Page 1

GE Oil & Gas

28000 Series

Masoneilan* VariPak*

Adjustable-Cv Control Valves

Instruction Manual

Page 2

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECTSPECIFIC REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL

OPERATION AND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE

PHILOSOPHIES VARY, GE (GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES AND

AFFILIATES) DOES NOT ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC

LIMITATIONS AND REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL

UNDERSTANDING OF THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL AND

ELECTRICAL EQUIPMENT IN POTENTIALLY HAZARDOUS ENVIRONMENTS. THEREFORE, THESE

INSTRUCTIONS SHOULD BE INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY

RULES AND REGULATIONS APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS

FOR OPERATION OF OTHER EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT

NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH

INSTALLATION, OPERATION OR MAINTENANCE. SHOULD FURTHER INFORMATION BE DESIRED

OR SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED SUFFICIENTLY FOR

THE CUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR ARE

STRICTLY LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE

SUPPLY OF THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY GE

REGARDING THE EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE

INSTRUCTIONS.

THESE INSTRUCTIONS CONTAIN PROPRIETARY INFORMATION OF GE, AND ARE FURNISHED TO

THE CUSTOMER/OPERATOR SOLELY TO ASSIST IN THE INSTALLATION, TESTING, OPERATION,

AND/OR MAINTENANCE OF THE EQUIPMENT DESCRIBED. THIS DOCUMENT SHALL NOT BE

REPRODUCED IN WHOLE OR IN PART NOR SHALL ITS CONTENTS BE DISCLOSED TO ANY

THIRD PARTY WITHOUT THE WRITTEN APPROVAL OF GE.

2 | GE Oil & Gas

Page 3

Contents

1. General ......................................................................................................4

1.1 Spare Parts ............................................................................................4

1.2 After Sales Department ................................................................................4

1.3 Training ................................................................................................4

2. Operation ...................................................................................................5

2.1 Precise Adjustment of the Varipak 28002 Adjustable-Cv Valve ............................................5

2.2 Flow Coefficient of Varipak 28001 Single-Lever and 28002 Adjustable-Cv Valves ..........................5

2.3 Actuator ...............................................................................................7

2.4 Handwheel ............................................................................................7

2.5 Reversing the Valve Action ..............................................................................8

3. Installation .................................................................................................10

3.1 Preliminary Steps ......................................................................................10

3.2 Valve Installation ......................................................................................10

3.3 Pneumatic and Electrical Circuit .......................................................................11

3.4 Limit Switches .........................................................................................11

4. Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1 Piston Rod Clevis Adjustment ..........................................................................12

4.2 Plug Stem Adjustment .................................................................................12

4.3 Limit Stop Adjustment .................................................................................13

4.4 Varipak 28002 Cv Adjustment ..........................................................................14

4.5 Positioner Start-Up Pressure Adjustment ...............................................................14

5. Maintenance ...............................................................................................14

5.1 Actuator Diaphragm Removal .........................................................................14

5.2 Adding Packing Ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.3 Disassembly ..........................................................................................15

5.4 Reassembly ...........................................................................................16

5.5 Packing Quick Change Method (Only For Valves With Max. Cv Of 0.6 To 3.8) ..............................18

5.6 7700P or 7700E Positioner Maintenance ................................................................18

5.7 Maintenance Operations Specific to the 7700E Positioner ...............................................19

5.8 Converting a 7700P Positioner (Pneumatic) into a 7700E Positioner (Electro-Pneumatic) ..................20

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 3

Page 4

1. General

These installation, operation, and maintenance instructions apply to Masoneilan VariPak* 28000 series control

valves. They also include a parts reference list with recommended spare parts (see page 21).

IMPORTANT REMARKS

Before installing, operating, or performing maintenance on this equipment, you should read

these instructions carefully and make sure you have understood them.

Work on this equipment should only be carried out by qualified personnel.

Failure to follow the instructions and precautions given in this document could lead to a

malfunction and seriously damage the equipment.

1.1 SPARE PARTS

For maintenance purposes, always use original

Masoneilan spare parts obtained through your local

GE representative or Spare Parts Department. When

ordering, always give the references of the original

order for the equipment concerned and, in particular,

the number indicated on the serial plate. (135).

1.3 TRAINING

GE organizes regular training courses in the operation,

maintenance, and application of its Masoneilan

control valves and instruments for customer service

and instrumentation personnel at its Condé-surNoireau plant. For further details, contact your local

GE representative or the Training Department at the

Condé-sur-Noireau plant, in France.

1.2 AFTER SALES DEPARTMENT

GE has a highly skilled After Sales Department to assist

customers with start-up, maintenance, and repair of

valves and instruments. Contact your nearest GE Sales

Office or Representative, or the After Sales Department

at the Condé-sur-Noireau plant, in France.

Based on general field failure data and product design analysis, a useful life period of

25 years or longer can be expected for the Masoneilan 28000 Series Varipak valves.

To maximize the useful life of the product it is essential to conduct annual inspections,

routine maintenance and ensure proper installation to avoid any unintended stresses

on the product. The specific operating conditions will also impact the useful life of the

product. Consult the factory for guidance on specific applications if required prior to

installation.

4 | GE Oil & Gas

Page 5

2. Operation

The Masoneilan VariPak microflow control valve

features a very wide range of rated flow coefficients

(Cv), from 0.004 to 3.8.

Two types of actuators are available:

- The VariPak 28001 with a single lever, designed for

just one rated Cv. This version is used when enough is

known about the operating conditions when sizing the

valve.

- The VariPak 28002 with an adjustable rated Cv. This

valve uses a patented lever system to adjust the rated

Cv on site to suit the actual operating conditions,

thereby avoiding any oversizing in flow capacity.

Each plug and seat ring combination can be adjusted

without changing the control signal.

2.1 PRECISE ADJUSTMENT OF THE VARIPAK 28002

ADJUSTABLE-Cv VALVE

The valve is adjusted using a simple, but robust,

crossed-lever system with an adjustable fulcrum. This

can be done easily by hand, either before installation or

during operation. For example, an application requiring

a theoretical Cv of 0.006 could be handled using a

VariPak 28002 with a maximum Cv of 0.010, that can

subsequently be calibrated on site between 0.004 and

0.010.

