Page 1

See more to know more!

GE

Measurement & Control

phoenix x|act

Intuitive software for manual and automated

X-ray inspection with high defect coverage

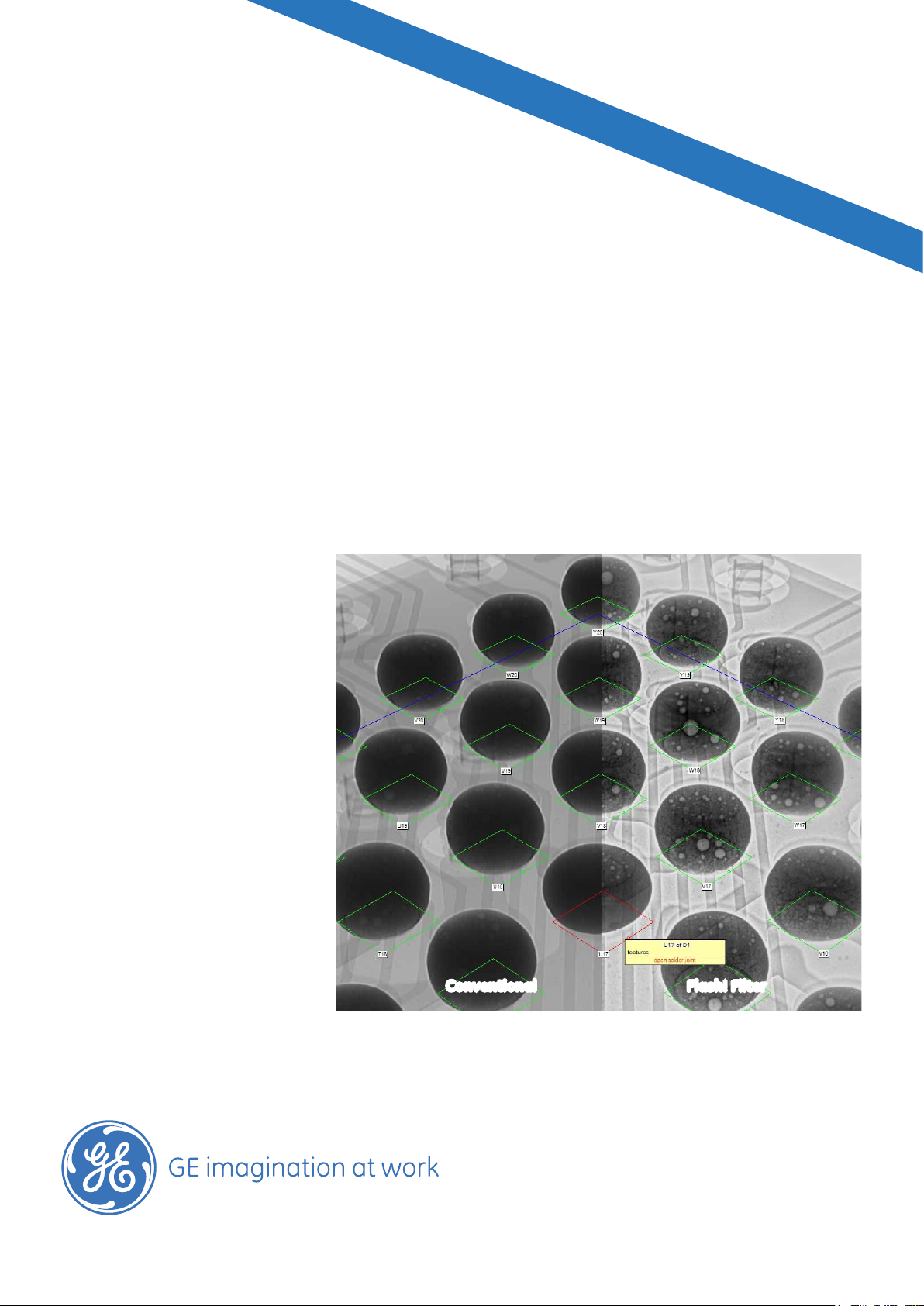

Conventional

X-ray inspection of PCB assemblies boosted by

Flash! Filters

Flash! Filter

TM

technology

Page 2

phoenix x|act:

Powerful software package for manual as well as

automated X-ray inspection

GE’s product line phoenix|x-ray provides calibrated high precision atline μAXI systems for extremely high defect coverage. These systems include the unique x|act software package, which

offers fast and easy CAD-based programming. Features such as views with resolution in the micrometer range, rotation and oblique viewing ensure that the highest quality standards can be

met. For manual X-ray inspection GE’s optional Flash! FiltersTM image optimization technology enables faster, more reliable failure detection.

