GE GFDN240GL0WW, GFDN245GL0MS, GFDN245GL1BB, GFDN245GL1MG, GFDN245GL1MS Installation Guide

...Page 1

Installation

Instructions

Questions on Installation? Call: 1-800-GECARES (US)or 1-800-561-3344 (Canada)

BEFORE YOU BEGIN

Readthese instructions

completely and carefully.

•IMPORTANT- save these

instructions for local inspector's

use.

•IMPORTANT- Observe all

governing codes and ordinances.

• Note to Installer - Be sure to

leave these instructions with the

customer.

• Note to Customer - Keep

these instructions with your

Useand Cure Book for future

reference.

• Before the old dryer is removed

from service or discarded,

remove the dryer door.

• Service information and the

wiring diagram are located in

the control console.

• Do not allow children on or in

the appliance. Closesupervision

of children is necessary when

the appliance is used near

children.

• Install the dryer where the

temperature isabove 50°F for

satisfactory operation of the

dryer control system.

GasDryer l@

20 ®

or Visit our Web site at: www.GEAppliances.com (US)

-&WARNING RISK OF FIRE

•To reduce the risk of severe injury or death, follow all installation instructions.

• Clothes dryer installation must be performed by a qualified installer.

• Install the clothes dryer according to these instructions and in accordance with local

codes.

• California Safe Drinking Water and Toxic Enforcement Act

This act requires the governor of California to publish a list of substances known to the

state to cause cancer, birth defects or other reproductive harm and requires businesses

to warn customers of potential exposure to such substances. Gas appliances can

cause minor exposure to four of these substances, namely benzene, carbon monoxide,

formaldehyde and soot, caused primarily by the incomplete combustion of natural gas

or LPfuels. Properly adjusted dryers will minimize incomplete combustion. Exposure to

these substances can be minimized further by properly venting the dryer to the outdoors.

• This dryer must be exhausted to the outdoors.

• Use only rigid metal 4" diameter ductwork inside the dryer cabinet and use only UL

approved transition ducting between the dryer and the home duct.

• DONOTinstall a clothes dryer with flexible plastic ducting materials. If flexible metal

(semirigid or foil-type) duct is installed, it must be ULlisted and installed inaccordance

with the instructions found in "Connecting The Dryer To House Vent" on page 5 of this

manual. Flexible venting materials are known to collapse, be easily crushed, and trap

lint. Theseconditions will obstruct dryer airflow and increase the risk of fire.

• Do not install or store this appliance in any location where it could be exposed to

water and or weather.

• Savethese instructions. (Installers: Be sure to leave these instructions with the

customer).

IN THE COMMONWEALTH OF MASSACHUSETTS

• This product must be installed by a licensed plumber or gas fitter.

• When using ball-type gas shut-off valves, they shall bethe T-handle type.

• A flexible gas connector, when used, most not exceed 3 feet.

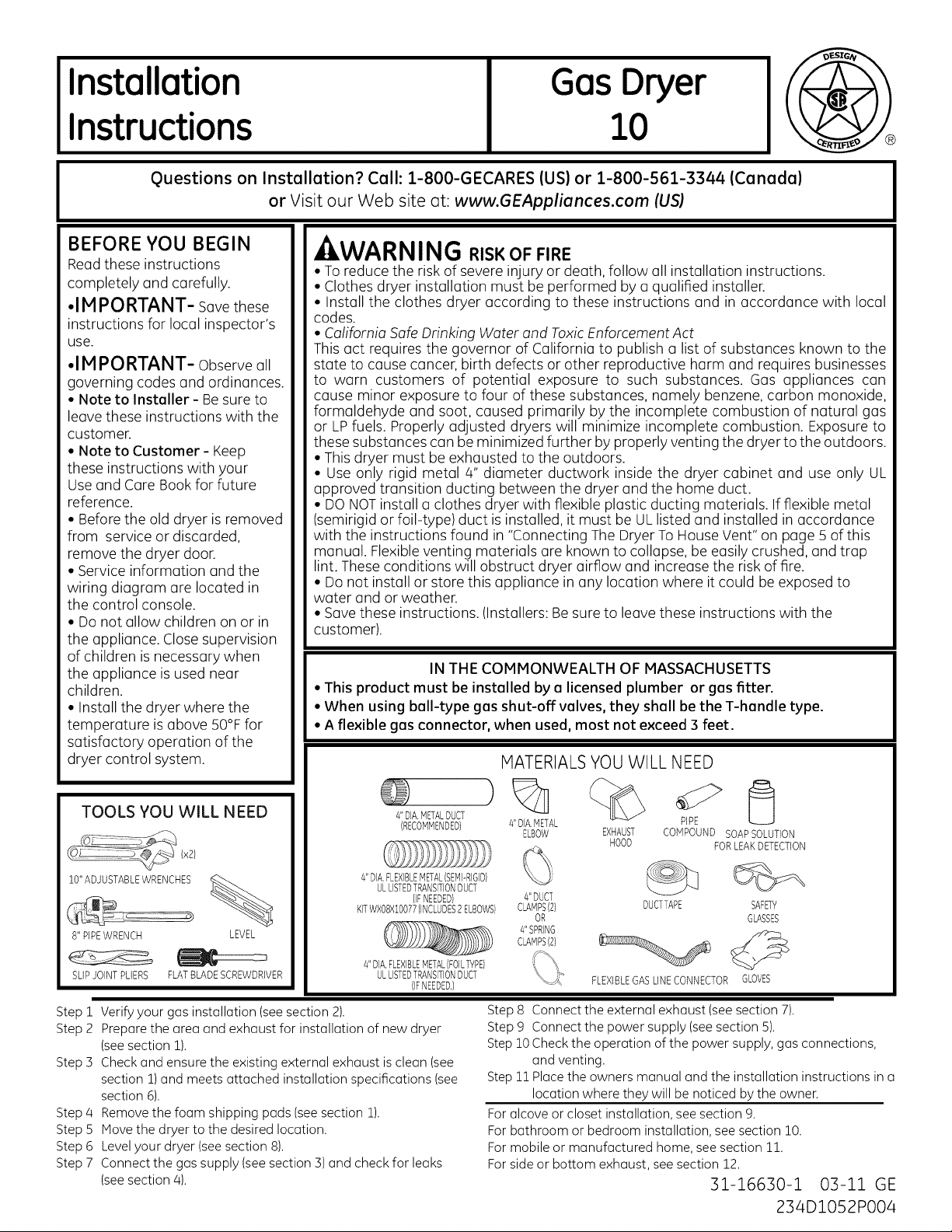

MATERIALSYOU WILL NEED

TOOLS YOU WILL NEED

10"ADJUSTABLEWRENCHES

8" PIPEWRENCH LEVEL

SLIPJOINTPLIERS FLATBLADESCREWDRIVER

Step 1

Verify your gas installation (see section 2).

Prepare the area and exhaust for installation of new dryer

Step 2

(seesection 1).

Step 5

Check and ensure the existing external exhaust is clean (see

section 1)and meets attached installation specifications (see

section 6).

Remove the foam shipping pads (see section 1).

Step 4

Step 5

Move the dryer to the desired location.

Step 6

Level your dryer (seesection 8).

Step 7

Connect the gas supply (seesection 3) and check for leaks

(seesection 4).

)

4"DIA,METALDUCT

(RECOMMENDED}

4"DIA,FLEXIBLEMETAL(SEMI-RIGID}

ULLISTEDTRANSITIONDUCT

KITWXO8X10077(INCLUDES2ELBOWS}

4"DIA,FLEXIBLEMETAL(FOILTYPE}

(IFNEEDED}

ULLISTEDTRANSITIONDUCT

(IFNEEDED.}

Step8 Connectthe externalexhaust(seesection7).

Step9 Connectthe powersupply(seesection5).

Step10Checkthe operationof the powersupply,gasconnections,

Step11Placethe ownersmanualandthe installationinstructionsina

Foralcoveor closet installation,see section9.

Forbathroomor bedroominstallation,seesection10.

Formobileor manufacturedhome,seesection 11.

Forsideor bottom exhaust,seesection12.

4"DIA,METAL

ELBOW EXHAUST

4"DUCT

CLAMPS(2}

OR

4"SPRING

CLAMPS(2}

FLEXIBLEGASLINECONNECTOR GLOVES

HOOD

PIPE

CONPOUND SOAPSOLUTION

FORLEAKDETECTION

DUCTTAPE SAFETY

GLASSES

and venting.

locationwheretheywillbe noticedbythe owner.

31-16630-1 03-11 GE

234D1052P004

Page 2

Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides, 1 in. front 3 in. rear.

Consideration must be given to provide adequate clearance for installation and service.

m PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better access when installing dryer exhaust.

