Page 1

GE

Grid Solutions

GE Information

Multilin D400

TM

Substation Gateway

Instruction Manual

994-0089

Version 2.30 Revision 0

Page 2

GE Grid Solutions

Copyright Notice

© 2006-2017, General Electric Company. All rights reserved.

The information contained in this online publication is the exclusive property of General Electric Company,

except as otherwise indicated. You may view, copy and print documents and graphics incorporated in this online

publication (the “Documents”) subject to the following: (1) the Documents may be used solely for personal, informational, non-commercial purposes; (2) the Documents may not be modified or altered in any way; and (3) General Electric Company withholds permission for making the Documents or any portion thereof accessible via the

internet. Except as expressly provided herein, you may not use, copy, print, display, reproduce, publish, license,

post, transmit or distribute the Documents in whole or in part without the prior written permission of General

Electric Company.

The information contained in this online publication is proprietary and subject to change without notice. The

software described in this online publication is supplied under license and may be used or copied only in accor

dance with the terms of such license.

Trademark Notices

GE and are trademarks and service marks of General Electric Company.

-

* Trademarks of General Electric Company.

CompactFlash is a registered trademark of SanDisk Corporation. ERNI is a registered trademark of ERNI Elektroapparate GMBH. Hyperterminal is a registered trademark of Hilgraeve, Incorporated. Tera Term is a registered

trademark of T. Teranishi, IEC is a registered trademark of Commission Electrotechnique Internationale. IEEE is a

registered trademark of the Institute of Electrical and Electronics Engineers, Inc. Internet Explorer, Microsoft, and

Windows are registered trademarks of Microsoft Corporation. JAVA and J2SE are registered trademarks of Sun

Microsystems, Inc. Maxell is a registered trademark of Hitachi Maxell, Ltd. MiniSQL is a trademark of Hughes

Technologies. Netscape is a registered trademark of Netscape Communications Corporation. Modbus is a regis

tered trademark of Schneider Automation Inc. Panduit is a registered trademark of Panduit Corp. Saft is a registered trademark of SAFT société anonyme. SEL is a registered trademark of Schweitzer Engineering Laboratories,

Inc. Silicon Systems is a registered trademark of Silicon Systems, Inc. Sonnenschein is a registered trademark of

Deutsche Exide GMBH. Tadiran is a registered trademark of Tadiran Israel Electronics Industries Ltd. Toshiba is a

registered trademark of Kabushiki Kaisha Toshiba, doing business as Toshiba Corporation. VESA is registered

trademark of Video Electronics Standards Association Corporation.

Other company or product names mentioned in this document may be trademarks or registered trademarks of

their respective companies.

This printed manual is recyclable.

Please return for recycling where facilities exist.

-

Page 3

D400 Substation Gateway

Table of contents

PRODUCT SUPPORT Access the GE Grid Solutions Web site....................................................................... 9

Search GE Grid Solutions technical support library.................................................9

Contact GE Grid Solutions technical support .........................................................10

GE Grid Solutions address ..........................................................................................10

Product returns.............................................................................................................10

Product documents......................................................................................................11

Upgrade your D400 firmware ....................................................................................11

ABOUT THIS

DOCUMENT

Purpose ..........................................................................................................................13

Intended audience ......................................................................................................13

Additional documentation .........................................................................................13

How to use this guide .................................................................................................14

Safety words and definitions......................................................................................14

BEFORE YOU START Safety precautions ......................................................................................................15

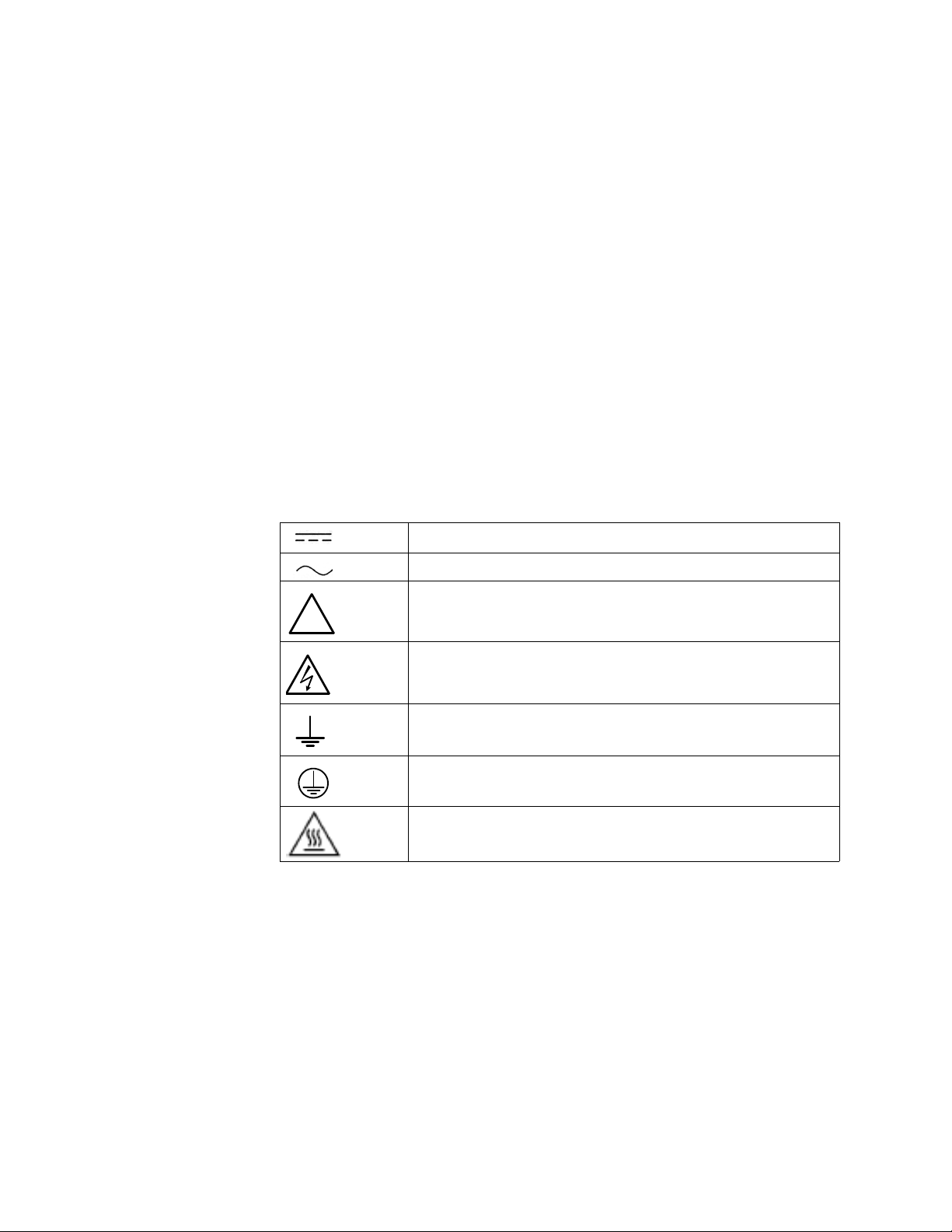

Warning symbols ......................................................................................................................................... 16

Regulatory compliance information ........................................................................17

CE Mark compliance .................................................................................................................................... 17

Restriction of Hazardous Substances (RoHS)................................................................................... 17

EAC compliance .............................................................................................................................................18

Product overview..........................................................................................................19

Functional overview.....................................................................................................19

Hardware overview...................................................................................................................................... 21

Features............................................................................................................................................................. 21

Firmware compatibility............................................................................................................................... 22

Ordering guide..............................................................................................................22

Upgrade kit....................................................................................................................................................... 23

Product identification number ................................................................................................................ 23

Product specifications ................................................................................................24

Approvals.......................................................................................................................27

Storage recommendations.........................................................................................27

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 3

Page 4

TABLE OF CONTENTS

Storage conditions .......................................................................................................................................27

Battery life .........................................................................................................................................................27

INSTALLING THE

D400

SETTING UP

COMMUNICATION

CARDS

Installation steps..........................................................................................................29

Required tools ...............................................................................................................30

Unpacking and inspecting the D400.........................................................................30

First look at the D400...................................................................................................31

Front Panel........................................................................................................................................................31

Rear panel .........................................................................................................................................................31

Physical installation.....................................................................................................32

Rack mounting ................................................................................................................................................32

Panel mount .....................................................................................................................................................33

Battery installation ........................................................................................................................................33

Battery removal..............................................................................................................................................33

Communication cards .................................................................................................35

Types of communication cards...............................................................................................................36

Changing card settings ...............................................................................................36

RS-232 adapter .............................................................................................................36

Configuration options ..................................................................................................................................37

Factory default................................................................................................................................................37

Switch SW1/SW2 configuration..............................................................................................................38

Switch SW3/SW4 configuration..............................................................................................................39

RS-485 adapter .............................................................................................................40

Configuration options ..................................................................................................................................40

Factory default................................................................................................................................................40

Switch SW1/SW2 configuration..............................................................................................................40

Switch SW3/SW4 configuration..............................................................................................................42

Fiber optic serial adapter............................................................................................43

Configuration options ..................................................................................................................................43

Factory default................................................................................................................................................43

Switch SW1 configuration .........................................................................................................................43

IRIG-B input adapter ....................................................................................................44

Configuration options ..................................................................................................................................45

Factory default................................................................................................................................................45

Switch SW1 configuration .........................................................................................................................45

Switch SW2 configuration .........................................................................................................................46

IRIG-B distribution adapter ........................................................................................47

Output Voltage................................................................................................................................................47

Configuration options ..................................................................................................................................47

4-Port twisted-pair ethernet switch .........................................................................48

Configuration options ..................................................................................................................................48

10Base-FL hot standby fiber optic ethernet switch...............................................49

Configuration options ..................................................................................................................................49

100Base-FX hot standby fiber optic ethernet adapter .........................................50

Configuration options ..................................................................................................................................50

COM2 port adapter ......................................................................................................51

Configuration options ..................................................................................................................................51

Redundant twisted-pair ethernet + COM2 port adapter ......................................52

Configuration options ..................................................................................................................................53

USB KVM and audio adapter.......................................................................................54

Configuration options ..................................................................................................................................54

4 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 5

TABLE OF CONTENTS

CONNECTING TO

DEVICES AND

NETWORKS

Connection types..........................................................................................................55

