Page 1

GE Oil & Gas

Module Solutions

Plug & play power-generation and compression solutions

to increase efficiency, reliability and power

Page 2

A fully engineered

Customized design

Optimized configuration of gas compression or power generation equipment

and auxiliaries, 100% tailored to customer needs

Integrated assembly

A fully transportable single package available with a dedicated control room

installed – ready for single lift or roll on/off

Complete testing

Fully engineered and tested solution designed to minimize risk during the installation

phase and enable cycle time reduction

Continuous evolution of proven technologies

& tested solution

and innovative processes

Buchan Field

1980

Gas lift

19902008

Brazilian Modules

Campos Basin system:

PG & EMC modules

assembled in Brazil

Page 3

There are three equally important parts to delivering

truly successful modular solutions. First, is the crossfunctional engineering expertise to design them using

the most advanced technologies available. Second,

is the capacity and project management strength to

assemble them. Finally, is the crucial ability to test

them and ensure they will perform as designed.

GE Oil & Gas has been systematically evolving the modular

approach to turbomachinery design since 1985. In that time,

we have supplied over 40 pre-assembled power generation and

compression modules, customized to meet the specific needs of

their increasingly challenging projects around the world.

Between December 2012 and the end of 2013, we will deliver

seven of the industry’s most advanced modules ever, five for

Australia and two for the North Sea. And we have the capacity to

produce more.

We continually invest significant resources in materials,

aerodynamics and every other conceivable area – including

perhaps the most important one of testing and qualification. We

also work closely with key industry-leading clients to ensure that

our direction is always true to their needs and where the industry

overall is moving.

As a result, GE’s latest modular solutions make the difference between

‘gathering acceptable parts’ and ‘creating an exceptional whole’.

