GE Power Quality Meter Series, PQM Series, PQM-T20-C-A Instruction Manual

g

GE Power Management

PQM

Power Quality Meter™

INSTRUCTION MANUAL

Software Revision: 3.5x

Manual P/N: 1665-0003-CG

Manual Order Code: GEK-106296A

Copyright © 2001 GE Power Management

g

GE Power Management

PQM Power Quality Meter

STATUS COMMUNICATE RELAYS

ALARM

PROGRAM

SIMULATION

SELF TEST

TX1

RX1

TX2

RX2

ALARM

AUX1

AUX2

AUX3

ACTUAL

SETPOINT

STORE

RESET

MESSAGE

VALUE

823787A3.CDR

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

Manufactured under an

ISO9001 Registered system.

These instructions do not purpor t to cover all detai ls or varia tions in equipment nor provide fo r every p ossibl

e

e

e

t

contingency to be met in connection with installation, operation, or maintenance. Should further information b

desired or should pa rticula r pro blems arise whi ch are no t cove red su ffici ently for the p urchas er’s purpose, th

matter should be referred to the General Electric Company.

To the extent required the products des cribed herein meet applic able ANSI, IEE E, and NEMA s tandards; bu

no such assurance is given with respect to local codes and ordinances because they vary greatly.

TABLE OF CONTENTS

1. OVERVIEW

2. INSTALLATION

1.1 INTRODUCTION

1.1.1 DESCRIPTION..........................................................................................1-1

1.1.2 FEATURE HIGHLIGHTS............................................................ ...............1-1

1.1.3 APPLICATIONS.................................... .....................................................1-3

1.2 STANDARD FEATURES

1.2.1 METERING................................................................................................ 1-4

1.2.2 FUTURE EXPANSION.............................................................................. 1-4

1.2.3 OPTIONAL FEATURES............................................... ..................... ......... 1-5

1.2.4 PQMPC SOFTWARE................................................................................ 1-9

1.2.5 O R D E R C O D E S . ............ .. ........... ............ .. ........... .. ........... .. ............ .. ...... 1 - 1 0

1.3 SPECIFICATIONS

1.3.1 PQM SPECIFICATIONS..........................................................................1-11

2.1 PHYSICAL

2.1.1 MOUNTING ...............................................................................................2-1

2.1.2 PRODUCT IDENTIFICATION....................................................................2-2

2.1.3 R EVISION HIS T ORY.......... ....................... .. ........... .. ........... .. .................... 2-3

2.2 ELECTRICAL

2.2.1 EXTERNAL CONNECTIONS............. ..................... ..................... .............2-4

2.2.2 CONTROL POWER.................................... ..................... ........................ 2-13

2.2.3 VT INPUTS ............... .. ............ . ............ .. ........... .. ............ ........... .. ........... . 2-13

2.2.4 CT INPUTS.............................................................................................. 2-13

2.2.5 OUTPUT RELAYS................................................... ..................... ........... 2-14

2.2.6 SWITCH INPUTS (OPTIONAL)............................................................... 2-15

2.2.7 ANALOG OUTPUTS (OPTIONAL).......................................................... 2-17

2.2.8 ANALOG INPUT (OPTIONAL)................................................................. 2-17

2.2.9 RS485 SERIAL PORTS........................................................................... 2-18

2.2.10 RS232 FRONT PANEL PORT......................................... ..................... ...2-20

2.2.11 DIELECTRIC STRENGTH TESTING......................................................2-21

3. OPERATION

3.1 FRONT PANEL & DISPLAY

3.1.1 FRONT PANEL.......................................................................................... 3-1

3.1.2 DISPLAY.................................................................................................... 3-1

3.2 STATUS INDICATORS

3.2.1 DESCRIPTION..........................................................................................3-2

3.2.2 STATUS.....................................................................................................3-2

3.2.3 COMMUNICATE........................................................................................ 3-2

3.2.4 RELAYS..................................................................................................... 3-3

3.3 KEYPAD

3.3.1 DESCRIPTION..........................................................................................3-4

3.3.2 SETPOINT KEY.........................................................................................3-4

3.3.3 ACTUAL KEY................................ .............................................................3-4

3.3.4 STORE KEY..............................................................................................3-4

3.3.5 RESET KEY...............................................................................................3-5

3.3.6 MESSAGE KEYS........ .................................. .. ....................... .. .. ............ . .. . 3-6

3.3.7 VALUE KEYS............................................................................................. 3-6

3.3.8 DATA ENTRY METHODS....................................... ..................... ............. 3-7

3.3.9 SETPOINT ACCESS SECURITY ..............................................................3-7

GE Power Management PQM Power Quality Meter

i

TABLE OF CONTENTS

3.4 DEFAULT MESSAGES

3.4.1 DESCRIPTION ..........................................................................................3-8

3.4.2 ADDING A DEFAULT MESSAGE.............................................................3-8

3.4.3 DEL ETING A DEFAU L T MESSAGE ..... .. ......................... ............. ............ 3-8

4. PROGRAMMING

4.1 INTRODUCTION

4.1.1 SETPOINT ENTRY METHODS.................................................................4-1

4.2 S1 PQM SETUP

4.2.1 DESCRIPTION ..........................................................................................4-3

4.2.2 PREFERENCES........................................................................................4-3

4.2.3 SETPOINT ACCESS.................................................................................4-4

4.2.4 RS485/RS232 SERIAL PORTS.................................................................4-6

4.2.5 DNP 3.0 CONFIGURATION........ ..................... .........................................4-7

4.2.6 CLOCK........................................................ ..................... ..................... ..... 4-8

