Page 1

General Electric Company

Appliance Park, Louisville, KY40225

Water Softening

System............................1

Owner’s Manual & installation instructions

Model GXOF18K

Sistema Suavizante

de Agua..........................21

Manual del Propietario e Instrucciones de Instalación

Modelos GXOF18K

Waterverzachter

Systeem..........................44

Gebruikers en Installatie Handleiding

Model GXOF18K

Système Adoucisseur

D’eau..............................65

Manuel du Proprietaire et Directives D’Installation.

Model GXOF18K

7310993 Rev B

Page 2

Water Softening

system

Safety Information . . . . . . . . . .2

Installation Instructions . .3–10

Step-by-step instructions . . .6–10

Operating Instructions

Breaking a salt bridge . . . . . . .12

Cleaning the nozzle and

venturi assembly . . . . . . . . . . .12

Features . . . . . . . . . . . . . . . . . .13

Service . . . . . . . . . . . . .11, 14–16

Water softener system . . . .11–16

Care and Cleaning . . . . . . . .17

Troubleshooting Tips . . . .18–20

Consumer Support

Parts list . . . . . . . . . . . . . . . . . . 87

www.GEAppliances.com

#30500 General GXOF18K Euro Version 10-01

Write the model and serial numbers here:

Model # ____________________________

Serial # ____________________________

To find these numbers, lift the cover and

look on the rim below the control panel.

GXOF18K

Owner’s Manual &

Installation Instructions

System tested and certified by NSF International against

NSF/ANSI Standard 44 for softener performance

and the reduction of barium and radium 226/228.

Page 3

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

SAFETY PRECAUTIONS

■ Check and comply with your state and local

codes. You must follow these guidelines.

■ Use care when handling the water softening

system. Do not turn upside down, drop, drag

or set on sharp protrusions.

■ Water softening systems using sodium chloride

(salt) for recharge add sodium to the water.

Persons on sodium restricted diets should consider

the added sodium as part of their overall intake.

Potassium chloride can be used as an alternative to

sodium chloride in your softener.

■

The water softening system works on 24 volt-50 Hz

electrical power only. Be sure to use only the

included transformer.

■ Transformer must be plugged into an indoor

220 - 240 volt, grounded outlet only.

■ Use clean water softening salts only, at least

99.5% pure. NUGGET, PELLET or coarse

SOLAR salts are recommended. Do not use rock,

block, granulated or ice cream making salts.

They contain dirt and sediments, or mush and

cake, and will create maintenance problems.

■ Keep the salt hole cover in place on the softener

unless servicing the unit or refilling with salt.

WARNING:Do not use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before or after

the system.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

PROPER INSTALLATION

■ Install or store where it will not be exposed to

temperatures below freezing or exposed to any

type of weather. Water freezing in the system will

break it. Do not attempt to treat water over 37°C.

■ Do not install in direct sunlight. Excessive sun or

heat may cause distortion or other damage to

non-metallic parts.

■ Properly ground to conform with all governing

codes and ordinances.

■ Use only lead-free solder and flux for all sweat-

solder connections, as required by state and

federal codes.

■

The water softening system requires a minimum

water flow of 11 litres per minute at the inlet.

Maximum allowable inlet water pressure is 8.6 Bar.

If daytime pressure is over 5.5 Bar, nighttime

pressure may exceed the maximum. Use a pressure

reducing valve to reduce the flow if necessary.

■

Softener resins may degrade in the presence of

chlorine above 1 ppm. If you have chlorine in

excess of this amount, you may experience

reduced life of the resin. In these conditions,

you may wish to consider purchasing a GE

point-of-entry household filtration system with

a chlorine reducing filter.

WARNING:Discard all unused parts

and packaging material after installation.

Small parts remaining after the installation

could be a choke hazard.

This water softening system must be properly installed and located in accordance with the Installation

Instructions before it is used.

2

For your safety, the information in this manual must be followed to minimize the risk of electric shock,

property damage or personal injury.

WARNING!

Page 4

3

CAUTION: Certain plumbing skills are needed for installation. If you are unsure about

any part of the installation of this product, consult a professional plumber.

Installation instructions.

Unpacking and Inspection

Be sure to check the entire softener for any

shipping damage or parts loss. Also note

damage to the shipping cartons. Contact the

transportation company for all damage and

loss claims. The manufacturer is not

responsible for damages in transit.

Small parts needed to install the softener are

packaged either in a bag or on a cardboard

sheet. To avoid loss of the small parts, keep

them packaged until you are ready to use them.

Be sure not to discard components hidden in

packaging.

■ Before you begin installation, read these

Installation Instructions completely. Then,

obtain all the materials and tools you will

need to make the installation. Failure to

properly install the softener voids the

warranty.

■ Check local codes. The installation must

conform to them.

■ Consult with your licend local plumber, if

you have questions on the Plumbing Code

■ Use only lead-free solder and flux for all

sweat-solder connections, as required by

state and federal codes.

■ Connect the softener to the main water

supply pipe before or ahead of the water

heater. DO NOT RUN HOT WATER THROUGH

THE SOFTENER. Temperature of water

passing through the softener must be

less than 49°C.

■ Use care when handling the softener.

Do not turn upside down, drop, drag

or set on sharp protrusions.

■ Maximum allowable inlet water pressure is

8.6 Bar. If daytime pressure is over 5.5 Bar,

nighttime pressure may exceed the

maximum. Use a pressure reducing valve

if necessary. (Adding a pressure reducing

valve may reduce the flow.)

■ The softener works on 24 volt-50 Hz

electrical power only. Be sure to use the

included transformer. Be sure the electric

outlet and transformer are in an inside

location to protect from moisture.

■ See Where to Install the Softener section for

more details.

WARNING:Do not use with water

that is microbiologically unsafe or of

unknown quality without adequate

disinfection before or after the system.

The water should be tested periodically

to verify that the system is performing

satisfactorily.

■ Small parts remaining after the installation

could be a choke hazard. Discard safely.

Important Installation Recommendations

Read entire manual. Failure to follow all guidelines and rules could cause personal injury or

property damage.

Page 5

4

Installation instructions.

Plan How You Will Install the Softener

You must first decide how to run in and out

pipes to the softener. Look at the house

main water pipe at the point where you will

connect the softener. Is the pipe soldered

copper, glued plastic, or threaded galvanized?

What is the pipe size?

WARNING: Use only lead-free

solder and flux to prevent lead poisoning.

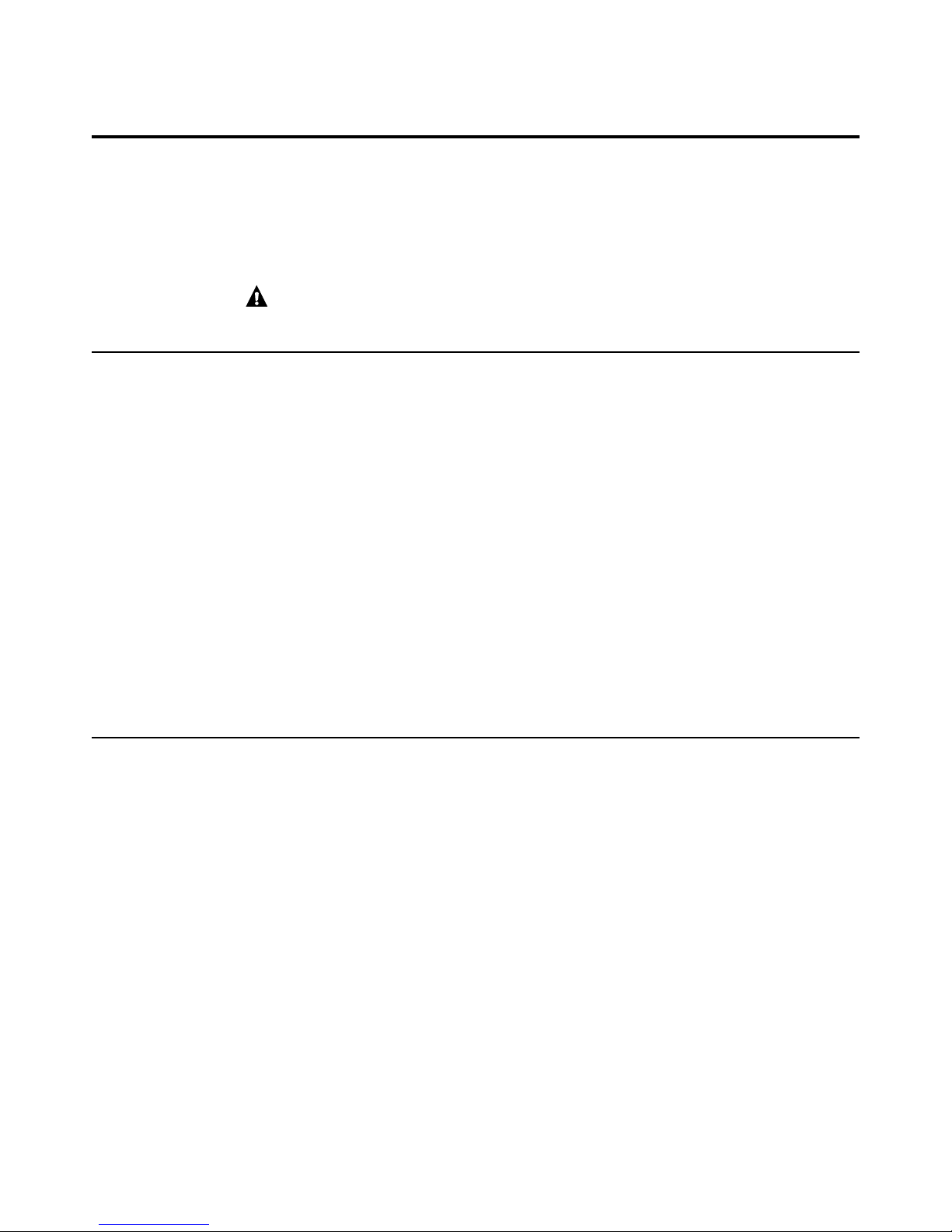

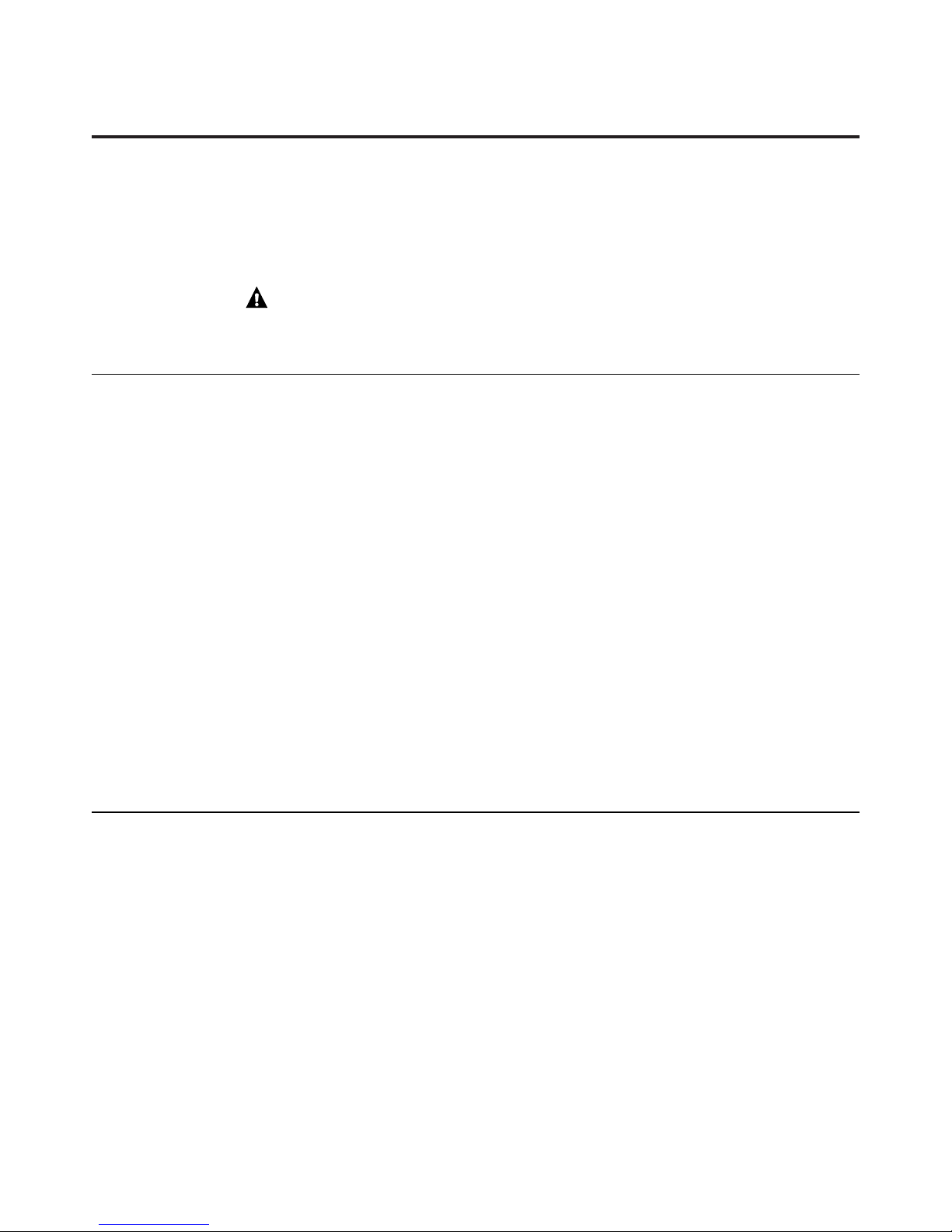

See Typical Installation Illustration, Fig. 1. Use

this as a guide when planning your particular

installation. Be sure to direct the incoming hard

water supply to the softener valve inlet fitting.

