Page 1

GE Energy Management

TM

Maintenance Action Planner

LTC-MAP 2130 Monitor

Product Manual

Part No. 70055MP

Rev. D, February 3, 2000

Page 2

GE Energy Management

LTC-MAP 2130 Monitor

Maintenance Action Planner

Monitoring System

Product Manual

70055MP Revision D February 3, 2000

Page 3

Copyright Information

Copyright 2000 Reuter-Stokes, Inc. All rights reserved. This manual may

not, in whole or part, be copied, photocopied, reproduced, translated or

reduced to any electronic medium or machine readable form without prior

consent, in writing, from Reuter-Stokes, Inc.

The illustrations shown in this manual are intended solely to illustrate the

text of this manual. Because of the many variables and requirements

associated with any particular installation, Reuter-Stokes, Inc. cannot

assume responsibility or liability for actual use based upon the illustrative

uses and applications.

Trademarks

LTC-MAP™, SAGE™, are trademarks of Reuter-Stokes, Inc.

Warranty

Reuter-Stokes, Inc. warrants each of our products to be free from defects in

material or workmanship. Our obligation under this warranty is to repair or

replace, at our discretion, any product or part of a product that proves to be

defective upon examination within 18 months of the date of shipment, or 12

months from the date of startup, whichever occurs first. No other warranty

is expressed or implied. Reuter-Stokes, Inc. does not warrant that your

monitoring system will operate as described in this manual in every

environment.

Reuter-Stokes, Inc. has thoroughly tested the equipment and reviewed the

documentation. However, Reuter-Stokes, Inc. does not warrant the

performance of the products for for any particular purpose. In no event is

Reuter-Stokes, Inc. liable for any damage resulting, directly or indirectly,

from the use of this product.

THE EXPRESS WARRANTY SET FORTH ABOVE IS EXCLUSIVE, AND NO

OTHER WARRANTY OF ANY KIND, WHETHER STATUTORY, WRITTEN,

ORAL, EXPRESS, OR IMPLIED (INCLUDING WARRANTIES OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY), SHALL APPLY.

Revision History

Revision Release Date

1.0 November 14, 1997

1.1 January 26, 1998

B July 6, 1998, July 19,1999

C October 14, 1999

D February 3, 2000

February 3, 2000 ii 70055MP Revi sion D

Page 4

Table of Contents

Section 1: Introduction

Product Overview......................................................................................................................................................1-1

Specifications...........................................................................................................................................................1-3

Input...................................................................................................................................................................1-3

General...............................................................................................................................................................1-4

Electrical...........................................................................................................................................................1-5

Environmental...................................................................................................................................................1-5

Physical Enclosure..........................................................................................................................................1-5

Available Options......................................................................................................................................................1-6

Typical Application..................................................................................................................................................1-7

Manual Conventions................................................................................................................................................1-9

Product Labels..........................................................................................................................................................1-9

Section 2: Getting Started

Receiving Inspection................................................................................................................................................2-1

Customer Support/Service.......................................................................................................................................2-1

Front Cover Layout....................................................................................................................................................2-2

Face Panel Layout....................................................................................................................................................2-3

Operating Conditions Button.............................................................................................................................2-4

Alarm Status & Settings Button.........................................................................................................................2-4

Acknowledge Alarm Button................................................................................................................................2-4

LCD Display...........................................................................................................................................................2-5

Serial Port ..............................................................................................................................................................2-5

Circuit Board Location.............................................................................................................................................2-6

I/O Board ...............................................................................................................................................................2-7

Power Supply Board ............................................................................................................................................2-8

CPU Board .............................................................................................................................................................2-9

Communications.....................................................................................................................................................2-10

Section 3: Installation

Selecting a Location................................................................................................................................................3-1

Mounting the Monitor..............................................................................................................................................3-2

Cable Installation......................................................................................................................................................3-3

I/O Board Configuration Jumpers..........................................................................................................................3-4

Channel Configuration........................................................................................................................................3-4

Modem Power Supply Configuration Jumper..................................................................................................3-5

Alarm Configuration Jumpers ............................................................................................................................3-6

Ground Jumpers...................................................................................................................................................3-6

Wiring.........................................................................................................................................................................3-7

Overview.................................................................................................................................................................3-7

Wiring the Sensors.............................................................................................................................................3-10

Wiring a Tap Position Indicator......................................................................................................................3-11

OEM Potentiometers......................................................................................................................................3-11

After-Market....................................................................................................................................................3-16

Wiring the AC Voltage Inputs...........................................................................................................................3-17

Wiring the AC Current Inputs...........................................................................................................................3-17

Wiring the Digital Inputs...................................................................................................................................3-17

Wiring the Annunciator Outputs.....................................................................................................................3-18

Wiring the Internal Heater................................................................................................................................3-19

Wiring Power.......................................................................................................................................................3-19

70055MP Revision D iii February 3, 2000

Page 5

Establishing Communications..............................................................................................................................3-20

Serial Port Communications.............................................................................................................................3-21

Modem Communications..................................................................................................................................3-22

Initial Start Up.........................................................................................................................................................3-23

Calibrate Tap Position............................................................................................................................................3-24

Section 4: Operation

Overview.....................................................................................................................................................................4-1

Operating Conditions Button..................................................................................................................................4-1

Analog Channel Readings Screens...................................................................................................................4-2

Digital Channel Readings Screens....................................................................................................................4-2

Tap Change Summary Screen ............................................................................................................................4-3

Alarm Status & Settings Button.............................................................................................................................4-5

LTC-MAP Status Screen......................................................................................................................................4-5

Current Time and Date Screen............................................................................................................................4-6

Acknowledging Alarms............................................................................................................................................4-6

Section 5: Troubleshooting Procedures

Appendix A: User-Specific Information Forms

Appendix B: Firmware Upgrades

Appendix C: Glossary of Terms

Index

February 3, 2000 iv 70055MP Revi sion D

Page 6

Section 1: Introduction

Product Overview

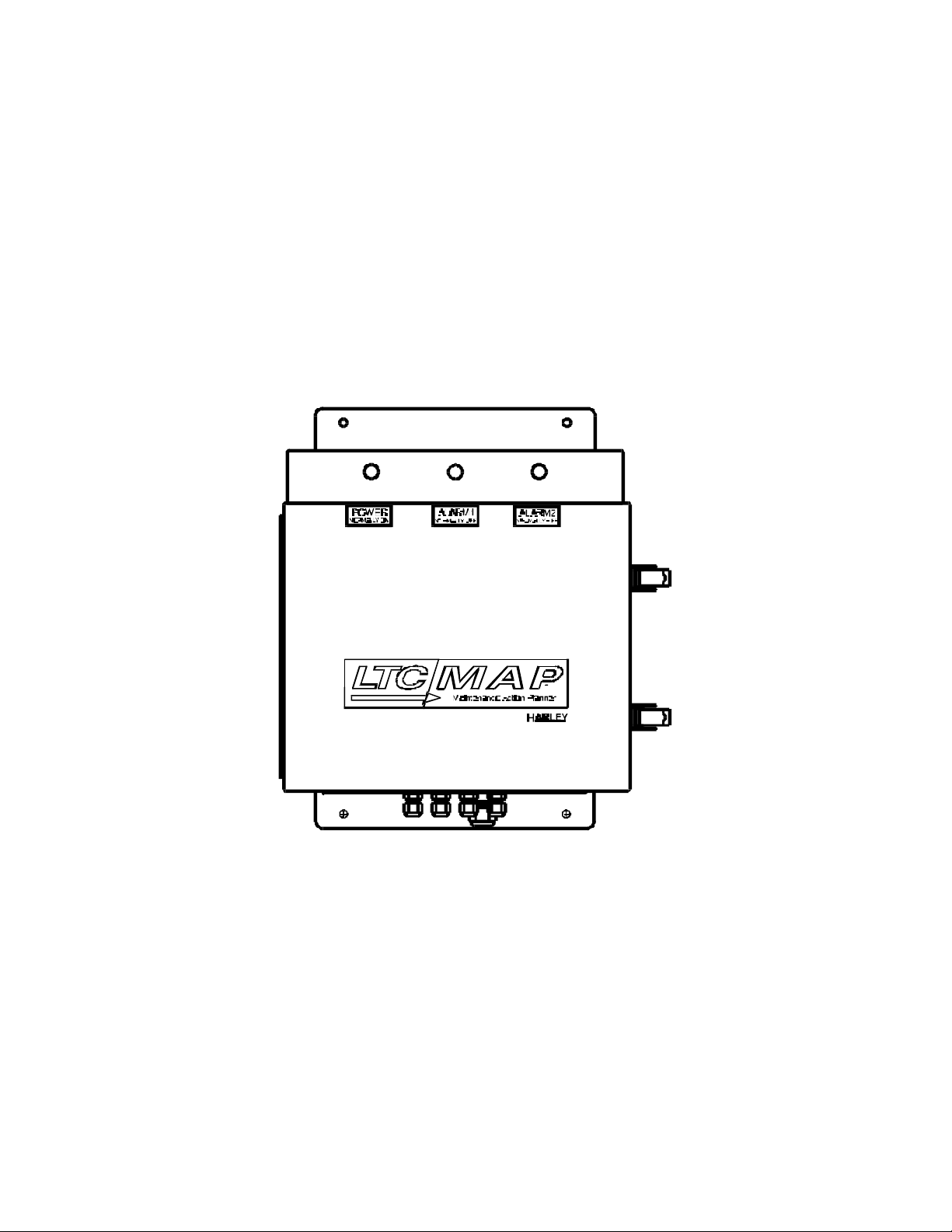

The LTC-MAP 2130 Monitor (Figure 1-1) is an on-line maintenance

action planner (MAP) for load tap changers (LTC). It continuously

monitors performance data from various types of sensors, such as

temperature and current. It stores this data in non-volatile memory for

downloading to a personal computer.

Figure 1-1: LTC -MAP 2130 Monitor

70055MP Revision D February 3, 2000

Page 7

1-2 Section 1: Introduction

LTC-MAP 2130 Monitor is a multi -input data storage and analysis

system. Each system features:

• Seventeen (17) analog input channels.

• Sixteen (16) digital input channels (via optional Control Isolator).

• One (1) serial port/modem line.

• Two annunciator relay outputs (form C contacts).

LTC-MAP 2130 uses state of the art technology to process, analyze,

and store data into a configurable profile. A built-in microprocessor

compares, computes, and relates stored data to set parameters.

Alarms are generated when data levels exceed the set parameters.

NOTE: Parameters are set via the SAGE host software package.

Refer to the SAGE Product Manual, Part No. 70057MP, for details

on parameter configuration and data retrieval and analysis.

Data profiles and alarm events are stored in non-volatile randomaccess memory. The stored information is then downloaded to a

personal computer, either directly through the serial port or via an

optional modem. The SAGE host software package allows data

retrieval and analysis.

