GE Entelliguard TU Conversion Kit, MicroVersaTrip Plus Conversion Kit, PM Conversion Kit Installation Instructions Manual

Page 1

INTRODUCTION

GE Conversion Kits are designed for upgrading existing Allis

Chalmers®, Siemens/Allis®, and Siemens® low-voltage

power circuit breakers, rather than replacing the entire breaker.

The Conversion Kits include Entelliguard TU™,

MicroVersaTrip Plus™ or MicroVersaTrip PM™ Trip Units,

the latest technological advance in GE trip systems.

Entelliguard, MicroVersaTrip Plus and MicroVersaTrip P

Conversion Kits are designed and tested to conform to ANSI

Standard C37.59, allowing the retrofitter to properly install the

kit and acceptance test the breaker.

This publication covers installation of Entelliguard,

MicroVersaTrip Plus and MicroVersaTrip PM Conversion Kits

on Allis Chalmers®, Siemens/Allis®, and Siemens® LA-4000

low-voltage power circuit breakers. Each Conversion Kit

contains all the components needed to convert from the existing

trip system.

DEH40015

Installation Instructions .

R01

Entelliguard TU™, MicroVersaTrip

Plus™ and PM™ Conversion Kits

for Allis Chalmers®, Siemens/Allis® LA-4000-Blue

Low-Voltage Power Circuit Breakers

Page 2

1

TABLE OF CONTENTS

Section 1. General Information ............................................................................................................ Page 3

Section 2. Before Installation ................................................................................................................ Page 3

Section 3. Breaker Preparation ............................................................................................................ Page 4

Section 4. Installing the Conversion Kit .............................................................................................. Page 5

Installing Flux Shifter Reset Bracket ............................................................................................................ Page 6

Installing ththe Trip Unit Wiring Harness ..................................................................................................... Page 7

Installing the Trip Unit Mounting Bracket .................................................................................................... Page 9

Installing the Current Sensors ..................................................................................................................... Page 10

Installing the Communications Harness ...................................................................................................... Page 11

Section 5. Installing the Trip Unit ...................................................................................................... Page 11

Section 6. Four-Wire Ground Fault Option ...................................................................................... Page 12

Section 7. Testing and Trouble-shooting ........................................................................................... Page 13

Testing ........................................................................................................................................................ Pages 13

Trouble-Shooting ........................................................................................................................................ Page 14

Nuisance Tripping on Ground Fault-Equipped Breakers .............................................................. Page 14

Page 3

2

LIST OF FIGURES

1. Primary disconnects removed from the bottom studs. ............................................................................................. Page 4

2. Components supplied with the conversion kit. ........................................................................................................ Page 5

3. Old and New Reset Assembly. ................................................................................................................................ Page 6

4. Installed Reset Assembly. ........................................................................................................................................ Page 6

5. Flux shifter mounting location. ................................................................................................................................ Page 6

6. Flux shifter mounting.. ............................................................................................................................................. Page 6

7. Flux shifter mounting. .............................................................................................................................................. Page 6

8. Installing Reset Link. ............................................................................................................................................... Page 6

9. 36-pin trip unit connector ......................................................................................................................................... Page 7

10. 36-pin connector adapter bracket ............................................................................................................................. Page 7

11. Adapter bracket locking tabs.................................................................................................................................... Page 8

12. Installing the push nuts ono the guide pins. ............................................................................................................. Page 8

13. Locking tabs on mounting plate.. ............................................................................................................................. Page 8

14. Trip unit bracket mounting. ..................................................................................................................................... Page 9

15. Securing trip unit bracket. ........................................................................................................................................ Page 9

16. Position of current sensors. .................................................................................................................................... Page 10

17. Installing current sensors ....................................................................................................................................... Page 10

18. Installing wire harness. .......................................................................................................................................... Page 10

19. Caution label to be applied to the breaker and compartment door... ...................................................................... Page 11

20. Trip unit installed on the breaker. .......................................................................................................................... Page 11

21. Neutral sensor outline for 3000A through 4000A breakers ................................................................................... Page 13

Page 4

3

SECTION 1. GENERAL

INFORMATION

GE Conversion Kit installation is straightforward, but does

require careful workmanship and attention to these

instructions. Familiarity with the breaker is highly desirable.

The general approach is to first remove the existing trip

devices from the breaker, then install the Entelliguard,

MicroVersaTrip Plus and MicroVersaTrip PM kit components.

