GE Pro Elite 268-716-150-1248, Pro Elite 268-716-200-1248, Pro Elite 268-716-100-1044 Operation Manual

Pro Elite™ Professional Series

Water Treatment System by GE

Operation Manual

Pro Elite Analyzer

Table of Contents

Performance Data Sheet .............................................................................................................................................................3

How To Use This Manual .............................................................................................................................................................4

Safety Information ........................................................................................................................................................................4

Valve Layout ....................................................................................................................................................................................5

Analyzer Control Layout .............................................................................................................................................................5

System Specications 716 ..........................................................................................................................................................5

Location Selection ........................................................................................................................................................................6

Outdoor Locations ........................................................................................................................................................................6

System Features .............................................................................................................................................................................7

Equipment Installation ................................................................................................................................................................8

Water Line and Bypass Connections ................................................................................................................................... 11

Drain Line Connection .............................................................................................................................................................. 12

Regenerant Line Connections ............................................................................................................................................... 12

Overow Line Connection ...................................................................................................................................................... 13

Electrical Connection ................................................................................................................................................................ 13

System Operation ....................................................................................................................................................................... 14

Cycle Water Flows ....................................................................................................................................................................... 14

Camshaft Cycle Positions .........................................................................................................................................................15

Valve Disc Location/Function ................................................................................................................................................ 15

Disinfection of Water Conditioning Systems .................................................................................................................... 16

Displays, Icons and Cursors .....................................................................................................................................................17

Button Functions ........................................................................................................................................................................ 17

Programming Overview .......................................................................................................................................................... 18

Analyzer Control Operation ....................................................................................................................................................18

Level I Programming ................................................................................................................................................................. 18

Level l Programming - Analyzer Conditioner .................................................................................................................. 19

Level II Programming – P Values .......................................................................................................................................... 20

Programming the Lockout Feature ...................................................................................................................................... 20

Level lll Cycle Programming – C Values .............................................................................................................................. 21

Level IV Viewing History - H Values ...................................................................................................................................... 22

Program Reset ............................................................................................................................................................................. 22

Placing 268 Water Conditioning System Into Operation (Fill Brine Tank Last) ..................................................... 23

Placing 268r Water Conditioning System Into Operation (Fill Brine Tank First) ................................................... 24

The Water Conditioning System is Now Fully Operational. ......................................................................................... 25

Manual Regeneration Options .............................................................................................................................................. 26

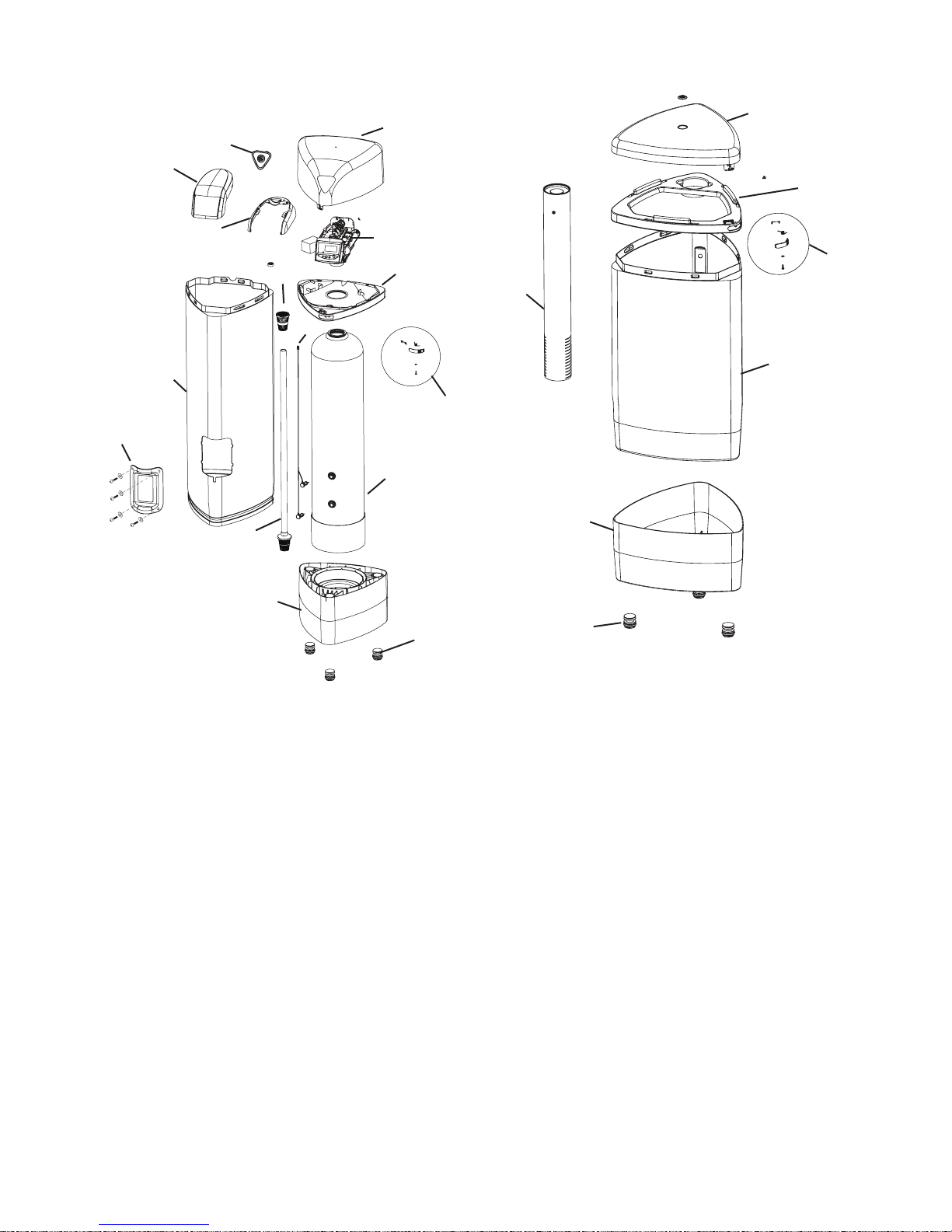

Pro Elite Valve - Exploded View and Parts List .................................................................................................................. 27

Conditioner Tank and Regenerant Tank Assembly - Exploded View and Parts List ............................................ 29

