Page 1

SAFETY INFORMATION .........3

SYSTEM OVERVIEW .............4

INSTALLATION INSTRUCTIONS

Cold Water Connection .................5

Control Valve Installation ...............6

Mounting the System ...................8

Filter Change Light ....................9

Filter Replacement .....................9

Flush Procedure .......................9

TROUBLESHOOTING TIPS ......10

PARTS LIST ...................... 11

PERFORMANCE

DATA SHEET ...................12

SYSTEM

WARRANTY ......................13

CONSUMER SUPPORT ..........14

OWNER’S MANUAL

& INSTALLATION

INSTRUCTIONS

GXK185KBL

ENGLISH/ESPAÑOL

GXK185KBL System is certified

by IAPMO R&T against NSF/ANSI

Standards 42,53, and 401 for the

reduction of claims specified on

the performance data sheet and at

iapmort.org.

WATER FILTRATION

GE is a trademark of the General Electric Company. Manufactured under trademark license.

49-6000061 07-16 GEA

Page 2

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances

product, and we think you will too.

2 49-6000061

Page 3

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING

IMPORTANT SAFETY INSTRUCTIONS

WARNING

To reduce the risk associated with choking, do not

allow children under 3 years of age to have access to

small parts during the installation of this product.

To reduce the risk associated with the ingestion

of contaminants, do not use with water that is

microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

To reduce the risk associated with hazardous voltage

due to an installer drilling through existing electric

wiring or water pipes in the area of installation, do not

To reduce the risk of fire, explosion, electric shock, or injury when using your

system follow these basic safety precautions:

install near electric wiring or piping which may be in

path of a drilling tool when selecting the position to

mount the system bracket.

If this device is not maintained and operated as

specified in the owner’s manual, there is a risk of

exposure to contaminants. For more information,

visit the manufacturer’s internet website at www.

geappliances.com or the California State Water

Resources Control Boards’ internet website at www.

waterboards.ca.gov.

SAFETY INFORMATION

CAUTION

To reduce the risk of physical injury, depressurize system as shown in manual prior to cartridge removal.

To reduce the risk of injury when using your system follow these basic safety precautions

NOTICE:

Read and follow Use Instructions before installation and

use of this system.

Installation and use MUST comply with all state and

local plumbing codes.

Do not use on a hot water supply (100°F max.). Install

on a cold water line only.

Protect from freezing, remove filter cartridge when

temperatures are expected to drop below 35° F (1.7° C).

Do not install if water pressure exceeds 125psi (8.8 Kg/

cm2). If your water pressure exceeds 80 psi (5.6 Kg/

cm2), you must install a pressure limiting valve. Contact

a plumbing professional if you are uncertain how to

check your water pressure.

Do not install systems in areas where ambient

temperatures may go above 110° F (43.3° C).

The disposable filter cartridge should be replaced every

6 months, at the rated capacity or sooner if a noticeable

reduction in flow rate occurs.

Where a back flow prevention device is installed on a

water system, a device for controlling pressure due to

thermal expansion must be installed.

Do not install where water hammer conditions may

occur. If water hammer conditions exist you must

install a water hammer arrester. Contact a plumbing

professional if you are uncertain how to check for this

condition.

Ensure all tubing and fittings are secure and free of

leaks.

On plastic fittings, never use pipe sealant or pipe

dope. Use PTFE thread tape only as pipe dope may

deteriorate the plastic.

Do not use a torch or other high temperature sources

near system, cartridges, plastic fittings or plastic

plumbing.

Do not install in direct sunlight or outdoors.

Do not install near water pipes which will be in path of

a drilling tool when selecting the position to mount the

bracket.

Mount system in such a position as to prevent it

from being struck by other items used in the area of

installation.

Ensure that the location and fasteners will support the

weight of the system when installed and full of water.

.

SAVE THESE INSTRUCTIONS

49-6000061 3

Page 4

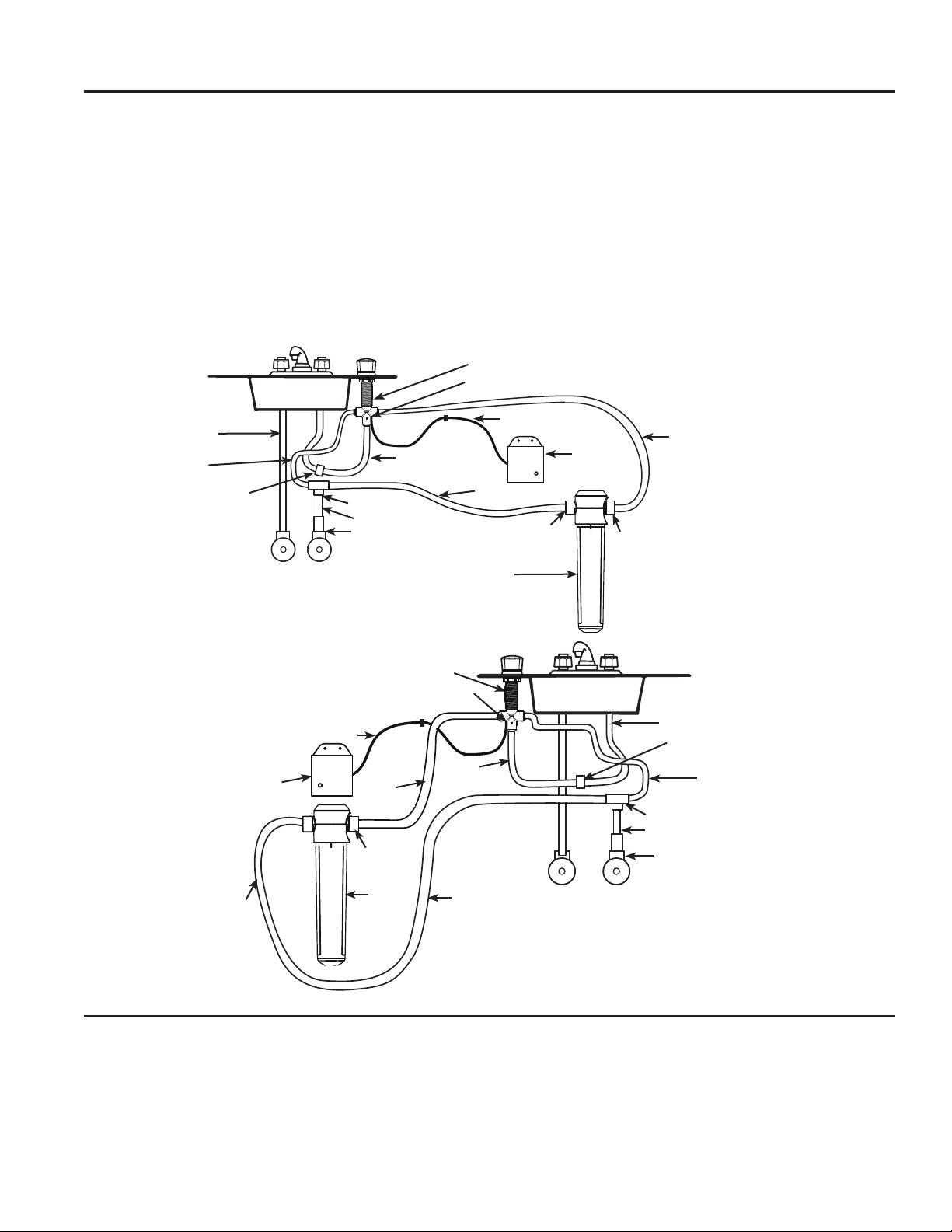

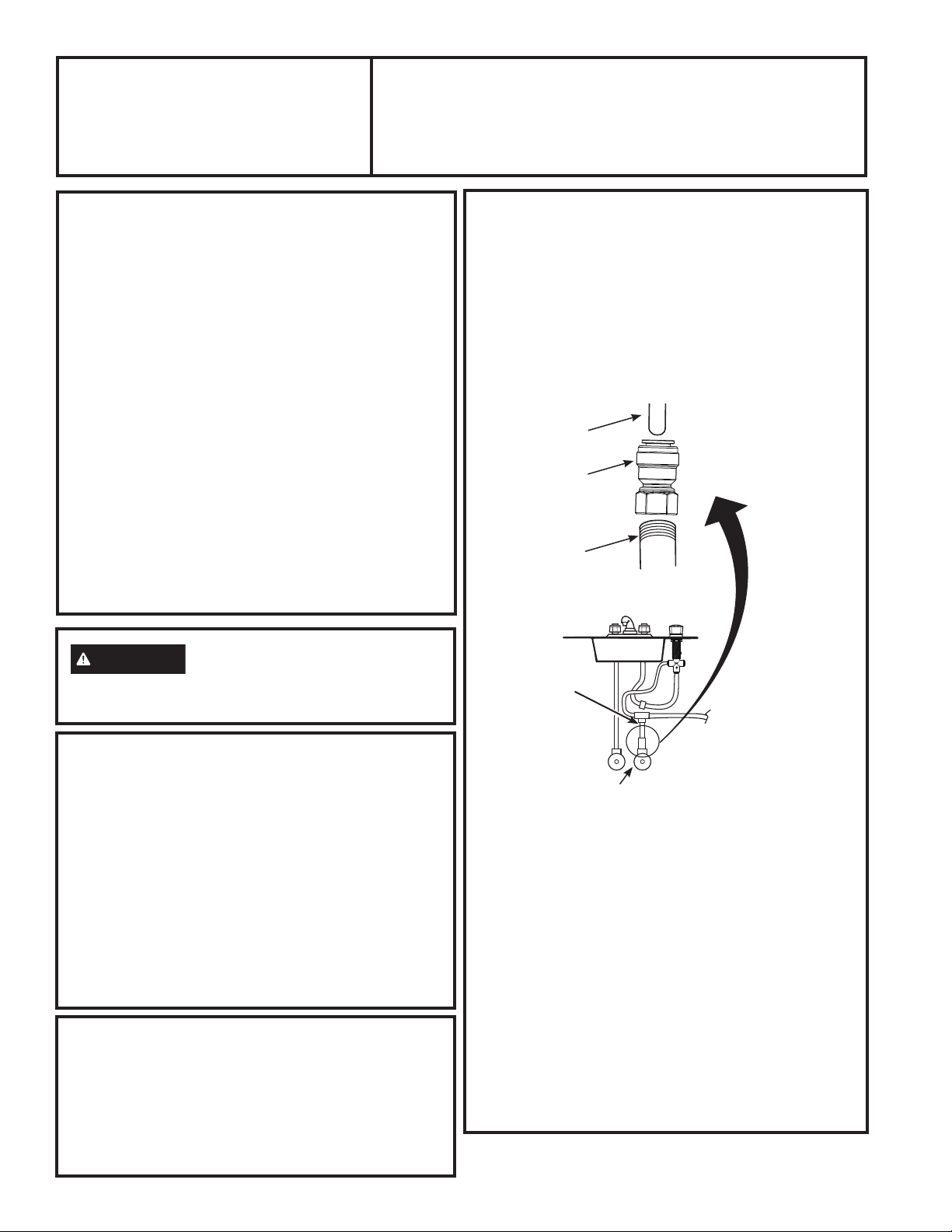

How it works

This system allows you to choose between filtered

and unfiltered water from your existing kitchen

faucet. The system consists of a control valve, timer,

and filters. The existing water line is split into two

lines. One line passes through the filtration system to

the control valve. The other line connects directly to the

control valve.

