GE NovaLT16 Brochure

GE Oil & Gas

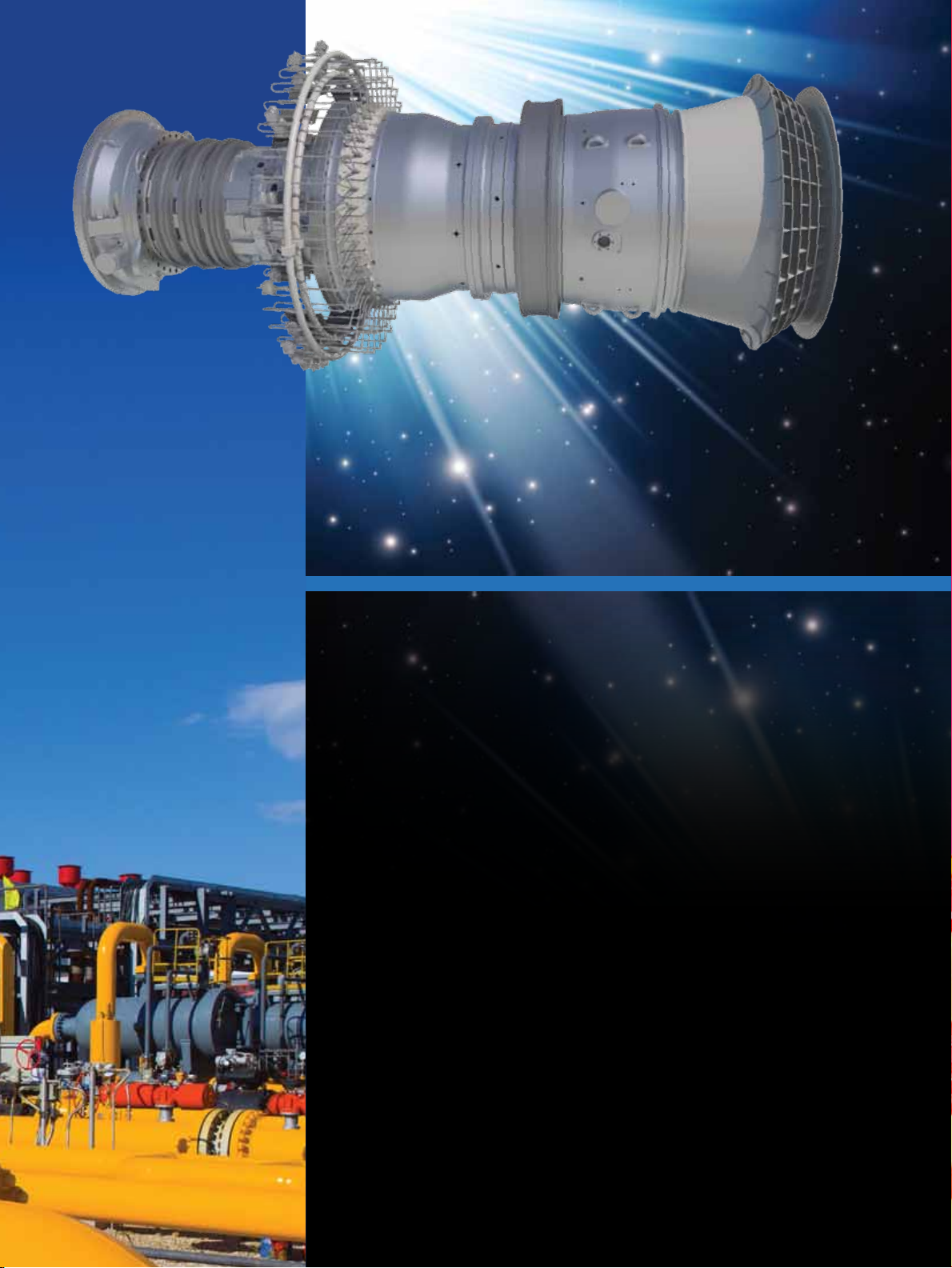

NovaLT16

Setting a new standard for 16 MW

class turbines in mechanical drive

and power generation applications

Our focus on technology development for oil and gas applications is at the

core of everything we do. GE Oil & Gas leverages the vast capability of the GE

global research organization to bring the best technology from a wide range of

industries into the oil and gas segment. We work closely with our customers to

create practical solutions to their most extreme operational challenges.

efficiency & flexibility

Our new 16.5 MW NovaLT16 gas turbine is designed to provide 37 per cent

mechanical efficiency for pipeline compression, power generation and oil

and gas plant compression to help meet increasing energy requirements

across the world.

The NovaLT16 is a two-shaft gas turbine specifically designed

for mechanical drive and power generation in oil and gas and

industrial applications. With a power turbine speed of 7,800 rpm, it

is ideally suited for pipeline compression – with direct coupling to

the latest generation of PCL pipeline compressors featuring high

performance stages and 89% or higher compressor efficiency.

It is full of exceptional advantages for any operation – including

up to 99% availability. It is designed for a 35,000-hour mean

time between maintenance, which translates into four years of

non-stop running for the gas generator module and eight years

for the power turbine module.

Adding to the benefit of long intervals without maintenance, the

NovaLT16 also enables extremely short intervals for conducting

maintenance activities. In fact, the modular maintenance

philosophy is so fully optimized that a cold-condition engine can

be swapped in just 24 hours.

Beyond the mechanics of the turbine itself, the complete

package is designed with the ultimate performance

and support features as standard – fully equipped with

integrated monitoring and diagnostics sensors and remote

tuning capability.

Topline Figures

• 16.5 MW shaft power

• 37% efficiency, mechanical drive

• 36% efficiency, electrical (simple cycle)

• 80% efficiency, CHP

• 99% availability

• 35,000 hours MTBM – 4 years of

continuous operation with no need

for maintenance stops

• Currently guaranteeing 25 ppm of

NOx emissions

Working with purpose

From manufacturing and testing to installation and lifecycle support, our people have

a sense of purpose that never falters. And wherever in the world they work — at our

own advanced facilities, a customer’s site or a remote location under the most extreme

conditions — their commitment to the environment, health and safety, quality and

integrity is unrelenting.

Integrity

Doing it right and striving to do it better is part of our culture. That means demanding

more of our processes and our technologies and operating with honesty and integrity,

whatever the challenge.

Environmental Health & Safety

We work hard to mitigate risk and consider people, communities and the natural world

in everything we do. That applies to everything from the layout of our workshops to

GE’s global ecomagination program, dedicated to delivering products that are better for

business and the environment.

Quality

Driven by practical industry challenges, our innovative solutions build on proven

technologies and undergo rigorous testing and qualification. Our objective is to deliver

improvements you can measure — in efficiency, reliability, availability and performance.

Loading...

Loading...