Page 1

ge.com

Water Filtration System

215C1219P003 49-50236-2 01-09 JR

GXSL55R

GXSV65R

Owner’s Manual and

Installation Instructions

Safety Instructions

. . . . . . . . . . . . . . . . . .2

System Overview . . . . . . . . . . . . . . . . . .3–7

Installation Instructions . . . . . . . .8–14

Battery Installation . . . . . . . . . . . . . . . . . . . . . .13

Faucet Installation . . . . . . . . . . . . . . . . . . . .9, 10

Filter Replacement . . . . . . . . . . . . . . . . . . . . . .14

Flush Procedure . . . . . . . . . . . . . . . . . . . . . . . . .14

Installing the Tubing . . . . . . . . . . . . . . . . . . . .13

System Installation . . . . . . . . . . . . . . . . . .11, 12

Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . .8, 9

Troubleshooting Tips . . . . . . . . . . . . . . .15

Consumer Support . . . . . . . . . . . . . . . . .16

Manuel d’utilisation

et d’installation

Manual del propietario

y instalación

La section française commence à la page 17

Système de

filtration d’eau

La sección en español empieza en la página 33

Sistema de

filtración de agua

GXSL55R is Tested and Certified by NSF

International against NSF/ANSI Standard 42

for the reduction of Chlorine: Taste and Odor

and Particulate Class I and Standard 53

for the reduction of Lead, Cyst, Turbidity,

Asbestos, Mercury, Lindane, Atrazine,

Toxaphene and 2,4-D.

GXSV65R is Tested and Certified by NSF

International against NSF/ANSI Standard 42

for the reduction of Chlorine: Taste and Odor

and Particulate Class I and Standard 53

for the reduction of Lead, Cyst, Turbidity,

Asbestos, Mercury, Lindane, Atrazine,

Benzene and VOC.

Page 2

2

IMPORTANT SAFETY INFORMATION.

WARNING:

Read entire manual. Failure to follow all guides and rules could cause personal injury or property

damage.

■ Check with your local public works department for plumbing codes. You must follow their guidelines as you install the Water Filtration

system.

SAFETY PRECAUTIONS

■ Use the Water Filtration system on a potable, safe-to-drink, home COLD water supply only. The filter canisters will not purify the water,

or make it safe to drink.

■ Do not use on a hot water supply (100°F max.). Install on cold water line only.

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the system. Systems certified for cyst reduction may be used on disinfected water that may contain

filterable cysts.

PROPER INSTALLATION

This Water Filtration system must be properly installed and located in accordance with the Installation Instructions before it is used.

CAUTION: To reduce the risk of property damage due to water leakage, install or store where it will not be exposed to

temperatures below freezing or exposed to any type of weather. Water freezing in the system may damage it and may result in water

leakage, damaging property. Change filter out if it was exposed to freezing temperatures. Do not attempt to treat water over 100°F.

WARNING: Discard all unused and packaging material after installation. Small parts remaining after installation could

be a choke hazard.

■ Your Water Filtration system will withstand up to 120 pounds per square inch (psi) water pressure. If your house water supply pressure is

higher than 80 psi, install a pressure reducing valve before installing the Water Filtration system.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

Page 3

3

Specifications Guidelines.

Many bad tastes and/or odors are removed from water using activated carbon filter canisters. They are most often used to

remove a chlorine taste and odor. They can also reduce other undesirable elements from drinking water supplies, such as organic

chemical contaminants and lead.

NOTE: Small amounts of hydrogen sulfide (noticeable as “rotten egg” odor) may be reduced by taste and odor filters for a short

time, but the carbon media is quickly exhausted. Other water conditioning equipment is usually required for the continuous

treatment of hydrogen sulfide.

The Water Filtration System Uses the Following Canisters

Model GXSL55R

FQSLF Filter

(1200 gallon capacity)

Filter—White canisters with yellow band

• Reduces dirt, rust and sediment

• Reduces Chlorine: Taste and Odor

• Reduces Lead

• Reduces filterable Cysts (such as cryptosporidium and giardia)

• Reduces Turbidity

• Reduces Asbestos

• Reduces Mercury

• Reduces Lindane

• Reduces Atrazine

• Reduces Toxaphene

• Reduces 2,4-D

• 0.5–1 micron nominal particulate reduction

This system conforms to NSF/ANSI 42 and 53 for the specific performance claims as verified and sustained by test data. See Performance

Data Sheet for details.

Page 4

Specifications Guidelines.

The Water Filtration System Uses the Following Canisters

Model GXSV65R

FQSVF Filter

(160 gallon capacity)

Filter—White canisters with green band

• Reduces dirt, rust and sediment

• Reduces Chlorine: Taste and Odor

• Reduces Lead

• Reduces filterable Cysts (such as cryptosporidium and giardia)

• Reduces Turbidity

• Reduces Asbestos

• Reduces Mercury

• Reduces Lindane

• Reduces Atrazine

• Reduces Benzene

• Reduces VOC

• 0.5–1 micron nominal particulate reduction

This system conforms to NSF/ANSI 42 and 53 for the specific performance claims as verified and sustained by test data. See Performance

Data Sheet for details.

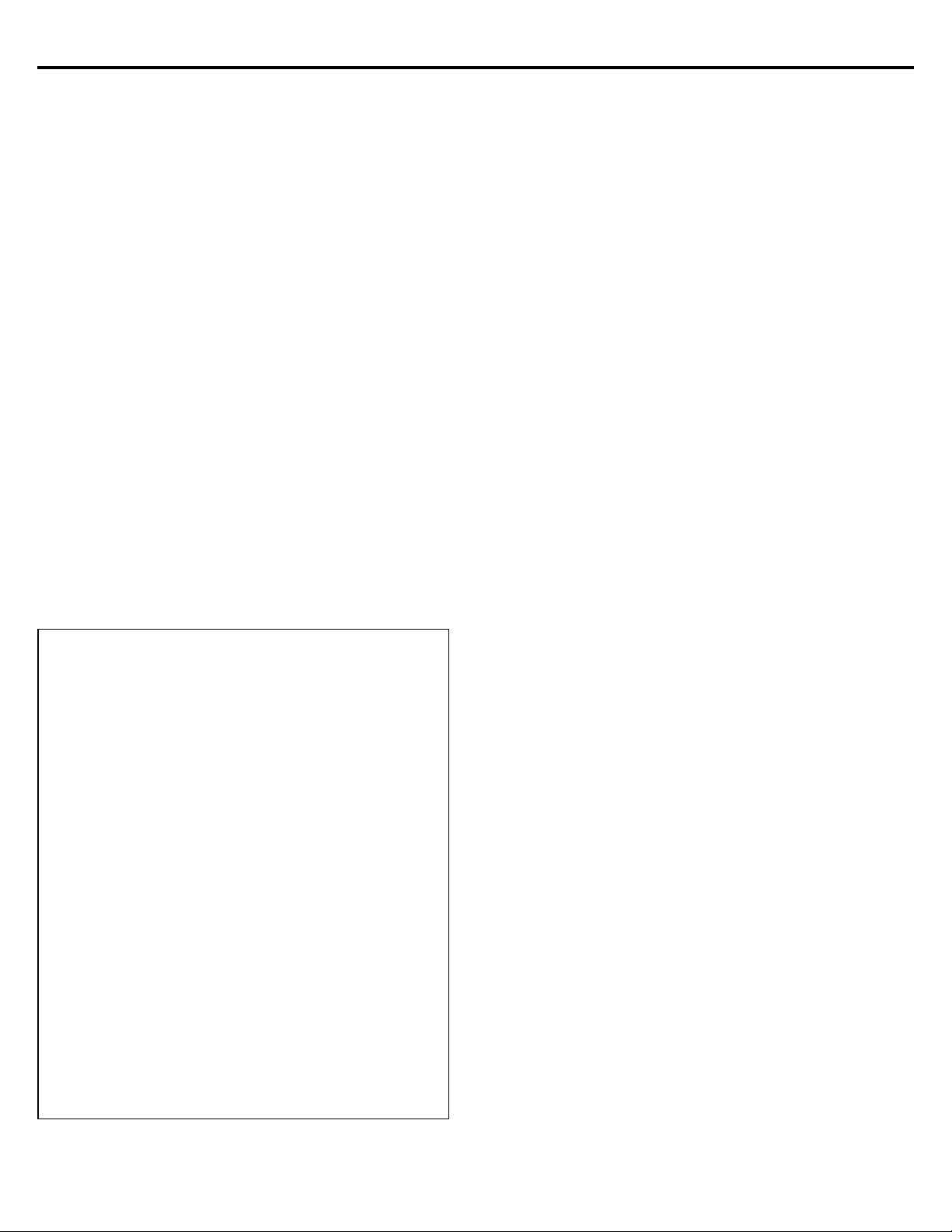

Installation Overview

Locate the drinking water system on the cold water supply pipe, under the kitchen and/or bathroom sink, to filter the cold

drinking water.

4

Sink

Water Supply Valve

Filtered Water Faucet

Inlet

Outlet

Filter Canisters

Manifold

Hot Cold

Page 5

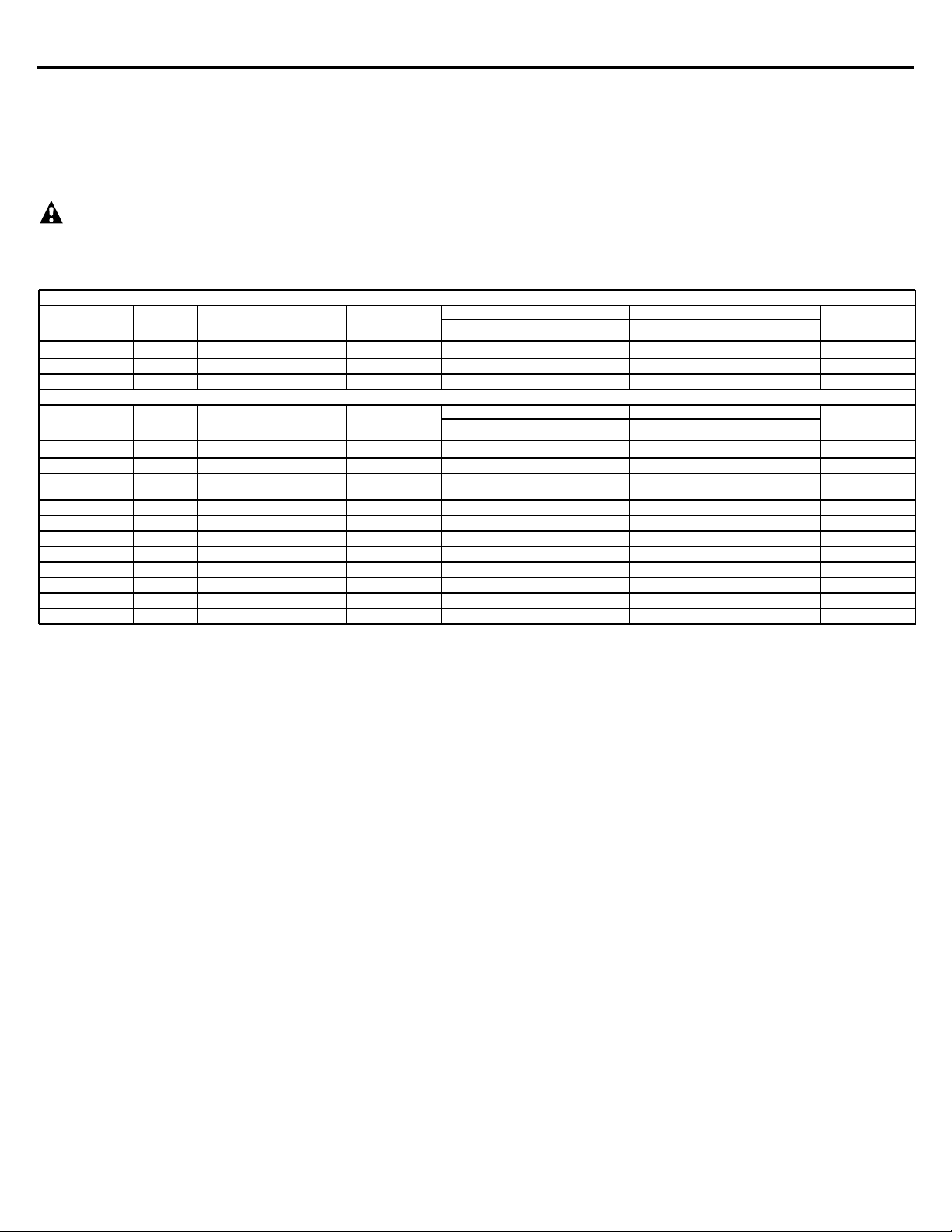

Performance Data Sheet.

SmartWater Filtration System GXSL55R Using Filter FQSLF

■ This System has been tested according to NSF/ANSI 42 and 53 for the reduction of the substances listed below. The concentration of the indicated

substances in water entering the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system,

as specified in NSF/ANSI 42 and 53.

■ Actual performance may vary with local water conditions.

WARNING:

Do not use with water that is microbiologically unsafe or with water of unknown quality without adequate disinfection

before or after the system. Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts.

