Page 1

REQUIRED TOOLS AND ACCESSORIES

FOR INSTALLATION

■ 2 Adjustable wrenches

■ Pipe cutter or hacksaw

■ File

■ Emery paper

■ Screwdriver

■ Additional installation parts may be required:

• 2 fittings to connect household plumbing to 1″female

NPT threads on filter housing. Installation Kit available

to connect to 3/4″copper plumbing:

– GE Part/Retail Part (HDKIT)

(Not performance tested or certified by NSF.)

• UL Approved grounding clamps and 6-gauge copper

grounding wire—Installation Kit available:

– GE Part/Retail Part (HDKIT)

(Not performance tested or certified by NSF.)

• Mounting Bracket (HDBRKT)

• Teflon Tape

• Sump Wrench

– Retail Part (HDWRNCH)

– GE Parts (WX5X3002)

Optional accessories are available (Visa, MasterCard or Discover cards

accepted) by visiting our Website at www.GEAppliances.com or from

Parts and Accessories, call 800.626.2002 (U.S.) or 800.663.6060 (Canada).

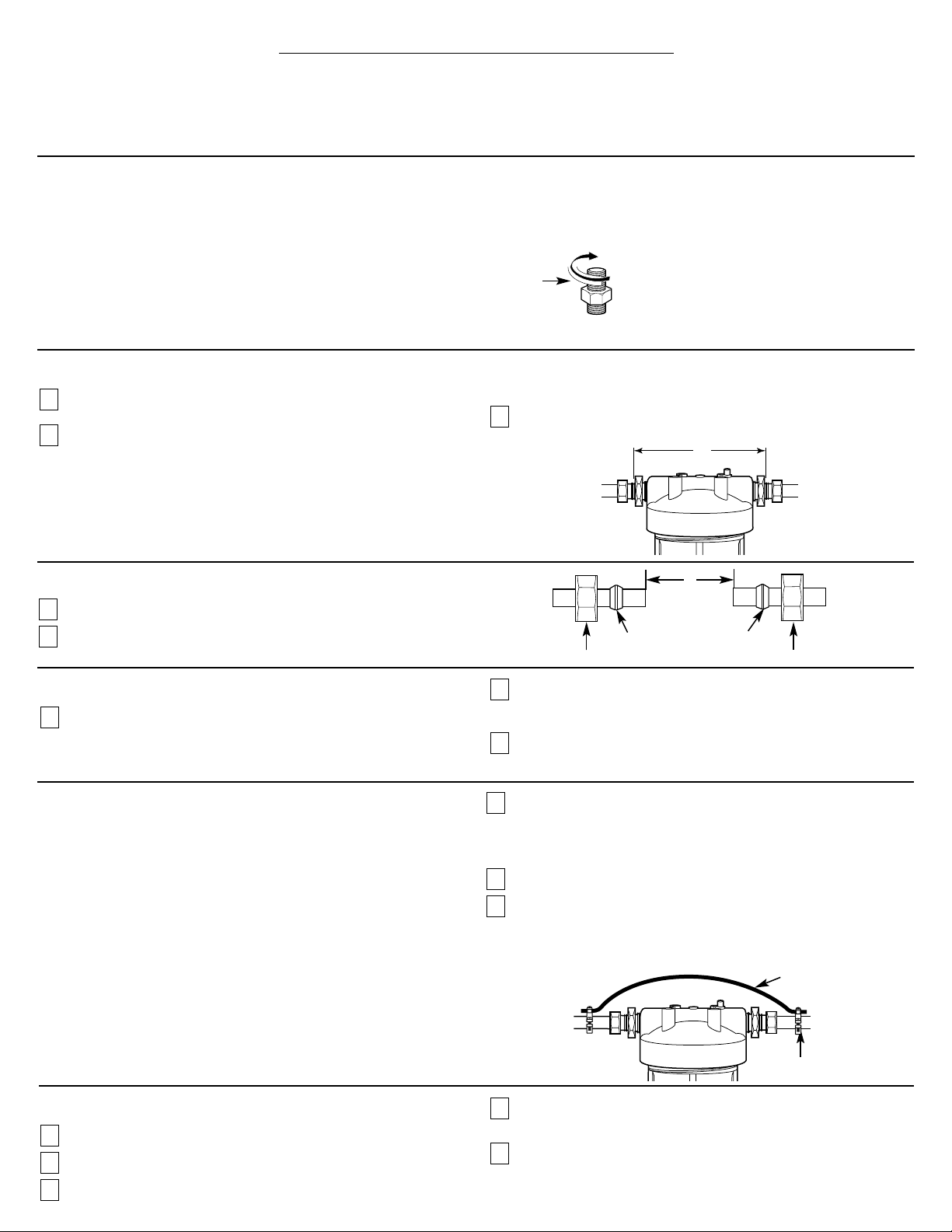

CONTENTS INCLUDED WITH PRODUCT

■ Filter housing and head

■ Product literature

1

GE SmartWater

™

INSTALLATION INSTRUCTIONS

Heavy Duty Water Filtration System—GXWH30C (filters not included)

SAFETY PRECAUTIONS

■ Check with your state and local public works department

for plumbing and sanitation codes. You must follow these

guidelines as you install the Heavy Duty Water Filtration

System. Using a qualified installer is recommended.

■

Be sure the water supply conforms with the Performance

Data. If the water supply conditions are unknown, contact

your municipal water company

.

WARNING: Do not use with water that is

microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

■ I

t is highly recommended that a water shut-off valve be

placed directly upstream of your household filter.

■

Check with your local public works department for plumbing

codes. You must follow their guides as you install the

Heavy Duty Water Filtration System.

■

Use the Heavy Duty Water Filtration System on a potable,

safe-to-drink, home COLD water supply only. The filter

cartridge will not purify water or make unsafe water safe

to drink. DO NOT use on HOT water (100°F max).

■

Protect the Heavy Duty Water Filtration System and piping

from freezing. Water freezing in the system will damage it.

■

Your Heavy Duty Water Filtration System will withstand up to

100 psi water pressure. If your house water supply pressure

is higher than 100 psi during the day (it may reach higher

levels at night), install a pressure reducing valve before the

system is installed.

■

Do not install on HOT WATER. The temperature of the

water supply to the Heavy Duty Water Filtration System

must be between the minimum of 40

°F. and the maximum

of 100°F

. See the

Performance Data

section

.

■

Do not install the Heavy Duty Water Filtration System using

copper solder fittings. The heat from the soldering process

will damage the unit.

