Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 15 – Model B

for Lathe

Operator's Manual (Operation)

GFZ-62554E-1/01 September 1994

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1994 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B-62554E-1

/Ol

PREFACE .

PREFACE

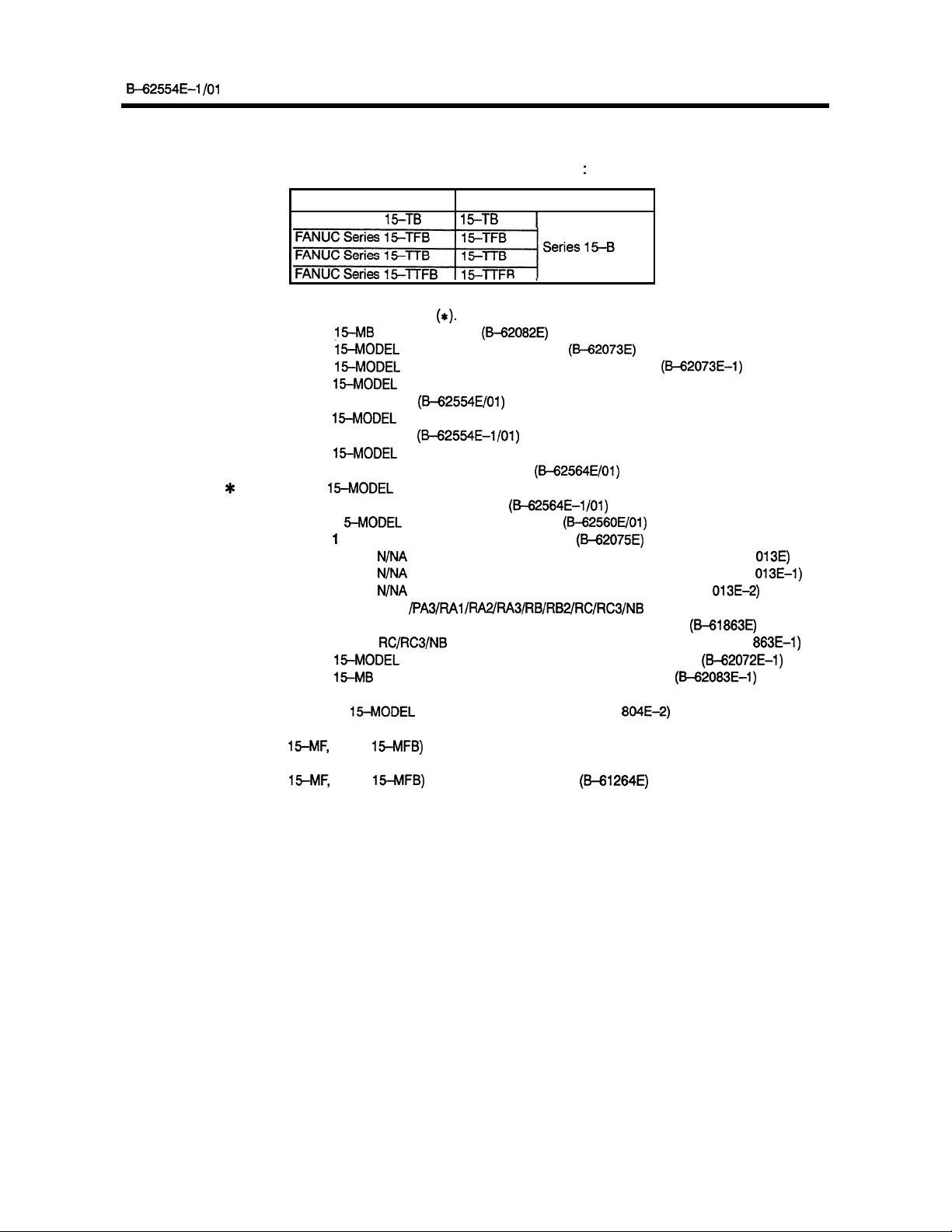

The models covered by this manual, and there abbreviations are

Product name

FANUC Series

Manuals related to FANUC Series 1 S-MODEL B are as follows.

This manual is marked with an asterisk

FANUC Series

FANUC Series i

FANUC Series

FANUC Series

FANUC Series

FANUC Series

*

FANUC Series

FANUC Series 1 &MODEL B PARAMETER MANUAL

FANUC Series 1 S-MODEL B MAINTENANCE MANUAL

FANUC PMC-MODEL

FANUC PMC-MODEL

FANUC PMC-MODEL

FANUC PMC-MODEL PA1 /PA3/RAl

FANUC PMC-MODEL

FANUC Series

FANUC Series

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR LATHE

(Series 16, Series

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series

15-MF,

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series

15-MF,

15-MB

15-MODEL

15-MODEL

15-MODEL

15-MODEL

15-MODEL

l5-MODEL

15-MB

Series

Series 15iVlFB) OPERATOR’S MANUAL (B-61264E)

1!5-TB

DESCRIPTIONS

5-MODEL

15-MODEL

B CONNECTION MANUAL (B62073E)

B CONNECTION MANUAL (BMI Interface) (B-62073E-1)

B For Lathe OPERATOR’S MANUAL (PROGRAMMING)

B For Lathe OPERATOR’S MANUAL (OPERATION)

B For Machining Center OPERATOR’S MANUAL

B For Machining Center OPERATOR’S MANUAL

N/NA

PROGRAMMING MANUAL (LADDER LANGUAGE) (B-61

N/NA

PROGRAMMING MANUAL (PASCAL LANGUAGE) (B-61

N/NA

PROGRAMMING MANUAL (C LANGUAGE) (B-61

PROGRAMMING MANUAL (LADDER LANGUAGE)

RC/RC3/NB

B Supplement for Remote Buffer DESCRIPTIONS @-62072E-1)

Multi-Teaching Function CONNECTION MANUAL (B-62083E-1)

15-MFB)

15-TB

(*).

(W2554E/Ol)

(&62554E-l/01)

(PROGRAMMING)

(OPERATION) @-62564E-l/01)

/RA2/RA3/RB/RB2/RC/RC3/NB

PROGRAMMING MANUAL (C LANGUAGE) (B-61 863E-1)

B) OPERATOR’S MANUAL (B-61 804E-2)

PROGRAMMING MANUAL (B-61 263E)

Abbreviation

I

(B-62082E)

(B62564E/Ol)

:

(B-6256OE/Ol)

(B-62075E)

013E-2)

(B-61863E)

013E)

013E-1)

Page 4

B-62554E-l/O1

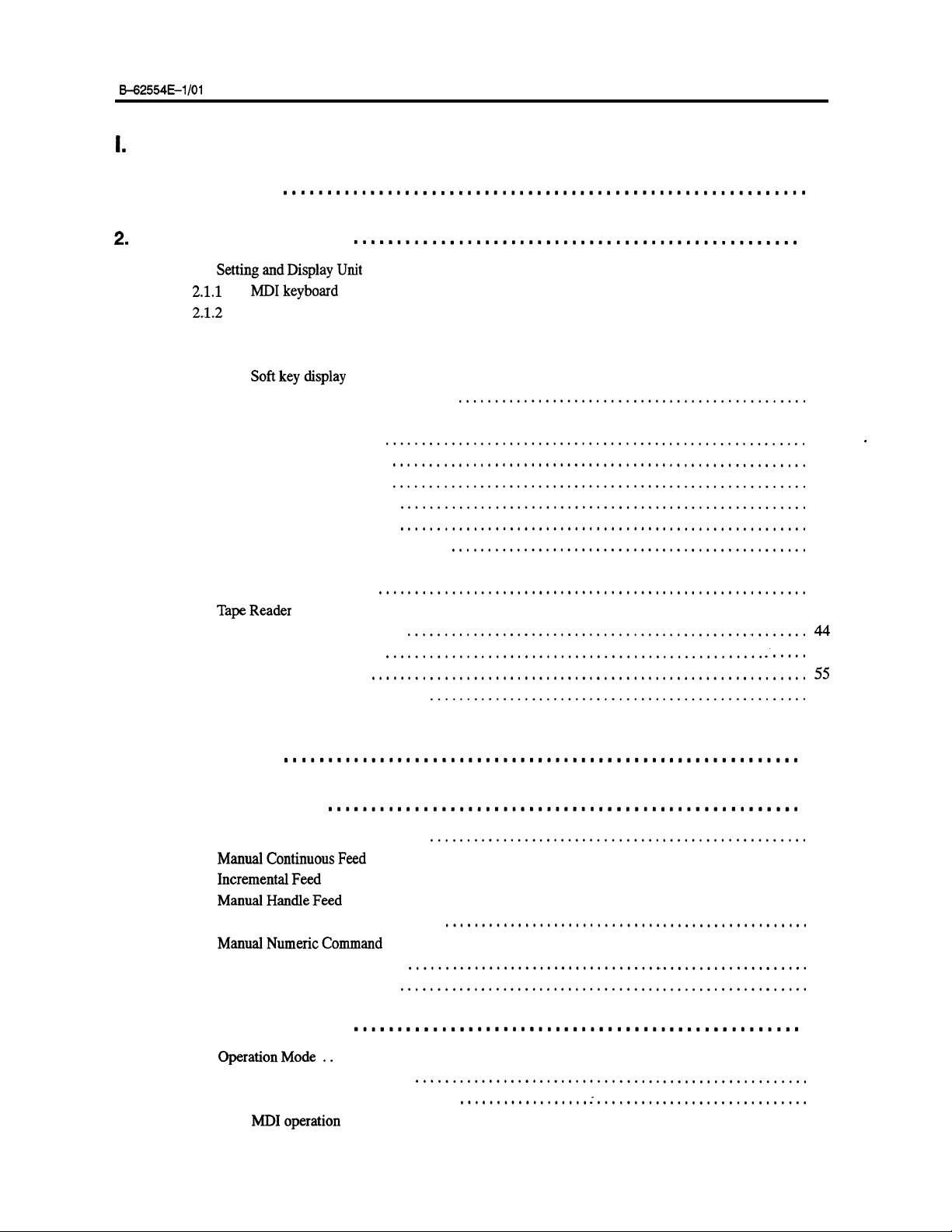

I.

OPERATION

Table of Contents

1. INTRODUCTION

2m

OPERATIONAL DEVICES

2.1

SettingandDisplayUnit

2.1.1

2..1.2

2.1.3

2.1.4

2.1.5

2.1.6

2.1.7

2.1.8

2.1.9

2.1.10

2.1.11

2.1.12

2.1.13

2.1.14

2.2

2.3

Machine Operator’s Panel

TapeReader ......................................................................

2.3.1

2.3.2

2.3.3

2.3.4

2.4

FANUCPPR

mmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmm8mm

MDIkeyboard

Contents to be displayed and operations when the MMC is installed

Changing the contents

Warningmessage

Softkeydisplay

When the soft keys are insufficient

Changingsoftkeys

Outline of operations.

Function selection keys

Chapter selection keys

Operation selection keys

Operation guidance keys

Changing language of the display

Arithmetic key (SHIFT or ALTER key)

Tape reader without reels

Tape reader with reels

Portable tape reader

Note for handling tape reader

.....................................................................

mmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

................................................................

.....................

of

the key input buffer

.......................................

.............................................................

...............................................................

................................................

............................................................

..........................................................

.........................................................

.........................................................

........................................................

........................................................

.................................................

............................................

...........................................................

.......................................................

:

....................................................

.....

............................................................

....................................................

3

19

25

29

29

29

29

30

31

33

33

34

36

37

38

39

42

44

44

46

55

57

58

.

3. POWER ON/OFF

4. MANUAL

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

OPERATION

Manual Reference Position Return

ManualContinuousFeed

IncrementalFeed

ManualHandIeFeed

Manual Feed in a Specified Direction

M~ualNumericCommand

Manual Absolute ON and OFF

Effect of Manual Intervention

mm8mmmmmmmmmmmmmmmmmm8mm88amm8mmmmmmm~mmmmmam~mmommmmm88mmm

mmmmmmmmmmmmmmmmm8mmmmmm8mmmmmmmmmmmmmmmmmmmmmmmmmmmmm

..................................................................

...............................................................

5. AUTOMATIC OPERATION

5.1

OperationMode..

5.1.1

5.1.2

5.1.3

Operation in the tape mode

Operation in the MEMORY mode

MDIoperation ................................................................

.................................................................

....................................................

............................................................

..................................................

..........................................................

........................................................

........................................................

mmmmmmm8mmmmmmmmommmmmmmmmmmmmmmmmmmm8mmmmmmmmmmamm

......................................................

.-

..................

.............................

c-l

59

60

60

62

64

65

67

68

70

74

75

75

75

75

77

Page 5

TABLE OF CONTENTS

&-62554E-1101

5.2

5.3

5.4

5.5

5.6

5.7

Selecting a Program to be Executed

5.2.1

52.2

5.2.3

55.1

5.5.2

5.5.3

5.5.4

5.5.5

5.5.4

5.6.1

5.6.2

5.6.3

5.6.4

5.6.5

Searching for a program number or sequence number

Rewindingaprogram

..........................................................

Usingtheprogramnametosearchforaprogram..

Starting Automatic Operation

Executing Automatic Operation

Stopping Automatic Operation

Programstop(MO0)

Optional stop

(MOl)

Program end (M02, M30)

Feedhold

Reset

....................................................................

.......................................................................

........................................................

.......................................................

.......................................................

...........................................................

............................................................

.......................................................

Single-block stop according to the comparison between sequence numbers

Restarting Automatic Operation

Programre-start

..............................................................

......................................................

ProgramrestartfunctionandoutputofM,S,T,andB,codes

Blockrestart

.................................................................

Tool retraction and recovery (15-T)

Tool retraction and recovery

(15-‘IT)

Manual Interrupt during Automatic Operation

5.7.1

57.2

ManuaIhandleinterrupt

Simultaneous automatic and manual operation

.......................................................

...................................................

.................................

...................................

................

...........................

..............................................

.............................................

..........................................

.....................................

79

79

80

80

82

82

83

83

83

83

83

84

84

86

87

91

93

101

112

116

116

118

8

8 8 8

120

120

120

120

121

121

123

123

123

124

126

127

127

128

128

129

130

131

131

6. TEST OPERATION

6.1

6.2

6.3

6.4

6.5

AllAxesMachineLock

MachineLockonEachAxis

AuxiIiaryFunctionLock

DryRun .........................................................................

SingleBlock

8888888888888D8888

888888888888888888888

............................................................

........................................................

...........................................................

.....................................................................

88888888888888888

7.SAFETYFUNCTlONS.....................888888888888888888888888888888888

7.1

7.2

7.3

Emergencystop..

Overtravel

.......................................................................

Pre-Travel Stroke Limit Check Function

................................................................

..............................................

8mAcT~Of’dSREQUlREDFORA~RMS 8888888888888888888888888888888888888888

98

STORING AND EDITING PART PROGRAMS

(INCLUDING

9.1

9.2

9.3

9.4

Preparations

RegisteringPartPrograrns..

9.2.1

9.2.2

DeletingPartPrograms

EditingPartPrograms

9.4.1

88888

PROGRAM

for

Storing and Editing Part Programs

REGISTRATION)

8 8 8

........................................................

Registering a part program from the tape

Registering part programs

from CRT/MD1

..........................................

panel

............................................................

.............................................................

Moving the cursor to the position to be edited

8l888 8 8

8 8

8 888

......................................

....................................

......................................

8 8

888 8 8 8

8

.

c-2

Page 6

Page 7

TABLE

OF coNlENTs

B=62554E-1101

10.16

Interference Prohibited Area for Checking Tool Post Interference

(Series15-TIBonIy)

10.16.1

10.17

10.17.1

10.17.2

Display and setting

Servo and Spindle Setting and Adjustment Screens and Spindle Monitor Screen

Servoscreens

Spindle screens

10.17.3 Operations

10.18

Function for Displaying Multiple Subscreens

10.181 Subscreen states

10.18.2

10.183

10.18.4

10.19

10.19.1

10.19.2

10.19.3

Subscreen operations

Data displayed on the subscreen

Subscreen operations

RS232C

Parameter Setting Screen

Selecting

DetaiIs of screens

Notes..

10.19.4 Help message

10.20

MCodeGroupFunction

10.20.1

Screen for displaying m codes currently being executed or

whichhaveaheadybeenexecuted

10.20.2

10.20.3

10.20.4

10.21

10.21.1

10.21.2

10.21.3

M,S,T,B codes output for program restart

M code group check function

Details of grouping M codes

Workpiece Zero Point Manual Setting Function

Screenselection

Operation method

Workpiece

............................................................

