Page 1

GE Oil & Gas

21000 Series

Masoneilan* Top Guided Globe Valve with

Lo-dB* / Anti-cavitation capabilities

Instruction Manual

GE Data Classification : Public

Page 2

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFIC

REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION

AND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE PHILOSOPHIES VARY,

GE (GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES AND AFFILIATES) DOES NOT ATTEMPT

TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND REQUIREMENTS

CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING

OF THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENT

IN POTENTIALLY HAZARDOUS ENVIRONMENTS. THEREFORE, THESE INSTRUCTIONS SHOULD

BE INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY RULES AND REGULATIONS

APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER

EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT

NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH

INSTALLATION, OPERATION OR MAINTENANCE. SHOULD FURTHER INFORMATION BE DESIRED

OR SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED SUFFICIENTLY FOR THE

CUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR ARE STRICTLY

LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY OF THE

EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY GE REGARDING THE

EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE INSTRUCTIONS.

THESE INSTRUCTIONS CONTAIN PROPRIETARY INFORMATION OF GE, AND ARE FURNISHED TO THE

CUSTOMER/OPERATOR SOLELY TO ASSIST IN THE INSTALLATION, TESTING, OPERATION, AND/OR

MAINTENANCE OF THE EQUIPMENT DESCRIBED. THIS DOCUMENT SHALL NOT BE REPRODUCED IN

WHOLE OR IN PART NOR SHALL ITS CONTENTS BE DISCLOSED TO ANY THIRD PARTY WITHOUT THE

WRITTEN APPROVAL OF GE.

Page 3

Table of Contents Page

IMPORTANT: SAFETY WARNING .......................................................... .................................................1

1. INTRODUCTION .................................................................................................................................. 2

2. GENERAL 2

3. UNPACKING ......................................................................................................................................... 2

4. INSTALLATION..................................................................................................................................... 2

5. AIR PIPING 3

6. BODY DISASSEMBLY ........................................................................................................................... 3

6.1 THREADED TRIM ...............................................................................................................................................3

6.2 QUICK-CHANGE TRIM ....................................................................................................................................3

7. MAINTENANCE/REPAIR ..................................................................................................................... 3

7.1 THREADED SEAT RING REMOVAL ..............................................................................................................3

7.2 BUSHING REMOVAL ........................................................................................................................................4

7.3 LAPPING SEATS .................................................................................................................................................4

7.3.1 THREADED TRIM.............................................................................................................................4

7.3.2 QUICK-CHANGE TRIM ..................................................................................................................4

7.4 Lo-dB PLUG .........................................................................................................................................................5

7.5 PLUG STEM PINNING ......................................................................................................................................5

7.6 PACKING BOX .....................................................................................................................................................6

7.6.1 KEVLAR/PTFE PACK. RING (STANDARD) ...............................................................................6

7.6.2 EXPANDED GRAPHITE P. RING (OPTION)..............................................................................6

7.6.3 LE PACKING (LOW EMISSION) (OPTION) ...............................................................................7

7.7 SOFT SEAT PLUG ...............................................................................................................................................8

8. VALVE BODY REASSEMBLY ................................................................................................................ 8

8.1 THREADED TRIM ...............................................................................................................................................8

8.2 QUICK-CHANGE TRIM ....................................................................................................................................9

8.3 HIGH PRESSURE & ANGLE DESIGN ..........................................................................................................9

9. ACTUATORS ......................................................................................................................................... 9

9.1 TYPES 87/88 ACTUATORS .............................................................................................................................9

10. BELLOWS SEAL ASSEMBLY ............................................................................................................... 9

10.1 BELLOWS VALVE DISASSEMBLY............................................................................................................14

10.1.1 THREADED TRIM ....................................................................................................................... 14

10.1.2 QUICK-CHANGE TRIM ............................................................................................................14

10.2 REPAIR .............................................................................................................................................................15

10.2.1 PLUG / STEM BELLOWS / BONNET EXTENSION S/A ................................................ 15

10.3 PLUG AND SEAT RING SEATING SURFACES ....................................................................................16

10.4 BONNET REASSEMBLY ..............................................................................................................................16

10.5 VALVE BODY REASSEMBLY ......................................................................................................................16

10.6 ACTUATOR TO BODY S/A AND PLUG STEM ADJUSTMENT .......................................................16

Page 4

Safety Information

Important - Please Read Before

Installation

The 21000 Series Control Valves instructions contain DANGER, WARNING, and CAUTION labels, where necessary, to

alert you to safety related or other important information.

Read the instructions carefully before installing and maintaining your control valve. DANGER and WARNING hazards

are related to personal injury. CAUTION hazards involve

equipment or property damage. Operation of damaged

equipment can, under certain operational conditions, result

in degraded process system performance that can lead to

injury or death. Total compliance with all DANGER, WARN-

ING, and CAUTION notices is required for safe operation.

This is the safety alert symbol. It alerts you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

About this Manual

• Theinformationin this manual is subjecttochangewithout

prior notice.

• Theinformationcontainedinthismanual,inwholeorpart,shall

not be transcribed or copied without ’s written permission.

• Pleasereportanyerrorsorquestionsabouttheinformationin

this manual to your local supplier.

• These instructions are written specifically for the 21000

Series Control Valves, and do not apply for other valves

outside of this product line.

Warranty

Items sold by General Electric are warranted to be free from

defects in materials and workmanship for a period of one

year from the date of shipment provided said items are used

according to GE's recommended usages. GE reserves the right

to discontinue manufacture of any product or change product

materials, design or specifications without notice.

This instruction manual applies to the

The control valves MUST BE:

• Installed, putintoserviceandmaintainedbyqualifiedand

competent professionals who have undergone suitable

training.

• Under certain operating conditions, the use of damaged

equipment could cause a degradation of the performance

of the system which may lead to personal injury or death.

• Changesto specifications,structure,andcomponentsused

may not lead to the revision of this manual unless such

changes affect the function and performance of the product.

21000 Series Control Valves.

Indicates a potentially hazardous situation which, if not

avoided, could result in serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

When used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could

result in property damage.

Note: Indicates important facts and conditions.

• All surrounding pipe lines must be thoroughly flushed to

ensure all entrained debris has been removed from the

system.

© 2014 General Electric Company. All rights reserved.