5

Standard No. 42: Aesthetic Effects

USEPA Influent Influent

Effluent % Reduction

Min. Required

Parameter MCL Challenge Concentration Average Average Maximum Average Minimum Reduction

Chlorine — 2.0 mg/L + 10% 2.00 mg/L 0.050625 mg/L 0.06 mg/L 97.52% 97.00% >50%

T & O — — — — — — — —

Nominal Particulate**

— at least 10,000 particles/mL 14,000,000 #/mL 196,666 #/mL 370,000 #/mL 99.00% 97.40% >85%

Standard No. 53: Health Effects

USEPA Influent Influent

Effluent % Reduction

Min. Required

Parameter MCL Challenge Concentration Average Average Maximum Average Minimum Reduction

Turbidity 0.5 NTU*** 11 + 1 NTU*** 10.5 NTU 0.125 NTU 0.30 NTU 98.80% 97.30% 0.5 NTU

Cysts 99.95% red. Minimum 50,000 L 122,500 #/L <1 #/L <1 #/L >99.99% >99.99% >99.95%

Asbestos 99% red. 10

7

and 108; 126.5 MF/L <.17 MF/L <.17 MF/L >99.99% >99.99% >99%

fibers >10 micrometers long

Lead, pH 6.5 0.010 mg/L 0.015 mg/L + 10% 0.150 mg/L <0.001 mg/L <0.001 mg/L >99.30% >99.30% 0.010 mg/L

Lead, pH 8.5 0.010 mg/L 0.015 mg/L + 10% 0.150 mg/L <0.001 mg/L <0.001 mg/L >99.30% >99.30% 0.010 mg/L

Mercury, pH 6.5 0.002 mg/L 0.006 mg/L ± 10% 0.006 mg/L 0.0003 mg/L 0.0005 mg/L 95.00% 91.70% 0.002 mg/L

Mercury, pH 8.5 0.002 mg/L 0.006 mg/L ± 10% 0.0059 mg/L 0.00073 mg/L 0.0018 mg/L 88.10% 69.20% 0.002 mg/L

Atrazine 0.003 mg/L 0.009 mg/L + 10% 0.0102 mg/L 0.00105 mg/L 0.0027 mg/L 89.40% 76.30% 0.003 mg/L

Lindane 0.0002 mg/L 0.002 mg/L + 10% 0.0019 mg/L 0.000035 mg/L 0.00016 mg/L 97.90% 91.80% 0.0002 mg/L

2,4-D 0.07 mg/L 0.200 mg/L ± 10% 0.2005 mg/L 0.017575 mg/L 0.064 mg/L 84.90% 69.00% 0.07 mg/L

Toxaphene 0.003 mg/L 0.015 ± 10% 0.015 mg/L <0.001 mg/L <0.001 mg/L >93.30% >93.30% 0.003 mg/L

*Tested using a flow rate of 0.78 gpm (2.95 l/min); pressure of 60 psig; pH of 7.5 ± 0.5; temp. of 68° ± 5°F (20° ± 3°C)

**Measurement in particles/mL. Particles used were 0.5–1 microns.

***NTU—Nephelometric Turbidity Units

Operating Specifications

Capacity: certified for up to 1200 gallons (4,542 l); up to six months

Pressure requirement: 35–120 psi (2.8–8.2 bar)

Temperature: 33–100°F (0.6–38°C)

Flow rate: 0.78 gpm (2.95 l/min)

Replacement Filter Canisters/Estimated Replacement Costs

FQSLF—Replacement filter canister $30–35

For replacement parts, call toll-free 800.626.2002 (U.S.),

800.663.6060 (Canada–English), 800.361.3869 (Canada–French)

Page 6

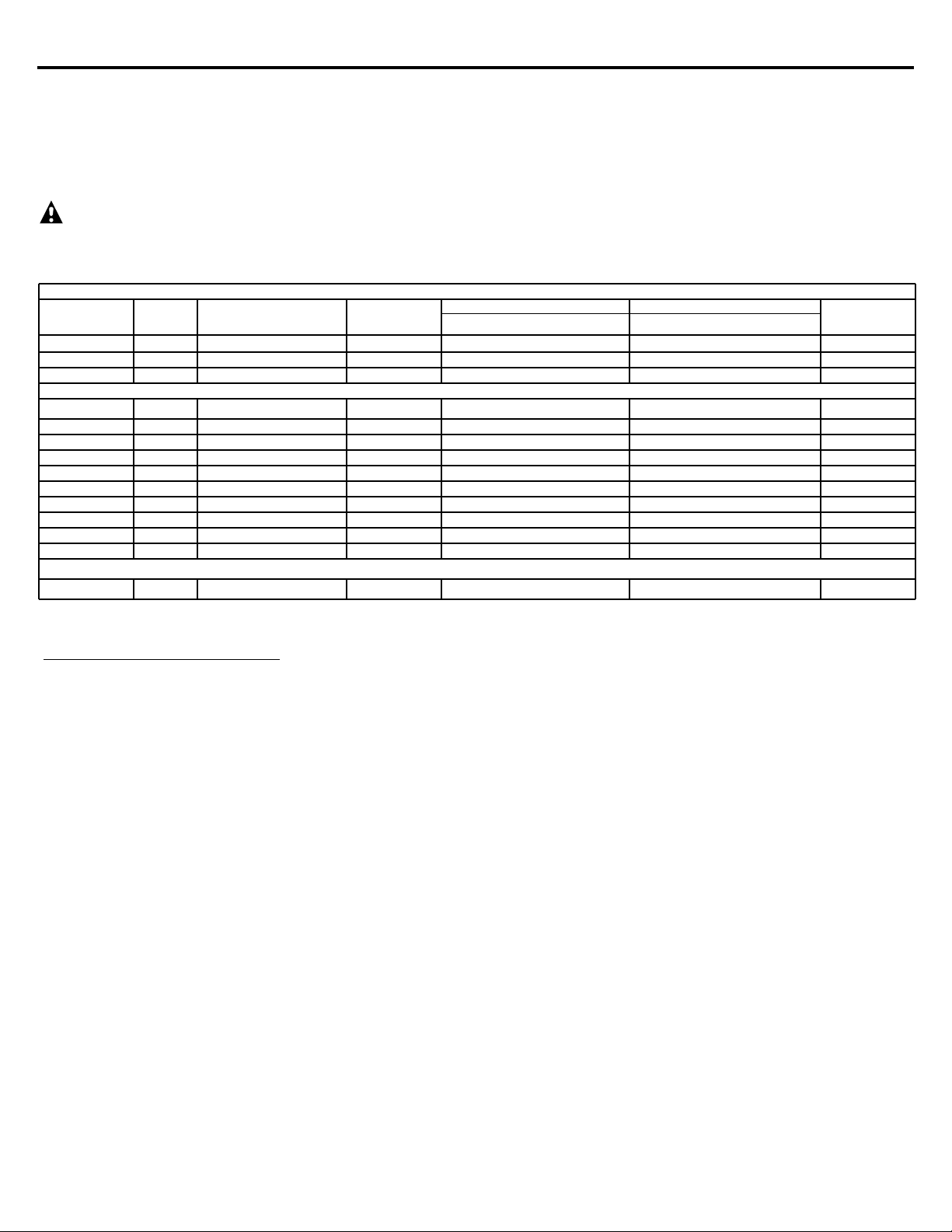

Performance Data Sheet.

SmartWater Filtration System GXSV65R Using Filter FQSVF

■ This System has been tested according to NSF/ANSI 42 and 53 for the reduction of the substances listed below. The concentration of the indicated

substances in water entering the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system,

as specified in NSF/ANSI 42 and 53.

■ Actual performance may vary with local water conditions.

WARNING:

Do not use with water that is microbiologically unsafe or with water of unknown quality without adequate disinfection

before or after the system. Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts.

Standard No. 42: Aesthetic Effects

USEPA Influent Influent

Effluent % Reduction

Parameter MCL Challenge Concentration Average Average Maximum Average Minimum

Chlorine — 2.0 mg/L + 10% 2.00 mg/L <0.05 mg/L <0.05 mg/L >97.50% >97.50% >50%

T & O — — — — — — — —

Particulate** — > 10,000 particles/mL 4,100,000 #/mL 76,500 #/mL 110,000 #/mL 98.10% 97.30% >85%

Standard No. 53: Health Effects

Turbidity 0.5 NTU*** 11 + 1 NTU*** 11.00 NTU 0.1 NTU 0.1 NTU 98.80% 98.20% 0.5 NTU

Cysts 99.95% red. Min. 50,000/L 140,000 #/L 1 #/L 1 #/L >99.99% >99.99% 99.95%

Asbestos 99% red. — 280 MF/L <0.17 MF/L <0.17 MF/L >99.00% >99.00% 99%

Lead, pH 6.5 0.010 mg/L 0.15 mg/L + 10% 0.150 mg/L <0.001 mg/L <0.001 mg/L >99.30% >99.30% 0.01 mg/L

Lead, pH 8.5 0.010 mg/L 0.15 mg/L + 10% 0.140 mg/L <0.001 mg/L <0.001 mg/L >99.30% >99.30% 0.01 mg/L

Mercury, pH 6.5 0.002 mg/L 0.006 mg/L ± 10% 0.0065 mg/L <0.0002 mg/L <0.0002 mg/L 96.60% >96.70% 0.002 mg/L

Mercury, pH 8.5 0.002 mg/L 0.006 mg/L ± 10% 0.0059 mg/L <0.0002 mg/L <0.0002 mg/L 96.60% >96.70% 0.002 mg/L

Lindane 0.0002 mg/L 0. 002 mg/L ± 10% 0.00193 mg/L <0.00002 mg/L 0.00005 mg/L >98.80% 98.80% 0.0002 mg/L

Benzene 0.001 mg/L 0.015 mg/L ± 10% 0.014 mg/L <0.0005 mg/L <0.0005 mg/L >96.40% >96.40% 0.005 mg/L

Atrazine 0.003 mg/L 0.009 mg/L ± 10% 0.00873 mg/L <0.0005 mg/L <0.0005 mg/L >94.10% >94.10% 0.003 mg/L

VOC Reduction

Chloroform 0. 080 mg/L 0.300 ± 10% 0.340 mg/L 0.00098 mg/L 0.00620 mg/L 97.90% 98.20% 95%

*Tested using a flow rate of 0.60 gpm (2.27 l/min); pressure of 60 psig; pH of 7.5 ± 0.5; temp. of 68° ± 5°F (20° ± 3°C)

**Measurement in particles/mL. Particles used were 0.5–1 microns.

***NTU—Nephelometric Turbidity Units / NTU—unités de turbidité néphélométrique

Operating Specifications / Spécifications d’opération

Capacity: certified for up to 160 gallons (605 l); up to six months

Pressure requirement: 35–120 psi (2.8–8.2 bar)

Temperature: 33–100°F (0.6–38°C)

Flow rate: 0.60 gpm (2.27 l/min)

6

Replacement Filter Canisters/Estimated Replacement Costs

FQSVF—Replacement filter canister $35–40

For replacement parts, call toll-free 800.626.2002 (U.S.),

800.663.6060 (Canada–English), 800.361.3869 (Canada–French)

Maximum Permissible

Product Water

Concentration

Page 7

1

Influent challenge levels are average influent concentrations determined in surrogate

qualification testing.

2

μg/L means Micrograms Per Liter.

3

Maximum product water level was not observed but was set at the detection limit

of the analysis.

4

Maximum product level is set at a value determined in surrogate qualification testing.

5

Chemical reduction percent and maximum product water level calculated at chloroform

95% breakthrough point as determined in surrogate qualification testing.

6

The surrogate test results for heptachlor Epoxide demonstrated a 98% reduction. These data

were used to calculate an upper occurrence concentration, which would produce a maximum

product water level at the MCL.

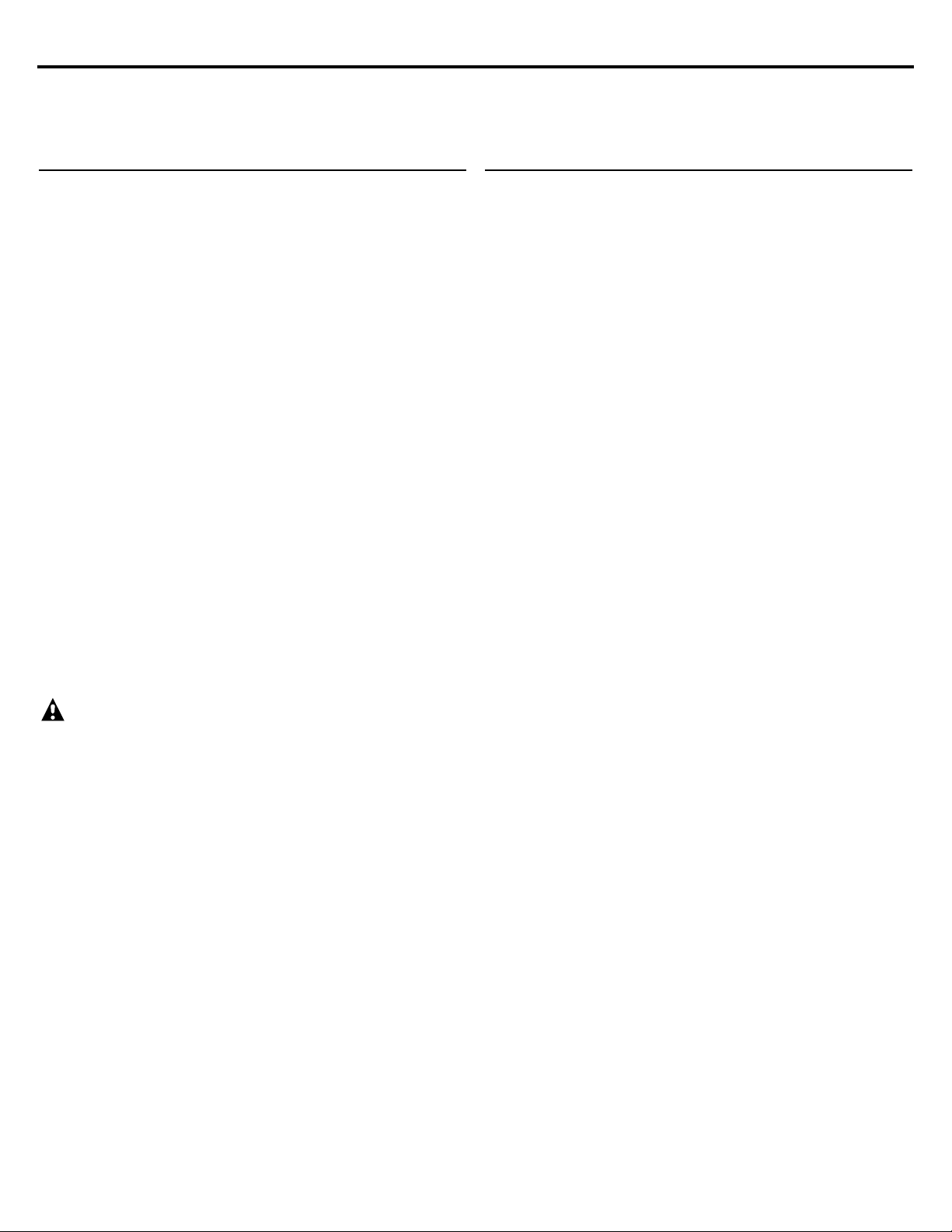

Organic Chemicals Reduced by Chloroform Surrogate Testing

Avg.1Influent Max. Effluent

Contaminant (μg/L)

2

(μg/L)

