Page 1

Sievers* Nitric Oxide Analyzer NOA 280i

Operation and

Maintenance Manual

Firmware Version 3.00 and later

6060 Spine Road

Boulder, CO 80301 USA

phone 800.255.6964 • 303.444.2009

fax 303.444.9543 DLM 14291 Rev A

www.geinstruments.com Printed in USA ©2006

Page 2

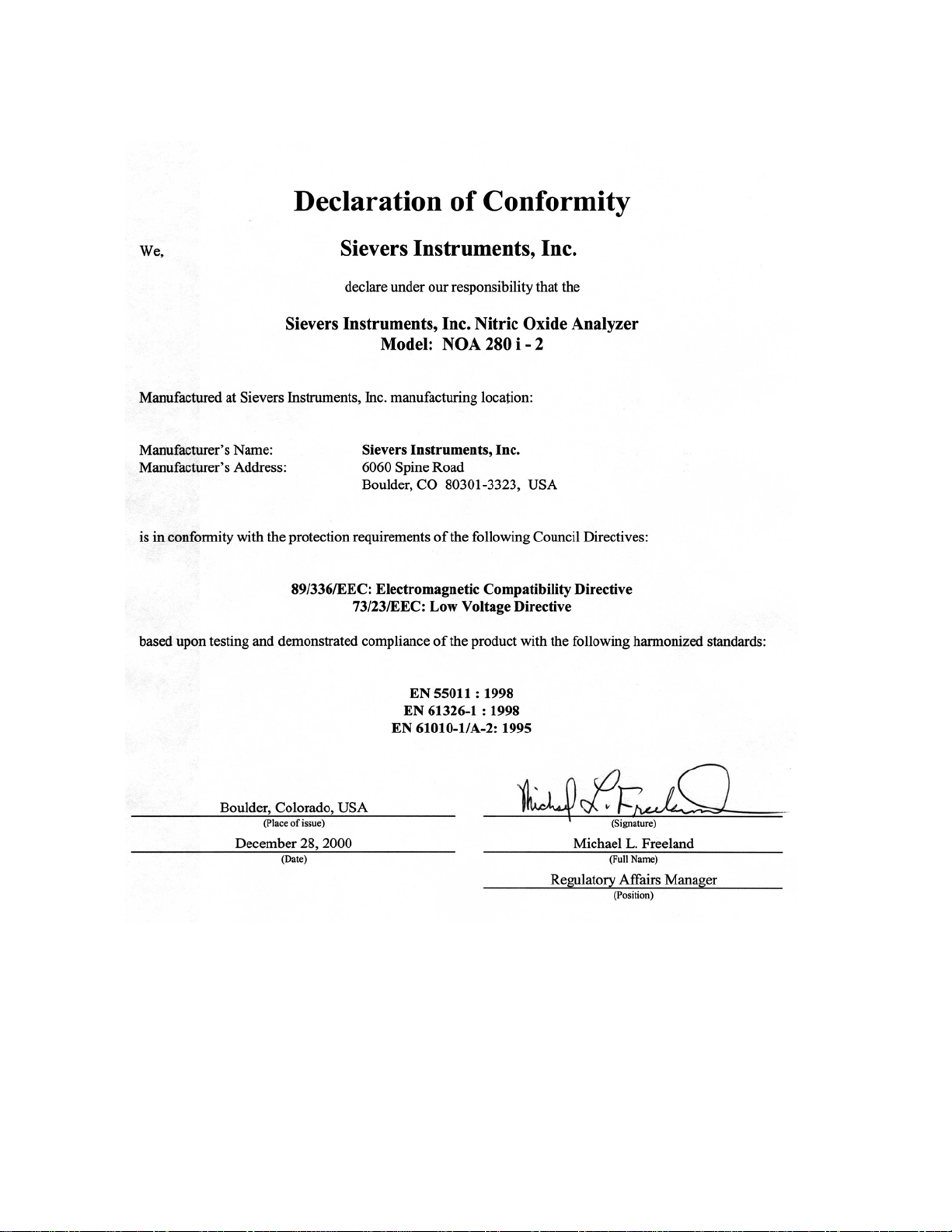

IDENTIFICATION RECORDS

Record the following numbers as they are listed on the identification labels

located on the back panel of the NOA and the front of the vacuum pump.

Analyzer serial no.

Pump serial no.

Warranty Start Date

Date of receipt/Installation

*Trademark of General Electric Company; may be registered in one or more countries.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

ii

Page 3

PRINTING HISTORY

The information contained in this document may be revised without notice.

Sievers Instruments makes no warranty of any kind with regard to this material.

Sievers Instruments shall not be liable for errors contained herein or for incidental,

or consequential damages in connection with the furnishing, performance or use of

this material.

No part of this document may be photocopied or reproduced without the prior

written consent of Sievers Instruments, Inc.

Initial Printing December 2000

DLM 14290-01 Revision A March 2001

DLM 14291 Revision A May 2006

Printed in USA

GE Analytical Instruments ©2006 DLM 14291 Rev. A

iii

Page 4

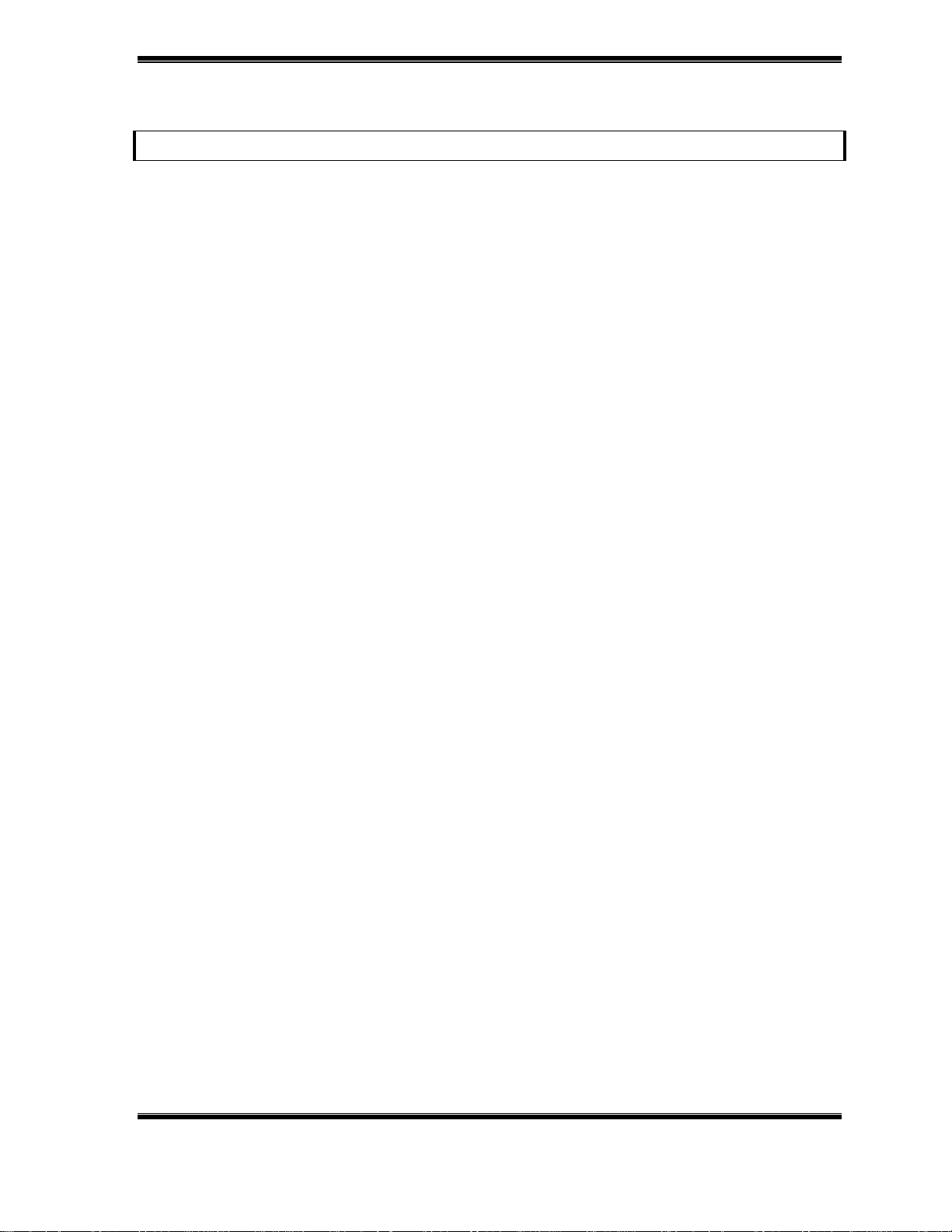

Standard Limited Warranty

GE Analytical Instruments warrants its products (Sievers®, GE Analytical™ and

Leakwise™) against defects in materials and workmanship. GE Analytical

Instruments will, at its option, repair or replace instrument components that prove

to be defective with new or remanufactured components (i.e., equivalent to new).

The warranty set forth is exclusive and no other warranty, whether written or

oral, is expressed or implied.