The valve is marked IN and OUT. See illustration

on page 5 to help you prepare.

Where to Install the Softener

■ Place the softener as close as possible to a

sewer drain, or other acceptable drain point

or standpipe.

■ It is recommended to keep outside faucets

on hard water to save soft water and salt.

■

Do not install the softener in a place where it

could freeze. Freeze damage is not covered by

the warranty.

■ Do not install the softener where it would

block access to the water heater or access to

the main water shutoff.

■ Put the softener in a place where water

damage is least likely to occur if a leak

develops. The manufacturer will not repair

or pay for water damage.

■ A 220 - 240-volt electric outlet is needed to plug

in the included transformer. The softener

has a 2 m power cable. If the outlet is

remote (up to 30 meters), use 0.8 mm2 wire

to connect. Be sure the electric outlet and

transformer are in an inside location, to protect

from wet weather. Be sure the outlet is

unswitched to prevent accidental shutoff.

■ If installing in an outside location, you must

take the steps necessary to assure the softener,

installation plumbing, wiring, etc., are as

well protected from the elements (sunlight,

rain, wind, heat, cold), contamination,

vandalism, etc., as when installed indoors.

Outdoor installation is not recommended, and

voids the warranty.

■ Keep the softener out of direct sunlight.

The sun’s heat may distort non-metallic

parts and may damage the electronics.

■ In and out fittings included with the softener

are 1″ .

You should maintain the same, or larger,

pipe size as the water supply pipe, up to the

softener inlet and outlet.

■ Use the included bypass valve to install the

softener. The bypass valve allows you to turn

off water to the softener for servicing, but

still have water in the house pipes.

■ Use copper, brass or galvanized pipe and

fittings. Some codes may also allow CPVC

plastic pipes.

■ If additional drain hose is needed for valve

and salt tank drains, it can be ordered from

GE Parts.

■ If a rigid valve drain is needed to comply

with plumbing codes, you can buy the parts

needed to connect a 1/2″ copper tubing or

plastic pipe drain.

■ Clean nugget or pellet water softener salt is

needed to fill the brine tank, see Step 8 in

the Step-by-Step Installation Instructions.

Tools and Materials Required for Installation

Page 6

5

Typical Installation Illustration

Soft water

Hard water to

outside faucets

MAIN WATER PIPE

Hard water

NOTE: See Drain Hose Connections section.

24V transformer

220 -240 volt outlet

Bypass valve

Hard water to

outside faucets

Inlet valve

Outlet valve

3-Valve Bypass System

For soft water service:

• Open the inlet and

outlet valves

• Close the bypass valve

For bypass hard water:

• Close the inlet and

outlet valves

• Open the bypass valve

SALT

GOES HERE

Brinewell

INLET

Washer (2) (not supplied)

Copper tube, 3/4″ (2) (not supplied)

Installation nut (2) (not supplied)

Bypass Valve

• Pull out for soft water service

• Push in for bypass

Nut (2) (not supplied)

Copper tube, 3/4″ (2) (not supplied)

Washer (2) (not supplied)

Installation adapter (2) (see above)

INLET

Union (not supplied) (2)

Optional 3-Valve Bypass Installation Illustration

Adapters for this installation are not supplied with the softener.

Fig. 1

CROSSOVER

Use if water supply flows from the left.

Include single or 3-valve bypass.

Hard water

From softener

outlet

Soft water

To softener

inlet

Fig. 2

CROSSOVER

Use if water supply flows from the left.

Include single or 3-valve bypass.

Hard water

From softener

outlet

Soft water

To softener

inlet

MAIN WATER PIPE

Hard water

Soft water

220 - 240 volt outlet

24V

transformer

Brinewell

SALT

GOES HERE

Drain

(not shown)

Drain

(not shown)

Salt hole

cover

Salt hole

cover

Page 7

6

Step-by-step installation instructions.

■ Turn off the gas or electric supply to the water heater, in the possibility that

the water heater may be drained while draining pipes.

■

Turn off the water supply to pipes to be cut and drain the house water pipes.

■

Open both hot and cold faucets at the lowest location possible

.

NOTE:

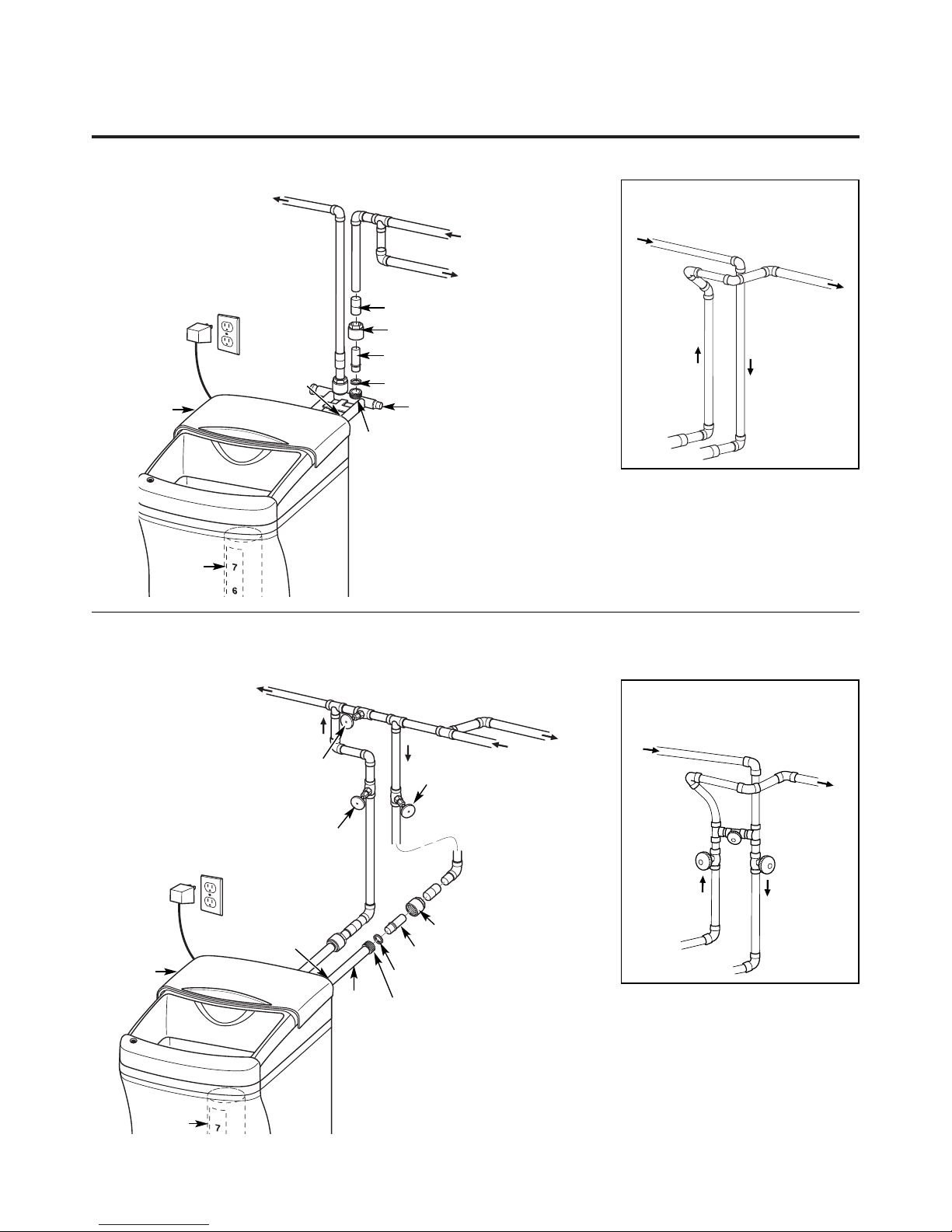

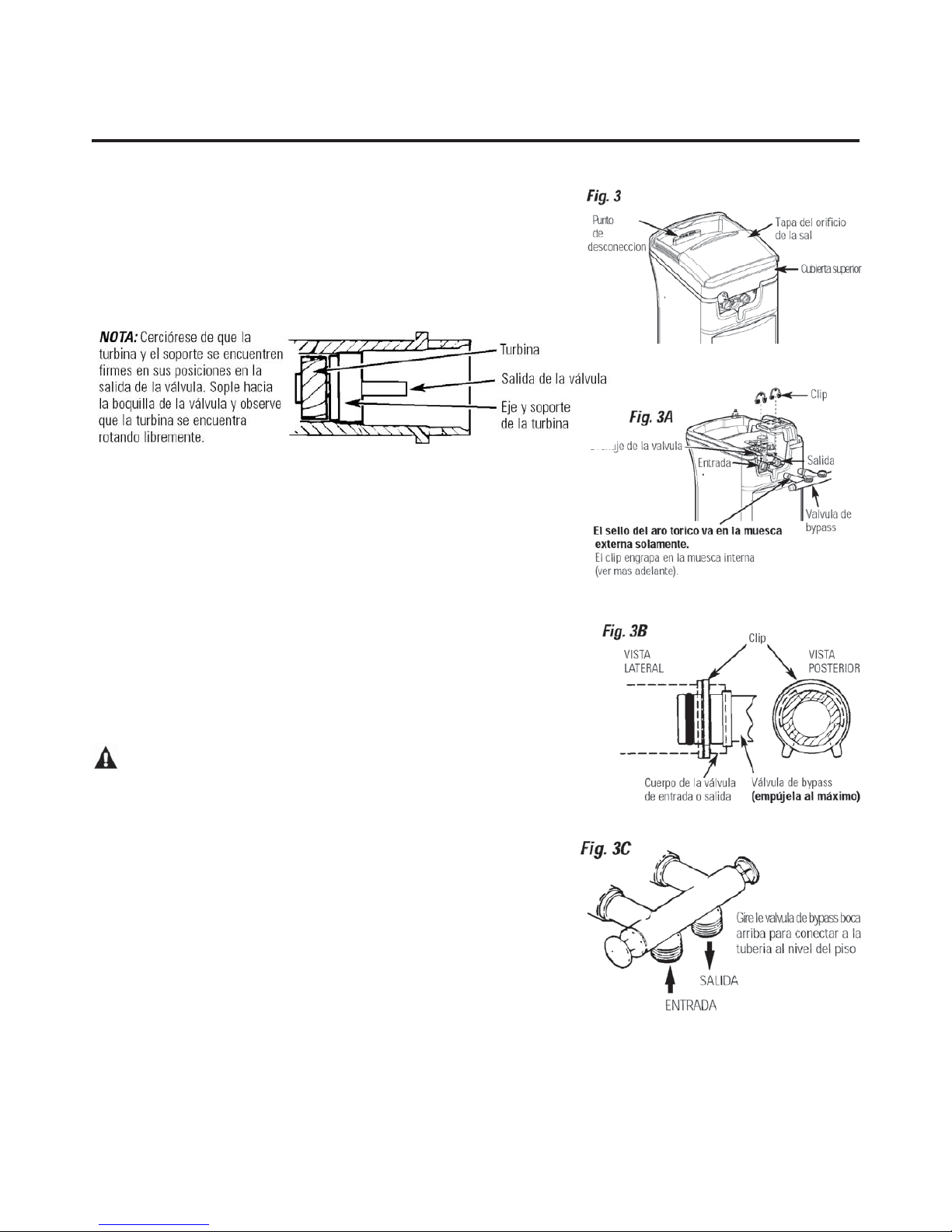

For easier installation, remove the top cover (Figure 3).

cover forward and lift up.