Easy manual X-ray inspection

phoenix x|act includes intuitive software tools making X-ray inspection easy. Many features allow even

unskilled operators to gain high quality results after minimal training. To reach a high defect coverage after short inspection time, it comes with manifold ease-of-use functions such as:

• Intuitive sample manipulation

• Wizard guided inspection modules for easy setup of

voiding calculation or BGA inspection tasks

• Instant clear live imaging with up to 30 fps and

automated Flash! image optimization

• Live Pad ID overlay for easy defect identication

• Simplied generation of inspection reports

Flash! FiltersTM image optimization

The Flash! Filters™ technology provides outstanding image enhancement

during live inspection tasks.

This innovative technology

automates the ltering process

of all grey scales present in each

Conventional

Obvious dierence between original X-ray image (left)

and Flash! optimized BGA image (right): all voids and

the annular ring are clearly visible

Flash! Filter

X-ray image – to optimize contrast

and brightness for the human eye, resulting in

faster and more reliable identication of defects.

Combined with GE’s advanced DXR detectors,

Flash! Filters™ technology leads to signicant time

savings and defect coverage improvements.

X-ray inspection

Flash! Filters™ Technology

boosted by

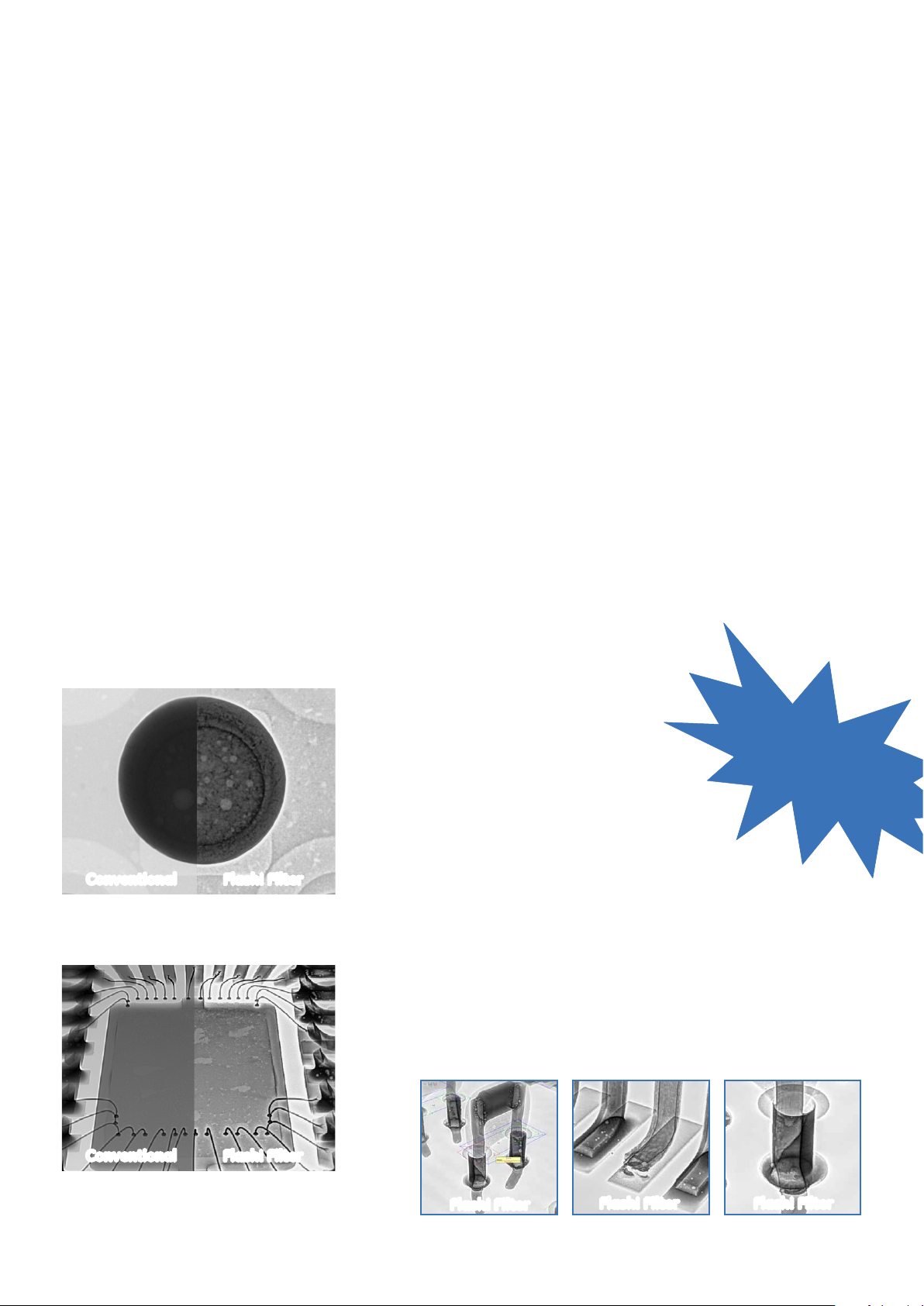

Conventional

Compared with the conventional X-ray image (left),

the Flash! Filters optimized image (right) allows easy

visual identiation of voids in the IC die attach

Flash! Filter

Flash! Filter

Flash! Filter

Flash! Filter

Page 3

Efficient CAD programming - minimized setup time

x|act provides not only a minimal setup time compared with

conventional view based AXI - once programmed, the inspection program is also portable to all x|act compatible systems.

