Page 1

Installation Instructions

Electric Slide-In Ranges

2

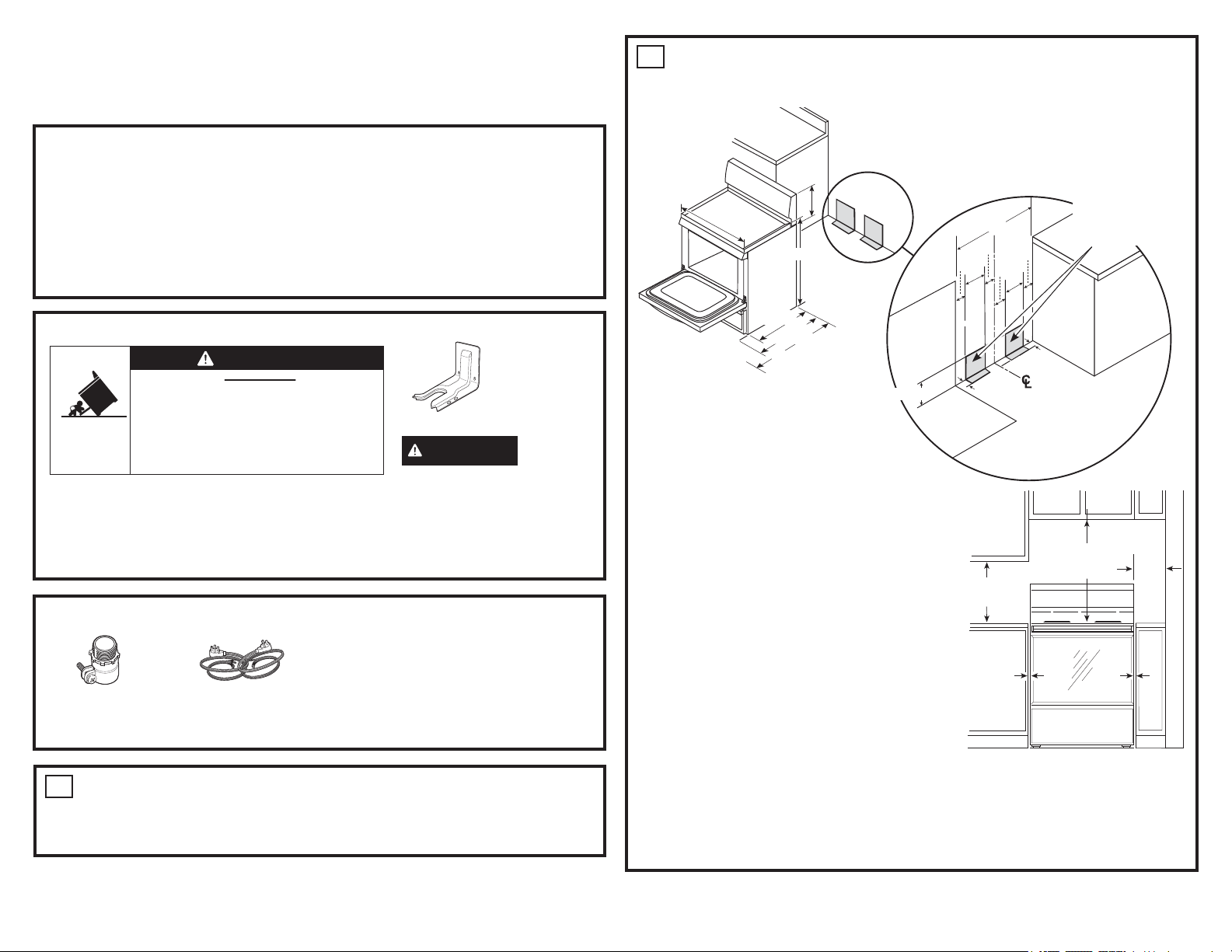

PREPARE THE OPENING (FOR INDOOR USE ONLY)

See illustrations for all rough-in and spacing dimensions. The range may be placed with 0”

clearance (flush) at the back wall and side walls of the cabinet.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT — Save these

instructions for local inspector’s use.

• IMPORTANT — Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with consumer.

• Note to consumer – Keep these

instructions for future reference.

• Skill level – Installation of this appliance

requires a qualified installer or electrician.

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is

not covered under warranty.

FOR YOUR SAFETY:

WARNING

• A child or adult can tip the range and be killed.

• Install the anti-tip bracket to the wall or floor.

• Engage the range to the anti-tip bracket by sliding the

range back such that the foot is engaged.

• Re-engage the anti-tip bracket if the range is moved.

• Failure to do so can result in death or serious burns

to children or adults.

If you did not receive an anti-tip bracket with your purchase,

call 1.800.626.8774 to receive one at no cost. (In Canada, call

1.800.561.3344.) For installation instructions of the bracket,

visit: www.GEAppliances.com.

(In Canada, www.GEAppliances.ca.)

Tip-Over Hazard

WARNING

beginning the installation, switch power

off at service panel and lock the service

disconnecting means to prevent power

from being switched on accidentally.

When the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a

tag, to the service panel.

MATERIALS YOU MAY NEED TOOLS YOU WILL NEED

Drill with 1/8” Bit

Safety Glasses

Adjustable Wrench

Squeeze Connector

(For Conduit

Installations Only)

1

REMOVE PACKAGING MATERIALS: Failure to remove packaging

materials could result in damage to the appliance. Remove all packing parts from oven,

racks, heating elements and drawer. Also, remove protective film and labels on the outer

door, cooktop and control panel.

(UL Listed 40 AMP)

4-Wire Cord 4’ long OR

3-Wire Cord 4’ long

Level

Anti-Tip Bracket

Kit Included

Before

Tin Snips

Tape Measure

Pliers

1/4” Nut Driver

Recommended

8 1/2”

30”

36 1/4”

26 1/4”

w/o handle

29”

with handle

46 3/4”

Install the

outlet box

on either

side of the C

NOTE: Use a 4’ power cord to prevent interference with

the storage drawer. Power cords 41»2’ to 6’ long may have

to be dressed to allow for proper drawer closing.

