GE Multilin MM300 Quick Start Manual

LISTED

52TL

IND.CONT. EQ.

E83849

GE

Grid Solutions

MM300

Motor Management System

MM300 Revision: 1.6x

Manual P/N: 1601-9022-AC

Manual Order Code: GEK-113336L

Quick Start Guide

*1601-9022-AC*

© 2016 GE Multilin Inc. All rights reserved.

The MM300 Motor Management System QuickStart Guide for revision 1.6x.

MM300 Motor Management System, EnerVista, EnerVista Launchpad, and EnerVista

MM300 Setup are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin Inc. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-9022-AC (April 2016)

Storage

Store the unit indoors in a cool, dry place. If possible, store in the original packaging. Follow

the storage temperature range outlined in the Specifications.

To avoid deterioration of electrolytic capacitors, power up units that are stored in a deenergized state once per year, for one hour continuously.

Warranty

For products shipped as of 1 October 2013, GE warrants most of its GE manufactured

products for 10 years. For warranty details including any limitations and disclaimers, see

our Terms and Conditions at

For products shipped before 1 October 2013, the standard 24-month warranty applies.

https://www.gegridsolutions.com/multilin/warranty.htm

Repairs

The firmware and software can be upgraded without return of the device to the factory.

For issues not solved by troubleshooting, the process to return the device to the factory for

repair is as follows:

• Contact a GE Grid Solutions Technical Support Center. Contact information is found in

the first chapter.

• Obtain a Return Materials Authorization (RMA) number from the Technical Support

Center.

• Verify that the RMA and Commercial Invoice received have the correct information.

• Tightly pack the unit in a box with bubble wrap, foam material, or styrofoam inserts or

packaging peanuts to cushion the item(s). You may also use double boxing whereby

you place the box in a larger box that contains at least 5 cm of cushioning material.

• Ship the unit by courier or freight forwarder, along with the Commercial Invoice and

RMA, to the factory.

Customers are responsible for shipping costs to the factory, regardless of whether the

unit is under warranty.

• Fax a copy of the shipping information to the GE Grid Solutions service department .

Use the detailed return procedure outlined at

https://www.gegridsolutions.com/multilin/support/ret_proc.htm

The current warranty and return information are outlined at

https://www.gegridsolutions.com/multilin/warranty.htm

This product cannot be disposed of as unsorted municipal waste in the European

Union. For proper recycling return this product to your supplier or a designated

collection point. For more information go to www.recyclethis.info.

TABLE OF CONTENTS

Table of Contents

OVERVIEW

Cautions and Warnings ....................................................................................................................... 3

Safety words and definitions......................................................................................................................3

General Safety Precautions - MM300.....................................................................................................3

For Further Assistance..........................................................................................................................4

INSTALLATION

Mechanical installation ........................................................................................................................1

Dimensions..........................................................................................................................................................1

Product identification .....................................................................................................................................2

Mounting ..............................................................................................................................................................2

Electrical installation .............................................................................................................................6

Module and terminal identification..........................................................................................................7

Full-voltage non-reversing starter ...........................................................................................................8

RS485 connections..........................................................................................................................................9

Phase current inputs (IO_A module) ..................................................................................................... 10

Phase voltage inputs (IO_B module).....................................................................................................12

Type IO_C module connections..............................................................................................................14

Type IO_D module connections .............................................................................................................15

Type IO_E module connections.............................................................................................................. 16

RTD sensor connections (IO_G module).............................................................................................. 16

Maintenance ...........................................................................................................................................17

In-service maintenance ............................................................................................................................. 17

Out-of-service maintenance....................................................................................................................18

Unscheduled maintenance (system interruption) ......................................................................... 18

Interfacing with the MM300.............................................................................................................18

MM300 graphical display pages............................................................................................................ 18

Introduction to the graphical control panel .....................................................................................20

Basic control panel....................................................................................................................................... 24

EnerVista MM300 Setup Software.................................................................................................25

Software requirements............................................................................................................................... 25

Troubleshooting the USB driver.............................................................................................................. 25

Installing the EnerVista MM300 Setup software............................................................................. 28

Upgrading the software.............................................................................................................................32

Connecting EnerVista MM300 Setup to the relay .................................................................32

Configuring serial communications ..................................................................................................... 32

Using the Quick Connect feature........................................................................................................... 33

Connecting to the relay.............................................................................................................................. 34

Working with setpoints and setpoint files.................................................................................35

Engaging a device......................................................................................................................................... 35

Entering setpoints .........................................................................................................................................35

File support....................................................................................................................................................... 36

Using setpoints files ..................................................................................................................................... 36

Downloading and saving setpoints files............................................................................................. 37

Adding setpoints files to the environment.........................................................................................37

Loading setpoints from a file ...................................................................................................................38

Uninstalling files and clearing data ...................................................................................................... 39

Upgrading relay firmware................................................................................................................39

Loading new relay firmware.................................................................................................................... 39

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE i

TABLE OF CONTENTS

ACTUAL VALUES

Actual values overview .........................................................................................................................1

SETPOINTS

Understanding setpoints......................................................................................................................1

Configuration setpoints ........................................................................................................................2

Motor setpoints................................................................................................................................................. 2

Current and voltage transformers........................................................................................................... 6

PROTECTION ELEMENTS

Thermal protection .................................................................................................................................1

Overload curve.................................................................................................................................................. 1

COMMUNICATIONS

Communications interfaces ...............................................................................................................1

SPECIFICATIONS

Protection specifications......................................................................................................................1

User interface specifications..............................................................................................................3

Metering and monitoring specifications.......................................................................................3

Control specifications............................................................................................................................4

Inputs specifications ..............................................................................................................................4

Outputs specifications...........................................................................................................................5

Power supply specifications...............................................................................................................6

Communications specifications .......................................................................................................6

Testing and certification.......................................................................................................................7

Physical specifications..........................................................................................................................8

Environmental specifications.............................................................................................................8

MM300 ORDER CODES

Example of an MM300 order code ..................................................................................................2

ii MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

GE

Grid Solutions

MM300 Motor Management System

Chapter 1: Overview

Overview

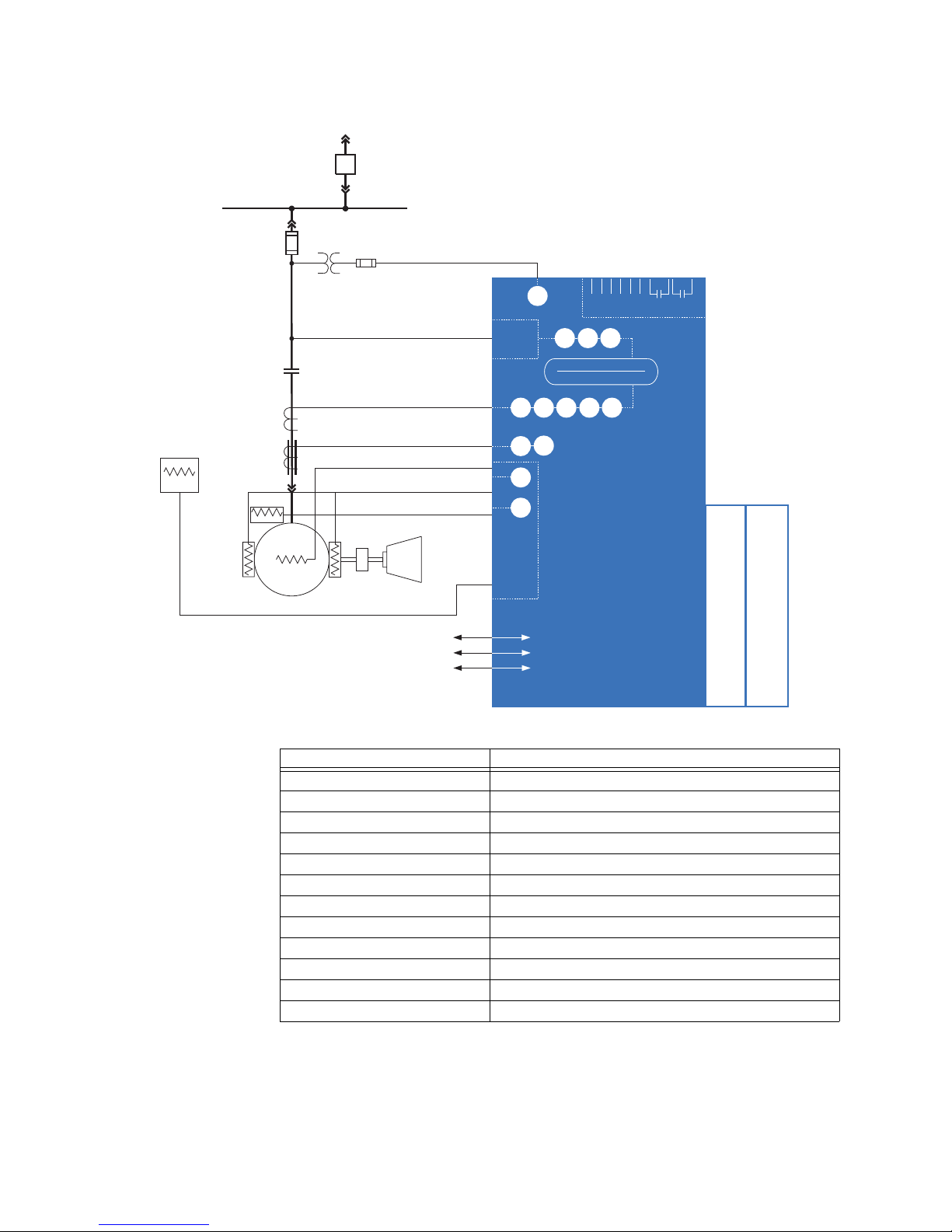

The MM300 is a modular motor protection and control system designed specifically for

low-voltage motor applications. The MM300 provides the following key benefits.

