GE PNRQ15RBL00 Owner’s Manual

0_

E

4.z

®l

4.z

E

0

0

GEAppliances.corn

Safety Instructions

Safety Instructions ................ 2, 5

Specification Guidelines ............. 4

Operating Instructions

About the ROSystem ............. 5, 6

Installation Instructions

Tools and Materials Required ........ 7

Before Beginning Installation ...... 7, 8

Mounting System Installation ........ 9

Feed Water Supply ............. 10-13

Faucet Assembly ............... 14, 15

Battery Installation ................ 15

Filtration Drain Connection ..... 16, 17

Storage Tank and Startup .......... 18

PNRQ15RBL

PXRQ15RBL

Osmose Invers

Syst_me de Filtration

La section fran_aise commence _ la page 27

0

>

®l

LL

Care and Cleaning

prefilter, Postfilter and

RO Cartridge Replacement ......... 19

Sanitization ........................ 20

Water Test Kit ..................... 21

Troubleshooting Tips ...... 22, 25

Consumer Support

Consumer Support ........ Back Cover

Parts List/Catalog .............. 24, 25

Warranty .......................... 26

PXRQ15RBLand PNRQ15RBLare Testedand

Certified to NSF/ANSI Standards 58and 42

and CSAB483.1for the reduction of the claims

as specified on the Performance Data Sheet.

Osmosis Inversa

Sistema de Filtrocidn

La secci6n en espafol empieza en la p6gina 55

Write the model and serial

numbers here:

Model #

Serial #

Youcan find them on the bracket.

1010190310 49-50261-1 09-10GE

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

SAFETY INFORIVlATION

Read,understand,and follow all safetyinformation containedin theseinstructionspriorto installationand useof the GEReverse

Osmosissystems.Retaintheseinstructionsfor future reference.

Intended use:

TheGEReverseOsmosissystemsare intendedfor use infiltering potable water in Residentialapplications,and has not been

evaluatedfor other uses.Thesystemistypicallyinstalledat the point of use,and mustbe installedas specifiedin the installation

instructions.Contacta plumbingprofessionalif you are uncertain how to install.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

_W WARNINGindicates a potentially hazardous situation which, if not avoided, could result in death

_, CAUTIONindicates a potentially hazardous situation which, if not avoided, may result in minor to

ARNING orseriousinjury.

CAUTION moderateinjury.

CAUTION CAUTIONused without the safety alert symbol indicates a potentially hazardous situation which, if

not avoided, may result property damage.

SAFETY PRECAUTIONS

I Besurethe water supplyconformswith the

SpecificationGuidelines.if the water supplyconditions

are unknown,contact your municipalwater company

or your local health department for a listof

contaminantsin your area and a listof laboratories

certified byyourstate to analyzedrinkingwater.

WARNINGTOreduce the risk associated

with choking:

• Do not allowchildrenunder 3years of age to have

accessto smallparts duringthe installationof this

product.

WARNINGTOreducethe riskassociatedwith

theingestionofcontaminants:

• Donotusewithwaterthatismicrobiologicallyunsafeorof

unknownqualitywithoutadequatedisinfectionbeforeor

afterthesystem.Systemscertifiedfor cystreductionmay

beusedondisinfectedwaterthat maycontainfilterable

cysts.EPAEstablishment#10350-iVlN-005.

installa water hammer arrester.Contacta plumbing

professionalif you are uncertainhow to checkfor this

condition.

• Wherea backflow preventiondeviceis installedona

water system,a deviceforcontrolling pressuredueto

thermal expansionmustbe installed.

_1_ WARNING To reducethe risk associated

with irritation from SodiumHetabisulphite during

installation:

• SodiumiVletabisulphite(CAS007681-57-/4)isusedina 1%

preservativesolutionwithinthe reverseosmosis

membrane.

• Torequest an HSDSrelating to this product call 203-

238-8965or visit the web at

http://sotutions.3m.com/wps/portat/3m/en_us/

msds(click HSDSsearch}.Foremergencies,call 800-

364-3577or 651-737-6501(24hours}.

A WARNINGToreducethe risk associated

A WARNINGTo reduce the riskassociated

with hazardousvoltage due to an installer drilling

through existing electric wiring or water pipesin the

area of installation:

• Do not install nearelectricwiring or pipingwhich may

be in path of a drillingtool when selectingthe position

to mount the filter bracket.

A WARNINGToreducetheriskofphysical

injury:

• Depressurizesystem as shown in manual prior to

cartridge removal.

WARNINGToreducetheriskofphysicalinjury

duetohydro-pneumotictankrupture:

• Do not install ifwater pressureexceeds120psi(827

kPa).if yourwater pressureexceeds80 psi(552kPa),

youmust installa pressurelimitingvalve.Contacta

plumbingprofessionalif you are uncertain how to

checkyour water pressure.

• Do not installwhere water hammer conditions may

occur,tf water hammer conditions existyou must

with ingesting of water contaminated with sanitizer:

• After installation,sanitizerMUSTbe flushedfrom the

systembeforefirst useas directedwithin the

installationinstructions.

Thissystemhasbeentestedforthe treatmentofwater

containingpentavalentarsenic(alsoknownasAs(V),As(+5)or

arsenate)atconcentrations

of0.050mg/Lorless.Thissystemreducespentavalent

arsenic,butmaynot removeotherformsofarsenic.This

systemisto beusedonwatersuppliescontaininga

detectablefreechlorineresidualoronwatersuppliesthat

havebeendemonstratedto containonlypentavalentarsenic.

Treatmentwithchloramine(.combinedchlorine)isnot

sufficienttoensurecompleteconversionoftrivalentarsenicto

pentavalentarsenic.PleaseseetheArsenicFactssectionof

thePerformanceDataSheetfor furtherinformation.

Thisreverseosmosissystemcontainsa replaceable

component criticalto efficiencyofthe system.

Replacementofthe reverseosmosiscomponent should

be with one of identicalspecifications,asdefinedbythe

manufacturer,to assurethesame efficiency and

contaminant reductionperformance.

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING. GEApplio,,cesco,,,

PROPER INSTALLATION AND MAINTENANCE

This Reverse Osmosis system must be properly installed and located in accordance with the

Installation Instructions before it is used.

i Extendednon-useofthe ReverseOsmosissystem.

If the system has not been usedfor one week or

more, open the ROwater faucet and allow the

system to drain. Closethe ROwater faucet and

allow the system to regenerate the water supply.

I Recommendedinstallationisunder the sink.

However,the unitcan be installedin a remote

location,up to 20 feet away from the sink.

, However,additional materials will be required.

Seeparts listto obtain additional materials

from GE.

, Locatingthe tank on a basementfloor,with the

faucet ata first floor sink may result in some lossof

flow rate and capacity (approximately20%).

Installinga secondtank will improvethis

performance.An RVKITcan be used.

I If ReverseOsmosissystemisconnectedto a

refrigerator icemaker,a specialicemakerconnection

kit is required(RVKIT).Do not use copper tubing for

the connectionbetween the ReverseOsmosis

systemand the refrigerator.

I Sanitizeupon installation of the ReverseOsmosis

systemand after servicinginner parts,including

replacementof prefilter,postfilter and Reverse

Osmosiscartridge.It isimportant to haveclean

handswhile handling innerparts of the system.

Seethe SanitizingtheReverseOsmosisSystem

section.

I This ReverseOsmosissystemcontains a replaceable

treatment component critical for effective reduction

of total dissolvedsolids.Thisproduct water shall be

tested periodicallyto verifythat the system is

performing satisfactorily.Seethe TheWater TestKit

section.

BESURETO FOLLOW ALL APPLICABLE STATE

AND LOCAL CODES.

CAUTION: TOreduce the risk associated

with property damage due to water leakage:

, Readand follow these instruction beforeinstallation

and use of this system.

, Installationand use IvlUSTcomply with all stateand

localplumbing codes.

, Protectfrom freezing,remove filter cartridge when

temperatures are expected to drop below 40° F

(4.4° C).

Do not install systems in areas where ambient

temperatures may go above 110°F(43.3° C).

Donot install if water pressure exceeds120 psi (827

kPa).Ifyour water pressureexceeds 80 psi(552 kPa),

you must install a pressure limiting valve.Contact a

plumbing professionalifyou are uncertain how to

checkyour water pressure.

Donot installwhere water hammer conditions may

occur.If water hammer conditions exist,you must

install a water hammer arrester. Contact a

plumbing professionalifyou are uncertain how to

checkfor this condition.

Where a back flow prevention device is installed on

a water system, a devicefor controlling pressure

due to thermal expansion must beinstalled.

CAUTION: TOreduce the risk associated

with property damage due to water leakage:

Donot usea torch or other hightemperature

sourcesnear filter system,cartridges, plasticfittings

or plastic plumbing.

Onplastic fittings, neveruse pipe sealantor pipe

dope.Use PTFEthread tape only, pipe dope

properties may deteriorate plastic.

Takecare when using pliersor pipewrenches to

tighten plastic fittings, as damage may occur if over

tightening occurs.

Donot install in direct sunlight or outdoors.

Donot install near water pipes which will be in path

of a drilling tool when selecting the position to

mount the bracket.

Mount filter in sucha positionas to prevent it from

being struck byother items used in the area of

installation.

Ensurethat the location and fasteners will support

the weight of the system when installed and full of

water.

Ensureall tubing and fittings are secureand free of

leaks.

Donot install unit if any collets (parts 27 and 28 on

page 24)are missing. Contact 800.626.2002(U.S.),

800.663.6060(Canada-English),

800.362-3869(Canada-French)if collets are missing

from any fittings to obtain replacements.

Replacethe disposable pre and post filter cartridges

every 6 months, at the rated capacity or sooner if a

noticeable reduction inflow rate occurs.

Replacethe disposable ROcartridge every24

months or sooner if a noticeable reduction in

filtration efficiency occurs.

READANDFOLLOWTHISSAFETYINFORHATIONCAREFULLY.

SAVETHESEINSTRUCTIONS

Specification guidelines.

The system makes a good supply of drinking water each day.

How much it will make depends primarily on these things...

Feed water pressure limits-pounds per square inch (psi) ...................... 40-!20 °

Feed water temperature limits--minimum/maximum degrees F ............... 40-!00

Maximum Total Dissolved Solids (TDS)--parts per million (ppm) ................ 2000

Naximum water hardness @ 6.9 pH recommended to optimize membrane

life-grains per gallon {gpg) ...................................................... ! 0

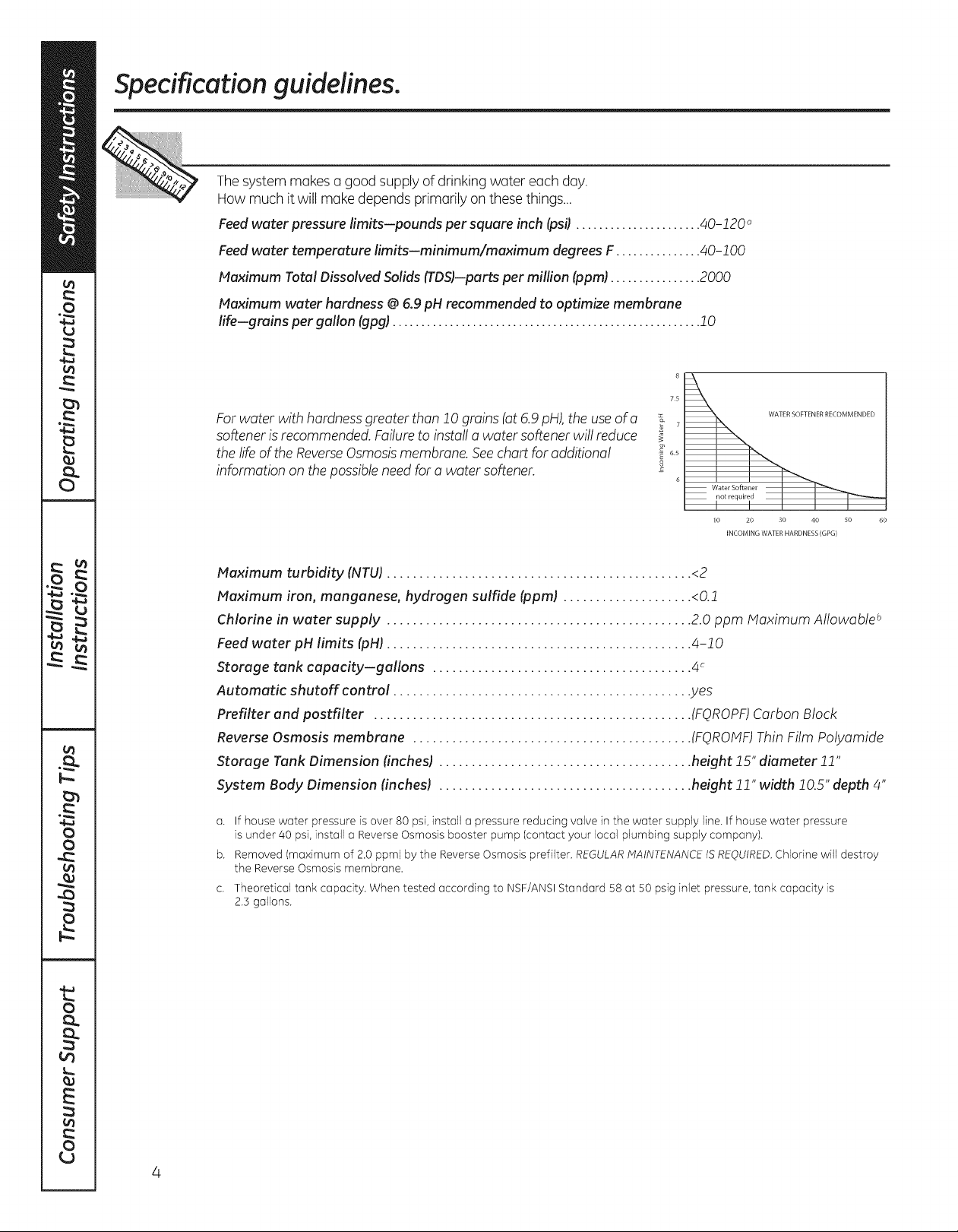

Forwater with hardness greater than !0 groins (at 6.9 pH),the use of a

softener is recommended. Failure to install a water softener willreduce

the life of the Reverse Osmosis membrane. See chart for additional

information on the possible need for a water softener.

_ 7

_ 65

8

75

WATERSOFTENERRECOMMENDED

6

Water Softener

I I I I

lO 20 30 40 50 60

INCOMING WATER HARDNESS (GPG)

Maximum turbidity (NTUJ ............................................... <2

Maximum iron, manganese, hydrogen sulfide (ppml .................... <0.!