WARNING: Discard all unused parts and

packaging material after installation. Small parts

remaining after installation could be a choke hazard.

■

Do not install filter in an outside location or anywhere it

will be exposed to sunlight.

PROPER INSTALLATION

This Heavy Duty Water Filtration System must be properly installed and located in accordance with the Installation Instructions

before it is used.

GXWH30C is

Tested and Certified by NSF International

against ANSI/NSF

Standard 42 with Cartridge FXHTC

for the reduction of Chlorine: Taste and Odor.

251B6021P002 (03-02 JR) 49-50048-6 145287 Rev. D

www.GEAppliances.com

GENERAL ELECTRIC COMPANY, Appliance Park, Louisville, KY 40225

Page 2

2

CARTRIDGE SPECIFICATIONS

Filter Cartridge Replacement

You should change your filter when the water flow is noticeably reduced or at least every three months.

Influent Challenge Reduction Average

Substance Concentration Requirements Reduction

Standard 42

Chlorine 2.0 mg/L ± 10% ≥ 50% 95.5%

Turn off water to filter. Water must be shut off

from an upstream valve.

Press the red pressure release button to release

pressure.

Unscrew the filter canister and discard used

filter. Wash the filter canister with mild soap

and water. Do not use harsh cleaners or hot

water.

Inspect the filter canister O-ring. Make sure

it is lightly lubricated and completely seated

in the groove. It is recommended that you

replace the O-ring if it is damaged.

Place a new filter cartridge into the canister,

making sure it is centered and completely

seated on the bottom seal.

Reinstall the filter canister to the unit. Hand

tightening is all that is required to seal the

unit. DO NOT OVERTIGHTEN.

Slowly turn on water to the filter by using the

upstream shut-off valve.

Press the red pressure release button to

remove trapped air.

After installation, flush the cartridge for

10 minutes, wait one hour, then flush again

for 10 minutes before using the water.

9

8

7

6

5

4

3

2

1

Installation Overview

NOTE: Be sure to allow a minimum space

of 1

1

⁄2 ″–2″ under the filter for removing

the sump to change the cartridge.

Turn sump wrench tool

clockwise to remove

Sump

Turn

clockwise

to remove

canister

Turn

counterclockwise

to tighten

Red pressure

release button

Filter

cartridge

O-ring seal

Filter canister

Head

Performance Data

This system has been tested according to ANSI/NSF 42

for the reduction of the substances listed below. The

concentration of the indicated substances in water

entering the system was reduced to a concentration

less than or equal to the permissible limit for water

leaving the system, as specified in ANSI/NSF 42.

STEP-BY-STEP INSTALLATION INSTRUCTIONS

Recommended

shut-off valve

Recommended

shut-off valve

Adapter

Ferrule

Hex nut

Adapter

Ferrule

Hex nut

11⁄2 ″–2″

Typical installation

FXHTC Cartridge

Test Conditions

Flow Rate: 3 gpm (11.4 Lpm)

pH: 7.5± 1

Inlet Pressure: 60 PSI (4.1 bar)

Temperature: 68°F ± 5°F (19.8°C ± 2.5°C)

Operating Requirements

Pressure: 30–100 PSI (2.1–6.9 bar)

Turbidity: 5 NTU Max.

Temperature: 40°F–100°F (4.4°C–37.7°C)

Capacity: 5,000 gallons (18,927L) or 3 months

Testing was performed under standard laboratory conditions, actual performance may vary.

Page 3

3

STEP-BY-STEP INSTALLATION INSTRUCTIONS (cont.)

Select Location

Select a location for the filter that is:

■

protected from freezing.

■

not exposed to direct sunlight.

It is recommended that a shut-off valve be placed on both sides

of the filter.

It is recommended that a mounting bracket be used.

Install Fittings

Instructions are for installing fittings for the HDKIT or similar

fittings onto copper plumbing. If the unit is to be installed on

any other type of tubing (plastic, PVC, galvanized), different

hardware must be purchased. See instructions with additional

hardware purchased or consult a qualified plumber.

Apply 4 or 5 wraps of Teflon tape, in a clockwise direction,

to the pipe threads (coarse) of each adapter. DO NOT use

joint compound on any parts connecting to filter housing.

Assemble an adapter to the inlet and outlet of the head. Start

each fitting by hand to make sure they don’t cross thread.

Use an adjustable wrench firmly. DO NOT OVERTIGHTEN.

About one to two thread(s) should remain visible.

Cut Water Line

Turn off water supply and open a nearby faucet to drain

water out of pipes.

Remove the nut and brass ferrule from both compression

fittings and set aside. Using a tape measure or ruler,

measure the distance “D” as shown.

■ NOTE: I

t is recommended that the shut-off valve be placed

before and after the filter as shown in the Installation

Overview illustration.

■ Select the location for the filter. Mark the distance “D”

on the pipe.

Using a pipe cutter or hacksaw, cut pipe. Sand (file) cut

ends of pipe to assure that they are square and smooth.

3

2

1

Installing the Unit

Align filter assembly with pipe ends making certain that

the incoming water supply is going into the filter opening

marked “IN”. It may be necessary to spread the pipe ends

apart to install filter assembly.

Using two adjustable wrenches, hold incoming adapter

securely with one wrench and tighten nut with second

wrench. Repeat this procedure for outgoing adapter.

If necessary, support the water pipe on either side of the

filter unit.

3

2

1

Final Check

Install filter (see Filter Cartridge Replacement Section).

Slowly turn on water supply.

Check entire system for leaks.

If leaking, shut off water pressure and tighten or reseal

fittings.

After installation, flush the cartridge for 10 minutes,

wait one hour, then flush again for 10 minutes before

using the water.

5

4

3

2

1

Teflon tape

Attach Fittings to Water Line

Slip a compression nut onto each pipe.

Next, slip the brass ferrule onto each pipe.