February 3, 2000 70055MP Revision D

Page 8

Section 1: Introduction 1-3

Specifications

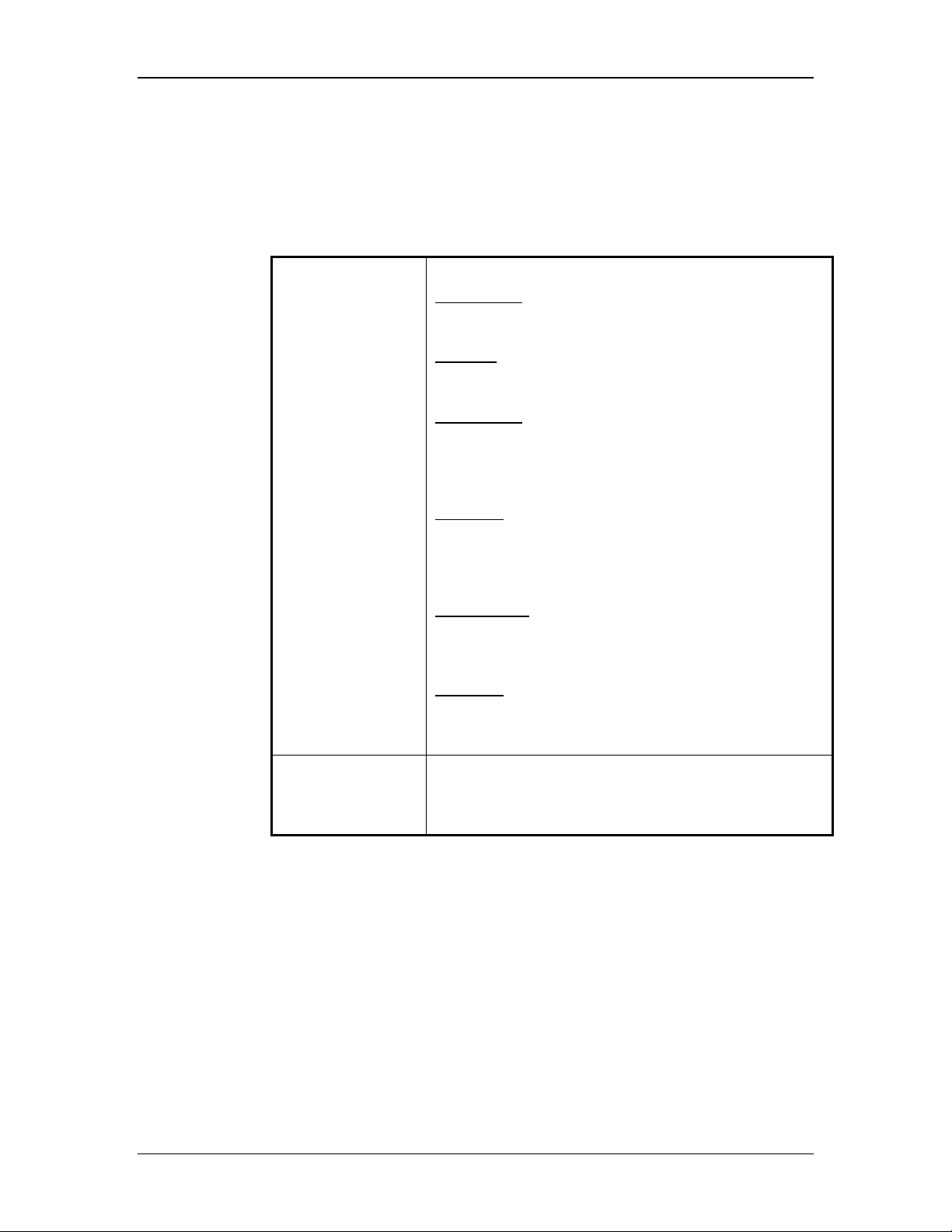

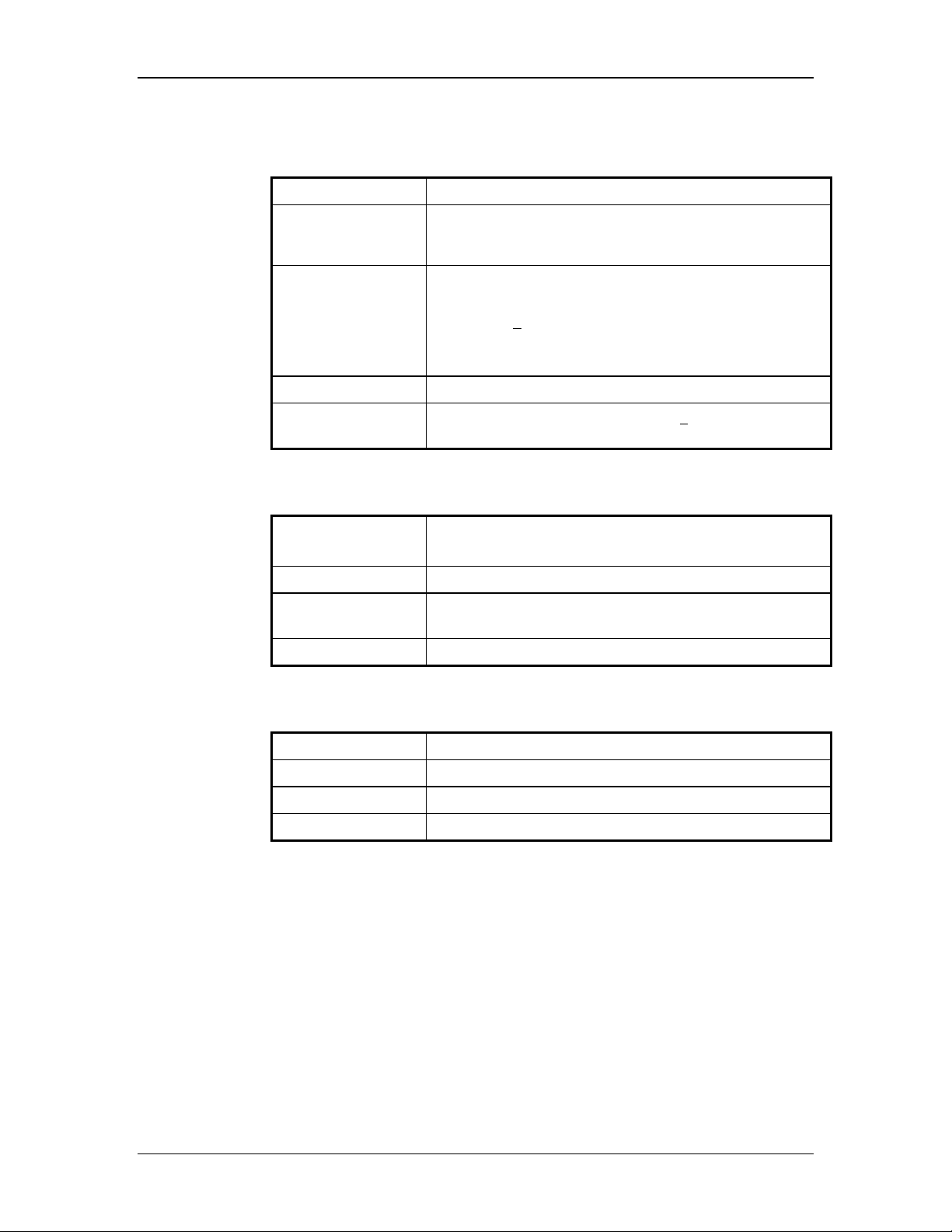

Input

Analog

Digital

Seventeen (17) channels.

Channels 1 - 7

Input: 4 to 20 mA.

Sample rate: 150 Hz.

Channel 8

Input: ±10 VDC.

Sample rate: 150 Hz.

Channels 9-11

Configurable input:

• 4 to 20 mA with a sample rate of 150 Hz, or

• 5A AC (as monitored by a CT) with a sample rate of 1920

Hz.

Channel 12

Configurable input:

• 4 to 20 mA with a sample rate of 150 Hz, or

• 50A AC (as monitored by a CT) with a sample rate of

1920 Hz.

Channels 13-16

Configurable input:

• 4 to 20 mA with a sample rate of 150 Hz, or

• 120/240 VAC with a sample rate of 1920 Hz.

Channel 17

Configurable input:

• 4 to 20 mA with a sample rate of 150 Hz, or

• Signal conditioned with a sample rate of 1920 Hz.

Sixteen channels via two optional control isolators (eight

channels each).

Input: ±120/240 VAC.

Sample rate: 960z.

70055MP Revision D February 3, 2000

Page 9

1-4 Section 1: Introduction

General

Relay Outputs

Front Panel

Indicators

Display

Communications

Data Storage

Controls

Installation Category

Maintenance

Cleaning

Intermittent

Operation

Two dry-contact relay outputs for alarm indication.

Three LEDs:

POWER: When lit, indicates that the monitor is receiving

power.

ALARM1: When lit, indicates that a software

configurable alarm has been activated; contact relay

driven.

ALARM2: When lit, indicates that a software

configurable alarm has been activated; contact relay

driven.

Front panel four line liquid crystal (LCD).

Resolution: 1 V, 1 A, 1 °C.

Standard: RS-232-C serial port; DB-9 connector.

Optional: 14.4k bps modem, installed on the back left side of

the monitor base.

Type: Non-volatile, solid state RAM.

Capacity: Up to 128 K, based on configuration.

Mode: Revolving loop.

Averaging Interval: Configurable from 1 to 60 minutes.

Three front panel push buttons:

Operating Conditions: Used to display present operating

conditions.

Alarm Status & Settings:

Used to display present alarm status.

Acknowledge Alarm:

Used to deactivate alarm relays.

One CPU Board mounted push button:

SETUP: Used to initiate setup procedure for tap position

calibrations.

III.

No regular maintenance is required.

No regular cleaning is required.

No specific limit; however, intermittent operation is

undesirable and should be corrected as soon as

possible.

February 3, 2000 70055MP Revision D

Page 10

Section 1: Introduction 1-5

Electrical

Sensor Power Supply

(Electrical Rating)

Power Consumption

Environmental

Temperature Range

Pollution Degree

Maximum Relative

Maximum Altitude

Power Input

Protection

Power Input

Supply Voltage

Fluctuation

Operating

Humidity

24 VDC @ 0.65A.

Fused (F1)

Type: AGC3 instant blow.

Rating: 3A @ 250 V.

AC: Standard: 120 VAC +10/-15%AC, 50 - 60 Hz.

Optional (factory set): 240 VAC +10/-15%AC, 50 - 60 Hz.

DC: 125 VDC +15%DC.

NOTE: Monitors supplied with internal heater option must

have AC power input.

Less than 16VA.

Mains supply voltage must not exceed +10% of nominal

supply voltage.

Standard: 0°C to +60 °C (+32°F to +140 °F).

With Heater Option: -40°C to +60 °C (-40°F to +140 °F).

4.

80%.

2000m.

Physical Enclosure

Material

Standard

Dimensions

NOTE: Specifications subject to change without notice.

Weight

Stainless steel, weather-proof.

NEMA Type 4.

12” (305 mm) x 12” (305 mm) x 6” (152 mm).

18 lbs. (8.16 kg); additional weight for accessories.