When the control valve is pointing away from your

kitchen faucet, normal unfiltered water is dispensed.

Right Hand Installation:

Existing Faucet

Cold Water Line

3’ Yellow Tube

Cold Water

Line Adapter

SYSTEM OVERVIEW: How it works

3’ Orange Tube

T-Fitting

Yellow Tube

Angle Stop

Valve Adapter

When the control valve is pointing toward your kitchen

faucet, filtered water is dispensed.

You will notice a slightly slower flow of water when

filtered water is being dispensed.

The base of the control valve will flash red when its time

to change filters and batteries. When it double flashes,

6 months have passed and its time to replace the filters.

When it flashes a single fading flash, 1 year has passed

and it is time to replace the filters and the timer batteries.

Control Valve

NOTE: Make sure “F” faces toward you during installation

Wire

4’ Blue Tube

Timer

4’ Yellow Tube

Inlet

Filter System

Outlet

Left Hand Installation:

NOTE: Make sure “F” faces toward you during installation

Timer

Inlet

Wire

Control Valve

4’ Blue

Tube

Outlet

Filter

System

3’ Orange

Tube

Specification Guidelines

Many bad tastes and/or odors are reduced in water

using activated carbon filter canisters. They are most

often used to reduce chlorine taste and odor. They can

also reduce other undesirable elements from drinking

water supplies.

Existing Faucet Cold

Water line

Cold Water

Line Adapter

3’ Yellow Tube

T-Fitting

Yellow Tube

Angle Stop

Valve Adapter

4’ Yellow Tube

NOTE: Small amounts of hydrogen sulfide (noticeable

as “rotten egg” odor) may be reduced by taste and

odor filters for a short time, but the carbon media is

quickly exhausted. Other water conditioning equipment

is usually required for the continuous treatment of

hydrogen sulfide.

4 49-6000061

Page 5

INSTALLATION INSTRUCTIONS

Installation

Instructions

Kitchen Faucet Filtration System

GXK185KBL

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT – Save these

instructions for local inspector’s use.

•

IMPORTANT – Check with your

local public works department for plumbing

codes. You must follow their guides as you

install the Water Filtration system.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these

instructions for future reference.

• Skill level – Installation of this appliance requires

basic mechanical and electrical skills.

• Completion time – 60-90 minutes

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

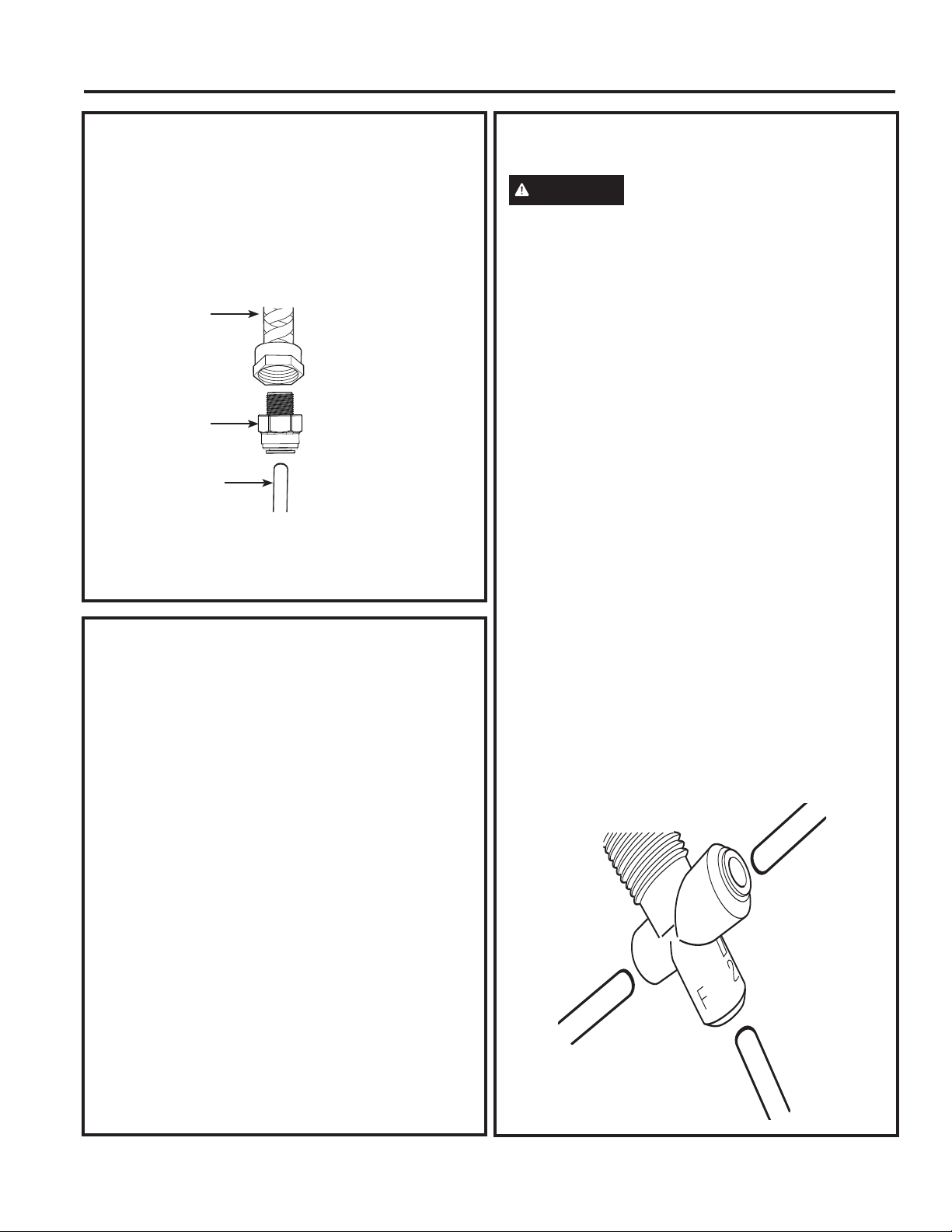

COLD WATER CONNECTION

A typical connection using the included water supply

fitting is shown in the illustration below.

1. Close the water shut-off valve that is immediately

in front of the supply tube and open the faucets to

drain water from the sink cold water pipe.

2. Remove line that connects the cold water from faucet

line to the supply valve. Some water may spill out.

1 foot Yellow

3/8” Tube

Angle Stop

Valve Adapter

Existing Cold

Water Valve

(Approximately 8

threads minimum)

WARNING

Information” on page 3 before beginning

installation.

—

Read “Important Safety

TOOLS AND MATERIALS

REQUIRED FOR INSTALLATION

• Phillips screwdriver

• Two (2) adjustable wrenches

• Electric drill and drill bit to drill 1.25” hole (type as

required) if mounting hole is needed for control valve

• Tape measure

•

If your main water line is a rigid pipe, you will require

a compression fitting and possibly other plumbing

hardware to complete the installation (sold separately).

NOTICE —

top, consult a qualified plumber or installer for drilling

procedures. Special drill bits may be needed for granite,

stone, porcelain or stainless steel.

To avoid damaging the sink or counter

CONTENTS INCLUDED

WITH THE PRODUCT

• Water filter system

assembly, including

mounting screws

• Water line adapters

and tubing

• Control Valve with LED

Lights

• Decorative Knob and Nut

• Timer Box

• Batteries

Fig. 1

T-Fitting

Cold Water Shutoff

3. Hand tighten the angle stop valve adapter onto

the cold water valve. NOTE: A minimum of

approximately 8 threads is required on valve

stem. Finish tightening 1/2 turn with adjustable

wrench. Be careful not to overtighten or cross-thread

as damage to threads can occur.

Some valve threads may be exposed when adapter is

fully seated.

4. Insert one foot long yellow tube fully into angle stop

valve adapter. Pull firmly on tube to make sure it is

secure.

5. Insert one foot long yellow tube into bottom of T-fitting

(see Figure 1). Insert 3 foot long yellow tube into one

side of T-fitting. Insert 4 foot long yellow tube into

other side of T-fitting. Pull firmly on tubes to make

sure they are secure.

49-6000061 5

Page 6

Installation Instructions

COLD WATER CONNECTION

(continued)

6. Hand tighten the cold water line adapter into the

cold water line from the faucet.

Finish tightening with two adjustable wrenches.

Be careful not to overtighten or cross thread as

damage to threads can occur. Some threads

may be exposed when adapter is fully seated.

Existing Cold

Water Line

from Kitchen

Faucet

Cold Water

Line Adapter

3 foot Orange

Tubing

INSTALLATION INSTRUCTIONS

7. Insert 3 foot orange tubing fully into cold water

line adapter. Pull firmly on tube to make sure it

is secure.

INSTALL THE CONTROL VALVE

Be sure there is room underneath and above the

sink to make the needed connections. Before

starting, make sure there is sufficient room

for the valve base. Select one of the following

places to install the valve (1.25” diameter hole

required):

A. In an existing sink spray attachment or soap

dispenser hole.