Following this procedure, the converted breaker is performance

tested before it is returned to service.

The majority of trip unit kit installations do not require any

customized assembly work. However, some conversions may

involve unusual mounting conditions or accessory

combinations that require minor modifications and/or

relocation of components. In most instances, this

supplementary work can be done on site.

In preparation for the conversion, the installer should verify

that the appropriate current sensors and trip unit have been

furnished. Whenever a ground-fault trip element is installed on

a breaker with a four-wire system, an associated neutral sensor

(CT) is required for separate mounting in the equipment.

Ensure that retrofitted breakers are applied within their shortcircuit ratings. For example, when the trip elements of the

breaker are to be changed from long-time instantaneous to

long-time short-time, the short-time rating will govern the

application.

As a service-related consideration, the installation of a

Entelliguard, MicroVersaTrip Plus and MicroVersaTrip PM kit

provides an excellent opportunity to perform normal

maintenance on the breaker. Such procedures are described in

the installation and maintenance manuals supplied with the

breaker and equipment.

SECTION 2. BEFORE INSTALLATION

Before starting any work, turn off and lock out all power

sources leading to the breaker, both primary and secondary.

Remove the breaker to a clean, well-lighted work area.

WARNING: Low-voltage power circuit breakers use highspeed, stored-energy spring operating mechanisms. The

breakers and their enclosures contain interlocks and safety

features intended to provide safe, proper operating sequences.

For maximum personnel protection during installation,

operation, and maintenance of these breakers, the following

procedures must be followed. Failure to follow these

procedures may result in personal injury or property damage.

• Only qualified persons, as defined in the National

Electrical Code, who are familiar with the installation and

maintenance of low-voltage power circuit breakers and

switchgear assemblies, should perform any work on these

breakers.

• Completely read and understand all instructions before

attempting any breaker installation, operation,

maintenance, or modification.

• Turn off and lock out the power source feeding the

breaker before attempting any installation, maintenance,

or modification. Follow all lock-out and tag-out rules of

the National Electrical Code and all other applicable

codes.

• Do not work on a closed breaker or a breaker with the

closing springs charged. Trip the breaker OPEN and be

sure the stored-energy springs are discharged, thus

eliminating the possibility that the breaker may trip open

or the closing springs discharge and cause injury.

• Trip the breaker OPEN, then remove the breaker to a

well-lighted work area before beginning work.

• Do not perform any maintenance that includes breaker

charging, closing, tripping, or any other function that

could cause significant movement of a draw-out breaker

while it is on the draw-out extension rails.

• Do not leave the breaker in an intermediate position in

the switchgear compartment. Always leave it in the

CONNECTED, TEST, or DISCONNECTED position.

Failure to do so could lead to improper positioning of the

breaker and flashback.

• Refer to DEH-4567 for supplementary instructions of

settings of the Entelliguard Electronic Trip Unit.

• Refer to DEH-3456 for supplementary instructions for

wiring the RELT circuit.

• Refer to DEH-6273 for supplementary instructions of

settings of the MicroVersaTrip Plus and MicroVersaTrip

PM.

Page 5

4

SECTION 3. BREAKER PREPARATION

The following steps are performed to prepare the breaker for

installation of the new conversion kit. Unless otherwise

indicated, the procedure is the same for LA-3000 Gold, LA4000 Gold, RL-3200 and RL-4000 breakers.

WARNING: Before installing the conversion kit, turn the

breaker OFF, disconnect it from all voltage sources, and

discharge the closing springs.

1. Open the breaker and remove it from its enclosure.

Carefully place the breaker on a suitable work surface so

that the rear of the breaker is initially accessible.

2. If the conversion kit is to be installed on a fused breaker

(LAF series), remove the fuse structure from the upper

(line) studs to allow easier access to the load studs.

Additional work may be required to install kit into fused

breaker.

3. Loosen the three Allen-head screws securing each of the

primary disconnects to the line (upper) and load (lower)

studs and remove the primary disconnects.

4. Remove the wires from the original current sensors (CTs),

if present, and slide off the CTs.

5. Remove manual charging handle. Remove the two bolts

holding the escutcheon to the breaker frame and lift off the

escutcheon.

6. Remove old flux shifter and mounting bracket. Also

remove old trip unit and its mounting bracket along with its

wire harness.