Brine Well Assembly - Exploded View and Parts List ..................................................................................................... 31

Troubleshooting ......................................................................................................................................................................... 32

2

Performance Data Sheet

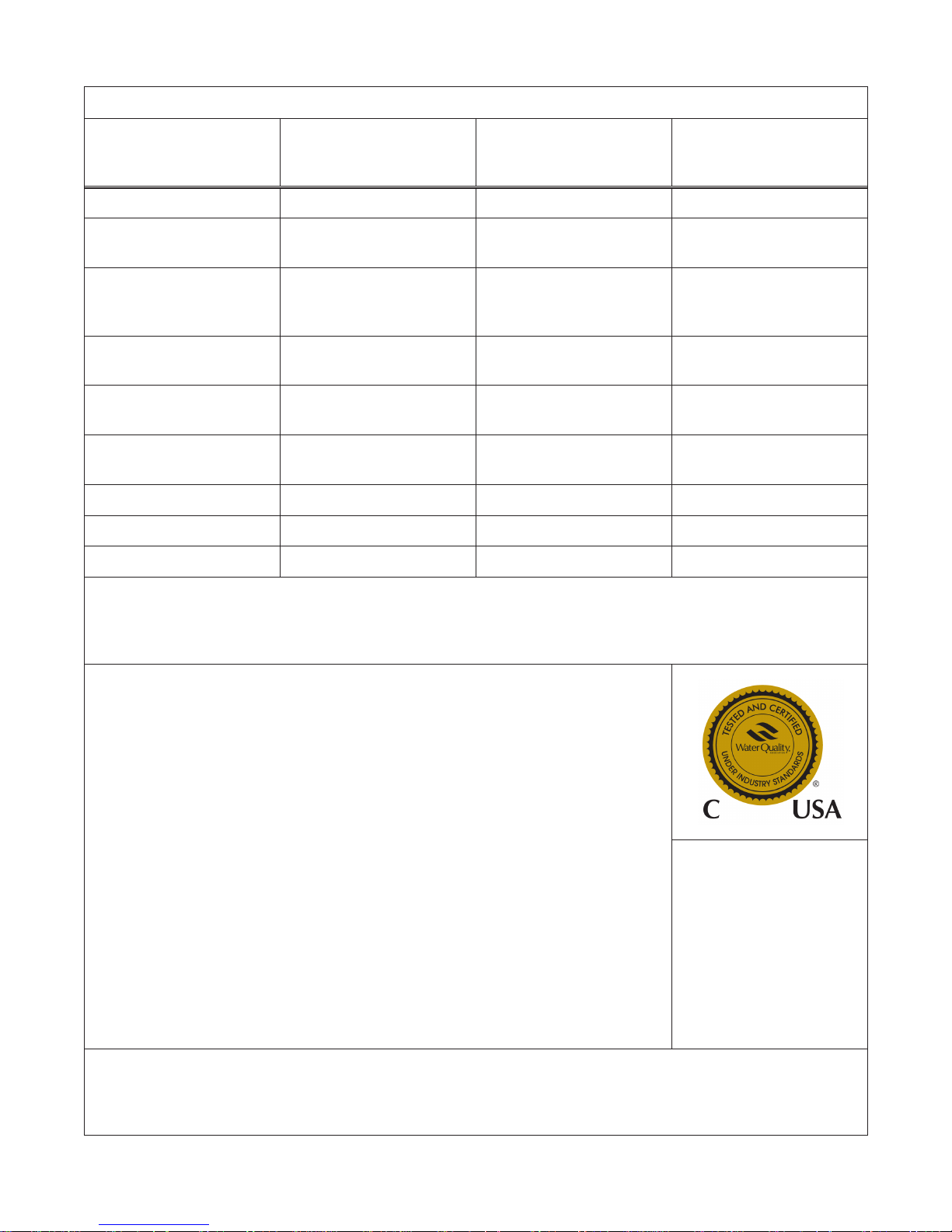

Pro Elite Analyzer Water Softener System Performance Data Sheet

Model Pro Elite

268-716-100-1044

Analyzer

Pro Elite

268-716-150-1248

Analyzer

Pro Elite

268-716-200-1248

Analyzer

Rated Service Flow (gpm) 8.0 13.0 15.0

Pressure Drop at Rated

Service Flow Rate (psi)

Rated Capacity

(grains @ lb of salt)

Rated Eciency

(grains/lb Salt @ lb of salt)

Maximum FLow Rate

During Regeneration (gpm)

10% Cross Linked Ion

Exchange Resin (cu ft)

4,033 grains/lb @ 3.3 lbs 4,045 grains/lb @ 4.95 lbs. 4,325 grains/lb @ 6.6 lbs

5.5 9.5 14.4

13,309 @ 3.3 lbs

26,327 @ 9.0 lbs

31,682 @ 15.0 lbs

20,023 @4.95 lbs

39,609 @ 13.5 lbs

47,665 @ 22.5 lbs

5.5 5.5 5.5

1.0 1.5 2.0

28, 548 @ 6.6 lbs

56,472 @ 18.0 lbs

67,958 @ 30.0 lbs

Tank Size 10" x 44" 12" x 48" 12" x 48"

Backwash - GPM 2.7 3.9 3.9

Rapid Rinse/Purge - GPM 5.5 5.5 5.5

Operating Pressure: 20-125 psi or 1.4-8.8 kg/cm2, Operating Temperature: 34-110°F or 1.1-43.3°C

Acceptable Salt Type: Sodium Chloride - Pellet salt

All Systems above tested at 35 psi ±5 psi, pH of 7.5 ±0.5, Capacity Testing Flow Rate = 50% of the rated service ow

rate for the various size systems.

These water softener systems have been tested by WQA and conform to NSF/ANSI 44 for specic

performance claims as veried and substantiated by test data. The rated salt eciencies above were also

determined in accordance with NSF/ANSI 44 and are only valid at the salt dosage referenced above. An

eciency rated water softener is a demand initiated regeneration (DIR) softener which also complies with

specic performance specications intended to minimize the amount of regenerant brine and water used

in its operation. Eciency rated water softeners shall have a rated salt eciency of not less that 3350

grains of total hardness exchanged per pound of salt (based on NaCl equivalency) (477 grams of total

hardness exchanged per kilogram of salt), and shall not deliver more salt than its listed rating. The rated

eciency of the water softener, the salt dosage at that eciency, the capacity at that salt dosage and

that of the eciency is only valid at the stated salt dosage. Eciency is measured by a laboratory test

described in NSF/ANSI 44. The test represents the maximum possible eciency the system can achieve.

