Page 1

Installation

30s Sealed Gas Cooktop

JGP329, JGP333, JGP940, PGP943

Instructions

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: GEAppliances.com

In Canada, call 1.800.561.3344 or Visit our Website at: www.geappliances.ca

IN THE COMMONWEALTH OF

MASSACHUSETTS:

• This product must be installed by a licensed

plumber or gas fitter.

• When using ball-type gas shut-off valves, they

shall be the T-handle type.

• A flexible gas connector, when used, must not

exceed 3 feet.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT ³ Save these instructions

for local inspector’s use.

•

IMPORTANT ³ Observe all governing

codes and ordinances.

•

Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions for

future reference.

• Product failure due to improper installation is not

covered under the Warranty.

WARNING

properly grounded.

This appliance must be

FOR YOUR SAFETY:

WARNING

instructions is not followed exactly, a fire, explosion

or gas leak may result causing property damage,

personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance!

Do not install this product with an air curtain hood

or other range hood that operates by blowing air

down on the cooktop. This airflow may interfere

with operation of the gas burners resulting in fire or

explosion hazard.

If the information in these

WHAT TO DO IF YOU SMELL

GAS:

• Do not try to light any appliance. Do not touch

any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

•

IMPORTANT ³Leak testing of the

appliance shall be conducted according to the

manufacturer’s instructions.

• Proper installation is the responsibility of the

installer and product failure due to improper

installation is NOT covered under warranty.

WARNING

at the main circuit breaker or fuse box before

installing.

31-10860-3 (05-17 GEA)

Disconnect all electrical power

This cooktop has been design certified by CSA

International. You’ll find safety precautions in your

Owner’s Manual. Read them carefully.

• Installation of this cooktop must conform with

local codes or in the absence of local codes with

the National Fuel Ga s Code, ANSI Z223.1/NFPA

54–Latest edition, or in Canada, the National Gas and

Propane installation Code, CSA B149.1-Latest edition.

• Be sure your cooktop is installed properly by a

qualified installer or service technician.

• To eliminate reaching over surface burners,

cabinet storage above burner should be avoided.

• Do not install the unit near an outside door or

where a draft may affect its use.

1

Page 2

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

ELECTRICAL REQUIREMENTS

This appliance must be supplied with the proper

voltage and frequency and connected to an

individual, properly grounded branch circuit,

protected by a circuit breaker or fuse having

amperage as noted on the rating plate.

We recommend you have the electrical wiring and

hookup of your cooktop connected by a qualified

electrician. After installation, have the electrician

show you where your main cooktop disconnect is

located.

Check with your local utilities for electrical codes

which apply in your area. Failure to wire your

cooktop according to governing codes could result

in a hazardous condition.

If there are no codes, your cooktop must be wired

and fused to meet the requirements of the National

(OHFWULFDO&RGH$16,1)3$1R³/DWHVWHGLWLRQ

You can get a copy by writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

PARTS INCLUDED

2 Screws

Foam Tape

MATERIALS YOU MAY NEED

Joint Sealant

CSA-Approved Flexible Gas Line

3/8s Min. ID, 1/2s NPT Connection,

3-foot Maximum Length (Massachusetts Only)

Pipe Fittings

2 Hold

Down Brackets

Shut-Off Valve

In Canada your cooktop must be wired and fused

to meet the requirements of the Canadian Electrical

Code, CSA C22.1-02.

Be sure the installation of this product in a mobile

home conforms with the Manufactured Home

Construction and Safety Standard, Title 24 CFR,

Part 3280. If this standard does not apply, you

must follow the standard for Manufactured Home

Installations, ANSI A225.1 and Manufactured Home

Installations, Sites and Communities and ANSI/

NFPA 501A or with local codes.

You can get a copy of the Federal Standard by

Writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

TOOLS YOU WILL NEED

FOR INSTALLATION

Pencil

Saber Saw

Phillips-Head

Screwdriver

Pipe Wrench

Ruler or Straightedge

1/8s Drill Bit & Electric or

Hand Drill

Safety Glasses

2

Page 3

Installation Instructions

PRE-INSTALLATION CHECKLIST

When preparing cooktop opening, make

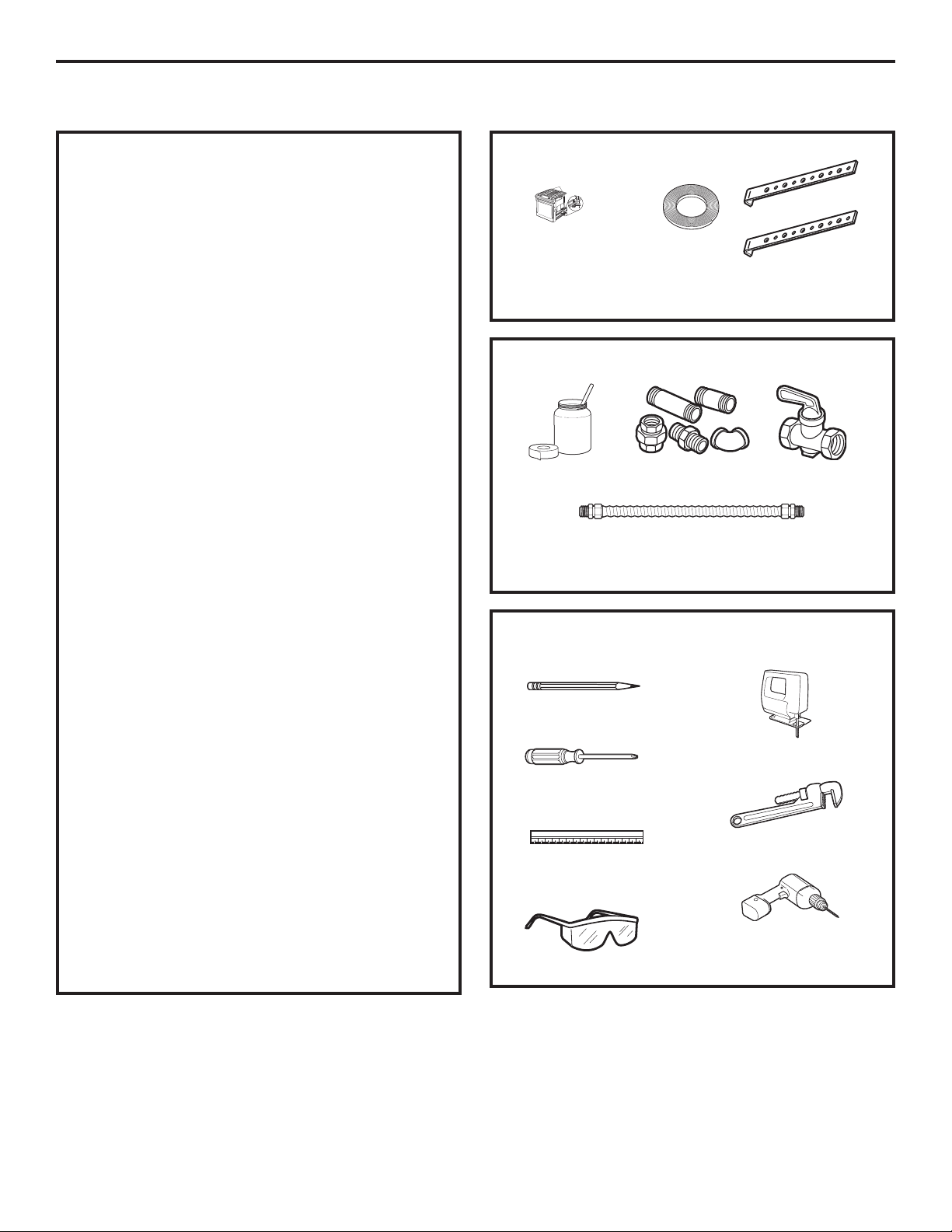

A

sure the inside of the cabinet and the

cooktop do not interfere with each other.

(See section on preparing the opening.)

Remove packaging materials, grate boxes,

B

regulator with literature, and literature

package from the cooktop before beginning

installation.

Literature Package

Foam

Packaging

Cooktop

Grate boxes

Remove Installation Instructions from

C

literature pack and read them carefully

before you begin.

Be sure to place all literature, Use and Care,

Installations, etc. in a safe place for future

reference.

Make sure you have all the tools and

D

materials you need before starting the

installation of the cooktop.

Your home must provide the adequate

E

electrical service needed to safely and

properly use your cooktop. (Refer to section

on electrical requirements.)

When installing your cooktop in your home,

F

make sure all local codes and ordinances

are followed exactly as stated.

Make sure the wall coverings, countertop

G

and cabinets around the cooktop can

withstand heat (up to 200°F) generated by

the cooktop.

