Page 1

269

MOTOR MANAGEMENT RELAY

Instruction Manual

Firmware Rev.: 269P.D6.0.4

Manual P/N: 1601-0013-D3

Copyright 1999 GE Multilin

®

CANADA

215 Anderson Avenue, Markham, Ont., L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.ge.com/edc/pm

Page 2

TABLE OF CONTENTS

1 INTRODUCTION

1.1 Motor Protection Requirements................1-1

1.2 269 Relay Features..................................1-1

1.3 Typical Applications.................................1-1

1.4 Order Code/Information..........................1-3

1.5 Technical Specifications...........................1-4

2 INSTALLATION

2.1 Physical Dimensions...............................2-1

2.2 Mounting.................................................2-6

2.3 External Connections...............................2-6

2.4 Control Power........................................2-12

2.5 Phase CT Inputs....................................2-12

2.6 Ground CT Input....................................2-15

2.7 Trip Relay Contacts...............................2-15

2.8 Alarm Relay Contacts............................2-16

2.9 Auxiliary Relay #1 Contacts...................2-16

2.10 Auxiliary Relay #2 Contacts.................2-16

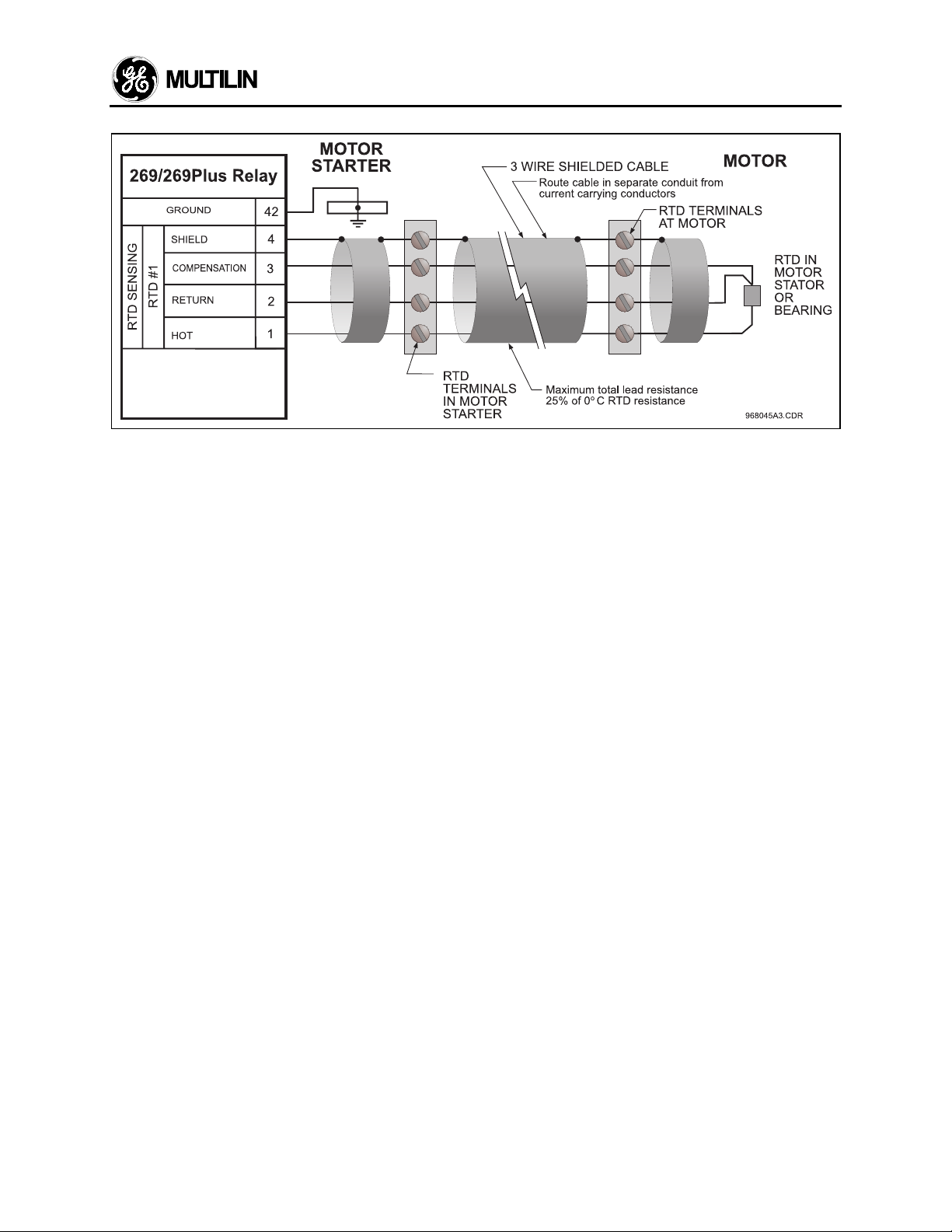

2.11 RTD Sensor Connections.....................2-17

2.12 Emergency Restart Terminals..............2-18

2.13 External Reset Terminals.....................2-18

2.14 Analog Output Terminals

(Non-Isolated)......................................2-18

2.15 Programming Access Terminals...........2-18

2.16 Display Adjustment..............................2-19

2.17 Front Panel Faceplate..........................2-19

2.18 269 Drawout Relay..............................2-19

2.19 Meter Option Installation......................2-23

3 SETUP AND USE

3.1 Controls and Indicators............................3-2

3.2 269 Relay Display Modes........................3-6

3.3 ACTUAL VALUES Mode..........................3-6

3.3a Starts/Hour Timer...............................3-16

3.3b Time Between Starts Timer..................3-16

3.3c Cause of Last Trip................................3-16

3.3d Cause of Last Event.............................3-16

3.4 SETPOINTS Mode.................................3-16

3.5 HELP Mode..........................................3-41

3.6 TRIP/ALARM Mode...............................3-41

3.7 Phase CT and Motor Full Load Current

Setpoints..............................................3-44

3.8 Acceleration Time Setpoint....................3-44

3.9 Inhibits..................................................3-44

3.10 Unbalance Setpoints............................3-45

3.11 Ground Fault (Earth Leakage)

Setpoints............................................ 3-46

3.12 Undercurrent Setpoints........................3-49

3.13 Rapid Trip / Mechanical Jam Setpoints3-49

3.14 Short Circuit Setpoints.........................3-50

3.15 Immediate Overload Alarm Level

Setpoint...............................................3-50

3.16 Stator RTD Setpoints...........................3-50

3.17 Other RTD Setpoints............................3-51

3.18 Overload Curve Setpoints....................3-51

3.19 Thermal Capacity Alarm......................3-55

3.20 Thermal Memory.................................3-55

3.21 Emergency Restart..............................3-56

3.22 Resetting The 269 Relay......................3-57

3.23 269 Relay Self-Test..............................3-57

3.24 Statistical Data Features.....................3-58

3.25 Factory Setpoints................................3-58

3.26 Meter Option.......................................3-58

4 TESTING

4.1 Primary Injection Testing.........................4-1

4.2 Secondary Injection Testing.....................4-1

4.3 Phase Current Input Functions................4-1

4.4 Ground Fault Current Functions..............4-4

4.5 RTD Measurement Tests.........................4-4

4.6 Power Failure Testing..............................4-5

4.7 Analog Current Output............................4-5

4.8 Routine Maintenance Verification.............4-5

4.9 Dielectric Strength (Hi-Pot) Test...............4-5

5 THEORY OF OPERATION

5.1 Hardware................................................5-1

5.2 Firmware.................................................5-1

6 APPLICATION EXAMPLES

6.1 269 Relay Powered from One of Motor

Phase Inputs..........................................6-1

6.2 Loss of Control Power Due to Short Circuit

or Ground Fault......................................6-1

6.3 Example Using FLC Thermal Capacity

Reduction Setpoint.................................6-1

APPENDIX A

269 UNBALANCE EXAMPLE........................A-1

APPENDIX B

269 Thermal Model.......................................B-1

269 RTD Bias Feature...................................B-2

APPENDIX C

269 RTD Circuitry.........................................C-1

APPENDIX D

2φ CT Configuration......................................D-1

APPENDIX E

Asymmetrical Starting Current......................E-1

APPENDIX F

269 Do's and Don'ts Checklist.......................F-1

APPENDIX G

Ground Fault and Short Circuit Instantaneous

Elements...............................................G-1

APPENDIX H

I. 269 CT Withstand......................................H-1

II. CT Size and Saturation.............................H-1

APPENDIX I

269 Commissioning Summary.......................I-1

i

Page 3

GLOSSARY

TABLE OF CONTENTS

ii

Page 4

1 INTRODUCTION

1.1 Motor Protection Requirements

Three phase AC motors have become standard in

modern industry. These motors are generally rugged

and very reliable when used within their rated limits.

Newer motors, however, tend to be designed to run

much closer to these operational limits and thus, there

is less margin available for any type of abnormal supply, load, or operating conditions.

In order to fully protect these motors, a modern protective device is required. Accurate stator and rotor thermal modeling is necessary to allow the motor to

operate within its thermal limits and still give the maximum desired output. As well, other features can be

incorporated into a modern relay to fully protect the

motor, the associated mechanical system, and the

motor operator from all types of faults or overloads.

Motor thermal limits can be exceeded due to increased

current from mechanical overloads or supply unbalance. Unbalance can greatly increase heating in the

rotor because of the large negative sequence current

components present during even small voltage unbalances. A locked or stalled rotor can cause severe

heating because of the associated large currents drawn

from the supply. Many motor starts over a short period

of time can cause overheating as well. Phase-to-phase

and phase-to-ground faults can also cause damage to

motors and hazards to personnel. Bearing overheating

and loss of load can cause damage to the mechanical

load being driven by the motor.

The ideal motor protection relay should monitor the

rotor and stator winding temperatures exactly and shut

off the motor when thermal limits are reached. This

relay should have an exact knowledge of the temperature and proper operating characteristics of the motor

and should shut down the motor on the occurrence of

any potentially damaging or hazardous condition.

The GE Multilin Model 269 Motor Management Relay

uses motor phase current readings combined with stator RTD temperature readings to thermally model the

motor being protected. The relay also monitors the

motor and mechanical load for faults and problems.

With the addition of a GE Multilin meter (MPM), the

269 may also monitor voltages and power and perform

several protection functions based on these values.

alphanumeric display. A built-in "HELP" function can

instruct the user on the proper function of each of the

programming keys and on the meaning of each displayed message.

One 269 relay is required per motor. Phase and

ground fault currents are monitored through current

transformers so that motors of any line voltage can be

protected. The relay is used as a pilot device to cause

a contactor or breaker to open under fault conditions;

that is, it does not carry the primary motor current.

All setpoints are stored in the 269 non-volatile memory

within the relay. Thus, even when control power is removed from the 269, all relay setpoints and pre-trip

values will remain intact.

The 269 can provide one of various output signals for

remote metering or programmable controller attachment. Analog signals of motor current as a percentage

of full load, hottest stator RTD temperature, percentage

of phase CT secondary current, motor thermal capacity, or bearing temperature are available by simple field

programming. A total of four output relays are provided

on the 269, including a latched trip relay, an alarm relay, and two auxiliary relays. All output relays may be

programmed via the keypad to trip on specific types of

faults or alarms.

When an output relay becomes active, the 269 will display the cause of the trip, and if applicable, the lock-out

time remaining. Pre-trip values of average and individual line motor current, unbalance, ground fault current,

and maximum stator RTD temperature are stored by

the 269 and may be recalled using the keypad.

The correct operation of the GE Multilin 269 relay is

continually checked by a built-in firmware self-test routine. If any part of the relay malfunctions under this

self-test, an alarm indication will tell the operator that

service is required.

®

1.3 Typical Applications

The many features of the 269 make it an ideal choice

for a wide range of motor protection applications. Versatile features and controls allow the relay to protect

associated mechanical equipment as well as the motor.

The 269 should be considered for the following and

other typical uses:

1.2 269 Relay Features

The GE Multilin Model 269 Motor Management Relay

is a modern microcomputer-based product designed to

provide complete, accurate protection for industrial

motors and their associated mechanical systems. The

269 offers a wide range of protection, monitoring, and

diagnostic features in a single, integrated package. All

of the relay setpoints may be programmed in the field

using a simple 12-position keypad and 48 character

1. Protection of motors and equipment from operator

abuse.

®

2. Protection of personnel from shock hazards due to

winding shorts or earth leakage current from

moisture.

3. Protection of gears, pumps, fans, saw mills, cutters, and compressors from mechanical jam.

1-1

Page 5

1 INTRODUCTION

Table 1-1 Model 269 Relay Features

Protection Features

-Overloads

-Stator Winding Overtemperature (Alarm, High Alarm and Trip)

-Multiple Starts

-Short Circuit

-Locked Rotor

-Rapid Trip/Mechanical Jam

-Unbalance/Single Phasing

-Ground Fault (Alarm and Trip)

-Bearing Overtemperature (Alarm and Trip)

-Undercurrent (Alarm and Trip)

-Variable Lock-Out Time

- Phase Reversal (Meter Option)

Operational Features

-Microcomputer controlled

-Keypad programmable

-48 character alphanumeric display

-Built-in "HELP" function

-Eight selectable standard overload curves

-Continual relay circuitry self-check

Monitoring and Display Features

-Negative sequence phase current unbalance measurement

-Ground fault (earth leakage) current measurement

-Up to six stator RTD inputs

-Two additional RTD inputs

-Monitoring of motor ambient air temperature

-Display of all SETPOINTS or ACTUAL VALUES upon request

-Display of relay TRIP/ALARM and HELP messages

Communications and Control Features

-One latched, main trip relay

-One alarm relay

-Two auxiliary relays

-Emergency restart capability

-Pre-trip alarm warnings

-4-20mA output of motor current as a percentage of full load, motor thermal capacity, hottest stator RTD temperature, percentage of phase CT secondary current, or bearing RTD

Statistical and Memory Features

-Recall of all pre-trip motor values

-Tamperproof setpoints stored in non-volatile memory

-Microcomputer "learns" motor inrush current

-Accumulation of motor running hours

Voltage and Power Metering (available with MPM)

-Display of 3 phase or line voltages, kWatts, kVars, Power Factor, and frequency.

-Protection features based on Voltage, Power Factor, kVars, and voltage sensed phase reversals.

-Pre-trip values of average voltage, kWatts, kVars, Power Factor, and frequency.

-Accumulated MegaWattHours.

4. Protection for loss of suction for pumps or loss of

air flow for fans using the undercurrent feature.

5. Protection of motor and load bearings from excessive heat buildup due to mechanical wear.

6. Protection of motors operated in environments with

varying ambient temperatures.

7. Complete protection, allowing maximum motor

utilization with minimum downtime, for all AC motors.

