Page 1

g

GE Consumer Home Services Training

TECHNICAL SERVICE GUIDE

Louisville Built

Top Mount No Frost

18-19 Cu. Ft. Energy Refrigerators

MODEL SERIES:

ETS

GTH

GTS

HTS

STS

PUB # 31-9078 12/01

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2001

All rights reserved. This service guide may not be reproduced in whole or in

part in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Specifications ................................................................................................................. 2

Nomenclature ................................................................................................................. 3

Warranty Information ...................................................................................................... 4

Operating Characteristics............................................................................................. 5

Mechanical Disassembly ............................................................................................... 8

Troubleshooting........................................................................................................... 18

Component Locator Views .......................................................................................... 22

Schematics ................................................................................................................... 24

– 1 –

Page 4

Specifications

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT - RECONNECT ALL GROUNDING DEVICES

All parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, clips, nuts or washers used to

complete a path to ground are removed for service,

they must be returned to their original position and

properly fastened.

ELECTRICAL SPECIFICATIONS

Temperature Control (Position 5) .............................. 24.5-12.5°F

Defrost Control ..................................................... 8 hrs. @ 30 min.

Defrost Thermostat ............................................................ 58-28°F

Electrical Rating: 115V AC 60Hz.

100V AC 50 Hz. .............................................................. 6.5 Amp.

Maximum Current Leakage ............................................. 0.75 mA.

Maximum Ground Path Resistance ........................... 0.14 Ohms

Energy Consumption

18' .............................................................................. 40 KWH/mo

19' .............................................................................. 41 KWH/mo

NO LOAD PERFORMANCE

Control Position, Fresh Food 5, Freezer 5

and Ambient Temperature of: .............................

70°F 90°F

Fresh Food, °F ....................................................... 34-40 35-39

Frozen Food, °F ..................................................... (-3) -4 (-3) -3

Run Time, % .......................................................... 20-30 41-53

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation

of this information, nor can it assume any liability

in connection with its use.

INSTALLATION

Clearance must be provided for air circulation

AT TOP .....................................................................................1-inch

AT SIDES ............................................................................. 1/8-inch

AT REAR .................................................................................. 1-inch

