Page 1

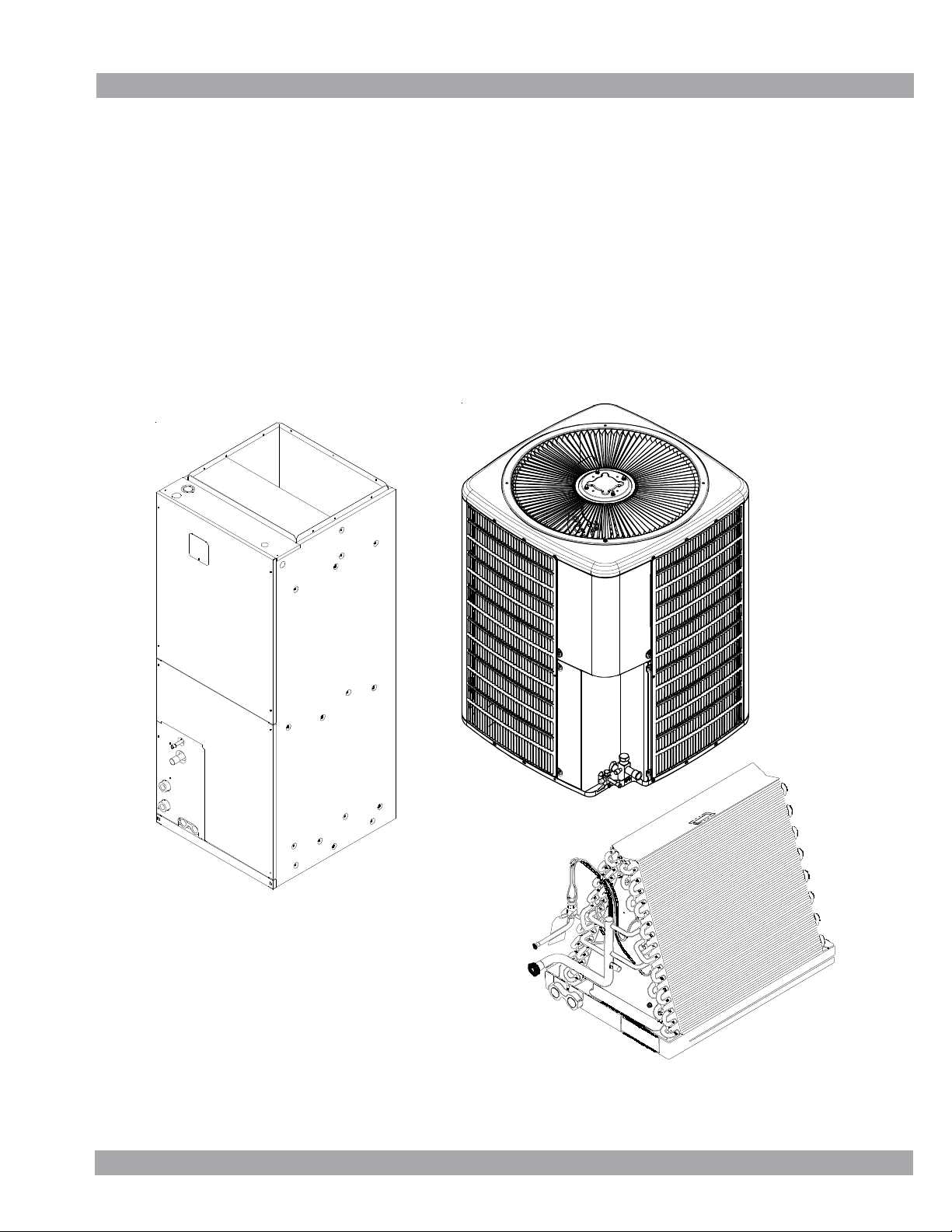

Service Instructions

Split System Air Conditioners,

Split System Heat Pumps

with R-22 Refrigerant

Blowers, Coils, & Accessories

This manual is to be used by qualified, professionally trained HVAC

technicians only. Goodman does not assume any responsibility for

property damage or personal injury due to improper service

procedures or services performed by an unqualified person.

Copyright © 2005 - 2011 Goodman Manufacturing Company, L.P.

RS6100004r25

August 2011

Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION ......................... 2 - 3

MODEL IDENTIFICATION ............................ 4 - 13

AIR HANDLER/COIL IDENTIFICATION ..... 13 - 18

ACCESSORIES ......................................... 19 - 23

PRODUCT DESIGN ................................. 24 - 25

SYSTEM OPERATION .............................. 26 - 31

TROUBLESHOOTING CHART ......................... 32

SERVICING TABLE OF CONTENTS ................33

SERVICING .................................................34 - 65

ACCESSORIES WIRING DIAGRAMS ........66 - 74

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

WARNING

This unit should not be connected to, or used in conjunction with, any devices that are not design certified for use with

this unit or have not been tested and approved by Goodman. Serious property damage or personal injury, reduced unit

performance and/or hazardous conditions may result from the use of devices that have not been approved or certified by

Goodman.

WARNING

To prevent the risk of property damage, personal

injury, or death, do not store combustible materials or

use gasoline or other flammable liquids or vapors

in the vicinity of this appliance.

WARNING

Goodman will not be responsible for any injury or property damage arising from improper service or service

procedures. If you perform service on your own product, you assume responsibility for any personal injury or property

damage which may result.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER INFORMATION LINE

GOODMAN® BRAND PRODUCTS

TOLL FREE 1-877-254-4729 (U.S. only)

email us at: customerservice@goodmanmfg.com

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

email us at: customerservice@goodmanmfg.com

CONSUMER INFORMATION LINE

AMANA® BRAND PRODUCTS

TOLL FREE 1-877-254-4729 (U.S. only)

fax us at: (713) 856-1821

(Not a technical assistance line for dealers.)

Outside the U.S., call 1-713-861-2500.(Not a technical assistance line for dealers.)

Your telephone company will bill you for the call.

2

Page 3

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

WARNING

Refrigerants are heavier than air. They can "push out"

the oxygen in your lungs or in any enclosed space.To

avoid possible difficulty in breathing or death:

•

Never purge refrigerant into an enclosed room or

space. By law, all refrigerants must be reclaimed.

•

If an indoor leak is suspected, thoroughly ventilate

the area before beginning work.

• Liquid refrigerant can be very cold. To avoid possible

frostbite or blindness, avoid contact with refrigerant

and wear gloves and goggles. If liquid refrigerant

does contact your skin or eyes, seek medical help

immediately.

• Always follow EPA regulations. Never burn refrig erant, as poisonous gas will be produced.

To avoid possible explosion, use only returnable (not

disposable) service cylinders when removing refrigerant from a system.

• Ensure the cylinder is free of damage which could

lead to a leak or explosion.

• Ensure the hydrostatic test date does not exceed

WARNING

To avoid possible injury, explosion or death, practice

safe handling of refrigerants.

5 years.

• Ensure the pressure rating meets or exceeds 400

lbs.

When in doubt, do not use cylinder.

WARNING

System contaminants, improper service procedure

and/or physical abuse affecting hermetic compressor

electrical terminals may cause dangerous system

venting.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes

associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the

compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the

hermetic compressor. The terminals and their dielectric

embedment are strongly constructed, but are vulnerable to

careless compressor installation or maintenance procedures and equally vulnerable to internal electrical short

circuits caused by excessive system contaminants.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the

compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a) hot lubricating oil and refrigerant

(b) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in the

vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be

electrically energized and/or operated without having the

terminal protective cover properly in place.

See Service Section S-17 for proper servicing.

3

Page 4

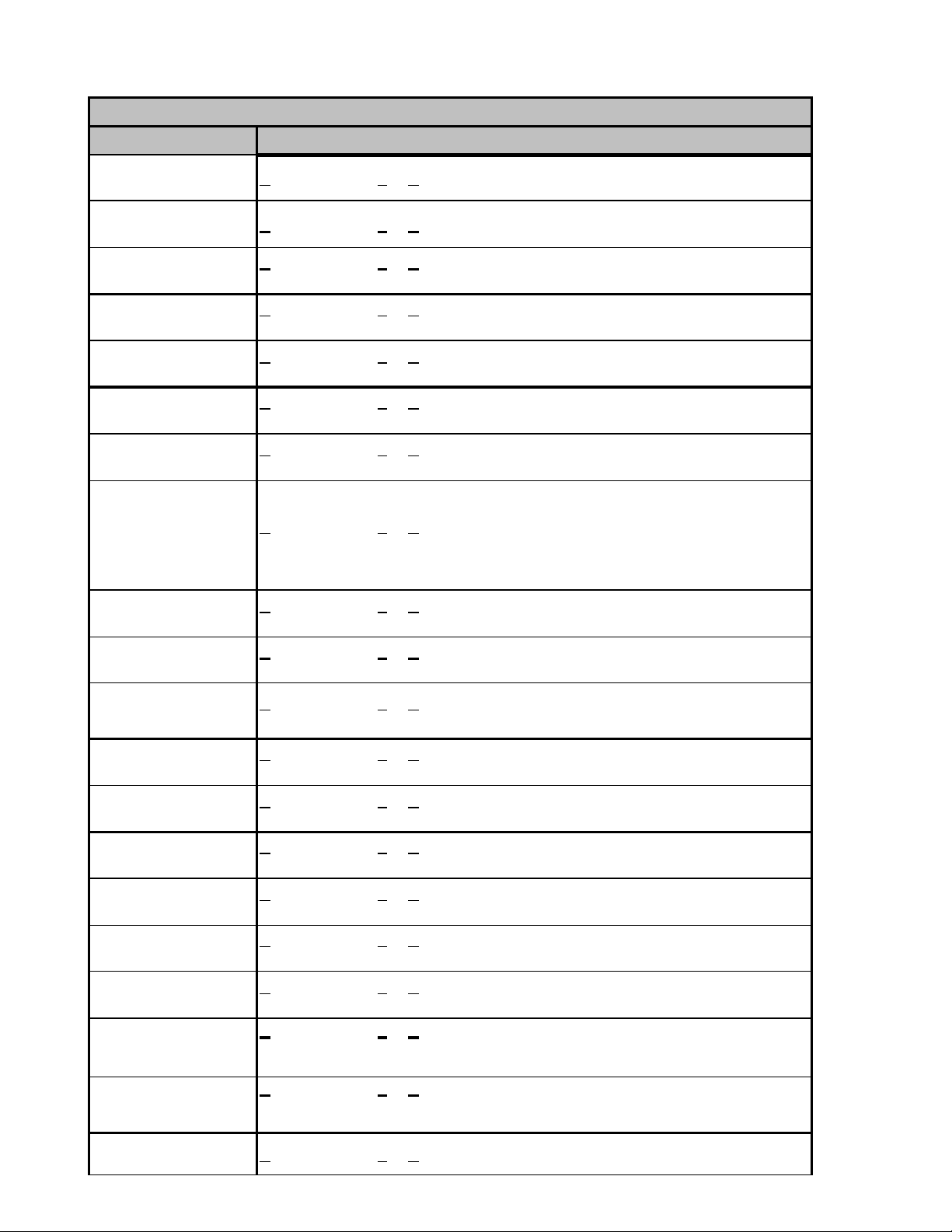

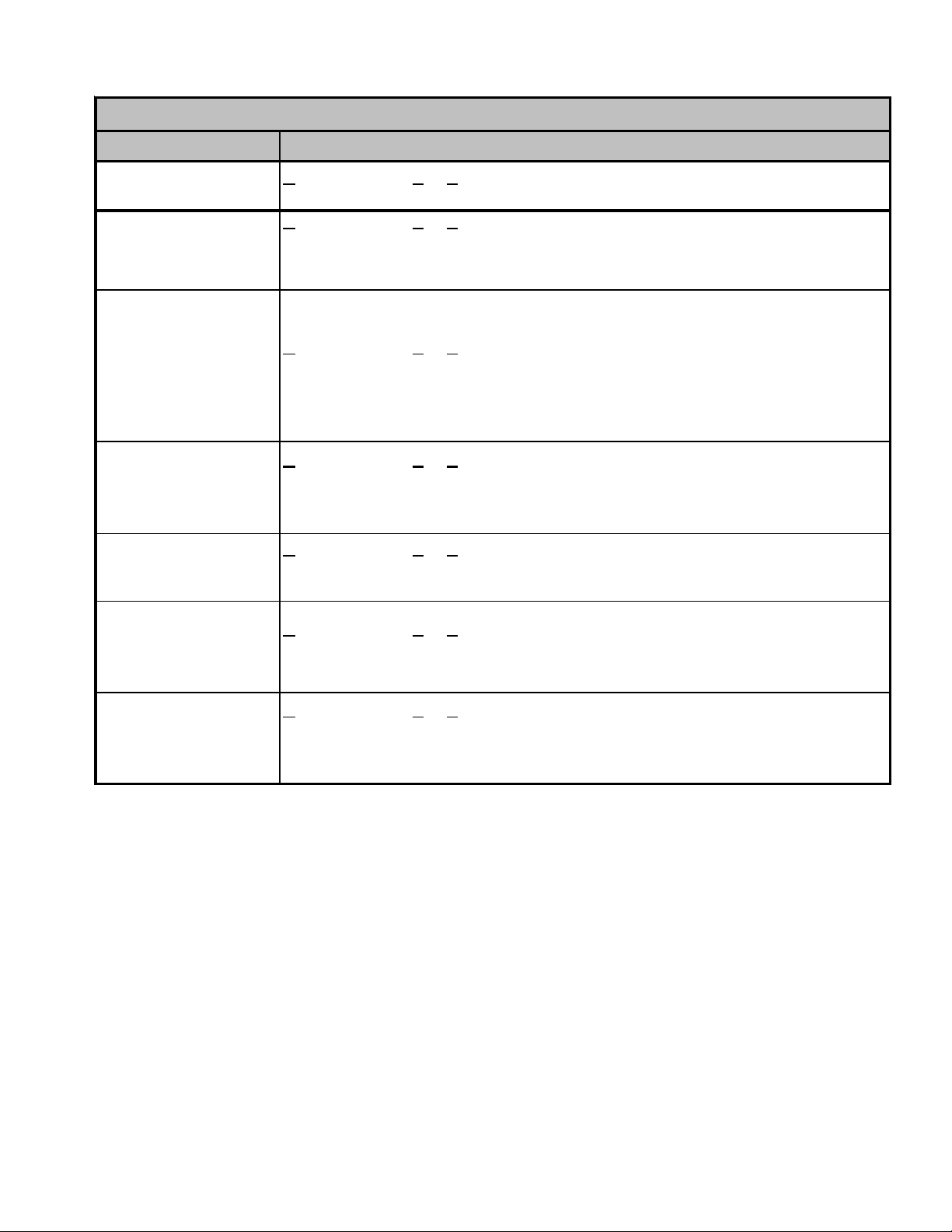

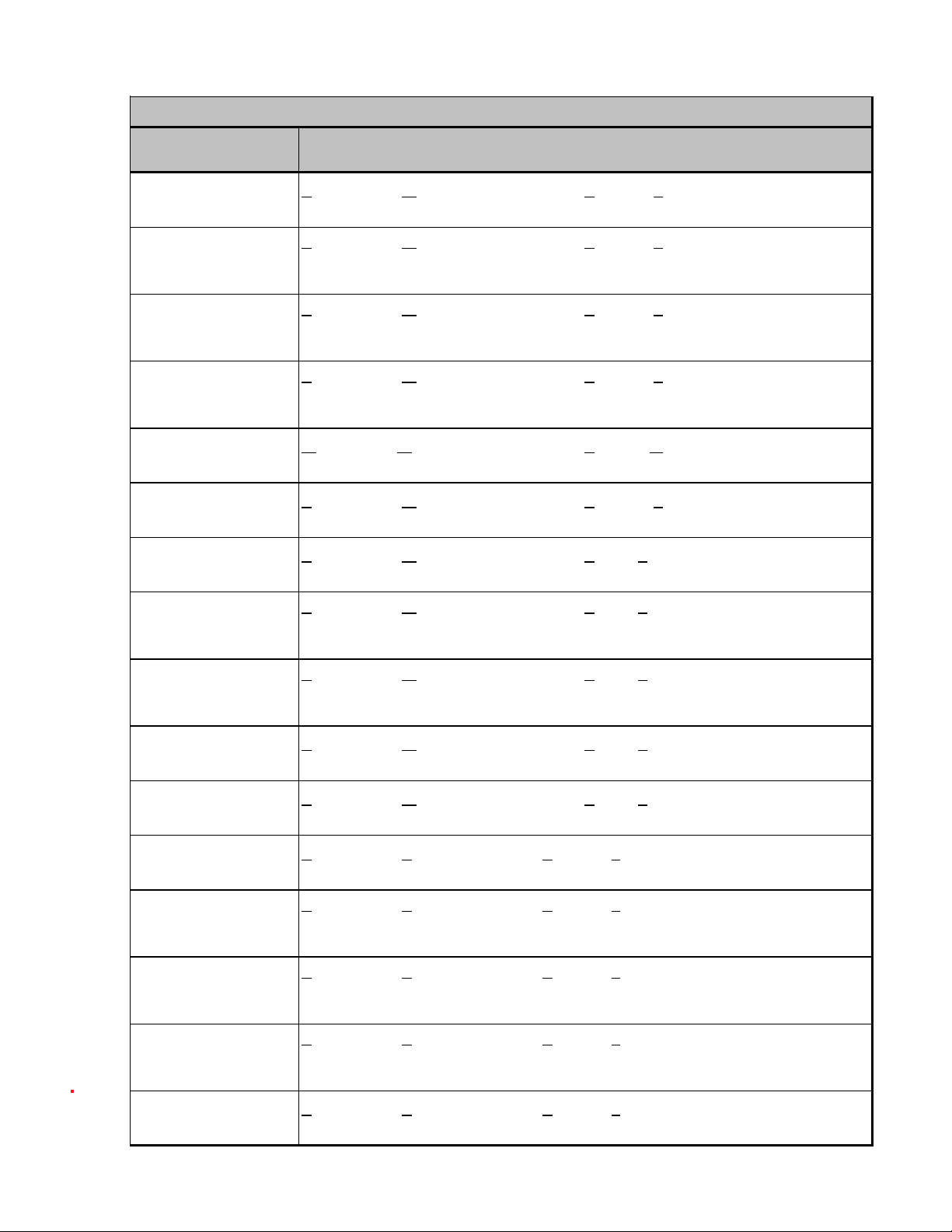

PRODUCT IDENTIFICATION

Split System Air Conditioners R-22

Model # Description

G

GSC13018-241AA

oodman® Brand Split Condenser 13 Seer condensing units. Initial release. 26" chassis

GSC13036-481AA

GSC13036,48*AA

GSC1 30**1AB

GSC13036,48*AB

GSC13048*AC

GSC13018-30AC

GSC13018,24, 301AD

GSC1300421AC, 484AC

GSC 13018 , 24, 301 AE

GSC130481, 483AE/AF

GSC130363AE/AF

GSC130361DE/DD

GSC13048*AD

GSC130481AG

oodman® Brand Split Condenser 13 Seer condensing units. Initial release. 29" chassis

G

G

oodman® Brand Split Condenser 13 Seer condensing units.