2

Alachlor 50 1.0

3

Atrazine 100 3.0

3

Benzene 81 1.0

3

Carbofuran 190 1.0

3

Carbon Tetrachloride 78 1.8

4

Chlorobenzene 77 1.0

3

Chloropicrin 15 0.2

4

2,4-D 110 1.7

4

Dibromochloropropane (DBCP) 52 0.02

3

o-Dichlorobenzene 80 1.0

3

p-Dichlorobenzene 40 1.0

3

1,2-Dichloroethane 88 4.8

5

1,1-Dichloroethylene 83 1.0

3

cis-1,2-Dichloroethylene 170 0.5

3

trans-1,2-Dichloroethylene 86 1.0

3

1,2-Dichloropropane 80 1.0

3

cis-1,3-Dichloropropylene 79 1.0

3

Dinoseb 170 0.2

4

Endrin 53 0.59

4

Ethylbenzene 88 1.0

3

Ethylene Dibromide (EDB) 44 0.02

3

Haloacetonitriles (HAN):

Bromochloroacetonitrile 22 0.5

4

Dibromoacetonitrile 24 0.6

4

Dichloroacetonitrile 9.6 0.2

4

Trichloroacetonitrile 15 0.3

4

Avg.1Influent Max. Effluent

Contaminant (μg/L)

2

(μg/L)

2

Haloketones (HK):

1,1-dichloro-2-propanone 7.2 0.1

4

1,1,1-trichloro-2-propanone 8.2

6

0.3

4

Heptachlor (H-34, Heptox) 80 0.4

3

Heptachlor Epoxide 10.7

6

0.2

6

Hexachlorobutadiene 44 1.0

3

Hexachlorocyclopentadiene 60 0.002

3

Lindane 55 0.01

3

Methoxychlor 50 0.1

3

Pentachlorophenol 96 1.0

3

Simazine 120 4.0

3

Styrene 150 0.5

3

1,1,2,2-Tetrachloroethane 81 1.0

3

Tetrachloroethylene 81 1.0

3

Toluene 78 1.0

3

2,4,5-TP (silvex) 270 1.6

3

Tribromoacetic acid 42 1.0

3

1,2,4-Trichlorobenzene 160 0.5

3

1,1,1-Trichloroethane 84 4.6

4

1,1,2-Trichloroethane 150 0.5

3

Trichlorothylene 180 1.0

3

Trihalomethanes (includes): 300 15

Chloroform (surrogate chemical)

Bromoform

Bromodichloromethane

Chlorodibromomethane

Xylenes (total) 70 1.0

3

Testing was performed under standard laboratory conditions; actual performance may vary.

NOTE: Substances reduced are not necessarily in your water. Filter must be maintained according to manufacturer’s instructions, including replacement of filter cartridges.

WARNING:Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system. Systems certified for cyst

reduction may be used on disinfected waters that contain filterable cysts.

Performance Data Sheet.

7

Page 8

8

Installation

Faucet Mount Filtration System –

Instructions

GXSL55R and GXSV65R

IMPORTANT INSTALLATION

RECOMMENDATIONS

WARNING —

Read entire manual. Failure

to follow all guides and rules could cause personal

injury or property damage.

•

Check with your local public works department

for plumbing codes. You must follow their guides

as you install the Water Filtration system.

TOOLS AND MATERIALS REQUIRED

FOR INSTALLATION

• Phillips screwdriver

• Two (2) adjustable wrenches

• Electric drill and drill bit to drill 1″ hole (type as

required) if mounting hole is needed for faucet

• Tape measure

• If your main water line is a rigid pipe, you will require

a compression fitting and possibly other plumbing

hardware to complete the installation.

CAUTION —

To avoid damaging the sink,

consult a qualified plumber or installer for drilling

procedures. Special drill bits may be needed for

porcelain or stainless steel.

CONTENTS INCLUDED

WITH THE PRODUCT

• Water filter system assembly,

including mounting screws

• Feed water adapter

• Faucet assembly with electronic base monitor

and tubing

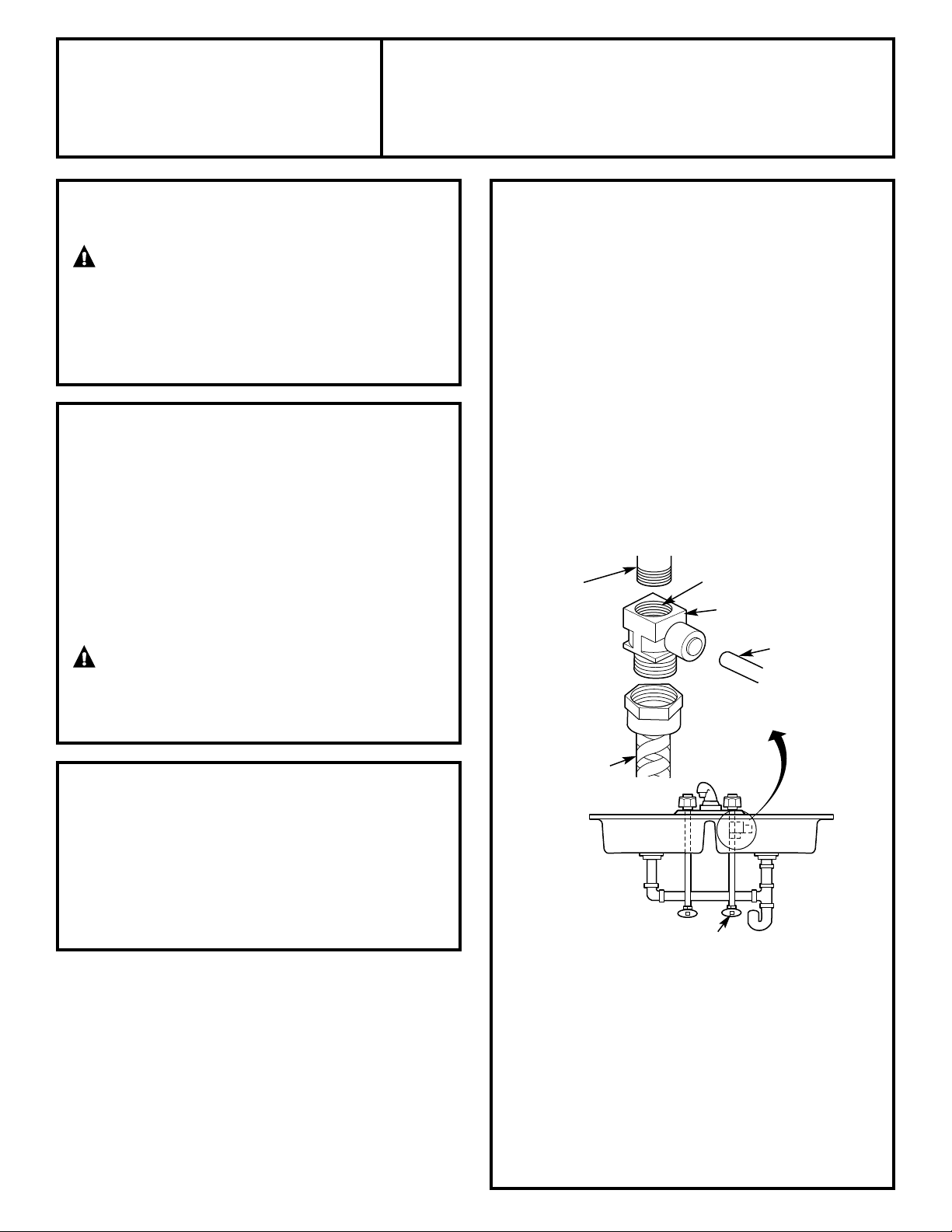

COLD WATER SUPPLY FITTING

A. PREFERRED INSTALLATION

(Utilizing existing kitchen sink water supply valve

and flexible faucet tubing)

A typical connection using the included water

supply fitting is shown in the illustration below.

1. Close the water shut-off valve that is immediately

in front of the supply tube and open the faucets

to drain water from the sink cold water pipe.

2. Remove the nut that connects the cold water faucet

to the supply tube. Some water may spill out.

NOTES:

• Be sure to turn off the water supply and open

a faucet to drain the pipe.

• Make sure the gasket is installed in the water

supply fitting.

3. Hand-tighten the water supply fitting onto the cold

water faucet. Be sure the gasket, as shown, is in

place before final assembly. Finish tightening with

an adjustable wrench. Be careful not to overtighten

or cross-thread, as damage to the threads can

occur. Make sure the 1/4″ quick connection is not

against a wall that causes the supply tubing

connection to bend. A quarter turn to tighten or

loosen the adapter may be necessary to avoid this.

4. Reconnect faucet tubing line to the fitting.

5. Install tubing. (See Installing the Tubing section.)

Cold Water

Faucet Stud

Cold

Water Pipe

Water Supply Fitting

1/4″ Tubing to

Water Filter Inlet

Cold Water Shutoff

Gasket

Fig. 1

Page 9

Installation Instructions

9

COLD WATER SUPPLY FITTING (CONT.)

B. OPTIONAL HOME INSTALLATION

(Where codes permit)

Saddle Valve: Saddle valve must be able to

connect with 1/4-inch tubing supplied with the

system. Not supplied with product; check your

local hardware or home service store for

product. Saddle valve typically requires 1/2″

OD tubing or larger.

NOTE: Codes in the state of Massachusetts

require installation by a licensed plumber and

do not permit the use of the saddle valve. For

installation, use plumbing code 248-CMR of the

Commonwealth of Massachusetts.

1. Turn off the cold water supply and install saddle

valve as required by product selection. (Be sure to

follow manufacturer’s installation instructions.)

DANGER —

If hole is required to be drilled

in pipe, to protect yourself from serious injury or

fatal shock, use a battery-powered hand drill only

to make the hole. DO NOT USE AN ELECTRIC DRILL.

2. Open saddle valve after complete system has

been installed.

C. OPTIONAL INSTALLATION

(For installation with rigid pipe between supply

valve and sink faucet)

Option 1

1. Remove pipe from supply valve and sink faucet.

2. Obtain flexible pipe sized to your plumbing.

3. Install flexible pipe.

4. Go back to A. Preferred Installation section

step 3.

Option 2

1. Obtain compression fittings to fit rigid pipe.

2. Obtain any other fittings required to connect

compression fittings to feed water adapter.

3. Remove pipe from supply valve.

4. Cut pipe to fit length of assembled fittings and

adapter.

5. Install compression fitting to pipe.

6. Go back to A. Preferred Installation section

step 3.

NOTE: Above described materials are not

included with the product.

INSTALL THE FAUCET

Be sure there is room underneath and above the

sink to make the needed connections. Before

starting, make sure there is sufficient room for the

faucet base and unit. Select one of the following

places to install the faucet:

A. In an existing sink spray attachment or soap

dispenser hole.

B. In a hole to be drilled in the sink top.

C. In a hole to be drilled in the countertop, next

to the sink.

NOTES:

• Be sure the faucet base will fit flat against the

surface at the selected location so the bottom

gasket between the base and surface area

will seal.

• Make sure to leave enough clearance at the back

of the faucet in case you need to remove it.

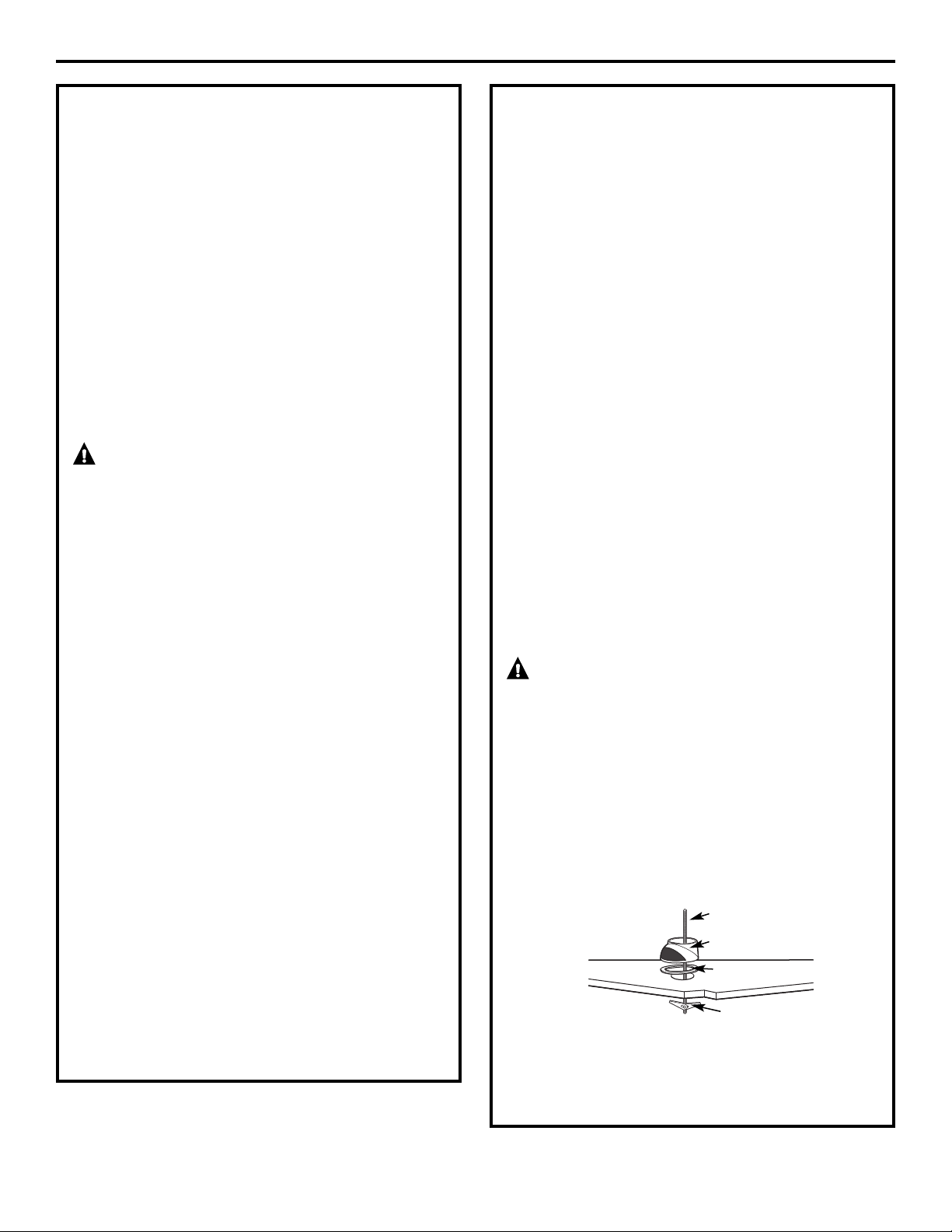

Installation Steps (refer to illustration below

for clarification)

1. If drilling is needed, make a 1″ diameter hole.

Be sure to use the proper procedure for drilling

porcelain or stainless steel. Special drill bits

may be needed. Consult a qualified plumber

for the proper procedure.