4.2.7 CALCULATION PARAMETERS................................................................4-9

4.2.8 CLEAR DATA ..........................................................................................4-11

4.2.9 EVENT RECORDER ...............................................................................4-13

4.2.10 TRACE MEMORY.................. ........................................ ..................... ..... 4-14

4.2.11 PROGRAMMABLE MESSAGE ...............................................................4-17

4.2.12 PRODUCT OPTIONS..............................................................................4-18

4.3 S2 SYSTEM SETUP

4.3.1 CURRENT/VOLTAGE CONFIGURATION......... .....................................4-19

4.3.2 ANALOG OUTPUTS......................................... ..................... ..................4-21

4.3.3 ANALOG INPUT............................ ..................... ..................... ................4-25

4.3.4 SWITCH INPUTS.................................. ..................... ..................... ......... 4-27

4.3.5 PULSE OUTPUT ..................................................................................... 4-29

4.3.6 PULSE INPUT .........................................................................................4-31

4.3.7 DATA LOGGER.................................... ........................................ ...........4-33

4.4 S3 OUTPUT RELAYS

4.4.1 DESCRIPTION ........................................................................................4-34

4.4.2 ALARM RELAY........................................................................................ 4-35

4.4.3 AUXILIARY RELAYS.................................. ............................................. 4-35

4.5 S4 ALARMS/CONTROL

4.5.1 CURRENT/VOLTAGE ALARMS.............................................................. 4-36

4.5.2 TOTAL HARMONIC DISTORTION............. ..................... ..................... ... 4-41

4.5.3 FREQUENCY ....................................... .......................................... ......... 4-42

4.5.4 POWER ALARMS....................................................................................4-43

4.5.5 POWER FACTOR.............. ..................... ................................................. 4-45

4.5.6 DEMAND ALARMS............ ......................................................................4-48

4.5.7 PULSE INPUT .........................................................................................4-50

4.5.8 TIME ........................................................................................................ 4-52

4.5.9 MISCELLANEOUS ALARMS...................................................................4-53

4.6 S5 TESTING

4.6.1 TEST OUTPUT RELAYS & LEDS........................................................... 4-54

4.6.2 CURRENT/VOLTAGE SIMULATION ...................................................... 4-55

4.6.3 ANALOG OUTPUTS SIMULATION.........................................................4-56

4.6.4 ANALOG INPUT SIMULATION ............................................................... 4-57

4.6.5 SWITCH INPUTS SIMULATION........... ..................... ..................... .........4-58

4.6.6 FACTORY USE ONLY............................................................................. 4-58

ii

PQM Power Quality Meter

GE Power Management

TABLE OF CONTENTS

5. MONITORING

5.1 ACTUAL VALUES VIEWING

5.1.1 DESCRIPTION..........................................................................................5-1

5.2 A1 METERING

5.2.1 CURRENT ................................................................................................. 5-2

5.2.2 VOLTAGE.................................................................................................. 5-4

5.2.3 PHASORS .................................................................................................5-6

5.2.4 POWER ..................................................................................................... 5-7

5.2.5 ENERGY..................................................................................................5-12

5.2.6 DEMAND ................................................................................................. 5-14

5.2.7 FREQUENCY ..........................................................................................5-16

5.2.8 PULSE COUNTER.................................................................................. 5-17

5.2.9 ANALOG INPUT......................................... ............................................. 5-19

5.3 A2 STATUS

5.3.1 ALARMS..................................................................................................5-20

5.3.2 SWITCH STATUS.................................................................................... 5-22

5.3.3 CLOCK..................................................................................................... 5-23

5.3.4 PR OGRAMMA BLE MESSAG E ....... .. ........... .. .. ............ .. ........... .. ........... . 5-23

5.4 A3 POWER ANALYSIS

5.4.1 POWER QUALITY................................................... ..................... ........... 5-24

5.4.2 TOTAL HARMONIC DISTORTION....... ..................... ..................... ......... 5-25

5.4.3 DATA LOGGER.................................. ..................... ................................5-26

5.4.4 EVENT RECO R D ER .... ........... .. ............ ........... .. ............ .. ........... .. .......... 5-27

5.5 A4 PRODUCT INFO

5.5.1 SOFTWARE VERSIONS & MODEL INFORMATION.............................. 5-31

6. SOFTWARE

6.1 INTRODUCTION

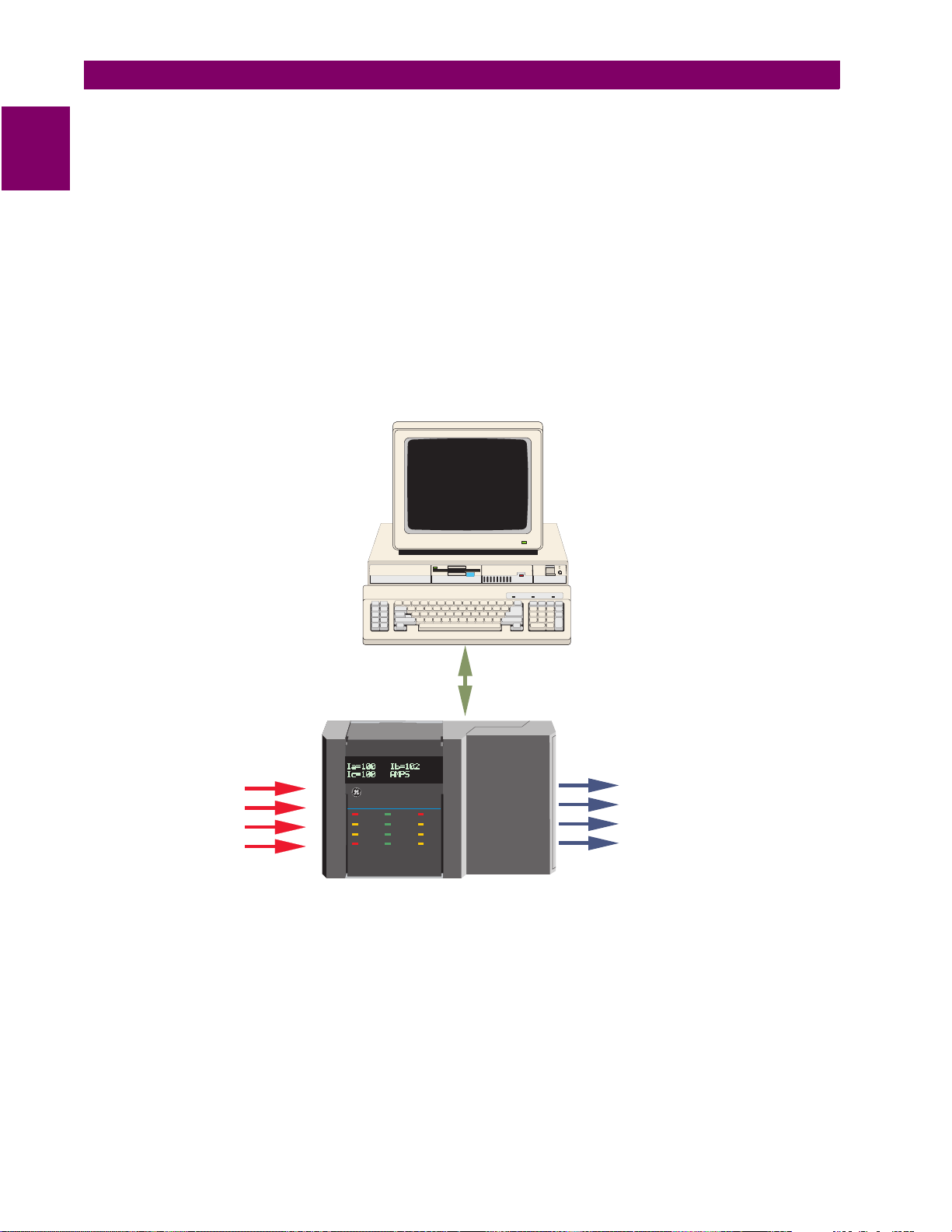

6.1.1 OVERVIEW................................................................................................ 6-1

6.1.2 HARDWARE CONFIGURATION................................... ..................... ....... 6-1

6.2 PQMPC INSTALLATION

6.2.1 CHECKING IF INSTALLATION/UPGRADE IS REQUIRED ...................... 6-3

6.2.2 INSTALLING/UPGRADING PQMPC................... ..................... .................6-4

6.2.3 CONFIGURING PQMPC COMMUNICATIONS......................................... 6-5

6.3 PQMPC MENUS

6.3.1 DESCRIPTION..........................................................................................6-6

6.4 UPGRADING FIRMWARE

6.4.1 DESCRIPTION..........................................................................................6-7

6.4.2 SAVE/PRINT PQM SETPOINTS TO A FILE............................................. 6-7

6.4.3 LOADING NEW FIRMWARE INTO THE PQM.......................................... 6-8

6.4.4 LOADING SAVED SETPOINTS INTO THE PQM................................... 6-10

6.5 USING PQMPC

6.5.1 ENTERING SETPOINTS......................................................................... 6-11

6.5.2 VIEWING ACTUAL VALUES................................................................... 6-12

6.5.3 SETPOINT FI L E S ......... ........... .. ............ .. ........... .. ............ ........... .. .......... 6-12

6.5.4 GETTING HELP.......................................................................................6-12

6.6 POWER ANALYSIS

6.6.1 WAVEFORM CAPTURE.......................................................................... 6-13

6.6.2 HARMONIC ANALYSIS.............. ..................... ..................... ...................6-13

6.6.3 TRACE MEMORY.................................................................................... 6-16

6.6.4 DATA LOGGER.................................. ..................... ................................6-18

GE Power Management PQM Power Quality Meter

iii

TABLE OF CONTENTS

7. MODBUS

COMMUNICATIONS

7.1 OVERVIEW

7.1.1 MODBUS PROTOCOL.............................................................................. 7-1

7.1.2 ELECTRICAL INTERFACE ................................... ..................... ...............7-1

7.1.3 DATA FORMAT & DATA RATE ................................................................. 7-1

7.1.4 DATA PACKET FORMAT........................................................ ..................7-2

7.1.5 ERROR CHECKING.................................................................................. 7-2

7.1.6 CRC-16 ALGORITHM................................................................................7-3

7.1.7 TIMING ...................................................................................................... 7-3

7.2 MODBUS FUNCTIONS

7.2.1 PQM SUPPORTED MODBUS FUNCTIONS................... ....................... ... 7-4

7.2.2 FUNCTION CODES 03/04 – READ SETPOINTS/ACTUAL VALUES....... 7-4

7.2.3 FUNCTION CODE 05 - EXECUTE OPERATION......................................7-5

7.2.4 FUNCTION CODE 05 – BROADCAST COMMAND.................................. 7-6

7.2.5 FUNCTION CODE 06 – STORE SINGLE SETPOINT .............................. 7-7

7.2.6 FUNCTION CODE 07 – READ DEVICE STATUS ....................................7-8

7.2.7 FUNCTION CODE 08 – LOOPBACK TEST.............................................. 7-9

7.2.8 FUNCTION CODE 16 – STORE MULTIPLE SETPOINTS...................... 7-10

7.2.9 FUNCTION CODE 16 - PERFORMING COMMANDS............................7-11

7.2.10 FUNCTION CODE 16 - BROADCAST COMMAND ................................7-12

7.2.11 ERROR RESPO N SES.. ..................................... ........... .. .. ....................... 7-13

7.3 MODBUS MEMORY MAP

7.3.1 MEMORY MAP INFORMATION........................................ ...................... 7-14

7.3.2 USER-DEFINABLE MEMORY MAP........................................................7-14

7.3.3 PQM MEMORY MAP...............................................................................7-15

7.3.4 MEMORY MAP DATA FORMATS.................. ........................................ .7-55

7.3.5 ANALOG OUTPUT PARAMETER RANGE ............................................. 7-63

8. DNP COMMUNICATIONS

9. COMMISSIONING

A. APPLICATION NOTES

8.1 DNP 3.0 PROTOCOL

8.1.1 DEVICE PROFILE DOCUMENT ................................. ..............................8-1

8.1.2 IMPLEMENTATION TABLE....................................................................... 8-3

8.1.3 DEFAULT VARIATIONS............................................................................8-4

8.1.4 INTERNAL INDICATION BITS ..................................................................8-4

8.1.5 BINARY INPUT / BINARY INPUT CHANGE POINT LIST.........................8-5

8.1.6 BINARY OUTPUT / CONTROL RELAY OUTPUT POINT LIST................ 8-7

8.1.7 POINT LIST FOR ANALOG INPUT/OUTPUT CHANGE........................... 8-9

8.1.8 POINT LIST FOR COUNTERS................................................................8-14

9.1 COMMISSIONING

A.1 PQM APPLICATION NOTES

A.1.1 EVENT RECORDER .................................................................................A-1

A.1.2 INT ERFACING U SING HYPERTERMINAL..... .. ............. ...........................A-4

A.1.3 PHASORS IMPLEMENTATION................................ ................................A-7

A.1.4 TRIGGERED TRACE MEMORY RESOLUTION.......................................A-9

A.1.5 PULSE OUTPUT APPLICATION.............................................................A-11

A.1.6 DATA LOGGER IMPLEMENTATI ON......................................................A-12

A.1.7 READING LONG INTEGERS FROM MEMORY MAP ................... .........A-16

A.1.8 PULSE INPUT APPLICATION.................................................................A-18

A.1.9 PULSE TOTALIZER APPLICATION ........................................................A-19

iv

PQM Power Quality Meter

GE Power Management

TABLE OF CONTENTS

B. TABLES AND FIGURES

C. WARRANTY

B.1 TABLES AND FIGURES

B.1.1 LIST OF TABLES.......................................................................................B-1

B.1.2 LIST OF FIGURES............................... ........................................ .............B-1

C.1 PQM WARRANTY

GE Power Management PQM Power Quality Meter

v

TABLE OF CONTENTS

vi

PQM Power Quality Meter

GE Power Management

1 OVERVIEW 1.1 INTRODUCTION

1 OVERVIEW 1.1 INTRODUCTION 1.1.1 DESCRIPTION

The GE Power Management PQM Power Quality Meter is an ideal choice for continuous monitoring of a single

or three-phase system. I t provides meter ing for current, voltag e, real power, reactive power, apparent power,

energy use, cost of power, power factor, and frequency. Programmable setpoints and four ass ignable output

relays allow contr ol functions to be added for specific applicatio ns. This includes basi c alarm on over/under

current or volta ge, unbalance, demand based load shedding, and capac itor power factor correction control.

More complex control is possible using the four sw itch inputs; these can also be used for status information

such as breaker open/closed, flow information, etc.

As a data gathering device for plant automation systems that integrate process, instrument, and electrical

requirements, all mon itored va lues are av aila ble via one of two RS48 5 commu nica tion por ts runnin g the Modbus protocol. If analog values are required for direct interface to a PLC, any of the monitored values can output

as a 4 to 20 mA ( or 0 t o 1 mA) s ignal to r eplace up to 4 separate t ransducer s. A thir d RS232 communica tion

port connects to a PC from the front panel for simultaneous access of information by other plant personnel.

With increasing us e o f el ec troni c lo ads s uc h as co mp uters , b all as ts , an d v ari abl e fr e quen cy d riv es , th e q ual ity

of the power system is importa nt. With the harm onic an alysis opti on, an y phase cu rren t or voltag e can be di splayed and the harmoni c cont ent calcu lated. K nowle dge of the harmo nic dist ribut ion all ows acti on to be ta ken

to prevent overheated tran sformer s, mo tors, c apaci tors, n eutral w ires , and nuisanc e break er t rips. Re distri bution of system loa ding can also be determined . The PQM can also provi de waveform and data printouts t o

assist in problem diagnosis.

Economical system mon itoring or control is possible by selecti ng the non-display chassis model as a syste m

component and adding required options to obtain the desired level of functionality.