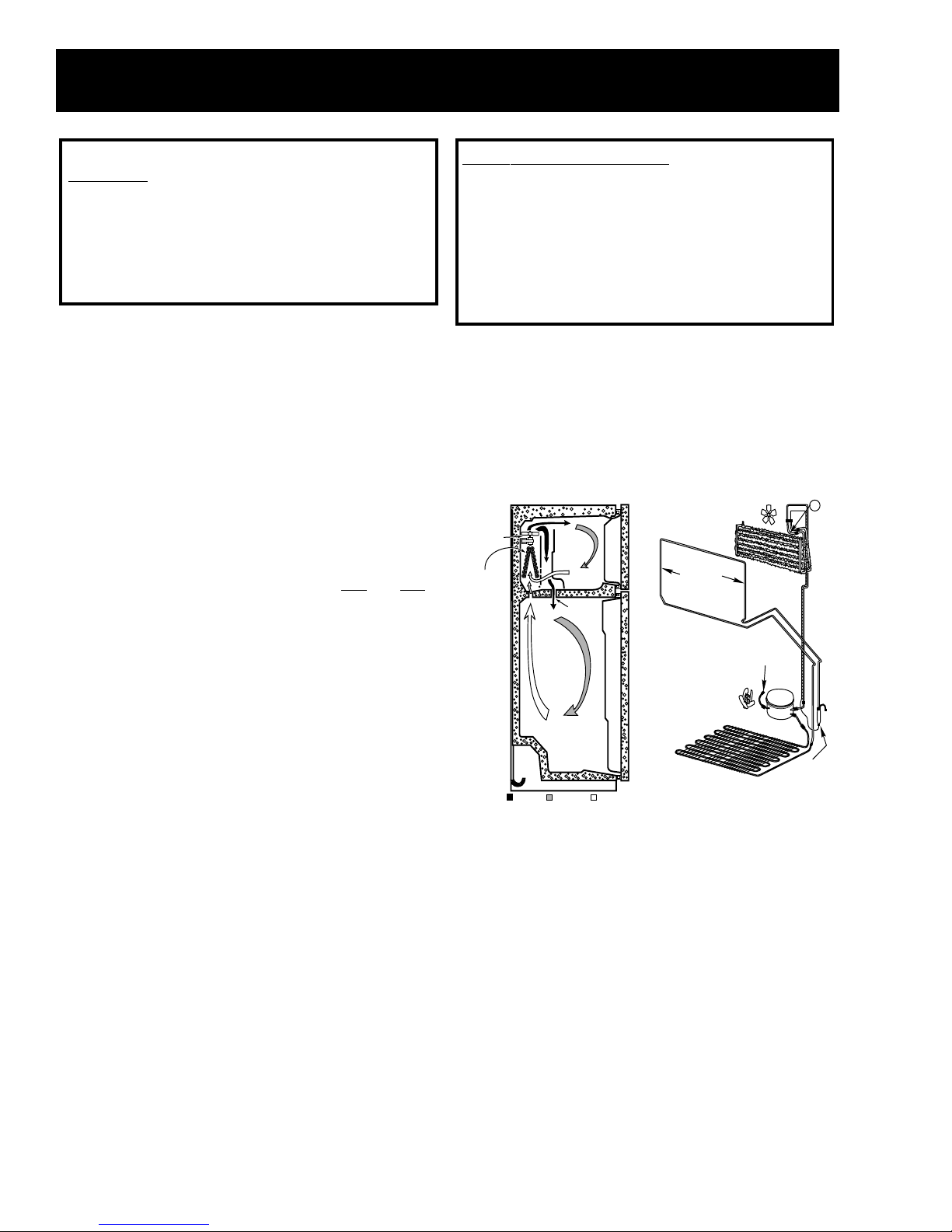

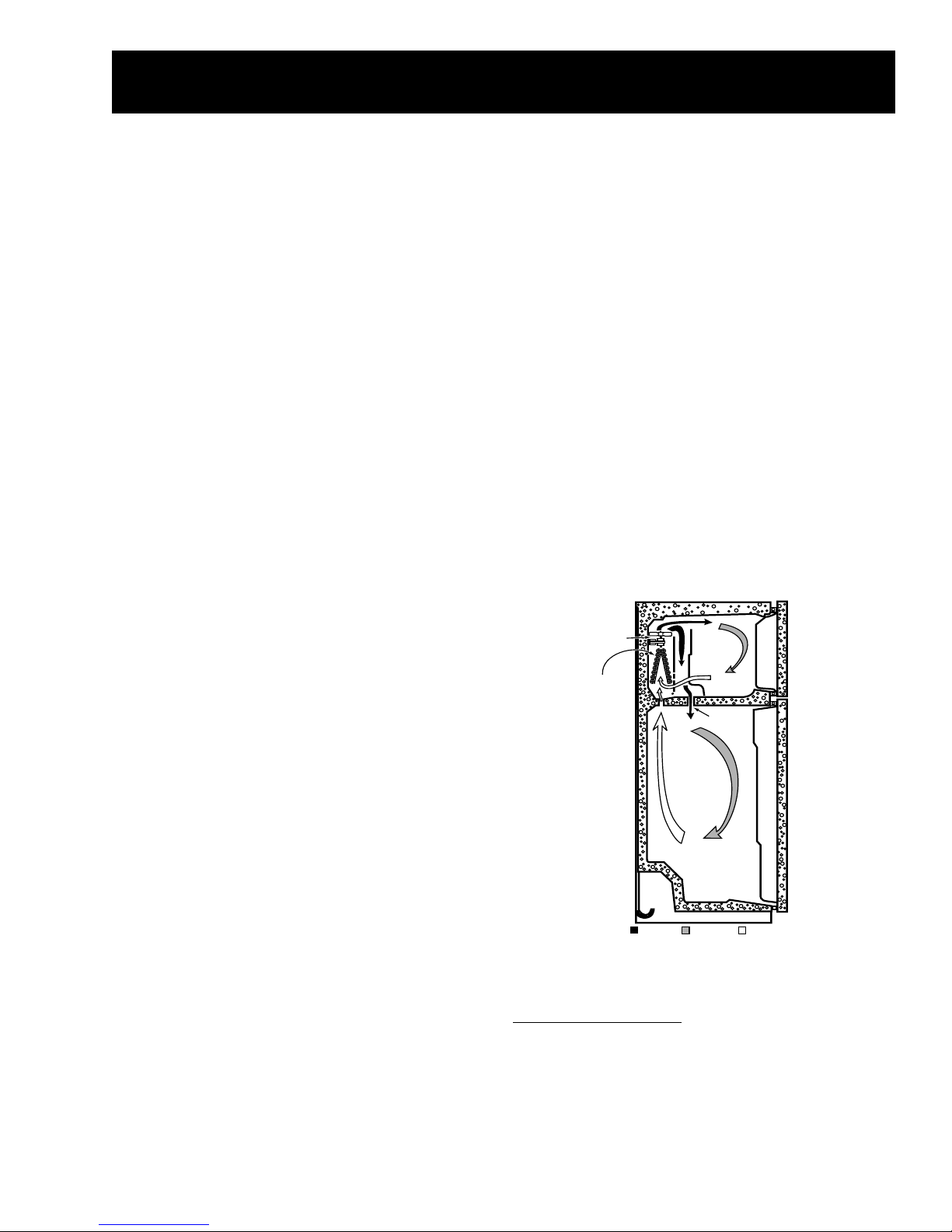

AIR FLOW SEALED SYSTEM

T

FAN

EVAPORATOR

DAMPER

CONDENSER

LOOP

PROCESS

TUBE

REFRIGERATION SYSTEM

Refrigerant Charge (R134a) ........................................ 4.0 ounces

Compressor ................................................................... 679 BTU/hr

Minimum Compressor Capacity ................................... 19 inches

Minimum Equalized Pressure

@70°F ............................................................................... 52 PSIG

@90°F ............................................................................... 66 PSIG

REPLACEMENT PARTS

Condenser Fan Motor ............................................... WR60X10044

Evaporator Fan Motor .............................................. WR60X10057

Defrost Heater ........................................................... WR51X10031

Relay ............................................................................WR07X10031

Overload ........................................................................ WR08X0167

Temperature Control .................................................WR09X10044

Defrost Control ................................................................ WR9X503

Defrost Thermostat ...................................................WR50X10025

Capacitor .................................................................... WR062X0087

COLD AIR

WARMER AIRMIXED AIR

ND103-02B

103-02A

DRYER

– 2 –

Page 5

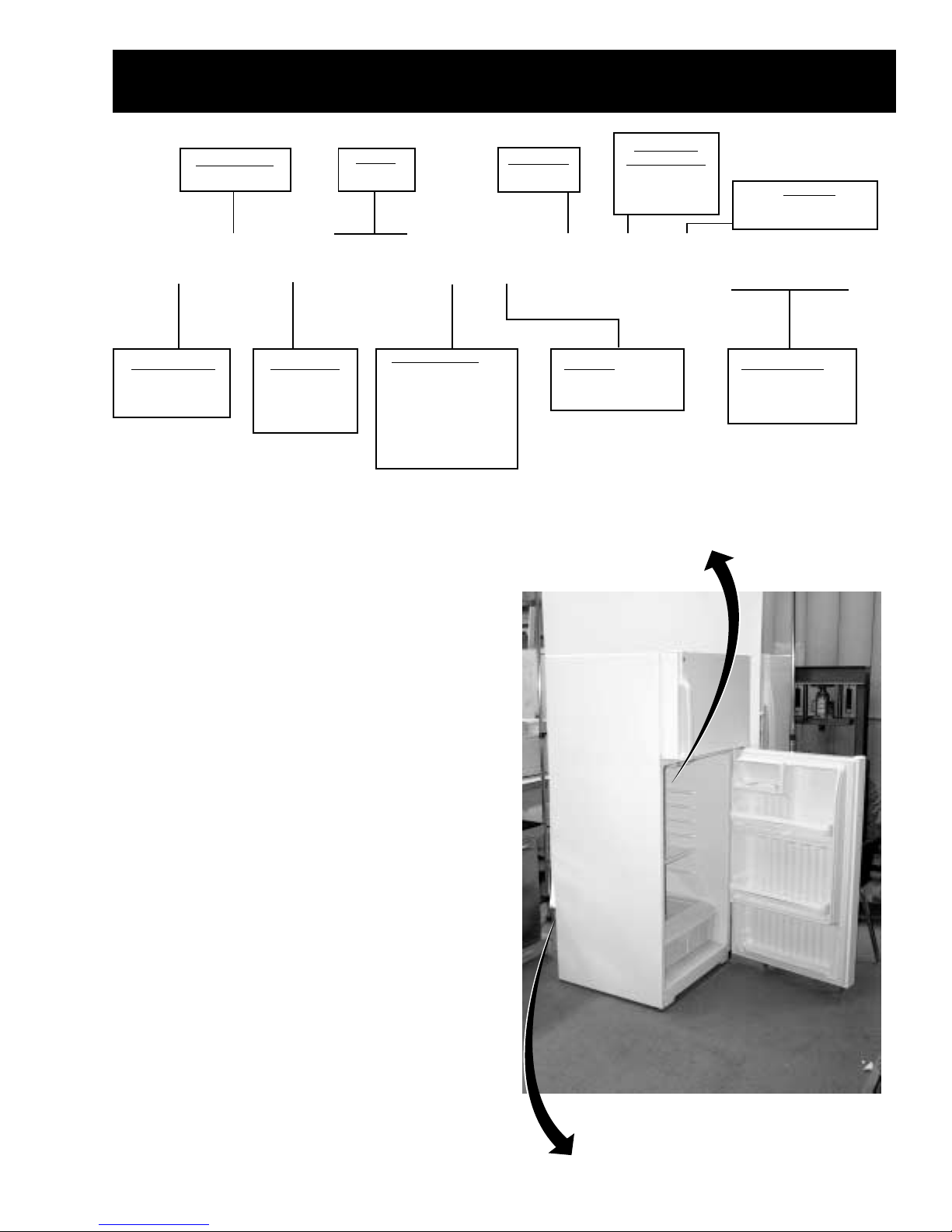

Nomenclature

CONFIGURATION

T = TOP FREEZER

VOLUME

18 / 19

MODEL YEAR

M = 2001

ENGINEERING

NOMENCLATURE

A = INITIAL DESIGN

B = 1ST REVISION

ETC.

R = RIGHT DOOR SWING -TF

L = LEFT DOOR SWING - TF

G T S 1 8 E B M B R W W

BRAND/PRODUCT

G = GE

S = SELECT

DEPTH/POWER

S = STANDARD

T = TROPICAL

R = RECESSED

HANDLE

Rating Plate

INTERIOR/SHELVES

A = LEADER WIRE

B = STANDARD WIRE

E = PREMIUM WIRE

F = SUPERIOR WIRE

H = UPGRADE GLASS

K = SPILL-PROOF GLASS

X = REGIONAL

ICEMAKER

B = ICEMAKER READY

C = FACTORY ICEMAKER

EXTERIOR COLOR

WW = WHITE/WHITE

AA = ALMOND/ALMOND

CC = BISQUE/BISQUE

T

DOOR TYPE

RATING PLATE

The rating plate, located inside the refrigerator on

the upper left-hand side, contains the model and

serial numbers. Additionally, the rating plate

specifies the minimum installation clearances,

electrical voltage, frequency, maximum

amperage rating, and refrigerant charge and

type.

