GE PQMII Instruction Manual

Digital Energy

Multilin

Software Revision: 2.2x

Manual P/N: 1601-0118-AD

Manual Order Code: GEK-106435M

Copyright © 2010 GE Multilin

PQMII Power Quality Meter

Instruction Manual

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet:

http://www.GEmultilin.com

*1601-0118-AD*

GE Multilin's Quality Management

System is registered to ISO9001:2000

QMI # 005094

UL # A3775

© 2010 GE Multilin Incorporated. All rights reserved.

GE Multilin PQMII Power Quality Meter instruction manual for revision 2.2x.

PQMII Power Quality Meter, is a registered trademark of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part numbers contained in this manual are subject to change without notice, and should

therefore be verified by GE Multilin before ordering.

Part number: 1601-0118-AD (May 2010)

TABLE OF CONTENTS

Table of Contents

1: OVERVIEW INTRODUCTION TO THE PQMII ................................................................................................... 1-1

D

ESCRIPTION ........................................................................................................................ 1-1

F

EATURE HIGHLIGHTS ......................................................................................................... 1-2

A

PPLICATIONS OF THE PQMII ........................................................................................... 1-2

STANDARD FEATURES ................................................................................................................... 1-5

M

ETERING ............................................................................................................................. 1-5

A

LARMS ................................................................................................................................. 1-5

C

OMMUNICATIONS .............................................................................................................. 1-5

F

UTURE EXPANSION ............................................................................................................ 1-5

O

PEN ARCHITECTURE ......................................................................................................... 1-6

OPTIONAL FEATURES ..................................................................................................................... 1-7

T

RANSDUCER INPUT/OUTPUTS ......................................................................................... 1-7

C

ONTROL OPTION ............................................................................................................... 1-7

P

OWER ANALYSIS OPTION .................................................................................................1-8

ENERVISTA PQMII SETUP SOFTWARE .....................................................................................1-12

O

VERVIEW ............................................................................................................................ 1-12

ORDER CODES ................................................................................................................................... 1-13

O

RDER CODE TABLE ........................................................................................................... 1-13

M

ODIFICATIONS ................................................................................................................... 1-13

A

CCESSORIES ....................................................................................................................... 1-13

C

ONTROL POWER ................................................................................................................ 1-13

SPECIFICATIONS ............................................................................................................................... 1-14

I

NPUTS/OUTPUTS ................................................................................................................ 1-14

T

RACE MEMORY TRIGGER .................................................................................................. 1-15

S

AMPLING MODES .............................................................................................................. 1-15

O

UTPUT RELAYS .................................................................................................................. 1-15

M

ETERING ............................................................................................................................. 1-16

M

ONITORING ........................................................................................................................ 1-16

S

YSTEM ................................................................................................................................. 1-18

T

ESTING AND APPROVALS .................................................................................................. 1-18

P

HYSICAL .............................................................................................................................. 1-20

2: INSTALLATION PHYSICAL CONFIGURATION ........................................................................................................ 2-1

M

OUNTING ........................................................................................................................... 2-1

P

RODUCT IDENTIFICATION .................................................................................................. 2-2

R

EVISION HISTORY .............................................................................................................. 2-2

ELECTRICAL CONFIGURATION ................................................................................................... 2-3

E

XTERNAL CONNECTIONS ..................................................................................................2-3

W

IRING DIAGRAMS ............................................................................................................. 2-5

3-

WIRE SYSTEM USING TWO CTS .................................................................................... 2-12

C

ONTROL POWER ................................................................................................................ 2-13

VT I

NPUTS ............................................................................................................................ 2-13

CT I

NPUTS ............................................................................................................................ 2-13

O

UTPUT RELAYS .................................................................................................................. 2-14

S

WITCH INPUTS (OPTIONAL) .............................................................................................. 2-14

A

NALOG OUTPUTS (OPTIONAL) ......................................................................................... 2-16

A

NALOG INPUT (OPTIONAL) ............................................................................................... 2-17

PQMII POWER QUALITY METER – INSTRUCTION MANUAL TOC–I

TABLE OF CONTENTS

RS485 SERIAL PORTS ........................................................................................................ 2-17

RS232 F

D

RONT PANEL PORT .............................................................................................2-19

IELECTRIC STRENGTH TESTING ........................................................................................2-19

3: OPERATION FRONT PANEL AND DISPLAY ....................................................................................................... 3-1

RONT PANEL ......................................................................................................................3-1

F

D

ISPLAY ................................................................................................................................. 3-1

LED INDICATORS .............................................................................................................................. 3-2

D

ESCRIPTION ........................................................................................................................ 3-2

S

TATUS .................................................................................................................................. 3-2

C

OMMUNICATE .....................................................................................................................3-2

R

ELAYS .................................................................................................................................. 3-3

KEYPAD ................................................................................................................................................. 3-4

D

ESCRIPTION ........................................................................................................................ 3-4

M

ENU KEY ............................................................................................................................ 3-4

E

SCAPE KEY ..........................................................................................................................3-4

E

NTER KEY ............................................................................................................................ 3-4

R

ESET KEY ............................................................................................................................3-4

M

ESSAGE KEYS ....................................................................................................................3-5

V

ALUE KEYS ......................................................................................................................... 3-6

D

ATA ENTRY METHODS ...................................................................................................... 3-6

S

ETPOINT ACCESS SECURITY ............................................................................................. 3-7

DEFAULT MESSAGES ...................................................................................................................... 3-8

D

ESCRIPTION ........................................................................................................................ 3-8

A

DDING A DEFAULT MESSAGE ..........................................................................................3-8

D

ELETING A DEFAULT MESSAGE ....................................................................................... 3-8

D

EFAULT MESSAGE SEQUENCE .........................................................................................3-9

4: SOFTWARE INTRODUCTION ................................................................................................................................ 4-1

O

VERVIEW ............................................................................................................................ 4-1

H

ARDWARE ........................................................................................................................... 4-2

I

NSTALLING THE ENERVISTA PQMII SETUP SOFTWARE ................................................ 4-3

CONFIGURING SERIAL COMMUNICATIONS .......................................................................... 4-7

D

ESCRIPTION ........................................................................................................................ 4-7

UPGRADING FIRMWARE ............................................................................................................... 4-8

D

ESCRIPTION ........................................................................................................................ 4-8

S

AVING SETPOINTS TO A FILE ............................................................................................ 4-8

L

OADING NEW FIRMWARE ................................................................................................. 4-8

L

OADING SAVED SETPOINTS .............................................................................................. 4-10

USING THE ENERVISTA PQMII SETUP SOFTWARE ............................................................. 4-11

E

NTERING SETPOINTS ......................................................................................................... 4-11

V

IEWING ACTUAL VALUES .................................................................................................. 4-12

S

ETPOINT FILES .................................................................................................................... 4-12

G

ETTING HELP ..................................................................................................................... 4-12

POWER ANALYSIS ............................................................................................................................ 4-13

W

AVEFORM CAPTURE .........................................................................................................4-13

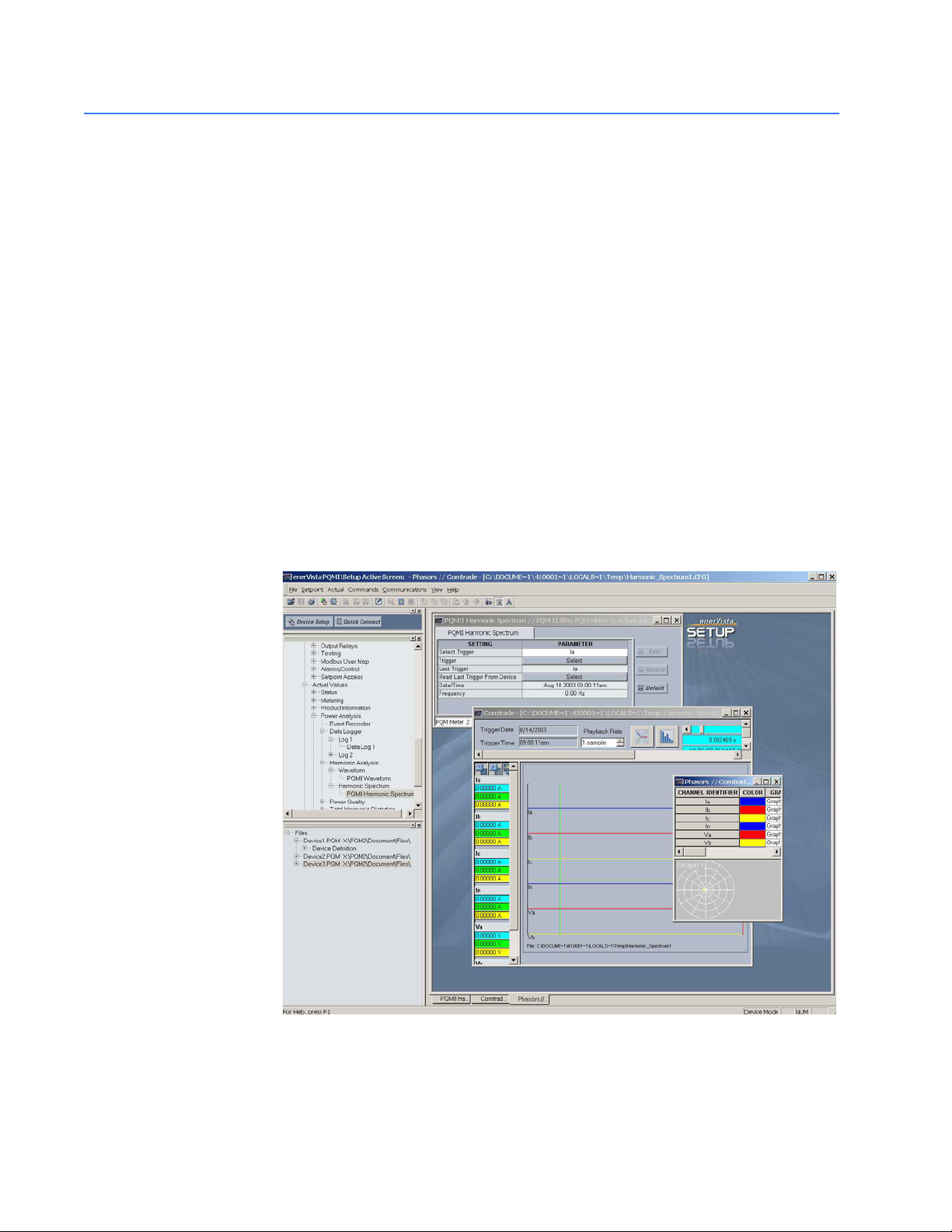

H

ARMONIC ANALYSIS .........................................................................................................4-13