• Flexible protection, control, and communication options to suit any low-voltage motor

application.

• Small footprint designed specifically for IEC and NEMA MCC applications.

• Modular design reduces the number of spare components for maintenance and

testing.

• Integrated pushbuttons and LED indicators reduce external components and wiring.

• DIN rail and Panel Mounting.

• Multiple, simultaneous communication protocols allows simple integration into

monitoring and control systems.

• Optional basic control panel or graphical control panel interface provides local control

and access to system information.

• Automation FlexLogic™ for applications requiring more complex starter control, or

multi-starter scenarios with interlocking or programmable logic control.

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 1

CHAPTER 1: OVERVIEW

RS485 - Modbus RTU

Ethernet - Modbus TCP/IP

Profibus/DeviceNet

52

27

59 47

METERING

V, A, W, va r, VA , PF, Hz

27X

51R

49

37

66 46

50G

51G

49

MOTOR

LOAD

Stator RTDs

Bearing RTDs

Phase CT 3

Ground CT 1

Power Fuse

BUS

MM300

MOTOR MANAGEMENT SYSTEM

Temperature

Thermistor

Control PT

Contactor

Control

fuse

Direct voltage inputs

(690 V AC maximum)

Ambient air

RTD

Expansion module,

two cards per module,

maximum of two modules

38

Optional

three-phase

voltage

card

Options:

Six inputs & two form-A outputs (max 5 cards)

?

?

Three-phase voltage card (max 1 card)

Options:

Three RTDs - 100 ohm Platinum (max 2 cards)

?

?

Four form-C contact outputs (max 4 cards)

853739A2.CDR

Six inputs and two outputs (standard)

Optional RTD card

Table 1-1: MM300 protection functions

ANSI device Description

27X Undervoltage, auxiliary input

27 Undervoltage, three-phase

37 Undercurrent and underpower

38 Bearing temperature RTD

46 Current unbalance

47 Voltage phase reversal

49 Thermal overload

50G Ground instantaneous overcurrent

51G Ground time overcurrent

51R Locked/stalled rotor, mechanical jam

59 Overvoltage, three-phase

66 Starts per hour and time between starts

2 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

CHAPTER 1: OVERVIEW CAUTIONS AND WARNINGS

NOTE

Cautions and Warnings

Before attempting to install or use the device, review all safety indicators in this document

to help prevent injury, equipment damage, or downtime.

Safety words and definitions

The following symbols used in this document indicate the following conditions

DANGER:

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

IMPORTANT:

CAUTION:

NOTE:

CAUTION:

Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Indicates practices not related to personal injury.

General Safety Precautions - MM300

Failure to observe and follow the instructions provided in the equipment manual(s)

could cause irreversible damage to the equipment and could lead to property damage,

personal injury and/or death.

Before attempting to use the equipment, it is important that all danger and caution

indicators are reviewed.

If the equipment is used in a manner not specified by the manufacturer or functions

abnormally, proceed with caution. Otherwise, the protection provided by the

equipment may be impaired and can result in Impaired operation and injury.

Caution: Hazardous voltages can cause shock, burns or death.

Installation/service personnel must be familiar with general device test practices,

electrical awareness and safety precautions must be followed.

Before performing visual inspections, tests, or periodic maintenance on this device or

associated circuits, isolate or disconnect all hazardous live circuits and sources of

electric power.

Failure to shut equipment off prior to removing the power connections could expose

you to dangerous voltages causing injury or death.

All recommended equipment that should be grounded and must have a reliable and

un-compromised grounding path for safety purposes, protection against

electromagnetic interference and proper device operation.

Equipment grounds should be bonded together and connected to the facility’s main

ground system for primary power.

Keep all ground leads as short as possible.

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 3

FOR FURTHER ASSISTANCE CHAPTER 1: OVERVIEW

At all times, equipment ground terminal must be grounded during device operation

and service.

In addition to the safety precautions mentioned all electrical connections made must

respect the applicable local jurisdiction electrical code.

Before working on CTs, they must be short-circuited.

For Further Assistance

For product support, contact the information and call center as follows:

GE Grid Solutions

650 Markland Street

Markham, Ontario

Canada L6C 0M1

Worldwide telephone: +1 905 927 7070

Europe/Middle East/Africa telephone: +34 94 485 88 54

North America toll-free: 1 800 547 8629

Fax: +1 905 927 5098

Worldwide e-mail: multilin.tech@ge.com

Europe e-mail: multilin.tech.euro@ge.com

Website: http://www.gegridsolutions.com/multilin

4 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

GE

Grid Solutions

MM300 Motor Management System

Chapter 2: Installation

Mechanical installation

Installation

This section describes the mechanical installation of the MM300 system, including

dimensions for mounting and information on module withdrawal and insertion.