...........................................................

...............

...............................................................

..............................................................

..................................................................

...........................................

.............................................................

......................................

................

.1.

.................................................

.........................................................

....................................................

RS232C

screen

......................................................

............................................................

....................................................................

...............................................................

.

............................

................................

...............................................

.........................................

...................................................

....................................................

.........................................

.............................................................

............................................................

zero point measurement B

............................................

220

220

222

222

224

229

231

231

232

235

237

239

239

239

243

244

245

245

246

250

250

253

253

254

259

.

.

11

s

DISPLAY

888m888888888e8888888888mm

11.1

Program Display

11.1.1

11.1.2

11.1.3

Execution program and program directory

Program check screens

Groupby-group

11.2 Status Display

11.3

11.4

.11.5

11.6

Current Position Display

11.3.1

11.3.2

11.3.3

Current-position screens

Presetting the current position display

Presetting the workpiece coordinate system

Operator Message Display

Alarm

MessageDisplay

Graphic Display

11.6.1

11.6.2

11.6.3

11.7

11.8

11.9

Selectirtg

Setting the graphic parameters

Drawing a tool path.

Directory of Floppy Disk Files

Displaying the

Load Meter Display

88888888888888mm8mm888m8m888888m888888

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*.....................

.........................................

........................................................

program directory display and punch-out

...........................

...................................................................

...........................................................

.......................................................

............................................

........................................

..........................................................

............................................................

..................................................................

the graphic screen

....................................................

..................................................

..........................................................

......................................................

Actual

Spindle Speed

..................................................

...............................................................

C-4

261

261

261

262

264

267

269

269

270

271

272

273

274

275

275

278

281

283

284

.

Page 8

B=62554E-l/O1

TABLE OF CONTENTS

11.10

11.11

11.12

11.13 HelpFunction

Display of Run Times and Parts Counts

..........................................................................

Clock

Waveform Diagnosis Function

11.12.1

11.12.2

11.12.3

11.12.4

11.125

11.12.6

11.12.7

Screens

Specifying the conditions for starting data sampling

Starting or terminating data sampling

Waveform display

Editing a displayed waveform

Erasing a displayed waveform

Waveform data input/output

....................................................................

....................................................................

11.13.1 Operation ...................................................................

11.13.2

11.14

11.14.1

11.14.2

11.14.3

11.14.4

11.15

11.16

CRTSCREENSAWNGFUNCTION

12

l

Help window states

Operation History

..................................................................

Operation history

Selectingsignals..

Alarmhistory

Restrictions..

...............................................................

...........

Internal Position Compensation Data Display Function

Coordinate System Related Data Display Function

...............................................

.......................................................

.................................

.............................................

............................................................

..................................................

..............................

...................

.:

....................................................

...........................................................

............................................................

...........................................................

.

...................................................

...................................

.......................................

n

88m8m88m88mm8m8m888m8mm8mmmmmmmmmmmm8mmm

286

287

289

289

291

293

293

293

294

294

297

297

301

302

302

309

311

312

313

316

319

12.1

12.2

12.3

DATA OUTPUT

l

13

13.1

13.2

DATA INPUT/OUTPUT TO AND FROM FANUC FLOPPY CASSETTE

14.

AND FANUC FA CARD

SmallCRT/MDIPanel

Panels Other than the

ScreenSaverFunction..

ToolOffsets

Parameters

WhatisaFiIe..

14.1

FiIeSearcMut

14.2

DataOutputOperation

14.3

14.3.1

14.3.2

14.3.3

14.4

14.4.1

14.4.2

14.4.3

14.5

CNCprogramoutput

Offset data output

CNC parameter output

DataInputOperation

CNCprograminput

Offset datainput

CNCparameterinput

FileDeletion

14.6 Precautions

14.6.1

14.6.2

Request for cassette replacement

Adaptor lamp conditions

.............................................................

Small CRT/MD1

.

...........................................

Panel

...........................................................

888m88888888888m8888888888888m88m8888

888m8mm88m88m8mmm8mm8m

.....................................................................

......................................................................

88m88888m8m88888

8mm8mmm8mm8mm8m88mmmmmm8m8mmmmm8888m

..................................................................

..................................................................

.............................................................

..........................................................

............................................................

........................................................

..............................................................

...........................................................

.............................................................

.........................................................

.....................................................................

.......................................................................

................................................

.......................................................

319

319

319

321

321

322

323

323

324

326

326

327

327

328

328

328

328

329

330

330

330

C-5

Page 9

TABLE OF

COfWENTS

B=62554E-l/O1

14.7

14.8

FiIeNameofFIoppyCassette

ExpandedFiIeControlFunction

14.8-l

14.82

148.3

Searching for, inputting/outputting, and deleting a file by specifying its file name

Two-drive floppy cassette control

Soft key operations

...........................................................

14.84 Notes ......................................................................

15.

ABSOLUTE-POSITION DETECTION

15.1

15.2

15.3

15.4

InitiaISettingatPower-On

Manual Reference Position Return at Machine Installation

Alarm.. ........................................................................

Setting the Zero Point for the Absolute

16. AXIS CONTROL

16.1

16.2 MirrorImageFunction

AxisControlbythePMC

88888888888888888888888888888888888

.........................................................

...........................................................

..............................................................

II. MAINTENANCE

1. ROUTINE MAINTENANCE

888888888888888~8888888888888888888888888888888888

.......................................................

.....................................................

..........

...............................................

88888888888888888888888888888888888888

................................

pulse

Coder through

MD1

Operation

88888888888888888888888

..................

331

332

332

333

334

334

335

335

335

336

338

339

339

340

343

1.1

1.2

1.3

1.4

2. REPLACING A FUSE

2.1

2.2

Cleaning the Tape Reader

TapeReaderLubrication

Adjusting the Photo-AmpIifier of the Tape Reader with Reels

Cleaning the Air Filter (For the

888888888888888888888888888888888888888888888888888888

Fuse Specifications

FuseMountingLocation

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

Power supply unit

Control units Al to A6

ControlunitsBltoB6

co~~on~t

Operator’s panel connection unit

I/o unit

....................................................................

Inputunit ...................................................................

3. REPLACING BATIERIES

3.1

3.2

4.

TROUBLESHOOTING

Replacing the Dry

Replacing the Batteries of the Absolute Pulse Coder

..........................................................

...........................................................

..............................

SelfStanding

Cabinet

..............................

OnIy)

...............................................................

...........................................................

............................................................

........................................................

........................................................

..............................................................

................................................

88888888888888888888888mm8m8888m888m08mm8888m88m88

Cells

for the Control Unit (for Memory Backup)

..........................

.....................................

888888888m88m8m88m8888m88m8888888mm8888888888mmm888m8

343

345

348

351

352

352

356

356

356

357

357

357

358

358

359

359

360

361

4.1

4.2

Symptom and Investigation . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Checking the Input Voltage, Ambient Conditions, Handling,

Programming, Operation, Machine, and Interface

C-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*...a..

361

362

Page 10

8-625541=-l/01

TABLE

OF

CONTENTS

4.3

4.4

Visually Checking the CNC System

CNC Status Indication

4.4.1

4.4.2

How to display the CNC internal status

Description of internal selection

.............................................................

5. FAILURE DIAGNOSIS GUIDANCE

...................................................

...........................................

.................................................

mm8mmm88m88mmmm8mmmm8mm8mmmmmm8mm88mmmmmmm

APPENDIX

APPENDIX

APPENDIX Bm

1. GENERAL

2.

INTERFACE CONNECTOR POSITIONS AND PIN ASSIGNMENT l l 8 8 l

3.

RS-232-C

3.1

3.2

3.3

3.4

A.

STATUS WHEN TURNING THE POWER ON, WHEN RESET

RS-232-C

mmmmm8mmmmmm88mmmmmmmmmmmmmmmmmmmmmmm8mmmmmmmmmmmmmmmm8mmmmmmmmm

AND

RS-“32

INTERFACES

INTERFACE SPECIFICATIONS

Names of RS-232-C Interface Signals

Signal Description of RS-232-C Interface

RS-232-C Interface Transmission Methods

Connection between

RS-232-C

Interface and I/O Device

................................................ 379

.............................................

m888888888888888m888888888888888888

............................................

l mmmm8mmmmmm8mm8mmmmmm8mmmm

.................................

l mmmmmm8

m

l

m

l l l l l l l 376

364

365

365

366

368

373

375

375

379

380

381

386

4. RS-422 INTERFACE SPECIFICATIONS

4.1

4.2

4.3

4.4

Names of RS-422 Interface Signals

Explanation of

R-22

Interface Signals

RS-422 Interface Transmission Methods

Connection between

RS-422.C

Interface and Input/Output Unit

APPENDIX Cm WARNING MESSAGE LIST

APPENDIX D. LIST OF OPERATIONS

8mmmm8mmm8mmmmmmmmmmmmmm8mmmmmm8mmm8m

..................................................

..............................................

..............................................

l 88mmmmmmm8m88mmm8mm8mmmmmmmmm8mmmmmmm

88mmmmmm888mmm8mmmmmmmmmmm8mmmmmm8mmmmomm

............................

388

388

389

390

390

392

394

.

c-7

Page 11

I. OPERATION

Page 12

&-62554E-1 /Ol

I l INTRODUCTION

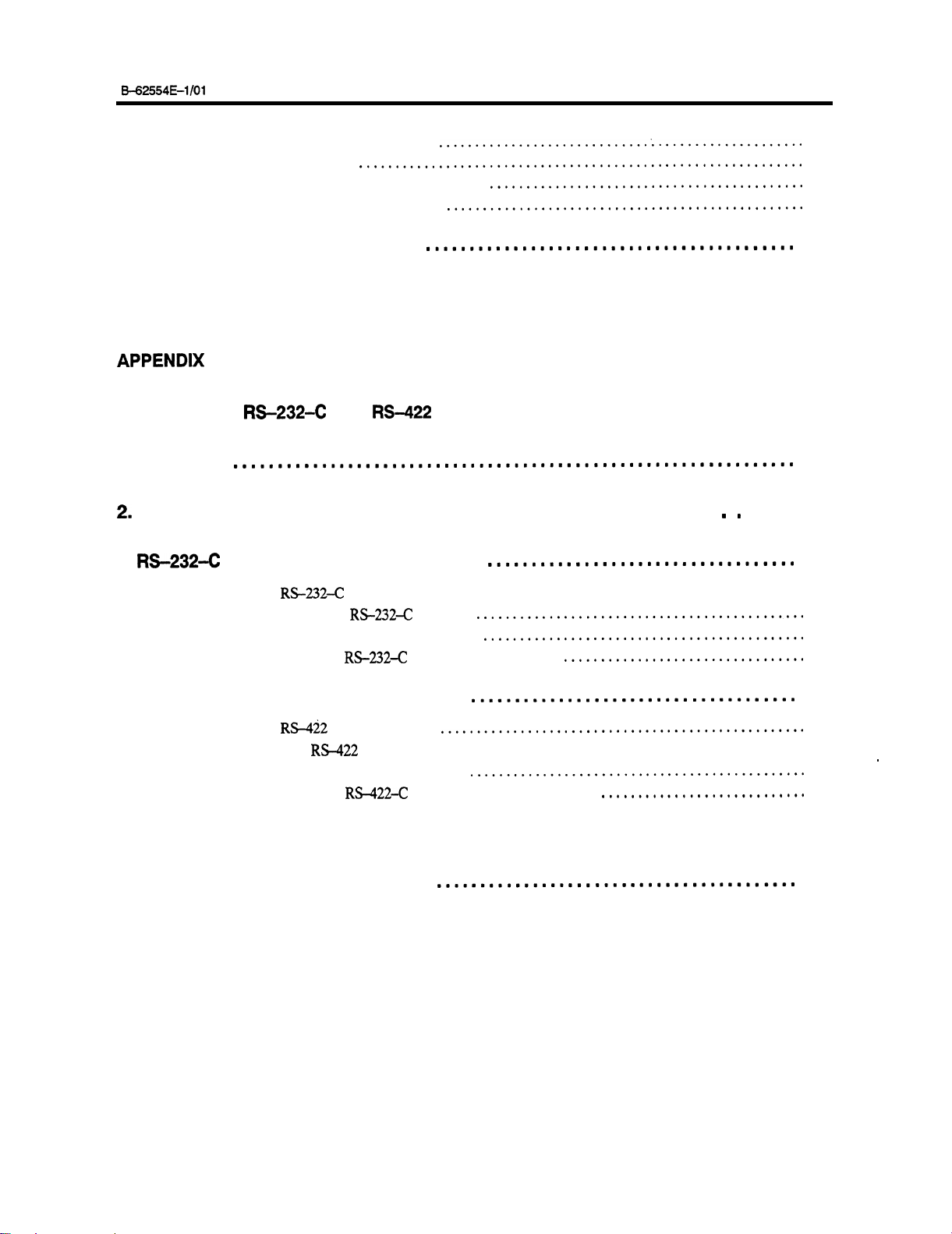

1) Manual operation

Manual reference position return (See Section 4.1)

a)

The memory in the CNC machine tool holds the positional data for setting the machine.

This position is called the reference position, where the tool is replaced or the coordinate are set.

narily, after the power is turned on, the tool is moved to the reference position.

Manual reference position return is to move the tool to the reference position using switches and push-

buttons located on the operator’s panel.

1.

INTRODUCTION

Ordi-

I1

Fig. 1 (a)

The tool can be moved to the reference position also with program commands.

This operation is called automatic reference position return. (See Section 7.1)

b) The tool movement by manual operation

Using operator’s panel switches, pushbuttons, or the manual handle, the tool can be moved along

each axis.

.

Manual Reference Position Return

Tool

7

Reference

msition

000

Operator’s

000

o”o

I

0 0 0

Operation panel

panel

0

8

1

I

0

Manual

handle

h

Fig. 1 (b) Tool Movement by Manual Operation

Page 13

1. INTRODUCTION

2)

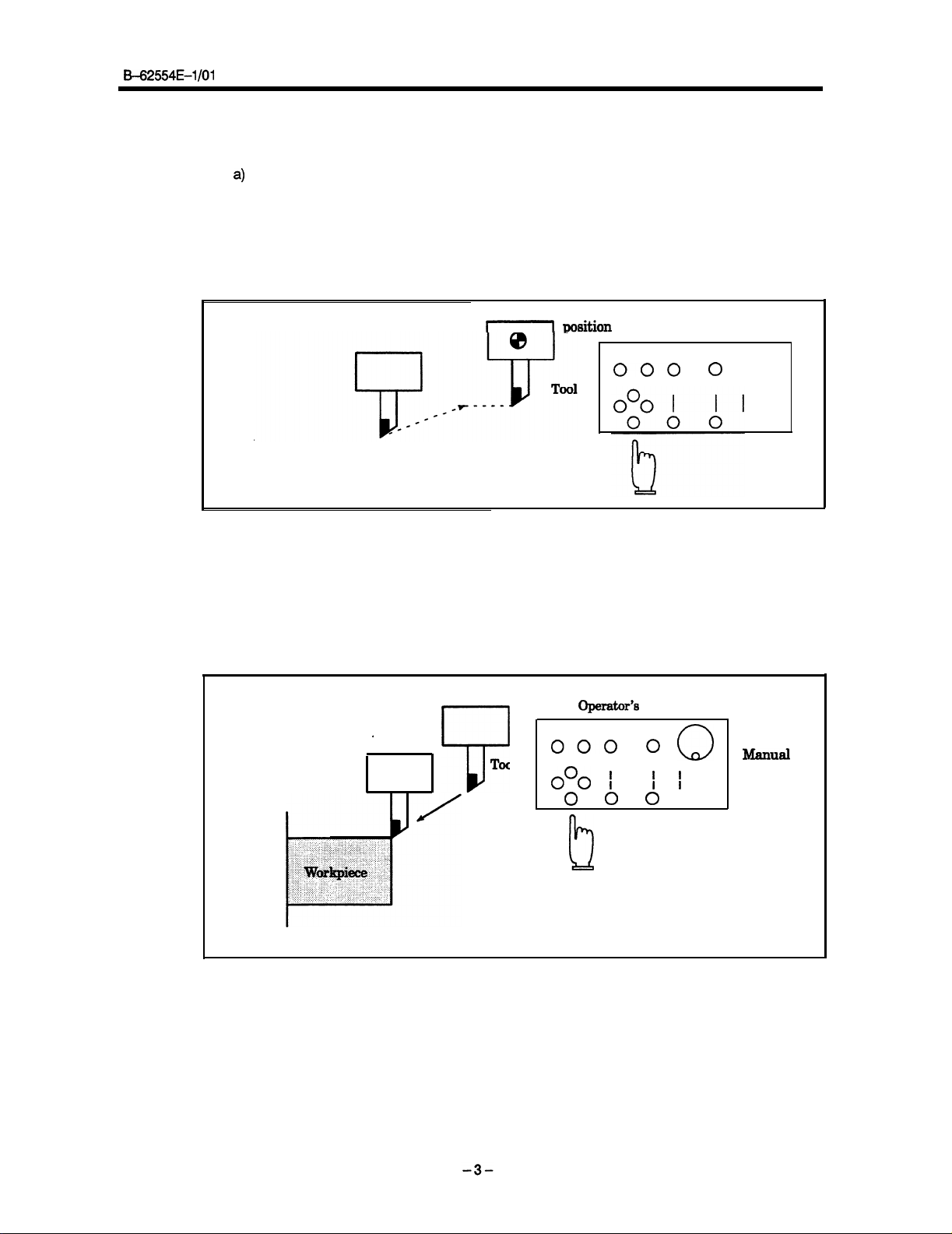

Tool movement by programing - Automatic operation (See Chapter 5)

B42554E401

The tool can be moved in the following ways:

i) Manual continuous feed (See Section 4.2)

The tool moves continuously while a pushbutton remains pressed.

ii) Step feed (See Section 4.3)

The tool moves by the predetermined distance each time a pushbutton is pressed.

iii) Manual handle feed (See Section

By rotating the manual handle,the tool moves by the distance corresponding to the

dle rotation.

iv) Manual feed at any angle

The tool is moved in any direction on the plane.

v) Manual numeric command

When numeric data is entered from the MDI keyboard, the tool is moved by the distance corresponding to the data

4.4)

degree of han-

.