1-2

Page 6

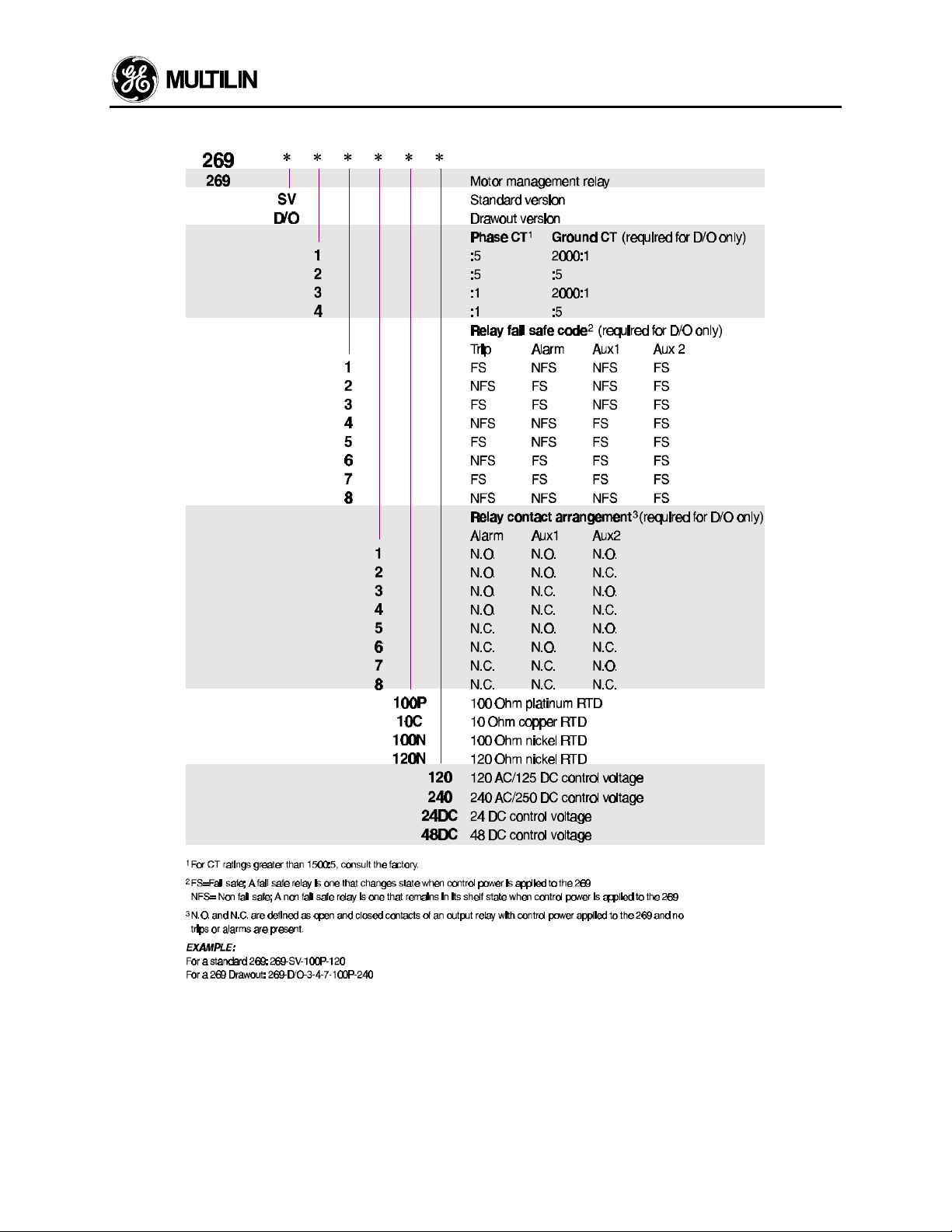

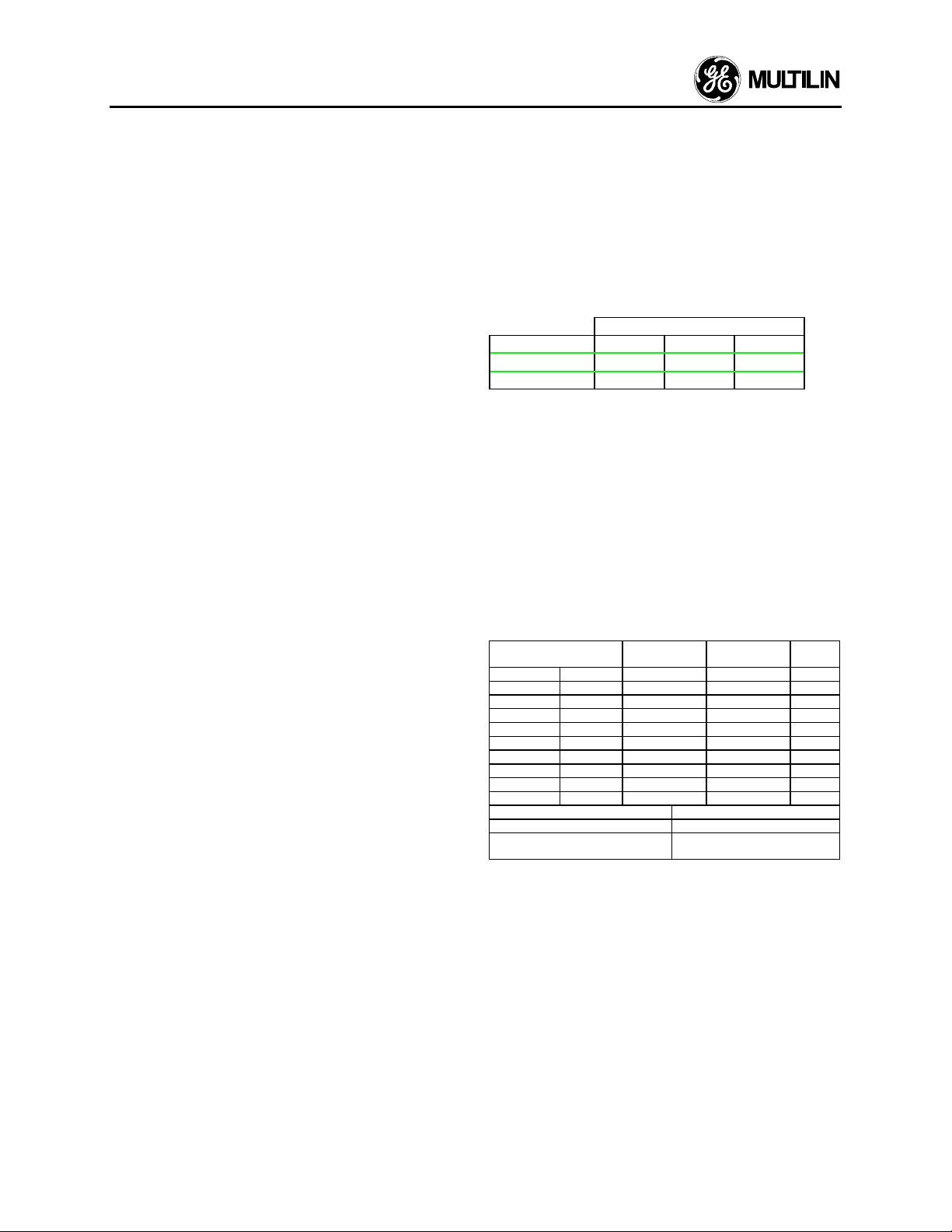

1.4 Order Code/Information

1 INTRODUCTION

The model 269 relay is almost entirely field programmable. The information shown above must be specified when the relay is ordered, as these options are not

selectable in the field. Additional features can be made

available on special order by contacting the GE Multilin

factory.

** See Glossary for definitions

* CT information, failsafe code, and contact ar-

rangement must be specified for drawout relays

only; on standard 269's these features are field

selectable.

1-3

Page 7

1 INTRODUCTION

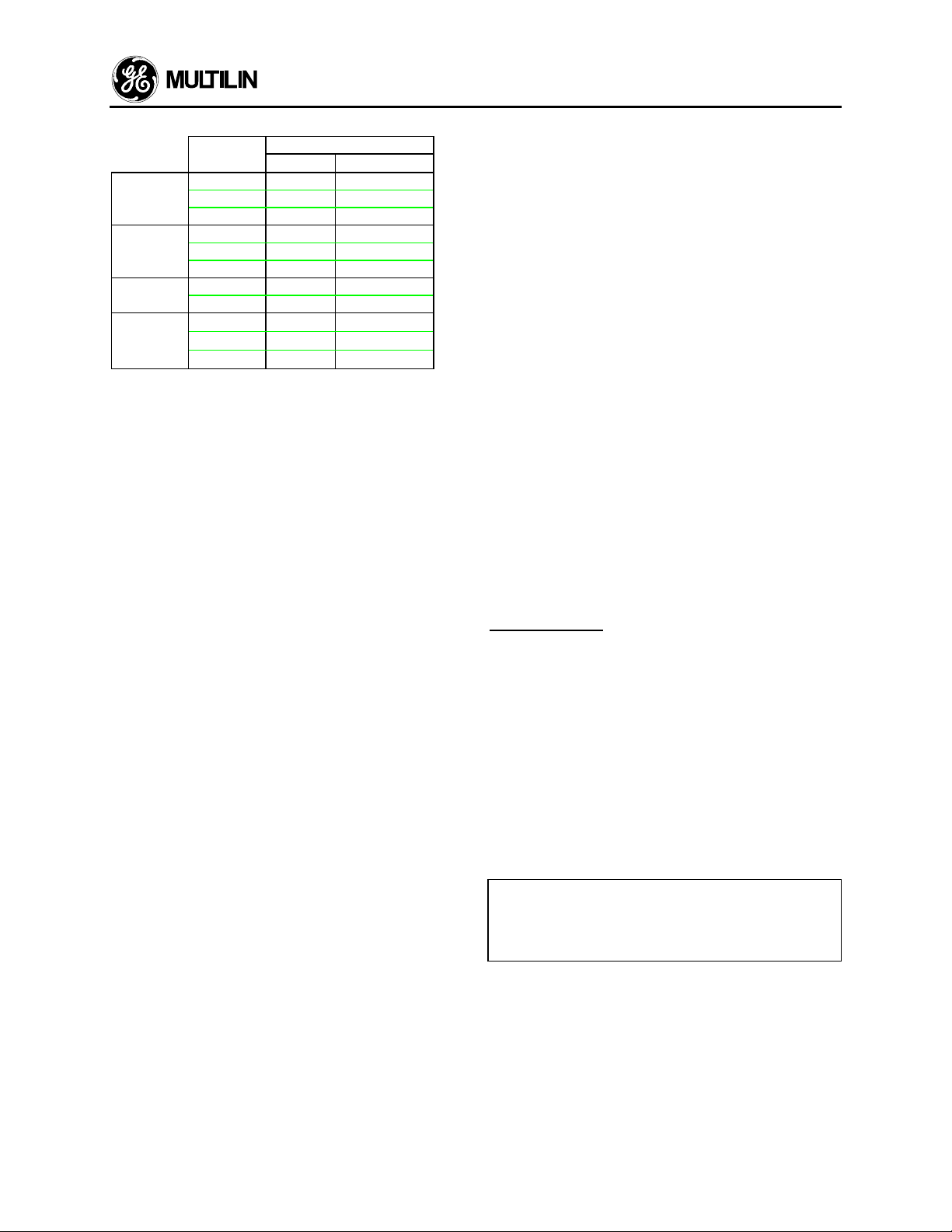

1.5 Technical Specifications

Phase Current Inputs

conversion: calibrated RMS, sample time 2ms

range: 0.05 to 12 × phase CT primary amps set-

point

full scale: 12 × phase CT primary amps setpoint

accuracy: ± 0.5% of full scale

(0.05 to 2 × phase CT primary amps set-

point)

± 1.0% of full scale

(over 2 × phase CT primary amps set-

point)

Frequency: 20–400 Hz

Ground Fault Current Input

conversion: calibrated RMS, sample time 2ms

range: 0.1 to 1.0 × G/F CT primary amps set-

point (5 Amp secondary CT)

1.0 to 10.0 amps 50:0.025A (2000:1 ratio)

full scale: 1 × G/F CT primary amps setpoint

(5 Amp secondary CT)

10 amps (2000:1 CT)

accuracy: ± 4% of G/F CT primary amps setpoint

(5 Amp secondary CT)

± 0.3 amps primary (2000:1 CT)

Frequency: 20–400 Hz

Overload Curves

curves: 8 curves fixed shape

trip time accuracy: ± 1 sec. up to 13 sec.

± 8% of trip time over 13 sec.

detection level: ± 1% of primary CT amps

Unbalance

display accuracy:± 2 percentage points of true negative

sequence unbalance (In/Ip)

Running Hours Counter

accuracy: ± 1%

Relay Lock-out Time

accuracy: ± 1 minute with control power applied

± 20% of total lock-out time with no con-

trol power applied

Trip/Alarm Delay Times

accuracy: ± 0.5 sec. or 2% of total time, whichever

is greater with the exception of:

1. "INST."setpoints: 20–45ms

2. Ground Fault 0.5 Second delay: +/150 msec.

3. Ground Fault 250 msec delay: +75

msec, -150 msec.

4. Metering setpoints (Page 7): +/- 1.5sec

or 2% of total time

RTD Inputs

sensor types: 10 OHM copper

100 OHM nickel

120 OHM nickel

100 OHM platinum

(specified with order)

display accuracy: ± 2 C

trip/alarm setpoint range: 0-200 °C

dead band: 3 C

maximum lead resistance:25% of RTD 0 °C resistance

Analog Current Output (4-20 mA standard)

PROGRAMMABLE

OUTPUT 0-1 mA 0-20 mA 4-20 mA

MAX LOAD

2000 Ω 300 Ω 300 Ω

MAX OUTPUT 1.01 mA 20.2 mA 20.2 mA

accuracy: ± 1% of full scale reading

polarity: terminal 58 ("-") must be at

ground potential (i.e. output is

not isolated)

Isolation: non-isolated, active source

Update Time: 250 ms max.

Communications

Type: RS485 2-wire, half duplex, isolated

Baud Rate: 300, 1200, 2400

Protocol: Subset of Modbus® RTU

Functions: Read/write setpoints (03/16),

Read actual values (03/04)

Relay Contacts

VOLTAGE

30 VDC 10 30 10

RESISTIVE 125 VDC 10 30 0.5

250 VDC 10 30 0.3

30 VDC 10 30 5

INDUCTIVE 125 VDC 10 30 0.25

(L/R=7ms) 250 VDC 10 30 0.15

RESISTIVE 120 VAC 10 30 10

250 VAC 10 30 10

INDUCTIVE 120 VAC 10 30 4

PF=0.4 250 VAC 10 30 3

CONFIGURATION FORM C NO/NC

CONTACT MATERIAL SILVER ALLOY

MINIMUM PERMISSIBLE LOAD 5 VDC, 100 mA

MAKE/CARRY

CONTINUOUS

MAKE/CARRY

0.2 sec

12 VAC, 100 mA

BREAK

Switch Inputs

Type: dry contacts

Differential Relay Input

relay response time: 100 msec. maximum (contact

closure to output relay activation)

1-4

Page 8

1 INTRODUCTION

CT Burden Due to Connection of 269 Relay

CT INPUT BURDEN

(AMPS) (VA)

1 0.04 43

PHASE CT 4 0.5 31

(1A) 13 4.8 28

5 0.06 2.4

PHASE CT 20 1 2.5

(5A) 65 8.5 2.01

G/F CT 5 0.08 3

(5A) 10 0.3 3

G/F CT 0.025 0.435

(50:0.025) 0.1 3.29

0.5 50

CT Thermal Withstand

Phase CT & G/F 5 amp tap:3 × - continuous

6 × - 40 sec

12 × - 3 sec

G/F 50:0.025 mA 6 × - continuous

Control Power (Includes Tolerances)

frequency: 50/60 Hz

24 VDC, range: 20-30 VDC

48 VDC, range: 30-55 VDC

120 VAC/125 VDC, range: 80-150 VAC/VDC

240 VAC/250 VDC, range: 160-300 VAC/VDC

max. power consumption: 20 VA

Voltage low ride-through time:

100ms (@ 120VAC/125VDC)

NOTE:Relay can be powered from either AC or DC

source. If Control Power input exceeds 250 V,

an external 3A fuse must be used rated to the

required voltage.

Fuse Specifications

T3.15A H 250V

Timelag high breaking capacity

Dielectric Strength

2200 VAC, 50/60 Hz for 1 sec.

GROUND (Terminal 42) to

Output Contacts (Terminals 29 through 40)

Control Power (Terminals 41 & 43)

Current Transformer Inputs (Terminals 72

through 83)

NOTE: If Hi-Pot tests are performed, jumper J201

beside terminal 43 should be placed in the "HIPOT" position. Upon completion of Hi-Pot tests, the

jumper should be placed in the "GND" position.

See Fig. 4.3.

(mΩ)

696 Ω

329 Ω

200 Ω

Type Tests

Dielectric Strength: 2.0 kV for 1 minute to relays,

CTs, power supply

Insulation Resistance:IEC255-5,500Vdc

Transients: ANSI C37.90.1 Oscillatory 2.5kV/1MHz

ANSI C37.90.1 Fast Rise 5kV/10ns

Ontario Hydro A-28M-82

IEC255-4 Impulse/High

Frequency Disturbance

Class III Level

Impulse Test: IEC 255-5 0.5 Joule 5kV

RFI: 50 MHz/15W Transmitter

EMI: C37.90.2 Electromagnetic Interference

@ 150 MHz and 450 MHz, 10V/m

Static: IEC 801-2 Static Discharge

Humidity: 95% non- condensing

Temperature: -25°C to +60°C ambient

Environment: IEC 68-2-38 Temperature/Humidity

Cycle

Dust/Moisture: NEMA 12/IP53

Ambient Temperature and Storage Temperature

-25°C to +60°C

Packaging

Shipping box: 11.40" x 7.50" x 16.00" (WxHxD)

290mm x 190mm x 410mm (WxHxD)

Ship weight: 3.5 kg

7.75 lb.

269 Plus drawout:

Shipping box: 13.25" x 12.50" x 20.50" (LxHxD)

340mm x 320mm x 520mm

Ship weight: 12 kg

26.4 lb.

Certifications

ISO: Manufactured to an ISO9001 certified program

UL: UL recognized under E83849

CSA: Approved under LR41286

CE: Conforms to IEC 947-1, IEC 1010-1

Overvoltage Category: II

Pollution Degree: 2

IP Code: 40X

Note: 269 Drawout does not meet CE compliance.

WARNING:HAZARD may result if the product is

not used for intended purposes.

This equipment can only be serviced

by trained personnel.