CAUTION:When drilling in Stainless Steel,

edges may be sharp and could puncture the tube.

Be careful to not cut yourself or damage the tube.

2. Remove the faucet body and base by turning

the base counterclockwise.

3. Remove the butterfly bracket from the screw.

Then insert the screw into the top of the base

and reattach the butterfly bracket.

4. Align the gasket to cover the hole completely.

Then place the butterfly bracket on the base

into the hole.

5. Tighten the screw to secure the butterfly bracket

to the underside of the sink top. The base should

be firmly in place and should not wobble or turn.

Base

Sink

Gasket

Butterfly Bracket

Screw

Page 10

Installation Instructions

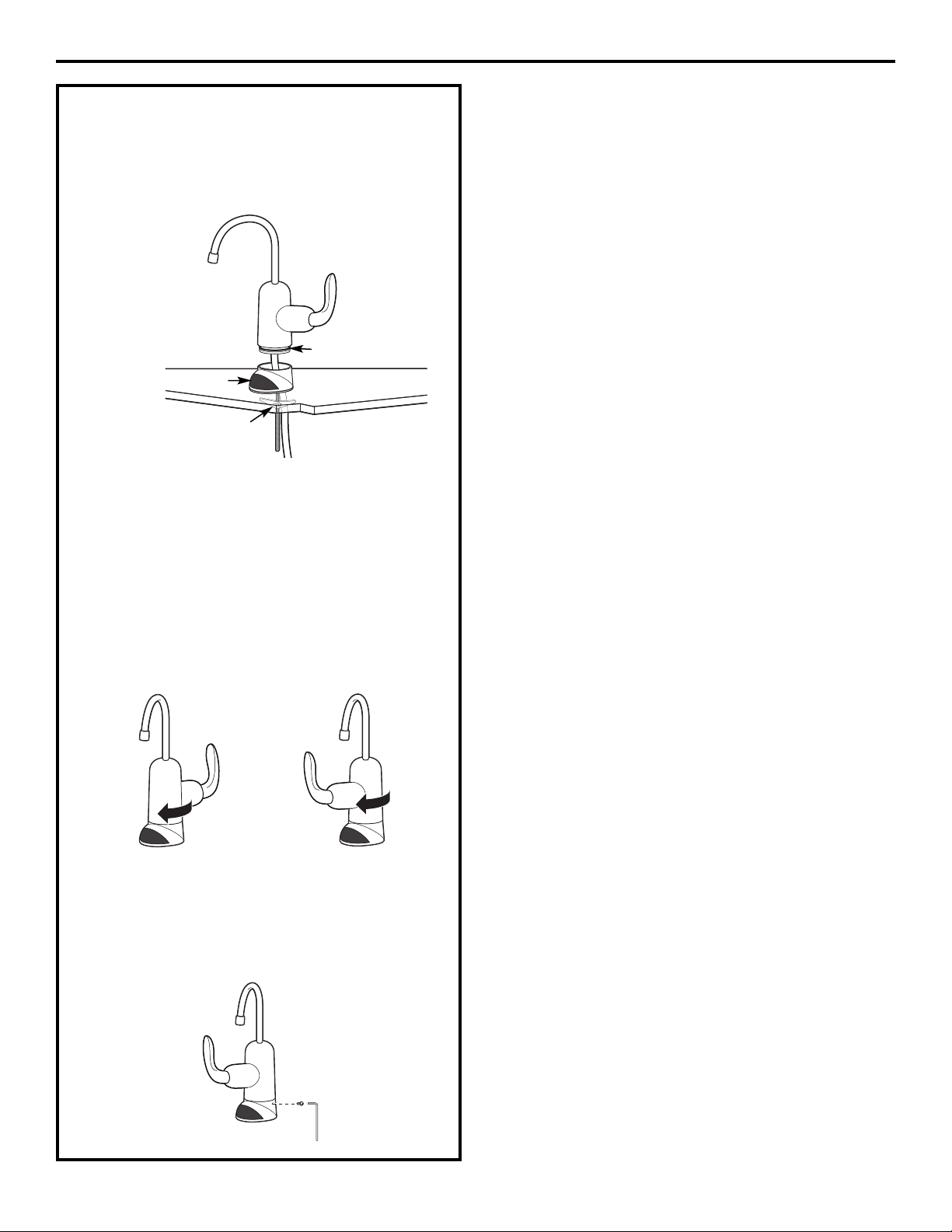

INSTALL THE FAUCET (CONT.)

6. Feed the water tube up through the faucet base.

Then push the tube into the fitting on the bottom

of the faucet body. It should go in about 3/4″.

Pull tube slightly to make sure it is secure.

7. Push the faucet body down into the faucet base

and twist clockwise until it clicks into place.

NOTE: You can install the faucet so the handle

is on the right or the left side.

If you want the faucet handle on the right,

position the handle at the back of the faucet

base before turning clockwise.

If you want the faucet handle on the left,

position the handle at the front of the faucet

base before turning clockwise.

7. Locate the hole at the rear of the base. Insert

set screw and begin to tighten by hand. Finish

tightening with the allen wrench provided

in the packet.

Faucet Body

Base

Sink

Gasket

Butterfly Bracket

Faucet Faucet

Faucet handle on the RIGHT Faucet handle on the LEFT

10

Page 11

Installation Instructions

11

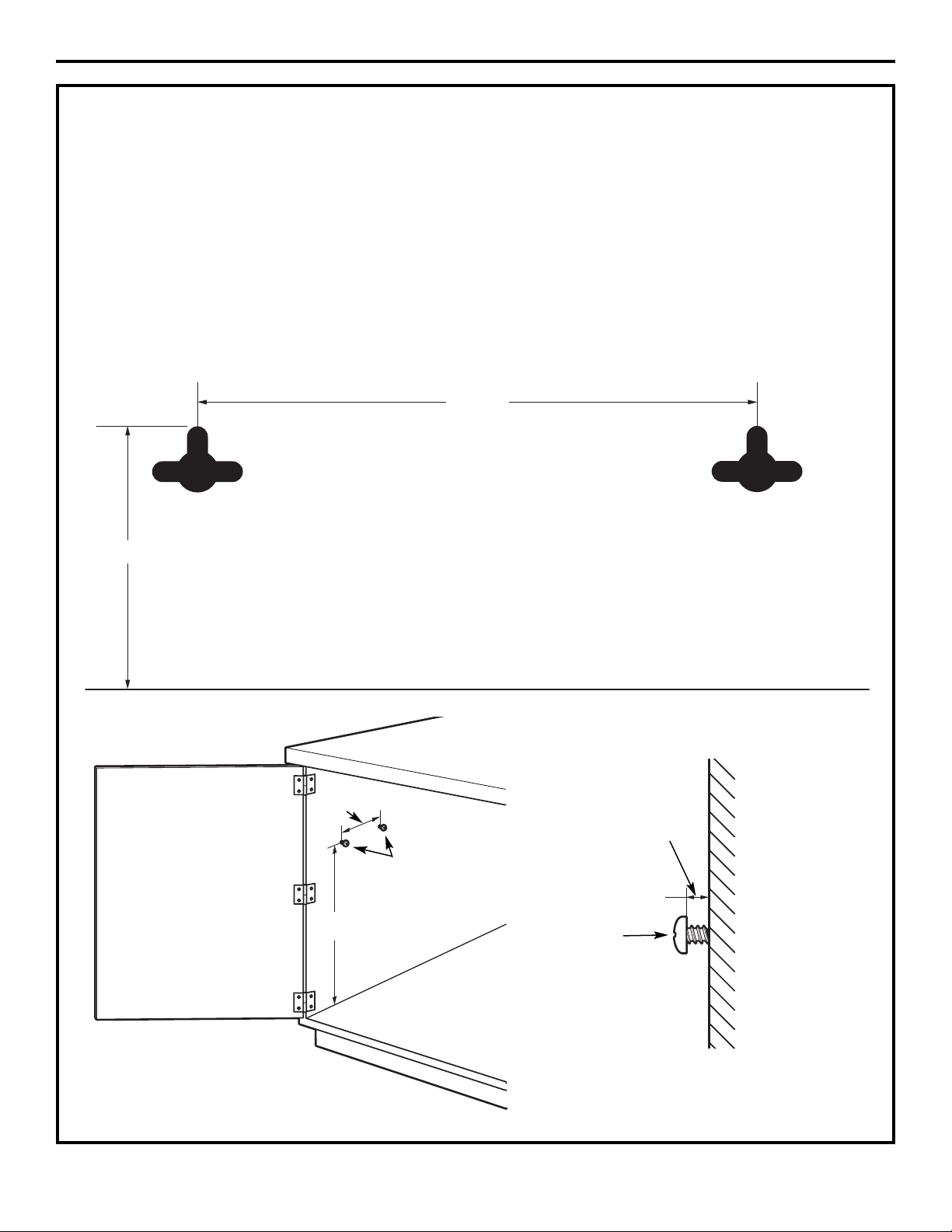

MOUNTING SYSTEM INSTALLATION

Pick a location under the sink to mount the system. Location should be easily accessible, with clearance between

the bottom of the filter canisters and the floor or bottom of the cabinet; any less will result in difficulty of removing

filter canisters (see Fig. 5). Allow enough space on either side of the system for the tubing connections.

SCREW INSTALLATION

1. Remove this template from the manual for easier installation.

2. The top of the template openings should be placed a minimum of 17 inches above the bottom of the cabinet

or floor where the system is to be mounted (Fig. 4 and 5). NOTE: Any distance lower may result in filter canisters

interfering with the floor when removed.

3. Tape template to wall, then mark the wall where the screws are to be installed.

Install screws into the wall, leaving 3/16 inch clearance between the head of the screw and wall (drill pilot holes

if needed) (Fig. 6).

17 inches

5 inches

Bottom of Cabinet or Floor

Template for screw hole pattern on back of filtration system

Fig. 4

17 inches

5 inches

Screws

Screw

3/16 inch

Fig. 6

Fig. 5

Wall

Page 12

Installation Instructions

12

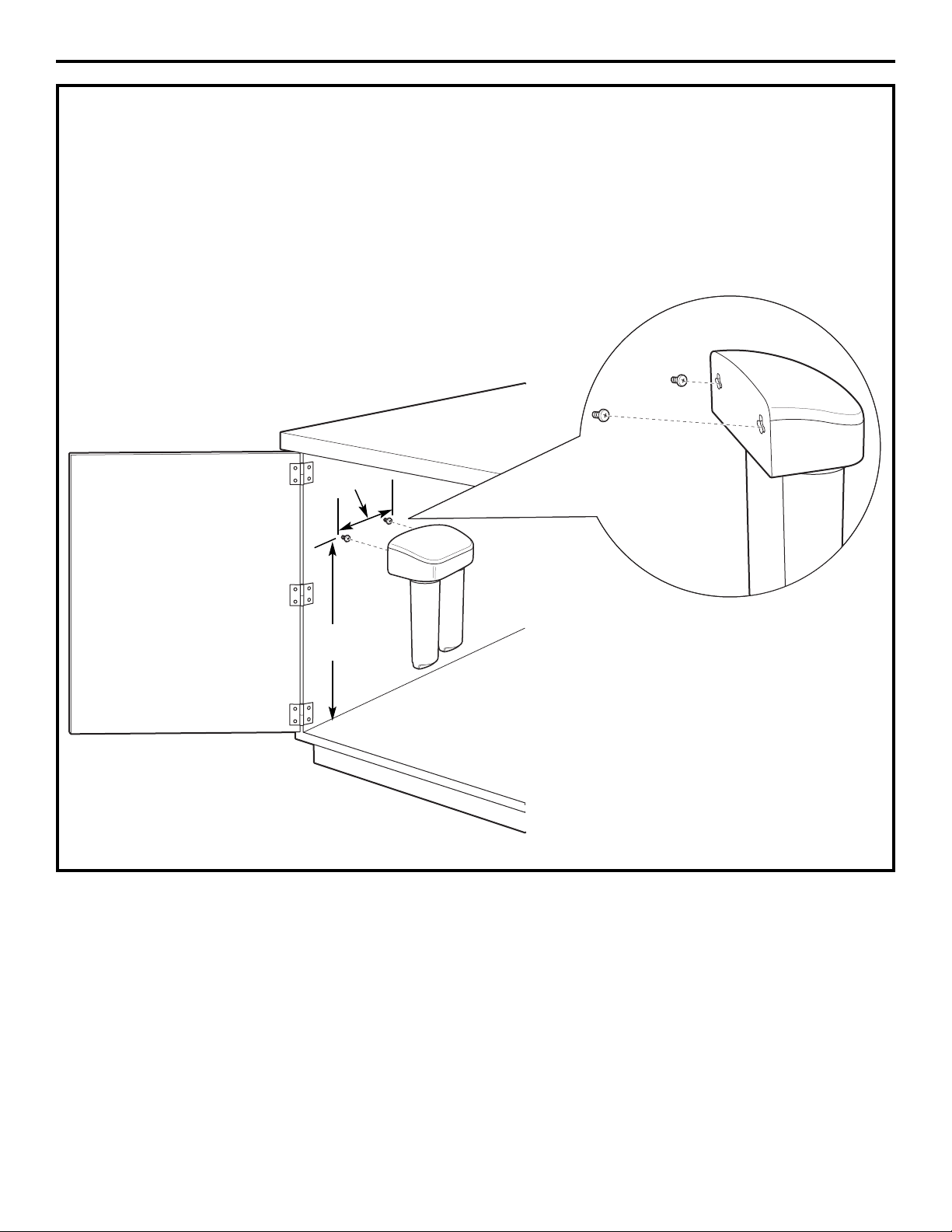

MOUNTING SYSTEM INSTALLATION (CONT.)

Mounting System to Screws Installed in Wall

1. Remove shrink wrap from filter system.

2. Hang the system on the previously installed screws using the openings on the back of the unit (Fig. 7).

3. If the head of the screw will not slide into the upper slot, back out the screw by 1/4 turn and try again.

4. If the system is too loose when placed on the wall, tighten the screws by 1/4 turn and try again until a desired

fit is achieved.

Min.

