GE GFD14ESSNWW Installation Manual

SAFETY INFORMATION ..........3

USING THE DRYER

Getting Started ...................... 4

Loading ..............................8

Features ..............................8

OWNER’S MANUAL &

INSTALLATION

INSTRUCTIONS

GFD14

CARE AND CLEANING ...........9

INSTALLATION

INSTRUCTIONS .....................11

Stacking (Optional) .....................24

Reversing The Door Swing (Optional). . . . . 26

TROUBLESHOOTING TIPS ......28

LIMITED WARRANTY ...........31

CONSUMER SUPPORT ..........32

ENGLISH/FRANÇAIS/

ESPAÑOL

Write the model and serial

numbers here:

Model # _________________

DRYERS

Serial # _________________

They are on the label on the front

of the dryer behind the door.

GE is a trademark of the General Electric Company. Manufactured under trademark license.

0020507767GE 49-3000087 12-18 GEA

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances

product, and we think you will too. Among other things, registration of your appliance ensures that we

can deliver important product information and warranty details when you need them.

Register your GE appliance now online. Helpful websites and phone numbers are available in the

Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration

card included in the packing material.

2 49-3000087

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

SAFETY INFORMATION

WARNING

Ŷ

Read all instructions before using the appliance.

Ŷ

DO NOT dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, or other flammable or explosive substances, as they give off vapors that could ignite or

explode.

Ŷ

DO NOT place items exposed to cooking oils in your dryer. Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch fire. To reduce the risk of fire due to contaminated loads, the final

part of the tumble dryer cycle occurs without heat (cool down period). Avoid stopping a tumble dryer before the end

of the drying cycle unless all items are quickly removed and spread out so that the heat is dissipated.

Ŷ

DO NOT allow children to play on or in this appliance. Close supervision of children is necessary when this

appliance is used near children.

Ŷ

Before the appliance is removed from service or discarded, remove the door to the drying compartment.

Ŷ

DO NOT reach into the appliance if the drum is moving.

Ŷ

DO NOT install or store this appliance where it will be exposed to the weather.

Ŷ

DO NOT tamper with controls.

Ŷ

DO NOT climb or stand on this unit.

Ŷ

DO NOT repair or replace any part of this appliance or attempt any servicing unless specifically recommended

in the user-maintenance instructions or in published user-repair instructions that you understand and have the

skills to carry out.

Ŷ

Follow all fabric care instructions and warnings to prevent melting of garments or damage to the appliance.

Ŷ

DO NOT use fabric softeners or products to eliminate static unless recommended by the manufacturer of the

fabric softener or product.

Ŷ

DO NOT dry articles containing foam rubber or similarly textured rubber-like materials.

Ŷ

Clean lint screen before or after each load.

Ŷ

DO NOT operate the dryer without the lint filter in place.

Ŷ

D O N O T store combustible materials, gasoline or other flammable liquids near the dryer. Keep area around the

exhaust opening and adjacent surrounding areas free from the accumulation of lint, dust and dirt.

Ŷ

The interior of the appliance and exhaust duct should be cleaned periodically by qualified service personnel.

Ŷ

Unplug the appliance or turn off the circuit breaker before servicing. Pressing the Power or Start/Pause button DOES

NOT disconnect power.

Ŷ

DO NOT operate this appliance if it is damaged, malfunctioning, partially disassembled, or has missing or

broken parts, including a damaged cord or plug.

Ŷ

DO NOT spray any type of aerosol into, on or near dryer at any time. DO NOT use any type of spray cleaner when

cleaning dryer interior. Hazardous fumes or electrical shock could occur

Ŷ

See “ELECTRICAL CONNECTION” located in the Installation Instructions for grounding instructions.

To reduce the risk of fire, explosion, electric shock, or injury to persons when using your appliance,

follow basic precautions, including the following:

.

READ AND SAVE THESE INSTRUCTIONS

49-3000087 3

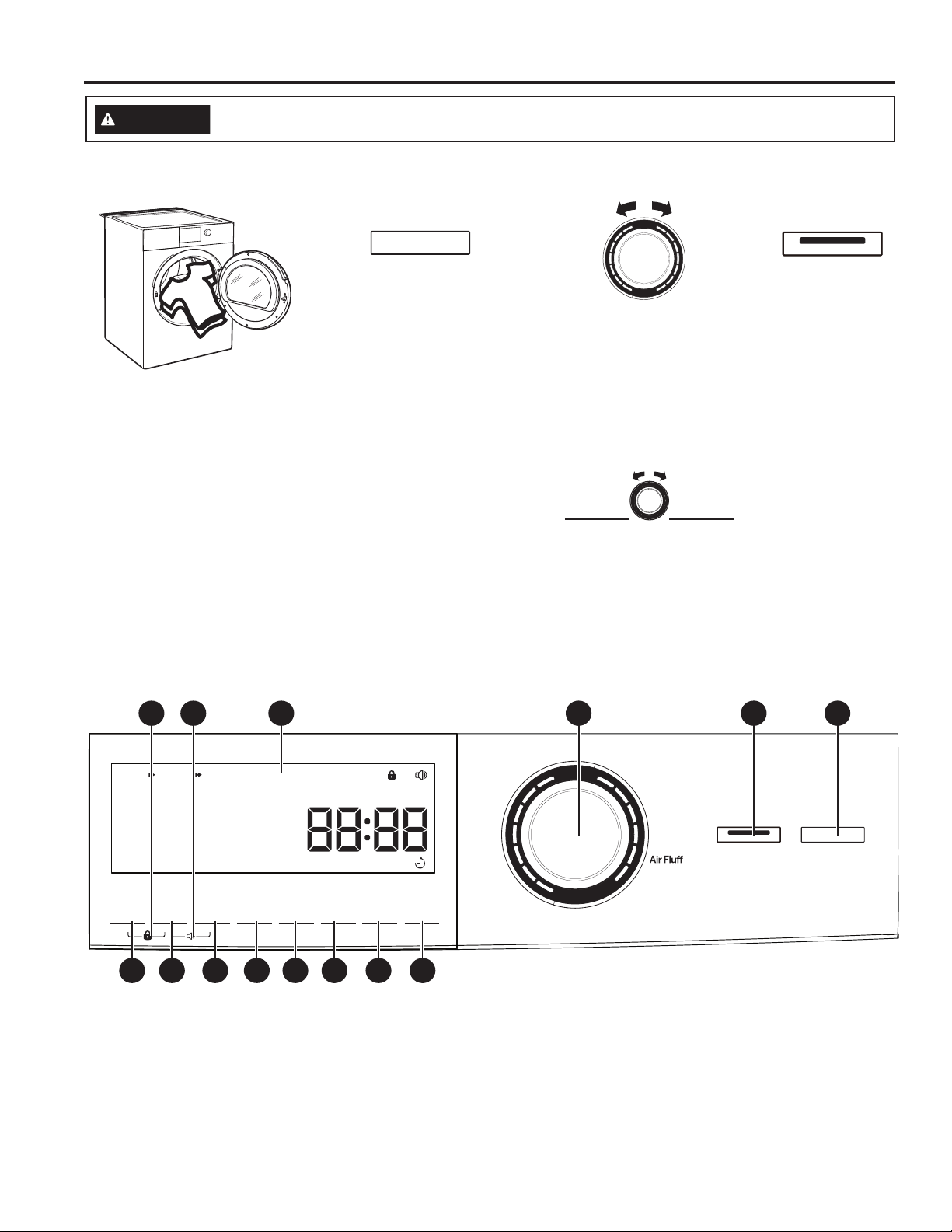

Getting started

WARNING

To reduce the risk of fire, electric shock, or injury to persons, read the IMPORTANT SAFETY

INFORMATION before operating this appliance.

Throughout this manual, features and appearance may vary from your model.

Step 1

Step 2 Step 3

Power

• If the screen is dark,

press the Power button

USING THE DRYER

• Loosely add items.

• Close door.

NOTE: Dryer will not start

with door open.

to “wake up” the display.

• Select a dry cycle.

(Defaults are set for

each dry cycle. These

default settings can

be changed. See

control settings for

more information.)

OR

Timed

Dry

• Press Timed Dry

button, rotate knob

to adjust time, and

press Temp button

to set your own

temperature.

Step 4

Start

Pause

• Press the

Start/Pause

button.

Temp

Controls

L AKBM

DRY DAMP COOL

Ex Dry

High

Medium

Low

No Heat

Level

Temp eDry

C

Clean Filter

Dry

LowAir eDry

Damp Timed

Damp

Alert

D E F H I J

Damp DelayDamp

Timed

Dry

N

Est Time Remaining

My Cycle

My Cycle

G

Hold to Set

Tumble

Ext

Tumble

Delay

Dry

Mixed Loads

Cottons

Heavy

Duty

To w e l s

Casuals

Active

Wea r

Sanitize

Quick Dry

Delicates

Dewrinkle

Rack Dry

Warm Up

Start

Pause

Power

4 49-3000087

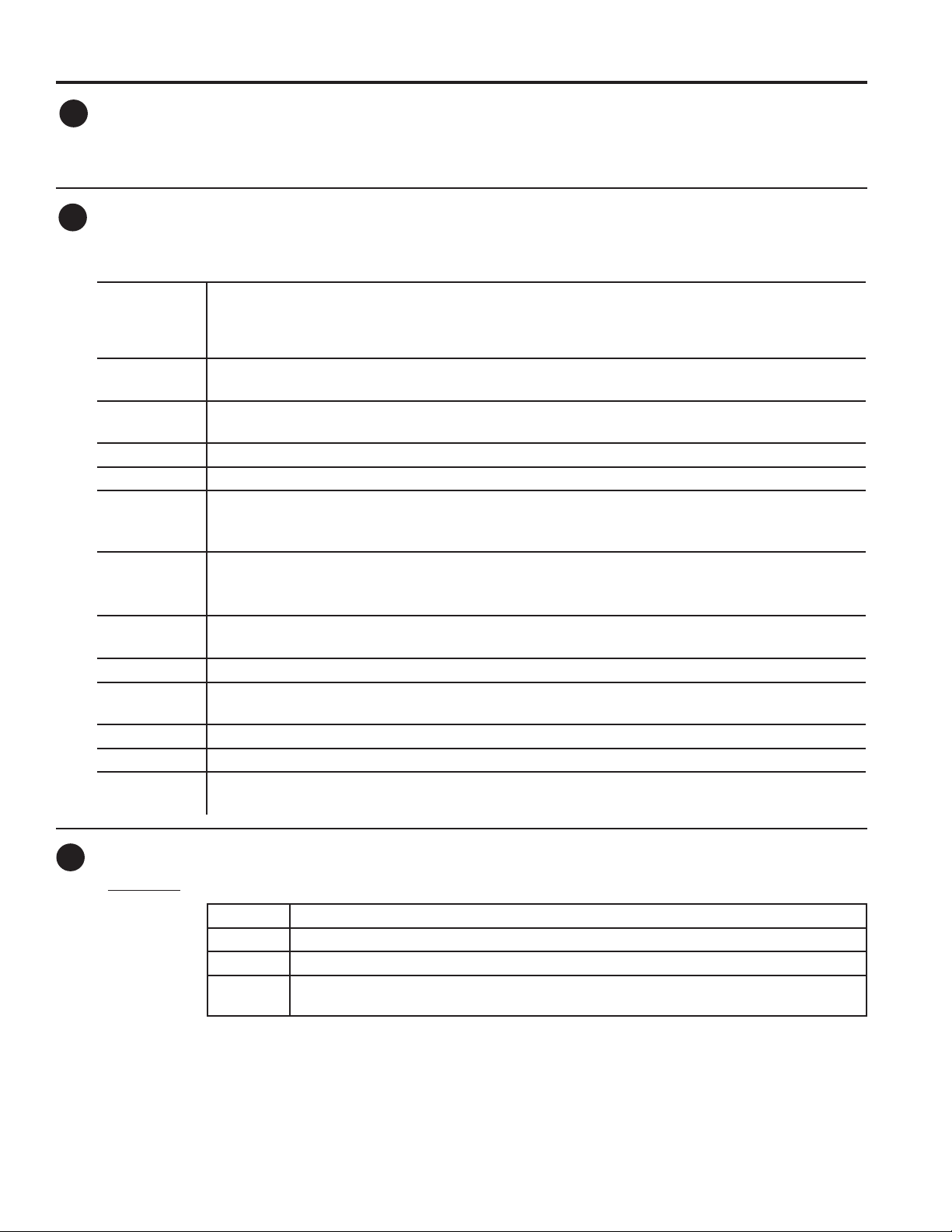

Getting started

Power

A

Press to “wake up” the display. If the display is active, press to turn the dryer off.

NOTE: Pressing Power does not disconnect the appliance from the power supply.

Dry Cycles

B

The dry cycle controls the cycle time for the drying process. The chart below will help you match

the dry setting with the loads.

USING THE DRYER

Mixed Loads

or Normal

(Depending on

model)

Cottons For cottons and most linens. NOTE: Energy Star

Heavy Duty For large coats, bed spreads, mattress covers, sleeping bags, blankets, comforters, jackets,

Towels Use for towels OR sheets. It is not recommended to mix towels and sheets in the same load.

Casuals For wrinkle-free, permanent press and delicate items, and knits.

Active Wear Clothing worn for active sports exercise and some casual wear. Fabrics include new technology

Sanitize Reduces certain types of bacteria by 96.7%, including: Staphylococcus aureus and Pseudomonas

Quick Dry For small loads that are needed in a hurry, such as sports or school uniforms. Can also be

Delicates For lingerie and special-care fabrics.

Dewrinkle For removing wrinkles from items that are dry or slightly damp. This cycle is not recommended

Warm Up Provides 25 minutes of warming time to warm up clothes.

Air Fluff Provides 30 minutes of tumbling time without heat.

Rack Dry For drying delicate items without tumbling, use drying rack accessory. Place items flat on the

For loads consisting of cottons and poly blends.

®

models are tested on Cottons with

default settings.

small rugs, and similar large and bulky items.

finishes and stretch fibers such as Spandex. Also for clothing labeled Easy Care or Perma Press:

For wrinkle-free and permanent press items.

aeruginosa. The antibacterial process occurs when high heat is used during a portion of this

drying cycle.

used if the previous cycle left some items damp, such as collars or waistbands.

for delicate fabrics.

drying rack such as wool sweaters and delicate fabrics. Dry with low heat.

C

49-3000087 5

Temp

Temp (Temperature)

You can change the temperature of your dry cycle.

High For regular to heavy cottons.

Medium For synthetics, blends and items labeled Permanent Press.

Low For delicates, synthetics and items labeled Tumble Dry Low.

No Heat This option may only be used with Air Fluff and Timed Dry, in which items are

tumbled without heat.

Getting started

D

E

USING THE DRYER

F

Level

Damp

Alert

Timed

Dry

Level

The sensor continuously monitors the amount of moisture in the load. When the moisture in

your clothes reaches your selected dry level, the dryer will stop.

NOTE: Sensor dry Level can be used with all cycles except Timed Dry, Air Fluff, Rack

Dry, Warm Up and Dewrinkle.

Ex Dry Use for heavy-duty fabrics or items that should be very dry, such as towels.

Dry Use for normal dryness level suitable for most loads. This is the preferred cycle for energy saving.

Damp For leaving items partially damp.

Damp Alert

This option causes the dryer to beep when clothes have dried to a damp level. Remove

items that you wish to hang dry. The Damp Alert will only beep when this option is selected,

and the dryer will continue to dry.