Masoneilan 21000 Series Top Guided Globe Valve | 1

Page 5

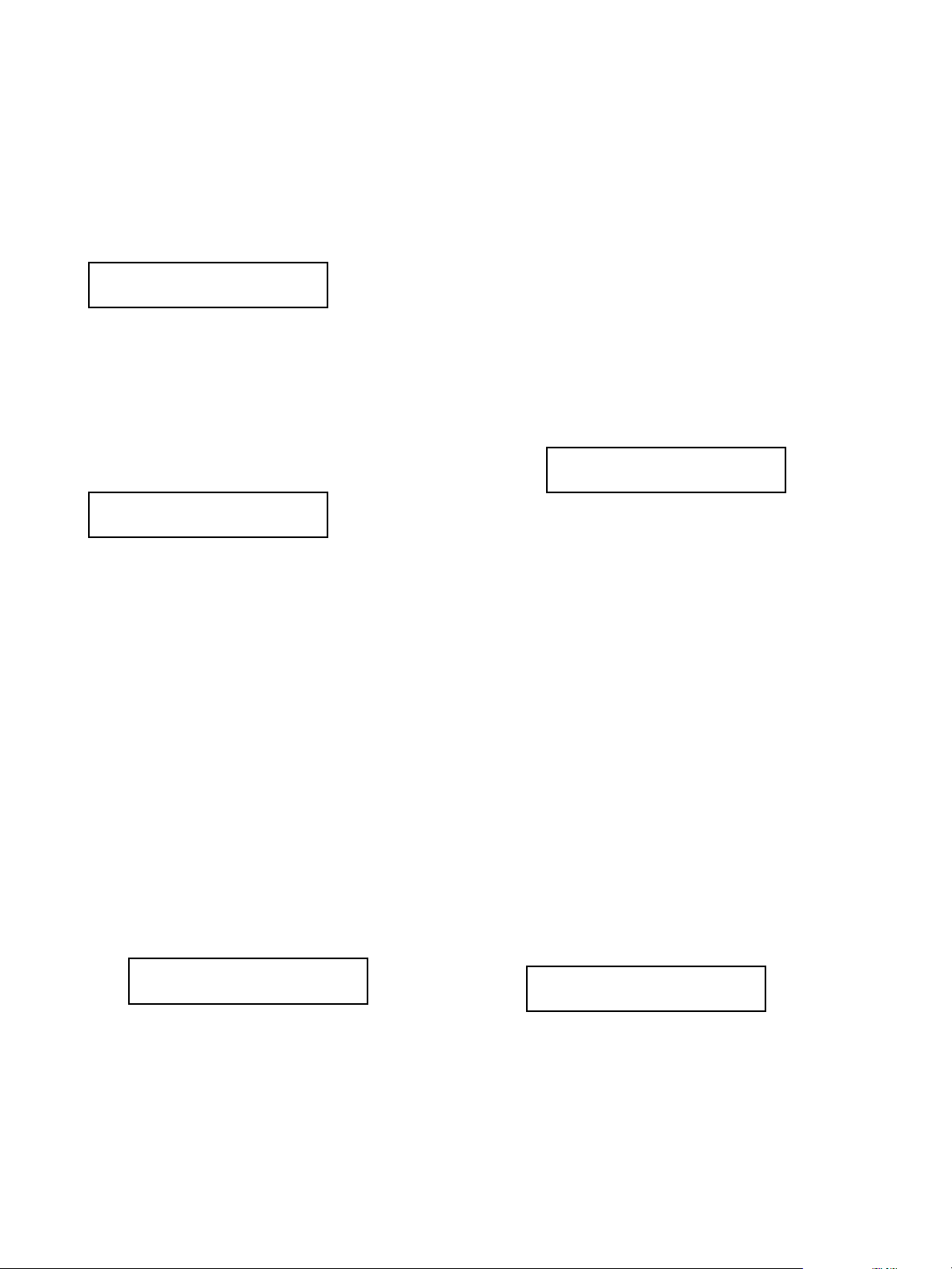

1st

2nd

1st

2nd

3rd

4th

5th

6th

Actuator Type

87 Spring Diaphragm

Air to Close

88 Spring Diaphragm

Air to Open

Body

Series

21

Plug Type

0. Undefined

1. Contoured

6. Soft Seat

7. Single Stage

Lo-dB/

Cavitation

Containment

8. Double Stage

Cavitation

Containment

9. Double Stage

Lo-dB

1. lntroduction

The following instructions should be thoroughly reviewed

and understood prior to installing, operating or performing

maintenance on this equipment. Throughout the text,

safety and/or caution notes will appear and must be strictly

adhered to, otherwise, serious injury or equipment malfunction

could result.

GE has a highly skilled After Sales Department available for startup, maintenance and repair of our valves and component parts.

Arrangements for this service can be made through your local GE's

Masoneilan representative or sales department. When performing

maintenance use only Masoneilan replacement parts. Parts

are obtainable through your local representative or spare parts

department. When ordering parts, always include Model and Serial

Number of the unit being repaired.

2. General

These installation and maintenance instructions apply to all sizes

and ratings of the 21000 Series control valves regardless of the

type of trim used.

21000 Series single ported top guided control valves are designed

with built in versatility making them well-suited to handle a wide

variety of process applications.

Standard construction offers a contoured plug (21100 Series) with a

threaded seat ring or a quick change seat ring. The heavy top plug

guiding provides maximum support to ensure plug stability.

A series of reduced area trim is available to provide wide flow

range capabilities in all valve sizes.

Tight Shutoff Class IV leakage is standard. Optional constructions

(one of which is the 21600 Series soft seat plug) meet IEC 534-4 and

ANSI/FCI 70.2 Class V and Vl requirements.

An optional Low Emission LE® Packing is available to assure

compliance with the fugitive emission containment requirements.

Replacing the conventional plug with the single stage Lo-dB

design (21700 Series) provides excellent noise attenuation or

anti-cavitation performance.

The 21800 Series double stage anti-cavitation valve is derived

from the 21700 single stage anti-cavitation valve through a

modification to the cage and plug. Substitution of the standard

Flow

Characteristics

0. Undefined

1. Linear

2. Equal

Percentage

3. Modified

Percent

Figure 1 - Numbering System

cage with an anti-cavitation cage permits the pressure drop to

be split between the two stages efficiently.

The 21900 Series double stage Lo-dB valve is also derived from

the 21700 single stage Lo-dB valve through a modification to the

cage and plug. Substitution of the standard cage, with a LodB cage permits the pressure drop to be split between the two

stages efficiently.

In the 21800/21900 Series designs, enlargement of the plug head up

to the cage diameter permits simultaneous throttling of the plug C

and the cage Cv. It also provides optimum allocation of the pressure

drop between the two stages along the entire plug travel.

Recommended spare parts required for maintenance are listed

in the Parts Reference table on page 17. The model number,

size, rating and serial number of the valve are shown on the

identification tag located on the actuator. Refer to Figure 1 for the

21000 series numbering system.

Seat Type

0. Undefined

4. Quick Change

5. Threaded

Optional

Configuration

A Angle Body

BS Bellows

Seal

EB Extension

Bonnet

C Cryogenic

Extension

Bonnet

3. Unpacking

Care must be exercised when unpacking the valve to prevent

damage to the accessories and component parts. Should any

problems arise, contact your local GE's Masoneilan representative

or sales department.

4. lnstallation

4.1 Before installing the valve in the line, clean piping and

valve of all foreign material such as welding chips, scale,

oil, grease or dirt. Gasket surfaces should be thoroughly

cleaned to ensure leak-proof joints.

4.2 To allow for in-line inspection, maintenance or removal of

the valve without service interruption, provide a manually

operated stop valve on each side of the 21000 Series

valve with a manually operated throttling valve mounted in

the by-pass line (See Figure 2).

4.3 The valve must be installed so that the controlled

substance will flow through the valve in the direction

indicated by the flow arrow located on the body.

• Withcontouredplug(21100/21600)

or Lo-dB plug (21700/21900) :flow-to-open

• Onanti-cavitationdesign(21700/21800) :ow-to-close

v

2 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 6

CAUTION

WARNING

CAUTION

WARNING

4.4 For heat-insulated installation, do not insulate the valve

CAUTION

WARNING

CAUTION

WARNING

CAUTION

WARNING

bonnet. Take necessary protective measures relate to

personal safety.

5. Air Piping

The actuators are designed to accept 1/4" NPT air supply piping.

1

/4" OD tubing (4 x 6 mm) or equivalent for all air lines. If the

Use

supply air line exceeds 25 feet in length (7 meters) or if the valve

is equipped with volume boosters, then 3/8" tubing (6 x 8 mm) is

preferred. AII connections must be free of leaks.

Do not exceed supply pressure indicated on serial plate located on

the yoke of the actuator.

6. Body Disassembly

Access to the internal components of the body should be

accomplished with the actuator removed. To remove the

actuator from the body, refer to the actuator instruction Ref.

GEA19530 for a type 87/88 multispring actuator.

Prior to performing maintenance on the valve, isolate the valve

and vent the process pressure. Shut off the supply air line and the

pneumatic or electric signal line.

6.1 Threaded Trim (Figure 12 or 14)

After removing the actuator, disassemble the body using the

following procedure :

A. If there is a leak detector connection on the lateral NPT

port of the bonnet, disconnect this piping as well.

B. Remove body stud nuts (10).

C. Remove bonnet (8), and plug stem (1) and plug (16) sub-

assembly together as one unit.

Note: Spiral wound body gaskets (11) are standard in the

21000 Series design and it is imperative that a new gasket

be installed each time the valve is disassembled.

D. Remove packing flange stud nuts (3), packing flange (4)

and packing follower (5).

E. Remove plug (16) and plug stem (1) sub-assembly from the

bonnet (8).

6.2 Quick-Change Trim (Figure 13 or 15)

After removing the actuator, disassemble the body using the

following procedure:

A. If there is a leak detection connection on the lateral NPT

port of the bonnet, disconnect this piping as well.

B. Remove body stud nuts (10).

C. Remove bonnet (8), and plug stem (1) and plug (16) sub-

assembly together as one unit.