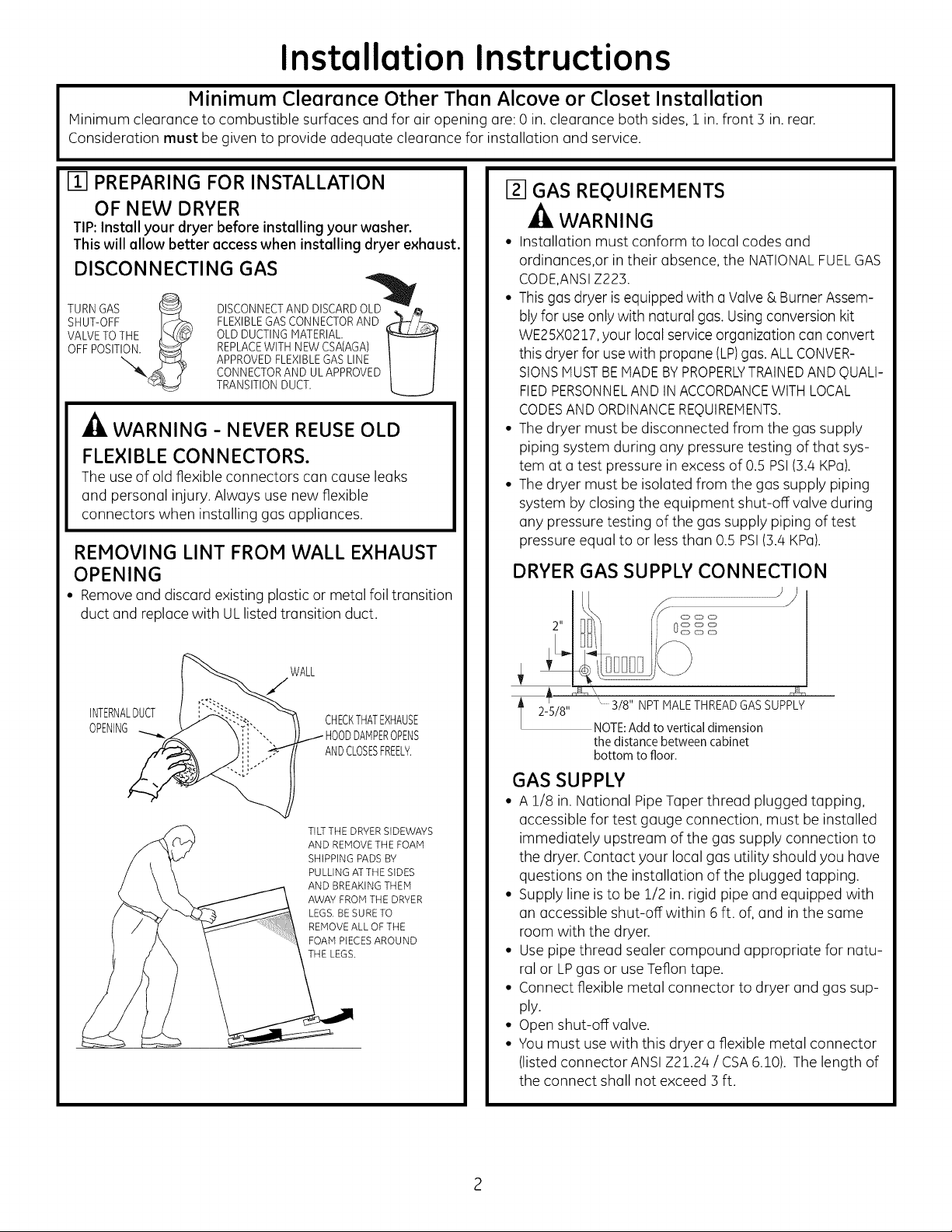

DISCONNECTING GAS

TURN GAS _ DISCONNECT AND DISCARD OLu_. _

SHUT-OFF IF:;_ FLEXIBLEGAS CONNECTOR AND _-h_-__,--_

VALVETOTHE _t_ _ OLD DUCTING MATERIAL

OFF POSITION._ REPLACEWITH NEW CSA(AGA)

APPROVED FLEXIBLEGAS LINE

CONNECTOR AND UL APPROVED

TRANSITIONDUCT.

A

WARNING - NEVER REUSE OLD

FLEXIBLE CONNECTORS.

The use of old flexible connectors can cause leaks

and personal injury. Always use new flexible

connectors when installing gas appliances.

REMOVING LINT FROM WALL EXHAUST

OPENING

• Removeand discard existing plastic or metal foil transition

duct and replace with ULlisted transition duct.

Izl GAS REQUIREMENTS

-_ WARNING

• Installation must conform to local codes and

ordinances,or intheir absence, the NATIONALFUELGAS

CODE,ANSIZ223.

• This gas dryer is equipped with o Valve & Burner Assem-

blyfor use only with natural gas. Usingconversion kit

WE25X0217,your local service organization con convert

this dryer for usewith propane (LP)gas. ALLCONVER-

SIONSMUSTBEMADEBYPROPERLYTRAINEDANDQUALI-

FIEDPERSONNELAND IN ACCORDANCEWITHLOCAL

CODESANDORDINANCEREQUIREMENTS.

• The dryer must be disconnected from the gas supply

piping system during any pressure testing of that sys-

tem at a test pressure in excess of 0.5 PSI(3.4 KPa).

• The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI(3.4 KPa).

DRYER GAS SUPPLY CONNECTION

J#

WALL

INTERNALDUCT

OPENING ODDAMPEROPENS

CHECKTHATEXHAUSE

ANDCLOSESFREELY.

TILTTHE DRYERSIDEWAYS

AND REMOVETHE FOAM

SHIPPING PADS BY

PULLING ATTHE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS, BE SURE TO

REMOVEALL OF THE

FOAM PIECESAROUND

THE LEGS,

3/8" NPT MALE THREADGAS SUPPLY

NOTE:Add to vertical dimension

the distance between cabinet

bottom to floor.

GAS SUPPLY

• A 1/8 in. National PipeTaper thread plugged tapping,

accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to

the dryer. Contact your local gas utility should you have

questions on the installation of the plugged tapping.

• Supply line is to be 1/2 in. rigid pipe and equipped with

an accessible shut-off within 6 ft. of, and in the same

room with the dryer.

• Use pipe thread sealer compound appropriate for natu-

ral or LPgas or use Teflon tape.

• Connect flexible metal connector to dryer and gas sup-

ply.

• Open shut-off valve.

• You must use with this dryer a flexible metal connector

(listed connector ANSIZ21.24 / CSA6.10). The length of

the connect shall not exceed 3 ft.