Removing clothes and hanging them when they are damp can reduce the need to iron some items.

Timed Dry

1. Press Timed Dry button. Lights around the knob will flash. Select the drying time by

rotating the knob to increase or decrease the time in 10-minute increments up to 2 hours

and 30 minutes.

2. Select the dry Temp.

3. Close the door.

4. Press Start/Pause.

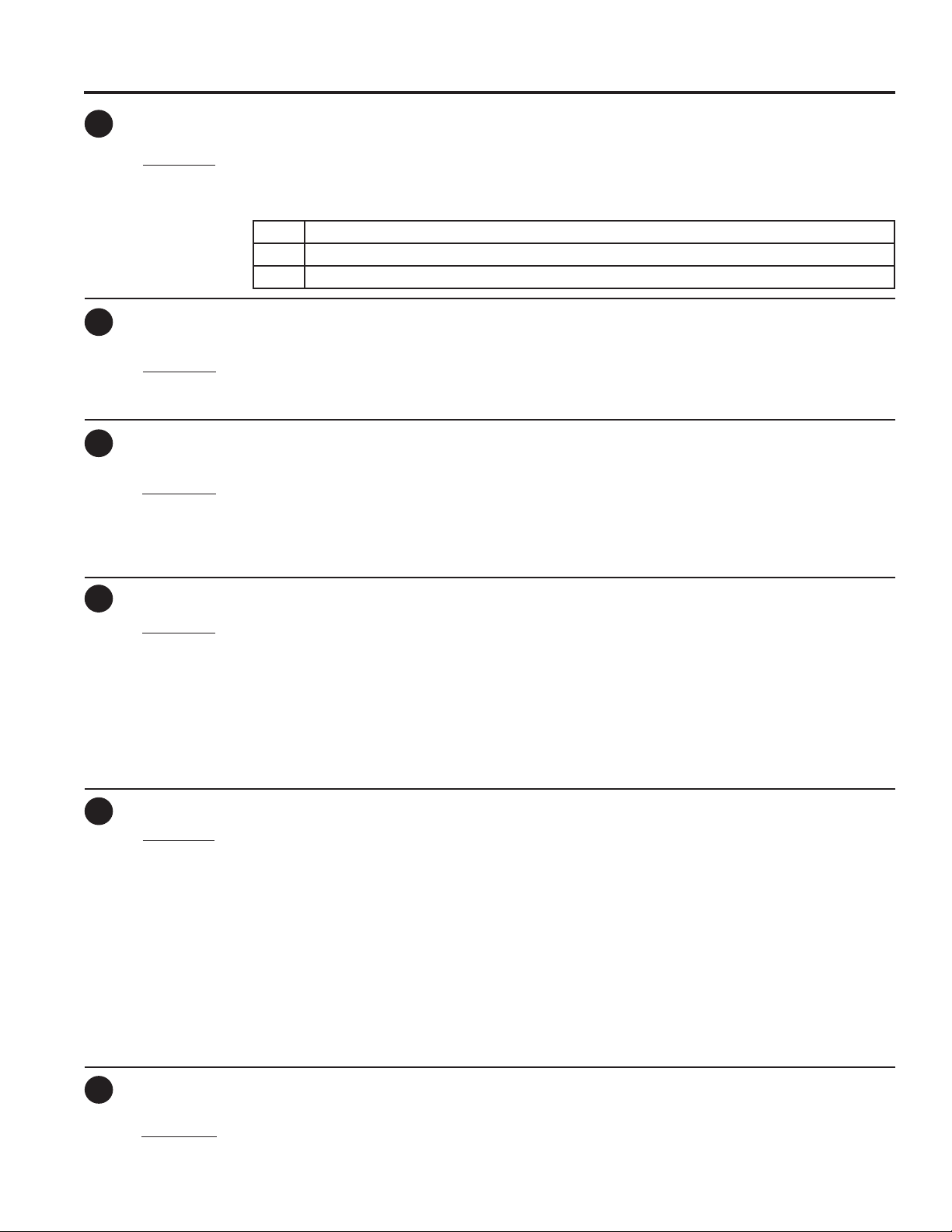

G

H

eDry

My Cycle

Hold to Set

eDry (on some models)

Reduces total energy consumption of specific dryer cycles by adjusting certain heat settings.

NOTE: Cycle times will change when eDry is selected.

Energy Star® models are tested on Cottons cycle with default settings to determine energy

use rating of this dryer. The eDry option will default to on for Cottons. Temperature settings

on High and dryness level setting on Dry are specifically designed for this cycle to reduce

energy consumption. For optimal energy savings, turn eDry on. For optimal drying times,

turn eDry off. Energy savings will vary across loads and cycles.

The eDry selection can be used with Mixed Loads, Cottons, Heavy Duty, Towels,

Casuals, Active Wear and Delicates.

My Cycle

Set up your favorite combination of settings and save them here for one touch recall. These

custom settings can be set while a cycle is in progress.

To store a My Cycle combination of settings:

1. Select your drying cycle.

2.

Change Temp and Level settings to fit your needs.

3. Select any drying options you want.

4. Press and hold the My Cycle button for 3 seconds to store your selection. A beep will

sound and the button will light up.

To recall your stored My Cycle combination:

Press the MY CYCLE button before drying a load.

To change your stored My Cycle combination:

Repeat steps 1–4.

I

Ext

Tumble

Extended Tumble

Minimizes wrinkles by adding approximately 2 hours of no-heat tumbling after clothes are

dry.

The estimated time remaining display will show “END”.

The extended tumble time does not get added to the cycle time on the display.

6 49-3000087

Getting started

USING THE DRYER

J

K

L

Delay

Temp

Dry

Start

Pause

Level

Delay Dry

Use to delay the start of your dryer.

1. Choose your dry cycle and any options.

2. Press Delay Dry. You can change the delay time in 1 hour increments, using the Delay Dry

button.

3. Press the Start/Pause button to start the countdown.

NOTE: If the door is opened while the dryer is in Delay Dry, the countdown time will not

restart unless the door is closed and Start/Pause button has been pressed again.

Start/Pause

Press to start a cycle. If the dryer is running, pressing it once will pause the dryer and unlock

the door. This function can be used to add garments during a cycle. Press again to restart

the cycle.

NOTE: If the dryer is paused and the cycle is not restarted within 15 minutes, the current

cycle will be cancelled.

Lock

You can lock the controls to prevent any selections from being made. Or you can lock or

unlock the controls after you have started a cycle.

Children cannot accidentally start the dryer by touching pads with this option selected.

To lock the dryer, press and hold the Temp and Level buttons together for 3 seconds.

To unlock the dryer controls, press and hold the Temp and Level buttons together for 3

seconds. A sound is made to indicate the lock/unlock status.

The control lock icon on the display will light up when it is on.

NOTE: The Power button can still be used when the machine is locked.

M

N

Damp

Alert

Timed

Dry

Signal

When the light is on, the dryer will beep at the end of the cycle and every time you press a

button on the control panel.

To turn the signal off, press and hold the Damp Alert and Timed Dry buttons together for 3

seconds. A sound is made to indicate the lock/unlock status.

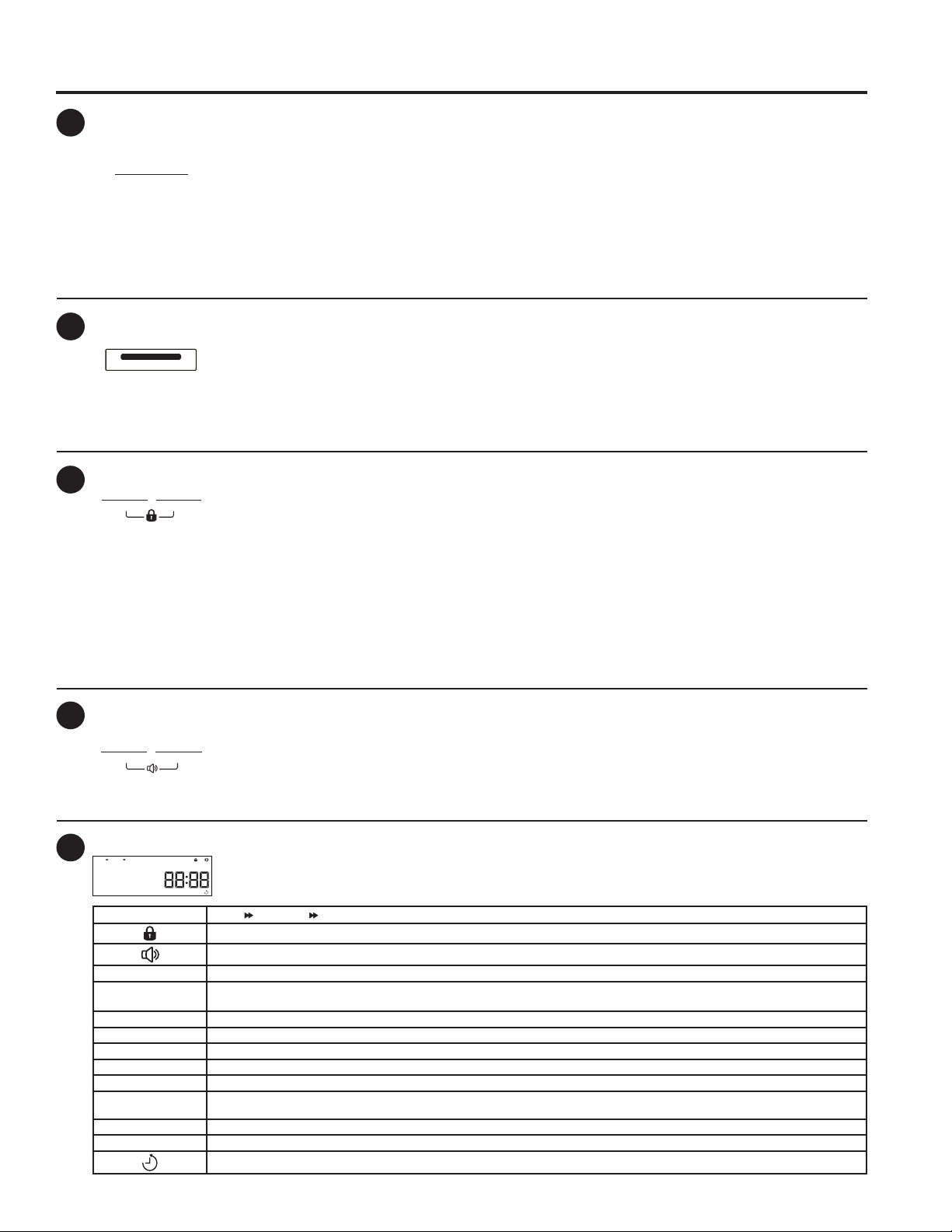

DRY DAMP COOL

Ex Dry

High

Medium

Dry

Low

No Heat

Clean Filter Time to clean the filter. See the Care and Cleaning section.

Damp Alert Indicates Damp Alert is set and will sound when the clothes have dried to a damp dryness level.

Est Time

Remaining

My Cycle Indicates the My Cycle feature is set.

Ext Tumble Indicates the Extended Tumble feature is set.

Est Time Remaining

Clean Filter

LowAir eDry

Damp DelayDamp

Damp Timed

My Cycle

Status

Low Air Indicates decrease in performance of the dryer and increase risk of lint accumulation in the ducts and

eDry Shows eDry setting selected.

Temp Shows High, Medium, Low or No Heat temperature setting selected.

Level Shows Extra Dry, Dry or Damp dryness setting selected.

Timed Indicates that a Timed Dry cycle is set. Will turn off after cycle is finished.

Display and Status Lights

The display shows the approximate time remaining until the end of the cycle.

In addition, this display will show the dryer status:

Tumble

DRY DAMP COOL

Controls locked on.

End of cycle signal on.

dryer.

Display shows the estimated time remaining until set cycle is completed.

Indicates Delay Dry is set time is selected.

49-3000087 7

Loading

Always follow fabric manufacturer’s care label when laundering.

Fabric Care Labels

Below are fabric care label “symbols” that affect the clothing you will be laundering.

Dry Labels

Tumble

dry

Heat

USING THE DRYER

Dry

Normal

setting

High Medium Low No heat/air

Special

instructions

Line dry/

hang to dry

Sorting and Loading Hints

Permanent Press/

wrinkle resistant

Drip dry

Dry flat

Gentle/

delicate

Do not tumble dry

In the shade

Do not dry

(used with

do not wash)

WARNING

• Keep flammable materials and vapors, such as

gasoline, away from dryer.

• DO NOT dry anything that has ever had anything

flammable on it (even after washing).

• No washer can completely remove oil.

As a general rule, if clothes are sorted properly for the washer, they are sorted properly for the dryer. Try also to

sort items according to size. For example, do not dry a sheet with socks or other small items.

Do not add fabric softener sheets once the load has become warm. They may cause fabric softener stains. Bounce®

Fabric Conditioner Dryer Sheets have been approved for use in this dryer when used in accordance with the

manufacturer’s instructions.

Do not overload. This wastes energy and causes wrinkling.

- Fire Hazard

• DO NOT dry anything that has ever had any type of oil

on it (including cooking oils).

• Items containing foam, rubber, or plastic must be dried

on a clothesline.

• Failure to do so can result in death, explosion, or fire.

Drying Rack

A handy drying rack may be used for drying delicate items such as washable sweaters. Place items flat on the

drying rack and block such items as wool sweaters and delicate fabrics. Dry with low heat.

To install the drying rack, extend the drying rack into the dryer drum and rest the front two

legs on the front angled ledge.

NOTES:

Ŷ

The drying rack is designed for use with the Timed Dry cycle. Use with sensor cycles

may result in damp items or extended cycle times.

Ŷ

Do not use this drying rack when there are other clothes in the dryer, that are not placed on the rack.

Ŷ

The drying rack, WE01X26416, is available as an accessory. Order on-line at GEApplianceparts.com, 24 hours

a day or by phone at 877.959.8688 during normal business hours.

8 49-3000087

Care and cleaning

Interior and Duct

The interior of the appliance and exhaust duct should be cleaned once a year by qualified service personnel.

The Exhaust Duct: Inspect and clean the exhaust ducting at least once a year to prevent clogging. A partially clogged

exhaust can lengthen the drying time.

The Exhaust Hood: Check with a mirror that the inside flaps of the hood move freely when operating. Make sure that there

is no wildlife (birds, insects, etc.) nesting inside the duct or hood.

Exterior

Wipe or dust any spills or washing compounds with a damp cloth. Dryer control panel and finishes may be damaged

by some laundry pretreatment soil and stain remover products. Apply these products away from the dryer. The fabric

may then be washed and dried normally. Damage to your dryer caused by these products is not covered by your

warranty.