D. Since the cage (13), seat ring (14) and seat ring gasket (15) are

held in place by the bonnet, they may now be removed.

Note: Spiral wound gaskets (11 & 15) are standard in the

21000 Series design and it is imperative that new gaskets be

installed each time the valve is disassembled.

E. Remove packing flange stud nuts (3), packing flange (4)

and packing follower (5).

F. Remove plug (16) and plug stem (1) sub-assembly from

the bonnet (8).

Care must be taken to avoid damage to the plug and plug

guide.

G. Remove old packing (6) [and optional lantern ring (7) if a

leak detection connection has been installed]. Refer to

Figure 5.

H. All components may now be inspected for wear and service

damage. After determining the maintenance required,

proceed to the appropriate Section of this instruction

manual.

7. Maintenance & Repair

The purpose of this section is to provide recommended

maintenance and repair procedures. These procedures assume

the availability of standard shop tools and equipment.

7.1 Threaded Seat Ring Removal (Figure 12 or 14)

Threaded seat rings (14) are installed tightly by the

manufacturer, and after years of service they may be difficult

to remove.

To facilitate removal, seat ring wrenches can be fabricated

to engage the seat ring lugs and adapted to a standard

wrench. If the seat ring is exceptionally resistant to removal,

the application of heat or penetrating oil should be helpful.

Care must be taken to avoid damage to the plug and plug

guide.

F. Remove old packing (6) [and optional lantern ring (7) if a

leak detection connection has been installed]. Refer to

Figure 5.

G. Bonnet (8), plug (16), bushing (12) and seat ring (14) may

now be inspected for wear and service damage. After

determining the maintenance required, proceed to the

appropriate Section of this instruction manual.

© 2014 General Electric Company. All rights reserved.

When using heating devices, ensure that proper safety

practices are observed. Flammability and toxicity of the

process fluid must be considered and proper precautions

taken.

7.2 Bushing Removal

The bushing (12) is press fit into the bonnet and does not

normally require replacement. If necessary, it may be pulled

or machined out. When machining the bushing out, care must

be taken to maintain proper dimensions and tolerances in the

Masoneilan 21000 Series Top Guided Globe Valve | 3

Page 7

CAUTION

WARNING

CAUTION

WARNING

CAUTION

WARNING

bonnet. These will be furnished upon request.

CAUTION

WARNING

CAUTION

WARNING

7.3 Lapping Seats

Lapping is the process of working the valve plug against

the seat ring with an abrasive to produce a close fit. If

valve leakage is excessive, lapping becomes necessary. The

plug and seat ring seating surfaces should be free of large

scratches or other defects, and the contact surfaces of the

seats should be as narrow as possible. This may require

dressing both parts in a lathe. The seating surface angle of the

plug is 28 degrees and the seat ring is 30 degrees (relative to

the centerline axis). A good grade of fine grinding compound

is required for the lapping operation.

The compound should be mixed with a small quantity of

lubricant such as graphite. This will slow the cutting rate

and prevent tearing of the seating surfaces. The amount

of lapping required depends on the materials, condition of

seating surfaces, and accuracy of machining. lf a short period

of lapping does not visibly improve seating, there is usually no

advantage in continuing as excessive lapping may result in

rough seats. The only remedy is replacement or re-machining

of one or both parts. When lapping new plugs and seat rings,

begin with a medium fine (240 grit) and finish with a finer

grade (600 grit).

Note: Lapping should produce a line contact area, not the

entire surface, due to the difference in seat angles.

Before lapping, the plug and stem sub-assembly must be

concentric. (See pinning operation, section 7.5).

7.3.1 Threaded Trim (Figure 12 or 14)

1. CIean body gasket surface areas.

2. When seat has been removed, ensure that the sealing

surface in the body bridge and the threads are

thoroughly cleaned.

Note: A sealant compatible with the process should be

applied sparingly to the seat ring threads and sealing

shoulder.

3. lnstall and tighten seat ring using fabricated wrench

used for removal.

Do not over-tighten. Do not strike seat ring lugs

directly. This could distort the seat ring resulting in seat

leakage.

4. Apply lapping compound on the plug at several spots

equally spaced around the seating area.

5. lnsert the stem and plug sub-assembly carefully into

the body until it is seated.

6. Place bonnet (8) on the body and fasten the bonnet to the

body using four body stud nuts (10) spaced equally apart.

Apply slight pressure and tighten evenly.

Do not tighten nuts to final torque specifications at

this time. The bonnet is used temporarily for guiding

purposes only.

7. lnsert two or three pieces of packing (6) into the packing

box to assist in guiding the stem and plug during lapping.

8. Screw a drilled and tapped rod with a T-handle onto the

plug stem and secure with a locknut (see Figure 4).

Note: As an alternative, drill a hole through a flat steel

plate and fasten to the plug stem using two locknuts.

9. Apply slight pressure on the stem, and rotate the stem

in short oscillating strokes (around 8 to 10 times).

Repeat this step as necessary.

Note: The plug should be lifted and turned 90° each

time before repeating Step (9). This intermittent lifting is

required to keep the plug and seat ring concentric during

lapping.

Avoid over-lapping as this can cause damage to

the seating surface rather than improve leakage

performance.

10.After completion of the lapping operation, remove bonnet

and plug. The seating area of the seat ring and the plug

must be cleaned of all lapping compound in preparation

for reassembly. Do not remove seat ring.

7.3.2 Quick-Change Trim (Figure 13 or 15)

1. CIean body gasket surface areas.

2. Install a new seat ring gasket (15) and insert seat ring

(14) in the body.

Note: Gasket (15) is temporarily placed to hold the seat

ring during lapping.

It is imperative to use a new gasket or a test part

having the same geometrical characteristics in

order to ensure the correct position of the seat ring

during lapping.

This gasket (or similar part) can be kept after lapping

for future use.

The gasket used for lapping must not be reused for

the body reassembly.

3. Apply lapping compound at several spots equally

spaced around the seating area of the seat ring.

4. Insert the cage (13) into the body.

5. lnsert the stem and plug sub-assembly carefully into

the body until it is seated.

6. PIace bonnet (8) on the body.

Ensure that the seat ring (14), cage (13) and bonnet (8)

are properly aligned.

4 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 8

7. Fasten the bonnet to the body using four body stud

CAUTION

WARNING

CAUTION

WARNING

nuts (10) spaced equally apart. Apply slight pressure

and tighten evenly.

Do not tighten nuts to final torque specifications at

this time. The bonnet is used temporarily for guiding

purposes only.

8. Insert two or three pieces of packing into the packing box

to assist in guiding the stem and plug during lapping.

9. Screw a drilled and tapped rod with a T-handle onto the

plug stem and secure with a locknut (see Figure 4).

Note: As an alternative, drill a hole through a flat steel

plate and fasten to the plug stem using two locknuts.

10. Apply slight pressure on the stem, and rotate the stem

in short oscillating strokes (around 8 to 10 times).

Repeat this step as necessary.

Note: The plug should be lifted and turned 90° each

time before repeating Step (10). This intermittent lifting

is required to keep the plug and seat ring concentric

during lapping.

11. After completion of the lapping operation, remove

bonnet and internal parts. The seating area of the

seat ring and the plug must be cleaned of all lapping

compound in preparation for reassembly.

7.4 Lo-dB PIug (Figure 8, 14 or 15)

The procedures used for performing maintenance on a valve

equipped with Lo-dB plugs (21700/21800/21900 Series) are the

same as those used for Threaded or Quick Change Trim.

B. Screwing Stem to Plug

•

Hold the plug (with vise jaw assembly) in a vise.

•

Lock two nuts against each other on the end of the new

plug stem, and screw the stem solidly into the plug using a

wrench on the upper nut.

When properly assembled, the reference mark (see Section A

above) should be flush with the end of the plug guide.

C. Drilling the New Parts

• If the plug is already fully drilled (typical for 440 C hardened

stainless steel material or solid Stellite or Equivalent), then

drill the stem to the same diameter (Diameter C in Figure 9)

as the plug shank hole.