3

Page 4

Installation Instructions

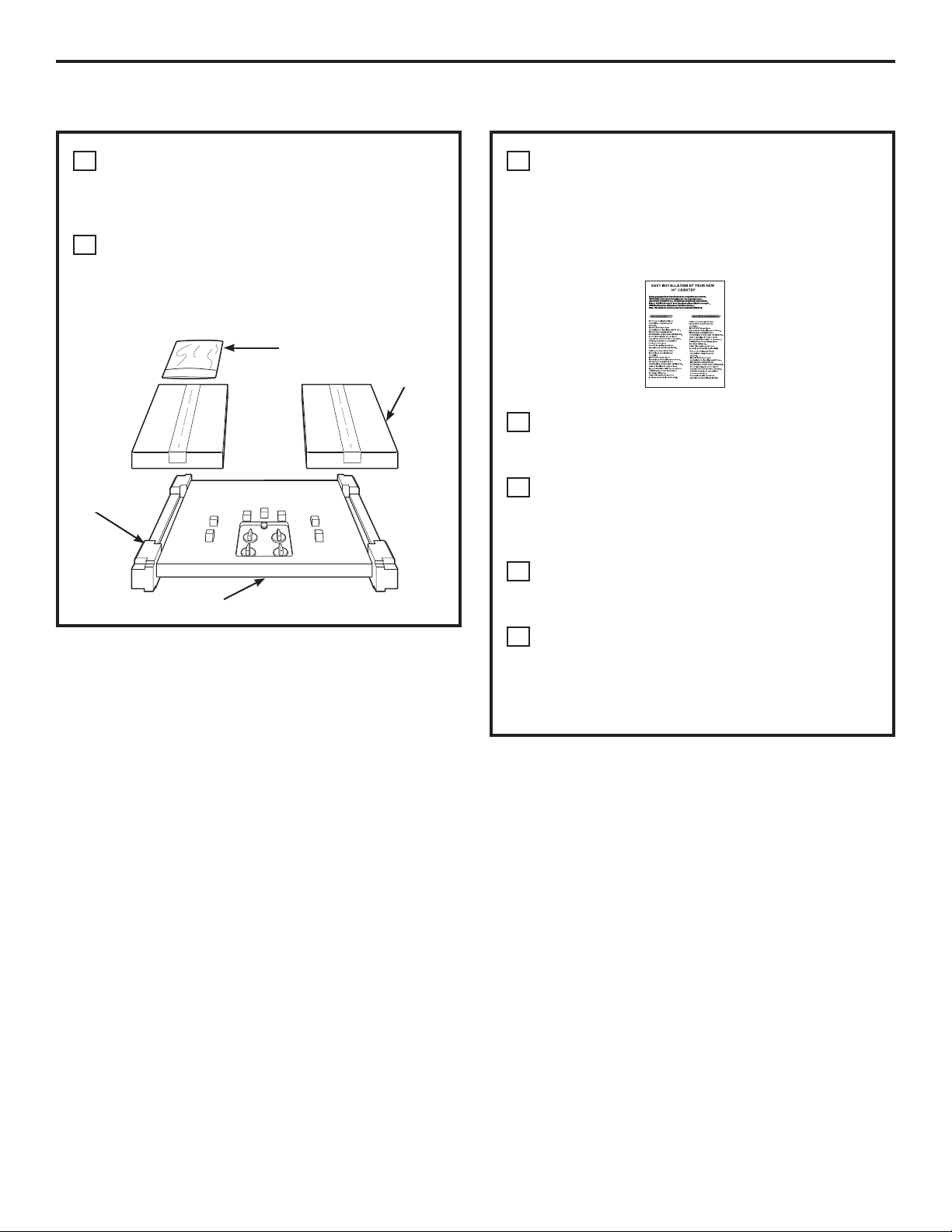

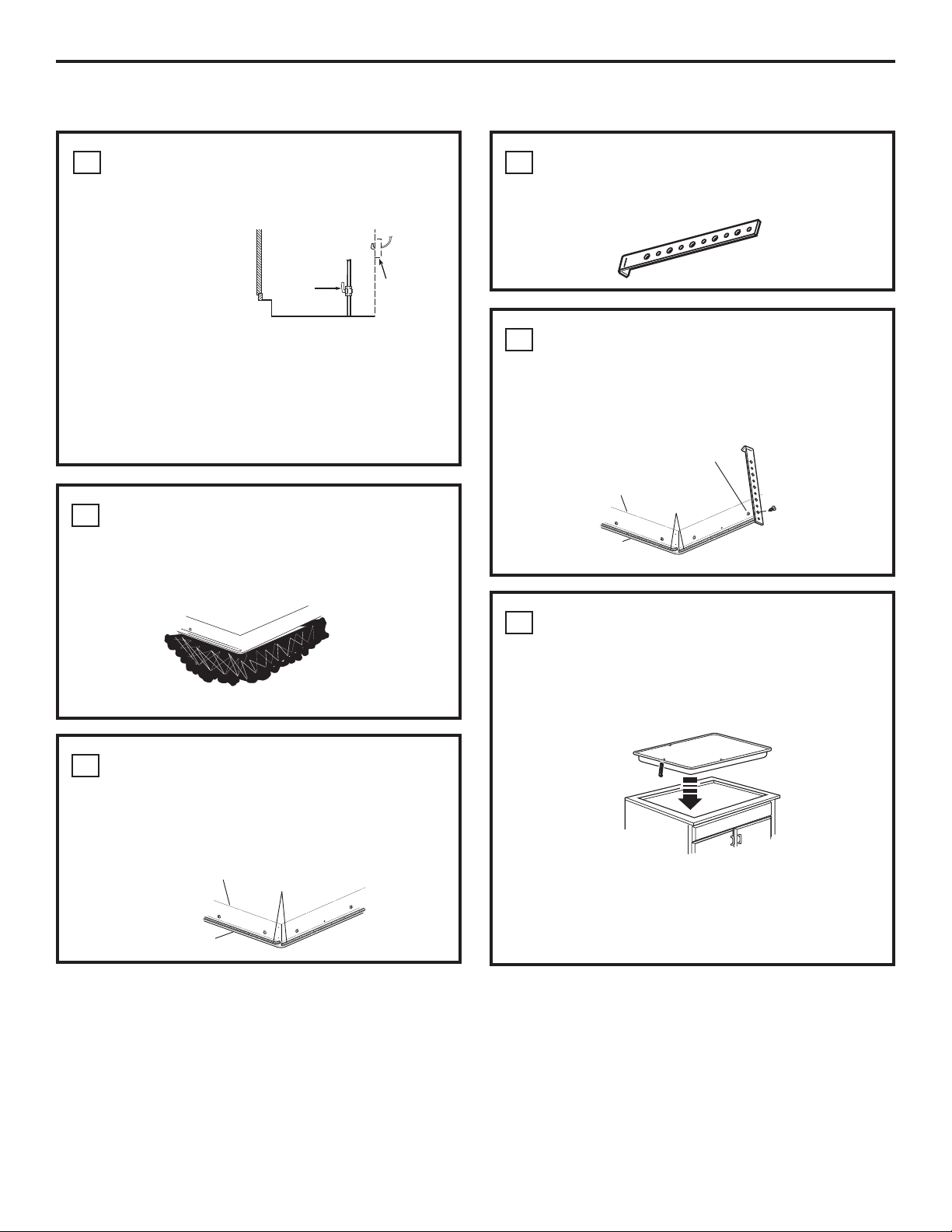

PREPARING THE OPENING

MAINTAIN THE FOLLOWING

1

MINIMUM CLEARANCE

DIMENSIONS

13s MAX. Depth of unprotected

overhead cabinets

30s MIN. clearance from countertop

to unprotected overhead surface

3-3/4s MIN. clearance from

cutout to side wall on the

left of the unit

NOTE: Allow 7/16”

minimum vertical

clearance from the

cooktop bottom (or 3-5/8”

minimum depth from

the countertop) to any

combustible surfaces,

such as a cabinet drawer.

For island installation, maintain 2-1/2 in. minimum

from cutout to front and back edge of countertop.

Maintain 3 in. minimum from cutout to side edges of

countertop.

6s MIN. clearance from

3 3/4 MIN.

cutout to side wall on the

right of the unit

18s MIN. height

from countertop to

nearest cabinet on

either side of unit

3-5/8s

7/16s

DRAWER

RECOMMENDED GAS SUPPLY

4

LOCATION FROM BACKWALL

1” Min. From Backwall

Recommended

gas supply

location

MAKE SURE WALL COVERINGS,

5

13-1/4s

From Cutout

Center Line

COUNTERTOP AND CABINETS

AROUND COOKTOP CAN

WITHSTAND HEAT (UP TO 200°F)

GENERATED BY COOKTOP

Wall covering,

cabinets and

countertop must

withstand heat

up to 200°F

OVERALL COOKTOP DIMENSIONS

2

21s(21-1/2s Max. for

30s

Cooktop

19-3/8s

CUTOUT DIMENSIONS OF

3

Glass Top models)

3-3/16s

28-1/4s

COUNTERTOP

To ensure accuracy, it is best to make a

template when cutting the opening in the

counter.

28-1/2”

length

of cut

2-1/4” Min. Between

cutout and the wall

behind the cooktop

2-1/2” Min. from front

edge of cutout and front

edge of countertop

19-5/8” width cut

14-1/4s

FOR AMERICANS WITH DISABILITIES

6

ACT (ADA) FORWARD APPROACH

INSTALLATION ONLY:

5”

Allow 5” minimum

depth between the

countertop and an

enclosure.

NOTE: The enclosure must be made of wood

material. Also, an access panel is required for the

electrical outlet , pressure regulator, shut-off valve,

hold-down brackets, and service.

4

Page 5

Installation Instructions

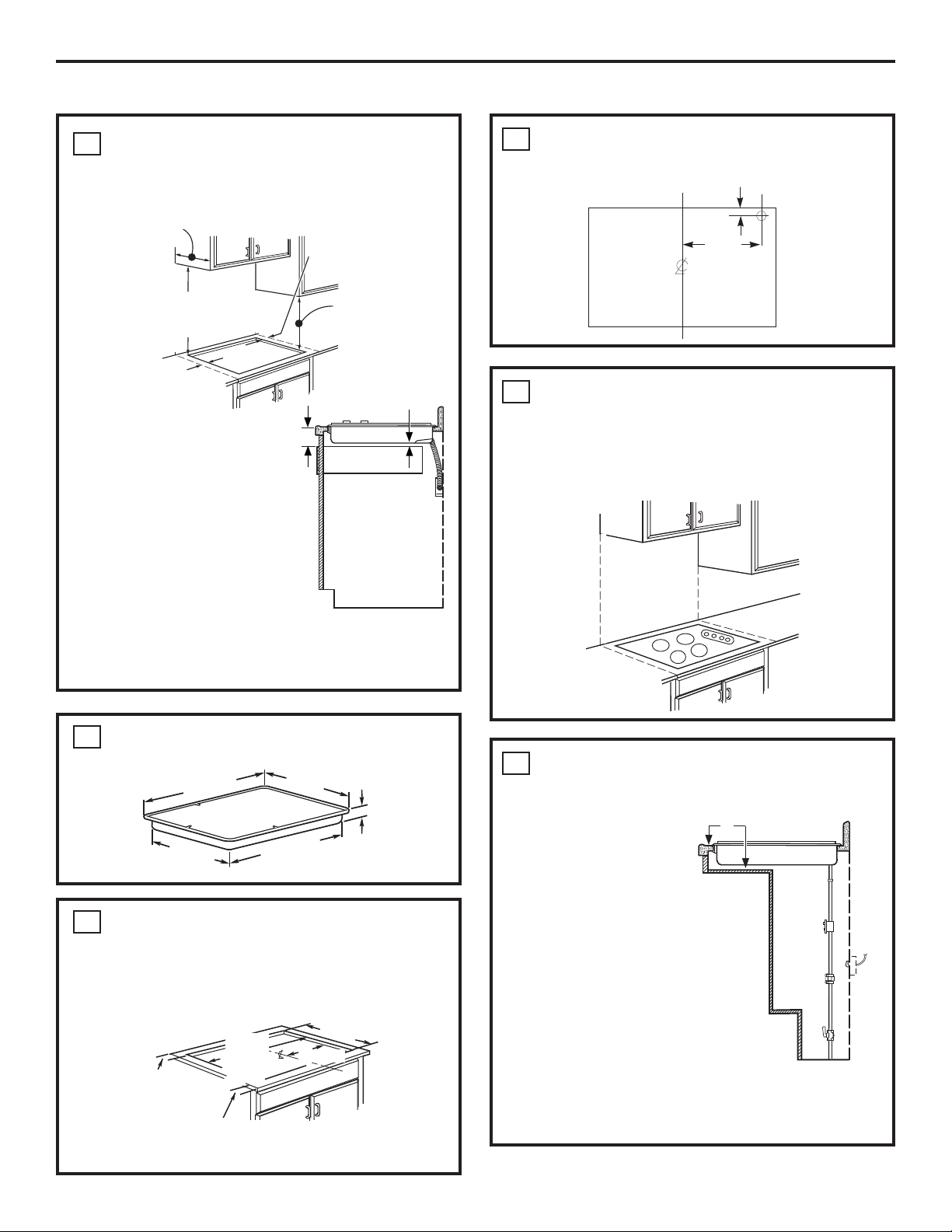

INSTALLING THE COOKTOP UNIT

LOCATE ELECTRICAL OUTLET AND

1

GAS SHUT-OFF VALVE BENEATH

CABINET

NEVER REUSE OLD

CONNECTORS WHEN

INSTALLING THIS

UNIT.

Install a manual shut-off valve in the gas line in an

easily accessible location outside the cooktop. Be

sure you know how and where to shut off the gas

supply to the cooktop. Install the electrical outlet

12s below the countertop.

PROTECT SURFACE OF COOKTOP

2

Place a towel or tablecloth onto the countertop.

Lay the cooktop upside down onto the protected

surface.

