GE phoenix nanotom s, v|tome|x s, v|tome|x m, v|tome|x L 240, v|tome|x L 300 Brochure

...

GE

Sensing & Inspection Technologies

phoenix|x-ray

phoenix diamond|window

Up to 2 times faster data acquisition at the same

high image quality level

Option for all phoenix|x-ray transmission

microfocus or high power nanofocus

X-ray tubes up to 180 kV / 20 W

phoenix diamond|window

high output with high resolution

At higher applied power for X-ray generation, the focal spot has to be wider in order to prevent the target material from melting. Therefore, the inspection of small features with high absorbing materials using traditional transmission micro- or nanofocus tubes is limited either by power (almost no penetration

resulting in noisy images or very long image acquisition time) or by resolution (increasing focal spot with

power resulting in blurred images). To solve this, phoenix|x-ray off ers its new CVD diamond|window – for

the full range of its transmission X-ray tubes up to 180 kV. Due to its high thermal conductivity, the nontoxic diamond|window allows higher power on a smaller focal spot. This ensures high resolution even at

a high output. The diamond|window can generate an image or CT acquisition up to 2 times faster with no

degradation in image quality.

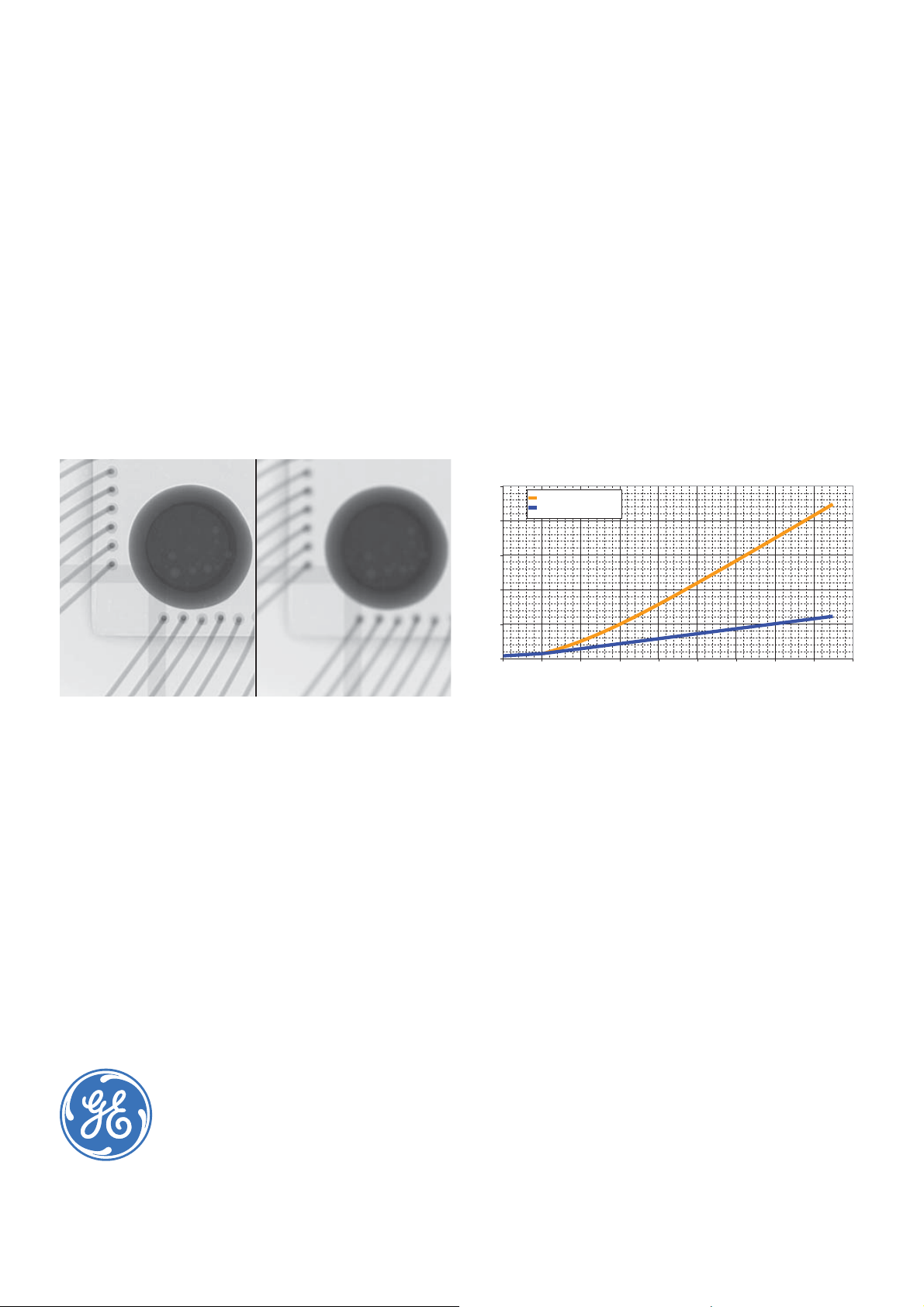

Comparison

detail detectability for diamond|window and Be window

25

20

15

Be window

diamond|window

10

detail detectability [μm]

5

0

diamond|window conventional beryllium window

3 5 7 9 111315171921

min. FOD (Focus-Object-Distance) 0.3 mm

(max. magnifi cation of high power nanofocus X-ray tubes increased)

min. spot size like W/Be target

power on target [W]

diamond|window - Your Advantages

• Up to 2 times faster data acquisition at the same high image quality level

• High output with high resolution

• Nontoxic target

Improved focal spot position stability within long term measurements

•

• Increased target lifetime due to less degradation with higher power density

• diamond|window allows up to 20 W max. power (depending on system shielding and tube type)

www.phoenix-xray.com

GEIT-31340EN (04/10)

© 2010 General Electric Company. All rights reserved. Specifi cations subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product names mentioned in

this document may be trademarks of their respective companies, which are not affi liated with GE.

Contact: GE Sensing & Inspection Technologies GmbH, phoenix|x-ray, Niels-Bohr-Str. 7, 31515 Wunstorf, Germany, T +49 (0)5031 172 0, phoenix-info@ge.com

Loading...

Loading...