GE J2S968BEK2BB, J2S968BEK3BB, J2S968BH1BB, J2S968BH2BB, J2S968BH3BB Installation Guide

...Page 1

IIinstallation ISelf-Cleanin DualFuel

nstructlons Slide-In Range J2S968,J2C968

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.com

In Canada, call 1.800.361.3400 or Visit our Website at: www.geappliances.ca I

IN THE COMMONWEALTH OF

MASSACHUSETTS:

• This product must be installed by a

licensed plumber or gas fitter.

= When using ball-type gas shut-off valves,

they shall be the T-handle type.

= A flexible gas connector, when used, must

not exceed 3 feet.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Observeall

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these

instructions for future reference.

• Product failure due to improper installation

is not covered under the Warranty.

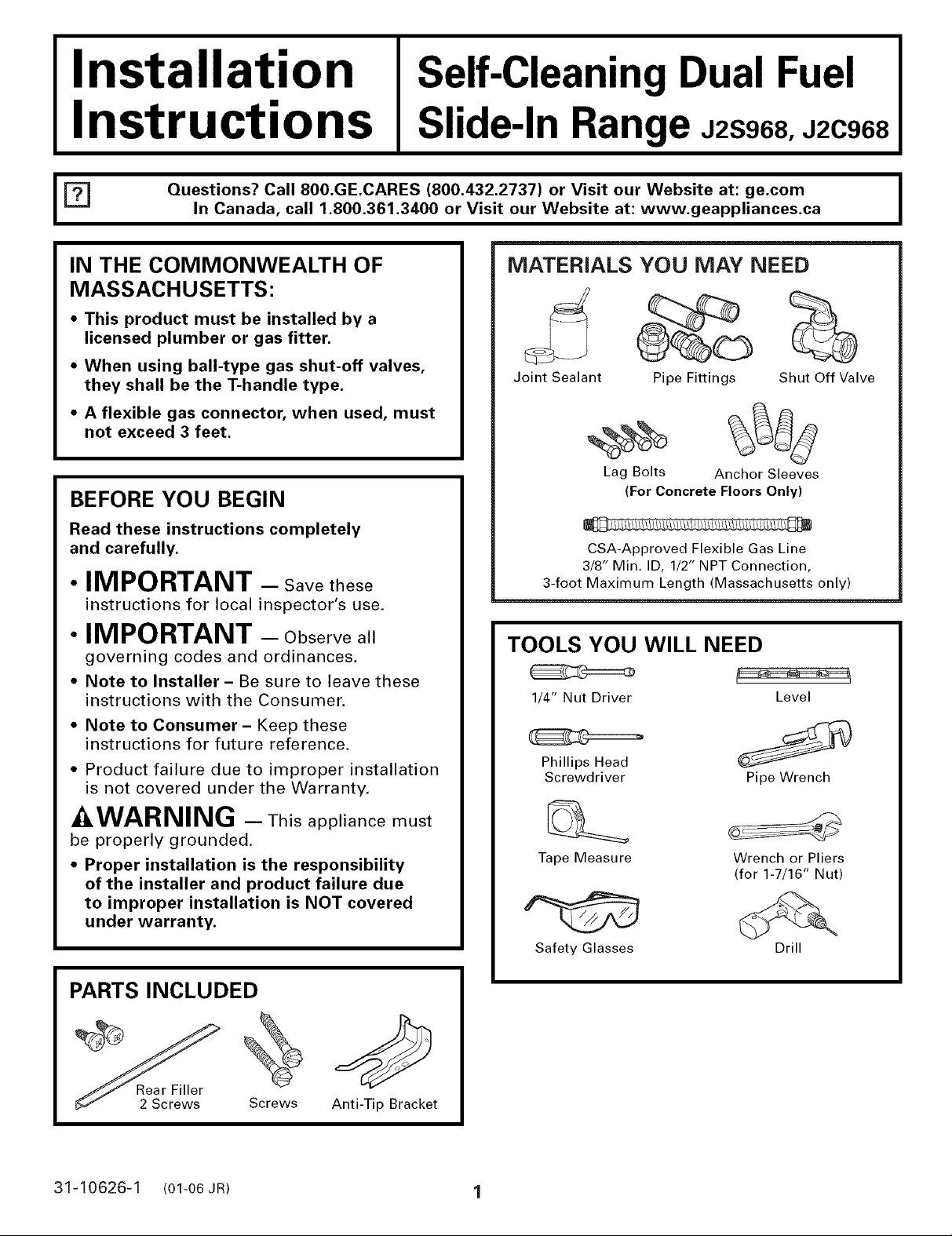

MATERIALS YOU MAY NEED

Joint Sealant Pipe Fittings Shut Off Valve

Lag Bolts Anchor Sleeves

(For Concrete Floors Only)

CSA-Approved Flexible Gas Line

3/8" Min. ID, 1/2" NPT Connection,

3-foot Maximum Length (Massachusetts only)

TOOLS YOU WILL NEED

1/4" Nut Driver

Phillips Head

Screwdriver

Level

Pipe Wrench

AWARNING - This appliance must

be properly grounded.

• Proper installation is the responsibility

of the installer and product failure due

to improper installation is NOT covered

under warranty.

PARTS INCLUDED

Screws

31-10626-1 (01-06 JR) 1

Anti-Tip Bracket

Tape Measure

Safety Glasses

Wrench or Pliers

(for 1-7/16" Nut)

Drill

Page 2

Installation instructions

IMPORTANT SAFETY INSTRUCTIONS

FOR YOUR SAFETY:

WARNING - Iftheinformationin

this manual is not followed exactly, a fire,

explosion or gas leak may result causing

property damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance!

WHAT TO DO iF YOU

SMELL GAS:

• Do not try to light any appliance. Do not

touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier,

call the fire department.

This range has been design certified by

UNDERWRITERS LABORATORIES for use in

the United States and Canada. You'll find

safety precautions in your Owner's Manual.

Read them carefully.

• Installation of this range must conform with

local codes or in the absence of local codes

with the National Fuel Gas Code, ANSI

Z223.1-Latest edition.

Be sure your range is installed properly by

a qualified installer or service technician.