Bottom of cooktop

Cloth under Cooktop

Shut Off

Valve

Electrical

Outlet 12s

Below

Countertop

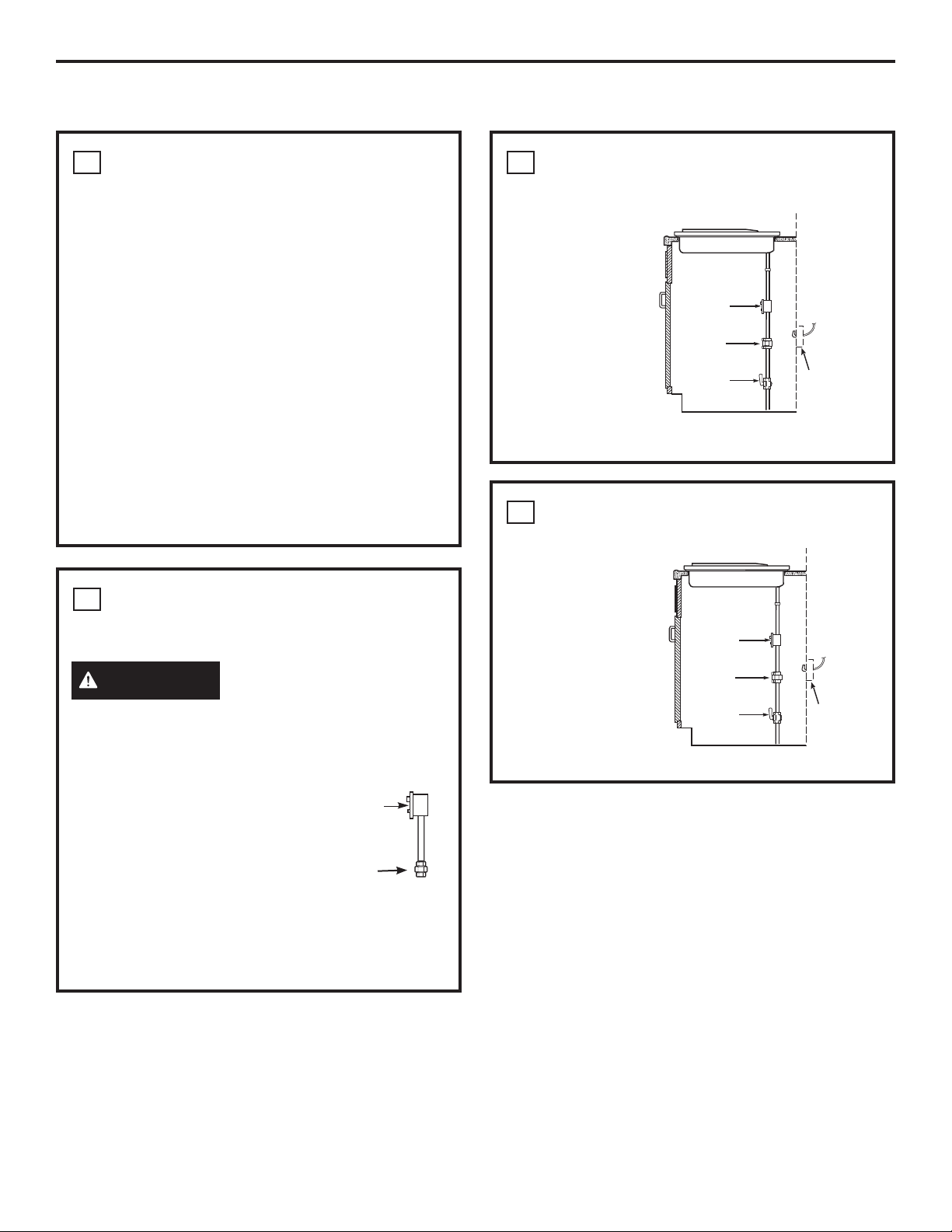

LOCATE MOUNTING PARTS

4

Remove the hold-down brackets from the literature

package.

ATTACH BRACKETS TO COOKTOP

5

Remove the screw from the side of the cooktop

and screw the hold-down bracket to the side of the

cooktop unit. Repeat for opposite side of cooktop.

Pre-drilled

Bottom of

Cooktop

Cooktop

Glass

INSERT COOKTOP INTO CUTOUT

6

Insert the cooktop centered into the cutout opening.

Make sure the front edge of the countertop is

parallel to the cooktop. Make final check that all

required clearances are met.

hole

Foam Tapes

ATTACH FOAM TAPE

3

(glass maintop models only)

Apply the foam tape around the outer edge

of the glass. Do not overlap the foam strips.

Bottom of Cooktop

Cooktop Glass

Foam Tapes

Cooktop

Once the unit is in place, screw the hold-down

bracket into the cabinet sides to secure the unit

into place.

5

Page 6

Installation Instructions

,167$//$7,21³*$6&211(&7,216

PROVIDE ADEQUATE GAS SUPPLY

1

This cooktop is designed to operate on natural

gas at 4s of water column manifold pressure and

7s of water column (W.C.) supply pressure. It is

shipped from the factory set for natural gas. The

convertible pressure regulator supplied with the

unit must be connected in series with the manifold

of the cooktop and must remain in series with the

supply line regardless of whether natural or L.P.

gas is being used. FOR PROPER OPERATION, THE

MAXIMUM INLET PRESSURE TO THE REGULATOR

MUST BE NO MORE THAN 14s OF WATER COLUMN

PRESSURE. For checking the regulator, the inlet

pressure must be at least 1s W.C.. (or 3.4 KPA)

greater than the regulator output setting. If

the regulator is set for 4s W.C. of water column

pressure, the inlet pressure must be at least 5sW.C.

If the regulator is set for 10sW.C., the inlet pressure

must be at least 11sW.C.. The gas supply line to

the cooktop should be 1/2s or 3/4s pipe.

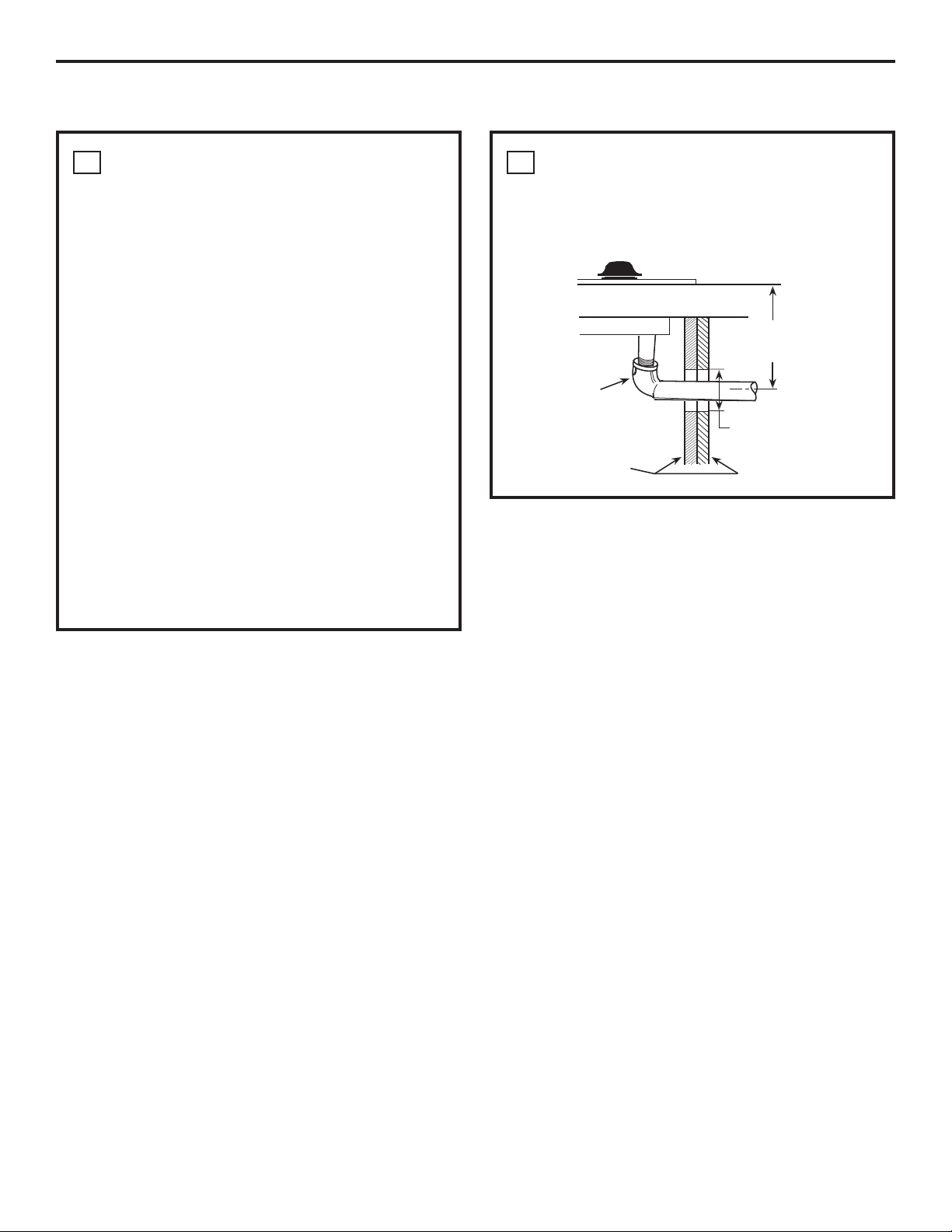

INSTALL REGULATOR

2

NEVER REUSE OLD CONNECTORS WHEN

INSTALLING THIS COOKTOP.

INSTALL REGULATOR ONTO

3

BURNER BOX BOTTOM

Screw the regulator

onto the burner

box bottom pipe

connection. Make

sure the top of

the regulator is

Pressure

Regulator

facing towards the

cabinet front, easily

accessible through

the cabinet doors.

COMPLETE CONNECTION WITH A

4

Coupling

Shut-Off

Valve

COUPLING

Complete the

connection between

the regulator, pipe

coupling, and

the shut-off valve.

Pressure

Regulator

Electrical

Outlet 12s

Below

Countertop

WARNING

Never reuse old flexible

connectors. The use of old flexible connectors

can cause gas leaks and personal injury. Always

use new flexible connectors when installing a gas

appliance.

Pressure

Screw a section of pipe onto

Regulator

the inlet end of the pressure

regulator and install the

coupling.

Coupling

To reduce the likelihood of gas leaks, apply teflon

tape or a thread compound approved for use

with Propane (LP) or Natural gases to all threaded

connections.

Coupling

Shut-Off

Valve

Electrical

Outlet 12s

Below

Countertop

6

Page 7

Installation Instructions

CHECK FOR LEAKS

5

Before testing for leaks, make sure all burner knobs

are in the OFF position.

After connecting the cooktop to gas, check system

for leaks with a manometer. If a manometer is not

available, turn the gas supply on to the cooktop

and use a liquid leak detector at all joints and

connections to check for leaks.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

DO NOT USE OPEN FLAME TO CHECK FOR

LEAKS!

Disconnect the cooktop and its individual shut-off

valve from the gas supply piping system during any

pressure testing of that system at test pressures

greater than 1/2 psig (3.5 kPa).

Isolate the cooktop from the gas supply piping

system by closing its individual shut-off valve

during any pressure testing of the gas supply

system at test pressures equal to or less than 1/2

psig (3.5 kPa).

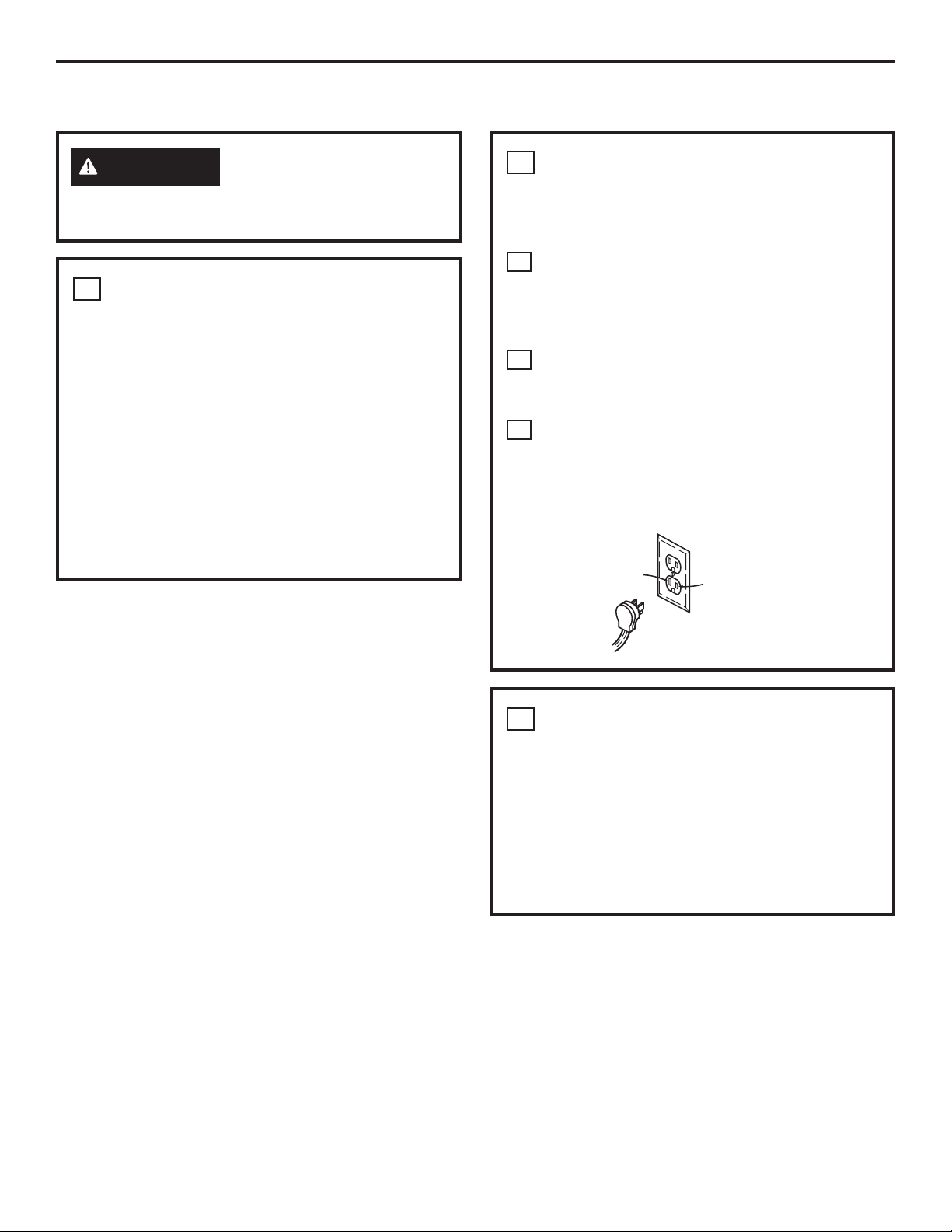

INSTALLATION OVER BUILT-IN

6

OVEN

See built-in oven installation for complete

installation instructions.

