Page 1

GE’s 2015 27” Top Load Washer

HTW200ASKWW

MTW200AMKWW

GTW220ACKWW

HTW240ASKWW

GTW330ASKWW

GTW460ASJWW

GTW485ASJWW

GE Appliances

GTW485ASJWS

GTW490ACJWW

GTW490ACJWS

GTW680BSJWS

1

11/16/2015

Page 2

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, &

mechanical experience. Any attempt to repair a major appliance may

result in personal injury & property damage. The manufacturer or seller

cannot be responsible for the interpretation of this information, nor can it

assume any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this product. If electrical power is required for diagnosis or

test purposes, disconnect the power immediately after

performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position & properly fastened.

Page 3

Although GE Factory Service Employees are required to use the personal

protection equipment (PPE) listed below, it is recommended for GE

authorized servicers to use them as well for your own protection.

Dyneema® Cut

Resistant Glove

Cut Resistant Sleeve(s)

Steel Toe Work

Boot

Electrically Rated Glove

and Dyneema® Cut

Resistant Glove Keeper

Brazing Glasses

Plano Type Safety

Glasses

Prescription

Safety Glasses

Safety Glasses

must be

ANSI Z87.1-2003

compliant

Page 4

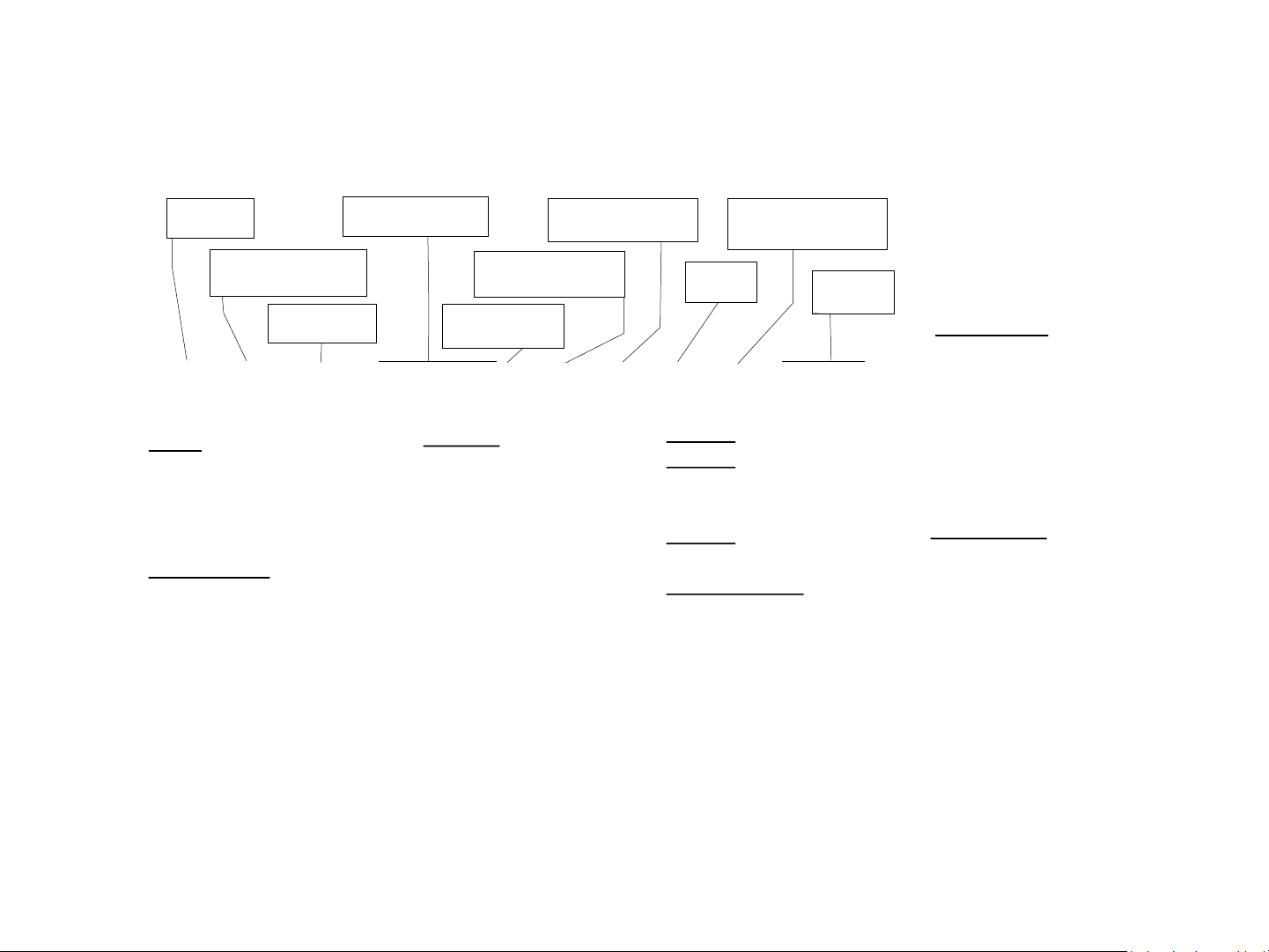

Prior to disassembly of the Washer to access components, GE Factory Service

technicians are REQUIRED to follow the Lockout / Tagout (LOTO) 6 Step Process

Step 1

Plan and Prepare

Step 2

Shut down the appliance

Step 3

Isolate the appliance

Step 4

Apply LOTO device & Lock

Step 5

Control (discharge) stored

energy

Step 6

“Try It” Verify that the

appliance is locked out

GE Appliances

Louisville, KY 40225

Page 5

Some Features & Benefits

GTW460 Models

Deep Fill: Adds more water for larger

loads.

Dual-Action Agitator: Provide gentle,

dual-wash action.

Deep Rinse: Removes any leftover soap

residue.

Auto Soak: Loosens stains by soaking

up to 2 hours.

Speed Wash: Delivers ready-to-go

results within minutes.

Load Size: Automatically measures load

size, and adjusts settings and water

levels accordingly. Settings are

customizable, so you always get the

wash you want.

GTW680 Models

Sanitize with Oxi: Remove 99.9 % of

bacteria with a dedicated cycle that

uses an Oxi additive to boost your

detergents cleaning power while

keeping fabric looking their best.

Stain Removal Guide: Assist removing

tough stains with preprogrammed

settings that modify your cycle to treat

the four most common stains.

Warm Rinse: Just what the consumer

ordered. The option to select between

a warm or cold rinse.

Deep Fill: Adds more water for larger

loads.

Deep Rinse: Removes any leftover soap

residue.

Auto Soak: Loosens stains by soaking

up to 2 hours.

5

11/16/2015

Page 6

Nomenclature

Brand

Configuration

Platform

Series 1, 2, 3

Fuel Type

Partner Type

Product Type

Engineering #

Year

G T W 6 8 0 B S J 0 W S

Brand

G-GE

H-Hot Point

M-Moffatt

Configuration

F-Front Load

T-Top Load - Rear control

N-Top Load - Front control

U-Unitized

Platform

W-Washer

D-Vented Dryer- Std

V-Vented Dryer- Long

C-Condenser Dryer

H-Heat Pump

Z-Flat Back Dryer- Long

X-Flat Back Dryer- Std

Series 1 1-9

Series 2 1-9

4 = 24” unitized

7 = 27” unitized

Series 3 1-9 Washer only

Fuel Type Dryer

E Electric

G Gas

P Propane

Color

Partner Type

P-Premium Cost (color)

H-Home Depot

L-Lowes

S-Standard

C-Contract (Hoses)

M-Mabe

Product Type

R Riser

A 2” Cover Top Load

B 4” Cover Top Load

S Standard/Stationary

P Portable

6

11/16/2015

Page 7

Nomenclature and Mini (MAXI) Manual Location

Serial Number

The nomenclature breaks down and explains what the letters and numbers

mean in the model number. The first two characters of the serial number

identify the month and year of manufacture. Example: LF123456S = June, 2015

A- JAN

D- FEB

F- MAR

G- APR

H- MAY

L- JUN

M- JUL

R- AUG

S- SEP

T- OCT

V- NOV

2024- Z

2023- V

2022- T

2021- S

2020- R

2019- M

2018- L

2017- H

2016- G

2015- F

2014- D

The mini (maxi) manual

Z- DEC

2013- A

Model ID Tag Location.

location. Tilt washer

back to retrieve.

The letter designating the year repeats every 12 years.

The Model Serial ID Tag is located on the bottom edge of the lid.

The Mini Manual is in a storage bag on the inside bottom left side of the outer cabinet.