To eliminate reaching over surface burners,

cabinet storage above burner should be

avoided,

• Do not install the unit near an outside door

or where a draft may affect its use,

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

2

Page 3

Installation instructions

FOR YOUR SAFETY:

WARNING - For personal safety,

remove house fuse or open circuit breaker

before beginning installation. Failure to do so

could result in serious injury or even death.

All rough-in and spacing dimensions must be

met for safe use of your range. Electricity to

the range can be disconnected at the outlet

without moving the range if the outlet is in

the preferred location (remove lower drawer).

To reduce the risk of burns or fire when

reaching over hot surface elements, cabinet

storage space above the cooktop should be

avoided. If cabinet storage space is to be

provided above the cooktop, the risk can be

reduced by installing a range hood that sticks

out at least 5" beyond the front of the

cabinets. Cabinets installed above a cooktop

must be no deeper than 13".

Be sure your appliance is properly installed

and grounded by a qualified technician.

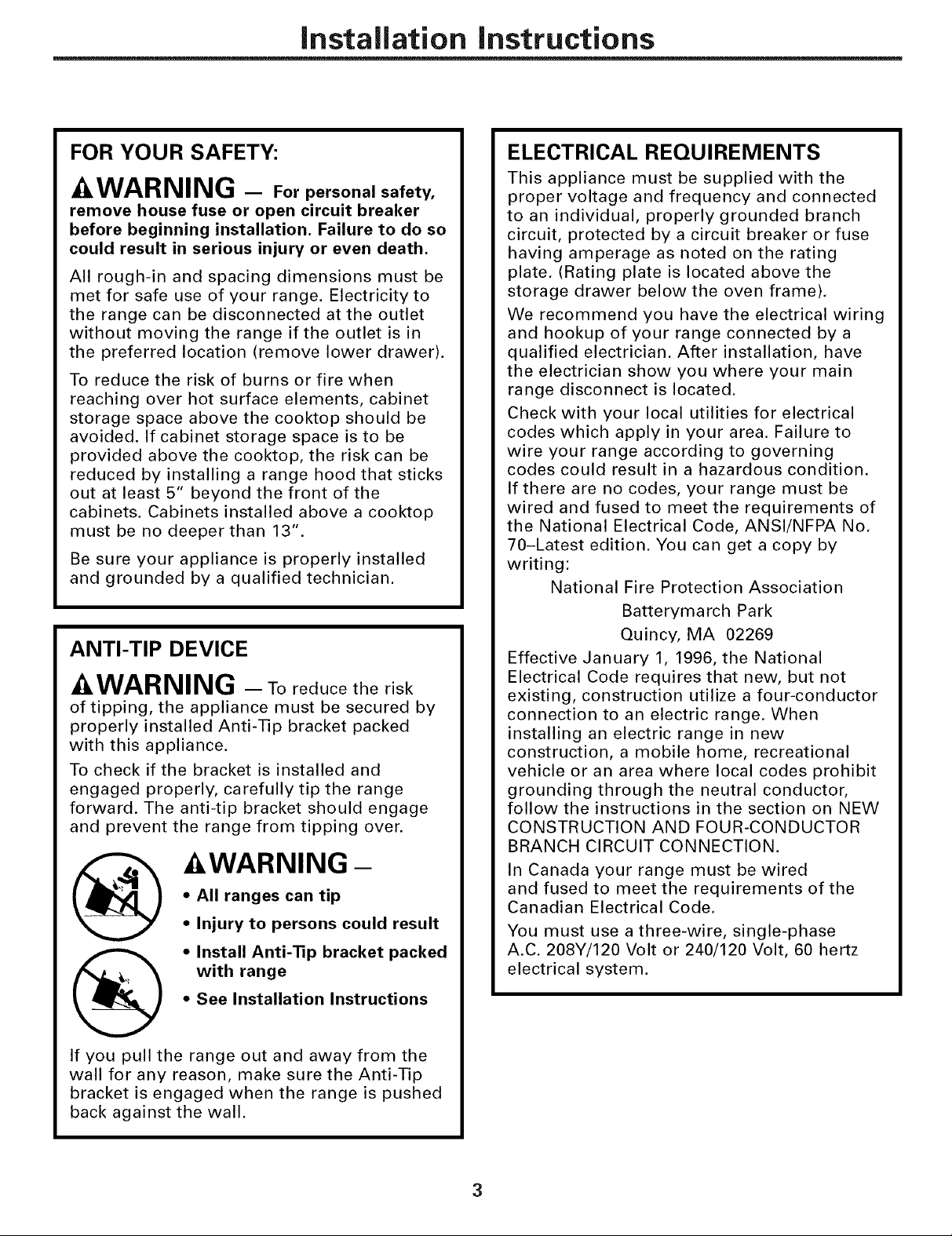

ANTI-TIP DEVICE

AWARNING - Toreducetherisk

of tipping, the appliance must be secured by

properly installed Anti-Tip bracket packed

with this appliance.

To check if the bracket is installed and

engaged properly, carefully tip the range

forward. The anti-tip bracket should engage

and prevent the range from tipping over.

WARNING -

• All ranges can tip

• Injury to persons could result

• Install Anti-]3p bracket packed

with range

• See Installation Instructions

ELECTRICAL REQUIREMENTS

This appliance must be supplied with the

proper voltage and frequency and connected

to an individual, properly grounded branch

circuit, protected by a circuit breaker or fuse

having amperage as noted on the rating

plate. (Rating plate is located above the

storage drawer below the oven frame).

We recommend you have the electrical wiring

and hookup of your range connected by a

qualified electrician. After installation, have

the electrician show you where your main

range disconnect is located.

Check with your local utilities for electrical

codes which apply in your area. Failure to

wire your range according to governing

codes could result in a hazardous condition.

If there are no codes, your range must be

wired and fused to meet the requirements of

the National Electrical Code, ANSI/NFPA No.

70-Latest edition. You can get a copy by

writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Effective January 1, 1996, the National

Electrical Code requires that new, but not

existing, construction utilize a four-conductor

connection to an electric range. When

installing an electric range in new

construction, a mobile home, recreational

vehicle or an area where local codes prohibit

grounding through the neutral conductor,

follow the instructions in the section on NEW

CONSTRUCTION AND FOUR-CONDUCTOR

BRANCH CIRCUIT CONNECTION.

