GE ZVC48L2SS, ZVC42L2SS, ZVC30L2SS, Monogram ZVC30, Monogram ZVC36 Installation Instructions Manual

...Page 1

Installation

Instructions

Custom Hood Inserts

Hotte Encastrable sur Mesure

Instructions d'installation

La section fran_aise commence _ la page 23

Encastres de campana a medida

Instrucciones de instalaci6n

La secci6n en espa_ol empieza en la pSgina 45

131-107191

10-08 JR

Page 2

Installation Instructions

BEFOREYOU BEGIN

Read these instructions completely and

carefully.

• IMPORTANT- savethese instructions for local

inspector's use.

• IMPORTANT- Observe oil governing codes

und ordinunces.

• Note to Installer - Be sure to leuve these

instructions with the Consumer.

• Note to Consumer - Keep these instructions for

future reference.

• Skill Level - Instullution of this vent hood requires

busic mechunicul und electricul skills.

• Completion time - 1to 3 hours.

• Proper instullution is the responsibility of the instuller.

• Product failure due to improper instullution is not

covered under the Wurrunty.

For Monogram local service in your area, call

1.800.444.1845.

For Monogram service in Canada, call 2.800.562.3344.

For Monogram Parts and Accessories, call

1.800.626.2002.

-A CAUTION:

Due to the weight und size of these vent hoods und

to reduce the risk of personul injury or dumuge to the

product, TWO PEOPLEARE REQUIRED FOR PROPER

INSTALLATION.

WARNING:

To reduce the risk of fire or electricul shock, do not use

this runge hood with ung externul solid-stute speed

control device. Any such ulterution from originul fuctory

wiring could result in dumuge to the unit und/or creute

on electricul sufety huzurd.

TO REDUCETHE RISKOF FIRE,USEONLY METAL

DUCTWORK.

^HWARNING:To REDUCETHERISKOFFIRE,

ELECTRICSHOCKORINJURYTO PERSONS,OBSERVE

THEFOLLOWING:

A. Usethisunit only in the mannerintended by the

munufucturer. If you hovequestions,contuct the

munufucturer.

B.Beforeservicingorcleuning unit, switch power off ut

servicepunelund lockthe servicedisconnecting meuns

to prevent power from being switched on uccidentully.

Whenthe servicedisconnectingmeunscunnot be locked,

securelyfasten u prominent wurning device,such us u tug,

to the servicepunel.

-ACAUTION: ForGenerulVentiluting Use

Only. DoNotUseTo ExhuustHuzurdousOrExplosive

iVluteriulsAnd Vupors.

WARNING:To REDUCETHERISKOFFIRE,

ELECTRICSHOCKORINJURYTO PERSONS,OBSERVE

THEFOLLOWING:

A. Instullutionwork und electricul wiring must be done by

quolified person(s)inuccordonce with ull upplicuble codes

ond stundurds,including fire-roted construction.

B. Sufficientuir isneededfor proper combustion und

exhousting of gusesthrough the flue (chimney)of fuel

burning equipment to prevent buck drufting. Followthe

heuting equipment munufucturer's guideline und sufety

stundurds such us those publishedby the NutionulFire

ProtectionAssociution(NFPA),und the Americun Society

for Heuting,Refrigerutionund AirConditioning Engineers

(ASHRAE),und the Iocul code uuthorities.

C. When cutting ordrilling into wull or ceiling,do not dumuge

electriculwiring und other hiddenutilities.

D. Ductedfuns must ulwuys be vented to the outdoors.

• Loculcodesvury. Instullutionof electricul connections

und grounding must comply with upplicuble codes.In

the ubsenceof Iocolcodes,the vent should be instulled

in occordunce with Nutionol ElectricolCodeANSI/NFPA

70-1990 or Iotestedition.

Page 3

Installation Instructions

^_ CAUTION:To reduceriskoffireandtoproperly

exhaust air,be sureto duct air outside.Donot vent exhaust

air intospaceswithin wallsor ceilingsor into attics,crawl

spacesorgarages.

,A WARNING:TO REDUCETHE RISKOF

A RANGE TOP GREASE FIRE:

A. Neverleave surface units unattended athigh settings.

Boiloverscause smokingand greasy spilloversthat may

ignite. Heat oilsslowly on low or medium settings.

B. Always turn hoodONwhen cookingat high heat or when

flambeing food (i.e.CrepesSuzette,CherriesJubilee,

PeppercornBeef Flamb_).

C. Cleanventilating fans frequently.Greaseshould not be

allowedto accumulate on fan or filter.

D. Useproper pan size.Always usecookware appropriate for

the sizeof the surface element.

_AWARNING:ToREDUCETHERISKOFINJURY

TO PERSONSINTHEEVENTOF A RANGE TOP GREASEFIRE,

OBSERVETHE FOLLOWINGR

A. SMOTHERFLAMESwith aclose-fittinglid,cookiesheet

or metaltroy,thenturn offtheburner.BECAREFULTO

PREVENTBURNS.Iftheflamesdo notgooutimmediately,

EVACUATEANDCALLTHEFIREDEPARTMENT.

B. NEVERPICKUPAFLAMINGPANiyou may be burned.

C. DONOTUSEWATER,includingwet dishclothsortowels-

a violentsteamexplosionwillresult.

D. Useon extinguisherONLYif:

l) Youknow youhavea ClassABCextinguisher,and you

alreadyknowhow to operateit.

2)Thefireissmallandcontainedinthe areawhereitstarted.

3)Thefiredeportmentisbeingcalled.

/4)Youcanfightthefirewith yourbacktoanexit.

aBasedon "KitchenFiresafetyTips"publishedbyNFPA.

Page 4

Design Information

CONTENTS

Design Information

Product Clearances ........................................................................../4

Product Dimensions ....................................................................5-8

Advance Planning

Advance Planning ............................................................................9

Remote Mounting of the Control (Wired)..............................9

Power Supply ......................................................................................9

Duct Fittings ....................................................................................10

Installation Preparation

Tools and Materials Required ....................................................11

Remove the Packaging ................................................................11

Parts Provided ..................................................................................12

Ductwork, Wiring Locations ......................................................13

Construct Ceiling Support ..........................................................14

Remote Mounting of the Control - Wired ....................15, 16

PRODUCT CLEARANCES

The vent hood and liner assembly must be installed

30" minimum and 36" maximum above the cooking

surface.

•Always refer to the cooktop or range installation

instructions for product-specific clearances.

NOTE: Installation height should be measured

from the cooking surface to the bottom edge

of the metal hood liner or cabinet surface.

NOTE: UL requires any combustible surface to be

a minimum of 30" above the cooking surface.

•This hood must be vented to the outdoors.

Installation Instructions

Step 1,Install Hood Liner ............................................................17

Step 2, Connect Electrical ............................................................18

Step 3, Install Insert Sleeve ........................................................19

Step 4, Install Damper Plate ......................................................20

Step S, Install Blower Motor........................................................21

Step 6, Connect Wiring Harness ..............................................21

Step 7,Install Filters ......................................................................22

Step 8, Finalize Installation ........................................................22

"30" Minimum required

"36" Maximum recommended

u_in.

•This hood may be mounted onto a wall or installed

over an island.

•This hood can be installed over any Monogram

electric/gas cooktop or Monogram Professional

cooktop or range of equivalent width.

*NOTE: Rear wall exhaust venting may affect

installation height. See page 13.

4

Page 5

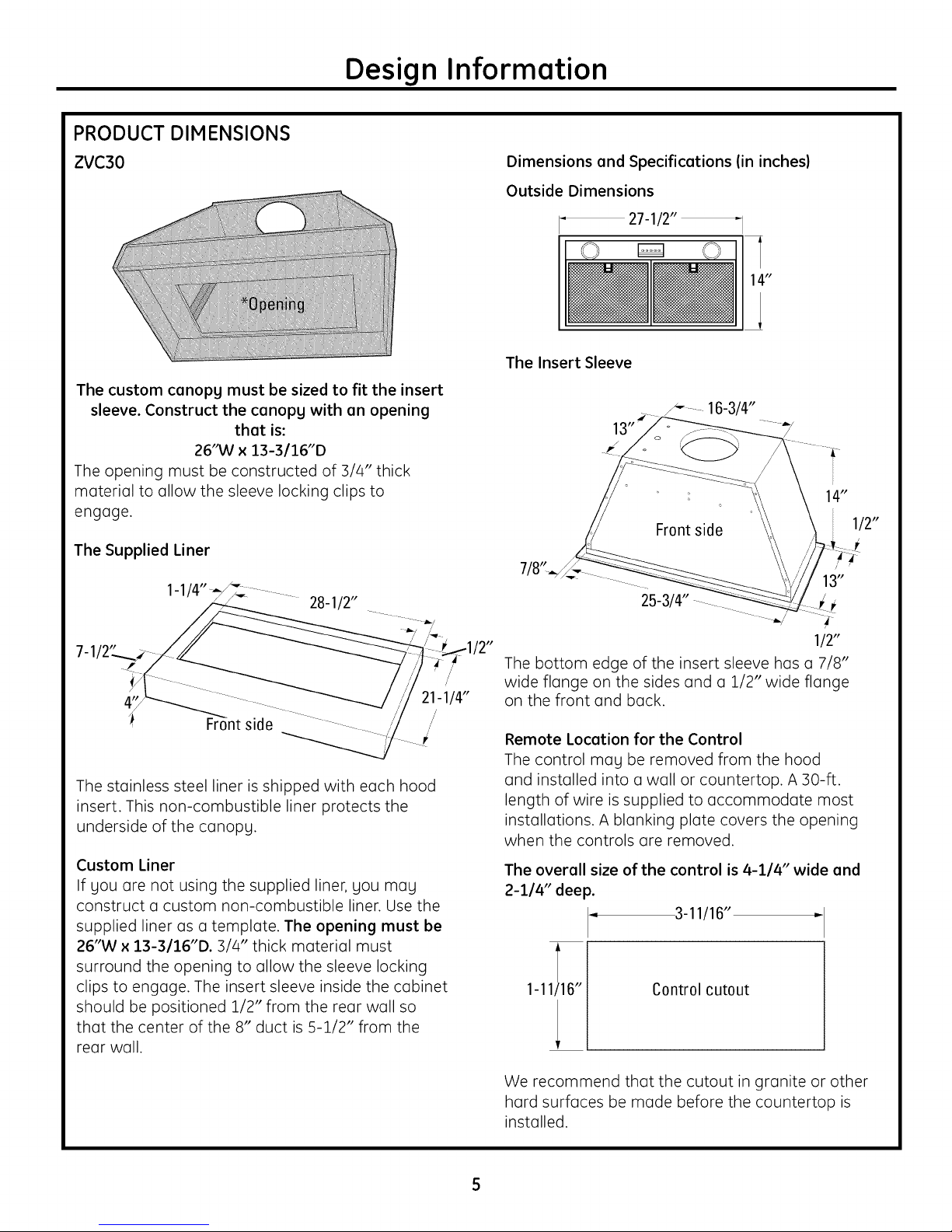

PRODUCT DIMENSIONS

Design Information

ZVC30

The custom cenopg must be sized to fit the insert

sleeve. Construct the cenopg with en opening

that is:

26'M/x 13-3/16"D

The opening must be constructed of :3/4" thick

material to allow the sleeve locking clips to

engage.

The Supplied Liner

28-1/2"

Dimensions and Specifications (in inches)

Outside Dimensions

27-1/2"

The Insert Sleeve

.....16-3/4"

14"

1/2"

13"

25-3/4"

21-1/4"

The stainless steel liner is shipped with each hood

insert. This non-combustible liner protects the

underside of the canopy.

Custom Liner

If you are not using the supplied liner, you may

construct a custom non-combustible linen Use the

supplied liner as a template. The opening must be

26"W x 13-3/16"D. 3/4" thick material must

surround the opening to allow the sleeve locking

clips to engage. The insert sleeve inside the cabinet

should be positioned 1/2" from the rear wall so

that the center of the 8" duct is 5-1/2" from the

rear wall.

/2"

/

/

The bottom edge of the insert sleeve has a 7/8"

wide flange on the sides and a 1/2" wide flange

on the front and back.

Remote Location for the Control

The control may be removed from the hood

and installed into a wall or countertop. A 30-ft.

length of wire is supplied to accommodate most

installations. A blanking plate covers the opening

when the controls are removed.

The overall size of the control is 4-1/4" wide end

2-1/4" dee _.

3-11/16"

1-11116"

Control cutout

1/2"

1

We recommend that the cutout in granite or other

hard surfaces be made before the countertop is

installed.

Page 6

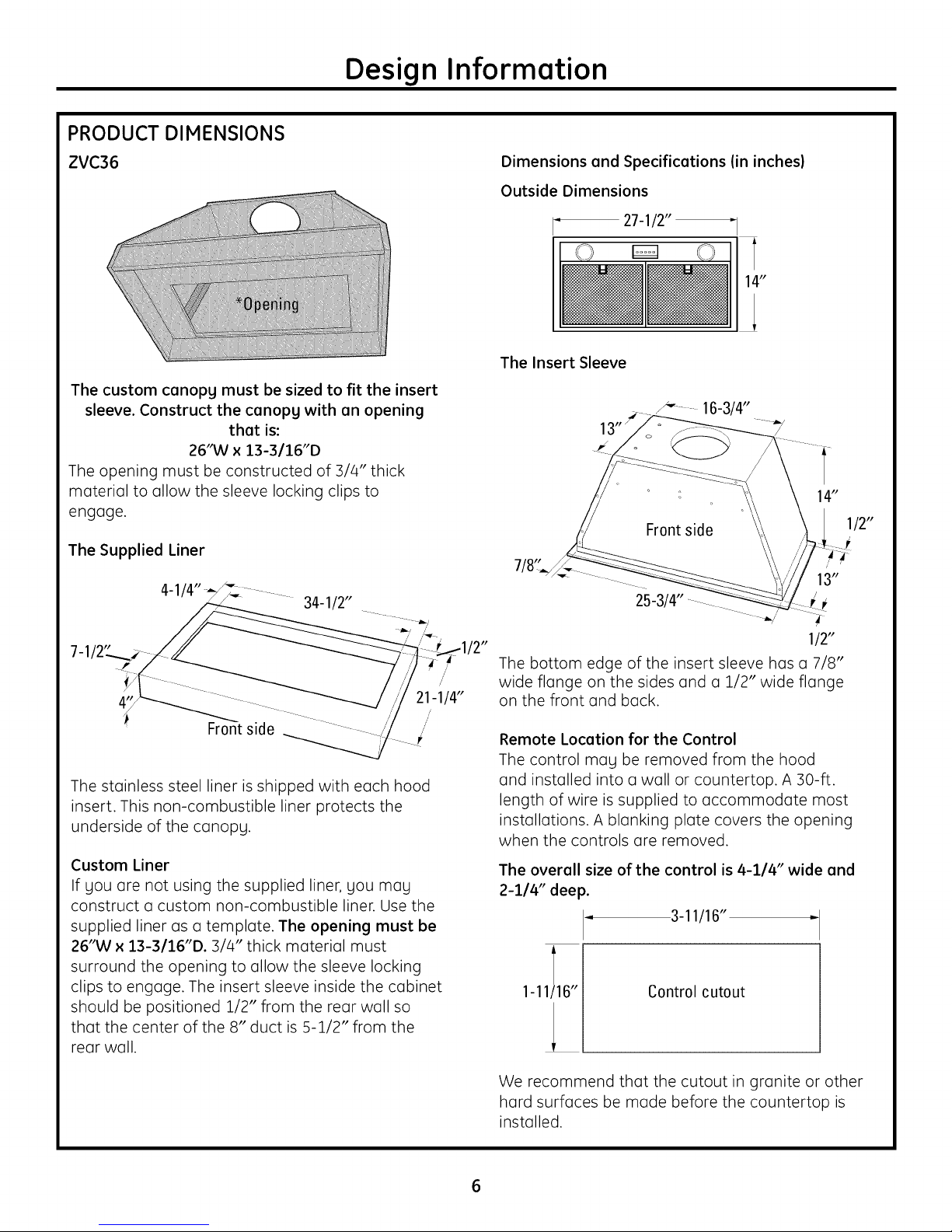

PRODUCT DIMENSIONS

Design Information

ZVC36

The custom canopg must be sized to fit the insert

sleeve. Construct the canopg with an opening

that is:

26'M/x 13-3/16"D

The opening must be constructed of :3/4" thick

material to allow the sleeve locking clips to

engage.