Figure 1: Primary disconnects removed from bottom studs

Page 6

5

SECTION 4. INSTALLING THE

CONVERSION KIT

This section describes the installation of the Entelliguard,

MicroVersaTrip Plus and MicroVersaTrip PM and conversion

kit. The components provided with the kit are shown in Fig 2.

Mounting Plate

Figure 2: Components supplied with the conversion kit

Current Sensor

(LA4000-Blue)

Wiring Harness

Trip Unit

Connector

Hardware

Flux Shifter

Assembly

Programmer

Bracket Assembly

Page 7

6

Installing Flux Shifter Reset Bracket

Replace existing reset bracket with new bracket as shown in

Figure 3 and Figure 4 below:

Install Flux Shifter Asm

The Flux shifter mounting location is shown in Figure 5 below:

Mount Flux Shifter assembly to breaker frame as shown in

figures 6 and 7.

Install the Reset Link between the reset Bracket and Flux

Shifter Assembly as shown in Figure 8.

Adjust Flux Shifter to breaker latch with breaker in the charged

position. Set the .031 dimension as shown in figure 8 and lock

with Jam nut.

Old Reset Asm

to be removed

New Reset Asm to

replace old Asm

Existing hardware

to be used to install

new reset Asm

Figure 3: Old and New Reset Assembly

Breaker

Cross bar

Existing

hardware

Figure 4: Installed Reset Assembly

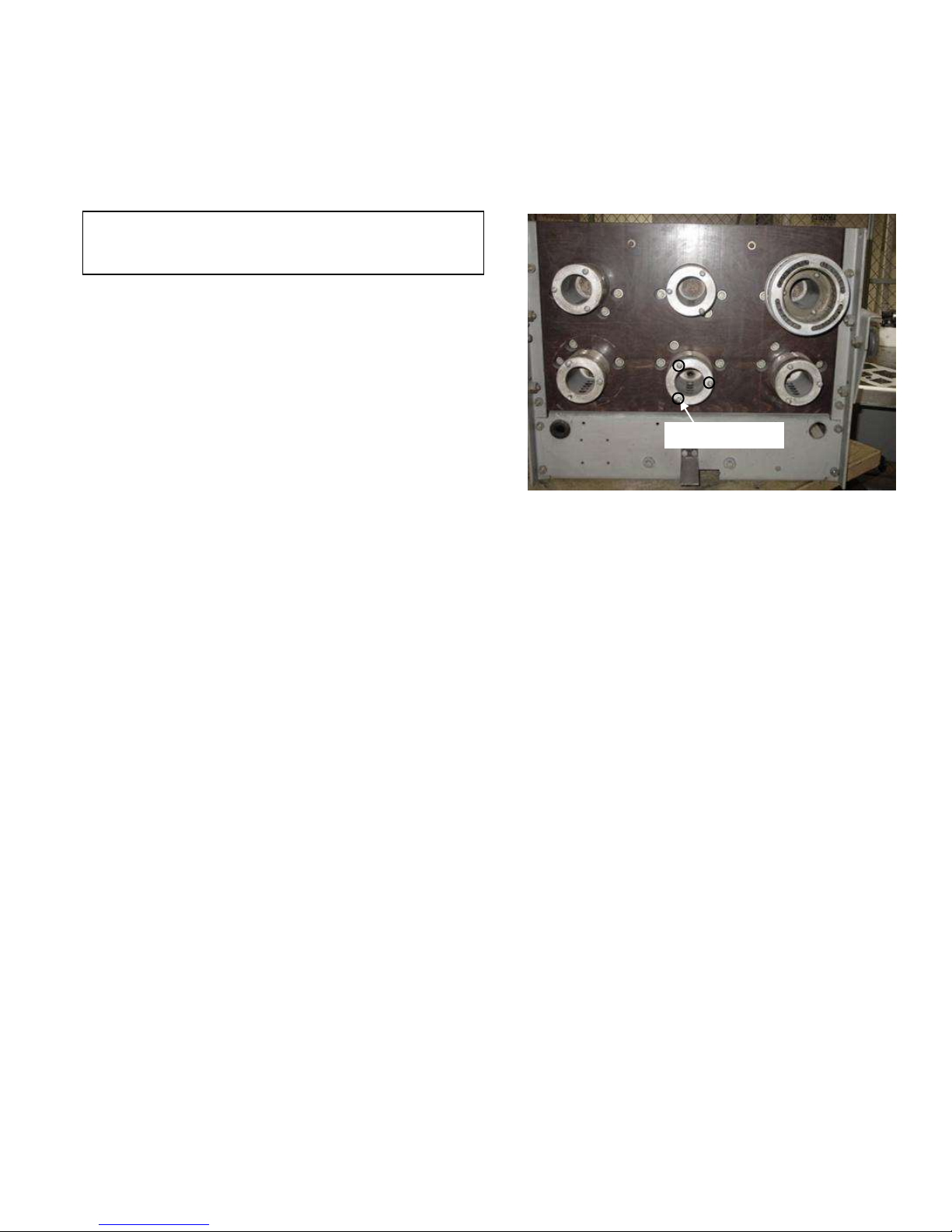

These 2 existing holes are to be

used to mount Flux shifter Asm

to side of breaker mech

Figure 5: Flux Shifter mounting location

MTG hardware 1/4 x3/4 Long Hex Head

F/S MTG

spacers

positioned

as shown to

space F/S

assy away

from

breaker

mech side

frame

Reset Link

Jam Nut

Set .031

Figure 6: Flux Shifter mounting

Figure 7: Flux Shifter mounting

Figure 8: Installing Reset Link

Page 8

7

Installing the Trip Unit Wiring Harness

CAUTION: Pins in the connectors may come loose in

shipping. Check all wiring harness connectors to ensure that

the pins are tight. Reseat pins as necessary.

Use the following procedure to install the trip unit wiring

harness to the mounting plate.

1. The wiring harness includes a 36-pin connector, shown in

Figure 9, that must be assembled and installed onto the trip

unit mounting plate before the trip unit can be installed.

CAUTION: The adapter bracket must be installed onto the

trip unit 36-pin connector and trip unit mounting plate as

described below. Failure to do so will result in harness plug

failure and the trip unit will not provide protection. If the