T

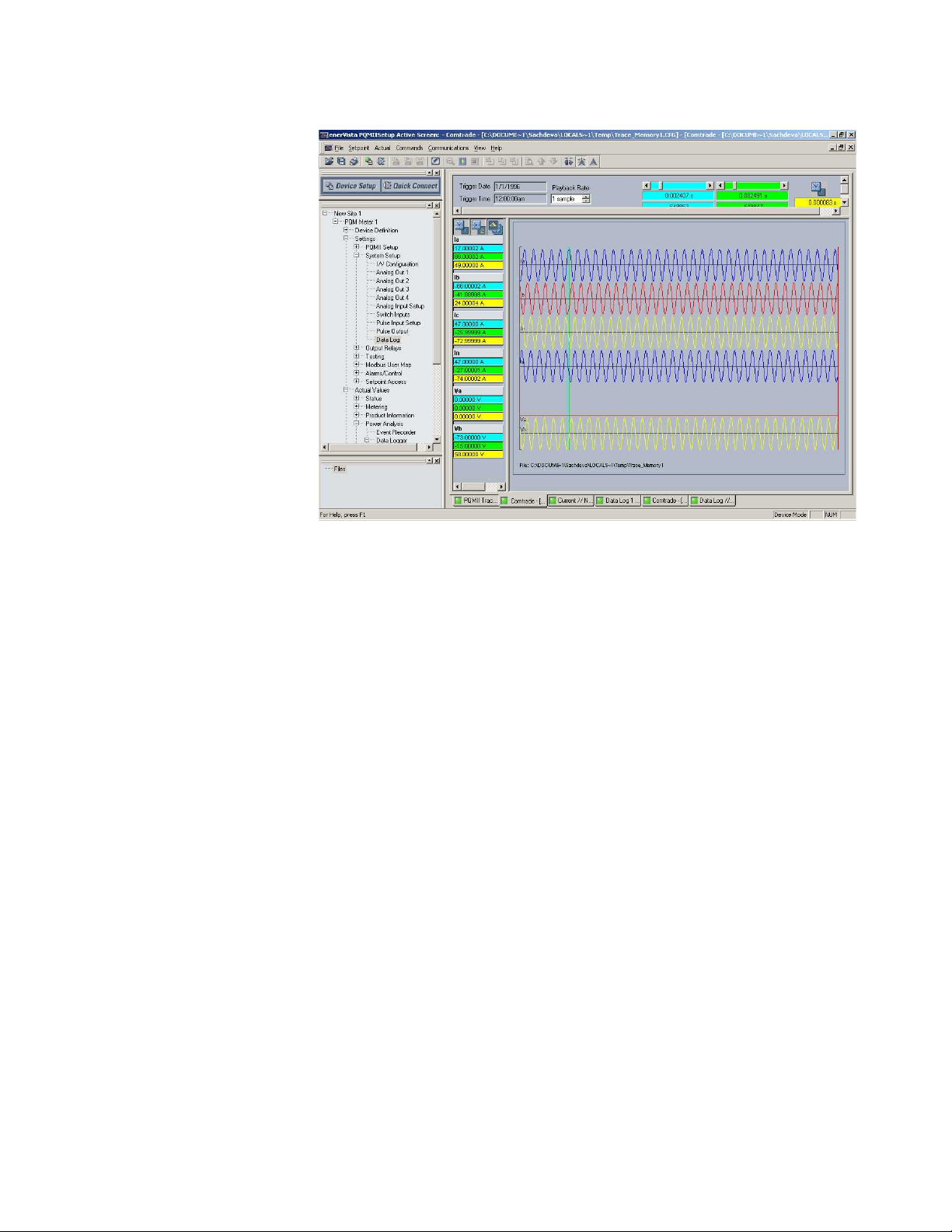

RACE MEMORY ................................................................................................................... 4-14

D

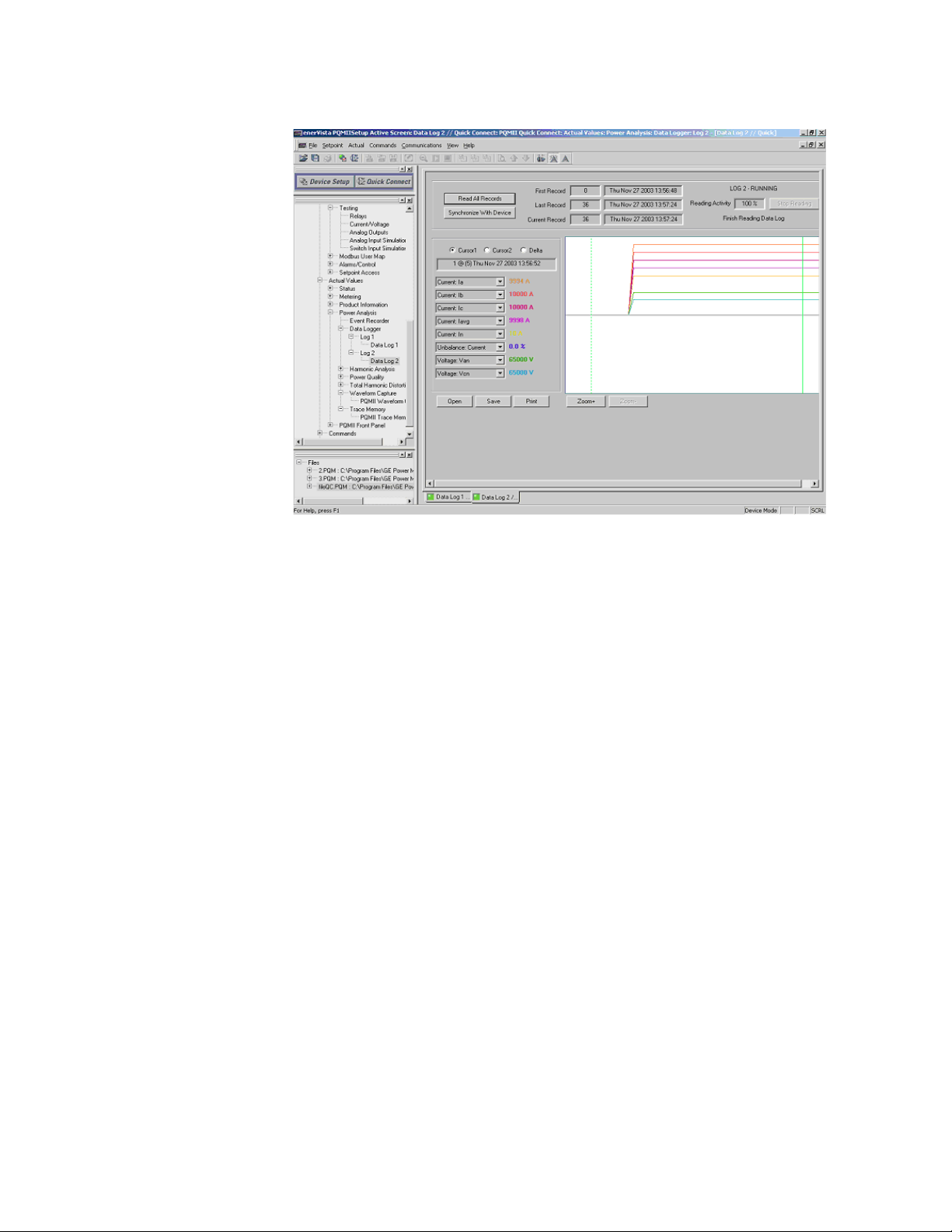

ATA LOGGER ...................................................................................................................... 4-16

V

OLTAGE DISTURBANCE RECORDER ................................................................................. 4-18

USING ENERVISTA VIEWPOINT WITH THE PQMII ............................................................... 4-21

P

LUG AND PLAY EXAMPLE .................................................................................................4-21

TOC–II PQMII POWER QUALITY METER – INSTRUCTION MANUAL

TABLE OF CONTENTS

5: SETPOINTS INTRODUCTION ................................................................................................................................ 5-1

S

ETPOINT ENTRY METHODS ............................................................................................... 5-1

S

ETPOINTS MAIN MENU ..................................................................................................... 5-2

S1 PQMII SETUP ................................................................................................................................ 5-5

D

ESCRIPTION ........................................................................................................................ 5-5