7

11/16/2015

Page 8

Water Levels

Approximate Minimum Water Levels

Impeller – 7 Gallons or 3 in. depth

from the bottom of the basket.

Agitator – 9 Gallons or 3-3/4 in.

depth from the bottom of the basket.

Approximate Maximum Water Levels

Impeller – 26 Gallons or 13-1/2 in.

depth from the bottom of the basket.

Press and hold for 3 seconds “Deep

Fill” to achieve.

Impeller “Bulky” setting water level is

25 gallons or 12-3/4 in. depth from

the bottom of the basket.

Agitator – 26 Gallons or 12-1/2 in.

depth from the bottom of the basket.

Set to super.

Tests are completed with an empty basket.

Page 9

Model Graphics

GTW460

GTW485 GTW490

GTW680

9

11/16/2015

Page 10

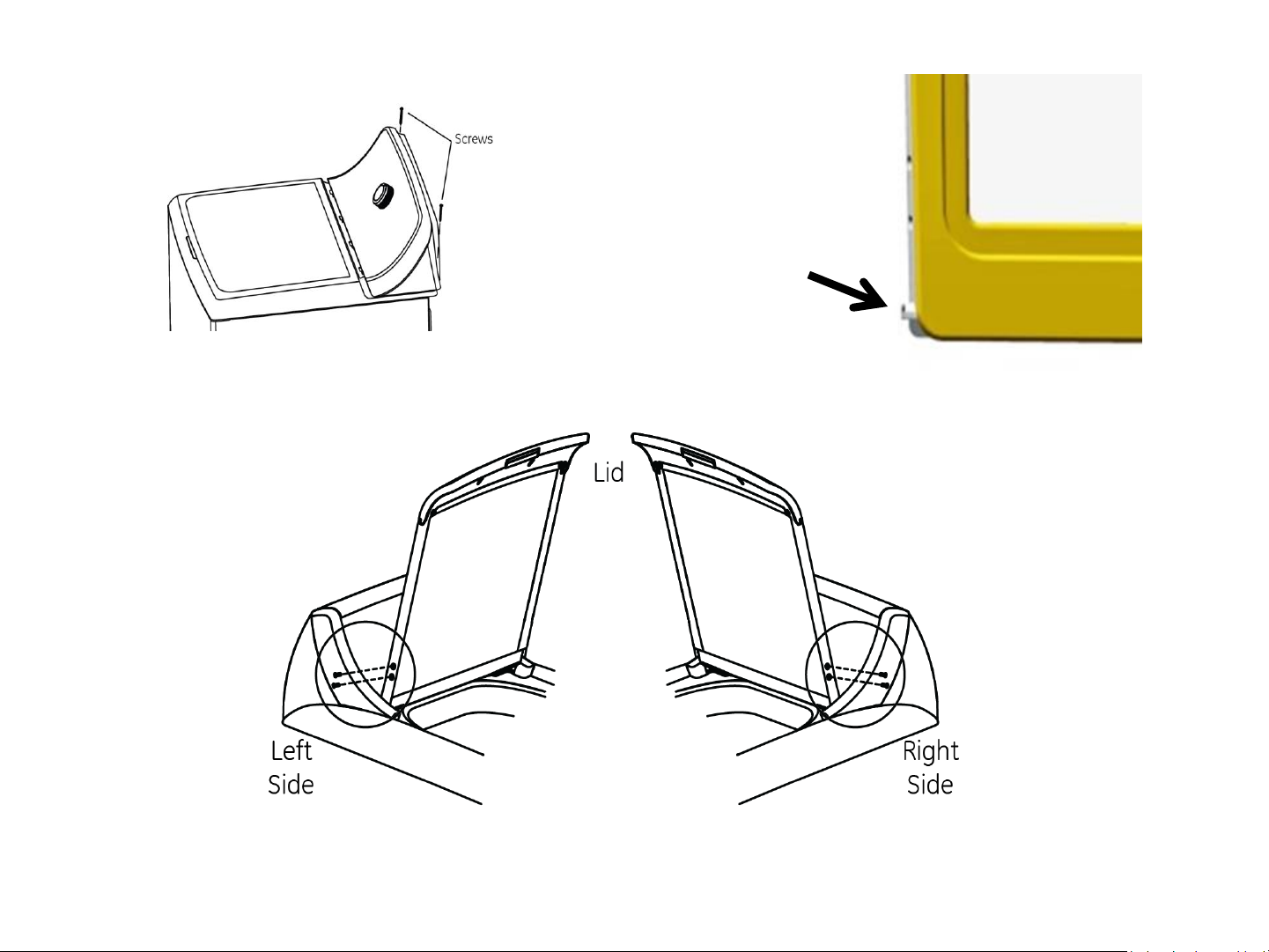

Lid Assembly Removal

Hinge Pin

Cover

Remove the two 1/4 in. hex

head screws that secure

the control panel assembly

to the top cover.

Remove the four Philips head screws (two on each side) and lift lid up to remove.

Slide the control panel

assembly toward the rear

of the washer to expose the

hinge pin cover.

