GE JGS968BEK4BB, JGS968SEK4SS, JGS968TEK4WW, PGS968BEM2BB, PGS968BEM3BB Installation Guide

...Page 1

IIlnstallation I Gas Slide-In Rangel

nstructions JGS905, JGS968, PGS968

Ir_ Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.comIn Canada, call 1.800.361.3400 or Visit our Website at: www.geappliances.ca I

IN THE COMMONWEALTH OF

MASSACHUSETTS:

• This product must be installed by a

licensed plumber or gas fitter.

• When using ball-type gas shut-off valves,

they shall be the T-handle type.

• A flexible gas connector, when used, must

not exceed 3 feet.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Observeall

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

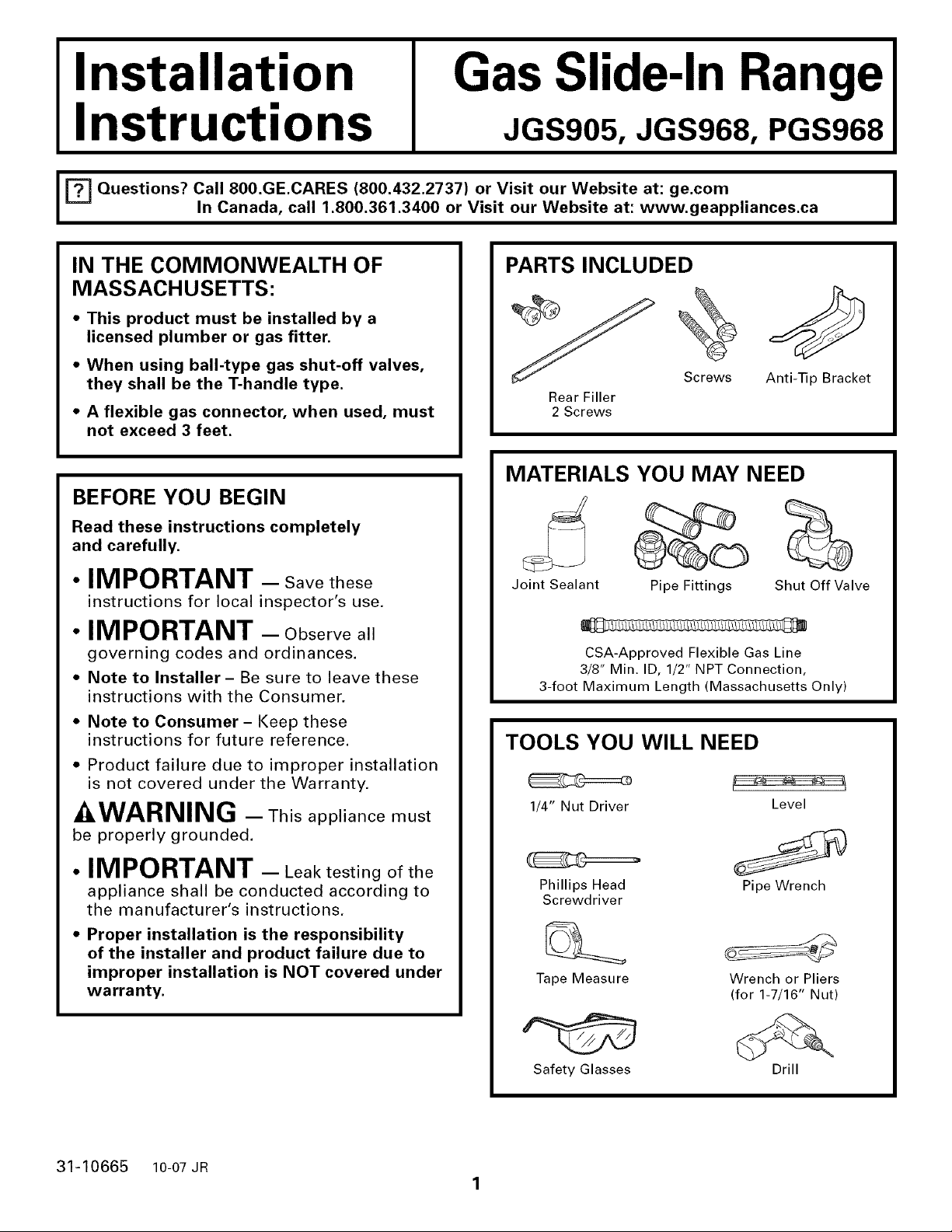

PARTS INCLUDED

Screws

Rear Filler

2 Screws

Anti-Tip Bracket

MATERIALS YOU MAY NEED

Joint Sealant Pipe Fittings Shut Off Valve

CSA-Approved Flexible Gas Line

3/8" Min. ID, 1/2" NPT Connection,

3-foot Maximum Length (Massachusetts Only)

• Note to Consumer - Keep these

instructions for future reference.

• Product failure due to improper installation

is not covered under the Warranty.

-&WARNING - This appliance must

be properly grounded.

• IMPORTANT - Leak testing of the

appliance shall be conducted according to

the manufacturer's instructions.

• Proper installation is the responsibility

of the installer and product failure due to

improper installation is NOT covered under

warranty.

31-10665 10-07 JR

TOOLS YOU WILL NEED

1/4" Nut Driver

Phillips Head

Screwdriver

Tape Measure

Safety Glasses

1

Level

Pipe Wrench

Wrench or Pliers

(for 1-7/16" Nut)

Drill

Page 2

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

FOR YOUR SAFETY:

WARNING - Iftheinformationin

this manual is not followed exactly, a fire,

explosion or gas leak may result causing

property damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance!

WHAT TO DO IF YOU

SMELL GAS:

• Do not try to light any appliance. Do not

touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

This range has been design certified by

UNDERWRITERS LABORATORIES for use in

the United States and Canada. You'll find

safety precautions in your Owner's Manual.

Read them carefully.

• Installation of this range must conform with

local codes or in the absence of local codes

with the National Fuel Gas Code, ANSI

Z223.1-Latest edition.

Be sure your range is installed properly by

a qualified installer or service technician.

To eliminate reaching over surface burners,

cabinet storage above burner should be

avoided.

• Do not install the unit near an outside door

or where a draft may affect its use.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

Page 3

Installation Instructions

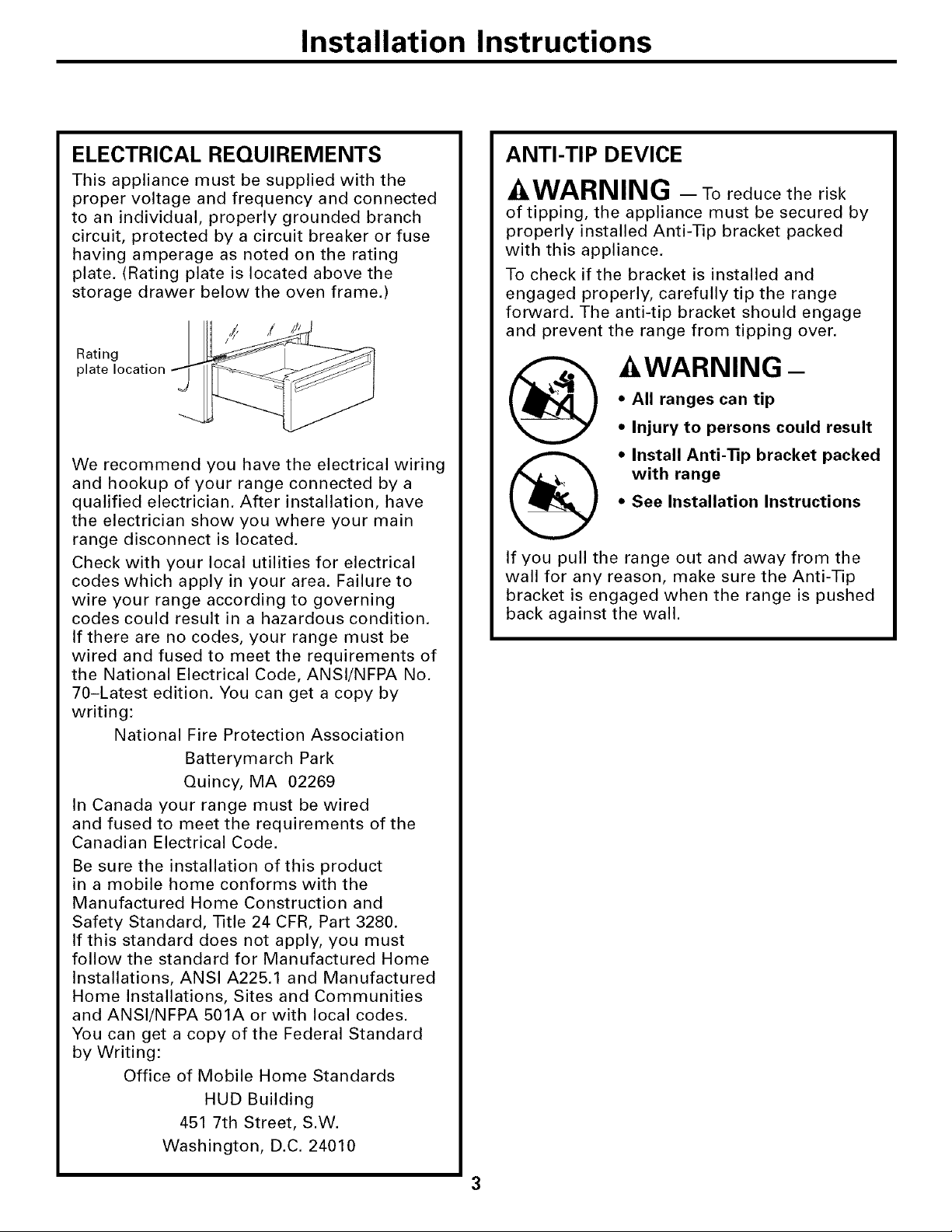

ELECTRICAL REQUIREMENTS

This appliance must be supplied with the

proper voltage and frequency and connected

to an individual, properly grounded branch

circuit, protected by a circuit breaker or fuse

having amperage as noted on the rating

plate. (Rating plate is located above the

storage drawer below the oven frame.)

Rating

plate location

We recommend you have the electrical wiring

and hookup of your range connected by a

qualified electrician. After installation, have

the electrician show you where your main

range disconnect is located.

Check with your local utilities for electrical

codes which apply in your area. Failure to

wire your range according to governing

codes could result in a hazardous condition.

If there are no codes, your range must be

wired and fused to meet the requirements of

the National Electrical Code, ANSI/NFPA No.

70-Latest edition. You can get a copy by

writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

In Canada your range must be wired

and fused to meet the requirements of the

Canadian Electrical Code.

Be sure the installation of this product

in a mobile home conforms with the

Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280.

If this standard does not apply, you must

follow the standard for Manufactured Home

Installations, ANSI A225.1 and Manufactured

Home Installations, Sites and Communities

and ANSl/NFPA 501A or with local codes.

You can get a copy of the Federal Standard

by Writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

ANTI-TIP DEVICE

AWARNING - Toreducetherisk

of tipping, the appliance must be secured by

properly installed Anti-Tip bracket packed

with this appliance.

To check if the bracket is installed and

engaged properly, carefully tip the range

forward. The anti-tip bracket should engage

and prevent the range from tipping over.

AWARNING-

• All ranges can tip

• Injury to persons could result

• Install Anti-Tip bracket packed

with range

• See Installation Instructions

If you pull the range out and away from the

wall for any reason, make sure the Anti-Tip

bracket is engaged when the range is pushed

back against the wall.