2

Page 3

Installation Instructions

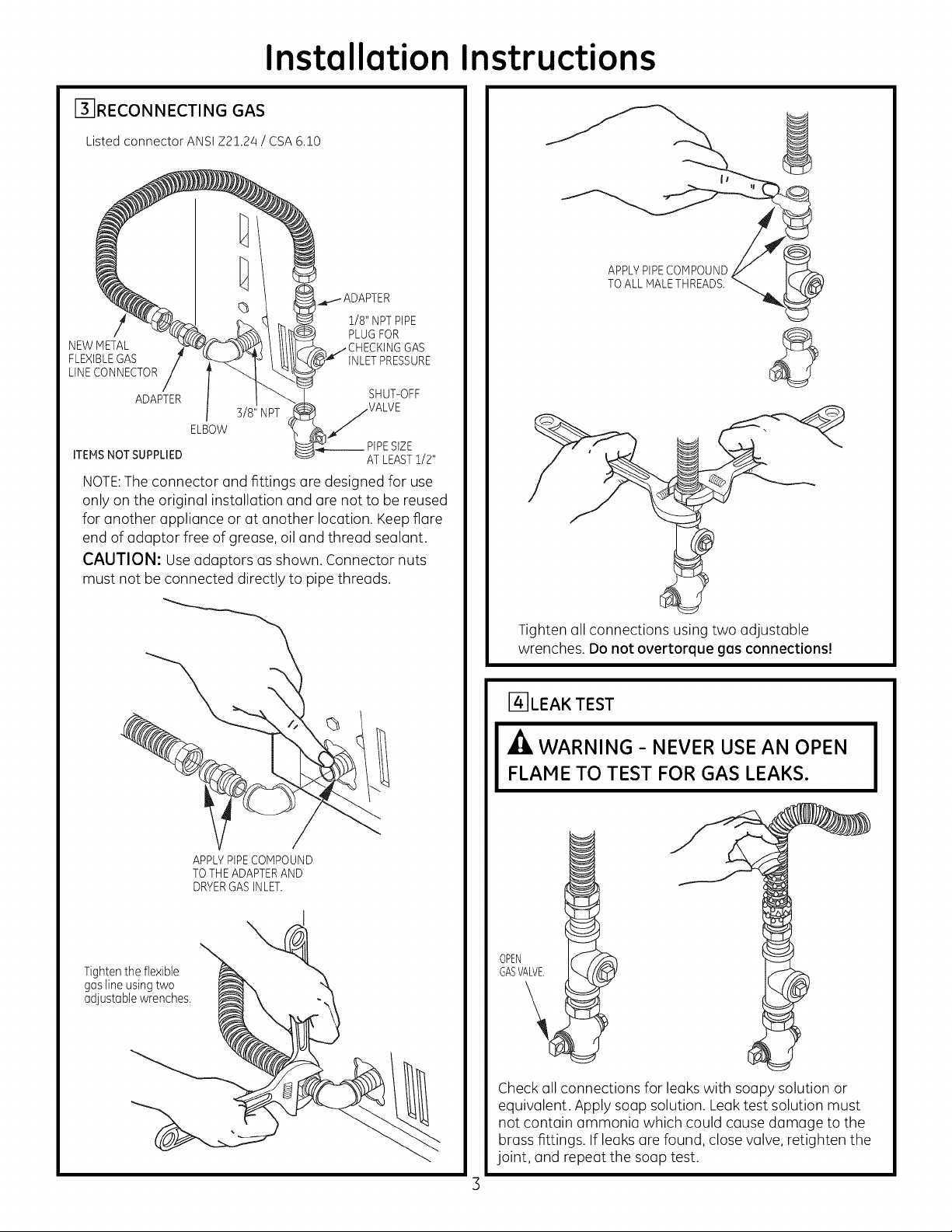

F3-IRECON NECTING GAS

Listed connector ANSI Z2!.24 / CSA 6.!0

1/8" NPTPIPE

PLUGFOR

NEWMETAL GAS

FLEXIBLEGAS INLETPRESSURE

LINECONNECTOR

ADAPTER SHUT-OFF

3/8" NPT VALVE

ELBOW

__PIPESIZE

ITEMSNOT SUPPLIED AT LEASTi/2"

NOTE: The connector and fittings are designed for use

only on the original installation and ore not to be reused

for another appliance or at another locution. Keep flare

end of adaptor free of grease, oil and thread sealant.

CAUTION: Use adaptors ms shown. Connector nuts

must not be connected directly to pipe threads.

APPLYPIPECOMPOUND

TOALL rVlALETHREADS.

©

Tighten the flexible

gas line using two

adjustable wrenches.

\

APPLYPIPECOMPOUND

TOTHE ADAPTERAND

DRYERGASINLET.

Tighten all connections using two adjustable

wrenches. Do not overtorque gas connections!

r4-]LEA K TEST

-_ WARNING- NEVER USE AN OPEN

FLAME TO TEST FOR GAS LEAKS.

GASVALVE.

OPEN

Check all connections for leaks with soapy solution or

equivalent. Apply soap solution. Leak test solution must

not contain (]mmonia which could cause damage to the

brass fittings. If leaks (]re found, close valve, retighten the

joint, and repeat the soup test.

Page 4

Installation Instructions

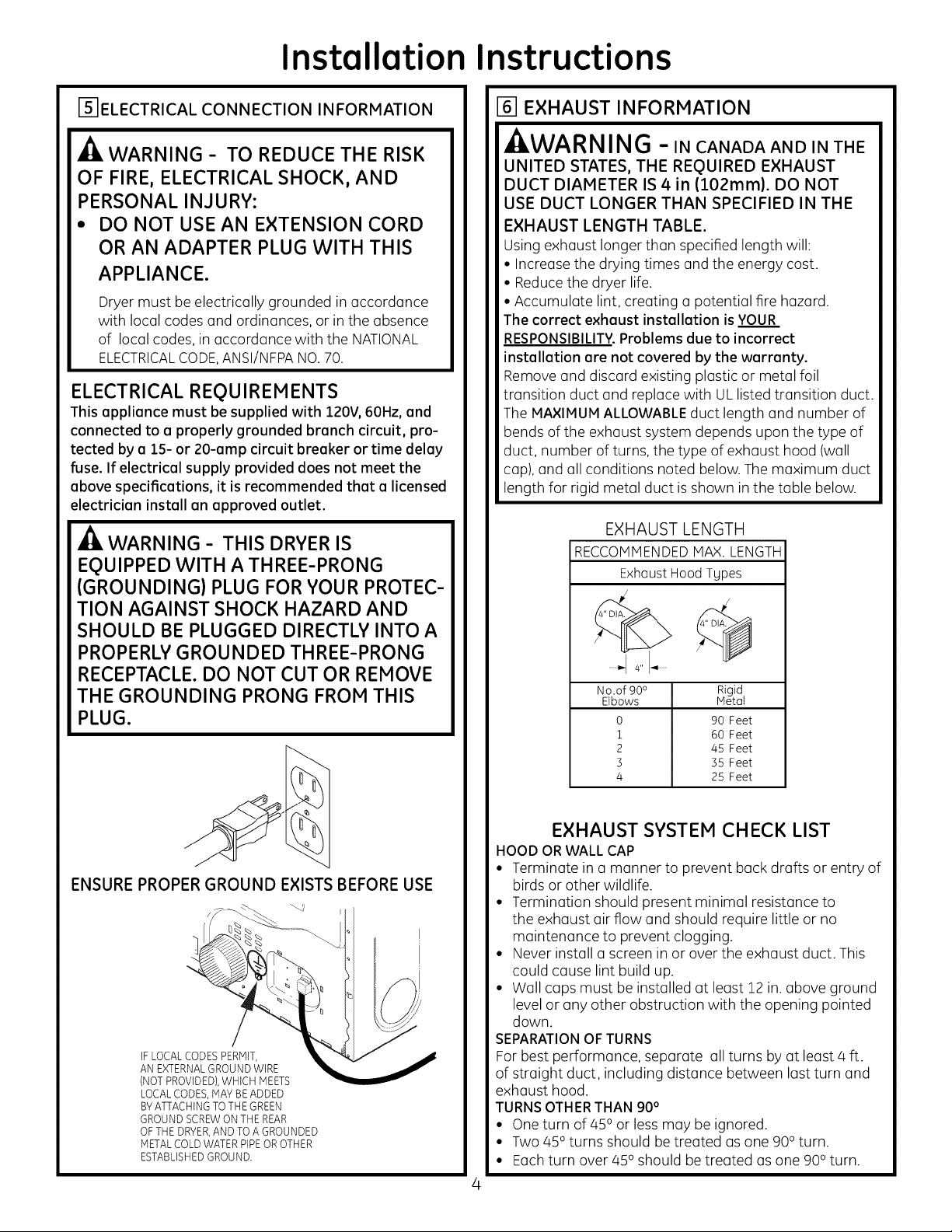

F5]ELECTRICAL CONNECTION INFORMATION

A

WARNING- TO REDUCE THE RISK

OF FIRE, ELECTRICAL SHOCK, AND

PERSONAL INJURY:

• DO NOT USE AN EXTENSION CORD

OR AN ADAPTER PLUG WITH THIS

APPLIANCE.

Dryer must be electrically grounded in accordance

with local codes and ordinances, or in the absence

of local codes, in accordance with the NATIONAL

ELECTRICALCODE,ANSI/NFPANO.70.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V,60Hz, end

connected to e properly grounded branch circuit, pro-

tected by e 15- or 20-amp circuit breaker or time delay

fuse. If electrical supply provided does not meet the

above specifications, it is recommended that a licensed

electrician install an approved outlet.

WARNING - THIS DRYER IS

EQUIPPED WITH A THREE-PRONG

(GROUNDING) PLUG FOR YOUR PROTEC-

TION AGAINST SHOCK HAZARD AND

SHOULD BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED THREE-PRONG

RECEPTACLE. DO NOT CUT OR REMOVE

THE GROUNDING PRONG FROM THIS

PLUG.

161EXHAUST INFORMATION

WARNÁNG -IN CANADAANDINTHE

UNITED STATES, THE REQUIRED EXHAUST

DUCT DIAMETER IS 4in (102mm). DO NOT

USE DUCT LONGER THAN SPECIFIED IN THE

EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reduce the dryer life.

• Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.Problems due to incorrect

installation are not covered by the warranty.

Remove and discard existing plastic or metal foil

transition duct and replace with UL listed transition duct.

The MAXIMUM ALLOWABLE duct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. The maximum duct

length for rigid metal duct is shown in the table below.

EXHAUST LENGTH

RECCOMMENDEDMAX. LENGTH

ExhaustHoodTypes

I

......._1 4" _ ......

No.of 90°

Elbows

0

1

2

3

4

Rigid

Metal

90 Feet

60 Feet

45 Feet

35 Feet

25 Feet

ENSURE PROPER GROUND EXISTS BEFORE USE

IF LOCAL CODES PERMIT,

AN EXTERNALGROUND WIRE

(NOT PROVIDED), WHICH MEETS

LOCAL CODES, MAY BEADDED

BYATTACHING TO THE GREEN

GROUND SCREW ON THE REAR

OF THE DRYER,AND TO A GROUNDED

METAL COLD WATER PIPE OR OTHER

ESTABLISHED GROUND.

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entry of

birds or other wildlife.

• Termination should present minimal resistance to

the exhaust air flow and should require little or no

maintenance to prevent clogging.

• Never install a screen in or over the exhaust duct. This

could cause lint build up.

• Wall caps must be installed at least 12 in. above ground

level or any other obstruction with the opening pointed

down.