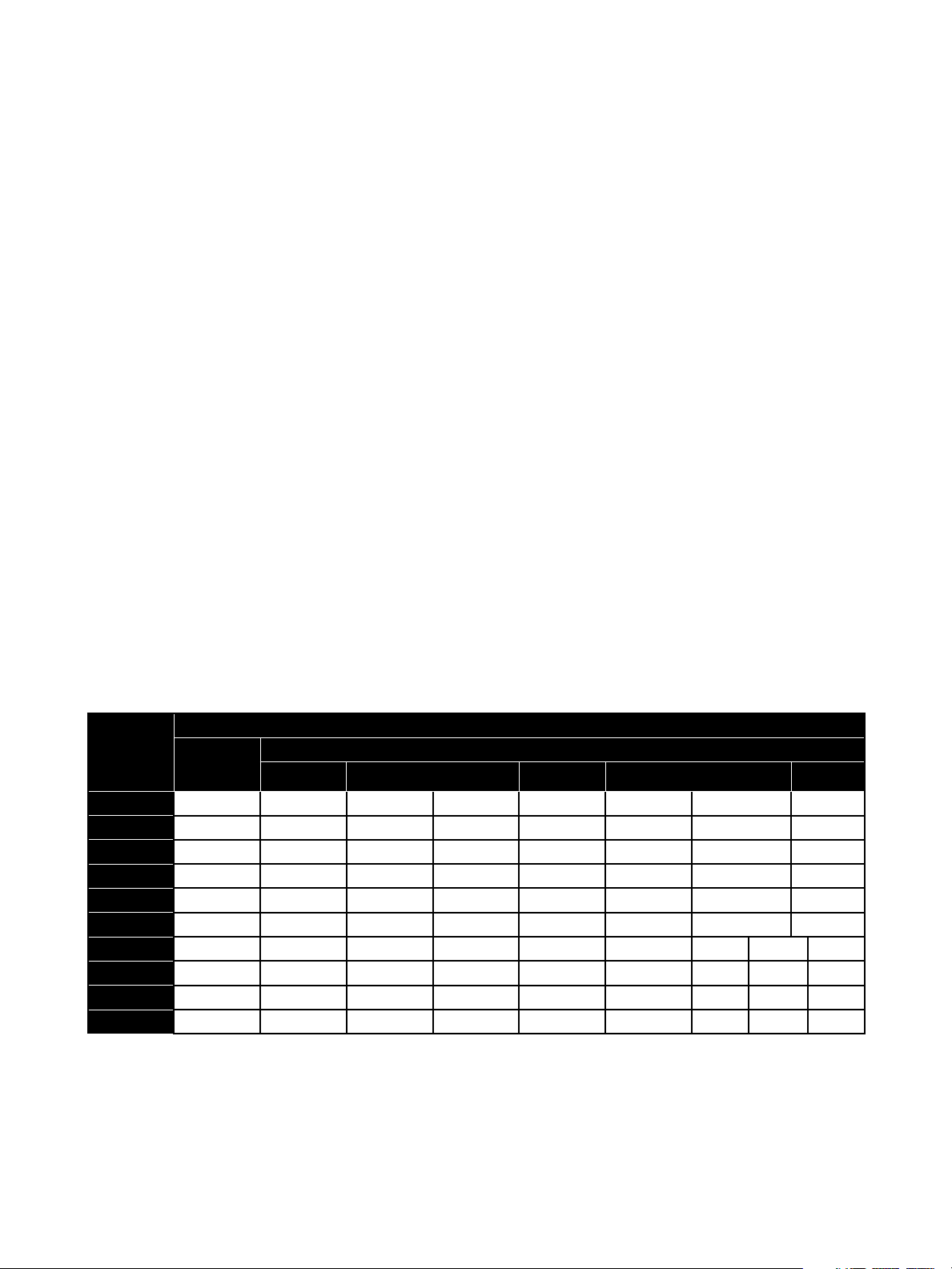

2.2 FLOW COEFFICIENT OF VARIPAK 28001

SINGLE-LEVER AND 28002 ADJUSTABLE-Cv

VALVES

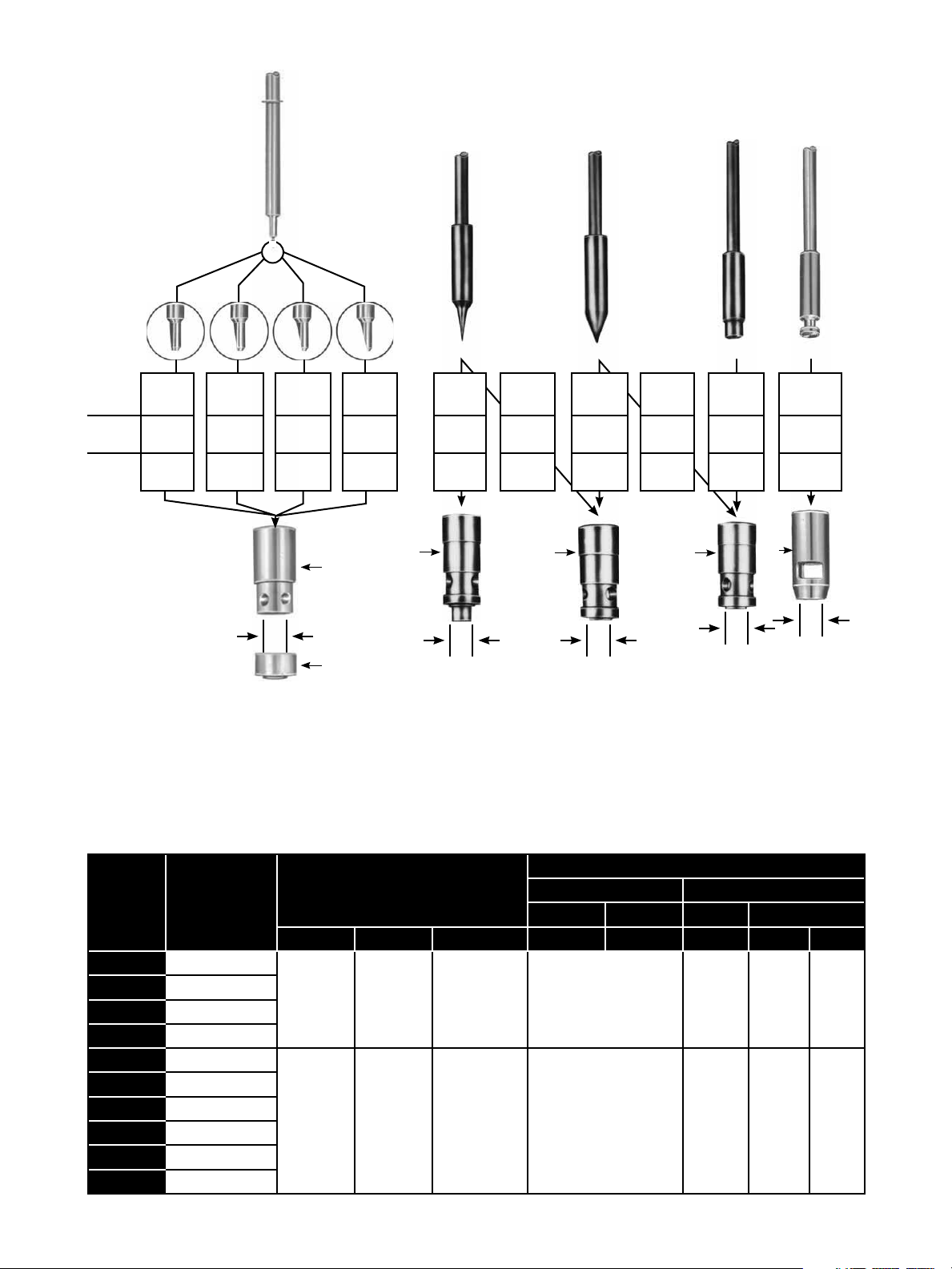

2.2.1 Plug/seat ring combinations (trim)

Eight plugs and five seat rings are used to

make up the ten available plug and seat ring

combinations, identified by codes from 0 to 9

(see figure 2). The shape of each plug and the

port diameter of the seat ring can be used to

match parts with the table in figure 2.

The difference between the four plugs in trim

Nos. 6 to 9 lies in the angle of the flat machined

on the tip. The same seat ring (3e) and the

same spacer (3f) are used in all four cases (see

figure 2).

Use the table in figure 1 to select the plug and

seat ring combination to obtain the Cv value or

range of Cv values you require.

Trim No.

9

8

7

6

5

4

3

2

1

0

FLOW COEFFICIENT C

VARIPAK

28001

0.0040 0.0016 0.0020 0.0024 0.0028 0.0032 0.0036 0.0040

0.010 0.004 0.005 0.006 0.007 0.008 0.009 0.010

0.025 0.010 0.013 0.016 0.019 0.021 0.023 0.025

0.050 0.020 0.025 0.030 0.035 0.040 0.045 0.050

0.10 0.04 0.05 0.06 0.07 0.08 0.09 0.10

0.25 0.10 0.13 0.16 0.19 0.21 0.23 0.25

0.6 0.25 0.30 0.35 0.4 0.45 0.5 0.55 0.6

1.2 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

2.3 0.9 1.1 1.3 1.5 1.7 1.9 2.1 2.3

3.8 1.5 1.9 2.3 2.6 2.9 3.2 3.5 3.8

MIN. RISK FREE MAX.

Figure 1

VARIPAK 28002

v

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 5

Page 6

VariPak

28001

VariPak

28002

Plug and

seat rin g

No. 9

Cv 0.004 Cv 0.010 Cv 0.010 Cv 0.050 Cv 0.10 Cv 0.25 Cv 0.60 Cv 0.2 Cv 2.3 Cv 3.8

Cv 0.00 4

to 0.0016

Plug and

seat rin g

No. 8

Cv 0.010

to 0.00 4

Plug and

seat rin g

No. 7

Cv 0.010

to 0.00 4

Plug and

seat rin g

No. 6

Cv 0.050

to 0.010

Plug and

seat rin g

No. 5

Cv 0.10

to 0.04

Plug and

seat rin g

No. 4

Cv 0.25

to 0.10

Plug and

seat rin g

No. 3

Cv 0.60 to

0.25

Plug and

seat rin g

No. 2

Cv 1.2 to

0.9

Plug and

seat rin g

No. 1

Cv 2.3 to

0.9

Plug and

seat rin g

No. 0

Cv 3.8 to

1.5

3f

3d

Orifice Dia.

