Page 1

GN1S04C/GX1S04C is

Tested and Certified

by NSF International against ANSI/NSF

Standard 42 for the reduction of

Particulate Class I, Chlorine, and

Taste/Odor, and Standard 53 for the

reduction of Cyst, Turbidity and Asbestos.

GX1S15C (rev. 2) is

Tested and Certified

by NSF International against ANSI/NSF

Standard 42 for the reduction of

Particulate Class I, Chlorine, and

Taste/Odor and Standard 53 for

the reduction of Lead, Mercury, Cyst,

Turbidity, Asbestos, Atrazine and Lindane.

215C1044P010-3 49-50040-3 05-02 JR

7239189

Write the model and serial numbers here:

Model # ______________________

Serial # ______________________

You can find them on the sump bracket.

GEAppliances.com

GN1S04C

GX1S04C

GX1S15C (Rev. 2)

Owner’s Manual

and Installation

Safety Instructions

. . . . . . . . . . . . .2

Operating Instructions

About the Water Filtration

System . . . . . . . . . . . . . . . . . . . . . . .3

Specification Guidelines . . . . . . . . .3

Installation Instructions

Faucet Installation . . . . . . . . . . . . . .6

Feed Water Supply . . . . . . . . . . . . .5

Filter Cartridge Installation or

Replacement . . . . . . . . . . . . . . . . . .8

Flush Procedure . . . . . . . . . . . . . . .9

Important Recommendations . . . . .4

Step-by-Step Instructions . . . . . . .6, 7

Tools/Materials Required . . . . . . . .4

Tubing Connections . . . . . . . . . . . .7

Wall Mounting . . . . . . . . . . . . . . . . .7

Troubleshooting Tips . . . . . . . . .10

Consumer Support

Consumer Support . . . . . . . . . . . .12

Parts List/Catalog . . . . . . . . . . . . .11

Warranty . . . . . . . . . . . . . . . . . . . .12

Manuel d’utilisation

et d’installation

Manual del propietario

y instalación

La section française commence à la page 13

Système de Filtration d’Eau

La sección en español empieza en la página 25

Sistema de Filtración de Agua

Water Filtration

system

Page 2

2

SAVE THESE INSTRUCTIONS

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

■

Install or store where it will not be exposed to temperatures

below freezing or exposed to any

type of weather. Water

freezing in the system will damage it. Do not attempt to treat

water over 100°F.

WARNING: Discard all unused and packaging

material after installation. Small parts remaining after

installation could be a choke hazard.

■

Your Water Filtration system will withstand up to 125 pounds

per square inch (psi) water pressure. If your house water

supply pressure is higher than 100 psi, install a pressure

reducing valve before installing the Water Filtration system.

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

For your safety, the information in this manual must be followed to minimize the risk of

property damage or personal injury.

SAFETY PRECAUTIONS

■

Check with your local public works department for

plumbing codes. You must follow these guidelines as you

install the Water Filtration system.

■ Use the Water Filtration system on a potable, safe-to-drink,

home COLD water supply only. The filter cartridges will not

purify the water, or make it safe to drink.

■ Do not use on a hot water supply (100°F. max.)

.

WARNING: Do not use with water that is

microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system. Systems

certified for cyst reduction may be used on disinfected

water that may contain filterable cysts.

PROPER INSTALLATION

This Water Filtration system must be properly installed and located in accordance with the Installation Instructions

before it is used.

WARNING!

Page 3

3

About the water filtration system. GEAppliances.com

Using the Water Filtration System and About the Filter Cartridge

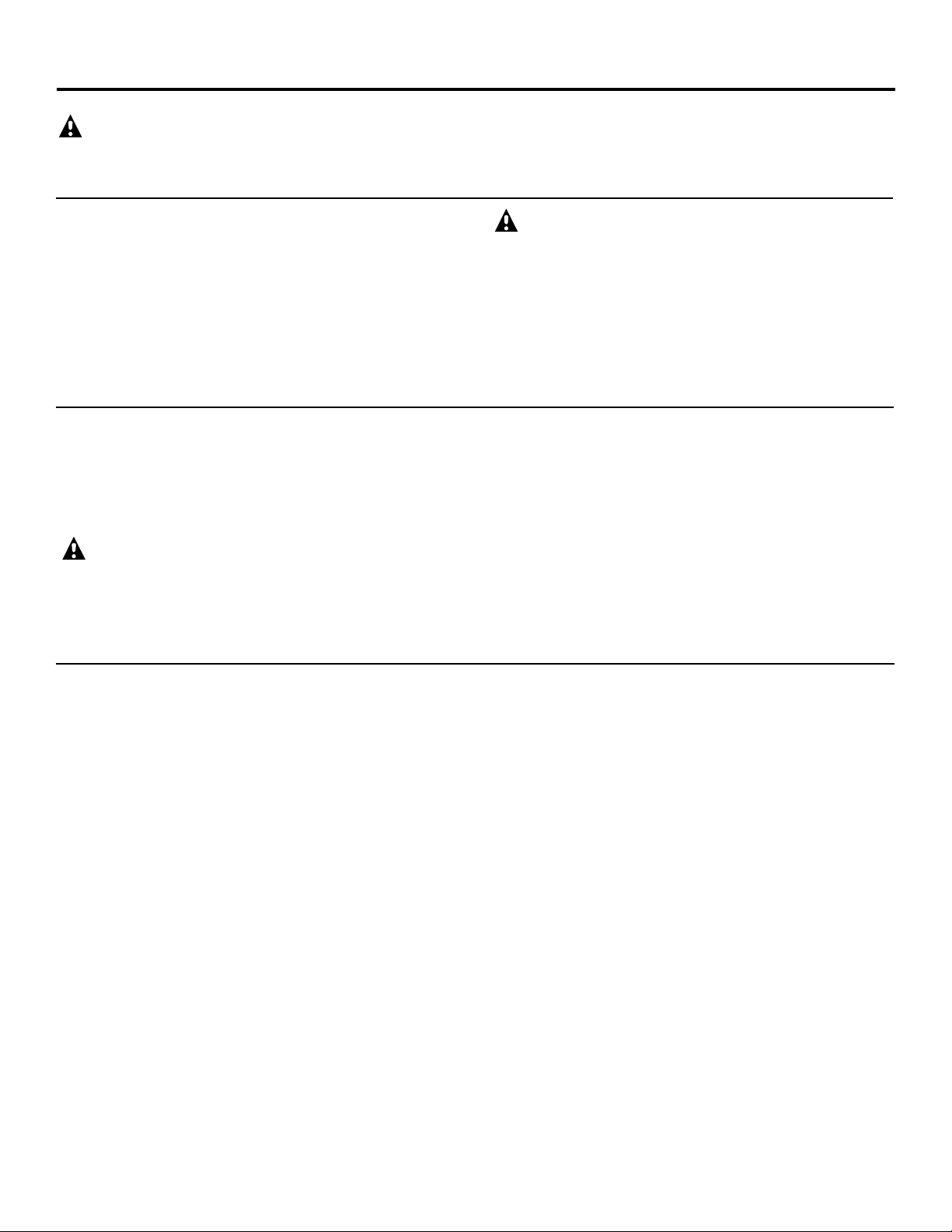

The countertop faucet dispenses filtered drinking water when opened. It has

a hand-operated, spring-loaded closed lever to prevent waste. You can keep the

faucet open by pushing upward on the lever to lock it against the faucet spout.

Filter Cartridge Life—Several variables determine how long the cartridges will last

in your Water Filtration system. These include:

How much water you use.

How much sediment, taste and/or odor, lead, or other unwanted substance,

is in the water.

No matter which Water Filtration system you have, you should replace the

cartridges every six months. In extremely poor water supplies, you may notice

the return of the unwanted substance in your water before the six months are up.

In this case the cartridges should be replaced immediately. If the system is also

for lead or chemical contaminant removal, it is MORE IMPORTANT to replace the

cartridges at least every six months.

NOTE: If the water supply contains high amounts of sediments, the carbon filters

may plug prematurely, reducing filtered water flow to the system faucet. Cartridge

replacement is needed to restore flow.

2

1

Filtered water faucet

Open

Lock

open

Specification guidelines.

Page 4

Tools and Materials Required for Installation

4

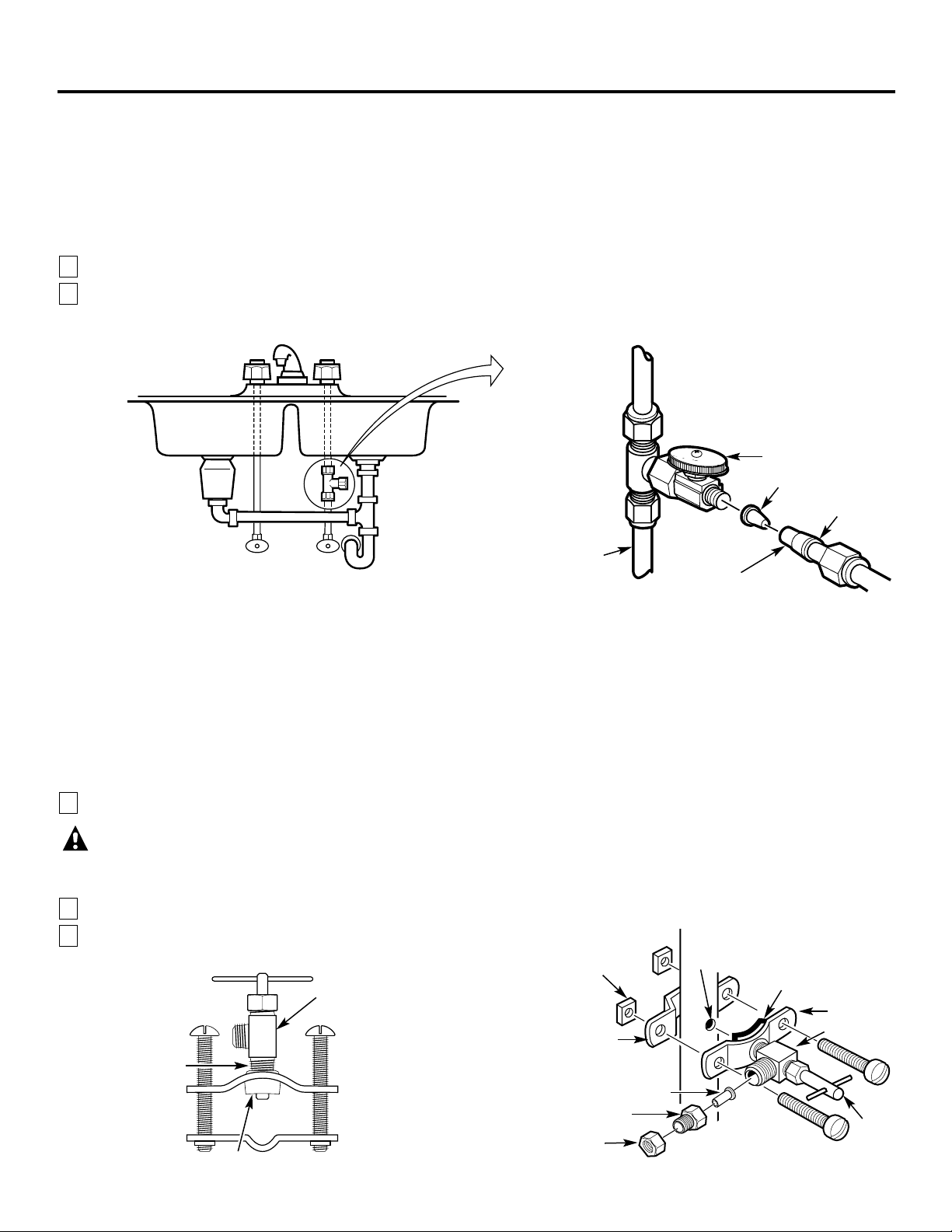

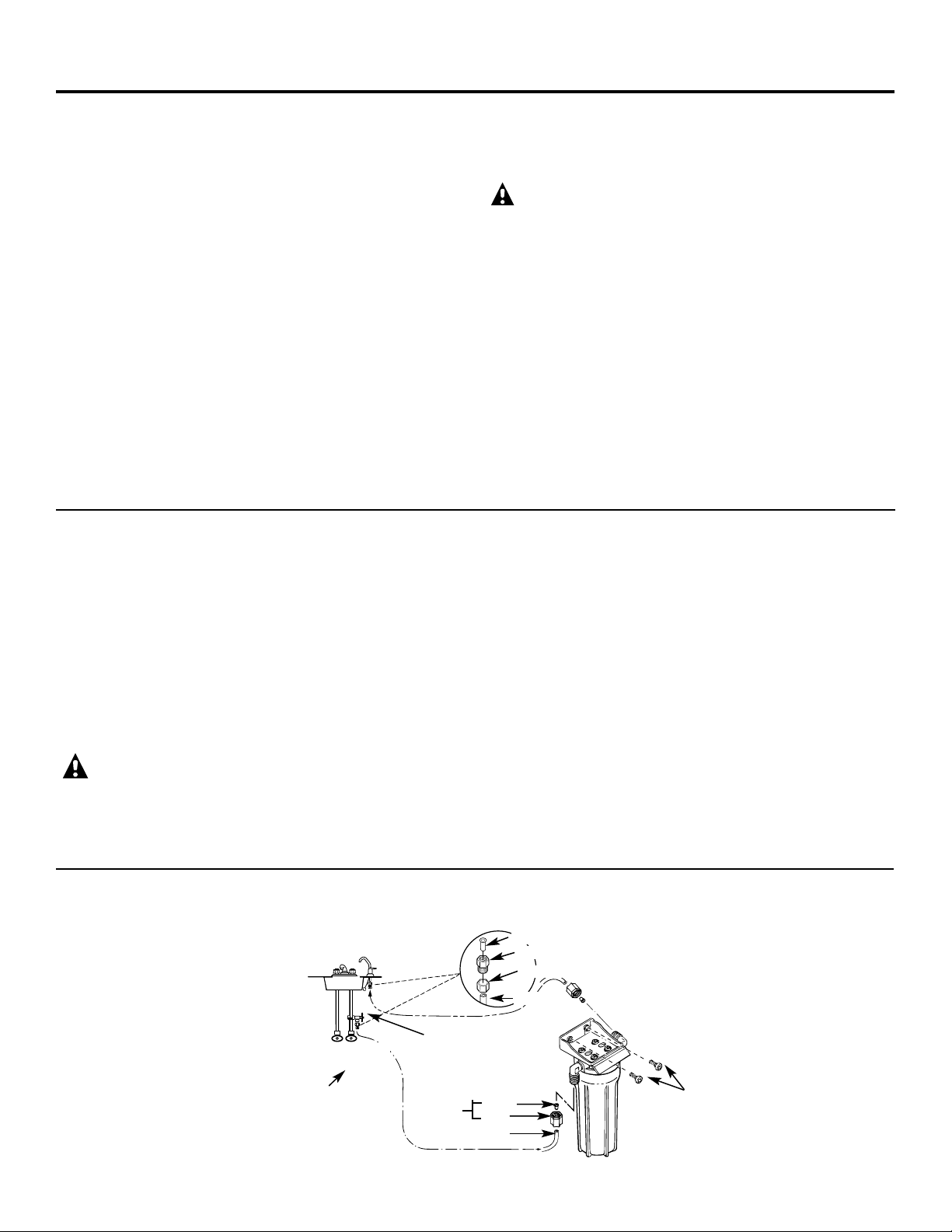

Installation Overview

Installation Instructions.