Serial.................................................................................................................................................................... 55

Network.............................................................................................................................................................. 56

Time synchronization ..................................................................................................56

Local substation computer....................................................................................................................... 56

Local maintenance ...................................................................................................................................... 56

Cabling overview..........................................................................................................57

General cabling requirements ................................................................................................................57

High-voltage installations ......................................................................................................................... 57

RS-232 connections......................................................................................................58

RS-485 connections......................................................................................................58

Cabling requirements..................................................................................................................................59

2-Wire connections ...................................................................................................................................... 59

4-Wire connections ...................................................................................................................................... 60

Fiber optic serial connections....................................................................................62

Glass optical fiber.......................................................................................................................................... 62

Plastic optical fiber ....................................................................................................................................... 62

IRIG-B connections.......................................................................................................63

IRIG-B input adapter ....................................................................................................................................63

IRIG-B distribution adapter ....................................................................................................................... 64

Hot standby fiber optic connections ........................................................................65

Network connections...................................................................................................65

Front network port........................................................................................................................................66

Modem connections.....................................................................................................67

Local HMI connection ..................................................................................................69

Front maintenance port..............................................................................................70

Minimal required connection................................................................................................................... 70

D400 connection to DNP3 I/O modules....................................................................71

D400 system redundancy ...........................................................................................71

Failover sequence ......................................................................................................................................... 71

Required components................................................................................................................................. 72

RS232 switch panel ...................................................................................................................................... 73

Redundancy wiring diagrams ................................................................................................................. 74

POWERING UP THE

D400

Power supply options ..................................................................................................81

Redundant power supply .......................................................................................................................... 82

Power configurations .................................................................................................................................. 82

Power input ranges ......................................................................................................................................82

Power connections.......................................................................................................82

Wiring requirements .................................................................................................................................... 83

External power requirements.................................................................................................................. 83

Power supply alarms ...................................................................................................85

Power fail alarm ............................................................................................................................................ 85

System fail alarm........................................................................................................................................... 86

Powering down the D400 ...........................................................................................87

SETTING UP THE

D400

Start the D400...............................................................................................................89

Task 1: Connect to the D400.......................................................................................90

Task 2: Create user accounts ....................................................................................91

Task 3: Change the root password............................................................................91

Task 4: Set up the network interface ........................................................................92

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 5

Page 6

TABLE OF CONTENTS

Task 5: Create a supervisor password......................................................................94

Task 6: Set up secure web access..............................................................................94

Installing the certificate and key ............................................................................................................95

Task 7: Access the D400 HMI ......................................................................................96

Task 8: Test the network connection ........................................................................96

SETTING UP THE

D400 FOR

REDUNDANCY

Prerequisites .................................................................................................................97

Configure Warm-Standby redundancy ....................................................................97

Task 1: Warm standby - Configure the D400s for operation ....................................................98

Task 2: Warm standby - Connect the D400s ....................................................................................98

Task 3: Warm standby - Create user accounts ...............................................................................98

Task 4: Warm standby - Configure the primary D400 for redundancy................................98

Task 5: Warm standby - Configure the secondary D400 for redundancy ..........................99

Task 6: Warm standby - Verify configuration ................................................................................ 100

Task 7: Warm standby - Verify redundant D400 operation....................................................100

Configure Hot-Standby redundancy...................................................................... 100

Task 1: Hot standby - Configure the D400s for operation .......................................................100

Task 2: Hot standby - Connect the D400s.......................................................................................101

Task 3: Hot standby - Create user accounts..................................................................................101

Task 4: Hot standby - Configure the primary D400 for redundancy ..................................101

Task 5: Hot standby - Configure the secondary D400 for redundancy............................. 102

Task 6: Hot standby - Verify configuration .....................................................................................103

Task 7: Hot standby - Verify redundant D400 operation .........................................................103

USING THE D400 Front panel LEDs........................................................................................................ 105

System status LEDs.................................................................................................................................... 106

Serial port status LEDs..............................................................................................................................106

Substation HMI........................................................................................................... 107

D400 HMI ........................................................................................................................................................107

Local HMI ........................................................................................................................................................108

System utilities........................................................................................................... 109

From the front maintenance port .......................................................................................................109

From the local substation computer ................................................................................................. 109

Over a network connection.................................................................................................................... 109

File transfer ................................................................................................................ 110

USB portable memory device ...............................................................................................................110

System status points ................................................................................................ 111

Shutting down the D400........................................................................................... 112

ABOUT THE D400

APPLICATIONS

How the D400 works ................................................................................................. 113

Types of applications................................................................................................ 114

Client application ........................................................................................................................................114

Server application....................................................................................................................................... 115

Automation application ........................................................................................................................... 115

System point database ............................................................................................................................115

D400 applications...................................................................................................... 116

Applications available with D400 redundant operation...........................................................116

About the DNP3 software ........................................................................................ 117

6 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 7

TABLE OF CONTENTS

INTRODUCING THE

D400

CONFIGURATION

INTRODUCING THE

D400 FEATURES

D400 online configuration tool............................................................................... 120

One-Line designer...................................................................................................................................... 120

IEC 61850 Loader (optional)..................................................................................... 121

LogicLinx (optional) ................................................................................................... 121

D400 system redundancy ........................................................................................ 122

D400 system utilities ................................................................................................ 122

Configuration steps .................................................................................................. 123

Configuration file format ......................................................................................... 123

Configuration management.................................................................................... 123

Timestamps and time zones on your D400 .......................................................... 124

Example System Configuration ........................................................................................................... 125

System security ......................................................................................................... 127

One-line designer ...................................................................................................... 128

One-line viewer.......................................................................................................... 128

Digital event management...................................................................................... 128

Viewing data............................................................................................................... 129

Executing commands ............................................................................................... 129

Operator Notes.......................................................................................................... 129

Analog reports ........................................................................................................... 130

System utilities........................................................................................................... 130

Internationalization .................................................................................................. 130

Hybrid model - redundancy .................................................................................... 130

Parallel Redundancy Protocol (PRP) ...................................................................... 131

Retrieve system logs................................................................................................. 132

Browse files and folders from a local USB ............................................................ 132

USING THE D400

LOCAL

CONFIGURATION

UTILITY

Start the D400 configuration utility....................................................................... 134

Configure authentication ........................................................................................ 136

Configure network settings..................................................................................... 136

Configure network interfaces ................................................................................. 137

Network summary ..................................................................................................................................... 139

Configure secure access .......................................................................................... 140

Configure Remote HMI Non Observer Privileges......................................................................... 141

Configure Rsyslog service ...................................................................................................................... 142

Configure firewall settings ...................................................................................... 143

Configure host names .............................................................................................. 145

Configure time and time synchronization ............................................................ 146

Reset system logs...................................................................................................... 146

Reset mSQL database tables .................................................................................. 147

Reset NVRAM.............................................................................................................. 147

Delete NVRAM Data................................................................................................................................... 147

Reset file persistence data ...................................................................................... 148

Configure local HMI................................................................................................... 148

Standby local HMI redirects to the active D400 .......................................................................... 149

Configure sync manager.......................................................................................... 151

Redundancy................................................................................................................ 154

Power supply.............................................................................................................. 156

Automatic record retrieval manager .................................................................... 156

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 7

Page 8

TABLE OF CONTENTS

Suppress forced qualities to masters .................................................................... 157

Restore factory default ............................................................................................ 157

SERVICING THE D400 Removing the D400 main module .......................................................................... 159

Replacing the battery ............................................................................................... 160

Before you remove the battery… .........................................................................................................161

Supported battery types..........................................................................................................................161

To insert or replace the D400 battery ...............................................................................................161

Checking voltage.........................................................................................................................................162

Cleaning and handling Lithium batteries ........................................................................................ 162

Recycling of batteries ...............................................................................................................................162

Battery life ......................................................................................................................................................162

Dual ethernet upgrade kit with card 580-3410 ................................................... 163

Valid combinations.....................................................................................................................................163

Installing the 580-3410 dual ethernet card ................................................................................... 163

Changing the CompactFlash .................................................................................. 166

Replacing the power supply .................................................................................... 167

REMOVING THE

D400 FROM SERVICE

Service life................................................................................................................... 169

Remove configuration data and sensitive information from the D400 .......... 169

Removing configuration data on a PC................................................................... 170

Equipment disposal................................................................................................... 170

STANDARDS &

Compliance standards ............................................................................................. 171

PROTECTION

INSTALLING AND

CONNECTING DNP3

I/O MODULES

Overall procedure to install and connect DNP3 I/O modules ........................... 175

Installing DNP3 I/O modules in a rack................................................................... 176

Rack spacing.................................................................................................................................................176

Required clearances..................................................................................................................................176

Rack mounting procedure...................................................................................................................... 176

Connecting to protective ground ........................................................................... 176

Connecting DNP3 I/O modules (Low Voltage) ...................................................... 178

DNP3 I/O module (LV) interconnect cabling ...................................................................................178

DNP3 I/O module (LV) connection to the Power Source...........................................................179

Connecting DNP3 I/O modules (High Voltage) ..................................................... 180

Connecting to a D400..............................................................................................................................180

LIST OF ACRONYMS Acronym Definitions ................................................................................................. 181

MISCELLANEOUS Warranty..................................................................................................................... 185

Revision history ......................................................................................................... 185

8 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 9

D400 Substation Gateway

Product Support

Product Support

If you need help with any aspect of your GE Grid Solutions product, you can:

• Access the GE Grid Solutions Web site

• Search the GE Technical Support library

• Contact Technical Support

Also covered are:

• The GE Grid Solutions address

• Instructions on returning a D400 to GE Grid Solutions

• Additional product documents which support

• Firmware upgrade information

Access the GE Grid Solutions Web site

The GE Grid Solutions Web site provides fast access to technical information, such as

manuals, release notes and knowledge base topics.

Visit us on the Web at: http://www.gegridsolutions.com

Search GE Grid Solutions technical support library

This site serves as a document repository for post-sales requests. To get access to the

Technical Support Web site, go to:

http://sc.ge.com/*SASTechSupport

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 9

Page 10

PRODUCT SUPPORT

NOTE

Contact GE Grid Solutions technical support

GE Grid Solutions Technical Support is open 24 hours a day, seven days a week for you to

talk directly to a GE representative.

