Page 1

Water Softening

Model GXSS20B

GE Appliances

system

7227938 215C1044P016 49-50062 08-00 JR

www.geappliances.com

Safety Instructions

Proper installation . . . . . . . . . . . . .3

Installation Instructions

Drain connections . . . . . . . . . . .7–8

Important recommendations . . . .4

Installation instructions . . . . . . .4–6

Planning and location . . . . . . . . . .5

Programming the timer . . . . . . . . .9

Sanitizing . . . . . . . . . . . . . . . . . . . .10

Specifications and dimensions . .11

Step-by-step instructions . . . . .7–11

Tools and materials required . . . .5

Unpacking and inspection . . . . . .4

Operating Instructions, Tips

Breaking a salt bridge . . . . . . . . . .13

Cleaning nozzle and

venturi assembly . . . . . . . . . . . . . .13

Face plate timer features . . . . . . .14

Regenerating the system . . . .15, 16

Service . . . . . . . . . . . . . . . . . . . . . .12

Water softener system . . . . . .12–13

Care and Cleaning

Cleaning out iron . . . . . . . . . . . . .17

Salt storage level and refilling . . .17

Troubleshooting Tips . . . . .18–20

Consumer Services

Important phone

numbers . . . . . . . . . . . . .Back Cover

Parts list/catalog . . . . . . . . . . .21–24

Warranty (U.S.) . . . . . . . . . . . . . .25

Warranty (Canada) . . . . . . . . . . .26

Owner’s Manual &

Installation Instructions

Modèle GXSS20B

Modelo GXSS20B

La section française commence à la page 27

La sección en español empieza en la página 53

Adoucisseur d’Eau

Descalcificación de Agua

Sistema de

Système

Manuel du Propriétaire et

Directives D’Installation

Manual del Propietario y

Instrucciones de Instalación

Page 2

2

FOR YOUR RECORDS

Write the model and serial numbers here:

#

#

You can find them on the sump bracket.

Staple sales slip or cancelled check here.

Proof of the original purchase date is needed to obtain service under the warranty.

Inside you will find many helpful hints on how to use and maintain your water system properly.

Just a little preventive care on your part can save you a great deal of time and money over the life of

your system. A video has been included with the product containing important use and care instructions.

READ THIS MANUAL

IF YOU NEED SERVICE

You’ll find many answers to common problems in the

Before You Call For Service

section. If you review

our chart of

Troubleshooting Tips

first, you may not need to call for service at all.

If you do need service, you can relax knowing help is only a phone call away. A list of toll-free customer

service numbers is included in the back section of this manual.

OR

Visit our Website at:

www.geappliances.com

IMPORTANT!

Fill out the Consumer Product Registration Card.

Two easy ways to register your appliance!

■ Through the internet at www.geappliances.com

■ Complete and mail the enclosed Product Registration Card

GE & You, A Service Partnership.

Page 3

3

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of

electric shock, property damage or personal injury.

SAFETY PRECAUTIONS

■ Check and comply with your state and local codes.

You must follow these guidelines.

■Use care when handling the water softening

system. Do not turn upside down, drop, drag, or

set on sharp protrusions.

■Water softening systems using sodium chloride

(salt) for regeneration add sodium to the water.

Persons on sodium restricted diets should consider

the added sodium as part of their overall intake.

Potassium chloride can be used as an alternative to

sodium chloride in your softener.

■

The water softening system works on 24 volt-60 Hz

electrical power only.

Be sure to use only the

included transformer.

■Transformer must be plugged into an indoor

120 volt, grounded outlet only.

■Use clean water softening salts only, at least 99.5%

pure. NUGGET, PELLET or coarse SOLAR salts

are recommended. Do not use rock, block,

granulated or ice cream making salts. They contain

dirt and sediments, or mush and cake, and will

create maintenance problems.

■Keep the salt hole cover in place on the softener

unless servicing the unit or refilling with salt.

WARNING:

Do not

use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before or after

the system.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

PROPER INSTALLATION

■Install or store where it will not be exposed to

temperatures below freezing or exposed to any type

of weather. Water freezing in the system will break

it. Do not attempt to treat water over 100°F.

■

Do not

install in direct sunlight. Excessive sun

heat may cause distortion or other damage to

non-metallic parts.

■Properly ground to conform with all governing

codes and ordinances.

■Use only

lead-free solder and flux

for all sweat-solder

connections, as required by state and federal codes.

■

The water softening system requires a minimum

water flow of three gallons per minute at the inlet.

Maximum allowable inlet water pressure is 125 psi.

If daytime pressure is over 80 psi, nighttime pressure

may exceed the maximum. Use a pressure

reducing

valve to reduce the flow if necessary.

■

Softener resins may degrade in the presence of

chlorine above 1 ppm. If you have chlorine in excess

of this amount, you may experience reduced resin

life. In these conditions, you may wish to consider

purchasing a GE point-of-entry household filtration

system with a chlorine reducing filter.

WARNING:

Discard all unused parts and

packaging material after installation. Small

parts remaining after the installation could

be a choke hazard.

This water softening system must be properly installed and located in accordance with the Installation

Instructions before it is used.

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

Page 4

Read entire manual. Failure to follow all guidelines and rules could cause personal injury or property damage.

• Before you begin installation, read these Installation Instructions completely. Then, obtain all the materials

and tools you will need to make the installation. Failure to properly install the softener voids the warranty.

• Check local codes. The installation must conform to them.

•

In the Commonwealth of Massachusetts, Plumbing Code 248 CMR shall be adhered to.

Consult with your licensed plumber.

• Use only lead-free solder and flux for all sweat-solder connections, as required by state and federal codes.

• Connect the softener to the main water supply pipe

before

or

ahead of the

water heater.

DO NOT RUN HOT WATER

THROUGH THE SOFTENER.

Temperature of water passing through the softener must be less than 120° F.

• Use care when handling the softener. Do not turn upside down, drop, drag, or set on sharp protrusions.

• Maximum allowable inlet water pressure is 125 psi. If daytime pressure is over 80 psi, nighttime pressure

may exceed the maximum. Use a pressure reducing valve if necessary. (Adding a pressure reducing valve

may reduce the flow.)

• The softener works on 24 volt-60 Hz electrical power only. Be sure to use the included transformer.

Be sure the electric outlet and transformer are in an inside location to protect from wet weather.

• See

Where to Install the Softener

section for more details.

WARNING:

Do not use with water that is microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system. The water should be tested periodically to verify

that the system is performing satisfactorily.

Small parts remaining after the installation could be a choke hazard. Discard safely.

4

Installation instructions.

CAUTION:

Certain plumbing skills are needed for installation. If you are unsure about any part

of the installation of this product, consult a professional plumber.

Unpacking and Inspection

The softener is shipped in one master carton. The softener is completely assembled at the factory,

except as required at installation.

Be sure to check the entire softener for any shipping damage or parts loss. Also note damage to the

shipping cartons. Contact the transportation company for all damage and loss claims. The manufacturer

is not responsible for damages in transit.

Small parts, needed to install the softener, are on a skin-packed cardboard piece. To avoid loss of the

small parts, keep them on the skin-pack until you are ready to use them.

Important Installation Recommendations

Page 5

5

• Place the softener as close as possible to a sewer drain, or other acceptable drain point or standpipe.

• It is recommended to keep outside faucets on hard water to save soft water and salt.

• Do not install the softener in a place where it could freeze.

Freeze damage is not covered by the warranty.

• Do not install the softener where it would block access to the water heater or access to the main water shutoff.

• Put the softener in a place where water damage is least likely to occur if a leak develops. The manufacturer

will not repair or pay for water damage.

• A 120 volt electric outlet is needed to plug in the included transformer. The softener has a 10 foot power

cable. If the outlet is remote (up to 100 feet), use 18 gauge wire to connect.

Be sure the electric outlet and

transformer are in an inside location, to protect from wet weather.

Be sure the outlet is unswitched to prevent

accidental shutoff.

• If installing in an outside location, you must take the steps necessary to assure the softener, installation

plumbing, wiring, etc., are as well protected from the elements (sunlight, rain, wind, heat, cold),

contamination, vandalism, etc., as when installed indoors.

•

Keep the softener out of direct sunlight.

The sun’s heat may distort non-metallic parts and may damage

the electronics.

Where to Install the Softener

• In and out fittings included with the softener are 3/4″nominal copper sweat tubes. To maintain full valve

flow, 1″pipes to and from the softener fittings are recommended. You should maintain the same, or larger,

pipe size as the water supply pipe, up to the water softener inlet and outlet.

• Use the included bypass valve to install the softener. The bypass valve allows you to turn off water to the

softener for servicing, but still have water in the house pipes. The in and out fittings referred to above connect

to the bypass valve with the included nuts and washers.

• Use copper, brass or galvanized pipe and fittings. Some codes may also allow CPVC plastic pipes.

• If additional drain hose is needed for valve and salt tank drains, it can be ordered from GE Parts at

800.626.2002.

• If a rigid valve drain is needed to comply with plumbing codes, you can buy the parts needed (Fig. 4A)

to

connect a 1/2″copper tubing or plastic pipe drain.

• Clean nugget or pellet water softener salt is needed to fill the brine tank, see

Step 8

in the

Step-by-Step

Installation Instructions.

Tools and Materials Required for Installation

You must first decide how to run in and out pipes to the softener. Look at the house main water pipe at the

point where you will connect the softener. Is the pipe soldered copper, glued plastic, or threaded galvanized?

What is the pipe size?

WARNING:

Use only lead-free solder and flux to prevent lead poisoning.

See

Typical Installation Illustration,

Fig. 1. Use this as a guide when planning your particular installation.

Be sure to direct the incoming hard water supply to the softener valve inlet fitting.

The valve is marked

IN

and

OUT.

See illustration on page 6 to help you prepare.

Plan How You Will Install the Softener

Page 6

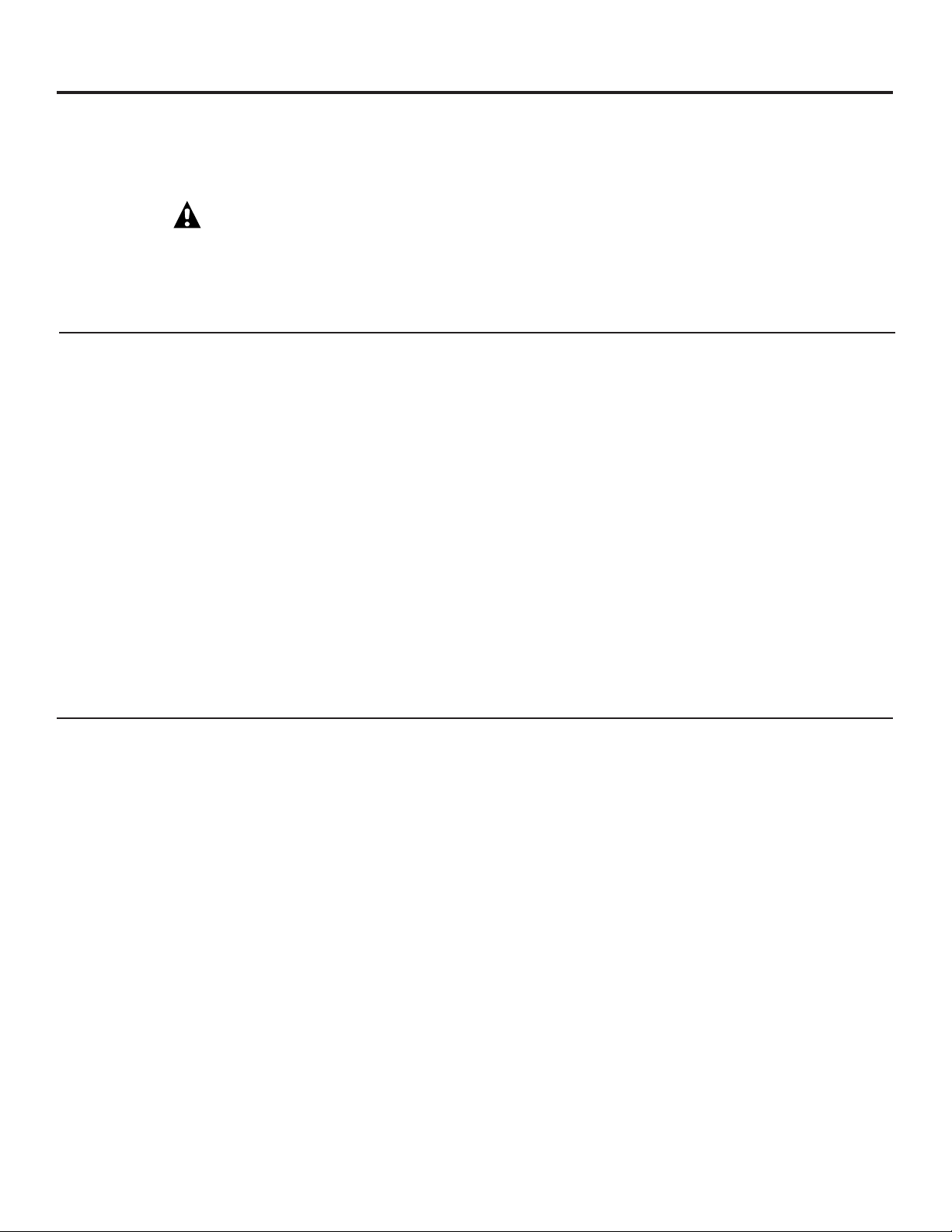

Fig. 1

Installation instructions.

Typical Installation Illustration

Optional 3-Valve Bypass Installation Illustration

Fig. 2

6

Adapters for this installation are not supplied with the softener.

To order these adapters, call GE Parts 800.626.2000.

Ask for part number WS60X10006.

Soft water

Hard water to

outside faucets

MAIN WATER PIPE

Hard water

Installation nut (2)

Copper tube, 3/4″(2)

Washer (2)

Bypass Valve

• Pull out for soft water service

• Push in for bypass

NOTE:

Threads on the bypass valve

are 1″male pipe. If 1″pipes are

needed, do not use the copper tubes

and nuts included. Buy 1″ pipe thread

female adapter, and plumb directly to

1″ threads.

INLET

Brinewell

NOTE:

See

Drain Hose

Connections

section.

SALT

GOES HERE

Salt hole

cover

removed

24V transformer

120-volt outlet

Hard water

Soft water

From softener outlet

To softener inlet

CROSS-OVER

Use if water supply flows from the left.

Include single or 3-valve bypass.

Hard water

Soft water

From softener outlet

To softener inlet

CROSS-OVER

Use if water supply flows from the left.

