Page 1

ge.com

Safety Instructions ........... 2-4

°_

U3

°_

U3

Operating Instructions

Automatic Icemaker ........... ] 0

Care and Cleaning .......... ] 9, ] 3

Drawers and Baskets ............ 9

Ice and _h'ater Dispenser ..... ] 0, ] ]

Refligerator Doors ............. 8

Replacing the Light Bulbs ....... ] 4

Shelves and Bins ............... 7

Temperature Controls ........... 5

_4'a te r Fil te r ................... 6

Installation Instructions

Anti-Tip Brackets .............. 30

Dimensions, Clearances ........ 17

Door, Grille Panels ......... 39, 33

Installation Space ............. 17

Leveling ..................... 31

Panel Dimensions .......... 91-26

Water Line ................ 99, 30

h'ater Supply ................. 34

Troubleshooting Tips ....... 37-39

Normal Operating Sounds ...... 36

Model4Z 48

Profile C6te fi C6te

R frig6rateurs

La section fran_aise commence h la page 47

Consumer Support

Consumer Support ..... Back Cover

Performance Data Sheet ........ 49

Product Registration ........ 45, 46

State of Calitbrnia ¼'ater

Treatment Device Certificate ..... 43

_'arranty (Canadian) ........... 40

_'arrantv (U.S.) ............... 41

Write the model and serial numbers here:

Model #

Serial #

Find these numbers on a label inside

the refl'igerator compartment at the

top on the right side.

197D6233002 49-60427 !1-05 Jfl

Page 2

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING!

Use this appliance only for its intended purpose as described in this Owner's Manual.

SAFETYPRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

_:i:This refrigerator must be properl_ installed

and located in accordance with the Installation

Instructions before it is used.

i)::Do not allow children to climb, st;rod or hang

on the shelves in the refl-igerato_: They could

damage the refl_igerator and seriously iqj m'e

themselves.

::_ Do not touch the cold sm_fi_ces in the fl'eezer

compartment when hands are damp or wet. Skin

mm stick to these extremeE cold sm_fhces.

_?_Do not store or use gasoline or other flammable

\:q)ms and liqtfids in the vicinity of this or any

other appliance.

i)::In refi_igeratoi_ with automatic icemake_,

avoid conmct with the moving parts of the

ejector mechanism, or with the headng element

locamd on the bottom _ff the icemake_: Do not

place finge_ or hands on the aUtOlnatic

icemaking mechanism while the refl_igerator

is plugged in.

i)::Keep finge_s out _ff the "pinch point" areas;

clearances between the dooi_ and between

the doors and cabinet are necessarily small.

Be careful closing doms when children are

in the area.

i)_:Set the master power switch to the 0 (0['[} position

before cleaning or making repai_.

NOTE: We strongly recommend that any servlc/ng be

performedbyaqualifiedindividual

i)_:Do not refi'eeze fl'ozen foods that have

thawed complemly:

Page 3

DANGER!RISKOFCHILDENTRAPMENT

PROPERDISPOSALOFTHEREFRIGERATOR

ge.com

Child entrai)ment and suffocation are not i)rol)lems

of the past, Junked or abandoned refl_igeratm_ are

still dangerous...even if they will sit fin" "just a few

days." If you are getting rid of yore" old reflJgeratoi;

please follow the instructions below to help prevent

accidents.

Before YouThrowAway YourOldRefrigerator

or Freezer:

iJi::Take off the dome.

!i_:I,eave the shelves in place so that children ma)

not easiE climb inside.

Refrigerants

_M1refl_igeration products contain refl'igerants,

which trader federal law must be removed prior

to product disposal. If wm are getting rid of an

old refrigeration product, check with the

company handling the disposal abo/it what

to do.

3

Page 4

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING!

HOWTOCONNECTELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. For

personal safe_ this appfiance must be properly grounded.

Tile power cord of this appliance is equipped

with a 3-prong (grounding) plug, which mates

with a standard 3-prong (grounding) wall outlet

to minimize tile possibili V of electric shock hazard

fi'om this appliance,

Have tile wall outlet and circuit checked by a

qualified electridan to make sure tile outlet is

propedy grounded.

If tile outlet is a standard 2-prong outlet, it is _mr

personal responsibili F and obligation to have it

replaced with a properly grounded %prong wall

outlet.

Tile refl-igerator, should ahvavs, be I)lugged,, into its

own indixidual electrical outlet which has a xoltage

rating that matches tile rating plate.

This provides tile best pe_imnance and also

I)rexents oxerloading, house wiring circuits, which

could cause a fire hazard fl'om oxerheated wires.

Never Iun )lug,,_our refl_igerator, 1)_,I)tilling, on tile

I)°wer cord . _Mwavs,,ii,gri) )lug fimdv, and pull .strai,d/t.,

out fl'om tile outlet.

Repair or replace immediately all power cords that

have become fl'ayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end.

\_]/en moving tile refiigerato_; be careflfl not to roll

over or daillage tile power cord.

DONOTUSEANADAPTERPLUGOREXTENSIONCORD

(Adapterplugs notpermitted in Canada)

Do not use an adapter plug to connect the refrigerator to a 2-prong outleL

Do not use an extension cord with this appliance.

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCTIONS

4

Page 5

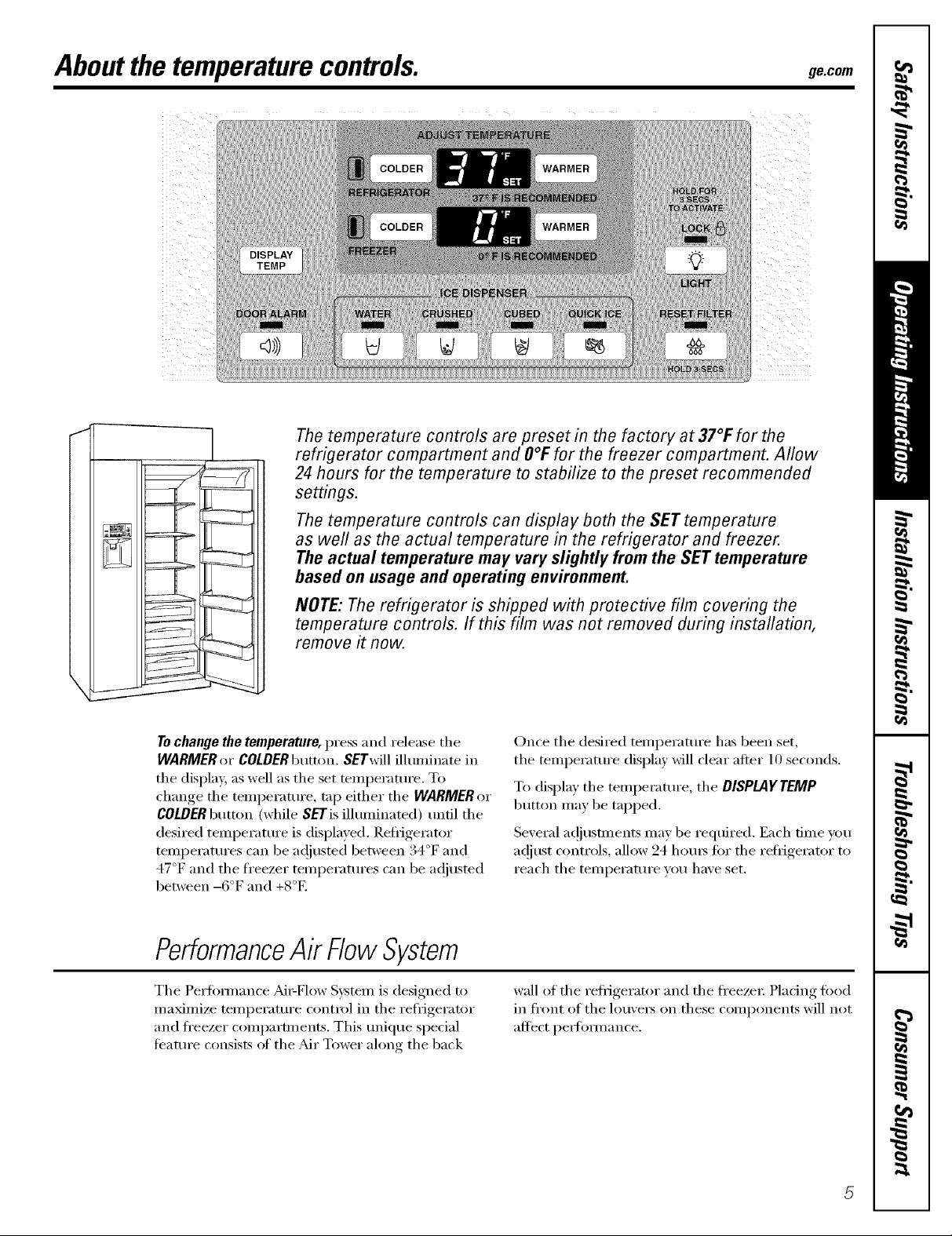

Aboutthe temperaturecontrols, gecom

The temperature controls are preset in the factory at 37°F for the

refrigerator compartment and O°Ffor the freezer compartment. Allow

--/

24 hours for the temperature to stabilize to the preset recommended

settings.

The temperature controls can display both the SET temperature

as well as the actual temperature in the refrigerator and freezer.

The actual temperature may vary slightly from the SET temperature

based on usage and operating environment.

NOTE:The refrigerator is shipped with protective film covering the

temperature controls. If this film was not removed during installation,

remove it now.

To change the temperature, press and release the

WARMER or COLDER button. SETwill ilhuninate in

the display, as well as the set telnperature. To

change the teinperature, tap either the WARMERor

COLDERbutUm (while sEris ilhuninated) until tile

desired tenlperature is displayed. ReliJgerator

telnperatures can be a@usted between 34°F and

47°F and the fl'eezer telnperamres can be ac!iusted

between -6°F and +S°E

PerformanceAk FlowSystem

The Perfimnance Ah=Fhm' System is designed to

nmxilnize telnperature control ill the refiigerator

and ti'eezer colnpartn/ents. This tlniqtle special

teamI'e consists of tile _MI"Tower along tile back

Once the desired telnperature has been set,

the telnperamre display will clear after 10 seconds.

To display tile telnperature, tile DISPLAYTEMP

button Inav be tapped.

Several ac!jusunents inav be required. Each dine ):ou

a@ust controls, allow 94 houls fi)r the refl_igei'ator to

reach the telnperamre you have set.

wall of the refligerator and the fl'eezei; Placing fi_od

ill fl'ont of tile lou',eI_ on these colnponents will not

affect pelt oi_nance.

Page 6

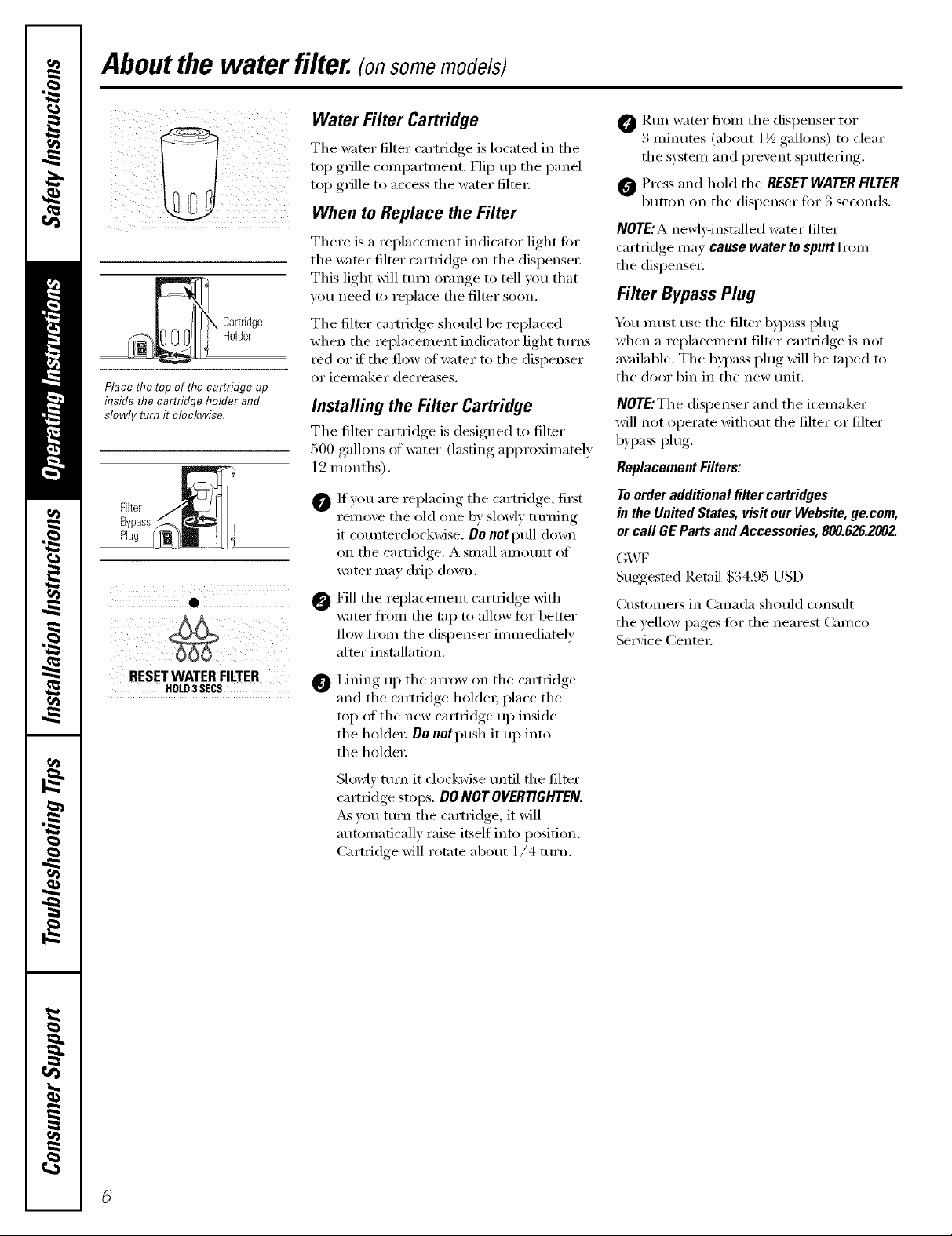

Aboutthe water filter.(onsomemode/s)

_ artridge

Holder

Place the top of the cartridge up

inside the cartridge holder and

slowly turn it clockwise.

Filter _

Bypass_ J

RESETWATERFILTER

HOLD3SECS 0

Water Filter Cartridge

The water filter ('art_i(lge is located in the

top grille c()ml)artn/ent. Flip up the panel

top grille to access the water filte_:

When to Replace the Filter

There is a replacement indicator light ti:,r

the water filter cartridge on the disi)ense_;

This light will turn orange to tell )'ou that

you need to replace the filter soon,

The filter cartridge should be rei)laced

when the rei)lacement indicator light turns

red or if the flow of water to the dispenser

or icemaker decreases.

Installing the Filter Cartridge

The filter cartridge is designed to filter

500 gallons ot water (lasting al)l)roximately

12 months).

O If you, are rei)lacing, the cartri(l(,e_, first

remoxe the old one bx slowly tm'nino

it counterclockwise. Do not pull down

on the cartridge. A small amotmt of

water may drip down.

Fill the replacement cartridge with

water from the tn I) to alh)w fi)r better

flow fl'om the dispenser immediately

after instnllation.

IJning uI) the arrow on the cartridge

and the cartridge hol(le_; place the

top (ff the new cartridge uI) inside

the holder: Do not push it up into

the holdex:

Slowly tm'n it clockwise tmtil the filter

cartridge stoi)s. DO NOTOVERTIGHTEN.

_s you tm'n the cartridge, it will

automatically raise itself into position.

Cartridge will rotate about l/4 turn.

O Rtm water fl'om the dispenser For

.'_ I//iIltltes (about 1½ gallons) to clear

the s_stem and prevent sputtering.

0 Press and hold the RESETWATERFILTER

button on the dispenser for 3 seconds.

NOTEJAnewly-installed water filter

cartridge may cause water to spurt fi'om

the dispense_:

Filter Bypass Plug

Y)u must use the filter 1))})ass plug

when a replacement filter cartridge is not

available. The bypass i)lug will be taped to

the door bin in the new trait.

NOTE:The dispenser and the icemaker

will not operate without the filter or filter

bypass plug.

Replacement Filters:

Toorder additional filter cartridges

in the United States,visitour Webs#e, ge.com,

or call GE Parts and Accessories, 800.626.2002.