2

1

Nut

Brass ferrule

Nut

Brass ferrule

D

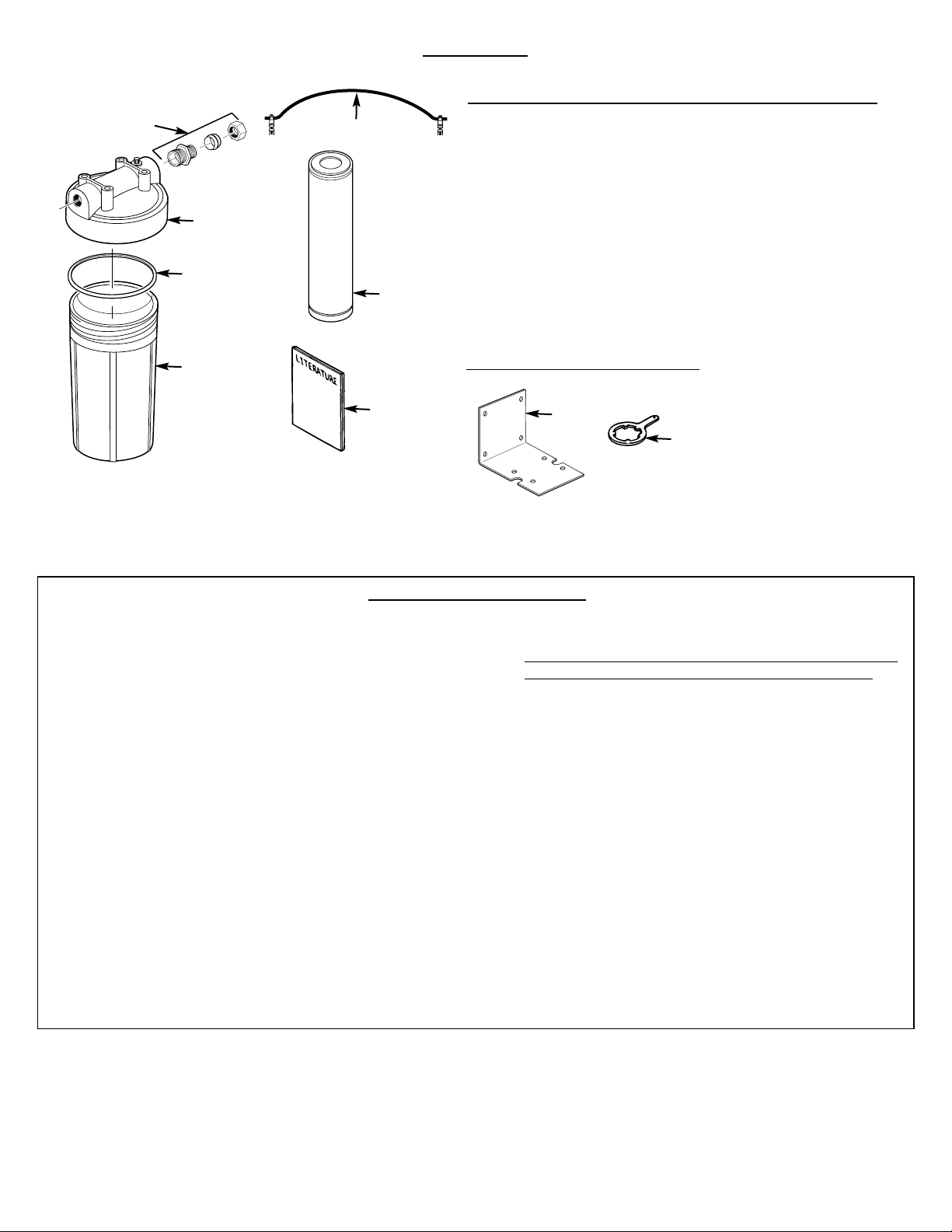

Installing the Ground Wire

IMPORTANT: A copper or galvanized house cold water pipe

is often used to ground electrical outlets in the home.

Grounding protects you from electrical shock. The water filter

housing may have broken this ground path. To restore

connection, install an 18″ long, 6-gauge copper wire across

the filter, tightly clamped using UL approved 1/2″–1″ bronze

grounding clamps at both ends as shown. Zinc clamps should

not be used on copper plumbing. Wire and clamps may be

purchased separately from your local hardware store, or are

available by visiting our Website at www.GEAppliances.com

or from Parts and Accessories, call 800.626.2002 (U.S.) or

800.663.6060 (Canada)—order part number HDKIT.

Clean copper pipe and ends of wire with emery paper.

Bare wire is recommended. If insulated wire is used,

it should be stripped 3/4″ at each end before cleaning

with emery paper.

Attach bronze clamps to copper pipe. Tighten screws.

Attach wire to clamps as shown. Tighten screws.

NOTE: I

f your house plumbing is plastic, it would not be used

as a grounding path, and this step should be skipped.

3

2

1

Clamp

Ground wire

D

Page 4

4

PARTS LIST

Ref. No. Part No. Part Description

001 HDKIT Grounding Clamps and Wire —

002 HDKIT

3

⁄4″ Copper Tube Fittings —

003 WS19X10014 Head Assembly with Vent 1

004 WS03X10039 O-Ring 1

005 WS30X10005 Sump—White 1

006 WX5X3002 Sump Wrench —

007 FXHTC Filter Element—Carbon Filter —

008 HDBRKT Mounting Bracket —

999 49-50048 PM Installation Instructions 1

To obtain replacement parts, call toll-free 800.626.2002 (U.S.),

800.663.6060 (Canada–English), 800.361.3869 (Canada–French).

999

007

005

004

003

006

002

001

OPTIONAL ACCESSORIES

008

LIMITED ONE YEAR WARRANTY

• What does this warranty cover?

— Any defect in materials or workmanship in the

manufactured product

• What does this warranty not cover?

— Filter Cartridges

— Service trips to your home to teach you how to use

the product

— Improper installation

— Failure of the product if it is abused, misused, altered

or used for other than the intended purpose

— Defects that result from improper installation or

damage not caused by GE

— Liability on the part of GE under this or any other

warranty for any indirect or consequential damage

— Products that are used for commercial or industrial

applications

— Use of this product where water is microbiologically

unsafe or of unknown quality, without adequate

disinfection before or after the system. Systems certified

for cyst reduction may be used on disinfected water

that may contain filterable cysts.

— Damage to the product caused by accident, fire, floods

or acts of God

— Incidental or consequential damage caused by possible

defects with this appliance, its installation or repair

• For how long after the original purchase?

— One Year

• How do I make a warranty claim?

— Return to the retailer from which it was purchased

along with a copy of the “Proof of Purchase.” This

warranty excludes the cost of shipping or service calls

to your home.

• How does state law relate to this warranty?

— This warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state. THIS WARRANTY IS INTENDED TO BE IN

LIEU OF ALL OTHER WARRANTIES, WHETHER

EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

Contact us at www.GEAppliances.com, or call 800.GE.CARES

(U.S.), or toll-free 866.777.7627 (Canada).

Page 5

■ Consulter le service local des travaux publics au sujet des codes

de plomberie. L’installation du système de filtration d’eau pour

service rigoureux doit être conforme aux prescriptions du code

de plomberie local.

