Page 1

GE

Grid Solutions

869

Motor Protection System

Motor Protection, Control and Management

Instruction manual

Product version: 1.7x

GE publication code: 1601-0450-A7 (GEK-119649F)

*1601-0450-A7*

Page 2

© 2016 GE Multilin Incorporated. All rights reserved.

GE Multilin 869 Motor Protection System instruction manual for revision 1.7x.

869 Motor Protection System, EnerVista, EnerVista Launchpad, and EnerVista 8 Series

Setup softw

are are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

f

urnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-0450-A7 (December 2016)

Note

May contain components with FCC ID: XF6-RS9110N1122

and IC ID: 8407A-RS9110N1122.

Page 3

Table of Contents

1.INTRODUCTION

Overview .............................................................................................................................................. 1 - 1

Description of the 869 Motor Protection System.............................................................. 1 - 2

Security Overview............................................................................................................................ 1 - 6

869 Order Codes............................................................................................................................... 1 - 7

Specifications..................................................................................................................................... 1 - 9

Device .............................................................................................................................................................1 - 9

Protection......................................................................................................................................................1 - 9

Control......................................................................................................................................................... 1 - 17

Monitoring.................................................................................................................................................. 1 - 18

Recording................................................................................................................................................... 1 - 19

User-Programmable Elements ........................................................................................................ 1 - 21

Metering...................................................................................................................................................... 1 - 22

Inputs ........................................................................................................................................................... 1 - 24

Outputs........................................................................................................................................................ 1 - 26

Power Supply............................................................................................................................................ 1 - 27

Communications .................................................................................................................................... 1 - 28

Testing & Certification.......................................................................................................................... 1 - 28

Physical ....................................................................................................................................................... 1 - 30

Environmental.......................................................................................................................................... 1 - 30

Cautions and Warnings ..............................................................................................................1 - 30

Safety words and definitions ............................................................................................................1 - 30

General Cautions and Warnings..................................................................................................... 1 - 31

Must-read Information................................................................................................................1 - 33

Storage........................................................................................................................................................ 1 - 34

For Further Assistance.................................................................................................................1 - 34

Repairs......................................................................................................................................................... 1 - 34

2.INSTALLATION

Mechanical Installation................................................................................................................. 2 - 1

Product Identification..............................................................................................................................2 - 1

Dimensions...................................................................................................................................................2 - 2

Mounting ....................................................................................................................................................... 2 - 3

Standard Panel Mount.............................................................................................................................2 - 4

Draw-out Unit Withdrawal and Insertion ......................................................................................2 - 5

Removable Power Supply......................................................................................................................2 - 6

Removable Magnetic Module .............................................................................................................. 2 - 7

Arc Flash Sensor ........................................................................................................................................ 2 - 8

Sensor Fiber Handling & Storage.......................................................................................................2 - 8

Sensor Installation.....................................................................................................................................2 - 8

Electrical Installation ...................................................................................................................... 2 - 9

Typical Wiring Diagram ..........................................................................................................................2 - 9

Terminal Identification ......................................................................................................................... 2 - 12

Wire Size......................................................................................................................................................2 - 17

Phase Sequence and Transformer Polarity ............................................................................... 2 - 17

Ground and Sensitive Ground CT Inputs ..................................................................................... 2 - 18

Zero-Sequence CT Installation ......................................................................................................... 2 - 19

Differential CT Inputs ............................................................................................................................ 2 - 20

Voltage Inputs..........................................................................................................................................2 - 21

Control Power........................................................................................................................................... 2 - 22

Contact Inputs ......................................................................................................................................... 2 - 23

Output Relays........................................................................................................................................... 2 - 24

Serial Communications ....................................................................................................................... 2 - 26

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL I

Page 4

IRIG-B............................................................................................................................................................2 - 27

3.INTERFACES

Front Control Panel Interface......................................................................................................3 - 2

Graphical Display Pages....................................................................................................................... 3 - 2

Working with Graphical Display Pages........................................................................................... 3 - 3

Single Line Diagram.................................................................................................................................3 - 6

LED Status Indicators .............................................................................................................................. 3 - 7

Home Screen Icons.................................................................................................................................. 3 - 8

Relay Messages ......................................................................................................................................... 3 - 9

Target Messages....................................................................................................................................... 3 - 9

Self-Test Errors.........................................................................................................................................3 - 10

Out of Service............................................................................................................................................3 - 14

Flash Messages........................................................................................................................................3 - 14

Label Removal..........................................................................................................................................3 - 14

Software Interface ........................................................................................................................ 3 - 15

EnerVista 8 Series Setup Software..................................................................................................3 - 15

Hardware & Software Requirements ............................................................................................3 - 15

Installing the EnerVista 8 Series Setup Software .....................................................................3 - 16

Upgrading the Software......................................................................................................................3 - 18

Connecting EnerVista 8 Series Setup software to the Relay ..............................................3 - 18

Using the Quick Connect Feature ...................................................................................................3 - 18

Configuring Ethernet Communications........................................................................................3 - 20

Connecting to the Relay ......................................................................................................................3 - 21

Working with Setpoints & Setpoints Files....................................................................................3 - 22

Engaging a Device..................................................................................................................................3 - 22

Entering Setpoints ..................................................................................................................................3 - 22

File Support................................................................................................................................................3 - 24

Using Setpoints Files..............................................................................................................................3 - 24

Downloading & Saving Setpoints Files..........................................................................................3 - 25

Adding Setpoints Files to the Environment.................................................................................3 - 25

Creating a New Setpoints File...........................................................................................................3 - 26

Upgrading Setpoints Files to a New Revision............................................................................3 - 26

Printing Setpoints....................................................................................................................................3 - 27

Loading Setpoints from a File ...........................................................................................................3 - 28

Uninstalling Files and Clearing Data..............................................................................................3 - 29

Quick Setup................................................................................................................................................3 - 29

Upgrading Relay Firmware ................................................................................................................3 - 32

Loading New Relay Firmware...........................................................................................................3 - 32

Advanced EnerVista 8 Series Setup Software Features .......................................................3 - 35

FlexCurve Editor.......................................................................................................................................3 - 35

Transient Recorder (Waveform Capture).....................................................................................3 - 36

Protection Summary .............................................................................................................................3 - 40

Offline Settings File Conversion........................................................................................................3 - 42

Convert SR 469 Files..............................................................................................................................3 - 42

Convert 369 Files.....................................................................................................................................3 - 43

Conversion Summary Report............................................................................................................3 - 43

Results Window .......................................................................................................................................3 - 44

4.SETPOINTS

Setpoints Main Menu ......................................................................................................................4 - 1

Setpoints Entry Methods........................................................................................................................ 4 - 2

Common Setpoints................................................................................................................................... 4 - 3