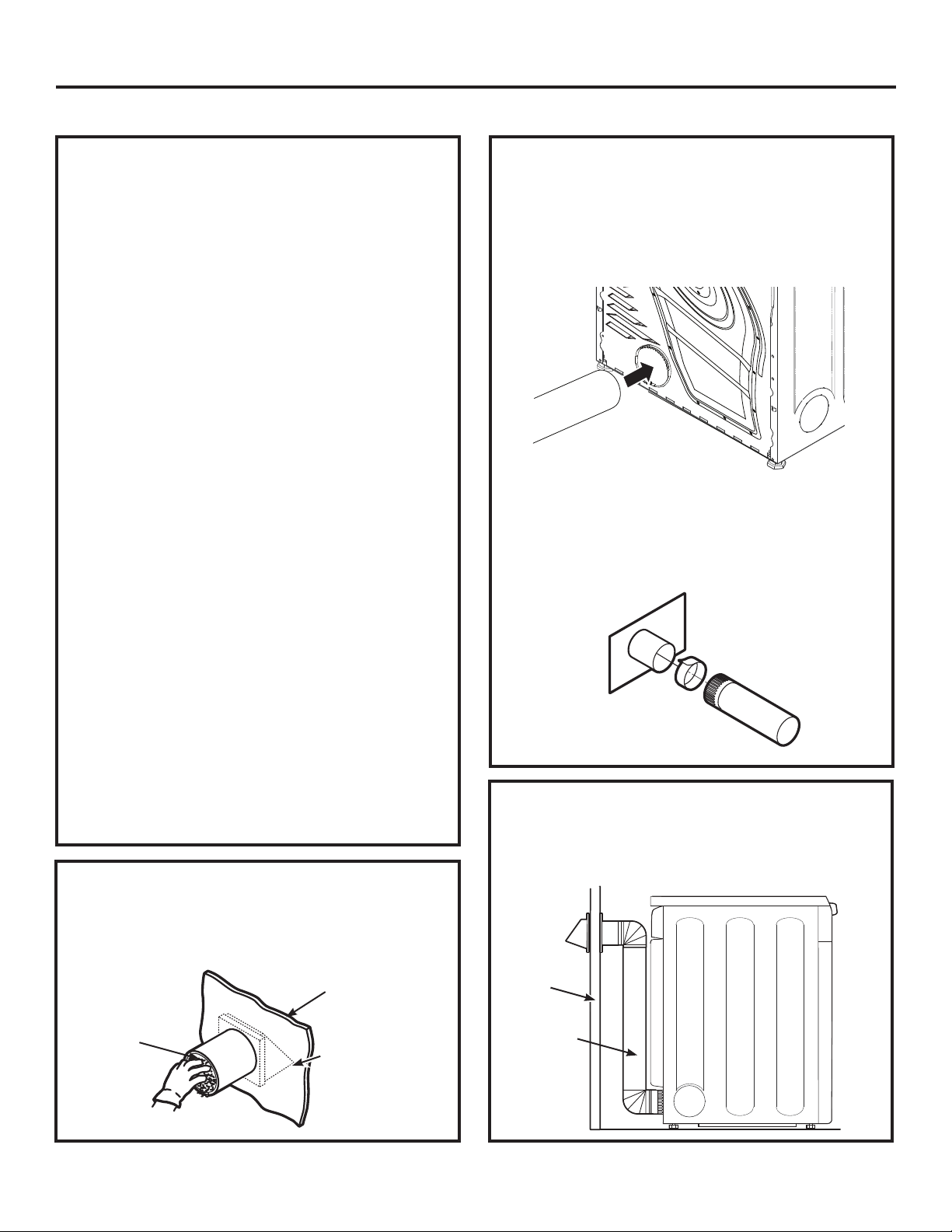

Lint Filter

Clean the lint filter before each use.

Pull out the lint filter. Moisten your fingers and remove the captured lint. Once clean, slide

the filter back into position. Have a qualified technician vacuum the lint from the dryer once

a year.

NEVER OPERATE THE DRYER WITHOUT ITS FILTER IN PLACE.

CARE AND CLEANING

Stainless Steel

To clean stainless steel surfaces use a damp cloth with a mild, non-abrasive cleaner suitable for stainless steel

surfaces. Remove the cleaner residue and then dry with a clean cloth.

The stainless steel used to make the dryer drum provides the highest reliability available in a GE Appliances dryer.

If the dryer drum should be scratched or dented during normal use, the drum will not rust or corrode. These surface

blemishes will not affect the function or durability of the drum.

49-3000087 9

Care and cleaning

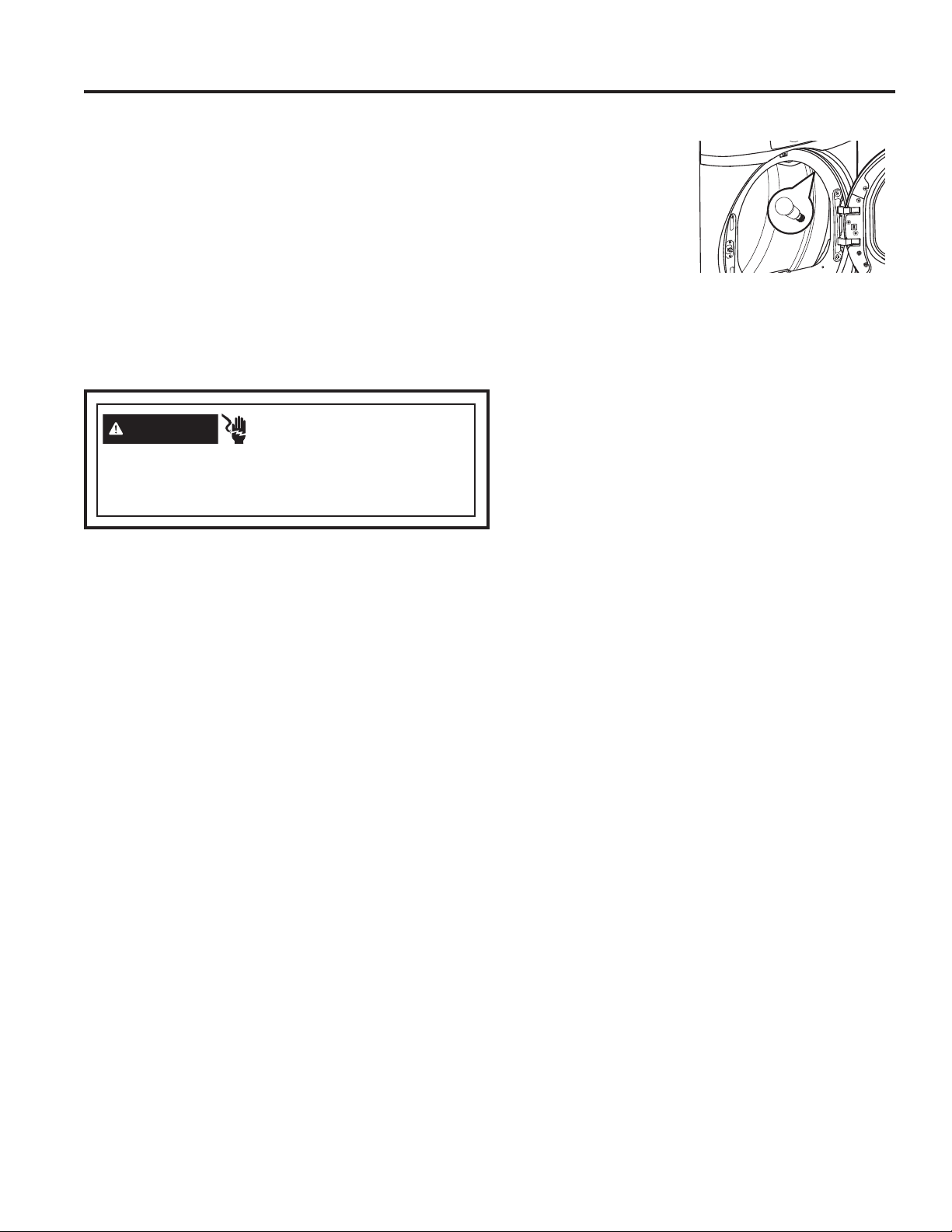

Drum Lamp

NOTE: The drum lamp is not consumer replaceable on models where there is a flat cover

over an LED bulb. If this light should ever stop working, call for service.

For models that have a domed cover over the bulb secured by a screw:

Before replacing the light bulb, be sure to unplug the dryer power cord or disconnect the

dryer at the household distribution panel by removing the fuse or switching off the circuit

breaker. Reach above dryer opening from inside the drum to locate the light.

Remove the screw and the plastic cover to access the bulb. Replace with the appropriate

bulb and then reaffix the cover and screw.

Order replacement bulb WE11X26351 on-line at GEApplianceparts.com, by phone at 877.959.8688 during normal

business hours, or purchase appliance bulb 7C7 from your local retailer.

When the door is opened, the drum lamp automatically turns on and remains on for 2 minutes. When the door is closed,

the drum lamp will remain on for 30 seconds.

CARE AND CLEANING

WARNING

Disconnect power supply before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

- Electrical Shock Hazard

10 49-3000087

Installation

Instructions

If you have any questions, call GE Appliances at 800.GE.CARES

(800.432.2737)

In Canada, call 800.561.3344

BEFORE YOU BEGIN

Read these instructions completely and carefully.

or visit our Website at: GEAppliances.com

or visit www.GEAppliances.ca

WARNING

Dryer

• IMPORTANT – Save these instructions for

local electrical inspector’s use.

• IMPORTANT – Observe all governing

codes and ordinances.

• Install the clothes dryer according to the

manufacturer’s instructions and local codes.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions for

future reference.

• Clothes dryer installation must be performed by a

qualified installer.

• This dryer must be exhausted to the outdoors.

• Before the old dryer is removed from service or

discarded, remove the dryer door.

• Service information and the wiring diagram are

located in the control console.

• Do not allow children on or in the appliance. Close

supervision of children is necessary when the

appliance is used near children.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Install the dryer where the temperature is above

50°F for satisfactory operation of the dryer control

system.

• Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

- Risk of Fire

• Clothes dryer installation must be performed by a

qualified installer.

• Install the clothes dryer according to these

instructions and local codes.

• DO NOT install a clothes dryer with flexible plastic

venting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found

in “Connecting the Dryer to House Vent” later in

this manual. Flexible venting materials are known

to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase

the risk of fire.

• DO NOT install or store this appliance in any

location where it could be exposed to water or

weather.

• To reduce the risk of severe injury or death, follow

all installation instructions.

• Save these instructions. (Installers: Be sure to

leave these instructions with the customer.)

If you are planning to stack the washer and dryer, order

Stacking Kit number GFA24KITL to be used for this

dryer. Kit sold separately.

49-3000087 11

Installation Instructions

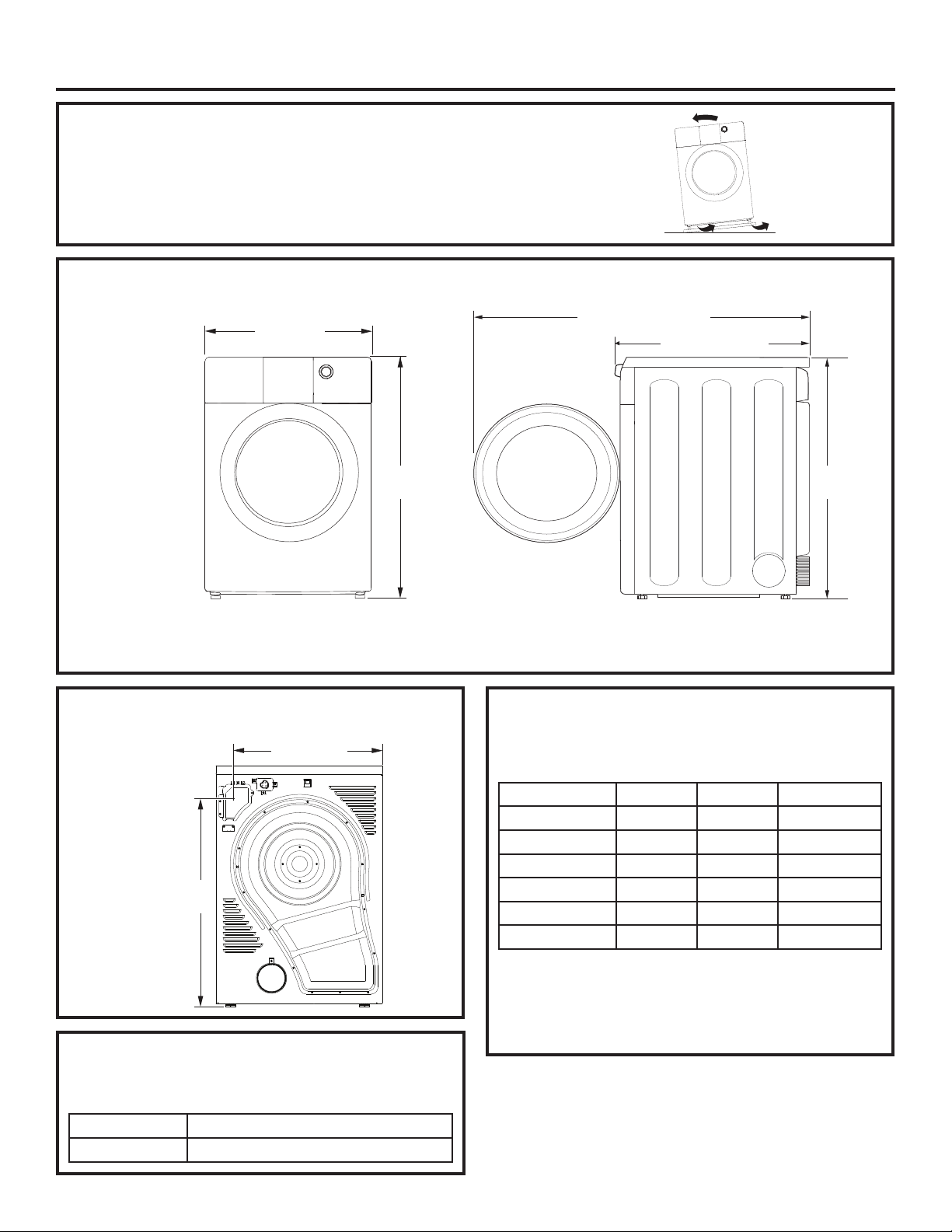

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam shipping pads by pulling at the sides and

breaking them away from the dryer legs. Be sure to remove all of the foam pieces

around the legs.

Remove the bag containing the literature.

DRYER

DIMENSIONS

Front

View

23-7/16”

(59.5 cm)

42-13/16” (108.7 cm)

*33-1/4”

(84.5 cm)

25-1/4” (64.1 cm)

*33-1/4”

(84.5 cm)

*NOTE:

With leveling legs retracted: 33-1/4 (84.5 cm)

With leveling legs fully extended: 33-5/8 (85.4 cm)

Stacked: 66-1/2” (168.9 cm)

ELECTRICAL CONNECTION

DIMENSIONS

30”

(76.2 cm)

20-1/2”

(52.1 cm)

Back

View

ACCESSORIES:

Order on-line at GEApplianceParts.com, 24 hours a day or

by phone at 877.959.8688 during normal business hours.

Side View

POWER CORDS

GE Appliances strongly recommends the use of

factory specified parts. Select the power cord to fit your

installation requirements.