In Canada your range must be wired

and fused to meet the requirements of the

Canadian Electrical Code.

You must use a three-wire, single-phase

A.C. 208Y/120 Volt or 240/120 Volt, 60 hertz

electrical system.

If you pull the range out and away from the

wall for any reason, make sure the Anti-Tip

bracket is engaged when the range is pushed

back against the wall.

3

Page 4

Installation Instructions

PRE-INSTALLATION CHECKLIST

[_ iNSPECT iNSTALLATiON

LOCATION

Refer to alternate construction section for

the following non-standard installations.

[] Counter opening extends to the wall:

Maintop Filler (supplied with the

range.) (See page 15 for Installation

Instructions) or

Backguard (Kit JXS36XX or JXS39SS).

[] Counter height greater than 36-3/4":

Lower Trim Slide-In (Kit JXS56XX).

[] One side is not enclosed by a cabinet:

Bodyside (Kit JXS76XX).

[] Island Installation:

To provide an optimum installation, the

top surface of the countertop must be

level and flat (lie on the same plane)

around the 3 sides that are adjacent to

range cooktop. Proper adjustments to

make the top flat should be made or

gaps between the countertop and

range cooktop may occur. Forcing the

cooktop to fit may cause excessive

gaps and could break the glass and

void the warranty.

_-I MOVE RANGE INDOORS IN

FRONT OF CABINET OPENING

Do not use hand trucks when moving the

unpackaged range. Cooktop glass may be

broken.

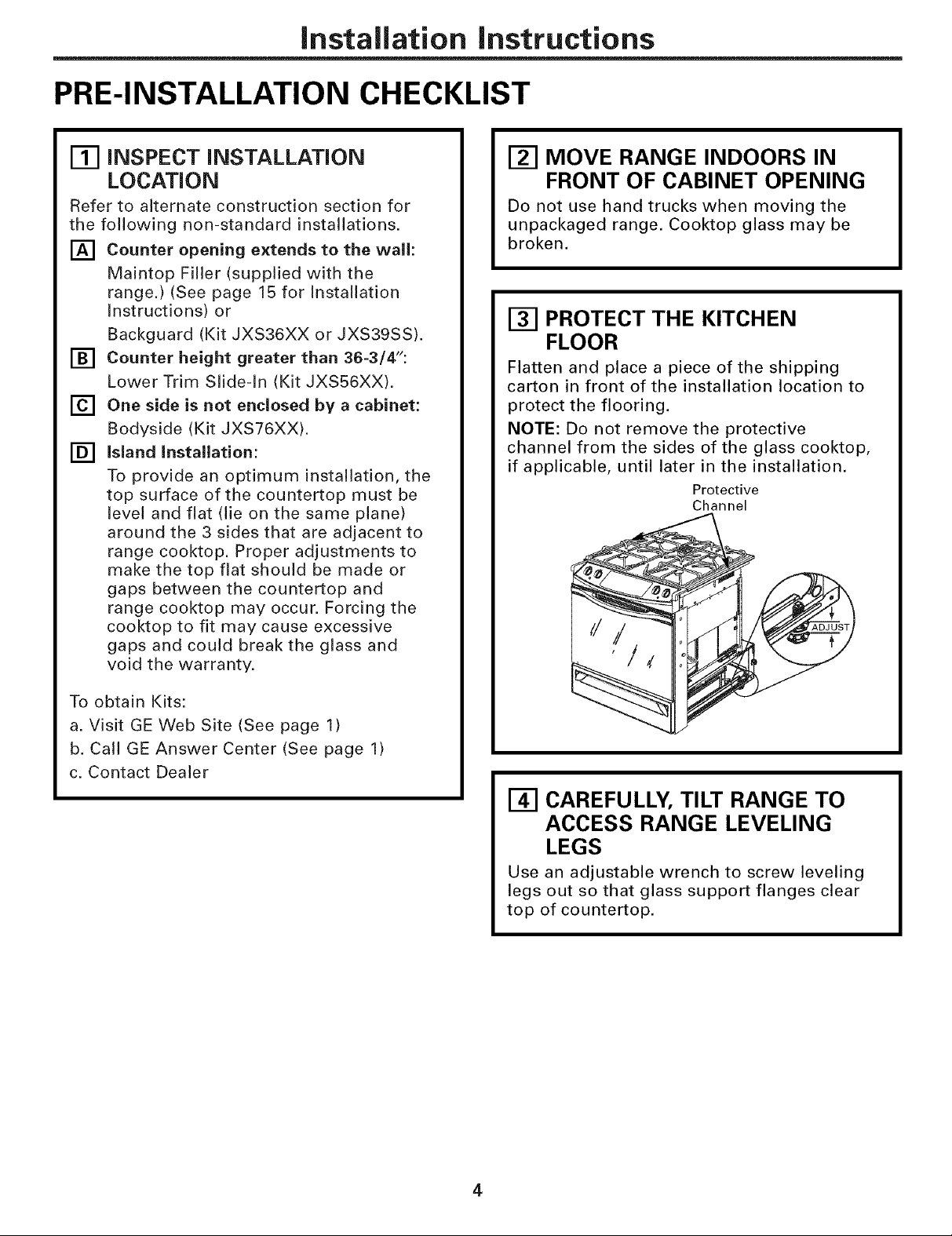

_-I PROTECT THE KITCHEN

FLOOR

Flatten and place a piece of the shipping

carton in front of the installation location to

protect the flooring.

NOTE: Do not remove the protective

channel from the sides of the glass cooktop,

if applicable, until later in the installation.

Protective

Channel

To obtain Kits:

a. Visit GE Web Site (See page 1)

b. Call GE Answer Center (See page 1)

c. Contact Dealer

[_] CAREFULLY, TILT RANGE TO

ACCESS RANGE LEVELING

LEGS

Use an adjustable wrench to screw leveling

legs out so that glass support flanges clear

top of countertop.