Fig. 1 (c) Tool Movement by programing

Operating the machine according

are classified into operations according to tape, memory, and the MDI.

(i) Operation according to tape

I.

The machine can be

reader. This is called the operation according to

operated based on a program, while the program is being loaded from the tape

to a coded program is called automatic operation. Automatic operations

CNC

.CNCtqe

Operation accordingthetape

Machine

1

tape.

-r

Page 14

&-62554E-1 /Ol

1.

INTRODUCTION

(ii) Memory operation

After the program is once registered in memory of CNC, the machine can be run according to the pro-

gram instructions. This operation is called memory operation.

CNC

Memory

pr--w-w.

1

.

e-----4

(iii) MDI operation

After the program is entered, as an command group, from the MDI keyboard, the machine can be run

according to the program. This operation is called MDI operation.

I J-‘, .

I I

._--a

I

fi

’

I

Fig. 1

CNC

’

MDIGyboard

.

Manual

input

(d)

Memory operation

program

Machine

Machine

4

Fig. 1 (e)

MDI

Operation

Page 15

1. INTRODUCTION

3) Automatic operation

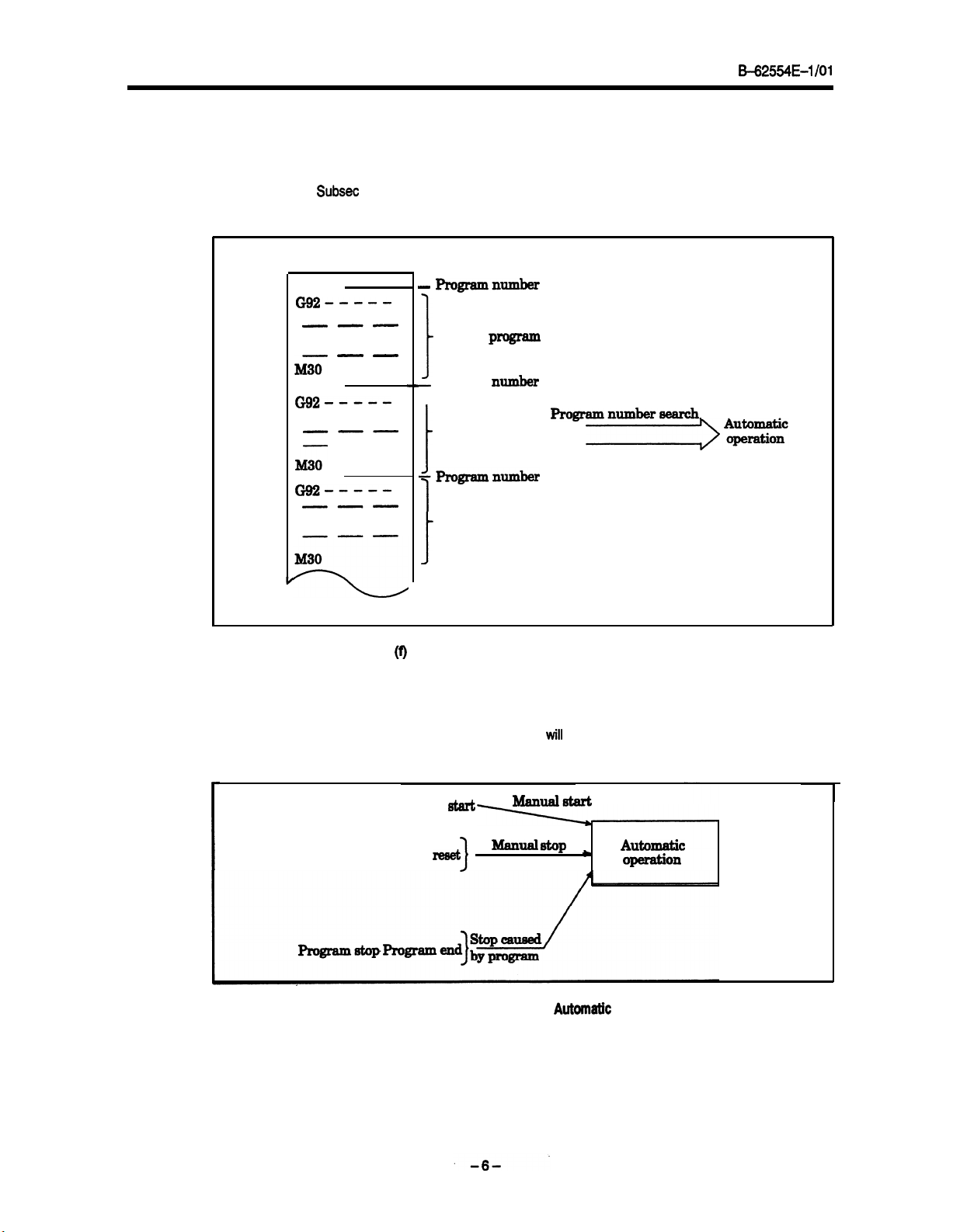

(i) Program selection

B=62554E-1 /Ol

Select the program used for the workpiece. Ordinarily, one program is prepared for one workpiece.

If two or more programs are in memory, select

ber (See Subset 5.2.1).

-

01001

G92-_---

---

-v-

---

Programnumber

Work-l

the

program

program to be used, by searching the program num-

iii - -

01002

G92-___-

---

-m-

--

M30

01003

Gg2-__--

-m-

---

-w

M30

I

Fig. 1

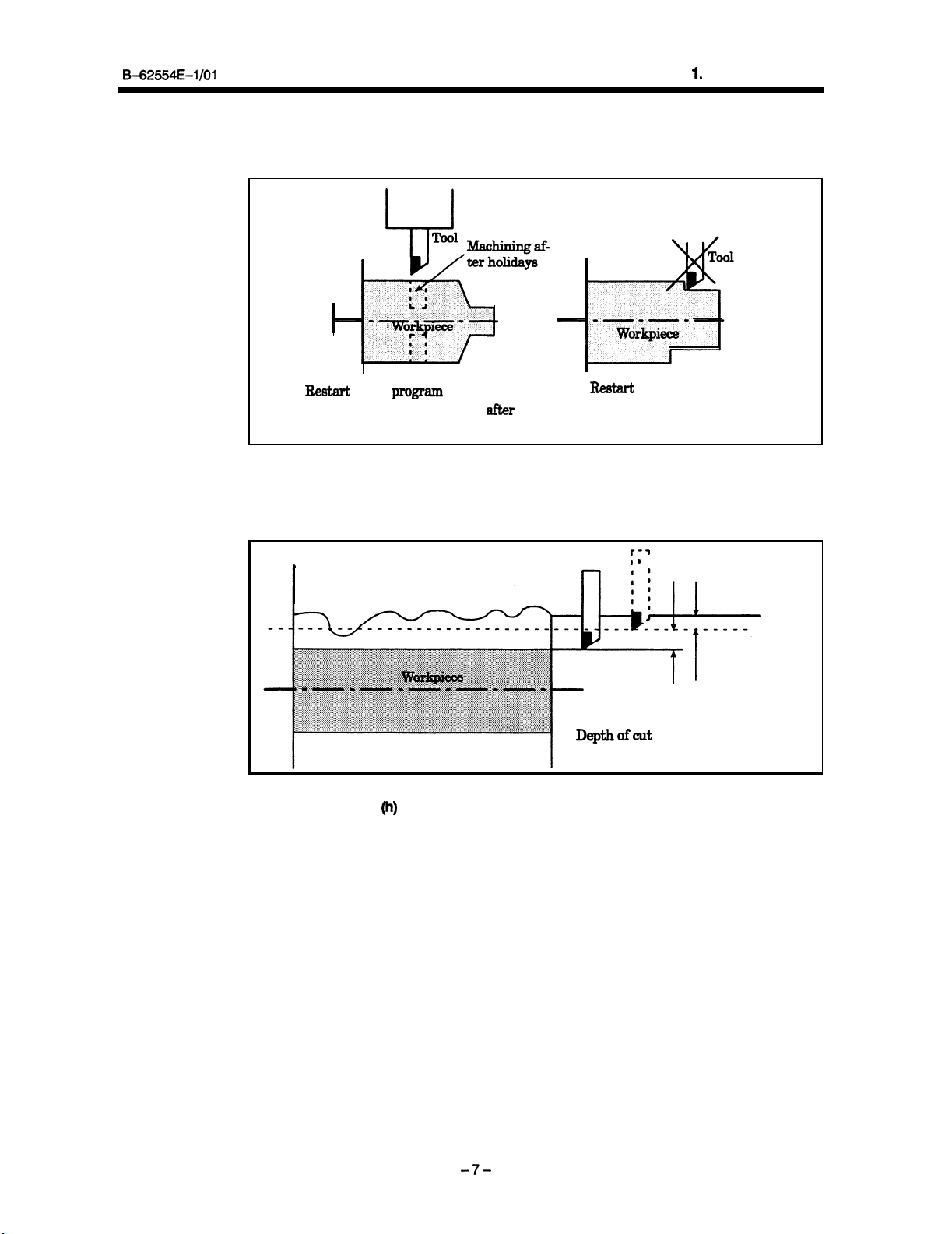

(ii) Start and stop (See Section 5.3 to 5.5)

Pressing the cycle start pushbutton causes automatic operation to start.

or reset pushbutton, automatic operation pauses or stops. By specifying the program stop or program

termination command in the program, the

cess machining is completed, automatic operation stops.

]

Program

1

Work-2

t

+zqgramnumber

1

Work-3 program

i

(f)

Program

Cycle

program

Selection for Automatic Operation

start

Ilumber

running

ManualBtart

Progsramnumber8earch

By pressing the feed hold

will

stop during automatic operation. When one pro-

Feed hold

Fig. 1 (g)

Manual

reset

3

atop

Start and Stop for

Automtic

Autcomatic

apeFafion

Operation

Page 16

B-62554E-1 /Ol

1.

INTRODUCTION

(iii) Restarting machining

Machining a workpiece can be stopped midway and restarted after several days’ holiday. Also, if the

tool is broken during machining, machining can be restarted after the tool is replaced.

Broken tool

Restart

Restart

of

the

progam

When machining is continued

afIx3r

of the block

When the tool is broken

holidays

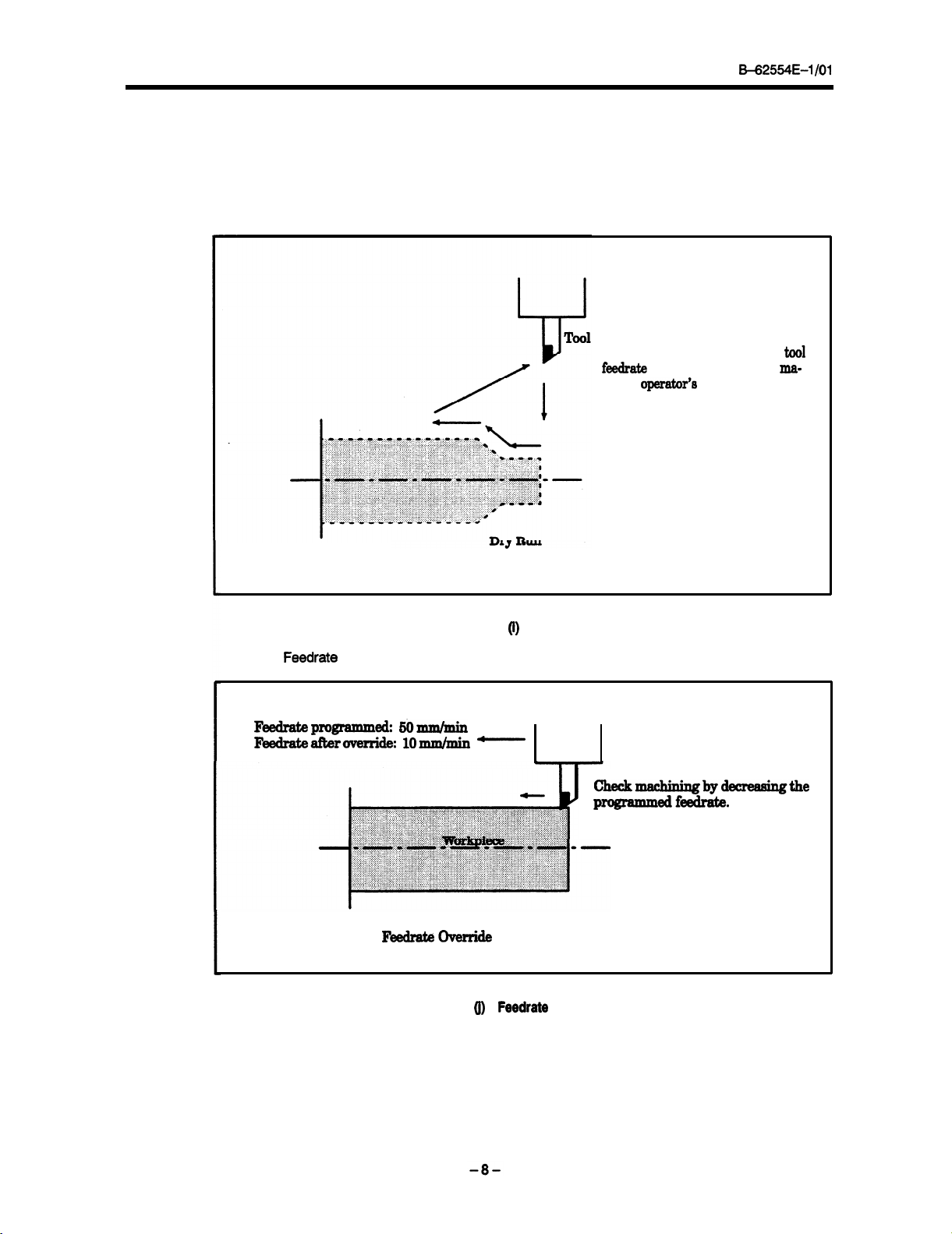

(iv) Handle interruption (See Section 5.7)

While automatic operation is being executed, tool movement can overlap automatic operation by rotating the manual handle.

r-3

fi 0

.

Tool

Depth of cut specified

by the program

ofcut

by manual handle feed

Fig.