P

REFERENCES ....................................................................................................................... 5-5

S

ETPOINT ACCESS ............................................................................................................... 5-6

S

ERIAL PORTS ...................................................................................................................... 5-7

DNP 3.0 C

C

LOCK ................................................................................................................................... 5-9

C

ALCULATION PARAMETERS .............................................................................................. 5-10

C

LEAR DATA ......................................................................................................................... 5-12

E

VENT RECORDER ............................................................................................................... 5-13

T

RACE MEMORY ................................................................................................................... 5-14

P

ROGRAMMABLE MESSAGE ............................................................................................... 5-17

P

RODUCT OPTIONS ............................................................................................................. 5-18

ONFIGURATION ................................................................................................ 5-8

S2 SYSTEM SETUP ............................................................................................................................ 5-19

C

URRENT AND VOLTAGE CONFIGURATION ...................................................................... 5-19

A

NALOG OUTPUTS .............................................................................................................. 5-21

A

NALOG INPUT ....................................................................................................................5-25

S

WITCH INPUTS ................................................................................................................... 5-27

P

ULSE OUTPUT .................................................................................................................... 5-28

P

ULSE INPUT ........................................................................................................................ 5-29

D

ATA LOGGER ...................................................................................................................... 5-30

V

OLTAGE DISTURBANCE ..................................................................................................... 5-30

S3 OUTPUT RELAYS ......................................................................................................................... 5-32

D

ESCRIPTION ........................................................................................................................ 5-32

A

LARM RELAY ...................................................................................................................... 5-32

A

UXILIARY RELAYS ............................................................................................................... 5-32

S4 ALARMS/CONTROL ................................................................................................................... 5-34

C

URRENT/VOLTAGE ALARMS ............................................................................................. 5-34

H

ARMONIC DISTORTION ..................................................................................................... 5-39

F

REQUENCY .......................................................................................................................... 5-40

P

OWER ALARMS ..................................................................................................................5-41

P

OWER FACTOR ................................................................................................................... 5-43

D

EMAND ALARMS ................................................................................................................ 5-46

P

ULSE INPUT ........................................................................................................................ 5-48

T

IME ....................................................................................................................................... 5-49

M

ISCELLANEOUS ALARMS .................................................................................................. 5-50

S5 TESTING ......................................................................................................................................... 5-51

T

EST RELAYS AND LEDS .................................................................................................... 5-51

C

URRENT/VOLTAGE ............................................................................................................ 5-51

A

NALOG OUTPUTS .............................................................................................................. 5-52

A

NALOG INPUT ....................................................................................................................5-53

S

WITCH INPUTS ................................................................................................................... 5-53

F

ACTORY USE ONLY ........................................................................................................... 5-54

6: MONITORING ACTUAL VALUES VIEWING ........................................................................................................... 6-1

ESCRIPTION ........................................................................................................................ 6-1

D

A

CTUAL VALUES MENU ......................................................................................................6-2

A1 METERING ..................................................................................................................................... 6-4

C

URRENT METERING ........................................................................................................... 6-4

PQMII POWER QUALITY METER – INSTRUCTION MANUAL TOC–III

TABLE OF CONTENTS

VOLTAGE METERING ........................................................................................................... 6-6

P

HASORS .............................................................................................................................. 6-8

P

OWER METERING ..............................................................................................................6-8

E

NERGY METERING .............................................................................................................. 6-12

D

EMAND METERING ............................................................................................................6-14

F

REQUENCY METERING ....................................................................................................... 6-15

P

ULSE INPUT COUNTERS ....................................................................................................6-16

A

NALOG INPUT ....................................................................................................................6-17

A2 STATUS ........................................................................................................................................... 6-18

A

LARMS ................................................................................................................................. 6-18

S

WITCH STATUS ................................................................................................................... 6-20

C

LOCK ................................................................................................................................... 6-21

P

ROGRAMMABLE MESSAGE ................................................................................................ 6-21

A3 POWER ANALYSIS ..................................................................................................................... 6-22

P

OWER QUALITY .................................................................................................................. 6-22

THD ...................................................................................................................................... 6-22

D

ATA LOGGER ...................................................................................................................... 6-24

E

VENT RECORDER ................................................................................................................ 6-24

V

OLTAGE DISTURBANCE ..................................................................................................... 6-28

A4 PRODUCT INFO ..........................................................................................................................6-30

S

OFTWARE VERSIONS ......................................................................................................... 6-30

M

ODEL INFORMATION ......................................................................................................... 6-30

7: APPLICATIONS EVENT RECORDER ............................................................................................................................ 7-1

IST OF EVENTS ................................................................................................................... 7-1

L

A

CCESS TO EVENT RECORDER INFORMATION .................................................................7-6

INTERFACING USING HYPERTERMINAL .................................................................................. 7-8

U

PGRADING FIRMWARE ...................................................................................................... 7-8

C

YCLING POWER ................................................................................................................. 7-8

H

YPERTERMINAL .................................................................................................................. 7-8

PHASOR IMPLEMENTATION ......................................................................................................... 7-11

T

HEORY OF PHASOR IMPLEMENTATION ............................................................................ 7-11

TRIGGERED TRACE MEMORY ......................................................................................................7-13

D

ESCRIPTION ........................................................................................................................ 7-13

PULSE OUTPUT ................................................................................................................................. 7-14

P

ULSE OUTPUT CONSIDERATIONS .................................................................................... 7-14

C

ONNECTING TO AN END RECEIVER USING KYZ TERMINALS ...................................... 7-14

DATA LOGGER IMPLEMENTATION ............................................................................................ 7-16

D

ATA LOGGER STRUCTURE ................................................................................................ 7-16

M

ODES OF OPERATION ....................................................................................................... 7-17

A

CCESSING DATA LOG INFORMATION .............................................................................. 7-17

I

NTERPRETING DATA LOG INFORMATION .........................................................................7-17

D

ATA LOG PARAMETERS ..................................................................................................... 7-20

READING LONG INTEGERS FROM THE MEMORY MAP ..................................................... 7-21

D

ESCRIPTION ........................................................................................................................ 7-21

E

XAMPLE ...............................................................................................................................7-21

PULSE INPUT APPLICATION ......................................................................................................... 7-23

D

ESCRIPTION ........................................................................................................................ 7-23

PQMII P

ULSE INPUT(S) WITH A PULSE INITIATOR USING KYZ TERMINALS ................ 7-23

PULSE TOTALIZER APPLICATION ............................................................................................... 7-24

D

ESCRIPTION ........................................................................................................................ 7-24

T

OTALIZING ENERGY FROM MULTIPLE METERING LOCATIONS .....................................7-24

TOC–IV PQMII POWER QUALITY METER – INSTRUCTION MANUAL

TABLE OF CONTENTS

8: WARRANTY GE MULTILIN DEVICE WARRANTY ............................................................................................8-1

W

ARRANTY STATEMENT ..................................................................................................... 8-1

APPENDIX A MOD 506: CAPACITOR BANK SWITCHING ............................................................................ A-1

D

ESCRIPTION ........................................................................................................................ A-1

S

ETPOINTS ............................................................................................................................ A-1

A

CTUAL VALUES ..................................................................................................................A-3

C

ONDITIONS REQUIRED TO ENERGIZE A STEP ............................................................... A-4

A

DDITIONS TO MODBUS MEMORY MAP .......................................................................... A-5

REVISION HISTORY .......................................................................................................................... A-7

R

ELEASE DATES ...................................................................................................................A-7

R

ELEASE NOTES ...................................................................................................................A-7

INDEX

PQMII POWER QUALITY METER – INSTRUCTION MANUAL TOC–V

TABLE OF CONTENTS

TOC–VI PQMII POWER QUALITY METER – INSTRUCTION MANUAL

Digital Energy

Multilin

PQMII Power Quality Meter

Chapter 1: Overview

Overview

1.1 Introduction to the PQMII

1.1.1 Description

The GE Multilin PQMII Power Quality Meter is an ideal choice for continuous monitoring of a

single or three-phase system. It provides metering for current, voltage, real power, reactive

power, apparent power, energy use, cost of power, power factor, and frequency.

Programmable setpoints and four assignable output relays allow control functions to be

added for specific applications. This includes basic alarm on over/under current or voltage,

unbalance, demand-based load shedding, and capacitor power factor correction control.

More complex control is possible using the four switch inputs; these can also be used for

status information such as breaker open/closed and flow information.

As a data gathering device for plant automation systems that integrate process,

instrument, and electrical requirements, all monitored values are available via one of two

RS485 communication ports running the Modbus protocol. If analog values are required

for direct interface to a PLC, any of the monitored values can output as a 4 to 20 mA (or 0

to 1 mA) signal to replace up to four (4) separate transducers. A third RS232

communication port connects to a PC from the front panel for simultaneous access of

information by other plant personnel.

With increasing use of electronic loads such as computers, ballasts, and variable

frequency drives, the quality of the power system is important. With the harmonic analysis

option, any phase current or voltage can be displayed and the harmonic content

calculated. Knowledge of the harmonic distribution allows action to be taken to prevent

overheated transformers, motors, capacitors, neutral wires, and nuisance breaker trips.

Redistribution of system loading can also be determined. The PQMII can also provide

waveform and data printouts to assist in problem diagnosis.