GEA01027

Mini Manual Location

– 3 –

Page 6

Warranty Information

Refrigerator Warranty.

(For customers in the United States)

For The Period Of: GE Will Replace:

One Year Any part

of the refrigerator which fails due to a defect in materials or workmanship.

From the date of the

During this

full one-year warranty,

GE will also provide,

free of charge,

all labor

original purchase

and in-home service to replace the defective part.

Five Years Any part of the sealed refrigerating system

(the compressor, condenser, evaporator

From the date of the

and all connecting tubing) which fails due to a defect in materials or workmanship.

original purchase

During this

additional four-year limited warranty,

GE will also provide,

free of charge,

all

labor and in-home service to replace the defective part.

■Service trips to your home to teach you how to use the

product.

■Improper installation.

■Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■Loss of food due to spoilage.

■Replacement of house fuses or resetting of circuit

breakers.

■Damage to the product caused by accident, fire, floods or

acts of God.

■Incidental or consequential damage caused by possible

defects with this appliance.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule service,

on-line, 24 hours a day, contact us at www.GEAppliances.com, or

call 800-GE-CARES.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

– 4 –

Page 7

Operating Characteristics

Note:

Refer to Component Locator Views.

Refer to Schematics.

Component Description

The compressor and dryer are located in the

machine compartment at the bottom, rear of the

unit. The condenser is located under the unit. The

evaporator is located in the freezer compartment

on the back wall.

The capillary is soldered to the compressor

suction line. The capillary is also taped to the

suction line near the dryer. This arrangement

serves as a heat exchanger.

The temperature control and defrost control are

located in the control console. The control

console is located in the top of the fresh food

compartment. The evaporator fan is located in the

freezer compartment behind the air tower.

operates only when the temperature control

(switch) is closed. After 8 hours of motor/cam

mechanism runtime in cooling mode, the defrost

control switches to defrost mode. The defrost

control will stay in defrost mode, providing 115 VAC

to the heater for 30 minutes of motor/cam

mechanism runtime. The defrost thermostat

switch is mounted on the evaporator and, when

closed, completes the neutral side of the defrost

heater circuit. The defrost thermostat switch

opens when the evaporator temperature raises to

58 °F and closes when the evaporator temperature

lowers to 28 °F. The defrost thermostat switch

typically opens during the defrost cycle, preventing

the heater from defrosting for the full 30 minutes.

The purpose for the 30-minute defrost mode at the

defrost control is to prevent the compressor from

operating and refreezing any water that may be

dripping from the evaporator.

Electrical Operation

The power source provides 115 VAC to the

temperature control. The temperature control is a

thermostatic switch that closes when the fresh

food compartment temperature is higher than the

control setting. When closed, the temperature

control provides 115 VAC to the defrost control.

The defrost control contains a motor/cam

mechanism that switches the defrost control

between defrost mode and cooling mode. When

in cooling mode, the defrost control provides

115 VAC to the compressor, condenser fan, and

evaporator fan. The compressor, condenser fan,

and evaporator fan should always operate at the

same time.

Defrost Operation

The automatic defrost function is controlled by the

defrost control. The defrost control contains a

motor/cam mechanism that switches the defrost

control between defrost mode and cooling mode.

The defrost control motor/cam mechanism

FAN

EVAPORATOR

DAMPER

COLD AIR

WARMER AIRMIXED AIR

ND103-02B

Airflow

Freezer Compartment

Cold air from the evaporator is forced up against

the top of the freezer and the back of the

evaporator cover. It is then discharged through

– 5 –

Page 8

slots along the air tower at the rear of the freezer

compartment.

Air is circulated by the evaporator fan throughout

the freezer compartment, where it picks up heat

and moisture. The evaporator fan then draws the

warmer, moisture-laden air through return louvers

in the bottom of the evaporator cover. The air is

then drawn through the evaporator where heat is

removed and moisture is deposited as frost.

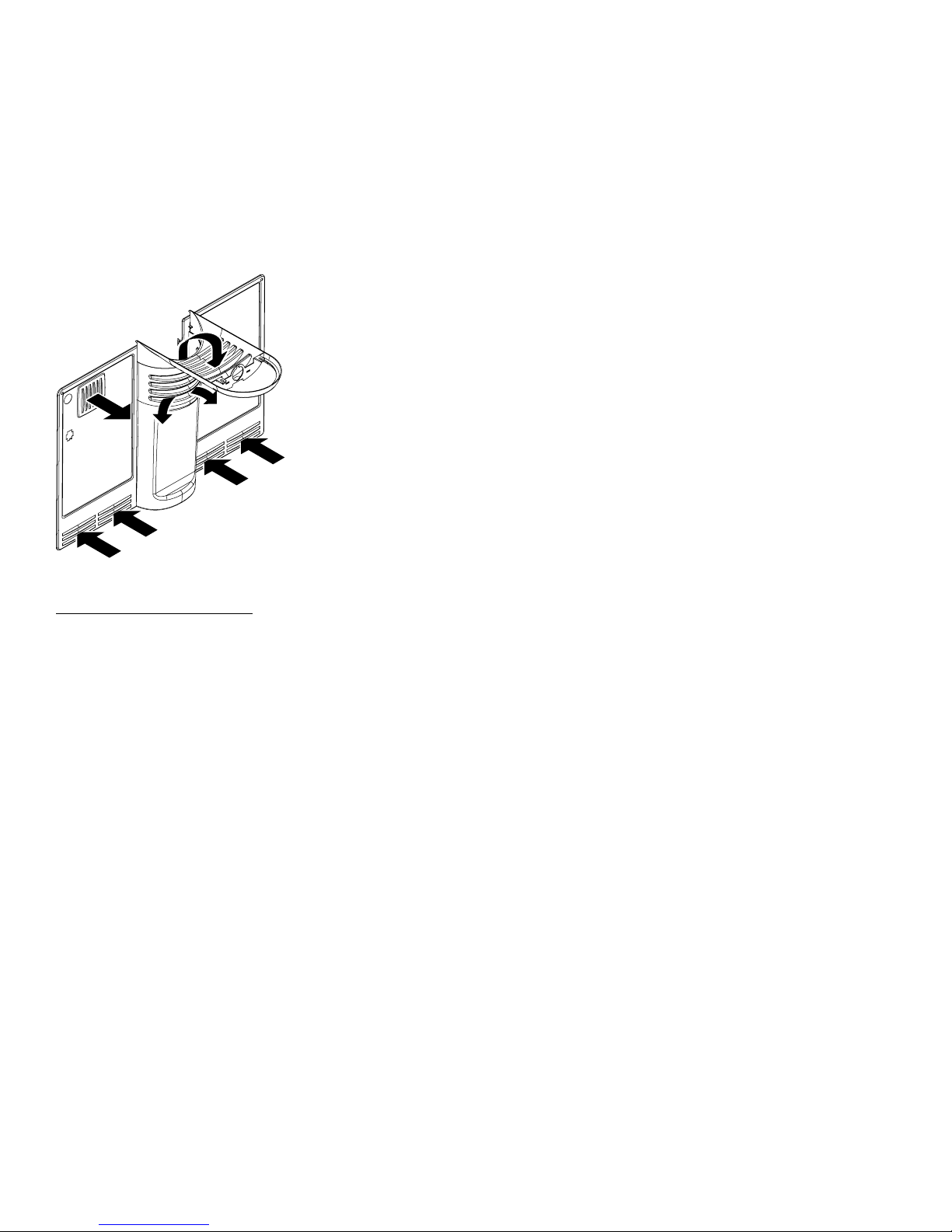

GEA01143

Fresh Food Compartment

Some of the cold air that is being forced against

the top of the freezer and back of the evaporator

cover is diverted through the lower portion of the

freezer air tower and is pushed through the mullion

hole into the damper (in control console).