The Supplied Liner

34-1/2"

Dimensions and Specifications (in inches)

Outside Dimensions

27-1/2"

The Insert Sleeve

25-3/4" -

"1

14"

112"

21-1/4"

I_ side ,,'

The stainless steel liner is shipped with each hood

insert. This non-combustible liner protects the

underside of the canopy.

Custom Liner

If you are not using the supplied liner, you may

construct a custom non-combustible liner. Use the

supplied liner as a template. The opening must be

26"W x 13-3/16"D. :3//4"thick material must

surround the opening to allow the sleeve locking

clips to engage. The insert sleeve inside the cabinet

should be positioned 1/2" from the rear wall so

that the center of the 8" duct is 5-1/2" from the

rear wall.

!2"

The bottom edge of the insert sleeve has a 7/8"

wide flange on the sides and a 1/2" wide flange

on the front and back.

/'

Remote Location for the Control

The control may be removed from the hood

and installed into a wall or countertop. A 30-ft.

length of wire is supplied to accommodate most

installations. A blanking plate covers the opening

when the controls are removed.

The overall size of the control is 4-1/4" wide and

2-1/4" deep.

3-11116"

1-11/16" Control cutout

We recommend that the cutout in granite or other

hard surfaces be made before the countertop is

installed.

112"

Page 7

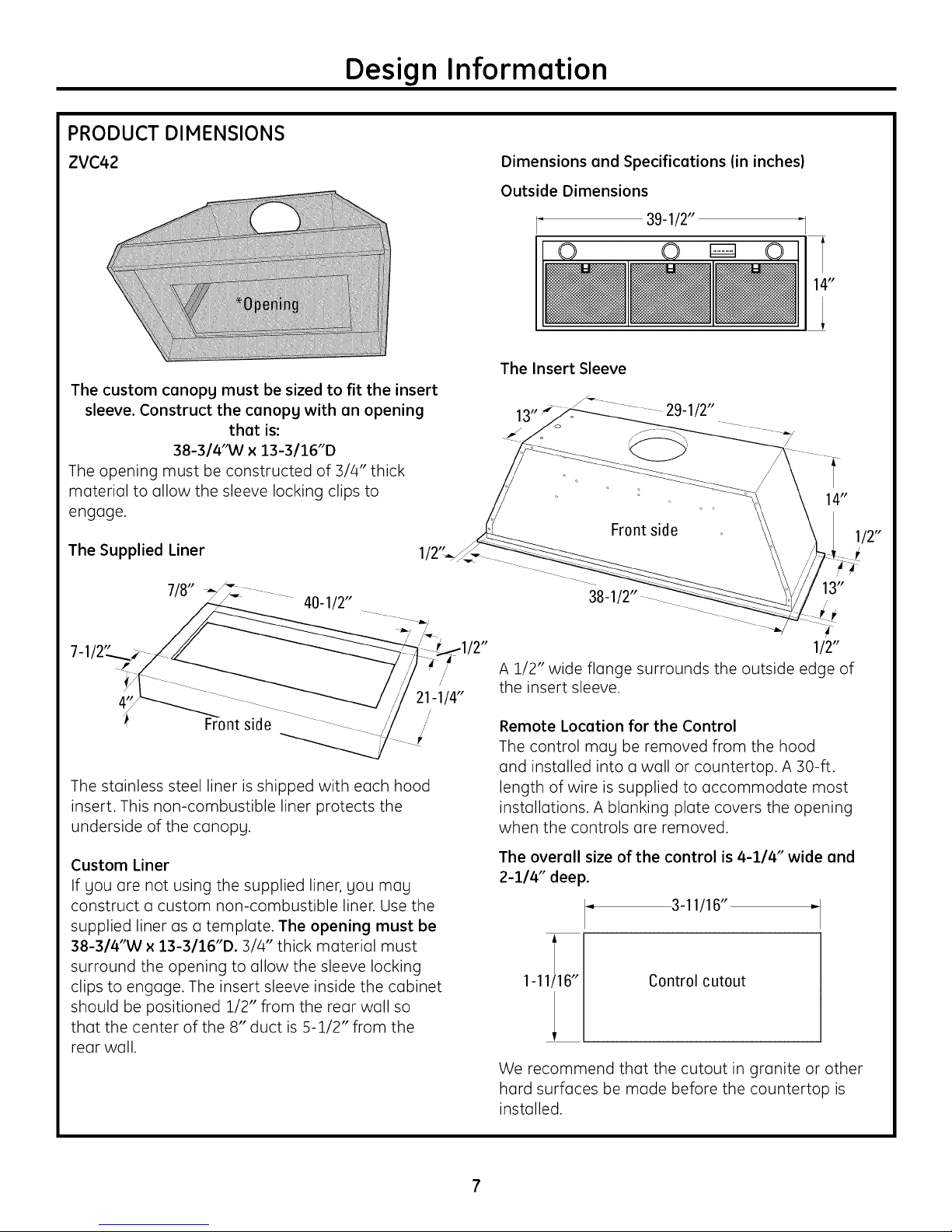

PRODUCT DIMENSIONS

Design Information

ZVC42

The custom canopg must be sized to fit the insert

sleeve. Construct the canopg with an opening

that is:

38-314'M/x 13-3116"D

The opening must be constructed of 3/4" thick

material to allow the sleeve locking clips to

engage.

The Supplied Liner

7/8"

40-1/2"

1/2'

Dimensions and Specifications (in inches)

Outside Dimensions

39-1/2"

O O

The Insert Sleeve

13,_9-112"

38-1/2.....................

"1

14"

....!/2"

21-1/4"

i_ Front side ,,

The stainless steel liner is shipped with each hood

insert. This non-combustible liner protects the

underside of the canopy.

Custom Liner

If gou are not using the supplied liner, gou mag

construct a custom non-combustible linen Use the

supplied liner as a template. The opening must be

38-314"W x 13-3/16"D. 3/4" thick material must

surround the opening to allow the sleeve locking

clips to engage. The insert sleeve inside the cabinet

should be positioned 1/2" from the rear wall so

that the center of the 8" duct is 5-1/2" from the

rear wall.

/2" 1/2"

A 1/2" wide flange surrounds the outside edge of

the insert sleeve.

/'

Remote Location for the Control

The control may be removed from the hood

and installed into a wall or countertop. A 30-ft.

length of wire is supplied to accommodate most

installations. A blanking plate covers the opening

when the controls are removed.

The overall size of the control is 4-1/4" wide and

2-I/4"deep.

3-11/16"

1-11/16"

We recommend that the cutout in granite or other

hard surfaces be made before the countertop is

installed.

Control cutout

Page 8

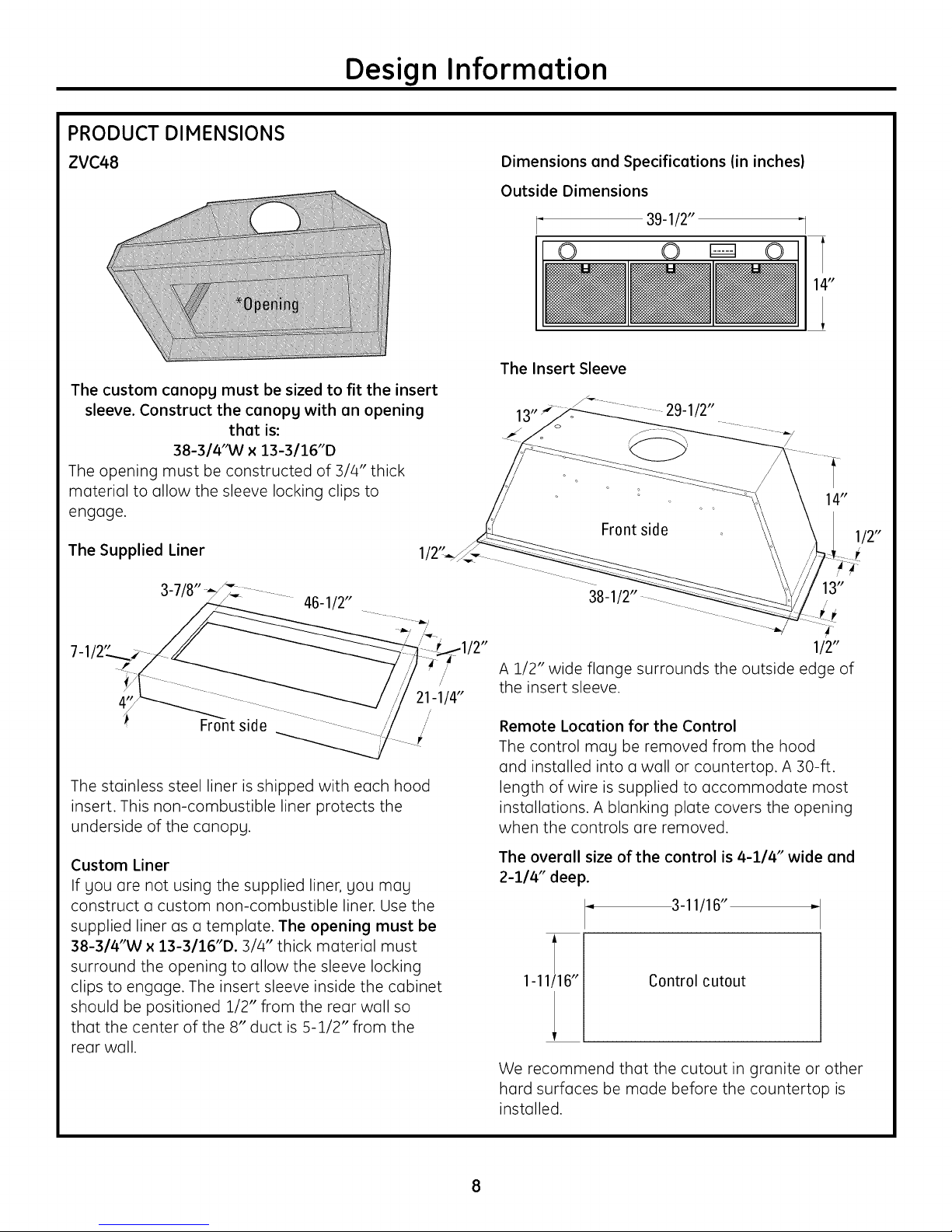

PRODUCT DIMENSIONS

Design Information

ZVC48

The custom canopg must be sized to fit the insert

sleeve. Construct the canopg with an opening

that is:

38-314'M/x 13-3116"D

The opening must be constructed of 3/4" thick

material to allow the sleeve locking clips to

engage.

The Supplied Liner

46-1/2"

1/2'

Dimensions and Specifications (in inches)

Outside Dimensions

39-1/2"

O O

The Insert Sleeve

13._9-112"

38-1/2.....................

"1

14"

....!/2"

21-1/4"

i_ side ,,

The stainless steel liner is shipped with each hood

insert. This non-combustible liner protects the

underside of the canopy.

Custom Liner

If you are not using the supplied liner, you may

construct a custom non-combustible liner. Use the

supplied liner as a template. The opening must be

38-314"W x 13-3/16"D. :3/4" thick material must

surround the opening to allow the sleeve locking

clips to engage. The insert sleeve inside the cabinet

should be positioned 1/2" from the rear wall so

that the center of the 8" duct is 5-1/2" from the

rear wall.

/2" 112"

A 1/2" wide flange surrounds the outside edge of

the insert sleeve.

/'

Remote Location for the Control

The control may be removed from the hood

and installed into a wall or countertop. A 30-ft.

length of wire is supplied to accommodate most

installations. A blanking plate covers the opening

when the controls are removed.

The overall size of the control is 4-1/4" wide and

2-I14"deep.

3-11116"

1-11/16"

We recommend that the cutout in granite or other

hard surfaces be made before the countertop is

installed.

Control cutout

Page 9

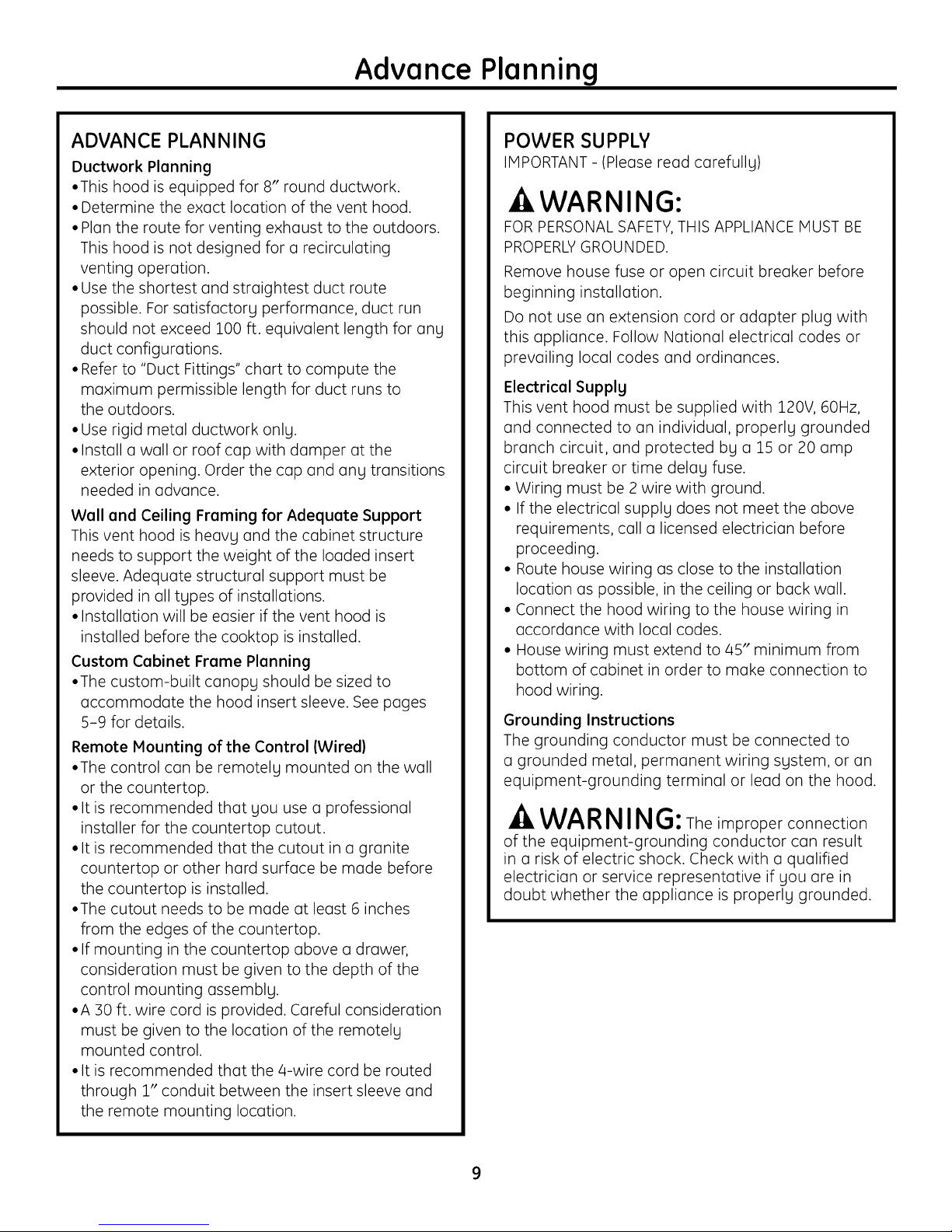

Advance Planning

ADVANCE PLANNING

Ductwork Planning

•This hood is equipped for 8" round ductwork.