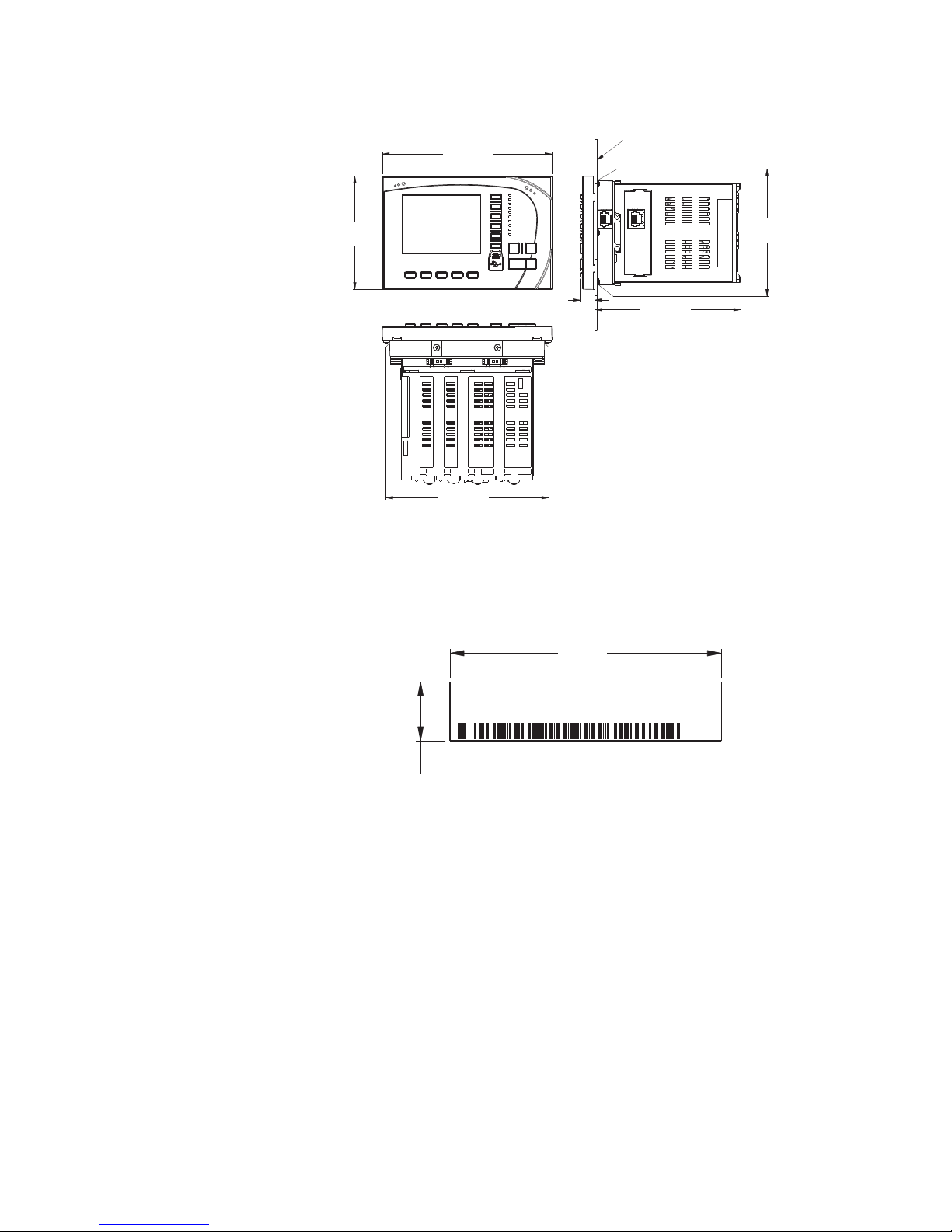

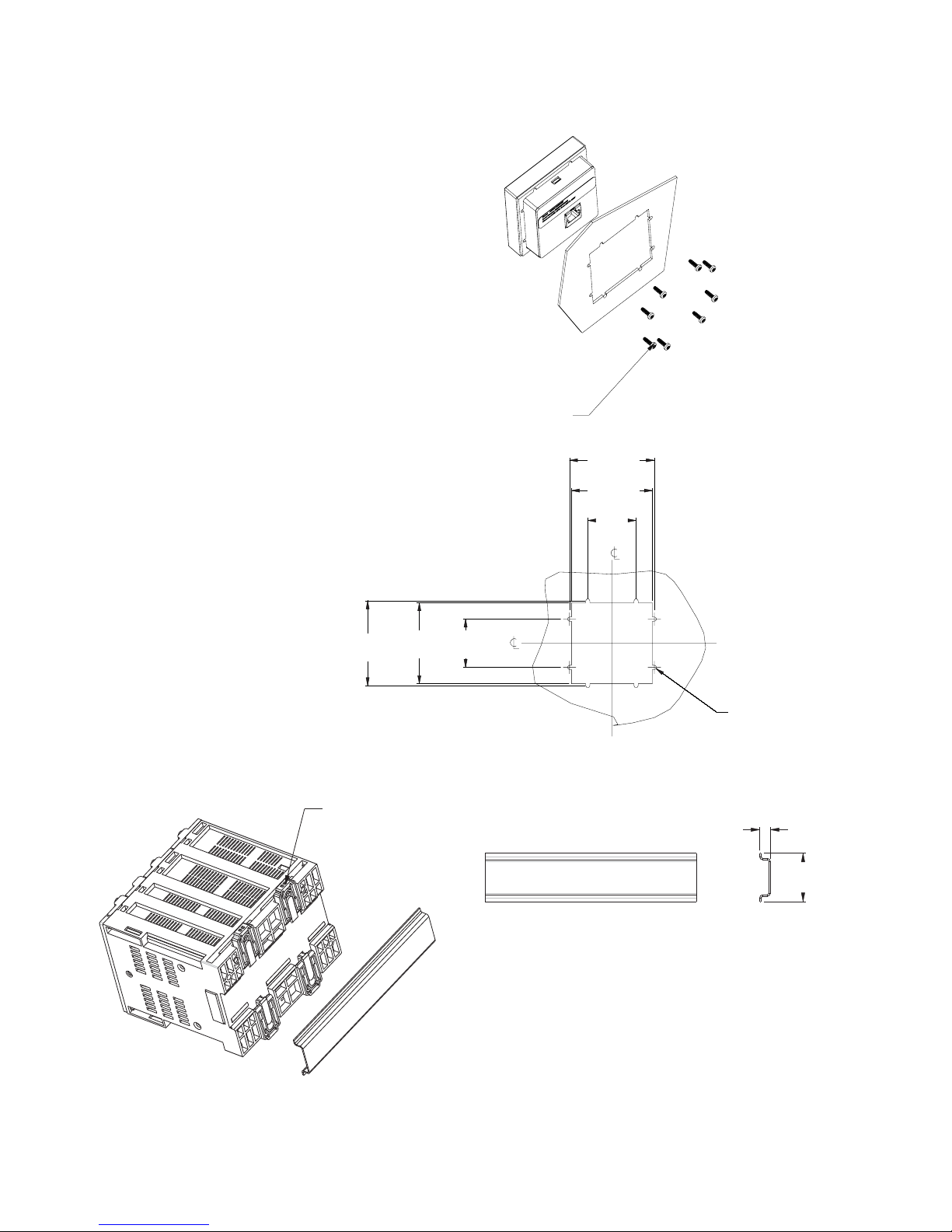

Dimensions

The MM300 is packaged in a modular arrangement.

The dimensions of the MM300 are shown below. Additional dimensions for mounting and

panel cutouts are shown in the following sections.

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 1

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

6.071”

(154,15 mm)

4.059”

(103,09 mm)

0.565”

(14,35 mm)

5.228”

(132,78 mm)

3.746”

(95,15 mm)

5.550”

(140,97 mm)

853724A1.CDR

PANEL

2.425”

(61.6 mm)

0.525”

(13.3 mm)

853748A1.CDR

Model:

Serial Number:

Firmware:

Mfg. Date:

Figure 2-1: MM300 dimensions

Product identification

The product identification label is located on the side panel of the MM300. This label

indicates the product model, serial number, firmware revision, and date of manufacture.

Figure 2-2: MM300 label

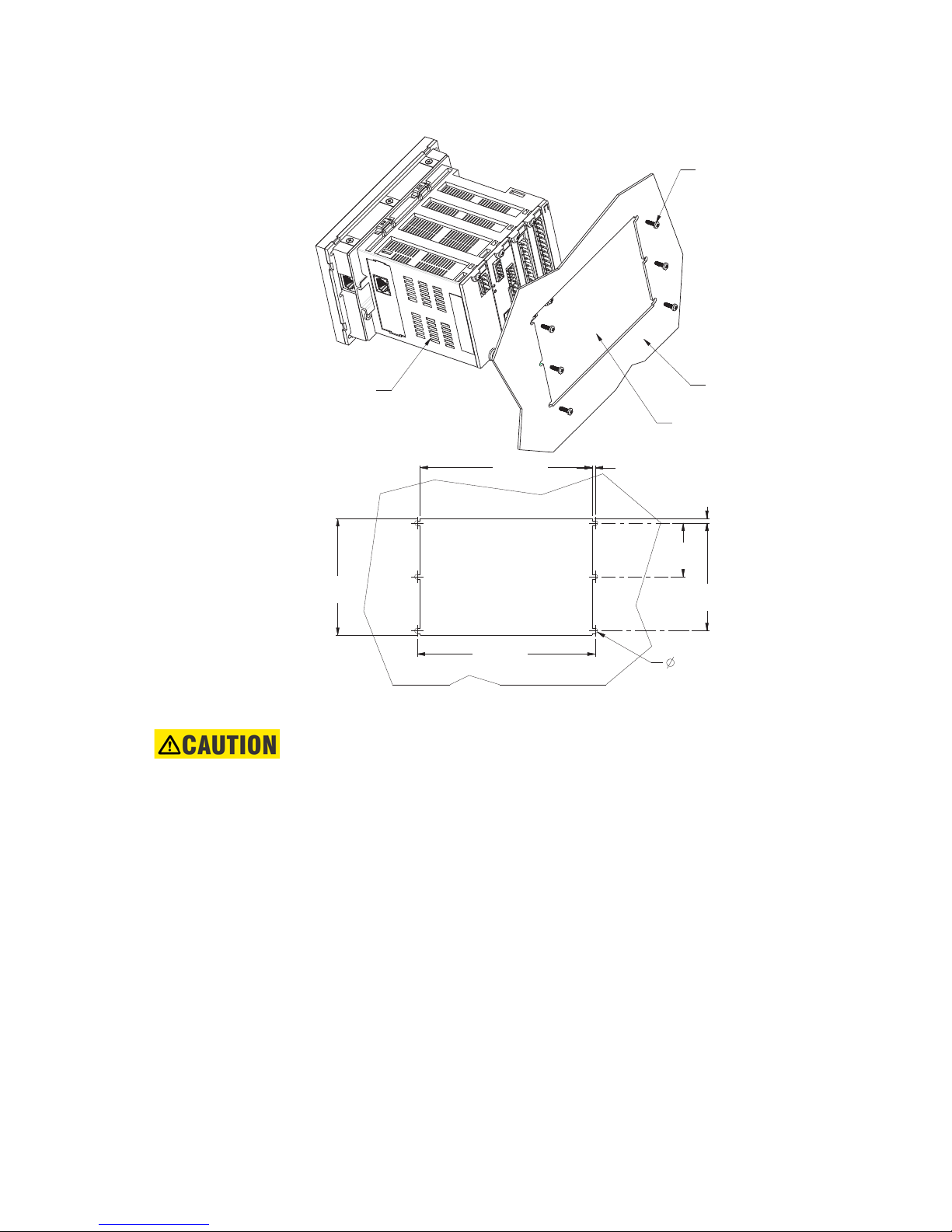

Mounting

The MM300 can be mounted three ways: standard panel mount, DIN rail mount , and screw

mount for high vibration environments.

The standard panel mount and cutout dimensions are illustrated below.

2 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

CHAPTER 2: INSTALLATION MECHANICAL INSTALLATION

#4 - 40x3/8in SELF-TAP PAN HD PHILIPS

QTY: 6 (SUPPLIED); GE PART NO. 1402-0017

TIGHTENING TORQUE: 8 lb-in

REAR OF PANEL

CUTOUT AND

MOUNTING HOLES

INSTALL RELAY

FROM FRONT

OF THE PANEL

3.775”

(95,89 mm)

5.580”

(141,73 mm)

0.105”

(2,67 mm)

0.138”

(3,49 mm)

3.500”

(88,90 mm)

0.130”

(3,30 mm)

(QTY: 6)

5.790”

(147,07 mm)

1.750”

(44,45 mm)