Air circulates throughout the fresh food

compartment, picking up heat and moisture. The

air is then returned to the evaporator through the

return air ducts located at the top right and left of

the fresh food compartment.

– 6 –

Page 9

Notes

– 7 –

Page 10

Mechanical Disassembly

Table of Contents

Door Gasket ............................................................................................................. 9

Doors ......................................................................................................................... 9

Roller ........................................................................................................................ 10

Crisper Drawers ...................................................................................................... 10

Temperature Control .............................................................................................. 10

Defrost Control ....................................................................................................... 11

Light Switches ......................................................................................................... 11

Air Tower and Evaporator Cover .......................................................................... 11

Defrost Thermostat ................................................................................................ 12

Defrost Heater ........................................................................................................ 12

Evaporator (Soldering Method) ............................................................................ 12

Evaporator (LOKRING Method) ............................................................................ 13

Evaporator Fan ....................................................................................................... 14

Condenser Fan ....................................................................................................... 14

PTCR Relay/Overload Cover (Compressor) ........................................................ 15

PTCR Relay (Compressor) ..................................................................................... 15

Overload (Compressor) ......................................................................................... 16

Capacitor (Compressor) ......................................................................................... 16

Compressor ............................................................................................................. 16

– 8 –

Page 11

Door Gasket

Top Hinge

The fresh food and freezer doors have magnetic

gaskets that create a positive seal to the front of

the steel cabinet. The magnetic door gaskets are

secured to the fresh food and freezer doors by a

barbed edge that locks into a retainer channel.

GEA01150

1. Starting at any corner, pull the old gasket out of

the retainer channel.

2. Soak the new gasket in warm water to make it

pliable.

3. Push the barbed edge of the gasket into the

retainer channel.

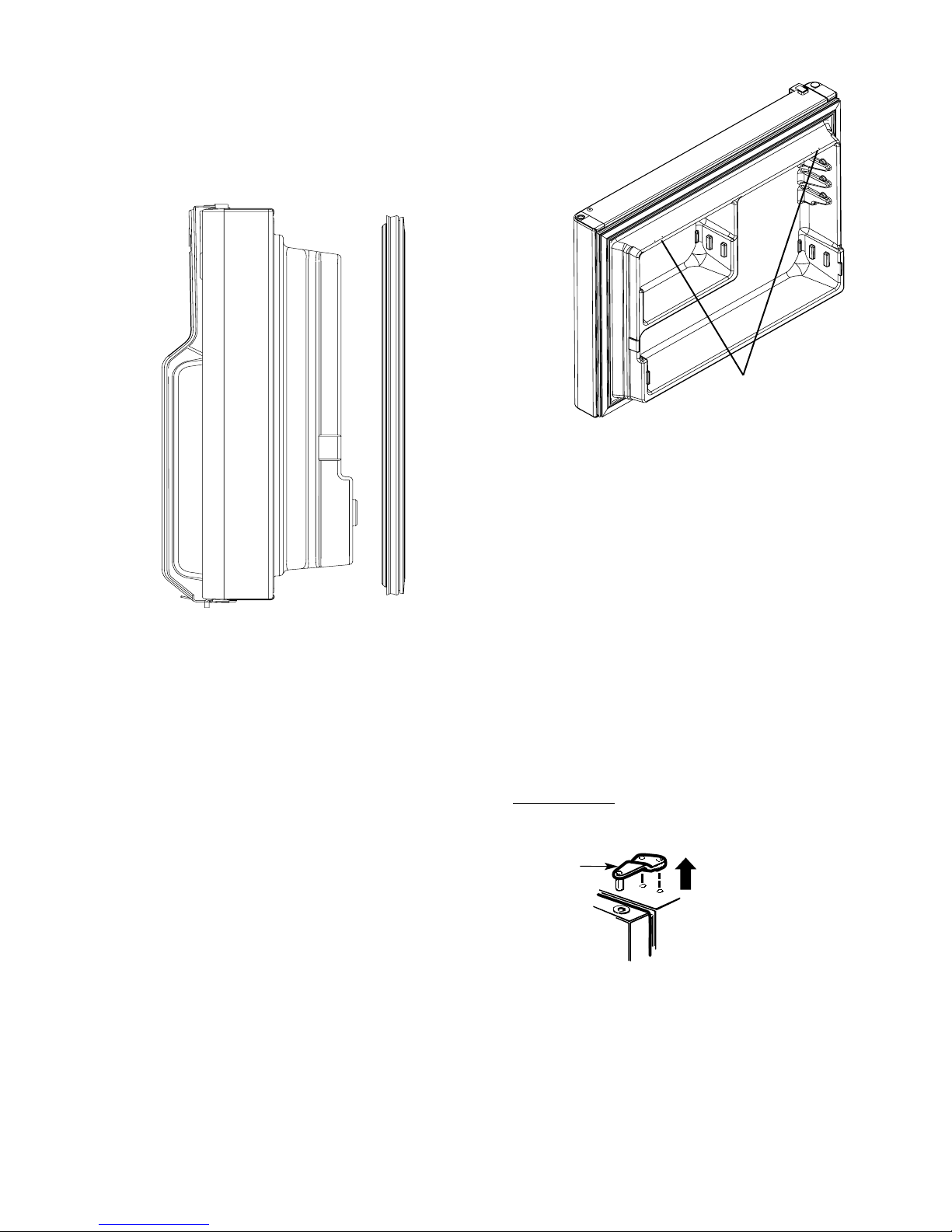

Doors

Vent Holes

GEA01138

The doors are of one-piece construction with foam

insulation. One-piece construction provides

superior thermal performance and reduces air

infiltration. During manufacturing, the doors are

filled with hot foam insulation. This may cause

slight distortion or ripples in the inner door liner.

This is a normal condition and is the result of the

insulating process. This process requires doors

to be equipped with vent holes that allow air to

escape when the door is filled with foam. A small

amount of foam may be visible around the vent

holes.

The inner door panels and outer door panels

cannot be separated and must be replaced as an

assembly.

Freezer Door

1. Remove all food from the inner door liner.

2. Remove 2 screws and the top hinge from the

cabinet.

Note: Do not lose plastic washers on center

hinge pin. Plastic washers are needed for proper

door adjustment.

3. Open the door and lift it off the center hinge pin

to remove.

– 9 –

Page 12

Fresh Food Door

Plastic Washer

Fresh Food Door

Hinge Pin

Center Hinge

Bracket

1. Remove all food from the inner door liner.

Note: Do not lose plastic washers on center

hinge pin and lower hinge pin. Plastic washers

are needed for proper door adjustment.

2. Remove pin and washer from center hinge.

To remove a front roller assembly from the base of

the cabinet:

1. Tilt the cabinet back and place a

3-in. block under the side of the unit.

2. Remove 3 hex head (1/4-in.) screws from the

roller assembly.

3. Loosen the adjustment screw until it

disengages from the assembly and remove

the assembly from the cabinet.

4. Remove the E-ring to remove the adjustment

screw from the base channel.

Note: When reinstalling the roller assembly,

position the nut with the flared thread toward the

rear of the unit.

3. Open the door and lift it off the bottom hinge to

remove.

Rollers

Rollers at the base of the cabinet enable the

customer to easily move the refrigerator. Cabinet

leveling is done by adjusting the front rollers. To

adjust the front rollers, use a 3/8-in. socket or a

large flat head screwdriver to turn the roller

adjustment screws located behind the base grille.

The rear rollers are not adjustable.

Crisper Drawers

Unload the bottom shelf before attempting to

remove the storage drawers.