B. In a hole to be drilled in the sink top.

C. In a hole to be drilled in the counter top, next

to the sink.

NOTES:

• Be sure the valve base will fit flat against the

surface at the selected location.

Installation Steps (refer to illustration

below for clarification)

Fig. 2

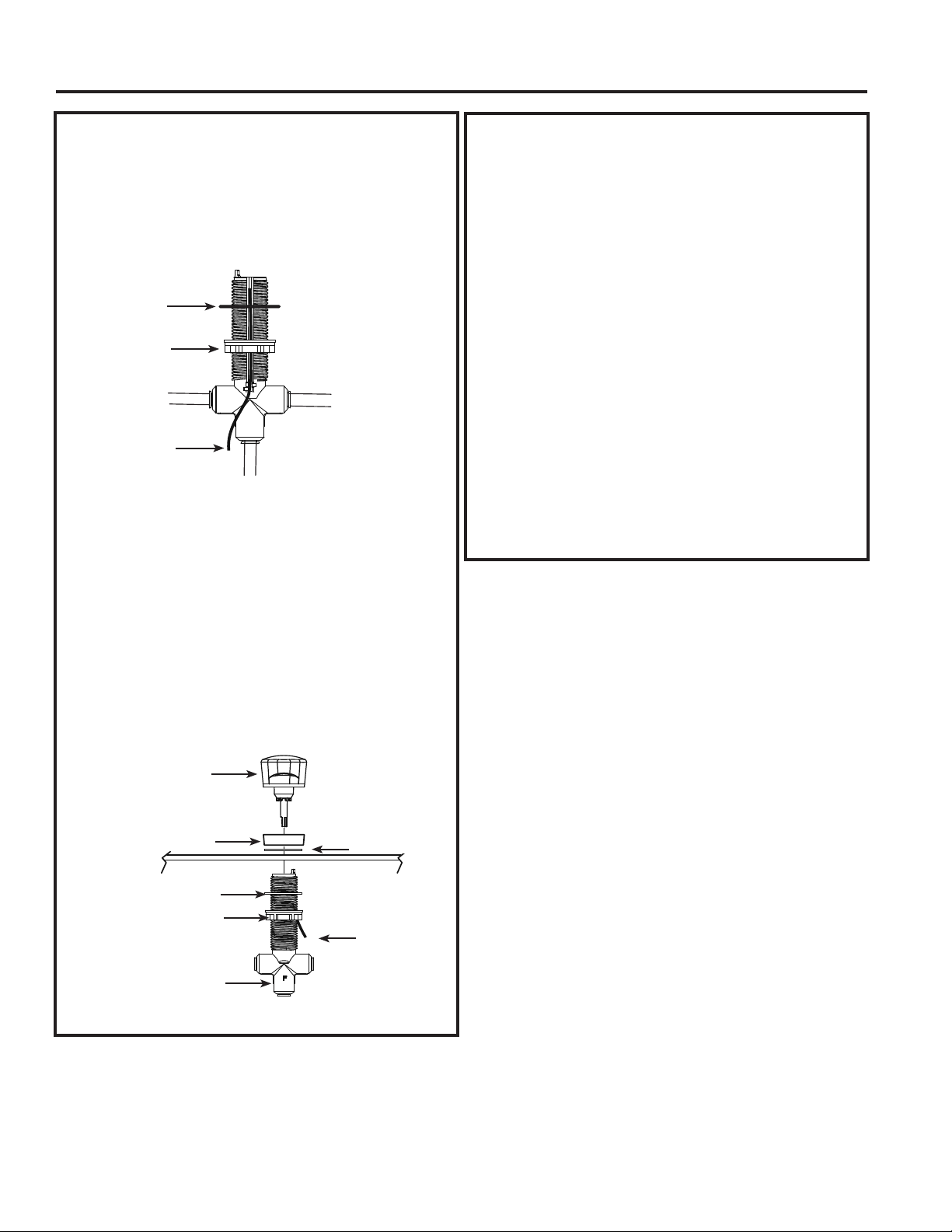

INSTALL THE CONTROL VALVE

(continued)

CAUTION

edges may be sharp and could damage wire. Be

careful to not cut yourself or damage the wire.

2. To have filtered water dispensed from kitchen

faucet when control valve is pointed toward

faucet connect tubes as follows:

NOTE: Refer to diagram on page 4 for tube

routing.

IF CONTROL VALVE IS ON RIGHT SIDE OF

FAUCET:

- Connect 4 foot long blue tube to port number

“2”.

- Connect 3 foot long yellow tube from T-fitting to

port number “1”.

- Connect 3 foot long orange tube to port “F”

(bottom port)

Pull firmly on all tubes to make sure they are

secure.

IF CONTROL VALVE IS ON LEFT SIDE OF

FAUCET:

- Connect 4 foot long blue tube to port number

“1”.

- Connect 3 foot long yellow tube from T-fitting to

port number “2”.

- Connect 3 foot long orange tube to port “F”

(bottom port)

Pull firmly on all tubes to make sure they are

secure.

When drilling in Stainless Steel,

Blue or Yellow

Tube (see above)

1. ,IGULOOLQJLVQHHGHGPDNHDƎGLDPHWHU

hole. Be sure to use the proper procedure

for drilling granite, stone, porcelain or

Blue or Yellow

Tube (see above)

Orange Tube

stainless steel. Special drill bits may be

needed. Consult a qualified plumber for the

proper procedure.

6 49-6000061

Page 7

Installation Instructions

INSTALLATION INSTRUCTIONS

INSTALL THE CONTROL VALVE

(continued)

3. With wire routed under rubber gasket and

locking nut (as shown below) thread nut at

least 3/4 toward bottom.

Rubber Gasket

Locking Nut

Wire

4. With “F” port label facing toward you (wire

groove facing back of cabinet) insert control

valve up through hole in sink/counter top.

5. Install 2nd rubber gasket on the control valve.

Insert decorative nut on top of control valve

turning fully until it stops, approximately two

turns of nut. Do not overtighten.

INSTALL THE CONTROL VALVE

(continued)

7. Insert control knob into valve body.

NOTE: Knob only inserts in one position,

rotate slowly until you feel it drop slightly

into place. Then push down firmly to snap

in place.

8. Check knob rotation. Knob should rotate 180

degrees and point towards you as it rotates

left/right. If point of knob rotates towards

wall, then unit is installed backwards. Please

review step 2.

9. Connect wire to timer box.

10. Find suitable location for timer box and

battery access. Mount timer box to side of

wall or cabinet with two screws (and drywall

anchor) provided. NOTE: Be careful not to

pinch or screw through the wire.

11.Install two AA, 1.5 volt, batteries into timer box.

6. Turn locking nut clockwise to tighten until it is

firmly secure against underside of sink/counter

top. Do not allow control valve body to rotate,

“F” port label should face toward you after

locking nut is tight.

Control Knob

Decorative Nut

Rubber Gasket

Locking Nut

NOTE:

“F” facing toward you.

Rubber Gasket

Wire

49-6000061 7

Page 8

Installation Instructions

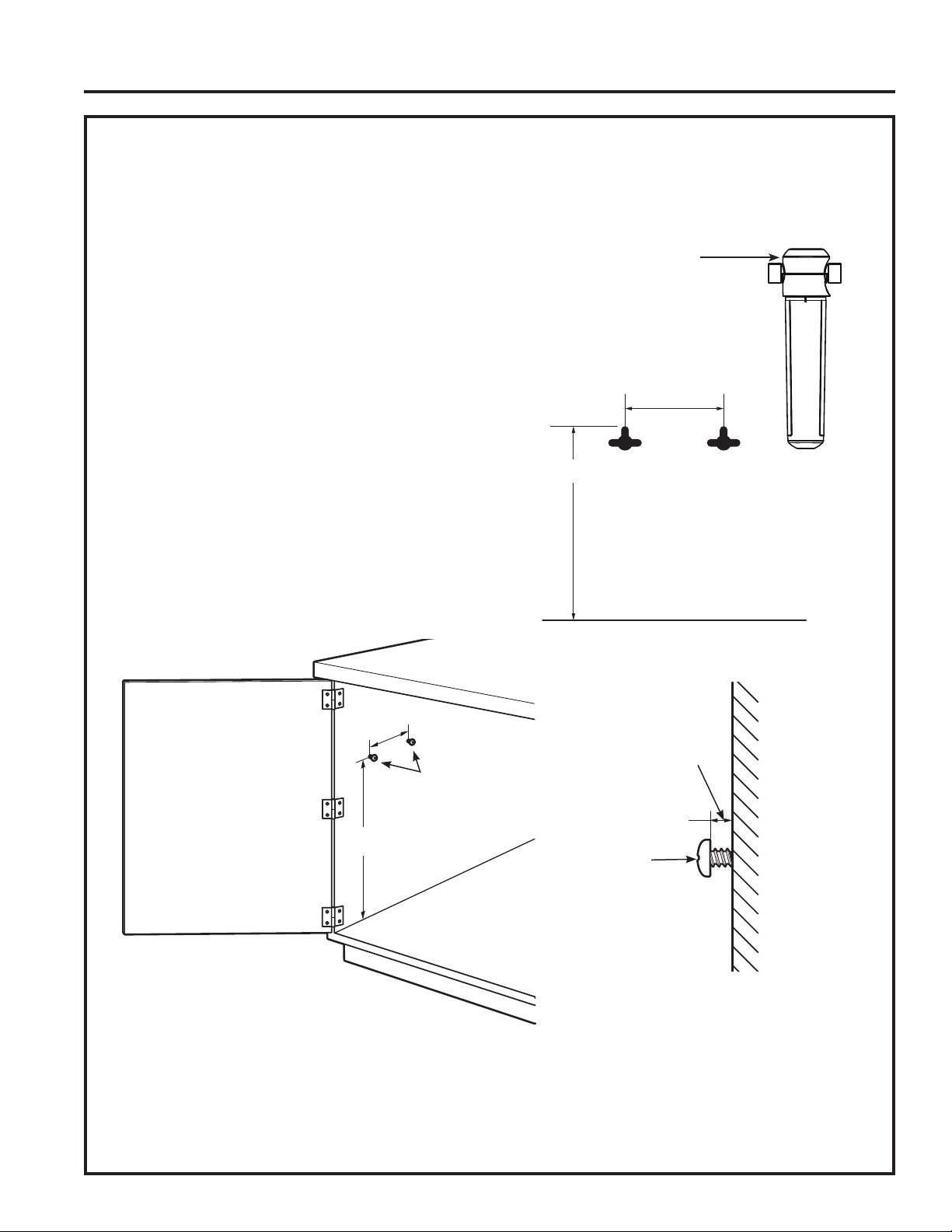

MOUNTING SYSTEM INSTALLATION

Pick a location under the sink to mount the system. Location should be easily accessible, with 4” of

clearance between the bottom of the filter canisters and the floor or bottom of the cabinet; any less

will result in difficulty of removing filter canisters (see Fig. 5). Allow enough space on either side of the

system for the tubing connections. System should be mounted at least 7” from front of cabinet to allow

proper routing of tubing.