■ Utiliser le système de filtration d’eau pour service rigoureux uniquement

sur une canalisation d’eau potable FROIDE. Les cartouches de filtration

ne purifient pas l’eau et ne peuvent rendre potable une eau qui ne

l’est pas. NE PAS utiliser ce produit sur une canalisation d’eau CHAUDE

(100

°

F maximum).

■ Protéger le système de filtration d’eau pour service rigoureux et la

tuyauterie contre le gel. La congélation d’eau dans le système lui fera

subir des dommages.

■ Le système de filtration d’eau pour service rigoureux peut résister à une

pression maximale de 100 lb/po

2

. Si la pression de distribution locale est

supérieure à 100 lb/po

2

durant la journée (elle peut atteindre un niveau

plus élevé la nuit), installer un robinet de réduction de pression en amont

du système de filtration d’eau.

■

Ne pas installer le système sur une canalisation D’EAU CHAUDE.

La température de l’eau à filtrer

pour service rigoureux

doit être

située entre 40

°

F (minimum) et 100°F (maximum). Voir les

Caractéristiques complètes.

■ Lors de l’installation du système de filtration d’eau

pour service

rigoureux

, ne pas utiliser des raccords de cuivre à souder.

La chaleur émise lors de l’opération de soudage fera subir des

dommages au système.

AVERTISSEMENT : Éliminer en sécurité les

petites pièces qui peuvent rester inutilisées après l’installation;

elles peuvent susciter un danger d’étouffement pour les jeunes

enfants.

■ Ne pas installer le filtre à l’extérieur ou à un endroit exposé au

rayonnement solaire.

OUTILLAGE ET ACCESSOIRES REQUIS POUR

L’INSTALLATION

■

2

Clés à molette

■

Coupe-tuyau ou scie à métaux

■

Lime

■

Papier Émeri

■

Tournevis

■

Il peut être nécessaire d’avoir des accessoires complémentaires :

• 2 raccords pour relier le tuyau de l’habitation au filetage du NPT

femelle de 1 po sur le logement du filtre. Trousse d’installation

disponible pour le raccordement au tuyau en cuivre de 3/4 po :

– Pièces GE/Ensemble disponible (HDKIT)

(La performance de l’appareil n’a pas été testée et celui-ci n’a

pas été homologué par NSF.)

• Attaches de mise à la masse homologuées UL et fil de mise à la

masse en cuivre de calibre 6—trousse d’installation disponible :

– Pièces GE/Ensemble disponible (HDKIT)

(La performance de l’appareil n’a pas été testée et celui-ci n’a

pas été homologué par NSF.)

• Un Support (HDBRKT)

• Ruban en Téflon

• Clef pour puisard

– Ensemble disponible (HDWRNCH)

– Pièces GE (WX5X3002)

Les accessoires en option sont disponibles (cartes Visa, Mastercard ou

Discovery acceptées) en visitant notre site Web à www.GEAppliances.com

ou en vous adressant à notre service des Pièces et Accessoires au

800.626.2002 (U.S.) ou 800.361.3869 (Canada).

ARTICLES FOURNIS AVEC LE PRODUIT

■

Corps de filtre et tête de filtre

■

Brochures descriptives

1

251B6021P002 (03-02 JR) 49-50048-6 145287 Rév. D

www.GEAppliances.com

GENERAL ELECTRIC COMPANY, Appliance Park, Louisville, KY 40225

MESURES DE SÉCURITÉ

■

Consulter le service local des travaux publics au sujet des codes

de plomberie et de raccordement aux égouts. L’installation

du système de filtration d’eau pour service rigoureux doit

être conforme aux prescriptions du code de plomberie local.

On recommande qu’un installateur qualifié soit chargé de

l’installation.

■

Vérifier que l’eau à traiter est conforme aux Caractéristiques

complètes. Si les caractéristiques de l’eau à traiter ne sont pas

connues, contacter le service municipal de distribution d’eau.

AVERTISSEMENT : Ne pas utiliser ce

produit avec de l’eau microbiologiquement polluée ou de

qualité inconnue sans avoir installé un dispositif de désinfection

approprié avant ou après le système.

■

On recommande fortement l’installation d’un robinet d’arrêt

directement en amont du système de filtration.

INSTRUCTIONS D’INSTALLATION

Avant toute utilisation, on doit installer le système de filtration d’eau (pour service rigoureux) à un emplacement adéquat conformément

aux instructions d’installation.

GE SmartWater

™

INSTRUCTIONS D’INSTALLATION

Système de filtration d’eau pour service rigoureux—GXWH30C (filtres non inclus)

Le système GXWH30C a été testé et homologué par

NSF International selon la norme ANSI/NSF 42 avec

la cartouche FXHTC pour la réduction du chlore,

au niveau du goût et de l’odeur.

Page 6

2

Remplacement de la cartouche de filtration

On doit changer la cartouche de filtration lorsque le débit d’eau diminue sensiblement, et au moins à intervalles

de trois mois.

Fermer l’arrivée d’eau au filtre. On doit fermer le

robinet d’arrêt en amont.

Dépressuriser le système : appuyer sur le bouton

rouge.

Dévisser le corps de filtre; jeter la vieille cartouche.

Laver le corps de filtre avec de l’eau et un savon

doux. Ne pas utiliser de l’eau chaude ou un produit

de nettoyage énergique.

Inspecter le joint torique du corps de filtre. Veiller

à ce qu’il soit légèrement lubrifié et bien emboîté

dans la rainure. Remplacer le joint torique s’il est

endommagé.

Placer la nouvelle cartouche de filtration dans le

corps de filtre; placer correctement et bien centrer

la cartouche sur le joint du fond.

Revisser le corps de filtre sur la tête. Il suffit de serrer

à la main.

NE PAS SERRER EXCESSIVEMENT.

Rétablir lentement l’arrivée d’eau au filtre avec le

robinet d’arrêt en amont.

Appuyer sur le bouton rouge pour permettre

l’évacuation de l’air piégé.

Après l’installation, rincer la cartouche pendant

10 minutes; attendre une heure, puis rincer de

nouveau pendant 10 minutes avant de puiser

de l’eau.

9

8

7

6

5

4

3

2

1

Illustration de l’installation

NOTE : Veiller à ce qu’il y ait un espace libre d’au moins

1

1

⁄2 –2 po sous le filtre pour l’extraction du corps de filtre

lors du changement de la cartouche.

