GE PRO AIR 107, PRO AIR I109, PRO AIR 109, PRO AIR I112, PRO AIR 218 Service Manual

...

g GE Consumer & Industrial Appliances

Service Manual & Installation Manual

Split System Air Conditioner

Model numbers:

PRO AIR 107

PRO AIR 109

PRO AIR 112

PRO AIR I109

PRO AIR I112

PRO AIR 218

GE AIR 326

GE AIR 428

—1—

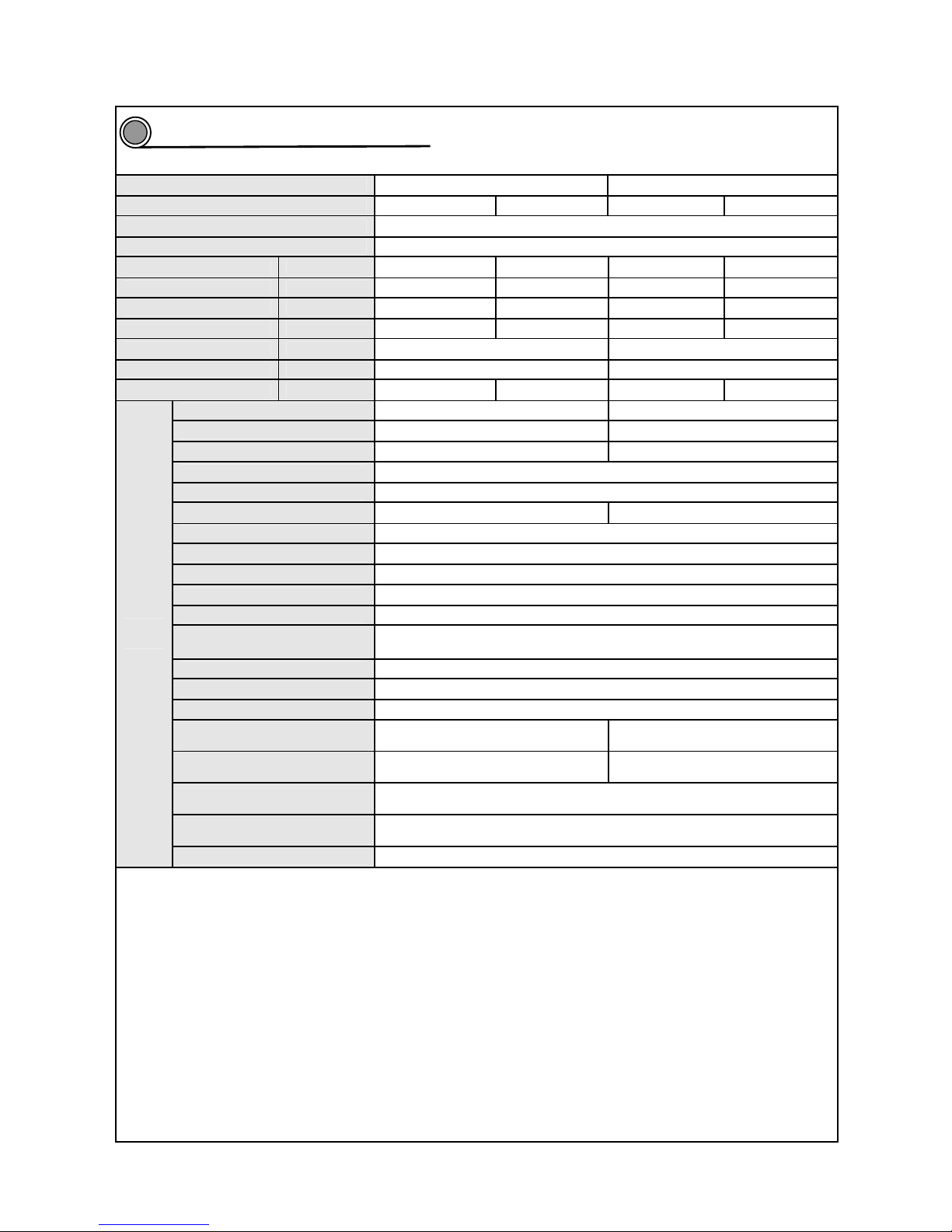

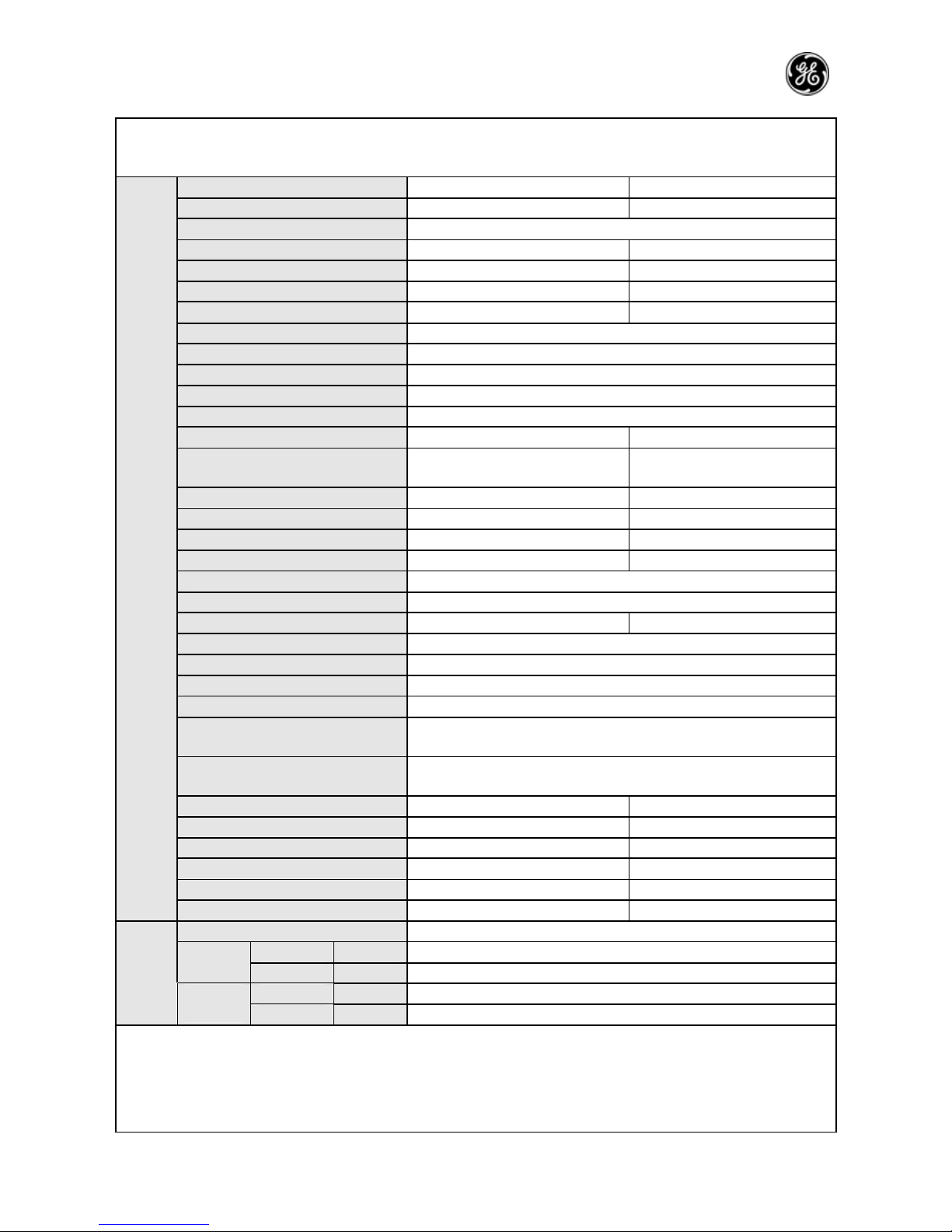

Summary and features

Model Remark

PRO AIR 107 IN / PRO AIR 107 OUT

1Ph 230V 50Hz R410A

1

—2—

Model Remark

PRO AIR 109 IN / PRO AIR 109 OUT PRO AIR 112 IN / PRO AIR 112 OUT

PRO AIR I109 IN / PRO AIR I109 OUT PRO AIR I112 IN / PRO AIR I112 OUT

1Ph 230V 50Hz R410A

—3—

Model Remark

PRO AIR 218 IN / PRO AIR 218 OUT

1Ph 230V 50Hz R410A

—4—

Model Remark

GE AIR 326 IN1 / GE AIR 326 IN2 / GE AIR 326 OUT

1Ph 230V 50Hz R407C

—5—

Model Remark

GE AIR 428 IN / GE AIR 428 OUT

1Ph 230V 50Hz R407C

—6—

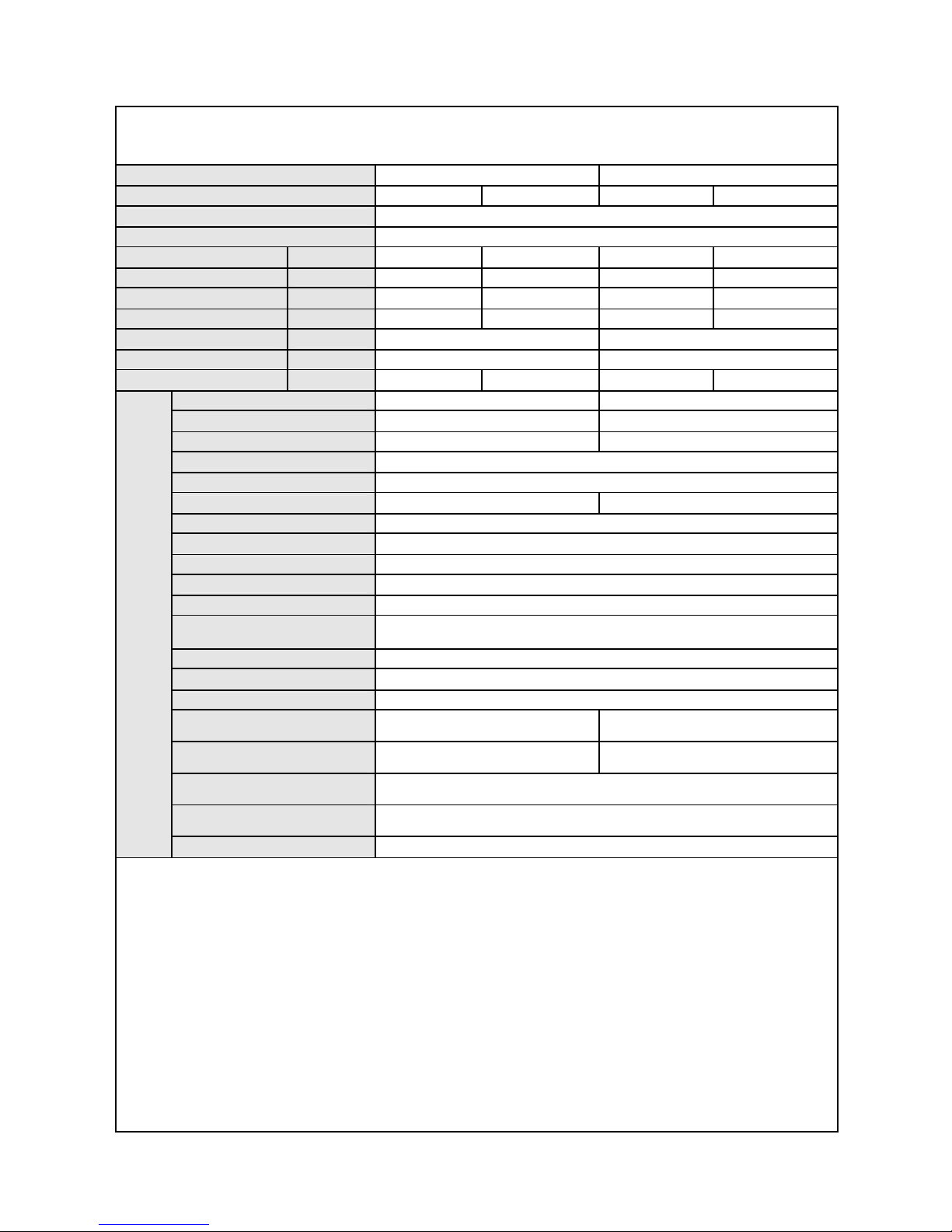

Technical and specifications

Model

PRO AIR 107 IN / PRO AIR 107 OUT PRO AIR 109 IN / PRO AIR 109 OUT

Function Cooling Heating Cooling Heating

Rated voltage 230V

Rated frequency 50Hz

Capacity (W) 2000 2200 2500 2600

Nominal power (W) 660 700 765 800

Max. power (W) 900 920 990 1050

Greatest currency (A) 4.1 4.3 4.8 5.5

Air flow (m3/h) 360 450

Dry capacity (L/h) 0.7 1.2

C.O.P/EER (W/W) 3.05 3.15 3.2 3.2

Model KFR-20G/NaA121-E KFR-25G/NaA121-E

Fan speed (r/min)(H/M/L) 1000/940/880 1160/1010/890

Output power (W) 8 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.035 0.12

Fan type-piece

Axial flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat

exchanger (I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

41/38/35

42/39/36

Noise (sound pressure level)

dB(A)