17 inches

5 inches

Fig. 7

Page 13

Installation Instructions

13

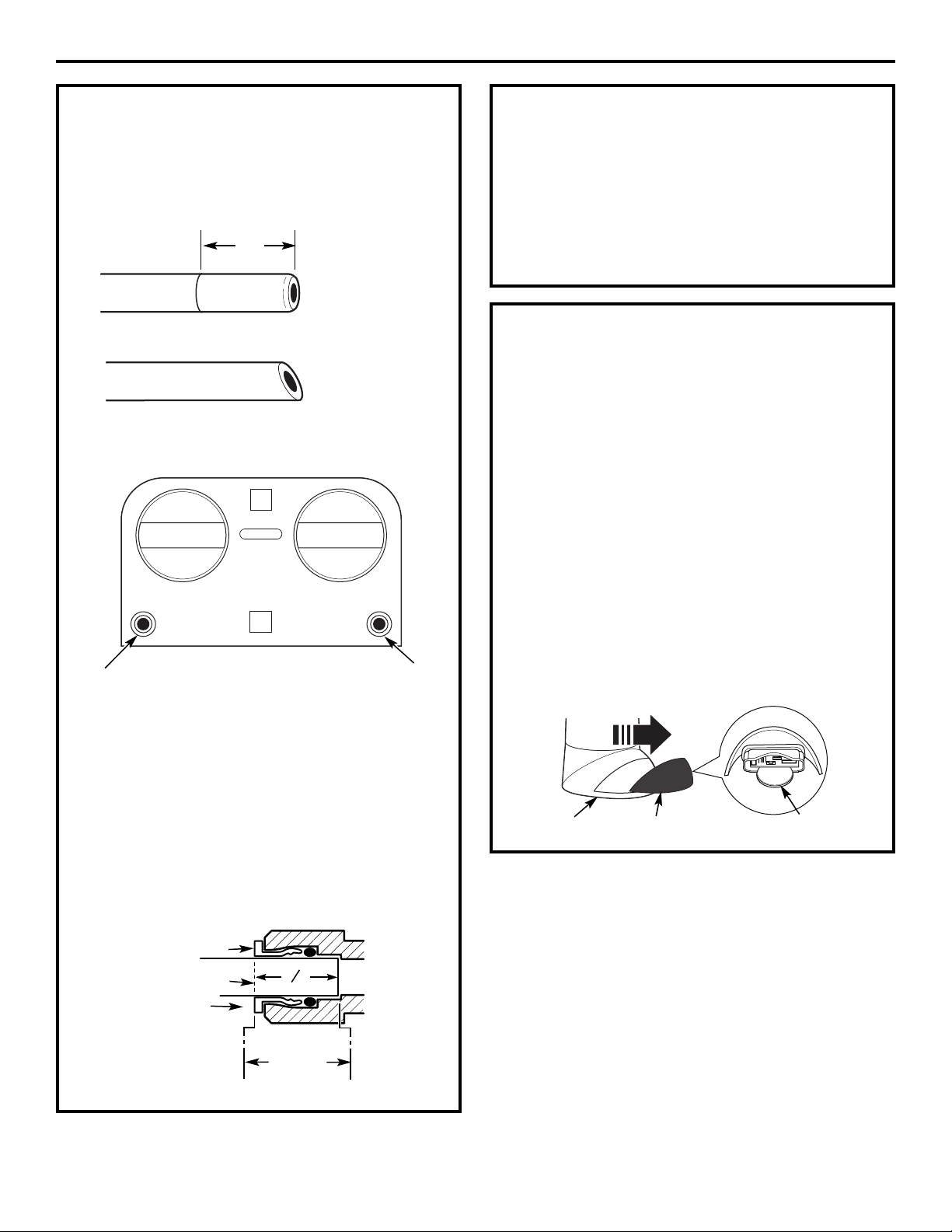

INSTALLING THE TUBING

1. Measure 3/4″ from the end of each remaining piece

of tubing (faucet end and inlet end) and mark with a

pencil (Fig. 8). (Check for roundness, smoothness,

cuts, nicks, flat spots and sharp edges. It may be

necessary to recut the tubing.)

2. Locate fittings for tubing on bottom of manifold.

3. NOTE: Water flow is from left to right. Water inlet

is on the left side and water outlet is on the right

side. Failure to follow will result in water leaks

when filter canisters are removed.

4. Push the tubing firmly into each fitting on the

manifold until the line is flush with the fitting collar.

(If the tubing is removed, re-cut the end, measure,

mark and re-insert). Tubing must be fully inserted to

avoid leaks (Fig. 9). (To remove tubing, depress and

hold white collet; pull tubing out to remove.)

3/4″

(19 mm)

Fig. 8

INCORRECT

Inlet from

supply valve

Outlet

to faucet

3

4

"

Engagement

3/4″ (3/8″ tubing)

White Collet

(DO NOT REMOVE)

Insertion line

Insert tubing

Fig. 9

INSTALLING THE TUBING (CONT.)

5. Pull out slightly on tubing to ensure a good seal.

6. Install the other end of the tubing from the inlet side

of the manifold to the feed water adapter.

NOTE: Inspect the ends of the tubing to be sure

there are no imperfections and that the end of the

tubing is cut square. It may be necessary to cut the

tubing again.

INSTALL THE BATTERY

1. Remove the lens cover from the faucet base.

Grip it from both sides and pull forward.

2. Install one CR2032 3V battery with the “+” side

down into the battery tray.

3. The amber LED light will flash 5 times, indicating

a proper installation and system reset. If the

amber light does not flash, check the position

of the battery and make sure it is installed correctly.

4. Slide the lens cover back into the faucet base.

5. Normally, the light is off. After 6 months of use,

the amber LED light will flash every 30 seconds,

indicating the time to replace the filter canister.

NOTE: The amber LED light may stop blinking

if it is allowed to blink for an extended period of

time. To ensure proper operation, the battery

should be replaced with every filter change.

Faucet Base

Lens Cover

Battery “+” Side Down

INLETOUTLET

Page 14

Installation Instructions

14

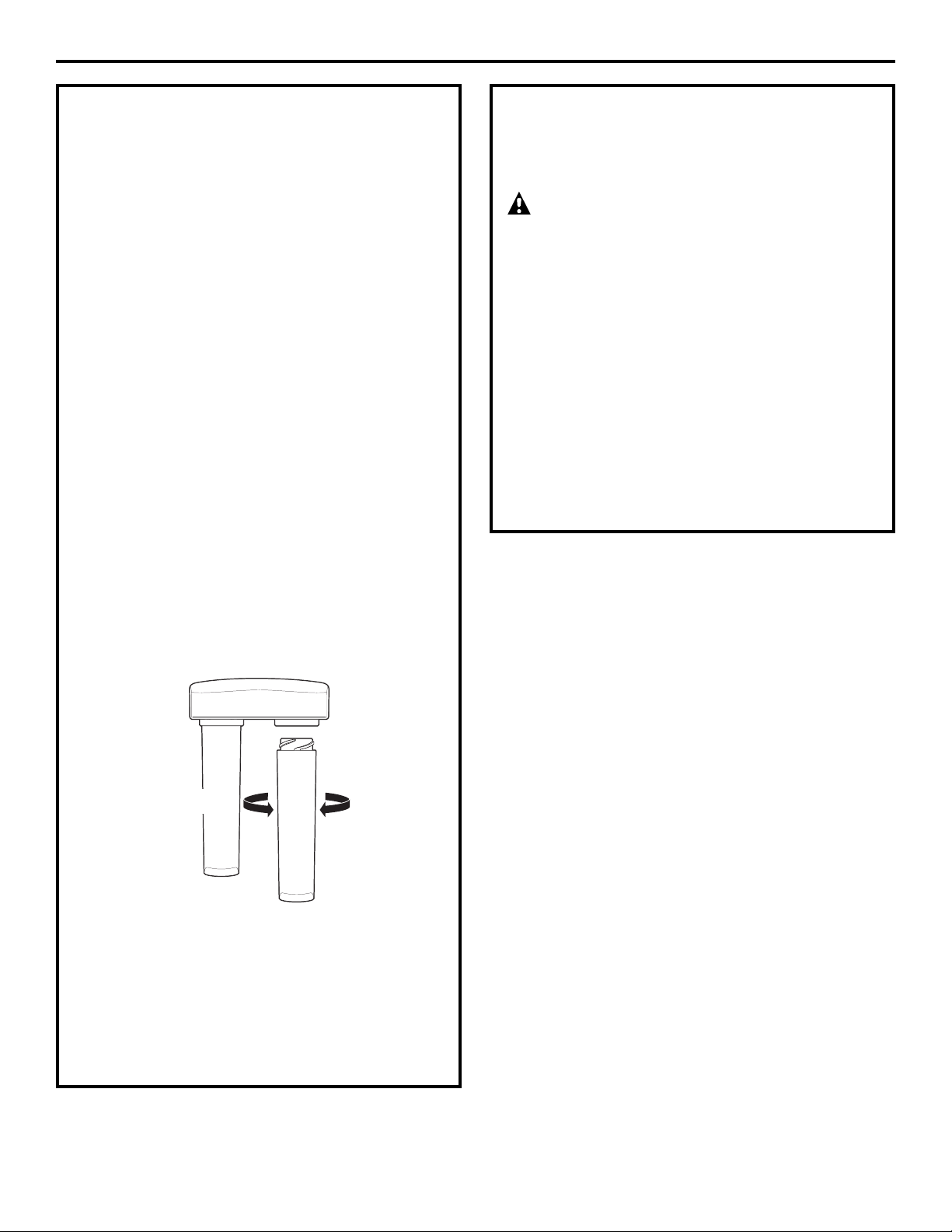

REPLACING THE FILTER CANISTERS

The amber light in the faucet base will flash every

30 seconds to indicate a filter change is needed.

This occurs every 6 months. TO PROPERLY MAINTAIN

SYSTEM, CHANGE FILTER AS REQUIRED.

1. Remove the filter canisters from the manifold by

rotating the canisters to the left about 1/3 turn

(Fig. 11). NOTE: A small amount of water from the

tubing between the filter and the faucet may come

out. A small towel should be able to catch it.

2. Remove foil on top of new replacement filter

canisters. Install the new canisters into the manifold

by turning to the right about 1/3 turn until the

alignment marks line up and the filter stops. DO

NOT OVERTIGHTEN. The filter will rise up as it

is turned.

3. Turn handle on faucet to allow trapped air to purge

from the system.

NOTE: System may make noise during this procedure.

4. Check for water leaks around the system.

5. Once water starts to flow out of the faucet, allow

the system to run for 4 gallons (or 5 minutes) to

flush out any harmless carbon fines that may be

present.

6. Turn off faucet and check around system for leaks.

7. Remove battery tray and replace battery to reset

timer. (See Battery Installation for proper procedure).

Replacement Filter Canisters/

Estimated Replacement Costs

FQSLF—Replacement filter canister $30–35

FQSVF—Replacement filter canister $35–40

For replacement parts, call toll-free 800.626.2002

(U.S.), 800.663.6060 (Canada–English), 800.361.3869

(Canada–French).

FLUSH PROCEDURE

Whenever water of unknown quality is passed through

the GE Water Filtration system, the filter canisters

should be discarded and the filtration system flushed.

WARNING: Do not use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before or after the

system. Systems certified for cyst reduction may be

used on disinfected water that may contain filterable

cysts.

Circumstances that may require flushing

the system are:

• Boil water advisory

• Flooding of the GE Water Filtration system

• Long-term non-use

The procedure for flushing the GE Water Filtration

system is:

1. See Replacing the Filter Canisters section and follow

steps 1–5.

To install

To remove

Fig. 11

Page 15

15

Before you call for service…

Problem Possible Causes What To Do

Water contains tiny New filter canisters contain • Turn on the filtered water faucet and allow these initial carbon

black particles activated carbon. particles to purge from the canisters. Turn off the faucet when the

water is clear.

Water has air bubbles Air in system after installation. • Will go away after water runs for a while.

and is cloudy

Indicator light on the Six months usage has occurred. •Replace both filter canisters and battery in the faucet base.

faucet base is flashing This is the maximum life of

the filter canisters.

Indicator light on the Normal operation. • Does not blink until 6 months of operation has passed.

faucet base is not blinking

Battery may need to be replaced. • Normally the light is not on. The light blinks every 30 seconds to

indicate a filter change is needed. This occurs about every 6 months.

• Replace battery. Indicator light will blink rapidly 5 times to indicate

proper installation and operation.

Indicator light on the Battery may need to be •Observe orientation markings on the holder. Install with battery

faucet base is not

replaced or it may have been “+” side down.

working

when new installed incorrectly.

battery is installed

Chlorine taste and/or The filter canisters are no •

Replace the filter canisters.

odor in the product water longer reducing chlorine

taste and odor from the

water supply.

Water dispenses The filters have been installed • A six-month change-out period is recommended. Replace both

very slowly

for too long. filter canisters.

The filter canisters have • High sediment levels can cause premature clogging. Replace both

become clogged. filter canisters.

Fittings are leaking Tubing may not be installed • Fully follow the installation instructions and be sure the tubing is

properly. free of nicks, burrs, etc., and is installed to the proper depth.

No water dispensing Filter canisters not fully installed. • Fully follow the filter replacement instructions.

from system

Troubleshooting Tips

Save time and money! Review the chart

below first and you may not need to call

for service.

Page 16

Consumer Support.

GE Appliances Website

ge.com

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day, any day of the year!

For greater convenience and faster service, you can now download Owner’s Manuals or order parts on-line.

Schedule Service ge.com

Expert GE repair service is only one step away from your door. Schedule your service at your convenience by calling 800.GE.CARES

(800.432.2737) during normal business hours.

Real Life Design Studio ge.com

GE supports the Universal Design concept—products, services and environments that can be used by people of all ages, sizes

and capabilities. We recognize the need to design for a wide range of physical and mental abilities and impairments. For details

of GE’s Universal Design applications, including kitchen design ideas for people with disabilities, check out our Website today.

For the hearing impaired, please call 800.TDD.GEAC (800.833.4322).

Extended Warranties ge.com

Purchase a GE extended warranty and learn about special discounts that are available while your warranty is still in effect. You can

purchase it on-line anytime, or call 800.626.2224 during normal business hours. GE Consumer Home Services will still be there after

your warranty expires.

Parts and Accessories ge.com

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes (VISA, MasterCard and

Discover cards are accepted). Order on-line today, 24 hours every day or by phone at 800.626.2002 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing generally should be referred

to qualified service personnel. Caution must be exercised, since improper servicing may cause unsafe operation.