Include single or 3-valve bypass.

MAIN WATER PIPE

Soft water

Hard water

Copper tube, 3/4″(2)

Washer (2)

Installation adapter (2) (see above)

INLET

NOTE:

Threads on the installation adapters are 1″male pipe. If 1″ pipes are

needed, do not use the copper tubes and nuts included. Buy 1″pipe thread

female adapter, and plumb directly to 1″threads on installation adapters.

24V transformer

120-volt outlet

Bypass valve

Hard water to outside faucets

Inlet valve

Outlet valve

Nut (2)

3-valve bypass system

For soft water service:

• Open the inlet and outlet valves

• Close the bypass valve

For bypass hard water:

• Close the inlet and outlet valves

• Open the bypass valve

Union (2) (not supplied)

Page 7

Step-by-step installation instructions.

• Turn off the gas or electric supply to the water heater, in the possibility that the

water heater may be drained while draining pipes.

• Turn off the water supply to pipes to be cut and drain the house water pipes.

• Open both hot and cold faucets.

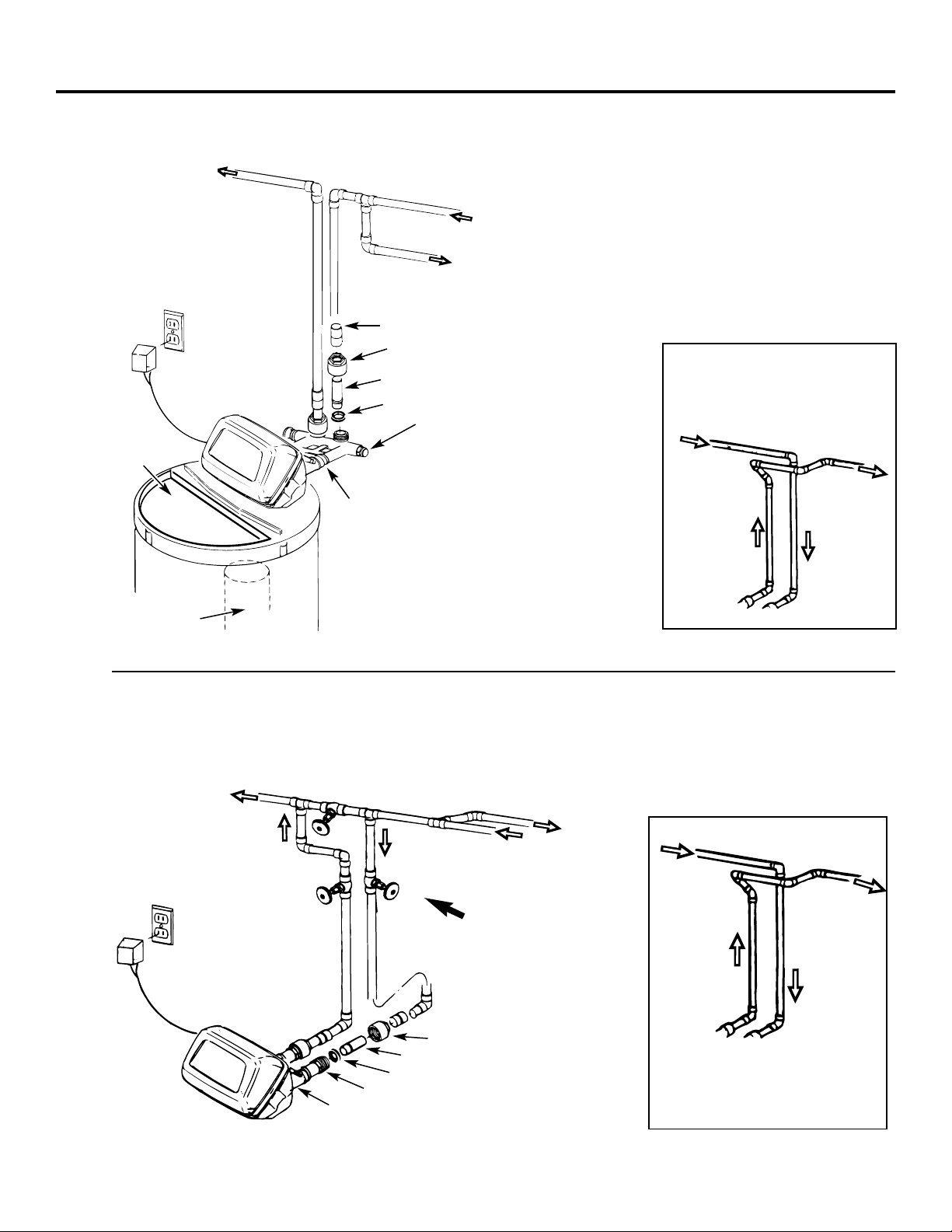

1. INSTALL BYPASS VALVE

• Remove plastic shipping plug and wire from valve outlet.

• Push the bypass valve (lubricate o-ring seals with silicone grease) into both ports

of the valve as shown in Fig. 3A.

• Snap the 2 large plastic clips in place, from the top, down as shown in Figures 3A

and 3B. Be sure they snap into place. Pull on the bypass valve to make sure it is

held securely in place.

2. MOVE THE SOFTENER ASSEMBLY INTO INSTALLATION POSITION:

• Be sure the installation surface is level and smooth. Sharp objects under the tank

may puncture it. If needed, place the tank on a section of 3/4″thick (minimum)

plywood. Then, place shims under the plywood as needed to level the softener.

3. PLUMB IN AND OUT PIPES TO AND FROM SOFTENER:

CAUTION: Observe all of the following cautions as you connect inlet and

outlet plumbing. See Fig. 1 or 2.

• BE SURE INCOMING HARD WATER SUPPLY IS DIRECTED TO THE

SOFTENER VALVE INLET PORT. If house water flow is from the left, use a

plumbing cross-over as shown in Fig. 1.

• If making a soldered copper installation, do all sweat soldering before

connecting pipes to the bypass valve. Torch heat will damage plastic parts.

• When turning threaded pipe fittings onto plastic fittings, use care not to cross-

thread.

• Use pipe joint compound on all external pipe threads.

• Support inlet and outlet plumbing in some manner (use pipe hangers) to keep

the weight off of the valve fittings.

4. CONNECT AND RUN THE VALVE DRAIN HOSE:

• Use the provided drain hose (20′length included) to attach to the valve drain

fitting. To keep water pressure from blowing the hose off, use a hose clamp to

secure in place.

• Locate the other end of the hose at a suitable drain point (floor drain, sump,

laundry tub, etc.) that terminates at the sewer. Check and comply with local codes.

IMPORTANT: If more drain hose is needed, it should be ordered from GE Parts

at 800.626.2002. The water softener will not work if water cannot exit this hose

during regenerations.

• Tie or wire the hose in place at the drain point. High water pressure will cause it

to whip during the back-wash and fast rinse cycles of regeneration. Also provide

an air gap of at least 1–1/2″between the end of the hose and the drain point. An

air gap prevents possible siphoning of sewer water into the softener, if the sewer

should “back-up.”

• If raising the drain hose overhead is required to get to the drain point, do not

raise higher than 8′above the floor. Elevating the hose may cause a back-pressure

that could reduce brine draw during regenerations.

Fig. 3A

Fig. 3B

Fig. 3C

Fig. 4

NOTE: Be sure the turbine

and support are firmly in

place in the valve outlet.

Blow into the valve port

and observe the turbine

for free rotation.

Drain

fitting

on

valve

Valve

drain

hose

FLOOR DRAIN

Turbine

Valve outlet

Turbine shaft

and support

IN

OUT

Turn bypass valve

upside down to

connect to floor

level plumbing

Valve body inlet or

outlet

Bypass valve

(push all the way in)

Clip

END

VIEW

Clip

Outlet

Inlet

O-ring seal goes into

the outer groove only.

The clip snaps into the

inner groove (see

below).

Bypass valve

NOTE:

Threads on the

bypass valve are 1″male

pipe. If 1″pipes are needed,

do not use the copper tubes

and nuts included. Buy 1″

pipe thread female adapter,

and plumb directly to 1″

threads.

SIDE

VIEW

Tie or wire hose

in place

STANDPIPE

LAUNDRY TUB

SUMP

7

Clamp

1

1

⁄2″air gap

Page 8

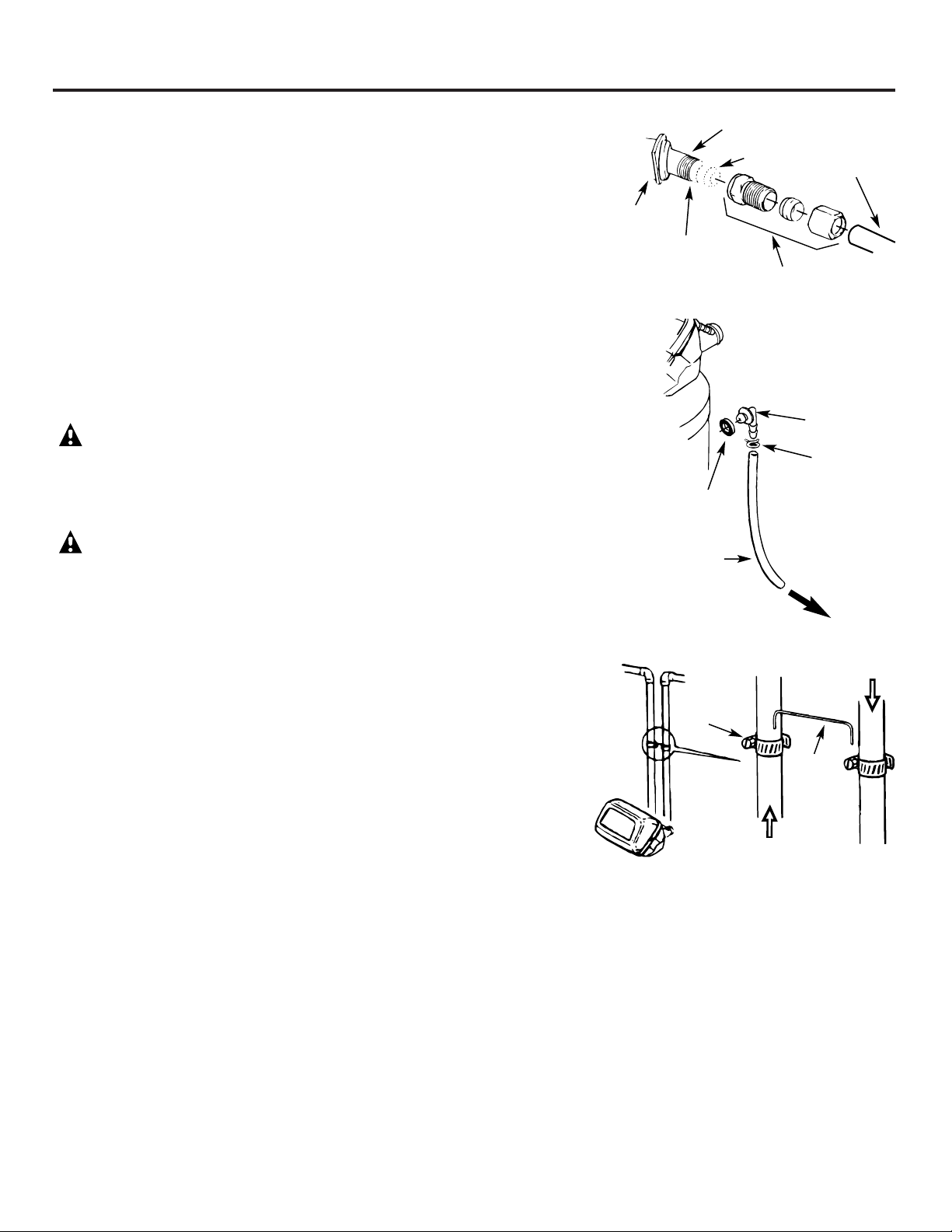

Step-by-step installation instructions.

8

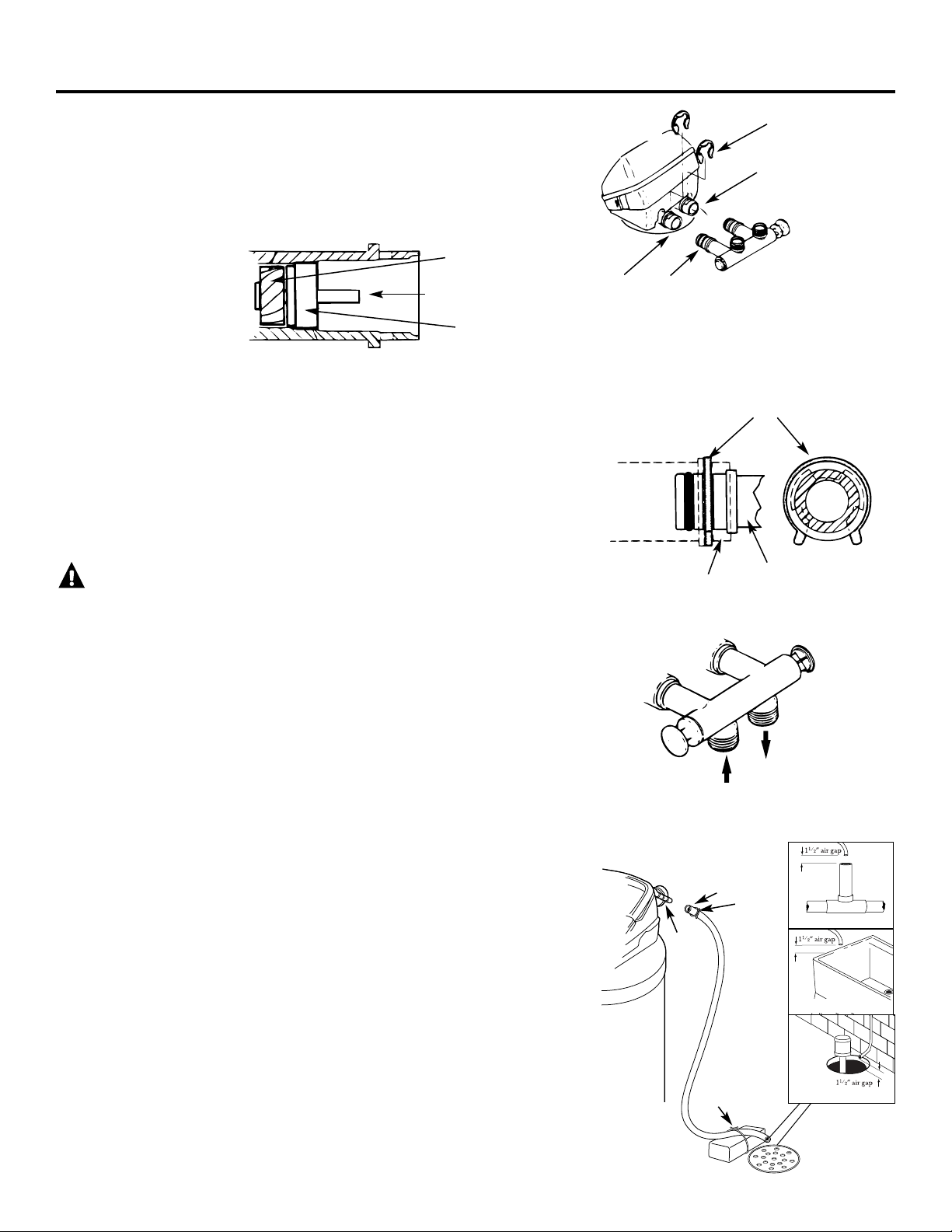

4A. CONNECTING A RIGID VALVE DRAIN TUBE

• To adapt a copper drain tube to the softener, use a hacksaw to cut the barbed end from the

drain fitting as shown in Fig. 4A. Rotate the drain fitting so the cutting blade clears the valve

housing to prevent damage to valve. Buy a compression fitting (1/4″female pipe thread x

1/2″O.D. tube) and needed tubing from your local hardware store.