51/49/45

52/49/46

Outline dimension (W/D/H)

(mm)

770×180×250

Package dimension (W/D/H)

(mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

2

—7—

Model

PRO AIR 107 IN / PRO AIR 107 OUT PRO AIR 109 IN / PRO AIR 109 OUT

Compressor type GK080PAD C-1RV096H1A

Compressor type Rotary type

Locked rotor current 17 17

Compressor running current 3.2 3.8

Compressor input power 682 810

Compressor overload model M RA12009-12026 M RA98635-9201

Throttling method Capillary

Starting mode Capacitor CBB65 (22.5uF/450VAC)

Working temperature range -7~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.6 2-1.4

Developed area of heat exchanger

(I×H×L)

673×406×44 791×508×44

Fan motor speed (rpm) 950 830

Motor rated power (W) 20 30

Fan motor running current (A) 0.42 0.26

Fan capacitor (μf) 1.5 2

Fan type-piece /

Fan type-piece Axial flow fan -1

Fan diameter (mm) Φ320 Φ400

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of

exhaust side (Mpa)

3.8

Maximum working pressure of

exhaust side (Mpa)

1.2

Noise(sound pressure level)

dB(A)

52 56

Noise (sound pressure level)

dB(A)

62 66

Outline dimension (W/D/H)(mm) 660×260×430 848×320 ×540

Package dimension (W/D/H)(mm) 765×350×500 878×360 ×600

Net weight/gross weight (kg) 25/29 30/34

Outdoor

unit

Refrigerant/refrigerant charge (kg) R410A /0.88 R410A /1.1

Length 4

Liquid pipe (mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection pipe

Maximu

m

distance

Length (m) 10

—8—

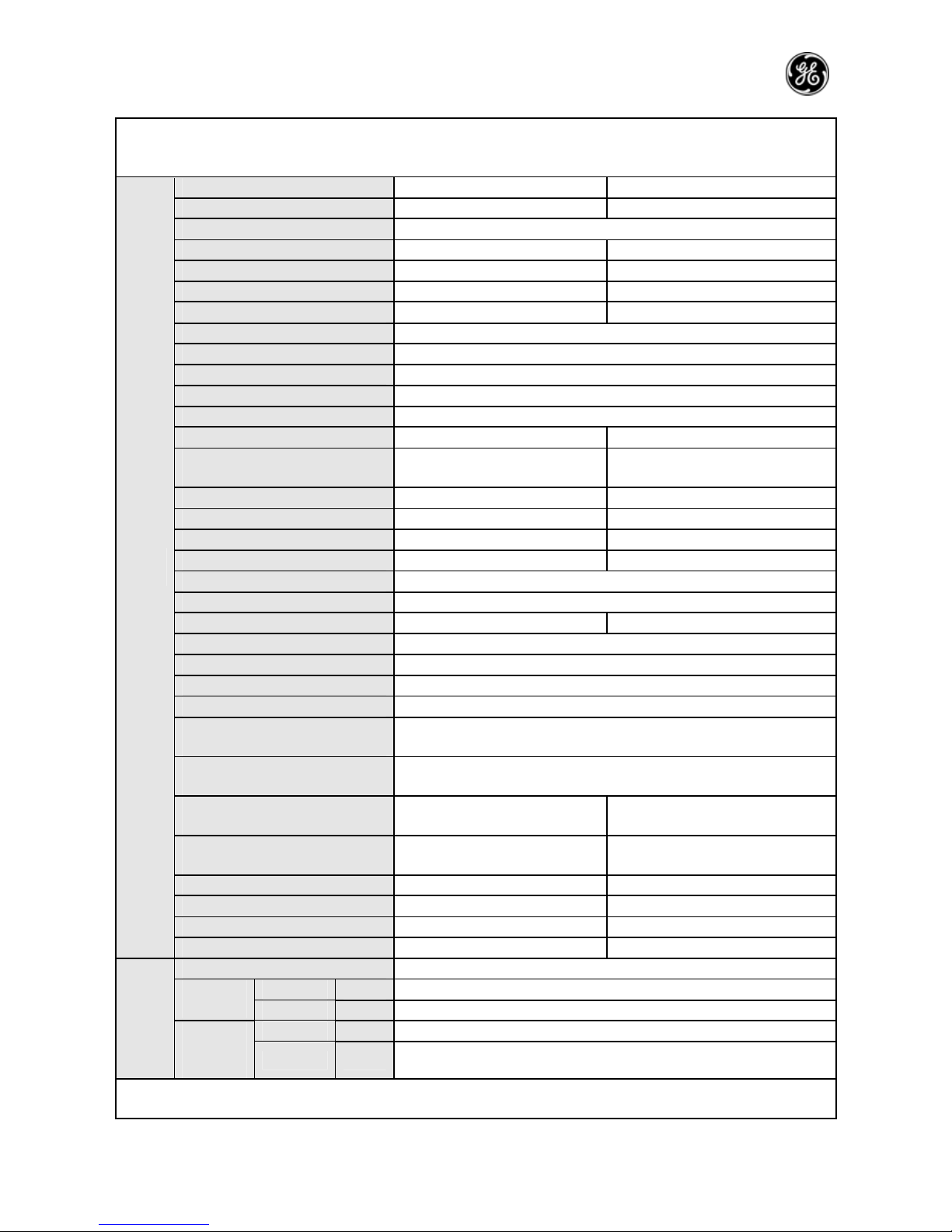

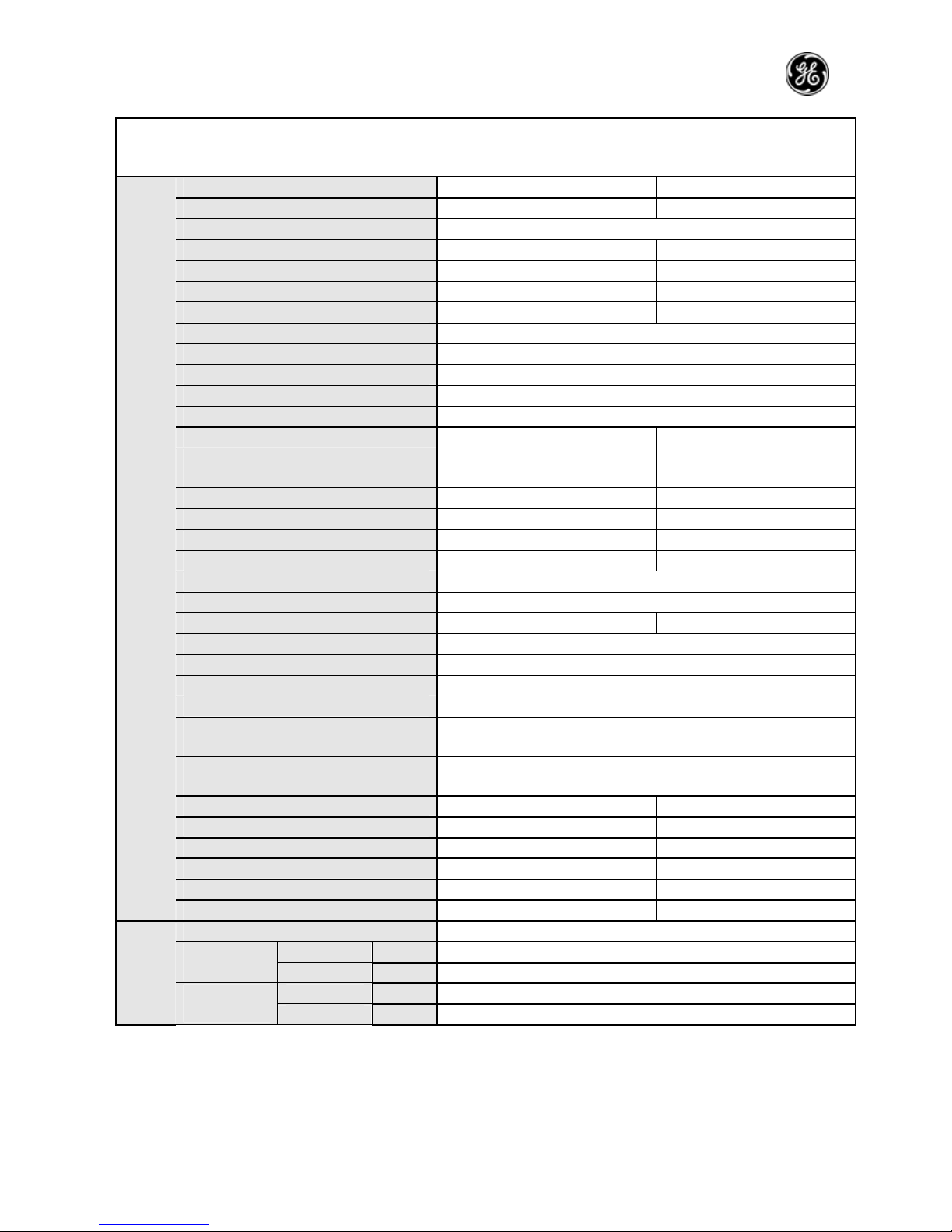

Model PRO AIR 112 IN PRO AIR I109 IN

Function Cooling Heating Cooling Heating

Rated voltage 230V

Rated frequency 50Hz

Capacity (W) 3200 3400 2500 2700

Nominal power (W) 1060 1220 730 800

Max. power (W) 1390 1370 1246 1297

Greatest currency (A) 7.2 7.4 5.7 6

Air flow (m3/h) 450 450

Dry capacity (L/h) 1.2 1.2

C.O.P/EER (W/W) 3 2.8 3.4 3.4

Model KFR-32G/NaA121-E KFR-25G/NaA12F-E

Fan speed (r/min)(H/M/L) 1160/1010/890 1190/1090/990

Output power (W) 14 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.12 0.12

Fan type-piece Cross flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat exchanger

(I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

42/39/36

42/39/36

Noise (sound pressure level)

dB(A)

52/49/46 52/49/46

Outline dimension (W/D/H) (mm) 770×180×250

Package dimension (W/D/H) (mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

—9—

Model PRO AIR 112 OUT PRO AIR 109 OUT

Compressor type C-RV133H1A EU1011DV

Compressor type Rotary type

Locked rotor current 24 33.5

Compressor running current 5.25 4

Compressor input power 1125 628

Compressor overload model B210-145-241E 4CYC11233

Throttling method Capillary

Starting mode Capacitor

Working temperature range -7~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.4 2-1.4

Developed area of heat exchanger

(I×H×L)

791×508×44 645×508×44

Fan motor speed (rpm) 830 830

Motor rated power (W) 30 30

Fan motor running current (A) 0.26 0.3

Fan capacitor (μf) 2.5 2.5

Fan type-piece /

Fan type-piece Axial flow fan-1

Fan diameter (mm) Φ400 Φ400

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of

exhaust side (Mpa)

3.8

Maximum working pressure of

exhaust side (Mpa)