70055MP Revision D February 3, 2000

Page 11

1-6 Section 1: Introduction

Available Options

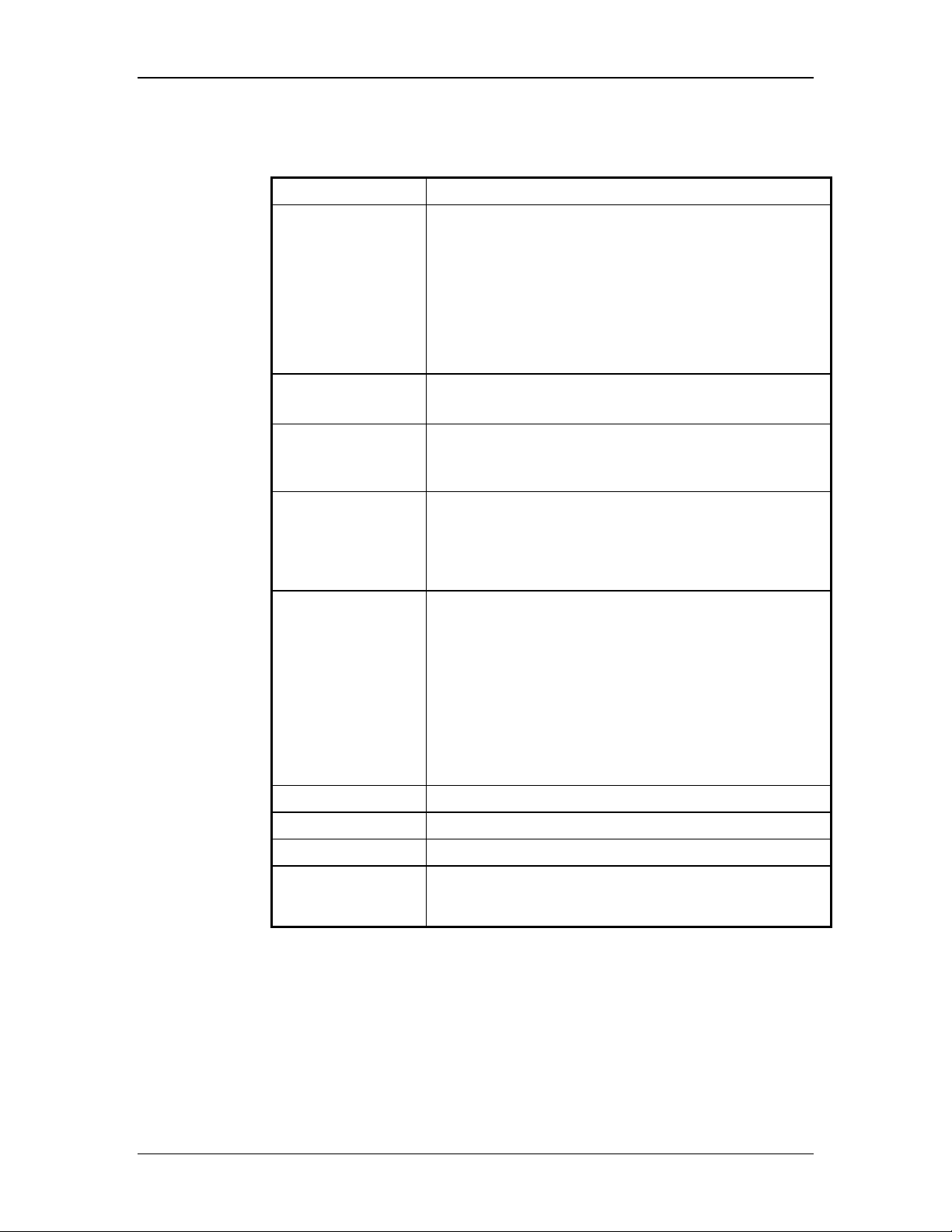

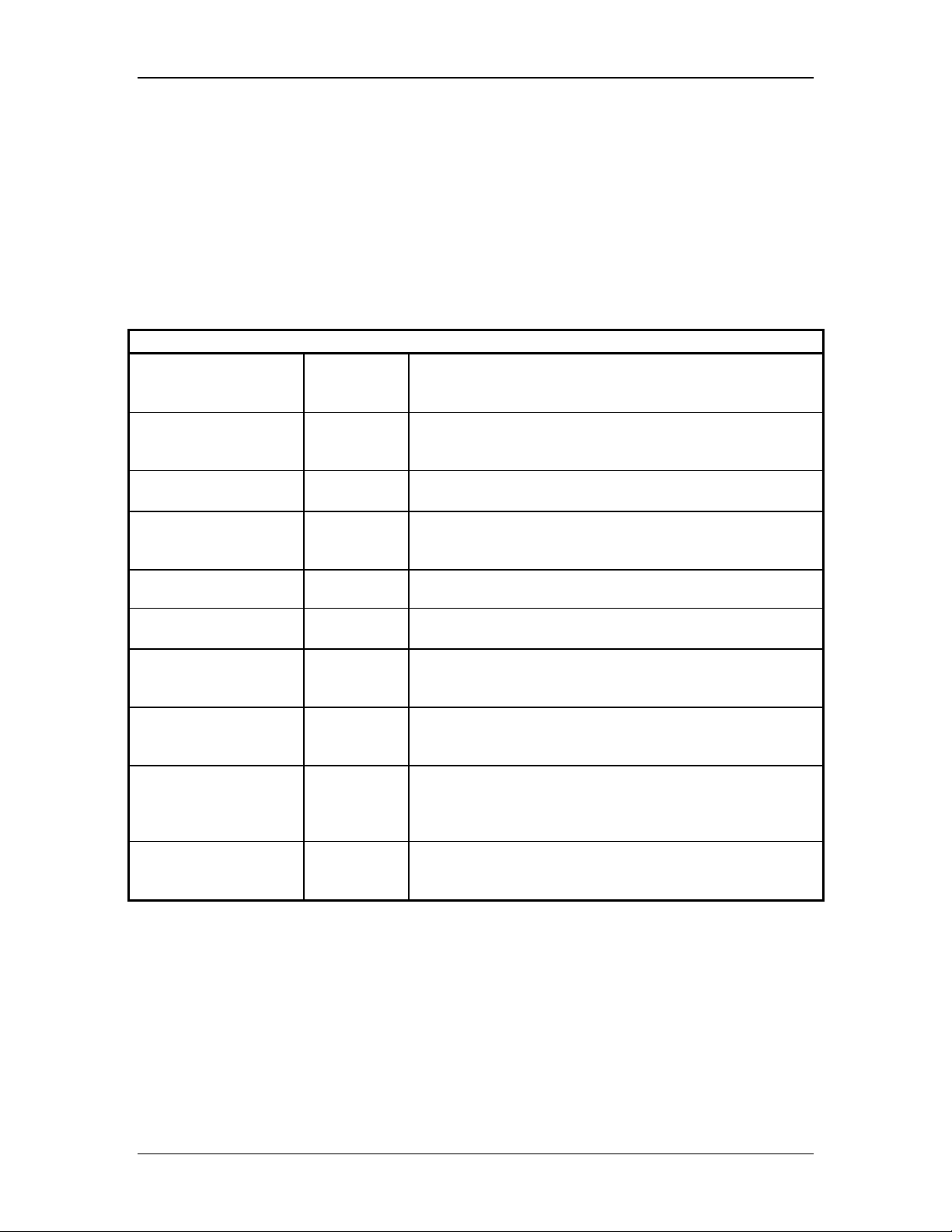

Available options for the LTC-MAP 2130 are listed in Table 1-1. Refer

to the applicable documentation for detailed information on the

available options.

Table 1-1: LTC -MAP 2130 Options

Option Part No. Description/Function

Magnetic Mount RTD

Temperature Sensor

RTD Transmitter T821028 Connects to an insertion-type temperature sensor and

Clamp-On AC Current

(CT) Sensor

Control Isolator 40041MP Optically isolates the monitoring system from the transformer

Combustible Gas Sensor 10384MP Measures hydrogen and hydrocarbon levels in the insulating

Moisture Sensor T801074 Measures moisture levels in the insulating oil.

Eight Line Phone

Multiplexer

Fifteen Line Phone

Multiplexer

14.4k bps Modem 20046MP Installed in the monitor; allows transfer of data and

SAGE Host Software

Package

30000MP Attaches magnetically to the transformer; has a built-in

4-20 ma transmitter.

Refer to Document No. 70063MP for more information.

transmits a 4-20 mA signal back to the monitor.

Refer to Document No. 70064MP for more information.

T821026 Clips onto a transformer lead and detects load current.

Refer to Document No. 70059MP for more information.

controls.

Refer to Document No. 70062MP for more information.

oil.

Refer to Document No. 70065MP for more information.

40047MPA Allows up to eight monitors (with installed modems) to be

connected to a single phone line for data transmission.

Refer to Document No. 70061MP for more information.

40047MPB Allows up to fifteen monitors (with installed modems) to be

connected to a single phone line for data transmission.

Refer to Document No. 70061MP for more information.

configuration parameters over a telephone line to an off-site

PC.

Refer to Document No. 70058MP for more information.

SAGE

Provides tools for parameter configuration, parameter

calibration, data retrieval, and data analysis.

Refer to Document No. 70057MP for more information.

February 3, 2000 70055MP Revision D

Page 12

Section 1: Introduction 1-7

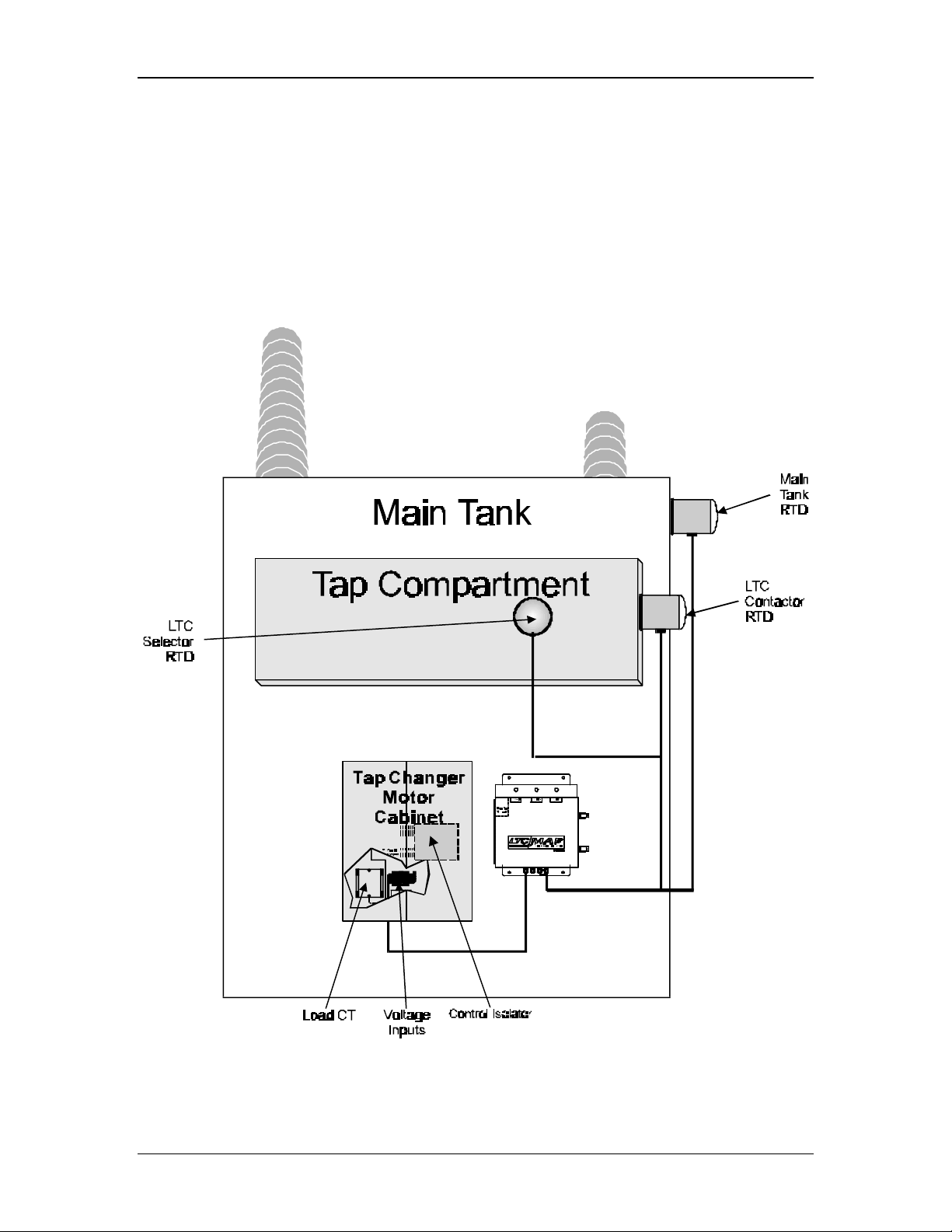

Typical Application

A transformer utilizing an LTC-MAP 2130 monitor is illustrated in Figure

1-2. The monitor is mounted on the transformer. Analog sensors

mounted on the transformer are connected to the monitor. Refer to the

example typical wiring diagram in Section 3 to determine specific

sensor input connections.

Figure 1-2: Typical LTC -MAP 2130 Application

70055MP Revision D February 3, 2000

Page 13

1-8 Section 1: Introduction

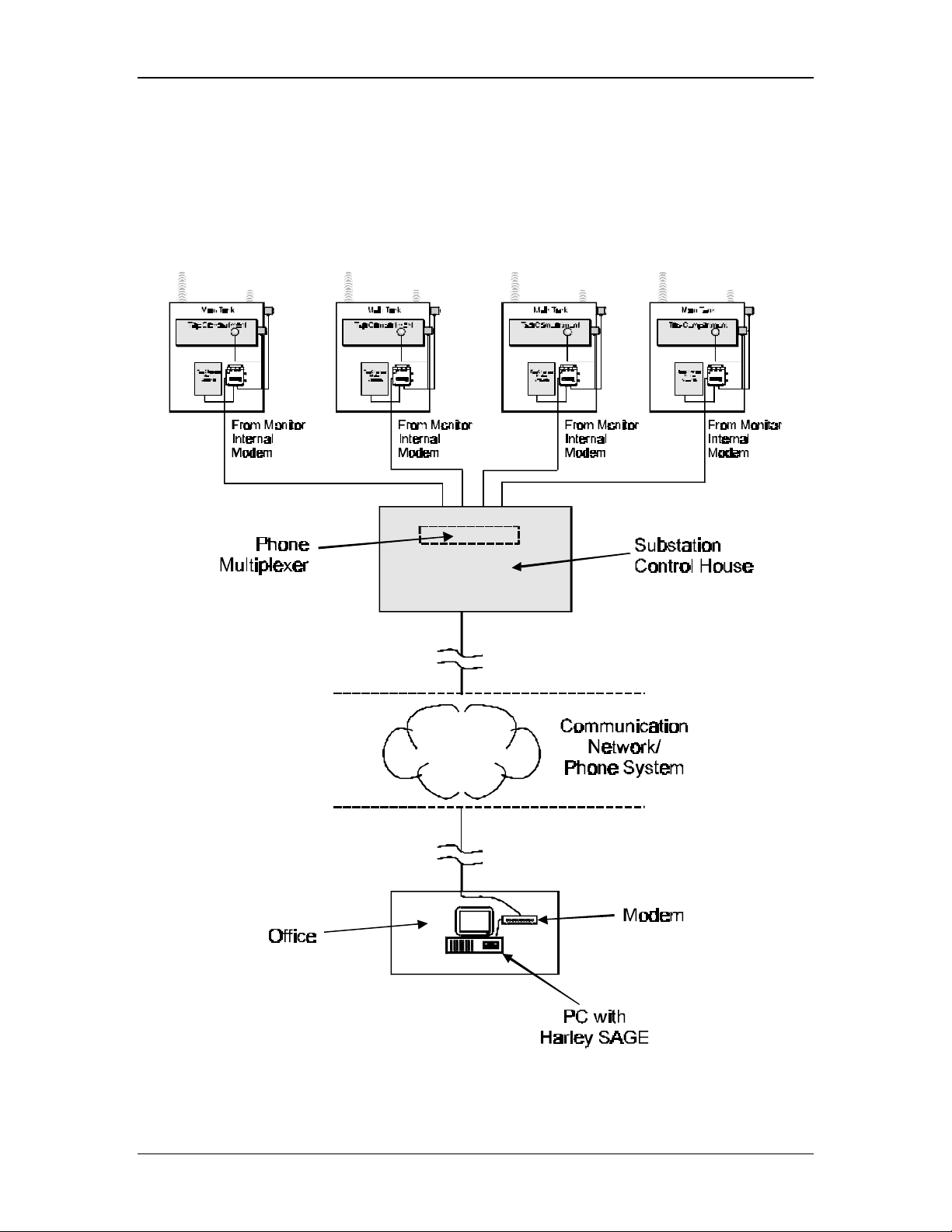

A typical system may include several monitors, one for each

transformer at the site, multiplexed together. The multiplexer is

typically located at the on-site substation. (See Figure 1-3). Data from

all monitors on site may then be downloaded to a remote personal

computer (PC). SAGE host software installed on the PC allows for

data retrieval and analysis.