MINIMUM DIMENSIONS BETWEEN COOKTOP,

WALLS AND ABOVE THE COOKTOP:

A. Make sure the wall covering, countertop, flooring and

cabinets around the range can withstand the heat (up

to 200°F) generated by the range. 0” to cabinets below

cooktop and at the range back.

B. Allow 30” minimum clearance between surface units

and bottom of unprotected wood or metal cabinet, or

allow a 24” minimum when bottom of wood or metal

cabinet is protected by no less than 1/4” thick flame

retardant millboard covered with not less than No. 28

MSG sheet metal, (.015”), .015” thick stainless steel,

.024” aluminum or .020” copper.

C. This appliance has been approved for 0” spacing to

adjacent surfaces above the cooktop. However, a 6” minimum spacing to surfaces less than 15”

above the cooktop and adjacent cabinet is recommended to reduce exposure to steam, grease

splatter and heat.

To reduce the risk of burns or fire when reaching over hot surface elements, cabinet storage space

above the cooktop should be avoided. If cabinet storage space is to be provided above the cooktop,

the risk can be reduced by installing a range hood that projects at least 5” beyond the front of the

cabinets. Cabinets installed above the cooktop must be no deeper than 16”.

L

7 1/2”

3”

3”

9”

2 1/4”

NOTE C

30”

3”

4”

8”

2 1/4”

A

acceptable

electrical outlet

area. Orient the

electrical receptacle

so the length is

parallel to the floor.

B

C

Both

Sides

A

Page 2

3

ELECTRICAL REQUIREMENTS

WARNING

WARNING

where local codes do not allow grounding through neutral, require a 4-conductor UL-listed range cord.

This appliance must be properly grounded.

All new constructions, mobile homes, recreational vehicles and installations

POWER CORD AND CONDUIT INSTALLATION

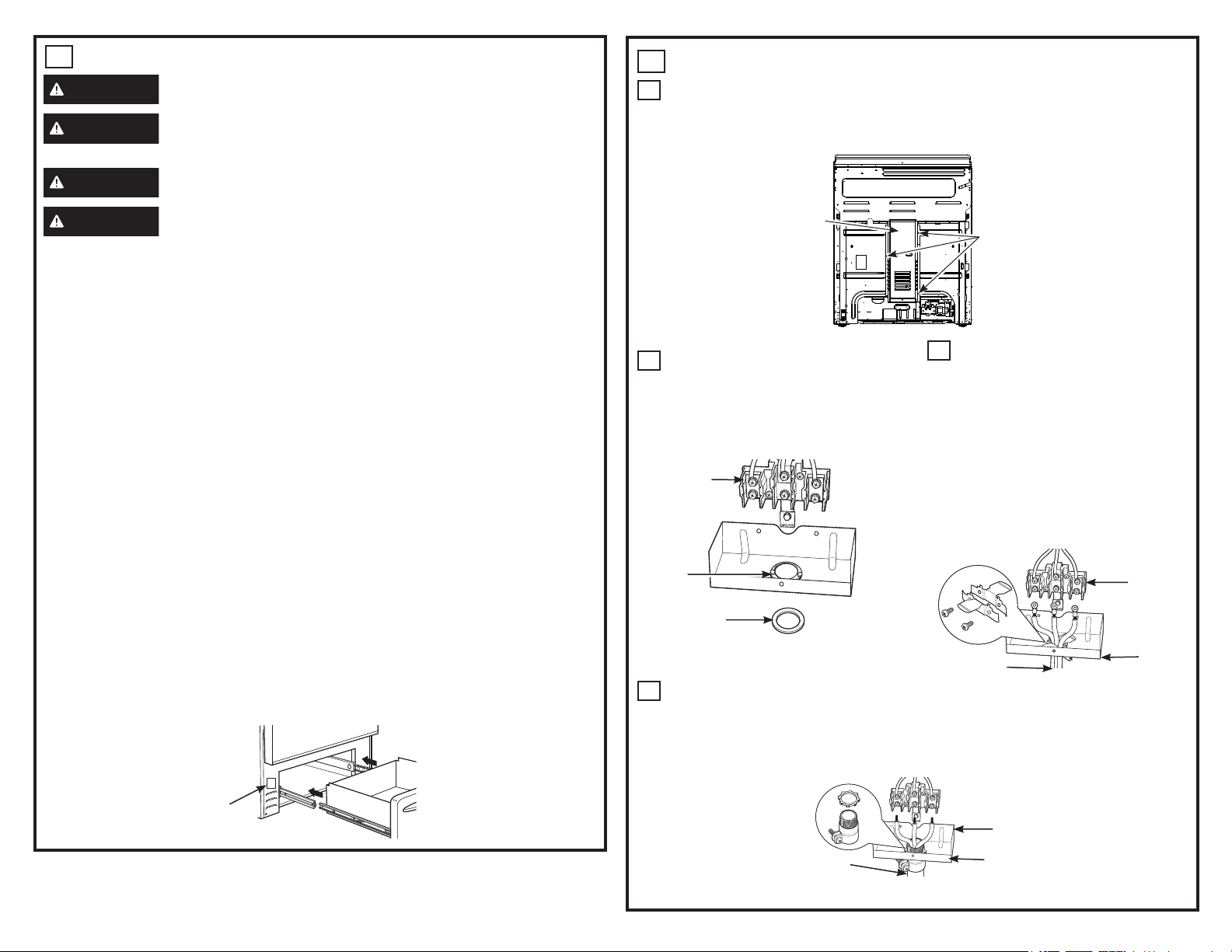

4

A

Remove wire cover (on the back of range) by removing screws using a 1/4” nut driver. You

can access the terminal block by either removing a terminal block cover (on some models) or

the wire cover. Do not discard these screws.

Rear of Range

WARNING

WARNING

beginning installation.