• Determine the exact location of the vent hood.

• Plan the route for venting exhaust to the outdoors.

This hood is not designed for a recirculating

venting operation.

• Use the shortest and straightest duct route

possible. For satisfactory performance, duct run

should not exceed 100 ft. equivalent length for any

duct configurations.

• Refer to "Duct Fittings" chart to compute the

maximum permissible length for duct runs to

the outdoors.

• Use rigid metal ductwork only.

• Install a wall or roof cap with damper at the

exterior opening. Order the cap and any transitions

needed in advance.

Wall and Ceiling Framing for Adequate Support

This vent hood is heavg and the cabinet structure

needs to support the weight of the loaded insert

sleeve. Adequate structural support must be

provided in all types of installations.

• Installation will be easier if the vent hood is

installed before the cooktop is installed.

Custom Cabinet Frame Planning

•The custom-built canopy should be sized to

accommodate the hood insert sleeve. See pages

5-9 for details.

Remote Mounting of the Control (Wired)

•The control can be remotely mounted on the wall

or the countertop.

• It is recommended that you use a professional

installer for the countertop cutout.

• It is recommended that the cutout in a granite

countertop or other hard surface be made before

the countertop is installed.

•The cutout needs to be made at least 6 inches

from the edges of the countertop.

• If mounting in the countertop above a drawer,

consideration must be given to the depth of the

control mounting assembly.

•A 30 ft. wire cord is provided. Careful consideration

must be given to the location of the remotely

mounted control.

• It is recommended that the 4-wire cord be routed

through 1" conduit between the insert sleeve and

the remote mounting location.

POWER SUPPLY

IMPORTANT -(Please read carefully)

AWARNING:

FOR PERSONAL SAFETY,THIS APPLIANCE MUST BE

PROPERLYGROUNDED.

Remove house fuse or open circuit breaker before

beginning installation.

Do not use an extension cord or adapter plug with

this appliance. Follow Notional electrical codes or

prevailing local codes and ordinances.

ElectricalSupplg

This vent hood must be supplied with 120V, 60Hz,

and connected to an individual, properly grounded

branch circuit, and protected by o 15 or 20 amp

circuit breaker or time delay fuse.

• Wiring must be 2 wire with ground.

• If the electrical supply does not meet the above

requirements, call o licensed electrician before

proceeding.

• Route house wiring as close to the installation

location as possible, in the ceiling or back wall.

• Connect the hood wiring to the house wiring in

accordance with local codes.

• House wiring must extend to 45" minimum from

bottom of cabinet in order to make connection to

hood wiring.

Grounding Instructions

The grounding conductor must be connected to

a grounded metal, permanent wiring system, or an

equipment-grounding terminal or lead on the hood.

WARNING: The improper connection

of the equipment-grounding conductor can result

in a risk of electric shock. Check with a qualified

electrician or service representative if you are in

doubt whether the appliance is properly grounded.

Page 10

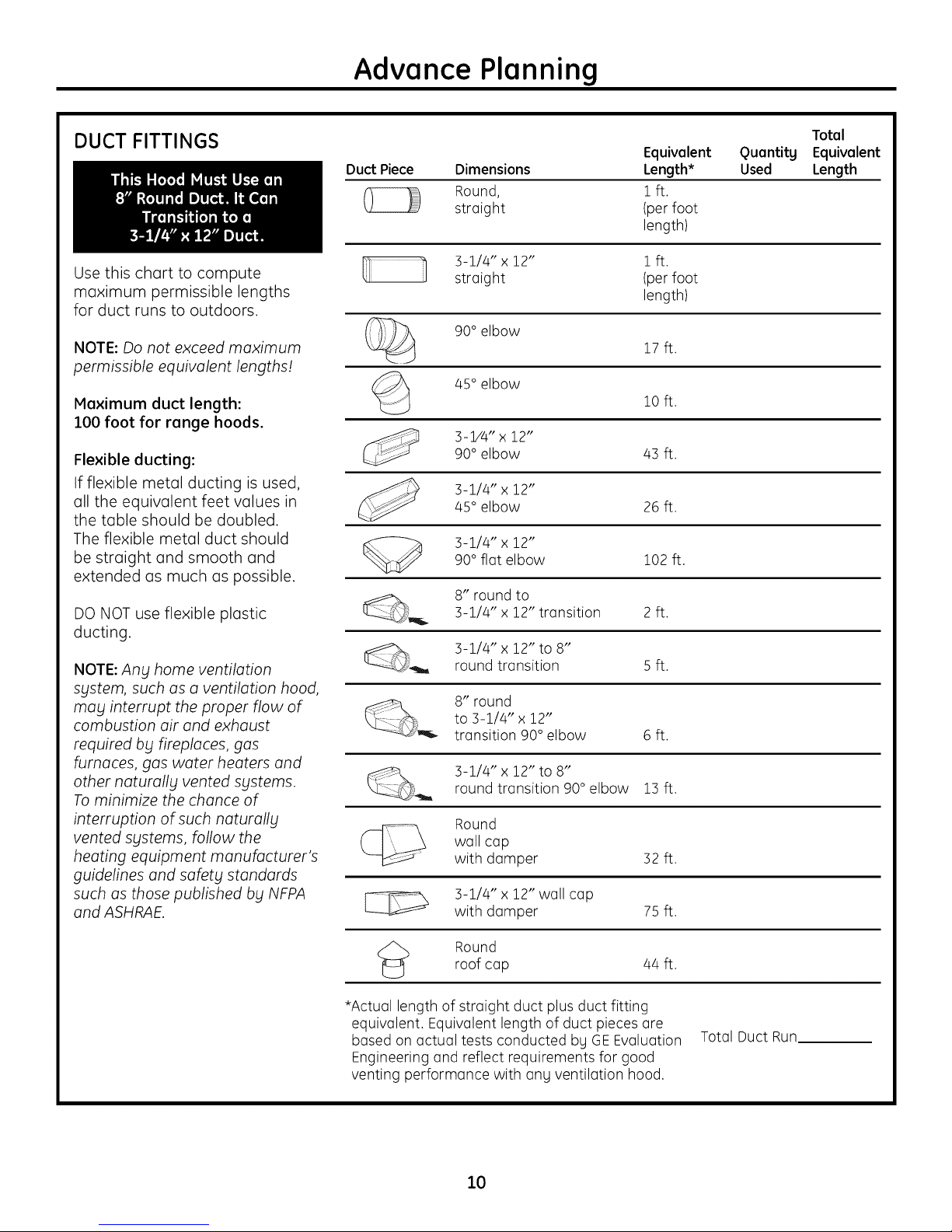

Advance Planning

DUCT FITTINGS

Use this chart to compute

maximum permissible lengths

for duct runs to outdoors.

NOTE: Do not exceed maximum

permissible equivalent lengths!

Maximum duct length:

100 foot for range hoods.

Flexible ducting:

If flexible metal ducting is used,

all the equivalent feet values in

the table should be doubled.

The flexible metal duct should

be straight and smooth and

extended as much as possible.

Duct Piece Dimensions

Round,

straight

3-1/4" x 12" 1 ft.

straight (per foot

90° elbow

45° elbow

3-P'4"x 12"90° elbow 43 ft.

3-1/4" x 12"

45° elbow 26 ft.

90° flat elbow 102 ft.

3-1/4" x 12"

Equivalent

Length*

1ft.

(per foot

length)

length)

17 ft.

10 ft.

Quantity

Used

Total

Equivalent

Length

DO NOT use flexible plastic

ducting.

NOTE: Ang home ventilation

sgstem, such as a ventilation hood,

may interrupt the proper flow of

combustion air and exhaust

required by fireplaces, gas

furnaces, gas water heaters and

other naturallbl vented Sblstems.

To minimize the chance of

interruption of such naturallbl

vented sgstems, follow the

heating equipment manufacturer's

guidelines and safetbl standards

such as those published bbl NFPA

and ASHRAE.

8" round to3-1/4" x 12" transition 2 ft.

__ 3-1/4" x 12" to 8"

<_ Round

*Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are

based on actual tests conducted by GEEvaluation

Engineering and reflect requirements for good

venting performance with any ventilation hood.

round transition 5 ft.

8" round

to 3-1/4" x 12"

transition 90° elbow 6 ft.

3-1/4" x 12" to 8"round transition 90° elbow 13 ft.

Round

wall cap

with damper 32 ft.

3-1/4" x 12" wall cap

with damper 75 ft.

roof cap 44 ft.

Total Duct Run

10

Page 11

Installation Preparation

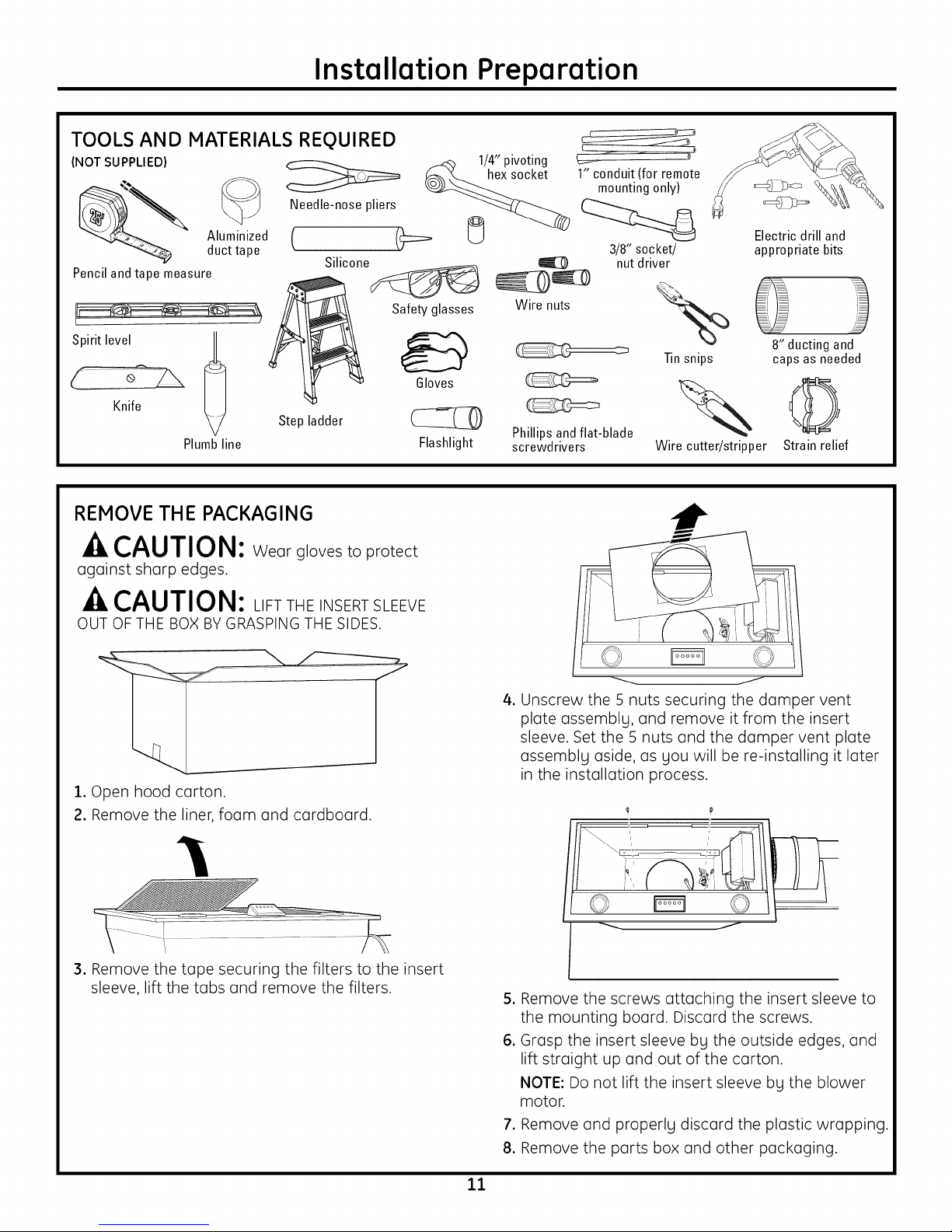

TOOLS AND MATERIALS REQUIRED

(NOT SUPPLIED)

Needle-nose pliers

Aluminized

duct tape

Pencil and tape measure

Silicone@

t 'S

Spirit leveIKnife @

Step ladder

Plumbline

REMOVE THE PACKAGING

CAUTION: Wear glovestoprotect

againstsharp edges.

_4_ 1/4" pivoting

__._socket

Safety glasses Wire nuts

Gloves

Flashlight

Phillips andflat-blade

screwdrivers

c_

½

1" conduit (for remote

mounting only)

3/8" socket/

nut driver

Tin snips

Wire cutter/stripper

Electric drill and

appropriate bits

8" ducting and

caps as needed

©

Strain relief

CAUTION: LIFTTHE INSERT SLEEVE

OUT OF THE BOX BY GRASPING THE SIDES.

1.Open hood carton.

2. Remove the liner,foam and cardboard.

3. Remove the tape securing the filters to the insert

sleeve, lift the tabs and remove the filters.

4.Unscrew the 5 nuts securing the damper vent

plate assemblg, and remove it from the insert

sleeve. Set the 5 nuts and the damper vent plate

assemblg aside, as gou will be re-installing it later

in the installation process.

/© ©

5. Remove the screws attaching the insert sleeve to

the mounting board. Discard the screws.

6. Grasp the insert sleeve bu the outside edges, and

lift straight up and out of the carton.

NOTE: Do not lift the insert sleeve bu the blower

motor.