SEPARATIONOFTURNS

For best performance, separate all turns by atleast 4 ft.

of straight duct, including distance between last turn and

exhaust hood.

TURNSOTHERTHAN 90°

• One turn of 45oor less may be ignored.

• Two 45° turns should be treated as one 900turn.

• Each turn over 45° should be treated as one 900 turn.

Page 5

Installation Instructions

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male end of

each section of duct must point away from the dryer.

• The duct shall not be assembled with screws or other

fastening means that extend into the duct and catch lint.

• Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

• Horizontal runs should slope down toward the outdoors

1/2 inch per foot.

INSULATION

Duct work that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint build-up.

I-7-1EXHAUST CONNECTION

- WARNING - TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

• This clothes dryer must be exhausted to the outdoors.

• Use only 4" rigid metal ducting for the home exhaust

duct.

• Use only 4" rigid metal or UL-listed flexible metal (semi-

rigid or foil-type) duct to connect the dryer to the home

exhaust duct. It must be installed in accordance with

the instructions found in "Connecting the Dryer to

House Vent" on pages 5-6 of this manual.

• Do not terminate exhaust in a chimney, a wall, a ceiling,

gas vent, crawl space, attic, under an enclosed floor,

or in any other concealed space of a building. The

accumulated lint could create a fire hazard.

• Never terminate the exhaust into a common duct with

a kitchen exhaust system. A combination of grease and

lint creates a potential fire hazard.

• Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint, creating

a potential fire hazard.

• Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

• Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

• Do not obstruct incoming or exhausted air.

• Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspected and cleaned at least once a year.

THIS DRYER COMES READY FOR REAR

EXHAUSTING. IF SPACE IS LIMITED, USE

THE INSTRUCTIONS IN SECTION 12 TO

EXHAUST DIRECTLY FROM THE SIDES OR

BOTTOM OF THE CABINET.

STANDARD REAR EXHAUST

(Vented at floor level)

For straight line installation, connect

the dryer exhaust to the external

exhaust hood using duct tape or

clamp.

DUCT TAPE OR

DUCT CLAMP

4" METALDUCT CUT

TO PROPERLENGTH

JCT

DUCT TAPEOR

DUCT CLAMP

NOTE: WE STRONGLYRECOMMENDSOLID

METALEXHAUSTDUCTING. HOWEVER,IF

FLEXIBLEDUCTING ISUSEDIT MUST BE

UL-LISTEDMETAL,NOT PLASTIC.

STANDARD REAR EXHAUST

(Vented above floor level)

ELBOWHIGHLY

ELBOW HIGHLY

RECOMMENDED--

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

CONNECTING THE DRYERTO HOUSE VENT

RIGID METAL TRANSITION DUCT

• For best drying performance, a rigid metal transition duct

is recommended.

• Rigid metal transition ducts reduce the risk of crushing and

kinking.

UL-LISTED FLEXIBLE METAL (SEMI-RIGID) TRANSITION

DUCT

• If rigid metal duct cannot be used, then UL-listed flexible

metal (semi-rigid) ducting can be used (Kit WXO8XlO077).

• Never install flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

• Total length of flexible metal duct should not exceed 8 feet

(2.4m).

Page 6

Installation Instructions

• For many applications, installing elbows at both the dryer

and the wall is highly recommended (see illustrations

below). Elbows allow the dryer to sit close to the wall

without kinking and or crushing the transition duct,

maximizing drying performance.

•Avoid resting the duct on sharp objects.

UL-LISTEDFLEXIBLEMETALIFOIL-TYPE}TRANSITIONDUCT

• In special installations, it may be necessary to connect

the dryer to the house vent using a flexible metal (foil-

type) duct. A UL-listed flexible metal (foil-type) duct may

be used ONLYin installations where rigid metal or flexible

metal (semi-rigid) ducting cannot be used AND where a 4"

diameter can be maintained throughout the entire length

of the transition duct.

• In Canada and the United States, only the flexible metal

(foil-type) ducts that comply with the "Outline for Clothes

Dryer Transition Duct Subject 2158A" shall be used.

• Never install flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

•Total length of flexible metal duct should not exceed 8 feet

(2.4m).

• Avoid resting the duct on sharp objects.

For best drying performance:

1.Slide one end of the duct over the clothes dryer outlet pipe.

2.Secure the duct with a clamp.

3.With the dryer in its permanent position, extend the duct

to its full length. Allow 2" of duct to overlap the exhaust pipe.

Cut off and remove excess duct. Keepthe duct as straight

as possible for maximum airflow.

4.Secure the duct to the exhaust pipe with the other clamp.

[] LEVELING AND STABILIZING YOUR

DRYER

Stand the dryer upright near the final location and adjust

the 4 leveling legs, at the corners, to ensure that the dryer

is levelfrom side to side and front to rear.

LEVEL LEVEL

FRONT-TO-BACK SIDE-TO-SIDE

4 LEVELING

LEGS

!

ELBOW

REOUIRED

oo;oLy4

191ALCOVE OR CLOSET INSTALLATION

• If your dryer is approved for installation in an alcove or

closet, it will be stated on a label on the dryer back.

•The dryer MUST be vented to the outdoors. See the

EXHAUSTINFORMATIONsection 6.

• Minimum clearance between dryer cabinet and adjacent

walls or other surfaces is:

0 in.either side

3 in.front

4 in. rear

• Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is 52 in.

•Closet doors must be Iouvered or otherwise ventilated

and must contain a minimum of 60 sq. in. of open area

equally distributed. If the closet contains both a washer

and a dryer, doors must contain a minimum of 120 sq. in.

of open area equally distributed.

•The closet should be vented to the outdoors to prevent

gas pocketing in case of a gas leak in the supply line.

• No other fuel-burning appliance shall be installed in the

same closet with the dryer.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT THE

REAROF THE DRYER,MINIMUM CLEARANCE FROM THE

WALL IS5.5 in.

Page 7

Installation Instructions

[i-6] BATHROOM OR BEDROOM INSTALLATION

•The dryer MUSTbe vented to the outdoors. See EXHAUST

INFORMATIONsection 6.

• The installation must conform with local codes or, in the

absence of local codes, with the NATIONALELECTRICAL

CODE,ANSI/NFPANO.70.

Iii]MOBILE OR MANUFACTURED HOME

INSTALLATION

•Installation must conform to the MANUFACTUREDHOME

CONSTRUCTION& SAFETYSTANDARD,TITLE 24, PART

32-80 or, when such standard is not applicable, with

AMERICAN NATIONAL STANDARDFOR MOBILE HOME,

ANSI/NFPANO.501B.

•The dryer MUST be vented to the outdoors with the

termination securely fastened to the mobile home

structure. (SeeEXHAUSTINFORMATIONsection 6).

•The vent MUSTNOT be terminated beneath a mobile or

manufactured home.

•The vent duct material MUSTBEMETAL.

• KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

•The vent MUST NOT be connected to any other duct,

vent, or chimney.

•Do not use sheet metal screws or other fastening devices

which extend into the interior of the exhaust vent.

• Provide an opening with a free area of at least 25 sq. in.

for introduction of outside air into the dryer room.

Detach and remove the bottom or left side knockout as

desired. Removethe screw inside the dryer exhaust duct

and save. Pullthe duct out of the dryer.Protect sharp edges

around the knockout and exhaust opening with the tape.

FIXING

B A

131/2"

(1B1/4" for bottom venting)

Cut the duct as shown and keep portion A.

TAB LOCATION

BENDTAB

UP45o

• Dryers installed in residential garages must be elevated

18 inches (46cm) above the floor.

ITJIDRYER EXHAUST TO LEFT OR BOTTOM

CABINET

- WARNING - PROTECTYOUR

HANDS AND ARMS FROM SHARP EDGES

WHEN WORKING INSIDE CABINET.

REMOVE

SCREW

ANDSAVE,

Through the rear opening, locate the tab inthe middle of

the appliance base. Lift the tab to about 450 using a flat

blade screwdriver.

ADDING NEW DUCT

i i

FIXING

HOLE

Reconnect the cut portion (A)of the duct to the blower

housing. Make sure that the fixing hole is aligned with the

tab in the base. Use the screw saved previously to secure

the duct in place through the tab on the appliance base.

PORTION"A"

RIGHTOR

LEFTSIDE

EXHAUST

REMOVE

DESIRED

KNOCKOUT

IONEONLV)

Page 8

Installation Instructions

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT OR RIGHT SIDE OF

CABINET

• Preassemble 4" elbow with 4" duct. Wrap duct tape

around joint.

• Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer internal duct.

CAUTION: Be sure not to pullor domage the

electricalwiresinsidethedryerwhen insertingtheduct.

DUCT

z TAPE

ADDING COVER PLATE TO REAR OF

CABINET

P_TELA X "" """

(KITWE1M454)

Connect standard metal elbows and ducts to complete the

exhaust system. Cover back opening with a plate (Kit

WEIM454) available from your local service provider.

Placedryer infinal location.

-/ILWARNING-NEVER LEAVE THE

BACK OPENING WITHOUT THE PLATE.