Part Number Type Length Amperage

WX9X2 3-Prong 4 Feet 30

WX9X3 3-Prong 5 Feet 30

WX9X4 3-Prong 6 Feet 30

WX9X18 4-Prong 4 Feet 30

WX9X19 4-Prong 5 Feet 30

WX9X20 4-Prong 6 Feet 30

Order on-line at GEApplianceparts.com today,

24 hours a day or by phone at 877.959.8688 during

normal business hours. In Canada, visit your local

GE Appliances parts distributor or call 800.661.1616

GEAppliances.ca/en/products/parts-filters-accessories.

or

Part Number Accessory

PM08X10085

Flexible Metal Dryer Transition Duct

12 49-3000087

Installation Instructions

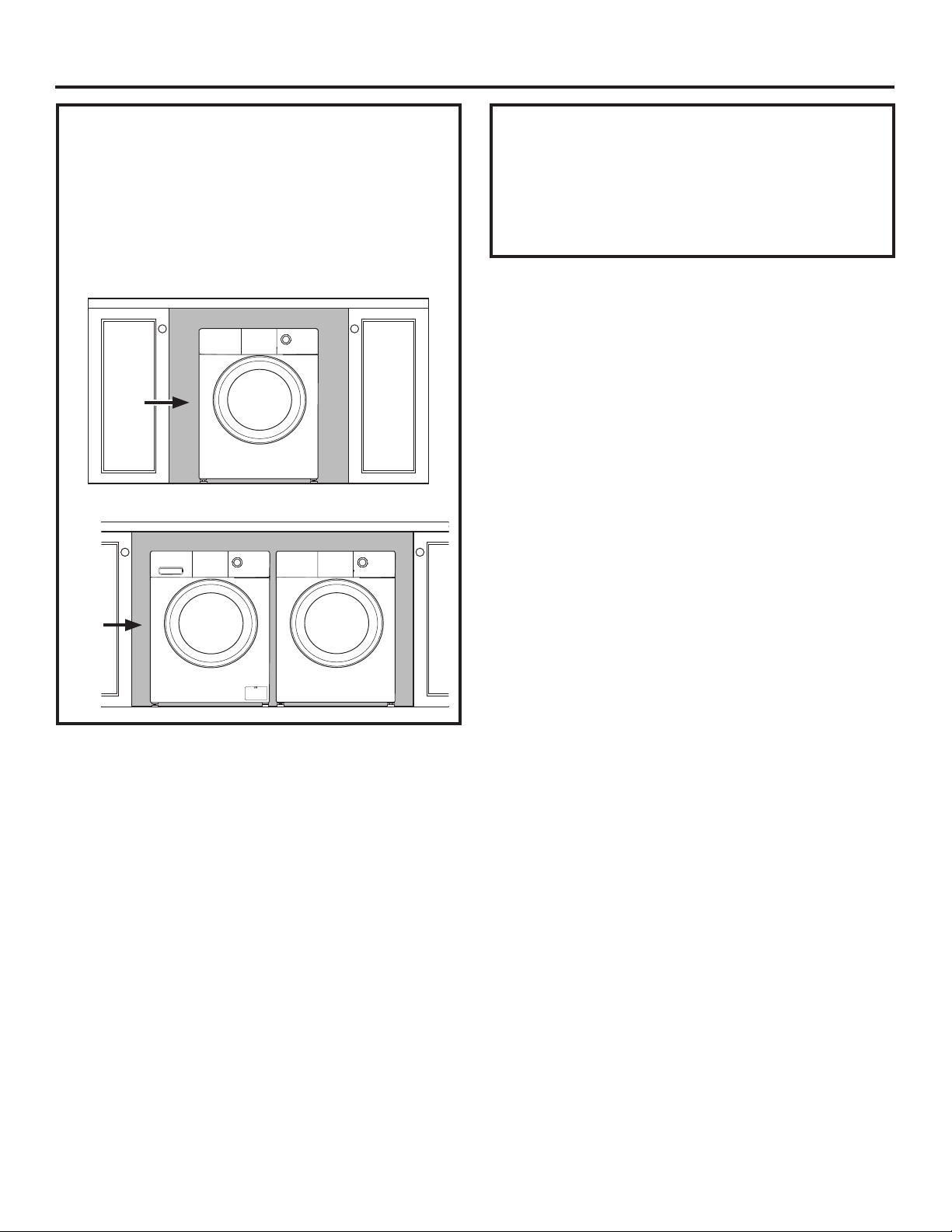

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

WARNING

Keep flammable materials and vapors, such as gasoline,

away from dryer.

Place dryer at least 18” (46 cm) above the floor for a

garage installation.

Failure to do so can result in death, explosion, or fire.

• The dryer MUST be vented to the outdoors.

• Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0” either side

1” front and rear

1” top

• The rear of the dryer should face a wall.

• Consideration must be given to provide adequate

clearance for installation and service.

• Closet doors must be louvered or otherwise

ventilated and have at least 60 square inches of

open area. If the closet contains both a washer

and a dryer, doors must contain a minimum of 120

square inches of open area.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, THE CONFIGURATION

OF THE DUCTING MAY REQUIRE GREATER THAN

3” OF REAR CLEARANCE.

- Explosion Hazard

MINIMUM CLEARANCE OTHER

THAN ALCOVE OR CLOSET

INSTALLATION

Minimum clearance to combustible surfaces and for

air opening are: 0” both sides, 1” rear and 1” top.

The rear of the dryer should face a wall.

Consideration must be given to provide adequate

clearance for installation and service.

MOBILE OR MANUFACTURED

HOME INSTALLATION

• Installation MUST conform to the

MANUFACTURED HOME CONSTRUCTION

AND SAFETY STANDARD, TITLE 24, PART

3280 or STANDARD FOR MOBILE HOMES

CAN/CSA-Z240 MH, or, when such standards

are not applicable, with AMERICAN NATIONAL

STANDARD FOR MOBILE HOME, ANSI/NFPA

NO. 501B.

• The dryer MUST be vented to the outdoors.

• The exhaust vent MUST be securely fastened to a

non-combustible portion of the mobile home.

• The vent MUST NOT be terminated beneath a

mobile or manufactured home.

• The vent duct material MUST BE METAL.

• KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

• The vent MUST NOT be connected to any other

duct, vent or chimney.

• DO NOT use sheet metal screws or other

fastening devices which extend into the interior of

the exhaust vent.

• Provide an opening with a free area of at least 25

square inches for introduction of outside air into

the dryer room.

• See the sections for electrical connection information.

49-3000087 13

Installation Instructions

UNDERCOUNTER INSTALLATION

If an undercounter installation is desired:

• No special dryer installation kit is required.

• If the dryer is installed alone, a minimum of 60

square inches of open area is required. If a washer

and dryer are installed together, a minimum of 120

square inches of open area is required.

Dryer Installed Alone

Countertop and side cabinets

60

square

inches

min.

open

area

Washer and Dryer Installed Together

Countertop and side cabinets

120

square

inches

min.

open

area

BATHROOM OR BEDROOM

INSTALLATION

The installation must conform with local codes or,

in the absence of local codes, with the NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70 (for electric

dryers).

14 49-3000087

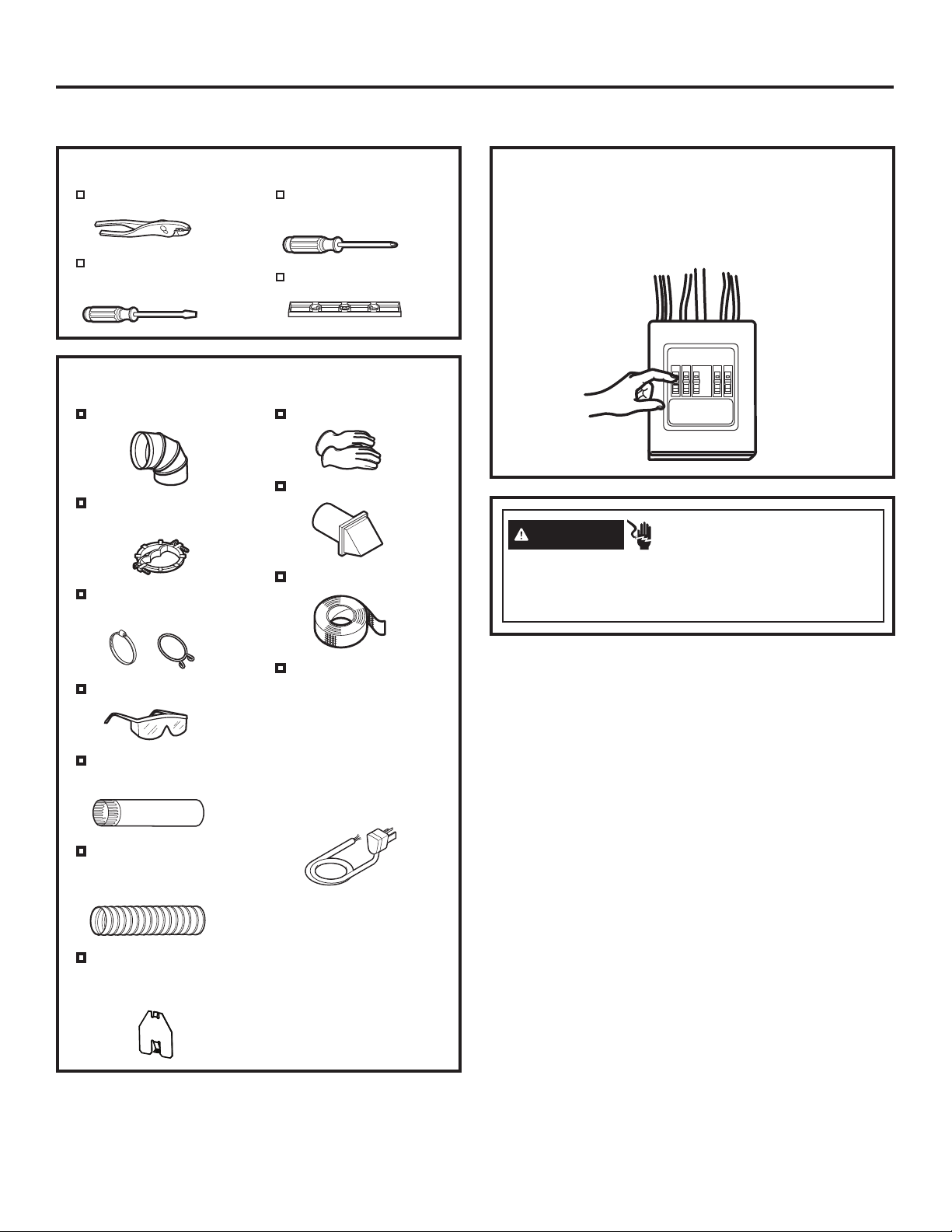

Installation Instructions

CONNECTING AN ELECTRIC DRYER

TOOLS YOU WILL NEED

Slip-joint pliers

Flat-blade

screwdriver

Phillips

screwdriver

Level

MATERIALS YOU WILL NEED

Ŷ

4” dia. metal elbow

Ŷ

3/4” Strain relief

(UL recognized)

Ŷ

4” Duct clamps (2) or

4” spring clamps (2)

Ŷ

Gloves

Ŷ

Exhaust hood

Ŷ

Duct tape

Before making the electrical connection, turn off the

circuit breaker(s) or remove the dryer’s circuit fuse(s) at

the electrical box. Be sure the dryer cord is unplugged

from the wall. NEVER LEAVE THE ACCESS COVER

OFF THE TERMINAL BLOCK.

WARNING

Disconnect power supply before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

- Electrical Shock Hazard

Ŷ

Safety glasses

Ŷ

4” dia. metal duct

(recommended)

Ŷ

4” dia., UL-listed

flexible metal duct

(if needed)

Ŷ

4” Cover Plate

(Kit WE49X22606)

(if needed)

Ŷ

Dryer power cord kit

(not provided with

dryer)

UL rated 120/240V,

30A with 3 or 4 prongs.

Identify the plug type

as per the house

receptacle before

purchasing line cord.

Stacking installations

may require a power

cord up to 6 feet in

length.

49-3000087 15

Installation Instructions

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC

DRYERS

For electrical connections using a

power cord:

WARNING

Use a new UL-listed 240V 30 amp dryer power supply

cord with closed ring terminals or spade terminals with

upturned ends.

Use a UL-listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining two supply wires to remaining two

terminals.

Securely tighten all electrical connections.

Replace the terminal block cover.

Failure to do so can result in death, fire or electrical shock.

- Fire Hazard

GROUNDING INSTRUCTIONS

For a grounded, cord-connected dryer: This dryer

must be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electric

shock by providing a path of least resistance for

electric current. This dryer uses a cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING

result in a risk of electric shock. Check with a qualified

electrician, or service representative or personnel, if

you are in doubt as to whether the appliance is properly

grounded. DO NOT modify the plug on the power supply

cord. If it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

WARNING

Improper connection of the

equipment-grounding conductor can

- Electrical Shock Hazard

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC

DRYERS

For direct wire connections:

WARNING

Use 10 gauge copper wire.

Use a UL-listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining two supply wires to remaining two

terminals.

Securely tighten all electrical connections.

Replace the terminal block cover.

Failure to do so can result in death, fire or electrical shock.

- Fire Hazard

GROUNDING INSTRUCTIONS

For a permanently connected dryer: This dryer

must be connected to a grounded metal, permanent

wiring system, or an equipment-grounding conductor

must be run with the circuit conductors and

connected to the equipment-grounding terminal on

the appliance.

WARNING

result in a risk of electric shock. Check with a qualified

electrician, or service representative or personnel, if

you are in doubt as to whether the appliance is properly

grounded.

SAVE THESE INSTRUCTIONS

WARNING

TO PREVENT ELECTRIC SHOCK, DISCONNECT

POWER BEFORE SERVICING.

This dryer should be connected to an individual branch

circuit with 10 gauge copper wire minimum through a

30 amp fuse or circuit breaker. DO NOT fuse neutral.

Use copper conductors only.

Improper connection of the

equipment-grounding conductor can

- Electrical Shock Hazard

TO PREVENT ELECTRIC SHOCK, DISCONNECT

POWER BEFORE SERVICING.

This dryer should be connected to an individual branch

circuit with 10 gauge copper wire minimum through a

30 amp fuse or circuit breaker. DO NOT fuse neutral.

Use copper conductors only.