20062008

Kashagan

The highest pressure

compressor ever built

2010

Gorgon

5 x MS9001E GTG

modules fully tested

Page 4

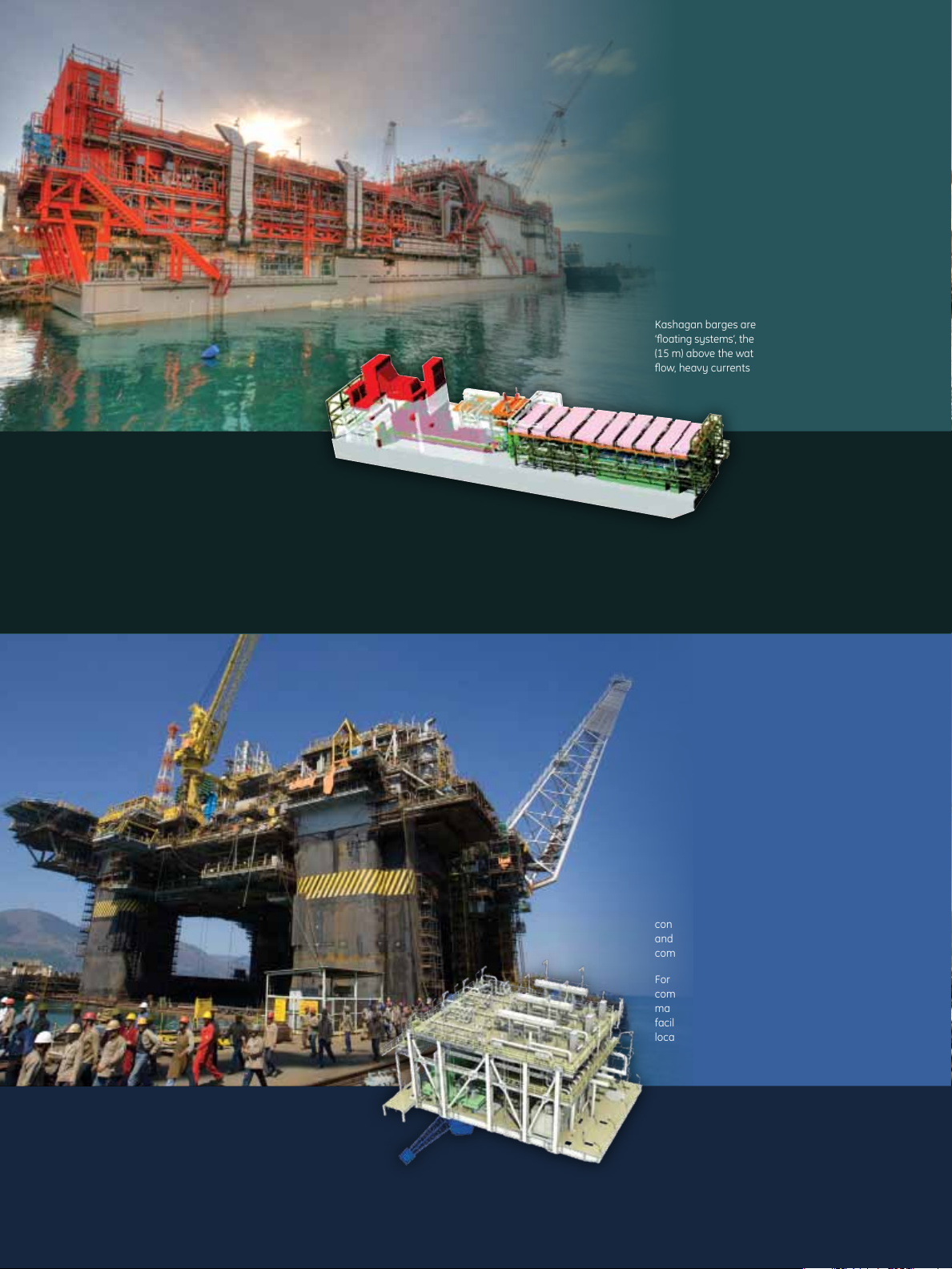

Kashagan gas compression system

• 2 full process floating modules

• 820 bar compression system

• Zero leakage technology for 33% H

• 95 x 16 x 25 m each barge

• 4,000 tons each barge

• 19,757 welded joints, 150 km of wires, 7 km of piping

S

2

With 18% H2S and pressures of 760 bar, Kashagan

is the most advanced project of its kind. The

modular gas compression system we designed for

it, is the highest-pressure re-injection train ever

built—capable of 820 bar and 33% H

The two trains were mounted on barges specially

designed for transport along the winding Volga

canal system. For improved maneuverability and

installation, our designs were about 500 tons lighter

than other existing barges for similar operations.

To pass under many bridges and other obstacles

during transport, all topside structures above 36 ft

were dismantled at our yard in La Spezia and

reassembled at the Caspian yard.

The barges then went 60 km into the Caspian Sea

in depths of just 3 m—each one carrying a full

32-MW/820-bar compression island. Although our

Kashagan barges are commonly referred to as

‘floating systems’, they are actually suspended 49 ft

(15 m) above the water to avoid damage by ice

flow, heavy currents and storms.

S.

2

Floating production modules

• 2 compression modules for P51

• 2 compression modules for P52

• 2 power generation modules for P54

• 2 compression modules for P56

To help Petrobras develop the 8 billion barrels

of oil in the Bay of Santos, our solution went far

beyond the usual capabilities of our own facilities

in Italy. We worked closely with Petrobras and local

contractors to design, build and operate a worldclass assembly yard in Brazil, developing the local

workforce and infrastructure in keeping with the

Petrobras vision.

We began in 2004 with two compression modules

for the P51 floating production unit (FPU) to be

deployed in the deepwater Marlim Sul Field. As

progress continued, we simultaneously built two

larger compression trains for P52 and two powergeneration modules for P54—so that there were

six modules under parallel construction using local

contractors for steel work, fabrication, engineering

and other activities. In 2010, we delivered two

compression modules for the P56 FPU.

For all these modules, core equipment (motorcompressor units and turbogenerator trains) was

manufactured and tested at the GE Oil & Gas

facilities in Massa, Italy and shipped to Brazil for

local assembly and construction.

Page 5

Driven by design

Modern oil and gas operations must respond to evolving resource

compositions and extreme operating conditions. They must adapt

to increasingly diverse fluid mixtures and processes, expand

their reach into more remote and demanding environments, and

continually incorporate new technologies for increased efficiency

and performance.

