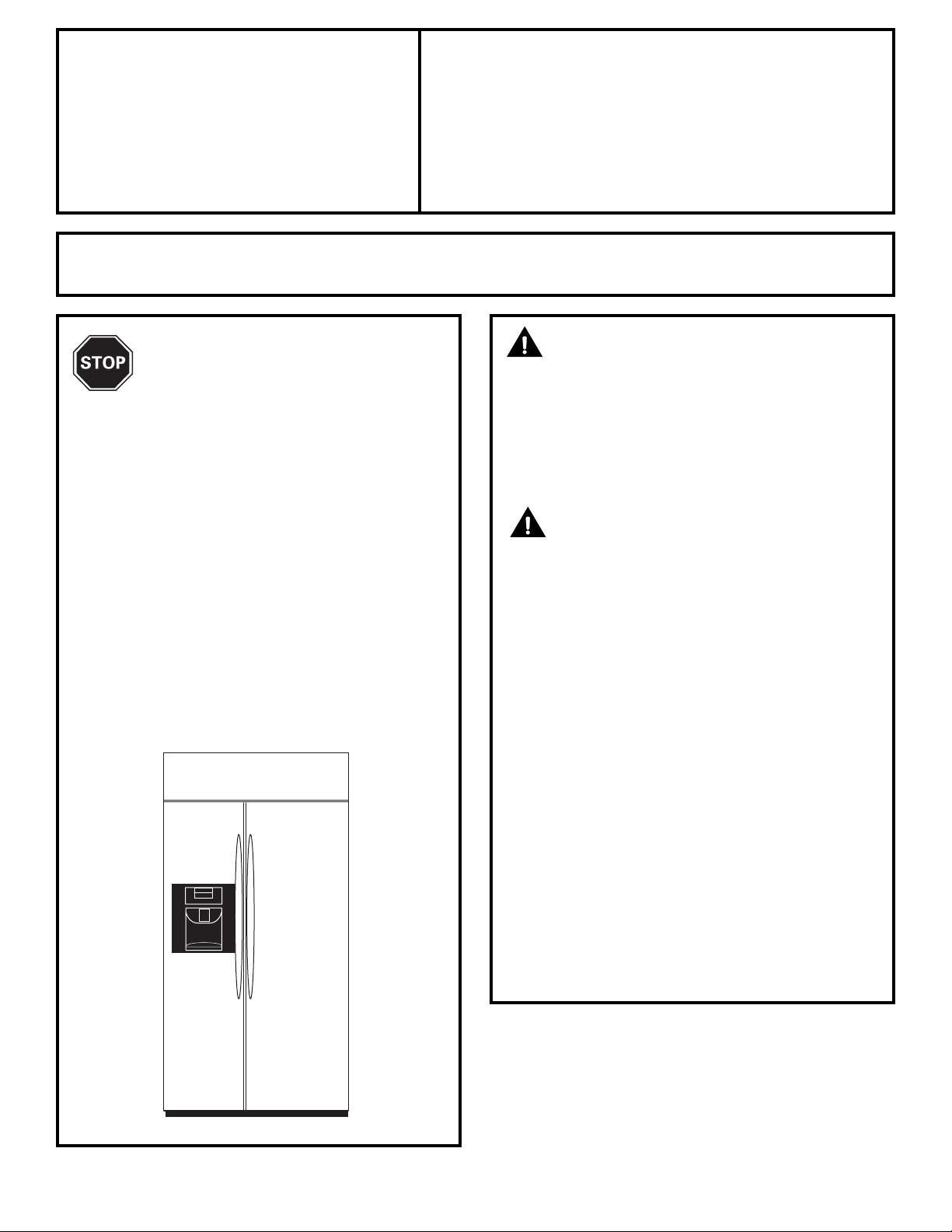

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

•

IMPORTANT — Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions for the consumer’s and local

inspector’s use.

• Note to Consumer – Keep these instructions

with your Owner’s Manual for future reference.

• Skill Level – Installation of this refrigerator

requires basic mechanical, carpentry and

plumbing skills. Proper installation is the

responsibility of the installer. Product failure

due to improper installation is not covered

under the GE Appliance Warranty.

See warranty information.

• Completion Time – 90 minutes (new installations

require more time than replacement installations).

CAUTION:

Due to the weight and size of this refrigerator,

and to reduce the risk of personal injury or

damage to the product, A MINIMUM OF 4 PEOPLE

ARE REQUIRED TO BRING THE UNIT INTO THE

HOME AND 2 PEOPLE ARE REQUIRED FOR PROPER

INSTALLATION.

WARNING:

• These refrigerators are top-heavy and must

be secured to prevent the possibility of tipping

forward. Anti-Tip protection is required.

See Step 4 on page 34 for details.

• Use this appliance only for its intended purpose.

• Immediately repair or replace electric power

supply cords that become frayed or damaged.

• Set the Master Power switch to the O (OFF)

position before cleaning or making repairs.

• Repairs should be made by a qualified service

technician.

For GE Profile

™

local service in your area,

call 1.800.432.2737.

For GE Profile service in Canada,

call 1.800.561.3344.

For GE Profile Parts and Accessories,

call 1.800.626.2002.

ge.com (in Canada, geappliances.ca)

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

15

Page 16

Installation Instructions

16

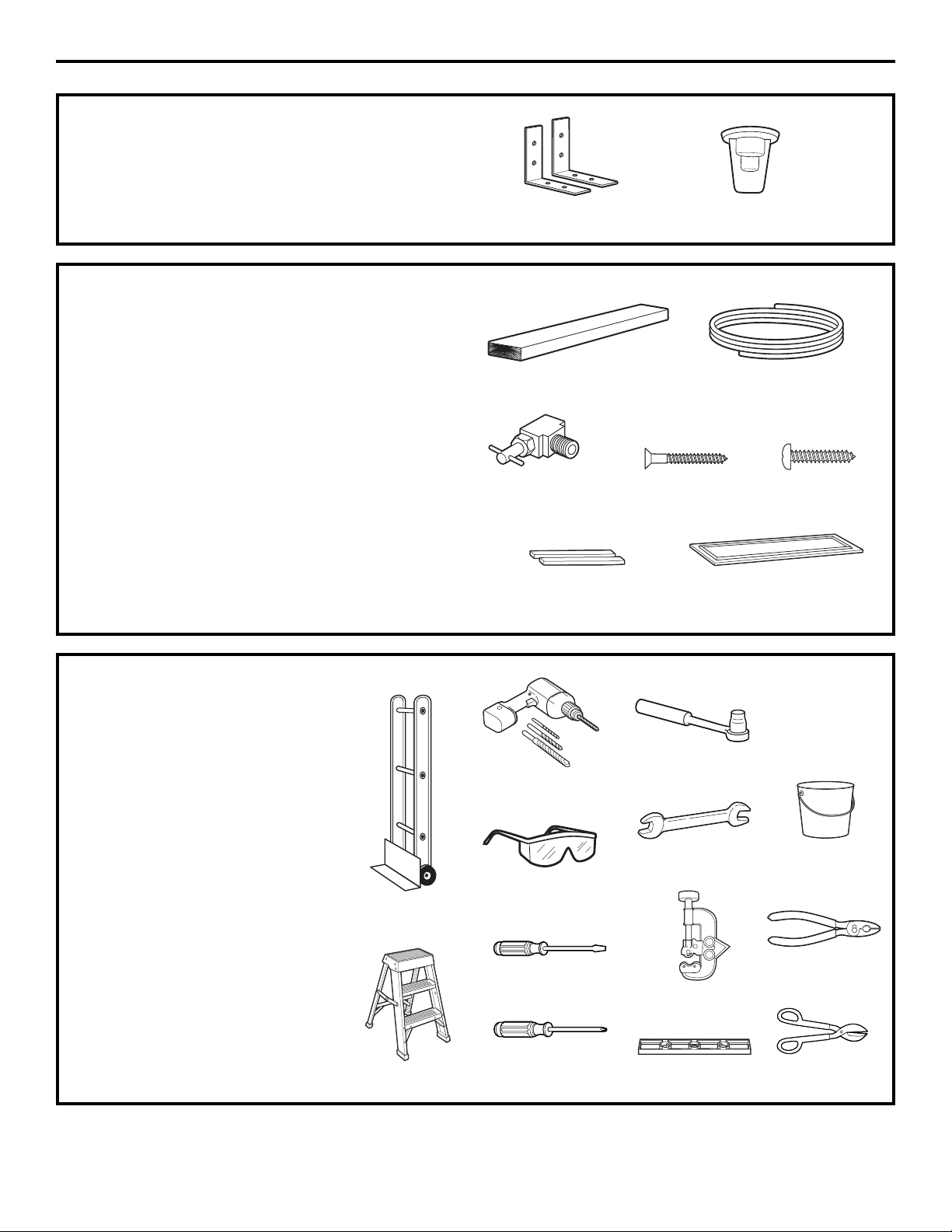

HARDWARE SUPPLIED

• Water filter bypass plug

• Anti-Tip brackets

Anti-Tip Brackets Water Filter Bypass Plug

MATERIALS REQUIRED

• 36″ long, 2″ x 4″ wood block for Anti-Tip bracket

installation

• #12 or #14 wood screws for Anti-Tip bracket

• Screws to secure refrigerator to cabinets

• 1/4″ O.D. copper water line tubing or GE

SmartConnect

™

refrigerator tubing kits

• Water shutoff valve

• Custom panels for doors and grille panel

(if installing custom panels)

• Special 3M Dual Lock adhesive strips for

1/4″ side panels (if installing side panels)

36″ Wood Block 1/4″ O.D. Copper Water Line

Tubing or GE SmartConnect™

Refrigerator Tubing Kit

TOOLS REQUIRED

• Tinsnips to cut banding

• Stepladder

• Bucket

• Level

• Appliance dolly

• Tubing cutter

• Flathead screwdriver

• 1/2″ open-end wrench

• #2 Phillips screwdriver

• Drill and appropriate bits

• 7/32″, 1/2″ sockets

• Safety glasses

• 7/16″ open-end wrench

• Pliers

Appliance Dolly

Stepladder

Safety Glasses

Water Shutoff Valve #12 or #14

Wood Screws

Screws

Special 3M Dual Lock

Adhesive Strips

Custom Panels

Sockets

Open-end Wrenches Bucket

Drill & Bits

Flathead Screwdriver

Tubing Cutter

Phillips Head

Screwdriver

Level

Pliers

Tinsnips

Page 17

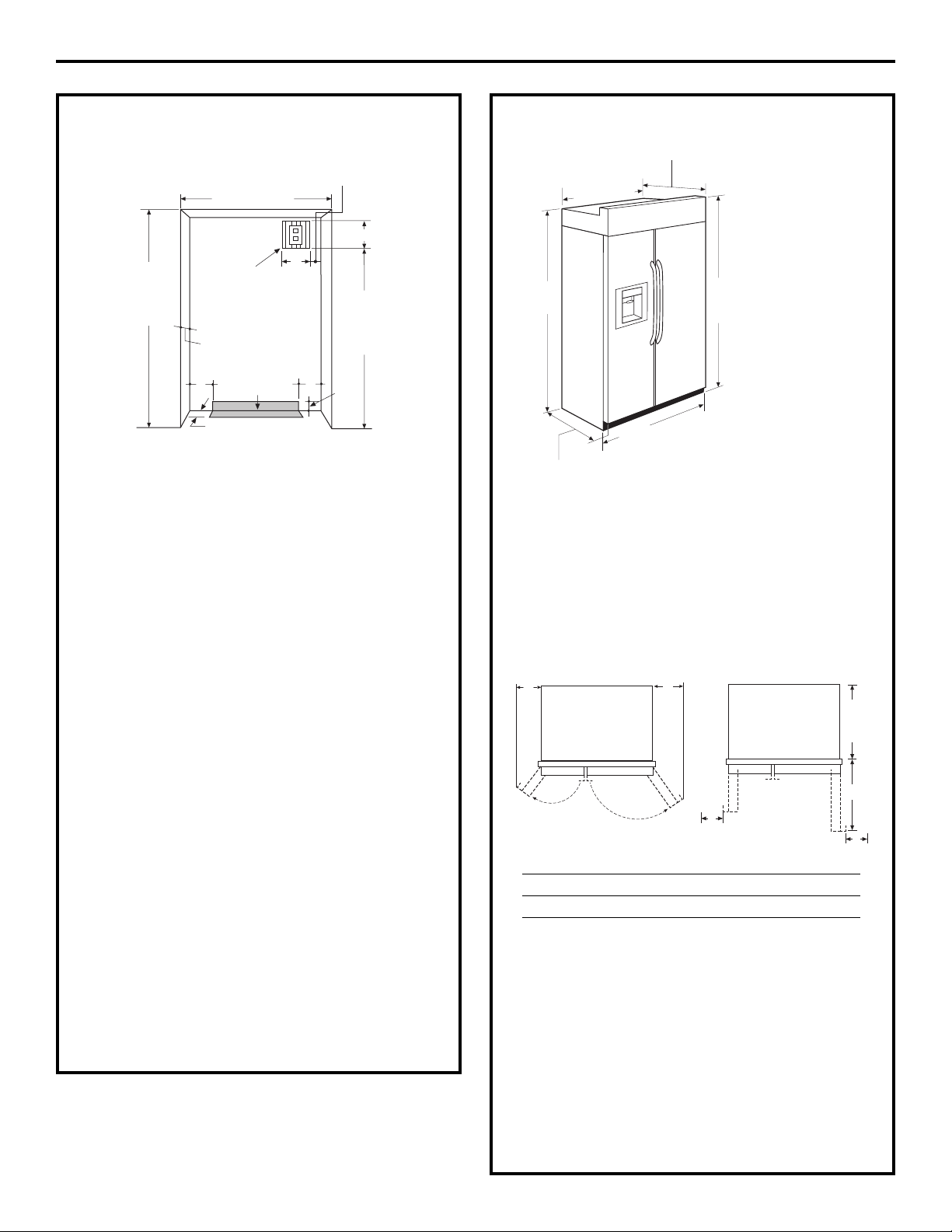

THE INSTALLATION SPACE

Water and Electrical Locations

The opening must be prepared with the electrical

and water supply located as shown.