We recommend you have the electrical wiring and hookup of your range connected by a qualified

electrician. After installation, have the electrician show you how to disconnect power from the range.

You must use a single-phase, 120/208 VAC or 120/240 VAC, 60 hertz electrical system. If you

connect to aluminum wiring, properly installed connectors approved for use with aluminum wiring

must be used.

Effective January 1, 1996, the National Electrical Code requires that new construction (not existing)

utilize a 4-conductor connection to an electric range. When installing an electric range in new

construction, mobile home, recreational vehicle, or an area where local codes prohibit grounding

through the neutral conductor, refer to the section on four-conductor branch circuit connections.

Check with your local utilities for electrical codes which apply in your area. Failure to wire your oven

according to governing codes could result in a hazardous condition. If there are no local codes,

your oven must be wired and fused to meet the National Electrical Code, NFPA No. 70 – latest

edition, available from the National Fire Protection Association.

This appliance must be supplied with the proper voltage and frequency, and connected to an

individual, properly grounded, 40 amp (minimum) branch circuit protected by a circuit breaker or

time-delay fuse.

Use only a 3-conductor or a 4-conductor UL-listed range cord. These cords may be provided with

ring terminals on wire and a strain relief device.

A range cord rated at 40 amps with 125/250 minimum volt range is required. A 50 amp range cord

is not recommended but if used, it should be marked for use with nominal 13»8” diameter connection

openings. Care should be taken to center the cable and strain relief within the knockout hole to

keep the edge from damaging the cable.

The rating plate is located on the oven frame or on the side of the drawer frame.

NOTE: Use of automatic, wireless or wired external switches that shut off power to the appliances,

are not recommended for this product.

To prevent fire or shock, do not use an extension cord with this appliance.

To prevent shock, remove house fuse or open circuit breaker before

SINGLE OVEN

Terminal

Block Cover

B

For power cord and 1” conduit only, remove

the knockout ring (13»8”) located on bracket

directly below the terminal block. To remove

the knockout, use a pair of pliers to bend the

knockout ring away from the bracket and

twist until ring is removed.

Terminal block

(appearance

may vary)

Knockout

ring in

bracket

Knockout ring

removed

D

For 3/4” conduit installations only, purchase a squeeze connector matching the diameter

of your conduit and assemble it in the hole. Insert the conduit through the squeeze connector

and tighten. Allow enough slack to easily attach the wires to the terminal block. NOTE: Do

not install the conduit without a squeeze connector. The squeeze connector MUST be

installed before reinstalling the rear terminal block.

C

NOTE: Do not install the power cord

Screws to

remove terminal

block cover

For power cord installations only (see

the next step if using conduit), assemble

the strain relief in the hole. Insert the

power cord through the strain relief and

tighten. Allow enough slack to easily

attach the cord terminals to the terminal

block. If tabs are present at the end of

the winged strain relief, they can be

removed for better fit.

without a strain relief. The strain relief

bracket MUST be installed before

reinstalling the rear range wiring cover.

Strain relief

Power cord

Terminal

block

Bracket

Rating plate

Squeeze

connector

Proceed to step 6 or 7.