1.1.2 FEATURE HIGHLIGHTS

1

• Monitor: A, V, VA, W, var, kWh, kvarh, kVAh, PF, Hz

• Demand metering: W, var, A, VA

• Setpoints for alarm or cont rol from most measur ed values, incl uding: unbalance, frequency, power factor,

voltage, and current

• 4 output relays / 4 switch inputs for flexible control configuration

• 4 isolated analog outputs replace transducers for PLC interface

• 1 4-20 mA analog input

• Modbus communications

• Three COM ports (two rear RS485 ports and one front RS232 port) for access by process, electrical, main-

tenance, and instrument personnel

• Harmonic analysis for power quality review and problem correction

• 40-character display and keypad for local programming

• Free PQMPC software for setpoint entry or monitoring from a PC

• Simulation mode for testing and training

• Compact design for panel or chassis mount

• AC/DC control power

GE Power Management PQM Power Quality Meter 1-1

1.1 INTRODUCTION 1 OVERVIEW

1

STATUS:

ALARM

PROGRAM

SIMULATION

SELF TEST

- Alarm condition present

- Setpoint programming is

enabled

- Simulated values being

used for test/training

- internal fault detected,

service required

PQM Power Quality Meter

g

STATUS COMMUNICATE RELAYS

ALARM

PROGRAM

SIMULATION

SELF TEST

TX1

RX1

TX2

RX2

COMMUNICATE:

For monitoring communication activity:

TX1

COM1 transmit data

RX1

COM1 receive data

TX2

COM2 transmit data

RX2

COM2 receive data

ACTUAL

SETPOINT RESET

MESSAGE

ALARM

AUX1

AUX2

AUX3

VALUE

RELAYS:

ALARM

AUX1

AUX2

AUX3

STORE

Alarm condition present.

See display for cause.

Auxiliary relay activated by

programmable function.

}

DISPLAY

40 character illuminated display for

programming, monitoring, status, fault

diagnosis, user programmable messages

and setpoints. Programmable auto scan

sequence for unattended operation.

DOOR:

Door covers keys and computer port

when not in use.

KEYPAD:

Rubber keypad is dust tight and

splash proof.

SETPOINT KEY:

Program all setpoints. Tamperproof

settings with passcode and access jumper

prevent unauthorized setpoint changes.

COMPUTER INTERFACE:

RS232 comm port for connecting to a PC.

Use for downloading setpoints, monitoring,

data collection, printing reports.

CT INPUTS:

3 isolated phase CT inputs

1 isolated neutral CT input

1 Amp or 5 Amp secondary

VT INPUTS:

0-600V, 3 wire or 4 wire voltage inputs.

Direct (up to 600V) or VT (>600V for

isolation) connections.

AC/DC CONTROL POWER

Universal control power

90-300 VDC

70-265 VAC

GROUND:

Separate safety and filter ground

All inputs meet C37.90 and IEC 801-2

EMI, SWC, RFI interference immunity.

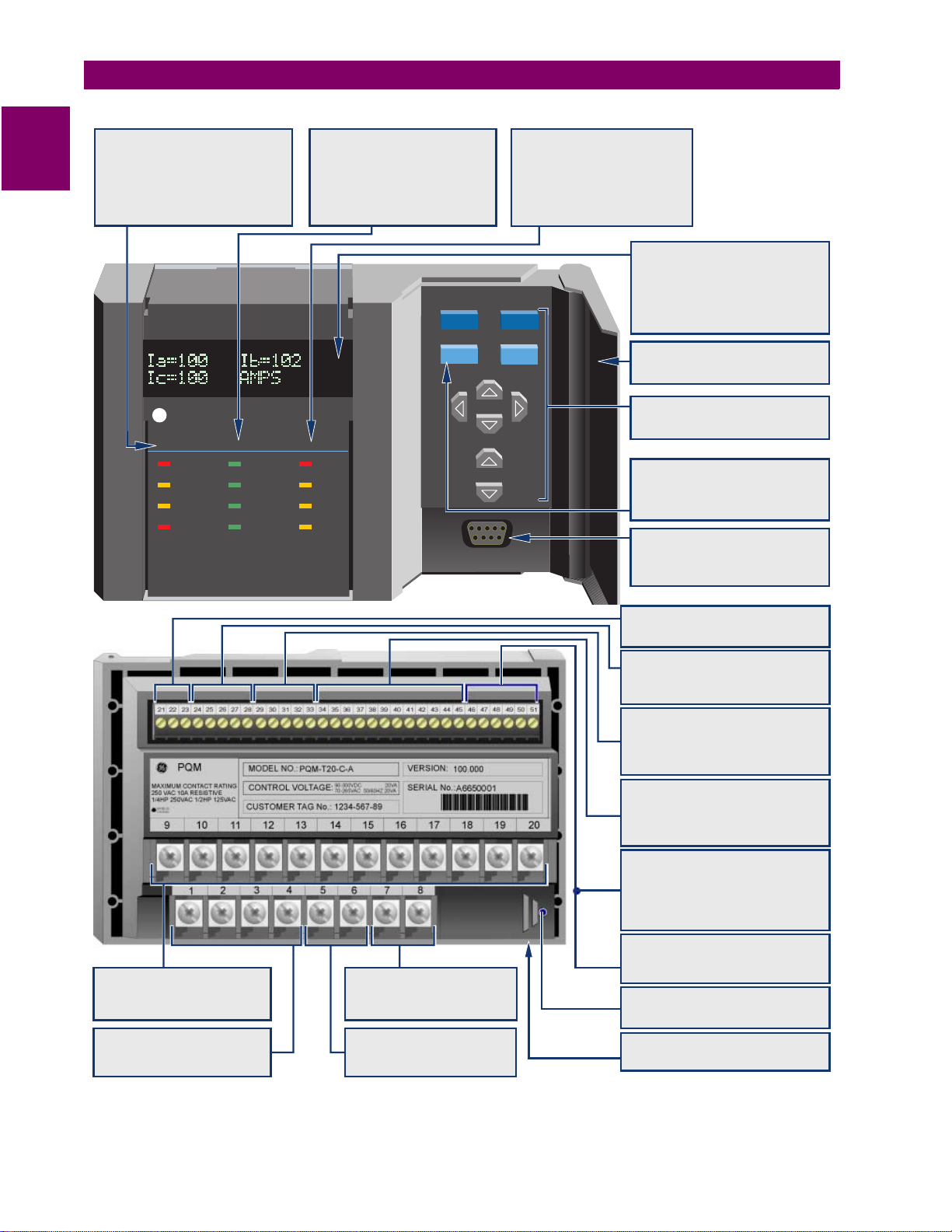

Figure 1–1: PQM FEATURE HIGLIGHTS

ANALOG INPUT

Accept 4-20mA analog inputs for transducer

interface.

823756AK.CDR

ANALOG OUTPUTS

4 isolated 0-1mA or 4-20 mA outputs replace

8 transducers. Programmable including:

A, V, W, var, VA, Wh varh, PF, Hz

SWITCH INPUTS

A

Programmable for relay activation,

B

counters, logic, demand synchronization,

C

setpoint access, alarm position

}

D

4 OUTPUT RELAYS

ALARM

Programmable alarm conditions

AUX1

actuated by programmable

AUX2

setpoints, switch inputs, remote

}

AUX3

communication control.

COMMUNICATIONS

Dual RS485 comm ports Modbus protocol.

Continuous monitoring/control via

COM1

SCADA system rear (RS485).

COM2/3

Front (RS232) or rear (RS485) access

allows simultaneous communication

via a PC or for redundant comms.

PROGRAM UPDATING

Flash memory storage of firmware for field

updating via communications port. Enables

product updating on-site for latest features.

FUSE ACCESS

Control power fuse accessible under sliding

door.

COMPACT DESIGN

Panel mount replaces many discrete

components with one standard model.

®

823755AL.CDR

1-2 PQM Power Quality Meter GE Power Management

1 OVERVIEW 1.1 INTRODUCTION

1.1.3 APPLICATIONS

• Metering of distribution feeders, transformers, generators, capacitor banks, and motors

• Medium and low voltage three-phase systems

• Commercial, industrial, utility

• Flexible control for demand load shedding, power factor, etc.

• Power quality analysis

• System debugging

3 PHASE

3/4 WIRE BUS

0-600V DIRECT

>600V CT/VTs

AC/DC

CONTROL

POWER

-

CTs

VTs

PQM RELAY

4 SWITCH

INPUTS FOR

CONTROL

1

MAIN

SCADA

INSTRUMENTATION

ELECTRICAL

MAINTENANCE

COM 1

4

OUTPUT

COM 2

RS232

PORT

RELAYS

4

TRANSDUCER

OUTPUTS

Figure 1–2: SINGLE LINE DIAGRAM

ALARM

CONTROL

4-20mA

1

2

3

4

823768A2.CDR

PLC

or

RTU

GE Power Management PQM Power Quality Meter 1-3

1.2 STANDARD FEATURES 1 OVERVIEW

SIMULATION

ALARM

STATUS

SELF TEST

PROGRAM

TX2

TX1

COMMUNICATE

RX2

RX1

AUX2

ALARM

RELAYS

AUX3

AUX1

1.2 STANDARD FEATURES 1.2.1 METERING

1

I

,

I

,

I

,

I

,

V

,

V

,

V

,

V

,

V

,

V

True RMS monitoring of

a

b

c

n

an

bn

cn

ab

frequency, watts, vars, VA, Wh, varh, VAh, and demand read ings for A, W, vars, and VA. Maximum and minimum values of measured quantities are recorded and are date and time stamped.

A 40-character displ ay with brightness control is us ed for programming setpoin ts and monitoring values an d

status.

a) ALARMS

Alarm conditions can be set up for all meas ured quantities. The se include overcurren t, undercurrent, neutral

current, current u nbalance, vol tage unbalance , phase revers al, overfreque ncy, underfrequency, pow er factor,

switch inputs, etc. The alarm messages are displayed in a simple and easy to understand English format.

b) COMMUNICATION

The PQM is equipped wit h one standard RS485 port utilizing the Modbus or DNP 3.0 pr otocols. This can b e

used to integrate pr ocess, instrume ntation, and ele ctrical requiremen ts in a plant automation sy stem by connecting PQM meters toge ther to a DCS or SCADA system. A PC r unning PQMPC can change sy stem setpoints and monitor values, status, and alarms. Continuous monitoring minimizes process downtime by

immediately identifying potential problems due to faults or changes from growth.

The PQM also includes a front RS232 port which may be employed to perform such tasks as:

• data monitoring

• problem diagnosis

, voltage/current unba lance, pow er factor, line

bc

ca

• viewing event records

• trending

• printing settings and/or actual values

• loading new firmware into the PQM

1.2.2 FUTURE EXPANSION

Flash memory is used to st ore firmw are with in the PQM. T his allo ws futur e produc t upgrad es to be loaded via

the serial port.

Product update

from GE Power

PQMWindowsApplication - PQM

Transfer new firmware

to the PQM

Management

CD-ROM

ForHelp,press F1

Seconds(ElapsedTime)

PQMPower Quality Meter

STATUS

ALARM

PROGRAM

SIMULATION

SELF TEST

COMMUNICATE

TX1

RX1

TX2

RX2

RELAYS

ALARM

AUX1

AUX2

AUX3

823774A5.CDR

Figure 1–3: DOWNLOADING PRODUCT ENHANCEMENTS VIA THE SERIAL PORT

PQM units can initially be used as standalone meters. Their open architecture allows connection to other Modbus compatible devi ces on the same com munication link. The se can be integrated in a complete plant-wid e

system for overall process monitoring and control.

