Page 1

GE Oil & Gas

Mooney*

Flowgrid* Regulator

Instruction Manual

GE Data Classification : Public

Page 2

i | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECTSPECIFIC REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL

OPERATION AND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE

PHILOSOPHIES VARY, GE (GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES AND AFFILIATES)

DOES NOT ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS

AND REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING

OF THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENT

IN POTENTIALLY HAZARDOUS ENVIRONMENTS. THEREFORE, THESE INSTRUCTIONS SHOULD BE

INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY RULES AND REGULATIONS

APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER

EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT

NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH

INSTALLATION, OPERATION OR MAINTENANCE. SHOULD FURTHER INFORMATION BE DESIRED

OR SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED SUFFICIENTLY FOR THE

CUSTOMER/OPERATOR’S PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR ARE

STRICTLY LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY

OF THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY GE REGARDING

THE EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE INSTRUCTIONS.

THESE INSTRUCTIONS ARE FURNISHED TO THE CUSTOMER/OPERATOR SOLELY TO ASSIST

IN THE INSTALLATION, TESTING, OPERATION, AND/OR MAINTENANCE OF THE EQUIPMENT

DESCRIBED. THIS DOCUMENT SHALL NOT BE REPRODUCED IN WHOLE OR IN PART WITHOUT

THE WRITTEN APPROVAL OF GE.

Page 3

Mooney Flowgrid Regulator Instruction Manual | 1© 2015 General Electric Company. All rights reserved.

Table of Contents

Product Description ............................................................................ 1

Regulator Markings ............................................................................. 3

Nameplate Information .................................................................... 3

Principles of Operation ...................................................................... 4

Hydrostatic Testing ............................................................................. 5

Installation ............................................................................................... 6

Product Description

The Mooney Flowgrid regulator is an easy to maintain

regulator designed to be used primarily with a self

contained pilot system. The Flowgrid regulator has

several unique features that add to its versatility such as:

In line maintenance

Replaceable trim

Reversible trim parts

Non stretching fabric reinforced diaphragm for

stability and fast response at all temperatures

Positive spring shutoff

Two-stage pressure drop and optional noise controller

to minimize noise and provide cavitation protection

Scope

This manual provides installation, operation, and maintenance instructions for the Mooney Flowgrid regulator.

Instructions for the Mooney Series 20 pilot and Mooney noise controller will be found in a separate manual.

Piping Details .......................................................................................... 7

Start-up and Operation .................................................................. 11

Maintenance ....................................................................................... 13

Troubleshooting ................................................................................. 15

Warranty ................................................................................................ 17

Product Support ................................................................................. 17

GE has secured global PED EN 334 certification for

its Mooney Flowgrid regulators demonstrating our

commitment to quality and safety. The certification was

awarded by DVGW (the German Technical and Scientific

Association for Gas and Water), one of the world’s most

recognized industry certification bodies and the largest

gas and water industry certification agency in Europe.

GE has also secured the following verifications: ISO 9901,

ISO 14001, CRN along with others ensuring the safety

and quality of the Mooney regulator.

Page 4

2 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Materials of Construction

Body & Spring Case

ASTM A 216 WCB Carbon Steel

Spacer

ASTM A 216 WCB Carbon Steel

Throttle Plate

17-4PH Stainless Steel

Diaphragm

Nitrile/Nylon (Optional - Viton/Nylon)

O-Ring & Seals

Nitrile (Optional - Viton)

Bolting

ASTM 193 GR B-7 or Equal

Spring

301 Stainless Steel

Specifications

Sizes

1” - 12” (DN 25 - DN300)

Body Style

Single Port

10 inch and 12 inch Dual Ports

End Connections

Screwed, Socket Weld

Flanged, Flangeless & Buttweld

Temperature

-20°F to 150°F (-29°C to 66°C)

Min/Max Temperature

-40°F to 175° F (-40°C to 79° C)

Maximum Operating

Differential

800 psi (55.16 bar)

Maximum Emergency

Differential

1000 psi (68.9 bar)

(unless limited by body rating)

Minimum Differential

Refer to individual product

specification sheets

Cracking Differential

Refer to individual product

specification sheets

Maximum Inlet Pressure

1480 psig (102.1 bar)

(limited by flange or pilot rating)

Outlet Pressure Range

Limited by pilot

Flow Direction

Bi-Directional

1

Body Taps

1/4” - 18 NPT

1

Reverse flow by changing pilot connections and reversing spring case.