1.2

Noise (sound pressure level) dB(A) 56 54

Noise (sound pressure level) dB(A) 66 64

Outline dimension (W/D/H) (mm) 848×320 ×540 848×320 ×540

Package dimension (W/D/H) (mm) 878×360 ×600 878×360 ×600

Net weight/gross weight (kg) 30/34 41/43

Outdoo

r unit

Refrigerant/refrigerant charge (kg) R410A /1.3 R410A /1.2

Length 4

Liquid pipe (mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection

pipe

Maximum

distance

Length (m) 10

—10—

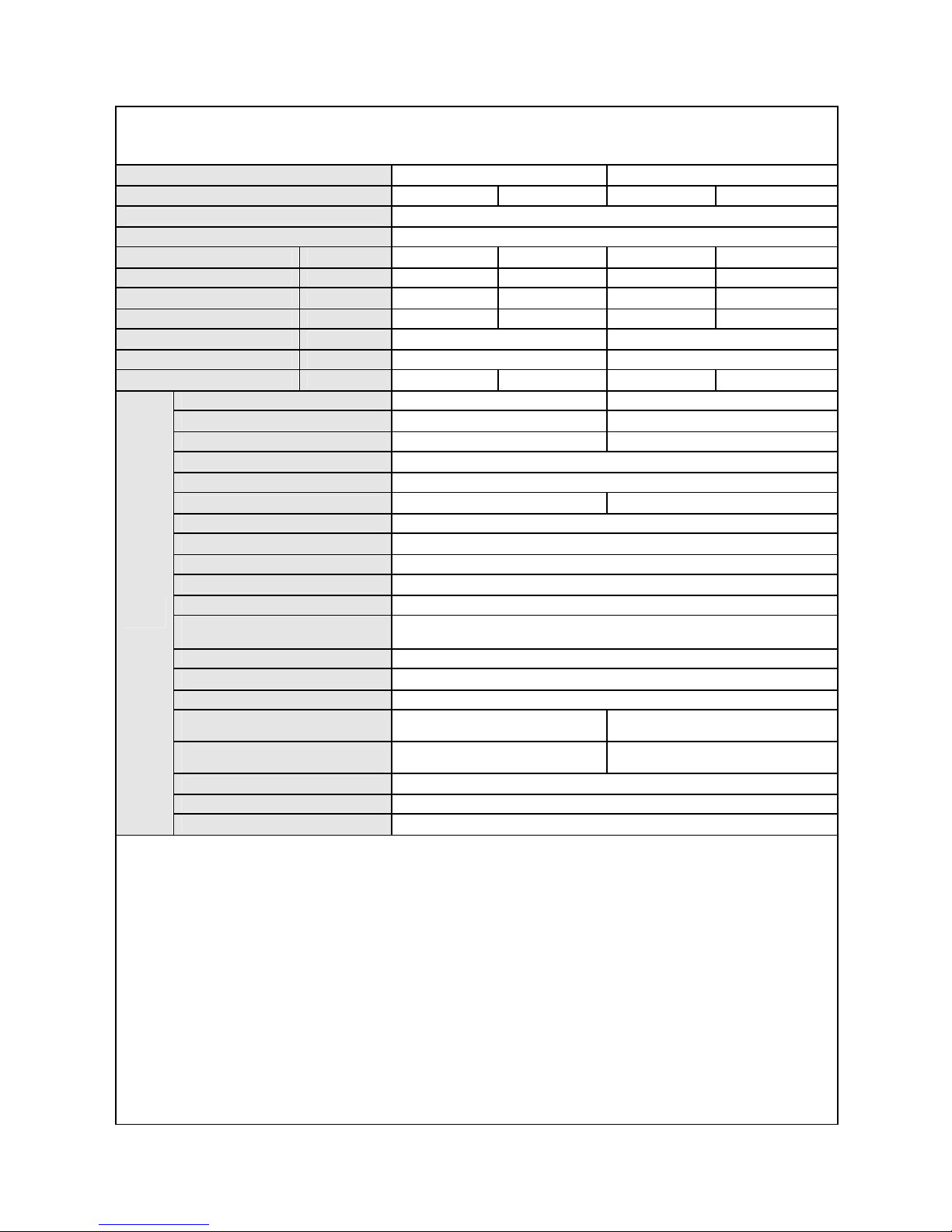

Model PRO AIR I112 IN PRO AIR 218 IN

Function Cooling Heating Cooling Heating

Rated voltage 230V

Rated frequency 50Hz

Capacity (W) 3200 3400 2500×2 2800×2

Nominal power (W) 1000 1100 830×2 900×2

Max. power (W) 1361 1383 1120×2 1100×2

Greatest currency (A) 5.9 6.1 5.9×2 5.4×2

Air flow (m3/h) 450 450

Dry capacity (L/h) 1.2

1.2×2

C.O.P/EER (W/W) 3.2 3.1 3 3.1

Model

KFR-32G/NaA12F-E KFR-25X2G/NaA121-E

Fan speed (r/min)(H/M/L) 1190/1090/990 1160/1010/890

Output power (W) 14 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.12 0.12

Fan type-piece Cross flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat

exchanger (I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

42/39/36

42/39/36

Noise (sound pressure level)

dB(A)

52/49/46 52/49/46

Outline dimension (W/D/H)

(mm)

770×180×250

Package dimension (W/D/H)

(mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

—11—

Model PRO AIR I112 OUT PRO AIR 218 OUT

Compressor type EU1011DV 5PS108EAA22

Compressor type Rotary type

Locked rotor current 33.5 18

Compressor running current 4 4.05

Compressor input power 628 880

Compressor overload model 4CYC11233 7100819 (KA-122-LPD021A)

Throttling method Capillary

Starting mode Capacitor

Working temperature range -7~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.4 2-1.8

Developed area of heat exchanger (I×H

×L)

645×508×44 730×660×44

Fan motor speed (rpm) 830 815

Motor rated power (W) 30 60

Fan motor running current (A) 0.3 0.6

Fan capacitor (μf) 2.5 3

Fan type-piece /

Fan type-piece Axial flow fan-1

Fan diameter (mm) Φ400 Φ400

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of exhaust

side (Mpa)

3.8

Maximum working pressure of exhaust

side (Mpa)

1.2

Noise (sound pressure level) dB(A) 54 60

Noise (sound pressure level) dB(A) 64 70

Outline dimension (W/D/H) (mm) 848×320 ×540 950×340×685

Package dimension (W/D/H) (mm) 878×360 ×600 1100×450×750

Net weight/gross weight (kg) 41/43 65/70

Outdoo

r unit

Refrigerant/refrigerant charge (kg) R410A /1.2 R410A /0.9×2

Length 4

Liquid pipe (mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection

pipe

Maximum

distance

Length (m) 10

—12—

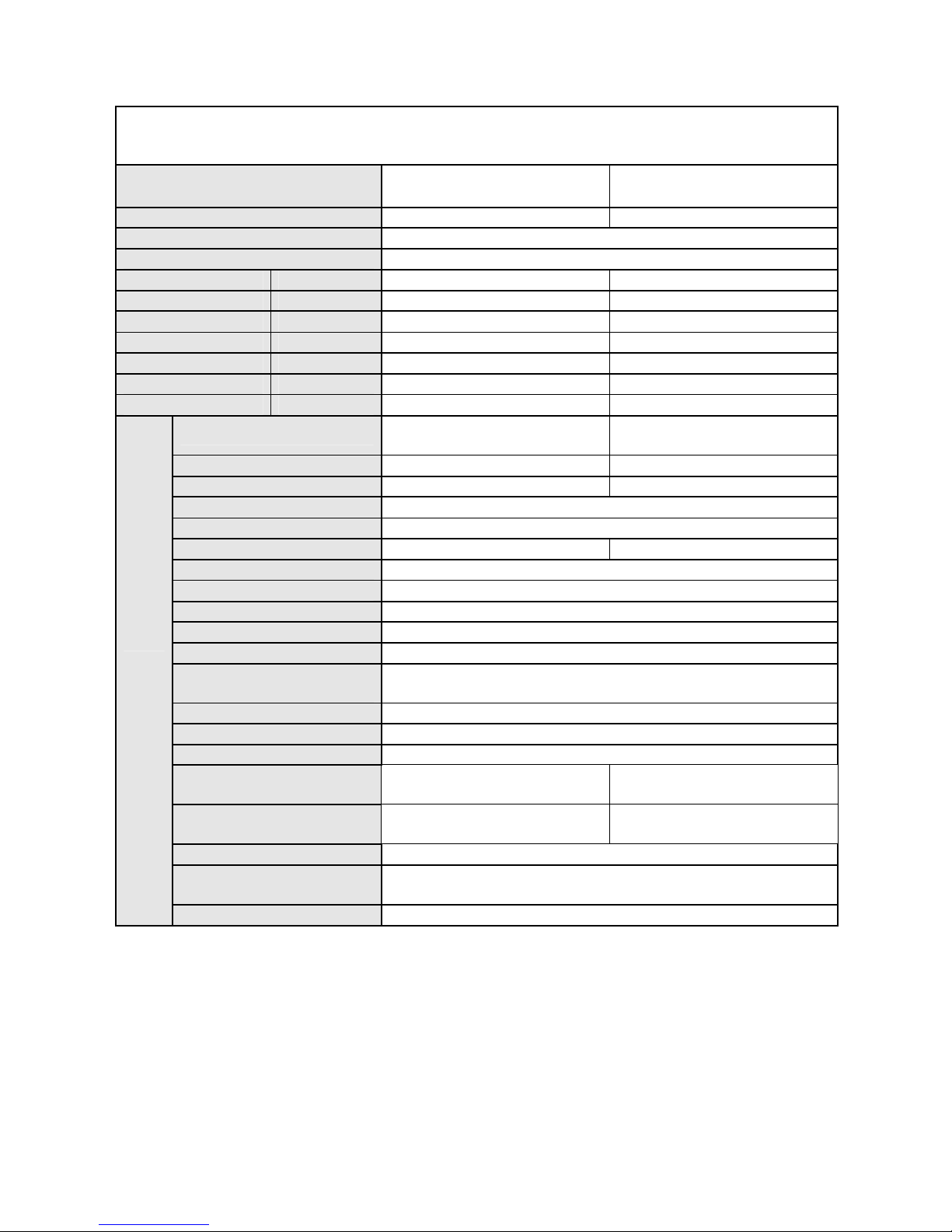

Model

GE AIR 326 IN1 / GE AIR 326 IN2 / GE

AIR 326 OUT

GE AIR 428 IN / GE AIR 428 OUT

Function Cooling Cooling

Rated voltage 230V

Rated frequency 50Hz

Capacity (W)

6800 (3200+1800×2) 7200 (1800X4)

Nominal power (W) 6800 (3200+1800×2) 2900 (1450X2)

Max. power (W)

3400 (1700×2) 3400 (1700X2)

Greatest currency (A) 6.5+6.5 6.5+6.5

Air flow (m3/h) 450 450

Dry capacity (L/h) 1.2×2 1.2×2

C.O.P/EER (W/W) 2.4 2.5

Model

KF-18X2G/NA12-E /

KF-32G/NA12-E

KF-18X4G/NA12-E

Fan speed (r/min) (H/M/L) 1160/1010/890 1160/1010/890

Output power (W) 14 14

Auxiliary electric heater power /

Fan capacitor 1

Fan motor running current 0.12 0.12

Fan type-piece Cross flow fan-1

Diameter-length (mm) Φ97×583

Evaporator Aluminum fin-copper tube

Pipe diameter Φ7

Row-fin distance (mm) 2-1.4

Developed area of heat

exchanger (I×H×L)

580mm ×228.6mm×25.4mm

Swing motor model MP24GA

Motor power (W) 2

Fuse (A) PCB3.15A Transformer 0.2A

Noise (sound pressure level)

dB(A)

42/39/36

42/39/36

Noise (sound pressure level)

dB(A)

52/49/46

52/49/46

Outline dimension (W/D/H) (mm) 770×180×250

Package dimension (W/D/H)

(mm)

855×270×336

Indoor

unit

Net weight/gross weight (kg) 8.5/12.5

—13—

Model

GE AIR 326 IN1 / GE AIR 326 IN2 /

GE AIR 326 OUT

GE AIR 428 IN / GE AIR 428 OUT

Compressor type C-RV237H01AA C-RV237H01AA

Compressor type Rotary type

Locked rotor current 31 31

Compressor running current 6.3 6.3

Compressor input power 1100 1100

Compressor overload model MRA98619-9200 MRA98619-9200

Throttling method Capillary

Starting mode Capacitor

Working temperature range -5~43℃

Condenser Aluminum fin-copper tube

Pipe diameter Φ9.52

Row-fin distance (mm) 2-1.8 2-1.8

Developed area of heat exchanger

(I×H×L)

791×508×44 791×508×44

Fan motor speed (rpm) 780 780

Motor rated power (W) 60 60

Fan motor running current (A) 0.56 0.56

Fan capacitor (μf) 3 3

Fan type-piece /

Fan type-piece Axial flow fan-1

Fan diameter (mm) Φ460 Φ460

Defrosting method Auto

Climate type T1

Insulation class I

Waterproof level IP24

Maximum working pressure of

exhaust side (Mpa)

2.5

Maximum working pressure of

exhaust side (Mpa)

0.6

Noise (sound pressure level) dB(A) 58 58

Noise (sound pressure level) dB(A) 68 68

Outline dimension (W/D/H) (mm) 950×412 ×840 950×412 ×840

Package dimension (W/D/H) (mm) 1100×450×920 1100×450×920

Net weight/gross weight (kg) 72/77 72/77

Outdoo

r unit

Refrigerant/refrigerant charge (kg) R407C /1.27×2 R407C /1.27×2

Length Length of connecting tube

Liquid

pipe

(mm) Φ6 Outer

diameter

Gas pipe (mm) Φ9.52

Height (m) 5

Connection pipe

Maximum

distance

Length (m) 10

The above data is subject to change without notice. Please refer to the nameplate of the unit.

