Page 1

LISTED

GE

Grid Solutions

Multilin

from M & MII Family, 239, 735/737, MLJ, & TOV relays

3 Series Retrofits

TM

Retrofit Guide

3 Series version: 2.3x

GE publication code: 1601-0380-A2 (GEK-130924A)

*1601-0380-A2*

Page 2

Copyright © 2017 GE Multilin Inc. All rights reserved.

3 Series Retrofit Guide.

3 Series Retrofit is a registered trademark of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin Inc. The content of this manual is for informational use only and is subject to

change without notice.

Part numbers contained in this manual are subject to change without notice, and should

therefore be verified by GE Multilin Inc. before ordering.

Part number: 1601-0380-A2 (September 2017)

For further assistance

For product support, contact the information and call center as follows:

GE Grid Solutions

650 Markland Street

Markham, Ontario

Canada L6C 0M1

Worldwide telephone: +1 905 927 7070

Europe/Middle East/Africa telephone: +34 94 485 88 54

North America toll-free: 1 800 547 8629

Fax: +1 905 927 5098

Worldwide e-mail: multilin.tech@ge.com

Europe e-mail: multilin.tech.euro@ge.com

Website: http://www.gegridsolutions.com/multilin

ii

Page 3

Safety words and definitions

NOTE

The following symbols used in this document indicate the following conditions:

Note

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

Note

Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Note

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Note

Indicates practices not related to personal injury.

Indicates general information and practices, including operational information and

practices, that are not related to personal injury.

General Cautions and Warnings

The following general safety precautions and warnings apply.

Note

Note

Disassembly of this unit will void the warranty. Do not attempt to open or repair the

retrofit enclosure. All repairs are to be conducted by the factory.

Before attempting to use the equipment, it is important that all danger and caution

indicators are reviewed.

If the equipment is used in a manner not specified by the manufacturer or functions

abnormally, proceed with caution. Otherwise, the protection provided by the

equipment may be impaired and can result in impaired operation and injury.

Note

Note

Hazardous voltages can cause shock, burns or death.

Installation/service personnel must be familiar with general device test practices,

electrical awareness and safety precautions must be followed.

Before performing visual inspections, tests, or periodic maintenance on this device or

associated circuits, isolate or disconnect all hazardous live circuits and sources of

electric power.

Failure to shut equipment off prior to removing the power connections could expose

you to dangerous voltages causing injury or death.

Ensure that all connections to the product are correct to avoid accidental risk of shock

and/or fire, for example from high voltage connected to low voltage terminals.

Follow the requirements of this manual, including adequate wiring size and type,

terminal torque settings, voltage, current magnitudes applied, and adequate isolation/

clearance in external wiring from high to low voltage circuits.

Use the device only for its intended purpose and application.

iii

Page 4

Ensure that all ground paths are un-compromised for safety purposes during device

operation and service.

All recommended equipment should be grounded and must have a reliable and uncompromised grounding path for safety purposes, protection against electromagnetic

interference and proper device operation.

Equipment grounds should be bonded together and connected to the facility’s main

ground system for primary power.

Keep all ground leads as short as possible.

In addition to the safety precautions mentioned all electrical connections made must

respect the applicable local jurisdiction electrical code.

It is recommended that a field external switch, circuit breaker be connected near the

equipment as a means of power disconnect. The external switch or circuit breaker is

selected in accordance with the power rating.

Ensure that the control power applied to the device, the AC current, and voltage input

match the ratings specified on the relay nameplate. Do not apply current or voltage in

excess of the specified limits.

Only qualified personnel are able to operate the device. Such personnel must be

thoroughly familiar with all safety cautions and warnings in this manual and with

applicable country, regional, utility, and plant safety regulations.

Hazardous voltages can exist in the power supply and at the device connection to

current transformers, voltage transformers, control, and test circuit terminals. Make

sure all sources of such voltages are isolated prior to attempting work on the device.

Hazardous voltages can exist when opening the secondary circuits of live current

transformers. Make sure that current transformer secondary circuits are shorted out

before making or removing any connection to the current transformer (CT) input

terminals of the device.

For tests with secondary test equipment, ensure that no other sources of voltages or

currents are connected to such equipment and that trip and close commands to the

circuit breakers or other switching apparatus are isolated, unless this is required by

the test procedure and is specified by appropriate utility/plant procedure.

When the device is used to control primary equipment, such as circuit breakers,

isolators, and other switching apparatus, all control circuits from the device to the

primary equipment must be isolated while personnel are working on or around this

primary equipment to prevent any inadvertent command from this device.

Use external disconnect equipment to isolate the mains voltage supply.

Note

To ensure the settings file inside the relay is updated, wait 30 seconds after a setpoint

change before cycling power.

Note

This product is rated to Class A emissions levels and is to be used in Utility, Substation

Industrial environments. Not to be used near electronic devices rated for Class B levels.

iv

Page 5

Table of Contents

1: OVERVIEW INTRODUCTION ................................................................................................................................ 1

MIF AND MIF II RELAYS .................................................................................................................. 3

MIV AND MIV II RELAYS ................................................................................................................. 5

MIG AND MIG II RELAYS ................................................................................................................ 7

MIN AND MIN II RELAYS ................................................................................................................ 11

MIW AND MIW II RELAYS .............................................................................................................. 13

239 RELAYS ........................................................................................................................................15

735/737 RELAYS ............................................................................................................................... 17

MLJ AND TOV RELAYS .................................................................................................................... 19

FINDING YOUR M AND MII FAMILY RELAY ORDER CODE ............................................... 21

2: CONVERTING

SETTINGS FILES

3: INSTALLING THE

3 SERIES RELAY

4: ELECTRICAL

INSTALLATION

DOWNLOADING AND SAVING MIF II OR MIV II SETPOINT FILES ................................. 24

CONVERTING A SAVED MIF II OR MIV II SETPOINT FILE .................................................. 25

CONVERSION REPORT ................................................................................................................... 27

LOADING SETPOINTS FROM A FILE .......................................................................................... 28

CONVERTING MIN II 67IG1 TO 350 32N ................................................................................ 29

3 SERIES DIMENSIONS AND MOUNTING ............................................................................... 34

M AND MII FAMILY RELAYS .......................................................................................................... 36

239 DIMENSIONS ............................................................................................................................. 43

735/737 DIMENSIONS AND 350 RETROFIT MOUNT ......................................................... 44

MLJ AND TOV DIMENSIONS AND MOUNTING .................................................................... 46

P40 AGILE DIMENSIONS ............................................................................................................... 49

350 WIRING ........................................................................................................................................ 52

345 WIRING ........................................................................................................................................ 53

339 WIRING ........................................................................................................................................ 54

MIF II WIRING ..................................................................................................................................... 56

MIV II WIRING .................................................................................................................................... 57

MIF II/MIV II TO 350 RETROFIT WIRING .................................................................................. 58

239 WIRING ........................................................................................................................................ 62

735/737 WIRING .............................................................................................................................. 65

A: APPENDIX WARRANTY ......................................................................................................................................... 67

CHANGE NOTES ................................................................................................................................ 67

3 SERIES RETROFIT – INSTRUCTION MANUAL v

Page 6

3 SERIES RETROFIT – INSTRUCTION MANUAL vi

Page 7

GE

Grid Solutions

3 Series Retrofit

Chapter 1: Overview

Overview

1.1 Introduction

As the Multilin MII Family, Multilin 239, and Multilin 735/737 digital relays age, the Multilin

Series (SR3) family of protection relays provide updated functional and economical

3

protection solutions for feeders, motors and transformers. The 3

the 350, 345, and 339, provide extensive diagnostic information allowing users to

troubleshoot and minimize downtime. 3

simplify engineering tasks such as configuration, wiring, testing, commissioning, and

maintenance.

The MultilinTM 3 Series Retrofit Instruction Manual offers a solution to upgrade previously

installed Multilin relays, providing detailed order code equivalencies, mechanical details,

and wiring diagrams. For common MII Family Digital relays a software conversion tool

provides conversion of existing settings files and Modbus Maps. This manual also provides

retrofit suggestions for Multilin M Family, MLJ, and TOV relays in less detail.

Series relays streamline work flow processes and

Series family, including

3 SERIES RETROFIT – INSTRUCTION MANUAL 1

Page 8

INTRODUCTION CHAPTER 1: OVERVIEW

The MultilinTM 3 Series Retrofit takes place in four general steps, as follows.

1. Select a replacement relay - see the summary tables and the specific order code

comparisons for the MII Family relays shown in this chapter. If you need to determine

your MII relay order code, refer to section

1.10 Finding your M and MII Family relay

order code.

2. Convert the existing settings file if applicable; MIF II, and MIV II file conversion is

currently supported for most models - see Chapter 2:

Converting Settings F iles.

3. Install the new 3 Series Retrofit - see Chapter 3: Installing the 3 Series Relay.

4. Wire the new 3 Series Retrofit - see Chapter 4: Electrical Installation.

3 Series relays have an IP54 rating, superior to that of the MII Family relays which have an

IP52 rating. In addition, vibration tests for 3

Series relays have been passed for both the 4screw mount (as used in the MII Family retrofit) and 8-screw mount (as used for new

installations).