converted breaker is energized or primary injected with the

mounting plate not installed or installed improperly, damage

will result to the trip unit, wire harness, 36-pin connector, and

current sensors. Failure to adhere to these instructions will

void all warranties.

2. Slide the adapter bracket onto the 36-pin connector, as

shown in Figure 10. Be sure that the beveled corners of the

trip unit connector are facing toward the right side, the

adapter bracket slides are in place behind the notches on

either side of the connector body, and the connector’s tabs

align with the notches on the bottom of the adapter bracket.

3. Hold the adapter bracket tight to the trip unit connector and

bend the two locking tabs on the adapter bracket over the

connector body, as shown in Figure 11.

Figure 9. 36-pin trip unit connector

Figure 10 36-pin connector adapter bracket

Page 9

8

Figure 11. Adapter bracket locking tabs

4.Slide the adapter bracket and connector assembly over the

guide pins of the trip unit bracket. Press the two steel push

nuts provided onto the guide pins using a nut driver, as

shown in Figure 12, until the assembly is held firmly

against the trip unit mounting plate.

5. While holding the adapter bracket and connector assembly

firmly in place against the mounting plate, bend the two

locking tabs on the mounting plate into the mating notches

on the adapter bracket using a screwdriver, as shown in

Figure 13.

Figure 12. Installing the push nuts onto the guide pins

Figure 13. Locking tabs on mounting plate

Page 10

9

Installing the Trip Unit Mounting Bracket

Install Trip Unit mounting bracket as shown in figure 14 and

secure in this position with locking plate shown in Figure 15.

Hardware ¼-20 Hex Hd ¾ Lg

Locking

Figure 14: Trip Unit bracket mounting

Figure 15: Securing Trip Unit bracket

Page 11

10

Installing the Current Sensors

Install current sensors as shown in Figure 16 and 17.

Use existing holes in the breaker back frame to mount C/T

support plate.

Next install the wire harness to the Current Sensors as

shown in Figure 18 below:

Connect the CT leads from the trip unit harness to each

of the CT’s. The leads are labeled with the letter of the

corresponding pole (A is the right pole from the rear of

the breaker, B is the center, C is the left), and are also cut

to the appropriate lengths. Attached the white wire to the

terminal marked white.