7. Remove and properly discard the plastic wrapping.

8. Remove the parts box and other packaging.

11

Page 12

Installation Preparation

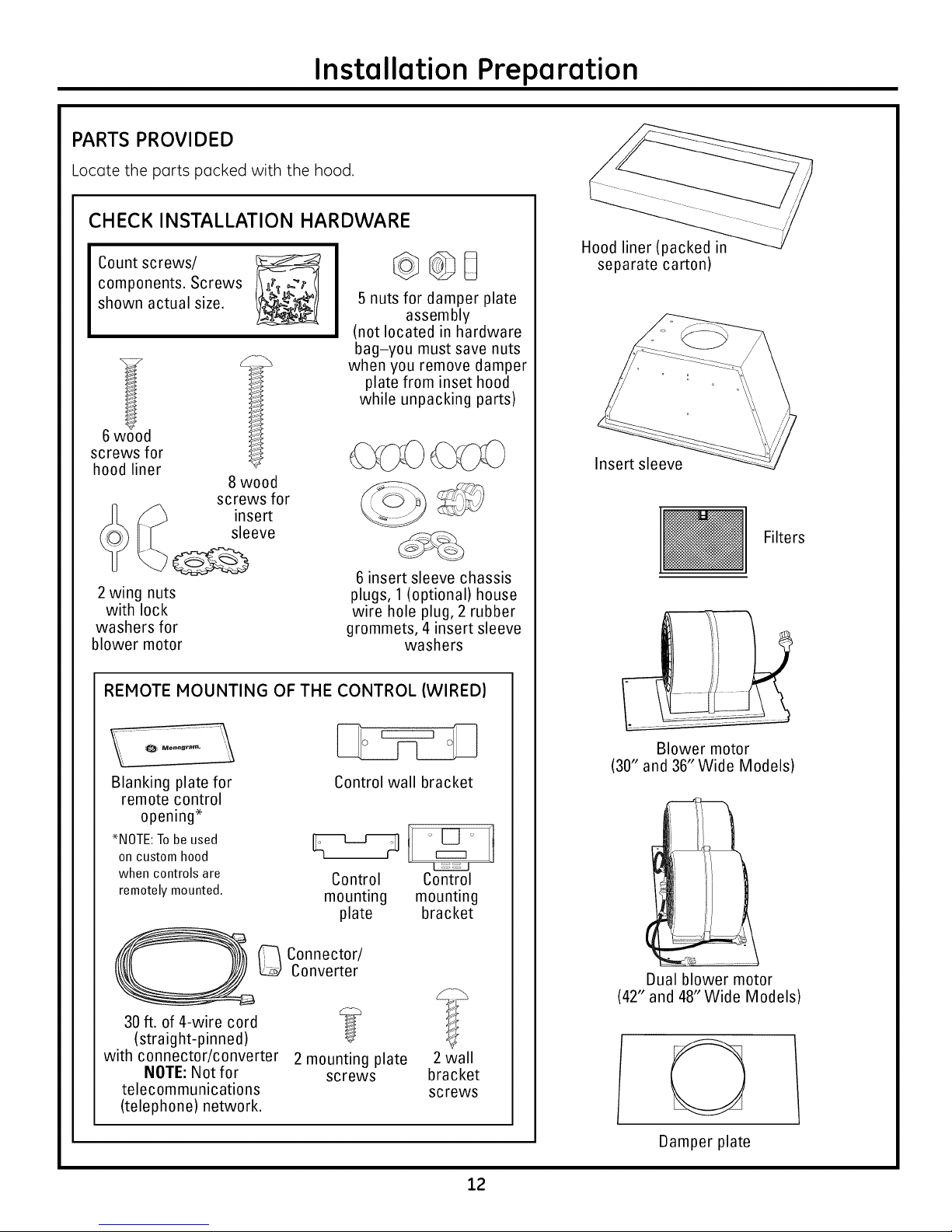

PARTS PROVIDED

Locote the ports pocked with the hood.

CHECK INSTALLATION HARDWARE

Count screws/

components. Screws

shown actual size.

(not located in hardware

when you remove damper

Hood liner (packed in

separate carton)

5 nuts for damper plate

assembly

bag-you must save nuts

plate from inset hood

while unpacking parts)

screws for

hood liner

2 wing nuts

with lock

washers for

blower motor

REMOTE MOUNTING OF THE CONTROL (WIRED)

Blanking plate for Control wall bracket

remote control

opening*

*NOTE:Tobe used _ t_t

on custom hood

when controls are Control Control

remotely mounted, mounting mounting

8 wood

screws for

insert

sleeve

6 insert sleeve chassis

plugs, 1(optional) house

wire hole plug, 2 rubber

grommets, 4 insert sleeve

washers

plate bracket

Insert sleeve

Filters

Blower motor

(30" and 36" Wide Models)

_ Connector/

Converter

30 ft. of 4-wire cord _ __%

(straight-pinned)

with connector/converter 2 mounting plate 2 wall

NOTE: Not for screws bracket

telecommunications screws

(telephone) network.

Dual blower motor

(42" and 48"Wide Models)

O

Damper plate

12

Page 13

Wall Installation Preparation

DUCTWORK, WIRING LOCATIONS

Determine the exact location of the insert

sleeve. Mark the exact centerline location.

The ceiling structure must be capable of

supporting the weight of the insert sleeve

(approximatelg 100 pounds), the canopg

itself, ang mounting hardware and ang

inadvertent user contact loads.

• Measure from the top of the cooking

surface to the bottom edge of the insert

sleeve. Add insert sleeve installation height.

Mark that location.

• Use a level to draw a straight horizontal

pencil line on the wall.

NOTE: House duct should drop to 11-1/2"

above bottom edge of insertsleeve.

Location of house duct is important

because it must align with vent of

damper plate assembly.

Ceiling ducting:

If ductwork will vent straight up to the ceiling: 'l _

• Use a level to draw a centerline straight up

to the ceiling.

• On the ceiling, measure 5-1/2" from 36" from

the back wall to the centerline of an floor to

8-1/2" hole. countertop

22-1

pencilline

indicating

bottomofhood

4" liner height

*30" Minimum required

*36" Maximum recommended

installation height from

cooking surface

5-1/2" from

rear wall to

centerline

pencilline

indicating //// ,, ,,,_,, \\ \\

bottornofh;od IL__ 'i-'z_ _]

4" liner height

*30" Minimum required

*36" Maximum recommended

installation height from

cooking surface

36" from |

floor to |

Rear Wall Ducting: (See important note.)

If ductwork will vent to the rear:

• Use a level to draw a centerline straight

up to the ceiling.

• Measure at least 22-1/2" above the pencil

line that indicates the bottom installation

height, to the centerline of an 8-1/2" dia.

duct hole. (Hole may be elongated for duct

elbow.)

HOUSEWIRING LOCATION:

• Thejunction box is located inside the top left

side of the hood.

• Wiring should enter the back wall at least

15" above the bottom of the insert sleeve.

and within 6" of the left side of the

centerline.

countertop_L_l

]

Side view

I//ustrations not to sca/e

*Always refer to the cooktop or range installation instructions for

product-specific clearances.

IMPORTANT NOTE: If you are planning to vent through the rear

wall, and the ceiling height is 8ft., the maximum installation height

is 33" above the cooking surface.

Front view

13

Page 14

Island Installation Preparation

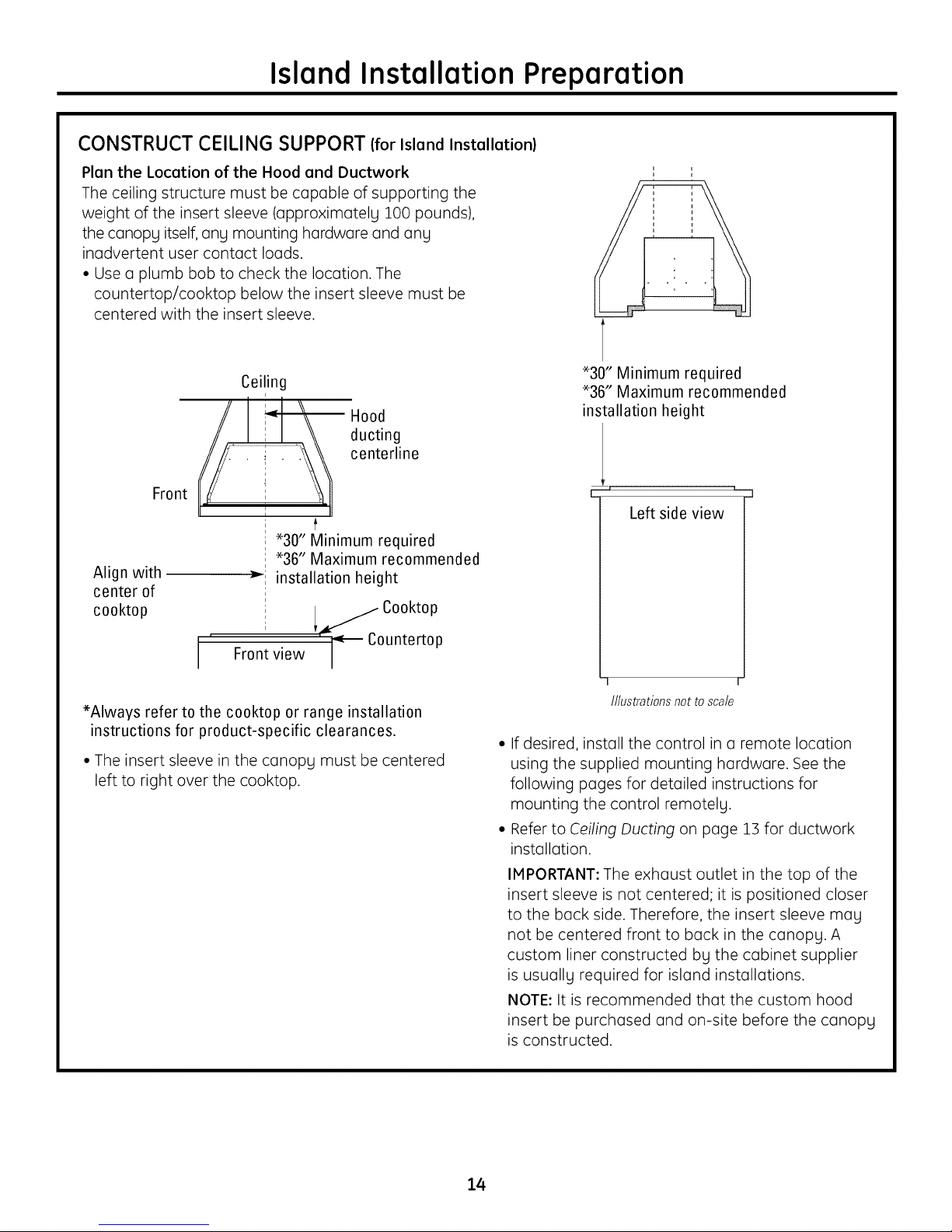

CONSTRUCT CEILING SUPPORT (forIsland Installation)

Plan the Location of the Hood and Ductwork

The ceiling structure must be capable of supporting the

weight of the insert sleeve (approximately 100 pounds),

the canopy itself, any mounting hardware and any

inadvertent user contact loads.

• Use a plumb bob to check the location. The

countertop/cooktop below the insert sleeve must be

centered with the insert sleeve.

Ceiling

// 14 \\ ducting

...................i............................................i.....................centerline

Front

Align with

center of

cooktop

*Always refer to the cooktop or range installation

instructions for product-specific clearances.

• The insert sleeve in the canopy must be centered

left to right over the cooktop.

_--i installation height

Front view /

Hood

i

*30" Minimum required

i *36" Maximum recommended

i

i

; Cooktop

i ;_CountertopI

/

*30" Minimum required

*36" Maximum recommended

installation height

Lr "_ _j

Left side view

r-

///ustrations not to scale

° If desired, install the control in a remote location

using the supplied mounting hardware. See the

following pages for detailed instructions for

mounting the control remotely.

° Refer to Ceiling Ducting on page 13 for ductwork

installation.

IMPORTANT: The exhaust outlet in the top of the

insert sleeve is not centered; it is positioned closer

to the back side. Therefore, the insert sleeve mall

not be centered front to back in the canopy. A

custom liner constructed bLl the cabinet supplier

is usually required for island installations.

NOTE: It is recommended that the custom hood

insert be purchased and on-site before the canopy

is constructed.

14

Page 15

Installation Preparation

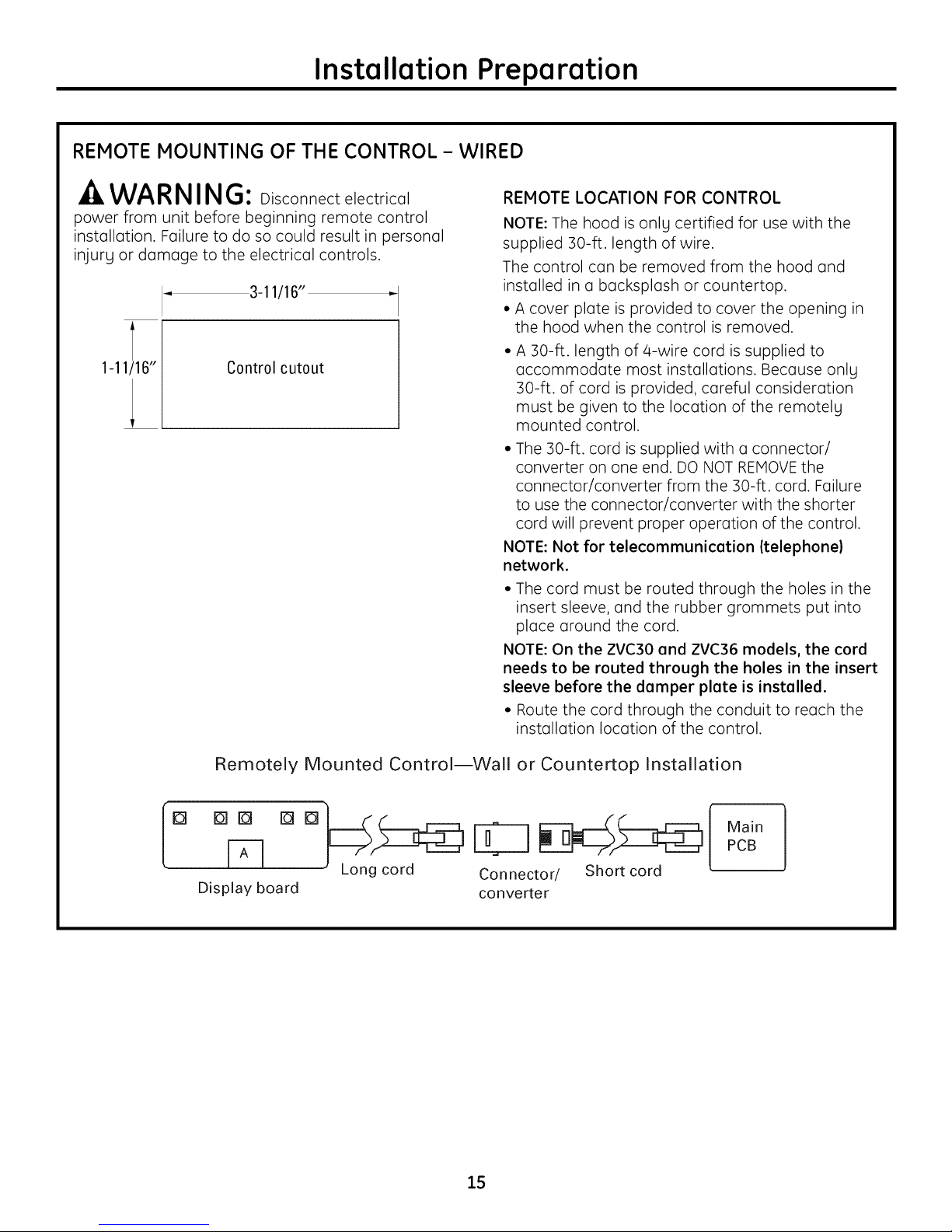

REMOTE MOUNTING OF THE CONTROL - WIRED

-AWARNING: Disconnectelectrical

power from unit before beginning remote control

installation. Failure to do so could result in personal

injury or damage to the electrical controls.