1-4 PQM Power Quality Meter GE Power Management

1 OVERVIEW 1.2 STANDARD FEATURES

1.2.3 OPTIONAL FEATURES

a) TRANSDUCER OPTION

Four isolated 4 to 20 mA (or 0 to 1 mA depending on the installed option) analog outputs are provided that can

replace up to eight trans duc ers . T he o utpu ts c an be a ssig ned to any measured param eters for dire ct inte r fac e

to a PLC.

One 4 to 20 mA analog inp ut i s prov i ded t o ac ce pt a transducer output for di sp lay i ng in for ma tio n such as temperature or water level.

An additional re ar RS 485 co mmunication port is pr ov id ed for sim ultaneous monitor ing by pr oc ess , in strument,

electrical, or maintenance personnel.

Main plant

control/monitoring

communication

interface

Use 2nd/3rd comm ports for simultaneous

access by electrical, maintenance,

process, instrumentation personnel

for

•Data monitoring

•Problem diagnosis

•Event records

RS485 RS485

•Trending

•Report printing

Print reports

PQMPower Quality Meter

STATUS COMMUNICATE RELAYS

TX1

ALARM

PROGRAM

RX1

SIMULATION

TX2

SELFTEST

RX2

ALARM

AUX1

AUX2

AUX3

ACTUAL

SETPOINT

MESSAGE

VALUE

STORE

RESET

File

ForHelp,pressF1

PQMWindowsApplication- PQM

Actual

Help

Setpoint

Communication

Actual-ChartRecorder

OK

RUN

Cancel

PRINT

TrendingChart

Seconds(ElapsedTime)

1

RS232

Figure 1–4: ADDITIONAL COMMUNICATION PORT

823779A7.CDR

GE Power Management PQM Power Quality Meter 1-5

1.2 STANDARD FEATURES 1 OVERVIEW

b) CONTROL OPTION

An additional thre e dry-co ntact form “C ” output rela ys and fou r dry-cont act switch inputs ar e provided. T hese

1

additional relays can be combined with setpoints and inputs/outputs for control applications. Possibilities

include:

• undercurrent alarm warnings for pump protection

• over/undervoltage for gener ato rs

• unbalance alarm warnings to protect rotating machines

• dual level power factor for capacitor bank switching

• underfrequency/demand output for load shedding resulting in power cost savings

• kWh, kvarh and kVAh pulse output for PLC interface

• Pulse input for totalizing quantities such as kWh, kvarh, kVAh, etc.

DCS

RS485

MODBUS

PQM

4

SWITCH

INPUTS

PQMPower Quality Meter

STATUS COMMUNICATE RELAYS

ALARM

PROGRAM

SIMULATION

SELFTEST

Figure 1–5: SWITCH INPUTS AND OUTPUTS RELAYS

ALARM

TX1

AUX1

RX1

AUX2

TX2

AUX3

RX2

RELAYS

4

ALARM

AUX 1

AUX 2

AUX 3

823775A6.DWG

1-6 PQM Power Quality Meter GE Power Management

1 OVERVIEW 1.2 STANDARD FEATURES

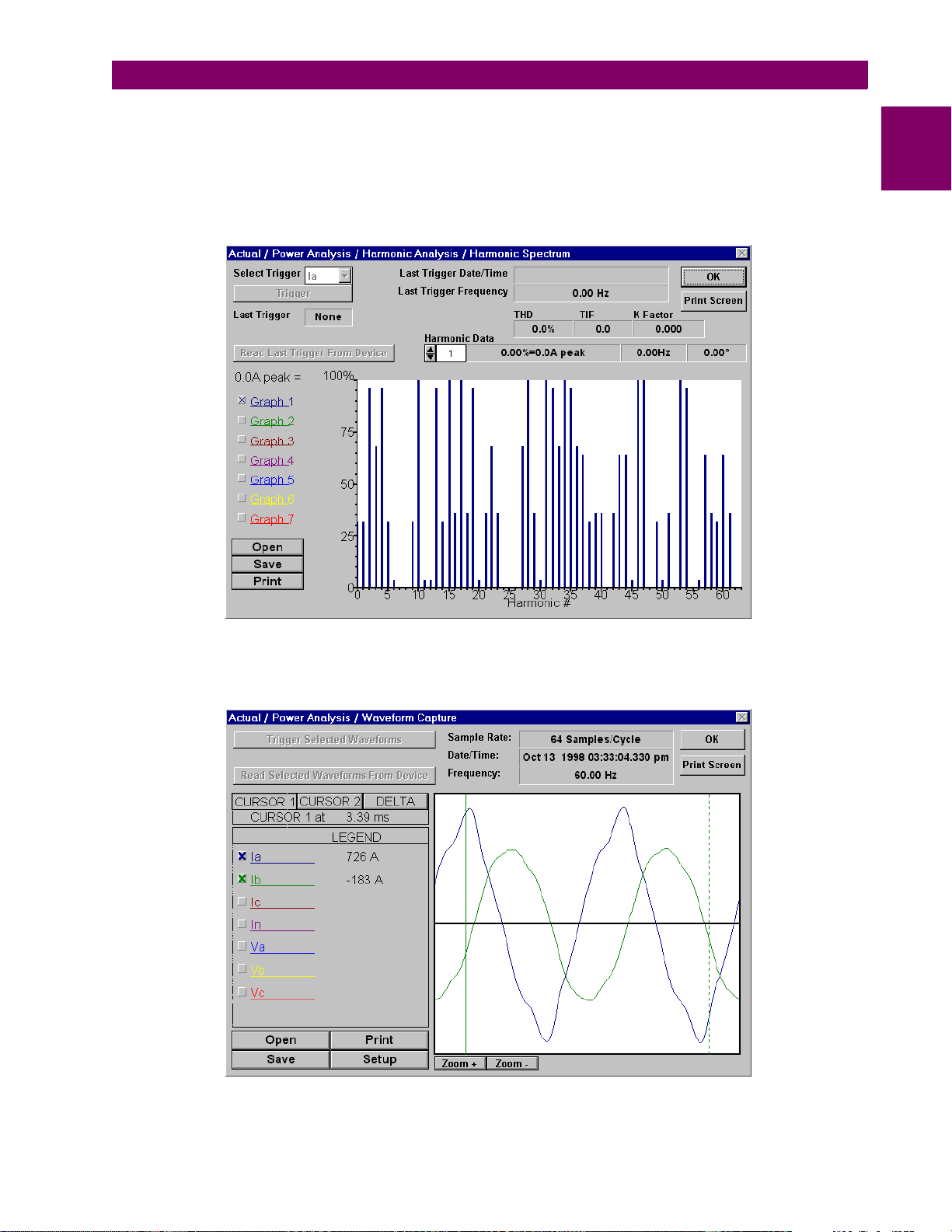

c) POWER ANALYSIS OPTION

Non-linear loads (such as variable speed drives, computers, and electronic ballasts) can cause unwanted harmonics that may lead to nuisance breaker tripping, telephone interference, and transformer, capacitor or motor

overheating. For fault dia gnostics such as detecting undersized ne utral wiring, assessing the need for harmonic rated transformers, or judging the effectiveness of harmonic filters, details of the harmonic spectrum are

useful and available with the power analysis option.

1

Figure 1–6: HARMONIC SPECTRUM

Voltage and current waveforms can be captured and displa yed on a PC with PQMPC or t hird party softwa re.

Distorted peaks or notches from SCR switching provide clues for taking corrective action.

Figure 1–7: CAPTURED WAVEFORM

GE Power Management PQM Power Quality Meter 1-7

1.2 STANDARD FEATURES 1 OVERVIEW

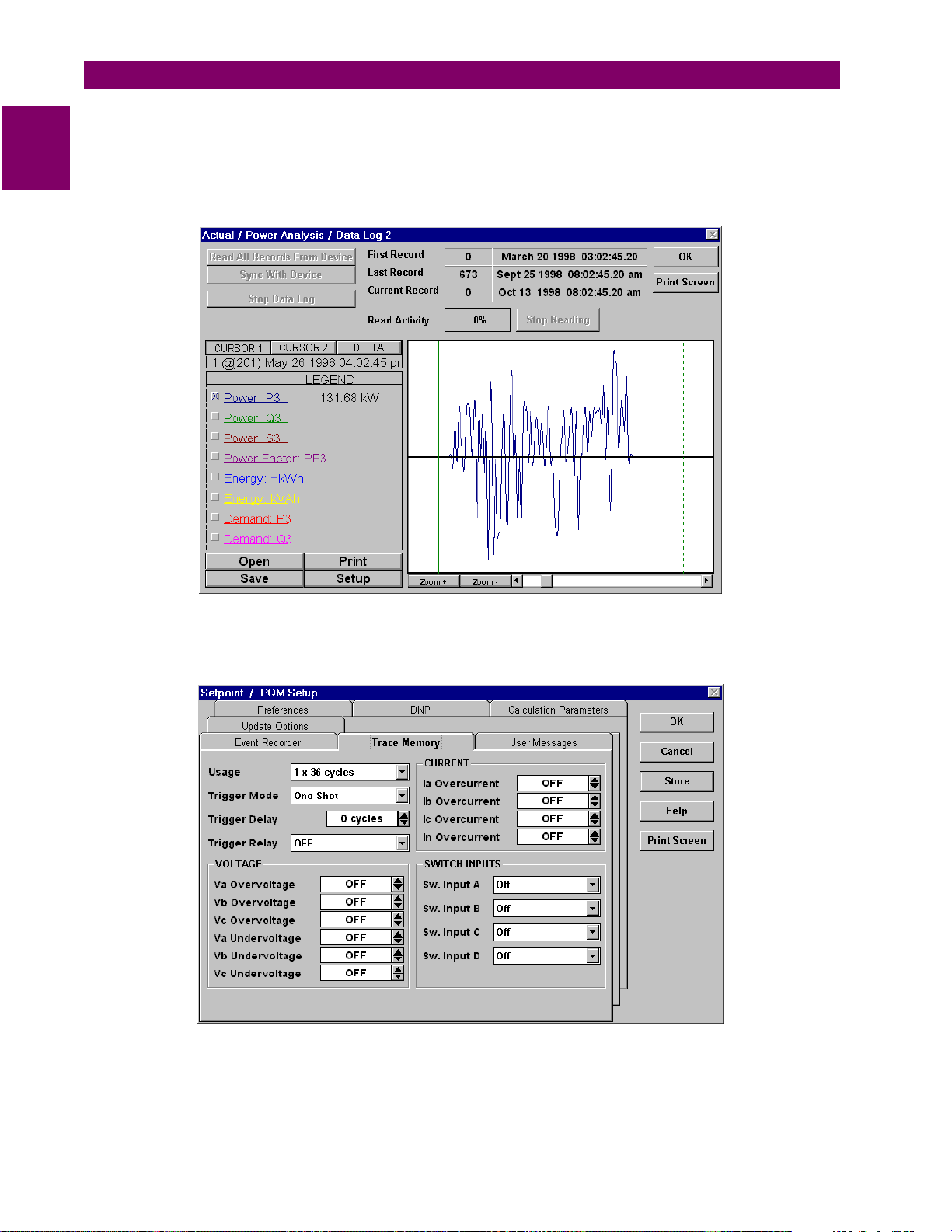

Alarms, setpoint triggers, and input and output events can be stored in a 40-event record and time/date

stamped by the inter nal clock . This is usefu l for diag nosing prob lems and s ystem acti vity. The event record is

1

available through serial communication. Minimum and maximum value s are also c ontinuously updated and

time/date stamped.