To Remove:

Lift the drawers up slightly while pulling

them past the stop location.

When the door cannot be fully opened:

Remove the drawer that is farthest from the door.

Slide the other drawer toward the middle and

remove it.

GEA01147

– 10 –

Page 13

Temperature Control

GEA01174

Connector

Defrost

Control

Locking Tabs

Connector

Defrost

Control

Locking Tabs

Release Tab

Light Switch

Defrost Control

1. Remove 3 screws and lower the control

console.

2. Disconnect the harness connector and

remove the control console.

Ground

Ground

Wire

Wire

Temperature

Temperature

Control

Control

Locking

Locking

Tabs

Tabs

Temperature

Temperature

Adjustment

Adjustment

Knob

Knob

Wire

Wire

Leads

Leads

3. Remove knob and clip from temperature

control.

1. Remove the control console (see Temperature

Control procedure).

2. Disconnect the wiring harness connector from

the defrost control.

GEA01172

3. Press the locking tabs back and slide the

defrost control out of the control console.

4. Remove styrofoam duct from control console.

5. Remove capillary from plastic sheath.

Note:

To avoid damage to capillary, it may be

necessary to remove wire connectors from defrost

control and from light socket(s).

Temperature control knob clip will be loose when

knob is pulled from temperature control. Use care

to avoid loosing clip. During installation, clip is

installed after knob is pushed on the temperature

control.

6. Press the locking tab back and slide the

temperature control out of the control console.

7. Disconnect 3 wire leads from the temperature

control.

Light Switches

1. Insert a small flat screwdriver under the right

side of the light switch and release the switch

locking tab.

Release Tab

Release Tab

Light Switch

Light Switch

GEA01171

2. Pull the switch out, disconnect the wire leads,

and remove the switch.

– 11 –

Page 14

Air Tower and Evaporator Cover

Defrost Thermostat

1. Remove all shelves.

1. Remove the evaporator cover (see Air Tower

and Evaporator Cover procedure).

Caution: The thermostat has a metal clip that

fastens it to the line. Defrost thermostat can be

damaged if handled improperly. Use clip to

remove and install thermostat.

Defrost

Defrost

Thermostat

Thermostat

GEA01160

Note: Some models are not equipped with a light

and lens in the light housing. Models without a

light have a plastic cover installed over the light

housing.

2. Remove light lens or plastic cover (models

without light).

3. Remove 2 screws from the bottom of the light

housing.

4. Slide light housing out from 2 pegs.

Disconnect light connector.

5. Remove 2 screws from the air tower.

6. Pull up and remove air tower.

7. Remove 2 screws and evaporator cover with

vent cover.

8. Disconnect ground wire from evaporator cover

and remove evaporator cover from freezer

compartment.

Note:

When installing light housing, ensure that back of

housing is installed on the 2 pegs.

When installing vent on left side of evaporator

cover, vents must direct air down.

2. Remove the thermostat from the line.

3. Cut the thermostat lead wires close to the

thermostat to replace.

Defrost Heater

1. Remove the evaporator cover (see Air Tower

and Evaporator Cover procedure).

Defrost

Defrost

Heater Support

Heater Support

Evaporator

Evaporator

Drain Probe

Wire LeadWire Lead

Drain Probe

2. Remove 2 defrost heater supports and the

evaporator drain probe from the evaporator.

Caution: Do not touch defrost heater glass. Oil

and dirt from hands can cause weak spots on the

glass.

3. Bend the aluminum tabs on the evaporator

back (located at each end of the defrost

heater) and lower the heater out of the

evaporator.

Wire LeadWire Lead

GEA01163

– 12 –

Page 15

4. Disconnect 2 wire leads and remove the

Screws

heater.

Note: Evaporator drain probe assists in defrosting

drain. During assembly, probe must be installed

on evaporator and in drain to prevent drain from

freezing closed.

10. Using a file, score the capillary tube just above

the old solder and break the solder-covered

section off. This will help prevent the capillary

tube from becoming plugged when resoldering.

11. Position the new evaporator in the cabinet.

Insert the suction line and capillary tube into

the evaporator.

Evaporator (Soldering Method)

1. Recover the refrigerant.

2. Remove the evaporator cover (see Air tower

and Evaporator Cover procedure).

3. Remove the defrost thermostat (see Defrost

Thermostat procedure).

4. Remove the defrost heater (see Defrost

Heater procedure).

5. Disconnect ground wire from evaporator and

position all wiring to allow for evaporator

removal.

6. Remove 2 screws that hold the evaporator to

the cabinet.

12. Solder the suction line to the evaporator using

silfos.

13. Solder the capillary tube to the evaporator

using silfos.

Note: Evaporator drain probe assists in defrosting

drain. During assembly, probe must be installed on

evaporator and in drain to prevent drain from

freezing closed.

14. Install a replacement dryer.

15. Evacuate and recharge the system using

currently accepted procedures.

Evaporator (LOKRING Method)

1. Recover the refrigerant.

2. Remove the evaporator cover (see Air Tower

and Evaporator Cover procedure).

3. Remove the defrost thermostat (see Defrost

Thermostat procedure).

Screws

Screws

GEA01164

Caution:

If desoldering the evaporator, HEAT SHIELD P/N

WR49X10025 must be used to prevent damage to

freezer liner.

Protect wiring from heat during desoldering and

resoldering.

To prevent damage to the capillary tube, the

capillary tube must be desoldered first.

7. Desolder the capillary tube from the

evaporator.

8. Desolder the suction line. Use a pair of pliers

to hold the evaporator.

9. Remove the evaporator.

4. Remove the defrost heater (see Defrost

Heater procedure).

5. Disconnect ground wire from evaporator and

position all wiring to allow for evaporator

removal.

6. Loosen 2 screws that hold the evaporator to

the cabinet.

Caution: Tubing must be clean and free from

burrs when using LOKRING.

Note: LOKRING connector P/N WR97X10021

must be used. Two LOKRING connectors are

required.

7. Replace the evaporator using the LOKRING

method (see Pub # 31-9067).

Cut the copper lines of the old evaporator as

close as possible to the aluminum evaporator

tubes.

Cut the copper lines of the new evaporator

1-1/8 in. from the edge of the aluminum

evaporator tubes.

– 13 –

Page 16

Cut

Here

Copper

Evaporator

Copper

Cut

Here

Cut

Here

Cut

Here

Aluminum

Evaporator Tubes

Aluminum

Evaporator Tubes

Copper

Evaporator

Defrost

Thermostat

Here

Copper

Evaporator

Evaporator

Lines

Lines

Cut

Cut

Here

Here

Aluminum

Aluminum

Evaporator Tubes

Cut

Cut

Here

Here

Evaporator Tubes

OLD EVAPORATOR

Defrost

Defrost

Thermostat

Thermostat

Here

Here

Evaporator Fan

1. Remove the evaporator cover (see Air tower

and Evaporator Cover procedure).

2. Disconnect the fan motor connector.

3. Carefully pull the fan off the shaft.

Note: Evaporator drain probe assists in defrosting

drain. During assembly, probe must be installed on

evaporator and in drain to prevent drain from

freezing closed.

Copper

Copper

Evaporator

Evaporator

Lines

Lines

Cut

Cut

Here

Here

1-1/8 inch

1-1/8

inch

Aluminum

Aluminum

Evaporator Tubes

Cut

Cut

Here

Here

Evaporator Tubes

NEW EVAPORATOR

GEA01108

4. Remove 2 screws and fan assembly.

5. Remove fan motor.

Note: The position of the fan blade in relation to

the shroud is critical. Refer to figure below for

specifications.