Logic Diagrams.......................................................................................................................................... 4 - 4

Setpoints Text Abbreviations............................................................................................................... 4 - 5

Device.....................................................................................................................................................4 - 6

Custom Configuration ............................................................................................................................ 4 - 7

Real-time Clock.......................................................................................................................................... 4 - 9

II 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 5

PTP Configuration......................................................................................................................................4 - 9

Clock..............................................................................................................................................................4 - 11

SNTP Protocol ...........................................................................................................................................4 - 12

Security ....................................................................................................................................................... 4 - 13

Basic Security ...........................................................................................................................................4 - 14

CyberSentry...............................................................................................................................................4 - 16

Communications .................................................................................................................................... 4 - 23

Modbus Protocol.....................................................................................................................................4 - 23

RS485............................................................................................................................................................4 - 28

WiFi................................................................................................................................................................4 - 28

USB ................................................................................................................................................................4 - 31

Ethernet Ports...........................................................................................................................................4 - 31

Routing.........................................................................................................................................................4 - 33

DNP Protocol.............................................................................................................................................4 - 36

DNP / IEC104 Point Lists ......................................................................................................................4 - 37

IEC 60870-5-104 .....................................................................................................................................4 - 40

IEC 60870-5-103 .....................................................................................................................................4 - 41

IEC 61850....................................................................................................................................................4 - 42

Remote Modbus Device.......................................................................................................................4 - 44

Transient Recorder ................................................................................................................................ 4 - 46

Data Logger .............................................................................................................................................. 4 - 48

Fault Reports ............................................................................................................................................ 4 - 50

Event Data ................................................................................................................................................. 4 - 52

Flex States.................................................................................................................................................. 4 - 52

Programmable LEDs ............................................................................................................................. 4 - 52

Programmable Pushbuttons............................................................................................................. 4 - 55

Front Panel ................................................................................................................................................ 4 - 59

Display Properties...................................................................................................................................4 - 59

Default Screens........................................................................................................................................4 - 60

Resetting..................................................................................................................................................... 4 - 60

Installation................................................................................................................................................. 4 - 61

System.................................................................................................................................................4 - 62

Current Sensing....................................................................................................................................... 4 - 63

Voltage Sensing ...................................................................................................................................... 4 - 64

Power System .......................................................................................................................................... 4 - 65

Motor............................................................................................................................................................ 4 - 66

Setup.............................................................................................................................................................4 - 66

Variable Frequency Drives..................................................................................................................4 - 71

Preset Values ............................................................................................................................................4 - 76

Switching Device .................................................................................................................................... 4 - 77

FlexCurves ................................................................................................................................................. 4 - 80

Inputs...................................................................................................................................................4 - 82

Contact Inputs ......................................................................................................................................... 4 - 82

Virtual Inputs ............................................................................................................................................ 4 - 85

Analog Inputs ........................................................................................................................................... 4 - 87

Remote Inputs.......................................................................................................................................... 4 - 92

Outputs ...............................................................................................................................................4 - 93

Output Relays........................................................................................................................................... 4 - 93

Output Relay 1 (F1) Trip........................................................................................................................4 - 94

Output Relay 2 (F4) programmed as Close.................................................................................4 - 97

Auxiliary Output Relays........................................................................................................................4 - 98

Output Relay 3 (F7) Start Inhibit .......................................................................................................4 - 99

Virtual Outputs.......................................................................................................................................4 - 100

Analog Outputs .....................................................................................................................................4 - 101

Protection .......................................................................................................................................4 - 103

Motor Elements .....................................................................................................................................4 - 105

Percent Differential.............................................................................................................................4 - 105

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL III

Page 6

Thermal Model.......................................................................................................................................4 - 112

Current Unbalance..............................................................................................................................4 - 134

Mechanical Jam ...................................................................................................................................4 - 139

Undercurrent..........................................................................................................................................4 - 142

Loss of Excitation.................................................................................................................................4 - 145

Overload Alarm.....................................................................................................................................4 - 151

Short Circuit............................................................................................................................................4 - 153

Ground Fault ..........................................................................................................................................4 - 156

Acceleration Time................................................................................................................................4 - 160

Underpower............................................................................................................................................4 - 163

2-Speed Motor.......................................................................................................................................4 - 166

Speed2 Thermal Model .....................................................................................................................4 - 166

Speed2 Acceleration ..........................................................................................................................4 - 168

Speed2 Undecurrent ..........................................................................................................................4 - 170

Current Elements ................................................................................................................................. 4 - 172

Inverse Time Overcurrent Curves.................................................................................................4 - 172

Percent of Load-To-Trip....................................................................................................................4 - 180

Phase Time Overcurrent Protection............................................................................................4 - 180

Phase Instantaneous Overcurrent Protection........................................................................4 - 184

Phase Directional Overcurrent Protection ...............................................................................4 - 186

Neutral Time Overcurrent Protection.........................................................................................4 - 189

Neutral Instantaneous Overcurrent Protection.....................................................................4 - 192

Neutral Directional Overcurrent Protection ............................................................................4 - 195

Ground Time Overcurrent Protection.........................................................................................4 - 200

Ground Instantaneous Overcurrent Protection.....................................................................4 - 202

Negative Sequence Instantaneous Overcurrent Protection...........................................4 - 204

Voltage Elements .................................................................................................................................4 - 207

Phase Reversal......................................................................................................................................4 - 207

Undervoltage Curves .........................................................................................................................4 - 210

Phase Undervoltage Protection....................................................................................................4 - 211

Phase Overvoltage Protection.......................................................................................................4 - 214

Auxiliary Undervoltage......................................................................................................................4 - 217

Auxiliary Overvoltage Protection.................................................................................................. 4 - 220

Neutral Overvoltage Protection ....................................................................................................4 - 223

Negative Sequence Overvoltage Protection...........................................................................4 - 226

Volts per Hertz.......................................................................................................................................4 - 228

Impedance Elements ......................................................................................................................... 4 - 234

Out-of-step .............................................................................................................................................4 - 234

Power Elements ....................................................................................................................................4 - 240

Directional Power.................................................................................................................................4 - 240

Reactive Power .....................................................................................................................................4 - 246

Frequency Elements ...........................................................................................................................4 - 249

Underfrequency....................................................................................................................................4 - 249

Overfrequency.......................................................................................................................................4 - 252

Frequency Rate of Change..............................................................................................................4 - 255

Monitoring...................................................................................................................................... 4 - 259

Breaker...................................................................................................................................................... 4 - 259

Trip and Close Circuit Monitoring .................................................................................................4 - 259

Breaker Arcing Current......................................................................................................................4 - 267

Breaker Health ......................................................................................................................................4 - 270

Broken Rotor Bar.................................................................................................................................. 4 - 274