2 mm

3e

Orifice Dia.

1.6 mm

2.2.2 Changing the plug and seat ring combination

The plug and seat ring combination can be changed

very easily for trim Nos. 1 to 9 inclusive. Simply replace

the following parts:

- The plug and seat ring (see figures 1 and 2 to select

the combination required for the new Cv).

Plug/Seat

No.

Coefficient C

0 3.8 to 1.5

1 2.3 to 0.9

2 1.2 to 0.5

3 0.6 to 0.25

4 0.25 to 1.10

5 0.10 to 0.04

6 0.050 to 0.020

7 0.025 to 0.010

8 0.010 to 0.004

9 0.004 to 0.0016

Flow

v

Spring Range (134)

m.bar Psi Color Code bar (Psi) bar (Psi) bar (Psi) ATO ATC

414

-

6-24 Red 2.1 (30) 2.1 (30) 2.1 (30)

1660

207

-

3-15 Green 1.4 (20) 1.4 (20) 1.4 (20)

1035

Figure 3 - Actuator spring ranges and supply pressures

3c

3b

3a

Orifice Dia.

Orifice Dia.

4.5 mm

Orifice Dia.

9.5 mm

14.3 mm

- The Cv adjustment plate (25) in the case of the VariPak

28002 adjustable-Cv valve.

- If necessary, the actuator spring (134) (see figure 3 to

check the spring range corresponding to the new Cv.

Max. Pressure Supply

Adjustable C

v

CI. IV CI. V CI. IV CI. V

Single Lever

2.8

(40)

1.7

(25)

6 | GE Oil & Gas

Page 7

Follow the procedure described in the "Disassembly/

Reassembly" section of the "Maintenance" chapter on

pages 14 to 18.

- Loosen adjustment knob (24) and slide it along the

lever to the required value. Tighten the adjustment

knob again firmly.

- Also change the serial plate (135) or correct the

information on the existing plate.

Caution: If the valve in question includes

a 1/2" or 3/4" NPT threaded end, the

maximum capacity of the body is

respectively limited to trim Nos. 9 to 3

inclusive or 9 to 2 inclusive. A trim No. 9

cannot be installed in a VariPak valve body

designed for a trim No. 0. Likewise, a trim

No. 0 cannot be installed in valve bodies

designed for other trim numbers.

2.2.3 Adjusting the Cv of a Varipak 28002 valve for

each plug and seat ring combination

This is done by moving adjustment knob (24) along

adjustment plate (25) fastened to the top of lever No.

1 (21).

The adjustment plate (25) gives the range of Cv

values offered by the selected plug and seat ring

combination. Carry out this adjustment operation as

follows:

Note:

- This operation entails moving lever No. 2, either

pneumatically (by allowing air into the actuator),

or manually (by pressing piston clevis (140b) with a

screwdriver or similar tool) so that the slides of the

two levers are perfectly parallel.

- It may be necessary to reset the zero to calibrate the

closure point after changing the Cv.

2.3 ACTUATOR

A single actuator allows VariPak valves to act in

direct Air-to-Close (ATC), or reverse Air-to-Open (ATO).

Valve action can be changed with no additional part

by simply shifting:

- the pivot pin and the attachment hole of the

positioner balance spring clamp for the singlelever

VariPak 28001 valve,

- the two pivot pins for the adjustable-Cv VariPak

28002 valve, then calibrating as required.

Follow the instructions given under "Reversing the

valve action" on page 8.

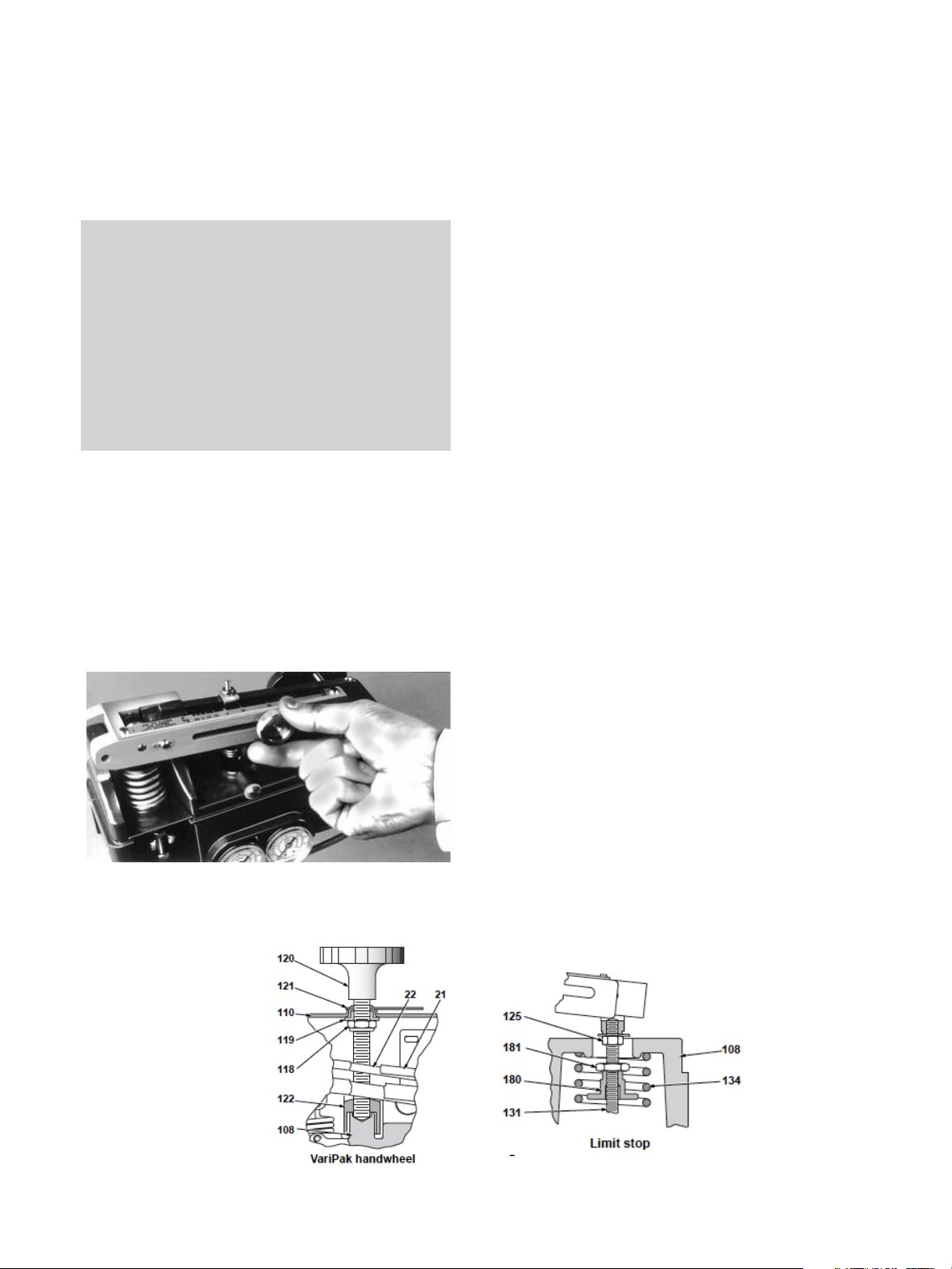

2.4 HANDWHEEL(Figure 5)

Figure 4 - Adjusting the Cv of VariPak 28002 valve for each

plug/seat ring combination

The handwheel is an optional feature located on top

of the cover and fitted with a locking lever. Access

can be gained to it directly without removing any

other parts. It consists of a threaded rod, equipped

with a handwheel (120) and a lever arm stop (122).

The threaded rod rests freely on the actuator bracket

(108) and is guided through the cover (110) by

handwheel bushing (119). The stop consists of a block

screwed onto the threaded rod. The block is guided

by the actuator bracket (108).

