Page 1

GE Consumer & Industrial

g

Multilin

W650

Wind Generator Protection System

Instruction manual

GEK-113032A

Firmware version: 3.02

GE Multilin

215 Anderson Avenue

L6E 1B3 Markham, ON -CANADA

T (905) 294 6222 F (905) 294 8512

E gemultilin@ge.com

EnerVista 650 Setup version: 3.0

Copyright © 2006 GE Multilin

GE Multilin

Avda. Pinoa, 10

48170 Zamudio SPAIN

T +34 94 485 88 00 F +34 94 485 88 45

E gemultilin.euro@ge.com

2

Internet: www.GEMultilin.com

Page 2

Page 3

TABLE OF CONTENTS

1. GETTING STARTED 1.1 IMPORTANT PROCEDURES

1.1.1 CAUTIONS AND WARNINGS....................................... ... .................................1-1

1.1.2 INSPECTION CHECKLIST..................................... ... .... ....................................1-4

1.1.3 SAFETY INSTRUCTIONS.................................................................................1-6

1.2 OVERVIEW

1.2.1 INTRODUCTION TO 650 FAMILY OF RELAYS...............................................1-7

1.2.2 HARDWARE ARCHITECTURE.........................................................................1-7

1.2.3 SOFTWARE ARCHITECTURE.........................................................................1-9

1.2.4 COMMUNICATIONS ARCHITECTURE............................................................1-9

1.3 ENERVISTA 650 SETUP SOFTWARE

1.3.1 SYSTEM REQUIREMENTS............................................................................1-11

1.3.2 INSTALLATION...............................................................................................1-11

1.3.3 CONNECTING ENERVISTA 650 SETUP WITHW650....................................1-16

1.4 W650 HARDWARE

1.4.1 MOUNTING & WIRING ...................................................................................1-17

1.4.2 W650 COMMUNICATIONS.............................................................................1-17

1.4.3 FACEPLATE DISPLAY....................................................................................1-18

1.4.4 MAINTENANCE...............................................................................................1-19

2. PRODUCT DESCRIPTION 2.1 OVERVIEW

2.1.1 W650 OVERVIEW.............................................. ...............................................2-1

2.2 SUMMARY

2.2.1 ANSI DEVICE NUMBERS AND FUNCTIONS...................................................2-3

2.3 ORDERING CODE

2.4 TECHNICAL SPECIFICATIONS

2.4.1 PROTECTION ELEMENTS...............................................................................2-6

2.4.2 CONTROL.......................................................................................................2-14

2.4.3 MONITORING .................................................................................................2-15

2.4.4 USER –PROGRAMABLE ELEMENTS............................................................2-17

2.4.5 METERING......................................................................................................2-18

2.4.6 INPUTS............................................................................................................2-19

2.4.7 REAL TIME CLOCK ......................................................... ...............................2-21

2.4.8 OUTPUTS........................................................................................................2-21

2.4.9 CONTROL POWER SUPPLY .........................................................................2-22

2.4.10 COMMUNICATIONS.......................................................................................2-22

2.4.11 OPTIC FEATURES..........................................................................................2-24

2.4.12 ENVIRONMENTAL CHARACTERISTICS.......................................................2-25

2.4.13 PACKAGING AND WEIGHT ...........................................................................2-25

2.4.14 TYPE TESTS........................................................................ ...........................2-25

2.4.15 APPROVALS...................................................................................................2-25

2.5 EXTERNAL CONNECTIONS

3. HARDWARE 3.1 MODULE DESCRIPTION

3.2 POWER SUPPLY

3.3 MECHANICAL DESCRIPTION

3.3.1 MOUNTING.......................................................................................................3-3

3.3.2 REAR DESCRIPTION.......................................................................................3-5

3.4 WIRING

3.4.1 EXTERNAL CONNECTIONS............................................................................3-9

3.4.2 DIGITAL INPUTS WITH TRIP CIRCUIT SUPERVISION..................................3-9

3.4.3 CABLE/FIBER ETHERNET BOARD.................................................................3-9

GEK-113032A W650 Wind Generator Protection System I

Page 4

TABLE OF CONTENTS

3.5 TRANSCEIVER OPTICAL POWER BUDGET VERSUS LINK LENGTH

4. HUMAN INTERFACES. 4.1 ENERVISTA 650 SETUP SOFTWARE INTERFACE

4.1.1 INTRODUCTION................................................................................................4-1

4.1.2 ENERVISTA 650 SETUP SOFTWARE OVERVIEW.........................................4-1

4.1.3 MAIN SCREEN......................... .... ................................................. ... ..................4-3

4.1.4 COMMUNICATION MENU............................................................ .....................4-4

4.1.5 FILE MANAGEMENT.........................................................................................4-6

4.1.6 ENERVISTA 650 SETUP MENUS STRUCTURE............................................4-12

4.1.7 FILE MENU OVERVIEW..................................................................................4-13

4.1.8 SETPOINT MENU OVERVIEW........................................................................4-17

4.1.9 ACTUAL VALUES MENU OVERVIEW............................................................4-26

4.1.10 OPERATIONS MENU OVERVIEW..................................................................4-30

4.1.11 COMMUNICATION MENU OVERVIEW..........................................................4-30

4.1.12 SECURITY MENU OVERVIEW.......................................................................4-33

4.1.13 VIEW MENU OVERVIEW........................................ ... .....................................4-33

4.1.14 HELP MENU OVERVIEW................................................................................4-33

4.2 HUMAN MACHINE INTERFACE (HMI)

4.2.1 DISPLAY..........................................................................................................4-34

4.2.2 FRONT LED INDICATORS......................................... .... ... ..............................4-35

4.2.3 PUSHBUTTONS.............................................................................................4-35

4.2.4 FRONT PORT AND COVER SEALING SYSTEM...........................................4-36

4.2.5 TEXT MENUS ............................................ ... .... ...............................................4-37

4.2.6 GRAPHIC DISPLAY.........................................................................................4-55

4.3 WEB SERVER

4.3.1 HOME...............................................................................................................4-64

4.3.2 SNAPSHOT EVENTS......................................................................................4-65

4.3.3 CONTROL EVENTS.........................................................................................4-66

4.3.4 ALARMS...........................................................................................................4-67

4.3.5 OSCILLOGRAPHY...........................................................................................4-68

4.3.6 FAULT REPORT..............................................................................................4-69

4.3.7 DATA LOGGER................................................................................................4-70

4.3.8 METERING.......................................................................................................4-71

5. SETTINGS 5.1 OVERVIEW

5.1.1 SETTING MAIN MENU......................................................................................5-1

5.2 PRODUCT SETUP

5.2.1 COMMUNICATION SETTINGS......................................... .... ............................5-3

5.2.2 MODBUS USER MAP................................... .... .................................................5-6

5.2.3 FAULT REPORT................................................................................................5-7

5.2.4 OSCILLOGRAPHY.............................................................................................5-9

5.2.5 DATA LOGGER................................................................................................5-12

5.2.6 DEMAND .........................................................................................................5-14

5.3 SYSTEM SETUP

5.3.1 GENERAL SETTINGS.....................................................................................5-20

5.3.2 FLEX CURVES......................... .... ... ................................................. .... ............5-20

5.3.3 BREAKER........................................................................................................5-22

5.3.4 SWITCHGEAR.................................................................................................5-24

5.4 PROTECTION ELEMENTS

5.4.1 CHANGE OF SETTING TABLES IN W650 ELEMENTS .................................5-25

5.4.2 INVERSE TIME CURVES CHARACTERISTICS.............................................5-29

5.4.3 PHASE CURRENT........................................................................ ...................5-39

5.4.4 NEUTRAL CURRENT......................................................................................5-49

5.4.5 GROUND CURRENT.......................................................................................5-56

5.4.6 SENSITIVE GROUND CURRENT...................................................................5-59

5.4.7 NEGATIVE SEQUENCE CURRENT................................................................5-62

5.4.8 VOLTAGE ELEMENTS....................................................................................5-63

5.4.9 POWER............................................................................................................5-68

II W650 Wind Generator Protection System GEK-113032A

Page 5

TABLE OF CONTENTS

5.5 CONTROL ELEMENTS

5.5.1 SETTING GROUP..................................................... .... ... ...............................5-74

5.5.2 UNDERFREQUENCY ELEMENT (81U)..........................................................5-75

5.5.3 OVERFREQUENCY ELEMENT (81O)............................................................5-75

5.5.4 AUTORECLOSE (79)......................................................................................5-76

5.5.5 BREAKER FAILURE ELEMENT (50BF)..........................................................5-83

5.5.6 VT FUSE FAILURE ELEMENT (VTFF)...........................................................5-86

5.6 INPUTS/OUTPUTS

5.6.1 INPUT/OUTPUT PLACEMENT.......................................................................5-88

5.6.2 CONTROL SETTINGS FOR INPUTS/OUTPUTS ...........................................5-89

5.6.3 INPUTS............................................................................................................5-91

5.6.4 OUTPUTS........................................................................................................5-93

5.6.5 CIRCUIT SUPERVISION AND CONTACT SEAL-IN CIRCUITS.....................5-95

5.6.6 ANALOG BOARDS SPECIFIC SETTINGS ...................................................5-105

5.6.7 VIRTUAL INPUTS .........................................................................................5-106

5.6.8 VIRTUAL OUTPUTS .....................................................................................5-106

5.7 TESTINGS

5.7.1 FORCE IO –INPUT TESTING.......................................................................5-107

5.7.2 FORCE IO –OUTPUT TESTING...................................................................5-107

5.8 RELAY CONFIGURATION

5.8.1 OUTPUTS......................................................................................................5-108

5.8.2 LEDS ............................................................................................................. 5-109

5.8.3 OPERATIONS...............................................................................................5-110

5.8.4 PROTECTION ELEMENTS........................................................................... 5-114

5.8.5 OSCILLOGRAPHY........................................................................................5-115

5.8.6 CONTROL EVENTS ......................................................................................5-116

5.8.7 SWITCHGEAR ............................................................................................. 5-118

5.8.8 HMI (HUMAN-MACHINE INTERFACE).........................................................5-119

5.9 LOGIC CONFIGURATION (PLC EDITOR)

5.9.1 INTRODUCTION ...........................................................................................5-122

5.9.2 THEORY OF OPERATION............................................................................5-123

5.9.3 MAIN MENU..................................................................................................5-126

5.9.4 CONFIGURATION GENERATION................................................................5-127

5.9.5 GENERATION OF LIBRARIES ....................................................................5-128

5.9.6 EXAMPLE OF APPLICATION.......................................................................5-130

6. ACTUAL VALUES 6.1 FRONT PANEL

6.1.1 LEDS .................................................................................................................6-1

6.2 STATUS

6.2.1 OPERATION BITS.............................................................................................6-2

6.2.2 BREAKER..........................................................................................................6-2