Depth

Handle Interruption for Automatic Operation

1

(h)

-f-

Page 17

1. INTRODUCTION

4) Program test (See Chapter 6)

Before machining is started, the automatic running check can be executed.

program can operate the machine as desired. This check can be accomplished by running the machine

actually or viewing the position display change (without running the machine).

a)

Check by running

i) Dry run (See Section 6.4)

B-62554E-1 /Ol

It checks whether the created

Remove the workpiece, and check

tool movement only Select a

f&ate

with the dial on the

chine

operator’s

panel

tool

ma-

Fig. 1

ii)

Feedrate

override

Feedrateprogramm& EiOm&nin

Feedrakeafberoverri~ 10mmhnin -

FbdrateWerride

Fig. 1 0,Feedtate

(i)

Dry Run

Override

Checkmbydecreaeingthe

programmedf-.

Page 18

B42554E-I/O1

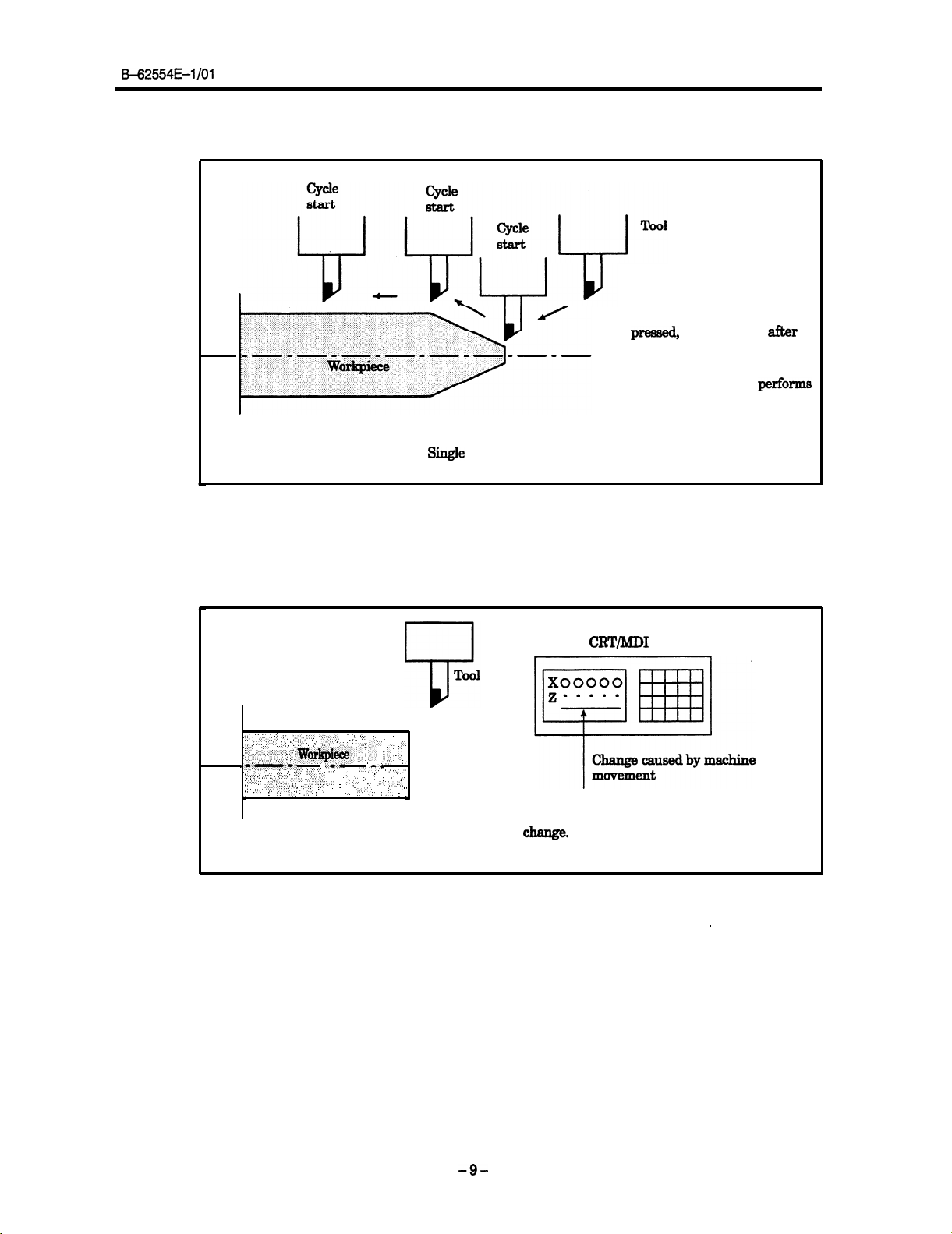

iii) Single block (See Section 6.5)

Singe Block

Fig. 1 (k) Single Block

1.

INTRODUCTION

When the CYCLE START button

is

pressed,

the tool stops

&r

performing one operation. When

the CYCLE START button is

pressed again, the tool

performs

another operation, then stops.

The program is checked in this

manner.

b)

How to view the position display change without running the machine

i) Machine lock (See Sections 6.1 and 6.2)

CRT/MD1

,_,_..: ., : ::

,:,:,: ..::..: .:,,:..: :._:::; :.I:

,:.I. Y:,,::_. ‘.. ,.,:,,_ ,. ,.‘f_:...

,,,, :.,. :::, ‘,: .. ‘.‘...

,,, .:...:.. ‘. ,. .,.:.::.

..::... .:... “.. ,,

::::.. ; ,.:.::.:,:. ..::::.::‘,.:‘:.::,:;

:::.

.I ::::,, ,,;: .: ,;,; ::;_ :.: ;:I .:.. :i,~&~~~.: ‘:::;i ; $ ,: .;

,I.: .:,,. ,. :.‘.‘.:.:, ,,,. .;:i:. .: : ... ,; .;:. .:. _,.

’ .“‘i:.::::@.

:.

._

., .‘,, 1.: :.:

_,_, ,:,__ : .,:,:, .:.I’

,:. .,.> .:. ..,._. :., ., .: ,.‘.‘. ‘.

_’,. ., . . .

,.:.:.,,

. .

.‘.:.O: ;

.

...,., .:: :i:.._.

. . . .

.,.

:.,;:

::..:..‘:.‘..’

:

,A._..‘. ‘.

“‘,” :.

‘,

.‘:‘, : .‘: .,:., .,;, :

I

:

,.:.:.. :. .,... .,.. :

:,

. .

,‘.‘,‘:‘,.:: .,.;,. 1.z.. “..,’

“. .,i..,:: .:,’

., ,, :. .:.,:

1.: .:.

.,. :... ‘: ., ‘.

‘.

. : : : _.I

.’ .“..., :,::,;:, ,,.,_.,. ,..‘. ._,,. .:.,

:.i:+::<

.

.,

:

“”

..;,& ::.:::::,i. ,,, .’ ‘.

.

.,... >.. Z.‘.‘, :, :.

.:‘: ,‘..‘. ..:

: ,.; :.,

,.

., _,

. : . .

:.‘:. ;.’ :.

._ ..,’ .:’ .;, :

.

1:;.

; :

I;.

,, ,.;.. ::

.*.*

I--

..‘. ,:‘.: .:

..,. ..; ..,.

:, ‘, : : ,..

.

‘_.:_’ ‘.,,‘,._,..

1: ,..

. .

\

The tool remains stopped, and

only the axis position indications

change.

Machine Lock

Fig. 1 (I) Machine Lock

ii) Auxiliary function lock (See Section 6.3)

.

When automatic running is placed into the auxiliary function lock mode during the machine lock

mode, all auxiliary functions (spindle rotation, tool replacement, coolant on/off, etc.) are disabled.

-9-

Page 19

1. INTRODUCTION

B=62554E-l/O1

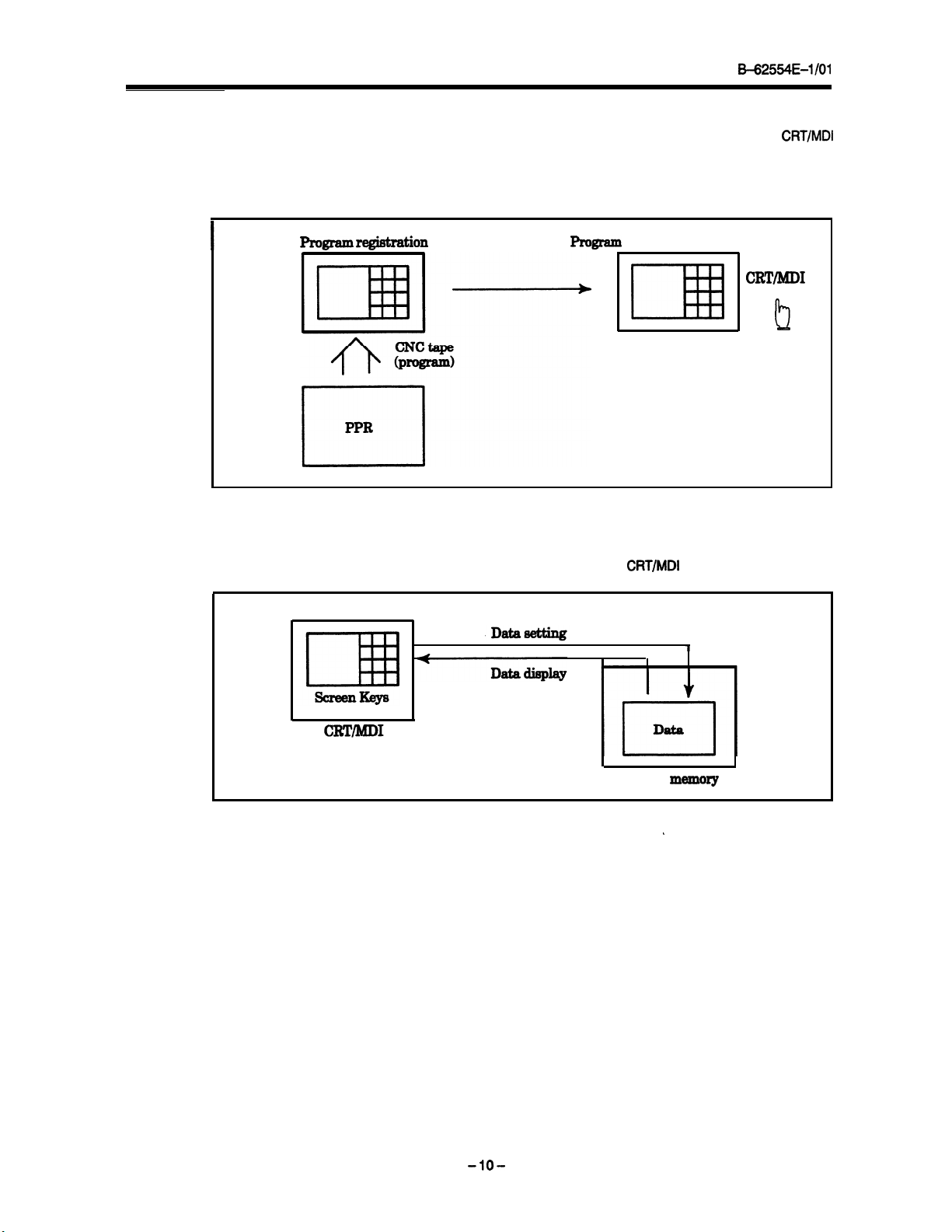

5) Part program editing (See Chapter

After a created program is once registered in memory, it can be corrected or modified from the

panel.

This operation can be executed using the part program storage/edit function.

Program

registmtion

9)

Progmm

correction or

modification

CRT/MIX

I

Fig. 1

(m)

Part

6)

Data display/setting (See Chapter

Data

stored in NC memory can be displayed and corrected via the

Program

IO)

Editing

CRT/MD1

screen.

CRT/MD1

1

!2

Fig. 1 (n) Data Display/Setting

-lO-

CNC

memory

,

Page 20

562554E-l/O1

1.

INTRODUCTION

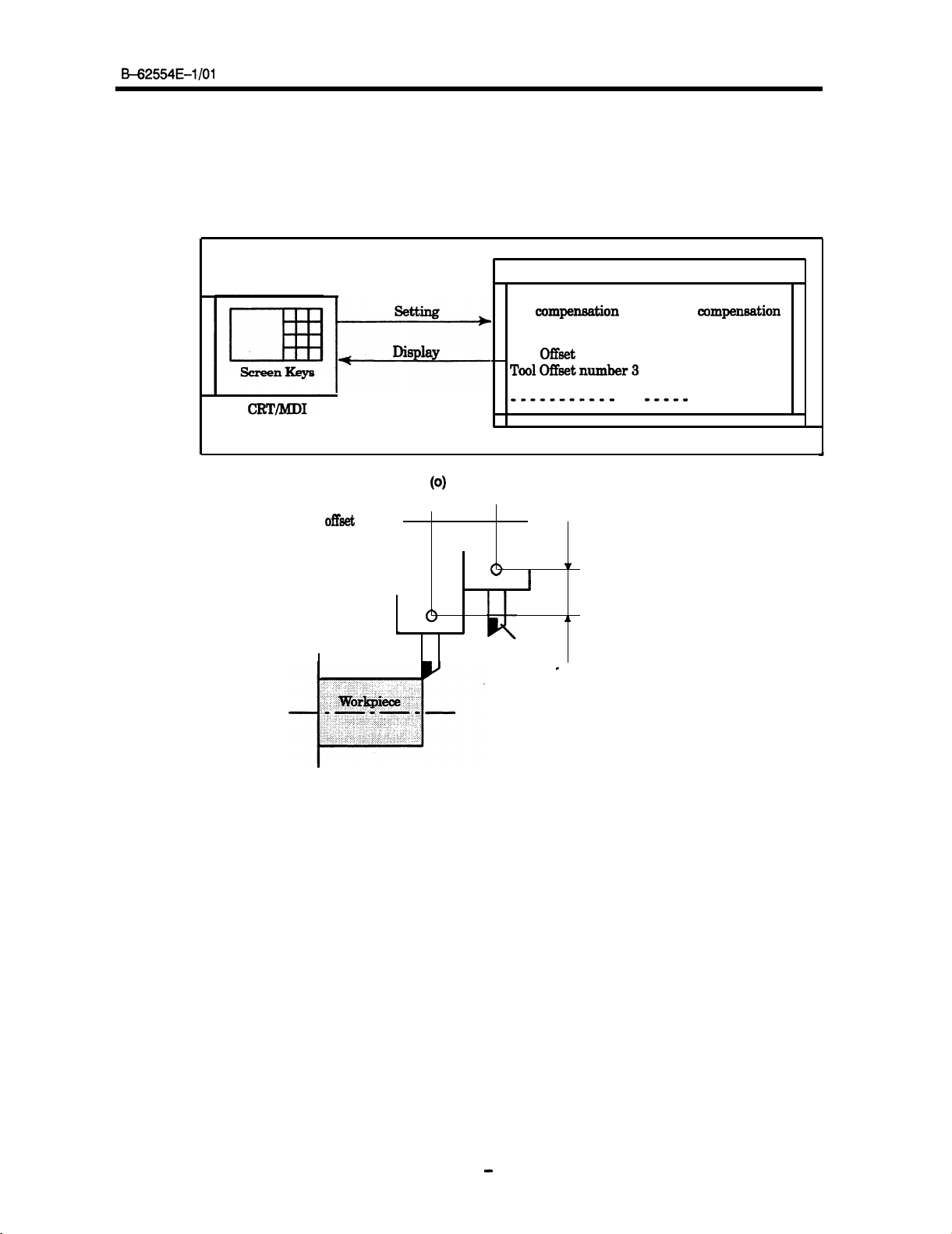

i) Offset value (See Section 10.1)

The tool has the tool dimension (length, diameter). When a workpiece is machined, the tool movement

route depends on the tool dimensions.

By setting tool dimension data in CNC memory beforehand, automatically generates tool routes that

permit any tool to cut the workpiece specified by the program.

value.