The cutout depth must be 24″

The refrigerator will project forward, slightly

beyond adjacent cabinets, depending on your

installation.

Additional Specifications

• A 120 volt, 60Hz, 15 or 20 amp power supply

is required. An individual properly grounded

branch circuit or circuit breaker is

recommended. Install a properly grounded

3-prong electrical receptacle recessed into

the back wall. Electrical must be located on

rear wall as shown.

Note: GFI (ground fault interrupter) is not

recommended.

• Water line can enter the opening through the

floor or rear wall. The water line installed should

be 1/4″ O.D. copper tubing or GE SmartConnect

™

tubing between the cold water line and water

connection location. The line should be long

enough to extend to the front of the refrigerator.

Installation of an easily accessible shutoff valve

in the water line is required.

DIMENSIONS AND CLEARANCES

Allow minimum clearances for Freezer door

(Dimension A) and Fresh Food door (Dimension B)

for a full 130° door swing and to allow for drawer

removal.

Four inch (4″) minimum clearance is required when

door swing is adjusted to 90°. If the 90° door stop

position is used, drawer access is maintained, but

drawer removal is restricted.

See illustrations, pages 18 and 19, to determine

door swing interaction with adjacent cabinets or

countertops.

*The finished cutout width must be: 41-1/2″

for 42″ models and 47-1/2″ for 48″ models

Product Clearances

These refrigerators are equipped with a 2 position

door stop. The factory set 130° door swing can be

adjusted to 90° if clearance to adjacent cabinets

or walls is restricted.

130° Door Swing 90° Door Swing

Models A B C D

42″ 12-3/16″ 16″ 24″ 5″

48″ 13-7/16″ 18-9/16″ 28″ 5″

Installation Instructions

*Shipping height

The front height may be

adjusted from 83-1/2″

to 84-1/2″ by adjusting

front and rear leveling

legs a maximum of 1″.

**The case width must be: 41″ for 42″ models and

47″ for 48″ models

17

3"

*Finished Width

7"

84 1/2" max

83 1/2" min

Finished

Opening

Electrical

Area

24"

5"

Water Supply

3 1/2"

7"

5"

74"

From Floor

to Bottom

of Electrical

3 1/2"

25-3/8" Case Depth

**Case Width

*81-3/4"

at Rear

42" Frame-to-Frame for 42" Models

48" Frame-to-Frame for 48" Models

Depth Including

Handles 26-7/8"

*84" From

Floor to

Top Frame

A

B

D

23-7/8"

Behind

Frame

C

D

Page 18

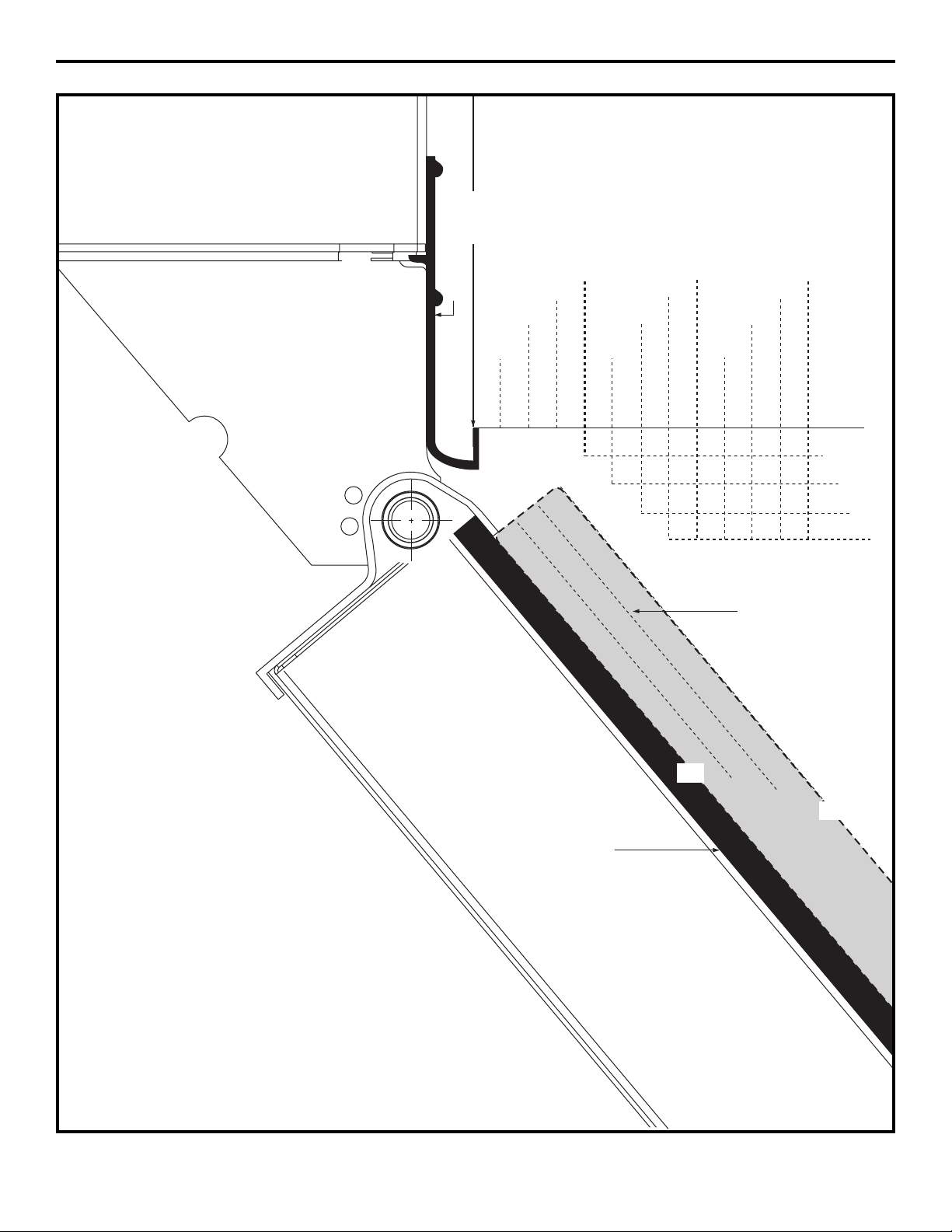

Top View

130° Door Swing

(factory setting)

Scale 1:1

Installation Instructions

18

Refrigerator

23-7/8" From

Rear of

Refrigerator

Case

Trim

1/4"

1/2"

3/4"

1"

1-1/4"

1-1/2"

1-3/4"

2"

3"

2-3/4"

2-1/2"

2-1/4"

1/4"

1/2"

3/4"

1"

3/4" Custom Panel

(Nominal Size)

Fresh Food

Door

Backer Panel

1/4"

1/2"

3/4"

1"

Page 19

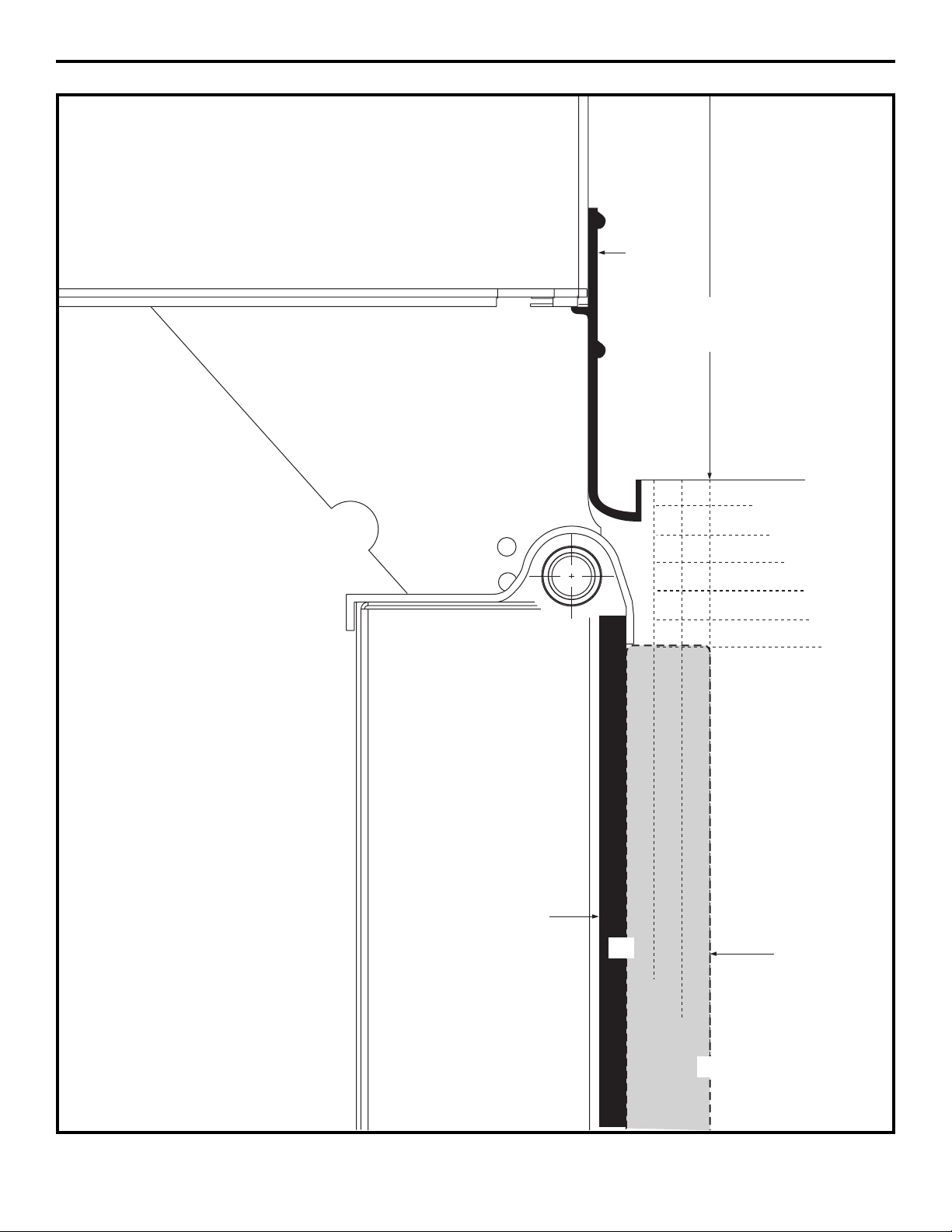

Top View

90° Door Swing

(optional setting)

Scale 1:1

Installation Instructions

19

Refrigerator

Case Trim

23-7/8"

From Rear of

Refrigerator

Fresh Food

Door

Backer Panel

1/4"

1/4"

1/2"

3/4"

1"

1-1/4"

1-1/2"

3/4" Custom Panel

(Nominal Size)

1/2"

3/4"

1"