SCREW INSTALLATION

1. Remove the top cover of system.

2. Screws should be placed a minimum of 15 inches above the bottom of the

cabinet or floor where the system is to be mounted (Fig. 5).

NOTE: Any distance lower may result in filter canisters interfering

with the floor when removed.

3. Use the system as a template to mark screw hole locations

where the screws are to be installed. Install screws into the

wall, leaving 3/16 inch clearance between the head of the screw

and wall (drill pilot holes if needed) (Fig. 6). Use anchors if

mounting to drywall. Anchors require a 1/4” hole.

4. Hang system on screws and tighten until system is held firmly.

INSTALLATION INSTRUCTIONS

5. Install top cover onto system.

6. Install 4 foot long yellow tube into inlet (left side) of system (inlet

and outlet are labeled on top of the system).

7. Install 4 foot long blue tube into outlet (right side) of system.

Pull firmly on tubes to make sure they are secure.

15 inches

Template for screw hole pattern

System

Top Cover

11/16

inches

on back of filtration system

(not to scale)

Bottom of Cabinet or Floor

3/16 inch

Screws

Wall

15 inches

Screw

Fig. 6

Fig. 5

8. Remove shrink wrap from filters and install in system by turning approximately 1/3 turn until locked into place. Filter

will raise up as it is turned. Filter label will be centered and facing forward when fully installed.

NOTE: System may exhibit low flow or no flow at all if the filter is not fully installed.

9. Turn on water supply valve and check for leaks.

10.

Perform Flush Procedure as described on page 9, steps 3-7.

8 49-6000061

Page 9

Installation Instructions

INSTALLATION INSTRUCTIONS

FILTER CHANGE LIGHT

The clear ring at the bottom of the control knob will

flash red to indicate it is time to change the filter and the

battery.

The ring will double flash at six months to indicate it is

time to replace the filter.

The ring will have a single fading flash at one year to

indicate it is time to replace the filters and the batteries.

INSTALLING OR REPLACING THE

FILTER CANISTERS

TO PROPERLY MAINTAIN SYSTEM AND

REDUCE THE RISK OF PROPERTY DAMAGE

DUE TO WATER LEAKAGE, CHANGING FILTER

AS REQUIRED.

If installing the system for the first time skip to step 3.

1. Remove the filter canisters from the manifold by

rotating the canisters to the left about 1/3 turn. NOTE:

A small amount of water from the tubing between

the filter and the faucet may come out. A small towel

should be able to catch it.

2. Remove shrink wrap on the new replacement filter

canisters. Install the new canisters into the manifold

by turning to the right about 1/3 turn until the filter

stops. The filter will rise up as it is turned.

EMERGENCY REPLACEMENT

PROCEDURE

Whenever water of unknown quality is passed

through the GE Water Filtration system, the filter

canisters should be discarded and the filtration

system flushed.

WARNING

of contaminants, do not use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before or after the

system.

Circumstances that may require replacing the

filters are:

• Boil water advisory

• Flooding of the GE Water Filtration system

• Long-term non-use

The procedure for flushing the GE Water

Filtration system is:

1. See Replacing the Filter Canisters section and

follow steps 1–7.

To reduce risk of ingestion

FLUSH PROCEDURE

3. Turn on cold side of kitchen faucet. Turn control valve

so it is pointing towards kitchen faucet (water will flow

slower when passing through filters).

NOTE: System may make noise during this procedure.

4. Check for water leaks around the system.

5. Allow the system to run for 6 gallons (or 10 minutes)

to flush out any harmless carbon fines that may be

present.

6. Turn off faucet and check around system for leaks.

7. Reset timer by holding reset button on timer box for 5

seconds. Ring in base of control valve will light for 5

seconds. If single fading flash was occurring, replace

batteries before resetting the timer.

Replacement Filter Canisters/

Estimated Replacement Costs

FQK2J—Replacement filter canister $45–55

For replacement parts, call toll-free 877.959.8688.

49-6000061 9

Page 10

Troubleshooting Tips... Before you call for service

Save time and money! Review the charts on the following pages first and you may not need to call for service.

Problem Possible Causes What To Do

Water contains tiny black particles New filter canisters contain

Water has air bubbles and is

cloudy

Indicator light on the control valve

is flashing

Indicator light on the control valve

is not blinking

TROUBLESHOOTING TIPS

Indicator light on the control valve

is not working

installed

Chlorine taste and odor in the

product water

Water dispenses

Fittings are leaking Tubing may not be installed

No water dispensing

when new battery is

very slowly

from system

activated carbon.

Air in system after

installation.

Six months usage has

occurred. This is the

maximum life of the filter

canisters.

Normal operation. • Does not blink until 6 months of operation has passed.

Battery may need to be

replaced.

Battery may have been

installed incorrectly or wire

not connected.

The filter canisters are no

longer reducing chlorine

taste and odor from the

water supply.

The filters have been

installed for too long.

The filter canisters have

become clogged.

Filter not installed fully • Ensure filter is fully installed, label should be centered and

properly .

Filter canisters not fully

installed.

• Turn on the filtered water faucet and allow to run for 6

gallons (or 10 minutes) to flush out any harmless carbon fines

that may be present.

• Will go away after water runs for a while.

• If double flash, replace filters.

• If single fading flash, replace filters and batteries.

• Normally the light is not on. The light blinks every 20

seconds to indicate a filter change is needed. This occurs

about every 6 months.

• Replace battery and press reset button for 5 seconds.

Indicator will light to indicate proper installation and operation.

Timer is reset for 6 months.

• Observe battery orientation markings on the holder.

• Ensure wire is connected from control valve to timer box.

•

Press reset button for 5 seconds to reset timer, indicator will

light and timer is reset for 6 months..

•

Replace the filter canisters.

• A six-month change-out period is recommended. Replace

both filter canisters.

• High sediment levels can cause premature clogging.

Replace both filter canisters.

facing forward.

• Fully follow the installation instructions and be sure the

tubing is free of nicks, burrs, etc., and is installed to the

proper depth.

• Fully follow the filter replacement instructions.

If you are still having trouble, please visit www.GEAppliances.com/ge/service-and-support/contact.htm

or call us at 800.626.2005.

10 49-6000061

Page 11

Parts List

005

004

PARTS LIST

Ref. No. Part No. Part Description

001 WS22X21084 Install Kit 1

002 WS15X21085 Timer 1

003 WS10X21083 Control Valve Assembly (Chrome) 1

004 WS19X21443 Filtration Manifold 1

005 FQK1K Filter Set 1

999 49-50306 Owner’s Manual 1

To obtain replacement parts, call toll-free 877.959.8688.

003

999

001

002

49-6000061 11

Page 12

Performance Data Sheet

Filtration System GXK185KBL, GXRLQK, TFWFSET using filter FQK1K

Ŷ 6\VWHPWHVWHGDQGFHUWLILHGE\,$30257DJDLQVW16)$16,6WDQGDUGVIRUWKHUHGXFWLRQRIFODLPV

specified on the performance data sheet at iapmort.org.

Ŷ $FWXDOSHUIRUPDQFHPD\YDU\ZLWKORFDOZDWHUFRQGLWLRQV

WARNING

Do not use with water that is microbiologically unsafe or with water of unknown quality

without adequate disinfection before or after the system.

Substance Influent challenge

Chlorine Taste and Odor 2.0 mg/L ± 10% N/A 97.2%

Particulate Class I particles 0.5 to

<1.0 μm

Atrazine 0.009 mg/L ± 10% N/A 0.003 mg/L 94.5%

Toxaphene 0.015 mg/L ± 10% N/A 0.003 mg/L >93.1%

Lindane 0.002 mg/L ± 10% N/A 0.0002 mg/L 98.5%

Lead @ 6.5 pH 0.15 mg/L ± 10% N/A 0.010 mg/L >99.3%

Lead @ 8.5 pH 0.15 mg/L ± 10% N/A 0.010 mg/L 98.7%

Mercury @ pH 6.5 0.006 mg/L ± 10% N/A 0.002 mg/L 96.2%

Mercury @ pH 8.5 0.006 mg/L ± 10% N/A 0.002 mg/L 81.5%

Atenolol 200 ± 20% ng/L N/A 30 ng/L >95.0%

PERFORMANCE DATA SHEET

Carbamazepine 1400 ± 20% ng/L N/A 200 ng/L 93.1%

Trimethoprim 140 ± 20% ng/L N/A 20 ng/L >96.5%

Linuron 140 ± 20% ng/L N/A 20 ng/L >96.3%

Estrone 140 ± 20% ng/L N/A 20 ng/L 95.0%

Bisphenol A 2000 ± 20% ng/L N/A 300 ng/L 94.8%

Nonyl phenol 1400 ± 20% ng/L N/A 200 ng/L 95.3%

Turbidity 11 +1 NTU 95.5% 0.5 NTU 98.1%

Cyst Minimum 50,000 cysts/L N/A >99.99%

concentration

At least 10,000 particles/mL N/A 93.3%

Reduction

Requirement

Maximum permissible product

water concentration

Average %

Reduction

Tested using a flow rate of 0.6 gpm (2.27 l/min); pressure of 60 psig; pH of 7.5 ± 0.5; temp. of 68° ± 5°F (20° ± 3°C)

Operating Specifications

Capacity: certified for up to 150 gallons (568 liters)

Pressure requirement: 35–125 psi (2.4–8.6 bar)

Temperature: 33–100°F (0.6–38°C)

Flow rate: 0.6 gpm (2.27 l/min)

Turbidity: < 1 NTU

Testing was performed under standard laboratory conditions; actual performance may vary.