1-5

Page 9

1 INTRODUCTION

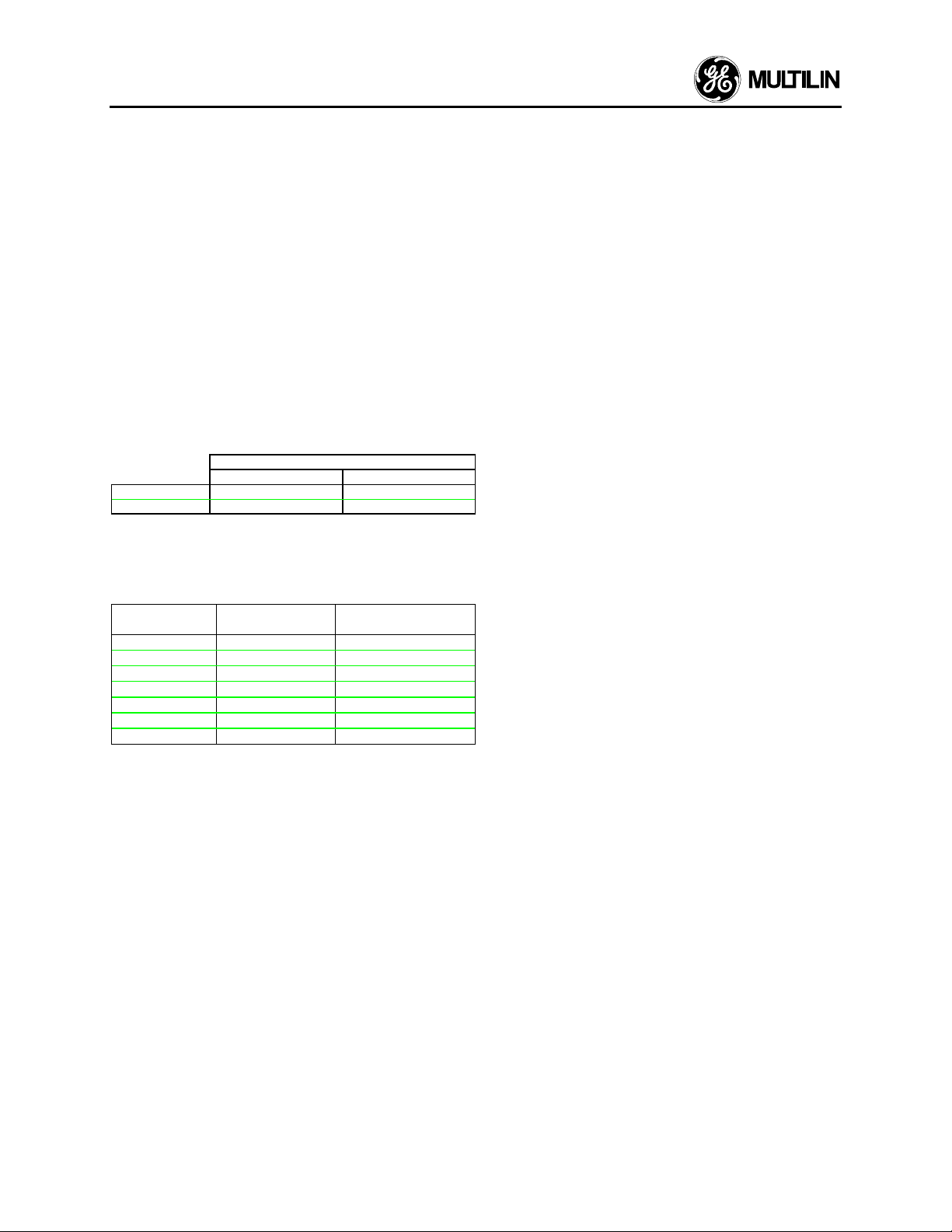

MPM OPTION SPECIFICATIONS

PHASE CURRENT INPUTS

Conversion: true rms, 64 samples/cycle

CT input: 1A & 5A secondary

Burden: 0.2 VA

Overload: 20xCT for 1s, 100xCT for 0.2s

Range: 1-150% of CT pri

Frequency: up to 32nd harmonic

Accuracy: ± 1% of display

VOLTAGE INPUTS

Conversion: true rms, 64 samples/cycle

VT pri/Sec: direct or 120-72000:69-240

Input range: 20-600 VAC

Full scale: 150/600 VAC autoscaled

Frequency: up to 32nd harmonic

Accuracy: ± 1% of display

ANALOG OUTPUTS

MAX LOAD

MAX OUTPUT 1.1 mA 21 mA

0-1 mA (T1 Option) 4-20 mA (T20 Option)

2400 Ω 600 Ω

Accuracy: ±2% of full scale reading

Isolation: 50V isolated, active source

MEASURED VALUES

OUTPUT

EMI: C37.90.2 Electromagnetic Inter-

ference @ 150 MHz and 450

MHz, 10V/m

Static: IEC 801-2 Static Discharge

Humidity: 95% non-condensing

Temperature: -10°C to +60°C ambient

Environment: IEC 68-2-38 Tempera-

ture/Humidity Cycle

Dust/moisture: NEMA 12/IP53

PACKAGING

Shipping box: 8½" × 6" × 6" (L×H×D) 215cm ×

152cm × 152 cm (L×H×D)

Ship weight: 5 lbs/2.3 kg

CERTIFICATION

ISO: Manufactured to an ISO9001 certified

program

UL: Recognized under E83849

CSA: Recognized under LR41286

Note: It is recommended that all relays be powered

up at least once per year to avoid deterioration of

electrolytic capacitors in the power supply.

Due to updating technology, specifications may be improved without notice.

PARAMETER ACCURACY (%

OF FULL SCALE)

VOLTAGE ±0.2% 20% TO 100% OF VT

kW ±0.4% 0-999,999.99 kW

kVar ±0.4% 0-999,999.99 kVar

kVA ±0.4% 0-999,999.99 kVA

kWh ±0.4% 0-999,999,999 kWh

PF ±1.0% ±0.00-1.00

FREQUENCY ±0.02Hz 20.00-70.00 Hz

RANGE

CONTROL POWER

Input: 90 – 300 VDC or

70 – 265 VAC, 50/60 Hz

Power: nominal 10VA

maximum 20VA

Holdup: 100 ms typical (@ 120 VAC/125

VDC)

TYPE TESTS

Dielectric strength: 2.0 kV for 1 minute to relays,

CTs, VTs, power supply

Insulation resistance: IEC255-5,500Vdc

Transients: ANSI C37.90.1 Oscillatory

2.5kV/1MHz

ANSI C37.90.1 Fast Rise

5kV/10ns

Ontario Hydro A-28M-82

IEC255-4 Impulse/High

Frequency Disturbance

Class III Level

Impulse test: IEC 255-5 0.5 Joule 5kV

RFI: 50 MHz/15W Transmitter

1-6

Page 10

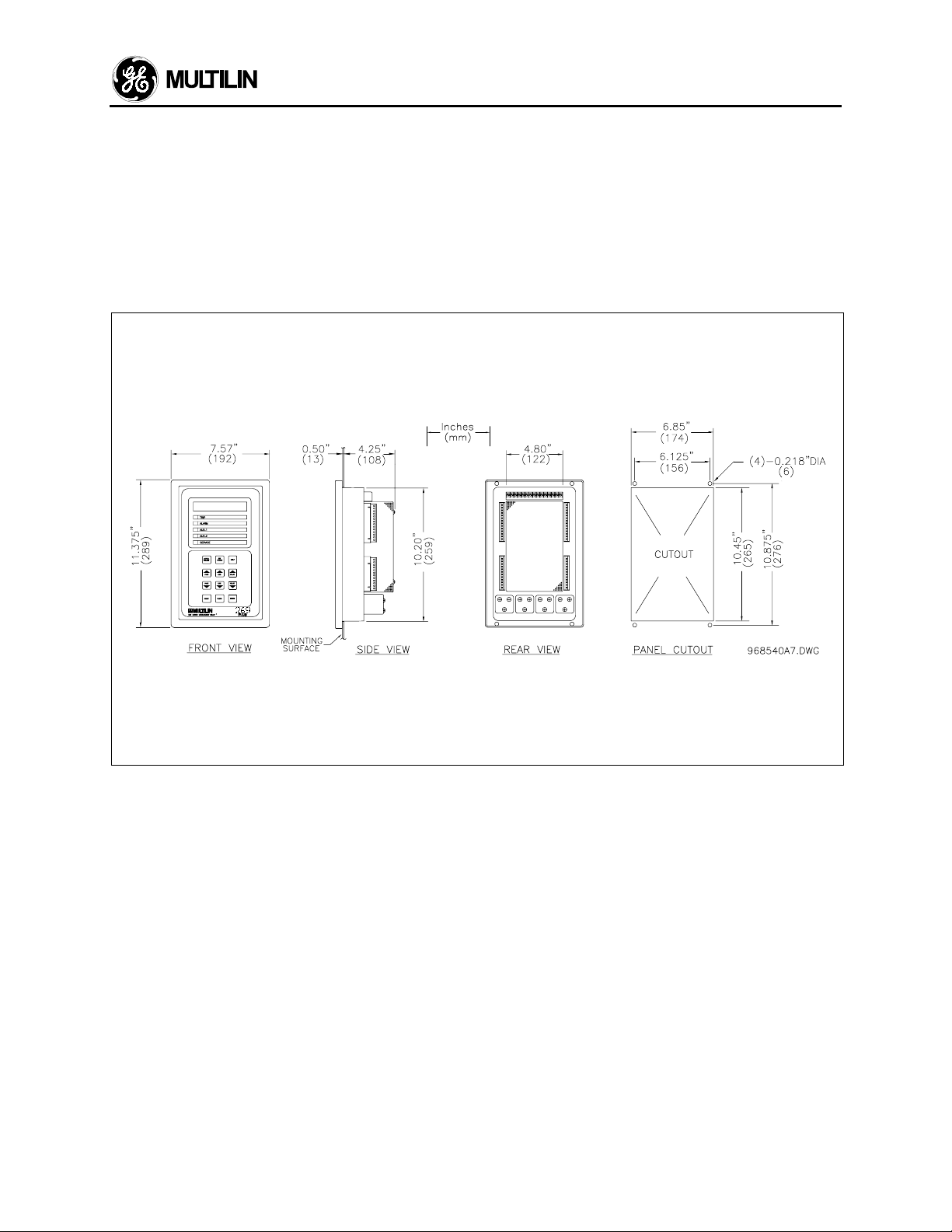

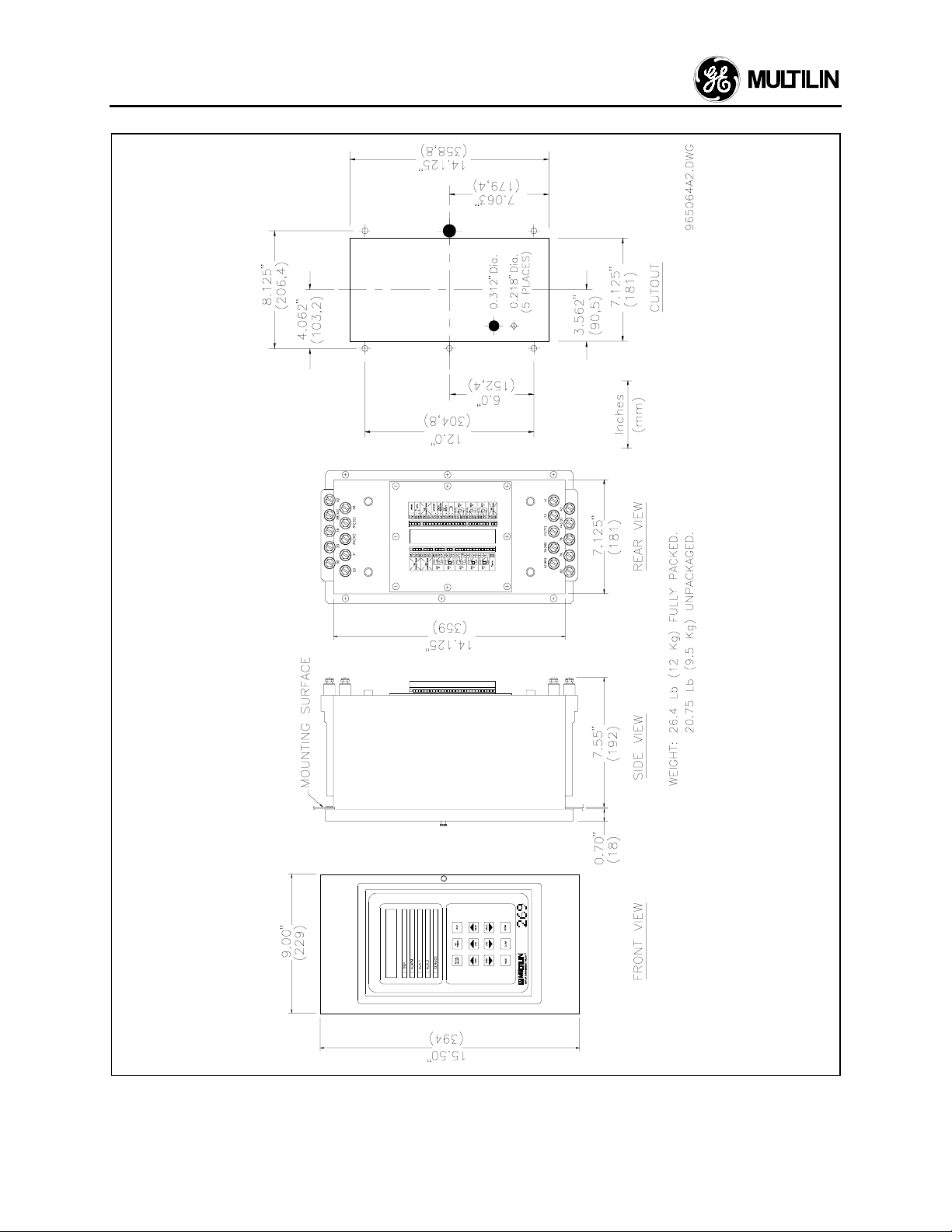

2.1 Physical Dimensions

2 INSTALLATION

The 269 relay is contained in a compact plastic and

metal housing with the keypad, display, and all

indicators located on the front panel. The physical

dimensions of the 269 unit are given in Figure 2.1.