853725A1.CDR

Figure 2-3: Base Unit standard panel mounting and cutout dimensions

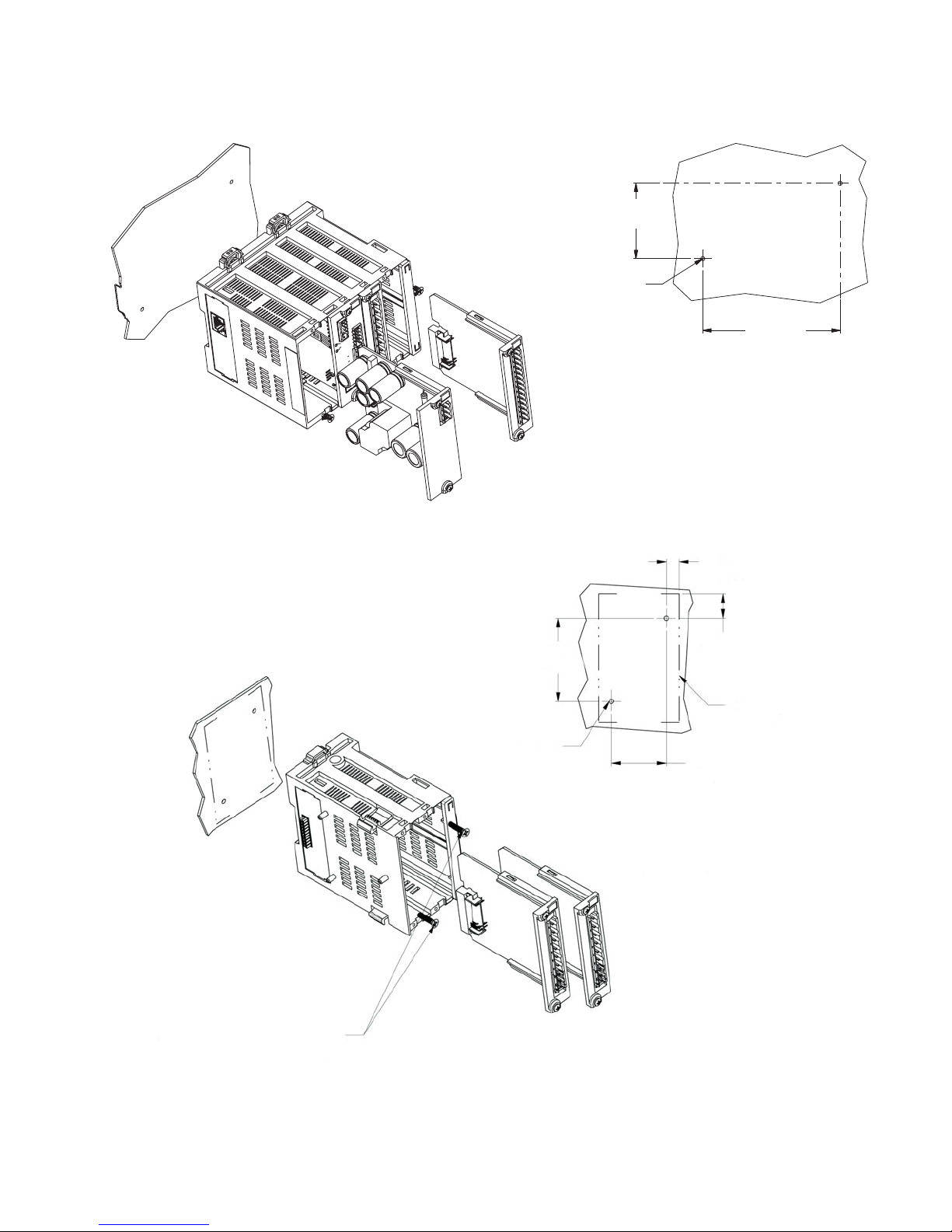

The DIN rail mounting is illustrated below. The DIN rail conforms to EN 50022.

CAUTION:

To avoid the potential for personal injury due to f ire hazards, ensure the unit is

mounted in a safe location and/or within an appropriate enclosure.

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 3

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

2.515"

63,88mm

[]

2.635"

66,93mm

[]

1.500"

38,10mm

[]

1.500"

38,10mm

[]

2.515"

63,88mm

[]

2.635"

66,93mm

[]

Ø

TypX8

.130"

3,30mm

[]

#4-40X3/8in SELF TAP PAN HD PHILIPS

QTY: 8; (SUPPLIED); GE PART# 1402-0017

TIGHTENING TORQUE: 7 lb-in

.

853825A1.cdr

SNAP-IN THE DIN CLIPS (QTY: 4)

FOR DIN RAIL MOUNTING

0.30”

(7,6 mm)

1.38”

(35,1 mm)

DIN 3 RAIL

853726A1.CDR

Figure 2-4: Basic Control Panel mounting and cutout dimensions

Figure 2-5: DIN rail mounting - Base and Expansion units

Screw mounts for high vibration environments are illustrated below.

4 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

CHAPTER 2: INSTALLATION MECHANICAL INSTALLATION

MEETS VIBRATION REQUIREMENT OF

IEC 60255 SEC 21.1, 21.2, & 21.3

2.250”

(57,15 mm)

#6 -32 THREADED HOLE

QTY: 2

4.100”

(104,14 mm)

853727A1.CDR

#6-32X1/2 FT FLAT HEAD PHIL ZINC

QTY: 2; (SUPPLIED); GE PART # 1406-0117

TIGHTENING TORQUE: 10 lb. in.

0.356”

[9.03 mm]

0.672”

[17.06 mm]

1.500”

[38.10 mm]

EXPANSION UNIT

OUTLINE

2.285”

[58.04 mm]

#6-32 THREADED HOLE

QTY: 2

853755A1.cdr

Figure 2-6: Base Unit screw mounting

Figure 2-7: Expansion Unit screw mounting

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 5

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

Expansion module

allows additional digital

inputs/outputs, RTDs, or

voltage inputs

Expansion module

to base unit with a single connector

•

•

•

I/O card includes:

two

contactor outputs

(form

-A)

six programmable inputs

single-phase VT input (60 to 300 V AC)