NOTE: Substances reduced are not necessarily in your water. Filter must be maintained according to manufacturer’s

instructions, including replacement of filter cartridges.

Replacement Filter Canisters/Estimated Replacement Costs

FQK1K—Replacement filter canister $35-45

Replace filter every 150 gallons (567 liters) or 6 months whichever occurs first.

12 49-6000061

Page 13

GE Appliances Water Filtration Warranty

LIMITED ONE-YEAR WARRANTY

• What does this warranty cover?

— Any defect in materials or workmanship in the

manufactured product.

• What does this warranty not cover?

— Filter canisters and batteries after 30 days from

date of purchase.

— Service trips to your home to teach you how to use

the product.

— Improper installation, delivery or maintenance.

— Failure of the product if it is abused, misused,

altered, used commercially or used for other than

the intended purpose.

— Use of this product where water is microbiologically

unsafe or of unknown quality, without adequate

disinfection before or after the system.

— Damage to the product caused by accident, fire,

floods or acts of God.

— Incidental or consequential damage caused

by possible defects with this appliance, its

installation or repair.

• For how long after the original purchase?

— One (1) year.

• How do I make a warranty claim?

— Return to the retailer from which it was purchased,

along with a copy of the “Proof of Purchase.” A

new or reconditioned unit will be provided. This

warranty excludes the cost of shipping or service

calls to your home.

EXCLUSION OF IMPLIED WARRANTIES—Your

sole and exclusive remedy is product exchange

as provided in this Limited Warranty. Any implied

warranties, including the implied warranties of

merchantability or fitness for a particular purpose,

are limited to one year or the shortest period

allowed by law.

This warranty is extended to the original purchaser

and any succeeding owner for products purchased

for home or office use within the USA. In Alaska, the

warranty excludes the cost of shipping or service to

your home or office.

Some states do not allow the exclusion or limitation

of incidental or consequential damages. This

warranty gives you specific legal rights, and you

may also have other rights, which vary from state

to state. To know what your legal rights are, consult

your local or state consumer affairs office or your

state’s Attorney General.

Contact us at www.GEAppliances.com/ge/serviceand-support/contact.htm, or call toll-free at

800.626.2005.

WARRANTY

For Purchases Made In Iowa: This form must be signed and dated by the buyer and seller prior to the consummation

of this sale.

This form should be retained on file by the seller for a minimum of two years.

Buyer:

Name

Address

City State Zip

Signature Date

49-6000061 13

Seller:

Name

Address

City State Zip

Signature Date

Page 14

Consumer Support

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day, any day

of the year! You can also shop for more great GE Appliances products and take advantage of all our on-line support

services designed for your convenience. In the US: GEAppliances.com

Parts and Accessories

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today 24 hours every day.

In the US: GEApplianceparts.com or by phone at 877.959.8688 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since improper

servicing may cause unsafe operation.

CONSUMER SUPPORT

Contact Us

If you are not satisfied with the service you receive from GE Appliances, contact us on our Website with all the

details including your phone number, or write to:

In the US: General Manager, Customer Relations | GE Appliances, Appliance Park | Louisville, KY 40225

GEAppliances.com/ge/service-and-support/contact.htm

14 49-6000061

Printed in Taiwan

Page 15

INFORMACIÓN

DE SEGURIDAD ................ 3

GENERALIDADES

DEL SISTEMA ..................4

INSTRUCCIONES

DE INSTALACIÓN

Suministro del agua ...................5

Instale la válvula de control ............6

Instalación del sistema de montaje ...... 8

Cambio del filtro de luz ................9

Reposición del filtro ...................9

Procedimiento para lavar ..............9

CONSEJOS PARA LA SOLUCIÓN

DE PROBLEMAS .............. 10

LISTA DE PARTES ............... 11

MANUAL DEL

PROPIETARIO E

INSTALACIÓN

GXK185KBL

ESPAÑOL

DE AGUA

FICHA TÉCNICA

DE RENDIMIENTO .............12

GARANTÍA .......................13

SOPORTE AL

CONSUMIDOR ................ 14

El Sistema GXK185KBL está

certificado por IAPMO R&T contra

los Estándares 42,53, y 401 de

NSF/ANSI para la reducción de

reclamos especificados en la

ficha técnica de rendimiento y en

aipmort.org.

SISTEMA DE FILTRADO

GE es una marca registrada de General Electric Company. Fabricado bajo licencia de marca.

49-6000061 07-16 GEA

Page 16

GRACIAS POR HACER QUE LOS ELECTRODOMÉSTICOS

GE SEAN PARTE DE SU HOGAR.

Ya sea que haya crecido usando Electrodomésticos GE, o que ésta es su primera vez, nos complace

tenerlo en la familia.

Sentimos orgullo por el nivel de arte, innovación y diseño de cada uno de los Electrodomésticos GE,

y creemos que usted también.

2 49-6000061

Page 17

INFORMACIÓN IMPORTANTE DE SEGURIDAD

LEA TODAS LAS INSTRUCCIONES ANTES DE USAR

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA

A fin de reducir el riesgo de incendio, explosión, descargas eléctricas

o lesiones al usar su refrigerador, siga estas precauciones básicas de

seguridad:

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

A fin de reducir el riesgo asociado con descargas, no permita

que los niños menores de tres años tengan acceso a las

partes pequeñas durante la instalación de este producto.

A fin de reducir el riesgo asociado con la ingestión de

contaminantes, no use con agua que no sea segura a

nivel microbacteriológico o de calidad desconocida, sin una

desinfección adecuada, antes o después, del sistema.

A fin de reducir el riesgo asociado con el peligro de voltaje

debido a una perforación durante una instalación a través de

un cableado eléctrico existente o tubería de agua en el área

PRECAUCIÓN

A fin de reducir el riesgo de lesiones al usar el refrigerador, siga estas

de la instalación, no instale cerca de cableados eléctricos ni

tuberías que se puedan interponer con una herramienta de

perforación al seleccionar la posición para montar el soporte

del sistema.

Si este dispositivo no es mantenido y operado de acuerdo con

lo especificado en el manual del propietario, existe el riesgo

de exposición a contaminantes. Para más información, visite

el sitio Web del fabricante en www.geappliances.com o el

sitio Web de California State Water Resources Control Board

(Junta de Control de los Recursos del Agua del Estado de

California) en www.waterboards.ca.gov.

precauciones básicas.

A fin de reducir el riesgo de lesión física, despresurice el sistema como se muestra en el manual antes de retirar un

cartucho.

ADVERTIR:

Lea y siga las Instrucciones de Uso antes de la instalación y

uso de este sistema.

La instalación y uso DEBERÁN cumplir con todos los códigos

de plomería estatales y locales.

No use en un suministro de agua caliente (máximo de 100°F).

Instale en un suministro de agua fría únicamente.

No instale en líneas de suministro de agua caliente. La

temperatura máxima de funcionamiento del agua para este

sistema de filtro es de 100°F (37.8°C).

No se deberá instalar si la presión del agua supera los 125psi

(8.8 Kg/cm

(5.6 Kg/cm2), deberá instalar una válvula limitadora de presión.

Si no está seguro sobre cómo controlar la presión del agua,

comuníquese con un plomero profesional.

No instale sistemas en áreas donde la temperatura ambiente

pueda ser superior a 110° F (43.3° C).

El cartucho del filtro descartable debería ser reemplazado

cada 6 meses, una vez agotada la capacidad indicada o antes

si se produce una reducción notoria en el caudal.

Cuando haya instalado un dispositivo anti retorno en el

sistema de agua, se deberá instalar un dispositivo para

controlar la presión debido a la expansión termal.

No instale cuando se puedan producir condiciones de golpe

de ariete. Si existen condiciones de golpe de ariete, deberá

instalar un suspensor de golpes de ariete. Si no está seguro

sobre cómo controlar esta condición, comuníquese con un

plomero profesional.

2

). Si la presión del agua es superior a los 80 psi

Esegúrese de que toda la tubería y los accesorios estén

seguros y libres de pérdidas.

Sobre los accesorios de plástico, nunca use sellador para

tuberías ni pegamento para tuberías. Use sólo cinta para

roscas PTFE, ya que el pegamento para tuberías podría

deteriorar el plástico.

No use una antorcha u otras fuentes de alta temperatura

cerca del sistema, del cartucho, de los accesorios de plástico

o tuberías de plástico.

No instale en contacto directo con la luz del sol ni en áreas

exteriores.

No instale cerca de tuberías de agua que puedan interponerse

en el camino de una herramienta para perforar, al seleccionar

la posición para montar el soporte.

Monte el sistema en una posición donde se pueda evitar que

quede atascado por otros artículos usados en el área de la

instalación.

Asegúrese de que la ubicación y los sujetadores puedan

resistir el peso del sistema cuando esté instalado y lleno de

agua

LEA Y GUARDE ESTAS INSTRUCCIONES

49-6000061 3

Page 18

Cómo funciona

Este sistema le permite elegir entre agua filtrada y no

filtrada del grifo actual de su cocina. El sistema consta de

una válvula de control, un temporizador y filtros. La tubería

de agua existente está dividida en dos tuberías. Una pasa a

través del sistema de filtrado hasta la válvula de control. La

otra tubería se conecta directamente a la válvula de control.

Cuando la válvula de control está apuntando hacia fuera del

grifo de su cocina, se dispensa agua normal no filtrada.

Cuando la válvula de control está apuntando hacia el grifo de

su cocina, se dispensa agua filtrada.

Instalación del Lado Derecho:

Válvula de Control

NOTA: Asegúrese de que “F” mire hacia usted durante la instalación.

Tubería de Agua

Fría del Grifo Actual

Tubería Amarilla de 3’

Adaptador de la

Tubería de Agua Fría

Tubería

Anaranjada de 3’

Conector T

Tubería Amarilla

Adaptador

para Válvula

de Detención

en Ángulo

Observará un flujo de agua levemente inferior cuando se esté

dispensando agua filtrada.