10

11/16/2015

Page 11

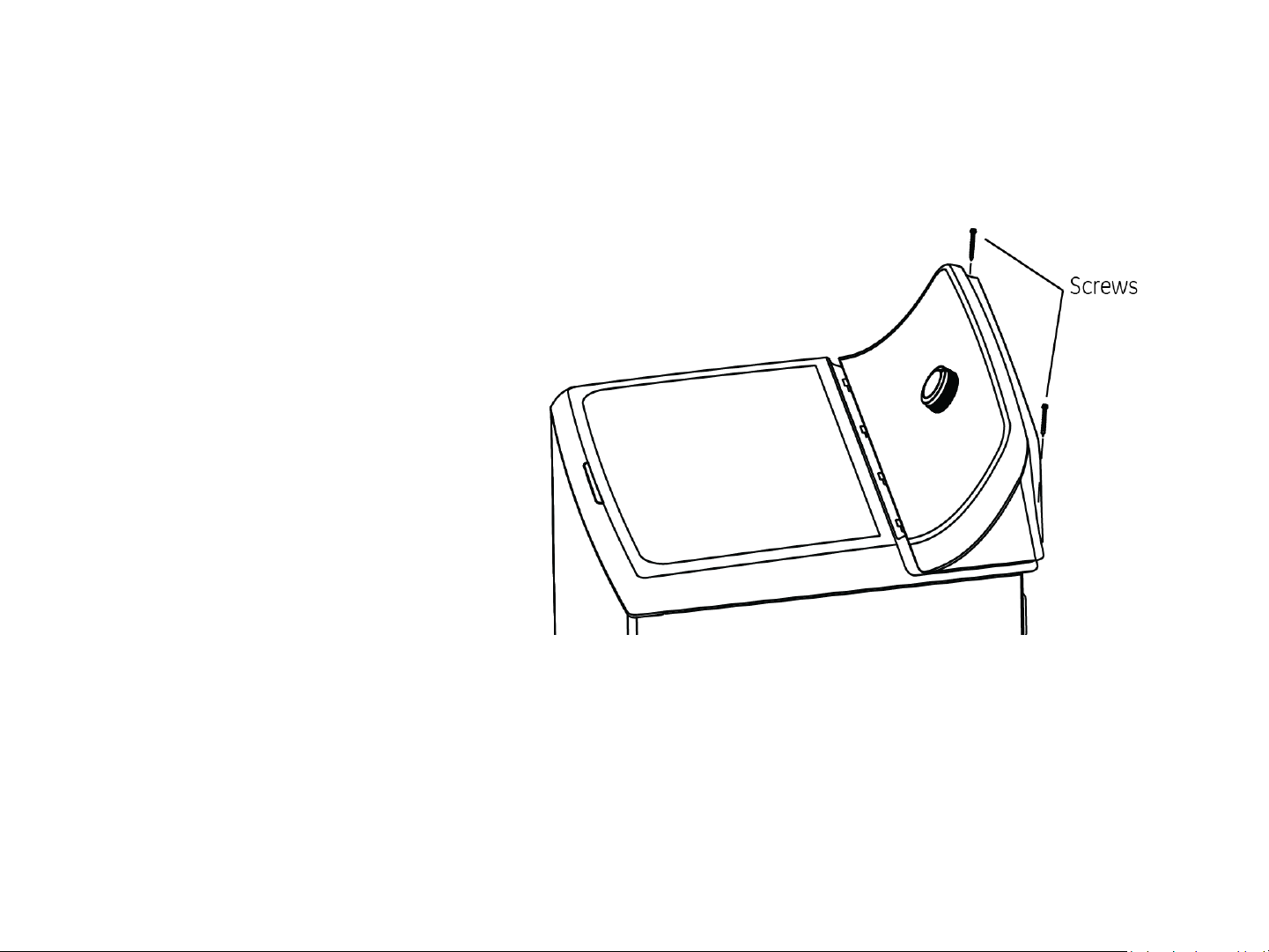

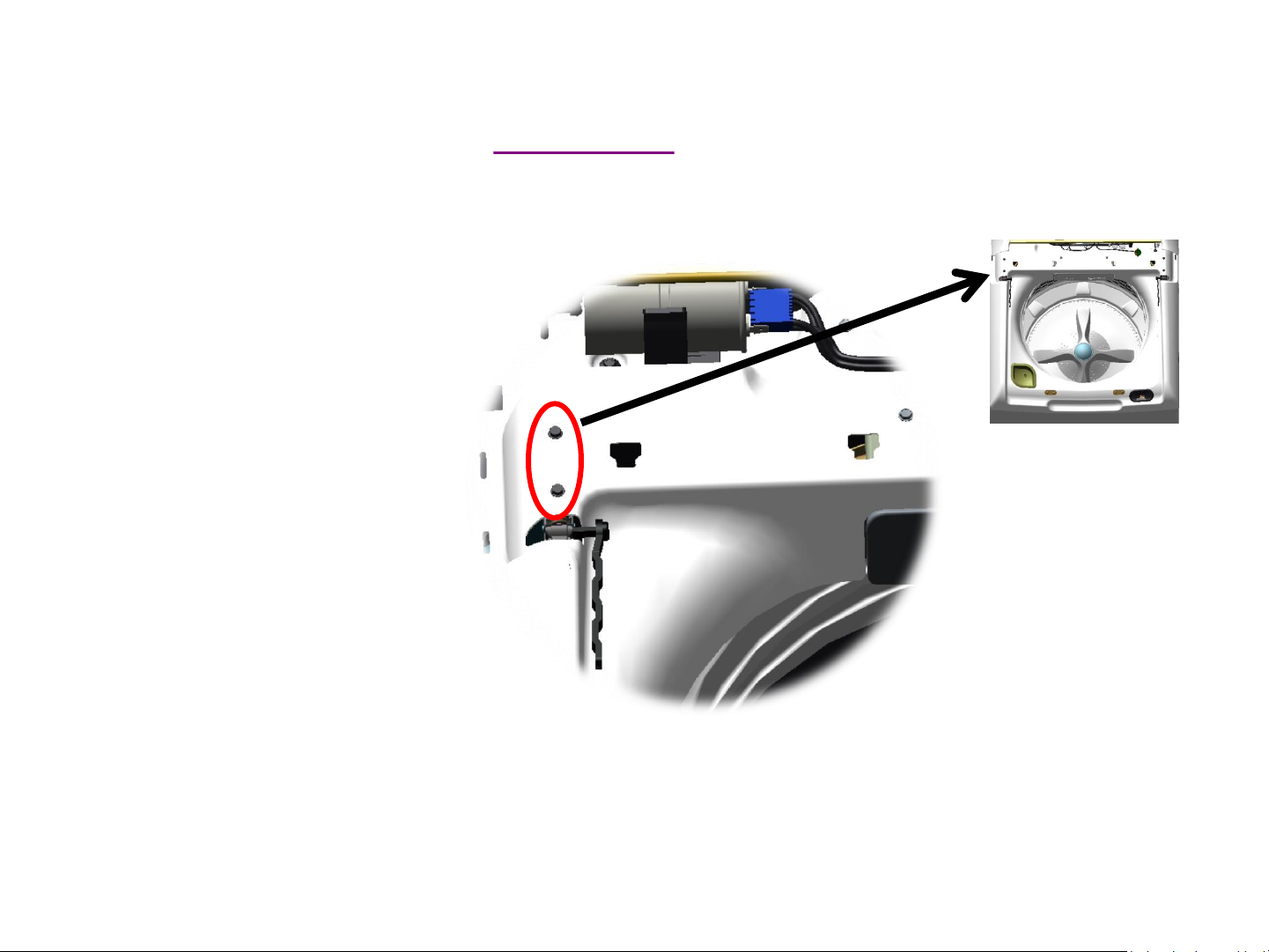

Control Panel Assembly Removal

To remove the control

panel assembly:

Remove two 1/4 in. hex

head screws from the rear

corners of the control

panel.

11

11/16/2015

Page 12

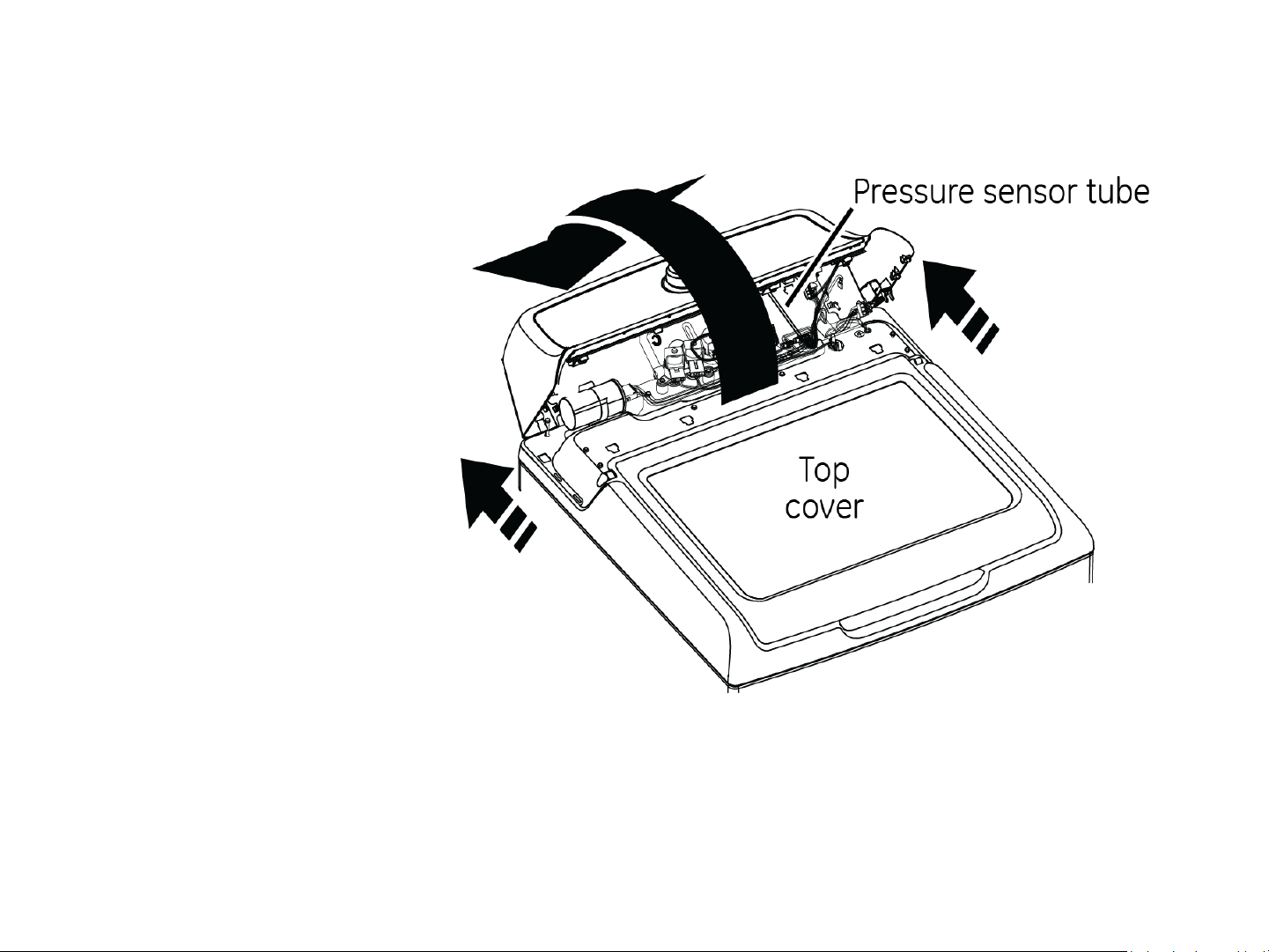

Control Panel Assembly Removal

Grasp the control panel

sides and push toward

the back of the washer

to disengage it from the

top cover.

Roll the control panel

toward the rear so the

pressure tube can be

seen and disconnected

from the control board.

IMPORTANT: To disengage the pressure tube from the control board, grasp the tube where it

connects to the pressure sensor on the board. Twist the tube while pulling it off the sensor.

12

11/16/2015

Page 13

Control Panel Assembly Removal

Roll the control panel

forward to lay on its face

and remove four 1/4 in.

hex screws securing the

rear panel to the control

panel assembly and

remove.