Utiliser l’outil spécial

pour dévisser le corps

de filtre–rotation

dans le sens horaire

Corps de filtre

Dévissage–

rotation dans

le sens horaire

Vissage–

rotation dans le

sens antihoraire

Bouton rouge de

dépressurisation

Cartouche

de filtration

Joint torique

Corps de filtre

Tête

ÉTAPES DE L’INSTALLATION

Robinet d’arrêt–

recommandé

Robinet d’arrêt–

recommandé

Adaptateur

Bague d’extrémité

Écrou hex

Adaptateur

Bague d’extrémité

Écrou hex

11⁄2 –2 po

Installation type

SPÉCIFICATIONS DE CARTOUCHE

Concentration

d’agents polluants Spécifications Réduction

Substance dans l’arrivée d’eau de réduction moyenne

Norme 42

Chlore 2,0 mg/l± 10% ≥ 50% 95,5%

Caractéristiques complètes

Ce système a été testé selon ANSI/NSF 42 pour la réduction

des substances répertoriées ci-dessous. La concentration des

substances indiquées dans l’arrivée d’eau du système a été

réduite à une concentration inférieure ou égale à la limite

admissible pour l’eau sortant de l’équipement, comme

spécifié par ANSI/NSF 42.

Cartouche FXHTC

Conditions de test

Débit : 11,4 l/min (3 gal/min)

pH : 7,5± 1

Pression d’entrée : 60 psi (4,1 bar)

Température : 19,8 ± 2,5 °C (68 ± 5 °F)

Spécifications de fonctionnement

Pression : 30 à 100 psi (2,1 à 6,9 bar)

Turbidité : 5 NTU max

Température : 4,4 à 37,7 °C (40 à 100 °F)

Capacité : 18.927 l (5 000 gal) ou 3 mois

Les tests sont effectués dans des conditions standard de laboratoire, la performance réelle de

l’équipement peut varier.

Page 7

3

ÉTAPES DE L’INSTALLATION (suite)

Emplacement d’installation

Choisir l’emplacement approprié comme suit :

■

pas d’exposition au gel.

■

pas d’exposition au rayonnement solaire direct.

On recommande d’installer un robinet d’arrêt de chaque côté du filtre.

Il est recommandé d'utiliser un support de fixation.

Pose des raccords

Les instructions sont destinées à l’installation des raccords du HDKIT

ou raccords similaires sur la tuyauterie en cuivre. Si l’unité doit être

installée sur tout autre type de tuyau (plastique, PVC, galvanisé),

il sera nécessaire de faire l’achat de quincaillerie différente. Voyez les

instructions couvrant le matériel complémentaire acheté ou consultez

un plombier qualifié.

Enrouler 4 ou 5 tours de ruban de Teflon (sens horaire) sur le filetage

pour chaque

adaptateur

. NE PAS utiliser un composé d’étanchéité sur

les pièces connectées au corps de filtre.

Installer deux

adaptateur

s sur la tête du filtre, à l’entrée et à la sortie.

Commencer le vissage à la main et veiller à ne pas détériorer le filetage.

Utiliser une clé à molette fermement. NE PAS SERRER EXCESSIVEMENT.

Un filet ou deux doivent rester visibles.

Sectionnement de la canalisation d’eau

Fermer l’arrivée d’eau; ouvrir un robinet pour purger l’eau des

tuyauteries.

Conserver à part l’écrou et la virole de laiton des raccords à

compression. À l’aide d’un ruban-mètre ou d’une règle, mesurer

la distance «D» indiquée sur l’illustration.

■ NOTE : On recommande d’installer un robinet d’arrêt avant et après

le filtre—voir l’illustration de l’installation.

■ Choisir l’emplacement d’installation du filtre. Marquer la distance

«D» sur la tuyauterie.

Avec un coupe-tuyau ou une scie à métaux, couper la canalisation.

Poncer à chaque extrémité pour éliminer les bavures.

3

2

1

Installation du conducteur de liaison à la terre

IMPORTANT : Fréquemment, on utilise un tuyau d’eau froide en cuivre

ou en métal galvanisé pour effectuer une liaison à la terre des prises

électriques de la maison. Cette mise à la masse vous protège contre les

chocs électriques et cette liaison à la terre peut voir été neutralisée par

le logement du filtre d’eau. Pour rétablir la connexion, montez un

fil en cuivre de 18 po et de calibre 6 le long du filtre, lequel sera fixé

solidement au moyen d’attaches en bronze homologuées par UL de

dimensions variant entre 1/2 po – 1 po à chaque extrémité comme

indiqué. N’utilisez pas d’attaches en zinc sur le cuivre. Il est possible

d’acquérir le fil et les attaches séparément chez votre quincaillier ou

en visitant notre site Web à www.GEAppliances.com ou en vous

adressant à notre service des Pièces et Accessoires au 800.626.2002

(aux Etats-Unis) ou 800.361.3869 (En Canada). Commandez la pièce

portant le numéro HDKIT.

Nettoyez le fil en cuivre et ses extrémités avec du papier Émeri. Il est

recommandé de dénuder le fil. Si le fil est isolé, il faut le dénuder sur

une longueur de 3/4

po

à chaque extrémité avant de les passer au

papier Émeri.

Placez les attaches en bronze sur le fil. Serrez les vis.

Fixez le fil sur les attaches comme indiqué. Serrez les vis.

NOTE : Si les tuyauteries de votre domicile sont en plastique, elles ne

peuvent être utilisées pour une liaison à la terre, dans ce cas, ignorez

cette étape.

3

2

1

Contrôle final

Installez le filtre (voir la partie de Remplacement de la cartouche

de filtration).

Ouvrir doucement l’arrivée d’eau.

Inspecter l’ensemble du système pour rechercher les fuites.

S’il y a une fuite, fermer l’arrivée d’eau et resserrer les raccords ou

améliorer leur étanchéité.

Après l’installation, rincer la cartouche pendant 10 minutes; attendre

une heure, puis rincer de nouveau pendant 10 minutes avant de

puiser de l’eau.

5

4

3

2

1

Ruban de Teflon

D

Bride

Conducteur de liaison

à la terre

Installation des raccords sur la canalisation

Sur chaque tuyau, enfiler l’écrou de compression.

Enfiler ensuite la bague d’extremite sur chaque tuyau.

2

1

Écrou

Bague d’extremite

Écrou

Bague d’extremite

D

Installation du filtre

Aligner le filtre avec les deux sections de la canalisation; veiller

à ce que la canalisation d’arrivée soit placée devant l’entrée du

filtre, marquée «IN». Il peut être nécessaire d’écarter les deux

sections de la tuyauterie pour installer le filtre.