5. INSTALL THE BRINE TANK OVERFLOW FITTINGS AND HOSE

• Insert the rubber grommet into the 3/4″ diameter hole in the brine tank sidewall as shown

in Fig. 5.

• Push the end of the hose adapter elbow into the grommet as shown in Fig. 5.

• Attach a length of hose (use remaining hose from Step 4) to the hose adapter elbow. Use a

hose clamp to hold it in place.

• Locate the other end of the hose at the drain point. DO NOT ELEVATE this hose higher

than the elbow on the brine tank.

IMPORTANT: DO NOT TEE OVERFLOW HOSE TO VALVE DRAIN HOSE.

NOTE: This drain is for safety only. If the cabinet (brine tank) should over-fill with water, the

excess is carried to the drain.

6. INSTALL GROUNDING CLAMPS AND WIRE

DANGER: Failure to properly attach ground wire could result in electrical shock.

• If plumbing is metal, to maintain electrical ground continuity in the house cold water

piping, install the included ground clamps as shown in Fig. 6. Be sure the pipes are

clean under the clamps to assure good contact.

7. FLUSH PIPES, EXPEL AIR FROM SOFTENER, AND TEST YOUR INSTALLATION

FOR WATER LEAKS:

CAUTION: To avoid water or air pressure damage to softener inner parts, be sure to

do the following steps in exact order.

A. Fully open 2 cold soft water faucets nearby the softener.

B. Place bypass valve in “bypass” position by pushing the stem inward.

C. Fully open the house main water pipe shutoff valve. Observe a steady flow from both

faucets opened in step A, above.

D. Place bypass valve in the “service” position EXACTLY as follows. KEEP SOFT WATER

FAUCETS OPEN.

SLOWLY pull or slide the valve stem (out) toward the service position pausing several

times to allow the softener to pressurize slowly.

E. After about 3 minutes, open a HOT water faucet for 1 minute, or until all air is expelled,

then close. NOTE: If water appears cloudy or has salty taste,allow to run for several more

minutes, or until clear.

F. Close all water faucets.

G. Check your plumbing work for leaks and fix right away if any are found. Be sure to

observe previous caution notes.

H. Turn on the gas or electric supply to the water heater. Light the pilot, if applicable.

Fig. 4A

Fig. 5

Fig. 6

Clamp (2)

Ground

wire

From valve outlet

To valve inlet

To sewer

drain

Overflow drain hose

Hose clamp

Grommet

Clip

1/4″NPT threads

Barbs

1/2″O.D.

copper tube (not

furnished)

Cut barbs

from drain

fitting

Compression fitting, 1/4″

NPT X 1/2″O.D. tube (not

furnished)

Do not connect to valve

drain hose.

8. ADD WATER AND SALT TO THE BRINE TANK:

• Lift the cabinet (brine tank) cover. Add about 3 gallons of water into the tank. Do not add into the brinewell.

• Fill tank with NUGGET, PELLET or coarse SOLAR water softener salt with a purity of 99.5% or higher. Do not use rock, block, granulated, and

ice cream-making salts, or salt with iron-removing additives (except for Diamond Crystal® Red•Out® brand salt). Salt storage capacity is

approximately 200 lbs. Keep the salt hole cover in place on the softener unless servicing the unit or refilling with salt.

NOTE: If the softener is installed in a humid basement or other damp area, it is better to fill the tank with less salt, more frequently. Eighty to 100

lbs. of salt will last for several months, depending on water hardness, family size and water softening system model.

9. CONNECT TO ELECTRICAL POWER:

• If transformer wiring is not visible at the back of the control head, remove control cover. DO NOT PULL ON OR DISCONNECT WIRING.

Locate the long wire with“U” shaped connectors on one end. Route this wire through the rear of the control housing. Replace the control

cover.

• Fasten the 2 power cable lugs (“U” shaped connectors) to the 2 screws on the transformer, and tighten the screws. Then, plug the transformer

into the electrical outlet.

• The softener works on 24 volt-60Hz electric power. The included transformer changes standard 120 volt AC house power to 24 volts. Plug the

transformer into a 120 volt outlet only. Be sure the outlet is always live so it can not be switched off by mistake.

10. PROGRAM THE TIMER:

• See Programming the Timer section.

Hose adapter

Page 9

9

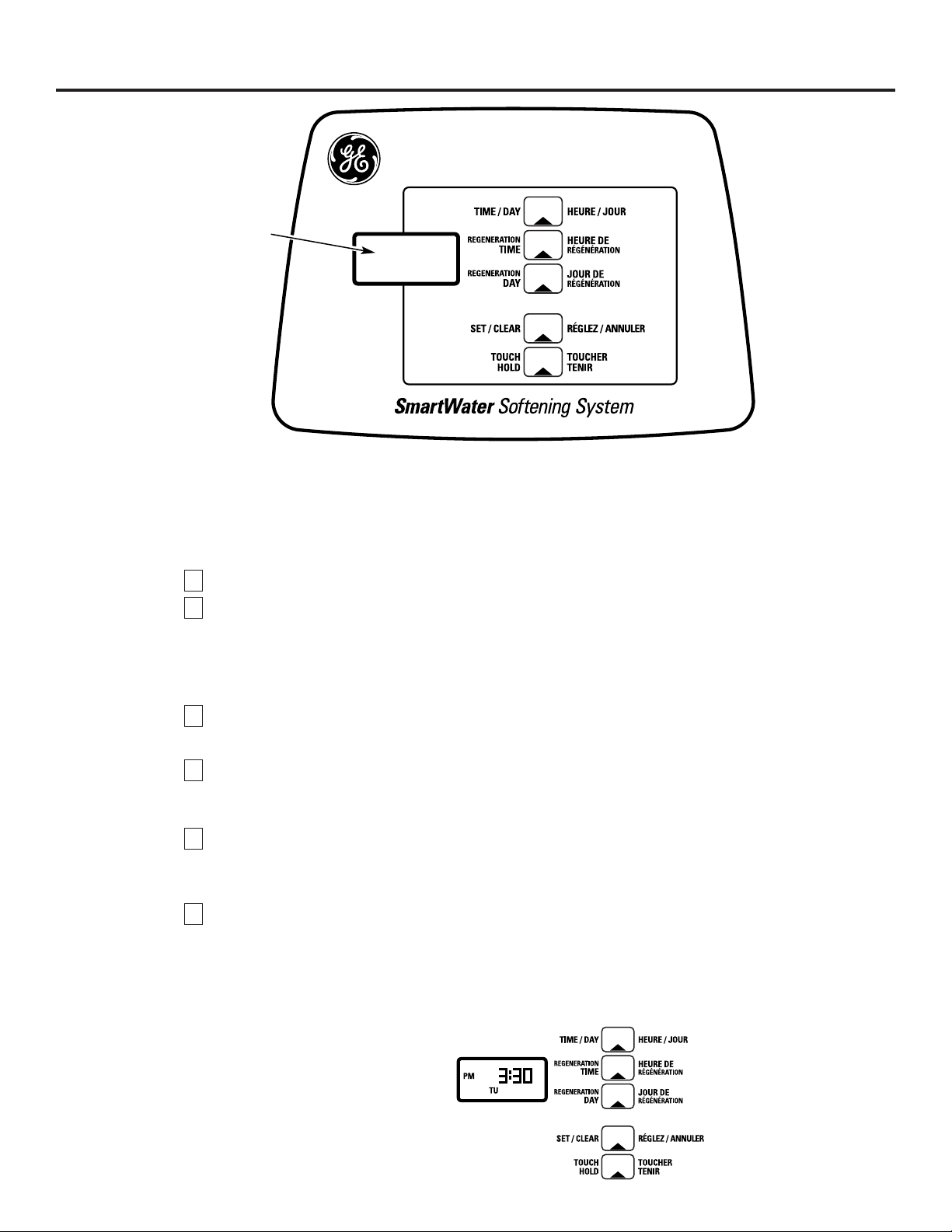

Programming the Timer

Set the timer:

When the transformer is plugged into electrical outlet, 12:00AM, SUnday will begin to flash in the time display.

Set the time of day and present day of week as follows:

A.

Set the time of day:

Press the

TIME/DAY

b

utton once and the hour display will begin to flash.

Press the

SET/CLEAR

b

utton until the present hour of the day shows in the display. Be sure AMshows

for morning hours, or PMfor afternoon and evening hours.

NOTE:

Press

SET/CLEAR

button and quickly release to move the hour display ahead 1 at a time to

the correct hour. Or, hold the

SET/CLEAR

button to move the display ahead 2 hours each second,

to the correct hour.

Press the

TIME/DAY

b

utton once to steady the hour display, and minutes begin to flash.

Repeat

Step A. 2

to set the correct minutes.

Press the

TIME/DAY

b

utton again to steady the minute display (day will begin flashing). Fig. 7 shows

the timer set at 3:30 PM.

B.

Set the present day of the week:

Press the

SET/CLEAR

b

utton to set the present day of the week in the display.

NOTE:

Press

SET/CLEAR

b

utton and quickly release to move the day display 1 at a time. Or hold the

SET/CLEAR

button to move the day display ahead 2 days each second.

Press the

TIME/DAY

button again to steady the entire display. Fig. 7 shows the timer set at

TUesday.

No other settings are needed

after installing your water softener. The softener is factory set to regenerate

every Monday, Wednesday and Saturday (beginning at 2:00 AM). For most families, this gives enough soft

water for their needs. However, if you want the softener to regenerate at a different time, or on different

days, or to set for the most efficiency, see

About the Water Softener System

section.

2

1

4

3

2

1

See the

Operating

section for other

timer controls and features.

Fig. 7

EXAMPLE: This drawing shows the

present time of day at 3:30 PM,

and the present day on TUesday.

Display

Page 10

Step-by-step installation instructions.

10

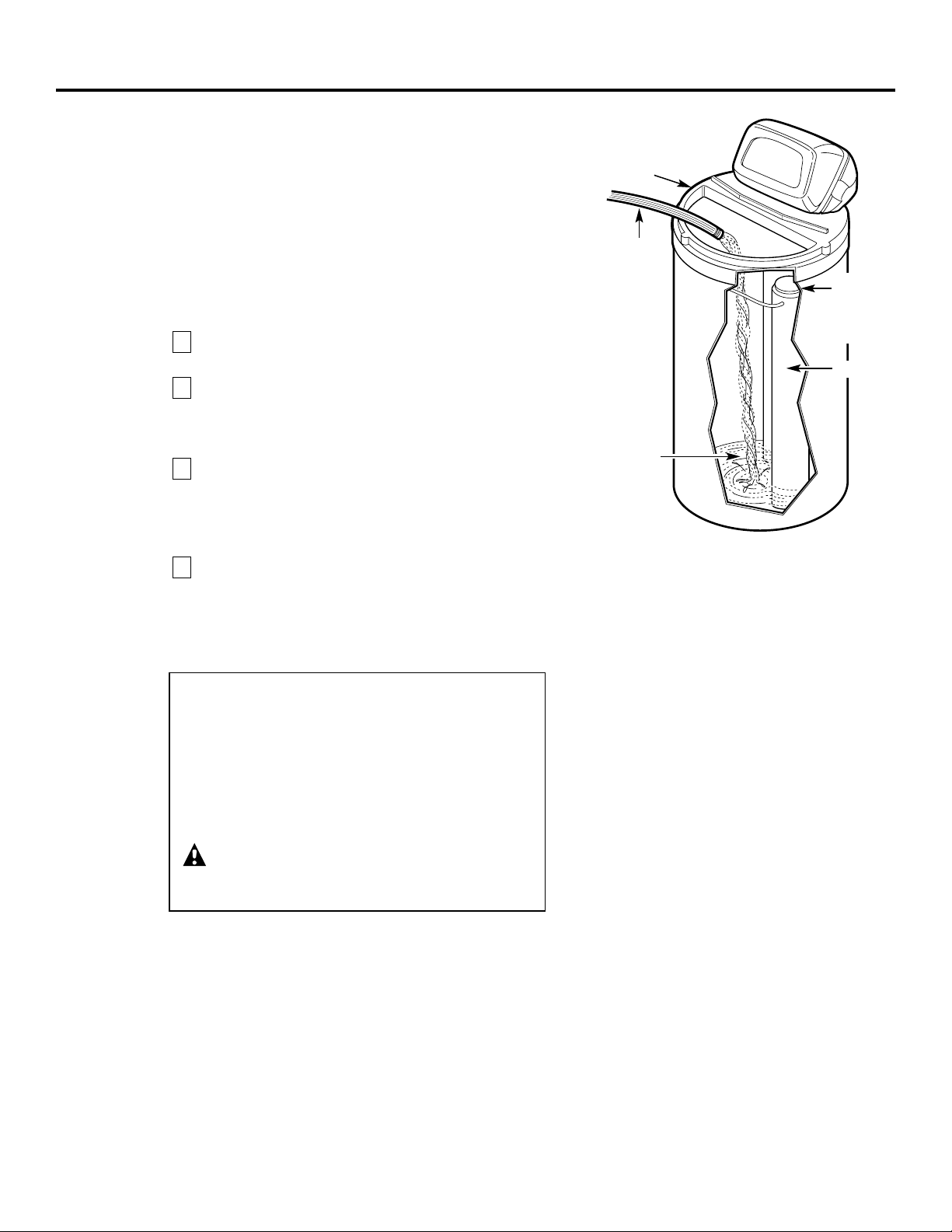

Sanitizing Procedures

Care is taken at the factory to keep your softener clean and

sanitary. Materials used to make the softener will not infect

or contaminate your water supply and will not cause

bacteria to form or grow. However, during shipping,

storage, installing and operating, bacteria could get into

the softener. For this reason, sanitizing as follows is

suggested when installing.

