Page 1

SAFETY INSTRUCTIONS .........4

USING THE DRYER

Controls ............................ 6

Getting Started ...................... 7

Loading ............................. 11

Features .............................12

CARE AND CLEANING ..........13

INSTALLATION

INSTRUCTIONS

Reversing the door swing ............. 33

Stacking .............................38

TROUBLESHOOTING TIPS ..... 42

CONSUMER SUPPORT

Warranty ........................... 46

Consumer Support ................... 48

..................14

OWNER’S MANUAL &

INSTALLATION

INSTRUCTIONS

GFD49

GFD48

GFDR485

GFDR480

GHDS365

GHDS360

GFDR275

GFDR270

GFDS265

GFDS260

ENGLISH/FRANÇAIS/

ESPAÑOL

Write the model and serial

numbers here:

Model # _________________

DRYERS

Serial # _________________

They are on the label on the front

of the dryer behind the door.

GE is a trademark of the General Electric Company. Manufactured under trademark license.

49-90519-3 09-16 GEA

Page 2

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances

product, and we think you will too. Among other things, registration of your appliance ensures that we

can deliver important product information and warranty details when you need them.

Register your GE appliance now online. Helpful websites and phone numbers are available in the

Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration

card included in the packing material.

2

Page 3

Notes.

GEAppliances.com

3

Page 4

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Read all instructions before using the appliance.

DO NOT dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, dry-cleaning

solvents, or other flammable or explosive substances, as they give off vapors that could ignite or explode.

DO NOT place items exposed to cooking oils in your dryer. Items contaminated with cooking oils may contribute to a chemical

reaction that could cause a load to catch fire. To reduce the risk of fire due to contaminated loads, the final part of the tumble

dryer cycle occurs without heat (cool down period). Avoid stopping a tumble dryer before the end of the drying cycle unless all

items are quickly removed and spread out so that the heat is dissipated.

DO NOT allow children to play on or in this appliance. Close supervision of children is necessary when this appliance is

used near children.

Before the appliance is removed from service or discarded, remove the door to the drying compartment.

DO NOT reach into the appliance if the drum is moving.

DO NOT install or store this appliance where it will be exposed to the weather.

DO NOT tamper with controls.

DO NOT repair or replace any part of this appliance or attempt any servicing unless specifically recommended in the

user-maintenance instructions or in published user-repair instructions that you understand and have the skills to carry out.

DO NOT use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric

softener or product.

DO NOT dry articles containing foam rubber or similarly textured rubber-like materials.

Clean lint screen before or after each load.

DO NOT operate the dryer without the lint filter in place.

DO NOT store combustible materials, gasoline or other flammable liquids near the dryer.

opening and adjacent surrounding areas free from the accumulation of lint, dust and dirt.

The interior of the appliance and exhaust duct should be cleaned periodically by qualified service personnel.

Unplug the appliance or turn off the circuit breaker before servicing. Pressing the Power or Start/Pause button DOES NOT

disconnect power.

DO NOT operate this appliance if it is damaged, malfunctioning, partially disassembled, or has missing or broken parts,

including a damaged cord or plug.

DO NOT spray any type of aerosol into, on or near dryer at any time. DO NOT use any type of spray cleaner when cleaning dryer

interior. Hazardous fumes or electrical shock could occur

See “ELECTRICAL CONNECTION” located in the Installation Instructions for grounding instructions.

To reduce the risk of fire, explosion, electric shock, or injury to persons when using your appliance, follow basic

precautions, including the following:

Keep area around the exhaust

.

SAVE THESE INSTRUCTIONS

4

Page 5

ADDITIONAL GAS DRYER WARNINGS

GEAppliances.com

WARNING

Failure to follow safety warnings exactly could result in serious injury, death, or property damage.

- DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch; DO NOT use any phone in your building.

• Clear the room, building, or area of any occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or the gas

supplier.

- Fire or Explosion Hazard

State of California Proposition 65 Warnings

WARNING

Gas appliances can cause low-level exposure to some of these substances, including benzene, carbon monoxide, formaldehyde, and

soot, caused primarily by the incomplete combustion of natural gas or LP fuels. Exposure to these substances can be minimized by

properly venting the dryer to the outdoors.

This product contains one or more chemicals known to the State of California to cause cancer, and birth defects

or other reproductive harm.

SAVE THESE INSTRUCTIONS

5

Page 6

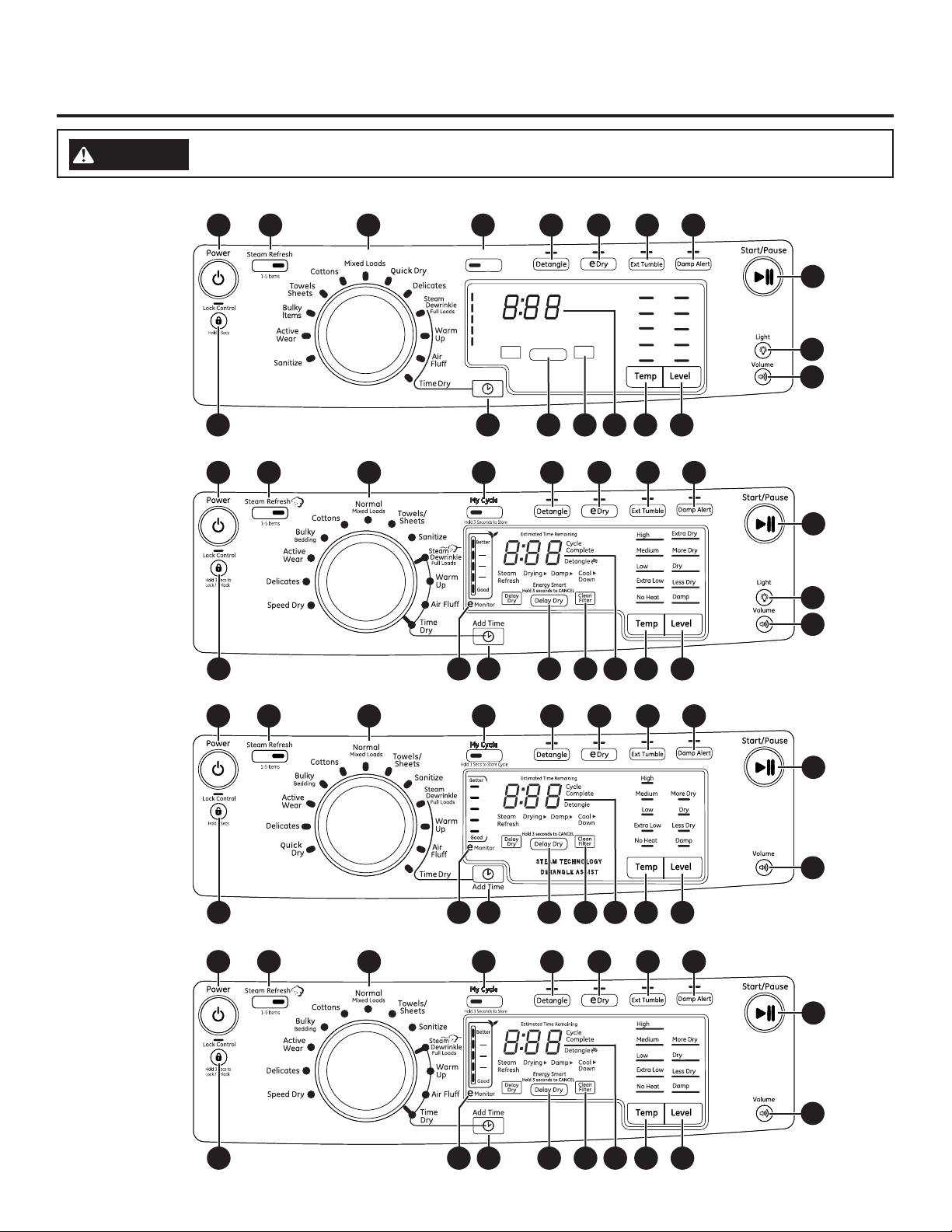

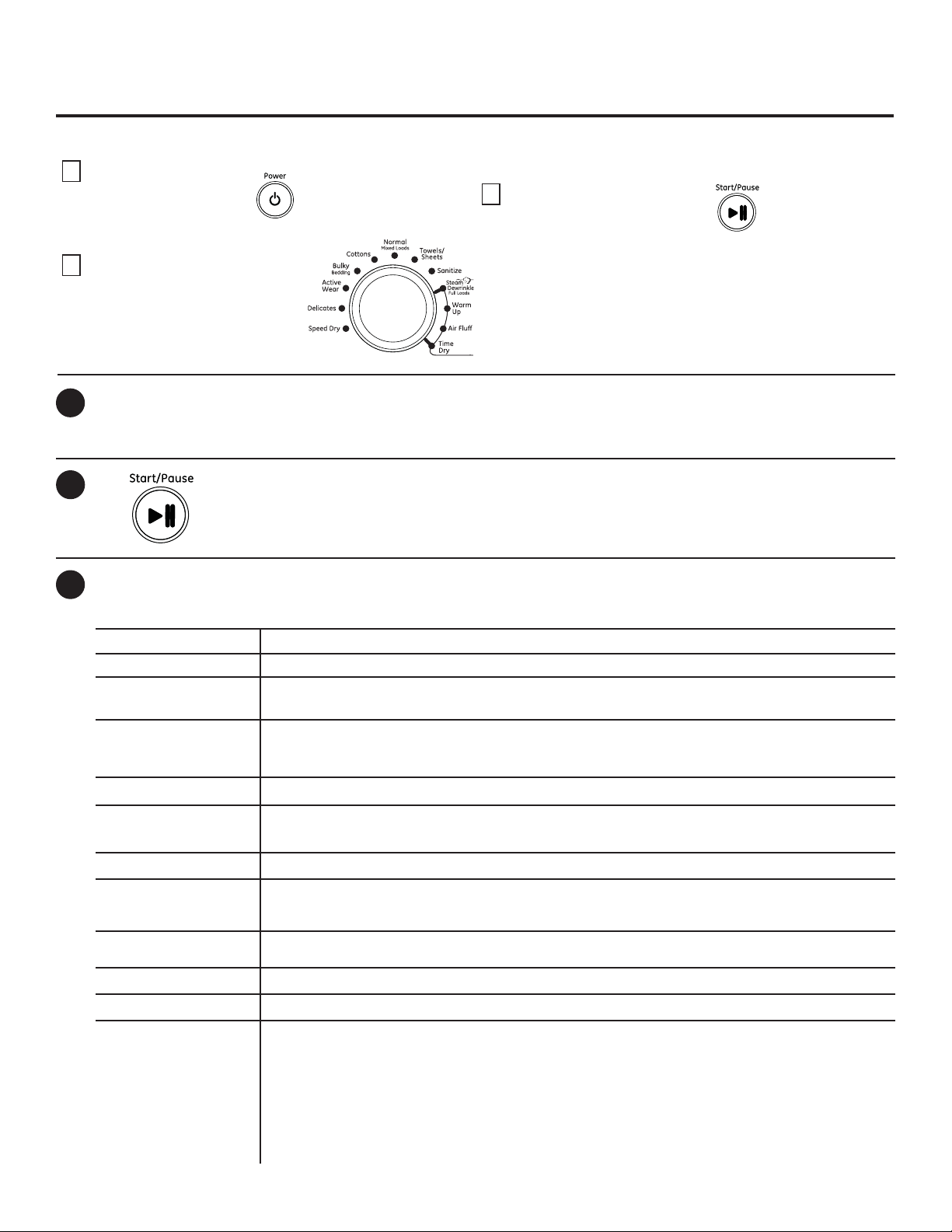

About the dryer control panel.

WARNING

To reduce the risk of fire, electric shock, or injury to persons, read the IMPORTANT SAFETY INSTRUCTIONS

before operating this appliance.

Throughout this manual, features and appearance may vary from your model.

Models:

GFD49

GFD48

1 8 3 13

Delay Dry

Hold 3 Secs to Cancel

Steam

Dry

Damp

Cool

Done

Status

Add Time

S

Refresh

Estima

t

eam

My

Cycle

9

t

ed Time

R

emaining

Tumble

My Cycle

Hold 3 Secs to Store Cycle

7 18 19

1 8 3 7

Models:

GFDR485

GFDR480

GHDS365

GHDS360

9 10 11 12

10 11 12

Detangle

Delay

Clean

Filter

Medium

Extra

No Heat

High

Extra Dr y

More Dr y

Low

Dry

Low

Less Dry

Damp

2

14

15

65416

2

Models:

GFDR275

GFDR270

Models:

GFDS265

GFDS260

17 13 18 19

1 8 3 7

17 13 18 19

1 8 3 7

14

15

65416

9 10 11 12

2

15

65416

9 10 11 12

2

15

6

17 13 18 19

65416

Page 7

Control settings.

Getting Started

GEAppliances.com

Press the

1

If the screen is dark, a press

of the Power button will

“wake up” the display.

Select a dry cycle. (Defaults are set

2

for each cycle. These default

settings can be changed. See

Control settings for more

information.)

Power

1

Press to “wake up” the display. If the display is active, press to turn the dryer off.

NOTE: Pressing Power does not disconnect the appliance from the power supply.

2

Dry Cycles

3

The dry cycle controls the length and tumble speed of the drying process. The chart below will help you match the dry

setting with the loads.

Power

button.

Press the Start/Pause button.

3

Start/Pause

Press to start a dry cycle. If the dryer is running,

press it once and it will pause the dryer. Press it

again to resume the dry cycle.

Normal/Mixed Loads

Cottons

Bulky/Bedding or

Bulky Items

Active Wear

Delicates

Speed Dry or

Quick Dry

Towels/Sheets

Sanitize

Steam Dewrinkle

Full Loads

Warm Up

Air Fluff

Time Dry

For loads consisting of cottons and poly-blends.

For cottons and most linens. NOTE: Energy Star® models are tested on Cottons with default settings.

For large coats, bed spreads, mattress covers, sleeping bags, blankets, comforters, jackets, small rugs,

and similar large and bulky items.

Clothing worn for active sports exercise and some casual wear. Fabrics include new technology

finishes and stretch fibers such as Spandex. Also for clothing labeled Easy Care or Perma Press: For

wrinkle-free and permanent press items.

For lingerie and special-care fabrics.

For small loads that are needed in a hurry, such as sports or school uniforms. Can also be used if the

previous cycle left some items damp, such as collars or waistbands.

Use for towels OR sheets. It is not recommended to mix towels and sheets in the same load.

Reduces certain types of bacteria by 99.8%, including: Staphylococcus aureus, Pseudomonas

aeruginosa, and Klebsiella pneumoniae. The antibacterial process occurs when high heat is used

during a portion of this drying cycle.

Provides 20 minutes of steam drying to assist with dewrinkling clothes.

for an extended time.

Provides 10 minutes of warming time to warm up clothes.

Provides 10 minutes of tumbling time without heat.

Use to set your own dry time. Time Dry is also recommended for small loads. To use:

1. Turn dry cycle dial to Time Dry.

2. Increase the drying time by pressing the Add Time button.

Note: This button only increases the time. When max time is reached, pressing the button again

will reset the counter to the lowest setting.