6.2.3 PROTECTION...................................................................................................6-2

6.2.4 CONTROL ELEMENTS.....................................................................................6-8

6.2.5 PROTECTION SUMMARY..............................................................................6-13

6.2.6 SNAPSHOT EVENTS SUMMARY..................................................................6-15

6.2.7 MODBUS USER MAP.................................................................................. ...6-17

6.2.8 SWITCHGEAR STATUS.................................................................................6-17

6.2.9 CALIBRATION.................................................................................................6-19

6.2.10 FLEX CURVES........................................................................ ........................6-20

6.2.11 SYSTEM INFO ................................................................................................6-20

6.2.12 RECORD STATUS.................................................... .... ..................................6-20

6.3 METERING

6.3.1 PRIMARY VALUES.........................................................................................6-25

6.3.2 SECONDARY VALUES...................................................................................6-28

6.3.3 PHASOR DIAGRAM........................................................................................6-30

6.3.4 FREQUENCY..................................................................................................6-30

6.3.5 INPUTS / OUTPUTS .......................................................................................6-31

6.4 RECORDS

6.4.1 EVENT RECORDER.......................................................................................6-37

6.4.2 WAVEFORM CAPTURE .................................................................................6-39

6.4.3 FAULT REPORT .............................................................................................6-40

GEK-113032A W650 Wind Generator Protection System III

Page 6

TABLE OF CONTENTS

6.4.4 DATA LOGGER................................................................................................6-42

7. IEC 61850 PROTOCOL 7.1 IEC61850 GENERIC SUBSTATION STATE EVENT (GSSE)

7.1.1 REMOTE DEVICES...................................... .... ... ..............................................7-1

7.1.2 REMOTE INPUTS......................................... ................................................. ....7-3

7.1.3 REMOTE OUTPUTS..................................... .... .................................................7-4

7.2 IEC 61850 PROFILE FOR W650

7.2.1 INTRODUCTION................................................................................................7-6

7.2.2 ACSI CONFORMANCE STATEMENT...............................................................7-6

7.2.3 LOGICAL NODES.............................................................. .... ... .......................7-11

7.2.4 COMMON DATA CLASS.................................................................................7-29

7.2.5 DATASETS.......................................................................................................7-44

7.2.6 MAPPINGS BETWEEN TOC CURVES IN IEC 61850 AND W650 RELAY

IMPLEMENTATION..........................................................................................7-46

7.2.7 ANALOG DATA UNITS AND SCALES............................................................7-47

8. W650 CANOPEN PROFILE 8.1 INTRODUCTION

8.1.1 DEFINITIONS.....................................................................................................8-1

8.2 CANOPEN INTERFACE SPECIFICATION

8.3 SERVICES

8.4 OBJECT DICTIONARY

8.4.1 STANDARD OBJECTS......................................................................................8-4

8.4.2 MANUFACTURER SPECIFIC OBJECTS..........................................................8-7

9. SECURITY 9.1 ADDING USERS

9.1.1 USER RIGHTS...................................................................................................9-1

9.2 CHANGING PASSWORDS

9.3 ENABLING SECURITY

9.4 LOGING INTO ENERVISTA 650 SETUP

10. BOOTCODE AND

FIRMWARE UPGRADE

10.1 INTRODUCTION

10.1.1 COMMUNICATION PARAMETERS.................................................................10-2

10.2 BOOT CODE UPGRADE

10.3 FIRMWARE VERSION UPGRADE

10.3.1 FIRMWARE UPGRADE...................................................................................10-9

10.3.2 BOOT CODE UPGRADE (*)..........................................................................10-11

10.3.3 FIRMWARE UPGRADE (*)............................................................................10-12

IV W650 Wind Generator Protection System GEK-113032A

Page 7

TABLE OF CONTENTS

11. COMMISSIONING 11.1 VISUAL INSPECTION

11.2 GENERAL CONSIDERATIONS ON THE POWER SUPPLY NETWORK

11.3 ISOLATION TESTS

11.4 INDICATORS

11.5 POWER SUPPLY TESTING

11.6 COMMUNICATIONS

11.7 VERIFICATION OF MEASUREMENT

11.7.1 VOLTAGES .....................................................................................................11-7

11.7.2 PHASE CURRENTS............................................................. ... ........................11-7

11.7.3 ACTIVE, REACTIVE POWER, AND COSJ METERING.................................11-8

11.7.4 FREQUENCY..................................................................................................11-8

11.8 INPUTS AND OUTPUTS

11.8.1 DIGITAL INPUTS.............................................................................................11-9

11.8.2 CONTACT OUTPUTS ...................................................................................11-10

11.8.3 CIRCUIT CONTINUITY SUPERVISION INPUTS .........................................11-10

11.8.4 LATCHING CIRCUITS...................................................................................11-10

11.9 CONNECTIONS FOR TESTING PROTECTION ELEMENTS

11.10 INSTANTANEOUS OVERCURRENT (50PH, 50PL, 50N, 50G Y 50SG)

11.11 TIME OVERCURRENT (51PH, 51PL, 51N AND 51G)

11.12 DIRECTIONAL ELEMENTS (67P, 67N, 67G, 67SG)

11.12.1 67P ELEMENT ..............................................................................................11-14

11.12.2 67N ELEMENT ..............................................................................................11-14

11.12.3 67G ELEMENT..............................................................................................11-15

11.12.4 67SG ELEMENT............................................................................................11-16

11.13 UNDERVOLTAGE ELEMENTS (27P, 27X)

11.13.1 27P ELEMENT ..............................................................................................11-17

11.13.2 27X ELEMENT ..............................................................................................11-17

11.14 OVERVOLTAGE ELEMENTS (59P, 59X, 59NH, 59NL)

11.14.1 59P ELEMENT ..............................................................................................11-18

11.14.2 59X ELEMENT ..............................................................................................11-18

11.14.3 59NH AND 59NL ELEMENTS.......................................................................11-19

11.15 RECLOSER (79)

11.15.1 RECLOSING CYCLE.....................................................................................11-20

11.15.2 RECLOSER STATUS....................................................................................11-21

11.15.3 EXTERNAL RECLOSE INITIATION............................................ ..................11-21

12. APPLICATION EXAMPLES 12.1 EXAMPLE 1: COMMUNICATION & PROTECTION SETTINGS

PROCEDURE

12.1.1 DESCRIPTION OF THE EXERCISE...............................................................12-1

12.1.2 PROCEDURE TO COMMUNICATE WITH THE RELAY.................................12-1

12.1.3 PROCEDURE TO SET THE PROTECTION FUNCTION................................12-3

12.1.4 TEST................................................................................................................12-4

12.2 EXAMPLE 2: TOC PROTECTION + RECLOSING SETTINGS

PROCEDURE

12.2.1 DESCRIPTION OF THE EXERCISE...............................................................12-5

12.2.2 PROCEDURE TO COMMUNICATE THE RELAY...........................................12-5

12.2.3 PROCEDURE TO SET THE PROTECTION FUNCTION................................12-5

12.2.4 PROCEDURE TO SET THE RECLOSER.......................................................12-6

12.2.5 PROCEDURE TO SET THE SYNCHRO CHECK...........................................12-6

12.3 EXAMPLE 3: PROCEDURE TO SET AN OPERATION

12.3.1 DESCRIPTION OF THE EXERCISE...............................................................12-8

12.3.2 PROCEDURE .................................................................................................12-8

12.3.3 TEST..............................................................................................................12-10

GEK-113032A W650 Wind Generator Protection System V

Page 8

TABLE OF CONTENTS

13. FREQUENTLY ASKED

QUESTIONS

13.1 COMMUNICATIONS

13.2 PROTECTION

13.3 CONTROL AND HMI

13.4 RELAY CONFIGURATION

14. TROUBLESHOOTING

14.1 SYMPTOMS AND RECOMMENDED ACTIONS

GUIDE

A. LOGIC OPERANDS A.1 LOGIC OPERANDS

B. MODBUS PROTOCOL B.1 ACCESS TO W650 DATA

B.2 MODBUS W650

B.2.1 FUNCTIONS USED...........................................................................................B-2

B.2.2 PHYSICAL LAYER............................................................................................B-3

B.2.3 DATA LINK LAYER ...........................................................................................B-4

B.2.4 GENERIC READING.........................................................................................B-5

B.2.5 GENERIC WRITING..........................................................................................B-6

B.2.6 FUNCTION CODES .........................................................................................B-7

B.2.7 EXCEPTIONS AND ERROR RESPONDS........................................................B-8

B.3 DATA TYPE

B.4 MODBUS APPENDIX

B.4.1 DATA MANAGEMENT ....................................................................................B-10

B.4.2 WRITING SETTINGS......................................................................................B-11

B.4.3 SNAP-SHOT EVENTS ....................................................................................B-12

B.4.4 OPERATIONS.................................................................................................B-15

B.5 OUTPUT WRITING

B.5.1 CONTROL EVENTS........................................................................................B-17

B.5.2 EVENT STRUCTURE......................................................................................B-18

B.6 EVENTS STATUS REQUEST (ALARMS)

B.6.1 CONTROL EVENTS RETRIEVAL FROM THE COMMAND LINE .................B-21

B.6.2 SERIAL COMMUNICATION............................................................................B-22

B.6.3 ETHERNET COMMUNICATION.....................................................................B-23

B.6.4 ACKNOWLEDGEMENT OF EVENTS (ALARMS)...........................................B-24

B.6.5 VIRTUAL INPUTS WRITING...........................................................................B-25

B.6.6 USER MAP......................................................................................................B-26

B.6.7 RETRIEVING OSCILOGRAPHY.....................................................................B-27

B.6.8 TIME SYNCHRONIZATION ............................................................................B-28

B.6.9 ENQUEUEING MESSAGES ..........................................................................B-29

B.6.10 TRACES AND TROUBLESHOOTING.............................................................B-30

B.6.11 MODBUS CHECK FUNCTION........................................................................B-31

B.7 MEMORY MAP

C. DNP 3.0 PROTOCOL FOR

W650

C.1 DNP 3.0 PROTOCOL SETTINGS

C.2 DNP 3.0 DEVICE PROFILE DOCUMENT

C.3 IMPLEMENTATION TABLE

C.4 BINARY INPUT POINTS

C.5 DNP CONFIGURATION EXAMPLES

C.5.1 CONFIGURING DNP USER MAP...................................................................C-11

VI W650 Wind Generator Protection System GEK-113032A

Page 9

TABLE OF CONTENTS

C.5.2 EXAMPLE OF CUSTOM BINARY INPUT POINTS MAP ................................C-13

C.5.3 MULTIPLE DNP 3.0 MASTERS COMMUNICATION WITH W650..................C-15

C.6 BINARY OUTPUT AND CONTROL RELAY OUTPUT

C.7 BINARY COUNTERS

C.8 ANALOG INPUTS

D. IEC 60870-5-104 PROTOCOL D.1 INTRODUCTION

D.2 TECHNICAL DESCRIPTION

D.3 BASIC APPLICATION FUNCTIONS

D.4 IEC 104 SETTINGS

D.5 IEC 60870-5-104 POINT LIST

E. FACTORY DEFAULT

CONFIGURATION

E.1 FACTORY DEFAULT SETTINGS

E.2 FACTORY DEFAULT CONFIGURATION

F. MISCELLANEOUS F.1 GE MULTILIN WARRANTY

GEK-113032A W650 Wind Generator Protection System VII

Page 10

TABLE OF CONTENTS

VIII W650 Wind Generator Protection System GEK-113032A

Page 11

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

1 GETTING STARTED 1.1IMPORTANT PROCEDURES 1.1.1 CAUTIONS AND WARNINGS

To help ensure years of trouble free operation, please read through the following chapter for information to help guide you

through the initial installation procedures of your new relay.

BEFORE ATTEMPTING TO INSTALL OR USE THE RELAY, IT IS IMPERATIVE THAT ALL WARNINGS AND CAUTIONS

IN THIS MANUAL ARE REVIEWED TO HELP PREVENT PERSONAL INJURY, EQUIPMENT DAMAGE, AND/OR

DOWNTIME.

CAUTION: THE OPERATOR OF THIS INSTRUMENT IS ADVISED THAT IF THE EQUIPMENT IS USED IN A MANNER

NOT SPECIFIED IN THIS MANUAL, THE PROTECTION PROVIDED BY THE EQUIPMENT MAY BE IMPAIRED.

1

Figure 1–1: FRONT VIEW OF W650 UNITS

GEK-113032A W650 Wind Generator Protection System 1-1

Page 12

1.1 IMPORTANT PROCEDURES 1 GETTING STARTED

1.1.1.1 COMMUNICATION BOARDS WITHDRAWAL / INSERTION

1

WARNING: MODULE WITHDRAWAL AND INSERTION SHALL ONLY BE PERFORMED BY DULY QUALIFIED

SERVICE PERSONNEL. FOR PERSONAL SECURITY PURPOSES, BEFORE ACCOMPLISHING ANY

WITHDRAWAL OR INSERTION OPERATION, THE RELAY MUST BE POWERED OFF AND ALL THE REAR

TERMINALS MUST BE POTENTIAL FREE. THE RELAY MUST BE GROUNDED USING THE REAR GROUNDING

SCREW.