•Apply duct tape as shown on thejoint between the dryer

internal duct and the elbow.

CAUTION:

Use4" rigid metal ducting only

inside the dryer. Internal duct

joints must be secured with

tape, otherwise they may sepa-

rate and cause a safety hazard.

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

• Insert the elbow through the rear opening and connect it

to the dryer internal duct.

•Apply duct tape on the joint between the dryer internal

duct and elbow, as shown above.

TO REGISTER YOUR DRYER

CALL TOLL-FREE

1-888-269-1192

Prompt registration confirms your right to protection under

the terms of your warranty.

www.GEAppliances.com (US}

For Questions on Installation, Call: 1-800-GECARES(US)or

1-800-:361-3400 (Canada).

CAUTION:

Internal ductjoints must be securedwith tape,

otherwise they may separate and cause a

safety hazard.

Page 9

Instrucciones

Secadoraagas

de instalaci6n

_Preguntas sabre la instalaci6n? Llame al: 1-800-GECARES (EE.UU.) o 1-800-561-3344 (Canad(_)

o visJte nuestro sJtio Web en: www.GEAppliances.com (EE.UU.)

ANTES DE COMENZAR

Lea estas instrucciones par

completo y con detenimiento.

•IM PORTANTE - Guarde

estasinstruccionesparaelusade

inspectoreslocales

•IMPORTANTE -sigatodos

losc6digosy ordenanzasvigentes

• Nota al instalador - AsegQrese

de dejar estas instrucciones con el

consumidor.

• Nota al consumidor -Mantenga

estasinstruccionescon elManual de

usay cuidados parareferenciafutura.

• Antes de que lasecadora antigua

sea retirada del servicio o elimi-

nada, quffele la puerta.

• Lainformaci6n sabre reparaciones

y eldiagrama delcableado se en-

cuentran en la consolade control.

• No permita que ni_os se suban

o se metan dentro del aparato. Se

requiere una supervisi6n estricta

cuando elaparato es utilizado

cerca de ni_os.

• Instale la secadora en lugares

donde la temperatura sea mayor

a 50°Fpara un funcionamiento

satisfactorio del sistema de control

de la secadora.

HERRAMIENTAS NECESARIAS

- ADVERTENCIA mESGODEINCENDIO

• Para reducir el riesgo de una lesi6n grave o de muerte, cumpla con todas las

instrucciones de instalaci6n.

• La instalaci6n de la secadora debe efectuarla un instalador calificado.

• Instale la secadora de ropa de acuerdo con estas instrucciones yen cumplimiento

con los c6digos locales.

• key de California para el agua potabley los t6xicos

Estaleyexigeque el Gobernadorde California publique una lista de sustancias que segOn

el estado provoquen c6ncer,defectoscong_nitos u otros da_os reproductivos,y exige alas

empresas que adviertan a los clientes sabre la exposici6n potencial a dichas sustancias.

Losaparatos a gas pueden provocar una exposici6n mfnima a estas sustancias,a saber,

benceno, mon6xido de carbono, formaldehfdo y hollfn, generados principalmente par la

combusti6n incompleta de gas natural o combustibles LR Siseajustan bien las secadoras,

la combusti6n incompleta se ver6 minimizada. La exposici6n a estas sustancias puede

minimizarse aLinm6s mediante unaventilaci6n adecuada haciaelexterior.

• Estasecadora debe tener una salida al exterior.

• Utilices61ounconductorfgidodemetaldeundi6metrode4"dentrodelgabinetedelasecadora

yuses61ounconductodetransici6naprobadoparULentrelasecadorayelconductodom_stico.

• NO instale una secadora de ropa con conductos de pl6stico flexible. Sise instala un

conducto flexible de metal (semi rfgidoo de tipo papel de aluminio),debe estar aprobado

par ULe instalarse de acuerdo con las instrucciones de "C6mo conectar la secadora a la

ventilaci6ndom_stica"de lap6gina 5 deeste manual. Losmaterialesde ventilaci6n flexibles

a menudo se desploman, se aplastan y atrapan pelusas. Estascondiciones obstruyen la

corriente de aire dela secadorae incrementanel riesgode incendio.

• No instale o almacene este aparato en un lugar donde sevea expuesto al agua y/o

alas inclemencias deltiempo.

• Guarde estas instrucciones. (Instaladores: AsegOrese de dejar estas instrucciones

al consumidor).

ENELESTADODEMASSACHUSETTS

• Esteproducto debeinstalarlo un plomero o ungasfitero matriculado.

• Cuandousev(ilvulas esf@ricasde cierre de gas,deber(in ser deltipo de manija enT.

•Si seusauna conexi6nflexible para gas, @stano debesuperar los 3 pies.

10

MATERIALESNECESARIOS

LLAVESAJUSTABLESDE10"

LLAVEPARATUBOSDE8"

ALICATESDE

JUNTADESLEANTE

DESTORNILLADORPLANO

(x2)

%

NIVEL

coNDuceD

(RECOMENDADO}

CONDUCTODETP_ANBICIONDE"vIET,BL ABRAZADERAB

FLEXIBLE(SEMIRIGIDO}DE4"DEDIA, DERESORTEDE4"(2}

APROBADOPORUL(ElFUERANECESARIO}

KITWXO8XlO077(INCLUYE2CODOS} _ ALIVIODETENSION

CONDUCTODETRANSICIONDE METAL

FLEXIBLE(TIPOPAPELDEALUMINIO}DE4"DEDIA, (KITWE1MaB4}

APROBADOPORUL(ElFUERANECEBARIO}

)

ABRAZADERABCODODEMETJ_L

DECONDUCTODE4"(2} DE4"DEDIA, CA'vIPANA GAFAS

0 DEBALIDA DEBEGURIDAD

GUANTEB DEY/' RECONOCIDO

CINTAADHEBIVA PORUL

(NOPROVISTACON

CLASIFICADOPOR

UL120/240V,30A

CON ] 0 4 CLAVIJAB

IDENTIFIQUEELTIPO

DEENCHUFEBEGUN

ELTOMACORRIENTE

DELAVIVIENDAANTES

DECOMPRARELCABLE.

KITDECABLE

DEENERG'A

DELASECADORA

LABECADORA}

I

Paso 1

Verifique su instalaci6n de gas (ver secci6n 2).

Paso 2

Prepare el area y la salida para la instalaci6n de la nueva

secadora (ver secci6n 1).

Paso 3

Verifique y asegOrese de que la salida al exterior existente

est# limpia (ver secci6n 1)y que cumpla con las especifica-

ciones de instalaci6n incluidas (ver secci6n 6).

Paso 4

Quite las almohadillas de espuma para env[o (versecci6n 1).

Paso 5

Desplace la secadora a la ubicaci6n deseada.

Paso 6

Nivele su secadora (ver secci6n 8).

Paso 7

Conecte el suministro de gas (ver secci6n 3)y controle la pres-

encia de p#rdidas (ver secci6n 4).

Paso 8 Conecte la salida al exterior (ver secci6n 7).

Paso 9 Conecte el suministro de energfa (versecci6n 5).

Paso 10 Verifique el funcionamiento del suministro de energfa, las

conexiones de gas y la ventilaci6n.

Paso 11 Coloque el manual del propietario y las instrucciones de

instalaci6n en un lugar de f(icil acceso para el propietario.

Parainstalaci6nen nicho o closet,ver secci6n9.

Parainstalaci6nen ba_oso dormitorios,versecci6n10.

Paracasasm6vileso prefabricadas,ver secci6n11.

Parasalidaslateraleso par laparte inferior,versecci6n12.

31-16630-1 03-11 GE

234D1052POO4

Page 10

Instruccionesde instalaci6n

Espacio minima diferente a instalaci6n en nichos o closets.

Losespacioslibresm[nimosrespectodesuperficiescombustiblesy deaberturasdeaireson:Espaciode0 pulg.a amboslados,1pulg.enel

frentey 3 pulg.enla partetrasera. Debetenerseencuentaunespaciolibreadecuadoparaunfuncionamientoy reparaci6ncorrectos.

I-_ PREPARACION PARA LA INSTALACION

DE UNA SECADORA NUEVA

CONSEJO:Instale su secadora antes de instalar la lava-

dora. Esto permitir6 un mejor acceso cuando instale la

salida de la secadora.

C6MO DESCONECTAR EL GAS

DESCONECTEY ELIMINE

ELCONECTOR DE GAS

FLEXIBLEANTIGUa Y

GIRE LAVALVULA ___'_

DE CIERRE DE GAS If-_'_

A hA POSICION OFF IL..((Y_;

/APAGADO) _'6_

LOSCONDUCTOS VIEJOS.

REEMPLACELOSCON ,% /_

UN N,UEVOCONECTOR _7_

DE LINEA DEGAS FLEXIBLE I--_l

APROBADOPaR CSA {AGA)Y. I I

UN CONDUCTO DE TRANSICIONI I

APROBADOPORUY L_S

A

ADVERTENCIA - NUNCA VUELVA A

USAR CONECTORES FLE×IBLES GAS-

TADOS.