Optional three-phase

voltage module

RTDModule

with three RTD inputs

Three-phase and

residual ground CT

inputs

Optional TCP/IP

Ethernet

Core-balance ground CT input

RS485 communications

and thermistor input

Profibus or DeviceNet

Optional fieldbus protocols

Switched power supply

allows AC or DC control

voltage

853740A2.CDR

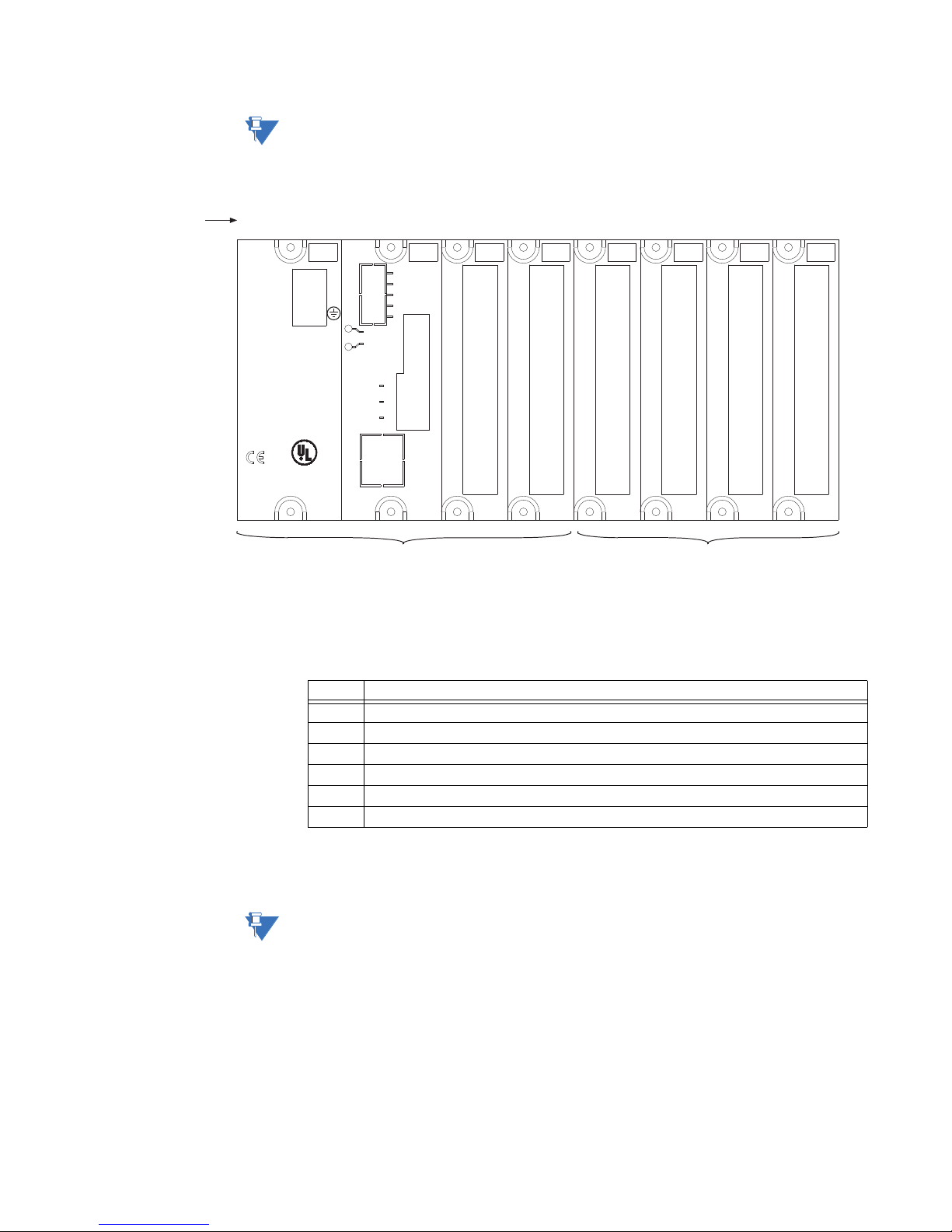

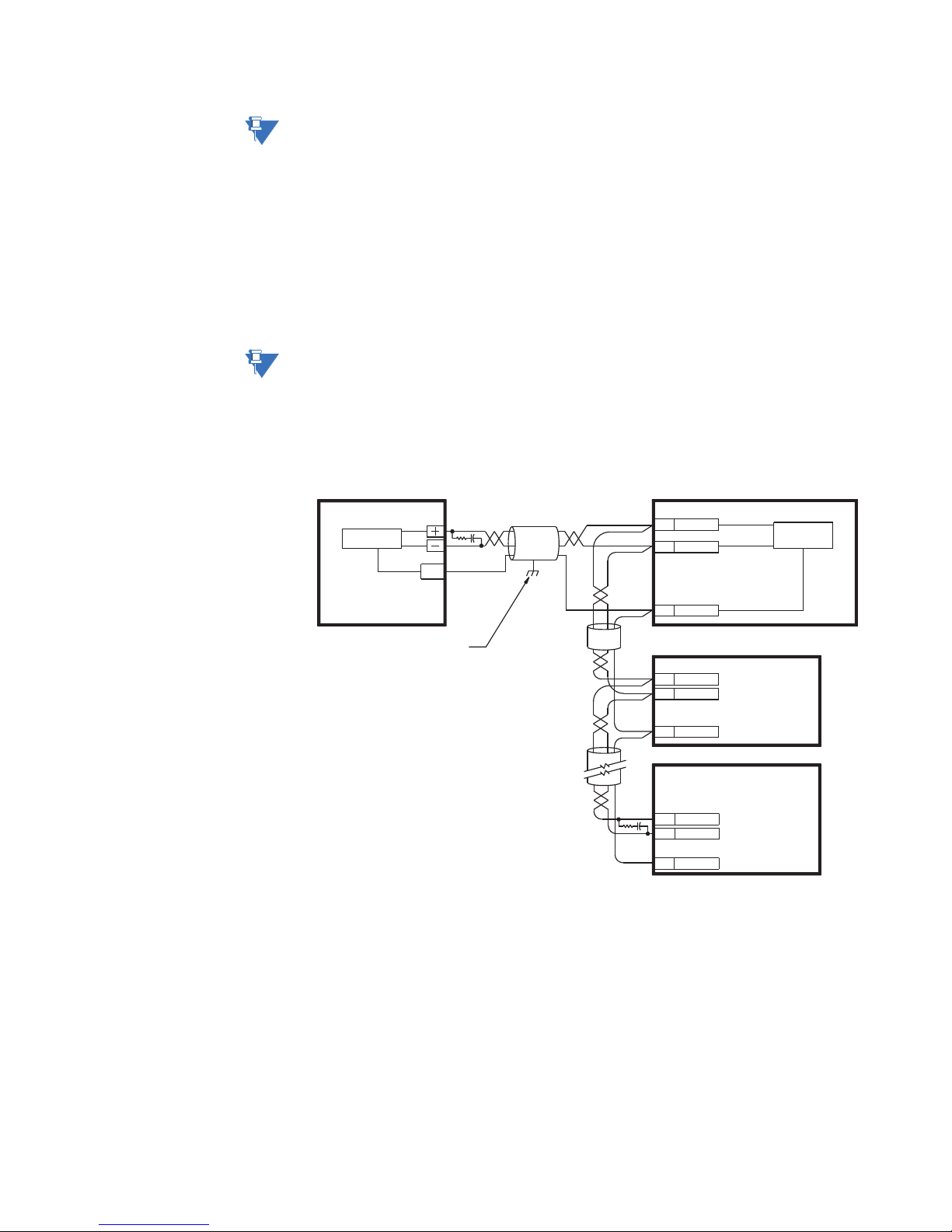

Electrical installation

This section describes the electrical installation of the MM300 system. An overview of the

MM300 terminal connections is shown below.

CAUTION:

MM300 is not to be used in any way other than described in this manual.

Figure 2-8: MM300 terminal connection overview

CAUTION:

The MM300 can contain up to eight modules. The first four modules (slots A through D)

comprise the base unit, and the next four modules (slots E through H) comprise the

optional expanded unit.

Table 2-1: Module slot position

Slot Module types

Base Unit A Power supply module (High or Low)

B CPU module with communications (1 of 3 Comm Types)

C IO_C or IO_E module

D IO_A module

Expansion Modules E IO_B or IO_C or IO_E or IO_D or IO_G module

F IO_C or IO_E or IO_D or IO_G module

G IO_C or IO_E or IO_D or IO_G module

H IO_C or IO_E or IO_D or IO_G module

The following figure shows a typical module arrangement for an expanded unit .

Use gauge size appropriate for the voltage and current draw of the device.

Table 2-2: Gauge Sizes

CPU Card: Themistor, RS485 and Fieldbus 16 AWG (3.50mm pitch terminals)

PSU / CBCT /IO_C / IO_E / IO_D / IO_G 12 AWG (5.00mm pitch terminals)

IO_A / IO_B 12 AWG (7.62mm pitch terminals)

1. Wire gauge size remains constant; increased pitch distance reflects higher voltage rating.

1

1

6 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PSU

60-300 VAC

84-250 VDC

L

gMULTILIN

LISTED

IND.CONT.EQ.

52TL

E200434

Technical Support:

Tel: (905) 294-6222

(North America) 1-800-547-8629

Fax: (905) 201-2098

www.GEMultilin.com

N

MS

NS

THERM RS485

V-

10/100

ETHERNET

GROUND

CT I/P

I

L

C

H

V+

+

–

C

+

–

FIELD BUS

8

7

6

5

4

3

2

1

ABCDEFGH

Slot position

Base unit Expansion modules

853749A1.CDR

14

13

12

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

R

SG

NOTE:

It is recommended that you install a circuit disconnection system for control power, near

the device, which should be easily accessible after installation of the unit. This is in case an

emergency power shut-down of the unit is required.

Figure 2-9: Example of module arrangement

Module and terminal identification

The MM300 input/output and protection modules are labeled with the “IO_” prefix followed

by a one-character identifier as follows.

Table 2-3: Input/output module nomenclature

Module Description

IO_A CT module

IO_B VT module

IO_C Two 10 A form-A relays, six 60 to 300 V AC digital inputs, and Aux VT input module.

IO_D Four 10 A form-C relays module.

IO_E Two 10 A form-A relays, six 20 to 60 V DC digital inputs.

IO_G 3 RTD module.

The MM300 terminals are labeled with a three-character identifier. The first character

identifies the module slot position and the second character identifies the terminals within

NOTE:

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 7

the module. For example, the first terminal in a module in slot C is identified as “C1”.

Do not confuse the slot designation with the module ordering designation. That is, terminal

“C1” does not imply an IO_C module. Rather, it indicates the first terminal of whatever

module is in slot C.