Important Installation Recommendations

Read entire manual. Failure to follow all guides and rules could cause personal injury or property damage.

■ Check with your local public works department for plumbing

codes. You must follow their guides as you install the Water

Filtration system.

■

Use the Water Filtration system on a potable, safe-to-drink, home

COLD water supply only. The filter cartridges will not purify water

or make unsafe water safe to drink. DO NOT use on HOT water

(100° F. max.).

■ Protect the Water Filtration system and piping from freezing.

Water freezing in the system will damage it.

■ Your Water Filtration system will withstand up to 125 psi water

pressure. If your house water supply pressure is higher than 100

psi during the day (it may reach higher levels at night), install a

pressure reducing valve before the system.

WARNING: Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system. GX1S15C (rev. 2)

is certified for cyst reduction and may be used on

disinfected water that may contain filterable cysts. The

water should be tested periodically to verify that the system

is performing satisfactorily. Small parts remaining after the

installation could be a choke hazard. Discard safely.

■ Slotted and Phillips screwdrivers

■ Pliers and adjustable jaw wrench

■ Hand or battery powered drill and 1 ⁄ 4 ″ bit (saddle valve

installation)

■ Electric drill and drill bit to drill 3⁄ 4 ″ hole (type as

required) if mounting hole is needed for faucet

Be sure to use the proper procedure for drilling porcelain or

stainless steel. Special drill bits may be needed.

CAUTION: To avoid damaging the sink, consult a qualified

plumber or installer for drilling procedures. Special drill

bits may be needed for porcelain or stainless steel.

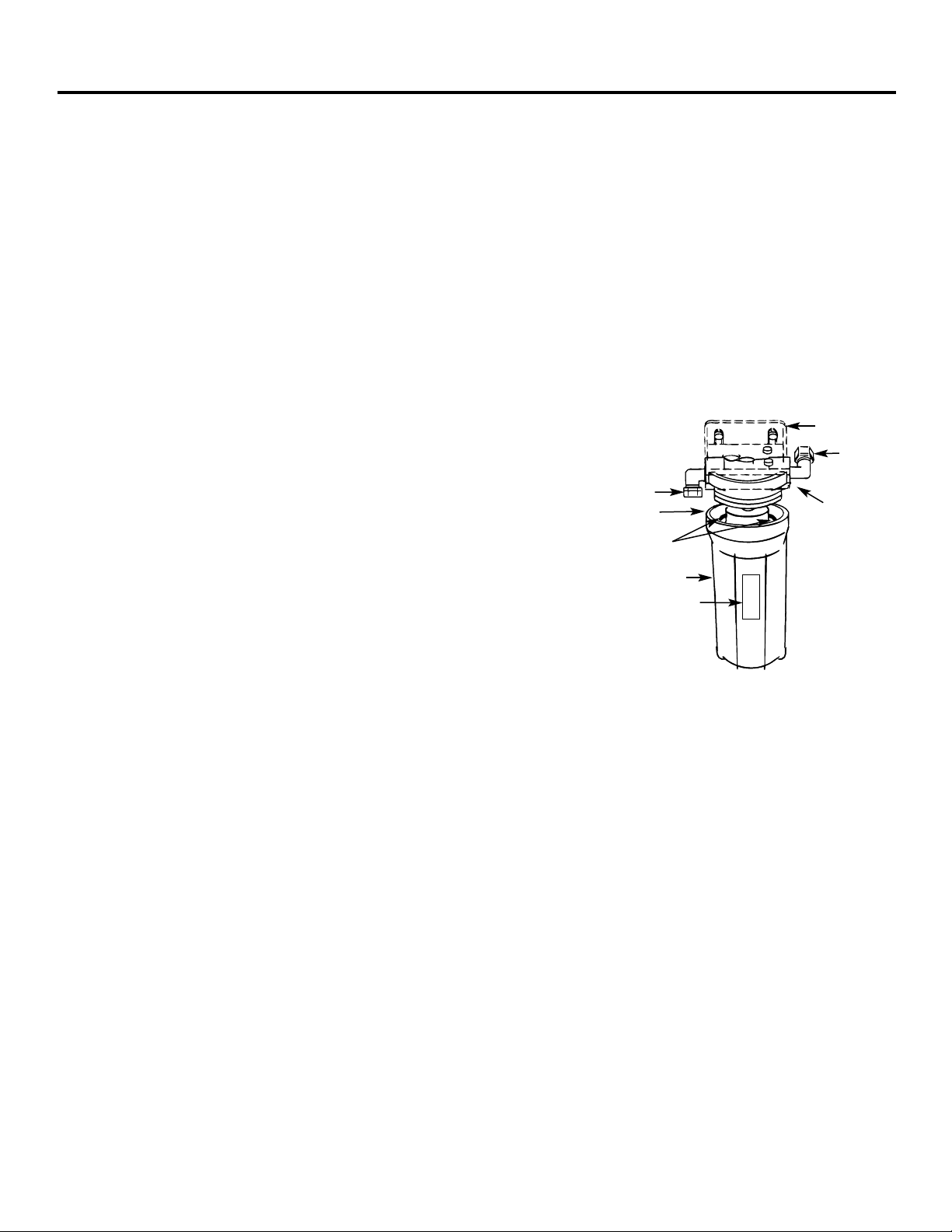

Contents included with the product:

■ Water filter assembly, including mounting bracket and

screws

■ Product Literature (Owner’s Manual and Installation,

Product Data Sheet, Owner Product Registration Card)

■ Water supply/saddle valve

■ Filtered water faucet, for sink or countertop mounting

■ 3

⁄

8″ tubing and fittings to make all needed connections

■ Sump wrench

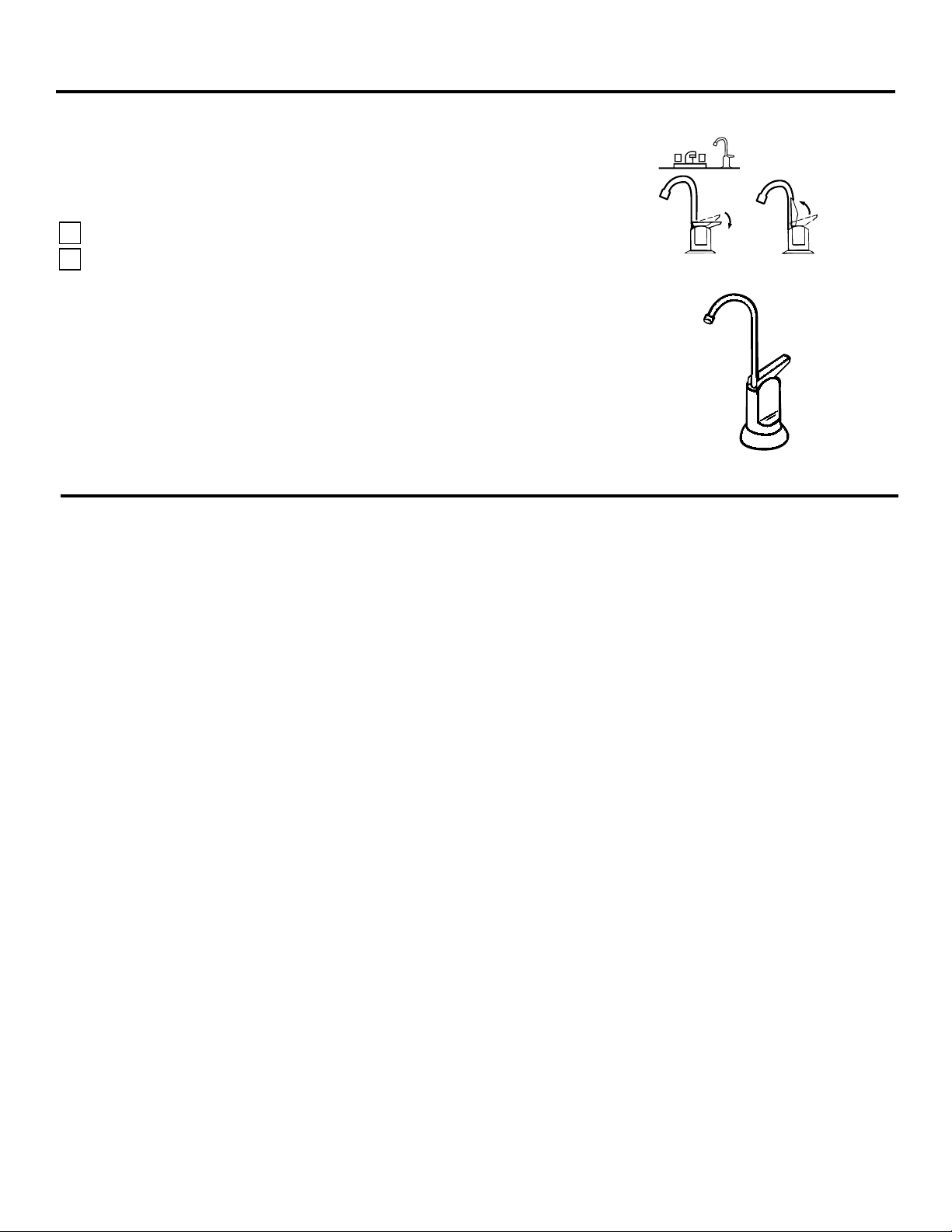

Filtered

water faucet

Sink

Hot

Shutoff valve

NOTE: To change the filter cartridge, you

must turn off the water. A nearby shutoff

valve is convenient. Most sinks already

have shutoff valves on the supply pipes.

Cold

Water supply valve

Tubing insert

Tubing adapter

Compression nut

Water in

Water out

Tubing

Insert

Mounting

screw (2)

Nut

Tubing

Locate the drinking water

system on the cold water

supply pipe, under the

kitchen and/or bathroom

sink, to filter the cold

drinking water.

Model

GX1S04C

only

Page 5

5

Feed Water Supply

Check and comply with local plumbing codes as you plan,

then install a cold feed water supply fitting. For new home installation

using standard plumbing fittings, see first two illustrations below. A typical

installation for existing homes using the saddle valve is shown in third

illustration below.

A. PREFERRED INSTALLATION

Turn off the cold water supply.

Complying with plumbing codes, install a fitting on the cold water pipe

to adapt 3 ⁄8″ OD tubing. A typical connection is shown in illustrations at

right (parts not included). Make sure a water supply valve is used.

2

1

B. OPTIONAL HOME INSTALLATION Where codes permit

*For 1/2" OD or larger metal tubing only.

NOTE: Codes in the state of Massachusetts require installation by a licensed

plumber and do not permit the use of the saddle valve. For installation,

use plumbing code 248-CMR of the Commonwealth of Massachusetts.

Turn off the cold water supply and attach saddle valve as shown in

illustration at right.

DANGER: To protect yourself from serious injury or fatal shock, use

a battery-powered hand drill only to make the hole. DO NOT USE AN

ELECTRIC DRILL.

Close the water supply valve by turning the handle clockwise.

Open the main water supply valve and several house faucets to purge

air from the system. Close faucets when water runs smoothly.

3

2

1

Optional water supply connection (using saddle valve)*

Pre-drill

1⁄4″ hole

Seal—make sure the

seal is in place

Clamp X

Nut (2)—not

required if holes

in clamp are

threaded

Valve

Handle

Tubing adapter

Tubing insert

Compression nut

Clamp Z

Preferred water supply connection

(using compression fitting)

Insert (not included)

Cold

water

pipe

3⁄8″ tubing to inlet

Ferrule

Water supply valve

Typical location

Cold

water

Use to connect the tubing

*For 1/2" OD or larger metal tubing only.

Snug valve into bracket

DO NOT OVERTIGHTEN

Some threads

should be visible

Rubber gasket

Page 6

6

Step-by-step installation instructions.

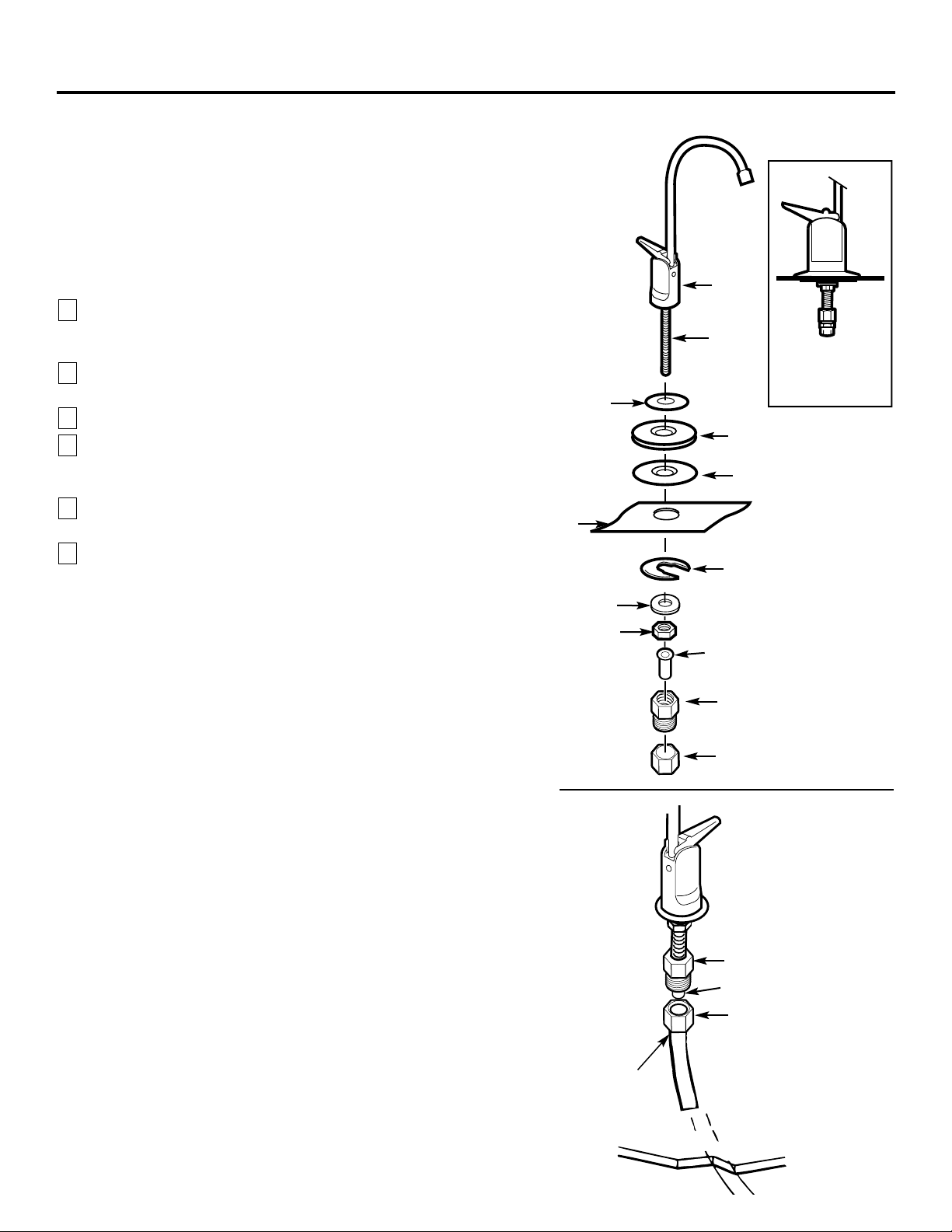

Faucet Installation

Be sure there is room underneath the sink to make the needed connections.