Stator Inter-Turn Fault....................................................................................................................... 4 - 279

Functions .................................................................................................................................................4 - 284

Power Factor..........................................................................................................................................4 - 284

Demand....................................................................................................................................................4 - 289

Pulsed Outputs......................................................................................................................................4 - 297

Digital Counters ....................................................................................................................................4 - 300

Harmonic Detection ........................................................................................................................... 4 - 304

IV 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 7

Speed .........................................................................................................................................................4 - 307

RTD Temperature .................................................................................................................................4 - 312

RTD Trouble.............................................................................................................................................4 - 317

Loss of Communications ..................................................................................................................4 - 318

Control..............................................................................................................................................4 - 320

Setpoint Group.......................................................................................................................................4 - 320

Start Supervision...................................................................................................................................4 - 323

Thermal Inhibit......................................................................................................................................4 - 323

Maximum Starting Rate....................................................................................................................4 - 326

Time Between Starts ..........................................................................................................................4 - 327

Restart Delay..........................................................................................................................................4 - 329

Reduced Voltage Starting.................................................................................................................4 - 330

Switching Device Control..................................................................................................................4 - 334

Trip Bus......................................................................................................................................................4 - 337

Breaker Failure ......................................................................................................................................4 - 339

Setup..........................................................................................................................................................4 - 340

Initiate .......................................................................................................................................................4 - 342

Arc Flash Protection ............................................................................................................................4 - 344

VT Fuse Failure.......................................................................................................................................4 - 346

FlexLogic .........................................................................................................................................4 - 348

Timers ........................................................................................................................................................4 - 357

Non-volatile Latches...........................................................................................................................4 - 358

FlexLogic Equation...............................................................................................................................4 - 359

Viewing FlexLogic Graphics............................................................................................................ 4 - 361

FlexElements...........................................................................................................................................4 - 362

Testing..............................................................................................................................................4 - 370

Simulation................................................................................................................................................4 - 370

Setup..........................................................................................................................................................4 - 371

Pre-Fault...................................................................................................................................................4 - 372

Fault ...........................................................................................................................................................4 - 372

Post-Fault ................................................................................................................................................4 - 373

Test LEDs ..................................................................................................................................................4 - 374

Contact Inputs .......................................................................................................................................4 - 374

Output Relays.........................................................................................................................................4 - 374

5.STATUS

Motor...................................................................................................................................................... 5 - 1

Breakers ............................................................................................................................................... 5 - 3

Last Trip Data..................................................................................................................................... 5 - 4

Arc Flash............................................................................................................................................... 5 - 4

Contact Inputs...................................................................................................................................5 - 4

Output Relays .................................................................................................................................... 5 - 5

Virtual Inputs......................................................................................................................................5 - 5

Virtual Outputs .................................................................................................................................. 5 - 6

Flex State ............................................................................................................................................. 5 - 6

Communications.............................................................................................................................. 5 - 7

GOOSE Rx and Tx.......................................................................................................................................5 - 7

Information .......................................................................................................................................5 - 10

Main CPU .................................................................................................................................................... 5 - 10

Comms CPU .............................................................................................................................................. 5 - 10

Hardware Versions ................................................................................................................................5 - 11

Environment ............................................................................................................................................. 5 - 11

Device Status ...................................................................................................................................5 - 12

Clock.....................................................................................................................................................5 - 13

PTP Status..........................................................................................................................................5 - 13

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL V

Page 8

6.METERING

Summary ..............................................................................................................................................6 - 4

Motor ......................................................................................................................................................6 - 5

Percent Differential Current ................................................................................................................. 6 - 5

Motor Load................................................................................................................................................... 6 - 5

Speed.............................................................................................................................................................. 6 - 6

Broken Rotor Bar....................................................................................................................................... 6 - 6

Stator Inter-Turn Fault............................................................................................................................ 6 - 7

Short Circuit................................................................................................................................................. 6 - 7

Impedance...........................................................................................................................................6 - 8

Positive Sequence Impedance............................................................................................................ 6 - 8

Currents.................................................................................................................................................6 - 8

Voltages .............................................................................................................................................6 - 10

Frequency .........................................................................................................................................6 - 11

Harmonics 1(Harmonics 2)........................................................................................................6 - 12

Harmonic Detection ..................................................................................................................... 6 - 13

Power...................................................................................................................................................6 - 14

Energy .................................................................................................................................................6 - 15

Power Factor....................................................................................................................................6 - 16

Current Demand 1.........................................................................................................................6 - 16

Power Demand...............................................................................................................................6 - 17

Directional Power ..........................................................................................................................6 - 17

Arc Flash ............................................................................................................................................6 - 17

RTDs .....................................................................................................................................................6 - 18

RTD Maximums...............................................................................................................................6 - 18

Analog Inputs...................................................................................................................................6 - 19

FlexElements.................................................................................................................................... 6 - 19

7.RECORDS

8.MAINTENANCE

A.APPENDIX A

Events.....................................................................................................................................................7 - 1

Transient Records.............................................................................................................................7 - 2

Fault Reports.......................................................................................................................................7 - 2

Data Logger.........................................................................................................................................7 - 2

Motor Start Records ........................................................................................................................7 - 3

Motor Start Statistics.......................................................................................................................7 - 4

Learned Data......................................................................................................................................7 - 4

Remote Modbus Device.................................................................................................................7 - 7

Breakers................................................................................................................................................7 - 9

Breaker Arcing Current........................................................................................................................... 7 - 9

Breaker Health ........................................................................................................................................... 7 - 9

Digital Counters.................................................................................................................................7 - 9

Remote Modbus Device..............................................................................................................7 - 10

Environmental Health Report .....................................................................................................8 - 1

Motor Health Report........................................................................................................................8 - 3

General Maintenance .....................................................................................................................8 - 6

In-service Maintenance ......................................................................................................................... 8 - 6

Out-of-service Maintenance................................................................................................................ 8 - 6

Unscheduled Maintenance (System Interruption) ..................................................................... 8 - 6

Application Notes .............................................................................................................................A - 1

Contactor Current Supervision........................................................................................................... A - 1

VI 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 9

B.APPENDIX B

Warranty..............................................................................................................................................B - 1

Revision history................................................................................................................................. B - 1

Major Updates ............................................................................................................................................B - 2

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL VII

Page 10

VIII 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 11

GE

Grid Solutions

869 Motor Protection System

Chapter 1: Introduction

Introduction

The Multilin 869 relay is a microprocessor-based unit intended for the management and

primary protection of medium and large sized motors. Base relay models provide thermal

overload and overcurrent protection plus a number of current and voltage based backup

functions.

Overview

The relay features an enhanced thermal model with custom curves, current unbalance

biasing, voltage dependent curves and running and stopped exponential cooling curves.