Disconnect harness from

the control board.

RJ45

Connection

IMPORTANT: When reinstalling the control panel assembly, ensure that all ground wires are

reconnected and tested for proper continuity to the ground terminal on the power cord.

13

11/16/2015

Page 14

Lid Hinge

Hinge removal can be

achieved without

removing the top cover or

disconnecting the control

panel assembly

completely.

Remove the lid assembly.

Disengage the control

panel from the top cover

and slide toward the rear

to expose the hinge

mounting screws.

Video Link

Page 15

Lid Hinge

Remove the hinge arm by

sliding it away from the

hinge assembly.

Slide a hand between the

tub cover and the top

cover and grasp the hinge

assembly.

This type hinge arm is only on the GTW680 model. All the other models will have the wire form hinge.

Page 16

Lid Hinge

Remove the two 1/4 in.

hex head hinge mounting

screws and remove hinge

assembly from under the

top cover.

Page 17

Lid Lock Striker

The lid lock striker slides into

the lid lock/switch assembly.

When a cycle is started the

lock assembly engages with

the striker preventing the lid

from opening during the cycle.

The latch has spring tension on

it to keep it engaged with the

switch/lock assembly.

Video Link

Page 18

Lid Lock Striker

To remove the striker from

the lid:

Open the lid.

Using a small screwdriver

insert it into the small hole

below the striker.

Push inward gently on the

locking tab and turn the

striker to the left.

Page 19

Lid Lock Striker

Pull the striker from the lid.

Page 20

Lid Switch/Lock Assembly

Video Link

The lid lock and switch are together in

one part. It requires 120 VAC to activate

the lock.

The approximate resistance of the lock

coil is 70 ohm from Red – Violet from

J512 board connector.

Checking between Red and Yellow wire at

the same board connector will show the

continuity of the lid switch.

Page 21

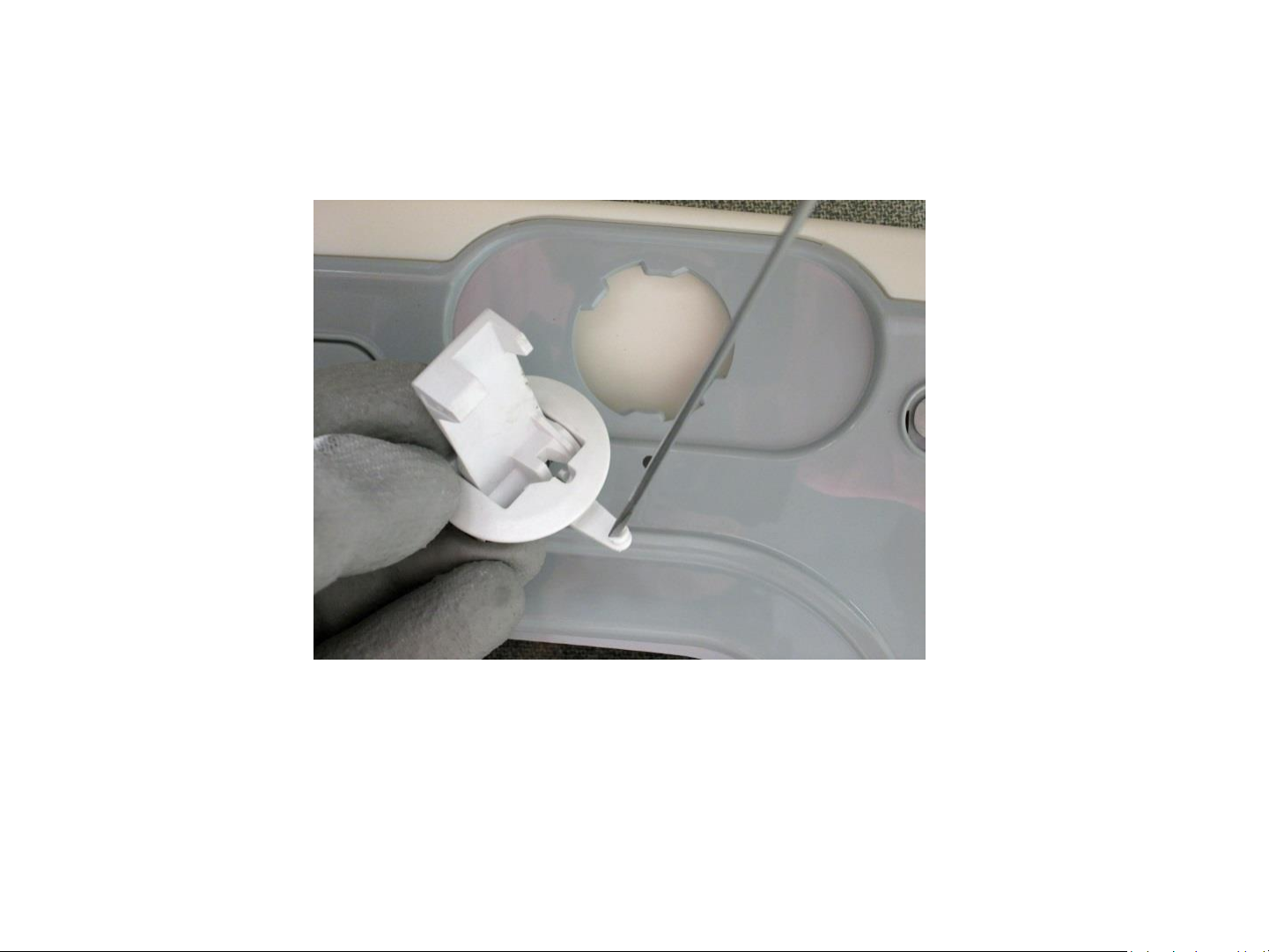

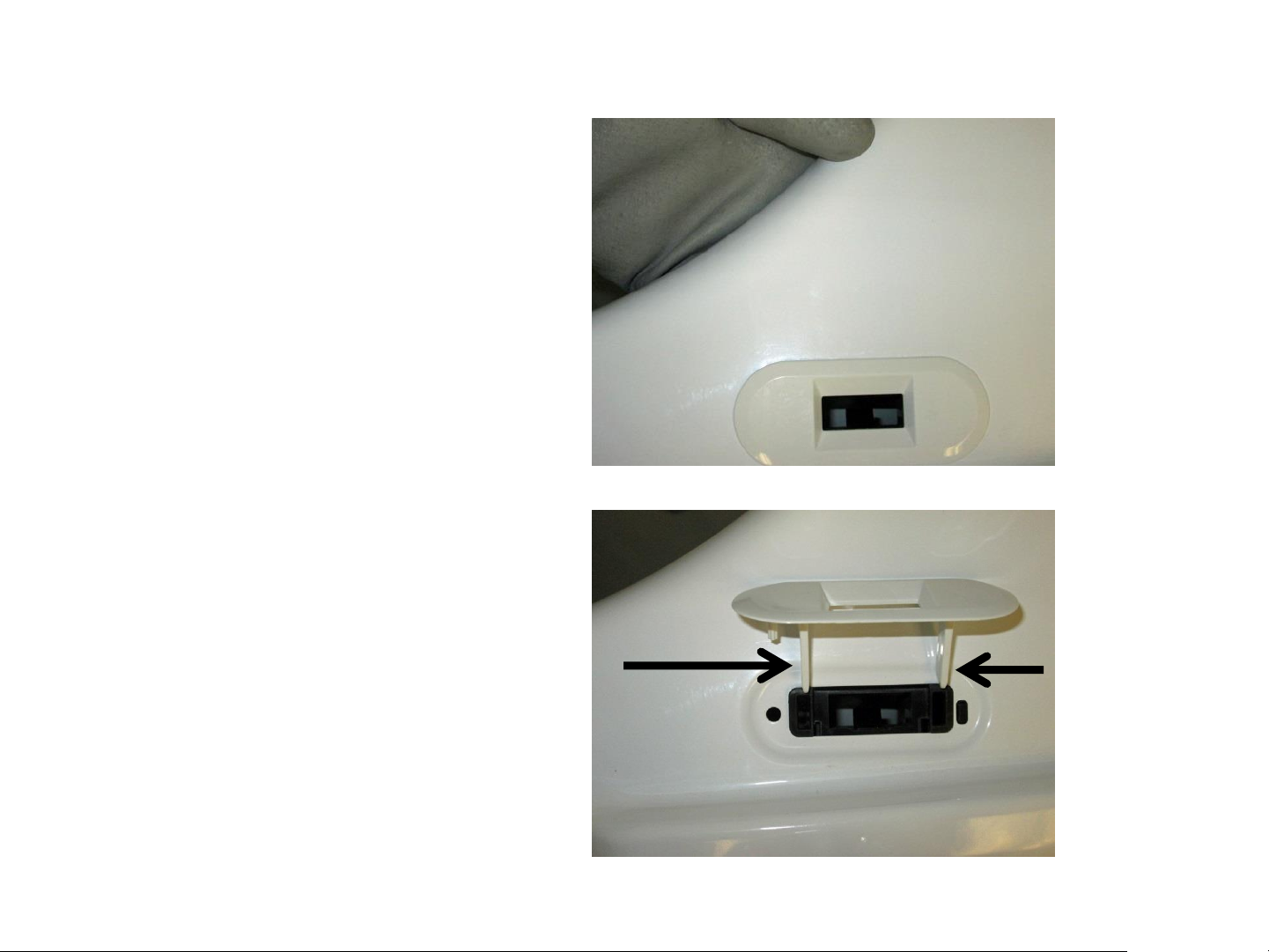

Lid Switch/Lock Assembly

To remove the lid switch/lock

assembly:

Remove the bezel from the

top cover by reaching under

the top cover toward the

lock assembly and feel for

the bezel tabs the extend

through the lock body.