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–1

1.1.2 Feature Highlights

• Monitoring: A, V, VA, W, var, kWh, kvarh, kVAh, PF, Hz

• Demand metering: W, var, A, VA

• Setpoints for alarm or control from most measured values, including: unbalance,

• four (4) output relays / four (4) switch inputs for flexible control configuration

• four (4) isolated analog outputs replace transducers for PLC interface

• one 4 to 20 mA analog input

• Modbus communications

• Three COM ports (two rear RS485 ports and one front RS232 port) for access by

• Harmonic analysis for power quality review and problem correction

• 40-character display and keypad for local programming

• No-charge EnerVista PQMII Setup Software

• Simulation mode for testing and training

• Compact design for panel mount

•AC/DC control power

CHAPTER 1: OVERVIEW

frequency, power factor, voltage, and current

process, electrical, maintenance, and instrument personnel

1.1.3 Applications of the PQMII

• Metering of distribution feeders, transformers, generators, capacitor banks, and

motors

• Medium and low voltage three-phase systems

• Commercial, industrial, utility

• Flexible control for demand load shedding, power factor, etc.

• Power quality analysis

• System debugging

1–2 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

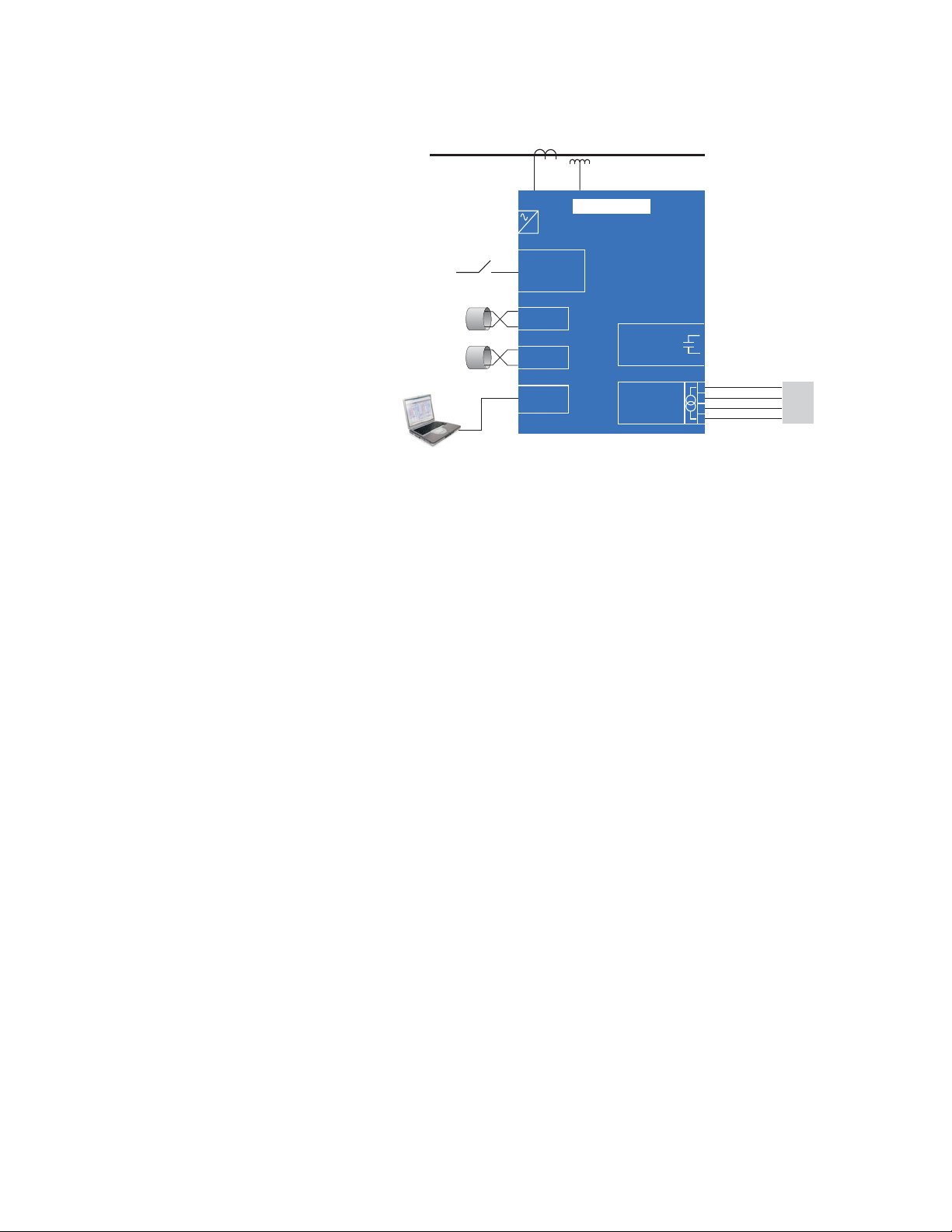

Four (4)

output

relays

Four (4)

transducer

outputs

4

3

2

1

COM 2

RS232

PORT

COM 1

Four switch

inputs for

control

–

4to20mA

Alarm

control

Instrumentation

Electrical

Maintenance

Main

SCADA

Three-phase

3/4-wire bus

CTs

VTs

0 to 600 V direct

> 600V CT/VTs

Control

power

(AC/DC)

PLC

or

RTU

PQMII

PC running

EnerVista PQMII Setup

746701A1.CDR

FIGURE 1–1: Single Line Diagram

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–3

CHAPTER 1: OVERVIEW

FIGURE 1–2: Feature Highlights

1–4 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

1.2 Standard Features

1.2.1 Metering

True RMS monitoring of Ia, Ib, Ic, In, Van, Vbn, Vcn, Vab, Vbc, Vca, voltage/current

unbalance, power factor, line frequency, watts, vars, VA, Wh, varh, VAh, and demand

readings for A, W, vars, and VA. Maximum and minimum values of measured quantities are

recorded and are date and time stamped.

A 40-character liquid crystal display is used for programming setpoints and monitoring

values and status.

1.2.2 Alarms

Alarm conditions can be set up for all measured quantities. These include overcurrent,

undercurrent, neutral current, current unbalance, voltage unbalance, phase reversal,

overfrequency, underfrequency, power factor, switch inputs, etc. The alarm messages are

displayed in a simple and easy to understand English format .

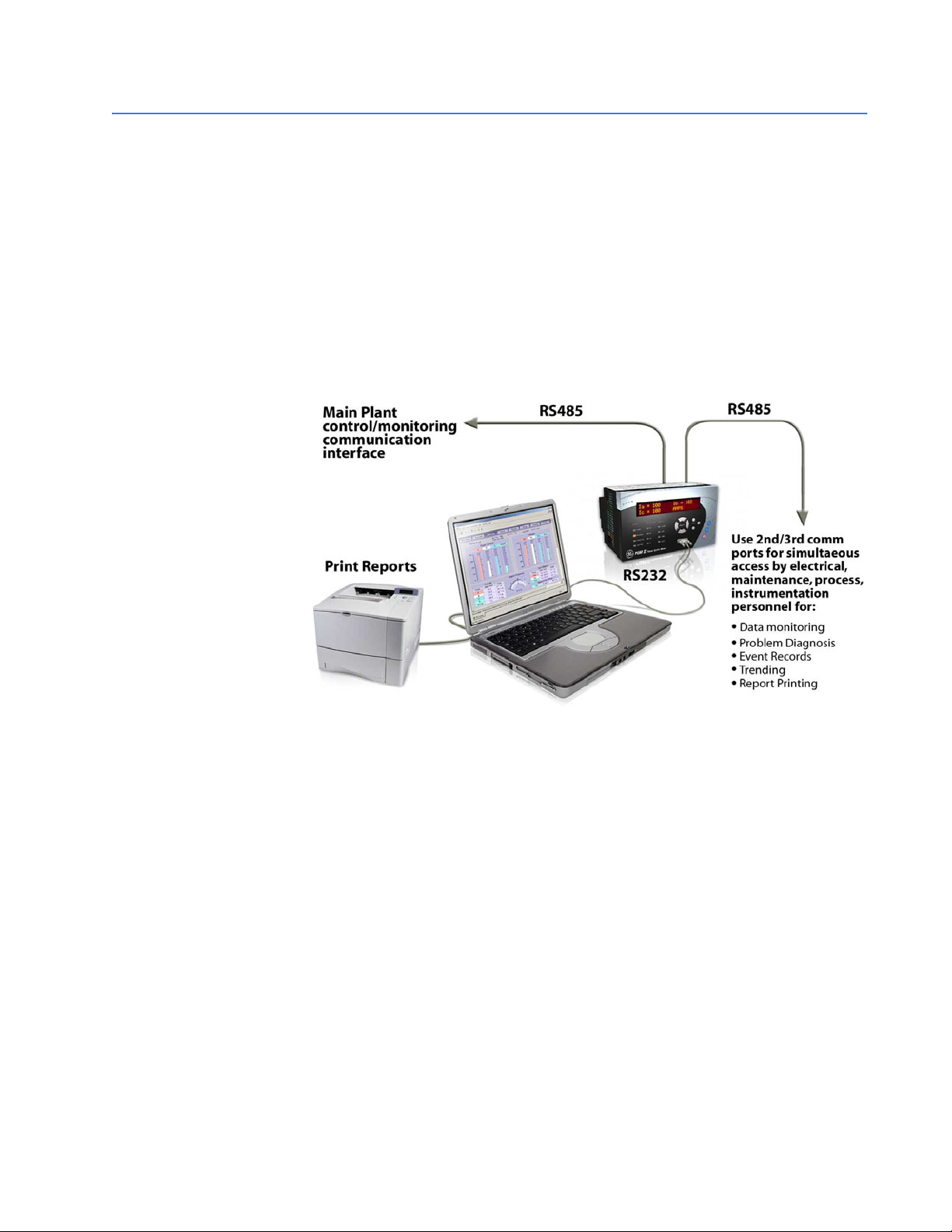

1.2.3 Communications

The PQMII is equipped with one standard RS485 port utilizing the Modbus or DNP

protocols. This can be used to integrate process, instrumentation, and electrical

requirements in a plant automation system by connecting several PQMII meters together

to a DCS or SCADA system. A PC running the EnerVista PQMII Setup Software can change

system setpoints and monitor values, status, and alarms. Continuous monitoring

minimizes process downtime by immediately identifying potential problems due to faults

or changes from growth.