The modular design of the relay allows for the withdra wal and insertion of the communication module.

Figure 1–2: shows the location of communication module s on the rear part of the relay. Qualified personnel must carry out

the insertion or extraction of the communication boards only after interrupting the relay auxiliary voltage and ensuring that

all the rear terminals are potential free.

Communication boards are installed on the rear of the unit, the upper port being reserved for the asynchronous

communications board and CAN, and the lower port for the ETHERNET board in any of its configurations.

Before performing any of these actions, control power must be removed fro m the relay and all the r ear terminals

must be potential free. A grounded anti static wristband must be u sed when manipul ating the mo dule in or der to avoid

electrostatic discharges that may cause damage to the electronic components.

WITHDRAWAL: Loosen the small screws that keep the faceplate in place and extract the module.

INSERTION: Insert the module and press it firmly in the case, until it is completely fixed. After this, bolt the facep late

screws and replace the control power. Check that the relay is fully operative.

Figure 1–2: MODULE WITHDRAWAL/INSERTION

GE Multilin will not be responsible for any damage of the re la y, connected equipment or personnel whenever

these safety rules are not followed.

1-2 W650 Wind Generator Protection System GEK-113032A

Page 13

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

1.1.1.2 MAGNETIC MODULE TERMINALS

The transformer module for the VTs and CTs is already connected to a female connector screwed to the case. The

current inputs incorporate shorting bars, so that the module can be extracted without the need to short-circuit the

currents externally. It is very important, for safety reasons not to change or switch the terminals for CTs and VTs.

AC Input Terminals

1

GE Multilin

Figure 1–3: REAR VIEW OF W650 UNIT

will not be responsible for any damage of the relay, connected equipment or personnel

whenever these safety rules are not followed.

GEK-113032A W650 Wind Generator Protection System 1-3

Page 14

1.1 IMPORTANT PROCEDURES 1 GETTING STARTED

1

Unwrap the relay and inspect the relay for physical damage.

Verify that the model on the label on the side of the relay matches the model ordered.

1.1.2 INSPECTION CHECKLIST

Figure 1–4: IDENTIFICATION LABEL (A4454P20)

Please ensure that you received the following items with your relay:

• Mounting screws for fixing the relay to a cabinet

• CD containing EnerVista 650 Setup software

• Wiring diagram

• Certificate of Compliance

1-4 W650 Wind Generator Protection System GEK-113032A

Page 15

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

For product information, instruction manual updates, and the latest software updates, please visit the GE Multilin Home

Page www.geindustrial.com/multilin.

Note: If there is any physical damage detected on the relay, or any of the contents listed are missing, please

contact GE Multilin immediately at:

EUROPE, MIDDLE EAST AND AFRICA:

GE MULTILIN

Av. Pinoa, 10

48170 Zamudio, Vizcaya (SPAIN)

Tel.: (34) 94-485 88 54, Fax: (34) 94-485 88 38

E-mail: multilin.tech.euro@ge.com

AMERICA, ASIA AND AUSTRALIA:

GE MULTILIN

215, Anderson Avenue

L6E 1B3 Markham, ON (CANADA)

Tel.: +1 905 294 6222, Fax: +1 905 201 2098

E-mail: multilin.tech@ge.com

1

The information provided herein is not intended to cover all the details of the variations of the equipment, nor does

it take into account the circumstances that may be present in your installation, operating or maintenance

activities.

Should you wish to receive additional information, or for any particular problem that cannot be solved by referring

to the information contained herein, please contact GENERAL ELECTRIC MULTILIN.

GEK-113032A W650 Wind Generator Protection System 1-5

Page 16

1.1 IMPORTANT PROCEDURES 1 GETTING STARTED

1.1.3 SAFETY INSTRUCTIONS

1

The W650 ground screw shown in Figure 1–5: must be correctly grounded.

Figure 1–5: LOCATION OF GROUNDING SCREW

Before communicating with a W650 unit through the front serial port, please ensure that the computer is grounded.

In case of using a laptop, it is recommended not to have it connected to its power supply. In many cases it might not be

correctly grounded either due to the power supply or to the connector cables used.

This is required not only for personal protection, bu t also to avoid a potential voltage difference between the

relay’s serial port and the computer’s port, which could produce permanent damage to the computer or the relay.

GE Multilin will not be responsible for any damage to the relay or connected equipment whenever this elemental

safety rule is not followed.

1-6 W650 Wind Generator Protection System GEK-113032A

Page 17

1 GETTING STARTED 1.2 OVERVIEW

1.2OVERVIEW 1.2.1 INTRODUCTION TO 650 FAMILY OF RELAYS

Historically, substation protection, control and metering functions were performed with electromechanical equipment. This

first generation of equipment was gradually replaced by analog electronic equipment (called static devices), most of which

emulated the single-function approach of their electromechanical precursors. Both of these technologies required

expensive cabling and auxiliary equipment to produce functioning systems.

Recently, digital electronic equipment has begun to provide protection, control and metering functions. Initially, this

equipment was either single function or had very limited multi-function capability, and did not significantly reduce the

cabling and auxiliary equipment required. However, recent digital relays have become quite multi-functional, reducing

cabling and auxiliaries significantly. These devices also transfer data to central control facilities and Human Machine

Interfaces using electronic communications. The functions pe rformed by these produ cts have become so broad that many

users prefer the term IED (Intelligent Electronic Device).

It is obvious to station designers that the amount of cabling and auxiliary equipment installed in stations can be even further

reduced, to 20% to 70% of the levels common in 1990, to achieve large cost r eductions. This requires placi ng even more

functions within the IEDs.

Users of power equipment are also interested in reducing cost by improving power quality and perso nnel productivity, and

as always, in increasing system reliability and efficiency. These objectives are realized through software which is used to

perform functions at both the station and supervisory levels. The use of these systems is growing rapidly.

High speed communications are required to meet the data transfer rates required by modern automatic control and

monitoring systems. In the near future, very high speed communications will be required to perform protection signalling.

This has been established by the IEC 61850 standard.

IEDs with capabilities outlined above will also provided significantly more power system data than is presently available,

enhance operations and maintenance, and permit the use of adaptative system configuration for protection and co ntrol

systems. This new generation of equipment must also be easily incorporated into automation systems, at both the station

and enterprise levels.