In the U.S. and Canada, call toll-free: 1 800-547-8629

International customers, please call: + 1 905-927-7070

Or e-mail to multilin.tech@ge.com

Have the following information ready to give to Technical Support:

• Ship to address (the address that the product is to be returned to)

• Bill to address (the address that the invoice is to be sent to)

•Contact name

• Contact phone number

• Contact fax number

• Contact e-mail address

• Product number / serial number

• Description of problem

Technical Support will provide you with a case number for your reference.

GE Grid Solutions address

The GE Grid Solutions company address is:

GE Grid Solutions

650 Markland Street

Markham, Ontario

Canada L6C 0M1

Product returns

A Return Merchandise Authorization (RMA) number must accompany all equipment being

returned for repair, servicing, or for any other reason. Before you return a product, please

contact GE Grid Solutions to obtain an RMA number and instructions for return shipments.

You are sent the RMA number and RMA documents via fax or e-mail. Once you receive the

RMA documents, attach them to the outside of the shipping package and ship to GE.

Product returns are not accepted unless accompanied by the Return Merchandise

Authorization number.

10 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 11

PRODUCT SUPPORT

Product documents

The D400 v4.10 and prior is supported by the:

• D400 Substation Gateway Instruction manual (this manual) which describes how to

install a D400 within a system.

• The D400 online help which allows you to configure the D400 within a system.

• D400 Substation Gateway Software Configuration Guide (SWM0066).

The D400 v5.01 and later is supported by the:

• D400 Substation Gateway Instruction manual which describes how to install a D400

within a system.

• The D400 online help which allows you to configure the D400 within a system.

The content of the Software Configuration Guide has been moved to the Instruction

manual and the online help for D400 V5.01 and later.

Upgrade your D400 firmware

The firmware of your D400 can be upgraded to provide the latest functionality and

improvements. Refer to the Multilin D400* Substation Gateway Upgrade Manager Quick

Start Guide which is available with the D400 Upgrade Kits.

The D400 Upgrade Kits are available for order though GE Grid Solutions Online store at:

http://store.gedigitalenergy.com/viewprod.asp?model=D400-UGK

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 11

Page 12

PRODUCT SUPPORT

12 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 13

D400 Substation Gateway

About this Document

About this Document

Purpose

This manual provides information about installing, setting up, using and maintaining your

TM

D400

the software of the D400.

Substation Gateway. This manual does not provide any procedures for configuring

Intended audience

This manual is intended for use by field technicians and maintenance personnel who are

responsible for the installation, wiring and maintenance of SCADA equipment. This guide

assumes that the user is experienced in:

• Electrical utility applications

• Electrical wiring and safety procedures

• Related other manufacturers’ products, such as protective relays and

communications equipment

Additional documentation

For further information about the D400, refer to the following documents.

• D400 online Help

• Module layouts, as available

For the most current version of the D400 Instruction Manual, please download a copy

from:

http://www.gegridsolutions.com/app/ViewFiles.aspx?prod=d400&type=3

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 13

Page 14

How to use this guide

This guide describes how to install the D400 and get it up and running for the first time.

Procedures are provided for all component options available for the D400. The

components included in your D400 depend on what was ordered for your substation

application. Follow only the procedures that apply to your D400 model. To check what

options are included in your D400, see

The software-related procedures in this guide are based on using a computer running

Windows

version of Windows.

®

XP. Some steps and dialog boxes may vary slightly if you are using another

See “Ordering guide” on page 22.

Safety words and definitions

Before attempting to install or use the device, review all safety indicators in this document

to help prevent injury, equipment damage or downtime.

The following safety and equipment symbols are used in this document:

Indicates a hazardous situation which, if not avoided, result in death or serious injury.

ABOUT THIS DOCUMENT

Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Indicates practices that are not related to personal injury.

14 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 15

D400 Substation Gateway

Chapter 1: Before You Start

Before You S tart

Before you begin installing and using the D400TM, review the information in this chapter,

including the following topics:

• Safety precautions

• Regulatory compliance information

•Product overview

• Product specifications

•Approvals

• Storage recommendations

Read and thoroughly understand this guide before installing and operating the unit. Save

these instructions for later use and reference.

Failure to observe the instructions in this manual may result in serious injury or death.

Safety precautions

Follow all safety precautions and instructions in this manual.

Only qualified personnel should work on the D400. Maintenance personnel should be

familiar with the technology and the hazards associated with electrical equipment.

• Never work alone.

• Before performing visual inspections, tests, or maintenance on this equipment, isolate

or disconnect all hazardous live circuits and sources of electric power. Assume that all

circuits are live until they have been completely de-energized, tested, and tagged. Pay

particular attention to the design of the power system. Consider all sources of power,

including the possibility of back feed.

• Turn off all power supplying the equipment in which the D400 is to be installed before

installing and wiring the D400.

• Operate only from the power source specified on the installed power supply module.

• Beware of potential hazards and wear personal protective equipment.

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 15

Page 16

• The successful operation of this equipment depends upon proper handling,

!

installation, and operation. Neglecting fundamental installation requirements may

lead to personal injury as well as damage to electrical equipment or other property.

• All AC voltage terminals are protected from accidental contact by a mechanical safety

shield.

• All electronic components within the D400 are susceptible to damage from

electrostatic discharge. To prevent damage when handling this product use approved

static control procedures.

• Hazardous voltages can cause shock, burns or death. To prevent exposure to

hazardous voltages, disconnect and lock out all power sources before servicing and

removing components.

• If the D400 is used in a manner not specified in this manual, the protection provided

by the equipment may be impaired.

• Changes or modifications made to the unit not authorized by GE Grid Solutions could

void the warranty.

Warning symbols

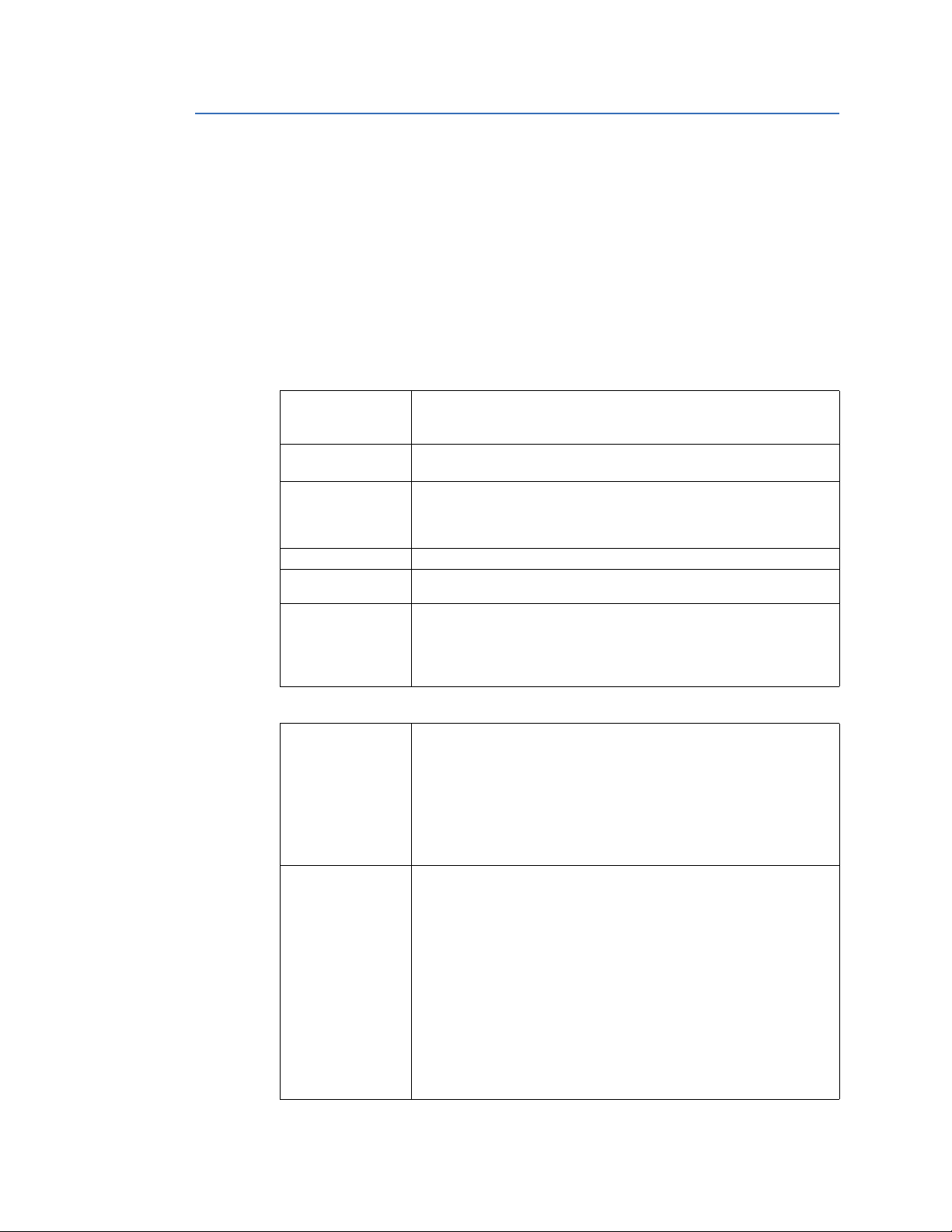

Table 1 explains the meaning of warning symbols that may appear on the D400 or in this

manual.

Table 1: Warning symbols that appear on the D400 and in this manual

CHAPTER 1: BEFORE YOU START

The relevant circuit is direct current.

The relevant circuit is alternating current.

Caution: Refer to the documentation for important operation and

maintenance instructions. Failure to take or avoid specified actions

could result in loss of data or physical damage.

Warning: Dangerous voltage constituting risk of electric shock is

present within the unit. Failure to take or avoid specified actions

could result in physical harm to the user.

Earth/Ground Terminal

Protective Ground Terminal

Caution: Hot Surface

16 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 17

CHAPTER 1: BEFORE YOU START

NOTE

Regulatory compliance information

CE Mark compliance

The D400 is rated as CISPR 11 Group 1 Class “A” equipment.

To provide higher EMC immunity and maintain CE Mark compliance, the serial cables used

for permanent RS-232 and RS-485 connections must comply with the following

requirements:

• Cables must be shielded

• D type connector covers must provide EMC shielding (e.g. metallized plastic or die cast

metal covers) for permanently connected RS-232 cables

Class “A” equipment is intended for use in an industrial environment. The equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with these instructions, may cause interference to other devices in the vicinity.