The PQMII also includes a front RS232 port which can be used for the following tasks:

• data monitoring

• problem diagnosis

•viewing event records

•trending

• printing settings and/or actual values

• loading new firmware into the PQMII

1.2.4 Future Expansion

Flash memory is used to store firmware within the PQMII. This allows future product

upgrades to be loaded via the serial port.

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–5

1.2.5 Open Architecture

PQMII units can initially be used as standalone meters. Their open architecture allows

connection to other Modbus compatible devices on the same communication link. These

can be integrated in a complete plant-wide system for overall process monitoring and

control.

CHAPTER 1: OVERVIEW

FIGURE 1–3: Downloading Product Enhancements via the Serial Port

1–6 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

1.3 Optional Features

1.3.1 Transducer Input/Outputs

Four isolated 4 to 20 mA (or 0 to 1 mA depending on the installed option) analog outputs

are provided that can replace up to eight transducers. The outputs can be assigned to any

measured parameters for direct interface to a PLC.

One 4 to 20 mA analog input is provided to accept a transducer output for displaying

information such as temperature or water level.

An additional rear RS485 communication port is provided for simultaneous monitoring by

process, instrument, electrical, or maintenance personnel.

FIGURE 1–4: Additional Communication Port

1.3.2 Control Option

An additional three dry-contact form “C” output relays and four dry-contact switch inputs

are provided. These additional relays can be combined with setpoints and inputs/outputs

for control applications. Possibilities include:

• undercurrent alarm warnings for pump protection

• overvoltage/undervoltage for generators

• unbalance alarm warnings to protect rotating machines

• dual level power factor for capacitor bank switching

• underfrequency/demand output for load shedding resulting in power cost saving

• kWh, kvarh and kVAh pulse output for PLC interface

• Pulse input for totalizing quantities such as kWh, kvarh, kVAh, etc.

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–7

FIGURE 1–5: Switch Inputs and Outputs Relays

CHAPTER 1: OVERVIEW

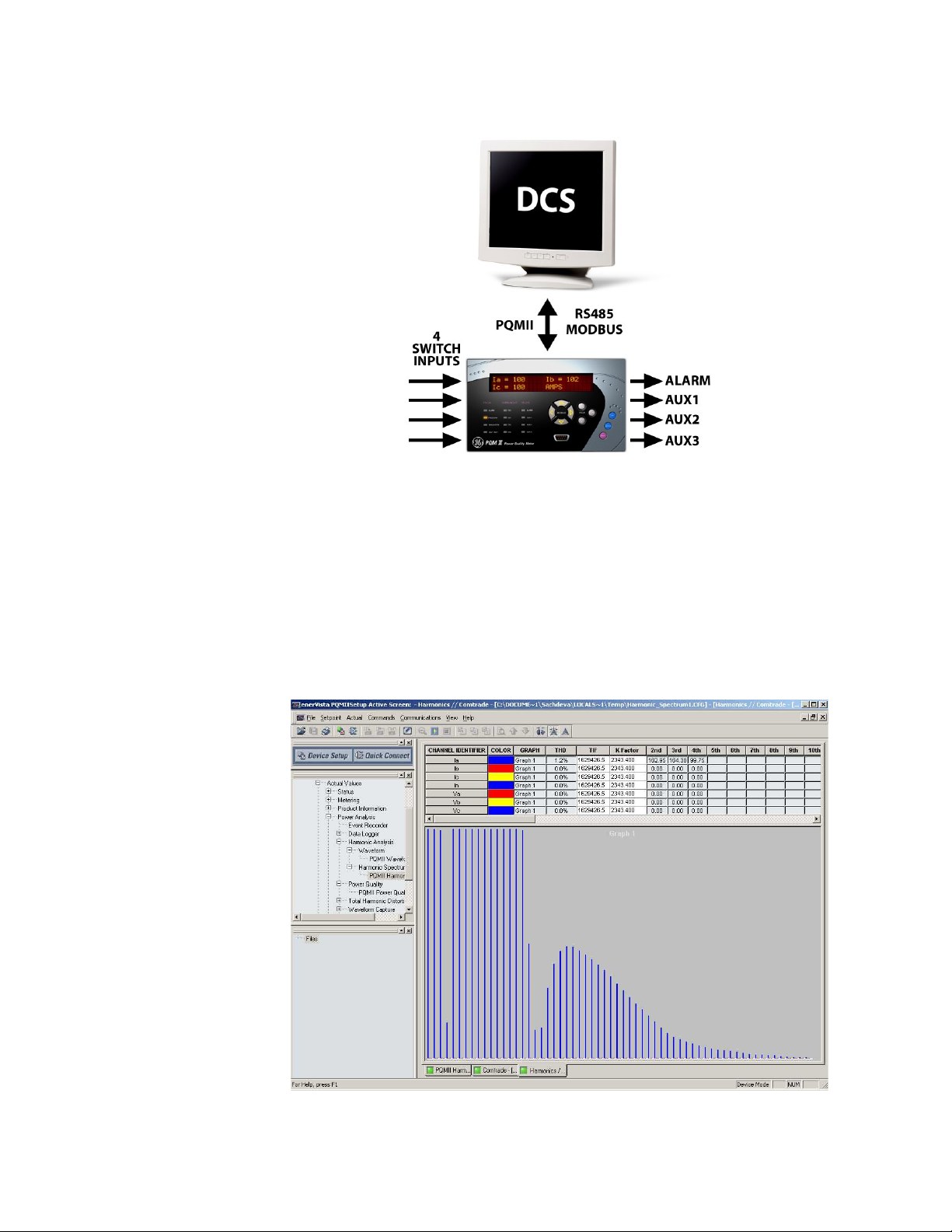

1.3.3 Power Analysis Option

Non-linear loads (such as variable speed drives, computers, and electronic ballasts) can

cause unwanted harmonics that may lead to nuisance breaker tripping, telephone

interference, and transformer, capacitor or motor overheating. For fault diagnostics such

as detecting undersized neutral wiring, assessing the need for harmonic rated

transformers, or judging the effectiveness of harmonic filters, details of the harmonic

spectrum are useful and available with the power analysis option.

FIGURE 1–6: Harmonic Spectrum

1–8 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

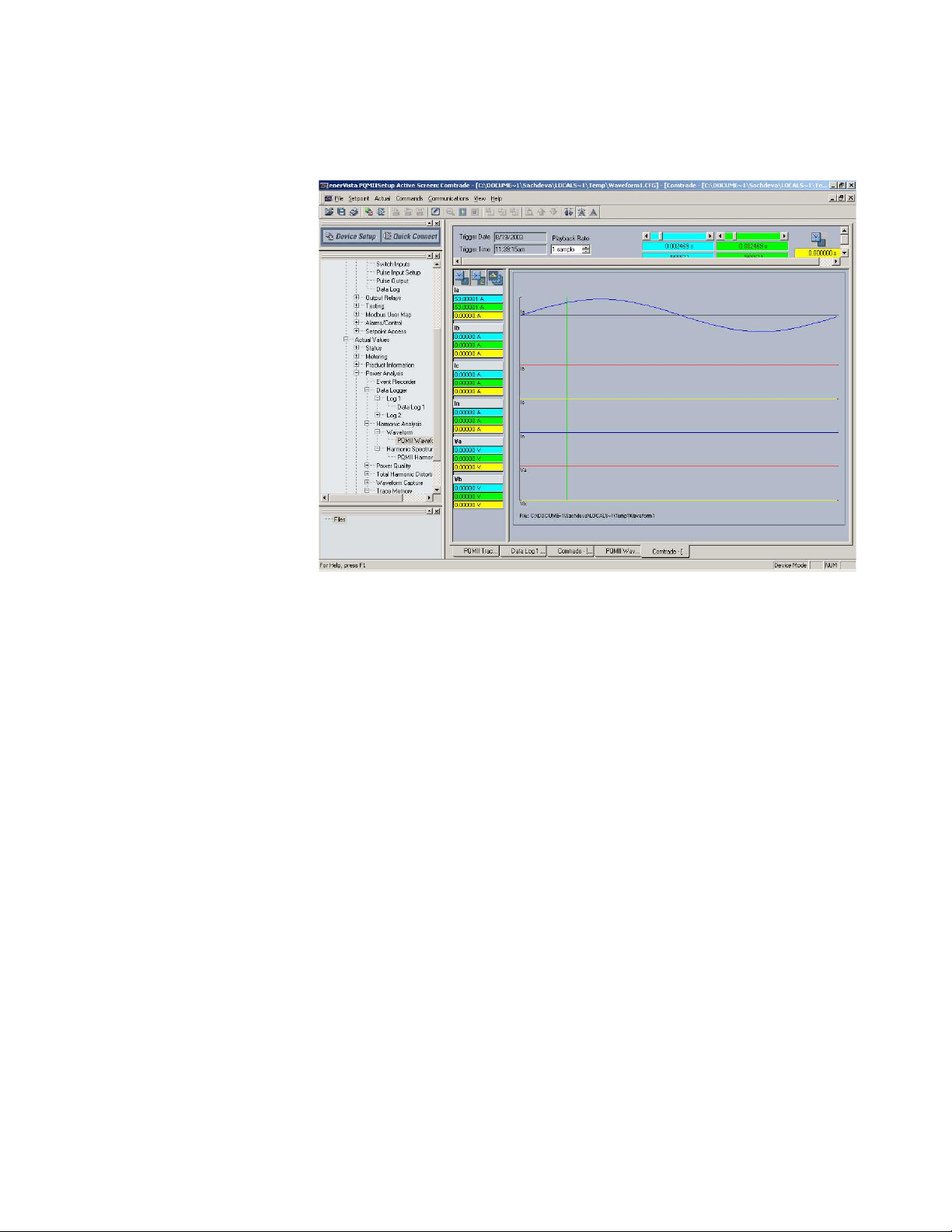

Voltage and current waveforms can be captured and displayed on a PC with the EnerVista

PQMII Setup Software or EnerVista Viewpoint. Distorted peaks or notches from SCR

switching provide clues for taking corrective action.