NOTE: Sanitizing is recommended by the Water Quality

Association for disinfecting.

Be sure to complete all installation steps, including

timer programming.

Remove the brinewell cover (see Fig. 8) and pour

about 3/4 ounce (11⁄2 tablespoons) of common 5.25%

household bleach (Clorox, Linco, BoPeep, White Sail,

Eagle, etc.) in the softener

brinewell

.

Press the

TOUCH/HOLD

button and hold for 3 seconds

to start a recharge. This first recharge does

several

things: fills the salt tank to the water level needed,

gets

all the air out of the resin tank, makes the resin bed

ready for service. See the

Recharging

section.

If after sanitation, water from house faucet tastes salty

or has a slight color, this is a preservative from the

resin tank. Turn on the cold soft water faucets and

drain for a few minutes or until clear.

NOTE: This recharge takes about 2 hours.

4

3

2

1

Fig. 8

Salt hole cover

removed

Hose

Brinewell

Brinewell

cover (remove

and add about

3/4 oz. bleach)

Water, about

3 gallons

NOTE:

When the above sanitizing regeneration is over,

your house COLD water supply is fully soft immediately.

However, your water heater is filled with hard water and

as hot water is used, it will refill with soft water. When all

the hard water is replaced in the water heater, hot only

and mixed hot and cold water will be fully soft. If you

want totally soft water immediately, after the above

regeneration, drain the water heater until the water

runs cold.

WARNING:

If you do drain the water heater, use

extreme care as the hot water could cause burns.

Turn the water heater off prior to draining.

Page 11

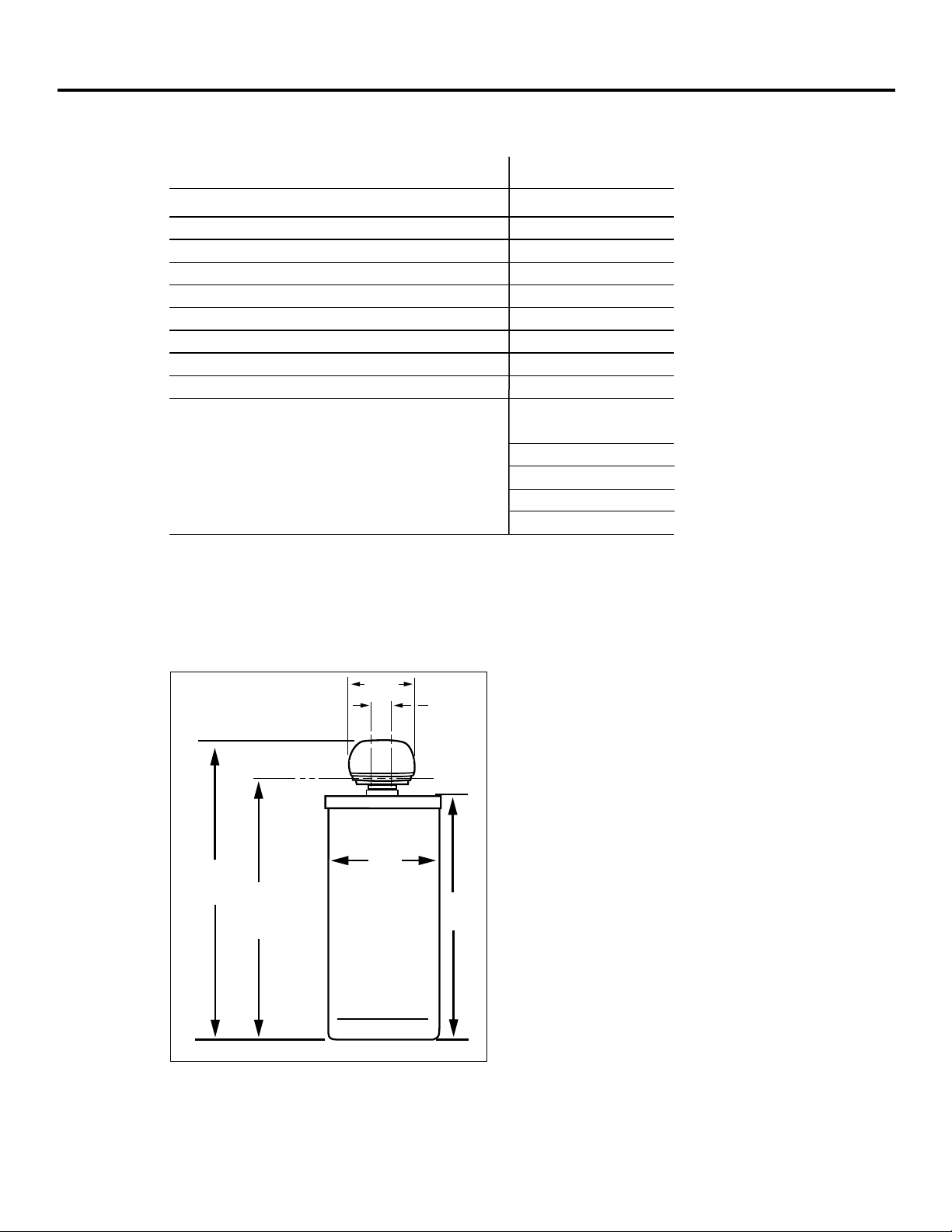

(See rating decal, located

Rated Capacity* on the Softener)

Amount of high capacity resin (lbs/cu. ft) 31.2/.6

Resin tank nominal size (in., dia. x height) 8 x 40

Service flow rate (gpm) 7.5

Water supply maximum hardness (gpg) 50

Water supply maximum clear water iron (ppm)** 3

Water pressure limits (min.-max. psi) 20-125

Pressure drop at rated service flow (psig) 15

Water temperature maximum (°F) 120

Water supply minimum flow rate (gpm) 3

Regeneration cycle flow rates (gpm)

Fill (flow to brine tank) .3

Brining .19

Brine Rinse .12

Backwash 1.8

Fast Rinse 1.8

}

(flow to drain)

11

Specifications/Dimensions

This system conforms to WQA S-100 for the specific capacity claims as verified and substantiated by test data.

* Testing was performed using pellet grade sodium chloride as the regenerant salt.

** Extent of iron removal may vary with conditions. Use of Diamond Crystal® Red•Out® or Super Iron Out® will

improve iron removal. Refer to

Cleaning Iron Out of the Water Softening System

section.

11

1

⁄2″

3

3

⁄8″

OUT

INLET

INLET-OUTLET

48

3

/4″

41

1

⁄4″

18

1

⁄4″

40

1

⁄2″

Page 12

Service

When the

water softening system

is providing soft water, it is called “Service.” During service,

hard water flows from the house main water pipe into the

water softening system

. Inside the

water softening system

resin tank is a bed made up of thousands of tiny, plastic resin beads.

As hard water passes through the bed, each bead attracts and holds the hard minerals. This is

called ion-exchanging. It is much like a magnet attracting and holding metals. Water without

hard minerals (soft water) flows from the

water softening system

and to the house pipes.

After a period of time, the resin beads become coated with hard minerals and they have to be

cleaned. This cleaning is called regeneration, or recharge. Regeneration is started at 2:00 AM

(factory setting) by the

water softening system

control, and consists of five stages or cycles.

These are

FILL, BRINING, BRINE RINSE, BACKWASH

and

FAST RINSE

.

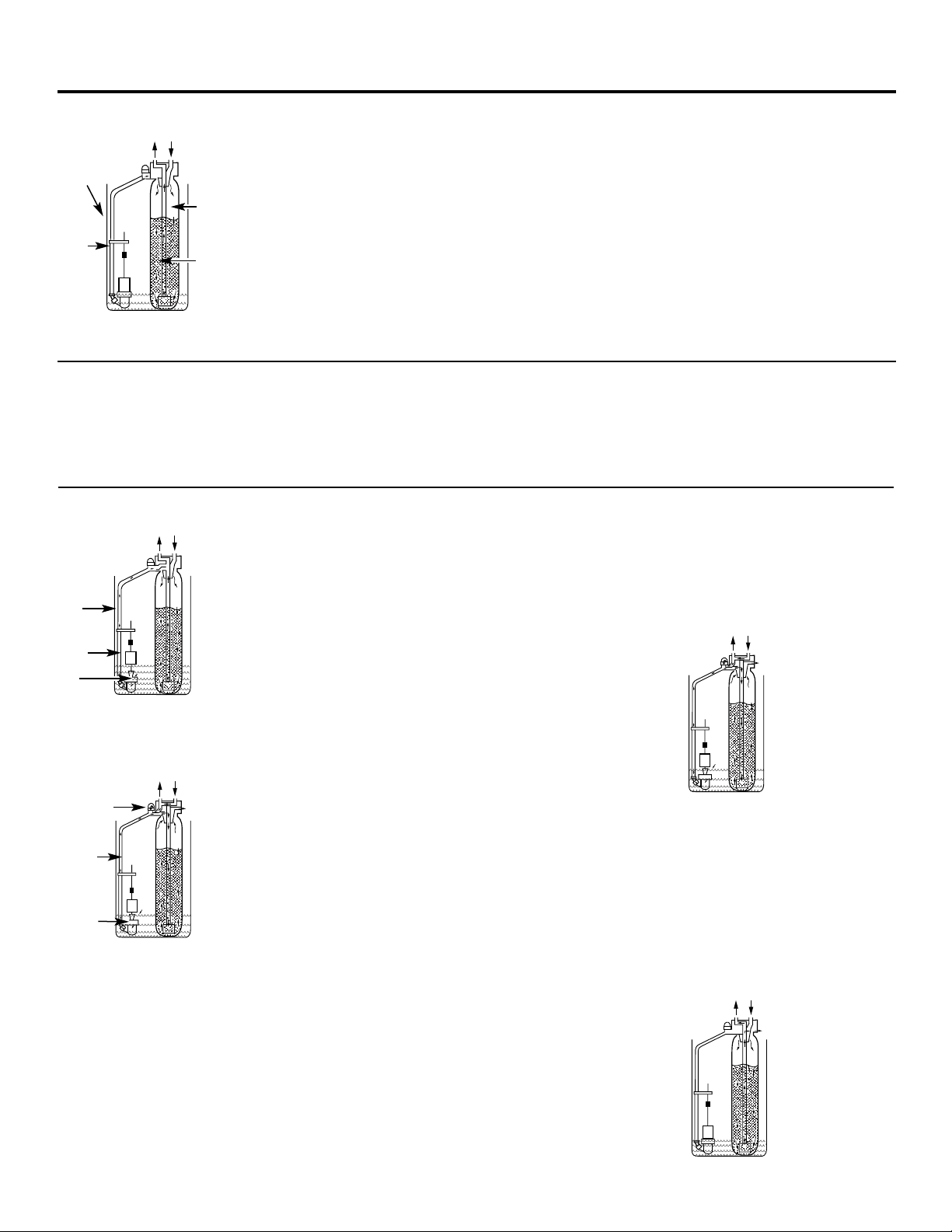

About the water softener system.

12

Automatic Hard Water Bypass During Regeneration

For emergency needs, hard water is available

to the home during the regeneration cycles.

However, you should avoid using HOT water

because the water heater will fill with the

hard water.

Fill Backwash

Salt dissolved in water is called brine. Brine is

needed to clean the hard minerals from resin

beads. To make the brine, water flows into the

salt storage area during the fill stage as shown.

Brining

During brining, brine travels from the salt

storage area into the resin tank. Brine is the

cleaning agent needed to remove hard

minerals from the resin beads. The hard

minerals and brine are discharged to

the drain.

The nozzle and venturi create a suction to

move the brine, maintaining a very slow

rate to get the best resin cleaning with the

least salt.

Brine Rinse

After a pre-measured amount of brine is

used, the brine valve closes. Water continues

to flow in the same path as during brining,

except for the discontinued brine flow. Hard

minerals and brine flush from the resin tank

to the drain.

During backwash, water travels upthrough

the resin tank at a fast flow rate, flushing

accumulated iron, dirt, and sediments from

the resin bed and to drain.

Fast Rinse

Backwash is followed by a fast flow of water

down

through the resin tank. The fast flow

flushes brine from the bottom of tank, and

packs the resin bed.

After fast rinse, the

water softening system

returns to soft water service.