5/16" ± 0.03

1.0" ± 0.05 Target

Blade tip

Motor

Air Flow

Airflow

Orifice

GEA01149

Condenser Fan

1. Remove the machine compartment cover.

2. Disconnect the fan motor connector.

3. Carefully push the fan off the motor shaft.

8. Install a replacement dryer.

9. Evacuate and recharge the system using

currently accepted procedures.

– 14 –

Page 17

Connector

GEA01207

Connector

Screws

Screws

Fan

Fan

Fan MotorFan Motor

GEA01175

4. Remove 2 screws, bracket, and the fan motor.

Caution: During installation, water valve

connector must be tied clear of fan operation.

Note:

PTCR Relay/Overload Cover (Compressor)

1. Remove the machine compartment cover.

Tab

Tab

Cover

Cover

GEA01169

2. Insert a flat screwdriver under the tab on the

covers top surface, pry up, and remove.

The position of the fan blade in relation to the

shroud is critical. Refer to figure below for

specifications.

Ensure that harness connectors are connected

completely and that connector clips are engaged.

If connectors are not connected correctly, they

may vibrate apart.

1/2"

Housing

Fan

0.375"

Motor

3. Remove the cover.

PTCR Relay (Compressor)

1. Remove the PTCR relay/overload cover (see

procedure).

Air Flow

Airflow

0.50" ± 0.05

Bracket

2. Pull the PTCR relay straight out from the

compressor.

3. Disconnect the wire leads from the relay.

GEA01148

– 15 –

Page 18

Overload (Compressor)

Capacitor

Wire Leads

Compressor

1. Remove the PTCR relay/overload cover (see

procedure).

2. Remove the PTCR relay (see procedure).

3. Pull the overload straight out from the

compressor.

4. Disconnect the wire lead from the overload.

Capacitor (Compressor)

1. Remove the machine compartment cover.

Wire Leads

Wire Leads

Capacitor

Capacitor

Note:

Capillary tube must be clipped to compressor

suction line near the dryer. If capillary tube is not

clipped to suction line, a knocking noise may occur

during compressor operation.

The channel in which the compressor is

mounted must be disengaged from the cabinet to

remove the compressor.

Ensure that harness connectors are connected

completely and that connector clips are engaged.

If connectors are not connected correctly, they

may vibrate apart.

Refer to the compressor replacement instructions

included with the replacement compressor.

GEA01168

2. Disconnect the wire leads from the capacitor.

3. Discharge the capacitor with a screwdriver.

4. Remove 1 screw and the capacitor.

– 16 –

Page 19

Notes

– 17 –

Page 20

Troubleshooting

Note:

Refer to Operating Characteristics before

choosing a troubleshooting procedure.

Refer to Schematics.

Refer to Component Locator Views.

Compressor Knock

Capillary tube not taped to suction line. Check

to see that capillary tube is clipped to the suction

line near the dryer.

Low or No Cooling

Check for the following problems:

1. Condenser dirty/clogged. Unplug unit and

clean condenser and underside of refrigerator.

2. Interior lights remain on. Check to see that

interior lights turn off when door switch is

pressed.

3. Door gasket does not seal. Check for

damaged or leaking door gasket.

4. Compressor does not operate. Go to

Compressor Does Not Operate

troubleshooting.

5. Condenser fan does not operate. Go to

Condenser Fan Does Not Operate

troubleshooting.

6. Evaporator fan does not operate. Go to

Evaporator Fan Does Not Operate

troubleshooting.

7. Evaporator is frosted. Go to Defrost System

Check.

Compressor Does Not Operate

Check for the following problems:

Note: The defrost control must be in cooling

mode to operate the compressor (provide

115 VAC to the compressor overload). It may be

necessary to manually rotate the defrost control

to cooling mode before checking for voltage at the

compressor overload.

1. 115 VAC not present at compressor

overload. If 115 VAC is not present at the

compressor overload, check for an open

temperature control or an open defrost control

(cooling mode - terminals 3 and 4 are closed).

Note: The compressor, condenser fan, and

evaporator fan should always operate at the same

time. If the condenser fan is operating, the

temperature control and defrost control

are OK.

2. Overload open. High heat or high current

draw will cause the overload to open. The

overload should close when the temperature

lowers to normal or when normal current draw

is present.

3. PTCR relay open.

4. Run capacitor faulty.

5. Open wire or faulty connector. Refer to

Schematics.

6. Compressor motor faulty. Check resistance

across the compressor motor. Refer to

Schematics for resistance values.

7. Compressor mechanically stalled.

8. Duct is clogged between freezer

compartment and fresh food compartment.

If fresh food compartment is warm and freezer

is normal or too cold, duct (diffuser) may be

clogged. Duct is accessed by removing air

tower.

9. Refrigeration system faulty. Go to

Refrigeration System Check.

Condenser Fan Does Not Operate

Check for the following problems:

1. Condenser fan faulty.

2. 115 VAC not present at condenser fan.

The compressor, condenser fan, and

evaporator fan should always operate at the

same time. If the compressor is operating, the

temperature control and defrost control are

OK.

3. Orange wire open on neutral side of

condenser fan. Refer to Schematics.

– 18 –

Page 21

Evaporator Fan Does Not Operate

Check for the following problems:

Check for the following problems:

1. Evaporator fan faulty.

2. 115 VAC not present at evaporator fan. The

compressor, condenser fan, and evaporator

fan should always operate at the same time. If

the compressor and condenser fan are

operating, the temperature control and defrost

control are OK.

3. Orange wire open on neutral side of

evaporator fan. Refer to Schematics.

Light Does Not Illuminate

Check for the following problems:

1. Lamp faulty.

2. Door switch open. Check continuity across

the door switch with the wires disconnected.

3. Open wire or faulty connector. Refer to

Schematics.

Defrost System Check (Freezer)

1. Defrost heater open. Check resistance

across the defrost heater. Refer to Schematics

for resistance values.

2. Defrost thermostat switch stuck open. The

defrost thermostat switch opens when the

evaporator temperature raises to 58 °F and

closes when the evaporator temperature

lowers to 28 °F.

3. Defrost control open in defrost mode.

Manually rotate the defrost control into defrost

mode. Check for continuity across the defrost

control between terminals 2 and 3. Refer to

Schematics.

4. Open wire or faulty connector. Refer to

Schematics.

5. Clogged or frozen drain. Check for a

clogged or frozen drain. If frozen, see Heat

conducting clip not installed below.

6. Heat conducting clip not installed. If the

heat conducting clip is not installed on the

evaporator and in the drain, the drain may

freeze closed.

The automatic defrost function is controlled by the

defrost control. The defrost control contains a

motor/cam mechanism that switches the defrost

control between defrost mode and cooling mode.

The defrost control motor/cam mechanism

operates only when the temperature control

(switch) is closed. After 8 hours of motor/cam

mechanism runtime in cooling mode, the defrost

control switches to defrost mode. The defrost

control will stay in defrost mode, providing

115 VAC to the heater for 30 minutes of motor/cam

mechanism runtime. The defrost thermostat

switch is mounted on the evaporator and, when

closed, completes the neutral side of the defrost

heater circuit. The defrost thermostat switch

opens when the evaporator temperature raises to

58 °F and closes when the evaporator

temperature lowers to 28 °F. The defrost

thermostat switch typically opens during the

defrost cycle, preventing the heater from

defrosting for the full 30 minutes. The purpose for

the 30-minute defrost mode at the defrost control

is to prevent the compressor from operating and

refreezing any water that may be dripping from the

evaporator.