2 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 9

CHAPTER 1: OVERVIEW MIF AND MIF II RELAYS

NOTE

1.2 MIF and MIF II relays

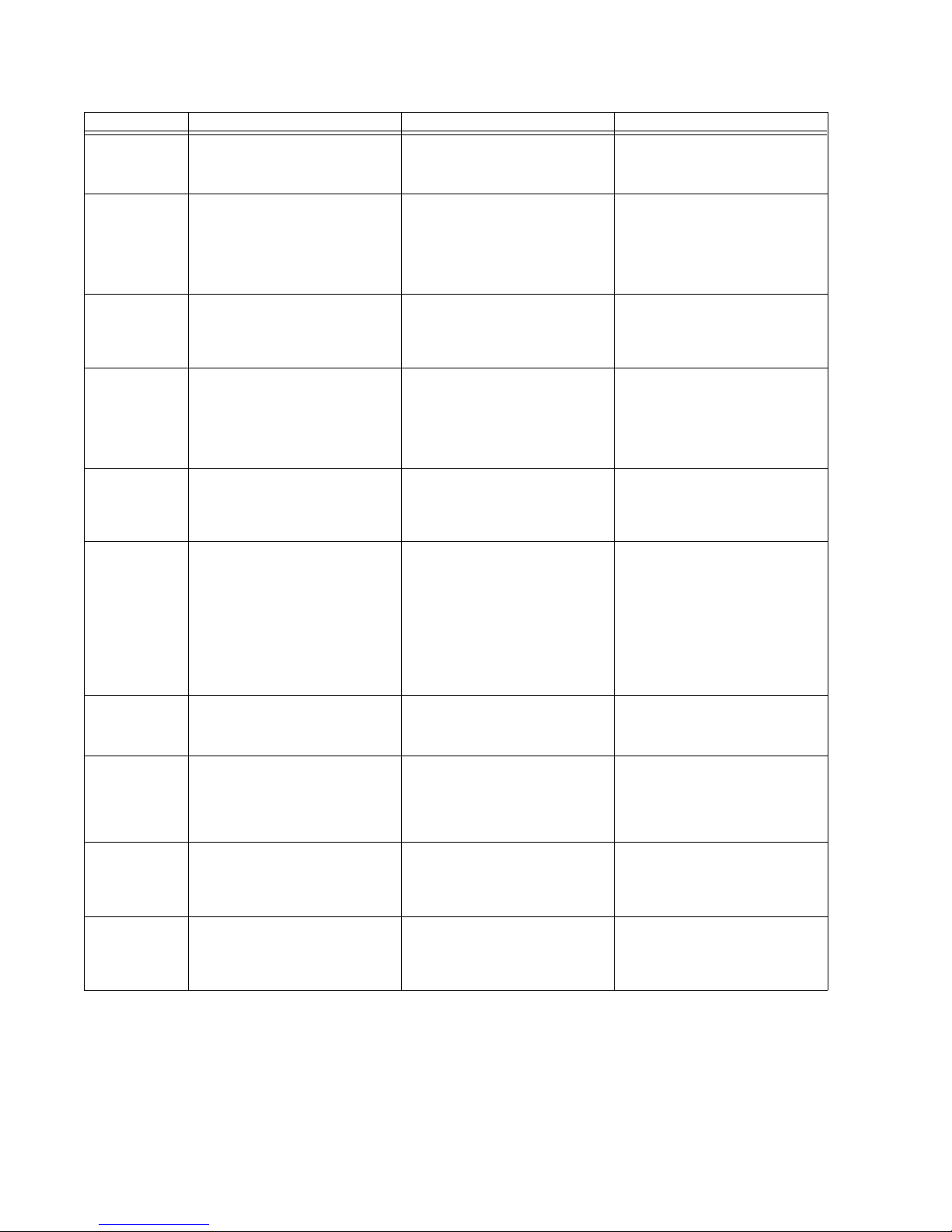

Installed Relay Retrofit Relay

MIFII Digital Feeder Relay

MIF Digital Feeder Relay

MIF and MIF II features are available in 350 relays as described in the table below:

Feature MIF MIF II

Protection &

Control

Monitoring &

Metering

Oscillography 8 samples/cycle

Communications Serial (RS232, RS485)

Hardware 2 digital inputs

1. For additional features, refer to the 350 Instruction Manual.

Thermal Overload: 49,

IOC: 50PH, 50PL, 50GH, 50GL, 50NH,

50NL

TOC: 51G, 51N, 51P

Cold Load Pickup: CLP

Breaker Failure: 50BF

Breaker Health

Event Recording

maximum length 24 cycles

protocols: Modbus RTU

6 relay outputs

Configurable I/O

Configurable Logic

4 configurable LEDs

2 fixed LEDs

Thermal Overload: 49(1)

IOC: 50P (2), 50G(2)

TOC: 51G(1), 51P(1)

Autoreclose: 79

Cold Load Pickup: CLP

Breaker Failure to Open

Breaker Health

Event Recording

8 samples/cycle

maximum length 24 cycles

Serial (RS232, RS485)

protocols: Modbus RTU, IEC 60870-5103

2 digital inputs

6 digital outputs

Configurable I/O

Configurable Logic

4 configurable LEDs

2 fixed LEDs

350 Feeder Protection System

350

Thermal Overload: 49

IOC: 50P(2), 50N(2), 50_2, 50G/SG(2)

TOC: 51P, 51N, 51_2, 51G/SG

Other protection: 67G/SG, 32N, VTFF,

27_1, 27X, 59X, 67P, 67N, 46BC, 32,

27P, 59P, 59_2, 59N, 81U(2), 81O(2),

Arc Flash

Autoreclose: 79

Cold Load Pickup: CLP

Breaker Failure: 50BF

Other control: 60CTS, 86, 25

Breaker Health

Event Recording

up to 32 samples per cycle

(user-selectable)

maximum length 192 cycles

USB

Serial (RS485) protocols: Modbus RTU,

DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC 61850

GOOSE, IEC 61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

10 LEDs (non-programmable LEDs)

12 LEDs (programmable LEDs)

1

The following table describes MIF and MIF II options, and the equivalent 350 options and

order codes. In some cases the 350 options have changed from those available for MIF and

MIF II relays, so read the descriptions carefully.

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

www.gegridsolutions.com/multilin for up-to-date order codes.

3 SERIES RETROFIT – INSTRUCTION MANUAL 3

Page 10

MIF AND MIF II RELAYS CHAPTER 1: OVERVIEW

Feature MIF order code options MIF II order code options 350 order code options

Application MIF-P-A11E100F00C

MIFII-P-A11E00HI00

All 350 relays come with 3 phase

and ground standard.

P: 3 Phase and Ground

N: Single Phase

Curves MIFP-A-11E100F00C

P: 3 Phase and Ground

N: Single Phase

MIFIIP-A-11E00HI00

All 350 relays come with ANSI, IEC,

and IAC curves standard.

A: ANSI Curves

I: IEC Curves

U: IAC Curves

C: EPTAR-C Curves (single phase

only)

Phase CT Range MIFPA-1-1100F00C

A: ANSI Curves

I: IEC Curves

U: IAC Curves

C: EPTAR-C Curves (single phase

only)

MIFIIPA-1-1E00HI00

350E-P0-G0HEENNSNNN

Ground CT

0: N models (single phase)

1: Phase CT = 1 A (0.1 - 2.4 A)

5: Phase CT = 5 A (0.5 - 12 A)

MIFPA1-1-E100F00C

0: Phase CT = 1/5 A

1: Phase CT = 1 A

5: Phase CT = 5 A

MIFIIPA1-1-E00HI00

Range

1: Ground CT In = 1 A (0.1 - 2.4 A)

5: Ground CT In = 5 A (0.5 - 12 A)

N: Sensitive Ground (0.005 - 0.12 A)

1: Ground CT In = 1 A (0.1 - 2.4 A)

5: Ground CT In = 5 A (0.5 - 12 A)

L: Extremely Sensitive Ground In

= 1 A (0.002 - 0.048 A)

N: Sensitive Ground (0.005 - 0.12 A)

Language All MIF relays come with English

MIFIIPA11-E-00HI00

standard.

E: English

F: French

T: Turkish

Options MIFPA11E-1-00F00C

0: Basic Model ()

1: Option 1 (Configurable I/O, Event

Recording, and Oscillography)

2: Option 2 (Option 1 and Cold Load

Pickup, Breaker Failure Protection,

Breaker Health, and Configurable

Logic)

MIFIIPA11E-0-0HI00

0: Basic Model ()

1: Option 1 (Event Recording,

Oscillography, Configurable I/O and

LEDs)

2: Option 2 (Option 1 and Cold Load

Pickup, Breaker Failure Protection,

Breaker Health, Configurable Logic,

and Circuit Breaker Control)

Recloser n/a MIFIIPA11E0-0-HI00

0: without Recloser

R: with Recloser

Power Supply MIFPA11E100-F-00C

MIFIIPA11E00-HI-00

P0: user selectable 1/5 A three-

phase current inputs (0.02 - 20 × CT)

350EP0-G0-HEENNSNNN

G0: user selectable 1/5 A Ground

current input (0.02 - 20 × CT)

S0: user selectable 1/5 A Sensitive

Ground current input (0.002 - 3 × CT)

All 350 relays come with English

standard.

350EP0G0HEE-N-NSNNN

N: CLP, Lockout (86)

C: CLP, 50BF, Autoreclose (79)

All 350 relays come with Event

Recording, Oscillography,

Configurable I/O and LEDs,

Configurable Logic (up to 16),

Breaker Health, and Circuit Breaker

Control standard.

1

350EP0G0HEE-N-NSNNN

N: CLP, Lockout (86)

C: CLP, 50BF, Autoreclose (79)

350EP0G0-H-EENNSNNN

H:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

F: 24 - 48 VDC (Range: 19~58 VDC)

Protocol All MIF relays come with Modbus

RTU standard.

Environmental

n/a MIFIIPA11E00HI0-0

Option

1. Some features are implemented or configured somewhat differently in the 350 relay. See the 350 Instruction Manual for details.

2. For details of 350 communications implementation, see the 3 Series Communications Guide.

4 3 SERIES RETROFIT – INSTRUCTION MANUAL

HI:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

LO: 28 - 48 VDC (Range: 19~58 VDC)

MIFIIPA11E00HI-0-0

0: Standard model (Modbus RTU)

C: IEC60870-5-103 with 2 Comms

ports

0: None

H: Conformal Coating

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

350EP0G0HEENN-SN-NN

SN: Standard: Front USB, Rear

RS485: Modbus RTU, DNP3.0,

IEC60870-5-103

2

350EP0G0HEENNSNN-N

N: None

H: Harsh Environment Conformal

Coating

Page 11

CHAPTER 1: OVERVIEW MIV AND MIV II RELAYS

1.3 MIV and MIV II relays

Installed Relay Retrofit Relay

MIV II Voltage/Frequency Relay

MIV Voltage/Frequency Relay

MIV and MIV II features are available in 350 relays as described in the table below:

350 Feeder Protection System

Feature MIV MIV II

Protection &

Control

Oscillography 8 samples/cycle

CommunicationsSerial (RS232, RS485)

Hardware 2 digital outputs

1. For additional features, refer to the 350 Instruction Manual.

UV: 27(2)

OV: 59(2), 59N(2)

Underfrequency: 81U(2)

Overfrequency: 81O(2)

Phase reversal: 47(1)

maximum length 24 cycles

protocols: Modbus RTU

6 relay outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

UV: 27P(4)

OV: 59P(4), 59N(4)

Underfrequency: 81U(4)

Overfrequency: 81O(4)

Phase reversal: 47(1)

Note: the number of elements

differs for different MIV II options.