An optional RTD module allows for the thermal model RTD bias function. Motor start and

supervision functions include thermal inhibit, maximum starting rate, time between starts,

restart delay, acceleration time, and emergency restart. Mechanical jam, current

unbalance elements and VFD application support are also included as basic functions.

Stator differential, sensitive directional power and phase/neutral directional elements are

more advanced features.

These relays contain many innovative features. To meet diverse utility standards and

indus

specific user needs. This flexibility will naturally make a piece of equipment difficult to

learn. To aid new users in getting basic protection operating quickly, setpoints are set to

typical default values and advanced features are disabled. These settings can be

reprogrammed at any time.

Programming can be accomplished with the front panel keys and display. Due to the

numer

programming and provide a more intuitive interface, setpoints can be entered with a PC

running the EnerVista 8 Setup software provided with the relay. Even with minimal

computer knowledge, this menu-driven software provides easy access to all front panel

functions. Actual values and setpoints can be displayed, altered, stored, and printed. If

settings are stored in a setpoint file, they can be downloaded at any time to the front panel

program port of the relay via a computer cable connected to the serial port of any

personal computer.

try requirements, these features have the flexibility to be programmed to meet

ous settings, this manual method can be somewhat laborious. To simplify

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–1

Page 12

DESCRIPTION OF THE 869 MOTOR PROTECTION SYSTEM CHAPTER 1: INTRODUCTION

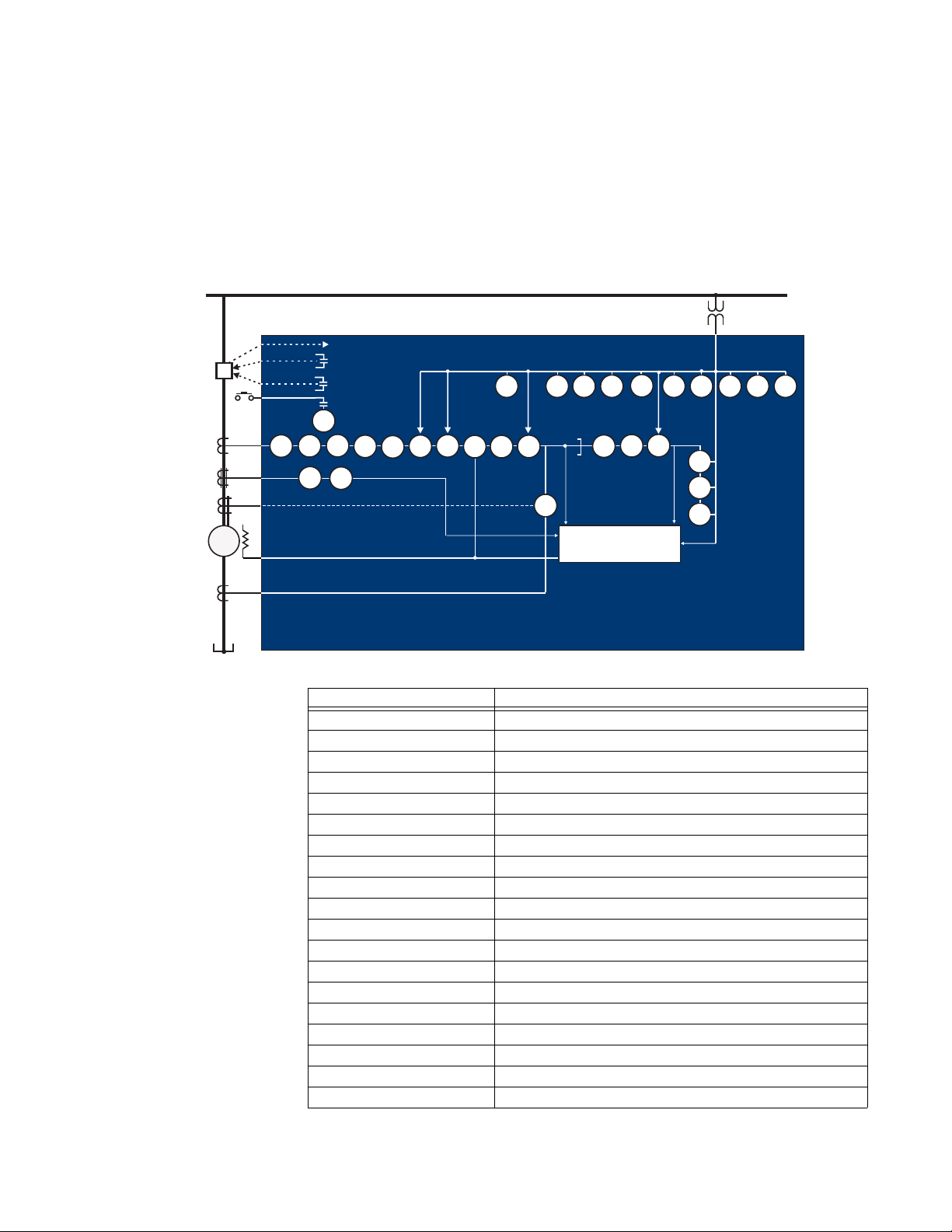

A summary of the available functions and a single-line diagram of protection and control

features is shown below. For a complete understanding of each feature operation, refer to

Chapter 4: Setpoints. The logic diagrams include a reference to every setpoint related to a

feature and show all logic signals passed between individual features. Information related

to the selection of settings for each setpoint is also provided.

Description of the 869 Motor Protection System

CPU

Relay functions are controlled by two pr

microprocessor that measures all analog signals and digital inputs and controls all output

relays, and a Freescale MPC8358 32-bit microprocessor that controls all the advanced

Ethernet communication protocols.

Analog Input and Waveform Capture

Magnetic transformers are used to scale-down the incoming analog signals from the

sour

ce instrument transformers. The analog signals are then passed through a 11.5 k Hz

low pass analog anti-aliasing filter. All signals are then simultaneously captured by sample

and hold buffers to ensure there are no phase shifts. The signals are converted to digital

values by a 16-bit A/D converter before finally being passed on to the CPU for analysis.

The 'raw' samples are scaled in software, then placed into the waveform capture buffer,

thus em

the EnerVista 8 Series Setup software for display and diagnostics.

Frequency

Frequency measurement is accomplished by m

of the composite signal of three-phase bus voltages, line voltage or three-phase currents.

The signals are passed through a low pass filter to prevent false zero crossings. Frequency

tracking utilizes the measured frequency to set the sampling rate for current and voltage

which results in better accuracy for the Discrete Fourier Transform (DFT) algorithm for offnominal frequencies.