5s To Center of

2s Dia. Hole From

Countertop

90° Elbow

2s Dia. Hole

(20 7/8s from front

of Countertop to

Cabinet Sides

Hole Center)

7

Page 8

Installation Instructions

,167$//$7,21³(/(&75,&$/&211(&7,216

ELECTRICAL SUPPLY AND OUTLET

2

WARNING

at the main circuit breaker or fuse box before

installing.

EXTENSION CORDS

1

Because of potential safety hazards under certain

conditions, we strongly recommend against the

use of an extension cord. However, if you still

elect to use an extension cord, it is absolutely

necessary that it be a UL listed 3-wire grounding

type appliance extension cord and that the

current carrying rating of the cord in amperes be

equivalent to or greater than the branch circuit

rating. Such extension cords are obtainable

through your local appliance dealer.

Disconnect all electrical power

IMPORTANT: (Please read carefully) FOR

PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

An adequate electrical supply and outlet must

be used to operate the electrical parts of your

cooktop.

The power cord of this appliance is equipped

A

with a 3-prong (grounding) plug which must

be used with a properly grounded 3-hole

outlet with a standard 120 Volt, 60 cycle AC

household current.

B

If you do not have a 3-hole grounded outlet,

have a qualified electrician change your old

one.

A grounding adaptor will be needed to convert

C

the old one until the outlet can be replaced.

This method is only temporary, and a qualified

electrician should test it to be sure it meets

requirements.

N

Insure proper

ground and

L

firm connection

before use

TWO-PRONG WALL RECEPTACLE

3

Where a standard 2-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with

a properly grounded 3-prong wall receptacle.

Do not under any circumstances cut or remove

grounding prong from the cooktop cord. Failure

to provide proper polarization may create a

hazardous condition.

8

Page 9

Installation Instructions

USAGE SITUATIONS WHERE

4

APPLIANCE POWER CORD

WILL BE DISCONNECTED

INFREQUENTLY

For 15 amp circuit only. Do not use an adaptor

on a 20 amp circuit. Where local codes permit, a

TEMPORARY CONNECTION may be made to a properly

grounded 2-prong wall receptacle by the use of a

UL-listed adaptor available at most hardware stores.

The larger slot in the adaptor must be aligned with

the large slot in the wall receptacle to provide proper

polarity in the connection of the power cord.

CAUTION

terminal to the wall receptacle cover screw does not

ground the appliance unless the screw is metal, and

not insulated, and the wall receptacle is grounded

through the house wiring. The customer should have

the circuit checked by a qualified electrician to make

sure the receptacle is properly grounded.

When disconnecting the power cord from the

adaptor, always hold the adaptor with one hand. If

this is not done, the adaptor ground terminal is very

likely to break with repeated use. Should this happen,

DO NOT USE the appliance until a proper ground has

again been established.

Attaching the adaptor ground

Ensure proper ground and firm

connection before use

Align large

prongs/slots

Temporary Method

(Adaptor plugs not permitted in Canada)

Usage situation where appliance power cord will be

disconnected frequently.

Do not use an adaptor plug in these situations

because disconnection of the power cord places

undue strain on the adaptor and leads to eventual

failure of the adaptor ground terminal. The customer

should have the 2-prong receptacle replaced with

a 3-prong (grounding) receptacle by a qualified

electrician before using the appliance.

9

Page 10

Installation Instructions

COOKTOP BURNERS

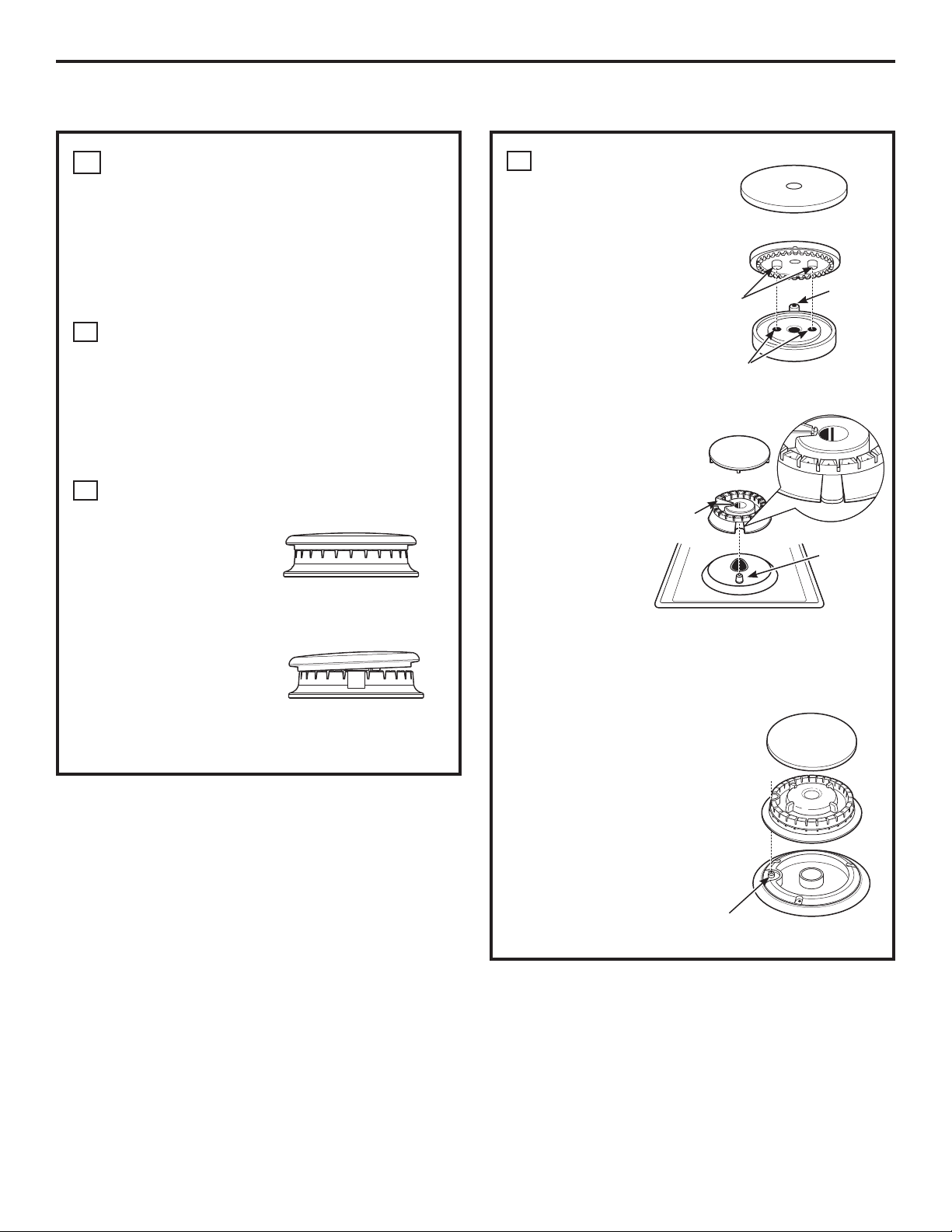

ASSEMBLING THE COOKTOP

1

BURNERS

The electrode of the spark igniter is exposed. Be

careful not to push any cooktop controls while the

top of the burner is removed.

Do not remove the top or touch the electrode

of any burner while another burner is turned on.

Electrical shock might result.

Replace the burner head onto the burner

A

base, making sure that the head is properly

oriented over the burner base and the

electrode. Make sure to place the correct

burner head on the correct burner base and

that the burner head sits level on the burner

base. The burner heads are not

interchangeable.

Place the burner

B

caps on the burner

heads, making sure

to place the correct

burner cap on the

correct burner

head. The burner

caps are not

interchangeable.

Make sure that the

burner caps are

properly seated on

the burner heads.

Burner cap properly seated

Burner cap not properly seated

Make sure the pins in

C

the burner heads

match the burner

base indentations

and that they are

properly seated in

them by rotating the

heads until they are

level.

Make sure the slot in

the burner head

is positioned

over the

electrode.

The burner cap

has three to

four pins.

When

Stability

chamber

replacing the

cap, make

sure none of

the pins sits

in the stability

chamber.

Make sure

the hole

in the burner

head assembly is

positioned over the

electrode and that

the burner head is

fully inserted inside

the burner base. A

small gap between

the base and head is

normal.

Locator

pins

Pin

indentations

Burner cap

Burner head

Burner base

Burner head

assembly

Burner cap

Burner head

Electrode

Burner

base

Electrode

Burner cap

10

Electrode

Burner

base

Page 11

Installation Instructions

CHECK IGNITERS

2

Operation of the electric igniters should be checked

after the cooktop and supply line have been

carefully checked for leaks and the cooktop has

been connected to the electrical power.

On models so equipped, check to be sure the

cooktop is in the UNLOCKED position.

Push and turn a burner valve to the LITE

A

position. All spark igniters will make a series of

sparks (ticking sounds), but only the burner

turned to LITE will light.

• The burner should light when gas is

available to the burner.

• Once the burner lights, it should be turned

out of the LITE position.

Try each valve separately until all burners

B

have been checked.

BURNER IGNITION

3

&RRNWRS6SDUN,JQLWLRQ³:KHQ\RXWXUQWKH

cooktop knob to LITE, the spark igniter makes a

series of electric sparks (ticking sounds) which light

the burner. During a power failure, the burners will

not light automatically. In an emergency, a cooktop

burner may be lit with a match by following the

steps below.

WARNING

match is dangerous. You should match light the

cooktop burners only in an emergency.

Lighting gas burners with a

THE BURNER FLAMES

4

Turn each burner on. Flames should be blue in color

with no trace of yellow. The burner flames should

not flutter or blow away from the burner. The flame

should be no less than 1/4s on the lowest setting

and no greater than 1-1/2s on highest setting.

WARNING

flame, please use caution. Burns could result.

1/4s to

1-1/2s

Burners should be checked frequently

BURNER GRATES

5

The cooktop grates are designed for specific

positions. For maximum stability, these grates

should only be used in their proper position: they

should not be interchanged. For your convenience,

the undersides of the left and right grates are

marked “OUTSIDE” and “INSIDE”. Make sure that the

side marked “OUTSIDE” is on the outer edge of your

cooktop.

If you attempt to measure the

Cooktop Burner

On models so equipped, check to be sure the

cooktop is in the UNLOCKED position.

Light a match and hold the flame near the

A

burner you want to light. Wooden matches

work best.

Push in and turn the control knob slowly. Be

B

sure you are turning the correct knob for the

burner you are lighting.

NOTE: If the burner does not light within five seconds,

turn the knob off and wait one minute before trying

again.

11

“OUTSIDE”

edge

“INSIDE”

edges

“OUTSIDE”

edge

Page 12

Installation Instructions

OPERATION CHECKLIST

Make sure all controls are left in the OFF

A

position. Check to be sure the cooktop is in the

UNLOCKED position (on models so equipped).

Make sure the flow of air to and from the

B

cooktop is unobstructed.