• Iftheplugguideareahasacentermark,

PIace the plug guide on a V-block and use a suitable drill

size to either:

— Match the hole size in the plug, or

— Match Diameter C (see Figure 9)

Drill through the plug-stem assembly.

• Ifthe plug guide area does not have any hole or any

center mark,

— Measure Dimension D based on the plug guide diameter

and stem diameter (see Figure 9).

— PIace the plug guide on a V-block, and make a center

mark on the plug guide area using a center punch.

— Drill through the plug-stem assembly using a suitable size

drill bit.

In all cases after drilling: Remove any burrs from the plug

guide hole by making a slight chamfer.

Maintenance of the plug should be limited to cleaning of the

ports and the procedures defined under Sections 7.3 (Lapping)

and 7.5 (Pinning) as required.

7.5 PIug Stem Pinning

Plug stem pinning in the field may be required for the following:

— Replacing existing plug and stem, or

— Replacing existing stem only

Replacing Plug and Stem

If it is necessary to replace the plug, then the plug stem

must be replaced at the same time. The original pin hole in

an existing stem will not provide the necessary fit, and might

seriously impair the strength of the assembly.

A. Reference Marking on the Plug Stem

Measure the depth of the pilot recess in the plug (Dimension X

in Figure 9), and make a reference mark on the plug stem at the

same distance from the thread.

Note: While pinning is being performed, care must be taken not

to damage the seating surface or plug guide. Always use a soft

metal or plastic vice jaws with cylindrical features to hold the

plug guide area (see Figure 9).

D. Pinning the Plug-Stem Assembly

1.

Select the correct size pin based on the plug guide diameter

and stem diameter (see Figure 9). Apply a small amount of

grease on the pin and hand assemble it into the hole in the

plug.

2. Press fit the pin into the hole using a hammer. Complete

the pinning operation by taking care to ensure that the pin

is recessed by the same amount at both sides (see Figure

9).

3. After the plug has been pinned, it should be placed in a

lathe to ensure it is concentric with the stem.

If the assembly is not running true, then the stem should

be placed in a collet with the plug guide against it and the

plug should be adjusted. Alignment of plug stem can be

performed by means of a soft faced mallet.

Replacing Existing Stem Only

A. Removing Existing Pin and Stem

1.

Place the plug guide on a V-block and use a drift punch to

drive out the old pin.

Note: If it is necessary to drill out the pin, use a drill bit

slightly smaller than the pin diameter.

2. Hold the plug guide in a vise (see note on opposite side of

page).

3. Lock one nut against another at the end of the plug stem.

© 2014 General Electric Company. All rights reserved.

Masoneilan 21000 Series Top Guided Globe Valve | 5

Page 9

CAUTION

WARNING

CAUTION

WARNING

Using a wrench on the lower nut, unscrew the stem from the

CAUTION

WARNING

plug. The stem is removed by turning it counter-clockwise.

B. Screwing Stem to Plug

Refer to step B of the previous section on “REPLACING PLUG

AND STEM”.

C. Drilling the New Stem

PIace the plug guide on a V-block and use a suitable size drill

bit to drill the stem (use the hole in the plug as a guide).

Note: If the hole in the plug guide has been slightly damaged

while removing the old pin, choose a drill bit and a pin with a

slightly larger diameter than the normal pin.

D. Pinning

Select the correct size pin based on the plug guide diameter

and pin hole diameter. Proceed as described in part D of the

previous section, taking care not to damage the plug guide

area.

Ensure plug stem alignment following the pinning operation.

7.6 Packing Box (Figures 12 to 15)

Packing box maintenance is one of the principle action items

of routine servicing. Tightness of the packing is maintained

by packing compression. Compression is achieved by evenly

tightening the packing flange nuts (3) against the packing flange

(4). Care must be taken not to over tighten as this could prevent

smooth operation of the valve. If all compression is used up and

the valve leaks, then new packing is required.

Valve must be isolated and the pressure vented before

performing packing box maintenance.

Proceed as follows :

7.6.1 Braided PTFE with Carbon or Aramid Core

(Standard) (Figures 12 to 15)

Note: The Braided PTFE/Carbon or Aramid packing rings

have a skive cut allowing packing replacement without

disconnecting the plug stem from the actuator connector

or actuator stem.

A. Loosen and remove packing flange nuts (3).

B. Lift the packing flange (4) and packing follower (5) up

the valve stem.

Note: They may be taped in place to keep them out of

the way before proceeding.

C. By means of a hooked instrument, remove packing (6)

ensuring not to damage the sealing surfaces of the

packing box or plug stem.

Note: On valves equipped with an optional lubricator

connection, the lantern ring (7) must also be removed to

gain access to lower packing rings.

D. Replace packing rings (6).

Note: Assemble and compress rings one at a time into

packing box. The skive cut of each packing ring must be

placed about 120 degrees apart.

Note: On valves equipped with an optional lubricator

connection, refer to Figure 10 for correct amount of

rings to place under the lantern ring (7).

E. Replace packing follower (5) and packing flange (4).

F. Replace and tighten packing stud nuts (3).

Do not overtighten.

G. Place valve back in service and only tighten packing as

necessary to stop external leakage.

Note: In an emergency, string packing may be used as

a temporary repair only. It must be replaced with the

correct packing as soon as possible.

7.6.2 Flexible Graphite Rings (Optional - See Figure 6)

Note: Flexible graphite packing rings replacement may

require disconnecting the plug stem from the actuator stem

and removal of the actuator if rings are not skive cut.

A. Remove actuator from the body S/A. Refer to actuator

instruction Ref. GEA19530 for a type 87/88 actuator.

B. Loosen and remove packing flange nuts (3).

C. Remove packing flange (4) and packing follower (5)

from the plug stem.

D. By means of a hooked instrument, remove packing (6)

ensuring not to damage the sealing surfaces of the

packing box or plug stem.

Note: On valves equipped with an optional lubricator

connection, the lantern ring (7) must also be removed to

gain access to lower packing rings.

E. Replace new packing set (6); first assemble a back-

up ring (Graphite Filament Yarn braided ring), then

the flexible graphite rings (smooth rings), and finally

another braided back-up ring (refer to Figure 6).

Note: Assemble and compress rings one at a time into

packing box.

Note: On valves equipped with an optional lubricator

connection, refer to Figure 10 for correct arrangement

according to valve size.

F. Assemble packing follower (5) and packing flange (4).

G. Assemble and tighten packing stud nuts (3).

Do not overtighten.

H. Proceed to appropriate instructions for actuator and

valve assembly adjustment.

I. Place valve back in service and only tighten packing as

necessary to stop external leakage.

*

7.6.3 LE

The Masoneilan LE (Low Emissions) Packing from GE is a

high performance packing system capable of containing

fugitive emissions well below the specifications of the

most severe recommendations. It is also available in a

firesafe configuration.

Packing (Optional - See Figure 7)

6 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 10

The packing is provided as a set of five pieces. It consists of

CAUTION

WARNING

two adapter rings and three V-rings. An alternating pattern

of Perfluoroelastomer (PFE) and long carbon fiber filled

Teflon (PTFE) V-rings are used.

Applied properly, this packing exhibits very little cold flow

(or creep). Consequently, it can effectively prevent fugitive

emissions leaks from a control valve. The LE Packing

system can directly replace conventional packing,

requiring no modification to the control valve or actuator.

A spring loaded, two-piece follower assembly is used to

maintain a constant load on the packing, and is necessary

for thermal cycling applications. As the definition of thermal

cycling can vary, and processes are potentially subject to

unpredicted thermal gradients, LE Packing is only available

with the spring loaded follower.

Installation should be performed as detailed in the

following paragraphs.

7.6.3.1 Preparation

7.6.3.1.1 Stem

Inspect stem for any nicks or scratches on the

surface finish. Reject the stem for any of these

reasons as they may damage packing.

Note: A properly etched part number on the stem in

the packing area will have no adverse effect on the

performance of the packing.

Stem finish should be 3-7 AARH (Ra 0,1/0,2).

7.6.3.1.2 Packing Box

Note: Bonnets that have a lube hole or leak detection

port are unacceptable for use with the packing

arrangement shown in Figure 7.

Packing box should be clean and free of burrs, rust,

and any foreign matter. Parts can be cleaned with

denatured alcohol.