Push the tabs out from the

side of the lock body and

then push up to remove the

bezel from the top cover

Tabs

Page 22

Lid Switch/Lock Assembly

Using a small screwdriver,

push down gently on the

tab that prevents the lock

assembly from sliding.

Slide the lock assembly to

the left first to disengage

the right tab, then slide to

the right allowing the lock

assembly disengage

from the top cover.

Page 23

Lid Switch/Lock Assembly

Pull the lock assembly from under the top cover and disconnect the harness connector.

Page 24

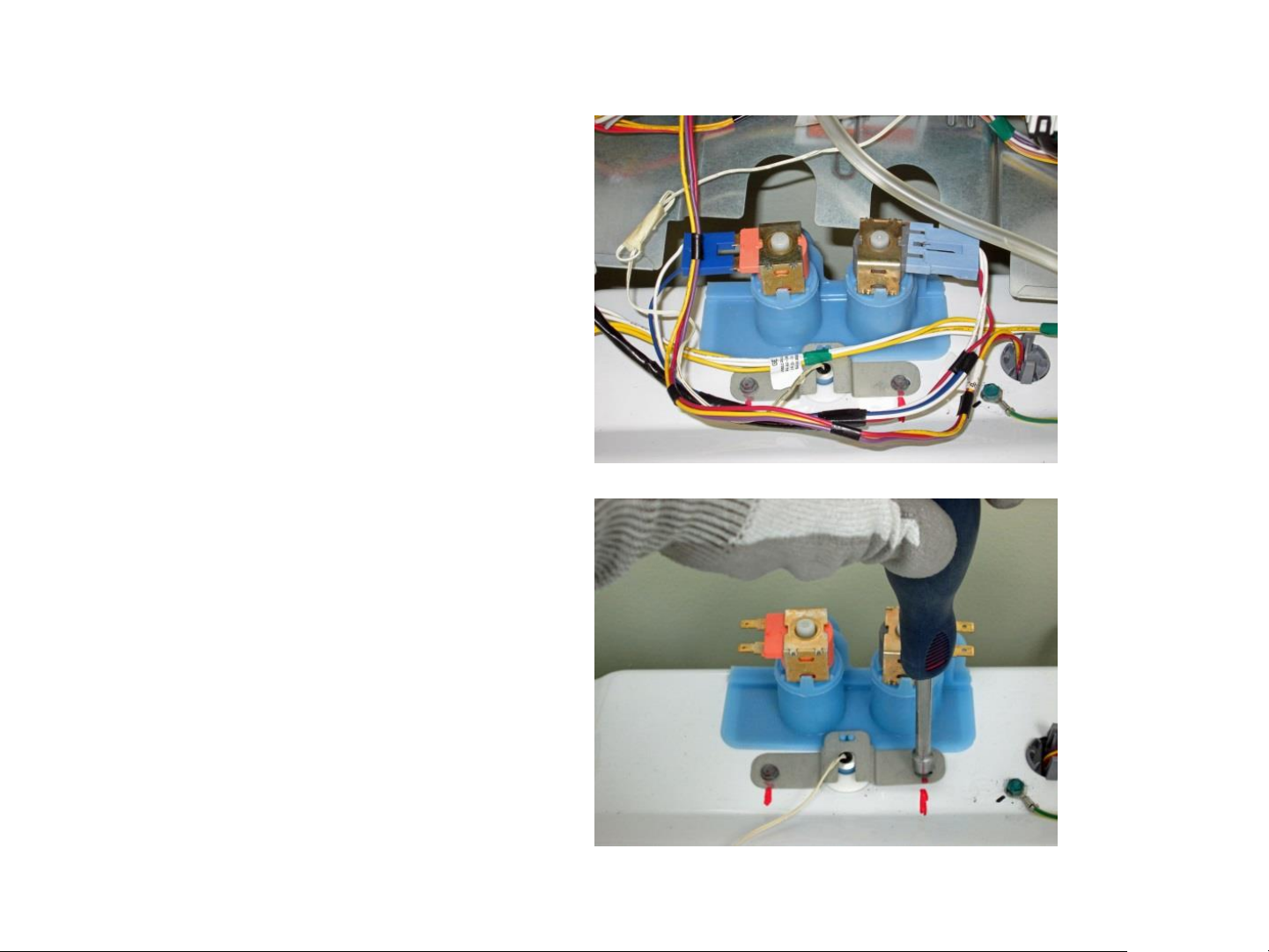

Two Coil Water Valve

Turn water supply off to

valve. Hoses do not need

to be disconnected at

this time.

Remove two 1/4 in. hex

head screws that go

through the thermistor

mounting bracket into

the body of the valve.

24

11/16/2015

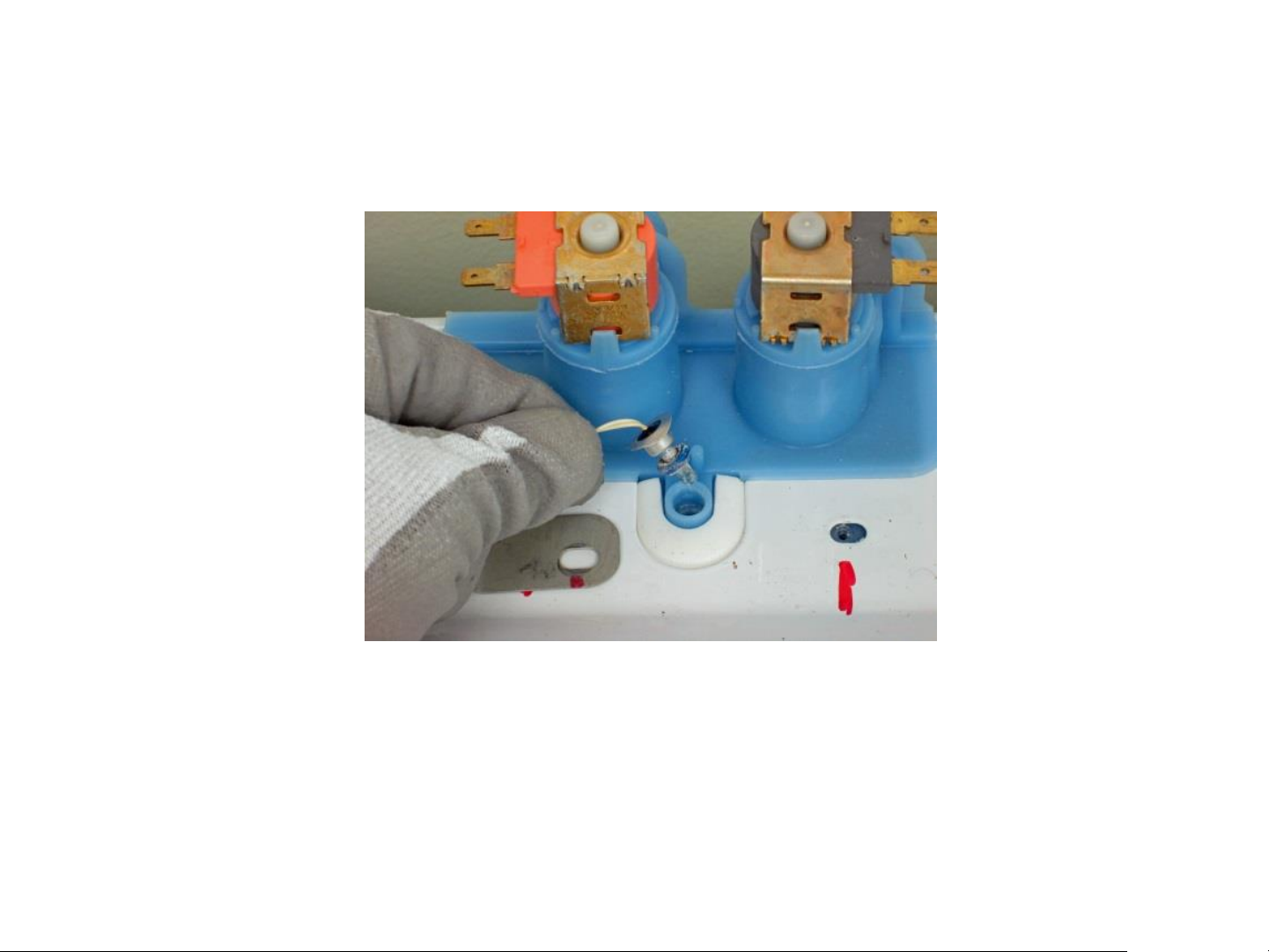

Page 25

Two Coil Water Valve

Remove thermistor by pulling up on lip of thermistor. Ensure O-ring is removed with thermistor.