4

Page 5

Installation instructions

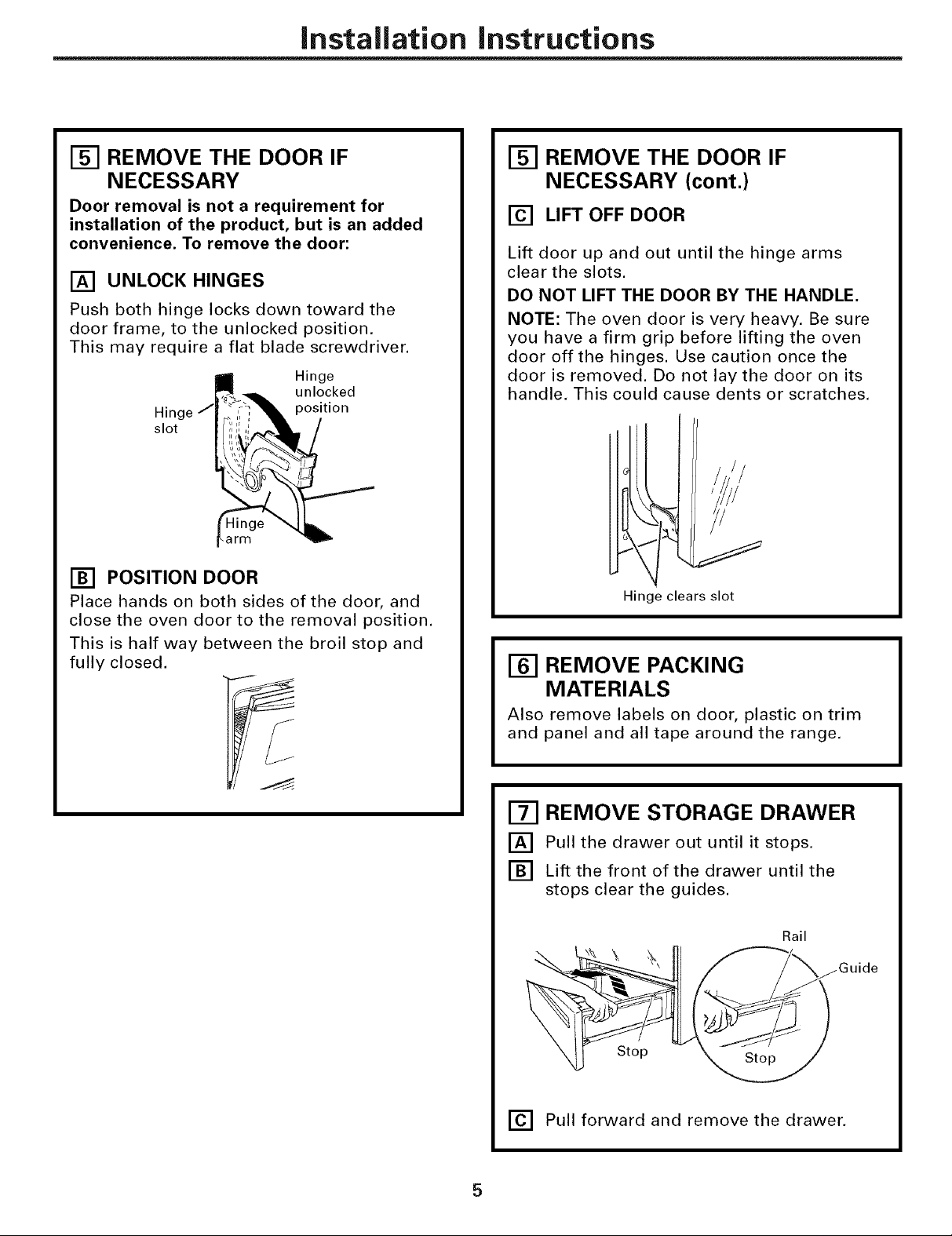

[] REMOVE THE DOOR IF

NECESSARY

Door removal is not a requirement for

installation of the product, but is an added

convenience. To remove the door:

[] UNLOCK HINGES

Push both hinge locks down toward the

door frame, to the unlocked position.

This may require a flat blade screwdriver.

Hinge

unlocked

Hin(

slot

-arm

[] POSITION DOOR

Place hands on both sides of the door, and

close the oven door to the removal position.

This is half way between the broil stop and

fully closed.

position

REMOVE THE DOOR IF

NECESSARY (cont.)

[] LIFT OFF DOOR

Lift door up and out until the hinge arms

clear the slots.

DO NOT LIFT THE DOOR BY THE HANDLE.

NOTE: The oven door is very heavy. Be sure

you have a firm grip before lifting the oven

door off the hinges. Use caution once the

door is removed. Do not lay the door on its

handle. This could cause dents or scratches.

Hinge clears slot

REMOVE PACKING

MATERIALS

Also remove labels on door, plastic on trim

and panel and all tape around the range.

[] REMOVE STORAGE DRAWER

[] Pull the drawer out until it stops.

[] Lift the front of the drawer until the

stops clear the guides.

Stop

[] Pull forward and remove the drawer.

5

Rail

_Guide

Page 6

Installation Instructions

PRE-INSTALLATION CHECKLIST (CONT.)