Page 4

Installation Instructions

PRE-INSTALLATION CHECKLIST

_-I INSPECT INSTALLATION

LOCATION

Refer to alternate construction section for

the following non-standard installations.

[] Counter opening extends to the wall:

Maintop Filler (supplied with the

range.) (See page 15 for Installation

Instructions) or

Backguard (Kit JXS36XX or JXS39SS).

[] Counter height greater than 36-314":

Lower Trim Slide-In (Kit JXS56XX).

[] One side is not enclosed by a cabinet:

Bodyside (Kit JXS76XX).

[] Island Installation:

To provide an optimum installation, the

top surface of the countertop must be

level and flat (lie on the same plane)

around the 3 sides that are adjacent to

range cooktop, Proper adjustments to

make the top flat should be made or

gaps between the countertop and

range cooktop may occur. Forcing the

cooktop to fit may cause excessive

gaps and could break the glass and

void the warranty.

_-I MOVE RANGE INDOORS IN

FRONT OF CABINET OPENING

Do not use hand trucks when moving the

unpackaged range. Cooktop glass may be

broken.

[] PROTECT THE KITCHEN

FLOOR

Flatten and place a piece of the shipping

carton in front of the installation location to

protect the flooring.

NOTE: Do not remove the protective

channel from the sides of the glass cooktop,

if applicable, until later in the installation.

Protective

Channel

To obtain Kits:

a. Visit GE Web Site (See page 1)

b. Call GE Answer Center (See page 1)

c. Contact Dealer

_-I CAREFULLY, TILT RANGE TO

ACCESS RANGE LEVELING

LEGS

Use an adjustable wrench to screw leveling

legs out so that glass support flanges clear

top of countertop.

4

Page 5

Installation Instructions

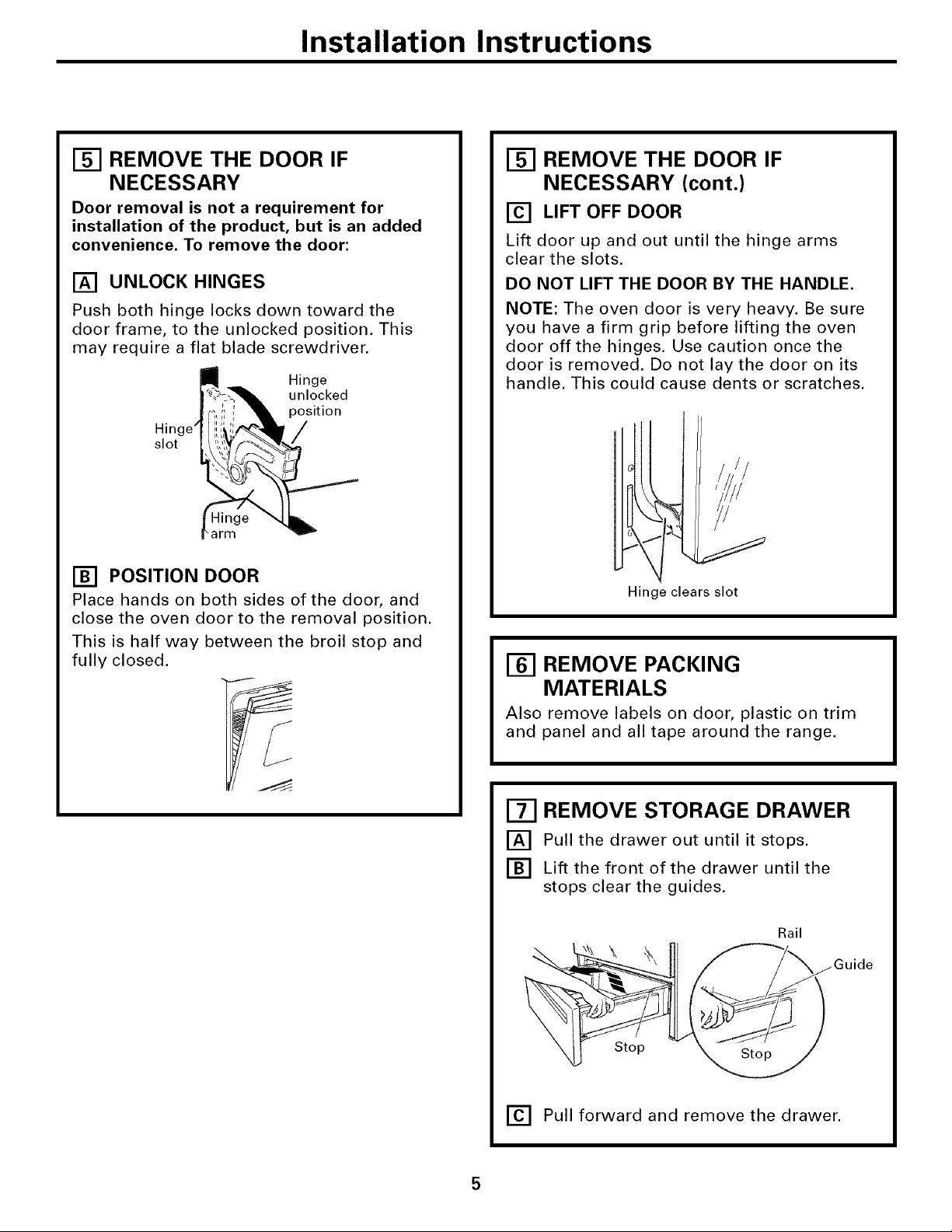

[] REMOVE THE DOOR IF

NECESSARY

Door removal is not a requirement for

installation of the product, but is an added

convenience, To remove the door:

[] UNLOCK HINGES

Push both hinge locks down toward the

door frame, to the unlocked position. This

may require a flat blade screwdriver.

Hinge

unlocked

position

Hinge' /

slot

arm

[] POSITION DOOR

Place hands on both sides of the door, and

close the oven door to the removal position.

This is half way between the broil stop and

fully closed.

REMOVE THE DOOR IF

NECESSARY (cont.)

[] LIFT OFF DOOR

Lift door up and out until the hinge arms

clear the slots.

DO NOT LIFT THE DOOR BY THE HANDLE.

NOTE: The oven door is very heavy. Be sure

you have a firm grip before lifting the oven

door off the hinges. Use caution once the

door is removed. Do not lay the door on its

handle. This could cause dents or scratches.

Hinge clears slot

REMOVE PACKING

MATERIALS

Also remove labels on door, plastic on trim

and panel and all tape around the range.

[] REMOVE STORAGE DRAWER

[] Pull the drawer out until it stops.

[] Lift the front of the drawer until the

stops clear the guides.

Rail

Stop

[] Pull forward and remove the drawer.

Page 6

Installation Instructions

PRE-INSTALLATION CHECKLIST (CONT.)

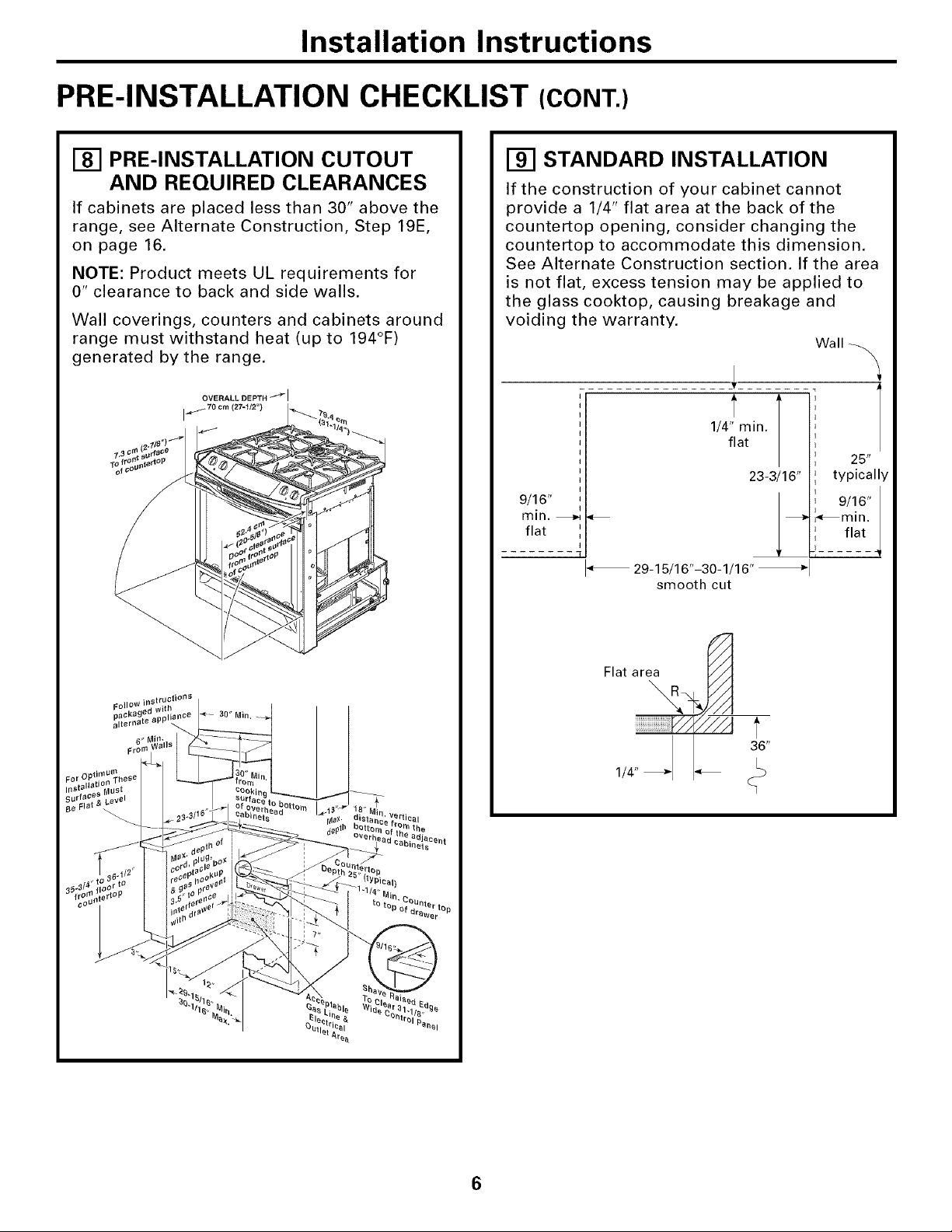

[] PRE-INSTALLATION CUTOUT

AND REQUIRED CLEARANCES

If cabinets are placed less than 30" above the

range, see Alternate Construction, Step 19E,

on page 16.

NOTE: Product meets UL requirements for

0" clearance to back and side walls.

Wall coverings, counters and cabinets around

range must withstand heat (up to 194°F)

generated by the range.

STANDARD INSTALLATION

If the construction of your cabinet cannot

provide a 1/4" flat area at the back of the

countertop opening, consider changing the

countertop to accommodate this dimension.

See Alternate Construction section. If the area

is not flat, excess tension may be applied to

the glass cooktop, causing breakage and

voiding the warranty.

Wall _._

1/4" min.

flat

25"

23-3/16"

9/16"

min.

flat

I

" 29-15/16"-30-1/16" _1

smooth cut

typically

9/16"

_min.

flat

-i ...... 4

FollOW

packa 30" Min,

Flat area

1/4" _ I_ _36"

I

6

Page 7

Installation Instructions

ELECTRICAL CONNECTIONS

INSTALLATIONmELECTRICAL

[]

CONNECTIONS

Because of potential safety hazards

[]

under certain conditions, we strongly

recommend against the use of an

extension cord. However, if you still

elect to use an extension cord, it is

absolutely necessary that it is a UL

listed 3-wire grounding-type appliance

extension cord and that the current

carrying rating of the cord in amperes

is equivalent to or greater than the

branch circuit rating. Such extension

cords are obtainable through your local

appliance dealer.