GWF

Suggested Retail $34.95 USD

Customers in Canada should constflt

the x,ellow pages tin" the nearest (;amco

Serxice Center:

Page 7

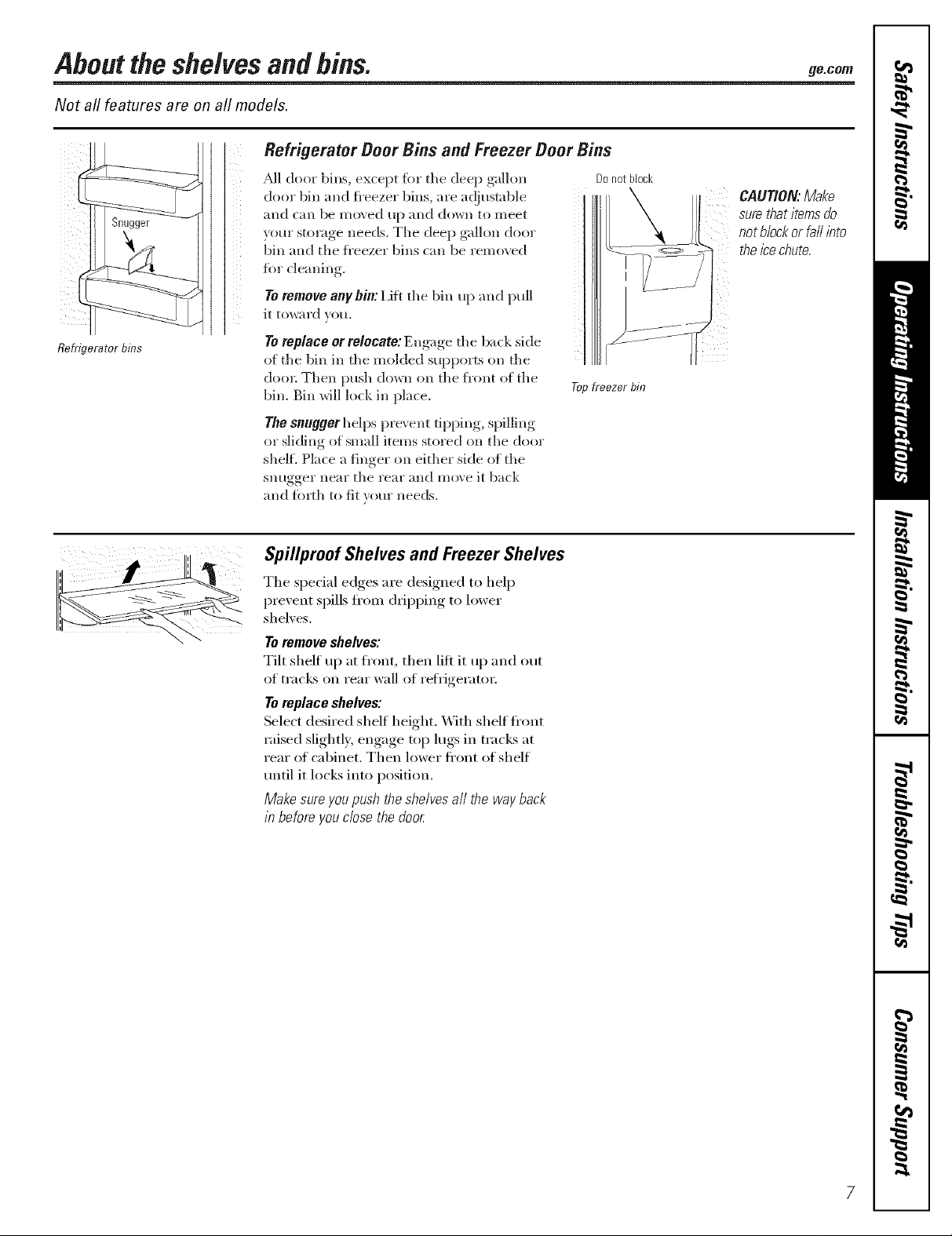

Abouttheshelves andbins. ge.cem

Not all features are on all models.

Refrigerator Door Bins and Freezer Door Bins

Refrigerator eros

_Mi door bins, except tbr tile deep gallon Do not block

door bin and fleezer bins, are ac!justabie

and can be mo;ed up and down to lneet

}()[lr storage needs. Tile deep gallon door

bin and tile fl'eezer bins can be removed

for cleaning.

To remove anyhiu: I,ift tile bin up and ptd]

it toward xou.

To replace or relocate: Engage tile back side

of tile bin in tile molded supports on tile

doe1: Then push down on tile Kent of tile

bin. gill will lock in place.

The snugger helps pro\ eat tipping, spilling

or sliding of small items stored on tlle door

shelf. Place a finger on either side of tile

smlgger near tile rear and move it back

and fin'th to fit your needs.

Topfreezer bin

Spillpmof Shelves and Freezer Shelves

Tile special edges are designed to help

prevent spills fl'om dripping to lower

shelves.

To remove shelves:

Tilt shelf up at front, then lift it up and out

of tracks on rear wall of refrigeratoi;

To replace shelves:

Select desired shelf height. _\]th shelf fl'ont

raised slightly; engage top lugs in tracks at

rear of cabinet. Then lower fl'ont of shelf

tmtil it locks into position.

Make sure you pushthe shelves all the way back

in before you close the door

CAUTION:Make

surethatiteflTsdo

notblockorfail bto

the/2echute.

Page 8

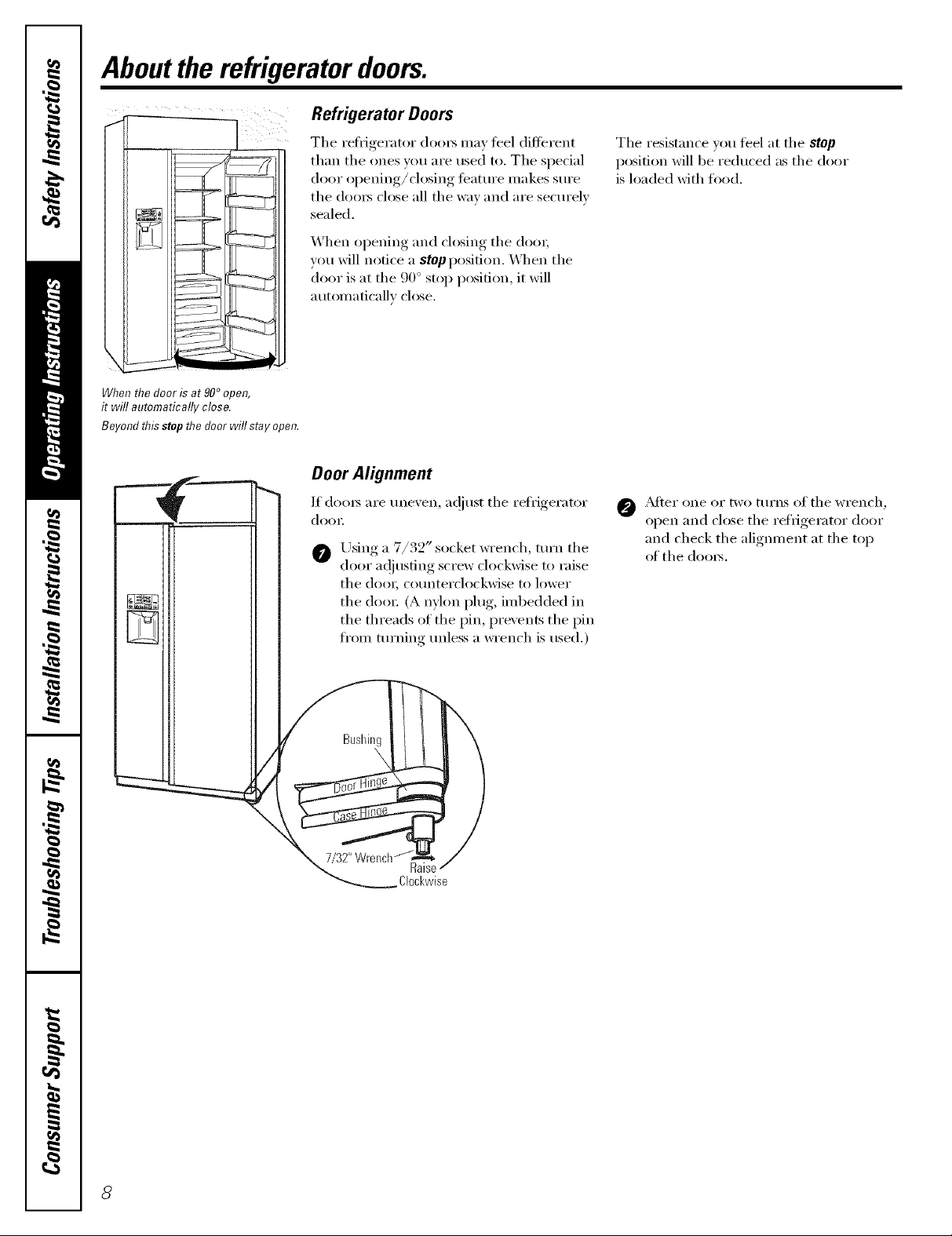

Abouttherefrigeratordoors.

Refrigerator Doors

When flTedoor is at 90° open,

it will automatically close.

Beyond flTisstop flTedoor will stay open.

r

Tile l'eii_igel'ator (lool_ nlav teel different

than the ones you are used to. The special

door oi)ening/closing teatul'e nlakes sure

the dool_ close all the way and are securely

sealed.

When oi)ening and closing tile dool;

you will notice a stopposition. _]/ell tile

door is at tile 90 ° stop position, it will

a utolnaticallv close.

Door Alignment

1t doolS are unexen, a(!iust tile l'eh_igel'ator

dool:

Using a 7/32" socket wrench, turn tile

door ad'usfing.1, screw chlckwise to raise

tile dool; counterclockwise to lower

tile dool: (A nyhnl phlg, inlbedded ill

the threads of the pin, Ill'events the pin

ti'oln turning unless a wrench is used.)

Tile resistance xou teel at tile stop

position will be reduced as tile door

is loaded with food.

O _d[ei" lille OI" tWO tt/I'ns of tile wI'ench,

oI)ell.... and close the l'efligel'ator, door

and check the alignnlent at the top

of the chlolS.

1

Page 9

Aboutthe drawers andbaskets, ge.cem

Not all features are on all models.

Fruit and Vegetable Drawers

Excess water that may ;/((lllIl[l];l[e ill the

bottom of the dra_ers should be _iped d] T.

HuI_il_|TT CONT£OI

xl .., LO

Adjustable Humidity Drawers

Slide the control all the way to the HIsetting

to proSde high humidi b' recommended %r

most vegetables.

Slide the control all the way to the LO

,settiw,_ to pro_i(le lower h umidi_' levels

reconm]ei]ded fi)r n]ost fl'uits.

How to Removeand Replace the Drawers and Freezer Baskets

To remove fresh food drawers: To replace fresh food drawers:

0 Pull the desired drawer out to the 0 Tip the back rolle_ oI the drawer

stop position, behind the rolle_ in the track.

0 I,ift up slightly on the front of the

dI'aweI:

Pull the drawer slightly forward and

out of the refiJgeratot:

To remove freezer baskets:

Pull the desired 1)asket out to the

stop position.

O I,ower the fl'ont of the drawer into

noI]l]_l| position.

Slide the drawer to the back of the

refiJgeratoi:

To replace freezer baskets:

Place the back corne_ in the rail

with the basket tilted up.

0 i,ift up slightly on the fl'ont of the

basket.

0 Pull the basket slightly forward and

out of the fl'eezer.

0 i,ower the basket down to the nomml

position.

Slide the basket to the back of the

ti'eezei:

Page 10

Aboutthe ice and water dispenserandautomaticicemaker.

A newly &staffed refrigerator may take 12to 24 hours to begin making ice.

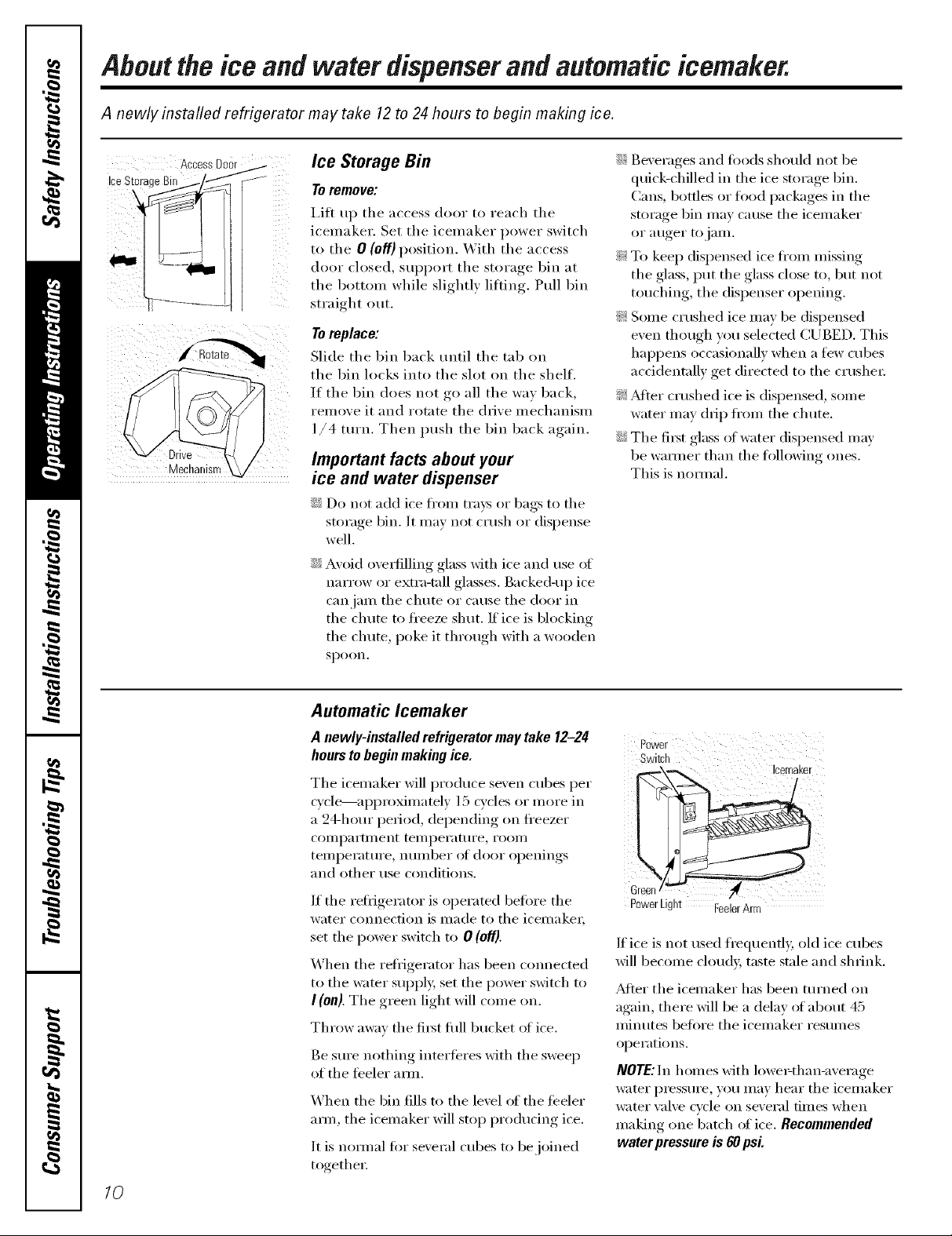

AccessDoor

IceStorageBin j@ /_

Mechanism

Ice Storage Bin

Toremove:

I,ift u I) the access door to reach the

icelnaker. Set the icelnaker power switch

to the 0 (off) position. With the access

door closed, support tile storage bin at

the bottoln while slightly litiing. Pull bin

straight out.

Toreplace:

Slide tile bin back until tile tab on

the bin locks into the slot on the shelf.

If tile bin does not go all tile way back,

relnove it aim rotate tile drive n_echaldsm

l/4 tm'n. Then push tile bin back again.

Important facts about your

ice and water dispenser

iJi::Do not add ice ti'oln trays or bags to tile

storage bin. It may not crush or dispense

well.

iJi::Avoid oveHilling glass with ice and use of

narrow or extra-tall glasses. Backed-up ice

canjaln tile chute or cause tile door in

the chute to fl'eeze shut. If ice is blocking

tile chute, poke it through with a wooden

spoon.

iJi::Beverages and fi)ods should not be

quick-chilled in tile ice storage bin.

Cans, bottles or food packages in tile

storage bin may cause tile icemaker

or auger to jam.

_: To kee I) dispensed ice fl'oln Inissing

tile glass, put tile glass close to, but not

touching, the dispenser opening.

_: Solne crushed ice Inay be disl)ensed

even though you selected CUBED. This

hal)pens occasionally when a ti_w cubes

accidentally get directed to the crushe_:

_: _Mter crushed ice is dispensed, some

water inay dri l) fl'Oln tile chute.

iJi::Tile fi_t glass of water dispensed inav

be wanner than tile ti)llowing ones.

This is nomml.

10

Automatic Icemaker

A newly-installed refrigerator may take 12-24

hours tobegin making ice.

Tile icelnaker will produce seven cubes per

cycle---al)l)roxinmtely 15 cycles or inoi'e in

a 24-hour period, del)ending on freezer

COI//l)_lI'[lllent [ei//l)ei'il[tli'e _ i'ooi//

temperatm'e, imlnber of door openings

and other use conditions.

If tile refl_igerator is operated before tile

water connection is tnade to the icetnaket;

set tile power switch to 0 (of'[).

When the x'efl_igex'ator has been coxmected

to tile water SUl)pl); set tile power switch to

I (on]. The green light will come on.

Throw away the first fifll bucket ot ice.

Be sure nothing interteres with tile sweep

of the teeler ann.

When tile bin fills to tile level ot tile teeler

aim, the icelnaker will stop produdng ice.

It is nomml fi)r several cubes to be joined

together:

Switch

If ice is not used fl'equenfly, old ice cubes

will become cloud); taste stale and shrink.

_MieI" tile icenlaker has been turned on

again, there will be a delay of about 45

ininutes before tile icelnaker resulnes

ol)erations.

NOtE:Inhomes with lowePthan-average

water pressure, you Inay hear tile icelnaker

water wdve cycle on several times when

inaking one batch of ice. Recommended

water pressure is 60 psi.