Warranty Term

The GE Analytical Instruments warranty term is thirteen (13) months ex-works, or

twelve (12) months from installation or start up by GE Analytical Instruments

certified service personnel. In no event shall the standard limited warranty

coverage extend

beyond thirteen (13) months from original shipment date.

Warranty Service

Warranty Service is provided to customers through telephone support (1-800-255-

6964), Monday - Friday, from 8:00 a.m. to 5:00 p.m. (Mountain Time), excluding

all company and legal holidays. Telephone support is provided for troubleshooting

and determination of parts to be shipped from GE Analytical Instruments to the

customer in order to return the product to operation. If telephone support is not

effective, the product may be returned to GE Analytical Instruments for repair or

replacement. In some instances, suitable instruments may be available for short

duration loan or lease.

GE Analytical Instruments warrants that any labor services provided shall conform

to the reasonable standards of technical competency and performance effective at

the time of delivery. All service interventions are to be reviewed and authorized

as correct and complete at the completion of the service by a customer

representative, or designate. GE Analytical Instruments warrants these services for

30 days after the authorization and will correct any qualifying deficiency in labor

provided that the labor service deficiency is exactly related to the originating

GE Analytical Instruments ©2006 DLM 14291 Rev. A

iv

Page 5

event. No other remedy, other than the provision of labor services, may be

applicable.

Repair components (parts and materials), but not consumables, provided in the

course of a repair, or purchased individually, are warranted for 90 days ex-works

for materials and workmanship. In no event will the incorporation of a warranted

repair component into an instrument extend the whole instrument’s warranty

beyond its original term.

Consumables (e.g., dilution standards, verification solutions, and UV lamps, etc.)

are warranted to the extent of their stated shelf life, provided these items are

maintained within the stated environmental limitations. Warranty claims for

consumables and verification standards are limited to the replacement of the

defective items, prorated from the time of claim to the expiration of shelf life.

Shipping

A Repair Authorization Number (RA) must be obtained from the Technical Support

Group before any product can be returned to the factory. GE Analytical

Instruments will pay freight charges, exclusive of any taxes and duties, for

replacement or repaired products shipped to the customer site. Customers shall

pay freight charges, including all taxes and duties, for all products returning to GE

Analytical Instruments. Any product returned to the factory without an RA number

will be returned to the customer.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

v

Page 6

GE Analytical Instruments ©2006 DLM 14291 Rev. A

vi

Page 7

TABLE OF CONTENTS

1. INTRODUCTION...................................................................................................................................... 1-1

SAMPLE INLET SYSTEMS.....................................................................................................................................1-5

SAMPLE FLOW CONTROL DEVICE ........................................................................................................................ 1-6

OZONE FLOW CONTROL MODULE.......................................................................................................................1-6

OZONE GENERATOR..........................................................................................................................................1-6

CHEMILUMINESCENT REACTION CHAMBER AND OPTICAL FILTER ............................................................................ 1-6

PHOTOMULTIPLIER TUBE AND COOLED HOUSING ................................................................................................. 1-7

VACUUM PUMP AND OZONE DESTRUCTION TRAP................................................................................................. 1-7

ELECTRONICS.................................................................................................................................................... 1-7

ANALOG, PRINTER AND RS-232 OUTPUTS ......................................................................................................... 1-8

EXHALATION PRESSURE TRANSDUCER .................................................................................................................1-9

THERMAL MASS FLOW METER ............................................................................................................................ 1-9

2. SPECIFICATIONS..................................................................................................................................... 2-1

3. MENUS AND CONTROL OVERVIEW ..................................................................................................... 3-1

MAIN MENU...................................................................................................................................................... 3-1

STATUS SCREEN................................................................................................................................................ 3-1

ANALYSIS ......................................................................................................................................................... 3-2

MEASUREMENT MENU ........................................................................................................................................ 3-3

MAIN MENU OPTIONS........................................................................................................................................ 3-6

Control..................................................................................................................................................... 3-6

Calibration..............................................................................................................................................3-7

Messages..................................................................................................................................................3-7

Maintenance............................................................................................................................................ 3-8

TIME-OUT FUNCTION ........................................................................................................................................3-8

4. INSTALLATION........................................................................................................................................ 4-1

LOCATION ........................................................................................................................................................ 4-1

POWER REQUIREMENTS .....................................................................................................................................4-1

ENVIRONMENTAL CONSIDERATIONS.....................................................................................................................4-2

TOOLS AND ADDITIONAL SUPPLIES...................................................................................................................... 4-2

Tools......................................................................................................................................................... 4-2

Gases........................................................................................................................................................4-2

Data Collection....................................................................................................................................... 4-2

VACUUM PUMP SETUP.......................................................................................................................................4-4

GE Analytical Instruments ©2006 DLM 14291 Rev. A

vii

Page 8

Step 1 – Add Oil to the pump...............................................................................................................

4-4

Step 2 - Install Pump Inlet Fitting ...................................................................................................... 4-4

Step 3- Install the Chemical Trap Mounting Bracket.......................................................................4-5

Step 4 - Install the Pump Outlet Fitting............................................................................................ 4-6

Step 5 - Install the Chemical Trap and Vacuum Hoses....................................................................4-6

Step 6 - Connect Power Cord to Vacuum Pump and Turn On Pump Power Switch.................... 4-9

CONNECTIONS TO NOA.....................................................................................................................................4-9

Vacuum Pump Power Cord and Vacuum Hose................................................................................... 4-9

Vacuum Test............................................................................................................................................ 4-9

Gas for Ozone Generator.................................................................................................................... 4-11

Frit Restrictor....................................................................................................................................... 4-12

Computer, Printer and Analog Signal Connections........................................................................ 4-12

Setting the Clock.................................................................................................................................. 4-13

CONFIGURATION MENU OPTIONS...................................................................................................................... 4-14

Com Port................................................................................................................................................ 4-14

Pressure Units.......................................................................................................................................4-15

SETTING THE CONSUMABLES INSTALLATION DATA..............................................................................................4-16

START-UP....................................................................................................................................................... 4-16

5. INSTALLATION AND SETUP: GAS-PHASE MEASUREMENTS............................................................5-1

INSTALLATION OF GAS SAMPLING PACKAGE .........................................................................................................5-1

INSTALLATION OF THERMAL MASS FLOWMETER....................................................................................................5-2

NOA SETUP FOR GAS-PHASE MEASUREMENTS..................................................................................................... 5-4

Exhalation Mode..................................................................................................................................... 5-4

Nitric Oxide Mode..................................................................................................................................5-7

6. CALIBRATION.......................................................................................................................................... 6-1

ZERO GAS CALIBRATION ....................................................................................................................................6-1

Calibration with Zero Air Filter..........................................................................................................6-2

Calibrating with Zero Air Cylinder.....................................................................................................6-2

Zero Gas Calibration Warnings............................................................................................................ 6-4

NO CALIBRATION GAS....................................................................................................................................... 6-4

Calibration Gas Warnings.....................................................................................................................6-6

Calculation of Gas Concentration....................................................................................................... 6-8

INDEPENDENT CALIBRATION OF PPB AND PPM RANGES..........................................................................................6-8

ACCURACY OF PPB LEVEL MEASUREMENTS USING PPM LEVEL CALIBRATION ............................................................. 6-9

FLOW/RESPONSE CHARACTERISTICS OF NOA 280I ...........................................................................................6-10

CALIBRATION AT LOWER FLOW RATES .............................................................................................................. 6-11

GE Analytical Instruments ©2006 DLM 14291 Rev. A

viii

Page 9

7.

ON-LINE EXHALED NITRIC OXIDE .......................................................................................................7-1

ASSEMBLY OF THE ACCURATE NO BREATH KIT.................................................................................................... 7-2

CONNECTION OF THERMAL MASS FLOWMETER..................................................................................................... 7-3

CONNECTION OF GAS SAMPLING AND PRESSURE TUBING ......................................................................................7-3

INSPIRATORY GAS CONNECTIONS........................................................................................................................ 7-4

Inspiratory Gas Filter............................................................................................................................ 7-4

NOA SETUP..................................................................................................................................................... 7-4

PERFORMING THE MANEUVER............................................................................................................................. 7-5

SELECTION OF NO PLATEAU..............................................................................................................................7-6

FLOW/PRESSURE CHARACTERISTICS OF ACCURATE NO RESTRICTORS ................................................................... 7-8

MODELS OF NITRIC OXIDE PRODUCTION IN THE AIRWAYS .....................................................................................7-8

CLEANING THE ACCURATE NO BREATH KIT AND FLOWMETER...............................................................................7-9

Disassemble the Valve........................................................................................................................... 7-9

Prewash the Components...................................................................................................................7-10

Sterilization.......................................................................................................................................... 7-10

Rinsing.................................................................................................................................................... 7-10

Drying..................................................................................................................................................... 7-10

CHECKING THE INSPIRATORY GAS FILTER..........................................................................................................7-11

8. OFF-LINE EXHALED NITRIC OXIDE (BAG SAMPLING) ...................................................................... 8-1