Elusa de conectores flexibles usados puede provocar

p#rdidas de gas y lesiones personales. Siempre utilice

conectores flexibles nuevos cuando instale aparatos

de gas.

I_ REQUERIMIENTOS DE GAS

ADVERTENCIA

• La instalaci6n debe cumplir con c6digos oordenanzas

locales, o si no las hubiera, con el CODIGONACIONALDE

GAS,ANSIZ223.

• Esta secadora agas est6 equipada con un montaje de

v61vulay quemador para utilizar s61ocon gas natural.

Mediante el kit de conversi6n WE25×0217, la organizaci6n

de atenci6n local puede convertir esta secadora para su

usa con gas propano (LP).TODASLASCONVERSIONES

DEBENLLEVARLASA CABOPERSONALCAPACITADOY

CALIFICADOENCUMPLIMIENTOCONCODIGOSLOCALESY

REQUERIMIENTOSDEORDENANZAS.

• Losecadora debe desconectarse del sistema de tuber[a de

suministro de gas durante cualquier prueba de presi6n del

sistema con una presi6n de prueba mayor a 0.5 PSI(:3.4KPa).

• La secadora debe aislarse del sistema de tuberfa de sum-

inistro de gas cerrando lav61vula de cierre del equipo du-

rante cualquier puesta a prueba del sistema en presiones

de prueba iguales o menores a 0.5 PSI(:3,4.4KPa).

CONE×I6N DE SUMINISTRO DE GAS DE

LA SECADORA

COMO QUITAR PELUSA DE LA ABERTURA

DE LA SALIDA DE LA PARED

• Quite y descarte elconducto de transici6n existente de

pl6stico ode papel de aluminio y coloque un conducto de

transici6n aprobado par UL.

PARED

ABERTURA DE

CONDUCTOINTERNA

VERIFIQUE QUE

EL REGULADOR

DE LA CAMPANA

DE SALIDA SE ABRA

Y CIERRE LIBREMENTE

INCLINE LA SECADORA

DE COSTADO YQUITE

LAS ALMOHADILLAS

DE ESPUMA PARA ENViO

TOM#,NDOLAS DE LOS

COSTADOS Y

ARRANCANDOLAS DELAS

PATASDE LA SECADORA.

ASEGURESE DEQUITAR

TODAS LAS PtEZAS

DE ESPUMA UBICADAS

ALREDEDOR DE LAS PATAS.

"-- SUMINISTRODE GAS ROSCAMACHO NPTDE 3/8"

NOTA: Agregue a la dimensi6n vertical la dJstancia

entre la parte inferior del gabinete yel piso.

SUMINISTRO DE GAS

Debe instalarse una toma a rosca de 1/8" NPT, accesible

para una conexi6n del man6metro de prueba, inme-

diatamente en sentido ascendente de la conexi6n de

suministro de gas hacia la secadora. Si tiene dudas sabre

la instalaci6n de la toma, comun[quese con su empresa

proveedora de gas local.

Lo I[nea de suministro debe ser de tuberfa r[gida de 1/2"y

debe contar con un cierre accesible dentro de los 6 pies

de la secadora, dentro de la misma habitaci6n donde se

encuentra la misma.

Utilice compuesto sellador para rosca de tuberia apropia-

do para gas natural o LP o utilice cinta de Teflon.

Una el conector de metal flexible a la secadora y al sum-

inistro de gas.

Abra la v61vulade cierre.

• Con esta secadora debe usarse un conector de metal

flexible (conector aprobado ANSIZ21.24 / CSA6.10). La

Iongitud de la conexi6n no deber6 superar los :3pies.

Page 11

Instruccionesde instalaci6n

F31COMO RECONECTAR EL GAS

Conector aprobado ANSIZ2124 / CSA6.t0

TAPON DETUBER[A

CONECTORNUEVO )LARLA

DEL[NEA DEGAS PRESIONDEENTRADA

DEMETAL FLEXIBLE DEGAS

ADAPTADOR VALVULADECIERRE

CoDoNPT DE 3/8" j

ITEMSNOT SUPPLIED TAP1ANODETUBER[A

NOTA:Elconector y los accesorios se encuentran dis-

eBados para usarse s61oen la instalaci6n original y no

deben volverse a usar en otro aparato o en otra ubi-

caci6n. Mantenga elextremo abocinado del adaptador

libre de grasa, aceite y sellador de roscas.

NPTDE 1/8" PARA

AL MENOS1/2"

APLIOUE COMPUESTO

PARA TUBERiA

EN TODAS

LAS ROSCAS MACHO.

©

%

PRECAUClON:Utilice los adaptadores como se indica.

Lastuercas de conexi6n no deben conectarse directa-

mente en las roscas de la tuber[a.

APLQUE COMPUESTOPARATUBER[A

AL ADAPTADORYA LA ENTRADA

DEGAS DE LASECADORA.

Ajuste la tube@ flexible

de gas utilizando

dos Ilaves ajustables.

Ajuste todas las conexiones mediante dos Ilaves ajustables.

iNo ajuste de m6s las conexiones de gas!

I-4-IPRUEBA DE DETECCION DE PI_RDIDAS

UNA LLAMA ABIERTA PARA DETECTAR

.4L ADVERTENCIA - NUNCA UTILICE

PERDIDAS DE GAS.

ABRA

DEGAS.

LAVALVULA

Controle todas lasconexiones con una soluci6n jabonosa o

un elemento equivalente. Aplique una soluci6n jabonosa.

Lasoluci6n para controlar p@rdidasno debe contener

amoniaco, ya que este producto puede da_ar losaccesorios

de bronce. Sisedetectan p@rdidas,cierre la v61vula,vuelva a

ajustar lajunta y repita la prueba de la soluci6n jabonosa.

Page 12

Instruccionesde instalaci6n

rS-11NFORIVlACIONSOBRE CONEXIONES EL¢CTRICAS

.4L ADVERTENCIA - PARA REDUCIR

EL RIESGO DE INCENDIO, DESCARGA

ELI_CTRICA Y LESIONES PERSONALES:

• NO UTILICE UN CABLE DE EXTEN-

SION O UN ENCHUFE ADAPTADOR

CON ESTE APARATO.

Lasecadora debe contar con una conexi6n

el6ctrica a tierra en cumplimiento con los c6digos

y ordenanzas locales, o si 6stos no existieran, de

acuerdo con el CODIGOELI_CTRICONACIONAL,

ANSI/NFPAN°. 70.

REQUISITOS ELI_CTRICOS

Este aparato debe contar con un suministro de 120V,

60Hz, debe estar conectado a un circuito derivado

individual con una adecuada conexi6n a tierra y deben

contar con la protecci6n de un interruptor de circuitos

o fusible de tiempo retardado de 15 o 20 amperios. Si

el suministro el_ctrico provisto no cumple con las espe-

cificaciones anteriores, se recomienda que un electri-

cista con licencia instale un tomacorriente aprobado.

-4L ADVERTENCIA - ESTASECADORAEST/_

EQUIPADACON UN ENCHUFEDETRES

CLAVIJAS(CONE×I6N A TIERRA)PARASU

PROTECCIONCONTRA DESCARGASELEC-

TRICASY DEBEENCHUFARSEDIRECTA-

MENTE EN UN TOMACORRIENTE DETRES

CLAVIJASCON ADECUADA CONEXION A

TIERRA. NO CORTE0 QUITE LACLAVIJADE

CONE×ION A TIERRADE ESTEENCHUFE.

INFORMACI6N DE SALIDA

A____..__m_..__.__

411ADVERTENCIA - EN CANADA Y LOS

ESTADOS UNIDOS, EL DIAMMETRO DE CON-

DUCTO DE SALIDA REQUERIDO ES DE4 PULG.

(102 mm). NO UTILICE UN CONDUCTO DE UNA

LONGITUD MMAYORA LA ESPECIFICADA EN LA

TABLA DE LONGITUD DE SALIDA.

AIutilizar una salidade mayor Iongituda laespecificada se:

• Incrementar@nlostiempos de secado y el costo de energia.

• Reducir5 la vida 0til de la secadora.

• Acumular5 pelusa, Ioque podria generar un riesgo

potencial de incendio. La correcta instalaci6n de salida

es SURESPONSABILIDAD.Los problemas generados

pot una instalaci6n incorrecta no se encuentran cubi-

ertos por la garantia. Quite y descarte el conducto de

transici6n existente de pl@sticoo de papel de aluminio y

coloque un conducto de transici6n aprobado por UL.

La Iongitud M/i,×IMAPERMITIDAdel conducto y la

cantidad de codos del sistema de salida dependen

del tipo de conducto, la cantidad de curvas, la clase

de campana de salida (cubierta de pared) y todas las

condiciones indicadas a continuaci6n. La Iongitud

mc_ximadel conducto para conductos rigidos de metal se

indica en la siguiente tabla.