Geometric Wear

compexwation

Tool Offset number 1

Tool

Offeet

ToolOffbetnumber3 -----

-----------

----------I

I--

Tool

offset

value

setting

Display

Fig. 1

(0)

Offset Value Display/Setting

Tool dimension data is called the offset

mmpendion

number 2

CNC memory

12.3

20.0

----- -----

----I)

25.0

40.0

-----

-----

1r

I

I

Tool

Fig. 1 (p) Offset Value

JL

c

-11

-

Page 21

1. INTRODUCTION

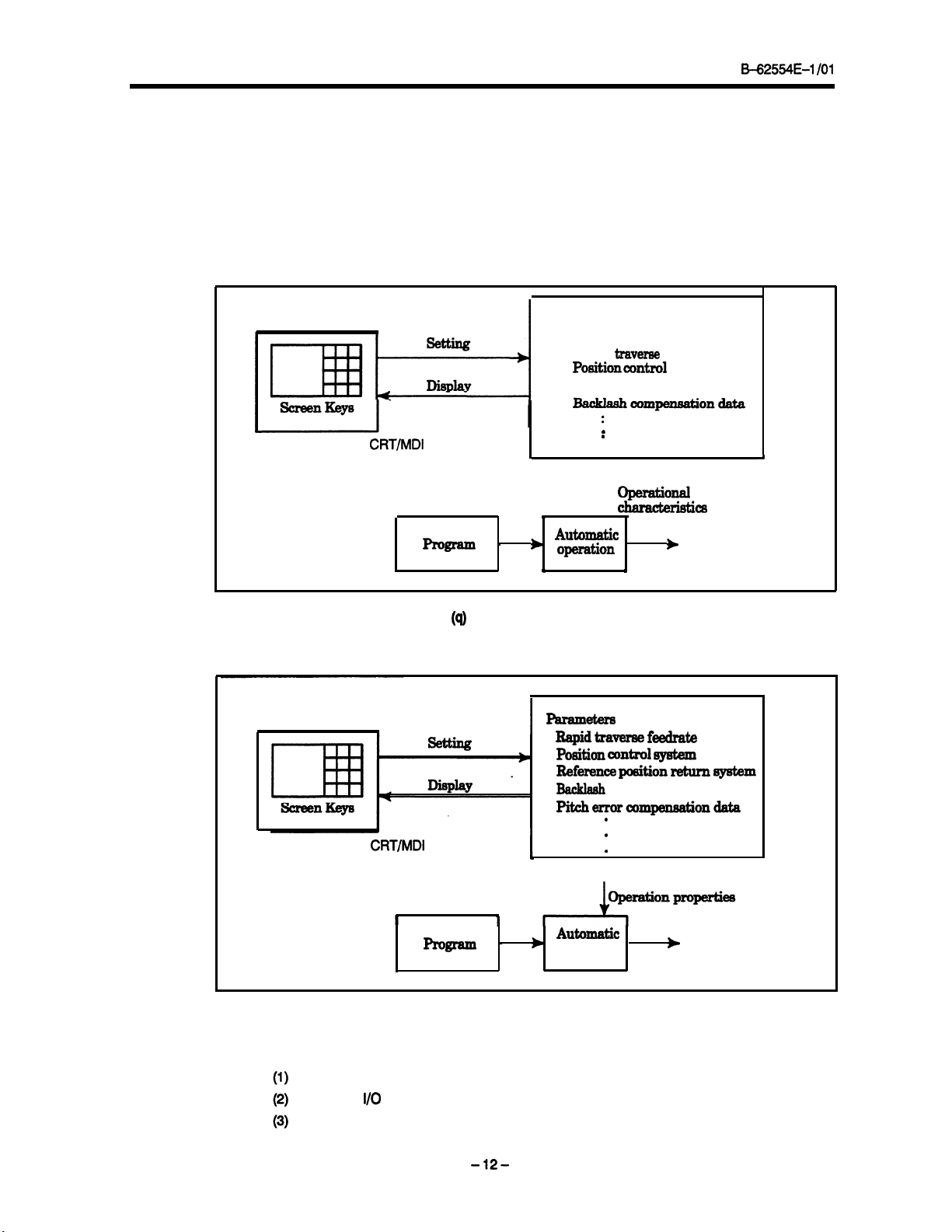

ii) Displaying and setting parameters (See Section 10.4)

H2554E-I /Ol

The CNC functions have versatility in order to take action in characteristics of various machines.

example, CNC can specify the following:

a) Rapid traverse rate of each axis

b) Whether the position is detected with digital or analog data

Whether reference position return is based on the grid or analog system

The data determining these items are called parameters (see Section 10.5).

The parameters are specific to the machine.

For

Parameter

Rapid

traverse

rate

Positioncontrol

I-

CRT/MD1

bfi!r=

Fig. 1

iii) Displaying and specifying data (see Section 10.3)

CRT/MD1

’

*

(cl)

Parameter Display/Setting

I

.

.

CNC

memory

operational

cthmacbMcf4

\

.

1

Automatic

operation

&

Machineoperation

.

Parameter8

Rapid&a- feedrate

Po8ition cOIltro1 system

Ref-nce position return 0y8tem

BacHash

PitcherraF~rnpensatioIldata

compensation data

.

.

.

CNC

memory

II

program

In addition to the parameters, settings for changing the attributes of the machine are provided. The

operator can set these items if necessary while the machine is operating..

For example, the following settings are provided:

Settings for the area the tool must not approach (stroke check)

Settings for

Amount of return and minimum depth of cut in the canned cycle

I/O

devices

-12-

’

b

operation

Automatic

b

Machine movement

Page 22

M2554E-I /Ol

1. INTRODUCTION

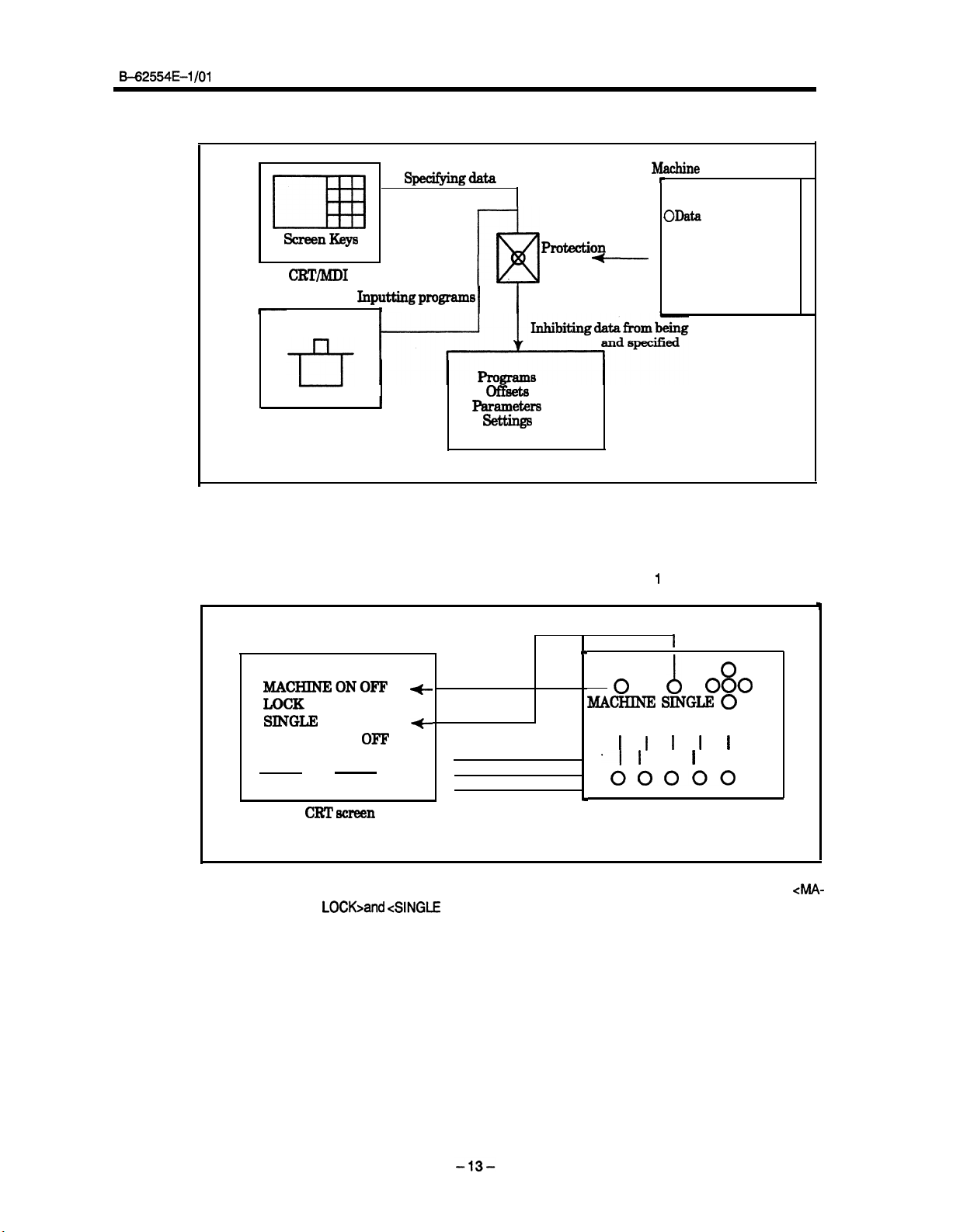

iv) Data protection key (See Section 10.8)

specifyingdata

1

J&chine

I

ScreenKeys

CRT/MD1

rnputtingpmgramB

1

I

Tape reader

Fig. 1 (r)

The protection key prevents the programs, offsets, parameters, and settings from being regis-

tered, changed, or deleted by mistake.

v) Menu switches and software operator’s panel (See Section 10.10 and I 0.12)

I

ollr3ets

Parameters

settings

CNC memory

Data Protection key

Pmtection

I

key

-

Signals

operator’s

r

I

OData

protection key

registered

panel

I

000

A

SINGLEi

I I I

0

0

I

MACHINEONOFF

LOCK

SINGLEi

BLOCK ON

OF’F

v

+

0

MA-

LOCK BLOCK

I I I I

-I I

00000

c

CRT screen

Turn on and off some of the switches provided for the machine operator’s panel

CHINE

LOCK>and ANGLE

BLOCK> switches on the CRT screen.

Machine

operator’s panel

such as

4MA-

Page 23

I.

INTRODUCTION

7) Display

Tool

p&ion

opelxdixlg CoxlditioIl

B=625!54E-1 /Ol

0

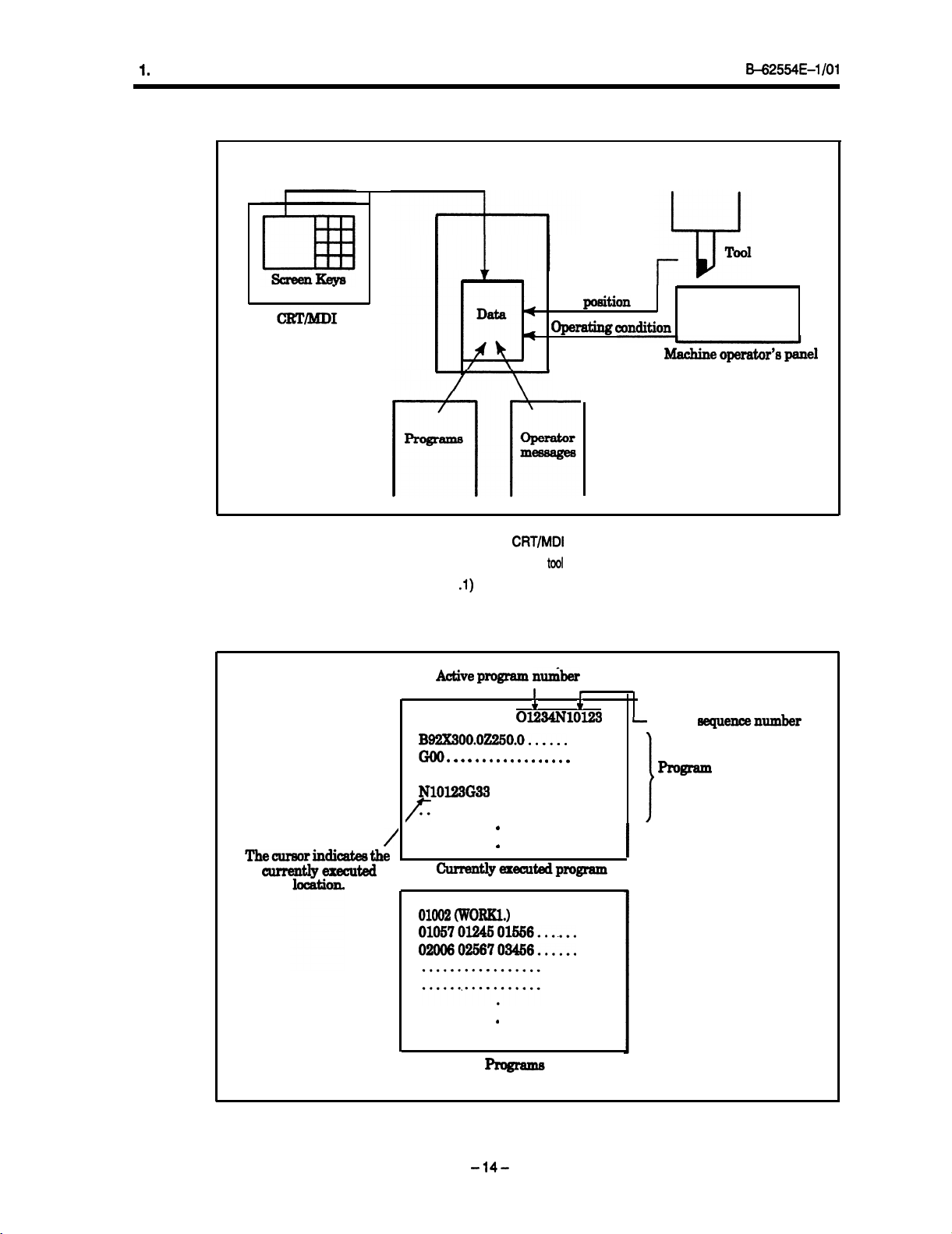

The contents of memory are displayed on the

The

memory contains information on

(i) Program display (See Section 11 A)

The contents of the currently active program are displayed.

and the program list are displayed.

Active program

CRT/MD1

programs,

tool

Ilkber

I

0

Ol234NlOl23

BQ2X300.02250.0......

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

GO1

Thecur8orindicate8the

/

currentlyexecuted

NlOl23G33

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

/’

currentlyeaecutedpmgram

. . . . . . . . . . .

.

.

Machine

screen.

position, and

I

+

suchlike.

In addition, the programs scheduled next

-

Active

program

content

opeator’s

mquencenumber

I

panel

01002(w0RlKl.)

01046

010570l24501556.......

0200602S6703456......

.

-14-

Page 24

B-62554E-1

/Ol

1.

INTRODUCTION

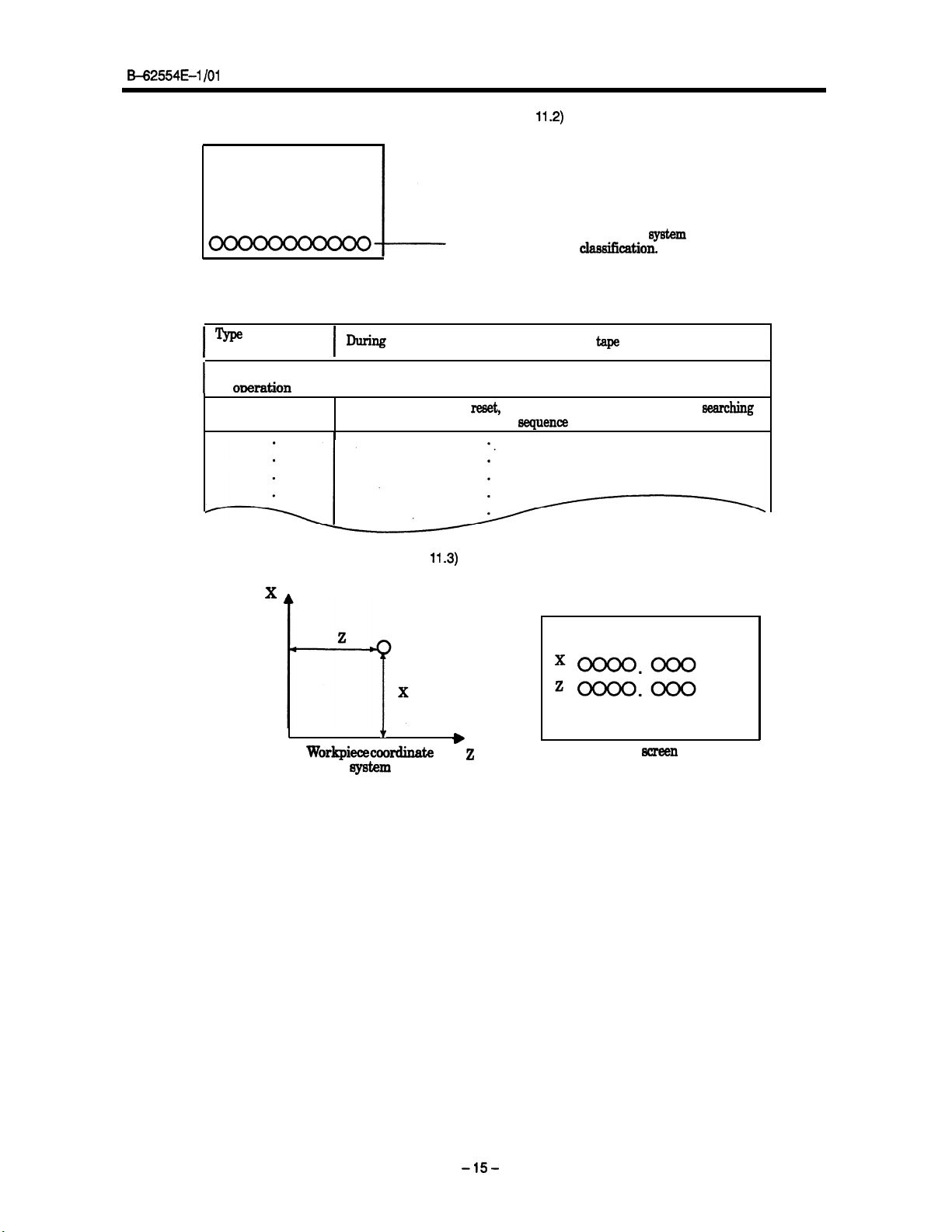

(ii) Displaying the state of the system (See Section

Displays the current state

CRT

screen

Type

of automatic

operation

I

Type of manual

oDeration

I

State of automatic When operation is

operation

(iii) Current position display (See

During

I

I

operation using memory,

During jog feed, handle feed, or incremental feed

11.3)

11.2)

of the

the

clawifkation.