Select one of the following places to install the faucet:

—IN an existing sink spray attachment or soap dispenser hole.

—IN a hole to be drilled in the sink top.

—IN a hole to be drilled in the countertop, next to the sink.

NOTE: Looking at second illustration at right, be sure the faucet base will fit

flat against the surface at the selected location so the gasket will seal.

If drilling is needed, make a 3⁄ 4″ dia. hole. Be sure to use the proper

procedure for drilling porcelain or stainless steel. Special drill bits

may be needed.

Place small gasket, base and large gasket (in that order) onto the

faucet stem. Next, place lock washer and hex nut onto faucet stud.

Insert tubing insert into tubing adapter. Securely tighten to faucet stud.

Feed the length of 3 ⁄8″ OD tube from the bottom, up through the

mounting hole. Connect to the tubing adapter as shown in second

illustration, tightening the compression nut securely.

Remove the short shipping tube and insert the spout into the

faucet body. Rotate spout into place.

Lower the faucet assembly into place on the underside of the mounting

hole. Place

the mounting bracket above the lock washer. While holding

the mounting bracket in place, securely tighten the hex nut.

6

5

4

3

2

1

Sink

Base

Lock washer

Faucet

Lever

Spout

Faucet

stud

Small gasket

Large gasket

Compression nut

Tubing adapter

Mounting bracket

Hex nut

Tubing insert

3/8″ tubing, (run

to Filter outlet)

Compression nut

ASSEMBLED

Tubing adapter

Tubing insert

Page 7

7

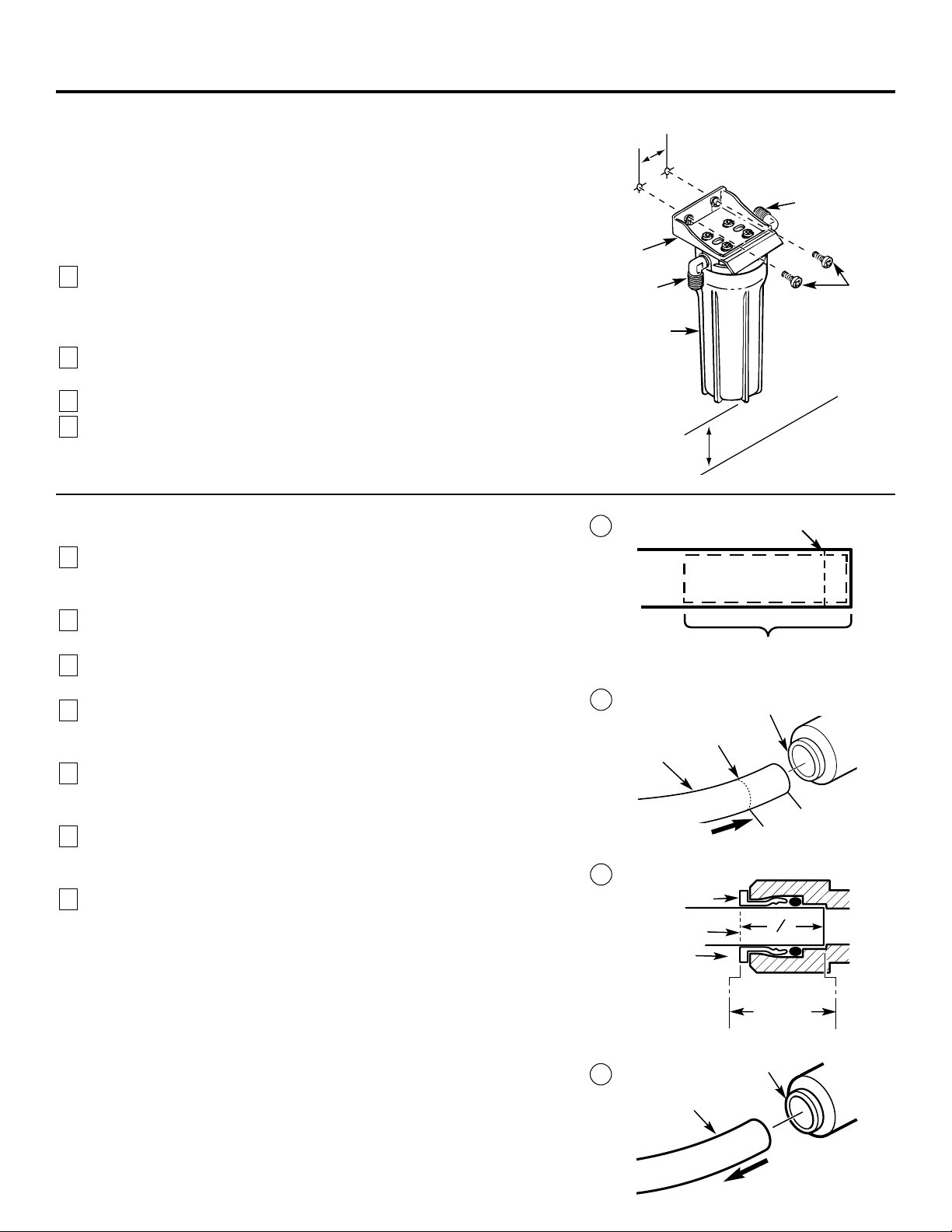

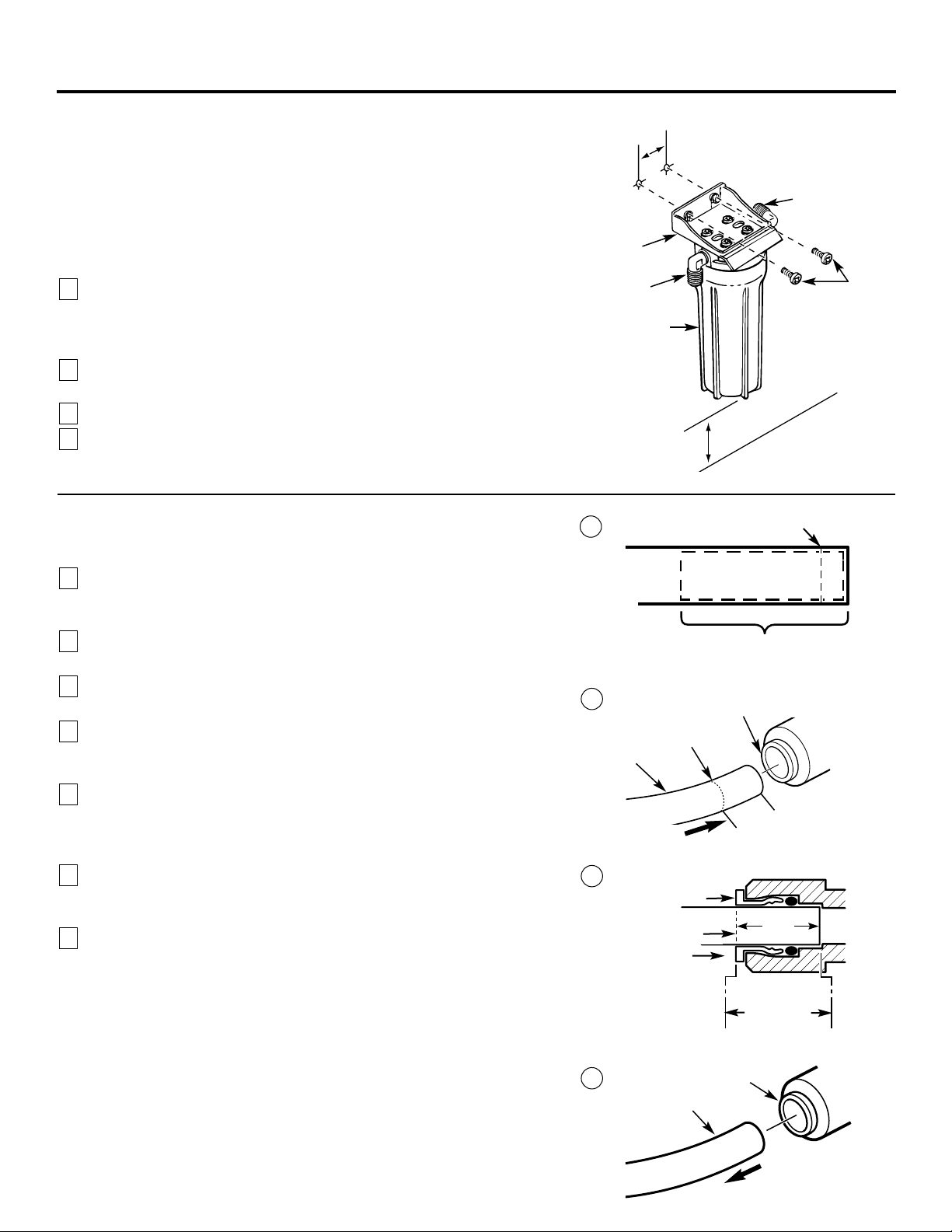

Mounting Bracket to Cabinet Wall

The bracket can be used as a template for marking the location of the

mounting screws. When determining the

location of the bracket make sure

you leave 1-1 ⁄2″ to 2″of free area under the sumps to allow for sump removal

and enough space on either side to make the tubing connections.

Tubing Connections—Compression Style

(Models GX1S04C and GN1S04C)

Run the length of 3⁄8″ tubing, connected to the bottom of faucet,

to the filter system outlet. Allow enough slack in the tubing so the unit

can be easily removed for filter changes. Measure and cut the end of

the tubing square.

Slide a compression nut onto the end of the tubing and push a tubing

insert into the tubing.

Connect the tubing and tighten the compression nuts securely.

Repeat the preceding steps to connect a length of tubing between

the filter system inlet and the water supply/saddle valve (illustration in

the Installation Overview section).

4

3

2

1

Mounting

screws

Tubing connector

(outlet)

Tubing connector

(inlet)

Mounting

bracket

Sump

2-3⁄4″

1-1⁄2″ to 2″

Tubing Connections—Push-In Style (Model GX1S15C [rev. 2])

Run the length of the 3⁄8″ tubing, connected to the bottom of the faucet,

to the filter system outlet (illustration above). Allow enough slack in the

tubing so that the unit can be easily removed.

Measure and cut the end of the tubing square using a sharp cutter or

knife. Remove any burrs (illustration A).

Inspect the end of the tubing, about 1 inch, to be sure there are no

imperfections. It may be necessary to cut the tubing again.

Mark the tubing for length of insertion. For 3/8″ OD tubing the insertion

length should be approximately 3/4 of an inch. Tubing must be fully

inserted to avoid leaks.

DO NOT REMOVE GRAY COLLET. Push the tubing all the way into the fitting

until it bottoms out. The insertion line should be hidden or barely visible

(illustration B and C). Slightly pull on the tubing to verify engagement.

Repeat the procedure to connect the tubing between the filter system

inlet and the water supply/saddle valve (illustration in the Installation

Overview section).

To remove tubing (illustration D), depress and hold gray collet.

Pull tubing to remove.

NOTE: Avoid installing the unit where the tubing is pulled at a sharp angle.

This type of installation may cause the fittings to leak. If using tubing other

than what is supplied, be sure it is high quality, exact size and roundness,

and has a smooth surface.

7

6

5

4

3

2

1

Engagement

3/4″ (3/8″ tubing)

Gray Collet

(DO NOT

REMOVE)

Gray Collet

Tubing

Cut tubing square

End of tubing round and smooth, with no cuts,

nicks or flat spots (approximately 1″)

Insertion line

A

C

D

Depress gray collet

and pull tubing

to remove

Insert tubing

B

Insert

Gray Collet

(DO NOT REMOVE)

Insertion line

Tubing

Tubing must

be fully inserted

to avoid leaks.

3⁄4″

3

"

4

Page 8

8

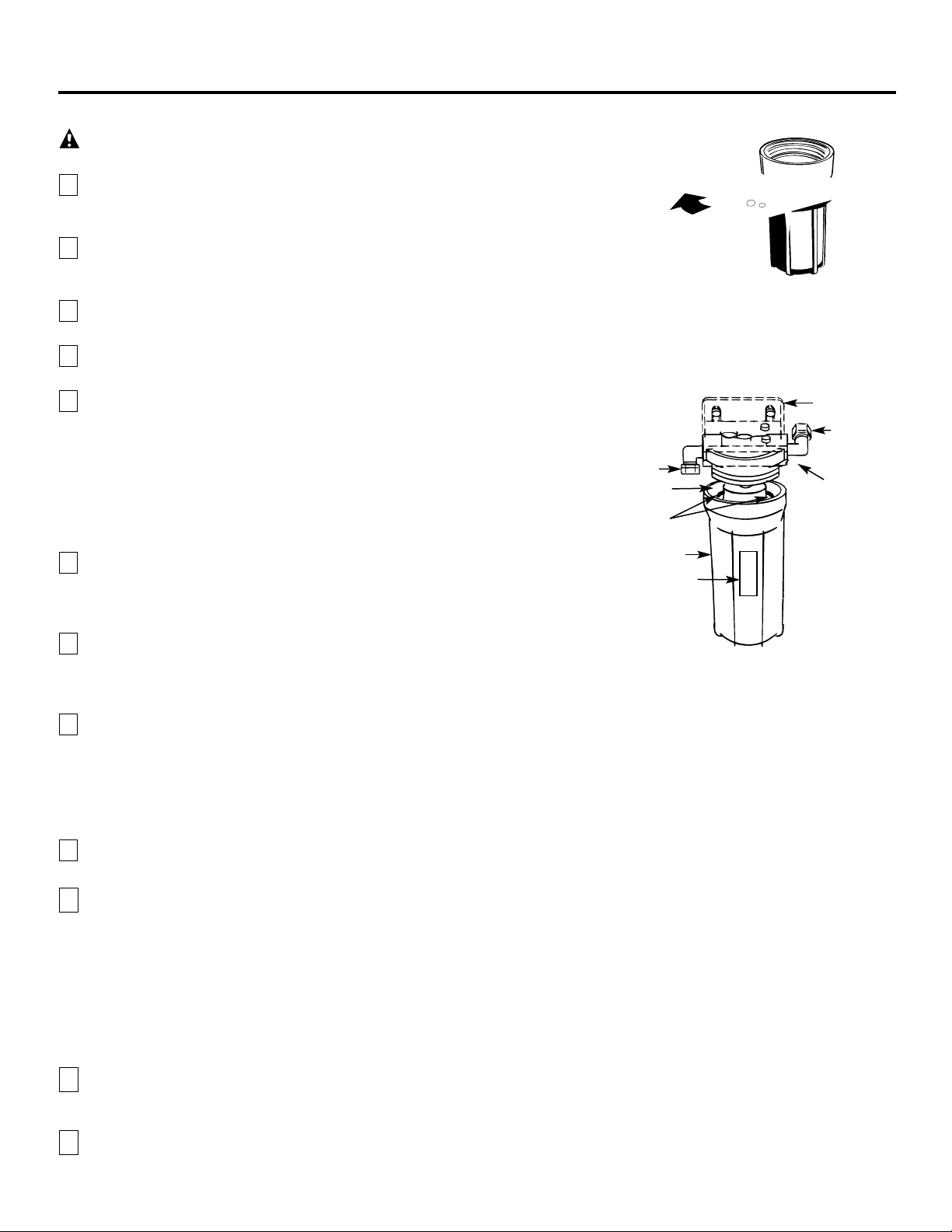

O-ring seal

Cartridge

Sump I

Label

Head

Bracket

OUTLET

INLET

About the water filtration system.