Contact Us ge.com

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details including your phone number,

or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

Register Your Appliance ge.com

Register your new appliance on-line—at your convenience! Timely product registration will allow for enhanced communication and

prompt service under the terms of your warranty, should the need arise. You may also mail in the preprinted registration card included

in the packing material.

LIMITED ONE-YEAR WARRANTY

• What does this warranty cover?

— Any defect in materials or workmanship in the manufactured product.

• What does this warranty not cover?

— Filter canisters and batteries after 30 days from date of purchase.

— Service trips to your home to teach you how to use the product.

— Improper installation, delivery or maintenance.

— Failure of the product if it is abused, misused, altered, used commercially

or used for other than the intended purpose.

— Use of this product where water is microbiologically unsafe or of unknown

quality, without adequate disinfection before or after the system. Systems

certified for cyst reduction may be used on disinfected water that may

contain filterable cysts.

— Damage to the product caused by accident, fire, floods or acts of God.

— Incidental or consequential damage caused by possible defects with this

appliance, its installation or repair.

• For how long after the original purchase?

— One (1) year.

• How do I make a warranty claim?

— Return to the retailer from which it was purchased, along with a copy

of the “Proof of Purchase.” A new or reconditioned unit will be provided.

This warranty excludes the cost of shipping or service calls to your home.

This warranty is extended to the original purchaser and any succeeding owner

for products purchased for home or office use within the USA. In Alaska, the

warranty excludes the cost of shipping or service to your home or office.

Some states do not allow the exclusion or limitation of incidental or consequential

damages. This warranty gives you specific legal rights, and you may also have

other rights, which vary from state to state. To know what your legal rights are,

consult your local or state consumer affairs office or your state’s Attorney General.

Contact us at ge.com, or call toll-free at 800.952.5039 in the U.S., or 866.777.7627

in Canada.

GE Water Filtration System Warranty.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is

product exchange as provided in this Limited Warranty. Any implied warranties,

including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

Printed in the United States

16

Page 17

La section Française.

Instructions de sécurité . . . . . . . . . . .18

Vue d’ensemble

sur le système . . . . . . . . . . . . . . . . . . . . .19–23

Instructions

d’installation

. . . . . . . . . . . . . . . . . . . . .24–30

Approvisionnement en eau . . . . . . . . .24, 25

Installation de la pile . . . . . . . . . . . . . . . . . . . .29

Installation du robinet . . . . . . . . . . . . . . .25, 26

Installation du système . . . . . . . . . . . . .27, 28

Installation du tuyau . . . . . . . . . . . . . . . . . . . .29

Procédure de rinçage . . . . . . . . . . . . . . . . . . .30

Remplacement du filtre . . . . . . . . . . . . . . . . .30

Conseils de dépannage . . . . . . . . . . . .31

Soutien au consommateur . . . . . . . .32

17

L’appareil GXSL55R a été essayé et certifié

par NSF International conformément à la

norme 42 NSF/ANSI en matière de réduction

de chlore : de saveur et d’odeur et de

particules de classe I et conformément à la

norme 53 en matière de réduction de plomb,

de spores, de turbidité, d’amiante, de

mercure, de lindane, d’atrazine, de toxaphene

et 2,4-D.

L’appareil GXSV65R a été essayé et certifié

par NSF International conformément à la

norme 42 NSF/ANSI en matière de réduction

de chlore : de saveur et d’odeur et de

particules de classe I et conformément à la

norme 53 en matière de réduction de plomb,

de spores, de turbidité, d’amiante, de

mercure, de lindane, d’atrazine, de benzène

et VOC.

Page 18

18

MESURES DE SÉCURITÉ IMPORTANTES.

AVERTISSEMENT :

Veuillez lire toute la notice. Le non-respect de toutes les recommandations et règles peut

entraîner des blessures corporelles ou des dommages à la propriété.

PRÉCAUTIONS DE SÉCURITÉ

■ Utilisez votre système de filtration d’eau uniquement sur une canalisation d’eau FROIDE potable. Les cartouches de filtration ne purifient

pas l’eau, ou ne la rend pas potable.

■

N’utilisez jamais votre système en l’alimentant d’eau chaude (37,7°C [100°F] max.).

Installez uniquement votre système sur une canalisation

d’eau froide.

AVERTISSEMENT : N’utilisez jamais votre système de filtration avec de l’eau microbiologiquement polluée ou

de qualité inconnue, sans avoir monté un dispositif de désinfection adéquat en amont ou en aval du système. Vous pouvez utiliser

un système certifié de réduction des spores sur de l’eau désinfectée qui peut contenir des spores filtrables.

INSTALLATION PROPRE

Avant son utilisation, le système de filtration doit être correctement installé et positionné conformément aux instructions

d’installation.

MISE EN GARDE: Pour réduire le risque de dommages à la propriété par des fuites d’eau, installez ou rangez votre

système dans un endroit où il ne sera pas exposé au gel ou aux intempéries. L’eau gelant dans le système peut endommager celui-ci et

entraîner des fuites d’eau et des dommages à la propriété. Remplacez le filtre si ce dernier a été exposé au gel.N’essayez pas de traiter de

l’eau dont la température est supérieure à 100 degrés F.

AVERTISSEMENT : Jetez tout matériau d’emballage et matériau que vous n’aurez pas utilisé après le montage.

Les petites pièces qui restent après le montage peuvent poser un risque d’étranglement.

■ Votre système de filtration d’eau tolère jusqu’à 120 livres par pouce carré (psi) de pression d’eau. Si la pression de votre alimentation d’eau

domestique est plus élevée que 80 psi, montez un robinet réducteur de pression en amont de votre système de filtration d’eau avant de

monter votre système de filtration d’eau.

VEUILLEZ LIRE ET SUIVRE ATTENTIVEMENT CES MESURES DE SÉCURITÉ.

CONSERVEZ CES INSTRUCTIONS

Page 19

19

Directives de caractéristiques techniques.

On peut atténuer de nombreuses mauvaises odeurs et de nombreux mauvais goûts de l’eau en utilisant des cartouches de filtre en

charbon actif. On utilise principalement celles-ci pour enlever le goût et l’odeur de chlore. On peut également les utiliser pour réduire

d’autres éléments indésirables dans l’approvisionnement en eau potable, comme le plomb et les contaminants de chimie organique.

NOTE : Les filtres d’odeurs et de saveurs peuvent réduire pendant peu de temps de petits montants d’hydrogène sulfuré (odeur d’œufs

pourris), mais le charbon qu’ils contiennent est rapidement épuisé. Il faut utiliser d’autres instruments de conditionnement d’eau pour

traiter de manière continue l’hydrogène sulfuré.

Le système de filtration d’eau utilise les cartouches suivantes

Modèle GXSL55R

Filtre FQSLF (capacité de 1200 gallons)

Cartouches de filtre blanches avec une bande jaune

• Réduit la saleté, la rouille et les sédiments

• Réduit le chlore : son goût et son odeur

• Réduit le plomb

• Réduit les spores filtrables (comme les cryptosporidies et les parasites lambia)

• Réduit la turbidité

• Réduit l’amiante

• Réduit le mercure

• Réduit le lindane

• Réduit l’atrazine

• Réduit le toxaphene

• Réduit 2,4-D

• Réduit le diamètre nominal de particules de 0,5–1 micron

Ce système se conforme aux normes 42 et 53 NSF/ANSI en ce qui concerne les caractéristiques annoncées de rendement, qui sont vérifiées

et soutenues par les données obtenues lors des essais. Consultez la Feuille de données de rendement pour de plus amples détails.

Page 20

Directives de caractéristiques techniques.

Le système de filtration d’eau utilise les cartouches suivantes

Modèle GXSV65R

Filtre FQSVF

(capacité de 160 gallons)

Cartouches de filtre blanches avec une bande vert

• Réduit la saleté, la rouille et les sédiments

• Réduit le chlore : son goût et son odeur

• Réduit le plomb

• Réduit les spores filtrables (comme les cryptosporidies et les parasites lambia)

• Réduit la turbidité

• Réduit l’amiante

• Réduit le mercure

• Réduit le lindane

• Réduit l’atrazine

• Réduit le benzène

• Réduit VOC

• Réduit le diamètre nominal de particules de 0,5–1 micron

Ce système se conforme aux normes 42 et 53 NSF/ANSI en ce qui concerne les caractéristiques annoncées de rendement, qui sont vérifiées

et soutenues par les données obtenues lors des essais. Consultez la Feuille de données de rendement pour de plus amples détails.

Vue d’ensemble sur l’installation

Placez le système d’eau potable sur le tuyau d’approvisionnement d’eau froide, sous l’évier de la cuisine ou le lavabo de la salle

de bain, pour filtrer l’eau potable froide.

20

Évier

Robinet

d’approvisionnement d’eau

Robinet d’eau filtrée

Entrée

Sortie

Cartouches de filtre

Collecteur

Chaud Froid

Page 21

Feuillet de données relatives à la performance.

Cartouche FQSLF du système de filtration d’eau GE SmartWater GXSL55R

■ Ce système a été essayé selon les normes NSF/ANSI 42 et 53 pour une réduction de substances énumérées ci-dessous. La concentration des

substances indiquées dans l’eau qui entre dans le système a été réduite à une concentration inférieure ou égale à la limite permise pour l’eau

quittant le système, telle que précisée par la norme NSF/ANSI 42 et 53.

■ Le rendement réel peut varier en fonction des conditions locales d’eau.

AVERTISSEMENT : N’utilisez jamais votre système de filtration avec de l’eau microbiologiquement polluée ou de qualité

inconnue, sans avoir monté un dispositif de désinfection adéquat en amont ou en aval du système. Vous pouvez utiliser un système certifié de

réduction des spores sur de l’eau désinfectée qui peut contenir des spores filtrables.

21

Norme No42 : Effets esthétiques

USEPA Qualité Influent

Effluent % Réduction

Réduction

Paramètre MCL influent concentration moyen Moyenne Maximum Moyenne Minimum exigeante min.

Chlore — 2,0 mg/L + 10% 2,00 mg/L 0,050625 mg/L 0,06 mg/L 97,52% 97,00% >50%

T & O — — — — — — — —

Particules nominales**

— au moins 10.000 particules/mL 14.000.000 #/mL 196.666 #/mL 370.000 #/mL 99,00% 97,40% >85%

Norme No53 : Effets de santé

USEPA Qualité Influent

Effluent % Réduction

Réduction

Paramètre MCL influent concentration moyen Moyenne Maximum Moyenne Minimum exigeante min.

Turbidité 0,5 NTU*** 11 + 1 NTU*** 10,5 NTU 0,125 NTU 0,30 NTU 98,80% 97,30% 0,5 NTU

Spores 99,95% red. Min. 50.000 L 122.500 #/L <1 #/L <1 #/L >99,99% >99,99% >99,95%

Amiante 99% red. 10

7

et 108; 126,5 MF/L <0,17 MF/L <0,17 MF/L >99,99% >99,99% >99%

fibres >10 micromètres de long

Plomb, pH 6,5 0,010 mg/L 0,015 mg/L + 10% 0,150 mg/L <0,001 mg/L <0,001 mg/L >99,30% >99,30% 0,010 mg/L

Plomb, pH 8,5 0,010 mg/L 0,015 mg/L + 10% 0,150 mg/L <0,001 mg/L <0,001 mg/L >99,30% >99,30% 0,010 mg/L

Mercure, pH 6,5 0,002 mg/L 0,006 mg/L ± 10% 0,006 mg/L 0,0003 mg/L 0,0005 mg/L 95,00% 91,70% 0,002 mg/L

Mercure, pH 8,5 0,002 mg/L 0,006 mg/L ± 10% 0,0059 mg/L 0,00073 mg/L 0,0018 mg/L 88,10% 69,20% 0,002 mg/L

Atrazine 0,003 mg/L 0,009 mg/L + 10% 0,0102 mg/L 0,00105 mg/L 0,0027 mg/L 89,40% 76,30% 0,003 mg/L

Lindane 0,0002 mg/L 0, 002 mg/L + 10% 0,0019 mg/L 0,000035 mg/L 0,00016 mg/L 97,90% 91,80% 0,0002 mg/L

2,4-D 0,07 mg/L 0,200 mg/L ± 10% 0,2005 mg/L 0,017575 mg/L 0,064 mg/L 84,90% 69,00% 0,07 mg/L

Toxaphene 0,003 mg/L 0,015 ± 10% 0,015 mg/L <0,001 mg/L <0,001 mg/L >93,30% >93,30% 0,003 mg/L

*Testé utilisant un débit de 2,95 l/min; une pression de 4,2 Kg/cm2; un pH de 7,5 ± 0,5; et une temp. de 20° C ± 3° C

**Mesures en particules/mL. Les particules utilisés étaient de 0,5–1 micron.

***NTU—unités de turbidité néphélométrique

Spécifications d’opération

Capacité : certifiée jusqu’à maximum de 4542 l; jusqu’à maximum de six mois

Exigence en matière de pressión : 2,8 à 8,2 bar

Température : 0,6°–38° C

Débit : 2,95 l/min

Remplacement des cartouches de filtre/Coûts estimés de remplacement

FQSLF—Cartouche de filtre de remplacement 30–35$

Pour les pièces de remplacement, appelez sans frais le numéro 800.626.2002 (aux États-Unis),

800.663.6060 (Canada anglais), 800.361.3869 (Canada français)

Page 22

Feuillet de données relatives à la performance.

Cartouche FQSVF du système de filtration d’eau GE SmartWater GXSV65R

■ Ce système a été essayé selon les normes NSF/ANSI 42 et 53 pour une réduction de substances énumérées ci-dessous. La concentration des

substances indiquées dans l’eau qui entre dans le système a été réduite à une concentration inférieure ou égale à la limite permise pour l’eau

quittant le système, telle que précisée par la norme NSF/ANSI 42 et 53.

■ Le rendement réel peut varier en fonction des conditions locales d’eau.

AVERTISSEMENT : N’utilisez jamais votre système de filtration avec de l’eau microbiologiquement polluée ou de qualité

inconnue, sans avoir monté un dispositif de désinfection adéquat en amont ou en aval du système. Vous pouvez utiliser un système certifié de

réduction des spores sur de l’eau désinfectée qui peut contenir des spores filtrables.