Soft water

OUT

Salt storage

tank (salt

not shown)

Brine

valve

Hard water

IN

Resin

tank

Resin

bed

Soft water

OUT

Hard water

IN

Salt

storage

tank

Fill

water

Brine

valve

Hard water

bypass OUT

Nozzle &

venturi

Hard water

IN

Brine

valve

Brine

Drain

Drain

Hard water

bypass OUT

Hard water

IN

Drain

Soft water

OUT

Hard water

IN

Page 13

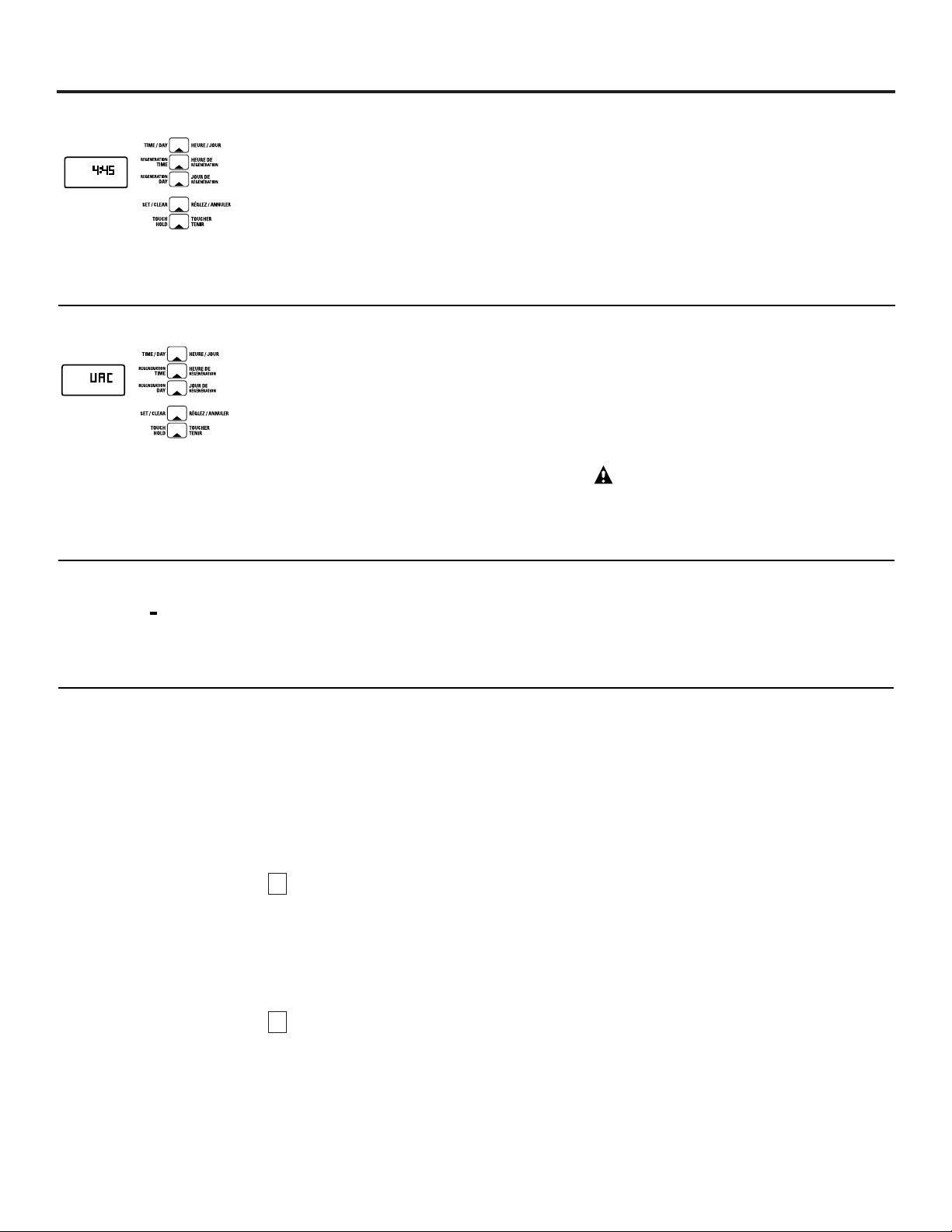

Cleaning the Nozzle and Venturi Assembly

A clean nozzle and venturi is needed for the water softening system to

work properly.

This small unit makes the suction to move brine from

the salt storage area to the resin tank during regeneration. If it

becomes plugged with sand, dirt, etc., the water softening system

will not work and you will get hard water.

To get to the nozzle and venturi, remove the water softening system

top cover. Be sure the water softening system is in service cycle (no

water pressure at nozzle and venturi). Then, while holding the

nozzle and venturi housing with one hand, remove the cap. Lift out

the screen support and screen, then the nozzle and venturi. Wash

and rinse the parts in warm water until clean. If needed, use a small

brush to remove iron or dirt. Also check and clean the gasket.

NOTE:

Some models have a small flow plug located in the nozzle and

venturi, and/or a small cone shaped screen in the housing. Be sure

to check and clean these parts, if your model is so equipped.

Carefully replace all parts in the correct order. Lightly lubricate the

o-ring seal with clean silicone grease or petroleum jelly and place in

position.

Install and tighten the cap, by hand only. Do not over-tighten

the cap or housing.

IMPORTANT: Be sure small holes in the gasket are

centered directly over the small holes in the nozzle and

venturi housing.

*Install with numbered side up, concave side down.

Cap

O-ring seal

Screen support

Screen

Screen

Nozzle & Venturi

Nozzle & Venturi housing

Gasket

*Fill Flow plug

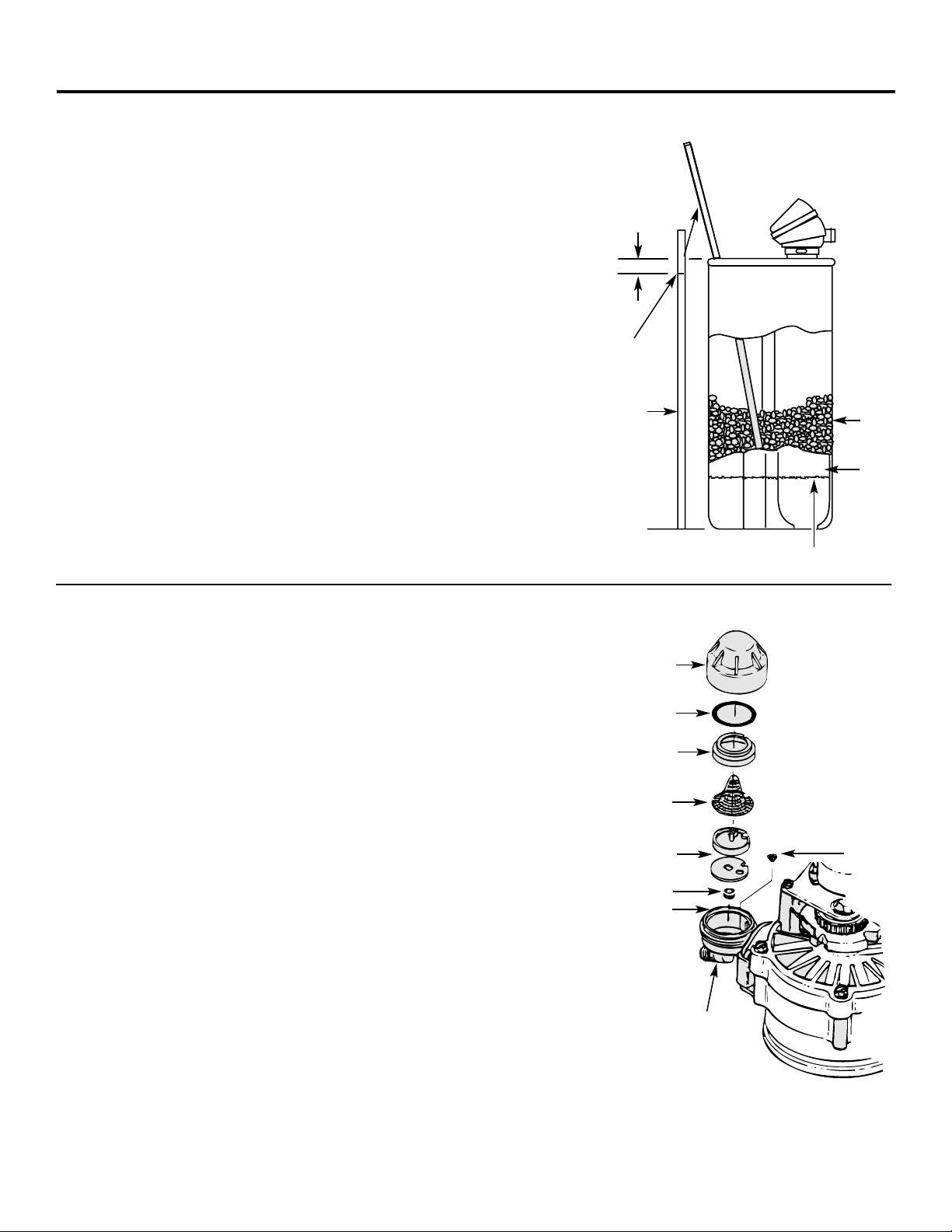

Breaking a Salt Bridge

Sometimes, a hard crust or salt bridge forms in the salt storage area.

It is usually caused

by high humidity or the wrong kind of salt. When

the salt bridges, an empty space forms

between the water and salt.

Then salt will not dissolve in the water to make brine.

If the brine tank is full of salt, it is hard to tell if you have a salt

bridge. Salt is loose on top, but the bridge is under it. The following

is the best way to check for a salt bridge.

Salt should be loose all the way to the bottom of the tank. Take a

broom handle or like

tool, and carefully push it down into the salt,

working it up and down. If the tool strikes a

hard object (be sure it’s

not the bottom or sides of the tank), it’s most likely a salt bridge.

Carefully break the bridge with the tool.

Do not

pound on the walls

of the tank.

If the wrong kind of salt made the bridge, take it out. Then fill the

tank with nugget or pellet salt only. In humid areas, it is best to fill

with less salt, more often.

Push tool into salt

bridge to break

Pencil

mark

Broom

handle

Salt

Salt

bridge

Water level

1″ – 2″

13

Page 14

14

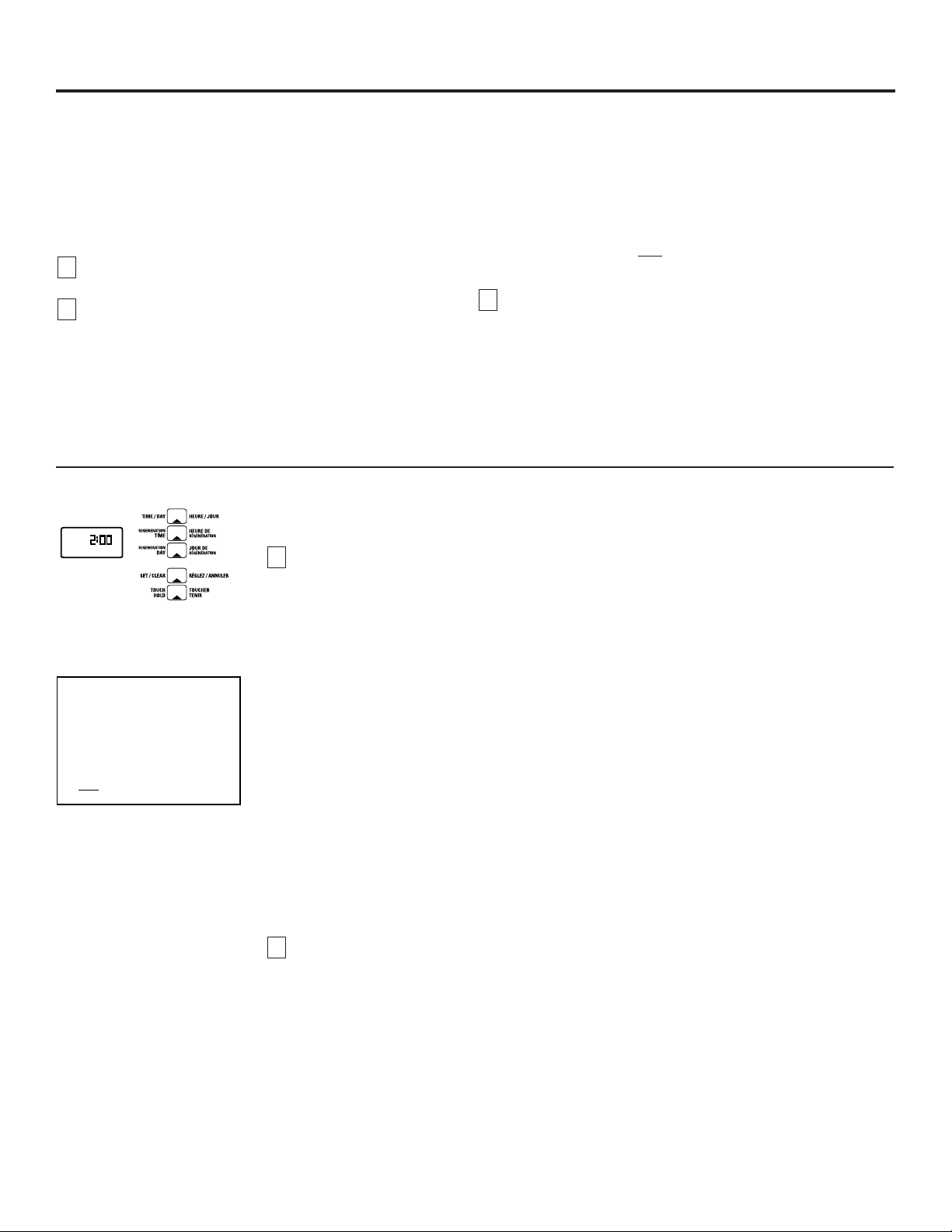

If electrical power to the timer goes off, the

memory built into the timer circuitry keeps

all settings for six hours (minimum) or more.

The display is blank and softener will not

regenerate.

When electrical power comes on…one of two

things will happen.

The present time of day will show, meaning

the timer memory has kept all settings.

NOTE:

If the softener was in a regeneration

when the power was lost, it will now finish

the cycle.

OR

The display will show a flashing time.

The timer memory did not keep the time

settings and they must be reset. See the

Program the Timer

section.

NOTE:

When the power comes on, the

flashing display returns to a time of

12:00 AM Sunday, then begins to keep

time again. If you do not reset all time

settings, the softener will regenerate three

days each week. However, regeneration

will most likely be on the wrong days and

at the wrong time.

If the softener was in a regeneration when

the power went off, the valve will return to

service position without finishing the

regeneration cycle.

If your water tastes salty:

—use

RECHARGE NOW

to start another

regeneration. See the

Recharging

section.

—open one or more soft water faucets and

allow to run until the salt taste is gone.

2

1

About the face plate timer features.

Recharging

If you have guests visiting, or other times when you use more water than usual, you could begin

to run out of soft water. If the softener is not scheduled to regenerate for another day or two,

you would get hard water until then. If this happens, or you think it might happen, press and

hold in the

TOUCH HOLD

button for three seconds until

RCHG

shows.

RCHG

will flash in the display

during the regeneration, which lasts under two hours.

NOTE:

Avoid using

HOT

water while the softener regenerates, because bypass hard water will refill

the water heater, see the

Automatic Bypass

section.

PM

RCHG

Going on Vacation?

The day you leave on vacation, or for a long

absence, press (do not hold) the

TOUCH HOLD

button.

VAC

begins to flash in the display. The

timer will keep time, but the softener will not

regenerate.

NOTE:

While on vacation, the softener will go

through a regeneration if the

RECHARGE NOW

feature is used.

To shut off the water supply to the softener,

use the plumbing bypass valve.

When you return, press the

VACATION

button

again to return the softener to service and also

return the softener to the correct time of day

in the display.

WARNING:

Remember to do this or the

softener will not regenerate and you will

soon have hard water.

Error Code

An error code could appear in the face plate display if a problem occurs in the softener electronics.

If you see an error code instead of the present time of day, see the

Trouble Shooting Tips

section or

call the GE Answer Center 800.626.2000 for service.