Maximum numbers are shown.

MIV 1000 & 3000:

8 samples/cycle

maximum length 24 cycles

MIV 2000:

2 samples per cycle

maximum length 432 cycles

Serial (RS232, RS485)

protocols: Modbus RTU

2 digital inputs

6 digital outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

1

350

UV: 27P(4), 27X(1), 27P_1(1)

OV: 59P(4), 59N(4), 59X(1), 59_2(2)

Underfrequency: 81U(4)

Overfrequency: 81O(4)

Other Protection: 25(1), VTFF(1),

Volt/Hz

24(1)

up to 32 samples per cycle

(user-selectable)

maximum length 192 cycles

USB

Serial (RS485) protocols: Modbus RTU,

DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC 61850

GOOSE, IEC 61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

10 LEDs (non-programmable LEDs)

12 LEDs (programmable LEDs)

3 SERIES RETROFIT – INSTRUCTION MANUAL 5

Page 12

MIV AND MIV II RELAYS CHAPTER 1: OVERVIEW

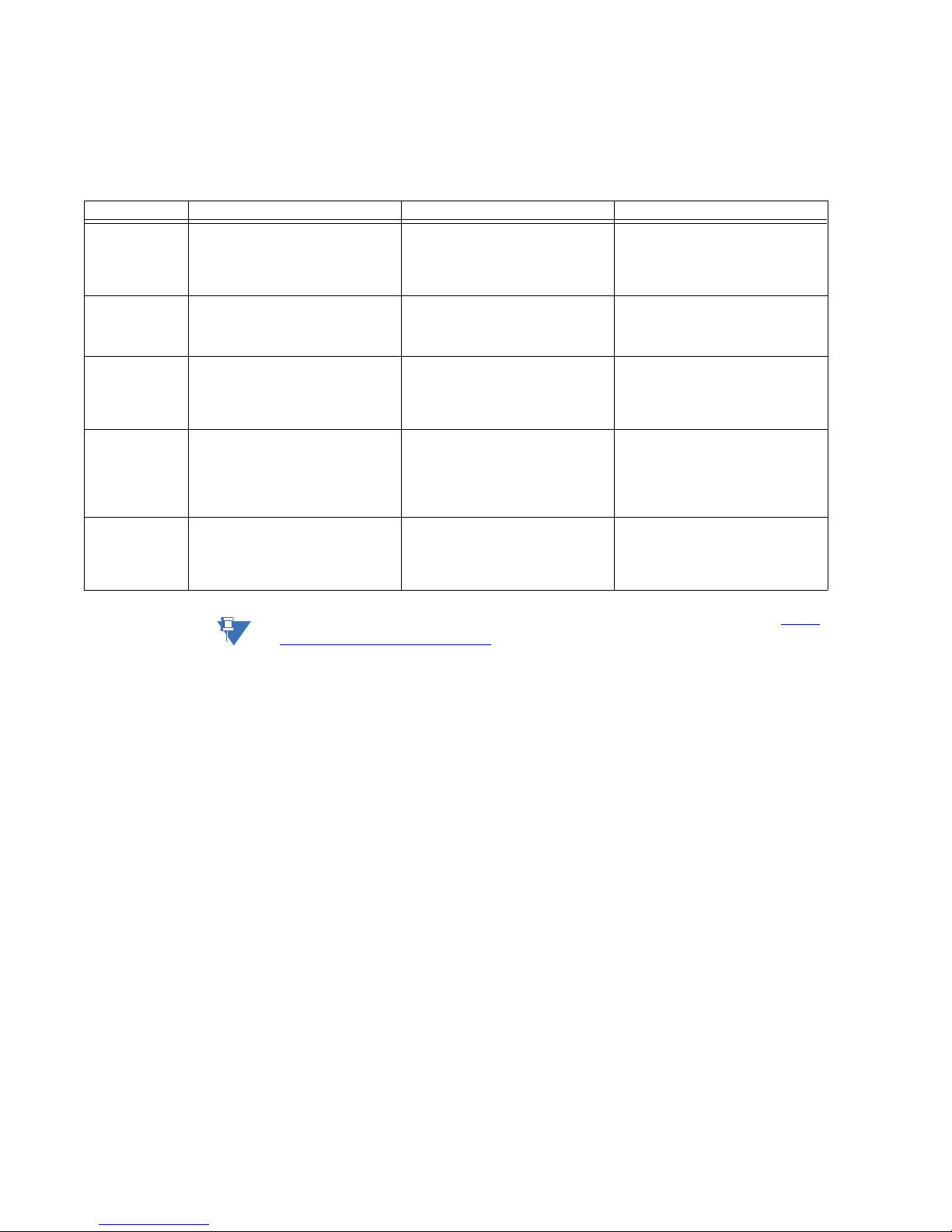

The following table describes MIV II options, and the equivalent 350 options and order

codes. In some cases the 350 options have changed from those available for MIV II relays,

so read the descriptions carefully.

Feature MIV order code options MIV II order code options 350 order code options

Function MIV-1-000E000F00C

MIVII-1-010E00HI00

350E-PXGX-HE-N-N-V-SNNN

1: Voltage Functions

2: Frequency Functions

3: Voltage and Frequency Function

Voltage Range MIV10-0-0E000F00C

0: 10 - 250 V Setting Range

1: 2 - 60 V Setting Range

Language All MIV relays come with English

standard.

Power Supply MIV1000E000-F-00C

H:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

F: 24 - 48 VDC (Range: 19~58 VDC)

Environmental

n/a MIVII1010E00HI-00

Option

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

www.gegridsolutions.com/multilin for up-to-date order codes.

1: Voltage Functions

2: Frequency Functions

3: Voltage and Frequency Function

MIVII10-1-0E00HI00

0: 10 - 250 V Setting Range

1: 2 - 60 V Setting Range

MIVII1010-E-00HI00

E: English

F: French

T: Turkish

MIVII1010E00-HI-00

HI:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

LO: 28 - 48 VDC (Range: 19~58 VDC)

00: None

0H: Conformal Coating

V: Voltage Metering - 27P(4), 27X(1),

27P_1(1), 59P(4), 59N(4), 59X(1),

59_2(2), 81O(4), 81U(4), 25(1), VTFF(1)

All 350 models with the VT module:

Primary VT range: 0.15 to 550kV

VT Secondary range: 50 to 220V

All 350 relays come with English

standard.

350EPXGX-H-ENNVSNNN

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

350EPXGXHENNVSNN-N

N: None

H: Harsh Environment Conformal

Coating

6 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 13

CHAPTER 1: OVERVIEW MIG AND MIG II RELAYS

NOTE

1.4 MIG and MIG II relays

Installed Relay

MIG II Generator Protection System

MIG Machine Protection Relay

Retrofit Relay

350 Feeder Protection System, 345 Transformer Protection System, 339 Motor Protection System, 850 Feeder Protection System,

or P40 Agile P14D Relay

Most MIG and MIG II features are available in 350, 345, or 339 relays as described in the

tables below. In some cases an 8 Series or P40 Agile relay may be required to replace full

functionality. For additional information, refer to the P40 Technical Manual or

850

Instruction Manual.

1.4.1 MIG and MIG II P to 350 or 345

For the MIG II P being used as a transformer, when 87R is not required, the 350 relay is an

option. When 87R is required, the 345 relay with 87G is an option.

For the MIG II P being used as a generator, the 350 relay is an option.

Note

Feature MIG MIG II P

Protection &

Control

Current Unbalance: 46

Thermal Protection: 49

IOC: 50P, 50G, 51G

TOC: 51P

Undercurrent: 37

66

Restricted Ground

Differential: 87R

The 350 Feeder Protection System does not support Restricted Ground Differential 87R. To

replace MIG and MIG II P relays when Restricted Ground Fault protection is required, the

345 relay with 87G can be used. a P40 Agile P14D relay or 850 Feeder Protection System

can also be used.

Current Unbalance: 46

Thermal Protection: 49

IOC: 50N, 50P, 50G

TOC: 51G, 51N, 51P

Restricted Ground

Differential: 87R

1

350

Current unbalance:

51_2 or 46(1), 50_2 (1) or 46(1)

Thermal Protection: 49

IOC: 50P(2), 50G/SG(2), 50N(2),

TOC: 51P(1), 51G/SG(1), 51N(1),

Other Protection: I1/I2(46BC)

2

345

Current unbalance:

51_2 or 46(1), 50_2 (1) or 46(1)

Thermal Protection: 49

IOC: 50P(2), 50G/SG(2), 50N(2),

TOC: 51P(1), 51G/SG(1), 51N(1),

Restricted Ground Fault:

87G/RGF(2)

3 SERIES RETROFIT – INSTRUCTION MANUAL 7

Page 14

MIG AND MIG II RELAYS CHAPTER 1: OVERVIEW

Feature MIG MIG II P

Metering &

Monitoring

Oscillography 8 samples/cycle

Communications Serial (RS232, RS485)

Hardware 2 digital outputs

1. For additional features, refer to the 350 Instruction Manual.

2. For additional features, refer to the 345 Instruction Manual.

Metering

Event Recording

maximum length 24

cycles

protocols: Modbus RTU

6 relay outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

Metering

Event Recording

8 samples/cycle

maximum length 24

cycles

Serial (RS232, RS485)

protocols: Modbus RTU

2 digital inputs

6 digital outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

The following table describes MIG II P options, and the equivalent 350 and 345 options and

order codes. In some cases the 350/345 options have changed from those available for

MIG II relays, so read the descriptions carefully.