IMPORTANT: (Please read carefully)

FOR PERSONAL SAFETY, THIS

APPLIANCE MUST BE PROPERLY

GROUNDED.

[] An adequate electrical supply and

outlet must be used to operate the

electrical parts of your range.

• The power cord of this appliance is

equipped with a three-prong (grounding)

plug which must be used with a properly

grounded three-hole outlet with standard

120 Volt, 60 cycle AC household current.

• When a standard two-prong wall

receptacle is encountered, it is the

personal responsibility and obligation

of the customer to have it replaced with

a properly grounded three-prong wall

receptacle by a qualified electrician.

Do not under any circumstances cut or

remove grounding prong from the range

cord. Failure to provide proper ground may

create a hazardous condition.

Page 8

Installation Instructions

GAS CONNECTIONS

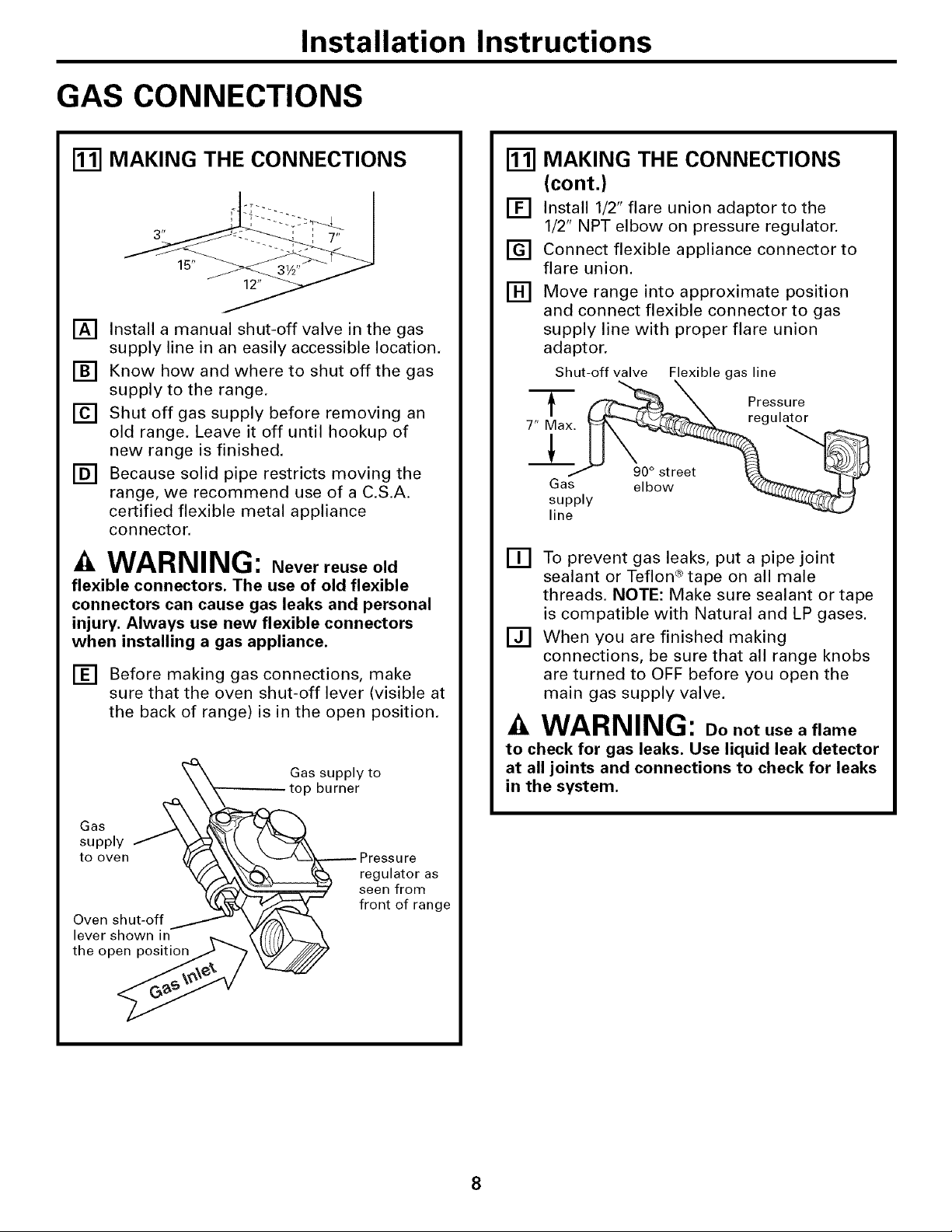

_] MAKING THE CONNECTIONS

15"

[]

Install a manual shut-off valve in the gas

supply line in an easily accessible location.

[]

Know how and where to shut off the gas

supply to the range.

[]

Shut off gas supply before removing an

old range. Leave it off until hookup of

new range is finished.

[]

Because solid pipe restricts moving the

range, we recommend use of a C.S.A.

certified flexible metal appliance

connector.

WARNING: Never reuse old

flexible connectors. The use of old flexible

connectors can cause gas leaks and personal

injury. Always use new flexible connectors

when installing a gas appliance.

[] Before making gas connections, make

sure that the oven shut-off lever (visible at

the back of range) is in the open position.

Gas supply to

top burner

_] MAKING THE CONNECTIONS

(cont.)

[] Install 1/2" flare union adaptor to the

1/2" NPT elbow on pressure regulator.

[] Connect flexible appliance connector to

flare union.

[] Move range into approximate position

and connect flexible connector to gas

supply line with proper flare union

adaptor.

Shut-off valve Flexible gas line

T __ Pressure

Gas elbow _ U

supply "_444_4_7_,(_

line

[] To prevent gas leaks, put a pipe joint

sealant or Teflon ®tape on all male

threads. NOTE: Make sure sealant or tape

is compatible with Natural and LP gases.

[] When you are finished making

connections, be sure that all range knobs

are turned to OFF before you open the

main gas supply valve.

-&WARNING: Do not use a flame

to check for gas leaks. Use liquid leak detector

at all joints and connections to check for leaks

in the system.

Gos

supply _X_ _{

tooven

Oven shut-off _ _

lever shown in

the op_

_ Pr;s_utr:r as

seen from

front of range

8

Page 9

Installation Instructions

INSTALL THE RANGE

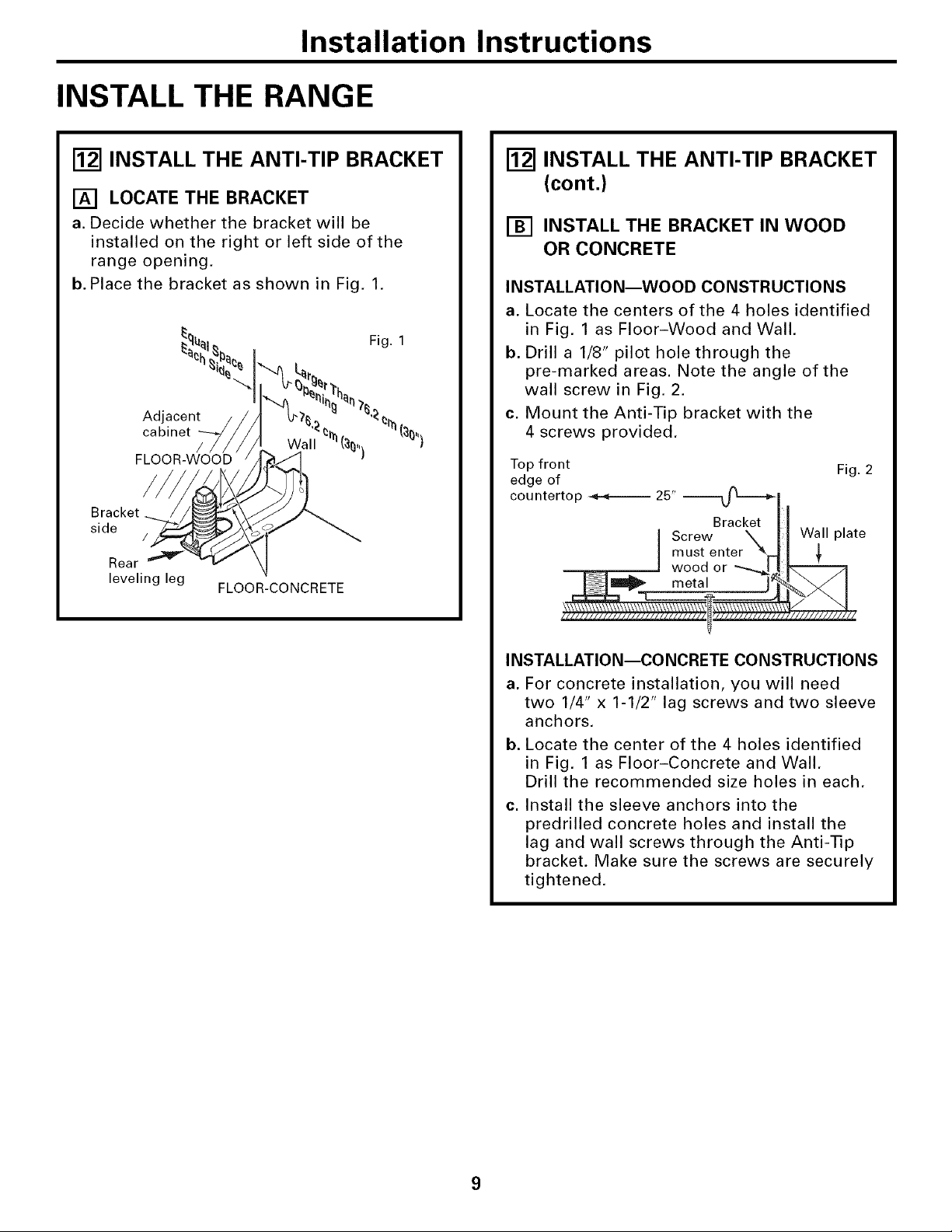

r_ INSTALL THE ANTI-TIP BRACKET

[] LOCATE THE BRACKET

a. Decide whether the bracket will be

installed on the right or left side of the

range opening.

b. Place the bracket as shown in Fig. 1,

Fig. 1

Adjacent

cabinet

/

FLOOR-CONCRETE

Bracket

side

Rear

leveling leg

FLOOR-WOOD

/

[] INSTALL THE ANTI-TIP BRACKET

(cont.)

[] INSTALL THE BRACKET IN WOOD

OR CONCRETE

INSTALLATION--WOOD CONSTRUCTIONS

a. Locate the centers of the 4 holes identified

in Fig. 1 as Floor-Wood and Wall.

b. Drill a 1/8" pilot hole through the

pre-marked areas. Note the angle of the

wall screw in Fig. 2.

c. Mount the Anti-Tip bracket with the

4 screws provided,

Top front Fig. 2

edge of

countertop _ 25" _,f_'="_l

Bracket_lll

I Screw \\ I1 Wall plate

INSTALLATION--CONCRETE CONSTRUCTIONS

a. For concrete installation, you will need

two 1/4" x 1-1/2" lag screws and two sleeve

anchors.

b. Locate the center of the 4 holes identified

in Fig. 1 as Floor-Concrete and Wall,

Drill the recommended size holes in each.

Install the sleeve anchors into the

C,

predrilled concrete holes and install the

lag and wall screws through the Anti-Tip

bracket. Make sure the screws are securely

tightened.