If this equipment does cause interference with other devices, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving device

• Increase the separation between the equipment

• Connect the equipment into an outlet on a circuit different from that to which the

other device(s) is connected

• Consult the manufacturer or field service technician for help

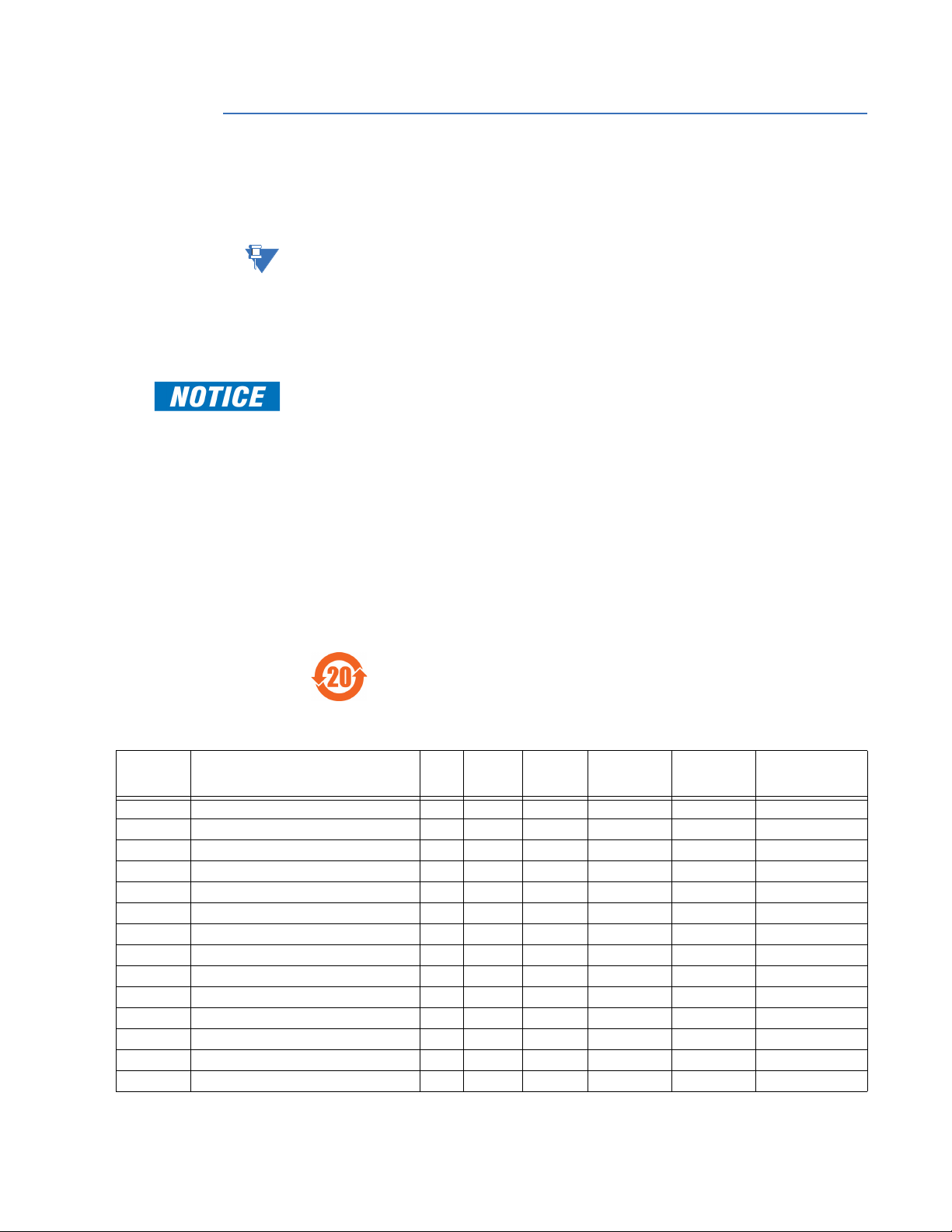

Restriction of Hazardous Substances (RoHS)

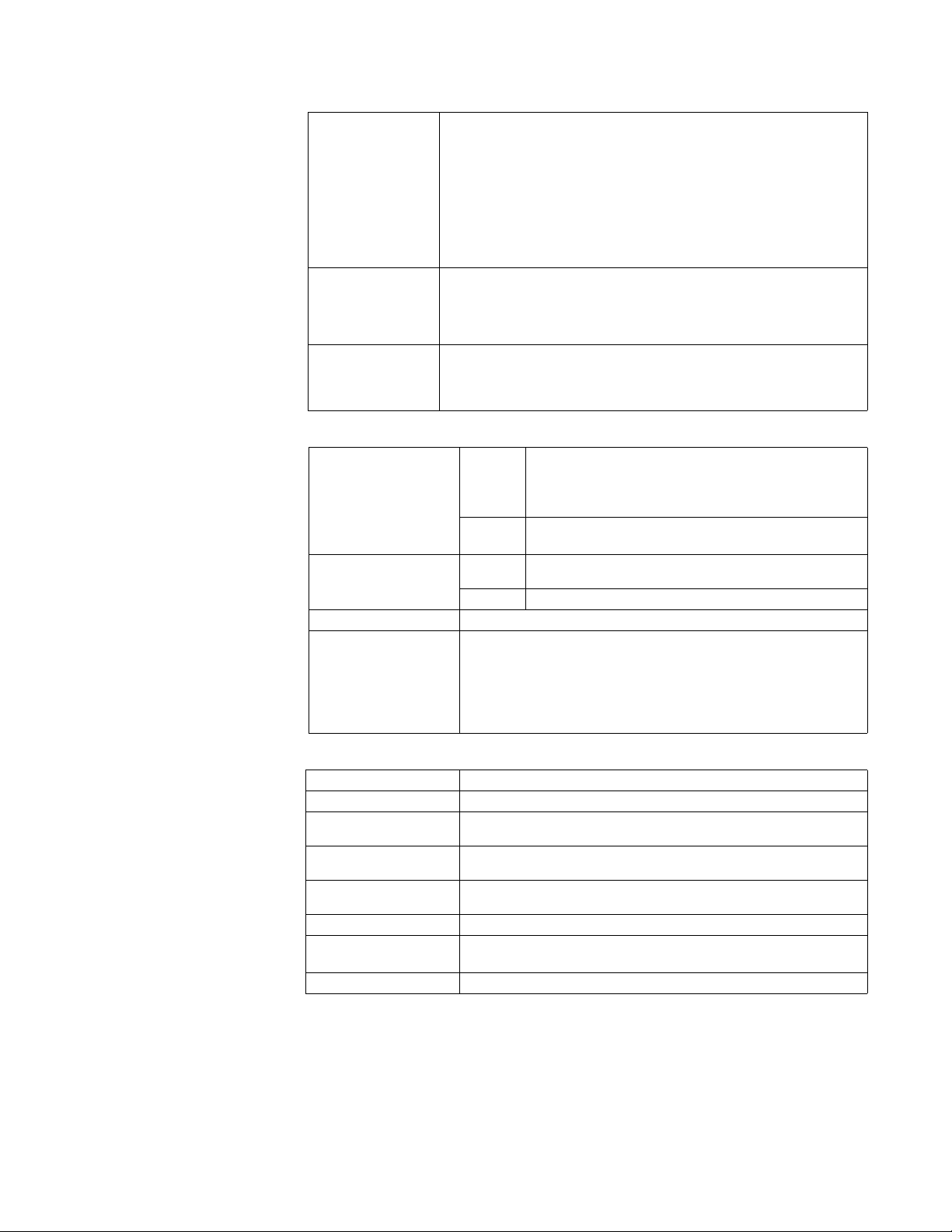

The environmental protection use period (EPUP), as defined in PRC SJ/T113632006, for the D400 hardware assemblies listed in Table 2, is in excess of 20

years.

Table 2: RoHS Material Declaration Data Content by Assembly

GE part

number

500-0340LF Chassis Assembly O O O O O O

520-0190 Power Supply Blank Assembly O O O O O O

520-0191 Adapter Blank Assembly O O O O O O

520-0204 650 MHz Celeron w Single Ethernet X O O O O O

520-0205LF 1.0 GHz Celeron w Single Ethernet O O O O O O

520-0232LF 1.6 GHz CPU (Atom) O O O O O O

520-0206LF USB KVM Assembly O O O O O O

520-0207LF RS-232 IO Assembly O O O O O O

520-0208LF RS-485 IO Assembly O O O O O O

520-0209LF Glass Fiber Optic IO Assembly O O O O O O

520-0210LF Plastic Fiber Optic IO Assembly O O O O O O

520-0211LF IRIG-B Input Assembly O O O O O O

520-0212LF IRIG-B Distribution Assembly O O O O O O

520-0213LF Ethernet 4 Port Switch Assembly O O O O O O

Description Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr6)

Polybromina

ted biphenyls

(PBB)

Polybrominated

diphenyl ethers

(PBDE)

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 17

Page 18

CHAPTER 1: BEFORE YOU START

GE part

number

520-0214LF Hot Standby Ethernet Glass Fiber Optic

520-0215LF 100Base-FX Hot Standby. Fiber Optic

520-0216LF DC-DC Supply 5V 12A Assembly O O O O O O

520-0217LF AC-DC Supply 5V 12A Assembly O O O O O O

520-0218LF Redundant TP Ethernet + COM2 Port

520-0219LF COM2 Port Assembly O O O O O O

580-3410 PC/104-Plus 10/1000 Base-TX Ethernet

977-0544 Cable Assy, C-GRID, 12SKT-10SKT+4SKT O O O O O O

977-0209 Cable, UTP Patch Cord Stranded, 60 Inch O O O O O O

977-0529 Cable, Null Modem DB9F-DB9F, 80°C,

Description Lead

(Pb)

O O O O O O

Assembly

O O O O O O

Ethernet Adapter.

O O O O O O

Assembly

O O O O O O

RTL8110SC

O O O O O O

150V, 72 Inch

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr6)

Polybromina

ted biphenyls

(PBB)

O Indicates that this toxic or hazardous substance contained in all of the

homogeneous materials for this item is below the limit required in PRC SJ/

T11363-2006 and EU Directive 2002/95/EC (RoHS)

X: Indicates that this toxic or hazardous substance contained in at least one of the

homogeneous materials used for this item is above the limit requirement in PRC

SJ/T11363-2006 and EU Directive 2002/95/EC (RoHS)

The maximum concentration limits (MCV's) apply.