– 19 –

Page 22

Refrigeration System Check

CHECK SUCTION PRESSURE

SUCTION PRESSURE IN VACUUM

MAKE LEAK-RESTRICTION TEST

CONDENSER TEMPERA TURE

INCREASES THROUGHOUT

SYSTEM HAS LEAK SYSTEM IS RESTRICTED

CHECK FOR LEAKS

AT ALL JOINTS

IN MACHINE COMPARTMENT

FOUND LEAK NO LEAK FOUND

REPAIR LEAK, INSTALL

DRYER AND RECHARGE

CHECK EVAPORATOR

FOR LEAKS

NO CHANGE IN CONDENSER

TEMPERATURE (LOWER 2/3)

INSTALL DRYER

AND RECHARGE

Check high pressure joints with

compressor running and condenser

fan stopped

Add refrigerant

3 oz. - systems <6 oz.

4-1/2 oz. - systems >6 oz.

Wait 4 minutes

REPLACE

COMPRESSOR

Check low pressure joints

with compressor stopped and

defrost heaters energized

SUCTION PRESSURE

ABOVE ZERO

MAKE COMPRESSOR

CAP A CITY TEST

P ASSED TESTFAILED TEST

COMPRESSOR IS OK

LOOK ELSEWHERE

FOUND LEAK

IN EVAPORATOR

REPLACE LO-SIDE

AND INSTALL DRYER

NO LEAK FOUND

IN EVAPORATOR

RECHECK TUBING IN

MACHINE COMPARTMENT

GEA00862

– 20 –

Page 23

Notes

– 21 –

Page 24

Component Locator Views

DryerDryer

Icemaker

Icemaker

Connector

Connector

Compressor

Compressor

Figure 1 - Machine Compartment

Relay and Overload

Relay and Overload

(Under Cover)

(Under Cover)

Condenser

CondenserCondenser

Evaporator FanEvaporator Fan

Condenser

Condenser

Fan

Fan

Evaporator Fan

Evaporator Fan

Connector

Connector

Machine

Machine

Harness Connector

Harness Connector

Water Valve

Water Valve

Connector

Connector

Overtemperature

Overtemperature

Thermostat

Thermostat

GEA01154

Defrost Heater

Defrost Heater

Support

Support

Figure 2 - Evaporator and Associated Parts

– 22 –

EvaporatorEvaporator

Evaporator

Evaporator

Drain Probe

Drain Probe

Defrost HeaterDefrost Heater

GEA01155

Page 25

Defrost

Defrost

Control

Control

Temperature

Temperature

Control

Control

Figure 3 - Control Console

Light

Light

Light

Light

Switch

Switch

Connector

Connector

GEA01166

– 23 –

Page 26

Schematics

FRESH FOOD LIGHT(S)

ORANGE

WHITE

WATER VALVE

(WHEN USED)

1

BROWN

ICEMAKER (WHEN USED)

OVERLOAD

CR

S

COMPRESSOR

7

6

25

T

P.T.C.

RELAY

ORANGE

ORANGE ORANGE

ORANGE

ORANGE

DEFROST

TIMER

1

3

TEMPERATURE

CONTROL

GRAY

BROWN

BROWN

BROWN

ORANGE

ORANGE

ORANGE

RED

FREEZER LIGHT

(WHEN USED)

BROWN

ORANGE

RED

ORANGE

BLACK

BLACK

CONDENSER FAN

BLACK

BLACK

6

EVAPORATOR FAN

ND103-02D

6

ORANGE

4

2

3

7

6

2

BLUE

DEFROST

HEATER

YELLOWPINK

DEFROST

THERMOSTATS

DEFROST

THERMOSTAT

36

(SEE DIAGRA M INSIDE ICEMAKER COVER)

4

8

78

100

190

ORANGE

– 24 –

Page 27

C

R

S

3

2

TO CABINET

WIRING

OVERLOAD

RELAY

RUN CAPACITOR

ORANGE

WHITE

BLACK

GREEN

(GROUND)

KB5006

TEMPERATURE

CONTROL

CONTROLCONTROL

CONNECTORCONNECTOR

CONTROL

CONNECTOR

LIGHT

SWITCH

TO COMPRESSOR

COMPRESSOR

GND

DEFROST

HEATER

FRESH

FOOD

LAMP(S)

DEFROST

TIMER

BROWN

RED

BROWN

GRAY

GRAY(3)

BLUE(2)

BLACK(4)

ORANGE(1)

BLACK

ORANGE

WHITE

3 BROWN

2 BLACK

1 WHITE

6 BLUE

ORANGEORANGE8 ORANGE

HARNESS CONNECTOR

4 PINK

BROWN

ORANGE

BLUE

GREEN

WHITE

WHITE

BLACK

G

Y

BLACK

EVAP

GROUND

EVAPEVAP

COVERCOVER

GROUNDGROUND

EVAP

COVER

GROUND

GREEN

YELLOW

RED

PINK

ORANGE

ORANGE

ORANGE

ORANGE

ORANGE

EVAPORATOR

FAN

CONNECTOR

FREEZER

LIGHT

(WHEN USED)

FREEZER

LIGHT

SWITCH

(WHEN USED)

DEFROST

THERMOSTAT

TO ICEMAKER

(WHEN USED)

POWER

CORD

TO WATER VALVE

(WHEN USED)

MACH

HARNESS

CONNECTOR

TOTO

CONDENSERCONDENSER

FAN MOTORFAN MOTOR

CONNECTORCONNECTOR

TO

CONDENSER

FAN MOTOR

CONNECTOR

ND103-02C

8

7

7

ORANGE

ORANGE

– 25 –

Page 28

Parts List

Note: The components shown in this drawing may

differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part

number for your unit.

– 26 –

Page 29

Note: The components shown in this drawing may

differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part

number for your unit.

– 27 –

Page 30

Note: The components shown in this drawing may

differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part

number for your unit.

– 28 –

Page 31

Note: The components shown in this drawing may

differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part

number for your unit.

– 29 –

Page 32

Note: The components shown in this drawing may

differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part

number for your unit.

– 30 –

Page 33

– 31 –

Page 34

Note: The components shown in this drawing may differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part number for your unit.