Page 11

Abouttheice andwater dispenser, gecem

m

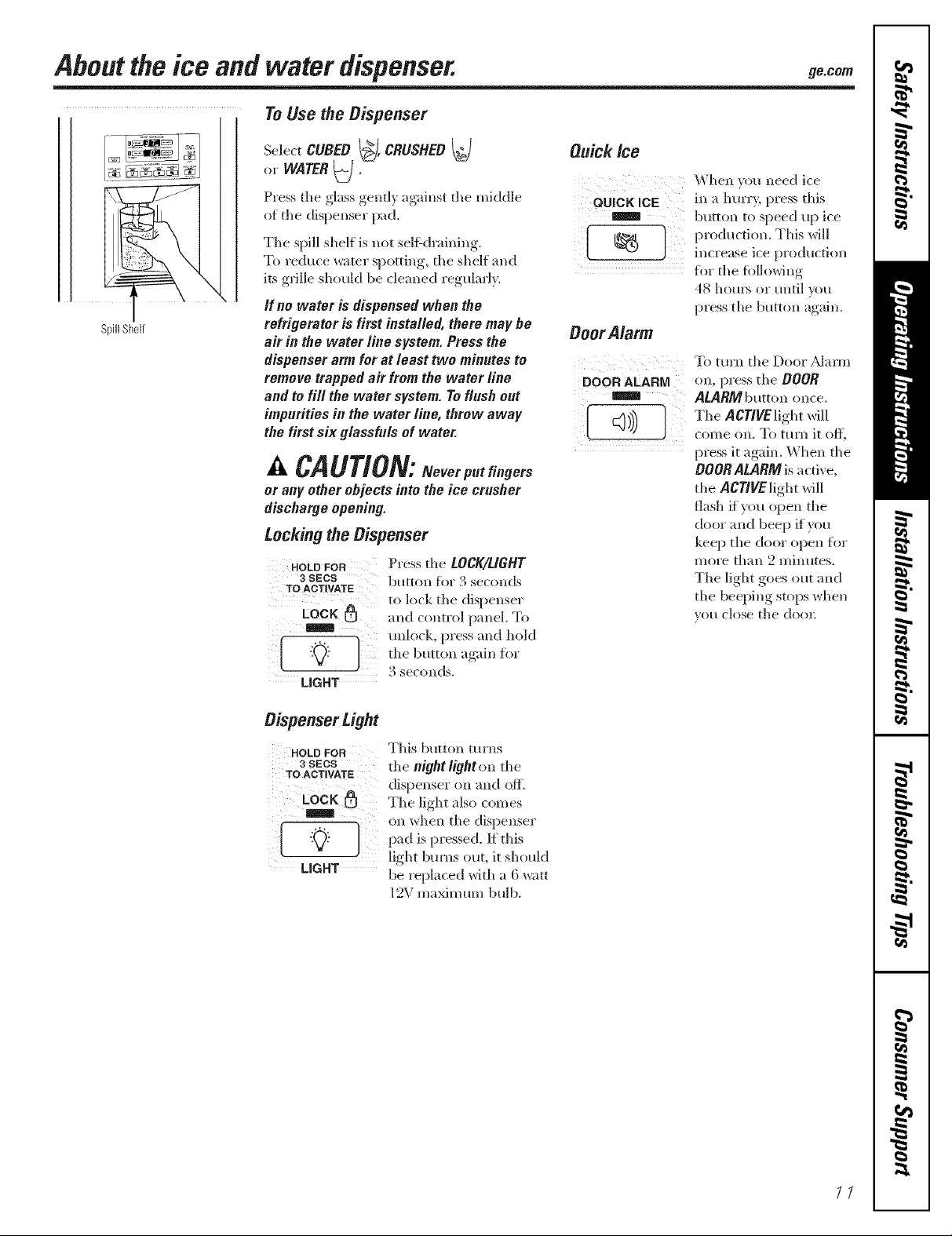

ToUsetheDispenser

SpillShelf

Select CUREDI_J, CRUSHEDt_)

or WATER_j

E

Press tile glass gently against tile middle

of tile dispenser pad.

Tile spill shelf is not seltZdraining.

To reduce _;tte_"spotting, tile shelf and

its grille should be cleaned regulafl>

If no water isdispensedwhen the

refrigeratoris first installed,there may he

air in thewater line system.Pressthe

dispenserarmfor at least two minutesto

removetrapped air fromthe water line

and tofig the water system.Toflushout

impuritiesin thewater line, throw away

thefirstsix glassfulsofwater.

CA UT_O_V: Neverputfingere

or any other objectsinto theice crusher

dischargeopening.

Lockingthe Dispenser

HOLD FOR Press tile LOCK/LIGHT

3SECS

TO ACTIVATE

LOCK[_

?

LIGHT

btlttOll for _4seconds

to lock tile dispenser

and control panel. To

unlock, piess and hold

tile button again for

_4secollds.

Quick Ice

_he. ,..,5.eedice

QUICK iCE ill a hmwv press this

button to speed up ice

il.l-e.sei eI)I'od,,,ti,,,l

for tile fi>llowing

48 hom_ or until you

press tile button again.

OoorAlarm

To ttll'n tile Door A]al'l//

DOORALARM

<,))

on, pIess tile ROOR

ALARMbutton once.

Tile AcrlVElight will

coi//e Oil. To tHI31 it off,

press it again. When tile

DOOR ALARM is active,

tile ACTIVElight will

flash if you opell tile

door and beep if you

kee I) tile door open ii)l

more than 2 minutes.

Tile light goes {tilt and

tile beeping stops when

you close tile dool:

Dispenser tight

HOLD FOR

3SECS

TO ACTIVATE

LOCK

[ -_2" pad is pressed. If this

LIGHT be replaced with a 6 watt

This button turns

tile nightlighton tile

dispenser on and ofl_

Tile light also comes

on when tile dispenser

light bums out, it sllould

12V maxim um bulb.

/7

Page 12

Careand cleaning oftherefrigerator.

Cleaning the Outside

Thespill shelf and the area beneath it shotfld

be cleaned periodicall)with a lnild liquid dish

detergent

Dispenserdriparea.

Dispenser pad. gefin'e cleaning, lock

the dispenser by pressing the LOCK/LIGHT

button fin" 3 seconds to prevent actiw_ting

the dispensel: Clean with waml water

and a lnild liquid dish detergent. Rinse

thoroughly and wipe dry. Lrnlock the

dispenser by pressing the LOCK/LIGHT

button fin" 3 seconds.

Doorhandles. Clean with a cloth danlpened

with soapy watel: Dry with a soft (loth.

Keep the outside clean. Wipe with a (lean

cloth lightly dampened with lnild liquid

dish detelgent. Dry with a clean, soft cloth.

Do licit Mpe the l'eti_igerator with a soiled

dish cloth or wet towel. These nlav leave a

residue that can danlage the finish. Do not

use scoulJng pads, powdered cleanel_,

bleach or cleanel_ containing bleach

because these prciducts can scratch and

danlage the finish.

Stainless steel. Regulalty clean and

polish the Stainless Steel L)OOl_ with a

conmlerciallv available stainless steel

cleaner such as Stainless Steel MagiU _'

to preserve and protect the fine finish,

Stainless Steel Magic is a\:filable through

GE Parts and Al'cessolJes, 800.626.9002,

or ge.coln. Order part ntli/lbei" _._)X10X15.

Dcl licit rise al)pliance wax or polish

on the stainless steel.

Cleaning the Inside

Turnoffpower at the circuit breaker or fuse

box before cleaning. If this is licit practical,

wlJng excess illoisttlre ()tit (IJ[ sponge or

cloth when cleaning around switches, lights

or ccintrols.

Use Waml water and baking soda solution--

about a tablespoon (15 nil) of baking soda

to a quart (l liter) of Waml: This both

cleans and neutralizes oclol_. Thoroughly

rinse and wipe dry.

Other parts of the refrigerator,inchlding door

gaskets, snack pan and vegetable dl'aWel_,

ice storage bin and all plastic parts, can be

cleaned the sanle way.

Do licit wash the tray or any plastic

l'eii_igel'ator parts in the dishwashel:

Avoid cleaning cold glass shelves with hot

water because the extreme temperature

difference may cause them tobreak. Handle

glass shelves carefully. Bumpingtempered

glass can cause itto shatter.

12

Page 13

Preparing for Vacation

For long ;_l('ations oi" absences, i'eillove

tood and unplug the refl_igerator. Clean the

interior with a baking soda solution ot one

tablespoon (15 ml) of baking soda to one

quart (1 liter) oI water. I,eave the doo_

open,

Set the icemaker power switch to the 0 (off)

position and shut off the water supply to

the reti_igeratm:

Preparing to Move

Secure all loose items such as shelves and

(h'awe_ by taping them secm'ely in place

to prevent damage.

CAUTION:Duetothe.,eight

and size of this refrigerator,and to reduce the

risk ofpersonal injury or damage to the

product,A MINIMUM OF4 PEOPLEARE

REQUIREDTO BRING THEUNIT INTO THE

HOME AND 2 PEOPLEAREREQUIREDFOR

PROPERINSTALLATION.

g_com

If the temperature can drop below fl'eezing,

have a qualified servicer drain the water

supply s)stem to prevent serious property

damage due u) flooding.

Besurethe refrigeratorstaysin anupright

positionduringmoving

13

Page 14

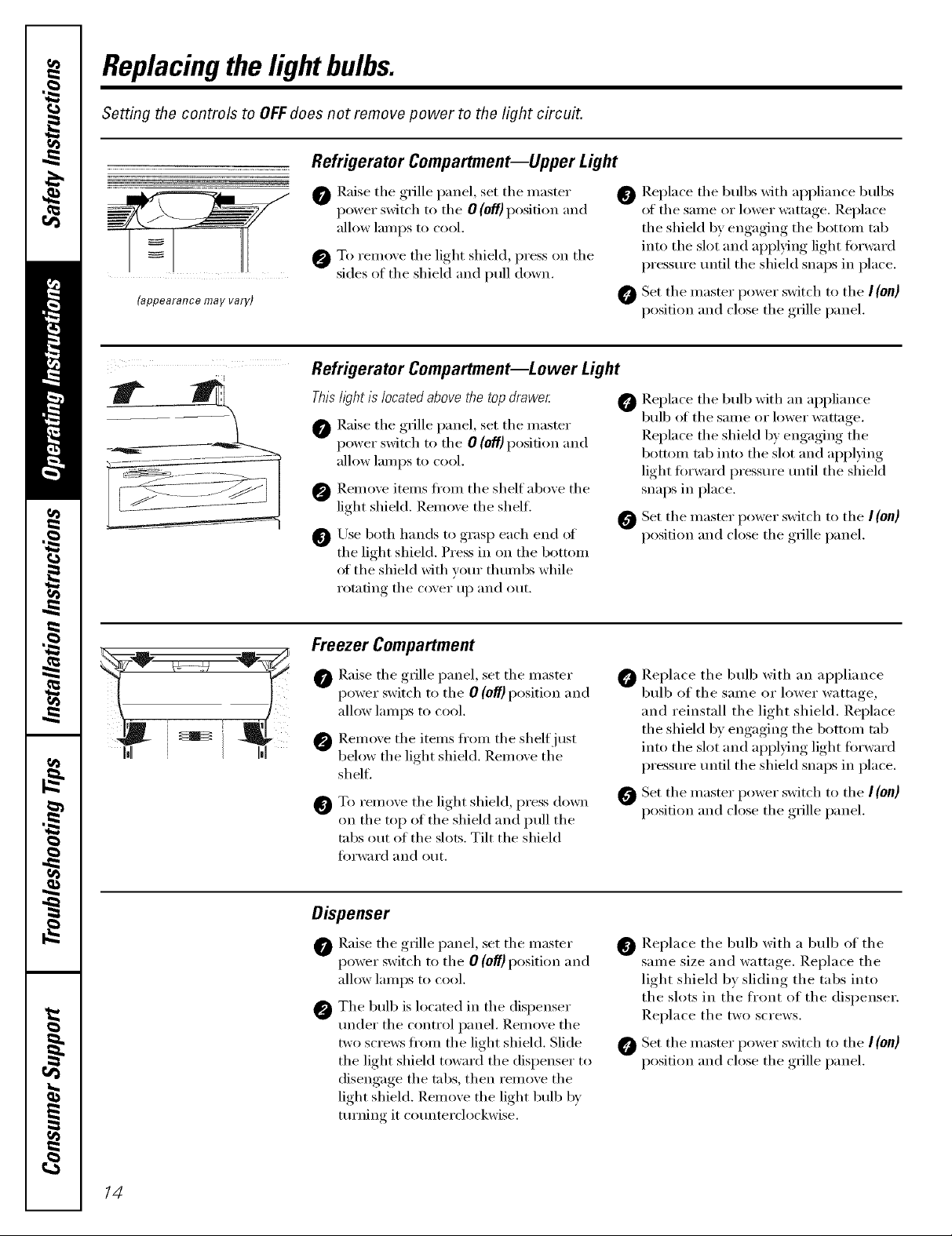

Replacingthe lightbulbs.

Setting the controls to OFFdoes not remove power to the light circuit.

.......................................................................................Refrigerator Compartment--Upper Light

(appearance may vary)

t

@ Raise the grille panel, set the master

power switch to the 0 (off)i_osifion and

allow lami)s to cool.

@ To remove the light shield, press on the

sides of the shield and pull down.

Refrigerator Compartment--Lower Light

Thishght is located above the top drawer

@ Raise the grille panel, set the master

power switch to the 0 (off) I)osifion and

allow lamps to cool.

Remove items flxm_ the shelf above the

light shield. Remove the shelfi

Use both hands to grasp each end of

the light shield. Press in on the bottom

ol the shield with your thumbs while

rotating the cover up and out.

Freezer Compartment

@ Replace the bulbs Mth appliance bulbs

of the same or lower wattage, . Rei)lace

the shield by engaging the bottom tab

into the slot and apI)lying light fiwward

pressure until the shield snaps in place.

@ Set the master power switch h) the I (On)

position and close the grille panel.

O Replace the bull) with an appliance

bulb of the same or lower wattage.

Replace the shield by engaging the

bottoln tab into the slot aim appl)h_g

light fiwward pressure until the shield

snaps in place.

O Set the inaster power switch to the I (On)

position and close the grille panel.

@ Raise the grille panel, set the inaster

power switch to the 0 (Off) position aim

allow lamps to cool.

@ ]_emoxe the items fl'om the shelf just

below the light shield. Remoxe the

shelfi

To remoxe the light shield, press down

@

on the top of the shield and pull the

tabs ()tit of the shits. Tilt the shield

fi)rward aild ()tit.

Dispenser

@ Raise the grille panel, set the master

power switch to the 0 (Off) position and

allow lamps to cool.

@ The bulb is located in the dispenser

under the control panel. Remove the

two screws fl'om the light shield. Slide

the light shield toward the dispenser to

disengage the tabs, then remove the

light shield. Renlove the light bulb by

turIfing it counterclockwise.

Replace the bull) with an appliance

bulb of the Salne or lower wattage,

and reinstall the light shield. ]),el)lace

the shield by engaging the bottoln tab

into the slot and aI_plying light torward

pressure until the shield snaps in place.

O Set the inaster power swimh to the I(On)

position and close the grille panel.

Replace the bulb with a bulb of the

same size and wattage. Replace the

light shield by sliding the tabs into

the slots in the fl'ont of the dispenser.

Replace the two screws.

@ Set the master power switch to the I (on)

position and close the grille panel.

14

Page 15

Installation

Built-InSide-By-Side

Refrigerators

Instructions

PSB42LGRWV,PSB42LGRBV,PSB42LSRBV,

PSB48LGRWV,PSB48LGRBV,PSB48LSRBV

l If you have questions, call 800.GE.CARES (800.432.2737) or visit our website at: ge.com I

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

• IMPORTANT - Observeall

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions for the consumer's and local

inspector's use.

• Note to Consumer - Keep these instructions

with your Owner's Manual for future reference.

• Skill Level - Installation of this refrigerator

requires basic mechanical, carpentry and

plumbing skills. Proper installation is the

responsibility of the installer. Product failure

due to improper installation is not covered

under the GE Appliance Warranty. See

warranty information.

• Completion Time - 90 minutes (new

installations require more time than

replacement installations).

,_ CAUTION:

Due to the weight and size of this refrigerator,

and to reduce the risk of personal injury or

damage to the product, A MINIMUM OF 4

PEOPLE ARE REQUIRED TO BRING THE UNIT

INTO THE HOME AND 2 PEOPLE ARE

REQUIRED FOR PROPER INSTALLATION.

,A WARNING:

• These refrigerators are top-heavy and must

be secured to prevent the possibility of

tipping forward. Anti-Tip protection is

required. See Step 4 on page 30 for details.

• Use this appliance only for its intended purpose.

• Immediately repair or replace electric power

supply cords that become frayed or damaged.

• Set the Master Power switch to the

O (OFF) position before cleaning or making

repairs.

• Repairs should be made by a qualified

service technician.

For Profile TM local service in your area,

call 1.800.432.2737.

For Profile TM service in Canada,

call 1.888.880.3030.