Operational eciency is the actual eciency achieved after the system has been installed. It is typically

less than the eciency due to individual application factors including water hardness, water usage, and

other contaminants that reduce the water softener’s capacity. These systems are not intended to be used

for treating water that is microbiologically unsafe or of unknown quality without adequate disinfection

before or after the system. Refer to the system Installation and Service Manals for set-up and programming

instructions.

Contact your local dealer for parts and service. See your owner’s manual for warranty information.

Iowa Requirement:

Seller: _________________________________________ Date: ______________________

Buyer: _________________________________________ Date: ______________________

12/4/13

Tested and Certied by

the WQA to NSF/ANSI

Standard 44 & 372 for

softener performance &

lead free compliance and

CSA B483.1.

PENTAIR Residential Filtration, LLC

5730 North Glen Park Road

Milwaukee, Wisconsin 53209

PHONE: (262) 238-4400

3

How To Use This Manual

This installation manual is designed to guide the installer

through the process of installing and starting water

conditioning systems featuring Pro Elite equipment.

This manual is a reference and will not include every

system installation situation. The person installing this

equipment should have:

• Training in the Pro Elite Demand systems.

• Knowledge of water conditioning and how to

determine proper control settings.

• Adequate plumbing skills and qualications per local

and state laws, codes, and ordinances.

Icons That Appear In This Manual

not use an O-ring seal. Do not use pipe dope type

sealants on the valve body. Do not use pliers or

pipe wrenches.

• Do not use petroleum-based lubricants such as

Vaseline, oils, or hydrocarbon-based lubricants. Use

only 100% silicone lubricants.

• Use only the power transformer supplied with this

water conditioning system.

• All electrical connections must be completed

according to local codes.

• The power outlet must be grounded.

Install an appropriate grounding strap across the inlet and

outlet piping of the water conditioning system to ensure

that a proper ground is maintained.

WARNING: Failure to follow this

instruction can result in personal injury or

Note: Helpful hint to simplify procedure.

damage to the equipment.

Safety Information

• Observe all warnings that appear in this manual.

• Please review the entire Installation and Operation

Manual before installing the water conditioning

system.

• As with all plumbing projects, it is recommended

that a trained professional water treatment dealer

install the water conditioning system. Please follow

all local plumbing codes for installing this water

conditioning system.

WARNING: Excessive Weight Hazard. Use

two or more people to move and install

• System is not intended to be used for treating water

that is microbiologically unsafe or of unknown

quality without adequate disinfection before or after

the system.

• This water conditioning system is to be used only for

potable water.

• Inspect the water conditioning system for carrier

shortage or shipping damage before beginning

installation.

• Use only lead-free solder and ux, as required by

federal and state codes, when installing soldered

copper plumbing.

• Use caution when installing soldered metal piping near

the water conditioning system. Heat can adversely

aect the plastic control valve and bypass valve.

• All plastic connections should be hand tightened.

plumber tape may be used on connections that do

the conditioner. Failure to do so can result

in injury (including back injury).

WARNING: Dry location use only, unless

used with a Listed Class 2 Power Supply

• To disconnect power, unplug the AC adapter from its

power source.

• Observe drain line requirements. The drain line must

be a minimum of 1/2-inch diameter. Use 3/4-inch

pipe if the backwash ow rate is greater than 5 gpm

(19 Lpm) or the pipe length is greater than 20 feet (6

m).

• Do not support the weight of the system on the

control valve ttings, plumbing, or the bypass.

• Do not allow this water conditioning system to

freeze. Damage from freezing will void this water

conditioning system’s warranty.

• Operating ambient temperature: 34° to 120°F

(1° to 49°C).

• Operating water temperature: 35° to 100°F

(1.7° to 38°C).

• Operating water pressure range : 20 to 125 psi

(1.38 to 8.62 bar). In Canada the acceptable

operating water pressure range is 20 to 100 psi

(1.38 to 6.89 bar).

• Keep the media tank in the upright position. Do not

turn upside down or drop. Turning the tank upside

down or laying the tank on its side can cause media

to enter the valve.

• Ensure that all wiring and plumbing connections on

the mineral and brine tanks are installed correctly.

Use only regenerants designed for water conditioning. Do

not use ice melting salt, block salt or rock salt.

suitable for outdoor use.

WARNING: The valve and tank

components of this Pro Elite unit have

been assembled and tightened to the

proper factory torque specications. Over

tightening may result in improper valve,

probe and tank alingnment and may

damage the tank O-ring (PN1010154).