FIGURE 1–7: Captured Waveform

Alarms, triggers, and input/output events can be stored in a 150-event record and time/

date stamped by the internal clock. This is useful for diagnosing problems and system

activity. The event record is available through serial communication. Minimum and

maximum values are also continuously updated and time/date stamped.

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–9

CHAPTER 1: OVERVIEW

FIGURE 1–8: Data Logger

Routine event logs of all measured quantities can be created, saved to a file, and/or

printed.

For additional information on waveform sampling and analysis features, see Power

Analysis on page 4–13.

The power analysis option also provides a Trace Memory feature. This feature can be used

to record specified parameters based on the user defined triggers.

1–10 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

FIGURE 1–9: Trace Memory Capture

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–11

1.4 EnerVista PQMII Setup Software

1.4.1 Overview

All data continuously gathered by the PQMII can be transferred to a third party software

program for display, control, or analysis through the communications interface. The

EnerVista PQMII Setup Software allows the user to view and manipulate this data and

assists in programming the PQMII. Some of the tasks that can be executed using the

EnerVista PQMII Setup Software package include:

• reading metered data

• monitoring system status

• changing PQMII setpoints on-line

• saving setpoints to a file and downloading into any PQMII

• capturing and displaying voltage and current waveforms for analysis

• recording demand profiles for various measured quantities

• troubleshooting communication problems with a built in debugger

• printing graphs, charts, setpoints, and actual values

CHAPTER 1: OVERVIEW

The EnerVista PQMII Setup Software is fully described in Software on page 4–1.

FIGURE 1–10: EnerVista PQMII Setup Software Main Window

1–12 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

1.5 Order Codes

1.5.1 Order Code Table

Power Analysis

The order code for all options is: PQMII-T20-C-A

Table 1–1: Order Codes

PQMII

Basic Unit PQMII –

Transducer

Option

Control

Option

Option

S S S

|

|

|

|

–

|

|

|

|

|

T1

|

|

|

|

|

|

|

C–||

T20 –

|

|

–

|

|

|

|

–

|

|

|

|

–

|

|

|

A

Basic unit with display, all current/voltage/power

measurements, one (1) RS485 communication port,

one (1) RS232 communication port

Four (4) isolated analog outputs, 0-20 mA and 4-20

mA assignable to all measured parameters, 4-20 mA

analog input, 2nd RS485 communication port

Four (4) isolated analog outputs, 0-1 mA assignable

to all measured parameters, 4-20 mA analog input,

2nd RS485 communication port

Three (3) additional programmable output relays (for

a total of 4), 4 programmable switch inputs

Harmonic analysis, triggered trace memory,

waveform capture, event recorder, data logger,

voltage disturbance recorder*

* The voltage disturbance recorder is only available with the 25 MHz processor.

1.5.2 Modifications

Consult the factory for any additional modification costs):

1.5.3 Accessories

Consult the factory for any additional accessory costs:

• MOD 501: 20 to 60 V DC / 20 to 48 V AC Control Power

• MOD 502: Tropicalization

• MOD 504: Removable Terminal Blocks

• MOD 506: 4-Step Capacitor Bank Switching (Available with Option "C" only)

• EnerVista PQMII Setup Software (included with the PQMII; also available at http://

www.enerVista.com)

• RS232 to RS485 converter (required to connect a PC to the PQMII RS485 ports)

• GE MultiNET RS485 serial-to-Ethernet converter (required for connection to an

Ethernet network)

• RS485 terminating network

1.5.4 Control Power

• 90 to 300 V DC / 70 to 265 V AC standard

• 20 to 60 V DC / 20 to 48 V AC (MOD 501)

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–13

1.6 Specifications

CHAPTER 1: OVERVIEW

Note

Specifications are subject to change without notice.

1.6.1 Inputs/Outputs

CURRENT INPUTS

Conversion:...................................................true RMS, 64 samples/cycle

CT Input: ......................................................... 1 A and 5 A secondary

Burden: ........................................................... 0.2 VA

Overload: .......................................................20 × CT for 1 sec.

100 × CT for 0.2 sec.

Range:............................................................. 1 to 150% of CT primary

Full Scale:.......................................................150% of CT primary

Frequency: ....................................................up to 32nd harmonic

Accuracy:.......................................................±0.2% of full scale at <1.20 x CT

VOLTAGE INPUTS

Conversion:...................................................true RMS, 64 samples/cycle

VT pri./sec.:....................................................120 to 72000 : 69 to 240, or Direct

VT Ratio: .........................................................1:1 to 3500:1

Burden: ........................................................... 2.2 MΩ

Input Range:.................................................40 to 600 V AC

Full scale:

for VT input ≤150 V AC: ...................... 150 V AC

for VT input >150 V AC: ...................... 600 V AC

Frequency: ....................................................up to 32nd harmonic

Accuracy:.......................................................±0.2% of full scale

SWITCH INPUTS

Type:.................................................................dry contacts

Resistance:....................................................1000 Ω max ON resistance

Output:............................................................24 V DC at 2 mA (pulsed)

Duration: ........................................................ 100 ms minimum

ANALOG OUTPUT (0–1 MA)

Max. load: ...................................................... 2400 Ω

Max. output: ................................................. 1.1 mA

Accuracy:.......................................................±1% of full-scale reading

Isolation:......................................................... ±36 V DC isolated, active source

ANALOG OUTPUT (4–20 MA)

Max. load: ...................................................... 600 Ω

Max. output: ................................................. 21 mA

Accuracy:.......................................................±1% of full-scale reading

Isolation:......................................................... ±36 V DC isolated, active source

PULSE OUTPUT

Parameters:..................................................+kWh, –kWh, +kvarh, –kvarh, kVAh

Interval:........................................................... 1 to 65000 in steps of 1

Pulse width: ..................................................100 to 2000 ms in steps of 10

Minimum pulse interval: ........................500 ms

Accuracy:.......................................................±10 ms

1–14 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

1.6.2 Trace Memory Trigger

1.6.3 Sampling Modes

PULSE INPUT

Max. inputs:.................................................. 4

Min. pulse width: ....................................... 150 ms

Min. off time:................................................ 200 ms

TRACE MEMORY TRIGGER

Input................................................................ 2 data cycles (current, voltage)

Time delay:................................................... 0 to 30 cycles

Current input full scale: ......................... 150% of CT primary

Voltage input full scale: ......................... 600 V AC

TRIGGER LEVEL PICKUP ACCURACY

Overcurrent:................................................. ±2% of full scale

Overvoltage: ................................................ ±2% of full scale

Undervoltage: ............................................ ±3% of full scale

METERED VALUES

Samples per cycle: ................................... 64

Inputs sampled at a time: .................... all

Duration:........................................................ 2 cycles

TRACE MEMORY

Samples per cycle: ................................... 16

Inputs sampled at a time: .................... all

Duration:........................................................ continuous

HARMONIC SPECTRUM

Samples per cycle: 256

Inputs sampled at a time: 1

Duration:........................................................ 1 cycle

VOLTAGE DISTURBANCE RECORDER

Samples per half-cycle: ......................... 8

Inputs sampled: ........................................ all measured voltages

Duration: ...................................................... 0.5 cycles to 1 minute

1.6.4 Output Relays

MAKE/CARRY

Continuous:.................................................. 5 A

0.1 second: ................................................... 30 A

BREAK

Resistive:........................................................ 5 A at 30 V DC, 125/250 V AC

0.5 A at 125 V DC

0.3 A at 250 V DC

Inductive (L/R = 7 ms):............................. 5 A at 30 V DC, 125/250 V AC

0.25 A at 125 V DC

0.15 A at 250 V DC

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–15

1.6.5 Metering

MEASURED VALUES ACCURACY (SPECIFIED FOR 0 TO 40°C)

Voltage:...........................................................±0.2% of full-scale

Current:........................................................... ±0.2% of full-scale

Voltage unbalance: ..................................±1% of full-scale

Current unbalance: ..................................±1% of full-scale

kW:....................................................................±0.4% of full scale

kvar: ................................................................ ±0.4% of full scale

kVA: .................................................................. ±0.4% of full scale

kWh: ................................................................±0.4% of full scale

kvarh: .............................................................. ±0.4% of full scale

kVAh: ...............................................................±0.4% of full scale