16 49-3000087

Installation Instructions

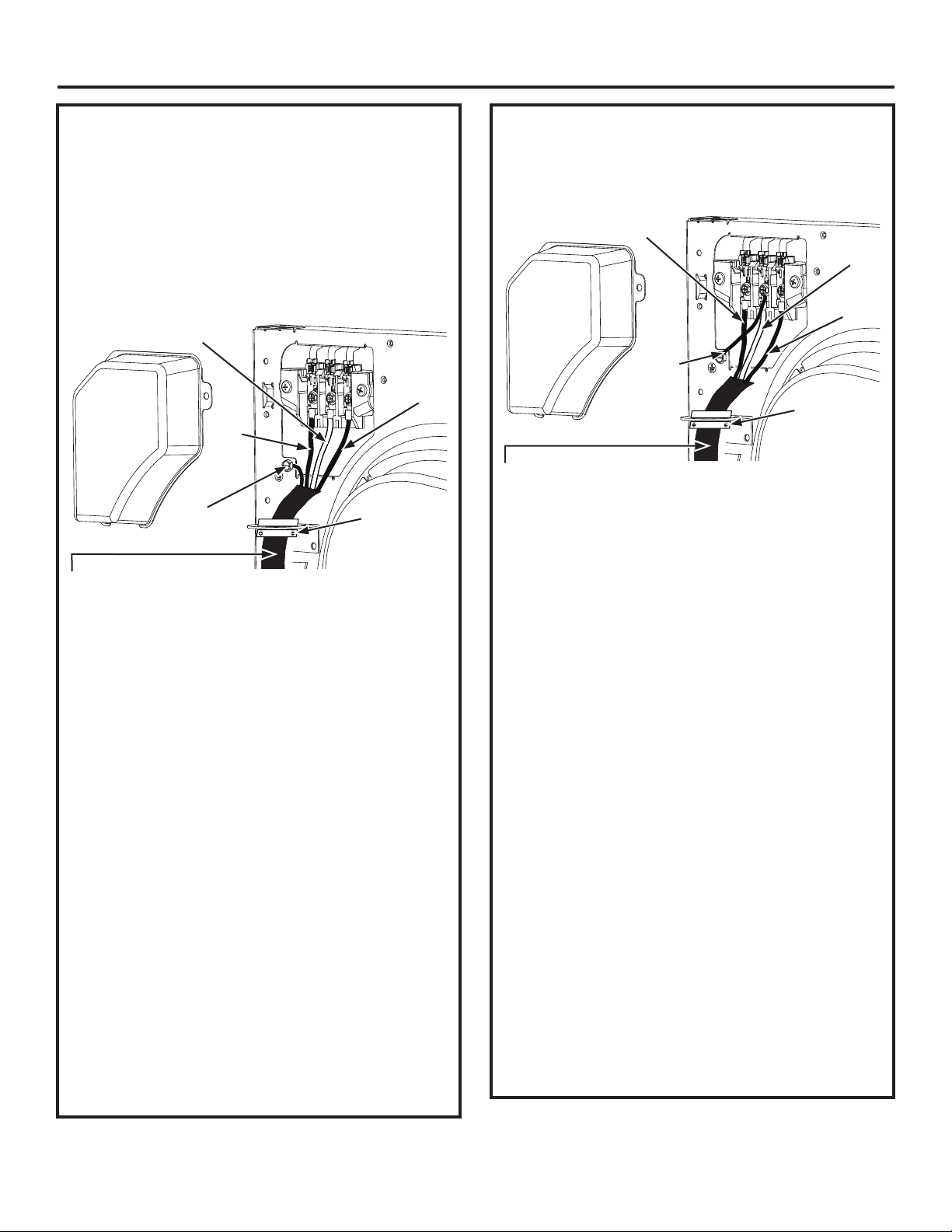

CONNECTING DRYER USING

4-WIRE CONNECTION (MUST

BE USED FOR MOBILE HOME

INSTALLATION)

NOTE: Since January 1, 1996, the National Electrical

Code requires that new constructions use a 4-wire

connection to an electric dryer. A 4-wire cord must

also be used where local codes do not permit grounding

through the neutral. 3-wire connection is NOT for use

on new construction.

White Wire

Black

Cover

Green wire

from power

cord

4 #10 AWG minimum copper conductors or 120/240V 30A

power supply cord kit marked for use with dryers and provided

with closed loop or spade terminals with upturned ends (not

supplied).

or

Red

Wire

1. Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall

receptacle.

3. Remove the power cord cover located at the upper

back.

4. Remove green ground screw and retain for use in

Step 7. Remove center screw (marked N) in terminal

block. Remove and discard ground strap.

5. Install 3/4 in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief and bracket.

6. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of the

terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

7. Attach ground wire of power cord with the green

ground screw (hole above strain relief bracket).

Tighten all terminal block screws (3) securely.

8. Properly secure power cord to strain relief and

bracket.

9. Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE

TERMINAL BLOCK.

L1

N

L2

Black

or Red

Wire

3/4” Strain

Relief and

Bracket

CONNECTING DRYER USING

3-WIRE CONNECTION

If required, by local code, install external ground (not

provided) to grounded metal, cold water pipe, or other

established ground determined by a qualified electrician.

Black or Red Wire

Cover

Ground

Strap

3 #10 AWG minimum copper conductors or 120/240V 30A

power supply cord kit marked for use with dryers and provided

with closed loop or spade terminals with upturned ends (not

supplied).

3-wire Connection

Not for use in Canada.

DO NOT use for Mobile Home Installations.

NOT for use on new construction.

NOT for use on recreational vehicles.

NOT for use in areas where local codes prohibit

grounding through the neutral conduction.

1. Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall

receptacle.

3. Remove the power cord cover located at the upper

back.

4. Install 3/4-in. UL-recognized strain relief to power

cord entry hole. Bring power cord through strain

relief and bracket.

5. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of

the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center of

the terminal block (marked N).

6. Be sure ground strap is connected to green ground

screw on cabinet rear. Tighten all terminal block

screws (3) securely.

7. Properly secure power cord to strain relief and

bracket.

8. Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE

TERMINAL BLOCK.

L1

N

L2

White Wire

Black

or Red

Wire

3/4” Strain

Relief and

Bracket

49-3000087 17

Installation Instructions

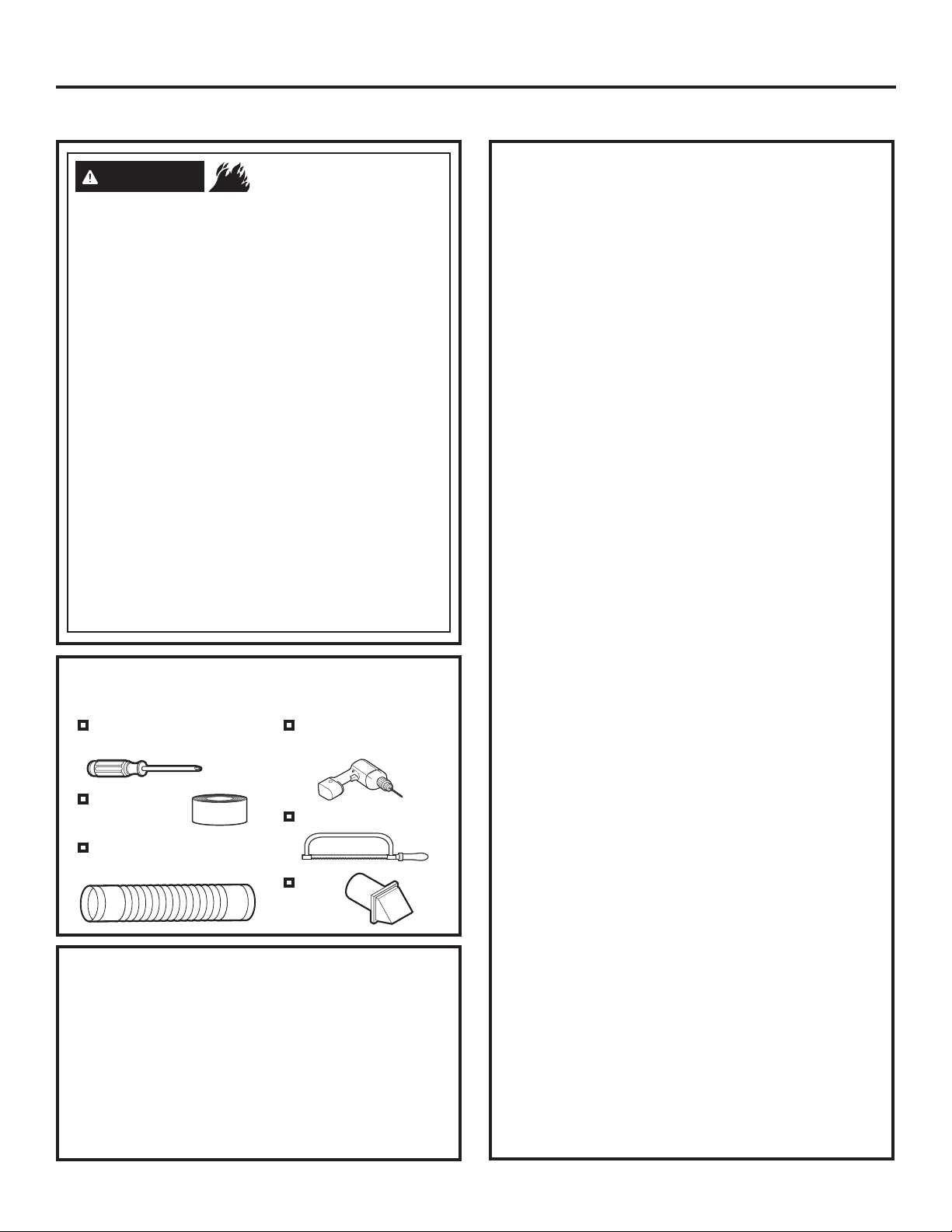

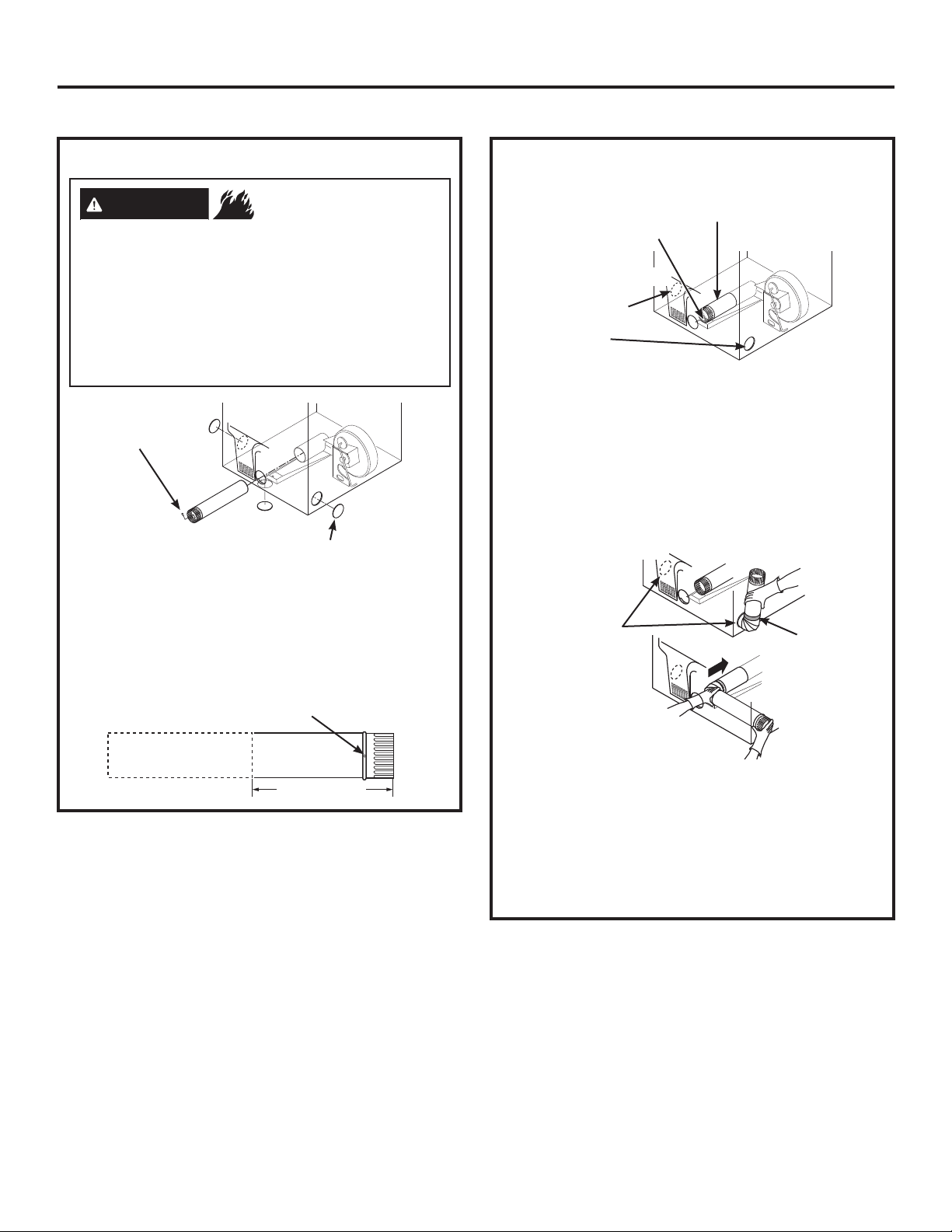

EXHAUSTING THE DRYER

WARNING

This dryer MUST be vented to the outdoors.

Use only 4” rigid metal ducting for the home

exhaust duct.

Use only 4" rigid metal, UL-listed flexible

metal, or UL-listed metal foil dryer transition

duct to connect the dryer to the home exhaust.

DO NOT use any plastic to vent the dryer,

this includes the home exhaust duct, dryer

transition duct, or within the dryer.

DO NOT use flexible metal or metal foil ducting

for a home exhaust duct or within the dryer.

DO NOT exhaust into a chimney, kitchen

exhaust, gas vent, wall, ceiling, attic, crawl

space, or concealed space of a building.

DO NOT install a screen in or over the exhaust

duct.

DO NOT install a booster fan in the exhaust duct.

DO NOT use duct longer than specified in the

exhaust length table.

Failure to follow these instructions can result in

death or fire.

TOOLS AND MATERIALS YOU WILL

NEED TO INSTALL EXHAUST DUCT

Ŷ

Phillips-head

screwdriver

Ŷ

Duct tape or

duct clamp

Ŷ

Rigid or UL-listed flexible

metal 4” (10.2 cm) duct

PARTS AVAILABLE FROM

GEAPPLIANCEPARTS.COM OR

LOCAL SERVICE ORGANIZATIONS

PM8X85

PM08X10085 8’ Flexible metal clothes dryer transition

WX08X10130 4” Dryer exhaust clamp

WE49X22606 Rear exhaust opening cover, for side or

Outdoor exhaust hood

duct with 2 clamps

bottom vented dryers

- Fire Hazard

Ŷ

Drill with 1/8” drill bit

(for bottom venting)

Ŷ

Hacksaw

Ŷ

Vent

hood

CONNECTING THE DRYER TO

HOUSE VENT

RIGID METAL TRANSITION DUCT

• For best drying performance, a rigid metal transition

duct is recommended.

• Rigid metal transition ducts reduce the risk of

crushing and kinking.

UL-LISTED FLEXIBLE METAL CLOTHES

DRYER TRANSITION DUCT

• If rigid metal cannot be used, then UL-listed flexible

metal clothes dryer transition duct (GE Appliances

part – PM08X10085) can be used.

• Never install transition duct in walls, ceilings, floors

or other enclosed spaces.

• Total length of transition duct should not exceed 8’

(2.4 m).

• For many applications, installing elbows at both

the dryer and the wall is highly recommended (see

illustrations in next section). Elbows allow the dryer

to sit close to the wall without kinking and/or crushing

the transition duct, maximizing drying performance.

• Avoid resting the duct on sharp objects.

UL-LISTED FLEXIBLE METAL (FOIL-TYPE)

TRANSITION DUCT

• In special installations, it may be necessary to

connect the dryer to the home exhaust vent

using flexible metal (foil-type) transition duct. UL–

LISTED universal flexible dryer transition duct

(GE Appliances parts – PM8X73 or WX8X73)

may be used ONLY in installations where rigid

metal or flexible metal transition ducting cannot be

used AND where a 4” diameter can be maintained

throughout the entire length of the transition duct.

• In Canada and the United States, only transition

ducts that comply with “UL 2158A STANDARD

FOR CLOTHES DRYER TRANSITION DUCT”

shall be used.

• Avoid resting the duct on sharp objects.

• For best drying performance:

1. Slide one end of the duct over the clothes

dryer outlet pipe.

2. Secure the duct with a clamp.

3. With the dryer in its permanent position,

extend the duct to its full length. Allow 2”

of duct to overlap the exhaust pipe. Cut off

and remove excess duct. Keep the duct as

straight as possible for maximum airflow.

4. Secure the duct to the exhaust pipe with the

other clamp.