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

A

B

C

M M M

MOTOR

M

Stator Thermistor

M

Field Stop

Field Start

Reset

Core Balance CT

Contactor

MM300

Low Voltage

Motor

Manager

D2

D1

D8

D7

D6

D5

D4

D3

CT Module

PSU

C1

C2

C3

C4

C5

C6

C7

C8

I/O Module- Typ e C

C9

C10

C11

C12

C13

C14

I

C

I

B

I

A

Aux VT

+

-

Com

+

CPU

-

R

I

Surge G d

Core

Balance

Thermistor

RS485

CT2

CT3

G/F

CT1

RS485 Serial Link

Ground at one point

N

L

IN 1 IN 2 IN 3 IN 4 IN 5 IN 6 Com

Relay1 Relay2

LN

GE Multilin

853704A3.cdr

n

Gd

n

G

M

M

Field Stop

Field Start

Reset

MM300

Low Voltage

Motor

Manager

PSU

C1

C2

C3

C4

C5

C6

C7

C8

I/O Module- Type C

C9

C10

C11

C12

C13

C14

Aux VT

N

L

IN 1 IN 2 IN 3 IN 4 IN 5 IN 6 Com

Relay 1 Relay 2

LN

GE Multilin

853704B3.cdr

Low Voltage

DC Supply to

IO Type E

+

-

AC

Control Power

G

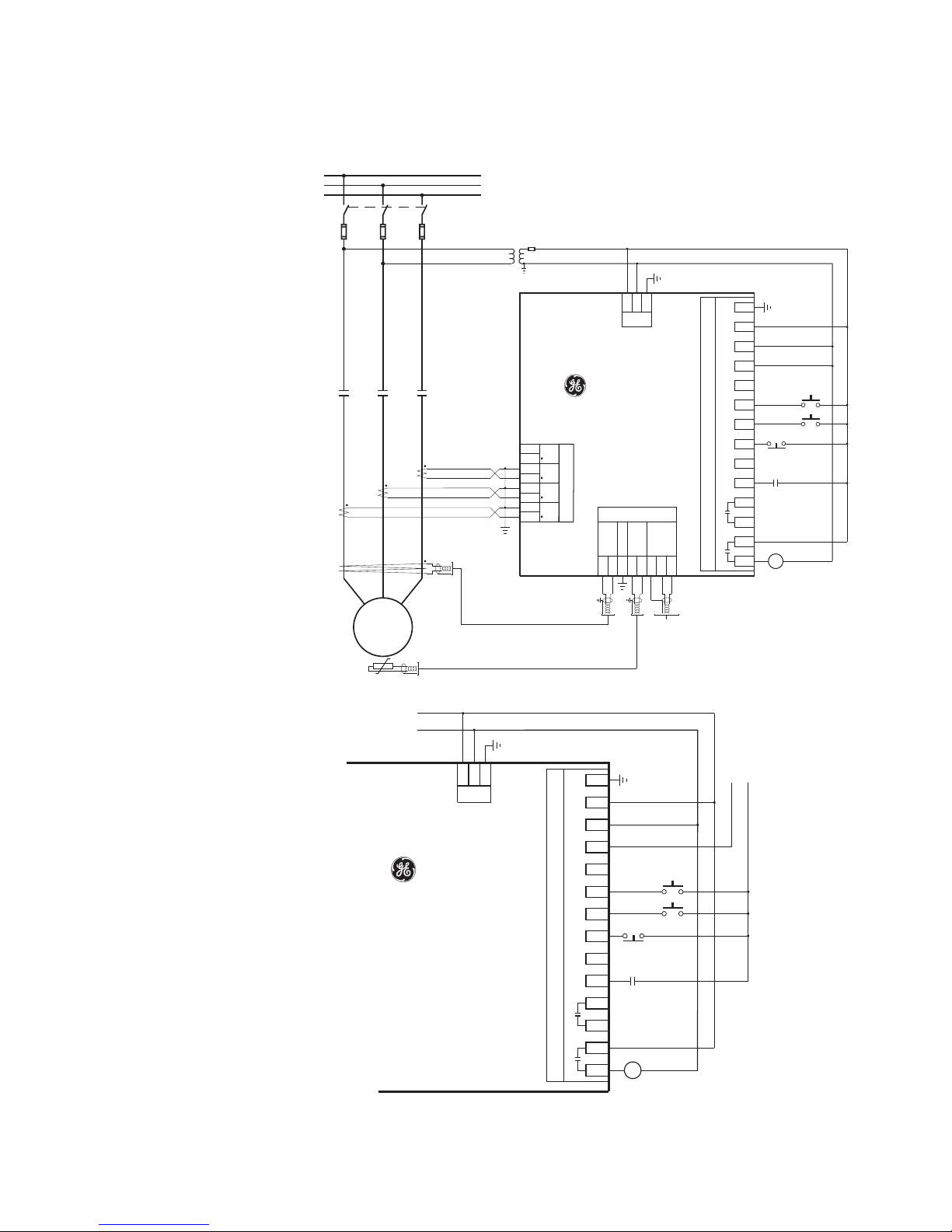

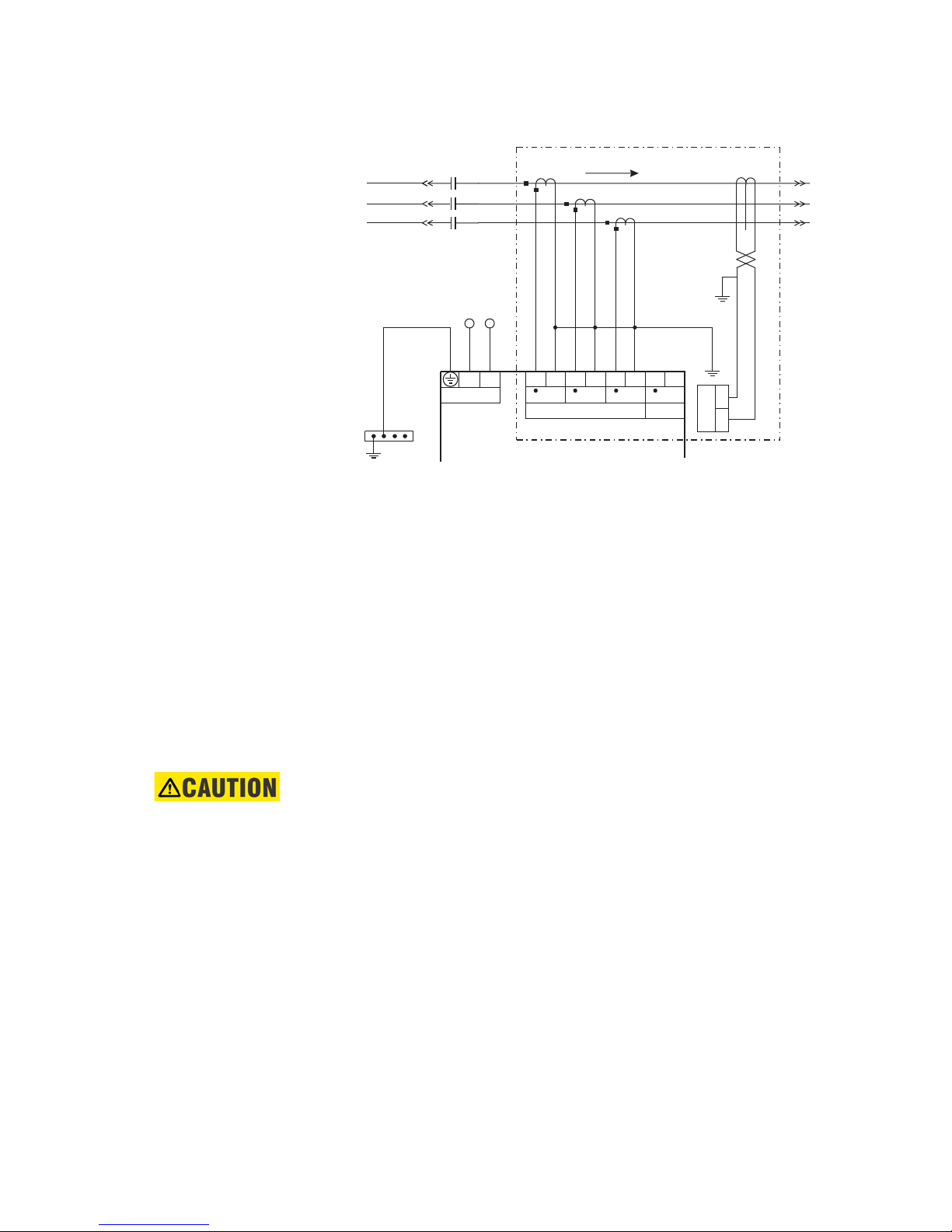

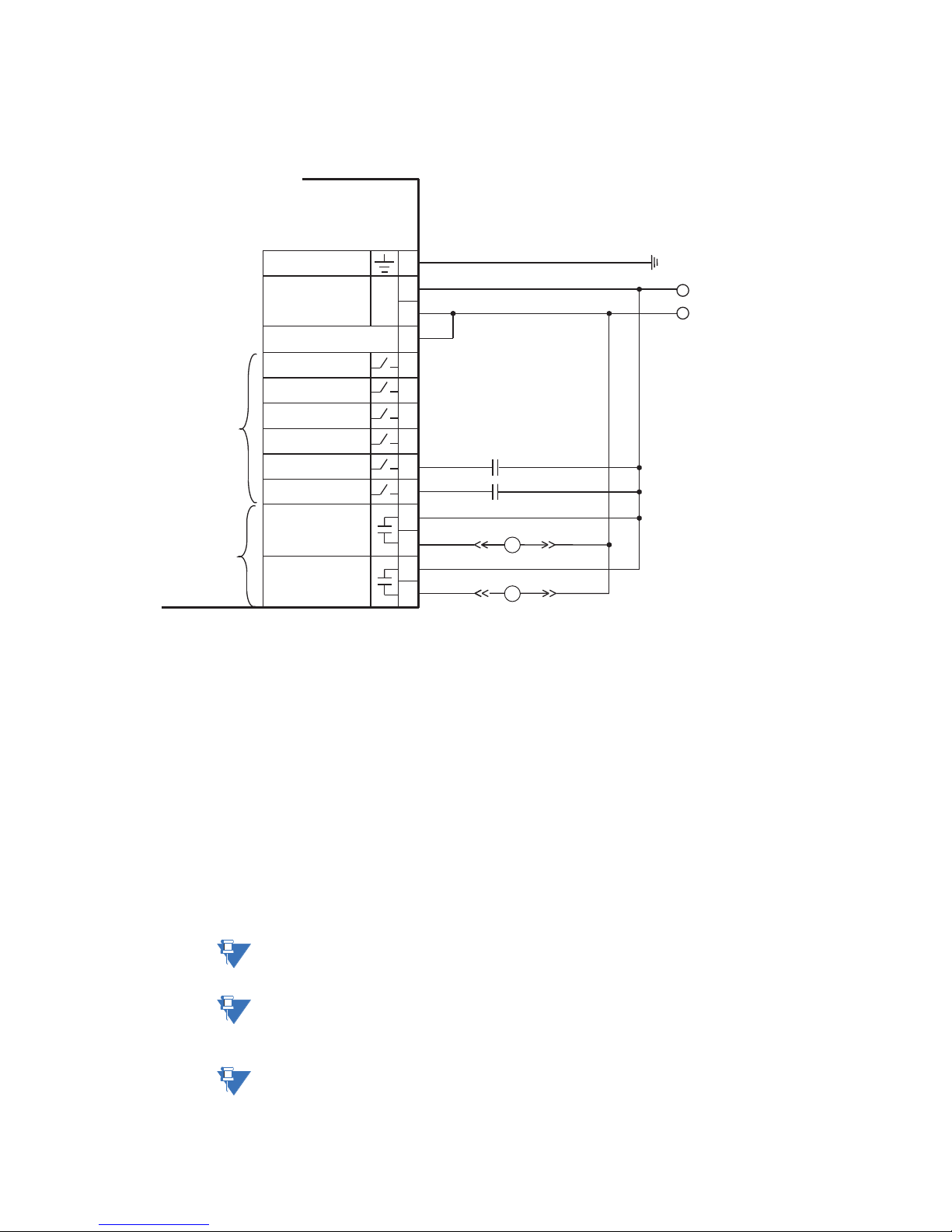

Full-voltage non-reversing starter

Figure 2-10: Full-voltage non-reversing starter wiring - IO_C

Figure 2-11: Full-voltage non-reversing starter control wiring - IO_E

8 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

NOTE

SCADA, PLC, OR

PERSONAL COMPUTER

COM

OPTOCOUPLER

DATA

MM300 IED

SHIELD

853745A1.CDR

UP TO 32 MM300

OR OTHER IEDs,

MAXIMUM CABLE

LENGTH OF

1200 m (4000 ft.)

LAST

DEVICE

(*) TERMINATING IMPEDANCE AT E ACH END

(typically 120 ohms and 1 nF)

TWISTED PAIR

ZT(*)

RS485 +

RS485 -

COMMON

RS485 +

RS485 -

COMMON

IED

RS485 +

IED

RS485 -

COMMON

GROUND THE SHIELD AT THE

SCADA/PLC/COMPUTER ONLY

OR THE MM300 ONLY

DATA

OPTOCOUPLER

B1

B2

B3

ZT(*)

NOTE:

The above drawing applies only to a high-voltage power supply. If a low-voltage (DC)

power supply is used, an appropriate DC voltage source must be used for this power

supply.

.

The full-voltage non-reversing starter type is a full voltage or across-the-line non-reversing

starter.

When a start control is received, the pre-contactor relay (if any) is picked up for the set precontactor time. When the pre-contactor timer times out, relay1 picks up and seals-in,

picking up contactor M, which starts the motor. When a stop control is received, relay1

drops out, contactor M drops out, and the motor stops. The pre-contactor is omitted on

forced starts (for example, UVR Immediate, External Start).

NOTE:

Connect AUX VT to the Control Supply for correct operation of the UV Restart feature and

correct input readings.

RS485 connections

Figure 2-12: Typical RS485 connection

One two-wire RS485 port is provided. Up to 32 MM300 IEDs can be daisy-chained together

on a communication channel without exceeding the driver capability. For larger systems,

additional serial channels must be added. Commercially available repeaters can also be

used to add more than 32 relays on a single channel. Suitable cable should have a

characteristic impedance of 120 ohms and total wire length should not exceed 1200

meters (4000 ft.). Commercially available repeaters will allow for transmission distances

greater than 1200 meters.

Voltage differences between remote ends of the communication link are not uncommon.

For this reason, surge protection devices are internally installed across all RS485 terminals.

Internally, an isolated power supply with an optocoupled data interface is used to prevent

noise coupling.