The main frequency tracking source uses three-phase bus voltages. The frequency

track

three-phase currents signal if the frequency detected from the three-phase voltage inputs

is declared invalid. The switching will not be performed if the frequency from the

alternative reference signal is detected invalid. Upon detecting valid frequency on the

main source, the tracking will be switched back to the main source. If a stable frequency

signal is not available from all sources, then the tracking frequency defaults to the nominal

system frequency.

Phasors, Transients, and Harmonics

All waveforms are processed eight times every cycle through a DC decaying removal filter

and a Disc

and all harmonics removed. This results in an overcurrent relay that is extremely secure

and reliable and one that will not overreach.

Processing of AC Current Inputs

The DC Decaying Removal Filter is a short window digital filter, which removes the DC

decaying

This is done for all current signals used for overcurrent protection; voltage signals use the

same DC Decaying Removal Filter. This filter ensures no overreach of the overcurrent

protection.

The Discrete Fourier Transform (DFT) uses exactly one cycle of samples to calculate a

phasor qua

components are removed. All subsequent calculations (e.g. power, etc.) are based upon the

ulating a digital fault recorder. The waveforms can be retrieved from the relay via

ing is switched automatically by an algorithm to the alternative reference source, i.e.,

rete Fourier Transform (DFT). The resulting phasors have fault current transients

component from the asymmetrical current present at the moment a fault occurs.

ntity which represents the signal at the fundamental frequency; all harmonic

ocessors: a Freescale MPC5125 32-bit

easuring the time between zero crossings

1–2 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 13

CHAPTER 1: INTRODUCTION DESCRIPTION OF THE 869 MOTOR PROTECTION SYSTEM

892825A3.CDR

Phase CT

RTD

27P

59P

59N

59_2

VTFF

81U

81O

4

87S

METERING

TRANSIENT RECORDER

EVENT RECORDER

FAULT REPORT

TRIP

52

CLOSE

MONITORING

50BF

51P

50P

67P

50_2

50LR

49

2

212

22

BUS

Breaker

32

2

869

Motor Protection System

Neutral CT

M

50G/N

51G/N

67N

86

55

START

3

3

Ground CT

1

Differential

core

balance CT

3

37

47

12

50G

51G

Internal Summation Percent Differential

Core Balance Percent Differential

81R

2

40

40Q

78

24

current and voltage phasors, such that the resulting values have no harmonic

components. RMS (root mean square) values are calculated from one cycle of samples

prior to filtering.

Protection Elements

All voltage, current and frequency protection elements are processed eight times every

cycle to determine if a pickup has occurred or a timer has expired. The voltage and current

protection elements use RMS current/voltage, or the magnitude of the phasor.

Figure 1-1: Single Line Diagram

Table 1-1: ANSI Device Numbers and Functions

ANSI Device Description

12/14 Over Speed Protection/ Under Speed Protection

24 Volts Per Hertz

27P (2) Phase Undervoltage

32 (2) Directional Power

37 Undercurrent

37P Underpower

40 Loss of Excitation

40Q Reactive Power

46 Current Unbalance

47 Voltage Reversal

49 Thermal Model

50BF Breaker Failure

50G Ground Instantaneous Overcurrent

50SG Ground Fault

50N (2) Neutral Instantaneous Overcurrent

50P (2) Phase Instantaneous Overcurrent

50_2 Negative Sequence Instantaneous Overcurrent

51G Ground Time Overcurrent

51N Neutral Time Overcurrent

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–3

Page 14

DESCRIPTION OF THE 869 MOTOR PROTECTION SYSTEM CHAPTER 1: INTRODUCTION

ANSI Device Description

51P Phase Time Overcurrent

52 AC Circuit Breaker

55 (2) Power Factor

59N Neutral Overvoltage

59P (2) Phase Overvoltage

59X Auxiliary Overvoltage

59_2 Negative Sequence Overvoltage

67N Neutral Directional Element

67P Phase Directional Element

78 Out-of-Step Protection

81O (2) Overfrequency

81U (4) Underfrequency

81R Frequency Rate of Change

86 Start Inhibit

87S Stator Differential

VTFF Voltage Transformer Fuse Failure

Table 1-2: Other Device Functions

Description

Analog Input

Analog Output

Arc Flash Protection

2

Breaker Arcing Current (I

Switching Device Control

Breaker Health

Output Relays

Demand

Digital Counters

Event Recorder

Fault Report

FlexLogic Equations

IEC 61850 Communications

Metering: current, voltage, power, PF, energy, frequency, harmonics, THD

Modbus User Map

Non-volatile Latches

Setpoint Groups (6)

Stator Inter-Turn Fault

Trip Bus (6)

Transient Recorder (Oscillography)

Trip and Close Coil Monitoring

User-programmable LEDs

User-programmable Pushbuttons

Virtual Inputs (32)

Virtual Outputs (32)

Mechanical Jam

Overload Alarm

Short Circuit

t)