Chlorine in water supply ............................................... 2.0 ppm Maximum Allowable b

Feed water pH limits (pHi ............................................... 4-10

Storage tank capacity-gallons ........................................ 4c

Automatic shutoff control ............................................. .yes

Prefilter and postfilter ................................................. (FQROPF)Carbon Block

Reverse Osmosis membrane ........................................... (FQROHF) Thin Film Polyamide

Storage Tank Dimension finches} ....................................... height !5" diameter !!"

System Body Dimension (inchesl ....................................... height !!" width !0.5" depth 4"

a. If housewater pressureisover80 psi,install a pressurereducingvalvein the water supply line.If housewater pressure

isunder 40 psi,installaReverseOsmosisbooster pump(contactyour local plumbingsupply company).

b. Removed(maximumof 2.0ppm) by the ReverseOsmosisprefilter. REGULARHAINTENANCEISREQUIRED. Chlorinewill destroy

the ReverseOsmosismembrane.

C.

Theoretical tank capacity. When tested according to NSF/ANSI Standard 58 at 50 psig inlet pressure, tank capacity is

2.3 gallons.

About the reverse osmosis system. GEApplio.ces.com

How the Reverse Osmosis System Works

ReverseOsmosisreducesTotal DissolvedSolids(TDS)and organic matter from water by diffusing it through u special

membrane (see Performance Data Sheet).The membrane separates minerals and impuritiesfrom the water and they are

flushed to the drain. Forthe reduction of the claims specified,see Performance Data Sheet. Highquality product water goes

directly to the drinking water faucet or to the storage tank. The system makes u good supply of drinking water each day. How

much it makes depends on the feed water supply pressure,temperature and quality.

The prefilter and postfilter are replaceable cartridges.Thecarbon prefilter reduceschlorine while alsofiltering sediments.

The postfilter reduces any other undesirabletastes and odors beforeyou usethe water.

Thesystem includesan electronic faucet assemblywith a prefilter and postfilter change reminder.When six months have

passed,a flashing light will remind you to change the two filters.

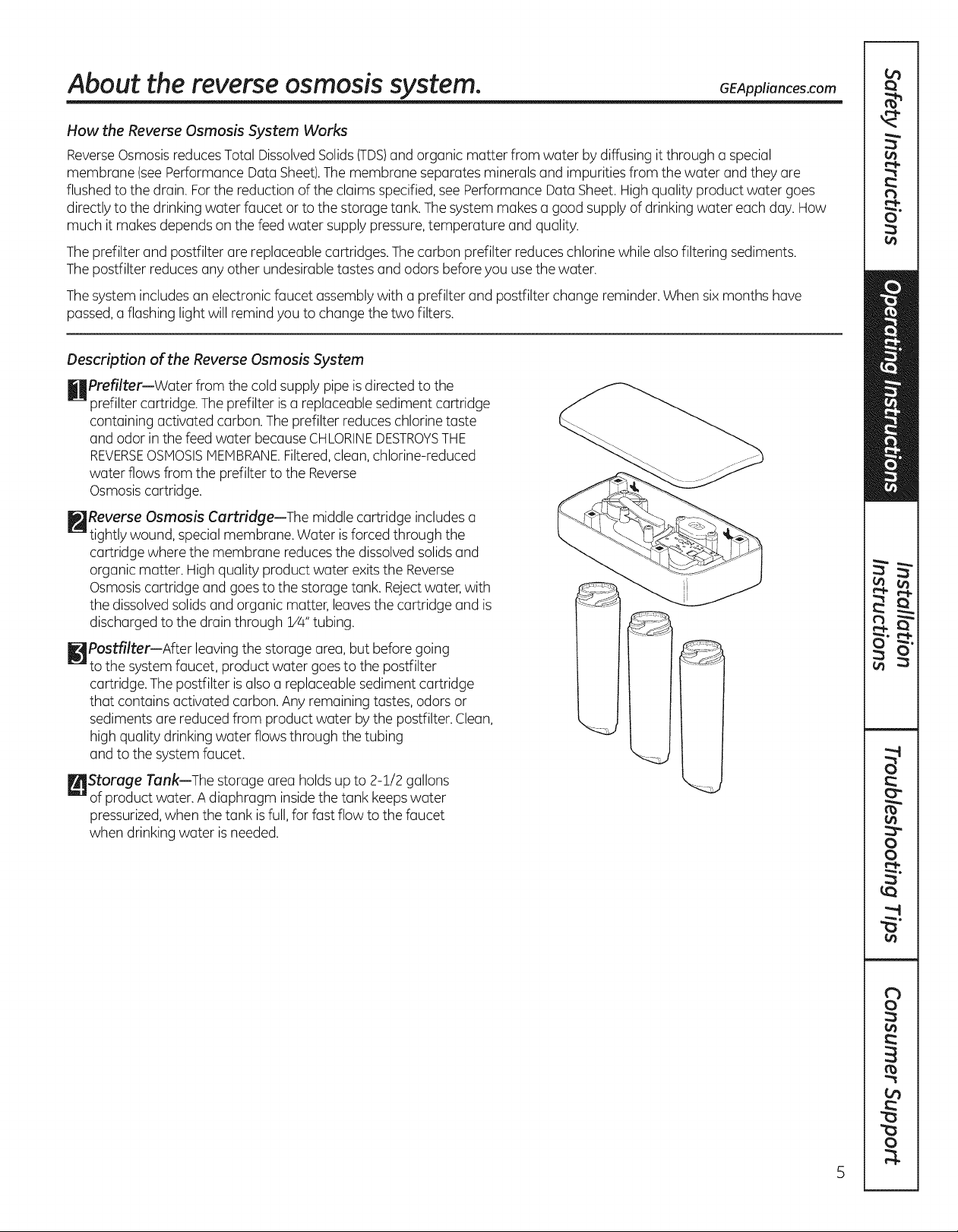

Description of the Reverse Osmosis System

HPrefilter-water from the cold supply pipe isdirected to the

prefilter cartridge. The prefilter isa replaceable sediment cartridge

containing activated carbon.The prefilter reduces chlorine taste

and odor in the feed water becauseCHLORINEDESTROYSTHE

REVERSEOSMOSISMEHBRANEFiltered,clean, chlorine-reduced

water flows from the prefilter to the Reverse

Osmosiscartridge.

_-_Reverse Osmosis Cartridge--The middle cartridge includes a

tightly wound, special membrane. Water isforced through the

cartridge where the membrane reducesthe dissolved solidsand

organic matter. High quality product water exits the Reverse

Osmosiscartridge and goesto the storage tank. Rejectwater,with

the dissolvedsolids and organic matter, leavesthe cartridge and is

discharged to the drain through !/4" tubing.

[]Postfilter--After leaving the storage area, but before going

to the system faucet, product water goes to the postfilter

cartridge.The postfilter is also a replaceable sediment cartridge

that contains activated carbon. Any remaining tastes, odors or

sediments are reduced from product water bythe posffilter. Clean,

high quality drinking water flows through the tubing

and to the system faucet.

_/'_Storuge Tunk--The storage area holdsup to 2-1/2 gallons

of product water. A diaphragm insidethe tank keepswater

pressurized,when the tank is full, for fast flow to the faucet

when drinking water is needed.

5

About the reverse osmosissystem.

_lJCheck Valve--The check valvepreventsa backward flow of product water from the storagetank. Abackward flow could

cause the ReverseOsmosismembrane to rupture.

[]Automatic Shutoff Assembly--To conservewater,the drinking water systemhasan automatic shutoff.Whenthe storagetank

hasfilled to capacityand the drinkingwater faucet isclosed,pressureclosesthe shutoff.Waterflow tothe ReverseOsmosis

housingisshut off untildrinkingwater is used again,and pressuredropsinthe ReverseOsmosissystem.

V_Flow Control--The flow control regulatesthe flow of water through the ReverseOsmosiscartridgeat the required rate to

producehigh quality water. Thecontrol is located inthe 1/4" drain lineexiting off the manifold.

_JFaucet and Electronics--The countertop faucet dispensesfiltered drinking water when opened. It hasa hand-operated

lever,with variable flow adjustment. Youcan keepthe faucet open byremoving your hand from the leveroncewater is

flowing.To comply with plumbing codes,an airgap is built into the faucet drainwater connection.

Theelectronic faucet provides a six month timer to remind you when it istime to replaceyour prefilter and postfilter.

Replacethe filters when the light beginsto flash in order to protect the ROmembrane and keepthe system functioning

properly.

Installatio

ReverseOsmosis Filtration System

I str ct"

i_ uestions? Call 800.GE.CARES {800.432.2737} or visit our Website at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

S

Models P×RQ15RBL and PNRQ15RBL

WARNING: Read entire manual. Failure to follow all guides and rules could cause

personal injury or property damage.

, Check with your state and/or local public works department for plumbing codes. You must follow their

guides as you install the Water Filtration system.

NOTE: Failure to comply with these installation instructions will void the product warranty, and the

installer will be responsible for any service, repair or damages caused thereby.

TOOLS AND MATERIALS REQUIRED FOR

INSTALLATION

, Electric drill and 1-1/4" Drill Bit (type as required)

if mounting is needed for faucet

, Two (2) Adjustable Wrenches

, 1/16" Drill Bit (optional for pilot holes)

, Tape Measure

, Phillips and Flat Blade Screwdrivers

, Utility Knife

, If your main water line is a rigid pipe,

you will require a compression fitting

and possibly other plumbing hardware

to complete the installation.

BEFORE BEGINNING INSTALLATION

Read these instructions completely

and carefully.

. IMPORTANT - Savetheseinstructions

for local inspector's use.

" IMPORTANT - Observe all governing

codes and ordinances.

, Note to Installer- Be sure to leave these

instructions with the Consumer.

, Note to Consumer - Keep these instructions for

future reference.

, Proper installation is the responsibility

of the installer.

i

IMPORTANT - To avoid damaging the sink,

consulta qualifiedplumber orinstallerfordrilling

procedures.Specialdrillbitsmay be needed for

porcelainor stainlesssteel.

CONTENTS INCLUDED

WITH PRODUCT

Reverse Osmosis Assembly and Tubing

Product Literature (Owner's Manual and

Installation Instructions)

Performance Data Sheet

Feed Water Adapter

Faucet Assembly with Electronic Base Monitor

and Tubing

Storage Tank

Drain Line Adapter

, Product failure due to improper installation is not

covered under the Warranty.

, A shutoff valve must be available or added near

the installation point.

Installation Instructions

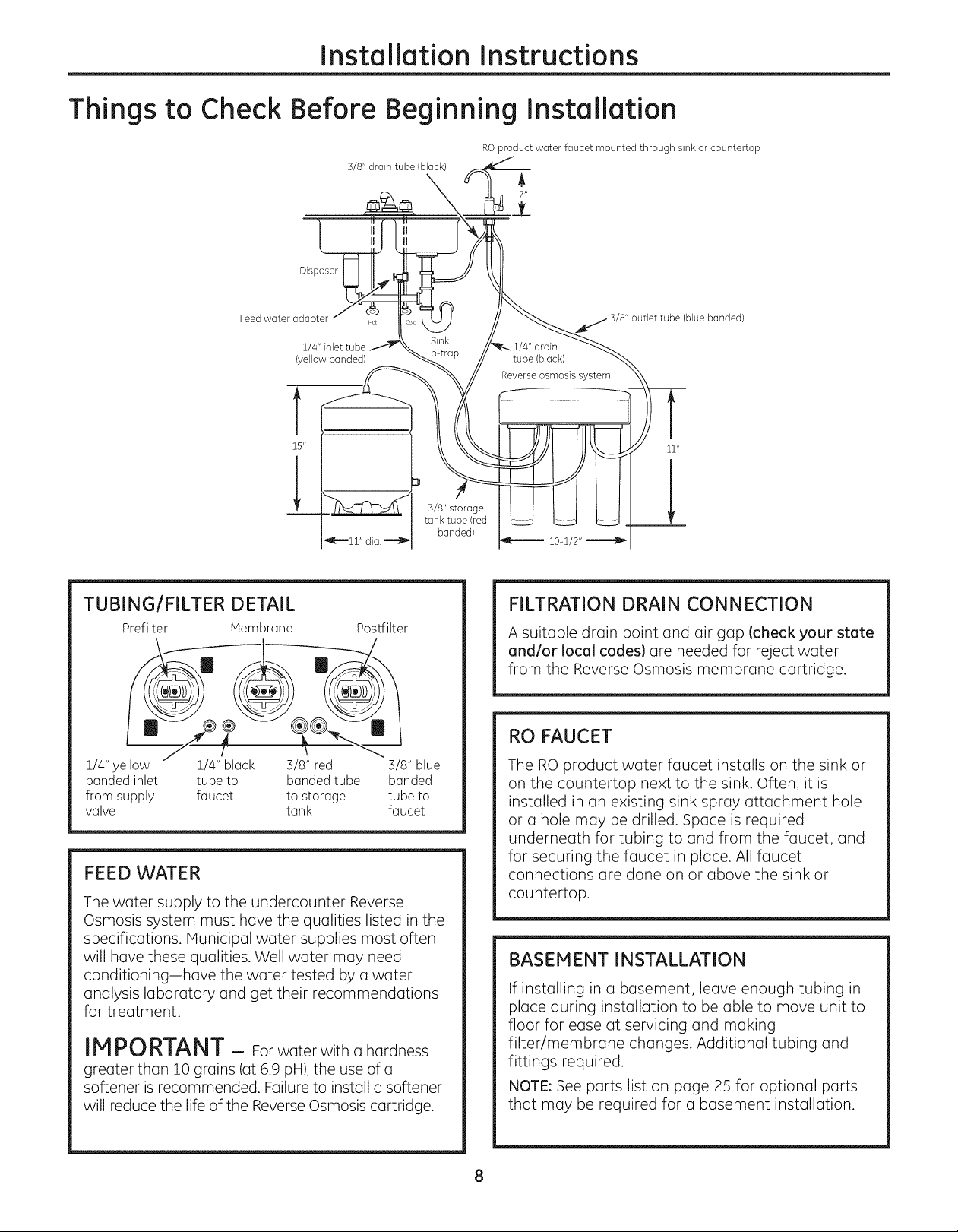

Things to Check Before Beginning Installation

ROproduct water faucet mounted through sink or countertop

5/8" drain tube {block/

Disposer

Feed water adopter

1/4"

/yellow bondedl

t

15"

TUBING/FILTER DETAIL

Prefilter Membrane Postfilter

3/8" storage

tunk tube (red

bonded)

3/8" outlet tube (blue bonded}

l

11"

lO_l/2,,=====-tl_

FILTRATION DRAIN CONNECTION

A suitable drain point and air gap Icheck your state

and/or local codes} ore needed for reject water

from the Reverse Osmosis membrane cartridge.