1

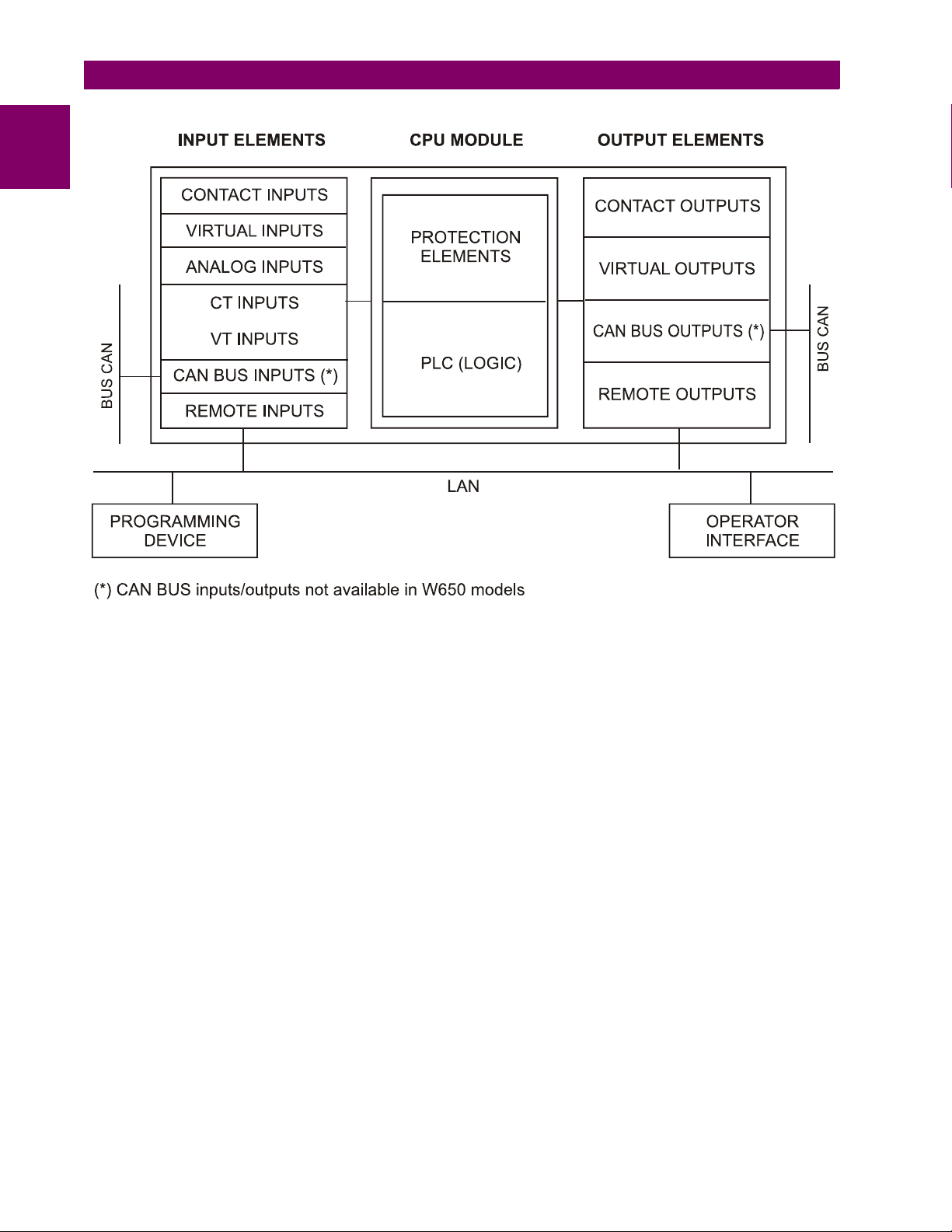

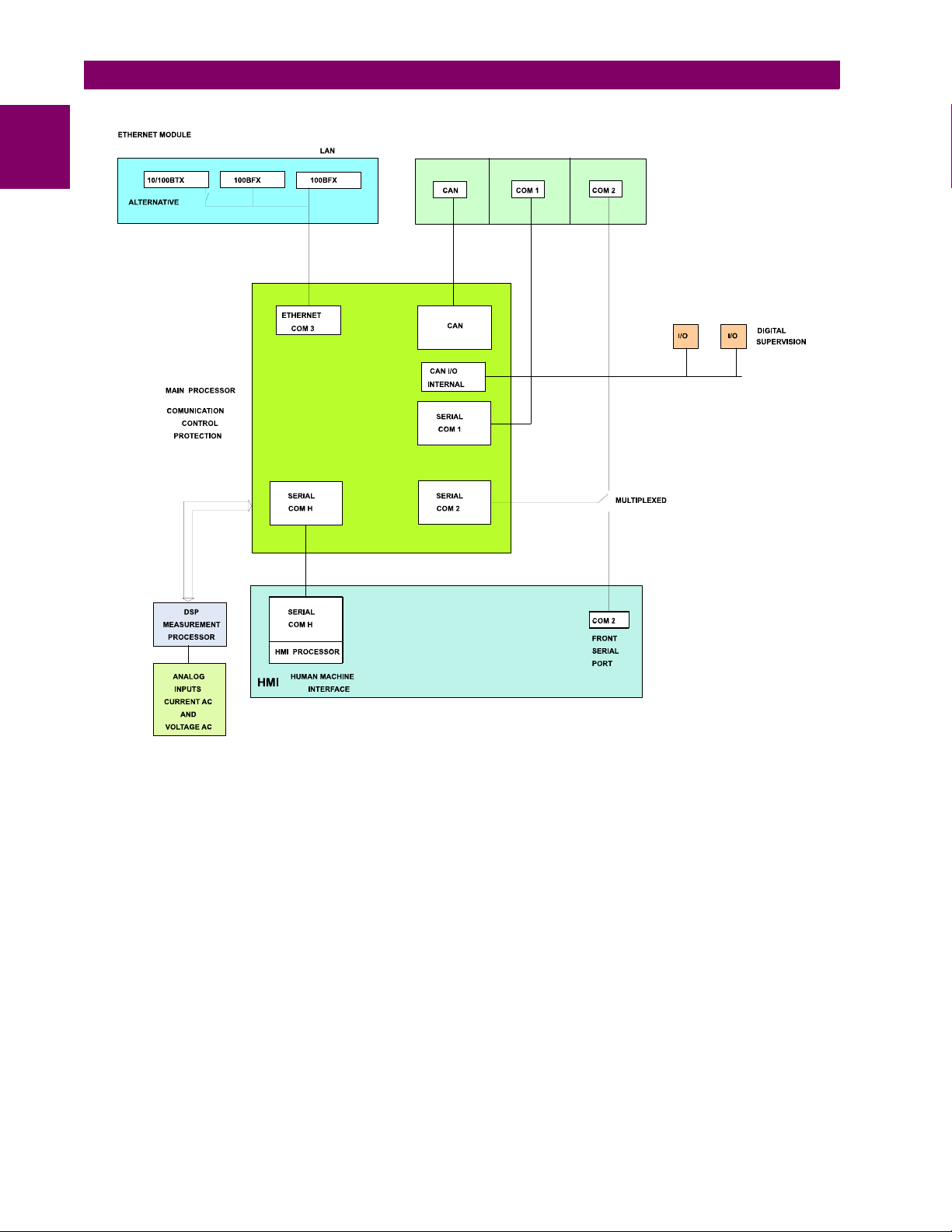

1.2.2 HARDWARE ARCHITECTURE

650 family of relays has been designed to meet the goals described above that are appearing nowadays in the environment

of new substations.

The 650 is a digital-based device containing a central processing unit (CPU) that handles multiple types of input and output

signals. The 650 family can communicate over a local area netwo rk (LAN) with an operator interface, a programming

device, or another 650 or UR device.

The CPU module contains firmware that provides protection elements in the form of logic algorithms, as well as

programming logic gates, timers, and latches for contro l features. It incorporates two internal processors, one for ge neric

use and a second one dedicated for communications.

Input Elements accept a variety of analog or digital signals from the field. The 650 isolates and converts these signals into

logic signals used by the relay.

Output Elements convert and isolate the logic signals generated by the relay into digital signals that can be used to control

field devices.

GEK-113032A W650 Wind Generator Protection System 1-7

Page 18

1

1.2 OVERVIEW 1 GETTING STARTED

Figure 1–6: 650 CONCEPT BLOCK DIAGRAM

Contact Inputs/Outputs are signals associated to the physical input/output contacts in the relay

CT and VT inputs are signals coming from the inputs of current and voltage transformers, used for monitoring the power

system signals.

CAN Bus Inputs/Outputs: are signals associated to physical input/output contacts from independent modules connected

to the 650 unit via a CAN Bus.

PLC: Programmable Logic Controller. Control module that enables the unit configuration (assignment of inputs/outputs)

and the implementation of logic circuits.

Protection Elements: Relay protection elements, for example: Overcurrent, overvoltage, etc.

Remote inputs and outputs provide a means of sharing digital point state information between remote devices using IEC

61850 GSSE messages.

Analog Inputs are signals associated with transducers.

1-8 W650 Wind Generator Protection System GEK-113032A

Page 19

1 GETTING STARTED 1.2 OVERVIEW

1.2.3 SOFTWARE ARCHITECTURE

The firmware (software embedded in the relay) has been designed usin g object oriented progra mming techniques (OOP).

These techniques are based on the use of objects and classes, and provide the software architecture with the same

characteristics as the hardware architecture, i.e., modularity, scalability and flexibility.

1.2.4 COMMUNICATIONS ARCHITECTURE

The main processor performs protection, control, and communication functions, incorporating two internal processors, one

for generic use and a second one dedicated for communications.

A dedicated serial port is used for communication between the main processor and the human-machine interface . The

serial connection provides great immunity against electromagnetic disturbances, thus increasing system safety.

All W650 units incorporate an RS232 serial port on the front of the relay. There is also a possibility to incorporate up to two

additional communication modules on the rear.

One of the modules provides asynchronous serial communications, using different physical media (RS485, plastic or glass

fiber optic) depending on the selected model. The module incorporates two id entical po rts, COM1 and COM2. The C OM2

port is multiplexed with the front port.

Available options are:

Table 1–1: REAR SERIAL COMMUNICATIONS BOARD 1

BOARD CODE FUNCTIONALITY

F None

A Redundant RS 485

p Redundant plastic fiber optic

G Redundant glass fiber optic

X Redundant RS485 + Can port (CANopen)

Y Redundant plastic fiber optic + Can port (CANopen)

Z Redundant glass fiber optic + Can port (CANopen)

C CAN port (CANopen)

M RS485 + CAN port (CANopen)

1

The other module provides Ethernet communications (COM3 port), using 10/100BaseTX (self-negotiable speed) or

100BaseFX connectors, depending on the selected model. The most complete models include a double redundant

100BaseFX fiber optic port. Redundancy is provided at the physical level; the unit incorporates internally du plicated and

independent controllers for extended system reliability and accessibility.

Available Options are:

Table 1–2: REAR ETHERNET COMMUNICATIONS BOARD 2

BOARD

CODE

B One 10/100BaseTX port (self-negotiable speed)

C One 10/100BaseTX port and one 100BaseFX port.

D One 10/100BaseTX port and redundant 100BaseFX ports

E Redundant 10/100BaseTX ports

FUNCTIONALITY

For options C and D it is required to select the active physical media, by means of an intern al selector inside the module.

The factory configuration for this selection is the 10/100BaseTX port.

Finally, internal communication with input and output modules is performed via an internal CAN bus. This fa ct provides

increased communication speed, as well as the possibility of acknowledgement of modules, abnormalitie s, etc. As this is a

serial port supporting a communications protocol, it provides extraordinary immunity against external or internal

disturbances.

GEK-113032A W650 Wind Generator Protection System 1-9

Page 20

1

1.2 OVERVIEW 1 GETTING STARTED

Figure 1–7: COMMUNICATIONS ARCHITECTURE (B6816F1)

1-10 W650 Wind Generator Protection System GEK-113032A

Page 21

1 GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

1.3ENERVISTA 650 SETUP SOFTWARE 1.3.1 SYSTEM REQUIREMENTS

The EnerVista 650 Setup software interface is the preferred method to edit settings and view actual values because the PC

monitor can display more information in a simple comprehensible format.

The following minimum requirements must be met for the EnerVista 650 Setup software to properly operate on a PC:

• Pentium® class or higher processor (Pentium® II 300 MHz or higher recommended)

• Windows® NT 4.0 (Service Pack 3 or higher), Windows® 2000, Windows® XP

• Internet Explorer® 5.0 or higher

• 64 MB of RAM (128 MB recommended)

• 40 MB of available space on system drive and 40 MB of available space on installation drive

• RS232C serial and/or Ethernet port for communications to the relay

1.3.2 INSTALLATION

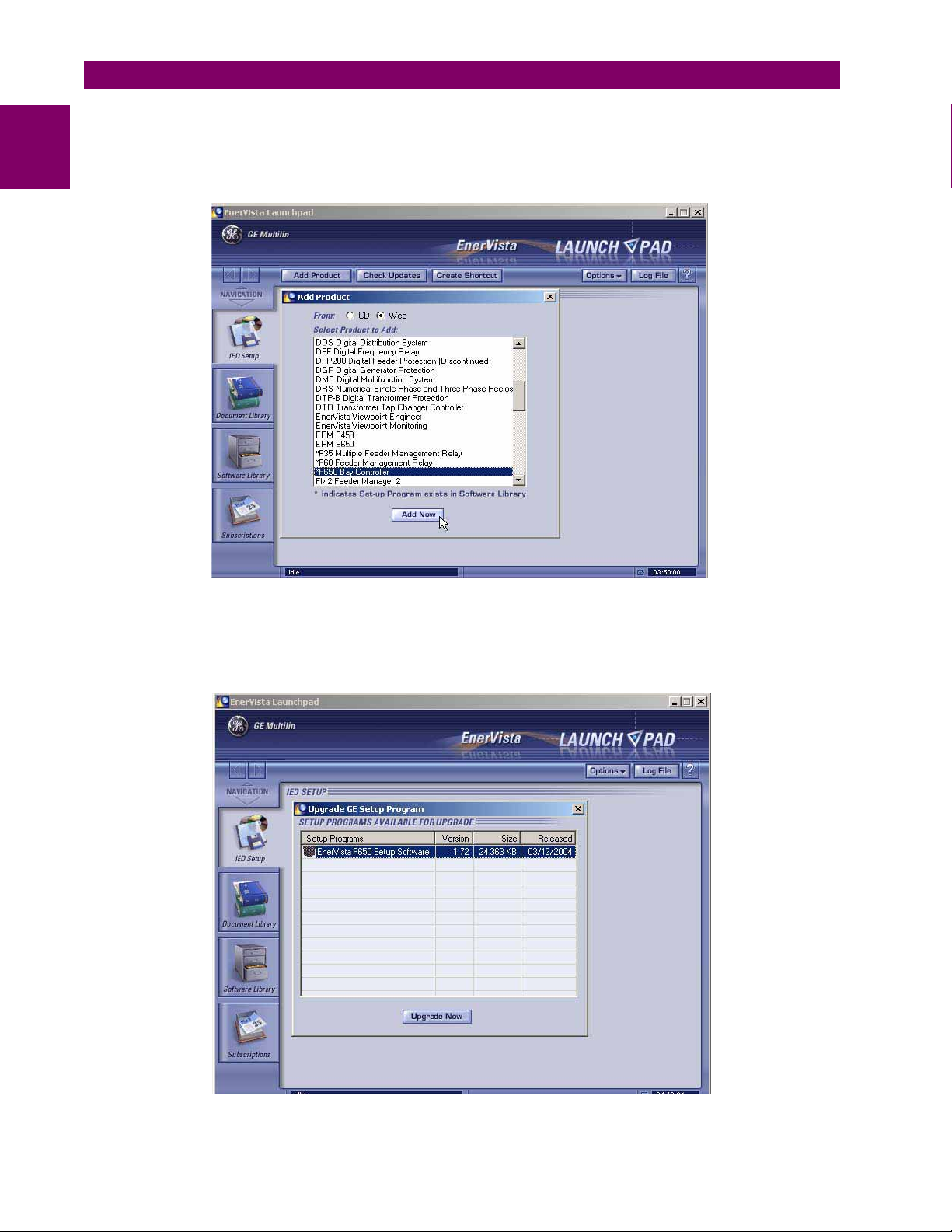

After ensuring the minimum requirements for using EnerVista 650 Setup are met (see previous section), use the following

procedure to install the EnerVista 650 Setup from the GE EnerVista CD.