Page 20

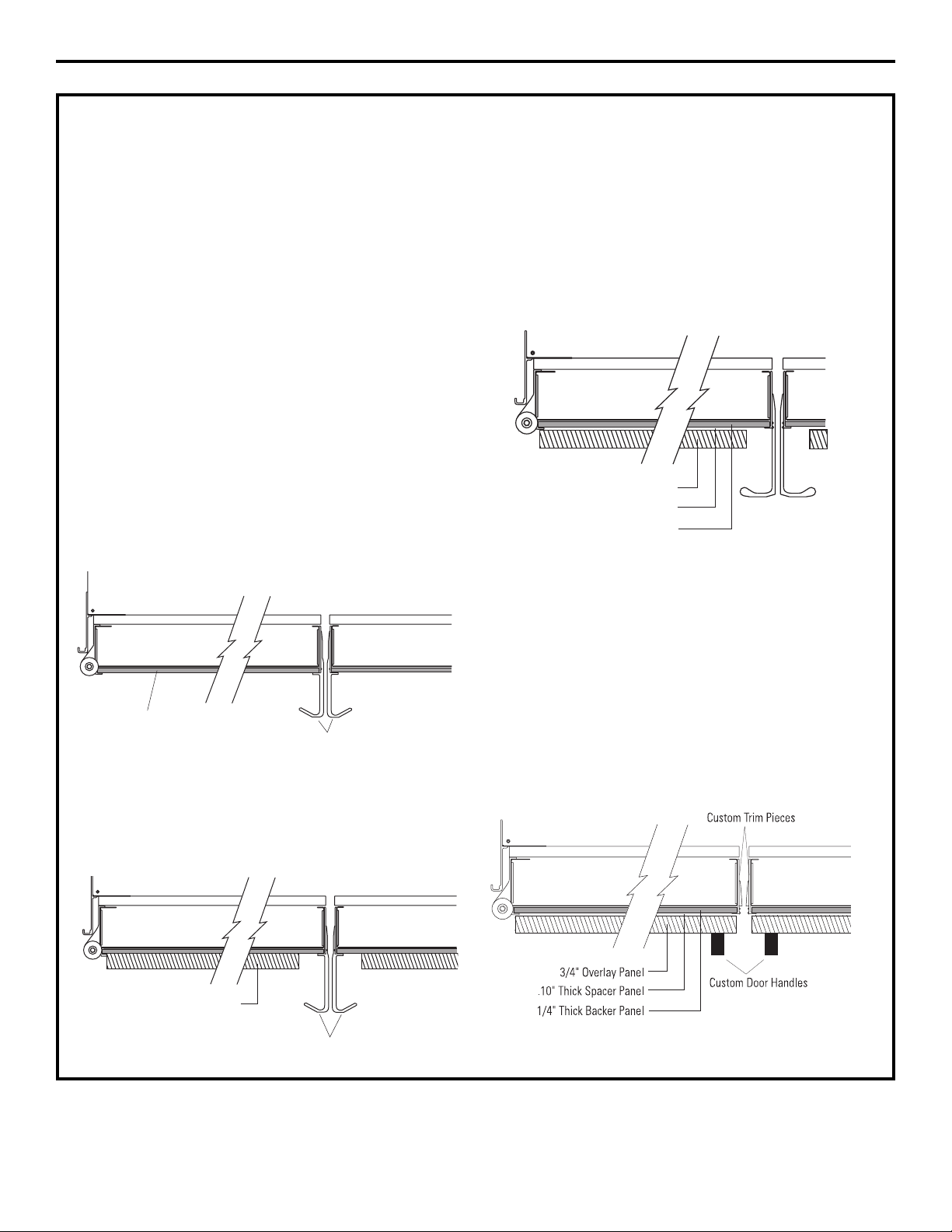

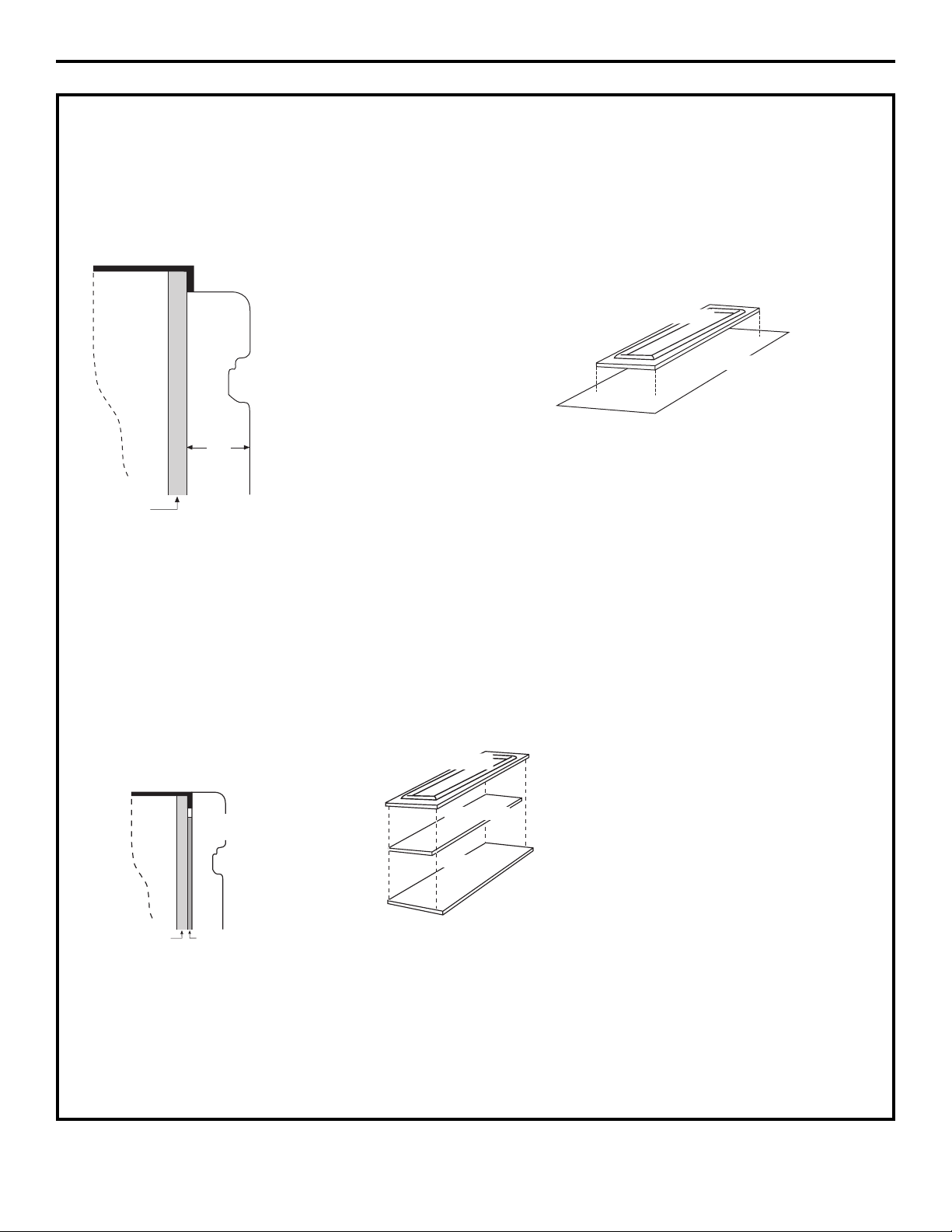

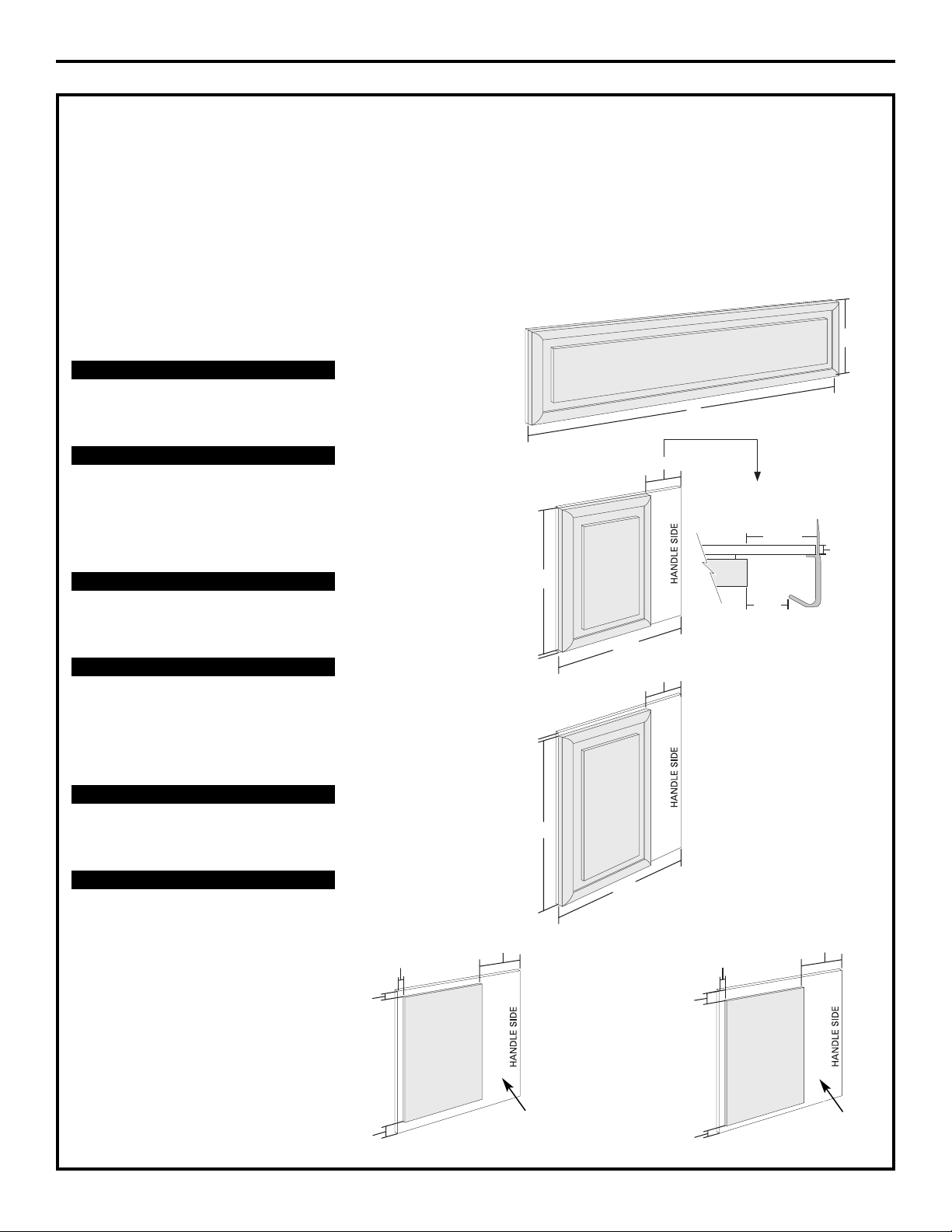

CUSTOMIZATION BASICS:

Stainless Steel Wrapped Models

42″ wide model—PSB42YS

48″ wide model—PSB48YS

Stainless Steel wrapped refrigerators have wrapped

doors and grille panels, and beveled edges. These

models are shipped ready for installation.

Trimmed Models

42″ wide models—PSB42YG

48″ wide models—PSB48YG

Trimmed refrigerators are designed to be

customized with decorative panels. Field installed

custom door and grille panels are required. Panels

can be framed or full-width and can use either the

pre-installed handles or custom handles provided

by your cabinet manufacturer.

Framed Custom Panels

You may install custom panels from your cabinet

manufacturer. The decorative panel slides into

the factory installed trim. A 1/4″ finished panel

can be used.

You may install a 3/4″panel attached to a 1/4″

backer panel. If the pre-installed door handles are

used, the backer panel will be exposed by the handle

and therefore must be finished (page 24). Custom

handles can also be used.

Full-Width Overlay Custom Panels

Full-width overlay custom panels are designed

to slide into the factory-installed trim, no kits

required. In this design, you can achieve a nearly

trimless appearance.

A 0.10″ spacer panel must be installed between

the finished 1/4″ backer panel and 3/4″

appearance panel. If the pre-installed door

handles are used, the backer panel will be

exposed near the handle and therefore

must be finished (page 24).

Door Handles

The pre-installed handles can accommodate

both framed or overlay panels. Custom handles

of your choice, supplied by your cabinet maker,

can be installed only on 3/4″ overlay panels.

When installing custom handles, measure to

ensure the mounting for the handles selected will

clear the dispenser when installed on the freezer

door. Handles need to mount on the upper and

lower wood panels of the freezer door and not

on the dispenser. If a custom handle is used, only

the 3/4″ overlay panel must be exposed, and the

custom trim pieces should be installed (page 38).