Table 1

Table 2

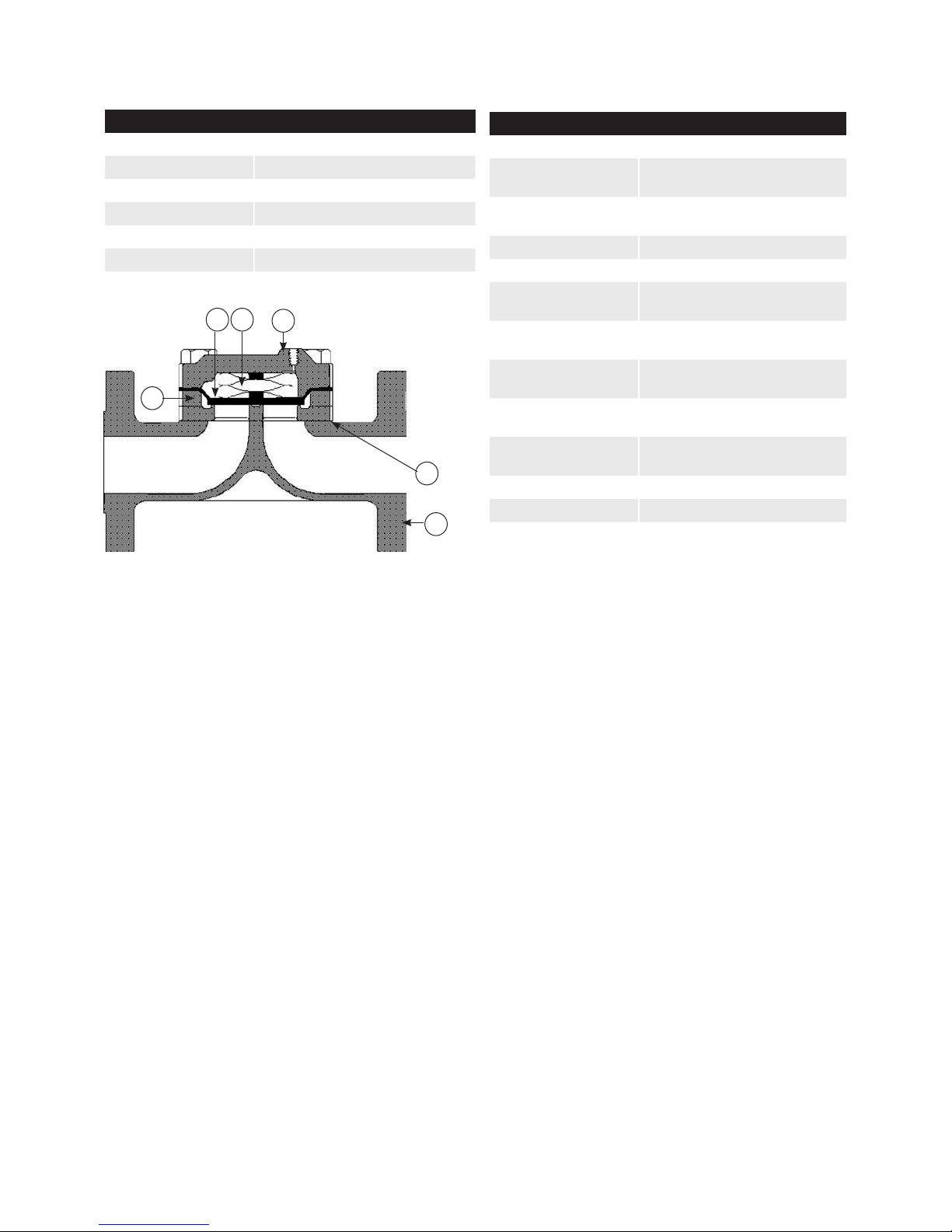

Figure 1 - Flowgrid Parts

All Mooney Flowgrid regulators have six main parts

(excluding bolting and O-rings); the body, throttle plate,

spacer, diaphragm, main spring, and spring case.

Although parts vary in size and design, all regulators

share the same principle of operation.

The body (1) is constructed with a single port (sizes

less than 10”) and a dual port (sizes greater than 10”).

The dual port design can provide redundant control if

equipped with dual pilots or be used with a single pilot

for maximum capacity.

The throttle plate (2) supports the diaphragm and

provides a machined surface that the diaphragm seals

against for bubble tight shutoff. Restricted capacity

plates of 35%, 50%, and 75% are available.

The spacer (3) creates a space between the throttle

plate and the diaphragm which forms a flow path

inside the regulator.

3

1

425

6

The fabric-reinforced diaphragm (4) is the main

working part of the Flowgrid regulator. The diaphragm

functions as both an actuator and the regulator

throttling element.

It is designed to provide stability, rangeability, and

fast response without stretching. It will not “take a set”

and is thick for durability and wear resistance.

The main spring (5) provides high frequency response,

proportional action for stability and a consistent

minimum differential regardless of temperature.

It also provides a positive closing force, which is

important in monitor regulation applications.

The spring case (6) is shaped to retain the main spring.

It provides a low volume cavity where loading pressure

from the pilot system is placed on top of the diaphragm

to control flow through the regulator.

Page 5

Front View

Back View

Top View

Mooney Flowgrid Regulator Instruction Manual | 3© 2015 General Electric Company. All rights reserved.

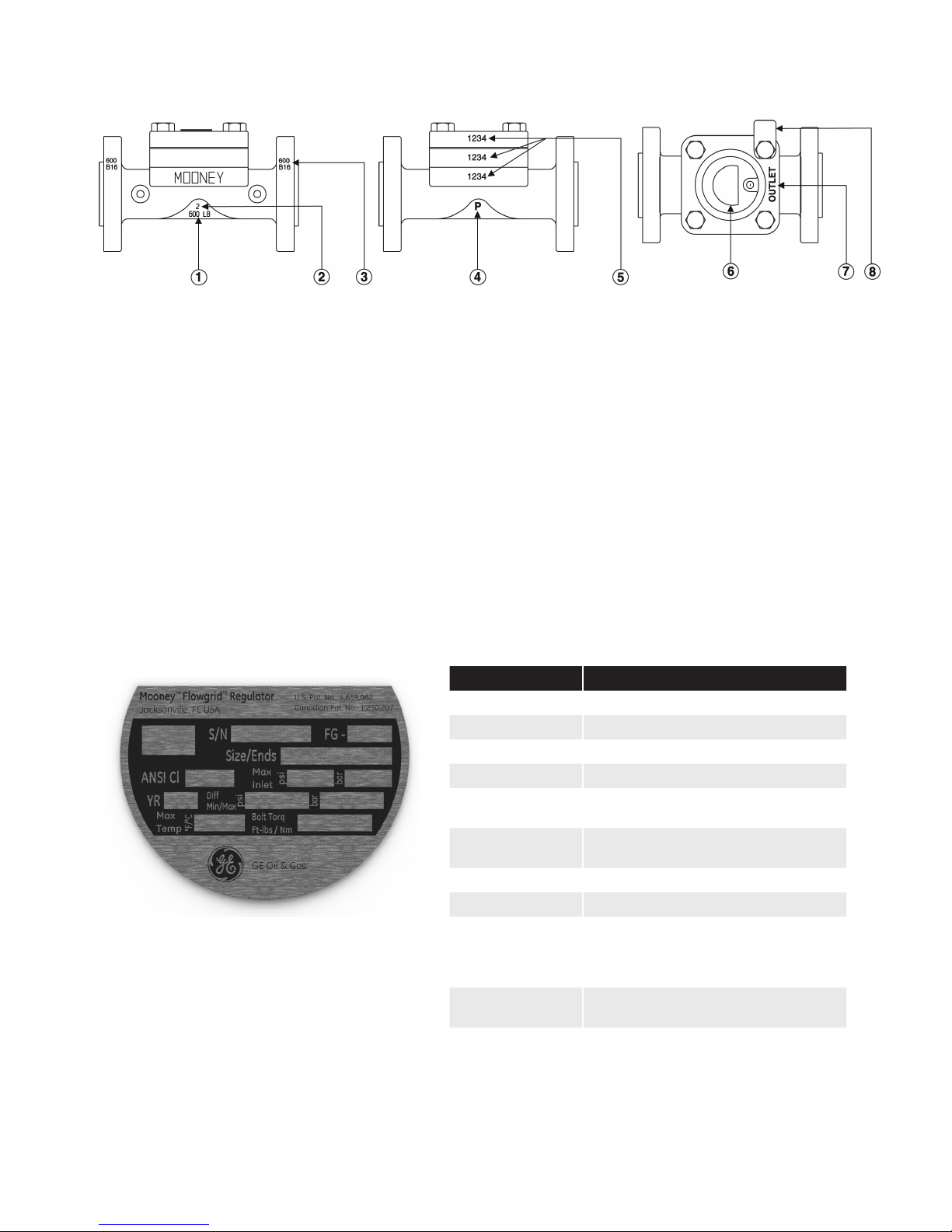

Regulator Markings

Nameplate Information

1. American National Standards Institute (ANSI) pressure class rating of the regulator.

2. Line size of body.

3. ANSI pressure class rating of the flange.

4. Indication that the regulator has been hydrostatically tested according to code requirements.

5. The serial number is stamped on the spring case, spacer1, and body.

6. The Nameplate location.

7. The flow direction is marked on the spring case (“INLET” or “OUTLET”). Proper alignment assures that the diaphragm

guide on the Spring Case is aligned toward outlet side of the regulator.

8. The % Capacity tag indicates the capacity of the throttle plate (100%, 75%, 50%, & 35%) in the regulator.

1

NOTE: On all 1” regulators and 2” standard regulators the throttle plate itself is stamped.