1

350

Metering

Event Recording

up to 32 samples per cycle

(user-selectable)

maximum length 192 cycles

USB

Serial (RS485) protocols:

Modbus RTU, DNP 3.0, IEC

60870-5-103

Ethernet protocols: Modbus

TCP/IP, DNP 3.0, IEC 60870-5104, IEC 61850 GOOSE, IEC

61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

10 LEDs (non-programmable

LEDs)

12 LEDs (programmable LEDs)

2

345

Metering

Event Recording

up to 32 samples per cycle

(user-selectable)

maximum length 192 cycles

USB

Serial (RS485) protocols:

Modbus RTU, DNP 3.0, IEC

60870-5-103

Ethernet protocols: Modbus

TCP/IP, DNP 3.0, IEC 60870-5104, IEC 61850 GOOSE, IEC

61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

10 LEDs (non-programmable

LEDs)

12 LEDs (programmable LEDs)

Feature MIG order code options MIG II P order code options 350/345 order code options

Application n/a MIGII-P-A11E00HI00

P: Generator Protection Elements

350EP0G0HE-M-NNSNNN

M: Advanced configuration: User

selectable 49, 50P(2), 50G/SG(2),

50N(2), 51P(1), 51G/SG(1), 51N(1),

51_2 or 46(1), 50_2 (1) or 46(1), I1/

I2(46BC)

345EP0G0HE-M-NNSNNN

M: Advanced configuration: 87T,

87T-50, 51P(2), 51N(2), 51G(2),

50P(2), 50G(2), 50N(2), 49P, 46 (51_2/

50_2)(2), 86, 50BF(2), 87G/RGF(2)

Curves MIGP-A-11E000F00C

MIGIIP-A-11E00HI00

All 350 and 345 relays come with

ANSI, IEC, and IAC curves standard.

A: ANSI Curves

I: IEC Curves

Phase CT Range MIGPA-1-1E000F00C

1: Phase CT = 1 A (0.1 - 2.4 A)

5: Phase CT = 5 A (0.5 - 12 A)

A: ANSI Curves

I: IEC Curves

MIFIIPA-1-1E00HI00

0: Phase CT = 1/5 A

1: Phase CT = 1 A

3xxE-P0-G0HEMNNSNNN

P0: P0 user selectable 1/5 A three-

phase current inputs

5: Phase CT = 5 A

Ground CT

MIGPA1-1-E000F00C

MIGIIPA1-1-E00HI00

3xxEP0-G0-HEMNNSNNN

Range

1: Ground CT In = 1 A (0.1 - 2.4 A)

5: Ground CT In = 5 A (0.5 - 12 A)

N: Sensitive Ground CT In = 1 A

(0.005 - 0.12 A)

1: Ground CT In = 1 A (0.1 - 2.4 A)

5: Ground CT In = 5 A (0.5 - 12 A)

N: Sensitive Ground (0.005 - 0.12 A)

G0: user selectable 1/5 A Ground

current input (0.02 - 20 × CT)

S0: user selectable 1/5 A Sensitive

Ground current input (0.002 - 3 × CT)

8 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 15

CHAPTER 1: OVERVIEW MIG AND MIG II RELAYS

NOTE

Feature MIG order code options MIG II P order code options 350/345 order code options

Power Supply MIGPA11E000-F-00C

MIGIIPA11E00-HI-00

3xxEP0G0-H-EENNSNNN

H:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

F: 24 - 48 VDC (Range: 19~58 VDC)

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

HI:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

LO: 28 - 48 VDC (Range: 19~58 VDC)

www.gegridsolutions.com/multilin for up-to-date order codes.

1.4.2 MIG and MIG II Q to 339

Feature MIG MIG II Q

Protection &

Control

Metering &

Monitoring

Oscillography 8 samples/cycle maximum length

Communications Serial (RS232, RS485)

Hardware 2 digital outputs

1. For additional features, refer to the 339 Instruction Manual.

Current Unbalance: 46

Thermal Protection: 49

IOC: 50P, 50G, 51G

TOC: 51P

Undercurrent: 37

66

Restricted Ground Differential: 87R

24 cycles

protocols: Modbus RTU

6 relay outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

Current Unbalance: 46

Acceleration Time: 48

Thermal Protection: 49

IOC: 50N, 50P, 50G

TOC: 51G, 51N, 51P

Undercurrent: 37

66

Metering

Event Recording

8 samples/cycle

maximum length 24 cycles

Serial (RS232, RS485)

protocols: Modbus RTU

2 digital inputs

6 digital outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

1

339

Current Unbalance: 46

Acceleration Time: 48

Thermal Protection: 49

IOC: 50G/SG(1), 50L, 50N(1), 50P(1)

TOC: 51N(1), 51P(1), 51R

Undercurrent: 37

66

Other Protection: 86, 50BF

Metering

Event Recording

up to 32 samples per cycle

(user-selectable)

maximum length 192 cycles

USB

Serial (RS485) protocols: Modbus RTU,

DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC 61850

GOOSE, IEC 61850

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

10 LEDs (non-programmable LEDs)

12 LEDs (programmable LEDs)

3 SERIES RETROFIT – INSTRUCTION MANUAL 9

Page 16

MIG AND MIG II RELAYS CHAPTER 1: OVERVIEW

NOTE

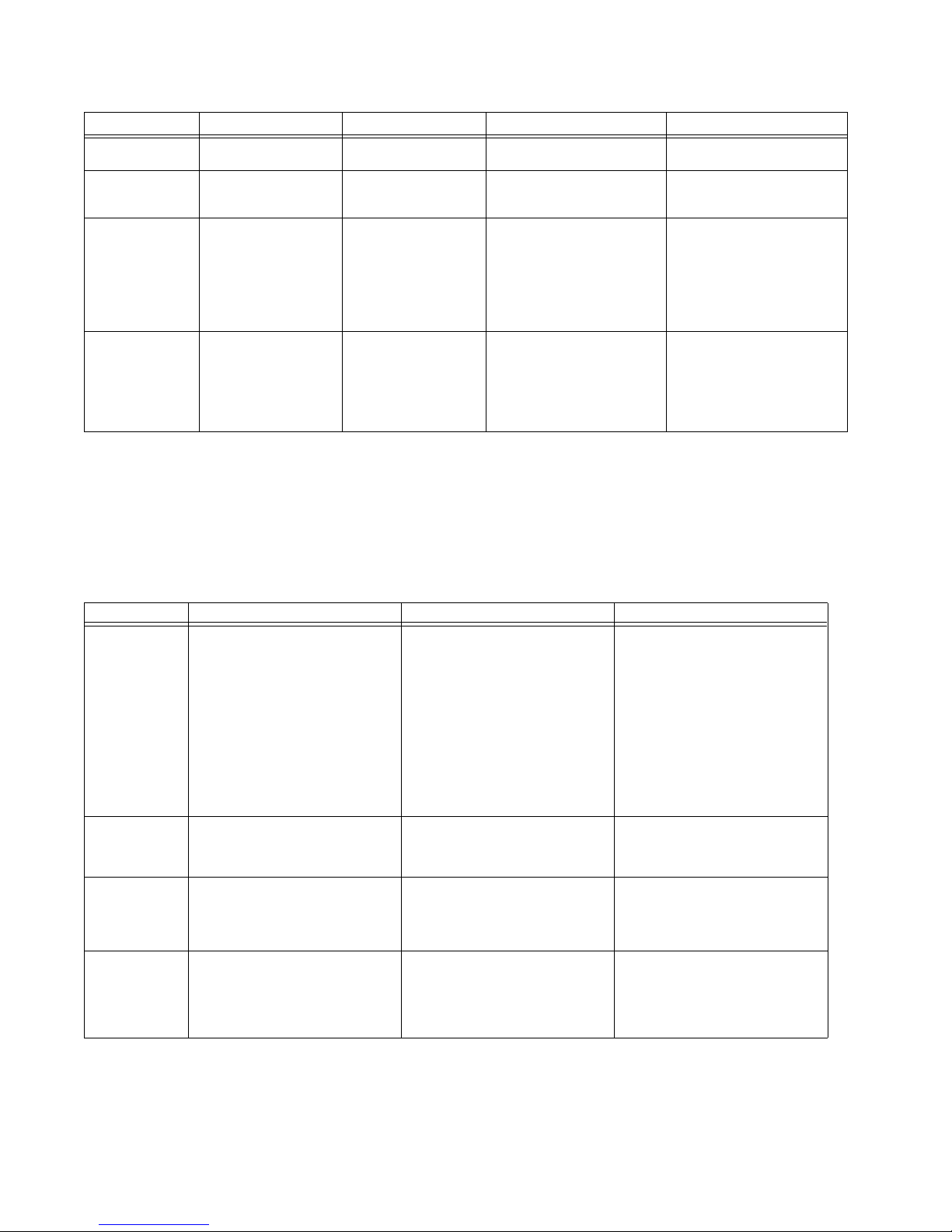

The following table describes MIG and MIG II Q options, and the equivalent 339 options and

order codes. In some cases the 339 options have changed from those available for MIG

and MIG II relays, so read the descriptions carefully.

Feature MIG order code options MIG II Q order code options 339 order code options

Application n/a MIGII-Q-A11E00HI00

339EP0G0HE-S-NNSNNN

Curves MIGP-A-11E000F00C

A: ANSI Curves

I: IEC Curves

Phase CT Range MIGPA-1-1E000F00C

1: Phase CT = 1 A (0.1 - 2.4 A)

5: Phase CT = 5 A (0.5 - 12 A)

Ground CT

MIGPA1-1-E000F00C

Range

1: Ground CT In = 1 A (0.1 - 2.4 A)

5: Ground CT In = 5 A (0.5 - 12 A)

N: Sensitive Ground CT In = 1 A

(0.005 - 0.12 A)

Power Supply MIFPA111-F-C

H:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

F: 24 - 48 VDC (Range: 19~58 VDC)

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

www.gegridsolutions.com/multilin for up-to-date order codes.