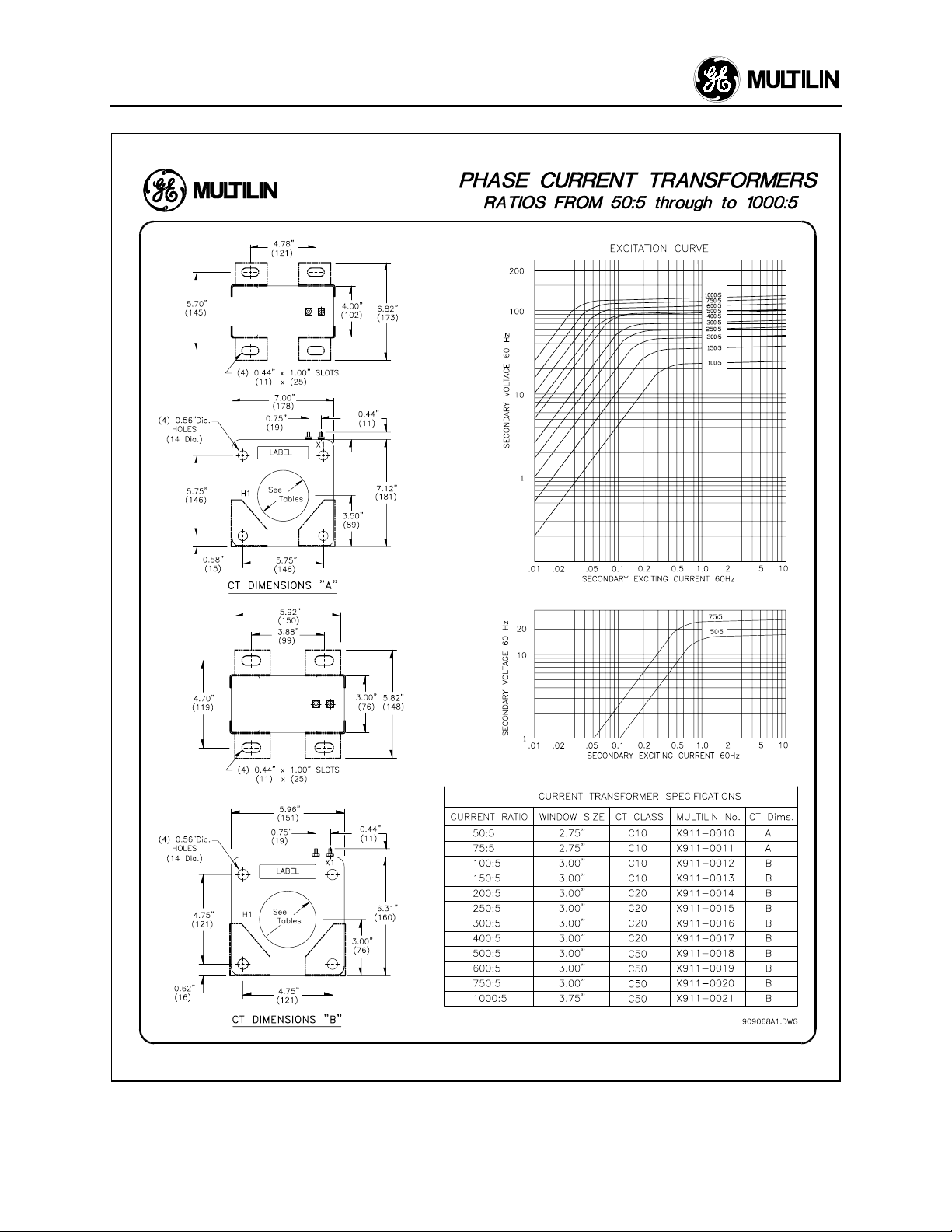

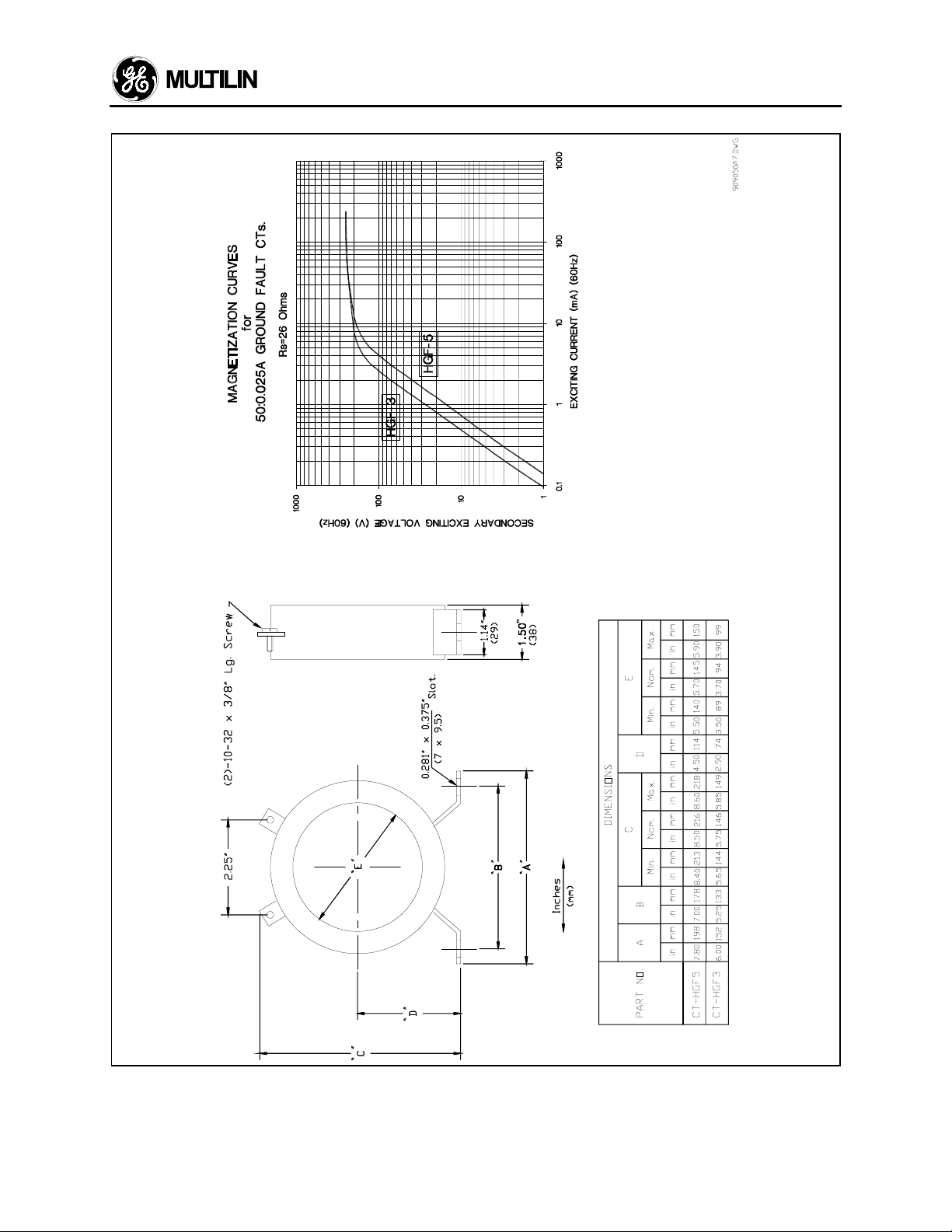

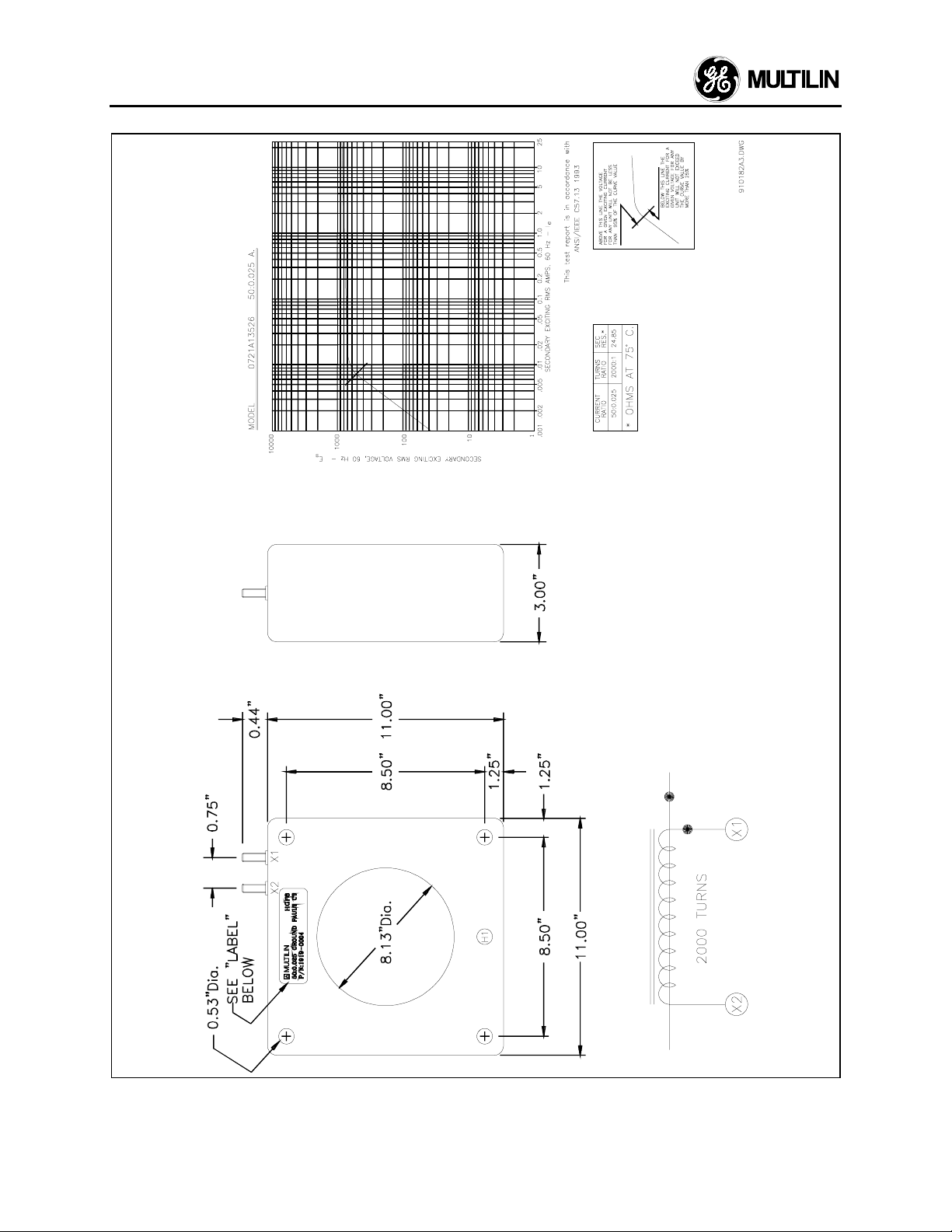

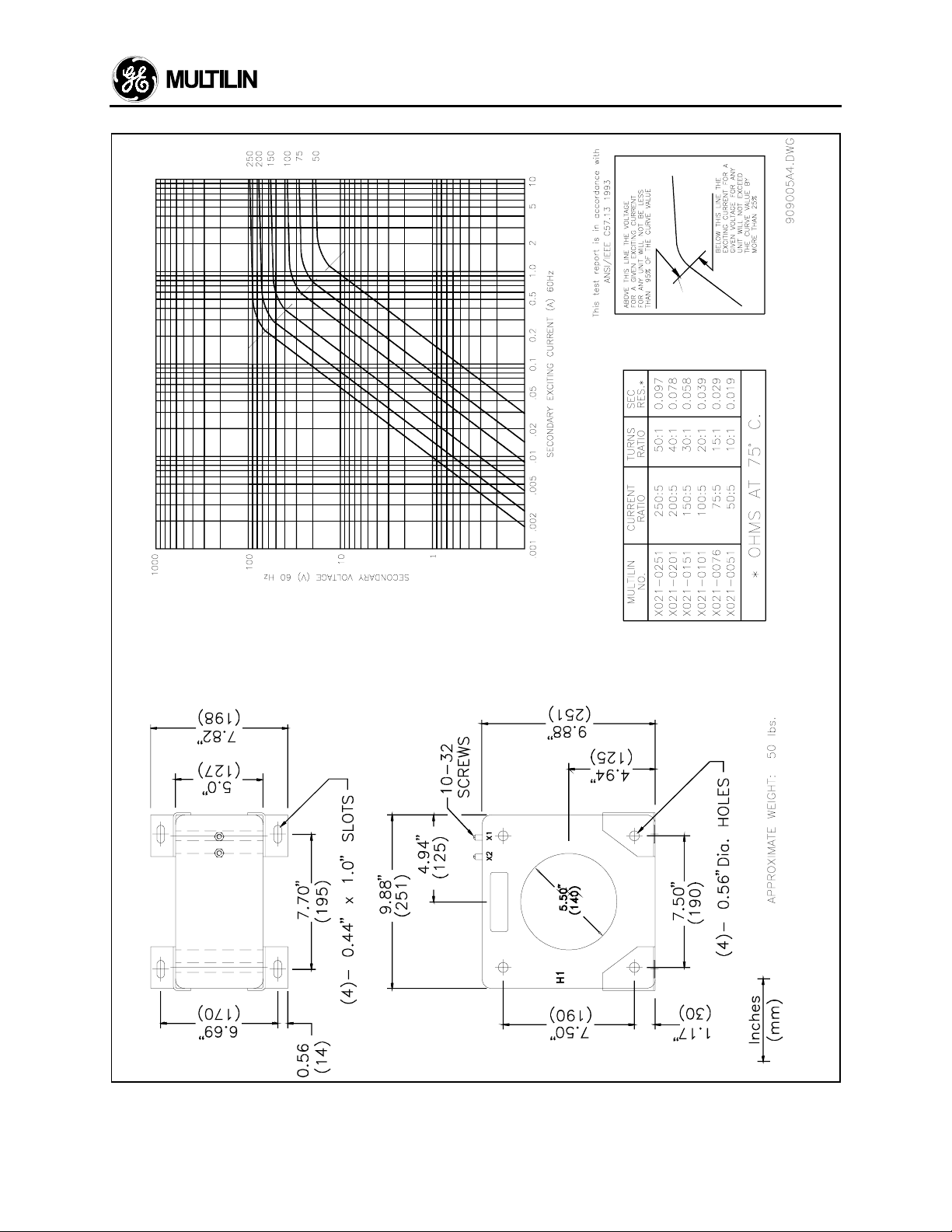

GE Multilin also provides phase and ground fault CTs

if required. Dimensions for these are shown in Figure

2.2a, Figure 2.2b, Figure 2.2c, and Figure 2.2d.

Dimensions of a are for 100:5 to 1000:5 phase CT's;

for the dimensions of 50:5 and 75:5 CT's, consult

factory.

Note

:

Figure 2.1

Physical Dimensions

2-1

Page 11

2 INSTALLATION

2-2

Figure 2.2a

Phase CT Dimensions

Page 12

2 INSTALLATION

Figure 2.2b

Ground CT (50:0.025) 3” and 5” window

2-3

Page 13

2 INSTALLATION

2-4

Figure 2.2c

Ground CT (50:0.025) 8” window

Page 14

2 INSTALLATION

Figure 2.2d

Ground CT (x:5) Dimensions

2-5

Page 15

2 INSTALLATION

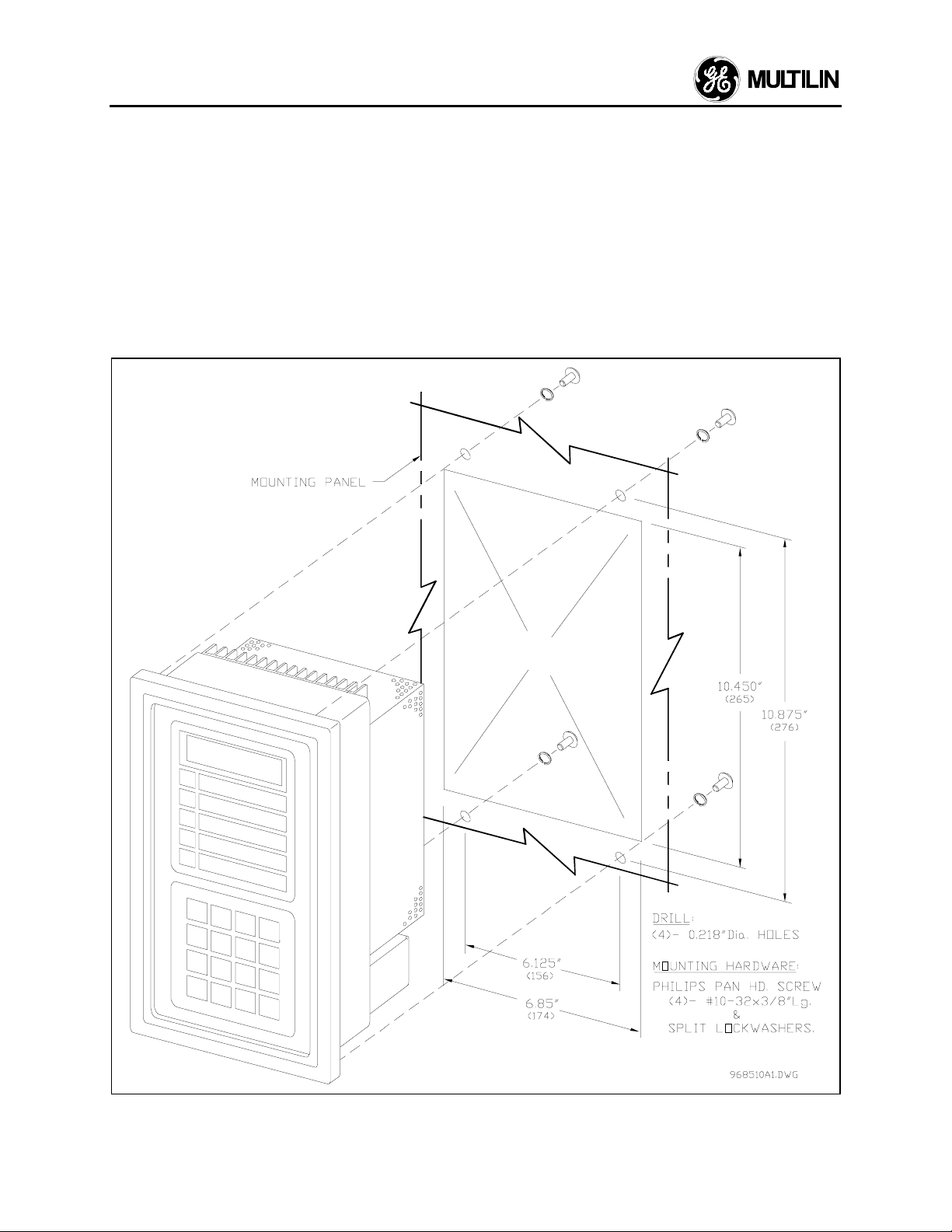

2.2 Mounting

The 269 should be positioned so that the display is

visible and the front panel keypad is accessible. A

cut-out is made in the mounting panel and the unit is

mounted as shown in Figure 2.3. Four washers and

10-32 × 3/8" mounting screws are provided.

Although the 269 circuitry is internally shielded, to

minimize noise pickup and interference the relay

should be placed away from high current conductors

or sources of strong magnetic fields. Connections to

the relay are made through terminal blocks and CTs

located on the rear of the unit.

2.3 External Connections

The connections made to the 269 relay will vary

depending on the programming of the unit. It is not

necessary to use all of the connections provided; a

minimal configuration would include supply power,

three phase current CT inputs and the Trip relay

contacts wired in series with the contactor control

relay or circuit breaker shunt trip coil. Connections to

these and the other terminals outlined below will be

explained in the following sections.