Au moyen de deux clés à molette, maintenir l’adaptateur d’arrivée

solidement avec une clé et serrer l’écrou avec la seconde clé.

Répéter le processus pour l’adaptateur de sortie.

Si nécessaire, soutenir la tuyauterie d’eau de chaque côté du filtre

.

3

2

1

Page 8

4

LISTE DES PIÈCES

Node

repérage Pièce n

o

Description

001 HDKIT

Brides et conducteur de mise

—

à la terre

002 HDKIT

Raccords de tuyau de cuivre

—

de 3⁄

4

po

003 WS19X10014 Tête du filtre, avec évent 1

004 WS03X10039 Joint torique 1

005 WS30X10005 Corps de filtre—blanc 1

006 WX5X3002 Clé pour corps de filtre —

007 FXHTC Élément filtrant : au charbon —

008 HDBRKT Brides de montage —

999 49-50048 Instructions d’installation et 1

d’utilisation

Pour obtenir des pièces de rechange, composez sans frais le 800.626.2002

(États-Unis), le 800.663.6060 (Canada, langue anglaise), le 800.361.3869

(Canada, langue française).

999

007

005

004

003

006

002

001

ACCESSOIRES FACULTATIFS

008

GARANTIE LIMITEE DE UN AN

• Que couvre la garantie?

— Tout défaut de matériel ou de main d’oeuvre du produit

• Q’est-ce qui n’est pas couvert par la garantie?

— Les cartouches de filtre

— Les déplacementl à votre domicile pour vous enseigner

comment utiliser le produit

— Une installation incorrecte

— Une panne du produit causée par un abus d’utilisation,

une mauvaise utilisation, toute modification ou une utilisation

du produit dans un but non prévu

— Défauts entraînés par une installation incorrecte ou tout

dommage non imputable à GE

— Responsabilité de GE couvert par cette garantie ou toute

autre garantie couvrant tout dommage indirect

— Produits utilisés pour des applications industrielles ou

commerciales

— Utilisation de ce produit lorsque l’eau est microbiologiquement

impure ou de qualité inconnue sans qu’une désinfection

adéquate n’ait eu lieu avant l’entrée et sortie dans le circuit.

Les systèmes homologués pour une réduction des microbes

peuvent être utilisés après désinfection de l’eau pouvant

contenir des microbes filtrables.

— Tout dommage causé au produit par accident, incendie,

inondation ou acte de Dieu

— T

out dommage for

tuit ou indirect causé par des défauts

éventuels de cet appareil, son installation ou les réparations

effectuées

• Quelle est la durée de la garantie après l’achat?

— Un an

• Comment dois-je faire ma réclamation?

— Ramenez le produit au magasin où vous l’avez acheté avec

une exemplaire de la “Preuve d’achat”. Cette garantie exclut

les coûts d’expédition ou les déplacements de service à votre

domicile.

• Quel est le statut de cette garantie vis-à-vis de la loi?

— Cette garantie vous donne des droits légaux spécifiques.

Il est possible que vous ayez d’autres droits qui varient

d’état en état. CETTE GARANTIE REMPLACE DE

TOUTE AUTRE GARANTIE, QU’ELLE SOIT EXPRIMEE

OU SOUS-ENTENDUE, INCLUANT LES GARANTIES

DE NEGOCE ET DE CONVENANCE DANS UN BUT

PARTICULIER.

Veuillez nous contacter à www.GEAppliances.com, ou composez

le 800.GE.CARES (États-Unis) et sans frais le 866.777.7627 (Canada).

Page 9

HERRAMIENTAS QUE SE NECESITAN Y ACCESORIOS PARA LA INSTALACION

■

2

llaves ajustables

■

Cortador de tubos o sierra para metales

■

Lima

■

Papel de esmeril

■

Destornillador

■

Es posible que se necesite partes adicionales para completar

la instalación:

• 2 accesorios para conectar la tubería de su residencia a las roscas

hembras NPT de 1″ en el alojamiento del filtro. El kit para la

instalación está disponible para conectar a una tubería de cobre

de 3/4″:

– Partes de GE/Venta al por menor, parte (HDKIT)

(Su desarrollo no ha sido probado ni ha sido certificado

por la NSF.)

• Abrazaderas de toma de tierra aprobadas por UL y cable de

toma de tierra de cobre calibre 6. El kit para la instalación

está disponible:

– Partes de GE/Venta al por menor, parte (HDKIT)

(Su desarrollo no ha sido probado ni ha sido certificado

por la NSF.)

• Una ménsula (HDBRKT)

• Cinta de teflón

• Llaves inglesas para sumideros

– Venta al por menor, parte (HDWRNCH)

– Partes de GE (WX5X3002)

Los accesorios opcionales están disponibles (usando Visa, MasterCard o

Discover) visitando nuestro Website a www.GEAppliances.com o en el

Departamento de Partes y Accesorios en el 800.626.2002.

CONTENIDOS INCLUIDOS CON EL PRODUCTO

■

Caja y cabeza del filtro

■

Literatura del producto

1

PRECAUCIONES DE SEGURIDAD

■

Consulte con su departamento de obras públicas local y estatal

para los códigos de plomería y sanidad. Usted debe seguir estas

reglas a medida que instale el sistema de filtración de agua

extrafuerte. El uso de un instalador calificado es recomendado.

■

Asegúrese que el abastecimiento de agua cumple con las Datos

del desarrollo. Si las condiciones del abastecimiento de agua son

desconocidas, póngase en contacto con su compañía de agua

municipal.

ADVERTENCIA: No use con agua que sea

bacteriológicamente insegura o de calidad desconocida sin

una desinfección adecuada antes o después del sistema.

■

Es altamente recomendado que la válvula de cierre sea colocada

directamente hacia arriba de su filtro de hogar.

INSTALACION CORRECTA

■ Consulte con su departamento de obras públicas local para los códigos

de plomería. Usted debe seguir sus guías a medida que instale el sistema

de filtración de agua extrafuerte.

■ Use el sistema de filtración de agua extrafuerte solamente en un

abastecimiento de agua potable FRIA de hogar, que sea buena para beber.

El cartucho del filtro no purificará el agua o hará que el agua que no sea

buena sea potable. NO USE en agua CALIENTE (100°F máx.).

■ Proteja el sistema de filtración de agua extrafuerte y las cañerías de la

congelación. El agua que se congele en el sistema lo dañará.