Routine event logs of all measured quantities can be created, saved to a file, and/or printed.

Figure 1–8: DATA LOGGER

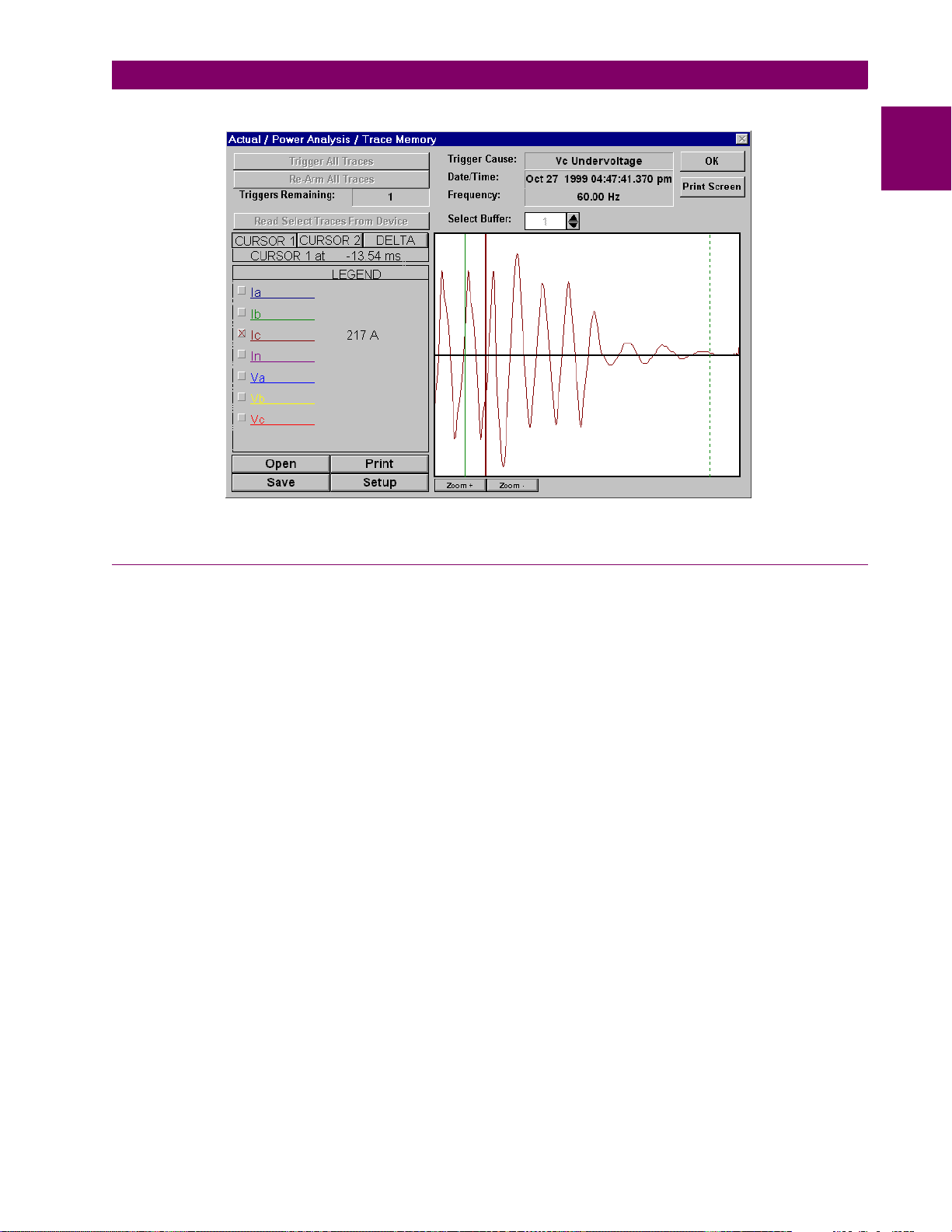

The power analysis option also provides a Trace Memory feature. This feature can be used to record specified

parameters based on the user defined triggers.

Figure 1–9: TRACE MEMORY TRIGGERS

1-8 PQM Power Quality Meter GE Power Management

1 OVERVIEW 1.2 STANDARD FEATURES

Figure 1–10: TRACE MEMORY CAPTURE

1

1.2.4 PQMPC SOFTWARE

All data continuously gathered by the PQM can be transferred to a third party software program for display,

control, or analys is t hr oug h th e c omm uni c atio ns in ter face. The PQMPC softwa r e ma ke s thi s d ata im med iate ly

useful and assists in pr ogramming the PQM. S ome of the task s that can b e executed us ing the PQMP C software package are:

• read metered data

• monitor system status

• change PQM setpoints on-line

• save setpoints to a file and download into any PQM

• capture and display voltage and current wave shapes for analysis

• record demand profiles for various measured quantities

• troubleshoot communication problems with a built in communications debugging tool

• print all graphs, charts, setpoints, and actual data

The PQMPC software is fully described in Chapter 6: SOFTWARE.

GE Power Management PQM Power Quality Meter 1-9

1.2 STANDARD FEATURES 1 OVERVIEW

1.2.5 ORDER CODES

1

The order code for all options is:

Table 1–1: ORDER CODES

S S S

|

|

T20

Basic Unit

Transducer

Option

PQM

PQM

T1

Control

Option

Power Analysis

Option

Modifications (consult the factory for any additional modification costs):

• MOD 500: Portable test/carrying case

• MOD 501: 20 to 60 V DC / 20 to 48 V AC control power

• MOD 502: Tropicalization

• MOD 504: Removable terminal blocks

• MOD 505: PQM Remote: Base Unit with Detachable Faceplate

PQM-T20-C-A

|

|

|

|

|

|

C

Basic Unit with display, all current/voltage/power measurements, 1 RS485

|

communication port, 1 RS232 communication port

|

4 isolated analog outputs, 0-20 mA and 4-20 mA assignable to all measured

|

parameters, 4-20 mA analog input, 2nd RS485 communication port

|

4 isolated analog outputs, 0-1 mA assignable to all measured parameters, 4-

|

20 mA analog input, 2nd RS485 communication port

|

3 additional programmable output relays (for a total of 4), 4 programmable

|

switch inputs

|

Harmonic analysis, triggered trace memory, waveform capture, event

A

recorder, data logger

• MOD 506: 4 Step Capacitor Bank Switching

• MOD 507: –40°C to +60°C Extended Temperature Operation

• MOD 508: 269/565 Communication Protocol

• MOD 513: Class 1, Division 2 Operation

• MOD 516: PQM Remote: Base Unit only

• MOD 517: PQM Remote: Detachable Faceplate only

Accessories (consult the factory for any additional accessory costs):

• PQMPC Windows software (free upon request)

• RS232 to RS485 converter (required to connect a PC to the PQM RS485 ports)

• 2.25” collar for limited depth mounting

• RS485 terminating network

• PQM mounting plate to replace MTM Plus

Control Power:

• 90 to 300 V DC / 70 to 265 V AC standard

• 20 to 60 V DC / 20 to 48 V AC (MOD 501)

1-10 PQM Power Quality Meter GE Power Management

1 OVERVIEW 1.3 SPECIFICATIONS

1.3 SPECIFICATIONS 1.3.1 PQM SPECIFICATIONS

CURRENT INPUTS

CONVERSION: true rms, 64 samples/cycle

CT INPUT: 1 A and 5 A secondary

BURDEN: 0.2 VA

OVERLOAD: 20 × CT for 1 sec.

100 × CT for 0.2 sec.

RANGE: 1 to 150% of CT primary

FREQUENCY: up to 32nd harmonic

ACCURACY: ±0.2% of full scale

VOLTAGE INPUTS

CONVERSION: true rms, 64 samples/cycle

VT PRI/SEC: direct or 120 to 72000:69 to 240

BURDEN: 2.2 MΩ

INPUT RANGE: 20 to 600 V AC

FULL SCALE: 150/600 V AC autoscaled

FREQUENCY: up to 32

ACCURACY: ±0.2% of full scale

nd

harmonic

TRACE MEMORY TRIGGER

INPUT 1 cycle of data (current, voltage)

TIME DELAY: 0 to 30 cycles

SAMPLING MODES

METERED

VALUES

TRACE

MEMORY

HARMONIC

SPECTRUM

SAMPLES

/CYCLE

64 ALL 2

16 ALL continuous

256 1 1

INPUTS SAMPLED

AT A TIME

DURATION

(cycles)

SWITCH INPUTS

TYPE: dry contacts

RESISTANCE: 1000 Ω max ON resistance

OUTPUT: 24 V DC @ 2 mA (pulsed)

DURATION: 100 ms minimum

ANALOG OUTPUTS

OUTPUT

0-1 mA

(T1 Option)

MAX LOAD

MAX OUTPUT 1.1 mA 21 mA

ACCURACY: ±1% of full scale reading

ISOLATION: 50 V isolated, active source

Ω

2400

4-20 mA

(T20 Option)

Ω

600

ANALOG INPUT

RANGE: 4 to 20 mA

ACCURACY: ±1% of full scale reading

INTERNAL BURDEN

RESISTANCE: 250 Ω

OUTPUT RELAYS

VOLTAGE MAKE/CARRY BREAK

continuous 0.1 sec.