ASSEMBLY OF VITAL CAPACITY BAG COLLECTION KIT........................................................................................... 8-1

ASSEMBLY OF DEADSPACE DISCARD BAG COLLECTION KIT .................................................................................... 8-2

CLEANING THE BAGS .........................................................................................................................................8-5

COLLECTING THE SAMPLES – VITAL CAPACITY BAG KIT........................................................................................8-6

Connecting the bag to the filler.........................................................................................................8-7

Instructing the Subject and Collecting the Samples ....................................................................... 8-7

Disconnecting the bag from the filler and sealing the bag...........................................................8-8

COLLECTING THE SAMPLES – DEADSPACE DISCARD BAG KIT.................................................................................. 8-9

Connecting the bag to the filler.........................................................................................................8-9

Instructing the Subject and Collecting the Samples ..................................................................... 8-10

Disconnecting the bag from the filler and sealing the bag.........................................................8-11

ANALYZING THE SAMPLES ................................................................................................................................ 8-11

Analysis Setup....................................................................................................................................... 8-11

NOA SETUP................................................................................................................................................... 8-11

CLEANING THE BAG KITS ................................................................................................................................. 8-13

Vital Capacity Bag Kit......................................................................................................................... 8-13

Deadspace Discard Bag Kit ................................................................................................................. 8-14

GE Analytical Instruments ©2006 DLM 14291 Rev. A

ix

Page 10

F

LOW/PRESSURE CHARACTERISTICS OF BAG KITS.............................................................................................. 8-14

STABILITY OF NO IN MYLAR BAGS....................................................................................................................8-15

OFF-LINE VERSUS ON-LINE EXHALED NO MEASUREMENTS..................................................................................8-17

TESTING BAGS FOR PINHOLE LEAKS.................................................................................................................. 8-17

9. BREATH-BY-BREATH AND CHAMBER SAMPLING FOR EXHALED NITRIC OXIDE..........................9-1

BREATH-BY-BREATH MEASUREMENTS.................................................................................................................. 9-1

Spontaneously Breathing Subjects......................................................................................................9-1

Ventilated Subjects...............................................................................................................................9-2

NOA SETUP.....................................................................................................................................................9-3

NO/Pressure Offset................................................................................................................................9-3

Humidified Circuits................................................................................................................................9-3

CHAMBER SAMPLING.......................................................................................................................................... 9-4

NOA SETUP.....................................................................................................................................................9-6

10. NASAL NITRIC OXIDE......................................................................................................................10-1

RECOMMENDED SETUP.....................................................................................................................................10-1

PERFORMING THE MANEUVER...........................................................................................................................10-2

NOA SETUP...................................................................................................................................................10-3

11. INSTALLATION AND SETUP: LIQUID MEASUREMENTS..............................................................11-1

SUPPLIES........................................................................................................................................................ 11-1

Gases......................................................................................................................................................11-1

Reagents................................................................................................................................................ 11-1

Lab Equipment...................................................................................................................................... 11-1

SETUP OF PURGE VESSEL.................................................................................................................................11-2

Connections of tubing to glassware.................................................................................................. 11-3

Procedure for Tightening Swagelok Fittings.................................................................................................11-4

DILUTION OF ANTI-FOAMING AGENT.................................................................................................................11-7

NOA SETUP FOR LIQUID MEASUREMENTS.......................................................................................................... 11-8

DEPROTEINIZATION PROCEDURES....................................................................................................................11-10

Cold ethanol precipitation............................................................................................................... 11-11

Zinc Sulfate/Sodium Hydroxide precipitation.............................................................................. 11-11

12. MEASUREMENT OF NITRIC OXIDE AND NITRITE IN LIQUID SAMPLES....................................12-1

APPARATUS FOR NITRITE REDUCTION ............................................................................................................... 12-1

PREPARATION OF THE NITRITE REDUCING AGENT ..............................................................................................12-2

ADJUSTMENT OF PURGE GAS FLOW RATE .........................................................................................................12-3

GE Analytical Instruments ©2006 DLM 14291 Rev. A

x

Page 11

A

DJUSTMENT OF LIQUID LEVEL......................................................................................................................... 12-3

Preparation of Stock Solution............................................................................................................ 12-5

Preparation of Dilute Standards....................................................................................................... 12-7

WATER BLANKS .............................................................................................................................................. 12-8

INJECTION TECHNIQUE .................................................................................................................................... 12-9

PREPARATION OF CALIBRATION CURVE .............................................................................................................12-9

LINEAR RANGE AND OFF-SCALE PEAKS.............................................................................................................. 12-9

REPEATABILITY ............................................................................................................................................. 12-10

NITRITE CONTAMINATION .............................................................................................................................. 12-10

SAMPLE ANALYSIS ......................................................................................................................................... 12-12

BACKGROUND NITRITE................................................................................................................................... 12-12

REPLACING THE REDUCING AGENT AND OPENING THE PURGE VESSEL ............................................................... 12-13

SEPTUM REPLACEMENT.................................................................................................................................. 12-14

CLEANING THE PURGE VESSEL........................................................................................................................ 12-14

CLEANING OF THE IFD FILTER ....................................................................................................................... 12-16

LONG-TERM MAINTENANCE OF THE PURGE VESSEL AND BUBBLER........................................................................ 12-16

13. MEASUREMENT OF NITRATE, NITRITE AND NITRIC OXIDE IN LIQUID SAMPLES................. 13-1

APPARATUS FOR NITRATE REDUCTION .............................................................................................................. 13-1

Preparation of the Nitrate Reducing Agent.................................................................................... 13-2

Preparation of 1M NaOH..................................................................................................................... 13-2

Startup Procedures for Nitrate Reduction...................................................................................... 13-3

ADJUSTMENT OF PURGE GAS FLOW RATE.........................................................................................................13-4

LEAK CHECK FOR PURGE VESSEL...................................................................................................................... 13-5

ADJUSTMENT OF LIQUID LEVEL......................................................................................................................... 13-5

Preparation of Stock Solution............................................................................................................ 13-6

Preparation of Dilute Standards....................................................................................................... 13-7

WATER BLANKS .............................................................................................................................................. 13-9

INJECTION TECHNIQUE .................................................................................................................................... 13-9

PREPARATION OF CALIBRATION CURVE ...........................................................................................................13-10

ANALYSIS OF SAMPLES AND STANDARDS...........................................................................................................13-10

Serum and Plasma Samples.............................................................................................................. 13-10

NITRATE CONTAMINATION ............................................................................................................................. 13-11

REPLACING THE REDUCING AGENT AND OPENING THE PURGE VESSEL ............................................................... 13-11

OPENING THE GAS BUBBLER .......................................................................................................................... 13-12

SEPTUM REPLACEMENT.................................................................................................................................. 13-13

CLEANING THE PURGE VESSEL........................................................................................................................ 13-13

GE Analytical Instruments ©2006 DLM 14291 Rev. A

xi

Page 12

C

LEANING THE GAS BUBBLER.........................................................................................................................13-15

CLEANING THE BUBBLER TUBING.................................................................................................................... 13-16

CLEANING OF THE IFD FILTER .......................................................................................................................13-16

Long-term maintenance of the purge vessel and bubbler..........................................................13-17

14. OTHER LIQUID MEASUREMENT TECHNIQUES............................................................................14-1

MEASUREMENT OF NITROSOTHIOLS ...................................................................................................................14-1

Cu(I)/Cysteine Reagent.......................................................................................................................14-1

Preparation of Reducing Agent.......................................................................................................................14-1

Preparation of Nitrosothiols Standards..........................................................................................................14-2

Copper(I)/Iodide/Iodine Reagent......................................................................................................14-2

Preparation of the Reducing Agent................................................................................................................ 14-2

Preparation of S-Nitroso-Albumin...................................................................................................................14-3

Treatment of Plasma Samples ........................................................................................................................14-3

MEASUREMENT OF IRON-BOUND NO ................................................................................................................. 14-3

HEADSPACE MEASUREMENT OF NITRIC OXIDE .................................................................................................... 14-4

Apparatus for Headspace Analysis.................................................................................................... 14-5

Sample Collection................................................................................................................................14-5

Preparation of Standards for Headspace......................................................................................... 14-6

DYNAMIC HEADSPACE ANALYSIS........................................................................................................................ 14-7

15. MAINTENANCE.................................................................................................................................15-1

CHANGING THE VACUUM PUMP OIL ..................................................................................................................15-1

CHANGING THE HOPCALITE TRAP.....................................................................................................................15-4

CLEANING THE CHEMILUMINESCENCE REACTION CELL......................................................................................... 15-5

VACUUM TEST .............................................................................................................................................. 15-10

RESET THE CELL CLEANING TIMER..................................................................................................................15-10

LIGHT LEAK TEST.......................................................................................................................................... 15-10

COOLER MAINTENANCE..................................................................................................................................15-11

TESTING AND CLEANING THE FLOW RESTRICTOR FRIT...................................................................................... 15-13

GAS SAMPLING PARTICLE FILTER.................................................................................................................... 15-14

SECURITY .....................................................................................................................................................15-14

16. TROUBLESHOOTING.......................................................................................................................16-1

ERRORS..........................................................................................................................................................16-1

POSSIBLE ERRORS AND REMEDIES...................................................................................................................... 16-2

E 01 – Setup Data Corrupted, Check Before Running .................................................................... 16-2

E 02 – Cell Pressure was Above the Limit........................................................................................ 16-2

GE Analytical Instruments ©2006 DLM 14291 Rev. A

xii

Page 13

E 03 – Ozone Supply Pressure was Below the Limit.......................................................................