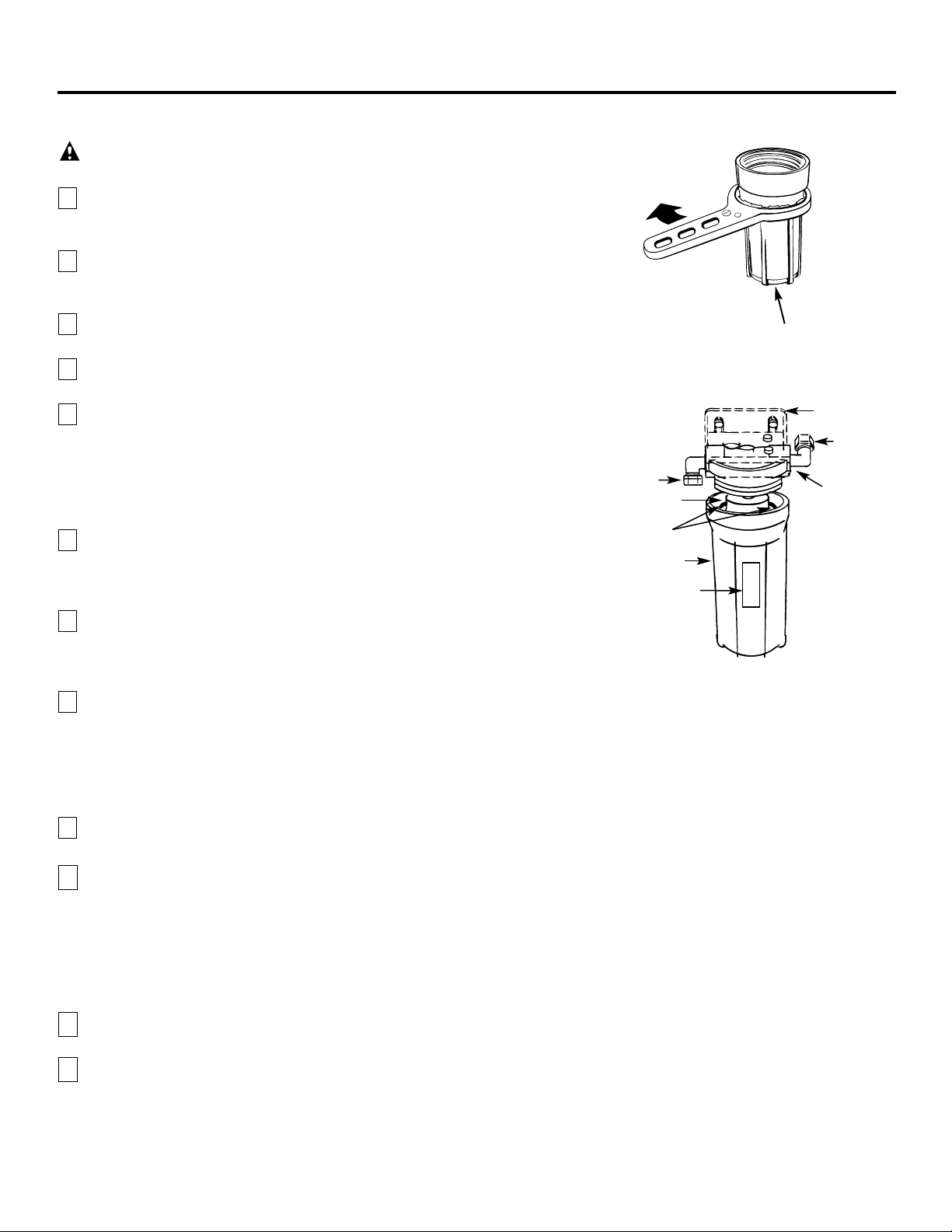

Filter Cartridge Installation or Replacement

CAUTION: Never remove the sumps when water pressure is in the

Water Filtration system.

Close the water supply/saddle valve to the filter. (See illustration in the

Installation Overview section for location of the water supply valve.)

Open the filtered water faucet.

Remove the sump, using the sump wrench tool*, from the filter head by

rotating the sump as shown. Be careful, the sump may be full of water.

Be sure to keep the large o-ring seal.

If you are replacing a filter cartridge, remove and discard the used

filter cartridge.

Be sure the inside of the sump is clean. Thoroughly wash the inside of

the sump with hot, soapy water and rinse.

Remove the wrapper from the new filter cartridge and insert the filter

cartridge in the sump.

Some cartridges fit either way, while others fit only

one way. Observe markings on the cartridge.

NOTE: The Water Filtration system uses two different types of filter

cartridges. Be sure to install them correctly. See Specification Guidelines

for a complete list of filter performance characteristics.

Lightly lubricate the o-ring seal in the sump with clean food grade

silicone grease (silicone grease is available through GE Parts and Services:

1-800-626-2002 Part number: WS60X10005). Be sure it is fully seated in

its groove.

Hold the sump up to the filter head, aligning the center hole in the

cartridge with the protrusion on the bottom of the head. Failure to

obtain proper alignment may cause damage to the filter and/or filtration

system, which will degrade filter performance.

Being careful not to cross-thread, rotate the sump onto the filter head

and tighten securely by hand.

NOTE: If the sump will not tighten up to the head or if you feel resistance,

you may have the cartridge in upside down or misaligned. Take the

cartridge out and check for correct orientation or alignment and

reassemble.

Turn on the filtered water faucet. Then, slowly open the water supply

valve and allow the filter housing to fill.

Close the filtered water faucet. Then, check for leaks between the sump

and the head.

NOTE: If leaking, turn off the water supply and turn on the filtered

water

faucet. Disassemble the filter housing and check the o-ring for cuts, flat

spots, etc., and sealing surfaces for foreign material. Clean the o-ring and

lightly lubricate with clean silicone grease. Carefully press into

the groove in the sump. Reassemble and check for leaks.

The filter cartridges contain activated carbon. When new, turn on the

filtered water faucet for five minutes to flush the system.

Place filter change label on sump, inside cabinet door, or in another

convenient location. Write in date of filter change for future reference.

Filters should be changed every six months.

12

11

10

9

8

7

6

5

4

3

2

1

Sump

*Turn sump wrench tool

provided clockwise to

remove sump

Page 9

9

Flush Procedure

Whenever water of unknown quality is passed through the GE Water Filtration

system, filter elements should be discarded and the filtration system flushed.

Circumstances that may require flushing the system are:

■ Boil-water advisory.

■ Flooding of the GE Water Filtration system.

■ Long-term non-use.

The procedure for flushing the GE Water Filtration system is:

See Filter Cartridge Replacement section and follow steps 1, 2, 3, and 4.

Next, reinstall the sumps (without the filter elements), turn water on, and

flush water through the faucet for one minute.

Then, turn water off, remove sumps, empty water out of sumps and install

new filter elements.

Follow steps 5-10 in the Filter Cartridge Replacement section to complete.

4

3

2

1

Page 10

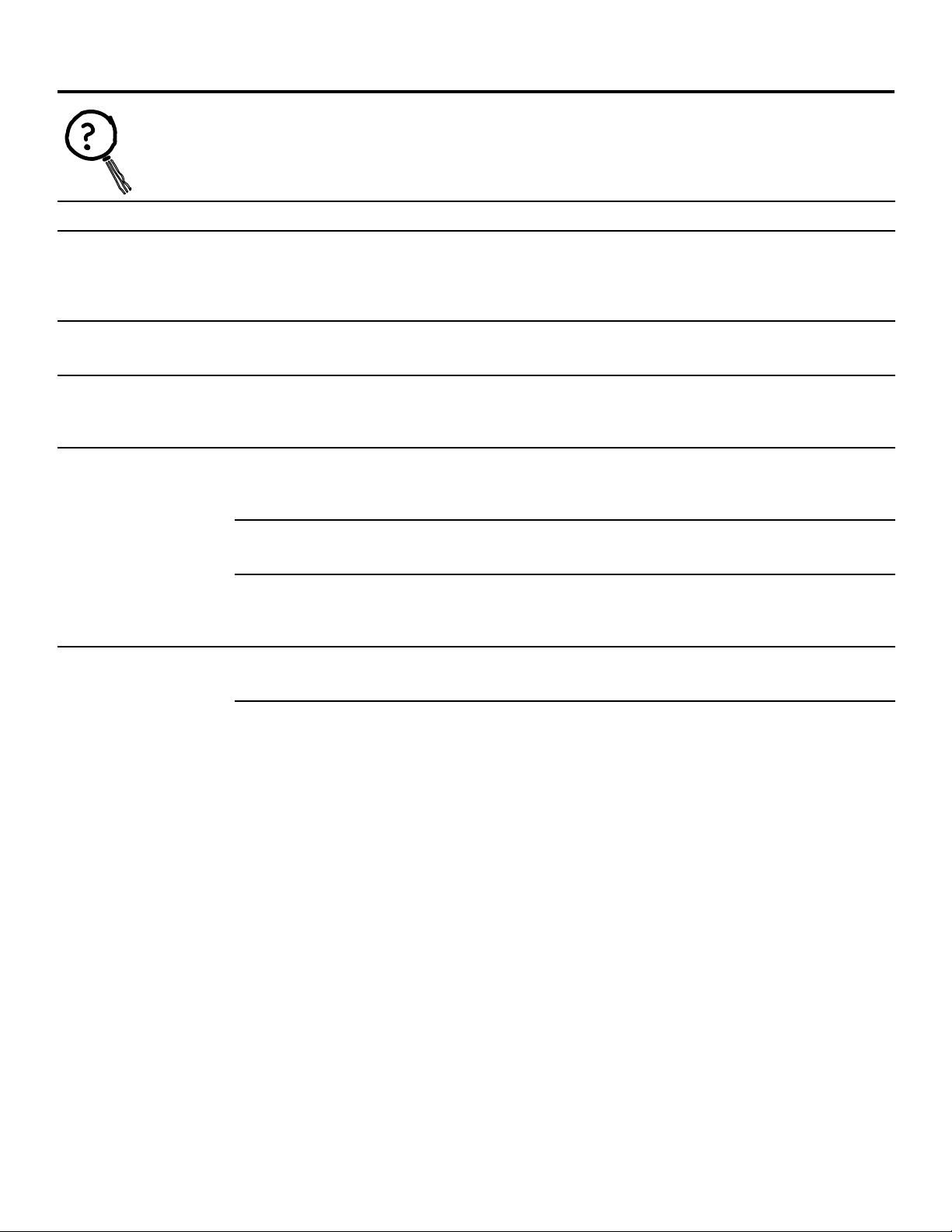

Before you call for service…

Problem Possible Causes What To Do

Water contains tiny New filter cartridges contain • Turn on the filtered water faucet and allow these harmless

black particles activated carbon, which is a carbon particles to purge from the cartridge. Turn off the

harmless black powder. faucet when the water is clear.

Water has air bubbles Air in system after installation. • Will go away after water runs for a while.

and is cloudy

Chlorine taste and /or The filter cartridge is no •

Replace filter cartridge.

odor in the product water longer removing chlorine

from the water supply.

Water dispenses Filter may have an integral • A slower flow (approx. 0.6 g/min.) is normal with this style of

very slowly

flow restrictor. filter. If flow rate is unacceptable replace the filter with one that

does not have an integral flow restrictor.

The filter has been installed • A six-month change-out period is recommended.

for too long. Replace filter cartridge.

The filter cartridge has • High sediment levels can cause premature clogging.

become clogged. Replace filter cartridge.

Push-in fittings are leaking Tubing may not be installed • Fully follow the installation instructions (page 7) and be sure

(GX1S15C [rev. 2]) properly. the tubing is installed to the proper depth.

Tubing may be damaged. • Examine the end of tubing (approx. 1 inch) for defects such

as scratches, grooves, roundness, etc. Trim tubing and fully

reinstall.

Troubleshooting Tips

Save time and money! Review the chart below

first and you may not need to call for service.