RESISTIVE 30 VDC 5A 30A 5A

125 VDC 5A 30A 0.5A

250 VDC 5A 30A 0.3A

INDUCTIVE

(L/R=7ms)

RESISTIVE 120 VAC 5A 30A 5A

INDUCTIVE

PF=0.4

CONFIGURATION: Form C NO/NC

CONTACT MATERIAL:Silver Alloy

30 VDC 5A 30A 5A

125 VDC 5A 30A 0.25A

250 VDC 5A 30A 0.15A

250 VAC 5A 30A 5A

120 VAC 5A 30A 5A

250 VAC 5A 30A 5A

1

GE Power Management PQM Power Quality Meter 1-11

1.3 SPECIFICATIONS 1 OVERVIEW

MEASURED VALUES

1

PARAMETER ACCURACY

(% of full scale)

VOLTAGE ±0.2% 20% to 100% of VT

CURRENT ±0.2% 1% to 150% of CT

V UNBALANCE ±1% 0 to 100%

I UNBALANCE ±1% 0 to 100%

kW see Accuracy Details 0 to ±999,999.99 kW

kvar see Accuracy Details 0 to ±999,999.99 kvar

kVA see Accuracy Details 0 to 999,999.99 kVA

kWh see Accuracy Detail s 2

kvarh see Accuracy Detail s 2

kVAh see Accuracy Details 2

PF ±1.0% ± 0.00 to 1.00

FREQUENCY ±0.02Hz 20.00 to 70.00 Hz

kW DEMAND ±0.4% 0 t o ±999 999.99 kW

kvar DEMAND ±0.4% 0 to ±999 999.99 kvar

kVA DEMAND ±0.4% 0 to 999999.99 kVA

AMP DEMAND ±0.2% 0 to 7500 A

AMPS THD ±2.0% 0.0 to 100.0%

VOLTS THD ±2.0% 0.0 to 100.0%

CREST FACTOR ±0.4% 1 to 9.99

RANGE

32

kWh

32

kvarh

32

kVAh

UNDERVOLTAGE MONITORING

REQ’D VOLTAGE: > 20 V applied in all phases

PICKUP: 0.50 to 0.99 in steps of 0.01 × VT

DROPOUT: 103% of pickup

TIME DELAY: 0.5 to 600.0 in steps of 0.5 sec.

PHASES: Any 1 / Any 2 / All 3 (prog rammable)

have to be ≤ pickup to operate

ACCURACY: Per voltage input

TIMING ACCURACY: –0 / +1 sec.

OVERVOLTAGE MONITORING

PICKUP: 1.01 to 1.25 in steps of 0.01 × VT

DROPOUT: 97% of pickup

TIME DELAY: 0.5 to 600.0 in steps of 0.5 sec.

PHASES: Any 1 / Any 2 / All 3 (prog rammable)

must be ≥ pickup to operate

ACCURACY: Per voltage input

TIMING ACCURACY: –0 / +1 sec.

UNDERFREQUENCY MONITORING

REQ’D VOLTAGE: > 30 V applied in phase A

PICKUP: 20.00 to 70.00 in steps of 0.01 Hz

DROPOUT: Pickup + 0.03 Hz

TIME DELAY: 0.1 to 10.0 in steps of 0.1 sec.

ACCURACY: 0.02 Hz

TIMING ACCURACY: ±3 cycles

OVERFREQUENCY MONITORING

REQ’D VOLTAGE: > 30 V applied in phase A

PICKUP: 20.00 to 70.00 in steps of 0.01 Hz

DROPOUT: Pickup – 0.03 Hz

TIME DELAY: 0.0 to 10.0 in steps of 0.1 sec.

ACCURACY: 0.02 Hz

TIMING ACCURACY: ±3 cycles

POWER FACTOR MONITORING

REQ’D VOLTAGE: > 20 V applied in phase A

PICKUP: 0.50 lag to 0.50 lead step 0.01

DROPOUT: 0.50 lag to 0.50 lead step 0.01

TIME DELAY: 0.5 to 600.0 in steps of 0.5 sec.

TIMING ACCURACY: –0 / +1 sec.

DEMAND MONITORING

MEASURED VALUES:Phase A/B/C/N Current (A)

3φ Real Power (kW)

3φ Reactive Power (kvar)

3φ Apparent Power (kVA)

MEASUREMENT TYPE:

Thermal Exponential 90% response time

(programmable): 5 to 60 min. step 1

Block interval: (programmable): 5 to 60 min. step 1

Rolling Demand

time interval: (programmable): 5 to 60 min. step 1

PICKUP: A: 10 to 7500 in steps of 1000

kW: 0.1 to 6500.0 in steps of 0.1

kvar: 0.1 to 6500.0 in steps of 0.1

kVA: 0.1 to 6500.0 in steps of 0.1

PULSE OUTPUT

PARAMETERS: +kWh, –kWh, +kvarh, –kvarh, kVAh

INTERVAL: 1 to 65000 in steps of 1

PULSE WIDTH: 100 to 2000 ms in steps of 10 ms

MIN. PULSE INTERVAL: 500 ms

ACCURACY: ±10 ms

PULSE INPUT

MAX INPUTS: 4

MIN PULSE WIDTH: 150 ms

MIN OFF TIME: 200 ms

1-12 PQM Power Quality Meter GE Power Management

1 OVERVIEW 1.3 SPECIFICATIONS

WARNING

COMMUNICATIONS

COM1/COM2 TYPE: RS485 2-wire, half duplex, isolated

COM3 TYPE: RS232 9-pin

BAUD RATE: 1200 to 19200

PROTOCOLS: Modbus

FUNCTIONS: Read/write setpoints

Read actua l values

Execute commands

Read Device Status

Loopback Test

®

RTU; DNP 3.0

CLOCK

ACCURACY: ±1 minute / 30 days at 25°C ± 5°C

RESOLUTION: 1 sec.

CONTROL POWER

INPUT: 90 to 300 V DC or

70 to 265 V AC, 50/60 Hz

POWER: nominal 10 VA

maximum 20 VA

HOLDUP: 100 ms typical

(@ 120 V AC / 125 V DC)

IT IS RECOMMENDED THAT THE PQM BE

POWERED UP AT LEAST ONCE PER YEAR

TO AVOID DETERIORATION OF THE ELECTROLYTIC CAPACITORS IN THE POWER

SUPPLY.

TYPE TESTS

DIELECTRIC STRENGTH:

2.0 kV for 1 minute to relays, CTs,

VTs, power supply

INSULATION RESISTANCE: IEC255-5, 500 V DC

TRANSIENTS: ANSI C37.90.1 Oscillatory

2.5 kV/1 MHz

ANSI C37.90.1 Fast Rise 5 kV/10 ns

Ontario Hydro A-28M-82

IEC255-4 Impulse/High Frequency

Disturbance Class III Level

IMPULSE TEST: IEC 255-5 0.5 Joule 5kV

RFI: 50 MHz/15 W Transmitter

EMI: C37.90.2 Electromagnetic Interfer-

ence @ 150 MHz and 450 MHz,

10V/m

STATIC: IEC 801-2 Static Discharge

HUMIDITY: 95% non-condensing

TEMPERATURE: –10°C to +60°C ambient

ENVIRONMENT: IEC 68-2-38 Temperature/Humidity

Cycle

PACKAGING

SHIPPING BOX: 8½" × 6" × 6" (L×H×D)

21.5cm × 15.2cm × 15.2 cm

(L×H×D)

SHIP WEIGHT: 5 lbs/2.3 kg

1

CERTIFICATION

ISO: Manufactured under an ISO9001

registered program

UL: recognized under E83849

CSA: recognized under LR41286

CE: Conforms to EN 55011 / CISPR 11,

EN50082-2, IEC 947-1, IEC 1010-1

GE Power Management PQM Power Quality Meter 1-13

1.3 SPECIFICATIONS 1 OVERVIEW

PQM POWER AND ENERGY ACCURACY

Accuracy is a per curves ±1 digit on PQM display.

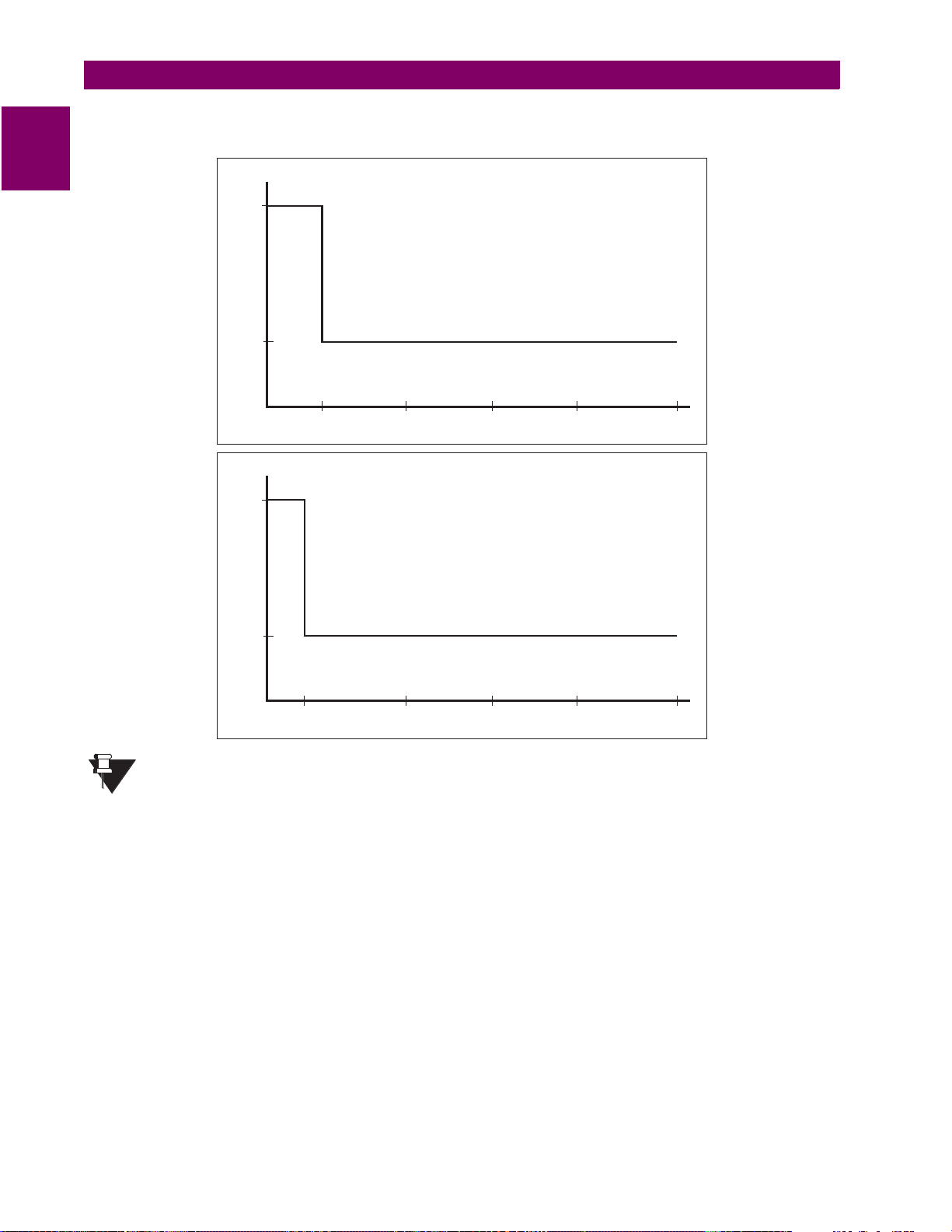

1

0.5

% Error of Reading

0.2

PQM Power Accuracy at P.F. > 0.95

(kW/kVAR/kVA)