Q: Motor Protection Elements

MIGIIQ-A-11E00HI00

A: ANSI Curves

I: IEC Curves

MIGIIQA-1-1E00HI00

1: Phase CT = 1 A (0.1 - 2.4 A)

5: Phase CT = 5 A (0.5 - 12 A)

MIGIIQA1-1-E00HI00

1: Ground CT In = 1 A (0.1 - 2.4 A)

5: Ground CT In = 5 A (0.5 - 12 A)

N: Sensitive Ground CT In = 1 A

(0.005 - 0.12 A)

MIFIIQA11E00-HI-00

HI:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

LO: 28 - 48 VDC (Range: 19~58 VDC)

S: Standard configuration: 37, 46,

48, 49, 50P(1), 50G/SG(1), 50N(1),

50L,51R, 66, 86, 51N(1), 51P(1), 50BF

All 339 relays come with ANSI, IEC,

and IAC curves standard.

339E-P0-G0HESNNSNNN

P0: user selectable 1/5 A three-

phase current inputs (0.02 - 20 × CT)

339EP0-G0-HESNNSNNN

G0: user selectable 1/5 A Ground

current input (0.02 - 20 × CT)

All 339 relays come with CBCT

(50:0.025) standard.

339EP1G1-H-ESNNSNNN

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

10 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 17

CHAPTER 1: OVERVIEW MIN AND MIN II RELAYS

1.5 MIN and MIN II relays

Installed Relay Retrofit Relay

MIN II Ground Protection System

MIN Digital Ground Protection

Most MIN and MIN II features are available in 350 relays as described in the table below:

350 Feeder Protection System,

or P40 Agile Relay

Feature MIN

Protection &

Control

Metering &

Monitoring

Oscillography 8 samples/cycle

Communications Serial (RS232, RS485)

Hardware 2 digital outputs

1. For a detailed example of converting the MIN II Option "S" 67IG1 function to the 350 32N function, see Converting MIN II 67IG1 to 350

32N on page 29.

2. For additional features, refer to the 350 Instruction Manual.

Directional: 67N1, 67N2

IOC: 50GH, 50GL

TOC: 51GH, 51GL

Cold Load Pickup: CLP

Breaker Failure: 50BF

Metering

Breaker Health

Event Recording

maximum length 24 cycles

protocols: Modbus RTU

6 relay outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

67G1, 67G2, 67PC1, 67PC2

50G1, 50G2

51G1, 51G2

Metering

Event Recorder

8 samples/cycle

maximum length 24 cycles

Serial (RS232, RS485)

protocols: Modbus RTU

2 digital inputs

6 digital outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

MIN II

1

Directional: 67P(1), 67N(1), 67G/SG(1)

IOC: 50P(2), 50N(2), 50_2, 50G/SG(2)

TOC: 51P(1), 51G/SG(1), 51N(1)

Cold Load Pickup: CLP

Breaker Failure: 50BF

Other: 49, 32N(2), VTFF + Voltage,

Power, and Energy Metering, 60CTS

Metering

Breaker Health

Event Recording

up to 32 samples per cycle

(user-selectable)

maximum length 192 cycles

USB

Serial (RS485) protocols: Modbus RTU,

DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC 61850

GOOSE, IEC 61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

10 LEDs (non-programmable LEDs)

12 LEDs (programmable LEDs)

350

2

3 SERIES RETROFIT – INSTRUCTION MANUAL 11

Page 18

MIN AND MIN II RELAYS CHAPTER 1: OVERVIEW

NOTE

The following table describes MIN and MIN II options, and the equivalent 350 options and

order codes. In some cases the 350 options have changed from those available for MIN

and MIN II relays, so read the descriptions carefully.

Feature MIN order code options MIN II order code options 350 order code options

Function MIN-N-A0E000H00C

MINII-N-A0EE00HI00

350EP0G0HE-E-N-R-SNNN

N: Ground directional relay

L1: Ground directional relay for

teleprotection schemes

N: Ground directional relay

L: Ground directional relay for

teleprotection schemes

Current Protection E: Extended

configuration: User selectable 49,

50P(2), 50G/SG(2), 50N(2), 51P(1),

51G/SG(1), 51N(1)

Other Options R: Phase, Neutral, and

Ground Directional Overcurrent

Protection: 67P(1), 67N(1), 67G/SG(1),

32N(2), VTFF + Voltage, Power, and

Energy Metering, 60CTS

Curves MINN-A-0E000H00C

A: ANSI Curves

I: IEC Curves

MINIIN-A-0EE00HI00

A: ANSI Curves

All 350 relays come with ANSI, IEC,

and IAC curves standard.

I: IEC Curves

Ground CT

MINNA0-E-000H00C

MINIINA0-E-E00HI00

350EP0-G0-HEENRSNNN

Range

E: Ground CT In = 1 A or 5 A (10240% of CT rating)

S2: Isolated ground and Peterson

coil

Power Supply MINNA0E000-H-00C

H:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

F: 24 - 48 VDC (Range: 19~58 VDC)

Environmental

n/a MINIINA0EE00HI-00

E: Ground CT In = 1 A or 5 A (10240% of CT rating)

S2: Isolated ground3 and Peterson

coil

MINIINA0EE00-HI-00

HI:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

LO: 28 - 48 VDC (Range: 19~58 VDC)

G0: user selectable 1/5 A Ground

current input (0.02 - 20 × CT)

S0: user selectable 1/5 A Sensitive

Ground current input (0.002 - 3 × CT)

350EP0G0-H-EENRSNNN

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

350EP0G0HEENRSNN-N

Option

00: None

0H: Conformal Coating

N: None

H: Harsh Environment Conformal

Coating

1. Option L is not available in the 3 Series.

2. Option S is not directly replaced in the 350 Feeder Protection System, however the Wattmetric Ground Fault element (32N) is a

substitute for MINII option S and detects feeder/line ground faults in solidly grounded, ungrounded, resistance grounded and res

onance grounded networks. It provides equivalent functionality to the Isolated Ground and Petersen Coil elements of the MIN II

relay.

Option S directional ground fault for Isolated or Peterson Coil grounded networks may also be replaced by P40 Agile P14D relays.

The P40 Agile P14D relay uses different algorithms to achieve more accurate High Impedance Fault detection; refer to the

P14D

Technical Manual, Chapter 6, Section 18.

3. For a detailed example of converting the MIN II Option "S" 67IG1 Isolated Ground function to the 350 32N function, see Converting

MIN II 67IG1 to 350 32N on page 29.

-

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

www.gegridsolutions.com/multilin for up-to-date order codes.

12 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 19

CHAPTER 1: OVERVIEW MIW AND MIW II RELAYS

1.6 MIW and MIW II relays

Installed Relay Retrofit Relay

MIW II Directional Power Protection System 350 Feeder Protection System or 889 Generator Protection System

Most MIW and MIW II features are available in 350 relays as described in the table below.

In some cases an 8 Series relay may be required to replace full functionality.

Feature MIW MIW II

Protection &

Control

Metering &

Monitoring

Oscillography 8 samples/cycle

Communications Serial (RS232, RS485)

Hardware 2 digital outputs

1. For additional features, refer to the 350 Instruction Manual.

Directional Power: 32RP, 32FP, 32LF

40

60

maximum length 24 cycles

protocols: Modbus RTU

6 relay outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

Directional Power: 32(4)

40

60

Metering

Event Recording

Configurable IO and LEDs

Configurable Logic

8 samples/cycle

maximum length 24 cycles

Serial (RS232, RS485)

protocols: Modbus RTU

2 digital inputs

6 digital outputs

Configurable I/O

Configurable Logic

2 fixed LEDs

4 configurable LEDs

1

350

Directional Power: 32(2)

Other Protection: 27P(2), 27X(1),

27P_1 (1), 59P(2), 59N(1), 59X(1),

59_2(1), 81O(2), 81U(2), 67P(1),

67N(1), 67G/SG(1), VTFF(1), 25(1),

60CTS

Metering

Breaker Health

Event Recording

Programmable Logic Elements

...

up to 32 samples per cycle

(user-selectable)

maximum length 192 cycles

USB

Serial (RS485) protocols: Modbus

RTU, DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC 61850

GOOSE, IEC 61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

10 LEDs (non-programmable LEDs)

12 LEDs (programmable LEDs)

3 SERIES RETROFIT – INSTRUCTION MANUAL 13

Page 20

MIW AND MIW II RELAYS CHAPTER 1: OVERVIEW

NOTE

The following table describes MIW and MIW II options, and the equivalent 350 options and

order codes. In some cases the 350 options have changed from those available for MIW

and MIW II relays, so read the descriptions carefully.

Feature MIW order code options MIW II order code options 350 order code options

Function n/a MIWII-1-000E00HI00

350EP0G0HEEN-W-SNNN

11: 3x Directional Power, 1x Loss of

Field, 1x Fuse Failure

2: 4x Directional Power

W: Advanced Protection: 27P(2),

27X(1), 27P_1 (1), 59P(2), 59N(1),

59X(1), 59_2(1), 81O(2), 81U(2),

67P(1), 67N(1), 67G/SG(1), VTFF(1),

25(1), 60CTS, 32(2)

Power Supply MIW1000E000-F-00C

H:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

F: 24 - 48 VDC (Range: 19~58 VDC)

1. To replace model MIW II 1000 and the Loss of Excitation protection function, refer to the 889 Instruction Manual.

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

MIWII1000E00-HI-00

HI:

110 - 250 VDC (Range: 88~300 VDC)

110 - 230 VAC (Range: 88~264 VAC)

LO: 28 - 48 VDC (Range: 19~58 VDC)

350EP0G0-H-EENWSNNN

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

www.gegridsolutions.com/multilin for up-to-date order codes.

14 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 21

CHAPTER 1: OVERVIEW 239 RELAYS

1.7 239 relays

Installed Relay Retrofit Relay

239 Motor Protection Relay 339 Motor Protection System

239 features are available in 339 relays as described in the table below:

Feature

Protection &

Control

Monitoring &

Metering

Communications RS485 port USB

Hardware 2 inputs and 3 fixed inputs.