Introduces new 13 SEER AC 3 PH R-22 Goodman Models

oodman® Brand Split Condenser 13 Seer condensing units. Move location of screw

G

hole.

G

oodman® Brand Split Condenser 13 Seer condensing units. Introduces new models

due to the replacement of 8-pole fan motors with 6-pole.

oodman® Brand Split Condenser 13 Seer condensing units. Move location of screw

G

hole.

G

oodman® Brand Split Condenser 13 Seer condensing units. Release Models

containing the broad ocean motor 0131M00060

oodman® Brand Split Condenser 13 Seer condensing units. Remove 1 hairpin from

G

coil.

G

oodman® Brand Split Condenser 13 Seer condensing units. Release Models contain

the broad ocean motor 0131M00061

oodman® Brand Split Condenser 13 Seer condensing units. Introduces new models

G

with Bristol compressors.

G

GSC130181BA

GSC130361BA

GSC130361BA

GSC130361BB

GSC130361DF

GSC130181CA

GSC13024 -3 01C A

GSC130241DA

GSC130361FA

GSC130363BA

GSC130301DA

GSC130601CA

GSC130603BA/4BA

oodman® Brand Split Condenser 13 Seer condensing units. Conversion of existing

m odels using 3/ 8" dia me ter tu be coils to 5 mm co ils.

oodman® Brand Split Condenser 13 Seer condensing units. Initial release. 35"

G

chassis.

G

oodman® Brand Split Condenser 13 Seer condensing units. Release Model with

Copeland Scroll Compressor.

oodman® Brand Split Condenser 13 Seer condensing units. Introduces new models

G

due to the replacement of 8-pole fan motors with 6-pole.

G

oodman® Brand Split Condenser 13 Seer condensing units. Introduces new models

with Bristol compressors.

oodman® Brand Split Condenser 13 Seer condensing units. Compressor changes

G

from a recip compressor to a Panasonic Rotary compressor

G

oodman® Brand Split Condenser 13 Seer condensing units. Introduces models with

re duced chas sis s ize fr om the cur ren t 29 x3 2.5 to 26x32

oodman® Brand Split Condenser 13 Seer condensing units. Release of Goodman 13

G

SEER Condensers, with 5 mm coils; compressor change:CR18K7-PFV-230; reduced

refrigerant charge.

oodman® Brand Split Condenser 13 Seer condensing units. Converts from 3/8" to

G

5mm. 2.5 & 3 ton units have new coil slab height and new louver panels. 2.5 - small

chassis; 3 ton medium chassis.

G

oodman® Brand Split Condenser 13 Seer condensing units with 5mm, 29" chassis.

4

Page 5

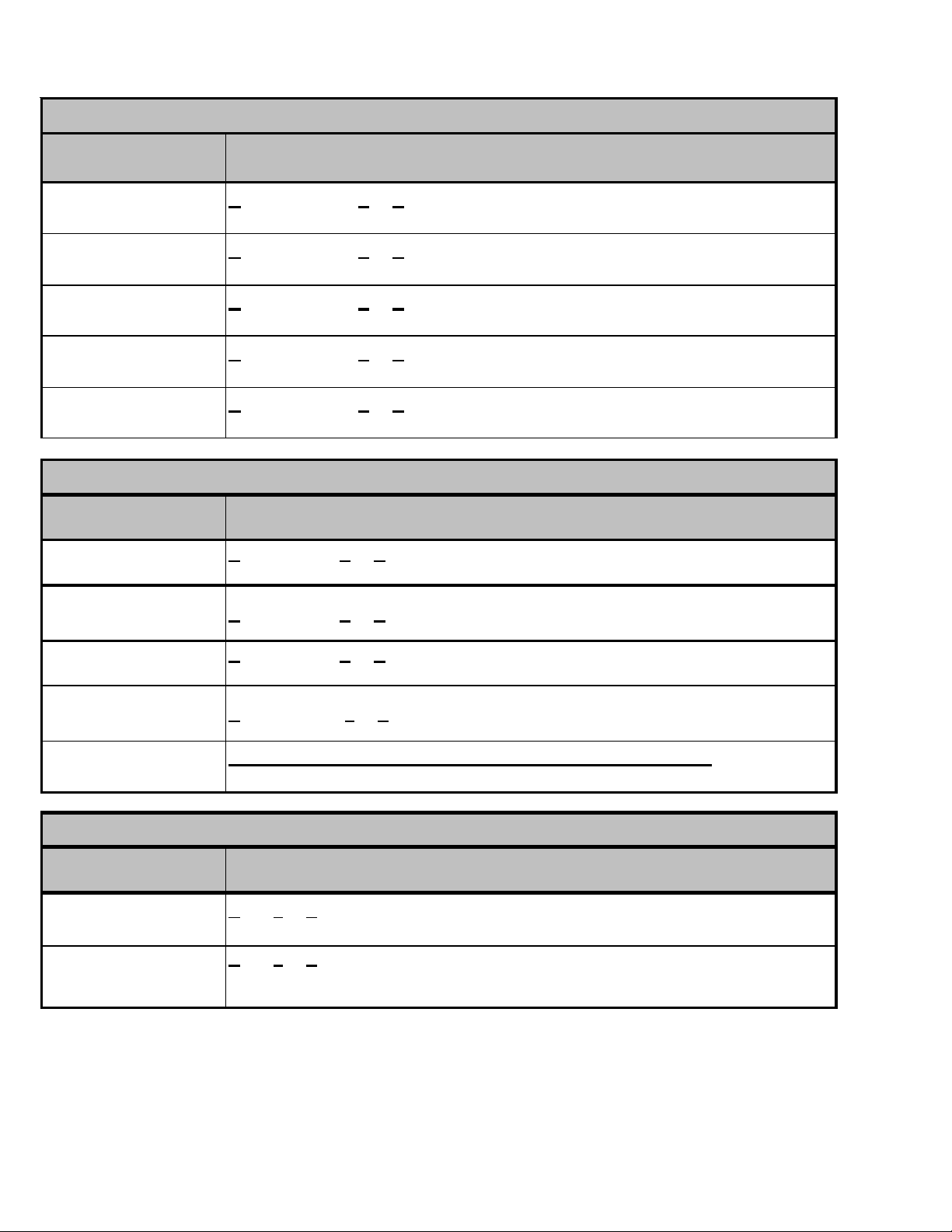

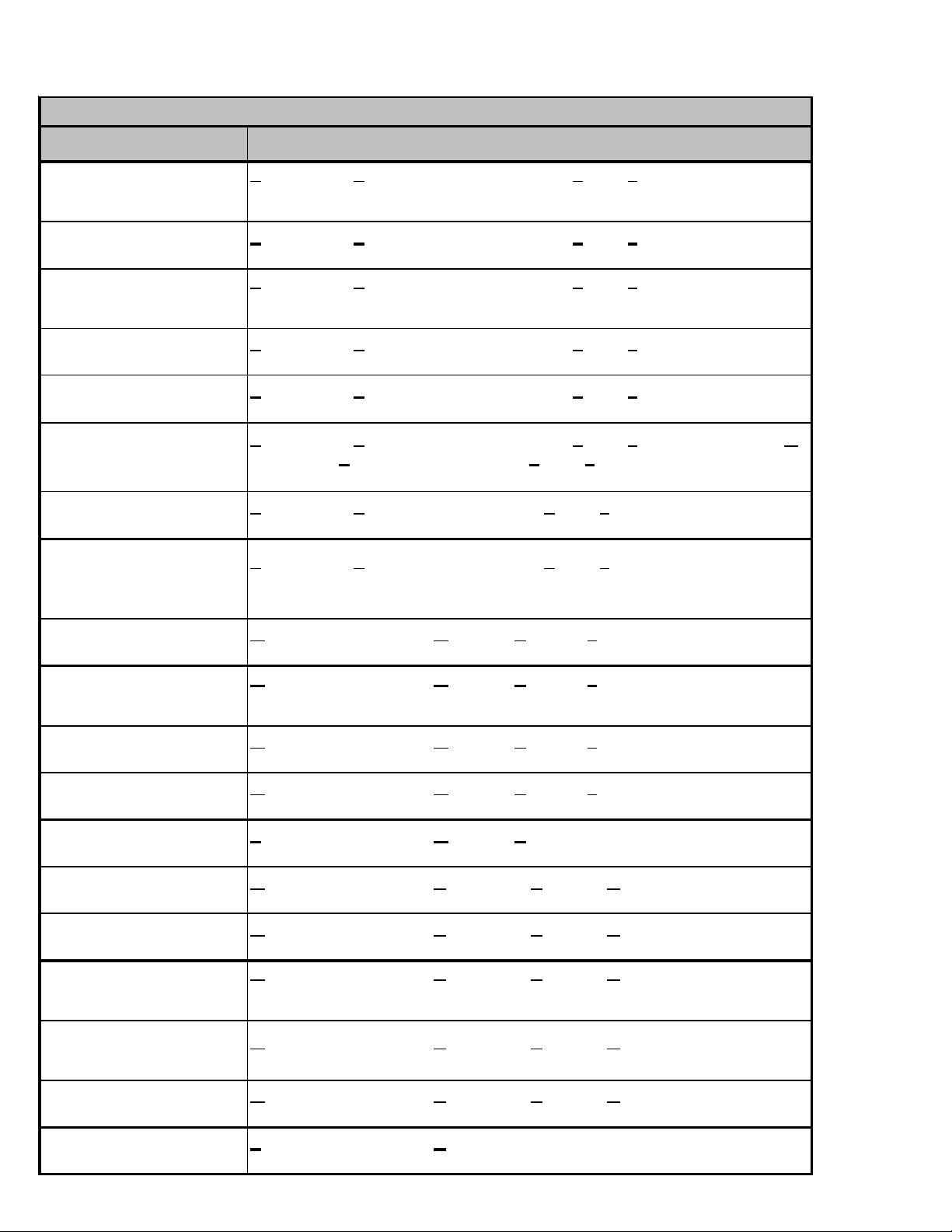

PRODUCT IDENTIFICATION

Split System Air Conditioners R-22

Model # Description

oodman® Brand Split Condenser 10 Seer condensing units with new ball

GSC100903AD

GSC100903BA

GSC101203BA

GSC130181BB

GSC130241DB

GSC130301DB

GSC130361FB

GSC130421BB

GSC130481BB

GSC130601CB

G

valve/brackets, suction tube/assembly and panel w/offset.

G

oodman® Brand Split Condenser 10 Seer condensing units. Initial release of light

commercial models with holding charge only in a double row coil.

CONTAIN REFRIGERANT

installation instructions.

oodman® Brand Split Condenser 13 Seer condensing units. Release models holding

G

charge only;

and charged with R-22 per the installation instructions.

MODELS DO NOT CONTAIN REFRIGERANT

MODELS DO NOT

. Units must be evacuated and charged with R-22 per the

. Units must be evacuated

GSC130181DA

GSC130241EA

GSC130301EA

GSC130361GA

GSC130363BB

GSC130483BB

GSC130603BB

GSC130181FA

GSC130241FA

GSC130301EB

G

oodman® Brand Split Condenser 13 Seer condensing units. Release models holding

charge only;

and charged with R-22 per the installation instructions. Replaces Copeland compressor

with Bristol reciprocating compressor.

oodman® Brand Split Condenser 13 Seer condensing units. Release models holding

G

charge only;

and charged with R-22 per the installation instructions.

oodman® Brand Split Condenser 13 Seer condensing units. Release models holding

G

charge only;

and charged with R-22 per the installation instructions. Reduction of chassis to 23".

G

oodman® Brand Split Condenser 13 Seer condensing units. Release models holding

charge only;

and charged with R-22 per the installation instructions. Model listed has new 6 pole

motor and corresponding fan blade.

MODELS DO NOT CONTAIN REFRIGERANT

MODELS DO NOT CONTAIN REFRIGERANT

MODELS DO NOT CONTAIN REFRIGERANT

MODELS DO NOT CONTAIN REFRIGERANT

. Units must be evacuated

. Units must be evacuated

. Units must be evacuated

. Units must be evacuated

5

Page 6

PRODUCT IDENTIFICATION

Split System Air Conditioners R-22

Model # Description

G

GSC140**1AA

GSC140**1AB

GSC140**1AC

GSC140**1AD

GSC14018-421BA

Model # Description

oodman® Brand Split Condenser 14 Seer condensing units. Introduces Goodman®

Brand 14 Seer AC R-22 models.

oodman® Brand Split Condenser 14 Seer condensing units. New revisions have screw

G

locations moved in the top panel, base pans, louvers, and control box covers.

G

oodman® Brand Split Condenser 14 Seer condensing units. Release models

containing the Broad Ocean motor 0131M00060 and 0131M00061

oodman® Brand Split Condenser 14 Seer condensing units. Revise condenser coils by

G

removing (1) hairpin. Reducing refrigerant quantities by 6 ounces.

G

oodman® Brand Split Condenser 14 Seer condensing units. Conversion of existing

models using 3/8" diameter tube coils to 5 mm coils.

Split System Air Conditioners R-22

mana® Brand Split Condenser 13 Seer condensing units. Initial release new models of

ASC130**1AA

ASC130**1AB

ASC130**1AC

ASC1301**1AD

ASC130601BD

A

Amana® Brand Deluxe 13 Seer AC R-22 conditioners.

A

mana® Brand Split Condenser 13 Seer condensing units. Move location of screw hole.

A

mana® Brand Split Condenser 13 Seer condensing units. Introduces horizontal style

louvers.

mana® Brand Split Condenser 13 Seer condensing unit s. Remove 1 hairpin from coil.

A

Special High Feature Split XCondenser 14 Seer condensing units.

hairpin from coil. Reduce refrigerant quantities by 6 ounces.

Split System Air Conditioners R-22

Model # Description

alue Split Condenser 13 Seer condensing units. Introduces Value 13 Seer AC R-22

VSC13018-601AA

VSC130181BA

VSC13030-361BA

V

models. 2 year part & 5 year compressor warranty in Bahama Beige.

V

alue Split Condenser 13 Seer condensing units. Converts models from 3/8" to 5mm

with new coil slab height & new louver panels. 2 year part & 5 year compressor warranty

in Bahama Beige.

. Remove 1

6

Page 7

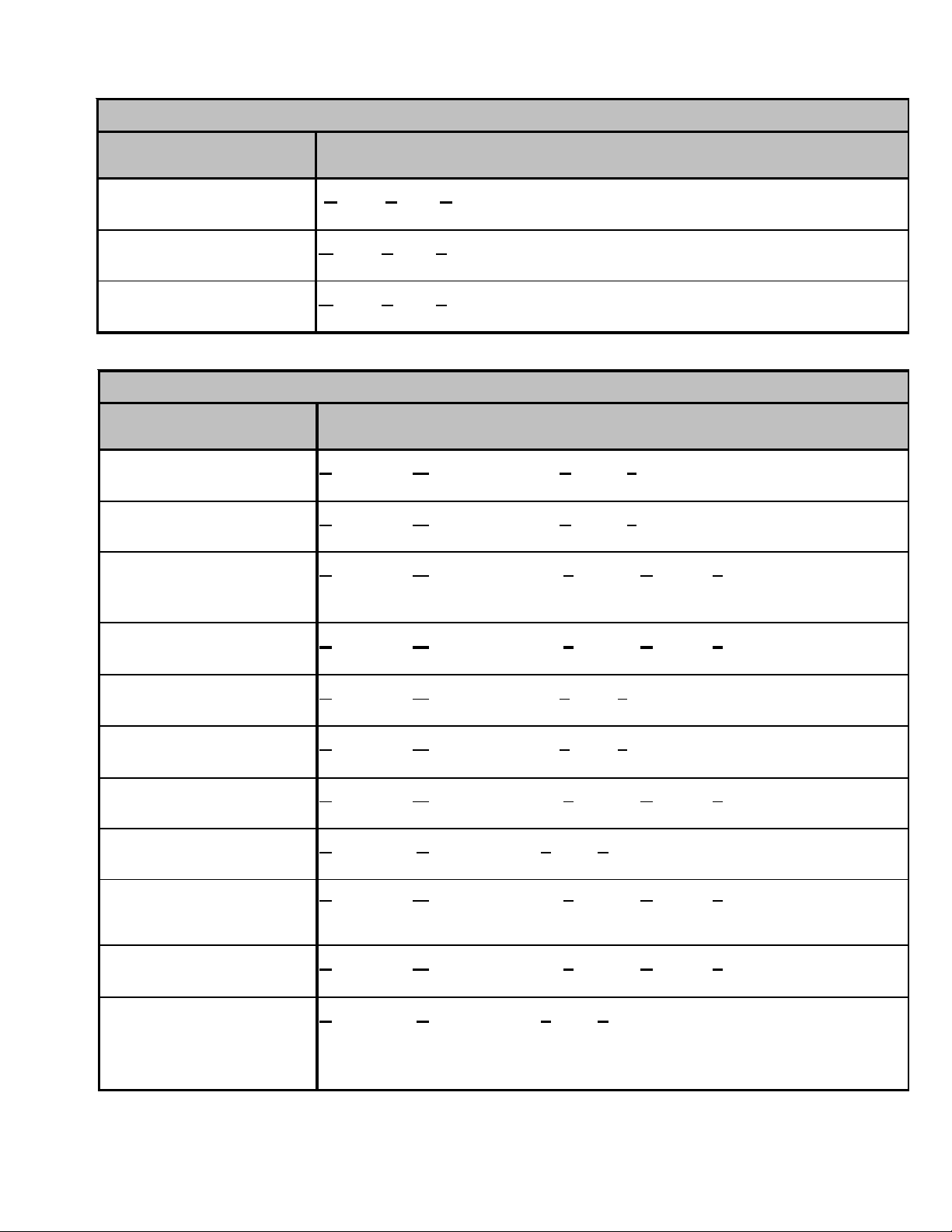

PRODUCT IDENTIFICATION

Sp lit System Heat Pumps R-22

Model # Description

GSH10***AA

GSH10***AB

GSH100903AC

GSH101203AC

GSH101203AD

GSH13***AA

GSH13**1AB

GSH13**1AC

GSH13036-48*AD

GSH13018-301BA

GSH130421AE

GSH13048*AG

G

oodman® B rand Split Heat Pump 10 S eer heat pump units. Initial release.