18 49-3000087

Installation Instructions

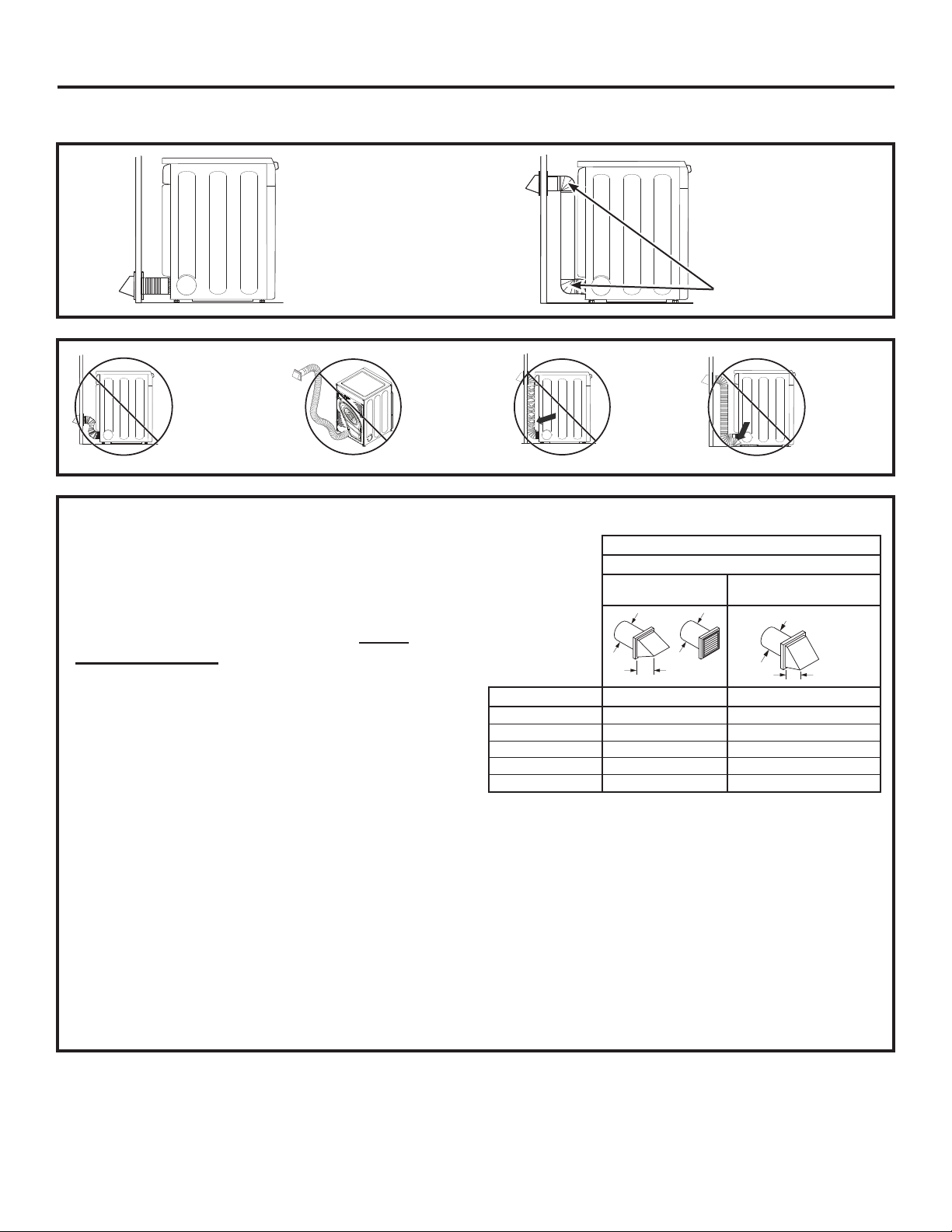

EXHAUSTING THE DRYER (cont.)

• DO cut duct as short

as possible and

install straight into

wall.

•

DO use elbows

when turns are

necessary.

Elbows

• DO NOT bend

or collapse

ducting.

Use elbows

if turns are

necessary.

• DO NOT use

excessive

exhaust

length. Cut

duct as short

as possible.

EXHAUST LENGTH

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reduce the dryer life.

• Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR

RESPONSIBILITY.

Problems due to incorrect installation are not

covered by the warranty.

The MAXIMUM ALLOWABLE length of the exhaust

system depends upon the type of duct, number of turns,

the type of exhaust hood (wall cap) and all conditions

noted on the chart.

• Internal elbows added for side or bottom vent

conversions must be included in the total elbow count.

• Any elbow greater than 45° should be treated as a 90°

elbow; one elbow of 45° or less may be ignored.

• Two 45° elbows will be treated like one 90° elbow.

• For the side exhaust installations, add one 90° elbow to

the chart.

• For every additional 90° elbow, reduce the allowable

vent system length by 10 feet.

• When calculating the total vent system length, you

must add all the straight portions and elbows of the

system (including the transition duct).

• DO NOT

crush duct

against

the wall

Recommended

.

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Use only for short run

EXHAUST

LENGTH

No. of 90° Elbows Rigid Metal Rigid Metal

0 90 Feet 60 Feet

1 60 Feet 45 Feet

2 45 Feet 35 Feet

3 35 Feet 25 Feet

4 25 Feet 15 Feet

4" DIA.

4" DIA.

4"

• DO NOT

set dryer

on duct

installations

4" DIA.

2-1/2"

.

49-3000087 19

Installation Instructions

EXHAUSTING THE DRYER (cont.)

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entry of

birds or other wildlife.

• Termination should present minimal resistance to

the exhaust airflow and should require little or no

maintenance to prevent clogging.

• Wall caps must be installed at least 12” above ground

level or any other obstruction with the opening pointed

down.

SEPARATION OF TURNS

• For best performance, separate all turns by at least

4 ft. of straight duct, including distance between

last turn and dampened exhaust hood (wall cap).

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male end

of each section of duct must point away from the dryer.

• Duct joints should be made air- and moisture-tight

by wrapping the overlapped joints with duct tape or

aluminum tape.

• Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

• Horizontal runs should slope down towards the

outdoors 1/4” per foot.

• Provide an access for inspection and cleaning of

the exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

INSULATION

• Ductwork that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint build-up.

BEFORE YOU BEGIN

• Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

• Remove any lint from the wall exhaust opening.

STANDARD REAR EXHAUST

We recommend that you install your dryer before

installing your washer. This will permit direct

access for easier exhaust connection.

Slide the end of the exhaust duct on the back of the

dryer and secure with duct tape or a hose clamp.

Duct

NOTE: We strongly recommend using rigid metal

exhaust duct. However, if flexible ducting is used it

must be UL-Listed metal, not plastic.

• For straight line installation, connect the dryer

exhaust to the external exhaust hood using duct

tape or clamp.

Wall Side

Duct Tape

Dryer

Side

RECOMMENDED CONFIGURATION

TO MINIMIZE EXHAUST BLOCKAGE

Using duct elbows will prevent duct kinking and

collapsing.

Wall

Internal

Duct

Opening

Check that exhaust

hood damper

opens and closes

freely.

Wall

Transition

Ducting

20 49-3000087

Installation Instructions

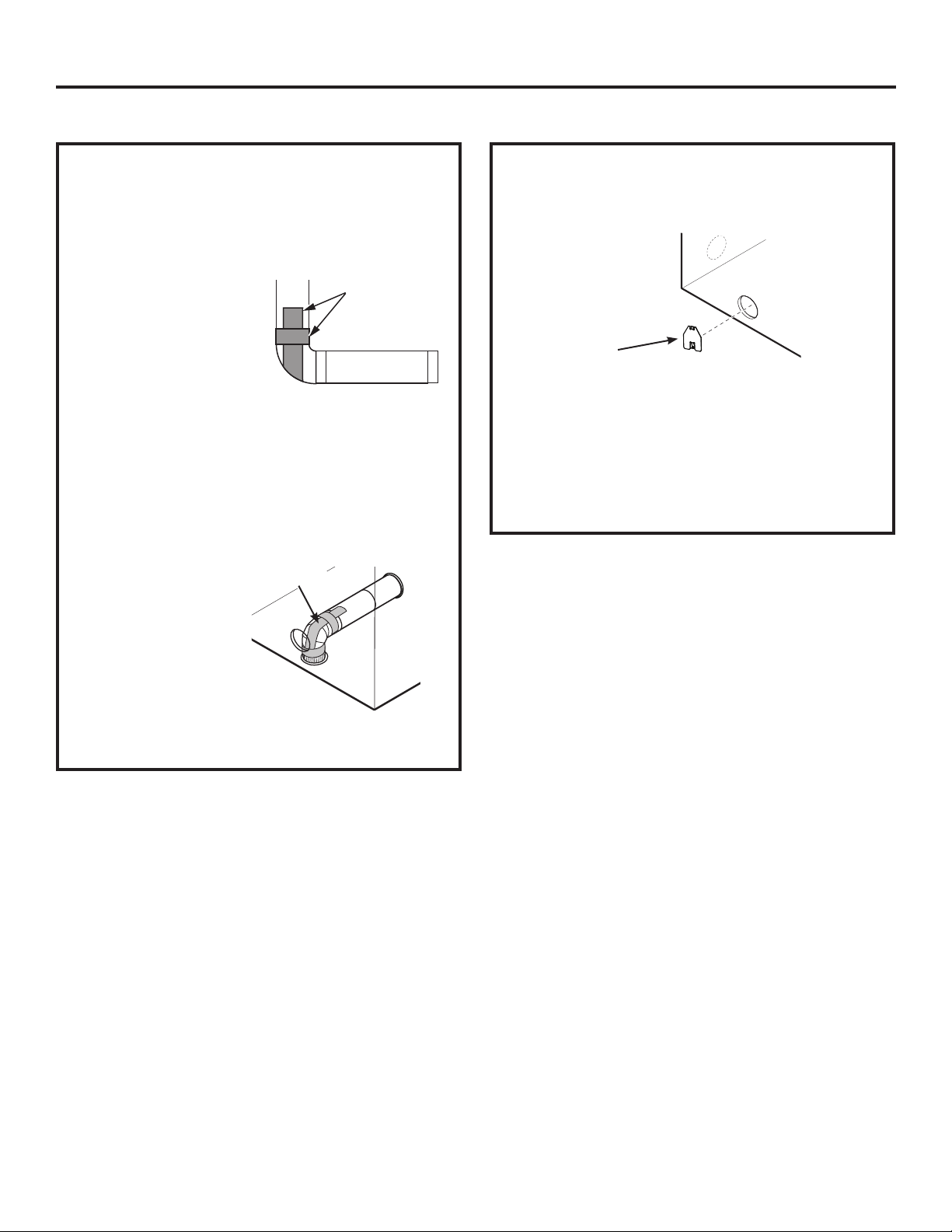

EXHAUSTING THE DRYER (cont.)

SIDE OR BOTTOM VENTING

WARNING

Disconnect dryer from electrical supply.

Wear gloves and arm guards.

Close the back opening with cover plate (Kit

WE49X22606).

Failure to do so may result in fire, electrical

shock or lacerations.

Remove

screw

and save

Detach and remove the right, left or bottom knockout

as desired. Remove the screw inside the dryer

exhaust duct and save.

Pull the duct out of the dryer.

Cut the duct as shown and keep portion A.

Right

- Fire Hazard

Bottom

Remove desired

knockout (one only)

Left

SIDE OR BOTTOM VENTING (cont.)

ADDING A NEW DUCT

Portion “A”

Fixing hole

Right

Right or left

side exhaust

Left

Reconnect the cut portion (A) of the duct to the blower

housing. Make sure that the shortened duct is aligned

with the tab in the base. Use the screw saved previously

to secure the duct in place through the tab on the

appliance base.

ADDING ELBOW AND DUCT FOR

EXHAUST TO RIGHT OR LEFT SIDE OF

CABINET

Right

Exhaust can be

added to right

or left side

Left

Duct

tape

Fixing hole

A

9” (22.86cm)

• Preassemble 4” elbow with 4” duct. Wrap duct tape

around joint.

• Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer internal

duct.

Be sure not to pull or damage the electrical

wires inside the dryer when inserting the duct.

49-3000087 21

Installation Instructions

EXHAUSTING THE DRYER (cont.)

SIDE OR BOTTOM VENTING (cont.)

ADDING ELBOW AND DUCT FOR

EXHAUST TO LEFT OR RIGHT SIDE OF

CABINET (cont.)

• Apply duct tape as shown

on the joint between the

dryer internal duct and

the elbow, and also the

joint between the elbow

and the side duct.

Use 4” rigid metal ducting

only inside the dryer. Internal duct joints must be

secured with tape, otherwise they may separate

and cause a safety hazard.

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

• Insert the elbow through the rear opening and

connect it to the dryer internal duct.

• Apply duct tape as

shown on the joint

between the dryer

internal duct and the

elbow, and also the

joint between the elbow

and the bottom duct.

Internal duct joints

must be secured with tape; otherwise, they may

separate and cause a safety hazard.

Duct tape

DUCT

TAPE

SIDE OR BOTTOM VENTING (cont.)

ADDING COVER PLATE TO REAR OF

CABINET

Plate

(Kit WE49X22606)

Connect standard metal elbows and ducts to complete

the exhaust system. Cover back opening with the plate

(kit WE49X22606) which can be purchased from

GEApplianceparts.com or a local service provider.

Place dryer in final location.

NEVER LEAVE THE BACK OPENING WITHOUT

THE PLATE.

22 49-3000087

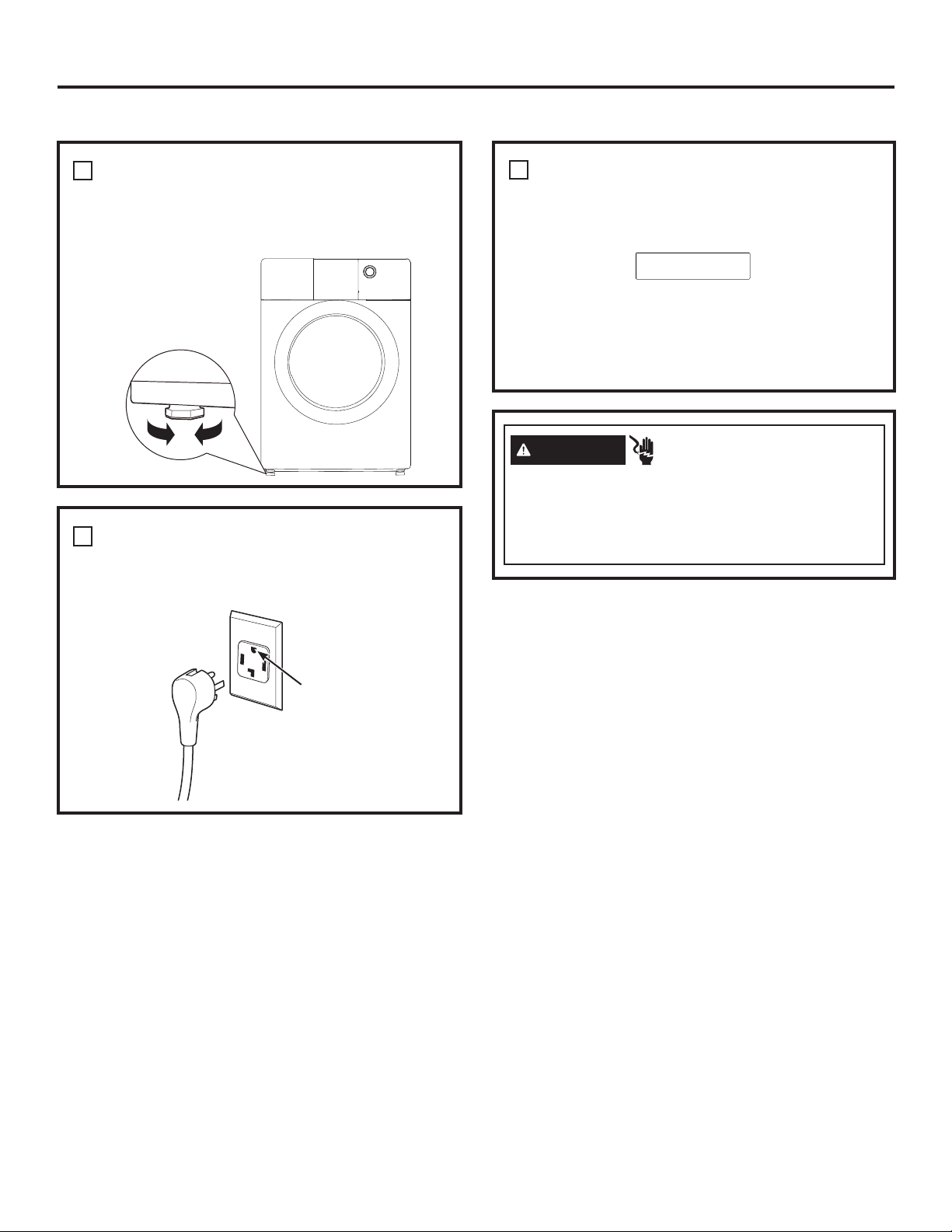

FINAL SETUP

Installation Instructions

1

LEVEL THE DRYER

Stand the dryer upright near the final location and

adjust the four leveling legs at the corners to ensure

that the dryer is level from side to side and front to

rear.