For Profile TM Parts and Accessories,

call 1.800.626.2002.

ge.com

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

15

Page 16

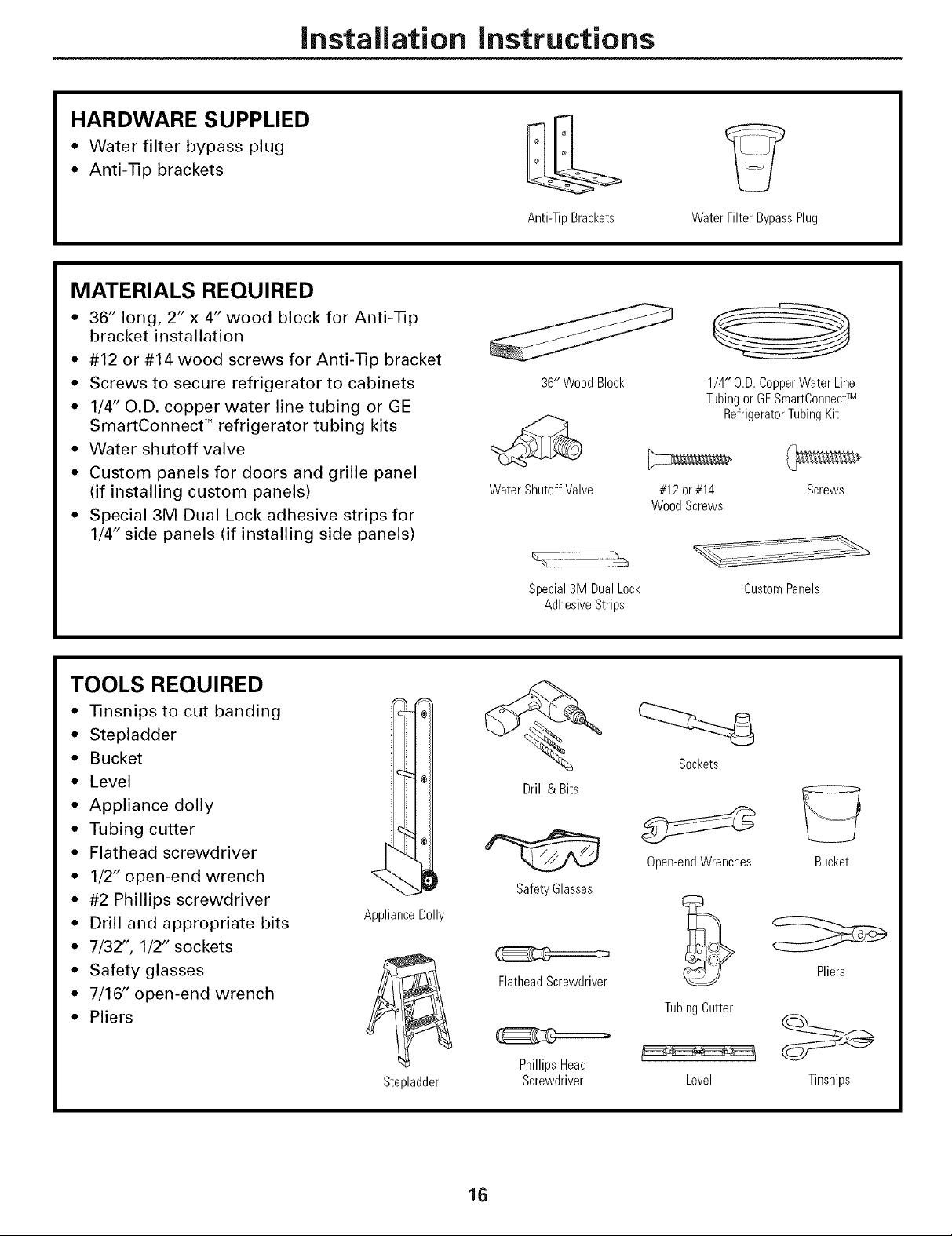

Installation instructions

HARDWARE SUPPLIED

• Water filter bypass plug

• Anti-Tip brackets

MATERIALS REQUIRED

• 36" long, 2" x 4" wood block for Anti-Tip

bracket installation

• #12 or #14 wood screws for Anti-Tip bracket

• Screws to secure refrigerator to cabinets

• 1/4" O.D. copper water line tubing or GE

SmartConnect T'_refrigerator tubing kits

• Water shutoff valve

• Custom panels for doors and grille panel

(if installing custom panels)

• Special 3M Dual Lock adhesive strips for

1/4" side panels (if installing side panels)

Anti-TipBrackets Water Filter Bypass Plug

36"WoodBlock

Water Shutoff Valve

#12or#14

WoodScrews

1/4" O.D.CopperWater Line

TubingorGESmartConnectTM

RefrigeratorTubingKit

Screws

TOOLS REQUIRED

• Tinsnipsto cut banding

• Stepladder

• Bucket

• Level

• Appliance dolly

• Tubing cutter

• Flathead screwdriver

• 1/2" open-end wrench

• #2 Phillips screwdriver

• Drill and appropriate bits

• 7/32", 1/2" sockets

• Safety glasses

• 7/16" open-end wrench

• Pliers

ApplianceDolly

Special3M DualLock

AdhesiveStrips

Drill & Bits

Safety Glasses

FlatheadScrewdriver

Sockets

Open-endWrenches

Tubing Cutter

Custom Panels

Bucket

Pliers

Stepladder

16

PhillipsHead

Screwdriver

Level

Tinsnips

Page 17

Installation Instructions

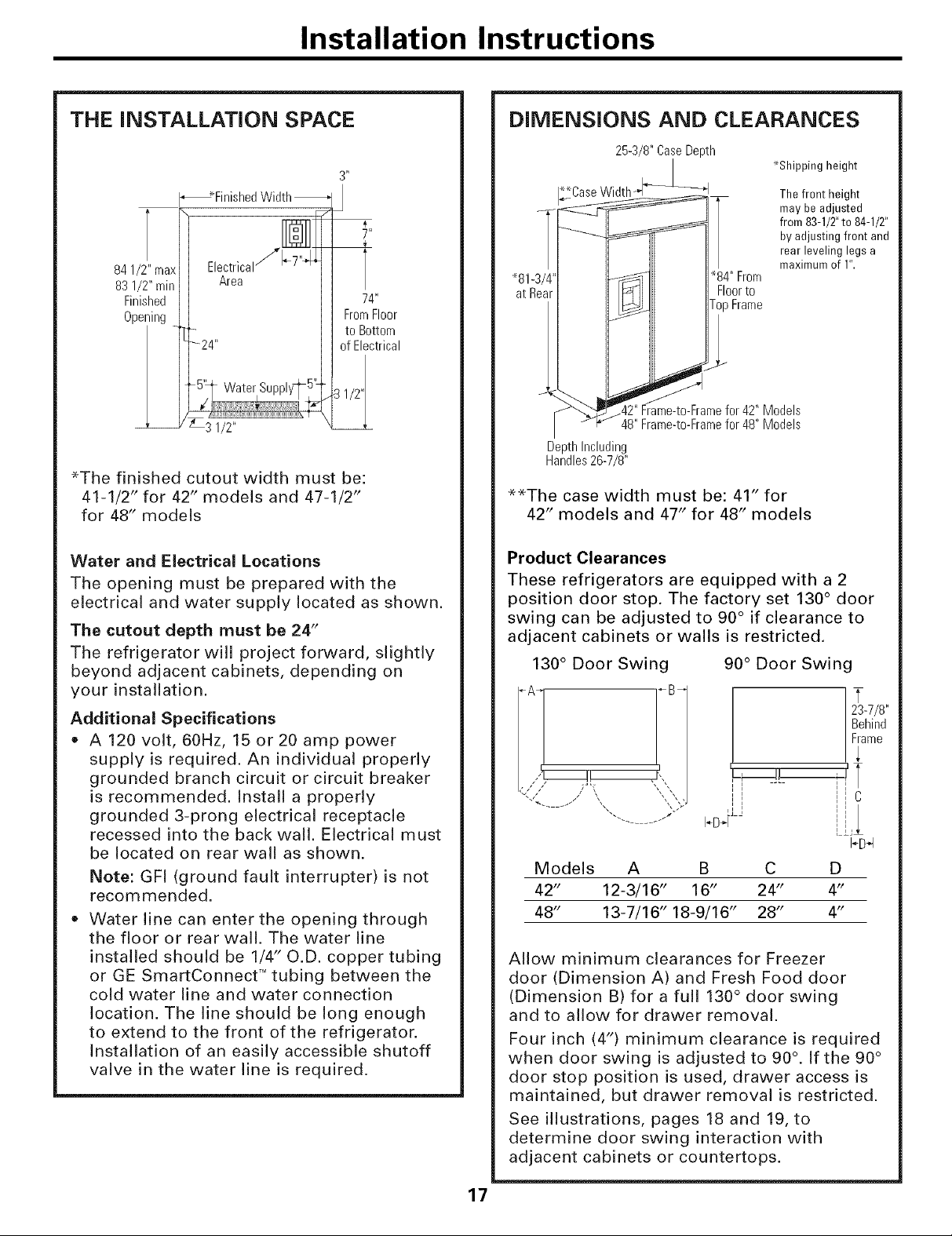

THE iNSTALLATiON SPACE

3"

I_Finished Width

74"

FromFloor

toBottom

of Electrical

*The finished cutout width must be:

41-1/2" for 42" models and 47-1/2"

for 48" models

Water and Electrical Locations

The opening must be prepared with the

electrical and water supply located as shown.

The cutout depth must be 24"

The refrigerator will project forward, slightly

beyond adjacent cabinets, depending on

your installation.

DIMENSIONS AND CLEARANCES

25-3/8" Case Depth

_Shipping height

_Case Width_ T The front height

__ | may be adjusted

1__ H _ | from 83-1/2"to 84-1/2"

11 -_-_: _ _ / by adjusting front and

/I II III / rear leveling legs a

II ]1 IH I maximum of 1".

_81-3/4"1 l} _flll _84"From

atRearl II _ I III Floorto

% ___or42 Models

_" _l_rrrrl;:tt_:_rr_mefor 48:[Models

DepthIncluding

Handles26-7/8"

**The case width must be: 41" for

42" models and 47" for 48" models

Product Clearances

These refrigerators are equipped with a 2

position door stop. The factory set 130 ° door

swing can be adjusted to 90 ° if clearance to

adjacent cabinets or walls is restricted.

130 ° Door Swing 90 ° Door Swing

Additional Specifications

• A 120 volt, 60Hz, 15 or 20 amp power

supply is required. An individual properly

grounded branch circuit or circuit breaker

is recommended. Install a properly

grounded 3-prong electrical receptacle

recessed into the back wall. Electrical must

be located on rear wall as shown.

Note: GFI (ground fault interrupter) is not

recommended.

• Water line can enter the opening through

the floor or rear wall. The water line

installed should be 1/4" O.D. copper tubing

or GE SmartConnect T_'tubing between the

cold water line and water connection

location. The line should be long enough

to extend to the front of the refrigerator.

Installation of an easily accessible shutoff

valve in the water line is required.

Flame

I+D+I

I_D4

Models A B C D

42" 12-3/16" 16" 24" 4"

48" 13-7/16" 18-9/16" 28" 4"

Allow minimum clearances for Freezer

door (Dimension A) and Fresh Food door

(Dimension B) for a full 130 ° door swing

and to allow for drawer removal.

Four inch (4") minimum clearance is required

when door swing is adjusted to 90 °. If the 90 °

door stop position is used, drawer access is

maintained, but drawer removal is restricted.

See illustrations, pages 18 and 19, to

determine door swing interaction with

adjacent cabinets or countertops.

17

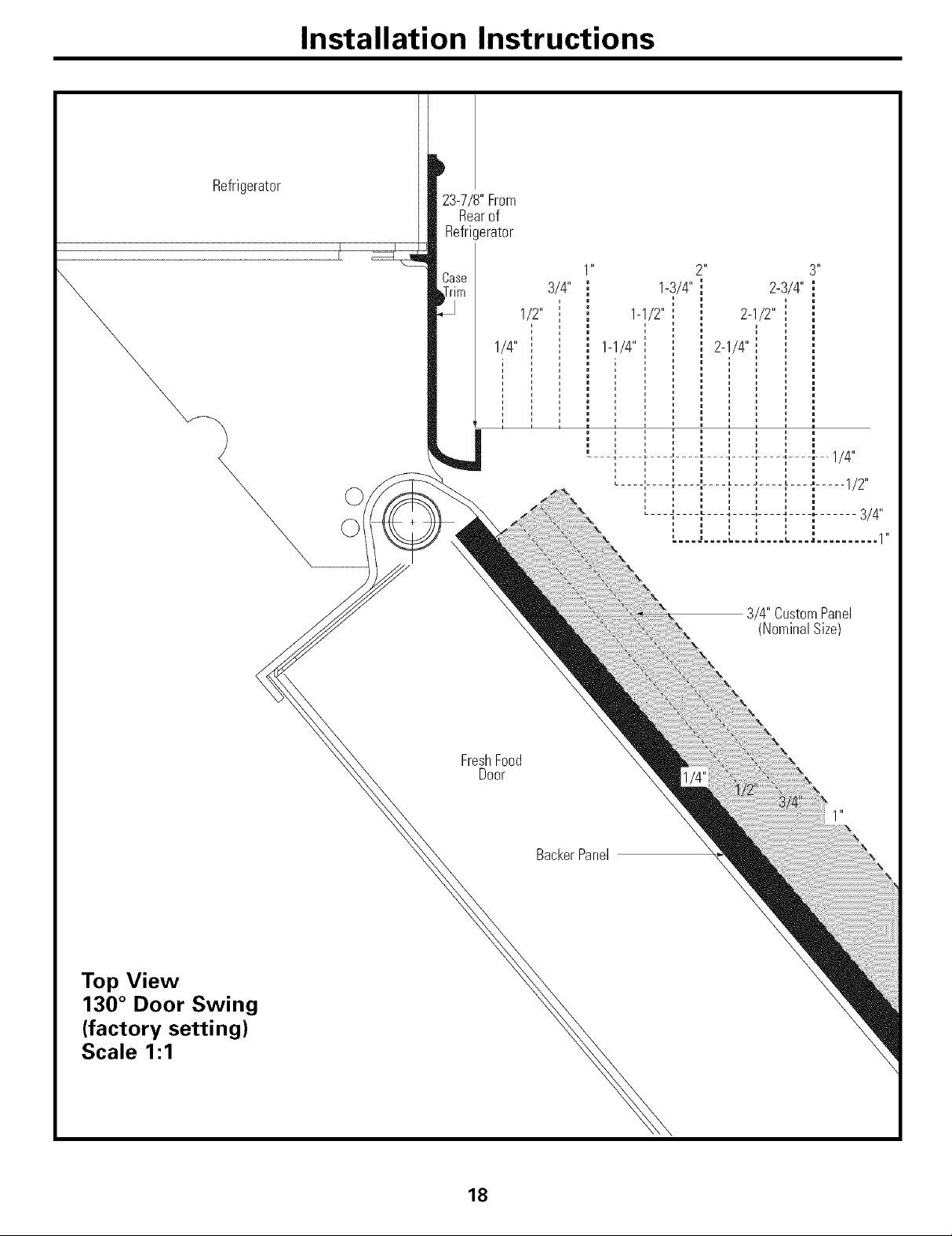

Page 18

Installation Instructions

Refrigerator

23-7/8"From

Rearof

Refrigerator

3/4"

1-1/4"

2-3/4"

2-1/2"

2-1/4"

3/4" CustomPanel

(NominalSize)

Top View

130 ° Door Swing

(factory setting)

Scale 1:1

FreshFood

Door

BackerPanel

i

18

Page 19

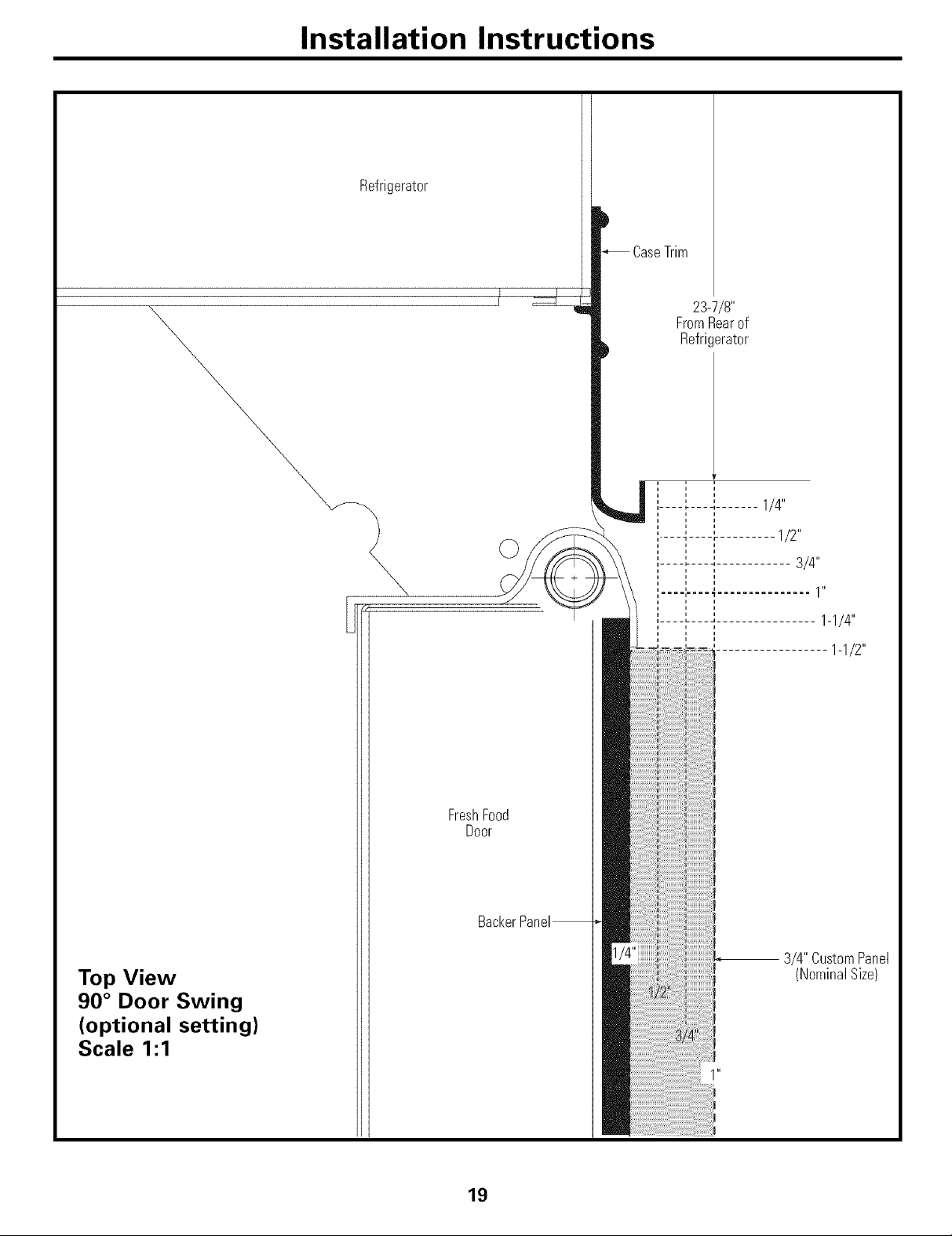

Installation Instructions

Refrigerator

b

CaseTrim

23-7/8"

FromRearof

Refrigerator

Top View

90 ° Door Swing

(optional setting)

Scale 1:1

©

FreshFood

Door

3/4" CustomPanel

(NominalSize)