La base de la válvula de control titilará en rojo cuando sea

el momento de cambiar los filtros y baterías. Cuando la luz

que titila es doble, significa que pasaron 6 meses y que es

necesario reemplazar los filtros. Cuando titila sólo una vez y la

luz se desvanece, significa que pasó 1 año y que es necesario

reemplazar los filtros y las baterías del temporizador.

Cable

Tubería

Amarilla de 4’

Sistema

de Filtrado

Temporizador

Inlet

Tubería Azul de 4’

Outlet

Instalación del Lado Izquierdo::

NOTA: Asegúrese de que “F” mire hacia usted durante la instalación.

VISIÓN GENERAL DEL SISTEMA: Cómo funciona.

Temporizador

Inlet

Válvula de Control

Cable

Tubería

Amarilla

de 4’

Outlet

Sistema

de

Filtrado

Pautas de las especificaciones

Se pueden reducir muchos malos olores y/o sabores del

agua usando cartuchos de carbono para el filtro. Se usan

principalmente para reducir el olor y sabor a cloro. También

pueden reducir otros elementos no deseados del suministro

de agua.

Tubería de Agua Fría

del Grifo Actual

Adaptador de la

Tubería

Anaranjada

de 3’

Tubería Azul de 4’

Tubería de Agua Fría

Tubería Amarilla de 3’

Conector T

Tubería Amarilla

Adaptador para

Válvula de

Detención en Ángulo

NOTA: Se pueden reducir por poco tiempo pequeñas

cantidades de sulfuro de hidrógeno como el olor a “huevo

podrido” usando filtros de olor y sabor, pero el medio de

carbono se agota rápidamente. Por lo general, se requieren

otros equipos acondicionadores de agua para el tratamiento

continuo del sulfuro de hidrógeno.

4 49-6000061

Page 19

INSTRUCCIONES DE INSTALACIÓN

Instrucciones

de instalación

Sistema de Filtrado del Grifo de la Cocina

GXK185KBL

ANTES DE INICIAR

Lea estas instrucciones completa y

cuidadosamente.

•

IMPORTANTE – Guarde estas

instrucciones para uso del inspector local.

•

IMPORTANTE – Consulte con su

departamento local de obras públicas para los códigos

de plomería. Usted debe seguir estas pautas a medida

que instala el sistema de filtración de agua.

• Nota al instalador – Asegúrese de dejar estas

instrucciones con el consumidor.

• Nota al consumidor – Conserve estas

instrucciones para referencia futura.

• Nivel de destreza – La instalación de este aparato

requiere de destrezas mecánicas básicas.

• Tiempo de ejecución – 60-90 minutos

• La instalación apropiada es la responsabilidad del

instalador.

• La falla del producto debido a una instalación

inadecuada no está cubierta por la garantía.

ADVERTENCIA

de seguridad “ en la página 3 antes de comenzar la

instalación

—

Leer “ Información importante

ACCESORIO PARA EL

SUMINISTRO DE AGUA FRÍA

En la ilustración que aparece a continuación se muestra una

conexión típica usando el accesorio para el suministro de agua

incluido.

1. Cierre la válvula de agua que se encuentra

inmediatamente en frente del tubo de suministro y abra

los grifos para dejar correr el agua de la tubería de agua

fría del lavaplatos.

2. Retire la entrada que conecta el agua fría desde la tubería

de agua a la válvula de suministro. Es posible que se

Tubería de 3/8”

Amarilla de 1 Pie

Adaptador para

Válvula de

Detención en Ángulo

Válvula de Agua

Fría Existente

(mínimo de 8

roscas en el

vástago de la

válvula)

Fig. 1

HERRAMIENTAS Y MATERIALES

NECESARIOS PARA LA INSTALACIÓN

• Destornillador de estrella

• Dos (2) llaves ajustables

• Taladro eléctrico y broca para el taladro para perforar

XQRULILFLRGHƎGHOWLSRQHFHVDULRSDUDHOJULIRVL

necesario

• Cinta métrica

• Si su línea de agua principal es de tubería rígida, usted

necesitará un accesorio de compresión y posiblemente

alguna otra herramienta de plomería para completar la

instalación (se vende por separado).

Notice — Para evitar daños al lavaplatos o mostrador,

consulte con un plomero o instalador calificado para los

procedimientos de perforación. Podrían necesitarse brocas

especiales pa

ra

granito,

piedra, porcelana o acero inoxidable.

CONTENIDO INCLUIDO CON

EL PRODUCTO

• Ensambladura del sistema de filtración de agua,

incluyendo los tornillos de instalación

•

Adaptadores y tuberías del suministro de agua

• Válvula de Control con Luces LED

• Perilla y Tuerca Decorativa

• Caja del Temporizador

• Baterías

Tubería T

Cierre de Agua Fría

derrame un poco de agua.

3. Ajuste manualmente el adaptador de la válvula de

detención en ángulo sobre la válvula de agua fría.

NOTA: Se requiere un mínimo de 8 roscas en el

vástago de la válvula. Termine de ajustar dando ½

giro con una llave de ajuste. Asegúrese de no forzar ni

presionar por demás a fin de evitar dañar la rosca.

Es posible que las roscas de algunas válvulas queden

expuestas cuando el adaptador esté completamente

colocado.

4. Inserte la tubería amarilla de un pie completamente en el

adaptador de la válvula de detención. Empuje hacia usted

de manera firme para controlar que esté segura.

5. Inserte la tubería amarilla de un pie de longitud en la parte

inferior del conector T (vea la Figura 1). Inserte una tubería

amarilla de 3 pies de longitud sobre un lado de la tubería T.

Inserte una tubería amarilla de 4 pies de longitud sobre el

otro lado de la tubería T. Empuje las tuberías hacia usted

de manera firme para controlar que estén seguras.

49-6000061 5

Page 20

Instrucciones de instalación

ACCESORIO PARA EL

SUMINISTRO DE AGUA FRÍA

(continúa)

6.

Ajuste de forma manual el adaptador de la tubería de agua

fría en la tubería de agua fría desde el grifo.

Termine de colocar con dos llaves de ajuste. Asegúrese

de no forzar ni presionar por demás a fin de evitar

dañar la rosca. Es posible que las roscas de algunas

válvulas queden expuestas cuando el adaptador esté

completamente colocado.

Tubería de

Agua Fría

Actual desde

el Grifo de la

Cocina

Adaptador de la

Tubería de Agua

Fría

Tubería Anaranjada

de 3 pies

7. Inserte la tubería anaranjada de 3 pies completamente en

el adaptador de la tubería de agua fría. Empuje hacia usted

INSTRUCCIONES DE INSTALACIÓN

de manera firme para controlar que esté segura.

INSTALE LA VÁLVULA DE CONTROL

Asegúrese de que haya lugar debajo y arriba del lavabo

a fin de realizar las conexiones necesarias. Antes de

comenzar, asegúrese de que haya suficiente espacio para

la base de la válvula. Seleccione uno de los siguientes

lugares para instalar la válvula (se requiere un agujero de

un diámetro de 1.25”):

A. En un orificio accesorio rociador existente en el lavaplatos u

orificio de dispensador de jabón.

B. En un orificio a perforar en la parte superior del lavaplatos.

C. En un orificio a perforar en el mostrador, al lado

del lavaplatos.

NOTAS:

• Asegúrese de que la base de la válvula se ajuste

de forma plana contra la superficie en la ubicación

seleccionada.

Pasos para la instalación (ver ilustración de abajo para

mayor clarificación)

1. Si es necesario perforar, haga un orificio de

ƎGe diámetro. Cerciórese de utilizar el

procedimiento correcto para perforar porcelana

o acero inoxidable. Podría necesitar brocas adicionales.

Consulte a un plomero calificado para el procedimiento

correcto.

Fig. 2

INSTALE LA VÁLVULA DE CONTROL

(continúa)

PRECAUCIÓN

inoxidable, es posible que los extremos sean filosos y esto

podría dañar el cable. Sea cuidadoso a fin de no sufrir un

corte ni dañar el cable.

2. A fin de contar con agua filtrada que sea dispensada

desde el grifo de la cocina cuando la válvula de

control apunte hacia el grifo, conecte las tuberías de la

siguiente manera:

NOTA: Para conocer el recorrido del tubo, consulte

el diagrama de la página 4.

SI LA VÁLVULA DE CONTROL SE ENCUENTRA DEL

LADO DERECHO DEL GRIFO:

- Conecte la tubería azul de 4 pies de longitud en el puerto

número “2”.

- Conecte la tubería amarilla de 3 pies de longitud desde el

conector T al puerto número “1”.

- Conecte la tubería anaranjada de 3 pies de longitud al

puerto “F” (puerto inferior).

Empuje todas las tuberías hacia usted de manera firme

para controlar que estén seguras.

SI LA VÁLVULA DE CONTROL SE ENCUENTRA DEL

LADO IZQUIERDO DEL GRIFO:

- Conecte la tubería azul de 4 pies de longitud en el puerto

número “1”.

- Conecte la tubería amarilla de 3 pies de longitud desde el

conector T al puerto número “2”.

- Conecte la tubería anaranjada de 3 pies de longitud al

puerto “F” (puerto inferior).

Empuje todas las tuberías hacia us

para controlar que estén seguras.

Tubería Azul o

Amarilla

(ver más arriba)

Al perforar sobre acero

ted de manera firme

Tubería Azul o

Amarilla

(ver más arriba)

Tubería

Anaranjada

6 49-6000061

Page 21

Instrucciones de instalación

INSTRUCCIONES DE INSTALACIÓN

INSTALE LA VÁLVULA DE CONTROL

(continúa)

3. Con el cable conducido debajo de la junta de goma y la

tuerca de bloqueo (como se muestra a continuación),

enrosque la tuerca por lo menos ¾ hacia abajo.

Junta de Goma

Tuerca de Bloqueo

Cable

4. Con el puerto “F” hacia usted (con la ranura por donde

pasa el cable hacia la parte trasera del gabinete), inserte

la válvula de control hacia arriba a través del agujero del

lavabo/ mesada.

5. Instale la 2da junta de goma en la válvula de control.

Inserte la tuerca decorativa sobre la válvula de control

girando completamente la misma hasta que se detenga,

aproximadamente dos giros de tuerca. No ajuste en

exceso.