RO FAUCET

1/4" yellow 1/4" black 3/8" red 3/8" blue

banded inlet tube to banded tube banded

from supply faucet to storage tube to

valve tank faucet

FEED WATER

The water supply to the undercounter Reverse

Osmosis system must have the qualities listed in the

specifications. Municipal water supplies most often

will have these qualities. Well water may need

conditioning-have the water tested by a water

analysis laboratory and get their recommendations

for treatment.

IM PORTANT - Forwaterwitha hardness

greaterthan i0 grains(at6.9pH),theuse ofa

softenerisrecommended. Failureto installa softener

willreducethelifeofthe ReverseOsmosis cartridge.

The RO product water faucet installs on the sink or

on the countertop next to the sink. Often, it is

installed in an existing sink spray attachment hole

or o hole may be drilled. Space is required

underneath for tubing to and from the faucet, and

for securing the faucet in place. All faucet

connections are done on or above the sink or

countertop.

BASEMENT INSTALLATION

If installing in a basement, leave enough tubing in

place during installation to be able to move unit to

floor for ease at servicing and making

filter/membrane changes. Additional tubing and

fittings required.

NOTE: See parts list on page 25 for optional parts

that may be required for a basement installation.

8

Installation Instructions

REVERSE OSMOSIS ASSEMBLY

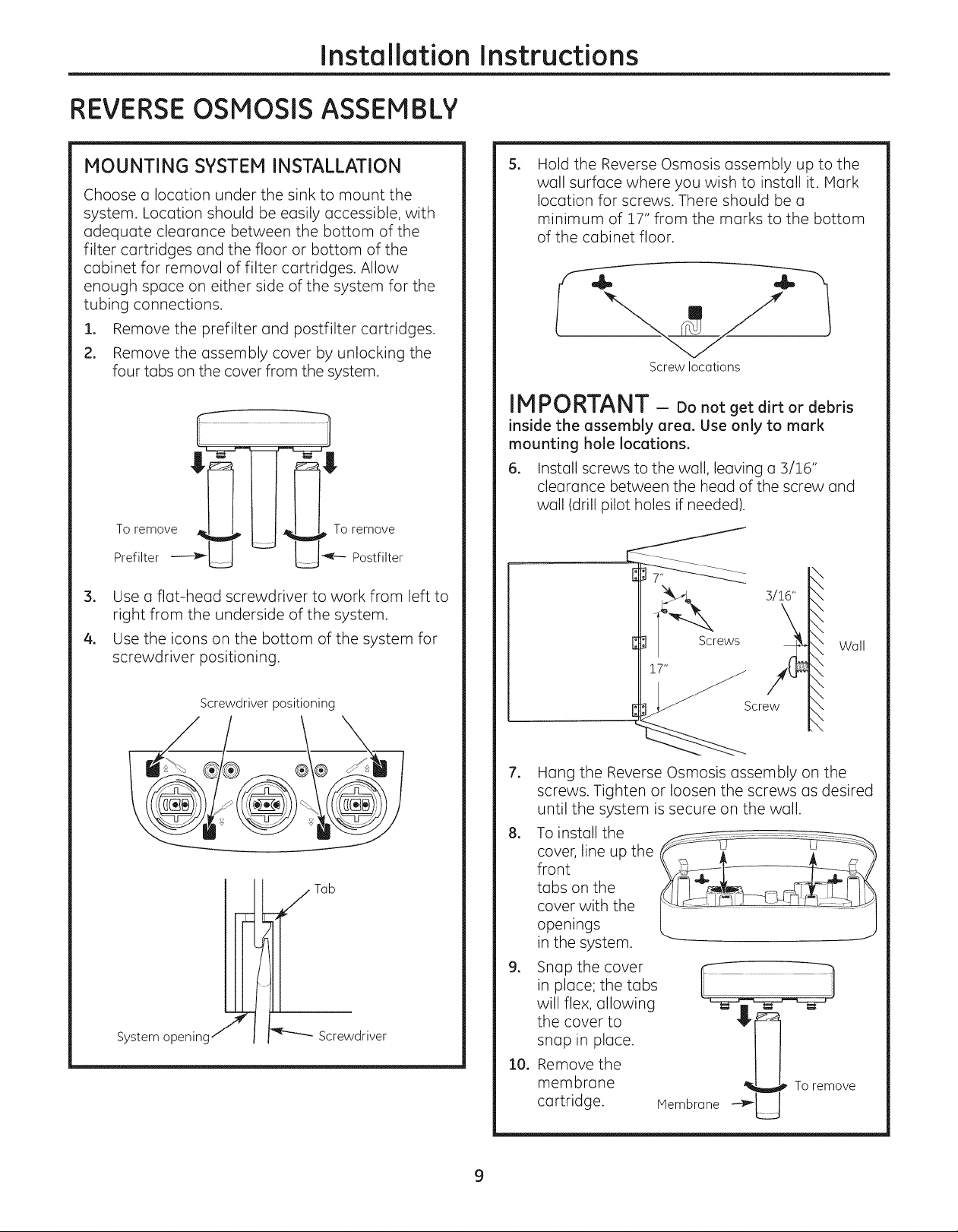

MOUNTING SYSTEM INSTALLATION

Choose a location under the sink to mount the

system. Location should be easily accessible, with

adequate clearance between the bottom of the

filter cartridges and the floor or bottom of the

cabinet for removal of filter cartridges. Allow

enough space on either side of the system for the

tubing connections.

1. Remove the prefilter and postfilter cartridges.

2. Remove the assembly cover by unlocking the

four tabs on the cover from the system.

To remove To remove

Prefilter _ _ Postfilter

3, Use a flat-head screwdriver to work from left to

right from the underside of the system.

4, Use the icons on the bottom of the system for

screwdriver positioning.

Screwdriver positioning

S,

Hold the Reverse Osmosis assembly up to the

wall surface where you wish to install it. Hark

location for screws. There should be a

minimum of 17" from the marks to the bottom

of the cabinet floor.

Screw locations

IMPORTANT - Do not get dirt or debris

inside the assembly area. Use only to mark

mounting hole locations.

6. Install screws to the wall, leaving a 3/16"

clearance between the head of the screw and

wall (drill pilot holes if needed).

\ Wall

\

\

\

\

\

\

\

\

System openinc Screwdriver

,

Hang the Reverse Osmosis assembly on the

screws. Tighten or loosen the screws as desired

until the system is secure on the wall.

,

To install the _._-_._...... .....

tabsfrontopen,ngscovercover,line up theonwiththethe _ ....:_lm- _--

in the system.

,

Snap the cover

in place; the tabs

will flex, allowing

the cover to

snap in place.

lO,

Remove the

membrane

cartridge.

Membrane

To remove

9

Installation Instructions

FEEDWATER SUPPLY

Check and comply with local plumbing codes as you plan, then install a cold feed water supply fitting.

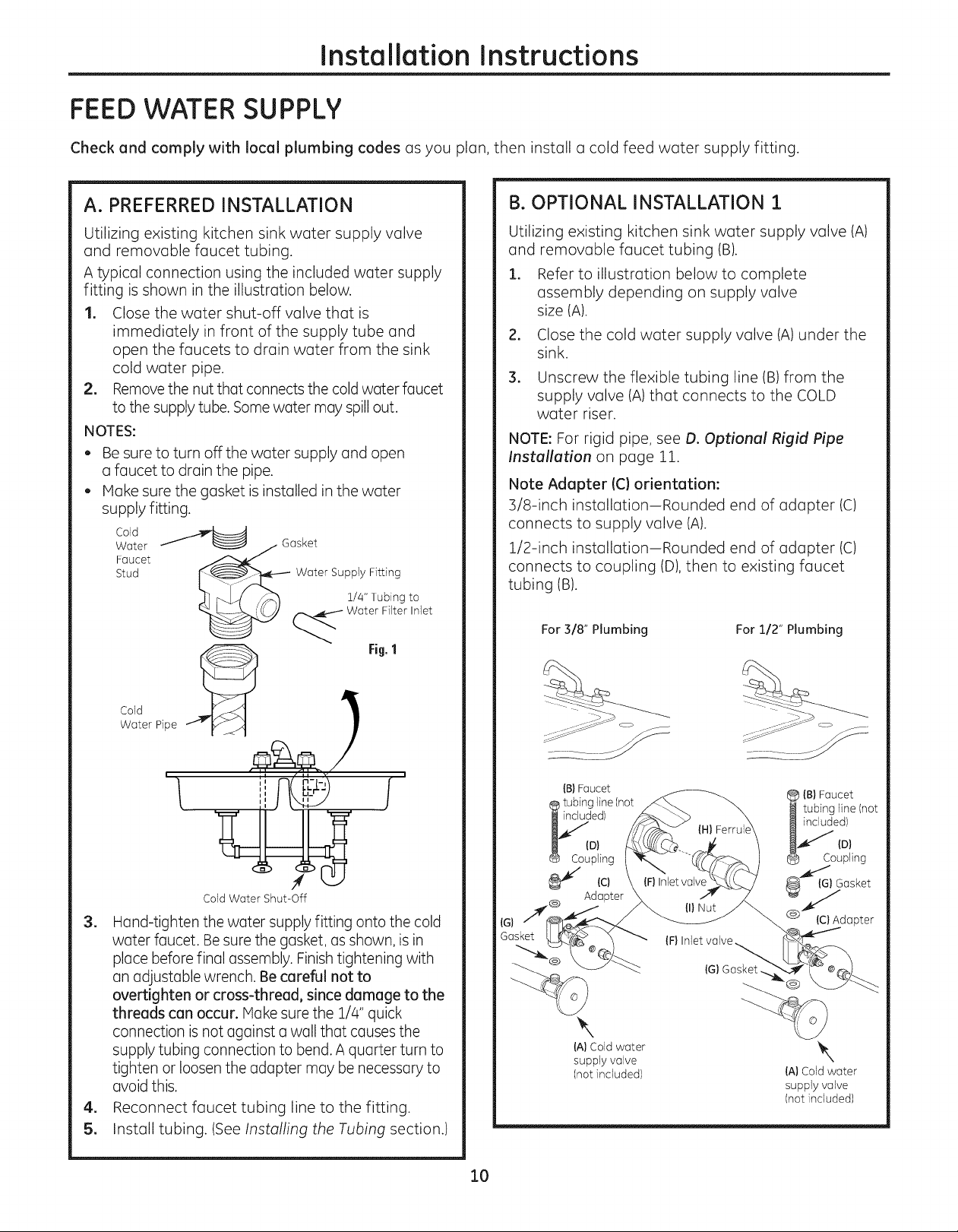

A. PREFERRED INSTALLATION

Utilizing existing kitchen sink water supply valve

and removable faucet tubing.

A typical connection using the included water supply

fitting is shown in the illustration below.

1. Closethe water shut-off valve that is

immediately in front of the supply tube and

open the faucets to drain water from the sink

cold water pipe.

2. Removethe nut that connectsthe coldwaterfaucet

to the supplytube.Somewater may spillout.

NOTES:

, Be sure to turn off the water supply and open

a faucet to drain the pipe.

, Make sure the gasket is installed in the water

supply fitting.

Cold

Water

Faucet

Stud

Gasket

Water Sup_,_,F_t_iLrlggto

-_ Water Filter Inlet

Fig,1

B. OPTIONAL INSTALLATION 1

Utilizing existing kitchen sink water supply valve (A)

and removable faucet tubing (B).

1. Refer to illustration below to complete

assembly depending on supply valve

size (A).

.

Close the cold water supply valve (A) under the

sink.

3.

Unscrew the flexible tubing line (B) from the

supply valve (A) that connects to the COLD

water riser.

NOTE: For rigid pipe, see D. Optional Rigid Pipe

Installation on page 11.

Note Adapter (C) orientation:

3/8-inch installation-Rounded end of adapter (C)

connects to supply valve (A).

1/2-inch installation-Rounded end of adapter (C)

connects to coupling (D), then to existing faucet

tubing (B).

For 318" Plumbing For 112" Plumbing

Cold Pipe

Water ,@_@,_ /_

f i

Cold Water Shut-Off

=

Hand-tighten the water supply fitting onto the cold

water faucet. Be sure the gasket, as shown, is in

place before final assembly. Finish tightening with

an adjustable wrench. Be careful not to

overtighten or cross-thread, since damage to the

threads can occur. Make sure the 1/4" quick

connection is not against a wall that causes the

supply tubing connection to bend. A quarter turn to

tighten or loosen the adapter may be necessary to

avoid this.

4. Reconnect faucet tubing line to the fitting.

5. Install tubing. (See Installing the Tubing section.)

Gasket

{G)__

{B)Faucet

tubing line (not

ed)

D)

Coupling

{c)

Adapter

\

{A) Cold water

supply valve

(not included)

{B} Faucet

tubing line (not

included)

ID)

oupling

i_ {G) Gasket

Q_dapter

IF} Inlet valve,

{G) Gasket.

\

{A} Cold water

supply valve

(not included)

10

Installation Instructions

FEEDWATER SUPPLY{cont.)