1–4 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 15

CHAPTER 1: INTRODUCTION DESCRIPTION OF THE 869 MOTOR PROTECTION SYSTEM

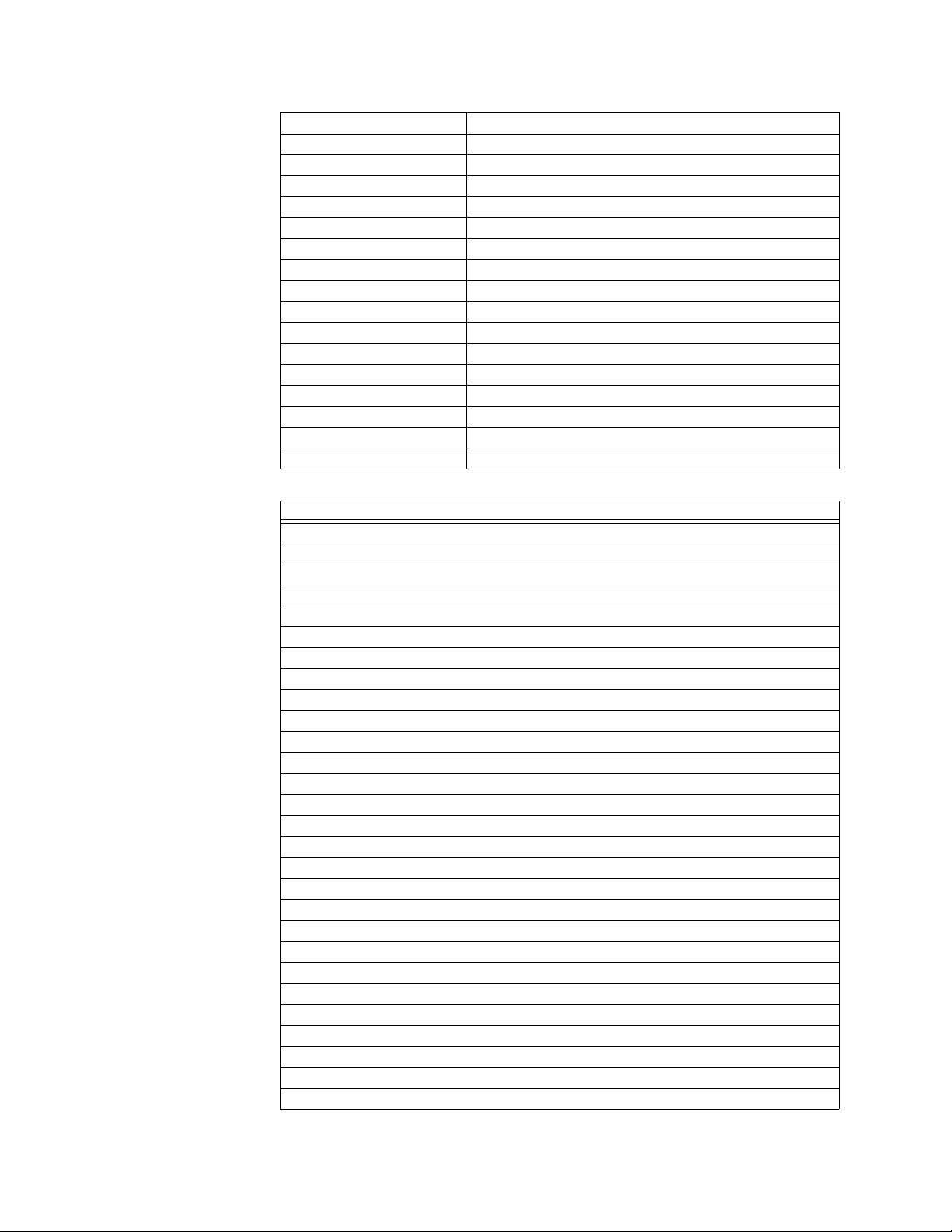

Level 1 Level 2

Level 1 Level 2

Setpoints

Device

System

Inputs

Outputs

Protection

Monitoring

Control

FlexLogic

S

tatus

Breakers

S ches

Contact Inputs

Output Relays

Virtual Inputs

Virtual Outputs

Targets

Motor

Metering

Records

Events

Transients

Motor Start Records

Breakers

Dig Counters

Clear Records

Currents

oltages

Frequenc

Harmonics

Power

Energy

V

y

RTDs

Data Logger

Fault Reports

Motor Start Statistics

Current Demand

Power Demand

Motor Learned Data

Directional Power

Arc Flash

Arc Flash

Testing

PTP Status

Clock

Device Status

Information

Communications

Flex States

Last Trip Data

Motor

Power Factor

Analog Inputs

RTD Maximums

FlexElements

Description

Acceleration Time

Phase Reversal

Broken Rotor Bar

Reduced Voltage Starting

RTD Temperature

Motor Start Records

Motor Start Statistics

Motor Learned Data

Motor Health Report

Data Logger

Figure 1-2: Main Menu Hierarchy

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–5

Page 16

SECURITY OVERVIEW CHAPTER 1: INTRODUCTION

Security Overview

The following security features are available:

BASIC SECURITY

The basic security feature is present in the default offering of the 869 relay. The

FASTPATH:

869 introduces the notion of roles for different lev

names with associated passwords stored on the device. The following roles are available

at present: Administrator, Operator, Factory and Observer, with a fixed permission

structure for each one. Note that the Factory role is not available for users, but strictly used

in the manufacturing process.

The 869 can still use the Setpoint access switch feat

done only by an Administrator. Setpoint access is controlled by a keyed switch to offer

some minimal notion of security.

CYBERSENTRY

The CyberSentry Embedded Security feature is a software option that provides advanced

security ser

vices. When the software option is purchased, the Basic Security is

automatically disabled.

CyberSentry provides security through the following features:

• An Authentication, Authorization, Accounting (AAA) Remote Authentication Dial-In

User Ser

vice (RADIUS) client that is centrally managed, enables user attribution, and

uses secure standards based strong cryptography for authentication and credential

protection.

• A Role-Based Access Control (RBAC) system that provides a permission model that

ows access to 869 device operations and configurations based on specific roles

all

and ind

ividual user accounts configured on the AAA server. At present the defined

roles are: Administrator, Operator and Observer.

• Strong encryption of all access and configuration network messages between the

EnerV

ista software and 869 devices using the Secure Shell (SSH) protocol, the

Ad

vanced Encryption Standard (AES), and 128-bit keys in Galois Counter Mode (GCM)

as specified in the U.S. National Security Agency Suite B extension for SSH and

approved by the National Institute of Standards and Technology (NIST) FIPS-140-2

standards for cryptographic systems.

• Security event reporting through the Syslog protocol for supporting Security

Informa

tion Event Management (SIEM) systems for centralized cyber security

monitoring.

There are two types of authentication supported by CyberSentry that can be used to

acc

ess the 869 device:

• Device Authentication – in which case the authentication is performed on the

869 device itself, using the predefined roles as users (No RADIUS involvement).

– 869 authentication using local roles may be done either from the front panel or

ough EnerVista.

thr

• Server Authentication - in which case the authentication is done on a RADIUS server,

using

individual user accounts defined on the server. When the user accounts are

created, they are assigned to one of the predefined roles recognized by the 869

– 869 authentication using RADIUS server may be done only through EnerVista.

WiFi and USB do not currently support CyberSentry security. For this reason WiFi is

disabled by default if the CyberSentry option is purchased. The user can enable WiFi, but

be aware that doing so violates the security and compliance model that CyberSentry is

supposed to provide.

els of authority. Roles are used as login

ure, but enabling the feature can be

1–6 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 17

CHAPTER 1: INTRODUCTION 869 ORDER CODES

When both 869 device and server authentication are enabled, the 869 automatically

directs authentication requests to the 869 device or the respective RADIUS server, based

on user names. If

the user ID credential does not match one of the device local accounts,

the 869 automatically forwards the request to a RADIUS server when one is provided. If a

R

ADIUS server is provided, but is unreachable over the network, server authentication

requests are denied. In this situation, use local 869 device accounts to gain access to the

869 system.

USER ROLES

User Access Levels are used to grant varying perm

issions to specific user roles. User roles

are used by both Basic Security and CyberSentry.

The following user roles are supported:

• Administrat

or: The Administrator role has complete read and write access to all

settings and commands. The role does not allow concurrent access. The Administrator

role also has an operand to indicate when it is logged on.

• Operat

or: The Operator role is present to facilitate operational actions that may be

programmed and assigned to buttons on the front panel. The Operator has read/write

access to all settings under the command menu/section. The Operator can view

settings from EnerVista or the front panel but does not have the ability to change any

settings. This role is not a concurrent role.