The serial plate for your cooktop is located on

C

the bottom of the burner box. In addition to the

model and serial numbers, it tells you the ratings

of the burners and the type of fuel and pressure

the cooktop was adjusted for when it left the

factory.

When ordering parts, always include the serial

D

number, model number and a code letter to

ensure proper replacement parts.

Recheck Steps:

E

Double check to make sure everything in this

guide has been completed. Rechecking steps

will ensure safe use of the cooktop.

12

Page 13

Installation Instructions

MAKING THE PROPANE (LP) CONVERSION

IF SOLD OUTSIDE THE U.S. AND CANADA:

WARNING

with Liquefied Petroleum (LP) gas containing greater

than 10% butane, you must purchase a butane

conversion kit. To order, please call 1.888.664.8403 or

1.787.276.4051.

JGP333 &

1

SAFETY INFORMATION YOU SHOULD KNOW

The pressure regulator and burner orifices are set for

natural gas. To use Propane (LP) gas, the regulator

and burner orifices must be converted. The Propane

(LP) orifice spuds for the cooktop burners are attached

to the regulator along with separate Propane (LP)

conversion instructions.

If you wish to use this product

Model Butane Kit #

JGP940 WB28T10228

PGP943

JGP329 WB28T10234

WB28T10283

TOOLS YOU WILL NEED

FOR PROPANE (LP) CONVERSION

Phillips-Head

Screwdriver

Pliers

Safety Glasses

CAUTION

factory, is set for use with natural gas. If you wish to

use your cooktop with Propane (LP) gas, you must first

replace the orifices and convert the pressure regulator.

The cooktop, as shipped from the

7mm Nutdriver

No. 15 Torx-Head

Driver

Small Flat-Head

Screwdriver (4mm or

5/32s tip size, 60mm or

2-3/8” long)

WARNING

be installed by a qualified service agency in

accordance with the manufacturer’s instructions

and all applicable codes and requirements of the

authority having jurisdiction. If the information

in these instructions is not followed exactly, a

fire, explosion or production of carbon monoxide

may result causing property damage, personal

injury or loss of life. The qualified service agency

is responsible for the proper installation of this kit.

The installation is not proper and complete until

the operation of the converted appliance is checked

as specified in the manufacturer’s instructions

supplied with the kit.

This conversion kit shall

CAUTION

be made before turning on the burner. Failure to do

so could result in serious injury. Be sure pressure

regulator has been converted as described in Step 2.

CAUTION

conversion, shut off the gas supply to the appliance

prior to disconnecting the electrical power.

The following adjustments must

Before proceeding with the

13

Page 14

Installation Instructions

MAKING THE PROPANE (LP) CONVERSION (CONT.)

ADJUST YOUR COOKTOP FOR USE

2

WITH PROPANE (LP) GAS

Disconnect all electrical power, at the main

A

circuit breaker or fuse box.

Shut off the gas supply to the cooktop

B

by closing the manual shut-off valve.

Adjust the pressure regulator, by the following

C

instructions:

• Unscrew the cap.

• Carefully look at the spring retainer to locate

the NAT or Propane (LP) position.

Gasket

NAT

LP

NAT

Spring

Retainer

LP

L.P./Propane

Position

NAT

LP

NAT

NAT.

Position

LP

Cap

CHANGE COOKTOP BURNER

3

ORIFICES (CONT.)

Remove the spark

B

igniters from the burner

base (if required to

access the orifices).

Using a No. 15 “Torx”

head driver bit, remove

the screws holding the

burner base in position.

Using a 7mm nut driver,

C

remove the top burner

orifices. These may be

accessed through the

hole in the cooktop.

Spark igniter

Burner

base

Burner cap

Burner

head

Burner

base

18,000 BTU Burner

(on some models)

Burner

cap

Burner

head

Pressure Regulator

• Turn the spring retainer over by rotating it

90 deg., pull it from the cap, turn the spring

retainer over so that LP is showing, insert it

back into the cap, and then rotate it 90 deg.

into position.

• Screw the cap back onto the regulator and

tighten.

CHANGE COOKTOP BURNER

3

ORIFICES

Remove the top grates,

A

burner caps, and burner

heads.

Remove This

Assembly

On most burners,

the orifices have a

spring-loaded retaining

ring around the hex

head to hold the orifice

in the nut driver during

installation and removal.

A slight amount of force

is required to push the nut

driver down over the ring.

NOTE: For orifices that

do not have a springloaded retaining ring, use

pliers to hold the orifice

in position during initial

thread engagement or final

removal to avoid dropping

the orifice in the cooktop.

Then use the nut driver to

tighten or loosen.

Spark igniter

Retainer

Ring

Orifice Spud Located

Through This Opening

14

Page 15

Installation Instructions

CHANGE COOKTOP BURNER

3

ORIFICES (CONT.)

Locate the Propane (LP) orifices attached to

D

the regulator along with separate Propane

(LP) conversion instructions. They will have a

digit for size, and a letter for type of gas, on

the top or side. (Important: Save the orifices

removed from the appliance for future use.)

Each orifice will show a series of engraved

marks, (I, II, III, X or none), located on the top.

These marks denote the precise location of each

orifice to the cooktop burner.

I II III

15,000 BTU/HR Burner

The 15,000 BTU/HR burner has two orifices with

markings located in the sides only. (See rating

plate on bottom of appliance).

(on some models)

X

JGP329

86 L

86 L

JGP333 & PGP943

92 L

86 L

JGP940

63 L

92 L

63 L

See

Below

Main: 99 HXL

Simmer: 34 SL

NOTE: The main orifice is located low in the center

of the burner while the simmer orifice is located

higher behind the center of the burner.

Simmer

orifice

Main orifice

84 L

91 L

Install the Propane (LP) orifices in their precise

E

74 L

104L

X

locations as noted in the illustrations above.

Return the natural gas orifices to the bracket

F

and reattach the bracket and the instruction

sheet to the pressure regulator using the

screw removed previously.

Replace the burner bases, heads, caps and

G

top grates. (NOTE: When re-attaching the

burner bases to glass top units, tighten screws

to a maximum of 10 in.-lbs torque.)

15

Page 16

Installation Instructions

MAKING THE PROPANE (LP) CONVERSION (CONT.)

Make the adjustment by slowly turning the

ADJUST BURNER FLAMES

4

Turn all burners full on and check the flames.

A

They should be blue in color with some yellow

tipping at the ends of the flame. Foreign

particles in the gas line may cause an orange

flame at first, but this will soon disappear.

NOTE: For the 15,000 BTU/HR burner (on some

models) the cooktop burner knob should be

turned to the setting before the lowest setting.

This will ensure that the entire burner is

operating.

Turn the cooktop burner knob to the lowest

B

setting while observing the flame.

Adjust the low flame setting using the valve bypass

screw as follows:

Low-setting adjustments must be made with two

other burners in operation on a medium setting.

This prevents the low flame from being set too low,

resulting in the flame being extinguished when

other burners are turned on.

To adjust the flame, remove the knobs. Insert

C

a screwdriver through the access hole in valve

switch. Engage

adjustment screw in

valve. Refer to the

illustration below that

matches the adjustment

screw location for your

model.

• If the flames were too

small or fluttered, open

the valve more than

the original setting.

• If the flames blew

away from the burner,

close the valve more

than the original

setting.

15K burner

only

D

screw until flame appearance is correct.

Note: Some models may contain a silicone shield

which covers the valve switch and access hole. A

flashlight may be required to locate the access hole. To

access the valve adjusting screw, push the screwdriver

through this shield. After adjustment, reseat the

shield around the switch hub with your fingers, after

withdrawing the screwdriver.

Reseat silicone shield

CORRECT INCORRECT

Testing Flame Stability:

E

Test 1 – Turn the knob from “HI” to the lowest

setting quickly. If the flame goes out

at the lowest setting, increase the

flame size and test again.

Test 2 – With the burner on the lowest setting,

open and close the cabinet door

under the cooktop. If the flame is

extinguished by the air currents

created by the door movement,

increase the flame height and test

again.

Flame Recheck:

F

After the adjustment is made, turn all burners off.

Ignite each burner individually. Observe the flame

at the “HI” position. Rotate the valve to the lowest

setting and be sure that the flame size decreases

as the valve is rotated counterclockwise.

TO CONVERT THE COOKTOP BACK TO NATURAL

GAS, REVERSE THE STEPS UNDER MAKING THE

PROPANE (LP) CONVERSION.

Once the conversion is complete and checked ok,

fill out the Propane (LP) sticker and include your

name, organization and date conversion was

made. Apply the sticker near the cooktop gas

inlet opening to alert others in the future that this

appliance has been converted to Propane (LP) gas.

If converting back to natural gas from Propane

(LP), please remove the sticker so others know the

appliance is set to use natural gas.

16

Page 17

Instructions Table de cuisson scellée

d’installation

au gaz de 76 cm (30”)

JGP329, JGP333, JGP940, PGP943

Questions? Appelez le Centre de réponse 1.800.561.3344 ou visitez notre site

Web à l’adresse : www.electromenagersge.ca

AVANT DE COMMENCER

Avant de commencer, lisez attentivement la totalité

de ces instructions.

•

IMPORTANT ³ Conservez ces

instructions pour votre inspecteur local.

•

IMPORTANT ³ Respectez toutes les

ordonnances et les codes locaux.

•

Note à l’installateur – Assurez-vous de laissez ces

instructions au consommateur.

• Note au consommateur – Conservez ces

instructions pour référence future.

• La garantie ne couvre aucune panne due

à une mauvaise installation.

AVERTISSEMENT

Cet appareil doit être bien mis à la terre.

•

IMPORTANT ³ Vous devez vérifier que

cet appareil n’ait pas de fuite conformément aux

instructions du fabricant.

• L’installateur est responsable d’une bonne

installation et la garantie ne couvre aucune

panne due à une mauvaise installation.

POUR VOTRE SÉCURITÉ

AVERTISSEMENT

Si les instructions de ce manuel ne sont pas

observées rigoureusement, vous risquez

d’occasionner un incendie, une explosion ou une

fuite de gaz, qui peuvent provoquer des dommages

matériels, des blessures corporelles ou la mort.

Ne conservez pas ou n’utilisez jamais d’essence

ou d’autres liquides ou vapeurs inflammables à

proximité de cet appareil ou de tout autre appareil

ménager!

Ne pas installer ce produit si l’on utilise une hotte à

rideau d’air ou une hotte de cuisinière soufflant l’air

au-dessus de la surface de cuisson. Le débit d’air

peut nuire au fonctionnement des brûleurs à gaz et

représente un risque d’incendie ou d’explosion.

CI QUE VOUS DEVEZ FAIRE SI

VOUS SENTEZ LE GAZ :

• N’essayez jamais d’allumer un appareil

électroménager. Ne touchez à aucun

commutateur d’électricité, n’utilisez jamais un

téléphone dans votre bâtiment.

• Appelez immédiatement votre fournisseur de

gaz à l’aide du téléphone d’un voisin. Suivez les

instructions de votre fournisseur de gaz.

AVERTISSEMENT

courant électrique au niveau du disjoncteur de la

maison ou de la boîte à fusibles avant d’installer.

31-10860-3 (05-17 GEA)

Débranchez tout

• Si vous ne pouvez pas entrer en contact avec

votre fournisseur de gaz, appelez les pompiers.

L’installation et le service de votre table de cuisson

doivent être faits par un installateur qualifié, un

technicien de service ou votre fournisseur de gaz.

1

Page 18

Instructions d’installation

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

La conception de votre table de cuisson a été

approuvé par l’ACNOR International. Vous trouverez

des précautions à prendre en matière de sécurité

dans votre Guide d’utilisation et de soins. Lisez-les

attentivement.

• L’installation de votre table de cuisson

doit se conformer aux codes locaux ou, en

l’absence de codes locaux, au National Gas and

Propane Installation Code, CSA B149.1 - Dernière

édition.

• Assurez-vous que votre table de cuisson soit

bien installée par un installateur qualifié ou un

technicien de service.

• Pour éliminer tout mouvement corporel

au dessus des brûleurs de votre table de cuisson,

évitez de placer des armoires de cuisine au

dessus des brûleurs.

• N’installez jamais votre appareil près d’une porte

d’entrée ou dans un emplacement où un courant

d’air peut gêner son usage.