25

11/16/2015

Page 26

Two Coil Water Valve

Tilt back of valve up

and slide out of top

cover. Once valve is

out and held over the

basket, disconnect

hoses.

Valve and funnel are

one part. Gasket can

be ordered separately.

26

11/16/2015

Page 27

Four Coil Water Valve On GTW680 Model

Video Link

27

11/16/2015

Page 28

Four Coil Water Valve Removal

To remove the water valve:

Shut off the water supply

to the washer. Hoses do

not need to be

disconnected at this time.

Lean the control panel

assembly back. It does not

have to be completely

removed.

Disconnect the harness

from the water valve.

28

11/16/2015

Page 29

Four Coil Water Valve Removal

Remove three 1/4 in.

hex head screws

securing the valve to

the top cover and pull

the valve up.

Hold valve over the

basket and disconnect

the supply hoses from

the valve.

There are four

replaceable rubber

seals that seal the

water valve to the

dispenser box.

29

11/16/2015

Page 30

Thermistor Removal

After the water valve is removed the

thermistor can be accessed and remove.

It is pushed into the dispenser box and

held in place by the water valve and is

sealed with an O-ring.

Thermistor

30

11/16/2015

Page 31

Dispenser Removal

The dispenser hold detergent and fabric softener and delivers it at precise times for the

cycle selected. Water is added to the dispenser from the water valve to fill and flush the

cups. After the valve turns off the remaining water in the cup siphons out.

Bleach Funnel

Removal Video

When bleach is added to the bleach cup it is funneled through to the tub cover and into the tub.

Page 32

Dispenser Removal

Remove the backsplash

assembly. water valve

and top cover.

Remove the dispenser

tray from the dispenser

body.

Remove four 1/4 in. hex

head screws from the

top cover securing the

dispenser body to the

top cover.

Page 33

Dispenser Removal

Remove the dispenser body

from the top cover by

pushing back slightly on the

dispenser body and pull

away from top cover.

The dispenser shower insert

can be removed at this time

for cleaning if necessary.

Dispenser shower insert

Page 34

Impeller and Agitators

Impeller

Dual Action

Agitator

Single Action

Agitator

34

11/16/2015

Page 35

Impeller

To remove the impeller, pop the center cap off with a small

screwdriver to access the 7/16th hex bolt. The splined coupler

is part of the impeller and agitators.

Note: Impeller bolt should be replaced any time it is removed

for service and torqued to 100 in-lbs.

35

11/16/2015

Page 36

Dual Stage Agitator

To remove the dual action

agitator, the auger section

needs to be removed to

access the 7/16th hex bolt.

Note: Agitator bolts should

be replaced any time it is

removed for service and

torqued to 100 in-lbs.

36

11/16/2015

Page 37

Dual Stage Agitator Auger Removal

Feel for the small

protrusion near the bottom

of the auger that mounts

to the agitator base.

Turn the top half of the

auger until you feel the

hole located under the

auger fin lines up with the

protrusion.

37

11/16/2015

Page 38

Dual Stage Agitator Auger Removal

Using a thin shanked

screwdriver, tap it

through the hole in the

auger. The inner wall of

the agitator where the

screwdriver pokes

through is thin.

While holding the

basket from spinning

with one hand, use the

screwdriver as a

leverage handle and

twist the auger

assembly clockwise to

remove it from the

agitator base.

Screwdriver

Tap

Through

38

11/16/2015

Page 39

Single Stage Agitator

Remove the single action agitator by taking the agitator cap off to access the 7/16th hex bolt.

The bolt is located inside the agitator at the bottom. A long socket extension (at least 17 in.

long) will be needed to remove it.

Note: Agitator bolts should be replaced any time it is removed for service and torqued to 100

in-lbs.

39

11/16/2015

Page 40

Top Cover Removal

Remove the control panel

assembly.

Slide the harness grommet

out toward the rear of the

washer.

Disengage the power cord

from the top cover by pulling

up on the front of the power

cord grommet.

Pull Up

40

11/16/2015

Page 41

Top Cover Removal

Slide the power cord

grommet forward.

Slide

Forward

41

11/16/2015

Page 42

Top Cover Removal

Pull up off of the top cover.

Pull Up

And Off

42

11/16/2015

Page 43

Top Cover Removal

The harness grommet for

the lid lock does not need to

be removed unless

replacing the top cover.

If replacing the top cover,

squeeze the two clips on

the grommet and push it

through the opening.

Transfer to the new cover.

Remove ground screws.

43

11/16/2015

Page 44

Top Cover Removal

Remove the control panel assembly.

Remove two 1/4 in. hex head screws (one

on each side) at the rear corners of the

top cover.

Slide the harness grommet out toward the

rear of the washer.

Disengage the power cord from the top

cover by lifting up on the front of the cord

grommet, slide forward and up off of the

top cover.

Raise the rear of the top cover up, then

pull forward slightly to disengage from the

front clips that secures the front of the top

cover to the cabinet.

44

11/16/2015

Page 45

Basket Removal

Remove the control panel assembly

and top cover.

Remove the 1-5/16th in. hub nut by

turning the nut clock-wise to loosen

(reverse threads).

A new hub nut should be used

when reinstalling the basket

assembly. Torque to 100 ft. lbs.

45

11/16/2015

Page 46

Basket Removal

Note: A torque limiter (WX05X10028)

should be used when removing or

installing the hub nut with an impact

gun.

Remove the tub cover by unclipping

eight clips around the edge and lift it

off.

Lift the basket out of the tub.

46

11/16/2015

Page 47

Tub And Cabinet Removal/Replacement

Remove the control panel

assembly and top cover.

Disengage the rod and spring

suspension from the tub assembly.

Prop blocks (WX05X10027) x2,

laying on it’s side can be used

under the belt protector.

This will raise the tub assembly up

to disengage the suspension

system.

47

11/16/2015

Page 48

Tub And Cabinet Removal/Replacement

One the suspension is disengaged,

remove the prop blocks letting the

tub assembly rest on the belt

protector.

Raise the cabinet up and over the

tub assembly and set aside.

Note: Be careful of the tub

assembly balance while removing

cabinet.

48

11/16/2015

Page 49

Harness Removal/Replacement

The cabinet needs to be removed to

replace the harness assembly.

Once the cabinet is removed there are

four 1/4 in. hex head screws that

secure the harness to the side of the

tub that need to be removed.

There is one ¼ in. hex head screw on

the bottom and up to six wire ties.

49

11/16/2015

Page 50

Bottom Component View

Front

Suspension

Rod and

Spring

Assembly

View shown without belt

protector and pulleys in place.

Recirculation Pump

(On some models)

Motor Pulley

Fan

Belt Protector

Drive

Motor

Transmission

Supports

Assembly

Belt

Mode

Shifter

Assembly

With Clutch

Harness

Connectors

Transmission

Pulley

Drain Pump

and Internal

Outlet Hose

50

11/16/2015

Page 51

Drain And Recirculation Pump

The drain pump is located on the right side

of the bottom of the tub. It is mounted

directly to the tub secured by three (3) 3/8th

hex head bolts.

The GTW680 model has a recirculation

pump located at the front of the bottom of

the tub. It mounts to the tub the same as

the drain pump.

Both pumps are 120 VAC.

The approximate resistances of the pumps

checked from J512 board connector are:

Drain pump – 13.2 ohms

Recirculation pump – 31.7 ohms

Drain Pump

Video Link

Recirculation Pump

Video Link

51

11/16/2015

Page 52

Drain And Recirculation Pump

Before removing the drain or

recirculation pump any water in the

basket must be removed. This is done by

using a transfer pump.