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 9

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

Power flow

D1

D2

D4D3

Phase current inputs

D5

D6 D7

CT1 CT2 CT3

D8

G/F

D1

D2

D4D3

Phase current inputs

D5

D6 D7

CT1 CT2 CT3

D8

G/F

D1

D2 D4D3

Phase current inputs

D5

D6 D7

CT1 CT2 CT3

D8

G/F

Two CT Connection

Direct Connection

Residual Ground Connection

Power flowPower flow

Power flowPower flow

853753A1.cdr

CAUTION:

To ensure that all devices in a daisy-chain are at the same potential, it is imperative

that the common terminals of each RS485 port are tied together and grounded only

once, at the master or at the MM300. Failure to do so may result in intermittent or

failed communications.

The source computer/PLC/SCADA system should have similar transient protection devices

installed, either internally or externally. Ground the shield at one point only, as shown in

the figure above, to avoid ground loops.

Correct polarity is also essential. The MM300 IEDs must be wired with all the positive (+)

terminals connected together and all the negative (–) terminals connected together. Each

relay must be daisy-chained to the next one. Avoid star or stub connected configurations.

The last device at each end of the daisy-chain should be terminated with a 120 ohm ¼

watt resistor in series with a 1 nF capacitor across the positive and negative terminals.

Observing these guidelines will ensure a reliable communication system immune to

system transients.

Phase current inputs (IO_A module)

Figure 2-13: Typical phase current input connections

10 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

A

C

B

Power flow

–

+

D1

D2

D4D3

Phase current inputs

MM300

Motor Management System

To switchgear

ground bus

853744A2.CDR

D5

D6 D7

CT1 CT2 CT3

Control power

LN

D8

G/F

Contactor

R

I

CBCT /

50 : 0.025

Core Balance (Zero Sequence)

The MM300 has three channels for phase current inputs, each with an isolating

transformer. The phase CTs should be chosen so the FLA is not less than 50% of the rated

phase CT primary. Ideally, the phase CT primary should be chosen such that the FLA is

100% of the phase CT primary or slightly less, never more. This will ensure maximum

accuracy for the current measurements. The maximum phase CT primary current is 1000

A.

The ground CT connection can either be a zero sequence (core balance) installation or a

residual connection. Note that only 1 A and 5 A secondary CTs may be used for the

residual connection. The zero sequence connection is shown in the diagram above, and

this is recommended. Unequal saturation of CTs, CT mismatch, size and location of motor,

resistance of the power system, motor core saturation density, etc. may cause false

readings in the residually connected ground fault circuit. Refer to section 2.2.2.1 for CBCT

connection.

Note that if residual ground connection is selected, the CT primary setpoint used by the

Phase CT's will also be used by the residual ground calculations.

CAUTION:

Polarity of the phase CTs is critical for negative-sequence unbalance calculation,

power measurement, and residual ground current detection (if used).

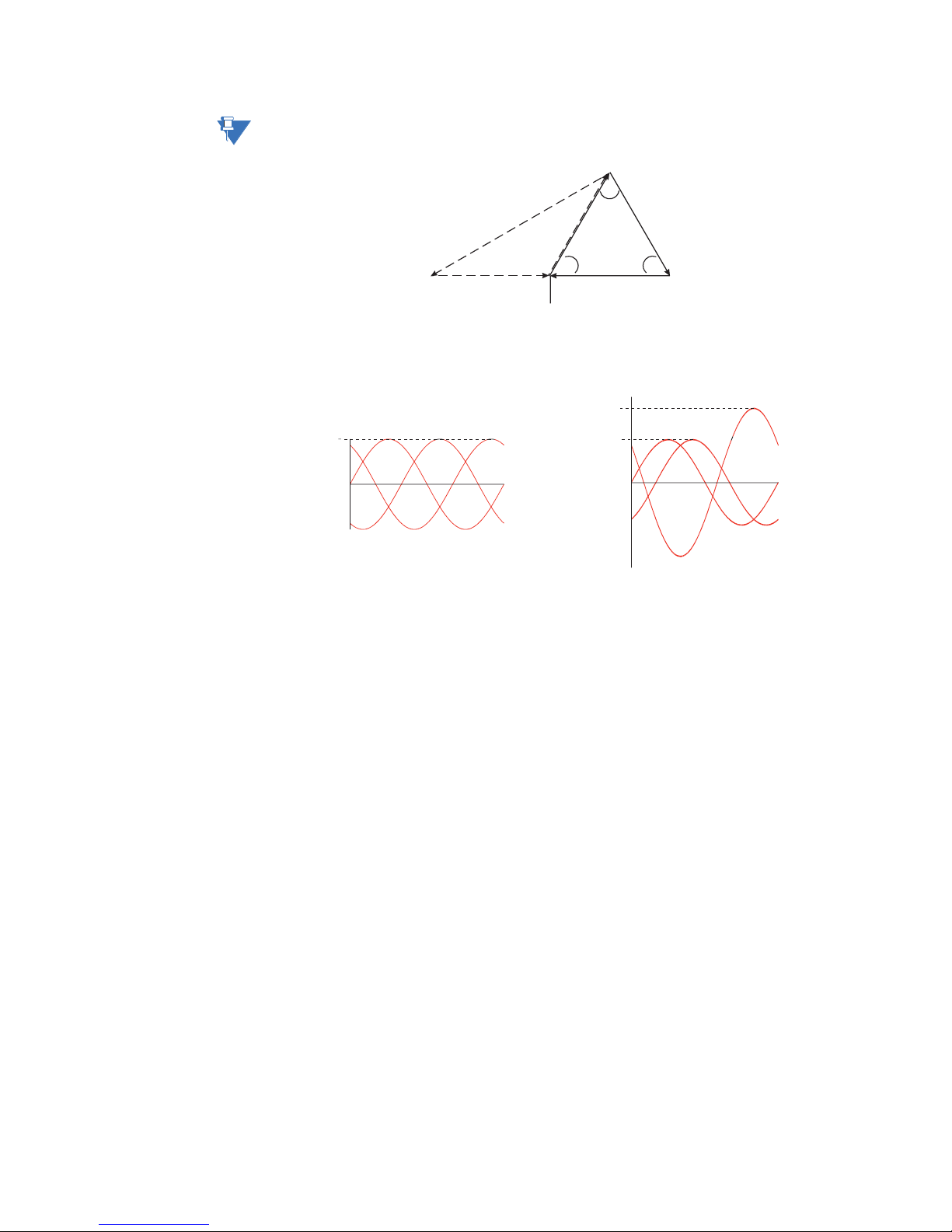

Two CT configuration Each of the two CTs acts as a current source. The current that comes out of the CT on

phase A flows into the interposing CT on the relay marked CT1. From there, the current

sums with the current that is flowing from the CT on phase C which has just passed

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 11

through the interposing CT on the relay marked CT3. This summed current flows through

the interposing CT marked CT2 and from there, the current splits up to return to its

respective source (CT).

Polarity is very important since the value of phase B must be the negative equivalent of

A

Only one ground connection should be made as shown. If two ground connections are

made, a parallel path for current has been created.

In the two CT configuration, the currents will sum vectorially at the common point of the

two CTs. The diagram illustrates the two possible configurations. If one phase is reading

high by a factor of 1.73 on a system that is known to be balanced, simply reverse the

polarity of the leads at one of the two phase CTs (taking care that the CTs are still tied to

ground at some point). Polarity is important.

+ C in order for the sum of all the vectors to equate to zero.

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

853715A1.CDR

1.73

11

11

60°

60° 60°

808701A1.CDR

1

C

A

B

1.73

1

B

A

C

Two-phase CT currents

Two-phase CT currents,

180° out-of-phase

NOTE:

Change CT wiring only if the system is de-energized!

Figure 2-14: Two CT connection vector diagram

To illustrate the point further, the following diagram shows how the current in phases A

and C sum up to create phase "B".

Figure 2-15: Two CT connection currents

Once again, if the polarity of one of the phases is out by 180°, the magnitude of the

resulting vector on a balanced system will be out by a factor of 1.73.

On a three-wire supply, this configuration will always work and unbalance will be detected

properly. In the event of a single phase, there will always be a large unbalance present at

the interposing CTs of the relay. If for example phase A was lost, phase A would read zero

while phase B and C would both read the magnitude of phase C. If on the other hand,

phase B was lost, at the supply, phase A would be 180° out-of-phase with phase C and the

vector addition would equal zero at phase B.