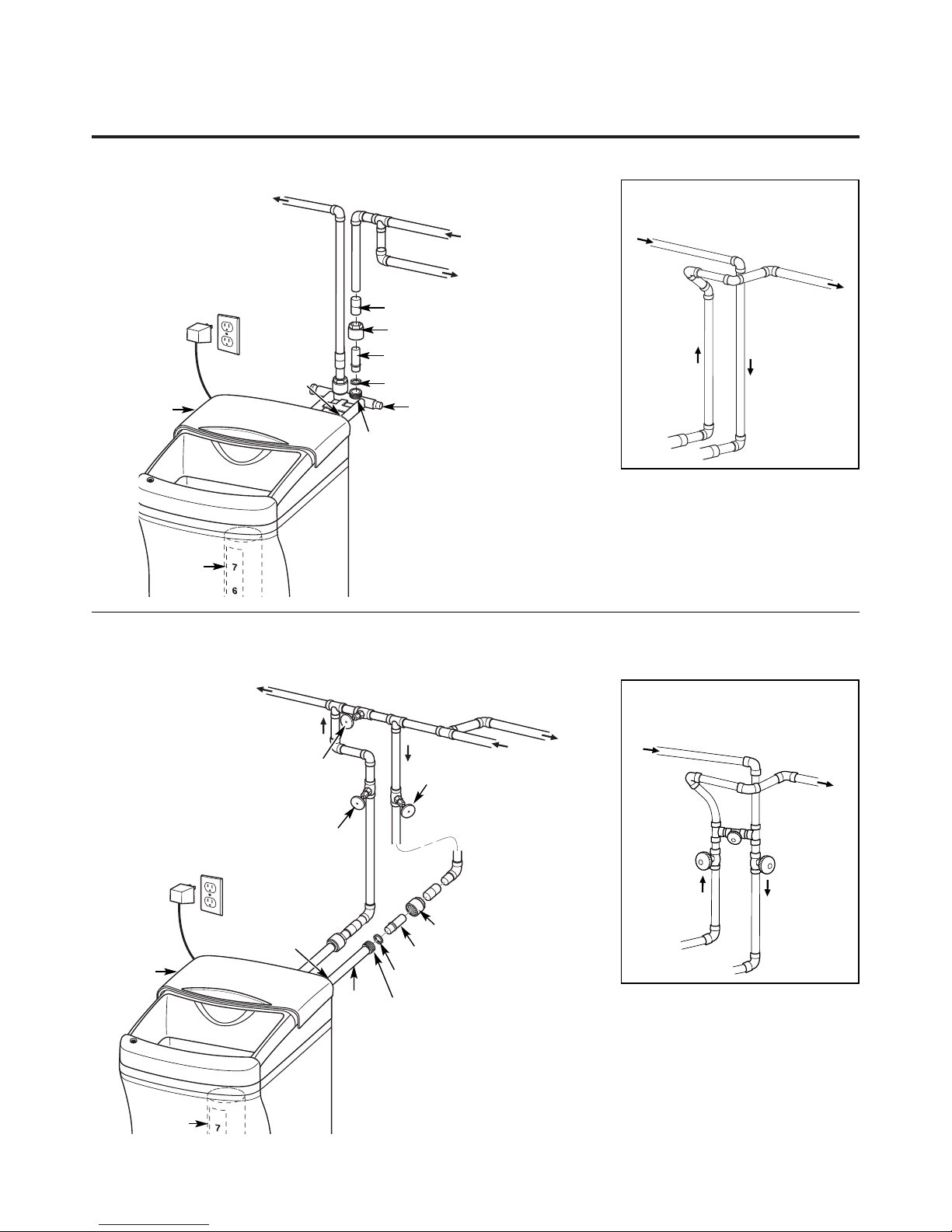

1. INSTALL BYPASS VALVE ( Actual bypass may differ from drawing)

• Remove top cover (fi gure 3) and remove plastic shipping plug and wire from valve outlet .

• Push the bypass valve (lubricate o-ring seals with silicone grease) into both ports of the

valve as shown in Fig. 3A.

• Snap the 2 large plastic clips in place, from the top, down as shown in Figures 3A and 3B.

Be sure they snap into place. Pull on the bypass valve to make sure it is held securely in place.

Make sure to read the the hardness bleed screw settings on page 91 of this manual

2. MOVE THE SOFTENER ASSEMBLY INTO INSTALLATION POSITION

Be sure the installation surface is level and smooth. Sharp objects under the tank may

puncture it. If needed, place the tank on a section of 2 cm thick (minimum) plywood.

Then, place shims under the plywood as needed to level the softener.

3. PLUMB “IN” AND “OUT” PIPES TO AND FROM SOFTENER

CAUTION:

Observe all of the following cautions as you connect inlet and

outlet plumbing. See illustrations on page 5.

• BE SURE INCOMING HARD WATER SUPPLY IS DIRECTED TO THE SOFTENER

VALVE INLET PORT. If house water fl ow is from the left, use a plumbing crossover as

shown in Fig. 1, page 5. If house water fl ows up from the fl oor level, turn the bypass valve

upside down as shown in Fig. 3C.

• If making a soldered copper installation, do all sweat soldering before connecting pipes

to the bypass valve. Torch heat will damage plastic parts.

• When turning threaded pipe fi ttings onto plastic fi ttings, use care not to

cross-thread.

• Use pipe joint compound on all external pipe threads.

• Support inlet and outlet plumbing in some manner (use pipe hangers) to keep the

weight off of the valve fi ttings.

4. CONNECT AND RUN THE VALVE DRAIN HOSE

IMPORTANT: If you want to attach the drain fi tting to a rigid tube, see Step 4A .

• Assemble drain fi tting as shown in Fig. 4.

• Use the provided drain hose to attach to the valve drain fi tting. To keep water

pressure from blowing the hose off, use a hose clamp to secure in place. Cut

the necessary length and use the remainder in Step 5.

• Locate the other end of the hose at a suitable drain point (fl oor drain, sump, laundry

tub, etc.) that terminates at the sewer. Check and comply with local codes.

IMPORTANT: If more drain hose is needed, it should be ordered from GE Parts.

The water softener will not work if water cannot exit this hose during

recharge.

• Tie or wire the hose in place at the drain point. High water pressure will cause it to whip

during the back-wash and fast rinse cycles of recharge. Also provide an air gap of at least

4cm between the end of the hose and the drain point. An air gap prevents possible

siphoning of sewer water into the softener, if the sewer should “back-up.”

• If raising the drain hose overhead is required to get to the drain point, do not raise

higher than 2 m above the fl oor. Elevating the hose may cause a back-pressure that could

reduce brine draw during recharge.

Page 8

8. ADD WATER AND SALT TO THE BRINE TANK

• Lift the salt hole cover. Add about 11 litres of water into the

tank. Do not add into the brinewell.

• Fill tank with NUGGET, PELLET or coarse SOLAR water softener

salt with a purity of 99.5% or higher. Do not use rock, block,

granulated and ice cream-making salts, or salt with iron-removing

additives

Maximum salt storage capacity is approxilately 45Kg.

Keep the salt hole cover closed unless servicing the unit or

refi lling with salt.

NOTE: If the softener is installed in a humid basement or other damp

area, it is better to fi ll the tank with less salt, more frequently. 25 Kg.

of salt will last for several months, depending on water hardness,

family size and water softening system model.

9. CONNECT TO ELECTRICAL POWER

To gain access to the transformer/power cord assembly, remove the

salt hole cover from the softener. Unclip the tabs on the rear of the

top cover and rotate the cover upwards to remove. DO NOT PULL

OR DISCONNECT WIRING.

• The softener works on 24 volt-50Hz electric power. The included

transformer changes standard 220 - 240 -volt AC house power to

24 volts.

Plug the transformer into a 220 - 240-volt outlet only. Be sure the

outlet is always live so it can not be switched off by mistake.

• Replace the top cover.

• Replace the salt hole cover.

7

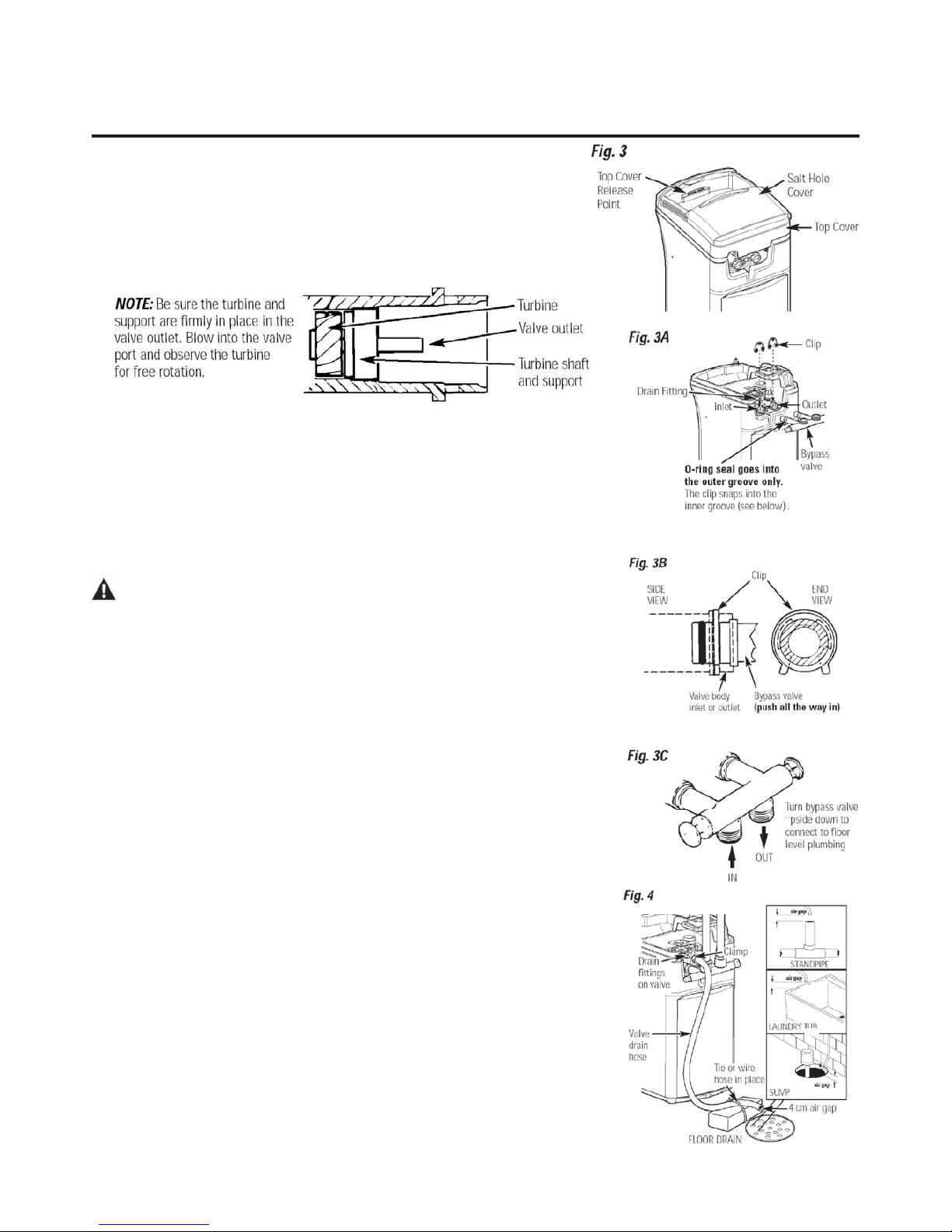

4A. CONNECTING A RIGID VALVE DRAIN TUBE

To adapt a copper drain tube to the softener, buy a compression fi tting (garden hose thread x

1/2” O.D. tube) and needed tubing from your local hardware store.

5. INSTALL THE BRINE TANK OVERFLOW FITTINGS AND HOSE

• Insert the rubber grommet into the 2 cm diameter hole in the brine tank sidewall as shown

in Fig. 5.

• Push the end of the hose adapter elbow into the grommet as shown in Fig. 5.

• Attach a length of hose (use remaining hose from Step 4) to the hose adapter elbow. Use a hose

clamp to hold it in place.

• Locate the other end of the hose at the drain point. DO NOT ELEVATE this hose higher than

the elbow on the brine tank.

IMPORTANT: DO NOT TEE OVERFLOW HOSE TO VALVE DRAIN HOSE.

NOTE: This drain is for safety only. If the cabinet (brine tank) should over-fi ll with water, the excess

is carried to the drain.

6. INSTALL GROUNDING CLAMP (not included)

DANGER:

Failure to properly attach ground clamp could result in electrical shock.

If plumbing is metal, to maintain electrical ground continuity in the house cold water piping, install

the ground clamp (not included) as shown in Fig. 6.

• Clean pipe with emery paper in the area where the clamp is to be installed.

• Install grounding clamps as shown, making sure clamps fi t freely around pipe.

• Make sure lock washer is in place.

• Handtighten screw, then one more full turn with screwdriver.

NOTE: When replacing an existing softener, also replace grounding clamps.

If removing softener completely, hard-plumb the water line with same type of pipes as the original

to assure plumbing integrity and ground continuity over the life of the home.

7. FLUSH PIPES, EXPEL AIR FROM SOFTENER, AND TEST YOUR INSTALLATION FOR

WATER LEAKS

CAUTION:

To avoid water or air pressure damage to softener inner parts, be sure to

do the following steps in exact order.

• Fully open 2 cold soft water faucets nearby the softener.

• Place bypass valve in “bypass” position by pushing the stem inward.

• Fully open the house main water pipe shutoff valve. Observe a steady fl ow from both faucets

opened in step A, above.

• Place bypass valve in the “service” position EXACTLY as follows. KEEP SOFT WATER

FAUCETS OPEN.

• SLOWLY pull or slide the valve stem (out) toward the service position, pausing several times to

allow the softener to pressurize slowly.

• After about 3 minutes, open a HOT water faucet for 1 minute, or until all air is expelled, then

close. NOTE: If water appears cloudy or has salty taste, allow to run for several more minutes, or

until clear.

• Close all water faucets.

• Check your plumbing work for leaks and fi x right away if any are found. Be sure to observe

previous caution notes.

• Turn on the gas or electric supply to the water heater. Light the pilot, if applicable.

Page 9

8

Step-by-step installation instructions.

Programming the Control

CONTROL SETTINGS REQUIRED upon installation and after an

extended power outage.

NOTES:

■ WHEN THE TRANSFORMER IS PLUGGED INTO THE

ELECTRICAL OUTLET, 12:00 PM (flashing), and an arrow is

displayed next to PRESENT TIME on the faceplate decal. The blue

indicator light will also flash. Program the control as instructed

below.

■ If - - - is flashing, use the UP button to set the correct code

F18 for GXOF18K

If you pass by the correct number, use the DOWN button. Then

press the MODE button to accept the correct model.

■ A “beep” sounds while pressing buttons for control programming.

One beep signals a change in the control display. Repeated beeps

mean the control will not accept a change from the button you

have pressed, and you should select another button.

■ To program the control, you will use the UP , DOWN and

MODE buttons.

■ Use the MODEbutton to scroll arrow to desired control function.

SET PRESENT TIME OF DAY

1. Press the MODE button until arrow

points to PRESENT TIME.

2. Press UP or DOWN button

to set. The UP button advances the time; the DOWN button moves

the time in reverse.

2. If the present time is between noon and midnight, be sure PM shows

in the display. If the present time is between midnight and noon, be

sure AM shows in the display.