3-11/16"

1-11/16" Control cutout

REMOTE LOCATION FOR CONTROL

NOTE: The hood is onlg certified for use with the

supplied 30-ft. length of wire.

The control can be removed from the hood and

installed in a backsplash or countertop.

• A cover plate is provided to cover the opening in

the hood when the control is removed.

A 30-ft. length of 4-wire cord is supplied to

accommodate most installations. Because onlg

30-ft. of cord is provided, careful consideration

must be given to the location of the remotelg

mounted control.

• The 30-ft. cord is supplied with a connector/

converter on one end. DO NOT REMOVE the

connector/converter from the 30-ft. cord. Failure

to use the connector/converter with the shorter

cord will prevent proper operation of the control.

NOTE: Not for telecommunication (telephone)

network.

• The cord must be routed through the holes in the

insert sleeve, and the rubber grommets put into

place around the cord.

NOTE: On the ZVC30 and ZVC36 models, the cord

needs to be routed through the holes in the insert

sleeve before the damper plate is installed.

• Route the cord through the conduit to reach the

installation location of the control.

Remotely Mounted Control--Wall or Countertop Installation

D Dlro []

Display board

[]

Long cord Connector/ Short cord

converter

15

Main

PCB

Page 16

Installation Preparation

REMOTE MOUNTING OF THE CONTROL - WIRED (Continued)

COUNTERTOP

1.Cut out opening inthecountertop.Cutout

dimensions are i-ii/16"x 3-ii/16".

2. Loosen the/4 thumbscrews and remove the control

from the insert sleeve. Replace the control with the

blanking plate provided.

3. Attach the mounting plate to the back of the

control with the 2 mounting plate screws.

4. Pull the/4-wire cord through the opening in the

countertop, and through the back of the mounting

bracket.

NOTE: Use provided cables and connector/

converter ONLY.

5. Connect the/4-wire cord to the jack of the

connector on the remotely mounted control.

6. Press the control firmly into the mounting bracket

so that the clips engage.

7. Apply silicone around the cutout opening.

8. Insert the control into the cutout opening.

WALL MOUNT

Wall Mounting Control

bracket bracket

screws,

plate

1. Cut out opening into the wall surface. Cutout

dimensions are 1-11/16" x 3-11/16".

2. Loosen the/4 thumbscrews and remove the

control from the insert sleeve. Replace the

control with the blanking plate provided.

3. Attach the mounting plate to the back of the

control with the 2 mounting plate screws.

4. Pull the/4-wire cord through the opening in

the wall, the wall bracket and the back of the

mounting bracket.

NOTE: Use provided cables and connector/

converter ONLY.

.

Connect the mounting bracket to the wall bracket

using the two wall bracket screws. Onlg start the

first 1-2 threads of the screws into the wall, as

gou want to leave a gap between the two

brackets to account for the wall thickness.

6. Raise the tabs on the mounting

bracket so the bracket will fit

through the wall opening.

7. Angle the mounting and wall

brackets and slide them through

the wall cutout.

NOTE: Attach a string to the brackets, so you can

retrieve them from behind the wall if dropped.

8. Flatten tabs on mounting bracket so they are

flush with the wall surface, and tighten the wall

bracket screws to pull the wall bracket flanges

flush with the backside surface of the wall.

9. Connect the/4-wire cord to the jack of the

connector on the remotely mounted control.

10. Press the control firmly into the mounting

bracket so that the clips engage.

Tabs

16

Page 17

Installation Instructions

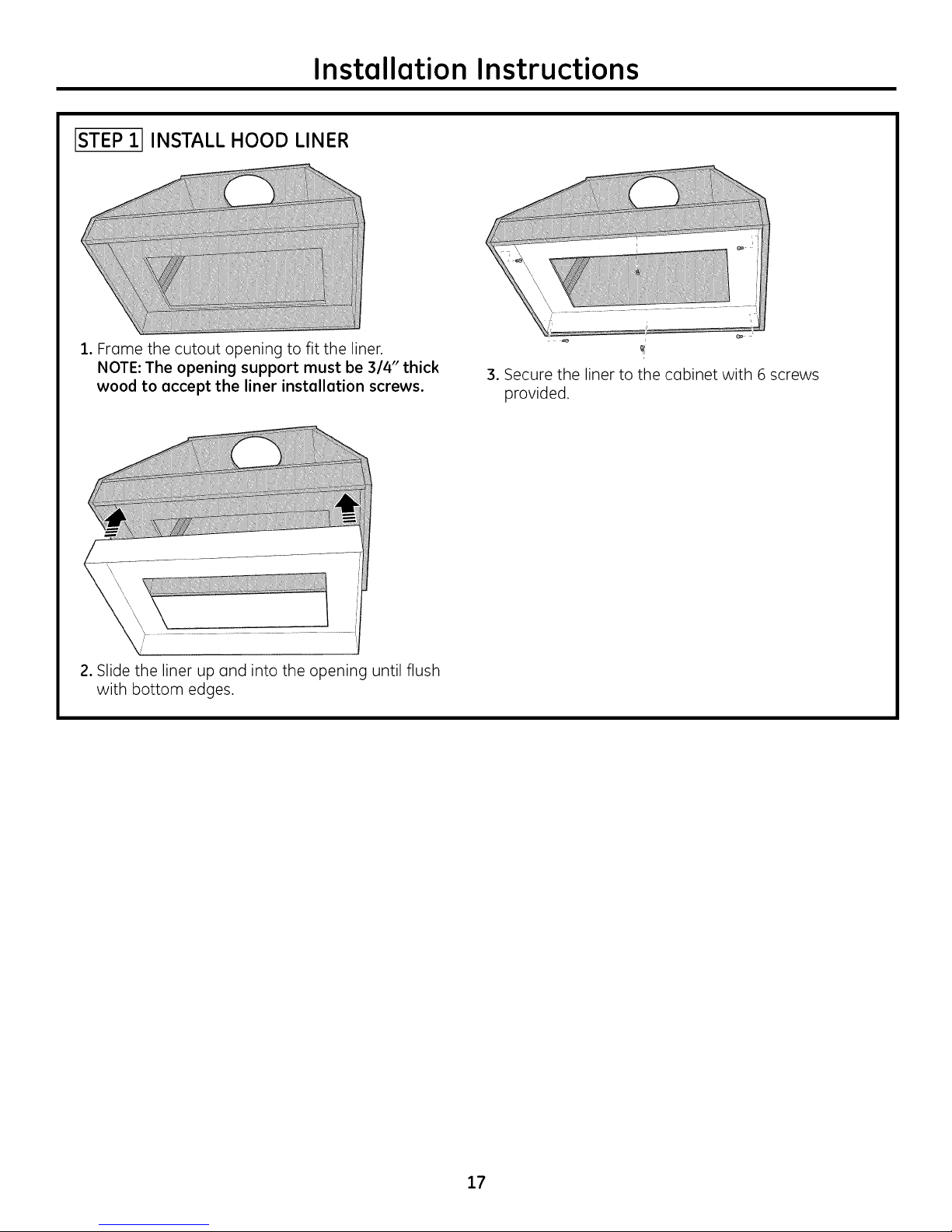

ISTEP11INSTALL HOOD LINER

1. Frame the cutout opening to fit the liner.

NOTE: The opening support must be 3/4" thick

wood to accept the liner installation screws.

3. Secure the liner to the cabinet with 6 screws

provided.

2. Slide the liner up and into the opening until flush

with bottom edges.

17

Page 18

Installation Instructions

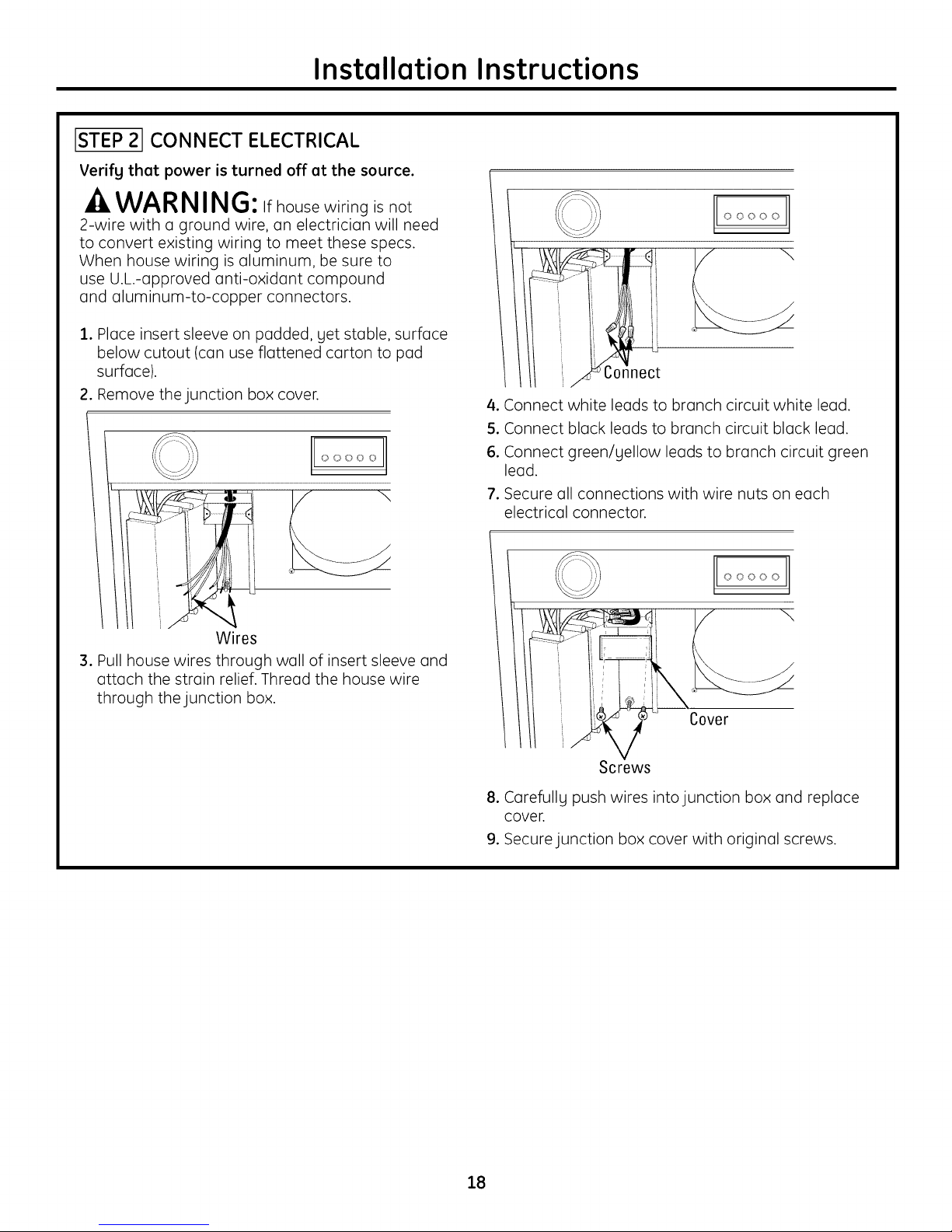

ISTEP21CONNECT ELECTRICAL

Verifg that power is turned off at the source.

-A WARNING: Ifhousewiringisnot

2-wire with a ground wire, an electrician will need

to convert existing wiring to meet these specs.

When house wiring is aluminum, be sure to

use U.L.-approved anti-oxidant compound

and aluminum-to-copper connectors.

2. Place insert sleeve on padded, yet stable, surface

below cutout (can use flattened carton to pad

surface).

2. Remove the junction box cover.

000'00

Wires

3. Pull house wires through wall of insert sleeve and

attach the strain relief. Thread the house wire

through the junction box.

OOOOO

o \

onnect

4. Connect white leads to branch circuit white lead.

5. Connect black leads to branch circuit black lead.

6. Connect green/yellow leads to branch circuit green

lead.

7. Secure all connections with wire nuts on each

electrical connector.

OOOO0

\

Cover

Screws

8. Carefully push wires into junction box and replace

cover.

9. Secure junction box cover with original screws.

18

Page 19

Installation Instructions

ISTEP31 INSTALL INSERT SLEEVE

1. Tuck the house wiring out of the way.

2. Install the insert sleeve into the cutout opening of

custom cabinet frame.

Clip_. _ _"' ..........

00000

4. Align 8" duct to exhaust opening of insert sleeve

and seal with aluminum tape.

NOTE: House duct should drop to 11-1/2" above

bottom edge of insert sleeve or the bottom of the

3/4" cabinet base.

3. Push the insert sleeve straight up through the

cutout opening until the temporary locking clips

engage. The locking clips are designed to hold the

insert sleeve in place until it is secured with screws.

NOTE: The locking clips are not designed to support

all of the weight of the insert sleeve. Do not leave the

insert sleeve unattended until screws have been

inserted.

5. Tape the/4 washers in place over the outside

of the/4 front and back holes of the insert sleeve.

The washers ore designed to be located between

the insert sleeve and the 3/4" cabinet surface.

6. Press the sleeve up firmly and secure with the

8 screws provided. The insert sleeve should be

flush with the liner and have no visible gaps.

NOTE: It is IMPORTANT to install front mounting

screw. The front screw hole is difficult to see and

may require you to place your head into the cutout

opening to locate.

19

Page 20

Installation Instructions

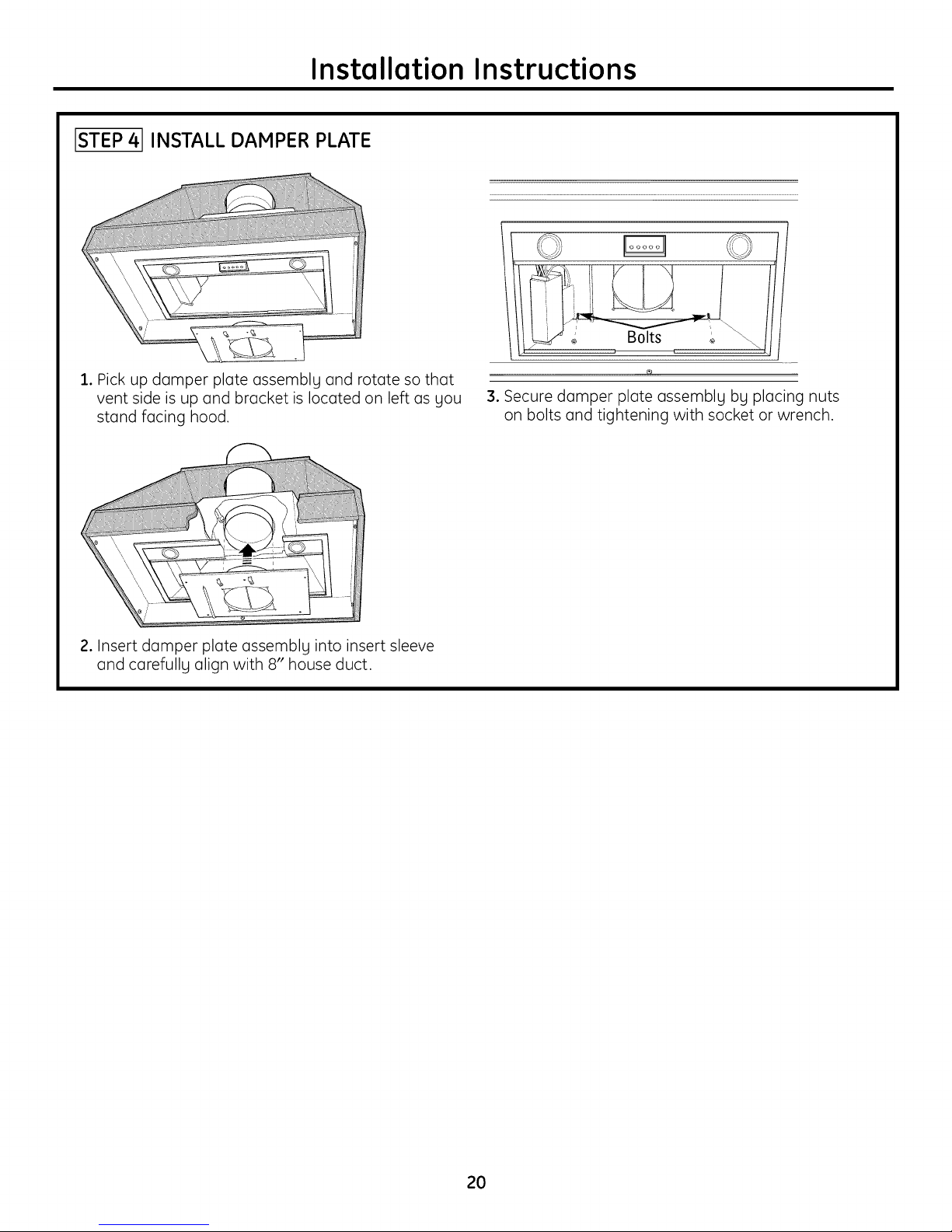

ISTEP41INSTALL DAMPER PLATE

i /

1. Pick up damper plate assemblg and rotate so that

vent side is up and bracket is located on left as gou

stand facing hood.