Our approach provides customers with the invaluable advantage

of total simplification and the potential to reduce site costs and

cycle time by as much as 30%. With extensive in-house design,

engineering and manufacturing capabilities for all major rotating

equipment, we create the most efficient solutions tailored to meet

all the unique weight, space, power distribution and performance

requirements of each project. All engineering, design, project

management, installation and maintenance are part of the package.

GE modules deliver impressive power and compression capabilities

in remarkably compact configurations. Individually proven in

the industry’s most extreme conditions, all core equipment is

seamlessly integrated with relevant auxiliary systems. The final

engineered solution is fully tested,

connected and wired before

30%

site costs &

cycle time

delivery. Any necessary thirdparty suppliers have already been

rigorously screened and qualified

to the highest quality standards.

Their balance-of-plant equipment

is integrated by our engineers at

the system-design stage.

Analysis & design to ensure

that the concept can be executed

• Erection and testing static analysis

• Land and sea transport analysis

• Lifting, jacking and skidding analysis

• In-service static analysis

• Blast analysis

• Modal and dynamic response analysis

• Fatigue analysis

• Design for operability and maintenance

• Space management — interference checks

• Robust design review process (30%-60%-90%)

• Construction studies

Single-source engineered solutions

• Fully integrated engineering approach at the system level

• Conceptual and process design, instrumentation and control

design, electrical systems design

• 3D modeling of piping and structures

• Materials management fully integrated with 3D modeling

• Structural dynamic analysis of modules and foundation

• Design for transportation, including fatigue analysis

• Maximized prefabrication enables far less on-site installation,

construction and testing

• Comprehensive testing, commissioning and start-up services

• Effective management and coordination at every phase of

the project

Page 6

Page 7

Massive manufacturing

Assembly

GE builds true ‘plug & play’ solutions – accelerating production,

minimizing infield construction requirements and ensuring

each unit’s suitability to the project’s final physical site and

ongoing operating requirements. All mechanical, electrical and

instrumentation work is managed by experienced GE personnel.

We can also design and transport module components for

construction localized at the customer’s site, if that is preferred.

Our operations team can still provide all project management,

engineering, quality, EHS and procurement functions. We regularly

provide this experience at integration yards around the world,

partnering with local companies to ensure GE’s high quality

standards are applied to each project.

Environmental Health & Safety

GE has a fully developed EHS program designed to meet the

most stringent regulations of all regions worldwide. Since our

modules are destined for a wide range of sites with equally

varying regulations and environments, all their needs are woven

into our integrated approach to every project. For example, we

developed innovative quarantine procedures to address the highly

sensitive environmental needs of Gorgon’s Barrow Island nature

reserve. This process can now be replicated and adapted to other

environmentally challenging projects in the future.

Dedicated customer support

Each module project is directed by a team of experienced Site

Operation Leaders who support each customer from design

through to commercial operation. This continuity ensures safe and

efficient execution of every project, with smooth transitions and

open communication from beginning to end.

Avenza at a glance

Avenza is strategically located on Italy’s west coast, close

to our Massa plant and even closer to the Marina di Carrara

port. From there, modules are easily readied for international

shipping to the Atlantic through the Strait of Gibraltar, to the

Indian Ocean through the Suez Canal and Red Sea, or eastward

through the various canal systems.

• 140,000 m

commissioning and testing

• 30,000 m

• 4,000 tons load-out capacity

2

(36 acres) for construction,

2

(7 acres) of dedicated storage

Page 8

Tested

to perform

In addition to advanced module design and integrated assembly,

our rigorous testing approach is what gives customers the

confidence that their modules will deliver ongoing reliability and

performance to achieve operating goals year after year.

Our Avenza facility includes the technologies and capacity to test

completely assembled modules of every size and configuration that

we build. This is a unique advantage – no other facility in Europe has

full module testing capabilities.

Full package testing

•Core turbocompression equipment

•Piping

We employ the most advanced techniques and seasoned

professionals – tried and true methods are combined with emerging

technologies to enhance testing capabilities. Our processes are

completely instrumented and furnished with real-time dataacquisition systems and integrated analysis tools to provide a

complete picture of equipment performance, even while the test is

still in progress.