Installation Instructions

20

Framed Panel

Door Handles

3/4" Overlay Panel

.10" Thick Spacer Panel

1/4" Thick Backer Panel

3/4" Custom Panel

Door Handles

Page 21

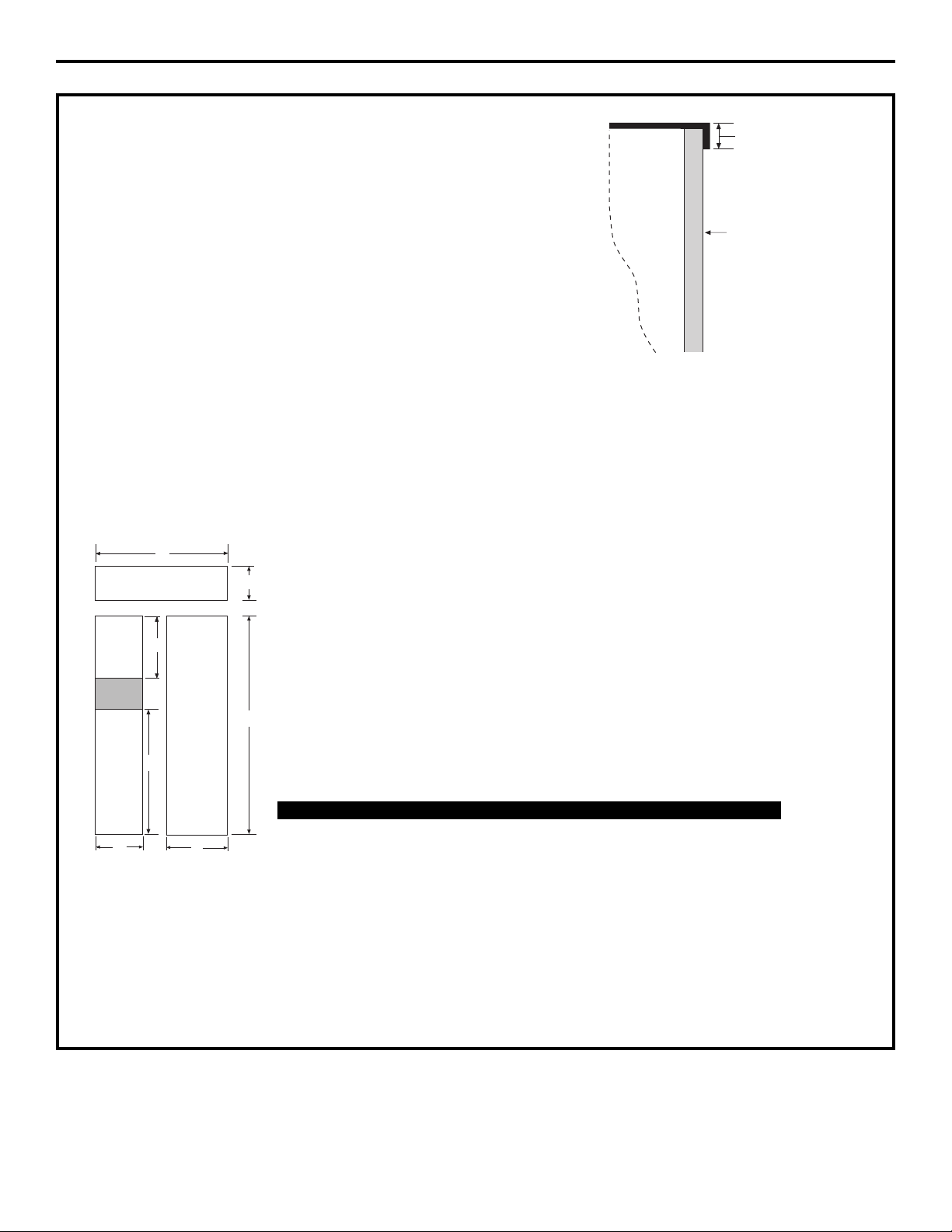

1/4″ FRAMED PANEL DIMENSIONS

If you choose to install framed panels, they must be

cut to the dimensions shown. The panels will slide

into the frame on the doors and grille.

IMPORTANT NOTE: Maximum weight

is 70 pounds for the Fresh Food panel,

45 pounds total for Freezer panels and

15 pounds for the grille panel.

IMPORTANT NOTE: Dispenser Trim

The refrigerator is supplied with factory installed dispenser trim.

• If panel is less than 1/4″ thick, a noticeable gap will be created

around the dispenser trim. Foam tape may be applied on

the door to improve the fit.

• If panel is more than 1/4″ thick, the panel will not fit behind

the trim.

Front Panel Dimensions (in inches)

ABCD E F G

42″ Models 39-15/16 10-3/4 67-7/8 22-11/32 16-7/16 35-5/32 17-13/16

48″ Models 45-31/32 10-3/4 67-7/8 26-15/32 18-15/32 35-5/32 17-13/16

Installation Instructions

21

A

Grille Panel

B

5/16"

Door

Trim

Reveal

1/4"

Panel

Dispenser

Cutout

Freezer

Panel

G

C

F

Panel

D

Fresh Food

E

Page 22

3/4″ FRAMED CUSTOM PANEL OPTION

For a more custom appearance, 3/4″ framed custom panels

may be installed on trimmed models. The overlay panel is

secured to a 1/4″ finished backer panel. The assembled custom

panel then slides into the trim with the same procedure

described on page 37.

3/4″ FULL-WIDTH OVERLAY

CUSTOM PANEL OPTION

This design provides a nearly trimless appearance. The full width

overlay panel covers most of the door trim. In this design, a spacer

panel must be installed between the finished backer and overlay panel.

NOTE: Left-to-right offset is not equal

to top-to-bottom offset.

NOTE: Left-to-right offset is not equal

to top-to-bottom offset.

.250 + .750 = 1.000 Maximum Total Panel Thickness

IMPORTANT NOTE: Maximum total weight

is 70 pounds for any assembled Fresh Food

panel, 45 pounds total for the Freezer panels

and 15 pounds for the grille panel.

Installation Instructions

22

.250 + .10 + .750 = 1.100 Maximum Total Panel Thickness

Door

3/4"

Custom

Overlay

Panel

3/4"

1/4"

Backer

Panel

Overlay Panel

Backer Panel

Custom

Overlay

Door

1/4"

Backer

Panel

Panel

.10 Inch

Spacer

Overlay Panel

Spacer Panel

Backer Panel

Page 23

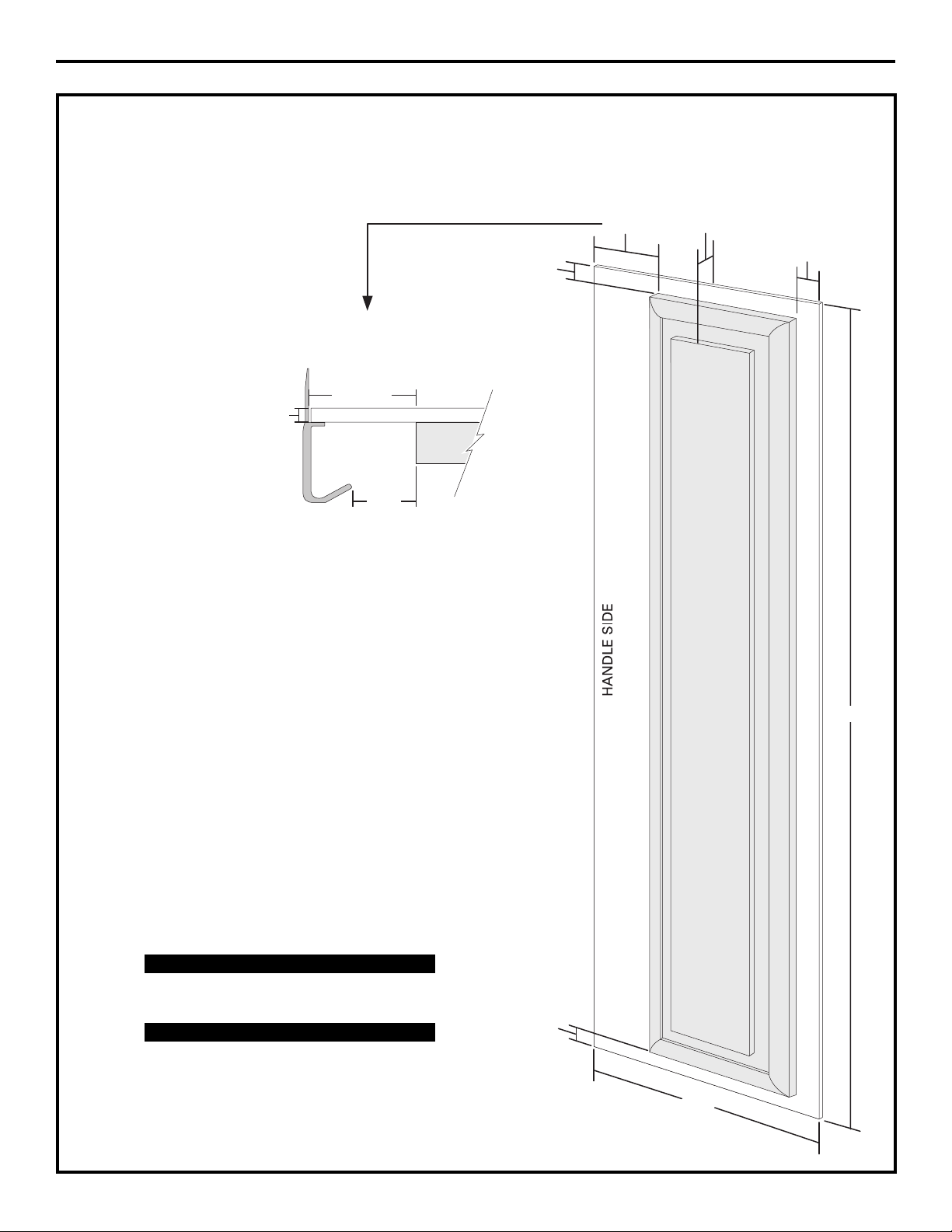

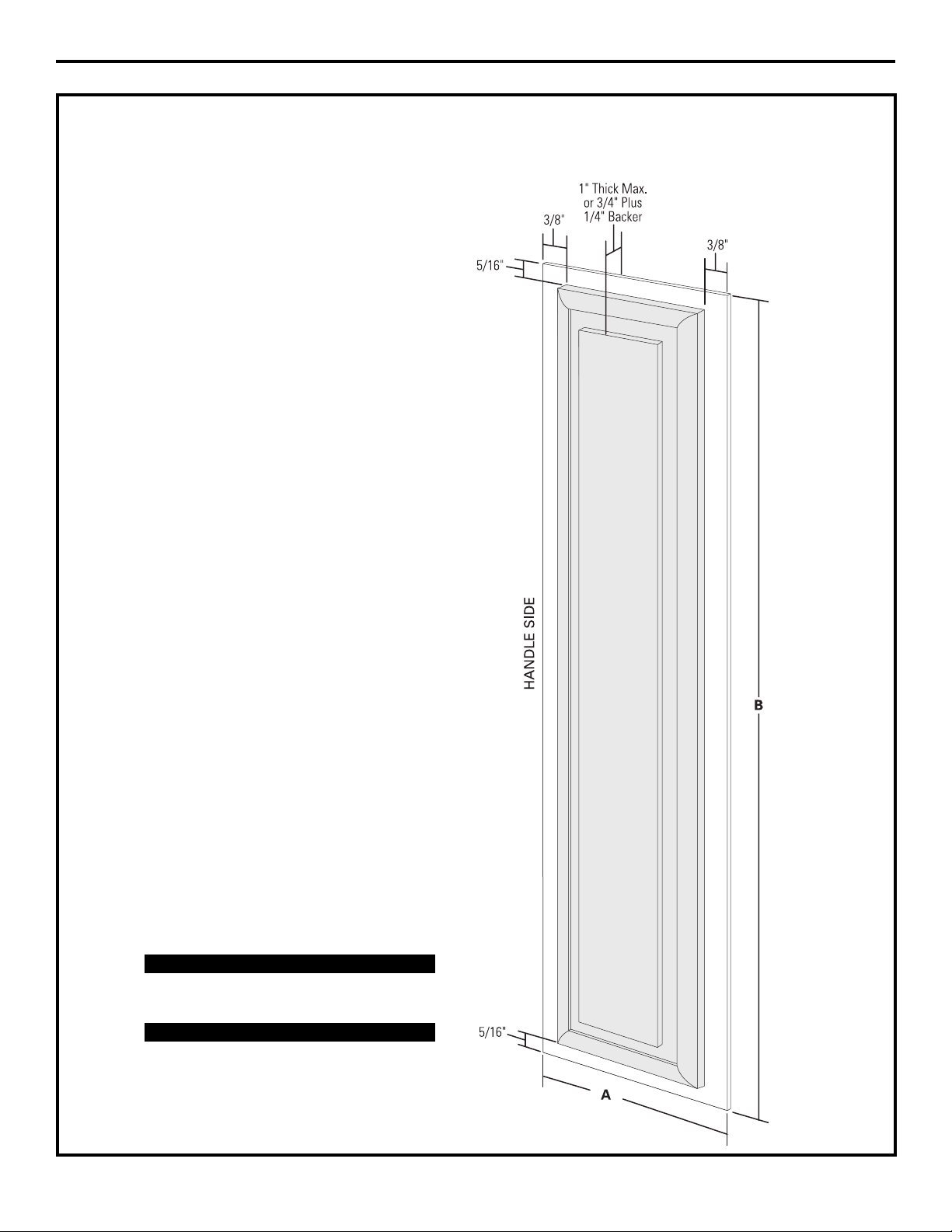

3/4″ FRAMED CUSTOM WOOD PANELS WITH PRE-INSTALLED HANDLES

Secured to a 1/4″ finished backer panel. This design provides a framed appearance.