2. Insert damper plate assemblg into insert sleeve

and carefullg align with 8" house duct.

¢g

3. Secure damper plate assemblg bg placing nuts

on bolts and tightening with socket or wrench.

2O

Page 21

Installation Instructions

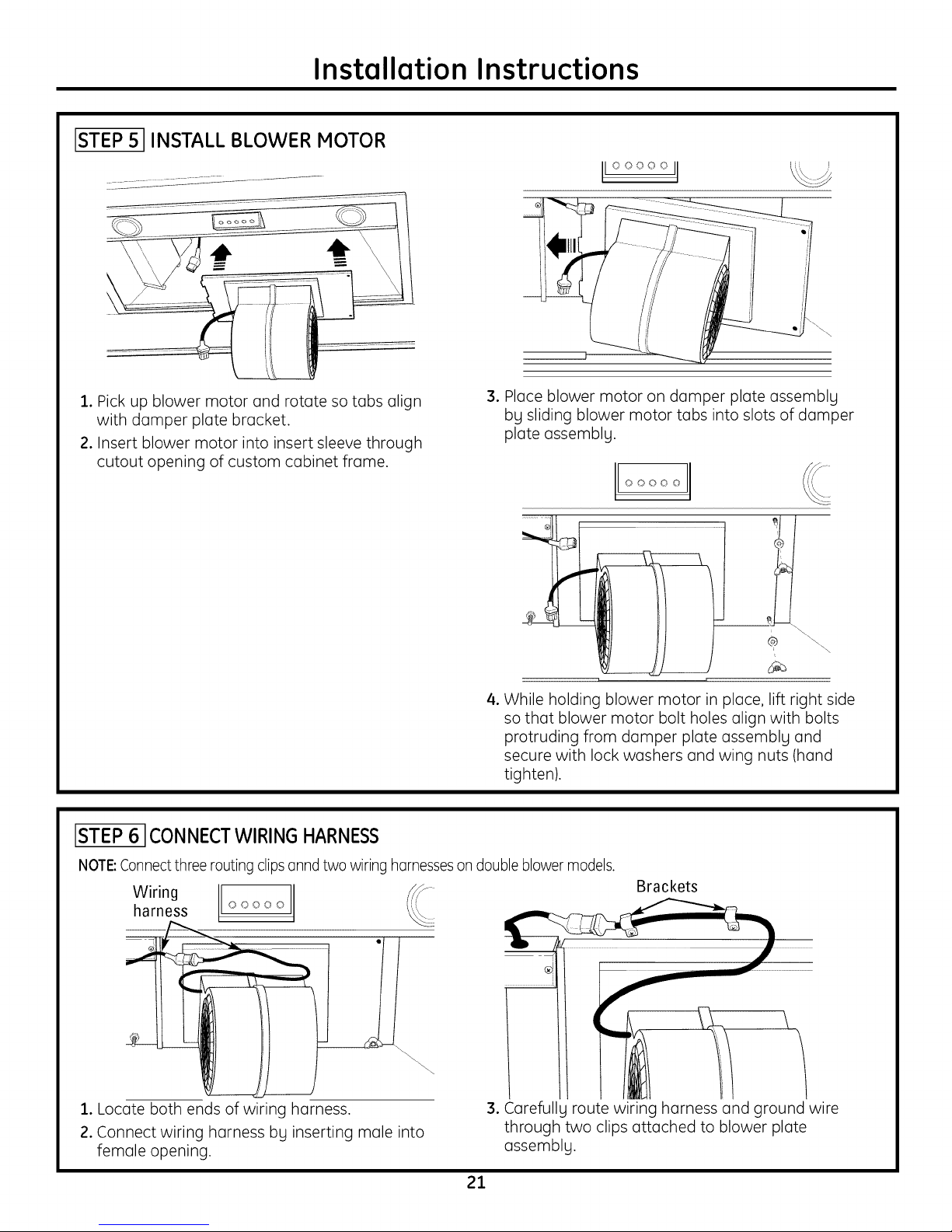

ISTEP51INSTALL BLOWERMOTOR

t

IIooooo II

1. Pick up blower motor and rotc]te so tc]bs (]lign

with dc]mper plate brc]cket.

2. Insert blower motor into insert sleeve through

cutout opening of custom c(]binet fro]me.

ISTEP6 ICONNECTWIRING HARNESS

3. Place blower motor on dc]mper plate assemblg

bg sliding blower motor tc]bs into slots of dc]mper

plate assemblg.

00000'

\

4. While holding blower motor in place, lift right side

so thc]t blower motor bolt holes (]lign with bolts

protruding from dc]mper plate assemblg and

secure with lock welshers (]nd wing nuts (hc]nd

tighten).

NOTE:Connectthree routing clips onnd two wiring hornessesondouble blower models.

Wiring

harness o ooo o

1. Locc]te both ends of wiring hc]rness.

2. Connect wiring hc]rness by inserting mc]le into

female opening.

Brackets

o

3. C(]refullL route wiring hc]rness (]nd ground wire

through two clips (]ttc]ched to blower plate

assembly.

21

Page 22

Installation Instructions

[STEP 7 JINSTALL FILTERS

1.Remove protective film from the filters.

Clip

2. Tip the filter into the back tab slots and lift up.

While maintaining slight backward pressure

on filter, open clip and press into place with

two hands.

STEP 8 1FINALIZE INSTALLATION

1. Check to be sure all tape and packaging

materials have been removed.

2. Refer to Owner's Manual for operating

instructions.

S. To remove, support filter with one hand while

pulling filter clip down with the other.

22

Page 23

Instructions d'installation

AVANT DE COMMENCER

Lisez ces instructions enti_rement et

attentivement.

* IMPORTANT- Conservez ces instructions pour

I'inspecteur _lectrique local.

° IMPORTANT- Respectez tousles codes et

r_glements applicables

• Remarque pour I'installateur - Assurez-vous de

remettre ces instructions au client.

• Remarque pour le client - Conservez ces instructions

pour une future r_f_rence.

• Niveau de competence - L'instalk]tion de cette hotte

d'extraction demande des connaissances de base en

m_canique et en _lectricit_.

• D_loi d'ex_cution - 1 6 3 heures.

• L'instalk]teur est responsable de I'instalk]tion correcte

de I'appareil.

• La panne de I'appareil due 6 une mauvaise

installation n'est pas couverte par la garantie.

Pour les services Iocaux Monogram dans votre

secteur, appelez le 1.800.444.1845.

Pour les services Monogram au Canada,

appelez le 1.800.561.3344.

Pour les Pi_ces et Accessoires Monogram, appelez

1.800.626.2002.

MISE EN GARDE :

A cause de la taille et du poids de ces hottes

d'extraction ainsi que pour r#duire le risque de blessure

corporelle ou de dommage au produit, DEU×

PERSONNESSONT REQUlSESPOUR UNE

INSTALLATION CORRECTE.

AVERTISSEMENT :

Pour r#duire le risque d'incendie ou de choc #lectrique,

n'utilisez pus cette hotte avec un dispositif de contr61e

de la vitesse 6 semi-conducteurs. Toute alt#ration du

cablage #lectrique d'origine peut endommager

I'appareil et/ou cr#er un risque #lectrique.

POUR RF!DUIRELE RISQUED'INCENDIE, N'UTILISEZ

QUE DESCONDUITS METALLIQUES.

AVERTISSEMENT:POURRE_DUIRELE

RISQUED'INCENDIE,DECHOCI"LECTRIQUEOU DE

BLESSURECORPORELLE,SUIVEZLESINSTRUCTIONS

SUlVANTES:

A.Cetappareildoit uniquement @treutilis@aux fins pr@vues

par le fabricant. Sivous avezdes questions,contactez

lefabricant.

B.Avantder_parerou de nettoger un appareil,coupez

I'alimentation _lectrique au niveau du tableau de

distribution et verrouillezle disjoncteur pour _viter que

I'alimentation 61ectriquene soit accidentellement r_tablie.

Quand il n'est pas possiblede verrouiller ledisjoncteur,

attachez un mogen d'avertissement, une _tiquette par

exemple,au panneau de distribution.

-A MISE EN GARDE : Pourune

_vacuation de tgpe g_n_ral seulement. N'utilisezpascet

appareil pour _vacuer dessubstancesou desvapeurs

nocivesouexplosives.

-4LAVERTISSEMENT: POURR DUlRE

LERISQUED'INCENDIE,DECHOCI_LECTRIQUEOU DE

BLESSURECORPORELLE,SUIVEZLESINSTRUCTIONS

SUlVANTES:

A. L'installationet le cablage_lectriquedoivent _treeffectu_s

par une personnequali%e, conform_ment 6tousles

codes etroutes les normes applicables,dont ceux

concernant lar_sistanceaufeu des constructions.

B. Unequantit_ d'air suffisante est n_cessaire6 une

combustion et une _vacuation appropri_es desgaz par

le conduit d'_vacuation (chemin_e)de I'_quipement6

combustible pour _viter tout refoulement. Suivezles

directiveset normesdes_curit6du fabricant de I'appareil

chauffant, comme callaspubli_esparla National Fire

ProtectionAssociation(NFPA),par I'AmericanSocietgfor

Heating,Refrigerationand Air Conditioning Engineers

(ASHRAE)et par lesautorit_s locales.

C. Lorsquevouseffectuezdes d6coupes ou que vous percez

un mur ou un plafond, n'endommagez pas lec_blage

_lectrique ou tout autre r_seau d'alimentation cache.

D. L'airdesventilateurs disposant de conduits d'a_ration

doit toujours _tre_vacu_ vers I'ext_rieur.

• Lescodes Iocauxpeuventvarier.L'installationde

branchements _lectriqueset la mise 6 laterre doivent _tre

conforme aux codesen vigueur. Les_vacuations doivent

_tre install_esconform_ment 6laderni_re_dition du Code

ElectriqueNational ANSI/NFPANo 70-1990.

23

Page 24

Instructions d'installation

_AMISEENGARDE:Pourr duirelerisque

d'incendieet pour _vacuer correctement I'air,assurez-vous

que leconduit d'airestdirig_versI'ext_rieur.N'_vacuezpas

I'airvers desespacesclos,des espacesagant des murs ou

desplafonds,vers le grenier,versun vide sGnitaireou un

garage.

AVERTISSEMENT: PourRI_DUIRE

LERISgUED'INCENDIEDE GRAISSESUR LA CUISINII_RE:

A. Nelaissezjamais les_l_ments de surface sans

supervisionIorsqu'ilssont r6gl_s6 une chaleur _lev_e.

Lesd_bordements par bouillonnement peuvent provoquer

desfum_es etfaire d_border des mati_res grassesqui

peuvent s'enflammer.FaiteschGufferI'huiledoucement

6 feu doux ou mogen.

B. Hetteztoujours la hotte en HARCHEIorsquevous

cuisinez6 feu fort ou que vous faites flamber desaliments

(parexemple,descr_pes Suzette,des cerisesjubil_ ou du

boeuf flamb_ au poivre).

C. Nettogezr_guli_rement lesventilateurs.Ne laissezpas

lesgraissess'accumuler sur leventilateur ousur lefiltre.

D. Utilisezla bonne taille d'ustensiles.Utiliseztoujours des

ustensilesdont lataille correspond 6 cellede I'_l_ment.

AVERTISSEMENT:PourRI_DUIRE

LERISgUEDE BLESSURECORPORELLEENCASDE FEU

DEGRAISSESUR LACUISINII_RE,SUIVE7LESCONSIGNES

SUIVANTES*:

A. _OUFFEZLESFLAMMES6 I'aided'uncouvercle,d'uneplaque

6 g_teauxoud'unplateaum_tallique,puis_teignezlebrOleur.

FAITESATTENTIONDENEPASVOUSBROLER.Silesflammesne

s'_teignentpasimm_diatement,EVACUEZLESLIEUXET

APPELEZLESPOMPIERS.

B. NESOULEVEZOUNEDEPLACEZJAMAISUNECASSEROLEEN

FEUiVouspourriezvousbrOler.

C. N'UTILISEZPASD'EAU,detorchonsoude serviettesmouill_s,

uneviolenteexplosiondevapeurpourraiten r_sulter.

D. Utilisezun extincteurSEULEMENTSI:

1)Vousavezun extincteurde classeABCetvoussavezI'utiliser.

2)LefeuestfaibleetcontenudanslazoneoL]ils'estd_clar_.

3)Vousavezappel_lespompiers.

/4)Vouspouvezcombattre lefeuenfaisantdos6 unesortie.

* Selonladocumentation<<KitchenFiresafetgTips>>publi_par

la NFPA.

24

Page 25

Information de conception

TABLE DES MATII_RES

Information de conception

D_gagements ....................................................................................25

Dimensions de I'appareil ......................................................26-29

Planification

Planification ......................................................................................30

Hontage des commandes _ distances (c6bl_es)..........30

Alimentation _lectrique ..............................................................30

Raccords de conduit ....................................................................31

Pr6paration pour I'installation

Outils et materiels n_cessaires ................................................32

Retrait de I'emballage ..................................................................32

Pi_cesfournies ................................................................................33

Emplacement des conduits et du c6blage ........................3/4

Construction du support de plafond ......................................35

Hontage des commandes _ distances -c6bl_es ....36,37

DI_GAGEMENTS

L'assemblage de la hotte d'extraction et de la

doublure doit _tre install_ (_30 po minimum et

36 po maximum de la surface de cuisson.

oVeuillez toujours vous r_f_rer aux instructions

d'installation pour connaTtre les d_gagements

n_cessaires sp_cifiques (_ce produit.

REMAROUE : Les hauteurs d'installation doivent _tre

mesur_es (_partir de la surface de cuisson jusqu'au

bord inf_rieur de la doublure m_tallique de la hotte

ou de la surface du meuble.

REMAROUE : Selon UL, toute surface combustible doit

_tre au minimum (_30 po au-dessus de la surface de

cuisson.

• L'air de cette hotte doit toujours _tre 6vacu6 vers

I'ext_rieur.