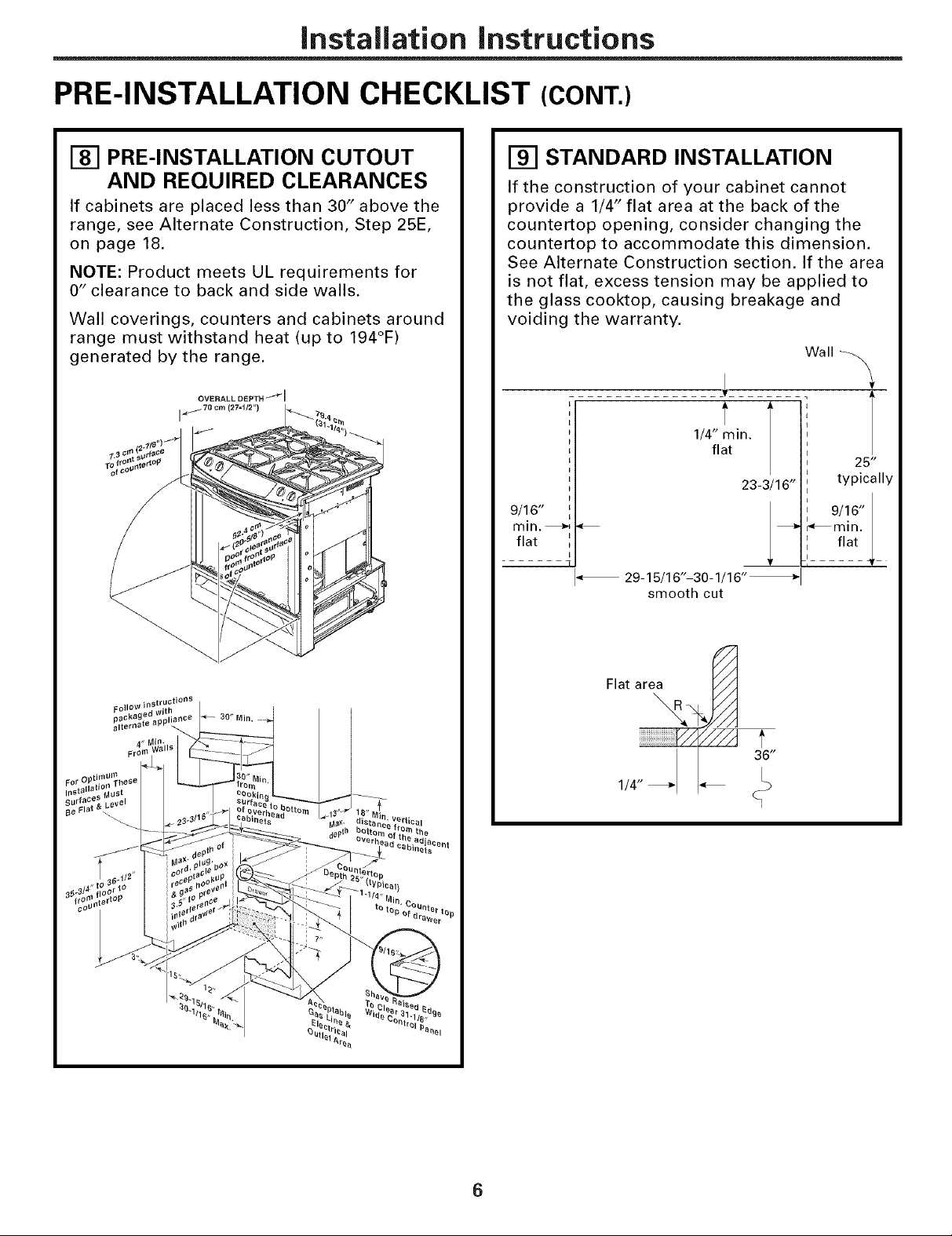

[] PRE-INSTALLATION CUTOUT

AND REQUIRED CLEARANCES

If cabinets are placed less than 30" above the

range, see Alternate Construction, Step 25E,

on page 18.

NOTE: Product meets UL requirements for

0" clearance to back and side walls.

Wall coverings, counters and cabinets around

range must withstand heat (up to 194°F)

generated by the range.

OVERALL DEPTH _ I

ij,___- 70 cm (27=1/2")

STANDARD INSTALLATION

If the construction of your cabinet cannot

provide a 1/4" flat area at the back of the

countertop opening, consider changing the

countertop to accommodate this dimension.

See Alternate Construction section. If the area

is not flat, excess tension may be applied to

the glass cooktop, causing breakage and

voiding the warranty.

=____

1/4" min.

flat

23-3/16" typically

9/16"

min._

flat

_ 29-15/16"-30-1/16"_ I

smooth cut

Wall

_min.

r

25"

flat

9/16" ]

FollOW

30" Bin,

area

Flat

36"

1/4" _ @

6

Page 7

Installation instructions

GAS CONNECTIONS

[] MAKING THE CONNECTIONS

15_

[]

Install a manual shut-off valve in the gas

supply line in an easily accessible location.

[]

Know how and where to shut off the gas

supply to the range.

Shut off gas supply before removing an

[]

old range. Leave it off until hookup of

new range is finished.

[]

Because solid pipe restricts moving the

range, we recommend use of a C.S.A.

certified flexible metal appliance

connector.

WARNING: Never reuse old

flexible connectors. The use of old flexible

connectors can cause gas leaks and personal

injury. Always use new flexible connectors

when installing a gas appliance.

Gas upply to

MAKING THE CONNECTIONS

(cont.)

[] Install 1/2" flare union adaptor to the 1/2"

NPT elbow on pressure regulator.

[] Connect flexible appliance connector to

flare union.

[] Move range into approximate position

and connect flexible connector to gas

supply line with proper flare union

adaptor.

Shut-off valve Flexible gas line

T _X Pressure

Gas elbow _ U

supply ""_4_4_]

line

[] To prevent gas leaks, put a pipe joint

sealant or Teflon ® tape on all male

threads. NOTE: Make sure sealant or tape

is compatible with Natural and LP gases.

[] When you are finished making

connections, be sure that all range knobs

are turned to OFF before you open the

main gas supply valve.

burner

Pressure

regulator as

seen from

front of range

WARNING: oo not use a flame

to check for gas leaks. Use liquid leak detector

at all joints and connections to check for leaks

in the system.

Page 8

Installation Instructions

ELECTRICAL CONNECTIONS

POWER CORD AND STRAIN

[]

RELIEF INSTALLATION

Remove the wire

[]

cover (on the back

of the range) by

removing 2

screws, using a

1/4" nut driver.

Do not discard

these screws,

[]

Remove the knockout ring (1-3/8")

located on bracket directly below the

terminal block. To remove the knockout,

use a pair of pliers to bend the knockout

ring away from the bracket and twist

until ring is removed.

Terminal block

(appearance

may vary)

eOover

[]

For power cord installations only (see the

next step if using conduit), assemble the

strain relief in the hole. Insert the power

cord through the strain relief and tighten.

Allow enough slack to easily attach the

cord terminals to the terminal block. If

tabs are present at the end of the winged

strain relief, they can be removed for

better fit.

NOTE: Do not install the power cord

without a strain relief. The strain relief

bracket should be installed before

reinstalling the rear range wiring cover.

Terminal

_ __o,_ block

Bracket

Knockout ring

in bracket

Knockout

ring removed

[]

For conduit installations only, purchase

a squeeze connector matching the

diameter of your conduit and assemble it

in the hole. Insert the conduit through

the squeeze connector and tighten. Allow

enough slack to easily attach the wires to

the terminal block.