19

Page 20

Installation Instructions

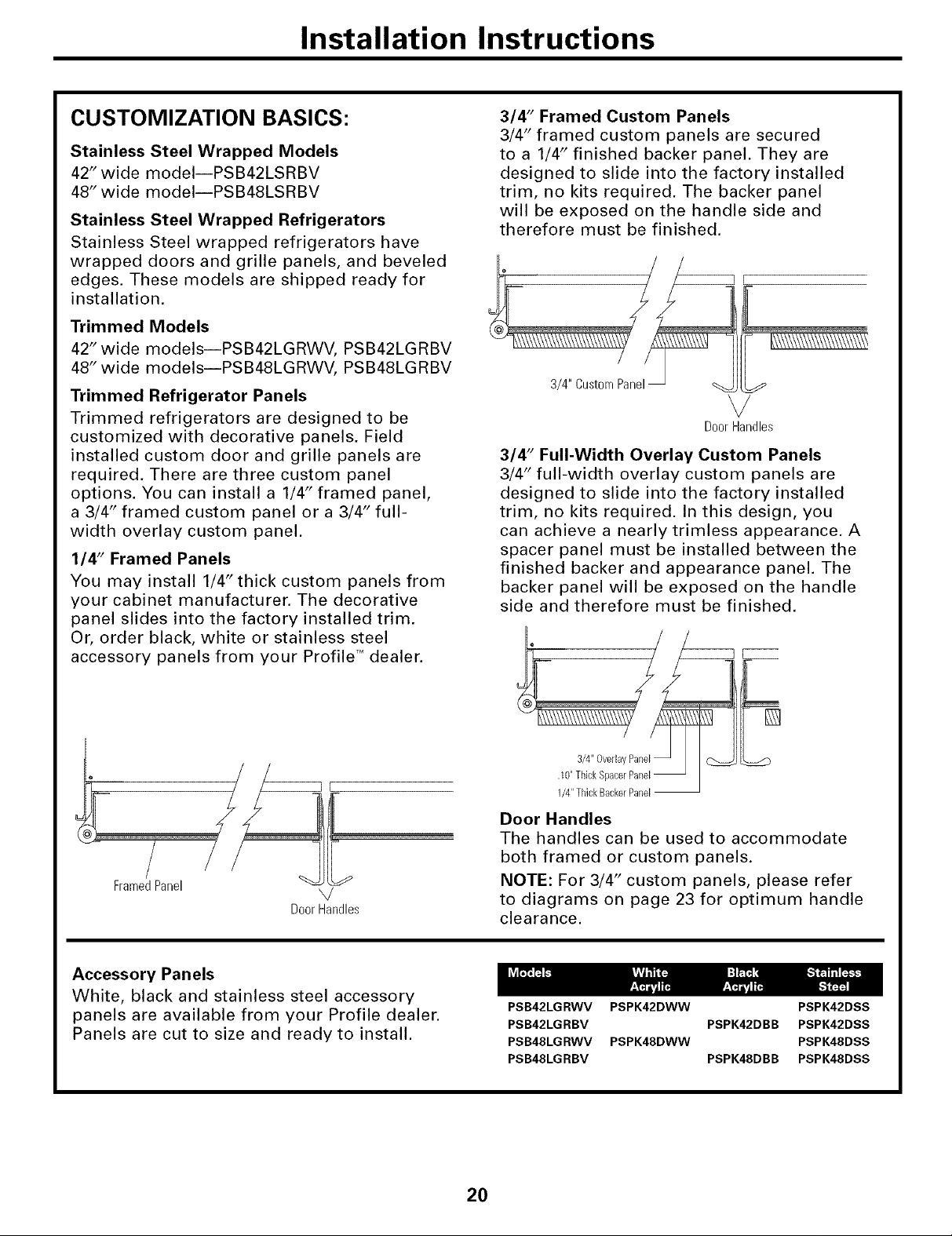

CUSTOMIZATION BASICS:

Stainless Steel Wrapped Models

42" wide modeliPSB42LSRBV

48" wide modeliPSB48LSRBV

Stainless Steel Wrapped Refrigerators

Stainless Steel wrapped refrigerators have

wrapped doors and grille panels, and beveled

edges. These models are shipped ready for

installation.

Trimmed Models

42" wide modelsipSB42LGRWV, PSB42LGRBV

48" wide modelsipSB48LGRWV, PSB48LGRBV

Trimmed Refrigerator Panels

Trimmed refrigerators are designed to be

customized with decorative panels. Field

installed custom door and grille panels are

required. There are three custom panel

options. You can install a 1/4" framed panel,

a 3/4" framed custom panel or a 3/4" full-

width overlay custom panel.

114" Framed Panels

You may install 1/4" thick custom panels from

your cabinet manufacturer. The decorative

panel slides into the factory installed trim.

Or, order black, white or stainless steel

accessory panels from your Profile *'_dealer.

3/4" Framed Custom Panels

3/4" framed custom panels are secured

to a 1/4" finished backer panel. They are

designed to slide into the factory installed

trim, no kits required. The backer panel

will be exposed on the handle side and

therefore must be finished.

DoorHandles

3/4" Full-Width Overlay Custom Panels

3/4" full-width overlay custom panels are

designed to slide into the factory installed

trim, no kits required. In this design, you

can achieve a nearly trimless appearance, A

spacer panel must be installed between the

finished backer and appearance panel. The

backer panel will be exposed on the handle

side and therefore must be finished.

Framed Panel

x/

DoorHandles

Accessory Panels

White, black and stainless steel accessory

panels are available from your Profile dealer.

Panels are cut to size and ready to install.

1/4"ThickBackerPanel

Door Handles

The handles can be used to accommodate

both framed or custom panels.

NOTE: For 3/4" custom panels, please refer

to diagrams on page 23 for optimum handle

clearance.

PSB42LGRWV PSPK42DWW PSPK42DSS

PSB42LGRBV PSPK42DBB PSPK42DSS

PSB48LGRWV PSPK48DWW PSPK48DSS

PSB48LGRBV PSPK48DBB PSPK48DSS

20

Page 21

Installation Instructions

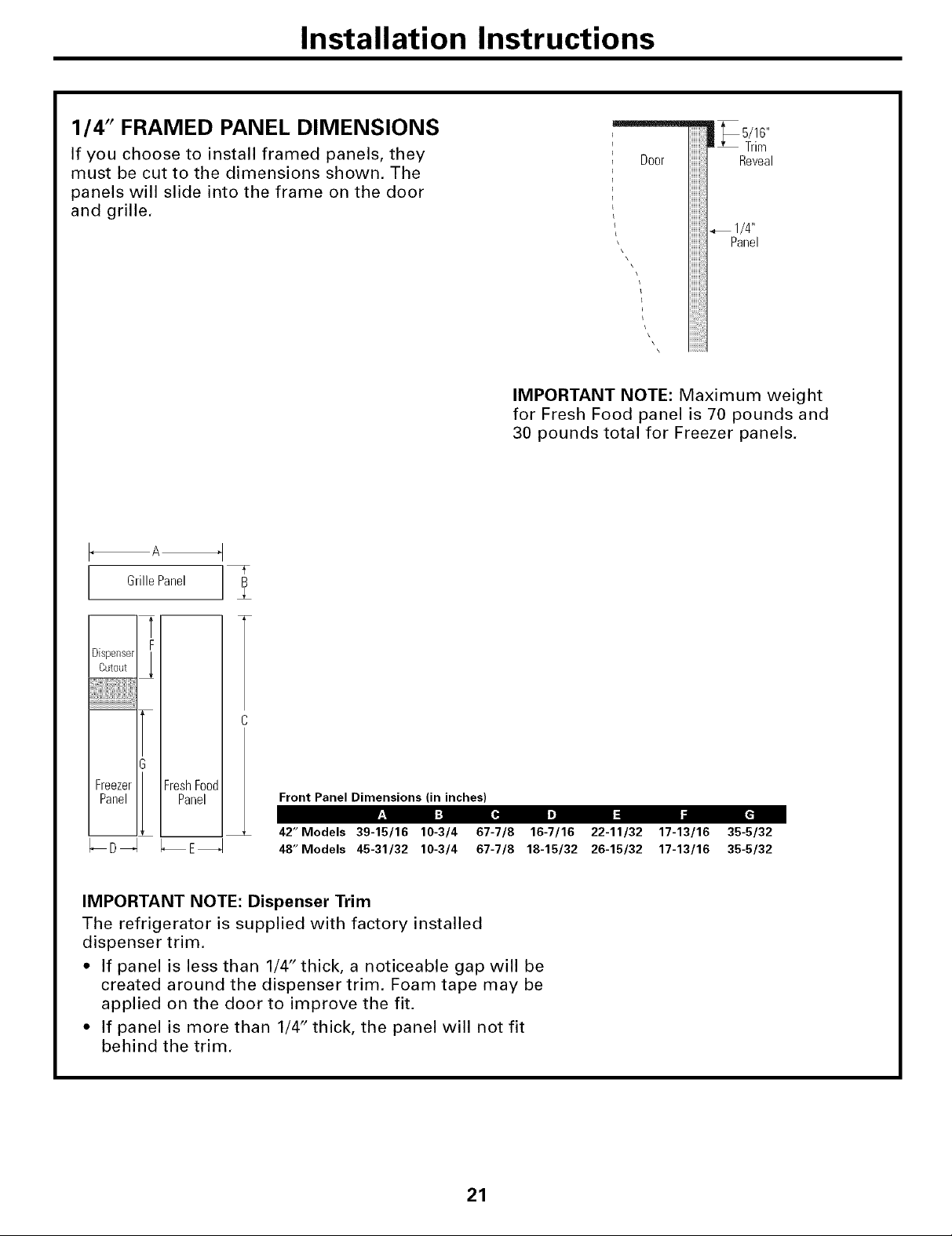

1/4" FRAMED PANEL DIMENSIONS

If you choose to install framed panels, they

must be cut to the dimensions shown. The

panels will slide into the frame on the door

and grille.

A

Door

\

\

IMPORTANT NOTE: Maximum weight

for Fresh Food panel is 70 pounds and

30 pounds total for Freezer panels.

L Trim

"

Reveal

[ GrillePanel ]_

F

Cutout

Dispenser _,

C

l

Freezer Fresh Food

Panel Panel Front Panel Dimensions (in inches)

1

42" Models 39-15/16 10-3/4 67-7/8

48" Models 45-31/32 10-3/4 67-7/8

IMPORTANT NOTE: Dispenser Trim

The refrigerator is supplied with factory installed

dispenser trim.

• If panel is less than 1/4" thick, a noticeable gap will be

created around the dispenser trim. Foam tape may be

applied on the door to improve the fit.

• If panel is more than 1/4" thick, the panel will not fit

behind the trim.

r.'l I:1 [7 Im] I:1 [tl

18-15/32 26-15/32 17-13/16 35-5/32

16-7/16 22-11/32 17-13/16 35-5/32

21

Page 22

Installation Instructions

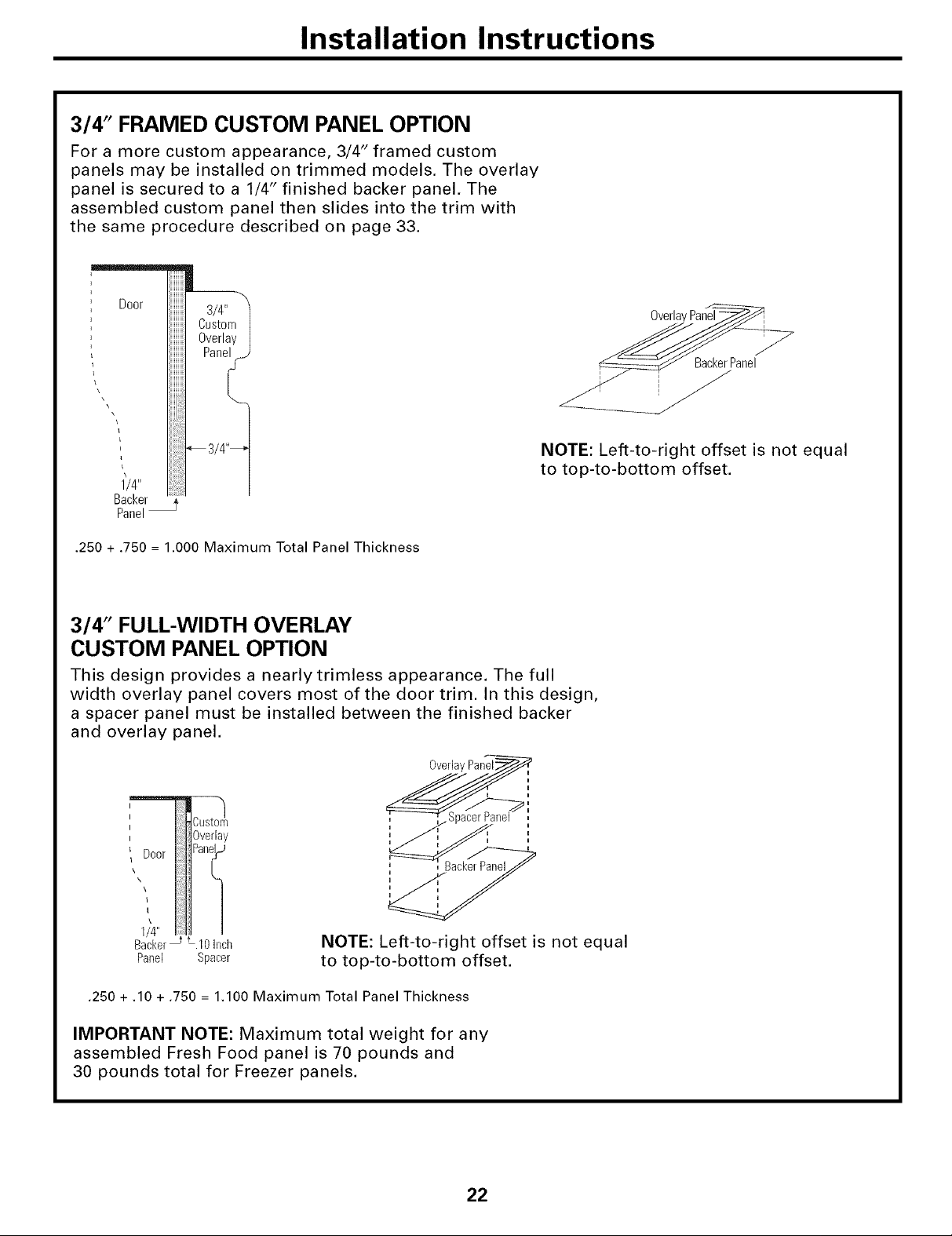

3/4" FRAMED CUSTOM PANEL OPTION

For a more custom appearance, 3/4" framed custom

panels may be installed on trimmed models. The overlay

panel is secured to a 1/4" finished backer panel. The

assembled custom panel then slides into the trim with

the same procedure described on page 33.

1'/4"

Backer

Panel

Overla

BackerPanel

NOTE: Left-to-right offset is not equal

to top-to-bottom offset.

,250 + ,750 = 1.000 Maximum Total Panel Thickness

3/4" FULL-WIDTH OVERLAY

CUSTOM PANEL OPTION

This design provides a nearly trimless appearance. The full

width overlay panel covers most of the door trim. In this design,

a spacer panel must be installed between the finished backer

and overlay panel,

OverlayPanel

I

I

I

, Overlay

Door

l

\\

\

I

I

Backer_ L.IO inch

Panel Spacer

NOTE: Left-to-right offset is not equal

to top-to-bottom offset.

.250 + .10 + .750 = 1.100 Maximum Total Panel Thickness

i

IMPORTANT NOTE: Maximum total weight for any

assembled Fresh Food panel is 70 pounds and

30 pounds total for Freezer panels.

22

Page 23

Installation Instructions

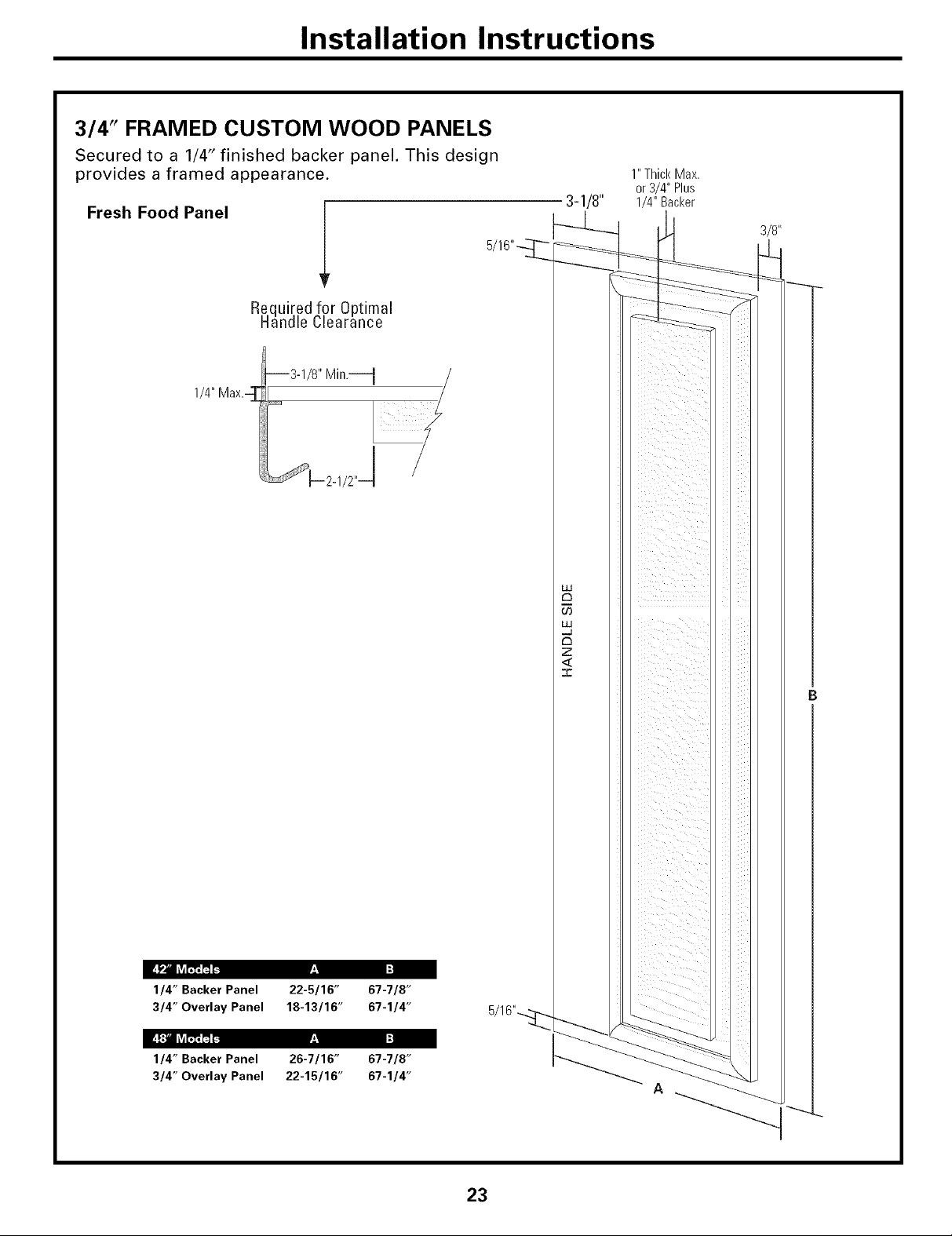

3/4" FRAMED CUSTOM WOOD PANELS

Secured to a 1/4" finished backer panel. This design

provides a framed appearance.