16-2

E 05 – Cooler Temperature Above the Limit................................................................................... 16-3

WARNINGS ..................................................................................................................................................... 16-3

W 09–Pump Oil Needs to be Replaced..............................................................................................16-4

W 10–Pump Oil Needs to be Replaced Soon..................................................................................... 16-4

W 11–Hopcalite Needs to be Replaced.............................................................................................16-4

W 12–Hopcalite Needs to be Replaced Soon.................................................................................... 16-4

W 13–Reaction Cell Needs to be Cleaned........................................................................................ 16-4

W 14–Reaction Cell Needs to be Cleaned Soon............................................................................... 16-4

W 15–Cooler Needs to be Serviced.................................................................................................... 16-5

W 16–Cooler Needs to be Serviced Soon..........................................................................................16-5

CLEARING THE ERROR AND WARNING STACKS ................................................................................................... 16-6

START-UP TESTS............................................................................................................................................. 16-6

Vacuum Pump....................................................................................................................................... 16-7

Cooler Temp......................................................................................................................................... 16-7

Supply Pressure....................................................................................................................................16-7

PMT Signal............................................................................................................................................. 16-7

TROUBLESHOOTING THE NOA.......................................................................................................................... 16-8

No Power to NOA.................................................................................................................................. 16-9

No Display............................................................................................................................................ 16-10

CELL PRESSURE TOO HIGH OR TOO LOW......................................................................................................... 16-11

GAS SAMPLING PROBLEMS.............................................................................................................................. 16-11

HIGH BACKGROUND NO AFTER CALIBRATION..................................................................................................16-12

LIQUID MEASUREMENTS PROBLEMS ................................................................................................................. 16-12

Low Sensitivity.................................................................................................................................................16-12

Leaks in Purge System....................................................................................................................................16-13

Low Conversion for Nitrate............................................................................................................................16-13

Poor Repeatability............................................................................................................................. 16-13

Syringe Problems.............................................................................................................................................16-14

Foaming of theVCl3 Reagent..........................................................................................................................16-14

Injection Technique........................................................................................................................................16-14

Contamination .................................................................................................................................................16-14

High background Signal and Rising Baselines................................................................................ 16-15

Ghost Peaks......................................................................................................................................... 16-15

GE Analytical Instruments ©2006 DLM 14291 Rev. A

xiii

Page 14

GE Analytical Instruments ©2006 DLM 14291 Rev. A

xiv

Page 15

1. INTRODUCTION

The Model 280i Nitric Oxide Analyzer (NOA™) from Sievers Instruments is a highsensitivity detector for measuring nitric oxide based on a gas-phase

chemiluminescent reaction between nitric oxide and ozone:

NO + O3 -> NO

*

NO

-> NO2+ hν

2

*

2

+ O2

Emission from electronically excited nitrogen dioxide is in the red and nearinfrared region of the spectrum, and is detected by a thermoelectrically cooled,

red-sensitive photomultiplier tube. The detection limit of the NOA for

measurement of gas-phase NO is ~0.5 part per billion by volume. The detection

limit for measurement of NO and its reaction products in liquid samples is ~ 1

picomole.

In biological systems, nitric oxide is produced from the enzymatic oxidation of

arginine. Three isoforms of the enzyme nitric oxide synthase (NOS) have been

identified in many cell types: endothelial NOS, neuronal NOS, and inducible NOS.

The biological functions of NO include action as a vasodilator, neurotransmitter,

cytotoxic agent, inhibit of platelet aggregation, and activator of smooth muscle

proliferation. Nitric oxide is also present in exhaled breath and may be a useful

marker of airway inflammation.

-

In solution, nitric oxide reacts with molecular oxygen to form nitrite (NO

with oxyhemoglobin and superoxide anion (O

-

) to form nitrate (NO- ) . NO also

2

), and

2

reacts with thiols to form S-nitroso compounds, amines to form nitrosamines, and

metals to form metal-nitrosyl complexes. In the gas phase, NO reacts with high

concentrations of oxygen to form nitrogen dioxide.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-1

Page 16

UNITED STATES REGULATORY REQUIREMENTS

CAUTION – INVESTIGATIONAL DEVICE:

Limited by United States Law to Investigational use.

EXHALED BREATH AND LIQUID APPLICATIONS:

For Research use Only. Not for Use in Diagnostic Procedures.

SAFETY WARNINGS

WARNING:

High voltage is present in the instrument when power cord is connected. To avoid

potentially dangerous shock, disconnect the power cord before removing the

cover.

WARNING:

This is a safety Class I product provided with a protective earthing ground

incorporated into the power cord. The mains plug shall only be inserted in a socket

outlet provided with a protective earth contact. Any interruption of the protective

conductor, inside or outside the instrument is likely to make the instrument

dangerous. Intentional interruption is prohibited.

WARNING:

This symbol indicates that to comply with European Union Directive 2002/96/EC for

waste electrical and electronic equipment (WEEE), the Analyzer should be disposed of

separately from standard waste.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-2

Page 17

ENGLISH

Any operation requiring access to the inside of the equipment, could result in

injury. To avoid potentially dangerous shock, disconnect from power supply before

For continued protection against fire hazard replace fuse with same type and

This symbol, on the instrument indicates that the user should refer to the

This is a safety Class I product. It must be wired to a mains supply with a protective

earthing ground incorporated into the power cord. Any interruption of the

protective conductor, inside or outside the equipment, is likely to make the

instrument dangerous. Intentional interruption is prohibited.

If this instrument is used in a manner not specified by Sievers Instruments Inc. USA,

the protection provided by the instrument may be impaired.

Disposal of RAM Card Lithium batteries must follow the local environmental

Chaque opération à l’intérieur de l’appareil, peut causer du préjudice. Afin

d’éviter un shock qui pourrait être dangereux, disconnectez l’appareil du

Afin de protéger l’appareil continuellement contre l’incendie, échangez le

Le symbol, indique que l’utilisateur doit consulter le manuel

Ceci est un produit de Classe de sécurité I. L’instrument doit être branché

sur l’alimentation secteur par un fil de secteur prévu d’une prise de masse.

Chaque interruption du conducteur protégeant, à l’intérieur ou á l’extérieur

de l’appareil peut rendre l’instrument dangereux. Interruption

Si l’instrument n’est pas utilisé suivant les instructions de Sievers

Instruments, Inc., USA, les dispositions de sécurité de l’appareil ne sont plus

Les batteries RAM Card Lithium doivent être déposés suivant les régulations

manual for operating instructions.

fusible par un fusible du même type et valeur.

WARNING:

opening the equipment.

WARNING:

rating.

WARNING:

WARNING:

WARNING:

WARNING:

regulations.

FRANÇAIS

ATTENTION:

réseau avant de l’ouvrir.

intentionnelle est interdite.

d’environnement locales.

ATTENTION:

ATTENTION:

d’instructions.

ATTENTION:

ATTENTION:

valables.

ATTENTION:

ESPAÑOL

ATENCION:

Cualquier operación que requiera acceso al interior del equipo, puede causar

una lesión. Para evitar peligros potenciales, desconectarlo de la alimentación a

Para protección contínua contra el peligro de fuego, sustituir el fusible por uno

Este símbolo, en el instrumento indica que el usuario debería referirse al

Esto es un producto con clase I de seguridad. Debe conectarse a una red que

disponga de tierra protectora en el cable de red. Cualquier interrupción del

conductor protector, dentro o fuera del equipo, puede ser peligroso. Se prohibe

Si este instrumento se usa de una forma no especificada por Sievers

Instruments, Inc., USA, puede desactivarse la protección suministrada por el

Las pilas de litio de la RAM Card deshechadas deben seguir las regulaciones

red antes de abrir el equipo.

del mismo tipo y características.

manual para instrucciones de funcionamiento.

la interrupción intencionada.

medioambientales locales.!

ATENCION:

ATENCION:

ATENCION:

ATENCION:

instrumento.

ATENCION:

DEUTSCH

Vor dem Öffnen des Gerätes Netzstecker ziehen!

Für kontinuierlichen Schutz gegen Brandgefahr dürfen bei

Sicherungswechsel nur Sicherungen der gleichen Stärke verwendet

Dieses, auf dem Gerät weist darauf hin, dab der Anwender zuerst

das entsprechende Kapitel in der Bedienungsanleitung lesen sollte.