Page 10

Installation Instructions

INSTALL THE RANGE (CONT.)

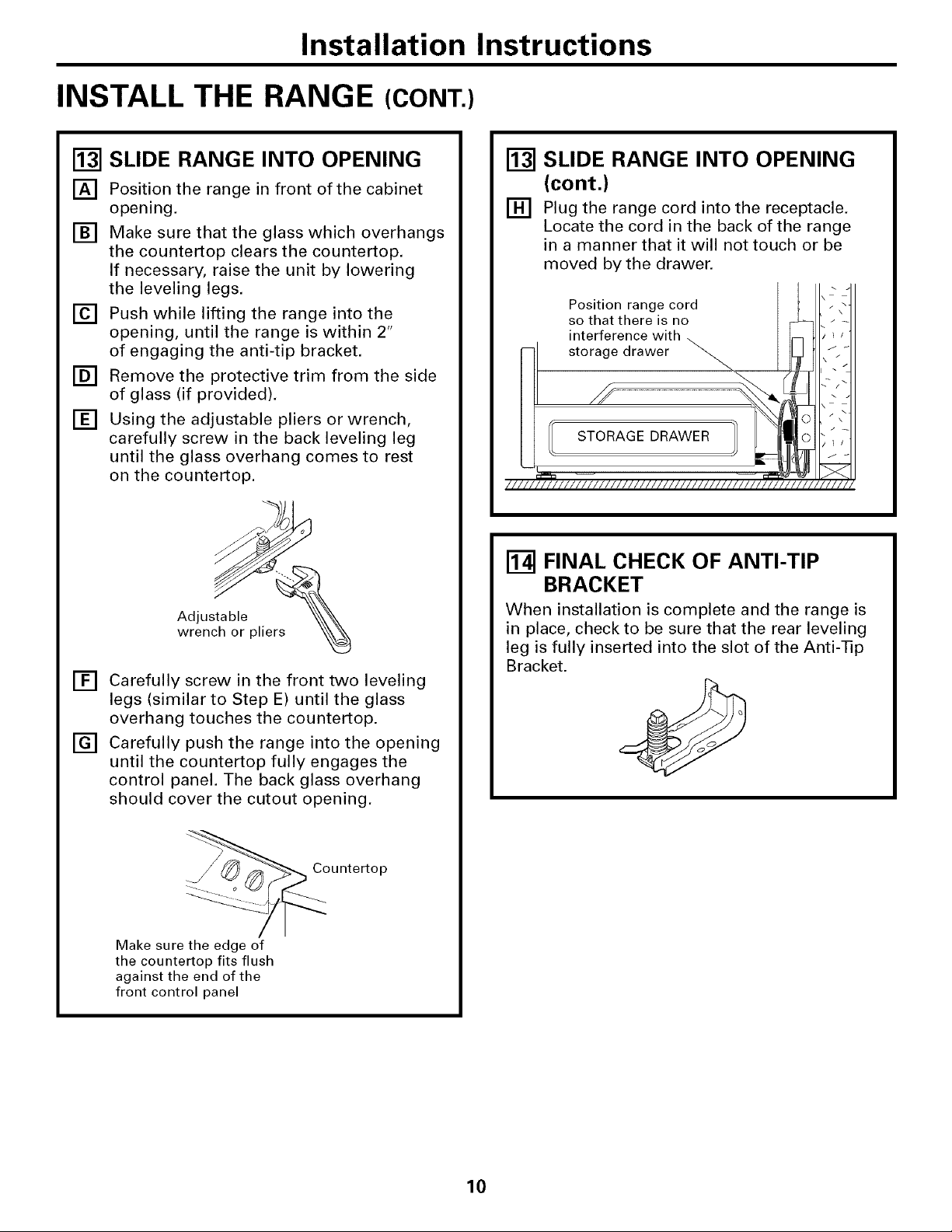

SLIDE RANGE INTO OPENING

[]

[]

Position the range in front of the cabinet

opening.

[] Make sure that the glass which overhangs

the countertop clears the countertop.

If necessary, raise the unit by lowering

the leveling legs.

[] Push while lifting the range into the

opening, until the range is within 2"

of engaging the anti-tip bracket.

[] Remove the protective trim from the side

of glass (if provided).

[] Using the adjustable pliers or wrench,

carefully screw in the back leveling leg

until the glass overhang comes to rest

on the countertop.

r_ SLIDE RANGE INTO OPENING

(cont.)

[] Plug the range cord into the receptacle.

Locate the cord in the back of the range

in a manner that it will not touch or be

moved by the drawer.

/////

\

/I/

\ //

\

/11

j _

i \

j _

Position range cord

so that there is no

interference with

\

[] Carefully screw in the front two leveling

legs (similar to Step E) until the glass

overhang touches the countertop.

[] Carefully push the range into the opening

until the countertop fully engages the

control panel. The back glass overhang

should cover the cutout opening.

Counte_op

Make sure the edge of

the countertop fits flush

against the end of the

front control panel

r_-z-4]FINAL CHECK OF ANTI-TIP

BRACKET

When installation is complete and the range is

in place, check to be sure that the rear leveling

leg is fully inserted into the slot of the Anti-Tip

Bracket.

10

Page 11

Installation Instructions

REPLACE THE OVEN DOOR

NOTE: The oven door is heavy. You may need

help lifting the door high enough to slide it

into the hinge slots. Do not lift the door by

the handle.

[] Lift the oven door by placing one hand on

each side. The door is heavy, so you may

need help. Do not lift the door by the

handle.

With the door at the same angle as the

[]

removal position (halfway between the

closed and broil stop position), seat the

notch of the hinge arm into the bottom

edge of the hinge slot. The notch of the

hinge arm must be fully seated into the

bottom of the slot.

Hinge arm

Bottom edge

REPLACE THE STORAGE

DRAWER

[] Place the drawer rail on the guides.

[] Push the drawer in until it stops.

[] Lift the front of the drawer and push in

until the stops clear the guides,

[] Lower the front of the drawer and push in

until it closes.

SPECIAL INSTRUCTIONS IF YOU ARE

HAVING PROBLEMS WHILE REPLACING

THE STORAGE DRAWER

If Drawer Won't Close:

Drawer

Drawer does front panel

Power cord not close _ . tipped away

may be comnletel,, I_ear arawer from body

obstructing '" Y support is side

drawer in _ I_ resting on top _ f_

] this area IFi I of guide rail I_

of slot !

Hinge notch

[] Open the oven door as far as it will open.

[] Push the hinge locks up against the front

frame of the oven cavity, to the locked

position.

Hinge in

locked position

Notch of hinge

secu rely fitted

into bottom of

hinge slot

[] Close the oven door.

Remove and replace, making sure the power

cord is not obstructing the drawer and/or the

rail is in the guide.

If Drawer is Crooked:

Rear drawer

support is on top

of guide rail on Drawer front panel

the high side _ tippeito one side

Remove and replace, making sure the rail is in

the guide.

11

Page 12

Installation Instructions

INSTALL THE RANGE (CONT.)

[] COOKTOP BURNERS

[] ASSEMBLING THE BURNERS

CAUTION: Theelectrodeofthe

spark igniter is exposed. Be careful not to

snag the electrode of the spark igniter with

a cleaning cloth. Damage to the igniter could

occur. Be careful not to turn on any cooktop

controls while cleaning. A slight electrical

shock might result, which could cause you

to knock over hot cookware.

FOR GLASS CERAMIC COOKTOPS

a. Place the burner head on the burner base,

so that the pins match up with the slots on

the base.

b. Position the burner cap on the burner head,

c. Place the burner grate over the burner

assembly. The grates fit over the raised

area on the burner head.

_-_ Spark

Burner

grate_

_ igniter

v location

[] CHECK FOR LEAKS

Turn the gas supply on and use a liquid leak

detector (soap solution) at all joints and

connections to check for leaks. Do not use an

open flame to look for leaks. Be sure all leaks

are stopped before lighting burners.

[] PRESSURE TEST INFORMATION

The maximum allowable supply pressure

for the regulator is 14" W.C, The minimum

supply pressure needed to check the regulator

setting is 7" W.C, for natural gas and 10" W.C,

for LP gas.

-&WARNING: The range and its

individual shut-off valve must be disconnected

from the gas supply piping system during any

pressure testing of the gas supply system at

test pressures of more than 1/2 psig (pounds

per square inch gauge). The range must be

isolated from the gas supply piping system

by closing its individual shut-off valve during

any pressure testing of the gas supply system

at test pressures equal to or greater than

1/2 psig. NOTE: 1/2 psig = 13.855" w.c.

Burner

cap --_

Burner _ Spark

head - _ igniter

Burner _ Glass

base _ maintop

Vent

cover

12

Page 13

Installation Instructions

[] CHECK THE IGNITERS

Operation of the electric igniters should be

checked after the cooktop and supply line

have been carefully checked for leaks and the

cooktop has been connected to the electrical

power.

a. Turn on gas.

b. Push and turn a burner valve to the LITE

position.

• The burner valve should light when gas

is available to the burner.

• Once the burner lights, it should be

turned out of the LITE position.

c. Try each valve separately until all burners

have been checked.

[] BURNER IGNITION

Cooktop Spark Ignition - When you turn

the cooktop knob to LITE, the spark igniter

makes a series of electric sparks (ticking

sounds) which light the burner. During a

power failure the burners will not light

automatically. In an emergency, a cooktop

burner may be lit with a match by following

the steps below.

[] BURNER FLAMES

Turn each burner on. Turn each burner knob

to the high position. Flames should be blue

in color with no or little trace of yellow. The

burner flames should not flutter or blow away

from the burner. The inner cone of the flame

should be between 1/2" to 3/4" long. If the

burner flames are yellow in color or not the

proper length, call GE Service.

COOKTOP

BURNER

Flames should circle burner

Burners should be checked frequently.

WARNING: ifyouattempt to

measure the inner cone of the flame, please

use caution. Burns could result.

- WARNING: Lighting gas burners

with a match is dangerous. You should match

light the cooktop burners only in an

emergency.

a. Light a match and hold the flame near the

burner you want to light. Wooden matches

work best.

b. Push in and turn the control knob slowly.

Be sure you are turning the correct knob

for the burner you are lighting.

NOTE: If the burner does not light within

five seconds, turn the knob off and wait five

minutes before trying again.

13

Page 14

Installation Instructions

INSTALL THE RANGE (CONT.)

[] BAKE AND BROIL BURNERS

If the bake and/or broil burners have lifting or

"lazy" (floating) flames or you have a yellow

flame, perform the following procedures:

[] CHECKING THE OVEN BURNERS

To check the bake burner flames with the

oven door in the closed position:

1. Open the door and remove it.

2. Remove the oven racks.

3. Remove the oven bottom,

Lift the oven bottom up at rear and pull

forward.

4. Remove the four screws holding the burner

baffle (flame spreader) to the burner box.

/

5. Install and close the oven door.

6. Turn on the bake burner.

As you watch the flames, check the

following:

• Burner flames should not flutter or blow

away from the burner.

• They should be blue in color with no trace

of yellow.

The broil burner flames may be seen without

removing the racks, oven bottom or bake

baffles.

[] ADJUST THE AIR SHUTTER

BAKE BURNER

1. Remove the orifice fitting cover.

2. Use a screwdriver to loosen the air shutter

screw.

3. Adjust the air shutter to 11/32".

4. Retighten the air shutter screw.

Orifice fitting

÷...