4

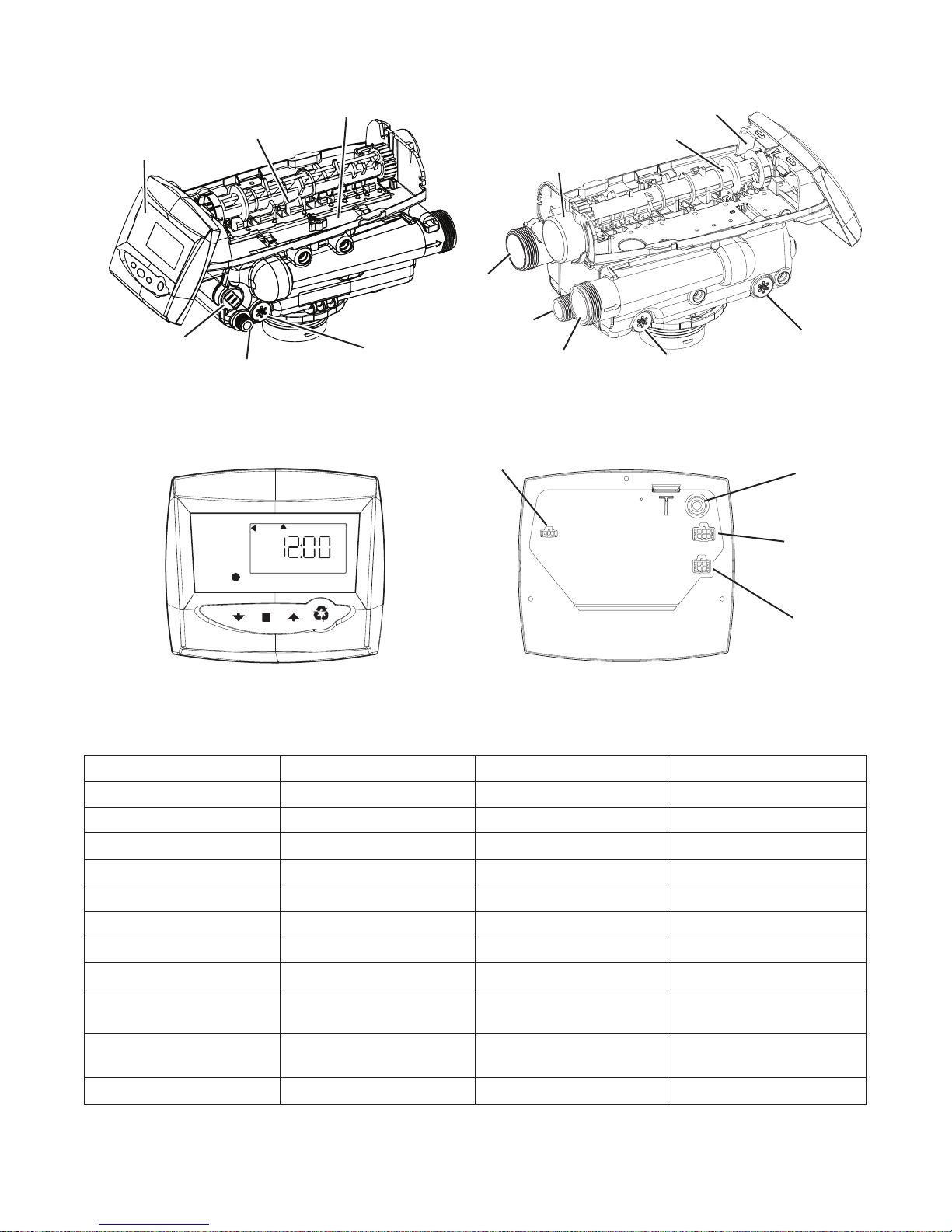

Valve Layout

Valve Discs

Analyzer Control

Rell Controller

Regenerant Tube Connection

Analyzer Control Layout

SU MO TU WE TH FR SA DAYS

Time/Day

Regeneration Time/Day

Salt Amount

Capacity

Check Salt

One Piece Valve Disc Spring

Injector and Cap

Status Light Connection

PM

Outlet

Drain

Motor

Inlet

Optical Sensor

Camshaft

Injector Screen Filter

Backwash Drain Control

AC Adapter Connection

(12 Volt Input)

Motor & Optical

Sensor Connection

Analyzer Probe

Connection

Front Back

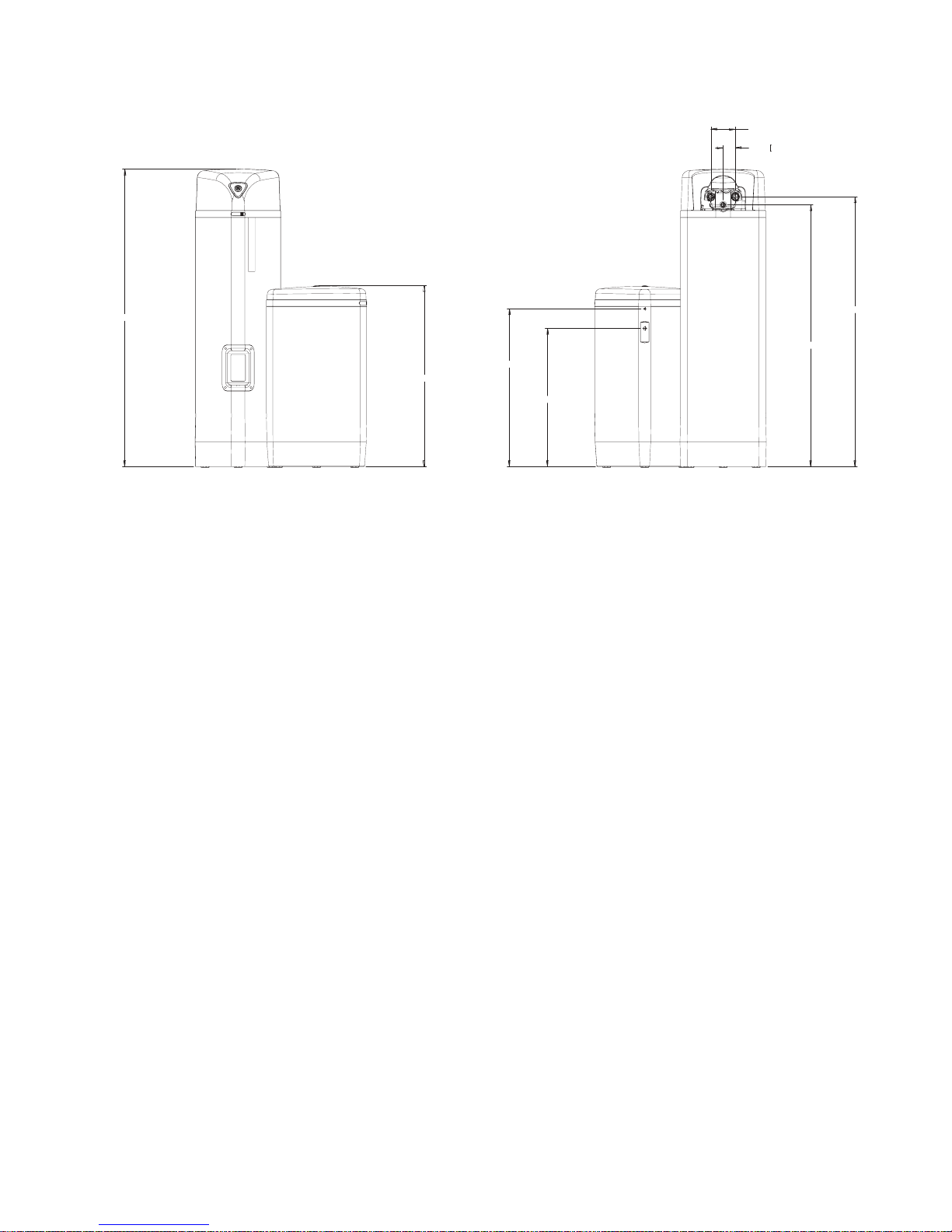

System Specications 716

Model Number 268-716-100-1044 268-716-150-1248 268-716-200-1248

Recharge Style Analyzer Analyzer Analyzer

Media Tank Size 10" x 44" (25 x 112 cm) 12" x 48" (30.5 x 122 cm) 12" x 48" (30.5 x 122 cm)