Conduit

Terminal block

Bracket

Page 3

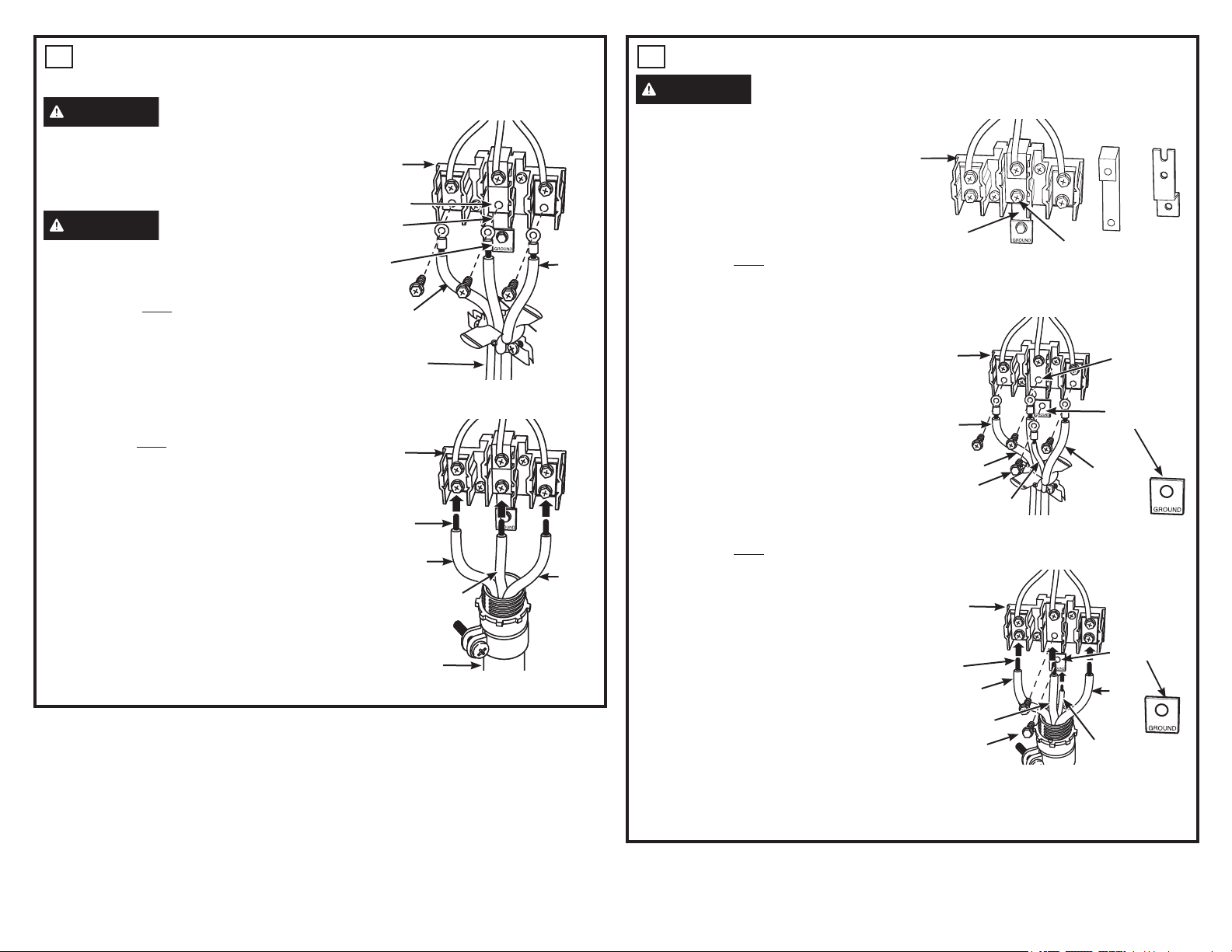

5

3-WIRE INSTALLATION (GROUND IS THROUGH THE

NEUTRAL WIRE)

WARNING

The neutral wire and ground strap must be

connected as shown below for the range to be

properly grounded. Do not remove the ground strap.

Failure follow this instruction may result in potential

shock hazard.

WARNING

Terminal block screws must be securely tightened.

Failure to do so may result in potential fire hazard.

FOR POWER CORD INSTALLATION

A. Remove the 3 lower screws from the terminal

block. Do not loosen the upper screws.

B. Do not cut or remove the ground strap.

C. Insert the 3 screws through each power cord

terminal ring and back into the terminal block. Be

certain the white wire is in the center. Securely

tighten each screw (35 to 50 in-lbs.)

FOR CONDUIT INSTALLATION

A. Loosen the 3 lower screws on the terminal block. Do

not loosen the upper screws.

B. Do not cut or remove the ground strap.

C. Insert the bare wire tip (insulation stripped 5/8”) into the

bottom terminal block openings. Be certain the white

wire is in the center. On certain models, the wire must

be inserted through an opening in the ground strap.

Securely tighten each screw onto each wire (35 to 50

in-lbs.).

D. Reinstall terminal block cover.

NOTE: Aluminum building wire may be used but it must

be rated for the correct amperage and voltage.

PROCEED TO STEP 8.

Shock Hazard

Terminal block

(appearance

may vary)

Fire hazard

Ground

plate

Neutral

terminal

Ground

strap

Red or

Black

Power cord

Terminal

block

Wire

tips

Red or

Black

Conduit

Power Cord

Conduit

White

Red or

Black

White

Red or

Black

6

4-WIRE INSTALLATION (SEPARATE GROUND WIRE)

WARNING

the supply circuit must be connected to the

neutral terminal located in the lower center

of the terminal block. The power leads must

be connected to the lower left and the lower

right terminals of the terminal block. The

grounding lead must be connected to the

frame of the range with the ground plate and

the green ground screw.

FOR POWER CORD INSTALLATION

A. Remove the 3 lower screws from the

terminal block. Do not loosen the upper

screws.

B. Remove the ground screw and ground plate

and retain them.

C. Cut the ground strap below the terminal

block and discard the lower section.

D. Insert the ground screw through the ground

plate (removed earlier) and back into the

range frame. Tighten securely, but do not

over-tighten (15 to 20 in-lbs.)

E. Insert the 3 terminal screws through each

power cord terminal ring and back into the

terminal block. Be certain the white wire is

in the center. Securely tighten each screw

(35 to 50 in-lbs.

F. Reinstall terminal block cover.

FOR CONDUIT INSTALLATION

A. Remove the 3 lower screws from the terminal

block. Do not loosen the upper screws.

B. Remove the ground screw and ground plate

and retain them.

C. Cut the ground strap below the terminal block

and discard the lower section.

D. Insert the bare ground bare wire tip (insulation

stripped 5/8”) between the range frame and the

ground plate (removed earlier) and secure it in

place with the ground screw. Tighten securely,

but do not over-tighten (15 to 20 in-lbs).

E. Insert the wire tips (insulation stripped 5/8”) into

the bottom terminal block openings. Be certain

the white wire is in the center. On certain

models, the wire must be inserted through an

opening in the ground strap. Securely tighten

each screw onto each wire (35 to 50 in-lbs.)

F. Reinstall terminal block cover.

NOTE: Aluminum building wire may be used but it must be rated for the correct amperage and voltage.

The neutral wire of

Before–Power Cord and Conduit

Terminal

block

Ground

strap

Neutral

terminal

After–Power Cord

Terminal

block

Red or

Black

White

Ground

screw

Green

or Bare

Red or

Black

After–Conduit

Terminal

block

Wire

tips

Red or

Black

White

Ground

screw

Green

or Bare

Ground strap

or

Neutral

terminal

Ground plate

(grounding to

range)

Ground plate

(grounding to

range)

Red or

Black

Page 4

7

ANTI-TIP DEVICE INSTALLATION

WARNING

• A child or adult can tip the range and be killed.

• Install the anti-tip bracket to the wall or floor.

• Engage the range to the anti-tip bracket by sliding the

range back such that the foot is engaged.

• Re-engage the anti-tip bracket if the range is moved.

• Failure to do so can result in death or serious burns

to children or adults.

leg is engaged in the bracket. On some models, the storage drawer or kick panel can be removed

for easier inspection. If visual inspection is not possible, slide the range forward, confirm the antitip bracket is securely attached to the floor or wall, and slide the range back so the leveling leg is

under the anti-tip bracket. If the range is pulled from the wall for any reason, always repeat this

procedure to verify the range is properly secured by the anti-tip bracket. Never completely remove

the leveling legs or the range will not be secured to the anti-tip bracket.

8

LEVEL THE RANGE

Tip-Over Hazard

To reduce the risk of tipping the

range, the range must be secured by

a properly installed anti-tip bracket.

See installation instructions shipped

with the bracket for complete details

before attempting to install.