Figure 5

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 7

Page 8

When the handwheel (120) is turned clockwise, the

stop (122) moves up the threaded rod, compressing the

spring (134) and raising lever No. 2 (22) (VariPak 28002)

or (113) (VariPak 28001). This closes the valve if the valve

is equipped with a direct-action actuator (Air-to-Close)

and opens the valve if it is equipped with a reverseaction actuator (Air-to- Open).

The valve can be returned to automatic mode (neutral

position), by turning the handwheel counterclockwise

until the stop (122) comes into contact with the bracket

(108).

Note: During this operation, the compression is released

when the stop (122) moves away from the lever (22)

(VariPak 28002) or (113) (VariPak 28001). Continue the

operation until a slight tension reappears, then tighten

the handwheel lock (121).

VariPak actuators are equipped with a limit stop. This

consists of parts (180) and (181), and is designed to

prevent damage to the plug and seat ring assembly

and/or the plug stem in the event of handwheel or

actuator overstroke.

Note: The limit stop is not used with air-to-open valves

fitted with a handwheel, and must be screwed down at

the bottom of the piston.

2.5.1 VariPak 28001 single-lever valve

E. Remove retainer clips (112b) from pin (18), and remove

the pin from lever (113) and plug clevis (104a).

Note: This operation will be simplified by relieving

the load exerted on the plug clevis by the conical

compression spring (106). To do this push against the

plug stem end with a screwdriver while driving out the

pins.

F. Remove the two retainer clips (112a) from the pin (105)

and disengage it to uncouple the lever (113) from the

bracket (108).

G. Refit the levers (113) making sure that the pin (105) is

fitted into the correct holes in the lever and bracket

for the new action of the actuator (see figure 6). Fit

the spring clamp (115) into the corresponding lever

hole.

Note: Ensure that the clevis is correctly positioned before

fitting the lever on the bracket.

H. Couple the plug stem clevis (104a) to the lever (113)

following the normal reassembly procedure (step

I. in the "Reassembly" section on page 17). Then

follow the same procedure as for the VariPak 28002

adjustable-Cv valve as from step L.

2.5 REVERSING THE VALVE ACTION

(Figures 5, 6, 26, 27 and 29)

Caution: The valve must be isolated and

pressure vented before disassembly.

A. Loosen and remove cover (110). On valves equipped

with a handwheel, loosen cover screw (109), back

off handwheel lock (121), and turn handwheel (120)

counter-clockwise to release cover (110).

B. Adjust the signal so that the valve closes. Change the

signal slightly so that the plug just moves off the seat

ring. On the VariPak 28002 adjustable-Cv valve, set

the adjustment knob (24) to the minimum Cv setting.

C. Loosen locknut (103) and, using a screwdriver,

turn the plug stem one and three-quarter turns

counter-clockwise. Shut off the signal and the supply

pressure. Slightly tighten locknut (103) against the

clevis.

D. Unlock nut (117) and completely loosen screw (116).

Unhook spring (114) from spring clamp (115).

2.5.2 VariPak 28002 adjustable-Cv valve (2 levers)

E. Remove retainer clips (112b) from each of the two

pins (184) and remove pins from lever (113) and plug

clevis (104a).

Note: This operation will be simplified by relieving

the load exerted on the plug clevis by the conical

compression spring (106). To do this push against the

plug stem end with a screwdriver while driving out the

pins.

F. Remove the two retainer clips (112a) from pin No. 1

(105) and disengage it to uncouple lever No. 1 from

bracket (108). Loosen adjustment knob (24) and slide

it to the maximum Cv setting. Disengage the smooth

end of the adjustment pin (23) from the groove in lever

No. 2 while removing lever No. 1.

G. Drive out pin No. 3 (18) and remove lever No. 2 (22)

from the bracket.

H. Remove the two screws (26) and refit Cv adjustment

plate (25) after turning it round to comply with the

new action.

I. Refit levers No. 1 and 2 in sequence, making sure that

pins (105) and (108) are fitted into the correct holes

in the levers and bracket for the new action of the

actuator (see figure 6).

8 | GE Oil & Gas

Page 9

Note: Ensure that the clevis is correctly positioned before

fitting the lever No. 1 on the bracket (108).

J. Reset adjustment knob (24) to the minimum Cv

position.

K. Couple plug stem clevis (104a) to lever No. 1 following

the normal reassembly procedure (step L. in the

"Reassembly" section on page 17).

L. Hook spring (114) in the appropriate hole in spring

clamp (115) (see figure 6).

M. Admit supply and signal pressures and complete

calibration. Refit cover (110) using the two screws

(109). If the valve is equipped with a handwheel, refit

the cover and turn the handwheel clockwise so that

it engages in lever arm stop (122). Tighten cover

screws (109).

AIR-TO-CLOSE ACTUATOR AIR-TO-OPEN ACTUATOR

N. Put the valve back into service.

Note:

- When replacing an Air-to-Close actuator with an Air-toOpen actuator, do not forget to neutralize the limit stop

by screwing it down at the bottom of the piston.

- When replacing an Air-to-Open actuator with an

Air-to-Close actuator, set the limit stop to the opening

position.

VariPak 28001

with single lever

VariPak 28002

with adjustable

Cv (2 levers)

*Only with type 7700 positioner

Figure 6 - Identification of lever pivot pin holes

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 9

Page 10

3. Installation

3.1 Preliminary Steps

A. Before installing the valve in the line, remove all

traces of foreign material from the piping such as

welding chips, scale, oil, grease, etc.

B. Note down all the data given on the serial plate.

C. For valve inspection without interrupting process

operation, a hand-operated stop valve will be

required on either side of the VariPak, together with a

hand-operated throttling valve mounted on a bypass

line.

3.2 Valve Installation (Figures 7, 8 and 9)

Connections: The body of the ANSI Class 1500* rated

VariPak valve can be:

- Bolted between 25 mm (1") pipe flanges machined to

standards ISO-PN 10 to PN 250 (ANSI 150 - 300 - 600 900 and 1500 lb).

Use ASTM A 193 Gr B 7 (or equivalent) carbon steel

bolting for temperatures between -29° and +350 °C.

For corrosive or cryogenic service, use ASTM A 193 Gr

B8 strain-hardened stainless steel. All the line bolting

required for installation can be supplied by GE on

request.

Figure 8 - VariPak flanged body

The VariPak valve body can be supplied on request with

1/2", 3/4", or 1" NPT threaded ends. Apply PTFE tape or a

sealing compound compatible with the process to the

threaded pipe ends.

Figure 7 - VariPak flanged connection

- Connected by 25 mm flanges machined to standards

ISO-PN 20, 50 and 100 (ANSI 150, 300 and 600 lb).

Fit gaskets compatible with service conditions between

the valve body and the pipe flanges.

10 | GE Oil & Gas

Figure 9 - VariPak screwed connection (option)

Alignment: This valve is small and light, making it easy

to install on the piping. Support the valve body when

fitting studs. Suitably shaped bosses are provided to

center the valve in the line and prevent rotation before

the studs are finally tightened.

The valve must always be installed with "flow tending

to open". The flow arrow on the valve body must be

pointing in the direction of flow. Fit the bolts and tighten

in criss-cross fashion.

Page 11

Insulation: If the valve is to be insulated, ensure that the

insulation does not exceed the shaded area shown in

figure 10 below.

Figure 12 - Connections with 7700E positioner

Figure 10 - Insulation limit for a VariPak valve

3.3 Pneumatic and Electrical Circuit

(Figures 3, 11 and 12)

- On-off valve: connect the air supply line directly to the

1/8" NPT threaded connection in diaphragm cover

(137).

- Control valve with 7700P positioner (air signal):

connect the supply and instrument signal lines to the

appropriate connections on the manifold block (144)

(figure 11). Use 4 x 6 mm (1/4" O.D.) tubing.

- Control valve with 7700E positioner (electrical signal):

connect the manifold block (144) air supply line and

make the electrical connection for the I/P module (20)

(figure 12).

Use 4 x 6 mm (1/4" O.D.) tubing for the air line.

Note: Check that the supply pressure is that indicated on

the serial plate.

7700P or 7700E positioners can be installed on

both VariPak 28001 single-lever and VariPak 28002

adjustable-Cv valves.