Note: Packing box finish should be 125 AARH (Ra 3,2)

or better.

The packing box may be bored or honed oversize by

up to 0.015" (0.38 mm) above the nominal diameter

to improve the finish. For instance, a nominal 0.875"

(22.22 mm) packing box may be bored or honed up

to 0.890" (22.60 mm) and the LE Packing will still seal

properly.

Packing box must be finished to the bottom of the

bore.

7.6.3.1.3 Packing

Inspect packing rings. Do not use packing if any

nicks or scratches on packing are observed.

Check packing and ensure that it is in the proper

arrangement (see Figure below). PFE material can

be identified by the gloss black molded finish. PTFE

material has a dull black machined finish.

PTFE - female adapter

PFE - V -Ring

PTFE - V-Ring

PFE - V -Ring

PTFE - male adapter

7.6.3.1.4 Spring Loaded Follower

The spring loaded follower consists of an upper and

lower follower and eight (8) disc springs (see Figure

below). The springs are installed inside the lower

follower and positioned alternately. The assembly

is held together by tape, which must be removed

before installation.

Upper

Scribe

Mark

Follower

Disc

Springs

Lower

Follower

7.6.3.2 Packing Installation

a. The packing must be lubricated with Krytox

®

fluorinated grease prior to installation (Krytox GPL206 or

equivalent).

b. Packing should be lubricated as a set (not

individually) to minimize getting lubricant

between the rings.

c. Packing should be lubricated with a generous

application to the O.D. and I.D. of the packing set.

Note: All exposed surfaces of the packing set must be

covered with the lubricant.

d. PFE/PTFE is to be installed as a set. Carefully slide

the packing set down the stem. Do not cock or

force the packing on the threads.

If the packing set separates while on the stem,

do not remove. Continue installing the remaining

pieces to put the set back together.

e. Gently press the packing into the packing box. Do

not tap the packing down into the box.

f. The spring loaded follower is installed on top of the

packing. This follower is installed as an assembly held

together by tape. This tape should be removed after

assembly. Proper assembly of the packing box will

leave the top of the Lower Follower 0.25 - 0.50 inches

(6 to 13 mm) above the bonnet.

A groove is scribed into the O.D. of the upper

follower. The packing flange is tightened evenly

until the top of the Lower Follower aligns with the

scribe mark (groove) in the Upper Follower.

Note: This is the optimum loading for this packing.

Further tightening will shorten life of the packing.

Thread locking compound can be used on packing

nuts.

g. The packing should be checked for leakage.

h. Packing load should be checked after the valve has

© 2014 General Electric Company. All rights reserved.

Masoneilan 21000 Series Top Guided Globe Valve | 7

Page 11

CAUTION

WARNING

CAUTION

WARNING

CAUTION

WARNING

cycled approximately 500 times. Adjust if necessary.

CAUTION

WARNING

CAUTION

WARNING

CAUTION

WARNING

No further adjustment should be required for the life

of the packing.

7.7 Soft Seat Plug (Figure 3)

The soft seat plug used in the 21000 Series valve has a

replaceable insert. To remove and replace the insert, proceed

as follows.

The shank OD is the plug guide. Extreme care must be taken to

prevent scoring or marring this surface. Failure to do so could

result in damage to the guide bushing and destruction of the

plug. Two flats are provided for holding.

A. Loosen set screw until the head of the set screw is flush

with the OD of the shank.

Note: On 3/4"‑ 2" size valves, the plug tip has a machined

slot into which a bar can be inserted for removal. On 3"‑ 6"

size valves, the plug tip has two machined holes into

which a tool (fabricated with appropriate size pins) can be

inserted for removal.

B. Carefully place plug sub-assembly into a soft jaw vise,

holding the plug by the flats provided on the upper end of

the shank.

When using a vise to hold the plug, extreme care must be

taken not to damage the plug shank.

C. Using the appropriate tool, unscrew plug tip (counter-

clockwise) from the shank sub - assembly.

D. Remove insert O-ring (for valve sizes 3"- 8" only) and insert

retainer. Discard existing insert and O-ring.

E. Thoroughly clean all remaining metallic components

and install new insert and O-ring as follows (according to

valve size):

For 3/4"- 2" valves :

a. Place new insert on shank and insert retainer as

shown in Figure 3.

b. lnstall plug tip into shank sub-assembly. Hand tighten

and ensure plug tip seats evenly against insert.

For 3" - 8" valves:

a. Apply a light coat of lubricant to the O-ring and install on

insert retainer.

Ensure any lubricant used is compatible with service

conditions.

b. Install new insert on insert retainer and assemble as

shown in Figure 3.

c. Install plug tip into insert retainer sub-assembly

insuring the plug tip seats evenly on the insert.

F. Carefully place the plug sub-assembly into a soft jaw vise,

holding the plug by the flats provided on the upper end of

the shank.

When using a vise to hold the plug, extreme care must be

taken not to damage the plug shank.

G. Using the appropriate tool used during disassembly, firmly

tighten the plug tip.

The plug tip must be tightened, allowed to set for

approximately 4 hours, re-tightened, allowed to set another

4 hours, then tightened one more time. The purpose of this

tightening sequence is to allow the insert material to “cold

flow” into place on the plug sub-assembly.

H. Following the above tightening sequence, securely

tighten the set screw down into the plug. Plug is ready for

assembly into the valve.

8. Valve Body Reassembly

After completion of the required maintenance, the valve should

be reassembled using the following procedures:

Note: If any of the following steps were completed during

maintenance, then proceed to the next step.

8.1 Threaded Trim (Figure 12 or 14)

A. CIean all gasket mating surfaces.

B. Apply a small amount of sealant to the seat ring threads

and sealing shoulder. Install seat ring into valve body.

Note: A sealant compatible with the process should be

applied sparingly.

C. lnstall and tighten seat ring using wrench used for removal.

Do not over-tighten. Do not strike seat ring lugs directly.

This could distort the seat ring resulting in unwarranted

seat leakage.

D. Carefully install plug and stem assembly.

Note: Valve should be lapped before final assembly. See

Section 7.3.

E. Install body gasket (11).

Note: Spiral wound body gaskets (11) are standard in the

21000 Series design. It is imperative that a new gasket be

installed each time the valve is disassembled.

F. Assemble bonnet (8) and body stud nuts (10). Bonnet must

be positioned so the packing flange studs are at 90° to the

flow center line.

8 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 12

CAUTION

WARNING

CAUTION

WARNING

3

/4" - 2" Valve Sizes 3" - 8" Valve Sizes

CAUTION

WARNING

CAUTION

WARNING

CAUTION

WARNING

Tighten nuts (10) until metal to metal contact is obtained

with proper bolt torque. Refer to Figure 11 for proper bolt

torque and tightening sequence specifications.

G. lnsert packing (6) [and lantern ring (7) on valve equipped

with an optional lubricator connection]. Refer to Section

7.6 for proper packing assembly procedure for standard

or optional designs.

H. Install packing follower (5) and packing flange (4).

I. lnstall packing flange stud nuts (3).

Do not overtighten (See Section “7.6. Packing Box”).

J. If a leak detection connection was installed, connect it on

the lateral NPT port in the bonnet. If not, ensure that the

1/4" NPT plug remained in place (Figure 5).

K. For actuator assembly and plug stem adjustment , proceed

to the actuator instruction Ref. GEA19530 for a type 87/88

actuator.

I. Install packing flange stud nuts (3).

Do not overtighten (See Section “7.6. Packing Box”).

J. If a leak detection connection was installed, connect it on

the lateral NPT port in the bonnet. If not, ensure that the

1/4" NPT plug remained in place (Figure 5).

K. For actuator assembly and plug stem adjustment , proceed

to the actuator instruction Ref. GEA19530 for a type 87/88

multispring actuator.

8.3 High Pressure & Angle Design (Figures 16 & 17)

Standard trim is used within these optional body configurations.

Refer to the applicable sections within this instructions manual.

9. Actuators

9.1 Types 87/88 Actuators

Refer to Instruction Ref. GEA19530 for removal, maintenance,

assembly and adjustment.