3. Select the Temp.

4. Close the door.

5. Press Start/Pause.

Ideal for loads left in dryer

7

Page 8

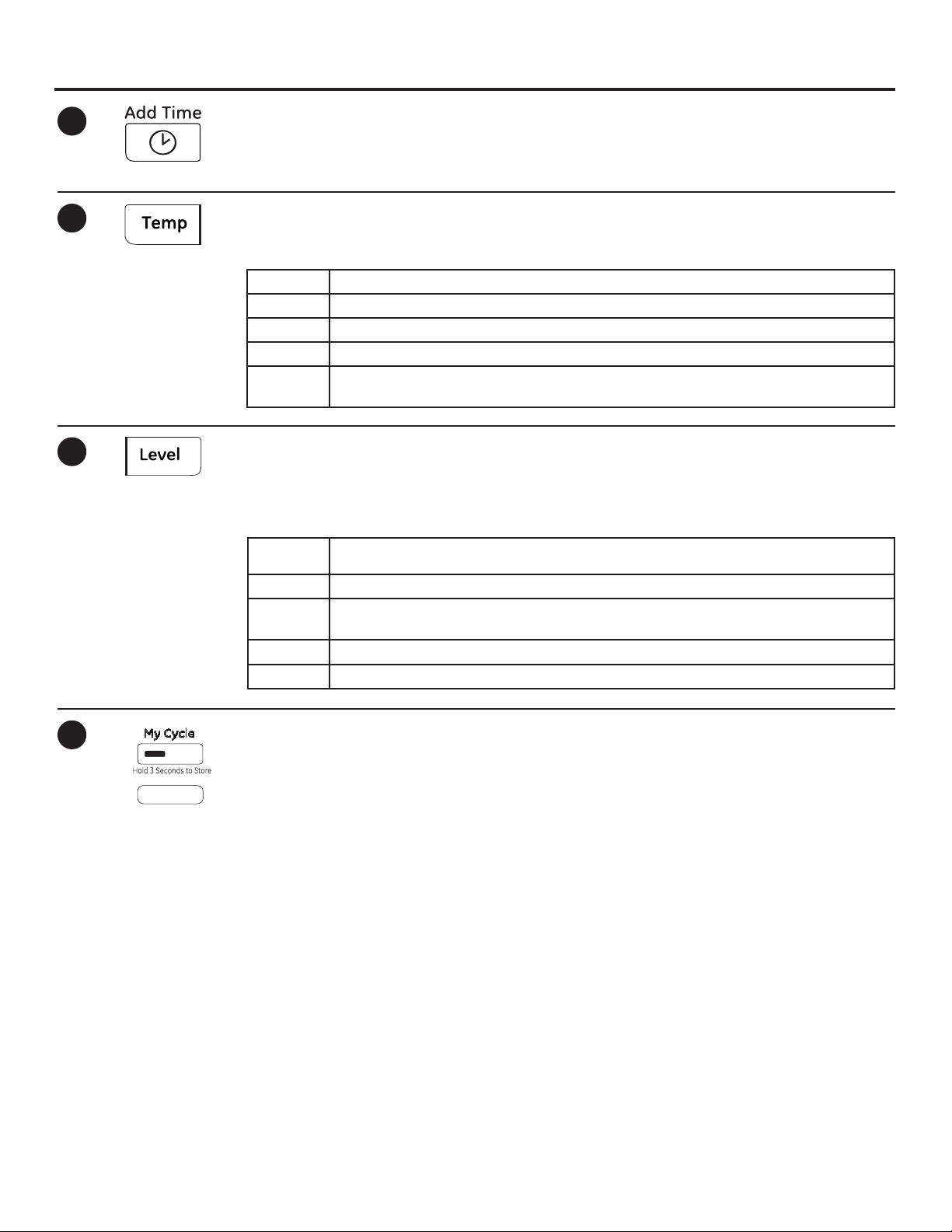

Control settings.

4

5

6

Add Time

Press to add time to the Steam Dewrinkle,

Warm Up, Air Fluff or Time Dry cycles in 10

minute increments.

Temp

You can change the temperature of your dry

cycle.

High For regular to heavy cottons.

Medium For synthetics, blends and items labeled Permanent Press.

Low For delicates, synthetics and items labeled Tumble Dry Low.

Extra Low For lingerie and special-care fabrics.

No Heat This option may only be used with Air Fluff, in which items are tumbled without

heat.

Level

The sensor continuously monitors the amount of

moisture in the load. When the moisture in your

clothes reaches your selected dry level, the dryer

will stop.

Extra Dry

(on some models)

More Dry Use for heavy or mixed type of fabrics.

Dry Use for normal dryness level suitable for most loads. This is the preferred cycle for energy

Less Dry

Damp For leaving items partially damp.

Use for heavy-duty fabrics or items that should be very dry, such as towels.

saving.

Use for lighter fabric (ideal for ironing).

NOTE: Sensor dry Level only works with

Cottons, Normal, Active Wear, Delicates,

Speed Dry, Bulky, Towels/Sheets, Sanitize

and Steam Dewrinkle cycles.

7

My Cycle

Hold 3 Secs to Store Cycle

(Depending

on model)

My Cycle

Set up your favorite combination of settings

and save them here for one touch recall. These

custom settings can be set while a cycle is in

progress.

To store a My Cycle combination of settings:

1. Select your drying cycle.

2. Change Temp and Level settings to fit your

needs.

3. Select any drying options you want.

4. Press and hold the My Cycle button for 3

seconds to store your selection. A beep will

sound and the button will light up.

To recall your stored My Cycle combination:

Press the MY CYCLE button before drying a

load.

To change your stored My Cycle combination:

Repeat steps 1–4.

8

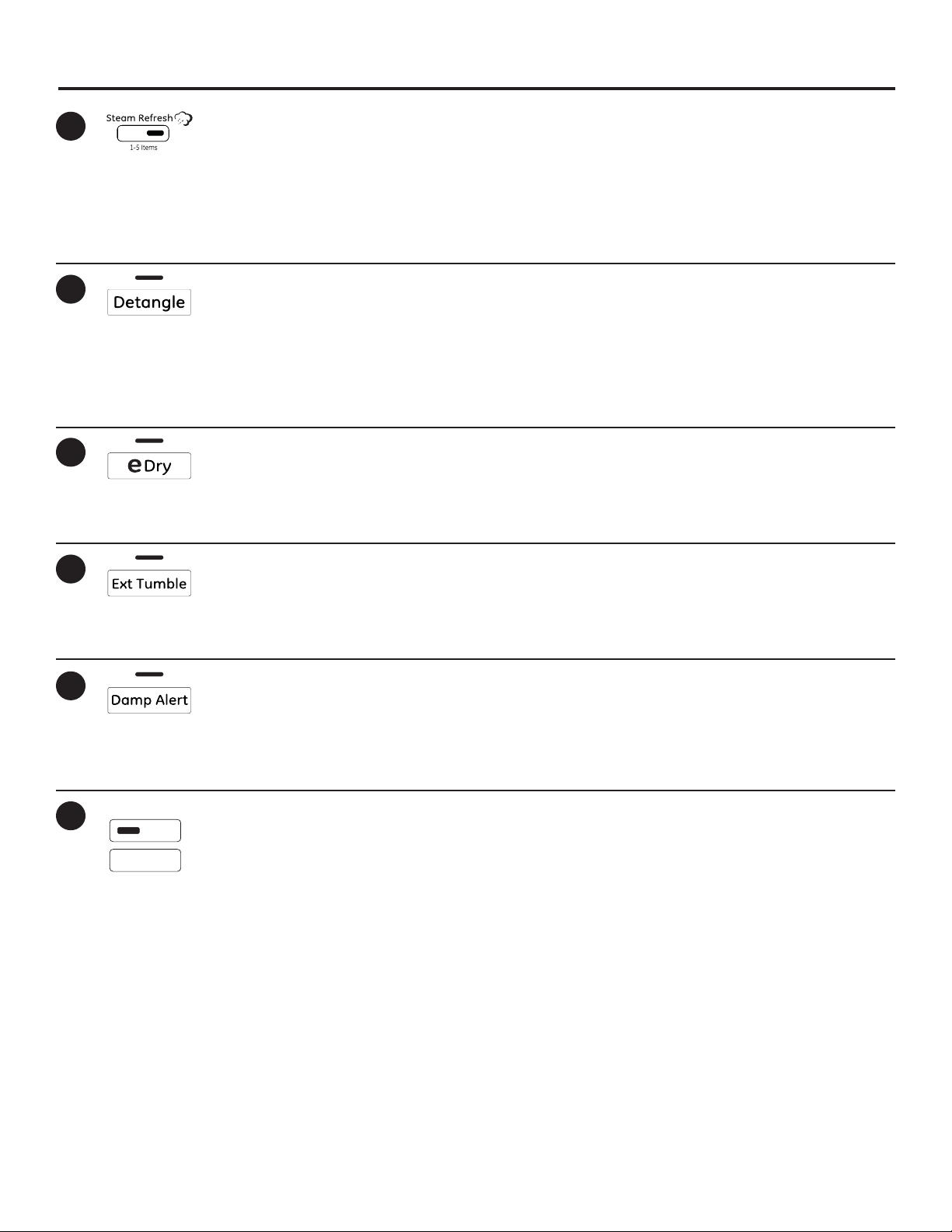

Page 9

GEAppliances.com

8

9

10

11

Steam Refresh Cycle

For slightly wrinkled dry garments. Significantly

reduces wrinkles on up to 5 garments. After the

Steam Refresh Cycle, the unit will beep and display

“0:00.” If the unit is not turned off or if the door is

not opened, the dryer will continue to tumble for

30 minutes. At the end of 30 minutes, it will display

“0:00” and the cycle will be complete.

Detangle (on some models)

Activates alternating forward and reverse tumbling

to reduce tangling, dry more evenly, and improve

drying times. Typical loads such as bed and bath

mixed loads, where sheets, towels and pillow cases

are laundered together, benefit from this capability.

When the dryer reverses direction, there will be a

slight pause and sound change. This is normal.

eDry

Reduces the total energy consumption of specific

dryer cycles by adjusting certain heat settings.

NOTE: Cycle times will change when e-Dry is

selected.

Extended Tumble

Minimizes wrinkles by adding approximately 60

minutes of no-heat tumbling after clothes are

dry. The beeper will sound every five minutes as a

reminder to remove the clothes.

NOTE: A single extremely light fabric item may need

to have an additional item included to achieve

optimum results.

NOTE: Detangle is selected by default for Towels/

Sheets and Bulky/Bedding cycles.

This cycle can be used with Cottons, Normal, Active

Wear, Delicates, Speed Dry, Bulky, Towels-Sheets,

Sanitize and Steam Dewrinkle.

The estimated time remaining display will show

“0:00”.

The extended tumble time does not get added to

the cycle time on the display.

12

13

Delay Dry

Delay Dry

(Depending

on model)

Damp Alert

This option causes the dryer to beep when clothes

have dried to a damp level. Remove items that you

wish to hang dry. The Damp Alert will only beep

when this option is selected, and the dryer will

continue to dry.

Delay Dry

Use to delay the start of your dryer.

1. Choose your dry cycle and any options.

2. Press Delay Dry. You can change the delay time

in 1 hour increments, using the Delay Dry button.

3. Press the Start/Pause button to start the

countdown.

Removing clothes and hanging them when they are

damp can reduce the need to iron some items.

NOTE: If the door is opened while the dryer is in

Delay Dry, the countdown time will not restart

unless the door is closed and Start/Pause button

has been pressed again.

9

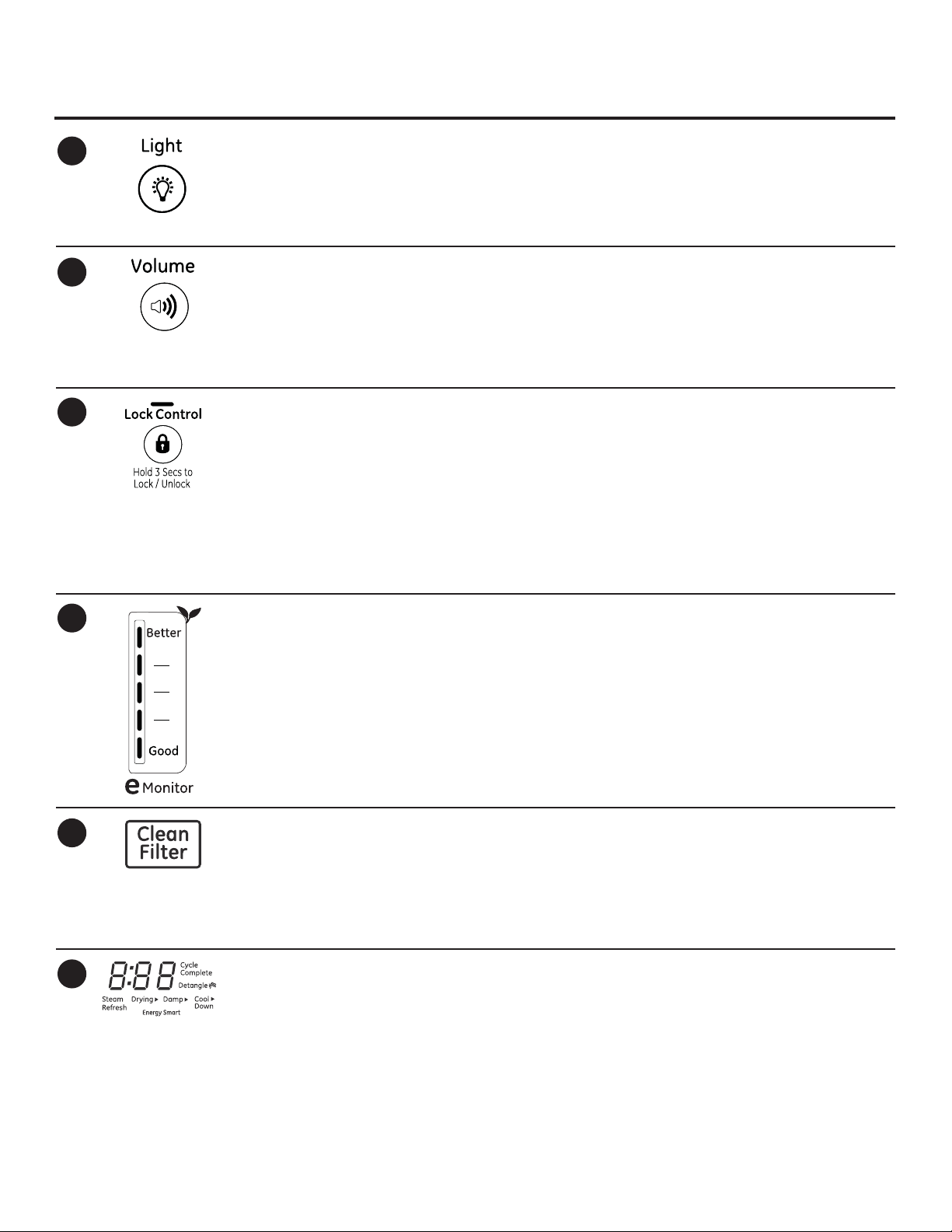

Page 10

Control settings.

14

15

16

Light (on some models)

Press the button to turn on the light in the

dryer.

Press the button again to turn the light off.

Volume

This button has two functions:

To change the loudness of the end of cycle

signal, press the button as many times as

needed to reach the desired volume. There are

four sound levels including OFF.

Lock Control

You can lock the controls to prevent any

selections from being made. Or you can lock

or unlock the controls after you have started a

cycle.

Children cannot accidentally start the dryer by

touching buttons with this option selected.

To lock the dryer, press and hold the Lock

Control button for 3 seconds.

This only controls the light when the door is

shut.

NOTE: The light will turn off by itself after one

minute when the door is shut.

To turn the button sounds ON/OFF, press

and hold the button for 3 seconds (on some

models).

To unlock the dryer controls, press and hold the

Lock Control button for 3 seconds.

A sound is made to indicate the lock/unlock

status.

The indicator light above the button will

illuminate when the controls are locked.

NOTE: The Power button can still be used when

the machine is locked.

17

18

19

eMonitor (on some models)

The eMonitor lights display the relative energy

use of your selected cycle and options. They are

provided as an energy guide and range from

Good (1 light) to Better (5 lights). Cycle (time),

dryness level, temperature, and additional

tumble options can increase or decrease your

energy efficiency. Some cycles will not provide

a display.

Clean Filter Message

This message represents only a reminder and

does not always appear when the filter needs

cleaning. The filter should be cleaned after every

drying cycle is complete.

Display

Displays the approximate time remaining until

the end of the cycle.

As the cycle begins, you will see an initial

approximate total cycle time in the display.

This message will disappear after the Start/

Pause button is pressed. Even though you may

have already cleaned the filter (before or after the

Power button has been pressed), the “Clean Filter”

message will still be displayed until the Start/

Pause button is activated.

Then lights will “race” in the display. This

means the dryer is continuously monitoring

the amount of moisture in the load. The lights

will continue until the dryer senses a low level

of moisture in the load. At that point, the dryer

will calculate and display the approximate time

remaining.

10

Page 11

Loading.

Always follow the fabric manufacturer’s care label when laundering.

Fabric Care Labels

Below are fabric care label “symbols” that affect the clothing you will be laundering.