Dies ist ein Gerät der Sicherheitsklasse I und darf nur mit einem

Netzkabel mit Schutzleiter betrieben werden. Jede Unterbrechung des

Schutzleiters auβerhalb oder innerhalb des Gerätes kann das Gerät

elektrisch gefährlich machen. Absichtliches Unterbrechen des

Schutzleiters ist ausdrücklich verboten.

Wenn das Gerät nicht wie durch die Firma Sievers Instruments, Inc.,

USA, vorgeschrieben und im Handbuch beschrieben betrieben wird,

können die im Gerät eingebauten Schutzvorrichtungen beeinträchtigt

Die Entsorgung der Lithium-Batterie in der RAM-Karte darf nur nach den

geltenden Umweltschutzregeln erfolgen.

WARNHINWEIS:

WARNHINWEIS:

werden!

WARNHINWEIS:

WARNHINWEIS:

WARNHINWEIS:

werden.

WARNHINWEIS:

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-3

Page 18

ITALIANO

ATTENZIONE:

Qualsiasi intervento debba essere effettuato sullo strumento può

essere potenzialmente pericoloso a causa della corrente elettrica.

Il cavo di alimentazione deve essere staccato dallo strumento prima

Per la protezione da rischi da incendio in seguito a corto circuito,

sostituire I fusibili di protezione con quelli dello stesso tipo e

Il simbolo, sullo strumento avverte l’utilizzatore di consultare il

Manuale di Istruzioni alla sezione specifica.

Questo strumento è conforme alle specifiche per I prodotti in Classe I

- Il cavo di alimentazione dalla rete deve essere munito di “terra”.

Qualsiasi interruzione del cavo di terra all’interno ed all’esterno dello

strumento potrebbe risultare pericolòsa. Son o proibite interruzioni

Se questo strumento viene utilizz ato in maniera non conforme alle

specifiche di Sievers Instruments, Inc. USA, le protezioni di cui esso è

Le batterie al Litio sulla RAM CARD, quando sono esaurite, devono

essere gettate secondo le regolamentazioni vigenti localmente.

della sua apertura.

ATTENZIONE:

caratteristiche.

ATTENZIONE:

ATTENZIONE:

intenzionali.

ATTENZIONE:

dotato potrebbero essere alterate.

ATTENZIONE:

DUTCH

Iedere handeling binnenin het toestel kan beschadiging

veroorzaken. Om iedere mogelijk gevaarlijke shock te vermijden

moet de aansluiting met het net verbroken worden, vóór het

Voor een continue bescherming tegen brandgevaar, vervang de

zekering door een zekering van hetzelfde type en waarde.

Het symbool, geeft aan dat de gebruiker de instructies in de

handleiding moet raadplegen.

Dit is een produkt van veiligheidsklasse I. Het toestel moet

aangesloten worden op het net via een geaard netsnoer. Bij

onderbreking van de beschermende geleider, aan de binnenzijde

of aan de buitenzijde van het toestel, kan gebruik het toestel

gevaarlijk maken. Opzettelijke onderbreking is verboden.

Indien het toestel niet gebruikt wordt volgens de richtlijnen van

Sievers Instruments, Inc., USA gelden de veiligheidsvoorzieningen

RAM kaart Lithium batterijen dienen volgens de lokale

afvalwetgeving verwijderd te worden.

OPGELET:

openen van het toestel.

OPGELET:

OPGELET:

OPGELET:

OPGELET:

niet meer.

OPGELET:

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-4

Page 19

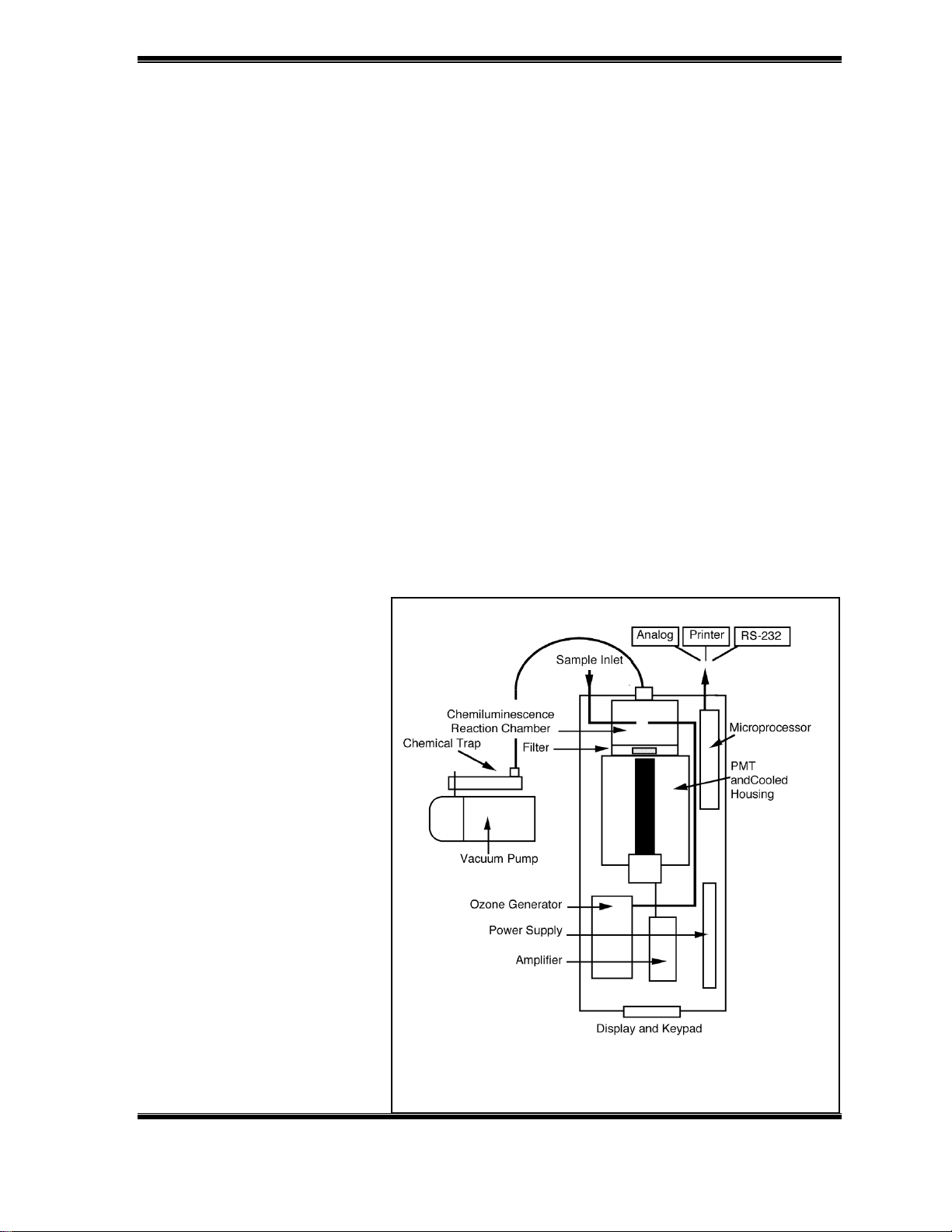

The Model 280i NOA is used for measurement of NO in exhaled breath and

measurement of nitrite, nitrate/nitrite and nitrosothiols in biological fluids, cell

culture media, and other liquid samples. A schematic of the 280i NOA is shown in

Figure 1-1 and consists of the following major components:

• Sampling Inlet Systems

• Sample Flow Control Device

• Ozone Flow Control Module

• Ozone Generator

• Chemiluminescence Reaction Chamber and Optical Filter

• Photomultiplier Tube and Cooled Housing

• Vacuum Pump and Chemical Trap

• Front Panel Display

• Four Button Keypad

• PMT Amplifier

• Power Supply

• Analog to Digital Converter

• Microprocessor and Output Electronics

• Analog, Printer, and RS-232 Outputs

• Exhalation Pressure Transducer

• Optional Thermal Mass Flowmeter

Sample Inlet Systems

The NOA 280i has a

complete range of sample

inlet systems for

measurement of NO and its

reaction products including:

• Gas Sampling Kit for

measurement of gasphase NO. The kit

®

includes a Nafion

drier,

0.45 µm particle filter,

PVC sampling lines with

Luer® adapters and a

calibration tee.

Figure 1-1: Schematic of Model 280i Nitric

Oxide Analyzer

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-5

Page 20

• Purge vessel for the measurement of NO, nitrite, nitrate and other reaction

products in liquid samples. The purge vessel can also be used for headspace

analysis with a gas-tight syringe.

• Accurate NO™ Exhaled Breath Kit for on-line measurement of exhaled NO using

elevated pressure to close the soft pallet and constant low exhalation flow (30

– 250 mL/s BTPS)

• Bag Collection and Sampling Kit for off-line measurement of exhaled NO using

collection in Mylar® bags.

Sample Flow Control Device

The vacuum pump continuously draws gas into the analyzer at a constant flow

rate. A porous metal frit restrictor sealed in a 1/8" adapter is connected to a

Swagelok® bulkhead union at the rear of the NOA. The standard restrictor provides

a flow rate of ~200 mL/min and restrictors for other flow rates are available from

Sievers Instruments.