3.4 Limit Switches (Figure 13)

In some cases, limit switches can be provided for the

VariPak valve, on request. These are wired and adjusted

in the factory to customer order. The black wire is

connected to either the normally open or normally

closed terminal of the upper limit switch. The black and

white wire is connected to the common terminal of this

switch. The red wire is connected to either the normally

open or normally closed terminal of the lower limit

switch.

The red and white wire is connected to the common

terminal of this switch. To adjust limit switches, loosen

their fasteners and move the valve to the required

position. Adjust the position of the switch until it trips.

Tighten fasteners (160 - 161 - 162).

Figure 11 - Connections with 7700P positioner

Figure 13 - Limit switch installation

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 11

Page 12

4. Calibration

VariPak valves are factory-calibrated according to

the components specified in the customer order. If for

any reason this calibration has been disturbed (e.g.

after changing from direct to reverse valve action, or

replacing the plug and seat ring), all or some of the

adjustments below must be carried out in the following

order:

- Piston rod clevis (104b) adjustment.

- Plug stem adjustment.

- Limit stop adjustment.

VariPak 28002 adjustable-Cv valve (Figures 14 and 27)

This adjustment is only required if the piston

(131) has been removed.

In this case, it should be carried out during

reassembly, before coupling the levers (21)

and (22) to the clevises (chap. MAINTENANCE

- Reassembly. step K., page 17).

- Cv adjustment.

- Positioner start-up pressure adjustment.

4.1 PISTON ROD CLEVIS ADJUSTMENT

4.1.1 Adjusting the piston rod clevis on the VariPak

28001 single-lever valve (Figures 14 and 26)

This adjustment is only required if the piston

(131) has been removed. In this case, it

should be carried out during reassembly,

before coupling the lever (113) to the clevises

(chap. MAINTENANCE - Reassembly. step H.,

page 17).

With the piston resting against diaphragm cover (137),

turn clevis (104b) so that the top of actuator bracket

(108) is 0.5 mm to 1 mm from the bottom of indicator

(126). A shim will simplify this operation. Admit enough

air pressure to disengage locknut (125) and tighten it

against indicator. Check that indicator (126) is correctly

positioned. Release air pressure.

With the piston resting against diaphragm cover (137),

turn clevis (104b) so that the top of the actuator bracket

(108) is 0.5 mm to 1 mm from the bottom of indicator

(126). A shim will simplify this operation.

Couple lever No. 2 (22) in this clevis position. Admit

enough air pressure to disengage locknut (125) and

tighten it against the indicator. Check that indicator

(126) is correctly positioned. Release air pressure.

4.2 PLUG STEM ADJUSTMENT

4.2.1 Adjusting the plug stem on the VariPak 28001

single-lever valve (Figures 15, 16 and 26)

This adjustment should be carried out during

reassembly, before coupling the lever (113) to

the clevises.

A. Loosen nut (103) and turn the plug stem using a

screwdriver while blocking clevis (104a) until the clevis is

in the position shown in figure 15. Lock nut (103).

4.1.2 Adjusting the piston rod clevis on the

Figure 14 - Piston rod clevis (104b) adjustment

12 | GE Oil & Gas

Figure 15 - Presetting the plug stem position

Page 13

B. Fit lever (113) with spring clamp (115) positioning hole

facing upwards, fit pin (105) into hole A, then fit pin

(18) into clevis (104a). Note: All pins should be greased

slightly before fitting.

C. Press the lever on the actuator side to check for plug/

seat ring leaks at ΔP 3.5 barg (50 psig). If the valve is

equipped with a handwheel, lever (113) should not

touch lever arm stop (122). If the valve leaks, release

the pressure at the inlet and remove pin (18) of clevis

(104a), then loosen nut (103). Loosen the plug stem in

order to move the clevis up (104a). A complete turn

moves the position up by 1 mm. Then tighten the

locknut (103) again.

D. Check that the distance between clevis (104b) pin

and the hole in lever (113) is approximately 2 mm.

If necessary, adjust the position of clevis (104a) to

obtain this distance, see figure 16. This value provides

the initial compression of actuator spring (134).

At this closing point where the plug is not

tightened onto the seating, the slides of

levers No. 1 and 2 should be perfectly

parallel. This characteristic makes it possible

to change the adjustment knob (24) position

later to obtain the required real Cv value.

B. Loosen adjustment knob (24) and slide it along lever

No. 1 to the maximum Cv position on adjustment

plate (25). Fully tighten adjustment knob (24).

C. Loosen locknut (103) and, using a screwdriver, turn

the plug stem until the plug is just touching the seat

ring. If the valve has been removed from the pipe,

a bubble test can be performed on the calibration

bench to obtain a very accurate adjustment. Using

the screwdriver to hold the plug stem in position,

tighten locknut (103) against clevis (104a).

D. Admit air pressure again to remove the shim, then

release the pressure.

Note: On an Air-to-Open actuator, shim thickness may

be increased or decreased by one or two-tenths of a

millimeter to ensure that levers No. 1 and 2 are perfectly

parallel and to obtain the required tightness on closing,

especially for very low Cv values (Cv < 0.10).

Figure 16 - Adjusting the lever (113)

E. Admit enough air pressure to the actuator to drive

piston clevis (104b) upwards. Couple the clevis to

lever (113) using pin (124).

F. Release the actuator pressure and repeat the plug/

seat ring leak test at ΔP 3.5 barg (50 psig). Dimension

A should be the same as in figure 16 . Release the

valve pressure once this step is completed.

4.2.2 Adjusting the plug stem on the VariPak 28002

adjustable-Cv valve (Figures 27, 28 and 29)

Once all the coupling operations are completed,

proceed as follows:

A. Admit enough pressure to the actuator to drive out

the piston rod far enough to place a shim under

the indicator (126). Use a 1.5 mm shim for an Air-toOpen actuator, and a 25 mm shim for an Air-to-Close

actuator. Release the air pressure after inserting the

shim.

4.3 LIMIT STOP ADJUSTMENT (Figure 5)

VariPak valves include a limit stop to prevent damage to

the plug and seat ring and/or plug stem in the event of

actuator or handwheel overstroke. This device consists

of a nut (180) acting as a stop, screwed onto the piston

rod inside the spring chamber, and a locknut (181).

If necessary, this device should be adjusted

immediately after plug stem adustment (see section

4.2).

A. Remove the shim (for VariPak 28002 adjustable- Cv

valve only) and admit sufficient supply pressure to

close the valve. Turn locknut (181) on the piston rod

until it touches locknut (125). Turn limit stop (180) until

it just touches the inside of actuator bracket (108).

B. Hold the limit stop with a 12 mm wrench and tighten

locknut (181). Release the air pressure.

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 13

Page 14

4.4 VARIPAK 28002 Cv ADJUSTMENT

This adjustment is carried out by moving adjustment

knob (24) along adjustment plate (25) fastened to the

top of lever No. 1 (21). See section “Adjusting the Cv

of a Varipak 28002 valve for each plug and seat ring

combination”, page 7.

4.5 POSITIONER START-UP PRESSURE ADJUSTMENT

(Figures 7, 25, 26 and 27)

A. Connect the air supply and signal lines to the 7700P

or 7700E (with electrical signal) positioner.

B. Set the supply pressure according to the valve Cv

value (see the table in figure 3).

C. Set the signal to the minimum value for an Air-to-

Open actuator, and to the maximum value for an Airto-Close actuator. Turn take-up screw (116) until the

piston rod just begins to move. Tighten locknut (117).

5. Maintenance

Figure 17 - Diaphragm replacement

5.2 ADDING PACKING RING (Figures 18, 26 and 27)

A. Before adding packing ring, the valve must be

isolated and all pressure released. Remove packing

flange nuts (8b), lift the packing flange and follower,

and insert a new packing ring. Tighten nuts (8b)

finger tight and then tighten one full turn with the

wrench.

Caution: Always ensure that there is no

pressure in the valve, actuator, or positioner

before maintenance or disassembly.