Item Definition

Flowgrid

Registered name of regulator

Blank

CE marking

S/N

Serial number assigned to regulator

FG

Flowgrid model description

Size/Ends

Line size of body and type of end

connection

ANSI Cl

American National Standards Institute

pressure class

Max Inlet

Maximum inlet pressure (psig)/(bar)

YR

Year manufactured

Diff

Min/Max

Minimum differential required to fully

open regulator

Maximum allowable operating pressure

differential (psig)/(bar)

Max Temp

Maximum operating temperature in

degrees Fahrenheit

Bolt Torq

Ft-lbs/Nm

Recommended bolt torque for spring

case in foot pounds

Figure 2 - Regulator Markings

Figure 3 - Flowgrid Regulator Nameplate

Table 3

Page 6

4 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

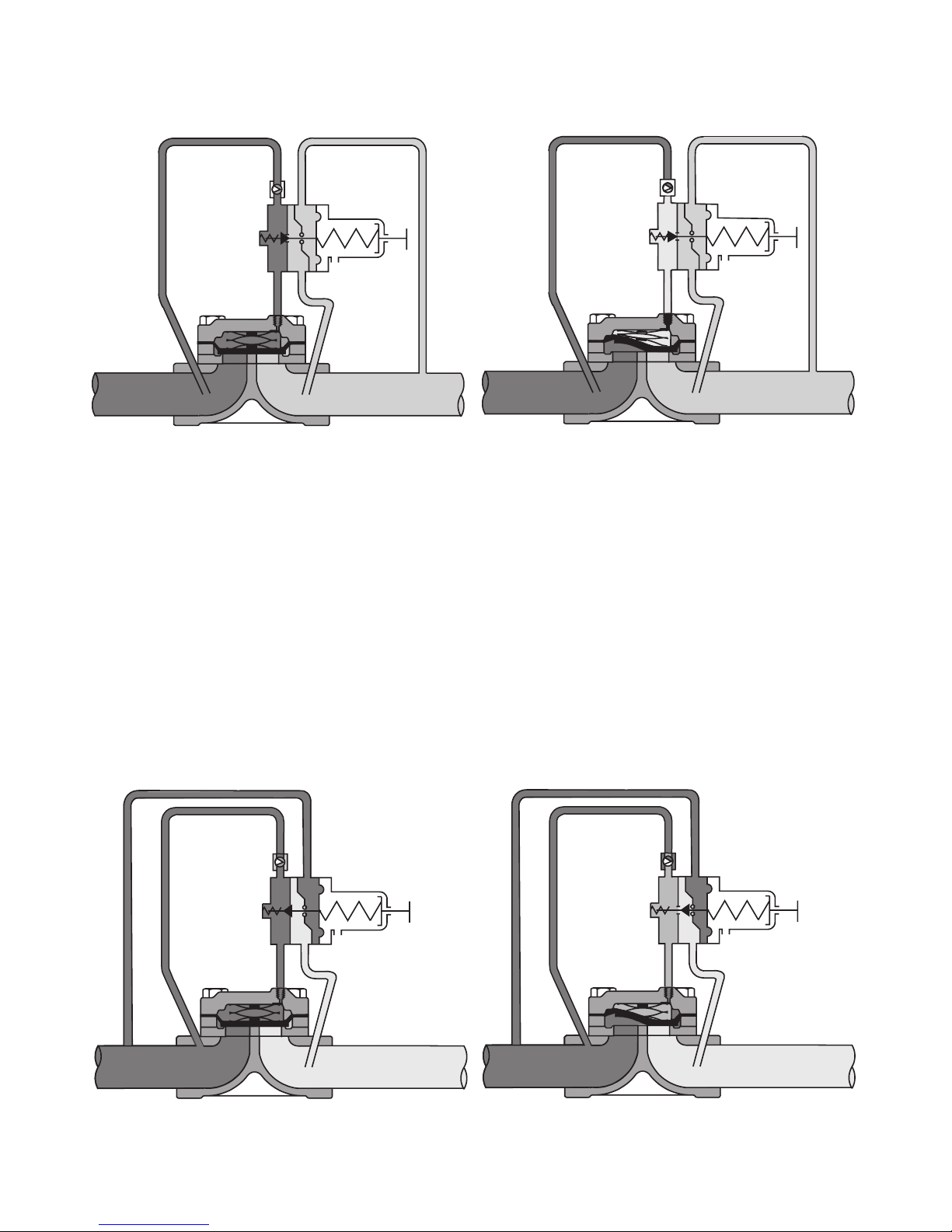

Figure 4 - Pressure Reducing Configuration Fully Closed

Principles of Operation

Pilot Supply Pilot Sense

Connection

Restrictor

Inlet Outlet

Pilot Outlet

Connection

Pilot Loading

Connection

INLET

Pilot Supply Pilot Sense

Connection

Restrictor

Inlet Outlet

Pilot Outlet

Connection

Pilot Loading

Connection

Figure 5 - Pressure Reducing Configuration Partially Open

At no flow, when the outlet pressure is greater than the

set point of the pilot regulator, the pilot is closed and full

inlet pressure loads the spring case through the pilot

loading connection. In this condition the diaphragm is

closed tightly against the throttle plate. The pressure

differential across the outlet half of the diaphragm adds

to the spring force in closing the Flowgrid regulator

(Refer to Figure 4).

As demand for flow occurs in the downstream system

the outlet pressure drops, causing the pilot regulator to

open and start bleeding pressure out of the spring case

faster than it can enter through the restrictor. Reducing

the pressure above the diaphragm allows the inlet pressure to progressively lift the diaphragm off the throttle

plate, opening the regulator and satisfying the demand

for flow in the downstream system. (Refer to Figure 5).

Pilot Supply

Pilot Sense

Connection

Restrictor

Inlet

Outlet

Pilot Outlet

Connection

Pilot Loading

Connection

Figure 7 - Back Pressure Configuration Partially Open

Figure 6 - Back Pressure Configuration Fully Closed

Pilot Supply Pilot Sense

Connection

Restrictor

Inlet Outlet

Pilot Outlet

Connection

Pilot Loading

Connection

When demand for flow ceases or is reduced, the

downstream pressure increases causing the pilot

regulator to close. Inlet pressure continues to pass

through the restrictor until the control pressure equals

the inlet pressure. The spring force, plus the pressure

differential across the outlet half of the diaphragm

closes the diaphragm against the throttle plate, shutting

off the flow (Refer to Figure 4).

Adjustment of the restrictor affects the response rate,

stability, and sensitivity of the regulator. Smaller restrictor openings result in higher gain (sensitivity) and slower

closing speeds. Larger openings result in lower gain

(greater proportional band), greater stability and faster

closing speeds.

Page 7

Mooney Flowgrid Regulator Instruction Manual | 5© 2015 General Electric Company. All rights reserved.

A back pressure regulator or relief regulator controls

upstream pressure instead of downstream pressure.