G

oodman® B rand Split Heat Pump 10 Seer heat pump units. Screw locations

moved in the top panel, base pans, louvers, and control box covers. .

G

oodman® B rand Split Heat Pump 10 S eer heat pump units. Initial release of light

commercial models without R-22 refrigerant.

REFRIGERANT

installation instructions.

oodman® B rand Split Heat Pump 10 S eer heat pump units without R-22

G

refrigerant with new ball valve/brackets, suction tube/assembly and panel w/offset.

oodman® B rand Split Heat Pump 13 S eer heat pump units. Initial release.

G

oodman® B rand Split Heat Pump 13 Seer heat pump units. Revision

G

introduces the following new models due to the replacement of 8-pole fan motors

with 6-pole and screw locations moved in the top panel, base pans, louvers, and

control box covers.

G

oodman® B rand Split Heat Pump 13 Seer heat pump units. Contain Broad

Ocean motors Screw locations moved in the top panel, base pans, louvers, and

control box covers. .

G

oodman® B rand Split Heat Pump 13 Seer heat pump units. Introduces models

that contain the broad ocean motor

oodman® B rand Split Heat Pump 13 Seer heat pump units. Reduction in

G

chassis size from medium to small.

G

oodman® B rand Split Heat Pump 13 Seer heat pump units. Replaces V10

reversing valve with V6 r eversing valve.

oodman® B rand Split Heat Pump 13 Seer heat pump units. Introduces

G

model with Bristol Compressors.

. Units must be evacuated and charged with R-22 per the

MODELS DO NOT CONTAIN

GSH13036*BA/BB

GSH130181BB

GSH130241BB

GSH130301BB

GSH130361BC

GSH130421AF

GSH130481AE

GSH130601AC

GSH130181CA

GSH130241CA

GSH130301CA

GSH130361CA

GSH130(18,24,30,36)1CB

GSH130421AG

GSH130481AF

GSH130363AE

GSH130483AE

GSH130603AC

oodman® B rand Split Heat Pump 13 Seer heat pump units. Improvements to

G

increase MOP values on 3 ton units.

oodman® B rand Split Pump 13 Seer condensing units. Release models holding

G

charge only;

evacuated and charged with R-22 per the installation instructions.

G

oodman® B rand Split Pump 13 Seer condensing units. Release models holding

charge only;

evacuated and charged with R-22 per the installation instructions. Changing

reciprocating compressor to scroll compressor.

oodman® B rand Split Pump 13 Seer condensing units. Release models holding

G

charge only;

evacuated and charged with R-22 per the installation instructions. Models listed

have new 6 pole motor and corresponding fan blades.

oodman® B rand Split Pump 13 Seer condensing units. Release models holding

G

charge only;

evacuated and charged with R-22 per the installation instructions.

MODELS DO NOT CONTAIN REFRIGERANT

MODELS DO NOT CONTAIN REFRIGERANT

MODELS DO NOT CONTAIN REFRIGERANT

MODELS DO NOT CONTAIN REFRIGERANT

. Units must be

. Units must be

. Units must be

. Units must be

7

Page 8

PRODUCT IDENTIFICATION

Split System Heat Pumps R-22

Model # Description

G

GSH140**1AA

GSH140**1AB

GSH140**1AC

oodman® Brand Split Heat Pump 14 Seer heat pump units. Initial release.

oodman® Brand Split Heat Pump 14 Seer heat pump units. Screw locations

G

moved in the top panel, base pans, louvers, and control box covers.

G

oodman® Brand Split Heat Pump 14 Seer heat pump units. Releases

models with the Broad Ocean motor.

GSH140361AF,

GSH140421-48AD

GSH140601AE

oodman® Brand Split Heat Pump 14 Seer heat pump units. Releases

G

m odels that replac e TXV & com pensator with flowrator & accumu lator.

Split System Heat Pumps R-22

Model # Description

mana® Brand Split Heat Pump 13 Seer heat pump units. Initial release new

ASH130**1AA

ASH130**1AB

ASH130**1AC

A

models of Amana® Brand Deluxe 13 Seer R-22 heat pumps.

mana® Brand Split Heat Pump 13 Seer heat pump units. New revisions have

A

screw locations moved in the top panel, base pans, louvers, and control box

covers.

mana® Brand Split Heat Pump 13 Seer heat pump units. New revisions have

A

horizontal style louvers.

Split System Heat Pumps R-22

Model # Description

VSH1318-601AA

8

alue Split Heat Pump 13 Seer heat pump units. Introduces Value 13 Seer HP R-

V

22 models. 2 year parts & 5 year compressor warranty in Bahama Beige.

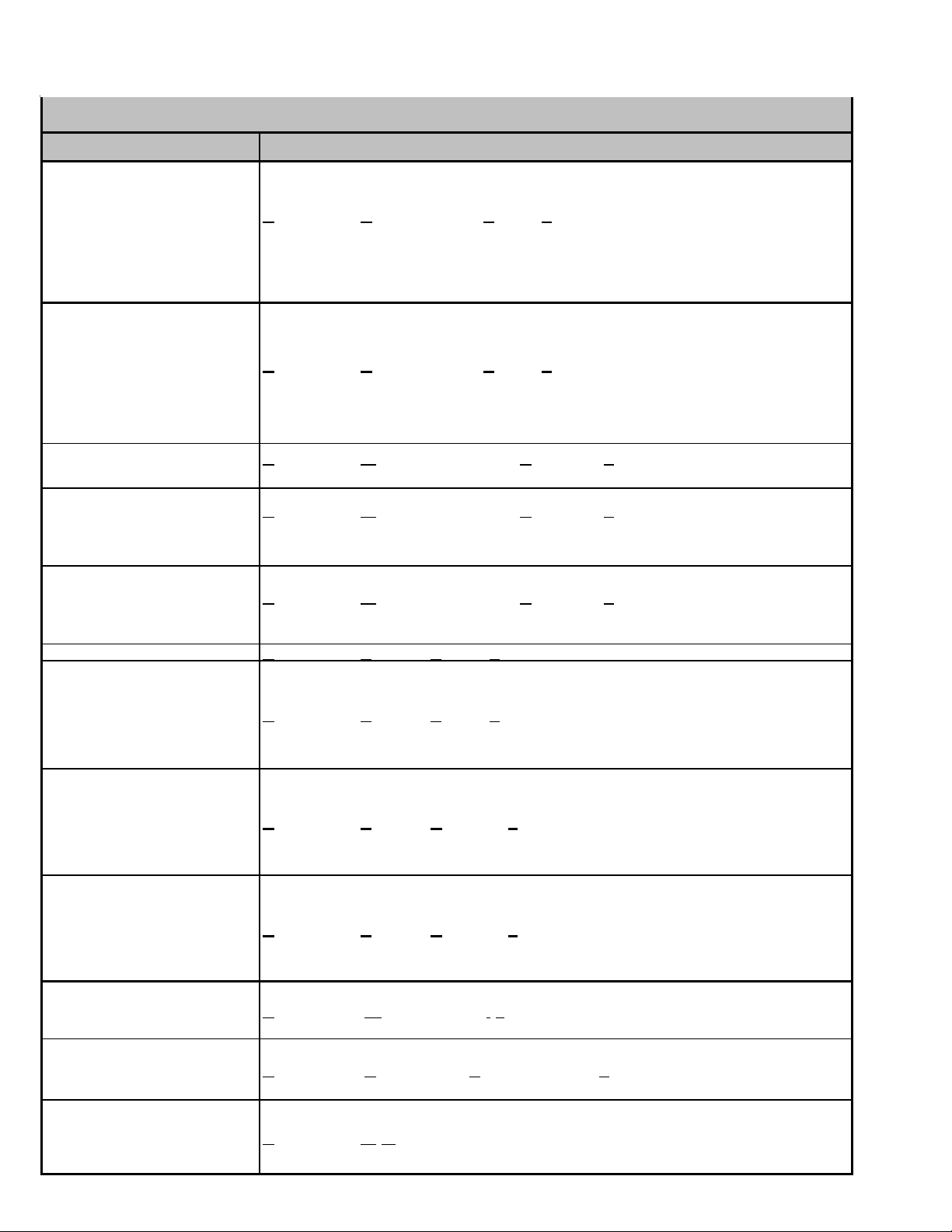

Page 9

PRODUCT IDENTIFICATION

Single Piece Air Handlers

Model # Description

Single Piece R Multi-Position PSC Motor Unpainted Flowrater Introduction of new 13

ARUF****16A A

ARUF364216AB

ARUF486016AB

ARUF364216AC

ARUF****16B A

ARUF****1BA

A

SEER Air Handler Models . All Models will be suitable for use with R-22 and R-410A

Single Piece R Multi-Position PSC Motor Unpainted Flowrater.Revision replaces the

A

current spot welded blower housing with the s ame cinched or crimped design used on

the 80% furnace line.

Single Piece R Multi-Position PSC Motor Unpainted Flowrater.Revision replaces the

A

current spot welded blower housing with the s ame cinched or crimped design used on

the 80% furnace line.

Single Piece R Multi-Position PSC Motor Unpainted Flowrater.Revision replaces the

A

current spot welded blower housing with the s ame cinched or crimped design used on

the 80% furnace line.

Single Piece R Multi-Position PSC Motor Unpainted Flowrater. Revision replaces all

A

ARUFcoils using wavy fin with louver enhanced fin.

Single Piece R Multi-Position PSC Motor Unpainted Flowrater Introducation of R-22

A

Only Air Handlers.

ARPF****16AA

ARPF364216AB

ARPF486016AB

ARPF****16BA

ARPF****1BA

ADPF****16AA

ADPF364216AB

ADPF486016AB

Single Piece R Multi-Position PSC Motor Painted Flowrater Introducation of new 13

A

SEER Air Handler Models . All Models will be suitable for use with R-22 and R-410A

Single Piece R Multi-Position PSC Motor Painted Flowrater. Revision replaces the

A

current spot welded blower housing with the s ame cinched or crimped design used on

the 80% furnace line.

Single Piece R Multi-Position PSC Motor Painted Flowrater. Revision replaces the

A

current spot welded blower housing with the s ame cinched or crimped design used on

the 80% furnace line.

Single Piece R Multi-Position PSC Motor Painted Flowrater. Revision replaces all

A

ARPFcoils using wavy fin with louver enhanced fin.

Single Piece R Multi-Position PSC Motor Painted Flowrater. Introducation of R-22

A

Only Air Handlers.

Single Piece Downflow PSC Motor Unpainted Flowrater. Introducation of new 13

A

SEER Air Handler Models . All Models will be suitable for use with R-22 and R-410A

Single Piece Downflow PSC Motor Unpainted Flowrater. Revision replaces the current

A

spot welded blower housing with the same c inched or crimped design used on the 80%

furnace line.

Single Piece Downflow PSC Motor Unpainted Flowrater. Revision replaces the current

A

spot welded blower housing with the same c inched or crimped design used on the 80%

furnace line.

ADPF304216AC

ADPF****1BA

Single Piece Downflow PSC Motor Unpainted Flowrater. Revision replaces the current

A

spot welded blower housing with the same c inched or crimped design used on the 80%

furnace line.

Single Piece Downflow PSC Motor Unpainted Flowrater Revision replaces all

A

ARPFcoils using wavy fin with louver enhanced fin.

9

Page 10

PRODUCT IDENTIFICATION

Single Piece Air Han dlers

Model # Description

Single Piece E Multi-Position Variable-Speed Painted Flowrator. Introducation of

A

AEPF****16AA

AEPF****16BA

AEPF****16BB

AEPF****16CA

AEPF****1BA

new 13 SEER Air Handler Models. All Models will be suitable for use with R-22 and

R-410A

A

Single Piece E Multi-Position Variable-Speed Painted Flowrator. Revision

introduces new models adding lower kw hit kits on the S&R plate

A

Single Piece E Multi-Position Variable-Speed Painted Flowrator. Revision

replaces the current spot welded blower housing with the same cinched or crimped

design used on the 80% furnace line.

Single Piece E Multi-Position Variable-Speed Painted Flowrator. Revision

A

replaces all ARPFcoils us ing wavy fin with louver enhanced fin.

A

Single Piece E Multi-Position Variable-Speed Painted Flowrator Introduction of R22 Only Air Handlers .

AEPF313716AA

ASPF313716AA

ASPF****16AA

ASPF****16BA

AW UF****1AA

AWUF****16AA

AWUF3005-101AA

AW UF****1BA

AWUF370**16AA

AWUF****16BA

Single Piece E Multi-Position Variable-Speed Painted Flowrator

A

Single Piece S Multi-Position EEM m otor Painted Flowrator

3-Ton Air Handler units with 3-row coil.

Single Piece S Multi-Position EEM motor Painted Flowrator. Introduces new

A

ASPF Air Handlers

Single Piece S Multi-Position EEM motor Painted Flowrator. Revision introuces

A

modified ASPF control scheme, to ensure blower operation during and after call for

heat on units with heat kits and replacing wavy fin with louver enhanced fin on coil

A

Single Piece Air Handler Wall Mount Unpainted Flowrator. Introduces 13 SEER

Dayton wall mount air handlers

A

Single Piece Air Handler Wall Mount Unpainted Flowrator. Introduces 13 SEER

Dayton wall mount air handlers. All Models will be suitable for use with R-22 and R410A

Single Piece Air Handler Wall Mount Unpainted Flowrator. Introduces 13 SEER

A

Dayton wall mount air handlers using a Burr Oak Louvered Fin coil.

A

Single Piece Air Handler Wall Mount Unpainted Flowrator. Revision replaces

current wavey fin design with new louvered fin design

A

Single Piece Air Handler Wall Mount Unpainted Flowrator. Introduction of

AWUF37 Air Handlers for use with R-22 and R410A.

Single Piece Air Handler Ceiling Mount N Uncased Flowrater. Revision has

A

louver fins & replaces copper tube hairpins with aluminum hairpins.

(AEPF)

(ASPF)

and

A

. Introduction of

10

ACNF****1AA

ACNF****16AA

ACNF****1AB

ACNF****1BA

AH**-1*

Single Piece Air Handler Ceiling Mount N Uncased Flowrater. Revision release

A

all models of 13 SEER Dayton uncased air handlers.

Single Piece Air Handler Ceiling Mount N Uncased Flowrater. Revision release

A

all models of 13 SEER Dayton uncased air handlers.All Models will be suitable for

use with R-22 and R-410A

A

Single Piece Air Handler Ceiling Mount N Uncased Flowrater. Drain pan material

change.

Single Piece Air Handler Ceiling Mount N Uncased Flowrater. Revision replaces

A

current wavey fin design with new louvered fin design

A

Single Piece Air Handler Hydronic Air Handler. Revision replaces the time delay

relay in the AH air handlers with the UTEC time delay control board.

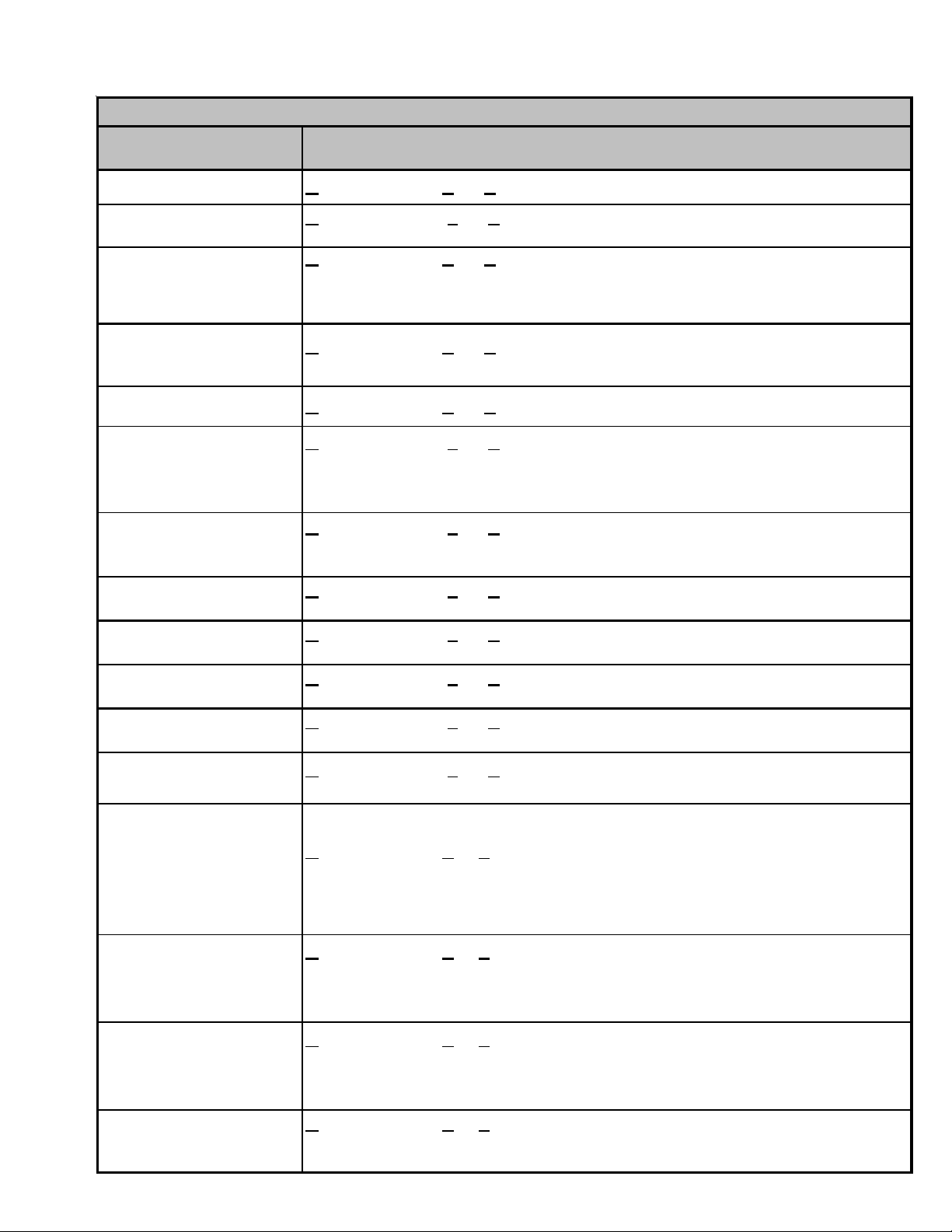

Page 11

PRODUCT IDENTIFICATION

MBR/MBE Air Handlers

Model # Description

odular Blower R Multi-Position PSC Motor. Introduces module blower with PSC

MBR****AA-1AA

MBE****AA-1AA

MBE****AA-1BA

Model # Description

CAUF*****6AA

CAUF*****6BA

M

blow er motor.