Reattach the primary disconnect assemblies to all the

studs. To aid in reinstalling disconnect 3-1/4-20 ¾ long

screws are supplied in hardware package. These screws

are used (only) to help force disconnects onto their

corresponding studs. Disconnects are to be secured in

position using the original breaker hardware.

Hardware ¼-20 Hex Hd ¾ Lg

Split Lk Washer

CT Support Plate

Figure 16: Position of current sensors

Figure 17: Installing Current sensors

Figure 18: Installing Wire Harness

Page 12

11

Installing the Communications Harness

The communications harness is used if the trip unit is to

communicate with a power management control system.

The communications connector, included in the trip unit

wiring harness, is mounted with the supplied angle

bracket. This bracket has two small holes on one arm for

attaching with screws to a convenient spot on the breaker

frame and a large rectangular hole in the other arm for

mounting the connector.

The communications connector should be installed on

the breaker on the same side as the breaker

compartment’s door hinge, to protect it from damage

when the compartment door is opened or closed. Attach

the supplied caution labels, shown in Figure 19, to both

the breaker and the compartment door as a warning to

disconnect the communications harness before removing

the breaker from the compartment.

Figure 19. Caution label to be applied to the breaker and

compartment door

Note: If communications is not required for this

application, install the two pin wire harness (supplied with

the kit) to provide 24V DC to the trip unit. Power supply of

24V DC is essential for advanced functions of the trip unit

such as backlight display, status LED indicator, event log

etc.

SECTION 5. INSTALLING THE TRIP

UNIT

Use the following procedure to install the trip unit.

1. Pull out the locking lever on the trip unit mounting plate

until it snaps into the open position, as shown in Figure 12.

2. Carefully line up the 36-pin connector mounting pins with

the two holes on the sides of the connector cutout on the

rear of the trip unit. The alignment pin on the rear of the

trip unit must fit through the hole in the locking lever.

3. Push the trip unit against the mounting plate until it locks

into position. The locking lever will automatically snap

back to secure the trip unit. Figure 26 shows an installed

trip unit.

CAUTION: Ensure that the trip unit connector is seated

firmly into the 36-pin connector on the mounting plate.

Improper mating of the connectors will cause damage to the

trip unit, wire harness, connector, and current sensors.

4. The breaker escutcheon may now be reattached. To

remove the trip unit, slide out the locking lever to release

the alignment pin, then carefully pull the trip unit straight

off the mounting plate.

Figure 20. Trip unit installed on the breaker

Page 13

12

SECTION 6. FOUR-WIRE GROUND

FAULT OPTION

The ground fault option for four-wire installations requires the

installation of an additional current sensor on the neutral bus in

the equipment. The sensor is connected to the trip unit through

the connector provided in the wiring harness.

1. Mount the neutral sensor on the outgoing neutral lead,

normally in the bus or cable compartment in the

equipment. Figure 27 shows the sensor outlines for the

3000 A through 4000 A frame sizes.

2. Connect the neutral sensor wire harness to the correct taps

on the sensor. To maintain the same polarity as the phase

sensors, connect the white wire to the common terminal,

black to the tap.

3. Route the wires through the equipment and connect to the

two-pin connector on the trip unit wiring harness, routed

through the rear of the breaker with the CT wires. The

wires should be tied to the breaker frame in an easily

accessible location.

Page 14

13

SECTION 7. TESTING AND TROUBLE-

SHOOTING

WARNING: Do not change taps on the current sensors or

adjust the trip unit settings while the breaker is carrying

current. Failure to adhere to these instructions will void all

warranties.

Testing

1. Verify that the trip unit is securely installed by performing

a continuity test on the CT wiring and the trip unit.

a. Disconnect the black CT wires at each phase sensor.

b. Check for continuity with a continuity tester or VOM

from the white lead of the phase A CT to the white lead

of the phase B CT.

c. Repeat this continuity test for the white leads of the

phase A and phase C CTs.

d. Measure the resistance across each phase sensor and

compare the values measured to the values listed in

Table 1.

e. Reconnect the black CT leads to all of the phase

sensors. Ensure that this is done before continuing with

performance testing of the breaker.

CAUTION: In addition to the continuity test described in Step

1 and before performance testing of the converted breaker,

each phase of the breaker should be primary injected with a

current level of about 10%, but no more than 20%, of the CT

rating. During the application of test current, activate the trip

unit screen by depressing the battery button on the trip unit

face and check that the test current is displayed on the screen

for each phase tested. If the trip unit fails to display the test

current, stop the test immediately and verify the installation of

the trip unit and wire harness before proceeding with any

additional testing.