-_--_. -_. _JJ

WHAT ADJUSTMENT TO MAKE:

a. If the flames are yellow, open the air

shutter more than the original setting.

b. If the flames blow away or fluttered from

the burner, close the air shutter more than

the original setting.

Burners should be checked frequently.

BROIL BURNER

1. The broil burner is located and accessible

in the top rear of the oven.

2. Using a Dim. "A"

screwdriver,

loosen the air

sh utter

adjustment screw.

3. Make the air

shutter Air shutter

adjustment, adjustment screw

4. Retighten the air

shutter screw,

5. Check the inner flame

cone of the flame. 1/2" to 3/4" i,_/ Oven broiler

It should be /'rl/_ burner

between 1/2" and

3/4" long for the

oven bake and

broil burners.

WHEN ALL ADJUSTMENTS ARE MADE AND

THE RESULTS ARE SATISFACTORY

1. Replace the orifice fitting cover.

2. Replace the burner baffle (flame spreader)

and screws.

3. Replace the oven bottom.

4. Replace the oven door.

14

Inner cone of

shutter

Page 15

Installation Instructions

[] ALTERNATE CONSTRUCTION

PREPARATION

[] OPTIONAL MAINTOP FILLER OR

BACKGUARD KIT

If counter opening extends to the wall, it will

require Maintop Filler Kit (supplied with the

range) or Backguard Kit (JXS36XX or

JXS39SS) to close the gap.

NOTE: If the countertop is greater than 25",

it will show a gap between the backguard

and wall or between filler kit and the wall.

If the countertop is less than 25", a gap will

occur between the countertop front and the

control panel ends (see Step 13G).

If you are using the optional backguard kit,

refer to the backguard kit instructions for

installation details.

, J

Wall

Must be

25" level

When the trim is set in the proper position,

tighten the 2 mounting screws. The top of the

trim should be located below the top surface

of the glass to prevent pots, pans and skillets

from damaging the painted parts.

Refer to the Standard Installation of the

Range on page 6.

I M°int°pfi"er

I"_ _ .......(2) #8

screws

[] FOR NON-BUILT-IN INSTALLATION

(END OF CABINET LOCATION)

When installing the range at the end of

a cabinet section which will expose the

unfinished side of the range, use Body Side

Kit (JXS76XX). Refer to the kit instructions

for installation details.

Must_l _ 30" _ Must be

be | smooth cut flat

flat _* Must be level

31-1/8"

If you use the filler kit, place the metal filler

piece supplied with the range to the back of

the range as shown in the figure below.

Start the 2 screws into the upper holes at the

outside rear of the range above the louvers

and through the slots in the trim, holding

the filler piece centered on the maintop

frame and pushing upward to close the gap

between the bottom of the glass and the

filler trim.

[] ISLAND INSTALLATION

Attach the Anti-Tip bracket per instructions

in Step 12, making sure that the rear of

the bracket is 25" from the front of the

countertop.

Be aware that the screws provided are long

and may penetrate through the back of the

island cabinets. In this event, use shorter

screws (not provided) or the screws provided

should be used in the floor (see Step 12B for

Wood/Concrete Floor Installation).

Do not use Backguard Kit JXS36XX or

JXS39SS.

15

Page 16

Installation Instructions

INSTALL THE RANGE (CONT.)

r_] ALTERNATE CONSTRUCTION

PREPARATION (cont.)

[] FOR CABINET OPENINGS

APPROXIMATELY 30-3/8"

If range is installed in cabinet opening

approximately 30-3/8", the Vertical Side Trim

Kit (JXS86XX) should be used to cover gaps

between range sides and cabinet. Refer to

the kit instructions for installation details.

[] CABINETS OVER THE RANGE LESS

THAN 30"

If a 30" clearance between cooking surface

and overhead combustible material or metal

cabinets cannot be maintained, protect the

underside of the cabinets above the cooktop

with not less than 1/4" insulating millboard

covered with sheet metal not less than

0.0122" thick.

[] OPERATION CHECKLIST

• Double check to make sure everything in

this guide has been completed. Rechecking

steps will ensure safe use of the cooktop.

• Make sure all controls are left in the OFF

position.

• Make sure the flow of combustion and

ventilation air to the cooktop is unobstructed.

• The serial plate for your Range is located

under the oven door above the storage

area. In addition to the model and serial

numbers, it tells you the ratings of the

burners and the type of fuel and pressure

the cooktop was adjusted for when it left

the factory.

• When ordering parts, always include the

serial number and model number to ensure

proper replacement parts.

• Recheck Steps: Double check to make

sure everything in this guide has been

completed. Rechecking steps will ensure

safe use of the Range.

Please see L.P. conversion instructions

supplied with this range when L.P. Gas

is used.

NOTE: Instructions are mounted on

regulator bracket.

IN SOME CASES

[] With L.P. gas, some yellow tipping on the

outer cone is normal.

[] Foreign particles in the gas line may

cause an orange flame at first, but this

will soon disappear.

SPECIAL NOTE:

To convert the oven back to natural gas,

reverse the instructions given in making L.P.

Adjustments.

Once the conversion is complete

and checked ok, fill out the LP

sticker and include your name,

organization and the date the

conversion was made. Apply the sticker near

the regulator to alert others in the future that

this appliance has been converted to LP gas.

If converting back to natural gas from LP,

please remove the sticker so others know the

appliance is set to use natural gas.

ADJUSTING LOW FLAME SETTING

ON COOKTOP BURNERS

Low setting adjustments must be made with

two other burners in operation on a medium

setting. This procedure prevents the low

flame from being set too low, resulting in the

flame being extinguished when other burners

are turned on.

[] Remove the valve control knobs.

[] Through the opening, locate the valve

bypass screw located on the lower right

side of the valves.

[] Using a small screwdriver, screw down

the bypass screw fully in a clockwise

rotation.

I

16 Printed in the United States

Page 17

Instructions

Cuisiniere encastr

d'installation

IF_ i vous avez des questions, appelez le 1.800.361.3400 ou visitez notre site Web a I'adresse :

www.electromenagersge.ca

AVANT DE COMMENCER

Lisez ces instructions completement et avec

soin.

au gaz

JGS905, JGS968, PGS968

MATI_RIAUX DONT VOUS POUVEZ

AVOIR BESOIN

• IMPORTANT - Conservezces

instructions pour I'inspecteur local.

• IMPORTANT - Respectez tousles

codes et les ordonnances en vigueur.

• Note a I'installateur : Assurez-vous de

donner toutes ces instructions au

consommateur.

• Note au consommateur : Conservez ces

instructions pour reference future.

• La garantie ne couvre aucune panne due

une mauvaise installation.

Produit d'obturation

des joints

Raccord flexible de gaz approuve par I'ACNOR

OUTILS DONT VOUS AUREZ BESOIN

Raccords de tugaux Nobinet d'arrgt

DI rain 3/8", Jonction NPT 1/2"

I

.4,AVE RTISSE ME NT - Cet

appareil menager doit _tre bien mis a la terre.

• IMPORTANT - vousdevezfaire

les essais de fuite de cet appareil en vous

conformant aux instructions du fabriquant.

• L'installateur est responsable d'une bonne

installation et la garantie ne couvre aucune

panne due a une mauvaise installation.

PIECES COMPRISES

Vis Soutien anti-

Entretoise arriere basculement

2 vis

Tourne-ecrou de 1/4"

Tournevis a t6te

Phillips

Metre

Lunettes de securite

Niveau

Cle a tube

Cle ou tenailles (pour

un ecrou de 1-7/16")

Perceuse

31-10665 10-07 JR 1

Page 18

Instructions d'installation

CONSEILS DE SI:!:CURITI:!:IMPORTANTS

VOTRE SI_CURITE_ :

AVERTISSEMENT -

Si vous ne suivez pas exactement les

renseignements contenus dans ce manuel,

vous pouvez occasionner un incendie, une

explosion ou une fuite de gaz qui peut causer

des dommages materiels, des blessures

corporelles ou la mort.

Ne conservez ou n'usez jamais d'essence

ou d'autre liquide ou vapeur inflammable

proximite de cet appareil ou de tout autre

appareil menager.

QUE FAIRE SI VOUS

SENTEZ LE GAZ :

• N'essayez jamais d'allumer un appareil

menager. Ne touchez aucun commutateur

electrique; n'utilisez aucun t616phone dans

votre b_timent.

• Appelez immediatement votre fournisseur

de gaz en utilisant le telephone d'un voisin.

Suivez les instructions du fournisseur de

gaz.

• Si vous n'arrivez pas a communiquer avec

votre fournisseur de gaz, appelez les

pompiers.

L'installation et le service doivent _tre faits

par un installateur qualifi_, une agence de

service ou votre fournisseur de gaz.

La conception de cette cuisiniere a

6te certifiee par les UNDERWRITERS

LABORATORIES du Canada. Vous trouverez

des precautions de securite dans votre

Manuel du proprietaire. Lisez-les avec soin.

• L'installation de cette cuisiniere doit

se conformer aux codes Iocaux ou, en

I'absence de codes Iocaux, au National Fuel

Gas Code, ANSI Z223.1 - Derniere edition.

• Assurez-vous que votre cuisiniere soit bien

install6e par un installateur qualifie ou un

technicien du service.

• Pour 6viter de vous pencher sur les

brQleurs de surface, vous devez _viter de

placer au-dessus des brQleurs une armoire

de rangement.

• N'installez jamais votre appareil pres d'une

porte donnant sur I'ext6rieur ou dans tout

endroit ou un courant d'air peut g6ner son

usage.

Page 19

Instructions d'installation

EXIGENCES ELECTRIQUES

Cet appareil menager doit 6tre livre avec le

bon voltage et la bonne frequence et branche

son propre circuit de derivation bien mis

la terre, prot6g6 par un disjoncteur ou un

fusible qui ont I'amperage note sur la plaque

signaletique (la plaque signaletique est situee

au dessus du tiroir de rangement sous le

chassis de la cuisiniere).

Emplacement

de la plaque

signaletique

Nous vous recommandons de faire brancher

le c_blage 61ectrique et la fiche de votre

cuisiniere par un electricien qualifi& Apres

I'installation, demandez a I'electricien de vous

montrer I'emplacement de votre coupe-circuit

principal.

Demandez a votre entreprise de services

publics les codes electriques en vigueur

dans votre region. En ne c_blant pas votre

cuisiniere conformement aux codes en

vigueur, vous provoquez une situation

dangereuse. En I'absence de codes, vous

devez c_bler et isoler votre cuisiniere

conformement aux exigences du Canadian

Electrical Code.

IVII CANISIVIE ANTI-BASCULANT

-&AVERTISSEMENT - Pourreduire

le risque de basculement, vous devez fixer votre

appareil en installant bien le support anti-

basculement livre avec votre appareil.

Pour verifier si ce support est bien installe

et engage, faites doucement basculer la cuisiniere

vers I'avant. Le support anti-basculement doit

s'engager et emp_cher la cuisiniere de basculer.

-&AVERTISSEMENT-

• Toutes les cuisinieres peuvent

basculer

• Cela peut occasionner des

• Installez le support anti-basculant

livre avec votre cuisiniere

_ blessures corporelles

Si vous tirez la cuisiniere pour I'ecarter du mur

pour quelque raison que ce soit, assurez-vous que

le support anti-basculement s'engage quand vous

repoussez la cuisiniere contre le mur.

• Consultez les instructions

d'installation

Page 20

Instructions d'installation

LISTE DE VITRIFICATION AVANT L'INSTALLATION

[] INSPECTEZ L'EMPLACEMENT

OU VOUS ALLEZ INSTALLER

Consultez la section d'autre construction

pour les installations suivantes qui ne sont

pas normales.