Lead (Pb) 0.1% by weight = 1000 mg/kg = 1000 ppm

Mercury (Hg) 0.1% by weight = 1000 mg/kg = 1000 ppm

Cadmium (Cd) 0.01% by weight = 100 mg/kg = 100 ppm

Chromium VI (Cr6) 0.1% by weight = 1000 mg/kg = 1000 ppm

PBB, PBDE 0.1% by weight = 1000 mg/kg = 1000 ppm

Polybrominated

diphenyl ethers

(PBDE)

EAC compliance

The EAC Technical Regulations (TR) for Machines and Equipment apply to the Customs

Union (CU) of the Russian Federation, Belarus, and Kazakhstan.

Product Description

Country of origin

Date of manufacture See label on rear of D400

Declaration of Conformity and/or Certificate of

Conformity

18 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Assembled in Canada; see label on rear of D400

Available upon request

Page 19

CHAPTER 1: BEFORE YOU START

Product overview

Functional overview

The D400 Substation Gateway is a secure, substation hardened and CE Marked

communications gateway that collects metering, status, event and fault report data from

intelligent electronic devices (IEDs). It summarizes the data from devices and makes it

available to a master station or host computer over standard SCADA protocols. TCP/IP

network connections are supported over the built-in 10/100 MB Ethernet interface and

dial-up (external modem required).

The D400 comes with a built-in human machine interface (HMI)/annunciator as part of the

base software. A Local HMI can be accessed through the Keyboard, Video, Mouse

interface. A full featured substation HMI is accessed using a standard Web browser (HTTP/

HTTPS) network connection. The D400 is configured “online” through a standard Web

browser.

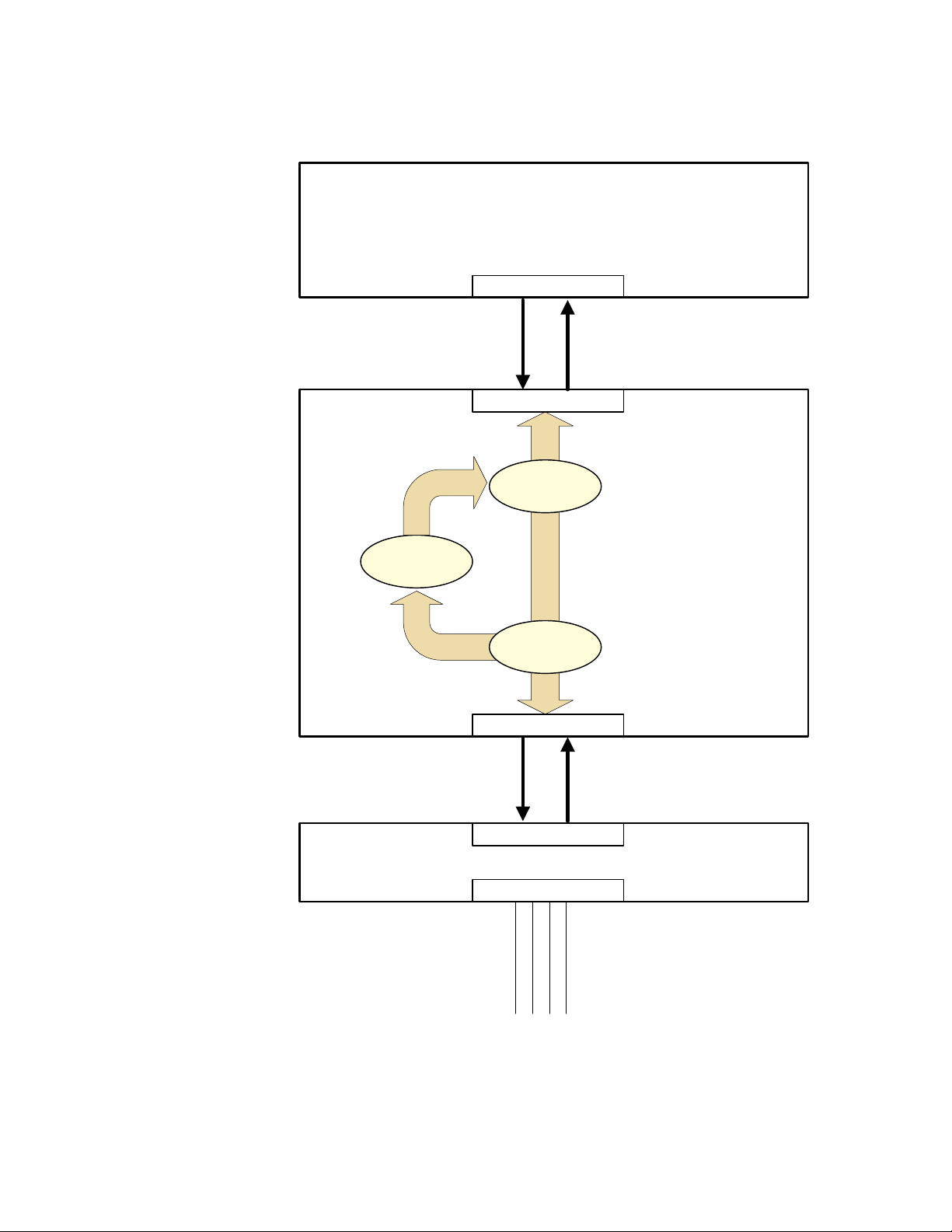

The data flow managed by a D400 is shown in Figure 1. The D400 communicates data with

the:

• Control Center which can comprise an EMS (Enterprise Management System) or a DMS

(Distribution Management System) SCADA (Supervisory Control and Data Acquisition)

system.

• IEDs (Intelligent Electronic Devices) to monitor and control field inputs and outputs.

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 19

Page 20

'

Server Connectors

Client Connectors

,('

)LHOG,QSXWDQG2XWSXW

'LJLWDO,QSXWV

'LJLWDO2XWSXWV

$QDORJ,QSXWV

$QDORJ2XWSXWV

Client Connectors

ServerConnectors

6HUYHU0DSV

$XWRPDWLRQ

$SSOLFDWLRQV

&OLHQW0DSV

&RQWURO&HQWUH

3VHXGR

SRLQWV

Client Connectors

(06RU'066&$'$6\VWHP

3URFHVVHVGDWDIRUFHQWUDOL]HGPDQDJHPHQWRIVXEVWDWLRQ

VZLWFKHVDQGEUHDNHUV

'DWDIORZWKURXJKSURWRFROV

VXFKDV'13,(&0RGEXV

'DWD&RQFHQWUDWLRQWKURXJKSURWRFROV

VXFKDV'13,(&

0RGEXV+\GUDQDQG6(/

CHAPTER 1: BEFORE YOU START

Figure 1: D400 - Data flow

20 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 21

CHAPTER 1: BEFORE YOU START

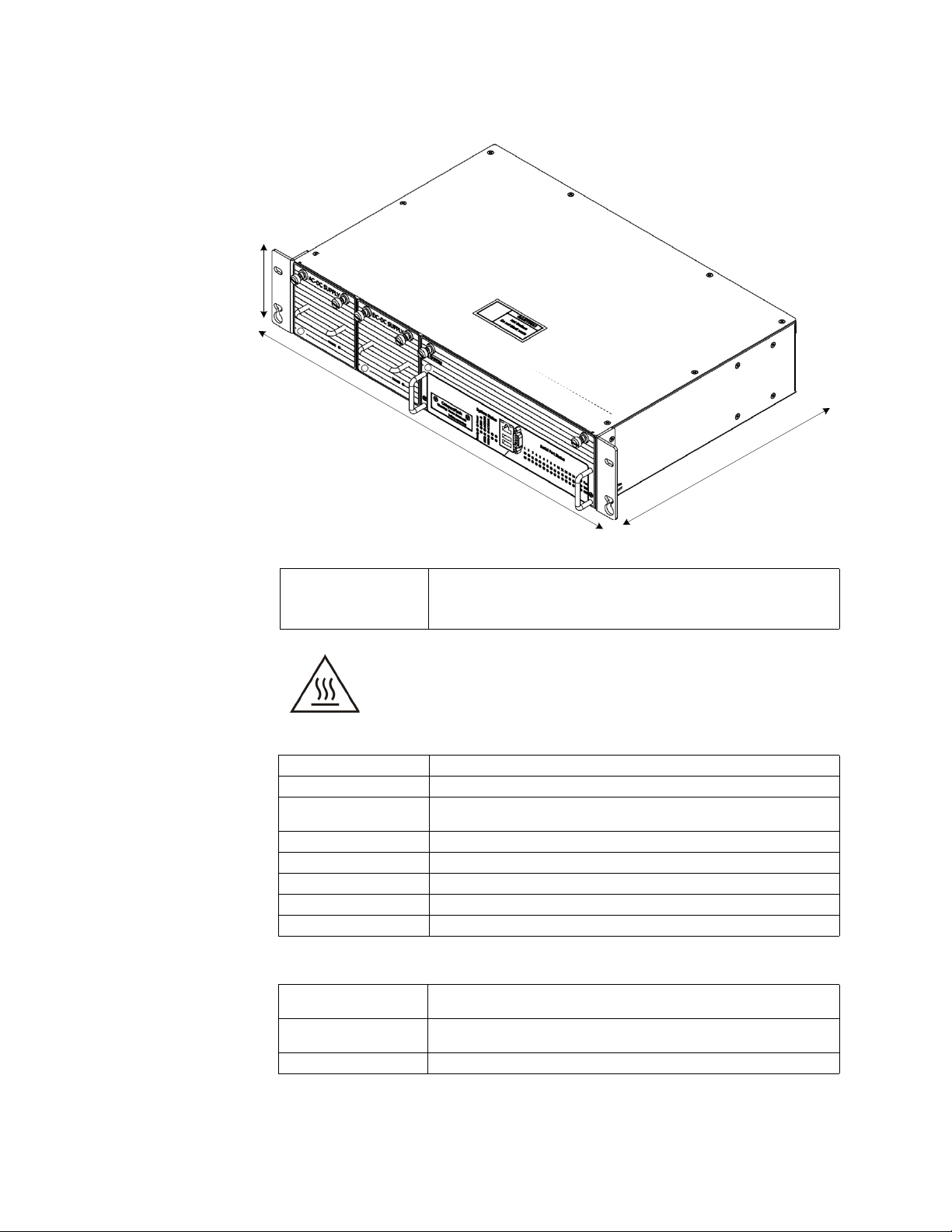

Hardware overview

The D400 is (see Figure 2) built on a flexible, high-performance, expandable platform

powered by a 1.6 GHz processor. It is distinguished by the noticeable lack of a hard drive

and fan, employing instead the rugged and reliable CompactFlash mass storage and

engineered heat sink and ventilation.