6. Ajuste la tuerca de bloqueo en dirección de las agujas

del reloj a fin de ajustar la misma hasta que quede

ajustada de manera firme contra el lado inferior del

lavabo/ mesada. No permita que el cuerpo de la válvula

de control gire; la etiqueta del puerto “F” debe mirar

hacia usted luego de haber ajustado la tuerca de

bloqueo.

INSTALE LA VÁLVULA DE CONTROL

(continúa)

7. Inserte la perilla de control en el cuerpo de la válvula.

NOTA: La perilla sólo se inserta en una posición;

gire lentamente hasta que sienta que está levemente

colocada en su posición. Luego empuje hacia abajo

de manera firma para ajustarla en su posición.

8. Controle la rotación de la perilla. La perilla debe rotar

180 grados y apuntar hacia usted a medida que rota

hacia la izquierda/ derecha. Si la punta de la perilla rota

hacia la pared, entonces la unidad está instalada hacia

atrás. Vuelva a consultar el paso 2.

9. Conecte el cable a la caja del temporizador.

10. Busque una ubicación conveniente para tener acceso a

la caja del temporizador y la batería. Monte la caja del

temporizador en el costado de la pared o del gabinete

con los dos tornillos (y el taco de anclaje) provistos.

NOTA: Tenga cuidado de no pellizcar ni atornillar a

través del cable.

11. Instale dos baterías AA, 1.5 voltios en la caja del

temporizador.

Perilla de Control

Tuerca Decorativa

Junta de Goma

Anillo de Bloqueo

NOTA:

“F” mira hacia usted.

49-6000061 7

Junta de

Goma

Cable

Page 22

Instrucciones de instalación

INSTALACIÓN DEL SISTEMA DE MONTAJE

Elija una ubicación debajo del lavabo para montar el sistema. La ubicación debe ser de fácil acceso, con un espacio de

4” entre la parte inferior de los cartuchos de los filtros y el piso o la parte inferior del gabinete; menos espacio dificultará

el retiro de los cartuchos de los filtros (vea la Fig. 5). Deje suficiente espacio sobre cualquiera de los lados del sistema

de conexión de las tuberías. El sistema debe ser montado por lo menos a 7” desde el frente del gabinete, a fin de

permitir que la tubería sea conducida de forma apropiada.

INSTALACIÓN DE LOS TORNILLOS

1. Retire la tapa superior del sistema.

2. Los tornillos deben ser colocados a por lo menos 15 pulgadas sobre

la parte inferior del gabinete o del piso donde el sistema será montado

(Fig. 5).

NOTA: Cualquier distancia inferior podrá hacer que los cartuchos de

los filtros interfieran con el piso cuando sean retirados.

3. Use el sistema como plantilla para marcar las ubicaciones de los

agujeros donde los tornillos serán instalados. Instale los tornillos

en la pared, dejando un espacio de 3/16 pulgadas entre la cabeza del

tornillo y la pared (perfore agujeros piloto si es necesario) (Fig. 6). Use

anclajes si se montarán en un taco. Los anclajes requieren un agujero

de ¼”.

4. Sostenga el sistema sobre tornillos y ajuste hasta que el sistema

quede firme.

5. Instale la tapa superior sobre el sistema.

6. Instale una tubería amarilla de 4 pies de longitud hasta la entrada (la

entrada y salida están etiquetadas en la parte superior del sistema).

7. Instale una tubería azul de 4 pies de longitud (lado derecho) del

INSTRUCCIONES DE INSTALACIÓN

sistema. Empuje las tuberías hacia usted de manera firme para

controlar que estén seguras.

15 pulgadas

Tapa Superior

del Sistema

11/16

pulgadas

Plantilla del patrón de agujeros

de los tornillos de la parte trasera

del sistema de filtrado

(no a escala)

Parte Inferior del Gabinete o Piso

3/16

pulgadas

tornillos

Pared

15

pulgadas

Fig. 5

tornillo

Fig. 6

8. Retire el film transparente de los filtros e instale los mismos en el sistema dando aproximadamente 1/3 de giro hasta

que se bloquee en su posición. El filtro se elevará al ser girado. La etiqueta del filtro estará centrada y enfrentada hacia

delante una vez completa la instalación.

NOTA: Es posible que el sistema cuente con un flujo bajo o que no tenga flujo en absoluto si el filtro no está

completamente instalado.

9. Active la válvula de suministro de agua y controle que no haya pérdidas.

10.

Realice el Proceso de Descarga como se describe en la página 9, pasos 3 a 7.

8 49-6000061

Page 23

Instrucciones de instalación

INSTRUCCIONES DE INSTALACIÓN

CAMBIO DEL FILTRO DE LUZ

El anillo de limpieza en la parte inferior de la perilla de

control titilará para indicar que es hora de cambiar el filtro y

la batería.

El anillo titilará de forma doble a los seis meses para indicar

que es hora de reemplazar el filtro.

El anillo titilará una vez de manera tenue al año para indicar

que es hora de reemplazar los filtros y las baterías.

INSTALACIÓN O REEMPLAZO DE

LOS CARTUCHOS DEL FILTRO

PARA UN MANTENIMIENTO ADECUADO DEL

SISTEMA Y PARA REDUCIR EL RIESGO DE

DAÑOS SOBRE LA PROPIEDAD DEBIDO A

PÉRDIDAS DE AGUA, CAMBIE EL FILTRO

SEGÚN SEA REQUERIDO.

Si va a instalar el sistema por primera vez, vaya al paso 3.

1. Retire los cartuchos de los filtros del recolector girando

los cartuchos hacia la izquierda 1/3 de giro. (Fig. 11).

NOTA: Podría salir una pequeña cantidad de agua de la

tubería entre el filtro y el grifo, la cual se puede absorber

con una toalla pequeña.

Retire el aluminio de la parte superior de los cartuchos de

2.

repuestos. Instale los nuevos cartuchos en el recolector

girándolos hacia la derecha alrededor de 1/3 de giro

hasta que las marcas de alineación queden en línea y el

filtro pare. El filtro podría levantarse a medida que se gira.

PROCEDIMIENTO PARA LAVAR

3. Active el lado frío del grifo de la cocina. Gire la válvula

de control de modo que apunte hacia el grifo de la

cocina (el flujo de agua será menor al pasar a través

de los filtros).

NOTA: Es posible que el sistema haga ruido durante

este procedimiento.

4. Busque fugas de agua alrededor del sistema.

5. Una vez que el agua empiece a fluir del grifo, deje que

el sistema opere por 6 galones (o 10 minutos) para

expulsar cualquier traza de carbono que pueda estar

presente.

6. Cierre el grifo y revise alrededor del sistema en busca

de fugas.

7.

Reinicie el temporizador sosteniendo el botón de reinicio

de la caja del temporizador durante 5 segundos. El anillo

en la base de la válvula de control se iluminará durante

5 segundos. Si la luz está titilando una sola vez de

manera tenue, reemplace las baterías antes de reiniciar

el temporizador.

Repuestos de los cartuchos de los filtros/

Costos estimados de reposición

FQK2J—Repuesto del cartucho del filtro $45-55

Para repuestos, llame gratis al 800.626.2002 (EE.UU.).

PROCEDIMIENTO DE REEMPLAZO

DE EMERGENCIA

Cada vez que agua de calidad desconocida es

pasada a través del sistema de filtración de agua

GE, los cartuchos de los filtros deberían ser

deshechados y el sistema de filtración lavado.

ADVERTENCIA

ingestión de contaminantes, no lo utilice con agua

no segura desde el punto de vista microbiológico

o de calidad desconocida sin una adecuada

desinfección antes o después de la instalación. Los

sistemas certificados para reducción de quistes

pueden usarse con agua desinfectada que puede

contener quistes filtrables.

Las circunstancias que pueden requerir el

reemplazo de los filtros son:

• Advertencia de que hay que hervir el agua

• Inundación del sistema de filtración de agua GE

• Largo tiempo sin ser usado

El procedimiento para lavar el sistema de

filtración de agua GE es:

1. Vea la sección Cómo reemplazar los cartuchos

de los filtros y siga los pasos 1–7.

Para reducir el riesgo de

49-6000061 9

Page 24

Consejos para la Solución de Problemas... Antes de solicitar el servicio técnico

Solucionar problemas

¡Ahorre tiempo y dinero! Revise la siguiente tabla primero y tal vez no necesitará de solicitar un servicio.

Problema Posibles causas Qué hacer

El agua contiene

pequeñas partículas

negras

El agua tiene burbujas de

aire y está turbia

La luz indicadora de la

válvula de control está

titilando

La luz indicadora de la

válvula de control no

está titilando

La luz indicadora de la

válvula de control no

está funcionando cuando

una nueva batería fue

instalada

Olor y sabor a cloro en el

agua producida

El agua se dispensa

lentamente

Los accesorios Es posible que la tubería • Siga las instrucciones de instalación en su totalidad y

CONSEJOS PARA LA SOLUCIÓN DE PROBLEMAS

No sale agua

del sistema

Los nuevos cartuchos de los filtros

contienen carbono activado

Hay aire en el sistema después de

la instalación.

Han transcurrido seis meses de

uso. Esta es la vida máxima de los

cartuchos de los filtros.

Esto es normal. • No parpadea hasta que 6 meses de operación han

Es posible que la batería necesite

reemplazo.

Es posible que la batería haya sido

instalada de forma incorrecta o que

el cable no esté conectado.

El cartucho del filtro ya no está

reduciendo el sabor y olor a cloro

del suministro de agua.

muy

El filtro ha estado instalado por

mucho tiempo.

Los cartuchos de los filtros están

obstruidos.

Filtro no se instala totalmente • Asegúrese de que el filtro esté completamente instalado; la

Los cartuchos de los filtros no

están instalados completamentes.

• Active el grifo de agua filtrada y deje que corran 6 galones (o

10 minutos) para eliminar cualquier polvo fino inofensivo que

pueda estar presente.

• Desaparecerá después de que el agua corra por un tiempo.

• Si titila dos veces, reemplace los filtros.

• Si titila una vez de forma tenue, reemplace los filtros y las

baterías.

transcurrido.

• Normalmente la luz no está encendida. La luz se enciende

cada 20 segundos para indicar que es necesario cambiar el

filtro. Esto ocurre cada seis meses.