M

odular Blower E Multi-Position Variable-Speed. Introduces module blower with

variable speed blower motor.

odular Blower E Multi-Position Variable-Speed.Revision introduces new models

M

adding lower kw hit kits on the S&R plate

Evaporator Coils

Indoor Coil A Upflow/Downflow Unca sed Flowrator. Introduces 13 SEER CAUF

C

Dayt on Up fl ow/Down fl ow coils.

C

Indoor Coil A Upflow/Downflow Unca sed Flowrator. Revision releases Burr Oak

Louvered Fin in place of the Wavy Fin currently in production.

CAUF****6*DA

CAUF*****6DB

CAPF*****6AA

CAPF*****6BA

CAPF/CAUF36***CA

CHPF*****6AA

CAPF*****6DA

CAPF*****6DB

CHPF*****6BA

Indoor Coil A Upflow/Downflow [Painted or Uncased] Flowrator. Revision

C

replaces existing copper coils and other associated parts with aluminum

components.

Indoor Coil A Upflow/Downflow [Painted or Uncased] Flowrator. Drai n pan

C

material change.

C

Indoor Coil A Upflow/Downflow Painted Flowrator. Introduces 13 SEER CAPF

Dayt on Up fl ow/Down fl ow coils.

Indoor Coil A Upflow/Downflow Painted Flowrator. Revision releases Burr Oak

C

Louvered Fin in place of the Wavy Fin currently in production.

C

Indoor Coil A Upflow/Downflow [Painted or Uncased] Flowrator. Revision

redesigns for performance improvement from 2 row to 3 row.

Indoor Coil Horizontal A Coil Painted Flowrator. Release 13 SEER CHPF

C

horizontal A coil.

Indoor Coil A Upflow/Downflow [Painted or Uncased] Flowrator. Revision

C

replaces existing copper coils and other associated parts with aluminum

components.

Indoor Coil A Upflow/Downflow [Painted or Uncased] Flowrator. Drai n pan

C

material change.

C

Indoor Coil Horizontal A Coil Painted Flowrator. Release 13 SEER CHPF

horizontal A coil. Revision releases Burr Oak Louvered Fin in place of the Wavy

Fin currently in production. The rows change by one, (i.e. 4 row to 3 row; 3 row to

2 row) where applicable.

11

Page 12

PRODUCT IDENTIFICATION

Evap orator Co ils

Mo d el # D escription

CHPF1824A6CA

CHPF2430B6CA

CHPF3636B6CA

CHPF3642C6CA

CHPF3642D6CA

CHPF3743C6BA

CHPF3743D6BA

CHPF4860D6DA

CHPF1824A6CB

CHPF2430B6CB

CHPF3636B6CB

CHPF3642C6CB

CHPF3642D6CB

CHPF3743C6BB

CHPF3743D6BB

CHPF4860D6DB

CSCF*****6AA

CSCF*****6BA

Indoor Coil Horizontal A Coil Painted Flowrator. 13 SEER CH PF horizontal A

C

coil, revision has louver fins & replaces copper tube hairpins with aluminum

hairpins.

C

Indoor Coil Horizontal A Coil Painted Flowrator. 13 SEER CH PF horizontal A

coil. Drain pan material change.

Indoor Coil S Horizontal Slab Coil C Upainted Flowrator. Release 13 SEER

C

CSCF slab horizontal coil.

Indoor Coil S Horizontal Slab Coil C Upainted Flowrator. Revision releases Burr

C

Oak Louvered Fin in place of the Wavy Fin currently in production. The rows

change by one, (i.e. 4 row to 3 row; 3 row to 2 row) where applicable.

CSCF1824N6BB

CSCF3036N6BB

CSCF3642N6CB

CSCF4860N6CB

CTPF*****6AA

CTPF1824*6AB

CTPF3030*6AB

CTPF3131*6AB

CTPF3636*6AC

CTPF3642*6AB

CTPF4860*6AB

CTUF1824*6AA

CTUF3030*6AA

CTUF3131*6AA

CTUF3636*6AA

CTUF3642*6AA

CTUF4860*6AA

CTUF1824*6AB

CTUF3030*6AB

CTUF3131*6AB

CTUF3636*6AC

CTUF3642*6AB

CTUF4860*6AB

CKF24-2PA

CKF36-2PA

CKF36-5PA

CPKF36-2PA

CPKF36-5PA

CPKF48-5PA

Indoor Coil S Horizontal Slab Coil C Upainted Flowrator. Drain pan material

C

change.

Indoor Coil T Coated Painted Flowrator. Initial release of coated coils.

C

Indoor Coil T Coated Painted Flowrator. Drain pan m aterial change.

C

C

Indoor Coil T Coated Unpainted Flowrator. Initial release.

C

Indoor Coil T Coated Unpainted Flowrator. Drain pan material change.

Indoor Coil K Air Conditioner Flowrator.

C

Indoor Coil P Heat Pump K Air Conditioner Flowrator.

C

12

CKL36-1PA

CKL49-1PA

CKL60-1PA

CKL60-3PA

Indoor Coil K

C

L

Page 13

PRODUCT IDENTIFICATION

p

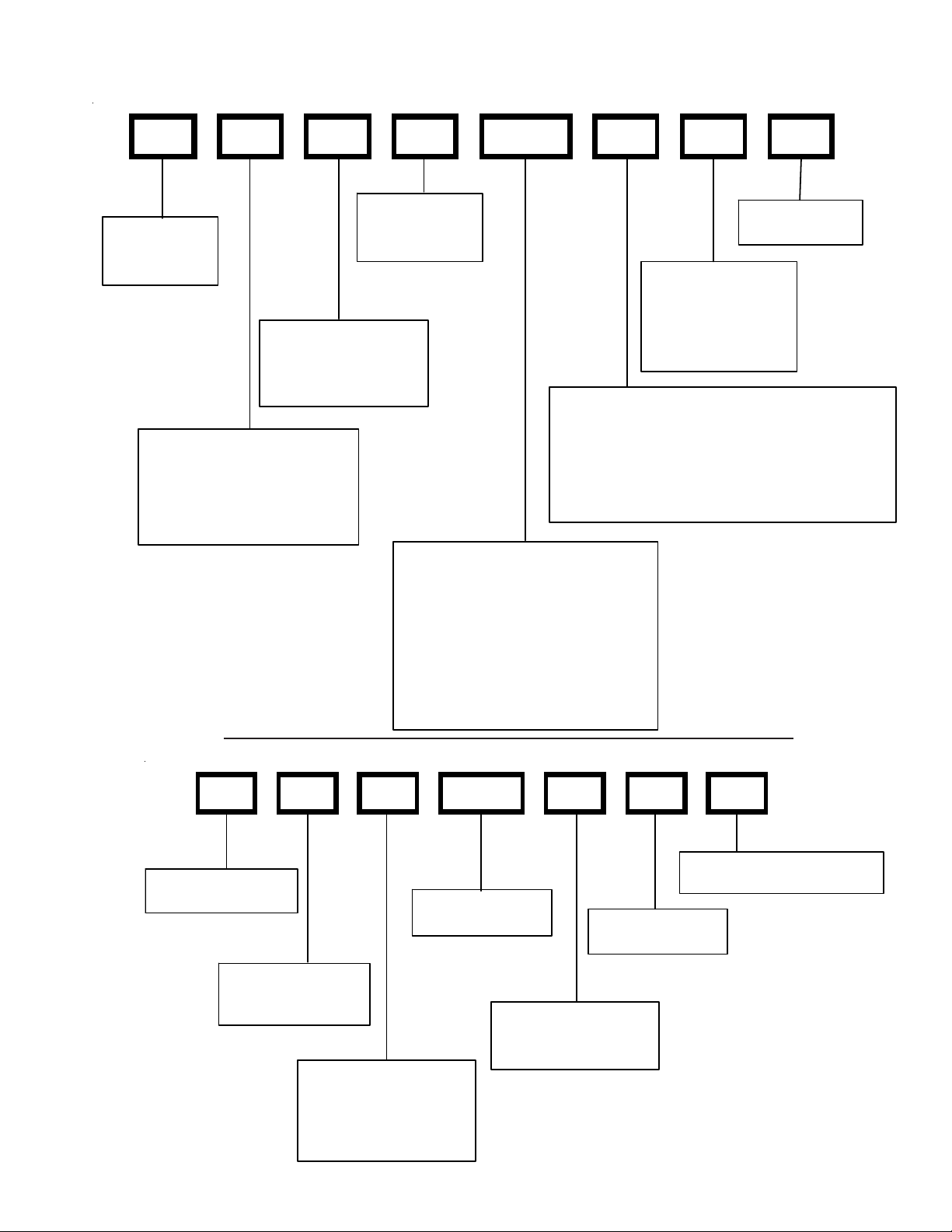

GSC140361AA

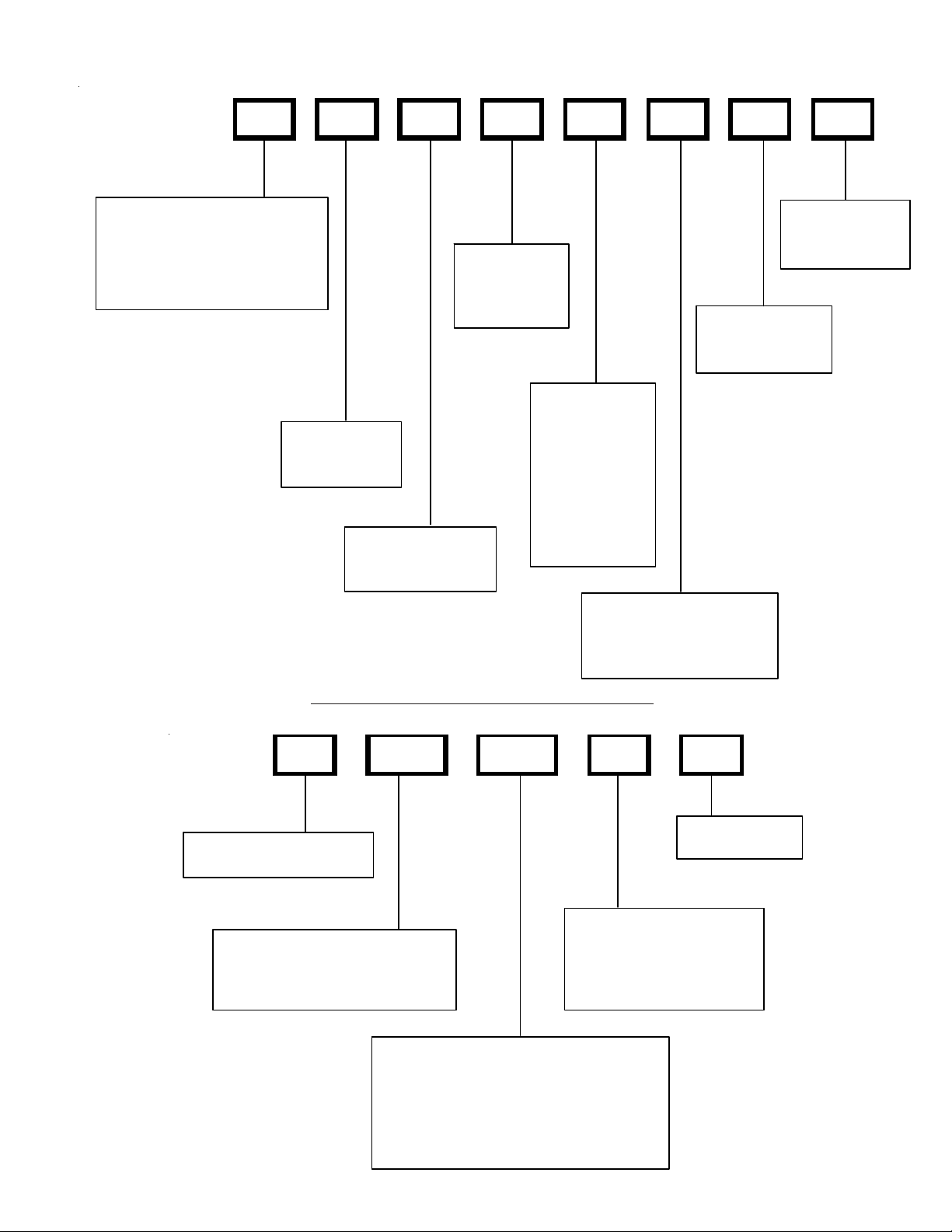

BRAND:

G: Goodman

Amana

A: Amana

V: Value

®

®

Brand Distinctions

®

Brand

Brand /

PRODUCT

CATEGORY:

S: Split System

UNIT T YPE:

C: Condenser R-22

H: Heat Pump R-22

SEER :

10: 10 SEER

13: 13 SEER

14: 14 SEER

NO MINAL

CAPACITY:

018: 1.5 Tons

024: 2 Tons

030: 2.5 Tons

036: 3 Tons

042: 3.5 Tons

048: 4 Tons

060: 5 Tons

MINOR

REVISI ON:

A: Initial Release

M AJOR

REVISION:

A: Initial Re l ease

ELECTRICAL:

1: 208-230 V/1ph/60 Hz

3: 208-230 v/3ph/60 Hz

4: 460v/3ph/60Hz

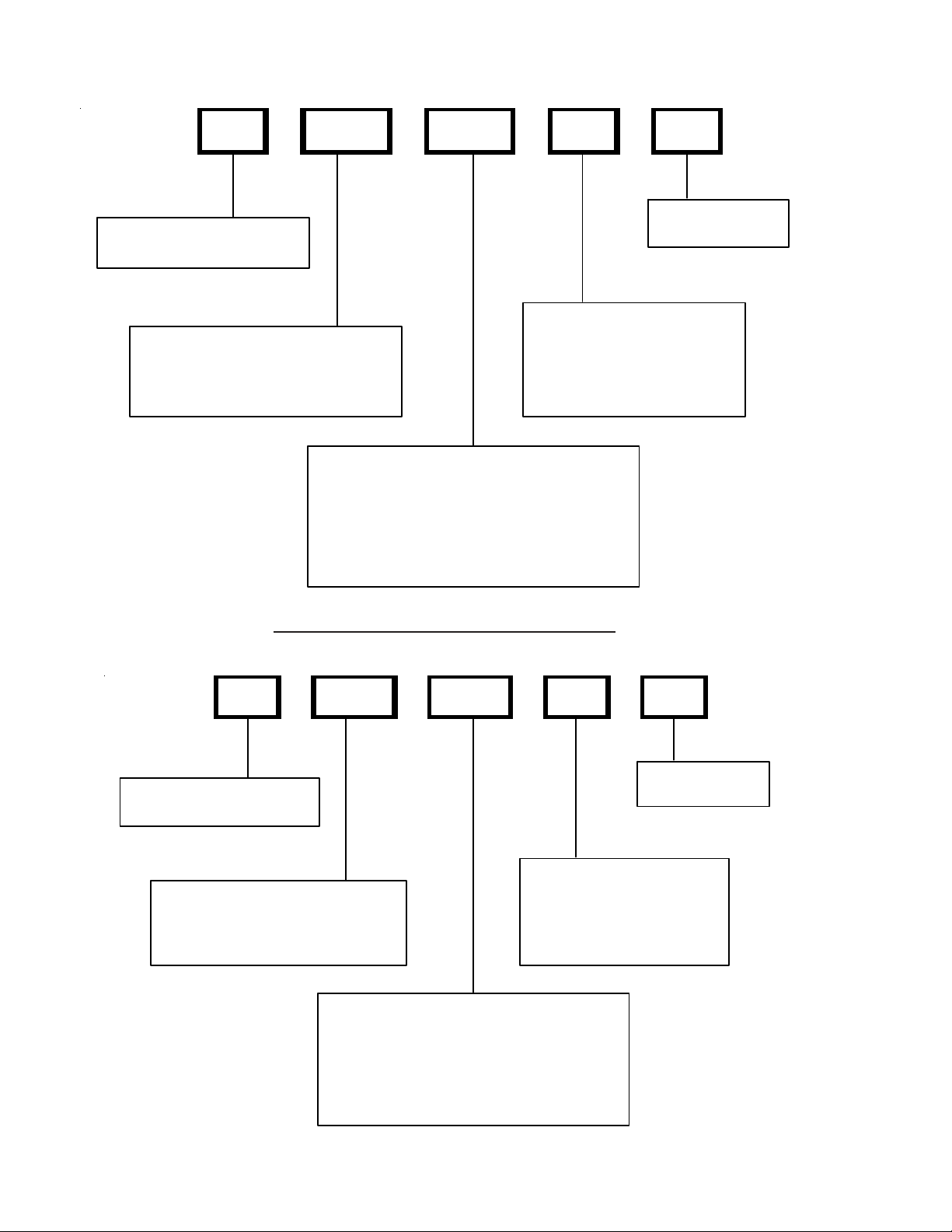

C PKF 036 2 A

PRODUCT CATEGORY:

C: Split System

UNIT TYPE:

E: Commercial Air Conditioner

K: Air Conditioner

P: Heat Pum

REVISION:

A: Revision

ELECTRICAL:

1: 208-230V/1ph/60Hz

2: 220-240V/1ph/50 Hz

3: 208-230v/3ph/60Hz

4: 308/415V/3ph/50Hz

NOMINAL CAPACITY:

018: 1.5 Tons 048: 4 Tons

024: 2 Tons 060: 5 Tons

030: 2.5 Tons 070: 5 Tons

036: 3 Tons 090: 7.5 Tons

042: 3.5 Tons 120: 10 Tons

13

Page 14

PRODUCT IDENTIFICATION

p

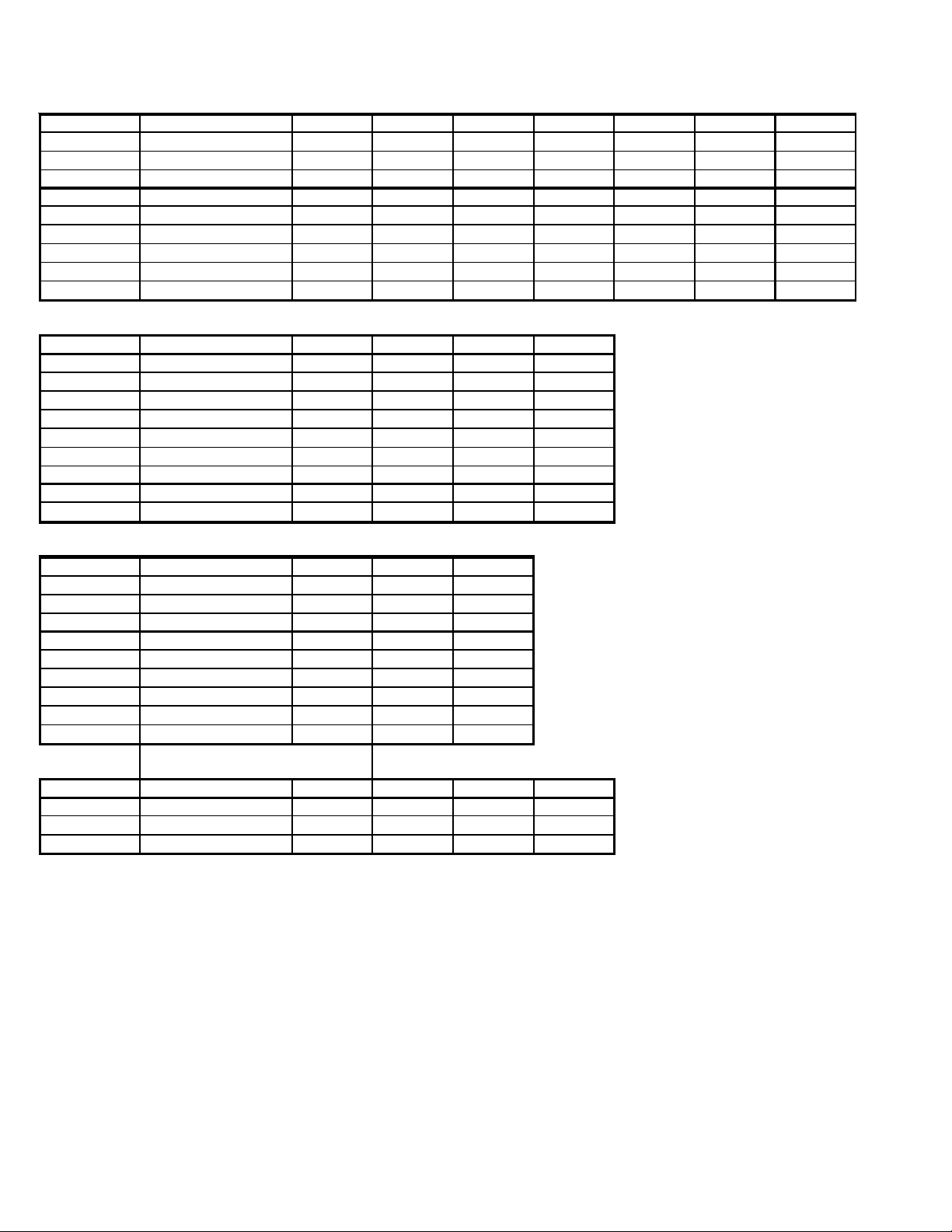

C KL 036 2 A

PRODUCT CATEGORY:

C: Split System

UNIT TYPE:

E: Commercial Air Conditioner

K: Air Conditioner

P: Heat Pum

NOMINAL CAPACITY:

018: 1.5 Tons 048: 4 Tons

024: 2 Tons 060: 5 Tons

030: 2.5 Tons 070: 5 Tons

036: 3 Tons 090: 7.5 Tons

042: 3.5 Tons 120: 10 Tons

REVISION:

A: Revision

ELECTRICAL:

1: 208-230V/1ph/60Hz

2: 220-240V/1ph/50 Hz

3: 208-230v/3ph/60Hz

4: 308/415V/3ph/50Hz

C KF 036 2 A

PRODUCT CATEGORY:

C: Split System

UNIT TYPE:

E: Commercial Air Conditioner

K: Air Conditioner

P: Heat Pump

REVISION:

A: Revision

ELECTRICAL:

1: 208-230V/1ph/60Hz

2: 220-240V/1ph/50 Hz

3: 208-230v/3ph/60Hz

4: 308/415V/3ph/50Hz

NOMINAL CAPACITY:

018: 1.5 Tons 048: 4 Tons

024: 2 Tons 060: 5 Tons

030: 2.5 Tons 070: 5 Tons

036: 3 Tons 090: 7.5 Tons

042: 3.5 Tons 120: 10 Tons

14

Page 15

PRODUCT IDENTIFICATION

A

A

A

A

A

A

p

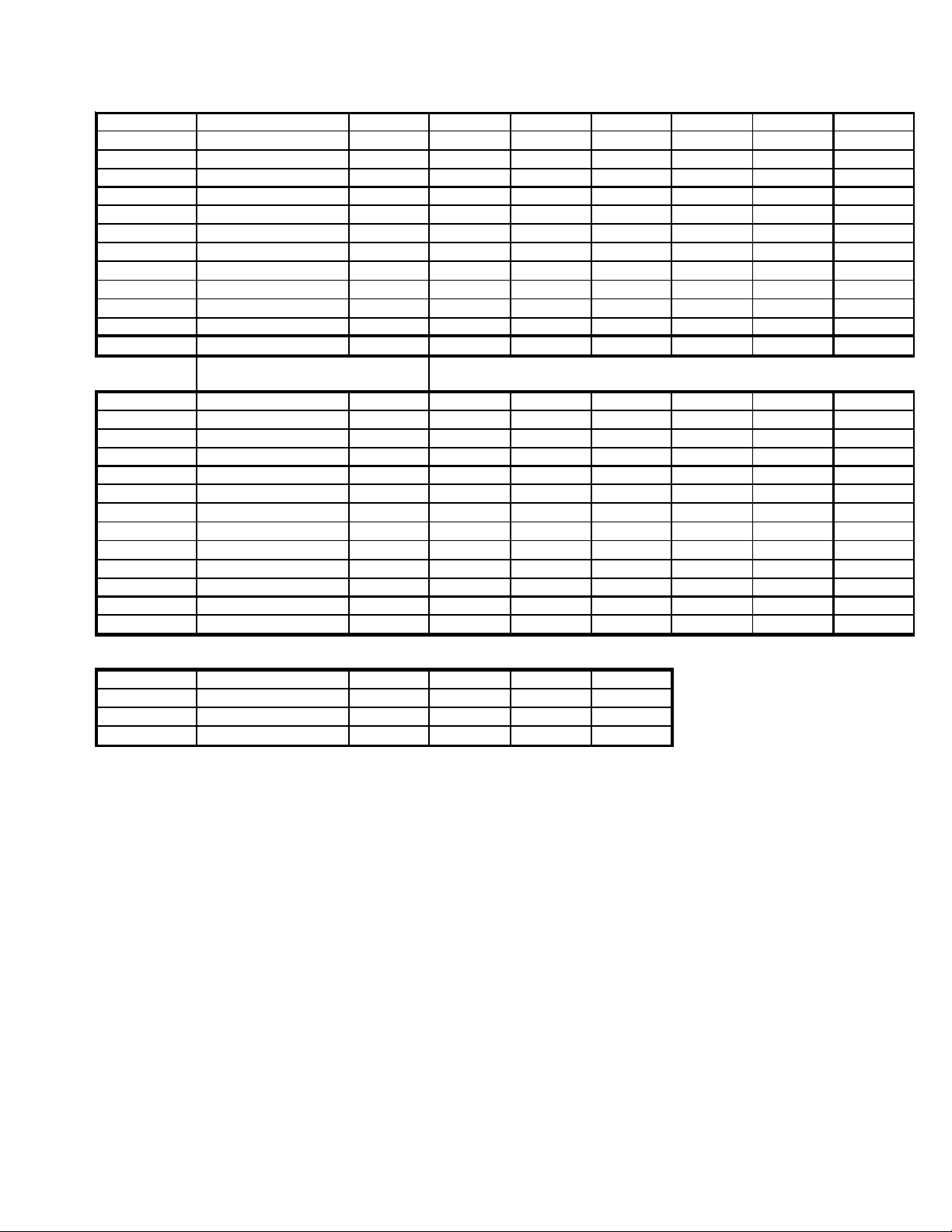

C E 120 5 A

PRODUCT CATEGORY:

C: Split System

UNIT T YPE:

E: Commercial Air Conditioner

K: Air Cojditioner

P: Heat Pum

NOMINAL CAPACITY:

018: 1.5 Tons 048: 4 Tons

024: 2 Tons 060: 5 Tons

030: 2.5 Tons 070: 5 Tons

036: 3 Tons 090: 7.5 Tons

042: 3.5 Tons 120: 10 Tons

REVISION:

A: Revision

ELECTRICAL:

1: 208-230V/1ph/60Hz

2: 220-240V/1ph/50 Hz

3: 208-230v/3ph/60Hz

4: 308/415V/3ph/50Hz

THIS NOMENCLATURE IS TO BE USED TRHOUGH JULY 2006

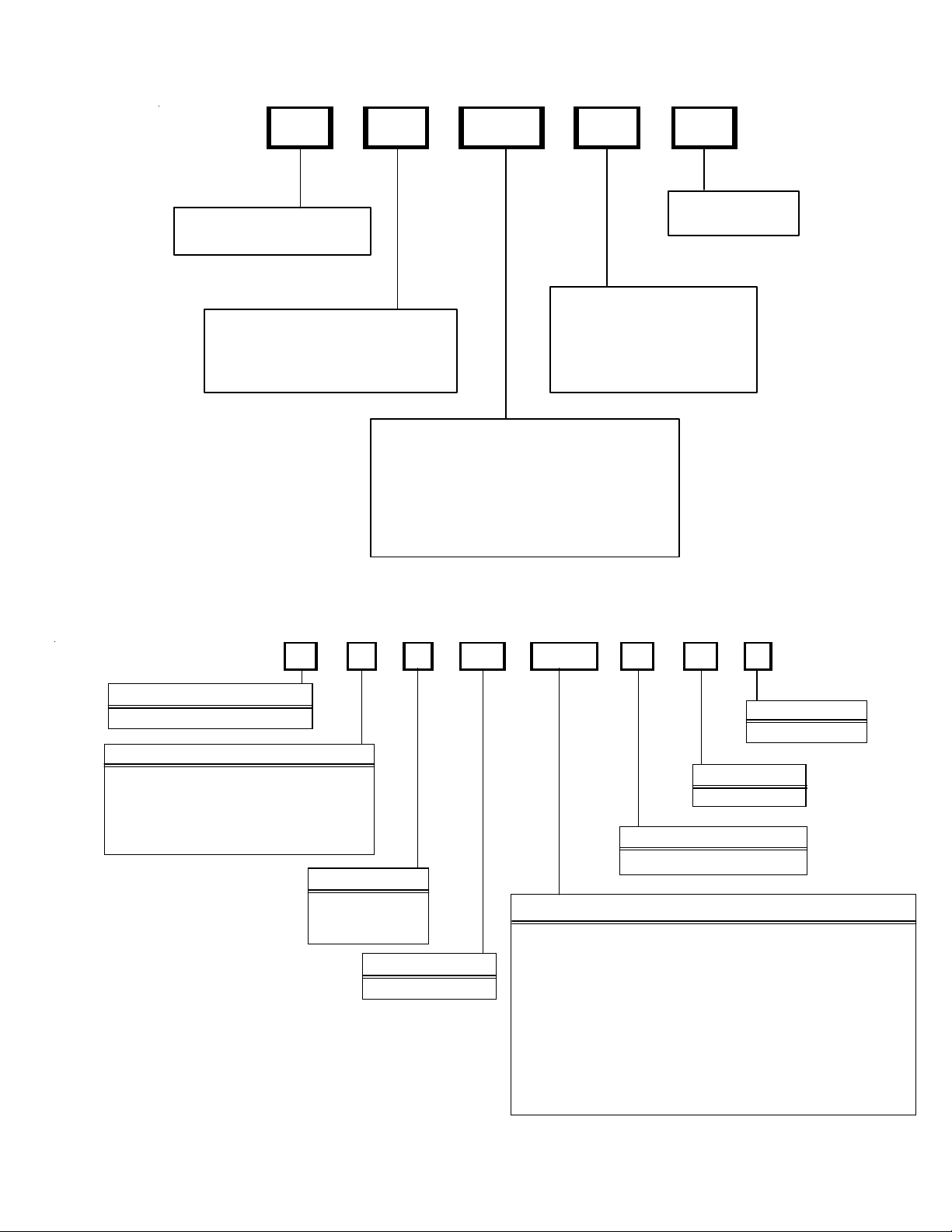

R U F 3642 1

Product Type

: Single Piece Air Handler

Application

C: Ceiling Mount PSC Motor

D: Downflow PSC Motor

E: Multi-Position Variable Speed Motor

R: Multi-Position PSC Motor

W: Wall Mount PSC Motor

Cabinet Finish

U: Unpainted

P: Painted

N: Uncased

Expansion Device

F: Flowrater

Nominal Capacity Range @ 13 SEER

Multi-Position & Downflow Applications

3642: 3 - 3 1/2 tons

1830: 1 1/2 - 3 1/2 tons

1729: 1 1/2 - 2 1/2 Tons 10 SEER (for export systems)

Ceiling Mount & Wall Mount Applications

1805: Nominal Cooling Capacity

Electric Heat kw - 1 1/2 tons Cooling/5 kw Electric Heat

2405: Nominal Cooling Capacity

Electric Heat kw - 2 Tons Cooling/5 kw Electric Heat

3608: Nominal Cooling Capacity

Electric Heat kw - 3 Tons Cooling/8 kw Electric Heat

Minor Revision

: Initial Release

Major Revision

: Initial Release

Electrical

1: 208/230V, 1 Phase, 60 Hz

15

Page 16

PRODUCT IDENTIFICATION

)

THIS NOMENCLATURE IS TO BE USED AFTER JULY 2006

A W U F 3642 1 6 A A

EXPANSION

PRODUCT

TYPE:

A: Air Handler

CABINET FINISH:

U: Unpainted

P: Painted

N: Uncased

APPLICATION

C: Ceiling Mount PSC Motor

D: Downflow PSC Motor

E: Multi-Position Varible Speed Motor

S: Energy-Efficient Motor

R: Multi-Position PSC Motor

T: Coated Coils

W: Wall Mount PSC Motor

DEVICE:

F: Flowrater

T: TXV

(Expansion

Device)

MINOR

REVISION*

MAJOR

REVISION*

REF RI GERAN T C HARGE :

No Digit: R-22 Only

6: R-410A or R-22

ELECTRICAL:

1: 208-2 30V/1ph/60 Hz

NOMINAL CAPACITY RANGE:

@ 13 SEER

Dedicated Application

3636: 3 Tons

Multi-Position & Downflow Applications

3 137: 3 Tons

3642: 3 - 3 1/2 Tons

1 830: 1 1/ 2 - 3 1/2 Tons

@10 SEER

1 729: 1 1/ 2 - 2 1/2 Tons (for export systems

All Airhandlers use DIRECT DRIVE MOTORS. Power supply is AC 208-230v, 60 hz, 1 phase.

16

Cei ling Mou nt & W all Mo unt Applic atio ns

(Nominal Cooling Capacity/Electric Heat kW)