2-6

Figure 2.3

Relay Mounting

Page 16

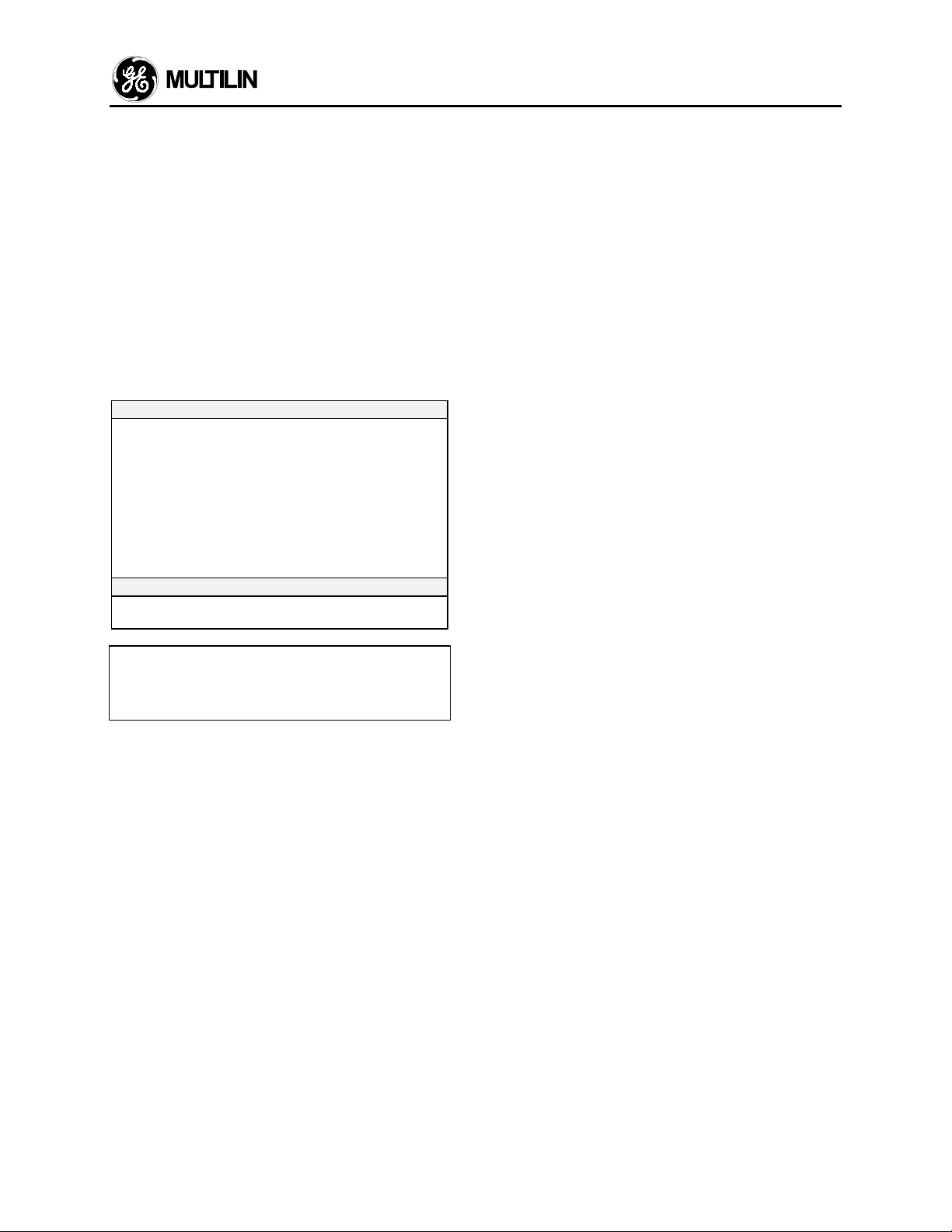

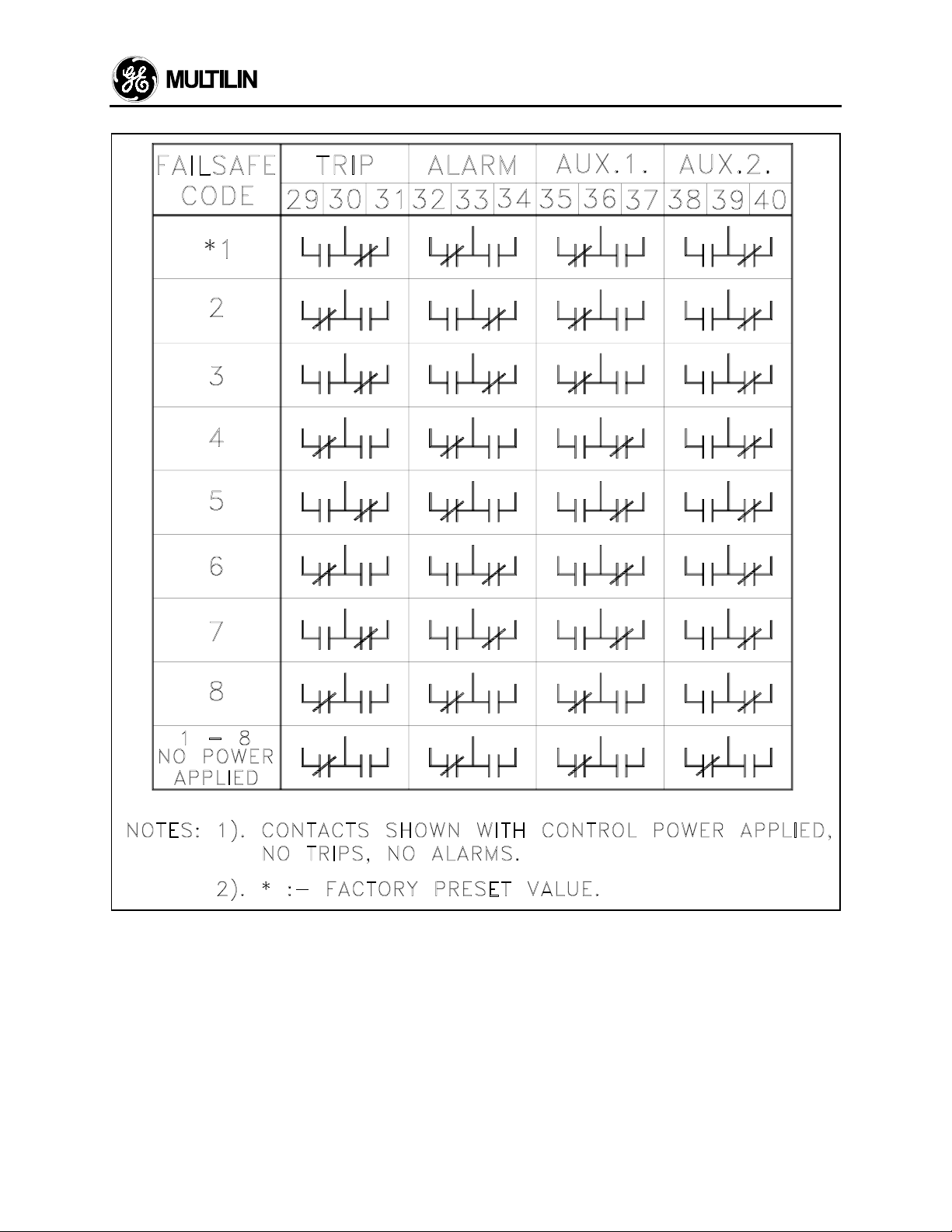

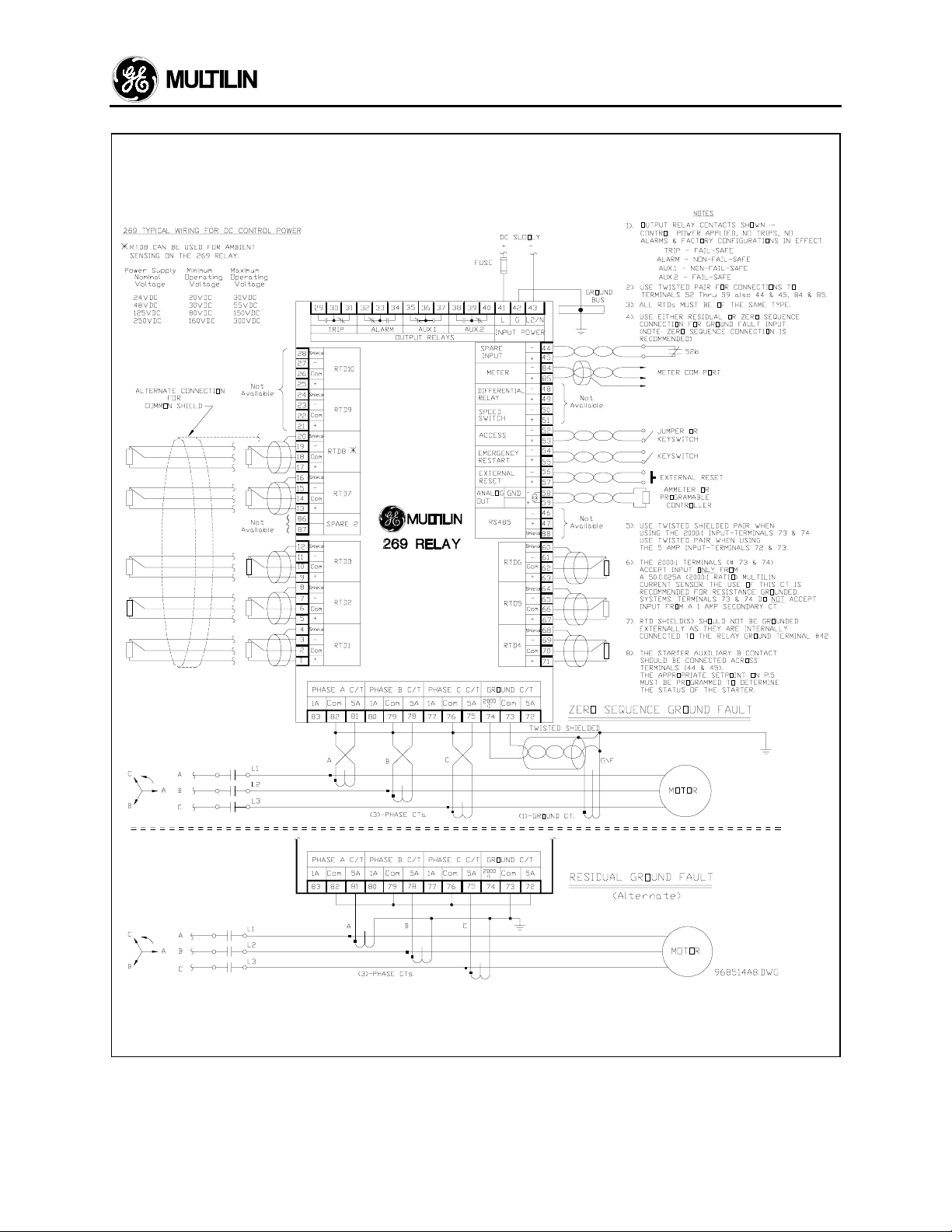

Figure 2.4, Figure 2.6, and Figure 2.7 show typical

connections to the 269 relay.

NOTE: The rear of the 269 relay shows output relay

contacts in their power down state. Figure 2.4, Figure

2.6, and Figure 2.7 show output relay contacts with

power applied, no trips or alarms, Factory

Configurations, i.e. TRIP - fail-safe, ALARM - non-failsafe, AUX.1 - non-fail-safe, AUX.2 - fail-safe). See

Figure 2.5 for a complete list of all possible output

relay contact states. See SETPOINTS page 5 for a

description of the RELAY FAILSAFE CODE.

2 INSTALLATION

Table 2-1

Inputs

-Supply Power L(+), G, N(–) - universal AC/DC

supply

-Phase CTs

-Ground Fault CTs (core balance CT)

-6 Stator RTDs

-2 additional RTDs

-Emergency Restart keyswitch

-External Reset pushbutton

-Programming Access jumper or keyswitch

-Meter Communication Port

Outputs

-4 Sets of Relay Contacts (NO/NC)

-Programmable Analog Current Output Terminals

WARNING: HAZARD may result if the product is

269 External Connections

not used for intended purposes. This

equipment can only be serviced by

trained personnel.

2-7

Page 17

2 INSTALLATION

2-8

Figure 2.4

Relay Wiring Diagram (AC Control Power)

Page 18

2 INSTALLATION

Figure 2.5

WARNING: In locations where system voltage

disturbances cause voltage levels to dip below the

range specified in the Specifications (1.5), any relay

contact programmed failsafe may change state.

Therefore, in any application where the "process" is

more critical than the motor, it is recommended that

the trip relay contacts be programmed non-failsafe. In

this case, it is also recommended that the AUX2

Output Relay Contact States

contacts be monitored for relay failure. If, however,

the motor is more critical than the "process," then the

trip contacts should be programmed failsafe.

2-9

Page 19

2 INSTALLATION

2-10

Figure 2.6

Relay Wiring Diagram (Two Phase CTs)

Page 20

2 INSTALLATION

Figure 2.7

Relay Wiring Diagram (DC Control Power)

2-11

Page 21

2 INSTALLATION

2.4 Control Power

The relay is powered on using any one of four

different switching power supplies: 120-125

VAC/VDC, 240-250 VAC/VDC, 48 VDC, or 24 VDC.

The first two versions have been designed to work

with either AC or DC control power. Maximum power

consumption for the unit is 20 VA.

The 269 will operate properly over a wide range of

supply voltages typically found in industrial

environments (see control power specifications in

section 1.5). When the supply voltage drops below

the minimum, the output relays will return to their

power down states but all setpoints and statistical

data will remain stored in the relay memory. Motor

lock-out time will be adhered to with or without control

power applied. If control power is removed, the relay

keeps track of the Motor Lockout time for up to an

hour.

Control power must be applied to the 269 relay, and

the relay programmed, before the motor is energized.

Power is applied at terminals 41, 42, and 43 which

are terminal blocks having #6 screws.

Note: Chassis ground terminal 42 must be

connected directly to the dedicated cubicle

ground bus to prevent transients from damaging

the 269 resulting from changes in ground

potential within the cubicle. Terminal 42 must be

grounded for both AC and DC units for this

reason.

Verify from the product identification label on the back

of the relay that the control voltage matches the

intended application. Connect the control voltage

input to a stable source of supply for reliable

operation. A 3.15A, slow blow mini fuse (see Fuse

Specifications in Technical Specifications) is

accessible from the back of the 269 by removing the

perforated cover. See Figure 2.8 for details on

replacing the fuse. Using #10 gauge wire or ground

braid, connect terminal 42 to a solid ground which is

typically the copper ground bus in the switchgear.

Extensive filtering and transient protection is built into

the 269 to ensure reliable operation under harsh

industrial operating environments. Transient energy

must be conducted back to the source through filter

ground. The filter ground is separated from the safety

ground terminal 42 at jumper J201 on the back of the

relay to allow dielectric testing of a switchgear with a

269 wired up. Jumper J201 must be removed during

dielectric testing. It must be put back in place once

the dielectric testing is done.

When properly installed, the 269 will meet the

interference immunity requirements of IEC 1000-43/EN61000-4-3; EN 61000-4-6. It also meets the

emission requirements of IEC CISPR11/EN55011

and EN50082-2.

2.5 Phase CT Inputs

One CT for each of the three motor phases is

required to input a current into the relay proportional

to the motor phase current. The phase sequence

must be as shown in Figure 2.4 and Figure 2.7. The

CTs used can have either a 1 amp or 5 amp

secondary and should be chosen so that the motor

full load current is between 75 and 95 percent of the

rated CT primary amps. The CT ratio should thus be

of the form n:1 or n:5 where n is between 20 and

1500. The ratio of the CT used must be programmed

into the 269 (see section 3.7).

The CT connections to the relay are made between

the ":1" and "COM" terminals for 1 amp CTs or

between the ":5" and "COM" terminals for CTs with a

5 amp secondary.

The connections to the 269 internal phase CTs are

made directly via #10 screws.

CTs should be selected to be capable of supplying

the required current to the total secondary load which

includes the 269 relay burden of 0.1 VA at rated

secondary current and the connection wiring burden.

The CT must not saturate under maximum current

conditions which can be up to 8 times motor full load

during starting or up to 20 times during a short circuit.

Only CTs rated for protective relaying should be used

since metering CTs are usually not rated to provide

enough current during faults. Typical CT ratings are:

CSA (Canada): Class10L100 10=accuracy,

L=protection,

100=capacity, higher is

better

ANSI (USA): Class C 100 B4 C or T=protection,

100=capacity, higher is

better, B4=accuracy

IEC (Europe): 20 VA Class 5P20 P=protection,

20VA=capacity, higher is

better

Refer to Appendix H for details on CT withstand, CT

size and saturation, as well as the safe use of 600V

class window type CTs on a 5 kV circuit.

2-12

Page 22

4

3

2 INSTALLATION

NOTES

REMOVE CONTROL POW ER FROM THE RELAY

BEFORE ATTEMPTING TO CHANGE THE FUSE.

WARNING :

CAUTION

CAUTION

ENSURE THAT THE PERFORATED COVER CLEARS ALL COMPONENTS

WHEN BEING RE-INSTALLED.

FOR DRAW OUTS, CONTACT THE FACTORY.

THIS PROCEDURE DOES NOT APPLY TO 269/269Plus DRAWOUT VERSIONS.

CAUTION

AND COMPLETELY PLUG GED IN THE MATING 968023A2.DWG

ENSURE THAT POWER SUPPLY PCB IS FIRM LY IN PLACE

CONNECTOR.

CAUTION

SWITCHGEAR PANEL

CAUTION

1

2

PROCEDURE

REMOVING FUSE:

REPLAC ING FU SE:4IN TECHNICAL SPECIFICATIONS.

USE MINI CARTRIDGE FUSE 3.15A/250V. SEE FUSE SPECIFIC ATIO NS

USING A FUSE PULLER, REMOVE THE FUSE FRO M HO LDER.