Fresh Food Panel

Installation Instructions

23

42″ Models A B

1/4″ Backer Panel 22-5/16″ 67-7/8″

3/4″ Overlay Panel 18-13/16″ 67-1/4″

48″ Models A B

1/4″ Backer Panel 26-7/16″ 67-7/8″

3/4″ Overlay Panel 22-15/16″ 67-1/4″

1" Thick Max.

3-1/8"

or 3/4" Plus

1/4" Backer

1/4" Max.

5/16"

3/8"

Required for Optimal

Handle Clearance

3-1/8" Min.

2-1/2"

B

5/16"

A

Page 24

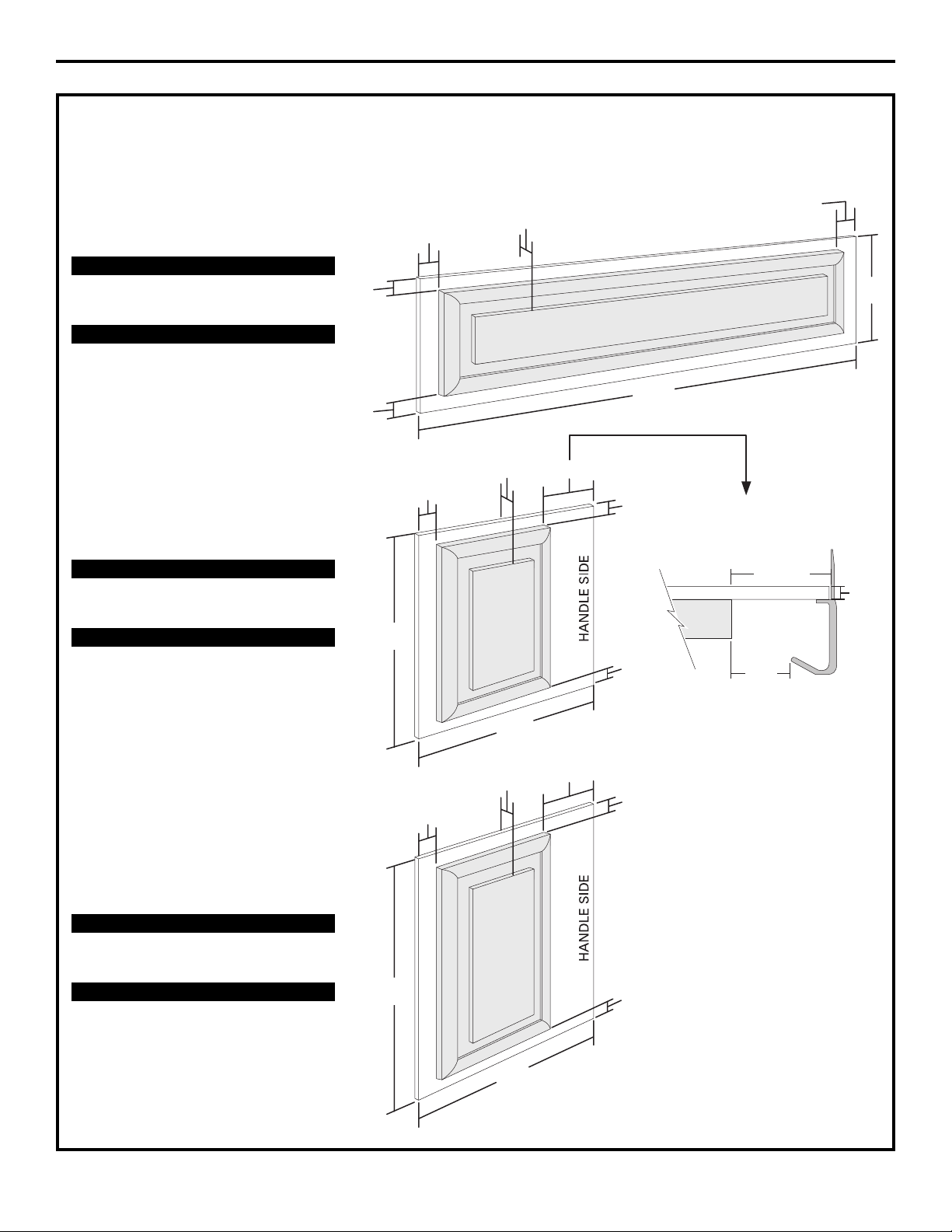

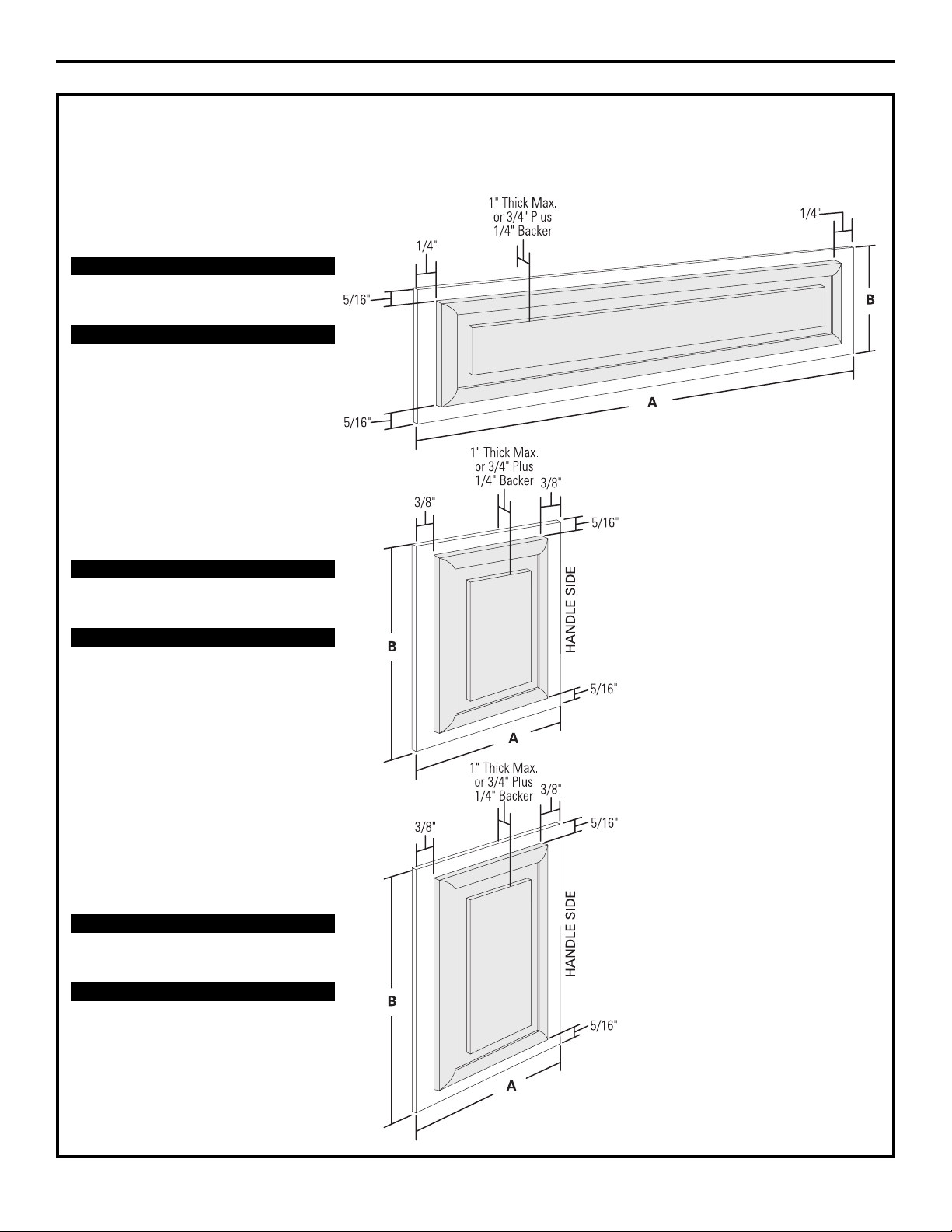

3/4″ FRAMED CUSTOM WOOD PANELS WITH PRE-INSTALLED HANDLES

Secured to a 1/4″ finished backer panel. This design provides a framed appearance.

Grille Panel

Upper Freezer Panel

Lower Freezer Panel

Installation Instructions

24

42″ Models A B

1/4″ Backer Panel 39-15/16″ 10-3/4″

3/4″ Overlay Panel 39-7/16″ 10-1/8″

48″ Models A B

1/4″ Backer Panel 45-15/16″ 10-3/4″

3/4″ Overlay Panel 45-7/16″ 10-1/8″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 17-13/16″

3/4″ Overlay Panel 12-15/16″ 17-3/16″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 17-13/16″

3/4″ Overlay Panel 14-15/16″ 17-3/16″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 35-1/8″

3/4″ Overlay Panel 12-15/16″ 34-1/2″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 35-1/8″

3/4″ Overlay Panel 14-15/16″ 34-1/2″

5/16"

5/16"

1/4"

3/8"

1" Thick Max.

or 3/4" Plus

1/4" Backer

1" Thick Max.

or 3/4" Plus

1/4" Backer

3-1/8"

5/16"

A

Required for Optimal

1/4"

B

Handle Clearance

3-1/8" Min.

1/4"

Max.

B

5/16"

2-1/2"

A

1" Thick Max.

or 3/4" Plus

1/4" Backer

3/8"

B

3-1/8"

5/16"

5/16"

A

Page 25

3/4″FULL-WIDTH OVERLAY CUSTOM PANELS WITH PRE-INSTALLED HANDLES

This panel design provides a nearly trimless appearance.

Assemble the spacer panel

onto the finished backer

panel. Allow 1/2″ clearance

on the top, bottom and

hinge side. Allow 3-5/8″on

the handle side. Secure the

panels with glue. Be sure to

observe clearances shown

on all sides.

Secure the overlay

panel to the assembled

backer/spacer panel.

Use glue and screws.

Countersink screws

into the backer panel.

Installation Instructions

25

42″ Models A B

1/4″ Backer Panel 22-5/16″ 67-7/8″

0.10″ Spacer Panel 18-3/16″ 66-7/8″

3/4″ Overlay Panel 19-5/16″ 68-1/8″

48″ Models A B

1/4″ Backer Panel 26-7/16″ 67-7/8″

0.10″ Spacer Panel 22-5/16″ 66-7/8″

3/4″ Overlay Panel 23-7/16″ 68-1/8″

Fresh Food Panel

Spacer

Panel

Finished

Backer

Panel

3-5/8"

1/2"

1/2"

Required for Optimal

Handle Clearance

1/4"

Max.

3-1/8" Min.