10

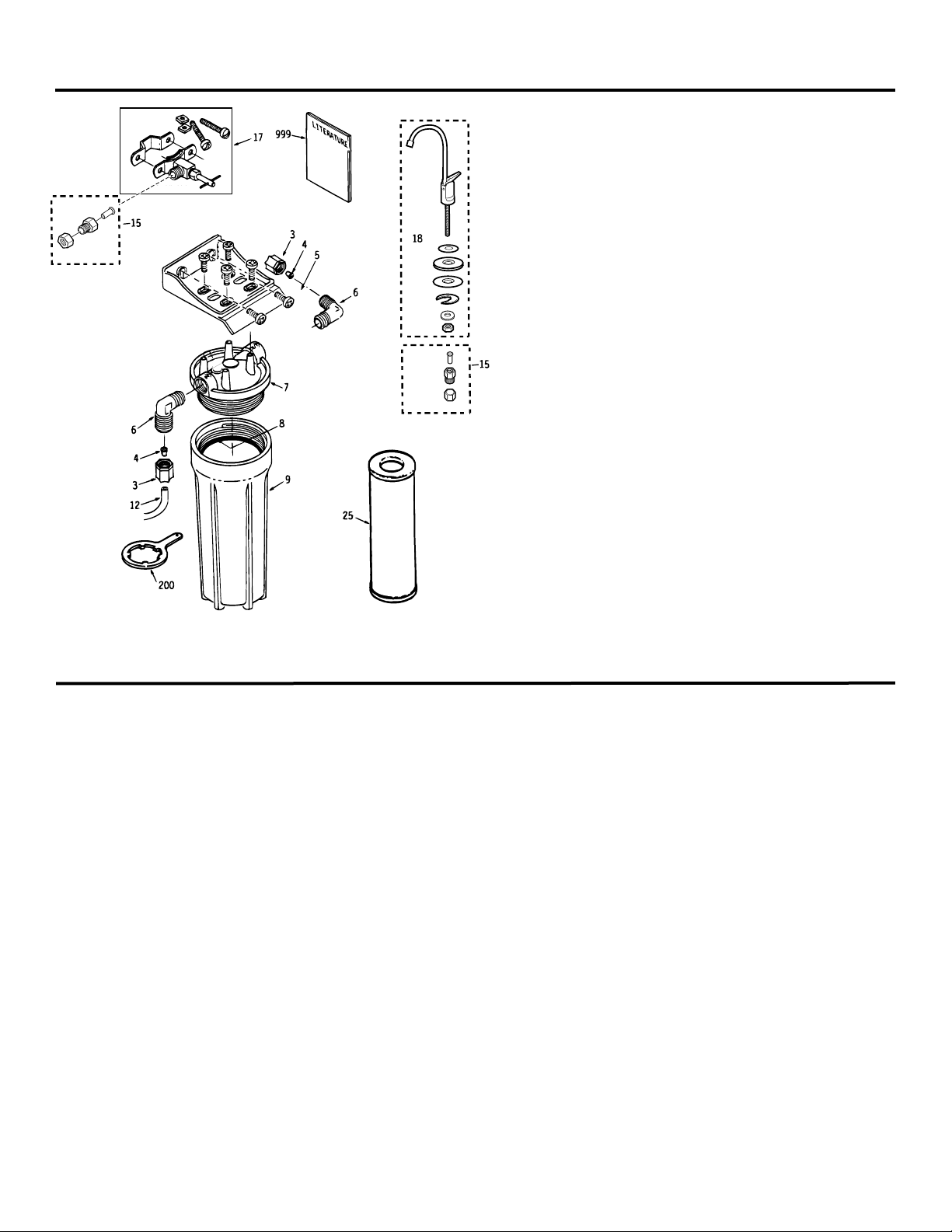

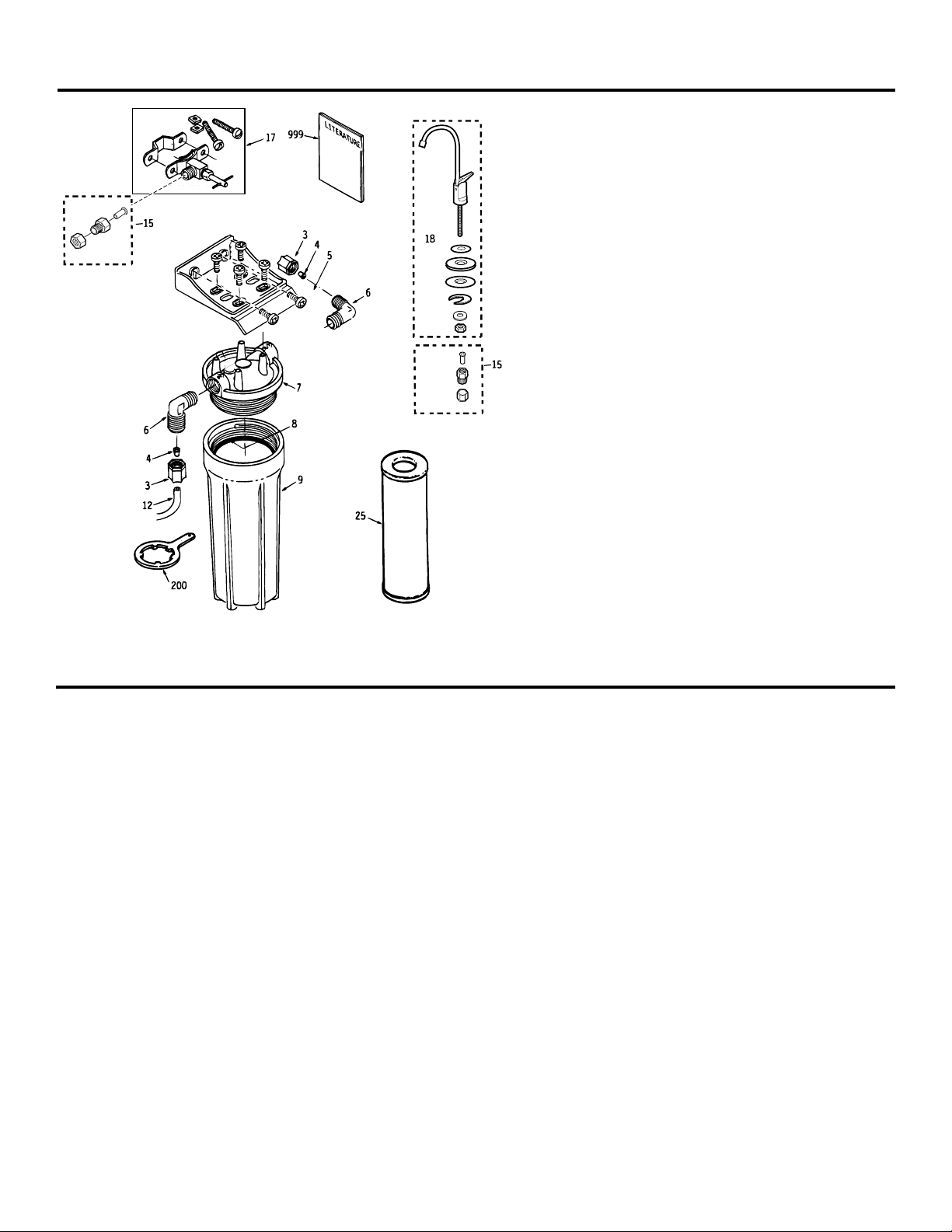

Page 11

11

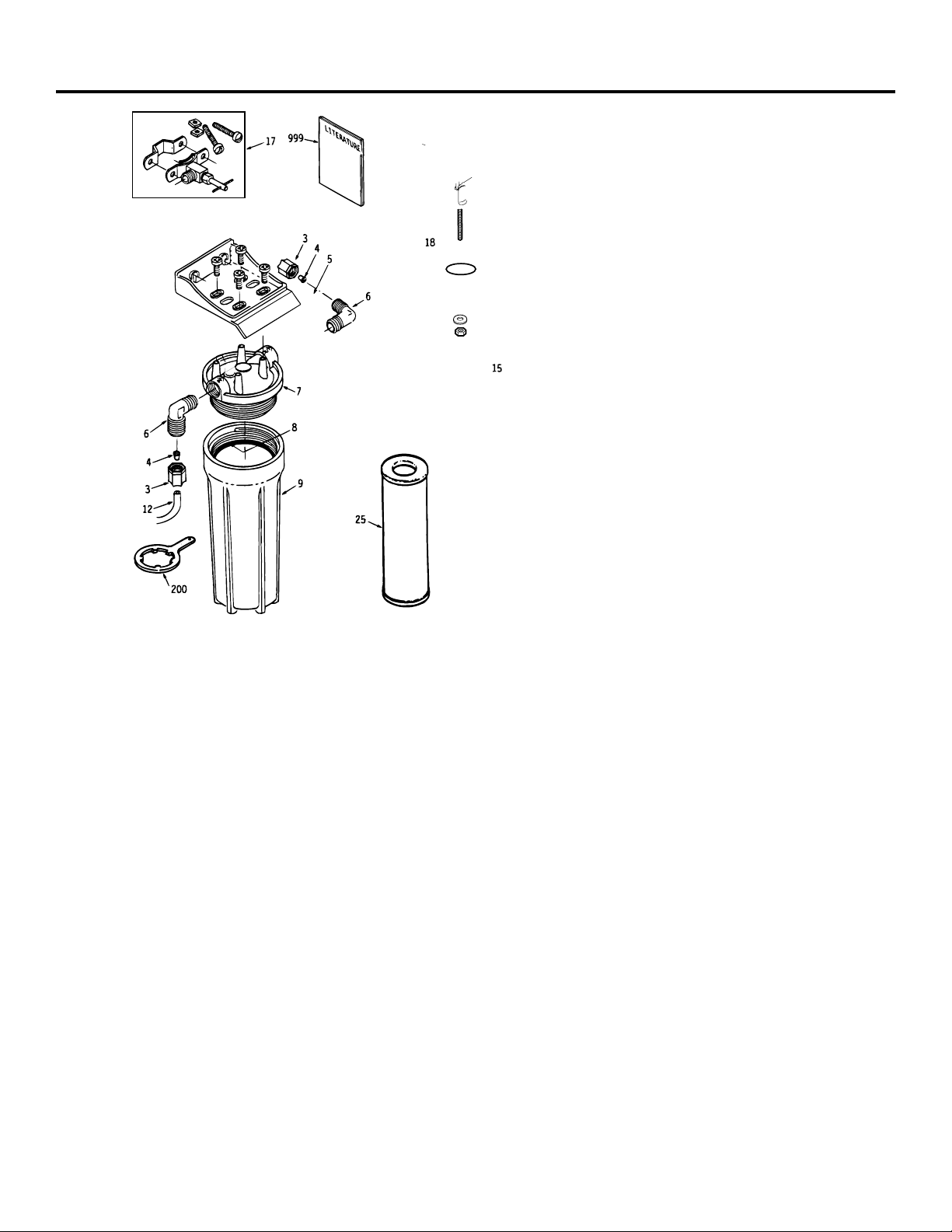

Parts List.

GEAppliances.com

Page 12

12

LIMITED ONE YEAR WARRANTY

• What does this warranty cover?

— Any defect in materials or workmanship in the manufactured product.

• What does this warranty not cover?

— Filter Cartridges.

— Service trips to your home to teach you how to use the product.

— Improper installation.

— Failure of the product if it is abused, misused, altered or used for other

than the intended purpose.

— Defects that result from improper installation or damage not caused

by GE.

— Liability on the part of GE under this or any other warranty for any

indirect or consequential damage.

— Products that are used for commercial or industrial applications.

— Use of this product where water is microbiologically unsafe or of

unknown quality, without adequate disinfection before or after the

system. Systems certified for cyst reduction may be used on disinfected

water that may contain filterable cysts.

— Damage to the product caused by accident, fire, floods or acts of God.

— Incidental or consequential damage caused by possible defects with this

appliance, its installation or repair.

• For how long after the original purchase?

— One year.

• How do I make a warranty claim?

— Return to the retailer from which it was purchased, along with a copy

of the “Proof of Purchase.” This warranty excludes the cost of shipping

or service calls to your home.

• How does state law relate to this warranty?

— This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state. THIS WARRANTY IS

INTENDED TO BE IN LIEU OF ALL OTHER WARRANTIES,

WHETHER EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

Contact us at www.GEAppliances.com, or call 800.GE.CARES (800.432.2737) in the

U.S., or toll-free 866.777.7627 in Canada.

Consumer Support.

GE Appliances Website

www.GEAppliances.com

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day, any day of the year! For

greater convenience and faster service, you can now download Owner’s Manuals, order parts, catalogs, or even schedule service

on-line. You can also “Ask Our Team of Experts™” your questions, and so much more...

Schedule Service www.GEAppliances.com

Expert GE repair service is only one step away from your door. Get on-line and schedule your service at your convenience 24

hours any day of the year! Or call 800.GE.CARES (800.432.2737) during normal business hours.

Real Life Design Studio www.GEAppliances.com

GE supports the Universal Design concept—products, services and environments that can be used by people of all ages, sizes

and capabilities. We recognize the need to design for a wide range of physical and mental abilities and impairments. For details

of GE’s Universal Design applications, including kitchen design ideas for people with disabilities, check out our Website today.

For the hearing impaired, please call 800.TDD.GEAC (800.833.4322).

Extended Warranties www.GEAppliances.com

Purchase a GE extended warranty and learn about special discounts that are available while your warranty is still in effect. You

can purchase it on-line anytime, or call 800.626.2224 during normal business hours. GE Consumer Home Services will still be

there after your warranty expires.

Parts and Accessories www.GEAppliances.com

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes (VISA, MasterCard and

Discover cards are accepted). Order on-line today, 24 hours every day or by phone at 800.626.2002 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing generally should be referred to qualified

service personnel. Caution must be exercised, since improper servicing may cause unsafe operation.

Contact Us www.GEAppliances.com

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details including your phone

number, or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

Register Your Appliance www.GEAppliances.com

Register your new appliance on-line—at your convenience! Timely product registration will allow for enhanced communication

and prompt service under the terms of your warranty, should the need arise. You may also mail in the pre-printed registration

card included in the packing material, or detach and use the form in this Owner’s Manual.

GE Water Filtration System Warranty.

Page 13

Instructions de sécurité . . . . . . . . . . . . .14

Instructions d’utilisation . . . . . . . . . . .15

Description sommaire du système

de filtration d’eau . . . . . . . . . . . . . . . . . .15

Spécifications . . . . . . . . . . . . . . . . . . . . . .15

Instructions d’installation . . . . . . .16–21

Cartouches de filtration–

installation ou remplacement . . . . . . . . .20

Étapes de l’installation . . . . . . . . . . .18, 19

Installation du robinet . . . . . . . . . . . . . .18

Montage mural . . . . . . . . . . . . . . . . . . . .19

Outillage/matériel nécessaire . . . . . . . .16

Processus de rinçage . . . . . . . . . . . . . . . .21

Raccordement des tubes . . . . . . . . . . . . .19

Recommandations importantes . . . . . . .16

Source d’alimentation du filtre . . . . . . . .17

Avant de contacter un dépanneur . . . .22

Soutien au consommateur

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . .24

Liste des pièces/catalogue . . . . . . . . . . .23

Soutien au consommateur . . . . . . . . . . .24

13

Le produit GN1S04C/GX1S04C a

été testé et homologué par NSF

International, selon la norme

ANSI/NSF no42 pour la réduction

de la concentration de particules

(classe I), la réduction de la

concentration de chlore et la

suppression des goûts et odeurs,

et la norme no 53 pour la

réduction des kystes, de la

turbidité et de l’amiante.

Le produit GN1S15C (rév. 2) a été

testé et homologué par NSF

International, selon la norme

ANSI/NSF n

o

42 pour la réduction

de la concentration de particules

(classe I), la réduction de la

concentration de chlore et la

suppression des goûts et odeurs,

et selon la norme no53 pour la

réduction de la turbidité et des

concentrations de plomb,

mercure, spores, amiante,

atrazine et Lindane.

Inscrire ci-dessous le numéro de

modèle et le numéro de série :

Modèle # __________________

Série #

____________________

On trouve ces numéros sur la bride

du corps de filtre.

Page 14

14

■

Installer ou remiser le produit à un emplacement qui n’est

pas exposé au gel ou aux intempéries. Le gel de l’eau fera

subir des détériorations au produit. Ne pas tenter de traiter

une eau dont la température est supérieure à 100OF.

AVERTISSEMENT : Éliminer après

l’installation tous les matériaux d’emballage et

matériaux non utilisés; les petites pièces qui ne

sont pas utilisées pourraient susciter un danger

d’étouffement pour un enfant.

■

Le système de filtration d’eau peut résister à une pression

maximale de 125 lb/po2. Si la pression de distribution locale

est supérieure à 100 lb/po2, installer un robinet de réduction

de pression en amont du système de filtration d’eau.

INFORMATION DE SÉCURITÉ IMPORTANTE.

LIRE LA TOTALITÉ DES INSTRUCTIONS AVANT D’UTILISER LE PRODUIT.

Observer toutes les instructions présentées dans ce manuel pour assurer la

sécurité et minimiser les risques de dommages matériels ou corporels.

MESURES DE SÉCURITÉ

■ Consulter le service local des travaux publics au sujet des

codes de plomberie. L’installation du système de filtration

d’eau doit être conforme aux prescriptions du code de

plomberie local.