10.Bellows Seal Assembly

8.2 Quick-Change Trim (Figure 13 or 15)

A. CIean all gasket mating surfaces.

B. Install seat ring gasket (15) and seat ring (14).

Note: Spiral wound gaskets (11 & 15) are standard in the

21000 Series design. It is imperative that a new gasket be

installed each time the valve is disassembled.

C. Install cage (13).

D. Carefully install plug and stem assembly.

Note: Valve should be lapped before final assembly. See

Section 7.3.

Note: For 2" valves with Cv 30 Lo‑dB / Anti‑Cavitation trim

only, steps C and D must be reversed such that the plug

and stem assembly is installed prior to the cage.

E. Install body gasket (11).

F. Assemble bonnet (8) and body stud nuts (10) and tighten.

Bonnet must be positioned so the packing flange studs

are at 90° to the flow center line.

Care must be taken to ensure that the cage, seat, and

bonnet are properly aligned in the body. Cage should be

installed with parts at lower end, near seat ring. Tighten

nuts (10) until metal to metal contact is obtained with

proper bolt torque. Refer to Figure 11 for proper bolt

torque and tightening sequence specifications.

G. lnsert packing (6) [and lantern ring (7) on valve equipped

with an optional lubricator or leak detection connection].

Refer to Section 7.6 for proper packing assembly

procedure for standard or optional designs.

H. Install packing follower (5) and packing flange (4).

SINCE THIS IS A SEALING

BELLOWS, THE PLUG STEM SHOULD NEVER BE TURNED UNDER

ANY CIRCUMSTANCES.

There is a built-in anti-rotation feature, consisting of a double flat

surface machined on the plug stem that slides into a rectangular

slot machined in the upper bushing (30) of the bellows (see Figure

19 - Section a).

IT IS IMPORTANT TO DISCONNECT THE ACTUATOR FROM THE

VALVE BEFORE CHANGING THE ACTUATOR ROTATIONAL POSITION.

Figure 2 - Typical Installation

Skirt &

Insert

Retainer

Set

Screw

Plug Tip

Figure 3 - Soft Seat Plugs (Optional)

Flats

Shank

Set

Screw

Insert

Retainer

Insert

Flats

O-ring

Plug

Tip

© 2014 General Electric Company. All rights reserved.

Masoneilan 21000 Series Top Guided Globe Valve | 9

Page 13

Figure 5 - Lubricator Connection (Optional)

T-Handle

Lock Nut

Figure 4 - Seat Lapping Device

Braided

Back-up Rings

®

Figure 7

LE

(Low Emission) Packing Arrangement (Optional)

Flexible

Graphite

Rings

Figure 6 - Flexible Graphite Rings Arrangement (Optional)

Figure 8

Lo-dB (Type 21900) and Anti-cavitation (Type 21800) Double

Stage Trim (Optional)

10 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 14

X

Reference Mark

D

C Dia.

X

Cylindrical machining

diameter of the jaws =

plug guide diameter “A”

AB

==

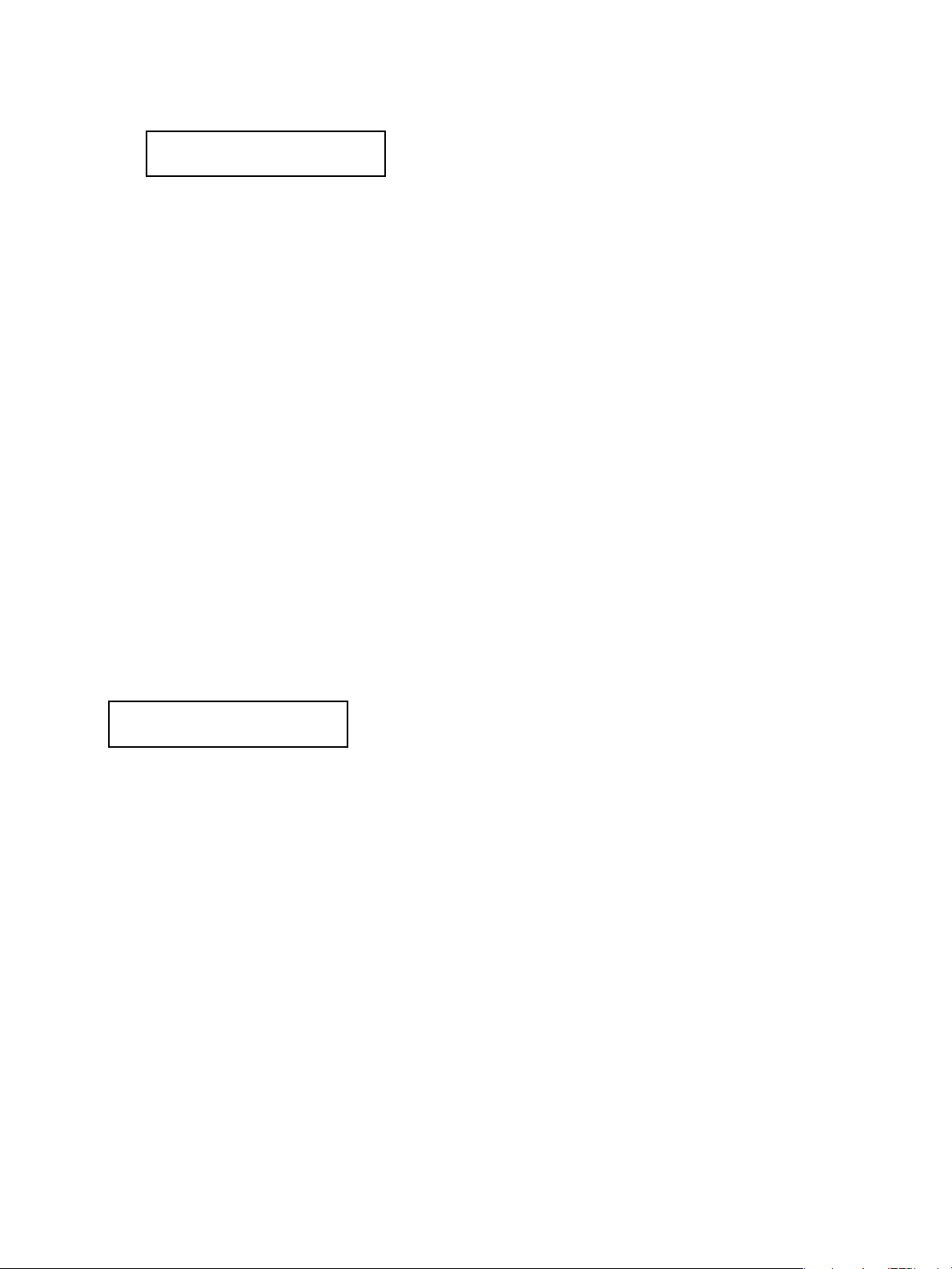

Packing box with Kevlar/PTFE

packing rings

Lantern

Ring

(7)

Plug Guide

Dia. “A”

in.

.87

1.50

2.38

2.75

Valve

Size

in.

3/4 to 4

6 to 8

mm

22.22

38.10

60.32

69.85

mm

20 to 100

150 to 200

Plug Stem

Dia. “B”

in.

1/2

1/2

3/4

3/4

mm

12.70

12.70

19.05

19.05

Pin Hole

Dia. “C”

in.

.138

.138

.197

.197

mm

3.50

3.50

5.00

5.00

Figure 9 - Plug Stem Pinning

Quantity of Packing Rings (6)

Total

6

7

“D” “X”

mm

in.

32

1.25

32

1.25

1.88

47.5

1.88

47.5

in.

.50

.50

.75

.75

mm

13

13

19

19

Total

6

7

Packing box with

Flexible Graphite packing rings

and Back-up rings

Braided

Back-up Rings

Lantern

Ring

(7)

Soft metal

or plastic

vise jaws

Flexible

Graphite Rings

Figure 10 - Packing Ring Arrangements with Optional Lubricator Connection

© 2014 General Electric Company. All rights reserved.

Masoneilan 21000 Series Top Guided Globe Valve | 11

Page 15

Assembly Torque Requirements

Valve

Size

1

&

1- 1/2

900

31

230 250

34

Min.

daN.m

Carbon Steel Bolting

Max.

Ft. Lbs.

daN.m

Ft. Lbs.