3-1/8"

2-1/2"

B

1/2"

A

Page 26

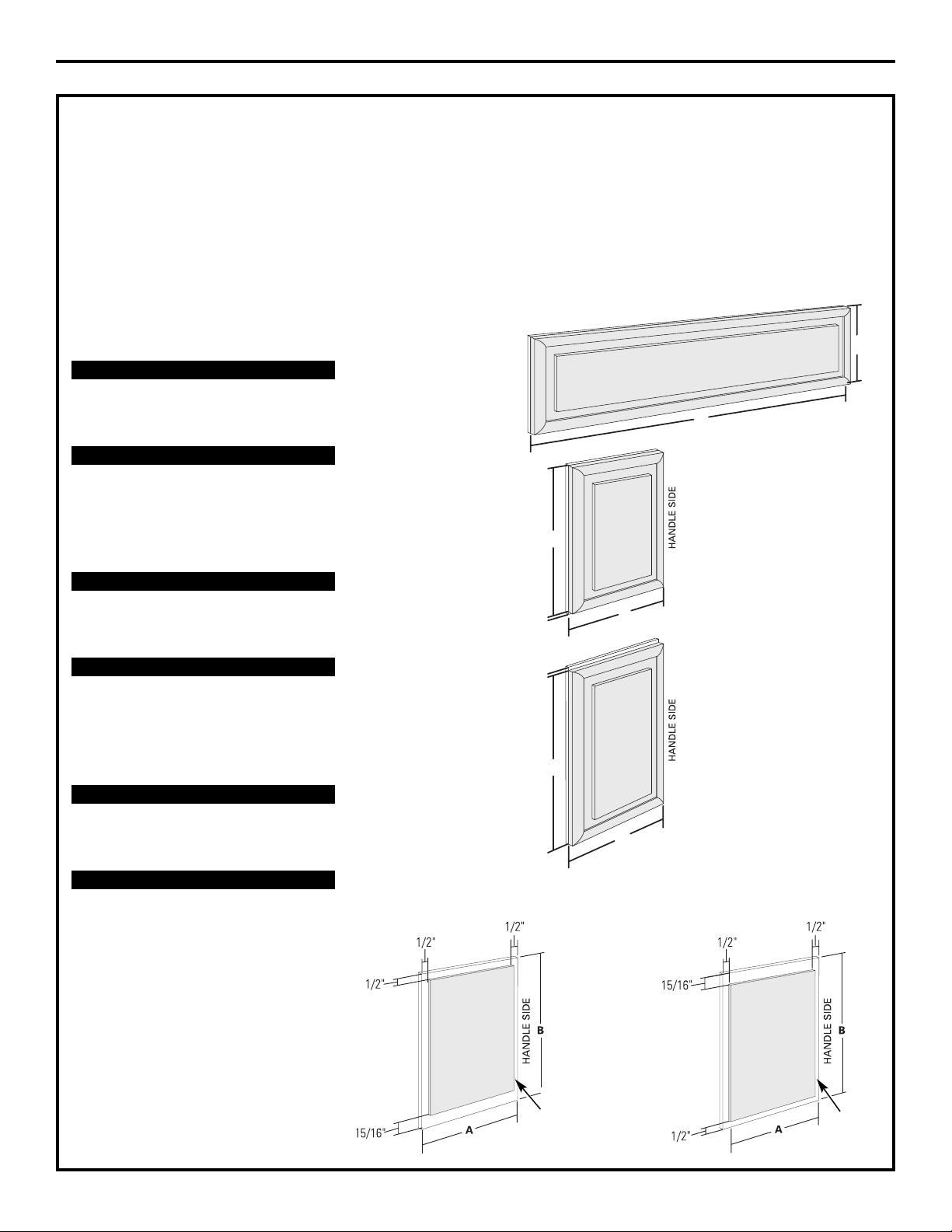

3/4″FULL-WIDTH OVERLAY CUSTOM PANELS WITH PRE-INSTALLED HANDLES

This panel design provides a nearly trimless appearance.

Assemble the spacer panel onto the backer panel. Allow 1/2″ clearance on all four sides of the grille spacer

panel. Allow 1/2″ clearance on the top and hinge side, 15/16″on the bottom and 3-5/8″ on the handle side of

the upper freezer door panel. Allow 15/16″ on the top, 1/2″ clearance on the bottom and hinge side and 3-5/8″

on the handle side of the lower freezer door panel. Secure the panels with glue. Be sure to observe clearances

on all sides.

Secure the appearance panel to the assembled backer/spacer panel. Use glue

and screws. Countersink screws into the backer panel.

Grille Panel

Lower Freezer Panel

Upper Freezer Panel

Installation Instructions

26

42″ Models A B

1/4″ Backer Panel 39-15/16″ 10-3/4″

0.10″ Spacer Panel 38-15/16″ 9-3/4″

3/4″ Overlay Panel 40-3/16″ 11″

48″ Models A B

1/4″ Backer Panel 45-15/16″ 10-3/4″

0.10″ Spacer Panel 44-15/16″ 9-3/4″

3/4″ Overlay Panel 46-3/16″ 11″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 35-1/8″

0.10″ Spacer Panel 12-5/16″ 33-11/16″

3/4″ Overlay Panel 13-7/16″ 34-15/16″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 35-1/8″

0.10″ Spacer Panel 14-5/16″ 33-11/16″

3/4″ Overlay Panel 15-7/16″ 34-15/16″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 17-13/16″

0.10″ Spacer Panel 12-5/16″ 16-3/8″

3/4″ Overlay Panel 13-7/16″ 17-5/8″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 17-13/16″

0.10″ Spacer Panel 14-5/16″ 16-3/8″

3/4″ Overlay Panel 15-7/16″ 17-5/8″

Spacer

Panel

Finished

Backer Panel

Spacer

Panel

Finished

Backer Panel

Upper Freezer Panel

Spacer Assembly

Lower Freezer Panel

Spacer Assembly

5/16"

5/16"

B

A

3-1/8"

Required for Optimal

Handle Clearance

3-1/8" Min.

B

2-1/2"

A

3-1/8"

1/4"

Max.

1/2"

1/2"

15/16"

3-5/8"

B

A

3-5/8"

1/2"

15/16"

1/2"

Page 27

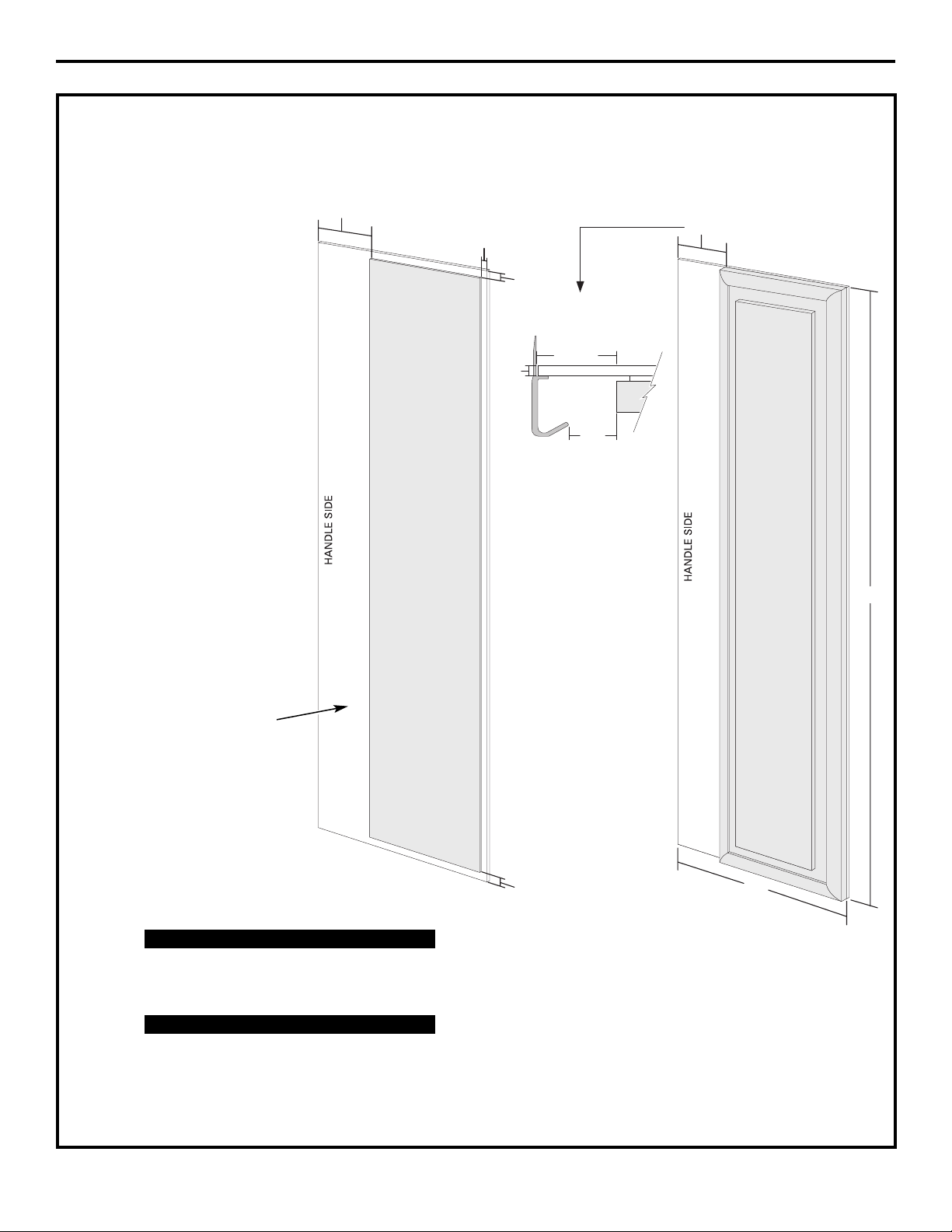

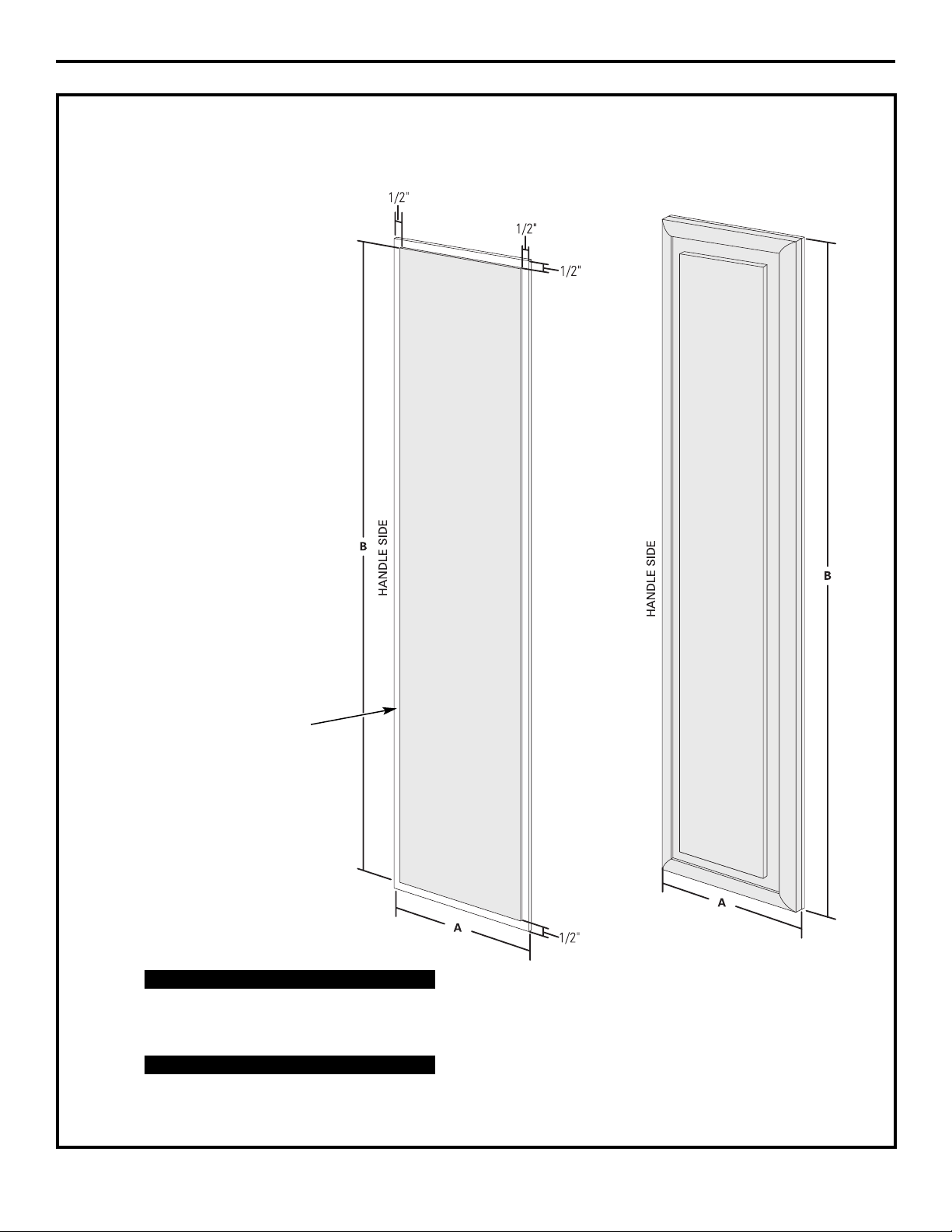

3/4″ FRAMED CUSTOM WOOD PANELS WITH CUSTOM HANDLES

Secured to a 1/4″ finished backer panel. This design provides a framed appearance.