PIÈCES COMPRISES

2 vis

Bandes de mousse (Pour

les modèles à surface en

verre seulement)

2 Supports de fixation

MATÉRIAUX DONT VOUS POUVEZ

AVOIR BESOIN

Agent de scellement

de tuyau

Raccord flexible de gaz approuvé par l’ACNOR

Raccords de tuyaux

DI min 3/8’’, Jonction NPT 1/2

Robinet d’alimentation

de gaz

BESOINS D’ÉLECTRICITÉ

Cet appareil ménager doit être livré avec le bon

voltage et la bonne fréquence et branché à son

propre circuit de dérivation bien mis à la terre,

protégé par un disjoncteur ou un fusible qui ont

l’ampérage noté sur la plaque minéralogique de

votre appareil.

Nous vous recommandons de faire brancher le

câblage électrique et la fiche de votre cuisinière

par un électricien qualifié. Après l’installation,

demandez à l’électricien de vous montrer

l’emplacement de votre coupe-circuit principal.

Demandez à votre entreprise de services publics les

codes électriques en vigueur dans votre région. En

ne câblant pas votre cuisinière conformément aux

codes en vigueur, vous provoquez une situation

dangereuse. En l’absence de codes, vous devez

câbler et isoler votre cuisinière conformément

aux exigences du Canadian Electrical Code, CSA

C22.1-02.

OUTILS DONT VOUS AUREZ BESOINS

Crayon

Scie sauteuse

Tournevis Phillips

Règle ordinaire ou de

vérification

Perceuse à main ou électrique

Lunettes de sécurité

Clé à tuyau

et foret de 1/8po

2

Page 19

Instructions d’installation

LISTE DE VÉRIFICATION AVANT INSTALLATION

Pour préparer l’ouverture de la surface de

A

cuisson, vous devez vous assurer que

l’intérieur de l’armoire ne touche pas la table

de cuisson (consultez la section sur la

préparation de l’ouverture).

Enlevez les matériaux d’emballage, les

B

boîtes de grille, le régulateur avec sa

documentation et la documentation de

votre table de cuisson avant de commencer

à l’installer.

Documentation

Emballage

en mousse

Table de

cuisson

Boîtes de

grille

Enlevez les instructions d’installation de la

C

trousse de documentation et lisez-les

soigneusement avant de commencer.

Assurez-vous de bien ranger toute la

documentation, le manuel d’utilisation et

d’entretien, etc. dans un endroit sûr pour

référence future.

Assurez-vous d’avoir tous les outils et tous

D

les matéraux nécessaires avant de

commencer à installer votre table de

cuisson.

Votre maison doit être alimentée en courant

E

électrique adéquat pour vous permettre de

bien utiliser en toute sécurité votre table de

cuisson. (Consultez la section sur les besoins

d’électricité.)

Pour installer votre table de cuisson dans

F

votre maison, assurez-vous de vous

conformer scrupuleusement à tous les

codes et à toutes les ordonnances locales.

Assurez-vous que les revêtements de mur, le

G

comptoir et les armoires autour de la table

de cuisson puissent supporter la chaleur

[pouvant atteindre 93°C (200°F)] produite

par la table de cuisson.

3

Page 20

Instructions d’installation

PRÉPARATION DE L’OUVERTURE

VOUS DEVEZ RESPECTER LES

1

DÉGAGEMENTS MINIMAUX

SUIVANT

Profondeur max

de 33 cm (13s) des

armoires en surplomb

non protégées

Dégagement min. de 76 cm (30s) du

comptoir à la surface en non surplomb

non protégées

Dégagement min

de 10 cm (3-3/4s) du

découpage au mur de côté

droite de l’appareil

REMARQUE : Laissez un

9,2 cm

3-5/8s)

(

dégagement vertical

minimum de 1,1 cm (7/16

po) entre le dessus de la

table de cuisson (ou une

profondeur minimum de

9,2 cm (3-5/8 po) et toute

surface combustible, par

exemple un tiroir d’armoire.

Pour une installation en îlot, maintenir

une distance minimum de 6,3 cm (2 ½ po) entre le bord

et le dos du comptoir. Garder un espace de 7,6 cm (3 po)

minimum sur les côtés du comptoir.

Dégagement min. de 15

cm (6s) découpage au

3 3/4 MIN.

mur de côté à droite de

l’appareil

Hauteur min de

45 cm (18s) du

comptoir

à l’armoire la

plus proche de

chaque côté de

l’appareil

7/16ȩ)

1,1 cm (

TIROIR

DRAWER

EMPLACEMENT RECOMMANDÉ DE

4

L’ALIMENTATION DE GAZ À PARTIR

DU MUR ARRIÈRE

2.5 cm (1s) min. du mur arrière

Emplacement

recommandé de

l’alimentation

de gaz

ASSUREZ-VOUS QUE

5

33.7 cm

(13-1/4s) Du

découpage

á la ligne du

centre

LES REVÊTEMENTS MUR, LE

COMPTOIR ET LES ARMOIRES

AUTOUR DE LA TABLE DE CUISSON

PUISSENT SUPPORTER LA CHALEUR

(POUVANT ATTEINDRE 93°C [200°F])

Les revêtements de

mur, les armoires et

le comptoir doivent

pouvoir supporter

une chaleru pouvant

atteindre 93°C (200°F)

DIMENSIONS DU DÉCOUPAGE DE

2

LA TABLE DE CUISSON

53 cm (21s)(54,6 cm [21-1/2s]

76 cm (30s)

Table de cuisson

49 cm (19-3/8s)

DIMENSIONS TOTALES DE

3

max. pour table de cuisson en

8,1 cm (3-3/16s)

72 cm (28-1/4s)

LA TABLE DE CUISSON

Pour assurer la justesse du découpage,

il vaut mieux faire un gabarit pour couper

l’ouverture dans le comptoir.

72,4 cm (28-1/2 po)

longueur du découpage

Distance min de 5,7

cm (2-1/4s)

de découpage au

mur derrière la table

de cuisson

6,4 cm (2-1/2s) Distance

min. de l’arête avant du

découpagede l’arrête avant de

la table de cuisson

Largeur du découpage

49,8 cm (19-5/8s)

36,2 cm

(14-1/4s)

verre)

INSTALLATION POUR PERSONNE

6

HANDICAPÉE SEULEMENT (É.-U.)

DISABILITIES ACT FORWARD

APPROACH) :

Laissez une

profondeur

minimum de 12,7

cm (5 po) entre la

table de cuisson et

une enceinte.

REMARQUE : L’enceinte doit être

construite en bois. Aussi, un panneau

d’accès est nécessaire pour la prise

électrique, le régulateur de pression, le

robinet de sectionnement , les supports de

retenue et l’entretien ou les réparations.

12,7 cm (5”)

4

Page 21

Instructions d’installation

INSTALLATION LA UNITÉ DE LA TABLE DE CUISSON

PLACEZ LA PRISE

1

D’ALIMENTATION

ÉLECTRIQUE ET LE ROBINET

D’ALIMENTATION DE GAZ

AU-DESSOUS DE L’ARMOIRE

N’UTILISEZ JAMAIS DES

RACCORDS USAGÉS

POUR INSTALLER CET

APPAREIL.

Montez le robinet d’alimentation manuel sur le

tuyau de gaz à un emplacement facile à atteindre

en dehors de la table de cuisson. Assurez-vous de

savoir où et comment couper l’alimentation de gaz

à la table de cuisson. Montez la prise électrique

30 cm (12s) au-dessous du comptoir.

PROTÉGEZ LA SURFACE DE LA

2

Robinet

d’alimentation

Prise électrique

30 cm (12s)

sous le comptoir

TABLE DE CUISSON

Placez une serviette ou un torchon sur le comptoir.

Posez la table de cuisson à l’envers sur la surface

protégée.

Envers de la table de cuisson

Linge sous la table de cuisson

TROUVEZ LES PIÈCES DE

4

MONTAGE

Retirez les supports de fixation de la trousse de

documentation.

FIXEZ LES SUPPORTS DE FIXATION

5

À LA TABLE DE CUISSON

Enlevez la vis d’un côté de la table de cuisson,

vissez un support de fixation à un côté de la table

de cuisson. Répétez la même opération de l’autre

côté de la table de cuisson.

Support de

Bas de la table de

cuisson

Verre de la table

de cussion

INSÉREZ LA TABLE DE CUISSON

6

fixation

Bandes de

mousse

DANS L’OUVERTURE DÉCOUPÉE

Insérez la table de cuisson centrée dans l’ouverture

découpée. Assurez-vous que l’arrête de devant

du comptoir soit bien parallèle à l’extrémité de la

surface de cuisson. Faites une vérification finale

pour vous assurer de bien respecter tous les

dégagements.

ATTACHEZ LA BANDE DE MOUSSE

3

(modèles de la table de verre seulement)

Appliquez la bande de mousse autour du bord

extérieur du verre. Ne superposez pas les bandes

de mousse.

Bas de la table de

cuisson

Verre de la table

de cuisson

Bandes de mousse

Table de cuisson

Une fois la table de cuisson en place, vissez les

supports de fixation aux côtés de l’armoire pour

tenir la table de cuisson bien en place.

5

Page 22

Instructions d’installation

INSTALLATION³%5$1&+(0(17'8*$=

FOURNISSEZ UN BON

1

APPROVISIONNEMENT EN GAZ

Cette table de cuisson est conçue pour fonctionner au

gaz naturel à une pression de tubulure d’admission

de 4 po. de colonne d’eau et à une pression

d’approvisionnement de 7 po. de colonne d’eau. Elle

est expédiée de l’usine réglée pour le gaz naturel.

Le régulateur de pression convertible fourni avec

l’appareil doit être branché en série à la tubulure

d’admission de la table de cuisson et doit rester

branché sur la ligne d’approvisionnement qu’il

s’agisse de gaz naturel ou de gaz propane (LP). POUR

OBTENIR UN BON FONCTIONNEMENT, LA PRESSION

MAXIMALE D’ENTRÉE AU RÉGULATEUR NE DOIT PAS

ÊTRE SUPÉRIEURE À 14 po. DE COLONNE D’EAU. Pour

vérifier le régulateur, la pression d’entrée doit être

au moins de 1 po. de colonne d’eau (ou 3,4 KPA) plus

grande que celle de réglage de sortie du régulateur.

Si le régulateur est réglé à une pression de 4 po. de

colonne d’eau, la pression d’entrée doit être au moins

égale à 5 po.. Si le régulateur est réglé à une pression

de 10 po., la pression d’entrée doit être au moins

égale à 11 po. La ligne d’approvisionnement de gaz à

la table de cuisson doit être un tuyau de 1/2po.

ou de 3/4 po.

INSTALLEZ LE RÉGULATEUR EN

3

BAS DE LA BOÎTE DE BRÛLEURS

Vissez le régulateur dans

le raccord du bas de

la boîte de brûleurs.

Assurez-vous que le

haut du régulateur

soit face à l’avant

Régulateur

de pression

de l’armoire, et

soit facilement

accessible à partir

des portes de

l’armoire.

TERMINEZ LE RACCORDEMENT

4

Raccord

Robinet

d’arrêt

Prise électrique

12 po.

au-dessous du

comptoir

AVEC UN RACCORD

Complétez la connexion entre le régulateur, le

raccord et le robinet

d’arrêt.

INSTALLEZ LE RÉGULATEUR

2

N’utilisez jamais de vieux raccords quand vous

installez votre table de cuisson.

AVERTISSEMENT

N’utilisez jamais des raccords flexibles usagés.

L’utilisation de raccords flexibles usagés peut

occasionner des fuites de gaz et des blessures

corporelles. Utilisez toujours des raccords flexibles

neufs quand vous installez un appareil à gaz.

Vissez une section du tuyau dans

l’extrémité d’entrée du régulateur

de pression et installez le

raccord.

Régulateur de

pression

Raccord

Pour réduire la possibilité de fuites de gaz, posez un

ruban de téflon ou mettez de la graisse pour filetage

approuvée pour le gaz naturel ou butane sur tous les

raccords filetés.