GTS18DBMBLAA

VIEW CATALOG NUMBER DESCRIPTION QTY

1 31-51377 PM MINI MANUAL WIRING 1

1 49-60102 USE & CARE MANUAL 1

2 WR12X10426 PK HANDLE SMALL ASM 1

7 WR12X10427 HANDLE ASM FZ AD 1

11 WR12X10428 HANDLE DOOR ASM FF AD 1

18 WR1X1726D SCR 10-16 AB 3/4 SS 7

23 WR24X10095 GASKET DOOR FZ WH 1

24 WR02X10740 STOP DOOR FF 1

26 WR02X10759 STOP DOOR FZ AD 1

29 WR02X8088 PLUG BUTTON INSERT AD 2

35 WR04X10029 LENS NAMEPLATE AD 1

36 WR02X10760 CAP DOOR CORNER AD 3

37 WR02X10761 CAP DOOR CORNER AD 3

38 WR02X10799 CAP DOOR CORNER AD 1

39 WR02X10800 CAP DOOR CORNER AD 1

101 WR02X10789 CAP SHELF FRONT RH 3

102 WR02X10790 CAP SHELF FRONT LH 3

103 WR02X10792 CAP SHELF FRONT LH 2

104 WR24X10094 GASKET DOOR FF WH 1

105 WR02X10791 CAP SHELF FRONT RH 2

106 WR22X10024 DOOR DAIRY CLEAR 1

108 WR71X10281 SHELF FRONT FULL 4

111 WR71X10282 SHELF FRONT FF HALF 1

112 WR02X8697 PLUG DOOR RVSBL AD 4

118 WR19X5003 BUTTER DISH 1

124 WR12X10125 PLUG BUTTON HANDLE AD 1

201 WR17X10850 COVER EVAP ASM 1

202 WR02X10717 GRILLE ICE SERVICE 1

207 WR14X10082 FOAM STRIP SE ADH 2

207 WR17X10867 HOUSING FAN EVAPORATOR 1

210 WR02X8999 PLUG BUTTON MTG 2

211 WR02X7973 SUPPORT SHELF 8

213 WR30X0311 TRAY ICE 2

214 WR02X7148 PLUG BUTTON 1

225 WR71X10269 SHELF ASM FZ 1

228 WR71X10285 SHELF CANT WIRE ASM 2

229 WR71X10284 SHELF CANT WIRE ASM 1

231 WR02X7018 SPACER TRACK 2

232 WR72X10057 TRACK CANT SIDE 2

233 WR72X10056 TRACK CANT CENTER 1

236 WR32X10178 PAN SNACK 1

238 WR17X11107 SUPPORT RAIL VP COVER 1

239 WR17X11089 SLIDE COVER CENTER 1

240 WR32X10181 PAN 1/2 HAMMER HEAD 2

242 WR32X10279 COVER VEG PAN 1

244 WR17X10852 HANDLE PAN (TRIM) SNACK 1

245 WR14X10075 GASKET CVR PAN FRONT 1

246 WR17X10904 HANDLE PAN (TRIM) 2

248 WR01X1737 SCREW HSG. 1

249 WR02X10736 SUPPORT TWIST VP 2

252 WR32X10180 COVER SNACK PAN 1

261 WR02X10804 GROMMET WATER FILL ASM 1

– 32 –

Page 35

Note: The components shown in this drawing may differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part number for your unit.

264 WR02X10695 WHEEL MOBILITY REAR 2

265 WR01X10039 AXLE WHEEL 2

267 WR82X10078 COVER ACCESS ASM 1

268 WR01X10219 SCREW MOBILITY 2

270 WR02X8247 PLUG BUTTON WATER FILL 1

271 WR02X10718 HOOD DUCT FF ASM L/SIDE 1

272 WR02X10719 HOOD DUCT FF ASM R/SIDE 1

273 WR14X10077 GASKET HOOD 2

275 WR13X10231 HINGE TOP & PIN ASM 1

276 WR13X10146 HINGE CENTER ASM AD 1

279 WR13X0587 PIN HINGE CTR 1

280 WR02X10696 CAP CORNER OC AD 2

281 WR01X10146 WASHER HINGE BROWN 2

282 WR13X10147 HINGE BTM & PIN ASM AD 1

286 WR01X1815 LEVELING NUT 2

287 WR02X10722 MOBILITY ASM 2

288 WR74X10067 GRILLE BASE AD 1

289 WR02X10738 CLIP GRILLE 2

290 WR02X10757 CAP GRILLE BASE AD 1

291 WR01X10221 SCR 8-10 PL PNP 1/2 S 3

294 WR02X10793 SHIELD LIGHT FZ 1

296 WR02X11123 COVER IM RECEPTACLE 1

297 WR02X10797 KNOB THUMB CONTROL FF 1

298 WR01X10216 RETAINER KNOB 1

300 WR09X10073 CONTROL TEMP 1

301 WR02X10796 KNOB THUMB CONTROL FZ 1

304 WR02X10723 NOZZLE CONTROL FOAM 1

305 WR02X10734 WHEEL DAMPER 1

306 WR17X10907 HOUSING CNTRL FRONT ASM 1

311 WR02X10709 BLOCK FOAM CONTROL 1

315 WR02X11006 SLEEVE VINYL 1

318 WR23X10208 HARNESS CNTRL MODULE 1

319 WR02X10727 SHAFT DAMPER 1

320 WR01X10220 SPRING KNOB 2

321 WR02X10731 SHIELD REFLECTOR FF 1

433 WR02X9391 SOCKET & TERMINAL ASM 1

437 60A LAMP 60W APPL 1

472 WR72X10086 SLIDE SNACK PAN RH 1

473 WR72X10055 SLIDE SNACK PAN LH 1

525 WR1X1763D SCR 8-18 T WAFER 5/8 6

566 WR01X1728 SCR 10-16 1/2 PH 4

570 WR01X1757 SCR 8-18 HXW 1 1/4S WH 4

599 WR02X10509 RING COMPRESSION FAN 1

602 WR01X1591 SCR 1/4-14 X 3/4 2

605 WR02X10795 PLUG HOUSING SWITCH 1

607 WR02X10710 BRACKET EVAP FAN INT 1

609 WR23X10143 SWITCH LIGHT FF/FZ 1

610 WR60X10057 MOTOR EVAPORATOR FAN 1

611 WR02X10762 BRACKET EVAP FAN MTG 1

613 WR60X10055 BLADE EVAP FAN ASM 1

614 WR02X10540 BUMPER LID 2

617 WR02X10098 GROMMET FAN 4

618 WR51X10038 HEATER DEF ASM 1

619 WR51X10046 CONDUCTOR HEAT 1

620 WR50X10025 THERMOSTAT DEF 1

621 WR02X10518 HOLDER ELEMENT 2

– 33 –

Page 36

Note: The components shown in this drawing may differ from the components in your unit. Refer to the

microfiche or GEA IPC for the component and part number for your unit.

622 WR17X10866 TROUGH DRAIN 1

623 WR02X10798 PLUG BUTTON WH 1

624 WR17X10855 HOUSING CONTROL REAR 1

626 WR23X0420 POWER CORD 1

628 WR01X5278 CLAMP CABLE 1

643 WR17X10906 TOWER TOP FZ 1

644 WB01T10017 SCR 8-18 AB IHW 3/8 S NS 2

645 WR17X10864 TOWER BOTTOM FZ 1

648 WR09X0502 CONTROL DEFROST 1

650 WR60X10044 MOTOR COND FAN 1

651 WR60X10030 BLADE COND FAN ASM 1

652 WR02X10323 RING COMPRESSION 1

653 WR02X10322 CAP DUST 2

676 WD02X5166 SCREW 10-16 AB HXW 1/2 5

684 WB01T10047 SCR 8-32 X .625 M HXW S 2

685 WR01X1804 SCR 8-18 AB HXW 1/2 WH 4

690 WZ5X158D SCR 8-32 T HXW 3/8 S 2

691 WR01X2139 SCREW 12-24 .7 AD 6

692 WZ04X0416 SCREW 8-18 AB HXW 3/4 10

693 WR01X2137 SCREW 12-24 .9 AD 5

695 WR01X10218 SCR 12-24 TT BHT 20 .73S 6

696 WR02X10843 COVER SCREW 3

725 WR87X10034 COMPRESSOR REPL KIT 1

726 WR85X10024 LOW SIDE ASM 1

729 WR62X0079 CAPACITOR 1

730 WR84X10009 CONDENSER REPL ASM 1

733 WR07X10031 RELAY PTCR 1

734 WR02X10556 COVER RELAY SNAP (MEI) 1

735 WR08X0167 OVERLOAD 1

736 WR02X8583 CLIP COMP MTNG 4

737 WR02X7238 GROMMET COMP MTG 4

740 WR86X0096 DRYER BIFURCATED XH9 1

741 WR01X1779 STUD MTG COMPR 4

750 WR01X1786 SCREW 10-32 TR 1/2 4

751 WR17X10849 BASEPLATE HIGH SIDE 1

753 WR02X10100 BRACKET COND FAN 1

754 WR17X10847 BAFFLE COND LH 1

755 WR17X10848 BAFFLE COND RH 1

756 WR17X10854 HOUSING COND FAN 1

757 WR01X2035 FASTENER PUSH 1

758 WD2X323D SCREW 8-32 X 3/8 SPH 4

760 WR14X10081 FOAM STRIP SE ADH 1

767 WR02X10712 CLIP COND (DL) 1

900 WR78X10421 DOOR FOAM ASM FZ AD 1

910 WR78X10420 DOOR FOAM ASM FF AD 1

921 WR02X10758 PLUG DOOR THIMBLE AD 2

– 34 –

Loading...

Loading...