To check if the bracket is installed and

engaged properly, look underneath

the range to see that the rear leveling

9

FINAL INSTALLATION CHECKLIST

• Check to make sure the circuit breaker is closed (RESET) or the circuit fuses are replaced.

• Be sure power is in service to the building.

• Check that all packing materials and tape have been removed. This will include tape on metal

panel under control knobs (if applicable), adhesive tape, wire ties, cardboard and protective

plastic. Failure to remove these materials could result in damage to the appliance once the

appliance has been turned on and surfaces have heated.

• Check that the door and drawer are parallel to each other and that both operate smoothly. If they

do not, see the Owner’s Manual for proper replacement.

• Check to make sure that the rear leveling leg is fully inserted into the Anti-Tip bracket and that the

bracket is securely installed.

OPERATION CHECKLIST

• Check that the oven control operates properly. If the oven control does not operate properly,

recheck the wiring connections.

• Be sure all range controls are in the OFF position before leaving the range.

WARNING

remove the leveling leg as the range will not

be secured to the anti-tip device properly.

A. Plug in the unit.

B. Measure the height of your countertop at the

rear of the opening (X).

C. Adjust two rear leveling legs so that the rear

of cooktop is at the same height or higher

than the counter (Y).

D. Slide unit into place.

E. Install oven shelves in the oven and position

the range where it will be installed.

F. Check for levelness by placing a spirit

level on one of the oven shelves. Take two

readings—with the level placed diagonally

first in one direction and then the other.

G. Adjust front leveling legs until the range is

level.

H. Look under the unit and verify that the rear

leg is fully engaged with the anti-tip device. If

not, remove the unit and adjust the height of

the rear leg so that it is properly engaged.

Never completely

X

Y

Cooktop

Counter

NOTE: Cooktop must be at or above counter.

Spirit level

0” or Greater

INSTALLATION INSTRUCTION

31-10892-3 08-18 GEA

JBS10, JBS30, JBS45, RB525, RB526, RBS160,

RBS360, JBS160, JBS360, JBS460, JB255, JB256,

JB450, JB480, VBS160, and XBS360

Page 5

Instrucciones de instalación

Cocinas eléctricas empotrables

ANTES DE COMENZAR

Lea estas instrucciones por completo y con

detenimiento.

•

IMPORTANTE – Guarde estas

instrucciones para el uso de inspectores locales.

•

IMPORTANTE – Siga todos los códigos y

ordenanzas vigentes.

• Nota al instalador – Asegúrese de dejar estas

instrucciones con el consumidor.

PARA SU SEGURIDAD

ADVERTENCIA

• Un niño o adulto pueden volcar la cocina y morir.

• Instale el soporte anti-volcaduras sobre la pared o el piso.

•

Asegúrese la estufa al soporte anti-volcaduras deslizando

la unidad hacia atras de tal manera que la pata niveladora

sea enganchada.

• Vuelva a adherir el soporte anti-volcaduras si la estufa

se mueve de lugar.

• Si esto no se hace, se podrá producir la muerte o

quemaduras graves en niños o adultos.

Si no recibió un soporte anti volcaduras con su compra, llame

al 1.800.626.8774 para recibir uno sin costo. (En Canadá,

llame al 1.800.561.3344). Para recibir instrucciones de

instalación del soporte, visite: GEAppliances.com

(En Canadá, GEAppliances.ca.).

Riesgo de Caída

MATERIALES QUE PUEDE NECESITAR HERRAMIENTAS

NECESARIAS

Conector de presión

(Sólo para instalaciones

con conductos

portacables)

1

QUITE LOS MATERIALES DE ENVÍO: No quitar los materiales de empaque

puede provocar daños al electrodoméstico. Quite todas las partes de empaque del horno, bandejas,

elementos calentadores y cajón. También, quite la película protectora y las etiquetas de la puerta exterior,

estufa y panel de control.

(Aprobados por UL de 40 AMP)

Cable de 4 alambres de 4’

de largo O Cable de 3 alambres

de 4’ de largo

• Nota al consumidor – Conserve estas

instrucciones para referencia futura.

• Nivel de destreza – La instalación de este aparato

debe efectuarla un instalador o electricista

calificado.

• El instalador tiene la responsabilidad de efectuar

una instalación adecuada.

• La garantía no cubre las fallas del producto debido

a una instalación incorrecta.

Kit de soporte

anti-volcaduras

incluido

ADVERTENCIA

comenzar la instalación, apague el

encendido en el panel de servicio y bloquee

el medio de desconexión del servicio a fin de

evitar que el encendido se active de forma

accidental. Cuando el medio de desconexión

del servicio no se pueda bloquear, ajuste

de manera segura un ítem de advertencia

que esté bien visible, tal como una etiqueta,

sobre el panel de servicio.

Perforadora con

broca de 1/8”

Gafas de seguridad

Llave ajustable

Nivel

Antes de

Tijeras para hojalata

Cinta métrica

Alicates

Llave de tuercas

de 1/4”

2

CÓMO PREPARAR LA ABERTURA (PARA USO EN EL

INTERIOR SOLAMENTE)

Ver ilustraciones con todas las dimensiones de empotrado y de espacio. La cocina puede ubicarse con un

espacio de 0” (alineado) sobre la pared trasera y las paredes laterales del gabinete.

Área recomendada

8 1/2”

30”

26 1/4”

Sin manija

with handle

36 1/4”

29”

30”

3”

3”

9”

3”

4”

8”

46 3/4”

Instale la caja de

distribución sobre

cualquier lado de

la línea central.

NOTA: Utilice un cable de energía de 4’ para evitar una

interferencia con el cajón de almacenamiento. Los cables de

energía de 4

poder cerrar el cajón correctamente.