REMOVE PER FORATED COVER BY U NSCREW ING THE (4)- #8 -32 SCREW S.

REMOVING PERFOR ATED COVER:

1

REMOVE PO WER SUPPLY BY UNSCREW ING THE (4)- #8 -32 x 3/8" LG. STAND OFFS

& UNPLUGG ING THE INTERBOARD CONN ECTO R.

REMOVING POW ER SUPPLY PCB:

THIS PROCEDURE APPLIES TO 269/269Plus RELAYS

WITH REVISION "C" ONLY.

C = REVISION "C" UNITS.

EXAMPLE: SERIAL N O. C5261392

2

3

POSITION THE FUSE IN THE PULLER AND PLACE BACK IN FUSE HOLDER.

PERFORATED COVER & SCREWS.

RE-INSTALL POWER SUPPLY PCB, STA NDOFFS,

5

6

Figure 2.8

Replacing a blown fuse

2-13

Page 23

2 INSTALLATION

SHIELDED

CABLE

Figure 2.9a

Core Balance Ground CT Installation using Shielded Cable

UNSHIELDED

CABLE

2-14

Figure 2.9b

Core Balance Ground CT Installation using Unshielded Cable

Page 24

2 INSTALLATION

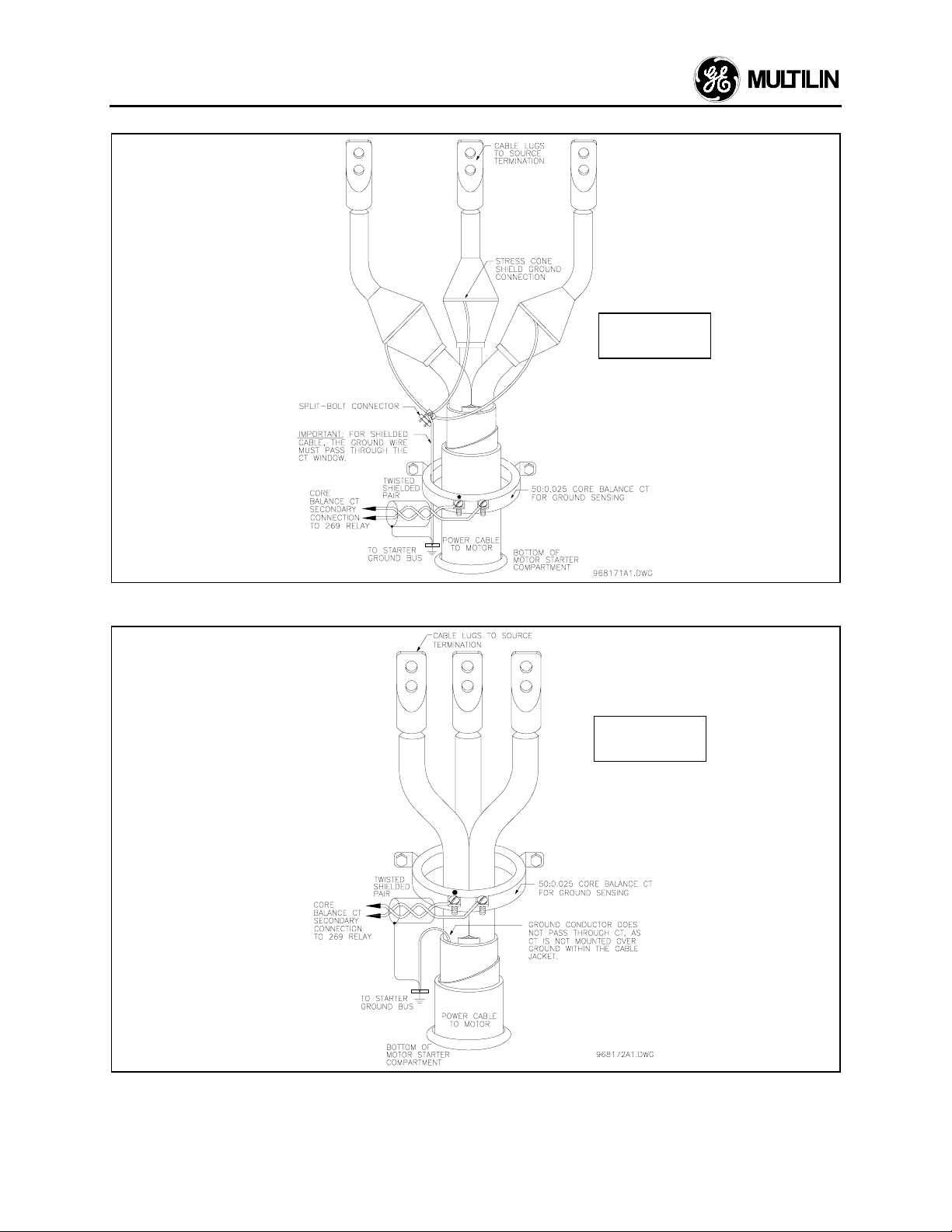

2.6 Ground CT Input

All current carrying conductors must pass through a

separate ground fault CT in order for the ground fault

function to operate correctly. If the CT is placed over

a shielded cable, capacitive coupling of phase current

into the cable shield during motor starts may be

detected as ground current unless the shield wire is

also passed through the CT window; see Figure 2.9a.

If a safety ground is used it should pass outside the

CT window; see Figure 2.9b.

The connections to the 269 internal ground CT are

made directly via #10 screws. The ground CT is

connected to terminals 73 and 72 for a 5 amp

secondary CTs, or to terminals 73 and 74 for a GE

Multilin 50:0.025A (2000:1 ratio) CTs, as shown in

Figure 2.4, Figure 2.5, and Figure 2.7. The polarity of

the ground CT connection is not important. It is

recommended that the two CT leads be twisted

together to minimize noise pickup. If a 50:0.025A

(2000:1 ratio) ground CT is used, the secondary

output will be a low level signal which allows for

sensitive ground fault detection.

NOTE: The GE Multilin 2000:1 CT is actually a

50:0.025A CT recommended for resistance

grounded systems where sensitive ground fault

detection is required. If higher levels are to be

detected, a 5 Amp secondary CT should be used.

For a solidly grounded system where higher ground

fault currents will flow, a 5 amp secondary CT with a

primary between 20 and 1500 A may be used to

surround all phase conductors. The phase CTs may

also be residually connected to provide ground

sensing levels as low as 10% of the phase CT

primary rating. For example, 100:5 CTs connected in

the residual configuration can sense ground currents

as low as 10 amps (primary) without requiring a

separate ground CT. This saves the expense of an

extra CT, however 3 phase CTs are required. If this

connection is used on a high resistance grounded

system verify that the ground fault alarm and trip

current setpoints are below the maximum ground

current that can flow due to limiting by the system

ground resistance. Sensing levels below 10% of the

phase CT primary rating is not recommended for

reliable operation.

2.7 Trip Relay Contacts

The main control relay or shunt trip coil of the motor

starter or circuit breaker should be connected to the

Trip relay contacts of the 269. These contacts are

available as normally open (NO), normally closed

(NC), and can switch up to 10 amps at either 250

VAC or 30 VDC with a resistive load. Silver cadmium

oxide contacts are used because of their ability to

handle high inrush currents on inductive loads.

Contact GE Multilin if these contacts are to be used

for carrying low currents since they are not

recommended for use below 0.1 amps. Connection to

the motor contactor or breaker is shown in Figure 2.4,

Figure 2.5, and Figure 2.7.

The Trip output relay will remain latched after a trip.

This means that once this relay has been activated it

will remain in the active state until the 269 is manually

reset. The Trip relay contacts may be reset by

pressing the RESET key (see section 3.1) if motor

conditions allow, or by using the Emergency Restart

feature (see section 2.12), or the External Reset

terminals, or by remote communications via the

RS485 port.

The Trip relay may be programmed to be fail-safe or

non-fail-safe. When in the fail-safe mode, relay

activation or a loss of power condition will cause the

relay contacts to go to their power down state. Thus,

in order to cause a trip on loss of power to the 269,

output relays should be programmed as fail-safe.

The Trip relay cannot be reset if a lock-out is in effect.

Lock-out time will be adhered to regardless of

whether control power is present or not. A maximum

of one hour lockout time is observed if control power

is not present.

The Trip relay can be programmed to activate on any

combination of the following trip conditions: overload,

stator RTD overtemperature, rapid trip, unbalance,

ground fault, short circuit, RTD overtemperature,

acceleration time, number of starts per hour, single

phase (see section 3.4 for factory preset

configurations).

Connections to the Trip relay contacts are made via a

terminal block which uses #6 screws.

When the phase CTs are connected residually, the

secondaries must be connected in such a way to

allow the 269 to sense any ground current that might

be flowing. To correctly display ground current and

trip or alarm on ground fault, the connection to the

269 must be made at terminals 72 and 73 as shown

in Figure 2.4 and Figure 2.7. These terminals are

designed to accept input from a 5A secondary CT.

The 269 must also be programmed for a 5A

secondary ground CT with the primary being equal to

the phase CT primary. This is done in SETPOINTS,

page 1.

NOTE: The rear of the 269 relay shows output relay

contacts in their power down state. Figure 2.4, Figure

2.6, and Figure 2.7 show output relay contacts with

power applied, no trips or alarms, and Factory

Configurations in effect (i.e. TRIP - fail-safe, ALARM non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe).

See Figure 2.5 for a list of all possible contact states.

WARNING: In locations where system voltage

disturbances cause voltage levels to dip below

the range specified in the Specifications (1.5), any

relay contact programmed failsafe may change

2-15

Page 25

2 INSTALLATION

state. Therefore, in any application where the

"process" is more critical than the motor, it is

recommended that the trip relay contacts be

programmed non-failsafe. In this case, it is also

recommended that the AUX2 contacts be

monitored for relay failure. If, how ever, the motor

is more critical than the "process" then the trip

contacts should be programmed failsafe.

2.8 Alarm Relay Contacts

These contacts are available as normally open (NO),

normally closed (NC), with the same ratings as the

Trip relay but can only be programmed to activate

when alarm setpoint levels are reached. (On a

Drawout version of 269, only one set of alarm

contacts is available and the user must specify

normally open or normally closed and failsafe or nonfailsafe when ordering). Thus these contacts may be

used to signal a low level fault condition prior to motor

shut-down.

Conditions which can be programmed to activate the

relay are alarm levels for the following functions:

immediate overload; mechanical jam; unbalance;

undercurrent; ground fault; stator RTD

overtemperature; RTD overtemperature; broken RTD;

low temperature or shorted RTD; and self-test alarm

(see section 3.4 for factory preset configurations).

The relay can be configured as latched or unlatched

and fail-safe or non-fail-safe.

These contacts may be used for alarm purposes or to

trip devices other than the motor contactor. For

example, the ground fault and short circuit functions

may be directed to Auxiliary relay #1 to trip the main

circuit breaker rather than the motor starter.

Connections to the relay contacts are made via a

terminal block which uses #6 screws.

NOTE: The rear of the 269 relay shows output relay

contacts in their power down state. Figure 2.4, Figure

2.6, and Figure 2.7 show output relay contacts with

power applied, no trips or alarms, and Factory

Configurations in effect (i.e. TRIP - fail-safe, ALARM non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe).

See Figure 2.5 for a list of all possible contact states.

2.10 Auxiliary Relay #2 Contacts

This relay provides another set of NO/NC contacts

with the same ratings as the other relays. (On a

Draw-out version of 269, only one set of Aux.2

contacts is available and the user must specify

normally open or normally closed when ordering).

This relay is different from the others in the fact that it

is permanently programmed as latched and fail-safe.

This relay may be programmed to activate on any

combination of alarm conditions (see section 3.4 for

factory preset configurations). The feature

assignment programming is thus the same as for the

Alarm relay.

Connections to the Alarm relay contacts are made via

a terminal block which uses #6 screws.

NOTE: The rear of the 269 relay shows output relay

contacts in their power down state. Figure 2.4, Figure

2.6 and Figure 2.7 show output relay contacts with

power applied, no trips or alarms, and Factory

Configurations in effect (i.e. TRIP - fail-safe, ALARM non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe).

See Figure 2.5 for a list of all possible contact states.

2.9 Auxiliary Relay #1 Contacts

Auxiliary relay #1 is provided to give an extra set of

NO/NC contacts which operate independently of the

other relay contacts. (On a Drawout version of 269,

only one set of Aux.1 contacts is available and the

user must specify normally open or normally closed

and failsafe or non-failsafe when ordering). This

auxiliary relay has the same ratings as the Trip relay.

Auxiliary relay #1 can be configured as latched or

unlatched and fail-safe or non-fail-safe. The

conditions that will activate this relay can be any trip

or alarm indications (see section 3.4 for factory preset

configurations).

Connections to the relay contacts are made via a

terminal block which uses #6 screws.

NOTE: The rear of the 269 relay shows output relay

contacts in their power down state. Figure 2.4, Figure

2.6, and Figure 2.7 show output relay contacts with

power applied, no trips or alarms, and Factory

Configurations in effect (i.e. TRIP - fail-safe, ALARM non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe).

See Figure 2.5 for a list of all possible contact states.

2-16

Page 26

2 INSTALLATION

Figure 2.10

2.11 RTD Sensor Connections

Up to six resistance temperature detectors (RTDs)

may be used for motor stator temperature monitoring.

The remaining RTD inputs may be used for motor

and load bearing, or other temperature monitoring

functions. All RTDs must be of the same type. RTD

#8 may be used to monitor ambient air temperature.

This is done to enhance protection in environments

where the ambient temperature varies considerably.

The number of stator RTDs used together with RTD

trip and alarm temperatures must be programmed

into the 269 (see sections 3.16, 3.17). The RTD type

to be used must be specified when ordering the 269

relay. If the type of RTD in use is to be changed, the

269 must be returned to the factory.

Each RTD has four connections to the 269 relay as

shown in Figure 2.4, Figure 2.6, and Figure 2.7.

Since the RTD indicates temperature by the value of

its resistance, it is necessary to compensate for the

resistance of the connecting wires, which is

dependent on lead length and ambient temperature.

The 269 uses a circuit to cancel this resistance and

reads only the actual RTD resistance. Correct

operation will occur providing all three wires are of the

same length and the resistance of each lead is not

greater than 25% of the RTD 0°C resistance. This

can be accomplished by using identical lengths of the

same type of wire. If 10 ohm copper RTDs are to be

used, special care should be taken to keep the lead

resistance as low as possible.

If RTD #8 is to be used for ambient air temperature

measurement, the RTD should be placed and

mounted somewhere in the motor cooling air intake

flow. The sensor should be in direct contact with the

cooling air but not with any surface that is at a

temperature other than the cooling air. This RTD is

RTD Wiring

selected for ambient temperature use in page 5 of

SETPOINTS mode.

If no RTD sensor is to be connected to any of the

RTD terminals on the 269, the terminals may be left

open.

If fewer than 6 stator RTDs are to be employed, they

should be connected to the lowest numbered relay

RTD connections. For example, if 3 stator RTDs are

to be used they should be connected to the terminals

for RTD1, RTD2, and RTD3 (terminals #1-12). Other

RTDs should be connected to the terminals for RTD7RTD10 (terminals #13-28) as shown in Figure 2.4.

The connections are made via terminal blocks which

can accommodate up to #16 AWG multi-strand wire.

Note: Shielded, three-wire cable must be used in

industrial environments to prevent noise pickup.

Wherever possible, the RTD leads should be kept

close to grounded metal casings and avoid areas

of high electromagnetic or radio frequency fields.

RTD leads should not run adjacent to, or in the

same conduit as high current carrying wires. It is

recommended to use a three wire shielded cable

of #18 AWG copper conductors. The shield

connection of the RTD should not be grounded at

the sensor end as there is an internal ground on

the 269. This arrangement prevents noise pickup

that would otherwise occur from circulating

currents due to differences in ground potentials

on a doubly grounded shield.

2-17

Page 27

2 INSTALLATION

2.12 Emergency Restart Terminals

If it is desired to override relay trips or lock-outs and

restart the motor, a normally open keyswitch should

be installed between terminals 54 and 55.

Momentarily shorting these terminals together will

cause the thermal memory of the 269 to discharge to

0% (if RTD input to thermal memory is enabled,

thermal memory can be reduced to 0% by keeping

terminals 54 and 55 shorted together for more than

11 seconds; see section 3.20). The Emergency

Restart terminals can thus be used to override an

OVERLOAD TRIP. Shorting the Emergency Restart

terminals together will also decrement the relay's

internal starts/hour counter by 1 and therefore allow

the operator to override a STARTS/HOUR inhibit or

time between starts inhibit.

Note: This option should be used only when an

immediate restart after a lock-out trip is required for

process integrity or personnel safety. Discharging

the thermal memory of the 269 gives the relay an

unrealistic value for the thermal capacity remaining in

the motor and it is possible to thermally damage the

motor by restarting it. Thus, complete protection may

be compromised in order to restart the motor using

this feature.

A twisted pair of wires should be used. Connection to

the 269 is made via a terminal block which can

accommodate up to #16 AWG multi-strand wire.