NOTE

120

1.0

% Error of Reading

0.4

15

50 75 100 150

% Load

PQM Energy Accuracy at P.F. > 0.95

(±kWh / ±kVARh / kVAh)

50 75 100 150

% Load

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

1-14 PQM Power Quality Meter GE Power Management

2 INSTALLATION 2.1 PHYSICAL

2 INSTALLATION 2.1 PHYSICAL 2.1.1 MOUNTING

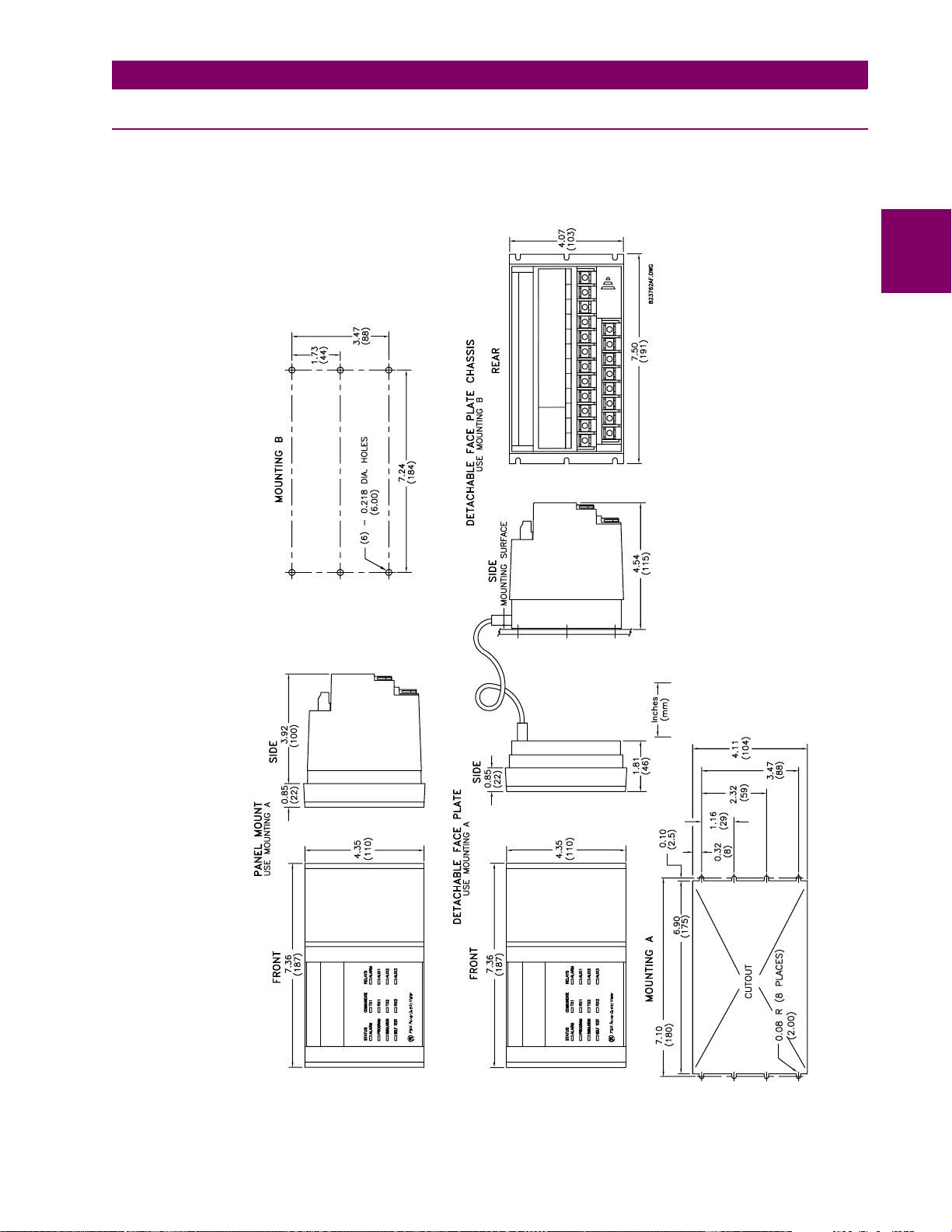

Physical dimensions and required cutout dimensions for the PQM are shown below. Once the cutout and

mounting holes are made in the panel, use the eight #6 self-tapping screws provided to secure the PQM.

Mount the unit on a panel or switchgear door to allow operator access to the keypad and indicators.

2

Figure 2–1: PHYSICAL DIMENSIONS

GE Power Management PQM Power Quality Meter 2-1

2.1 PHYSICAL 2 INSTALLATION

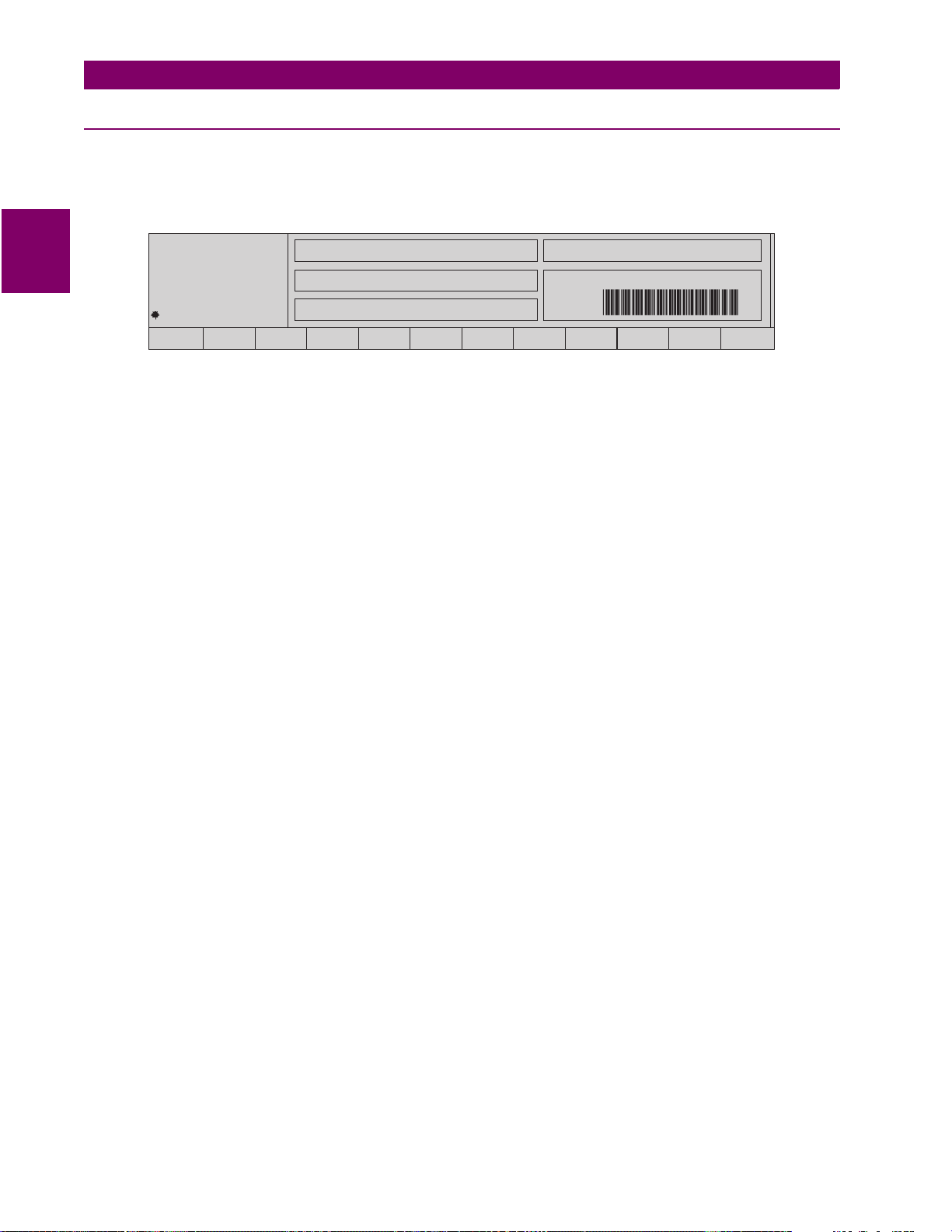

2.1.2 PRODUCT IDENTIFICATION

Product attributes vary according to the configuration and options selected on the customer order. Before

applying power to the PQM, examine the label on the back and ensure the correct options are installed.

The following section explains the information included on the label shown below:

2

PQM

g

MAXIMUM CONTACT RATING

250 VAC 10A RESISTIVE

1/4HP 250VAC 1/2HP 125VAC

MADE IN

CANADA

9

10

MODEL NO.:

CONTROL VOLTAGE: SERIAL No.:

CUSTOMER TAG No.: 1234-567-89

11

PQM-T20-C-A

90-300VDC 20VA

70-265VAC 50/60HZ 20VA

141312

15

VERSION:

16

17

340.000

C6560001

18

19

20

Figure 2–2: PRODUCT LABEL

MODEL NO

1.

: Shows the PQM con figuration. The m odel number for a basic panel mount PQM is “PQ M”.

The model number for a basic chassis mount PQM is “PQM\ND”. T20, C, and A appear in the model number only if the Transducer, Control, or Power Analysis options are installed.

SUPPLY VOLTAGE

2.

: Indicates the power supply input configuration installed in the PQM. The PQM shown

in this example c an ac cept a ny AC 50/60H z vo ltage f rom 7 0 to 26 5 V A C o r DC vol tage f rom 9 0 to 30 0 V

DC.

TAG#

3.

4.

: An optional identification number specified by the customer.

MOD#

: Used if uniqu e features have be en installed for special customer orders. This num ber should be

available when contacting GE Power Management for technical support.

VERSION

5.

: An internal GE Power Man agement number that should be av ailable when contacting us for

technical support.

SERIAL NO

6.

: Indicates the serial number for the PQM in numeric and barcode formats that should be avail-

able when contacting GE Power Management for technical support.