Figure 1-3: Typical System

February 3, 2000 70055MP Revision D

Page 14

Section 1: Introduction 1-9

Manual Conventions

This manual provides the information you will need to install, operate,

and maintain the LTC-MAP 2130 Monitor.

Throughout this manual CAUTIONS, WARNINGS, and NOTES are

provided.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, may result in death or serious injury.

NOTE: Contains supplemental information.

70055MP Revision D February 3, 2000

Page 15

Section 2: Getting Started

Receiving Inspection

On receipt of the LTC-MAP 2130 Monitor:

1. Carefully inspect the packing containers and contents for physical

damage.

2. Carefully unpack the monitor, checking that all items listed on the

packing slip are present and in good condition.

NOTE: If damage is evident, or any items are missing, contact

Support Services at (330-425-3755) for further instructions.

Customer Support/Service

For service or support for your LTC-MAP 2130 Monitor, contact:

Field Service/Customer Support Department

Reuter-Stokes, Inc.

Edison Park

8499 Darrow Rd.

Twinsburg, OH 44087

PH: 330-425-3755

FAX: 330-425-1812

www.gepower.com

GE Syprotec

179 Boulevard Brunswick

Pointe-Claire, Quebec H9R 5N2

Canada

PH: 514-694-3637

FAX: 514-694-9245

70055MP Revision D February 3, 2000

Page 16

2-2 Section 2: Getting Started

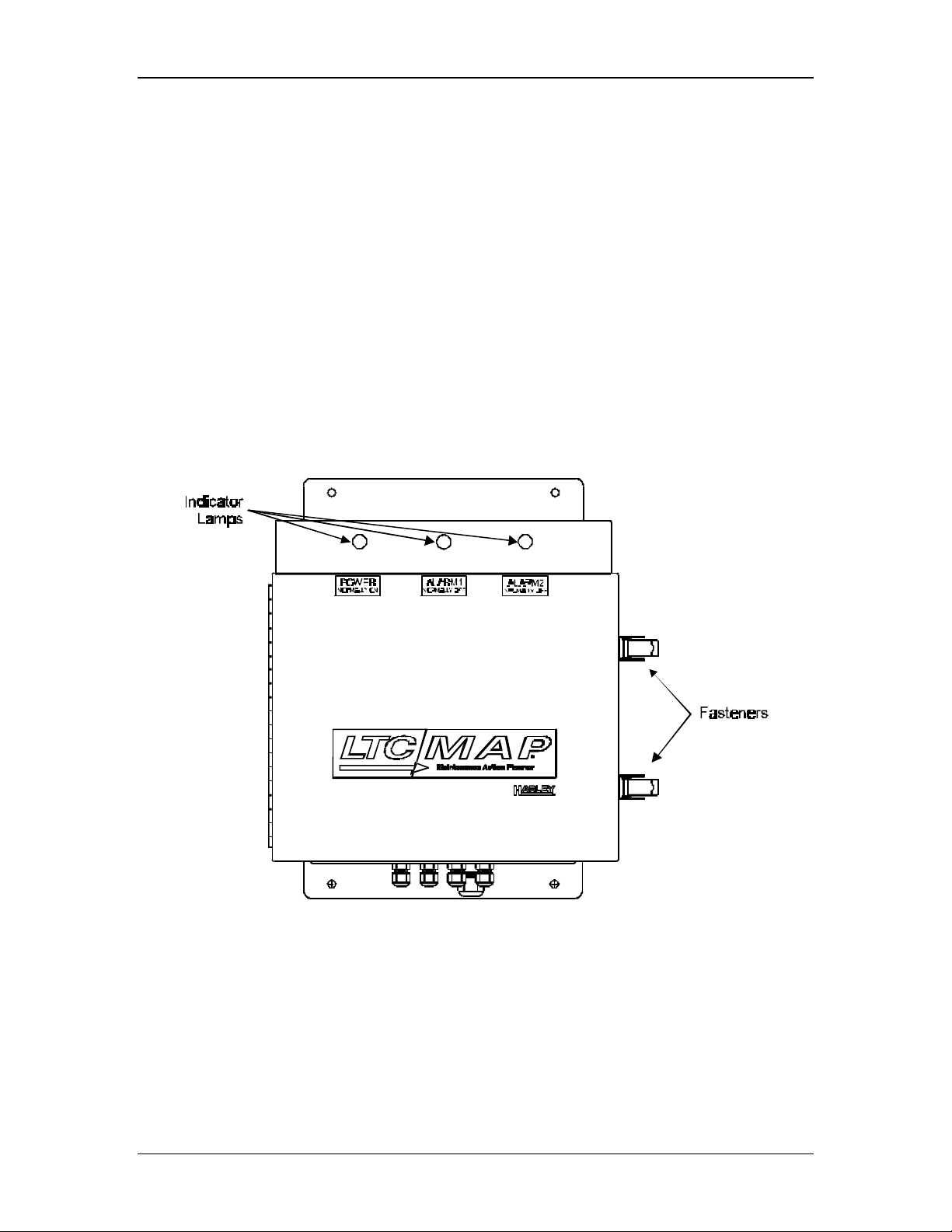

Front Cover Layout

There are three indicator lights on the front cover of the LTC-MAP 2130

Monitor (see Figure 2-1):

• The yellow POWER indicator illuminates whenever the monitor is

receiving power.

• The red ALARM1 indicator illuminates whenever a configured

contact relay alarm is activated.

• The red ALARM2 indicator illuminates whenever a configured

contact relay alarm is activated.

The fasteners on the right side of the front cover allow access to the

inside face panel of the monitor.

Figure 2-1: LTC -MAP 2130 Monitor (Front Cover)

February 3, 2000 70055MP Revision D

Page 17

Section 2: Getting Started 2-3

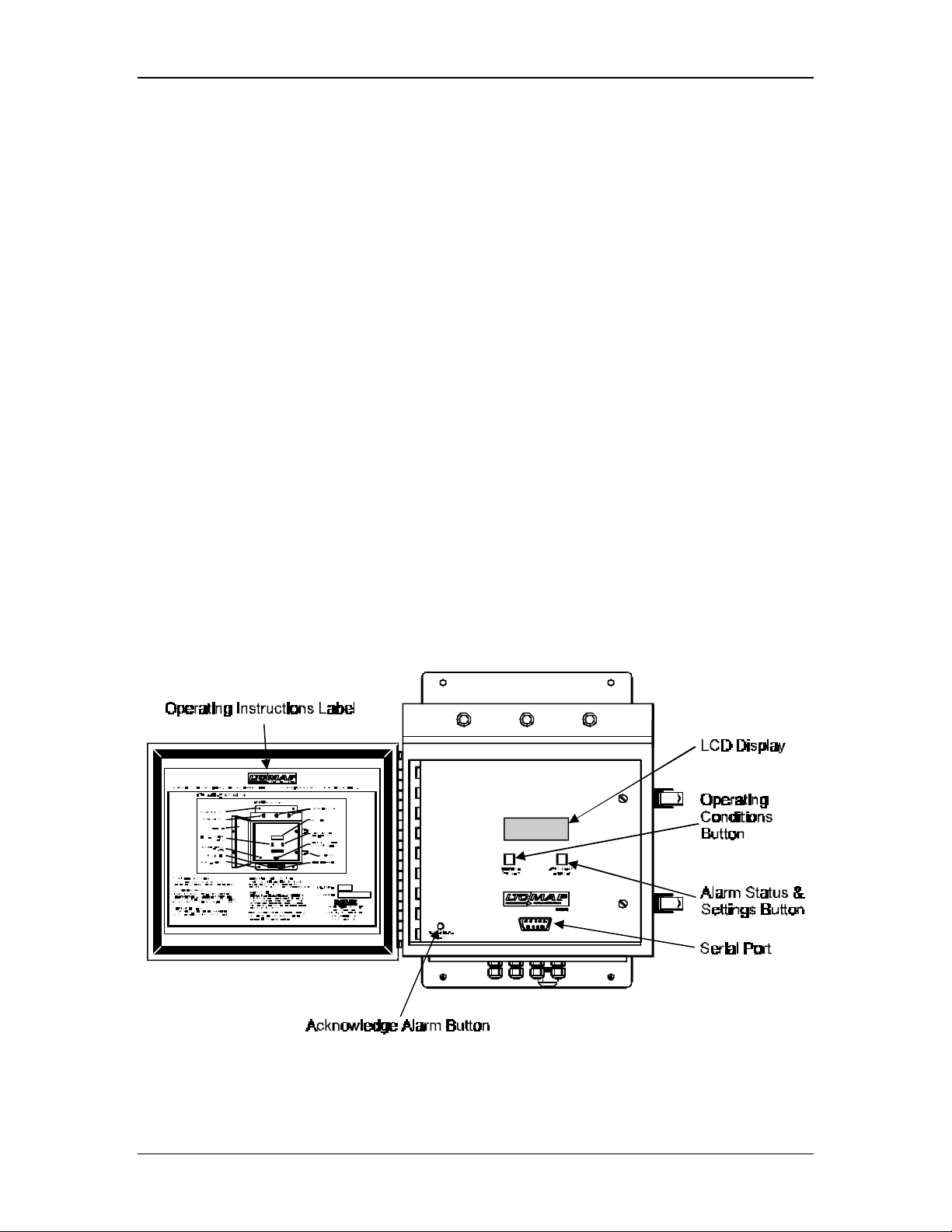

Face Panel Layout

The face panel is accessed by releasing the fasteners on the right side

of the front cover. The front panel features (see Figure 2-2):

• A four-line LCD display.

• Operating Conditions button.

• Alarm Status & Settings button.

• Acknowledge Alarm button.

• A serial port.

Present operating conditions, alarm settings, and alarm status may be

viewed on the display by pressing the appropriate buttons.

The serial port allows direct connection, utilizing a null modem cable,

between the LTC-MAP 2130 and a portable computer for data transfer.

NOTE: A null modem cable is available from Reuter-Stokes (Part No.

10101MP).

The two thumb screws on the right side of the face panel provide

access to the CPU and I/O circuit boards.

Figure 2-2: LTC -MAP 2130 Monitor (Face Panel)

70055MP Revision D February 3, 2000

Page 18

2-4 Section 2: Getting Started

Operating Conditions Button

The Operating Conditions button is located directly below and left

aligned with the display. Pressing the Operating Conditions button

displays the sensor value readings. Four channels are displayed

simultaneously. The display includes:

• Channel number.

• Channel name.

• Present reading.

• Units.

After all sensor screens are displaye d, pressing the Operating

Conditions button again displays the tap change summary screen.

During tap position calibration, the Operating Conditions button is used

to adjust settings.

Alarm Status & Settings Button

The Alarm Status & Settings button is located directly below and right

aligned with the display. Pressing Alarm Status & Settings displays

the monitor status and the date and time. If there are alarm conditions,

pressing Alarm Status & Settings scrolls through descriptions of alarm

conditions.

During tap position calibration, the Alarm Status & Settings button is

used to adjust settings.

Acknowledge Alarm Button

The Acknowledge Alarm button is located in the lower left corner of

the face panel. Pressing Acknowledge Alarm resets the alarm relay;

however, the indicator remains lit for the duration of the alarm

condition.

February 3, 2000 70055MP Revision D

Page 19

Section 2: Getting Started 2-5

LCD Display

The LCD is a 20 character by 4 line display (Figure 2-3). It displays

operating and status conditions. Screens are scrolled through using

the Operating Conditions and Alarm Status & Settings buttons.

L T C - M A P 2 1 3 0

r e v 2 1 3 0 . x x . y y

c o p y r I g h t ( C ) 1 9 9 7

< <

Operating Alarm Status

Conditions & Settings

Figure 2-3: Display with Control Buttons

Serial Port

CAUTION: The serial port and the modem cannot function

simultaneously. When using the serial port for communications, the

internal modem (if installed) must be disconnected at JP8; otherwise

the serial port will not function.

The serial port is a 9-pin male DB-9 connector. This port allows direct

connection, utilizing a null modem cable, between the LTC-MAP 2130

and a portable computer for data transfer. Data transfer rate is

19.2 kbps.

The serial port does not support dumb terminal operation. In order for

communications to take place:

• A null modem cable must be installed between the monitor serial

port and personal computer serial port.

• SAGE host software must be installed on the personal computer.

NOTE: A null modem cable is available (Part No. 10101MP ).