1 803: 1 1/ 2 Tons Coo ling / 3 kW Electri c He at

1 805: 1 1/ 2 Tons Coo ling / 5 kW Electri c He at

2 405: 2 Tons Coo ling / 5 kW Electri c He at

3 608: 3 Tons Coo ling / 8 kW Electri c He at

3105: 1.5 - 2.5 To ns Cooling / 5kW Ele ctric Heat

3210: 2 - 2.5 Tons Cooling / 10kW Electric Heat

3 705: 3 Tons Coo ling / 5 kW Electri c He at

3 708: 3 Tons Coo ling / 8 kW Electri c He at

3 710 : 3 Tons Coo ling / 10 kW Electric Heat

Page 17

PRODUCT IDENTIFICATION

r

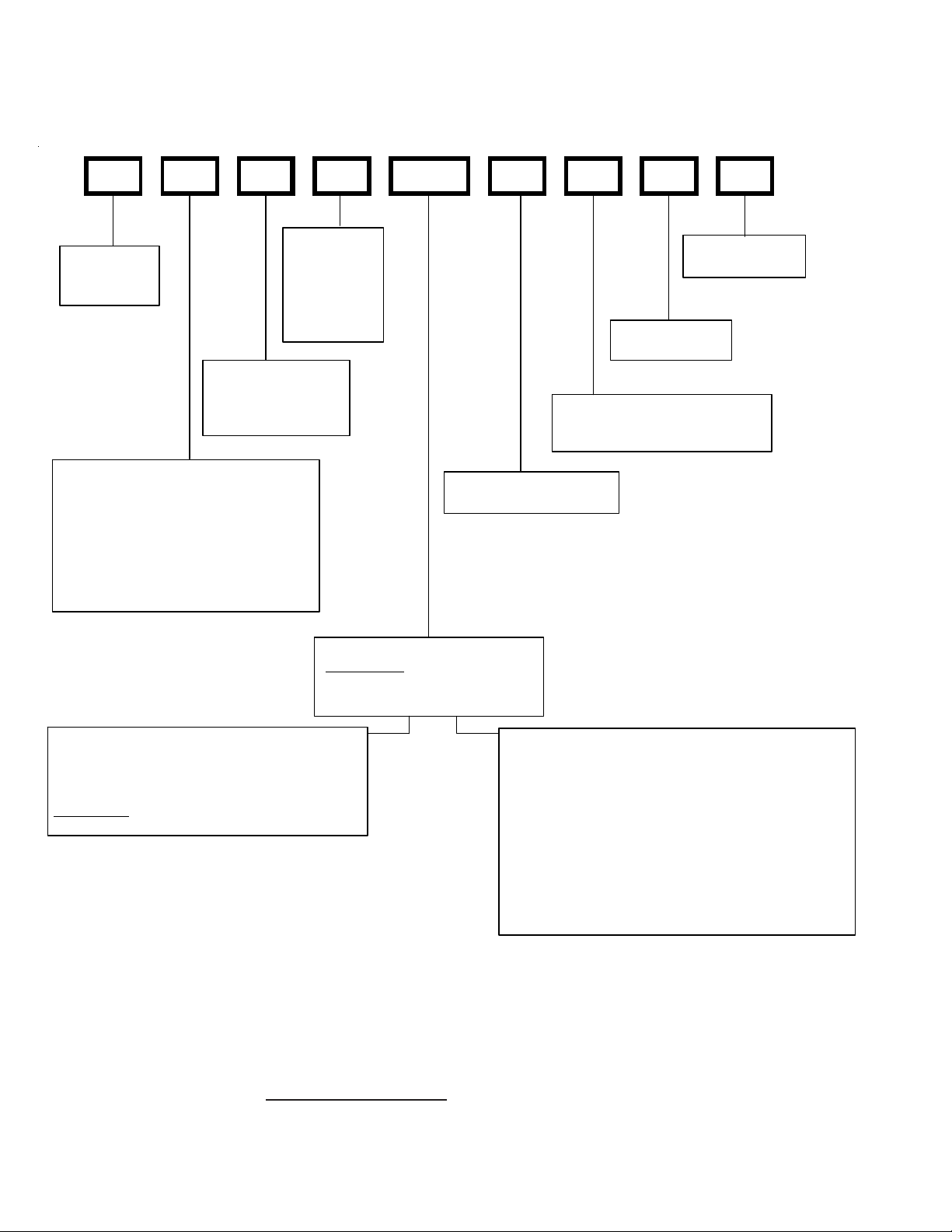

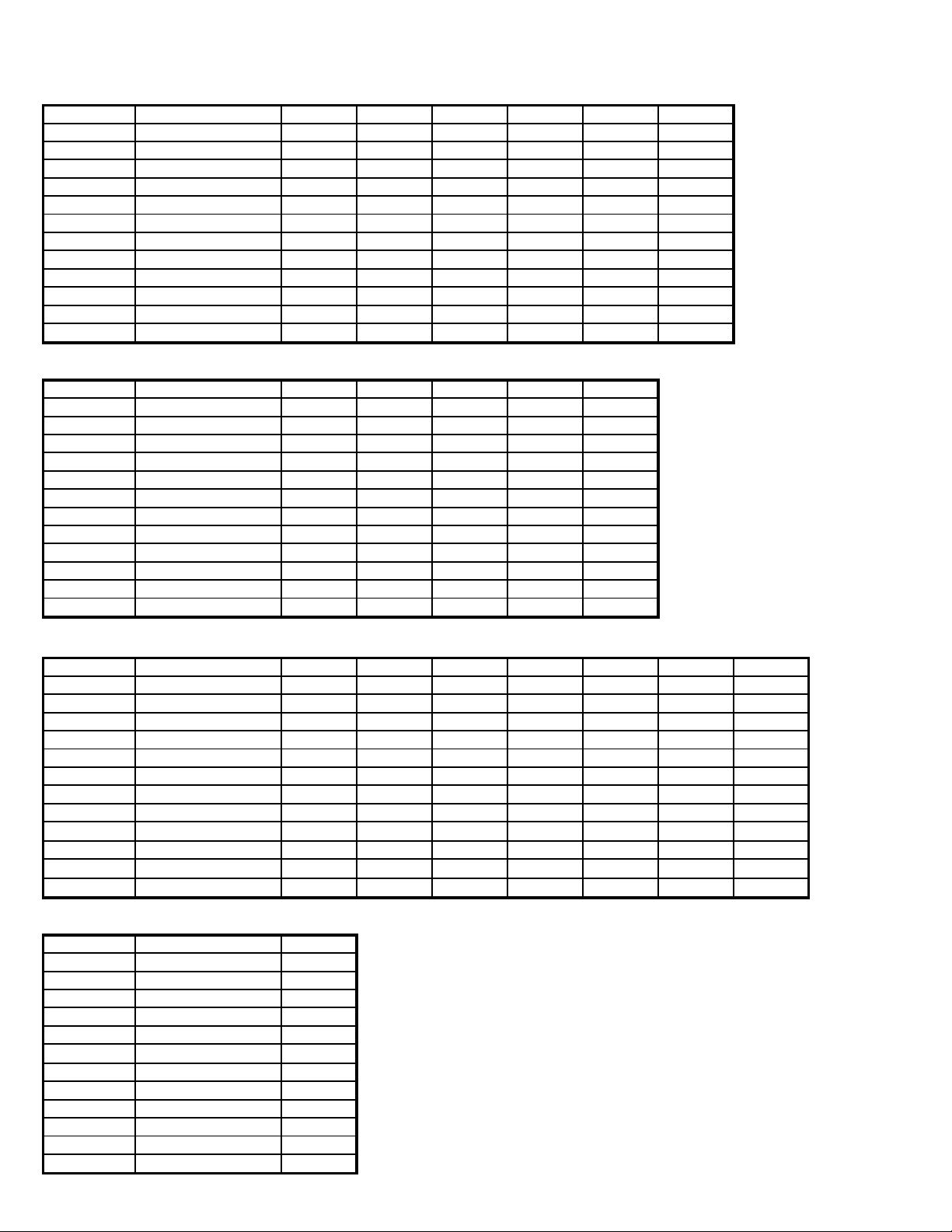

CAPF1824A6A

PRODUCT

TYPE:

C: Indoor Coil

APPLICATION

A: Upflow/Downflow Coil

H: Horizo ntal A Coil

S: Horizontal Slab Coil

T: Coated C oil

EXPANSION

DEVICE:

F: Flowrate

CABINET FINI SH:

U: Unpainted

P: Painted

N: Unpainted Case

NOMINAL CAPACITY RANGE

@ 13 SEER

1824: 1 1/2 to 2 Tons

3030: 2 1/2 Tons

3636: 3 Tons

3642: 3 to 3 1/2 Tons

3743: 3 to 3 1/2 Tons

4860: 4 & 5 Tons

4961: 4 & 5 Tons

REVISION

A: R evi s i on

REF RIGER AN T

CHARGE:

6: R-410A or R-22

2: R-22

4: R-410a

NOMINAL WIDTH FOR GAS FURNACE

A: Fits 14" Furnace Cabinet

B: F it s 17 1/ 2" Furnace Cabinet

C: Fits 21" Furnace Cabinet

D: Fits 24 1/2" Furnace Cabinet

N: Does Not Apply (Horizontal Slab Coils)

MB R 8 00 A A 1

ELECTRICAL SUPPLY:

DESIGN SERIES:

MB: Modular Bl ower

MOTO R TYPE:

R: Constant Speed

E: Variable Speed

AIRFLOW DELIVERED

08: 800 CFM

12: 1200 CFM

16: 1600 CFM

20: 2000 CFM

FACTORY HEAT

00: No Heat

CIRCUIT BREAKER

A: No Circuit Breaker

B: Ci rcuit Breaker

DESIGN SERIES

A: First Series

1: 208-230V/60hZ/1 ph

MODEL MFG. #

MBR0800 MBR0800

MBR1200 MBR1200

MBR1600 MBR1600

MBR2000 MBR2000

MBE1200 MBE1200

MBE1600 MBE1600

MBE2000 MBE2000

17

Page 18

ACCESSORIES

X X X

X X

p

6

X X X

p

Model

OT18 -60A

FSK01A*

AS C 01

TX 2N2 *

TX 3N2 *

TX 5N2 *

CSR-U-1

CSR-U-2

CSR-U-3

Model

OT18 -60A

FSK01A*

AS C 01

TX 2N2 *

TX 3N2 *

TX 5N2 *

CSR-U-1

CSR-U-2

CSR-U-3

Descripti on AS C130 18 ASC1 302 4 ASC13 030 ASC13036 ASC1304 2 ASC13048 ASC 13060

Outd oor Thermos ta t

Freeze Protection Kit

Anti Short Cycle Kit

TXV Kit

TXV Kit

TXV Kit

Hard Start Kit

Hard Start Kit

Hard Start Kit

Descri

Outd oor Thermos ta t

Freeze Protection Kit

Anti Short Cyc le K it

Hard Start Kit

Hard Start Kit

Hard Start Kit

tion G/VSC13018G/VSC13024G/V SC13030 G/VS C1303

TXV Kit

TXV Kit

TXV Kit

--- --- --- --- - -- --- ---

X

X

X

X

X

X

X

X

--- --- --- --- --- ---

X

X

xxxx---------

--- --- --- ---

X

--- --- ---

X

X

X

X

--- --- ---

--- --- --- --- - --

X

X

X

X

X

X

X

X

--- --- --- ---

X

X

X

X

X

X

X

--- --- ---

X

X

xxxx

--- --- --- ---

--- --- ---

X

X

--- --- --- ---

Model

OT18 -60A

FSK01A*

AS C 01

TX 2N2 *

TX 3N2 *

TX 5N2 *

CSR-U-1

CSR-U-2

CSR-U-3

Model

FSK01A*

AS C 01

OT/EHR18-60

*Installed on indoor coil.

Description G/VSC13042 G/VSC13048 G/VSC13060

Outd oor Thermos ta t

Freeze Protection Kit

Anti Short Cyc le K it

TXV Kit

TXV Kit

TXV Kit

Hard Start Kit

Hard Start Kit

Hard Start Kit

Descri

Freeze Protection Kit

Anti Short Cyc le K it

Emergency Heat relay kit

tion

--- --- ---

X

X

X

X

X

X

--- --- ---

--- --- ---

X

X

X

--- --- ---

X

---

GSC100903 GSC100904 GSC101203 GSC101204

X

X

X

X

xxxx

xxxx

--- --- --- ---

18

Page 19

ACCESSORIES

X X X

X X

X X

X X X

X X

X X

Model

AF E 18 -6 0 A

OT18-60A

FSK01A*

AS C 01

TX 2N2*

TX 3N2*

TX 5N2*

OT18-60A

OT/EHR18 -60

CSR-U-1

CSR-U-2

CSR-U-3

Model

AF E 18 -6 0 A

OT18-60A

FSK01A*

AS C 01

TX 2N2*

TX 3N2*

TX 5N2*

OT18-60A

OT/EHR18 -60

CSR-U-1

CSR-U-2

CSR-U-3

Description G/VSH13018 G/VSH13024 G/VSH13030 G/VSH13036 G/VSH13042 G/VSH13048 G/VSH13060

All Fuel Kit

Ou tdoor Th ermo sta t

Freeze Protection Kit

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Anti Short Cycle Kit X X X X X X X

TXV Kit

TXV Kit

x --- --- --- --- --- --x X

X

X

--- --- ---

TXV Kit --- --- --- --- X X X

Outdoor Lockout Stat

Emergency Heat relay kit

Hard Start Kit

Hard Start Kit

Hard Start Kit

Description ASH13018 ASH13024 ASH13030 ASH13036 ASH13042 ASH13048 ASH13060

All Fuel Kit

Ou tdoor Th ermo sta t

Freeze Protection Kit

Anti S hort Cycle K it

TXV Kit

X X X X X X X

X

X

X

X

X

X

X

X

X

X

--- --- ---

--- --- --- X

--- --- --- --- - --

X

X X X X X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

x --- --- --- --- --- ---

X

X

X

X

X

X

TXV Kit x X X X - -- --- ---

TXV Kit

Outdoor Lockout Stat X X X X X X X

Emergency Heat relay kit

Hard Start Kit

Hard Start Kit

Hard Start Kit

--- --- --- ---

X

X

X X X X X X X

X

--- --- ---

--- --- --- --- - --

X

X

X

X

--- --- ---

X

X

X

X

Model Description GSH100903 GSH100904 GSH101203 GSH101204

FSK01A*

AS C 01

OT/EHR18 -60

*Installed on indoor coil.