5.1 ACTUATOR DIAPHRAGM REMOVAL

(Figures 17, 24, 25, 26 and 27)

A. Unscrew the two pressure connection nuts (138a)

and pull tubing (140) out. Remove the four cap screws

(139) and diaphragm cover (137). Remove the worn

diaphragm. Form new diaphragm (136) and fit it on

the piston as shown in figure 17. Fit the diaphragm

roll into the bracket groove. Take care not to twist

or bend the diaphragm during replacement. Refit

diaphragm cover (137) with the four screws (139)

and reconnect the tubing with the two pressure

connection nuts (138a). Check that all connections

are leaktight.

Figure 18 - Adding a packing ring

14 | GE Oil & Gas

Page 15

5.3 DISASSEMBLY (Figures 5, 24, 25, 26, 27, 28 and 29)

remove balance spring (114) from the positioner.

In some cases, it may be necessary to disassemble the

VariPak valve, for example, to replace the plug/seat ring

assembly (fitting new parts or changing the maximum

Cv value) or to change the packing rings when the

maximum Cv is less than 0.6.

Note: If the maximum Cv ≥ 0.6, a quick change method

can be used to avoid disassembling the valve (see page

18).

Caution: The valve must be isolated and

pressure vented before disassembly.

A. Loosen cover screws (109) and remove cover (110). If

the valve is equipped with a handwheel, loosen cover

screws (109) and handwheel lock (121), then turn

handwheel (120) counterclockwise to release cover

(110).

Disassembly procedure for the VariPak 28001 singlelever valve:

B. Unlock nut (117) and completely loosen screw (116).

Remove spring clamp (115) from lever (113) and

remove spring (114) from the positioner.

C. Remove the two retainer clips (112c) from pin (124)

and disengage the pin to uncouple piston clevis

(104b) from lever (113).

Note: To simplify this operation, admit air pressure to the

actuator to drive the piston clevis (104b) upwards, then

release the air pressure.

D. Remove retainer clips (112b) from pin (18) and

disengage the pin from lever (113) and plug clevis

(104a).

E. Remove two retainer clips (112a) from pin (105)

and disengage the pin to uncouple lever (113) from

actuator bracket (108). Now proceed in the same way

as for the VariPak 28002 adjustable- Cv valve, as from

step I.

Disassembly procedure for the VariPak 28002

adjustable-Cv valve:

B. Adjust the signal to close the valve. Change the signal

slightly so that the plug just moves off the seat ring.

Set adjustment knob (24) to the minimum Cv position.

C. Loosen locknut (103) and, using a screwdriver, turn

the plug stem one and three-quarter turns counterclockwise. Shut off signal and supply pressure.

Slightly tighten locknut (103) against the clevis.

D. Completely loosen locknut (117) and screw (116).

Remove spring clamp (115) from lever No. 2 and

E. Remove the retainer clip (112b) from each of the two

pins (184) and disengage the pins from lever No. 1

and clevis (104a).

Note: This operation will be simplified by relieving

the load exerted on the plug clevis by the conical

compression spring (106). To do this push against the

plug stem end with a screwdriver while driving out the

pins.

F. Remove the two retainer clips (112c) from pivot pin

No. 4 (124) and disengage the pin to uncouple piston

clevis (104b) from lever No. 2 (22).

G. Remove the two retainer clips (112a) from pivot pin

No. 1 (105) and disengage the pin to uncouple lever

No. 1 from the actuator bracket (108). Disengage the

smooth end of adjustment pin (23) from the groove

in lever No. 2 and remove adjustment knob (24) and

adjustment pin (23) from lever No. 1.

H. Drive out pivot pin No. 3 (18) and remove lever No. 2

(22).

I. Hold the plug stem in place using a screwdriver and

unlock nut (103). Loosen clevis (104a) and locknut (103).

Remove spring button (102), spring (106), and grommet

plate (101).

J. Remove the two packing flange nuts (8b), packing

flange (10) and packing follower (9). Remove the two

bracket mounting nuts (8a) as well as the bracket

(108).

K. Using a packing hook, remove as many packing rings

(6) as possible from the packing box. Remove safety

pin (11) and pull the plug stem to remove the packing

spacer (5), the plug and its stem and, if necessary, the

rest of the packing.

L. Using a 9/16" or 14 mm piece of hex stock and a

wrench, unlock and pull out the seat-ring retainer (4).

M. Remove seat ring (3) and gasket (2) using a hook

made from steel wire, approx. diameter 3 mm.

Carefully fettle the hook end.

Note:

- The seat-ring of VariPak valves with Cv max.< 0.10

consists of two parts: the seat ring proper (3e), and

a spacer (3f). These parts have a small orifice and

so cannot be removed using a hook. It is therefore

necessary to remove the body from the pipe and turn

it over and, if necessary, hit the bottom with a wooden

mallet. If the seat ring (3a) is jammed in its housing, it

can be removed by inserting a screwdriver through the

outlet orifice.

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 15

Page 16

- VariPak valves with Cv max. 3.8 do not have seatring

gaskets (2).

5.4 REASSEMBLY (Figures 5, 15, 19, 20, 24, 25, 26, 27,

28 and 29)

Before reassembly, thoroughly clean the inside of the

valve body and parts, paying particular attention to

gasket seating surfaces and contact surfaces. Make

sure to use a new seat-ring gasket (2) and new packing

(6) during reassembly.

A. Insert a new seat-ring gasket (2) into valve body (13),

then fit seat ring (3), making sure that the gasket is

correctly centered on the seat-ring shoulder. Turn it

so that one of its ports is lined up with the valve body

outlet orifice.

Note: If the maximum Cv is less than 0.10, first fit the

seat ring (3e) on the new gasket (2), taking the same

precautions as above. Then fit the spacer (3f), turning it

so that one of its ports is turned towards the body outlet

orifice.

VariPak valves with a maximum Cv of 3.8 do not include

a seat-ring gasket (2).

B. Carefully apply Never Seez grease or equivalent to

the threads and bottom of the seat-ring retainer

(4). Using a 9/16" or 14 mm piece of hex stock and a

wrench, torque the retainer to 59 ftlb or 8 daN.m for

stainless-steel reinforced graphite gaskets or 40 ft-lb

or 5.5 daN.m for glass-filled PTFE gaskets (see figure

19).

Note: Torque the retainer to 30 ft-lb or 4 daN.m for

valves with a maximum Cv of 3.8.

C. Insert the plug and stem assembly into the seat

ring. For valves with a maximum Cv < 0.10, check

that there are no friction points in the plug stroke.

If a friction point is detected, loosen retainer (4)

and reposition seat ring (3e) until the stem slides

smoothly. Fit spacer (5), turning it so that one of its

holes is aligned with safety pin (11) hole in the valve

body.

Note: For valves with a maximum Cv less than 0.10,

check that the retaining ring (182) is fitted on the plug

before fitting the plug in the spacer (3f). If the retaining

ring is worn or damaged, replace it.

Figure 19 - Tightening the seat-ring retainer (4)

D. Wind two layers of PTFE tape around the safety pin

(11). Screw the pin into the bonnet five and a half to

six turns as from the thread engagement point.

Note: To determine the thread engagement point:

- Screw the safety pin about one turn.

- Pull the safety pin out while unscrewing it.

E. Fit the packing, making sure that the skive cut of

each packing ring is located 120° away from the that

of the adjacent ring. Push the rings down slightly

using a 1/2" sch., size 160 tube. Fit the packing

follower (9) onto the plug stem.

F. Fit actuator bracket (108) and secure it with two

nuts (8a). Slip packing flange (10) onto plug stem.

Handtighten the two packing flange nuts and add

one full turn with the wrench.

G. Fit, in the following order, grommet plate (101),

conical compression spring (106) and its spring

button (102) (see position in figure 26 and 27). Screw

nut (103) and clevis (104a) on the plug stem.

Adjust the nut and clevis without locking them together

until the clevis holes are positioned approximately:

- 2.3 mm below the alignment of the pin holes in

the actuator bracket (108) for the VariPak 28001

single-lever valve (see figure 15).

- 1.5 mm above the alignment of the pin holes in

the actuator bracket (108) for the VariPak 28002

adjustable-Cv valve (see figure 20).

Note: Measuring this distance can be simplified by fitting

pins (105), (184) and (18) into their holes.

16 | GE Oil & Gas

Page 17

Figure 20 - Plug stem pre-adjustment for

VariPak 28002 adjustable-C

v

Reassembly procedure for the VariPak 28001 singlelever valve (continued):

H. Couple lever (113) to actuator bracket (108) using pin

(105) and the 2 retainer clips (112a). Ensure that the

holes in lever (113) where spring clamp (115) is fitted

is located above.