—14—

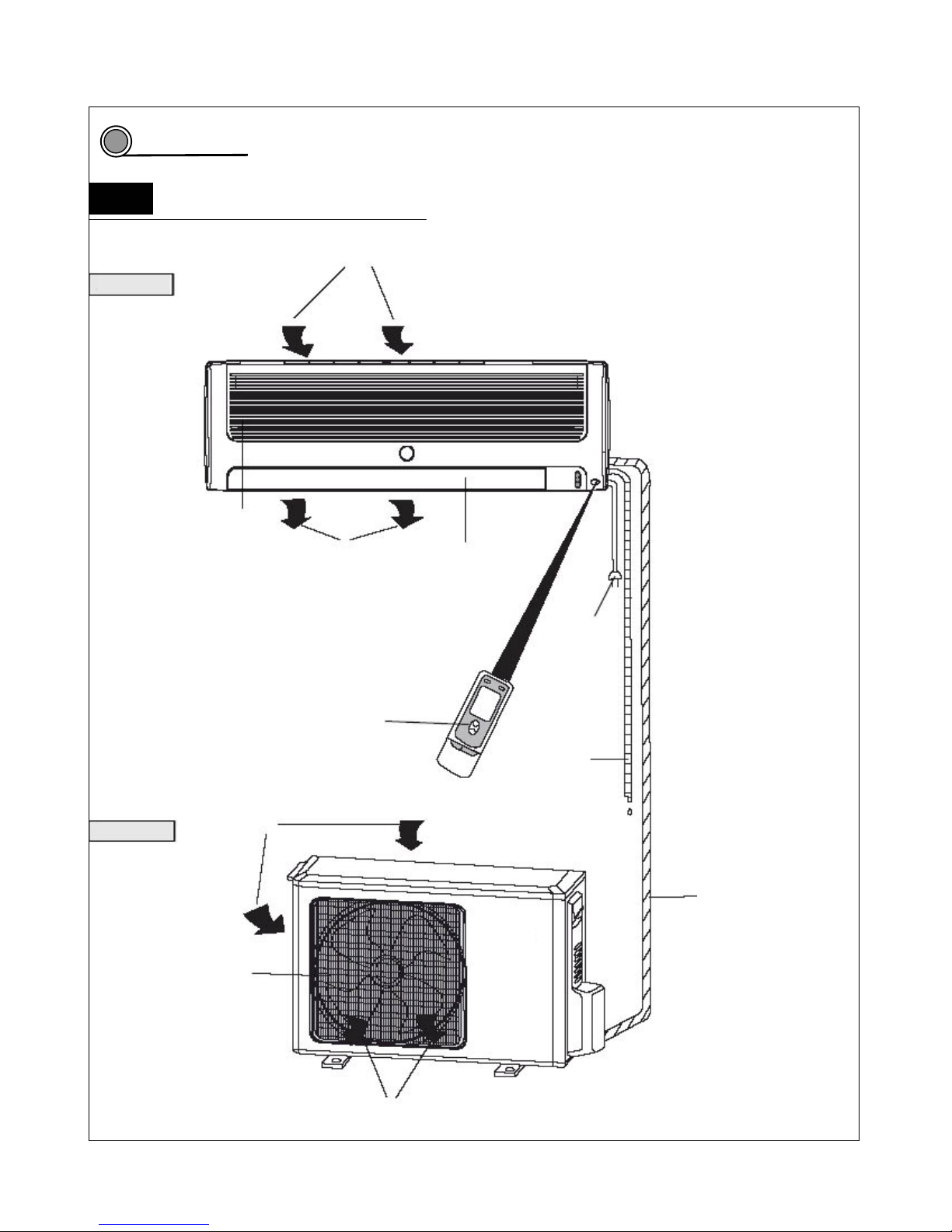

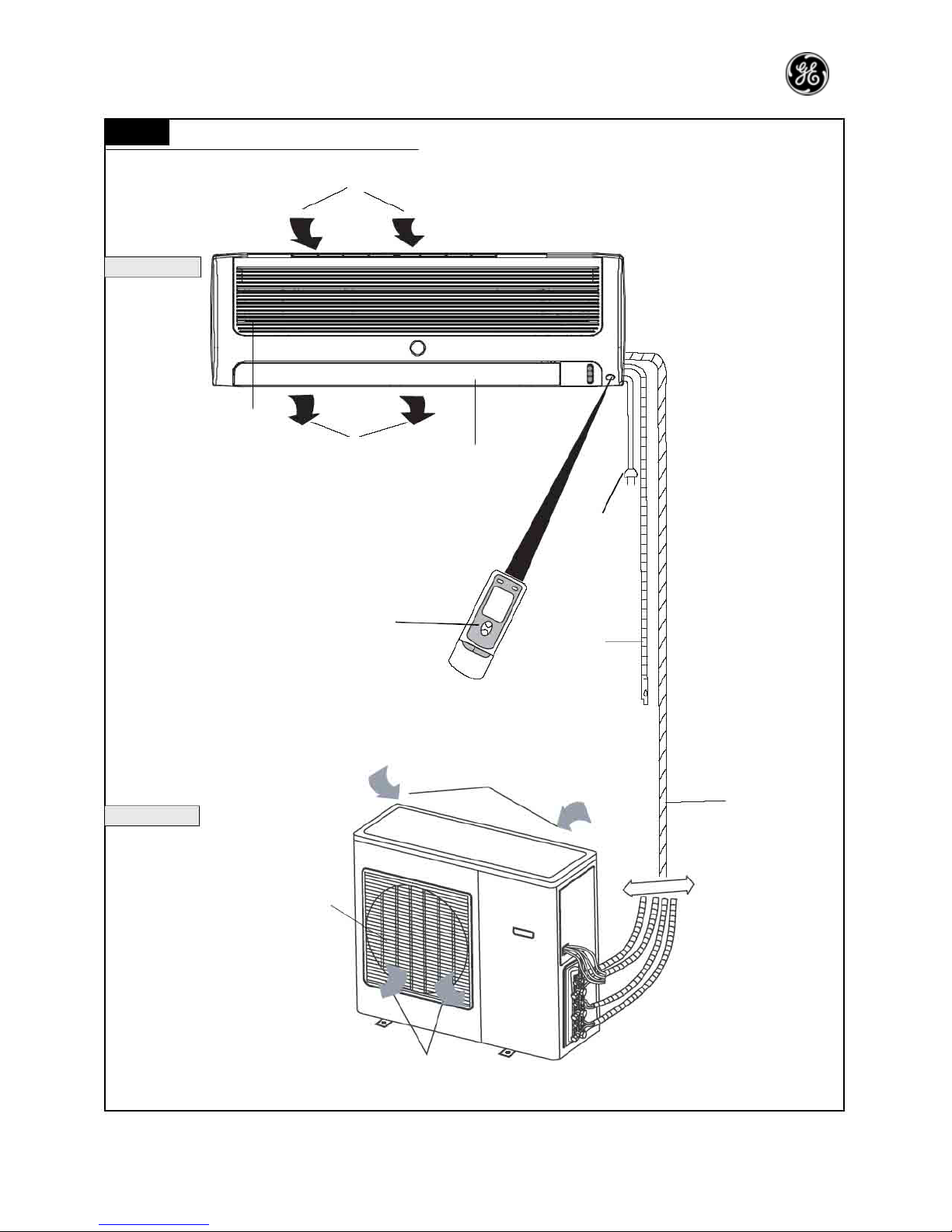

Part name

Part name of one driving one unit

Air in

Indoor unit

Panel

Air out Air guide board

Power plug

Remote controller

Drainage pipe

utdoor unit Air in

Connecting pipe and

connecting wire

Air outlet vent grill

Air out

3

3.1

—15—

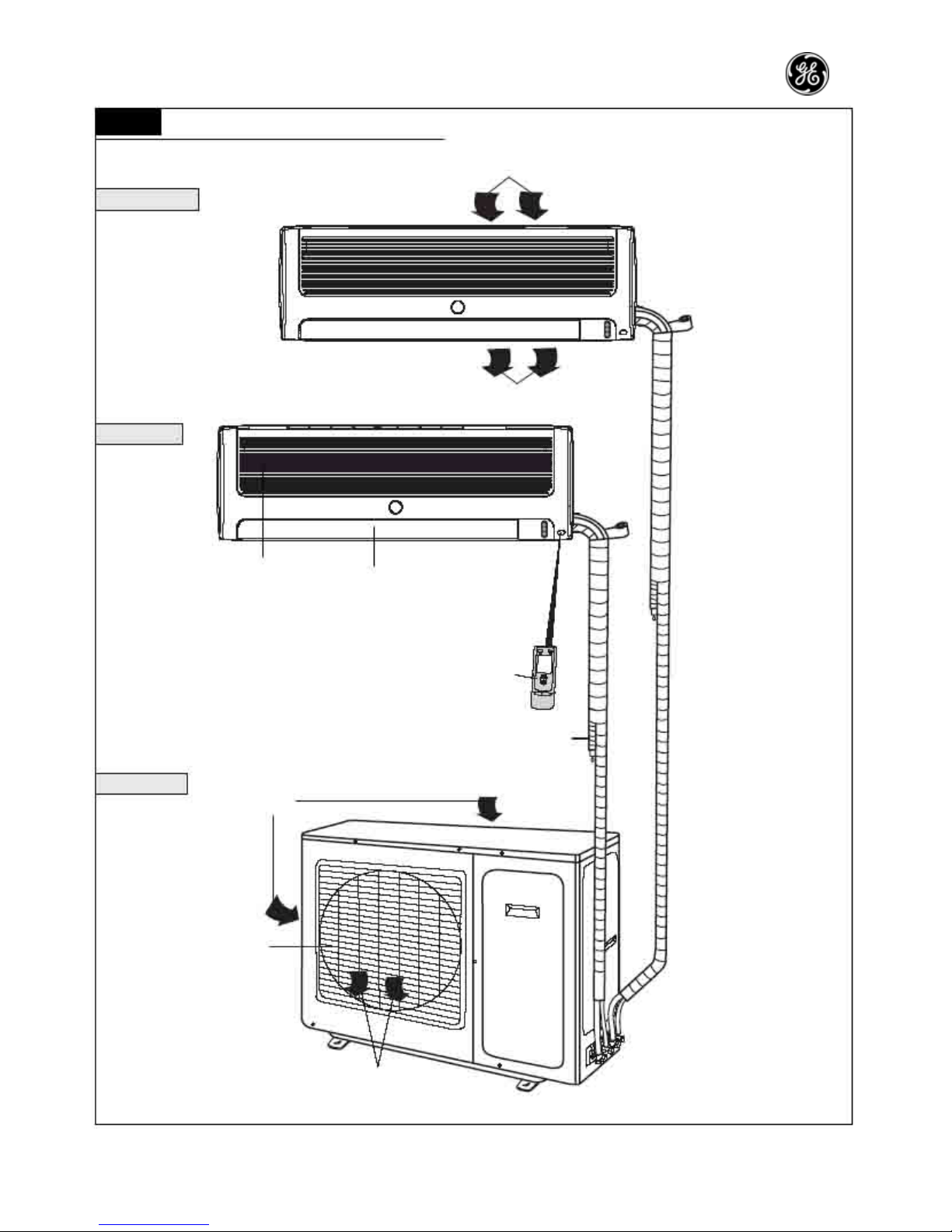

3.2 Part name of one driving two unit

Air in

Indoor unit A

Wrapping tape

Air out

Indoor unit B

Panel

Air guide board

Remote controller

Drainage pipe

Outdoor unit

Air in

Air outlet vent grill

Air out

—16—

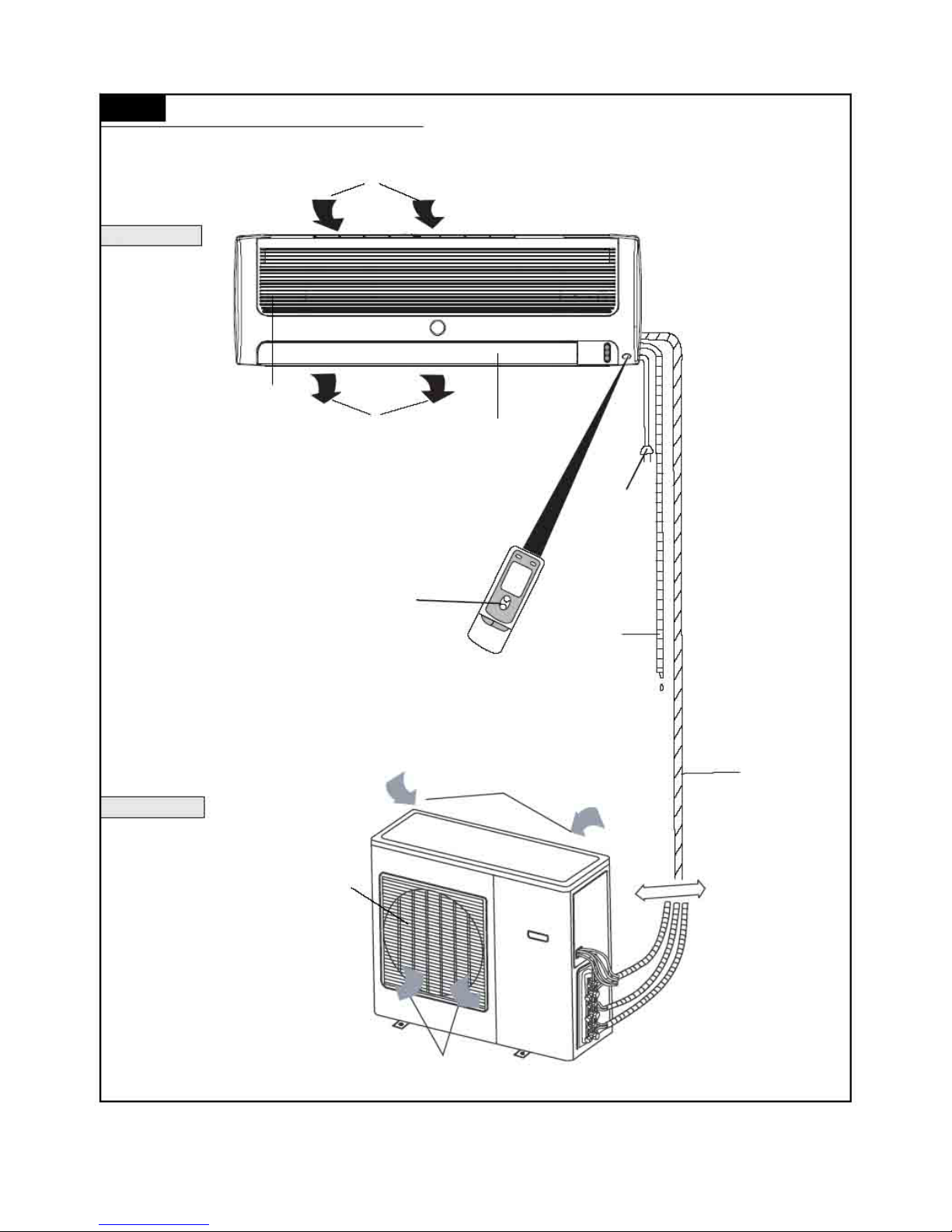

3.3 Part name of one driving three unit

Air in

Indoor unit

Panel

Air out Air guide board

Power plug

Remote controller

Drainage pipe

Air in

Outdoor unit

Air outlet vent grill

Air out

Connecting

pipe and

connecting

wire

—17—

P17

3.4

Part name of one driving four unit

Air in

Indoor unit

Panel

Air out Air guide board

Power plug

Remote controller

Drainage pipe

Air in

Outdoor unit

Air outlet vent grill

Air out

Connecting

pipe and

connecting

wire

—18—

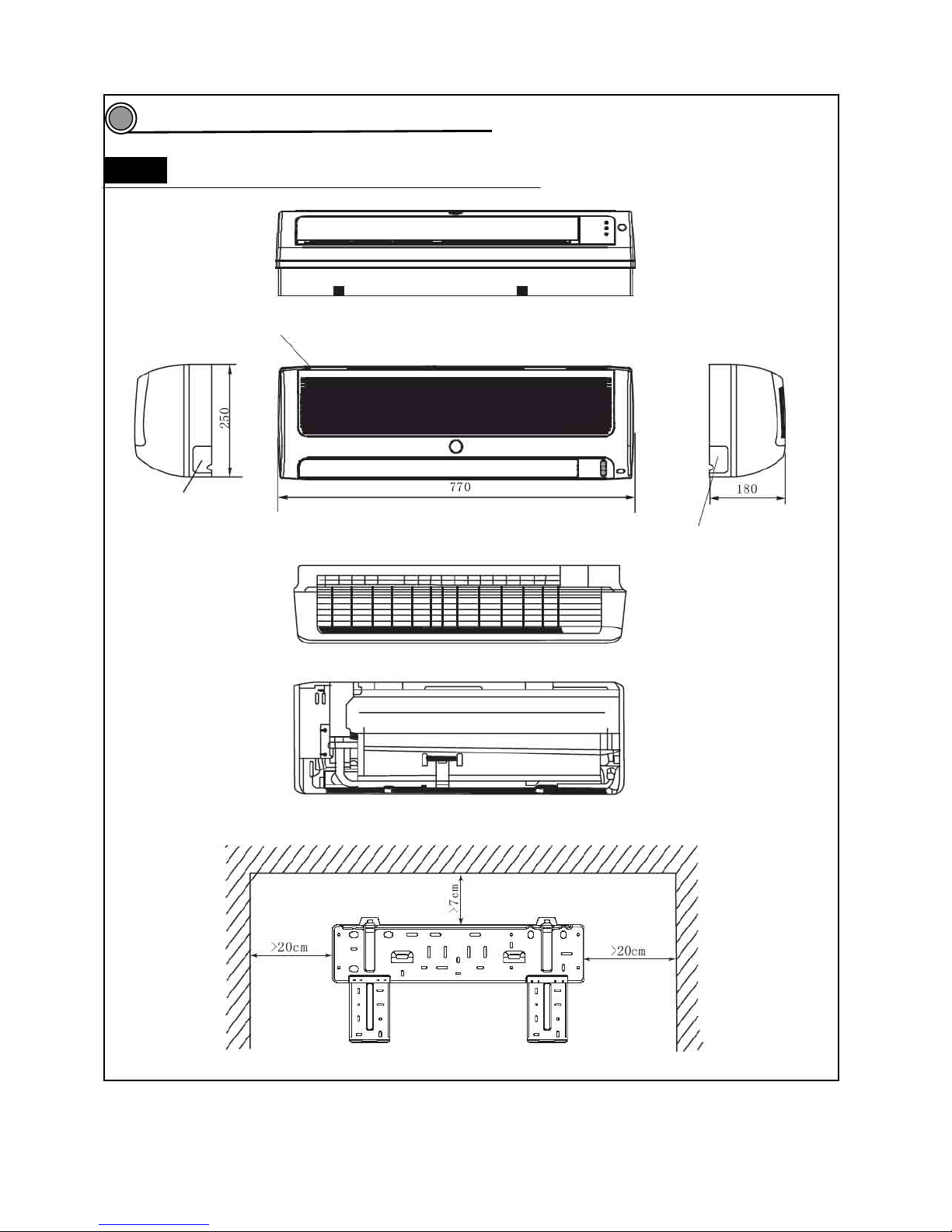

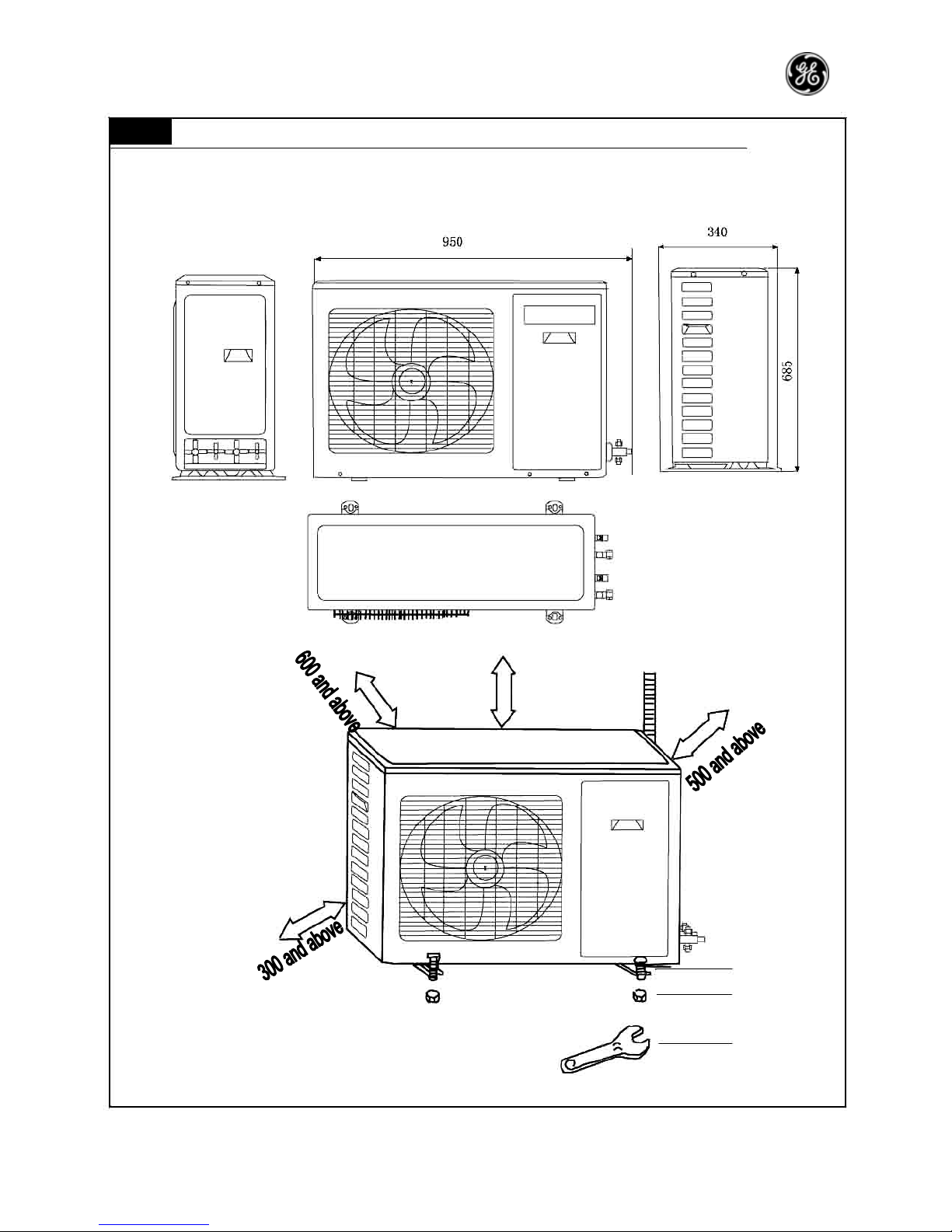

Outline and installation dimensions

4.1 Outline and installation dimensions of indoor unit