1. The 239 relay with MOD 509 is designed to provide ground directional protection. Similar protection can be obtained using the 339 relay neutral instantaneous protection using either the

current, voltage, or both.

2. For additional features, refer to the 339 Instruction Manual.

Undercurrent/minimum load: 37

Motor/load bearing, Overtemperature: 38

Mechanical jam:39

Current unbalance: 46

Stator winding overtemperature: 49

Phase short circuit: 50

Timed overload: 51

Ground fault instantaneous or definite

time: 50G/50N

Alarm relay: 74

Lockout and trip relay: 86/94

Metering

Event Recording

4 Form C contacts

6 Fixed LEDs

239

1

Undercurrent: 37

Current Unbalance: 46

Acceleration Time: 48

Thermal Protection: 49

IOC: 50G/SG(1), 50L, 50N(1), 50P(1)

TOC: 51N(1), 51P(1), 51R

Other Protection: 66, 86, 50BF

Metering

Event Recording

Serial (RS485) protocols: Modbus

RTU, DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC

61850 GOOSE, IEC 61850

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

8 configurable and 4 fixed LEDs

10 fixed LED (drawout unit)

12 fixed LEDs (non-drawout unit)

339

2

3 SERIES RETROFIT – INSTRUCTION MANUAL 15

Page 22

239 RELAYS CHAPTER 1: OVERVIEW

NOTE

The following table describes 239 options, and the equivalent 339 options and order codes.

In some cases the 339 options have changed from those available for 239 relays, so read

the descriptions carefully.

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

www.gegridsolutions.com/multilin for up-to-date order codes.

Feature 239 order code options 339 order code options

Application 239RTD-AN-H

AN: Single isolated, analog output:

0 – 1, 0 – 20, 4 – 20 mA

Programmable output parameters:

thermal capacity,% full load, phase

current, RTD1, RTD2, RTD3 temperature

Phase CT

239 standard phase CT Input:

Range

1 A and 5 A secondary

Range: 0.1 to 11 x phase CT primary

Ground CT

239 standard ground CT input:

Range

5 A secondary and 50:0.025

Range:

0.03 to 1.4 x CT primary (5 A CT)

0.05 to 16.0 A (50:0.025 CT)

Power

Supply

239 standard power supply:

90 – 300 VDC or 70 – 265 VAC,

50 / 60 Hz

Harsh

239RTDAN-H

Environment

H: Harsh Environment Conformal

Coating

RTDs 239-RTD-ANH

3 RTDs: stator/bearing; programmable

type: platinum, nickel, copper

339EP0G0HE-S-NNSNNH

S: Standard configuration: 37, 46, 48, 49,

50P(1), 50G/SG(1), 50N(1), 50L,51R, 66,

86, 51N(1), 51P(1), 50BF

339E-P0-G0HESNNSNNH

P0: user selectable 1/5 A three-phase

current inputs (0.02 - 20 × CT)

339EP0-G0-HESNNSNNH

G0: user selectable 1/5 A Ground current

input (0.02 - 20 × CT)

All 339 relays come with CBCT (50:0.025)

standard.

339EP1G1-H-ESNNSNNH

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

339EP1G1HESNNSNN-H

H: Harsh Environment Conformal

Coating

The 339 can support 3 - 100 ohm Pt

RTDs.

The RMIO module supports up to

12 - 100 ohm Pt RTDs.

16 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 23

CHAPTER 1: OVERVIEW 735/737 RELAYS

1.8 735/737 relays

Installed Relay Retrofit Relay

735/737Feeder Protection System 350 Feeder Protection System

735 and 737 features are available in 350 relays as described in the table below.

Feature 735/737

Protection &

Control

Metering &

Monitoring

Communications RS485 2-wire communications

Hardware 8 LED trip indicators

1. For additional features, refer to the 350 Instruction Manual.

50/51, 50G/51G 50P(2), 50G/SG(2), 50N(2), 51P(1),

Current Metering shown in % Metering

or RS422 4-wire communications

4 LED status indicators

3 standard outputs

737 has 8 additional output relays to

provide separate dry contact

outputs for each overcurrent

protection element.

1

350

51G/SG(1), 51N(1)

User selectable 49, 86

Breaker Health

Event Recording

Programmable Logic Elements

...

USB

Serial (RS485) protocols: Modbus

RTU, DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC 61850

GOOSE, IEC 61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

8 configurable and 4 fixed LEDs

10 fixed LED (drawout unit)

12 fixed LEDs (non-drawout unit)

3 SERIES RETROFIT – INSTRUCTION MANUAL 17

Page 24

735/737 RELAYS CHAPTER 1: OVERVIEW

The following table describes 735 and 737 options, and the equivalent 350 options and

order codes. In some cases the 350 options have changed from those available for 735/

737 relays, so read the descriptions carefully.

Feature 735/737 order code options 350 order code options

Function 735-55HI485

735: Standard 735 Relay with 50/51,

50G/51G protection

737: 737 Relay (same as 735 with 8

additional output relays)

Phase CT Range 735-5-5HI485

1: 1 A Phase CT Secondaries 5: 5 A

Phase CT Secondaries

Ground CT

7355-5-HI485

Range

1: 1 A Ground CT Secondaries 5: 5 A

Ground CT Secondaries

Power Supply 73555-HI-485

HI: 90 to 300 V DC; 70 to 265 V AC at

50/60 Hz

LO: 20 to 60 V DC; 20 to 48 V AC at

50/60 Hz

Comms 73555HI-485

350EP0G0HE-E-NNSNDN

E: Extended configuration: User

selectable 49, 50P(2), 50G/SG(2),

50N(2), 51P(1), 51G/SG(1),

51N(1)

350E-P0-G0HEENNSNDN

P0: P0 user selectable 1/5 A threephase current inputs

350EP0-G0-HEENNSNDN

G0: user selectable 1/5 A Ground

current input (0.02 - 20 × CT)

350EP0G0-H-EENNSNDN

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

350EP0G0HEENN-SN-DN

485: RS485 2-wire communications

(standard)

422: RS422 4-wire communications

SN: Standard: Front USB, Rear

RS485: Modbus RTU, DNP3.0, IEC

60870-5-103

(optional)

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

www.gegridsolutions.com/multilin for up-to-date order codes.

18 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 25

CHAPTER 1: OVERVIEW MLJ AND TOV RELAYS

1.9 MLJ and TOV relays

Installed Relay Retrofit Relay

MLJ Digital Synchronism Check

Relay

350 Feeder Protection System, option V

or P40 Agile P14D Relay

TOV Modular Voltage Relay

Most MLJ and TOV features are available in 350 relays as described in the table below:

Feature MLJ TOV

Protection &

Control

Communications Serial (RS232, RS485, fiber)

Hardware 2 digital outputs

1. For additional features, refer to the 350 Instruction Manual.

UV: 27

Synchrocheck: 25

protocols: GEPCE

6 relay outputs

Configurable I/O

Configurable Logic

3 fixed LEDs

UV: 27

OV: 59

2 digital inputs

6 digital outputs

Configurable I/O

Configurable Logic

3 fixed LEDs

350 Feeder Protection System, option V,

or P40 Agile P14D Relay

UV: 27P(4), 27X(1), 27P_1(1)

OV: 59P(4), 59N(4), 59X(1), 59_2(2)

Underfrequency: 81U(4)

Overfrequency: 81O(4)

Synchrocheck: 25(1)

Voltage Fuse Failure: VTFF(1)

USB

Serial (RS485) protocols: Modbus RTU,

DNP 3.0, IEC 60870-5-103

Ethernet protocols: Modbus TCP/IP,

DNP 3.0, IEC 60870-5-104, IEC 61850

GOOSE, IEC 61850, OPC-UA

10 inputs

7 outputs (2 Form A, 5 Form C)

Configurable I/O

Configurable Logic

8 configurable and 4 fixed LEDs

10 fixed LED (drawout unit)

12 fixed LEDs (non-drawout unit)

350

1

For voltage and frequency functionality, P40 Agile P94V Voltage and Frequency IEDs are

another option. Refer to the P40 Agile P94V Technical Manual for details.

3 SERIES RETROFIT – INSTRUCTION MANUAL 19

Page 26

MLJ AND TOV RELAYS CHAPTER 1: OVERVIEW

NOTE

The following table describes MLJ and TOV options, and the equivalent 350 options and

order codes. In some cases the 350 options have changed from those available for MLJ

and TOV relays, so read the descriptions carefully.

Feature MLJ order code options TOV 4 order code options 350 order code options

Application n/a TOV-4-013I030F00C

4: 3 Phase voltage relay

5: Single Phase

Function n/a TOV4013-I-030F00C

All 350 relays come with 3 phase

and ground standard.

350E-PXGX-HE-N-N-V-SNNN

I: Undervoltage

M: Overvoltage

Protocol MLJ100-5-B010F00C

n/a 350EPXGXHENENV-SN-NN

5: RS485 communications

6: RS485 + RS232 + plastic fiber

optics communications

7: RS485 + RS232 + glass fiber

optics communications

Power Supply MLJ1005B010-F-00C

H: 110/250 VDC input and auxiliary

voltage

F: 24/48 VDC input and auxiliary

voltage

1. For details of 350 communications implementation, see the 3 Series Communications Guide.

Note

Order codes are subject to change without notice. See the GE Multilin website at: http://

TOV4013I030-F-00C

F: Aux voltage 24 - 48 VDC/VAC

G: Aux voltage 48 - 125 VDC/VAC

H: Aux voltage 110 - 240 VDC,

110 - 220 VAC

www.gegridsolutions.com/multilin for up-to-date order codes.