1. Insert the GE EnerVista CD into your CD-ROM drive.

2. Click the Install Now button and follow the installation instructions to install the no-charge EnerVista software.

3. When installation is complete, start the EnerVista Launchpad application.

4. Click the IED Setup section of the Launch Pad window.

1

Figure 1–8: LAUNCHPAD WINDOW

GEK-113032A W650 Wind Generator Protection System 1-11

Page 22

1.3 ENERVISTA 650 SETUP SOFTWARE 1 GETTING STARTED

5. In the EnerVista Launch Pad window, click the Add Product button and select the “W650 Wind Generator Protection

1

System” relay from the Install Software window as shown below. Select the “Web” option to ensure the most recent

software release, or select “CD” if you do not have a web connection , then click the Add Now button to list software

items for the W650.

Figure 1–9: ADD PRODUCT WINDOW

6. If “Web” option is selected, chose the W650 software program and release notes (if desired) from the list and cl ick the

Download Now button to obtain the installation program.

Figure 1–10: WEB UPGRADE WINDOW

1-12 W650 Wind Generator Protection System GEK-113032A

Page 23

1 GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

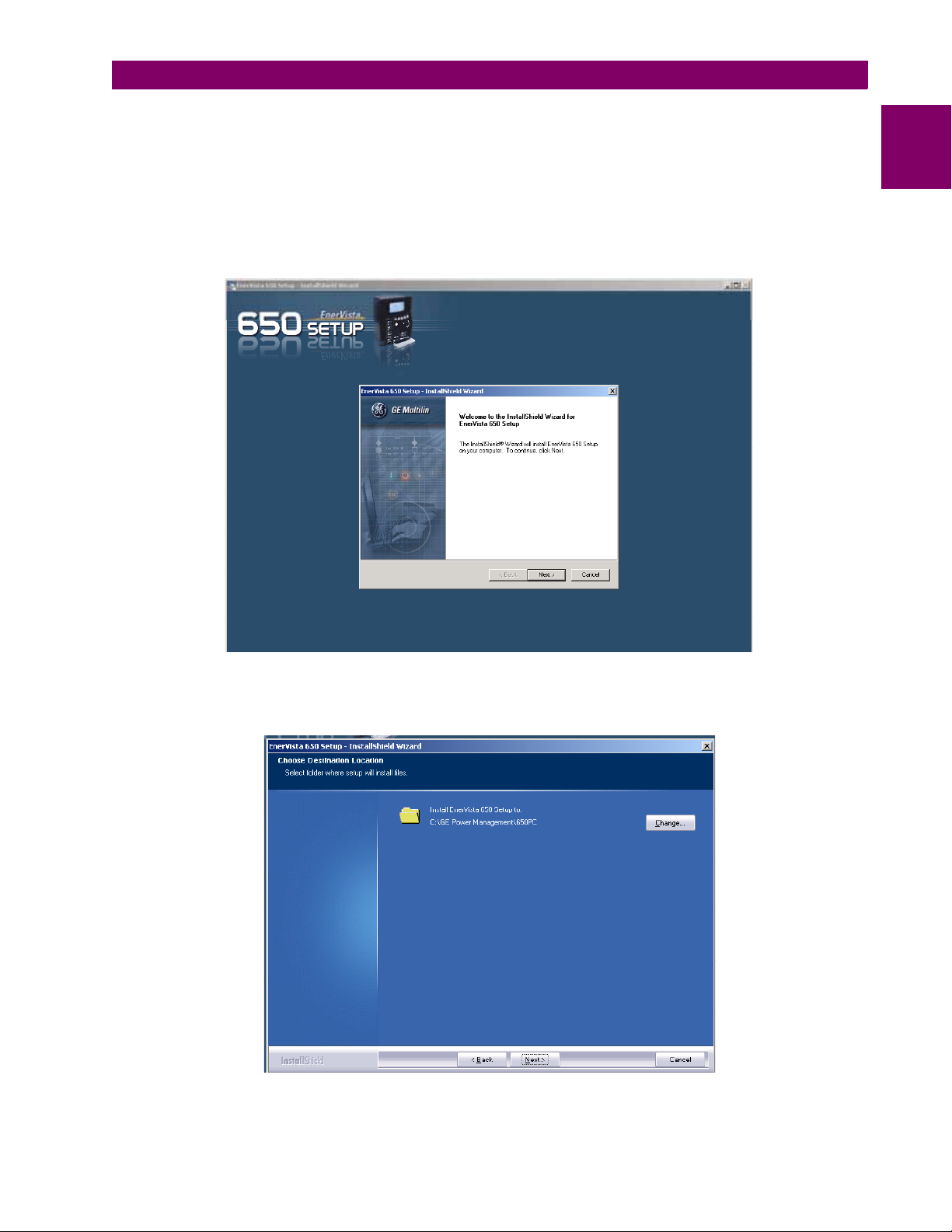

7. EnerVista Launchpad will obtain the installation program from the Web or CD. Once the download is complete, double-

click the installation program to install the EnerVista 650 Setup software.

8. Select the complete path, including the new directory name, where the EnerVista 650 Setup will be installed.

9. Click on Next to begin the installation. The files will be installed in the directory indicated and the in stallation program

will automatically create icons and add EnerVista 650 Setup to the Windows start menu.

10. Follow the on-screen instructions to install the EnerVista 650 Setup software. When the Welcome window appears,

click on Next to continue with the installation procedure.

1

Figure 1–11: ENERVISTA 650 SETUP INSTALLATION

11. When the Choose Destination Location window appears, and if the software is not to be located in the default

directory, click Change… and type in the comple te path name including the new directory name and click Next to

continue with the installation procedure.

Figure 1–12: ENERVISTA 650 SETUP INSTALLATION CONT.

GEK-113032A W650 Wind Generator Protection System 1-13

Page 24

1.3 ENERVISTA 650 SETUP SOFTWARE 1 GETTING STARTED

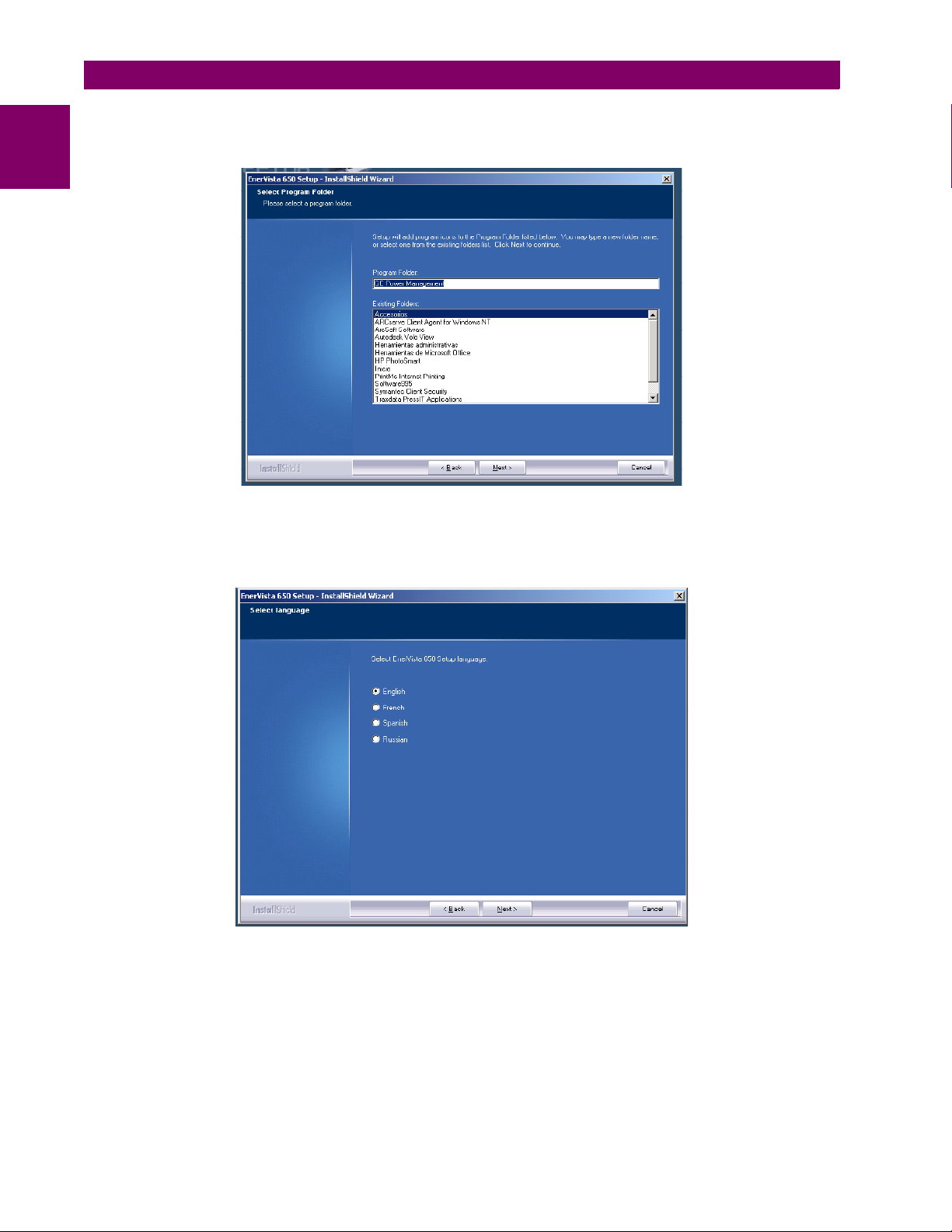

12. The default program group where the application will be added to is shown in the Sele cted Program F older window.

Click Next to begin the installation process, and all the necessary program files will be copied into the chosen directory.

1

Figure 1–13: SELECT PROGRAM FOLDER

13. To finish with the installation proce ss, select the desired language for startup.

Figure 1–14: LANGUAGE WINDOW

1-14 W650 Wind Generator Protection System GEK-113032A

Page 25

1 GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

14. Click Finish to end the installation. The W650 device will be added to the list of installed IEDs in the EnerVista

Launchpad window, as shown below.

1

Figure 1–15: ENERVISTA LAUNCHPAD

GEK-113032A W650 Wind Generator Protection System 1-15

Page 26

1.3 ENERVISTA 650 SETUP SOFTWARE 1 GETTING STARTED

1.3.3 CONNECTING ENERVISTA 650 SETUP WITHW650

1

This section is intended as a quick start guide to using the EnerVista 650 Setup software. Please refer to section 4.1 in this

manual for more information about the EnerVista 650 Setup software interface.

a) CONFIGURING AN ETHERNET CONNECTION

Before starting, verify that the Ethernet network cable is properly connected to the Ethernet port on the back of the relay.

1. Install and start the latest version of the EnerVista 650 Setup software (available from the GE EnerVista CD or online

from http://www.GEindustrial.com/multilin (see previous section fo r installation instructions).

2. Go to “Communication>Computer” and enter the following data refering to communications:

3. Select Control Type as MODBUS TCP/IP from the drop-down list. This option will display a number of interface

parameters that must be entered for proper Ethernet communications.

4. Enter the relay IP address (from “Setpoint>Product Setup >Communication Settings>Network>IP ADDRESS”) in

the IP Address field in MODBUS TCP/IP SETUP.

5. Enter the relay ModBus address (from “Setpoint>Product Setup >Communication Settings>ModBus

Protocol>ModBus Address COM1/COM2 setting”) in the Unit Identifier (Sl ave Address) fi eld.

6. Enter the ModBus port address (from “Setpoint>Product Setup >Communication Settings>ModBus

Protocol>ModBus Port Number” setting) in the ModBus Port field.

7.The Device has now been configured for Ethernet communications. Proceed to press the ON button to begin

communicating.

b) CONFIGURING AN RS232 CONNECTION

Before starting, verify that the RS232 serial cable is properly connected to the RS232 port on the front panel of the relay.

1. Install and start the latest version of the EnerVista 650 Setup software (available from the GE EnerVista CD or online

from http://www.GEindustrial.com/multilin (see previous section fo r installation instructions).

2. Go to “Communication>Computer” and enter the following data referred to communications:

3. Select Control Type as No Control Type from the drop-down list. This option will display a number of interface

parameters that must be entered for proper serial communications.