70055MP Revision D February 3, 2000

Page 20

2-6 Section 2: Getting Started

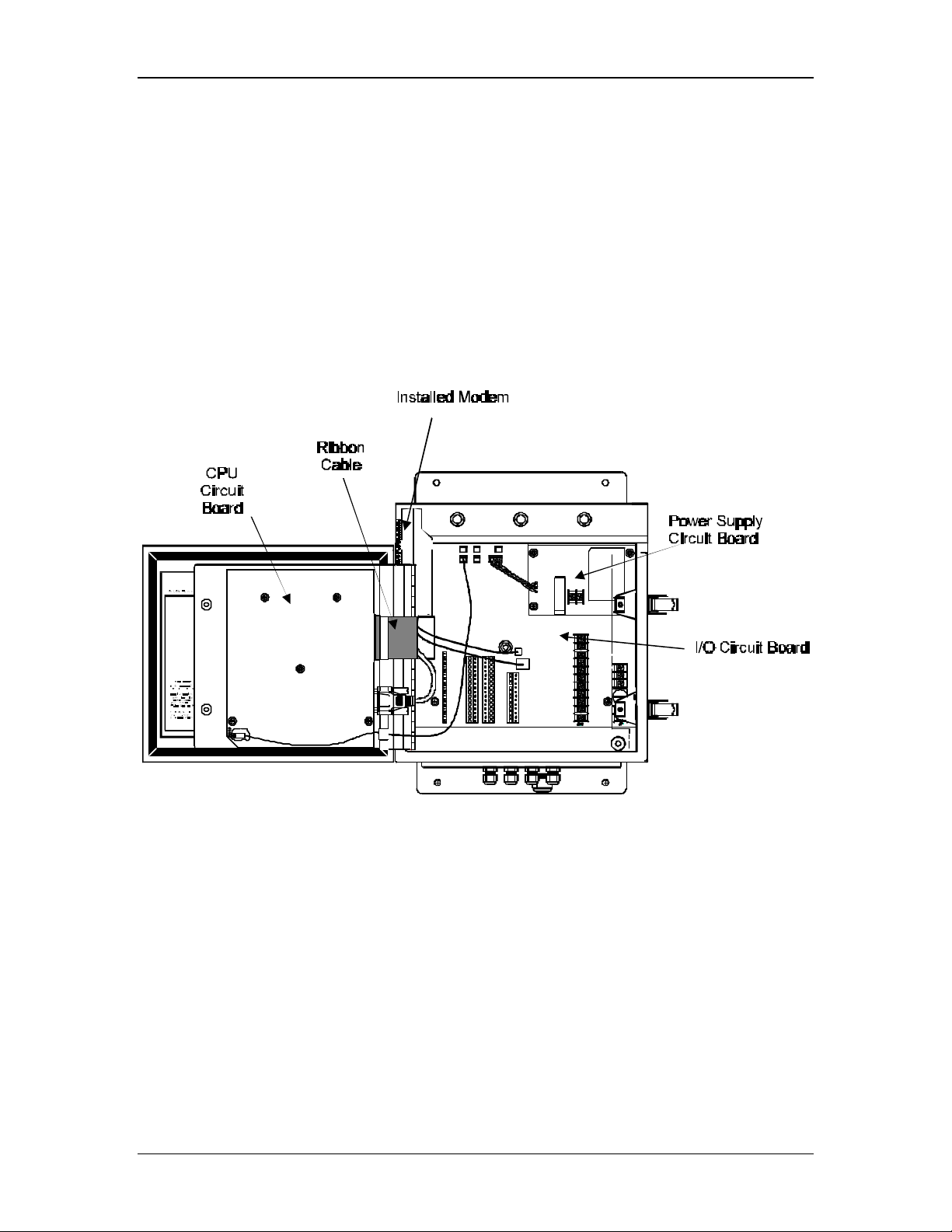

Circuit Board Location

The CPU and I/O circuit boards are accessed by loosening the two

thumb screws on the right side of the face panel (see Figure 2-4).

The CPU circuit board is mounted to the back side of the face panel.

The I/O Circuit board is mounted to the inside rear panel of the Monitor

cabinet. The Power Supply board is mounted on the I/O Circuit board.

A ribbon cable connects the CPU and I/O circuit boards.

Figure 2-4: LTC -MAP 2130 (Top View with Face Panel Open)

February 3, 2000 70055MP Revision D

Page 21

Section 2: Getting Started 2-7

Alarm #1

Alarm #2

Power

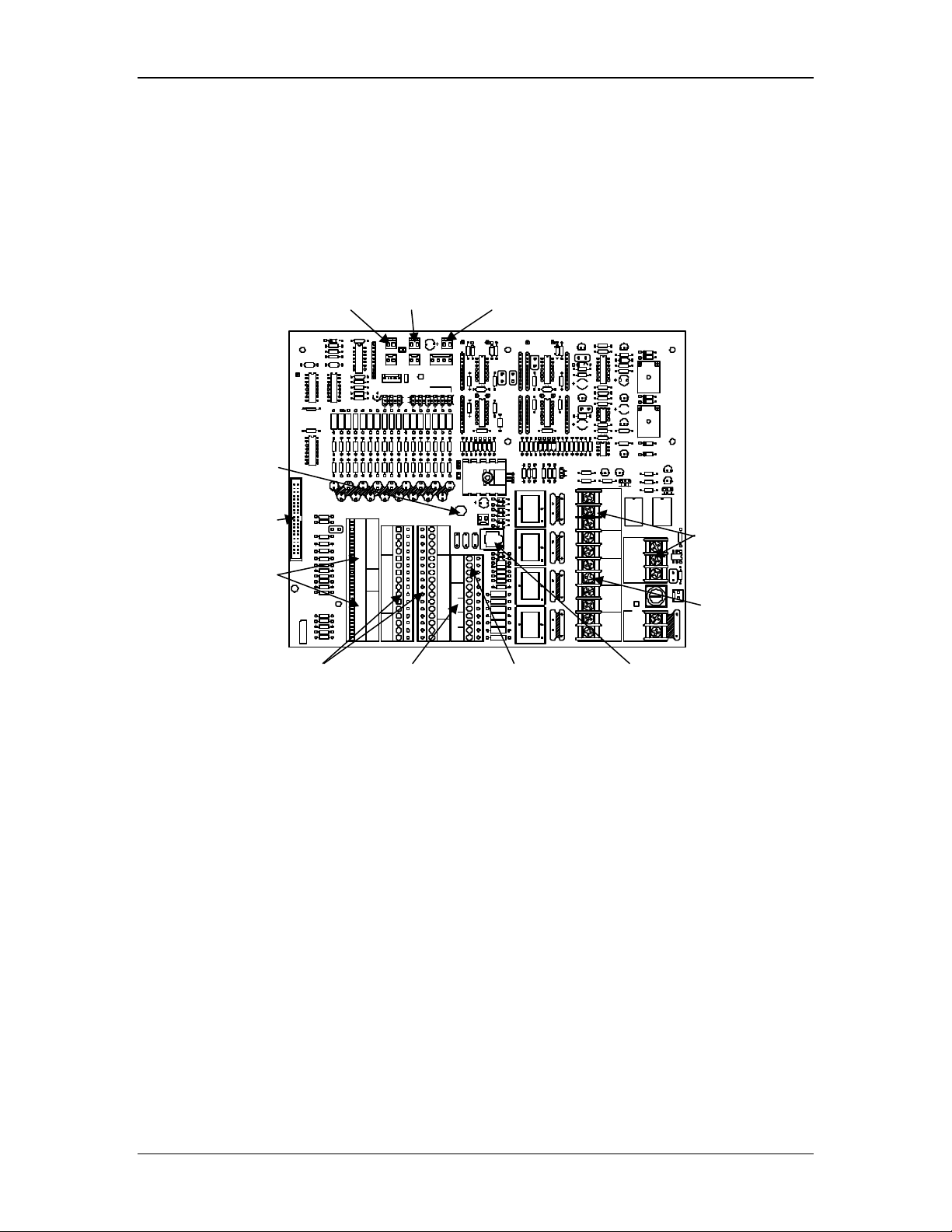

I/O Board

The I/O Circuit board (Figure 2-5) contains sensor signal conditioning

circuitry and hardware to interface to the sensors mounted on the

transformer.

Sensor

Ground

Ribbon Cable

Connector

(To CPU Board)

Control

Isolator

Inputs Voltage

Jumper

D10

R18

R17

R15

U6

TP1

C7

C9

U4

J4

C27

Sensor

Inputs

C11

RN6

U2

C8C10

U5

C16

R68

R67

U7

R70

R69

GT1 GT3 GT5 GT7

J15

C20

R71

Y

EN

R44

C

R38

B

Z9

A

Z13

R43

+12

Z8

REL

R37

A3

Z10

R41

A2

Z12

Y

EN

C

B

R39

R40

A

Z11

R42

COM COM

+12

Z14

DIGITAL ANALOG 2ANALOG 1 CURRENT

Jumper

J1

J7J6J3

JP13

J2

J17

17

J8

CHANNEL

1 16 141715 13 12 11 10 9

A

B

JP7

JP5JP9

GT14 GT16

GT12GT6GT4GT2GT17

J14 J16

COMMON

SENSOR

8

1ST CONTROL ISOLATOR2ND CONTROL ISOLATOR

7

SENSOR INPUTS

6

5

4

3

2

1

(24 VDC)

SENSOR

POWER

Current

Inputs

Jumper

C4

TP2

TP3 TP4

RN1

U9

C12

A

TP9 TP6

U12

B

JP1JP2JP3JP4JP6JP8

C17

GT10

GT8

C30

GT9GT11GT13GT15

J10

RJ1

GND

SENSOR

COMMON

J13

D1

COM

D2

RED GRN

R7

PHONE

16

15

14

13

12

11

10

9

SENSOR

POWER

COM

MOTOR

SENSOR INPUTS

CURRENT

C

B

A

(24 VDC)

R50

R53

R8

R12

R99

D25

R98

D24

R97

D12

R92

D16

Outside Phone

Line Connection

TP5

RN4

RN2

U1

C34

C31

C13

C32

TP7 TP8

U11

C18

U14

D3

D4

D17

D18

D13

D14

MODEM VOLTS

OPEN = 12V

MOV1

T1

MOV5

T2

MOV6

T3

MOV7

T4

Figure 2-5: I/O Circuit Board

Q6

R101

Q5

C19

R100

C33

U13

D9

D8

R6

R64

C3

C2

R3

C14

Q2

R102

Q4

R24

C23

C24

R48

U10

C22

9V

6V

C1

Q1

R49

R16

C15

C21

R20

U3

Q8

Q7

R108

R109

J18R110

ANN1

K4

#2

ANNUNCIATOR

NC COM NO

C25

C26

C28

#4

INPUT

VOLTAGE

#1

#3

INPUT

VOLTAGE

#2

INPUT

VOLTAGE

HEATER

#1

INPUT

VOLTAGE

J20

VOLTAGE

Internal Modem

Connection

D31

D30

D11

D32

D29

Q3

R111

R112

NORMINV

R113

K1

NC COM NO

ANNUNCIATOR

F1

LINENEUT

D28

K3

K2

Q9

Q10

J19

ANN2

NORMINV

J12

Annunciator

U8

Inputs

C6

J5

C5

Inputs

J9

70055MP Revision D February 3, 2000

Page 22

2-8 Section 2: Getting Started

Power Supply Board

The Power Supply circuit board (Figure 2-6) contains the low voltage

supplies, incoming power terminals, and the power fuse (F1) for the

monitor. F1 is a type AGC3 fuse, rated for 3 Amp at 250 V.

Figure 2-6: Power Supply Circuit Board

February 3, 2000 70055MP Revision D

Page 23

Section 2: Getting Started 2-9

CPU Board

The CPU circuit board (Figure 2-7) contains the microprocessor (CPU),

LCD Display, front panel buttons, and serial port.

Figure 2-7: CPU Circuit Board

70055MP Revision D February 3, 2000

Page 24

2-10 Section 2: Getting Started

Communications

The SAGE host software installed on a personal computer allows for

data retrieval and analysis. Communications with the LTC-MAP 2130

must be established in order to download data to the PC or upload

configuration information to the terminal. Communication between the

PC and the monitor can be established:

• Directly via the front panel serial port and a null modem cable

to a personal computer running the SAGE host software.

NOTE: SAGE host software must be installed on the PC for

proper communication to take place. The front panel serial

port does not support dumb terminal operation.

• Over phone lines using an optional modem installed inside the

monitor.

• Over phone lines via a phone multiplexer installed in the

control house and connected to several LTC-MAP 2130

monitors. Refer to Document No. 70061MP for detailed

information on the phone multiplexers available from ReuterStokes, Inc.

CAUTION: The serial port and the modem cannot function

simultaneously. When using the serial port for communications, the

internal modem (if installed) must be disconnected at J8; otherwise

the serial port will not function.

February 3, 2000 70055MP Revision D

Page 25

Section 3: Installation

This Section includes procedures for installation, configuration, wiring,

setting up communications, and initial start-up of the LTC -MAP 2130

Monitor.