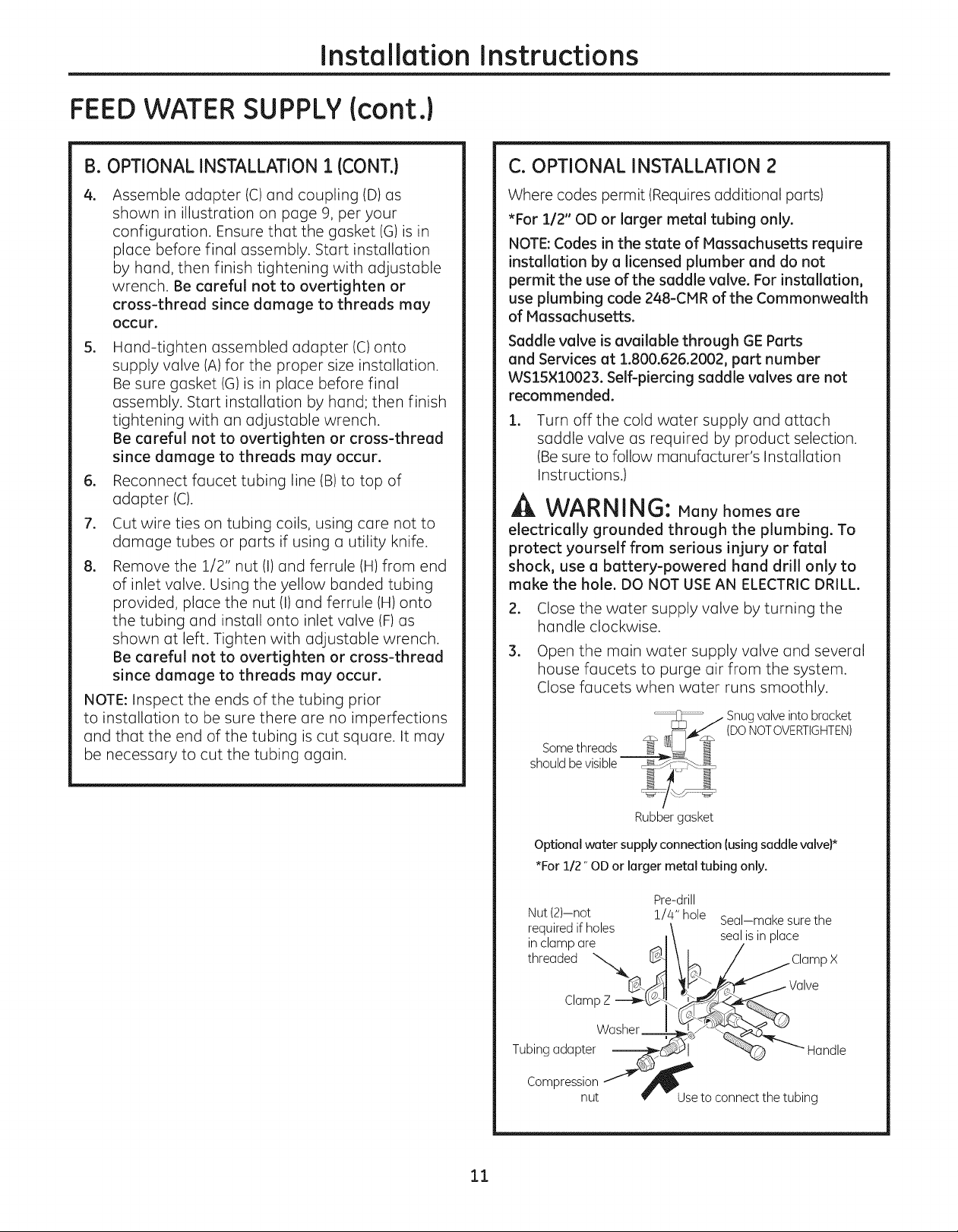

B. OPTIONAL INSTALLATION 1 {CONT.}

.

Assemble adapter (C)and coupling (D)as

shown in illustration on page 9, per your

configuration. Ensure that the gasket (G)is in

place before final assembly. Start installation

by hand, then finish tightening with adjustable

wrench. Be careful not to overtighten or

cross-thread since damage to threads may

occur.

S.

Hand-tighten assembled adapter (C)onto

supply valve (A) for the proper size installation.

Be sure gasket (G)is in place before final

assembly. Start installation by hand; then finish

tightening with an adjustable wrench.

Be careful not to overtighten or cross-thread

since damage to threads may occur.

.

Reconnect faucet tubing line (B) to top of

adapter (C).

7.

Cut wire ties on tubing coils, using care not to

damage tubes or parts if using a utility knife.

8.

Remove the 1/2" nut (I)and ferrule (H) from end

of inlet valve. Using the yellow banded tubing

provided, place the nut (I)and ferrule (H) onto

the tubing and install onto inlet valve (F) as

shown at left. Tighten with adjustable wrench.

Be careful not to overtighten or cross-thread

since damage to threads may occur.

NOTE: Inspect the ends of the tubing prior

to installation to be sure there are no imperfections

and that the end of the tubing is cut square. It may

be necessary to cut the tubing again.

C. OPTIONAL INSTALLATION 2

Where codes permit (Requires additional parts)

*For 1/2" OD or larger metal tubing only.

NOTE:Codes in the state of Massachusetts require

installation by a licensed plumber and do not

permit the use of the saddle valve. For installation,

use plumbing code 248-CIVlR of the Commonwealth

of Massachusetts.

Saddle valve is available through GE Parts

and Services at 1.800.626.2002, part number

WS15×10023. Self-piercing saddle valves are not

recommended.

.

Turn off the cold water supply and attach

saddle valve as required by product selection.

(Be sure to follow manufacturer's Installation

Instructions.)

WARNING: Many homes are

electrically grounded through the plumbing. To

protect yourself from serious injury or fatal

shock, use a battery-powered hand drill only to

make the hole. DO NOT USEAN ELECTRIC DRILL.

.

Close the water supply valve by turning the

handle clockwise.

3.

Open the main water supply valve and several

house faucets to purge air from the system.

Close faucets when water runs smoothly.

Snugvalve into bracket

(DONOTOVERTIGHTEN)

Rubber gasket

Optional water supply connection (using saddle valve)*

*For 1/2" OD or larger metal tubing only.

Pre-drill

Nut (2)--not !/4" hole Seal-make surethe

required if holes \ ....

it_rCe_admePare_ I_J\l se,_'lSInplac_lamp x

ClampZ ---_ks>-_

TubingadapterWa_ _'- Handle

C°mpreSSntt __Use to connect the tubing

11

Installation Instructions

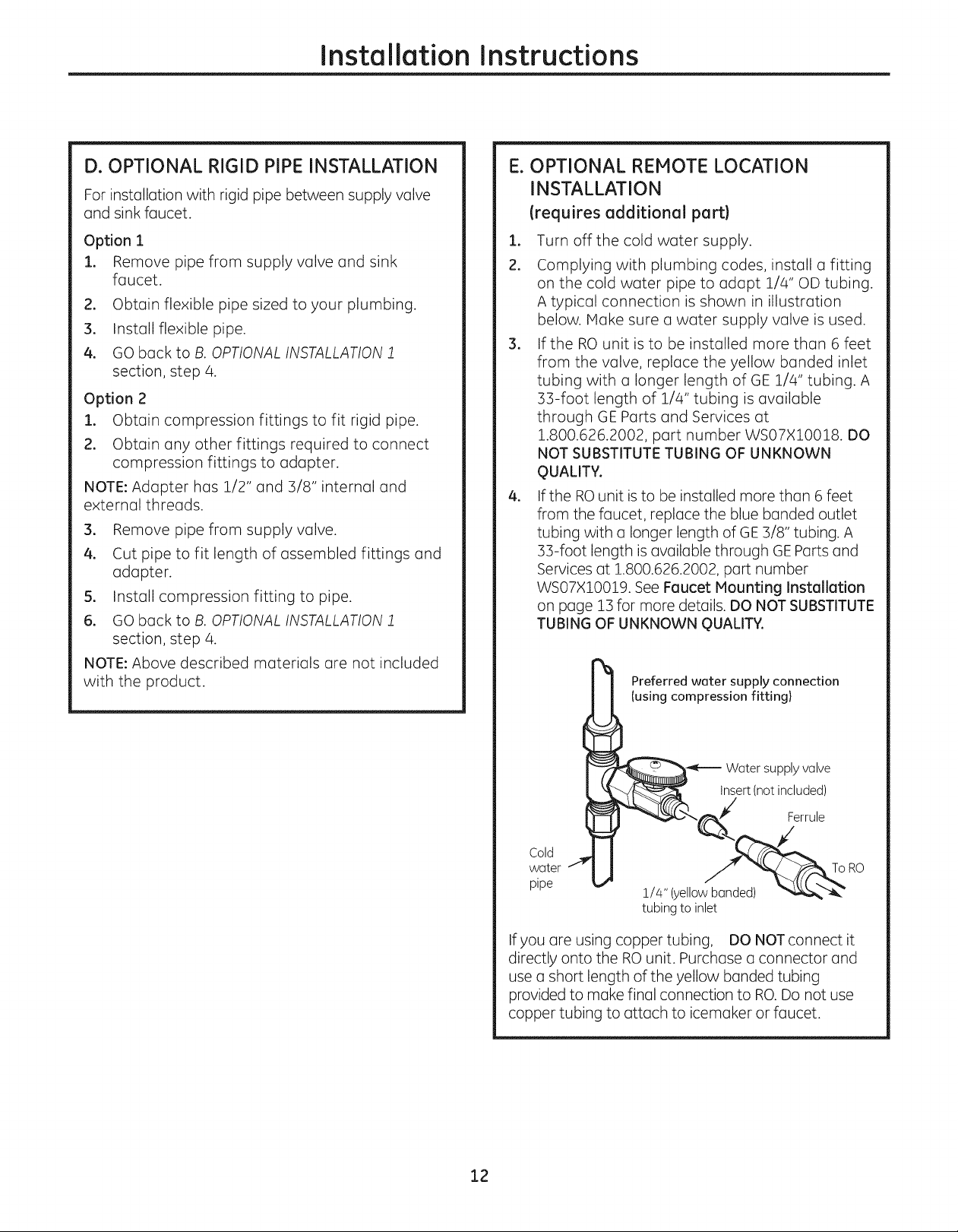

D. OPTIONAL RIGID PIPE INSTALLATION

For installation with rigid pipe between supply valve

and sink faucet.

Option 1

1. Remove pipe from supply valve and sink

faucet.

2. Obtain flexible pipe sized to your plumbing.

3. Install flexible pipe.

4. GO back to B. OPTIONAL INSTALLATION 1

section, step 4.

Option 2

1. Obtain compression fittings to fit rigid pipe.

2. Obtain any other fittings required to connect

compression fittings to adapter.

NOTE: Adapter has 1/2" and 3/8" internal and

external threads.

3. Remove pipe from supply valve.

4. Cut pipe to fit length of assembled fittings and

adapter.

5. Install compression fitting to pipe.

6. GO back to B. OPTIONAL INSTALLATION 1

section, step 4.

NOTE: Above described materials are not included

with the product.

E. OPTIONAL REMOTE LOCATION

INSTALLATION

(requires additional part)

I.

Turn off the cold water supply.

2.

Complying with plumbing codes, install a fitting

on the cold water pipe to adapt 1/4" OD tubing.

A typical connection is shown in illustration

below. Make sure a water supply valve is used.

.

If the RO unit is to be installed more than 6 feet

from the valve, replace the yellow banded inlet

tubing with a longer length of GE 1/4" tubing. A

33-foot length of 1/4" tubing is available

through GE Parts and Services at

1.800.626.2002, part number WS07X10018. DO

NOT SUBSTITUTE TUBING OF UNKNOWN

QUALITY.

.

If the ROunit is to be installed more than 6 feet

from the faucet, replace the blue banded outlet

tubing with a longer length of GE 3/8" tubing. A

33-foot length is available through GEParts and

Services at 1.800.626.2002, part number

WS07X10019. See Faucet Mounting Installation

on page 13 for more details. DO NOT SUBSTITUTE

TUBING OF UNKNOWN QUALITY.

Preferred water supply connection

(using compression fitting}

Water supply valve

insert(not included)

Cold

water

pipe

1/4" (yellow banded) _'_"_

tubing to inlet

If you are using copper tubing, DO NOT connect it

directly onto the RO unit. Purchase a connector and

use a short length of the yellow banded tubing

provided to make final connection to RO.Do not use

copper tubing to attach to icemaker or faucet.

12

Installation Instructions

FEEDWATER SUPPLY{cont.)

INSTALLING THE TUBING TO TANK AND

FAUCET

.

Measure 3/4" from the end of each remaining

piece of tubing (faucet end and inlet end) and

mark with a pencil. (Check for roundness,

smoothness, cuts, nicks, flat spots and sharp

edges).

19 mm}

INCORRECT

.

Push the tubing firmly into each fitting on the

manifold until the line is flush with the fitting

collar. (if the tubing is removed, re-cut the end,

measure, mark and re-insert). Tubing must be

fully inserted to avoid leaks. To remove tubing:

depress and hold red or blue collet; pull tubing

out to remove.

Red or Blue Collet b_

(DONOTREMOVE) --e__

insertion line -_'_---- 3/4"--_

insert tubing ---_V]_,__

i

i

Engagement ',

3/4" -_

3/8" tubing) I

FLOW RESTRICTOR

REPLACEMENT PROCEDURE Icont.}

l. Remove drain line tubing by pushing up on the

drain line caller with one hand (11and

removing the drain line with the other hand (21.

. Once the drain line has been removed from the

system base, grasp the end of the flow

restrictor and pull it straight out from the tube*.

If the restrictor is difficult to remove by hand, a

pair of pliers may be used to grip the end of the

restrictor

to aid in removal from the tubing.

*In some instances, the restrictor may slide out of the drain

tubing as it is removed from the drain line port. If, after

removing the drain line as described in step !, the restrictor is

no longer in the end of the tubing, check the drain line port.

Remove the restrictor from the port and proceed to step 3.

. Take new restrictor and slide it back into the drain

tubing. Insert the restrictor by hand only. Do not

use pliers to insert. Make sure to insert restrictor

all the way into the tubing. Failure to do so could

result in improper operation of the ROsystem.

3. Pull out slightly on tubing to ensure a good

seal.

FLOW RESTRICTOR

REPLACEMENT PROCEDURE

Each time the Reverse Osmosis cartridge is

changed, you will need to replace the flow

restrictor in the drain line as well.

Be sure to wash your hands before handling inner

parts of the system.

13

.

Reinsert drain line tubing in system base. Tug

lightly on the tubing to ensure that the caller is

engaged and has a proper grip on the tubing.