Air inlet vent

Left pipe outlet

Right pipe outlet

Rear view

Ceiling

Left side Right side

Installation dimensions

4

—19—

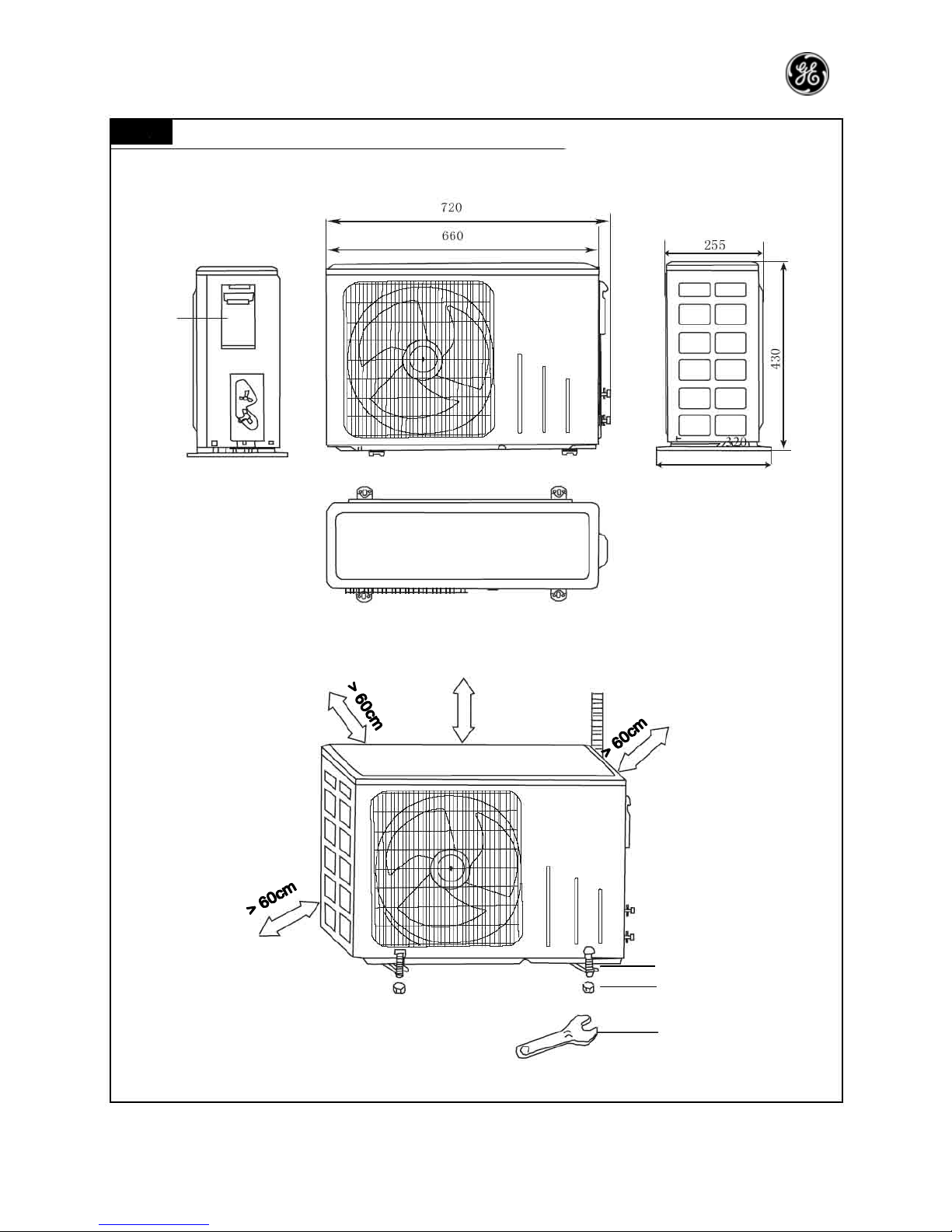

4.2 Outline and installation dimensions of indoor unit 20

Handle

> 60cm

Bolt

Nut

Spanner

—20—

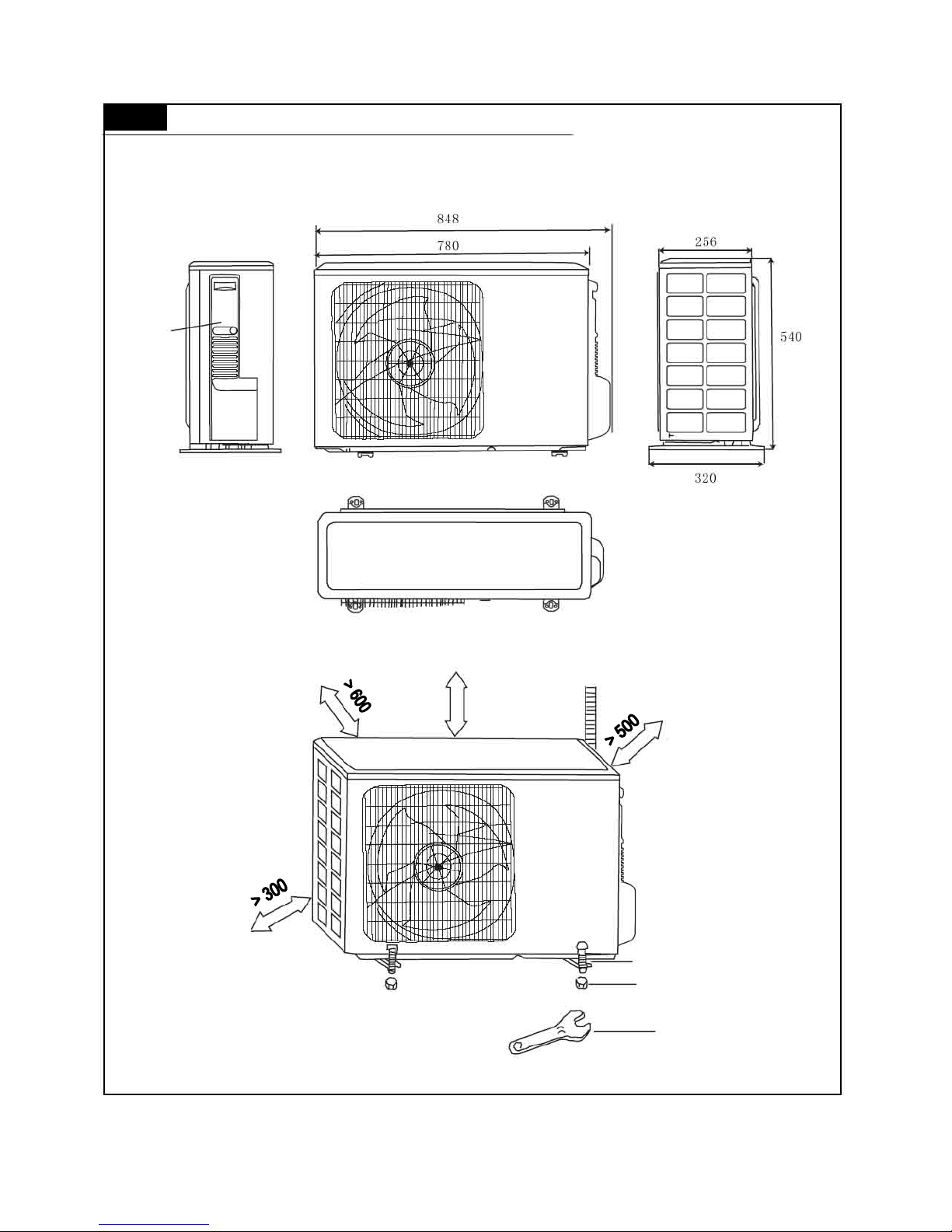

4.3 Outline and installation dimensions of indoor units 2 5, 32

Handle

Unit: mm

> 500

Bolt

Nut

Spanner

—21—

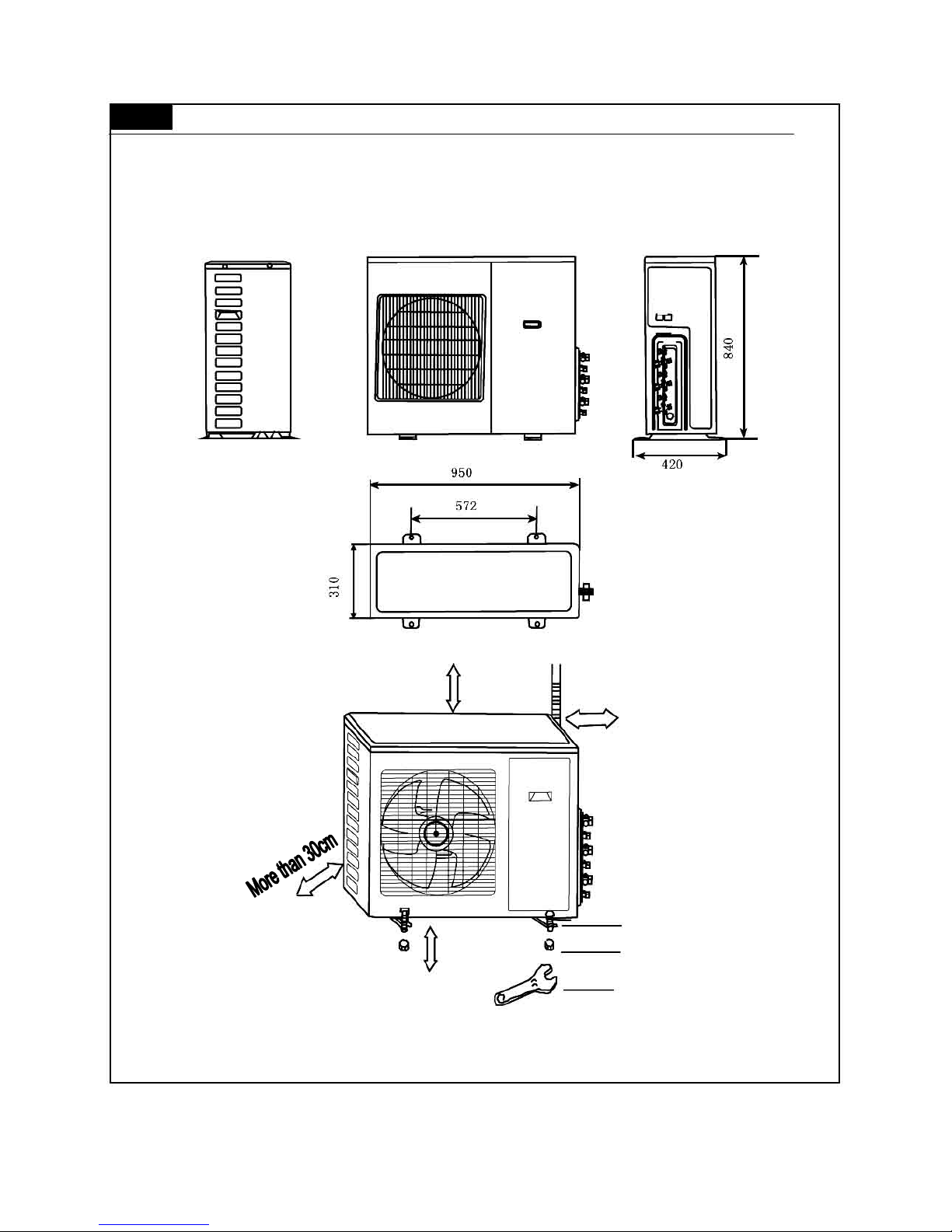

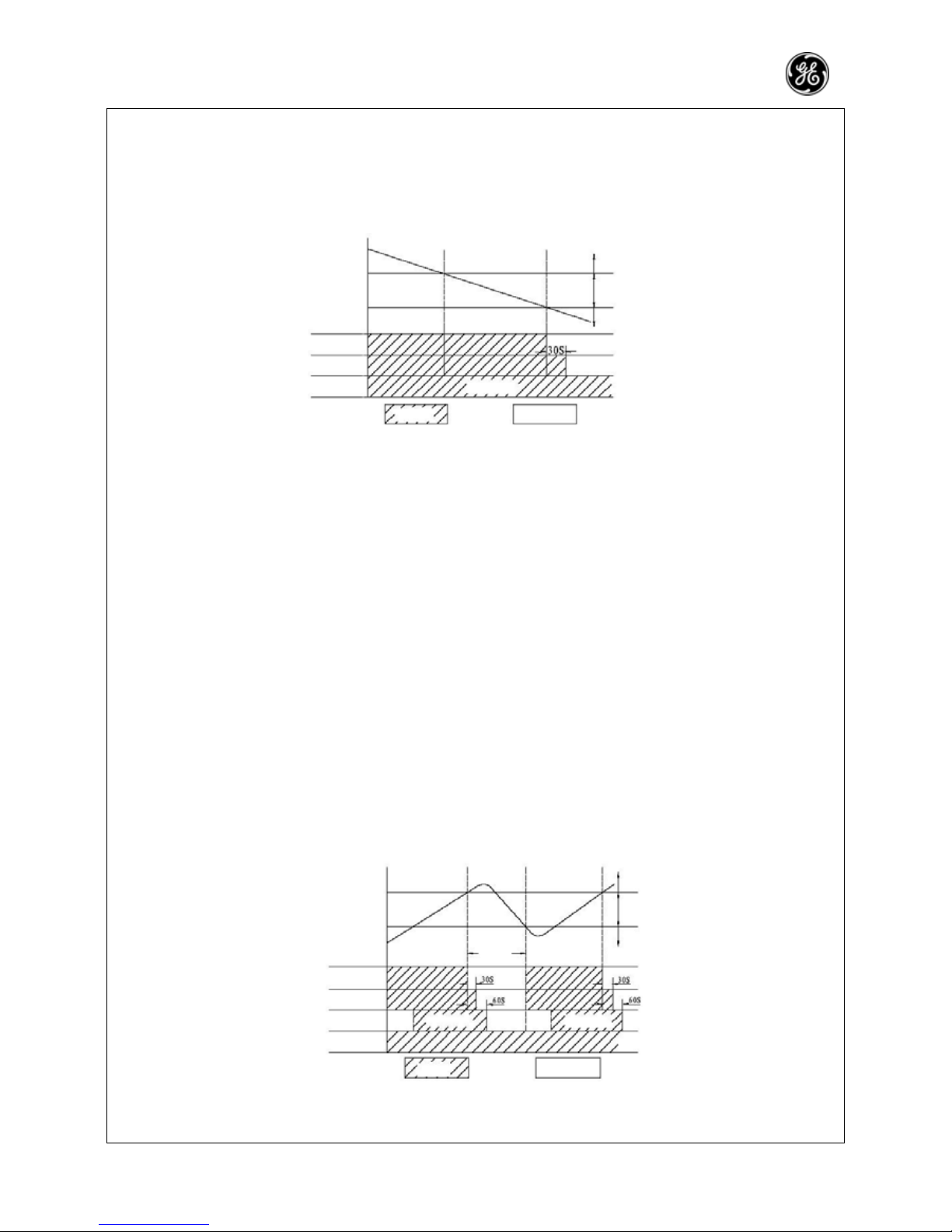

4.4 Outline and installation dimensions of one driving two outdoor unit

Unit: mm

500 and above

Bolt

Nut

Spanner

—22—

4.5 Outline and installation dimensions of one driving three outdoor unit

More than 50cm

More than 30cm

Bolt

More than 200cm Nut

Spanner

—23—

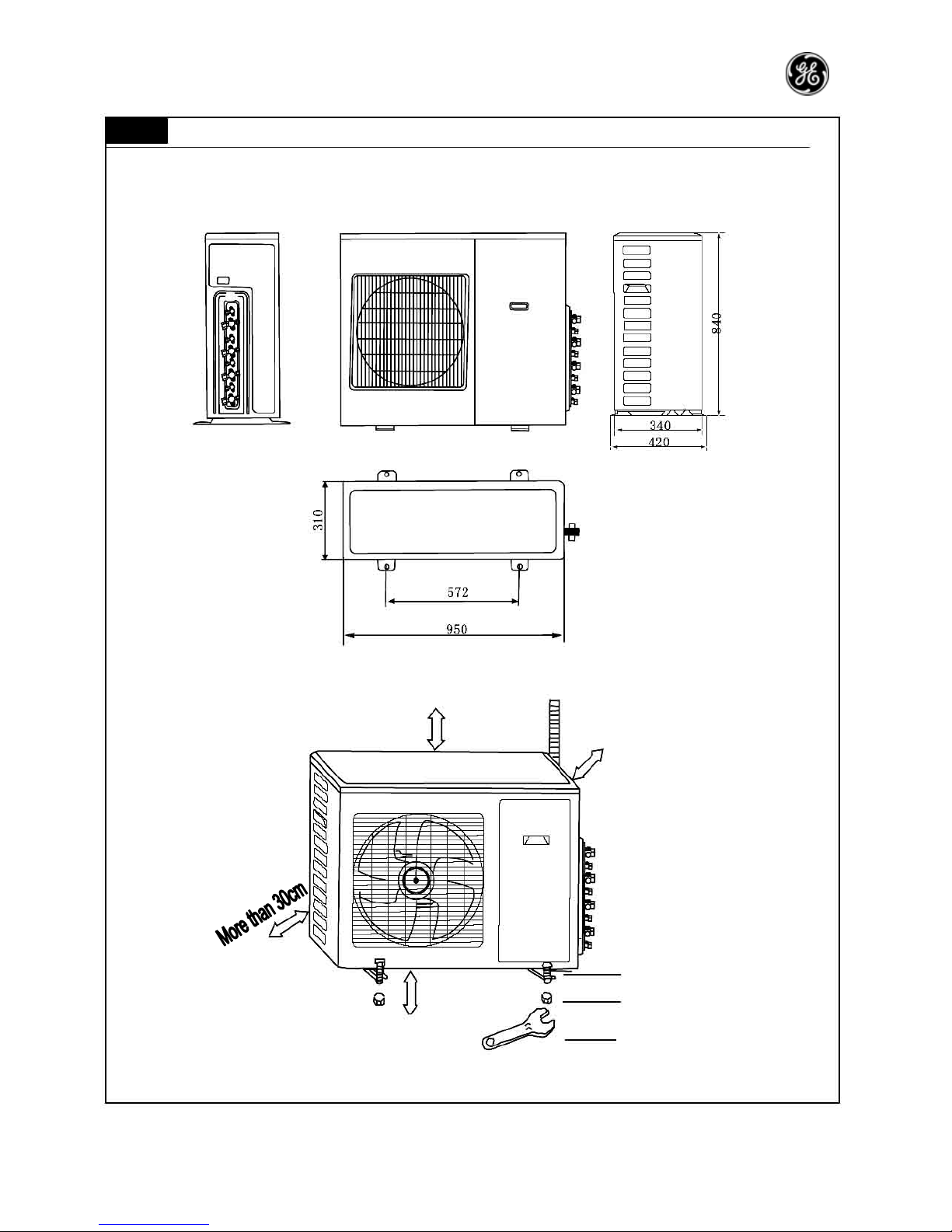

4.6 Outline and installation dimensions of one driving four outdoor unit

More than 50cm

More than 30cm

Bolt

More than 200cm Nut

Spanner

—24—

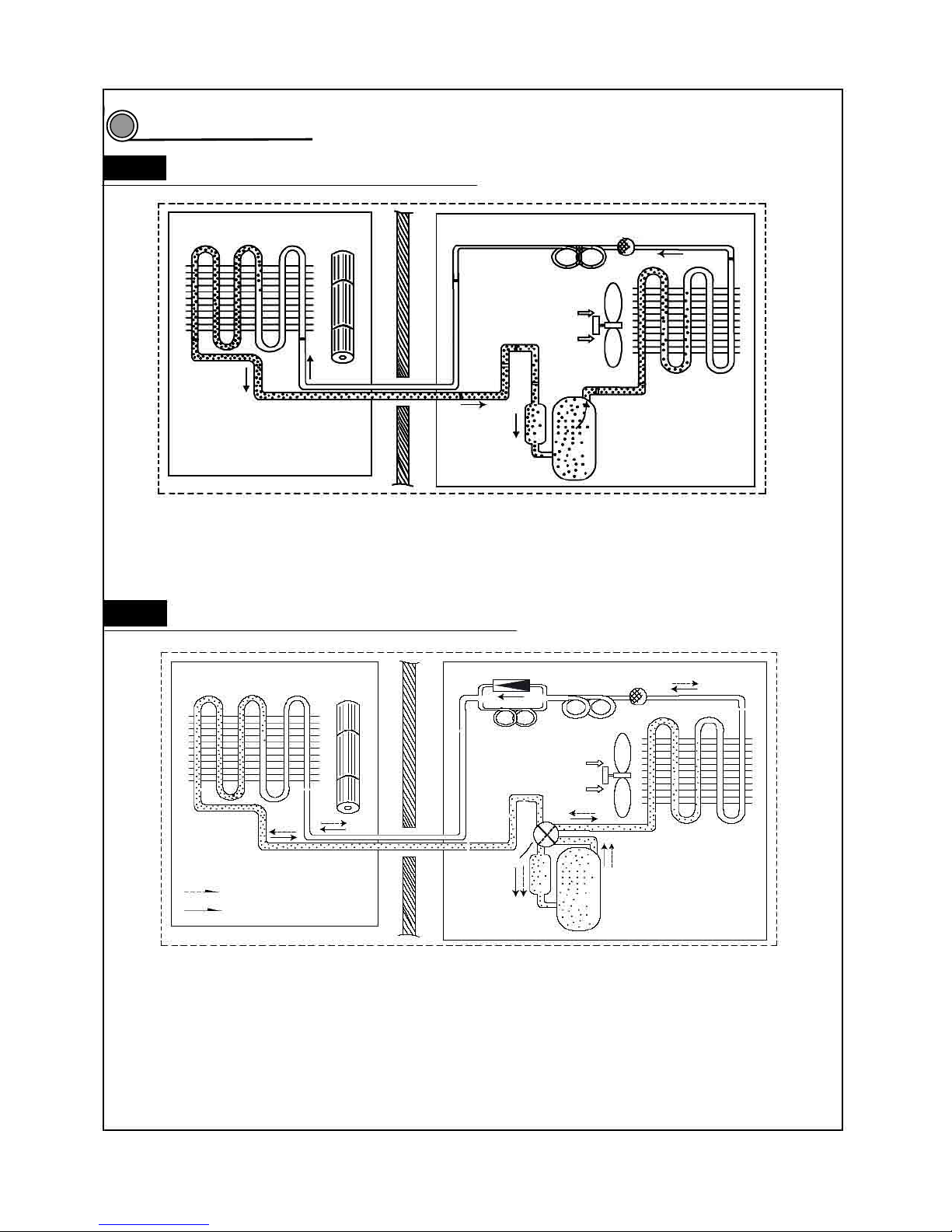

5

System diagram

5.1 Cool only system circuit diagram

Evaporator Cross flow fan

Capillary Filter

Axial flow fan

Condenser

Gas liquid

separator Compressor

When the power is on, indoor and outdoor units will start to run. The compressor sucks low-pressure refrigerant gas from