■ Su sistema de filtración de agua extrafuerte soportará hasta 100 psi de

presión de agua. Si la presión de agua de su casa es más de 100 psi

durante el día (podría alcanzar niveles más altos durante la noche),

instale una válvula para reducir la presión antes de que el sistema

sea instalado.

■

No instale en AGUA CALIENTE. La temperatura de la línea de agua

hacia el sistema de filtración de agua extrafuerte debe estar entre el

mínimo de 40°F, y el máximo de 100°F. Vea las Datos del desarrollo.

■ No instale el sistema de filtración de agua

extrafuerte

usando

uniones de cobre soldadas. El calor del proceso de las soldaduras

dañará la unidad.

ADVERTENCIA: Bote todas las partes y los

materiales de empaque sin usar después de la instalación.

Las partes pequeñas que sobren después de la instalación

podrían ser un peligro para atragantarse.

■ No instale el filtro en una ubicación exterior o en un lugar donde

esté expuesto a la luz del sol.

Este sistema de filtración de agua extrafuerte debe ser instalado y ubicado correctamente de acuerdo con las instrucciones de

instalación antes de ser usado.

GE SmartWater

™

INSTRUCCIONES DE INSTALACION

Sistema de filtración de agua extrafuerte—GXWH30C (filtros no incluidos)

251B6021P002 (03-02 JR) 49-50048-6 145287 Rev. D

www.GEAppliances.com

GENERAL ELECTRIC COMPANY, Appliance Park, Louisville, KY 40225

GXWH30C es probado y certificado por

la NSF International contra el Estándar

ANSI/NSF 42 con Cartucho FXHTC para

la reducción de cloro: Sabor y olor.

Page 10

Reemplazo del cartucho del filtro

Usted debería cambiar el filtro cuando el paso del agua disminuye notablemente o por lo menos cada tres meses.

Cierre el paso del agua al filtro. El agua se debe

cerrar en una válvula paso arriba.

Empuje el botón rojo para reducir la presión para

bajar la presión.

Desatornille el receptáculo y bote el filtro usado.

Lave el receptáculo del filtro con un jabón suave y

agua. No use limpiadores fuertes o agua caliente.

Inspeccione el anillo del receptáculo. Asegúrese que

esté levemente lubricado y completamente asentado

en la ranura. Se recomienda que cambie el anillo si

está dañado.

Coloque un filtro nuevo en el receptáculo

asegurándose de que esté centrado y completamente

asentado sobre el fondo del sello.

Reinstale el receptáculo del filtro a la unidad.

Apretarlo con la mano es todo lo que se necesita

para sellar la unidad.

NO APRIETE DEMASIADO.

Lentamente abra el paso del agua hacia el filtro

usando la válvula de cierre paso arriba.

Empuje el botón rojo para reducir la presión para

sacar el aire atrapado.

Después de la instalación, lave el cartucho por

10 minutos, espere una hora, luego lave nuevamente

por 10 minutos antes de usar el agua.

9

8

7

6

5

4

3

2

1

Sumario de la instalación

NOTA: Asegúrese de dejar un espacio mínimo de

1

1

⁄2 ″–2″ debajo del filtro para sacar el receptáculo,

para cambiar el cartucho.

Haga girar la llave

para el receptáculo

en dirección del reloj

para sacarlo

Receptáculo

Haga girar en

dirección del

reloj para sacar

el receptáculo

Haga girar

contra el reloj

para apretar

Botón rojo

para reducir

la presión

Cartucho

del filtro

Sello tipo anillo

Receptáculo

del filtro

Cabeza

INSTRUCCIONES DE INSTALACION PASO A PASO

Válvula de cierre

recomendada

Válvula de cierre

recomendada

Adaptador

Férula

Tuerca hexagonal

Adaptador

Férula

Tuerca hexagonal

11⁄2 ″–2″

2

Instalación típica

ESPECIFICACIONES DEL CARTUCHO

Concentración de Requisitos de Reducción

Substancia reto entrante reducción promedio

Estándar 42

Cloro 2,0 mg/L ± 10% ≥50% 95,5%

Datos del desarrollo

Este sistema ha sido probado de acuerdo con ANSI/NSF 42

para la reducción de las substancias mostradas a continuación.

La contracción de las substancias indicadas en el agua que entra

en el sistema fue reducida a una concentración menor o igual

al límite permisible para el agua que sale del sistema, de acuerdo

a las especificaciones de ANSI/NSF 42.

Cartucho FXHTC

Condiciones de prueba

Ritmo de flujo: 3 gpm (11,4 Lpm)

pH: 7,5± 1

Presión de entrada: 60 PSI (4.1 bar)

Temperatura: 68°F ± 5°F (19,8°C ± 2,5°C)

Requisitos de operación

Presión: 30–100 PSI (2,1–6,9 bar)

Turbidez: 5 NTU Max.

Temperatura: 40°F–100°F (4,4°C–37,7°C)

Capacidad: 5000 galones (18927 L) o 3 meses

La prueba fue llevada a cabo bajo condiciones de laboratorio estándares, y el desarrollo real

podría variar.

Page 11

INSTRUCCIONES DE INSTALACION PASO A PASO (cont.)

Seleccione la ubicación

Seleccione una ubicación para el filtro que esté:

■

protegida de la congelación.

■

que no esté expuesta a la luz directa del sol.

Se recomienda instalar una válvula de cierre en ambos lados del filtro.

Sugerimos que se utilice una ménsula de instalación.

Instalación de las uniones

Instrucciones para instalar accesorios del HDKIT o accesorios parecidos

en la tubería de cobre. Si la unidad va a ser instalada sobre cualquier

otro tipo de cañería (plástico, PVC, galvanizado), debe comprarse

diferente tipo de herramienta. Lea las instrucciones para la compra

adicional de herramientas, o consulte con un plomero calificado.

Aplique 4 o 5 vueltas de cinta de teflón, en la dirección del reloj, a los

hilos de la cañería (basto) de cada

adaptador

. No use compuestos para

uniones en ninguna de las partes que conecten la caja del filtro.

Arme una

adaptador

en la entrada y la salida de la cabeza. Empiece

cada unión con la mano para estar seguro que los hilos no se crucen.

Use una llave inglesa ajustable firmemente. NO APRIETE DEMASIADO.

Uno o dos hilos deberían permanecer visibles.

Corte de la línea de agua

Cierre el paso del agua y abra una llave de agua cercana para sacar

el agua de las cañerías.