Power factor: ...............................................±1% of full-scale

Frequency: ....................................................±0.02 Hz

kW demand:.................................................±0.4% of full-scale

kvar demand:...............................................±0.4% of full-scale

kVA demand:................................................ ±0.4% of full-scale

Current demand: .......................................±0.4% of full-scale

Current THD:.................................................±2.0% of full-scale

Voltage THD: ................................................ ±2.0% of full-scale

Crest factor:..................................................±0.4% of full-scale

MEASURED VALUES RANGE

Voltage:...........................................................20 to 100% of VT

Current:........................................................... 1 to 150% of CT

Voltage unbalance: ..................................0 to 100%

Current unbalance: ..................................0 to 100%

Real power:...................................................0 to ±999,999.99 kW

Reactive power: ......................................... 0 to ±999,999.99 kvar

Apparent power: .......................................0 to 999,999.99 kVA

32

Real energy:.................................................. 2

Reactive energy: ........................................2

Apparent energy: ......................................2

32

32

kWh

kvarh

kVAh

Power factor: ............................................... 0.00 to ±1.00

Frequency: ....................................................20.00 to 70.00 Hz

kw demand:.................................................. 0 to ±999,999.99 kW

kvar demand:...............................................0 to ±999,999.99 kvar

kVA demand:................................................ 0 to 999,999.99 kVA

Current demand: .......................................0 to 7500 A

THD (current and voltage): ...................0.0 to 100.0%

Crest factor:..................................................1 to 9.99

CHAPTER 1: OVERVIEW

1.6.6 Monitoring

UNDERVOLTAGE MONITORING

Req’d voltage: ............................................. >20 V applied in all phases

Pickup:.............................................................0.50 to 0.99 × VT in steps of 0.01

Dropout: .........................................................103% of pickup

Time delay: ...................................................0.5 to 600.0 s in steps of 0.5

Phases:............................................................Any 1 / Any 2 / All 3 (programmable) have to be ≤

pickup to operate

Accuracy:.......................................................per voltage input

1–16 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

Timing accuracy: ...................................... –0 / +1 sec.

OVERVOLTAGE MONITORING

Pickup: ............................................................ 1.01 to 1.25 × VT in steps of 0.01

Dropout:......................................................... 97% of pickup

Time delay:................................................... 0.5 to 600.0 s in steps of 0.5

Phases:........................................................... Any 1 / Any 2 / All 3 (programmable) must be ≥ pickup

to operate

Accuracy: ...................................................... Per voltage input

Timing accuracy: ...................................... –0 / +1 sec.

UNDERFREQUENCY MONITORING

Req’d voltage: ............................................ >30 V applied in phase A

Pickup: ............................................................ 20.00 to 70.00 Hz in steps of 0.01

Dropout:......................................................... Pickup + 0.03 Hz

Time delay:................................................... 0.1 to 10.0 s in steps of 0.1

Accuracy: ...................................................... 0.02 Hz

Timing accuracy: ±100 ms

OVERFREQUENCY MONITORING

Req’d voltage: ............................................ >30 V applied in phase A

Pickup: ............................................................ 20.00 to 70.00 Hz in steps of 0.01

Dropout:......................................................... Pickup – 0.03 Hz

Time delay:................................................... 0.0 to 10.0 s in steps of 0.1

Accuracy: ...................................................... 0.02 Hz

Timing accuracy: ±100 ms

POWER FACTOR MONITORING

Req’d voltage: ............................................ >20 V applied in phase A

Pickup: ............................................................ 0.50 lag to 0.50 lead step 0.01

Dropout:......................................................... 0.50 lag to 0.50 lead step 0.01

Time delay:................................................... 0.5 to 600.0 s in steps of 0.5

Timing accuracy: ...................................... –0.5/+1 sec.

DEMAND MONITORING

Measured values: ..................................... Phase A/B/C/N Current (A)

3φ Real Power (kW)

3φ Reactive Power (kvar)

3φ Apparent Power (kVA)

Measurement type (programmable):

Thermal Exponential, 90% response time: 5 to 60 min. in steps of 1

Block interval: ............................................ 5 to 60 min. in steps of 1

Rolling Demand Time Interval: .......... 5 to 60 min. in steps of 1

Pickup: ............................................................ 10 to 7500 A in steps of 1

1 to 65000 kW in steps of 1

1 to 65000 kvar in steps of 1

1 to 65000 kVA in steps of 1

VOLTAGE DISTURBANCE RECORDER

Required voltage: ..................................... >20 V or 10% (whichever is greater) applied in each

measured phase

Minimum nominal voltage: .................. 60 V

Phases recorded: ...................................... all three phases recorded independently

Conversion: .................................................. true RMS, 8 samples/half-cycle

Sag:

Pickup level: .............................................. 0.20 to 0.90 × VT in steps of 0.01

Dropout level: .......................................... pickup + 10% of nominal

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–17

1.6.7 System

CHAPTER 1: OVERVIEW

Swell:

Pickup level: ..............................................1.01 to 1.50 × VT in steps of 0.01

Dropout level: ...........................................pickup – 10% of nominal

COMMUNICATIONS

COM1/2: .........................................................RS485 2-wire, half duplex, isolated

COM3:..............................................................RS232 9-pin

Baud rate:......................................................1200 to 19200

®

Protocols:.......................................................Modbus

RTU; DNP 3.0

Functions:......................................................Read/write setpoints, read actual values, execute

commands, read device status

loopback test

CLOCK

Accuracy:.......................................................±1 min. / 30 days at 25±5°C

Resolution:.....................................................1 sec.

CONTROL POWER

Input:................................................................ 90 to 300 V DC or 70 to 265 V AC at 50/60 Hz

Power: ............................................................. nominal 10 VA, max. 20 VA

Holdup: ........................................................... 100 ms typical (at 120 V AC / 125 V DC)

It is recommended that the PQMII be powered up at least once per year to avoid

deterioration of the electrolytic capacitors in the power supply.

FUSE TYPE/RATING

5 × 20mm, 2.5 A, 250V

Slow blow, High breaking capacity

1.6.8 Testing and Approvals

TYPE TESTS

TEST REFERENCE STANDARD TEST LEVEL

Dielectric voltage withstand 2300-3700VAC

Impulse voltage withstand EN60255-5 5KV

Insulation resistance 500VDC >100mohm

Damped Oscillatory IEC61000-4-18IEC60255-22-1 2.5KV CM, 1KV DM

Electrostatic Discharge EN61000-4-2/IEC60255-22-2 Level II

RF immunity EN61000-4-3/IEC60255-22-3 10V/m 80-1Ghz

Fast Transient Disturbance EN61000-4-4/IEC60255-22-4 Class A and B

Surge Immunity EN61000-4-5/IEC60255-22-5 4Kv, 2KV

Conducted RF Immunity EN61000-4-6/IEC60255-22-6 10Vrms

Radiated & Conducted Emissions CISPR11 /CISPR22/ IEC60255-25 Class A

1–18 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

CHAPTER 1: OVERVIEW

Sinusoidal Vibration IEC60255-21-1 Class 1

Shock & Bump IEC60255-21-2 Class 1

Power magnetic Immunity IEC61000-4-8 Level 4

Pulse Magnetic Immunity IEC61000-4-9 Level 4

Voltage Dip & interruption IEC61000-4-11

0,40,70,% dips,250/

300cycle interrupts

Ingress Protection IEC60529 IP40 front , IP20 Back

Environmental (Cold) IEC60068-2-1 -10C 16 hrs

Environmental (Dry heat) IEC60068-2-2 70C 16hrs

Relative Humidity Cyclic IEC60068-2-30 6day variant 2

EFT IEEE/ANSI C37.90.1 4KV, 2.5Khz

Damped Oscillatrory IEEE/ANSI C37.90.1 2.5KV,1Mhz

Altitude: 2000m (max)

Pollution Degree: II

Overvoltage Category: II

Ingress protection: IP40 Front , IP20 back

APPROVALS

APPROVALS

Applicable Council Directive According to

Low voltage directive EN60255-5

CE compliance EMC Directive EN61000-6-2

UL508

North America cULus e83849 NKCR/7 UL1053

C22.2.No 14

ISO

Manufactured under a registered

quality program

ISO9001

ENVIRONMENTAL

Ambient temperatures:

Operating range: -10C to 60C

Humidity:

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 1–19

Operating up to 95% (non condensing) @ 55C (As per

IEC60068-2-30 Variant 2, 6days)

1.6.9 Physical

CHAPTER 1: OVERVIEW

No special ventilation required as long as ambient

Ventillation:

temperature remains within specifications.

Ventilation may be required in enclosures exposed to

direct sunlight.

Cleaning: May be cleaned with a damp cloth.