The D400 supports various communication media types through a choice of input/output

(I/0) adapter cards:

• Serial (up to 8 configurable 2-port adapter cards): RS-232, RS-485, Fiber Optic (Glass or

Plastic)

• Ethernet: 10/100BaseT, 100BaseFX, or 10BaseFL

Figure 2: D400 - front view

Features

• Secure Web server (128-bit encryption)

• Secure SCADA communications through Secure Sockets Layer or Transport Layer

Security (SSL/TLS)

• Secure access using SSH (Secure Shell)/SCP (Secure Copy)/HTTPS

• Secure terminal server, gateway, and/or data concentrator using SSL

• User configurable access level

• Support for remote user authentication

• Built-in alarm annunciator

• Support for time synchronization signals, including Network Time Protocol (NTP) and

IRIG-B

• Support for DNP protocol for communications to multiple masters

• High-performance real-time database engine

• Internal Mini SQL™ database for archival of SOE and alarm records

• Built-in basic math/logic functions

• Event notification (e-mail)

• Portable memory device plug-in

• Dual CompactFlash cards for main and user storage

• Dual hot swappable power supply units

• Communication adapter cards

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 21

Page 22

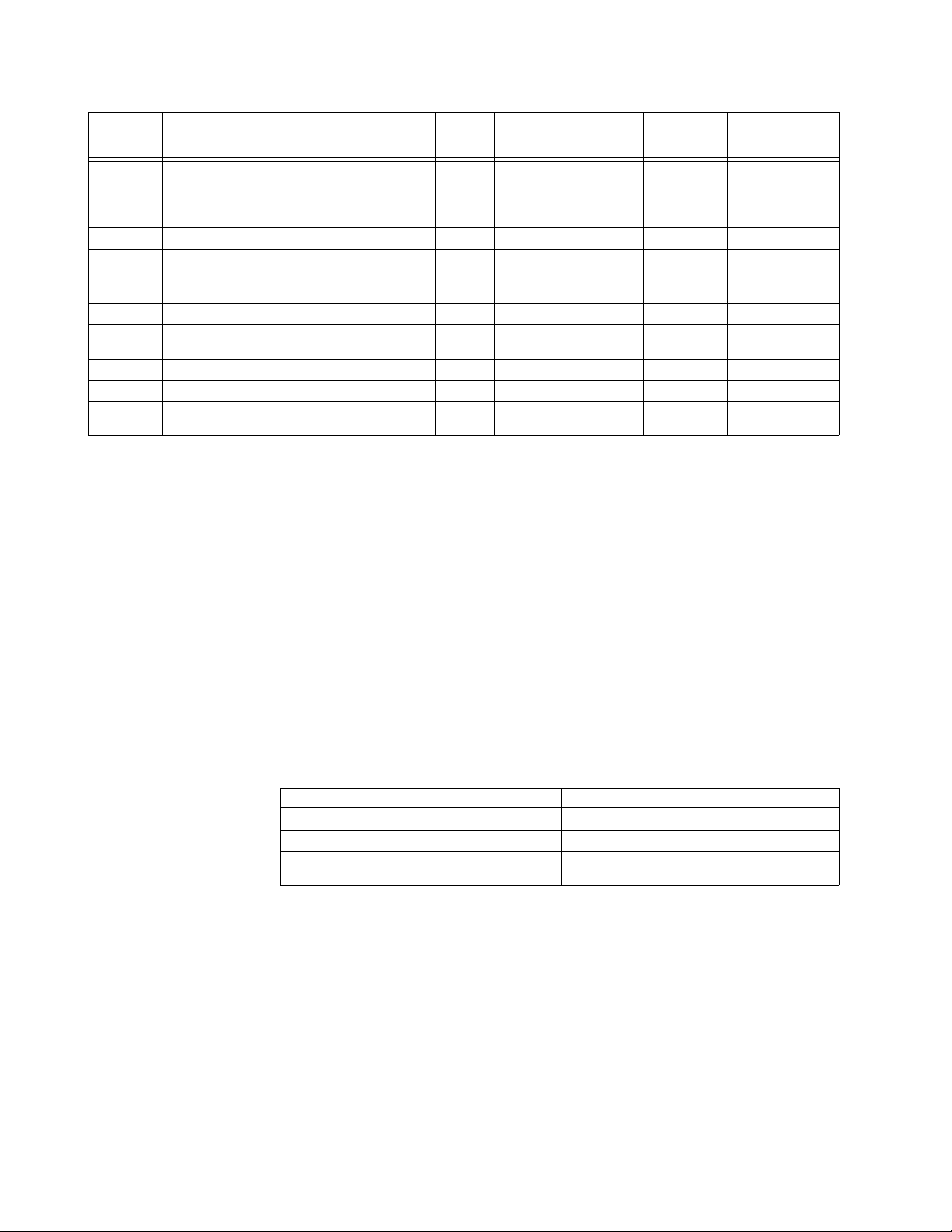

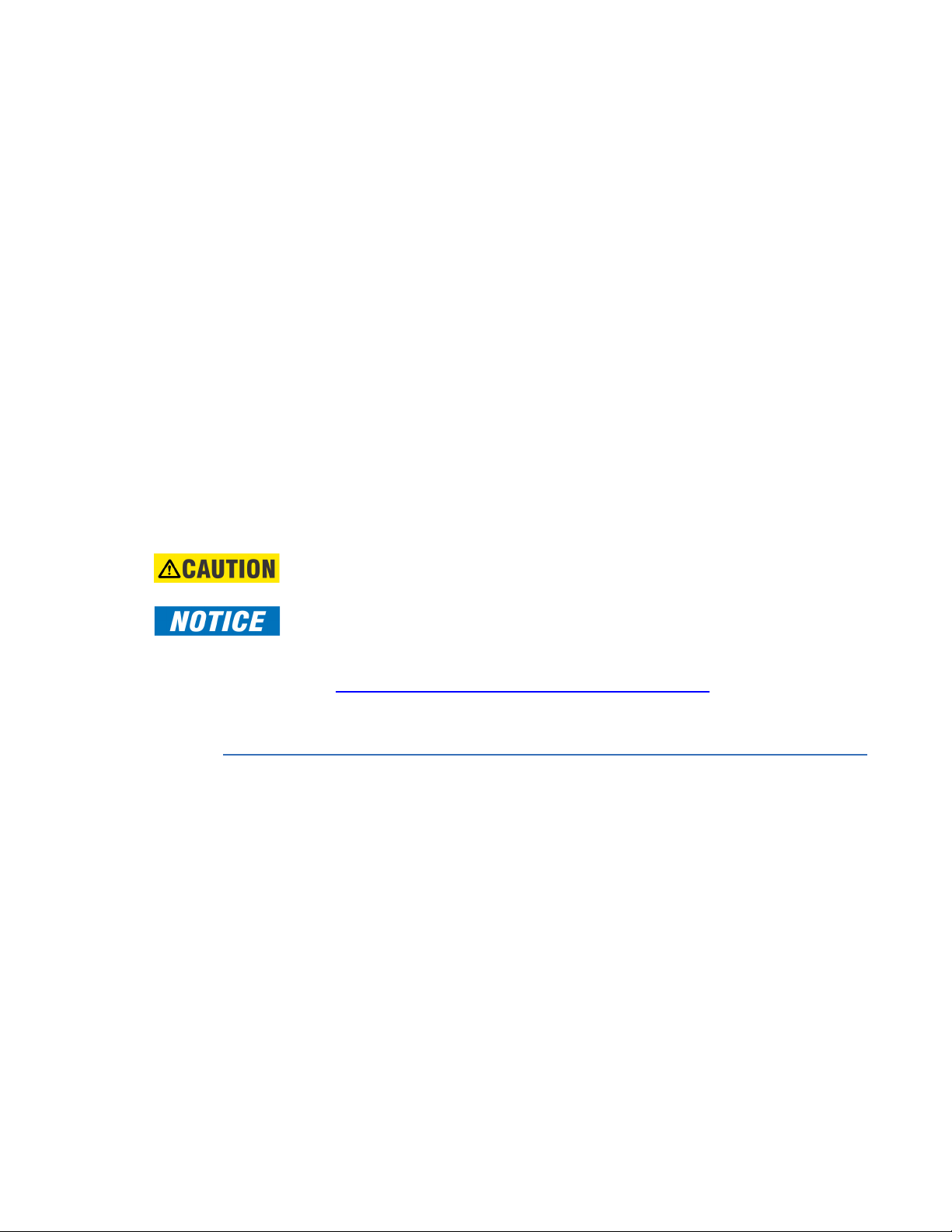

Firmware compatibility

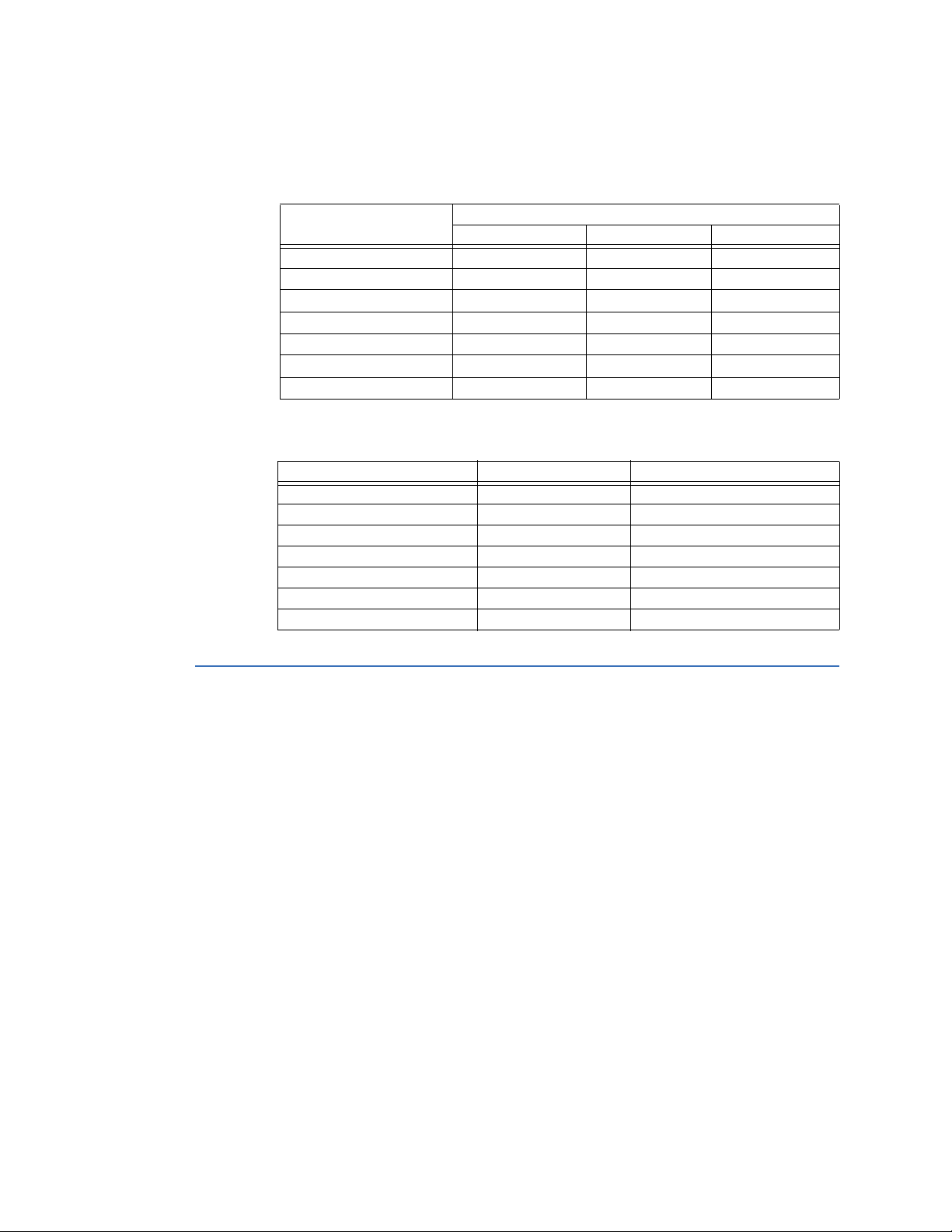

Table 3 lists the released D400 firmware versions and indicates the CPUs that support

those firmware versions.

Table 3: D400 firmware and CPU compatibility

D400 Firmware Version

2.75

3.00

3.20

3.20 with Service Pack 1

3.20 with Service Pack 2

4.10

5.01

Table 4 lists the released D400 firmware versions and indicates the JRE supported.

Table 4: D400 firmware and JRE version compatibility

D400 firmware version

2.75 JRE 6 JRE 6 update 22

3.00 JRE 6 JRE 6 update 22

3.20 JRE 6 JRE 6 update 27

3.20 with Service Pack 1 JRE 7 JRE 7 update 11

3.20 with Service Pack 2 JRE 7 JRE 7 update 11

4.10 JRE 7 JRE 7 update 17

5.01 JRE 7 JRE 7 update 71

CHAPTER 1: BEFORE YOU START

CPU

650 MHz 1.0 GHz 1.6 GHz

JRE supported JRE version tested with ...

Ordering guide

The latest D400 Substation Gateway ordering guide, which includes accessories, is

available on the GE Grid Solutions website:

http://store.gegridsolutions.com/viewprod.asp?Model=D400

You can select the required options from the available Product Option items. The Order

Code automatically updates as each option is selected.

The Product Options are:

• D400 CPU Options

• Main and Redundant (optional) Power Supply Options

• Up to 8 Serial Communication Slots

• IRIG-B Input Card Option (Slot 9)

• IRIG-B Distribution Card Options (Slot 10)

• Primary and Secondary (optional) Network Slots

•USB KVM, Audio

• D400 Local HMI (One Line Viewer)

• D400 IEC61850

• D400 Logiclinx Executor License

• D400 Setup Software

• D400 Image Firmware

22 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 23

CHAPTER 1: BEFORE YOU START

Location of ID number label

Upgrade kit

The D400 Upgrade Kits can be configured to include all the components necessary to

upgrade existing D400 units. An Upgrade Kit comprises the:

• Hardware (as selected),

• Upgrade Manager, and

• Migration Tool

The D400 Upgrade Kits are available for order though GE Grid Solutions Online store at:

http://store.gegridsolutions.com/viewprod.asp?model=D400-UGK

Upgrade manager The Upgrade Manager allows you to:

• Upgrade the D400 firmware release, and

• Automatically transfer configuration and license files

Migration tool The Migration Tool allows you to migrate existing firmware and configuration files for the

D400 Main Module from a 1.0 GHz CPU to a 1.6 GHz CPU. The Migration Tool is a orderable

option from the D400 upgrade kits though GE Grid Solutions Online store.

Product identification number

The D400 comes with an ID number that identifies the supplied options and hardware

configuration of the unit. This ID number (see

alphanumeric characters. The ID number is listed on a label located next to Slot 1 on the

rear panel of the D400.

Figure 3) is composed of * followed by 6

Figure 3: D400 identification number

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 23

Page 24

Product specifications

The D400 adheres to the following product specifications:

• System

• Communications

• Electrical

• Physical

• Environmental

• Software