Instructions d'installation

Etape 1, Installation de Iodoublure de lahotte ....................38

Etape 2, Branchement _lectrique ..................................................39

Etape 3, Installation de la gaine de hotte encastrable ....../40

Etape/4,Installation du registre _ guillotine ............................/41

Etape 5, Installation des moteurs de ventilateurs ................/42

Etape 6, Branchement du faisceau _lectrique ....................../42

Etape 7, Installation des filtres ......................................................../43

Etape 8, finalisation de I'installation ............................................../43

*Minimum de 30 po requis

*Maximum de 36 po recommand6

*REMARQUE:L'6vacuation par le mur arri6re peut affecter

la hauteur d'installation. Se r6f6rer page34.

oCette hotte peut _tre install_e contre un mur ou

au-dessus d'un ?lot.

oCette hotte peut _tre install_e au-dessus de routes

les surfaces de cuisson (_gaz ou _lectriques

Monogram ou les surfaces de cuisson ou cuisini_res

Monogram Professional d'une largeur _quivalente.

25

Page 26

Information de conception

DIMENSIONS DE L'APPAREIL

ZVC30

Uhabillage sur mesure doit _tre con_;upour accepter

la gaine 6 encastrer. Fabriquez un habillage dont

I°ouverture a les dimensions suivantes :

Largeur de 26 po x Profondeur de 13-3116 po

Elle doit _tre fabriqu_e en mat_riau d'une

_paisseur de ::3/4po pour permettre aux fixations

autobloquantes de la gaine de s'accrocher.

Doublure de hotte fournie

1-1/4 po

28-1/2 po

Dimensions et specifications (en pouces)

Dimensions externes

. 27-1/2po

14po

1

Gaine de la hotte

....... 16-3/4 po

13 po

14po

1/2 po

7/8 po

13 po

25-3/4po

7-1/2 po

4po/

F'_ceavant

Une doublure de hotte en acier inoxydable est

expedite avec chaque hotte encastrable. Cette

doublure incombustible protege la face inf_rieure

de I'habillage de la hotte.

Doublure sur mesure

Si vous n'utilisez pas la doublure fournie, vous

pouvez fabriquer une doublure incombustible

sur mesure. Utilisez la doublure fournie comme

module. L'ouverture doit 6tre de 26 po de large

et de 13-3/16 po de profondeur. Un mat_riau

d'une _paisseur de 3//4 po doit constituer le tour

de I'ouverture pour permettre aux fixations

autobloquantes de s'accrocher. La gaine (_

I'int_rieur du meuble doit _tre positionn_e (_

1/2 po du mur arri_re de faqon (_ce que le milieu

du conduit de diam_tre 8 po soit e 5-1/2 po du

mur arri_re.

1/2 po

21-1/4po

/

/

/

1/2po

Le bord inf_rieur de la gaine de la hotte

encastrable est _quip_ de brides d'une largeur

de 7/8 po sur les c6t_s et de 1/2 po (_I'avant et

(_I'arri_re.

Emplacement 6 distance des commandes

Les commandes peuvent _tre retirees de la hotte

et install_es dans un mur ou sur un comptoir. Un

c6ble d'une Iongueur de :SOpieds est fourni pour

permettre d'effectuer la majorit_ des installations.

Un cache permet de recouvrir I'ouverture apr_s

le retrait de commandes.

Le bloc de commandes a les dimensions suivantes :

4-1/4 po de largeur et 2-1/4 de profondeur.

3-11/16 po

1-11/1 po

Pour des surfaces en granit ou pour toute autre

surface dure, il est preferable de d_couper

I'ouverture avant d'installer le comptoir.

0uverture d6coup6e pour

les commandes

26

Page 27

Information de conception

DIMENSIONS DE L'APPAREIL

ZVC36

L'habillage sur mesure doit _tre conqu pour accepter

la gaine 6 encastrer. Fabriquez un habillage dont

I'ouverture a les dimensions suivantes :

Largeur de 26 po x Profondeur de 13-3/16 po

Elle doit _tre fabriqu6e en mat6riau d'une

6paisseur de :3/4 po pour permettre aux fixations

autobloquantes de la gaine de s'accrocher.

Doublure de hotte fournie

4-1/4 po

34-1/2po

7-1/2 po

4po/

Face avant

Une doublure de hotte en acier inoxgdable est

exp6di6e avec chaque hotte encastrable. Cette

doublure incombustible protege la face inf6rieure

de I'habillage de la hotte.

Doublure sur mesure

Si vous n'utilisez pas la doublure fournie, vous

pouvez fabriquer une doublure incombustible

sur mesure. Utilisez la doublure fournie comme

module. L'ouverture doit 6tre de 26 po de large

et de 13-3/16 po de profondeur. Un mat6riau

d'une 6paisseur de 3//4 po doit constituer le tour

de I'ouverture pour permettre aux fixations

autobloquantes de s'accrocher. La gaine

I'int6rieur du meuble doit _tre positionn6e

1/2 po du mur arri_re de faqon _ ce que le milieu

du conduit de diam_tre 8 po soit _ 5-1/2 po du

mur arri_re.

21-1/4po

/

Dimensions et specifications (en pouces)

Dimensions externes

27-1/2po

Gaine de la hotte

13 po

7/8 po

25-3/4po

po

Le bord inf6rieur de la gaine de la hotte

encastrable est 6quip6 de brides d'une largeur

de 7/8 po sur les c6t6s et de 1/2 po (_I'avant et

(_I'arri_re.

Emplacement 6 distance des commandes

Les commandes peuvent 6tre retir6es de la hotte

et install6es dans un mur ou sur un comptoir. Un

c6ble d'une Iongueur de 30 pieds est fourni pour

permettre d'effectuer la majorit6 des installations.

Un cache permet de recouvrir I'ouverture apr_s

le retrait de commandes.

Le bloc de commandes a les dimensions suivantes :

4-1/4 po de largeur et 2-1/4 de profondeur.

= 3-11/16po

1-11/lj

po

Ouverture d6coup6e

pour les commandes

Pour des surfaces en granit ou pour toute autre

surface dure, il est pr6f6rable de d6couper

I'ouverture avant d'installer le comptoir.

14po

1/2 po

13'po

,/

1/2 po

27

Page 28

Information de conception

DIMENSIONS DE L°APPAREIL

ZVC42

Dimensions et specifications (en pouces)

Dimensions externes

Gaine de la hotte

L'habillage sur mesure doit 6tre conqu pour accepter

la gaine 6 encastrer. Fabriquez un habillage dont Y ...................

I'ouverture a les dimensions suivantes : ° -..............

13po __-1/2

J

Largeur de 38-3/4 po x Profondeur de 13-3/26 po

Elle doit _tre fabriqu_e en mat_riau d'une

_paisseur de 3/4 po pour permettre aux fixations

autobloquantes de la gaine de s'accrocher.

Doublure de hotte fournie

7/8 po

40-1/2po

7-1/2 po

1/2 po

38-1/2 po.....

1/2po

Les brides de :1/2 po de largeur entourent le bord

ext_rieur de la gaine.

Emplacement 6 distance des commandes

4po /

21-1/4po

//

/

Les commandes peuvent #tre retirees de la hotte

et install_es dans un mur ou sur un comptoir. Un

Une doublure de hotte en acier inoxydable est

expedite avec chaque hotte encastrable. Cette

doublure incombustible protege la face inf_rieure

de I'habillage de la hotte.

Doublure sur mesure

cable d'une Iongueur de 30 pieds est foumi pour

permettre d'effectuer la majorit_ des installations.

Un cache permet de recouvrir I'ouverture apr_s

le retrait de commandes.

Le bloc de commandes ales dimensions suivantes :

4-1/4 po de largeur et 2-1/4 de profondeur.

Si vous n'utilisez pas la doublure fournie, vous

pouvez fabriquer une doublure incombustible

sur mesure. Utilisez la doublure fournie comme

module. L'ouverture doit 6tre de 38-1/4 po de

1-11/16!o

large et de 13-3/16 po de profondeur. Un

mat_riau d'une _paisseur de 3/4 po doit constituer

le tour de I'ouverture pour permettre aux fixations

autobloquantes de s'accrocher. La gaine (_

I'int_rieur du meuble doit _tre positionn_e (_

1/2 po du mur arri_re de fagon ece que le milieu

du conduit de diam_tre 8 po soit e 5-:1/2 po du

mur arri_re.

Pour des surfaces en granit ou pour toute autre

surface dure, il est preferable de d_couper

I'ouverture avant d'installer le comptoir.

39-1/2 po

0 0

po

14po

/2 po

13po

/

1/2 po

3-11/16po

Ouvertured6coup6e

pour les commandes

28

Page 29

Information de conception

DIMENSIONS DE L°APPAREIL

ZVC48

Dimensions et specifications (en pouces)

Dimensions externes

39-1/2 pc

O O

Gaine de la hotte

L'habillage sur mesure doit 6tre conqu pour accepter

la gaine 6 encastrer. Fabriquez un habillage dont 13pc __-1/2 pc.....

I'ouverture a les dimensions suivantes : j ................

Largeur de 38-3/4 pc x Profondeur de 13-3116 pc

Elle doit _tre fabriqu_e en mat_riau d'une

_paisseur de 3/4 pc pour permettre aux fixations

autobloquantes de la gaine de s'accrocher.

Doublure de hotte fournie

3-7/8 po

46-1/2 pc

7-1/2 pc

4pc /

Faceavant

Une doublure de hotte en acier inoxydable est

expedite avec chaque hotte encastrable. Cette

doublure incombustible protege la face inf_rieure

de I'habillage de la hotte.

Doublure sur mesure

Si vous n'utilisez pas la doublure fournie, vous

pouvez fabriquer une doublure incombustible

sur mesure. Utilisez la doublure fournie comme

module. L'ouverture doit 6tre de 38-1/4 pc de

large et de 13-3/16 pc de profondeur. Un

mat_riau d'une _paisseur de 3/4 pc doit constituer

le tour de I'ouverture pour permettre aux fixations

autobloquantes de s'accrocher. La gaine

I'int_rieur du meuble doit _tre positionn_e

1/2 pc du mur arri_re de fagon e ce que le milieu

du conduit de diam_tre 8 pc soit e 5-:1/2 pc du

mur arri_re.

1/2

po

' //

21-1/4pc

/

/

3a-1/2po.....

1/2 pc

Les brides de :1/2 pc de largeur entourent le bord

ext_rieur de la gaine.

Emplacement 6 distance des commandes

Les commandes peuvent #tre retirees de la hotte

et install_es dans un mur ou sur un comptoir. Un

cable d'une Iongueur de 30 pieds est foumi pour

permettre d'effectuer la majorit_ des installations.

Un cache permet de recouvrir I'ouverture apr_s le

retrait de commandes.

Le bloc de commandes ales dimensions suivantes :

4-114 pc de largeur et 2-114 de profondeur.

3-11/16 pc

1-11/!6

po

Pour des surfaces en granit ou pour toute autre

surface dure, il est preferable de d_couper

I'ouverture avant d'installer le comptoir.

0uverture d6coup6e

pour les commandes

14pc

/2 pc

13 p0

/

1/2pc

29

Page 30

Planification

PLANIFICATION

Plonificotion des conduits

• Cette hotte est _quip_e de conduit de section

circulaire de 8 po de diam_tre.

• D@erminez I'emplacement exact de la hotte

d'extraction.

• Planifiez le cheminement des conduits de ventilation

vers I'ext@ieur. Cette hotte n'est pas congue pour

un fonctionnement avec recgclage de I'air.

• Utilisez les cheminements de conduit les plus droits

et les plus courts possibles. Pour une performance

satisfaisante, la Iongueur du conduit ne doit pas

d_passer un _quivalent de 100 pieds quelque que

soit la configuration du conduit.

• R_f@ez-vous au tableau "Raccords de conduit" pour

calculer la Iongueur maximale admise du conduit

vers I'ext@ieur.

• Utilisez seulement des conduits m@alliques rigides.

• Installez des _vents muraux ou de toiture avec un

registre sur I'ouverture vers I'ext@ieur. Commandez

(_I'avance les _vents et tout autre raccord de

transition requis.

Cadres murou× ou ou plofond pour un support

od@quot

Cette hotte d'extraction est Iourde et la structure du

meuble doit soutenir le poids de la gaine de la hotte.

Tous les types d'installation doivent avoir un support

structurel appropri_.

• L'installation sera facilit_e si la hotte d'extraction

est install_e avant la surface de caisson.

Plonificotion du cadre pour les meubles sur mesure

• L'habillage sur mesure doit @re adapt_ _ la taille

de la gaine de la hotte encastrable. Voir pages 5 et

9 pour plus de d_tails.

Montage des commondes 6 distances (cabl@es)

• Les commandes peuvent @re install_es _ distance

sur un mur ou sur un comptoir.

• II est recommand_ d'utiliser un installateur

professionnel pour preparer I'ouverture d_coup_e

dans le comptoir.

• Pour des surfaces en granit ou pour toute autre

surface dure, il est pr_f@able de d_couper

I'ouverture avant d'installer le comptoir.

• L'ouverture doit @re d_coup_e _ plus de 6 po

du bard du comptoir.

• Si vous installez les commandes au-dessus

d'un tiroir, tenez compte de la profondeur du bloc

de commandes.

• Un ceble d'une Iongueur de 30 pieds est fourni.

L'emplacement des commandes (_distance doit

@re soigneusement r_fl_chi.

• II est recommand_ de faire passer le ceble (_

/4brins par un conduit d'un diam_tre d'l po entre

la gaine de la hotte encastrable et I'emplacement

des commandes.

ALIMENTATION I_LECTRIQUE

IMPORTANT- (,Alire attentivement)

-A AVERTISSEMENT :

POUR DESRAISONS DE St_CURITt_,CET APPAREIL

DOlT t_TRECORRECTEIVlENTIVllSA LA TERRE.

Retirez le fusible du domicile ou ouvrez

le disjoncteur avant de commencer I'installation.

Les rallonges et les adaptateurs ne doivent pas @tre

utilis@s avec cet appareil. Veuillez suivre les codes

@lectriques nationaux ou les codes et r@glements

Iocaux.

Alimentotion @lectrique

Cette hotte d'extraction doit @tre aliment@e par du

120V, 60Hz, et branch@e @un circuit de d@ivation

mis @la terre et prot@g@par un disjoncteur de

15 ou 20 A ou par un fusible @action diff@r@e.

• Le c@blage @lectrique doit @treconstitu@ de 2 brins

et d'une terre.

• Si I'alimentation @lectrique n'est pas conforme

ces exigences, appelez un @lectricien qualifi@ avant

de commencer.

• Faites passer le c@blage du domicile le plus pr@s

possible de I'emplacement de la hotte, soit dans

le plafond soit dans lemur.

• Raccordez le c@blage de la hotte au c@blage du

domicile conform@ment aux codes Iocaux.

• Le ceblage du domicile doit avoir une Iongueur

de 45 po @partir du bas du meuble de fagon

pouvoir @trebranch@ au c@blage de la hotte.

Instructions de mise 6 Io terre

Le fil de mise _ la terre doit @re connect_ _ une

partie m_tallique mise _ la terre, _ une borne de

terre ou _ un fil de sortie de la hotte.

-A AVERTISSEMENT :

Une connexion incorrecte de ce fil de terre pourrait

provoquer un risque de choc _lectrique. V_rifiez

aupr_s d'un _lectricien quali% ou d'un

repr_sentant si vous n'@es pas s0r que votre

appareil soit correctement mis (_la terre.