Resin Volume

Recharge (Salt) Tank Size 19" x 36" (48.3 x 91.5 cm) 19" x 36" (48.3 x 91.5 cm) 19" x 36" (48.3 x 91.5 cm)

Salt Storage 240 lbs (109 kg) 240 lbs (109 kg) 240 lbs (109 kg)

Drain Water Rate 2.7 gpm (10.2 L/m) 3.9 gpm (14.7 L/m) 3.9 gpm (14.7 L/m)

Service Connection Size 1" NPT 1" NPT 1" NPT

Drain Connection Size 3/4" NPT 3/4" NPT 3/4" NPT

Recharge (Brine)

Connection Size

Installation Space

Requirements

Shipping Weight 140 lbs (63.5 kg) 165 lbs (74.8 kg) 200 lbs (90.7 kg)

1 ft3 (0.03 m3) 1.5 ft3 (0.04 m3) 2 ft3 (0.056 m3)

3/8" NPT 3/8" NPT 3/8" NPT

21" x 42" x 72"

(53.3 x 106.6 x 182.8 cm)

21" x 42" x 72"

(53.3 x 106.6 x 182.8 cm)

21" x 42" x 72"

(53.3 x 106.6 x 182.8 cm)

5

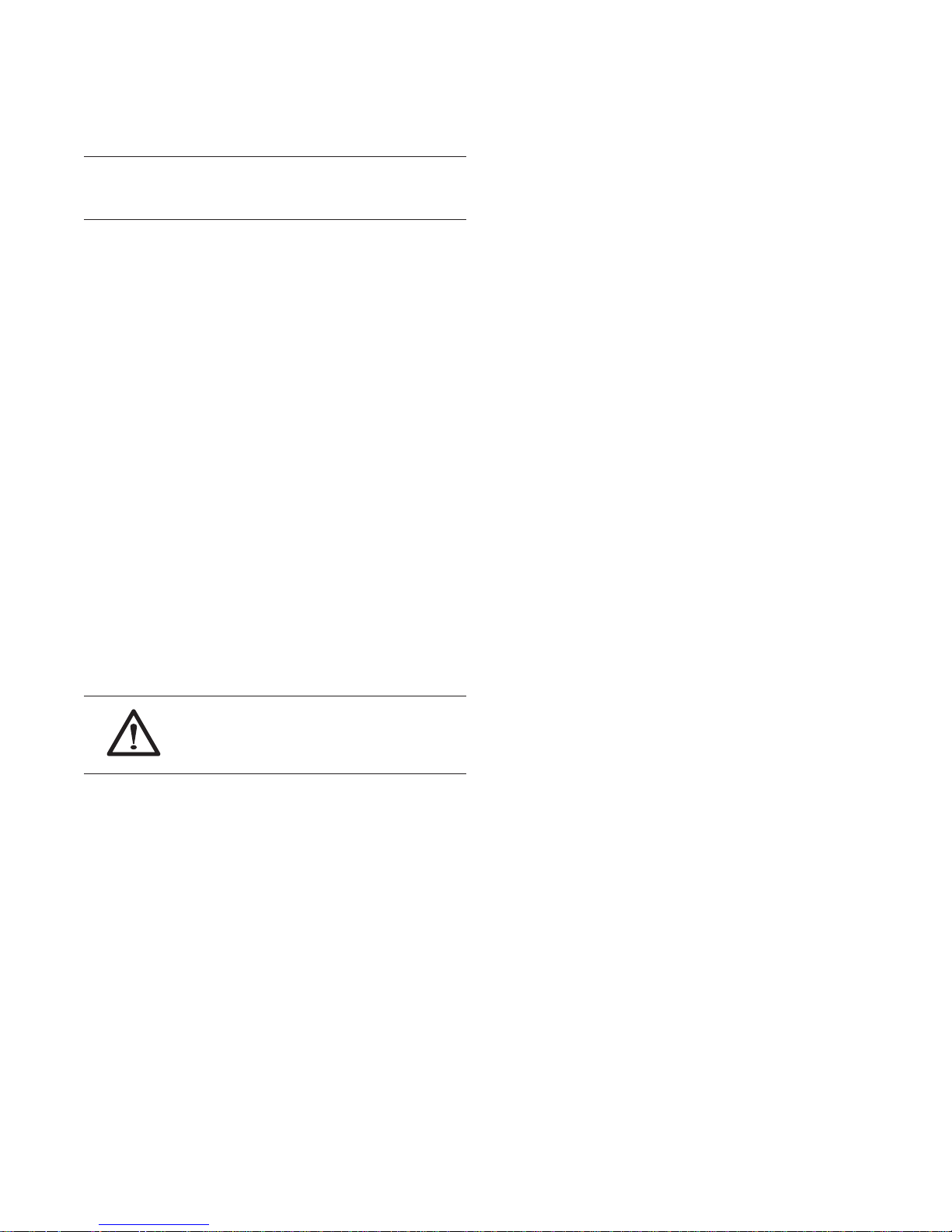

Location Selection

Location of a water conditioning system is important. The

following conditions are required:

• Level platform or oor.

Note: The Pro Elite System can be provided with optional

leveling feet that may be used on the two tanks. Order

part number 4000409.

• Room to access equipment for maintenance and

adding regenerant (salt) to tank.

• Ambient temperatures over 34°F (1°C and below

120°F (49°C).

• Water pressure below 125 psi (8.62 bar) and above

20 psi (1.38 bar).

• In Canada the water pressure must be below 100 psi

(6.89 bar).

• Constant electrical supply to operate the control.

• Total minimum pipe run to water heater of ten feet

(three meters) to prevent backup of hot water into

system.