Additional Standards and Protection are listed in Appendix A, Standards & Protection.

CHAPTER 1: BEFORE YOU START

System

Communications

Processor 1.6 GHz Embedded CPU

1.0 GHz Embedded CPU (obsolete)

650 MHz Embedded CPU (obsolete)

Memory 512 MB of PC133 SDR RAM or 1.0 GB of PC133 DDR RAM

16 MB NVRAM standard for persistent event storage

Storage No hard drive

1 GB of Main and 1 GB of User CompactFlash card ship standard

Both expandable to 16 GB, depending on available capacity of industrial

CompactFlash cards

Operating system Linux

Embedded Mini SQL

database

LED indicators Main module

Network connections Single or optional redundant Ethernet interface

Serial

communications

Archive of SOE reports, alarm records, operator notes, HMI quality changes,

PRFs, and point tags

System status: Power, Ready, IRIG-B and Network port status

Serial port status: Transmit and Receive status per port

Power Supplies

Power on (Green)

Fiber Optic and/or Twisted Pair

10/100BaseT (Isolated RJ-45 connector)

100BaseFX (Fiber Optic: 1300 nm, 50/125 µm, 62.5/125 µm multi-mode

duplex fiber cable-ST connectors)

10BaseFL (Fiber Optic: 820 to 850 nm, 50/125 µm, 62.5/125 µm, 100/140

µm, and 200 µm HCS (hard clad silica) multimode duplex fiber cable-ST

connectors)

Data rate: 10 MBps and 100 Mbps

16 channels: RS-232/RS-485/Fiber optic

Data rate: 300 to 115.2 Kbps

RS-232

Configurable for DCE/DTE operation

Galvanic isolation

Can drive IRIG-B signal to RS-232 ports (with optional IRIG-B Input card)

RS-485

2-Wire/4-Wire support

Galvanic isolation

Fiber Optic

Glass Optical Fiber serial port: (820 to 850 nm) 50/125 µm, 62.5/125 µm,

100/140 µm and 200 µm HCS multi-mode fiber with ST connectors

Plastic Optical Fiber (POF) serial port: (660 nm), 1 mm core with Agilent

Versatile Link Simplex connectors. POF is limited to a maximum of 38.4 kbps.

Configurable ambient state (ON/OFF)

24 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 25

CHAPTER 1: BEFORE YOU START

Time synchronization IRIG-B Input Module

IRIG-B format pulse width coded (PWC) signal, HCMOS or TTL levels on

terminal block, IRIG-B format 1kHz AM modulated signal on BNC connector,

and IRIG-B PWC signal on Fiber Optic (820 to 850 nm) ST connector.

CPU time sync for internal database time stamping

Distribution Module

Can drive IRIG-B TTL signal from the input module for 16 IEDs

Signal Propagation

Propagated to all 16 RS-232 ports for devices

Propagated to the distribution module

USB KVM & Audio Three USB v1.1 compliant Type A ports for connecting keyboard, mouse, or

touchscreen

HD D-Sub 15 socket for connecting an industrial SVGA display (in

accordance with VESA

®

Plug & Display Standard)3.5 mm stereo audio jack

for audible alarms

User connections Front Ethernet port for local connection to HMI

Two USB v1.1 compliant Type A ports for USB device plug-in, such as

keyboard, mouse, or touchscreen

Front serial communication port (RS-232) for local maintenance

Electrical

Physical

Rated power supplies AC-DC 100 to 240 VAC (±10%) 127 VA maximum

Minimum/Maximum AC voltage: 90 VAC / 265 VAC

100 to 300 VDC (±10%) 135 W maximum

Minimum/Maximum DC voltage: 88 VDC / 330 VDC

DC-DC 20 to 55 VDC (±10%) 135 W maximum

Minimum/Maximum DC voltage: 18 VDC / 60 VDC

Peak inrush current at

25 °C on cold start

AC-DC 26.5 A

40 A

DC-DC 35 A

(< 145 VAC or 205 VDC)

peak

(< 264 VAC or 370 VDC)

peak

(< 60 VDC)

peak

Rated frequency (AC-DC) 47 to 63 Hz (50/60 Hz)

Contact closures Solid-state photo-MOS device

Output ratings at maximum ambient temperature:

– Continuous current: 0.1 A continuous at 300 VAC or 300 VDC

– Peak current: 0.28 A peak for 10 ms

– Maximum on resistance: 35 ohm

– Dielectric isolation: 2 kV

RMS

Overall height 2U (3.47”) [88.12 mm]

Width 19” rack mount [482.59 mm]

Depth 12.24” [310.95 mm] for chassis and rear connectors

13.04” [331.34 mm] with front clearance for protruding parts

Recommended cable

clearance

Recommended work area

3.75” [95.25 mm] for units with fiber optic connections

2.0” [50.8 mm] for units without fiber optic connections

36” [0.91 m] depth by 30” [0.76 m] width on front and back of device.

clearance

Unit gross weight 15.4 lb [7.0 kg]

Packing carton Size: 23.6” x 16.1” x 14.6” [600 mm x 410 mm x 372 mm]

Gross Weight: 20.0 lb [9.1 kg]

Material/Finish Galvannealed steel with black powder coat

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 25

Page 26

Figure 4: D400 dimensions

1

1

.