Fresh Food Panel

Installation Instructions

27

42″ Models A B

1/4″ Backer Panel 22-5/16″ 67-7/8″

3/4″ Overlay Panel 21-15/16″ 67-1/4″

48″ Models A B

1/4″ Backer Panel 26-7/16″ 67-7/8″

3/4″ Overlay Panel 26-1/16″ 67-1/4″

Page 28

3/4″ FRAMED CUSTOM WOOD PANELS WITH CUSTOM HANDLES

Secured to a 1/4″ finished backer panel. This design provides a framed appearance.

Grille Panel

Upper Freezer Panel

Lower Freezer Panel

Installation Instructions

28

42″ Models A B

1/4″ Backer Panel 39-15/16″ 10-3/4″

3/4″ Overlay Panel 39-7/16″ 10-1/8″

48″ Models A B

1/4″ Backer Panel 45-15/16″ 10-3/4″

3/4″ Overlay Panel 45-7/16″ 10-1/8″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 17-13/16″

3/4″ Overlay Panel 16-1/16″ 17-3/16″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 17-13/16″

3/4″ Overlay Panel 18-1/16″ 17-3/16″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 35-1/8″

3/4″ Overlay Panel 16-1/16″ 34-1/2″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 35-1/8″

3/4″ Overlay Panel 18-1/16″ 34-1/2″

Page 29

3/4″ FULL-WIDTH OVERLAY CUSTOM PANELS WITH CUSTOM HANDLES

This panel design provides a nearly trimless appearance.

Assemble the spacer panel

onto the finished backer

panel. Allow 1/2″ clearance

on all sides. Secure the

panels with glue. Be sure to

observe clearances shown

on all sides.

Secure the overlay

panel to the assembled

backer/spacer panel.

Use glue and screws.

Countersink screws

into the backer panel.

42″ Models A B

1/4″ Backer Panel 22-5/16″ 67-7/8″

0.10″ Spacer Panel 21-13/16″ 66-7/8″

3/4″ Overlay Panel 22-5/16″ 68-1/8″

48″ Models A B

1/4″ Backer Panel 26-7/16″ 67-7/8″

0.10″ Spacer Panel 25-13/16″ 66-7/8″

3/4″ Overlay Panel 26-7/16″ 68-1/8″

Fresh Food Panel

Spacer

Panel

Finished

Backer

Panel

Installation Instructions

29

Page 30

3/4″ FULL-WIDTH OVERLAY CUSTOM PANELS WITH CUSTOM HANDLES

This panel design provides a nearly trimless appearance.

Assemble the spacer panel onto the backer panel. Allow 1/2″ clearance on all four sides of the grille spacer

panel. Allow 1/2″ clearance on the top, hinge side and handle side, and 15/16″ on the bottom of the upper

freezer door panel. Allow 15/16″ on the top and 1/2″ clearance on the bottom, hinge side and handle side

of the lower freezer door panel. Secure the panels with glue. Be sure to observe clearances on all sides.

Secure the appearance panel to the assembled backer/spacer panel. Use glue

and screws. Countersink screws into the backer panel.

Grille Panel

Lower Freezer Panel

Upper Freezer Panel

Installation Instructions

30

42″ Models A B

1/4″ Backer Panel 39-15/16″ 10-3/4″

0.10″ Spacer Panel 38-15/16″ 9-3/4″

3/4″ Overlay Panel 40-3/16″ 11″

48″ Models A B

1/4″ Backer Panel 45-15/16″ 10-3/4″

0.10″ Spacer Panel 44-15/16″ 9-3/4″

3/4″ Overlay Panel 46-3/16″ 11″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 35-1/8″

0.10″ Spacer Panel 15-7/16″ 33-11/16″

3/4″ Overlay Panel 16-7/16″ 34-15/16″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 35-1/8″

0.10″ Spacer Panel 17-7/16″ 33-11/16″

3/4″ Overlay Panel 18-7/16″ 34-15/16″

42″ Models A B

1/4″ Backer Panel 16-7/16″ 17-13/16″

0.10″ Spacer Panel 15-7/16″ 16-3/8″

3/4″ Overlay Panel 16-7/16″ 17-5/8″

48″ Models A B

1/4″ Backer Panel 18-7/16″ 17-13/16″

0.10″ Spacer Panel 17-7/16″ 16-3/8″

3/4″ Overlay Panel 18-7/16″ 17-5/8″

Spacer

Panel

Finished

Backer Panel

Spacer

Panel

Finished

Backer Panel

Upper Freezer Panel

Spacer Assembly

Lower Freezer Panel

Spacer Assembly

5/16"

A

B

5/16"

A

B

A

B

Page 31

GROUNDING THE REFRIGERATOR

IMPORTANT—Please read carefully

FOR PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERLY GROUNDED.

The power supply cord of this appliance is

equipped with a three-prong (grounding) plug

which mates with a standard three-prong

(grounding) wall receptacle to minimize the

possibility of electric shock hazard from this

appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall outlet

is encountered, it is your personal responsibility

and obligation to have it replaced with a properly

grounded 3-prong wall outlet.

DO NOT, UNDER ANY

CIRCUMSTANCES, CUT

OR REMOVE THE THIRD

(GROUND) PRONG

FROM THE POWER CORD.

DO NOT USE AN ADAPTER

PLUG TO CONNECT THE REFRIGERATOR

TO A 2-PRONG OUTLET.

DO NOT USE AN EXTENSION CORD WITH

THIS APPLIANCE.

SIDE PANELS

Side panels (not

supplied) must be used

whenever the sides of

the refrigerator will be

exposed. The 1/4″ side

panels will slip into the

side case trim. Order

side panels from your

cabinet manufacturer.

*Depending on

installation height.

FLOORING

For proper installation, this refrigerator must be

placed on a level surface of hard material that is

at the same height as the rest of the flooring. This

surface should be strong enough to support a fully

loaded refrigerator, or approximately 1500 lb.

NOTE: Protect the finish of the flooring. Cut a large

section of the cardboard carton and place under

the refrigerator where you are working.

Installation Instructions

31

*84"

24"

*3" to 4"

1-1/2"

Page 32

1 REMOVE PACKAGING

CAUTION: Refrigerator is

Top-Heavy—be careful when moving.

When using an appliance dolly, handle

from Freezer side only.

• Carefully cut banding at the top and bottom;

remove outer carton.

• Slide out rear corner posts (2).

• Slide carton off top of cabinet.

NOTE: DO NOT LAY CABINET DOWN

IN ORDER TO REMOVE SKID!

• The unit is secured to the skid with

six 7/16″ bolts and six 1/2″nuts.

• Remove all six 7/16″bolts that secure metal

brackets to the refrigerator.

• Remove the three 1/2″ nuts and washers

from the Freezer side.

• Remove nut from rear wood block

on Freezer side.

• Tilt unit up on Freezer side toward

Fresh Food side.

• Push bolts down, remove metal bracket

from Freezer side. Remove wood block

from Freezer side.

• Slide the appliance dolly underneath

the Freezer side.

• Using corner posts (2 on front corners)

to prevent damage, secure unit to

appliance dolly.

NOTE: If corner posts are too long, cut the posts

to a shorter length.

• Lift the unit off the skid with the appliance dolly.

• Remove toekick taped to the top of the unit.

• Set toekick aside for final installation.

CAUTION: DO NOT ATTEMPT TO ROLL

OR DRAG UNTIL UNIT IS OFF SKID.

CAUTION: MAKE SURE THE WATER

LINE IS CLEAR OF APPLIANCE DOLLY TO AVOID

DAMAGE.

Installation Instructions

32

Toekick Taped to

Top of Unit

Metal

Bracket

1/2" Nuts

Bolts

Page 33

2 INSTALL WATER LINE

• A cold water supply is required for automatic

icemaker operation. The water pressure must

be between 40 and 120 psi.

• Route 1/4″ O.D. copper tubing or GE

SmartConnect

™

tubing between cold water

line and the water connection location.

• Tubing should be long enough to extend to the

front of the refrigerator. Allow enough tubing to

accommodate bend leading into the water line

connection.

NOTE: The only GE approved plastic tubing is

supplied in the GE SmartConnect

™

Refrigerator

Tubing kits. Do not use any other plastic water

supply line; the line is under pressure at all times.

Certain types of plastic may crack or rupture with

age and cause water damage to your home.

GE SmartConnect

™

refrigerator tubing kits are

available in the following lengths:

2′ (0.6m) WX08X10002

6′ (1.8m) WX08X10006

15′ (4.6m) WX08X10015

25′ (7.6m) WX08X10025

Shut off the main water supply.

Turn on the nearest faucet long enough

to purge all the water from the line.

• Install a shutoff valve between the icemaker

water valve and cold water pipe in a basement

or cabinet. The shutoff valve should be located

where it will be easily accessible.

NOTE: It is best to install the valve into a vertical

water pipe. If you install the valve into a horizontal

water pipe, make the connection at the top

or side to avoid drawing off any sediment

from the water pipe.

• Drill a 1/4″ hole in the water pipe.

• Fasten the shutoff valve to the pipe with pipe

clamp.

• Tighten the clamp screws until the sealing

washer begins to swell. Do not OVERTIGHTEN.

• Place a compression nut and ferrule (sleeve) for

copper tubing onto the end of the tubing and

connect it to the shutoff valve. Make sure the

tubing is fully inserted into the valve and ferrule

is tightened.

• For plastic tubing from a GE SmartConnect

™

refrigerator tubing kit, insert the molded end of

the tubing into the shutoff valve and tighten the

compression nut until it is hand tight, and then

tighten an additional turn with a wrench.

• Turn on the main water supply and

flush debris. Run about a quart of water

through the tubing into a bucket. Shut

off water supply at the shutoff valve.

NOTE: Saddle type shutoff valves are included in

many water supply kits. Before purchasing, make

sure a saddle type valve complies with your local

plumbing codes.

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR must be adhered to.

Saddle valves are illegal and use is not permitted

in Massachusetts. Consult with your licensed

plumber.

Installation Instructions

33

Floor

Copper Tubing,

or GE SmartConnect™ Tubing

Saddle Type

Shutoff Valve

Packing Nut

Outlet Valve

Compression Nut

Ferrule

(Sleeve)

Page 34

3 INSTALL SIDE PANELS

SKIP THIS STEP WHEN NOT USING SIDE PANELS

If you are using 1/4″side panels, they should be

inserted into the case trim. Fasten the panels to the

refrigerator with the 3M Dual Lock adhesive strips

before setting refrigerator in place.

4A ALTERNATE ANTI-TIP PRECAUTIONS

SKIP THIS STEP WHEN USING ANTI-TIP BRACKETS

All GE Profile

™

built-in refrigerators are Top-Heavy.

They must be secured to prevent the possibility

of tipping forward. Use this alternative method to

secure the refrigerator whenever steel wall studs

are encountered.

• Adjust height of refrigerator to match

installation cutout opening 83-1/2″to 84-1/2″.

The refrigerator must be level and plumb with

cabinets. The top case trim at the front is 2-1/8″

higher than the rear and will overlap upper

cabinets or cabinet trim.

• Open grille panel to access the top case trim.

• Use a 3/16″ bit to drill 4 evenly spaced clearance

holes through the metal top case trim.

• Use a 1/16″ bit to drill pilot holes through the

metal clearance holes and into wood soffit. The

holes should be centered in the soffit or a 3/4″

minimum wood brace. The brace spanning the

enclosure must be securely fastened to cabinets

on both sides.

• Install four 1-1/2″ drywall screws into the pilot

holes.

2A WATER LINE INSTALLATION WITH

A REVERSE OSMOSIS SYSTEM

SKIP THIS STEP WHEN NOT USING AN RO SYSTEM

NOTE: If the water supply to the refrigerator

is from a Reverse Osmosis Water System, use

the refrigerator’s filter bypass plug. Using the

refrigerator’s water filtration cartridge with

the RO filter can result in hollow ice cubes.

• Open the top grille to view the filtration cartridge.

Rotate the filtration cartridge counterclockwise

until removed.

• Insert filter bypass plug. Rotate the filter bypass

plug clockwise until tightly secured in place.

4

INSTALL ANTI-TIP BRACKETS

WARNING:

The refrigerator is Top-Heavy and must be secured

to prevent the possibility of tipping forward.

•

Cut a 2″ x 4″ wood block 36″long,

and secure the block

to the mounting

brackets

provided, using

#12 or #14

wood screws.

•

Secure the brackets

with wood block to

the back wall so that

it is 82″ (or the rear

installation height) from the finished floor. Use #12

or #14 wood screws.

•

Screws must penetrate at least 1″ into vertical

wall studs.

ANTI-TIP

PRECAUTIONS

Positioned

Anti-Tip

Bracket

Wall Stud

(Behind

Drywall)

Wood Screws

Mounted into

Vertical

Wood Studs

36"

Installation Instructions

34

Master Power Switch

Water Filter

Rotate Counterclockwise To Remove

Side View

Top Case Trim

Install (4) 1-1/2" Drywall Screws

Through Trim and Into Soffit

or 3/4" Min. Wood Brace

Top Case Trim

3/4"

Min.