Note: Check that the clevis (104a) is correctly positioned

before fitting the lever (113) on the actuator support

(108).

To identify the position of the lever connecting holes and

the spring clamp (115) attachment hole, with respect to

the required action, see figure 6.

I. Couple clevis (104a) to lever (113). To do this, press the

end of the plug stem with a screwdriver until the holes

in the clevis and lever are aligned. Couple using the

pin (18) and retainer clips (112b).

Note: Slightly grease all pins before fitting. Perform the

adjustment operation described in "Calibration", section

4.2.1, page 12.

J. If piston rod clevis (104b) has not been disturbed

during disassembly, couple it to the end of lever (113)

by admitting air pressure to the actuator to drive

clevis (104b) upwards. Couple the clevis to lever (113)

using pin (124) and two retainer clips (112c).

Note: If the clevis (104b) has been disturbed, proceed

with adjustment and coupling as described in

"Calibration", section 4.1.1, page 12.

K. Release the pressure from the actuator and check

tightness again (see "Calibration", section 4.2.1, page

12). Then continue from step M. of the VariPak 28002

procedure.

Reassembly procedure for the VariPak 28002

adjustable-Cv valve (continued):

H. Couple lever No. 2 (22) to the actuator bracket (108)

using pin (18). Ensure that the hole in lever No. 2

where spring clamp (115) is fitted is located above

and in line with balance spring (114).

I. Fit adjustment pin (23) in the slide of lever No. 1 and

screw adjustment knob (24) on its threaded end. Insert

the smooth end of pin (23) into the groove in lever

No. 2 and place lever No. 1 on support bracket (108).

Couple lever No. 1 to actuator bracket (108) using pin

(105) and two retainer clips (112a).

Note: Check that the clevis (104a) is correctly positioned

before fitting lever No. 1 on the actuator support (108)

To identify the position of the connecting holes of levers

No. 1 and 2 with respect to the required action, see

figure 6.

J. Set adjustment knob (24) to the minimum Cv position.

K. If piston rod clevis (104b) has not been disturbed

during disassembly, couple it to the end of lever No. 2

using pin (124) and two retainer clips (112c).

Note: This operation will be simplified by applying air

pressure to the diaphragm (136) to set the piston rod to

an intermediate position, and by setting the adjustment

knob to a position where lever No. 2 is most accessible.

If the clevis (104b) has been disturbed, proceed with

adjustment and coupling as described in "Calibration",

section 4.1.1, page 12.

L. Couple clevis (104a) to lever No. 1. To do this, press

the end of the plug stem with a screwdriver until the

holes in the clevis and lever No. 1 are aligned. Couple

using the two pins (184) and retainer clips (112b).

Note: The clips are inserted on the pins between the

sides of the clevis and lever No. 1.

M. Fully unscrew take-up screw (116) from spring clamp

(115), then fit clamp, after hooking balance spring

(114) first to the positioner spring bracket of the

diaphragm S/A (152), and then to spring clamp (115).

Note: The spring clamp (115) has two holes. If an Air-toOpen actuator is used, the spring must be hooked to the

top hole. If an Air-to-Close actuator is used, the spring

must be hooked to the bottom hole (see figure 6).

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 17

Page 18

N. Admit the signal and supply pressure and complete

calibration. Refit cover (110) using the two screws

(109). If the valve is equipped with a handwheel, refit

the cover, then turn the handwheel clockwise until

it is engaged in lever arm stop (122). Tighten cover

screws (109).

O. If the valve body has been removed, reinstall it taking

the precautions given under "Valve Installation" on

page 10. Put the valve back into service.

5.5 PACKING QUICK CHANGE METHOD (ONLY FOR

VALVES WITH MAX. Cv OF 0.6 TO 3.8)

(Figures 21, 26 and 27)

The quickest and easiest way to replace packing is

to remove the entire actuator from the valve body,

taking care not to modify the actuator setting. This

method is not recommended, however, for valves with

a maximum Cv less than 0.6 because of their extremely

fine plugs. For these valves, disassemble the valve to

replace the packing (see "DISASSEMBLY", page 15).

spacer (5). The function of the safety pin and spacer

is to prevent the plug from being pushed out if the

actuator is accidentally removed while the valve is

still pressurized. The internal parts of the valve cannot

be removed unless the safety pin is removed first.

Remove the two packing flange nuts (8b) and back off

the two actuator bracket mounting nuts (8a) as far as

possible.

C. Remove the actuator-plug assembly from the valve

body, tapping it off with a block of wood and mallet if

necessary. Clean the packing box in the valve body.

Remove the worn packing, then clean the plug stem

thoroughly. Carefully fit new packing rings around

the stem, positioning the skive cut of each ring 120°

from that of the adjacent ring.

D. Refit the actuator-plug assembly on the valve body,

taking care to: - align hole in packing spacer (5) with

safety pin (11) hole,

- and refit the two mounting nuts (8a).

- Take extra care when guiding each packing ring

into the packing box.

Figure 21 - Packing replacement (for Cv maxi ≥ 0.6)

Vent the valve pressure and proceed as follows:

A. Check that the plug is not resting on the seat ring.

For valves equipped with an Air-to-Open actuator,

admit air pressure under the diaphragm and turn the

handwheel to move the plug off its seat ring.

B Remove safety pin (11) from the valve body. The

safety pin stub engages with the hole in packing

E. Wind two layers of PTFE tape around the safety pin.

Screw the pin into the bonnet five and a half to six

turns as from the thread engagement point.

Note: To determine the thread engagement point:

- Screw the safety pin about one turn,

- Pull the safety pin out while unscrewing it.

F. Refit the packing follower, packing flange, and flange

nuts (8b). Tighten the packing assembly correctly. If

the valve is equipped with an Air-to- Open actuator,

release the air pressure or turn the handwheel to

bring the plug back into contact with the seat ring.

Put back into service.

5.6 7700P OR 7700E POSITIONER MAINTENANCE

(Figures 22, 23, 24, 25, 26 and 27)

Caution: Shut off the signal and supply

pressure. Isolate and depressurize the valve

body.

A. Disconnect the two pressure connection nuts (138a)

and pull tubing (140) out.

18 | GE Oil & Gas

Page 19

B. Loosen the two cap screws (141a) and remove

manifold block (144), spring (158), gasket (146) and its

three O-rings, pilot valve assembly (155 to 157), shims

(145), and O-ring (153).

Caution: Handle the shims carefully (145).

C. Loosen locknut (117) and take-up screw (116), unhook

the spring clamp from lever (22) or (113).

D. Unscrew cap screws (141b) from positioner block (147)

and remove the positioner block from the actuator

bracket.

Remove screws (148) to separate positioner diaphragm

assembly (152) and spring (154) from the positioner

block. Examine all the parts and replace if worn or

damaged.

E. Refit positioner diaphragm assembly (152) and spring

(154) to positioner block and tighten screws (148).

Check that the small signal port Oring is in its recess

in the diaphragm assembly.

F. Reinstall the block assembly on the actuator bracket.

Note: When installing the positioner block (147), turn it

so that when the manifold block (144) is installed, the

gauge(s) is(are) facing in the right direction (figure 22).

Note: The ports in gasket (146) must be aligned with

those in the positioner block (147).

To ensure correct positioner performance, check that all

gaskets are perfectly leaktight.

I. Hook spring clamp (115) to lever (22) or (113). In the

case of VariPack 28001 valve, see figure 6 to position

the spring clamp (115) according to the actuator

required action. Admit the supply pressure and

the signal. Set the start-up pressure following the

instructions given in the "Calibration" chapter. Put

back into service.

Positioner Signal (Psi)

3-15

or

6-30

or

7700P

7700E 4-20 mA

Figure 23 - Color code for positioner springs

3-27

3-9

9-15

(114 and 154)

Spring ref.

No.

114

154

114

154

114

154

114

154

Spring color

code

Yellow

Red

White

Blue

White

Green

Yellow

Red

Figure 22 - Positioner assembly

Note how the positioner (147) and gasket (146) are oriented

G. Check that gasket (146), three O-rings, and seats are

not worn or damaged and replace if necessary.