•Wiring

•Control systems

•Auxiliary systems

Page 9

• Maximum module test footprint: 60 x 22 m

• Turbine fuel gas flow rate: 40,000 SCM/hour

Page 10

Built

to deliver

Gas compression and power generation modules can range

from simple configurations to large modules that include both

turbo compression and gas processing equipment in the same

prefabricated structure. Where there are significant transportation

and logistic constraints, large modules can be divided into different

preassembled components that are easily interconnected at the

final installation site. Modules can be designed for transport by

single-lift or roll on–roll off (RO-RO) skidding – depending on the

project’s specific requirements.

Avenza: strategically located for global shipping

• 2 km from GE’s Massa plant

• 1.5 km from Marina di Carrara port

Page 11

Containing about 40 trillion cubic feet of gas and including

the world’s largest carbon capture and sequestration

project, Gorgon is the largest single-resource natural gas

venture in Australian history and one of the largest natural

gas projects in the world.

GE Oil & Gas is supplying five fully assembled and tested

126-MW power generation modules to enable Gorgon’s

LNG output of 15 MTPA. The first of these left our Avenza

yard on October 3, 2012 and was shipped from the nearby

Italian port of Marina di Carrara. The other four modules

will all be delivered before the end of 2013.

The installation site is on Australia’s Barrow Island, a Class

A Nature Reserve, where the Gorgon facilities occupy just

1.3% of the island’s uncleared land mass. Our Quarantine

Management System was recognized as “First class”

during the “Pursuing Excellence in Quarantine” conference

in Singapore.

Gorgon power generation modules

•5modules@126MWeach

•Frame9gasturbinedriver

•50x22x27meachmodule

•2,300tonseachmodule

At depths of about 600 m in the North Sea, the Laggan and

Tormore fields are the UK’s deepest offshore production

wells. They will be developed using a 140-km subsea

tie-back and control umbilical, connecting to a new gas

processing plant being built at Sullom Voe on the Shetland

Islands. An estimated 500 million standard cubic feet per

day (MMscfd) of gas will be separated at the plant and

compressed for export and delivery to the UK National Grid.

Plant design and construction is being undertaken with

high degrees of care and efficiency, since the Shetlands

are home to protected species. Equipment must also be

resilient to the extreme site conditions, unprotected from

the harsh salty Atlantic—including 18-m average wave

heights and high winds.

Benefits of our module designs include long-term reliability

and availability to best manage the lifecycle maintenance

challenges common with such remote sites. The high

pressure (165 barg) export pipeline required careful core

equipment selection and configuration. Each module is a

complete compression train with a compact and powerful

PGT25+ gas turbine driving two BCL centrifugal compressors.

The three fully assembled and tested modules—plus external

auxiliaries and waste heat recovery systems—were shipped

in January 2013.

Laggan-Tormore compression modules

• 3 modules, each including a PGT25+ gas turbine driver, gear box,

BCL454 and BCL405A compressors, external auxiliaries and

waste heat recovery unit

• 34 x 8 x 17 m each module

• 362 tons each module

Page 12

GE Oil & Gas

ge.com/oilandgas

Global Headquarters

Via Felice Matteucci, 2

50127 Florence, Italy

T +39 055 423 211

F +39 055 423 2800

customer.service.center@ge.com

Nuovo Pignone S.p.A.

Nuovo Pignone S.r.l.

Americas Regional Headquarters

4424 West Sam Houston Parkway North

Houston, Texas 77041

P.O. Box 2291

Houston, Texas 77252-2291

T +1 713 683 2400

F +1 713 683 2421

For complete contact information,

please refer to our website.

The information contained herein is general in nature

and is not intended for specific construction, installation

or application purposes. GE reserves the right to make

changes in specifications or add improvements at any

time without notice or obligation.

GE, the GE Monogram, and imagination at work are

registered trademarks of the General Electric Company.

©2013 General Electric Company

All Rights Reserved

GE imagination at work

GE_Module_Solutions_brochure-030813

Loading...

Loading...