WARNING: If the converted breaker is energized or tested by

primary injection with a sufficiently high test current with a

loose or open circuit between the CTs and the trip unit,

damage will occur to the trip unit, wire harness, 36-pin trip

unit connector, and CTs. Failure to adhere to these

instructions will void all warranties.

2. Check the insulation on the primary circuit with a 1,000-

volt Meggar.

3. Measure the resistance across the line and load terminals

for each phase using a micro-ohmmeter or millivolt tester.

If the resistance differs considerably from phase to phase,

Figure 21. Neutral sensor outline for 3000A through 4000A breakers

Page 15

14

the electrical connections may not be properly tightened or

it could also indicate improper contact wipe.

4. To verify that the breaker has been properly retrofitted,

perform a primary injection test on each phase. This test

will check the CTs, bus, wiring harness, flux shifter, and

trip unit as a complete system.

a. A high-current, low-voltage power supply should be

connected across each line and load terminal to simulate

an overcurrent fault.

b. Set the long-time trip at 0.5 to minimize the breaker

stress.

c. When ground fault is installed, the test can be

performed by wiring two adjacent poles in series or by

using the GE Digital Test Kit, cat. no. TVRMS2. This

will prevent the breaker from tripping because of an

unbalanced current flow. For Entelliguard TU use

GTUTK20.

CAUTION: Do not attempt to use GE Test Kit cat. no.

TVTS1 or TVRMS on Entelliguard trip unit and do not use

GTUTK20 on MVT trip unit.

Trouble-Shooting

When malfunctioning is suspected, first examine the breaker

and its power system for abnormal conditions such as the

following:

• The breaker is not tripping in response to overcurrent

conditions or incipient ground faults.

• The breaker is remaining in a trip-free state because of

mechanical interference along its trip shaft.

• The shunt trip (if present) is activating improperly.

Nuisance Tripping on Ground Fault-Equipped Breakers

When nuisance tripping occurs on breakers equipped with

ground fault trip, a probable cause is the existence of a false

ground signal. Each phase sensor is connected to summing

circuitry in the trip unit. Under no-fault conditions on threewire load circuits, the currents add to zero and no ground signal

is developed. This current sum is zero only if all three sensors

have the same electrical characteristics. If one sensor differs

from the others (such as by a different rating or wrong tap

setting), the circuitry can produce an output sufficient to trip the

breaker. Similarly, a discontinuity between any sensor and the

trip unit can cause a false trip signal.

The sensors and their connections should be closely examined

if nuisance tripping is encountered on any breaker whose

Entelliguard, MicroVersaTrip Plus or MicroVersaTrip PM trip

unit has previously demonstrated satisfactory performance.

After disconnecting the breaker from all power sources,

perform the following procedure:

1. Check that all phase sensors are the same type (current

range).

2. Verify that the tap settings on all three phase sensors are

identical.

3. Verify that the wiring harness connections to the sensors

have the proper polarity (white lead to common, black lead

to tap), as shown in the cabling diagrams1.

4. On ground fault breakers serving four-wire loads, check

that the neutral sensor is properly connected, as indicated

in Figure 27. In particular, check the following:

a. Verify that the neutral sensor has the same rating and

tap setting as the phase sensors.

b. Verify continuity between the neutral sensor and its

equipment-mounted secondary disconnect block. Also

check for continuity from the breaker-mounted neutral

secondary disconnect block through to the trip unit

wiring harness connector.

c. If the breaker’s lower studs connect to the power

source, then the neutral sensor must have its load end

connected to the source.

d. Verify that the neutral conductor is carrying only the

neutral current associated with the breaker’s load

current (the neutral is not shared with other loads).

5. If the preceding steps fail to identify the problem, then

measure the sensor resistances. The appropriate values are

listed in Table 1. Since the phase and neutral sensors are

electrically identical, their resistances should agree closely.

Breaker

CT Rating, A

Resistance, ohms

LA-4000-Blue

4000

29–39

Table 1. CT resistance values.

Page 16

15

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH40015 R01 © 2010 General Electric Company

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that may be

met in connection with installation, operation, or maintenance. Should further information be desired or should particular problems

arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the GE Company.

Loading...

Loading...