NOTE: Each press of an UP or DOWN button changes the time

by one minute. Holding the button changes the time at a rapid rate.

3. When the present time is correct, press MODE to accept.

SET WATER HARDNESS NUMBER

1. Press the MODE button until

arrow points to HARDNESS.

2. Press UP or DOWN button to

set your water hardness number in the display. DOWN decreases the

hardness value. UP increases the hardness value.

NOTE: Each press of a button changes the display by 1, between 1 and

25. Above 25, the display changes 5 at a time (25, 30, 35, etc.). Holding

a button in changes the numbers at a rapid rate.

3. When the display shows your water hardness (in grains per gallon),

press MODE to accept.

NOTE: If there is clear water iron in your water supply, you will need to

increase the hardness setting by 5 for each 1 ppm of clear water iron in

your water supply.

You can get the grains per gallon (gpg) hardness of your

water supply from a water analysis laboratory. If you are on

a municipal supply, call your local water department. To calculate the

gpg hardness from German degrees divide by 0.953, to calculate gpg

hardness from French degrees divide by 1.71. If your report

shows hardness in parts per million (ppm) or milligrams per liter

(mg/l), simply divide by 17.1 to get the equivalent number of grains

per gallon.

SET RECHARGE (STARTING) TIME

1. Press the MODE button until arrow

points to RECHARGE TIME.

NOTE: A flashing 2:00 AM (factory

default) should show in the display. This is a good time for recharge to

start (takes about 2 hours) in most households because water is not in

use. HARD WATER is bypassed to house faucets during recharge.

If no change is needed, go to step 3. To change the recharge starting

time, follow step 2.

2. Press UP or DOWN button to set the desired recharge start

time. Be sure to observe the AM or PM as you did when setting the

time of day.

NOTE: Each press of a button changes the time by 1 hour. Holding the

buttons in changes the time at a rapid rate.

3. Press the MODE button to accept.

SET SALT LEVEL

1. Press the MODE button until

arrow points to SALT LEVEL.

2. Determine level of salt in brine tank

using yellow indicator on side of brine well, inside brine tank

(see illustration on page 5).

3. Press UP or DOWN button to

set the SALT LEVEL to correspond to

level on yellow indicator in brine tank.

NOTE: Each press of a button changes the

level by increments of 0.5 up to 8.0. As the number increases, the salt

level bars increase on each whole number. Lowering the salt level

below zero turns the SALT LEVEL indicator OFF.

4. Press the MODE button to accept. The display

shows the present time of day and DAYS TO

EMPTY. RECHARGE TONIGHT may appear if

unit is new.

SALT

LEVEL

PM

SALT

LEVEL

SALT

LEVEL

DAYS TO EMPTY

PM

RECHARGE TONIGHT

E

SALT

LEVEL

SALT

LEVEL

AM

SALT

LEVEL

Page 10

9

Optional Control Settings

The controller display has several options and features.

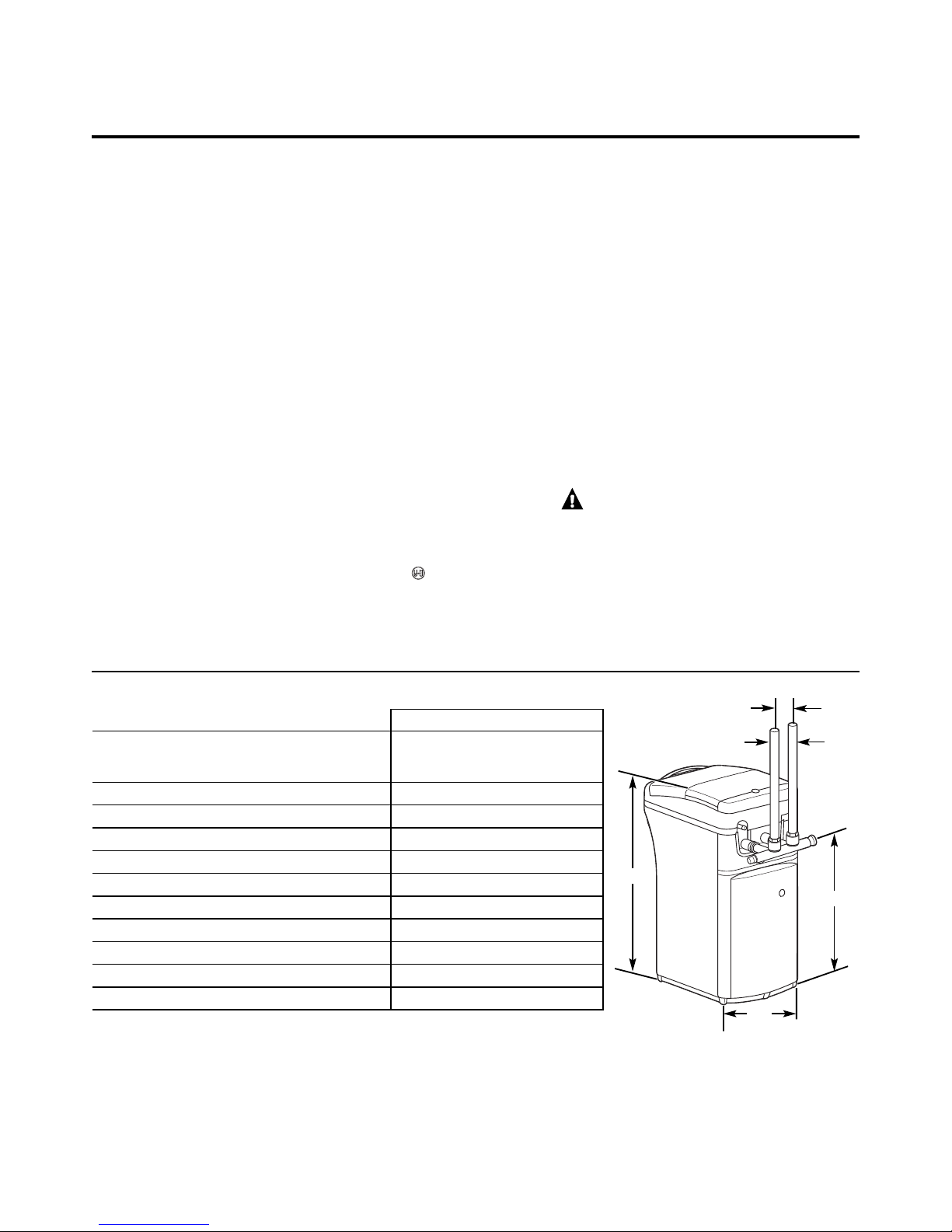

LOW SALT ALARM

The LOW SALT ALARM, when enabled,

will sound the beeper when the DAYS

TO EMPTY value is 15 days or less. To

change this setting, press and hold

the MODE button for 3 seconds. ON

(factory default) or OFF will fl ash in

the display. Press the UP ▲ or DOWN ▼ buttons to toggle this feature

ON or OFF. Press the MODE button to accept, and the display will

move to SALT EFFICIENCY.

SALT EFFICIENCY

When the SALT EFFICIENCY feature

is ON, the unit will operate at a salt

effi ciency of 4000 grains of hardness

removed per pound of salt (59fm3/

kg salt). This mode of operation

is the most effi cient setting for salt

usage, because the system will tend to

recharge more often, with less salt usage. Turning the feature OFF will

tend to lengthen the time between recharge cycles, which will provide

the most effi cient usage of water, but may use more salt. The degree of

difference between these two cycles is highly dependent on the water

usage and hardness at a particular installation.

To change the setting, press the UP ▲ or DOWN ▼ buttons to toggle

the feature ON or OFF. Press the MODE button to accept. The display

will move to SYSTEM/ELECTRONIC DIAGNOSTICS.

SYSTEM/ELECTRONIC DIAGNOSTICS

This display contains system diagnostics

information to assist in troubleshooting

problems with the system.

See page 15 for details. Press the MODE

button to return to the normal run

display.

LOST TIME SIGNAL

If time is lost on the display due to power interruption, the blue

indicator light will fl ash 4 times every second, until the present time of

day is entered.

LOW SALT SIGNAL

When the DAYS TO EMPTY drops to 15, the blue indicator light and

DAYS TO EMPTY in the display will fl ash every second and the alarm will

beep every 30 seconds (from 8:00 AM to 8:00 PM), to notify the user

that the unit is running low on salt. As soon as any button is pressed,

the alarm will stop beeping. The blue indicator light and DAYS TO

EMPTY will continue to fl ash. Once salt is added to the brine tank and

the SALT LEVEL is reset, the DAYS TO EMPTY wil l

be reset.

ERROR SIGNALS

If there is an error code detected, the

blue indicator light will fl ash 4 times

every second, the display will fl ash

Err, and the alarm will beep every 30

seconds (from 8:00 AM to 8:00 PM),

to signal that the softener requires

service. The alarm can be turned off by pressing any button, but the

blue indicator light and display will continue to fl ash.

See page 14 for information to assist in troubleshooting error codes.

Once the problem is corrected, disconnect the transformer from the

wall outlet momentarily, and plug it back in. The normal display will

appear. The motor may run for several minutes, as the unit resets.

If the problem is not corrected, the error code will reappear in 6

minutes.

BLUE INDICATOR LIGHT

Steady blue light indicates that the unit is working correctly. The light

fl ashes

when the unit needs attention from the user.

• Light fl ashes and DAYS TO EMPTY fl ashes—check salt level and add

salt as required.

• Light fl ashes and Err is in the display˜electrical problem

with system˜see page 16.

• Light will also fl ash when power to the unit has been

interrupted. Check the PRESENT TIME setting.

Programming the Control (cont.)

DAYS TO EMPTY

The words DAYS TO EMPTY and a number

are shown in the lower half of the display.

This information is shown in the normal

run display. This is to inform the user of

the number of days before the salt level in

the brine tank reaches Level 0. There will

be salt left in the salt tank, but it may not be suffi cient to fully recharge

the system. Salt should be added at this time to avoid hard water. The

value is updated daily and whenever the SALT LEVEL value is changed.

NOTE: For the fi rst several weeks of operation the DAYS TO EMPTY may

provide erratic operation. For example, the blue indicator light may

fl ash, showing that more salt is required when the actual salt level in

the tank is well above the Level 0. In some cases, the DAYS TO EMPTY

may even increase over a several week period.

It takes a couple of months for the water softener to learn your water

usage pattern. Once it does this, it will accurately determine actual

salt usage pattern. During this fi rst period, check salt level when blue

indicator light fl ashes. If the salt level in the tank is at Level 1 or above,

allow system to run. Be sure to reset your salt level indicator each time

you add salt to the system.

Page 11

10

This system conforms to NSF/ANSI 44 for the specific capacity claims as verified and substantiated by test data.

* Testing was performed using pellet grade sodium chloride as the regenerant salt.

** Efficiency rating is valid only at the lowest stated salt dosage and service flow rate. This softener was efficiency

rated according to NSF/ANSI 44.

*** Extent of iron removal may vary with conditions. The capacity to reduce clear water iron is substantiated by

independent laboratory test data.

Refer to Cleaning Iron Out of the Water Softening System section.

Step-by-step installation instructions.

Sanitizing Procedures

To complete the installation, do the following

sanitizing procedures.

Care is taken at the factory to keep your

water softener clean and sanitary. Materials

used to make the softener will not infect or

contaminate your water supply and will not

cause bacteria to form or grow. However,

during shipping, storage, installing and

operating, bacteria could get into the

softener. For this reason, sanitizing as

follows is suggested when installing.

NOTE: Sanitizing is recommended by the

Water Quality Association for disinfecting.

1. Be sure to complete all installation steps,

including programming the control.

2. Pour about 22.ml (1

1

⁄2 tablespoons) of

common 5.25% unscented household bleach

(Clorox, Linco, Bo Peep, White Sail, Eagle,

etc.) into the brinewell. Refer to illustration

on page 5.

3. IMPORTANT: Press and hold for 3 seconds

the faceplate RECHARGE button to start

an immediate recharge. RECHARGE begins

to flash in the display. The bleach will be

drawn through the water softener and out

the drain. This process takes approximately

2 hours.

4. If, after sanitization, water from the house

faucet tastes salty or has a slight color, this is

a preservative from the resin tank. Turn on

the cold soft water faucets and drain for a

few minutes or until clear.

NOTE: When the above sanitizing regeneration

is over, all remaining bleach is flushed from the

conditioner and your house COLD water supply

is fully soft immediately. However, your water

heater is filled with hard water and as hot water

is used, all remaining bleach is flushed from

the system and it will refill with soft water.

When all the hard water is replaced in the

water heater, hot only and mixed hot and cold

water will be fully soft. If you want totally soft

water immediately, after the above recharge,

drain the water heater until the water runs

cold.

WARNING:If you do drain the

water heater, use extreme care as the hot

water could cause burns. Turn the water

heater off prior to draining.