4. Enter the relay Slave Address (“Setpoint>Product Setup >Communication Settings>ModBus Pro tocol” menu) in the

Slave Address field.

5. Enter the physical communications parameters (Baudrate and parity settings) from “Setpoint>Product Setup

>Communication Settings>Serial Ports” menu, in their respective fields.

6.The Device has now been configured for RS232 communications. Proceed to press the ON button to begin

communicating.

1-16 W650 Wind Generator Protection System GEK-113032A

Page 27

1 GETTING STARTED 1.4 W650 HARDWARE

1.4W650 HARDWARE 1.4.1 MOUNTING & WIRING

Please refer to Chapter 3. Hardware for detailed mounting and wiring instructions.

1.4.2 W650 COMMUNICATIONS

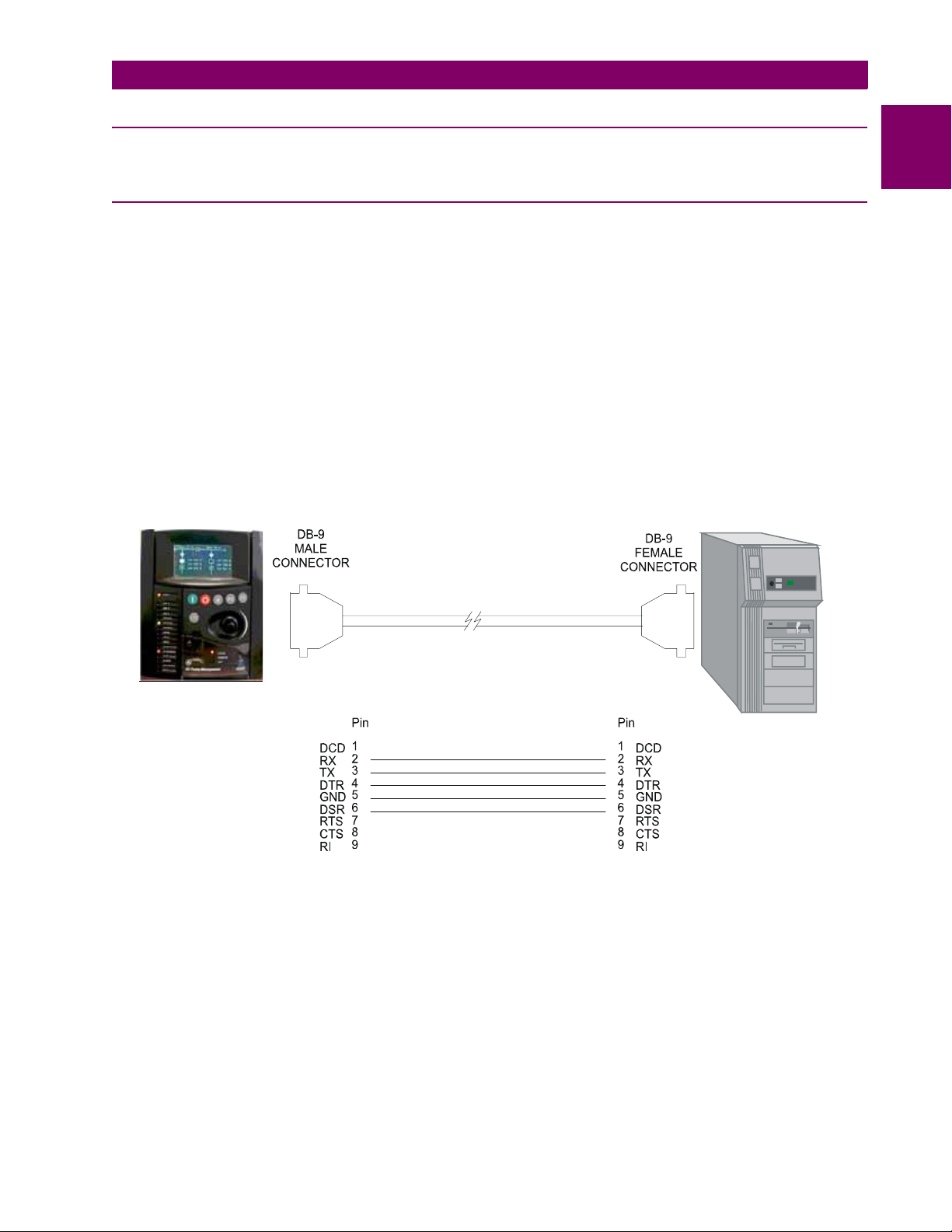

The Enervista 650 Setup software communicates to the relay via the fa ceplate RS232 port or the rear RS485/Ethernet

ports. To communicate via the faceplate RS232 port, a standard “straight-through” serial cable is used. The DB-9 male end

is connected to the relay and the DB-9 or DB-25 female en d is connected to the PC COM1 or COM2 po rt as described in

Figure 1–16:.

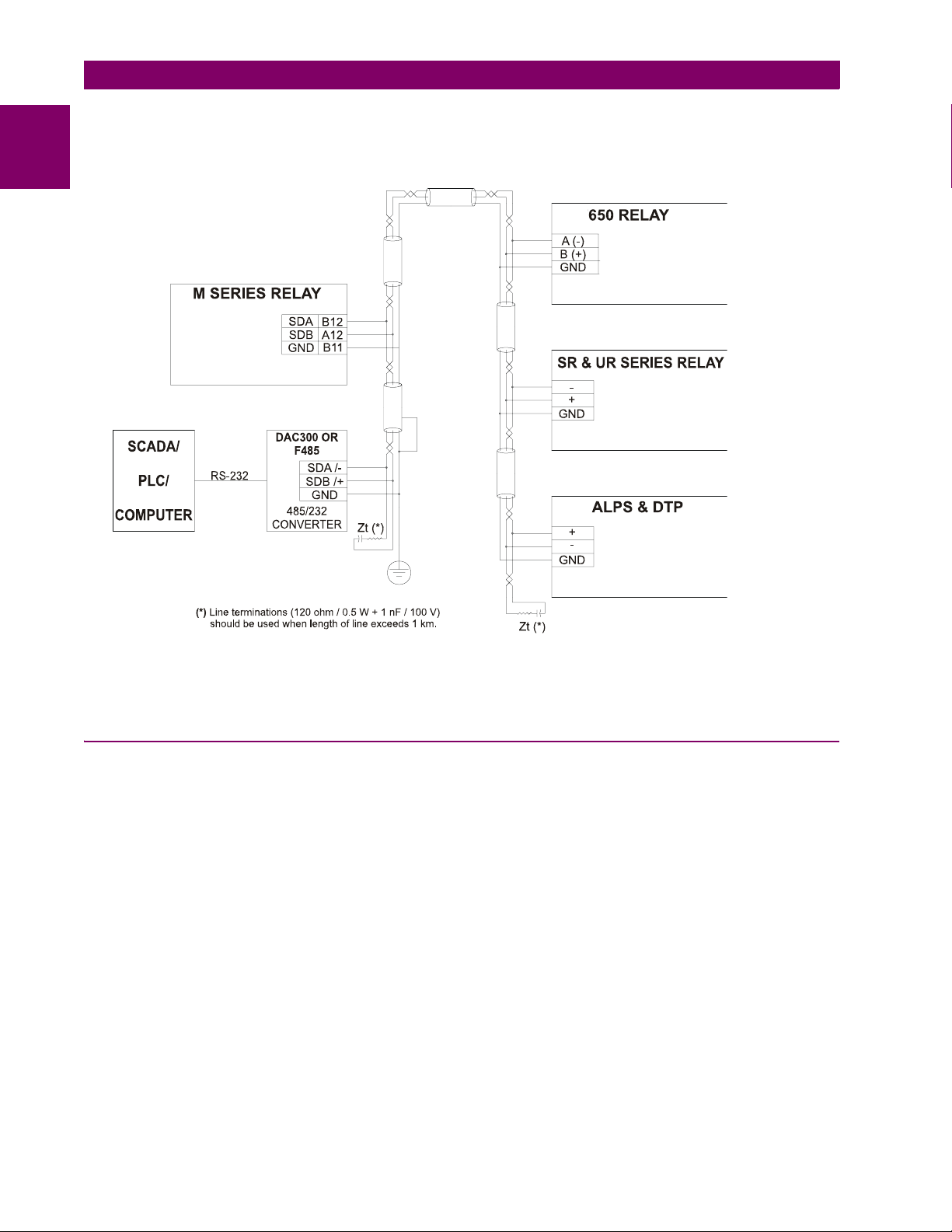

To communicate through the W650 rear RS485 port from a PC RS232 port, the GE Multilin RS232/RS485 converter box is

required. This device (catalog number F485) connects to the computer using a “straight-through” serial cable. A shi elded

twisted-pair (20, 22 or 24 AWG according to American standards; 0.25, 0.34 or 0.5 mm2 according to European standards)

connects the F485 converter to the W650 rear communication port.

In order to minimize communication errors that could be caus ed by external noise, it is recommended to use a shi elded

twist pair. In order to avoid loops where external currents could flow, the cabl e shield must be grounded only at one end.

The converter box (-, +, GND) terminals are connected to the relay (SDA, SDB, GND) terminals respectively. For long

communications cables (longer than 1 km), the RS485 circuit must be terminated in an RC network (i.e. 120 ohm, 1 nF).

This circuit is shown on Figure 1–17: RS485 CONNECTION FOR 650 UNITS, associated to text Zt(*).

1

Figure 1–16: RELAY- PC CONNECTION FOR RS232 FRONT PORT

To minimize errors from noise, th e use of shielded twisted pair wire is recommended. For correct operation, po larity must

be respected, although a different polarity will not damage the unit. For instance, the relays must be connected with all

RS485 SDA terminals connected together, and all SDB terminals connected together. This may result confusing

sometimes, as the RS485 standard refers only to terminals named “A” and “B”, although many devices use terminals

named “+” and “-“.

As a general rule, terminals “A” should be connected to terminals “-“, and terminals “B” to “+”. The GND terminal should be

connected to the common wire inside the shield, when provi ded. Otherwise, it should be connected to the shield. Each

relay should also be daisy chained to the next one in the link. A maximum of 32 relays can be connected in thi s manner

without exceeding driver capability. For larger systems, additional serial channels must be added. It is also possible to use

commercially available repeaters to increase the number of relays on a single channel to more th an 32. Do not use other

connection configurations different to the recommended.

GEK-113032A W650 Wind Generator Protection System 1-17

Page 28

1.4 W650 HARDWARE 1 GETTING STARTED

Lightning strikes and ground surge currents can cause large mo mentary voltage differences between remote ends of the

communication link. For this reason, surge protection devices are internally provided. To ensure maximum reliability, all

1

equipment should have similar transient protection devices installed.

Figure 1–17: RS485 CONNECTION FOR 650 UNITS

To comunícate through theW650 rear Ethernet port from a PC a crossover cable is required. If the connection is

performedthrough a hub or a switch, a direct Ethernet cable is required.

1.4.3 FACEPLATE DISPLAY

All messages are displayed on a 20x4 character LCD display. An optional graphic display is also available. Messages are

displayed in different languages according to selected model.

1-18 W650 Wind Generator Protection System GEK-113032A

Page 29

1 GETTING STARTED 1.4 W650 HARDWARE

1.4.4 MAINTENANCE

W650 requires a minimum amount of maintenance when it is commissioned into service.W650 is a microprocessor based

relay and its characteristics do not change over time. As such no further functional tests are required. However, it is

recommended that maintenance on theW650 be scheduled with other system maintenance. The maintenance may involve

the following:

In-service maintenance:

1. Visual verification of the analog values integrity such as voltage and current (in comparison to other devices on the

corresponding system).