• Obser

ver: The Observer role has read-only access to all 869 settings. This role allows

concurrent access. The Observer is the default role if no authentication has been done

to the device. This role can download settings files and records from the device.

• F

actory: This is an internal non-user accessible role used for manufacturing

diagnostics. The ability to enable or disable this role is a security setting that the

Administrator controls.

GENERAL RULES FOR USER ROLES WITH CYBERSENTRY

1. The only concurrent role is Observer. If the user is logged in through serial, front panel,

or over the network, that counts as the role being logged in for concurrency reasons.

2. Both EnerVista and the front panel provide a one-step logoff. For the front panel, the

root menu has a logoff command. From EnerVista right-clicking on a device and

providing a logoff function from the context menu is sufficient.

3. The EnerVista Login Screen has “User Name:” and “Password:” fields for the default

remote (Radius) authentication, but when a “Local Authentication” checkbox is

selected the “User Name:” field changes to a drop down menu where the user can

select one of the predefined roles on the 869.

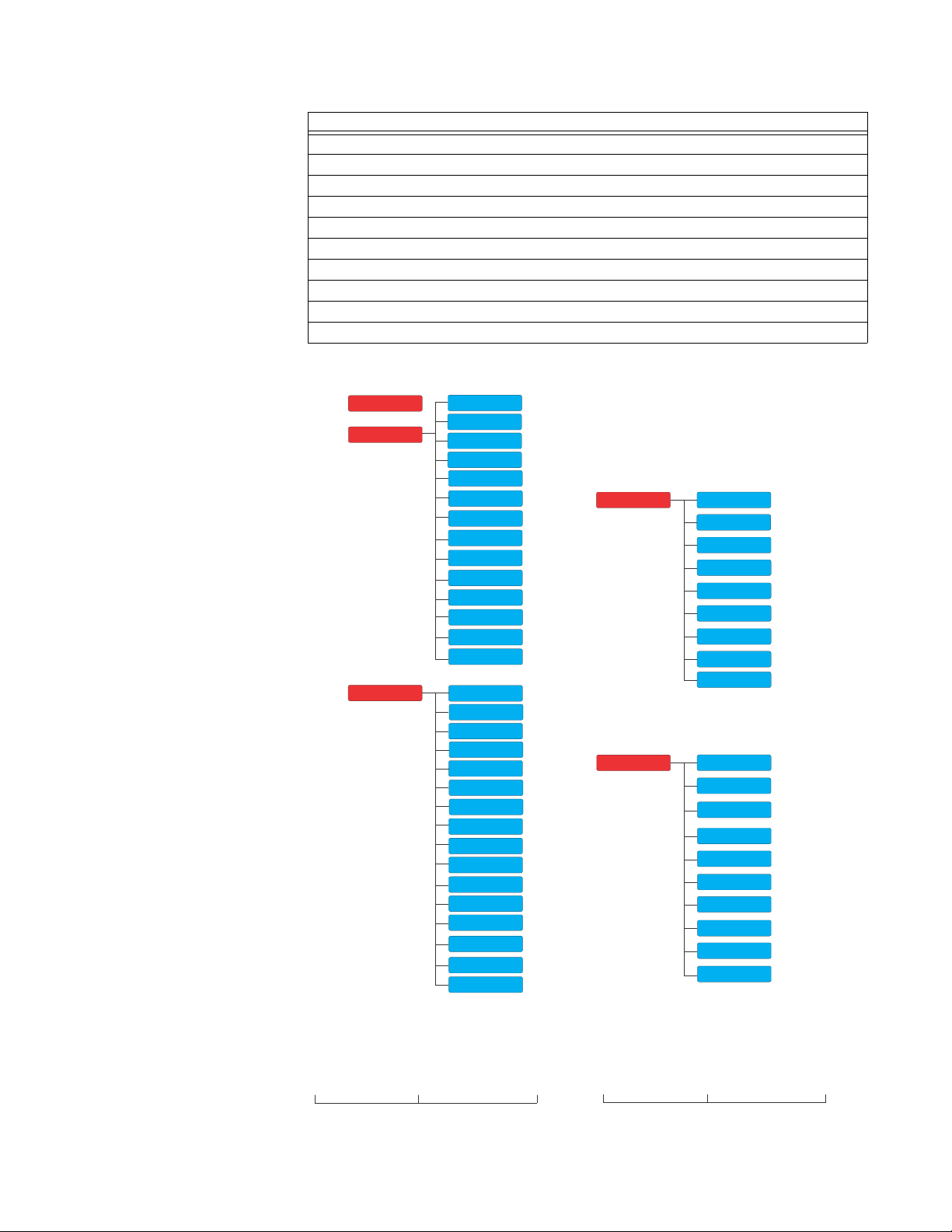

869 Order Codes

NOTE:

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–7

Support of some of the features described in the "Setpoints" section are order code

dependent. The 8 Series unit is ordered with a number of required and optional modules.

Each of these modules can be supplied in a number of configurations specified at the time

of ordering.

The information to specify an 869 relay is provided in the following Order Code figure:

Page 18

869 ORDER CODES CHAPTER 1: INTRODUCTION

892800B8.PDF

869 E ** ** ** H * * A * N G * * * * * * * * * N

Interface 869 | | | |||||||||||||||||| 869 Motor Protection System

Language E | | | | | | | | | | | | | | | | | | | | English

Phase Currents ³

Slot J Bank 1/2

P1| |||||||||||||||||| 1A 3-phase current inputs (J1)

P5| |||||||||||||||||| 5A 3-phase current inputs (J1)

Phase Currents ³

Slot K Bank 1

NN | | | | | | | | | | | | | | | | | | No phase current inputs

P1 | | | | | | | | | | | | | | | | | | 1A 3-phase current inputs (K1)

P5 | | | | | | | | | | | | | | | | | | 5A 3-phase current inputs (K1)

Ground Currents G1 ||||||||||||||||| 1A ground input (J1)

G5||||||||||||||||| 5A ground input (J1)

B1|||||||||||||||||

1A ground (J1) + 50:0.025A

(K1, included with current protection M option only)

B5|||||||||||||||||

5A ground (J1) + 50:0.025A

(K1, included with current protection M option only)

0B||||||||||||||||| 50:0.025A (J1), only available if NN is selected for Slot K Bank 1

Power Supply L | | | | | | | | | | | | | | | | 24 to 48 V DC

H | | | | | | | | | | | | | | | | 110 to 250 V DC/110 to 230 V AC

Slot B - LV

IO

N||||||||||||||| None

R||||||||||||||| 6 X RTDS (PT100, NI100, NI120)

S||||||||||||||| 6 X RTDS (PT100, NI100, NI120, CU10)