3O

Page 31

Planification

RACCORDS DE CONDUITS

Utilisez ce tableau pour calculer

les Iongueurs maximales

permissibles des conduits vers

I'ext6rieur.

REMARQUE : Ne d@assez pas la

Iongueur @uivalente admissible!

Longueur moximole de conduit :

100 pieds pour des hottes de

cuisini_res.

Conduit flexible :

Si vous utilisez des conduits

m6talliques flexibles, routes

les valeurs en pieds 6quivalents

de ce tableau doivent 6tre

multipli6es par deux. Le conduit

m6tallique flexible doit 6tre droit,

lisse et aussi 6tir6 que possible.

N'UTILISEZ PAS de conduit en

plastique flexible.

REMARQUE : Tout sgst_me de

ventilation domestique, tel qu'une

hotte d'extraction, peut inter@rer

avec le d6bit ad@uat de I'air de

combustion et d'6vacuation des

foyers de chemin@, des brOleurs

6 gaz, des chauffe-eau 6 gaz et

de tout autre syst_me 6 ventilation

naturelle. Afin de minimiser

les risques d'interruption de tels

syst_mes 6 ventilation naturelle,

veuillez suivre les directives

du fabricant de I'@uipement

de chauffage ainsi que les normes

de s6curit6 publi@s par la NFPA

et I'ASHRAE.

Section

deconduit Dimensions

Rand droit

Oroit de

3-1/4 pox 12 po

Coude de 90°

Coude de 45°

Coude 90°

3-11/4pox 12 po 43 pi.

Coude 45°

3-:]/4 pox 12 po 26 pi.

Coude plat de 90°

3-:]/4 pox 12 po 102 pi.

Raccorddesection circulaire

de 8 po _ une section

rectangulaire de

3-1/4 pox 12 po 2 pi.

Raccord de section

rectangulaire de

3-1/4 pox 12 po _ une

section circulaire de 8 po

Raccordencoude de 90°

d'une sectioncirculairede8 po

une section rectangulaire

de 3-1/4 pox 12po 6 pi.

Raccordencoude de 90°

d'une section rectangulaire

de 3-1/4 po x 12 po _ une

section circulaire de 8 po

avec registre

Event mural

Event mural rectangulaire

3-i14po x 12 po

de avec registre 75 pi.

Event de toiture

circulaire 44 pi.

Longueur

_quivolente*

1 pi.

(par pied

de Iongueur)

1 pi.

(par pied

de Iongueur)

17 pi.

10 pi.

5 pi.

13 pi.

32 pi.

Quontit_

utilis_e

Longueur

_quivolente

totole

*Equivalent a la Iongueur r6elle du conduit droit et du

raccord. Les Iongueurs 6quivalentes des sections de

conduit sont bas6es sur desessaisr6els effectu6s

par GEEvaluation Engineeringet repr6sentent les

Iongueurs n6cessaires a une bonne ventilation pour

tout type dehotte deventilation.

31

Longueur

totale

de conduit

Page 32

Preparation pour I'installation

OUTILS ET MATI_RIELS NI_CESSAIRES

(NON FOURNIS)

Pince & bec effil_

Ruban

aluminium

Crayon et re@re

Couteau

Fil &plomb Escabeau

Silicone _)

kunettes de s6curit6 Serre-fils

RETRAIT DE L'EMBALLAGE

MISE EN GAR DE : Po_tezdesgants

pour vous prot_ger les mains des bords coupants.

_ hexagonale

_ plvotante

__d'1/4 po

Gants

Tournevis cruciforme

Torche

Douille

et &t_te plate

Conduit d'l po (pour le

montage des commandes

distance seulement)

Perceuse et forets appropri_s

douille 3/8 po

illes _t61e

Coupe-fils/Outil & R_ducteur

d_nuder les ills de tension

conform_ment aux

Conduit de 8 poet _vents,

besoins de I'installation

MISE EN GARDE : SORTEZLA

GAINE DE HOTTE ENCASTRABLE DE LA BOITE EN

TENANT FERMEMENT LESCOTt_S.

1. Ouvrez la boTte en carton de la hotte.

2. Sortez la doublure, la mousse et le carton.

3. Retirez le ruban maintenant les filtres 6 la gaine,

levez les languettes et sortez les filtres.

J

4. D6vissez les 5 6crous maintenant I'assemblage

de registre 6 guillotine d'6vent et retirez-le de

la gaine de hotte encastrable. Mettez de c6t6

les 5 @crouset I'assemblage de registre d'@vent,

vous les r6installerez plus tard dans le processus

d'installation.

5. Retirez les vis fixant la gaine de hotte encastrable

6 la plaque de montage. Jetez les vis.

6. Attrapez la gaine par les bords ext@ieurs et

tirez-la vers le haut pour la sortir du carton.

REMARQUE : Ne levez pas la gaine de hotte

encastrable par le moteur du ventilateur.

7. Retirez et jetez d'une fagon appropri6e I'emballage

en plastique.

8. Retirez la boite contenant les pi@ceset le reste

de I'emballage.

32

Page 33

Preparation pour I'installation

PII[CES FOURNIES

Localisez les pi_ces emba%es avec la hotte.

VI[RIFICATION DU MATI[RIEL D'INSTALLATION

Comptezles vis/les

616ments.Lesvis sont

pr6sent6es _ leur

taille actuelle. /_/)

6vis _ bois

pour la

doublure

de hotte

8vis bois

pour la gaine

de hotte

56crous pour I'assemblage du

registre _ guillotine (ne sont pas

contenus dans le sac de

quincaillerie - vous devez

conserver les 6crous Iorsque

vous retirez le registre

guillotine de lagaine Iors du

d6ballage de la hotte)

Doublure de hotte (emball6e

dans un carton s6par6)

Gaine de la hotte

Filtres

6 bouchons de cadre pourla

26crous _ oreilles avec

rondelles freins pour

le moteur du ventilateur

gaine encastrable, 1bouchon

trou pour lec_ble 61ectrique

du domicile, 2passe-fils en

caoutchouc et 4 rondelles

pour gaine encastrable

MONTAGE DES COMMANDES ,,&,DISTANCE {CABLI[ES)

Cache pour I'ouverture

des commandes

distance*

*REMARQUE: Ce cache

doit _tre utilis_ avec la

hotte sur mesure Iorsque

les commandes sont

install_es &distance.

30 pieds d'un c_ble _ 4 brins

(_ broches droites) 6quip6 d'un

connecteur/convertisseur

REMARQUE: Ne doit pas _tre

utilis6 pour les r6seaux de

t616communications (t616phone).

Support mural de commandes

Plaque de Support de

montage des montage des

commandes commandes

Connecteur/

Convertisseur

2vis pour 2vis pour

plaque de support

montage mural

Moteur de ventilateur

(Mod61esdelargeur 30 et36po)

Moteur de ventilateurs jumel6s

(Mod61esdelargeur 42 et48po)

0

Registre _ guillotine

33

Page 34

Preparation du mur pour I'installation

EMPLACEMENT DES CONDUITS

ET DU C/_,BLAGE

D@terminezremplacement exact de la gaine

de la hotte encastrable. IVlarquez

I'emplacement exact de la ligne centrale.

La structure du plafond doit @trecapable de

supporter lepoids de la gaine _ encastrer

(environ 100 livres), I'habillage de la hotte,

tout @quipement de fixation ainsi que

toutes charges dues _ des contacts par

inadvertance avec les utilisateurs.

• IViesurezdu dessus de la surface de cuisson

au bard inf#rieur de la gaine encastrable.

Ajoutez la hauteur d'installation de la gaine

encastrable. IViarquezcet emplacement.

• Utilisez un niveau pour tracer une ligne

droite horizontale au crayon sur lemur.

REMARQUE : Le conduit de ventilation du

domicile doit descendre 6 11-1/2 po au

dessus du bard inf_rieur de la gaine de

la hotte. L'emplacement du conduit de

ventilation du domicile est important car

ce dernier doit #tre align# avec I'#vent

de I'assemblage du registre _ guillotine.

Conduit de ventilation de plefond :

Si le conduit passe directement par

le plafond :

• Utilisez un niveau pour tracer une ligne

droite m@dianejusqu'au plafond.

• Au plafond, mesurez 5-1/2 po du mur

arri@re_ la ligne m@diane d'un trou

de 8-1/2 po de diam@tre.

Conduit mural :(Se r@f@rer_ la remarque

importante.) Si le conduit passe par lemur

arri@re:

• Utilisez un niveau pour tracer une ligne

droite m@dianejusqu'au plafond.

• IViesurezau mains 22-1/2 po au-dessus de

la ligne au cragon indiquant la hauteur du

bas de I'installation jusqu'@ la ligne m@diane

d'un trou de 8-1/2 po de diam@tre pour le

passage d'un conduit. (Letrou peut @tre

agrandi pour le passage d'un coude.)

5-1/2 po du mur

arri_re _ la

ligne m6diane

22-1/2po audessus

de la lignetrac6e au

crayon indiquant

le basde la hotte

22-1/2 po au dessus

dela lignetrac6eau////. __-:---i .\\\\

crayon indiquant //// ..... \_ \\

lebasdelahotte l( // I I-I/zpo \\ ]]

, Lt/ t

Hauteur de la doublure 4 po

T

*Minimum de30po requis

*Hauteur maximale recommand6e

de 36po pour I'installation de

la surface de cuisson

36 po du sol

jusqu'au

comptoir

]

Vue lat6rale

Lediagrammen'est pas_ /_che//e

*Veuillez toujours vous r6f6rer aux instructions d'installation de la surface de

cuisson ou de la cuisini_re pour canna\re lesd6gagements n6cessaires.

REMARQUEIMPORTANTE: Si vous envisagez de faire passer le conduit par

lemur arri_re et que la hauteur de plafond est de 8 pi, la hauteur maximale

d'installation de la surface de cuisson sera de 33 po.

]Hauteur_ de la doublure 4 po

/

*Minimum de 30 po requis

*Hauteur maximale recommand6e

de 36 po pour rinstallation de

la surface de cuisson

A Lm

Vuefrontale

EMPLACEMENT DU C_,BLAGE DU DOMICILE:

• La boTtedejonction est situ_e (_I'int_rieur

de la hotte sur le c6t_ sup_rieur gauche.

• Le ceblage du domicile doit sortir du mur

du fond au mains 15 po au dessus du bas

de la gaine de la hotte et 5 mains de 6 po

sur le c6t_ gauche de la ligne m_diane.

34

Page 35

Preparation pour I'installation en riot

CONSTRUCTION DU SUPPORT DE PLAFOND (pour une installation enTlot)

Pr_vogez I'emplacement de la hotte et du conduit

La structure du plafond dolt _tre capable de supporter

le poids de la gaine (_encastrer (environ 100 livres),

I'habillage de la hotte, tout _quipement de fixation

ainsi que toutes charges dues (_des contacts par

inadvertance avec les utilisateurs.

• Utilisez un fil (_plomb pour v_rifier I'emplacement.

Le comptoir/surface de cuisson sous la gaine

encastrable dolt _tre centr_ avec la gaine.

Plafond

//

...................i............................................i..................... conduit de

_ Lignede

Avant _" _ J

Aligner avec

le centre de

la surface

de cuisson

*Veuillez toujours vous r6f6rer aux instructions d'installation

de la surface de cuisson ou de la cuisini_re pour connakre

les d6gagements n6cessaires.

_! d'installation reeommand6e

I

Vue fl mptoir

\\

14 centrage du

la hotte

,

i

; *Minimum de 30pc requis

i *36 pc max. de hauteur

i

; _ Table de cuisson

ontale

• La gaine encastrable _ I'int@rieur de I'habillage de la

hotte dolt @trecentr@e de gauche (_droite au-dessus

de la surface de cuisson.

*Minimum de 30 pc requis

*36 pc max.de hauteur

d'installation recommand6e

Vue lat6rale gauche

F

Le diagramme n'est pas _ I_che//e

Si vous le souhaitez, installez les commandes

dans un emplacement (_distance en utilisant

les @l@mentsde fixation fournis. R@f@rez-vousaux

pages suivantes pour des instructions d@taill@es

de montage des commandes (_distance.

R@f@rez-vousau paragraphe Conduit au Plafond

(_la page :3/4pour I'installation du conduit.

IMPORTANT: La sortie d'@vacuation sur le haut

de la gaine de la hotte n'est pas centr@e, elle est

positionn@e plus pr@sde I'arri@re. Ainsi, la gaine

de la hotte ne peut pas @trepositionn@e (_I'envers

dans la hotte. Une doublure sur mesure, fabriqu@e

par le fournisseur de meubles, est en g@n@ral

requise pour les installations en Tlot.

REMARQUE : II est recommand@ d'acheter et

de faire livrer la partie encastrable de la hotte

avant de construire I'habillage de la hotte.

35

Page 36

Preparation du mur pour I'installation

MONTAGE DES COMMANDES _, DISTANCE (CABLI_ES)

AVERTISSEMENT: Coupez

I'alimentation _lectrique de I'appareil avant

d'effectuer I'installation des commandes 6 distance.

Le non-respect de ces r@glespeut entraTner des

blessures corporelles ou des dommages aux

commandes @lectriques.

3-11/16 po

1-11/1!

po

0uverture d6coup6e pour

les commandes

.POSITIONNEMENT DES COMMANDES

A DISTANCE

REMARQUE : La hotte est certifi@e pour une

utilisation avec le c0ble fourni d'une Iongueur

maximale de 30 pieds.

Les commandes peuvent @re retir@es de la hotte

et install@es sur un dosseret ou un comptoir.

• Un cache est fourni pour couvrir I'ouverture dans

la hotte oO les commandes ant @t@retir@es.

• Un cOble 6 4 brins d'une Iongueur de 30 pieds

est fourni pour permettre d'effectuer la majorit_

des installations. Parce que seul un c_ble d'une

Iongueur de :30 pieds est fourni, I'emplacement

des commandes 6 distance doit @re

soigneusement r_%chi.

• Le c_ble de :30pieds est _quip_ d'un connecteur/

convertisseur 6 une des extr_mit_s. NE RETIREZPAS

le connecteur/convertisseur du c_ble de :30 pieds.

Si le connecteur/convertisseur n'est pas utilis_

avec le c_ble plus court, les commandes ne

fonctionneront pas correctement.

REMARQUE : Ne doit pus _tre utilis_ pour les

r_seaux de t_l_communications (t_l_phone).

• Le c_]ble doit passer par les trous dans la gaine

encastrable et les passe-ills en caoutchouc

doivent @re places autour du cSble.

REMARQUE : Pour les modules ZVC30 et ZVC36,

le cable doit _tre enfil_ dens les trous de la gaine

encastrable event d'installer le registre.

• Faites passer lec_]ble par le conduit pour atteindre

I'emplacement d'installation des commandes.

Commandes install6es _ distance -installation murale ou sur un comptoir

r_Q

Affichage

Circuit

imprim6

principal

C_blelong Connecteur/ C_blecourt

Convertisseur

36

Page 37

Preparation du mur pour I'installation

MONTAGE DES COMMANDES A DISTANCE - C/_BLI:!ES (Suite)

CO M PTOI R

Commandes

C_ble _ 4 brins i..._t i Connecteur

_ Plaque de montage

Support de montage_=j_ P.osez.dusilicone sur le

/_ pe.'rim_t[ede I'ouverture

df0UP!e

1. D_coupez une ouverture dons le comptoir.