The control action in the pilot is the reverse of a pilot

for a pressure reducing regulator (increasing pressure

in the sense chamber opens the pilot regulator). At no

flow, when the inlet pressure is less than the set point

of the pilot regulator, the pilot is closed and full inlet

pressure loads the spring case through the pilot loading

connection. In this condition, the diaphragm is closed

tightly against the throttle plate. The pressure differential

across the outlet half of the diaphragm adds to the

spring force in closing the Flowgrid regulator (Refer to

Figure 6).

As inlet pressure increases above the set point of the pilot regulator, it will open and start bleeding pressure out

of the spring case faster than it can enter through the

restrictor. Reducing the pressure above the diaphragm

allows inlet pressure to progressively lift the throttling

element off the throttle plate opening the regulator and

satisfying the demand for flow in the upstream system

(Refer to Figure 7).

When upstream pressure decreases, causing the pilot

regulator to close, pilot supply pressure continues to

pass through the restrictor until the control pressure

equals the inlet pressure. The spring force, plus the pressure differential across the outlet half of the throttling

element closes the diaphragm against the throttle plate,

shutting off the flow (Refer to Figure 6).

Adjustment of the restrictor affects the response rate,

stability, and sensitivity of the regulator. Smaller restrictor openings result in higher gain (sensitivity) and slower

closing speeds. Larger openings result in lower gain

(greater proportional band), greater stability and faster

closing speeds.

Hydrostatic Testing

All Flowgrid regulators are hydrostatically tested at the

factory prior to shipment according to ISA-S75.19-1989

and MSS-SP-61 standards. If it is necessary to retest the

regulator, follow one of the procedures listed below to

prevent damage to the diaphragm.

Option 1

1. Disconnect and remove all control line(s) and the

pilot from the Flowgrid regulator.

2. Loosen main spring case nuts in a crisscross pattern.

The main spring will lift the spring case as the nuts

are removed.

3. Remove main spring and diaphragm from regulator.

For all 1”, 2”, 4”, 6” (and 10”-V6) Flowgrid Regulators

4. Replace diaphragm with a used

diaphragm that has the thick padded

area cut out leaving the outer sealing

surface (see below).

This area removed

For 3” and 4” x 3” Flowgrid Regulators

4. Remove diaphragm but leave diaphragm O-ring in

place. Make sure O-ring is properly seated.

5. Reassemble spring case on Flowgrid regulator.

6. Tighten main bolts in increments using a crisscross

pattern. Torque bolting as indicated on regulator

nameplate (or refer to Table 6, Page 14).

7. Plug spring case loading port, pilot inlet and outlet

taps on Flowgrid regulator.

8. Refer to Table 4 for the maximum hydrostatic test

pressure of each Flowgrid regulator.

9. After hydrostatic test is completed follow the

Dissassembly, Cleaning, and Assembly procedures in

the Maintenance section of this manual

Option 2

1. Disconnect and remove all control line(s) and pilot

from the Flowgrid regulator.

2. Pipe regulator with the inlet, outlet, and loading

connections all common so that pressure is

equalized in the entire regulator during the

hydrostatic test (See Figure 8).

3. Refer to Table 4 for Maximum hydrostatic test

pressure of each Flowgrid regulator.

4. After hydrostatic test is completed follow the

Disassembly, Cleaning, and Assembly procedures

in the Maintenance section of this manual.

End Connection Max. Hydrostatic Test Pressure

Screwed & Socket Weld 2225 psi (153.41 bar)

150# Flange & Flangeless 450 psi (31.02 bar)

300# Flange & Flangeless 1125 psi (77.56 bar)

600# Flange & Flangeless 2225 psi (153.41 bar)

Flowgrid 250

1

375 psi (25.86 bar)

1

The Flowgrid 250 is a ductile iron construction.

Table 4 - Maximum Hydrostatic Test Pressures

Figure 8 - Flowgrid Tee Connections

A. Inlet connection on regulator body joined to “Tee”.

B. “Tee” connected to loading connection on

spring case.

C. Outlet of “Tee” connected to outlet connection on

regulator

Page 8

6 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Installation

WARNING

1. PERSONNEL: Installation of the Flowgrid regulator

should be made by qualified personnel familiar with

high pressure piping and pilot operated regulators.

2. PRIOR INSPECTION: Inspect the main regulator,

pilot, and tubing for any damage that might have

occurred in shipping. Make sure the body, pilot lines,

and inlet piping are clear and free from foreign

material.

3. ORIENTATION: The Flowgrid regulator may be

installed in any position - the best position being one

that provides easiest access for pilot adjustment

and regulator maintenance.

4. SCREWED END REGULATORS: Apply pipe

compound to the male threads starting one or two

threads back from the end prior to assembling the

joint.

5. FLANGED END REGULATORS: Use suitable line

gaskets and good bolting practices with flanged

bodies. A crisscross pattern of incrementally

tightening the line bolts is recommended.

6. WELD END BODIES: Remove the Spring Case and

all trim parts including diaphragm and O-rings

before welding a buttweld and/or a socket weld

end Flowgrid regulator. Electric arc welding is

recommended to minimize heat build-up on the

body assembly. Reassemble regulator (refer to the

Maintenance section of this manual for Disassembly

and Assembly procedures) and pressurize with air

to check for leaks prior to putting the regulator in

service.

Personal injury, equipment damage, or leakage due

to explosion of accumulated gas or bursting of pressure containing parts may result if this regulator is

overpressured or is installed where service conditions

could exceed the limits given in the specification of

this manual or on the nameplate, or where conditions

exceed any ratings of the adjacent piping or piping

connections. Verify the limitations of both regulator

and pilot to ensure neither device is overpressured.

To avoid such injury or damage, provide pressure

relieving or pressure limiting devices (as required

by Title 49, Part 192, of the U.S. code of Federal

Regulations, by the National Fire Codes of the

National Fire Protection Association, or applicable

codes) to prevent service conditions from exceeding those limits. Additionally, physical damage to

the regulator/regulator could break the pilot off the

main regulator, causing personal injury and/or property damage due to explosion of accumulated gas. To

avoid such injury and damage, install the regulator

in a safe location.

WARNING

Gas Regulators installed in confined or enclosed

spaces should be provided with adequate ventilation

to prevent the possibility of gas buildup or accumulation from leaks and venting. Leaks or vented gas may

accumulate causing personal injury, death, or property

damage. Pilot spring cases and the regulator enclosure

should be vented to a safe area away from air intakes,

or any hazardous location. The vent lines and stacks

must be protected against condensation and clogging.

7. PILOT SUPPLY LINES: Run a 3/8” or 1/2”pilot supply

line from the regulator body connection on the inlet

side of the Flowgrid regulator to the pilot supply

Filter or directly to the pilot Restrictor.

NOTE: A shutoff regulator is not required in the supply

to the pilot, but if one is installed it should be a full

opening ball regulator type.

8. A TYPE 30 FILTER in the pilot supply line is recom-

mended to clean dirt and other particulates that

could affect the restrictor or variable orifice in the

pilot. Use a 1/4” nipple to mount the filter to the

body tap on the Flowgrid regulator.

9. FILTER OUTLET: Run 3/8” tubing or 1/4” pipe from

the filter OUTLET port to the INLET side of the restrictor in the pilot system of the regulator. The TYPE

30/30A/30S FILTER has two OUTLET ports for ease of

tubing. Block the other port with the plug provided or

mount a gage to monitor inlet pressure if desired.