FAUCET ASSEMBLY

Installation Instructions

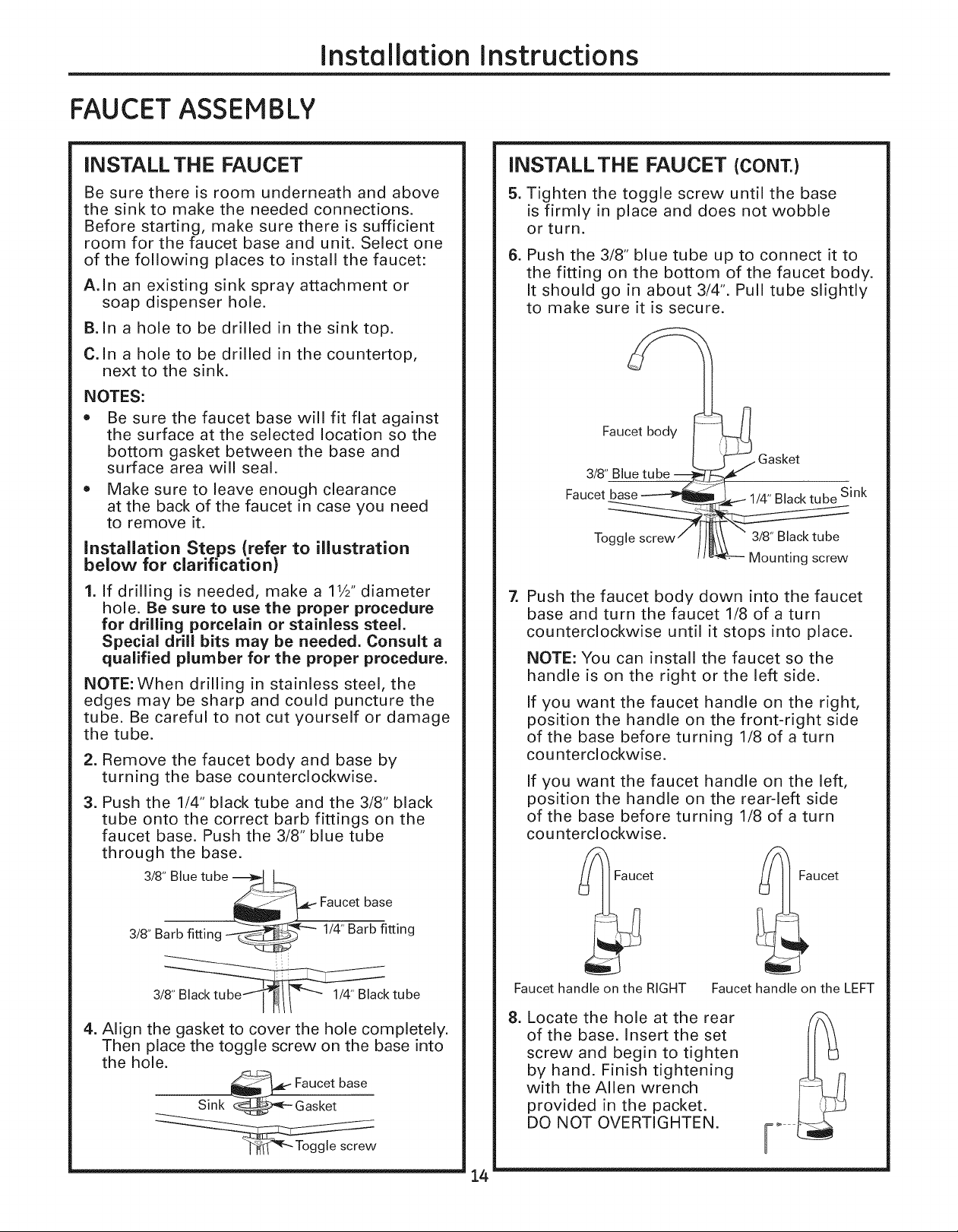

INSTALL THE FAUCET

Be sure there is room underneath and above

the sink to make the needed connections.

Before starting, make sure there is sufficient

room for the faucet base and unit. Select one

of the following places to install the faucet:

A. In an existing sink spray attachment or

soap dispenser hole.

B. In a hole to be drilled in the sink top.

C. In a hole to be drilled in the countertop,

next to the sink.

NOTES:

Be sure the faucet base will fit flat against

the surface at the selected location so the

bottom gasket between the base and

surface area will seal.

• Make sure to leave enough clearance

at the back of the faucet in case you need

to remove it.

Installation Steps (refer to illustration

below for clarification)

1. If drilling is needed, make a 11/2"diameter

hole. Be sure to use the proper procedure

for drilling porcelain or stainless steel,

Special drill bits may be needed. Consult a

qualified plumber for the proper procedure.

NOTE:When drilling in stainless steel, the

edges may be sharp and could puncture the

tube. Be careful to not cut yourself or damage

the tube.

2. Remove the faucet body and base by

turning the base counterclockwise.

3. Push the 1/4" black tube and the 3/8" black

tube onto the correct barb fittings on the

faucet base. Push the 3/8" blue tube

through the base.

3/8" Blue tube ---___

INSTALL THE FAUCET (CONT.)

5. Tighten the toggle screw until the base

is firmly in place and does not wobble

or turn.

6. Push the 3/8" blue tube up to connect it to

the fitting on the bottom of the faucet body.

It should go in about 3/4". Pull tube slightly

to make sure it is secure.

n

Faucet body _

Gasket

3/8" Blue

Faucet 1/4" Black tube Sink

Toggle 3/8" Black tube

Z

Push the faucet body down into the faucet

base and turn the faucet 1/8 of a turn

counterclockwise until it stops into place.

NOTE: You can install the faucet so the

handle is on the right or the left side.

If you want the faucet handle on the right,

position the handle on the front-right side

of the base before turning 1/8 of a turn

cou nterclockwise.

If you want the faucet handle on the left,

position the handle on the rear-left side

of the base before turning 1/8 of a turn

cou nterclockwise.

_ Faucet

>

Mounting screw

__ Faucet base

3/8" Barb fitting 1/4" Barb fitting

3/__k tube

4. Align the gasket to cover the hole completely.

Then place the toggle screw on the base into

the hole.

_ Faucet base

Sink _ Gasket

Faucet handle on the RIGHT

8. Locate the hole at the rear

of the base. Insert the set

screw and begin to tighten

by hand. Finish tightening

with the Allen wrench

provided in the packet.

DO NOT OVERTIGHTEN.

14

aucet

Faucet handle on the LEFT

Installation Instructions

FAUCETASSEMBLY {cont.)

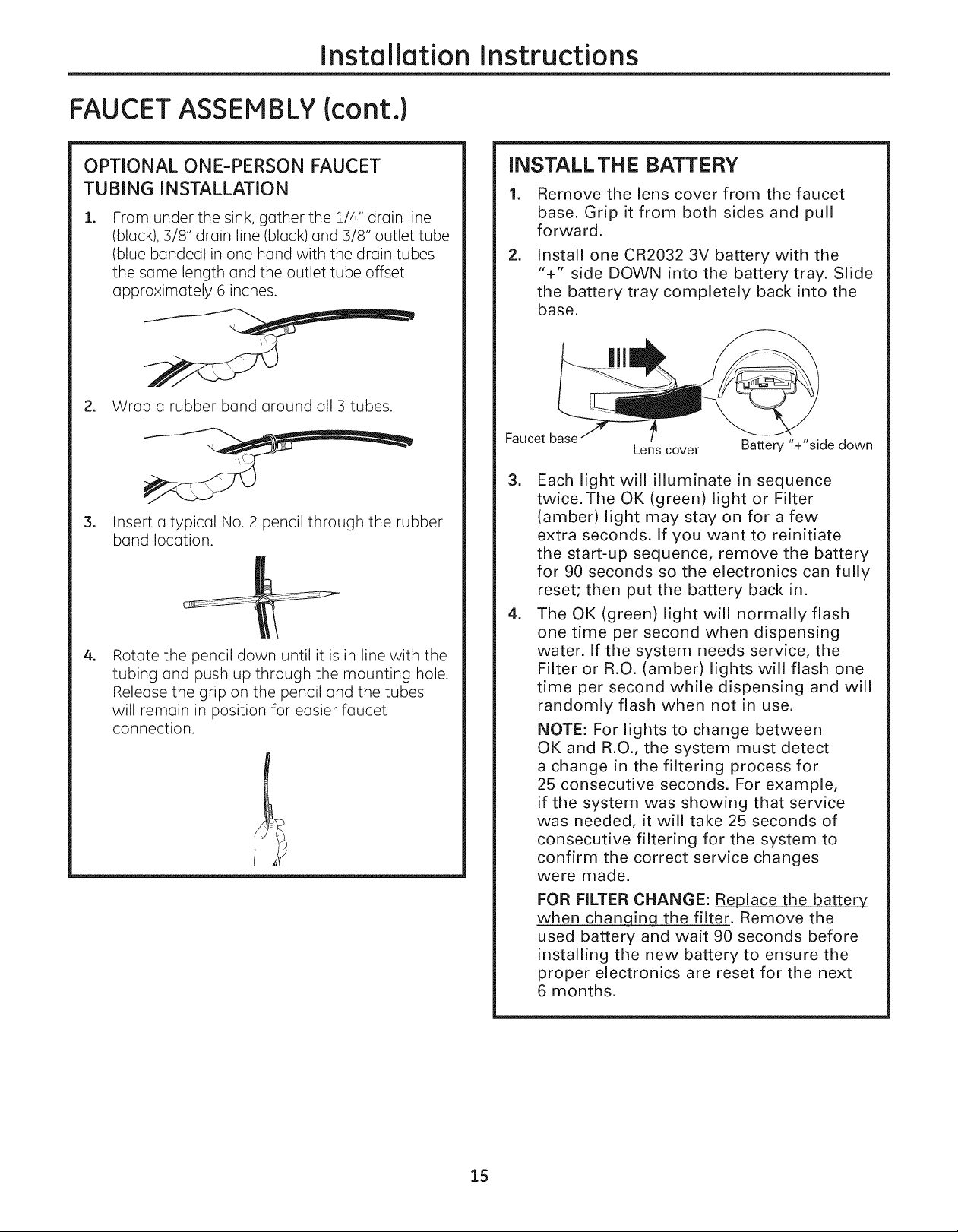

OPTIONAL ONE-PERSON FAUCET

TUBING INSTALLATION

I.

From under the sink, gather the 1/4" drain line

(black), 3/8" drain line (black) and 3/8" outlet tube

(blue banded)in one hand with the drain tubes

the same length and the outlet tube offset

approximately 6 inches.

2. Wrap a rubber band around all 3 tubes.

.

Insert a typical No. 2 pencil through the rubber

band location.

.

Rotate the pencil down until it is in line with the

tubing and push up through the mounting hole.

Release the grip on the pencil and the tubes

will remain in position for easier faucet

connection.

INSTALL THE BATTERY

=

Remove the lens cover from the faucet

base. Grip it from both sides and pull

forward.

=

Install one CR2032 3V battery with the

"+" side DOWN into the battery tray. Slide

the battery tray completely back into the

base.

Faucet base

=

Each light will illuminate in sequence

Lens cover

twice.The OK (green) light or Filter

(amber) light may stay on for a few

extra seconds. If you want to reinitiate

the start-up sequence, remove the battery

for 90 seconds so the electronics can fully

reset; then put the battery back in.

=

The OK (green) light will normally flash

one time per second when dispensing

water. If the system needs service, the

Filter or R.O. (amber) lights will flash one

time per second while dispensing and will

randomly flash when not in use.

NOTE: For lights to change between

OK and R.O., the system must detect

a change in the filtering process for

25 consecutive seconds. For example,

if the system was showing that service

was needed, it will take 25 seconds of

consecutive filtering for the system to

confirm the correct service changes

were made.

FOR FILTER CHANGE: Replace the battery_

when changing the filter. Remove the

used battery and wait 90 seconds before

installing the new battery to ensure the

proper electronics are reset for the next

6 months.

Battery "+"side down

15

Installation Instructions

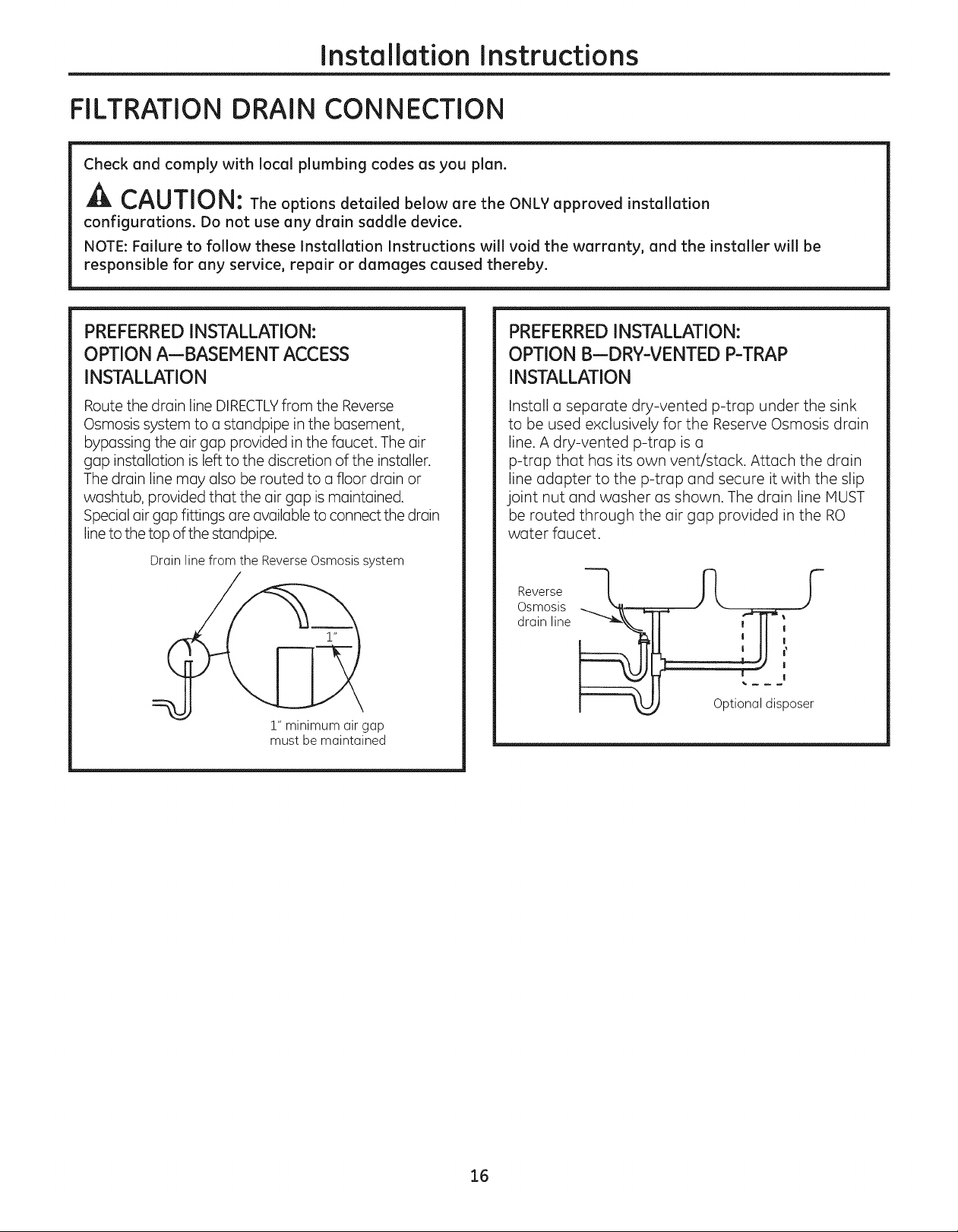

FILTRATION DRAIN CONNECTION

Check and comply with local plumbing codes as you plan.

A CAUTION: The options detailed below are the ONLY approved installation

configurations. Do not use any drain saddle device.

NOTE: Failure to follow these Installation Instructions will void the warranty, and the installer will be

responsible for any service, repair or damages caused thereby.

PREFERRED INSTALLATION:

OPTION A--BASEM ENT ACCESS

INSTALLATION

Route the drain line DIRECTLYfrom the Reverse

Osmosis system to a standpipe in the basement,

bypassing the air gap provided in the faucet. The air

gap installation is left to the discretion of the installer.

The drain line may also be routed to a floor drain or

washtub, provided that the air gap is maintained.

Special air gap fittings are available to connect the drain

line to the top of the standpipe.