• Easy and pad-based offline programming

• Specific inspection strategies for different pad types

• Fully automated inspection program generation even in oblique view

Easy programming: just assign the inspection strate-

gies and let x|act generate the inspection program

and multiple angular positions

Live 3D CAD data overlay

• Pad ID available at any time

• Easy pad identication even in manual inspection

• High reproducibility on large PCBs

• Perfect orientation through live overlay of CAD-data and inspection

results also in rotated oblique inspection views

Flash! Filter

Flash! Filters optimized inspection results and

CAD and result data live overlay in the X-ray live

image - at any time and at any viewing angle

x|act-capable µAXI systems

The unique x|act software package is available in base and uncalibrated operator configuration for the phoenix x|aminer,

and additionally also in calibrated operator and pro configuration for the phoenix microme|x and phoenix nanome|x systems. Both systems come standard with an open 180 kV microfocus or nanofocus X-ray tube with 15 or 20 W maximum

power in order to achieve a detail detectability down to 200 nanometer with the phoenix nanome|x or down to 0.5 microns

with the phoenix microme|x.

The excellent combination of high-resolution 2D X-ray technology and 3D CT in one system, innovative and easyto-use features and the outstanding positioning accuracy make these systems the effective and reliable solution for a

wide spectrum of 2D and 3D inspection tasks: R&D, failure analysis, process and quality control as well as automated

offline inspection.

Unique features of the phoenix microme|x and nanome|x

• Live inspection rich in detail due to high dynamic GE DXR detectors with 30 fps and instant

Flash!TM Filters image optimization

• 180 kV / 20 or 15 W high-power submicron tube

with down to 0.5 or 0.2 µm detail detectability

• diamond|window for up to 2 times faster data

acquisition at the same high image quality level

• Optionally 3D computed tomography scans

within 10 seconds

Page 4

Features & Congurations

phoenix x|act base phoenix x|act operator phoenix x|act pro

Manual inspection x x x

Easy macro programming x x x

Measurement functions x x x

Semi-automatic inspection modules x x x

TM

Filters image optimization Option Option Option

Flash!

Xe² development toolkit Option x

Fully automatic inspection x x

Live CAD overlay (ASCII data based) x x

CAD-based programming x x

CAD-based image processing x

Statistic review based on inspection results x

Automated height referencing x

CAD-based inspection modules:

BGA, PTH, QFP and QFN check strategies

customized check strategies

View based inspection modules:

bga|module (included in basic package)

vc|module (included in basic package)

c4|module

ml|module

qfp|module

qfn|module

pth|module

quality|review

converter

report|engine

Automated CAD based analysis of BGA, PTH, QFP and QFN solder joints

Customization of image processing for automated analysis

Intuitive automated analysis of BGA solder joints incl. automated wetting analysis

together with ovhm (oblique view at highest magnification).

Intuitive automated inspection of multiple IC die attaches and area solderings in power electronics. Manual inspection even of unregulary shaped area solderings.

Automated voiding analysis of round solder joints with background structure, such

as C4 bumps

Semi automated inspection of IC multi-layer PCBs

Xe² module for automated analysis of QFP solder joints

Xe² module for automated analysis of QFN solder joints

Xe² module for automated analysis of PTH (THT) solder joints

Repair station software for visualizing and manual review of results from an

automatic program run, e.g. BGA check strategy or vc|module

Conversion of result files, generated by x|act, into other formats, required by third

party software

Helpful tool for easier documentation by integrated and simplied generation of

inspection reports

Your Advantages

www.ge-mcs.com/phoenix

• Combining ease of use with excellence in intuitive X-ray inspection

• Live CAD overlay with PAD-ID and inspection results – at any time and at any viewing angle

TM

• Exclusive Flash! Filters

© 2013 General Electric Company. All Rights Reserved. Specications are subject to change without notice. GE and Flash! Filters are registered trademarks of General Electric Company. Other company or

product names mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not aliated with GE.

technology enabling faster, more reliable failure detection

GE Sensing & Inspection Technologies GmbH

phoenix|x-ray

Niels-Bohr-Str. 7

D-31515 Wunstorf / Germany

Tel.: +49 5031 172 0

Fax: +49 5031 172 299

E-mail: phoenix-info@ge.com

GE Inspection Technologies, LP

50 Industrial Park Rd

Lewistown, PA 17044

USA

Tel.: 717 242 03 27

Fax: 717-242-2606

E-mail: phoenix-usa@ge.com

GEIT-31342EN (11/13)

Loading...

Loading...