NOTE: To avoid galling when stainless steel to stainless steel connections are made use a lubricant (such

as NEVER SEEZ by Bostik). For best results Lightly

lubricate the female threads. Mixing the lubricant with

pipe dope is also acceptable. Do not exceed more than

1/4 turn past the point the threads start to bind.

10. PILOT GAS HEATERS (OPTIONAL): Pilot supply gas

can be heated to prevent the formation of ice or

hydrates in the pilot system. Pilot supply gas heaters

should be connected after the pilot filter (if one is

used). Do not directly heat to entire Flowgrid

regulator to prevent freezing; internal rubber

components can be heated beyond their max

temperature rating causing potential damage.

11. SENSE LINES (CONTROL LINES): Sense lines should

be run from the pilot mounted on the Flowgrid

regulator to a point 8 to 10 pipe diameters away

from the regulator (Refer to Piping Schematics). Use

Table 5 as a guide for the ideal tubing to use. Reduce

as necessary to connect to the pilot.

Page 9

Piping Schematics

1. Single Port Regulator (PRV)

2. Single Port Regulator (BPV)

3. Dual Port Regulator/Single Pilot/(PRV)

4. Dual Port Regulator/Single Pilot/(BPV)

5. Dual Port Regulator/Dual Pilot/(PRV).

6. Dual Port Regulator/Dual Pilot/(BPV)

7. Standby Monitor with differential greater than

60 psig (4.13 bar)

8. Standby Monitor with differential less than

60 psig (4.13 bar)

9. Working Monitor

All drawings show installations with the Series 20 Flowgrid

pilot equipped with Type 24 restricting regulator & Type 30

Filter. Consult factory for installation schematics of other

manufacturer’s pilot on the Flowgrid regulator.

Mooney Flowgrid Regulator Instruction Manual | 7© 2015 General Electric Company. All rights reserved.

NOTE: The Sense line (control line) connection should

be 8-10 pipe diameters away from areas of turbulence

(such as regulators, reducers, and elbows) and should

have a full opening into the pipe free from burrs,

drill peels, and weld slag. Shutoff regulators are not

required in the control line(s), but if installed, they

should be of the full opening type. Gas velocity at the

sense line connection should not exceed 100 ft/sec

(30m/sec).

12. PILOT discharge: Run 3/8 inch tubing from the pilot

OUTLET port to the downstream piping or to the

connection provided on the outlet of the Flowgrid

1. Single Regulator/Single Pilot

(Pressure Reducing Regulator)

1. Filter supply connected from inlet connection on regulator body to Type 30 Filter inlet.

2. Pilot supply from outlet connection on Type 30 Filter to Type 24 Restrictor inlet.

3. Type 24 Restrictor mounted to Inlet port of Series 20 Pilot.

4. Loading Port of Series 20 Pilot connected to Loading connection on Spring Case of Flowgrid regulator.

5. Sense line connecting Sense port on Series 20 Pilot to upstream (BPV) or downstream (PRV) piping.

6. Outlet port of Series 20 Pilot connected to Outlet connection of Flowgrid regulator.

7. Pilot cartridge in PRV mode (pressure reducing) BPV (back pressure/relief) mode.

regulator as shown in the piping schematics.

STANDBY MONITOR-NOTE: To ensure full capac-

ity of a Standby Monitor regulator station, it is

important that the pilot discharge of the upstream

regulator be connected downstream of the station

if the minimum pressure drop (across the entire

station) is below 60 psig (4.13 bar) (Refer to page 9

and page 12).

13. VENT REGULATORS AND GAUGE CONNECTIONS:

Vent regulators and gauge connections are recommended in the inlet and outlet piping to the Flowgrid

regulator. A gauge connection may be installed on

the loading pressure connection to the Spring Case

of the Flowgrid regulator. These would be a great

convenience during start up, maintenance, and

operation.

14. INTERSTAGE PIPING (WORKING MONITOR):

Please refer to page 10 for interstage piping and

sense line connection recommendations.

2. Single Regulator/Single Pilot

(Back Pressure Regulator)

Outlet Pressure

Pilot Regulator

with:

Less than 2 psi

(0.14 bar)

2 – 5 psi (0.14

– 0.35 bar)

Greater than

5 psi (0.35 bar)

Static Sense Line

(No Flow)

1

1/2” Pipe minimum 1/2” Tubing 3/8” Tubing

Sense Line w/Flow

1

3/4” – 1” Pipe 1/2” Pipe 1/2” Tubing

Table 5 - Outlet Pressure

1

The Flowgrid Series 20 Pilot has a static sense line.

Page 10

Piping Schematics (cont.)

3. Dual Port/Single Pilot (Pressure Reducing Regulator)

4. Dual Port/Single Pilot (Back Pressure Regulator)

5. Dual Port/Dual Pilot (Pressure Reducing Regulator)

NOTE: The dual port regulator offers redundant control with two separate control

loops. Ports #1 & #2 are piped identically.

6. Dual Port/Dual Pilot (Back Pressure Regulator)

8 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

1. Filter supply connected from inlet connection on regulator body to Type 30 Filter inlet.

2. Pilot supply from outlet connection on Type 30 Filter to Type 24 Restrictor inlet.

3. Type 24 Restrictor mounted to “Tee” connection.

3A. Type 24 Restrictor mounted to Inlet port of Series 20 Pilot.

4. Tee mounted to Inlet Port of Series 20 Pilot.

5. Loading Port of Series 20 Pilot connected to Loading connection on Spring Case (Port #1) of Flowgrid Regulator.

6. From “Tee” to Spring Case (Port #2) of Flowgrid regulator.

7. Outlet port of Series 20 Pilot connected to Outlet connection of Flowgrid regulator.

8. Sense line connecting Sense port on Series 20 Pilot to downstream (PRV) or upstream (BPV) piping

9. Pilot cartridge in PRV mode (pressure reducing) BPV (back pressure/relief) mode.

NOTE: Dual port regulators in 1” - 8” sizes have been discontinued. Schematics for reference only.

Page 11

Piping Schematics (cont.)

7. Standby Monitor with Differential Pressure Greater than 60 psi (4.13 bar)

Operating Regulator

Monitor Regulator

8. Standby Monitor with Differential Pressure Less than 60 psi (4.13 bar)

Operating Regulator

Monitor Regulator

Mooney Flowgrid Regulator Instruction Manual | 9© 2015 General Electric Company. All rights reserved.

1. Filter supply connected from inlet connection on regulator body to Type 30 Filter inlet.

2. Pilot supply from outlet connection on Type 30 Filter to Type 24 Restrictor inlet.

3. Type 24 Restrictor mounted to Inlet port of Series 20 Pilot.

4. Loading Port of Series 20 Pilot connected to Loading connection on Spring Case of Flowgrid regulator.

5. Sense line connecting Sense port on Series 20 Pilot to downstream piping.

6. Outlet port of Series 20 Pilot connected to Outlet connection of Flowgrid regulator.

6A. Outlet port of Series 20 Pilot connected to downstream piping.