Dry Labels

Tumble

dry

Dry

Normal

Heat

setting

High

Medium

Special

instructions

Line dry/

hang to dry

Sorting and Loading Hints

Permanent Press/

wrinkle resistant

Low

Drip dry

Gentle/

delicate

No heat/air

Do not tumble dry

Dry flat

Do not dry

(used with

do not wash)

In the shade

GEAppliances.com

WARNING

- Fire Hazard

• Keep flammable materials and vapors, such as gasoline,

away from dryer.

• DO NOT dry anything that has ever had anything flammable

on it (even after washing).

• No washer can completely remove oil.

As a general rule, if clothes are sorted properly for the washer,

they are sorted properly for the dryer. Try also to sort items

according to size. For example, do not dry a sheet with socks or

other small items.

• DO NOT dry anything that has ever had any type of oil on it

(including cooking oils).

• Items containing foam, rubber, or plastic must be dried on a

clothesline.

• Failure to do so can result in death, explosion, or fire.

Do not add fabric softener sheets once the load has become

warm. They may cause fabric softener stains. Bounce® Fabric

Conditioner Dryer Sheets have been approved for use in this

dryer when used in accordance with the manufacturer’s

instructions.

Do not overload. This wastes energy and causes wrinkling.

11

Page 12

About dryer features.

Rest rear legs on

rear angled ledge

Rest front legs on

front angled ledge

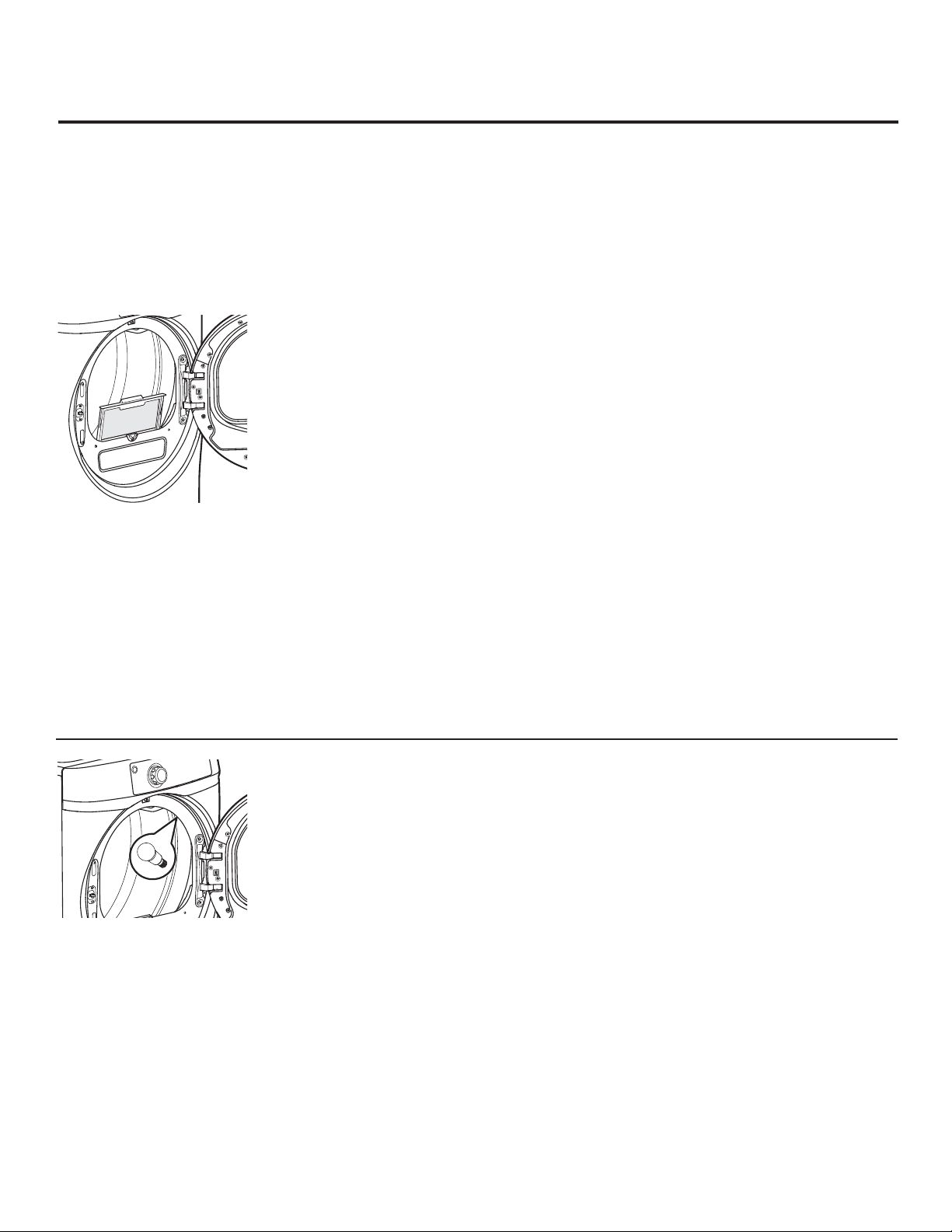

Drying Rack (on some models)

A handy drying rack may be used for drying

delicate items such as washable sweaters.

Place items flat on the drying rack and block

such items as wool sweaters and delicate

fabrics. Dry with low heat.

To install the drying rack, extend the drying

rack into the dryer drum. Rest the front two

legs on the front angled ledge and then rest

the rear two legs on the rear angled edge.

NOTES:

The drying rack is designed for use with

the Time Dry cycles. Use with sensor

cycles may result in damp items or

extended cycle times.

Do not use this drying rack when there

are other clothes in the dryer, that are not

placed on the rack.

The drying rack, WE01X22274, is available

as an accessory. Order on-line at

GEApplianceParts.com, 24 hours a day or

by phone at 877.959.8688 during normal

business hours.

12

Page 13

Care and Cleaning of the Dryer.

GEAppliances.com

The Exterior: Wipe or dust any spills or

washing compounds with a damp cloth.

Dryer control panel and finishes may be

damaged by some laundry pretreatment

soil and stain remover products. Apply these

products away from the dryer. The fabric

may then be washed and dried normally.

Damage to your dryer caused by these

products is not covered by your warranty.

The Lint Filter: Clean the lint filter before

each use.

Pull out the lint filter. Moisten your fingers

and remove the captured lint. Once clean,

slide the filter back into position. Have a

qualified technician vacuum the lint from the

dryer once a year.

NEVER OPERATE THE DRYER WITHOUT ITS

FILTER IN PLACE.

Stainless Steel: To clean stainless steel

surfaces use a damp cloth with a mild, nonabrasive cleaner suitable for stainless steel

surfaces. Remove the cleaner residue and

then dry with a clean cloth.

Dryer Interior and Duct: The interior of

the appliance and exhaust duct should be

cleaned once a year by qualified service

personnel.

The Exhaust Duct: Inspect and clean the

exhaust ducting at least once a year to

prevent clogging. A partially clogged exhaust

can lengthen the drying time.

The Exhaust Hood: Check with a mirror that

the inside flaps of the hood move freely when

operating. Make sure that there is no wildlife

(birds, insects, etc.) nesting inside the duct or

hood.

The stainless steel used to make the dryer

drum provides the highest reliability available

in a GE Appliances dryer. If the dryer drum

should be scratched or dented during normal

use, the drum will not rust or corrode. These

surface blemishes will not affect the function

or durability of the drum.

Drum Lamp

(consumer replaceable on some models)

NOTE: The drum lamp is not consumer

replaceable on models where there is a

domed cover over an LED bulb. If this light

should ever stop working, call for service.

For models that have a flat cover over the

bulb secured by a screw:

Before replacing the light bulb, be sure to

unplug the dryer power cord or disconnect

the dryer at the household distribution panel

by removing the fuse or switching off the

circuit breaker. Reach above dryer opening

from inside the drum to locate the light.

Remove the screw and the plastic cover to

access the bulb. Replace with the appropriate

bulb and then reaffix the cover and screw.

Order replacement bulb WE4M305 on-line

at GEApplianceParts.com, by phone at

877.959.8688 during normal business hours,

or purchase appliance bulb 7C7 from your

local retailer.

The drum lamp turns on automatically when

the dryer door is open. On some models, it

can also be activated from the control panel.

13

Page 14

Installation Dryers

Instructions

Questions? Call GE Appliances at 800.GE.CARES (800.432.2737) or visit our Web site at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT – Save these instructions for local

•

electrical inspector’s use.

•

IMPORTANT – Observe all governing codes and

ordinances.

Install the clothes dryer according to the manufacturer’s

•

instructions and local codes.

Note to Installer – Be sure to leave these instructions

•

with the Consumer.

Note to Consumer – Keep these instructions for future

•

reference.

Clothes dryer installation must be performed by a

•

qualified installer.

This dryer must be exhausted to the outdoors.

•

Before the old dryer is removed from service or

•

discarded, remove the dryer door.

Service information and the wiring diagram are located

•

in the control console.

Do not allow children on or in the appliance. Close

•

supervision of children is necessary when the appliance

is used near children.

Proper installation is the responsibility of the installer.

•

Product failure due to improper installation is not

•

covered under the Warranty

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

• Remove and discard existing plastic or metal foil duct

and replace with UL-listed duct.

.

WARNING

• Clothes dryer installation must be performed by a

qualified installer.

Install the clothes dryer according to these

•

instructions and local codes.

DO NOT install a clothes dryer with flexible plastic

•

venting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found

in “Connecting the Dryer to House Vent” later in

this manual. Flexible venting materials are known

to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase

the risk of fire.

DO NOT install or store this appliance in any

•

location where it could be exposed to water or

weather.

To reduce the risk of severe injury or death, follow

•

all installation instructions.

Save these instructions. (Installers: Be sure to leave

•

these instructions with the customer.)

- Fire Hazard

FOR GAS DRYERS ONLY

IN THE COMMONWEALTH OF

MASSACHUSETTS, THE FOLLOWING

INSTALLATION INSTRUCTIONS APPLY:

• Installation must be performed by a qualified

or licensed contractor, plumber, or gasfitter

qualified or licensed by the State.

•

If using a ball valve, it shall be a T-handle type.

•

A flexible gas connector, when used, must not

exceed 3 feet.

14

Page 15

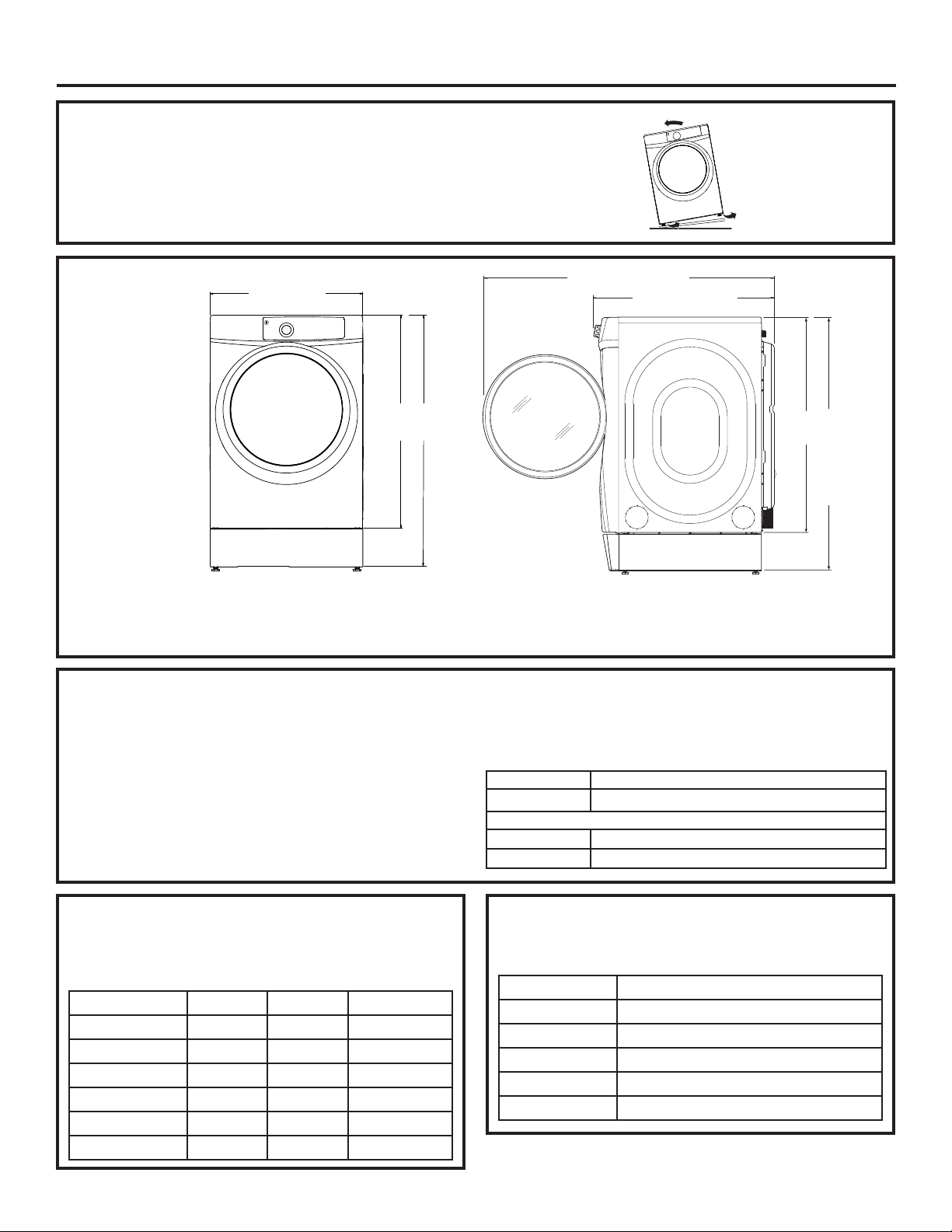

Installation Instructions

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam shipping pads by pulling

at the sides and breaking them away from the dryer legs. Be sure to

remove all of the foam pieces around the legs.

Remove the bag containing the literature.

DRYER

DIMENSIONS

Front View

*NOTE:

With Legs: 40 1/2” (102.5 cm) - (3/4” (1.9 cm) adjustability)

With Built-In Pedestal™: 46” (117 cm) - (3/4” (1.9 cm) adjustability)

With Optional Pedestal (GFXP1308): 52” (132.1 cm) - (3/4” (1.9 cm) adjustability)

Stacked: 78 1/4” (198.8 cm) - Not applicable for models with Built-In Pedestal

28”

(71.12cm)

39”*

(99cm)

46”*

(117cm)

STEAM WATER HOSES

GE Appliances strongly recommends the use of factory

specified parts. These hoses are manufactured and tested to

meet GE Appliances specifications.

GE Appliances strongly recommends the use of new water

supply hoses. Hoses degrade over time and need to be

replaced every 5 years to reduce the risk of hose failures and

water damage.

54 3/8”* (138.1cm)

32 7/8” (83.5cm)

39”*

(99cm)

46”*

(117cm)

Built-In

Pedestal™

models

only

Side View

™

Parts and Accessories

Order on-line at GEApplianceParts.com, 24 hours a day or

by phone at 877.959.8688 during normal business hours.

Part Number

WE25X20060

OR

WH41X10356

WH41X10357 Short Hose

Complete Kit (hoses, Y-adapter washers)

Long Hose and

Accessory

POWER CORDS:

GE Appliances strongly recommends the use of factory

specified parts. Select the power cord to fit your installation

requirements.

Part Number Type Length Amperage

WX9X2 3-Prong 4 Feet 30

WX9X3 3-Prong 5 Feet 30

WX9X4 3-Prong 6 Feet 30

WX9X18 4-Prong 4 Feet 30

WX9X19 4-Prong 5 Feet 30

WX9X20 4-Prong 6 Feet 30

ACCESSORIES:

Order on-line at GEApplianceParts.com, 24 hours a day or

by phone at 877.959.8688 during normal business hours.

Part Number Accessory

GFP1328SK

GFP1328PK

GEFLSTACK Stacking Kit for Dryer over Washer

PM08X10085

WE01X22274

15

28” width White Pedestal

28” width Color Matched Pedestal

Flexible Metal Dryer Transition Duct

Clothes Dryer Shoe Rack

Page 16

Installation Instructions

REQUIREMENTS FOR ALCOVE OR CLOSET

INSTALLATION

WARNING

Keep flammable materials and vapors, such as gasoline,

away from dryer.