2-2 PQM Power Quality Meter GE Power Management

2 INSTALLATION 2.1 PHYSICAL

2.1.3 REVISION HISTORY

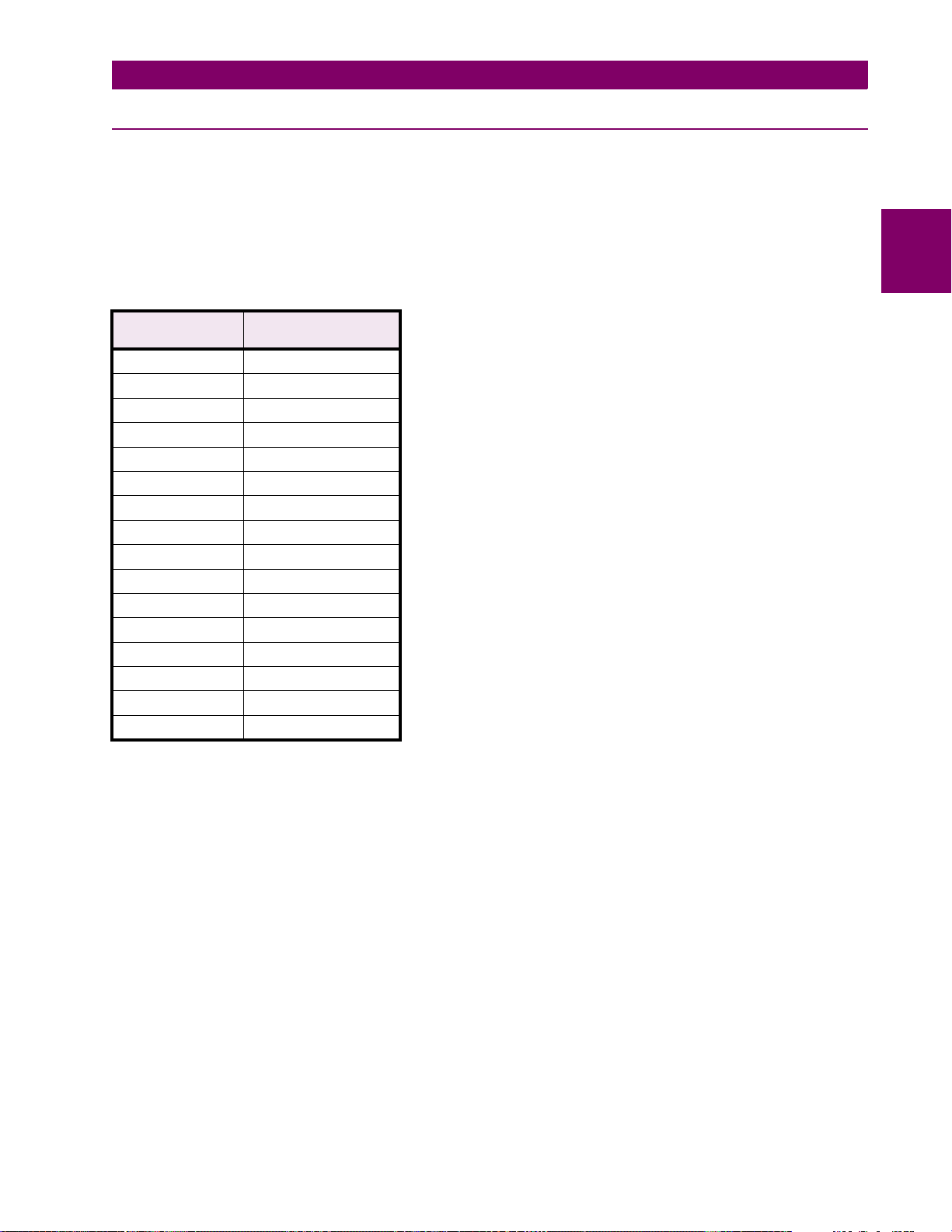

The following table shows the PQM revision h istory. Each revision of t he instr uction man ual cor responds to a

particular firmware revision. The manual revision is located on the title page as part of the manual part number

(the format is 1665-0003-

A4 PRODUCT INFO \ SOFTWARE VERSIONS \ MAIN PROGRAM VERSION

to the

revision

). The firmware revision is loa ded in the PQ M and ca n be vi ewed by sc r oll in g

actual value message.

When using the instruction manual to determine PQM features and settings, ensure that the instruction manual

revision corresponds to the firmware revision installed in the PQM using the table below.

Table 2–1: REVISION HISTORY TABLE

INSTRUCTION

MANUAL P/N

1665-0003-C1 0.10

1665-0003-C2 0.20

1665-0003-C3 1.00

1665-0003-C4 1.10

1665-0003-C5 1.20

1665-0003-C6 1.21, 1.22

1665-0003-C7 2.00

1665-0003-C8 2.01

1665-0003-C9 2.02

1665-0003-CA 3.00

1665-0003-CB 3.01

1665-0003-CC 3.10

1665-0003-CD 3.13

1665-0003-CE 3.2x, 3.3x

1665-0003-CF 3.4x

1665-0003-CG 3.5x

MAIN PROGRAM

VERSION

2

GE Power Management PQM Power Quality Meter 2-3

2.2 ELECTRICAL 2 INSTALLATION

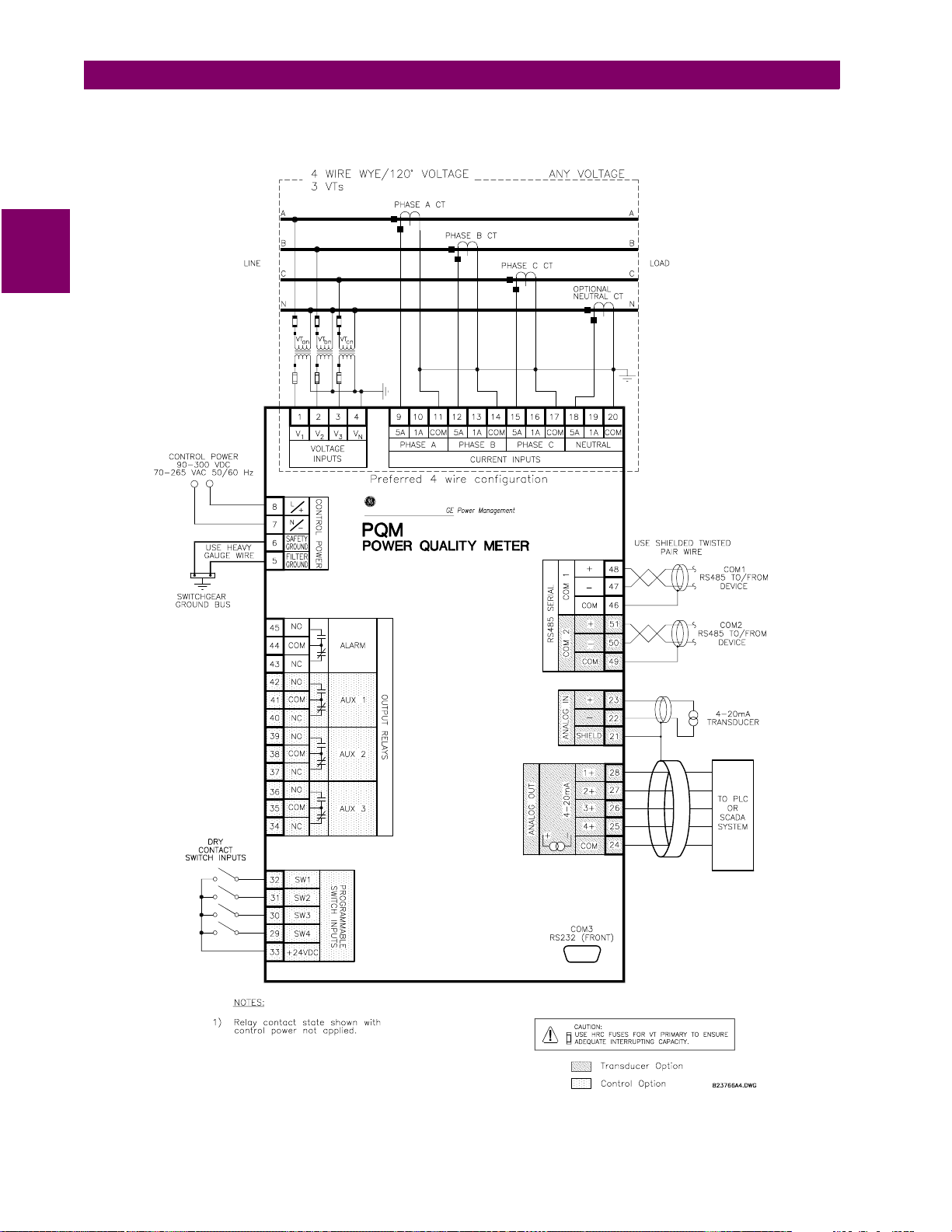

2.2 ELECTRICAL 2.2.1 EXTERNAL CONNECTIONS

Signal wiring is to Terminals 21 to 51. These termin al s a ccom modate wires sizes up to 1 2 g auge.

that the maximum torque that can be applied to terminals 21 to 51 is 0.5 Nm (or 4.4 in ·lb.)

. CT, VT, and control

power connections are made using Terminals 1 to 20. These #8 screw ring terminals accept wire sizes as large

as 8 gauge. Consult the wiring diagrams for suggested wiring. A minimal configuration includes connections for

control power, phase CTs/VT s, and the alarm relay; other features can be wired as required. Considerations for

2

wiring each feature are given in the sections that follow.

Table 2–2: PQM EXTERNAL CONNECTIONS

VT / CONTROL POWER ROW CT ROW SIGNAL UPPER ROW

1 V1 Voltage input 9 Phase A CT 5A 21 Analog shield

2 V2 Voltage input 10 Phase A CT 1A 22 Analog in –

3 V3 Voltage input 11 Phase A CT COM 23 Analog in +

4 Vn Voltage input 12 Phase B CT 5A 24 Analog out com

5 Filter ground 13 Phase B CT 1A 25 Analog out 4+

6 Safety ground 14 Phase B CT COM 26 Analog out 3+

7 Control neutral (–) 15 Phase C CT 5A 27 Analog out 2+

8 Control live (+) 16 Phase C CT 1A 28 Analog out 1+

17 Phase C CT COM 29 Switch 4 input

18 Neutral CT 5A 30 Switch 3 input

19 Neutral CT 1A 31 Switch 2 input

20 Neutral CT COM 32 Switch 1 input

33 +24 V DC switch com

34 Aux3 relay NC

35 Aux3 relay COM

36 Aux3 relay NO

37 Aux2 relay NC

38 Aux2 relay COM

39 Aux2 relay NO

40 Aux1 relay NC

41 Aux1 relay COM

42 Aux1 relay NO

43 Alarm relay NC

44 Alarm relay COM

45 Alarm relay NO

46 Comm 1 COM

47 Comm 1 –

48 Comm 1 +

49 Comm 2 COM

50 Comm 2 –

51 Comm 2 +

Please note

2-4 PQM Power Quality Meter GE Power Management

2 INSTALLATION 2.2 ELECTRICAL

2

Figure 2–3: REAR TERMINALS

GE Power Management PQM Power Quality Meter 2-5

2.2 ELECTRICAL 2 INSTALLATION

This wiring diagram sho ws the typical 4-wire wye connecti on which will cover any voltage range. Select the

S2 SYSTEM SETUP \ CURRENT/VOLTAGE CONFIGURATION \ VT WIRING: 4 WIRE WYE (3 VTs)

setpoint.

2

Figure 2–4: WIRING DIAGRAM 4-WIRE WYE (3 VTs)

2-6 PQM Power Quality Meter GE Power Management

Loading...

Loading...