Drain line from the Reverse Osmosis system

!" minimum air gap

must be maintained

PREFERREDINSTALLATION:

OPTION B--DRY-VENTED P-TRAP

INSTALLATION

Install a separate dry-vented p-trap under the sink

to be used exclusively for the Reserve Osmosis drain

line. A dry-vented p-trap is a

p-trap that has its own vent/stack. Attach the drain

line adapter to the p-trap and secure it with the slip

joint nut and washer as shown. The drain line MUST

be routed through the air gap provided in the RO

water faucet.

Reverse

Osmosis

drain line

Optional disposer

16

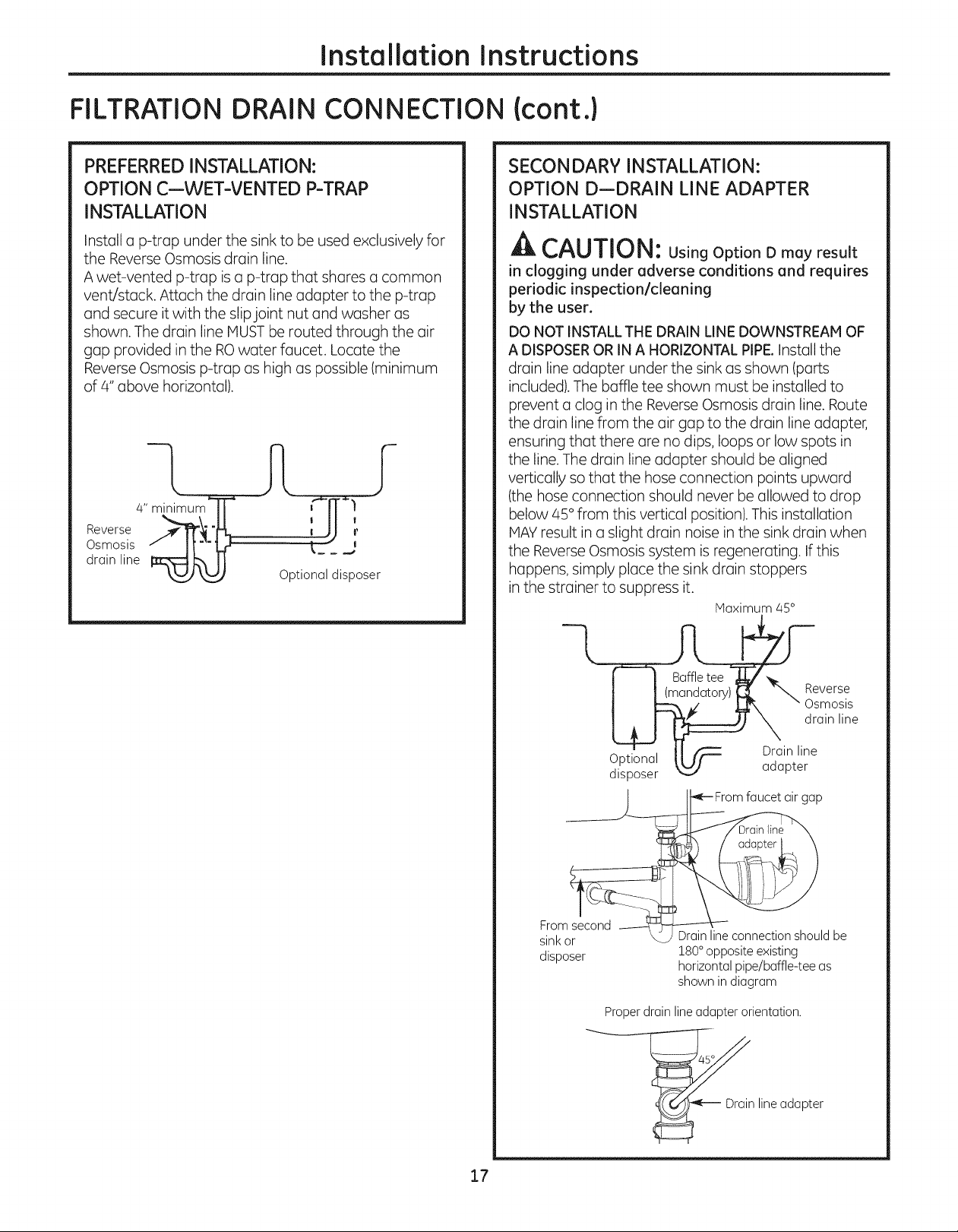

Installation Instructions

FiLTRATiON DRAIN CONNECTION (cont.)

PREFERREDINSTALLATION:

OPTION C--WET-VENTED P-TRAP

INSTALLATION

Install a p-trap under the sink to be used exclusively for

the Reverse Osmosis drain line.

A wet-vented p-trap is a p-trap that shares a common

vent/stack. Attach the drain line adapter to the p-trap

and secure it with the slipjoint nut and washer as

shown. The drain line MUST be routed through the air

gap provided in the ROwater faucet. Locate the

Reverse Osmosis p-trap as high as possible (minimum

of 4" above horizontal).

-t

4" minimum" T

Reverse _--_ "lu_

Osmosis _" [ ["" W-

drain line

Optional disposer

SECONDARY INSTALLATION:

OPTION D--DRAIN LINE ADAPTER

INSTALLATION

A CAUTION: UsingOption D may result

in clogging under adverse conditions and requires

periodic inspection/cleaning

by the user.

DO NOT INSTALLTHE DRAIN LINE DOWNSTREAM OF

A DISPOSEROR IN A HORIZONTAL PIPE.Install the

drain line adapter under the sink as shown (parts

included). The baffle tee shown must be installed to

prevent a clog in the Reverse Osmosis drain line. Route

the drain line from the air gap to the drain line adapter,

ensuring that there are no dips, loops or low spots in

the line. The drain line adapter should be aligned

vertically so that the hose connection points upward

(the hose connection should never be allowed to drop

below 45° from this vertical position). This installation

HAY result in a slight drain noise in the sink drain when

the Reverse Osmosis system is regenerating. If this

happens, simply place the sink drain stoppers

in the strainer to suppress it.

Haximum 45°

_everse

I _ _ " _X " Osmosis

L_ _ 7 . drainline

.' , II _Druinline

up_lonal II/f _ .....

di'sposer _ aaap_er

From

sink or \

disposer

Properdrain lineadapter orientation.

•_-- From faucet air gap

Drain line connection should be

180°opposite existing

horizontal pipe/baffle-tee as

shown in diagram

45°

line adapter

17

Installation Instructions

STORAGE TANK AND STARTUP

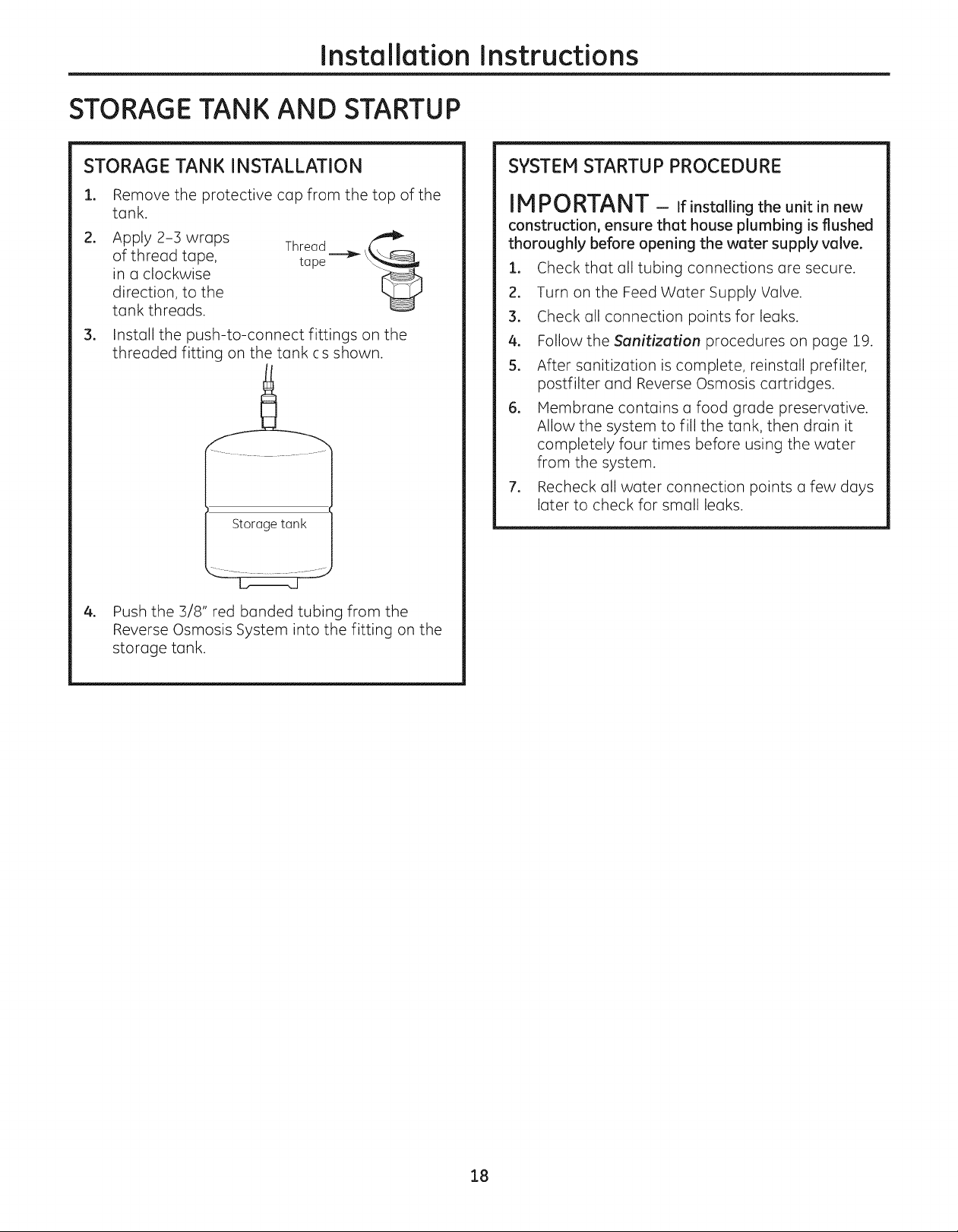

STORAGE TANK INSTALLATION

1. Remove the protective cap from the top of the

tank.

.

Apply 2-3 wraps

of thread tape,

in a clockwise

direction, to the

tank threads.

.

Install the push-to-connect fittings on the

threaded fitting on the tank cs shown.

Storage tank

Thread _

tape

SYSTEM STARTUP PROCEDURE

IMPORTANT - if installing the unit in new

construction, ensure that house plumbing is flushed

thoroughly before opening the water supply valve.

1. Check that all tubing connections are secure.

2. Turn on the Feed Water Supply Valve.

3. Check all connection points for leaks.

4. Follow the Sanitization procedures on page 19.

S.

After sanitization is complete, reinstall prefilter,

postfilter and Reverse Osmosis cartridges.

6.

Membrane contains a food grade preservative.

Allow the system to fill the tank, then drain it

completely four times before using the water

from the system.

7. Recheck all water connection points a few days

later to check for small leaks.

4. Push the 3/8" red banded tubing from the

Reverse Osmosis System into the fitting on the

storage tank.

18

Careand cleaningof the reverse osmosissystem. GEAppliances.com

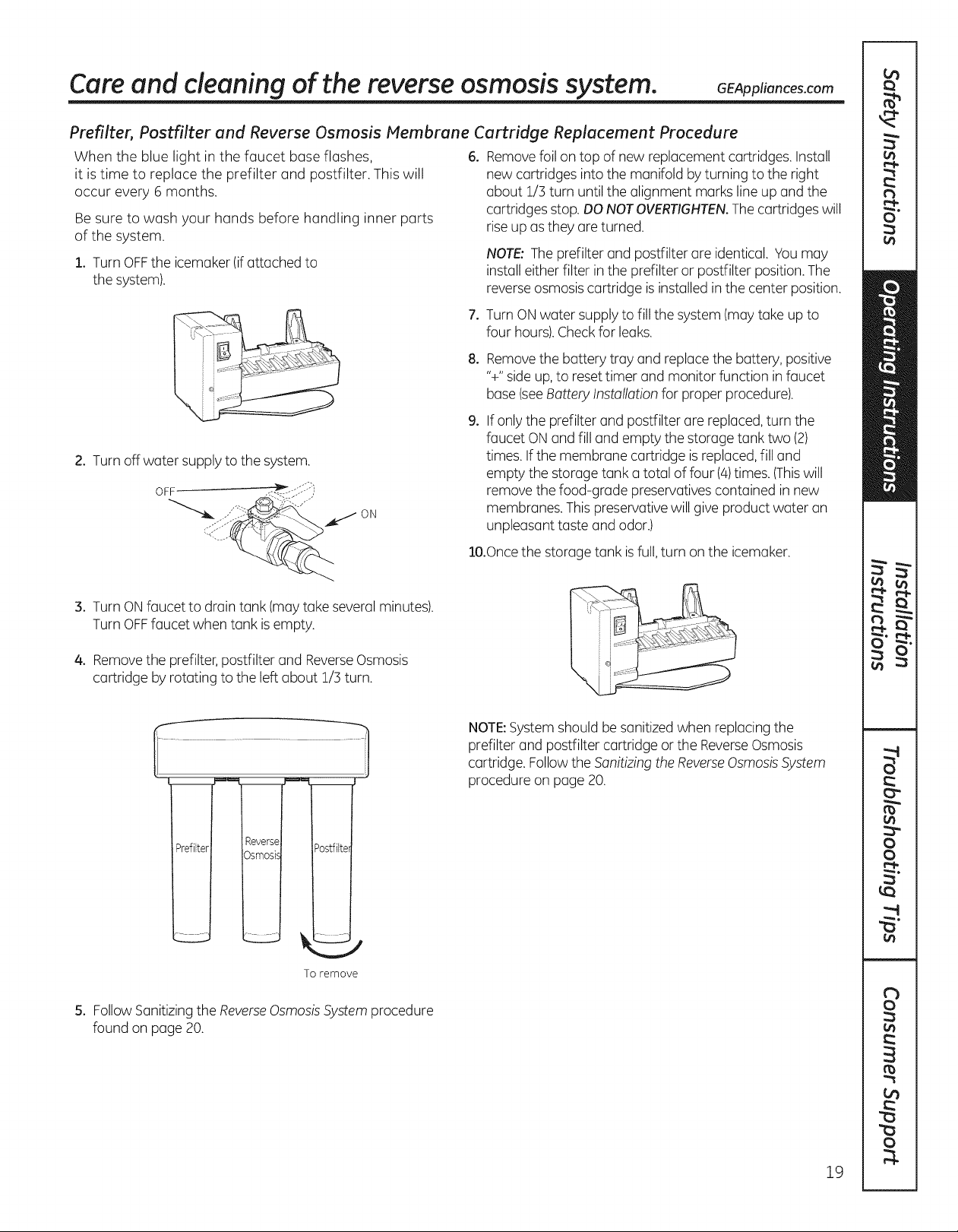

Prefilter, Postfilter and Reverse Osmosis Membrane Cartridge Replacement Procedure

When the blue light in the faucet base flashes,

it is time to replace the prefilter and Dostfilter. This will

occur every 6 months.