Norme No42 : Effets esthétiques

USEPA Qualité Influent

Effluent % Réduction

Paramètre MCL influent concentration moyen Moyenne Maximum Moyenne Minimum

Chlore — 2,0 mg/L + 10% 2,00 mg/L <0,05 mg/L <0,05 mg/L >97,50% >97,50% >50%

T & O — — — — — — — —

Particules ** — >10.000 particules/mL 4.100.000 #/mL 76.500 #/mL 110.000 #/mL 98,10% 97,30% >85%

Norme No53 : Effets de santé

Turbidité 0,5 NTU*** 11 + 1 NTU*** 11,0 NTU 0,1 NTU 0,1 NTU 98,80% 98,20% 0,5 NTU

Spores 99,95% red. Min. 50.000/L 140.000 #/L 1 #/L 1 #/L >99,99% >99,99% 99,95%

Amiante 99% red. — 280 MF/L <0,17 MF/L <0,17 MF/L >99,00% >99,00% 99%

Plomb, pH 6,5 0,010 mg/L 0,15 mg/L + 10% 0,150 mg/L <0,001 mg/L <0,001 mg/L >99,30% >99,30% 0,010 mg/L

Plomb, pH 8,5 0,010 mg/L 0,15 mg/L + 10% 0,140 mg/L <0,001 mg/L <0,001 mg/L >99,30% >99,30% 0,010 mg/L

Mercure, pH 6,5 0,002 mg/L 0,006 mg/L ± 10% 0,0065 mg/L <0,0002 mg/L <0,0002 mg/L 96,60% >96,70% 0,002 mg/L

Mercure, pH 8,5 0,002 mg/L 0,006 mg/L ± 10% 0,0059 mg/L <0,0002 mg/L <0,0002 mg/L 96,60% >96,70% 0,002 mg/L

Lindane 0,0002 mg/L 0, 002 mg/L ± 10% 0,00193 mg/L <0,00002 mg/L 0,00005 mg/L >98,80% 98,80% 0,0002 mg/L

Benzene 0,001 mg/L 0,015 mg/L ± 10% 0,014 mg/L <0,0005 mg/L <0,0005 mg/L >96,40% >96,40% 0,005 mg/L

Atrazine 0,003 mg/L 0,009 mg/L ± 10% 0,00873 mg/L <0,0005 mg/L <0,0005 mg/L >94,10% >94,10% 0,003 mg/L

Réduction de VOC

Chloroform 0, 080 mg/L 0,300 ± 10% 0,340 mg/L 0,00098 mg/L 0,00620 mg/L 97,90% 98,20% 95%

*Testé utilisant un débit de 2,27 l/min; une pression de 4,2 Kg/cm2; un pH de 7,5 ± 0,5; et une temp. de 20° C ± 3° C

**Mesures en particules/mL. Les particules utilisés étaient de 0,5–1 micron.

***NTU—unités de turbidité néphélométrique

Spécifications d’opération

Capacité : certifiée jusqu’à maximum de 605 l; jusqu’à maximum de six mois

Exigence en matière de pressión : 2,8 à 8,2 bar

Température : 0,6°–38° C

Débit : 2,27 l/min

22

Remplacement des cartouches de filtre/Coûts estimés de remplacement

FQSVF—Cartouche de filtre de remplacement 35–40$

Pour les pièces de remplacement, appelez sans frais le numéro 800.626.2002 (aux États-Unis),

800.663.6060 (Canada anglais), 800.361.3869 (Canada français)

Concentration

maximum permise

de produit dans l’eau

Page 23

1

Les niveaux critiques d’entrée d’eau sont des concentrations d’entrée d’eau moyennes

en essais de qualification indirects.

2

μg/L signifie microgrammes par litre.

3

Un niveau maximal de produit dans l’eau n’a pas été observé mais a été établi à la limite

de détection de l’analyse.

4

Le niveau de produit maximal est établi à une valeur déterminée en essais de qualification

indirects.

5

La réduction chimique en pourcentage de produit et le niveau maximal d’eau ont

été calculés au point critique de 95 % de chloroforme tel que déterminé en essais

de qualification indirects.

6

Les résultats des essais indirects pour l’époxyde d’heptachlore a montré une réduction de 98 %.

Nous avons utilisé ces données pour calculer une concentration de présence supérieure, qui

produirait un niveau maximal de produit dans l’eau au niveau de concentration le plus grand.

Produits de chimie organique réduits par essais indirects au chloroforme

Moyen1Influent Max. Effluent

Contaminant (μg/L)

2

(μg/L)

2

Alachlor 50 1,0

3

Atrazine 100 3,0

3

Benzene 81 1,0

3

Carbofuran 190 1,0

3

Carbon Tetrachloride 78 1,8

4

Chlorobenzene 77 1,0

3

Chloropicrin 15 0,2

4

2,4-D 110 1,7

4

Dibromochloropropane (DBCP) 52 0,02

3

o-Dichlorobenzene 80 1,0

3

p-Dichlorobenzene 40 1,0

3

1,2-Dichloroethane 88 4,8

5

1,1-Dichloroethylene 83 1,0

3

cis-1,2-Dichloroethylene 170 0,5

3

trans-1,2-Dichloroethylene 86 1,0

3

1,2-Dichloropropane 80 1,0

3

cis-1,3-Dichloropropylene 79 1,0

3

Dinoseb 170 0,2

4

Endrin 53 0,59

4

Ethylbenzene 88 1,0

3

Ethylene Dibromide (EDB) 44 0,02

3

Haloacetonitriles (HAN):

Bromochloroacetonitrile 22 0,5

4

Dibromoacetonitrile 24 0,6

4

Dichloroacetonitrile 9,6 0,2

4

Trichloroacetonitrile 15 0,3

4

Moyen1Influent Max. Effluent

Contaminant (μg/L)

2

(μg/L)

2

Haloketones (HK):

1,1-dichloro-2-propanone 7,2 0,1

4

1,1,1-trichloro-2-propanone 8,2

6

0,3

4

Heptachlor (H-34, Heptox) 80 0,4

3

Heptachlor Epoxide 10,7

6

0,2

6

Hexachlorobutadiene 44 1,0

3

Hexachlorocyclopentadiene 60 0,002

3

Lindane 55 0,01

3

Methoxychlor 50 0,1

3

Pentachlorophenol 96 1,0

3

Simazine 120 4,0

3

Styrene 150 0,5

3

1,1,2,2-Tetrachloroethane 81 1,0

3

Tetrachloroethylene 81 1,0

3

Toluene 78 1,0

3

2,4,5-TP (silvex) 270 1,6

3

Tribromoacetic acid 42 1,0

3

1,2,4-Trichlorobenzene 160 0,5

3

1,1,1-Trichloroethane 84 4,6

4

1,1,2-Trichloroethane 150 0,5

3

Trichlorothylene 180 1,0

3

Trihalomethanes (includes): 300 15

Chloroform (surrogate chemical)

Bromoform

Bromodichloromethane

Chlorodibromomethane

Xylenes (total) 70 1,0

3

Les essais ont été accomplis dans des conditions normales de laboratoire, le rendement réel peut varier.

NOTE : Les substances réduites ne sont pas nécessairement dans votre eau. Vous devez entretenir le filtre conformément aux instructions du fabricant , et suivre ces instructions pour remplacer

les cartouches.

AVERTISSEMENT : N’utilisez jamais l’appareil avec de l’eau qui n’est pas saine sur le plan microbiologique ou qui est de qualité inconnue sans désinfection adéquate en amont et en aval du système.

Les systèmes certifiés pour réduire les spores peuvent être utilisés sur des eaux désinfectées qui contiennent des spores filtrables.

Feuillet de données relatives à la performance.

23

Page 24

24

Instructions

Système de filtration monté sur robinet –

d’installation

GXSL55R et GXSV65R

RECOMMANDATIONS IMPORTANTES

D’INSTALLATION

AVERTISSEMENT — Lisez tout

le manuel. Si vous ne suivez pas toutes les directives

et les règles, vous pouvez occasionner des blessures

corporelles et des dommages matériels.

•

Vérifiez vos codes de plomberie auprès de votre

service de travaux publics. Vous devez vous

y conformer pour monter votre système

de filtration d’eau.

OUTILS ET MATÉRIAUX NÉCESSAIRES

POUR L’INSTALLATION

• Un tournevis Phillips

• Deux (2) clés anglaises

• Une perceuse électrique et une mèche de perceuse

pour percer un trou de 1-1/2 po (de la catégorie

requise) si un trou de montage est nécessaire pour

le robinet

• Mètre-ruban

• Si votre conduite principale d’eau est un tuyau

rigide, vous aurez besoin d’une bague de

compression et peut-être d’autres articles

de plomberie pour terminer l’installation.

MISE EN GARDE — Pour éviter

d’endommager l’évier, consultez un plombier ou un

installateur qualifié pour trouver la bonne procédure

de percement du trou. Des mèches de perceuse

spéciales peuvent être requises pour la porcelaine

ou l’acier inoxydable.

PIÈCES COMPRISES AVEC LE PRODUIT

• L’ensemble du système de filtre d’eau, comprenant

les vis de montage

• Un adaptateur d’eau d’alimentation

• Un mécanisme de robinet avec moniteur de base

électronique et tuyau

RACCORD D’APPROVISIONNEMENT

D’EAU FROIDE

A. INSTALLATION PRÉFÉRÉE

(Utilisant le robinet existant d’approvisionnement d’eau

de l’évier de cuisine et un tuyau du robinet flexible)

Un branchement typique au moyen du raccord

d’approvisionnement d’eau fourni est illustré ci-dessous.

1. Fermez le robinet d’arrêt qui se trouve juste en

face du tube d’approvisionnement et ouvrez les

robinets pour drainer l’eau de la conduite d’eau

froide de l’évier.

2. Retirez l’écrou qui relie le robinet d’eau froide au tube

d’approvisionnement. Une fuite d’eau peut se produire.

NOTES :

• Assurez-vous de couper l’alimentation d’eau

et d’ouvrir un robinet pour drainer la conduite.

• Vérifiez que le joint est posé dans le raccord

d’approvisionnement d’eau.

3. Vissez à la main le raccord d’approvisionnement d’eau

sur le robinet d’eau froide. Assurez-vous que le joint

est en place, comme illustré, avant l’assemblage final.

Terminez le serrage avec une clé à molette. Veillez à

ne pas trop serrer et ne pas endommager le filetage.

Assurez-vous que le raccord rapide 1/4 po ne repose

pas contre le mur pour éviter de courber le raccordement

de la conduite d'approvisionnement. Un quart de tour en

serrant ou desserrant peut s’avérer nécessaire pour

éviter cette situation.

4. Rebranchez la conduite du robinet au raccord.

5. Installez la tuyauterie. (Voir la section Installation du tuyau.)

Goujon de

robinet d’eau

froide

Conduite

d’eau froide

Raccord

d’approvisionnement d’eau

Tube de 1/4 po

à l’entrée du

filtre à eau

Robinet d’arrêt d’eau froide

Joint

Fig. 1

Page 25

Instructions d’installation

25

RACCORD D’APPROVISIONNEMENT

D’EAU FROIDE

(SUITE)

B. INSTALLATION À DOMICILE FACULTATIVE

(là où la réglementation le permet)

Robinet-vanne à étrier : Le robinet-vanne doit

pouvoir se raccorder à la conduite 1/4 po fournie

avec le système. Non fournie avec le produit;

demandez le produit auprès de votre quincaillerie

ou centre de rénovation local. Le robinet-vanne

à étrier nécessite habituellement un tuyau de

dia. ext. de 1/2 po ou plus.

NOTE : Les codes de l’État du Massachusetts exigent

que l’installation soit faite par un plombier agréé et

ils interdisent l’utilisation d’un robinet-vanne à étrier.

Pour procéder à l’installation, se référer au code de

plomberie 248-CMR du Commonwealth of Massachusetts.

1. Coupez l’alimentation d’eau froide et installez le robinet-

vanne à étrier selon le produit choisi. (Assurez-vous

d’observer les instructions d’installation du fabricant.)

DANGER —

S’il faut percer un trou dans

le tuyau, utilisez une perceuse à main alimentée par

batterie pour vous protéger contre l’électrocution.

N’UTILISEZ PAS UNE PERCEUSE ÉLECTRIQUE.

2. Ouvrez le robinet-vanne à étrier une fois l’installation

complète du système terminée.

C. INSTALLATION FACULTATIVE

(Pour installation avec conduite rigide entre le

robinet d’approvisionnement et le robinet d’évier)

Option 1

1. Déconnectez la conduite du robinet

d’approvisionnement et du robinet d’évier.

2. Procurez-vous une conduite flexible adaptée

à votre tuyauterie.

3. Installez la conduite flexible.

4. Retournez à la section A, rubrique Installation

préférée, étape 3.

Option 2

1. Procurez-vous des raccords à compression

pour raccorder la conduite rigide.

2. Procurez-vous tout autre raccord nécessaire pour

raccorder les raccords à compression à l’adaptateur

de conduite d’approvisionnement.

3. Déconnectez le tuyau du robinet d’approvisionnement.

4. Coupez le tuyau pour qu’il s’adapte à la longueur

de l’assemblage des raccords et de l’adaptateur.

5. Installez le raccord à compression sur le tuyau.

6. Retournez à la section A, rubrique Installation

préférée, étape 3.

NOTE : Le matériel décrit ci-dessus n’est pas inclus

avec le produit.

INSTALLATION DU ROBINET

Assurez-vous qu’il y ait suffisamment de place

au-dessous et au-dessus de l’évier pour faire les

branchements nécessaires. Avant de commencer,

assurez-vous qu’il y ait suffisamment de place pour

la base de robinet et l’unité. Choisissez l’un des

emplacements suivants pour installer le robinet :

A. Dans un trou existant de distributeur de savon

ou de douchette.

B. Dans un trou à percer en haut de l’évier.

C. Dans un trou à percer dans le comptoir, près de

l’évier.

NOTES :

•

Assurez-vous que la base de robinet soit bien plate

contre la surface de l’emplacement choisi de

manière à ce que le joint placé entre la base et la

surface de l’emplacement choisi soit bien étanche.

• Laissez suffisamment d’espace à l’arrière du

robinet au cas où vous devriez l’enlever.

Étapes d’installation (voir l’illustration cidessous pour plus de clarté)

1. Si vous devez faire un trou, faites un trou de 11/2 po

de diamètre. Assurez-vous d’utiliser la bonne

procédure pour percer la porcelaine ou l’acier

inoxydable. Vous pouvez avoir besoin d’une

mèche spéciale de perceuse. Consultez un

plombier qualifié pour trouver la bonne procédure.

NOTE : Le perçage de l’acier inoxydable engendre

souvent des rebords coupants qui peuvent percer

le tube. Prenez soin de ne pas vous couper ni

endommager le tube.