■ Utiliser le système de filtration d’eau uniquement sur une

canalisation d’eau potable FROIDE. Les cartouches de filtration

ne purifient pas l’eau et ne peuvent rendre potable une eau

qui ne l’est pas.

■ Ne pas utiliser ce produit sur une canalisation d’eau chaude

(100OF maximum).

AVERTISSEMENT : Ne pas utiliser ce

produit avec de l’eau microbiologiquement polluée ou

de qualité inconnue sans avoir installé un dispositif de

désinfection approprié avant ou après le système.

Les systèmes homologués pour la retenue des spores

peuvent être utilisés pour la filtration d’une eau

désinfectée qui peut contenir des spores filtrables.

INSTALLATION

Avant toute utilisation, on doit installer le système de filtration d’eau soit à un emplacement adéquat conformément aux

instructions d’installation.

AVERTISSEMENT!

LIRE ATTENTIVEMENT ET RESPECTER CES PRESCRIPTIONS DE SÉCURITÉ.

CONSERVER CES INSTRUCTIONS

Page 15

15

Description sommaire du système de filtration d’eau. GEAppliances.com

Utilisation du système de filtration, et description des cartouches de filtration

Le robinet installé sur le plan de travail d’une cuisine permet de puiser de l’eau de

consommation filtrée. Il comporte une manette à manoeuvre manuelle chargée par ressort,

qui permet la fermeture automatique. Pour maintenir le robinet ouvert, pousser la manette

vers le haut pour la mettre en appui contre le col de cygne.

Longévité de la cartouche de filtration—La longévité en service de la cartouche de filtration

dépend de divers paramètres, comme les suivants :

Volume de consommation d’eau.

Quantité dans l’eau de sédiments, composés responsables de goûts et/ou odeurs, plomb et autres

substances indésirables.

Quel que soit le système de filtration utilisé, on doit remplacer les cartouches de filtration à

intervalles de six mois. Si l’eau traitée est de très médiocre qualité, on peut observer la

réapparition de substances indésirables dans l’eau avant l’expiration d’une période de six mois.

Dans ce cas on doit immédiatement remplacer les cartouches de filtration. Si le système est

utilisé également pour l’élimination du plomb et de contaminants chimiques, il est PLUS

IMPORTANT de remplacer les cartouches à intervalles de six mois ou moins.

NOTE : Si l’eau traitée contient une quantité élevée de sédiments les filtres à charbon peuvent

s’obstruer prématurément, ce qui réduit le débit d’eau filtrée au niveau du robinet de puisage.

On doit remplacer la cartouche pour rétablir le débit usuel.

2

1

Page 16

Outillage et matériel nécessaires pour l’installation

16

Illustration de l’installation

Instructions d’installation.

Recommandations importantes concernant l’installation

Lire la totalité du manuel. Le non-respect de certaines instructions ou règles pourrait susciter des dommages matériels

ou corporels.

■ Consulter le service local des travaux publics au sujet des

codes de plomberie. L’installation du système de filtration d’eau

doit être conforme aux prescriptions du code de plomberie

local.

■ Utiliser le système de filtration d’eau uniquement sur une

canalisation d’eau potable FROIDE. Les cartouches de filtration

ne purifient pas l’eau et ne peuvent rendre potable une eau qui

ne l’est pas. NE PAS utiliser ce produit sur une canalisation

d’eau CHAUDE (100OF maximum).

■ Protéger le système de filtration d’eau et la tuyauterie contre le

gel. La congélation d’eau dans le système lui fera subir des

dommages.

■ Le système de filtration d’eau peut résister à une pression

maximale de 125 lb/po2. Si la pression de distribution locale est

supérieure à 100 lb/po2durant la journée (elle peut atteindre un

niveau plus élevé la nuit), installer un robinet de réduction de

pression en amont du système de filtration d’eau.

AVERTISSEMENT : Ne pas utiliser ce produit avec de l’eau

microbiologiquement polluée ou de qualité inconnue sans

avoir installé un dispositif de désinfection approprié avant

ou après le système. Le système de filtration GX1S15C

(rév. 2) est homologué pour la rétention des spores; on

peut l’utiliser pour la désinfection d’une eau qui peut

contenir des spores filtrables. Tester périodiquement l’eau

filtrée pour vérifier que la performance du système

demeure satisfaisante. Éliminer en sécurité les petites

pièces qui peuvent rester inutilisées après l’installation;

elles peuvent susciter un danger d’étouffement pour les

jeunes enfants.

■ Tournevis Phillips et à lame plate

■ Pince et clé à molette

■ Perceuse électrique ou à piles, et foret de 1/4 po

(pour l’installation du robinet de prise en charge)

■ Perceuse électrique et foret pour trou de 3/4 po

(type approprié), si un trou de montage est nécessaire

pour l’installation du robinet.

Veiller à employer la méthode convenable pour le perçage dans

l’acier inoxydable ou un matériau émaillé; l’emploi d’un foret

spécial peut être nécessaire.

MISE EN GARDE : Pour éviter d’endommager l’évier,

consulter un installateur ou plombier qualifié au sujet

de la méthode de perçage; l’emploi d’un foret spécial

peut être nécessaire pour le perçage sur acier inoxydable

ou matériau émaillé.

Articles fournis avec le produit :

■ Système de filtration d’eau, avec bride de montage et vis

■ Brochures descriptives du produit (manuel de l’utilisateur,

instructions d’installation, fiche technique du produit, carte

d’enregistrement du produit)

■ Robinet de prise en charge

■ Robinet de puisage de l’eau filtrée–montage sur évier ou

plan de travail

■ Tube de 3/8 po et raccords, pour les raccordements

■ Clé pour corps de filtre

Robinet de

puisage de

l’eau filtrée

Évier

Eau

chaude

Robinet d’arrêt

NOTE : Pour changer les cartouches de

filtration, on doit fermer l’arrivée d’eau.

Il est pratique d’avoir un robinet d’arrêt

à proximité. Un robinet d’arrêt est

fréquemment installé sur la canalisation

d’alimentation du robinet principal de l’évier.

Eau

froide

Robinet d’alimentation

du filtre

Pièce rapportée du tuyau

Raccord d’adaptation pour tube

Écrou de compression

Entrée de l’eau

Sortie de l’eau

Tube

Virole de

renfort

Vis de

montage (2)

Écrou

Tube

Installer le système de

filtration d’eau sur la

canalisation d’eau froide,

sous l’évier de cuisine

et/ou salle de bains, pour

filtrer l’eau de

consommation froide.

Modèle

GX1S04C

seulement

Page 17

Page 18

18

Étapes de l’installation.

Installation du robinet

Vérifier qu’il y a suffisamment d’espace sous l’évier pour les raccordements.

Choisir l’un des emplacements suivants pour l’installation du robinet.

—Trou existant pour douchette d’évier ou distributeur de savon.

—Trou à percer dans le rebord de l’évier.

—Trou à percer dans le plan de travail, près de l’évier.

NOTE : Consulter la seconde illustration à droite; vérifier que la base du

robinet d’arrêt reposera à plat contre la surface d’appui à l’emplacement

choisi, pour que les joints assurent une bonne étanchéité.

Si une opération de perçage est nécessaire, percer un trou de 3/4 po.

Veiller à employer la méthode convenable pour le perçage dans l’acier

inoxydable ou l’émail. Il peut être nécessaire d’utiliser un foret spécial.

Enfiler les pièces suivantes sur la tige tubulaire du robinet, dans l’ordre

indiqué : petit joint, base et grand joint. Placer ensuite la rondelle-frein

et l’écrou hexagonal sur la tige tubulaire du robinet.

Insérer la pièce de rapportee du tuyau dans le raccord d’adaptation du

tube. Bien serrer sur la tige du robinet.

Par le dessous et à travers le trou de montage, faire passer la section

de tube de dia. ext. 3/8 po. Installer l’adaptateur (voir la seconde

illustration); bien serrer l’écrou de compression.

Enlever le tube d’emballage court; insérer le col de cygne dans le corps

du robinet. Faire pivoter le col de cygne pour le mettre en place.

Mettre le robinet en place. Par le dessous du trou de montage, placer la

bride de montage au-dessus de la rondelle-frein. Tout en immobilisant

la bride de montage, bien serrer l’écrou hexagonal.

6

5

4

3

2

1

Évier

Base

Rondellefrein

Robinet

Manette

Col de

cygne

Tige

tubulaire

du robinet

Petit joint

Grand joint

Écrou de compression

Raccord d’adaptation

pour tube

Bride de montage

Écrou

hexagonal

Pièce

rapportée

du tuyau

ROBINET ASSEMBLÉ

tube 3/8 po (pour

raccordement à la

sortie du Filtre)

Compression nut

Raccord d’adaptation

pour tube

Pièce rapportée du tuyau

Page 19

19

Fixation de la bride de montage sur la paroi du placard

On peut utiliser la bride de montage comme un gabarit pour marquer

l’emplacement des vis de fixation. Lors du choix de l’emplacement de fixation

de la bride de montage, veiller à disposer d’un espace libre de 1 1/2 po à 2 po

au-dessous des corps de filtre pour permettre leur démontage, et d’un espace

suffisant sur les deux côtés pour le raccordement des tubes.

Raccordement des tubes–raccord à compression

(modèles GX1SO4C et GN1SO4C )

Installer une section de tube de 3/8 po entre le robinet et la sortie du

système de filtration. Utiliser une section de tube suffisamment longue

pour qu’il soit facile de démonter l’ensemble pour le changement des

cartouches de filtration. Mesurer, et couper le tube à l’équerre.

Enfiler un écrou de compression sur l’extrémité du tube; insérer une

virole de renfort dans le tube.

Connecter le tube; bien serrer les écrous de compression.

Répéter les étapes précédentes pour installer une section de tube entre

l’entrée du système de filtration et le robinet de prise en charge ou le point

d’arrivée d’eau (voir l’illustration à la section Illustration de l’installation).

4

3

2

1

Vis de

montage

Raccord

de sortie

Raccord

d’entrée

Bride du

montage

Corps de filtre

2-3⁄4 po

1 1/2 po

à 2 po

Raccordement des tubes par enfoncement

(modèle GX1S15C [rév. 2])

Installer une section de tube de 3/8 po entre le robinet et la sortie du

système de filtration (voir l’illustration ci-dessus). Utiliser une section de

tube suffisamment longue pour qu’il soit facile de démonter l’ensemble.

Mesurer, et couper l’extrémité du tube à l’équerre avec un couteau

acéré ou un autre instrument. Éliminer les bavures (illustration A).

Inspecter l’extrémité du tube; il faut que sur une distance de 1 po il n’y ait

pas d’imperfection. Il peut être nécessaire de couper le tube de nouveau.

Marquer la limite d’insertion sur le tube. Pour un tube de diamètre

externe 3/8 po, la distance d’insertion est d’environ 3/4 po. Le tube doit

être completement inséré pour éviter les fuites.

NE PAS ENLEVER LA VIROLE GRISE. Enfoncer complètement le tube dans

le raccord, jusqu’à la position de butée. La limite d’insertion devrait être

cachée ou à peine visible (illustration B et C). Tirer légèrement sur le

tube pour vérifier l’engagement.

Répéter les étapes précédentes pour installer une section de tube entre

l’entrée du système de filtration et le robinet de prise en charge ou le point

d’arrivée d’eau (voir l’illustration à la section Illustration de l’installation).

Pour enlever le tube (illustration D), enfoncer et maintenir la virole grise.

Tirer sur le tube pour l’extraire.

NOTE : Éviter une configuration d’installation dans laquelle le tube devrait

former un angle. Ce type d’installation pourrait produire des fuites au niveau

des raccords. Dans le cas de l’utilisation de tube flexible autre que celui qui

est fourni, veiller à ce qu’il s’agisse d’un produit de grande qualité, à surface

lisse, parfaitement rond et de même taille.

7

6

5

4

3

2

1

Zone

d’engagement

3/4 po (pour tube

de 3/8 po)

Virole grise

(NE PAS

ENLEVER)

Couper à l’équerre

Extrémité du tube ronde et lisse, sans coupure,

déformation ou zone plate (environ 1 po)

Canalisation

à insérer

3/4 po

A

C

Insérer le tube

B

Insérer

Virole grise

(NE PAS ENLEVER)

Canalisation

à insérer

Tube

Le tube doit être

completement inséré

pour éviter les fuites.

3⁄4po

Virole grise

Tube

D

Enfoncer la virole grise

et tirer sur le tube

pour l’extraire.

3

"

4

Page 20

20

Joint torique

Cartouche

de filtration

Corps de filtre I

Étiquette

Tête de filtre

Bride de montage

RACCORD

DE SORTIE

RACCORD

D’ENTRÉE

Utilisation du système de filtration de l’eau.

Cartouches de filtration–Installation ou remplacement

MISE EN GARDE : Ne jamais enlever le corps de filtre lorsque le système

de filtration est pressurisé.

Fermer le robinet d’arrêt de la canalisation qui alimente le filtre. (Pour

l’emplacement de ce robinet, voir l’illustration à la section Illustration

de l’installation). Ouvrir le robinet de puisage de l’eau filtrée.

Pour enlever le filtre, faire tourner le corps de filtre selon les indications

de l’illustration, avec l’outil spécial*. Travailler prudemment–le corps de

filtre peut être plein d’eau. Veiller à conserver le grand joint torique.

Pour le remplacement de la cartouche de filtration, enlever et jeter la

cartouche usée.

Vérifier la propreté de l’intérieur du corps de filtre. Laver parfaitement

l’intérieur du corps de filtre avec de l’eau chaude savonneuse, puis rincer.

Retirer la cartouche de filtration neuve de son emballage; insérer la

cartouche dans le corps de filtre. Il peut être nécessaire de respecter une

orientation particulière; ceci est alors indiqué par des marques apposées

sur la cartouche.

NOTE : Diverses cartouches de filtration sont utilisables avec le système

de filtration d’eau. Veiller à installer chaque type de cartouche

correctement. Pour les caractéristiques de performance des filtres,

voir la section Spécifications.

Lubrifier légèrement le joint torique avec une graisse aux silicones de

qualité alimentaire (graisse aux silicones disponible auprès de GE—Pièces et

services au : 1-800-626-2002 Numéro de pièce : W560X10005.) Veiller à ce

que le joint soit bien placé dans la rainure.

Tenir le corps de filtre sous la tête de montage; aligner le trou central de

la cartouche avec la pièce en saillie sous la tête. Un défaut d’alignement

pourrait faire subir des dommages au filtre et/ou au système de filtration,

ce qui en dégraderait la performance.

Visser le corps de filtre sur la tête de montage–veiller à ne pas détériorer

le filetage; bien serrer à la main.

NOTE : Si on perçoit une résistance ou si le corps de filtre ne se visse pas

bien, c’est peut-être parce que la cartouche de filtration n’est pas

correctement alignée, ou est incorrectement orientée. Retirer la cartouche

et veiller à l’orienter correctement avant de visser le corps de filtre.

Ouvrir le robinet d’eau filtrée. Ouvrir ensuite lentement le robinet d’arrêt

sur la canalisation, et laisser le corps de filtre se remplir d’eau.