Saque la tuerca y la férula de las dos uniones de compresión y

póngalas a un lado. Usando una cinta para medir o una regla,

mida la distancia “D” como se muestra.

■ NOTA: Se recomienda que la válvula de cierre sea colocada antes y

después del filtro como se muestra en la ilustración Sumario de la

Instalación.

■ Seleccione la ubicación para el filtro. Marque la distancia “D” sobre

el tubo.

Usando un cortador de cañerías o una sierra para cañerías, corte

el tubo. Lije (lime) las puntas cortadas para asegurarse que estén

cuadradas y suaves.

3

2

1

Instalación del cable de tierra

IMPORTANTE: Una tubería de agua fría galvanizada interiormente o de

cobre es usada muy a menudo para conectar a tierra los tomacorrientes

eléctricos en las casas. Una toma de tierra lo protege de descargas eléctricas.

El alojamiento del filtro de agua pudo haber interrumpido la trayectoria

de tierra. Para restablecer la conexión, instale un cable de cobre de 18

″

,

de calibre 6 a través del filtro, fuertemente sujeto utilizando abrazaderas

de tierra de bronce de 1/2

″

a 1″aprobada por UL en ambos extremos

de la línea como se muestra en la ilustración. Usted no debe usar

abrazaderas de cinc en tubería de cobre. El cable y las abrazaderas

pueden ser compradas por separado en su ferretería local, o están

disponibles para la compra visitando nuestro Website a

www.GEAppliances.com o en nuestro Departamento de Partes y

Accesorios al 800.626.2002—ordene el número de la parte HDKIT.

Limpie la tubería de cobre y los extremos del cable con papel de

esmeril. Se recomienda que utilice cable desnudo. Si utiliza cable

aislado, las puntas deberían estar desnudas de su protector,

aproximadamente 3/4″ antes de proceder a limpiarlas con papel

de esmeril.

Sujete las abrazaderas de bronce a la tubería de cobre. Apriete los

tornillos.

Sujete el cable a las abrazaderas tal como se muestra en la figura.

Apriete los tornillos.

NOTA: Si la tubería de su casa es de plástico no debería ser usada para

efectuar la conexión de tierra, y este paso puede ser obviado.

3

2

1

Revisión final

Instale el filtro (vea la sección para Reemplazo del cartucho del filtro).

Lentamente abra el paso del agua.

Revise todo el sistema para que no hayan goteras.

Si hay goteras, cierre la presión del agua o reselle las uniones.

Después de la instalación, lave el cartucho por 10 minutos,

espere una hora, luego lave nuevamente por 10 minutos antes

de usar el agua.

5

4

3

2

1

Cinta de teflón

D

Abrazadera

Alambre para hacer tierra

3

Conecte las uniones a la línea del agua

Deslice una tuerca de compresión en cada cañería.

Luego, deslice la férula de bronce en cada cañería.

2

1

Tuerca

Férula de bronce

Tuerca

Férula de bronce

D

Instalación de la unidad

Ponga en línea el juego del filtro con las puntas de la cañería

asegurándose que la entrada de la línea del agua vaya hacia la

abertura marcada “IN”. Podría ser necesario abrir las puntas de

las cañerías para instalar el juego del filtro.

Usando dos llaves ajustables, sujete el adaptador de entrada

firmemente con una de las llaves y apriete la tuerca con la segunda

llave. Repita el procedimiento para el adaptador de salida.

Si es necesario, sujete la cañería de agua en cualquier lado de la

unidad del filtro.

3

2

1

Page 12

4

LISTA DE PARTES

No. de ref. Parte No. Descripción

001 HDKIT

Alambre y abrazaderas de tierra

—

002 HDKIT

Uniones de cañerías de cobre de 3⁄4″

—

003 WS19X10014 Juego de la cabeza con ventilación 1

004 WS03X10039 Anillo 1

005 WS30X10005 Receptáculo—Blanco 1

006 WX5X3002 Llave para receptáculo —

007 FXHTC Elemento de filtro: Filtro de carbón —

008 HDBRKT Abrazadera de montaje —

999 49-50048 Instrucciones de Instalación 1

Para obtener partes de repuesto, llame sin costo al 800.626.2002 (EE.UU.),

800.663.6060 (Canadá–inglés), 800.361.3869 (Canadá–francés).

999

007

005

004

003

006

002

001

ACCESORIOS OPCIONALES

008

GARANTÍA LIMITADA POR UN AÑO

• ¿Qué cubre esta garantía?

— Cualquier defecto de fábrica en los materiales o

la manufactura del producto

• ¿Qué no cubre esta garantía?

— Cartuchos del filtro

— Viajes a su casa para enseñarle cómo usar el producto

— Instalación inadecuada

— Falla del producto debido a abuso, mal uso, o alteración

o uso diferente al propósito deseado con este producto

— Defectos que resulten de una instalación inadecuada o

daños no causados por GE

— Responsabilidad de parte de GE bajo esta o cualquier otra

garantía por cualquier daño indirecto o por consecuencia

de otro evento

— Productos que son usados con fines comerciales o industriales

— Uso de este producto donde el agua está microbiológicamente

insegura o de calidad desconocida, sin la adecuada

desinfección, antes y después de ser procesada por el sistema.

Los sistemas certificados para reducir el nivel de quistes

pueden ser usados en agua desinfectada que pueda contener

quistes que se puedan filtrar.

— Daños causados al producto debido a accidentes, incendio,

inundaciones o actos de la naturaleza

— Daños secundarios o por consecuencia causados por posibles

defectos en el producto, su instalación o reparación

• ¿Por cuánto tiempo después de la compra?

— Un año

• ¿Cómo hago la reclamación de la garantía?

— Devuélvala al minorista a quien le compró el producto con

una copia de “Proof of Purchase”(prueba de compra).

Esta garantía excluye los costos de envío o llamadas de

servicio a domicilio.

• ¿Cómo la ley estatal se relaciona con esta reclamación de garantía?

— Esta garantía le otorga derechos legales específicos, y también

puede tener otros derechos que varían de estado a estado.

ESTA GARANTÍA PROCURA SUBSTITUIR OTRAS

GARANTÍAS, HAYAN SIDO ESTAS GARANTÍAS

EXPRESADAS O IMPLICADAS, INCLUYENDO LAS

GARANTÍAS DE MERCADEO Y APTAS PARA UN

PROPÓSITO EN PARTICULAR.

Contáctenos en www.GEAppliances.com, o llame al

800.GE.CARES (EE.UU.), llamada sin costo 866.777.7627 (Canadá).

Loading...

Loading...