Specifications/Dimensions

GXOF18K

Rated Capacity 5.2 mols with 0.80 kg of salt

8.6 mols with 1.7 kg of salt

12.2 mols with 4.6 kg of salt

Rated Efficiency 6.2 mols/kg @ 0.8 kg salt dose

Amount of High Capacity Resin (kg/liters) 15.1/18

Resin Tank Nominal Size (in., dia. x height) 10 x 21

Service Flow Rate (l/min) 26.5

Water Supply Maximum Hardness (gpg) 95

Water Supply Maximum Clear Water Iron (ppm) 5

Water Pressure Limits (min.–max. bar) 1.4 - 8.6

Pressure Drop at Rated Service Flow (bar) 0.55

Water Temperature Limits (min.–max. °C) 4 - 49

Maximum Flow Rate to Drain (l/min) 8.3

Inlet Outlet

8.6 cm

58.2 cm

36.8 cm

76.2 cm

Page 12

11

About the water softener system. GEAppliances.com

Service

When the water softening system is providing

soft water, it is called “Service.” During service,

hard water flows from the house main water

pipe into the water softening system. Inside the

water softening system resin tank is a bed made

up of thousands of tiny, plastic resin beads. As

hard water passes through the bed, each bead

attracts and holds the hard minerals. This is

called ion-exchanging. It is much like a magnet

attracting and holding metals. Water without

hard minerals (soft water) flows from the water

softening system and to the house pipes.

After a period of time, the resin beads become

coated with hard minerals and they have to be

cleaned. This cleaning is called recharge.

Recharge is started at 2:00 AM (factory setting)

by the water softening system control, and

consists of five stages or cycles. These are

FILL, BRINING, BRINE RINSE, BACKWASH and

FAST RINSE.

For emergency needs, hard water is available

to the home during the recharge cycles.

However, you should avoid using HOT water

because the water heater will fill with the

hard water.

Automatic Hard Water Bypass During Recharge

Fill

Salt dissolved in water is called brine. Brine is

needed to clean the hard minerals from resin

beads. To make the brine, water flows into the

salt storage area during the fill stage.

Brining

During brining, brine travels from the salt

storage area into the resin tank. Brine is the

cleaning agent needed to remove hard minerals

from the resin beads. The hard minerals and

brine are discharged to the drain.

The nozzle and venturi create a suction to

move the brine, maintaining a very slow rate

to get the best resin cleaning with the least salt.

Brine Rinse

After a pre-measured amount of brine is used,

the brine valve closes. Water continues to flow

in the same path as during brining, except for

the discontinued brine flow. Hard minerals and

brine flush from the resin tank to the drain

.

Backwash

During backwash, water travels up through

the resin tank at a fast flow rate, flushing

accumulated iron, dirt and sediments from

the resin bed and to the drain.

Fast Rinse

Backwash is followed by a fast flow of water

down through the resin tank. The fast flow

flushes brine from the bottom of tank, and

packs the resin bed.

After fast rinse, the water softening system

returns to soft water service.

Page 13

12

About the water softener system.

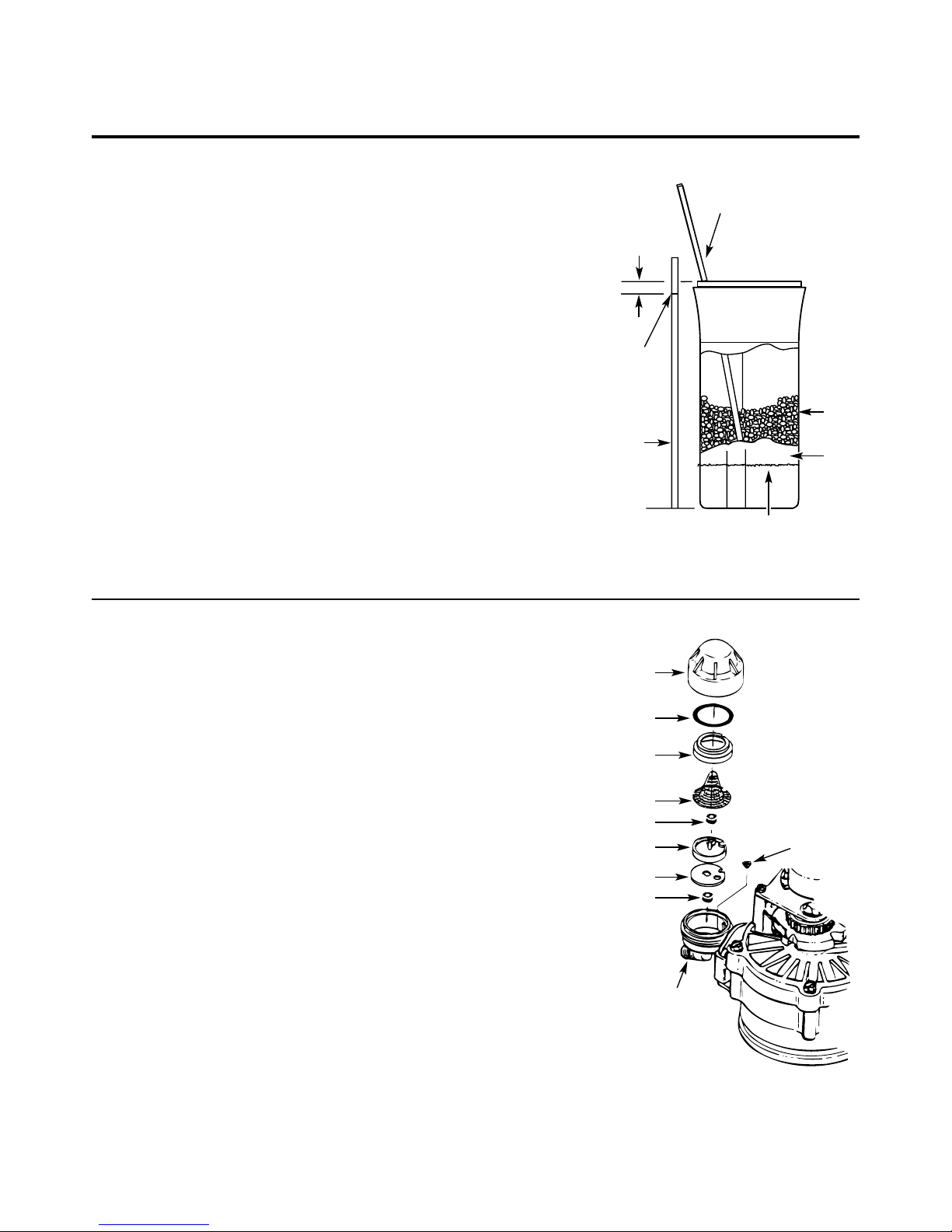

Breaking a Salt Bridge

Sometimes, a hard crust or salt bridge forms in

the salt storage area. It is usually caused by high

humidity or the wrong kind of salt. When the

salt bridges, an empty space forms between the

water and salt. Then salt will not dissolve in the

water to make brine.

If the brine tank is full of salt, it is hard to tell

if you have a salt bridge. Salt is loose on top,

but the bridge is under it. The following is the

best way to check for a salt bridge.

Salt should be loose all the way to the bottom

of the tank. Take a broom handle or like tool,

and carefully push it down into the salt,

working it up and down. If the tool strikes

a hard object (be sure it’s not the bottom or

sides of the tank), it’s most likely a salt bridge.

Carefully break the bridge with the tool.

Do not pound on the walls of the tank.

If the wrong kind of salt made the bridge, take

it out. Then fill the tank with nugget or pellet

salt only. In humid areas, it is best to fill with

less salt, more often to prevent a salt bridge

from forming.

A clean nozzle and venturi is needed for the

water softening system to work properly. This

small unit makes the suction to move brine

from the salt storage area to the resin tank

during recharge. If it becomes plugged with

sand, dirt, etc., the water softening system

will not work and you will get hard water.

To get to the nozzle and venturi, remove

the water softening system top cover. Be sure

the water softening system is in service cycle

(no water pressure at nozzle and venturi).

Then, while holding the nozzle and venturi

housing with one hand, remove the cap. Lift

out the screen support and screen, then the

nozzle and venturi. Wash and rinse the parts in

warm water until clean. If needed, use a small

brush to remove iron or dirt. Also check and

clean the gasket.

NOTE: Some models have a small flow plug

located in the nozzle and venturi, and/or

a small cone shaped screen in the housing.

Be sure to check and clean these parts,

if your model is so equipped.

Carefully replace all parts in the correct order.

Lightly lubricate the o-ring seal with clean

silicone grease or petroleum jelly and place in

position. Install and tighten the cap, by hand only.

Do not overtighten the cap.

Cleaning the Nozzle and Venturi Assembly

Push tool into salt

bridge to break

Pencil

mark

Broom

handle

Salt

Salt

bridge

Water level

2−5 cm

IMPORTANT: Be sure small holes in the gasket are

centered directly over the small holes in the nozzle and

venturi housing.

*Install with numbered side up, concave side down.

Cap

O-ring seal

Screen support

Screen

Screen

Nozzle & Venturi

Nozzle & Venturi

housing

Gasket

*Flow plug

*Flow plug

Page 14

13

GEAppliances.com

During normal operation, the present time of

day and AM or PM and DAYS TO EMPTY show

in the control display area. When the demand

computer determines a recharge is needed,

RECHARGE TONIGHT begins to flash in the

display along with the present time. RECHARGE

TONIGHT flashes until the next recharge start

time, then changes to RECHARGE, which flashes

until the recharge is over.

Normal Operation, Control Displays

Sometimes, a manually started recharge may

be desired or needed. Two examples:

■ You have used more water than usual

(house guests, extra washing, etc.) and

you may run out of soft water before the

next recharge.

■ The system ran out of salt.

Use one of the following features to start

a recharge immediately, or at the next preset

recharge start time.

RECHARGE TONIGHT

Touch (do not hold) the RECHARGE button.

RECHARGE TONIGHT flashes in the control

display area. A recharge will occur at the next

preset recharge start time. If you decide to

cancel this recharge, touch the same button

once more.

RECHARGE

Press and hold the RECHARGE button until

RECHARGE starts to flash in the control display

area. The water softening system begins an

immediate recharge and, when over in about

two hours, you will have a new supply of soft

water. Once started, you cannot cancel this

recharge.

Feature: Optional Recharge Controls

Feature: Memory

If electrical power to the water softening system

is interrupted, the control display is blank, and

the blue indicator light is off, but the control

keeps correct time for about 6 hours. When

power is restored, you have to reset the present

time only if the display and blue indicator light

are flashing. All other settings are maintained

and never require resetting unless a change

is desired.

If the time is flashing after a long power outage,

the water softening system continues to work

as it should to provide you with soft water.

However, recharge may occur at the wrong time

of day until you reset the control to the correct

time of day.

The control computer has a self-diagnostic

function for the electrical system (except

input power and water meter). The computer

monitors the electronic components and

circuits for correct operation. If a malfunction

occurs, an error code appears in the

control display.

The chart on Error Codes shows the error codes

that could appear and possible reasons for each

code. See Manually Initiated Electronic Diagnostics

to further isolate the defect.

Feature/Service: Automatic Electronic Diagnostics

Page 15

14

To remove an error code: 1. Unplug transformer.

2. Correct defect.

3. Plug transformer in.

4. Wait for at least 6 minutes. The error code will return if the reason for

the error code was not corrected.

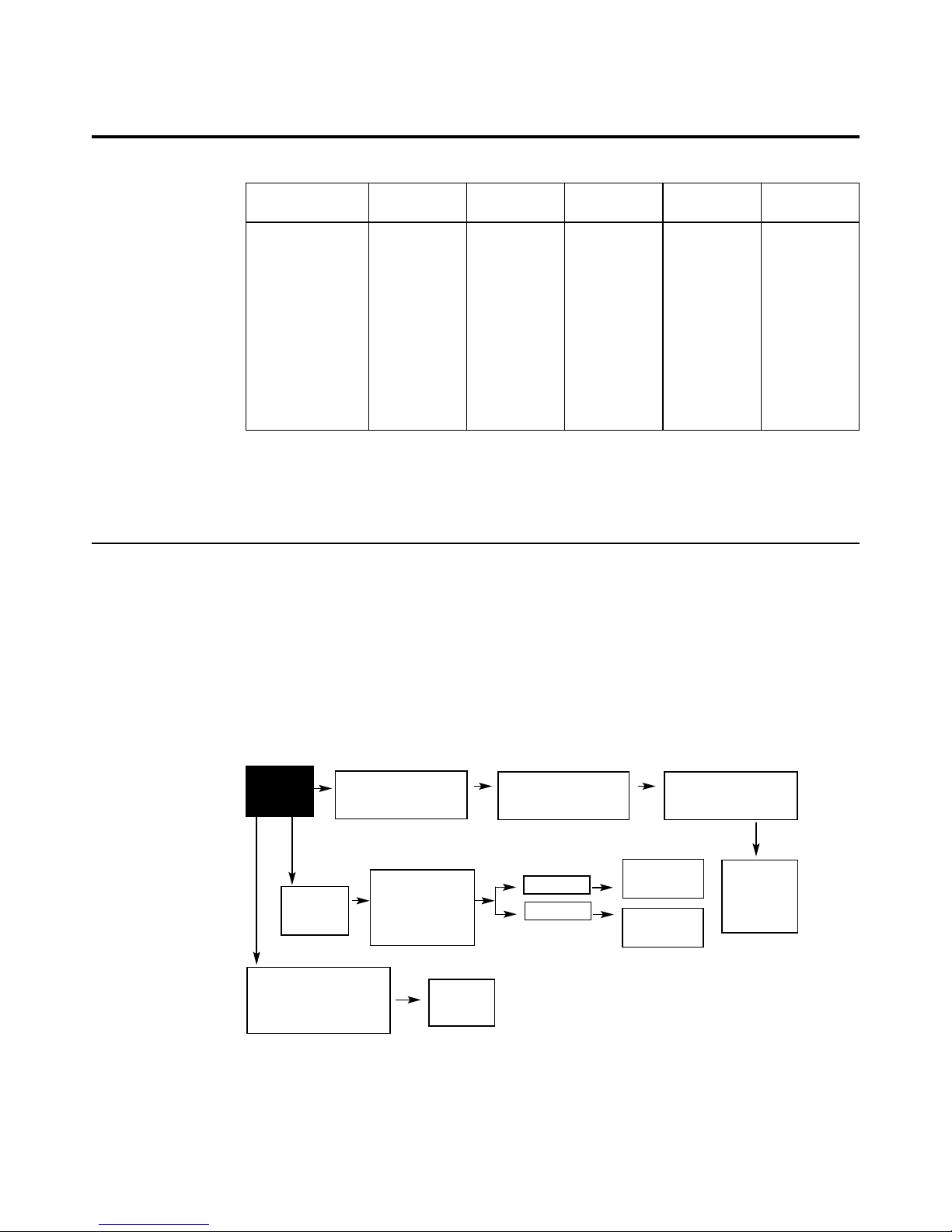

NO SOFT

WATER

CONTROL SHOWS

WRONG TIME AND DAY,

AND/OR IS FLASHING.