NOTE: Do not install the conduit without

a squeeze connector. The squeeze

connector should be installed before

reinstalling the rear range wiring cover.

block

Squeeze

connector

Conduit

Bracket

8

Page 9

Installation instructions

[] NEW CONSTRUCTION AND

FOUR-CONDUCTOR BRANCH

CiRCUiT

All New Constructions, Mobile

Homes, Recreational Vehicles

and Installations Where Local

Codes Do Not Allow Grounding

Through Neutral Must Use the

4-Wire Cord Provided

NEMA 14-50R

4-wi re

r_] FOR EXISTING

CONSTRUCTION,

A THREE-WIRE FLEXIBLE

CORD KiT MAY BE USED

Follow instructions in step

14 if you require a 3-wire

cord:

208/240 40 Amp

3-prong cord

3-WIRE POWER CORD

INSTALLATION

WARNING: The neutral or ground

wire of the power cord must be

connected to the neutral terminal

located in the center of the terminal

block. The power leads must be

connected to the lower left and the

lower right terminals of the terminal

block.

Remove the 3 lower terminal screws

[]

from the terminal block. Insert the 3

terminal screws through each power

cord terminal ring and into the lower

terminals of the terminal block. Be

certain that the center wire

(white/neutral) is connected to the center

lower position of the terminal block.

Tighten screws securely into the terminal

block.

DO NOT remove the ground strap

connection.

Terminal block

(appearance

may vary)

/

Neutral

terminal

Ground

plate

Power cord /

[] Skip to Step 18 and proceed with the

installation.

9

Ground

strap

Page 10

Installation Instructions

ELECTRICAL CONNECTIONS (CONT.)

4-WIRE POWER CORD

[]

INSTALLATION

WARNING: The neutral wire of

the supply circuit must be connected to

the neutral terminal located in the lower

center of the terminal block. The power

leads must be connected to the lower

left and the lower right terminals of the

terminal block. The ground lead must be

connected to the frame of the range

with the ground plate and the ground

screw.

Remove the 3 lower terminal screws

[]

from the terminal block. Remove the

ground screw and ground plate and

retain them.

[]

Cut and discard the ground strap. DO

NOT DISCARD ANY SCREWS.

[]

Insert the one ground screw into the

power cord ground wire terminal ring,

through the ground plate and into the

frame of the range.

Insert the 3 terminal screws (removed

[]

earlier) through each power cord

terminal ring and into the lower

terminals of the terminal block. Be

certain that the center wire (white/

neutral) is connected to the center lower

position of the terminal block. Tighten

screws securely into the terminal block.

3-WIRE CONDUIT INSTALLATION

Loosen the 3 lower terminal screws from

[]

the terminal block. Insert the center bare

wire (white/neutral) tip through the

bottom center terminal block opening.

On certain models, the wire will need to

be inserted through the ground strap

opening and then into the bottom center

block opening. Insert the two side bare

wire tips into the lower left and the lower

right terminal block openings. Tighten

the screws until the wire is firmly

secured (35 to 50 inch-lbs.). Do not over-

tighten the screws since it could damage

the wires.

NOTE: ALUMINUM WIRING:

Aluminum building wire may be used

but it must be rated for the correct

amperage and voltage to make

connection. Connect wires according

to this Step 16 or Step 17 depending on

number of wires.

Terminal

Wire til:

Before ._SL_jj//X_\ Ground strap

Terminal ,_, i__fr__

strap _J _Neutral

After l/H\\ terrninal

Terminal / _/_ _ /(grounding

block _/,, _to \ange)

screw

Ground _____

[] Skip to Step 18 and proceed with the

installation.

_ _,._-r_ _j{_' L,_a plate

//,_J _;_ / Ground

,_ / &J ','_

/ o / /

Bracket

Wire used, location and enclosure of

splices, etc., must conform to good

wiring practices and local codes.

[] Skip to Step 18 and proceed with the

installation.

10

Page 11

Installation instructions

r_ 4-WIRE CONDUIT INSTALLATION

Loosen the three lower terminal screws

[]

from the terminal block. Remove the

ground screw and ground plate and

retain them. Cut and discard the ground

strap. DO NOT DISCARD ANY SCREWS.

Insert the ground bare wire tip between

[]

the range frame and the ground plate

(removed earlier) and secure it in place

with the ground screw (removed earlier).

Insert the bare wire (white/neutral) tip

through the bottom center of the

terminal block opening. Insert the two

side bare wire tips into the lower left and

the lower right terminal block openings.

Tighten the screws until the wire is firmly

secured (35 to 50 inch-lbs.). Do not over-

tighten the screws since it could damage

the wires.

Terminal

Before

block

_ound strap

[_] REINSTALL WIRE COVER.

NOTE: When reinstalling the wire cover,

make sure that wires do not become pinched

between the wire cover and the housing.

NOTE: The ground strap must be attached

when using the 3-wire cord.

• Terminations must be either closed loop

terminals or open-end spade lugs.

On some models, a filter capacitor may

be connected between the black and

ground leads on the junction block.

Do not remove capacitor.

BREAKER OR FUSE SIZE

240V 40 Amps

208V 40 Amps

NOTE: Check Local Codes for required

breaker size.

Ground strap _

After

blTeorcr_inal _YA_',JLV:IJ_ re/ _1_)lll Ground

_.[,_I j,0_"_ I_ plate

W_'_ Etj_ _/t_J_---'_" (grounding

Wire tips -- =--------I, _.---" "_ to range)

\Neutral

terminal

oroun, \

screwrac

[] Proceed to Step 18.

11

Page 12

Installation instructions

INSTALL THE RANGE

[] INSTALL THE ANTI-TIP BRACKET

[] LOCATE THE BRACKET

a. Decide whether the bracket will be

installed on the right or left side of the

range opening.

b. Place the bracket as shown in Fig. 1.

Fig. 1

Adjacent

ca b inet _lh

/ Wall {;_(_,,)

FLOOR-WOOD / .__

side /__,_

Rear _ _ \

leveling leg FLOOR-CONCRETE

r_ INSTALL THE ANTI-TIP BRACKET

(cont.)