Ozone Flow Control Module

The connection for the gas supply for the ozone generator (oxygen or 95% O2/ 5%

CO2) is made using Teflon tubing and a Swagelok bulkhead connector. The gas

must be a regulated supply from an external cylinder, lecture bottle or house

oxygen. The flow rate of gas into the ozone generator (~30 mL/min) is controlled

using a regulator and small diameter tubing restrictors. The regulator and

bulkhead connectors are located on the back of the NOA. The regulator is adjusted

to 6 psi pressure, which is measured by a pressure transducer, and monitored on

the front panel display.

Ozone Generator

An electrostatic ozone generator and high voltage transformer are used to

generate ozone at a concentration of ~2% by volume from oxygen. This large

excess of ozone is sufficient for measurement of NO up to 500 ppm.

Chemiluminescent Reaction Chamber and Optical Filter

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-6

Page 21

Nitric oxide and ozone are mixed in a small volume (~20 mL) reaction cell. This

small volume permits measurement of low concentrations of NO at low flow rates

and produces sharp peaks for analysis of liquid samples. For maximum sensitivity,

the reaction cell is operated at low pressure (typically 4-7 torr). A few other

chemicals such as sulfur-containing compounds, undergo a chemiluminescent

reaction with ozone but emit light at shorter wavelengths. To minimize

interference from these species, an optical filter that transmits only red

wavelengths (>600 nm) is installed between the reaction cell and the

photomultiplier tube.

Photomultiplier Tube and Cooled Housing

The light from the chemiluminescent reaction of NO with O3 is measured using a

red-sensitive photomultiplier tube. For maximum sensitivity, the PMT is cooled to 12 °C using a thermoelectric cooled housing. The cooler is operated continuously

whenever the main power switch is on. The temperature of the cooled housing is

measured using a K-type thermocouple and monitored on the front panel display.

Vacuum Pump and Ozone Destruction Trap.

A vacuum pump is used to draw the sample into the NOA and maintain the reaction

cell at low pressure. The exhaust from the reaction cell exits the analyzer at the

rear of the instrument using a metal tube connected to Tygon tubing. Ozone in the

exhaust is removed using a chemical trap containing Hopcalite™. This material

reacts with ozone, removing it from the exhaust before the gas reaches the

vacuum pump. Since the Hopcalite is consumed, the chemical trap must be

periodically replaced. The oil used in the vacuum pump is a synthetic motor oil

(Mobil 1™ weight 10W-30) which provides better protection than conventional

pump oil. For long pump lifetime, the oil must be changed at regular intervals.

The exhaust from the pump contains some oil mist, which can be removed using a

charcoal trap. The microprocessor keeps track of the trap and oil lifetimes, and

notifies the user when it is time to replace the traps or change the oil.

Electronics

There are 7 circuit boards in the NOA:

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-7

Page 22

• PMT amplifier

• Analog to digital converter (ADC) board

• Microprocessor and Outputs board

• Power supply board

• 24 V power supply

• Front panel display

• Keypad.

The PMT amplifier processes the signal from the PMT. To provide both high

sensitivity and wide dynamic range, the amplifier has two gain ranges. High Gain is

used for measurements requiring high sensitivity (liquid samples and exhaled

breath). The amplifier in high gain has a linear response up to ~1 ppm of NO gas or

~400 picomoles of NO

-

or NO

2

-

for liquid samples. The low gain decreases the

3

sensitivity of the amplifier, permitting measurement of up to ~500 ppm of NO gas

or ~200 nanomoles of NO

-

or NO

2

-

for liquid samples. The analog output signal (mV

3

only) is obtained from the amplifier. A switch on the amplifier sets the full-scale

voltage. When the switch is in the down position the output range is 0–1V. When

the switch is in th eup position, the output range is 0–10V.

The amplifier is also connected to the ADC board which also monitors three

pressure transducers (cell, supply and exhalation), the cooler thermocouple and

the thermal mass flowmeter. The microprocessor and firmware calculate gas

concentration, monitor the performance of the analyzer, keep track of

maintenance items, and control the output of data. The power supply board and

24V power supply provides the high voltage for the PMT, power to the PMT cooler

and the DC power for the electronics. The front panel display and keypad are used

for display of the data and the operation of the analyzer.

Analog, Printer and RS-232 Outputs

In addition to displaying data on the front panel, data can also be: sent to a

recorder or integrator using the analog output, sent to a computer using the RS232 output, and printed using the parallel printer port. The analog output can be

set to 0-1 V or 0-10 V full-scale. The printer output shows the minimum, maximum

and average value for a selected print interval ranging from 5 seconds to 10

minutes. The RS-232 output provides data at sampling rates from 32 samples per

second to 6 samples per minute.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-8

Page 23

Exhalation Pressure Transducer

An exhalation pressure transducer is present in the analyzer for use with the

Accurate NO breath kit and for detection of exhalations during breath-by-breath

measurements.

Thermal Mass Flow Meter

On-line measurement of exhalation flow rates can be performed using a optional

flow meter. The signal from the flow meter is included in the RS-232 output.

This completes the introduction to the NOA and its components:

• Chapter 2 lists the specifications of the analyzer.

• Chapter 3 has an overview of the firmware and controls.

• Chapter 4 contains the basic installation procedures.

• Chapter 5 contains the installation and setup for gas-phase measurements.

• Chapter 6 describes how to calibrate the NOA for gas-phase measurements.

• Chapter 7 describes on-line measurement of NO in exhaled breath.

• Chapter 8 describes off-line measurement of exhaled NO.

• Chapter 9 describes breath-by-breath and chamber sampling for exhaled NO

measurements.

• Chapter 10 describes measurement of nasal nitric oxide.

• Chapter 11 contains the installation and setup liquid measurement.

• Chapter 12 describes the setup and measurement of nitrite in liquid

samples.

• Chapter 13 describes the setup and measurement of nitrate in liquid

samples

• Chapter 14 describes the measurement of nitrosothiols and other reaction

products in liquid samples.

• Chapter 15 describes maintenance of the NOA.

• Chapter 16 lists troubleshooting procedures and error and warning

messages.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

1-9

Page 24

Page 25

2. SPECIFICATIONS

Sensitivity

.................................................... Gas < 1 ppb

.................................................... Liquid ~1 picomole

Range

.................................................... Gas < 1 – 500,000 ppb

.................................................... Liquids nanomolar to millimolar

Response Time

.................................................... Electronics 67 msecs to 90% full

scale

.................................................... Lagtime 1 second

Repeatability

.................................................... Gas ± 5%

.................................................... Liquid ± 5 10%

Sample Size

.................................................... Gas 10 – 300 mL/min

.................................................... Liquid 0.001 – 5 mL

Display ........................................... Back-lit LCD screen

.................................................... ppb/ppm or mV

Outputs

.................................................... Analog 0 – 1V, 0 – 10 V

.................................................... Digital RS-232 (9600-38.4K baud)

.................................................... Printer parallel port

Data Sampling Rate............................ 0.002 - 32 samples/second

GE Analytical Instruments ©2006 DLM 14291 Rev. A

2-1

Page 26

Power Requirements................................120 V, 60 Hz (6A)

100 V, 50 or 60 Hz (7A)

230 V, 50 Hz (3A)

NOA

.........................................................Height 16 in. (41 cm)

.........................................................Width 6.2 in. (16 cm)

.........................................................Length 20 in. (51

cm) ....................................................

.........................................................Weight 35 lbs. (16

kg)

Vacuum Pump with installed trap

.........................................................Height 14.5 in. (37 cm)

.........................................................Width 7.5 in. (19 cm)

.........................................................Length 19 in. (48

cm)

.........................................................Weight 47 lbs. (21.5

kg)

Operating Environment

Ambient Temperature ....................................32°F to 86°F (0°C to 30°C)