Slot C- LV IO

N | | | | | | | | | | | | | | None

R | | | | | | | | | | | | | | 6 X RTDS (PT100, NI100, NI120)

S | | | | | | | | | | | | | | 6 X RTDS (PT100, NI100, NI120, CU10)

Slot F - HV IO A

||||||||||||||||||||||||||2 Form A (Vmon), 3 Form C, 7 Digital Inputs (Low/High Voltage, Int/Ext

Supply)

Slot G - HV

IO

N | | | | | | | | | | | | None

A |

||||||||||||||||||||||2 Form A (Vmon), 3 Form C, 7 Digital Inputs (Low/High Voltage, Int/Ext

Supply)

L | | | | | | | | | | | | 7 DcmA O/P + 4 DcmA I/P + 1 RTD (PT 100, NI 100, NI 120)

Slot H - HV

IO

N||||||||||| None (High Voltage I/O)

F||||||||||| 10 Digital Inputs + 4 Arc Flash Inputs

A

||||||||||||||||||||||2 Form A (Vmon), 3 Form C, 7 Digital Inputs (Low/High Voltage, Int/Ext

Supply)

Faceplate M | | | | | | | | | | Basic = Membrane Keypad

G | | | | | | | | | | Standard = Rugged Keypad

Current Protection S | | | ||||||

Basic configuration: 14, 19, 37, 38, 46, 49, 50P, 50N, 50G, 50_2, 50LR,

51P, 51N, 51G, 66, 86

M

||||||||||||||||||Standard configuration: Basic configuration +67P, 67N, 87 (2nd CT Bank

required for 87)

Voltage Monitoring and Protection S

||||||||||||||||Standard Voltage Monitoring & Protection: 24, 27P, 40, 40Q, 47, 59P, 59N,

59X, 81O, 81U, VTFF

P

||||||||||||||||Advanced Voltage Monitoring & Protection: Standard Voltage

Monitoring & Protection +32, 55, 59_2, 78, 81R

Control B | ||||||

Basic control: Setpoint Group Control, Breaker/Contactor Control, Virtual

Inputs, Trip Bus

F||||||| Standard control: Basic control + FlexLogic, 50BF

Monitoring B||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Basic monitoring: Motor Health Report, Motor Start Report, Motor

Learned Data, Data Logger, Breakers Coil Monitoring, Breaker Arcing,

Harmonics, THD, Demand

C

||||||||||||Standard monitoring: Basic monitoring + Breaker Health Report, Broken

Rotor Bar

A | | | | | | Advanced: Standard + Harmonic Detection, Stator Inter-Turn Fault

Communications S E

||||||||Standard = USB, 1xRS485: Modbus RTU, DNP3.0, IEC60870-5-103 +

1xEthernet Copper: Modbus TCP, DNP3.0

1E

||||||||Advanced = USB, 1xRS485: Modbus RTU, DNP3.0, IEC60870-5-103 +

2xEthernet, Modbus TCP/IP, DNP3.0, IEC 60870-5-104, SNTP, 1588

1P|||| Advanced communications + PRP

2A|||| Advanced communications + IEC 61850

2E|||| Advanced communications + PRP + IEC 61850

Advanced Communications Connector N | | | None

S | | | ST, Multi-mode 1310 nm

C | | | RJ45, Copper 10/100M

Wireless Communication N | | None

W| | WiFi 802.11

Security B | Basic security

A | Advanced security: CyberSentry Level 1

Future Option N Not Available

Figure 1-3: 869 Order Codes

1–8 869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 19

CHAPTER 1: INTRODUCTION SPECIFICATIONS

FASTPATH:

Harsh Environment Coating is a standard feature on all 8 Series units.

Advanced security is only available with advanced communications (1E, 1P, 2A, 2E). When

the advanced communications option is selected, the Ethernet port on the main CPU is

disabled.

The “A” option on Slot H is only available if the “L” option is selected on Slot G.

Specifications

To obtain the total operating time, i.e. from the presence of a trip condition to initiation of a

trip, add 8 ms output relay time to the operate times listed below.

Device

CUSTOM CONFIGURATIONS

Config Mode:.........................................................Simplified, Regular

Protection

ARC FLASH HS PHASE/GROUND INSTANTANEOUS OVERCURRENT HS 50P/50G

Current:....................................................................Phasor Magnitude (special high speed algorithm)

Pickup Level:..........................................................0.050 to 30.000 x CT in steps of 0.001 x CT

Dropout Level: ......................................................97 to 98% of Pickup

Level Accuracy:....................................................For 0.1 to 0.2 x CT: ± 0.2% of reading or 1.5% of rated,

whichever is greater

For > 0.2 x CT: ± 1.5% of reading

Operate Time:.......................................................4 ms at >6 x Pickup at 60 Hz

5 ms at >6 x Pickup at 50 Hz

4-8 ms at > (3-6) x Pickup at 60 Hz

4-10 ms at > (3-6) x Pickup at 50 Hz

PERCENT DIFFERENTIAL (87S)

Methods: .................................................................Internal summation and Core balance

Pickup Level:..........................................................0.05 to 1.00 x CT in steps of 0.01

Slope 1 and 2:.......................................................1 to 100% in steps of 1

Break 1:....................................................................0.50 to 2.00 x CT in steps of 0.01

Break 2:....................................................................2.00 to 30.00 x CT in steps of 0.01

Operate Time:.......................................................<16 ms at >3 × Pickup at 60 Hz;

<20 ms at >3 × Pickup at 50 Hz

THERMAL MODEL (49)

Thermal Overload Curves: ..............................Motor curve, FlexCurve, Standard Motor curve with voltage

dependent function, FlexCurve with voltage dependent

function, IEC curve

Motor Curve Time Multiplier:.........................0.00 to 25.00 in steps of 0.01

FlexCurve Time Multiplier: ..............................0.00 to 600.00 in steps of 0.01

IEC Curve Time Constant: ...............................0 to 1000 in steps of 1

Thermal Overload Pickup:...............................Overload factor x FLA

Overload Factor (OL):.........................................1.00 to 1.50 in steps of 0.01

Motor Full Load Current (FLA):.......................1 to 5000 A in steps of 1

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–9

Page 20

SPECIFICATIONS CHAPTER 1: INTRODUCTION

Standard Overload Curve, Cutoff

Effect:.................................................................

Standard Overload Curve, Shift

Effect:.................................................................

Motor Rated Voltage:........................................1 to 50000 V in steps of 1

Thermal Model Biasing: ...................................Current Unbalance, RTDs

Thermal Model Update Rate: ........................ 1 power cycle

Stopped/Running Cool Time Constants: .1 to 1000 min. in steps of 1

Stopped/Running Cool Time Constant

Decay:.................................................................Exponential