CONTROL

DISPLAY

BLANK.

CONTROL DISPLAY SHOWS

CORRECT TIME AND DAY

AND IS STEADY.

Check electrical

power to control

(outlet, transformer,

power cable, all

connections).

Do manual

diagnostics.

NOPOWER

POWER OK

REPAIR AS

NEEDED

CONTROL

DEFECTIVE

Do manual

diagnostics to

verify proper

function.

Electrical power was off.

Reset the correct time of

day.

Investigate reason for

power loss.

About the water softener system.

Service: Electronic Demand Time Features and Service

If you are not getting soft water, and an error

code is not displayed, use the procedures below

to find the problem. First make the following

visual checks.

VISUAL CHECKS:

1. Is there electrical power to the outlet the

water softening system transformer is

plugged into?

2. Is there sufficient salt in the storage tank?

3. Is the softener bypass valve directing water

for soft water service?

4. Is the valve drain hose open to the drain,

not more than 2m above the softener, and

unobstructed?

If you do not find a problem with the visual checks,

continue below.

Service: Timer/Softener, Service Checkout Procedure

ERROR CODE

DISPLAYED ERR 01 ERR 02 ERR 03 ERR 04 ERR 05

POSSIBLE DEFECT • Motor • Position • Motor • Position • Control

inoperative switch inoperative switch or

or wiring wiring

harness harness

• Wiring • Control • Control • Control

harness or

connection

to switch

• Position

switch

• Control

Page 16

15

GEAppliances.com

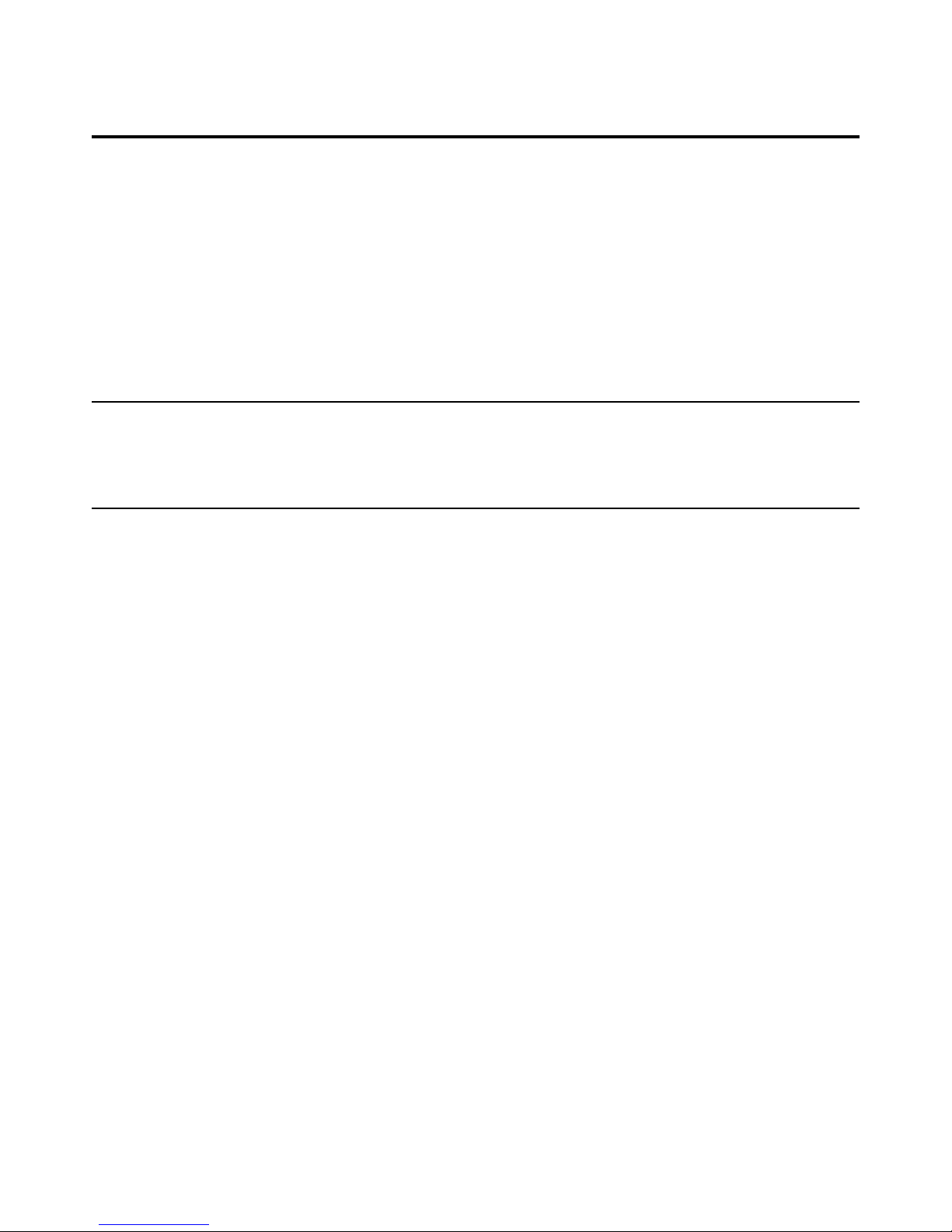

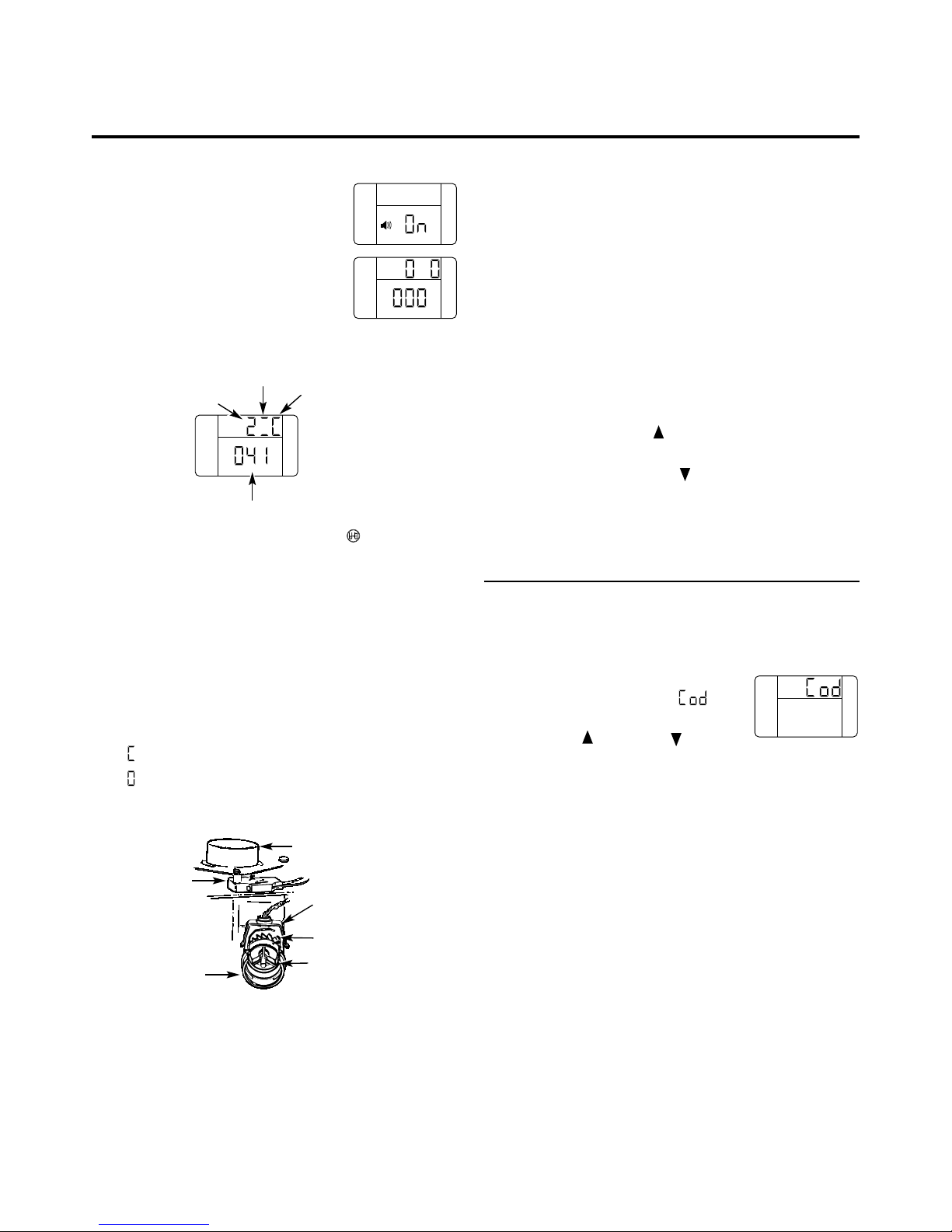

1. To enter diagnostics, press and hold

the MODE button for 3 seconds until

the Low Salt Alarm screen shows.

2. Press the MODE button 2 times to

advance through Low Salt Alarm

and Salt Efficiency options. See

Programming the Control for details

on these two options.

3. OPERATION OF DIAGNOSTICS

• Valve Position – Press the RECHARGE button to

initiate a recharge cycle. Press again to manually index

valve to next position. See Service: Manually Advance

Recharge Check for details.

0 – Service

1 – Fill

2 – Brine

3 – Backwash

4 – Fast Rinse

• Motor Operation – Two dashes will circulate around

when motor should be running.

• Position Switch Operation –

– Closed – valve rotating to next position

– Open – valve in position, service, fill, brine, etc.

• Water Meter – Indicates whether water is flowing

through valve.

– 000 indicates no water is flowing through the valve

– Open nearby soft water faucet

– 000 to 199(continual) shows water is flowing.

Display repeats for each gallon of water passing through the

meter. Control will beep at every gallon. (1 gallon= 3.78 litres)

– If there is no reading in the display, with faucet

open, check the sensor. Pull the sensor from the

valve outlet port, and pass a small magnet in front

of the sensor. Counter should index in the display.

If counter does not index, check to make sure

harness is connected to board properly. If there is

a reading in the display, there may be a problem

associated with the turbine. Turn off water supply,

close the by-pass valve, and disconnect by-pass valve

from valve body. Check turbine for binding or

restriction due to debris. If this does not correct

the problem, the Timer, Sensor, or Turbine may

require replacement.

4. Historical data about the softener is available.

• Press and hold the UP button to display the number

of days this control has had electrical power applied.

• Press and hold the DOWN button to display the

number of recharges initiated by this control since the

model code number was entered.

5. Press the MODE button to return to normal operation

and display.

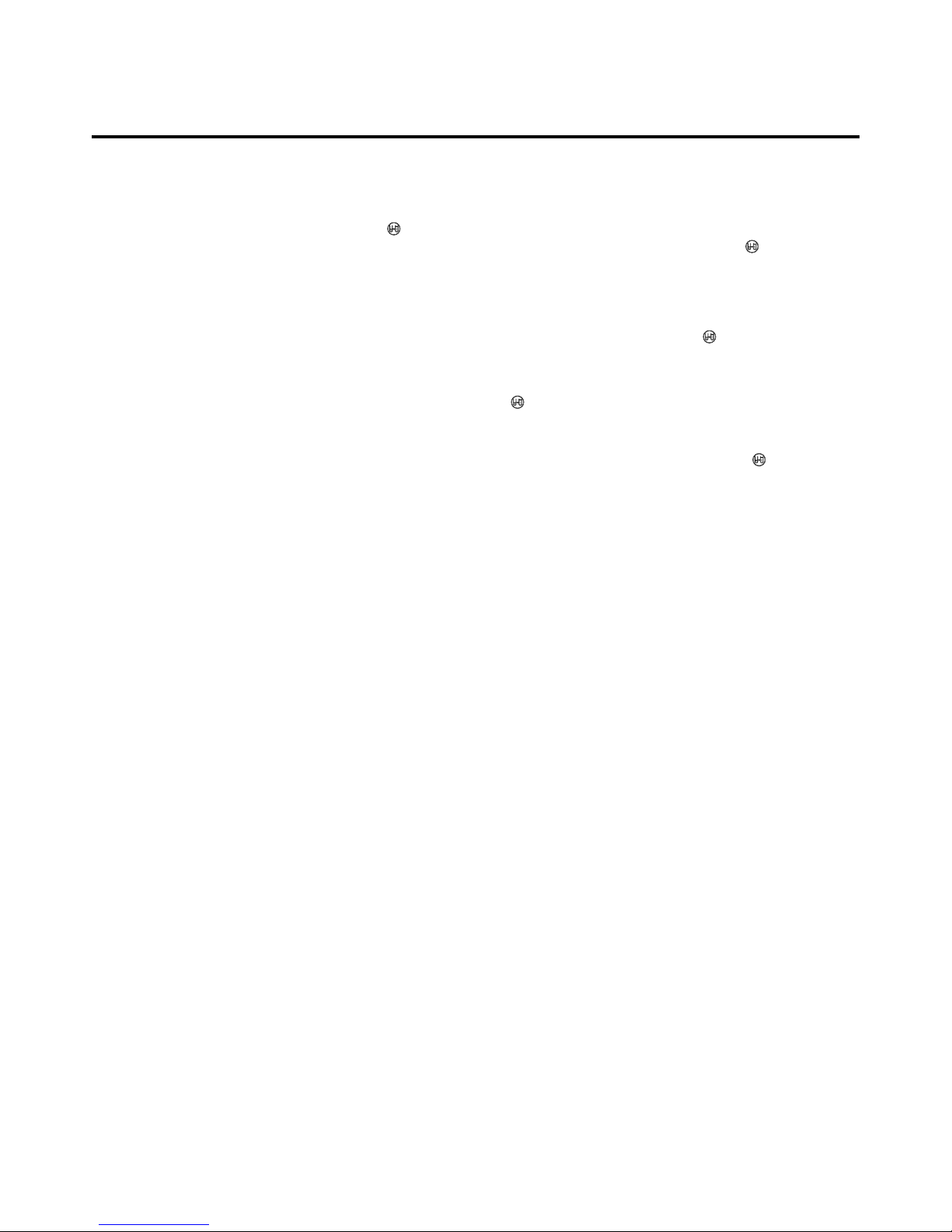

Service: Set Model (F) Code

1. To change or check model code, first press and hold the

MODE button for 3 seconds until the Low Salt Alarm

screen shows.