the evaporator of indoor unit and then discharges high-temperature, high-pressure refrigerant gas into outdoor

condenser. Then air exchanges the heat with outdoor air and becomes refrigerant liquid. The liquid is throttled by the

capillary and changes into low-temperature and low-pressure liquid and then flows into indoor evaporator. Then liquid

exchanges the heat with the required air and changes into low-temperature and low-pressure refrigerant gas. The cycle

introduced above goes on and on, and the demanded low temperature environment is maintained

5.2 Cool/Heat system circuit diagram

Evaporator Cross flow fan

Flow direction of refrigerant when heating

Flow direction of refrigerant when cooling

One-way valve

Main capillary Filter

Auxiliary Capillary

Axial flow fan

Condenser

Electromagnetic

four-way valve

Gas liquid

Separator Compressor

When the power is on, indoor and outdoor units will start to run. When the system operates in cool mode, the

compressor sucks low-temperature, low-pressure refrigerant gas from indoor evaporator and then discharges

high-temperature, high-pressure refrigerant gas into outdoor heat exchanger. With the help of axial flow fan, the gas

transfers its latent heat into outdoor air and becomes high-pressure refrigerant liquid. The liquid is throttled by the

capillary and changes into low-temperature and low-pressure liquid and then flows into indoor heat exchanger. With the

help of centrifugal fan, the liquid evaporates into low-temperature refrigerant gas and indoor air is cooled down. The

refrigerant gas is sucked into the compressor and the cycle introduced above goes on and on, and the demanded low

temperature environment is maintained. When the system operates in heat mode, four-way valve changes its way and

the refrigerant flows into the reversible cycle as the cool mode. The refrigerant discharges its latent heat in the indoor

heat exchanger, and sucks heat from outdoor heat exchanger and forms the heat pump cycle. This cycle goes on and on,

and the demanded high temperature environment is maintained.

5

—25—

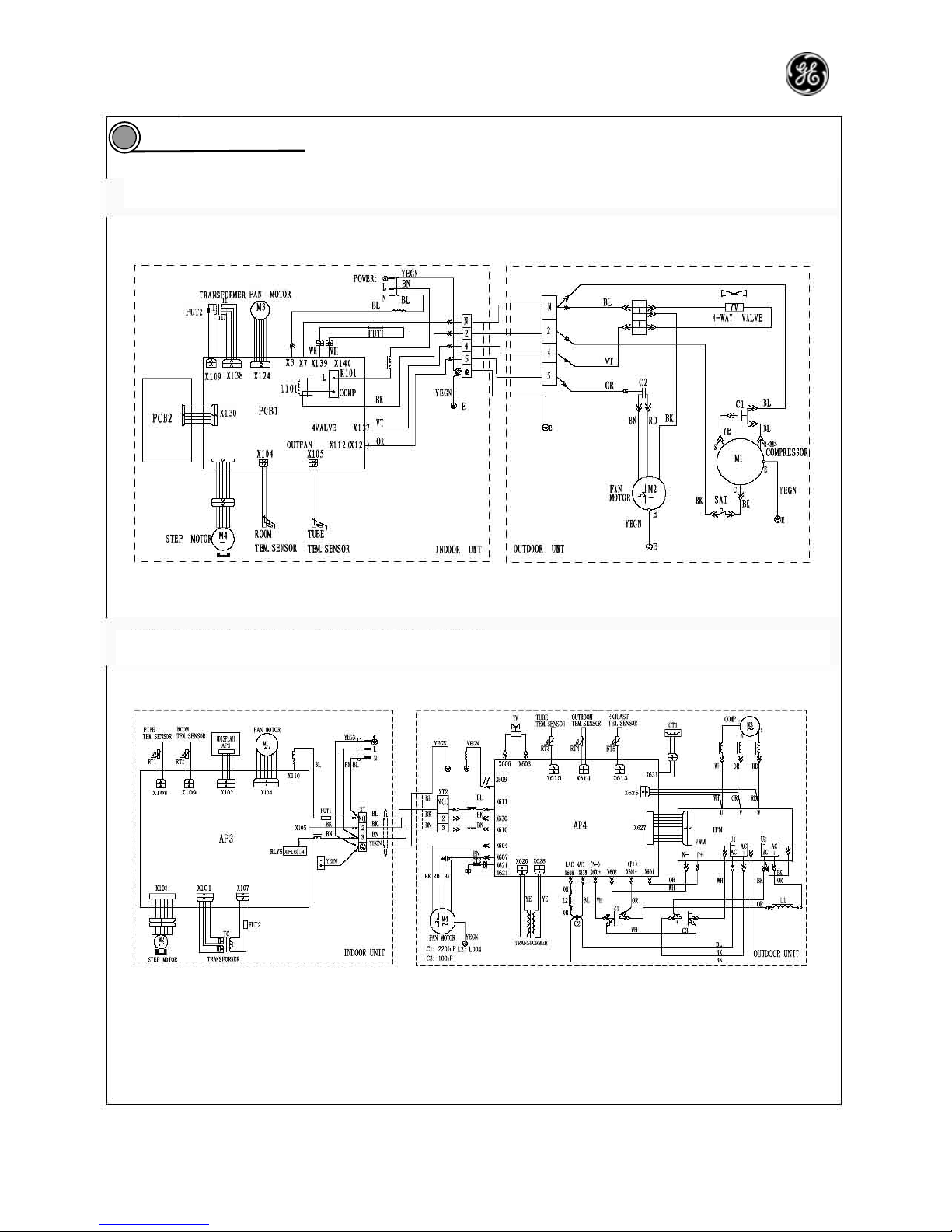

Circuit diagram

6

PRO AIR 107 IN / PRO AIR 107 OUT; PRO AIR 109 IN / PRO AIR 109 OUT; PRO AIR 112 IN / PRO

PRO AIR I109 IN / PRO AIR I109 OUT; PRO AIR I112 IN / PRO AIR I112 OUT

—26—

Circuit

diagram is

same as

above.

Circuit

diagram is

same as

above.

PRO AIR 218 IN / PRO AIR 218 OUT

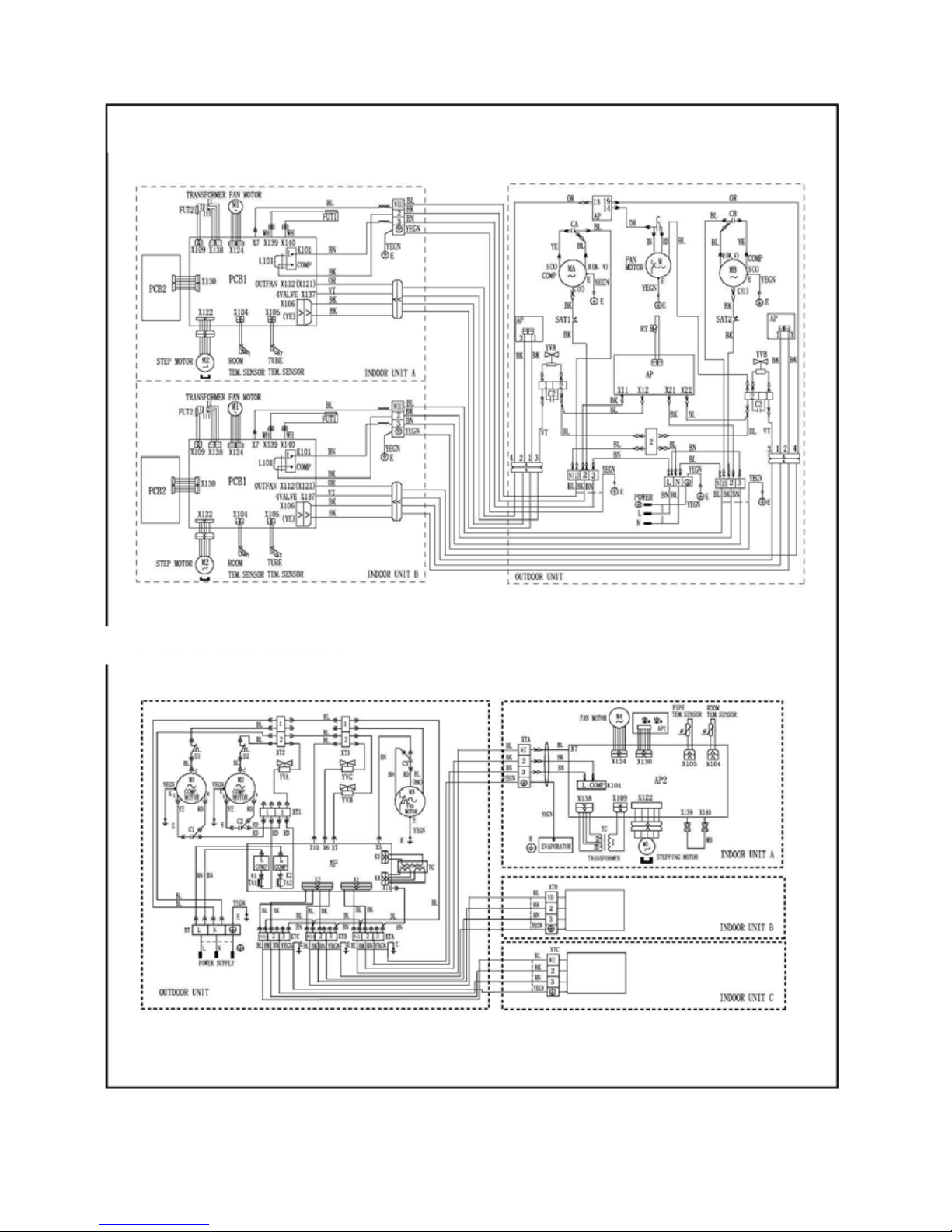

GE AIR 326 IN1 / GE AIR 326 IN2 / GE AIR 326 OUT

—27—

Circuit

diagram is

same as

above.