The transfer pump only comes with one

(1) hose. A standard washer hose can be

used for the outlet side of the pump. Part

number WH41X10207.

Pump out as much of the standing

water in the basket as possible.

Lean the washer back and pump out

the water seen in the basket.

When the drain pump is removed

approximately 1–2 cups of water will

drain out of the pump opening in the

tub.

Transfer Pump WX05X23817

52

11/16/2015

Page 53

Drain And Recirculation Pump

Once the bolts are removed the pump can be pulled from the tub.

Have something to catch excess water. The seal is a separate part

that can be replace if leaking.

53

11/16/2015

Page 54

Drive Belt

The drive belt has six ribs

and can be removed

easily turning the pulley

to walk the belt off.

To reinstall the belt, put

it on the motor pulley

first.

Stretch the belt around

the transmission pulley

as far as it can go.

Then rotate the pulley

until the belt is in place.

Be sure all the ribs of the

belt.

Page 55

Drive Motor

Video Link

Push here

Pull out

There are two different horsepower

motors. One third and one half

horsepower motors. The GTW485,

GTW490 and GTW680 models have the

half horsepower motor. They are both

120 VAC reversible motors .

Resistances are 1/2 hp.- Blue - Red

and Blue - Yellow approx. 3.1 ohm.

1/3rd hp. Approx. 3.8 ohm from J511

board connector.

To remove the motor:

Remove the belt and fan pulley. The

pulley is held on by a 9/16 in. lock nut.

Use a new nut when reinstalling the

pulley and torque to 110 in-lbs.

Disconnect the motor harness

connector.

Page 56

Drive Motor

Hall/Speed

Sensor

Unclip the hall/speed sensor

from the motor.

Remove two 1/2 in. bolt

mounting the motor to the tub

letting the motor come loose

from the platform.

When reinstalling the motor

mounting bolts torque to 170

in-lbs.

Note: If the hall/speed sensor is wire tied to the motor when

replacing the motor. Order both the motor and hall/speed sensor.