V: Voltage Metering - 27P(4), 27X(1),

27P_1(1), 59P(4), 59N(4), 59X(1),

59_2(2), 81O(4), 81U(4), 25(1), VTFF(1)

SN: Standard: Front USB, Rear

RS485: Modbus RTU, DNP3.0,

IEC60870-5-103

1

350EPXGX-H-ENNVSNNN

H: 110 - 250 VDC

110 - 230 VAC

L: 28 - 48 VDC

20 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 27

CHAPTER 1: OVERVIEW FINDING YOUR M AND MII FAMILY RELAY ORDER CODE

1.10 Finding your M and MII Family relay order code

M Family (MIF, MIG, MIN, MIV, and MIW) relay order codes are in the format MIFPA111FC,

and are shown on the faceplate of the relay. The order code is also shown on the relay

display from the Information menu, and can be found in the Enervista MII Setup software

under File > Properties.

MII Family (MIF II, MIG II, MIN II, MIV II, MIW II, and MIB) relay order codes are in the format

MIFIIPA11E00HI00. To find the order code for your existing MII relay, check the label on the

side of the relay. The model listed on the label is the complete order code. The order code is

also shown on the relay display, and can be found in the Enervista MII Setup software

under File > Properties.

3 SERIES RETROFIT – INSTRUCTION MANUAL 21

Page 28

FINDING YOUR M AND MII FAMILY RELAY ORDER CODE CHAPTER 1: OVERVIEW

22 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 29

GE

NOTE

Grid Solutions

3 Series Retrofit

Chapter 2: Converting Settings

Files

Converting Setting s Files

Before any mechanical or electrical changes are made, the settings file from the Multilin

MII relay in use must be backed up. The existing settings file can then be converted to a

3

Series settings file. All converted settings and new settings (set to default values) must be

carefully reviewed before the file is uploaded to the new 3

Series relay.

Note

Settings file conversion is currently available for converting most MIF II and MIV II relay

settings files to EnerVista 3 Series Setup software version 2.3x files.

Table 2–1: File conversion support

Series release 2.3x

for 3

MII models FW versions

MIFP V2.14

MIFIIP V301

MIFIIP V502

All MIV II models V310

V401

V402

V403

V404

V503

V504

V505

V506

V507

V401

V402

V403

V404

V405

3 SERIES RETROFIT – INSTRUCTION MANUAL 23

Page 30

DOWNLOADING AND SAVING MIF II OR MIV II SETPOINT FILES CHAPTER 2: CONVERTING SETTINGS FILES

NOTE

2.1 Downloading and saving MIF II or MIV II setpoint files

Use the following procedure to download and save MIF II or MIV II setpoint files to a local

PC.

4.Note the location of the saved setpoint file. Two files will be generated, *.txt and *.ajs,

and both are necessary for converting to *.sr3 setting file.

1. Start the EnerVista MII Setup software.

Note

Only MIF II or MIV II setpoint files from EnerVista MII Setup version 2.70 and firmware

versions listed at the beginning of this chapter are supported for conversion. Older file

versions must be converted to the latest version using the latest EnerVista MII Setup

software.

To download the latest MII setup software, see http://www.gegridsolutions.com

Ensure that the site and corresponding device(s) have been properly defined and

configured. (Refer to the MIF II Instruction Manual for more information on the

Enervista MII Setup software.)

2. Obtain settings information from the connected relay using File > Get info from relay.

3. The EnerVista MII Setup software prompts for the name and destination path of the

setpoint file. The corresponding file extension is automatically assigned (*.ajs). Press

Save to complete the process. After a few seconds of data retrieval the file is saved.

4. Note the location of the saved setpoint file. Two files will be generated: *.txt and *.ajs.

Both files are needed for conversion to a *.sr3 setting file.

24 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 31

CHAPTER 2: CONVERTING SETTINGS FILES CONVERTING A SAVED MIF II OR MIV II SETPOINT FILE

NOTE

2.2 Converting a saved MIF II or MIV II setpoint file

The Enervista 3 Series Setup software allows the user to create new setpoint files based on

existing MII setpoint files. These can be uploaded to a relay at a later date. The following

procedure illustrates how to convert existing MII setpoint files.

Note

Only MIF II and MIV II setpoint files from EnerVista MII Setup version 2.70 and firmware

versions listed at the beginning of this chapter are supported for conversion.

1. Install and start the latest version of the EnerVista 3 SeriesSetup software (available

from the GE EnerVista CD or Website). (See the 350 Feeder Protection Instruction

Manual for more information.)

2. Select Offline > New Settings File from the top menu bar. The following box appears,

allowing for the configuration of the setpoint file for the correct firmware version and

relay order code.

3 SERIES RETROFIT – INSTRUCTION MANUAL 25

It is important to define the correct firmware version and order code to ensure that

only available setpoints are downloaded into the relay.

Page 32

CONVERTING A SAVED MIF II OR MIV II SETPOINT FILE CHAPTER 2: CONVERTING SETTINGS FILES

NOTE

If the MIF II or MIV II setpoint file cannot be converted due to an incompatible 350

order code, the following message is shown.

Notehe one that is added in

3. Select the Firmware Version, and Order Code options for the new setpoint file.

4. For future reference, enter some useful information in the Description box to facilitate

the identification of the device and the purpose of the file.

5. To select a file name and path for the new file, click the button beside the File Name

box.

6. Select the f ile name and path to store the file, or select any displayed file name to

replace an existing file. All 3

Series setpoint files should have the extension ‘.sr3’ (for

example, ‘350 1.sr3’).

File names for setting files cannot have a decimal point other than the one that is added in

front of sr3.

7. Click the box beside Initialize Settings from MIF II or MIV II Settings File.

8. To select an existing MIIF II or MIV II file, click the button beside the Initialize Settings

from MIF II/MIV II Settings File box and navigate to the file.

9. Click OK to complete the process. Once this step is completed, the new file, with a

complete path, is added to the 3

Series software environment. In addition a

Conversion Report is generated, as described in the following section.

For more information on the EnerVista 3 Series Setup software, refer to the 350 Feeder

Protection System Instruction Manual at

http://www.gegridsolutions.com

26 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 33

CHAPTER 2: CONVERTING SETTINGS FILES CONVERSION REPORT

2.3 Conversion report

Once the file conversion process is complete, the conversion results are summarized in a

Conversion Report. The report is found under Device Definition in the Offline pane of the

EnerVista 3 Series Setup Setup software.

The Conversion Report can be printed using the File/Print command in the EnerVista

taskbar or can be printed from the "GUI" print button.

Note

All Conversion Reports are removed when the converted file is edited in the EnerVista 3

Series Setup software. Save the conversion report promptly after each conversion.

3 SERIES RETROFIT – INSTRUCTION MANUAL 27

Page 34

LOADING SETPOINTS FROM A FILE CHAPTER 2: CONVERTING SETTINGS FILES

NOTE

• The Display Filter checkboxes at the top of the conversion report can be used to

change the setpoint display to include or exclude Successfully Converted setpoints

(green), setpoints that Need Verification (orange), and setpoints that Need Manual

Configuration (red).

• Save a copy of the Conversion Report immediately after the conversion, to use for

future reference. All Conversion Reports are removed and become inaccessible if the

user removes or modifies the converted file from the EnerVista 3 Series Setup

software.

• Only settings converted from the original MIF II/MIV II setpoint file are shown in the

Conversion Report. All other settings available in the new setpoint file are set to the

default value, and must be verified by the user before putting the relay into service.

Note

The settings file conversion process is provisioned to reduce the effort of manually

converting settings. This conversion process does not guarantee settings accuracy. Each

successfully converted setting must be reviewed before putting the relay in service.

Settings in the Conversion Report window are linked to the appropriate settings screens.

Use the Conversion report window to navigate to the corresponding settings window to

review converted settings.

2.4 Loading setpoints from a file

Once the converted settings file has been thoroughly reviewed, it can be uploaded to the

Series Relay.

3

An error message occurs when attempting to upload a setpoint file with a revision number

that does not match the relay firmware. If the firmware has been upgraded since saving

the setpoint file, see the 3

revision number of a setpoint file.

The following procedure illustrates how to load setpoints from a file.

1. Start the latest version of the EnerVista 3 Series Setup software.

2. Select the previously saved setpoints file from the File pane of the 3 Series software

main window.

Series Instruction Manual for instructions on changing the

3. Select the Offline > Edit Settings File Properties menu item and verify that the

corresponding file is fully compatible with the hardware and firmware version of the

target relay. If the versions are not identical, see Upgrading Setpoint Files to a New

Revision for details on changing the setpoints file version.

4. Right-click on the selected file and select the Write Settings File to Device item.

5. Select the target relay from the list of devices shown and click Send.

If there are no incompatibilities between the target device and the settings file, the data is

transferred to the relay. An indication of the percentage completed is shown in the bottom

of the main window.

28 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 35

CHAPTER 2: CONVERTING SETTINGS FILES CONVERTING MIN II 67IG1 TO 350 32N

2.5 Converting MIN II 67IG1 to 350 32N

The 67IG function in MIF II, Option "S", is overcurrent protection specifically designed for

detecting ground faults for isolated ground systems.

Isolated Ground Directional Control in the MIN II relay provides directional protection for

ungrounded systems. In this type of system the neutral is completely isolated from the

ground, as a result of this the ground fault current value is minimum and produced only by

the line capacitive coupling. The relay operation is based on the presence of this capacitive

current plus the detection of an overvoltage condition.

Figure 2-1: MIN II functional block diagram, option S

This same protection can be provided by the 350 relay using the Wattmetric Ground Fault

(32N) element. The Wattmetric ground fault element, also called the Wattmetric Zerosequence Directional element, responds to power derived from zero-sequence voltage and

zero-sequence current in a direction specified by the element characteristic angle. The

angle can be set within all four quadrants, so the measured power can be active or

reactive or some combination thereof. Therefore the element can be used to sense either

forward or reverse ground faults in either inductively, capacitively, or resistively grounded

networks.

In order to convert the settings from MIN II 67IG to 350 32N, the settings must be

transferred using the Enervista Setup software, and the Power pickup must be calculated.