Relative Humidity.......................................... 0% to 90%

Fuse Requirements

Main Fuse ...................................100 VAC model: T, 10A, 250V

120 VAC model: T, 5A, 250V

230 VAC model: T, 5A, 250V

Ozone Fuse..................................100VAC model: T, 200mA, 250V

120 VAC model: T, 200mA, 250V

230 VAC model: T, 100mA, 250V

GE Analytical Instruments ©2006 DLM 14291 Rev. A

2-2

Page 27

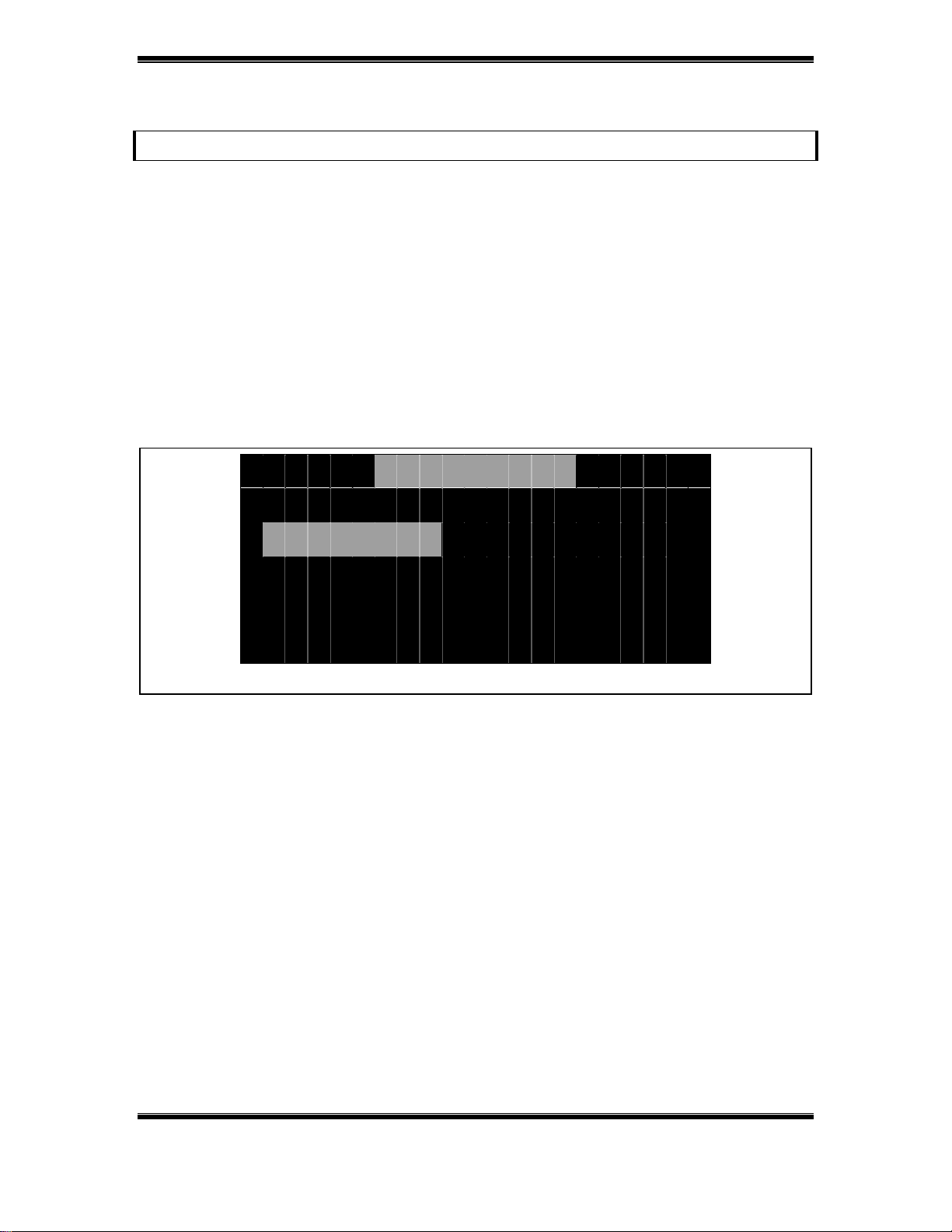

3. MENUS AND CONTROL OVERVIEW

Operation of the NOA 280i is performed using the four front panel buttons (UP

Arrow, DOWN Arrow, ENTER, and CLEAR) to run the menu-based firmware. Use

the UP or DOWN Arrow buttons to scroll through the menu options and select

values. The ENTER Button is used to select menu options and to save setpoints.

The CLEAR Button is used to exit menus and clear entries. The CLEAR Button is

also used to display the Status Menu from the Main Menu, select the Main Menu

from the Measurement Menu or to return to the Measurement Menu from the

Main Menu. A cursor is used for selection of the menu options and the location

M A I N M E N U

A N A L Y S I S C A L I B R A T I O N

C O N T R O L M E S S A G E S

0 4 J U L 0 0 0 8 : 1 7 : 3 1

of the cursor is indicated by a highlighted menu option.

Main Menu

There are five options in the Main Menu: Analysis, Control,, Calibration,,

Messages, and Maintenance,. A title field is located at the top of the menu, and

the date and time are displayed in the message line at the bottom of the

display. Select an option by using the Arrow buttons to highlight the desired

M A I N T E N A N C E

Figure 3-1: Main Menu

option, and press the ENTER button.

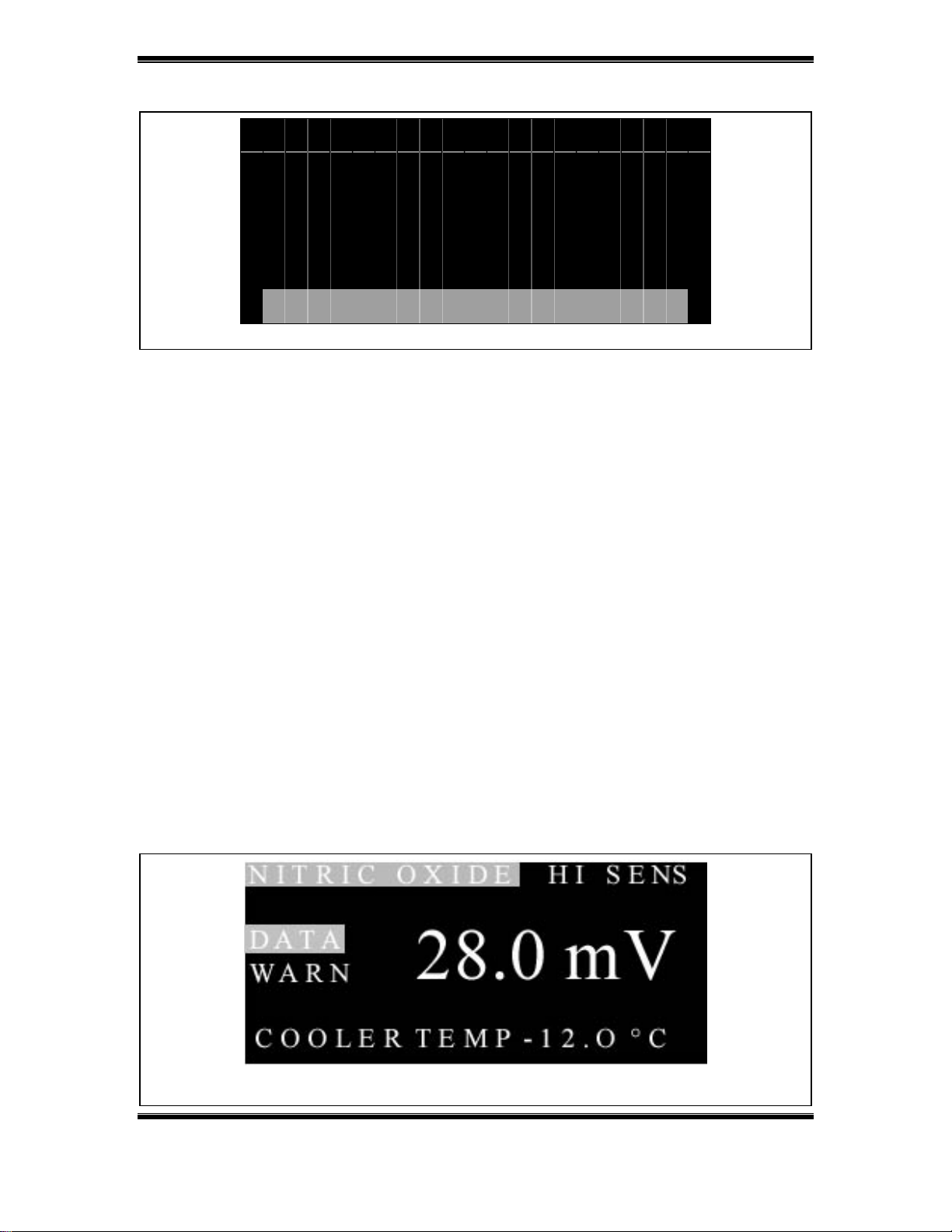

Status Screen

Press the CLEAR button from the Main Menu to display the Status Screen. This

screen shows the current values for the PMT cooler temperature, reaction cell

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-1

Page 28

ff)

S T A T U S

C O O L E R T E M P – 1 2 . 0 ° C

C E L L P 7 6 0 . 0 T o r r

S U P P L Y P 0 . 0 P S I G

P M T S I G N A L 0

E N T E R / C L E A R c o n t i n u e

Figure 3-2: Status Screen (PMT O

pressure, oxygen supply to the ozone generator, and the PMT signal, (counts at

analog to digital converter). Before starting the NOA, the status screen should

be checked to confirm that the cooler temperature, cell and supply pressures

are within the specifications required for the start-up tests.

Pressing either the ENTER or CLEAR button will return to the Main Menu.

Analysis

The Analysis option is used to start and stop the NOA. The NOA has three modes

.

of operation: Start, Stand-by and Stop. From the Main Menu, pressing the

ENTER button with the Analysis option highlighted will display the Analysis

Menu.

Selecting the Start option will:

• Switch to the Startup Screen.

• Check the cell pressure to see if it is above 300 torr, then turn on the

pump.