Place dryer at least 18” (46 cm) above the floor for a

garage installation.

Failure to do so can result in death, explosion, or fire.

• The dryer MUST be vented to the outdoors.

• Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0” either side

1” front and rear

1” top

•

Consideration must be given to provide adequate

clearance for installation and service.

•

Closet doors must be louvered or otherwise

ventilated and have at least 60 square inches of

open area. If the closet contains both a washer

and a dryer, doors must contain a minimum of

120 square inches of open area.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, THE CONFIGURATION OF

THE DUCTING MAY REQUIRE GREATER THAN 3” OF

REAR CLEARANCE.

Gas Dryers Only:

•

No other fuel burning appliance shall be installed

in the same closet as a gas dryer.

•

The dryer must be disconnected from the gas

supply piping during pressure testing at pressures

greater than ½ psi (3.5 kPa).

•

A 1/8 inch NPT minimum plugged tapping,

accessible for test gauge connection, must be

installed immediately upstream of the gas supply

connection to the dryer.

- Explosion Hazard

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air opening are: 0” both sides, 1” rear and 1” top.

Consideration must be given to provide adequate

clearance for installation and service.

MOBILE OR MANUFACTURED HOME

INSTALLATION

• Installation MUST conform to the

MANUFACTURED HOME CONSTRUCTION AND

SAFETY STANDARD, TITLE 24, PART 3280 or

STANDARD FOR MOBILE HOMES CAN/CSA-Z240

MH, or, when such standards are not applicable,

with AMERICAN NATIONAL STANDARD FOR

MOBILE HOME, ANSI/NFPA NO. 501B.

•

The dryer MUST be vented to the outdoors.

•

The exhaust vent MUST be securely fastened to

a non-combustible portion of the mobile home.

•

The vent MUST NOT be terminated beneath a

mobile or manufactured home.

•

The vent duct material MUST BE METAL.

•

KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

•

The vent MUST NOT be connected to any other

duct, vent or chimney.

•

DO NOT use sheet metal screws or other

fastening devices which extend into the interior

of the exhaust vent.

•

Provide an opening with a free area of at least

25 square inches for introduction of outside air

into the dryer room.

•

See the sections for electrical connection

information.

16

Page 17

Installation Instructions

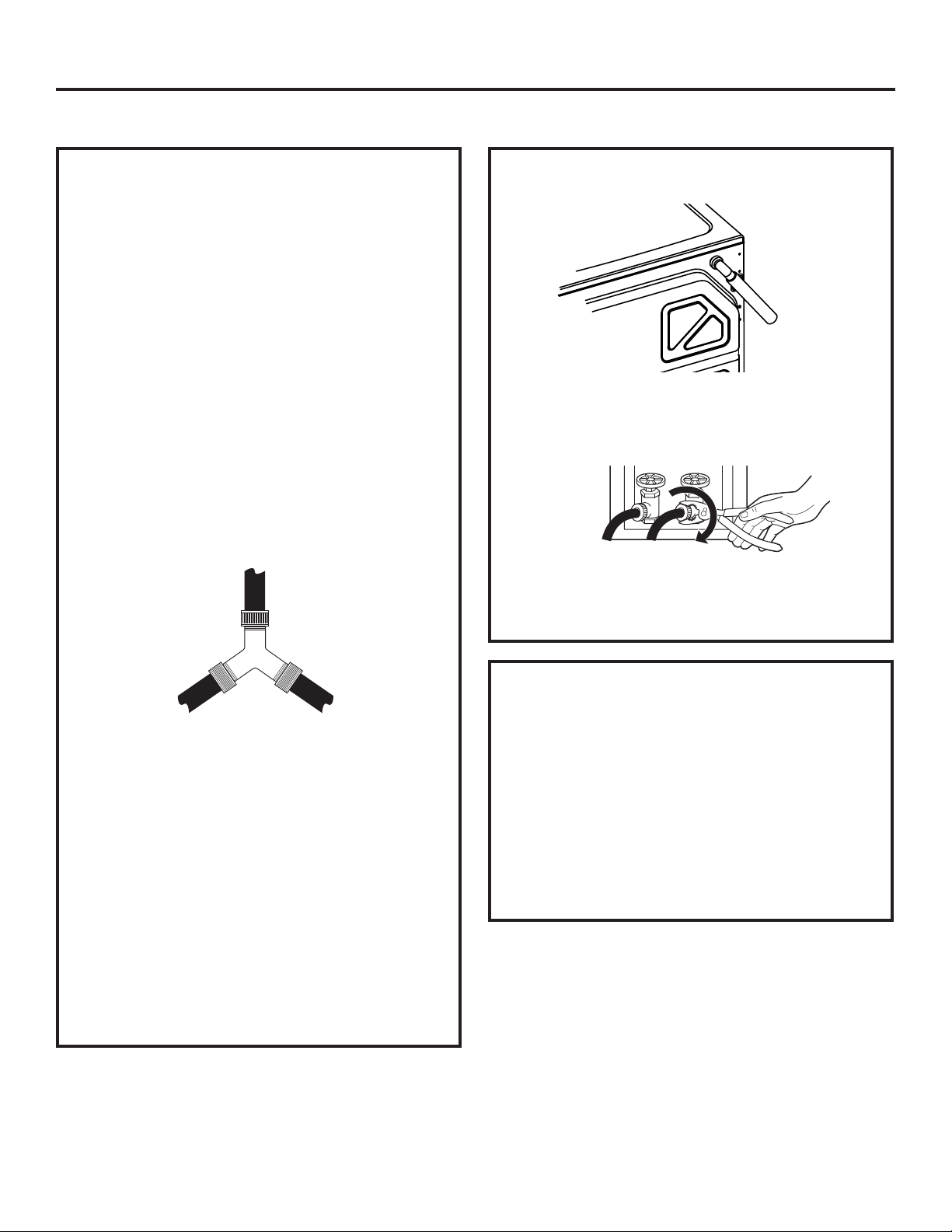

CONNECTING INLET HOSES

CONNECTING INLET HOSES

To produce steam, the dryer must connect to

the cold water supply. Since the washer must

also connect to the cold water, a “Y” connector

is inserted to allow both inlet hoses to make that

connection at the same time.

NOTE: Use new inlet hoses; never use old hoses.

1. Turn the cold water faucet off. Remove the

washer inlet hose from the washer fill valve

connector (cold).

2. Ensure the rubber flat washer is in place and

attach one female coupling of the short hose

provided onto the washer fill valve connector.

Tighten by hand until firmly seated.

3. Attach one male end of the “Y” connector to the

other female coupling of the short hose. Ensure

the rubber flat washer is in place. Tighten by

hand until firmly seated.

CONNECTING INLET HOSES (cont.)

7. Using pliers, tighten all the couplings with an

additional two–thirds turn.

NOTE: Do not overtighten. Damage to the couplings

may result.

8. Turn the water faucet on.

9. Check for leaks around the ‘’Y’’ connector, faucet

and hose couplings.

4. Insert the filter screen in the coupling of the

washer’s inlet hose. If a rubber flat washer is

already in place remove it before installing the

filter screen. Attach this coupling to one male end

of the ‘’Y’’ connector. Tighten by hand until firmly

seated.

5. Ensure the rubber flat washer is in place and

attach a 4 ft. to 6 ft. long water inlet hose (may

need to be purchased separately) to one male

end of the ‘’Y’’ connector. Tighten by hand until

firmly seated.

6. Ensure the rubber flat washer is in place and

attach the other end of the dryer’s long inlet

hose to the fill valve connector at the bottom of

the dryer back panel. Tighten by hand until firmly

seated.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed

within 42 in. (107 cm) of your washer’s water

inlet. The faucets MUST be 3/4 in. (1.9 cm) garden

hose-type so inlet hoses can be connected. Water

pressure MUST be between 10 and 120 pounds

per square inch. Your water department can

advise you of your water pressure.

NOTE: A water softener is recommended to reduce

buildup of scale inside the steam generator if the

home water supply is very hard.

17

Page 18

Installation Instructions

CONNECTING A GAS DRYER (skip for electric dryers)

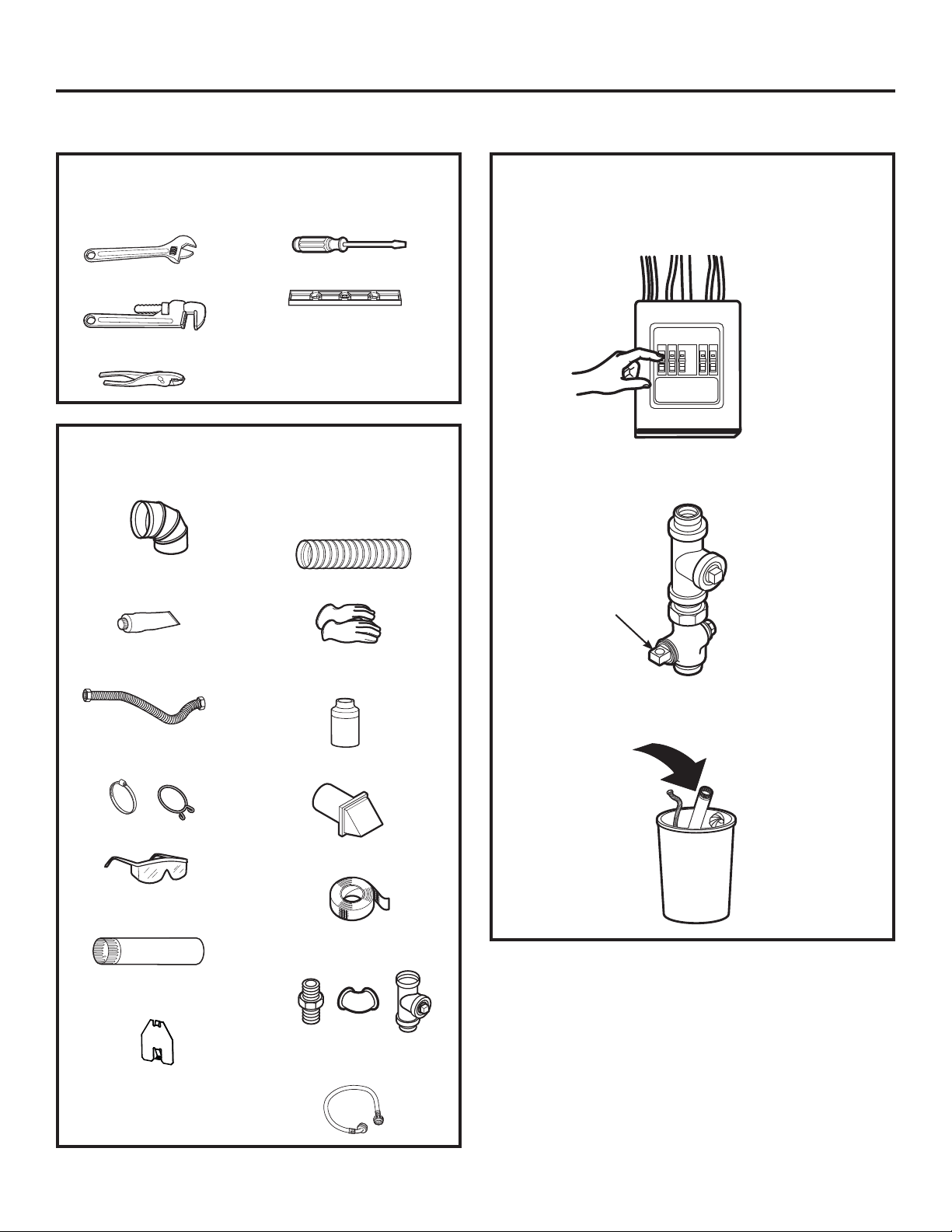

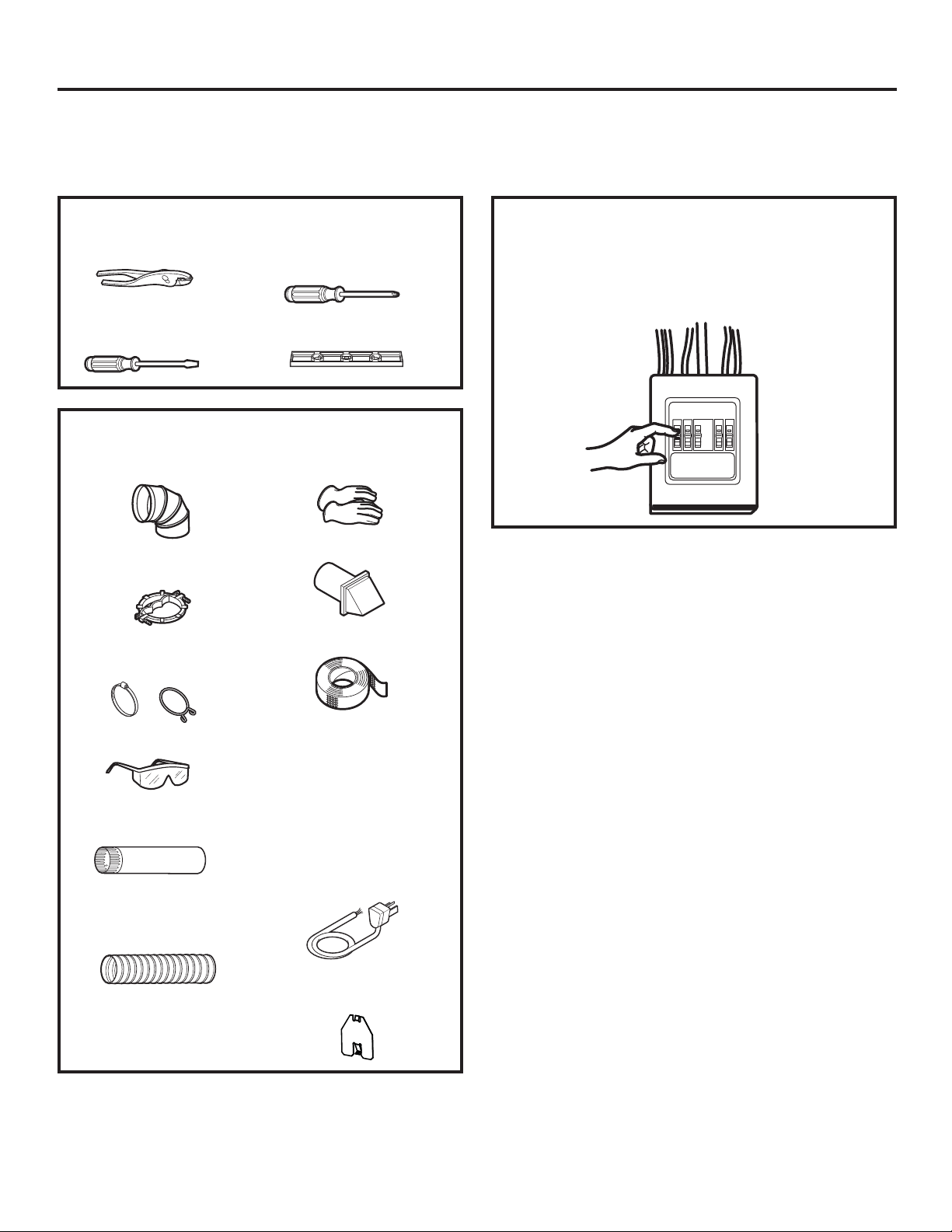

TOOLS YOU WILL NEED

10” Adjustable

wrenches (2)

8” Pipe wrench

Slip-joint pliers

Flat-blade

screwdriver

Level

MATERIALS YOU WILL NEED

4” dia. metal elbow

Pipe compound or

PTFE tape

4” dia., UL-listed

flexible metal duct

(if needed)

Gloves

• Before beginning the installation, turn off the

circuit breaker(s) or remove the dryer’s circuit

fuse(s) at the electrical box. Be sure the dryer

cord is unplugged from the wall.

• Turn the dryer’s gas shut-off valve in the supply

line to the OFF position.