Freeze Protection Kit

Anti Short Cycle Kit xxxx

Emergency Heat relay kit

xxxx

--- --- --- ---

19

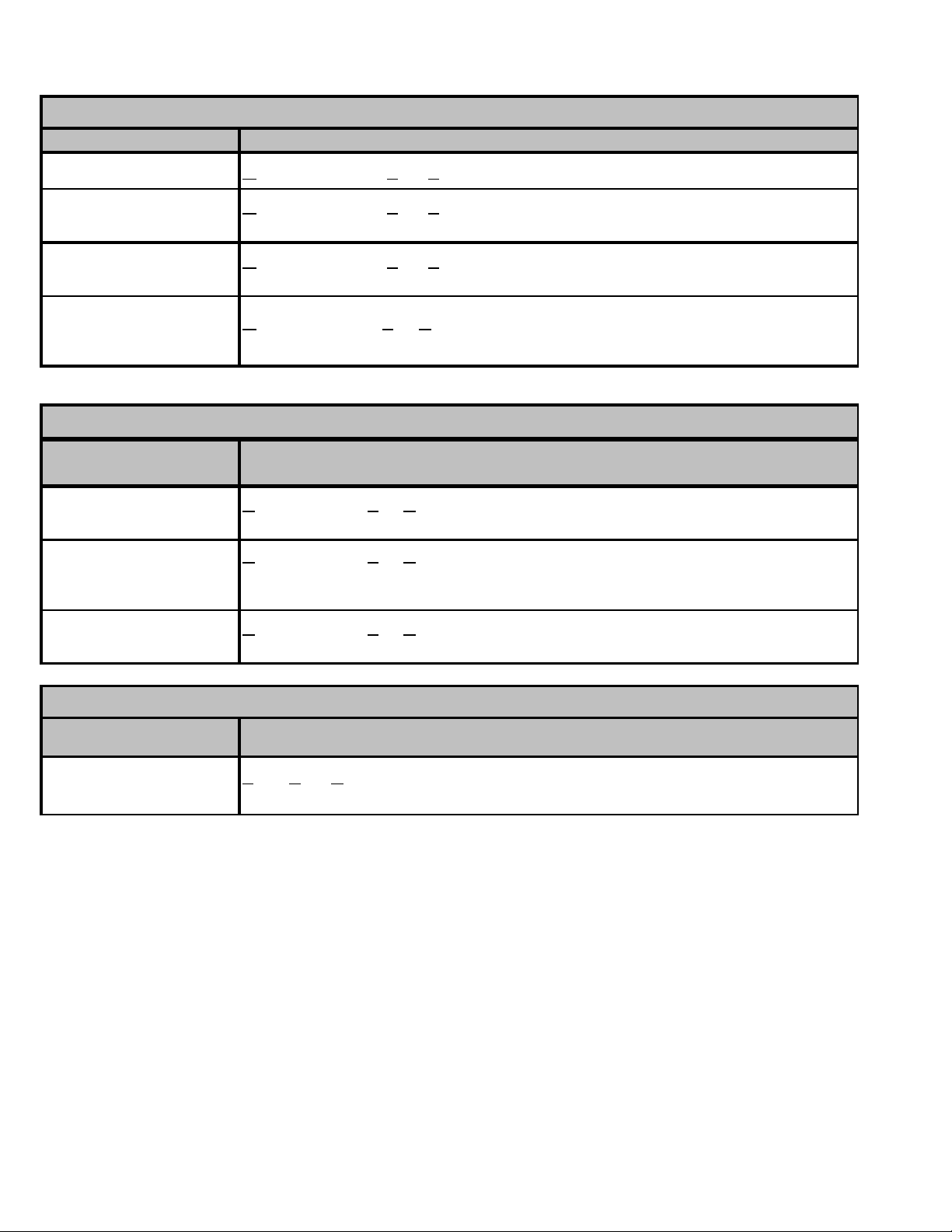

Page 20

ACCESSORIES

Model

AFE18-60A

OT18-60A

FSK01A*

ASC0 1

TX2N2*

TX3N2*

TX5N2*

OT18-60A Outdoor Lockout Stat

OT/EHR18-60

CSR-U-1 Hard Start Kit

CSR-U-2

CSR-U-3 Hard Start Kit

Model

AFE18-60A

OT18-60A

FSK01A* Freeze Protection Kit

ASC0 1

TX2N2*

TX3N2*

TX5N2*

OT18-60A

OT/EHR18-60

CSR-U-1

CSR-U-2

CSR-U-3

Description

All Fuel Kit

Outdoor Thermostat

Freeze Protection Kit

Anti Short Cycle Kit

TXV Kit

TXV Kit

TXV Kit

Emergency Heat relay kit

Hard Start Kit

Description

All Fuel Kit

Outdoor Thermostat

Anti Short Cycle Kit

TXV Kit

TXV Kit

TXV Kit

Outdoor Lockout Stat

Emergency Heat relay kit

Hard Start Kit

Hard Start Kit

Hard Start Kit

CPKF24 CPKF36 CPKF42 CPKF48 CPKF60 CPKF61

xxxxxx

xxxxxx

xxxxxx

xxxxxx

--- --- --- --- --- --x x --- --- --- ---

--- ---

xxxx

xxxxxx

xxxxxx

x x --- --- --- ---

---xxxxx

--- --- --- x x x

CKF24 CKF36 CKF48 CKF60 CKF70

--- --- --- --- ---

--- --- --- --- --xxxxx

xxxxx

--- --- --- --- --x x --- --- ---

--- ---

xx

---

--- --- --- --- ---

--- --- --- --- --x x --- --- ---

--- x x x ---

--- --- x x ---

Model

AFE18-60A

OT18-60A

FSK01A*

ASC0 1

TX2N2*

TX3N2*

TX5N2*

OT18-60A

OT/EHR18-60

CSR-U-1

CSR-U-2

CSR-U-3

Model

AFE18-60A

OT18-60A

FSK01A*

ASC0 1

TX2N2*

TX3N2*

TX5N2*

OT18-60A

OT/EHR18-60

CSR-U-1

CSR-U-2

CSR-U-3

Description

Outdoor Thermostat

Freeze Protection Kit

Anti Short Cycle Kit

TXV Kit

TXV Kit

Outdoor Lockout Stat

Emergency Heat relay kit

Hard Start Kit

Hard Start Kit

Hard Start Kit

Description

Outdoor Thermostat

Freeze Protection Kit

Anti Short Cycle Kit

TXV Kit

Outdoor Lockout Stat

Emergency Heat relay kit

Hard Start Kit

Hard Start Kit

Hard Start Kit

20

All Fuel Kit

TXV Kit

All Fuel Kit

TXV Kit

TXV Kit

CKL18 CKL24 CKL30 CKL36 CKL42 CKL49 CKL60

--- --- --- --- --- --- ---

--- --- --- --- --- --- --xxxxxxx

xxxxxxx

x --- --- --- --- --- --xxxx---------

--- --- --- --- x x x

--- --- --- --- --- --- ---

--- --- --- --- --- --- --xxxx---------

--- --- --- x x x x

--- --- --- --- --- x x

CE120

---

--x

x

---

---

---

---

---

---

---

---

Page 21

ACCESSORIES

A

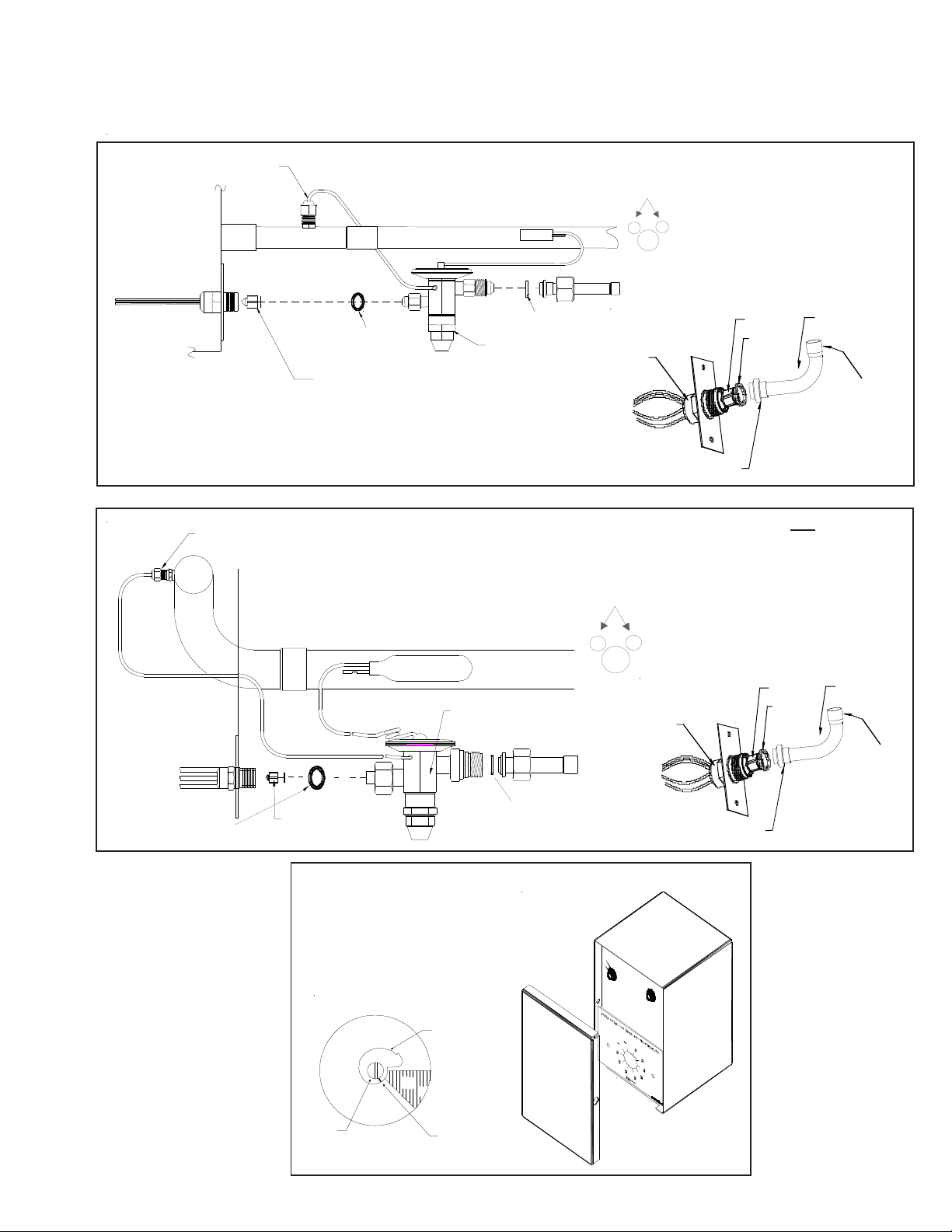

EXPANSION VALVE KITS

1/4 FLARE CONNECTION

BULB TO BE LOCATED

AT 10 OR 2 O'CLOCK

For Applications requiring

a field installed access fitting

EVAPORATOR COIL

EVAPORATOR COIL

1/4' F LARE

CONNECTION

SEAL SUPPLIED W/ KIT

REMOVE BEFORE INSTALLING EXPANSION VALVE

SUCTION LINE

BULB

EXPANSION VALVE

SUCTION LINE

EXPANSION VALVE

BULB

SEAL SUPPLIED W/ KIT

BULB TO BE LOCATED

AT 10 OR 2 O'CLOCK

DISTRIBUTOR

BODY

For Applications not requiring

a field installed access fitting

DISTRIBUTOR

BODY

7/8" NUT

PISTON

SEAL

PISTON

SEAL

TAILPIECE

3/8"SWEAT

TAILPIECE

3/8"SWEAT

SEAL SUPPLIED W/ KIT

7/8" NUT

SEAL SUPPLIED W/ KIT

REMOVE BEFORE

INSTALLING

EXPANSION VALVE

OT/EHR18-60

OUTDOOR THERMOSTAT &

EMERGENCY HEAT RELAY

OT18-60

Thermo sta t

DEAD

DIAL

45º

Dial

COLD

WARM

Set Point

Indicator

Mark

(Shown @ Oº F)

(Turn Clockwise)

(Turn Counterclockwise)

21

315º

Set Point

djustmen t

Screw

Page 22

ACCESSORIES

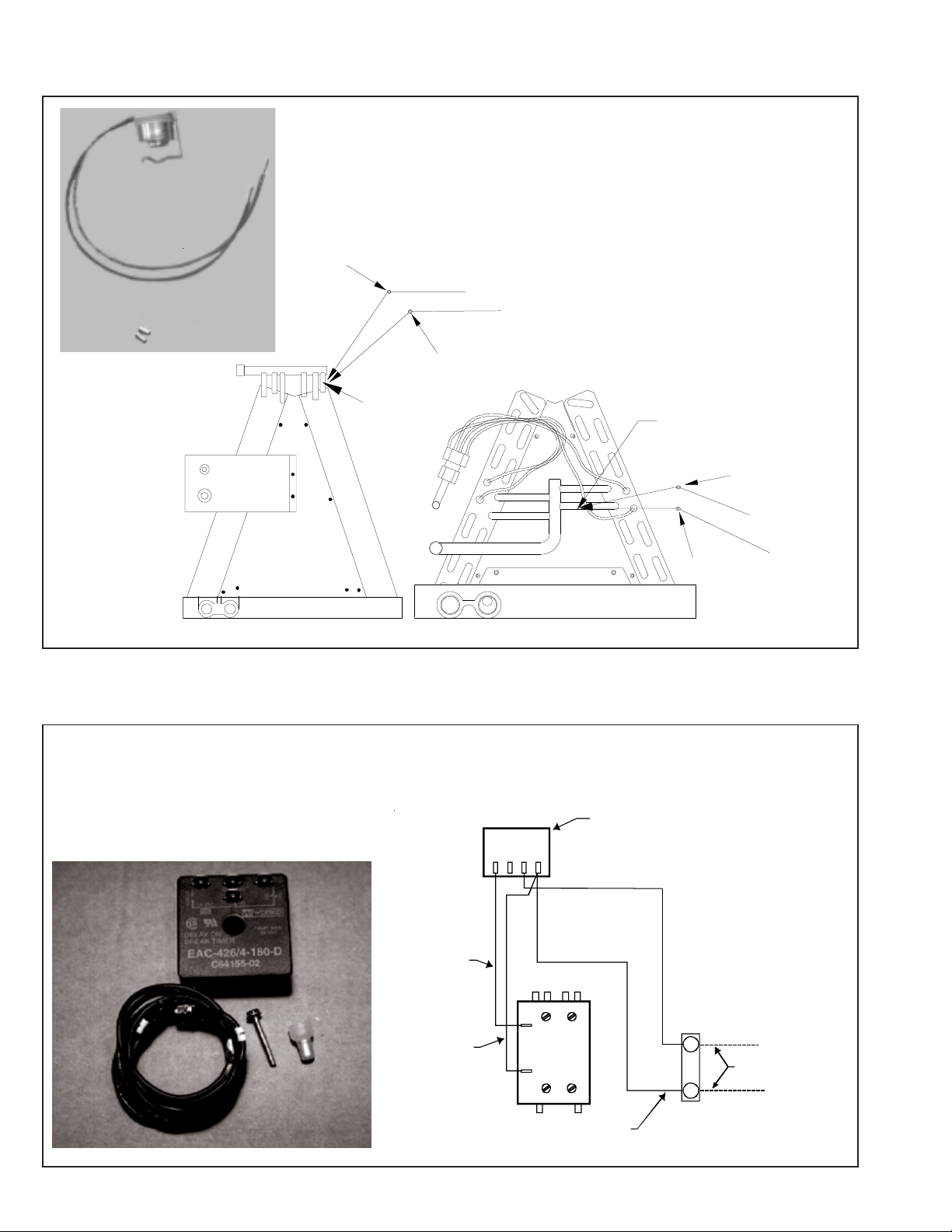

Y

Wire Nut

FSK01A

FREEZE THERMOSTAT

KIT

Y

k

c

a

l

B

k

c

a

l

B

Wire Nut

Y

Install Line

Thermostat

Here

ASC01A

ANTI-SHORT -CYCLE CONTROL KIT

SHORT CYCLE

Y1Y2R1

R2

PROTECTOR

Install Line

Thermostat

Here

B

l

a

c

B

l

Wire Nut

Wire Nut

Y

k

a

c

k

Y

ELLOW 1

CONTACTOR

BLACK 1

T2 T1

L2

L1

BLACK 1

Y

THERMOSTAT

WIRE

C

UNIT

TERMINAL

BOARD

22

Page 23

ACCESSORIES

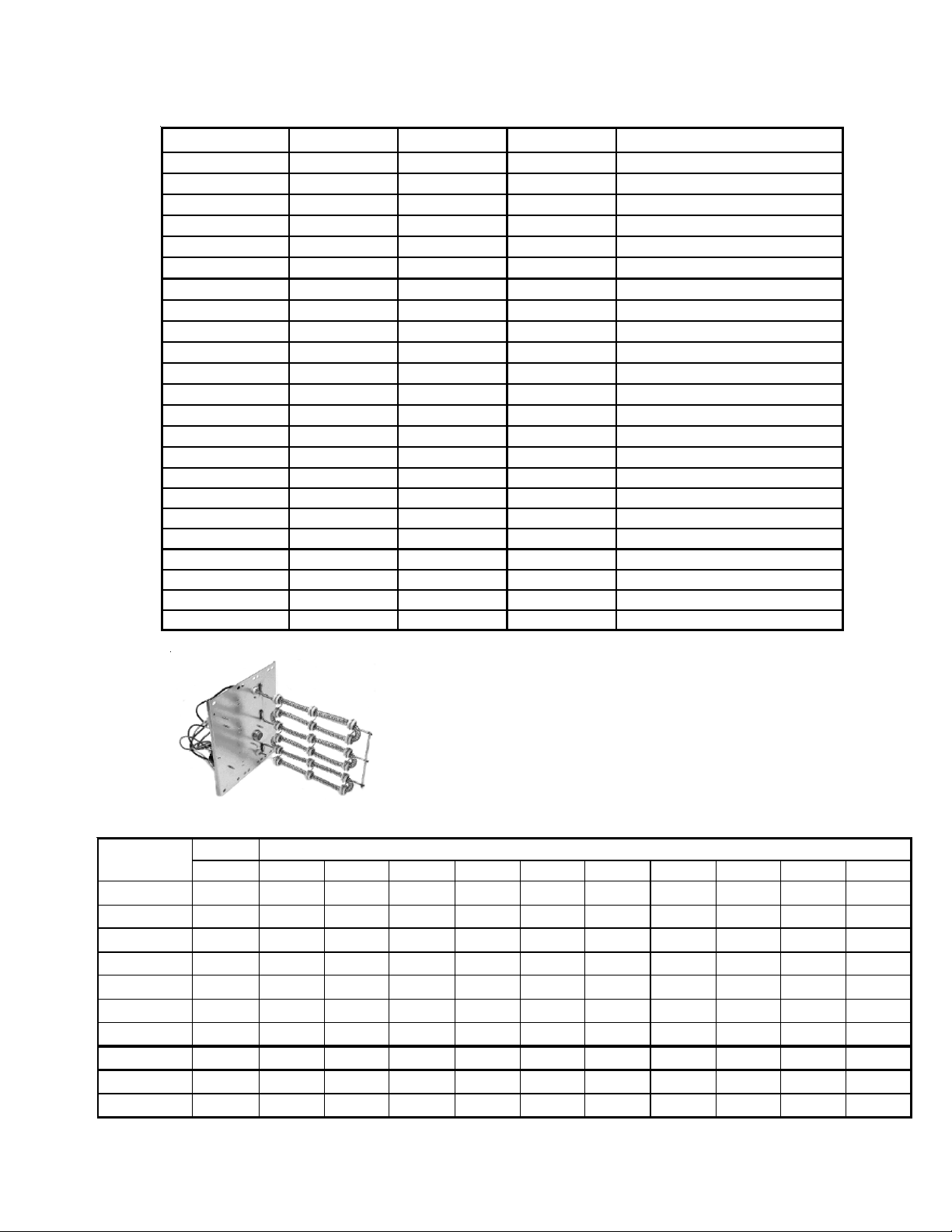

COIL MODEL TX2N2 TXV KIT TX3N2 TXV KIT TX5N2 TXV KIT FSK01A FREEZE PROTECTION KIT

CA*F030B4* --- X --- X

CA*F036B4* --- X --- X

CA*F042C4* --- --- X X

CA*F048C4* --- --- X X

CA*F057D4* --- --- X X

CA*F060D4* --- --- X X

CHPF030A4* --- X --- X

CHPF036B4* --- X --- X

CHPF042A4* --- --- X X

CHPF048D4* --- --- X X

CHPF060D4* --- --- X X

CH36FCB --- X --- X

CH48FCB --- --- X X

CH60FCB --- --- X X

CA*F18246* X X --- X

CA*F30306* --- X --- X

CA*F36426* --- X X X

CHPF18246* X --- X X

CHPF30306* --- --- X X

CHPF36426* --- --- X X

CSCF1824N6* X --- --- X

CSCF303N6* --- X --- X

CSCF3642N6* --- X X X

COIL ACCESSORIES

HKR SERIES ELECTRIC HEAT KITS

ELECTRIC HEAT KIT APPLICATIONS

MBR & MBE

BLOWER

MBR0800AA-1AA - X X X X X

MBR1200AA-1AA- X XXXXXXXXX

MBR1600AA-1AA- X XXXXXXXXX

MBR2000AA-1AA- X XXXXXXXXX

MBE1200AA-1AA - - - - X X X - - - -

MBE1600AA-1AA - - - - - X X - - - -

MBE2000AA-1AA - - - - - X X X - - -

MBE1200AA-1BA - X X X X X X - - - -

MBE1600AA-1BA - X X X X X X - - - -

MBE2000AA-1BA - X X X X X X X - - -

X = Allowable combination s ^ = Circuit 1: Single Phas e for Air Handl er Motor * = Revision lev el that my or may not b e designated

- = Restric ted combinati ons Circuit 2: 3-Phase for HKR3 Heater Kits C = Ci rcuit Breaker option

NO HEAT HKR-03* HKR05-(C)' HKR-06* HKR-08(C)* HKR-10(C)* HKR-15(C)* HKR-20(C)* HKR-21( C)* ^HKR3-15* ^HKR3-20A

ELECTRIC HEAT KIT

23

Page 24

PRODUCT DESIGN

This section gives a basic description of cooling unit operation, its various components and their basic operation. Ensure your system is properly sized for heat gain and loss

according to methods of the Air Conditioning Contractors

Association (ACCA) or equivalent.

CONDENSING UNIT

These units are designed for free air discharge. Condensed

air is pulled through the condenser coil by a direct drive

propeller fan and then discharged from the cabinet top. The

unit requires no additional resistance (i.e. duct work) and

should not be added.

The GSH13, GSH14, ASH13 and VSH13 Heat Pump condensing units are designed for 208-230 dual voltage single

phase applications. The GSH13 3 ton model is available in

230V, 3 phase applications. The GSH13 4 and 5 ton models

are available for 230V, 3-phase and 460V, 3-phase applications.

The units range in size from 1.5 to 5-ton and have a rating of

13 and 14 SEER. SEER efficiency is dependent upon the unit

and its components. Refer to the "Technical Information"

manual of the unit you are servicing for further details.

The GSC13, GSC14 and ASC13 and VSC13 Condensing

Units are made in 1.5 through 5 ton sizes. They are designed

for 208-240 volt single phase applications. The GSC13 3 ton

model is available in 230V, 3 phase applications. The GSC13

4 and 5 ton models are available for 230V, 3-phase and 460V,

3-phase applications.

Suction and Liquid Line Connections

All units come equipped with suction and liquid valves designed

for connection to refrigerant-type copper. Front seating valves

are factory-installed to accept the field-run copper. The total

refrigerant charge needed for a normal operation is also

factory-installed. For additional refrigerant line set information,

refer to the "Technical Information" manual of the unit you are

servicing.

Compressors

GSC13, VSC13, GSH13 and VSH13 use a mix of reciprocating and scroll compressors, except for the VSC130181AA/BA

which uses a rotary compressor. The ASC13 and ASH13 use

the Copeland Scroll® Compressor. There are a number of

design characteristics which differentiate the scroll compressor from the reciprocating compressor. One is the scroll.

A scroll is an involute spiral which, when matched with a

mating scroll form, generates a series of crescent-shaped gas

pockets between the members (see following illustration).

During compression, one scroll remains stationary while the

other form orbits. This motion causes the resulting gas pocket

to compress and push toward the center of the scrolls. When

the center is reached, the gas is discharged out a port located

at the compressor center.

GSC130361D* and GSC130481AG use Bristol® BENCHMARK™ compressors, the most advanced compressors in

the industry today. The BENCHMARK™ reciprocating compressor can be recognized by a “J” in the fourth character of the

compressor model number. Innovative mechanical design and

gas management make the BENCHMARK™ compressor very

efficient and remarkably quiet. The sound content (frequency)

delivers exceptional acoustical characteristics and the virtually round housing design is compact and also helps to reduce

the overall sound and vibration.

GSC130181BA and GSC130181CA use Panasonic® rotary

compressors.

COILS AND BLOWER COILS

MBR/MBE blower cabinets are designed to be used as a twopiece blower and coil combination. MBR/MBE blower sections

can be attached to cased evaporator coil. This two-piece

arrangement allows for a variety of mix-matching possibilities

providing greater flexibility. The MBE blower cabinet uses a

variable speed motor that maintains a constant airflow with a

higher duct static.

It is approved for applications with cooling coils of up to 0.8

inches W.C. external static pressure and includes a feature

that allows airflow to be changed by +15%. The MBR blower

cabinet uses a PSC motor. It is approved for applications with

cooling coils of up to 0.5 inches W.C. external static pressure.

24

Page 25

PRODUCT DESIGN

The MBR/MBE blower cabinets with proper coil matches can

be positioned for upflow, counterflow, horizontal right or

horizontal left operation. All units are constructed with R-4.2

insulation. In areas of extreme humidity (greater than 80%

consistently), insulate the exterior of the blower with insulation having a vapor barrier equivalent to ductwork insulation,

providing local codes permit.

The CAPX/CHPX coils are equipped with a thermostatic

expansion valve that has a built-in internal check valve for

refrigerant metering. The CACF/CAPF/CHPF coils are

equipped with a fixed restrictor orifice.