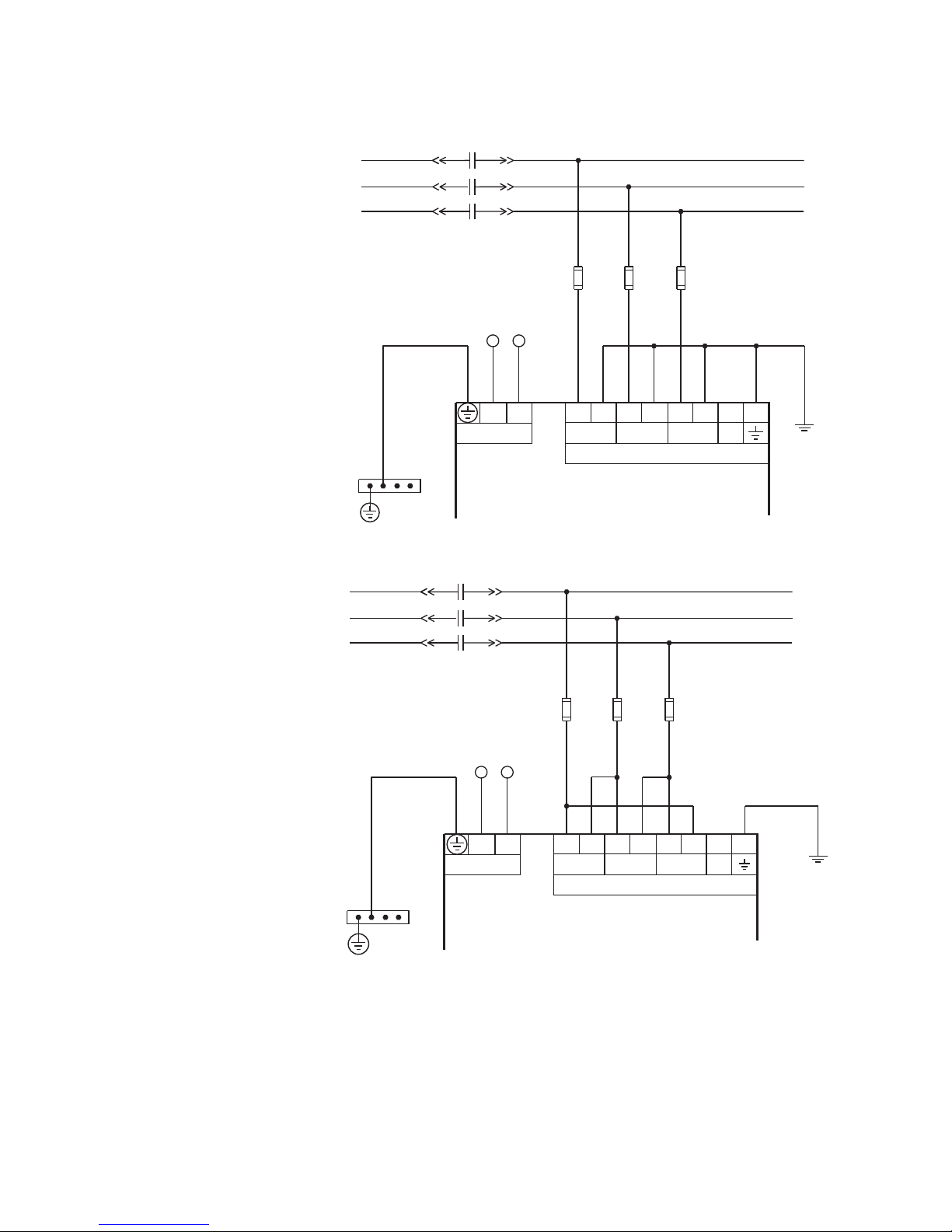

Phase voltage inputs (IO_B module)

The MM300 has three channels for AC voltage inputs. There are no internal fuses or ground

connections on the voltage inputs. Polarity is critical for correct power measurement and

voltage phase reversal operation.

12 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

A

C

B

Contactor

–

+

FUSES - 100 ma typical

E1

E2 E4E3

Phase voltage inputs

MM300

Motor Management System

To switchgear

ground bus

853735A2.CDR

E5

E6 E7

VT1 VT2 VT3

Control power

LN

E8

N/C

A

C

B

Contactor

–

+

FUSES

E1

E2 E4E3

Phase voltage inputs

MM300

Motor Management System

To switchgear

ground bus

853736A2.CDR

E5

E6

VT1 VT2 VT3

Control power

LN

E7 E8

N/C

Figure 2-16: Wye voltage connection

Figure 2-17: Delta voltage connection

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 13

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

NOTE

NOTE

NOTE

Contactors

~1

~2

~4

~3

853741A3.CDR

~5

~6

MM300

Motor Management System

~8

~9

~11

~10

~12

~13

~7

~14

Two form-A

contact outputs

CONTACT OUTPUT 2

CONTACT INPUT 1 +

Six contact

(digital) inputs

CONTACT OUTPUT 1

CONTACT INPUT 2 +

CONTACT INPUT 3 +

CONTACT INPUT 4 +

CONTACT INPUT 5 +

CONTACT INPUT 6 +

COMMON

VT INPUT

SURGE

L

N

AC

Control power

–

+

B

A

A

B

Type IO_C module connections

Figure 2-18: Typical wiring for type IO_C module

The IO_C module contains two form-A contact output relays, six digital inputs and control

voltage input.

Contact inputs can be programmed to any of the input functions, such as field stop or

process interlock. The exception is that contactor A status is fixed as the first contact input,

and contactor B status (where used) is fixed as the second contact input.

An AC auxiliary supply must be connected to terminals 12 and 13. This auxiliary voltage

(from slot C only) is also used for actual value indication, for auxiliary undervoltage, and for

undervoltage restart. When three-phase voltages are not available, it is also used to

calculate power quantities and is used as a phase angle reference.

When the IO_C module, located in slot C, senses an interruption to its auxiliary supply, it

raises an AC Low Aux Voltage Inhibit, and forces the input state of the contact inputs to

OFF, as the interruption prevents sensing the actual states.

The two contact outputs can be programmed to follow any one of the digital signals

NOTE:

NOTE:

NOTE:

14 MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE

developed by the MM300, such as alarms and status signals. The exception is that the

contactor A relay is fixed as the first contact output, and contactor B relay is fixed as the

second contact output (where used).

Connect AUX VT to the Control Supply for correct operation of the UV Restart feature and

readings of inputs.

All IO_C cards must have the auxiliary input VT wired for proper input sensing. If the

auxiliary voltage on any IO-C module is too low, the contact inputs states for the affected

module will be forced to OFF.

Substitute the slot position of the input/output module (C, E, F, G, H) wherever the tilde

symbol “~” appears in the diagrams above.

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

Control

power

~1

~2

~4

~3

853742A1.CDR

~5

~6

MM300

Motor Management System

~8

~9

~11

~10

~12

~13

~7

~14

Four form-C

contact outputs

CONTACT OUTPUT 1

NOT USED

N

CONTACT OUTPUT 2

CONTACT OUTPUT 3

CONTACT OUTPUT 4

NOT USED

–

STOP

TRIP

COIL

+

START

CLOSE

COIL

52a

52b

L

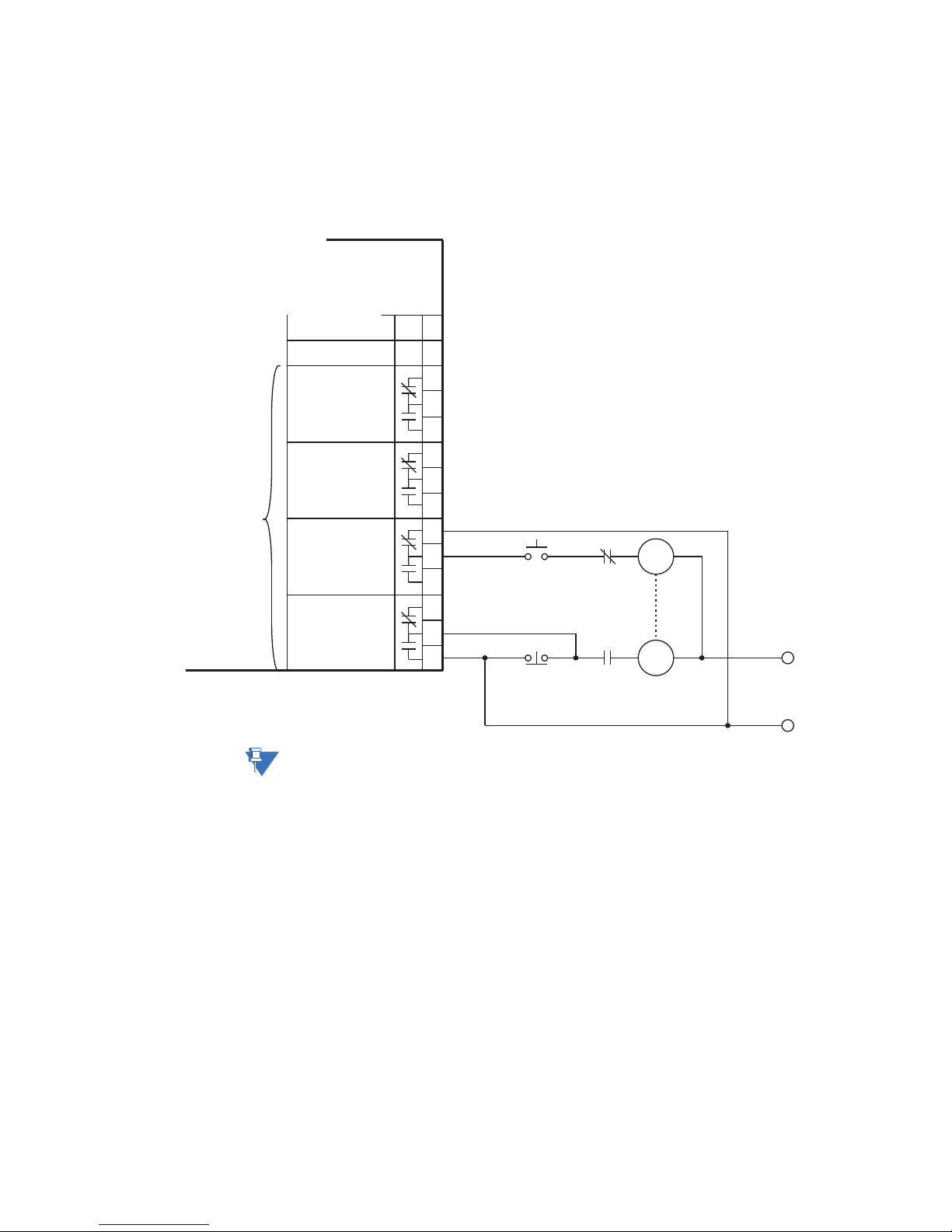

Type IO_D module connections

The IO_D module contains four form-C contact output relays.

In general, contact outputs can be programmed to follow any one of the digital signals

developed by the MM300, such as alarms and status signals.

Figure 2-19: Typical wiring for type IO_D contact output module

NOTE:

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 15

Substitute the slot position of the input/output module (E, F, G, or H) wherever the tilde

symbol “~” appears in the diagrams above.

Loading...

Loading...