Shut-off

Valve

Flexible gas line

connector

Duct clamps (2) or

Spring clamps (2)

Safety glasses

4” dia. metal duct

(recommended)

4” Cover plate (Kit

WE49X22606)

Soap solution for

leak detection

Exhaust hood

Duct tape

Gas pipe adapters (2),

elbow and pipe plug

4’-6’ Water Hose

(on some models)

• Disconnect and discard old flexible gas connector

and ducting material.

18

Page 19

Installation Instructions

GAS REQUIREMENTS

WARNING

• Use a new CSA International approved flexible

gas supply line. Never reuse old flexible

connectors.

• Install an individual manual shut-off valve

within 6ft. of the dryer in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• Securely tighten all gas connections.

• If connected to LP gas, have a qualified person

make sure gas pressure DOES NOT exceed 13”

water column.

• Examples of a qualified person include: licensed

heating personnel, authorized gas company

personnel, and authorized service personnel.

• Failure to do so can result in death, explosion,

or fire.

• The installation must conform with local codes,

or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54,

or the Natural Gas and Propane Installation

Code, CSA B149.1.

- Explosion Hazard

GAS SUPPLY

• A 1/8” National Pipe Taper thread plugged

tapping, accessible for test gauge connection,

must be installed immediately upstream of the

gas supply connection to the dryer. Contact

your local gas utility should you have questions

on the installation of the plugged tapping.

•

Supply line is to be 1/2” rigid pipe and equipped

with an accessible shutoff within 6 feet of, and

in the same room with, the dryer.

•

Use pipe thread compound appropriate for

natural or LP gas or use PTFE tape.

•

Connect flexible metal connector to dryer and

gas supply.

WARNING

FOR USE WITH NATURAL GAS ONLY

Dryer as produced by manufacturer is to be used only

with a natural gas supply. A manufacturer-supplied

conversion kit is required to convert this dryer for

propane gas supply. Use propane gas conversion

kit WE25M87. Conversion must be made by properly

trained and qualified personnel in accordance with

local codes and ordinances.

- Fire Hazard

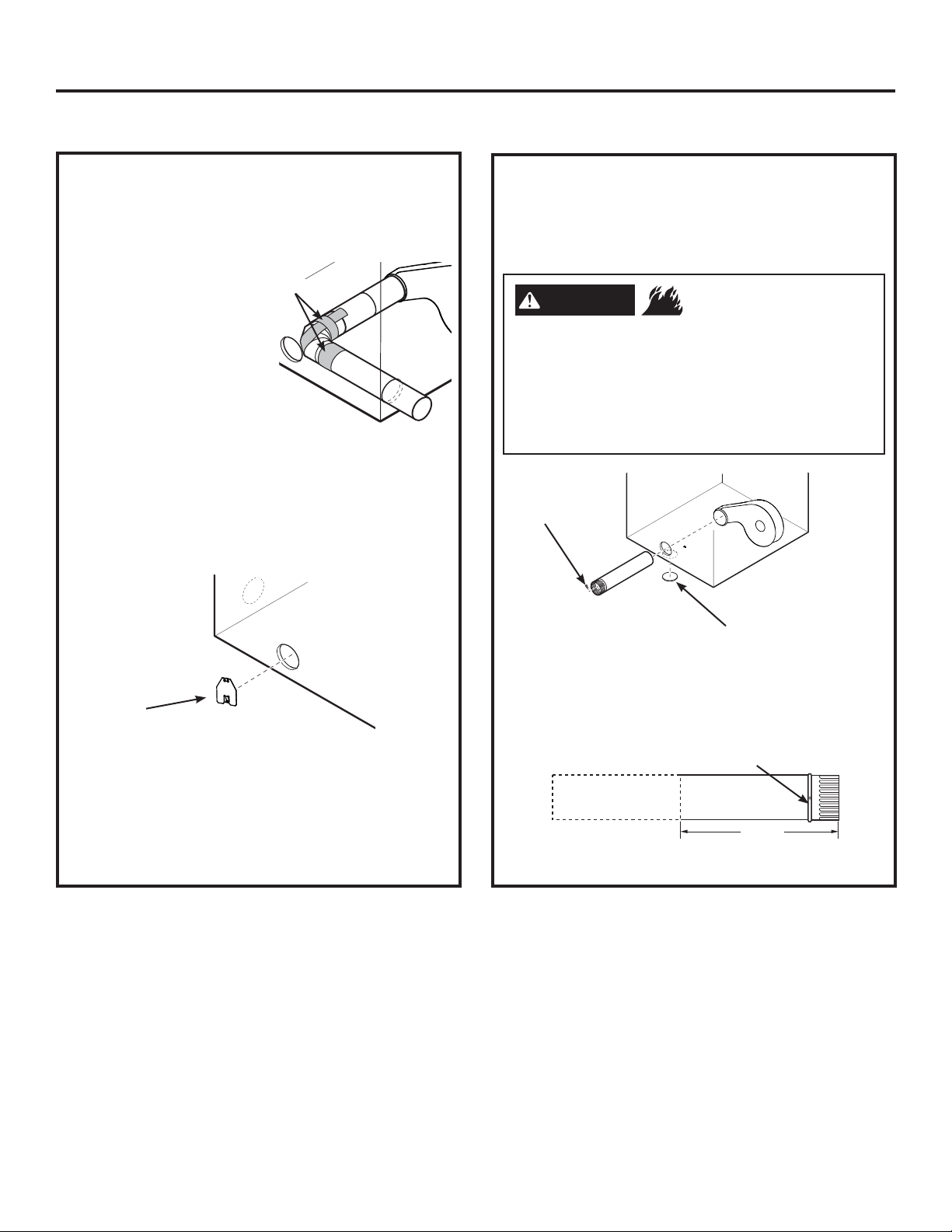

DRYER GAS SUPPLY CONNECTION

1 19ø32”

(4.05 cm)

3/8” NPT MALE THREAD GAS SUPPLY

47ø16” (11.27 cm)

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

You must use with this dryer a flexible metal

connector (listed connector ANSI Z21.24 / CSA 6.10).

The length of the connect shall not exceed 3 ft.

ADJUSTING FOR ELEVATION

• Gas clothes dryers input ratings are based on

sea level operation and need not be adjusted

for operation at or below 2000 ft. elevation. For

operation at elevations above 2000 ft., input

ratings should be reduced at a rate of 4 percent

for each 1000 ft. above sea level.

•

Installation must conform to local codes and

ordinances or, in their absence, the NATIONAL

FUEL GAS CODE, ANSI Z223.

19

Page 20

Installation Instructions

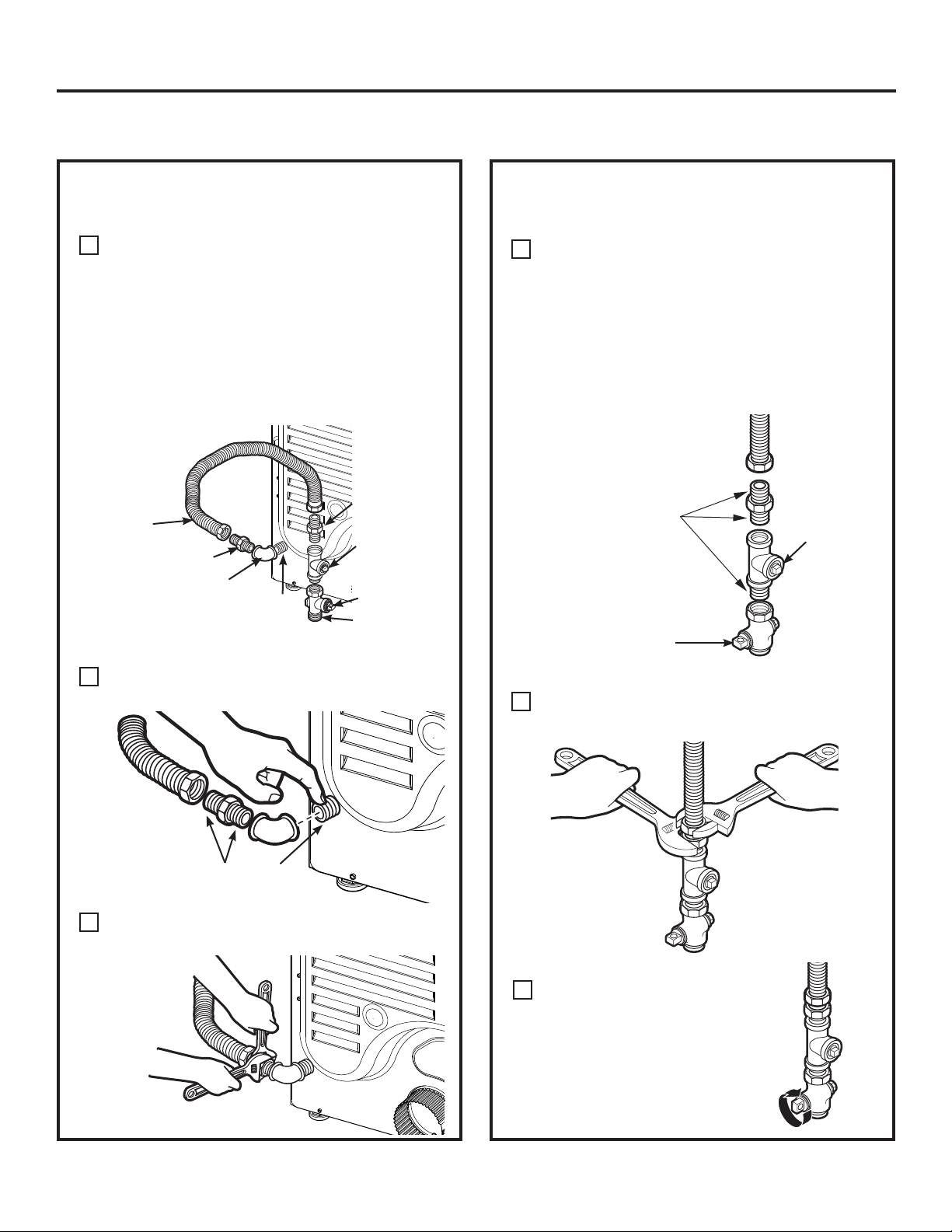

CONNECTING A GAS DRYER (cont.)

CONNECTING THE DRYER TO THE GAS

SUPPLY

Install a female 3/8” NPT elbow at the end of the

A

dryer gas inlet.

Install a 3/8” flare union adapter to the female

elbow.

IMPORTANT: Use a pipe wrench to securely hold

on to the end of the dryer gas inlet to prevent

twisting the inlet.

NOTE: Apply pipe compound or PTFE tape to the

threads of the adapter and dryer gas inlet.

New Metal

Flexible Gas

Line Connector

Adapter

Elbow

Items not supplied

Attach the flexible metal gas line connector to

B

3/8” NPT

the adapter.

Adapter

1/8” NPT

Pipe Plug for

Checking Gas

Inlet Pressure

Shut-Off Valve

Pipe size at

least 1/2”

CONNECTING THE DRYER TO THE GAS

SUPPLY (cont.)

Install a 1/8” NPT plugged tapping to the dryer

D

gas line shut-off valve for checking gas inlet

pressure.

Install a flare union adapter to the plugged

tapping.

NOTE: Apply pipe compound or PTFE tape

to the threads of the adapter and plugged

tapping.

Apply pipe compound

or PTFE tape to all

male threads.

Shut-Off

Valve

Tighten all connections, using two adjustable

E

wrenches. Do not overtighten.

Plugged

Tapping

Apply pipe compound to the

adapter and dryer gas inlet.

Tighten the flexible gas line connection, using

C

two adjustable wrenches.

20

Open the gas shut-off valve.

F

Page 21

Installation Instructions

TEST FOR LEAKS

Never use an open flame to test for gas leaks.

Check all connections for leaks with soapy solution

or equivalent.

Apply a soap solution. The leak test solution must

not contain ammonia, which could cause damage

to the brass fittings.

If leaks are found, close the valve, retighten the

joint and repeat the soap test.

Open Gas

Valve

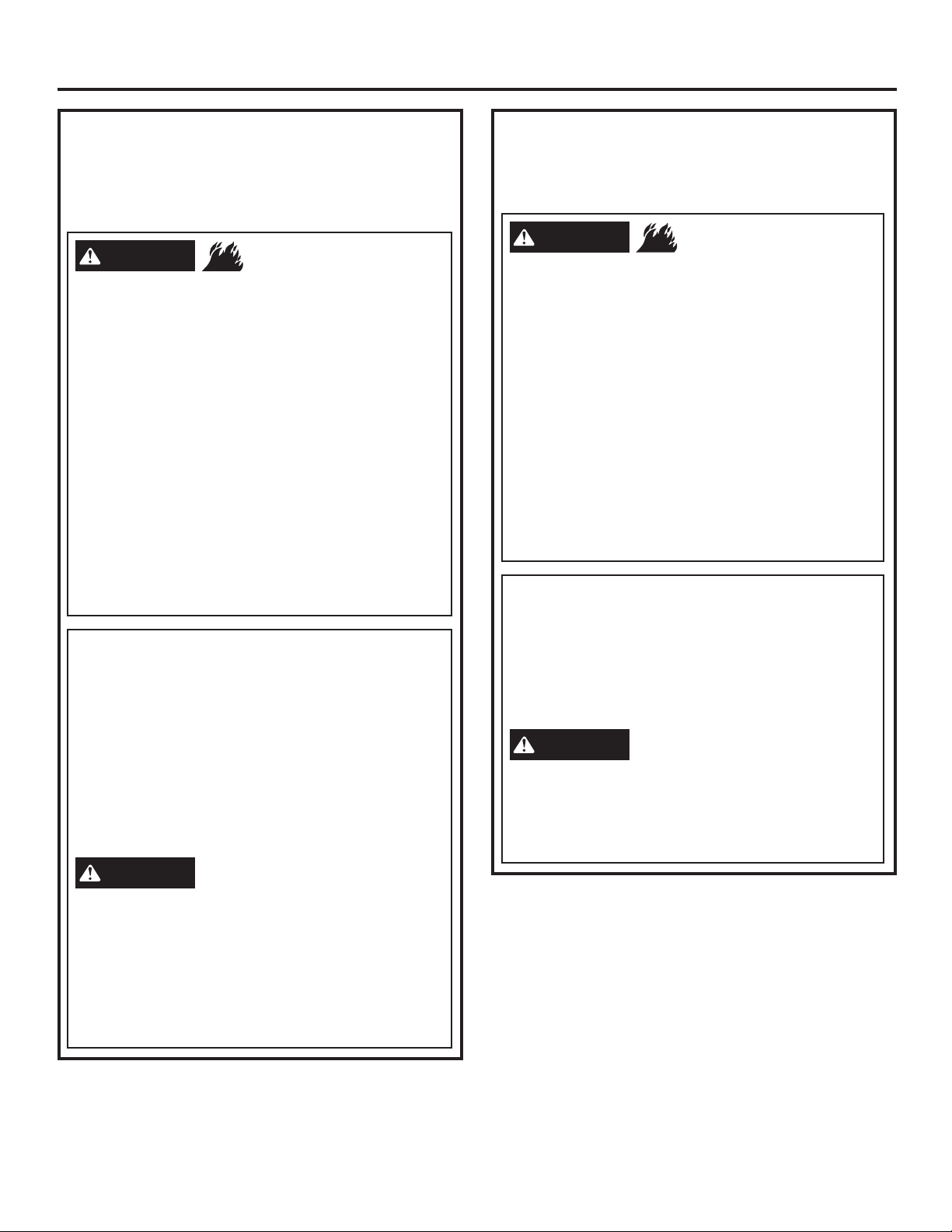

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS

WARNING

Plug into a grounded 3 prong outlet.

DO NOT remove ground prong.

DO NOT use an adapter.

DO NOT use an extension cord.

Failure to do so can result in death, fire or electrical

shock.

• Circuit – Individual properly polarized and grounded

15 or 20 amp circuit breaker or time-delay fuse.

•

Power Supply – 2-wire plus ground, 120 Volt,

single phase, 60 Hz, alternating current.

•

Outlet Receptacle –

Properly grounded

3-prong receptacle to

be located so the power

cord is accessible when

the dryer is in an installed

position. If a 2-prong

receptacle is present, it

is the owner’s responsibility to have a licensed

electrician replace it with a properly grounded

3-prong grounding type receptacle.

- Electrical Shock Hazard

Ensure proper

ground exists

before use.

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS (cont.)