Régulateur

de pression

Raccord

Robinet

d’arrêt

Prise électrique

12 po.

au-dessous du

comptoir

6

Page 23

Instructions d’installation

VÉRIFIEZ QU’IL N’Y A PAS

5

DE FUITE

Avant de vérifier qu’il n’y a pas de fuite, assurezvous que tous les boutons de brûleurs soient en

position OFF (arrêt).

Après avoir branché la table de cuisson au gaz,

vérifiez qu’il n’y a pas de fuite dans le système

à l’aide d’un manomètre. Si vous n’avez pas de

manomètre, ouvrez l’approvisionnement de gaz à

la table de cuisson et utilisez un détecteur de fuite

liquide à tous les raccords et joints pour trouver les

fuites.

Resserrez tous les raccords le cas échéant pour

arrêter les fuites de gaz de la table de cuisson ou

de la ligne d’approvisionnement.

N’UTILISEZ JAMAIS DE FLAMME POUR

VÉRIFIER LES FUITES!

Débranchez la table de cuisson et son robinet

d’arrêt du système de tuyau d’alimentation en gaz

avant de procéder à un essai de pression de ce

système à des pressions de test supérieures à 1/2

psig (3,5 kPa).

INSTALLATION SUR UN FOUR

6

ENCASTRÉ

Consultez l’installation du four encastré pour y

trouver les instructions d’installation.

5 po. depuis le comptoir

jusqu’au centre du trou

de 2 po.

Coude

de 90°

Côtés de

l’armoire

Trou de 2 po. (20 7/8 po.

de l’avant du comptoir

jusqu’au centre du trou)

IIsolez la table de cuisson du système de tuyau

d’alimentation en gaz avant de procéder à un essai

de pression du système d’alimentation en gaz à

des pressions de test égales ou inférieures à 1/2

psig (3,5 kPa).

7

Page 24

Instructions d’installation

,167$//$7,21³5$&&25'6e/(&75,48(6

ALIMENTATION ÉLECTRIQUE

2

AVERTISSEMENT

courant électrique au niveau du disjoncteur de la

maison ou de la boîte à fusibles avant d’installer.

RALLONGES

1

À cause du danger qu’elles font courir dans

certaines conditions, nous vous recommandons

instamment de nes pas utiliser de rallonge.

Cependant, si vous devez utiliser une rallonge,

il faut absolument qu’elle soit homologuée UL,

triphasée à trois fils pour appareil électroménager

et que sa capacité électrique en ampères soit

équivalente ou supérieure à celle du circuit

électrique. Vous pourrez trouver une telle rallonge

chez votre revendeur d’appareils électroménagers.

Débranchez tout

IMPORTANT : (Veuillez lire avec soin)

POUR VOTRE SÉCURITÉ PERSONNELLE, VOUS DEVEZ

BIEN METTRE À LA TERRE CET APPAREIL.

ET PRISE

Vous devez utiliser une bonne alimentation

électrique et une bonne prise pour faire fonctionner

les éléments électriques de

votre table de cuisson.

Le cordon d’alimentation de votre appareil est

A

muni d’une fiche à trois broches (avec mise à

la terre) qui doit être utilisée dans une prise

électrique bien mise à la terre, qui alimente

en courant ménager CA normal de

120 volts, 60 cycles.

Si vous n’avez pas de prise triphasée,

B

demandez à un électricien qualifié de changer

votre ancienne prise.

Vous aurez besoin d’une fiche d’adaptation de

C

mise à la terre pour convertir votre ancienne

prise jusqu’à son remplacement. Cette

méthode est temporaire et un électricien

qualifié doit tester votre installation pour

s’assurer qu’elle se conforme aux exigences.

N

PRISE BIPHASÉE

3

Si vous avez une prise normale biphasée, c’est

la responsabilité et l’obligation personnelle du

client de la faire remplacer par une prise murale

triphasée bien mise à la terre.

Ne coupez ou ne retirez jamais, en aucun

cas, la broche de mise à la terre du cordon

d’alimentation de la table de cuisson. Si vous ne

mettez pas bien votre appareil à la terre, vous

pouvez créer une situation dangereuse.

Assurez une bonne

mise à la terre et un

L

bon contact avant

l’usage

8

Page 25

Instructions d’installation

,167$//$7,21³5$&&25'6e/(&75,48(6 (SUITE)

SITUATION D’UTILISATION OÙ LE

4

CORDON D’ALIMENTATION D’UN

APPAREIL ÉLECTROMÉNAGER EST

INFRÉQUEMMENT DÉBRANCHÉ

Pour un circuit électrique de 15 ampéres uniquement.

N’utilisez jamais de fiche d’adaptation sur un

circuit de 20 ampéres. Quand les codes locaux

le permettent, vous pouvez établir UN CONTACT

TEMPORAIRE avec une prise murale biphasée bien

mise à la terre en utilisant une fiche d’adaptation

homologuée UL en vente dans la plupart des

quincailleries. La broche la plus grande de

l’adaptateur doit être alignée à la plus grande fente

de la prise murale pour obtenir une bonne polarité

avec le cordon d’alimentation.

ATTENTION

mise à la terre de l’adaptateur à une vis du couvercle

de la prise murale, cela ne met pas à la terre

l’appareil, à moins que la vis soit en métal et ne soit

pas isolée et que la prise murale soit mise à la terre

par l’intermédiaire du câblage de la maison. Vous

devez faire vérifier le circuit par un électricien qualifié

pour vous assurer que la prise est bien mise à la

terre.

Quand vous débranchez le cordon d’alimentaiton

d’un appareil, tenez toujours l’adapateur à la main.

Si vous ne le faites pas, vous casserez probablement

la broche de mise à la terre de l’adaptateur par un

usage répété. Si cela se produit, N’UTILISEZ JAMAIS

l’appareil avant de bien le remettre à la terre.

Si vous fixez la broche de

Alignez les grandes

broches aux grandes

fentes

Méthode temporaire

(les fiches d’adaptation ne sont

pas autorisée au Canada)

Assurez une bonne

mise à la terre et un bon

contact avant l’usage

Situations d’utilisation où le cordon d’alimentation

d’un appareil électroménager est fréquemment

débranché.

N’utilisez jamais un adaptateur dans cette situation,

car en débranchant le cordon d’alimentation, vous

faites subir une tension imprévue à l’adapateur et

cela risque de provoquer une panne de sa mise à la

terre. Le client doit faire remplacer sa prise biphasée

par une prise triphasée par un électricien qualifié

avant d’utiliser son appareil.

9

Page 26

Instructions d’installation

BRÛLEURS DE LA TABLE DE CUISSON

ASSEMBLEZ LES BRÛLEURS DE LA

1

TABLE DE CUISSON

L’électrode de l’allumeur est exposée. Faites

attention de ne pas pousser un contrôle de la table

de cuisson quand le haut du brûleur est enlevé.

N’enlevez jamais le haut d’un brûleur ou son

électrode quand un autre brûleur est allumé. Cela

risque de produire une secousse électrique.

Remettez en place la tête de brûleur sur la

A

base du brûleur, en vous assurant que la tête

soit bien orientée sur la base de brûleur et

l’électrode. Assurez-vous de bien mettre la

bonne tête de brûleur sur la bonne base de

brûleur et de bien mettre horizontalement la

tête de brûleur sur sa base. Les têtes de

brûleur ne sont pas interchangeables.

Placez les capuchons de brûleur sur les têtes

B

de brûleur, en vous assurant de mettre le bon

capuchon de

brûleur sur la bonne

tête de brûleur. Les

capuchons

de brûleur

ne sont pas

interchangeables.

Assurez-vous que

les capuchons

de brûleur tiennent

bien sur

les têtes de brûleur.

Capuchon de brûleur bien placé

Capuchon de brûleur

pas bien placé

Assurez-vous que les

C

Capuchon de brûleur

broches des têtes de

brûleur

correspondent aux

creux de la base de

brûleur et qu’elles

tiennent bien sur

elles en tournant les

têtes jusqu’à ce

Broche de

localisation

qu’elles soient bien

horizontales.

Creux de

broche

Assurez-vous

que la fente

Capuchon

de brûleur

de la tête de

brûleur soit

bien placée

Tête de brûleur

sur l’électrode.

Le capuchon

de brûleur a

trois ou quatre

Chambre de

stabilité

broches. Quand

vous remettez

en place le

Base de brûleur

capuchon,

assurez-vous

qu’aucune

broche ne repose sur la chambre de stabilité.

Assurez-vous que le

trou de l’ensemble

de tête de brûleur

soit bien placé sur

l’électrode de manière

à ce que la tête de

Ensemble

de tête de

brûleur

brûleur pénètre

bien dans la base

de brûleur. Un petit

espace libre entre

la base et la tête est

normal.

Électrode

Tête de brûleur

Électrode

Base de

brûleur

Électrode

Capuchon de brûleur

Base de

brûleur

10

Page 27

Instructions d’installation

VÉRIFIEZ LES ALLUMEURS

2

Vous devez vérifier le fonctionnement

des allumeurs électriques après vous être

soigneusement assuré que la table de cuisson et la

ligne d’approvisionnement n’ont pas de fuite et que

la table de cuisson est bien branchée au courant

électrique.

Sur les modèles qui sont ainsi équipés, assurez-vous

que la table de cuisson soit en position UNLOCKED

(déverrouillée).

Appuyez sur un robinet de brûleur et tournez-le

A

en position LITE (allumage). Tous les allumeurs

feront une série d’étincelles (crépitement) mais,

seul, le brûleur en position LITE (allumage)

s’allumera.

• Le brûleur doit s’allumer quand du gaz lui

parvient.

• Quand le brûleur s’allume, vous devez

l’enlever de sa position LITE (allumage).

Essayez tous les robinets pour vérifier le

B

fonctionnement de tous les brûleurs.

ALLUMAGE DES BRÛLEURS

3

Allumage de la table de cuisson – Quand vous

mettez le bouton de la table de cuisson en position

LITE (allumage), l’allumeur fait une série d’étincelles

(crépitement) pour allumer le brûleur. Pendant

une panne de courant, les brûleurs ne s’allument

pas automatiquement. En cas d’urgence, allumez

un brûleur de la table de cuisson à l’aide d’une

allumette en suivant les étapes suivantes :

AVERTISSEMENT

Il est dangereux

d’allumer des brûleurs à gaz à l’aide d’une

allumette. Vous ne devez allumer des brûleurs à

l’aide d’une allumette qu’en cas d’urgence.

Sur les modèles ainsi équipés, vérifiez que la

table de cuisson soit en position UNLOCKED

(déverrouillée).

Allumez une allumette et approchez la flamme

A

du brûleur que vous voulez allumer. Il vaut

mieux utiliser une allumette en bois.

Poussez et tournez doucement le bouton de

B

contrôle. Assurez-vous de tourner le bouton

de contrôle qui correspond au brûleur que

vous voulez allumer.

NOTE: ISi le brûleur ne s’allume pas en cinq secondes,

tournez le bouton en position OFF (arrêt) et attendez

une minute avant d’essayer à nouveau.

11

Page 28

Instructions d’installation

BRÛLEURS DE LA TABLE DE CUISSON (SUITE)

LES FLAMMES DU BRÛLEUR

4

Allumez chaque brûleur. Les flammes doivent être

bleu sans trace de jaune. Les flammes du brûleur

ne doivent pas scintiller ou s’écarter du brûleur. La

flamme ne peut pas être plus petite que 1/4 po. en

réglage le plus bas et ne doit pas être plus grande

que 1-1/2s po. en réglage le plus haut.

1/4 à

1-1/2

po.

Vous devez vérifier fréquemment les brûleurs

Brûleur de table

de cuisson

AVERTISSEMENT : Si vous essayez

de mesurer la flamme, faites bien attention. Vous

pouvez vous brûler.

GRILLES DE BRÛLEUR

5

Les grilles de brûleur sont conçues pour leur

emplacement particulier. Pour obtenir une stabilité

maximum, vous ne pouvez utiliser ces grilles qu’en

bonne position : vous ne pouvez pas les changer de

place. Pour faciliter leur utilisation, l’extérieur des

grilles de gauche et de droite est marqué OUTSIDE

(extérieur) et INSIDE (intérieur). Assurez-vous

que le côté marqué OUTSIDE (extérieur) soit vers

l’extérieur de votre table de cuisson.