H. Fit O-ring (153), shims (145), pilot valve assembly,

gasket (146) and its three O-rings, spring (158) and

manifold block (144). Tighten the screws (141a), refit

tubing (140) and tighten pressure connection nuts

(138a).

5.7 MAINTENANCE OPERATIONS SPECIFIC TO THE

7700E POSITIONER

REFER TO ATEX INSTRUCTION MANUAL

No. 185977 FOR ALL MAINTENANCE ON

THE ELECTRICAL PARTS OF THE 7700E

POSITIONER.

A. Loosen screws (27) and remove I/P module (20).

Note: If damaged, the I/P module must be replaced.

B. Check that O-rings (28, 29 and 30) and their seats are

not worn or damaged.

Note: All worn or damaged parts must be replaced.

C. Fit O-rings (28, 29 and 30) in their recesses on the I/P

module (20). Refit I/P module (20) on manifold block

(144). Tighten screws (27).

Note: To ensure correct positioner performance, check

that all gaskets are perfectly leaktight.

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 19

Page 20

5.8 CONVERTING A 7700P POSITIONER (PNEUMATIC)

INTO A 7700E POSITIONER (ELECTROPNEUMATIC)

C. If the parts mentioned above have been removed,

proceed as follows:

A kit comprising the manifold block (144) and the I/P

module (20) is available from your local Masoneilan

representative or the Spare Parts Department.

REFER TO ATEX INSTRUCTION MANUAL

No. 185977 FOR ALL MAINTENANCE ON

THE ELECTRICAL PARTS OF THE 7700E

POSITIONER.

Shut off the signal and supply pressure. Isolate and

depressurize the valve body.

A. Disconnect the two pressure connection nuts (138a)

and pull the tubing (140) out.

B. Loosen the two cap screws (141a) and remove

manifold block (144). The spring (158), gasket (146)

and the three O-rings, the pilot valve assembly (155

to 157), shims (145), and O-ring (153) do not need to

be removed unless you have new parts. Otherwise,

simply check that parts are in perfect condition

before refitting.

Fit the O-ring (153), shims (145), pilot valve assembly (155

to 157), gasket (146) and the three O-rings, the spring

(158) and manifold block (144) - I/P module (20). Tighten

screws (141a), refit tubing (140) and tighten pressure

connection nuts (138a).

Note: The ports in gasket (146) must be aligned with

those in positioner block (147).

To ensure correct positioner performance, check that all

gaskets are perfectly leaktight.

D. Hook spring clamp (115) to lever (22) (VariPak 28002)

or (113) (VariPak 28001). In the case of VariPack

28001 valve, see figure 6 to position the spring clamp

(115) according to the actuator required action.

Admit the supply pressure and enable the electrical

signal. Adjust the start-up pressure following the

instructions under "Calibration". Put back into service.

Caution: Handle the shims carefully (145).

20 | GE Oil & Gas

Page 21

Figure 24 - Cross-section of the VariPak 28002 adjustable-Cv actuator and the 7700P positioner

PARTS LIST

Ref. Qty Part Name Ref. Qty Part Name Ref. Qty Par t Name

Δ ☐ 1

Ο 2

b

3

d

☐ e

☐ 3 f

4

5

Ο 6

7

8 a

8 b

9

10

11

12

13 a

13 b

18

20

21

22

23

24

25

26

27

Ο 28

Ο 29

Ο 30

Ο Recommended spare parts

☐ Complete subassembly includes: plug and stem (183),

retaining ring (182), seat ring (3e) and spacer (3f) (see

figure 2).

Only for pneumatic positioner.

See Figure 2.

1

1/4" NPT pipe plug 101 1 Grommet support plate

1

Seat-ring gasket 102 1 Spring button

1

Seat ring Cv max. 3.8 103 1 Locknut

a

1

Seat ring Cv max. 2.3 and 1.2 104 2 Clevis

1 Seat ring Cv max. 0.25 and

c

0.60

1

Seat ring Cv max . 0.10 106 1 Conical compression spring

1

Seat ring Cv max. < 0.10 Ο 107 1 Grommet

1

Spacer Cv max. < 0.10 108 1 Actuator bracket

1

Seat-ring retainer 109 2 Cover screw

1

Packing spacer 110 1 Cover

1

Packing ring

2

Packing flange stud

2

Mounting nut

2

Packing flange nut

1

Packing follower

1

Packing flange

1

Safety pin

1

a

Plug/stem Cv max. 3.8

1

b

Plug/stem Cv max. 2.3

1

c

Plug/stem Cv max. 1.2 & 0.6

1

d

Plug/stemCv max. 0.25 & 0.10 123 1 Cover plug

1

Body Cv max. < 3.8 124 1 Pivot pin No. 4

1

Body Cv max. 3.8 125 1 Locknut ■ 165 2 Logo

1

Pivot pin No. 3 (22/108) 126 1 Indicator 168 1 Cover washer

1

I/P module 127 1 Indicator plate

1

Lever No. 1 129 2 Indicator plate screw

1

Lever No. 2 130 2 Speed nut

1

Adjustment pin 131 1 P isto n S/A 173 1 Cover plug

1

Cv adjustment knob 133 2 Serial plate screw ▼ 180 1 Limit stop

1

Cv adjustment plate 134 1 Actuator spring ▼ 181 1 Locknut

2

Adjustment plate screw 135 1 Serial plate 182 1 Retaining ring (Cv max . <0.10)

4

Screw Ο 136 1 Diaphragm 183 1 Plug (Cv max . <0.10)

1

O-ring 137 1 Diaphragm cover 184 2 Pivot pin No. 2

1

O-ring

1

O-ring 139 1 Cover cap screw

105 1 Pivot pin No. 1

112 (a, b, c)

114

115

116

117

118

119

120

121

122

138

See table in figure 23.

Only for handwheel (optional) (fig. 5).

Ο Complete subassembly includes Ref. Nos. (155, 156

and157).

■ Not shown.

6 Retainer clip

1 Balance spring

1 Spring clamp

1 Take-up screw

1 Locknut

1 Handwheel locknut

1 Handwheel bushing

1 Handwheel

1 Handwheel lock

1 Lever arm stop

1 Union elbow t(incl. 138a)

140

141 (a, b)

142

143

144

145

Ο

146

147

148

Ο

152

Ο

153

♥ 154

Ο

155

Ο

156

Ο

157

158

Δ 159

Δ 16 0

Δ 161

Δ 162

Δ 163

Δ 16 4

170

171

■

172

■

▲ Only for cast bodies.

▼ Only on actuator with handwheel and/or Model 8013

E.P. positioner (fig. 5).

Δ Only for optional limit-switch adaptation: quantity

given for two limit switches (see fig. 13).

1 Tubin g

4 Screw

1 Output gauge

1 Instrument gauge

1 Manifold block

1 to 5 Shim

1 Gasket (includes 171 & 172)

1 Positioner block

2 Slotted flat. c screw

1 Positioner diaphragm S/A

1 O-ring

1 Spring

1 Sleeve

1 Spool

1 Spring

1 Spring

2 Switch

4 Screw

4 Washer

4 Nut

4 Wire

1 Terminal

2 Signal decal

1 O-ring

1 O-ring

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 21

Page 22

18 0

18 1

Figure 25 - Cross-section of the VariPak 28001

single-lever actuator and the

7700E positioner

22 | GE Oil & Gas

Figure 26 - Partial cross-section of VariPak

28001 single-lever, air-to-open

valve

Page 23

Masoneilan VariPak Adjustable Cv Control Valves Instruction Manual | 23

Page 24

18 0

18 1

Figure 27 - Partial cross-section of VariPak 28002

adjustable-Cv, air-to-open valve

Figure 28 - Partial top view

24 | GE Oil & Gas

Figure 29 - Coupling detail of levers No. 1 and 2

Page 25

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane:

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth:

Phone: +61-8-6595-7018

Fax: +61 8 6595-7299

Melbourne:

Phone: +61-3-8807-6002

Fax : +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Masoneilan and VariPak are registered trademarks of the General Electric Company.

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2014 General Ele ctric Compa ny. All rights res erved.

GEA30857 03/2014

Loading...

Loading...