A N A L Y S I S

S T A R T

S T A N D - B Y

Figure 3-3: Analysis Menu with NOA in Stop Mode.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-2

Page 29

V A C U U M P U M P P A S S

C O O L E R T E M P P A S S

C E L L P R E S S P A S S

S U P P L Y P R E S S T E S T I N G

P M T S I G N A L

E N T = S T A T U S C L R = S T O P

Figure 3-4: Start-up Screen.

• Check the PMT cooler temperature to see if it is –12 ± 2 °C.

• Wait until the reaction cell pressure is < 100 torr.

• Check the ozone supply pressure is >4 psig (6 psig recommended).

• Turn on the PMT and record an ozone-off baseline signal.

• Turn on the ozone generator, and wait for an increase in the PMT signal

due to the background chemiluminescence from ozone.

• Display the PMT signal in the Measurement Display.

If any of the above conditions are not met, the start-up screen will FAILED for

that test. Pressing ENTER from the Start-up Screen will display the Status

Screen to aid in troubleshooting failed tests. Pressing CLEAR will return to the

Analysis Menu.

Measurement Menu

Once the start-up testing is completed, the Measurement Menu is displayed.

Figure 3-5:Measurement Menu (Nitric Oxide Mode)

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-3

Page 30

D A T A O U T P U T

O U T P U T E N A B L E D

E N T E R t o g g l e o u t p u t

Figure 3-6: Data Output Menu.

This menu shows that NOA’s mode (Nitric Oxide or Exhalation), the PMT

amplifier’s setting (HI or LO sensitivity) and the signal from the PMT (mV or

gas concentration). Two shortcuts are available from the Measurement Menu;

DATA and WARN. When DATA is highlighted, pressing the ENTER button moves

to the Data Output Menu. The data output (Com port and printer) are enabled

at start-up, but can be disabled to pause data collection by pressing the ENTER

button. The outputs are re-enabled by pressing the ENTER button. Pressing

CLEAR returns to the Measurement Menu.

The firmware keeps track of usage and when maintenance is required, a WARN

shortcut is displayed in the Measurement Menu. The UP or DOWN Arrow buttons

can be used to scroll between DATA and WARN. With the WARN shortcut

highlighted, pressing the ENTER button will display the Warning Menu with a

list of the current warnings (see Chapter 14 for information on maintenance

and warnings).

In the Nitric Oxide mode the current values for the cooler temperature, cell

pressure and ozone supply pressure are displayed at the bottom of the

Measurement Menu. In the Exhalation mode, a bar graph of the exhalation

pressure is displayed.

From the Measurement Menu, pressing the CLEAR button will return to the Main

Menu and from the Main Menu, pressing CLEAR will return to the Measurement

Menu.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-4

Page 31

When the NOA is in the Start mode, selecting Analysis from the Main Menu will

display two options; Stand-by and Stop.

The Stand-by option is always available from the Analysis Menu. If the analysis

has been started, selecting the Stand-by option will turn off the PMT and ozone

generator, but leave the vacuum pump on. If the analysis was stopped,

selecting the Stand-by option will turn on the vacuum pump.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-5

Page 32

A N A L Y S I S

S T O P

S T A N D - B Y

Figure 3-7: Analysis Menu (NOA in Start Mode).

When the NOA is in the start mode, selecting Stop will:

• Display a confirmation screen “Are you sure? continue / stop”

• If the Stop option is selected, turn off the PMT, and ozone generator.

• Run the vacuum pump for 2 minutes to clear residual ozone from the

system.

• Turn off the vacuum pump.

Main Menu Options

The other options from the Main Menu are used to configure the NOA for the

different applications, perform the calibration for gas-phase measurements,

view warnings and errors, and view and install consumables.

Control

The Control Menu is used to setup the NOA for liquid or gas-phase

measurements, set the output intervals and the sensitivity of the NOA. The

setup can be stored as a method to permit easy switching between

applications. The Control Menu also permits viewing of the cooler temperature

C O N T R O L

M E T H O D

S E T U P

S T A T U S

Figure 3-8: Control Menu.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-6

Page 33

and pressure via the Status Screen.

Calibration

C A L I B R A T I O N

C A L I B R A T E

V I E W

P R I N T

Figure 3-9: Calibration Menu.

The Calibration Menu is used to perform the calibrations for gas-phase

measurements and can be used to view and print the gas and pressure

transducer calibration values.

Messages

The Messages Menu is used to view warnings and errors. Warnings indicate that

maintenance is required and a WARN shortcut is displayed in the Measurement

M E S S A G E S

W A R N I N G S

E R R O R S

Figure 3-10: Messages Menu.

Menu. Errors indicate that the cooler temperature or the supply or cell

pressures are out of range. When an error is detected, the NOA is placed in the

Stop Mode and the firmware switches to the Errors menu.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-7

Page 34

Maintenance

The Maintenance Menu is used to setup the security, view and install

consumable and delete old warnings and errors.

M A I N T E N A N C E

C O N S U M A B L E S

D E L E T E WA R N & E R R

S E C U R I T Y

Figure 3-11: Maintenance Menu.

Time-out Function

The NOA’s firmware monitors keyboard activity and if no button pushes are

detected for 10 minutes, the firmware will return to the Main Menu, if the NOA

is in the Stop or Standby Mode or the Measurement Menu if the NOA is in the

Start Mode.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

3-8

Page 35

4. INSTALLATION

Location

Place the analyzer on a clean, unobstructed surface approximately 25" (60 cm)

deep by 6.2" (16 cm) wide that can support at least 35 pounds (16 kg) in addition

to existing equipment. For proper heat dissipation, ensure that an additional 6" (16

cm) is available at the rear and on both sides of the detector. Leave ~ 24" (60 cm)

of additional space on one side of the detector for the purge vessel. Additional

space will be required for computers, printers and integrators.

Place the vacuum pump on a space of nearby floor or bench 7.5" (19 cm) by 19" (48

cm) with a minimum height clearance of 14.5" (37 cm). Pump weight is 47 lbs.

(21.5 kg).

The analyzer and pump can also be placed on a cart for mobile operation. The cart

should have a bottom shelf with enough clearance for the vacuum pump and

should be sturdy enough to support the total weight of the analyzer and pump (82

lbs. 38 kg), plus any additional equipment or gas cylinders that will be placed on

the cart.

Power Requirements

The detector and vacuum pump are powered from a standard, 15 amp, 120 VAC 60

Hz grounded AC outlet. The NOA and pump will draw ~6 amps in normal operation,

and slightly higher instantaneous current with the pump running.

For 230 VAC versions of the detector, a standard (230 VAC, 50 Hz) grounded AC

outlet (~3 amps) is required.

For 100 VAC versions, a standard (100 VAC, 50 or 60 Hz) grounded AC outlet (~7

amps) is required.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

4-1

Page 36

Environmental Considerations

Operate the NOA 280 in an environment comfortable for human habitation with

reasonably constant temperature and humidity. Avoid elevated temperatures;

operating at temperatures greater than 85° F (30° C) may cause problems with the

LCD display and the PMT cooler..

Tools and Additional Supplies

The following items will be needed to install and operate the NOA 280:

Tools

The following tools will be required for all applications:

• Open End Wrenches - 1/4", 5/16", 7/16", 1/2", 9/16", 13/16" and 7/8"

(Adjustable wrenches can also be used)

• Adjustable wrench or 11/8" open-end wrench is required for

connecting regulators to gas cylinders.

• Phillips-head Screw Driver

• Hexdriver or regular screwdriver

Gases

A cylinder of oxygen or 95% oxygen, 5% CO2 equipped with a two stage regulator

is required for the ozone generator. House oxygen and a flow controller may

also be used. If oxygen is not available, air can be used, however, the NOA will

need to recalibrated for gas measurements if air is used for the ozone

generator.

Data Collection

A computer (PC or Macintosh) is required for collection of data using the RS-232

output. For PCs, a Pentium is required. For Mac’s a PowerPC is required. The

computers should have at least 32 megabytes of RAM. For computers without a

internal serial port, a USB-Serial adapter is required.

For real-time display of the analog signal, a strip chart recorder or integrator

may be used. The analog signal can also be sent to a computer using an analog-

GE Analytical Instruments ©2006 DLM 14291 Rev. A

4-2

Page 37

to-digital converter. For the printer output, any Centronics® style printer can

be used. Contact Sievers Instruments with any questions regarding data

collection equipment.

GE Analytical Instruments ©2006 DLM 14291 Rev. A

4-3

Page 38

Pump

Oil Fill Caps

Pump Outlet

Power Switch

Oil Return/Gas Ballast

Oil Level

Sight Glass

Drain Plug

Figure 4-1: Schematic of RV 3 Pump.

Vacuum Pump Setup

Open the vacuum pump box and remove the pump, pump oil (Edwards Ultra

Grade), and the power cord. The accessories kit (pump fittings, Tygon tubing, hose

clamps and mounting bracket) is shipped in a separate box.

Step 1 – Add Oil to the pump

Remove one of the two oil fill plugs from the top of the pump (see Figure 4-1) and