DIMENSIONES MÍNIMAS ENTRE LA ESTUFA, LAS PAREDES

Y SOBRE LA PARTE SUPERIOR DE LA ESTUFA:

A. Verifique que el revestimiento de las paredes, el mostrador, el

piso y los gabinetes ubicados alrededor de la cocina puedan

soportar el calor (hasta 200°F) generado por la cocina. 0” para

gabinetes debajo de la superficie de cocción y para la parte

trasera de la cocina.

B. Deje un espacio de 30” como mínimo entre las unidades

de superficie y la parte inferior de gabinetes de madera o

de metal sin protección o deje un mínimo de 24” cuando la

parte inferior del gabinete de madera o metal se encuentre

protegida por cartón aislante de un grosor no menor a 1/4”

y con retardo de llama cubierto con una placa de metal no

menor a MSG Nº 28, acero inoxidable de un grosor de .015”,

aluminio de .024” o cobre de .020”.

C. Este aparato ha sido aprobado para un espacio de 0” respecto de superficies adyacentes sobre la estufa. Sin

embargo, se recomienda un espacio mínimo de 6” respecto de superficies menores a 15” sobre la estufa y

gabinete adyacente para reducir la exposición al vapor, salpicaduras de grasa y calor.

Para reducir el riesgo de quemaduras o incendios cuando se incline sobre los elementos de superficie calientes,

debe evitarse la instalación de espacios de almacenamiento en gabinetes sobre la estufa. Si debe contarse con

espacio para almacenamiento en gabinetes sobre la estufa, puede reducirse el riesgo instalando una campana

de cocina que sobresalga por lo menos 5” más allá del frente de los gabinetes. Los gabinetes instalados por

encima de la estufa no deben tener una profundidad mayor a los 16”.

1

»2’ a 6’ de largo pueden tener que cubrirse para

7 1/2”

2 1/4”

NOTA C

A

para una salida

eléctrica aceptable.

Oriente el receptáculo

eléctrico de modo

que la longitud sea

paralela al suelo.

2 1/4”

B

C

Ambos

lados

A

Page 6

3

REQUERIMIENTOS ELÉCTRICOS

ADVERTENCIA

ADVERTENCIA

instalaciones donde los códigos locales no permiten una conexión a tierra a través de un neutral requieren un

cable para cocina de 4 conductores aprobado por UL.

Esta unidad debe contar con una adecuada conexión a tierra.

Todas las construcciones nuevas, casas rodantes, vehículos recreativos e

4

INSTALACIÓN DE CABLE DE ENERGÍA Y DE PASACABLES

A

Quite la tapa del cable (en la parte trasera de la cocina) quitando tornillos mediante una llave de tuercas

de 1/4”. Usted puede acceder el bloque terminal quitando la tapa del bloque terminal (en algunos

modelos) o la tapa de los cables. No elimine esos tornillos.

Parte trasera de la cocina

ADVERTENCIA

de extensión con este aparato.

ADVERTENCIA

circuitos antes de comenzar la instalación.

Recomendamos que un electricista calificado conecte el cableado eléctrico y su cocina. Después de la

instalación, solicite al electricista que le indique cómo desconectar la energía de la cocina.

Usted debe usar un sistema eléctrico de 60 hercios CA de fase única de 120/280 voltios o 120/240 voltios. Si

tiene una conexión con cableado de aluminio, deben utilizarse conectores adecuadamente instalados para utilizar

con cableado de aluminio.

Si el servicio eléctrico provisto no cumple con las especificaciones anteriores, haga que un electricista con

licencia instale un tomacorriente aprobado.

Vigente desde el 1 de enero de 1996, el Código Eléctrico Nacional requiere que las nuevas construcciones

(no existentes) utilicen una conexión de cuatro conductores a una cocina eléctrica. Cuando instale una cocina

eléctrica en una nueva construcción, una casa rodante, un vehículo recreativo o un área donde los códigos

locales prohíben la conexión a tierra a través de un conductor neutral, consulte la sección sobre conexiones en

circuito derivado de cuatro conductores.

Consulte a las empresas de servicio público sobre los códigos eléctricos que se aplican en su área. No realizar el

cableado de su horno de acuerdo con los códigos vigentes puede provocar una situación peligrosa. Si no existen

códigos locales, su cocina debe contar con cables y fusibles que cumplan con los requisitos del Código Eléctrico

Nacional, ANSI/NFPA No. 70–Última edición.

Este electrodoméstico debe recibir el voltaje y frecuencia adecuados, y debe conectarse a un circuito derivado

individual con adecuada conexión a tierra de 40 amperios (mínimo) protegido por un interruptor de circuitos o

fusible con retraso.

Utilice sólo un cable para cocinas de 3 o 4 conductores aprobado por UL. Estos cables pueden contar con

terminales de anillo en alambre y un dispositivo de alivio de tensión.

Se requiere un cable para cocinas clasificado para 40 amperios con rango de voltios mínimo de 125/250. No se

recomienda un cable de 50 amperios, pero si se utiliza, debe señalizarse para usarse con aberturas de conexión

de un diámetro nominal de 1-3/8”. Debe tenerse cuidado al centrar el cable y el alivio de tensión dentro del

orificio de expulsión para evitar que el borde dañe el cable.

La placa de clasificación se encuentra ubicada sobre el cajón de almacenamiento en el marco del horno o en el

lado del marco del cajón.

NOTA: No se recomienda para este producto el uso de interruptores automáticos, inalámbricos o con cableado

externo que apagan la corriente del electrodoméstico.

Para prevenir un incendio o descarga eléctrica, no utilice un cable

Para prevenir una descarga eléctrica, quite el fusible o abra el interruptor de

HORNO SIMPLE

Tapa del Bloque

Terminal

B

Para cable de energía y pasacables de 1”

solamente, quite el anillo de expulsión (1-3/8”)

ubicado en el soporte directamente debajo del

bloque terminal. Para quitar el anillo, utilice un par

de alicates para doblar el anillo de expulsión lejos

del soporte y gire hasta remover el anillo.