Lower

2

PLUG DRYER IN

NOTE: Stacking installations may require a power

cord up to 6 feet in length.

Raise

3

DRYER START-UP

Press the Power button.

Power

NOTE: If the dryer has been exposed to temperatures

below freezing for an extended period of time, allow it to

warm up before pressing Power. Otherwise, the display

will not come on.

The dryer is now ready for use.

WARNING

Disconnect power supply before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical

shock.

- Electrical Shock Hazard

Ensure proper

ground exists

before use.

49-3000087 23

Installation Instructions

STACKING THE WASHER AND DRYER (if desired)

If you are planning to stack the washer and dryer, order Stacking Kit number GFA24KITL to be used for this dryer.

Kit sold separately.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT – Save these instructions for

local electrical inspector’s use.

• IMPORTANT – Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions for

future reference.

• Service must be performed by a qualified installer.

• Do not allow children on or in the appliance. Close

supervision of children is necessary when the

appliance is used near children.

• Proper installation is the responsibility of the installer.

GE APPLIANCES STACK KIT

Order on-line at GEApplianceParts.com, 24 hours

a day or by phone at 877.959.8688 during normal

business hours.

Part Number Accessory

GFA24KITL Complete Stack Kit

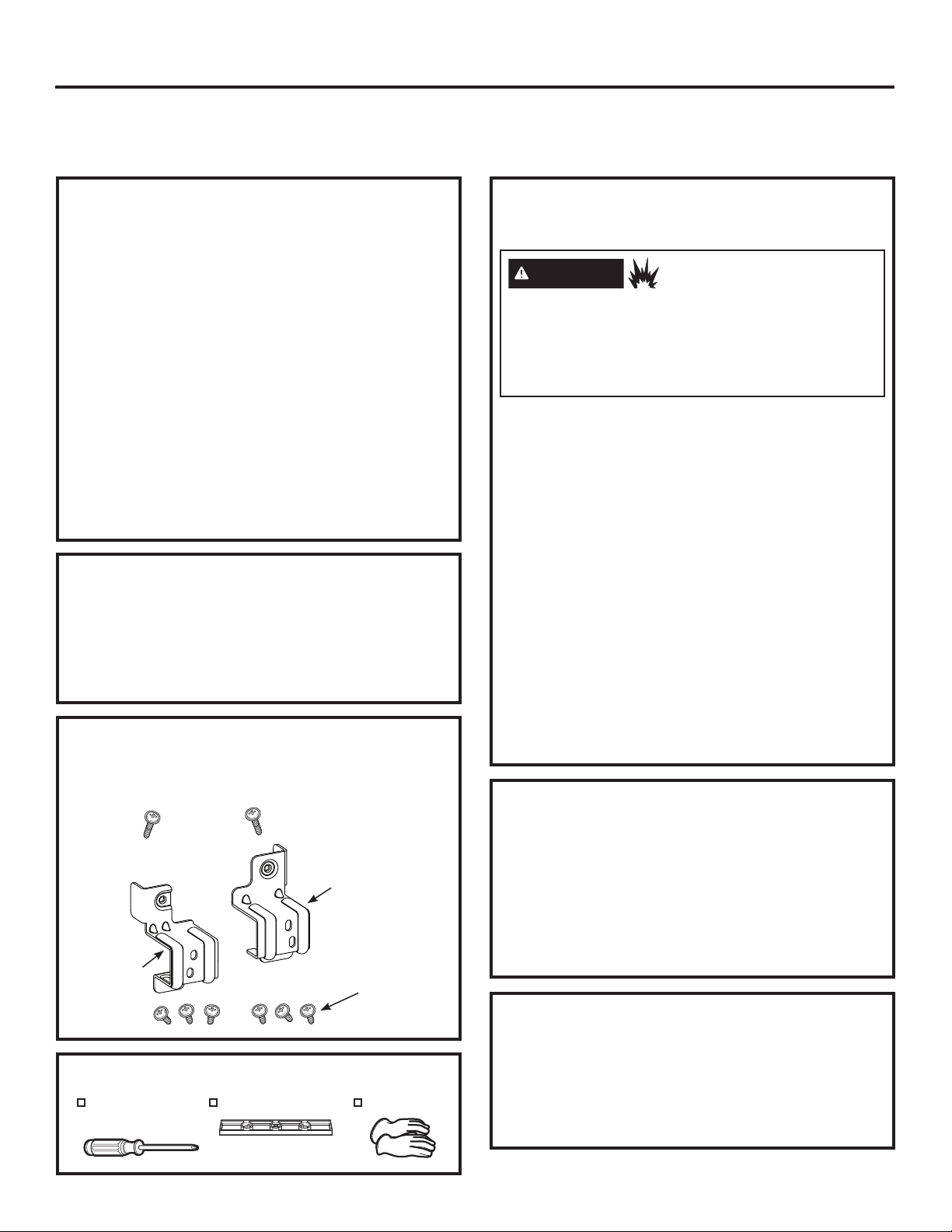

KIT CONTENTS (GE APPLIANCES

KIT # GFA24KITL)

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

WARNING

Keep flammable materials and vapors, such as gasoline,

away from dryer.

Place dryer at least 18” (46 cm) above the floor for a

garage installation.

Failure to do so can result in death, explosion, or fire.

• The dryer MUST be vented to the outdoors.

• Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

1” either side

3” front and rear

1” top

• The rear of the dryer should face a wall.

• Consideration must be given to provide adequate

clearance for installation and service.

• Closet doors must be louvered or otherwise

ventilated and have at least 60 square inches of

open area. If the closet contains both a washer

and a dryer, doors must contain a minimum of 120

square inches of open area.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, THE CONFIGURATION

OF THE DUCTING MAY REQUIRE GREATER THAN

3” OF REAR CLEARANCE.

- Explosion Hazard

Screws (2) Long

For dryer

attachment

MINIMUM CLEARANCE OTHER

THAN ALCOVE OR CLOSET

INSTALLATION

Minimum clearance to combustible surfaces and for

air opening are: 1” both sides, 3” rear and 1” top.

The rear of the dryer should face a wall.

Consideration must be given to provide adequate

clearance for installation and service.

Bracketstack (R)

Bracketstack (L)

Screws (6) Short

For washer attachment

INSTALLATION PREPARATION

Remove the packaging.

TOOLS YOU WILL NEED

Phillips

screwdriver

Level

24 49-3000087

Gloves

Flatten the product carton to use as a pad to lay the

dryer down on its side. Continue using the carton to

protect the finished floor in front of the installation

location.

Installation Instructions

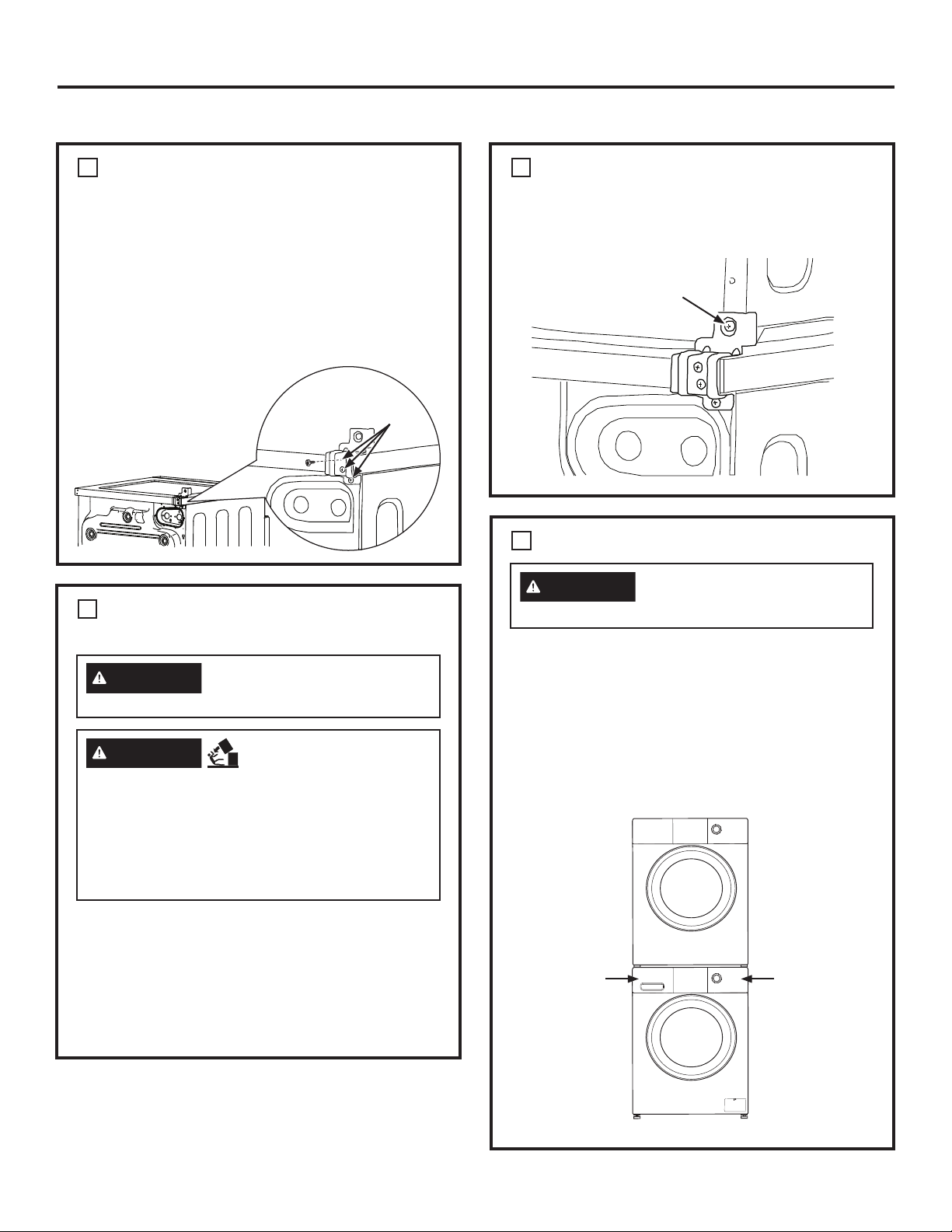

INSTALLING THE STACK BRACKET KIT

1

INSTALL BRACKET TO WASHER

A. Remove washer top cap screw from the rear

left. Align left bracket holes with top cap screw

hole on rear left of the unit and replace screw.

NOTE: Leave screws loose so dryer hole

alignment will be easier.

B. Drive next screw through the bracket into the

rear of the washer.

C. Repeat the above steps with the right side.

Short screws into

brackets and washer

Washer

Top

2

INSTALL DRYER AND BRACKET

ON DRYER

WARNING

serious injury or death.

Disconnect power before installing.

Failure to do so could result in

2

INSTALL DRYER AND BRACKET

ON DRYER (CONT.)

C. Tighten the dryer bracket screws; then tighten all

stacking kit screws.

Long screws into

brackets and dryer

3

FINALIZE THE INSTALLATION

CAUTION

Pushing on the dryer may result in pinched fingers.

A. Refer to the washer Installation Instructions to

complete the washer installation.

B. Refer to the dryer Installation Instructions to

complete the dryer installation.

Do not push on the dryer once

installed to top of the washer.

WARNING

Failure to do so may result in back or other injury,

or property damage.

• Use two or more people to install dryer.

• Avoid tipping and rupture of utility services.

• Dryer must be securely attached to the washer.

• DO NOT place the washer on top of the dryer.

A. Lift the dryer on top of the washer. Protect the

washer control panel with cardboard or other

protection. Be sure to lift the dryer high enough to

clear the washer control panel.

B. Align the holes in the bracket with the holes in the

back of the dryer. Using a Phillips screwdriver,

attach the 2 #8 x 1/2” tapping screws.

- Excessive Weight

Hazard

C. Carefully slide or walk the stacked washer and

dryer into place. Use felt pads or other sliding

device to assist moving and to protect flooring.

Dryer

Place

hands

here

Washer

Place

hands

here

49-3000087 25

Installation Instructions

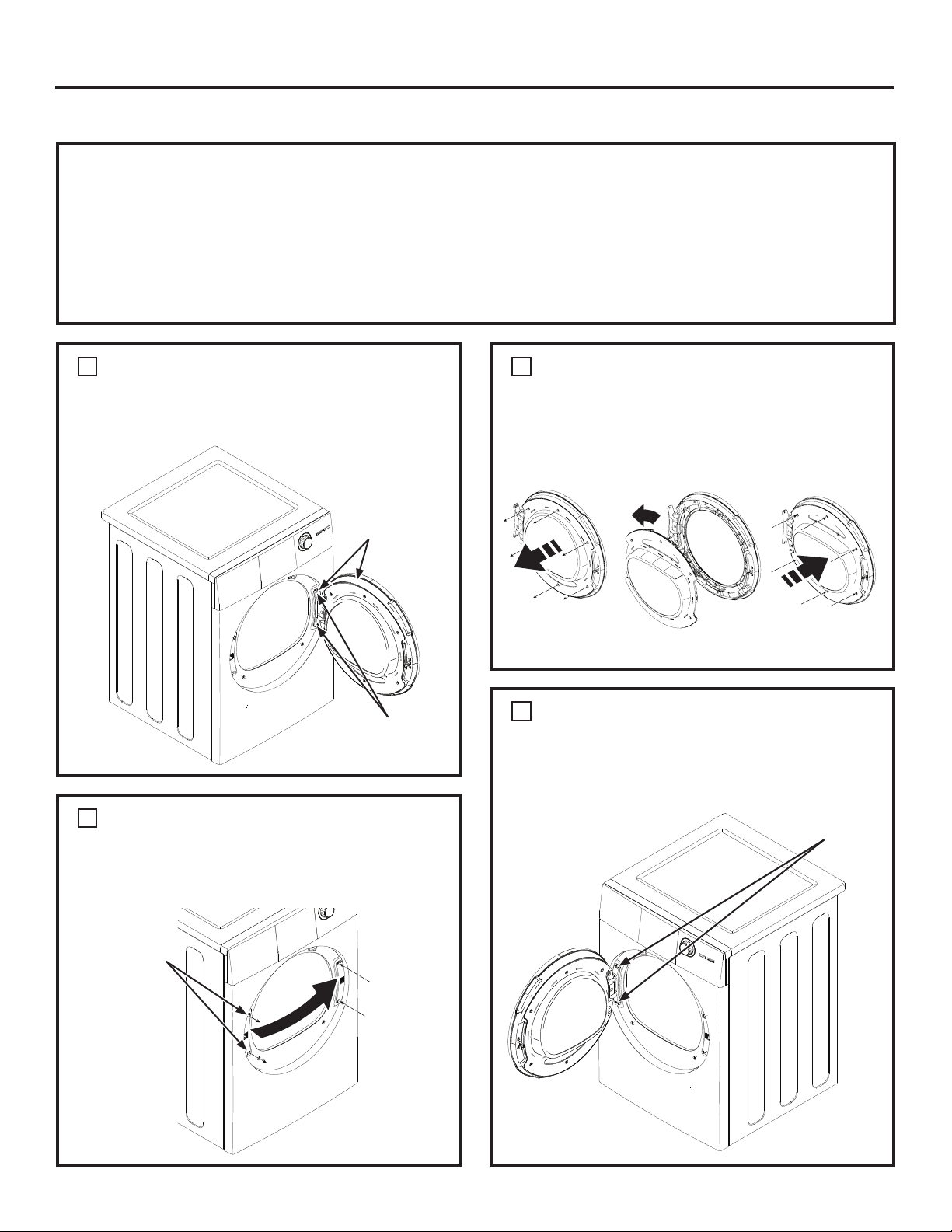

REVERSING THE DOOR SWING (Optional)

IMPORTANT NOTES

• Before you start, unplug the dryer from its electrical

outlet.