PACKAGING

Shipping box: .............................................. 8½” × 6” × 6” (L × H × D)

21.5cm × 15.2cm × 15.2 cm

1–20 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

Digital Energy

Multilin

PQMII Power Quality Meter

Chapter 2: Installation

Installation

2.1 Physical Configuration

2.1.1 Mounting

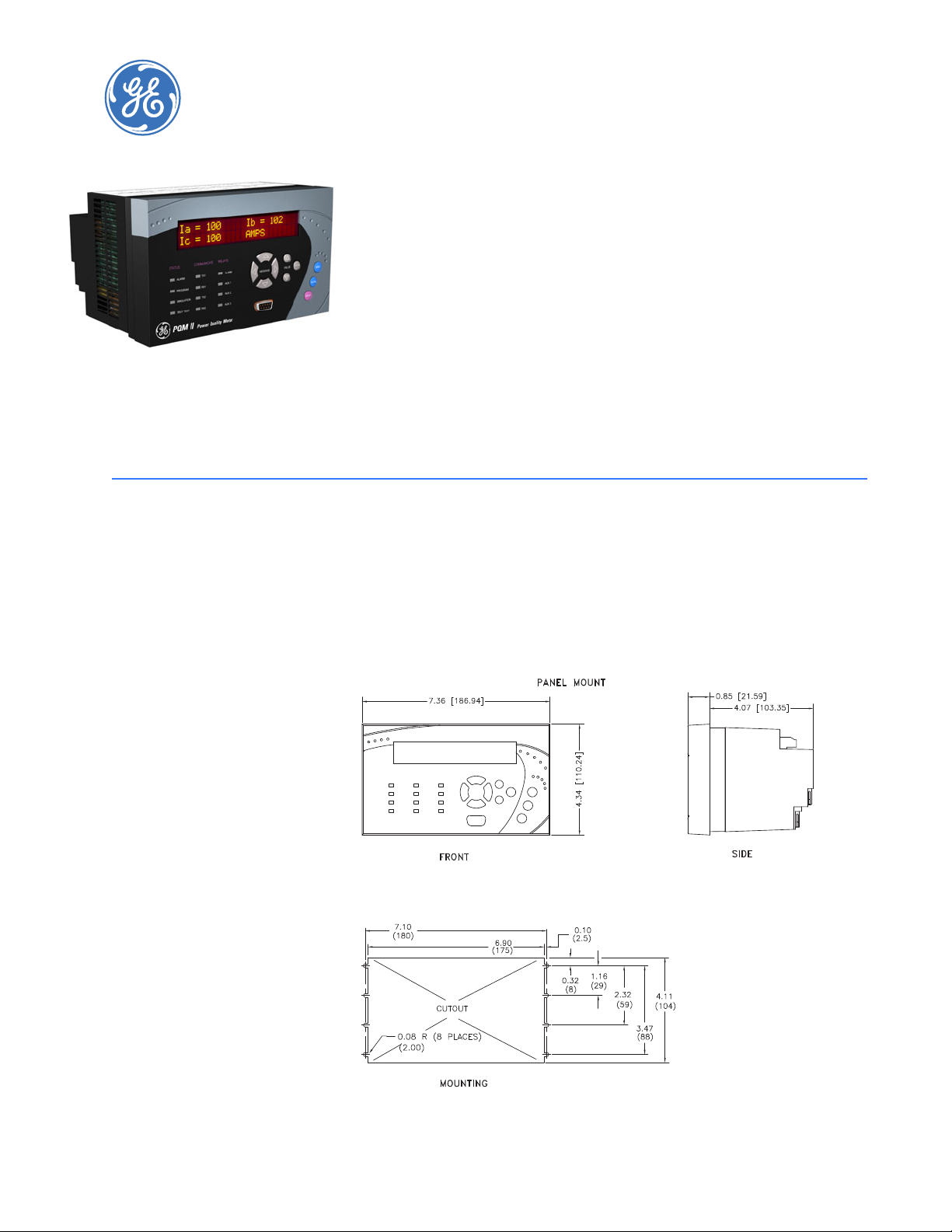

Physical dimensions and required cutout dimensions for the PQMII are shown below. Once

the cutout and mounting holes are made in the panel, use the eight #6 self-tapping screws

provided to secure the PQMII. Mount the unit on a panel or switchgear door to allow

operator access to the keypad and indicators.

FIGURE 2–1: Physical Dimensions

PQMII POWER QUALITY METER – INSTRUCTION MANUAL 2–1

2.1.2 Product Identification

20

19

18

17

16

15

141312

11

10

9

MAXIMUM CONTACT RATING

250 VAC 10A RESISTIVE

1/4HP 250VAC 1/2HP 125VAC

PQM II

MODEL NO.:

CONTROL VOLTAGE: SERIAL No.:

VERSION:

CUSTOMER TAG No.: 1234-567-89

90-300VDC 20VA

70-265VAC 50/60HZ 20VA

100.000

C7360001

PQMII-T20-C-A

MADE IN

CANADA

g

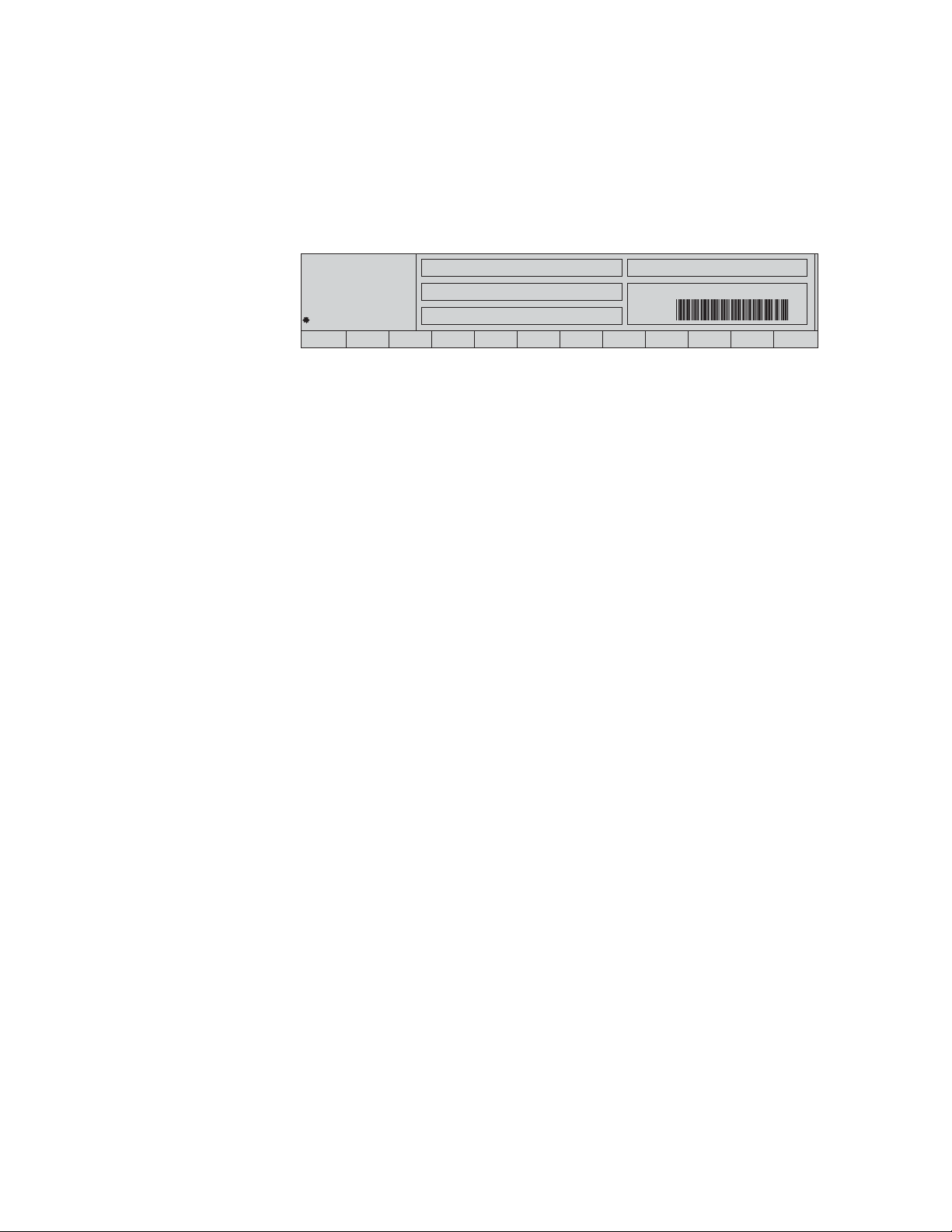

Product attributes vary according to the configuration and options selected on the

customer order. Before applying power to the PQMII, examine the label on the back and

ensure the correct options are installed.

The following section explains the information included on the label shown below:

• Model No: Shows the PQMII configuration. The model number for a basic panel

mount PQMII is “PQMII”. T20, C, and A appear in the model number only if the

Transducer, Control, or Power Analysis options are installed.

• Supply Voltage: Indicates the power supply input configuration installed in the

PQMII. The PQMII shown in this example can accept any AC 50/60Hz voltage from

70 to 265 V AC or DC voltage from 90 to 300 V DC.

• Tag#: An optional identification number specified by the customer.

• Mod#: Indicates if any unique features have been installed for special customer

orders. This number should be available when contacting GE Multilin for technical

support.

• Version: An internal GE Multilin number that should be available when contacting

us for technical support.

• Serial No.: Indicates the serial number in numeric and barcode formats. Record

this number when contacting GE Multilin for technical support .

CHAPTER 2: INSTALLATION

FIGURE 2–2: Product Label

2–2 PQMII POWER QUALITY METER – INSTRUCTION MANUAL

2.1.3 Manual and Firmware Revisions

Each instruction manual revision corresponds to a particular firmware revision. The

manual revision is located on the title page as part of the manual part number (the format

is 1601-nnnnmanual part number, and is also loaded in the PQMII, where it can be viewed by scrolling

to the

A4 PRODUCT INFO ÖØ SOFTWARE VERSIONS ÖØ MAIN PROGRAM VERSION message.

When using the instruction manual to determine PQMII features and settings, ensure that

the instruction manual revision corresponds to the firmware revision installed in the PQMII.

revision). The firmware revision is located on that same page, just above the

Loading...

Loading...