L©lXItul I UlJ IDL 3ALIIDA

LONGITUDMAXIMARECOMENDADA

Tipos de compono de solido

Cantidad de codos

de90grados

0

1

2

3

4

Metal

rigido

90 Feet

60 Feet

45 Feet

35 Feet

25 Feet

VERIFIQUE OUE HAYA UNA CONE×ION A TIERRA

ADECUADA ANTES DEL USO.

SILO PERMITENLOSCODIGOS

LOCALES,PUEDEAGREGARSE

UN CABLEATIERRAEXTERNO

(NOPROVISTO),q)UECUMPLA

CONLOSCODIGOSLOCALES,SUJETANDOLOALTORNILLOVERDE

DECONEXIONATIERRAENLA PARTETRASERADELASECADORA,

YALATUBERJADEAGUAFR[ADEMETALCONCONEXION

ATIERRAUOTRACONEXIONATIERRAESTABLECIDA.

LISTA DECONTROL DEL SISTEMA DESALIDA

CAMPANA O CUBIERTADE PARED

• Instale la salida de modo de evitar contracorrientes o el

ingreso de p@jarosu otros insectos o animales.

• La boca de salida debe presentar una resistencia

minima al flujo de salida y debe requerir poco o ning0n

mantenimiento para evitar las obstrucciones.

• Nunca instale un filtro dentro o sobre el conducto de

salida. Esto podrfa provocar una acumulaci6n de pelusa.

• Las cubiertas de pared deben instalarse por Io menos a

12" sobre el nivel del suelo o cualquier otra obstrucci6n

con laabertura apuntando hacia abajo.

SEPARACIONDECURVAS

Para un mejor desempeflo, separe todas las curvas con por

Io menos 4 pies de conducto recto, incluyendo la distancia

entre la Oltima curva y la campana de salida.

GIROSQUE NO SON DE 90°

• Un giro de 45o o menos puede ignorarse.

• Dos giros de 45odeben tratarse como un giro de 90°.

• Todos los giros de mc_sde/45odeben tratarse como un

giro de 90°.

Page 13

Instruccionesde instalaci6n

SELLADODEJUNTAS

• Todaslosjuntas deben estar bien selladaspara evitar

p@didas.Elextremo macho de cada secci6n deconducto

debe apuntar en direcci6n opuesta a la secadora.

• Elconducto no deber6 instalarse con tornillos u otros

medios de sujeci6n que seextiendan dentro del

conducto y enganchen pelusas

• Lasjuntas de los conductos deben ser herm6ticas al aire

y a la humedad mediante lasuperposici6n dejuntas con

cinta aislante o cinta de aluminio

• Los tramos horizontales deben tener una inclinaci6n

hacia el exterior de 1/2"por pie

AISLACION

Losconductos instalados a trav_s de un 6rea sin calefacci6n

o ubicados cerca de un acondicionador deaire deben aislarse

para reducir la condensaci6n y la acumulaci6n de pelusas.

I-7-1CONE×IeN A LA SALIDA

-4LADVERTENCIA - PARAREDUCIR

EL RIESGO DE INCENDIO O DE

LESIONES PERSONALES:

• Estasecadora de ropa debe tener una salida al exterior.

• Utilice s61oun conducto de metal r[gido de 4" para el

conducto de salida dom6stico

• Use s61oun conducto de metal rigido de 4" o de metal

flexible (semirigido o de tipo papel de aluminio)aprobado

por UL para conectar la secadora al conducto de

salida dom@stico. Debe instalarse de acuerdo con las

instruccionesincluidasen "C6moconectar lasecadoraa la

ventilaci6n dom_stica" de lasp6ginas 5-6 de estemanual.

• No instale la boca de salida dentro de una chimenea,

pared, cielorraso, ventilaci6n de gas, espacio entre

pisos,6tico, bajo un piso con cerramiento o en cualquier

otro espacio oculto de un edificio. La acumulaci6n de

pelusas podria provocar un riesgo de incendio.

• Nunca instale la boca de salida dentro de un conducto

comOn con el sistema de salida de la cocina La

combinaci6n de grasa y pelusas podr[a provocar un

riesgo de incendio

• No utilice un conducto de una Iongitud mayor a la

especificada en la tabla de Iongitud de salida Los

conductos m6s largos acumulan pelusa, Ioque genera

un riesgo potencial de incendio

• Nunca instale un filtro dentro o sobre el conducto de

salida Esto provocar6 la acumulaci6n de pelusas, Io

que genera un riesgo potencial de incendio

• No arme la red de conductos con sujeciones que

se extiendan dentro del conducto Estas sujeciones

pueden acumular pelusa, Io que genera un riesgo

potencial de incendio

• No obstruya elaire que entra y sale.

• Incluya unacceso para inspecci6n y limpieza del sistema

de salida, especialmente en las curvas y juntas. El

sistema desalida debe inspeccionarse y limpiarse por Io

menos una vez al aSo.

ESTASECADORAVIEN ELISTA PARAUTI LIZAR UNA

SALIDA POR LA PARTETRASERA. SI EL ESPACIO

ES LIMITAI;)O, UTILICE LAS INSTRUCCIONES DE

LA SECCION 22 PARA UNA SALIDA DIRECTA

DESDE LOS LADOS O PARTE INFERIOR DEL

GABINETE.

SALIDA TRASERA ESTANDAR

(Ventilaci6n a nivel del suelo)

Para una instalaci6n en linea recto, conecte

la salida de la secadora a la campana

de salida al exterior con cinta aislante

o una abrazadera.

ABERTURA DE

CONDUCTO EXTERIOR

CINTA AISLANTE

O

DE CONDUCTO

CONDUCTO DE METAL

DE 4" CORTADO

CON LA LONGITUD ADECUADA

CINTA AISLANTE O

ABRAZADERA DE CONDUCTO

NOTA: RECOMENDAMOS ENFATICAM ENTE EL USO

DECONDUCTOS DE SALIDA DE METAL SOLIDO,

SIN EMBARGO, SI SE USAN CONDUCTOS FLE×IBLES

ESTOSDEBEN SER DE METAL APROBADOS POR UL,

NO DE PL/_STICO,

SALIDA TRASERA EST_,NDAR

(Ventilaci6n sobre el nivel del suelo)

SERECOHIENDA

ELUSODECODOS _

CONFIGURACION

RECOHENDADA

PARAHINIHIZAR

LAS OBSTRUCCIONES

DELA SALIDA.

i I J

SERECOHIENDA

ELUSO DECODOS-

NOTA: LOS CODOS EVITAN QUE LOS

CONDUCTOS SE DOBLEN O CAIGAN.

C6MOCONECTAR LA SECADORA A LA VEN-

TILACI6N DOMI_STICA

CONDUCTO DETRANSICI6N DEMETALRIGIDO

• Para un mejor desempe_o de secado, se recomienda un

conducto de transici6n de metal rigido.

• Los conductos de transici6n de metal rigidos reducen el

riesgo de aplastamientos y torceduras.

CONDUCTODETRANSICIONDE METALFLEXIBLE

(SEMI-RJGIDO)APROBADOPORUL

• Si no puede utilizarse un conducto de metal r[gido, en-

tonces puede usarse un conducto de metal flexible (semi-

r[gido) aprobado por UL (Kit WX08X10077).

• Nunca instale conductos de metal flexibles en paredes,

cielorrasos, pisos u otros espacios cerrados.

• La Iongitud total del conducto de metal flexible no deber6

superar los 8 pies (2./4m).

Page 14

Instruccionesde instalaci6n

• Para muchas aplicaciones, se recomienda enf6ticamente la

instalaci6ndecodosenlasecadorayen lapared(verilustraciones

de abajo).Loscodos permitenque la secadorase ubiquecerca

de la paredsin torcero aplastarel conductode transici6n,Ioque

potenciaal m6ximo eldesempe_ode secado.

• No coloque el conducto sobre objetos afllados.

CONDUCTO DE TRANSICION DE METAL FLEXIBLE

(SEMI-RJGIDO)APROBADOPORUL

• Eninstalaciones especiales, puede ser necesario conectar la

secadora a la ventilaci6n dom6stica utilizando un conducto

de metal flexible (tipo papel de aluminio). Puede utilizarse

un conducto de metal flexible (tipo papel de aluminio)

aprobado por UL SOLO en instalaciones en las que no

pueden usarse conductos de metal r[gidos o flexibles (semi-

r[gidos)Yen las que puede mantenerse un di6metro de 4" a

Iolargo de todo el conducto de transici6n.

• En Canad6 y los Estados Unidos, solamente deber6n

utilizarse los conductos de metal flexibles (tipo papel de

aluminio) que cumplan con el "Resumen para conductos

de transici6n para secadoras de ropa, Tema 2158A".

• Nunca instale conductos de metal flexibles en paredes,

cielorrasos, pisos u otros espacios cerrados.

• La Iongitud total del conducto de metal flexible no deber6

superar los 8 pies (2.4m).

• No coloque el conducto sobre objetos afllados.

Para un mejor desempeflo de secado:

1. Desliceun extremo del conducto sobre la tuber[a de salida

de la secadora de ropa.