3 SERIES RETROFIT – INSTRUCTION MANUAL 29

Page 36

CONVERTING MIN II 67IG1 TO 350 32N CHAPTER 2: CONVERTING SETTINGS FILES

MIN II Settings

350 Settings

2.5.1 Mapping settings

Figure 2-2: Sample settings screens

Table 2–2: Enervista setting conversion

67IG1 (MIN II) 67IG1

(MIN II)

67IG1 Enable Ready WGN 1 Function Trip

67IG1 Trip Ready

67IG1 Voltage Low 10 Volts WGN 1 Voltage PKP 0.1 x VT convert V to x VTn

67IG1 Current Low 0.01 A WGN 1 Current PKP 0.01 x CT convert 0.01 A to x CTn

67IG1 Direction Forward WGN 1 ECA 90° setting the ECA angle to 90 deg. provides for

67IG1 Charact. Angle 90°

67IG1 Time Delay 0.5 s WGN 1 Power PKP Delay 0.5 s

32N WGN1 (350) 32N WGN1

(350)

WGN 1 Voltage Calculated (Vn)

(for example, if Vn = 100 V, the new setting is 0.1 x VT)

WGN 1 Current Calculated (In)

(for example: if CTn = 1 As the new setting is 0.01 xCT)

WGN 1 Power PKP 0.003 xCTxVT enter in x CTxVT as explained below

WGN 1 Ref Power PKP 0.500 xCTxVT Applicable only if Curve is selected under WGN 1

Curve

FORWARD direction (positive power)

WGN 1 Curve Definite Time Applicable only if Curve is selected under WGN 1

Curve

WGN 1 Multiplier 1 s Applicable only if Curve is selected under WGN 1

Curve

WGN 1 Relays Relay:

Disabled

WGN 1 Block 1 Off

WGN 1 Block 2 Off

WGN 1 Block 3 Off

Notes

30 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 37

CHAPTER 2: CONVERTING SETTINGS FILES CONVERTING MIN II 67IG1 TO 350 32N

2.5.2 Calculation of power pickup

To achieve the same operation zone with the 32N function, we need to calculate the

minimum power for the WGN 1 Power PKP setpoint.

1. Compute the average point between Voltage High (Vh) and Voltage Low (Vl) from the

MIN 67IG1 settings.

2. Compute the average point between Current High (Ih) and Current Low (Il) settings

from 67IG1

3. Compute the power corresponding to the middle point from the line between Vh/Il

and Vl/Ih points, as indicate din the figure below. Express the result in x CTxVT. This will

be the setting for WGN 1 Power PKP.

Example: (matching screenshots above)

Voltage average = (0.1 +0.3)/2 = 0.2 xVT

Current average = (0.025+0.01)/2 = 0.0175 xCT

Compute average power: 0.2 xVT * 0.0175 xCT = 0.0035 x CTxVT

Since the relay allows only three decimal places, select 0.003 xVTxCT as the more sensitive

setting. If a more conservative setting is required, select 0.004 xCTxVT

The 32N function operates if the computed neutral current is bigger than the Current PKP

level, the computed neutral voltage is bigger than the Voltage PKP level, the computed

power is bigger than the Power PKP level, and the direction of the power is detected in the

Forward direction.

3 SERIES RETROFIT – INSTRUCTION MANUAL 31

Page 38

CONVERTING MIN II 67IG1 TO 350 32N CHAPTER 2: CONVERTING SETTINGS FILES

32 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 39

GE

Grid Solutions

3 Series Retrofit

Chapter 3: Installing the 3 Series

Relay

Installing the 3 Series Relay

This chapter describes the mechanical installation of the 3 Series Retrofit for various

installed Multilin relays.

3 SERIES RETROFIT – INSTRUCTION MANUAL 33

Page 40

3 SERIES DIMENSIONS AND MOUNTING CHAPTER 3: INSTALLING THE 3 SERIES RELAY

3.1 3 Series dimensions and mounting

All 3 Series relays (350, 345, and 339) have the same dimensions, with small differences

between the drawout and non-drawout models.

Figure 3-1: 3 Series Dimensions

Drawout Non-drawout

in mm in mm

H 7.93 201.5 7.98 202.7

W 6.62 168.2 6.23 158.2

D 9.62 244.2 9.35 237.5

W1 3.96 100.6 3.96 100.6

D1 7.89 200.4 7.88 200.2

D2 1.73 43.8 1.47 37.3

D3 1.087 27.6 0.755 19.17

H1 6.82 173.2 6.82 173.2

34 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 41

CHAPTER 3: INSTALLING THE 3 SERIES RELAY 3 SERIES DIMENSIONS AND MOUNTING

5.350” 0.010”

(135.9 mm 0.25mm)

±

±

4.100” 0.010”

(104.1 mm 0.25 mm)

±

±

0.200”

(5.1 mm)

Φ

6.900” 0.010”

(175.3 mm 0.25 mm)

±

±

6.000” 0.010”

(152.4 mm 0.25 mm)

±

±

4.000” 0.010”

(101.6 mm 0.25 mm)

±

±

C

L

C

L

Figure 3-2: 3 Series panel cutout

The panel cutout used to mount the 3 Series relays is the same for the 350, 345, and 339

models. Eight screws are used to mount the relay from the back of the cutout panel.

Depth reducing collars are available in two widths as accessories:

• 18L0-0076 3 Series depth reducing collar - 1.375” (34.92 mm)

• 18L0-0075 3 Series depth reducing collar - 3.00” (76.20 mm)

Straight terminal block connectors are available for the non-drawout (NDO) 3 Series relays,

providing screws parallel to the wires for easier access when space is limited.

• 3S-NDO-STCONKIT 3 Series NDO straight terminal block kit

3 SERIES RETROFIT – INSTRUCTION MANUAL 35

Page 42

M AND MII FAMILY RELAYS CHAPTER 3: INSTALLING THE 3 SERIES RELAY

NOTE

3.2 M and MII Family relays

The 3 Series relays have a smaller depth than the M and MII Family relays, so no depth

adjustment should be required. If the installed M or MII relay is using a depth-reducing

collar, one is also required for the replacement 3

dimensions and mounting for details.

All MII Family panel cutouts and most M Family panel cutouts (MIF, MIG, MIN, and MIW) can

be reused to install new 3

Series relays. (The MIV cutout is a different size.)

• The four screw holes in the MII/M cutout have identical spacing to those in the 3 Series

relays.

• The small difference in size of the panel cutout (<6 mm) does not affect the relay

mount.

• M4 Din9021 zinc plated washers must be used to compensate for the slightly wider

screw holes in the MII/M cutout panel.

• Four screws (#8 - 32 x 3/8) must be used to secure the 3 Series relay from the back

(instead of the front as for the MII/M relays).

Series unit. Refer to section 3.1 3 Series

Note

Using four mounting screws instead of eight does not affect the stability of the relay

mount. The 4-screw 3

8-screw 3

Series relay mount used for new installations, as listed below.

Series relay mount has passed the same vibration tests as the

Table 3–1: 3 Series vibration tests, 4-screw and 8-screw mounts

IEC 60255-21-1 Class 1 Vibration, Bump and Seismic Test. Section 1: Vibration Test

IEC 60255-21-2 Class 1 Vibration, Bump and Seismic Test. Section 2: Shock and Bump Test

IEC 60255-21-3 Class 2 Shock, Bump, and Seismic Test. Section 3: Seismic

36 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 43

CHAPTER 3: INSTALLING THE 3 SERIES RELAY M AND MII FAMILY RELAYS

NOTE

3.2.1 M Family of relays

Most of the M Family of relays (MIF, MIG, MIN, and MIW), like the MII Family, have a slightly

larger cutout panel than the 3

to secure the relay.

The MIV relay has a smaller cutout panel than the 3 Series relays.

Series relays, and uses four mounting screws from the front

Note

Replacing an MIV relay with a 3 Series relay requires panel modification.

Figure 3-3: M Family: MIF, MIG, MIN, MIW, MIV (note MIV is smaller)

3 SERIES RETROFIT – INSTRUCTION MANUAL 37

Page 44

M AND MII FAMILY RELAYS CHAPTER 3: INSTALLING THE 3 SERIES RELAY

3.2.2 MII Family of relays

The MII Family of relays (MIF II, MIG II, MIN II, MIW II, and MIB) has a slightly larger cutout

panel than the 3

relay.

Series relays, and uses four mounting screws from the front to secure the

Figure 3-4: MII Family: MIF II, MIG II, MIN II, MIV II, MIW II, MIB

38 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 45

CHAPTER 3: INSTALLING THE 3 SERIES RELAY M AND MII FAMILY RELAYS

NOTE

NOTE

3.2.3 Replacing an M or MII relay

To replace an MII or M Family relay with a 3 Series relay, follow these steps.

Note

Four M4 Din9021 zinc plated washers are required (not included) to install a 3 Series relay

in an existing MII or M cutout.

Note

Ensure the MII settings file has been saved before disconnecting an installed MII relay.

The pictures show an MII relay, however the same steps also apply to an M relay (with the

exception of the MIV) unless otherwise noted.

1. Disconnect power and unplug all wires from the installed MII or M unit.

2. For an MII relay, pull open the sides to access the screw heads.

3. Unscrew the four mounting screws.

3 SERIES RETROFIT – INSTRUCTION MANUAL 39

Page 46

M AND MII FAMILY RELAYS CHAPTER 3: INSTALLING THE 3 SERIES RELAY

4. Carefully remove the MII relay.

5. Remove the mounting clips from the screw holes.

40 3 SERIES RETROFIT – INSTRUCTION MANUAL

Page 47

CHAPTER 3: INSTALLING THE 3 SERIES RELAY M AND MII FAMILY RELAYS

6. Insert the 3 Series relay into the empty panel cutout.

7. To complete the installation, go around to the back of the panel.

3 SERIES RETROFIT – INSTRUCTION MANUAL 41

Page 48

M AND MII FAMILY RELAYS CHAPTER 3: INSTALLING THE 3 SERIES RELAY

NOTE

8. From the back of the relay, secure the relay with the new 3 Series screws and M4

Din9021 zinc plated washers (not included) with a torque of 18 in/lb.

Note

The M and MII screws cannot be reused for the 3 Series relay installation, as they are a

different size.