[] INSTALL THE BRACKET IN WOOD OR

CONCRETE

INSTALLATION--WOOD CONSTRUCTIONS

a. Locate the centers of the 4 holes identified

in Fig. 1 as Floor-Wood and Wall.

b. Drill a 1/8" pilot hole through the

pre-marked areas. Note the angle of the

wall screw in Fig. 2.

c. Mount the Anti-Tip bracket with the

4 screws provided,

Top front Fig. 2

edge of

countertop _ 25" _---_l._l

I Screw \. |1 Wall plate

_ mustenter _'-r_l

_ I=llll_ metal J_l

Bracket II

wood or "_._1_

INSTALLATION--CONCRETE CONSTRUCTIONS

a. For concrete installation, you will need

two 1/4" x 1-1/2" lag screws and two sleeve

anchors.

b. Locate the center of the 4 holes identified

in Fig. 1 as Floor-Concrete and Wall, Drill

the recommended size holes in each,

c. Install the sleeve anchors into the

predrilled concrete holes and install the

lag and wall screws through the Anti-Tip

bracket. Make sure the screws are securely

tightened.

12

Page 13

installation instructions

SLIDE RANGE iNTO OPENING

[]

Position the range in front of the cabinet

[]

opening.

[] Make sure that the glass which overhangs

the countertop clears the countertop.

If necessary, raise the unit by lowering

the leveling legs.

[] Push while lifting the range into the

opening, until the range is within 2"

of engaging the anti-tip bracket.

[] Remove the protective trim from the side

of glass (if provided).

[] Using the adjustable pliers or wrench,

carefully screw in the back leveling leg

until the glass overhang comes to rest

on the countertop.

SLIDE RANGE INTO OPENING

(cont.)

Plug the range cord into the receptacle.

[]

Locate the cord in the back of the range

in a manner that it will not touch or be

moved by the drawer.

Position range cord

so that there is no

interference with

fl storage drawer _

///////////////////////////////////////////////

/// /////

\

t I /

\ /

\

/11

. \

\

[] Carefully screw in the front two leveling

legs (similar to Step E) until the glass

overhang touches the countertop.

[] Carefully push the range into the opening

until the countertop fully engages the

control panel. The back glass overhang

should cover the cutout opening.

Counte_op

Make sure the edge of

the countertop fits flush

against the end of the

front control panel

I_1 FINAL CHECK OF ANTI-TIP

BRACKET

When installation is complete and the range is

in place, check to be sure that the rear leveling

leg is fully inserted into the slot of the Anti-Tip

Bracket.

13

Page 14

Installation Instructions

INSTALL THE RANGE (CONT.)

REPLACE THE OVEN DOOR

NOTE: The oven door is heavy. You may need

help lifting the door high enough to slide it

into the hinge slots. Do not lift the door by

the handle.

[] Lift the oven door by placing one hand

on each side. The door is heavy, so you

may need help. Do not lift the door by

the handle.

[] With the door at the same angle as the

removal position (halfway between the

closed and broil stop position), seat the

notch of the hinge arm into the bottom

edge of the hinge slot. The notch of the

hinge arm must be fully seated into the

bottom of the slot.

Hinge arm

Bottom edge

of slot

[] REPLACE THE STORAGE

DRAWER

[] Place the drawer rail on the guides.

[] Push the drawer in until it stops.

[] Lift the front of the drawer and push in

until the stops clear the guides.

[] Lower the front of the drawer and push in

until it closes.

P

SPECIAL INSTRUCTIONS IF YOU ARE

HAVING PROBLEMS WHILE REPLACING

THE STORAGE DRAWER

If Drawer Won't Close:

Drawer

Drawer does front panel

Power cord not close tipped away

may be completely Rear drawer from body

i_b:tru:t i_ _11_ S:is_iPgte°iati_P side I f_

Hinge notch

[] Open the oven door as far as it will open.

[] Push the hinge locks up against the front

frame of the oven cavity, to the locked

position.

Hinge in

locked position

Notch of hinge

secu rely fitted

into bottom of

hinge slot

[] Close the oven door.

Remove and replace, making sure the power

cord is not obstructing the drawer and/or the

rail is in the guide.

If Drawer is Crooked:

Rear drawer

support is on top

of guide rail on Drawer front panel

the high side _ tipped to one side

J

Remove and replace, making sure the rail is in

the guide.

14

Page 15

Installation Instructions

[] COOKTOP BURNERS

[] ASSEMBLING THE BURNERS

CAUTION: Theelectrodeofthe

spark igniter is exposed. Be careful not to

snag the electrode of the spark igniter with

a cleaning cloth. Damage to the igniter could

occur. Be careful not to turn on any cooktop

controls while cleaning. A slight electrical

shock might result, which could cause you

to knock over hot cookware.

FOR GLASS CERAMIC COOKTOPS

a. Place the burner head on the burner base,

so that the pins match up with the slots on

the base.

b. Position the burner cap on the burner head.

c. Place the burner grate over the burner

assembly. The grates fit over the raised

area on the burner head.

_. -_-_ Spark

Burner

grate_

_._ igniter

_ location

[] CHECK FOR LEAKS

Turn the gas supply on and use a liquid leak

detector (soap solution) at all joints and

connections to check for leaks. Do not use an

open flame to look for leaks. Be sure all leaks

are stopped before lighting burners.

[] PRESSURE TEST INFORMATION

The maximum allowable supply pressure

for the regulator is 14" W.C, The minimum

supply pressure needed to check the regulator

setting is 7" W.C, for natural gas and 10" W.C,

for LP gas.

-&WARNING: The range and its

individual shut-off valve must be disconnected

from the gas supply piping system during any

pressure testing of the gas supply system at

test pressures of more than 1/2 psig (pounds

per square inch gauge). The range must be

isolated from the gas supply piping system

by closing its individual shut-off valve during

any pressure testing of the gas supply system

at test pressures equal to or greater than

1/2 psig. NOTE: 1/2 psig = 13.855" w.c.

Burner

cap

Burner _ Spark

head - _ igniter

Burner _ Glass

base _ maintop

15

Page 16

Installation Instructions

INSTALL THE RANGE (CONT.)

[] CHECK THE IGNITERS

Operation of the electric igniters should be

checked after the cooktop and supply line

have been carefully checked for leaks and the

cooktop has been connected to the electrical

power.

a. Turn on gas.

b. Push and turn a burner valve to the LITE

position.