7. Pilot cartridge in PRV mode.

8. Pilot supply from inlet connection on regulator body to Type 30 Filter inlet.

9. Pilot supply from outlet connection on Type 30 Filter to Type 24 Restrictor inlet.

10. Type 24 Restrictor mounted to Inlet port of Series 20 Pilot.

11. Loading Port of Series 20 Pilot connected to Loading connection on Spring Case of Flowgrid regulator.

12. Sense line connecting Sense port on Series 20 Pilot to downstream piping.

13. Outlet port of Series 20 Pilot connected to Outlet connection of Flowgrid regulator.

14. Pilot cartridge in PRV mode.

Page 12

2nd Stage Regulator

1st Stage Regulator

Pilot #1

Pilot #2

10 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

1st Stage Regulator

1. Filter supply connected from inlet connection on regulator body to Type 30 Filter inlet.

2. Pilot supply from outlet connection on Type 30 Filter to Type 24 Restrictor inlet.

3. Type 24 Restrictor mounted to Inlet port of Series 20 Pilot (#1).

4. Loading Port of Series 20 Pilot (#1) connected to Loading connection on Spring Case of the

Flowgrid regulator.

5. Outlet port of Series 20 Pilot (#1) connected to Inlet port of the monitor Series 20 Pilot (#2).

6. Sense line connecting sense port on Series 20 Pilot to interstage piping.

7. Sense line connecting sense port on the monitor Series 20 Pilot (#2) to downstream piping.

8. Outlet port of Series 20 Pilot (#2) connected to Outlet connection of Flowgrid regulator.

9. Loading port on the monitor Series 20 pilot (#2) is plugged.

10. Pilot cartridges in PRV mode.

2nd Stage Regulator

11. Filter supply connected from inlet connection on regulator body to Type 30 Filter inlet.

12. Pilot supply from outlet connection on Type 30 Filter to Type 24 Restrictor inlet.

11. Pilot supply tubing from inlet connection on regulator body to Type 24 Restrictor inlet.

13. Type 24 Restrictor mounted to Inlet port of Series 20 Pilot (#3).

14. Loading Port of Series 20 Pilot (#3) connected to Loading connection on Spring Case of the

Flowgrid regulator.

15. Outlet port of Series 20 Pilot (#3) connected to Outlet connection of Flowgrid regulator.

16. Sense line connecting Sense port on Series 20 Pilot (#3) to downstream piping.

17. Pilot (#3) cartridge in PRV mode.

NOTE: In a working Monitor system with less than 25 psig (1.72 bar) differential across the second stage regulator the pilot supply (11) may be connected to

the piping upstream of the first stage regulator. This will improve the shutoff of the second stage regulator.

Piping Schematics (cont.)

9. Working Monitor (Refer to schematic on page 13)

General recommendations: To reduce the adverse

effects on the sense signal due to high gas velocity and

turbulence:

Pipeline diameters may need to be increased in pipe

sections containing sense connections.

Gas velocity should be less than 100 ft/sec (30m/sec).

Sense connections should be 8-10 pipeline diamters

away from turbulent areas

Follow EN12186 piping specification

Page 13

Mooney Flowgrid Regulator Instruction Manual | 11© 2015 General Electric Company. All rights reserved.

WARNING

The instruction manual for the PILOT(S) being used

should be consulted to ensure that the installation

and start up instructions for the pilot are followed.

Some pilots can be damaged if not installed and put

into operation correctly.

Pressure Reducing Regulator

1. Adjust the pilot restrictor to an intermediate opening

(a “4” setting on the Mooney Type 24 Restrictor).

2. Back off on the pilot adjusting screw to fully relieve all

the spring compression.

3. If installed, open hand regulator(s) in the control

line(s), and the pilot supply line.

4. Slightly open downstream block regulator or open

vent in piping downstream of the Flowgrid regulator.

5. Slowly open the upstream block regulator to pressurize the Flowgrid regulator and pilot system. The

Flowgrid regulator should lock up (shut off) with zero

pressure downstream.

6. Use vent in the downstream piping or slowly open

the outlet block regulators.

7. Slowly increase the pilot spring setting until some

flow is achieved through vent or into downstream

system. Adjust the pilot restrictor for stability and

performance as follows:

a. If the system is stable, adjust the pilot

restrictor to a more closed position (towards

MIN setting). Change the flow rate or increase

the pilot setting to check the operation of the

system during an upset.

b. If the system is stable, repeat step (a) until the

system is unstable (oscillating).

c. Now readjust the restriction to a more open

position (towards MAX setting) where the

system is stable.

d. Vary the flow rate over as wide a range as

possible to make sure the system will be

stable under all flow conditions.

NOTE: Adjustment of the restrictor affects the

response rate, stability, and sensitivity of the regulator. CLOSING the pilot restrictor (moving adjustment

towards MIN setting) will result in higher gain (narrow

the proportional band), more sensitivity, and slower

closing speeds. OPENING the pilot restrictor (moving

the adjustment towards MAX setting) will result in less

gain (widen the proportional band), less sensitivity,

and faster closing speeds.

8. Slowly increase the pilot spring setting until the

desired downstream pressure is achieved.

9. Slowly close the downstream block regulator or vent

to check the Flowgrid regulator for lockup (shut off).

10. Slowly open the downstream block regulator. to

begin normal operation

Back Pressure Regulator or Relief Regulator

1. Adjust the pilot restrictor to an intermediate opening

(a “4” setting on the Mooney Type 24 Restrictor).

2. Increase pilot spring compression to maximum or

some margin above desired setting.

3. If installed, open hand regulators(s) in the control

line(s), and the pilot supply line.

4. Check that the Flowgrid regulator is vented to

atmosphere or the downstream system is ready to

accept flow.

5. Open the downstream block regulator or open vent

in piping downstream of the Flowgrid regulator.

6. Slowly open the upstream block regulator to pressurize the Flowgrid regulator and pilot system.

The Flowgrid regulator should lock up (shut off) with

zero pressure downstream.

7. Slowly decrease the pilot spring setting until some

flow is achieved. The flow may only be through the

pilot system.

8. Adjust the pilot restrictor for stability and

performance as follows:

a. If the system is stable, adjust the pilot restrictor

to a more closed position (towards MIN setting).

Change the flow rate or increase the pilot

setting to check the operation of the system

during an upset.

b. If the system is stable, repeat step (a) until the

system is unstable (oscillating).

c. Now readjust the restriction to a more open

position (towards MAX setting) where the

system is stable.

d. Vary the flow rate over as wide a range as

possible to make sure the system will be stable

under all flow conditions.

NOTE: Adjustment of the restrictor affects the

response rate, stability, and sensitivity of the

regulator.

CLOSING the pilot restrictor (moving adjustment towards

MIN setting) will result in higher gain (narrow the proportional band), more sensitivity, and slower closing speeds.

OPENING the pilot restrictor (moving the adjustment

towards MAX setting) will result in less gain (widen the

proportional band), less sensitivity, and faster closing

speeds.

9. Slowly adjust the pilot spring setting until the desired

upstream pressure (relief setting) is achieved.