Bloque terminal (la

apariencia puede

cambiar)

Anillo de

expulsión

en el

soporte

Anillo de

expulsión

quitado

D

Sólo para instalaciones con conducto portacables de 3/4”, adquiera un conector de presión que se ajuste

al diámetro de su conducto e instálelo en el orificio. Introduzca el conducto a través del conector de

presión y ajuste. Deje un largo suficiente para poder pegar los cables al bloque terminal. NOTA: No

instale el conducto sin un conector de presión. El conector de presión DEBERÁ ser instalado antes de

volver a instalar el bloque terminal trasero.

C

NOTA: No instale el cable de energía sin un

Alivio de tensión

Tornillos para

retirar la tapa del

bloque terminal

Sólo para instalaciones de cable de energía

(ver el paso siguiente si utiliza un conducto

portacables), instale el alivio de tensión en el

orificio. Introduzca el cable de energía a través

del alivio de tensión y ajuste. Deje un largo

suficiente para poder conectar las terminales

de cable al bloque terminal. Si hay lengüetas

al final del alivio de tensión con alas, éstas

pueden quitarse para un ajuste mejor.

alivio de tensión. El soporte del alivio de tensión

DEBE instalarse antes de volver a colocar la

tapa del cableado trasero de la cocina.

Bloque

terminal

Cable de

energía

Soporte

Placa de

clasificación

Conector de

presión

SIGA CON EL PASO 6 O 7.

Conducto

portacables

Bloque terminal

Soporte

Page 7

5

INSTALACIÓN DE TRES (3) ALAMBRES (LA CONEXIÓN A

TIERRA SE REALIZA A TRAVÉS DEL CABLE NEUTRO)

ADVERTENCIA

El cable neutro y la cinta de conexión a tierra deben

estar conectados como se muestra a continuación, de

modo que la cocina esté correctamente conectada a

tierra. No retire la cinta de conexión a tierra. Si no se

siguen estas instrucciones, podrán existir riesgos de

descarga eléctrica.

ADVERTENCIA

Los tornillos del bloque terminal deben estar ajustados

de forma segura. Si esto no se cumple, existen riesgos

de incendio.

PARA INSTALACIÓN DE CABLE DE ENERGÍA

A. Retire los 3 tornillos inferiores del bloque terminal.

No afloje los tornillos superiores.

B. No corte ni retire la cinta de conexión a tierra.

C. Inserte los 3 tornillos a través de cada anillo terminal

del cable de corriente y nuevamente al bloque

terminal. Asegúrese de que el cable blanco se

encuentre en el centro. Ajuste de forma segura cada

tornillos (entre 35 y 50 pulgadas/libra).

PARA INSTALACIÓN DE CONDUCTO PORTACABLES

A. Afloje los 3 tornillos inferiores del bloque terminal. No afloje

los tornillos superiores.

B. No corte ni retire la cinta de conexión a tierra.

C. Inserte la punta del cable pelado (sin aislante de 5/8”) en

las aberturas inferiores del bloque terminal. Asegúrese de

que el cable blanco se encuentre en el centro. En ciertos

modelos, el cable deberá ser insertado a través de una

abertura de la cinta de conexión a tierra. Ajuste de forma

segura cada tornillo en cada cable (entre 35 y 50 pulgadas/

libra).

D. Reinstale la tapa del bloque terminal.

NOTA: Puede utilizarse cable de construcción de aluminio

pero debe clasificarse para el amperaje y voltaje correctos.

SIGA CON EL PASO 8.

Riesgo de Descarga

Riesgo de incendio

Bloque

terminal (la

apariencia

puede

cambiar)

Terminal

neutral

Cinta de

conexión a

tierra

Placa de

conexión

a tierra

Rojo o

Negro

Cable de

energía

Bloque

terminal

Puntas

de los

cables

Rojo o

Negro

Conducto

portacables

Cable de energía

Conducto portacables

Blanco

Rojo o

Negro

Blanco

Rojo o

Negro

6

INSTALACIÓN DE 4 ALAMBRES (CABLE DE CONEXIÓN A

TIERRA SEPARADO)

ADVERTENCIA

circuito de suministro debe estar conectado a la

terminal neutral ubicada en el centro inferior del

bloque terminal. Los cables de energía deben estar

conectados a las terminales inferior izquierda e

inferior derecha del bloque terminal. El cuarto cable

a tierra debe estar conectado al marco de la cocina

con la placa de conexión a tierra y el tornillo a tierra.

PARA INSTALACIÓN DE CABLE DE ENERGÍA

A. Retire los 3 tornillos inferiores del bloque

terminal. No afloje los tornillos superiores.

B. Retire el tornillo de conexión a tierra y la placa

de conexión a tierra y retenga los mismos.

C. Corte la cinta de conexión a tierra que está debajo

del bloque terminal, y descarte la sección inferior.

D. Inserte el tornillo de conexión a tierra, a través

de la placa de conexión a tierra (retirada

anteriormente) y nuevamente en la estructura

de la cocina. Ajuste de forma segura, pero sin

ajustar en exceso (entre 15 y 20 pulgadas/libra).

E. Inserte los 3 tornillos de la terminal a través

de cada anillo terminal del cable de corriente y

nuevamente al bloque terminal. Asegúrese de

que el cable blanco se encuentre en el centro.

Ajuste de forma segura cada tornillo (entre 35 y

50 pulgadas/libra).

F. Reinstale la tapa del bloque terminal.

PARA INSTALACIÓN DE CONDUCTO

PORTACABLES

A. Retire los 3 tornillos inferiores del bloque

terminal. No afloje los tornillos superiores.

B. Retire el tornillo de conexión a tierra y la placa de

conexión a tierra y retenga los mismos.

C. Corte la cinta de conexión a tierra que está debajo

del bloque terminal, y descarte la sección inferior.

D. Inserte la punta del cable descubierto de conexión

a tierra (sin aislante de 5/8”) entre el marco de

la cocina y la placa de conexión a tierra (retirada

previamente) y asegure el mismo con el tornillo de

conexión a tierra. Ajuste de forma segura, pero sin

ajustar en exceso (entre 15 y 20 pulgadas/libra).