ANSI Class

Stud (9)

150 - 300

600

4,5

33 37

5

1/2” -13 NC - 2A

26

192 207

28

1- 1/4” - 8 NC - 2A

Size Qty

8

12

1500

35

260 295

40

1” - 8 NC - 2A 4

2500

40

295 370

50

5,5

40 48

6,5

150

300

600

8

60 63

8,5

5/8” -11 NC - 2A 6

19

140 148

20

3/4” -10 NC - 2A 8

150 - 300

600

8,5

63 70

9,5

5/8” -11 NC - 2A 8

28

207 220

30

1” -8 NC - 2A 8

150 - 300

600

8,5

63 66

9

5/8” -11 NC - 2A 12

28

207 221

30

1” -8 NC - 2A 12

8

60 63

8,5

5/8” -11 NC - 2A 6

23

170 184

25

Min.

daN.m

Stainless Steel Bolting

Max.

Ft. Lbs.

daN.m

Ft. Lbs.

3,5

26 30

4

26

192 207

28

4,5

33 37

5

23 *

170 * 184 *

25 *

7

52 59

8

28

207 221

30

9

66 74

10

Req’d. Torque

28

207 221

30

Valve Size

ANSI Class

Bolting Requirements

Minimum Maximum Pre-Load

Torque Requirements

inch mm Qty. Size (inch) Lbs.Ft N.m Lbs.Ft N.m Lbs.Ft N.m

150 & 300 4 1/2"-13NC-2A 25 34 66 89 5 7

.75 & 1

1.5 & 2

20 &

25

40 &

50

1.5 40 2500 8 7/8"-9NC-2A 100 136 300 407 30 41

2 50 2500 8 1-1/8"-7NC-2A 160 217 640 868 60 81

80

3

4 100

6 150

8 200 150 - 600 12 1-1/4"-8NC-2A 235 319 1200 1627 100 136

600 4 1/2"-13NC-2A 25 34 66 89 5 7

900 & 1500 4 1"-8NC-2A 125 169 560 759 45 61

2500 4 1"-8NC-2A 125 169 560 759 45 61

150 & 300 8 1/2"-13NC-2A 25 34 66 89 5 7

600 8 1/2"-13NC-2A 25 34 66 89 5 7

900 & 1500 8 7/8"-9NC-2A 100 136 300 407 30 41

150 & 300 6 5/8"-11NC-2A 45 61 132 179 10 14

600 8 3/4"-10NC-2A 80 108 230 312 20 27

900 & 1500 8 1-1/8"-8NC-2A 225 305 830 1125 75 102

150 & 300 8 5/8"-11NC-2A 45 61 132 179 10 14

600 8 1"-8NC-2A 125 169 560 759 45 61

900 & 1500 8 1-1/2"-8NC-2A 400 542 2100 2847 115 156

150 & 300 12 5/8"-11NC-2A 45 61 132 179 10 14

600 12 1"-8NC-2A 125 169 560 759 45 61

Notes: 1. Do not exceed Maximum Torque values listed.

2. Tighten in increments until required torque levels are reached.

3. Reject assembly if metal-to-metal contact is not achieved after reaching Maximum Torque.

4. Torque requirements shown are for standard B7 studs and 2H nuts.

Bellows Bonnet Assembly Torque Requirements

Bolting Requirements

Minimum Maximum Increments Pre-Load

Qty. Size (inch) Lbs.Ft N.m Lbs.Ft N.m Lbs.Ft N.m Lbs.Ft N.m

8 1/2"-13NC-2A 20 27 30 41 5 7 5 7

8 5/8"-11NC-2A 25 34 55 75 10 14 5 7

1

2

3

5

Notes: 1. Do not exceed Maximum Torque values listed.

2. Tighten in increments noted until required torque levels are reached.

3. Torque requirements shown are for standard B7 studs and 2H nuts.

4

1

2

Figure 11 - Bolting Torques and Tightening Sequence

3

6

4

Torque Requirements

4

1

8

6

5

3

7

2

8

4

10

1

12

6

2

5

9

3

7

11

12 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 16

Figure 12

Threaded Seat Ring - Contoured Plug - Full Capacity

Figure 13

Quick Change Trim - Contoured Plug - Full Capacity

Figure 14

Threaded Seat Ring - Lo-dB Plug

Quick Change Trim - Lo-dB Plug

Figure 15

PARTS REFERENCE

Ref. Part Name Ref. Part Name Ref. Part Name

l 1 Plug Stem

2 Packing Flange Stud

3 Packing Flange Stud Nut

4 Packing Flange

5 Packing Follower

l 6 Packing

7 Lantern Ring (optional)

8 Bonnet

l Recommended spare parts

© 2014 General Electric Company. All rights reserved.

Only on Quick Change Trim

*

9 Body Stud

10 Body Stud Nut

l11 Body Gasket

12 Plug Guide Bushing (Incl. w/ref. 8)

l13 Cage *

l14 Seat Ring

l15 Seat Ring Gasket *

l16 Plug

l17 Plug Pin

18 Body

19 Drive Nut

Masoneilan 21000 Series Top Guided Globe Valve | 13

Page 17

Figure 16 - 21000 Series

CAUTION

WARNING

3/4" to 2" Valve Sizes ANSI Class 900 to 2500

10.1 Bellows Valve Disassembly (Figure 19)

Note: Spiral wound gaskets are standard in the 21000 BS

Series design. IT IS RECOMMENDED THAT NEW GASKETS ARE

INSTALLED EACH TIME THE VALVE IS DIS ASSEMBLED.

10.1.1 Threaded Trim

After removing the actuator, disassemble the body S/A

using the following procedure:

• Disconnect the leak-off circuit from the bonnet (if this

option is included). Remove nuts (27) and bonnet studs

(26) from the bonnet (25).

• Remove packing flange stud nuts (3), packing flange (4)

and packing follower (5). Remove bonnet (25).

• Remove existing packing (6).

• Remove body stud nuts (10).

• Remove bonnet extension (29), stem bellows S/A (30)

and plug (16) at the same time.

• Remove the plug pin (17), then remove the plug (16)

from the plug stem (30). (See section 10.2.1.1 for

unpinning the plug stem).

• Remove stem bellows S/A (30) by the top of the bonnet

extension (29). If necessary, disengage the upper

bushing of assembly (30) using a screwdriver in the

groove provided for this purpose.

Figure 17 - Angle Body Design

3/4" to 6" Valve Sizes ANSI Class 150 to 600

3/4" to 2" Valve Sizes ANSI Class 900 to 2500

Be careful not to damage the seating surfaces of the

bellows bushing.

• Remove the bonnet and spacer gaskets (28) and the

body gasket (11).

• Bonnet extension (29), plug (16), guide bushings and seat

ring (14) may now be inspected for wear and service

damage. After determining the maintenance required,

proceed to the appropriate section of these instructions.

10.1.2 Quick-Change Trim

Removal of the quick-change trim is accomplished using

the same procedures as removal of the threaded trim.

However, after the bonnet extension (29) has been

removed from the body, remove the cage (13), the seat

ring (14) and the seat ring gasket (15).

10.2 Repair

The purpose of this section is to provide recommended

maintenance and repair procedures. These procedures assume

the availability of standard shop tools and equipment.

10.2.1 Plug/Stem Bellows/Bonnet Extension S/A

Plug stem pinning in the field may be required for:

14 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 18

• Replacing existing plug and stem-bellows S/A

• Replacing stem-bellows S/A only

If the plug needs replacing, the stem-bellows sub-

assembly should be replaced at the same time.

The original pin hole in a stem which is being reused

sometimes prevents a satisfactory result being obtained and

can also weaken the plug-stem assembly.

If the stem-bellows sub-assembly is being replaced, the

new assembly can be fitted on an existing plug as long as

it is in good condition and the removal of the pin has not

deformed the hole or damaged it in any other way.

Note: Always use soft metal vise jaws to hold the plug

guide surface. Failure to take this precaution could result

in damage to the plug guide surface during pinning (see

Figure 18).

Be careful not to damage the plug seating surface during

pin removal and assembly operations.

10.2.1.1 Unpinning the Plug Stem

• Pull and hold the plug (16) out of the bonnet

extension (29) to allow access to the plug pin (17).