Start up and Operation

The following procedures are suggested for start up of

the Flowgrid regulator Start up of the Flowgrid regulator

should be made by qualified personnel familiar with high

pressure systems and pilot operated regulators.

Page 14

12 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Standby Monitor

NOTE: This procedure is based on the 1st Regulator

being the operating regulator and the 2nd regulator

being the monitor regulator.

1. Set operating pilot (#1) spring at the MAXIMUM

setting.

2. Set monitor pilot (#2) spring to the MINIMUM (zero)

setting.

3. Purge station and open outlet regulator or vent to

allow flow through the station

4. Slowly open inlet block regulator. Full inlet pressure

should be present at the Monitor Regulator and the

Monitor Regulator should be closed.

5. Increase the pilot spring setting of the Monitor

Regulator until the desired monitor override setting is

reached. Lock in pilot setting.

6. With some flow going through the station, begin to

lower the operating pilot setting of the Operating

Regulator until the desired outlet pressure is

achieved.

NOTE: When the set point of the Operating Regulator

becomes less than the set point of the Monitor

regulator, the interstage pressure will drop from

approximately full inlet pressure to 5-10 psi (0.35 -

0.68 bar) above the outlet pressure at low flow rates.

Checking Standby Monitor Operation

1. With flow going through the station, slowly increase

the setting of the Operating Regulator. When

the pressure reaches the setpoint of the Monitor

Regulator, the monitor should take control and the

interstage pressure should increase to almost full

inlet pressure.

2. Reduce the setting of the Operating Regulator

back to the required outlet pressure. The interstage

pressure should drop to 5-10 psi (0.35 - 0.68 bar)

above the outlet pressure as the Operating Regulator

takes control.

NOTE: When the differential across the entire station

(P1-P2) is less than 60 psig (4.13 bar) then alternate

outlet piping as shown below, is recommended for

added station capacity. This applies to the Series 20

Pilot only; consult with GE for applicability to other

manufacturer’s pilots.

Figure 9 - Standby Monitor Schematic

Page 15

Mooney Flowgrid Regulator Instruction Manual | 13© 2015 General Electric Company. All rights reserved.

Standby Monitor

Working Monitor

1. Purge station and open outlet regulator or vent to

allow flow through the station.

2. Set pilot (#3) to a high setting above desired setpoint.

3. Set pilot (#1) to a high setting above desired setpoint.

4. Set the Monitor pilot (#2) at a zero setting.

5. Set restrictor on Pilot (#1) at an intermediate opening

(a “4” setting on the Mooney Type 24 Restrictor).

6. Slowly open the inlet block regulator to station. The

1st Stage Regulator should remain closed as a result

of the Monitor Pilot (#2) being set to zero.

7. Increase the setting of the Monitor Pilot (#2) to the

desired pressure setting. If the regulator is unstable,

increase the restrictor opening until it becomes

stable.

8. Lower the setpoint of the 2nd stage regulator (Pilot

#3) to the desired outlet pressure setting. Tune the

restrictor on Pilot (#3) at this time. The 1st stage

regulator should open or begin to control the interstage pressure at the setpoint of Pilot (#1).

9. Adjust the setpoint of Pilot (#1) to achieve the desired

Interstage pressure. Tune the restrictor on Pilot (#1) at

this time.

10. Raise the setpoint of Pilot (#3) to verify the setpoint

of the Monitor Pilot (#2). Adjust if necessary. Check for

system stability and adjust the restrictor on Pilot (#1)

if required.

11. Return setpoint of Pilot (#3) to maintain the desired

outlet pressure.

Figure 10 - Working Monitor Schematic

NOTE: In a working Monitor system with less than 25 psig (1.72 bar) differential across the second stage

regulator the pilot supply may be connected to the piping upstream of the first stage regulator.

This will improve the shutoff of the second stage regulator.

Maintenance

Regulator parts are subject to normal wear and must

be inspected and replaced as necessary. The frequency

of inspection and replacement of parts depends on

severity of service conditions or the requirements of

local, state, and federal regulations. Be certain that the

name plates are updated to accurately indicate any

field changes in equipment, materials, service conditions, or pressure settings.

Before disassembly make sure the regulator has been

isolated from the process by closing block regulators on

the inlet and outlet sides of the regulator. Safely release

pressure and process fluid from body and pilot system.

Failure to complete these steps can result in personal

injury and property damage.

Page 16

14 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Maintenance (cont’d)

Assembly

1. Disconnect control lines(s) and pilot supply line from

pilot system.

2. Loosen main spring case nuts in a crisscross pattern.

The main spring will lift the spring case as the nuts

are removed.

3. Remove spring, diaphragm/throttling element,

spacer, throttle plate and O-rings in that order.

4. Inspect all parts for wear and damage. Replace as

necessary.

NOTE: The periphery of the downstream (outlet)

portion of the throttling plate is the primary shutoff

surface and should be inspected most closely for wear

and damage. Nicks and/or wear on the support ribs

will usually not affect shutoff.

The outside “rib” on the downstream side of the throttle

plate is where shutoff takes place in the Flowgrid

Regulator.

NOTE: Nitrile O-rings can swell after disassembly

of a regulator that has been in service (due to

gas permeating the nitrile rubber). This does not

necessarily mean they must be replaced. Set O-ring

aside for several hours and it will gradually return

to normal size. Placing the O-ring(s) on ice will speed

the process considerably. Before placing the O-ring

back into service inspect for defects.

Cleaning

1. DO NOT clean O-ring grooves with sharp metal

tools. The bottom of the groove must have a

smooth finish to prevent leakage. The mating

surface of adjacent parts must also be smooth to

prevent leakage.

Assembly

NOTE: Do not lubricate diaphragm sealing surface.

1. Reassemble parts on the body per the assembly

drawing in the parts supplement for the particular

regulator size.

NOTE: Both the throttle plate and the diaphragm can

be rotated 180 degrees (not turned upside down) to

renew the shutoff capability if the inlet side is in better

condition than the outlet.

2. Tighten main bolts in increments using a crisscross

pattern. Torque bolting as indicated on regulator

nameplate (or refer to Table 6).

Bolting Torque Values

Clean Dry Bolts- Non-Lubricated

Regulator Size Min. Torque

Ft/Lbs (n-m)

Flowgrid 250 20 (27.09)

1” (ALL)

1

25 (33.86)

2’ x 1” (ALL)

1

25 (33.86)

2” (ALL)

1

60 (81.26)

3” (ALL)

1

125 (169.28)

4” x 3” (ALL)

1

125 (169.28)

4” (ALL)

1

125 (169.28)

6” CL 150 & CL 300 Flanged 125 (169.28)

6” CL 600 Flanged 200 (270.86)

10” CL 150 & CL 300 Flanged 125 (169.28)

10” CL 600 Flanged 200 (270.86)

12” CL 150 & CL 300 Flanged 125 (169.28)

12” CL 600 Flanged 200 (270.86)

All Flowgrid Pilots 10 (13.54)

1

Refer to WARNING below.

Table 6

WARNING

Overtightening the bolting can damage the diaphragm

in the 1” and 2” sizes of the Flowgrid regulator.