Selecting a Location

The LTC -MAP 2130 is enclosed in a weatherproof stainless steel box that

can be mounted indoors or outdoors. When selecting a mounting location

for the monitor, verify that:

• The mounting surface is able to support a minimum of 25 pounds (11.3

kg).

• The mounting surface allows ample space for mounting the stainless

steel box and allows for a 12-inch (305 mm) door clearance (see Figure

3-1).

• Sensors are located nearby to minimize cable length.

• Wiring and cables can access the monitor gland plate.

• The face panel display is at a readable level.

• An operating temperature of 0 ºC to +60 ºC (+32 ºF to +140 ºF) can be

maintained at the monitor location.

NOTE: With the heater option installed, an operating temperature of

-40 ºC to +º60 C (-40 ºF to +140 ºF) must be maintained at the

monitor location.

CAUTION: Select a mounting location that assures an operating

temperature of 0 ºC to +60 ºC (+32 ºF to +140 ºF), otherwise system operation

could be interrupted.

70055MP Revision D February 3, 2000

Page 26

½"

3-2 Section 3: Installation

Mounting the Monitor

Secure the monitor to the selected location using four ¼-20# stainless

steels bolts through the mounting holes (see Figure 3-1).

(12.7 mm)

14"

(356 mm)

½" (12.7 mm)

Front Door Clearance -- 12" (305 mm)

8" (203 mm)

8" (203 mm)

1/4-20 UNF

(4PL.)

12"

(305 mm)

1 ½"

(38.1 mm)

Mounting

Holes

Figure 3-1: LTC-MAP 2130 Monitor Mounting Dimensions

February 3, 2000 70055MP Revision D

Page 27

Section 3: Installation 3-3

Cable Installation

After securely mounting the LTC -MAP 2130 monitor, route the input and

output cables back to the gland plate.

CAUTION: Do not apply power to the LTC -MAP 2130 until all input and

output cables are connected.

The removable gland plate on the bottom of the LTC -MAP 2130 Monitor has

pre-punched conduit hol es (see Figure 3-2) and strain relief cable

connectors. Weep holes are provided to allow drainage of excess

moisture.

Additional holes can be drilled into the gland plate if required. Remove the

plate by removing the two nuts and washers securing it to the monitor. The

nuts are accessed from inside the monitor.

CAUTION: Do not drill additional holes into the gland plate while it is installed

on the monitor. Metal chips can damage the circuit boards.

4.194"

(106 mm)

1.25"

(31.8 mm)

Weep Holes

1"

(25.4 mm)

10.25" (260 mm)

Strain Relief Connector

Figure 3-2: Gland Plate

.875"

22.2 mm

70055MP Revision D February 3, 2000

Page 28

Channel

3-4 Section 3: Installation

I/O Board Configuration Jumpers

The I/O board configuration jumpers allow you to customize the LTC -MAP

2130 monitor to your application’s specific sensor (channel type input),

alarm, and modem requirements.

Channel Configuration

Channels 9 through 12 are configurable for a 4-20 mA sensor input or a

5A/50A current input (as monitored through a CT). Channels 13 through 16

are configurable for a 4-20 mA sensor input or a voltage input. Refer to

Table 3-1 for specific jumper numbers and positions for each channel.

Refer to Figure 3-3 for A and B jumper positions.

JP13

RN6

J1

JP13

J2 J17

J8

17

U7

GT6GT4

CHANNEL

1 16 1415 13 12 11 10 9

A

B

JP7

GT14 GT16

JP5JP9

GT12

JP10

Configuration

Jumpers

C4

J7

J3

TP2

RN1

J6

A

B

JP1JP2JP3JP4JP6JP8

TP3

U9

C12

TP9 TP6

C17

U1

C1

+

C4

J2 MOV1

J1

LINE NEUT

POWER

U14

GT10

GT8

C30

D3

MODEM VOLTS

9V

6V

OPEN = 12V

JP14

Modem Power Supply

Configuration Jumper

(JP12)

Figure 3-3: I/O Board Configuration Jumper Locations

C3

+

C2

+

Z1

U2

J.W.HARLEY INC.

ASSY NO.

U3

R108

R109

20065MPA

20065MPB

Q8

Q7

R111

J18R110

ANN1

R112

NORMINV

R113

K4

Q10

J19

INV

K1

Annunciator (Alarm)

Configuration Jumpers

(JP18 and JP19)

Q9

ANN2

NORM

February 3, 2000 70055MP Revision D

Page 29

Section 3: Installation 3-5

Table 3-1: Channel Configuration Jumpers and Positions

Jumper Position Selected Input

JP1 A

B

JP2 A

B

JP3 A

B

JP4 A

B

JP5 A

B

JP6 A

B

JP7 A

B

JP8 A

B

JP9 A

B

5A (CT) Current Input A.

4-20 mA Sensor Input #9.

5A (CT) Current Input B.

4-20 mA Sensor Input #10.

5A (CT) Current Input C.

4-20 mA Sensor Input #11.

50 A (CT) Motor Current.

4-20 mA Sensor Input #12.

Voltage Input 1.

4-20 mA Sensor Input #13.

Voltage Input 2.

4-20 mA Sensor Input #14.

Voltage Input 3.

4-20 mA Sensor Input #15.

Voltage Input 4.

4-20 mA Sensor Input #16.

Temperature Inside the monitor.

4-20 mA Sensor Input #1.

Modem Power Supply Configuration Jumper

Jumper JP12 sets the modem power supply. Refer to Table 3-2 for jumper

positions.

NOTE: Refer to the modem specifications to determine the modem power

supply requirements. Refer to Figure 3-3 for jumper location.

Table 3-2: Modem Power Supply Configuration (JP12)

JP12 Position Selected Modem Power Supply

1-2 6 VDC

2-3 9 VDC

No Jumper 12 VDC

70055MP Revision D February 3, 2000

Page 30

3-6 Section 3: Installation

Alarm Configuration Jumpers

Jumpers JP18 and JP19 set the annunci ator relay outputs to normal or

inverted. Jumper JP13 configures the Acknowledge Alarm button. Refer to

Table 3-3 for jumper positions. Refer to Figure 3-3 for jumper locations.

NOTE: JP13 must always be installed.

Table 3-3: Alarm Configuration

Jumper Position Description

JP18 INV

NORM

JP19 INV

NORM

JP13 Installed

Removed

Annunciator 1 Output Inverted.

Annunciator 1 Output Normal.

Annunciator 2 Output Inverted.

Annunciator 2 Output Normal.

Configures the Alarm Acknowledge button for use.

Not applicable.

Ground Jumpers

Jumpers JP10 and JP14, when installed, are set to earth ground. These

jumpers must always be installed for accurate and safe operation.

WARNING: Jumpers JP10 and JP14 must always be installed for accurate

and safe monitor operation.

February 3, 2000 70055MP Revision D

Page 31

Section 3: Installation 3-7

Wiring

Overview

Prior to starting any wiring procedures:

Pull the power fuse (F1) on the Power Supply board.

• Securely ground the LTC -MAP 2130 at the ground lug.

CAUTION: Pull the power board fuses or remove F1 on the I/O board before

making connections.

WARNING: The LTC -MAP 2130 Monitor must be properly grounded before

placing the unit in service. An improper or missing ground can create a

safety hazard.

Refer to Figure 3-4 for fuse and ground lug locations.

LTC-MAP 2130 wiring consists of:

• Wiring the sensors.

• Wiring a tap position indicator (if used).

• Wiring the AC current inputs.

• Wiring the AC voltage inputs.

• Wiring the digital inputs.

• Wiring the annunciator outputs.

• Wiring the internal heater.

• Wiring power.

Refer to Figure 3-4 for I/O Board Terminal Locations. Refer to Figure 3-5 for

an example of a typical wiring diagram.

70055MP Revision D February 3, 2000

Page 32

Line Connection

3-8 Section 3: Installation

Sensor Ground

1/4-20 Stud

First Control

Isolator Input

Second Control

Isolator Input

TP1

C7

C9

U4

J4

D10

R18

R17

R15

U6 U5

C8C10

R67

R70

R69

GT1 GT3 GT5 GT7

C20

R71

C27

R44

R38

Z9

Z13

R43

Z8

R37

Z10

R41

Z12

R39

R40

Z11

R42

Z14

C16

R68

U2

C11

J15

J1

RN6

J2

J8

U7

1 16 14

15 13 12 11 10 9

JP7

GT14 GT16

Y

COMMON

EN

SENSOR

C

B

A

8

1ST CONTROL ISOLATOR2ND CONTROL ISOLATOR

7

+12

SENSOR INPUTS

6

REL

5

A3

4

A2

3

Y

2

EN

1

C

(24 VDC)

B

SENSOR

POWER

A

COM COM

+12

JP13

17

CHANNEL

A

B

JP5JP9

GT12GT6GT4GT2GT17

J14 J16

C4

J7

J3

TP2

TP3

RN1

JP1JP2JP3JP4JP6JP8

GT8

GT9GT11GT13GT15

SENSOR

COMMONSENSOR INPUTS

POWER

SENSOR

(24 VDC)

J6

A

B

GND

COM

PHONE

COM

CURRENT

RED GRN

MOTOR

C

B

A

U9

C12

TP9 TP6

C17

C30

J10

RJ1

J13

R50

R53

R99

D25

R98

D24

R97

D12

R92

D16

C1

+

C4

J1

U14

D3

D4

D17

D18

D13

D14

D1

D2

R7

R8

R12

MOV1

T1

MOV5

T2

MOV6

T3

MOV7

T4

J17

GT10

17

16

15

14

13

12

11

10

9

U1

J2 MOV1

LINE NEUT

MODEM VOLTS

9V

6V

OPEN = 12V

C1

C25

C26

C28

Z1

POWER

R108

J20DIGITAL ANALOG 2ANALOG 1 CURRENT VOLTAGE

C3

+

C2

+

J.W.HARLEY INC.

ASSY NO.

U3

Q8

R109

J18R110

#2

ANNUNCIATOR

NC COM NO

#4

INPUT

VOLTAGE

#3

INPUT

VOLTAGE

#2

INPUT

VOLTAGE

#1

INPUT

VOLTAGE

20065MPA

20065MPB

Q7

ANN1

NORMINV

K4

ANNUNCIATOR

#1

HEATER

F1

NC COM NO

LINE NEUT

Power Fuse

Type ADC2

Rated for 3A @ 250 V

U2

Power

Input

Q9

R111

Q10

R112

J19

ANN2

R113

K1

J12

J9

NORMINV

U8

C6

J5

C5

Annunciator

Outputs

Voltage

Inputs

Heater Power

Input

Sensor

Inputs 1-8

Configurable

Sensor Inputs 9-16

Figure 3-4: Fuse, Input Terminals, and Ground Locations

Current

Inputs

External Phone

Ground Lug

Internal Modem

Connection

February 3, 2000 70055MP Revision D

Page 33

Section 3: Installation 3-9

Figure 3-5: Example of a Typical Wiring Diagram for the LTC-MAP 2130

70055MP Revision D February 3, 2000

Page 34

3-10 Section 3: Installation

Wiring the Sensors

Refer to Table 1-1 for a list of sensors available for use with the

LTC-MAP 2130 Monitor. Detailed installation information for each sensor is

provided in the referenced documentation.

Some general notes to consider during sensor selection and installation:

• Thermowell RTD sensors require a signal conditioning transmitter to

provide a 4-20 mA output to the monitor.

• Figure 3-4 provides Sensor and Input Connection locations on the I/O

board.

• We recommend using #18 AWG shielded, twisted pair wire for sensor

input connections to the I/O board, unless stated otherwise in the

documentation provided with the sensor. Use of shielded twisted pair

improves noise immunity; the shield should be grounded at one end

only.

February 3, 2000 70055MP Revision D

Page 35

Section 3: Installation 3-11

Wiring a Tap Position Indicator

OEM Potentiometer s

The OEM potentiometer is a voltage divider containing a resistor string.

Each position on the string represents a tap position. In the examples in

this Section, the potentiometers have thirty three positions containing thirty

two 40-ohm resistors. The actual number of positions and number and

values of resistors may be different on your potentiometer.

The power supplied to the OEM potentiometer depends on the utility. The

variations include:

• -5 to +5 VDC or -10 to +10 VDC.

• 0 to +5 VDC or 0 to +10 VDC.

• No voltage (connect with LTC -MAP power).

Determine the voltage across your potentiometer and follow the

appropriate wiring instructions.

In general, two signals are utilized between the OEM potentiometer and the

LTC-MAP. The signal is a linearly varying DC voltage (+10 V maximum).

For proper tap position recording by the LTC -MAP, the linearly varying DC

voltage from the OEM potentiometer must have a uniform increment for

each tap position. For example, a potentiometer used for a 33 tap device

(16 lower, 16 raise, and neutral) with a 10 Volt drop across the entire bridge

must show a 10V/32 = 0.3125 V change per tap step on the potentiometer

wiper.