2. Visual verification of active alarms, relay display messages and LED indications.

3. Visual inspection for any damage, corrosion, dust or loose wires.

4. Event recorder file download with further event analysis.

Out-of-service maintenance:

1. Check wiring connections for firmness.

2. Analog values (current, voltages, analog inputs) injection test and metering accuracy verification. Calibrated test

equipment is required.

3. Protection elements setpoints verification (analog values injection or visua l verification of setting file entries against

relay settings schedule).

4. Contact inputs and outputs verification. This test can be conducted by direct change of state forcing or as part of the

system functional testing.

5. Visual inspection for any damage, corrosion or dust.

6. Event recorder file download with further events analysis.

1

Unscheduled maintenance such as during a disturbance causing system interruption:

1. View the event recorder and oscillography or fault report for correct operation of inputs, outputs and elements.

If it is concluded that the relay or one of its modules is of concern, contact GE Multilin or one of its representative for prompt

service.

GEK-113032A W650 Wind Generator Protection System 1-19

Page 30

1

1.4 W650 HARDWARE 1 GETTING STARTED

1-20 W650 Wind Generator Protection System GEK-113032A

Page 31

2 PRODUCT DESCRIPTION 2.1 OVERVIEW

2 PRODUCT DESCRIPTION 2.1OVERVIEW 2.1.1 W650 OVERVIEW

The modular W650 unit has been designed as a comprehensive generator controller specially adapted to wind turbine

generators. Based on the state of the art 650 family, it utilizes modern 32 bit processor platform to provide a complete

solution not only for the needs of present systems but also ready for the future. W650 simplifies the design of systems in

wind turbine generation due to the complete set of protection, measurement, control and recording functions. Maintenance

is eased thanks to the modular design wherea s cost is scalabl e de pending on th e options to allow a cost effective solution

from medium to large size generators.

The main features of W650 devices include:

• Directional overcurrent protection for phases, neutral, ground and sensitive ground

• High Speed Under and overvoltage protection

• Neutral Overvoltage

• Voltage Unbalance

• Under and overfrequency protection

• Autorecloser

• Metering

• Oscillography registers, fault reports, data logger

• Bay control (open/close commands, etc.)

• Bay mimic.

• Communications (RS232/RS485/CAN/Ethernet)

2

GEK-113032A W650 Wind Generator Protection System 2-1

Page 32

2.1 OVERVIEW 2 PRODUCT DESCRIPTION

• Fully programmable front buttons, 15 LED’s and input/output contacts

Figure 2–1: FUNCTIONAL BLOCK DIAGRAM

2

2-2 W650 Wind Generator Protection Syst em GEK-113032A

Page 33

2 PRODUCT DESCRIPTION 2.2 SUMMARY

2.2SUMMARY

2.2.1 ANSI DEVICE NUMBERS AND FUNCTIONS

DEVICE NUMBER FUNCTION

27P (4) Phase Undervoltage

27X (3) Auxiliary Undervoltage

32 (4) Directional Power

46 (3) Negative Sequence Time Overcurrent

50G (3)

50N (3) Neutral Instantaneous Overcurrent (calculated from the phase currents)

50P (6) Phase Instantaneous Overcurrent (two elements, High and Low)

50SG (3)

51G (3)

51N (3) Neutral Time Overcurrent (calculated from the phase currents)

51P (6) Phase Time Overcurrent with Voltage Restraint (two elements, High and Low)

51SG (3)

59N (6) Neutral Overvoltage (two elements, High and Low)

59P (4) Phase Overvoltage

59X (3) Auxiliary Overvoltage

60V (3) Voltage Unbalance

67P (3) Phase Directional

67N (3) Neutral directional

67G (3) Ground Directional

67SG (3) Sensitive Ground Directional

79 (1) Autoreclose (Four shot recloser)

810 (4) Overfrequency

81U (4) Underfrequency

50BF (1) Breaker Failure

VTFF (1) VT Fuse Failure

Ground Instantaneous Overcurrent (measured from 4

Ground Instantaneous Overcurrent for sensitive ground systems (measured from 5

transformer)

Ground Time Overcurrent (measured from 4

Ground Time Overcurrent for sensitive ground systems (measured from 5

th

th

current transformer)

current transformer)

th

current

th

current transformer)

2

GEK-113032A W650 Wind Generator Protection System 2-3

Page 34

2.2 SUMMARY 2 PRODUCT DESCRIPTION

OTHER DEVICE FUNCTIONS

INPUTS/OUTPUTS METERING COMMUNICATIONS

9 Analog Inputs: 5 current inputs (3 for phases,

1 for ground, 1 for sensitive ground), 4 voltage

inputs (3 for phases, 1 for auxiliary voltage)

Digital Programmable Contact Inputs (up to

64)

Digital Programmable Contact Outputs (up to

2

16)

32 Latched Virtual Inputs

32 Self-Reset Virtual Inputs

Virtual Outputs (up to 512) Frequency ModBus User Map

Tripping and closing circuit supervision Sequence components of currents and

Remote Inputs/Outputs (GSSE messages) CANopen protocol

USER INTERFACE RECORDS OTHERS

Alphanumerical display (4x20) Data Logger

Graphic display (16 x 40) Demand Breaker Control

User Programmable LEDs (15) Event Recorder (up to 128 configurable

User Programmable Keys (up to 5) Fault Locator and Fault report (up to 10

Easy menu management thanks to shuttle key Oscillography (up to 20 records) Settings Groups (up to 4)

Configurable One-Line Diagram (Graphic

model only)

Phasor Diagram (available in EnerVista 650

Setup)

Metering Current for phases, ground and

sensitive ground inputs

Voltages phase to phase and phase to

ground

Real, Reactive and Apparent Power and

Power Factor

Three Phase Energy IEC 870-5-104

voltages

events)

records)

Snapshot Events (up to 479) Operations (up to 24)

Front RS232 port, Two rear RS485/

fibre optic ports, 10/100 TX and 100

FX Mbps Ethernet port

ModBus Communications RTU and

over TCP/IP

DNP Multimaster (3.0 Level 2)

IEC 61850

Breaking Arcing Current (I

IRIG-B synchronization/SNTP

Logic Equations (PLC Editor)

Web Server Application

2

t)

2-4 W650 Wind Generator Protection Syst em GEK-113032A

Page 35

2 PRODUCT DESCRIPTION 2.3 ORDERING CODE

2.3ORDERING CODE

W650 units are supplied as ½ 19” rack, 6 units high, containing the followi ng modules: power supply, CPU, I/O modules,

communication modules. The required information to completely define an W650 model is shown on Table 2–1:

Table 2–1: ORDERING CODE

W650 - - - F - G - - - - - DESCRIPTION

B Basic display (4x20 characters)

M Graphic display (240x128 pixels)

REAR SERIAL COMMUNICATIONS BOARD 1

F None

A Redundant RS485

P Redundant plastic fiber optic

G Redundant glass fiber optic

X Redundant RS485 + fiber Can port (CANopen)

Y Redundant plastic fiber optic + fiber Can port (CANopen)

Z Redundant glass fiber optic + fiber Can port (CANopen)

C CableCan port (CANopen)

M Cable can port (CANopen)+RS485

REAR ETHERNET COMMUNICATIONS BOARD 2

B 10/100 Base TX

C 10/100 Base TX + 100 Base FX

D 10/100 Base TX + Redundant 100 Base FX

E Redundant 10/100 Base TX

I/O BOARD IN SLOT F

1 16 Digital Inputs + 8 Outputs

2 8 Digital Inputs + 8 Outputs + 2 trip/close circuit supervision

4 32 Digital Inputs

5 16 Digital Inputs + 8 Analog Inputs

0 None

1 16 Digital Inputs + 8 Outputs

4 32 Digital Inputs (see Note 1)

5 16 Digital Inputs + 8 Analog Inputs (See Note 1)

LO 24-48 Vdc (range 19.2 – 57.6)

HI 110-250 Vdc (range 88 – 300)

LOR Redundant LO

HIR Redundant HI

- Without IEC 61850 protocol

6 IEC 61850

circuits

I/O BOARD IN SLOT G

AUXILIARY VOLTAGE

120-230 Vac (range 96 – 250)

COMMUNICATION PROTOCOL

ENVIRONMENTAL PROTECTION

- Without Harsh (Chemical) Environment Conformal Coating

H Harsh (Chemical) Environment Conformal Coating

2

Notes:

(1) The digit selected for option G must be equal or higher than the digit selected for option F:

W650***F1G5*****: is a valid selection W650***F5G1*****: is an invalid selection

As exceptions to this rule, 0 is always available for option G, and F2G1 is also a valid selection.

GEK-113032A W650 Wind Generator Protection System 2-5

Page 36

2.4 TECHNICAL SPECIFICATIONS 2 PRODUCT DESCRIPTION

2.4TECHNICAL SPECIFICATIONS

NOTE: TECHNICAL SPECIFICA TIONS ARE SUBJECT T O CHANGE WITHOUT NOTICE

2.4.1 PROTECTION ELEMENTS

Phase and ground units use as operation magnitude the current value received by the unit in current inputs, while the

neutral unit uses the calculated current value fro m the three ph ase currents.

2

The isolated ground unit will be used only fo r those applications where the neutral is comp letely isolated, and it uses the

fifth CT of the unit. This CT has a sensitivity that is 10 times higher than the universal model (connected to 1A or 5A

transformers). Therefore, it does not admit such a high permanent overload.

2.4.1.1 PHASE TIME OVERCURRENT (51PH/51PL)

Current Input Phasor (without harmonics) or RMS

Rated current For connection to 1 or 5 A CTs.

Pickup level 0.05 to 160.00 A in steps of 0.01 A

Dropout level 98% of the pickup level

Level Accuracy

Curve Shapes IEEE extremely / very / moderately inverse

Curve Multiplier (Time Dial) 0.00 to 900.00 s in steps of 0.01 s

Reset type Instantaneous or time delayed according to IEEE

Timing accuracy Operate at > 1.03 times the pickup ±3% of operate time or

Voltage restraint Selectable by setting

Saturation Level 48 times the pickup level

Snapshot Events Selectable by setting

±0.5% of the reading ± 10 mA from 0.05 to 10 A

±1.5% of the reading for higher values.

IEC A/B/C/long-time inverse/short time inverse curve

IAC extremely / very / normally / moderately inverse

ANSI extremely / very / normally / moderately inverse

2

t

I

Definite time

Rectifier curve

FlexCurve™ A/B/C/D user curve

30 ms. (whichever is greater)

2.4.1.2 GROUND TIME OVERCURRENT (51G)

Current Input Phasor (without harmonics) or RMS

Rated current For connection to 1 or 5 A CTs.

Pickup level 0.05 to 160.00 A in steps of 0.01 A

Dropout level 98% of the pickup level

Level Accuracy

2-6 W650 Wind Generator Protection Syst em GEK-113032A

±0.5% of the reading ± 10 mA from 0.05 to 10 A

±1.5% of the reading for higher values.

Page 37

2 PRODUCT DESCRIPTION 2.4 TECHNICAL SPECIFICATIONS

Curve Shapes IEEE extremely / very / moderately inverse

IEC A/B/C/long-time inverse/short time inverse curve

IAC extremely / very / normally / moderately inverse

ANSI extremely / very / normally / moderately inverse

2

I

t

Definite time

Rectifier curve

FlexCurve™ A/B/C/D user curve

Curve Multiplier (Time Dial) 0.00 to 900.00 s in steps of 0.01 s

Reset type Instantaneous or time delayed according to IEEE

Timing accuracy Operate at > 1.03 times the pickup ±3% of operate time or

30 ms. (whichever is greater)

Saturation Level 48 times the pickup level

Snapshot Events Selectable by setting

2.4.1.3 NEUTRAL TIME OVERCURRENT (51N)

Current Input Fundamental Phasor (without harmonics)

Pickup level 0.05 to 160.00 A in steps of 0.01 A

Dropout level 98% of the pickup level

Level Accuracy

Curve Shapes IEEE extremely / very / moderately inverse

Curve Multiplier (Time Dial) 0.00 to 900.00 s in steps of 0.01 s

Reset type Instantaneous or time delayed according to IEEE

Timing accuracy Operate at > 1.03 times the pickup ±3% of operate time

Saturation Level 48 times the pickup level

Snapshot Events Selectable by setting

±0.5% of the reading ± 10 mA from 0.05 to 10 A

±1.5% of the reading for higher values.