2. Fijeel conducto con una abrazadera.

3. Con la secadora en su posici6n permanente, extienda el

conducto en su Iongitud total. Deje que se superpongan 2"

de conducto con la tuber[a de salida. Corte y quite el tramo

de conducto que sobre. Mantenga el conducto Io m6s recto

posible para Iograr una corriente de aire m6xima.

4. Fijeelconducto a la tuber[a de salida con laotra abrazadera.

_DOS

NECESARIOS

DE SALIDA E@

[] C6MO NIVELAR Y ESTABILIZAR SU

SECADORA

Coloque la secadora en posici6n vertical cerca de la

ubicaci6n definitiva y ajuste lascuatro patas de nivelaci6n, en

los extremos, para garantizar que la secadora se encuentre

nivelada de lado a lado y del frente a la parte trasera.

NIVELAR NIVELAR

FRENTEA PARTETRASERA LADO A LADO

4 PATAS

DENIVELACION

[] INSTALACI6N EN NICHO O EN CLOSET

• Su secadora puede instalarse en un nicho o closet,

como se indica en la etiqueta de la parte trasera del

aparato.

• Esta secadora DEBEtener una ventilaci6n al exterior.

Ver la INFORMACIONSOBRESALIDAsecci6n 6.

• Elespacio librem[nimo entre el gabinete dela secadora

y las paredes adyacentes u otras superficies es de:

0 pulg. sobre ambos lados

3 pulg. en el frente

4 pulg. en la parte trasera

• El espacio vertical minimo desde el piso a los

gabinetes superiores, cielorraso, etc., es de 52 pulg.

• Las puertas clel closet deben contar con rejillas u

otro tipo de ventilaci6n y cleben tener por Io menos

60 pulg. cuadradas de espacio abierto igualmente

distribuido. Si el closet incluye una lavaclora y una

secaclora, las puertas cleben contener un minimo de

120 pulg. cuadradas de espacio abierto distribuido

uniformemente.

• El closet debe tener ventilaci6n hacia el exterior

para evitar la acumulaci6n de gas en caso de que

haya una p6rdida de gas en la linea de suministro.

• No deber6n instalarse otros aparatos a combustible

en el mismo closet con la secaclora.

NOTA: CUANDO EL CONDUCTO DE SALIDA EST/_

UBICADO ENLA PARTETRASERADELA SECADORA,EL

ESPACIOLIBREMINIMO DESDELA PAREDDEBESERS.S

PULGADAS.

Page 15

Instruccionesde instalaci6n

[Z-6]INSTALACI6N EN BANES O

DORMITORIOS

• Esta secadora DEBEtener una ventilaci6n al exterior. Ver la

INFORIACIONSABRESAUDAsecci6n6.

• Lainstalaci6ndebecumplirconc6digoslocaleso,si noexistieran,

conelCODIGOELECTRICONACIONAL,ANSt/NFPAN° 70.

I_INSTALACI6N EN CASASMOVILESO PRE-

FABRICADAS

• Lainstalaci6ndebecumplirconlaNORiVlASABRECONSTRUCC!ON

Y SEGURIDADDE CASASPREFABRICADAS,T[TULO2/4,PARTE

32-80 o, cuando dicha norma no seaaplicable,con la NORIVlA

NACIONALESTADOUNIDENSEPARACASASivlOVILES,ANSI/NFPA

NO501B.

• La secadora DEBE tener ventilaci6n al exterior con la

terminaci6nbiensujetaa la estructurade la casem6vil. (Verla

INFORiVlACIONSABRESALIDA,secci6n6).

• Lo ventilaci6n NODEBEterminar debajo de una case m6vil o

prefabricada.

• Elmaterialdel conductodeventilaci6nDEBESERiVlETAL.

• DEBEutilizarseel KIT14@346-33pareconectarbienlasecadora

ala estructura.

• La ventilaci6n NO DEBEconectarsea ning0n otro conducto,

ventilaci6no chimenea.

• No utilice tornillos pareplacesde metal u otros dispositivosde

sujeci6nqua seextiendanal interiorde laventilaci6nde salida.

• Debecanter con una abertura con un espacio libre de par Io

manes 25 pulgadascuadradas pare el ingresode aire exterior

dentrodel cuarto dela secadora.

Despegue y quite el recorte inferior o izquierdo, segOn

corresponda. Quite eltornillo ubicado dentro del conducto

de salida de la secadora y cons@vale. Saque el conducto

de la secadora. Proteja losbordes afilados del recorte y de

la abertura de la salida con cinta. ORIFICIODEMONTAJE

\

I

B " A

!_ 13i/2"

(13 1/4" para ventilaci6n inferior)

Corteelconducto como puedeverseUconservela porci6nA

UBICACI6N DE LA LENGI]ETA

GIRE LA LENGOETA

HASTA 45 °

A trav6s de la abertura trasera, ubique la lengOetaen

el medio de la base delaparato. Levante la leng0eta

hasta alrededor de 45°, utilizando un destornillador de

lados pianos.

C6MO AGREGAR CONDUCTOS NUEVOS

I_] INSTALACION EN GARAGE

RESIDENCIAL

oSecadoras instaladas en garages residenciales deben ser

elevadas 18 pulgadas (46cm) del nivel del piso.

I_]SALIDA DE LA SECADORA HACIA LA

IZQ)UIERDA O PARTE INFERIOR DEL

GABINETE

- ADVERTENCIA - PROTEJASUS

MANOS Y BRAZOS DE LOS LADOS

AFILADOS CUANDO TRABAJE DENTRO

DEL GABINETE.

QUITE EL

TORNILLO

ORIFICIO

DE MONTAJE

PORCION "A" _ .....

SALIDA LATERAL

PaR DERECHA O IZQUIERDA

Vuelva a conectar la porci6n cortada (A)del conducto ala

carcase del ventilador. Aseg0rese de qua el conducto m6s

carte se encuentre alineado con la lengOeta de la base.

Utilice el tornillo conservado con anterioridad pare sujetar

el conducto en su lugar atrav6s de la leng(Jeta de la base

del artefacto.

"_ QUITE

ELRECORTE

DESEADO (SOLO UNO)

Despegue y quite el recorte inferior, derecho o izquierdo,

segOn corresponda. Quite el tornillo ubicado dentro

del conducto de salida de la secadora y cons@vale.

Saque el conducto de la secadora.

Page 16

Instruccionesde instalaci6n

C6MO AGREGAR CODOS Y CONDUCTOS

DE SALIDA HACIA LA IZQUIERDA O DERE-

CHA DEL GABINETE

• Arme previamente un coda de 4" con un conducto de 4".

Coloque cinta aislante alrededor de la junta.

• Introduzca el montuje del conducto, el coda primero,

a trav6s de la abertura lateral y conecte el coda al

conducto interno de la secadora.

PRECAUCION: Aseg6resede no tiraro da6ar

loscablesel_ctricosubicadosdentrode lasecadora

cuando introduzcaelconducto.

LA SALIDA PUEDE _ __

AGREGARSEALOS___ _

LADOS DERECHO _ _J

0 IZQUIERDO NXX_ ,

I"_ CINTA

AISLANTE

C6MO AGREGAR LA PLACA DE CUBIERTA

A LA PARTE TRASERA DEL GABINETE

O. A ".

PLACA

(KIT WE1M454)

Conecte los codas y conductos de metal est6ndar para

completar el sistema de salida. Cubra la abertura trasera

con la placa (KitWEllV1454),disponible en su proveedor de

servicios local. Coloque la secadora en su ubicaci6n final.

- ADVERTENCIA -NUNCA DEJE

LA ABERTURA TRASERA SIN LA PLACA

EN SU LUGAR.

•Aplique cinta aislante coma puede verse en la junta

entre elconducto interno de la secadora y el coda.

PRECAUCION:

CINTA

C6HOAGREGARUNCODO DESALIDAA

TRAVES DE LA PARTE INFERIOR DEL GABINETE

• Introduzca el coda a trav6s de la abertura trasera y

con6ctelo al conducto interno de la secadora.

•Aplique cinta aislante en lajunta entre el conducto interno

de lasecadoray elcodo,como puedeverseabajo.

Utilice un conducto demetal

rigido de 4" s61odentro de la

secadora. Lasjuntas del con-

ducto interno deben sujetarse

con cinta; caso contrario,

pueden separarse y provocar

un riesgo de seguridad.

PARA REGISTRAR SU SECADORA LLAME EN

FORMA GRATUITA

1-888-269-1192

Registrarse r6pidamente confirma su derecho de

protecci6n bajo los t@minos de su garantfa.

www.GEAppliances.com (EE.UU.)

Para preguntas sabre la instalaci6n, Ilame al:

1-800-GECARES(EE.UU.)o 1-800-361-3/400 (Canad6).

-4LPRECAUCION:

Lasjuntas del conducto interno deben

sujetarse con cinta; caso contrario, pueden

separarse y provocar un riesgo de seguridad.

Loading...

Loading...