2. Press and hold the MODE button again

for 3 seconds. A display with at

the top will appear.

3. Press the UP or DOWN buttons

to select the correct model code.

F18 = GXOF18K

4. Press the MODE button one time to return to normal

operation and display. If the model code was changed:

• the display will go blank momentarily, then display the

model code entered.

• the display will then return to the set present time

display, and the blue indicator light will flash. The

control will have to be reprogrammed. See Programming

the Control.

NOTE: If the control is left in any of the above diagnostic

displays, or a flashing display when setting time, hardness,

etc., it will revert back to the normal display in 4 minutes.

Service: Manually Initiated Electronics Diagnostics

SALT

LEVEL

SALT

LEVEL

SALT

LEVEL

Water meter

Valve

position

Position

switch

Motor

Motor

Turbine

Turbine support

and shaft

Sensor

housing

Position

switch

Valve

outlet

SALT

LEVEL

H45

Page 17

16

About the water softener system.

NOTE: The control display must show a steady

time (not flashing).

1. Press the RECHARGE button and hold in

for three seconds. RECHARGE begins to flash

as the water softening system enters the fill

cycle of recharge. Remove the brinewell

cover and, using a flashlight, observe fill

water entering the brine tank. If water does

not enter the tank, look for an obstructed

nozzle, venturi, fill flow plug or brine tubing.

See Care and Cleaning of the Water Softener

System section.

2. After observing fill, press the RECHARGE

button to move the water softening system

into brining. A slow flow of water to the drain

will begin. Verify brine draw from the brine

tank by shining a flashlight into the brinewell

and observing a noticeable drop in the liquid

level over an extended period of time.

NOTE: Be sure a salt bridge is not preventing

water from contacting salt. See Care and

cleaning of the water softening system section.

If the water softening system does not draw brine,

check:

■ nozzle and/or venturi dirty or defective.

■ defective nozzle and venturi seal.

■ nozzle and venturi not seated properly

on gasket.

■ other inner valve defect (rotor seal, rotor

and disc, wave washer, etc.).

■ restricted drain (check drain fitting and

hose).

NOTE: If water system pressure is low, an

elevated drain hose may cause back pressure,

stopping brine draw.

3. Again, press the RECHARGE button to move

the water softening system into backwash.

Look for a fast flow of water from the drain

hose. A slow flow indicates a plugged top

distributor, backwash flow plug or drain hose.

4. Press the RECHARGE button to move the

water softening system into fast rinse. Again

look for a fast drain flow. Allow the water

softening system to rinse for a few minutes

to flush out any brine that may remain in

the resin tank from the brining cycle test.

5. To return the water softening system to

service, press the RECHARGE button.

Service: Manually Advance Recharge Check

Page 18

17

Care and cleaning of the water softening system. GEAppliances.com

Brine (salt dissolved in water) is needed for

each and every recharge. The water for making

brine is metered into the salt storage area by

the water softening system valve and control.

However, you must keep the tank supplied

with salt.

When to refill with salt: If the blue indicator

light and DAYS TO EMPTY are flashing, there is

less than 15 days supply of salt. Refill with salt.

In humid areas it is best to refill with less salt

and more often, to avoid the forming of a salt

bridge, see page 12. After adding salt,

remember to reset the SALT LEVEL in the

control, see page 8. Never allow the salt level

to drop below zero on the yellow indicator

before you refill it. Without enough salt, you

will soon have hard water.

Use clean water softening salts only, at least

99.5% pure. NUGGET, PELLET or coarse

SOLAR salts are recommended. Do not use rock,

block, granulated or ice cream making salts.

They contain dirt and sediments, or mush and

cake, and will create maintenance problems.

CAUTION: Water softening salt with

iron removing additives: Some salts may have

an additive to help the water softening

system handle iron in the water supply.

Although this additive may help to keep the

water softening system resin clean, it may

also release corrosive fumes that weaken

and shorten the life of some water softening

system parts.

Checking the Salt Storage Level and Refilling

Your water softening system takes hardness

minerals (calcium and magnesium) out of

the water. Also, it can control some (see the

Specification Guidelines section) “clear water”

iron. With clear water iron, water from a faucet

is clear when first put into a glass. After 15 to

30 minutes, the water begins to cloud or turn

rust colored. A water softening system will not

remove any iron that makes the water cloudy

or rusty as it comes from the faucet (called red

water iron). To take red water iron out of water,

or over the maximum of clear water iron,

an iron filter or other equipment is needed.

If your water supply has clear water iron,

periodic resin bed cleaning is needed.

Clean the bed at least every six months, or more

often if iron appears in the soft water between

cleanings.

IMPORTANT: It is important to mix the resin bed

cleaner with water (following the manufacturer’s

instructions), pour it into the brinewell tube

(see page 5) and recharge the softener

immediately. Do not pour the resin bed cleaner

in with the salt, as it will not be as effective in

cleaning the resin, and can cause damage to

the softener if it is left in the brine tank for an

extended period due to the corrosive gases that

are formed.

Cleaning Iron Out of the Water Softening System

Page 19

18

Troubleshooting Tips

Save time and money! Review the chart on this

page first and you may not need to call for service.

Problem Possible Causes What To Do

No soft water Faucet or fixture where sample was •

To conserve salt, the installer

may have isolated some fixtures

taken not plumbed to soft water.

(outside faucets, toilets, etc.)

from soft water. From the outlet

NOTE:

Be sure sample is from a faucet of the water softening system, trace the water flow path,

that does not mix soft and hard water. in house plumbing. If soft water is not directed to a faucet

For example, a single lever kitchen faucet, or

fixture where wanted, consult a plumber.

if the cold side is plumbed to hard water.

No salt in the brine tank or • Check for a salt bridge or, if the

tank is empty, refill with

salt bridged recommended salt. Press (for 3 seconds) the RECHARGE

button to start an immediate recharge and restore

soft water supply.

Transformer unplugged at wall outlet or

• Check for a loss of electrical power to the water softening

power cable to softener not connected. system, due to any of these conditions and correct as needed.

Fuse blown or circuit breaker popped With the power supply restored, observe the faceplate time

on circuit to electrical outlet. display and read Programming the Control section.

Electrical outlet on a circuit that can

NOTE: The electrical outlet for the softener should be continuously

be switched off

live

so it cannot be accidentally switched off.

Manual bypass valve in bypass position • Be sure the bypass valve stem

is positioned properly, with the

knob in the OUT position. Observe i

nstructions on the decal

at the end of the stem. Check the position of bleed screw.

Valve drain hose pinched, plugged, •

Any restriction in this drain hose

may prevent proper

elevated too high or otherwise

operation of the

nozzle and venturi and reduce or prevent

restricted brine draw during recharge.

Nozzle and venturi dirty, incorrectly • Refer to Cleaning the Nozzle and Venturi Assembly

instructions.

assembled or damaged

With water pressure to the

water softening system off, take

the nozzle assembly apart. Inspect, clean and replace as

needed. Any foreign particle(s), scratches, nicks, etc., in the

passages can

prevent operation. Be sure holes in the gasket are

centered over holes in the housing.

NO SOFT WATER – Most Common Problems:

Check the following before calling for service:

•

Not enough salt—should be at least 1/3 full.

•

Bypass valve in “Bypass” position—knob should be in the “OUT” (service) position.

•

Hardness setting too low. Check hardness setting and adjust. Verify hardness of

supply water—from local water company, water test or call the GE Answer Center.

•

Salt Bridge—salt solidifies above water level so that brine water is not in contact

with salt. See the Breaking a Salt Bridge section.

Before you call for service…

Page 20

19

Problem Possible Causes What To Do

Water hard sometimes Using hot water while the water • Avoid using hot water during water softening system

softening system is regenerating recharge because the water heater will refill with hard water.

See Automatic Hard Water Bypass During Recharge section,

page 11.

Control HARDNESS number setting • Press the MODE button until arrow points to HARDNESS.

too low Be sure the number shown is the same as the actual grains

per gallon hardness of your water supply. See the

Programming the Control section if a change in the setting

is needed.

Grains of hardness in your water •

Water hardness can change

over time, especially in well water.

supply have increased To check, have the water tested by a water analysis laboratory

or call your local water department. Adjust the HARDNESS

number setting as needed.

Water feels slippery Absence of hardness minerals • This is normal. Hardness in water gives it the abrasive feel

after installation of you may have been accustomed to. The slippery feel is the

water softening system clean feel of soft water.

Water softening system Water softening system is a • Does not use much salt to regenerate—very efficient.

not using any salt “demand” unit

Possible salt bridge • See the About the Water Softener System section, page 12.

Possible plugged nozzle and venturi • See the About the Water Softener System section, page 12.

Water is blue color Acidic water in copper plumbing • Have the water tested at once.

after water softening

system was installed

Water softening system Meter turbine stuck • See the Service: Manually Initiated Electronics Diagnostics

not regenerating section for troubleshooting procedures, page 15.

• Call for service.

Sensor wire not plugged into • See the Service: Manually Initiated Electronics Diagnostics

the control section for troubleshooting procedures, page 15.

• Call for service.

No power to unit • Check the circuit breaker or fuses.

Mechanical defect • Call for service.

Cloudiness on glassware Combination of soft water and • This is called etchingand is permanent. To prevent this

(automatic dishwashers) too much detergent from happening, use less detergent if you have soft water.

Wash glassware in the shortest cycle that will get them clean.

Excessive/high level Valve drain hose pinched, • Any restriction in this drain hose may prevent proper

of water in brine tank plugged, elevated too high operation of the nozzle and venturi and reduce or prevent

or otherwise restricted brine draw during recharge.

Nozzle and venturi dirty, incorrectly • See the Cleaning the Nozzle and Venturi Assembly section,

assembled or damaged page 12. With water pressure to the water softening system

off, take the nozzle assembly apart. Inspect, clean and

replace as needed. Any foreign particle(s), scratches, nicks,

etc., in the passages can prevent operation. Be sure holes

in the gasket are centered over holes in the housing.

GEAppliances.com

Page 21

20

Problem Possible Causes What To Do

Salty tasting or Unit not sanitized • Complete the Sanitization Procedureson page 10.

brown/yellow colored

• At completion of recharge cycle(approx. 2 hrs), run water

water after installation

from faucets to purge the salty water.

Low water pressure • Check pressure; should be minimum1.4 Bar.

Restricted drain hose • Clean and reconnect hose.

• Check for kinks in drain line.

Brown/yellow Unit was idle for a period of time • Complete the Sanitization Procedures on page 10.

colored water

Resin beads showing Cracked distributor • Call for service.

up in drinking water

and sink

Sounds you might hear Running water from the unit •This is normal.

into a drain during recharge

Water has air bubbles Air in system after installation •Will go away after it runs for a while.

and is cloudy

Error Code on control Wiring may have worked loose • See page 14 for details.

in the control

• Unplug transformer.

• Remove control cover, release clips on side.

• Check for loose/incorrect wiring connections to electronic

board or switch. Reconnect as required.

• Reassemble control cover.

• Plug in Transformer.

• Wait six minutes for Error Code to reappear.

• If Error Code reappears, call for service.

Troubleshooting Tips

Before you call for service…

Blue light flashing

When power applied Control needs to be programmed • See the Programming the Controlsection, page 8.

to the system (a power outage may have occurred)

If “DAYS TO EMPTY” Low salt level, less than 15 days • Fill with salt.

is flashing

•Reset salt level.

If “Err” in display Electrical problem with system • See page 14 for details.

•See procedure above, Error code on control.