[] L'ouverture du eomptoir se poursuit

jusqu'au mur :

Entretoise arriere (fournie avec la

cuisiniere (consultez les installations

d'instruction a la page 15) ou

Dosseret (trousse JXS36XX ou

JXS39SS).

[] La hauteur du compteur est plus

grande que 93,4 cm (36-3/4"):

Garniture du bas a glisser (trousse

JXS56XX).

[] Un e6te n'est pas enferme clans une

armoire :

CSte d'appareil (trousse JXS76XX).

[] Installation dans un ilot :

Pour obtenir une bonne installation, la

surface du haut du comptoir doit _tre

horizontale et plate (au m_me niveau)

des trois c6tes qui sont adjacents a la

table de cuisson de la cuisiniere. Vous

devez bien ajuster la surface du haut

afin de bien I'aplatir, autrement il se

produira des ecarts entre le comptoir et

la table de cuisson de votre cuisiniere.

En poussant la table de cuisson pour

aller dans le comptoir, vous pouvez

occasionner des ecarts excessifs et

vous pouvez casser la vitre et annuler

la garantie.

_-I AMENEZ LA CUISINII=RE A

L'INTI_RIEUR EN FACE DE

L'OUVERTURE DE L'ARMOIRE

N'utilisez pas de chariot a main pour

transporter la cuisiniere sans emballage. La

vitre de la table de cuisson peut se casser.

[] PROTEGEZ LE PLANCHER DE

LA CUISINE

Aplatissez et placez un morceau de carton

d'emballage devant I'emplacement ou vous

allez installer votre cuisiniere pour proteger

le plancher.

NOTE : Attendez plus tard au cours

de I'installation pour enlever les rails

protecteurs des c6tes de la table de

cuisson en verre, le cas echeant.

Rail

protecteur

Pour obtenir les trousses :

a. Visitez le site Web GE (voir page 1)

b. Appelez le centre de reponse GE

(voir page 1)

c. Appelez le vendeur

[] FAITES BASCULER AVEC SOIN

LA CUISINII=RE POUR AVOIR

ACCI=S AUX PIEDS

D'INCLINAISON DE LA

CUlSINIERE

Utilisez une cle ajustable pour visser les

pieds d'inclinaison afin de mettre a niveau

le soutien de la vitre avec le haut du

comptoir.

4

Page 21

Instructions d'installation

[] ENLEVEZ LA PORTE SI C'EST

NECESSAIRE

II n'est pas indispensable d'enlever la porte

pour installer votre cuisiniere, mais cela

peut vous faciliter la t&che, Pour enlever

la porte :

[] DI_VERROUILLEZ LES CHARNIERES

Poussez les deux verrous de charnieres

vers le bas, vers le chassis de la porte, en

position deverrouillee. Cela peut necessiter

un tournevis a t6te plate.

Position

deverrouillee

Fente de

charniere

Bras de

,charniere

[] METTEZ EN PLACE LA PORTE

Placez vos mains des deux c6tes de la

porte et fermez la porte de la cuisiniere en

position d'enlevement. C'est a mi-chemin

entre I'arr6t de grillade et la fermeture

totale.

de charniere

ENLEVEZ LA PORTE Sl C'EST

NI_CESSAIRE (suite)

[] ENLEVEZ LA PORTE EN LA

SOULEVANT

Enlevez la porte en la soulevant et en la

faisant sortir jusqu'a ce que les bras de

charniere sortent des fentes.

NE SOULEVEZ JAMAIS LA PORTE .&,UN

ANGLE.

NOTE : La porte de la cuisiniere est

tres Iourde. Assurez-vous de bien la saisir

avant de la soulever pour I'enlever de ses

charnieres. Faites bien attention une fois

que vous avez enleve la porte. Ne posez

jamais la porte sur sa poignee. Cela peut

occasionner des rayures ou des bosses.

La charniere sort de sa fente

[] ENLEVEZ LES MATI_RIAUX

D'EMBALLAGE

Enlevez les etiquettes de la porte, la matiere

plastique de la garniture et du panneau et

tout le ruban colle autour de la cuisiniere.

[] ENLEVEZ LE TIROIR DE

RANGEMENT

[] Tirez le tiroir vers I'exterieur jusqu'a ce

qu'il s'arr6te.

[] Soulevez I'avant du tiroir jusqu'a ce

que les arr6ts sortent des guides.

Arr6t

[] Tirez vers I'avant et enlevez le tiroir.

5

Rail

Page 22

Instructions d'installation

LISTE DE VITRIFICATION AVANT L'INSTALLATION (SUITE)

[] DECOUPE AVANT L'INSTALLATION

ET DCGAGEMENT REQUIS

Si les armoires sont placees a moins de

76,2 cm (30") au-dessus de la cuisiniere,

consultez la section d'autre construction,

etape 19E, a la page 16.

NOTE : Votre appareil remplir les exigences

UL de 0" de degagement aux murs arriere et

de c6t&

Les rev_tements de mur, les comptoirs et

les armoires autour de la cuisiniere doivent

supporter la chaleur (pouvant atteindre 194°F)

produite par la cuisiniere.

Profondeur ,

totale 70 c_-_!

(27-1__ 79,4 cm (31-1/4")

Depuis la

surface avant

7,30ml27/8'1 -

du com_

Espace libre pour

la porte, depuis la

surface avant du

comptoir

52,4 cm (20-5/8") 1

INSTALLATION NORMALE

Si la construction ou votre armoire ne peut

fournir une surface plate de 6 mm (1/4")

I'arriere de I'ouverture du comptoir, envisagez

changer le comptoir pour obtenir cette

dimension. Consultez la section d'autre

construction. Si la surface n'est pas plate,

vous risquez de mettre trop de pression sur

la table de cuisson en verre, et la casser en

annulant la garantie.

Mur--

14 mm

(9/16")

Plat m_

6 mm (1/4")

Plat min.

58,9 cm (23-3/16")

76 cm a 76,4 cm _

{29-15/16"-30-1/16")

Coupe douce

63,5 cm

(25")

Typiquement

14 mm

(9/16")

Plat min.

Suivez les instructions

emballees avec I'autre 76 2 cm

appareil menag _ (_60"_cl;/n -_

15,2 cm (6") k --_ ,

min depuis ........

Pour une bonne L....._ 2 cm (30") min

installation, ces depuis la table de

surfaces doivent cuisson jusqu'au

¢tre plates et bas de I'armoire

horizontales 58,9 superieure

90,8 cm

(35-3/4") a 92,7 prise, la prise

cm (36-1/2") electrique et le

depuis le

plancher

jusqu'au

comptoir

7,6 cm (3")

76 cm (29-15/16") min

76,5 cm (30-1/16") max

Endroit acceptable

pour la conduite de

gaz et la prise

............ min de

_33_m (13") verticale

max de depuis le bas

profondeur des armoires

_ _ adjacentes

63,5 cm (25") Profondeur de

comptoir (normal)

comptoir jusqu'en

saillante pour liberer

electrique

panneau de contr61e

45,7 cm (18")

_ distance

superieures

3,2 cm (1-1/4")

min depuis le

haut du tiroir

Rabotez Par_te

79,1 cm (31=1/8 ")

d'epaisseur de

Surface plate

6 mm (1/4") _ 91,4 cm (36")

]

6

Page 23

Instructions d'installation

BRANCHEMENT I:!:LECTRIQUE

INSTALLATIONm

[]

BRANCHEMENT I LECTRIQUE

[]

cause des risques de securite

dans certaines conditions, nous vous

recommandons fortement de ne pas

utiliser de rallonge. Cependant, si vous

decidez tout de m_me d'utiliser une

rallonge, il est absolument necessaire

que cette rallonge soit une rallonge

pour appareil electromenager a trois

fils et mise a la terre, dont I'amperage

soit egal ou sup6rieur a celui du circuit

de d6rivation. Vous trouverez cette

rallonge chez votre revendeur local

d'appareils electromenagers.

IMPORTANT : (Veuillez life

attentivement) POUR VOTRE SI_CURITI_

PERSONNELLE, VOUS DEVEZ BIEN

METTRE A LA TERRE CET APPAREIL

Vous devez utiliser une bonne

[]

alimentation electrique et une bonne

prise pour faire fonctionner les pieces

electriques de votre appareil.

• Le cordon d'alimentation de votre appareil

est equipe d'une fiche a trois broches (mise

la terre) que vous devez brancher dans

une prise a trois trous bien mise a la terre,

qui alimente en courant electrique menager

normal alternatif de 120 Volts, 60 cycles.

• Si vous avez une prise normale

deux broches, le consommateur est

personnellement responsable et oblige

de la faire remplacer par une prise murale

triphasee mise a la terre par un electricien

qualifi&

Ne coupez ou n'enlevez en aucun cas la

broche de raise a la terre du cordon de la

cuisiniere. Vous creerez une situation

dangereuse en ne mettant pas bien

la terre votre appareil.

Page 24

Instructions d'installation

BRANCHEMENT DU GAZ

BRANCHEMENT

7,6 cm (3") ', 17,8 cm (7")

38,1 cm (15")

30,5 cm (12")

[] Installez le robinet d'arr6t manuel dans la

conduite d'alimentation de gaz dans un

emplacement facile d'acces.

[] Trouvez comment couper I'alimentation

de gaz a la cuisiniere, et ou se trouve le

robinet d'alimentation.

[] Coupez I'alimentation de gaz avant

d'enlever une vieille cuisiniere, Laissez-la

coup6e jusqu'a la fin du branchement de

la nouvelle cuisiniere.

[] Comme les conduites rigides limitent le

deplacement de la cuisiniere, nous vous

recommandons I'utilisation d'un raccord

flexible en metal certifi6 par I'ACNOR.

-&AVERTISSEMENT: N'utilisez

jamais un vieux raccord flexible. L'utilisation

d'un vieux raccord flexible peut occasionner

des fuites de gaz et des blessures corporelles.

Utilisez toujours un raccord flexible neuf pour

installer un appareil menager a gaz.

[] Avant de brancher le gaz, assurez-vous

que le levier de fermeture de I'alimentation

en gaz du four (visible a I'arriere de la

cuisiniere) soit en position ouverte.

. . . \ _'----------de gaz au brQleur

Approvisionnement_ X dehaut

en.gaz de la _

cutsmtere -........_\ \

Approvisionnement

BRANCHEMENT (suite)

[] Installez I'adaptateur evase de 13 mm

(1/2") au coude NPT de 13 mm (1/2") sur

le r_gulateur de pression.

[] Branchez le raccord flexible d'appareil

manager a I'adapteur.

[] Mettez la cuisiniere dans son

emplacement approximatif et

branchez le raccord flexible a la conduite

d'approvisionnement de gaz avec le bon

adaptateur _vas&

Robinet d'arr6t Raccord flexible

_- ___X Regul.ateur de

Max , E:_" _ L4_ "f-yj_ \ presston

Conduite / provenance _-,4_??tz_.,_ _[

d approvisionnement de la rue "__j

de gaz 90 °

[] Pour emp_cher les fuites de gaz, mettez

un agent d'etancheite pour joint de tuyau

ou un ruban Teflon ® sur tousles filetages

m_les. NOTE : Assurez-vous que

I'agent d'etancheite ou le ruban soient

compatible avec le gaz naturel et le gaz

de p_trole liquefi&

[] Quand vous avez termine de faire les

branchements, assurez-vous que tousles

boutons de la cuisiniere soient en position

OFF (arr_t) avant d'ouvrir le robinet

d'approvisionnement de gaz principal.