• Local drain for discharge as close as possible.

• Water line connections with shuto or bypass

valves.

• Must meet any local and state codes for site of

installation.

• Valve is designed for minor plumbing misalignments.

Do not support weight of system on the plumbing.

• Be sure all soldered pipes are fully cooled before

attaching plastic valve to the plumbing.

WARNING: Dry location use only, unless

used with a Listed Class 2 Power Supply

suitable for outdoor use.

Outdoor Locations

It is recommended that the Pro Elite conditioner be

installed in a protected environment.

When installing the water conditioning system outdoors,

several items must be considered:

• Moisture – The valve and control are rated for

NEMA 3 locations. Falling water should not aect

performance. The system is not designed to

withstand extreme humidity or water spray from

below. Examples are: constant heavy mist, near

corrosive environment, or upwards spray from

sprinkler. Ensure that the Analyzer probe access

panel is installed on the unit.

• Direct Sunlight – The materials used will fade or

discolor over time in direct sunlight. The integrity

of the materials will not degrade to cause system

failures.

• Temperature – Extreme hot or cold temperatures

will cause damage to the valve or control. Freezing

temperatures will freeze the water in the valve. This

will cause physical damage to the internal parts as

well as the plumbing and conditioning resin. High

temperatures will aect the control. The display may

become unreadable but the control should continue

to function. When the temperature returns to

normal operating limits, the display will re-appear. A

protective cover should assist with high temperature

applications.

• Insects – The control and valve have been designed

to keep all but the smallest insects out of the critical

areas. Any holes in the top plate can be covered with

duct tape. The top cover should be installed securely

in place.

6

System Features

Brine Tank

Resin Tank

7

14

1

2

15

13

8

3

12

1

2

5

7

11

5

3

10

6

4

1 Cover

2 Cap, Cover

3 Jacket,Resin Tank

4 Base

5 268 Logix PE Valve

w/716 Control

6 Resin Tank

7 Door, Access,

Sensor

Sensors Wired

8

Probes

4

9 Foot, Leveling

10 Latch Mechanism

11 Tank Collar

12 Riser Tube

13 Upper Basket

14 Cover

15 Shield

9

1 Cover 5 Brine Tube

2 Collar, Tank 6 Foot, Leveling

3 Tank, Brine 7 Latch Mechanism

4 Base, Tank

6

Assembly

7

Equipment Installation

60.7 (1541.6)

55 (1398.1)

5.0 (127)

Dimensions

2.5 (63.5)

53.4 (1356.6)

32.2 (817.5)

36.9 (938.1)

28.2 (715.9)

8

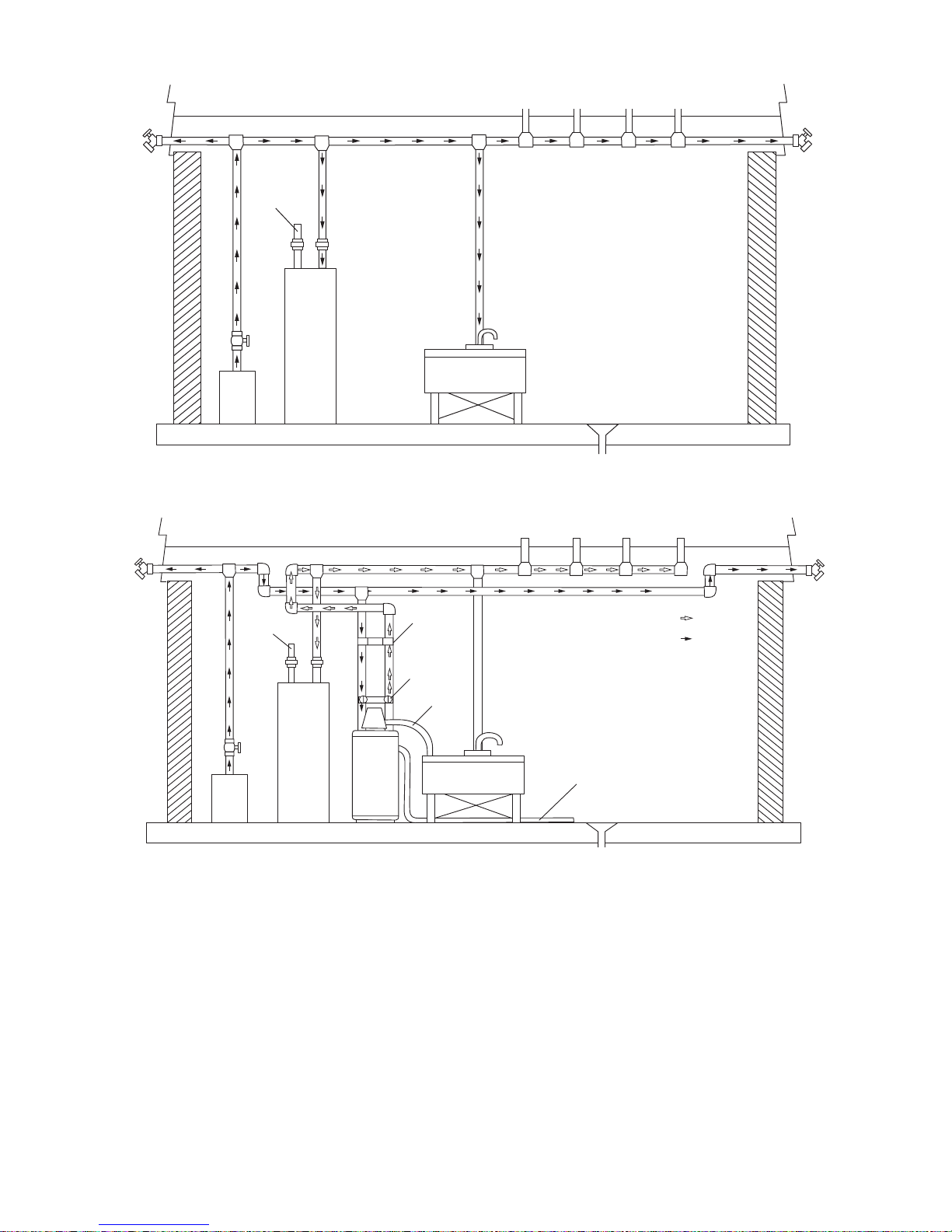

Typical System Layout

Bath TubLavatoryToilet Kitchen

Outside

Faucet

Outside

Faucet

Hot Water

Outlet

Water

Heater

Pump

Laundry Tubs

or

Meter

Floor Drain

Figure 1 Standard Basement Before Installation. Cold water lines shown.