Place the plug guide on a V-block.

Note: A lower mechanical stop has been provided to

prevent damage of the bellows during this step.

• Using a drift punch, drive out the existing pin (17).

Note: If it is necessary to drill out the pin, use a drill

bit slightly smaller than the pin diameter. Be careful

not to damage the hole of the plug guide.

• Lock two nuts against each other on the end of

the plug stem, and use a flat spanner on the lower

nut to prevent rotation while unscrewing the plug

from the stem. The plug is removed by turning it

counter-clockwise.

• Remove the two nuts from the plug stem. Complete

step 10.1.1.

• Inspect the parts and carry out any necessary

repairs, then reassemble the stem-bellows subassembly (30) through the upper hole in the bonnet

extension (29) (see section 10.2.1.2).

10.2.1.2 Mounting of the Plug-Stem/Bellows S/A into

the Bonnet Extension

• Clean all contact surfaces of the bonnet extension

(29) and the plug-stem/bellows S/A.

• Assemble a new gasket (28) on the upper flange of

the bonnet extension.

• Insert the new stem-bellows S/A through the top

hole into the bonnet extension (29).

• Pin the plug on the stem (See section 10.2.1.3).

10.2.1.3 Plug Stem Pinning

Replacing Plug and Stem/Bellows S/A

A. Screw Stem into Plug

– Lock two nuts against each other on the end of the

plug stem and use a flat spanner on the upper nut

to prevent rotation of the stem-bellows S/A. Screw

the plug onto the lower part of the stem while

inserting the plug shank into the guide bushing (12) in

the bonnet extension (29).

– Pull and hold the plug (16) out of the bonnet extension

(29) to allow access to the plug pin (17).

B. Drilling the New Parts

• Iftheplugisalreadyfullydrilled,

(typical for 440C hardened stainless steel material or

solid Stellite or Equivalent), then drill the stem to the

same diameter (Diameter C in Figure18) as the Plug

Shank Hole.

• Iftheplugguideareahasacentermark,

Place the plug guide on a V-block and use a suitable

size drill to either:

– Match the hole size in the plug, or

– Match Diameter C (see Figure 18),

– Drill through the plug-stem assembly.

• Iftheplugguideareahasnohole or any center

mark,

– Measure Dimension D based on the plug guide

diameter and stem diameter (see Figure 18).

– Place the plug guide on a V-block, and make a

center mark on the plug guide area using a center

punch.

– Drill through the plug-stem assembly using a

suitable size drill bit.

In all cases after drilling: Remove any burrs from

the plug guide hole by making a slight chamfer.

C. Pinning the Plug-Stem Assembly

– Select the correct size pin based on the plug guide

diameter and stem diameter (see Figure 18). Apply

a small amount of grease on the pin and handassemble it into the hole in the plug.

– Press fit the pin into the hole using a hammer.

Complete the pinning operation by ensuring that

the pin is recessed by the same amount from both

sides (see Figure 18).

Replacing Stem/Bellows S/A Only

A. Screw Stem into Plug

– Refer to paragraph A of the previous section

“REPLACING PLUG AND STEM/BELLOWS S/A”.

B. Drilling the New Stem

– Place the plug guide on a V-block and use a

suitable size drill bit to drill the stem (use the hole

in the plug as a guide).

Note: If the hole in the plug guide has been slightly

damaged while removing of the old pin, choose a drill

bit and a pin with a slightly larger diameter than the

normal pin.

C. Pinning

– Select the correct size pin based on plug guide

diameter and pin hole diameter. Proceed as

described in Paragraph C above, taking care not to

damage the plug guide area.

© 2014 General Electric Company. All rights reserved.

Masoneilan 21000 Series Top Guided Globe Valve | 15

Page 19

CAUTION

WARNING

Plug Guide

Dia. “E”

mmin.

22.227/8

38.101 1/2

60.322 3/8

69.852 3/4

Plug Stem

Dia. “F”

mm

in.

12.70

1/2

12.70

1/2

19.05

3/4

19.05

3/4

Pin Hole

Dia. “C”

in.

.138

.138

.197

.197

mm

3.50

3.50

5.00

5.00

“D” “L”

mm

in.

42

1.65

55

2.17

70

2.75

70

2.75

in.

.70

1.25

2.00

2.00

mm

18

32

50

50

29

Pull plug out of the Bonnet

Extension (29) for access to

the plug pin

16

Cylindrical machining

diameter of the jaws

=

plug guide diameter “E”

Soft metal

or plastic

vise jaws

30

28

Figure 18 - Unpinning and Pinning of the Plug to Stem

10.3 Plug and Seat Ring Seating Surfaces

It is not possible to lap the plug and seat ring seating

surfaces after the bellows has been assembled to the

stem.

If the seat ring shows signs of minor wear, it should be turned

on a lathe to clean up the worn area. The seating surface of

the seat ring is 30 degrees from centerline axis. However, no

more than 0.010 in. (0.25 mm) of material should be removed.

In cases where the seat ring cannot be repaired, or if the plug is

also damaged the only alternative is to replace both parts.

Lower Mechanical Stop

to Protect the Bellows

=

L

=

E Dia.

17

C Dia.

D

F Dia.

Plug and Plug Stem-Bellows S/A Stem

Assembly of the No. 6 actuator on a bellows seal valve requires

a three-sectioned coupling. Follow coupling instructions as

described for the No. 10, 16 and 23 actuators.

The bellows assembly causes a “spring back” effect. Measure this

plug spring back before referring to Instruction Ref. GEA19530. Be

sure to add this spring back length to the over seat adjustment.

10.4 Bonnet Reassembly

Place new gasket (28) into the groove of the bonnet spacer.

Install the bonnet (25) and assemble nuts (27) and studs (26).

Bonnet must be positioned so the packing flange studs are at a

90° angle to the flow centerline.

Refer to table in Figure 11 for proper bolt torque and

tightening sequence.

10.5 Valve Body Reassembly

Refer to instructions stated in Section 8 for the specific trim

type involved.

10.6 Actuator to Body S/A and Plug Stem

Adjustment

Refer to instruction Ref. GEA19530.

16 | GE Oil & Gas © 2014 General Electric Company. All rights reserved.

Page 20

aa

2

22

3

4

5

6

25

31

28

28

27

26

9

10

11

12

19

Section a

(✚) 30 (✚) 29

DETAIL OF THE PLUG

STEM ANTI-ROTATION

DEVICE

17

18

13

14

15

16

Threaded Trim detail

Quick Change Trim

Figure 19 — 21000 BS Valve

PARTS REFERENCE

Ref. Part Name Ref. Part Name Ref. Part Name

l 1 Plug Stem

2 Packing Flange Stud.

3 Packing Flange Nut

4 Packing Flange

5 Packing Follower

l 6 Packing

9 Body Stud

10 Body Stud Nut

l11 Body Gasket

12 Guide Bushing

n 13 Cage

l14 Seat Ring

lRecommended Spare Parts + These parts included in welded subassembly n Quick change trim only

n 15 Seat Ring Gasket

l16 Plug

l17 Plug Pin

18 Valve Body

19 Drive Nut

22 Plug Stem Locknut

25 Valve Bonnet

26 Bonnet Stud

27 Bonnet Stud Nut

l28 Bonnet Spacer Gasket

29 Bonnet Extension Assembly

+ Upper Flange

+ Spacer

+ Lower Flange

30 Bellow and Stem Assembly

+ Stem

Guide Bushing

+ Bellows

+ Upper Adapter (Bellows)

+ Lower Adapter (Bellows)

31 1/8" NPT Plug

© 2014 General Electric Company. All rights reserved.

Masoneilan 21000 Series Top Guided Globe Valve | 17

Page 21

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane:

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth:

Phone: +61-8-6595-7018

Fax: +61 8 6595-7299

Melbourne:

Phone: +61-3-8807-6002

Fax : +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Masoneil an and Lo-dB are r egistered tr ademarks of t he General Ele ctric Compa ny.

Other company names and product names used in this document are the registered trademarks or trademarks of their respective owners.

© 2014 General Ele ctric Compa ny. All rights res erved.

GEA19821A 04/2014

Loading...

Loading...