-&AVERTISSEMENT: N'utilisez

jamais une flamme pour verifier s'il y a une

fuite de gaz. Utilisez un detecteur de fuite

liquide au niveau de tous les joints et les

raccords pour verifier les fuites dans le

systeme.

Lev!e r de ferm _ur_e k _ _nl_alni i_e

de I alimentation f_"_ _

en gaz du four en _ /f'_

posltlO__

8

Page 25

Instructions d'installation

INSTALLATION DE LA CUISINII RE

[] INSTALLEZ LE SUPPORT

ANTI-BASCULEMENT

[] TROUVEZ LE SUPPORT

a. Decidez si vous devez installer le support

du cSte droit ou du cSte gauche de

I'ouverture pour la cuisiniere.

b. Placez le support comme I'indique

la figure 1.

Fig. 1

Lespace egale sur, . L'ouverture plus large

cha que c6te _1[_..._ V- que 76,2 cm ,(30")

Armoire //A_'76,2cm(30')

adjacente/_//J M ur

PLANCHER - BOIS

C6te du

support /

Pied

d'inclinaison

de I'arriere

PLANCHER - CIMENT

INSTALLEZ LE SUPPORT

ANTI-BASCULEMENT (suite)

[] INSTALLEZ LE SUPPORT DANS DU

BOIS OU DANS DU ClMENT

INSTALLATION--CONSTRUCTIONS EN BOIS

a. Trouvez le centre des 4 trous indiques darts

la figure 1 comme Plancheribois et mur.

b. Percez un trou pilote de 3 mm (1/8") dans

les surfaces pre-marquees. Notez I'angle

de la vis de mur dans la figure 2,

c. Montez le support anti-basculement avec

les 4 vis fournies,

Tranche Fig. 2

avant du

haut du -_-_-63,5 cm (25")

comptoir _ Plaque

•

bupport I I

La vis doit \| murale

entrer dans "_kr__

_ I le bois ou-_J_.._

_ le metal J_ [

____

I

INSALLATIONS--CONSTRUCTIONS

EN CIMENT

a. Pour une installation dans le ciment,

vous aurez besoin de deux vis tire-fonds

de 6 mm x 3,8 cm (1/4" x 1-1/2") et deux

manchons ancrages,

b. Trouvez le centre des 4 trous indiques

dans la figure 1 comme Plancher--

ciment et Mur. Percez les trous de taille

recommandee dans chaque centre.

c. Mettez les manchons ancrages dans les

trous pre-perces dans le ciment et mettez

les vis tire-fonds et les vis a mur dans le

support anti-basculement. Assurez-vous

de bien serrer les vis.

Page 26

Instructions d'installation

INSTALLATION DE LA CUISINII RE (SUITE)

FAITES GLISSER LA CUlSINII_RE

DANS L'OUVERTURE

Placez la cuisiniere en face de I'ouverture

[]

de I'armoire,

Assurez-vous que le verre qui surplombe

[]

le comptoir libere le comptoir. Si

necessaire, soulevez I'appareil en

descendant les pieds d'inclinaison.

Poussez tout en soulevant la cuisiniere

[]

dans I'ouverture, jusqu'a ce que la

cuisiniere se trouve a 5.1 cm (2") d'entrer

dans le soutien anti-basculant.

[]

Enlevez la garniture protectrice du c6te

du verre (s'il yen a une).

_, I'aide de la cle anglaise ou des

[]

tenailles, vissez avec soin la vis du pied

d'inclinaison de I'arriere jusqu'a ce que le

surplomb de verre repose sur le comptoir.

I'_ FAITES GLISSER LA CUlSINII_RE

DANS L'OUVERTURE (suite)

[] Branchez le cordon de la cuisiniere dans le

receptacle. Placez le cordon a I'arriere de la

cuisiniere de maniere a ce qu'il ne touche

pas le tiroir ou ne change pas de place

cause du tiroir.

Placez le cordon

de la cuisiniere de

maniere ace qu'il ne

touche

de rangement

TIROIR DE RANGEMENT

iii

/////,

_J

/\

zz

/

/ --

-C

/ --

\

/

/

\.

\

[] VITRIFICATION FINALE DU

SUPPORT ANTI-BASCULEMENT

Quand I'installation est terminee et la cuisiniere

est en place, verifiez pour vous assurer que le

pied d'inclinaison arriere est bien entre dans la

fente du support anti-basculement.

[] Vissez avec soin les deux pieds

d'inclinaison de devant (comme dans

I'etape E) jusqu'a ce que le surplomb

de verre touche le comptoir.

[] Poussez avec soin la cuisiniere dans

I'ouverture jusqu'a ce que le comptoir

entre dans le panneau de contr61e. Le

surplomb de verre arriere doit couvrir

I'ouverture.

, Comptoir

Assurez-vous que I'ar6te

du comptoir soit bien

alignee au panneau de

contr61e avant

10

Page 27

Instructions d'installation

r_ REMETTEZ EN PLACE LA

PORTE DE LA CUISINII_RE

NOTE : La porte de la cuisiniere est Iourde.

Vous aurez peut-_tre besoin d'aide pour

soulever la porte suffisamment haut pour la

faire glisser dans les fentes de charnieres.

Ne soulevez jamais la porte par la poignee.

[] Soulevez la porte de la cuisiniere en

pla£ant une main de chaque c6t& La porte

est Iourde, et vous aurez peut-6tre besoin

d'aide. Ne soulevez jamais par la poignee.

[]

Avec la porte au m6me angle que dans

la position d'enlevement (a mi-chemin

entre la position d'arr6t de grillade et la

position femee), mettez I'encoche du

bras de charniere dans I'extremit6 du bas

de la fente de charniere. L'encoche du

bras de charniere doit bien reposer dans

le bas de la fente.

Extremit6 du

bas de la

fente _ /

Bras de charniere

F

REMETTEZ EN PLACE LE TIROIR

DE RANGEMENT

Placez les rails du tiroir sur les guides.

[]

Poussez le tiroir a I'int6rieur jusqu'a ce qu'il

[]

s'arr6te

[]

Soulevez I'avant du tiroir et poussez vers

I'interieur jusqu'a ce que les arr6ts sortent

des guides.

[] Abaissez le devant du tiroir et poussez-le

vers I'interieur jusqu'a ce qu'il ferme.

INSTRUCTIONS SPI_CIALES SI VOUS

AVEZ DES PROBLI_MES A REMETTRE EN

PLACE LE TIROIR DE RANGEMENT

Si le tiroir ne ferme pas :

Le cordon Le tiroir ne

d'alimentation fermepas

electriquepeut completement arrieredu

I obstruer le I repose sur _ /_

_ce_ ___ lerailguide J_

Le soutien

tiroir I'armoire

Le panneau

avant du

tiroir a

bascule en

s'ecartant

du c6te de

!j//

!f/J

J

Enco_

he de charniere

[] Ouvrez la porte du four autant que vous

le pourrez.

[] Poussez les verrous de charniere vers le

haut, contre le devant du chassis de la

cavite de cuisiniere, jusqu'en position

verrouillee.

Charniere en I =!1

posi.ooverroo,,ee

c C°Chee" i a

entree d ans le bas / I] _"-4_

de a fente de a I_._'_=

charniere

[] Fermez la porte du four.

Enlevez et remettez en place, en vous assurant

que le cordon d'alimentation ne gene pas le

tiroir et/ou que le rail est dans le guide.

Si le tiroir est tordu :

Le soutien arriere

du tiroir est en haut

du rail guide du Le panneau avant du

c6t6 elev6 tiroir a bascule d'un c6t6

-! !

Enlevez et remettez en place, en vous assurant

que le rail est dans le guide.

11

Page 28

Instructions d'installation

INSTALLATION DE LA CUISINII RE (SUITE)

r_] BRULEURS DE LA TABLE DE

CUISSON

[] ASSEMBLAGE DES BROLEURS

-&ATTENTION: L'electrode

de I'allumeur etincelle est exposee. Faites

attention de ne pas decrocher I'electrode de

I'allumeur bougie avec un linge de nettoyage.

Vous risquez d'endommager I'allumeur.

Prenez soin de ne pas tourner un bouton de

contr61e de la table de cuisson quand vous

nettoyez. Cela pourra provoquer une petite

secousse electrique, qui peut vous faire

toucher la table de cuisson chaude.

POUR LES TABLES DE CUISSON EN

VITROCI_RAMIQUE

a. Placez la t6te de brQleur sur la base de

brQleur, de maniere ace que les tiges

correspondent aux fentes de la base.

b. Placez le capuchon du brQleur sur la t_te

de brQleur.

c. Placez la grilles de brQleur sur I'ensemble

de brQleur. Les grilles vont sur les surfaces

6levees sur les t_tes de brQleur.

_--- Emplacement

de I'allumeur

Grille de

etincelle

[] VI_RIFIEZ QU'IL N'Y A PAS DE FUlTE

Allumez I'alimentation de gaz et utilisez un

detecteur de fuite liquide (solution savonneuse)

sur tousles joints et les connexions pour

v6rifier qu'il n'y a pas de fuite. N'utilisez jamais

une flamme vive pour chercher les fuites.

Assurez-vous d'arr6ter toutes les fuites avant

d'allumer les brQleurs.

[] INFORMATION D'ESSAI DE

PRESSION

La pression d'alimentation maximum permise

pour le regulateur est 14" W.C. La pression

d'alimentation minimum necessaire pour

verifier le regulateur 7" W.C. pour le gaz naturel

et 10" W.C. pour le gaz de petrole liquefi&

-&AVERTISSEIVIENT :vous

devez debrancher la cuisiniere et son robinet

d'arr6t du systeme de conduite d'alimentation

de gaz pendant tout essai de pression du

systeme d'alimentation de gaz de plus de

1/2 psig (livre par pouce au carte). Vous devez

isoler la cuisiniere du systeme de conduite

d'alimentation de gaz en fermant son robinet

d'arr6t pendant tout essai de pression du

systeme d'alimentation de gaz a des

pressions d'essai egales ou superieures

1/2 psig. NOTE : 1/2 psig = 13.855" w.c.

brQleur_

Capuchon

de brQleur--t_:_

T6te de _ Allumeur

brQleur _ etincelle

Base de E(_"- I Table de

bruleur _ - verre

Couvercle

de I'event

12

Page 29

Instructions d'installation

[] VI_RIFIEZ LES ALLUMEURS

Vous devez verifier le fonctionnement des

allumeurs electriques apres avoir verifie

soigneusement I'absence de fuite et apres avoir

branche la table de cuisson a I'alimentation

electrique,

a. Ouvrez I'alimentation de gaz.

b. Poussez et tournez le robinet en position

LITE (allumer).

• Le robinet du brQleur doit s'allumer

quand il y a du gaz dans le brQleur.

• Une fois que le brQleur s'allume, il faut

I'enlever de la position LITE (allumer).

c. Essayez chaque robinet separement jusqu'a

avoir verifi6 tousles brQleurs,

[] ALLUMAGE DES BRULEURS

Ignition par etincelle de la table de cuisson--

Quand vous mettez le bouton de la table de

cuisson en position LITE (allumer), I'allumeur

etincelle fait une serie d'etincelles

electriques (sons de crepitement) qui

allument le brOleur. Pendant une panne

de courant, les brGleurs n'allumeront pas

automatiquement. En cas d'urgence, vous

pouvez allumer un brQleur de la table de

cuisson a I'aide d'une allumette en suivant

les etapes suivantes :

[] FLAMMES DU BRULEUR

Tournez chaque brQleur en position ON

(marche). Tournez chaque bouton de brQleur

en position elevee. Les flammes doivent _tre

bleues, sans traces ou avec peu de traces de

jaune. Les flammes du brQleur ne doivent pas

scintiller ou s'ecarter du brQleur. Le c6ne

interieur de la flamme doit avoir entre de

13 mm a 19 mm (1/2" a 3/4") de long, Si les

flammes du brQleur sont de couleur jaune

et ne sont pas de bonne Iongueur, appelez le

service GE.