Bath TubLavatoryToilet Kitchen

Hot Water

Outlet

Grounding

Strap

Outside

Faucet

Outside

Faucet

Soft Water

Hard Water

Pump

or

Meter

Water

Heater

Bypass

Drain Line

Softener

Laundry Tubs

Brine Tank Overow Drain

Figure 2 Softened Water Flow Diagram.

Floor Drain

9

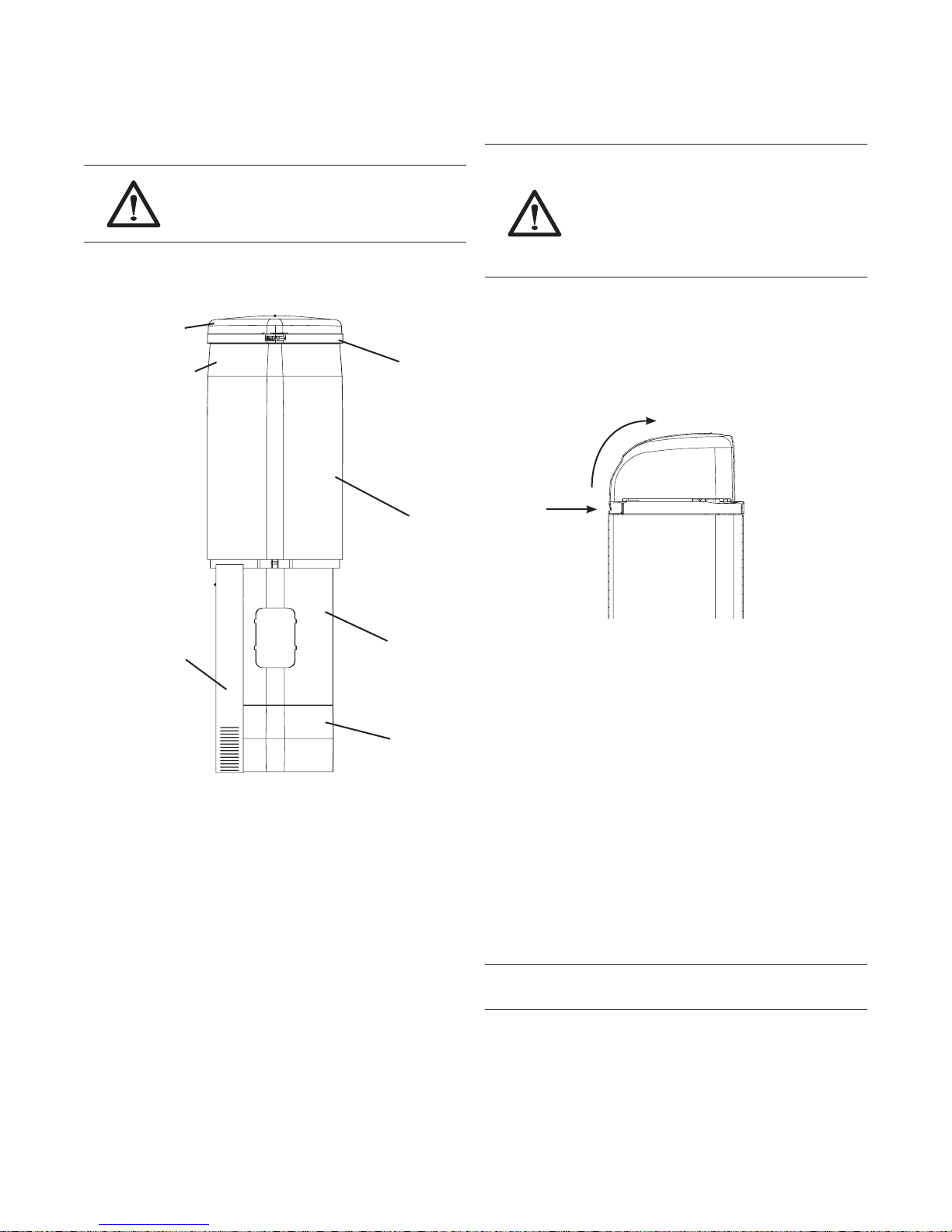

Inspection

The Pro Elite system is shipped with several parts

unassembled. When parts are removed from the packing,

they should be inspected for damage. If any parts are

damaged or missing, contact your supplier.

WARNING: When handling the media

tank do not turn it upside down or drop

When the carton is rst opened, the softener will be

standing upright. The salt tank will be turned over and

covering the softener (Figure 3).

Salt Tank Cover

Salt Tank Base

on its side.

Salt Tank Collar

Salt Tank

(Upside Down)

To Assemble the Media Tank:

1. If the oor under the media tank is uneven, the

leveling feet may be installed. Slowly lay the tank on its

side. Press or tap the feet into the pockets.

WARNING: The media tank contains

loose particles that will shift. If the tank is

turned upside down or laid back quickly,

the particles may enter the valve. If

this happens, the valve may need to be

disassembled and cleaned.

2. Stand the tank up and in position. Level as needed.

3. Remove cover by pressing in on the latch and lifting

cover (Figure 4). When the cover is removed, the valve

is visible. Remove the power adapter. They should

be secured to the tank collar near the inlet/outlet

connections.

Lift

Press in

Brine Tube

Assembly

Media Tank

(Softener)

Media Tank Base

Figure 3

To assemble the system, remove the salt tank

components (cover, collar, base and brine tube assembly)

from the shipping container. The media tank can now be

removed. Locate the miscellaneous parts bag.

To assemble the Salt Tank:

1. If the oor under the salt tank is uneven, the leveling

feet may be installed. Lay the empty salt tank on its

side. Press or tap the feet into the pockets.

2. Stand the salt tank up and in position. Level as needed.

The tank has two ports that will be connected. One to

a drain and one to the valve.

3. Place the brine tube in position inside the pocket at

the bottom of the tank. Install the overow tting.

4. Place the tank collar over the top of the brine tube.

Position the collar and push it down into the tank. Lay

the cover aside for now.