Bord

OUTSIDE

(extérieur)

Bord INSIDE

(intérieur)

Bord

OUTSIDE

(extérieur)

LISTE DE VÉRIFICATION DE FONCTIONNEMENT

Assurez-vous que tous les contrôles restent en

A

position OFF (arrêt). Vérifiez que la table de

cuisson soit en position UNLOCKED

(déverrouillée) (sur les modèles ainsi équipés).

Assurez-vous que la circulation d’air autour de la

B

table de cuisson ne soit pas gênée.

La plaque minéralogique de votre table de

C

cuisson est située en bas de la boîte de brûleurs.

En plus des numéros de modèle et de série, elle

indique la cote des brûleurs, et la catégorie de

carburant et la pression de votre table de

cuisson au départ de la fabrique.

Quand vous commandez des pièces. indiquez

D

toujours le numéro de série, le numéro de

modèle et les lettres de code pour obtenir les

bonnes pièces de rechange.

Re-vérification :

E

Vérifiez à nouveau pour vous assurer d’avoir

bien suivi toutes les instructions de ce guide.

Cela assure une bonne utilisation sécuritaire de

la table de cuisson.

12

Page 29

Instructions d’installation

CONVERSION AU GAZ PROPANE (LP)

OUTILS NÉCESSAIRES

À LA CONVERSION AU GAZ LP

Tournevis Phillips

Pinces

RENSEIGNEMENTS RELATIFS À LA SÉCURITÉ QUE VOUS DEVEZ CONNAÎTRE

1

Les diaphragmes du régulateur de pression et du brûleur

sont réglés pour le gaz naturel. Pour utiliser du gaz

propane (LP), vous devez convertir les diaphragmes du

régulateur de pression et du brûleur. Les orifices des

éléments de gaz PL des brûleurs de la surface de cuisson

sont rattachés aux régulateur de pression et accompagnés

des instructions de conversion du gaz PL.

Tourne-écrou de 7 mm

Tournevis à tête de Torx No 15

Lunettes de sécurité

ATTENTION

de l’usine, est réglée pour le gaz naturel. Si vous désirez

utiliser votre table de cuisson avec du gaz en bouteille

(LP), vous devez d’abord remplacer les diaphragmes, puis

convertir le régulateur de pression.

ATTENTION

AVERTISSEMENT

Cette conversion

doit être effectuée par un installateur qualifié ou un

fournisseur de gaz conformément aux instructions du

fabricant et à tous les codes et exigences de l’autorité

compétente. Si vous ne suivez pas ces instructions, vous

risquez d’occasionner des blessures corporelles et des

dommages matériels importants. L’agence qualifiée qui

fait ce travail assume la responsabilité de la conversion.

être effectués avant d’allumer le brûleur. Si vous ne les

faites pas, vous risquez d’occasionner des blessures

sérieuses. Assurez-vous que le régulateur de pression soit

bien converti conformément à l’étape 2.

ATTENTION

conversion, fermer d’abord la source d’alimentation

en gaz de l’appareil, puis débrancher le cordon

d’alimentation en électricité.

Petit tournevis à tête plate

(tête de 4 mm ou 5/32 po.,

60 mm. ou (2 3/8 po de

La table de cuisson, au départ

Les ajustements suivants doivent

Avant de procéder à la

long))

13

Page 30

Instructions d’installation

CONVERSION AU GAZ PROPANE (LP) (SUITE)

AJUSTEZ VOTRE PLAQUE DE

2

CUISSON À UN USAGE AU GAZ LP

Débranchez tout le courant électrique, au niveau

A

du disjoncteur principal ou de la boîte à fusibles.

Coupez l’approvisionnement de gaz à la table de

B

cuisson en fermant à la main le robinet d’arrêt.

Ajustez le régulateur de pression en suivant les

C

instructions suivantes :

• Dévissez le capuchon.

• Trouvez, sur l’étrier de ressorts, les positions NAT

(gaz naturel) et LP (gaz propane).

Capuchon

LP

NAT

LP

NAT

Position

NAT

Joint

NAT

LP

Position LP/

Propane

NAT

LP

Étrier de

ressorts

CHANGEZ LES DIAPHRAGMES DES

3

BRÛLEURS DE LA TABLE DE

CUISSON (Suite)

Enlevez les allumeurs des

B

bases de brûleur (si c’est

nécessaire pour atteindre

les diaphragmes). À l’aide

d’un tournevis à tête de

“Torx” No 15, enlevez les vis

qui tiennent la base de

brûleur en position.

À l’aide d’un tourne écrou

C

de 7 mm., enlevez les

diaphragmes du brûleur du

haut, Vous pouvez les

atteindre en passant par

le trou de la table de

cuisson.

Capuchon de brûleur

Tête de

brûleur

Allumeur

Brûleur de 18000 BTU

(sur certains modèles)

Base de

brûleur

Base de

brûleur

Capuchon de

brûleur

Tête de

brûleur

Régulateur de pression

• Tournez l’étrier de ressorts de 90 degrés,

retirez-le du capuchon, tournez l’étrier de

ressorts jusqu’à ce que LP apparaisse, réinsérezle dans le capuchon, puis tournez-le de 90 degrés

en position

• Revissez le capuchon sur le régulateur et serrez.

CHANGEZ LES DIAPHRAGMES DES

3

BRÛLEURS DE LA TABLE DE

CUISSON

Enlevez les grilles du haut,

A

les capuchons de brûleur et

les têtes de brûleur.

Enlevez cet

ensemble

Sur la plupart des

Allumeur

brûleurs, les diaphragmes

ont une bague de rétention

à ressort autour de la tête

hexagonale pour retenir le

diaphragme dans le tourne-

Bague de

rétention

écrou pendant l’installation

et l’enlèvement. Il faut

exercer un peu de force

pour pousser le tourneécrou vers le bas de la

bague.

NOTE: Dans le cas de diaphragmes

non dotés d’une bague de retenue

à ressort, utilisez une pince pour

maintenir le diaphragme en position

pendant le vissage initial du filetage

ou lors du dévissage final, de façon

à éviter d’échapper le diaphragme

dans la surface de cuisson. Pour le

reste, utilisez un tournevis à douille pour serrer ou

desserrer.

Goujon diaphragme accessible

par cette ouverture.

14

Page 31

Instructions d’installation

CHANGEZ LES DIAPHRAGMES DES

3

BRÛLEURS DE LA TABLE DE

CUISSON (SUITE)

Repérez les orifices PL fixés au régulateur de

D

pression et accompagnés des instructions

de conversion du gaz PL.

par un chiffre et le type de gaz par une lettre,

sur le dessus ou le côté.

Conservez les diaphragmes que vous avez

enlevés de votre appareil pour une

utilisation future.)

Chaque diaphragme indique une série de

signes gravés (I, II, III, X ou rien) en haut.

Ces signes indiquent l’emplacement précis de

chaque diaphragme sur le brûleur de la table de

cuisson.

I II III

Brûleur de 15,000 BTU/HR

Le brûleur de 15 000 BTU/HR a deux

diaphragmes qui portent des marques de côté

seulement (consultez la plaque minéralogique en

bas de votre appareil).

NOTE : Le diaphragme principal est situé en bas

au centre du brûleur alors que le diaphragme de

mijotage est situé plus haut derrière le centre du

brûleur.

Diaphragme de

mijotage

La taille est indiquée

(Important :

X

(sur certaines modèles)

Diaphragme

principal

JGP329

86 L

86 L

63 L

92 L

JGP333 & PGP943

92 L

86 L

63 L

Voir ci-

See

contre

Below

Principal

Main: 99 HXL

Mijotage

Simmer: 34 SL

JGP940

84 L

91 L

Installez les diaphragmes pour gaz Propane

E

74 L

104L

X

(LP) à leur emplacement précis, conformément

aux illustrations ci-dessus.

Remettez les diaphragmes pour gaz naturel

F

sur le support et fixez à nouveau le support et

la feuille d’instructions au régulateur de

pression à l’aide de la vis enlevée

précédemment.

15

Remettez en place les bases, les têtes, les

G

capuchons de brûleur et les grilles du haut.

(NOTE : Quand vous fixez à nouveau les bases

de brûleur aux appareils à table de cuisson en

verre, vissez au maximum à une tension de 10

po.-lbs.)

Page 32

Instructions d’installation

CONVERSION AU GAZ PROPANE (LP) (SUITE)

Continuez à ajuster en tournant lentement la

AJUSTEZ LES FLAMMES DES

4

BRÛLEURS

Allumez tous les brûleurs au maximum et

A

vérifiez les flammes. Elles doivent être bleu

avec un peu de jaune à leur extrémité. Des

particules étrangères dans la ligne de gaz

peuvent occasionner une flamme orange au

début, mais cette couleur doit disparaître

rapidement.

NOTE : Pour le brûleur de 15 000 BTU/HR

(sur certains modèles), vous devez tourner le

bouton du brûleur de la table de cuisson à son

réglage normal avant son réglage le plus bas.

Cela vous donnera l’assurance que le brûleur

fonctionne dans sa totalité.

Tournez le bouton du brûleur de la table de

B

cuisson à son réglage le plus bas tout en

observant la flamme.

Ajustez le réglage de flamme basse à l’aide de la vis

de dérivation de robinet comme suit :

Vous devez ajuster le réglage de flamme basse

avec deux autres brûleurs en fonctionnement

en réglage moyen. Cela vous empêche de régler

trop bas la flamme basse, et qui risque d’éteindre

la flamme quand d’autres brûleurs sont en

fonctionnement.

Pour ajuster la flamme, enlevez les boutons.

C

Insérez un tournevis

dans commutateur de

robinet en passant

par le trou d’accès.

Faites entrer la vis

de réglage dans le

robinet. Consultez

l’illustration

ci-dessous qui

correspond à

l’emplacement de la vis

de réglage pour votre

modèle.

• Si les flammes sont

trop petites ou si elles

clignotent, ouvrez le

robinet davantage

que dans le réglage

original.

• ISi les flammes s’éloignent du brûleur,

fermez le robinet davantage que dans le

réglage original.

Brûleur 15 000 BTU

seulement

D

vis jusqu’à ce que les flammes soient normales.

Remarque : Quelques modèles sont équipés d’un écran

en silicone recouvrant les volants et le trou d’accès.

Une lampe de poche peut être nécessaire pour repérer

le trou d’accès. Introduisez le tournevis par l’écran pour

accéder à la vis de réglage de la soupape. Après le

réglage, réinstallez l’écran autour du moyeu de volant

avec vos doigts sans oublier de retirer le tournevis.

Essai de stabilité de la flamme :

E

Réinstallation de l’écran de silicone

CORRECT INCORRECT

Essai 1 – Tournez rapidement le bouton de

Essai 2 – Mettez le brûleur à son réglage le

Nouvelle vérification des flammes :

F

Après avoir ajusté, éteignez tous les brûleurs.

Allumez chaque brûleur séparément. Observez les

flammes en position HI (température élevée). Faites

tourner le robinet jusqu’à son réglage le plus bas

et assurez-vous que la taille de la flamme diminue

quand vous tournez le robinet en sens inverse à

celui des aiguilles d’une montre.

POUR RECONVERTIR LA TABLE DE CUISSON AU

GAZ NATUREL, FAITES À L’ENVERS TOUTES LES

ÉTAPES DE CONVERSION AU GAZ PROPANE (LP).

Quand vous avez terminé la conversion et avez vérifié

que tout va bien, remplissez l’étiquette Propane (LP)

et inscrivez votre nom, le nom de votre organisme

et la date de conversion. Collez l’étiquette près de

l’ouverture d’entrée de gaz de la table de cuisson pour

signaler aux autres que cet appareil a été converti au

gaz Propane (LP). Si vous reconvertissez votre appareil

au gaz naturel, enlevez l’étiquette pour signaler aux

autres que cet appareil fonctionne au gaz naturel.

HI (température élevée) jusqu’au

réglage le plus bas. Si la flamme

s’éteint au réglage le plus bas,

augmentez la taille de la flamme et

essayez à nouveau.

plus bas, ouvrez et fermez la porte

de l’armoire située au-dessous de

la table de cuisson. Si la flamme

s’éteint à cause du courant d’air

créé par le mouvement de la porte,

augmentez la taille de la flamme et

essayez à nouveau.

16

Loading...

Loading...