IEC A/B/C/long-time inverse/short time inverse curve

IAC extremely / very / normally / moderately inverse

ANSI extremely / very / normally / moderately inverse

2

I

t

Definite time

Rectifier curve

FlexCurve™ A/B/C/D user curve

or 30 ms. (whichever is greater)

2

GEK-113032A W650 Wind Generator Protection System 2-7

Page 38

2.4 TECHNICAL SPECIFICATIONS 2 PRODUCT DESCRIPTION

2.4.1.4 SENSITIVE GROUND TIME OVERCURRENT (51SG)

Current Input Phasor (without harmonics) or RMS

Rated current For connection to 1 or 5 A CTs.

Pickup level 0.005 to 16.000 A in steps of 0.001 A

Dropout level 98% of the pickup level

Level Accuracy

2

Curve Shapes IEEE extremely / very / moderately inverse

Curve Multiplier (Time Dial) 0.00 to 900.00 s in steps of 0.01 s

Reset type Instantaneous or time delayed according to IEEE

Timing accuracy Operate at > 1.03 times the pickup ±3% of operate time

Saturation Level 48 times the pickup level

Snapshot Events Selectable by setting

±1.5% of the reading ± 1 mA from 0.005 to 16 A

IEC A/B/C/long-time inverse/short time inverse curve

IAC extremely / very / normally / moderately inverse

ANSI extremely / very / normally / moderately inverse

2

I

t

Definite time

Rectifier curve

FlexCurve™ A/B/C/D user curve

or 30 ms. (whichever is greater)

2.4.1.5 PHASE AND GROUND INSTANTANEOUS OVERCURRENT (50PH/50PL/50G)

Current Input Phasor (without harmonics) or RMS

Rated current For connection to 1 or 5 A CTs.

Pickup level 0.05 to 160.00 A in steps of 0.01 A

Dropout level 97% of the pickup level

Level Accuracy

Overreach < 2%

Trip delay 0.00 to 900.00 s. in steps of 0.01 s.

Reset delay 0.00 to 900.00 s. in steps of 0.01 s.

Operate time 20 ms at 3 x Pickup at 50 Hz, typically

Timing accuracy ±3% of operate time or 30 ms. (whichever is greater)

Snapshot Events Selectable by setting

±0.5% of the reading ± 10 mA from 0.05 to 10 A

±1.5% of the reading for higher values

2-8 W650 Wind Generator Protection Syst em GEK-113032A

Page 39

2 PRODUCT DESCRIPTION 2.4 TECHNICAL SPECIFICATIONS

2.4.1.6 NEUTRAL INSTANTANEOUS OVERCURRENT (50N)

Current Input Fundamental Phasor (without harmonics)

Pickup level 0.05 to 160.00 A in steps of 0.01 A

Dropout level 97% of the pickup level

Level Accuracy

Overreach < 2%

Trip delay 0.00 to 900.00 s. in steps of 0.01 s.

Reset delay 0.00 to 900.00 s. in steps of 0.01 s.

Operate time 20 ms at 3 x Pickup at 50 Hz, typically

Timing accuracy ±3% of operate time or 30 ms. (whichever is greater)

Snapshot Events Selectable by setting

2.4.1.7 SENSITIVE GROUND INSTANTANEOUS OVERCURRENT (50SG)

Current Input Phasor (without harmonics) or RMS

Rated current For connection to 1 or 5 A CTs.

Pickup level 0.005 to 16.000 A in steps of 0.001 A

Dropout level 97% of the pickup level

Level Accuracy

Overreach < 2%

Trip delay 0.00 to 900.00 s. in steps of 0.01 s.

Reset delay 0.00 to 900.00 s. in steps of 0.01 s.

Operate time 20 ms at 3 x Pickup at 50 Hz

Timing accuracy ±3% of operate time or 30 ms. (whichever is greater)

Snapshot Events Selectable by setting

±0.5% of the reading ± 10 mA from 0.05 to 10 A

±1.5% of the reading for higher values

±1.5% of the reading ± 1 mA from 0.005 to 16 A

2

GEK-113032A W650 Wind Generator Protection System 2-9

Page 40

2.4 TECHNICAL SPECIFICATIONS 2 PRODUCT DESCRIPTION

2.4.1.8 NEGATIVE SEQUENCE CURRENT (46)

Current Input Fundamental Phasor (without harmonics)

Pickup level 0.05 to 160.0 A in steps of 0.01 A

Dropout level 98% of the pickup level

Level Accuracy

2

Curve Shapes IEEE extremely / very / moderately inverse

Curve Multiplier (Time Dial) 0.00 to 900.00 s in steps of 0.01 s

Reset type Instantaneous or time delayed according to IEEE

Timing accuracy Operate at > 1.03 times the pickup ±3% of operate time

Saturation Level 48 times the pickup level

Snapshot Events Selectable by setting

±0.5% of the reading ± 10 mA from 0.05 to 10 A

±1.5% of the reading for higher values

IEC A/B/C/long-time inverse/short time inverse curve

IAC extremely / very / normally / moderately inverse

ANSI extremely / very / normally / moderately inverse

2

I

t

Definite time

Rectifier curve

FlexCurve™ A/B/C/D user curve

or 30 ms. (whichever is greater)

2.4.1.9 PHASE DIRECTIONAL (67P)

Directionality Forward and reverse selectable by setting

Polarizing Quadrature Voltage:

ABC seq: Phase A (VBC), Phase B (VCA), Phase C

(VAB)

ACB seq: Phase A (VCB), Phase B (VAC), Phase C

(VBA)

Polarizing voltage threshold 0 to 850 V ac in steps of 1 V

Characteristic angle -90º to +90º in steps of 1º

Block Logic Permission or Block selectable by setting

Angle accuracy

Operate time <30ms, typically

2.4.1.10 GROUND DIRECTIONAL (67G)

Directionality Forward and reverse selectable by setting

Polarizing Voltage, current, dual

Polarizing V o ltage VN (measured or calculated, selected by setting)

Polarizing Current

Operating Current

Polarizing Voltage threshold 0 to 500 Vac in steps of 1 V

Polarizing Current threshold 0.005 A

±2º for I>0.1 A and V>5 Vac

Isg (measured from 5

Ig (measured from 4

th

current transformer)

th

current transformer)

2-10 W650 Wind Generator Protection System GEK-113032A

Page 41

2 PRODUCT DESCRIPTION 2.4 TECHNICAL SPECIFICATIONS

Characteristic angle -90º to +90º in steps of 1º

Block Logic Permission or Block selectable by setting

Angle accuracy

Operate time <30ms, typically

±2º for I>0.1 A and V>5 Vac

2.4.1.11 NEUTRAL DIRECTIONAL (67N)

Directionality Forward and reverse selectable by setting

Polarizing Voltage, current, dual

Polarizing V o ltage V

Polarizing Current

Operating Current I

Polarizing Voltage threshold 0 to 500 Vac in steps of 1 V

Polarizing Current threshold 0.005 A

Characteristic angle -90º to +90º in steps of 1º

Block Logic Permission or Block selectable by setting

Angle accuracy

Operate time <30ms, typically

2.4.1.12 SENSITIVE GROUND DIRECTIONAL (67SG)

Directionality Forward and reverse selectable by setting

Polarizing Voltage

Polarizing V o ltage V

Operating Current

Polarizing Voltage threshold 0 to 500 Vac in steps of 1 V

Characteristic angle -90º to +90º in steps of 1º

Block Logic Permission or Block selectable by setting

Angle accuracy

Operate time <30ms, typically

(measured or calculated, selected by setting)

N

th

Isg (measured from 5

N

±2º for I>0.1 A and V>5 Vac

(measured or calculated, selected by setting)

N

Isg (measured from 5

±2º for I>0.1 A and V>5 Vac

current transformer)

th

current transformer)

2

2.4.1.13 PHASE OVERVOLTAGE (59P)

Voltage Input Fundamental Phasor (without harmonics) of phase-to-

phase voltages

Pickup level 3 to 850 in steps of 1 V

Dropout level 97% of the pickup level

Level Accuracy

Trip delay 0.00 to 900.00 s. in steps of 0.01 s.

Reset delay 0.00 to 900.00 s. in steps of 0.01 s.

Timing accuracy ±3.5% of op erate time or 30 ms. (whichever is greater)

Logic Any/Two/All phases logic selectable by setting

GEK-113032A W650 Wind Generator Protection System 2-11

±1% reading ±0.1% Full Scale from 10 to 500 V

Page 42

2.4 TECHNICAL SPECIFICATIONS 2 PRODUCT DESCRIPTION

Snapshot Events Selectable by setting

2.4.1.14 PHASE UNDERVOLTAGE (27P)

Voltage Input Fundamental Phasor of phase-to-ground or phase-to-

2

Pickup level 3 to 850 in steps of 1 V

Dropout level 103% of the pickup leve l

Level accuracy

Curve Shapes Fixed time or inverse curve

Reset type Instantaneous

Curve Multiplier (Time Dial) 0.00 to 900.00 s. in steps of 0.01 s.

Timing accuracy ±3.5% of operate time or 30 ms. (whichever is greater)

Minimum Voltage Threshold 0 to 850 in steps of 1 V

Logic Any/Two/All phases logic selectable by setting

Supervised by Breaker Selectable by setting

Snapshot Events Selectable by setting

phase voltages (selectable by setting)

±1% reading ±0.1% Full Scale from 10 to 500 V

2.4.1.15 NEUTRAL OVERVOLTAGE (59NH/59NL)

Voltage Input Fundamental Phasor of the neutral voltage

Pickup level 3 to 500 in steps of 1 V

Dropout level 97% of the pickup level

Level accuracy

Trip delay 0.00 to 900.00 s. in steps of 0.01 s

Reset delay 0.00 to 900.00 s. in steps of 0.01 s

Timing accuracy ±3.5% of operate time or 30 ms. (whichever is greater)

Snapshot Events Selectable by setting

2.4.1.16 AUXILIARY OVERVOLTAGE (59X)

Voltage Input Fundamental Phasor

Pickup level 3 to 500 in steps of 1 V

Dropout level 97% of the pickup level

Level accuracy

Trip delay 0.00 to 900.00 s. in steps of 0.01 s

Reset delay 0.00 to 900.00 s. in steps of 0.01 s

Timing accuracy ±3.5% of operate time or 30 ms. (whichever is greater)

Snapshot Events Selectable by setting

±1% reading ±0.1% Full Scale from 10 to 500 V

±1% reading ±0.1% Full Scale from 10 to 500V

2-12 W650 Wind Generator Protection System GEK-113032A

Page 43

2 PRODUCT DESCRIPTION 2.4 TECHNICAL SPECIFICATIONS

2.4.1.17 AUXILIARY UNDERVOLTAGE (27X)

Voltage Input Fundamental Phasor

Pickup level 3 to 500 V in steps of 1 V

Dropout level 97% of the pickup level

Level accuracy

Curve Shapes Fixed time or inverse curve

Reset type Instantaneous

Curve Multiplier (Time Dial) 0.00 to 900.00 s. in steps of 0.01 s

Timing accuracy ±3.5% of operate time or 30 ms. (whichever is greater)

Snapshot Events Selectable by setting

2.4.1.18 UNDERFREQUENCY (81U)

Pickup level 20.00 to 65.00 Hz in steps of 0.01 Hz

Dropout level Pickup + 0.03 Hz