E

E

What to Do When a Power Outage Occurs

PM

RCHG

Page 15

Setting the Timer for Days and Fill Minutes of Regeneration

NOTE:

The timer is factory set for Monday, Wednesday and Saturday with regenerations starting

at 2:00 AM. Fill time is factory set for 16 minutes.

Set days and time of regeneration or recharge.

Step 1—

Press the

REGENERATION TIME

button once to display the factory set regeneration days

and starting time (flashing). To change the regeneration start time, do

Step 2

following

this. Otherwise go to

Step 3.

NOTE:

See

Automatic Bypass

section, when choosing a regeneration starting time other

than 2:00 AM.

Step 2—

Press the

SET/CLEAR

button until the desired regeneration starting time shows in

the display.

NOTE:

Press

SET/CLEAR

and quickly release to move the display ahead 1 hour at a

time.

Or, hold the

SET/CLEAR

button to move display ahead 2 hours each

second.

Step 3—

Press the

REGENERATION DAY

button and

SUnday

begins to flash.

—

If you do want regenerations on Sunday, see the

Regeneration Chart

, press the

SET/CLEAR

button to display

ON.

—

If you do

NOT

want regenerations on Sunday, press

SET/CLEAR

button to display

OFF.

Step 4—

Press

REGENERATION DAY

button again to display a flashing

MOnday

and

ON

(factory set

recharge). Use the

SET/CLEAR

button to change display from ONto

OFF

or from

OFF

to

ON.

Step 5—

Press

RECHARGE DAY

button to display a flashing

TUesday, WEdnesday,

etc., each time

using the

SET/CLEAR

button to display either ONor

OFF

as needed.

Set the Fill Cycle Minutes

Step 1—

Press and hold the

REGENERATION TIME

button until

FILL

shows in the display, then

release button. After a few seconds, the fill cycle minutes (factory setting…8) will flash.

Step 2—

Press the

SET/CLEAR

button to set the minutes of fill cycle needed, as shown in the

Regeneration Chart

section.

NOTE:

You may get hard water between regenerations if you set the timer for fewer fill

minutes than the

Regeneration Chart

shows you to set. A higher setting than needed will

waste salt.

NOTE:

Press

SET/CLEAR

and quickly release to move the display ahead 1 minute at a time.

Or, hold the

SET/CLEAR

button to move the display ahead 2 minutes each second.

The display begins over at 0 after passing 59.

2

1

15

It is not hard to fine-tune your softener, but it does take a few

minutes of your time to do it right.

Read the following carefully.

To have soft water all the time, the softener must regenerate,

or recharge a certain number of times in each seven day

period. How many times to regenerate (set the timer) depends

on three things:

The number of people in your home tells you how much

water is used.

The grains per gallon (GPG) hardness of your water

supply.

NOTE: If your water supply contains iron, compensate for it by

adding to the water hardness number. For example, assume

your water is 15 gpg hard and contains 2 ppm iron. Add 5 to

the hardness number for each 1 ppm of iron, thus making the

example water hardness number 25.

You can get the grains per gallon (gpg) hardness of your water

supply from a water analysis laboratory, or call and ask your

local water department, if you are on a municipal supply, or

call GE Answer Center®to request a water hardness test kit.

If your report shows hardness in parts per million (ppm) simply

divide by 17.1 to get the equivalent number of grains per gallon.

15 gpg hardness

2 ppm iron x 5 = 10 +10

(times) 25 HARDNESS NUMBER

How much salt used in each regeneration is determined

by the length of the fill cycle. See the

Regeneration Chart

section.

3

2

1

About regenerating the system.

AM

MO

WE SA

Write in your results here.

1. M T W TH F S SU

—circle suggested days—

Suggested days to regenerate

2.

Fill Cycle minutes needed

Page 16

16

About regenerating the system.

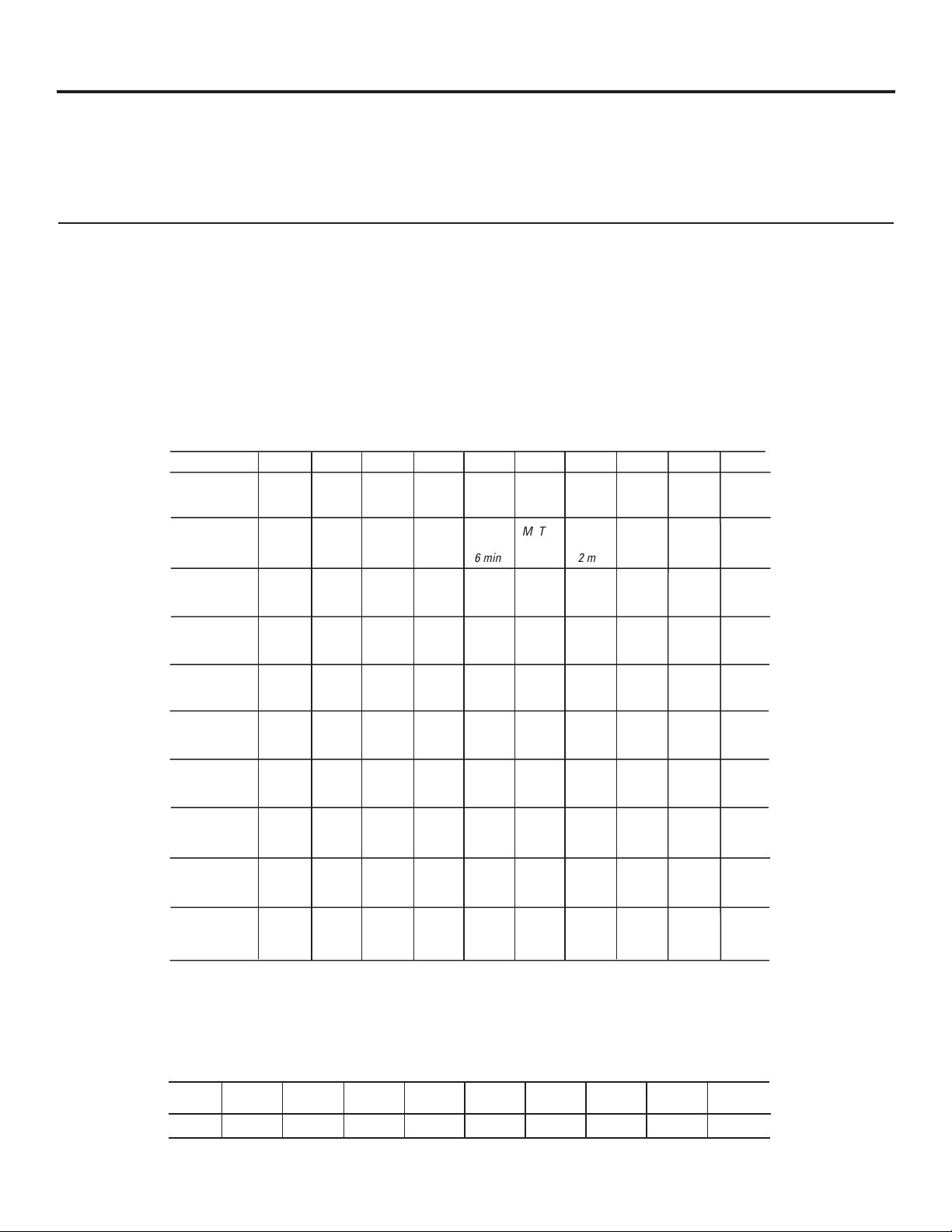

Regeneration Chart

This makes it easy for you to pick the best regeneration and fill time setting to use.

Step 1—

Go down the side of the chart to the number of persons in your family, or the number of people

in the house using water.

Step 2—

Across the top of the chart, find the column listing the grains per gallon hardness of your water,

or hardness number for iron water.

Step 3—

Read across and down the chart to find the point where

Steps 1

and 2meet. At this point,

suggested days to regenerate, and fill cycle minutes needed are shown.

Up to 5 6 to 10 11 to 15 16 to 20 21 to 25 26 to 30 31 to 35 36 to 40 41 to 45 46 to 50

M

2 min.

M

2 min.

M

2 min.

M

2 min.

M

3 min.

M

3 min.

M

4 min.

M

5 min.

M TH

2 min.

M TH

3 min.

M

2 min.

M

2 min.

M

3 min.

M

5 min.

M TH

3 min.

M TH

3 min.

M W S

2 min.

M W S

3 min.

M W S

3 min.

M T TH

F S

2 min.

M

2 min.

M

3 min.

M TH

2 min.

M TH

3 min.

M W S

3 min.

M W S

3 min.

M W S

3 min.

M T TH

S

3 min.

M T TH

F S SU

2 min.

M T TH

F S

3 min.

M

2 min.

M

5 min.

M TH

3 min.

M W S

3 min.

M T TH

F S

2 min.

M W S

2 min.

M T TH

F S SU

2 min.

Every

Day

2 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

M

3 min.

M TH

6 min.

M W S

3 min.

M T TH

F S

2 min.

M T TH

F S SU

2 min.

M T TH

S

3 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

4 min.

M

3 min.

M TH

3 min.

M W S

3 min.

M T TH

S

3 min.

M T TH

F S

3 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

7 min.

M

4 min.

M W S

2 min.

M W S

3 min.

M T TH

F S SU

2 min.

M T TH

F S SU

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

8 min.

M

5 min.

M W S

3 min.

M T TH

S

3 min.

Every

Day

2 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

8 min.

M TH

2 min.

M W S

3 min.

M T TH

F S SU

2 min.

M T TH

F S SU

3 min.

Every

Day

4 min.

Every

Day

5 min.

Every

Day

8 min.

M TH

6 min.

M T TH

F S

2 min.

M T TH

F S

3 min.

Every

Day

3 min.

Every

Day

4 min.

Every

Day

7 min.

Step 3—

Press

TIME/DAY

button to return the present time and day display.

To set the present time of day and day of week see

Program the Timer

section.

If you need help to program the timer, call the GE Answer Center 800.626.2000.

# in household

1

2

3

4

5

6

7

8

9

10

Water Hardness—Grains Per Gallon

Days to Regenerate:

M=Monday, T=Tuesday, W=Wednesday, TH=Thursday, F=Friday, S=Saturday, SU=Sunday

(factory set for Monday, Wednesday and Saturday)

Min.= length of fill cycle needed (factory set for 8 minutes)

Salt

usage

Time

1.8 pounds 2.7 pounds 3.6 pounds 4.5 pounds 5.4 pounds 6.3 pounds 7.2 pounds 8.1 pounds 9.0 pounds

2 minutes 3 minutes 4 minutes 5 minutes 6 minutes 7 minutes 8 minutes 9 minutes10minutes

Pounds of Salt Used Each Regeneration

Minutes of Fill is at 0.3 GPM

Page 17

17

Care and cleaning of the water softening system.

Checking the Salt Storage Level and Refilling

Brine (salt dissolved in water) is needed for each and every regeneration. The water for making brine is

metered into the salt storage area by the water softening system valve and control.

However, you must keep the

tank supplied with salt.

When to refill with salt:

Check the salt level a few weeks after you install the water softening system and every

week after that. Refill when the brine tank is from 1/3 to 1/2 full. In humid areas it is best to fill with less salt

more often. Never allow the water softening system to use all the salt before you refill it. Without salt, you will

soon have hard water.

Use clean water softening salts only, at least 99.5% pure. NUGGET, PELLET or coarse SOLAR salts are

recommended.

Do not use rock, block, granulated or ice cream making salts.

They contain dirt and sediments,

or mush and cake, and will create maintenance problems.

CAUTION: Water softening salt with iron removing additives:

Some salts may have an additive to help the

water softening system handle iron in the water supply. Although this additive may help to keep the water

softening system resin clean, it may also release corrosive fumes that weaken and shorten the life of some

water softening system parts. GE recommends using only Diamond Crystal® Red•Out® brand salt.

Your water softening system takes hardness minerals (calcium and magnesium) out of the water. Also, it can

control some (see

Specification Guidelines

section) “clear water” iron. With clear water iron, water from a faucet

is clear when first put into a glass. After 15 to 30 minutes, the water begins to cloud or turn rust colored.

A water softening system

will not

remove any iron that makes the water cloudy or rusty as it comes from the

faucet (called red water iron). To take red water iron out of water, or over the maximum of clear water iron,

an iron filter or other equipment is needed.

GE recommends using only Diamond Crystal® Red•Out® brand salts with Iron Fighter® additive to help keep

the resin bed clean of clear iron. If your water supply has clear water iron, periodic resin bed cleaning is needed.

GE recommends using Super Iron Out® brand resin bed cleaner to thoroughly clean your resin bed if your

iron content is high. Clean the bed at least every six months, or more often if iron appears in the soft water

between cleanings.

IMPORTANT:

It is important to mix the resin bed cleaner with water (following the manufacturer’s instructions),

pour it into the

brine well tube

(see page 6) and regenerate the softener immediately. Do not pour the resin bed

cleaner in with the salt, as it will not be as effective in cleaning the resin, and can cause damage to the softener

if it is left in the brine tank for an extended period due to the corrosive gases that are formed.

Cleaning Iron Out of the Water Softening System

Page 18

18

Before you call for service…

Troubleshooting Tips

Save time and money! Review the chart on this

page first and you may not need to call for service.

Problem Possible Causes What To Do

No soft water

Faucet or fixture where sample was •

To conserve salt, the installer

may have isolated some fixtures

taken not plumbed to soft water.

(outside faucets, toilets, etc.)

from soft water. From the outlet

NOTE:

Be sure sample is from a faucet

of the water softening system, trace the water flow path in

that does not mix soft and hard water.

house plumbing. If soft water is not directed to a faucet or

For example, a single lever kitchen faucet,

fixture where wanted, consult a plumber.

if the cold side is plumbed to hard water.

No salt in the storage tank. •Refill with salt. See the

Step-by-Step Installation Instructions.

Use the

TOUCH HOLD

button to start a regeneration.

See the

About the Face Plate Timer

section.

Salt in storage tank bridged. •See the

Breaking a Salt Bridge

section.

Transformer unplugged at wall outlet

•Check for a loss of electrical power to the water softening

or

power cable to softener not system, due to any of these conditions and correct as needed.

connected. Fuse blown or circuit With the power supply restored, observe the faceplate time

breaker popped on circuit to electrical display and read

Program Memory

section.

outlet. Electrical outlet on a circuit that

NOTE: The electrical outlet for the softener should be continuously

can be switched off.

live

so it cannot be accidentally switched off.

Manual bypass valve in bypass •Be sure the bypass valve stem

is positioned properly, with the

position.

knob in the OUT position. Observe i

nstructions on the decal

at the end of the stem.