Fresh Food Panel

Required for Optimal

Handle Clearance

--3-1/8" Min.'--_

1/4" Maxs--T

?

I--2-I/2"J

3-1/8"

1"ThickMax.

or3/#' Plus

1/4" Backer

3/8"

Ir.,_ I:]

1/4" Backer Panel 22-5/16" 67-7/8"

3/4" Overlay Panel 18-13/16" 67-1/4"

Ir.,_ I:]

1/4" Backer Panel 26-7/16" 67-7/8"

3/4" Overlay Panel 22-15/16" 67-1/4"

A

23

Page 24

Installation Instructions

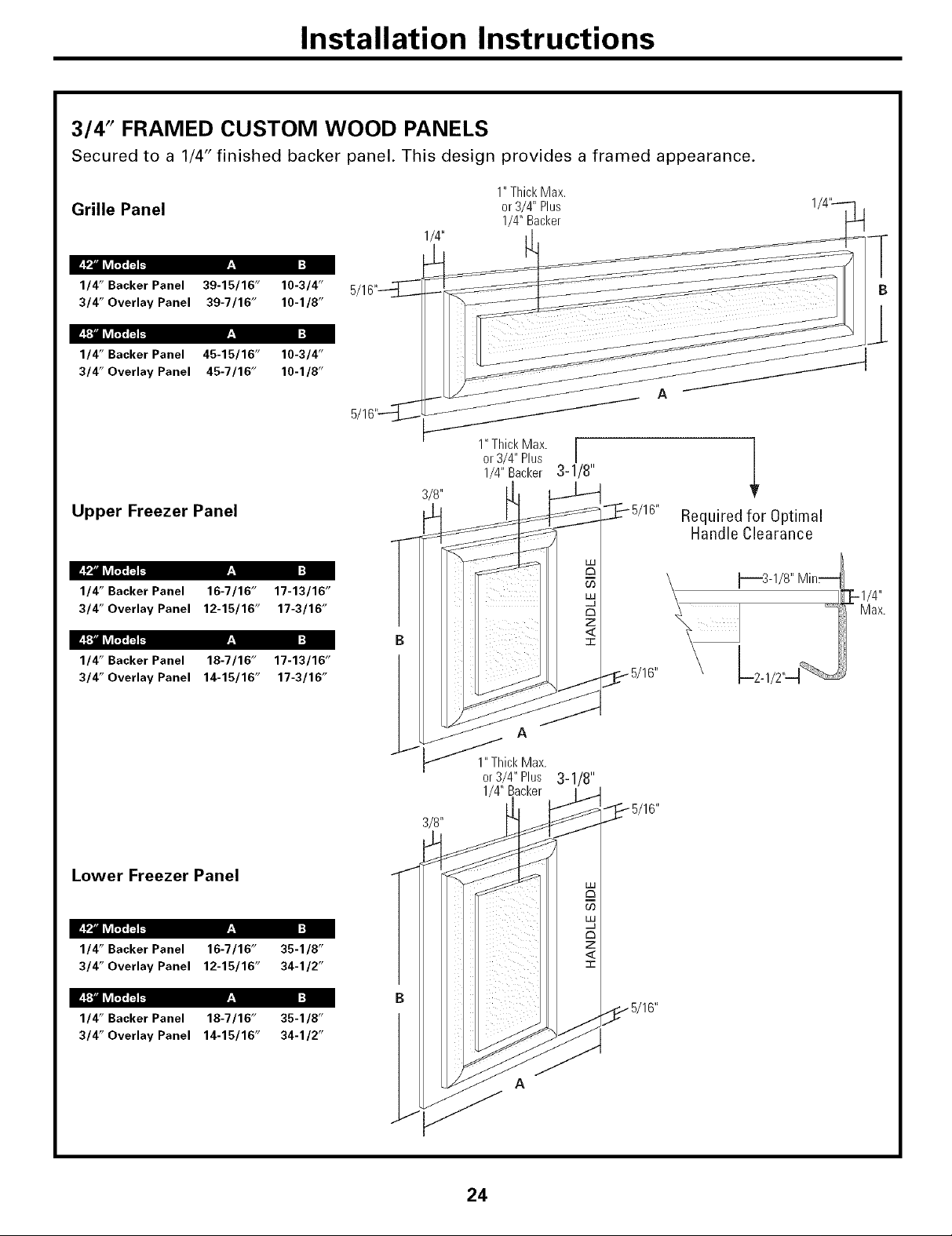

3/4" FRAMED CUSTOM WOOD PANELS

Secured to a 1/4" finished backer panel. This design provides a framed appearance.

1"ThickMax.

Grille Panel

F:I I:]

1/4" Backer Panel 39-15/16" 10-3/4" 5/16"----T'--

3/4" Overlay Panel 39-7/16" 10-1/8"

F:I I:]

1/4" Backer Panel 45-15/16" 10-3/4"

3/4" Overlay Panel 45-7/16" 10-1/8"

_A

5/16"---_

Upper Freezer Panel

F:I I:]

1/4" Backer Panel 16-7/16" 17-13/16"

3/4" Overlay Panel 12-15/16" 17-3/16"

I-'1 I:]

1/4" Backer Panel 18-7/16" 17-13/16"

3/4" Overlay Panel 14-15/16" 17-3/16"

Lower Freezer Panel

S/B"

_'J'_icl<Max.

3/8"

1" Thick Max.

or 3/4" Plus I

1/4" Backer 3-1/8"

A

or3/4" Plus

1/4" Backer

3-1/8"

I

Required for Optimal

Handle Clearance

I-'1 I:]

1/4" Backer Panel 16-7/16" 35-1/8"

3/4" Overlay Panel 12-15/16" 34-1/2"

I-'1 I:]

1/4" Backer Panel 18-7/16" 35-1/8"

3/4" Overlay Panel 14-15/16" 34-1/2"

24

Page 25

Installation Instructions

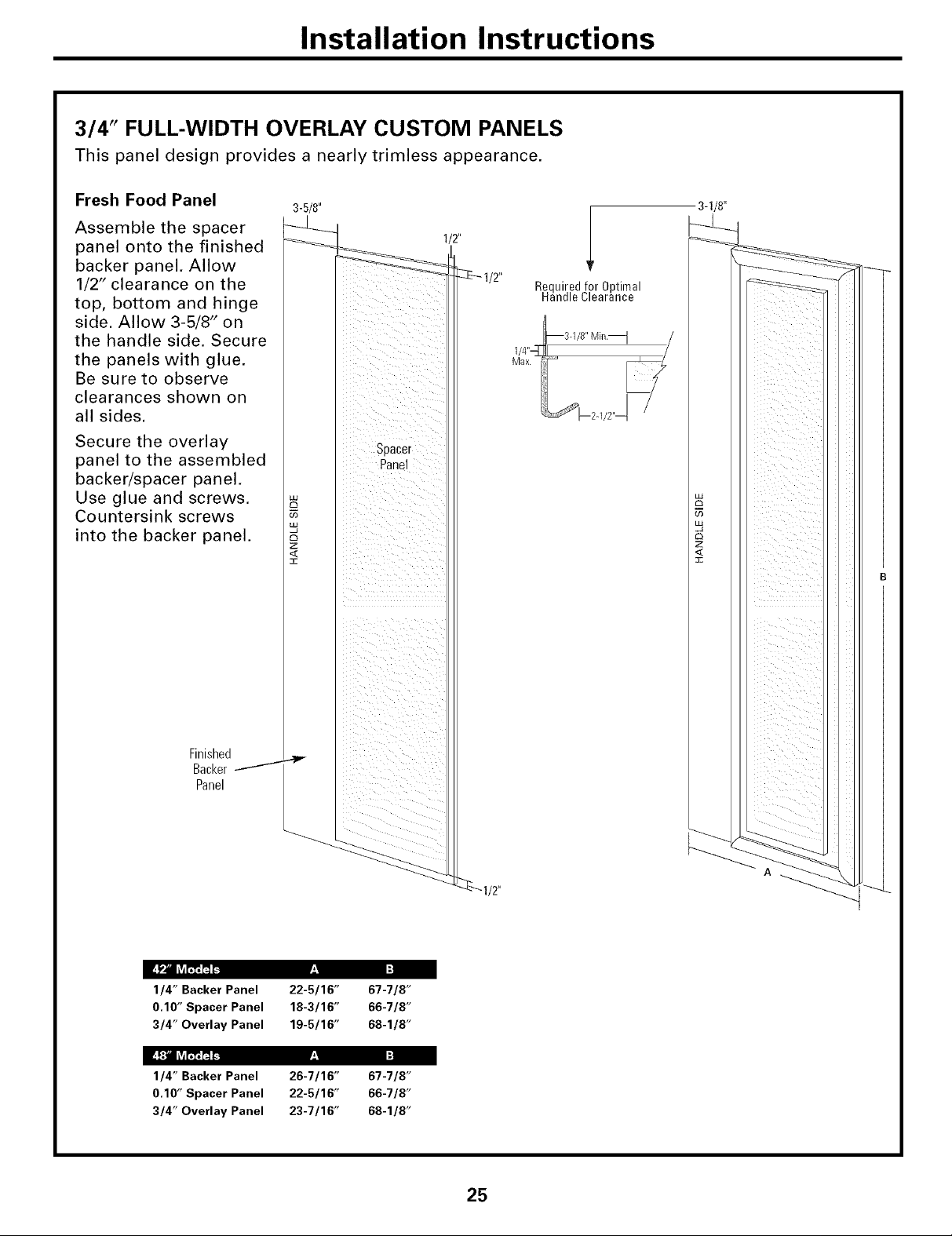

3/4" FULL-WIDTH OVERLAY CUSTOM PANELS

This panel design provides a nearly trimless appearance.

Fresh Food Panel

Assemble the spacer

panel onto the finished

backer panel, Allow

1/2" clearance on the

top, bottom and hinge

side. Allow 3-5/8" on

the handle side. Secure

the panels with glue.

Be sure to observe

clearances shown on

all sides.

Secure the overlay

panel to the assembled

backer/spacer panel,

Use glue and screws,

Countersink screws

into the backer panel.

3-5/8"

(3

Z

I

Spacer

Panel

112"

_-_ 1/2"

Required for Optimal

r_andle Clearance

3-1/8"

Finished

Backer/

Panel

_vM?_CT_L_I Ir.,_ I:]

114" Backer Panel 22-5116" 67-7/8"

0.10" Spacer Panel 18-3/16" 66-7/8"

3/4" Overlay Panel 19-5/16" 68-1/8"

Ir.,_ I:]

1/4" Backer Panel 26-7/16" 67-7/8"

0.10" Spacer Panel 22-5/16" 66-7/8"

3/4" Overlay Panel 23-7/16" 68-1/8"

_"-1/2"

25

Page 26

Installation Instructions

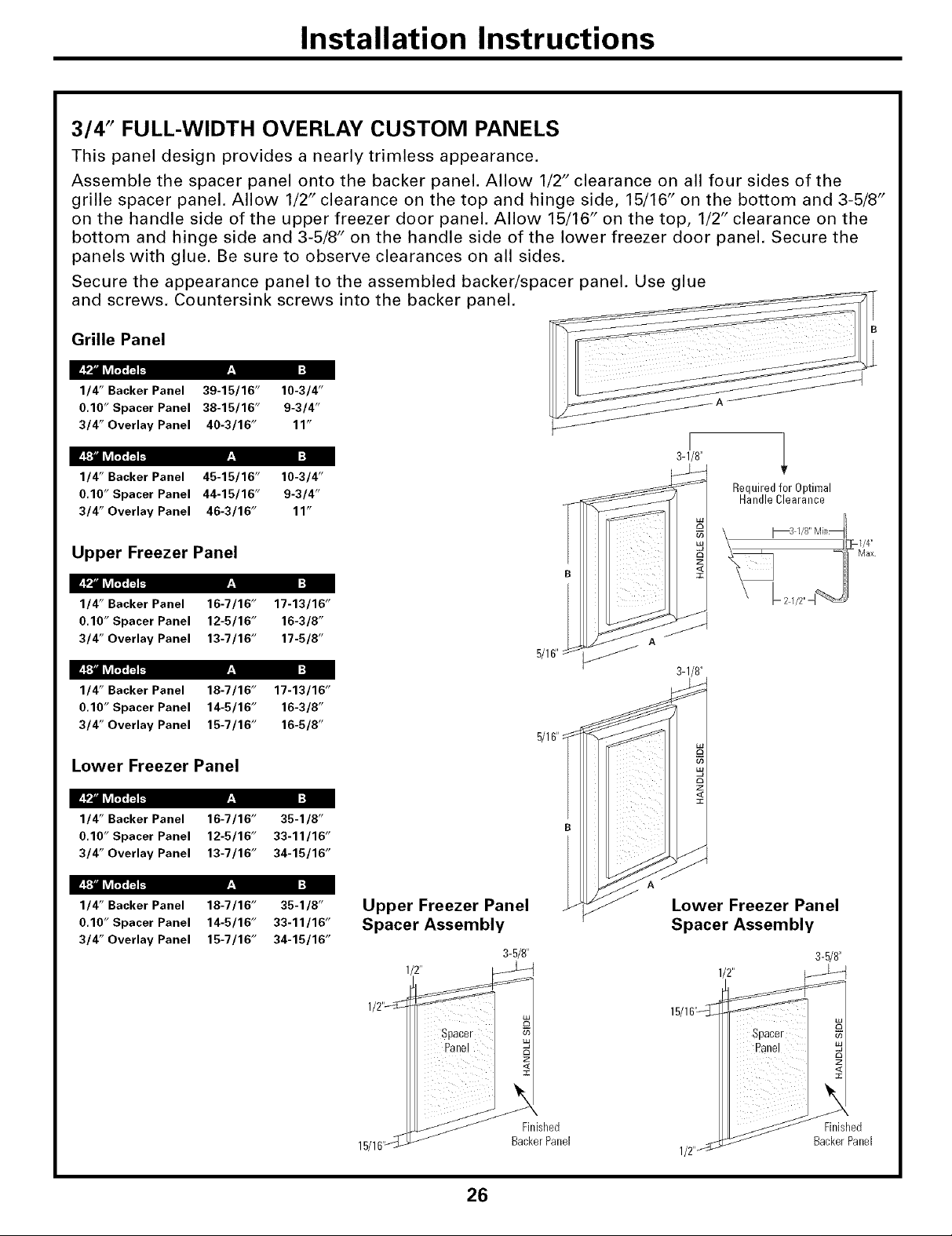

3/4" FULL-WIDTH OVERLAY CUSTOM PANELS

This panel design provides a nearly trimless appearance.

Assemble the spacer panel onto the backer panel. Allow 1/2" clearance on all four sides of the

grille spacer panel. Allow 1/2" clearance on the top and hinge side, 15/16" on the bottom and 3-5/8"

on the handle side of the upper freezer door panel. Allow 15/16" on the top, 1/2" clearance on the

bottom and hinge side and 3-5/8" on the handle side of the lower freezer door panel. Secure the

panels with glue. Be sure to observe clearances on all sides.

Secure the appearance panel to the assembled backer/spacer panel. Use glue

and screws. Countersink screws into the backer panel.

Grille Panel

F:I I:]

1/4" Backer Panel 39-15/16" 10-3/4"

0.10" Spacer Panel 38-15/16" 9-3/4"

3/4" Overlay Panel 40-3/16" 11"

F:I I:]

1/4" Backer Panel 45-15/16" 10-3/4"

0.10" Spacer Panel 44-15/16" 9-3/4" Requiredfor Optimal

3/4" Overlay Panel 46-3/16" 11"

HandleClearance

Upper Freezer Panel

F:I I:]

1/4" Backer Panel 16-7/16" 17-13/16"

0.10" Spacer Panel 12-5/16" 16-3/8"

3/4" Overlay Panel 13-7/16" 17-5/8"

F:I I:]

1/4" Backer Panel 18-7/16" 17-13/16"

0.10" Spacer Panel 14-5/16" 16-3/8"

3/4" Overlay Panel 15-7/16" 16-5/8"

Lower Freezer Panel

F:I I:]

1/4" Backer Panel 16-7/16" 35-1/8"

0.10" Spacer Panel 12-5/16" 33-11/16"

3/4" Overlay Panel 13-7/16" 34-15/16"

F:I I:]

1/4" Backer Panel 18-7/16" 35-1/8"

0.10" Spacer Panel 14-5/16" 33-11/16"

3/4" Overlay Panel 15-7/16" 34-15/16"

Upper Freezer Panel

Spacer Assembly

3-5/8"

1/2,, 1/2_

Spacer

Pane!