Page 57

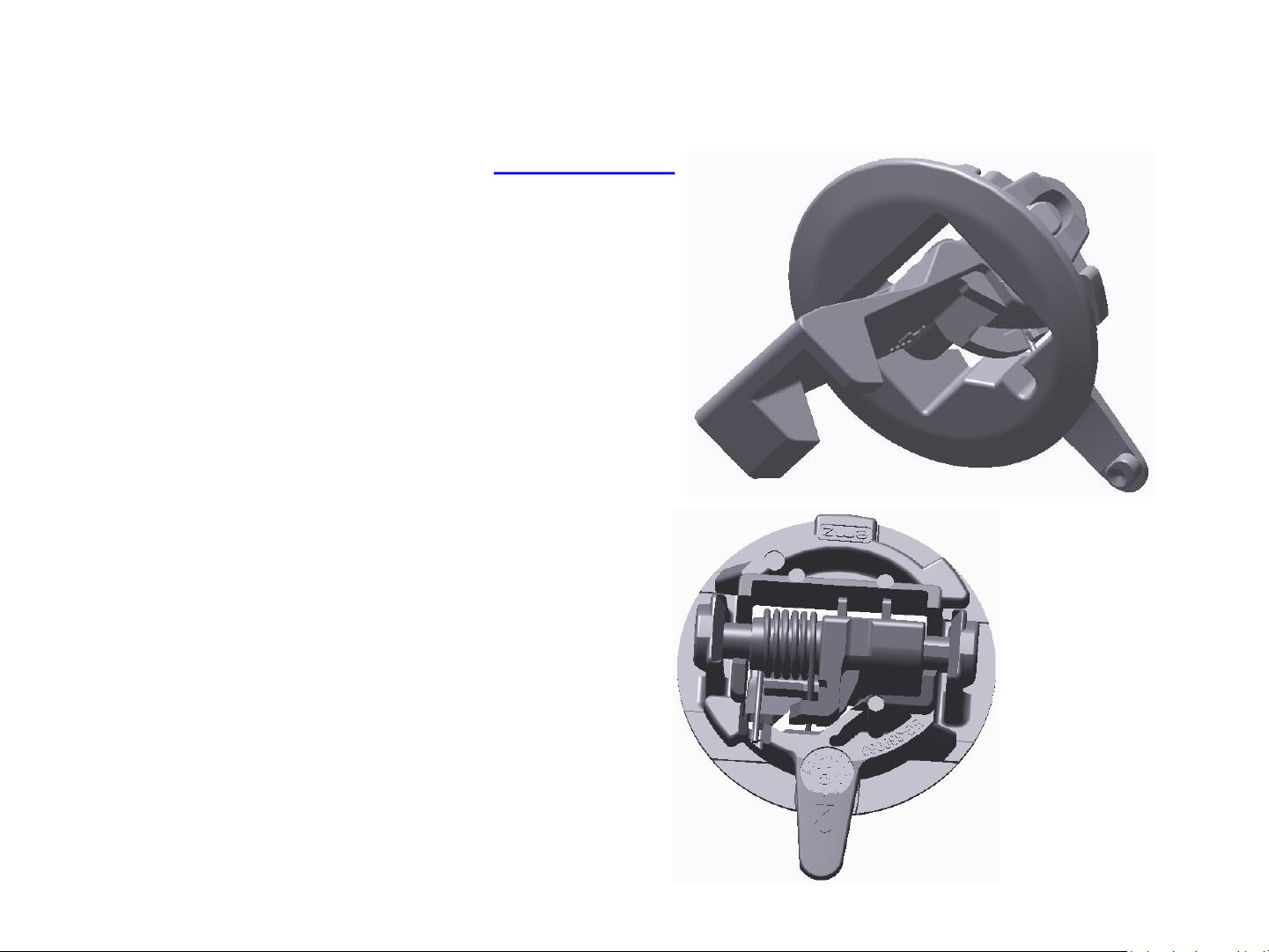

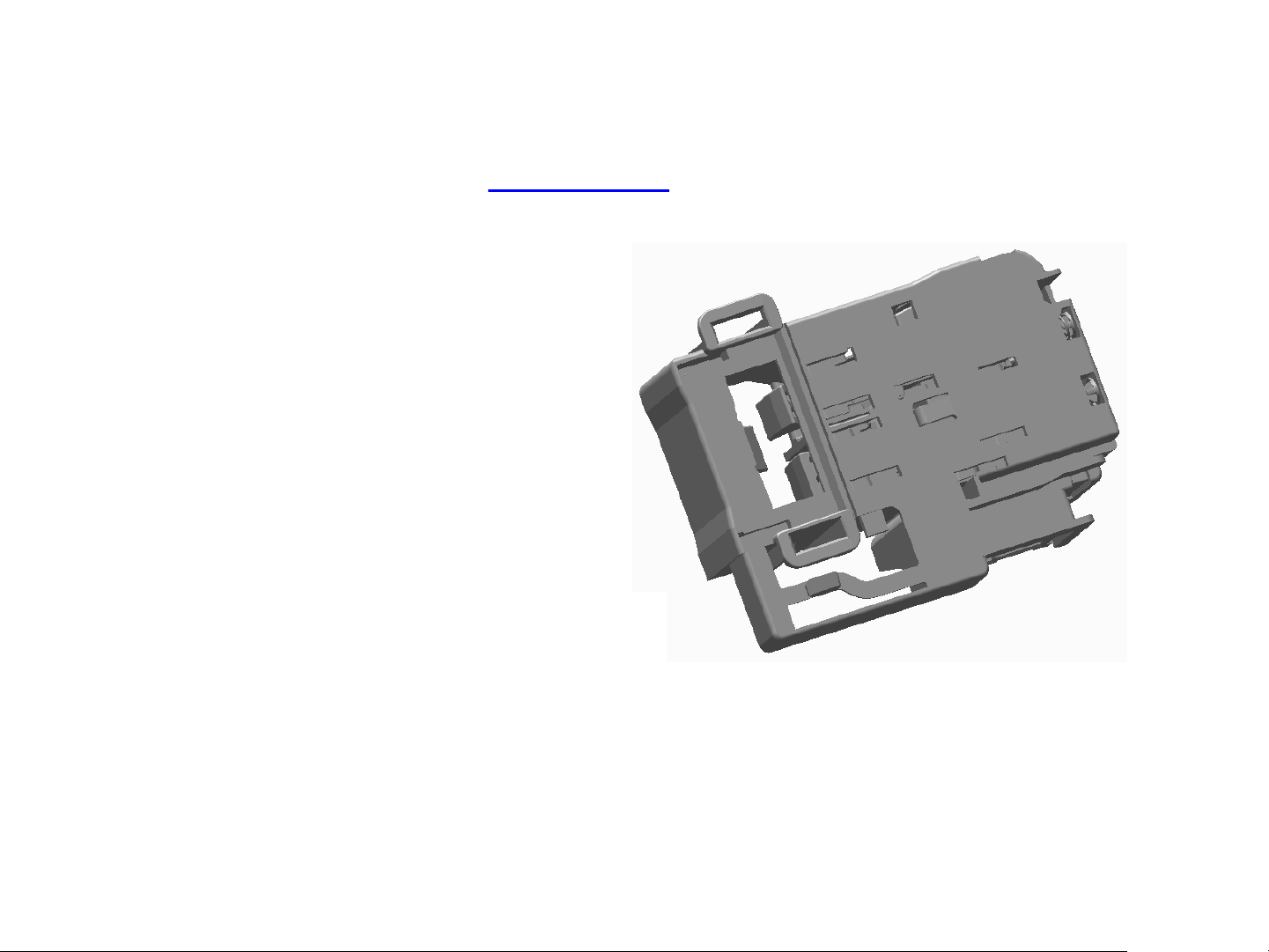

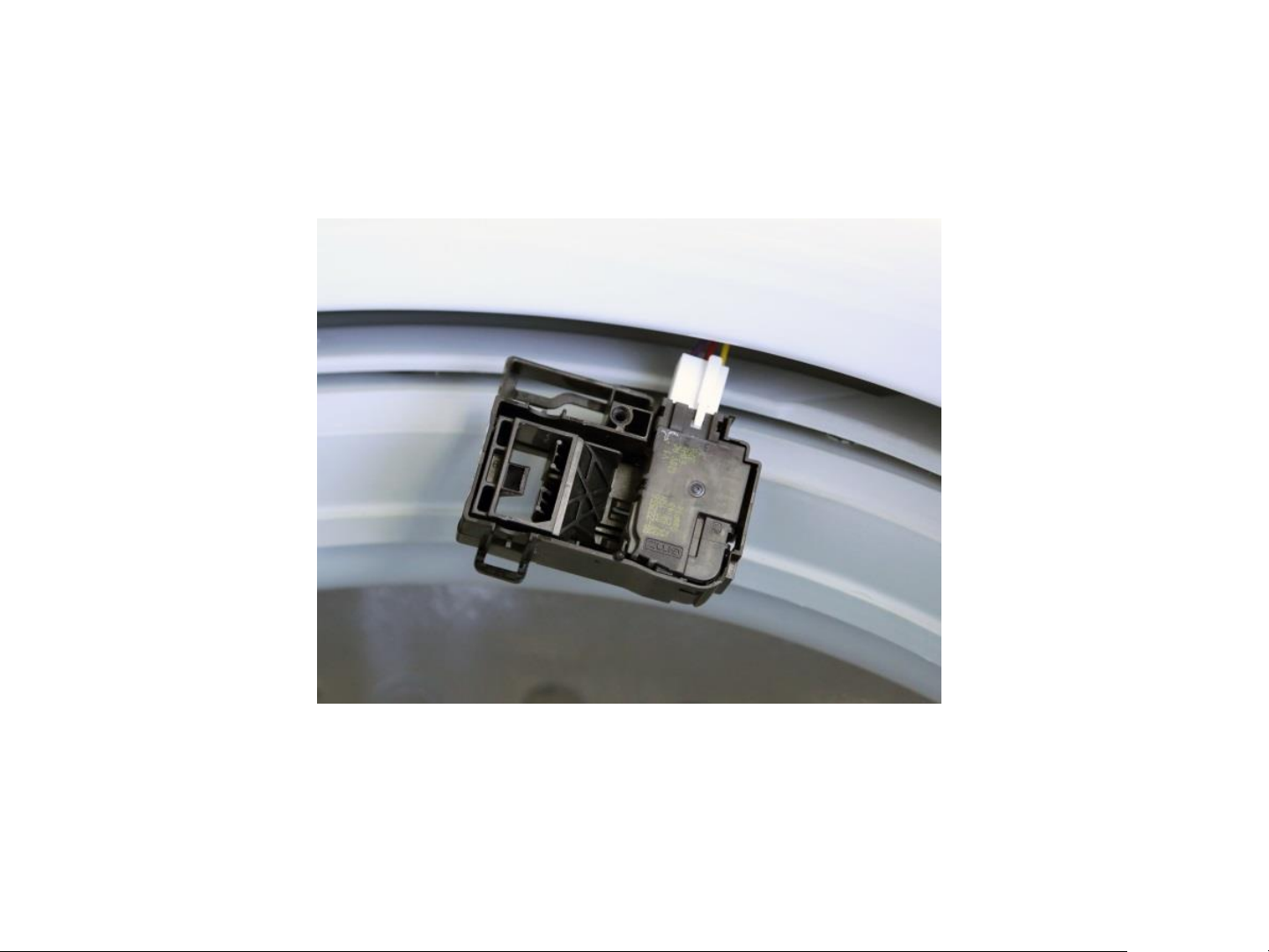

Mode Shifter Assembly

The mode shifter either engages or

disengages the clutch with the

transmission pulley depending on

whether the cycle is in spin or

agitate.

The clutch home position is engaged

with the pulley or ready for spin.

It has a 120 VAC motor.

Resistance of the mode shift motor

from Brown – Blue is 5700 ohm

from J512 board connector.

To remove the Mode shifter:

Remove the transmission pulley and

nut. The pulley is held on by a 9/16

in. lock nut. Use a new nut when

reinstalling the pulley and torque

to 110 in-lbs.

Guide Pins

Page 58

Mode Shifter Assembly

Disconnect the mode shifter motor

harness connector.

Remove two 3/8th hex head mounting

bolts. This will allow the complete mode

shifter assembly to be removed with the

clutch.

The clutch spring and spring washer will

come off as well. When reinstalling be

sure to install the spring washer before

the clutch spring.

Guide Pin

Location Holes

Page 59

Platform Transmission Assembly

The platform transmission assembly is one

complete part with the exception of two

harness connector brackets and one motor

splash guard. These will need to be

transferred to the new platform assembly

when replacing the platform transmission

assembly.

The platform assembly is secured to the tub

by eight 3/8th hex head bolts circled . One of

these bolts also holds one of the harness

brackets to the platform.

Harness

Connector

Bracket

Motor Shield

Harness

Connector

Bracket

Page 60

Platform Transmission Assembly

To remove the platform assembly after all

other components have been removed

remove the eight 3/8th hex head bolts and

pull the platform away from the tub.

Note: The bottom of the tub can be used to

pry the platform transmission assembly off of

the tub.

The tub seal is pressed on to the platform

transmission assembly. If there is a leak from

the seal, the complete transmission will need

to be replaced.

Triple Lip

Tub Seal

Page 61

Platform Transmission Assembly

To reinstall the platform assembly to

the tub, slide the shaft of the

transmission into the opening of the

tub.

Press the tub seal into the tub

opening.

Note: Line the guide post with the

opening in the platform.

Tighten the eight hex head bolts in a

crisscross pattern so that the seal is

pulled into the tub evenly and

securely.

This is done by tightening each bolt

about 1/4 of the way in at a time.

Torque to 65 in-lbs.

2

3

8

6

5

7

4

1

Guide

Post

Page 62

Schematic

62

11/16/2015

Page 63

Control Board User Interface

J401

J615

J513

J514

J511

J101

J701

J602 J512

63

11/16/2015

Page 64

Consumer Error Mode Entry

64

11/16/2015

Page 65

Consumer Help Indicator

65

11/16/2015

Page 66

Service Mode Entry

66

11/16/2015

Page 67

Binary Display Test and Fault Chart

67

11/16/2015

Page 68

Service Mode Tests

68

11/16/2015

Page 69

Service Mode Tests

69

11/16/2015

Page 70

Service Mode Tests

70

11/16/2015

Page 71

Service Mode Tests

71

11/16/2015

Page 72

Service Mode Tests

72

11/16/2015

Page 73

Service Mode Tests

73

11/16/2015

Page 74

Service Mode Tests

74

11/16/2015

Page 75

Service Mode Tests

75

11/16/2015

Page 76

Service Mode Tests

76

11/16/2015

Page 77

Fault Codes

77

11/16/2015

Page 78

Fault Codes

78

11/16/2015

Page 79

Fault Codes

79

11/16/2015

Page 80

Fault Codes

80

11/16/2015

Page 81

Warranty

81

11/16/2015

Loading...

Loading...