Valve drain hose pinched, plugged, •

Any restriction in this drain hose

may prevent proper operation

elevated too high or otherwise

of the

nozzle and venturi and reduce or prevent brine draw

restricted. during regenerations.

Nozzle and venturi dirty, incorrectly •Refer to

Cleaning the Nozzle and Venturi Assembly

instructions.

assembled or damaged.

With water pressure to the

water softening system off, take the

nozzle assembly apart. Inspect, clean and replace as needed.

Any foreign particle(s), scratches, nicks, etc., in the passages

can

prevent operation. Be sure holes in the gasket are centered

over holes in the housing.

Timer in the vacation (VAC) • See

VACATION

feature to return the softener to service.

position.

See the

About the Face Plate Timer

section.

NO SOFT WATER – Most Common Problems

:

Check the following before calling for service

•

Salt in softener...at least 1/3 full.

•

By pass valve in “Service” position. Knob should be in the OUT position.

•

Check hardness setting in control. Verify hardness of supply water.

Water hardness can vary throughout the year.

•

Salt Bridge, water not in contact with salt (see Breaking a Salt Bridge section).

Page 19

19

Problem Possible Causes What To Do

Water hard sometimes

Using hot water while the water •Avoid using hot water during water softening system

softening system is regenerating regenerations because the water heater will refill with

hard water. See

Automatic Hard Water Bypass During

Regeneration

section.

Too few regenerations or more •See

Regeneration Chart

for correct setting.

water being used

Grains of hardness in your water •

Water hardness can change

over time, especially in well water.

supply have increased To check, have the water tested by a water analysis laboratory

or call your local water department. Adjust the timer settings

as needed. See

Regeneration Chart

.

Water feels slippery

Absence of hardness minerals •This is normal.

after installation of

water softening system

Water softening system

Water softening system is a •Does not use much salt to regenerate—very efficient.

not using any salt

“demand” unit

Possible salt bridge •See the

Operating Instructions, Tips

section.

Possible plugged nozzle and venturi •See the

Operating Instructions, Tips

section.

Water is blue color

Acidic water in copper plumbing •Have the water tested at once.

after water softening

system was installed WARNING:

Do not drink the water until

problem has

been corrected.

Water softening system

Meter turbine stuck •Call for service.

not regenerating

Sensor wire corroded •Call for service.

No power to unit •Check the circuit breaker or fuses.

Mechanical defect •Call for service.

Cloudiness on glassware

Combination of soft water and •This is called

etching

and is permanent. To prevent this

(automatic dishwashers)

too much detergent from happening, use less detergent if you have soft water.

Wash glassware in the shortest cycle that will get them clean.

Salty tasting water

Insufficient backwash and •Press and hold

TOUCH or HOLD

button until

RECHARGE

after installation

rinse time starts to flash to start a regeneration.

•At completion of regeneration cycle (approx. 2 hrs) run water

from faucets to purge the salty water.

Low water pressure •Check pressure; should be minimum 20 psi.

Restricted drain hose •Clean and reconnect hose.

Page 20

20

Before you call for service…

Problem Possible Causes What To Do

Resin beads showing

Cracked distributor •Call for service.

up in drinking water

and sink

Sounds you might hear

Running water from the unit •This is normal.

into a drain

Water has air bubbles

Air in system after installation •Will go away after it runs for a while.

and is cloudy

Error Code on control

Wiring may have worked loose •Unplug transformer.

in control

•Remove control cover, release clips on side.

•Check for loose/incorrect wiring connections to electronic

board or switch. Reconnect as required.

•Reassemble control cover.

•Plug in Transformer.

•Wait six minutes for Error Code to reappear.

•If Error Code reappears call for service.

Troubleshooting Tips

Page 21

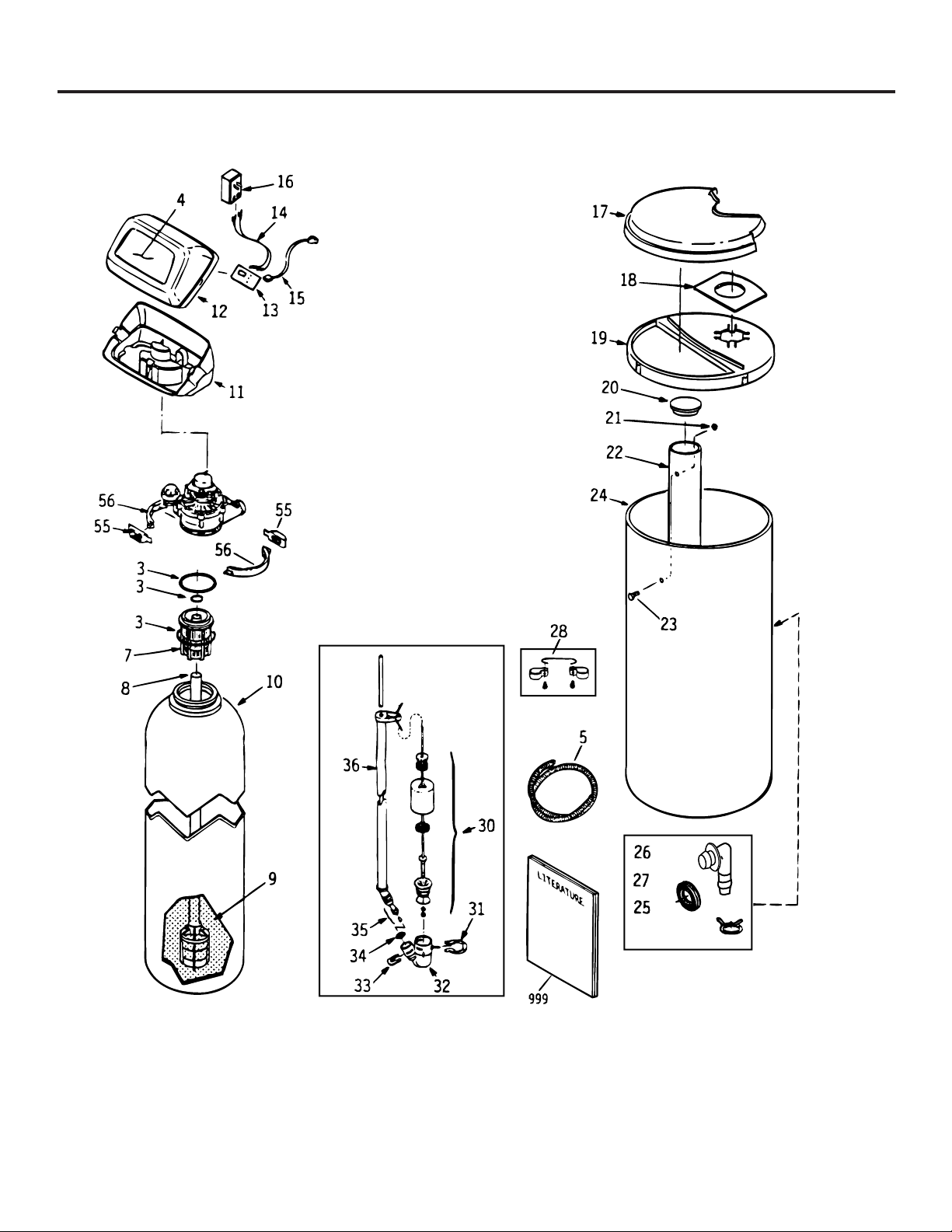

21

Parts list.

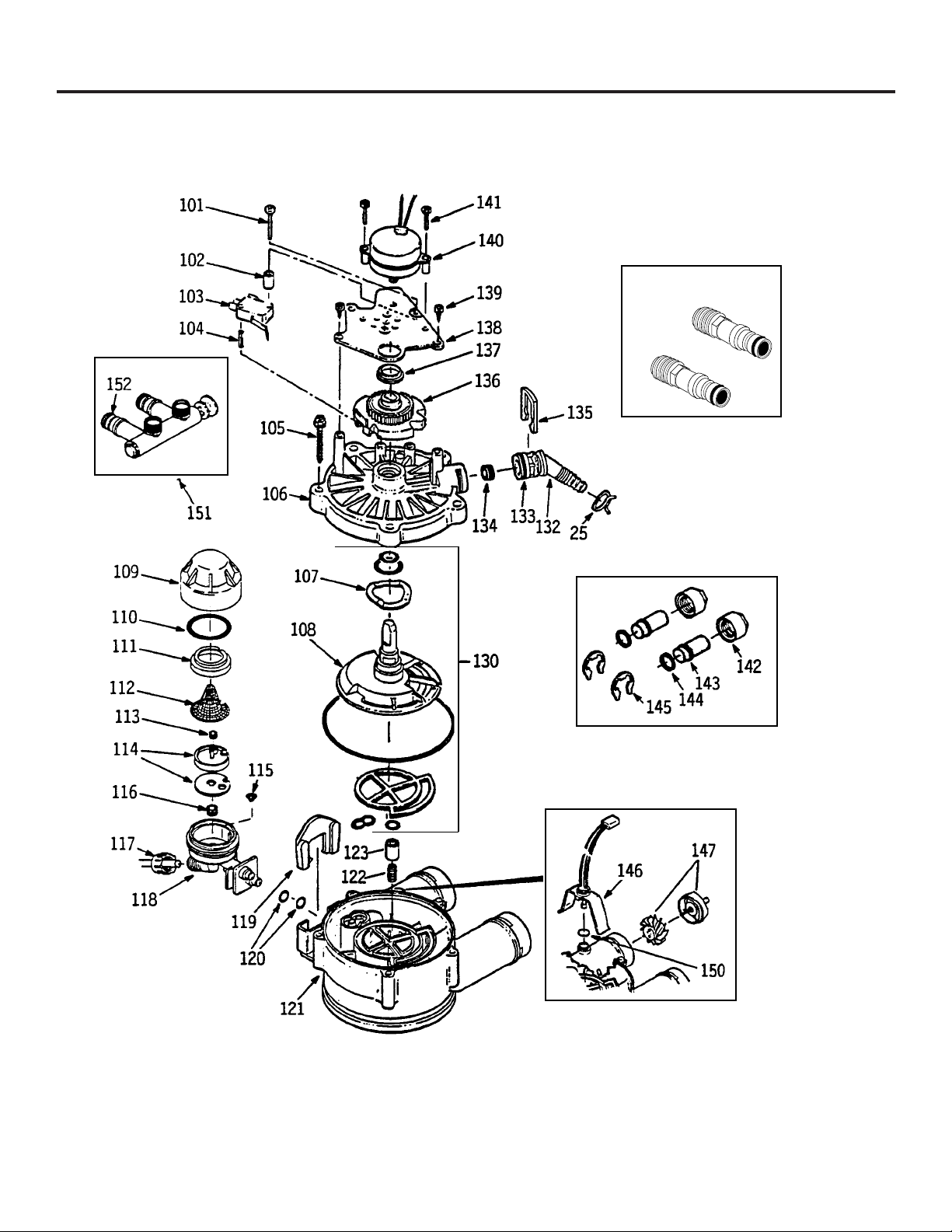

Page 22

Parts list.

22

153

Page 23

23

Parts catalog.

REF. NO. PART NO. PART DESCRIPTION

0003 WS35X10001 O-RING SEAL KIT 1

0004 DECAL 1

0005 WS07X10004 HOSE DRAIN, 20 FT. 1

0007 WS14X10002 DISTRIBUTOR TOP 1

0008 WS14X10001 DISTRIBUTOR BOTTOM 1

0009 WS01X10002 RESIN - 1 CU. FT. 1

0010 WS32X10001 TANK RESIN 1

0011 WS31X10001 COVER BOTTOM 1

0012 WS31X10002 COVER CONTROL

0013 WS21X10007 TIMER 1

0014 WS19X10003 HARNESS WIRE 1

0015 WS06X10003 POWER CORD 1

0016 WS26X10001 TRANSFORMER 1

0017 WS31X10010 COVER SALT HOLE 1

0018 WS33X10001 SEAL VAPOR BARRIER 1

0019 WS33X10002 RIM 1

WS31X10003 COVER BRINEWELL 1

0021 WS02X10009 WING NUT, 1/4 ″ - 20 1

0022 WS32X10002 TANK BRINEWELL, ROUND 1

0023 WS02X10011 SCREW, 1/4 ″ - 20 NYLON 1

0024 WS32X10003 TANK BRINE, ROUND 1

0025 WS18X10003 CLAMP HOSE 1

0026 WS22X10016 ADAPTER HOSE 1

0027 WS22X10017 GROMMET 1

0028 WS35X10002 GROUND CLAMP KIT 1

0029 WS15X10005 BRINE VALVE ASM. 1

0030 WS35X10003 FLOAT, STEM & GUIDE ASM. 1

0031 WS03X10006 CLIP 1

0032 WS15X10006 VALVE BODY, BRINE 1

0033 WS03X10007 CLIP 1

0034 WS03X10008 SCREEN 1

0035 WS07X10002 TUBING ASM. 1

0036 WS07X10003 TUBE BRINE 1

0055 WS28X10003 RETAINER CLAMP 2

0056 WS28X10004 CLAMP 2

0999 49-50062 PM MANUAL USE & CARE/ 1

INSTALLATION

Page 24

24

Parts catalog.