E. Inserte las puntas de los cables (sin aislante de

5/8”) en las aberturas inferiores del bloque terminal.

Asegúrese de que el cable blanco se encuentre

en el centro. En ciertos modelos, el cable deberá

ser insertado a través de una abertura de la cinta

de conexión a tierra. Ajuste de forma segura cada

tornillo en cada cable (entre 35 y 50 pulgadas/libra).

F. Reinstale la tapa del bloque terminal.

NOTA: Puede utilizarse cable de construcción de aluminio pero debe clasificarse para el amperaje y voltaje

correctos para poder realizar la conexión.

El cable neutral del

Bloque

terminal

Bloque

terminal

Tornillo de

conexión

a tierra

Bloque

terminal

Tornillo de

conexión a tierra

Antes–Cable de energía

y conducto portacables

Cinta de

conexión

a tierra

Después–Cable de energía

Rojo o

Negro

Blanco

Verde o

Pelado

Después–Conducto portacables

Puntas

de los

cables

Rojo o

Negro

Blanco

Cinta de

conexión a tierra

o

Terminal

neutral

Terminal

neutral

Placa de conexión

a tierra (conexión a

tierra de la cocina)

Rojo o

Negro

Placa de conexión

a tierra (conexión

a tierra de la

cocina)

Rojo o

Negro

Verde o

Pelado

Page 8

7

INSTALACIÓN DE DISPOSITIVO ANTI-VOLCADURAS

ADVERTENCIA

• Un niño o adulto pueden volcar la cocina y morir.

• Instale el soporte anti-volcaduras sobre la pared o el piso.

•

Asegúrese la estufa al soporte anti-volcaduras deslizando

la unidad hacia atras de tal manera que la pata niveladora

sea enganchada.

• Vuelva a adherir el soporte anti-volcaduras si la estufa

se mueve de lugar.

• Si esto no se hace, se podrá producir la muerte o

quemaduras graves en niños o adultos.

la pata niveladora esté adosada al soporte. En modelos que no poseen un cajón de almacenaje o parte inferior

delantera, incline con cuidado la cocina hacia adelante. El soporte debería detener la cocina dentro de las cuatro

pulgadas. De no ser así, el soporte deberá ser instalado nuevamente. Si la cocina es expulsada de la pared por

alguna razón, siempre repita este procedimiento a fin de verificar que esté asegurado de forma correcta con un

soporte anti volcaduras. Nunca elimine completamente las patas niveladoras, ya que de ser así la cocina no

estará adecuadamente asegurada por el dispositivo anti volcaduras.

8

NIVELACIÓN DE LA

Riesgo de Caída

A fin de reducir el riesgo de inclinar la cocina,

ésta deberá estar asegurada con un soporte

anti volcaduras. Lea las instrucciones de

instalación que se enviaron con el soporte

para obtener un detalle completo antes de

comenzar la instalación.

A fin de controlar que el soporte esté

instalado y adosado correctamente, retire

el cajón de almacenaje o la parte inferior

delantera y observe debajo de la cocina que

COCINA

9

LISTA DE CONTROL FINAL DE LA INSTALACIÓN

• Verifique que el interruptor de circuitos se encuentre cerrado (RESET) o que los fusibles del circuito se hayan

reemplazado.

• Asegúrese de que se cuente con suministro eléctrico en el edificio.

• Controle que se haya quitado todo el material de empaque y la cinta. Esto incluye cinta sobre el panel de metal

bajo las perillas de control (si corresponde), cinta adhesiva, ataduras de alambre, cartón y plástico protector. No

quitar estos materiales puede provocar daños al electrodoméstico una vez que el aparato se haya encendido y

las superficies se hayan calentado.

• Controle que la puerta y el cajón se encuentren paralelos y que los dos funcionen correctamente. Si no es así,

consulte el Manual del propietario para un reemplazo adecuado.

• Controle que la pata de nivelación trasera esté bien introducida dentro del soporte anti-volcaduras y que el

soporte se encuentre bien instalado.

LISTA DE CONTROL DE FUNCIONAMIENTO

• Controle que el control del horno funcione correctamente. Si el control del horno no funciona de forma correcta,

vuelva a controlar las conexiones de los cables.

• Asegúrese de que los controles de la cocina se encuentren en la posición OFF (apagado) antes de alejarse de

la cocina.

ADVERTENCIA

completamente las patas niveladoras, ya que la

cocina no estará asegurada de forma adecuada al

dispositivo anti-volcaduras.

A. Enchufe la unidad.

B. Mida la altura de su mostrador de encimera en la

parte trasera de la abertura (X).

C. Ajuste las dos patas de nivelación traseras para

que la parte trasera de la estufa se encuentre a la

misma altura o más arriba que la mesada (Y).

D. Deslice la unidad en su lugar.

E. Instale los estantes del horno en la unidad y

coloque la cocina donde se instalará.

F. Controle la nivelación colocando un nivel de

burbuja de aire sobre uno de los estantes

del horno. Haga dos lecturas–con el nivel ubicado

en diagonal primero en una dirección

y luego en la otra.

G. Ajuste las patas de nivelación frontales hasta que

la cocina quede nivelada.

Observe debajo de la unidad y verifique que la

H.

pata trasera esté completamente adherida al

dispositivo antivolcaduras. De no ser así, retire

la unidad y ajuste la altura de la pata trasera de

modo que quede correctamente adherida.

Nunca retire

X

Y

Placa de

Cocción

Mesada

NOTA: La placa de cocción debe estar a la

misma altura o más arriba que la mesada.

Nivel de Agua

0” o Superior

INSTRUCCIONES DE INSTALACIÓN

31-10892-3 08-18 GEA

JBS10, JBS30, JBS45, RB525, RB526, RBS160,

RBS360, JBS160, JBS360, JBS460, JB255, JB256,

JB450, JB480, VBS160, and XBS360

Loading...

Loading...