• The burner valve should light when gas

is available to the burner.

• Once the burner lights, it should be

turned out of the LITE position.

c. Try each valve separately until all burners

have been checked.

[] BURNER IGNITION

Cooktop Spark Ignition--When you turn

the cooktop knob to LITE, the spark igniter

makes a series of electric sparks (ticking

sounds) which light the burner. During a

power failure the burners will not light

automatically. In an emergency, a cooktop

burner may be lit with a match by following

the steps below.

[] BURNER FLAMES

Turn each burner on. Turn each burner knob

to the high position. Flames should be blue

in color with no or little trace of yellow. The

burner flames should not flutter or blow away

from the burner. The inner cone of the flame

should be between 1/2" to 3/4" long. If the

burner flames are yellow in color or not the

proper length, call GE Service.

1/2" to 3/4"_

/ COOKTOP

BURNER

Flames should circle burner

Burners should be checked frequently.

WARNING: ifyouattempt to

measure the inner cone of the flame, please

use caution. Burns could result.

- WARNING: Lighting gas burners

with a match is dangerous. You should match

light the cooktop burners only in an

emergency.

a. Light a match and hold the flame near the

burner you want to light. Wooden matches

work best.

b. Push in and turn the control knob slowly.

Be sure you are turning the correct knob

for the burner you are lighting.

NOTE: If the burner does not light within

five seconds, turn the knob off and wait

5 minutes before trying again.

16

Page 17

Installation instructions

[] ALTERNATE CONSTRUCTION

PREPARATION

[] OPTIONAL MAINTOP FILLER OR

BACKGUARD KIT

If counter opening extends to the wall, it will

require Maintop Filler Kit (supplied with the

range) or Backguard Kit (JXS36XX or

JXS39SS) to close the gap.

NOTE: If the countertop is greater than 25",

it will show a gap between the backguard

and wall or between filler kit and the wall.

If the countertop is less than 25", a gap will

occur between the countertop front and the

control panel ends (see Step 8).

If you are using the optional backguard kit,

refer to the backguard kit instructions for

installation details.

_ ----q

Wall

25 H

Must be

level

When the trim is set in the proper position,

tighten the 2 mounting screws. The top of the

trim should be located below the top surface

of the glass to prevent pots, pans and skillets

from damaging the painted parts.

Refer to the Standard Installation of the

Range on page 6.

nge

filler

(2) #8

screws

[] FOR NON-BUILT-IN INSTALLATION

(END OF CABINET LOCATION)

When installing the range at the end of

a cabinet section which will expose the

unfinished side of the range, use Body Side

Kit (JXS76XX). Refer to the kit instructions

for installation details.

flaMUSt_'1._ 30" _ Must be

bet smooth cut flat

Must be level

31-1/8"

If you use the filler kit, place the metal filler

piece supplied with the range to the back of

the range as shown in the figure below. Start

the 2 screws into the upper holes at the

outside rear of the range above the louvers

and through the slots in the trim, holding

the filler piece centered on the maintop

frame and pushing upward to close the gap

between the bottom of the glass and the

filler trim.

17

Page 18

Installation Instructions

INSTALL THE RANGE (CONT.)

[] ALTERNATE CONSTRUCTION

PREPARATION (cont.)

[] ISLAND INSTALLATION

Attach the Anti-Tip bracket per instructions

in Step 19, making sure that the rear of the

bracket is 25" from the front of the

countertop.

Be aware that the screws provided are long

and may penetrate through the back of the

island cabinets. In this event, use shorter

screws (not provided) or the screws provided

should be used in the floor (see Step 19B for

Wood/Concrete Floor Installation).

Do not use Backguard Kit JXS36XX or

JXS39SS.

[] FOR CABINET OPENINGS

APPROXIMATELY 30-3/8"

If range is installed in cabinet opening

approximately 30-3/8", the Vertical Side Trim

Kit (JXS86XX) should be used to cover gaps

between range sides and cabinet. Refer to

the kit instructions for installation details.

OPERATION CHECKLIST

= Double check to make sure everything in

this guide has been completed. Rechecking

steps will ensure safe use of the cooktop.

• Make sure all controls are left in the OFF

position.

• Make sure the flow of combustion

and ventilation air to the cooktop is

unobstructed.

• The serial plate for your Range is located

under the oven door above the storage

area. In addition to the model and serial

numbers, it tells you the ratings of the

burners and the type of fuel and pressure

the cooktop was adjusted for when it left

the factory.

• When ordering parts, always include the

serial number and model number to ensure

proper replacement parts.

• Recheck Steps: Double check to make

sure everything in this guide has been

completed. Rechecking steps will ensure

safe use of the Range,

[] CABINETS OVER THE RANGE LESS

THAN 30"

If a 30" clearance between cooking surface

and overhead combustible material or metal

cabinets cannot be maintained, protect the

underside of the cabinets above the cooktop

with not less than 1/4" insulating millboard

covered with sheet metal not less than

0.0122" thick.

18

Page 19

Installation instructions

Please see L.P. conversion instructions

supplied with this range when L.P. Gas

is used.

NOTE: Instructions are mounted on

regulator bracket.

iN SOME CASES

[] With L.R gas, some yellow tipping on

the outer cone is normal.

[] Foreign particles in the gas line may

cause an orange flame at first, but this

will soon disappear.

SPECIAL NOTE:

To convert the oven back to natural gas,

reverse the instructions given in making L.P.

Adjustments.

Once the conversion is complete

and checked ok, fill out the LP

sticker and include your name,

organization and the date the

conversion was made. Apply the sticker near

the regulator to alert others in the future that

this appliance has been converted to LP gas.

If converting back to natural gas from LP,

please remove the sticker so others know

the appliance is set to use natural gas.

ADJUSTING LOW FLAME SETTING

ON COOKTOP BURNERS

Low setting adjustments must be made with

two other burners in operation on a medium

setting. This procedure prevents the low

flame from being set too low, resulting in the

flame being extinguished when other burners

are turned on.

[] Remove the valve control knobs.

[] Through the opening, locate the valve

bypass screw located on the lower right

side of the valves.

[] Using a small screwdriver, screw down

the bypass screw fully in a clockwise

rotation.

19

Page 20

20

Printed in the United States

Loading...

Loading...