REF. NO. PART NO. PART DESCRIPTION

0025 WS18X10003 CLAMP HOSE 1

0101 WS02X10012 SCREW, #4 - 24 X 1-1/8″ 1

0102 WS02X10013 SPACER 1

0103 WS21X10003 SWITCH 1

0104 WS03X10009 PIN EXPANSION 1

0105 WS02X10014 SCREW, #10 - 14 X 2″ 5

0106 WS31X10006 COVER VALVE 1

0107 WS03X10010 WASHER WAVE 1

0108 WS26X10002 ROTOR & DISC 1

0109 WS19X10004 CAP 1

0110 WS03X10011 SEAL O-RING 1.1″ X 1.4″ 1

0111 WS19X10005 SUPPORT SCREEN 1

0112 WS03X10013 SCREEN 1

0113 WS22X10020 FLOW PLUG, .1 GPM 1

0114 WS08X10005 GASKET, NOZZLE/VENT 1

0115 WS03X10015 CONE SCREEN 1

0116 WS22X10021 PLUG, FILL FLOW, .3 GPM 1

0117 WS03X10017 NUT FERRULE 1

0118 WS15X10009 NOZZLE/VENTURI ASM. 1

0119 WS03X10018 RETAINER 1

0120 WS03X10019 SEAL O-RING 1/4″ X 3/8″ 2

0121 WS15X10010 BODY VALVE 1

0122 WS03X10020 SPRING 1

0123 WS22X10022 PLUG, DRAIN SALT 1

0130 WS35X10005 SEAL KIT 1

0132 WS22X10023 ADAPTER DRAIN HOSE 1

0133 WS03X10021 O-RING 5/8″ X 13/16″ 1

0134 WS03X10022 PLUG FLOW, RINSE CONTROL 1

0135 WS03X10023 CLIP 1

0136 WS26X10003 CAM & GEAR 1

0137 WS26X10004 BEARING 1

0138 WS26X10005 PLATE MOTOR 1

0139 WS02X10015 SCREW, #6 - 20 X 3/8″ 2

0140 WS26X10006 MOTOR ASM. 1

0141 WS02X10016 SCREW, #6 - 20 X 7/8″ 2

0142 WS60X10001 NUT INSTALLATION 2

0143 WS60X10002 TUBE INSTALLATION 2

0144 WS60X10003 WASHER 2

0145 WS60X10004 CLIP 2

0146 WS28X10005 HOUSING SENSOR 1

0147 WS19X10006 TURBINE & SUPPORT ASM. 1

0150 WS03X10024 SEAL, O-RING 1

0151 WS15X10012 VALVE BYPASS ASM. 1

0152 WS03X10025 SEAL, O-RING 2

0153 WS60X10006 ADAPTER 2

Page 25

What Is Not Covered:

For The Period Of: We Will Replace:

One Year Any part

of the Water Softening System which fails due to a defect in materials or workmanship.

From the date of the

During this

full one-year warranty,

GE will also provide,

free of charge,

all labor and in-home

original purchase

service to replace the defective part.

Three Years The electronic monitor,

if it fails due to a defect in materials or workmanship. During this

From the date of the three-year limited warranty,

you will be responsible for any labor or in-home service costs.

original purchase

Ten Years A replacement cabinet (brine tank) or resin tank,

if either fails due to a defect in materials or

From the date of the

workmanship. During this

ten-year limited warranty,

you will be responsible for any labor

original purchase

or in-home service costs.

25

GE Water Softening System Warranty.

(For Customers in the United States)

All warranty service provided by our Factory Service Centers, or an authorized Customer Care®technician.

For service, call 800-GE-CARES.

■ Service trips to your home to teach you how to use the

product.

■ Improper installation.

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■ Filters, membranes or batteries.

■ Replacement of house fuses or resetting of circuit breakers.

■ Damage to the product caused by accident, fire, floods or

acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state. To know what your legal rights

are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Page 26

For The Period Of: We Will Replace:

One Year Any part

of the Water Softening System which fails due to a defect in materials or workmanship.

From the date of the

During this

full one-year warranty,

GE will also provide,

free of charge,

all labor and in-home

original purchase

service to replace the defective part.

Three Years The electronic monitor,

if it fails due to a defect in materials or workmanship. During this

From the date of the three-year limited warranty,

you will be responsible for any labor or in-home service costs.

original purchase

Ten Years A replacement cabinet (brine tank) or resin tank,

if either fails due to a defect in materials or

From the date of the

workmanship. During this

ten-year limited warranty,

you will be responsible for any labor

original purchase

or in-home service costs.

26

What Is Not Covered:

■ Service trips to your home to teach you how to use the

product.

■ Improper installation.

If you have an installation problem, contact your dealer

or installer. You

are responsible for providing adequate

electrical, exhausting and other connecting facilities.

■

Replacement of house fuses or resetting

of circuit

breakers.

■ Failure of the product if it is misused, or used for other

than the intended purpose or used commercially.

■

Damage to product caused by accident,

fire, floods or acts

of God.

WARRANTOR IS NOT RESPONSIBLE FOR CONSEQUENTIAL DAMAGES.

Warrantor: CAMCO INC.

GE Water Softening System Warranty.

(For Customers in Canada)

All warranty service provided by our Factory Service Centers or an authorized technician.

For service, call toll free 1-866-777-7627.

Page 27

Sécurité

Installation adéquate . . . . . . . . . .29

Directives d’installation

Branchement de la conduite

de vidange . . . . . . . . . . . . . . . .33–34

Déballage et inspection . . . . . . .30

Directives d’installation . . . . .30–32

Directives d’installation

étape par étape . . . . . . . . . . . .33–37

Outillage et matériel requis pour

l’installation . . . . . . . . . . . . . . . . . .31

Planification et localisation . . . . .31

Programmation de la minuterie

. .35

Recommandations

importantes pour

l’installation . . . . . . . . . . . . . . . . . .30

Sanitization . . . . . . . . . . . . . . . . . .36

Spécifications et dimensions . . . .37

Instructions d’utilisation, conseils

Caractéristiques de la

minuterie du panneau

de commande . . . . . . . . . . . . . . . .40

Élimination d’un pont de sel . . .39

Nettoyage de l’ensemble

gicleur et venturi . . . . . . . . . . . . . .39

Service . . . . . . . . . . . . . . . . . . . . . .38

Système adoucisseur d’eau . .38–39

Système de régénération . . . .41, 42

Entretien et nettoyage

Élimination du fer . . . . . . . . . . . .43

Niveau de l’entreposage du sel

et remplissage . . . . . . . . . . . . . . . .43

Conseils de dépannage . . . .44–46

Service aux consommateurs

Garantie . . . . . . . . . . . . . . . . . . . . .51

Liste des pièces/catalogue . .47–50

Numéros de téléphone

importants . . . . . . . . . . . . . . . . . . .52

La section Française.

27

Page 28

28

À CONSERVER SOIGNEUSEMENT

Transcrivez les numéros de modèle et de série ici.

No

No

Vous les trouverez sur l’attache du réservoir.

Agrafez le reçu de vente ou le chèque annulé ici.

Pour obtenir le service sous garantie, il est nécessaire de disposer de la preuve de la date d’achat.

Vous y trouverez de nombreux conseils pour l’utilisation et l’entretien de votre adoucisseur d’eau.

Ces quelques mesures préventives vous permettront d’économiser du temps et de l’argent pour

la durée de vie de l’appareil. Nous avons inclus une cassette vidéo avec l’appareil laquelle comporte

des instructions importantes pour l’utilisation et l’entretien.

LISEZ VOTRE MANUEL

SI VOUS AVEZ BESOIN DE SERVICE

Vous trouverez des solutions aux problèmes courants que vous pourriez rencontrer dans la section

Avant

d’appeler un réparateur

. Et, en consultant d’abord nos

Conseils de dépannage

, vous pourriez peut-être éviter

de faire appel à un réparateur.

Si vous avez besoin de service, vous savez que vous n’avez qu’à nous téléphoner. Vous trouverez à la fin

de ce présent manuel les numéros sans frais du service à la clientèle.

OU

Visitez notre site Web au

www.geappliances.com

IMPORTANT!

Remplissez la carte d’enregistrement du produit.

Il y a deux manières faciles d’enregistrer votre appareil!

■ Par l’Internet en saisissant l’adresse www.geappliances.com

■ En remplissant et en expédiant la carte d’enregistrement du produit ci-incluse

Vous et GE, un partenariat de service.

Page 29

VEUILLEZ LIRE ET SUIVRE ATTENTIVEMENT CES MESURES DE SÉCURITÉ.

CONSERVEZ CES DIRECTIVES

29

AVERTISSEMENT!

Pour votre sécurité, suivez les directives fournies dans le présent

manuel afin de minimiser les risques de chocs électriques, des dégâts

matériels et de blessures graves.

SÉCURITÉ

■

Vérifiez et respectez les codes de sécurité locaux et ceux

de l’état où vous résidez. Vous devez suivre les lignes de

conduite suivantes.

■

Faites attention lors de l’utilisation de l’appareil

adoucisseur d’eau. Ne le placez pas la tête en bas, ne le

laissez pas tomber, ne le tirez pas ou ne le faites pas

passer sur des aspérités pointues.

■

Pour les adoucisseurs utilisant le chlorure de sodium

(sel) pour la régénération, ajoutez du sodium à l’eau.

Les personnes soumises à des restrictions concernant

les diètes à base de sodium doivent considérer le

sodium complémentaire comme faisant partie de la

dose quotidienne qu’elles prennent. Il est possible de

remplacer le chlorure de sodium par du chlorure de

potassium dans votre l’adoucisseur.

■

L’adoucisseur d’eau fonctionne avec une alimentation

électrique de 24 volts sous 60 Hz seulement.

Assurez-

vous d’utiliser uniquement le transformateur ci-inclus.

■

Le transformateur doit être branché dans une prise

murale ordinaire de 120V (3 alveoles, mise à la terre).

■

N’utilisez que du sel adoucisseur d’eau propre avec une

pureté minimale de 99,5%. Nous recommandons le sel

NUGGET, PELLET ou du sel brut SOLAR.

N’utilisez pas

du sel à l’état solide, en blocs, granulé ou le sel servant à la

fabrication de crème glacée.

Ce type de sel contient des

saletés, des sédiments, du charbon et du cake qui

engendreront des problèmes d’entretien.

■

Gardez le couvercle de l’orifice du sel en place sur

l’adoucisseur excepté pour l’entretien de l’appareil ou si

ce dernier est en cours de remplissage avec du sel.

AVERTISSEMENT

:

N’utilisez pas

l’appareil si l’eau n’est pas pure sur le plan

microbiologique ou si sa qualité n’est pas éprouvée

sans qu’elle n’ait été désinfectée avant ou après

avoir été traitée par l’appareil.

UNE INSTALLATION ADÉQUATE

■

Installez ou entreposez l’appareil à l’abri de

températures inférieures au point de congélation, des

intempéries au autres types de temps. Le gel de l’eau

entraînera le bris de l’appareil. Ne pas tenter de traiter

de l’eau dont la température est supérieure à 100

degrés F.

■

N’installez pas

l’appareil dans une zone soumise

directement à la lumière du soleil. Une chaleur excessive

engendrée par le soleil peut entraîner des déformations

ou d’autres dommages aux composants non-métalliques.

■

Effectuez les mises à la masse conformément aux codes

et règlements en cours.

■

N’utilisez que de la

soudure et du flux

décapant sans

plomb pour toutes les soudures faites sous la base de

soudure tendre, telles que requises par les codes

fédéraux et ceux de l’état intéressé.

■

L’adoucisseur exige un débit minimum de trois

gallons/minute à l’orifice d’entrée. La pression

maximale autorisée est de 125psi. Si au cours de la

journée, la pression est supérieure à 80 psi, la pression

au cours de la nuit peut être supérieure à la valeur

maximale. Si nécessaire, utilisez une valve réductrice

de pression pour réduire le débit.

■

En présence de chlore dépassant la proportion

de 1 ppm, il est possible que les résines de l’adoucisseur

se dégradent. Si le chlore dépasse cette valeur, il est

possible que vous constatiez une durée de vie réduite des

résines. Dans un tel cas, vous pourriez envisager de faire

l’achat d’un système de filtrage de GE.

AVERTISSEMENT :

Débarrassez-vous de tout composant inutilisé

et du matériel d’emballage après l’installation

Les petits composants restant après l’installation

peuvent constituer un danger d’étouffement

après ingestion.

Avant d’utiliser votre adoucisseur, assurez-vous qu’il a été correctement installé, conformément aux

Directives d’installation.

MESURES DE SÉCURITÉ IMPORTANTES.

LISEZ D’ABORD TOUTES LES DIRECTIVES.

Page 30

Veuillez prendre connaissance du manuel au complet. Négliger de suivre toutes les consignes et règles

peut entraîner des blessures personnelles ou des dommages.

• Avant le début de l’installation, prendre connaissance de toutes les instructions correspondantes.

Ensuite, réunissez tout le nécessaire et l’outillage requis pour cette opération. Une installation

incorrecte annule la garantie.

• Prendre connaissance des codes locaux. L’installation doit être conforme à ces codes.

•

Dans l’état du Massachusetts, il y a lieu de respecter le code de plomberie 24 R CMR.

Veuillez consulter votre plombier qualifié

.

• Utilisez seulement la soudure et le flux décapant sans plomb pour tous les branchements effectués à

l’aide de soudures tendres comme prescrit par les codes fédéraux et ceux de l’état considéré.

• Branchez l’adoucisseur à la conduite d’alimentation d’eau

avanteten amont

du chauffe-eau.

NE FAITES

PAS PASSER DE L’EAU BOUILLANTE DANS L’ADOUCISSEUR.

La température de l’eau qui traverse l’appareil

doit être inférieure à 120 degrés F.

• Manipulez l’adoucisseur avec précaution. N’ inversez pas l’appareil, ne le laissez pas tomber, ne le tirez

pas ou ne l’installez pas sur des surfaces comportant des aspérités acérées.

• La pression maximale d’arrivée d’eau est de 125 psi. Si au cours de la journée la pression s’établit à 80

psi, elle peut dépasser le maximum toléré au cours de la nuit. Si nécessaire, utilisez une soupape de

réduction de pression (L’ajout d’un tel dispositif peut réduire le débit d’eau).

• L’adoucisseur ne fonctionne que sous une tension de 24 volts, 60Hz. Assurez-vous de bien utiliser le

transformateur inclus. Assurez-vous que le transformateur et la prise de courant soient à l’abri de

l’humidité.

• Référez-vous à la section

Où installer l’adoucisseur

pour de plus amples détails.

AVERTISSEMENT :

N’utilisez pas cet appareil avec de l’eau qui n’est pas microbiologiquement

sécuritaire ou de qualité inconnue sans que l’eau n’a pas été désinfectée avant ou après avoir

pénétré dans l’adoucisseur. Testez l’eau périodiquement pour vous assurer que l’appareil

fonctionne de manière satisfaisante.

Les petits composants accompagnant l’appareil qui n’ont pas été utilisés au montage peuvent

présenter des dangers d’étouffement. Débarrassez-vous en.

30

Directives d’installation.

ATTENTION :

Il est nécessaire de posséder une certaine expérience en plomberie pour effectuer

l’installation. Si vous n’êtes pas certain en ce qui concerne une ou plusieurs étapes d’installation de

l’appareil, veuillez consulter un plombier professionnel.

Déballage et inspection

L’appareil adoucisseur d’eau est expédié dans une boîte principale. Il est complètement assemblé en

usine sauf pour les éléments nécessaires à l’installation.

Assurez-vous de vérifier si l’appareil n’a pas été endommagé au cours de l’expédition et si tous les

composants sont présents. Veuillez également noter si la boîte ayant servi pour l’expédition n’a pas été

endommagée. Contactez la Compagnie ayant effectué le transport en cas de dommage ou de perte. Le

fabricant n’est pas responsable en cas de dommages au cours du transport.