• Dryer must be electrically grounded in

accordance with local codes and ordinances,

or in the absence of local codes, with the latest

edition of the NATIONAL ELECTRICAL CODE,

ANSI/NFPA NO. 70 or CANADIAN ELECTRICAL

CODE, CSA C22.1. Check with a licensed

electrician if you are not sure that the dryer is

properly grounded.

GROUNDING INSTRUCTIONS

This dryer must be grounded. In the event of a

malfunction or breakdown, grounding will reduce

the risk of electric shock by providing a path of

least resistance for electric current. This dryer uses

a cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed

and grounded in accordance with all local codes

and ordinances.

WARNING

can result in a risk of electric shock. Check with a

qualified electrician, or service representative or

personnel, if you are in doubt as to whether the

appliance is properly grounded. DO NOT modify the

plug on the power supply cord. If it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

SAVE THESE INSTRUCTIONS

•

If required by local codes, an external 18 gauge

or larger copper ground wire (not provided)

may be added. Attach to dryer cabinet with a

#8-18 x ½” sheet metal screw (available at any

hardware store) to rear of dryer as illustrated.

Improper connection of the

equipment-grounding conductor

Ground

Screw

21

Page 22

Installation Instructions

CONNECTING AN ELECTRIC DRYER

(Skip for gas dryers and if your dryer already has a power cord attached)

TOOLS YOU WILL NEED

Slip-joint pliers

Flat-blade

screwdriver

Phillips

screwdriver

Level

MATERIALS YOU WILL NEED

4” dia. metal elbow

3/4” Strain relief

(UL recognized)

4” Duct clamps (2) or

4” spring clamps (2)

Gloves

Exhaust hood

Duct tape

Before making the electrical connection, turn off

the circuit breaker(s) or remove the dryer’s circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall.

NEVER LEAVE THE

ACCESS COVER OFF THE TERMINAL BLOCK.

Safety glasses

4” dia. metal duct

(recommended)

4” dia., UL-listed

flexible metal duct (if

needed)

Dryer power cord kit

(not provided with

dryer)

UL rated 120/240V,

30A with 3 or 4 prongs.

Identify the plug type

as per the house

receptacle before

purchasing line cord.

4” Cover plate (Kit

WE49X22606)

22

Page 23

Installation Instructions

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

For electrical connections using a

power cord:

WARNING

Use a new UL-listed 240V 30 amp dryer power supply

cord with closed ring terminals or spade terminals with

upturned ends.

Use a UL-listed strain relief.

Disconnect power before making electrical

connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining two supply wires to remaining two

terminals.

Securely tighten all electrical connections.

Replace the terminal block cover.

Failure to do so can result in death, fire or electrical

shock.

- Fire Hazard

GROUNDING INSTRUCTIONS

For a grounded, cord-connected dryer: This dryer

must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk

of electric shock by providing a path of least

resistance for electric current. This dryer uses a

cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed

and grounded in accordance with all local codes

and ordinances.

WARNING

can result in a risk of electric shock. Check with a

qualified electrician, or service representative or

personnel, if you are in doubt as to whether the

appliance is properly grounded. DO NOT modify the

plug on the power supply cord. If it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

SAVE THESE INSTRUCTIONS

Improper connection of the

equipment-grounding conductor

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

For direct wire connections:

WARNING

Use 10 gauge copper wire.

Use a UL-listed strain relief.

Disconnect power before making electrical

connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining two supply wires to remaining two

terminals.

Securely tighten all electrical connections.

Replace the terminal block cover.

Failure to do so can result in death, fire or electrical

shock.

- Fire Hazard

GROUNDING INSTRUCTIONS

For a permanently connected dryer: This

dryer must be connected to a grounded metal,

permanent wiring system, or an equipmentgrounding conductor must be run with the circuit

conductors and connected to the equipmentgrounding terminal on the appliance.

WARNING

can result in a risk of electric shock. Check with a

qualified electrician, or service representative or

personnel, if you are in doubt as to whether the

appliance is properly grounded.

SAVE THESE INSTRUCTIONS

Improper connection of the

equipment-grounding conductor

23

Page 24

Installation Instructions

CONNECTING AN ELECTRIC DRYER (cont.)

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION)

NOTE: Since January 1, 1996, the National Electrical

Code requires that new constructions use a 4-wire

connection to an electric dryer. A 4-wire cord must

also be used where local codes do not permit

grounding through the neutral.

3-wire connection is NOT for use on new

construction.

Remove ground

strap and

discard. Keep

green ground

screw

Cover

1.

Turn off the circuit breaker(s) (30 amp) or remove

Screw

Screws

Neutral

(white)

Hot Wire

Hot Wire

3/4” UL Recognized

Strain Relief

4 #10 AWG minimum copper

conductors or 120/240V 30A

power supply cord kit marked

for use with dryers and provided

with closed loop or spade

terminals with upturned ends

(not supplied)

the dryer’s circuit fuse at the electrical box.

2.

Be sure the dryer cord is unplugged from the wall

receptacle.

3.

Remove the power cord cover located at the

lower back.

4.

Remove and discard ground strap. Keep the

green ground screw for Step 7.

5.

Install 3/4 in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief.

6.

Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

7.

Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket).

Tighten all terminal block screws (3) securely.

8.

Properly secure power cord to strain relief.

9.

Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE TERMINAL

BLOCK.

Relocate green

ground screw here

Green Wire

Strain Relief

Bracket

CONNECTING DRYER USING 3-WIRE

CONNECTION

If required,

by local code,

install external

ground (not

provided) to

grounded metal,

cold water

pipe, or other

established

ground

determined

by a qualified

electrician.

Green Ground

Screw

Cover

3-wire Connection

Not for use in Canada.

DO NOT use for Mobile Home Installations.

NOT for use on new construction.

NOT for use on recreational vehicles.

NOT for use in areas where local codes prohibit

grounding through the neutral conduction.

1.

Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

2.

Be sure the dryer cord is unplugged from the wall

receptacle.

3.

Remove the power cord cover located at the

lower back.

4.

Install 3/4-in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief.

5.

Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

6.

Be sure ground strap is connected to neutral

(center) terminal of block and to green ground

screw on cabinet rear. Tighten all terminal block

screws (3) securely.

7.

Properly secure power cord to strain relief.

8.

Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE TERMINAL

BLOCK.

Ground

Strap

Screw

Hot Wire

Screws

Neutral

(white)

3/4” UL Recognized

Strain Relief

3 #10 AWG minimum copper

conductors or 120/240V 30A

power supply cord kit marked for

use with dryers and provided with

closed loop or spade terminals

with upturned ends (not supplied)

Hot

Wire

Strain

Relief

Bracket

24

Page 25

Installation Instructions

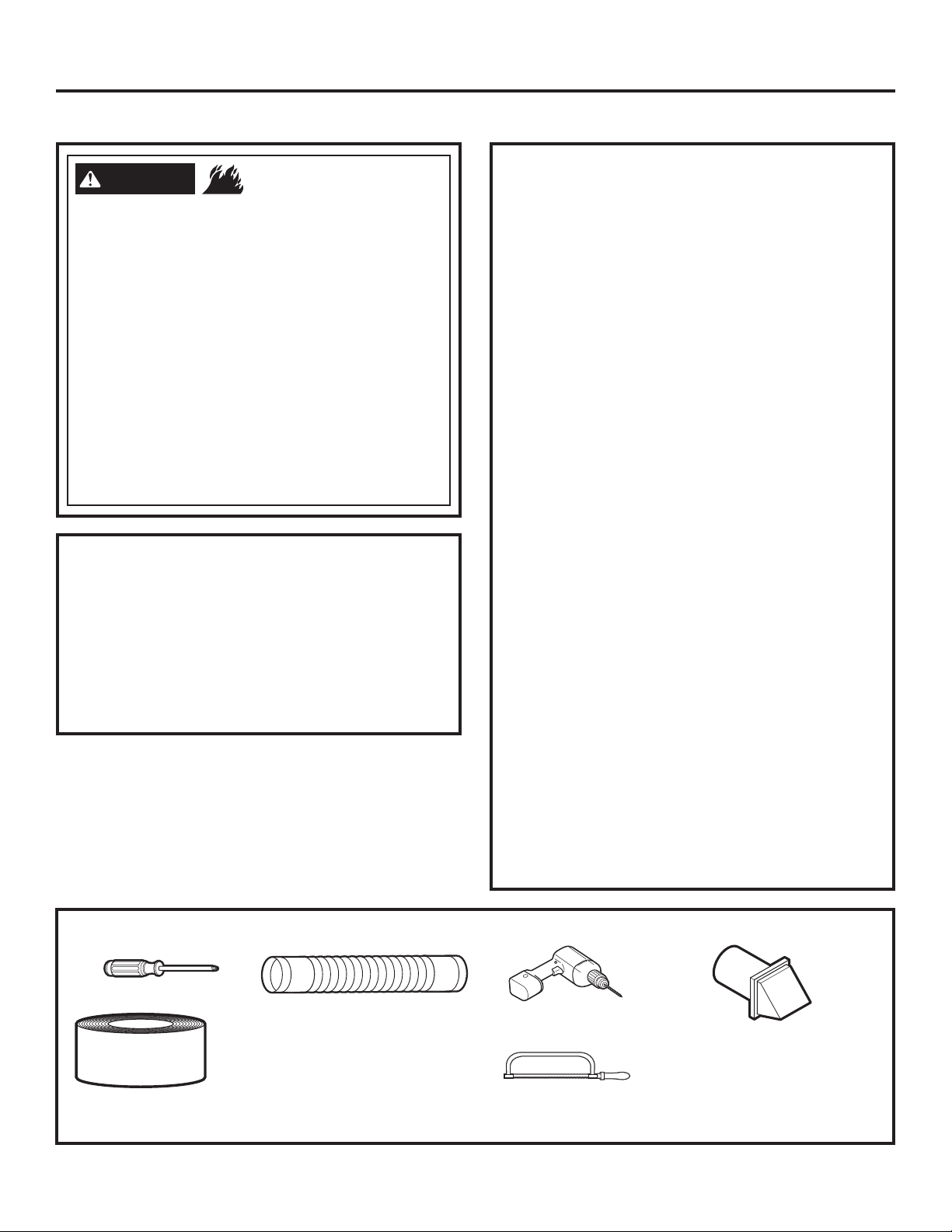

EXHAUSTING THE DRYER

WARNING

This dryer MUST be vented to the outdoors.

Use only 4” rigid metal ducting for the home

exhaust duct.

Use only 4” rigid metal or UL-listed dryer transition

duct to connect the dryer to the home exhaust.

DO NOT use a plastic vent.

DO NOT exhaust into a chimney, kitchen exhaust,

gas vent, wall, ceiling, attic, crawl space, or

concealed space of a building.

DO NOT install a screen in or over the exhaust duct.

DO NOT install a booster fan in the exhaust duct.

DO NOT use duct longer than specified in the

exhaust length table.

Failure to follow these instructions can result in

death or fire.

PARTS AVAILABLE FROM GEAPPLIANCES.COM

- Fire Hazard

OR LOCAL SERVICE ORGANIZATIONS

PM8X85

PM08X10085

WX08X10130

WE49X22606

Outdoor exhaust hood

8’ Flexible metal clothes dryer

transition duct with 2 clamps

4” Dryer exhaust clamp

Rear exhaust opening cover, for side

or bottom vented dryers

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

Terminate in a manner to prevent back drafts or entry

•

of birds or other wildlife.

Termination should present minimal resistance to

•

the exhaust airflow and should require little or no

maintenance to prevent clogging.

Wall caps must be installed at least 12” above ground

•

level or any other obstruction with the opening

pointed down.

Never vent the dryer out of the roof.

•

SEPARATION OF TURNS

For best performance, separate all turns by at least

•

4 ft. of straight duct, including distance between last

turn and dampened wall cap.

SEALING OF JOINTS

All joints should be tight to avoid leaks. The male end

•

of each section of duct must point away from the

dryer.

Duct joints should be made air- and moisture-tight

•

by wrapping the overlapped joints with duct tape or

aluminum tape.

Do not assemble ductwork with any fasteners

•

that extend into the duct. These fasteners can

accumulate lint, creating a potential fire hazard.

• Horizontal runs should slope down towards the

outdoors 1/4” per foot.

•

Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

INSULATION

Ductwork that runs through an unheated area or is

•

near air conditioning should be insulated to reduce

condensation and lint buildup.

TOOLS AND MATERIALS YOU WILL NEED TO INSTALL EXHAUST DUCT

Phillips-head screwdriver

Duct tape or duct

clamp

Rigid or UL-listed

flexible metal 4” (10.2

cm) duct

Drill with 1/8” drill bit

(for bottom venting)

Hacksaw

25

Vent hood

Page 26

Installation Instructions

EXHAUSTING THE DRYER (cont.)

CONNECTING THE DRYER TO HOUSE

VENT

RIGID METAL TRANSITION DUCT

•

For best drying performance, a rigid metal transition

duct is recommended.

•

Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTED FLEXIBLE METAL (SEMI-RIGID) TRANSITION

DUCT

If rigid metal duct cannot be used, then UL-listed

•

flexible metal (semi-rigid) ducting can be used (Kit

PM08X10085).

•

Never install flexible metal duct in walls, ceilings, floors

or other enclosed spaces.

•

Total length of flexible metal duct should not exceed 7’

9” (2.4 m).

•

For many applications, installing elbows at both

the dryer and the wall is highly recommended (see

illustrations at right). Elbows allow the dryer to sit

close to the wall without kinking and/or crushing the

transition duct, maximizing drying performance.

•

Avoid resting the duct on sharp objects.

UL-LISTED FLEXIBLE METAL (FOIL-TYPE) TRANSITION

DUCT

In special installations, it may be necessary to connect

•

the dryer to the house vent using a flexible metal

(foil-type) duct. A UL-listed flexible metal (foil-type) duct

may be used ONLY in installations where rigid metal or

flexible metal (semi-rigid) ducting cannot be used AND

where a 4” diameter can be maintained throughout

the entire length of the transition duct.

•

In Canada and the United States, only the flexible

metal (foil-type) ducts that comply with the “Outline for

Clothes Dryer Transition Duct Subject 2158A” shall be

used.

•

Never install flexible metal duct in walls, ceilings, floors

or other enclosed spaces.

•

Total length of flexible metal duct should not exceed 7’

9” (2.4 m).

•

Avoid resting the duct on sharp objects.

•

For best drying performance:

1. Slide one end of the duct over the clothes dryer

outlet pipe.

2. Secure the duct with a clamp.

3. With the dryer in its permanent position, extend

the duct to its full length. Allow 2

overlap the exhaust pipe. Cut off and remove

excess duct. Keep the duct as straight as

possible for maximum airflow.

4. Secure the duct to the exhaust pipe with the

other clamp.

”

of duct to

FOR TRANSITION VENTING (DRYER TO

WALL), DO

:

• DO cut duct as

short as possible

and install

straight into wall.

•

DO use elbows

when turns are

necessary.

Elbows

DO NOT:

• DO NOT bend or

collapse ducting.

Use elbows

if turns are

necessary.

DO NOT use

•

excessive

exhaust length.

Cut duct as short

as possible.

• DO NOT crush

duct against the

wall.

DO NOT set

•

dryer on duct.