5/16":

Lower Freezer Panel

Spacer Assembly

3-5/8"

1/2" _

15/16'-_

Spacer

Panel

26

J

Finished

BackerPallel

1/2"_

Finished

BackerPallel

Page 27

Installation Instructions

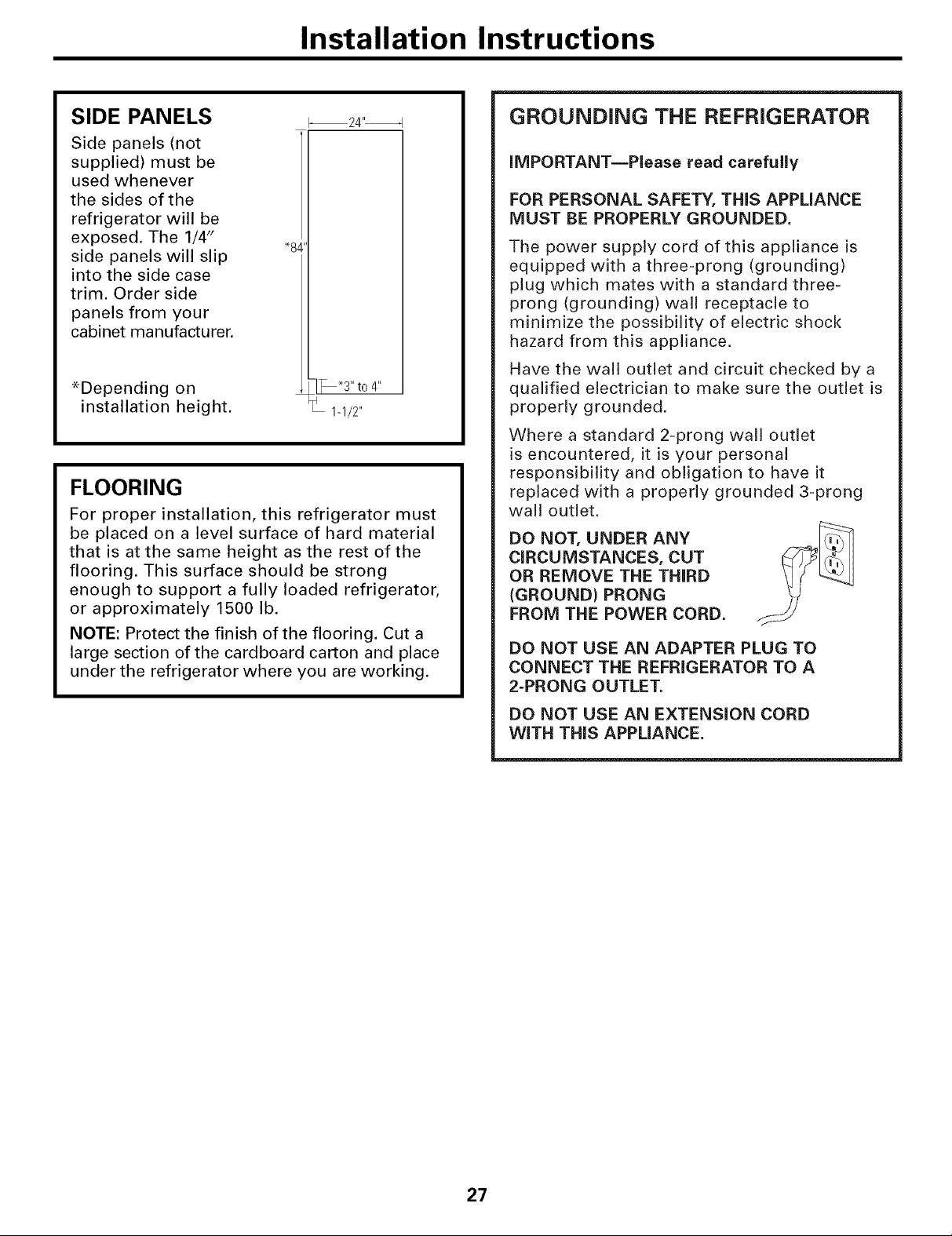

SIDE PANELS

Side panels (not

supplied) must be

used whenever

the sides of the

refrigerator will be

exposed. The 1/4"

side panels will slip

into the side case

trim. Order side

panels from your

cabinet manufacturer.

*Depending on

installation height.

FLOORING

For proper installation, this refrigerator must

be placed on a level surface of hard material

that is at the same height as the rest of the

flooring. This surface should be strong

enough to support a fully loaded refrigerator,

or approximately 1500 lb.

NOTE: Protect the finish of the flooring. Cut a

large section of the cardboard carton and place

under the refrigerator where you are working.

GROUNDING THE REFRIGERATOR

IMPORTANT--Please read carefuly

FOR PERSONAL SAFETY, THiS APPLIANCE

MUST BE PROPERLY GROUNDED.

The power supply cord of this appliance is

equipped with a three-prong (grounding)

plug which mates with a standard three-

prong (grounding) wall receptacle to

minimize the possibility of electric shock

hazard from this appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall outlet

is encountered, it is your personal

responsibility and obligation to have it

replaced with a properly grounded 3-prong

wall outlet.

DO NOT, UNDER ANY __

CIRCUMSTANCES, CUT

OR REMOVE THE THIRD

(GROUND) PRONG

FROM THE POWER CORD.

DO NOT USE AN ADAPTER PLUG TO

CONNECT THE REFRIGERATOR TO A

2-PRONG OUTLET.

Z

DO NOT USE AN EXTENSION CORD

WiTH THiS APPLIANCE.

27

Page 28

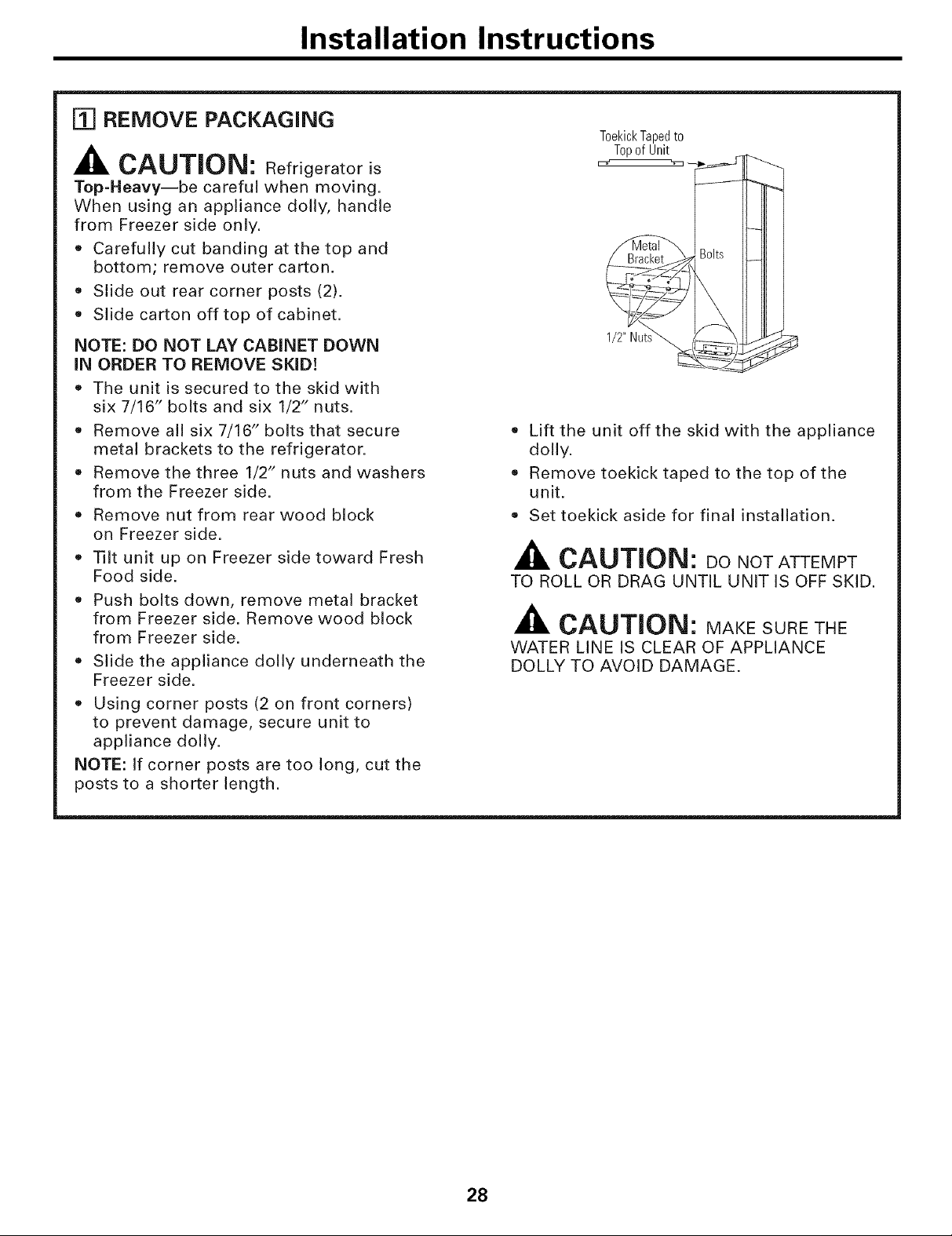

Installation Instructions

[] REMOVE PACKAGING

A, CAUTION: Refrigeratoris

Top-Heavy--be careful when moving.

When using an appliance dolly, handle

from Freezer side only.

• Carefully cut banding at the top and

bottom; remove outer carton.

• Slide out rear corner posts (2).

• Slide carton off top of cabinet.

NOTE: DO NOT LAY CABINET DOWN

IN ORDER TO REMOVE SKID!

• The unit is secured to the skid with

six 7/16" bolts and six 1/2" nuts.

• Remove all six 7/16" bolts that secure

metal brackets to the refrigerator.

Remove the three 1/2" nuts and washers

from the Freezer side.

• Remove nut from rear wood block

on Freezer side.

• Tilt unit up on Freezer side toward Fresh

Food side.

• Push bolts down, remove metal bracket

from Freezer side. Remove wood block

from Freezer side.

• Slide the appliance dolly underneath the

Freezer side.

• Using corner posts (2 on front corners)

to prevent damage, secure unit to

appliance dolly.

NOTE: If corner posts are too long, cut the

posts to a shorter length.

Toekick Taped to

Topof Unit

Eo "3_

1/2" Nut

• Lift the unit off the skid with the appliance

dolly.

Remove toekick taped to the top of the

unit.

• Set toekick aside for final installation.

CAUTION: DO NOT ATTEMPT

TO ROLL OR DRAG UNTIL UNIT IS OFF SKID.

CAUTION: MAKE SURE THE

WATER LINE IS CLEAR OF APPLIANCE

DOLLY TO AVOID DAMAGE.

28

Page 29

Installation Instructions

[] iNSTALL WATER LINE

• A cold water supply is required for

automatic icemaker operation. The water

pressure must be between 40 and 120 psi.

• Route 1/4" O.D. copper tubing or GE

SmartConnect TM tubing between cold water

line and the water connection location.

• Tubing should be long enough to extend

to the front of the refrigerator. Allow

enough tubing to accommodate bend

leading into the water line connection.

NOTE: The only GE approved plastic tubing

Nssupplied in the GE SmartConnect T_'

Refrigerator Tubing kits. Do not use any

other plastic water supply line; the line is

under pressure at all times. Certain types

of plastic may crack or rupture with age

and cause water damage to your home.

GE SmartConnect TMrefrigerator tubing kits

are available in the following lengths:

2' (0.6m) WX08X10002

6' (1.8m) WX08X10006

15' (4.6m) WX08X10015

25' (7.6m) WX08X10025

Shut off the main water supply.

Turn on the nearest faucet long enough

to purge all the water from the line.

• Install a shutoff valve between the

icemaker water valve and cold water pipe

in a basement or cabinet. The shutoff

valve should be located where it will be

easily accessible.

NOTE: It is best to install the valve into a

vertical water pipe. If you install the valve into

a horizontal water pipe, make the connection

at the top or side to avoid drawing off any

sediment from the water pipe.

• Drill a 1/4" hole in the water pipe.

• Fasten the shutoff valve to the pipe with

pipe clamp.

• Tighten the clamp screws until the

sealing washer begins to swell. Do not

OVERTIGHTEN.

• Place a compression nut and ferrule

(sleeve) for copper tubing onto the end

of the tubing and connect it to the shutoff

valve. Make sure the tubing is fully inserted

into the valve and ferrule is tightened.

CopperTubing,j

or GESmartC0nnectTMTubing

SaddleType

Shuto_ _

Packin_

Outlet Valve

• For plastic tubing from a GE SmartConnect TM

refrigerator tubing kit, insert the molded

end of the tubing into the shutoff valve

and tighten the compression nut until it is

hand tight, and then tighten an additional

turn with a wrench.

• Turn on the main water supply and

flush debris. Run about a quart of water

through the tubing into a bucket. Shut

off water supply at the shutoff valve.

NOTE: Saddle type shutoff valves are

included in many water supply kits. Before

purchasing, make sure a saddle type valve

complies with your local plumbing codes.

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR must be adhered

to. Saddle valves are illegal and use is not

permitted in Massachusetts. Consult with

your licensed plumber.

Compression Nut

\

Ferrule

(Sleeve)

29

Page 30

Installation Instructions

[_ WATER LiNE iNSTALLATiON

WITH A REVERSE OSMOSIS

SYSTEM

SKIP THIS STEP WHEN NOT USING AN

RO SYSTEM

NOTE: If the water supply to the refrigerator

is from a Reverse Osmosis Water System, use

the refrigerator's filter bypass plug. Using the

refrigerator's water filtration cartridge with

the RO filter can result in hollow ice cubes.

MasterPowerSwitch Water Filter

Rotate CounterclockwiseTo Remove

• Open the top grille to view the filtration

cartridge. Rotate the filtration cartridge

counterclockwise until removed.

Insert filter bypass plug. Rotate the filter

bypass plug clockwise until tightly secured

in place.

ALTERNATE ANTI-TIP

PRECAUTIONS

SKIP THIS STEP WHEN USING ANTI-TIP

BRACKETS

All Profile built-in refrigerators are Top-Heavy.

They must be secured to prevent the possibility

of tipping forward. Use this alternative method

to secure the refrigerator whenever steel wall

studs are encountered.

SideView

TopCaseTrim

Install(4)1-1/2"DrywallScrews

ThroughTrimandInt0Soffit

or3/4" Min. WoodBrace

[] INSTALL SIDE PANELS

SKiP THiS STEP WHEN NOT USING SIDE PANELS

If you are using 1/4" side panels, they should be

inserted into the case trim. Fasten the panels to

the refrigerator with the 3M Dual Lock adhesive

strips before setting refrigerator in place.

[] INSTALL ANTI-TIP BRACKETS

ANTI-TIP

WARNING: PRECAUTIONS

The refrigerator is Top-Heavy and must be secured

to prevent the possibility of tipping forward.

Cut a 2" x 4" wood block 36" long,

and secure the block to ',i

the mounting

brackets

provided,

using #12 or

#14 wood screws.

Secure the

brackets with

wood block to the

back wall so that it is Drywall)

82" (or the rear installation height) from the

finished floor. Use #12 or #14 wood screws.

Screws must penetrate at least 1" into vertical

wall studs.

Wood Screws i ', Brac<et

Mounted into i h_, ',

Vertical =' '

WoodStudsi W0,Stud

......po i_

..... i- / o_Anti-Tip

I i i

4',

i \

, ,, (Behind

Positioned

Adjust height of refrigerator to match

installation cutout opening 83-1/2" to

84-1/2". The refrigerator must be level and

plumb with cabinets. The top case trim at

the front is 2-1/8" higher than the rear and

will overlap upper cabinets or cabinet trim.

Open grille panel to access the top case trim.

• Use a 3/16" bit to drill 4 evenly spaced

clearance holes through the metal top

case trim.

Use a 1/16" bit to drill pilot holes through

the metal clearance holes and into wood

soffit. The holes should be centered in the

soffit or a 3/4" minimum wood brace. The

brace spanning the enclosure must be

securely fastened to cabinets on both sides.

,, Install four 1-1/2" drywall screws into the

pilot holes.

30

Page 31

Installation Instructions

[] CONNECT POWER

,, Connect refrigerator power cord plug to

a properly grounded receptacle. Set the

Master Power switch to the I (ON) position.

o o o

====_Baise _j_ [_

_Grille J I,,_,J

EE_Panel _a] _\\_

7

M0ster W0ter

Filter

%

powerBwitchIII/

Check to make sure power to refrigerator

is on by opening refrigerator door to see if

interior lights are on.

CAUTION:

= After power has been established, turn the

Master Power switch to the O {OFF) position.

1-67MOVE iNTO

iNSTALLATiON SPACE

[] LEVEL REFRIGERATOR

All models have 4-point leveling. The front and

back are supported by leveling legs. Both are

accessible from the front of the refrigerator.

* To level the back of the refrigerator, turn

the 1/2" hex nut located above the front

wheels. Turn clockwise to raise or

counterclockwise to lower the refrigerator.

* For front leveling, use a 7/16" open-end

wrench.

Adjust height of refrigerator to match

installation cutout opening 83-1/2" to

84-1/2". The refrigerator should be level

and plumb with cabinets.

Levelinq

HexNutAdjusts

RearLevelingLegs

/

• Slide the unit into the installation space.

• Place excess slack in the power cord on top

of the refrigerator.

• Use care to ensure the power cord is not

pinched behind the unit.

Height

from

Floorto

Bottom

ofWood

Block

82"

IMPORTANT NOTE: The refrigerator must

be level. If it is not, the doors may not align

evenly at the top. See Step 16.

CAUTION:

The rear leveling legs and front leveling legs

are limited to a maximum height adjustment

of 1". If the installation requires more than

84-1/2" height, the installer should elevate the

refrigerator on a sheet of plywood or runners.

Cabinet trim could be added across the top

of the opening to shorten the opening, if you

attempt to raise the refrigerator more than

1", you will damage the front and rear

JeveJing Jegs.

31

Page 32

Installation Instructions

[] SECURE REFRIGERATOR

TO CABINETS

Whenever possible, perform this step for

anti-tip security.

The refrigerator must be secured to prevent

tipping.

• Raise the grille panel to access case trim.

• Drive a screw through the trim and into the

adjacent cabinet using holes provided.

• Follow the same procedure on the opposite

side.

Through CaseTrim Int0

Adjacent Cabinets

INSTALL GRILLE PANEL

• Raise the grille panel to the stop position.

• Remove 4 screws on bottom trim; retain

all screws.

• Remove bottom trim.

• NOTE: Stainless steel and acrylic panels

are covered with a protective film. Remove

the film before installing the panel.

• Slide panel over the metal backer panel

and under the trim.

I-9-1ADJUST DOOR SWING

NOTE: This refrigerator has a 2-position door

stop. When space does not allow the door to

swing open fully to 130 °, you may change the

door swing to a 90 ° opening.

SKIP THIS STEP IF DOOR OPENING IS

SATISFACTORY FOR YOUR INSTALLATION

SITUATION.

• Open the door to view the bottom hinge.

Note the door stop pin location. The pin is

factory installed in the 130 ° position.

• Partially close the door. From above, use a

flat-head screwdriver to unscrew the door

stop pin and reinstall into the 90 ° position.