MDI, or

tape

reset,

stopped, or suspended, or when

for a

6equence

number

system

accordingto

searching

x

f

CRT

Workpiececoordinate

system

The current position of the tool is displayed with the coordinate values.

position to the target position can also be displayed.

z

screen

The distance from the current

-1%

Page 25

1. INTRODUCTION

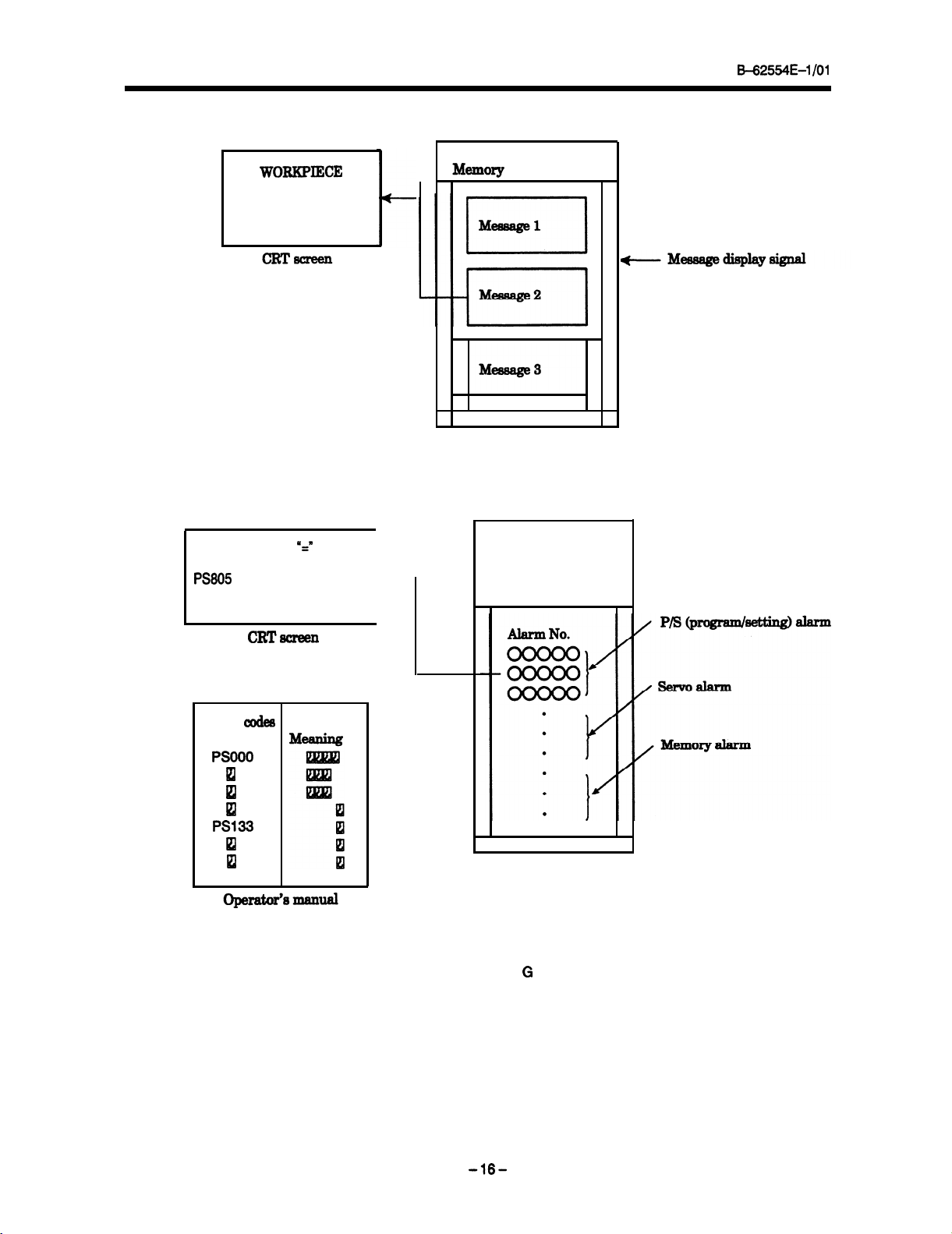

(iv) Displaying operator messages (See Section 11.4)

SET

(v) Displaying alarms (See Section 11.5)

B+2554E-1 /Ol

WORKPIEXE

When the system must notify the operator of necessary information during machining, the system dis-

plays the message preset in memory.

PSI33

MISSING

PS605

ILLEGAL COMMAND

CRTaxeen

Error

axles

Code

PSOOO

El

I

B

PS133

lzl

lzl

If a failure occurs while the machine is operating, the system displays the corresponding error code

and alarm message on the CRT screen.

For details of the error codes, see Appendix G in Operator’s Manual (Programming).

Y=w

t

-169

Page 26

B-62554E-1

/Ol

(Vi) Displaying the operating times

The system displays the following three operating times on the CRT

.

Value obtained by adding the automatic operating time

The system displays as follows the value obtained by adding the automatic operating time:

Example

10 hours 43 minutes 8 seconds

l

Value obtained by adding the cutting time

The system displays the value obtained by adding the time required for the machine to move by

cutting

feed (linear or circular interpolation).

.

General-purpose time display

The system adds and displays the elapsed time while the operating time count signal (an input

signal) is on. For the type of time displayed, refer to the manual issued by the machine tool builder.

These three types of operating times are displayed on the setting screen. For how to display data

on the setting screen, see Section 10.3.

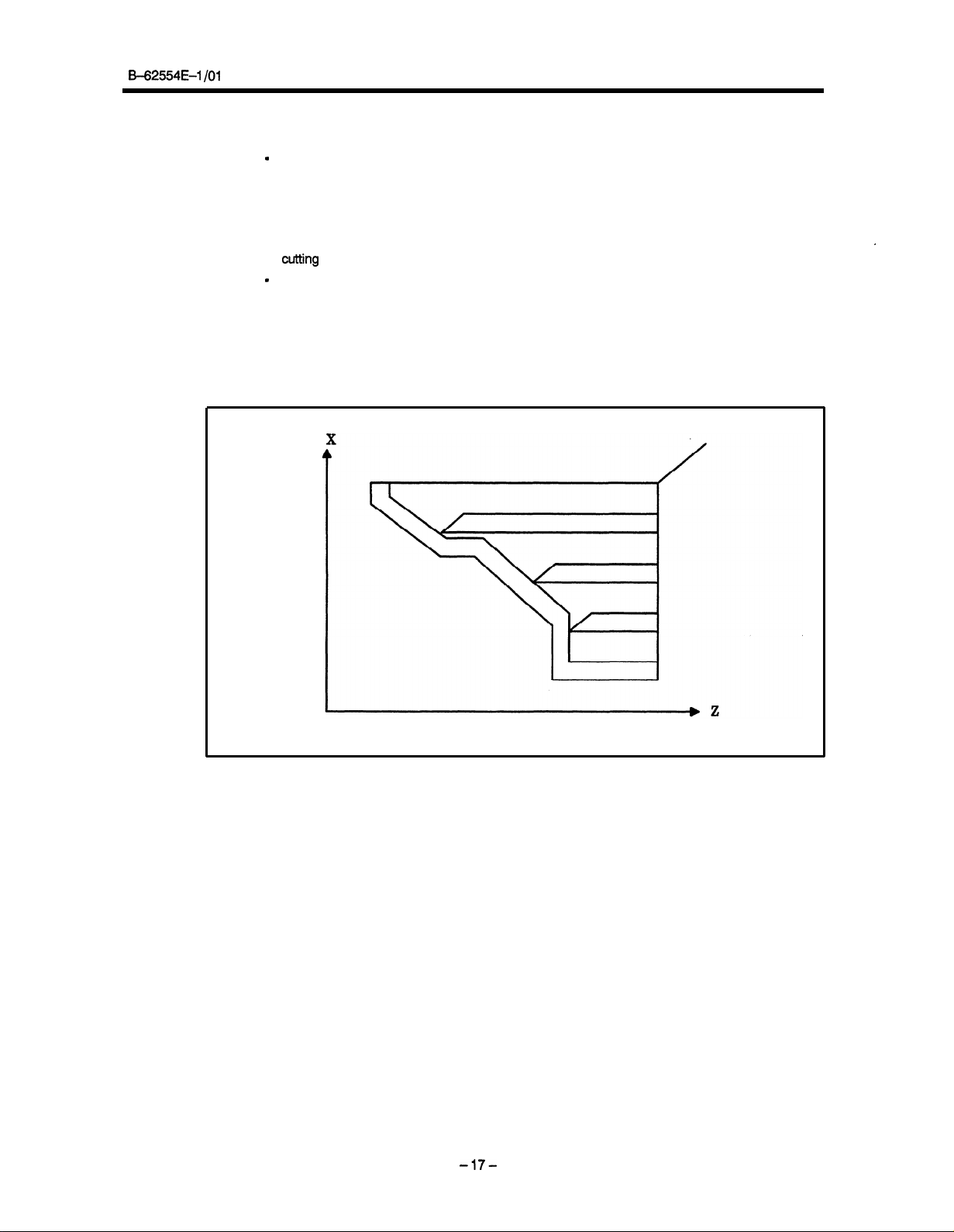

(vii) Graphic display

1.

INTRODUCTION

.

-17-

Page 27

1. INTRODUCTION

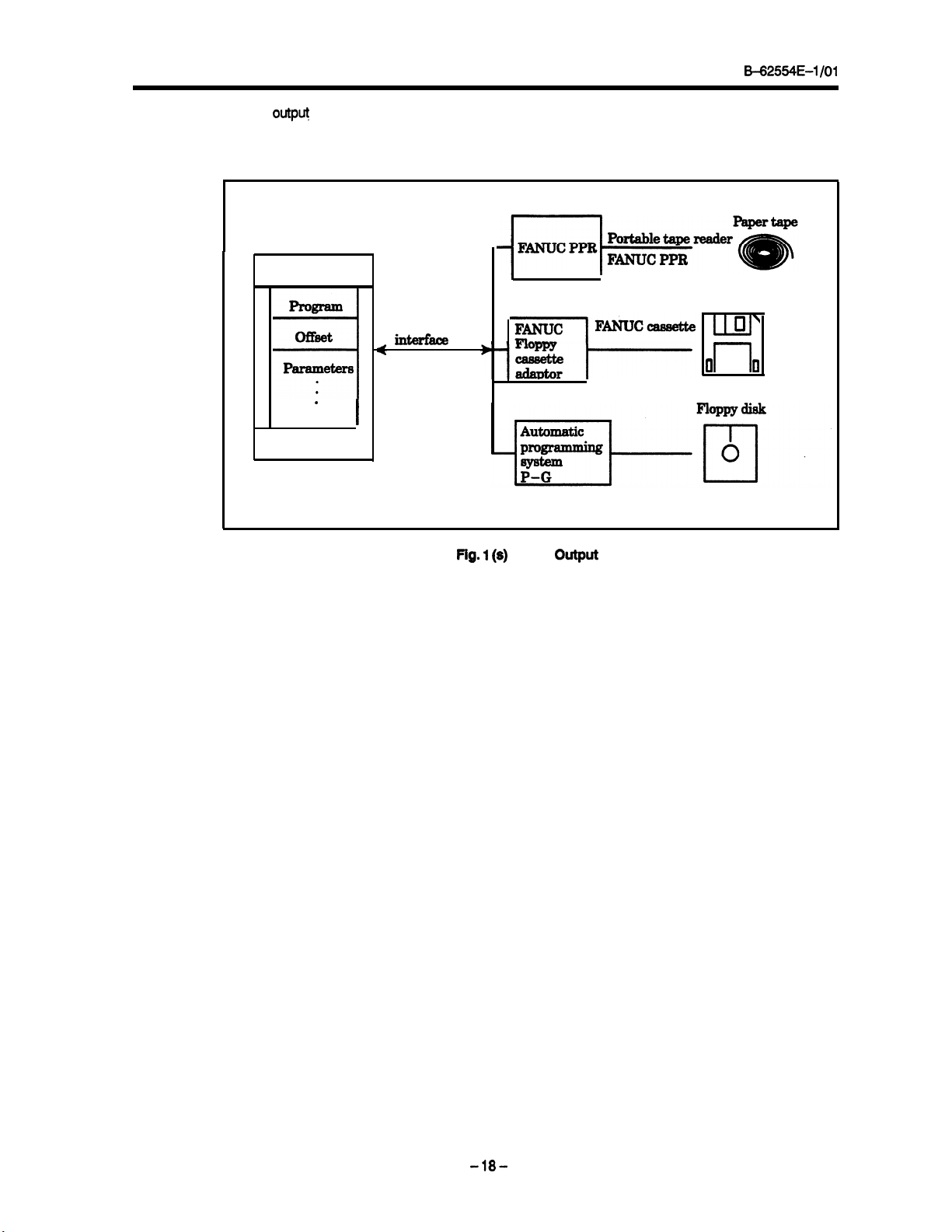

8) Data

Programs, offset values, parameters, etc. input in CNC memory can be output to paper tape, cassette,

or a floppy disk for saving. After once output to a medium, the data can be input into CNC memory.

output

(See Chapter 13)

Memory

B=62554E-1 /Ol

1

prograna

of&et

Parameters

.

.

4

.

CNC

Reader/puncher

iIlMB

I

Fig.

1

(s)

Data Output

LLU

0

rl

\

II

-18-

Page 28

B-62554~01 /Ol

2.