1

8

"

[

2

8

4

.

0

5

m

m

]

1

9

"

r

a

c

k

m

o

u

n

t

[

4

8

2

.

5

9

m

m

]

2U [3.47" /88.12 mm]

CHAPTER 1: BEFORE YOU START

Environmental

Software

Operating temperature −20 °C to +65 °C

Maximum ambient temperature is +50 °C for unit to fully comply with IEC

61010-1 Section 10.1 regarding surface temperature limits for protection

against burns.

The top cover of the D400 can get hot during peak operation. Ensure

that there is at least 1U (1.75 inch [44.45 mm]) of free space above the

D400 unit for proper ventilation.

When the unit is operating above 50 °C ambient temperature, safe

handling precautions are recommended to prevent burns.

Humidity rating

Environmental rating Ingress protection: IP30 (IEC 60529)

Installation /

overvoltage category

Pollution degree 2

Use Indoor use only

Altitude Maximum altitude 6,560 ft [2000 m]

MTBF (MIL-217F) 39,400 hours at 40 °C in a fully loaded single Ethernet configuration

Noise 0 dB(A)

Firmware Supports various IED and host protocols as well as web-based user

Human machine

interface

Configuration Built-in graphical user interface (Web browser-based)

5% to 95% relative humidity, non-condensing

CAT II (2)

interface and secure access

Built-in graphical user interface (Web browser-based)

26 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 27

CHAPTER 1: BEFORE YOU START

Approvals

Storage recommendations

Storage conditions

Table 5: Compliance approvals

Compliance

CE Low voltage directive IEC 61010-1

EAC Machines and Equipment TR CU 0102011

Always store the D400 in an environment compatible with operating conditions.

Recommended environmental conditions for storage are:

•Temperature: −40 °C to +90 °C

• Relative humidity: 5% to 95%, non-condensing

Exposure to excessive temperature or other extreme environmental conditions might

cause damage and/or unreliable operation.

Applicable council directive ... According to ...

EMC directive EN 61326-1

Battery life

To maintain the life of the battery, the battery should be removed if the D400 is to be

powered down or stored for more than two weeks.

See “Replacing the battery” on page 160.

The battery sustains the NVRAM. If the battery is removed, the NVRAM storage is lost.

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 27

Page 28

CHAPTER 1: BEFORE YOU START

28 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 29

D400 Substation Gateway

Chapter 2: Installing the D400

Installing the D400

This chapter covers the following topics:

• Overview of the steps and tools required to install the D400

• Tour of the product features

• Physical installation the D400 in a rack or substation panel

Before you install and operate the D400, read and follow the safety guidelines and

instructions in “Safety precautions” on page 15.

It may be necessary to install a Service Pack or Service Updates for D400 v3.20 firmware. A

Service Pack comprises a set of all of the individual Service Updates.

Visit GE Multilin Technical Support website for the latest D400 R3.20 Service Pack and

Service updates:

http://www.gegridsolutions.com/events/signup.asp?sid=208

After logging in, navigate to: Substation Automation Products > D400 > Firmware.

Installation steps

The installation procedure varies depending on the components ordered and shipped with

your D400. Follow the procedures in this manual that apply to the specific hardware

configuration of your D400.

Follow these main

steps to install and set

up the D400

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 29

1. Mount the D400 in the rack or panel. See “Physical installation” on page 32.

2. Install the supplied battery on the D400 main board. See “Replacing the battery” on

page 160.

3. Set up the communication cards. See Chapter 3, Setting Up Communication Cards.

4. Make device and network connections. See Chapter 4, Connecting to Devices and

Networks.

5. Make power connections and verify operation. See Chapter 5, Powering Up the D400.

6. Set up the D400 network interface. See Chapter 6, Setting Up the D400.

7. Start using the D400 tools and utilities to configure and monitor the operation of the

D400. See Chapter 8, Using the D400.

Page 30

Required tools

Before beginning the installation procedures, have the following tools and equipment

available:

• Appropriate device cables for serial connections

• CAT5 network cables for RJ-45 Ethernet connections

• Flathead screwdriver with 0.6 mm by 3.5 mm blade (for terminal block wiring)

• Flathead screwdriver with 0.3 mm by 2.5 mm blade (for removing and installing the

adapter cards and changing switch positions)

• #1 Phillips screwdriver (for power terminal block wiring and adapter card removal)

• #2 Phillips screwdriver (for rack mounting the unit)

• Needle-nose pliers

• Wire cutters

• Wire strippers

• Wire-crimping tool (Panduit® CT-1525 or equivalent)

• 6 fork connectors, Panduit part number PV14-6F for 16-14 AWG [1.3-2.1 mm²] wire or

PV18-6F for 22-18 AWG [0.3-0.8 mm²] wire (or equivalent) for terminal block

connections

• 1 ring connector, Panduit part number PV10-14R for 12 AWG [3.3 mm²] wire for

protective earth terminal

• Approved network settings for the device

• Windows-based PC with Tera Term® (or any Windows-based terminal emulation

software) and Web browser software installed

CHAPTER 2: INSTALLING THE D400

Unpacking and inspecting the D400

To unpack and inspect the D400:

1. Carefully remove the D400 from its packaging.

2. Open the product package and check that the following items have been delivered:

– D400 unit (Product ID D400*XXXXXX)

– Ethernet cable, 60 inch [1.5 m], (GE Item No. 977-0209/60) for local network

connection

– Serial null modem cable, 72 inch [1.8 m], (GE Item No. 977-0529/72) for local

maintenance connection

– ½ AA 3.6 V Lithium Battery (GE Item No. 980-0038)

– Substation Automation products - Documentation CD (GE Item No. 581-0002)

– Mini SQL Proof of License (GE Item No. 580-1703)

3. Visually inspect the unit to ensure it has not sustained any visible damage during

transit. If there are visible signs of damage, report it immediately to the carrier.

4. \Verify that you have received all items. GE parts include a unique number, typically in

the format XXX-XXXX, that can be used as a reference.

5. Verify the hardware configuration of the D400 using the Product ID number. For an

explanation of the Product ID. See “Ordering guide” on page 22.

30 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 31

CHAPTER 2: INSTALLING THE D400

Power

Supply

Optional Redundant

Power Supply

Main Module

User CompactFlash

access panel

System Status

LED indicators

Serial Port Status

LED indicators

Ethernet port for local connection to HMI

Two USB Type A ports for USB device plug-in

Serial communication

port for local

maintenance

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Slot 8

Slot 9

Slot 10

Slot 11

Slot 12

Slot 13

Serial Communication Slots

IRIG-B Input Slot

IRIG-B Distribution Slot Network Slots

USB KVM Slot

Power Supply and

System Fail Alarms

External Power Source

First look at the D400

Front Panel

The front panel of the D400 provides easy access to the status indicators, user connections

and power supply units.

Figure 5: D400 front panel

Rear panel

The rear panel provides access to the communication ports, field wiring connections and

power connections.

Figure 6: D400 rear panel

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 31

Page 32

The D400 contains 13 I/O adapter card slots for the communication cards. The

communication cards are powered from the backplane of the D400. The types of

communication cards included in your D400 depend on what was ordered for your

substation application.

Physical installation

The D400 can be installed in a standard 19-inch rack or substation panel. The D400 is

supplied with a ½ AA 3.6

board when the D400 is installed.

The top cover of the D400 can get hot during peak operation. Ensure

that there is at least 1U (1.75 inch [44.45 mm]) of free space above the

D400 unit for proper ventilation.

When the unit is operating above 50 °C ambient temperature, safe

handling precautions are recommended to prevent burns.

Rack mounting

The D400 mounts directly into an industry standard 19-inch [482.6 mm] equipment

mounting rack with EIA universal mounting rail hole spacing.

CHAPTER 2: INSTALLING THE D400

V 0.9 Ah Lithium battery that you must insert on the D400 main

To mount the D400 on

a rack

1. Position the D400 in the rack.

2. Holding the D400 firmly in the rails of the mounting rack, insert and tighten the four

rack screws.

The recommended tool torque settings for zinc-plated mounting screws are:

– 10-32 UNF screws use 22.2 in-lb [2.50 Nm]

– 12-24 UNC screws use 31.0 in-lb [3.51 Nm]

– M5x0.45 screws use 18.1 in-lb [2.04 Nm]

– M6x0.5 screws use 33.3 in-lb [3.76 Nm]

For information on wiring the D400, see “Power connections” on page 82.

It is not recommended to ship the D400 installed in a rack without support brackets and

adequate conductive foam blocking in place.

32 GE INFORMATION D400 SUBSTATION GATEWAY INSTRUCTION MANUAL

Page 33

CHAPTER 2: INSTALLING THE D400

1.75 in.

[44.46 mm]

3.50 in.

[88.90 mm]

Cutout for panel mounting

18.3 in. [464.8 mm]

17.5 in. [444.5 mm]

.162 in.

[4.1 mm]

Panel mount

Battery installation

If you are using a panel cutout, use the following cutout dimensions:

Figure 7: D400 front panel dimensions

To insert the Lithium

battery

Battery removal

J12 - battery backup

enable/disable

Remove the D400 main module from the chassis and insert the battery in the battery

holder BT1. See

The D400 card contains a 3.6V lithium battery to maintain NVRAM contents (processor and

date/time) in the event of a power failure. Move jumper J12 to position 2-3 when storing

board for extended periods. Return jumper J12 to position 1-2 for normal operation.

Table 6 describes the J12 jumper positions and associated functions.

Table 6: Jumper J12 positions

Jumper Position Function

J12 pin 1 to 2 Connects the battery to the NVRAM and date/time

Disconnect the battery if the board is to be stored for extended periods. This conserves the

battery energy.

“Replacing the battery” on page 160 for more information.

pin 2 to 3 Disconnects the battery from the NVRAM and date/time

D400 SUBSTATION GATEWAY INSTRUCTION MANUAL GE INFORMATION 33