• Handle parts carefully to avoid scratching paint.

• Provide a non-scratching work surface for the doors.

• Tools you will need: Phillips-head screwdriver.

• Once you begin, do not move the cabinet until

door-swing reversal is completed.

• These instructions are for changing the hinges from

the right side to the left side—if you ever want to

switch them back to the right side, follow these same

instructions and reverse all references to the left and

right.

1

REMOVE THE DOOR ASSEMBLY

• Open the door. Remove the two screws holding the

hinge/door assembly to the dryer. Carefully set the

hinge/door assembly aside.

Hinge and Door

Assembly

Hold the Door and

Remove Hinge Screws

from the Dryer

2

REMOVE, ROTATE AND

REPLACE THE STRIKE PLATE

• Remove the two screws holding the strike plate.

Rotate it and install it on the opposite side.

3

REMOVE, ROTATE AND

REPLACE THE INNER DOOR

• Remove the six screws securing the inner door to

the outer door. Remove the inner door, rotate it 180

and reinstall it into the outer door using the same

six screws.

Remove six

screws and the

inner door

4

ROTATE AND REPLACE THE

Inner door shown

rotated 180

o

Replace the

inner door and

six screws

HINGE/DOOR ASSEMBLY

• Rotate and replace the hinge/door assembly, on the

opposite side, using the same two screws.

Secure with

same two screws

o

Strike Plate

and Screws

Reinstall

Strike Plate

and Screws

26 49-3000087

Notes

49-3000087 27

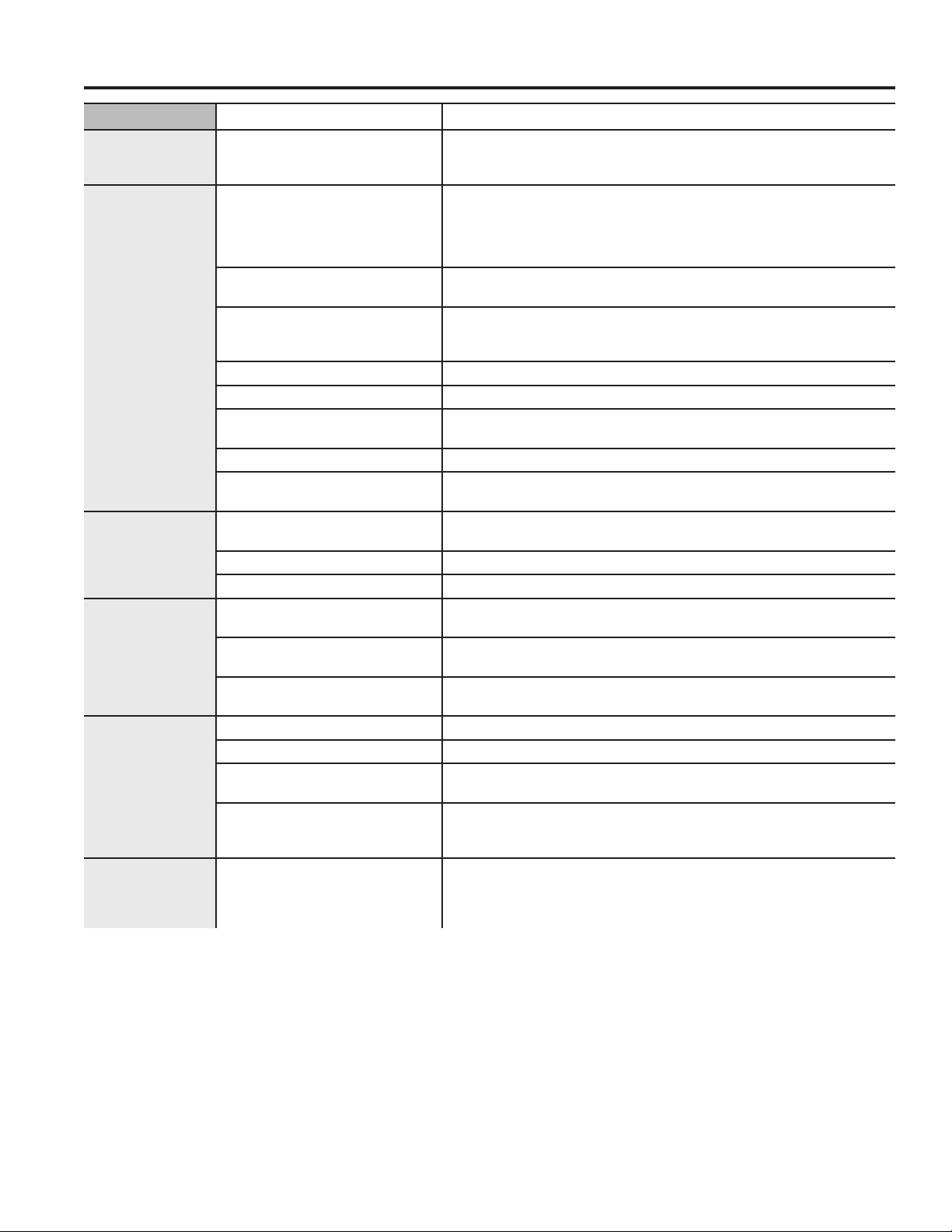

Troubleshooting Tips... Before you call for service

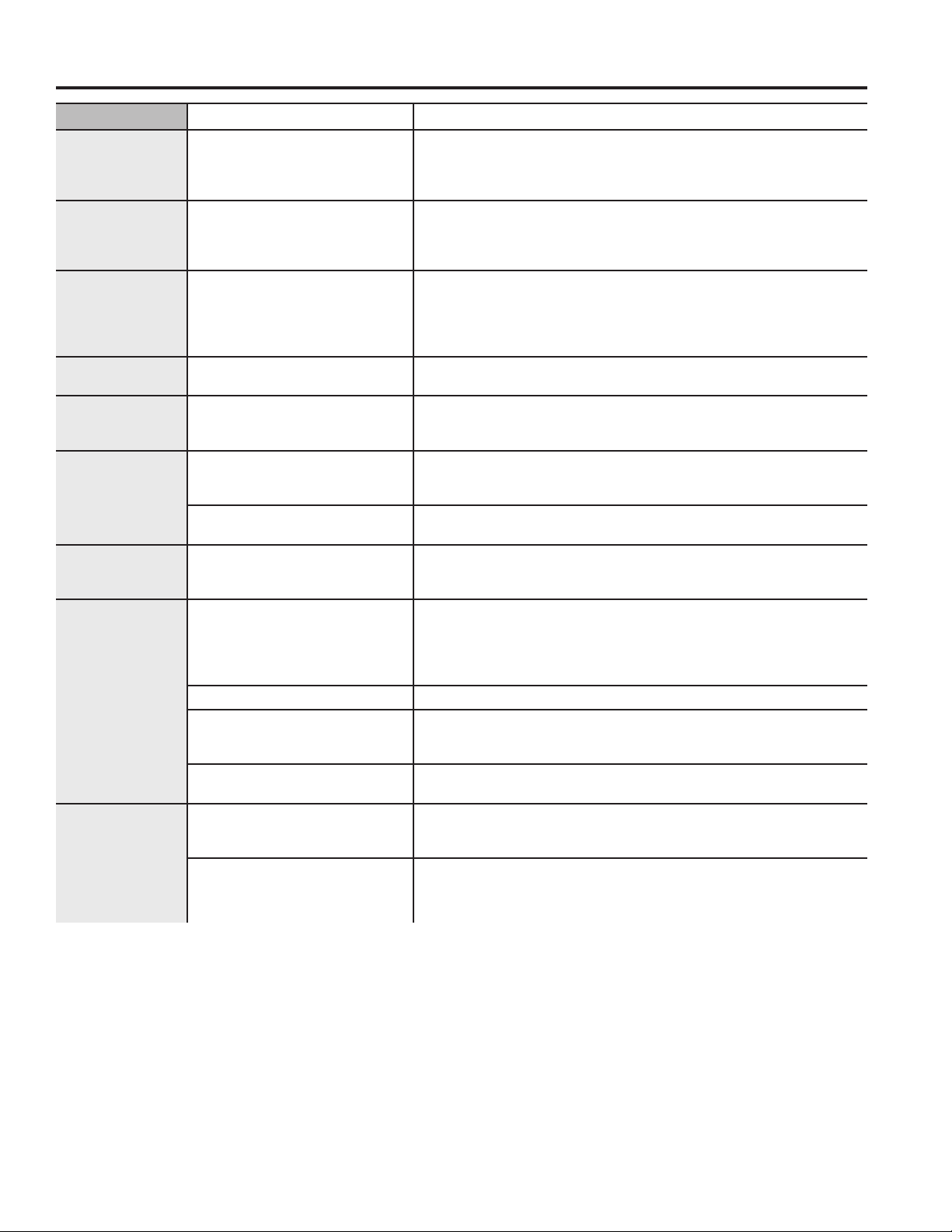

Problem Possible Cause What To Do

Dryer shakes or

makes noise

Clothes take

too long to dry

TROUBLESHOOTING TIPS

The Dry

dryness level

was chosen

but load is still

damp

Control buttons

not responding

Dryer doesn’t

start

No numbers

displayed

during cycle,

only lights

Some shaking/noise is

normal. Dryer may be sitting

unevenly.

Improper or obstructed

ducting

Improper sorting Separate heavy items from lightweight items (generally, a

Large loads of heavy fabrics

(like beach towels)

Controls improperly set Match control settings to the load you are drying.

Lint filter is full Clean lint filter before every load.

Blown fuses or tripped

circuit breaker

Overloading/combining loads Do not put more than one washer load in the dryer at a time.

Underloading If you are drying only one or two items, add a few items to ensure

Load consists of a mixture of

heavy and light fabrics

Lint filter is blocked Inspect and clean lint filter.

Dry Sensor is dirty Clean the sensor with a moist cloth.

Controls accidentally put in

service mode

Controls accidentally put in

lock mode

Controls performed an

incorrect operation

Control panel is “asleep” This is normal. Press Power to activate the control panel.

Dryer is unplugged Make sure the dryer plug is pushed completely into the outlet.

Fuse is blown/circuit breaker

is tripped

Dryer was accidentally

paused when starting Delay

Dry

Dryer is continuously

monitoring the amount of

moisture in the clothes

Move dryer to an even floor space, or adjust leveling legs as

necessary until even.

Check the Installation Instructions to make sure the dryer venting

is correct.

Make sure ducting is clean, free of kinks and unobstructed.

Check to see if outside wall damper operates easily.

well-sorted washer load is a well-sorted dryer load).

Large, heavy fabrics contain more moisture and take longer to dry.

Separate large, heavy fabrics into smaller loads to speed drying

time.

Replace fuses or reset circuit breakers. Since most dryers use 2

fuses/breakers, make sure both are operating.

proper tumbling.

When combining heavy and light fabrics in a load, choose More

Dry.

Press Start/Pause.

Hold the Lock Control button for 3 seconds to unlock the dryer.

Reset the in-house breaker.

Check the building’s fuse/circuit breaker box and replace fuse or

reset breaker. NOTE: Electric dryers use two fuses or breakers.

If the light on the Start/Pause button is flashing, the dryer is

paused. Press Start/Pause to restart the countdown.

This is normal. When the dryer senses a low level of moisture in

the load, the dryer will display the dry time remaining.

28 49-3000087

Troubleshooting Tips... Before you call for service

Problem Possible Causes What To Do

Time

Remaining

jumped to a

lower number

Cannot make a

selection and

the dryer beeps

twice

Dryer is

running but 00

is displayed

in Time

Remaining

Clean Lint Filter

(message)

Dryer doesn’t

heat

Inconsistent

drying times

Glow at the rear

of the drum

Clothes are still

wet and dryer

shut off after a

short time

Clothes are

wrinkled

The estimated time may

change when a smaller load

than usual is drying

The dryness Level, Temp or

option that you are trying to

select is incompatible with

the chosen dry cycle

The Ext Tumble option was

chosen

Power button was activated Press Start/Pause to begin a dry cycle and the message will

Fuse is blown/circuit breaker

is tripped; the dryer may

tumble but not heat

Type of load and drying

conditions

Type of load and drying

conditions

Heaters behind the drum This is normal. Under certain drying conditions and room ambient

The door was opened

mid-cycle. The load was then

removed from the dryer and

a new load put in without

selecting a new cycle

Small load When drying 3 items or less, choose Quick Dry or Time Dry.

Load was already dry except

for collars and waistbands

Dryer is not level Move dryer to an even floor space or adjust leveling legs as

Overdrying Select a shorter drying time.

Letting items sit in dryer after

cycle ends

Overloading Separate large loads into smaller ones.

This is normal.

This is normal.

This is normal. During extended tumbling, the time remaining is

not displayed. The extended tumbling option lasts approximately

60 minutes.

disappear.

Check the building’s fuse/circuit breaker box and replace both

fuses or reset both breakers. Your dryer may tumble if only one

fuse is blown or one breaker tripped.

The load size, types of fabric, wetness of clothes and the condition

of the lint filter and/or air intake vent located on the front of the

dryer will affect drying times.

The load size, types of fabric, wetness of clothes and the length

and condition of the exhaust system will affect drying times.

lighting, the glow of the heaters may be visible at the rear of the

drum.

A dry cycle must be reselected each time a new load is put in.

Choose Quick Dry or Time Dry to dry damp collars and

waistbands. In the future, when drying a load with collars and

waistbands, choose More Dry.

necessary until even.

Remove items while they still hold a slight amount of moisture.

Select a Less Dry or Damp setting.

Remove items when cycle ends and fold or hang immediately, or

use the Ext Tumble option.

TROUBLESHOOTING TIPS

49-3000087 29

Loading...

Loading...