OPERATIONAL DEVICES

2.1

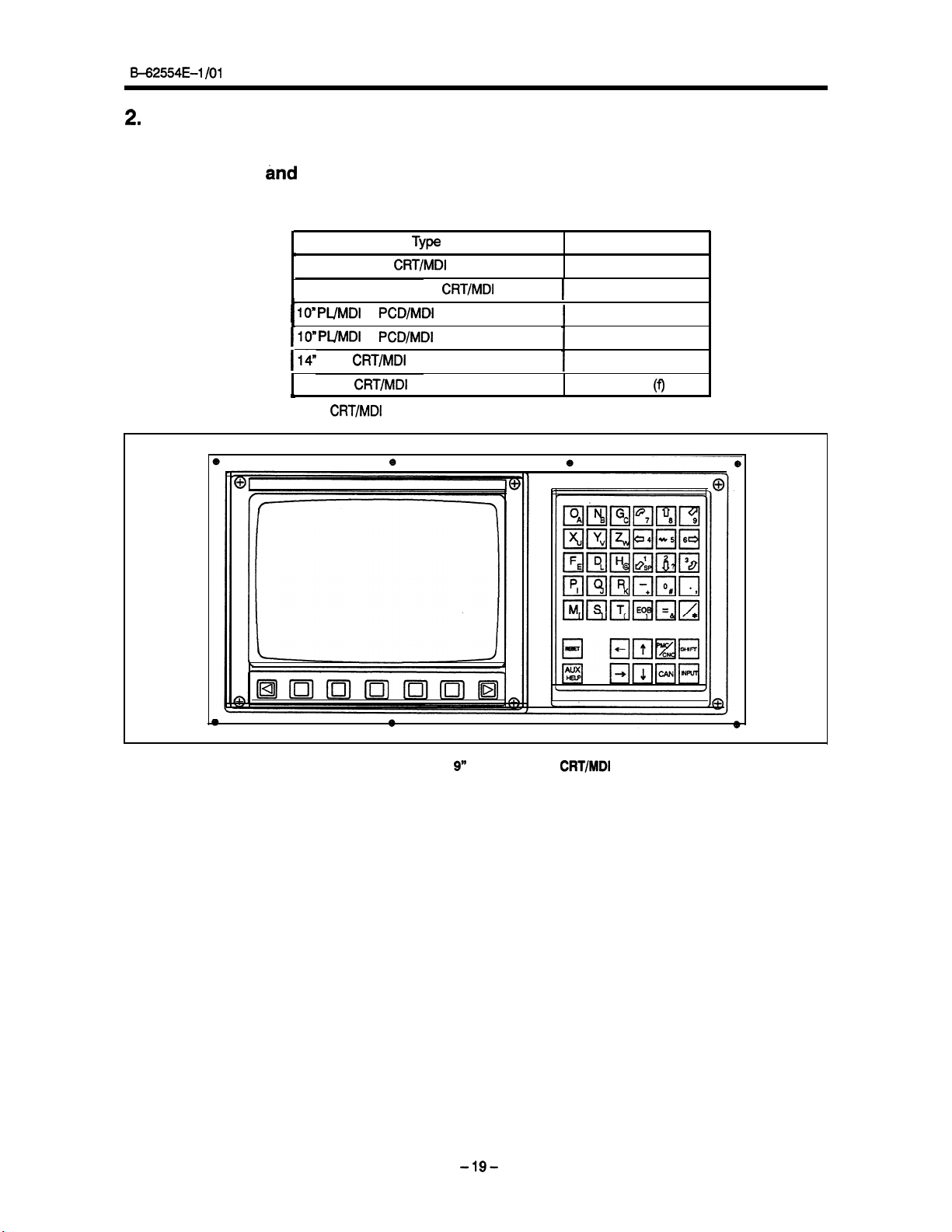

Setting

Setting and display units are classified into the following types.:

and

Display Unit

2. OPERATIONAL DEVICES

L

9” monochrome

9” color or monochrome

1 lo” PUMDI

110” PUMDI

114”

color

14” color

/

(a) 9” monochrome

or

or

CRT/MD1

CRT/MD1

CRT/MD1

Type

CRT/MD1

PCD/MDI

PCD/MDI

(Vertical)

(Horizontal)

(Small)

(Small)

CRT/MD1

(Vertical)

(Horizontal)

(Standard)

1

Remarks

Fig.

2.1

(a)

Fig. 2.1 (b)

Fig. 2.1 (c)

Fig. 2.1 (d)

Fig. 2.1 (e)

Fig. 2.1

(f)

Fig. 2.1

(a)9” monochrome

-19-

CRT/MD1

(Small)

Page 29

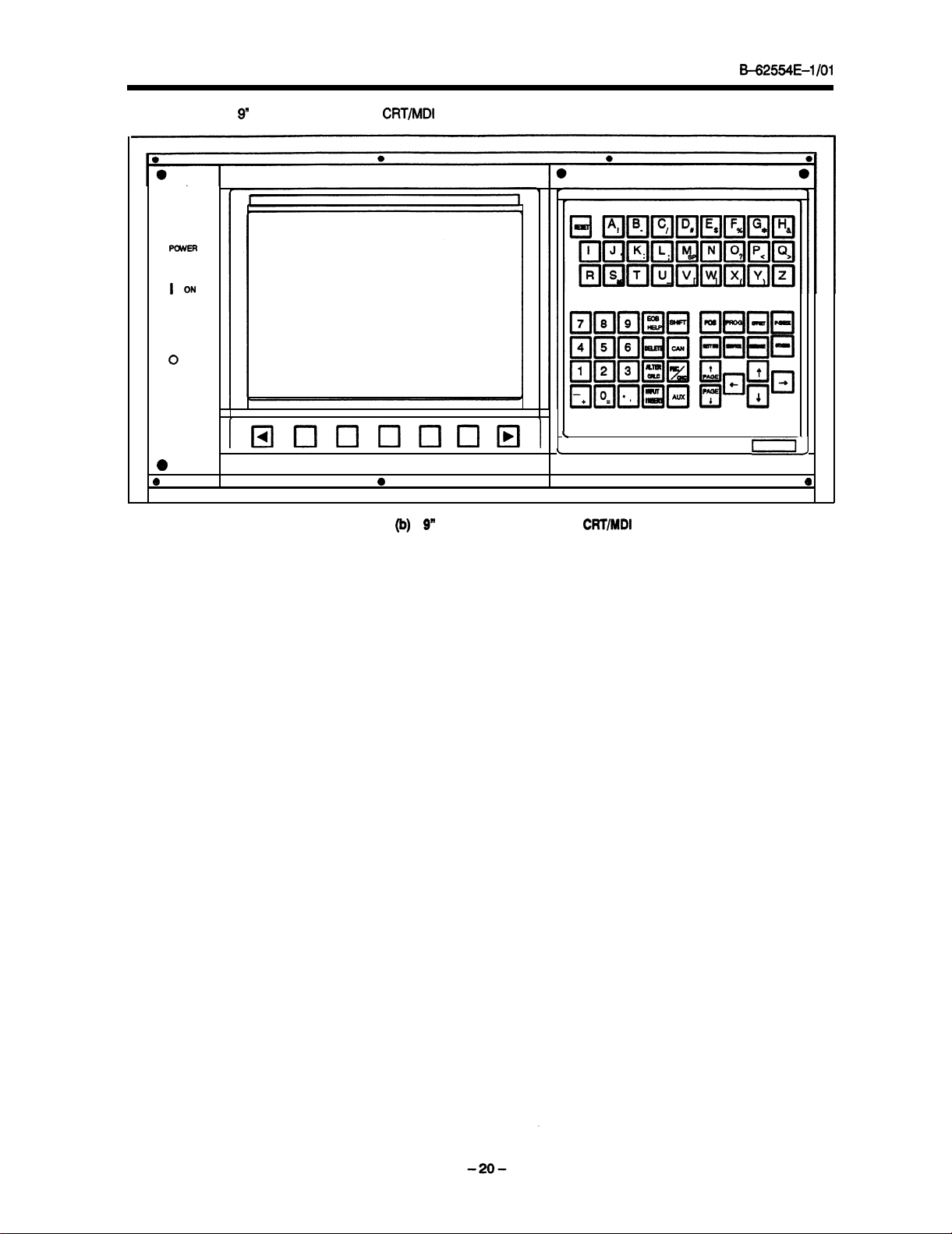

2. OPERATIONAL DEVICES

562554E-1 /Ol

PCMER

I

q

0

q

e

6

(b) 9” color or monochrome

ON

OFF

loooooool

CRT/MD1

6

Fig. 2.1

(Standard)

(b) 9”

color or monochrome

\

L

l

CRT/MD1

l

(Standard)

Q

El

El

J

0;

l

e

Page 30

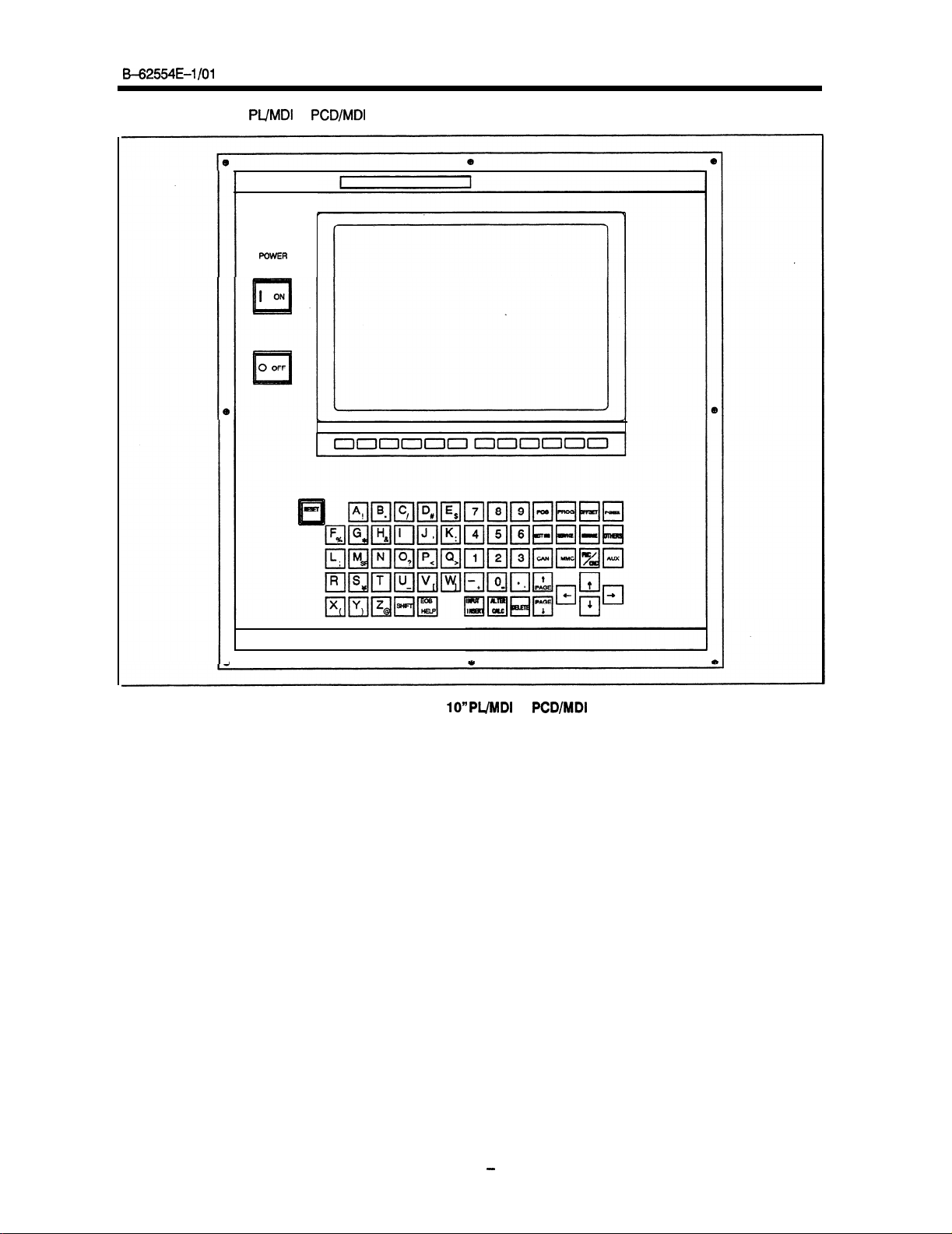

B+2554E-1 /Ol

(c) IO”

PIJMDI

POWER

or

PCD/MDI

(Vertical)

2.

OPERATIONAL DEVICES

a

Fig.

2.1 (c)

IO” PlJMDI

or

PCD/MDl

(Vertical)

-21

-

Page 31

2.

OPERATIONAL DEVICES

(d)

lO”PL/MDI

POWER

0

OFF

0

1

000000000000

or

PCD/MDI

(Horizontal)

B=62554E-1 /Ol

El

HH

Eiil

QQRliiil

1

Fig. 21

(d) 1O”PUlUDI

or

PCD/MDI

(Horizontal)

Page 32

B-625541=-1 101

(e)

14”color CRT/MD1

(Vertical)

2.

OPERATIONAL DEVICES

Fig. 2.1 (e)

14”color CRT/MD1

-23-

(Vertical)

Page 33

2. OPERATIONAL DEVICES

B-62554E-I /Ol

(f) 14”color CRT/MD1

1

000000000000

(Horizontal)

I

,

Fig. 2.1

0

(f) 14Volor

CFWMDI (Horizontal)

Page 34

B-62554E-l/O1

2.1.1

MDI

2. OPERATIONAL DEVICES

keyboard

POWER

(4)Function

)POWERon/offbuttons

menu key

e

(3)soft

keye

(2)RESET

(6)Opaation menu key

(6)Numerical keys

key

(6)Address

b

key

(oDlPwr/

-w t(13)m

(23)OTHERS key

(lS)P-CHECK key

q

change

key8

(24)EOB/HELP

key

(14)PMCYCNC

key

Page 35

2. OPERATIONAL DEVICES

B=62554E-1 /Ol

No.

(1)

<Power>

<RESET> key

(2)

(3) Soft key

(4)

Function menu key

Table 21.1

Name

ON/OFF button Press this button to turn CNC power ON and OFF

Press this key to reset the CNC, to cancel an alarm, etc.

The soft key has various functions, according to the Ap-

plications. The soft key functions are displayed at the

bottom of the CRT screen.

Pressing this key

selection keys (see Subsection 2.1.8) returns the soft

keys to the states of the function selection keys.

ing the key when the soft keys are function selection

keys changes the soft keys

that do not fit on the screen. (The 9”

five soft keys. The

However,

plications. In this case, a plus sign (+) is displayed at the

extreme right of the bottom line on the CRT The plus

sign indicates that some soft keys do

MDl

Keyboard

when the soft

these soft

14”

functions

Functions

to

CRT/MD1

keys are not sufficient for some ap-

(l/3)

keys are not function

the function selection keys

CRT/MD1

panel has ten soft keys.

not fit on the

screen.)

(5)

Operation menu key The functions of the soft keys vary according to the ap-

(6) Address/numerical key

(7)

<SHIFT> key

(8)

<INPUT/INSERT>

(9) ALTER key

key

plications. Pressing this key when the soft keys are not

operation selection keys changes the soft keys to the

operation selection keys that are effective on the selected CRT screen (see Subsection 2.1 .l 0).

this key when the soft keys are operation selection keys

changes the soft keys to the operation selection keys

that do not fit on the screen. (The 9”

five soft keys. The

However, these soft keys are not

plications. In this case, a plus sign (+) is displayed in the

rightmost frame of the bottom line on the CRT. The plus

sign indicates that some soft keys do not fit on the

screen.)

Press these keys to input alphabetic, numeric, and other

characters.

Some address keys are marked with two characters. To

enter the lower right character, press the shift key first.

When the shift key is pressed, A is displayed in the key

input buffer. This indicates that pressing the address key

enters the

I, *I $,

These characters can be used on the MMC screen.

When an address or numeric key is pressed, the data is

entered in the key input

CRT Press the input key to store the data entered in the

key input buffer in the offset register.

The input key is equivalent to an

ther may be used.

Pressing this key on the program editing screen inserts

the contents of the key input buffer after the position

where the cursor is located. The INSERT soft key has

the equivalent function. Either key can be used.

Pressing this key on the program editing screen replaces

the word where the cursor is located with the contents of

the key input buffer. The ALTER soft key has the equivalent function. Either key can be used.

,lower

\I -9 <, % :, ;, %

14”

CRT/MD1

c

right character.

’

buffer,

CRT/MD1

panel has ten soft keys.

sufficient

then displayed on the

<INPUT>

for some ap-

soft key.

Press-

panel has

Pressing

panel has

Ei-

.

-260

Page 36

B-62554E-1

/Ol

v

No.

(10) DELETE key

(11) Cancel

(12) Cursor move keys

(I 3)

Page change keys

(14)

PMC/CNC

(15) MMC key

(16) POS key

(17) PROG key

Name

<CAN>

switch key

key

2. OPERATIONAL DEVICES

MDI

Table 21.1

Pressing this key on the program editing screen deletes

’

the word where the cursor is located. The DELETE

WORD soft key has the equivalent function. Either key

can be used.

Pressing this key deletes a character or symbol input to

the key input buffer.

The contents of the buffer are displayed on the CRT The

position where a new entry is to be input is displayed with

an underscore

letes the character immediately before the underscore.