• Reemplace la batería y presione el botón de reinicio durante

5 segundos. El indicador se iluminará a fin de indicar una

instalación y funcionamiento adecuados. El temporizador fue

reiniciado por 6 meses.

• Observe las marcas de orientación de la batería en el

suspensor.‘

• Asegúrese de que el cable esté conectado desde la válvula

de control hasta la caja del temporizador.

Presione el botón de reinicio durante 5 segundos para

•

reiniciar el temporizador; el indicador se iluminará y el

temporizador será reiniciado por 6 meses.

•

Reemplace los cartuchos de los filtros.

• Se recomienda un periodo de cambio de seis meses.

Reemplace los cartuchos de los filtros.

• Altos niveles de sedimento pueden causar una obstrucción

prematura. Reemplace los cartuchos de los filtros.

etiqueta debe quedar centrada y enfrentada hacia delante.

asegúrese tienen fugas no esté instalada correctamente.

que la tubería no posea rasguños, rebabas, etc. y que esté

instalada a una profundidad adecuada.

• Siga completamente las instrucciones para reemplazo.

Para más información sobre el funcionamiento, visite www.GEAppliances.com/ge/service-and-support/

contact.htm o comuníquese al 800.626.2005.

10 49-6000061

Page 25

Lista de partes

005

004

LISTA DE PARTES

Ref. No. PARTE NO. DESCRIPCION DE LA PARTE

001 WS22X21084 Instale el Juego 1

002 WS15X21085 Temporizador 1

003 WS10X21083 Conjunto de válvula de control

(Cromo) 1

004 WS19X21443 Colector de Filtración 1

005 FQK1K Conjunto de Filtros 1

999 49-6000061 Manual del Propietario 1

Para obtener piezas de recambio o las herramientas

opcionales, llámenos gratuitamente al 877.959.8688.

003

999

001

002

49-6000061 11

Page 26

Ficha Técnica de Rendimiento

Filtración Sistema GXK185KBL, GXRLQK, TFWFSET usando FQK1K filtro

Ŷ Sistema evaluado y certificado por IAPMO R&T contra los Estándares 42,53, y 401 de NSF/ANSI para la reducción de

reclamos especificados en la ficha técnica de rendimiento y en aipmort.org.

Ŷ (OUHQGLPLHQWRUHDOSXHGHYDULDUGHDFXHUGRFRQODVFRQGLFLRQHVORFDOHVGHODJXD

ADVERTENCIA

No usar con agua que no sea segura a nivel microbiológico o que sea de calidad desconocida sin

una desinfección adecuada, antes o después, del sistema.

Sustancia Concentración del Peligro de

Gusto y Olor a Cloro 2.0 mg/L ± 10% N/A 97.2%

Partícula Nominal Clase I, 0.5 a

<1.0 μm

Atrazina 0.009 mg/L ± 10% N/A 0.003 mg/L 94.5%

Toxafeno 0.015 mg/L ± 10% N/A 0.003 mg/L >93.1%

Lindano 0.002 mg/L ± 10% N/A 0.0002 mg/L 98.5%

Plomo en pH 6.5 0.15 mg/L ± 10% N/A 0.010 mg/L >99.3%

Plomo en pH 8.5 0.15 mg/L ± 10% N/A 0.010 mg/L 98.7%

Mercurio en pH 6.5 0.006 mg/L ± 10% N/A 0.002 mg/L 96.2%

Mercurio en pH 8.5 0.006 mg/L ± 10% N/A 0.002 mg/L 81.5%

Atenolol 200 ± 20% ng/L N/A 30 ng/L >95.0%

Carbamazepina 1400 ± 20% ng/L N/A 200 ng/L 93.1%

Trimetoprima 140 ± 20% ng/L N/A 20 ng/L >96.5%

FICHA TÉCNICA DE RENDIMIENTO

Linuron 140 ± 20% ng/L N/A 20 ng/L >96.3%

Estrona 140 ± 20% ng/L N/A 20 ng/L 95.0%

Bisfenol A 2000 ± 20% ng/L N/A 300 ng/L 94.8%

Nonilfenol 1400 ± 20% ng/L N/A 200 ng/L 95.3%

Turbiedad 11 +1 NTU 95.5% 0.5 NTU 98.1%

Quistes Min 50,000 Quistes/L N/A >99.99%

Por lo menos 10,000 partículas/mL

Intrusión

Requisitos de

Reducción

N/A 93.3%

Máxima concentración

permitida de productos de

agua

Reducción

del %

Promedio

Evaluado usando un promedio de flujo de 0.6 gpm (2.27 l/mín.; presión de 60 psig; pH of 7.5 ± 0.5; temperatura de 68° ± 5°F (20° ± 3°C)

Especificaciones de Funcionamiento

Capacidad: certificado hasta 150 galones (568 litros)

Requisitos de presión: 35–125 psi (barra 2.4–8.6)

Temperatura: 33–100°F (0.6–38°C)

Promedio de flujo: 0.6 gpm (2.27 l/mín)

Turbiedad: < 1 NTU

La evaluación se realizó de acuerdo con condiciones estándares de laboratorio; el rendimiento puede variar.

NOTA: Las sustancias reducidas no necesariamente están en su agua. El filtro se deberá mantener de acuerdo con

las instrucciones del fabricante, incluyendo el reemplazo de cartuchos de filtro.

Reemplazo de Recipientes del Filtro/Costos Estimados de Reemplazo

FQK1K—Reemplazo de Recipientes del Filtro $35-45

Reemplace el filtro cada 150 galones (567 litros) o cada 6 meses, dependiendo de qué suceda primero.

12 49-6000061

Page 27

Garantía del Sistema de Filtrado de Agua de GE Appliances

GARANTÍA LIMITADA POR UN AÑO

• ¿Qué cubre esta garantía?

— Cualquier defecto de fábrica en los materiales o la

manufactura del producto.

• ¿Qué no cubre esta garantía?

— Cartuchos de los filtros y las baterías después de treinta

días a partir de la fecha de la compra.

— Viajes a su casa para enseñarle cómo usar el producto.

— Instalación o entrega inapropiada, o mantenimiento

impropio.

— Falla del producto debido a abuso, mal uso, alteración,

uso comercial o uso diferente al propósito deseado con

este producto.

— Uso de este producto donde el agua está

microbiológicamente insegura o de calidad desconocida,

sin la adecuada desinfección, antes y después de ser

procesada por el sistema.

— Daños causados al producto debido a accidentes,

incendio, inundaciones o actos

de la naturaleza.

— Daños secundarios o por consecuencia causados

por posibles defectos en el producto, su instalación

o reparación.

• ¿Por cuánto tiempo después de la compra?

— Un año.

• ¿Cómo hago la reclamación de la garantía?

— Devuélvala al minorista a quien le compró el producto

con una copia de “Proof of Purchase”(prueba de

compra). Se le proporcionará una unidad nueva o

reacondicionada. Esta garantía excluye los costos de

envío o llamadas de servicio a domicilio.

EXCLUSIÓN DE GARANTÍAS IMPLÍCITAS—Su único

y exclusivo derecho es el cambio del producto, tal y

como se indica en esta Garantía limitada. Cualquier

garantía implícita, incluyendo las garantías implícitas de

comerciabilidad o adecuación para un fin determinado,

están limitadas a un año o el período de tiempo más breve

permitido por la ley.

Esta garantía se extiende al comprador original y

cualquier comprador posterior de productos comprados

para uso residencial o en la oficina dentro de Estados

Unidos. En Alaska, la garantía excluye el costo de envío o

las visitas de servicio a su casa u oficina.

Algunos estados no permiten la exclusión o las

limitaciones de daños incidentales o consecuenciales.

Esta garantía da derechos legales específicos, y usted

podría tener otros derechos que variarán de estado a

estado. Para saber cuáles son sus derechos legales,

consulte a la oficina de asuntos del consumidor local o la

oficina del Attorney General en su localidad.

Póngase en contacto con nosotros en www.

GEAppliances.com/ge/service-and-support/contact.htm, o

llame sin cargo al 800.626.2005.

GARANTÍA

Para Adquisiciones Realizadas en Iowa: Este formulario debe poseer la firma y fecha del comprador y del vendedor

antes de la consumación de esta venta.

Este formulario debe ser conservado por el vendedor en un archivo durante un mínimo de dos años.

Comprador:

Nombre

Domicilio

Ciudad Estado Código

Postal

Firma Firma

49-6000061 13

Vendedor:

Nombre

Domicilio

Ciudad Estado Código

Postal

Firma Firma

Page 28

Soporte para el Consumidor

Sitio Web de GE Appliances

¿Desea realizar una consulta o necesita ayuda con su electrodoméstico? ¡Intente a través del Sitio Web de GE Appliances las

24 horas del día, cualquier día del año! Usted también puede comprar más electrodomésticos maravillosos de GE Appliances y

aprovechar todos nuestros servicios de soporte a través de Internet, diseñados para su conveniencia.

En EE.UU.: GEAppliances.com

Piezas y Accesorios

Aquellos individuos calificados para realizar el servicio técnico de sus propios electrodomésticos podrán solicitar el envío de

piezas o accesorios directamente a sus hogares (se aceptan las tarjetas VISA, MasterCard y Discover). Ordene hoy a través de

Internet durante las 24 horas, todos los días. En EE.UU.: GEApplianceparts.com o de forma telefónica al 877.959.8688 durante

el horario de atención comercial.

Las instrucciones que figuran en este manual cubren los procedimientos que serán realizados por cualquier usuario.

Otros servicios técnicos generalmente deben ser derivados a personal calificado del servicio. Se deberá tener cuidado,

ya que una reparación indebida podrá hacer que el funcionamiento no sea seguro.

Contáctenos

Si no se encuentra satisfecho con el servicio que recibió de GE Appliances, comuníquese con nosotros a través de nuestro sitio

Web con todos los detalles, incluyendo su número telefónico, o escriba a:

En EE.UU.: General Manager, Customer Relations | GE Appliances, Appliance Park | Louisville, KY 40225

GEAppliances.com/ge/service-and-support/contact.htm

SOPORTE PARA EL CONSUMIDOR

14 49-6000061

Impreso en Taiwán

Loading...

Loading...