70055MP Revision D February 3, 2000

Page 36

3-12 Section 3: Installation

0 to +5 VDC or 0 to +10 VDC Power

Connect the OEM potentiometer to the LTC -MAP Circuit Board, as follows

(refer to Figure 3-6):

1. Connect the OEM Potentiometer Wiper to Sensor Input #8.

2. Connect the OEM Potentiometer 0 VDC Common Point to Sensor

Common.

Figure 3-6: Typical OEM Potentiometer with 0 to +5 VDC Power

February 3, 2000 70055MP Revision D

Page 37

Section 3: Installation 3-13

-5 to +5 VDC or -10 to +10 VDC Power

Connect the OEM potentiometer to the LTC -MAP Circuit Board, as follows

(refer to Figure 3-7):

1. Connect the OEM Potentiometer Wiper to Sensor Input #8.

2. Connect the OEM Potentiometer Center Point to the Sensor Common.

Figure 3-7: Typical OEM Potentiometer with -5 to +5 VDC Power

70055MP Revision D February 3, 2000

Page 38

3-14 Section 3: Installation

LTC-MAP Power

OEM potentiometers that are not powered require power from the LTC MAP’s 24 VDC Sensor Power Supply. To use the LTC -MAP supply, you

must:

• Select a Voltage Drop Resistor (Rd).

• Connect the Power Supply wires to the OEM Potentiometer.

• Connect the wires at the Monitor Circuit board.

In order to use this power, you must first calculate the value of the required

voltage drop resistor (Rd). The voltage drop resistor limits the current and

voltage across the potentiometer (see Figure 3-8).

Figure 3-8: Typical OEM Potentiometer Powered by LTC-MAP

To calculate Rd:

1. Determine the value and number of resistors in the potentiometer.

NOTE: LTC -MAP can accommodate any value or number of tap

position resistors.

2. Calculate the String Resistance (Rs) where:

Rs = (Resistor Value) x (Number of Resistors).

February 3, 2000 70055MP Revision D

Page 39

Section 3: Installation 3-15

3. Calculate the Voltage Drop Resistor value (Rd):

Rd = Rs x 1.4.

4. Select a voltage drop resistor as follows:

Resistance: first standard value greater than the Rd.

Power rating: 2 watts.

Tolerance: 5% or less

As an example, consider a potentiometer with thirty-two 40 ohm

resistors. The calculated string resistance would be:

Rs = (40 ohms) x (32 Resistors) - 1280 ohms.

And

Rd = Rs x 1.4 = 1280 x 1.4 = 1792 ohms.

The next standard resistor value greater than 1792 is 1800 ohms.

Therefore, the selected voltage drop resistor should be an 1800 ohm,

5%, 2 watt resistor.

Connect the wires to the OEM Potentiometer as follows:

1. Connect the designated positive point lead to the OEM Potentiometer

Positive Point.

2. Connect the designated common point lead to the OEM Potentiometer

Common Point.

3. Connect the designated wiper lead to the OEM Potentiometer Wiper.

Connect the wires to the circuit board as follows:

1. Connect one end of the Voltage Drop Resistor (Vd) to a sensor power

supply terminal.

2. Connect the positive point lead to the other end of the Voltage Drop

Resistor (Vd).

3. Connect the common point lead to the designated Sensor Common

terminal.

4. Connect the wiper lead to Sensor Input #8.

NOTE: Tap Position must be calibrated to operate correctly (see Calibrate

Tap Position).

CAUTION: The positive lead must be connected to Sensor Input #5 and the

negative lead to Sensor Common. Failure to comply can damage the LTC MAP.

70055MP Revision D February 3, 2000

Page 40

3-16 Section 3: Installation

After-Market

Use the following procedure to wire an After-Market Tap Position Indicator.

1. Verify that the signal output is one of the following:

• - 5V to + +5 VDC

• -10 to + 10 VDC,

• 0 to +5 VDC, or

• 0 to +10 VDC.

2. Connect the signal output to Sensor Input #8.

3. Connect the signal reference to a Sensor Common Terminal.

NOTE: Tap Position must be calibrated to operate correctly (see Calibrate

Tap Position).

February 3, 2000 70055MP Revision D

Page 41

Section 3: Installation 3-17

Wiring the AC Voltage Inputs

Connect voltage signals to the designated terminals (Voltage Input #1, #2,

#3, #4) on the wiring and installation diagrams. Refer to Figure 3-5 for

terminal location.

NOTE: The signal specification range for Voltage Inputs #1, #2, #3, and #4

are 0 to 300 Vrms. If your signal input is different, contact Support Services

as noted on back cover.

Wiring the AC Current Inputs

There are two types of current inputs - powered CT and unpowered CT

(e.g., Clamp On AC Current Transducer).

Connections for unpowered CT’s are not polarity sensitive. Connect the CT

between the A, B, or C Current terminals (refer to Figures 3-4 and 3-5).

Connections for powered (active) CT’s are polarity sensitive. Refer to

information on the active CT’s connection points for proper polarity.

Wiring the Digital Inputs

The LTC -MAP 2130 monitor collects output data from the Control Isolator at

the digital inputs. (See Figure 3-4 for Control Isolator Input terminal

locations.)

NOTE: Refer to Document No. 70062MP for specific information on

the Control Isolator, Part No. 40041MP.

1. Mount the Control Isolator(s) per the guidelines provided in the

documentation provided with the Control Isolator.

NOTE: The control Isolators are provided with a 10 foot cable;

therefore, when selecting a mounting location, be sure it is within 10

feet of the monitor.

2. Connect the output cable of the Control Isolator to the First Control

Isolator Input (digital channels 1-8) as designated on the wiring and

installation diagrams.

3. If there is a second Control isolator installed, connect the output cable

of the Control Isolator to the Second Control Isolator Input (digital

channels 9-16) as designated on the wiring and installation diagrams.

NOTE: If only one Control Isolator is installed, it must be connected to the

First Control Isolator input terminals on the I/O board.

70055MP Revision D February 3, 2000

Page 42

3-18 Section 3: Installation

Wiring the Annunciator Outputs

Wire the alarms by connecting the alarm activation signal to the Alarm

normally opened or Alarm normally closed contacts. Refer to Figure 3-5 for

Alarm Contact (Annunciator Output) locations.

NOTE: The signal specification range for the Alarm Inputs are 120 VAC @ ¼

HP, 240 VAC @ 10 A, or 150 VDC @ 10 A. If your signal is different, contact

Support Services as noted on back cover.

Be sure to configure the alarm jumpers (JP18 and JP19) for either normal or

inverted output as required by your application.

Figure 3-9: I/O Board Terminal Locations

February 3, 2000 70055MP Revision D

Page 43

Section 3: Installation 3-19

Wiring the Internal Heater

The monitor’s internal heater requires 110 VAC power input. Refer to Figure

3-9 for Heater Terminal locations.

WARNING: Do not bridge the heater power terminals to the monitor power

supply terminals if DC is used to supply the monitor. The heater is AC only.

Wiring Power

The LTC -MAP 2130 is factory configured for either 120 VAC or 240 VAC

operation per the customer order. Refer to Figure 3-9 for the location of the

Power Input Terminals.

1. Connect the “hot” phase of the 120 or 210 power line to the LINE Power

Input Terminal.

2. Connect the neutral line to the NEUT Power Input Terminal.

70055MP Revision D February 3, 2000

Page 44

3-20 Section 3: Installation

Establishing Communications

The SAGE host software installed on a personal computer allows for

data retrieval and analysis. Communications with the LTC -MAP 2130 must

be established in order to download data to the PC or upload configuration

information to the LTC -MAP. Communication between the PC and the

monitor can be established:

• Directly via the front panel serial port and a null modem cable to a

personal computer running SAGE .

NOTE: The SAGE host software must be installed on the PC for

proper communication to take place. The front panel serial port

does not support dumb terminal operation.

• Over phone lines using an optional modem installed inside the

monitor.

• Over phone lines via a phone multiplexer installed in the control

house and connected to several LTC -MAP 2130 monitors. Refer to

Document No. 70061MP for detailed information on the phone

multiplexers available from Reuter-Stokes.

CAUTION: The serial port and the modem cannot function simultaneously.

When using the serial port for communications, the internal modem (if

installed) must be disconnected at J8; otherwise the serial port will not

function.

February 3, 2000 70055MP Revision D

Page 45

Section 3: Installation 3-21

Serial Port Communications

To establish communications via the front panel serial port:

1. Be sure the modem, if installed, is disconnected at J8.

2. Be sure the SAGE host software is installed on the personal

computer.

3. Connect a null modem cable between the front panel serial port and the

serial port on the personal computer. See Figure 3-10 for serial port

location.

4. From within the SAGE host software, set the serial port rate to 19200

bps.

Figure 3-10: Serial Port Location

70055MP Revision D February 3, 2000

Page 46

3-22 Section 3: Installation

Modem Communications

To establish communications via a modem:

1. If not already installed, mount the modem inside the monitor using the

supplied Velcroattachments.

2. Connect the modem per the instructions supplied with it.

See Figure 3-11 for modem mounting location and typical connections.

3. Set JP12 on the I/O board to select the modem power supply. Refer to

Modem Power Supply Configuration earlier in this section.

4. Be sure the serial port speed rate is set to 19200 bps (positions 3 and 4

on SW4 on the CPU board should be open).

Figure 3-11: Modem Location and Connections

February 3, 2000 70055MP Revision D

Page 47

Section 3: Installation 3-23

Initial Start Up

1. Before applying power to the system, verify that:

• All sensors are mounted and connected properly.

• None of the wiring or cables are shorted.

• All connections follow the wiring and installation diagrams.

• All monitored input signals are within specified input ranges.

• Phone lines are properly connected to a phone multiplexer (if used).

WARNING: Check all wiring before applying power to the unit. Wiring

errors can damage the device and create a safety hazard.

2. Connect the power input wires to the 120 V AC/DC Power terminal.

3. Apply power to the monitor.

NOTE: Copyright information will be displayed for approximately

ten seconds. After that, the display will go blank.

L T C - M A P 2 1 3 0

r e v 2 1 3 0 . x x . y y

c o p y r I g h t ( C ) 1 9 9 7

4. Configure and set system parameters using the SAGE host software

package. (Refer to the SAGE documentation for specific

procedures.)

5. Upload the SAGE configuration files to the LTC-MAP, either through

the RS232 Serial port or via a modem. (Refer to the SAGE

documentation for specific procedures.)

6. Verify the current date and time.

• Press the Alarm Status & Settings button two times or until the

Current Time and Current Date screen is displayed:

C u r r e n t T i m e :

1 2 : 3 0 : 2 2

C u r r e n t D a t e :

W e d 0 9 / 1 7 / 1 9 9 7

• If the time and date are incorrect, reset them using the procedures

outlined in the SAGE documentation.

NOTE: The date and time must be set accurately to insure that LTC MAP 2130 properly acquires data.

70055MP Revision D February 3, 2000

Page 48

3-24 Section 3: Installation

Once power is applied, and conf iguration parameters have been uploaded

to the monitor, the monitor enters normal operation and begins monitoring

sensor and voltage inputs.

Refer to Section 4 - Operation for further operation procedures.

Calibrate Tap Position

1. Press the Setup button to display the Tap Position Input Calibration

Low Point screen.

T A P P O S I T I O N I N P U T

C A L I B R A T I O N

L O W P O I N T :

5

â

The Setup button is located on the upper left corner of back side the

CPU board.

á

2. Observe and record the actual tap position of the LTC at the TAP

Position Indicator.

3. Adjust the value of the low tap position calibration point to the value

observed in Step 2 by pressing â or á until the correct value is

displayed

4. Press Setup to display the Tap Position High Point Calibration screen.

T A P P O S I T I O N I N P U T

C A L I B R A T I O N

H I G H P O I N T :

6

â

5. Manually move the tap up one position.

á

6. Adjust the value of the high tap position calibration point up one

position from the low calibration point by pressing â or á until the

correct value is displayed.

7. Press Setup to exit the Calibration and return to normal operation.

February 3, 2000 70055MP Revision D

Page 49

Section 4: Operation

Overview

Once power is applied, the LTC -MAP starts monitoring sensor, voltage,

current, and relay timing inputs. Monitoring functions continue

uninterrupted while operating conditions and alarm status & settings are

viewed and during system setup procedures. Channel readings, alarm

status, and current time and date as set from the SAGE host software

package, can be viewed on the LTC -MAP Monitor display.

Refer to the SAGE documentation for detailed channel configuration,

parameter setting procedures, and monitoring capabilities.

CAUTION: To keep the enclosure weatherproof, close and latch the door

when not using the LTC -MAP. Failure to comply can result in equipment

damage.

Operating Conditions Button

Operating conditions, including current analog and digital channel

readings and a tap change summary, are displayed by pressing the

Operating Conditions button.

• Pressing Operating Conditions during normal operation displays the first

Analog Channels Screen.

• Pressing Operating Conditions repeatedly during normal operation

continuously scrolls through the following screens:

• Analog Channels 1 through 4 Readings.

• Analog Channels 5 through 8 Readings.

• Analog Channels 9 through 12 Readings.

• Analog Channels 13 through 16 Readings.