Page 35

7 LEVEL REFRIGERATOR

All models have 4-point leveling. The front and back

are supported by leveling legs. Both are accessible

from the front of the refrigerator.

• To level the back of the refrigerator, turn the 1/2″

hex nut located above the front wheels. Turn

clockwise to raise or counterclockwise to lower

the refrigerator.

• For front leveling, use a 7/16″ open-end wrench.

• Adjust height of refrigerator to match

installation cutout opening 83-1/2″to 84-1/2″.

The refrigerator should be level and plumb with

cabinets.

IMPORTANT NOTE: The refrigerator must be level.

If it is not, the doors may not align evenly at

the top. See Step 16.

CAUTION:

The rear leveling legs and front leveling legs

are limited to a maximum height adjustment

of 1″. If the installation requires more than 84-1/2″

height, the installer should elevate the refrigerator

on a sheet of plywood or runners. Cabinet trim

could be added across the top of the opening

to shorten the opening. If you attempt to raise

the refrigerator more than 1″, you will damage

the front and rear leveling legs.

5 CONNECT POWER

• Connect refrigerator power cord plug to

a properly grounded receptacle. Set the

Master Power switch to the I (ON) position.

• Check to make sure power to refrigerator

is on by opening refrigerator door to see

if interior lights are on.

CAUTION:

• After power has been established, turn the

Master Power switch to the O (OFF) position.

6 MOVE INTO INSTALLATION SPACE

• Slide the unit into the installation space.

• Place excess slack in the power cord on top

of the refrigerator.

• Use care to ensure the power cord is not pinched

behind the unit.

Installation Instructions

35

Raise

Grille

Panel

Master

Power Switch

Water Filter

Leveling Leg

Hex Nut Adjusts

Rear Leveling Legs

Height

from

Floor to

Bottom

of Wood

Block

82"

Page 36

10 INSTALL GRILLE PANEL

• Raise the grille panel to the stop position.

• Remove 4 screws on bottom trim; retain

all screws.

• Remove bottom trim.

• NOTE: Stainless steel and acrylic panels are

covered with a protective film. Remove the film

before installing the panel.

• Slide panel over the metal backer panel and

under the trim.

• If necessary, tap with a wood block until panel

slips under the top trim piece.

• Reassemble bottom trim. Tighten screws.

8 SECURE REFRIGERATOR

TO CABINETS

Whenever possible, perform this step for anti-tip

security.

The refrigerator must be secured to prevent

tipping.

• Raise the grille panel to access case trim.

• Drive a screw through the trim and into

the adjacent cabinet using holes provided.

• Follow the same procedure on the opposite side.

9 ADJUST DOOR SWING

NOTE: This refrigerator has a 2-position door stop.

When space does not allow the door to swing open

fully to 130°, you may change the door swing to

a 90° opening.

SKIP THIS STEP IF DOOR OPENING IS

SATISFACTORY FOR YOUR INSTALLATION

SITUATION.

• Open the door to view the bottom hinge.

Note the door stop pin location. The pin is

factory installed in the 130° position.

• Partially close the door. From above, use

a flat-head screwdriver to unscrew the door

stop pin and reinstall into the 90° position.

Installation Instructions

36

Raise Grille Panel

to Stop Position

Drive Screws

Through Case Trim Into

Adjacent Cabinets

Raise

Grille

Panel

Interior

Hinge

90°

130°

Door

Page 37

11 INSTALL DOOR PANELS

WITH PRE-INSTALLED HANDLES

Install 1/4″ Decorative Panels:

• Remove Handles

Open door to 90°. Remove 5 Phillips head

screws from the Fresh Food and Freezer door

handles; retain all screws. Lift off door handles.

• Install Door Panels

NOTE: Carefully push the Fresh Food panel in until

it slides into the slot behind the trim. Gently push

to opposite side. Repeat procedure for upper and

lower Freezer panels.

• Reinstall Handles

Reinstall Fresh Food door handle with

the original 5 Phillips head screws. Tighten.

Repeat for Freezer door handle.

NOTE: Ensure that the edge of the handle does

not pinch the door gasket.

• 3/4″ Custom Decorative Panels

If you choose to install custom wood panels,

they must be cut to dimensions shown on

pages 23–30. The panels will slide into the

frame on the doors and grille.

IMPORTANT NOTE: Maximum custom panel

thickness must not exceed 1-1/8″ thick and 70 lbs

for the Fresh Food door, 45 lbs total for the Freezer

door and 15 lbs for the Grille panel.

Installation Instructions

37

Handle

Fresh Food

Refrigerator

Door

3/4" Custom Panel

if Required

Page 38

11A INSTALL DOOR PANELS

Install 1/4″ Decorative Panels:

• Remove Pre-Installed Handles

Open door to 90°. Remove 5 Phillips head

screws from the Fresh Food and Freezer door

handles; retain all screws. Lift off pre-installed

door handles.

• Install Door Panels

NOTE: Carefully push the Fresh Food panel in until

it slides into the slot behind the trim. Gently push

to opposite side. Repeat procedure for upper and

lower Freezer panels.

• Install Custom Trim

Install the custom trim with the original

5 Phillips head screws. Tighten. Repeat

for Freezer door.

NOTE: Ensure that the edge of the custom trim

does not pinch the door gasket.

• 3/4″ Custom Decorative Panels

If you choose to install custom wood panels,

they must be cut to dimensions shown

on pages 23–30. The panels will slide

into the frame on the doors and grille.

If using custom handles, please see Door

Handles on page 20.

IMPORTANT NOTE: Maximum custom panel

thickness must not exceed 1-1/8″ thick and 70 lbs

for the Fresh Food door, 45 lbs total for the Freezer

door and 15 lbs for the Grille panel.

Installation Instructions

38

Custom Trim

Handle

Fresh Food

Refrigerator

Door

3/4" Custom Panel

if Required

Page 39

13 TURN ON THE POWER

• Set the Master Power switch to the I (ON)

position.

• Check to make sure power to refrigerator is on

by opening refrigerator door to see if interior

lights are on.

• The temperature controls are preset at 37°F

for the Fresh Food section and 0°F for the

Freezer section.

• Allow 24 hours to stabilize before making

adjustments.

12 CONNECT WATER SUPPLY

Check to make sure that Master Power switch

is in the O (OFF) position.

• Locate and bring GE SmartConnect

™

tubing

to the front of the cabinet.

• Turn the water on to flush debris from line.

Run about a quart of water through tubing

into a bucket, then shut off water.

Copper Tubing

• Slip a 1/4″ nut and ferrule onto end

of copper tubing. Insert tube into the union

fitting on the unit and tighten nut to union.

• Turn on the water to check for leaks.

GE SmartConnect

™

Tubing

• Insert the molded end of the tubing

into the refrigerator connection. Tighten

the compression nut until it is just hand tight.

• Tighten one additional turn with a wrench.

Overtightening can cause leaks.

• Turn on the water to check for leaks.

Note: Make sure excess tubing length does not

interfere with toekick installation.

Installation Instructions

39

Refrigerator

Water Supply

House

Water Supply

Raise

Grille

Panel

Master

Power Switch

Water Filter

Page 40

16 DOOR ALIGNMENT

• Stand back from the refrigerator to inspect

the door alignment.

• Shipping or the addition of heavy door panels

may have caused the doors to move slightly

out of alignment.

• If necessary, the Fresh Food door

may be adjusted up or down to align

with the Freezer door.

• Loosen the leveling mechanism.

• Use a 7/32″ wrench to adjust the hinge pin

as shown.

• Tighten the leveling mechanism.

IMPORTANT NOTE: After the unit has been leveled,

if the fresh food door is higher than the freezer

door, adjust the front right leveling leg lower to

align the doors and, if required, raise the left

leveling leg to level the unit side to side.

14 START ICEMAKER

• Flip the switch to I (ON). The icemaker will begin

operation automatically.

• Make sure nothing interferes with the sweep

of the feeler arm.

• Discard the first full bucket of ice cubes.

• To turn the icemaker off, set the switch to

O (OFF).

15 INSTALL TOEKICK

• Locate the supplied toekick (shipped taped

to the top of the refrigerator). Install with

2 screws provided.

• The vented toekick must remain unobstructed for

proper air flow.

Installation Instructions

40

Power Switch

Feeler Arm

Green Power Light

Supplied Toekick

Bushing

Door Hinge

Case Hinge

7/32" Wrench

Raise

Clockwise

Page 41

41

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

Installation

Instructions

Normal operating sounds. ge.com

Newer refrigerators sound different from older

refrigerators. Modern refrigerators have more features and

use newer technology.

HUMMM...

WHOOSH...

■

The new high efficiency compressor may run faster

and longer than your old refrigerator and you may

hear a high-pitched hum or pulsating sound while

it is operating.

■

You may hear a whooshing sound when the doors

close. This is due to pressure equalizing within

the refrigerator.

■

You may hear the fans spinning at high speeds.

This happens when the refrigerator is first plugged in,

when the doors are opened frequently or when a large

amount of food is added to the refrigerator or freezer

compartments. The fans are helping to maintain the

correct temperatures.

■

If either door is open for over 3 minutes, you may hear

the fans come on in order to cool the light bulbs.

■

The fans change speeds in order to provide optimal

cooling and energy savings.

CLICKS, POPS,

CRACKS and CHIRPS

■

You may hear cracking or popping sounds when the

refrigerator is first plugged in. This happens as the

refrigerator cools to the correct temperature.

■

The compressor may cause a clicking or chirping

sound when attempting to restart (this could take

up to 5 minutes).

■

The electronic control board may cause a clicking

sound when relays activate to control refrigerator

components.

■

Expansion and contraction of cooling coils during and

after defrost can cause a cracking or popping sound.

■

After an icemaking cycle, you may hear the ice cubes

dropping into the ice bucket.

WATER SOUNDS

■

The flow of refrigerant through the freezer cooling

coils may make a gurgling noise like boiling water.

■

Water dropping on the defrost heater can cause

a sizzling, popping or buzzing sound during the

defrost cycle.

■

A water dripping noise may occur during the defrost

cycle as ice melts from the evaporator and flows

into the drain pan.

■

Closing the door may cause a gurgling sound due

to pressure equalization.

Do you hear what I hear? These sounds are normal.

For additional information on normal

icemaker and dispenser operating sounds,

see the About the automatic icemaker

and About the ice and water dispenser

sections.

Page 42

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Troubleshooting tips…

Troubleshooting Tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

Problem Possible Causes What To Do

Refrigerator does not Refrigerator in defrost cycle. • Wait about 30 minutes for defrost cycle to end.

operate

Master power control set to OFF. •Set the control to an on setting.

Refrigerator is unplugged. • Push the plug completely into the outlet.

The fuse is blown/circuit •Replace fuse or reset the breaker.

breaker is tripped.

The refrigerator is in •Unplug the refrigerator and plug it back in.

showroom mode.

Vibration or rattling Refrigerator is not level. •See Level refrigerator.

(slight vibration

•See Door alignment.

is normal)

Motor operates for Normal when refrigerator • Wait 24 hours for the refrigerator to completely

long periods or cycles is first plugged in. cool down.

on and off frequently.

Often occurs when large • This is normal.

(Modern refrigerators

amounts of food are

with more storage

placed in refrigerator.

space and a larger

Door left open. • Check to see if package is holding door open.

freezer require more

Hot weather or frequent • This is normal.

operating time. They

door openings.

start and stop often

Temperature controls • See About the temperature controls.

to maintain even

set at the coldest

temperatures.)

setting.

Refrigerator or freezer Temperature control not set • See About the temperature controls.

compartment too warm cold enough.

Warm weather or frequent • Set the temperature control one step colder.

door openings. See About the temperature controls.

Door left open. • Check to see if package is holding door open.

Frost or ice crystals Door left open. • Check to see if package is holding door open.

on frozen food

Too frequent or too long

(frost within package

door openings.

is normal)

Divider between Automatic energy saver •This helps prevent condensation on the outside.

refrigerator and freezer system circulates warm

compartments liquid around front edge

feels warm of freezer compartment.

Automatic icemaker Icemaker power switch • Set the power switch to the on position.

does not work is in the off position.

Water supply turned off or • See Install water line.

not connected.

Freezer compartment • Wait 24 hours for the refrigerator to completely

too warm. cool down.

Piled up cubes in the storage •Level cubes by hand.

bin cause the icemaker

to shut off.

Ice cubes stuck in icemaker. •Turn off the icemaker, remove cubes and turn

(Green power light on the icemaker back on.