WARNING

DO NOT replace the studs or nuts with any bolt or

stud and nut combination that does NOT have an SAE

Grade 7 or ASTM Grade B7 rating.

3. Reconnect the pilot system. Follow Start up

procedures when returning to operation.

Page 17

Mooney Flowgrid Regulator Instruction Manual | 15© 2015 General Electric Company. All rights reserved.

Troubleshooting

First Steps

1. Verify the regulator specifications fit the application

conditions.

Min/max inlet pressure, control pressure range &

min/max operating differentials should be checked

to make sure the regulator and pilot are designed to

operate in the present conditions.

2. Verify the regulator is piped correctly.

Even though the regulator may have operated in the

past, check that current piping connections match

recommendations on pages 7-10.

3. Verify the regulator is sized correctly.

Regulators operating below 10% or above 80% of

their maximum capacity given current application

conditions tend to have more problems. Consider

reduced capacity trim or a larger regulator in these

cases.

Potential Issues

Regulator does not shut off.

1. Refer to the failure mode chart to diagnose

potential causes.

2. Clean or replace regulator and pilot components as

necessary.

Erratic Control.

1. Check for damage, debris in the restrictor and

control pilot. Replace, clean and lubricate components as necessary. Consider pilot supply filtration

(Type 30 Filter).

2. Check for the potential of hydrate formation or

freezing liquids in the pilot system. If liquids are present consider gas conditioning before the pilot and/or

regulator, heating the supply gas to the regulator, or

heating the pilot supply gas (pilot gas heater).

3. Check the sense line location and assure it is away

from turbulent locations. Moving the sense line to a

new location often solves control problems.

4. Check to make sure needle regulators are not used

on any pilot system connections. Full opening type

such as ball regulators are recommended.

5. Check for pilot vent port blockage.

Instability & Speed of response issues.

1. Change restrictor setting. Refer to page 11.

2. Check the sense line location and assure it is away

from turbulent locations. Moving the sense line to a

new location often solves control problems. Factory

recommendation is 8-10 pipe diameters away from

sources of turbulence such as tee’s, elbows, reducers,

regulators, etc.

3. Check to make sure needle regulators are not used

on any pilot system connections. Full opening type

regulators are recommended.

4. Check for pilot vent port blockage.

The regulator will not regulate to set point or

“droops-off”.

1. Check for proper sizing. The regulator may be running

out of capacity during peak demand periods.

2. Adjust the restrictor to a higher gain (smaller) setting.

Refer to page 11.

The regulator fails open or fails closed.

1. Refer to the table below to diagnose failure modes.

Problem

Failure Mode

Fail

Open

Fail

Closed

Damage to the flexible element X X

Damage to the flexible element on the

upstream side (less likely)

X

Damage to the flexible element on the

downstream side (more likely)

X

Debris between the flexible element and

the seat

X

Blockage of pilot supply pressure X

Blockage1 of the restrictor X

Blockage1 of the pilot supply line X

Loss of the sense line (PRV pilot) X

Loss of the sense line (Relief Pilot) X

Blockage1 of pilot discharge X

Pilot diaphragm rupture if (PRV pilot) X

Pilot diaphragm rupture if (BPV relief pilot) X

Blockage1 of pilot orifice X

1

Blockage can be caused by debris, hydrates, freezing or damage to the

component involved.

Table 7

Page 18

16 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Page 19

Mooney Flowgrid Regulator Instruction Manual | 17© 2015 General Electric Company. All rights reserved.

Limited Warranty

Seller warrants that Products shall be delivered free from defects in material, workmanship and title and that Services shall be performed in a

competent, diligent manner in accordance with any mutually agreed specifications. The warranty for Products shall expire one (1) year from

first use or eighteen (18) months from delivery, whichever occurs first, except that software is warranted for ninety (90) days from delivery.

The warranty for Services shall expire one (1) year after performance of the Service, except that software-related Services are warranted for

ninety (90) days. If Products or Services do not meet the above warranties, Buyer shall promptly notify Seller in writing prior to expiration of the

warranty period. Seller shall (i) at its option, repair or replace defective Products and (ii) re-perform defective Services. If despite Seller’s reasonable

efforts, a non-conforming Product cannot be repaired or replaced, or non-conforming Services cannot be re-performed, Seller shall refund or

credit monies paid by Buyer for such non-conforming Products and Services. Warranty repair, replacement or re-performance by Seller shall

not extend or renew the applicable warranty period. Buyer shall obtain Seller’s agreement on the specifications of any tests it plans to conduct

to determine whether a non-conformance exists. Buyer shall bear the costs of access for Seller’s remedial warranty efforts (including removal

and replacement of systems, structures or other parts of Buyer’s facility), de-installation, decontamination, re-installation and transportation

of defective Products to Seller and back to Buyer. The warranties and remedies are conditioned upon (a) proper storage, installation, use,

operation, and maintenance of Products, (b) Buyer keeping accurate and complete records of operation and maintenance during the warranty

period and providing Seller access to those records, and (c) modification or repair of Products or Services only as authorized by Seller in writing.

Failure to meet any such conditions renders the warranty null and void. Seller is not responsible for normal wear and tear. The above sets forth

the exclusive remedies for all claims based on failure of or defect in Products or Services, regardless of when the failure or defect arises, and

whether a claim, however described, is based on contract, warranty, indemnity, tort/extra-contractual liability (including negligence), strict liability

or otherwise. The warranties provided above are exclusive and are in lieu of all other warranties, conditions and guarantees whether written,

oral, implied or statutory. NO IMPLIED OR STATUTORY WARRANTY, OR WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE APPLIES.

Product Support

Local support is available through our manufacturers representative and distributor network.

Contact the factory:

GE Oil & Gas

12970 Normandy Drive

Jacksonville, FL 32221

Tel. +1-844-VALVE-GE

or refer to our web site for your support representative contact information. Factory support is available from

8:00 AM to 4:30 PM MST Monday through Friday. Limited after hours support is also available. Complete product

specifications, parts lists, and flow calculation software is available on our web site www.geoilandgas.com/valves.

Page 20

AUSTRALIA

Brisbane:

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth:

Phone: +61-8-6595-7018

Fax: +61 8 6595-7299

Melbourne:

Phone: +61-3-8807-6002

Fax : +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-19-2104-6900

CHINA

Phone: +86-10-5689-3600

Fax: +86-10-5689-3800

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Tokyo

Phone: +81-03-6871-9008

Fax: +81-03-6890-4620

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-55-3640-5060

THE NETHERLANDS

Phone: +31-15-3808666

Fax: +31-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Bracknell

Phone: +44-1344-460-500

Fax: +44-1344-460-537

Skelmersdale

Phone: +44-1695-526-00

Fax: +44-1695-526-01

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

Jacksonville, Florida

Phone: +1-844-VALVE-GE

DIRECT SALES OFFICE LOCATIONS

*Denotes a trademark of the General Electric Company.

Other company names and product names used in this document are

the registered trademarks or trademarks of their respective owners.

©2015 General Electric Company. All rights reserved.

GEA19583A 11/2015

www.geoilandgas.com/valves

Loading...

Loading...