Interior

• If necessary, tap with a wood block until

panel slips under the top trim piece.

• Reassemble bottom trim. Tighten screws.

Hinge

32

Page 33

Installation Instructions

iNSTALL DOOR PANELS

install 1/4" Decorative Panels:

• Remove Handles

Open door to 90 °. Remove 5 Phillips head

screws from the Fresh Food and Freezer

door handles; retain all screws. Lift off

door handles.

Handle_

FreshFood

Refrigerator

Door

i

3/4" Custom Panel

if Required

= install Door Panels

NOTE: Stainless steel and acrylic panels are

covered with a protective film. Remove the

film before installing the panel. Carefully

push the Fresh Food panel in until it slides

into the slot behind the trim. Gently push to

opposite side. Repeat procedure for upper

and lower Freezer panels.

• Reinstall Handles

Reinstall Fresh Food door handle with the

original 5 Phillips head screws. Tighten.

Repeat for Freezer door handle.

NOTE: Ensure that the edge of the handle

does not pinch the door gasket.

= 3/4" Custom Decorative Panels

If you choose to install custom wood

panels, they must be cut to dimensions

shown on pages 23-26. The panels will

slide into the frame on the doors

and grille.

IMPORTANT NOTE: Maximum custom panel

thickness must not exceed 1-1/8" thick and

70 Ib for Fresh Food door, 30 Ib total for

Freezer door and 15 Ib for Grille panel.

33

Page 34

Installation Instructions

CONNECT WATER SUPPLY

Check to make sure that Master Power

switch is in the O (OFF) position,

I

• Locate and bring GE SmartConnect T'_tubing

to the front of the cabinet.

• Turn the water on to flush debris from line.

Run about a quart of water through tubing

into a bucket, then shut off water.

TURN ON THE POWER

• Set the Master Power switch to the I (ON)

position.

• Check to make sure power to refrigerator is

on by opening refrigerator door to see if

interior lights are on.

Master

PowerSwitch

• The temperature controls are preset at 37°

for the Fresh Food section and 0° for the

Freezer section.

• Allow 24 hours to stabilize before making

adjustments.

Water Filter

Copper Tubing

• Slip a 1/4" nut and ferrule onto end of

copper tubing. Insert tube into the union

fitting on the unit and tighten nut to union.

• Turn on the water to check for leaks.

GE SmartConnect TM Tubing

• Insert the molded end of the tubing into

the refrigerator connection. Tighten the

compression nut until it is just hand tight.

• Tighten one additional turn with a wrench.

Overtightening can cause leaks.

• Turn on the water to check for leaks.

Note: Make sure excess tubing length does

not interfere with toekick installation.

34

Page 35

Installation Instructions

START ICEIVIAKER

Switch

}reenPowerLight

• Flip the switch to I (ON). The icemaker will

begin operation automatically.

• Make sure nothing interferes with the

sweep of the feeler arm.

• Discard the first full bucket of ice cubes.

• To turn the icemaker off, set the switch to

0 (OFF}.

iNSTALL TOEKICK

• Locate the supplied toekick (shipped taped

to the top of the refrigerator). Install with

2 screws provided.

SuppliedT0ekick

__3 =======m_-W_"

%

• The vented toekick must remain unobstructed

for proper air flow.

DOOR ALIGNMENT

• Stand back from the refrigerator to inspect

the door alignment.

• Shipping or the addition of heavy door

panels may have caused the doors to move

slightly out of alignment.

Clockwise

• If necessary, the Fresh Food door may

be adjusted up or down to align with the

Freezer door.

• Loosen the leveling mechanism.

• Use a 7/32" wrench to adjust the hinge pin

as shown.

• Tighten the leveling mechanism.

iMPORTANT NOTE: After the unit has been

leveled, if the fresh food door is higher than

the freezer door, adjust the front right leveling

leg lower to align the doors and, if required,

raise the left leveling leg to level the unit side

to side.

35

Page 36

Normal operatingsounds.

Newer refrigerators sound different from older refrigerators.

Modem refrigerators have more features and use newer

technology.

Do you hear what I hear? These sounds are normal

HUMMM...

--WHOOSH...

• The new high efficiency conq)ressor may Hm taster

and hmger than your old refl'igerator and you mav

hear a high-pitched hum or pulsating sotmd while

it is operating.

• You mav hear a whooshing sotmd when the doors

close. This is due to pressm'e equalizing within

the refl'igera tot.

CLICKS, POPS,

CRACKS and CHIRPS

• You may hear cracking or popping sounds when the

refl'igerator is first plugged in. This hai)pens as the

refl'igerator cools to the correct temperature.

• The compressor may cause a clicking or chiq)ing

sotmd when attempting to restart (this could take

up to 5 minutes).

• The electronic control board may cause a clicking

sound when relays activate to control refl'igerator

COIl/poileiltS,

• Expansion and contraction of cooling coils during

and after defrost can cause a cracking or I)oI)ping

SOtlnd.

• After an icemaking cycle, you may hear the ice cubes

dropping into the ice bucket.

WHIRl

• You may hear the tans spinning at high speeds.

This happens when the refrigerator is fiI_t plugged

in, when the (loo_ are opened ti'equently or when

a large ai//Otlilt of tood is added to the refrigerator

or fl'eezer compartments. The tans are helping to

maintain the correct temperatm'es.

• If either door is open fl)r over 3 minutes, you may

hear the rims come on in order to cool the light

bulbs.

• The rims change speeds in order to provide optimal

cooling and energy savings.

WATERSOUNDS

6

• The flow of refl'igerant through the fl'eezer cooling

coils may make a gm'gling noise like boiling water.

• Water dropping on the defl'ost heater can cause a

sizzling, popping or buzzing sotmd dm'ing the

defl'ost cycle.

• A water dripping noise may occur during the defl'ost

cycle as ice melts fl'om the evaporator and flows into

the drain pan.

• Ch)sing the door may Catlse a gurgling sound dtle to

pressure equalization.

36

Page 37

Troubleshootingtips.., ge.com

Troubleshooting -tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

Possible Causes What To Do

Refrigerator does not Refrigerator in defrost cycle. * _,%fit about 30 minutes for defl'ost cxcle to end.

Master power control set to OFF. * Set the control to an on, _.

Refrigerator is unplugged. * Push the I)lu"_ COlnpletelv, into the outlet.

The fuse is blown/cireuit * Replace fllse or reset the breaker.

breaker is tripped.

The refrigerator is in * Unplug the refrigerator, and [)lug, it back in.

showroom mode.

Vibrationorrattling Refrigerator is not level. * See Level refrigerator

(slight vibration • See Ooor alignment.

is normal)

Motor operates for Normal when refrigerator * _,_dt 24 hems for the refl_gerator to completel}

long periods or cycles is first plugged in. cool down.

onandofffrequently.

(Modern refrigerators Often occurs when large • This is mmnal.

withmom storage

mnom_ts of food m'e

space anda larger placed in refrigerator.

freezer require more Door left open. • Check to see I

if )ackaoe is holding door open.

operatingtime,They

start and stop often Hot weather or frequent * This is n(mnal.

tomaintaineven door opmmlgs.

temperatures.) Temperature controls * See About the temperaturecontrols.

set at the coldest

setting.

Refrigeratororfreezer Telnperature control not set • See About the temperaturecontrols.

compartmenttoowarm cold enough.

Waacm weather or frequent * Set the temperatm'e control one step col(le_:

door openings. See About thetemperaturecontrols.

Door left open. * Check to see if I)ackage, is holding door open.

setting

onfrozenfood

if )acka_*e is holding door open.Frostorice crystals Door left open. * Check to see I

(fromwithinpackage Too frequent or too long

isnormal) door openhlgs.

Divider between Automatic energy saver • This helps prevent condensation on the outside.

refrigerator and freezer sTstem circtdates warm

compartments liquid around front edge

feels warm o f freezer compartment.

Automaticicemaker lcemaJ_er power switch • Set the power switch to the on position.

does not work is ha the off position.

Water supply tttnaed off or • See Install water line.

not commcted.

Freezer compartment * _'%fit 24 houls for the reflJgerator to colnpletel}

too warm. cool do_,Vll.

Piled up cubes in the storage • I,exel cul)es 1)x hand.

bin cattse the icema_ker

to shut off.

i ii ii iii ii iii ii ii ii ii

iiiiiiiii

Ice cubes stuck in icemaker.

(Green power light on

icema_ker blinking).

• Turn off the icemakex, remove cubes and turn the

iceulaker back on.

,37

Page 38

Troubleshootingtips...

,!_ii(i i (_ Possible Causes What To Do

Frequent "buzzing"sound Icemaker power s_vitch is in the * _Settile ])ower ,s_itch to the 0 (off)}_osition.... Keel_ing, it

I (On)position, but the water supply in tile I (on) position \_ill dmnage tile \_ater _dve.

to the refrigerator has not been

commcted.

Ice cubes have odor/taste Ice storage bin needs clemfing. * Empty and wash bin. Discard old cubes.

Food lrmlsmitfng odor/taste * Vfi'ap foods \_ell.

to ice cubes.

Interior of refrigerator * See Careandcleaning,

needs clemfing.

Smallorhollowcubes Water filter clogged. * Replace filter cartridge with l/e\v cartridge or with plug.

Slowice cubefreezing Door left open. * Check to ,see if })ackage,is holding, door o}.)en

Temperature conlrol not set * See About the temperaturecontrols.

cold enough.

Cube dispenser does not work Icemaker turned off or * Turn on icemaker or water suppl}_

water supply turned off.

An item is blocking or has fallen into * Remo_e am, item that might be blocking, or has fldlen into,

the ice chute htside the top door the chute.

bin of the freezer.

Ice cubes are frozen to * Remo_e cubes.

iceraaker feeler arm.

Irregular ice clumps in * Break up with fingertip pressure and discard remaining clumps.

storage container. * Freezer me} be too \wren. Adjust the ti'eezer control to a

colder setting, one position at a time, until chunps do not fonn.

Dispextser is LOCKED. * Press and hold the LOCKbuttonfbr 3 seconds.

Waterhaspoortaste/odor Water dispenser has not been * Dis})euse \_ater until all \_ater in s)stem is replenished.

used for a long lime.

Water in firstglass is warm Normal when refrigerator * _Aait24 houl_ for the refl'igerator to completely cool do\re.

Water dispenser does Water supply line turned *See Install waterline.

network off or not comlected.

is first htstalled.

Water dispe_tser has not been * Dispeuse \_ater until all \_ater in system is replenished.

used for a long lime.

Water system has been drained. *A1]o_ se\eral hours fbr replenished supply to chill.

Water filter clogged. * Replace filter cartridge or remove filter and install phtg.

Air may be trapped in the water system. * Press the dispenser ann for at least two minutes.

Dispextser is LOCKED. * Press and hold the LOCKbuttonfor 3 seconds.

Refrigemtorcontmlsetthtgistoocold. " Set toa\_armersetdng.

Waterspurtingfrom Newly-htstalled filter carlridge. * Run \rater thim the dispenser fi)r 3 minutes (about

dispenser ()lie and a half g_,dhms).

Waterisnotdispensed Water in reservoir is frozen. * (:all filr sex_ice.

buticemakerisworking Refrigerator control setf_tg is too cold. * Set to a \_armer settfilg.

No water orice cube production Supply line or shutoff valve is clogged. * (:all a plumber,

Water filter clogged. * Replace filter cartridge or remove filter and install plug.

Dispe_tser is LOCKED. * Press and hold the LOCKbuttonfor 3 seconds.

CUBEDwasselectedbut Lastset_lg wasCRUSHED.

CRUSHEDwasdispensed

• A fe\_ cubes \_ere left in the crasher th)m the })re\ious

settin )"This isnormal.

' m

38

Page 39

Possible Causes What To Do

Orange glow in Defrost heater is on. * This is nominal.

Refrigerator has odor Foods trmasntitthag * Foods with strong odox_ should be tightly wrapped.

odor to refrigerator. * Keep an open box of baking soda in tile refi-igerator;

replace every three months.

Interior needs clemlhag. * See Care and cleaning.

Door not closing properly Door gasket on hinge side * _ll4'_ )lx',l)araitin wax to tile tilce of tile ,gasket' .

sticking or folding over.

A door bin is hitting a shelf * Move tile door bin up one position.

inside the refrigerator.

Refrigerator is not level. * See Level refrigerator.

• See Door alignment.

Moisture forms on Not unusual durhag • Wipe suriil('e dry.

outside of refrigerator periods of high humidity.

Moisture collects inside Too frequent or too

(in humid weather, air long door openhags.

carries moisture into

refrigerator when doors

are opened)

ge.com

Interiorlightdoes No power at outlet. • Replace tUse or reset tile breaker:

not work

Water on kitchen flooror Cubes jmnmed ha chute. • Poke ice through with a wooden spoon.

on bottom offreezer

Hot air from top Normal air flow cooling motor.

of refrigerator ha the refrigeration process, it is

Refrigerator never Adaptive defrost keeps • This is nominal. Tile refrigerator will cycle off after tile

shuts off, butthe compressor rtumhag during door remains closed for 2 hl)u_.

temperatures are OK door openings.

Refrigerator beeping Door open. • Clt)se (_It)()r

Actual temperature not Ulfit jttst plugged ha. • _dlow 24 hotH_ for system tl) stabilize.

equal to Set temperature

Light bulb burned out. • See Replacing the light bulbs.

normal that heat be expelled ha

the area above the refrigerator.

Door open for too long. • _dlow 24 hotn_ tbr system to stabilize.

Warm food added to refrigerator. • _dlow 24 horns tor system to stabilize.

Defrost cycle is ha process. • _dlow 24 hotn_ t6r system to stabilize.

39

Page 40

CUSTOMER WARRANTY

(forcustomersin Canada)

Yourrefrigeratoriswarrantedto befree ofdefectsin materialandworkmanship.

Whatis covered HowLongWarranted Parts Labour

(FromDateofSale) Repairor Replace

at Camco'sOption

Compressor GEProfile:Ten(10)Years GEProfile:Ten(10)Years GEProfile:Five(5)Years

SealedSystem(including GEProfile:Five(5)Years GEProfile:Five(5)Years GEProfile:Five(5)Years

evaporator,condenser GEandAll Other GEandAll Other GEandAll Other

tubingand refrigerant) Brands:One(1)Year Brands:One(1) Year Brands:One(1)Year

All OtherParts One(1)Year One(1)Year One(1)Year

TERMS AND CONDITIONS:

Thiswarrantyappliesonlyfor singlefamilydomesticusein

CanadawhentheRefrigeratorhasbeenproperlyinstalled

accordingtothe instructionssuppliedbyCamcoandis

connectedto an adequateandproperutilityservice.

Damageduetoabuse,accident,commercialuse,andalteration

or defacingoftheserialplatecancelsallobligationsofthis

warranty.

Serviceduringthis warrantyperiodmustbe performedbyan

AuthorizedCamcoServiceAgent.

NeitherCamconortheDealerisliableforanyclaimsor

damagesresultingfromfailureof theRefrigeratororfrom

servicedelaysbeyondtheirreasonablecontrol.

Toobtainwarrantyservice,purchasermustpresenttheoriginal

BillofSale.Componentsrepairedorreplacedarewarranted

throughtheremainderoftheoriginalwarrantyperiodonly.

Thiswarrantyisextendedtotheoriginalpurchaserandany

succeedingownerforproductspurchasedforhomeusewithin

Canada.Inhomewarrantyservicewillbeprovidedinareas

whereit isavailableanddeemedreasonablebyCamcoto

provide.

Thiswarrantyis inadditionto anystatutorywarranty.

GEandAll Other GEandAll Other GEandAll Other

Brands:One(1)Year Brands:One(1) Year Brands:One(1)Year

WHAT IS NOT COVERED:

• Owneris responsibleto payforservicecallsrelatedto

productinstallationand/orteachinghowtousetheproduct.

• Damagetofinish mustbereportedwithin48 hoursfollowing

thedeliveryoftheappliance.

• Damagetofinishafterdelivery.

• Improperinstallation--properinstallationincludesadequate

air circulationtotherefrigerationsystem,adequateelectrical,

plumbingandotherconnectingfacilities.

• Replacementof housefusesor resettingof circuitbreakers.

• Replacementof light bulbs.

• Damageto productcausedbyaccident,fire,floodsoracts

of God.

• Lossoffoodduetospoilage.

• Properuseandcareofproductaslistedin theowner's

manual,propersettingofcontrols.

• Productnotaccessibleto providerequiredservice.

• WARRANTORISNOTRESPONSIBLEFORCONSEQUENTIAL

DAMAGES.

EXCLUSIONOFIMPLIED WARRANTIES--Your sole and exclusive remedy is product repair asprovided in this Limited

Warranty.Any implied warranties, including the implied warranties of merchantability orfitness for a particular purpose,

are limited toone year or the shortestperiod allowed by law.

IMPORTANT

Keep this warranty and your bill of sale as proof of original purchase and purchase date.

Please have serial number and model number available when calling for service.

CamcoServiceis availablecoastto coast.If further help is

neededconcerningthis warranty,contact:

Manager,ConsumerRelations

CamcoInc.,ConsumerService

1 FactoryLane,Suite 310

Moncton,NewBrunswickE1C9M3

1.800.361.3400

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

40

11

under the warrant_

Page 41

RefrigeratorWarranty. (forc.sto.,ersi,,theU,itedstates)

Aft warranty service provided by our Factory Service Centers,

or an authorized Customer Care® technician. Toschedule service,

on-line, 24 hours a day, visit us at ge.com, or call 800.GE.CARES

(800.432.2737).Please have serial number and model number

Staple your receipt here.

Proofof the original purchase

date is needed to obtain service

under the warrant}<

available when caring for service.

For ThePeriod Of." GE Will Replace:

GEandGEPROFILEMODELS:

OneYear Anypartof the reti_igerator which fifils due to a (lele(t in materials or wor!unanship.

Fromthedateof the During this limited one-year warranty,GE will also pr(wide, free of charge, all labor and

originalpurchase related service to replace the defective part.

ThirtyDays

(Waterfilter,if included)

Fromtheoriginal

purchase dateof

therefrigerator

GEPROFILEMODELSONLY'.

FiveYears

(GEProfilemodelsonly)

Fromthedateof the

originalpurchase