13mma 19mm_

(1/2" a 3/4") I I

kes flammes doivent encercler le brQleur.

Vous devez verifier frequemment les brGleurs.

AVERTISSEMENT : sivous

essayez de mesurer le c6ne interieur de la

flamme, faites bien attention. Vous pouvez

vous brGler.

AAVERTISSEMENT :, est

dangereux d'allumer les brGleurs a gaz avec

une allumette. Vous ne devez allumer un

brGleur avec une allumette qu'en cas

d'urgence.

a. Allumez une allumette et tenez la flamme

pres du brQleur que vous voulez allumer.

Les allumettes en bois fonctionnent le

mieux.

b. Poussez vers I'interieur et tournez

lentement le bouton de contr61e.

Assurez-vous de tourner le bon bouton

pour le brQleur que vous allumez.

NOTE : Si le brQleur ne s'allume pas en

cinq secondes, tournez le bouton en

position OFF (arr6t) et attendez cinq

minutes avant de recommencer.

13

Page 30

Instructions d'installation

INSTALLATION DE LA CUISINII RE (SUITE)

BRULEURS DE CUlSSON ET

DE GRILLADE

Si les brQleurs de cuisson et/ou de grillade

ont des flammes {{paresseuses>> (flottantes)

ou des montees de flammes ou si leurs

flammes sont jaunes, faites les operations

suivantes :

[] VITRIFICATION DES BRULEURS

DU FOUR

Pour verifier les flammes du breleur de

cuisson avec la porte du four fermee :

1. Ouvrez la porte et enlevez-la.

2. Enlevez les clayettes de four.

3. Enlevez le plancher de four.

Soulevez I'arriere du plancher du four et

tirez vers I'avant.

[] AJUSTEZ LE VOLET A AIR

BRULEUR ARRII_RE

1. Enlevez le couvercle recouvrant I'orifice.

2. Utilisez un tournevis pour desserrer la vis

du volet a air.

3. Ajustez le volet a air a 11/32".

4. Revissez la vis du volet a air.

Couvercle

recouvrant I'orifice

u Volet a air

air ///

RI_GLAGES :

a. Si les fiammes sont jaunes, ouvrez le

volant a air par rapport a sa position

initiale.

b. Si les flammes vacillent ou s'ecartent

trop du brQleur, fermez le volant a air

par rapport a sa position initiale.

Vous devez verifier les breleurs frequemment.

BRULEUR DE GRILLADE

4. Enlevez les quatre vis qui tiennent I'ecran

du brQleur (qui 6tale la flamme) au boitier

du brQleur.

5. Installez la porte du four et fermez-la.

6. Allumez le brQleur de cuisson.

Regardez les flammes, et verifiez ce qui suit :

• Les flammes du brQleur ne doivent pas

vaciller ou trop s'_carter du brQleur.

• Elles doivent _tre bleues sans trace de

jaune.

Vous devez pouvoir les flammes du brQleur

de grillade sans enlever les clayettes, le

plancher du four ou les ecrans a cuisson.

1. Le brQleur de grillade est situe et accessible

I'avant arriere du four.

2. A I'aide d'un

tournevis, devissez

la vis de reglage du

volet a air.

3. Reglez le volet a air.

4. Revissez la vis du glage du

volet a air. volet a air

5. Verifiez le c6ne

interieur de la 13mm

flamme. II doit a 19 mm

avoir entre 1/2" et (1/2"

3/4" de Iongueur

pour les brQleurs

de cuisson et de

grillade.

APRILS TOUS LES RI_GLAGES, QUAND LES

RI_SULTATS SONT SATISFAISANTS

1. Remettez en place le couvercle recouvrant

I'orifice.

2. Remettez en place I'ecran de brQleur

(qui etale la flamme) et les vis.

3. Remettez en place le plancher du four.

4. Remettez en place la porte du four.

Dim. <{A>>

C6ne interieur de

la flamme

14

BrQleur de

grillade du four

Page 31

Instructions d'installation

[] PRI PARATION POUR UNE

AUTRE CONSTRUCTION

[] TROUSSE DE REMPLISSAGE DU

HAUT OU TROUSSE D'APPUI EN

OPTION

Si I'ouverture s'6tend jusqu'au mur, elle

necessitera la trousse de remplissage du haut

(fournie avec la cuisiniere) ou la trousse de

dosseret (JXS36XX ou JXS39SS) pour

remplir la fente.

NOTE : Si le comptoir est plus grand que

63,5 cm (25"), il y aura une fente entre le

dosseret et lemur ou entre la trousse de

remplissage et lemur.

Si le comptoir est inferieur a 63,5 cm (25"),

il y aura une fente entre le devant du

comptoir et le extremites du panneau de

contr61e (voir I'etape 13G).

Si vous utilisez la trousse de dosseret

en option, consultez les instructions de la

trousse de dosseret pour obtenir les details

de I'installation.

Mur

63,5 cm (25")

Doit 6tre

horizontal

Quand la garniture est posee dans la bonne

position, serrez les 2 vis de montage. Le haut

de la garniture doit se trouver au-dessous de

la surface du haut du verre pour emp6cher

les casseroles, les poelles et les ustensiles de

cuisine d'endommager les pieces peintes.

Consultez I'installation normale de la

cuisiniere page 6.

_ Table de

7 ¸

"_ I_ Cuisiniere

I _Remplissage

[ du haut

["_ _ (2) #8 Vis

[] POUR UNE INSTALLATION NON

ENCASTREE (EMPLACEMENT EN

EXTREMITE DE L'ARMOIRE)

Quand vous installez la cuisiniere

I'extremite d'une section d'armoire qui

expose le cSte non fini de la cuisiniere,

utilisez la trousse de c6te de cuisiniere

(JXS76XX). Consultez les instructions de la

trousse pour les d6tails de I'installation.

Doit _ _ 76,2 cm (30") _ _ Doit 6tre

6tre I Coupe douce _ plat

plat I_ Doit 6tre horizontal

79,1 cm (31-1/8")

Si vous utilisez la trousse de remplissage,

placez la piece de remplissage en metal

fournie avec la cuisiniere dans I'arriere de

la cuisiniere comme le montre la figure ci-

dessus. Engagez les 2 vis dans les trous du

haut a I'exterieur arriere de la cuisiniere au

dessus des aerateurs a lames et par les

fentes de la garniture, en tenant la piece de

remplissage centree sur le chassis du haut et

en poussant vers I'avant pour reduire I'ecart

entre le bas du verre et la garniture de

remplissage.

[] INSTALLATION EN JLOT

Fixez le support anti-basculement selon les

instructions de I'etape 12, en vous assurant

que I'arriere du support est a 63,5 cm (25")

de I'avant du comptoir.

Soyez conscient que les vis fournies sont

Iongues et peuvent transpercer les armoires

de Hlot. Dans ce cas, utilisez des vis plus

courtes (pas fournies) ou les vis fournies

pour 6tre utilisees dans le plancher (consultez

I'etape 12B pour I'installation sur un plancher

en bois/ciment).

N'utilisez pas la trousse de dosseret

JXS36XX ou JXS39SS.

15

Page 32

Instructions d'installation

INSTALLATION DE LA CUISINII RE (SUITE)

[] PRI_PARATIONS POUR UNE AUTRE

CONSTRUCTION (suite)

[] POUR LES OUVERTURES D'ARMOIRE

D'ENVIRON 77,2 CM (30-3/8")

Si la cuisiniere est installee dans une ouverture

d'armoire d'environ 77,2 cm (30-3/8"), vous devez

utiliser la trousse de garniture verticale de c6te

(JXS86XX) pour couvrir les fentes entre les c6tes

de la cuisiniere et I'armoire. Consultez les

instructions de la trousse pour les details

de I'installation.

[] ARMOIRES SUR LA CUlSINIERE A MOINS

DE 76,2 CM (30")

Si vous ne pouvez pas assurer un espace libre

de 76,2 cm (30") entre la surface de cuisson et un

materiau combustible place au-dessus ou des

armoires de metal, protegez le bas des armoires

situees au-dessus de la table de cuisson par au

moins un carton isolant d'au moins 6 mm (1/4")

couvert de tole epaisse au moins .3098 mm

(0,0122").

[] LISTE DE

VITRIFICATION

DE FONCTIONNEMENT

• Verifiez deux fois pour vous assurer de bien

avoir tout termine, dans ce guide. Les etapes

de re-verification assureront une utilisation

securitaire de la table de cuisson.

• Assurez-vous que tous les boutons de contr61e

se trouvent en position OFF (arr_t).

• Assurez-vous que la circulation de la combustion

et de I'air de ventilation de la table de cuisson ne

soit pas g_nee.

• La plaque mineralogique de votre cuisiniere est

situee sous la porte du four au-dessus de I'aire

de rangement. Elle vous indique les valeurs des

brQleurs et la categorie de carburant et la

pression a laquelle la table de cuisson a ete

ajustee au depart de la fabrique.

• Quand vous commandez des pieces, indiquez

toujours le numero de serieet le numero de

modele pour assurer de bonnes pieces de

rechange.

• I_tapes de double verification : Verifiez une

deuxieme fois pour vous assurer d'avoir bien

suivi toutes les instructions de ce guide. Cette

deuxieme verification assurera une utilisation

de la cuisiniere en toute securit&

Veuillez consulter les instructions de

conversion au gaz de petrole liquefie fournies

avec cette cuisiniere quand vous utilisez du

gaz de petrole liquefi&

NOTE : Les instructions sont fixees au support

de regulateur.

DANS CERTAINS CAS

[] Avec du gaz de petrole liquefie, il est normal

d'avoir un peu de couleur jaune sur le cone

exterieur.

[] Des particules etrangeres dans le conduit de

gaz peuvent occasionner une flamme orange

au debut, mais cette couleur doit vite

disparaTtre.

NOTE SPI_CIALE :

Pour reconvertir le four au gaz naturel, renversez

les instructions donnees pour faire les

ajustements au gaz de petrole liquefi&

Quand la conversion est terminee et

verifiee, remplissez I'etiquette de gaz

de petrole liquefie et inscrivez votre

nom, votre organisation et la date

laquelle vous avez fait la conversion.

Posez I'etiquette pres du regulateur pour avertir

les autres dans I'avenir que cet appareil a ete

converti au gaz de petrole liquefi& Si vous

convertissez a nouveau cet appareil du gaz de

petrole liquefie au gaz naturel, veuillez enlever

I'etiquette de maniere a avertir les autres que cet

appareil est regle pour utiliser du gaz naturel.

AJUSTEMENTDESBRULEURSDELATABLE

DECUlSSONAUXFLAMMESFAIBLES

Vous devez ajuster les flammes faibles avec deux

autres breleurs en fonctionnement a reglage

moyen. Cette procedure emp6che la flamme faible

d'6tre reglee trop basse, et de risquer de s'eteindre

quand les autres breleurs sont mis en marche.

[] Enlevez les boutons de contr61e du robinet.

[] Par I'ouverture, trouvez la vis de derivation

du robinet stue en bas et a droite des

robinets.

[] _, I'aide d'un petit tournevis, vissez

completement la vis de derivation dans le

sens des aiguilles d'une montre.

16 Imprim6 aux I_tats-Unis

Loading...

Loading...