Example) When the contents of the key input buffer are

displayed as shown below,

>NOOI

Xl OOZ

pressing the

tents change as follows:

>NOOl

The following four cursor keys are provided:

--,

:

This key moves the cursor

ments.

The cursor is moved in the direction of order.

+

:

This key moves the cursor

ments.

The cursor is moved to the opposite direction.

4

:

This key moves the cursor for the key input buffer

forward when a character is entered in the key input buff-

er. The position of the cursor for the key input buffer is

indicated by an underscore. Pressing an address or nu-

meric key enters an address or number at the cursor

position. Pressing the cancel

character before the cursor position.

This key moves the cursor on the CRT

large increments when no data is entered in the key input

buffer.

The cursor is moved in the direction of order.

7

:

This cursor key moves the cursor for the key input

buffer backward. This key moves the cursor on the CRT

screen backward in large increments when no data is

entered in the key input buffer.

The cursor is moved to the opposite direction.

Two kinds of page change keys

c11x

CRT screen in the forward direction.

<

t

CRT

screen in

The small 9” monochrome

vided with page keys. Pressing the

keys simultaneously is equivalent to pressing the

page key. Pressing the c- and I’ cursor keys simultaneously is equivalent to pressing the t page key.

This key is used to determine whether the

el is used for the CNC or PMC.

Pressing this key enables the

MMC. This key is valid only when a CNC having the

MMC is used.

Pressing this key selects the current position display

screen. The POSITION soft key has the equivalent function. Either key can be used.

Pressing this key selects the part program display

screen. The PROGRAM soft key has the equivalent

function. Either key can be used.

Keyboard functions

Functions

(J.

Pressing the

CAN

key deletes Z and the displayed con-

Zl 00

This key is used to changeover the page on the

x

This key is used to changeover the page on the

the reverse direction.

CRT/MD1

(2/3)

CAN

(cancel) key de-

forward

backward

<CAN>

CRT/MD1

in small incre-

key deletes the

screen

are

described below.

panel is not pro-

--,

and 4 cursor

to be used in the

in small incre-

CRT/MD1

forward in

J1

pan-

-270

Page 37

2. OPERATIONAL DEVICES

B42554E-1 /Ol

No.

1

OFFSET key

P-CHECK key

WV

SETTING key

m

SERVICE key

(21)

MESSAGE key

(23

(23) OTHERS key

(24) HELP key

(SHlFT/EOB)

Arithmetic

(25)

<SHIFT>+<ATER>

(26) 1

<AlJX>

Name

<CALC>

key

Table 21.1

I

Pressing this key selects the tool’offset display screen or

the screen displaying offset from the workpiece reference

position. The OFFSET soft key has the equivalent func-

tion. Either key can be used.

Pressing this key selects the program check screen. The

P CHECK soft key has the equivalent function.

key can be used.

Pressing this key selects the setting screen. The SET-

TING soft key has the equivalent function. Either key

CanbeuSed.

Pressing this key selects the parameter and diagnosis

screen. The MAINTENANCE soft key has the equivalent

function. Either key can be used.

Pressing this key selects the screen for alarm messages

and operator messages. The MESSAGE soft key has

the equivalent function. Either key can be used.

Pressing this key selects and displays the screen speci-

fied with parameter No.

Pressing this key displays the help window on a screen.

Alarm help, soft key help, and G code guide can be dis-

played. For details, see Help Functions.

Press this key to execute operation commands in the key

key

input buffer.

Example) When the data in the key input buffer is

20 x 30 +

the data in the key input buffer is changed to 660.

The arithmetic key is standard.

1

Auxiliary key

MDI

Keyboard functions

Functions

2215.

400/8],

the arithmetic key is pressed. Then,

(3/3)

Either

[lo

+

-280

Page 38

&-62554E-1

2.1.2

2.1.3

/Ol

2. OPERATIONAL DEVICES

Contents to be displayed and operations when the MMC is installed

The data to be displayed and key input operations vary entirely according to whether the MMC screen or CNC/

PMC screen is displayed on the

The MMC switch key and

PMC screen is displayed.

When the

cal to those for the Series 15-MB.

This manual describes the contents displayed and the operations when the CNC screen is selected.

to the machine tool builder’s manual for the contents displayed and the operations when the MMC screen is

selected.

(1) Selecting the MMC screen

(2) Selecting the

CNC/PMC

Press the MMC switch key to select the MMC screen.

Press the

screen

played displays the CNC screen.

Press the

CNC or PMC screen) before pressing the MMC switch key.

screen is selected, the contents displayed on the

CNC/PMC

CNC/PMC

is displayed displays the PMC screen.

CNC/PMC

key while the MMC screen is displayed to change the display mode (to display the

CRT/MD1

CNC/PMC

screen

key to display the

panel.

switch key are used to determine whether the MMC screen or the

CNC/PMC

Pressing the

screen.

CRT/MD1

Pressing the

CNC/PMC

key while the PMC screen is dis-

CNC/

and the operations are identi-

Refer

CNC/PMC

key while the

CNC

Changing the contents of the key input buffer

Inserting characters

(1)

The contents of the key input buffer are displayed on the CRT. When the next address or numeric key is

pressed, the corresponding character is inserted at the cursor position indicated by an underscore.

the +- or

Move the cursor to the desired position, then enter the desired characters.

Example

To enter

@ Press the

@ Enter 690 by pressing the corresponding address and numeric keys.

@ Press the

Deleting characters

(2)

Move the cursor to the position after the characters to be deleted, then press the

key is pressed in the shift

Example

To delete

@ Press the -+ cursor key to move the cursor to the desired position:

@ Press the

@ Press the

t-e

cursor key to move the cursor.

Contents of the key input

GQO

after NO01 in this case, perform the following:

+--,

cursor key to move the cursor to the desired position:

>NOOl

Xl OO.OY2OO.OF1OO.O;

>NOOl

GQO Xl OO.OY2OO.OF1OO.O;

&-

cursor key to move the cursor to the following position:

>NOOl GQOXI

>NOOl

>NOOl

>NOOl

OO.OY2OO.OF1OO.O;

state,

all data in the key input buffer is deleted.

Contents of the key input buffer displayed:

Y200.0,

perform the following:

Xl

OO.OY200.0 FlOO.0;

<CAN>

key five times.

Xl 00.0

Xl

FlOO.0;

+-Ccursor

OO.OF100.0;

key to move the cursor to the following position:

buffer

-

displayed:

>NOOl

Xl

OO.OY2OO.OFl

>NOOl Xl OO.OY2OO.OF1

OO.O;_

<CAN>

OO.O;_

key.

If the

Press

<CAN>

.

2.1.4

Warning message

Data must be input in the specified format.

in the key input buffer in order to execute some operations, a warning message is displayed.

The warning message is displayed in highlighted characters in the line above the key input buffer field.

characters are displayed at higher intensity on the 9” monochrome CRT or in purple on the 14” color CRT.

When a warning message is displayed, the soft keys function as cancel keys. When the cancel key (soft key)

is pressed, the warning message is canceled.

fied format. Then, the operations specified by the data can be executed again.

2.1.5

Soft key display

The 9”

CRT/MD1

the five soft keys on the 9”

panel has five soft keys. The 14”

.

CRT/MD1

If an attempt is made to input data that violates the specified format

Change

panel. The soft keys are displayed as follows:

the

format of the data in the key input buffer to the speci-

CRT/MD1

panel has ten soft keys. This manual describes

The

Page 39

2.OPERATlONALDEVlCES

B-62554E-1

/Ol

b

POSITION PROGRAM

OFFSE'f PRG-CHK CHAPTER

/

+

The plus sign in the rightmost frame indicates that there are other soft keys that do not fit on the CRT

The same basic method for operating soft keys applies to both the 14”

the 9”

CRT/MD1

panel with five soft keys.

Obviously, it is not necessary to scroll the soft keys on the 14” CRT/

CRT/MD1

panel with ten soft keys and

MDI panel.

When some soft keys for setting operations or operation guidance are pressed, processing is executed immediately. These keys are underlined on the screen.

1

EXEC

t

Underlined soft keys are displayed at higher intensity on the 9” monochrome CRT They are displayed in green

on the 14” color CRT

Some soft keys are displayed in parentheses on the screen.

When these soft keys are pressed, a message prompting the operator to enter the corresponding data is dis-

played.

When the soft keys are Insufficient

2.1.6

As

mentioned above, the 9”

equipped with ten. These soft keys may be insufficient for some applications. When the soft keys are used

as function selection keys, for example, up to seven functions can be selected.

is displayed in the rightmost frame of the bottom line on the 9”

(1) When the soft keys are used as function selection keys

When

the

function

of the bottom line, the soft keys change to the function selection keys that do not fit on the screen.

(2) When the soft keys are used as operation selection keys

When the operation menu key (rightmost key) is pressed while the plus sign is displayed in the rightmost

frame of the bottom line, the soft keys change to the operation selection keys that do not fit on the screen.

(3) When the soft keys are used as chapter selection keys

When the chapter selection menu key (soft key) is pressed

frame of the bottom line, the soft keys change to the chapter selection keys that do not fit

CRT/MD1

panel is equipped with five soft keys and the

14” CRT/MD1

In this case, the plus sign (+)

CRT/MD1

CRT

menu key (leftmost key) is pressedwhilethe plus sign is displayed in the rightmost frame

while the

plus sign is displayed in the rightmost

on the screen.

panel is

-3o-

Page 40

B-62554E-1 /Ol

2.1.7

The soft keys are used as either function selection keys, chapter selection keys, operation selection keys, or

operation guidance keys.

The procedure for changing the function of the soft keys is tis follows:

2. OPERATIONAL DEVICES

Changing soft keys

(1) Changing the soft keys to the function selection keys

Pressing the leftmost function menu key changes the soft keys to the function selection keys.

(2) Changing the soft keys to the chapter selection keys

a

Selecting chapters in the function selection key state

( 1

The currently selected function key is displayed at higher intensity on the 9”

on the 14”

sequence.

Changing the soft keys from the function selection keys to the chapter selection keys

(b)

Pressing the

tion keys to the chapter selection keys. Select the desired chapter by pressing the soft keys. To return

the soft keys to the function selection keys, press the function menu key. To return the soft keys to

the operation selection keys, press the operation menu key.

C

Selecting chapters in the operation selection key state

0

To enable chapter selection when the soft keys are used as operation selection keys, use the soft keys

as both the operation selection keys and the chapter selection keys. To switch between these modes,

press the operation menu key. Pressing the chapter selection keys selects new chapters. To return

the soft keys to the operation selection keys, press the operation menu key.

(3) Changing the soft keys to the operation selection keys

(a) Pressing the rightmost operation menu key changes the soft keys to the operation selection keys in

whichever state the soft keys may be.

(b) Entering data in the key input buffer when the soft keys are used as the function selection keys is as-

sumed to be an attempt by the operator to execute an operation.

change to the operation selection keys.

(4) Changing the soft keys to the operation guidance keys

(a) Changing the

Press the operation selection key.

The following block diagram (Fig2.1.7) shows how to change the soft keys through their various

modes.

CRT/MD1

panel. Whenever the function key is pressed, new chapters can be selected in

<CHAPTER>

s@t

soft key (rightmost soft key) changes the soft keys from the function

keys from the operation selection keys to the operation guide keys

CRT/MD1

The soft keys then automatically

panel or in green

selec-

-31.

Page 41

2. OPERATIONAL DEVICES

B=62554E-I/O1

bww~w--w-----J

-w

Function menu key

~---r~-----rJ

.

r---~---r.w-rr---r-~

i kxt

operation selection key

~-~~-r-rrr~~~--~r-r-J

T

Operationmenukey

t

4

Not empty

Function

:

BelectioIl

4

Key

key

.l

input

I

Operationkey

cbapterselection

@oft

hnction menu key

.

I

Operation menu key

J

I

I

v

key)

v ‘I

.

I

.

Fig.

21.7

Changing method of

-320

*

softkey

Page 42

B-62554&1 /Ol

2.1.8 Outline of operations

Select the data to be displayed and the major item to be entered on the

selection key (soft key).

Each major item is divided into minor items (called chapters). Select a chapter with the chapter selection

soft key.

To perform a certain operation such as data input, select the operation with the operation selection soft key.

Pressing the operation selection key changes the soft key to the operation guide key. The executable operations can be checked with the operation guidance key.

Pressing some operation guidance keys immediately executes the corresponding operation. However,

pressing other operation guidance keys displays a prompt for the operator to enter the data required for

starting the corresponding operation.

Operation guidance keys that immediately execute an operation are displayed in higher intensity on the

9” monochrome CRT or in green on the

displayed in blue-green.

When operation guidance keys that displays a prompt for the operator to enter the required data is pressed,

if the address that corresponds to the data has been determined, the system automatically enters the address into the key-input buffer. Otherwise, the operator determines the address and inputs the data.

When the necessary data is entered in the key input buffer, the soft key changes to the EXEC key which

starts execution.

Press the EXEC key after the necessary data is entered in the key input buffer. The corresponding opera-

tion is then performed.

14”

color CRT

2.

OPERATIONAL DEVICES

CRT/MD1

Operation guidance keys that display a prompt are

panel with the function

2.1.9 Function selection keys

Both soft keys and the keys on the MDI panel (hard keys) can be used to select a function. When using the

soft keys to select a function, first press the function selection menu key to display the function selection soft

keys, then press the corresponding function selection soft key.

You can also select a function by pressing the corresponding hard key on the MDI panel.

Functions can be selected in any mode.

Detailed function selection is performed with the chapter selection soft keys.

The following function selection keys are provided:

(Soft key)

POSITION PROGRAM

SETTING SERVICE MESSAGE CHAPTER +

(Hard key)

POS PROG OFFSET P CHECK SETTING SERVICE MESSAGE OTHERS

IIIIIIL-IInn

(1)

[POSITION] soft key or

Press this key to select the current-position screen.

(2) [PROGRAM] soft key or

Press this key to select the part-program screen.

.

OFFSET

<PO&

<PROG>

PRG-CHK CHAPTER +

4

\

hard key

hard key

-330

Page 43

2. OPERATIONAL DEVICES

B=62554E-l/O1

[OFFSET] soft key or

Press this key to select the tool offset screen or the screen for the offset from the workpiece reference point.

[PRG-CHK] soft key or <P-CHECK> hard key

Press this key to select the program check screen.

[SETTING] soft key or

Press this key to select the setting screen.

[SERVICE] soft key or

Press this key to select the parameter or diagnosis screen.

[MESSAGE] soft key or <MESSAGE> hard key

Press this key to select the alarm or operator message screen.

OTHERS

Press this key to display the screen for a function other than those described in steps (1) to

a graphics screen. Parameter No. 2275 is used to assign a function to this soft key.

2.1.10

Chapter selection keys

The function selection keys are used to select major items. Each major item is divided into minor items called

chapters. The chapter selection keys are used to select the chapters.

To select a chapter, change the soft keys to

key.

(1) Chapter selection keys on the position screen

The chapter selection keys on the position screen are as follows:

<OFFSET>

<SETTING>

<SERVICE>

hard key

hard key

hard key

the

chapter selection keys, then press the desired chapter selection

(select<POSITION>function

key)

(7),

such as

OVERALL

(a) [OVERALL] key

Press this key to select the overall-position screen on the position screen.

(b)

[RELATIV]

Press this key to select the relative-position screen on the position screen.

(c)

WSOLLCTJ

Press this key to select the screen for the positions in the workpiece coordinate system on the position

screen.

(d)

[MACHINEI

Press this key to select the screen for the positions in the machine coordinate system on the position

screen.

(2) Program chapter selection keys

The program chapter selection keys are as follows:

Press this key to select the program text screen.

(b) [DIR.MEM] key

Press this key to select the screen for the programs stored in the program memory (directory).

screen displays the program numbers, program names, and other information.

RELATIV ABSOLUT

key

key

key

(select<PROGRAM>function

MACHINE

.

key)

This

-34-

Page 44

B-62554E-1

/Ol

2. OPERATIONAL DEVICES

(3) Offset chapter selection keys

(selectcOFFSET>function

key)

The offset chapter selection keys are as follows:

GEOM.

WRKZER

(a) WEAR] key, [GEOM.] key

Press this key to select the tool offset screen.

(b) wRK.ZER] key

Press this key to select the screen for the offset from the workpiece reference point.

(4)

Command-value chapter selection keys (select <PRG-CHK> function key)

The command-value chapter selection keys are as follows:

\

LAST

BUFFER3

a

LAST

( 1