Be sure to wash your hands before handling inner parts

of the system.

1. TurnOFFthe icemaker(ifattached to

the system).

2. Turnoff water supply to the system.

OFf _ -..- )

ON

6. Removefoil on top of new replacement cartridges. Install

new cartridges into the manifold by turning to the right

about 1/3 turn until the alignment marks line up and the

cartridges stop.DONOTOVERTIGHTEN.Thecartridges will

riseup as they are turned.

NOTE:Theprefilter and postfilter are identical. Vou may

install either filter in the prefilter or postfilter position.The

reverseosmosis cartridge isinstalled inthe center position.

7. Turn ONwater supply to fill the system (may take up to

four hours).Checkfor leaks.

8. Removethe battery tray and replacethe battery, positive

'%"side up,to reset timer and monitor function infaucet

base(seeBattery Installation for proper procedure).

.

If only the prefilter and postfilter are replaced,turn the

faucet ONand fill and empty the storage tank two (2)

times. Ifthe membrane cartridge isreplaced,fill and

empty the storage tank a total of four (4)times. (Thiswill

remove the food-grade preservativescontained in new

membranes. Thispreservative will give product water an

unpleasant taste and odor.)

lO.Oncethe storage tank isfull,turn on the icemaker.

3. TurnONfaucet to drain tank (may takeseveral minutes).

TurnOFFfaucet when tank is empty.

4. Removethe prefilter,postfilter and ReverseOsmosis

cartridge by rotating to the left about 1/5 turn.

m

To remove

5. Follow Sanitizingthe ReverseOsmosisSystemprocedure

found on page 20.

NOTE:Systemshould be sanitized when replacing the

prefilter and postfilter cartridge or the ReverseOsmosis

cartridge. Followthe Sanitizing theReverseOsmosisSystem

procedure on page 20.

19

Care and cleaning ofthe reverse osmosissystem.

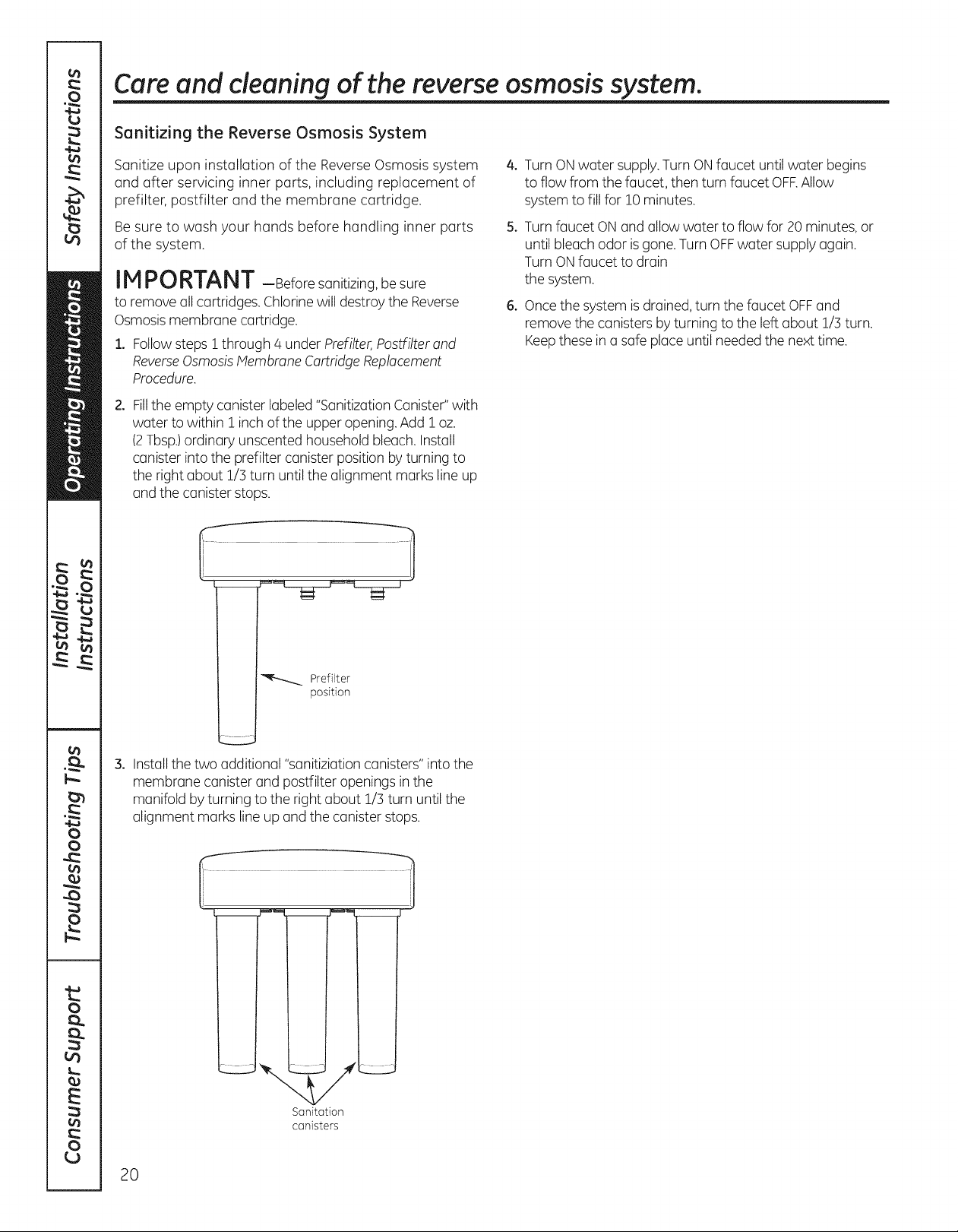

Sanitizing the Reverse Osmosis System

Sanitize upon installation of the Reverse Osmosis system

and after servicing inner parts, including replacement of

prefilter, postfilter and the membrane cartridge.

Besure to wash your hands before handling inner parts

of the system.

IMPORTANT --Beforesanitizing, besure

to remove all cartridges. Chlorine will destroy the Reverse

Osmosismembrane cartridge.

1. Followsteps i through 4 under Prefi/ter,Postfi/ter end

ReverseOsmosisMembraneCartridge Replacement

Procedure.

2. Fillthe empty canister labeled "SanitizationCanister"with

water to within 1 inchof the upper opening.Add 1oz.

(2Tbsp.)ordinary unscented household bleach.Install

canister into the prefilter canister position by turning to

the right about !/3 turn until the alignment marks line up

and the canister stops.

4. TurnONwater supply.Turn ON faucet until water begins

to flow from the faucet, then turn faucet OFF.Allow

system to fill for 10 minutes.

5. Turnfaucet ONand allow water to flow for 20 minutes, or

until bleach odor is gone. Turn OFFwater supply again.

TurnONfaucet to drain

the system.

6. Oncethe system is drained,turn the faucet OFFand

remove the canisters by turning to the left about 1/3 turn.

Keepthese ina safe placeuntil needed the nexttime.

'_--_...._ Prefi4ter

21.Installthe two additional "sanitiziationcanisters" into the

membrane canister and postfilter openings inthe

manifold by turning to the right about 1/3 turn until the

alignment marks line up and the canister stops.

position

J

Sanitation

canisters

20

Careand cleaning of the reverse osmosissystem. GEAppliances.com

To obtain replacement filters, call toll-free GEAppliance Parts at 800.626.2002 (U.S.),

800.663.6060 (Canada-English), 800.361.3869 (Canada-French), or visit the store where

you purchased your reverse osmosis system.

Prefilter/Postfilter Cartridge Replacement FQROPF Carbon Block

Reverse Osmosis Cartridge Replacement FQROMF Thin Film Polyamide

WARNING: To reduce the risk of physical injury:

Depressurize system as shown in manual prior to catridge removal.

The Water Test Kit

Toobtain an independent laboratory water test kit, please call Legend Technical Services at

1.800.826.8553 ext. 47 and leave your contact details. They will contact you to find out what water tests

you are interested in, and inform you of the cost of the testing. You will then receive a kit that will include

all necessary tests to properly indicate the performance level of your system. Product water should be

tested a minimum of every six months.

NOTE:When the TDS reduction of the system falls below 75%, it istime to replace the reverse osmosis

cartridge in addition to the prefilter and postfilter.

21

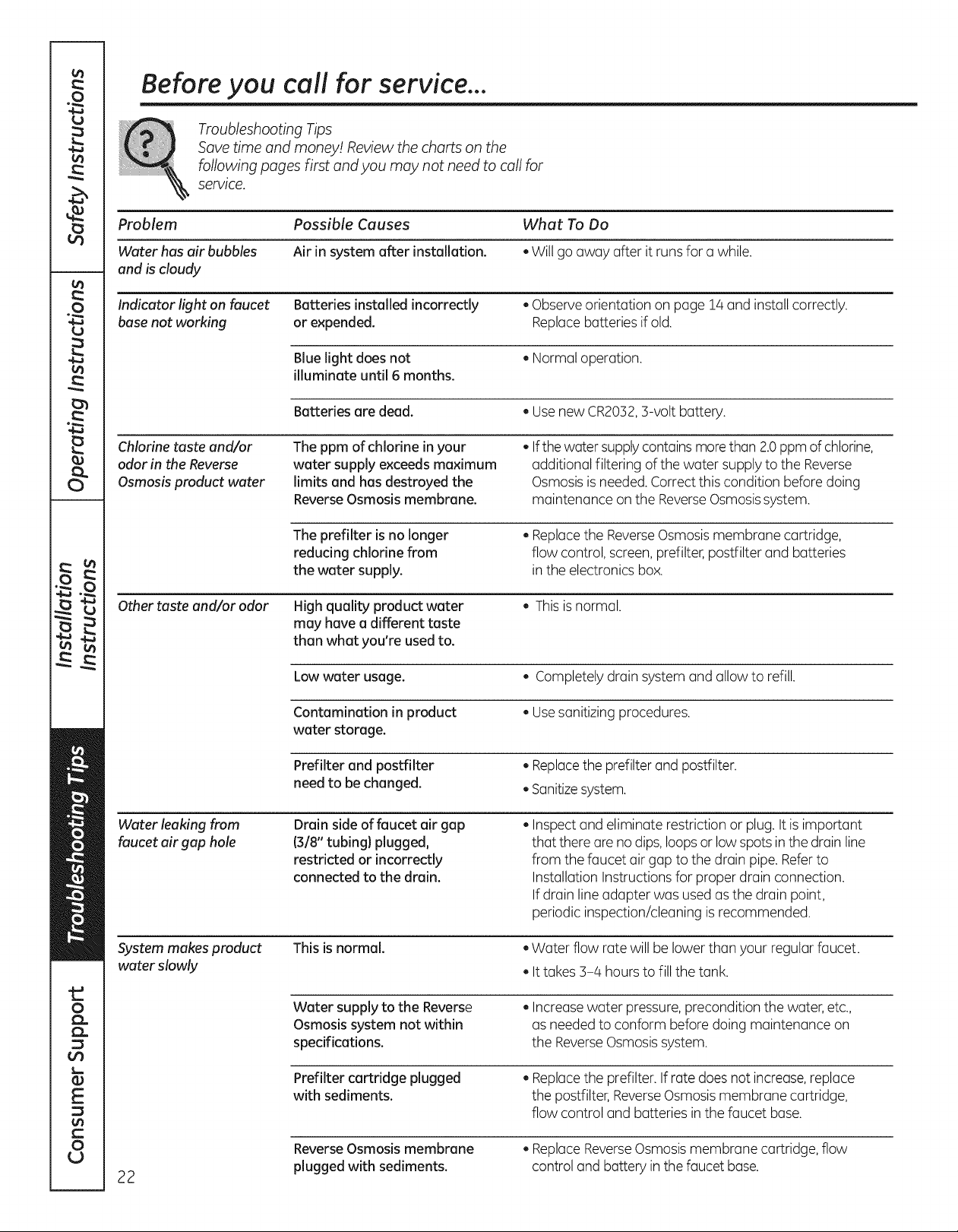

Before you call for service...

Troubleshooting Tips

Save time and money! Review the charts on the

following pages first and you may not need to call for

service.

Problem Possible Causes What To Do

Water has air bubbles Air in system after installation. . Will go away after it runs for a while.

and is cloudy

Indicator light on faucet Batteries installed incorrectly . Observeorientation on page 14 and install correctly.

base not working or expended. Replacebatteries if old.

Blue light does not . Normal operation.

illuminate until 6 months.

Batteries are dead. . Usenew CR2032,3-volt battery.

Chlorine taste and/or

odor in the Reverse

Osmosis product water

Other taste and/or odor

Water leaking from

faucet air gap hole

The ppm of chlorine in your

water supply exceeds maximum

limits and has destroyed the

ReverseOsmosis membrane.

The prefilter is no longer

reducing chlorine from

the water supply.

High quality product water

may have a different taste

than what you're used to.

Low water usage. . Completely drain system and allow to refill.

Contamination in product . Usesanitizing procedures.

water storage.

Prefilter and postfilter • Replacethe prefilter andpostfilter.

need to be changed. • Sanitizesystem.

Drain side of faucet air gap

(318"tubing} plugged,

restricted or incorrectly

connected to the drain.

• Ifthe water supplycontains more than 2.0ppmof chlorine,

additional filtering of the water supply to the Reverse

Osmosisisneeded.Correctthis condition before doing

maintenance on the ReverseOsmosissystem.

. Replacethe ReverseOsmosismembrane cartridge,

flow control, screen, prefilter, postfilter and batteries

in the electronics box.

. Thisisnormal.

. Inspect and eliminate restriction or plug. It is important

that there are no dips, loopsor lowspots inthe drain line

from the faucet air gap to the drain pipe.Referto

Installation Instructions for proper drain connection.

If drain line adapter was usedasthe drain point,

periodic inspection/cleaning isrecommended.

System makes product

water slowly

22

This is normal.

Water supply to the Reverse

Osmosis system not within

specifications.

Prefilter cartridge plugged

with sediments.

ReverseOsmosis membrane

plugged with sediments.

. Water flow rate will be lower than your regular faucet.

. It takes 3-4 hoursto fill the tank.