2. Enlevez la corps et la base du robinet en tournant

la base dans le sens antihoraire.

3. Alignez le joint de façon à recouvrir le trou

entièrement. Placez ensuite le boulon à ailettes

de la base dans le trou.

Base

Évier

Joint

Boulon à ailettes

Page 26

Instructions d’installation

26

INSTALLATION DU ROBINET (SUITE)

4. Serrez le boulon à ailettes jusqu’à bien fixer la base

en place pour l’empêcher de branler ou de tourner.

5. Insérez le tube d’eau par en haut à travers la base

du robinet. Poussez ensuite le tube dans le raccord

dans le bas du corps du robinet. Il devrait rentrer sur

environ 3/4 po. Tirez légèrement sur le tube pour

vérifier sa solidité.

6. Poussez le corps du robinet vers le bas dans sa

base puis tournez dans le sens horaire jusqu’à

l’enclencher en place.

NOTE : Vous pouvez installer le robinet pour que

sa poignée se trouve à droite ou à gauche.

Si vous la souhaitez à droite, placez la poignée

à l’arrière de la base avant de tourner dans le

sens horaire.

Pour la gauche, placez la poignée au devant

de la base avant de tourner dans le sens horaire.

Corps du robinet

Base

Évier

Joint

Boulon à ailettes

Robinet Robinet

Poignée du robinet à DROITE Poignèe du robinet à GAUCHE

INSTALLATION DU ROBINET (SUITE)

Pour retirer le robinet :

1. Coupez l’alimentation d’eau.

2. Retirez le corps du robinet de la base en le

tournant dans le sens antihoraire et en tirant

le robinet vers le haut.

Robinet

Page 27

Instructions d’installation

27

INSTALLATION DU SYSTÈME DE MONTAGE

Choisissez un emplacement sous l’évier pour monter le système. Cet emplacement doit être facilement accessible,

avec espace libre entre le bas de les cartouches de filtre et le plancher ou le bas de l’armoire; tout espace inférieur

rendra difficile l’enlèvement de les cartouches de filtre (Fig. 5). Prévoyez suffisamment d’espace des deux côtés du

système pour brancher les tuyaux.

INSTALLATION DE VIS

1. Enlevez ce gabarit du manuel afin d’installer plus facilement.

2. Le haut des ouvertures du gabarit doivent être placées au moins à 43,2 cm (17 po) au-dessus du plancher ou

du bas de l’armoire où vous devez monter le système (Fig. 4 et 5). NOTE : Si vous avez un écart moins important,

vous aurez des problèmes à enlever la cartouche à filtre parce qu’elle touchera le plancher.

3. Collez le gabarit au mur, à l’aide de ruban adhésif, à l’endroit où vous devez mettre les vis.

Mettez les vis dans le mur, en laissant un espace de 0,5 cm (3/16 po) libre entre la tête de la vis et le mur (percez des

trous pilotes le cas échéant) (Fig. 6).

43,2 cm

(17 po)

12,7 cm

(5 po)

Bas de l’armoire ou plancher

Gabarit pour les emplacements de trous à l’arrière du système de filtration

Fig. 4

43,2 cm

(17 po)

12,7 cm (5 po)

Vis

Vis

0,5 cm

(3/16 po)

Fig. 6

Fig. 5

Mur

Page 28

Instructions d’installation

28

INSTALLATION DU SYSTÈME DE MONTAGE (SUITE)

Montage du système aux vis installées dans le mur

1. Enlevez l’emballage rétrécissable du système de filtre.

2. Pendez le système aux vis précédemment installées à l’aide des ouvertures situées à l’arrière de l’appareil (Fig. 7).

3. Si la tête des vis ne glisse pas dans la fente du haut, dévissez la vis d’un quart de tour et essayez à nouveau.

4. Si le système est trop lâche, resserrez les vis d’un quart de tour et essayez à nouveau jusqu’à ce qu’il soit bien

rapproché.

Min.

43,2 cm

(17 po)

12,7 cm (5 po)

Fig. 7

Page 29

Instructions d’installation

INSTALLATION DU TUYAU

1. Mesurez 19 mm (3/4 po) à partir de chaque

extrémité de chaque morceau restant de tuyau

(extrémité du robinet et extrémité d’entrée d’eau)

et marquez avec un crayon (Fig. 8). (Vérifiez que le

tuyau soit bien rond, lisse, bien coupé, bien indenté,

sans des bords tranchants. Il peut s’avérer

nécessaire de couper le tuyau de nouveau.)

2. Localisez les raccords des tuyaux en la bas

du collecteur.

3. NOTE : L’eau circule de gauche à droite. Le robinet

d’entrée de l’eau est à gauche et celui de sortie de

l’eau est à droite. Si vous ne suivez pas cette

disposition, vous aurez des fuites quand vous

enlèverez les cartouches de filtre.

4. Poussez fortement le tuyau dans chaque raccord

du collecteur jusqu’à ce que la ligne soit au niveau

du collier de raccord. (Si le tuyau est enlevé, recoupez

l’extrémité, mesurez, marquez et ré-insérez).

Le tuyau doit être bien inséré pour éviter les fuites

(Fig. 9). (Pour enlever le tuyau : Pressez et tenez

la bague blanche; tirez le tuyau pour l’enlever.)

19 mm

(3/4 po)

Fig. 8

MAUVAIS

Entrée à partir du robinet

d’alimentation d’eau

Sortie vers

le robinet

3

4

"

Engagement de

19 mm (3/4 po)

(tube de 3/8 po)

Bague blanche

(NE PAS ENLEVER)

Ligne d’insertion

Insérez le tube

Fig. 9

INSTALLATION DU TUYAU (SUITE)

5. Tirez légèrement le tuyau pour assurer un joint

étanche.

6. Installez l’autre extrémité du tuyau depuis le côté

entrée d’eau vers l’adaptateur d’eau d’alimentation.

NOTE : Inspectez les extrémités du tuyau pour

être certain qu’il n’y a pas d’imperfections et que

la coupe est d’équerre. Il peut s’avérer nécessaire

de couper le tuyau de nouveau.

INSTALLATION DE LA PILE

1. Retirez le couvercle de la lentille de la base

du robinet. Agrippez-le des deux côtés et tirez

vers l’avant.

2. Installez une pile CR2032 3V avec le côté “+”

vers le bas dans le logement de pile.

3. La lumière ambre clignotera 5 fois, indiquant une

bonne installation et remise à zéro du système.

4. Glissez le couvercle de lentille dans la base

de robinet.

5. Normalement, la lumière est éteinte. Après 6 mois

d’utilisation, la lumière ambre se remet à clignoter

toutes les 30 secondes, indiquant qu’il est temps de

changer la cartouche de filtre.

NOTE : La lumière ambre peut s’arrêter de clignoter

si on la laisse clignoter longtemps. Pour assurer un

bon fonctionnement, il faut changer la pile à chaque

changement de filtre.

Base du robinet

Couvercle de lentille

Pile avec le côté “+” vers le bas

29

INLETOUTLET

Page 30

Instructions d’installation

30

REMPLACEMENT DES CARTOUCHES

DE FILTRE

La lumière amber située sur la base du robinet

clignotera toutes les 30 secondes pour indiquer qu’il

faut changer le filtre. Cela se produit tous les 6 mois.

POUR ENTRETENIR CORRECTEMENT LE SYSTÈME,

CHANGEZ LE FILTRE LORSQUE NÉCESSAIRE.

1. Enlevez les cartouches de filtre du collecteur en

faisant tourner les cartouches vers la gauche

environ 1/3 de tour (Fig. 11). NOTE : Un peu d’eau

peut sortir du tuyau entre le filtre et le robinet.

Vous pouvez utiliser une serviette pour l’éponger.

2. Enlevez le feuillet situé en haut de les nouvelles

cartouches de filtre de remplacement. Installez les

nouvelles cartouches dans le collecteur en la tournant

vers la droite environ 1/3 de tour, jusqu’à ce que les

marques s’alignement soient alignées et le filtre

s’arrête. NE SERREZ PAS TROP. Le filtre se soulève

quand vous le tournez.

3. Tournez la poignée du robinet pour purger

le système, en permettant à l’air emprisonné

de s’échapper.

NOTE : Le système peut faire du bruit pendant

cette procédure.

4. Vérifiez qu’il n’y ait pas de fuite d’eau autour

du système.

5. Quand l’eau commence à couler du robinet, laissez

le système couler pendant 4 gallons (ou 5 minutes)

pour éliminer toute fibre de charbon présente.

6. Fermez le robinet et vérifiez autour du système qu’il

n’y a pas de fuite.

7. Enlevez le tiroir à pile et remettez en place la

batterie pour remettre à zéro la minuterie (consultez

la section Installation de la pile pour bien mettre

en place).

Remplacement des cartouches de filtre/

Coûts estimés de remplacement

FQSLF—Cartouche de filtre de remplacement 30–35$

FQSVF—Cartouche de filtre de remplacement 35–40$

Pour les pièces de remplacement, appelez sans frais

le numéro 800.626.2002 (aux États-Unis), 800.663.6060

(Canada anglais), 800.361.3869 (Canada français).

PROCÉDURE DE RINÇAGE

Chaque fois que le système de filtration d’eau GE est

exposé à de l’eau de qualité inconnue, on devrait jeter

les cartouches de filtre et rincer le système.

AVERTISSEMENT : N’utilisez jamais

votre système de filtration avec une eau

microbiologiquement insalubre ou de qualité inconnue

sans avoir un dispositif de désinfection adéquate en

amont ou en aval de votre système. Les systèmes

homologués pour la réduction des kystes peuvent être

utilisés sur une eau désinfectée pouvant contenir des

kystes filtrables.

Circonstances qui peuvent nécessiter un rinçage

du système :

• Notification de la nécessité de faire bouillir l’eau

• Inondation du système de filtration d’eau GE

• Inutilisation prolongée

Méthode de rinçage du système de filtration

d’eau GE :

1. Voir la section Remplacement des cartouches

de filtre et suivez les étapes 1–5.

Pour

installer

Pour

enlever

Fig. 11

Page 31

31

Avant d’appeler un réparateur…

Problème Causes possibles Correctifs

L’eau contient des petites Les nouvelles cartouches de filtre • Ouvrez le robinet d’eau filtrée et laissez ces premières particules de

particules noires contiennent du charbon actif. charbon sortir de la cartouche. Fermez le robinet quand l’eau

est limpide.

L’eau a des bulles d’air Il y a de l’air dans le système • L’air disparaîtra après que l’eau ait coulé pendant un instant.

et est trouble après l’installation.

L’indicateur lumineux Il y a eu six mois d’usage. C’est • Remplacez les cartouches de filtre et la pile dans la base de robinet.

scintille sur la base la durée de vie maximale de les

de robinet cartouches de filtre.

L’indicateur lumineux C’est normal. • Ne clignote pas avant 6 mois de fonctionnement.

sur la base de robinet

Il faut peut-être remplacer la pile. • Normalement, la lumière est éteinte. La lumière clignote toutes les

ne clignote pas

30 secondes pour indiquer qu’il faut changer le filtre. Cela se produit

tous les 6 mois.

• Remplacez la pile. L’indicateur clignotera rapidement 5 fois pour

indiquer une bonne installation et un bon fonctionnement.

L’indicateur lumineux sur Il est possible que la pile ait • Observez les marques d’orientation sur le tiroir à pile.

la base de robinet ne

besoin d’être remplacée, ou vous Installez la pile avec le côté “+” par en bas.

fonctionne pas quand vous

pouvez l’avoir mal installée.

installez une nouvelle pile

Il y a un goût et une La cartouche de filtre ne réduit •

Remplacez les cartouches de filtre.

odeur de chlore dans plus le taux de chlore, le goût et

l’eau du produit l’odeur de l’approvisionnement

d’eau.

L’eau coule Les filtres ont étés installés • Nous recommandons de changer le filtre tous les six mois.

très lentement

trop longtemps. Remplacez les cartouches de filtre.

Les cartouches de filtre •Des niveaux de sédiments importants peuvent occasionner

sont bouchées. un engorgement prématuré. Remplacez les cartouches de filtre.

Les raccords coulent Il est possible que les tuyaux • Suivez bien les instructions d’installation et assurez-vous que

ne soient pas bien installés. les tuyaux sont exempts d’ébréchures, bavures, etc., et soient installés

à la bonne profondeur.

Il n’y a pas d’eau qui Les cartouches de filtre ne sont • Suivez bien les instructions de remplacement du filtre.

sorte du système

pas complètement installés.

Conseils de dépannage

Économisez du temps et de l’argent! Consultez d’abord le tableau

ci-dessous et vous pourrez peut-être éviter de faire appel à un réparateur.

Page 32

GARANTIE LIMITÉE D’UN AN

• Que couvre la garantie?

— Tout défaut de matériel ou de main d’oeuvre du produit.

• Q’est-ce qui n’est pas couvert par la garantie?

— Les cartouches de filtre et les piles après trente jours à partir de la date d’achat.

— Les déplacements à votre domicile pour vous enseigner comment utiliser le produit.

— Une installation, remise ou entretien incorrecte.

— Une panne du produit causée par un abus d’utilisation, une mauvaise utilisation, toute

modification, exploitation commerciale ou une utilisation du produit dans un but non

prévu.

— Utilisation de ce produit lorsque l’eau est microbiologiquement impure ou de qualité

inconnue sans qu’une désinfection adéquate n’ait eu lieu avant l’entrée et sortie dans le

circuit. Les systèmes homologués pour une réduction des microbes peuvent être utilisés

après désinfection de l’eau pouvant contenir des microbes filtrables.

— Tout dommage causé au produit par accident, incendie, inondation ou acte de Dieu.

— Tout dommage fortuit ou indirect causé par des défauts éventuels de cet appareil,

son installation ou les réparations effectuées.

• Quelle est la durée de la garantie après l’achat?

—Un an.

• Comment dois-je faire ma réclamation?

— Ramenez le produit au magasin où vous l’avez acheté avec une exemplaire de

la “Preuve d’achat”. Une unité neuve ou remise à neuf sera fournie. Cette garantie exclut

les coûts d’expédition ou les déplacements de service à votre domicile.

Cette garantie couvre l’acheteur original et tout propriétaire subséquent des produits

achetés à des fins résidentielles ou de bureau à l’intérieur des États-Unis. En Alaska, cette

garantie exclut le coût d’expédition ou les appels de service à votre maison ou bureau.