Figure 4

Tank and Probe Assembly

The probes are preinstalled to the media tank. The probes

are located behind an access panel on the jacket of the

media tank. To remove the access panel, remove the four

screws and washers.

Use only 100% silicone lubricant on the probe O-rings

(Figure 5). Do not allow the lubricant to come into contact

with the probe pins. Install the probe assemblies into the

tank and secure with the locking clasp (Figure 6).

Important: The pins on the probes will only t into the

bulkhead ttings one way. The pins must go into the

matching holes at the bottom of the tting. The probe with

the shortest length of wire must be on top.

Install the protective shield (Figure 6 ).

Note: Do not attempt to tighten or loosen the Bulkhead

ttings, as they are secured with a locking adhesive.

10

Normal Operation

In Bypass

O-ring

Probe

Probe Pins

Lubricate

Figure 5

Locking Clasp

Bulkhead

Fitting

Figure 6

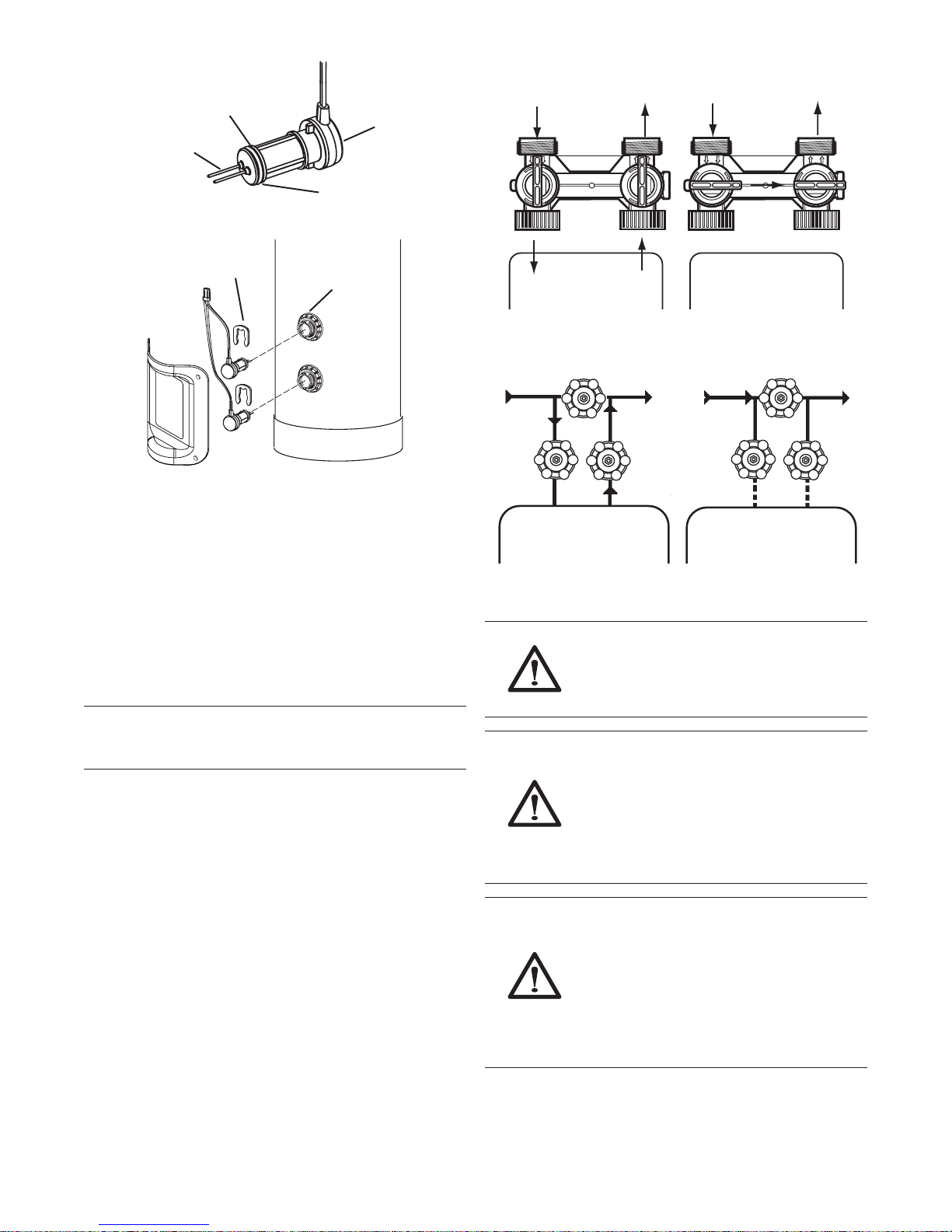

Water Line and Bypass Connections

A bypass valve system should be installed on all water

conditioning systems. A model 1265 bypass is included

with this system. The bypass valve isolates the conditioner

from the water system and provides unconditioned water

to service during routine maintenance and servicing

procedures. See Figure 7 Model 1265 Bypass (Included)

and Figure 8 Typical Three Valve Bypass Conguration

(Not provided by manufacturer).

Note: Before turning on the water to the valve, rotate

the two handles on the bypass valve 2-3 times. This will

help seat the O-rings and prevent leaking.

In

B

Y

P

A

S

S

Out

B

Y

P

A

S

S

In

A

P

S

Y

S

B

Water Conditioner Water Conditioner

Figure 7 Model 1265 Bypass (Included)

Normal Operation

Water Conditioner Water Conditioner

In Bypass

Figure 8 Typical Three Valve Bypass Conguration

(Not provided by manufacturer)

WARNING: Do not use tools to tighten

plastic ttings. Over time, stress may

break the connections. Hand tighten the

nuts.

WARNING: Do not use petroleum grease

on gaskets when connecting bypass

plumbing. Use only 100% silicone grease

products when installing any Pro Elite

brand valve. Non-silicone grease may

cause plastic components to fail over

time.

Out

A

S

S

P

Y

B

11

WARNING: The inlet water must be

connected to the inlet port of the valve.

When replacing non-Pro Elite valves,

it is possible that the inlet and outlet

plumbing is installed in a reversed

position. Ensure that the plumbing is

not installed in the opposite order. Tank

media may be pushed into the valve.

Loading...

Loading...