2.13 External Reset Terminals

An external reset switch, which operates similarly to

the keypad RESET key (see section 3.1), can be

connected to terminals 56 and 57 for remote reset

operation. The switch should have normally open

contacts. Upon closure of these contacts the relay

will be reset. This external reset is equivalent to

pressing the keypad RESET key. Keeping the

External Reset terminals shorted together will cause

the 269 to be reset automatically whenever motor

conditions allow.

A twisted pair of wires should be used. Connection to

the 269 is made via a terminal block which can

accommodate up to #16 AWG multi-strand wire.

2.14 Analog Output Terminals (NonIsolated)

Terminals 58 and 59 of the 269 are available for an

analog current output representing one of:

percentage of motor thermal capacity used; motor

current as a percentage of full load (i.e. 0.25-2.5

XFLC); hottest stator RTD temperature as a

percentage of 200°C; RTD#7 (bearing) temperature

as a percentage of 200°C; or CT secondary current

as a percentage of CT secondary amps rating. The

choice of output is selected in page 5 of SETPOINTS

mode. This selection can be made or changed at any

time without affecting the protective features of the

relay.

The output current range is factory default at 4-20

mA. However, this range may be enlarged in page 5

of SETPOINTS mode. 4 mA output corresponds to a

low scale reading (i.e. 0% thermal capacity used,

0.25xFLC, 0

RTD#7 temperature, or 0 A phase CT secondary

current). 20 mA output current corresponds to a high

scale reading (i.e. 100% thermal capacity used,

2.5xFLC or lower phase current, 200

stator RTD and RTD#7 temperature, or either 1 A or

5 A phase CT secondary depending on the CT used).

This output is an active, non isolated current source

suitable for connection to a remote meter, chart

recorder, programmable controller, or computer load.

Current levels are not affected by the total lead and

load resistance as long as it does not exceed 300

ohms for the 4-20 mA or the 0-20 mA range (2000

ohms for 0-1 mA range). For readings greater than

100% of full scale the output will saturate at 20.2 mA.

This analog output is not isolated. Terminal 58 is

internally connected to system ground. Consequently

the negative terminal of the connected load device

must be at ground potential. When isolation is

necessary, an external two-wire isolated transmitter

should be used between the 269 and the load (e.g.

PLC).

A twisted pair of wires should be used. Connection to

the 269 is made via a terminal block which can

accommodate up to #16 AWG multi-strand wire.

o

C hottest stator RTD temperature,

o

C for hottest

2.15 Programming Access Terminals

When a jumper wire is connected between ACCESS

terminals 52 and 53 all setpoints and configurations

can be programmed using the keypad. Once

programming is complete the jumper will normally be

removed from these terminals. When this is done all

actual and setpoint values can still be accessed for

viewing; however, if an attempt is made to store a

new setpoint value the message "ILLEGAL ACCESS"

will appear on the display and the previous setpoint

will remain intact. In this way all of the programmed

setpoints will remain secure and tamperproof.

Alternatively, these terminals can be wired to an

external keyswitch to permit setpoint programming

upon closure of the switch. For additional tamper

proof protection, a software access code may be

programmed on Page 6 of SETPOINTS. See section

3 (Setup and Use).

2-18

Page 28

A twisted pair of wires should be used for connection

to an external switch. Connection to the 269 is made

via a terminal block which can accommodate up to

#16 AWG multi-strand wire.

2.16 Display Adjustment

Once the 269 relay has been installed and input

power applied, the contrast of the LCD display may

have to be adjusted. This adjustment has been made

at the factory for average lighting conditions and a

standard viewing angle but can be changed to

optimize the display readability in different

environments. To alter the display contrast the

trimpot on the rear of the unit marked "CONTRAST"

must be adjusted with a small slotted screwdriver.

2 INSTALLATION

thin panels, the relay will not seat properly and the

door will not shut over the relay when installed on a

thick panel. Loosening the screws and moving the

relay forward before retightening will fix the problem.

RELAY REMOVAL - Open the hinged door. Next

remove the two ten finger connecting plugs making

sure the top one is removed first. Swivel the cradleto-case hinged levers at each end of the 269 cradle

assembly and slide the assembly out of the case.

RELAY INSTALLATION - Slide the 269 cradle

assembly completely into the case. Swivel the hinged

levers in to lock the 269 cradle assembly into the

drawout case. Install the two ten finger connecting

plugs making sure the bottom plug is installed first.

Close the hinged door and secure with the captive

screw.

2.17 Front Panel Faceplate

The front panel faceplate is composed of a

polycarbonate material that can be cleaned with

isopropyl or denatured alcohol, freon, naphtha, or

mild soap and water.

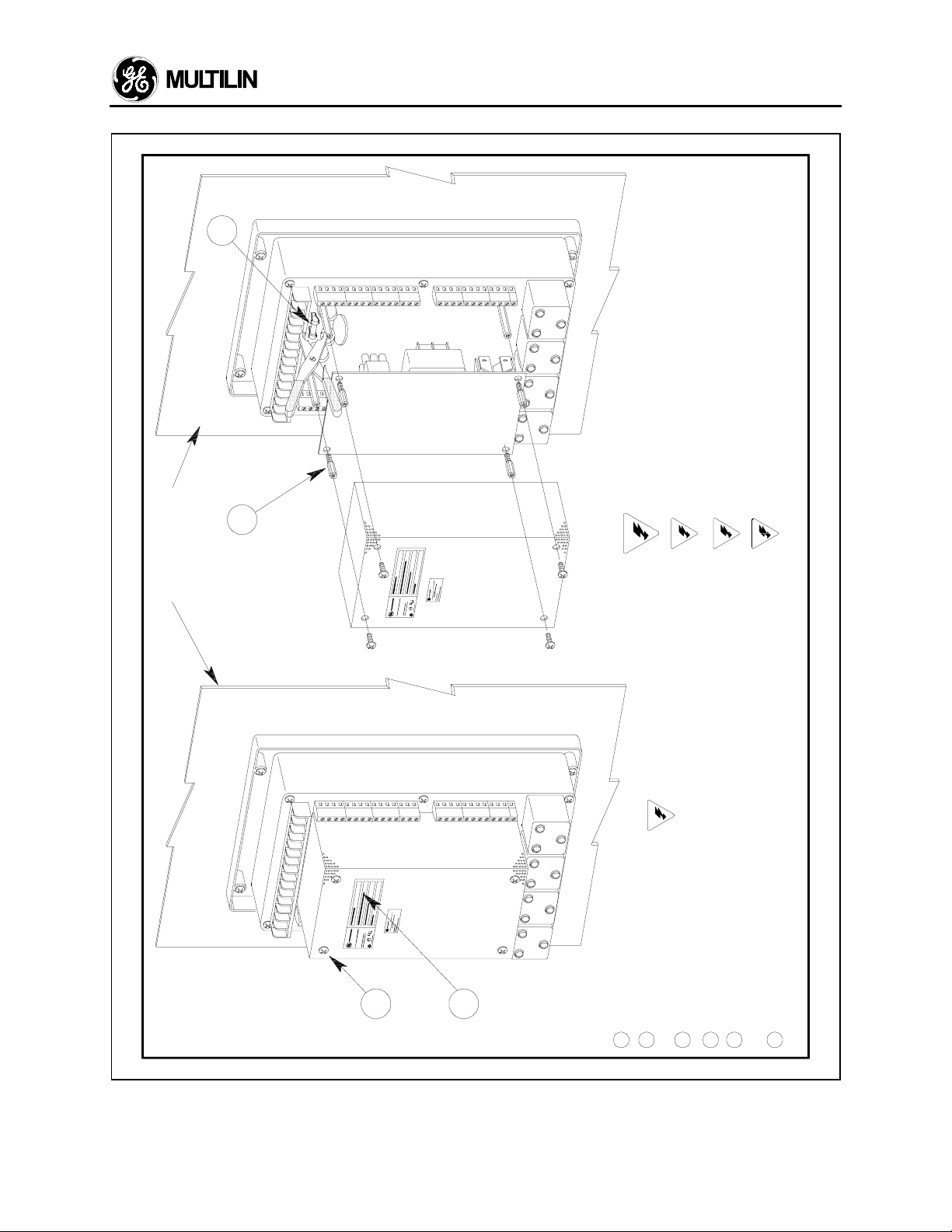

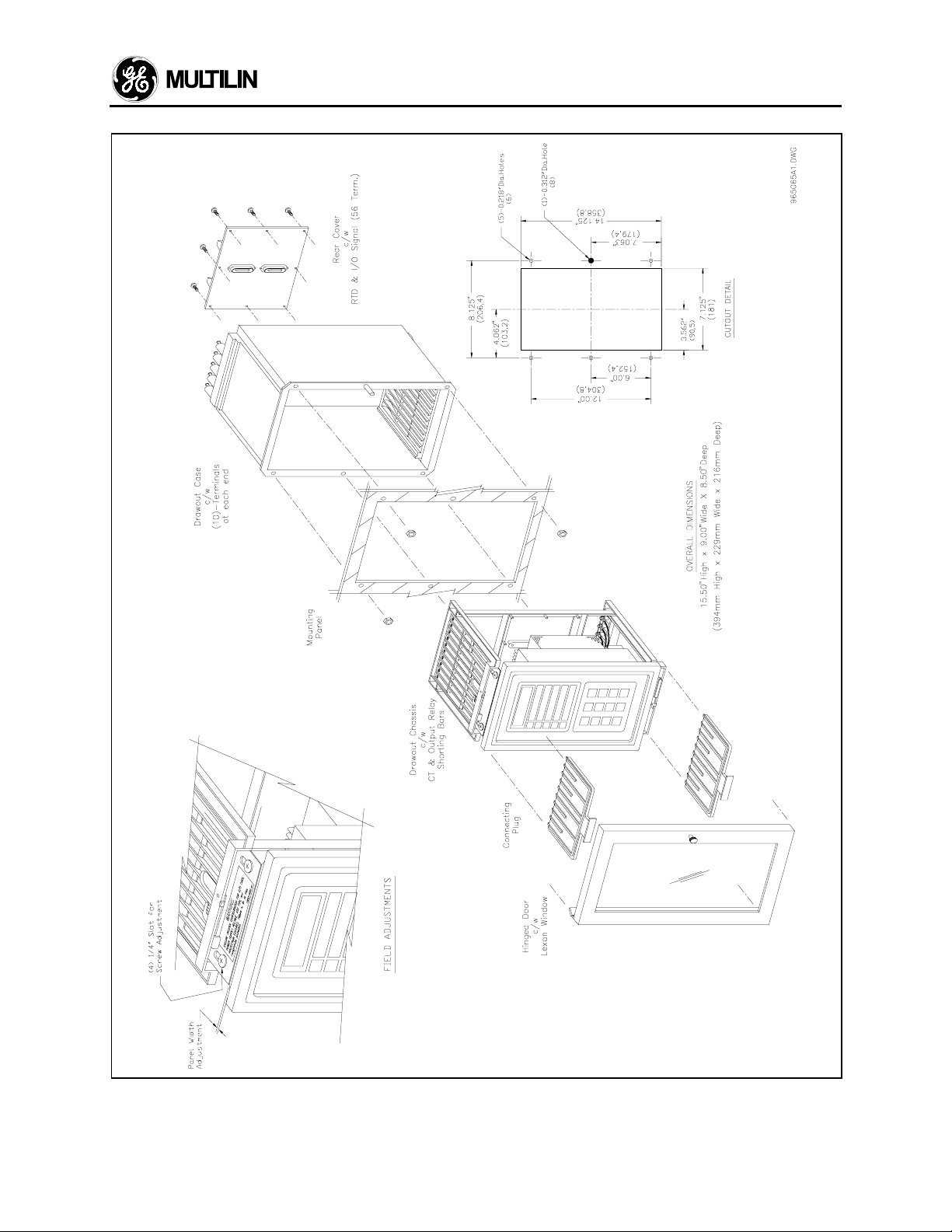

2.18 269 Drawout Relay

The model 269 relay is available in a drawout case

option. The operation of the relay is the same as

described elsewhere in this manual except for the

differences noted in this section. The physical

dimensions of the drawout relay are as shown in

Figure 2.11. The relay should be mounted as shown

in Figure 2.12.

The drawout 269 relay can be removed from service

without causing motor shut-down. This can be useful

for replacing, calibrating, or testing units.

RELAY MOUNTING - Make cutout as shown and drill

six 7/32" holes on mounting panel. Approximately 21/2" should be clear at the top and bottom of the

cutout in the panel for the hinged door. Ensure that

the five #6-32 nuts are removed from the threaded

studs in the mounting flange and that the drawout

chassis has been removed from the drawout case.

Install the case from the rear of the mounting panel

by aligning the five #6-32 threaded case studs to the

previously drilled holes. With the studs protruding

through the holes secure the case on the right hand

side with two #6-32 nuts provided. Install the hinged

door on the front of the mounting panel using three

#6-32 nuts provided.

NOTE: There must be at least ½" clearance on the

hinged side of the drawout relay to allow the door

to open.

IMPORTANT NOTE

relay cradle assembly the top ten finger connecting

plug must be withdrawn first. This isolates the 269

output relay contacts before power is removed from

the relay. When installing the drawout relay cradle

assembly the bottom ten finger connecting plug must

be installed first. This causes power to be applied to

the 269 relay before the output relay contacts are

placed in the circuit.

After a 269 relay cradle assembly has been removed

from the drawout case it is recommended that the

hinged door be closed in order to reduce the risk of

electric shock.

Due to the hardware configuration of the drawout

relay shorting bars, the RELAY FAILSAFE CODE

(SETPOINTS, page 5) should not be changed without

consulting the factory. Spare shorting bars are

included with each drawout specifically for the

required modification. Wiring for the 269 drawout is

shown in Figure 2.13. If it is required that any of the

output relay configurations in Figure 2.13 be different

than shown, this information must be stated when the

relay is ordered.

The 269 Drawout does not meet the IEC947-1 and

IEC1010-1.

No special ventilation requirements need to be

observed during the installation of this unit

: When removing the drawout

.

FIELD ADJUSTMENTS - There are four screws

holding the plastic 269 case to the drawout cradle.

These screw into holes which are slotted to

compensate for panel thickness. If the 269 case is

mounted at the extreme end of the slot intended for

2-19

Page 29

2 INSTALLATION

2-20

Figure 2.11

269 Drawout Relay Physical Dimensions

Page 30

2 INSTALLATION

Figure 2.12

269 Drawout Relay Mounting

2-21

Page 31

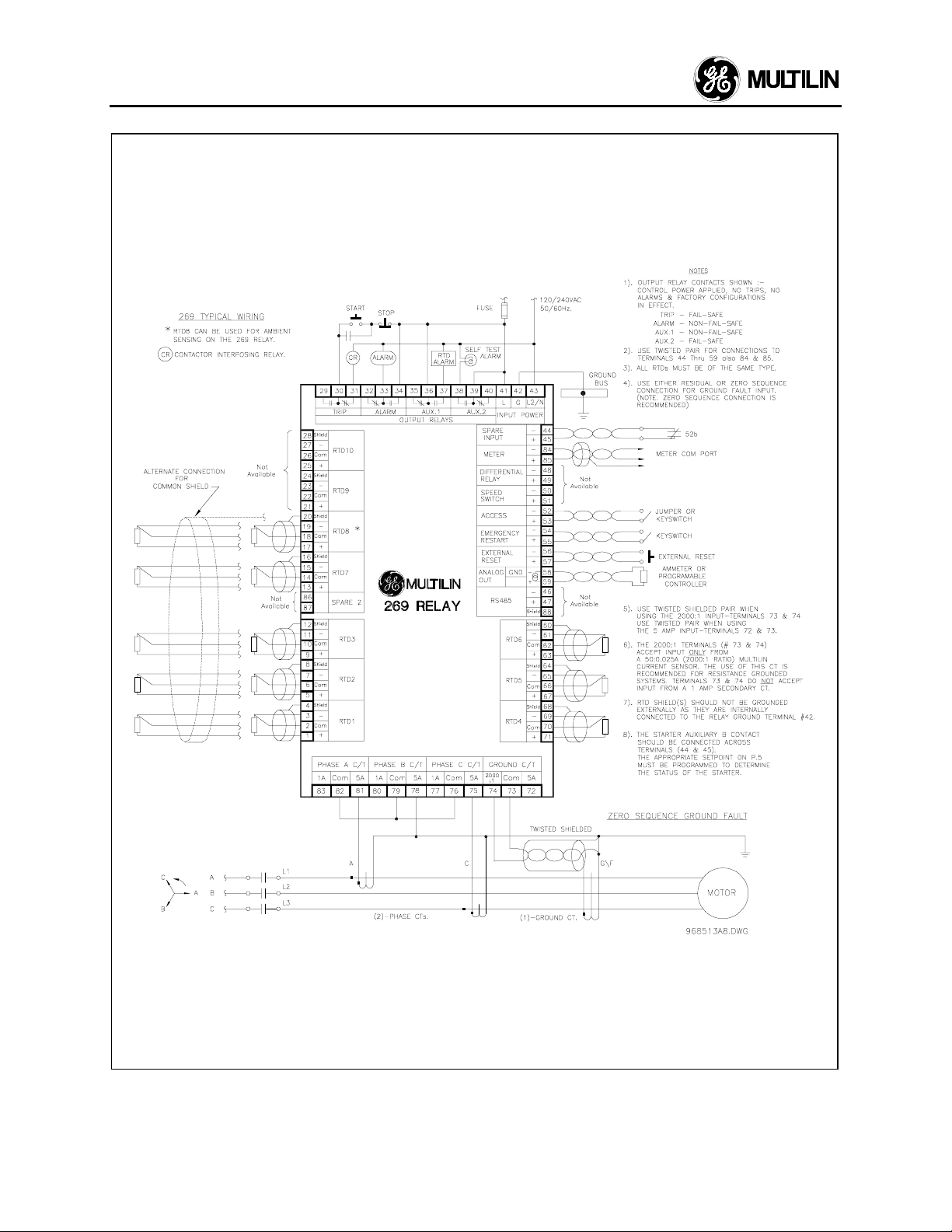

2 INSTALLATION

2-22

Figure 2.13

269 Drawout Relay Typical Wiring Diagram

Page 32

2 INSTALLATION

2.19 Meter Option Installation

The addition of a GE Multilin MPM (Motor Protection

Meter) option allows the 269 user to monitor and

assign protective features based on voltage and

power measurement. Either meter also provides four

isolated analog outputs representing: Current, Watts,

Vars, and Power Factor. These outputs from the

meter can provide the signals for the control of the

motor or a process.