26

Page 27

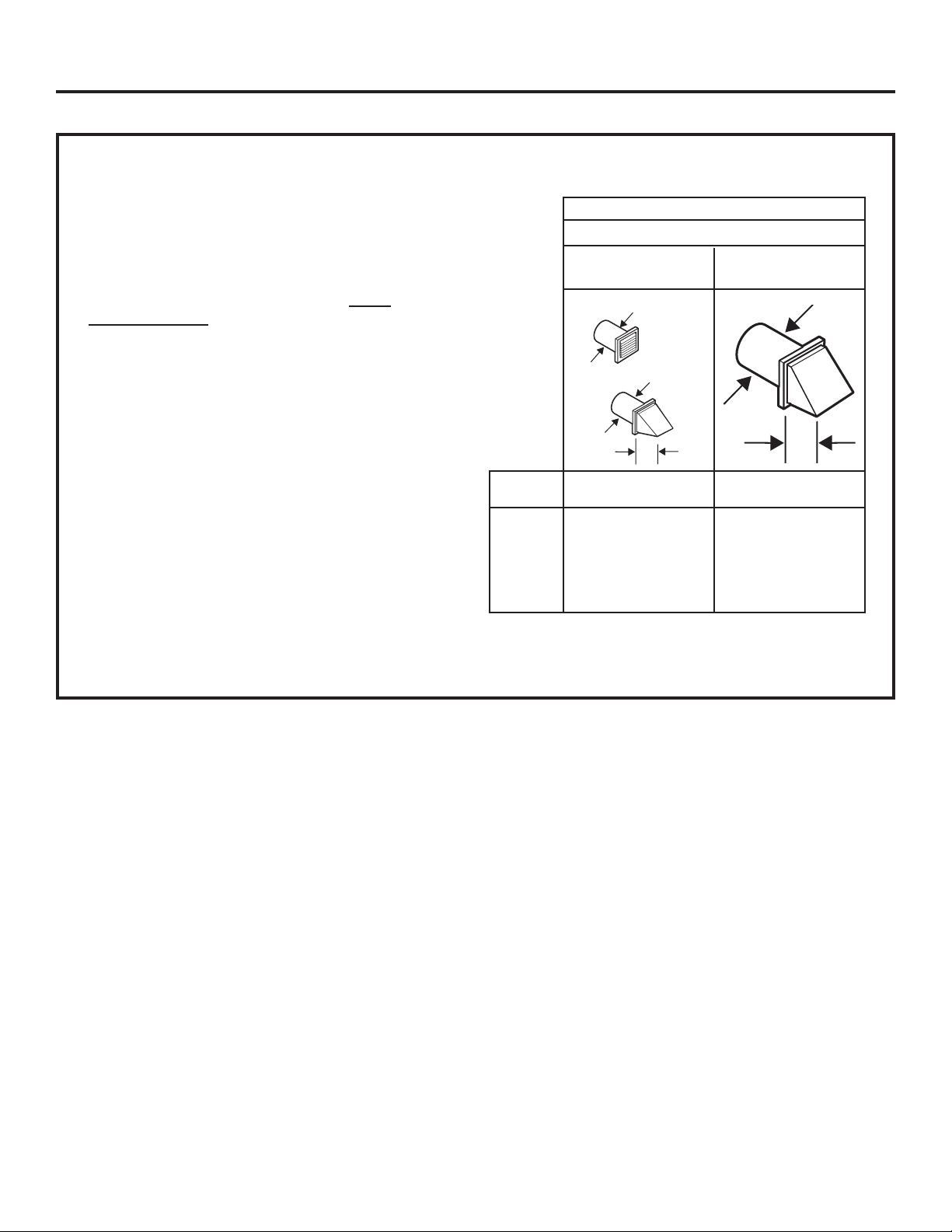

EXHAUST LENGTH

Installation Instructions

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reduce the dryer life.

• Accumulate lint, creating a potential fire

hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.

Problems due to incorrect installation are not

covered by the warranty.

The MAXIMUM ALLOWABLE length of the exhaust

system depends upon the type of duct, number

of turns, the type of exhaust hood (wall cap) and

all conditions noted on the chart.

• Internal elbows added for side or bottom vent

conversions must be included in the total elbow

count.

• Any elbow greater than 45° should be treated as a

90° elbow.

• Two 45° elbows will be treated like one 90° elbow.

• For the side exhaust installations, add one 90°

elbow to the chart.

• When calculating the total vent system length,

you must add all the straight portions and elbows

of the system (including the transition duct).

EXHAUST LENGTH

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended Use only for short- run

installations

4” DIA

4” DIA

1

”

4

No. of 90º Rigid Rigid

Elbows Metal Metal

0 90 Feet 60 Feet

1 60 Feet 45 Feet

2 45 Feet 35 Feet

3 35 Feet 25 Feet

4 25 Feet 15 Feet

2

4

”

DIA

ø2”

27

Page 28

Installation Instructions

EXHAUSTING THE DRYER (cont.)

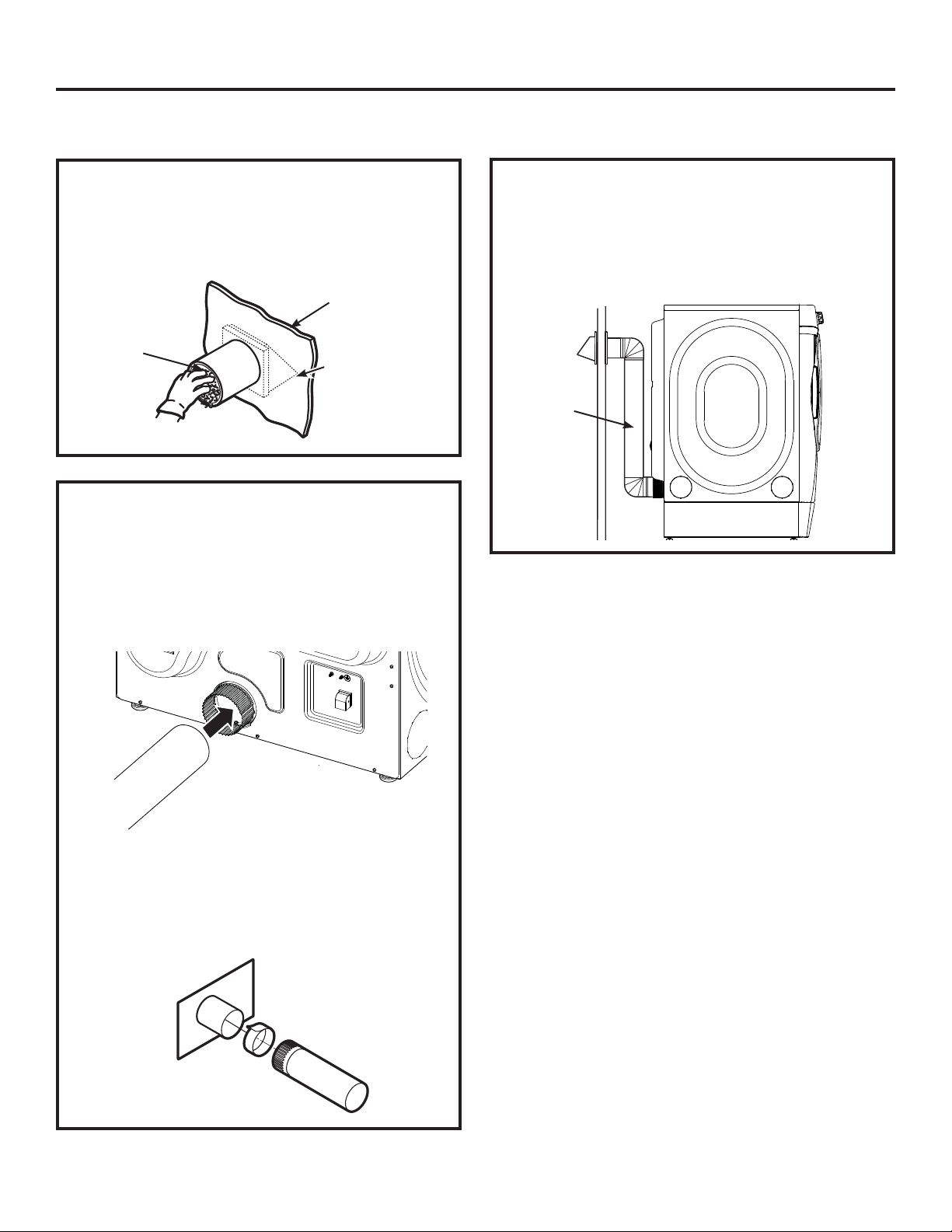

BEFORE YOU BEGIN

• Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

•

Remove any lint from the wall exhaust opening.

Wall

Internal

Duct

Opening

Check that exhaust

hood damper opens

and closes freely.

STANDARD REAR EXHAUST

RECOMMENDED CONFIGURATION TO

MINIMIZE EXHAUST BLOCKAGE

Using duct elbows will prevent duct kinking and

collapsing.

Transition

Ducting

We recommend that you install your dryer before

installing your washer. This will permit direct

access for easier exhaust connection.

Slide the end of the exhaust duct on the back of the

dryer and secure with duct tape or a hose clamp.

Duct

NOTE: We strongly recommend using rigid metal

exhaust duct. However, if flexible ducting is used it

must be UL-Listed metal, not plastic.

• For straight-line installation, connect the dryer

exhaust to the wall, using duct tape.

Wall Side

Duct Tape

Dryer

Side

28

Page 29

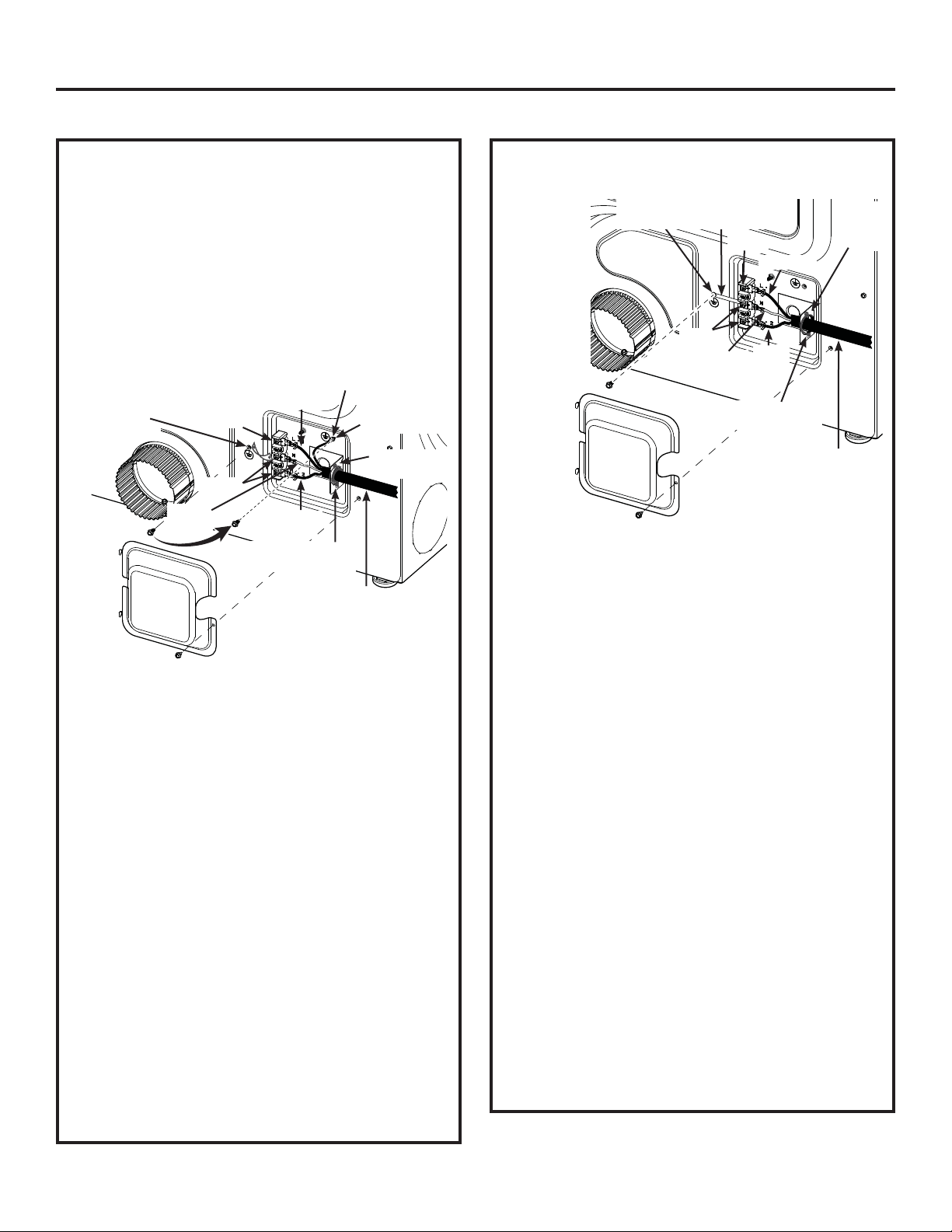

Installation Instructions

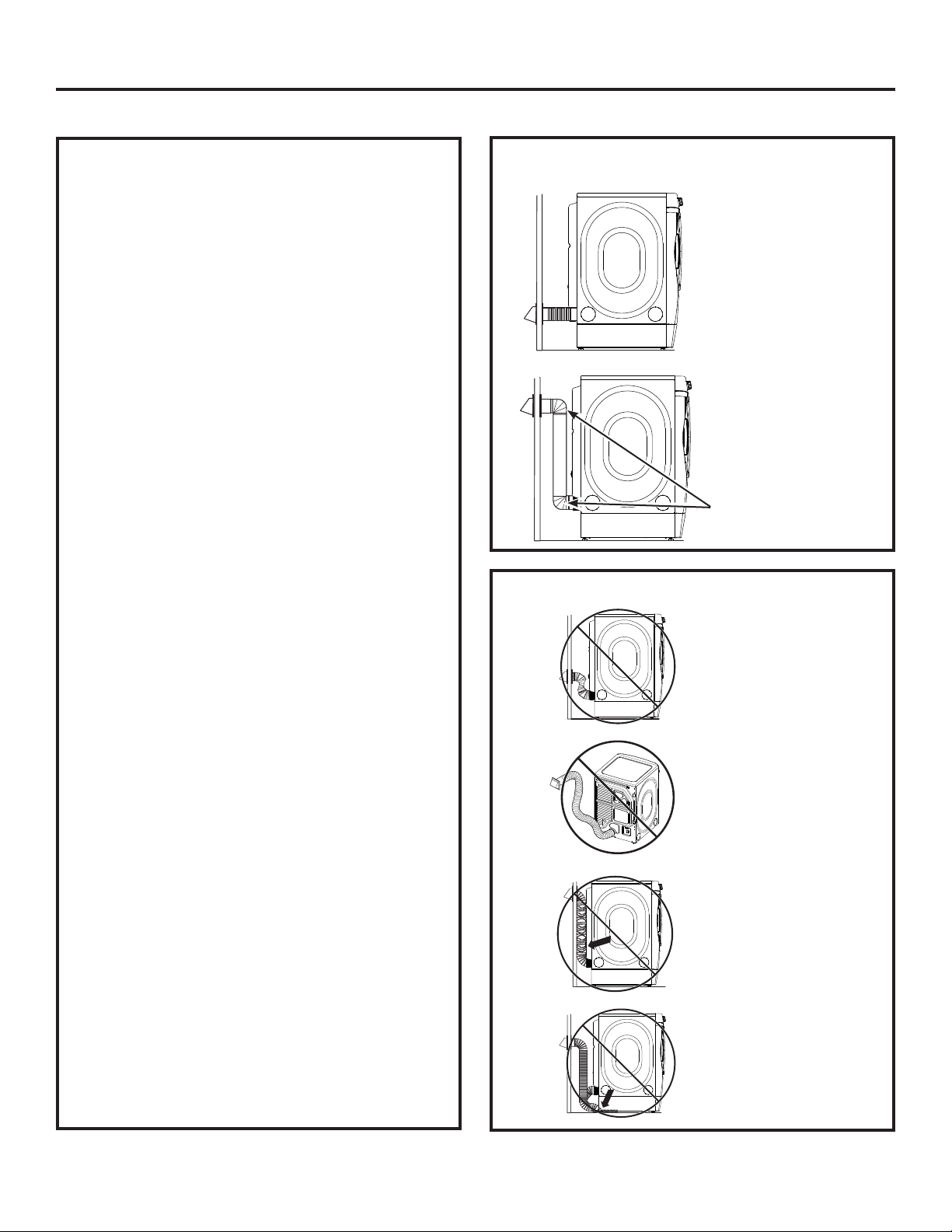

SIDE VENTING:

Dryer Exhaust to right of cabinet for Electric

models only.

Dryer Exhaust to left of cabinet for Gas and

Electric models.

WARNING

Disconnect dryer from electrical supply.

Wear gloves and arm guards.

Close the back opening with cover plate (Kit

WE49X22606).

Failure to do so may result in fire, electrical shock

or lacerations.