Circuit

diagram is

same as

above.

Circuit

diagram is

same as

above.

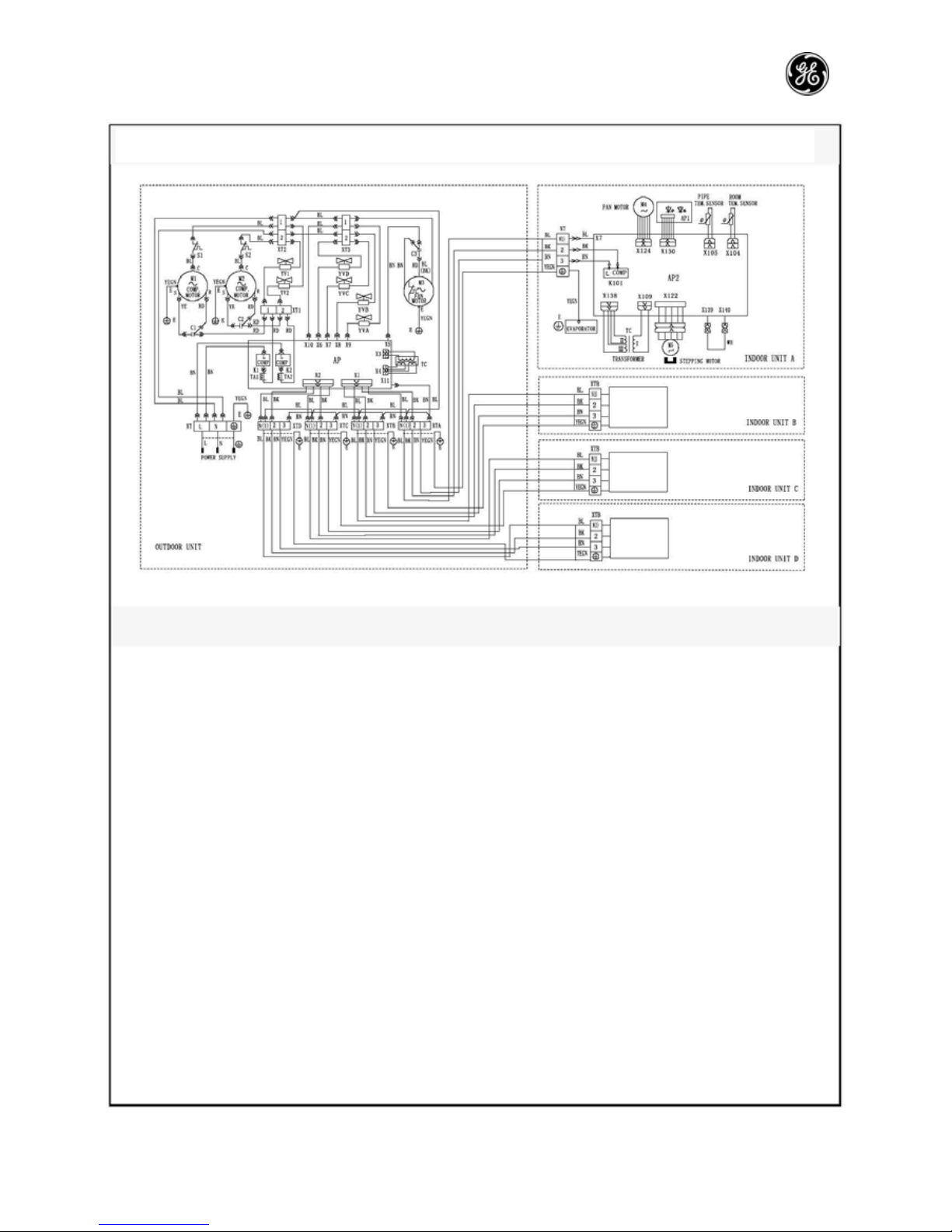

These circuit diagrams are subject to change without notice. Please refer to the one supplied with the unit.

GE AIR 428 IN / GE AIR 428 OUT

—28—

Function manual and operation method of remote controller

PRO AIR I112 IN / PRO AIR I112 OUT, suitable for frequency converter

Function manual of remote controller

7.1.1 Temperature parameter

Room set temperature: (T

set

)

Room ambient temperature: (T

amb

)

7.1.2 Basic function of system

No matter what mode the compressor is in, the minimum time interval between two startups should be 3

minutes after it is powered on.

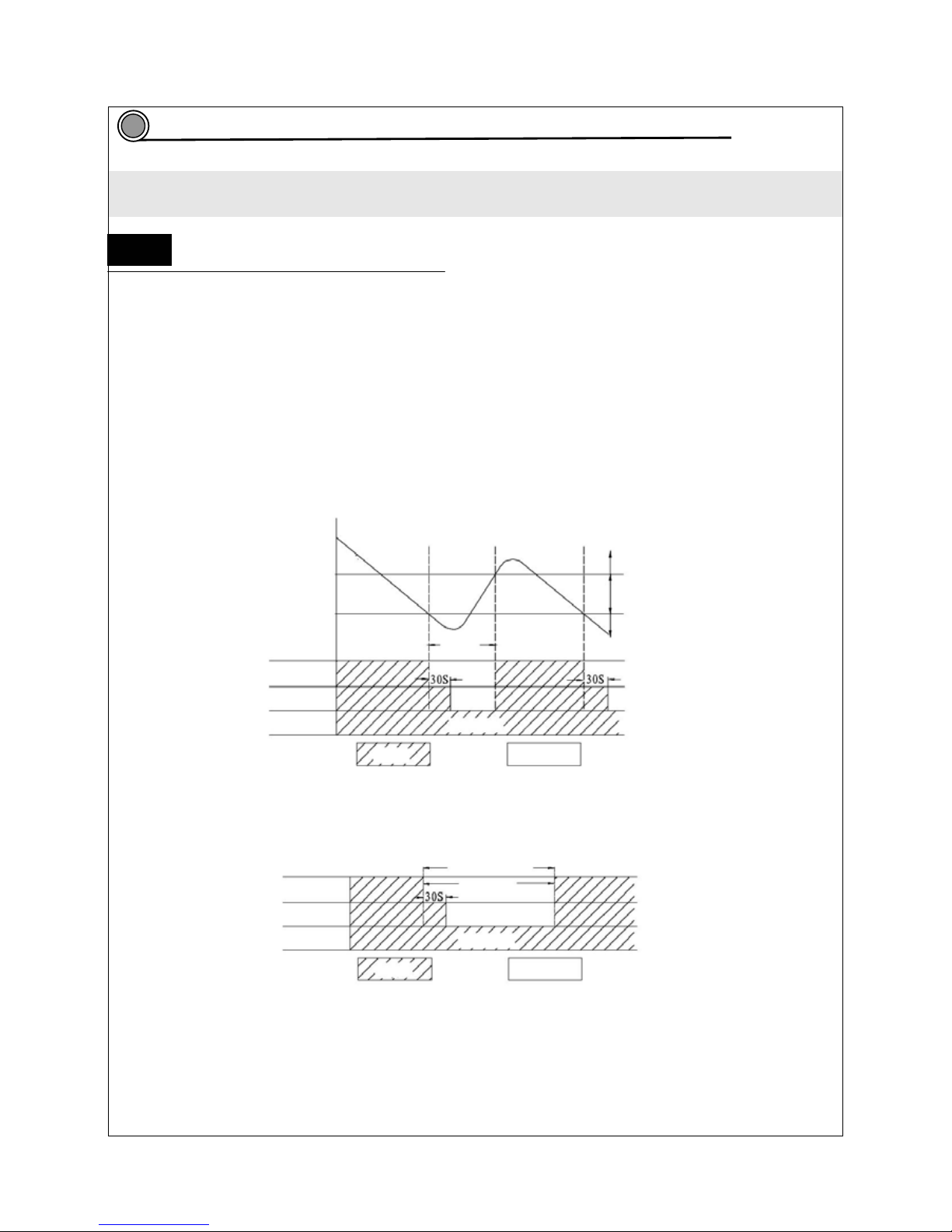

7.1.2.1 Cooling mode

7.1.2. 1.1 The condition and process of cooling

If T

amb>Tset

, COOL mode will act, compressor and external fan will run, the indoor fan will run at the set

speed.

If T

amb≤Tset

-2℃, compressor will stop and external fan will stop after a delay of 30s. The indoor fan will

run at the setting speed.

If Tset-2℃<T

amb<Tset

, the unit will keep ℃ on running in the original mode.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is

16 ~30℃℃.

T

set

+1℃ T

amb

Start cooling

T

set

-1℃ Keep running in the original mode

Stopping cooling

≥3min

Compressor

Outdoor fan

Indoor fan Set fan speed

Run Stop

7.1.2.1.2 Protection function

Anti-freezing Protection

When the anti-freezing protection is detected, the compressor will stop, the outdoor fan will stop after a

delay of 30 seconds. The indoor fan and swing motor will keep on running in the original mode. When

anti-freezing protection is eliminated and compressor has stopped for 3min, the machine restores its

former operation mode.

Anti-freezing Protection

Compressor ≥3min

Outdoor fan

Indoor fan Set fan speed

Run Stop

Over current protection

The compressor will run at a limited frequency when the total current is high. The compressor will stop

when the total current is too high and the outdoor unit will stop after a delay of 30s.

7.1.2.2 Dry mode

7.1.2.2.1 The condition and process of dry mode

If T

amb>Tset

, the drying mode will act. The compressor and external fan will run, and the indoor fan will run

at a low speed.

7

7.1

—29—

If T

set

-2℃≤T

amb≤Tset

, the unit will keep on running in the original mode.

If T

amb≤Tset

-2℃, the compressor will stop. The external fan will stop after a delay of 30s, and the indoor

fan will run at a low speed.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is

16 ~30℃℃

T

amb

T

set

T

set

-2℃

Compressor

Outdoor fan

Indoor fan Low fan speed

Run Stop

Cooling running

Dry running

Stop running

7.1.2.2.2 Protection function

Anti-freezing protection

Anti-frost protection same as cooling

Over current protection

Over current protection is the same as the cooling mode.

7.1.2.2.3 SWING mode

At this mode, the inner fan will select among high, medium, low and auto modes and the compressor,

outer fan and 4-way fan will stop running.

¾ In this mode, the reversal valve will not be powered on and the temperature setting range is

16 ~30℃℃

7.1.2.3 HEAT mode

7.1.2.3.1 Running condition and process of heating mode

If T

amb≤Tset

+2 , HEAT mode will act, the compressor, outdoor fan and reversal valve will run at the same ℃

time, the indoor fan will run after 3 minutes’ delay at the latest.

If T

amb≥Tset

+4 , the compressor will stop℃ first and 15s later, the outdoor unit will stop. The reversal valve

will keep power-on and the indoor fan will run at a low speed and will stop 30s later.

If T

set

+2℃<T

amb<Tset

+4 ,℃ the unit will keep running in the previous mode.

¾ In this mode, the temperature setting range is 16 ~30 .℃℃

¾ The air conditioner will adjust the running frequency of the compressor automatically according to the

change of ambient temperature.

¾ The 4-way valve will be cut off 2min after the compressor stops operation when heating cut-off, or

heating mode changed to other mode.

T

set

+5℃

T

set

+2℃ T

amb

≥3min

Stop heating

Original running state

Start heating

Compressor

Outdoor fan

Indoor fan ≤3min Set fan speed ≤3min Set fan speed

Reversal valve

Run Stop

7.1.2.3.2 The condition and process of defrosting

When frost is detected in the condenser, the system will enter into defrosting mode. When the defrosting starts,

the compressor and indoor fan stop running. The outdoor fan will stop after a delay of 30s, and the four-way

Loading...

Loading...