MPM External Connections

Physical dimensions for the MPM and the required

cutout dimensions are shown in Figure 2.16. Once

the cutout and mounting holes are made in the panel,

use the eight #6 self tapping screws to secure the

relay.

MPM Wiring

Signal wiring is to box terminals that can

accommodate wire as large as 12 gauge. CT, VT and

control power connections are made using #8 screw

ring terminals that can accept wire as large as 8

gauge.

Consult the wiring Figure 2.17 through 2.22 for

suggested wiring. For proper operation of the MPM

and 269 set, MPM control power and phase CTs/VTs

must be connected. Other features may be wired

depending on the MPM model ordered.

Control Power (5/6/7/8)

Control power supplied to the

MPM must match the installed

power supply. If the applied

voltage does not match, damage

to the unit may occur.

A universal AC/DC power supply is standard. It

covers the range 90 - 300 VDC and 70 - 265 VAC

50/60 Hz. It is not necessary to make any adjustment

to the MPM as long as the control voltage falls within

this range. A low voltage power supply is available as

an option. It covers the range 20 - 60 VDC and 20 48 VAC 50/60 Hz. Verify from the product

identification label on the back of the MPM that the

control voltage matches the intended application.

Connect the control voltage input to a stable source

of supply for reliable operation. A 2 amp fuse is

accessible from the back of the MPM by sliding back

the fuse access door. Using #8 gauge wire or ground

braid, connect terminals 5 & 6 to a solid system

ground which is typically a copper bus in the

switchgear. Extensive filtering and transient

protection is built into the MPM to ensure reliable

operation under harsh industrial operating

environments. Transient energy must be conducted

back to the source through filter ground terminal 5.

The filter ground terminal (5) is separated from the

safety ground terminal (6) to allow dielectric testing of

switchgear with a MPM wired up. Connections to the

filter ground terminal must be removed during

dielectric testing.

030

Figure 2.14 Control Power Wiring

When properly installed, the MPM will meet the

interference immunity requirements of IEC 801 and

ANSI C37.90.1.

VT Inputs (1-4)

The MPM can accept input voltages from 0 - 600VAC

between the voltage inputs (V

common (Vn). These inputs can be directly

connected or supplied via external VTs. If voltages

greater than 600VAC are to be measured, external

VTs are required. When measuring line to line

quantities using inputs V

voltage common input Vn is grounded. This input is

used as a reference for measuring the voltage inputs.

, V2, V3) and voltage

1

, V2 and V3, ensure that the

1

All connections to the MPM

voltage inputs should be

connected using HRC fuses with

a 2 AMP rating to ensure

adequate interrupting capacity.

CT Inputs (9-20)

5 amp or 1 amp current transformer secondaries can

be used with the MPM for phase and neutral sensing.

Each current input has 3 terminals: 5 amp input, 1

amp input and common. Select either the 1 amp or 5

amp terminal and common to match the phase CT

2-23

Page 33

2 INSTALLATION

secondary. Correct polarity as indicated in the wiring

Figure 2.17 through Figure 2.21 is essential for

correct measurement of all power quantities.

CTs should be selected to be capable of supplying

the required current to the total secondary load which

includes the MPM relay burden of 0.2 VA at rated

secondary current and the connection wiring burden.

Serial Communications Port (COM1 - 46,47,48)

The MPM will communicate with 269 via COM1. The

connection must be made as shown below. The MPM

must be connected to only one 269 relay at any given

time for successful communication.

MPM Analog Output

The Analog Out Scale Factor setpoint is entered to

set the Full Scale value for the MPM analog outputs

(KWATTS and KVARS). The value entered here is

the multiplier that is multiplied by 100 kW to

determine the meter’s analog output Full Scale for

KWATTS, or by 30 KVAR to determine the meter’s

analog output Full Scale for KVAR. 4 mA represents

0 KWATTS and 0 KVARS and 20 mA represents full

scale. Average RMS current is produced in analog

form where the MPM 4-20 mA is equivalent to 0 A to

1×CT rating. Power factor is produced in analog form

where 4/12/20 mA represents -0/1/+0 power factor

value respectively.

MPM

RS485 CO M1

46 47 48

C O M - +

Figure 2.15 MPM and 269 Communication Wiring

The 269 communicates the following information to

the meter module: 1) 269/meter Protocol Revision; 2)

Reset MWH; 3) CT Primary; 4) VT Ratio; 5) Analog

Output Scale Factor; and 6) Checksum.

The meter, in turn, sends back the following

information to the 269:

1) Echo Protocol Revision

2) Vab, Vbc, Vca or Van, Vbn, Vcn (depending on

whether the VTs are connected phase to phase or

phase to neutral)

3) Average Voltage

4) kW

5) kvar

6) Frequency

7) Voltage Phase Reversal Status

8) VT Wiring Configuration (open delta or 2 input

wye)

9) kW sign

10) kvar sign

11) Meter Revision

12) Power Factor

13) Power Factor sign indication

+: Lead

–: Lag

14) MWh

15) Checksum

This exchange of information takes place once every

0.5 second.

269

Meter

85 84

+ -

2-24

Page 34

2 INSTALLATION

Figure 2.16

MPM Mounting Dimensions

2-25

Page 35

2 INSTALLATION

2-26

Figure 2.17

MPM to 269 Typical Wiring (4-wire Wye, 3 VTs)

Page 36

2 INSTALLATION

Figure 2.18

MPM to 269 Typical Wiring (4-wire Wye, 2 VTs)

2-27

Page 37

2 INSTALLATION

2-28

Figure 2.19

MPM to 269 Typical Wiring (3-wire Delta, 2 VTs)

Page 38

2 INSTALLATION

Figure 2.20

MPM to 269 Typical Wiring (2 CT)

2-29

Page 39

2 INSTALLATION

2-30

Figure 2.21

MPM Wiring (Open Delta)

Page 40

3 SETUP AND USE

Figure 3.1 Front Panel Controls and Indicators

3-1

Page 41

3 SETUP AND USE

3.1 Controls and Indicators

Once the 269 relay has been wired and control power

applied, it is ready to be programmed for the given

application. Programming is accomplished using the

Table 3-1 Controls and Indicators

No. Name Description

1

FUNCTION: The ACTUAL VALUES key allows the user to examine all of the actual

motor operating parameters. There are seven pages of ACTUAL VALUES data:

page 1: Phase Current Data

page 2: RTD Temperature Data

page 3: Motor Capacity Data

page 4: Statistical Data

page 5: Pre-trip Data

page 6: Learned Parameters

page 7: Metering Data

EFFECT: Pressing this key will put the relay into ACTUAL VALUES mode. The

flash message,

ACTUAL VALUES HAS SEVENACTUAL VALUES HAS SEVEN

PAGES OF DATAPAGES OF DATA

will be displayed for 2 seconds. The beginning of page 1 of ACTUAL VALUES mode

will then be dhown:

12 position keypad and 48 character alphanumeric

display shown in Figure 3.1. The function of each key

on the keypad and each of the indicators is briefly

explained in Table 3-1.

PAGE 1: ACTUAL VALUESPAGE 1: ACTUAL VALUES

PHASE CURRENT DATAPHASE CURRENT DATA

USE: This key can be pressed at any time, in any mode to view actual motor values. To go from page to page the PAGE UP and PAGE DOWN keys can be used.

To go from line to line within a page the LINE UP and LINE DOWN keys can be

used.

2

FUNCTION: The SET POINTS key allows the user to examine and alter all trip,

alarm, and other relay setpoints. There are seven pages of setpoints data:

page 1: Motor Amps Setpoints

page 2: RTD Setpoints

page 3: O/L Curve Setpoints

page 4: Relay Configuration

page 5: System Configuration

page 6: GE Multilin Service Codes

page 7: Metering Setpoints

EFFECT: Pressing this key will put the relay into SETPOINTS mode. The flash

message,

SETPOINTS HAS SEVENSETPOINTS HAS SEVEN

PAGES OF DATAPAGES OF DATA

will be displayed for 2 seconds. The beginning of page 1 of SETPOINTS mode will

then be shown:

PAGE 1: SETPOINT VALUESPAGE 1: SETPOINT VALUES

MOTOR AMPS SETPOINTSMOTOR AMPS SETPOINTS

3-2

Page 42

No. Name Description

USE: This key can be pressed at any time, in any mode, to view or alter relay setpoints. To go from page to page the PAGE UP and PAGE DOWN keys can be

used. To go from line to line within a page the LINE UP and LINE DOWN keys can

be used. To alter a setpoint, the VALUE UP and VALUE DOWN keys can be used.

All setpoints will increment and decrement to pre-determined limits. When the desired value is reached, the STORE key must be used to save the new setpoint. If an

altered setpoint is not stored the previous value will still be in effect. If the Access

jumper is not installed a STORE will not be allowed and the flash message

"ILLEGAL ACCESS" will be displayed for 2 seconds.

3

FUNCTION: The HELP key allows the user to obtain information on the function

and use of each of the other keys on the keypad and on each of the ACTUAL

VALUES, SETPOINTS, and TRIP/ALARM messages.

EFFECT: Pressing this key will put the relay into HELP mode. If this key is pressed

with the first line of a page (ie. a page header) on the display the message,

Press KEY of interest orPress KEY of interest or

HELP again for detailsHELP again for details

will be displayed. To obtain information on the function of a particular key, the key

must be pressed. To obtain information on the previously displayed ACTUAL

VALUES, SETPOINTS, or TRIP/ALARM message the HELP key should be pressed

again. If this key is pressed with any other message shown on the display, only

information on the previous line will be available.

USE: This key will have no effect when a flash message or HELP message is

shown on the display. Once HELP mode is entered the LINE UP and LINE DOWN

keys can be used to view the HELP message. The CLEAR key is used to exit from

HELP mode and return to the previous display mode. The ACTUAL VALUES and

SET POINTS keys can also be used to exit HELP mode.

4,5

6,7

FUNCTION: The PAGE DOWN and PAGE UP keys allow the user to scan the next

or previous pages of either ACTUAL VALUES or SETPOINTS modes. If either key

is held for more than 1/2 second the next or previous pages will be selected at a fast

rate.

EFFECT: Pressing the PAGE DOWN key will cause the display to show the first

line of the next page of information. Pressing the PAGE UP key will cause the display to show the first line of the previous page.

USE: These keys can be used any time the relay is in either the ACTUAL VALUES

or SETPOINTS modes.

FUNCTION: The LINE DOWN, and LINE UP keys allow the user to scan the next

or previous lines of the currently selected page. If either key is held for more than

1/2 second the next or previous lines will be selected at a fast rate.

EFFECT: Pressing the LINE DOWN key will cause the display to show the next line

of the currently selected page of information. Pressing the LINE UP key will cause

the display to show the line immediately in front of the currently displayed line.

USE: These keys can be used at any time in any relay mode of operation. If the

display shows the last line of a page the LINE DOWN key will have no effect. If the

display shows the first line of a page the LINE UP key will have no effect.

3 SETUP AND USE

3-3

Page 43

3 SETUP AND USE

No. Name Description

8,9

10

11

CLEAR

FUNCTION: The VALUE UP and VALUE DOWN keys allow the user to alter the

currently selected setpoint. If either key is held for more than 1/2 second the setpoint selected will increment or decrement at a fast rate. If either key is held for

more than 2 seconds the setpoint selected will increment or decrement at a very

fast rate.

EFFECT: Pressing the VALUE UP key will cause the currently displayed setpoint

value to increment. Pressing the VALUE DOWN key will cause the currently displayed setpoint value to decrement. For YES/NO questions, pressing either key will

cause the answer to change. Any changed setpoint will not be used internally until

the STORE key is pressed.

USE: These keys can be pressed any time a setpoint is displayed in SETPOINTS

mode or when a YES/NO question is displayed in ACTUAL VALUES mode (see

STORE key). When the desired setpoint value is reached the STORE key is used to

save it. If an altered setpoint is not stored the previous value will still be in effect.

FUNCTION: The RESET key allows the user to reset the 269 after any of the

latched output relays have become active so that a motor start can be attempted.

EFFECT: Pressing this key will reset (ie. return to an inactive state) any of the active output relay contacts if motor conditions allow (see below). The message,

RESET NOT POSSIBLE -RESET NOT POSSIBLE Condition still presentCondition still present

will be displayed if any active output relays cannot be reset

USE: A latched relay cannot be reset if the trip/alarm condition persists (eg. an

OVERLOAD TRIP lock-out or a high RTD temperature).Pre-trip motor values may

be viewed in ACTUAL VALUES mode page 5 (Pre-trip Data). If an immediate restart is required after an OVERLOAD or INHIBIT LOCKOUT the Emergency Restart

terminals (see section 2.12) may be shorted together. This will reduce the lock-out

time to 0 minutes.

FUNCTION: In SETPOINTS mode the CLEAR key allows the user to return an altered, non-stored setpoint to its original value. In HELP mode the CLEAR key allows the user to return to the previous display mode.

EFFECT: When this key is pressed in SETPOINTS mode any altered, currently

displayed setpoint will be returned to its original value. When this key is pressed in

HELP mode the relay will return to the line and page of the mode active when the

HELP key was pressed.

USE: This key can be used in SETPOINTS or HELP modes only. In SETPOINTS

mode it can only be used when a displayed setpoint has been changed with the

VALUE UP/VALUE DOWN keys but has not yet been stored. After a setpoint has

been stored the CLEAR key will have no effect. In HELP mode the CLEAR key can

be used any time there is a HELP message on the display.

3-4

Page 44

3 SETUP AND USE

No. Name Description

12 FUNCTION: The STORE key allows the user to store new setpoints into the 269

relay's internal memory.

EFFECT: When this key is pressed in SETPOINTS mode the currently displayed

setpoint will be stored and will immediately come into effect. When a setpoint is

stored the flash message,

NEW SETPOINT STOREDNEW SETPOINT STORED

will appear on the display.

The STORE key can be pressed in ACTUAL VALUES mode to clear the maximum

actual temperature data. To do this the following message from page 2 of ACTUAL

VALUES mode must be displayed after the "NO" value is altered to say "YES" by

pressing the VALUE UP/VALUE DOWN key:

CLEAR LAST ACCESS DATA?CLEAR LAST ACCESS DATA?

YESYES

Then when the STORE key is pressed the following flash message will appear on

the display:

last access data clearedlast access data cleared

13

14

15

16

17

TRIP

ALARM

AUX. 1

AUX. 2

SERVICE

The maximum actual temperature data (see section 3.24) will then be cleared. The

STORE key can be pressed in ACTUAL VALUES mode to start a new motor commissioning (ie. clear statistical data). To do this the following message from page 4

of ACTUAL VALUES mode must be displayed after the "NO" value is altered to say

"YES" by pressing the VALUE UP/VALUE DOWN key:

START COMMISSIONING?START COMMISSIONING?

YESYES

Then when the STORE key is pressed the following flash message will appear on

the display:

COMMISSIONING DATACOMMISSIONING DATA

clearedcleared

All statistical data (see section 3.24) will then be cleared.

USE: The STORE key can be used only in SETPOINTS mode to store new set-

points, or in ACTUAL VALUES mode to clear the maximum actual temperature data

or start a new commissioning (ie. clear statistical data). This key will have no effect

unless the Access terminals are shorted together.

LED indicator used to show the state of the Trip output relay. When on, the trip

relay is active. When off, the Trip relay is inactive.

LED indicator used to show the state of the Alarm output relay. When on, the Alarm

relay is active. When off, the Alarm relay is inactive.

LED indicator used to show the state of Auxiliary relay #1. When on, Aux. relay #1

is active. When off, Aux. relay #1 is inactive.

LED indicator used to show the state of Auxiliary relay #2. When on, Aux. relay #2

is active. When off, Aux. relay #2 is inactive.

LED indicator used to show the result of the 269 self-test feature. When flashing,

the relay has failed the self-test and service is required. When on steady, the supply