Right

(electric

Remove

screw

and save

Detach and remove the right (electric models only)

or left side knockout as desired. Remove the screw

inside the dryer exhaust duct and save. Pull the

duct out of the dryer.

models

only)

- Fire Hazard

Left

Remove desired

knockout (one only)

Fixing hole

A

TAB LOCATION

Not for gas

Bend tab

up 45°

Through the rear opening, locate the tab in the

middle of the appliance base. Lift the tab to about

45°,

using a flat-blade screwdriver.

ADDING A NEW DUCT

Portion “A”

Fixing hole

Right

Right (electric

models only)

or left side

exhaust

Left

Reconnect the cut portion (A) of the duct to the

blower housing. Make sure that the shortened duct

is aligned with the tab in the base. Use the screw

saved previously to secure the duct in place through

the tab on the appliance base.

ADDING ELBOW AND DUCT FOR EXHAUST TO

SIDE OF CABINET

• Insert the 4” elbow through the rear opening and

connect the elbow to the dryer internal duct.

Internal duct

15 3ø4”

Cut the duct as shown and keep portion A.

Right

Exhaust can be

added to right

(electric models

only) or left side

Left

• Insert the 4” duct through the side opening and

connect it to the elbow.

Side opening

Do not pull or damage the electrical wires and

do not remove the vinyl cover from the electrical

components inside the dryer when inserting the

duct. A slight interference may occur between the

exhaust and the wire components.

29

Rear

opening

Page 30

Installation Instructions

EXHAUSTING THE DRYER (cont.)

SIDE VENTING (cont.)

ADDING ELBOW AND DUCT FOR EXHAUST TO

LEFT OR RIGHT SIDE OF CABINET (cont.)

• Apply duct tape as

shown on the joint

between the dryer

internal duct and the

elbow, and also the joint

between the elbow and

the side duct.

Use 4” rigid metal ducting

only inside the dryer. Internal duct joints must be

secured with tape, otherwise they may separate

and cause a safety hazard

ADDING COVER PLATE TO REAR OF CABINET

(SIDE EXHAUST)

Duct tape

.

BOTTOM VENTING:

Dryer Exhaust to the bottom of cabinet for

Gas and Electric models WITHOUT Built-In

Pedestal™.

WARNING

Close the back opening with cover plate (Kit

WE49X22606).

Disconnect dryer from electrical supply.

Wear gloves and arm guards.

Failure to do so may result in fire, electrical shock

or lacerations.

Remove

screw

and save

Bottom

- Fire Hazard

Remove desired

knockout (one only)

Plate

(Kit WE49X22606)

Connect standard metal elbows and ducts to

complete the exhaust system. Cover back opening

with a plate (Kit WE49X22606) available from your

local service provider. Place dryer in final location.

NEVER LEAVE THE BACK OPENING WITHOUT THE

PLATE.

(Kit WE49X22606.)

Remove the screw inside the dryer exhaust duct

and save. Pull the duct out of the dryer. Detach

and remove the bottom knockout.

Fixing hole

A

15 3ø4”

Cut the duct as shown and keep portion A.

30

Page 31

Installation Instructions

BOTTOM VENTING (cont.)

ADDING A NEW DUCT

• Through the rear

opening, locate

the tab in the

middle of the

appliance base.

Lift the tab to

about 45° using

a flat-blade

screwdriver.

Reconnect the cut

•

portion (A) of the

Portion “A”

duct to the blower

housing. Make

Fixing hole

sure that the

shortened duct is

aligned with the

tab in the base.

Use the screw saved previously to secure the duct

in place through the tab on the appliance base.

Insert the 4” elbow

•

through the bottom

opening and connect to

the dryer internal duct.

Be sure not to pull or damage the electrical wires

inside the dryer when inserting the duct.

Bend tab

up 45°

Apply duct tape as

•

shown on the joint

Duct tape

between the dryer

internal duct and the

elbow, and also the

joint between the

elbow and the bottom

duct.

Internal duct joints must be secured with tape;

otherwise, they may separate and cause a safety

hazard.

ADDING COVER PLATE TO REAR OF CABINET

(BOTTOM EXHAUST)

Plate

(Kit WE49X22606)

Connect standard metal elbows and ducts to

complete the exhaust system. Cover back opening

with a plate (Kit WE49X22606) available from your

local service provider. Place dryer in final location.

NEVER LEAVE THE BACK OPENING WITHOUT THE

PLATE.

(Kit WE49X22606.)

31

Page 32

FINAL SETUP

Installation Instructions

1

LEVEL THE DRYER

Stand the dryer upright near the final location and

adjust the four leveling legs at the corners to ensure

that the dryer is level from side to side and front to

rear.

Raise

2

PLUG DRYER IN

Lower

Ensure proper

ground exists

before use.

3

DRYER START-UP

Press the Power button.

NOTE: If the dryer has been exposed to

temperatures below freezing for an extended

period of time, allow it to warm up before pressing

Power. Otherwise, the display will not come on.

The dryer is now ready for use.

32

Page 33

Installation Instructions

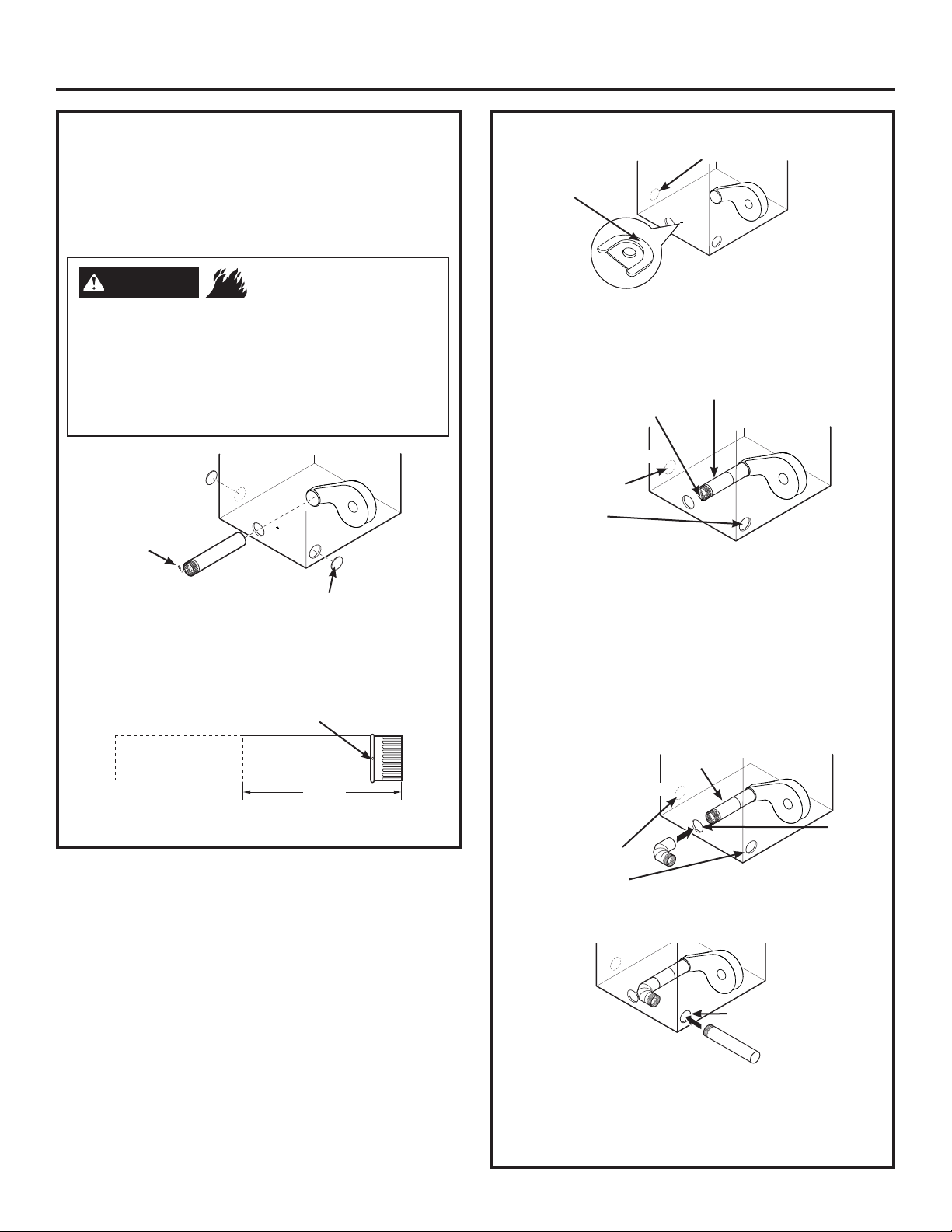

REVERSING THE DOOR SWING (if desired)

IMPORTANT NOTES

• Read the instructions all the way through before

starting.

• Handle parts carefully to avoid scratching paint.

• Set screws down by their related parts to avoid

using them in the wrong places.

• Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is completed.

These instructions are for changing the hinges

IURPWKHULJKWVLGHWRWKHOHIWVLGH³LI\RXHYHUZDQW

to switch them back to the right side, follow these

same instructions and reverse all references

to the left and right.

• Normal completion time to reverse the door swing

is 30–60 minutes.

TOOLS YOU WILL NEED

#2 Phillips-head screwdriver T-25 torx driver 1/4” nut driver

DOOR PARTS

6 - #8 x 1/2” Screws

(hinge assembly and

handle spacer)

1 - Door Mask 1 - Chrome Door Cover

10 - #8 x 7/8” Screws

(door assembly)

2 - Panel Plugs

(on some models)

2 - #8 x 1/2” Screws

(striker plate)

1 - Door Striker

(on some models)

BEFORE YOU START

Unplug the dryer from its electrical outlet.

2 - #8 x 1/2” Screws

(door mask)

Assembly

2 - #10 x 5/8” Screws

(hinge)

1 - Handle Spacer

(on some models)

2 - #10 x 5/8” Screws

(panel plug)

1 - Handle

Spacer/Latch

Assembly

(on some models)

1 - Inner Door

Assembly

1 - #8 x 3/8” Screws

(hinge pin)

1 - Door Plug

(on some models)

33

Page 34

Installation Instructions

REVERSING THE DOOR SWING (if desired)

1

REMOVE THE DOOR ASSEMBLY

A. Open the door fully.

B. Remove 2 screws (#10 x 5/8”) from the hinge,

starting with the bottom screw. The door will tilt

away from the front panel, but will come to rest

in place.

C. Lift the door slightly and unhook if from the front

panel.

D.

Place the door on a soft and flat surface.

RE-LOCATE THE HINGE STRIKER AND

2A

FRONT PANEL PLUGS (on some models

- see step 2B below for other models)

IMPORTANT: Note the location of the hinge (left or

right) before removing.

A. Remove 2 screws (#10 x 5/8”) and front panel

plugs from the front panel.

B. Re-install front panel plugs and screws on

opposite side of the door opening.

C. Remove 2 screws (#8 x 1/2”) and hinge striker

from the front panel.

D. Rotate hinge striker 180 degrees and re-install

with screws on the opposite side of the door

opening.

2B

RE-LOCATE THE HINGE STRIKER

(on some models - see step 2A above

for other models)

IMPORTANT: Note the location of the hinge (left or

right) before removing.

A. Remove 2 screws (#10 x 5/8”) from top and

bottom of door striker.

B. Remove 2 screws (#8 x 1/2”) from center of door

striker and remove door striker from front panel.

C. Rotate door striker 180 degrees and re-install

with screws on the opposite side of the door

opening.

34

Page 35

Installation Instructions

3

DISASSEMBLE THE DOOR ASSEMBLY

A. Place door on a soft and flat surface with the

inner door frame facing upward.

B. Remove 10 screws (#8 x 7/8”) from the perimeter

of the door frame.

C. Separate the inner door frame from the chrome

door cover. Set the inner door frame aside on a

soft and flat surface.

RE-LOCATE THE DOOR MASK

4

A. Place the chrome door cover on a soft and flat

surface so that the door mask is facing upwards.

B. Remove 2 screws (#8 x 1/2”) that secure the door

mask in place.

C. Rotate the door mask 180 degrees and re-install

screws to secure door mask.

BEFORE

AFTER

D. Re-location is complete. Set chrome door cover

aside.

35

Page 36

Installation Instructions

REVERSING THE DOOR SWING (if desired)

RE-LOCATE HINGE ASSEMBLY AND

5

HANDLE SPACER

A. Place the inner door frame on a soft and flat

surface so that the inner door gasket is facing

updwards.

B. Remove 6 screws (#8 x 1/2”) that secure the

hinge assembly and handle spacer.

RE-LOCATE HINGE ASSEMBLY AND

5

HANDLE SPACER (cont.)

D. Rotate hinge assembly 180 degrees and

re-locate it and the door plug (on some models)

on the opposite side of the inner door frame.

E. Rotate the handle spacer or handle spacer/latch

assembly (depending on model) 180 degrees and

re-locate on the opposite side of the inner door

frame.

Handle spacer/

Latch assembly

(on some models)

or

Door plug

(on some models)

C. Separate the hinge assembly, door plug (on

some models), handle spacer or handle spacer/

latch assembly (depending on model) from the

inner door frame.

Handle spacer/

Door plug

(on some models)

Hinge

assembly

Latch assembly

(on some models)

Handle spacer

(on some models)

or

Handle spacer

(on some models)

F. Re-install screws securing hinge assembly and

handle spacer.

Hinge

assembly

36

Page 37

Installation Instructions

RE-ASSEMBLE DOOR ASSEMBLY

6

A. Place the chrome door cover on a soft flat

surface with the plastic outer protect cover

facing down.

B. Lower the inner door frame onto the chrome

door cover.

C. Ensure that all screw holes are aligned and

re-install 10 screws (#8 x 7/8”).

8

RE-INSTALL DOOR ASSEMBLY

A. Install the door assembly by guiding the hinge

pin screw head through the key hole on the

front panel and lowering the door assembly into

place.

B. Open the door approximately 140 degrees to

provide access to the screw hole locations.

C. Starting with the top screw, re-install the 2

screws (#10 x 5/8”) which secure the door to the

front panel.

RE-LOCATE HINGE PIN SCREW

7

A. Remove the hinge pin screw from the hole

labeled “D”.

B. Re-install the hinge pin screw into the hole

labeled “W”.

37

Page 38

Installation Instructions

STACKING THE WASHER AND DRYER (if desired)

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these instructions for

local electrical inspector’s use.

•

IMPORTANT – Observe all governing

codes and ordinances.

Note to Installer – Be sure to leave these

•

instructions with the Consumer.

Note to Consumer – Keep these instructions for

•

future reference.

Service must be performed by a qualified

•

installer.

Proper installation is the responsibility of the

•

installer.

• Disconnect power before installing. Failure to do

so could result in serious injury or death.

WARNING

Use two or more people to install dryer.

Failure to do so may result in back or other injury.

• Avoid Tipping and Rupture of Utility Services.

Dryer must be securely attached to the washer.

DO NOT place the washer on top of the dryer.

Failure to do so could result in personal injury/

death or property damage.

• Mobile Home or Manufactured Home Installation

– Stacking of a gas dryer is not permitted in a

mobile home or manufactured home.

- Excessive Weight Hazard

GE APPLIANCES STACK KIT:

Order on-line at GEApplianceParts.com, 24 hours a day or

by phone at 877.959.8688 during normal business hours.

Part Number Accessory

GEFLSTACK Complete Stack Kit

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air opening are: 0” both sides, 1” rear and 1” top.

Consideration must be given to provide adequate

clearance for installation and service.

REQUIREMENTS FOR ALCOVE OR CLOSET

INSTALLATION

WARNING

Keep flammable materials and vapors, such as gasoline,

away from dryer.

Place dryer at least 18” (46 cm) above the floor for a

garage installation.

Failure to do so can result in death, explosion, or fire.

• The dryer MUST be vented to the outdoors.

• Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0” either side

1” front and rear

1” top

•

Consideration must be given to provide adequate

clearance for installation and service.

•

Closet doors must be louvered or otherwise

ventilated and have at least 60 square inches of

open area. If the closet contains both a washer

and a dryer, doors must contain a minimum of

120 square inches of open area.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, THE CONFIGURATION OF

THE DUCTING MAY REQUIRE GREATER THAN 3” OF

REAR CLEARANCE.

Gas Dryers Only:

•

No other fuel burning appliance shall be installed

in the same closet as a gas dryer.

•

The dryer must be disconnected from the gas