Page 22

Sistema Suavizante

De Agua

Información de seguridad . . . . . . 22

Instrucciones para la instalación 23–32

Instrucciones paso por paso . . . . . . . . . .26-32

Instrucciones para la operación

Cómo romper un puente de sal . . . . . . . . . 34

Cómo limpiar la ensambladura

de la boquilla y el Venturi . . . . . . . . . . . . .35

Funciones . . . . . . . . . . . . . . . . . . . . . . . . .36

Servicio . . . . . . . . . . . . . . . . . . . . . .33,37,38

Sistema de descalcificación de agua . . . . . . 33-38

Cuidado y limpieza . . . . . . . . . . 40

Consejos para la solución de averías .41-43

Soporte al cliente

Lista de parte. . . . . . . . . . . . . . . . . . . . . 87

Lista de partes/cat logo

La Página 87

GEAppliances.com

#30500 General GXOF18K EURO Version 10-01

Escriba aquíel modelo y los números

de la serie:

Modelo No. ____________________

Serie No. ______________________

Para encontrar estos n múeros,

levante la cubierta y mire en el

borde, debajo del panel del control.

Modelos GXOF18K

Manual del Propietario e

Instrucciones de Instalación

Sistema Suavizante

de Agua

Page 23

INFORMACIÓN IMPORTANTE DE SEGURIDAD.

LEA TODAS LAS INSTRUCCIONES ANTES DEL USO.

PRECAUCIONES DE SEGURIDAD

■ Revise y cumpla con todos los códigos estatales y

locales. Observe las pautas aquí presentadas.

■ Tenga cuidado al manipular el sistema de

descalcificación de agua. No lo voltee, deje caer,

arrastre o coloque en protuberancias extremas.

■ Los sistemas de descalcificación de agua que utilicen

cloruro de sodio (sal) para la recarga agregan sodio

al agua. Las personas que siguen dietas con

restricciones de sodio deben considerar el sodio

adicional como parte de su consumo general. El cloruro

de potasio puede servir como una alternativa para el

cloruro de sodio de su descalcificador.

■

El sistema de descalcificación de agua funciona

solamente con 24 voltios-50 Hz.

Cerciórese de usar

exclusivamente el transformador incluido.

■ El transformador se debe conectar únicamente

a un tomacorriente interior con conexión a tierra

de 220 - 240 voltios.

■ Utilice únicamente sales para descalcificación

del agua, al menos con 99.5% de pureza. Se

recomiendan las sales en PEPITAS, BOLITAS

o SAL GRUESA SOLAR. No utilice sales en roca,

bloque, granuladas o sales para la elaboración

de helados. Éstas pueden contener suciedad y

sedimentos, o pasta y masa y podrían crear

problemas de mantenimiento.

■ Mantenga la tapa del orificio de la sal en su lugar en

el descalcificador a menos que esté realizando

mantenimiento o reponiendo la sal.

ADVERTENCIA: No use con agua que

sea microbiológicamente insegura o de calidad

desconocida sin llevar a cabo la desinfección

adecuada antes o después del sistema.

LEA Y SIGA ESTA INFORMACIÓN DE SEGURIDAD CUIDADOSAMENTE.

GUARDE ESTAS INSTRUCCIONES

INSTALACIÓN CORRECTA

■ Instale o almacene donde no quede expuesto a

temperaturas por debajo del punto de congelación

ni esté expuesto a ningún tipo de inclemencias

atmosféricas. Si el agua llega a congelarse dentro

del sistema, éste podría romperse. No intente dar

tratamiento al agua si se encuentra a una

temperatura por encima de 37 ºC.

■ No instale expuesto a los rayos directos del sol.

Exposición al sol a calor excisivos podrían causar

distorsión u otros daños a las partes no metálicas.

■ Conecte a tierra de manera apropiada según los

códigos y ordenanzas aplicables.

■ Use solamente fundente y soldadura sin plomo para

todas las conexiones de condensación soldadas,

según los códigos estatales y federales aplicables.

■

El sistema de descalcificación de agua requiere un

flujo de agua mínimo de 11 litros por minuto en

la entrada. La presión de entrada máxima permitida

es de 8.6 bar. Si la presión durante el día es por

encima de 5.5 bar, la presión nocturna podría exceder

el máximo. Use una válvula reductora de presión

para reducir el flujo si es necesario.

■

Las resinas de descalcificación podrían degradarse

ante la presencia de cloro por encima de 1 ppm.

Si usted tiene una cantidad de cloro mayor a ésta,

quizás experimente una vida menor de la resina.

En estas condiciones, es posible que quiera

considerar la compra de un sistema de filtración

del punto de admisión para casas GE con un filtro

reductor de cloro.

ADVERTENCIA:Deseche todas las

partes y los materiales de embalaje no utilizados

después de la instalación. Partes pequeñas

restantes después de la instalación podrían

representar un peligro de asfixia.

Este sistema de descalcificación de agua debe instalarse correctamente y colocarse de acuerdo a las

instrucciones de instalación antes de su uso.

22

Por su seguridad, se debe seguir la información en este manual con el fin de reducir el riesgo de una

descarga eléctrica, daños a la propiedad o daños personales.

ADVERTENCIA

Page 24

23

PRECAUCIÓN: Se necesita cierta habilidad de plomería para la instalación.

Si usted no está seguro acerca de la instalación de alguna de las partes de este producto,

consulte a un plomero profesional.

Instrucciones de instalación.

Desempacado e inspección

Cerciórese de inspeccionar completamente el

descalcificador en busca de daños durante el

envío o partes que puedan haberse perdido.

También revise en busca de daños en la caja

de envío. Póngase en contacto con la compañía

de transporte para cualquier reclamo por daño

o pérdida. El fabricante no es responsable por

daños sufridos durante el tránsito.

Las partes pequeñas necesarias para instalar el

descalcificador se encuentran en una pieza de

cartón termoconformada. Para evitar la pérdida

de las partes pequeñas, manténgalas en el

paquete termoconformado hasta que usted

esté listo para usarlas. Cerciórese deno

descartar componentes que podrían estar

escondidos en el embalage.

■ Antes de comenzar la instalación, lea estas

Instrucciones de instalación completamente.

Luego, obtenga todos los materiales y

herramientas que necesita para llevar a cabo

la instalación. No instalar correctamente el

descalcificador invalida la garantía.

■ Revise los códigos locales. La instalación

debe cumplir tales requisitos.

■ Consulte a su plomero certificado, si tiene

alguna pregunta sobre el código de Plomería.

■ Use solamente fundente y soldadura sin

plomo para todas las conexiones de

condensación soldadas, según los códigos

estatales y federales aplicables.

■ Conecte el descalcificador en la tubería

de suministro principal antes del calentador

de agua. NO HAGA PASAR AGUA CALIENTE

A TRAVÉS DEL DESCALCIFICADOR. La

temperatura del agua que pase a través

del descalcificador debe ser menor de

49 ºC.

■ Tenga cuidado cuando manipule el

descalcificador. No lo coloque boca arriba,

ni lo deje caer, ni lo arrastre, ni lo apoye

en protuberancias.

■ La presión de entrada máxima permitida

es de 8.6 bar. Si la presión durante el día es

por encima de 5.5 bar, la presión nocturna

podría exceder el máximo. Use una válvula

reductora de presión para reducir el flujo si

es necesario. (Agregar una válvula reductora

de presión podría reducir el flujo.)

■ El sistema de descalcificación funciona

solamente con 24 voltios-50 Hz. Cerciórese

de usar exclusivamente el transformador

incluido. Cerciórese de que el tomacorriente

eléctrico y el transformador están en el

interior de un recinto para protegerlos

de la humedad.

■ Consulte la sección Dónde instalar el

descalcificador para más detalles.

ADVERTENCIA:No use con

agua que sea microbiológicamente

insegura o de calidad desconocida sin

llevar a cabo la desinfección adecuada

antes o después del sistema. El agua debe

probarse periódicamente para verificar

que el sistema se encuentra funcionando

satisfactoriamente.

■ Partes pequeñas restantes después de la

instalación podrían representar un peligro

de asfixia. Deseche con toda seguridad.

Recomendaciones importantes para la instalación

Lea el manual completo. Ignorar las directrices y reglas podría causar lesiones personales o

daños a la propiedad.

Page 25

24

Instrucciones de instalación.

Dónde instalar el Descalcificador

■ Coloque el descalcificador lo más cercano

posible a un sumidero, o a otro punto de

drenaje o columna de suministro.

■ Se recomienda que los grifos externos se

dejen con agua dura para así ahorrar agua

descalcificada y sal.

■

No instale el descalcificador en un lugar

donde se pueda congelar. Los daños debido al

congelamiento no están cubiertos por la garantía.

■ No instale el descalcificador donde pueda

bloquear el acceso al calentador de agua o el

acceso a la válvula de cierre principal del agua.

■ Coloque el descalcificador en un lugar donde

sea menos probable que ocurra daño causado

por el agua si es que eventualmente ocurriese

alguna fuga. El fabricante no reparará ni pagará

por daños ocasionados por agua.

■ Un tomacorriente de 220-240 voltios es necesario

para conectar el transformador que viene

incluido. El descalcificador tiene un cable

eléctrico de 2 métros. Si el tomacorriente está

colocado demasiado lejos (hasta 30 métros),

use un cable de 0.8 mm2 para conectarlo.

Cerciórese de que el tomacorriente eléctrico y el

transformador estén en el interior de un recinto

para protegerlos de la humedad. Cerciórese de

que el tomacorriente esté desconectado para

prevenir un corte eléctrico accidental.

■ Si se dispone a llevar a cabo la instalación en

el exterior, debe tomar las medidas necesarias

para asegurarse de que el descalcificador, la

instalación de plomería, el cableado, etc.

están también protegidos de los elementos

(rayos del sol, lluvia, viento, calor, frío), de la

contaminación, vandalismo, etc. tal y como lo

estarían si fueran instalados internamente. La

instalación en el exterior no es recomendada, y

anula la garantía.

■ Mantenga el descalcificador alejado de los rayos

directos del sol. El calor del sol podría causar

distorsión u otros daños a las partes no

metálicas y podría hacer daño a las partes

electrónicas.

■ Los accesorios de entrada y salida incluidos

con el descalcificador son de 1".

Debe mantener un tamaño igual o mayor de

tubos que los tubos del suministro del agua,

hacia la entrada y salida del descalcificador.

■ Use la válvula de bypass incluida para instalar el

descalcificador. La válvula de bypass le permite

desconectar el suministro de agua hacia el

descalcificador para efectuar servicio, pero aún

mantiene el agua llegando a las tuberías de la

casa.

■ Use accesorios y tuberías de cobre, latón o

galvanizados. Algunos códigos podrían permitir

el uso de tuberías plásticas CPVC.

■ Si una manguera adicional es necesaria para el

drenaje de la válvula y el tanque de sal, usted la

puede.

■ Si necesita una válvula rígida de drenaje para

cumplir con los códigos de plomería, podrá

comprar las partes necesarias para conectar

un drenaje de tubería de cobre o plástico de

1/2″ (1.27 cm).

■ Sal del descalcificador en una pepita limpia o

bolita de agua es necesaria para llenar el tanque

de agua salmuera, consulte las Instrucciones de

Instalación Paso por Paso en el Paso 8.

Herramientas y materiales necesarios para la instalación

Lo primero que debe decidir es cómo instalar las

tuberías que entran y salen del descalcificador.

Fíjese en la tubería de agua en el punto donde

conectará el descalcificador. ¿La tubería está

soldada con cobre, pegada con plástico, o roscada

galvanizada? ¿Cuál es el tamaño de la tubería?

ADVERTENCIA: Use solamente

fundente y soldadura sin plomo para todas las

conexiones de condensación soldadas, según

los códigos estatales y federales aplicables.

Consulte la Ilustración de instalación normal, Fig. 1.

Úsela como una guía para planificar su instalación

particular. Cerciórese de dirigir el suministro de

agua dura entrante al acoplamiento de admisión

de la válvula del descalcificador. La válvula está

marcada IN (ENTRADA) y OUT (SALIDA). Consulte

la ilustración en la página 25 como ayuda para la

preparación.

Planifique la instalación del Descalcificador

Page 26

25

GEAppliances.com

Illustracióon de instalacion normal

Agua descalcificada

Agua dura hacia los

grifos externos

TUBERIA DE AGUA PRINCIPAL

Agua dura

NOTA: Ver la seccion Conexiones de la manguera de drenaje.

Transformador de 24V

Tomacorriente de 220 -240 voltios

Valvula de bypass

Agua dura hacia

los grifos externos

Valvula de entrada

Valvula de salida

Sistema de derivacion de 3 valvulas

Para el servicio de agua descalcificada:

• Abra las valvulas de entrada

y saldia

• Cierre la valvula de bypass

Para circunvalar el agua dura:

• Cierre las valvulas de entrada

y salida

• Abra la valvula de bypass

LA SAL

VA ACQUI

Deposito de la salmuera

ENTRADA

Arandela (2) (no incluida)

Tubo de cobre, 3/4″ (2) (no incluido)

Tuerca de instalacion (2) (no incluida)

Valvula de bypass

• Tire hacia afuera para servicio de agua descalcificada

• Empuje para bypass

NOTA: Las acesorios proporcionados son para

plomeria de cobre de 3/4″. Si usted tiene plomeria de 1", no use los tubos de cobre y las tuercas incluidas. Compre

adaptadores hembras NPT de 1" y conectelos directamente a las rocas macho NPT de 1" de la valvula de bypasss.

Tuerca (2) (no incluida)

Tubo de cobre de 3/4″ (2) (no incluido)

Arandela (2) (no incluida)

Adaptador de instalacion (2) (ver ariba)

NOTA: Los acesorios proporcionados son para plomeria de cobre de 3/4". Si usted tiene plomeria de 1", no

use los tubos de cobre y las tuercas incluidas. Compre adaptadores hembras NPT de 1" y conectelos directamente

a las roscas macho NPT de 1" del adaptador.

ENTRADA