Fermer le robinet d’eau filtrée. Rechercher ensuite d’éventuelles fuites entre

le corps de filtre et la tête de montage.

NOTE : S’il y a une fuite, fermer l’arrivée d’eau et ouvrir le robinet d’eau

filtrée. Démonter le corps du filtre; rechercher d’éventuelles détériorations

du joint torique (coupure, zone d’écrasement, etc.) ou la présence de

matières étrangères sur les surfaces d’étanchéité. Nettoyer le joint torique;

lubrifier légèrement le joint avec de la graisse aux silicones propre. Veiller à

bien placer le joint dans la rainure du corps de filtre. Visser le corps de filtre;

puis inspecter pour rechercher des fuites

.

Les cartouches de filtration contiennent du charbon actif. Laisser

initialement le robinet d’eau filtrée ouvert pendant cinq minutes pour

rincer le système.

Inscrire la date de changement du filtre sur l’étiquette, et placer l’étiquette

sur le corps du filtre, à l’intérieur de la porte du placard ou en un autre

endroit pratique. On devrait changer les filtres à intervalles de six mois.

12

11

10

9

8

7

6

5

4

3

2

1

Page 21

21

Processus de rinçage

Chaque fois que le système de filtration GE est exposé à de l’eau de qualité

inconnue, on devrait jeter les éléments de filtration et rincer le circuit.

Circonstances qui peuvent nécessiter un rinçage du circuit :

■ Notification de la nécessité de faire bouillir l’eau.

■ Inondation du système de filtration d’eau GE.

■ Inutilisation prolongée.

Méthode de rinçage du système de filtration GE :

Voir la section Cartouches de filtration–Installation ou remplacement;

exécuter les étapes 1, 2, 3 et 4.

Réinstaller le corps de filtre (sans l’élément de filtration); faire circuler

l’eau et laisser l’eau s’écouler par le robinet.

Fermer l’arrivée d’eau; enlever les corps de filtre; vider toute l’eau des

corps de filtre, puis installer des éléments de filtration neufs.

Pour terminer le processus, voir la section Cartouches de

filtration–Installation ou remplacement; exécuter les étapes 5–10.

4

3

2

1

Page 22

Avant de contacter un dépanneur…

Problème Causes possibles Remèdes

Présence de petites Les cartouches de filtration • Ouvrir le robinet de puisage de l’eau filtrée; laisser l’eau

particules noires dans l’eau neuves contiennent du entraîner les particules de carbone. Refermer le robinet

charbon actif; il s’agit d’une lorsque l’eau est limpide.

poudre noire inoffensive.

Présence de bulles dans Présence d’air dans le système • Ceci cessera après le puisage d’une quantité d’eau suffisante.

l’eau, et apparence trouble après l’installation.

Goût et/ou odeur de chlore Les cartouches de filtration •

Remplacer la cartouche de filtration.

dans l’eau filtrée ne retiennent plus le chlore

contenu dans l’eau.

Débit d’eau réduit Le filtre comporte peut-être • Un débit modéré (environ 0,6 g/min) est normal avec ce type

un dispositif de limitation de filtre. Si ce débit est insuffisant, remplacer les filtres par des

du débit. filtres qui ne comportent pas un dispositif de limitation du débit.

Les filtres sont en service • On recommande de remplacer les deux cartouches de

depuis trop longtemps. filtration à intervalles de six mois.

Les cartouches de filtration • Une concentration élevée de sédiments peut provoquer une

sont obstruées. obstruction prématurée. Remplacer les deux cartouches de

filtration.

Fuites au niveau des Les tubes n’ont pas été • Respecter scrupuleusement les instructions d’installation

raccords (GX1S15C [rév. 2]) installés correctement. (page 19) et vérifier que le tube est installé à la profondeur

correcte.

Les tubes peuvent être • Examiner l’extrémité du tube (environ 1 po) pour rechercher

endommagés. des défauts comme éraflures, rayures, défauts de rondeur, etc.

Si nécessaire, couper l’extrémité du tube et réinstaller.

Conseils pour le diagnostic

Pour économiser temps et argent! Consulter

d’abord le tableau ci-dessous….cela permettra

peut-être d’éviter l’intervention d’un dépanneur.

22

Page 23

23

Liste des pièces. GEAppliances.com

*NOTE : Dans l’État du Massachusetts, les codes en

vigueur exigent que cet équipement soit installé par

un plombier licencié, et que le raccordement à la

canalisation d’alimentation ne soit pas effectué par

un robinet de prise en charge. Avant l’installation,

consulter le code de plomberie 248-CMR du

Commonwealth of Massachusetts.

Catalogue des pièces General Electric.

NODE RÉF. NODE PCE DESCRIPTION

0001 WS02X10001 Vis n

O

10-14 x 3/4 po 4 4 8

0002 WS28X10010 Bride de montage 1 1 1

0003 WS22X10008 Écrou – tube 3/8 po 2 – –

0004 WS22X10007 Virole de renfort – tube 3/8 po – 2 –

0005 WS02X10003 Vis nO10-14 x 1 1/4 po 2 2 2

0006 WS22X10002 Coude 3/8 po NPT x 3/8 po(compression) 2 – –

0006 WS22X10032 Coude 3/8 po NPT x 3/8 po(enfoncement)– 2 2

0007 WS19X10011 Tête de filtre 1 1 1

0008 WS03X10001 Joint torique 3 3/8 po x 3 5/8 po 1 1 1

0009 WS30X10002 Corps de filtre 1 1 1

0012 WS07X10008 Tube 3/8 po x 20 pi (blanc) 1 1 1

0015 WS03X10044 Assemblage de raccord d’adaptation 2 2 2

pour tube

0017 WS15X10008 Robinet de prise en charge 1 1 1

0018 WS15X10022 Robinet de puisage (sans témoin) 1 1 –

0025 FXUTC Cartouche de filtration – goût et odeur – 1 –

FXULC (rév. 2) Cartouche de filtration – plomb/spores 1 – –

0200 WX5X140 Clé pour corps de filtre 1 1 –

0999 49-50040 Manuel – Utilisation et entretien/ 1 1 1

installation

Robinet de prise

en charge*

Pour obtenir des pièces de rechange, appelez sans

frais au 800.626.2002 (États-Unis), au 800.663.6060

(Canada-Anglais), au 800.361.3869 (Canada-Français).

GG G

XXN

11 1

SS S

10 0

54 4

CC C

(Rev. 2)

*

Saddle Valve

Page 24

Système de filtration d’eau GE–Garantie.

24

GARANTIE LIMITÉE D’UN AN

• Que couvre la garantie?

— Tout défaut de matériel ou de main d’oeuvre du produit.

• Q’est-ce qui n’est pas couvert par la garantie?

— Les cartouches de filtre.

— Les déplacements à votre domicile pour vous enseigner comment utiliser le

produit.

— Une installation incorrecte.

— Une panne du produit causée par un abus d’utilisation, une mauvaise utilisation,

toute modification ou une utilisation du produit dans un but non prévu.

— Défauts entraînés par une installation incorrecte ou tout dommage

non imputable à GE.

— Responsabilité de GE couvert par cette garantie ou toute autre garantie couvrant

tout dommage indirect.

— Produits utilisés pour des applications industrielles ou commerciales.

— Utilisation de ce produit lorsque l’eau est microbiologiquement impure ou de

qualité inconnue sans qu’une désinfection adéquate n’ait eu lieu avant l’entrée et

sortie dans le circuit. Les systèmes homologués pour une réduction des microbes

peuvent être utilisés après désinfection de l’eau pouvant contenir des microbes

filtrables.

— Tout dommage causé au produit par accident, incendie, inondation ou acte de

Dieu.

— T

out dommage fortuit ou indirect causé par des défauts éventuels de cet appareil,

son installation ou les réparations effectuées.

• Quelle est la durée de la garantie après l’achat?

— Un an.

• Comment dois-je faire ma réclamation?

— Ramenez le produit au magasin où vous l’avez acheté avec une exemplaire de la

“Preuve d’achat”. Cette garantie exclut les coûts d’expédition ou les déplacements

de service à votre domicile.

• Quel est le statut de cette garantie vis-à-vis de la loi?

— Cette garantie vous donne des droits légaux spécifiques. Il est possible que vous

ayez d’autres droits qui varient d’état en état. CETTE GARANTIE REMPLACE

DE TOUTE AUTRE GARANTIE, QU’ELLE SOIT EXPRIMÉE OU SOUSENTENDUE, INCLUANT LES GARANTIES DE NÉGOCE ET DE

CONVENANCE DANS UN BUT PARTICULIER.

Veuillez nous contacter à www.GEAppliances.com, ou composez le 800-GE-CARES (États-Unis)

et sans frais le 866.777.7627 (Canada).

Soutien au consommateur.

Site Web appareils électroménagers GE

www.GEAppliances.com

Vous avez une question ou vous avez besoin d’aide pour votre appareil électroménager? Contactez-nous par

Internet au site www.GEAppliances.com 24 heures par jour, tous les jours de l’année.

Service de réparations www.GEAppliances.com

Service de réparations GE est tout près de vous.

Pour faire réparer votre électroménager GE, il suffit de nous téléphoner (800.432.2737).

Studio de conception réaliste www.GEAppliances.com

Sur demande, GE peut fournir une brochure sur l’aménagement d’une cuisine pour les personnes à mobilité

réduite. Appelez-nous au 800.833.4322.

Prolongation de garantie www.GEAppliances.com

Achetez un contrat d’entretien GE avant que votre garantie n’expire et bénéficiez d’un rabais substantiel. Ainsi le

service après-vente GE sera toujours là après expiration de la garantie.

Visitez notre site Web ou appelez-nous au 800.626.2224

Pièces et accessories www.GEAppliances.com

Ceux qui désirent réparer eux-mêmes leurs électroménagers peuvent recevoir pièces et accessoires directement à la maison (cartes VISA,

MasterCard et Discover acceptées).Visitez notre site Web ou appelez-nous au 800.626.2002 (EU), au 800.663.6060 (Canada-Anglais), au

800.361.3869 (Canada-Français).

Les directives stipulées dans le présent manuel peuvent être effectuées par n’importe quel utilisateur. Les autres réparations doivent généralement être

effectuées par un technicien qualifié. Soyez prudent, car une réparation inadéquate peut affecter le fonctionnement sécuritaire de l’appareil.

Contactez-nous www.GEAppliances.com

Si vous n’êtes pas satisfait du service après-vente dont vous avez bénéficié :

Premièrement, communiquez avec les gens qui ont réparé votre appareil.

Ensuite, si vous n’êtes toujours pas satisfait envoyez tous les détails—numéro de téléphone compris—au Manager, Customer Relations,

GE Appliances, Appliance Park, Louisville, KY 40225.

Inscrivez votre appareil électroménager www.GEAppliances.com

Inscrivez votre appareil électroménager en direct, aussitôt que possible. Cela améliorera nos communications et notre service

après-vente. Vous pouvez également nous envoyer par la poste le formulaire d’inscription joint à votre documentation.

Page 25

Instrucciones de seguridad . . . . . . . . . .26

Instrucciones de funcionamiento . . . . .27

Cómo usar el sistema . . . . . . . . . . . . . . .27

Guías de especificaciones . . . . . . . . . . . .27

Instrucciones de instalación . . . . .28–33

Abastecimiento de agua . . . . . . . . . . . . .29

Conexiones de los tubos . . . . . . . . . . . . .31

Herramientas/Materiales requeridos . . .28

Instalación de la llave de agua . . . . . . . .30

Instalación o reemplazo del cartucho

del filtro . . . . . . . . . . . . . . . . . . . . . . . . . .32

Instrucciones paso a paso . . . . . . . . .30, 31

Montaje sobre la pared . . . . . . . . . . . . . .31

Procedimiento para lavado . . . . . . . . . . .33

Recomendaciones importantes . . . . . . . .28

Consejos para detectar problemas . . . .34

Soporte al consumidor

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . .36

Lista/Catálogo de partes . . . . . . . . . . . . .35

Soporte al consumidor . . . . . . . . . . . . . .36

25

GN1S04C/GX1S04C está probados y

certificados por NSF Internacional,

contra la norma 42 de ANSI/NSF

para la reducción de Partículas

Clase I, Cloro, y Sabor/Olor, y el

estándar 53 para la reducción

de quistes, turbidez y asbesto.

GN1S15C (rev. 2) está probados y

certificado por NSF Internacional

contra la norma 42 de ANSI/NSF

para la reducción de Partículas

Clase I, Cloro, y Sabor/Olor y el

estándar 53 para la reducción de

plomo, mercurio, quistes, turbidez,

asbestos, atrazina y lindano.

Escriba los números de modelo y serie

aquí:

Número de modelo ________________

Número de serie

__________________

Los puede encontrar en la abrazadera del

receptáculo.

Page 26

26

GUARDE ESTAS INSTRUCCIONES

LEA Y SIGA ESTA INFORMACIÓN DE SEGURIDAD CUIDADOSAMENTE.

■

Instale o guarde donde no estará expuesto a temperaturas

bajo el punto de congelación o expuesto a cualquier tipo de

clima. El agua que se congele en el sistema lo dañará. No

trate de tratar el agua a más de 100°F.

ADVERTENCIA:

Bote todos los materiales sin

usar y de empaque después de la instalación. Las partes

pequeñas que quedan después de la instalación podrían

ser un peligro para atragantarse.

■

Su sistema de Filtración de Agua soportará hasta 125 libras

de presión de agua por pulgada cuadrada (psi). Si la presión

de la línea de agua de su casa es más alta que 100 psi, instale

una válvula reductura de presión antes de instalar el sistema

de Filtración de Agua.

INFORMACION IMPORTANTE DE SEGURIDAD.

LEA TODAS LAS INSTRUCCIONES ANTES DEL USO.

Para su seguridad, la información en este manual debe ser seguida para

minimizar el riesgo de daño a la propiedad o herida personal.

PRECAUCIONES DE SEGURIDAD

■ Consulte con su departamento local de obras públicas para

los códigos de plomería. Usted debe seguir estas reglas

cuando instale su Sistema de Filtración de Agua.

■ Use el sistema de Filtración de Agua con una línea de

abastecimiento de agua FRIA de hogar, potable y segura

para beber.

■ No lo use con una línea de agua caliente (100°F. máx.).

ADVERTENCIA: No use con agua que sea

microbiológicamente insegura o de calidad desconocida

sin una desinfección adecuada antes o después del

sistema. Sistemas certificados para reducción de quistes

pueden ser usados en agua desinfectada que podrían

contener quistes filtrables.

INSTALACION ADECUADA

Este sistema de Filtración de Agua debe ser instalado y ubicado adecuadamente de acuerdo con las Instrucciones de

Instalación antes de ser usado.

¡ADVERTENCIA!

Page 27

27

Acerca del sistema de filtración de agua. GEAppliances.com

Cómo usar el sistema de filtración de agua y acerca del cartucho del filtro

La llave de agua de la superficie del gabinete dispensa agua para beber filtrada. Tiene una

manilla cerrada manual a resorte para prevenir pérdida. Usted puede mantener la llave

abierta empujando la manilla hacia arriba para engancharla en la punta de la llave.