• Analog Channel 17 Reading.

• Digital Channels 1 through 4 Readings.

• Digital Channels 5 through 9 Readings.

• Digital Channels 10 through 12 Readings.

• Digital Channels 13 through 16 Readings.

• Tap Change Summary.

• If Alarm Status & Settings is pressed while any one of the operating

condition screens is displayed, the Status screen is displayed.

70055MP Revision D February 3, 2000

Page 50

4-2 Section 4: Op eration

Analog Channel Readings Screens

The Analog Channel Readings screens di splay up to four channels each

(see Figure 4-1). There is one line of display (20 columns) available for each

channel:

• Columns 1 through 10 display the channel’s description as uploaded

from the SAGE configuration file.

• Columns 11through 16 display a numeric representation of the current

value being read at the channels input.

• Columns 17 through 20 display the units of the reading.

• If a channel is not connected, no information is displayed for the

channel; down arrows indicate that pressing Operating Conditions will

display more information (e.g., other configured analog channel

readings, or digital channel readings).

R M T E M P 3 7 . 5 d e g C

T o p O i l 4 5 . 3 d e g C

â

o a d C u r r e 6 8 9 A m p

L

ââ

â

Figure 4-1: Sample Analog Channel Display

Digital Channel Readings Screens

The Digital Channel Readings screens display up to four channels each

(see Figure 4-2). There is one line of display (20 columns) available for each

channel:

• Columns 1 through 17 display the channel’s description as uploaded

from the SAGE configuration file.

• Columns 18 through 20 display the channels status as ON or OFF.

C N T R L I S O 1 C H 1 O N

C N T R L I S O 1 C H 2 O N

C N T R L I S O 1 C H 3 O N

C N T R L I S O 1 C H 4 O F F

Figure 4-2: Sample Digital Channel Display

February 3, 2000 70055MP Revision D

Page 51

Section 4: Operation 4-3

Tap Change Summary Screen

The Tap Change Summary screen (Figure 4-3) displays:

• Tap Changes in the last hour.

• Tap Changes so far this hour.

• Total number of tap changes since power up.

T a p C h a n g e S u m m a r y

L a s t H o u r = 3

T h i s H o u r = 3

T o t a l = 2 3 6

á

Figure 4-3. Tap Change Summary Screen

70055MP Revision D February 3, 2000

Page 52

4-4 Section 4: Op eration

Alarm Status & Settings Button

Alarm Status & Settings screens are accessed by pressing the Alarm Status

& Settings button:

• Pressing Alarm Status & Settings during normal operation displays the

LTC-MAP Status screen.

• Pressing Alarm Status & Settings repeatedly during normal operation

continuously scrolls through the Alarm and Status screens, in the

following order:

• LTC-MAP Status Screens

• Current Date and Time Screen

• Pressing Operating Conditions, while an Alarm Status & Setting screen is

displayed, will display the first Analog Channels readings screen.

LTC-MAP Status Screen

The LTC -MAP status screen displays current alarm status. If there are no

alarm conditions, the Normal Status screen (Figure 4-4) is displayed.

If one or more alarms are present, each alarm will be displayed sequentially

and on a separate screen (see Figure 4-5). There are two lines of text

available to display the alarm description; also displayed is the present

value of the parameter triggering the alarm.

A l a r m S t a t u s :

N o r m a l

Figure 4-4: LTC-MAP Status Screen (No Alarms)

* * * A L A R M * * *

T a n k 2 D I f f T e m p

a b o v e s e t l i m i t

V a l u e N O W : 2 4 . 5 d e g C

Figure 4-5: LTC-MAP Alarms Screen

February 3, 2000 70055MP Revision D

Page 53

Section 4: Operation 4-5

Current Time and Date Screen

The Current Time and Current Date screen (Figure 4-6) displays:

• The current time as read from the system clock and displayed in 24

hour format (HH/MM/SS).

• The current date as read from the system clock and displayed as:

Day MM/DD/YYYY.

NOTE: The system clock must be set to the correct date and time to

ensure that the LTC -MAP properly acquires data. If the date or time are

incorrect, refer to the SAGE documentation for procedures for setting

the date and time.

C u r r e n t T i m e :

1 2 : 3 0 : 2 2

C u r r e n t D a t e :

W e d 0 9 / 1 7 / 1 9 9 7

Figure 4-6: Current Time and Date Screen

Acknowledging Alarms

Alarms are acknowledged by pressi ng the Acknowledge Alarm button,

located in the lower left corner of the face panel. Pressing Acknowledge

Alarm deactivates the alarm relay on the LTC -MAP so subsequent alarms

can trip the annunciator outputs.

NOTE: The LTC -MAP remains in alarm mode, and the

corresponding ALARM indicators remain lit, until the alarm

condition goes away.

70055MP Revision D February 3, 2000

Page 54

Section 5: Troubleshooting Procedures

Refer to Table 5-1 for common troubleshooting procedures.

Table 5-1: Common Troubleshooting Procedures

Condition Possible Cause(s) Corrective Action

Incorrect Temperature Reading on a

4-20 mA Channel.

Unrecorded tap change events. Incorrect wiring.

Incorrect Current Readings. Incorrect installation.

Incorrect Voltage Readings. Incorrect wiring.

Defective sensor.

Loose wiring connection from sensor

to circuit board

Defective circuit board.

Ribbon cable between CPU and I/O

circuit boards loose.

Ground loop exists with another

connection.

Incorrect parameter settings.

No current present.

Incorrect parameter settings.

Incorrect parameter settings.

Power glitch.

Swap suspect sensor with a known good sensor.

Check wiring connection from the sensor to the

circuit board; ensure that the wire is correctl y

inserted into the screw down connector block.

Swap suspect circuit board with a known good

board.

Temporarily move the suspect RTD sensor wire to

an unused 4-20 mA channel to determine

whether fault follows sensor or circuit board.

Inspect ribbon cable connection at CPU board and

at I/O board.

Systematically remove other connections to the

circuit board until the cause of the loop is found.

For example, problems may be caused having

the individual wire (color) order incorrect for the

cable between the control isolator and the I/O

board.

Check wiring diagram and installation.

Check event start and stop parameters.

Check for a minimum motor current parameter.

Check wiring diagram and installation.

Verify current with a handheld meter.

Check CT Ratio.

Check Calibration Parameters.

Check wiring diagram and installation.

Check Calibration Parameters.

Cycle Power.

70055MP Revision D February 3, 2000

Page 55

5-2 Section 5: Troubleshooting Procedures

Table 5-1: Common Troubleshooting Procedures (Cont’d)

Condition Possible Cause(s) Corrective Action

Incorrect Tap Position

Displayed/Recorded.

Heater ON at ambient over

60 ºF (15.5 ºC).

Heater not ON at ambient under 50 ºF

(10 ºC).

Sensor Input and Sensor Common

connections reversed.

Battery supply for OEM resistor string

not stable or floating to ground

causing a ground loop.

Faulty heater.

Faulty connections. Check heater connections.

Disconnect inputs and test voltage on the wires

with a volt meter referenced to earth ground.

Disconnect inputs and test voltage on the wires

with a volt meter referenced to earth ground.

Cut or remove the strap for Sensor Common input

to chassis ground connection on the circuit

board.

Use a DC voltage from the monitor, rather than a

battery, to supply the OEM resistor string.

Disconnect heater from I/O board; contact Reuter-

Stokes, Inc..

February 3, 2000 70055MP Revision D

Page 56

Appendix A: User-Specific Information

Forms

Use the Analog Channel Configuration form to document LTC -MAP 2130

channel settings.

Use the Tap Position Calibration form to document tap position calibration

settings.

Use the wiring diagram forms to document specific system connections.

Analog Channel Configuration

Jumper Position

A or B

N/A N/A 4-20 mA Sensor Input #1.

N/A N/A 4-20 mA Sensor Input #2.

N/A N/A 4-20 mA Sensor Input #3.

N/A N/A 4-20 mA Sensor Input #4.

N/A N/A 4-20 mA Sensor Input #5.

N/A N/A 4-20 mA Sensor Input #6.

N/A N/A 4-20 mA Sensor Input #7.

N/A N/A +10 VDC Input Channel #8.

JP1

(5A Input per CT or 4-20 mA Input #9)

JP2

(5A Input per CT or 4-20 mA Input #10)

JP3

(5A Input per CT or 4-20 mA Input #11)

JP4

(50 A Current per CT or 4-20 mA Input #12)

JP5

(Voltage Input 1 or 4-20 mA Input #13)

JP6

(Voltage Input 2 or 4-20 mA Input #14)

JP7

(Voltage Input 3 or 4-20 mA Input #15)

JP8

(Voltage Input 4 or 4-20 mA Input #16)

Selected Input Input Description

70055MP Revision D February 3, 2000

Page 57

A-2 Appendix A: User-Specific Information Forms

Tap Position Calibration

Low Point High Point

February 3, 2000 70055MP Revision D

Page 58

Appendix A: User-Specific Information Forms A-3

LTC-MAP 2130 Customer Installation Information (Part 1)

70055MP Revision D February 3, 2000

Page 59

A-4 Appendix A: User-Specific Information Forms

LTC-MAP 2130 Customer Installation Information (Part 2)

February 3, 2000 70055MP Revision D

Page 60

Appendix A: User-Specific Information Forms A-5

LTC-MAP 2130 Customer Installation Information (Part 3)

70055MP Revision D February 3, 2000

Page 61

Appendix B: Firmware Upgrades

Use the following procedure to replace the EPROM for firmware upgrades:

NOTE: Be sure to download to the PC the LTC -MAP 2130 monitor

configuration, calibration, and parameter settings via SAGE host

software package before replacing the EPROM.

1. Open the front cover by releasing the fasteners on the right side of the

LTC-MAP 2130.

2. Loosen the thumbscrews on the face panel.

3. Swing out the panel to access the I/O and CPU circuit boards.

4. Slip the supplied static control wrist strap over your hand and connect

the other end to any convenient electrical ground.

5. Remove the F1 power fuse from the power board.

CAUTION: To avoid equipment damage, you must remove F1 on the I/O

board when installing the EPROM.

6. Unplug the ribbon cable and modem serial port connector from the CPU

circuit board.

CAUTION: To avoid damage to the ribbon cable, pull the ribbon cable by the

hard plastic connector.

7. Using a No.1 Phillips head screwdriver, remove the five screws

securing the CPU circuit board to the face panel.

8. Carefully remove the CPU circuit board and turn it component side up.

70055MP Revision D February 3, 2000

Page 62

B-2 Appendix B: Firmware Upgrades

9. Using a 3/16” slotted screwdriver, carefully remove the existing EPROM.

Note the orientation of the EPROM notch and the location within the

socket. See Figure B-1 for EPROM location.

NOTE: Pin number 1 of the EPROM is placed into contact number 3

of the socket.

Figure B-1: EPROM Replacement

10. Remove the new EPROM from the protective packaging.

CAUTION: To avoid damage to the component, do not remove the EPROM

from the protective packaging until you are ready to install it.

11. Determine the proper notch orientation and location within the socket.

12. Carefully bend the pins on the EPROM until they align with the socket

contacts.

CAUTION: To avoid damage to the component , do not push the EPROM into

the socket until all pins are perfectly aligned with the contacts.

13. Once all pins are aligned with the socket contacts, push down on the

EPROM until it is fully seated.

14. Verify that all pins are inserted in the socket contacts.

NOTE: Carefully inspect each pin and contact to verify that none of the

pins are bent under the EPROM.

15. Carefully re-install the CPU circuit board into the face panel.

NOTE: The Operating Conditions and Alarm Status & Settings buttons must

be aligned and inserted into the face panel.

February 3, 2000 70055MP Revision D

Page 63

Appendix B: Firmware Upgrades B-3

16. Re-install the hardware that secures the CPU board to the face panel.

17. Re-install the ribbon cable and modem serial port connector.

18. Remove the static control wrist strap.

19. Re-install F1 in the power circuit board.

20. Depress the Operating Conditions and Alarm Status & Settings buttons

while applying power to the system.

21. Verify that the LTC -MAP displays copyright information for ten seconds

before going blank.

NOTE: If the copyright information does not appear, and you have

checked the EPROM installation, contact Reuter-Stokes, Inc..

22. Place the old EPROM in the protective packaging and return it to

Reuter-Stokes, Inc.

70055MP Revision D February 3, 2000

Page 64

Appendix C: Glossary of Terms

Amperes.

A

Alarm

Averaging Interval

Calibration Parameters

Clear Memory

COM

Combustible Gas

CPU

CT

Download

Gland Plate

Event

I/O

Operating condition occurring when data point value exceeds

the alarm parameter set point.

Configurable time period, up to 60 minutes, when the monitor

automatically takes incoming data levels and transfers them

into memory.

Calibration setpoints for voltage, current, temperature,

combustible gas, and tap position.

Action removes the monitored input data from the monitor non-

volatile memory.

Serial communication port on a personal computer.

Fault gas in the dielectric oil.

Central Processing Unit.

Current transducer.