. Increasewater pressure,precondition the water, etc.,

asneeded to conform before doing maintenance on

the ReverseOsmosissystem.

. Replacethe prefilter. If rate doesnot increase,replace

the postfilter,ReverseOsmosismembrane cartridge,

flow control and batteries in the faucet base.

. ReplaceReverseOsmosismembrane cartridge, flow

control and battery in the faucet base.

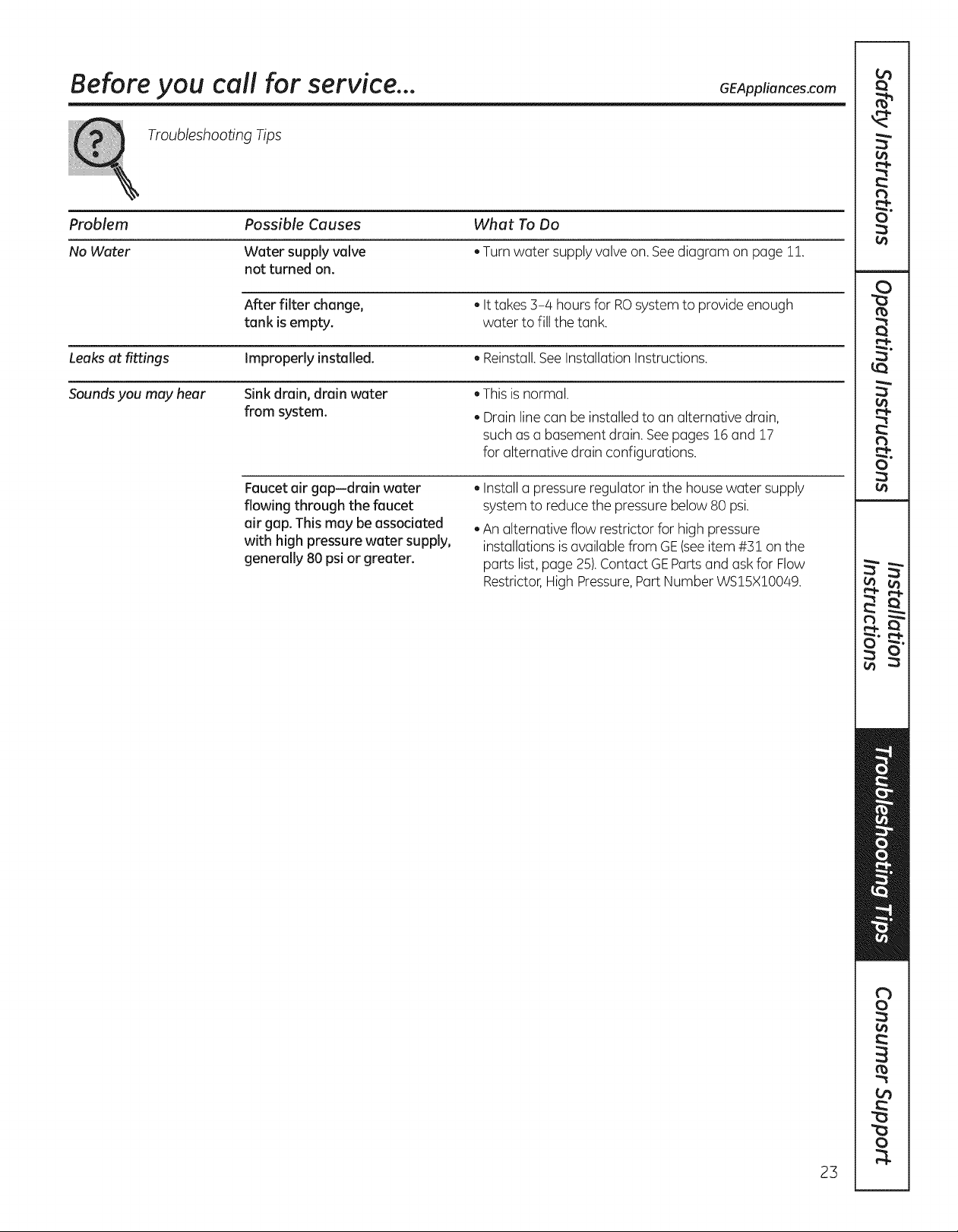

Before you call for service...

Troubleshooting Tips

Problem Possible Causes What To Do

No Water Water supply valve . Turn water supply valve on. See diagram on page 11.

not turned on.

After filter change, . Ittakes 3-4 hours for RO system to provide enough

tank is empty, water to fillthe tank.

Leaks at fittings Improperly installed. . Reinstall.See InstallationInstructions.

Sounds you may hear Sink drain, drain water . This is normal.

from system.

. Drain linecan be installedto an alternative drain,

such as a basement drain. Seepages 16 and 17

for alternative drain configurations.

GEAppliances.com

Faucet air gap-drain water

flowing through the faucet

air gap. This may be associated

with high pressure water supply,

generally 80 psi or greater.

. Installa pressure regulator in the house water supply

systemto reduce the pressure below 80 psi.

An alternative flow restrictor for high pressure

installations is available from GE(seeitem #51 on the

parts list, page 25).Contact GEPartsand askfor Flow

Restrictor,High Pressure,Part Number WS15X10049.

23

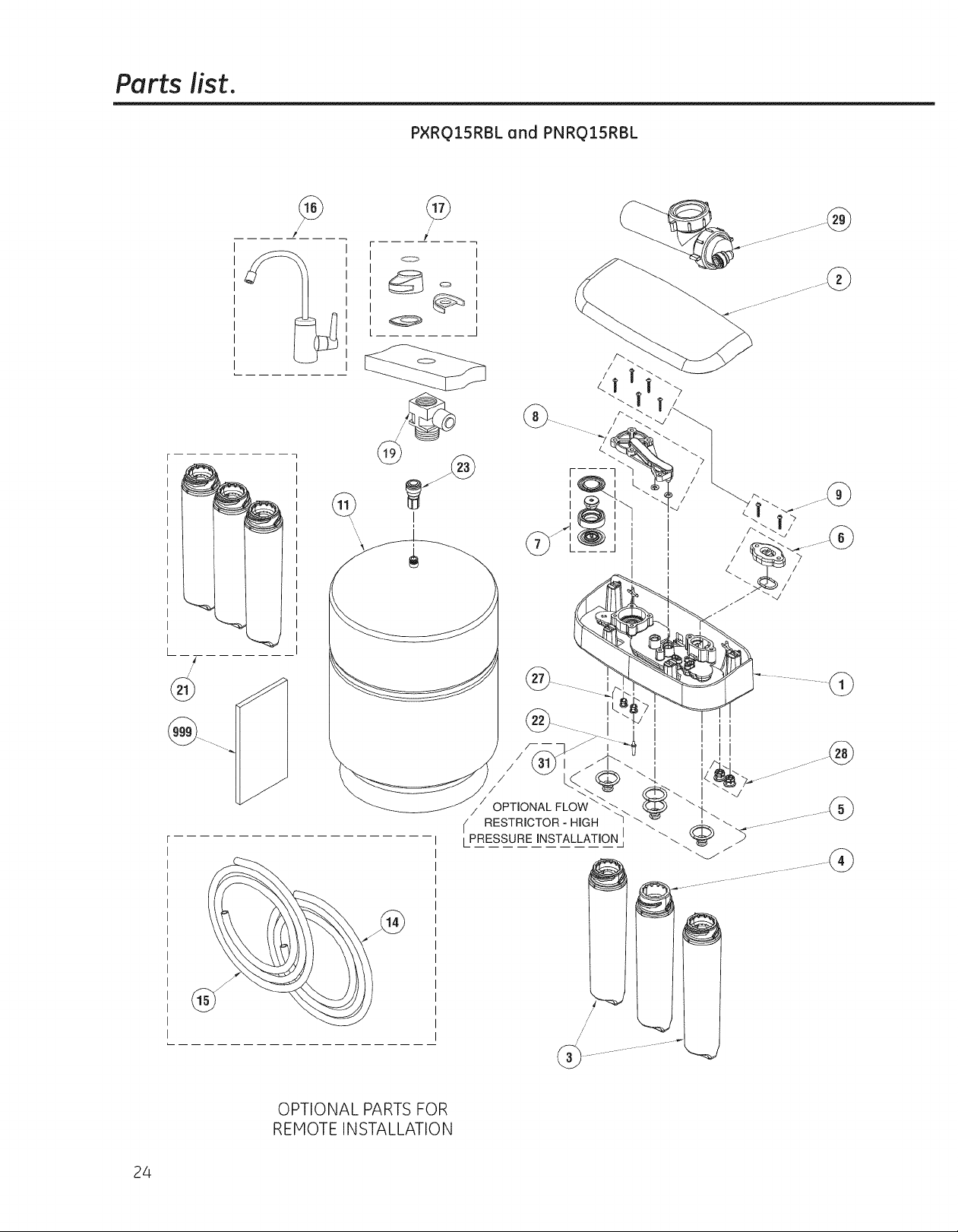

Parts list.

@

PXRQ15RBL and PNRQ15RBL

@

/'

#

Q

24

®

OPTIONAL PARTS FOR

REMOTE INSTALLATION

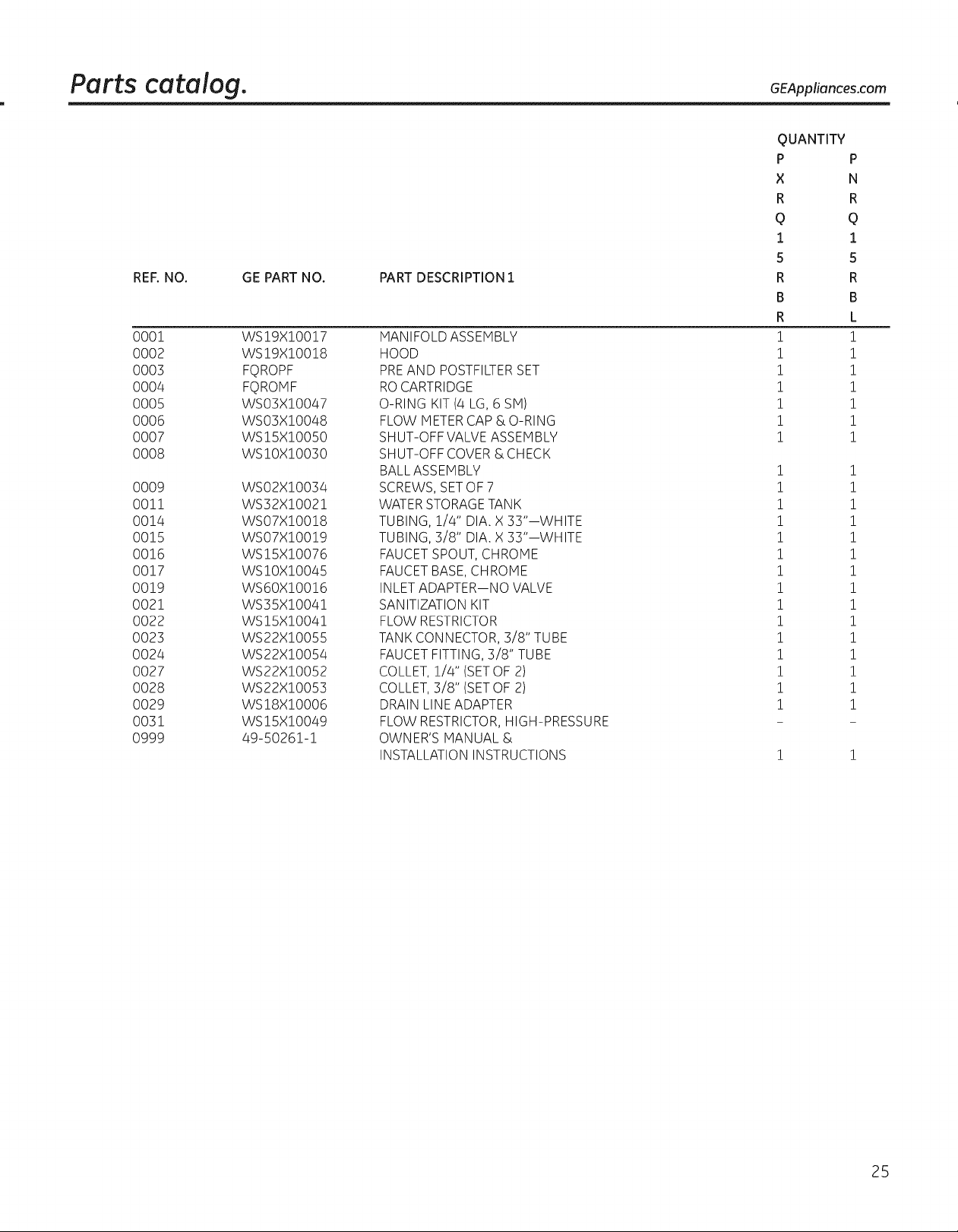

Parts catalog. GEApp,on . om

QUANTITY

P P

X N

R R

Q Q

1 1

5 5

REF. NO.

0001

0002

0003

0004

0005

0006

0007

0008

0009

0011

0014

0015

0016

0017

0019

0021

0022

0023

0024

0027

0028

0029

0031

0999

GE PART NO. PART DESCRIPTION 1

WS19X10017

WS19X10018

FQROPF

FQROMF

WSO3X10047

WSO3X10048

WS15X10050

WSIOXIO030

WSO2X10034

WS32X10021

WSO7X10018

WSO7X10019

WS15X10076

WS10X10045

WS60X10016

WS35X10041

WS15X10041

WS22X10055

WS22X10054

WS22X10052

WS22X10053

WS18X10006

WS15X10049

49-50261-1

MANIFOLD ASSEMBLY

HOOD

PREAND POSTFILTERSET

ROCARTRIDGE

O-RING KIT (4 LG, 6 SM)

FLOW METER CAP & O-RING

SHUT-OFF VALVE ASSEMBLY

SHUT-OFF COVER & CHECK

BALLASSEM BLY

SCREWS, SETOF 7

WATER STORAGETANK

TUBING, 1/4" DIA. X 33"--WHITE

TUBING, 3/8" DIA. X 33"--WHITE

FAUCET SPOUT, CHROME

FAUCET BASE, CHROME

INLET ADAPTER--NO VALVE

SANITIZATION KIT

FLOW RESTRICTOR

TANK CONNECTOR, 3/8" TUBE

FAUCET FITTING, 3/8" TUBE

COLLET, 1/4" (SETOF 2)

COLLET, 3/8" (SETOF 2)

DRAIN LINE ADAPTER

FLOW RESTRICTOR, HIGH-PRESSURE

OWNER'S MANUAL &

INSTALLATION INSTRUCTIONS

R R

B B

R L

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

! !

1 1

1 1

1 1

1 1

1 1

1 1

25

Loading...

Loading...