Vida del cartucho del filtro—Varias variables determinan cuánto durarán los cartuchos en

su sistema de Filtración de Agua. Estas incluyen:

Cuánta agua usa.

Cuánto sedimento, sabor y/u olor, plomo u otra sustancia indeseada hay en el agua.

Sin importar qué sistema de Filtración de Agua usted tiene, usted debería reemplazar los

cartuchos cada seis meses. En abastecimientos de agua extremadamente malos, usted podría

notar el retorno de sustancias indeseadas en sus agua antes que terminen los seis meses.

En este casos los cartuchos deberían ser cambiados inmediatamente. Si el sistema es también

para sacar plomo o contaminantes químicos, es MAS IMPORTANTE reemplazar los cartuchos

por lo menos cada seis meses.

NOTA: Si la línea de agua contiene altas cantidades de sedimento, los filtros de carbón se

podrían tapar prematuramente, reduciendo el paso del agua filtrada a la llave del sistema.

El reemplazo del cartucho es necesario para restaurar el paso.

2

1

Page 28

Herramientas y Materiales requeridas para la instalación

28

Sumario de la instalación

Instrucciones de instalación.

Recomendaciones importantes de instalación

Lea el manual completo. La falla de seguir todas las guías y reglas podría causar heridas personales o daño a la propiedad.

■ Consulte con su departamento local de obras públicas para los

códigos de plomería. Usted debe seguir sus guías a medida que

instala el sistema de Filtración de Agua.

■ Use el sistema de Filtración de Agua solamente en una línea

de agua FRIA de casa, potable, segura para beber. Los filtros

de agua no purificarán el agua o harán que el agua mala sea

buena para beber. NO use con agua CALIENTE (100°F. Máx.).

■ Proteja el sistema de Filtración de Agua y las cañerías del

congelamiento. El agua que se congele en el sistema

lo dañará.

■ Su sistema de Filtración de Agua soportará hasta 125 psi de

presión de agua. Si la presión de agua en su casa es más de 100

psi durante el día (podría alcanzar ese nivel durante la noche),

instale una válvula reductora de presión antes del sistema.

ADVERTENCIA: No use con agua que sea

microbiológicamente insegura o de calidad desconocida

sin una desinfección adecuada antes o después del

sistema. GX1S15C (rev. 2) está certificado para reducción

de quistes y podría ser usado con agua desinfectada que

podría contener quistes filtrables. El agua debería ser

inspeccionada periódicamente para verificar que el

sistema está funcionando satisfactoriamente. Las partes

pequeñas que sobren después de la instalación podrían

ser un peligro para atragantarse. Desheche en forma

segura.

■ Destornilladores “slotted” y Phillips.

■ Alicates y llaves inglesas ajustables.

■ Taladro y punta de 1/4″ manual o a batería (instalación de

la válvula tipo “saddle”).

■ Taladro eléctrico y punta para hacer un hoyo de 1″ a 1-1/4″

(tipo como sea requerido) si se necesita un hoyo para el

montaje de la llave de agua.

Asegúrese de usar el procedimiento adecuado para hacer hoyos

en porcelana o acero inoxidable. Se podrían necesitar puntas de

taladros especiales.

PRECAUCION: Para evitar daño al lavaplatos, consulte con

un plomero o un instalador para los procedimientos para

hacer los hoyos. Taladros especiales podrían ser

necesitados para porcelana o acero inoxidable.

Contenidos incluidos con el producto:

■ Juego de filtro de agua, incluyendo abrazaderas de montaje

y tornillos.

■ Literatura sobre el producto (Manual del Consumidor e

Instalación, Hoja de Información del Producto, Tarjeta de

Registración del Producto del Cliente).

■ Válvula tipo “saddle”/línea de agua.

■ Llave para el agua filtrada, para instalación en el lavaplatos o

sobre el gabinete.

■ Tubos y uniones de 3/8″para hacer todas las conexiones

necesarias.

■ Llave inglesa para el receptáculo.

Llave para

agua filtrada

Lavaplatos

Caliente

Válvula de cierre.

NOTA: Para cambiar el cartucho del filtro,

debe cerrar el paso del agua. Una válvula

de cierre cercana es conveniente. La

mayoría de los lavaplatos/lavamanos ya

tienen válvulas de cierre en las cañerías

de abastecimiento.

Fría

Válvula de línea de agua

Inserto de la tubería

Adaptador de la tubería

Tuerca de compresión

Entrada de agua

Salida de agua

Cañería

Inserto

Tornillos de

montaje (2)

Tuerca

Cañería

Ubique el sistema de agua para

tomar en la cañería para agua

fría, debajo del lavaplatos de la

cocina o del lavamanos del

baño, para filtrar el agua fría

para tomar.

Modelo

GX1S04C

solamente

Page 29

29

Línea de abastecimiento de agua

Consulte y cumpla con los códigos de plomería locales a medida que planee,

luego instale una unión para abastecimiento de agua fría. Para la instalación

en una casa nueva usando uniones de plomería normales, vea primero las dos

ilustraciones de abajo. Una instalación típica para casas existentes usando la

válvula tipo “saddle” se muestra en la tercera ilustración de abajo.

A. INSTALACION PREFERIDA

Cierre el paso de agua fría.

Cumpliendo con los códigos de plomería, instale una unión en la cañería

de agua fría para adaptar una cañería OD de 3/8″. Una conexión típica

se muestra en la ilustración de la derecha (partes no incluidas). Asegúrese

de usar una válvula para paso de agua.

2

1

B. INSTALACION DE CASA OPCIONAL donde lo permitan los códigos

*Para un tubo OD de 1/2” o más grande solamente.

NOTA: Los códigos del estado de Massachusetts requieren que la instalación

sea hecha por un plomero licenciado y no permiten el uso de una válvula tipo

“saddle”. Para la instalación, use el código de plomería 248-CMR del

Commonwealth de Massachusetts.

Cierre el paso de agua fría y coloque la válvula tipo “saddle” como se

muestra en la ilustración de la derecha.

PELIGRO: Para protegerse de una herida seria o un golpe de corriente

fatal, use solamente un taladro manual o a baterías para hacer el hoyo.

NO USE UN TALADRO ELECTRICO.

Cierre el paso del agua haciendo girar la manilla en dirección del reloj.

Abra la válvula de paso principal del agua y varias llaves de agua de la

casa para sacar el aire del sistema. Cierre las llaves cuando el agua corra

suavemente.

3

2

1

Conexión opcional a línea de agua (usando una válvula “saddle”)*

*Para un tubo OD de 1/2” o más grande solamente.

Ubicación típica

Agua fría

Apriete la válvula dentro

de la abrazadera. NO

APRIETE DEMASIADO

Algunos hilos

deberían estar

visibles.

Sello de goma

Conexión preferida a línea de agua

(usando unión a compresión)

Inserto (no incluido)

Cañería

de agua

fría

Tubo de 3/8″ hacia

la entrada

Ferrule

Válvula para paso de agua

Page 30

30

Instrucciones de instalación paso a paso.

Instalación de llaves de agua

Asegúrese de que haya lugar debajo del lavaplatos/lavamanos para hacer las

conexiones necesarias. Seleccione uno de los siguientes lugares para instalar

la llave:

—EN un hoyo de rociador o dispensador de jabón de lavaplatos existente.

—EN un hoyo que se hará en la superficie del lavaplatos.

—EN un hoyo que se hará sobre la superficie del gabinete, al lado del

lavaplatos.

NOTA: Mirando la segunda ilustración de la derecha, asegúrese que la base

de la llave quedará puesta en forma plana contra la superficie de la ubicación

seleccionada para que la empaquetadura selle.

Si se necesita hacer un hoyo, haga un hoyo de 3/4″ de diámetro.

Asegúrese de usar el procedimiento adecuado para hacer hoyos en la

porcelana o acero inoxidable. Se podrían necesitar puntas de taladro

especiales.

Coloque la empaquetadura pequeña, la base y la empaquetadura grande

(en ese orden) en el tallo de la llave. Luego, coloque la arandela de

enganche y la tuerca hexagonal en el tallo de la llave.

Inserte el inserto de la tuberîa en el adaptador del tubo. Apriete bien al

tallo de la llave.

Haga pasar el largo del tubo OD de 3/8″ desde el fondo, a través del

hoyo de montaje. Conecte el adaptador del tubo como se muestra en

la segunda ilustración, apretando bien la tuerca de compresión.

Saque el tubo corto de empaque y meta la punta en el cuerpo

de la llave. Haga girar la punta hacia su lugar.

Baje el juego de la llave a su lugar sobre el lado de abajo del hoyo de

montaje. Coloque la abrazadera de montaje sobre la arandela de

enganche. Mientras sujete la arandela de montaje en su lugar, apriete

bien la tuerca hexagonal.

6

5

4

3

2

1

Lavaplatos

Base

Arandela de

enganche

Llave del

agua

Manilla

Punta de

la llave

Tallo de la

llave

Empaquetadura

pequeña

Empaquetadura grande

Tuerca de compresión

Adaptador de la

tubería

Abrazadera de

montaje

Tuerca

hexagonal

Inserto de

la tubería

ARMADO

Tubo de 3/8″ (corre

al filtro II salida)

Tuerca de

compresión

Adaptador de la tubería

Inserto de la tubería

Page 31

31

Cómo montar la abrazadera en la pared del gabinete

La abrazadera se puede usar como molde para marcar la ubicación de los

tornillos de montaje. Cuando determine la ubicación de la abrazadera

asegúrese de dejar un área libre de 1-1/2

″

a 2″debajo de los receptáculos para

permitir sacar los receptáculos y espacio suficiente en cualquiera de los lados

para hacer las conexiones de los tubos.

Conexiónes de los tubos—Estilo compresión (Modelos GX1S04C

y GN1S04C)

Pase el largo del tubo de 3/8″, conectado al fondo de la llave, a la salida

del sistema de filtro. Permita una soltura suficiente en el tubo para que la

unidad se pueda sacar fácilmente para cambiar los filtros. Mida y corte las

puntas de los tubos en forma cuadrada.

Deslice la tuerca de compresión en la punta del tubo y empuje el inserto

del tubo dentro del tubo.

Conecte el tubo y apriete bien la tuerca de compresión.

Repita los pasos anteriores para conectar el largo del tubo entre la

entrada del sistema del filtro y la línea del agua/válvula “saddle”

(ilustración en la sección Sumario de la Instalación).

4

3

2

1

Tornillos de

montaje

Conector de

tubo (salida)

Conector de

tubo (entrada)

Abrazadera

de montaje

Receptáculo

2-3⁄4″

1-1/2″ a 2″

Conexiones de los tubos—Estilo empuje (Modelo GX1S15C [rev. 2])

Pase el largo del tubo de 3/8″, conectado al fondo de la llave, a la salida

del sistema de filtro (ilustración arriba). Permita suficiente soltura en el

tubo para sacar fácilmente la unidad.

Mida y corte la punta de los tubos en forma cuadrada usando un cortador

o un cuchillo afilado. Saque las astillas (ilustración A).

Inspeccione la punta del tubo, como 1 pulgada, para estar seguro de que

no hayan imperfecciones. Podría ser necesario cortar el tubo nuevamente.

Marque el tubo para el largo de la inserción. Para tubos OD de 3/8″ el

largo de la inserción debería ser aproximadamente 3/4″. El tubo debe

completamente serconectado para evitar que gotee.

NO SAQUE EL ANILLO GRIS TIPO “COLLET”. Empuje el tubo hasta el fondo

de la unión. La línea de inserción debería quedar escondida o casi

Page 32

32

Sello tipo anillo

Cartucho

Receptáculo I

Etiqueta

Cabeza

Abrazadera

SALIDA

ENTRADA

Acerca del sistema de filtración de agua.

Instalación o reemplazo del cartucho del filtro

PRECAUCION: Nunca saque los receptáculos cuando hay presión de agua

en el sistema de filtración.

Cierre el paso del agua/válvula “saddle” hacia el filtro. (Vea la ilustración en

la sección Sumario de la Instalación para la ubicación de la válvula de la

línea de abastecimiento del agua.) Abra la llave del agua filtrada.

Saque el receptáculo, usando la llave para receptáculo que se provee, de

la cabeza del filtro haciendo girar el receptáculo como se muestra. Tenga

cuidado, el receptáculo podría estar lleno de agua. Asegúrese de guardar

el sello de anillo grande.

Si está reemplazando un cartucho de filtro, saque y bote el cartucho del

filtro usado.

Asegúrese que el interior del receptáculo esté limpio. Lave bien el

interior del receptáculo con agua caliente con jabón y enjuague.

Saque el envoltorio del cartucho del filtro nuevo y meta el cartucho del

filtro en el receptáculo. Algunos cartuchos calzan de cualquier forma,

mientras otros calzan sólo de una manera. Observe las marcas sobre el

cartucho.

NOTA: El sistema de filtración de agua usa dos tipos diferentes de

cartuchos de filtro. Asegúrese de instalarlos correctamente. Vea la

página 27 para una lista completa de las características de

funcionamiento del filtro.

Lubrique levemente el sello tipo anillo en el receptáculo con grasa de

silicón limpia para cocinar.(La grasa de silicón se puede comprar a través

de las Partes y Servicios GE: 1-800-626-2002 Parte número:

WS60X10005). Asegúrese que quede bien puesto en la ranura.

Sujete el receptáculo hacia la cabeza del filtro, alineando el centro del

hoyo del cartucho con la marca sobre el fondo de la cabeza. La falla

de obtener un alineamiento adecuado podría causar daño al filtro y/o

el sistema de filtración, lo cual degradará el funcionamiento del filtro.

Teniendo cuidado de no cruzar los hilos, haga rotar el receptáculo sobre

la cabeza del filtro y apriete bien con la mano.

NOTA: Si el receptáculo no se aprieta a la cabeza o si usted siente

resistencia, es posible que usted tenga el cartucho invertido o fuera

de alineamiento. Saque el cartucho y revise la correcta orientación

o alineamiento y arme nuevamente.

Abra la llave del agua filtrada. Luego, lentamente abra la válvula de paso

del agua y permita que la caja del filtro se llene.

Cierre la llave del agua filtrada. Luego, revise que no hayan goteras entre

el receptáculo y la cabeza.

NOTA: Si hay goteras, cierre el paso del agua y abra la llave del agua filtrada.

Desarme la caja del filtro y revise el sello tipo anillo por cortaduras, marcas

Page 33

33

GEAppliances.com

Procedimiento para lavar.

Cada vez que agua de calidad desconocida es pasada a través del sistema de

Filtración de Agua GE, los elementos del filtro deberían ser deshechados y

el sistema de filtración lavado.

Las circunstancias que podrían requerir el lavado del sistema son:

■ Advertencia de que hay que hervir el agua.

■ Inundación del sistema de Filtración de Agua GE.

■ Largo tiempo sin ser usado.

El procedimiento para lavar el sistema de Filtración de Agua GE es:

Vea la sección de Reemplazo del Cartucho del Filtro y siga los pasos

1, 2, 3, y 4.

Luego, reinstale los receptáculos (sin los elementos del filtro),

abra el agua, y lave a través de la llave por un minuto.