The coils are designed for upflow, counterflow or horizontal

application, using two-speed direct drive motors on the

CACF/CAPF/CHPX models and BPM (Brushless Permanent Magnet) or ECM motors on the MBE models.

The ARUF is a multi-position air handler (upflow/horizontal

or downflow) and is equipped with a flowrator for cooling and

heat pump applications. Because of its seamless copper

tubing and aluminum fins, there are fewer leaks. The steel

cabinet of the ARUF is fully insulated and rust resistant.

Thermal expansion kits for air conditioning and heat pump

applications are available.

ARPF*B 2 to 5 ton air handlers are dedicated for downflow

operation and are approved for modular homes. Flowrater.

transformer and blower time delay are on all standard ARPF

units. Both the ARUF and ARPF have direct-drive multispeed motors.

AEPF is a multi-position, variable-speed air handler and can

be used with R-410A or R-22 (models ending in 1/16). The

unit's blower design includes a variable-speed DC motor and

is compatible with heat pumps and variable-capacity cooling

applications.

ASPF is a multi-position air handler that can be used with R410A or R-22 and it features a X-13 motor. This motor is a

constant torque motor with very low power consumption and

it is energized by a 24V signal. The X-13 features an

integrated control module and is compatible with heat pumps

and cooling applications.

25

Page 26

SYSTEM OPERATION

COOLING

The refrigerant used in the system is R-22. It is a clear,

colorless, non-toxic, non-irritating, and non-explosive liquid.

The chemical formula is CHCLF

atmospheric pressure is -41.4°F.

A few of the important principles that make the refrigeration

cycle possible are: heat always flows from a warmer to a

cooler body, under lower pressure a refrigerant will absorb

heat and vaporize at a low temperature, the vapors may be

drawn off and condensed at a higher pressure and temperature to be used again.

The indoor evaporator coil functions to cool and dehumidify

the air conditioned spaces through the evaporative process

taking place within the coil tubes.

NOTE: The pressures and temperatures shown in the

refrigerant cycle illustrations on the following pages are for

demonstration purposes only. Actual temperatures and pressures are to be obtained from the "Expanded Performance

Chart."

Liquid refrigerant at condensing pressure and temperatures,

(270 psig and 122°F), leaves the outdoor condensing coil

through the drier and is metered into the indoor coil through

the metering device. As the cool, low pressure, saturated

refrigerant enters the tubes of the indoor coil, a portion of the

liquid immediately vaporizes. It continues to soak up heat and

vaporizes as it proceeds through the coil, cooling the indoor

coil down to about 48°F.

Heat is continually being transferred to the cool fins and tubes

of the indoor evaporator coil by the warm system air. This

warming process causes the refrigerant to boil. The heat

removed from the air is carried off by the vapor.

As the vapor passes through the last tubes of the coil, it

becomes superheated, that is, it absorbs more heat than is

necessary to vaporize it. This is assurance that only dry gas

will reach the compressor. Liquid reaching the compressor

can weaken or break compressor valves.

The compressor increases the pressure of the gas, thus

adding more heat, and discharges hot, high pressure superheated gas into the outdoor condenser coil.

In the condenser coil, the hot refrigerant gas, being warmer

than the outdoor air, first loses its superheat by heat transferred from the gas through the tubes and fins of the coil. The

refrigerant now becomes saturated, part liquid, part vapor and

then continues to give up heat until it condenses to a liquid

alone. Once the vapor is fully liquefied, it continues to give up

heat which subcools the liquid, and it is ready to repeat the

cycle.

. The boiling point, at

2

HEATING

The heating portion of the refrigeration cycle is similar to the

cooling cycle. By energizing the reversing valve solenoid coil,

the flow of the refrigerant is reversed. The indoor coil now

becomes the condenser coil, and the outdoor coil becomes

the evaporator coil.

The check valve at the indoor coil will open by the flow of

refrigerant letting the now condensed liquid refrigerant bypass the indoor expansion device. The check valve at the

outdoor coil will be forced closed by the refrigerant flow,

thereby utilizing the outdoor expansion device.

The restrictor orifice used with the CA*F, CHPF coils and the

AR*F air handler will be forced onto a seat when running in

the cooling cycle, only allowing liquid refrigerant to pass

through the orifice opening. In the heating cycle it will be

forced off the seat allowing liquid to flow around the restrictor.

A check valve is not required in this circuit.

COOLING CYCLE

When the contacts of the room thermostat close making

terminals R to Y & G, the low voltage circuit of the transformer

is completed. Current now flows through the magnetic holding coils of the compressor contactor (CC) and fan relay

(RFC).

This draws in the normally open contact CC, starting the

compressor and condenser fan motors. At the same time

contacts RFC close starting the indoor fan motor.

When the thermostat is satisfied, it opens its contacts,

breaking the low voltage circuit, causing the compressor

contactor and indoor fan relay to open, shutting down the

system.

If the room thermostat fan selector switch should be set on

the "on" position, then the indoor blower would run continuous

rather than cycling with the compressor.

Heat pumps energize the reversing valve thorough the "O"

circuit in the room thermostat. Therefore the reversing valve

remains energized as long as the thermostat subbase is in

the cooling position. The only exception to this is during

defrost.

26

Page 27

SYSTEM OPERATION

DEFROST CYCLE

The defrosting of the outdoor coil is jointly controlled by the

defrost timing board, defrost (30/60) control, and compressor

run time.

Solid State Defrost Control

During operation the power to the circuit board is controlled

by a temperature sensor, which is clamped to a return bend

(3/8" coils) or a feeder tube (5 mm coils) entering the outdoor

coil. Defrost timing periods of 30, 60, or 90 minutes may be

selected by connecting the circuit board jumper to 30, 60, or

90 respectively. Accumulation of time for the timing period

selected starts when the sensor closes (approximately 31°

F), and when the room thermostat calls for heat. At the end

of the timing period, the unit’s defrost cycle will be initiated

provided the sensor remains closed. When the sensor opens

(approximately 75° F), the defrost cycle is terminated and the

timing period is reset. If the defrost cycle is not terminated

due to the sensor temperature, a ten minute override interrupts the unit’s defrost period. The new upgraded defrost

control has a 12 minute override interrupt.

DF2

90

60

30

W2 DFT

DF1

HEATING CYCLE

The reversing valve on the heat pump models is energized in

the cooling cycle through the "O" terminal on the room

thermostat.

These models have a 24 volt reversing valve coil. When the

thermostat selector switch is set in the cooling position, the

"O" terminal on the thermostat is energized all the time.

Care must be taken when selecting a room thermostat. Refer

to the installation instructions shipped with the product for

approved thermostats.

27

Page 28

SYSTEM OPERATION

COOLING CYCLE

Reversing Valve

(Energized)

Indoor

Coil

HEATING CYCLE

Outdoor

Coil

Accumulator

Thermostatic

Expansion

Valve

Bi-Flow

Filter Dryer

Check Valve

28

Indoor

Coil

Reversing Valve

(De-Energized)

Outdoor

Coil

Accumulator

Thermostatic

Expansion

Valve

Bi-Flow

Filter Dryer

Check Valve

Page 29

SYSTEM OPERATION

EXPANSION VALVE/CHECK VALVE ASSEMBLY

IN COOLING OPERATION

Most expansion valves used in current Amana

use an internally checked expansion valve.

This type of expansion valve does not require an external check valve as shown above.

However, the principle of operation is the same.

RESTRICTOR ORIFICE ASSEMBLY

IN COOLING OPERATION

EXPANSION VALVE/CHECK VALVE ASSEMBLY

IN HEATING OPERATION

®

Brand Heat Pump products

RESTRICTOR ORIFICE ASSEMBLY

IN HEATING OPERATION

In the cooling mode, the orifice is pushed into its

seat, forcing refrigerant to flow through the metered

hole in the center of the orifice.

In the heating mode, the orifice moves back off its

seat, allowing refrigerant to flow unmetered around

the outside of the orifice.

29

Page 30

SYSTEM OPERATION

COOLING CYCLE - CONDENSING UNIT

Indoor

Coil

Outdoor

Coil

Thermostatic

Expansion

Valve

30

In the cooling mode, the orifice is pushed into its

seat, forcing refrigerant to flow through the metered

hole in the center of the orifice.

Page 31

SYSTEM OPERATION

AFE18-60A CONTROL BOARD

DESCRIPTION

The AFE18 control is designed for use in heat pump applications where the indoor coil is located above/downstream of a

gas or fossil fuel furnace. It will operate with single and two

stage heat pumps and single and two stage furnaces. The

AFE18 control will turn the heat pump unit off when the

furnace is turned on. An anti-short cycle feature is also

incorporated which initiates a 3 minute timed off delay when

the compressor goes off. On initial power up or loss and

restoration of power, this 3 minute timed off delay will be

initiated. The compressor won’t be allowed to restart until the

3 minute off delay has expired. Also included is a 5 second

de-bounce feature on the “Y, E, W1 and O” thermostat inputs.

These thermostat inputs must be present for 5 seconds

before the AFE18 control will respond to it.

An optional outdoor thermostat, OT18-60A, can be used with

the AFE18 to switch from heat pump operation to furnace

operation below a specific ambient temperature setting, i.e.

break even temperature during heating. When used in this

manner, the “Y” heat demand is switched to the “W1” input

to the furnace by the outdoor thermostat and the furnace is

used to satisfy the first stage “Y” heat demand. On some

controls, if the outdoor thermostat fails closed in this position

during the heating season, it will turn on the furnace during

the cooling season on a “Y” cooling demand. In this

situation, the furnace produces heat and increases the

indoor temperature thereby never satisfying the cooling

demand. The furnace will continue to operate and can only

be stopped by switching the thermostat to the off position or

removing power to the unit and then replacing the outdoor

thermostat. When the AFE18 receives a “Y” and “O”

input from the indoor thermostat, it recognizes this as a

cooling demand in the cooling mode. If the outdoor thermostat is stuck in the closed position switching the “Y” demand

to the “W1” furnace input during the cooling mode as

described above, the AFE18 won’t allow the furnace to

operate. The outdoor thermostat will have to be replaced to

restore the unit to normal operation.

HIGH VOLTAGE!

Disconnect ALL power before servicing

or installing. Multiple power sources

may be present. Failure to do so may

cause property damage, personal injury

or death.

31

Page 32

TROUBLESHOOTING CHART

COOLING/HP ANALYSIS CHART

Complaint

POSSIBLE CAUSE

DOTS IN ANAL YSI S

GUIDE INDICATE

"POSSIBLE CAUSE"

Power Failure

Blown Fuse

Unbalanced Power, 3PH

Loose Connection

Shorted or Broken Wires

Open Fan Overload

Faulty Thermostat

Faulty Transformer

Shorted or Open Capacitor

Internal Compressor Overload Open

Shorted or Grounded Compressor

Compressor Stuck

Faulty Compressor Contactor

Faulty Fan Relay

Open Control Circuit

Low Voltage

Faulty Evap. Fan Motor

Shorted or Grounded Fan Motor

Improper Cooling Anticipator

Shortage of Refrigerant

Restricted Liquid Line

Open Element or Limit on Elec. Heater

Dirty Air Filter

Dirty Indoor Coil

Not enough air across Indoor Coil

Too much air across Indoor Coil

Overcharge of Refrigerant

Dirty Outdoor Coil

Noncondensibles

Recirculation of Condensing Air

Infiltration of Outdoor Air

Improperly Located Thermostat

Air Flow Unbalanced

System Undersized

Broken Internal Parts

Broken Valves

Inefficient Compressor

Wrong Type Expansion Valve

Expansion Device Restricted

Oversized Expansion Valve

Undersized Expansion Valve

Expansion Valve Bulb Loose

Inoperative Expansion Valve

Loose Hold-down Bolts

Faulty Reversing Valve

Faulty Defrost Control

Faulty Defrost Thermostat

Flowrator Not Seating Properly

No Cooling Unsatisfactory Cooling/Heating

SYMPTOM

System will not start

Compressor will not start - fan runs

Comp. and Cond. Fan will not start

Evaporator fan will not start

Condenser fan will not start

Compressor runs - goes off on overload

Compressor cycles on overload

System runs continuously - little cooling/htg

Too cool and then too warm

Not cool enough on warm days

•

•••

•••

•••

••••••

••

••• •

••

• ••••

•

••

•••

•••

•

•

•••

••

••

••

••

•• •• •

♦♦

••• •

••• •

••• •

•• •

•• •

••

•• •

•••

••

••

••

•• ••

•

••• • ••

••• • •• •

••

••• • •

•• •

•

•

•

Cooling or Heating Cycle (Heat Pump) ♦

•••

System

Operating

Pressures

Certain areas too cool, others too warm

Compressor is noisy

System runs - blows cold air in heating

Unit will not terminate defrost

Unit will not defrost

Low suction pressure

Low head pressure

High suction pressure

High head pressure

Test Voltage S-1

Inspect Fuse Size & Type S-1

Test Voltage S-1

Inspect Connection - Tighten S-2, S-3

Test Circuits With Ohmmeter S-2, S-3

Test Continuity of Overload S-17A

Test Continuity of Thermostat & W iring S-3

Check Control Circuit with Voltmeter S-4

Test Capacitor S-15

♦

♦

♦

♦

♦

♦

•

♦

••

♦

♦

••

••

•

♦♦♦ ♦♦♦

♦♦♦♦♦ ♦

♦♦♦♦♦♦♦

Heating Cycle Only (Heat Pump)

Test Continuity of Overload S-17A

Test Motor Windings S-17B

Use Test Cord S-17D

Test Continuity of Coil & Contacts S-7, S-8

Test Continuity of Coil And Contacts S-7

Test Control Circuit with Voltmeter S-4

Test Voltage S-1

Repair or Replace S-16

♦

Test Motor Windings S-16

Check Resistance of Anticipator S-3B

Test For Leaks, Add Refrigerant S-101,103

Remove Restriction, Replace Restricted Part S-112

Test Heater Element and Controls S-26,S-27

Inspect Filter-Clean or Replace

♦

Inspect Coil - Clean

♦

Check Blower Speed, Duct Static Press, Filter S-200

♦

Reduce Blower Speed S-200

•

Recover Part of Charge S-113

••

Inspect Coil - Clean

•

Recover Charge, Evacuate, Recharge S-114

•

Remove Obstruction to Air Flow

Check Windows, Doors, Vent Fans, Etc.

Relocate Thermostat

Readjust Air Volume Dampers

Refigure Cooling Load

Replace Compressor S-115

Test Compressor Efficiency S-104

Test Compressor Efficiency S-104

Replace Valve S-110

♦

Remove Restriction or Replace Expansion Device S-110

Replace Valve

Replace Valve

Tighten Bulb Bracket S-105

Check Valve Operation S-110

Tighten Bolts

Replace Valve or Solenoid S-21, 122

Test Control S-24

Test Defrost Thermostat S-25

Check Flowrator & Seat or Replace Flowrator S-111

Test Method

Remedy

See Service Procedure Ref.

32

Page 33

SERVICING

TABLE OF CONTENTS

S-1 Checking Voltage .......................................... 34

S-2 Checking Wiring ............................................ 34

S-3 Checking Thermostat, Wiring & Anticipator .. 34

S-3A Thermostat & Wiring ..................................... 34

S-3B Cooling Anticipator ........................................ 35

S-3C Heating Anticipator ........................................ 35

S-3D Checking Encoded Thermostats ................... 35

S-4 Checking Transformer & Control Circuit ....... 36

S-5 Checking Cycle Protector ............................. 36

S-6 Checking Time Delay Relay .......................... 36

S-7 Checking Contactor and/or Relays ................ 37

S-8 Checking Contactor Contacts ....................... 37

S-9 Checking Fan Relay Contact ........................ 37

S-10 Copeland Comfort™ Alert Diagnostics .......... 38

S-11 Checking Loss of Charge Protector ............... 40

S-15 Checking Capacitor ....................................... 40

S-15A Resistance Check ......................................... 40

S-15B Capacitance Check ....................................... 41

S-16A Checking Fan & Blower Motor

Windings (PSC Motors) ............................... 41

S-16B Checking Fan & Blower Motor (ECM Motors) 41

S-16C Checking ECM Motor Windings .................... 42

S-16D ECM CFM Adjustments ................................ 42

S-16E Checking GE X13™ Motors .......................... 46

S-17 Checking Compressor Windings ................... 46

S-17A Resistance Test ............................................ 46

S-17B Ground Test .................................................. 47

S-17D Operation Test .............................................. 47

S-18 Testing Crankcase Heater (optional item) ..... 48

S-21 Checking Reversing Valve Solenoid .............. 48

S-24 Testing Defrost Control .................................. 48

S-25 Testing Defrost Thermostat ........................... 48

S-40 MBR & AR*F Electronic Blower Time Delay .. 49

S-41 MBE & AEPF with Single Speed

Air Conditioning ............................................ 50

S-41A MBE & AEPF with Single Speed

Heat Pumps ................................................. 51

S-60 Electric Heater (optional item) ....................... 52

S-61A Checking Heater Limit Control(S) .................. 53

S-61B Checking Heater Fuse Line ........................... 54

S-62 Checking Heater Elements ........................... 54

S-100 Refrigeration Repair Practice ......................... 54

S-101 Leak Testing ................................................. 54

S-102 Evacuation .................................................... 55

S-103 Charging ........................................................ 55

S-104

S-105A Piston Kit Chart ............................................ 57

S-105B Thermostatic Expansion Valve ...................... 58

S-106 Overfeeding ................................................... 58

S-107 Underfeeding ................................................. 58

S-108 Superheat ..................................................... 58

S-109 Checking Subcooling .................................... 59

S-110 Checking Expansion Valve Operation ........... 60

S-111 Fixed Orifice Restriction Devices .................. 60

S-112 Checking Restricted Liquid Line .................... 61

S-113 Refrigerant Overcharge .................................. 61

S-114 Non-condensables ........................................ 61

S-115 Compressor Burnout ..................................... 61

S-120 Refrigerant Piping .......................................... 62

S-122 Replacing Reversing Valve ............................ 64

S-202 Duct Static Pressure

S-203 Air Handler External Static ........................... 64

S-204 Coil Static Pressure Drop ............................. 65

Checking Compressor Efficiency .................. 56

& Static Pressure Drop Across Coils ............ 64

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

33

Page 34

SERVICING

S-1 CHECKING VOLTAGE

1. Remove outer case, control panel cover, etc., from unit

being tested.

With power ON:

WARNING

Line Voltage now present.

S-2 CHECKING WIRING

2. Using a voltmeter, measure the voltage across terminals

L1 and L2 of the contactor for the condensing unit or at the